Patents

Literature

129results about "Collector without external energy sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

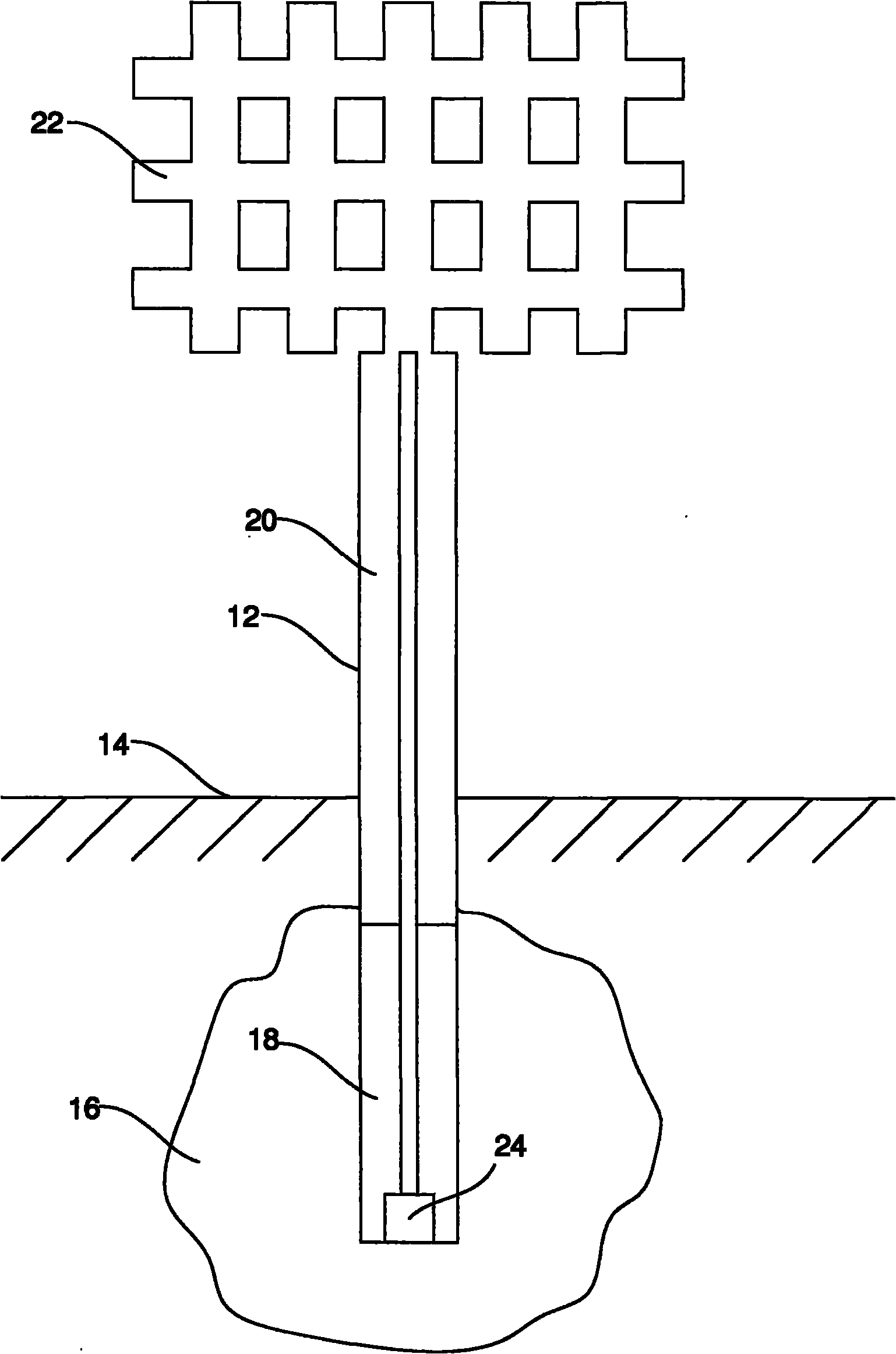

Geothermal Exchange System Using A Thermally Superconducting Medium With A Refrigerant Loop

A geothermal exchange system is couplable to a ground coil formed from a thermal superconductor material, and transfers heat using a refrigerant loop. The device includes a compressor, a reversible refrigerant loop with two heat exchangers, one of which couplable to a thermal superconductor ground loop. The device uses a high thermal transfer superconductor to efficiently move heat to and from the earth source for the purpose of heating and cooling. The device operates in cooling or heating modes by controlling the thermal switches and activating the heat intensification circuit in response to the difference between a set point and a measured temperature. Alternatively, the system can be configured for heating only or cooling only modes, by operating the refrigerant loop in one direction.

Owner:FREE ENERGY SOLUTIONS

Heat tube device utilizing cold energy and application thereof

InactiveUS20090211727A1Reduction factorHeat pumpsDomestic cooling apparatusEngineeringAir conditioning

The present invention relates to a refrigeration system, associated system of heating and refrigeration, geothermal energy utilizing system, cold storing apparatus, heat storing apparatus and the accessories thereof, and in particular relates to an air conditioning system utilizing natural cold energy, geothermal energy, thermal waste, residual heat and environmental friendly energy.

Owner:YIN XUEJUN

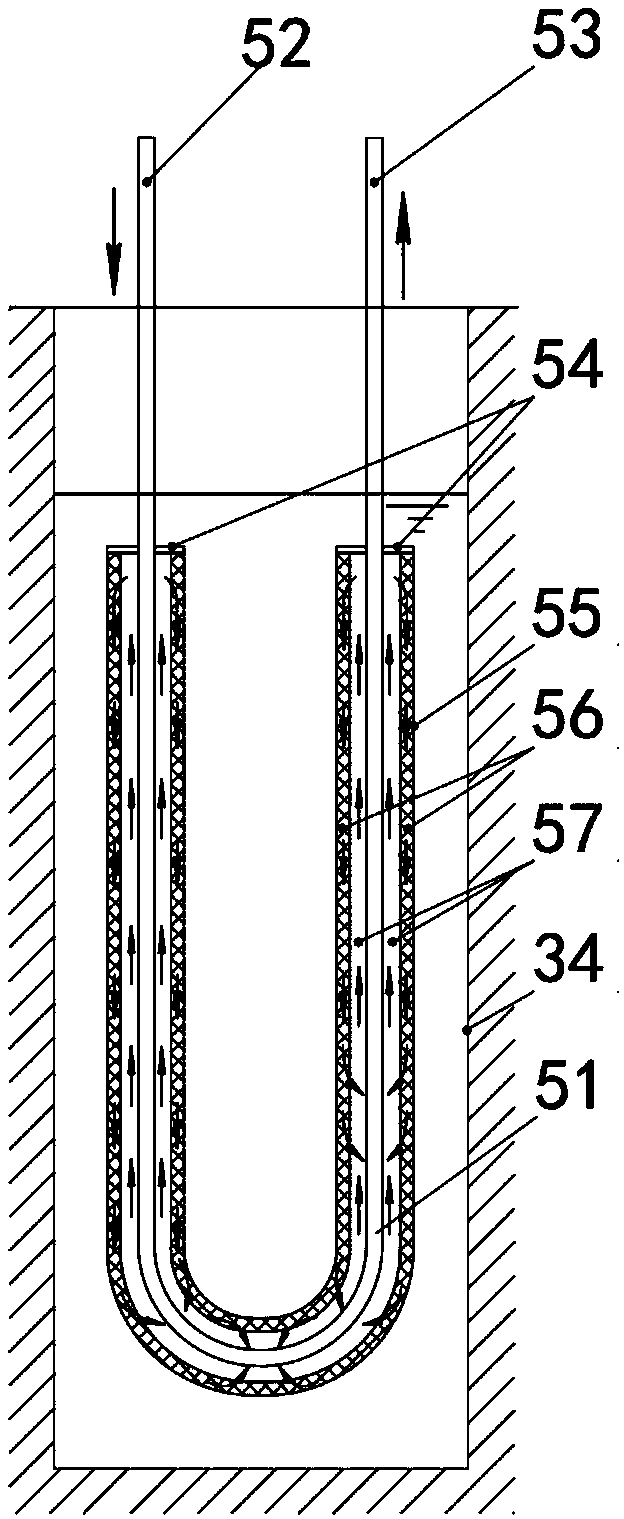

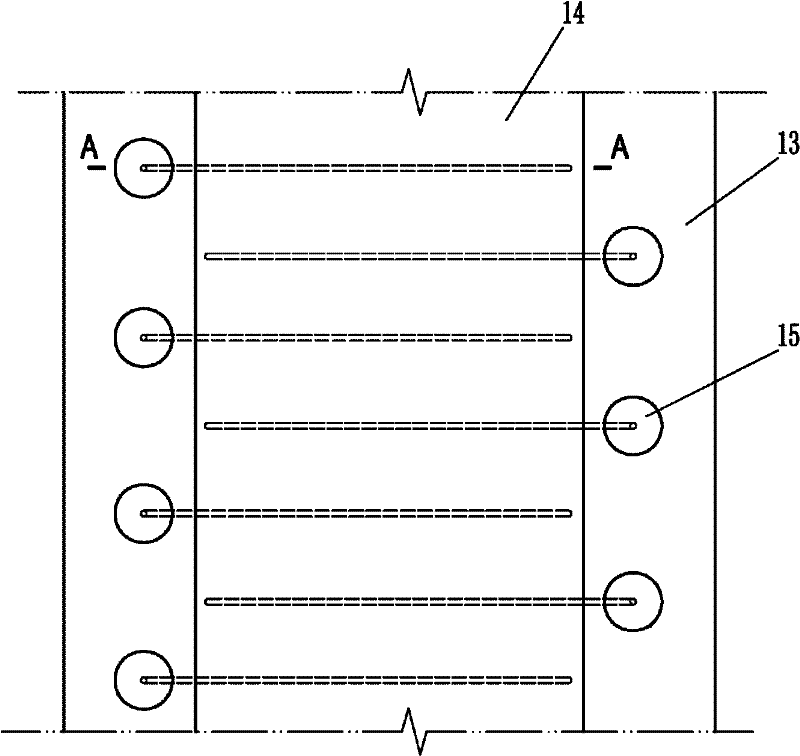

PCC (Large Diameter Pipe Pile by using Cast-in-place Concrete) energy pile and manufacturing method thereof

ActiveCN102808405AImprove sealingAbsorb moreOther heat production devicesGeothermal energy generationHeat conductingClassical mechanics

The invention discloses a PCC (Large Diameter Pipe Pile by using Cast-in-place Concrete) energy pile. The PCC energy pile comprises a PCC pile, a heat conducting liquid, a cover plate, a bottom plate, a heat conducting pipe, a heat collecting device and an inspection channel, wherein the bottom of the PCC pile is fully closed; a cover plate with holes is arranged at the top of the PCC pile; prepared holes are formed in one side at the upper part of the PCC pile; the heat conducting liquid is filled up in a cavity in the PCC pile; the heat conducting pipe penetrates through the holes in the cover plate and extends into the heat conducting liquid in the cavity in the PCC pile; the heat conducting pipe extending into the cavity in the PCC pile can adopt opened and closed modes; the inspection channel is formed in the side wall of the PCC pile; and the heat conducting pipe is led out of the cavity in the PCC pile through the holes in the cover plate or the inspection channel and connected with the heat collecting device to form a circulating channel of the heat conducting liquid. The invention further discloses a manufacturing method for the pile. The manufacturing method comprises the technical steps as follows: pouring the PCC pile; excavating pile core soil; making a bottom plate; mounting the heat conducting pipe and the cover plate; filling the heat conducting liquid; and starting a ground heat pump for forming a loop. The PCC energy pile is convenient to overhaul and maintain, wide in application range and low in construction cost, does not influence the bearing capacity, and is an economic, efficient, energy-saving and emission-reducing pile.

Owner:HOHAI UNIV +1

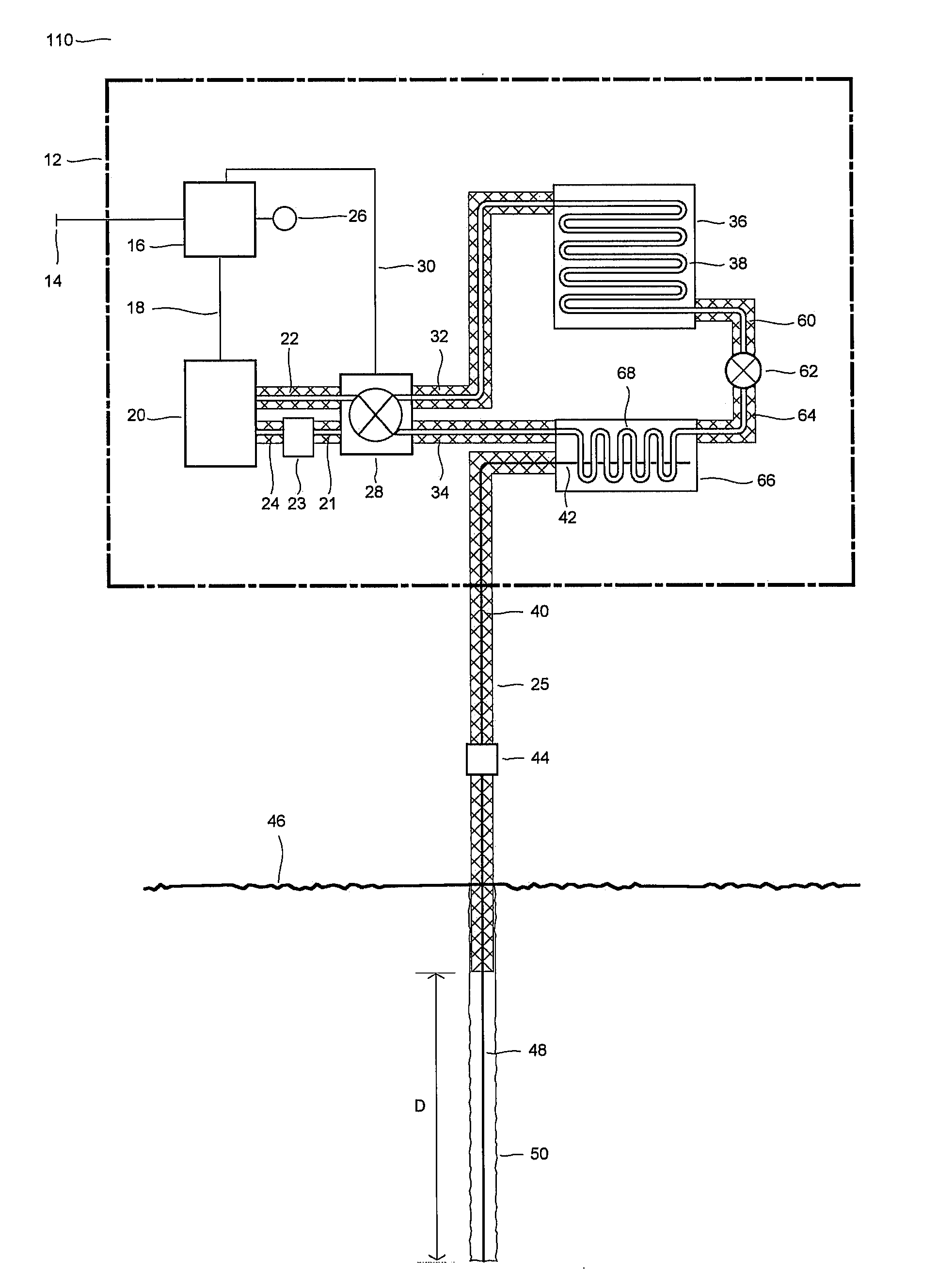

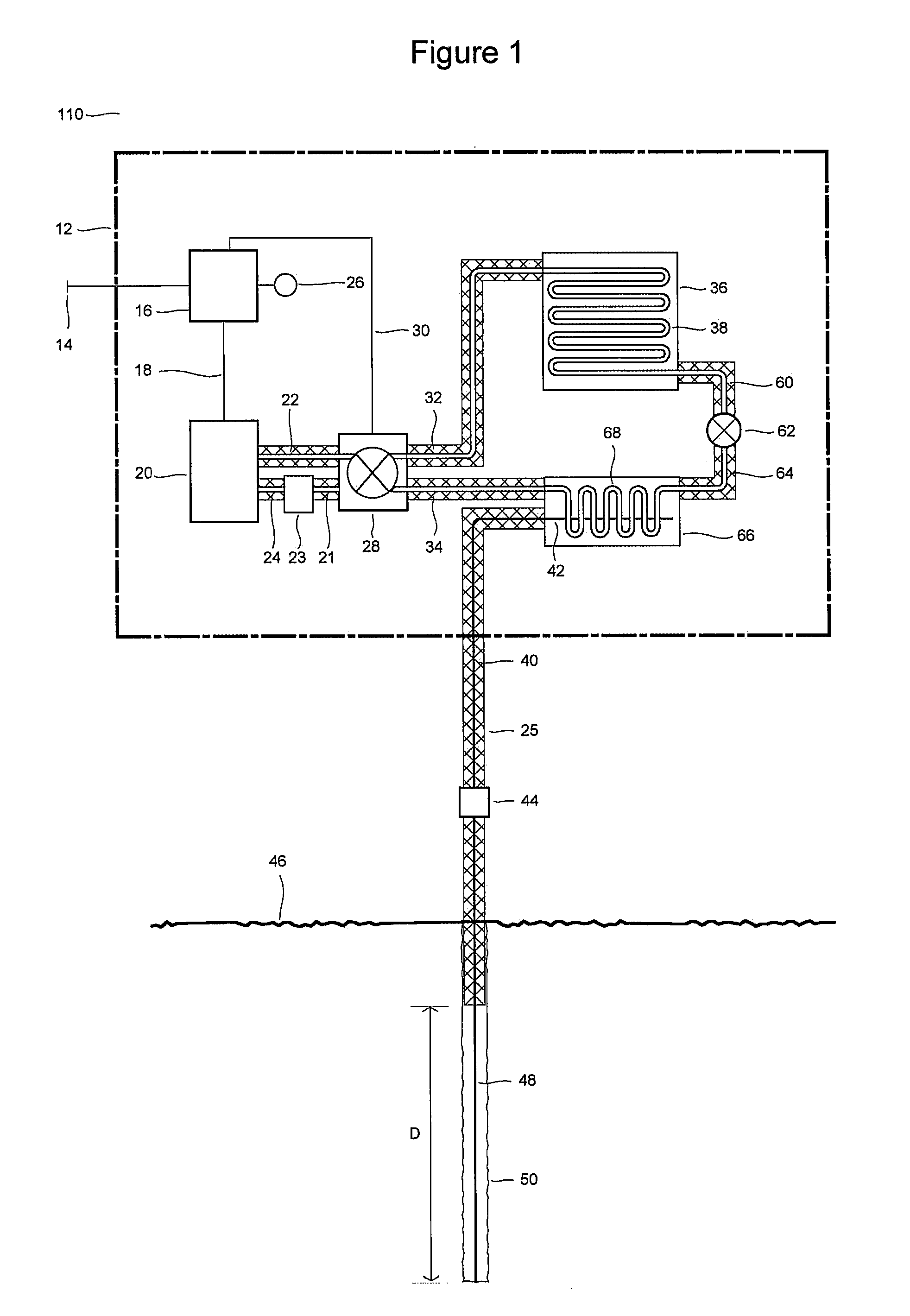

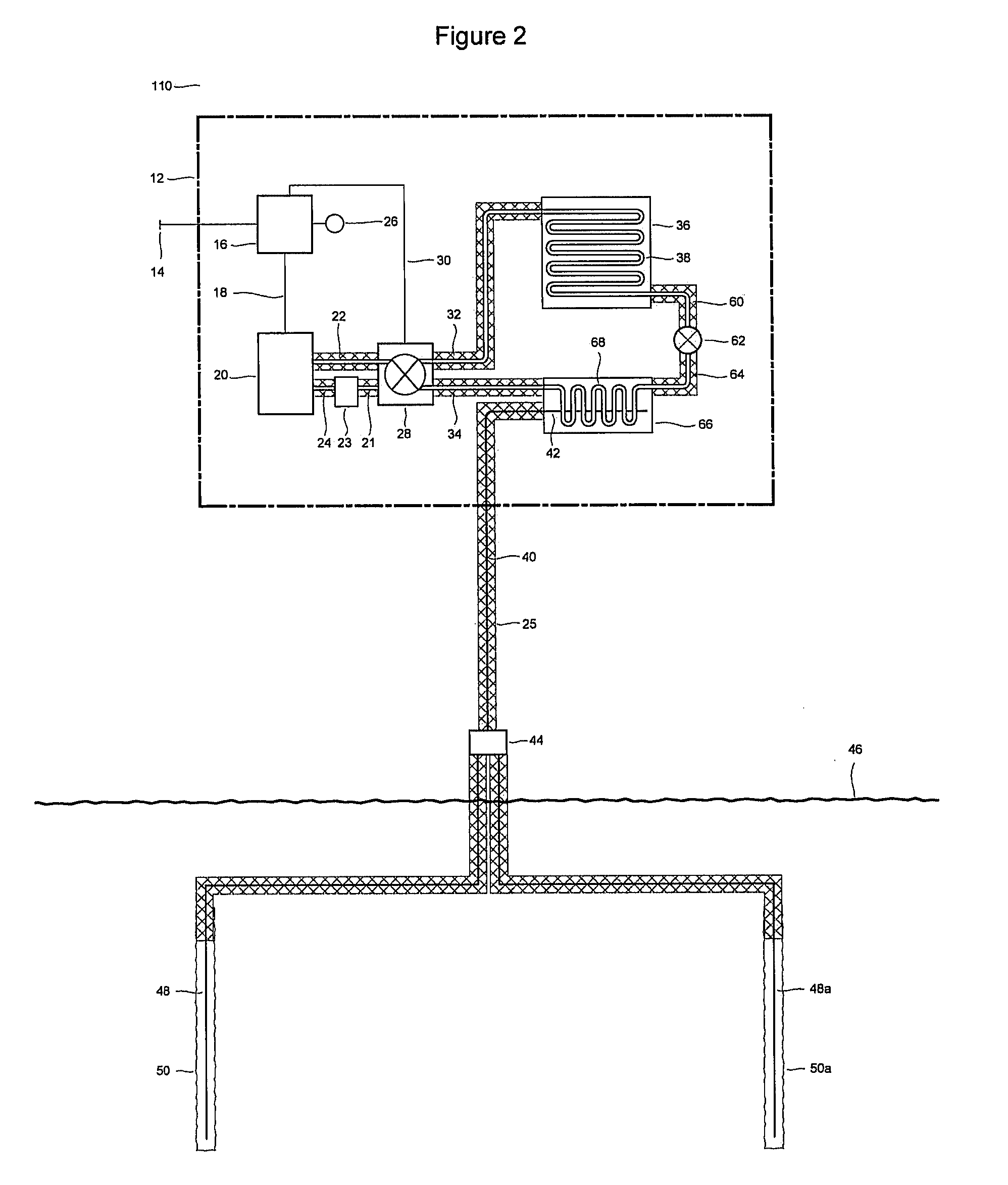

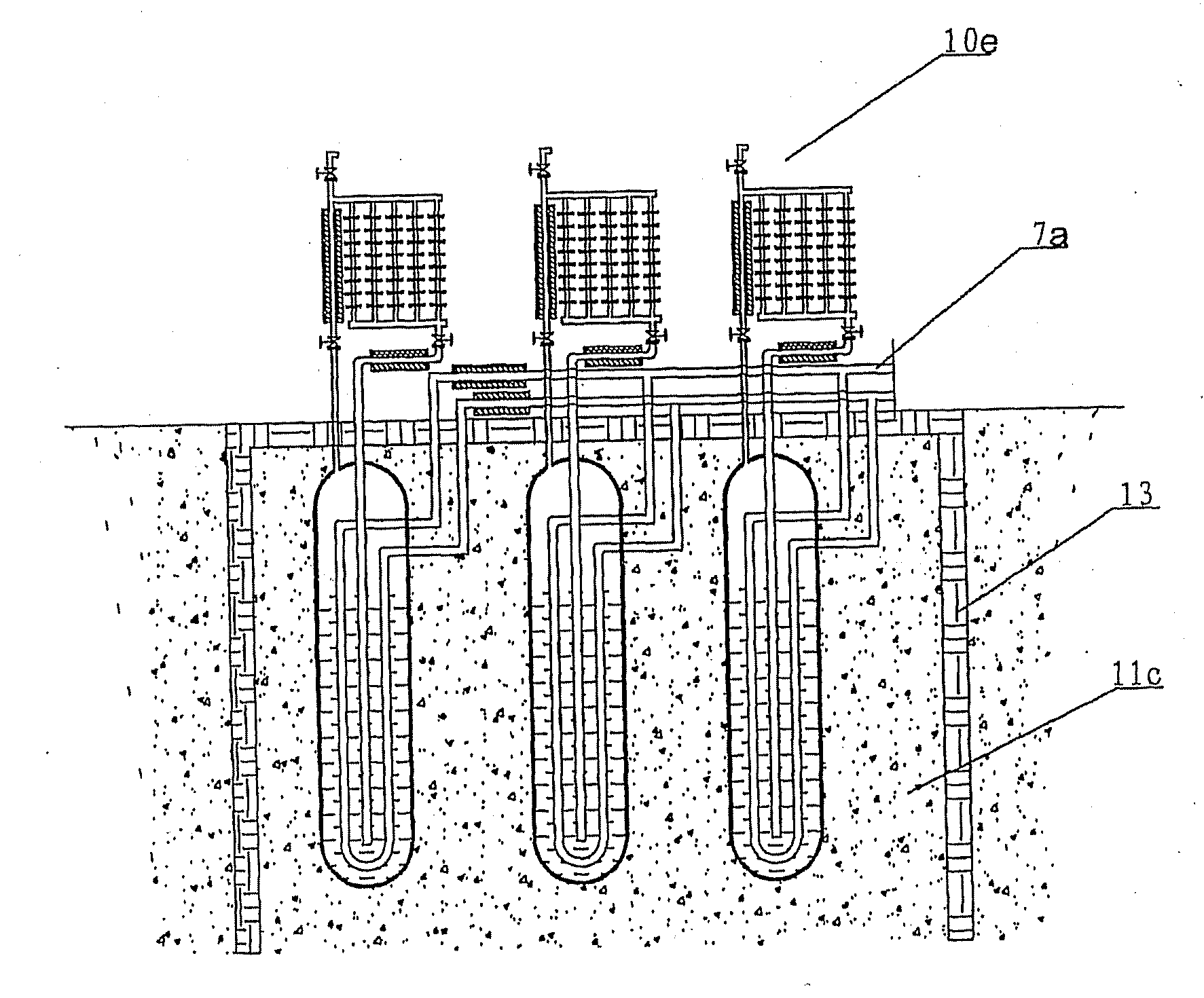

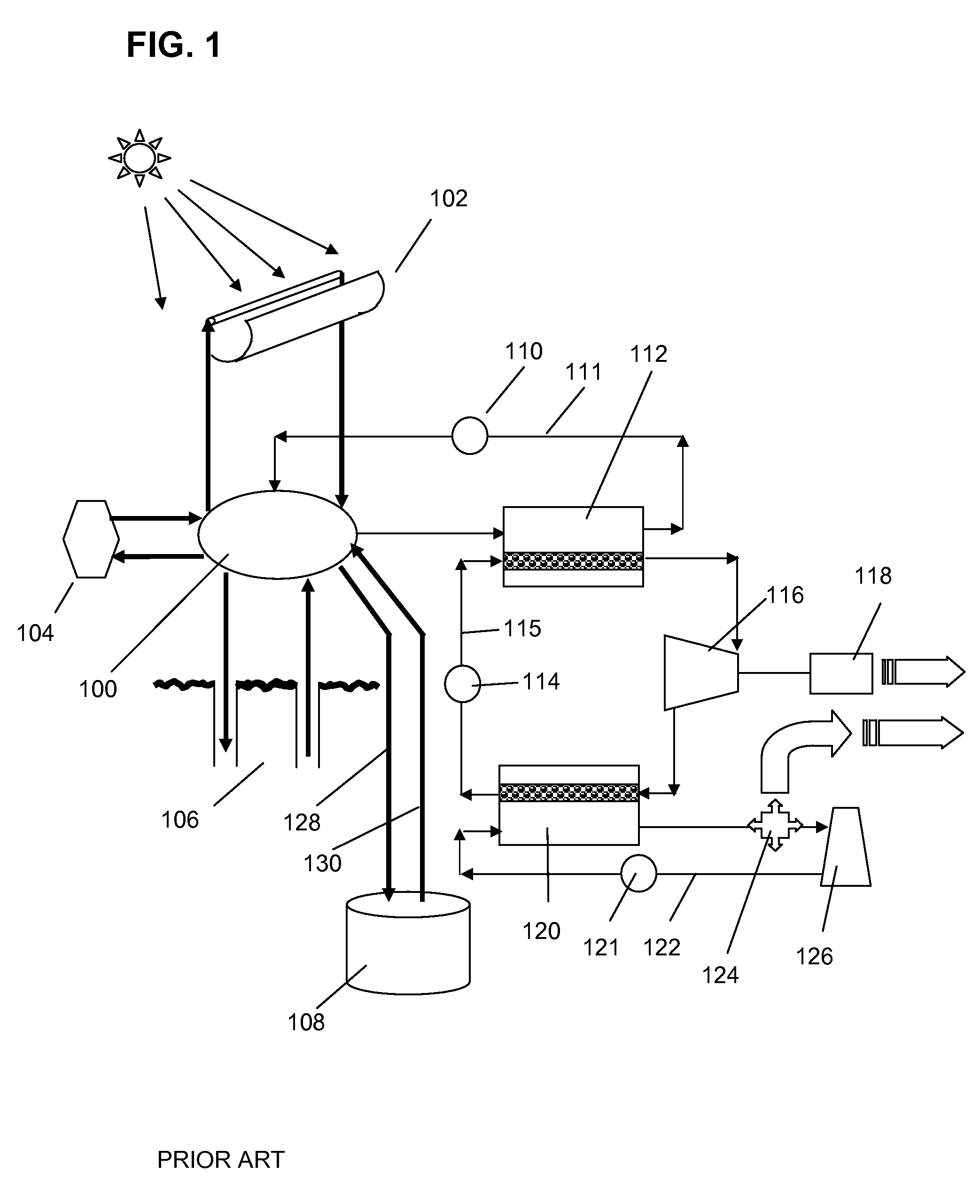

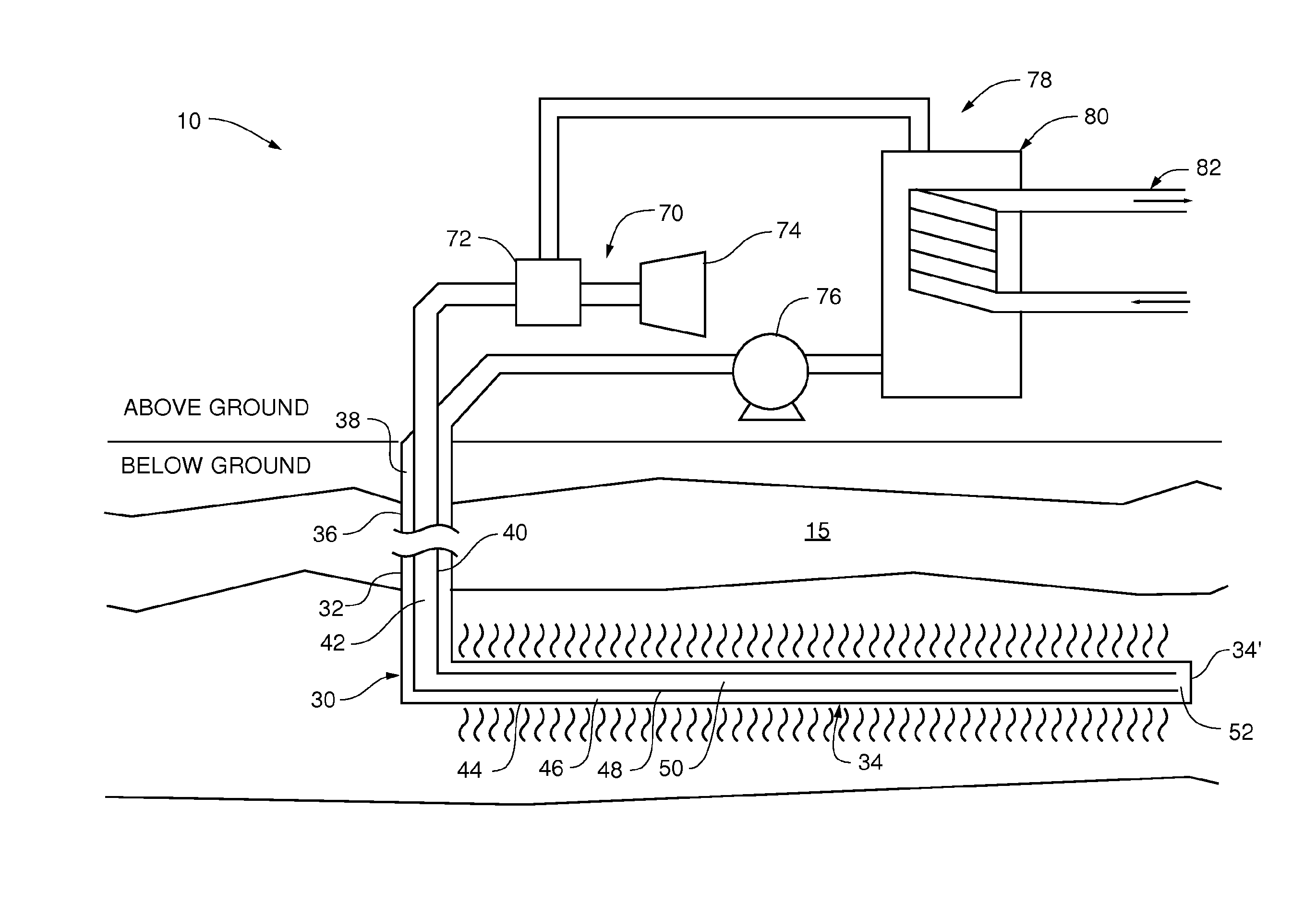

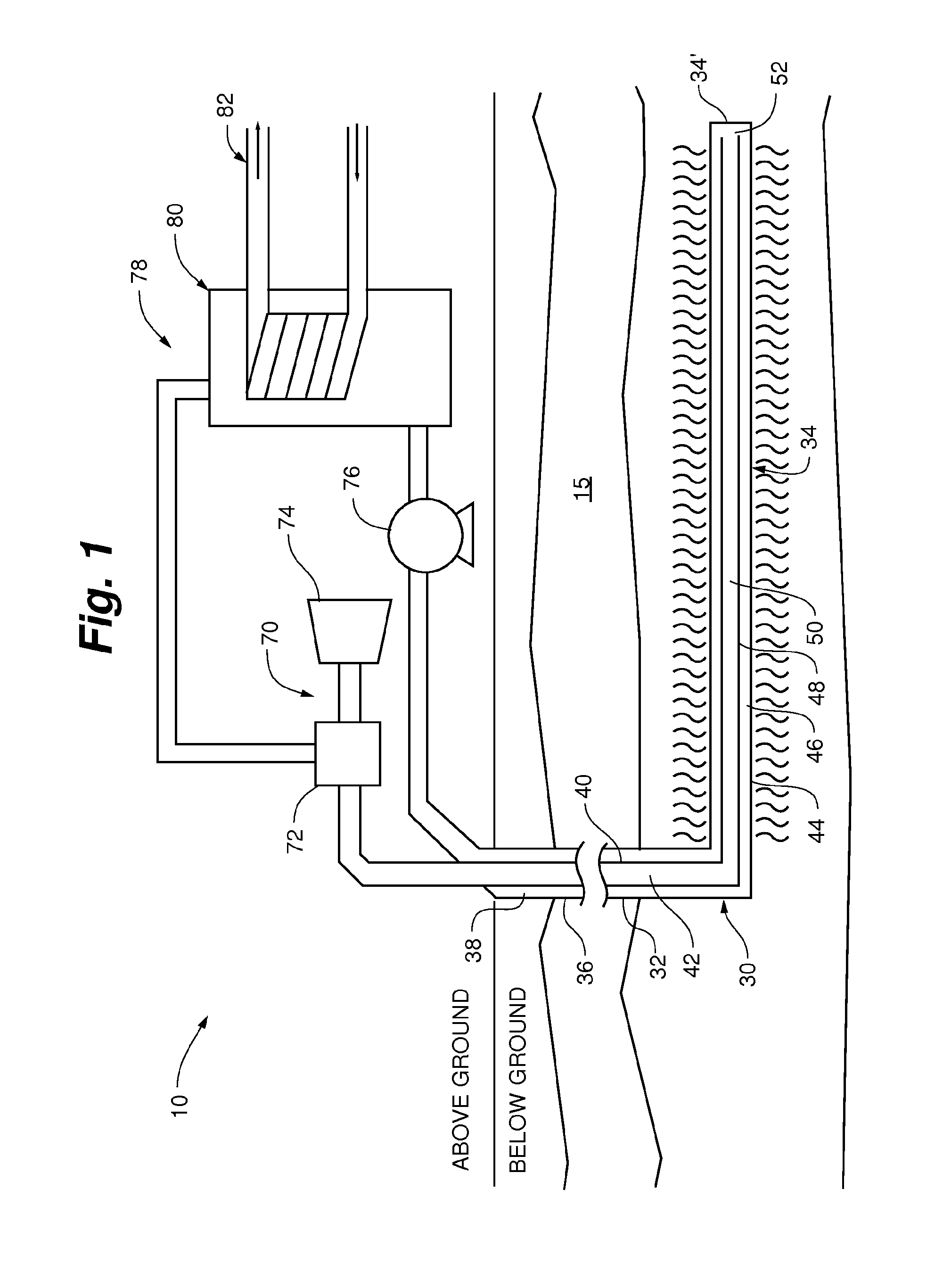

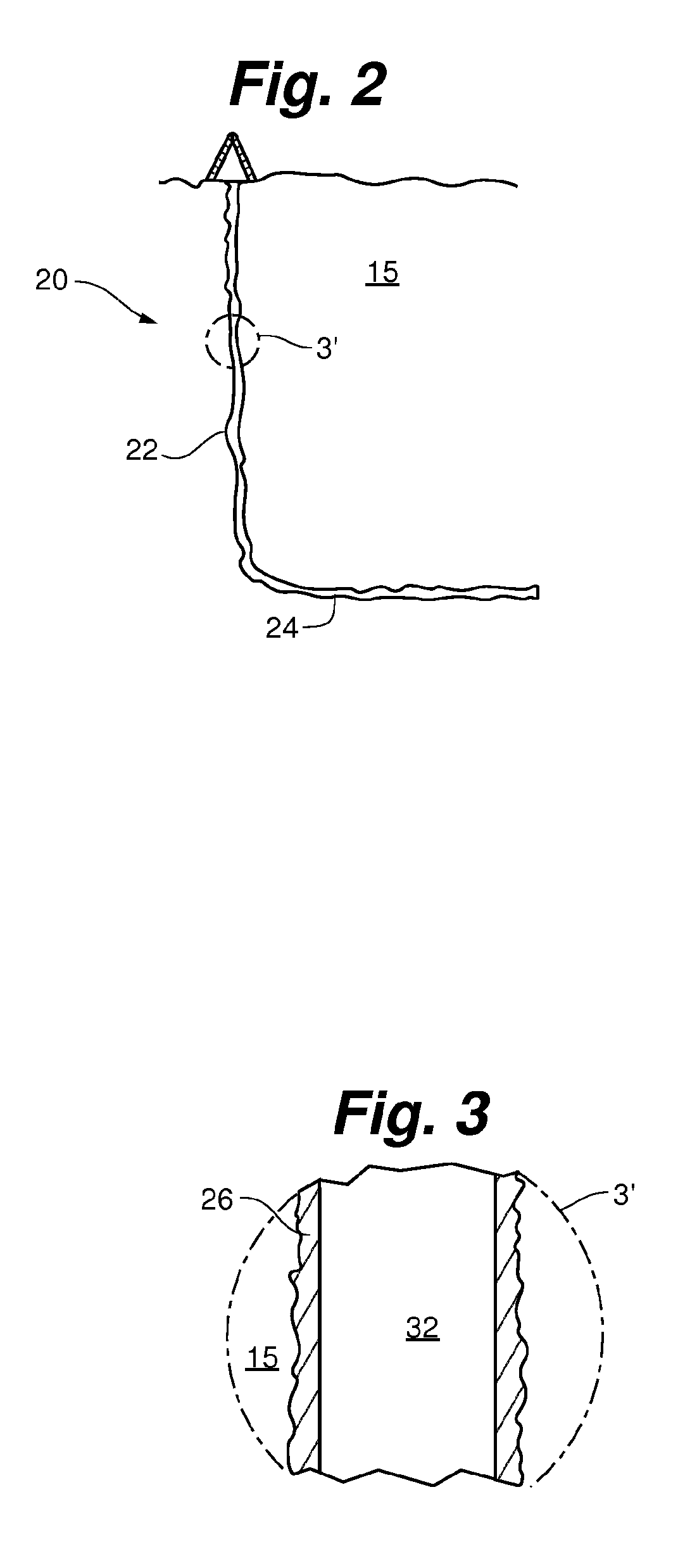

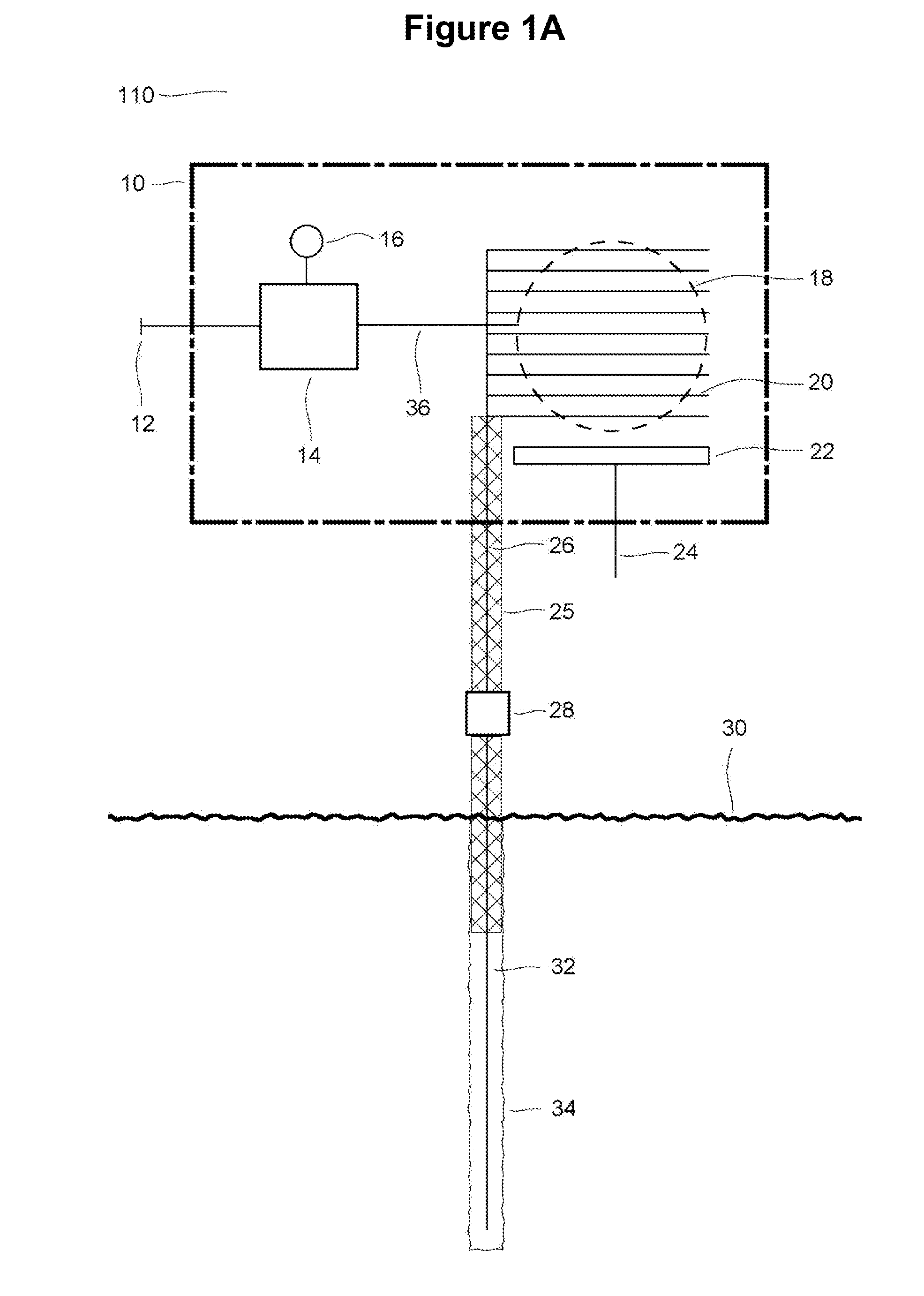

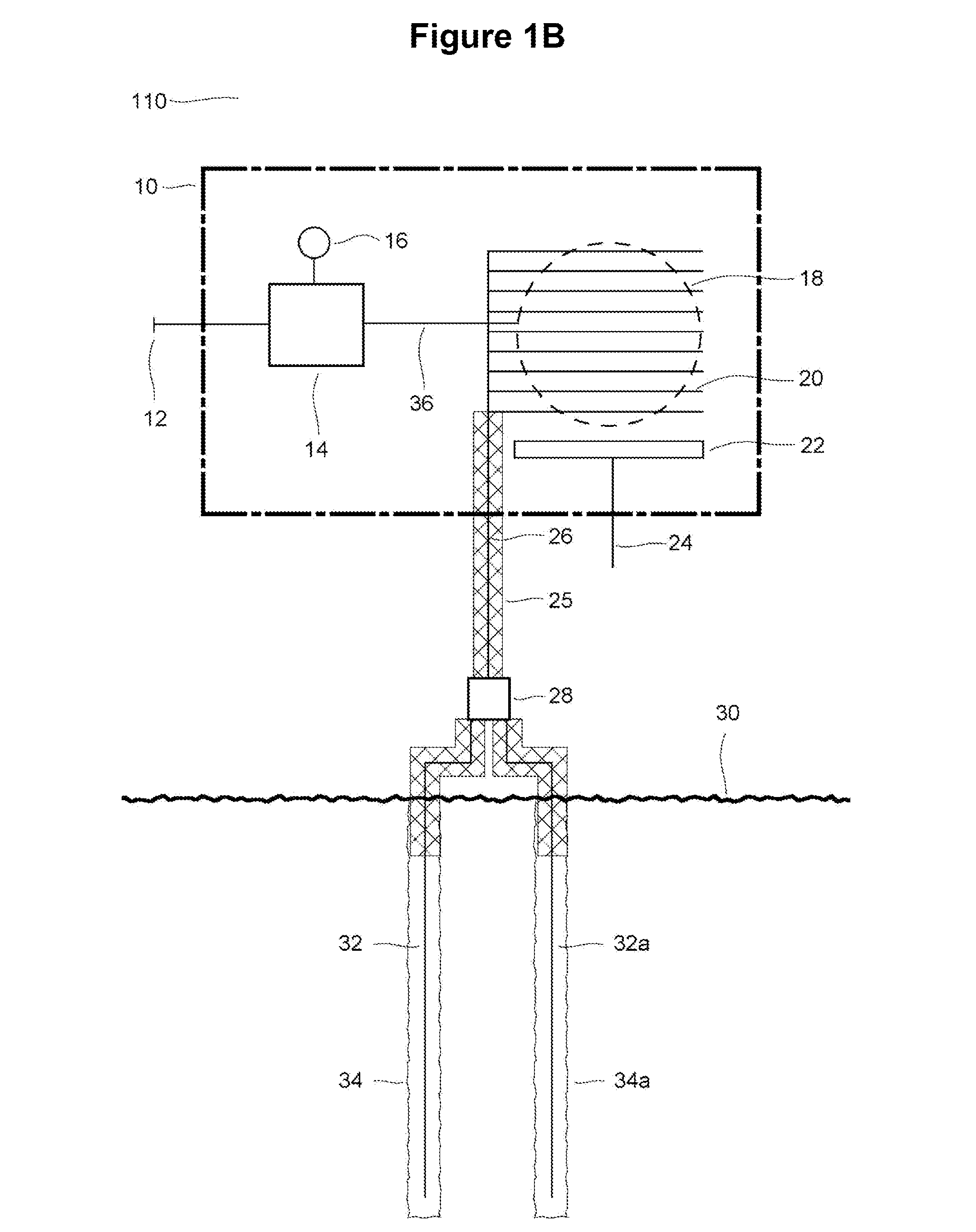

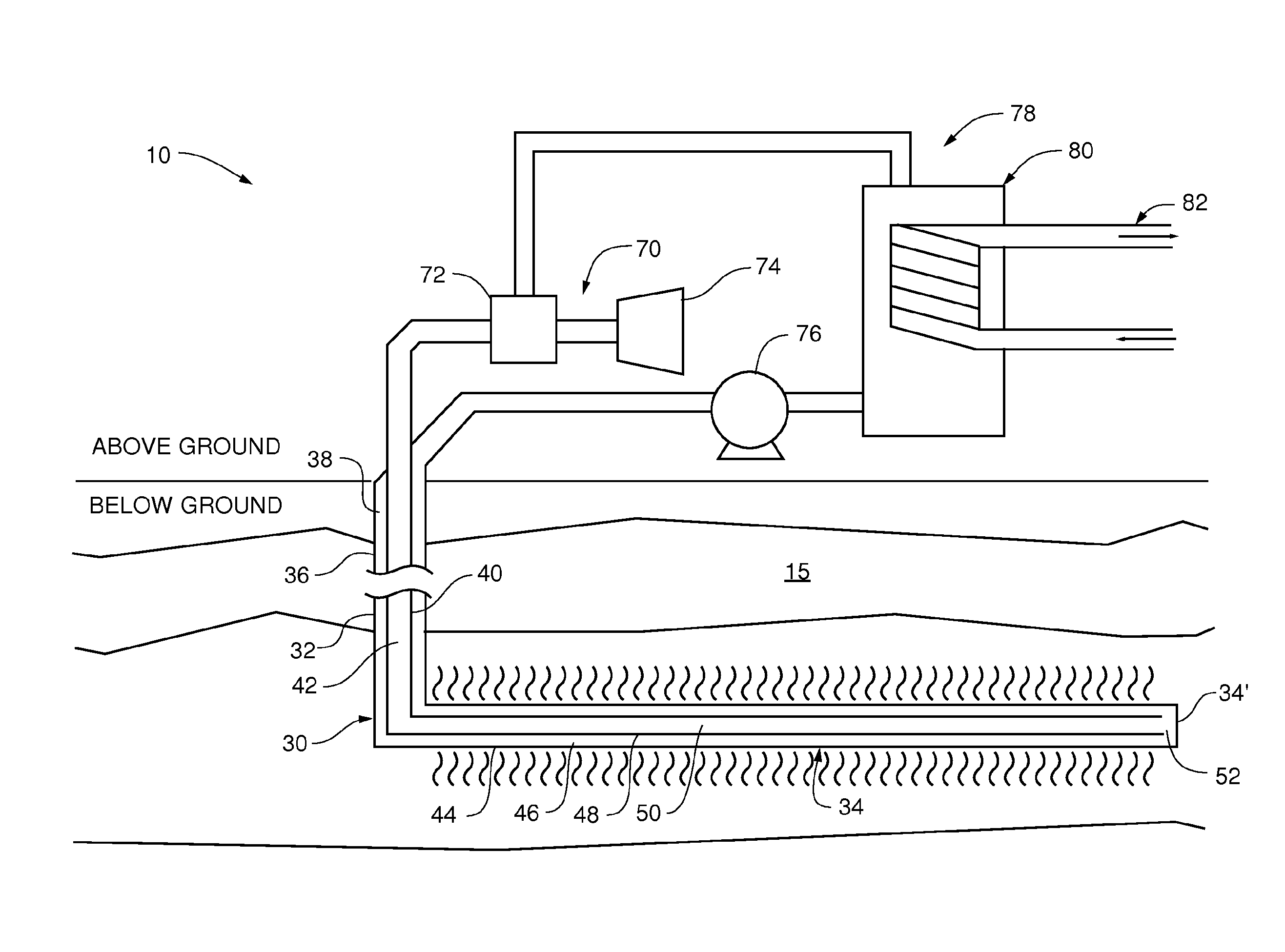

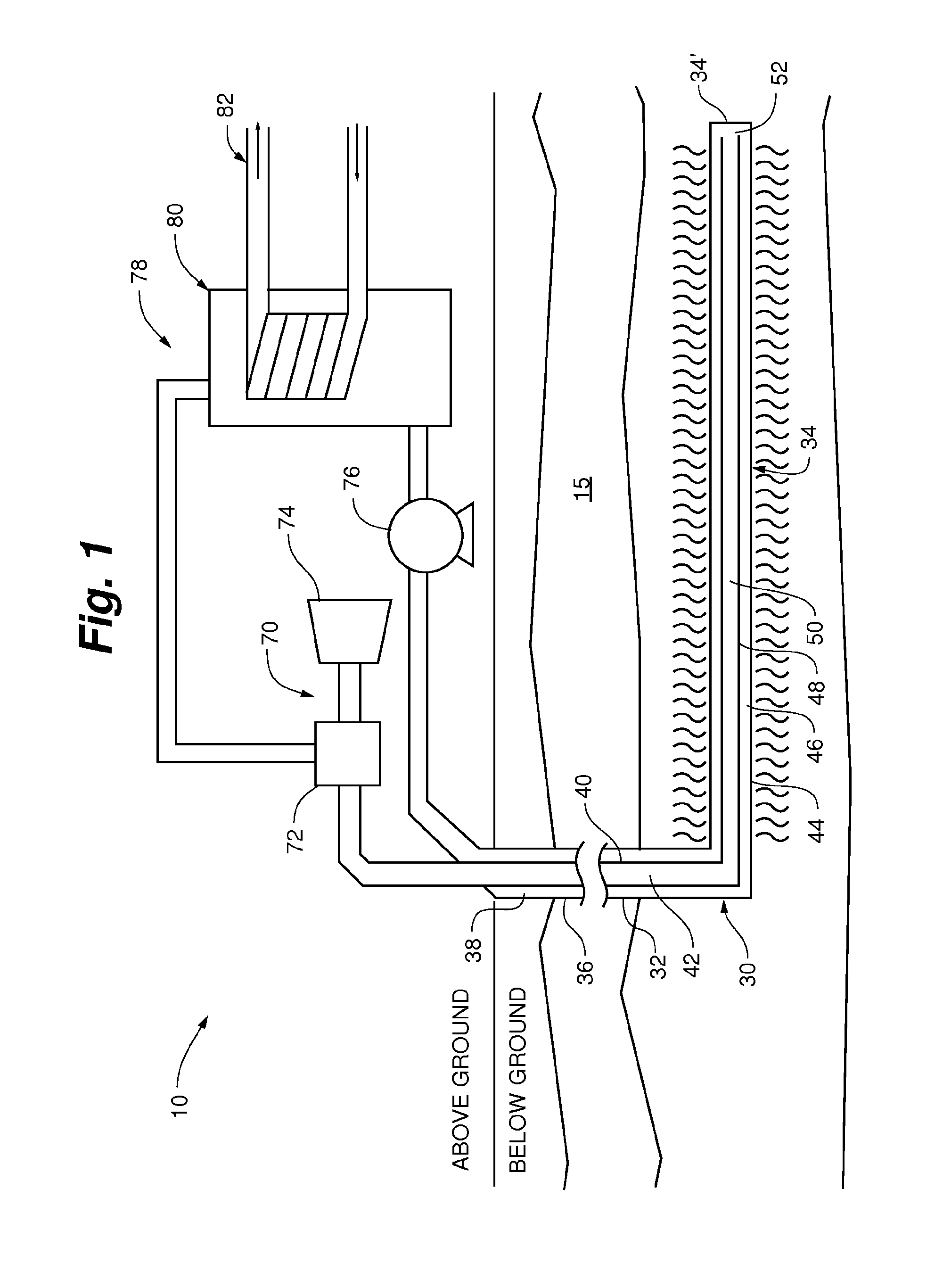

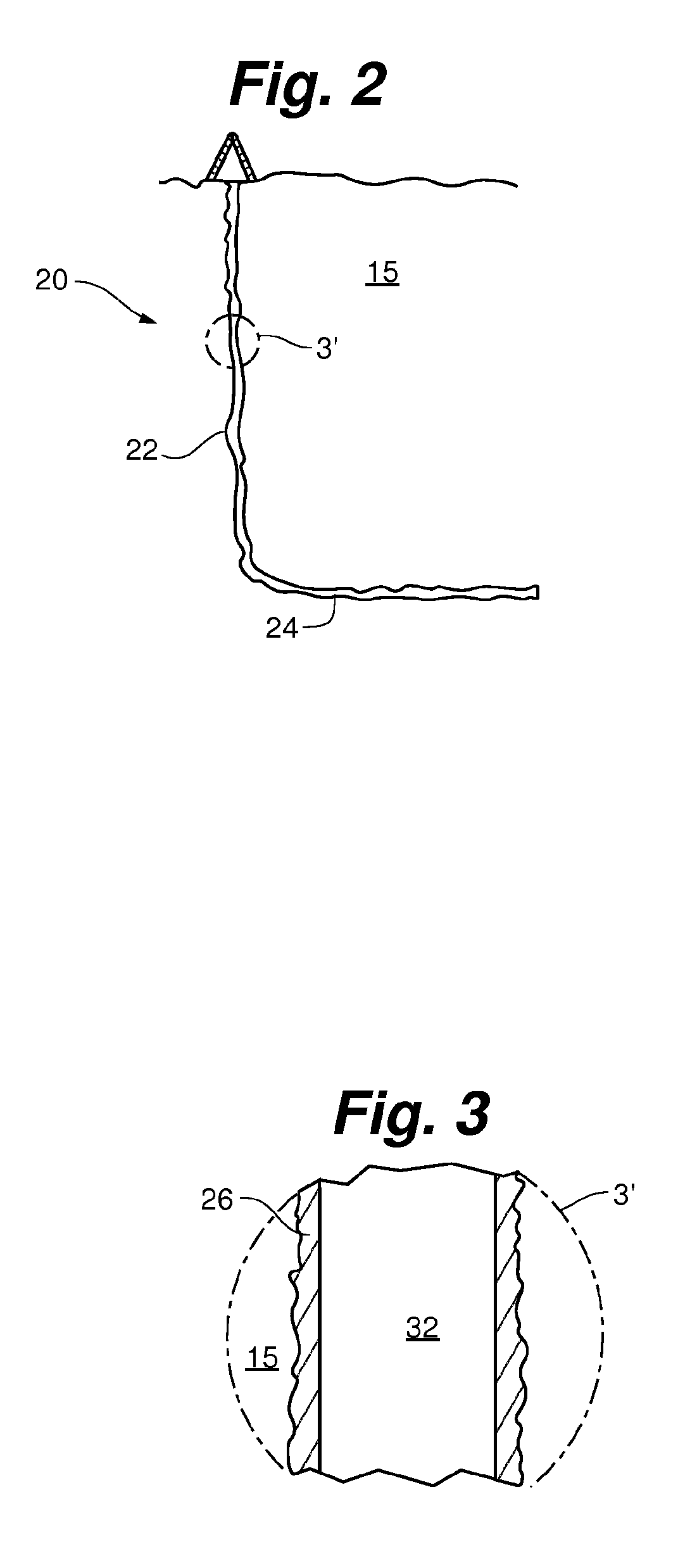

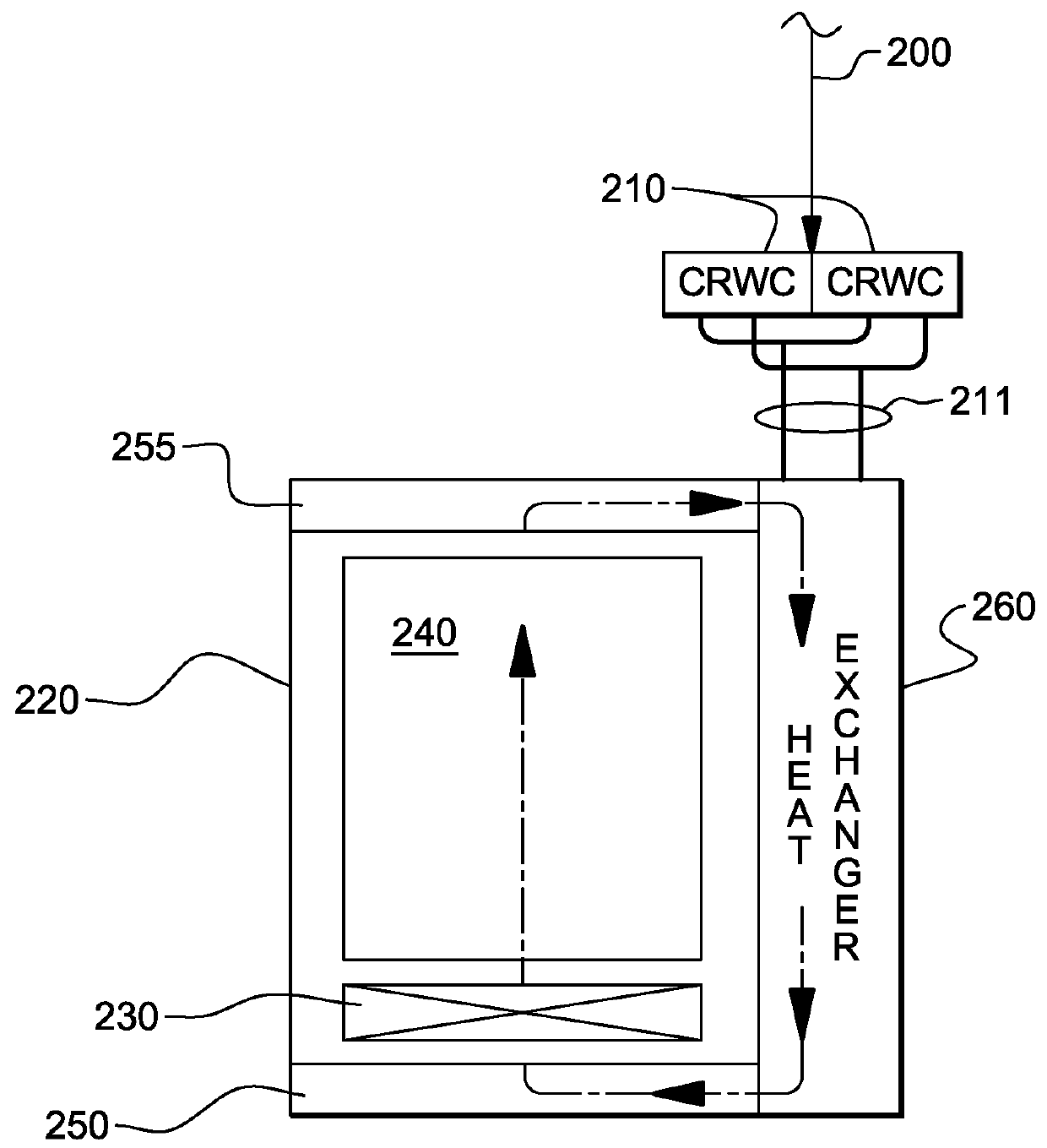

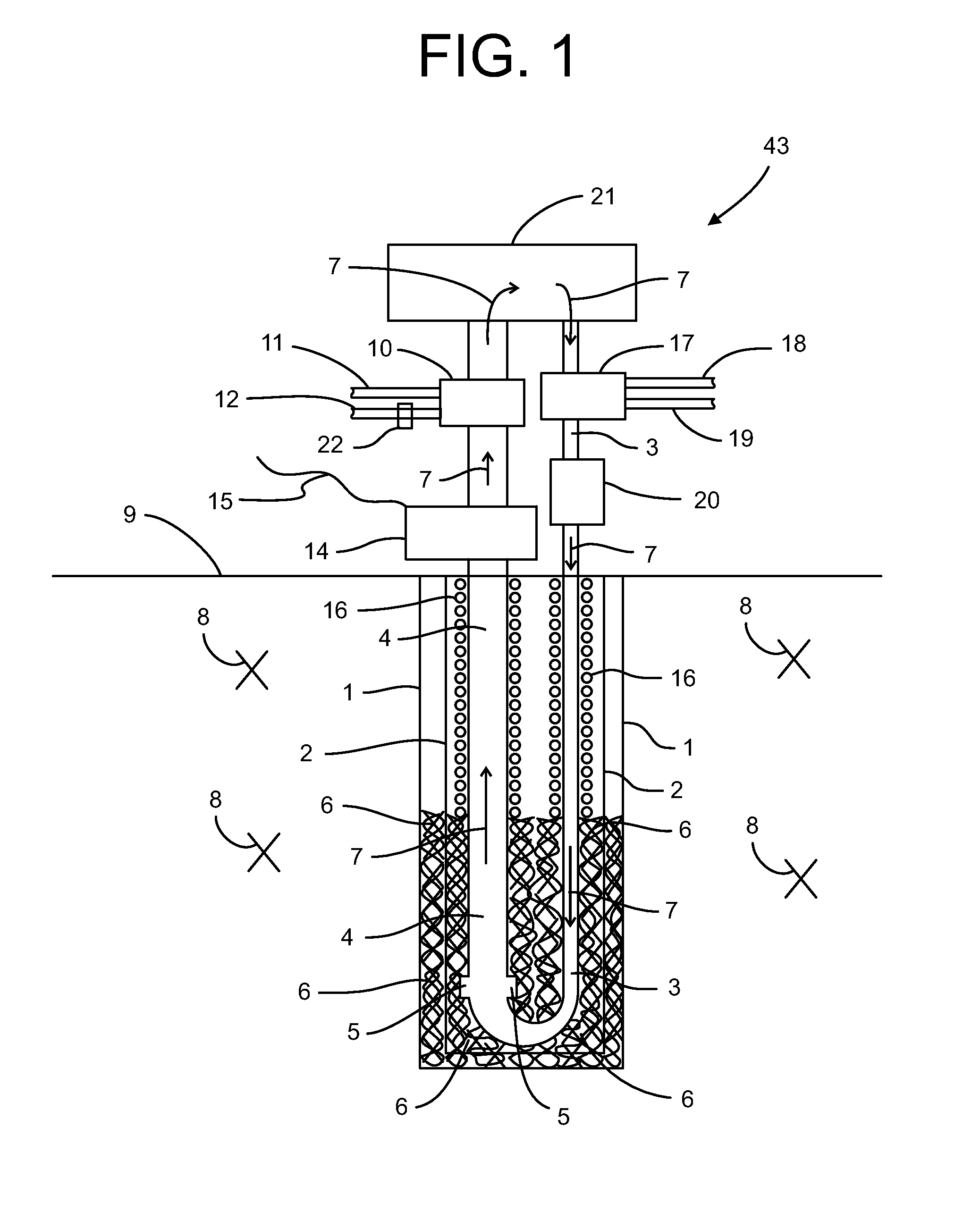

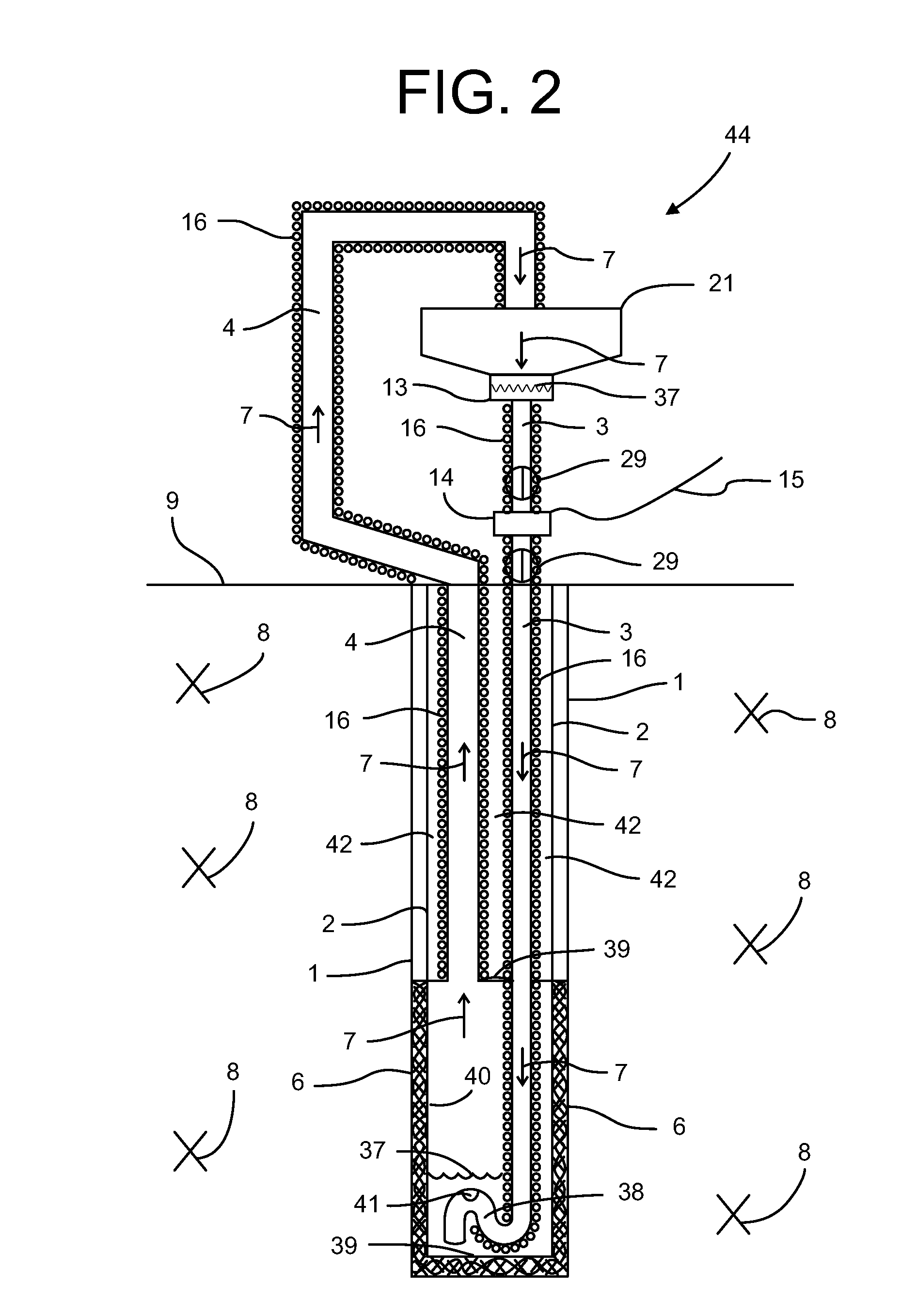

Ground-Coupled Heat Exchange for Heating and Air Conditioning Applications

InactiveUS20100305918A1Minimal energy requirementCost-effectiveHeat pumpsOther heat production devicesThermal energyEngineering

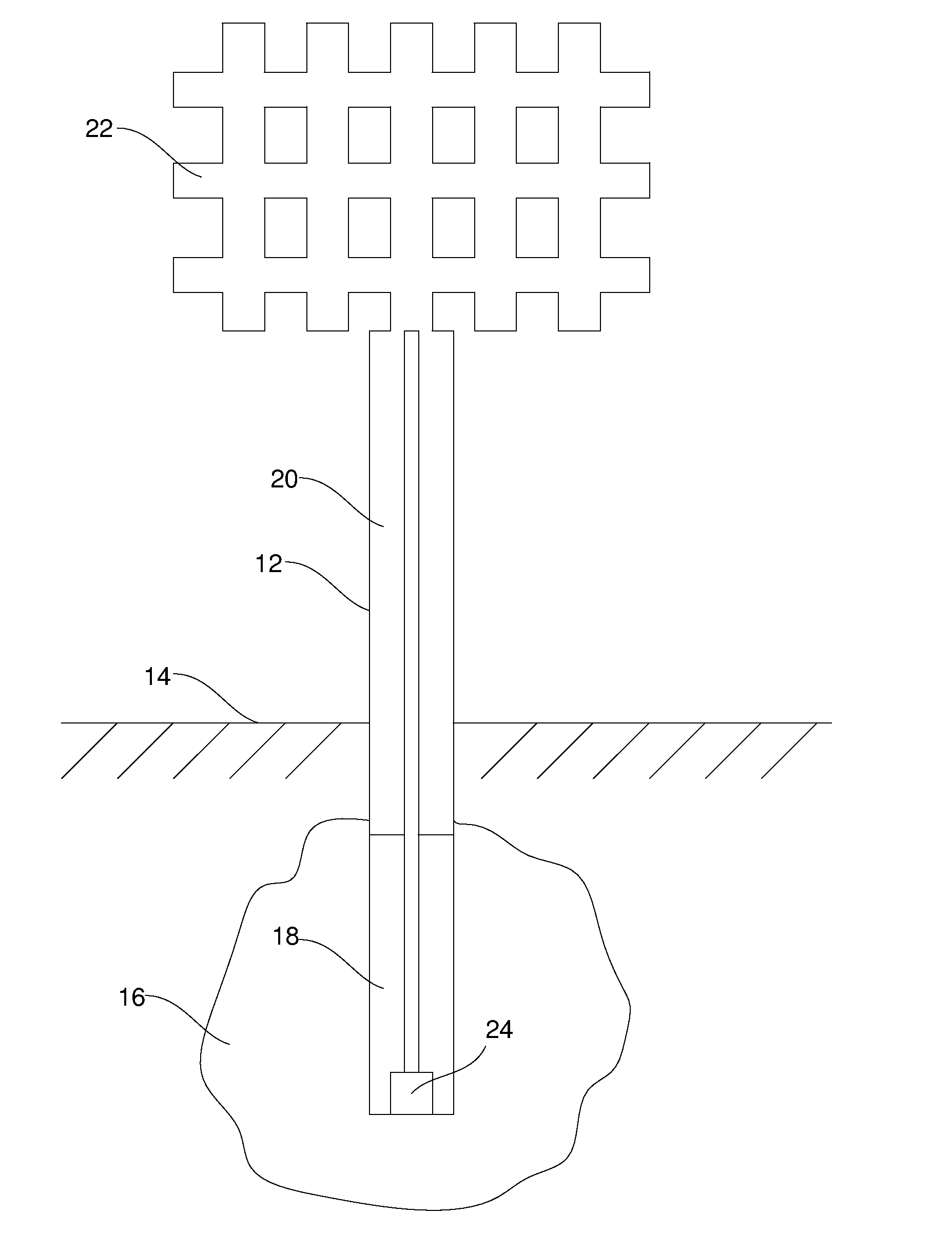

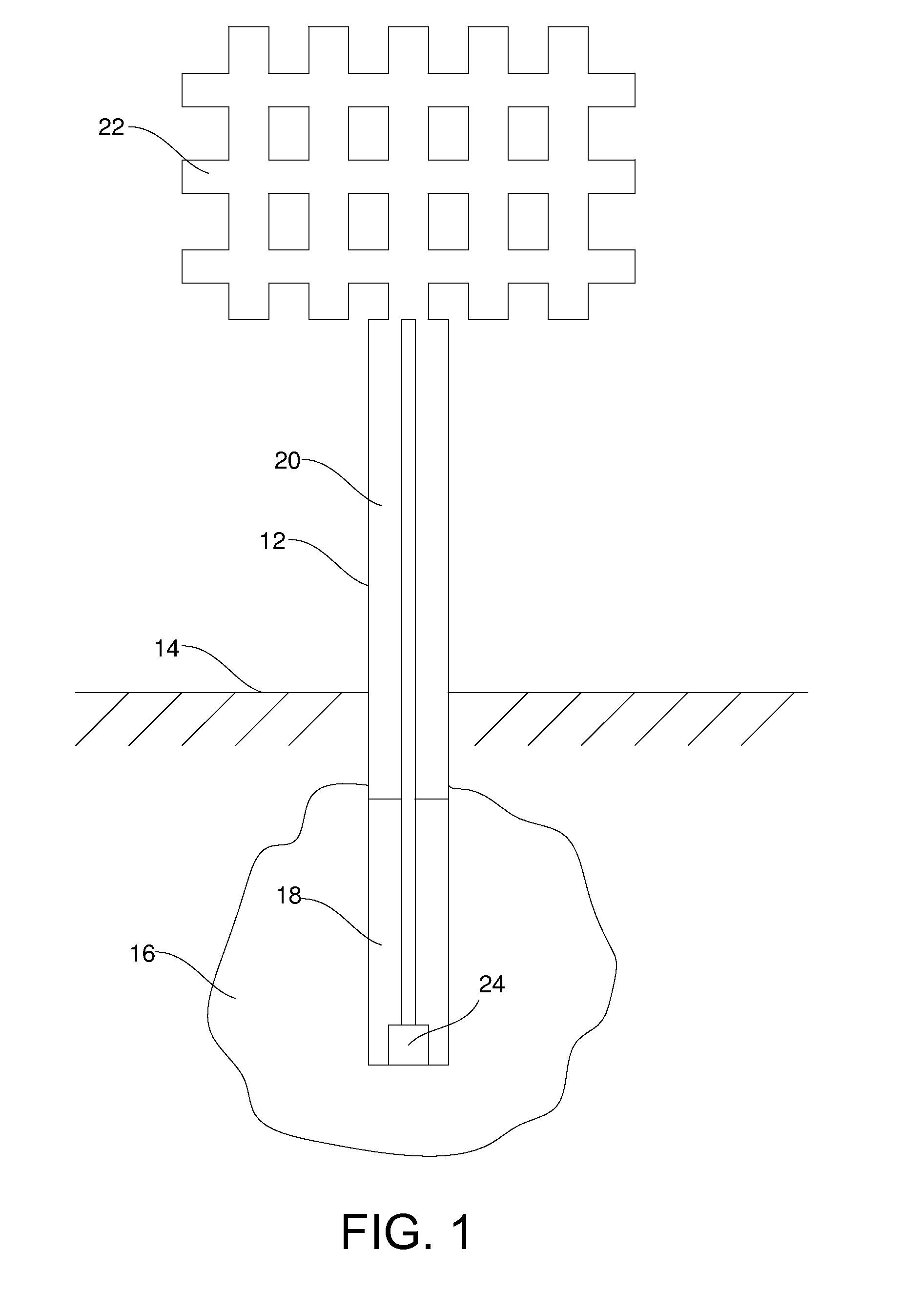

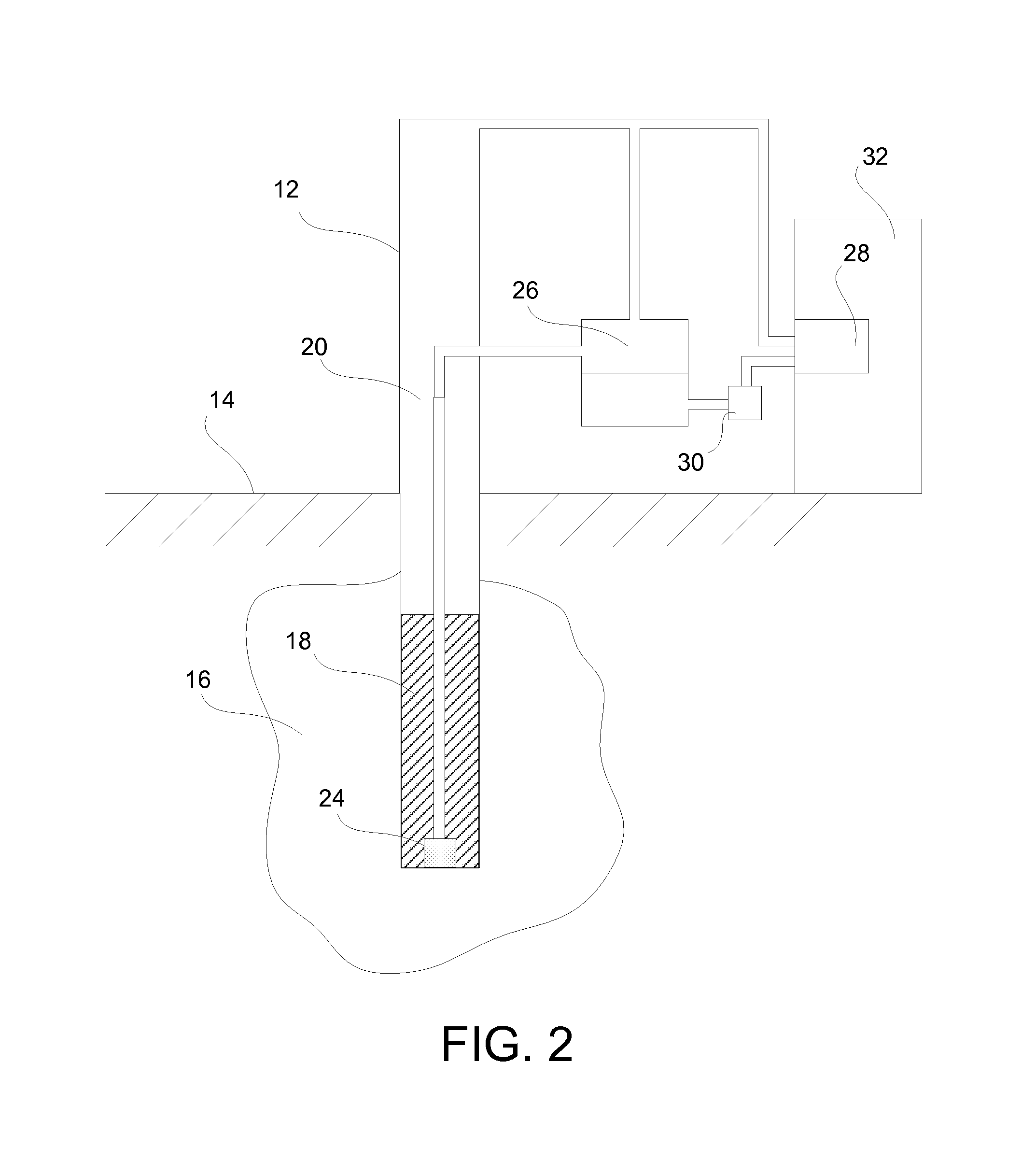

The invention provides systems and methods for cooling and / or heating a structure. Generally, a system for heating or cooling a structure can include at least one thermosiphon in thermal communication with a thermal storage material such as a volume of earth. The thermosiphon can be partially filled with a heat transfer fluid and a heat exchanger operatively connected to the thermosiphon which is in thermal communication with the structure. Thermal energy can be transferred between the thermal storage material and the structure in either a passive or assisted mode, depending on whether the system is charging or in use.

Owner:UNIV OF UTAH RES FOUND

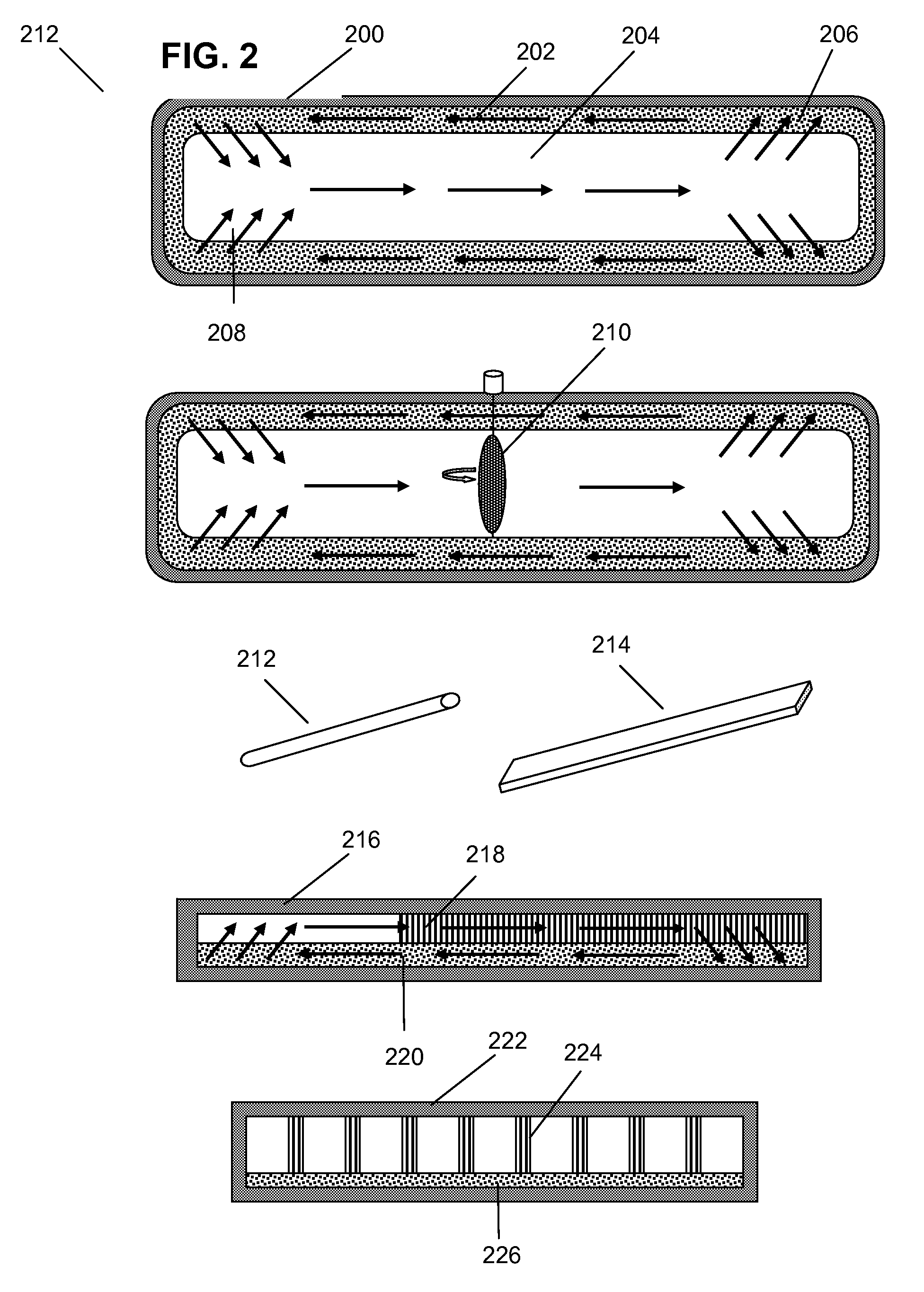

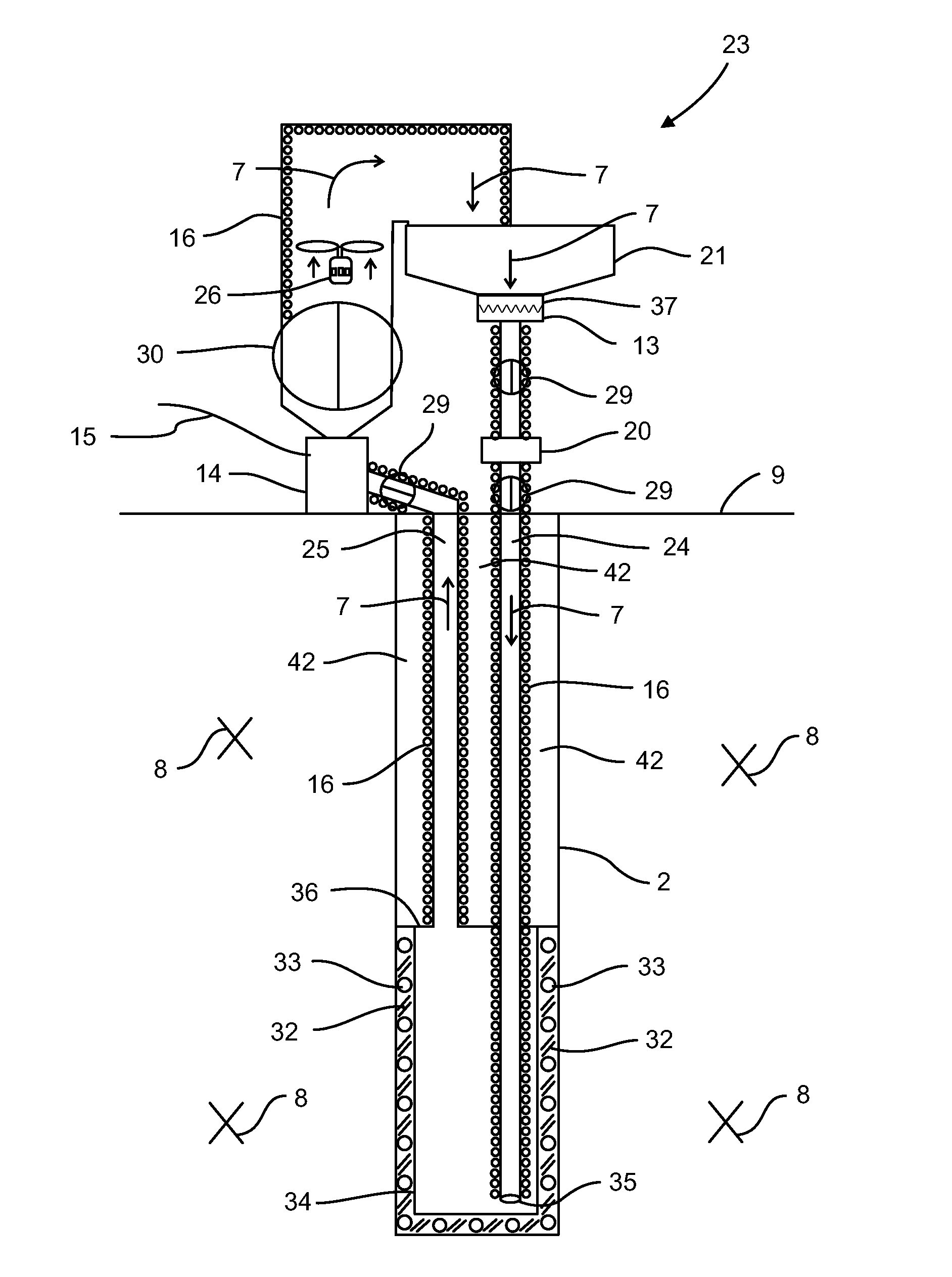

Passive heat engine systems and components

Methods for harnessing a heat source to produce energy are provided. One method comprises transferring heat from the heat source to a working fluid using at least one heat pipe; and performing work via the heated working fluid. Another method comprises operating a thermodynamic cycle to convert heat into work, comprising displacing a working fluid within a closed loop, said closed loop being defined by a first pathway within a working chamber, and a return pathway external to the return chamber; wherein displacement of the working fluid along the first pathway causes sympathetic displaced of a movable member held captive in the working chamber, and displacement of the working fluid along the external pathway is under influence of capillary forces; and transferring heat to the working fluid using at least one first heat pipe. Components and systems for implementing the methods are also provided.

Owner:MILES MARK W

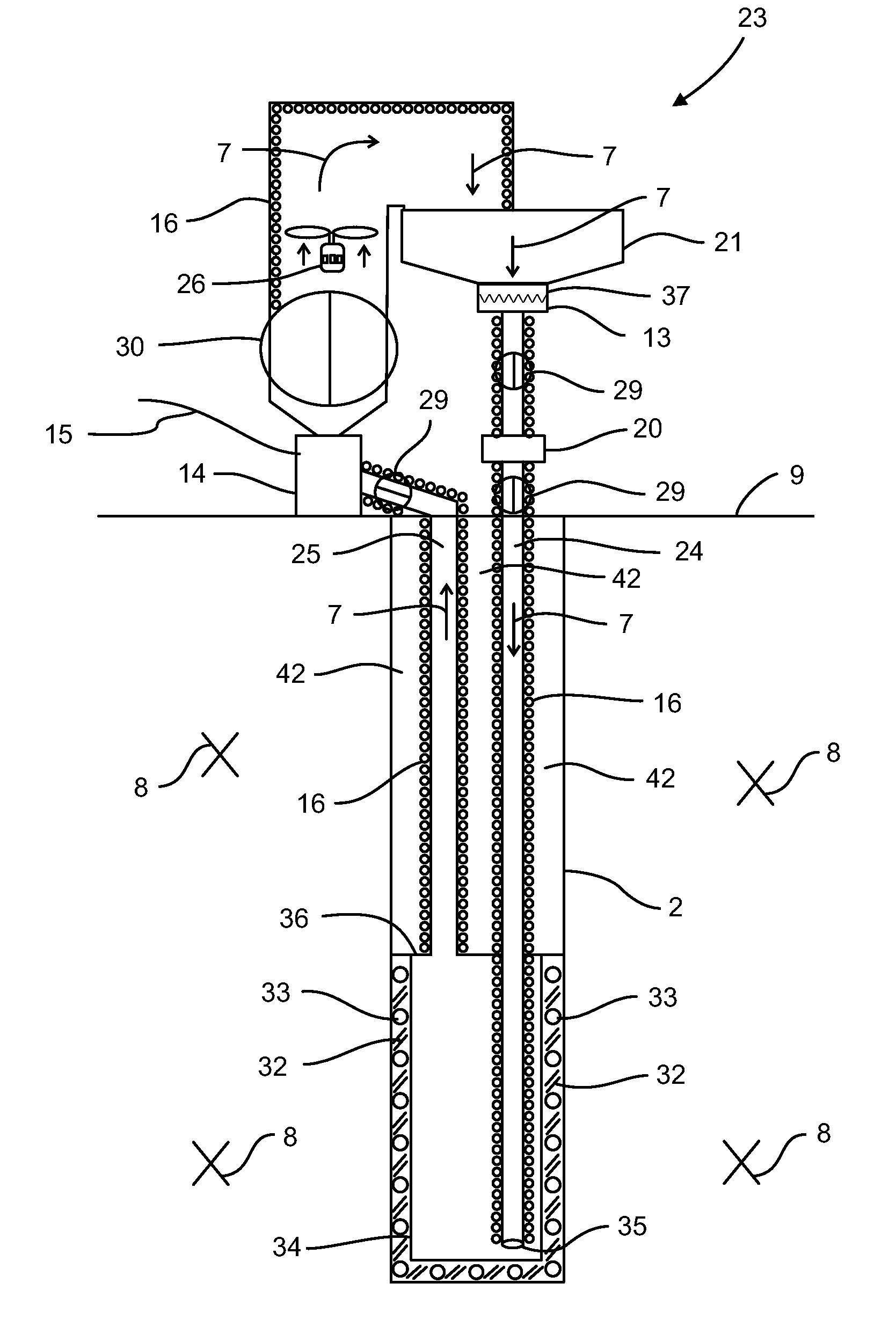

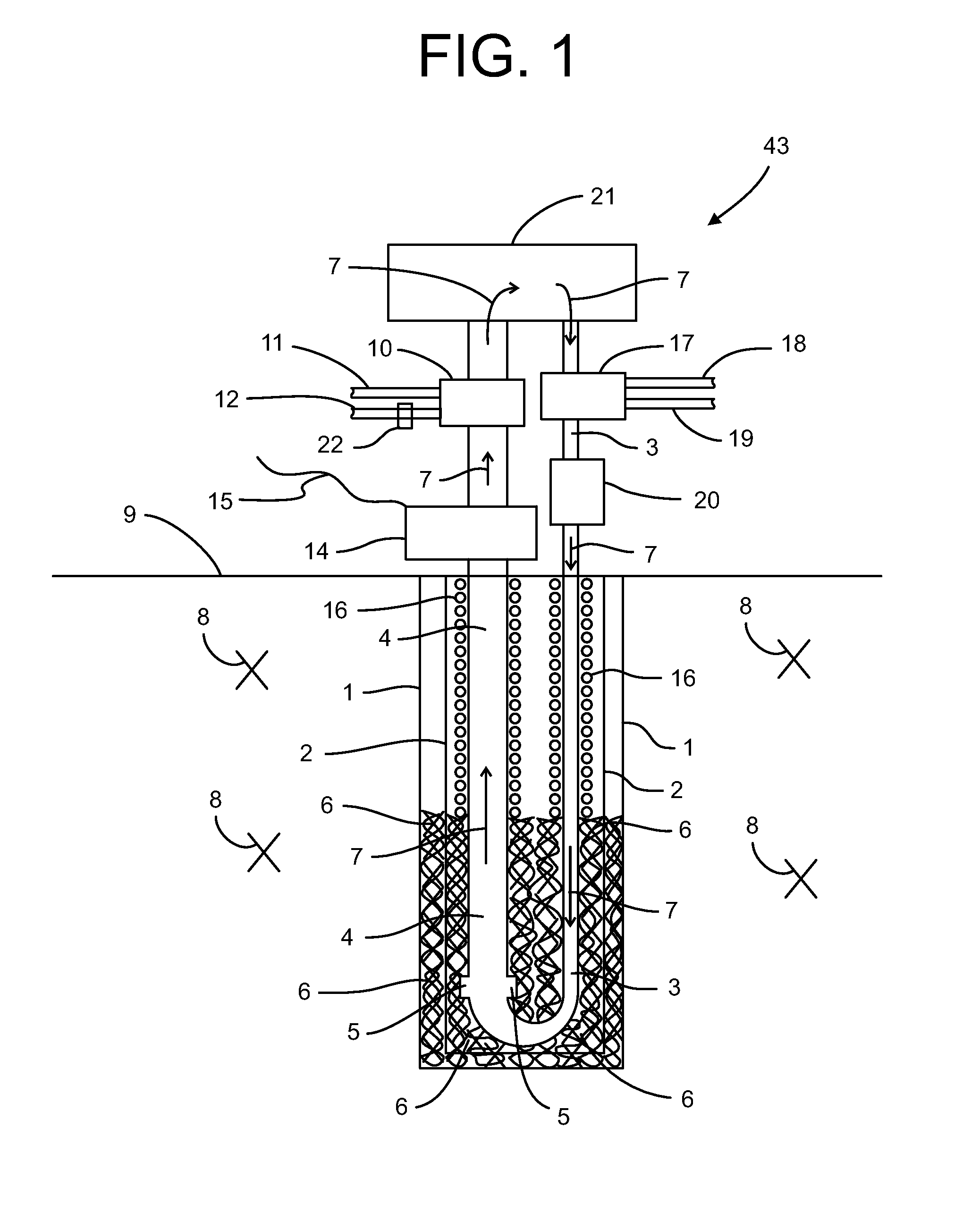

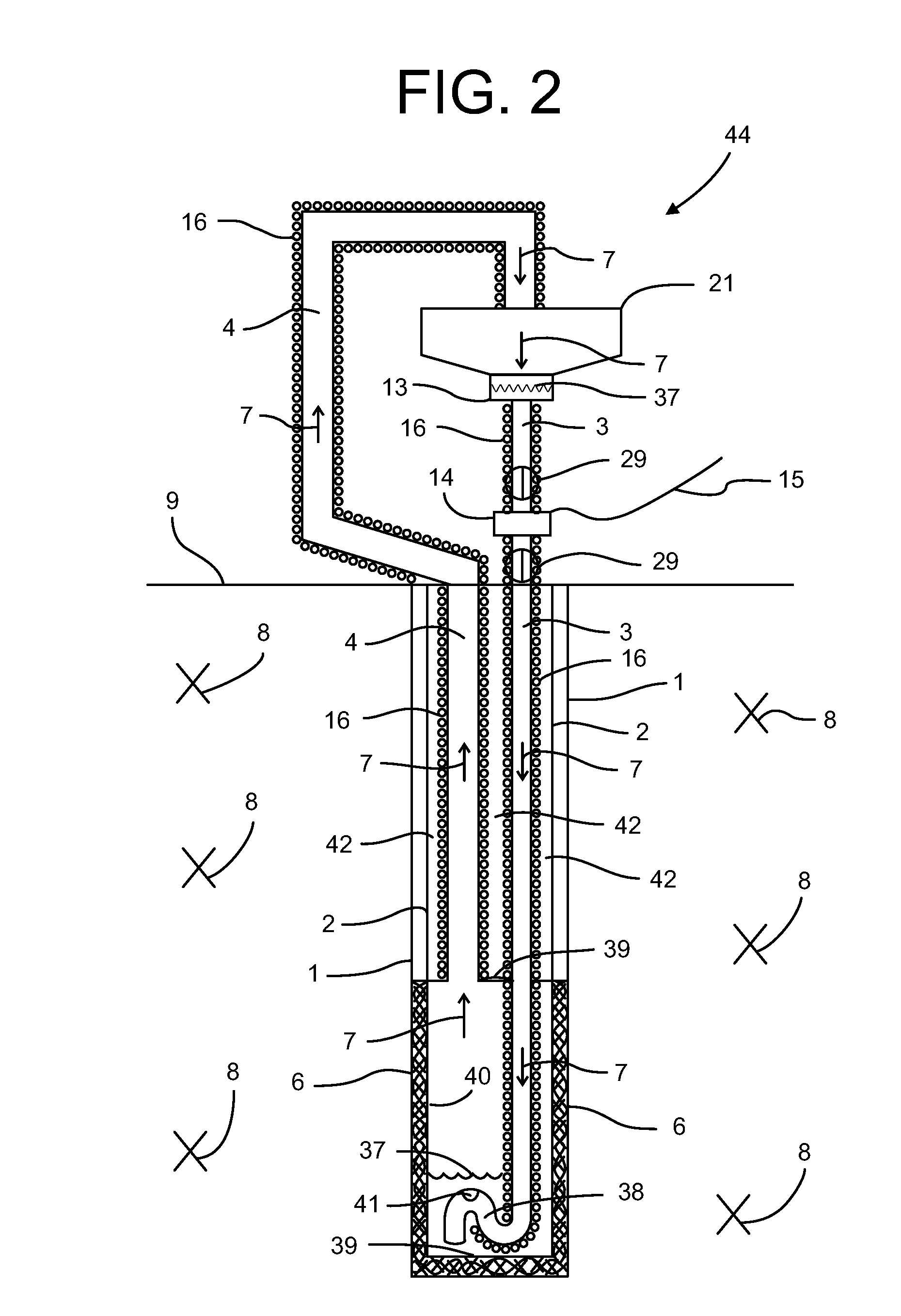

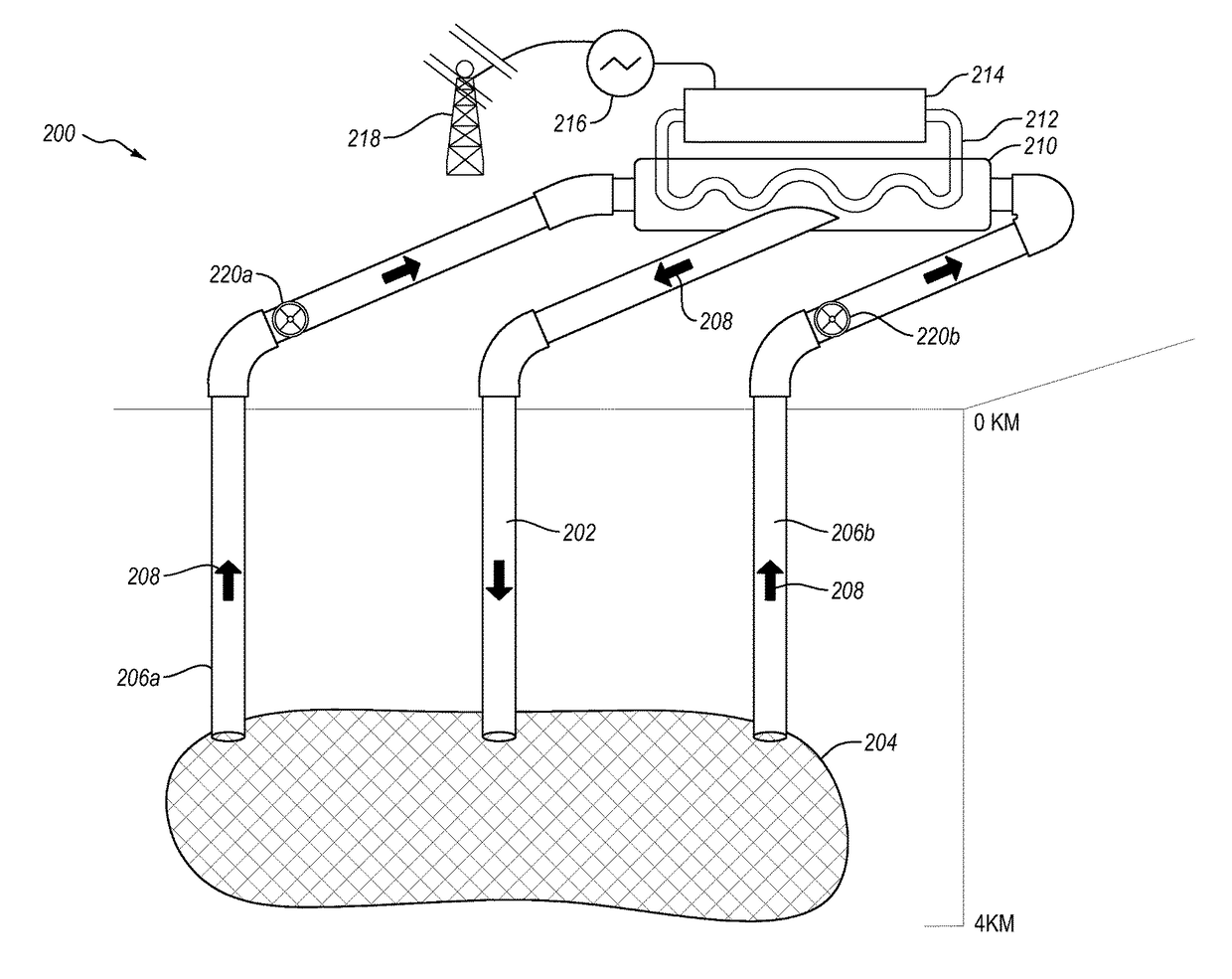

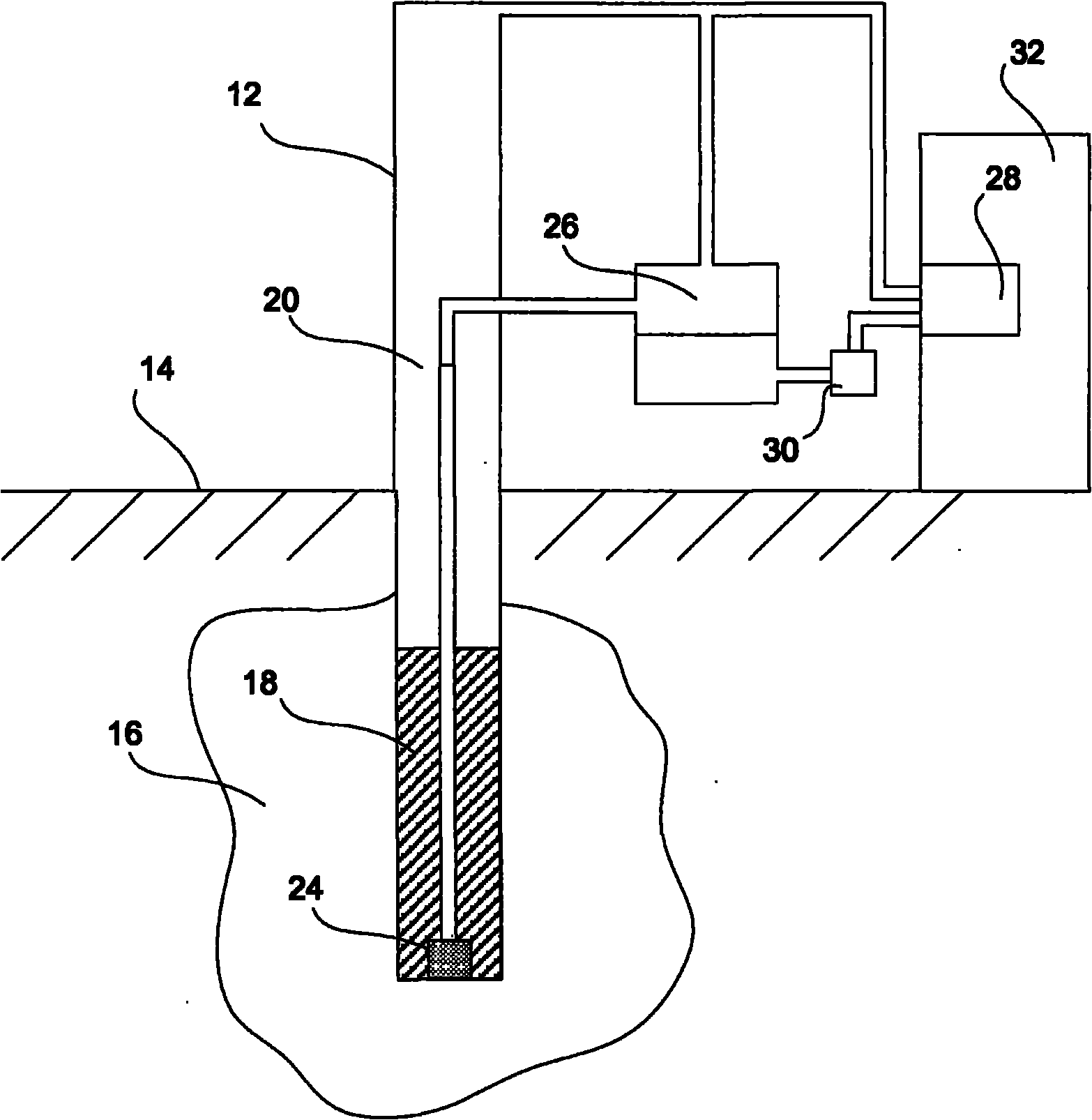

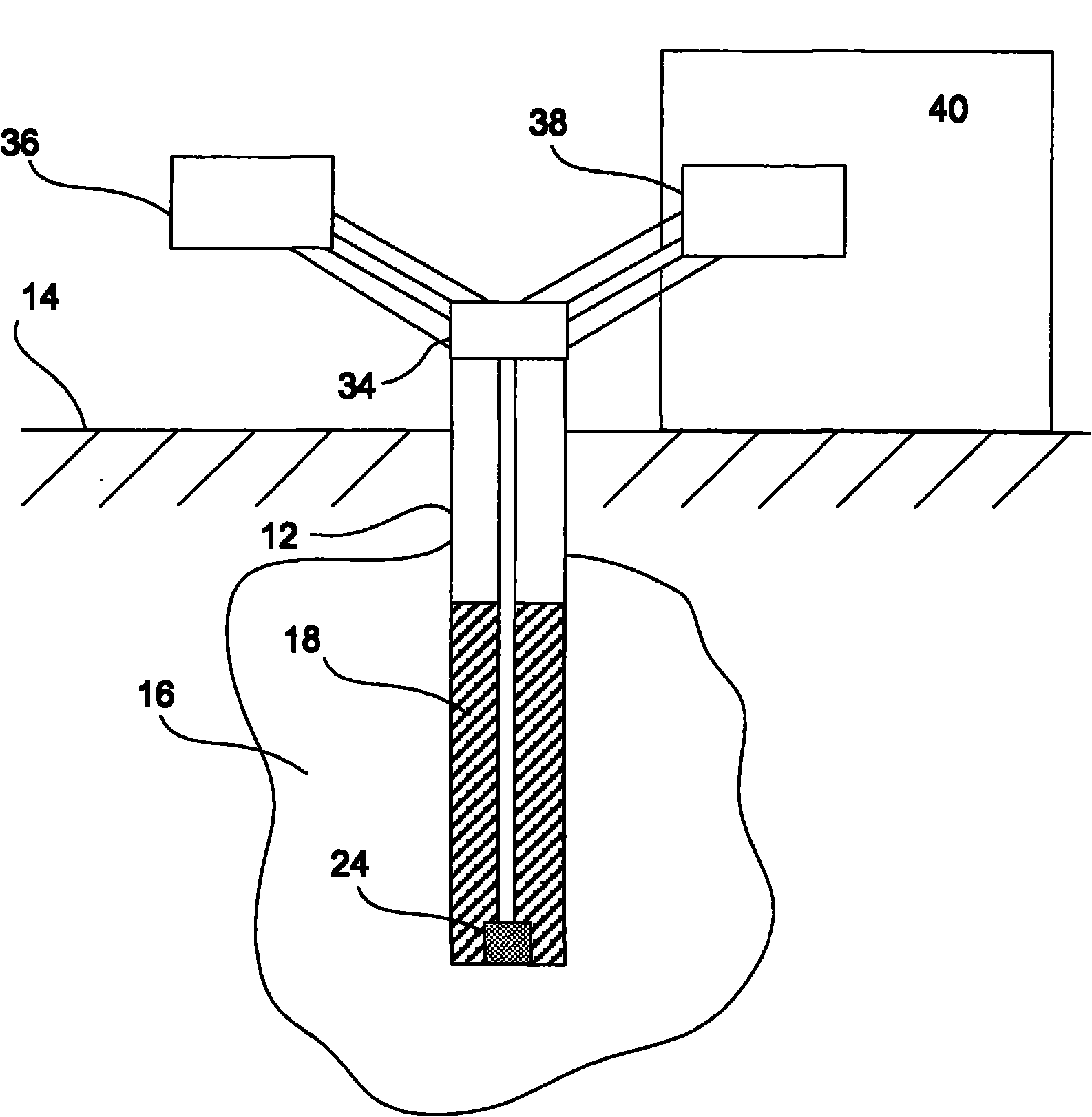

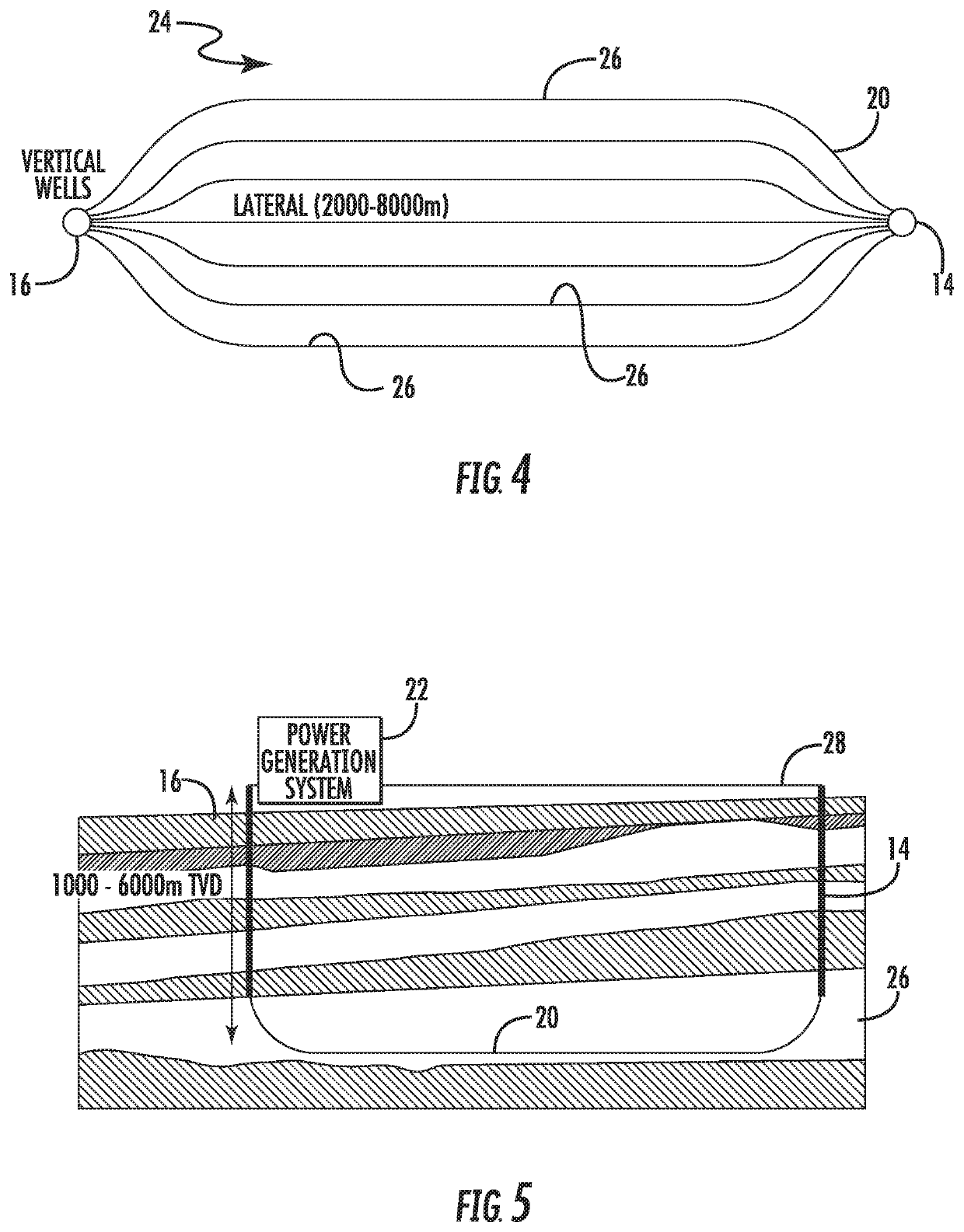

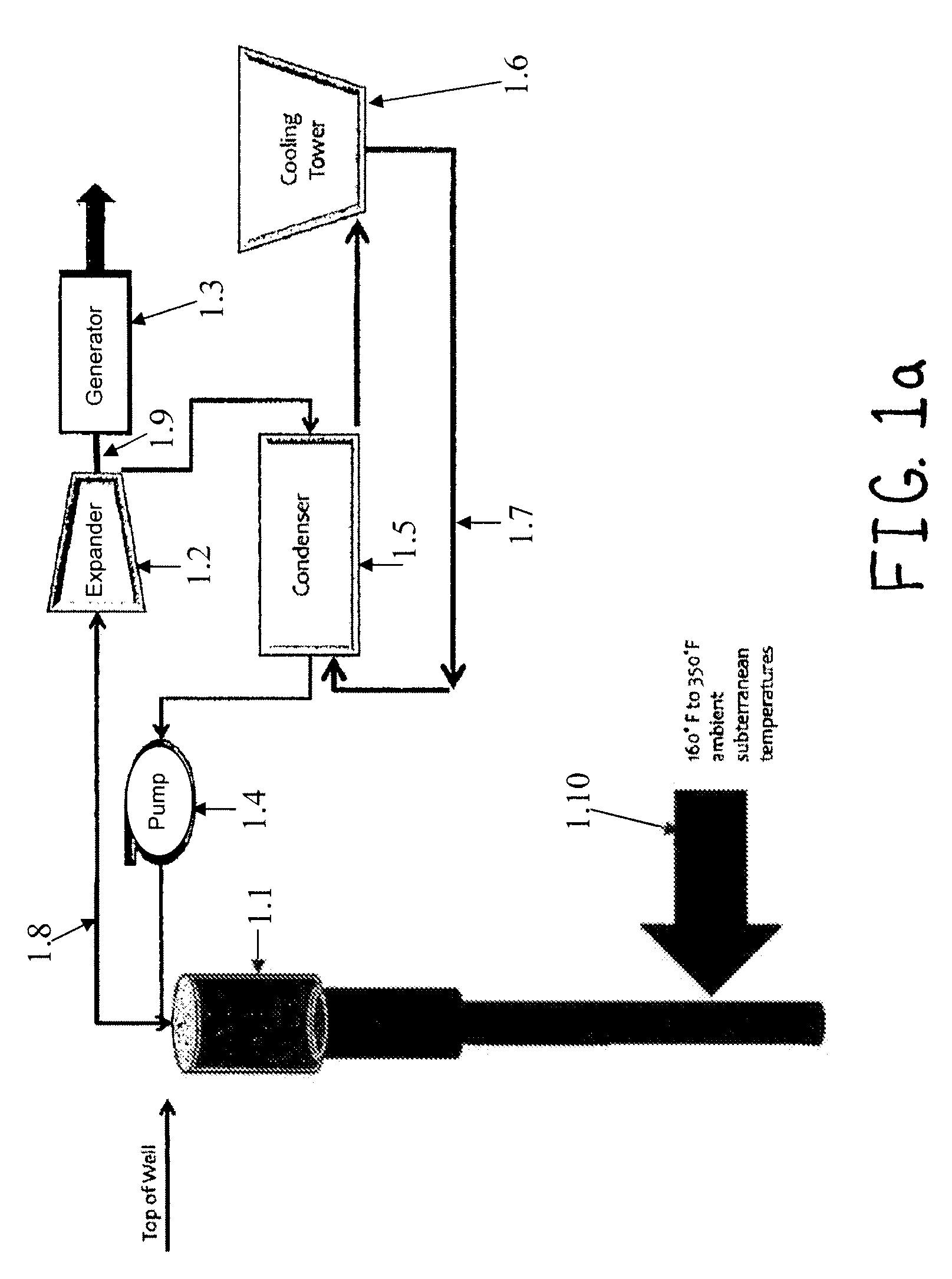

Direct exchange geothermal refrigerant power advanced generating system

ActiveUS20120144829A1Improve power generation efficiencyBoiling point/temperatureLighting and heating apparatusGeothermal energy generationWorking fluidClosed loop

A single closed loop direct exchange geothermal power production system that utilizes a refrigerant working fluid in at least one of three primary designs to generate electrical power from deep wells: with a first version of a direct exchange geothermal power generating system operating primarily on refrigerant vapor pressure; with a second version of a direct exchange geothermal power generating system operating primarily on liquid refrigerant gravitational pressure; and with a third version of a direct exchange geothermal power generating system operating primarily on both liquid refrigerant gravitational pressure and refrigerant phase change / expansion from a liquid to a vapor state.

Owner:DEEP WELL POWER

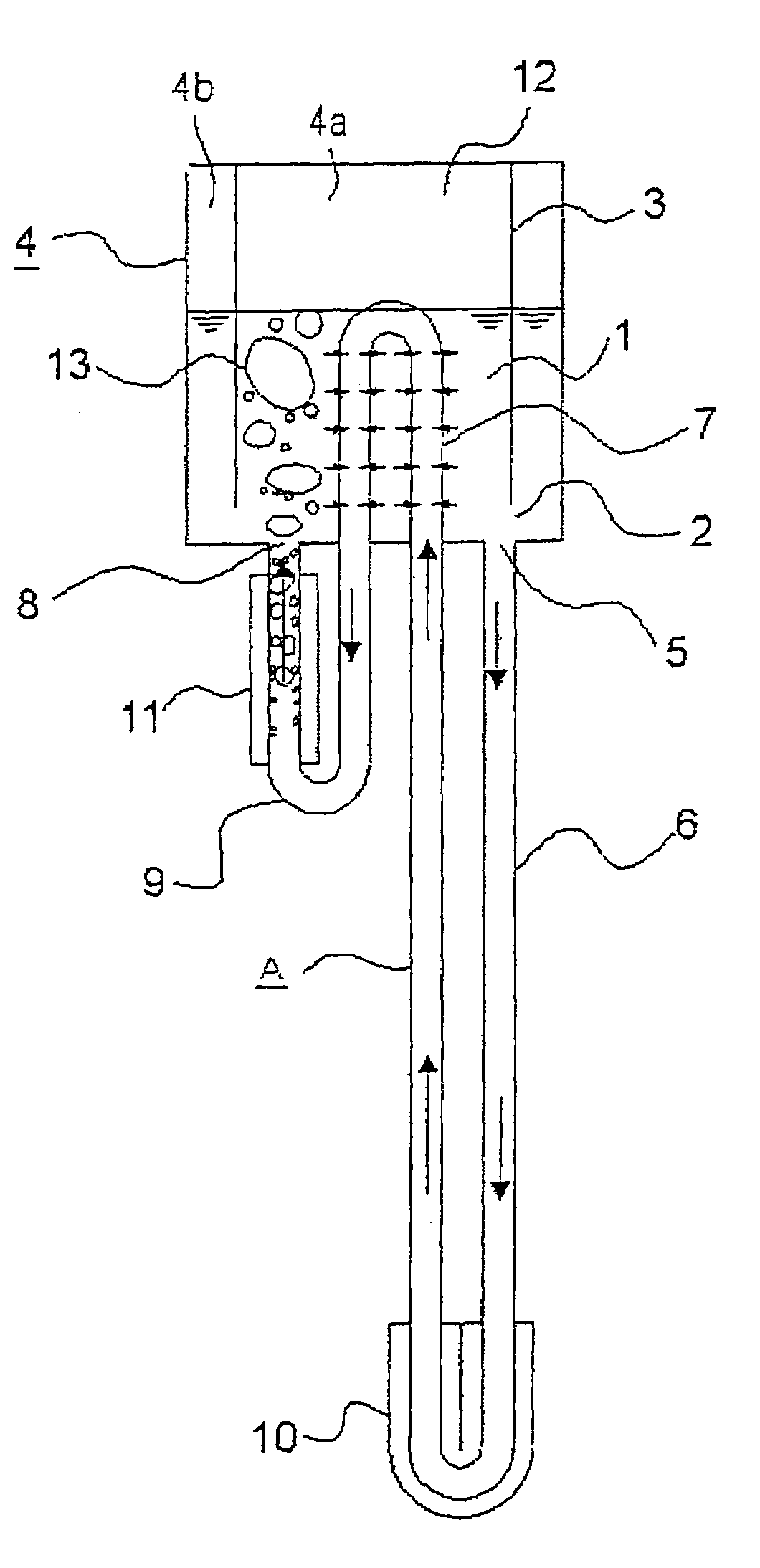

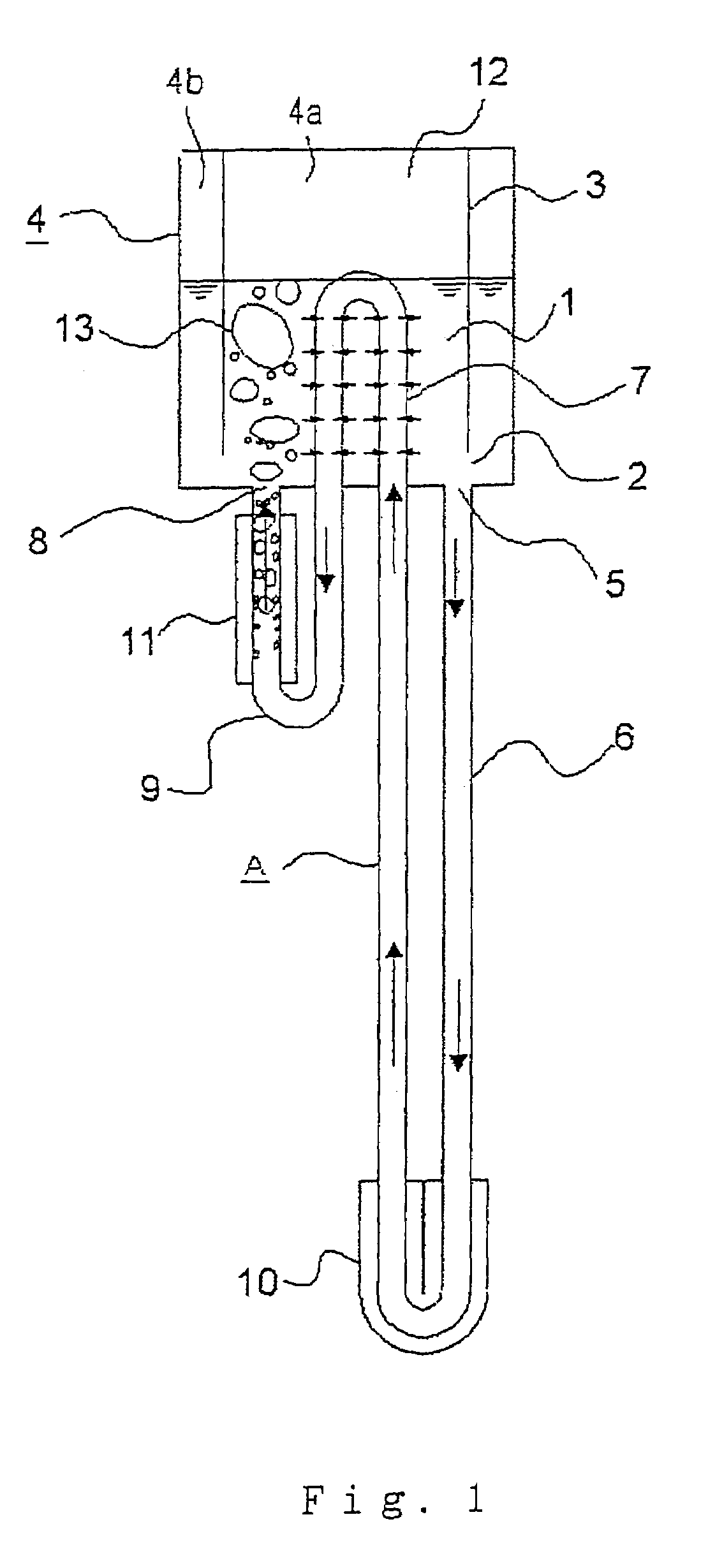

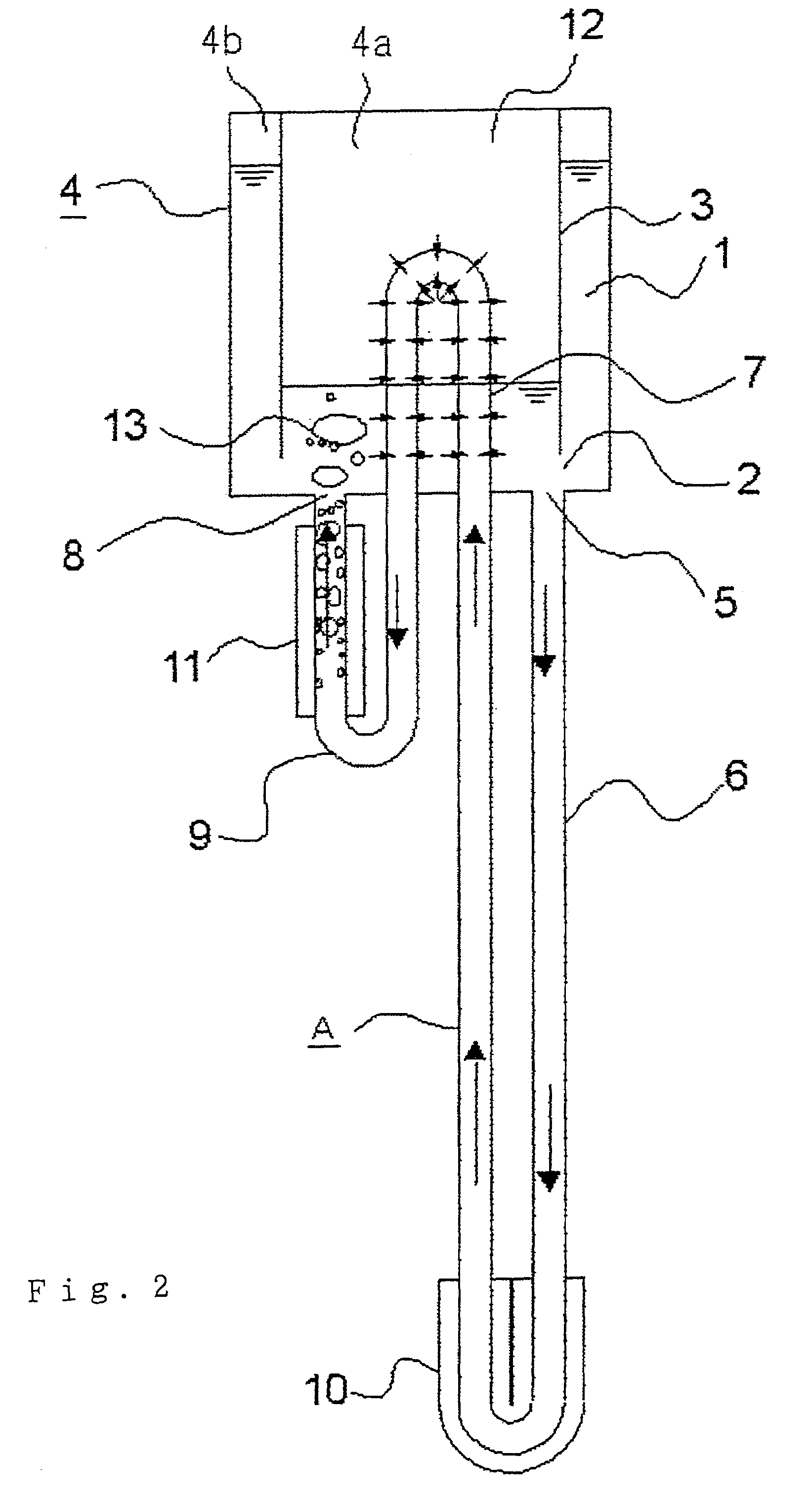

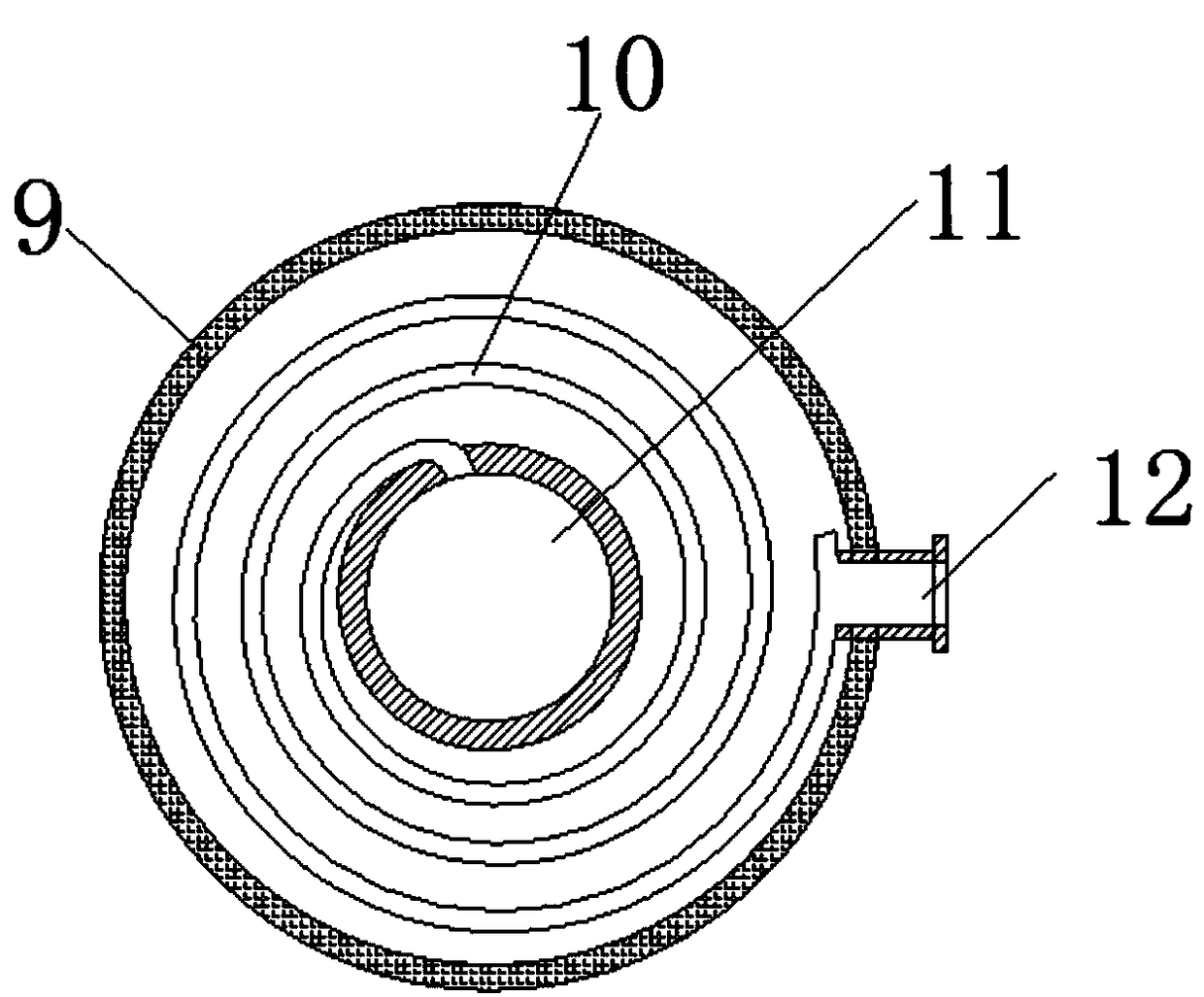

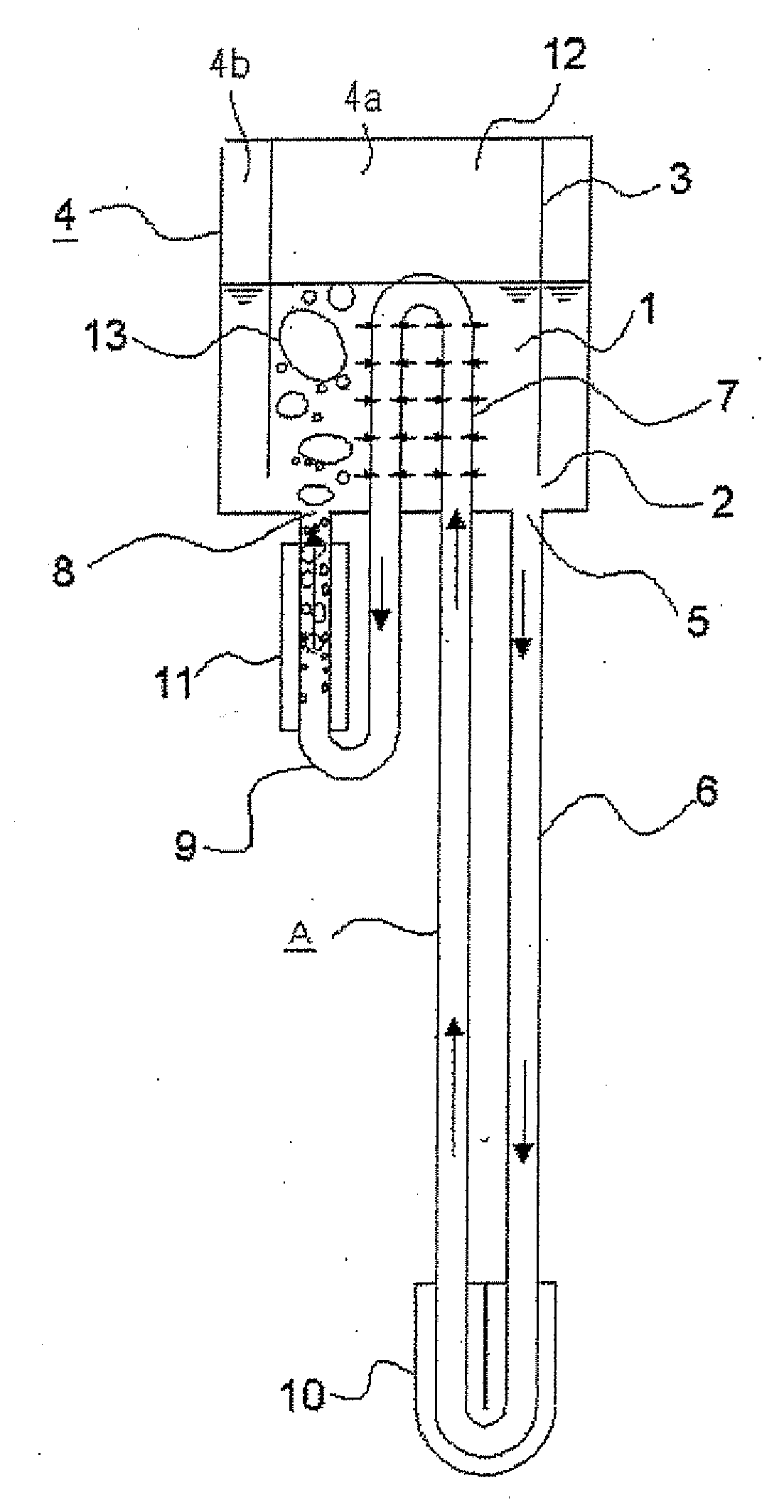

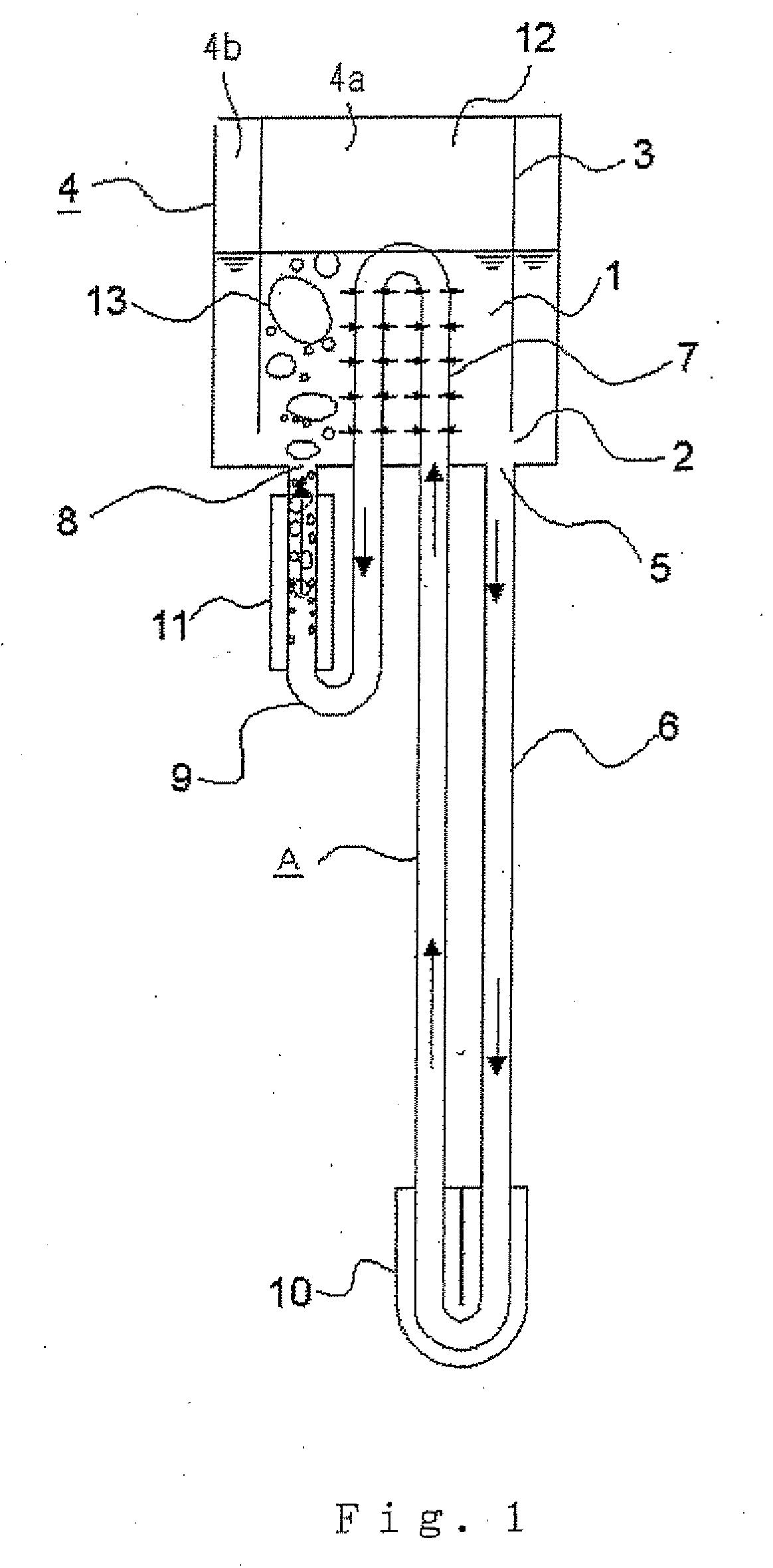

Vapor-lift pump heat transport apparatus

ActiveUS7201215B2Small resistanceLarge capacityOther heat production devicesGeothermal energy generationVapor liquidHeat resistance

A vapor-lift pump heat transport apparatus having a small heat resistance and a large heat transport capacity. A heat exchange circulating solution container has a first space and a second space communicating with the first space through a communication opening and contains a heat exchange circulating solution, and vapor thereof, in each space. A circulating solution transport passage includes a pipe connected to the solution outlet of the container and provided with a sensible heat releasing heat exchanger, a pipe disposed in the container, and a pipe connected to a vapor-liquid two-phase fluid inlet and provided with a heating heat exchanger. A vapor-liquid two-phase fluid flows into only the first space through the vapor-liquid two-phase fluid inlet. When the entrance of the vapor-liquid two-phase fluid has caused a pressure difference between the first and second spaces, a difference occurs between the positions of the vapor-liquid interfaces in the first and second spaces.

Owner:MITSUBISHI ELECTRIC CORP

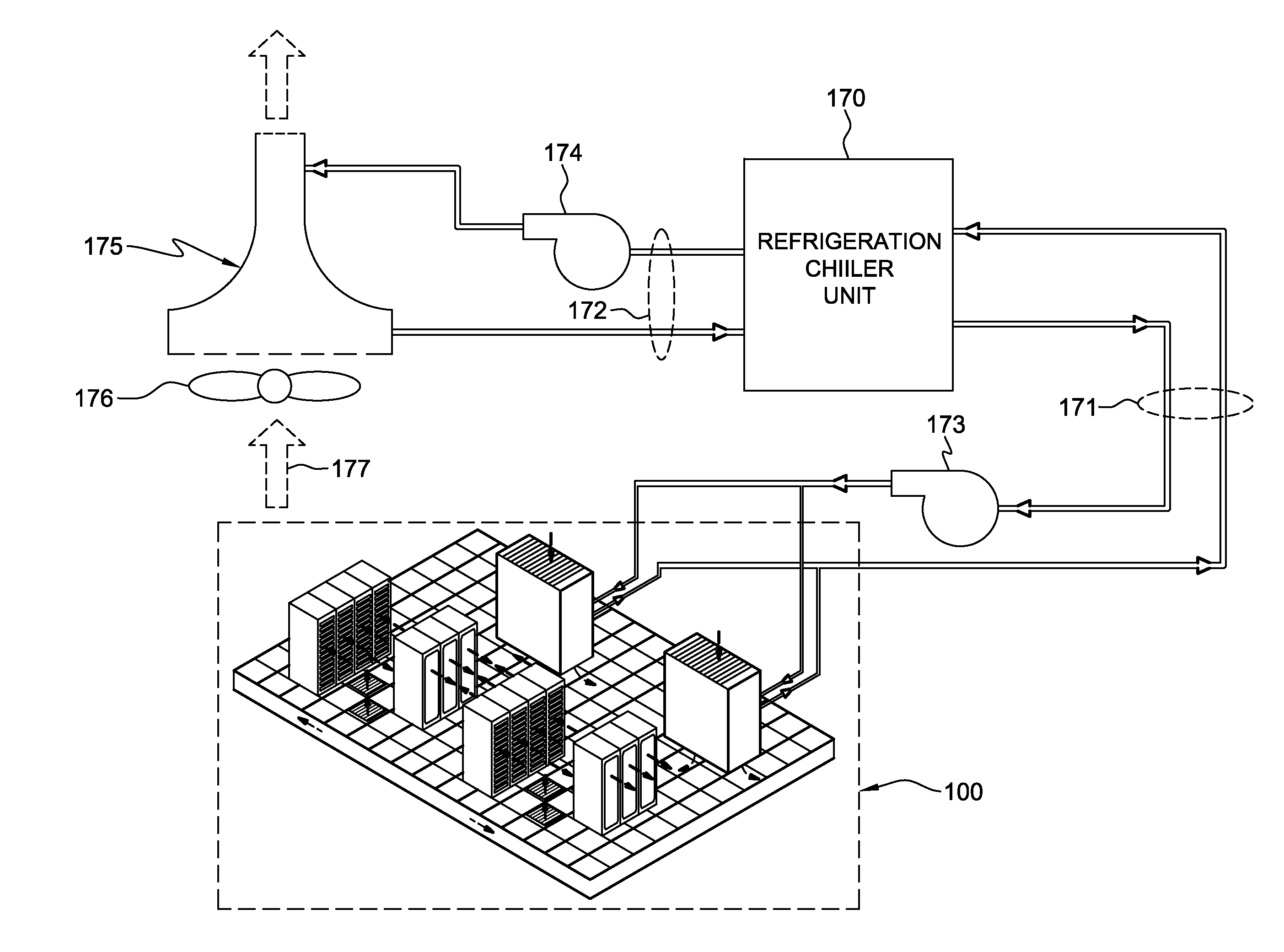

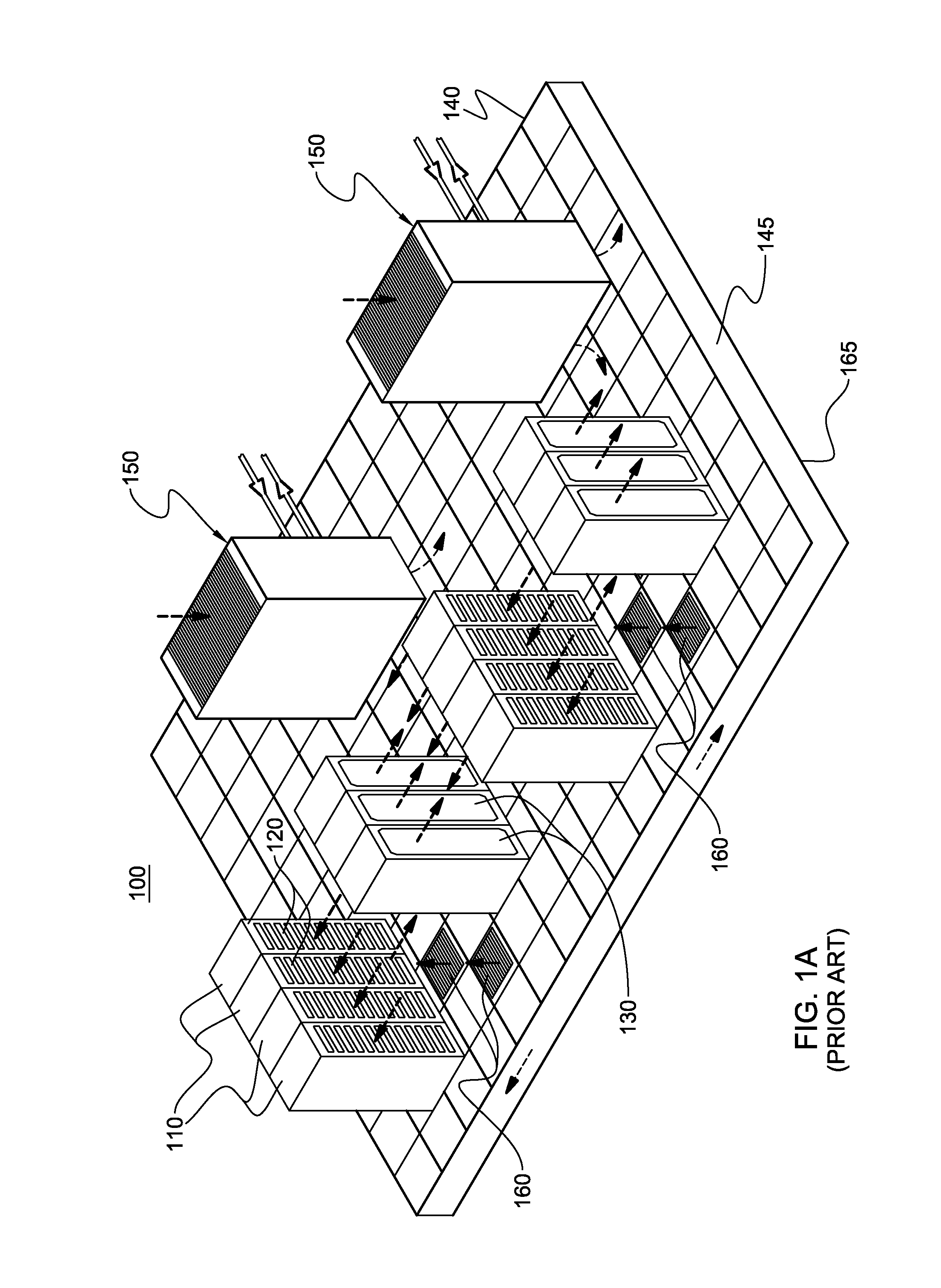

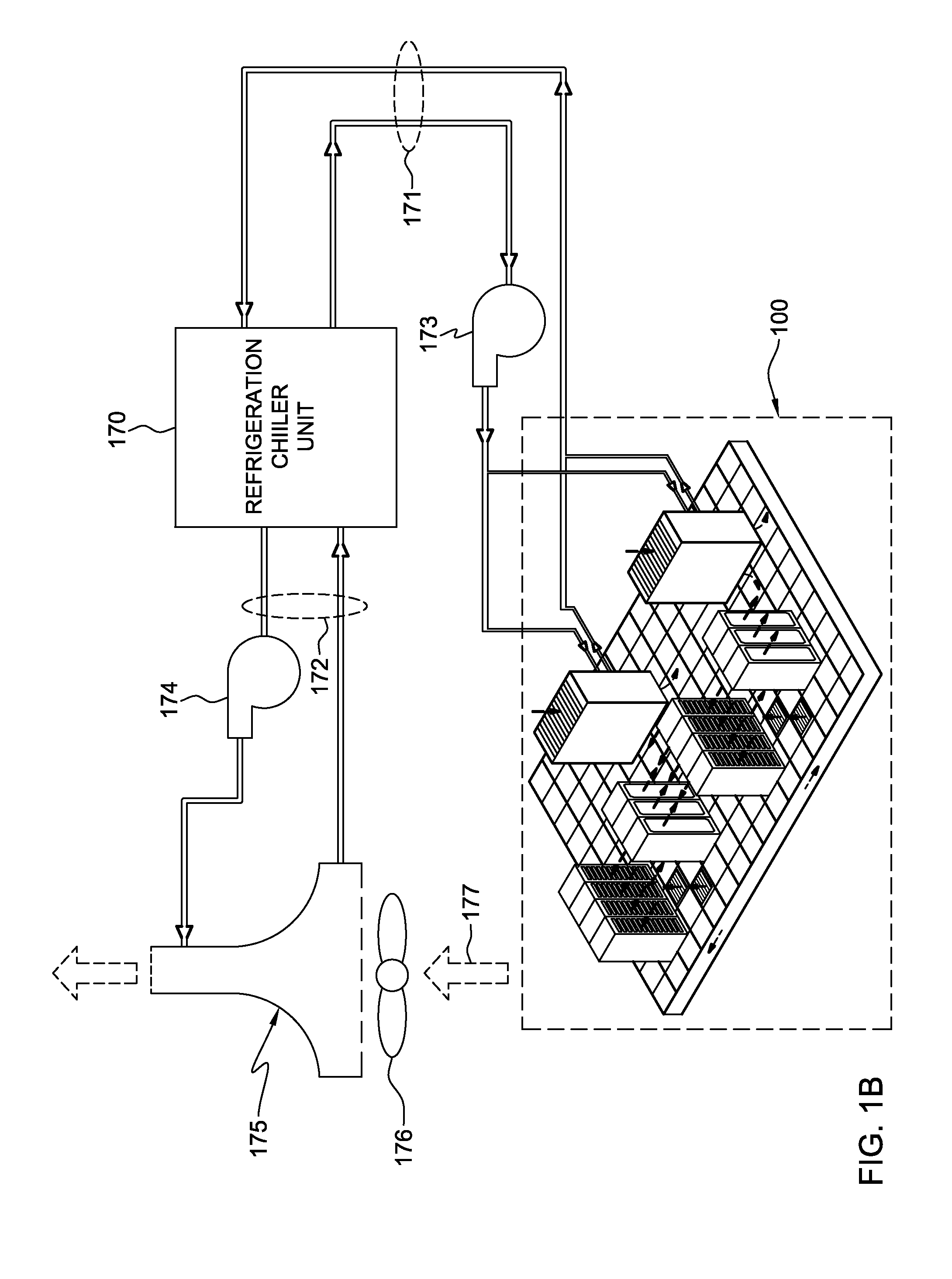

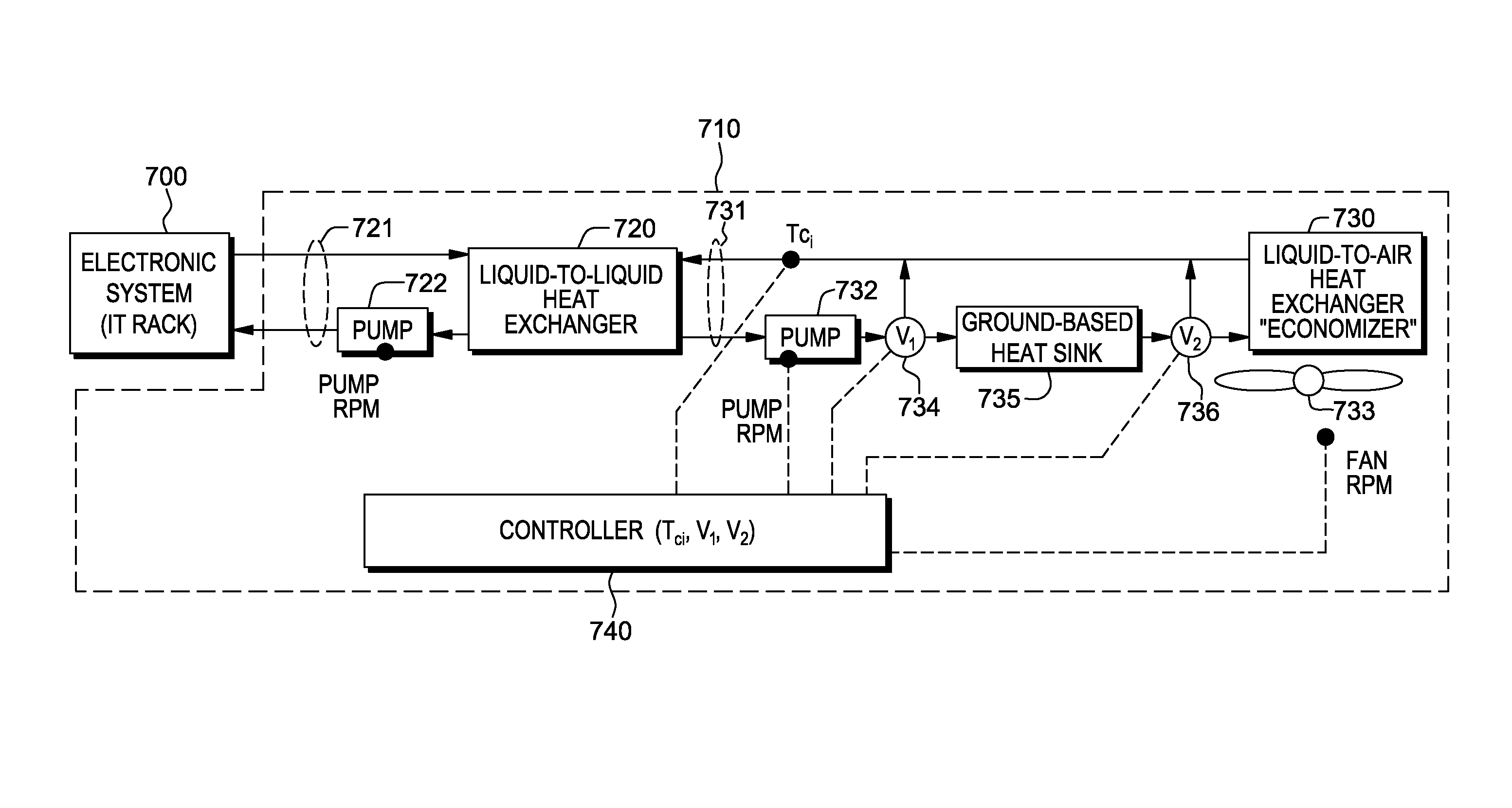

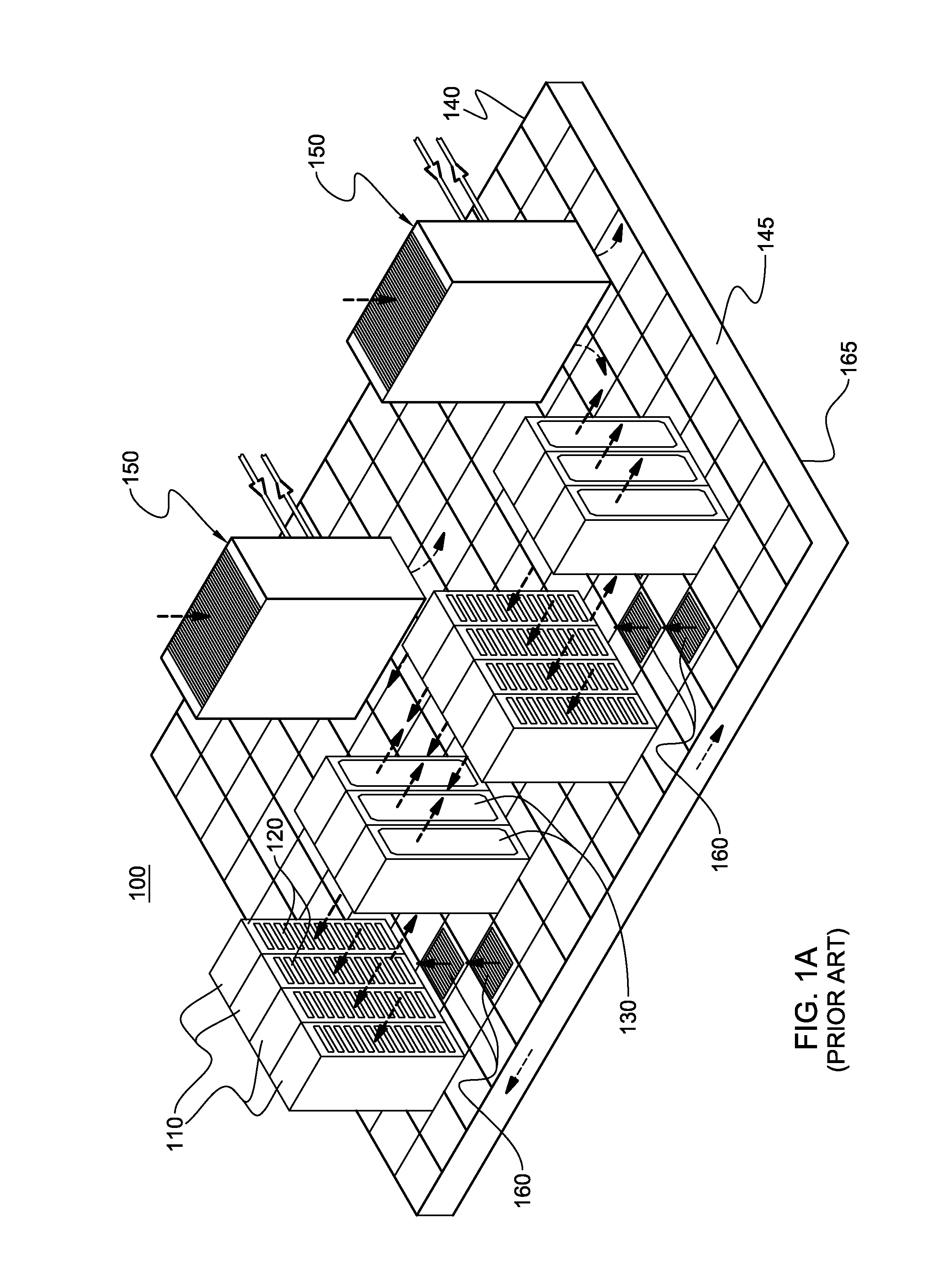

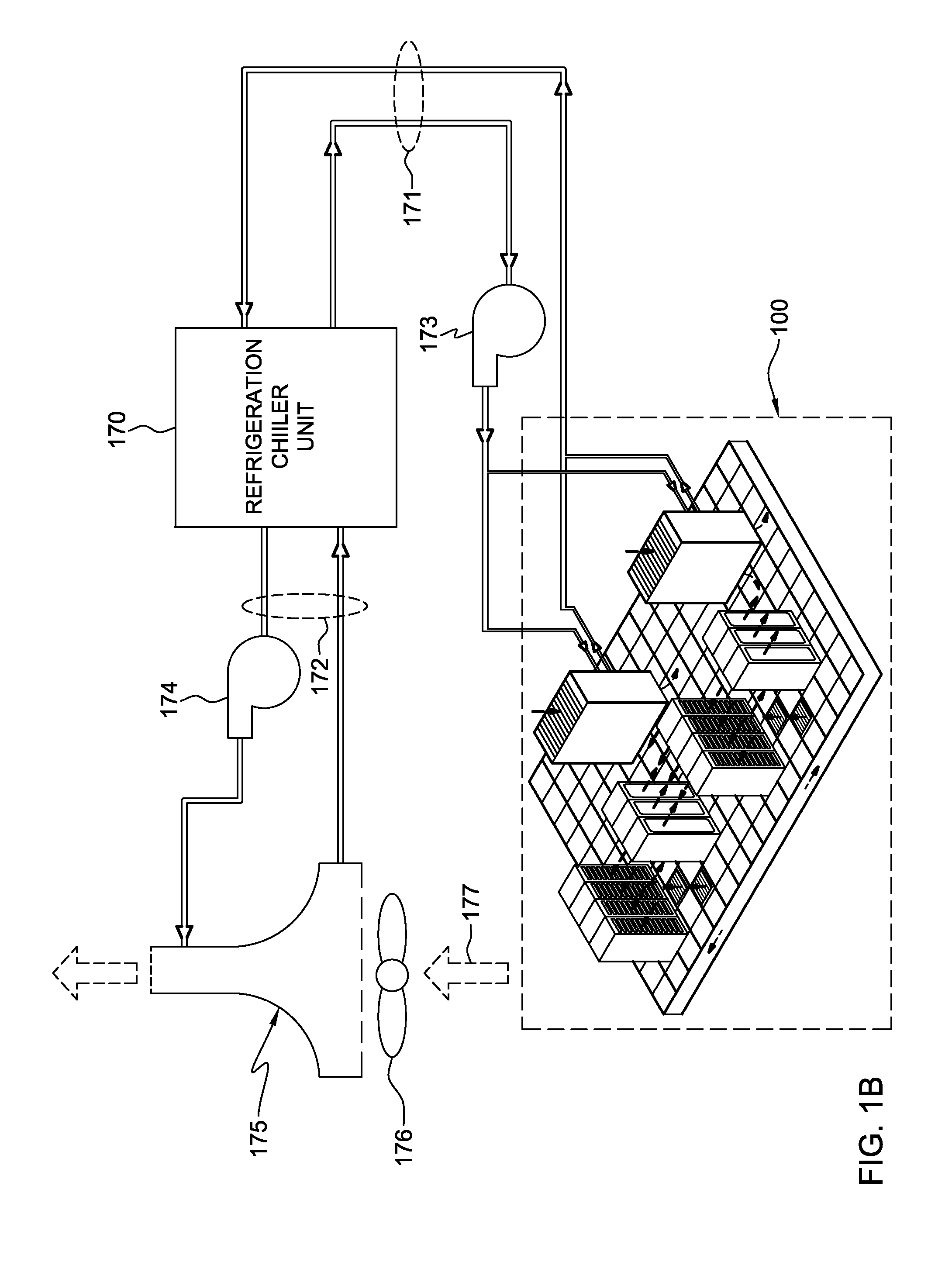

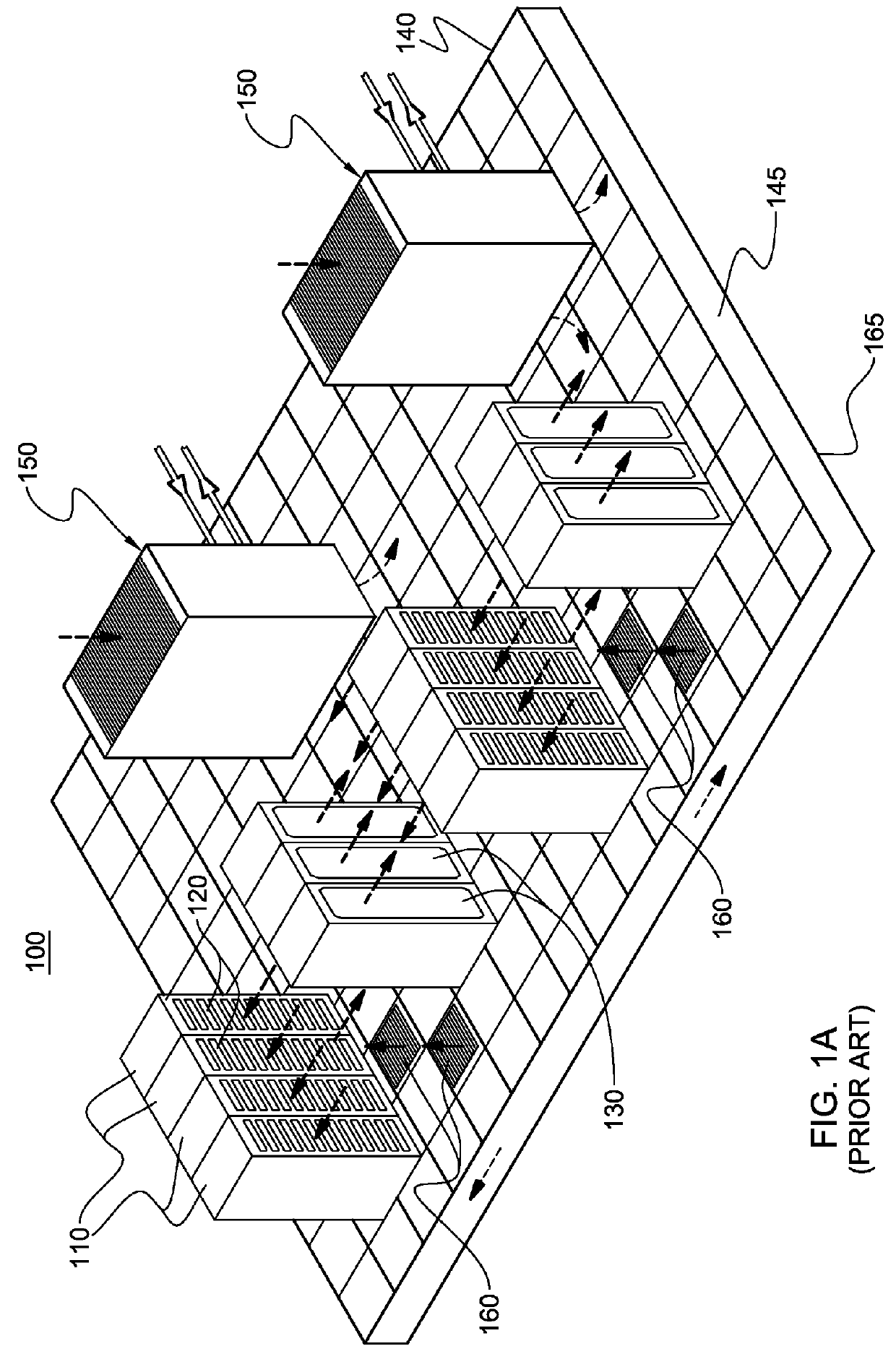

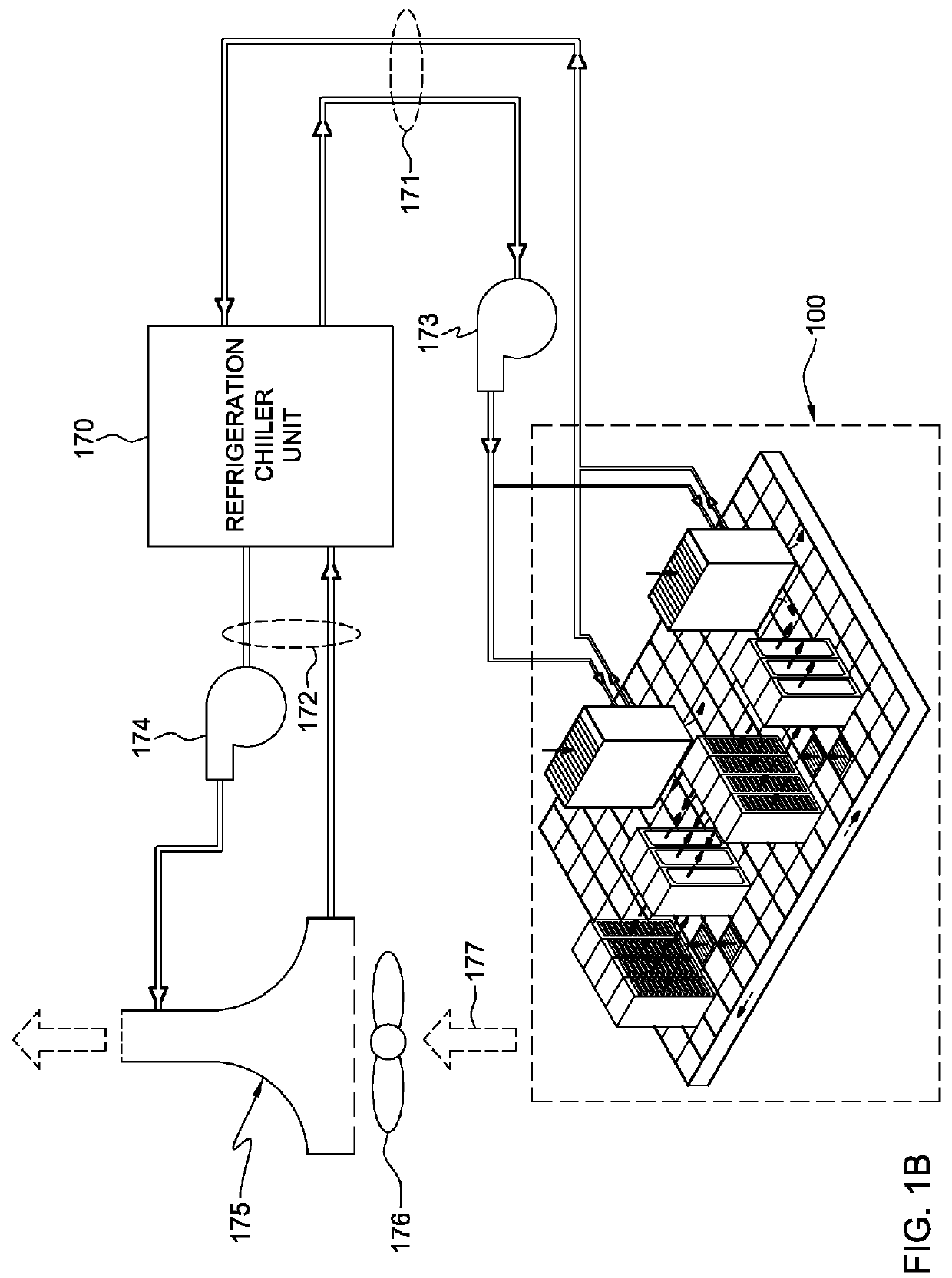

Ground-based heat sink facilitating electronic system cooling

InactiveUS20140124163A1Facilitate conductionOvercomes shortcomingOther heat production devicesGeothermal energy generationElectronic systemsCoolant flow

Cooling systems and methods are provided which include a heat sink having a housing with a compartment, a coolant inlet, and a coolant outlet. The housing is configured for a coolant to flow from the coolant inlet through the compartment to the coolant outlet, wherein the coolant is transferring heat extracted from one or more electronic components. The heat sink further includes one or more heat pipes having a first portion disposed within the compartment of the housing and a second portion disposed outside the housing. The heat pipe(s) is configured to extract heat from the coolant flowing through the compartment, and to transfer the extracted heat to the second portion disposed outside the housing. The second portion outside the housing is disposed to facilitate conducting the extracted heat into the ground.

Owner:IBM CORP

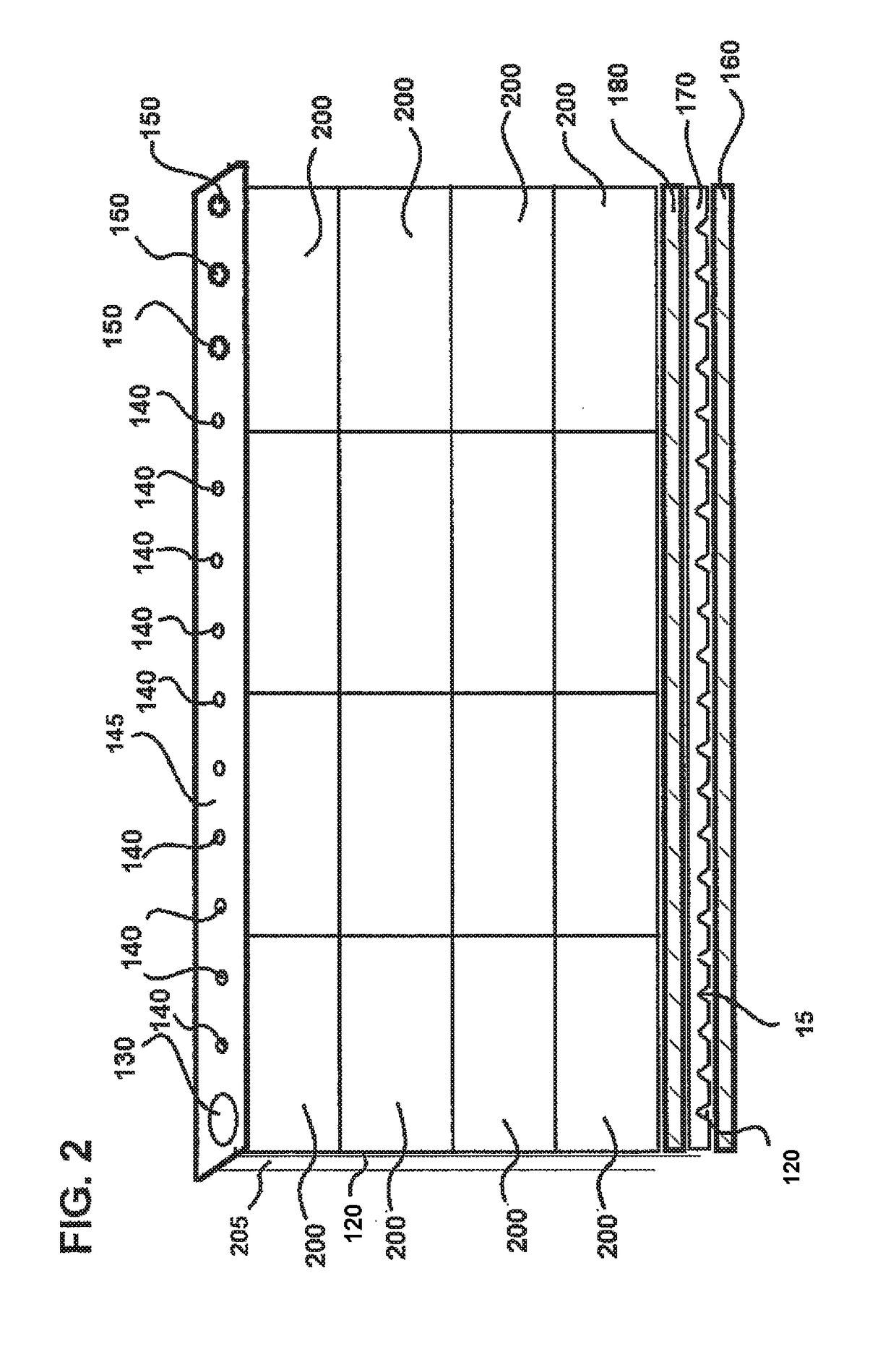

Passive heat extraction and electricity generation

ActiveUS20130333383A1Increased contact surface areaImprove heat transfer efficiencyOther heat production devicesGeothermal energy generationThermal energyWorking fluid

A closed-loop heat exchange system and related methods for harnessing subterranean heat energy from a subterranean zone having a passive heat transfer device with multiple operational modes for targeting hotspots within the subterranean zone and adjusting the rate of energy harnessed according to consumption demands. The system can also have at least one enhanced surface section for increasing the heat exchange efficiency and / or a variable pump for controlling the rate at which the working fluid travels through the passive heat transfer device.

Owner:SCHWARCK STRUCTURE

Geothermal Cooling Device

InactiveUS20080053130A1Efficiently indoor spaceReduced Power RequirementsDomestic cooling apparatusOther heat production devicesElectrical conductorThermostat

A geothermal cooling device is couplable to a ground coil formed from a thermal superconductor material. The device includes a thermal superconductor heat exchange coil, and a thermostat controller and a blower. The device uses a high thermal transfer superconductor to efficiently move heat to the earth source for the purpose of cooling. The device operates by controlling the blower operation in response to the difference between a set point and a measured temperature. Optionally cooling device is enclosed in a housing mounted in standard structural spaces. Alternative simplified versions, without a thermostat, operate manually with a switch or power connection.

Owner:FREE ENERGY SOLUTIONS

Convective earrh coil

InactiveUS20080128108A1Promote stratificationOther heat production devicesGeothermal energy generationThermal energyHeat rejection

The present invention relates to a method of heat rejection and extraction between a fluid and the earth, providing for a high efficiency convective heat exchanger located in ground water, a means for inducing flow of said ground water at its initial temperature from ground water pool through said heat exchanger, a means of inducing heat transfer from said ground water to said heat transfer fluid or gas, a means of discharging said ground water at a new temperature back into said ground water pool, and a piping system suitable to transport said heat transfer fluid from a thermal load at some remote location at a first temperature, though the said convective heat exchanger and transporting the heat transfer fluid at a new temperature to the location(s) where the thermal energy is utilized.

Owner:CLARK STEVEN JOSEPH

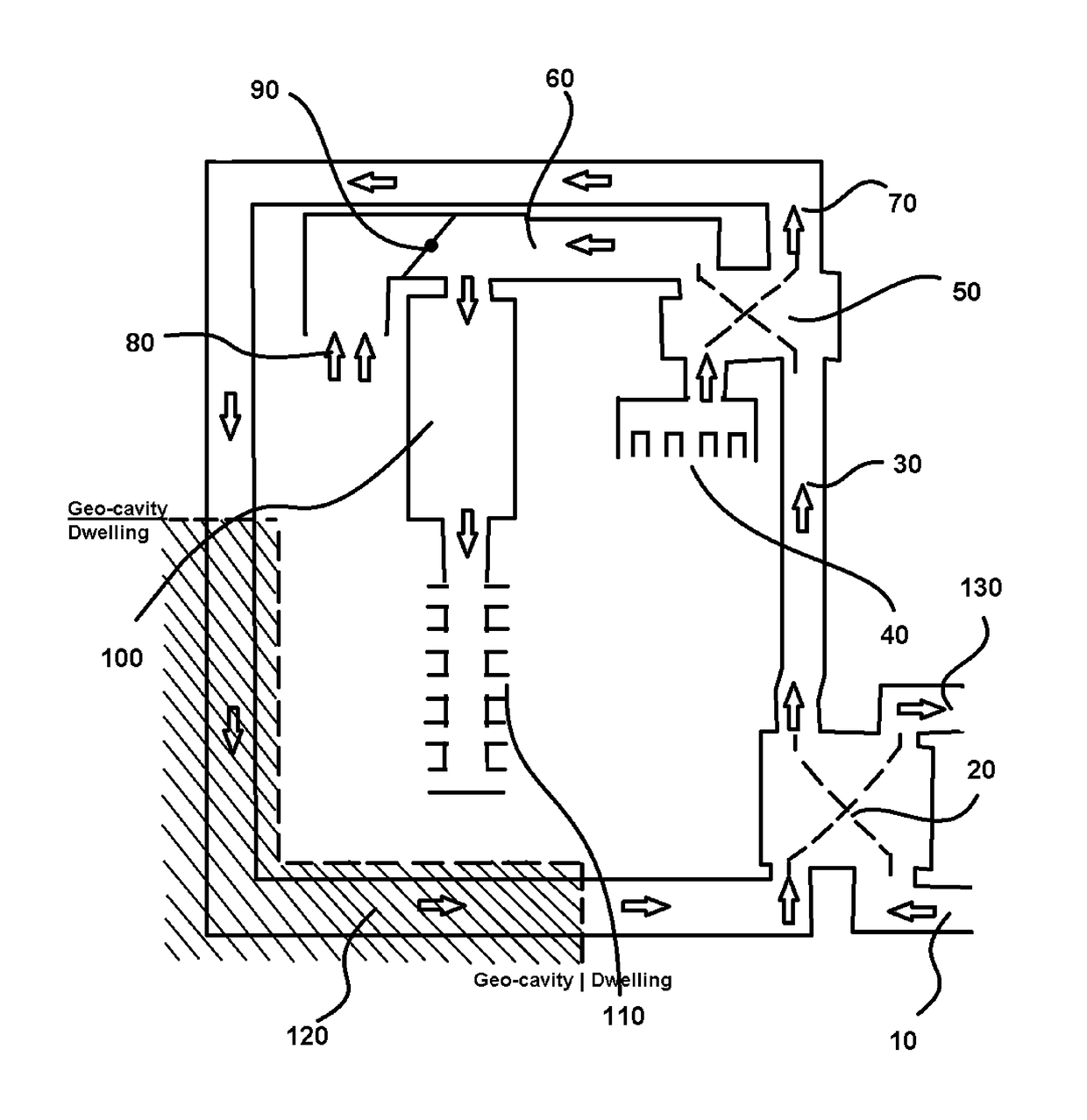

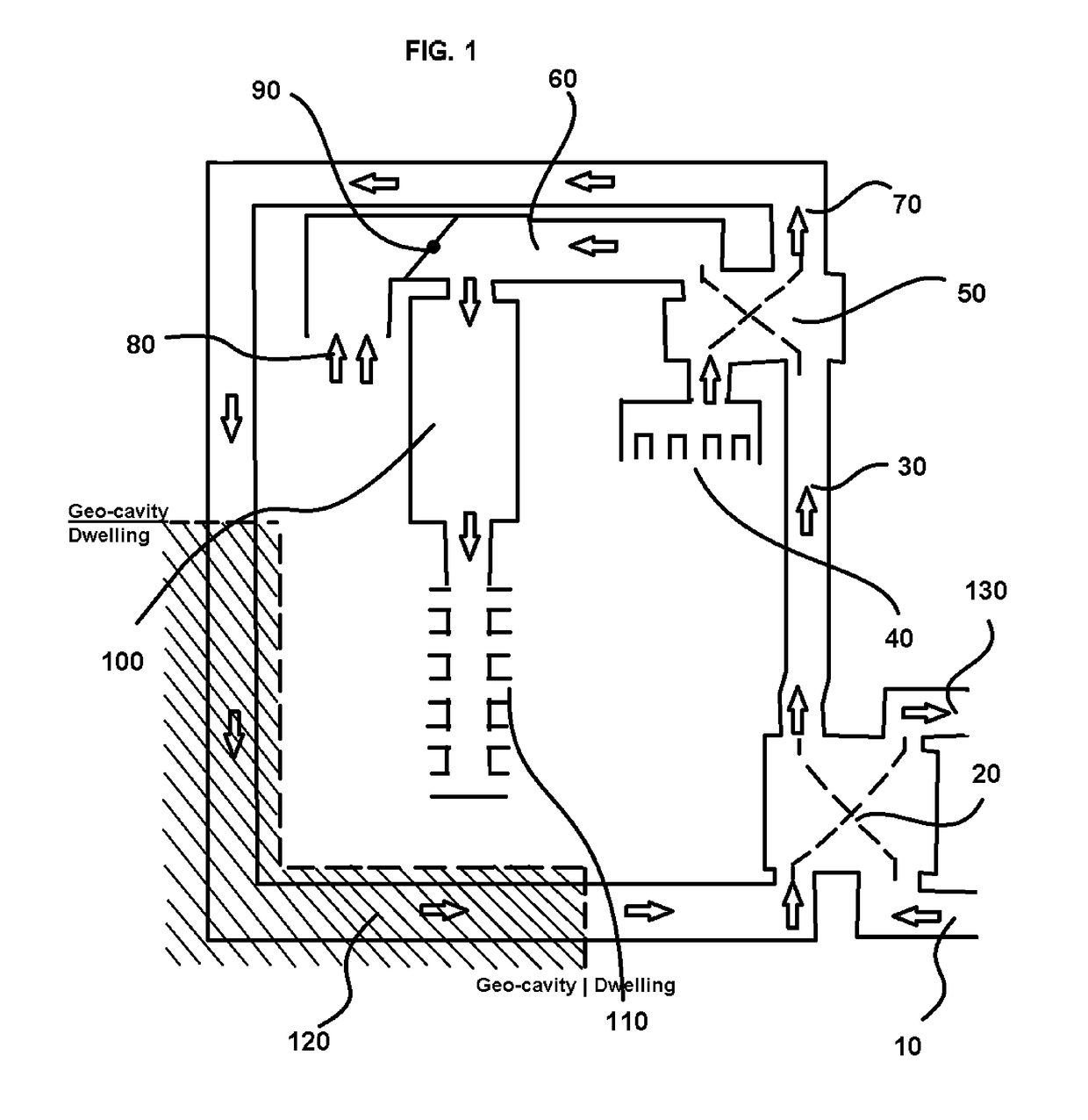

Geothermal Heating, Cooling, and Dehumidification Ventilation System

InactiveUS20170248332A1Relieve pressureIncrease air circulationEnergy recovery in ventilation and heatingCondensate preventionBasementSystems design

A system designed to introduce fresh air ventilation into the living space, eliminate contaminants, and add fresh air to augment a building's HVAC system. This is done in order to save energy, and the costs associated with heat loss or gain in a building. The system employs the use of geothermal energy conferred to air via a cavity which is constructed in the basement, on the slab, foundation, in the crawl space and / or attic of a building. This cavity is created to circulate, absorb and store / release the geo-solar characteristics of a building, taking advantage the consistent subterranean temperature of the earth and / or sun, in order to warm air from outside during the winter minimizing the foundation heat sink, and cool air during the summer. One or more heat exchangers are used to transfer the energy from contaminated air in the cavity to clean air destined for the HVAC system.

Owner:WRIGHT JAMES P +1

Passive heat extraction and electricity generation

ActiveUS9121393B2Increased contact surface areaImprove heat transfer efficiencyOther heat production devicesGeothermal energy generationWorking fluidClosed loop

A closed-loop heat exchange system and related methods for harnessing subterranean heat energy from a subterranean zone having a passive heat transfer device with multiple operational modes for targeting hotspots within the subterranean zone and adjusting the rate of energy harnessed according to consumption demands. The system can also have at least one enhanced surface section for increasing the heat exchange efficiency and / or a variable pump for controlling the rate at which the working fluid travels through the passive heat transfer device.

Owner:SCHWARCK STRUCTURE

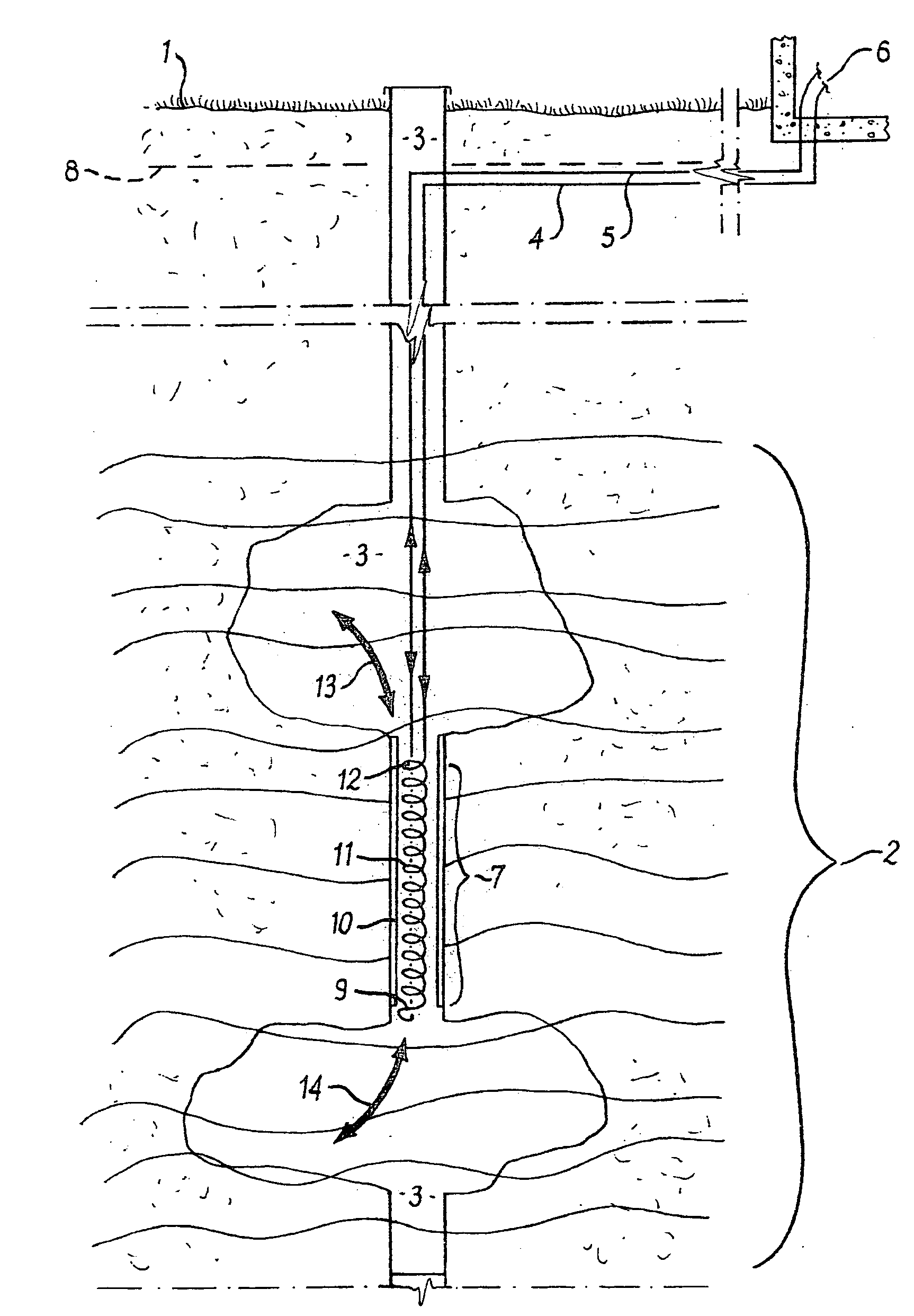

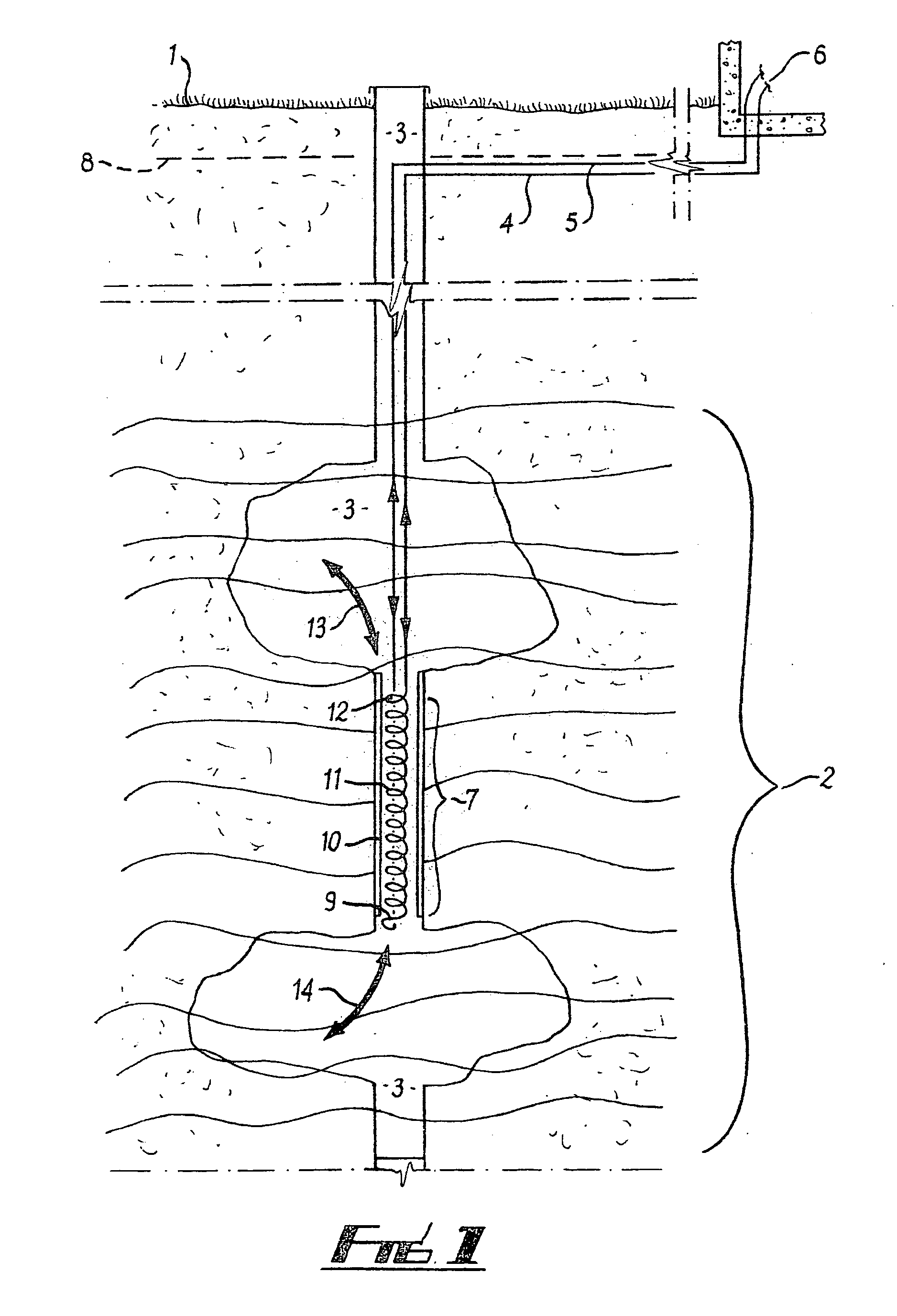

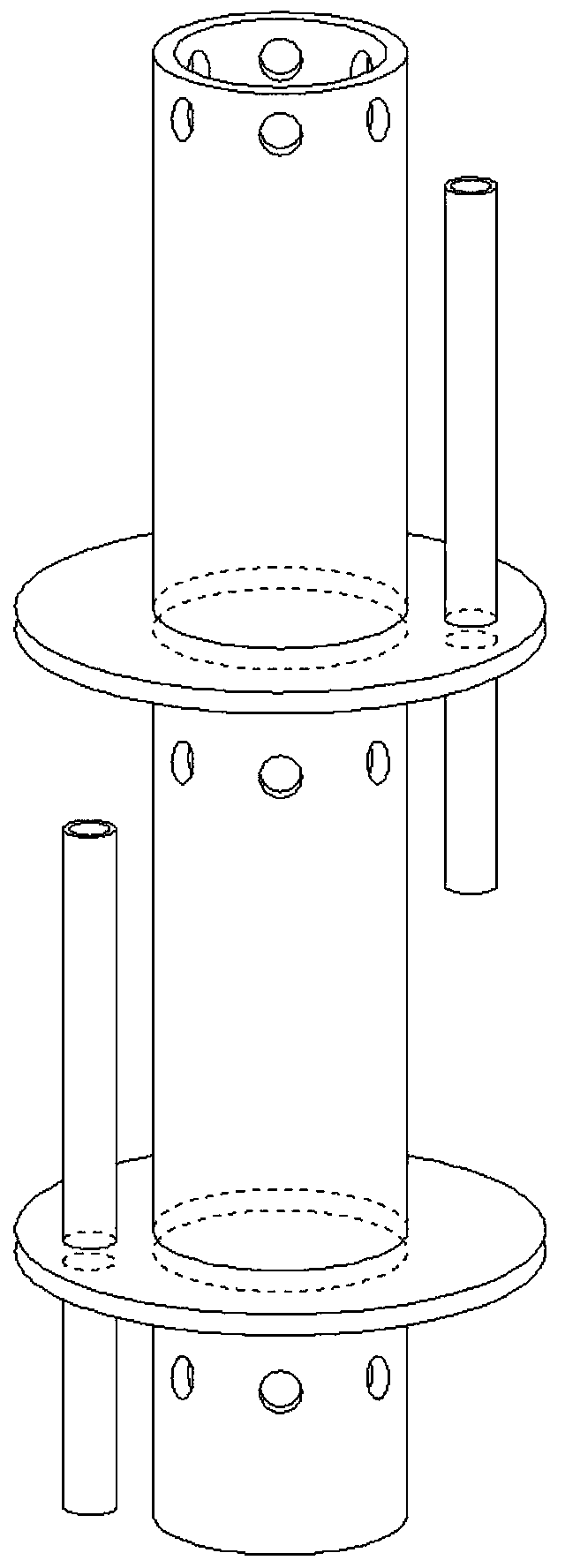

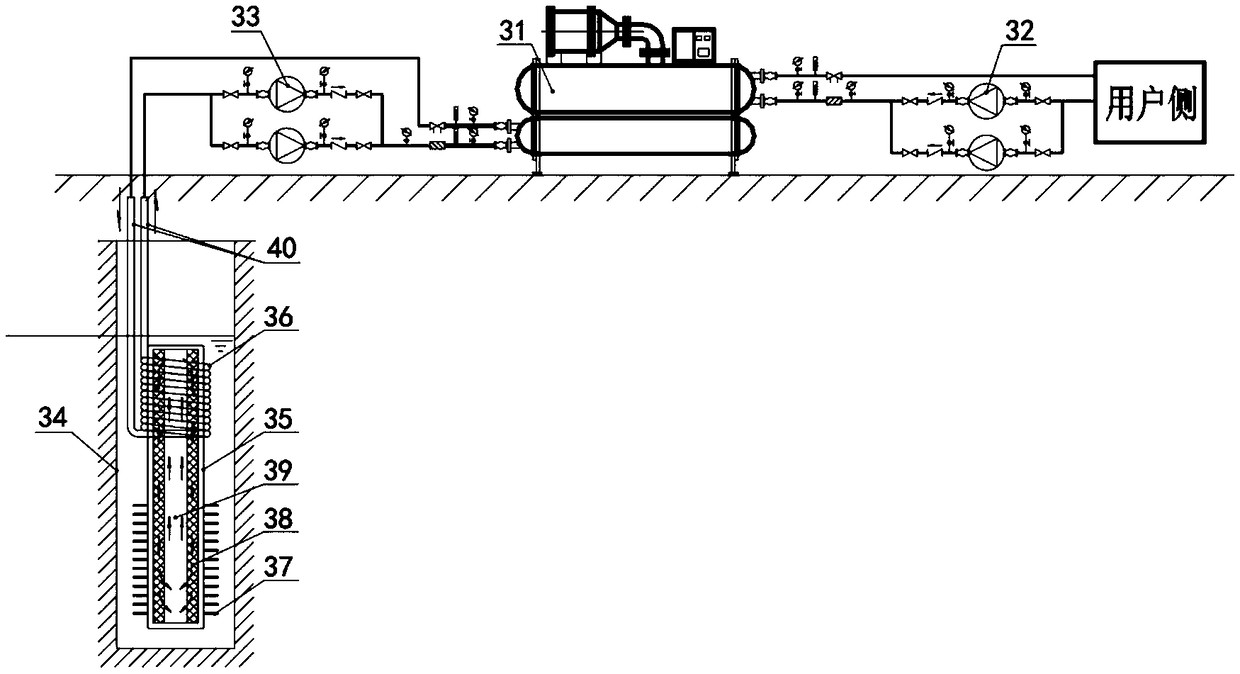

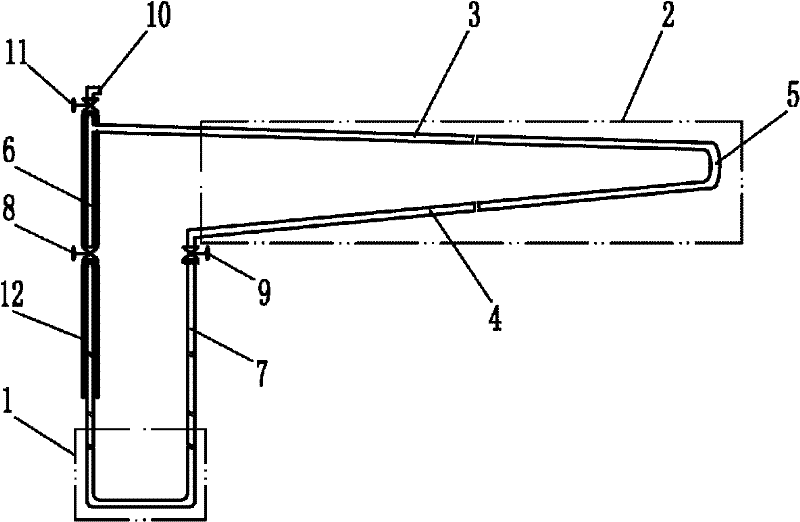

Stepped gravity heat pipe geothermal exploitation system without liquid accumulation effect

ActiveCN110030746AAchieve miningFully moistenedCollector components/accessoriesGeothermal energy generationLiquid storage tankHeat transfer efficiency

The invention provides a stepped gravity heat pipe geothermal exploitation system without a liquid accumulation effect. The system comprises a gravity heat pipe, a condenser and a liquid storage tank,wherein the gravity heat pipe comprises a liquid return pipe, an outer pipe and an inner pipe, the liquid return pipe is located in a gap between the outer pipe and the inner pipe and is connected with the liquid storage tank, the gap between the outer pipe and the inner pipe adopts a stepped separation structure, a liquid working medium sequentially flows into the separation sections of all stages from the liquid storage tank through the liquid return pipe, and passes through the pipe wall of the outer pipe to absorb heat from high-temperature rock and then is gasified, and after the liquidworking medium becomes a gaseous working medium, then the gaseous working medium enters the inner pipe again and flows into the condenser, and then flows into the liquid storage tank again for circulation after being subjected to heat release condensation. Compared with the prior art, the heat pipe heat absorption section is designed to be of the stepped separation structure, and the liquid levelof each separation section is limited to a certain height through corresponding liquid level control pipe; and the design can solve the problem that the working medium is difficult to evaporate due toexcessively high liquid level while the heat absorption section is fully wetted, so that the heat transfer efficiency when a super-long heat pipe is used for exploiting the geothermal energy is greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

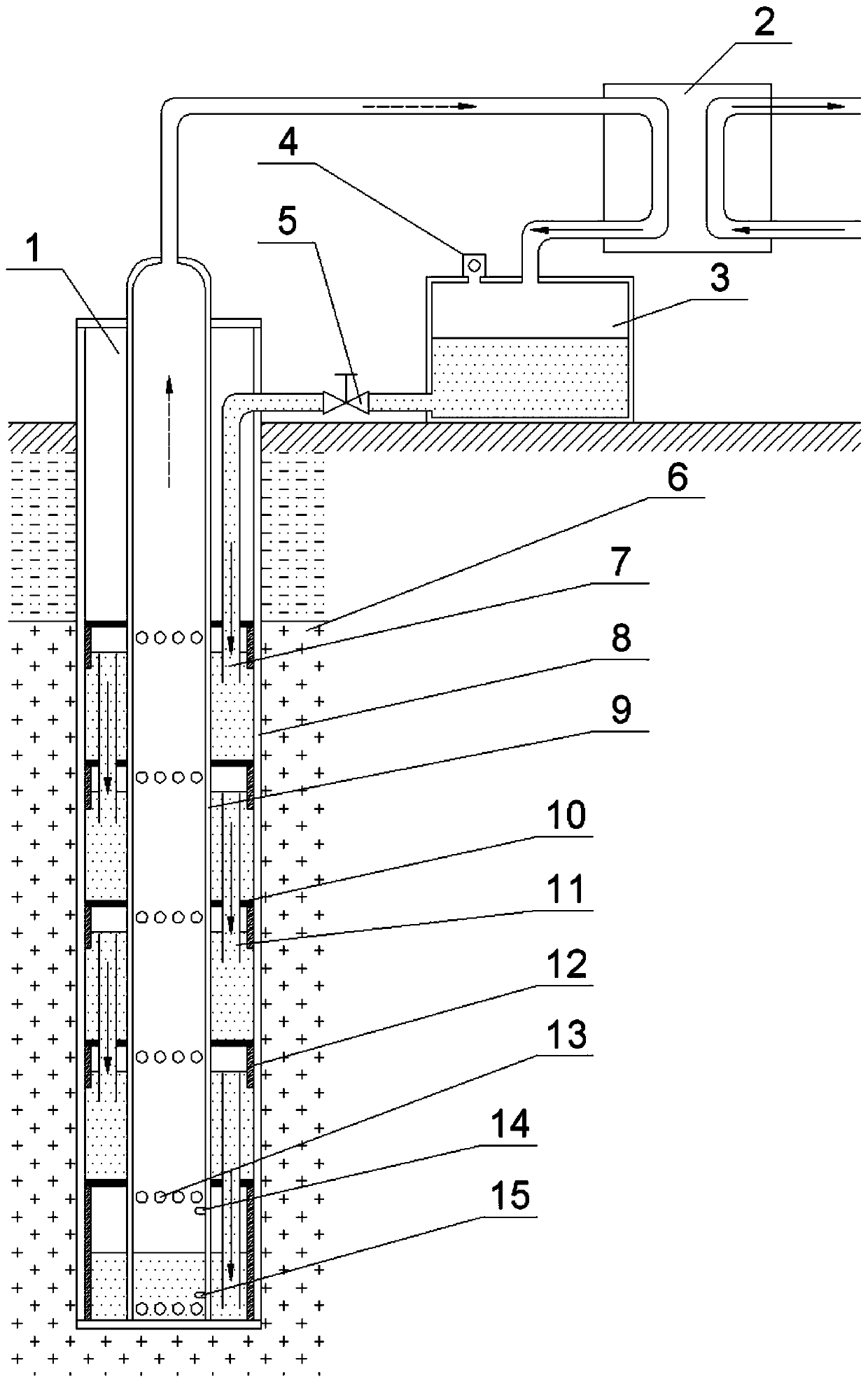

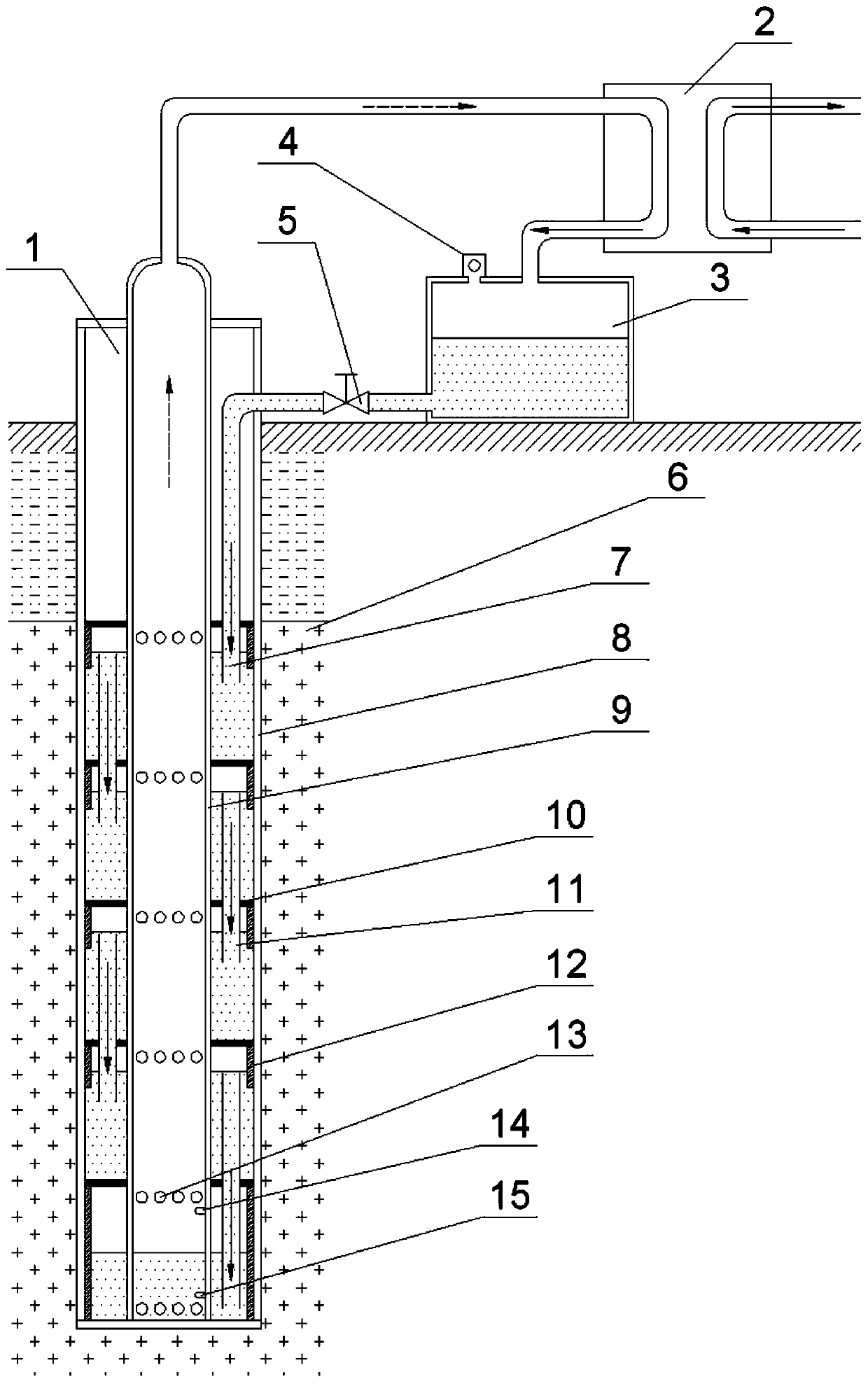

Technology for improving heat production capacity of geothermal wells

ActiveCN109403917AImprove efficiencyIncrease heat productionGeothermal energy generationFluid removalThermal insulationWell cementing

The invention relates to the technical field of geothermal energy development, in particular to a geothermal well novel technology. The technology improves the ability of leading geothermal energy inrock strata into geothermal wells through a heat conduction well cementing technology and a enhanced conductivity fracturing technology, and achieves high efficiency heat taking and heat transferringusing through spiral plate type condensing section gravity heat pipe heat exchanger. The technology comprises the following concrete process that after completing drilling a geothermal well and casinga sleeve pipe, the heat conduction well cementing is carried out, that is, thermal insulation cement slurry is injected in the low temperature section of the formation, and heat conduction cement slurry is injected into a stratum high temperature section to complete well cementing; after solidification of the heat insulation cement slurry and the heat conduction cement slurry of the well cementing, subsection perforation fracturing is carried out in the sleeve pipe of the stratum high temperature section, cracks are produced in high temperature strata, and heat conduction material is filled into the cracks to form a heat guiding belt extending from the sleeve pipe to the stratum; and finally, the condensing section of gravity heat pipe heat exchanger connected with the sleeve pipe is installed on the ground to form a high-yield geothermal well system in which rapid heat transfer in the stratum and high efficiency heat transfer in a well cylinder finally.

Owner:田振林

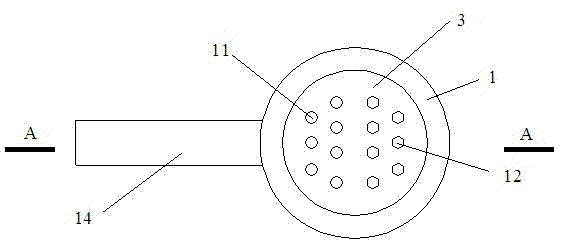

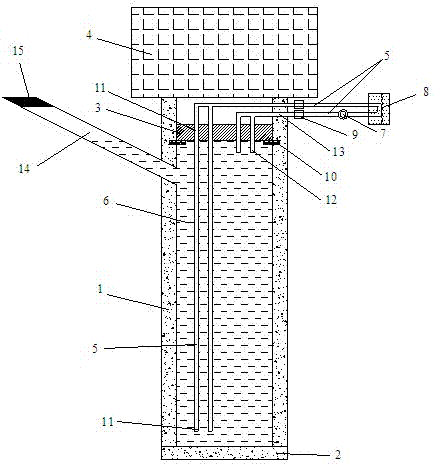

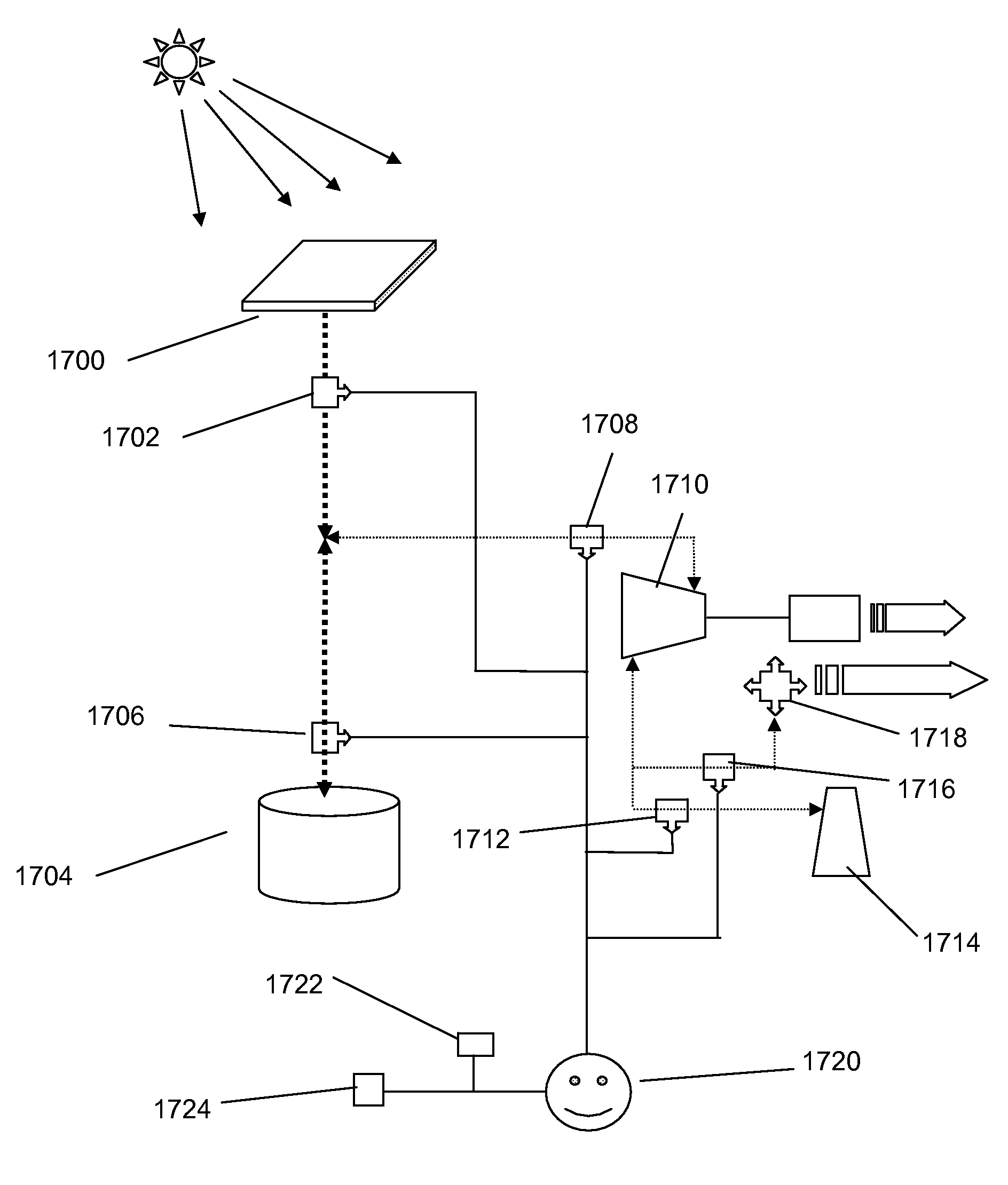

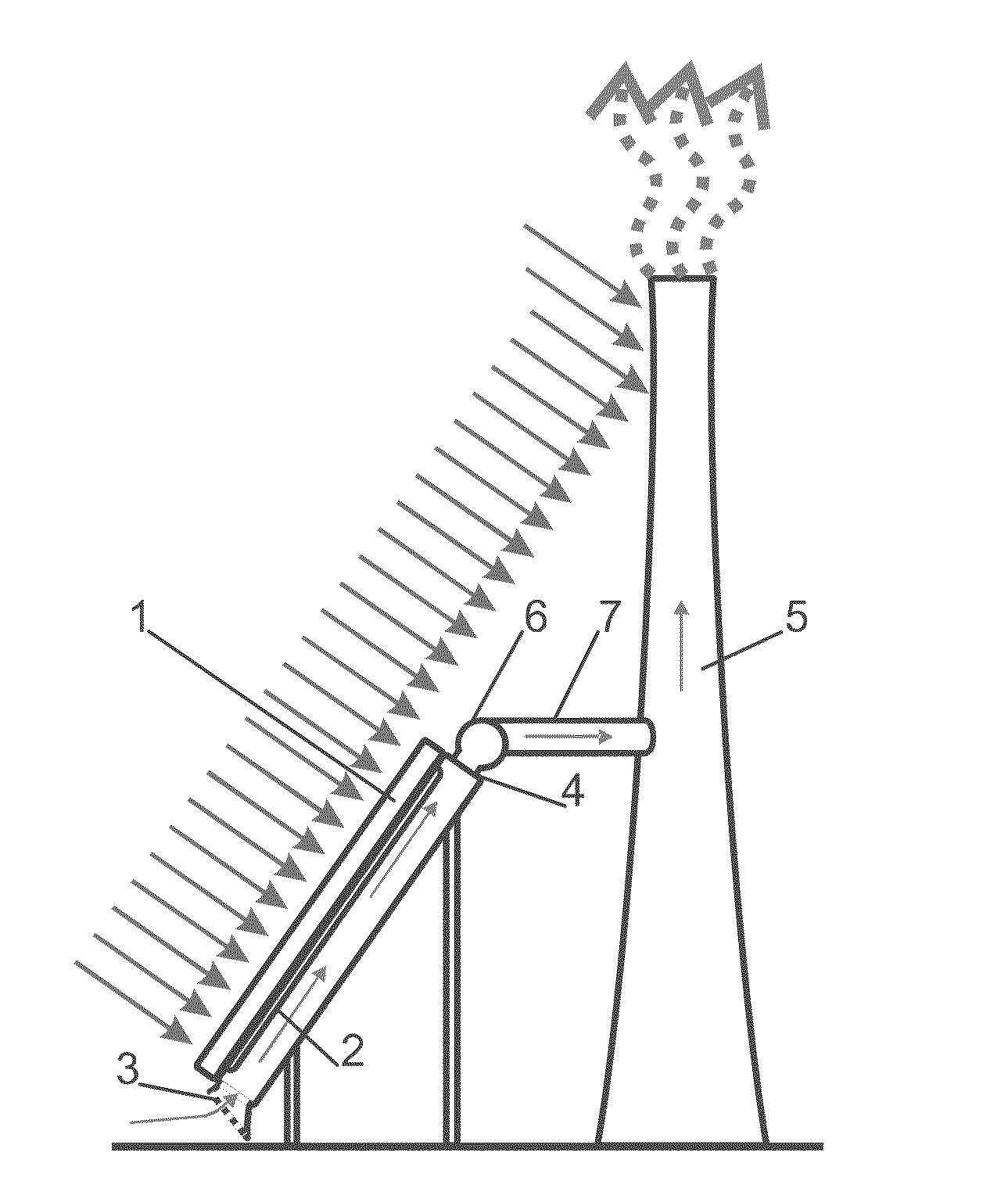

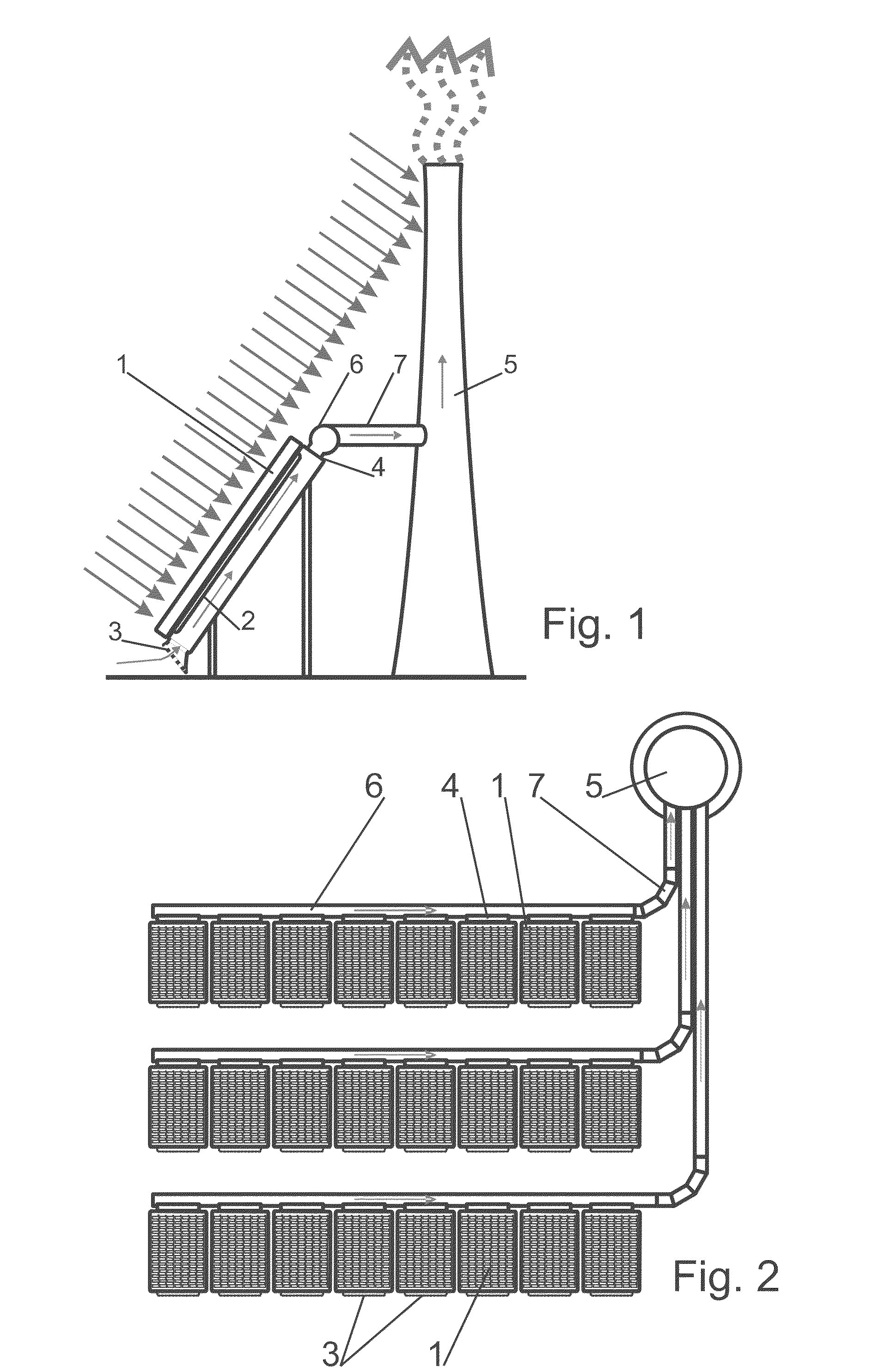

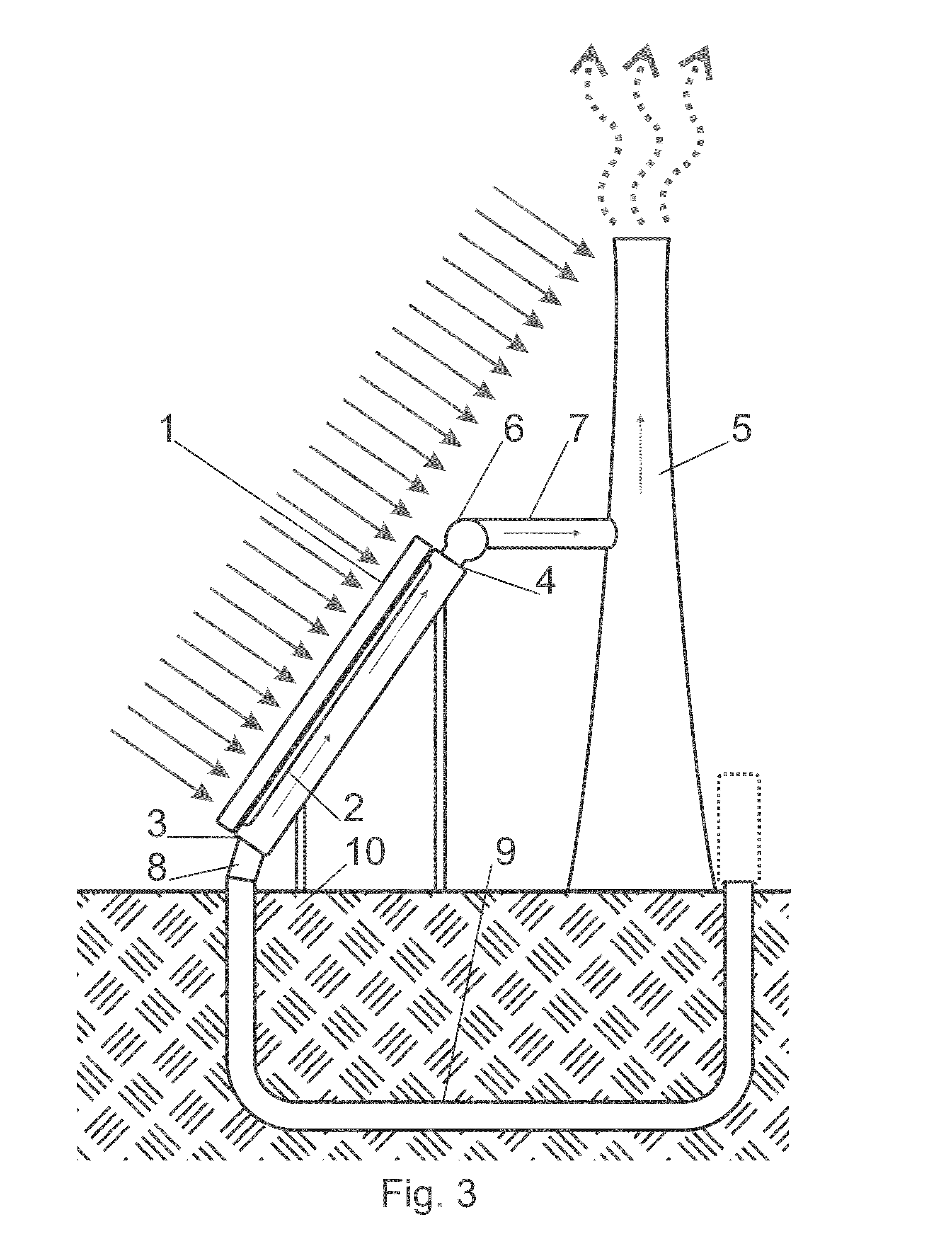

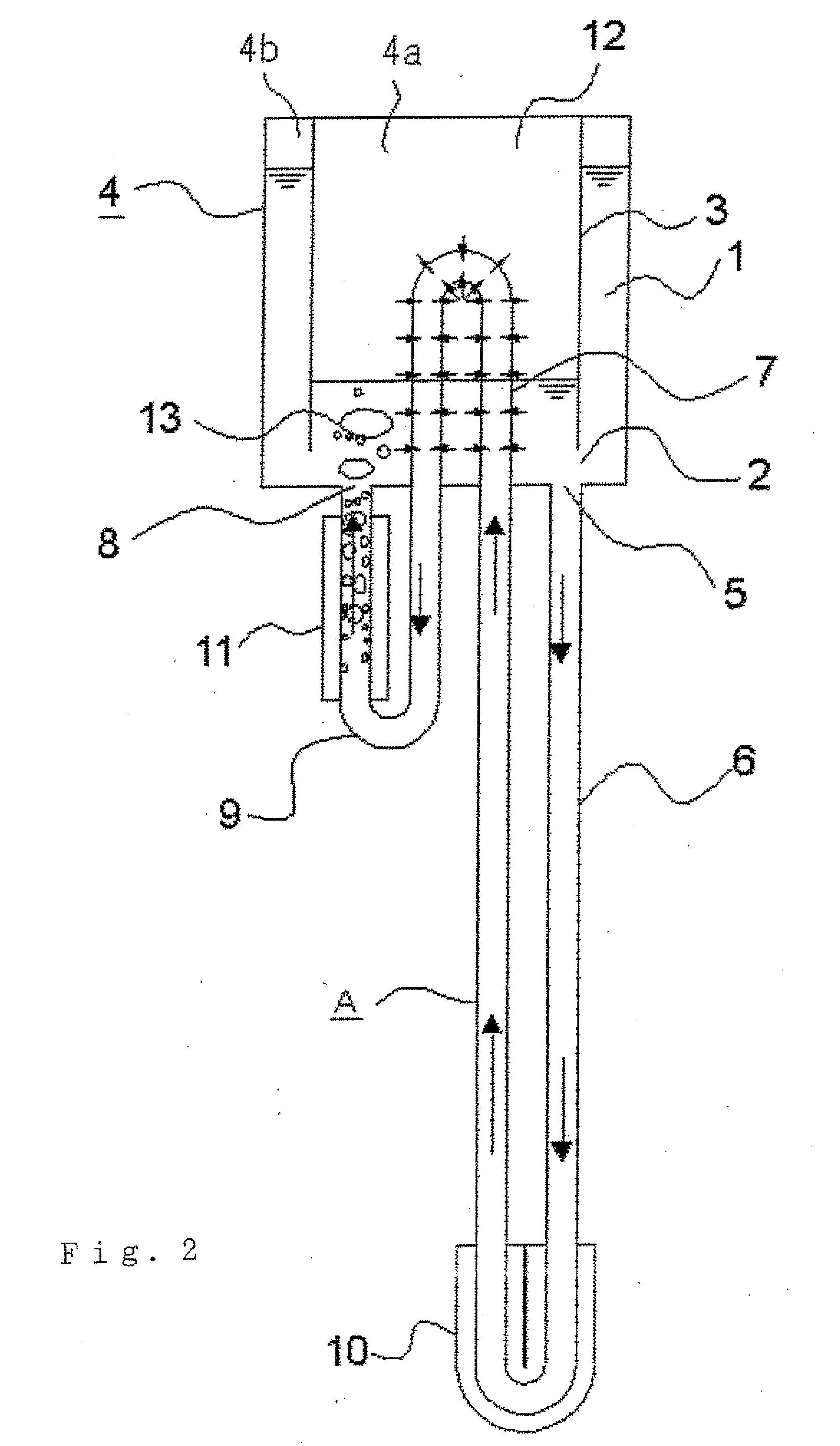

System and method of cooling of photovoltaic panel and method of installation of system

InactiveUS20150155826A1Increase airflowReduce the temperatureSolar heating energyPV power plantsNatural ventilationGround-coupled heat exchanger

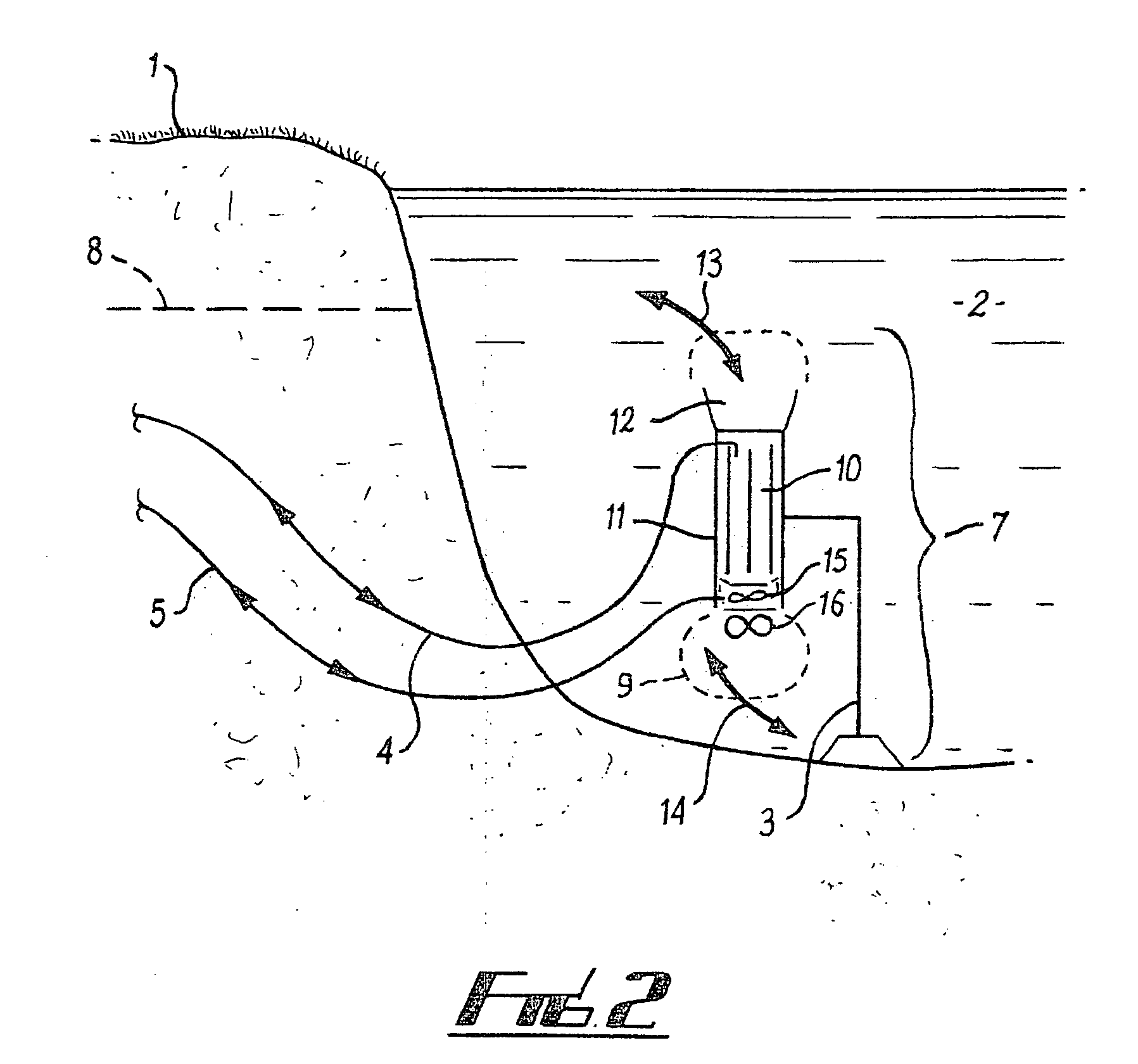

A heat is taken from a photovoltaic panel (1) using air that flows through the photovoltaic panel (1) unit with an air cooler (2). The unit has an air intake opening (3) and an outtake vent (4) and the air flow is enforced by a natural draft of a chimney (5), to which the photovoltaic panel (1) unit is connected to. At least a part of the chimney (5) is exposed to solar radiation. Outtake vents (4) of several photovoltaic panel (1) units can lead to one chimney (5), preferably through thermal collectors (6) and piping. The air in the chimney is warmed up by solar radiation, the air ascends towards the chimney (5) mouth and the chimney (5) natural draft created in this way enforces air flow within the photovoltaic panel (1) unit. Even the air cooler (2) of the sucked air can form part of the system—preferably in the form of a ground-coupled heat exchanger (9). The chimney (5) can be equipped with heat-absorbing surface and it can also have a supporting wind device transforming wind energy into a natural draft within the chimney (5).

Owner:MASARYK MICHAL

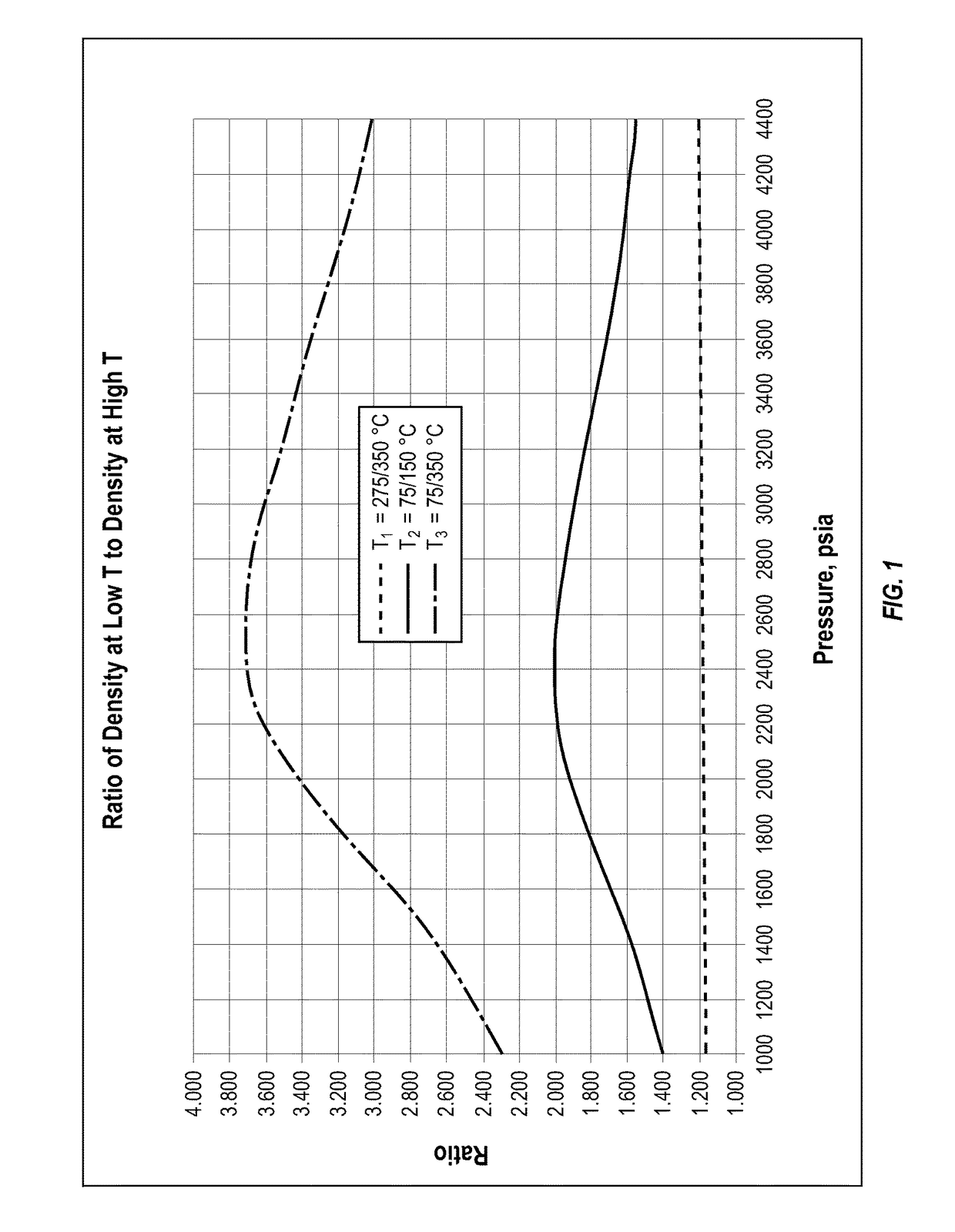

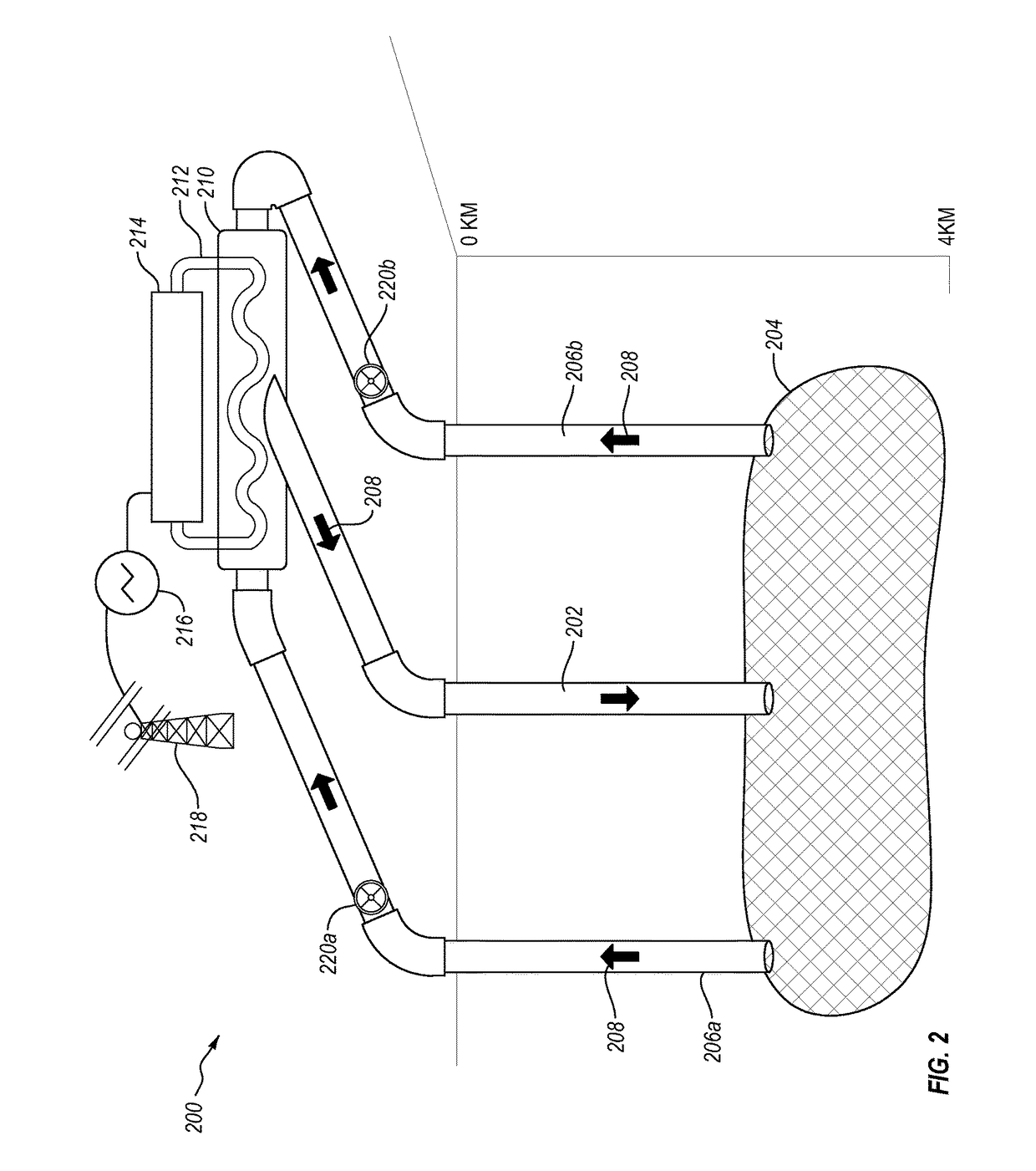

Thermosiphoning supercritical CO2 in geothermal energy production

ActiveUS9803626B1Minimize and eliminate needThermosiphoning is maximizedOther heat production devicesGeothermal energy generationInjection wellGeothermal energy

Methods for thermalsiphoning supercritical CO2 within a geothermal formation includes providing a geothermal energy system that includes an underground hot rock reservoir, a production well, and an injection well that together form a fluid path suitable for circulating supercritical CO2. The supercritical CO2 flows by thermosiphoning. Thermosiphoning is maximized by maintaining a pressure between 1400-4000 psia, an injection temperature in a range from 50-200 C and a production temperature in a range from 150-600 where injection temperature and the production temperature differ by at least 50° C.

Owner:GREENFIRE ENERGY

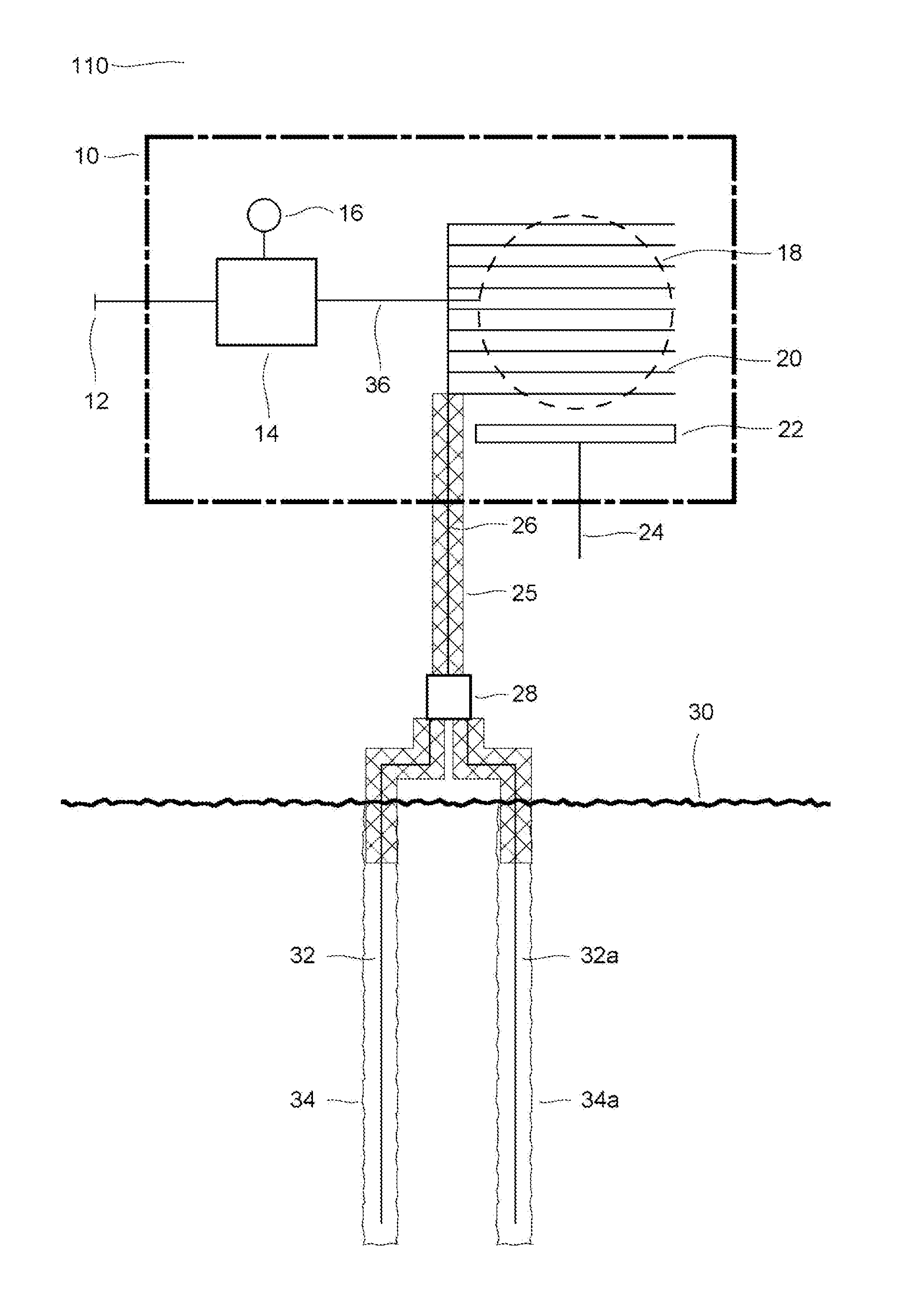

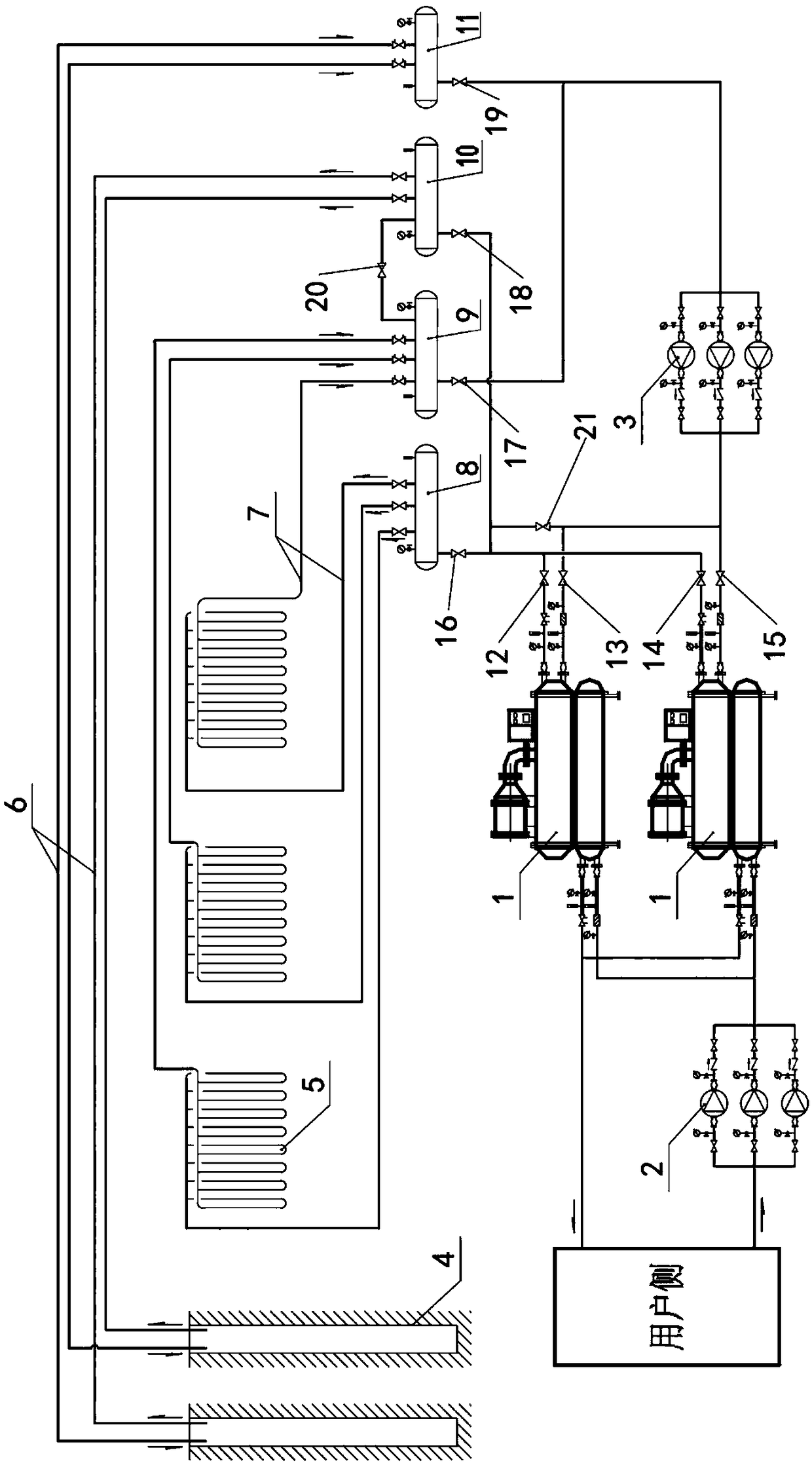

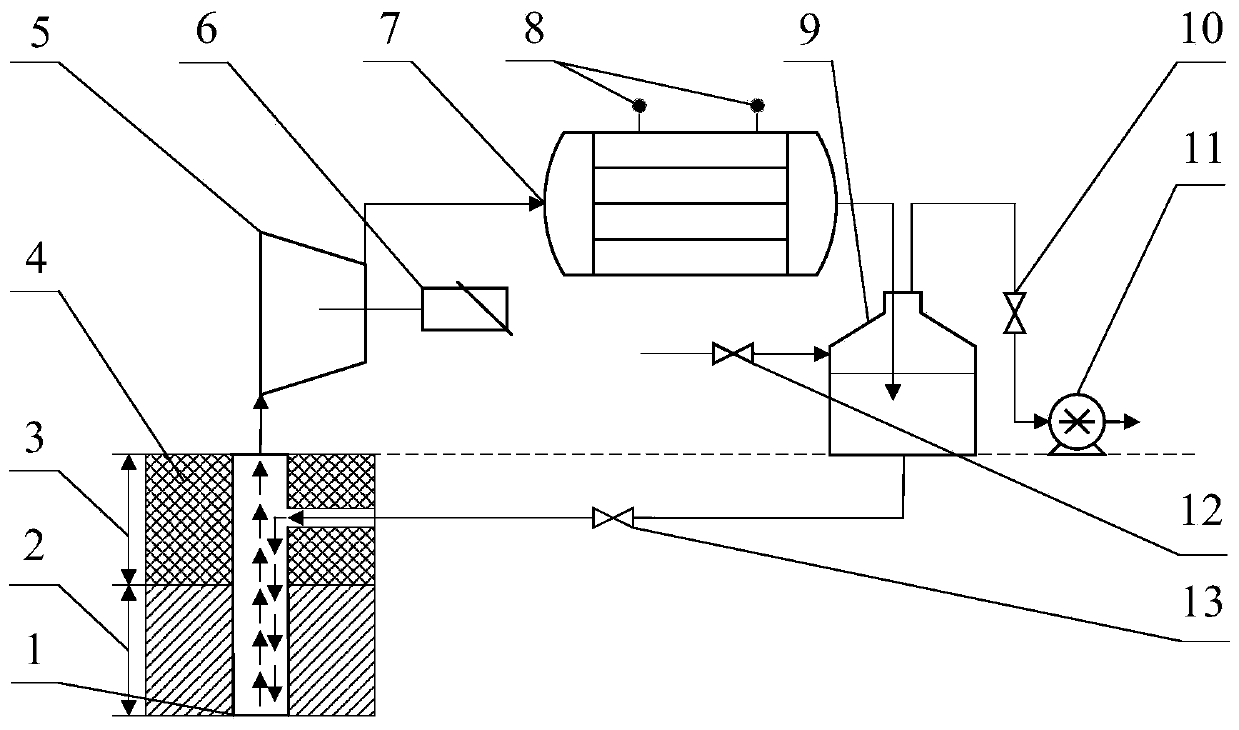

Medium-deep strata and superficial strata geothermal energy combined heat supply and superficial strata geothermal energy heat supplement system

PendingCN109340864AIncrease profitAchieve non-disruptive clean utilizationHeat pumpsIndirect heat exchangersProcess engineeringEnergy supply

The invention provides a medium-deep strata and superficial strata geothermal energy combined heat supply and superficial strata geothermal energy heat supplement system. The system comprises internalswitching heat pump units, user side circulating pumps, ground source side circulating pumps, medium-deep strata geothermal well heat exchange systems and superficial strata buried pipe heat exchangesystems. The system has the advantages of being high in geothermal energy utilization rate, low in engineering investment and operation cost and high in heat pump unit heat supply system efficiency.Meanwhile, the technology is simple, the process of an energy supply system is clear, and efficient combination of the medium-deep strata geothermal energy and the superficial strata geothermal energyis achieved; in the whole geothermal energy utilization process, the heat is obtained, the water is not obtained, interference-free clean utilization of the geothermal energy is achieved, and zero emission of pollutants is achieved in the heat and cold supply process; and the ratio of the medium-deep strata geothermal energy to the superficial strata geothermal energy is allocated according to the user load demand and the actual project situations, and the problem that due to the fact that only the medium-deep strata geothermal energy is used for achieving heat supply, the construction cost is excessively high is effectively solved.

Owner:陕西省煤田地质集团有限公司

Ground-based heat sink facilitating electronic system cooling

InactiveUS9288932B2Other heat production devicesGeothermal energy generationElectronic systemsCoolant flow

Cooling systems and methods are provided which include a heat sink having a housing with a compartment, a coolant inlet, and a coolant outlet. The housing is configured for a coolant to flow from the coolant inlet through the compartment to the coolant outlet, wherein the coolant is transferring heat extracted from one or more electronic components. The heat sink further includes one or more heat pipes having a first portion disposed within the compartment of the housing and a second portion disposed outside the housing. The heat pipe(s) is configured to extract heat from the coolant flowing through the compartment, and to transfer the extracted heat to the second portion disposed outside the housing. The second portion outside the housing is disposed to facilitate conducting the extracted heat into the ground.

Owner:INT BUSINESS MASCH CORP

Ground-based heat sink facilitating electronic system cooling

InactiveUS9363924B2Other heat production devicesGeothermal energy generationElectronic systemsNuclear engineering

Cooling methods are provided which include providing a heat sink having a housing with a compartment, a coolant inlet, and a coolant outlet. The housing is configured for a coolant to flow from the coolant inlet through the compartment to the coolant outlet, wherein the coolant is transferring heat extracted from one or more electronic components. The heat sink further includes one or more heat pipes having a first portion disposed within the compartment of the housing and a second portion disposed outside the housing. The heat pipe(s) is configured to extract heat from the coolant flowing through the compartment, and to transfer the extracted heat to the second portion disposed outside the housing. The second portion outside the housing is disposed to facilitate conducting the extracted heat into the ground.

Owner:INT BUSINESS MASCH CORP

Ground-coupled heat exchange for heating and air conditioning applications

The invention provides systems and methods for cooling and / or heating a structure. Generally, a system for heating or cooling a structure can include at least one thermosiphon in thermal communication with a thermal storage material such as a volume of earth. The thermosiphon can be partially filled with a heat transfer fluid and a heat exchanger operatively connected to the thermosiphon which is in thermal communication with the structure. Thermal energy can be transferred between the thermal storage material and the structure in either a passive or assisted mode, depending on whether the system is charging or in use.

Owner:犹他州立大学研究基金会

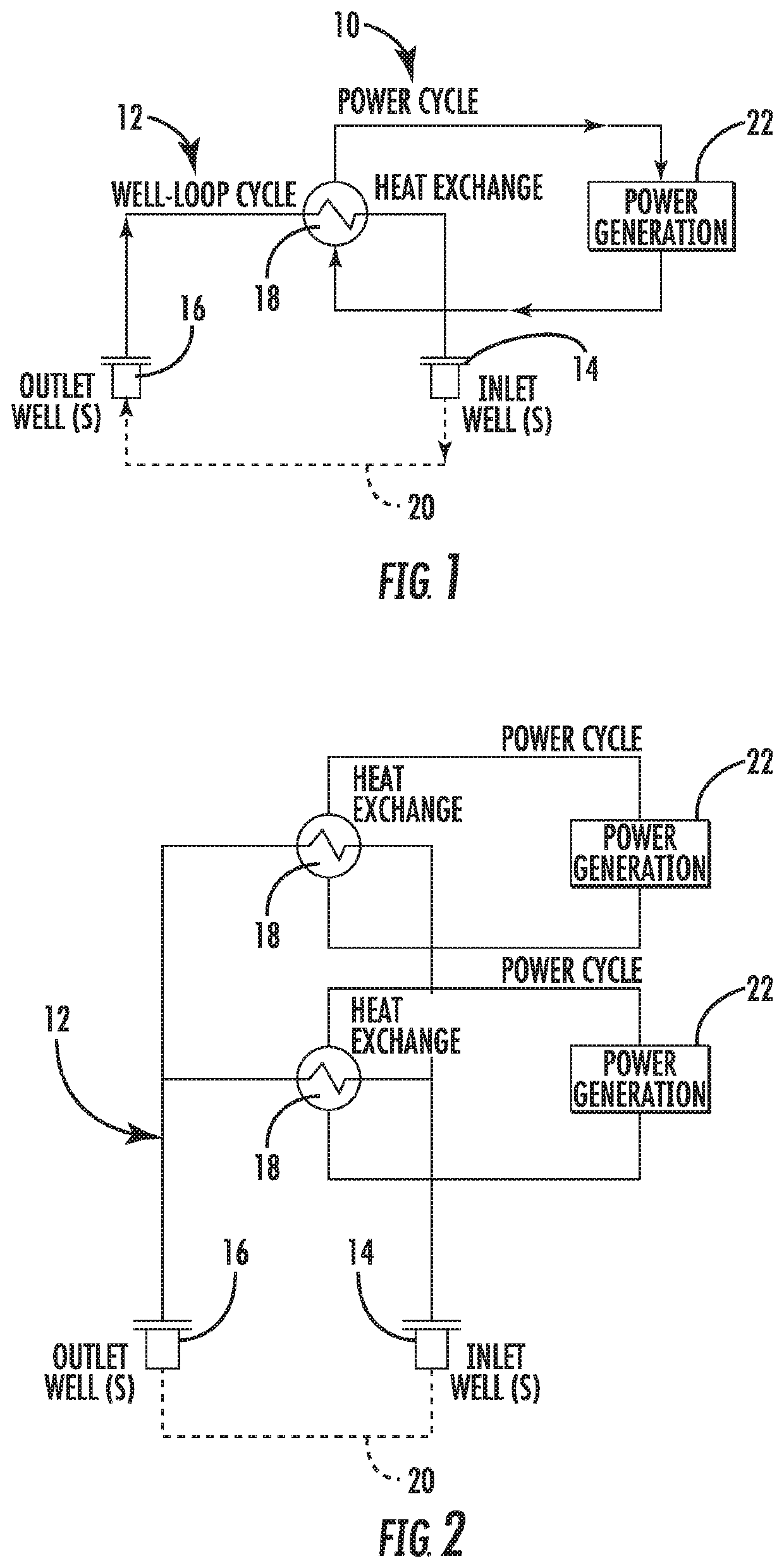

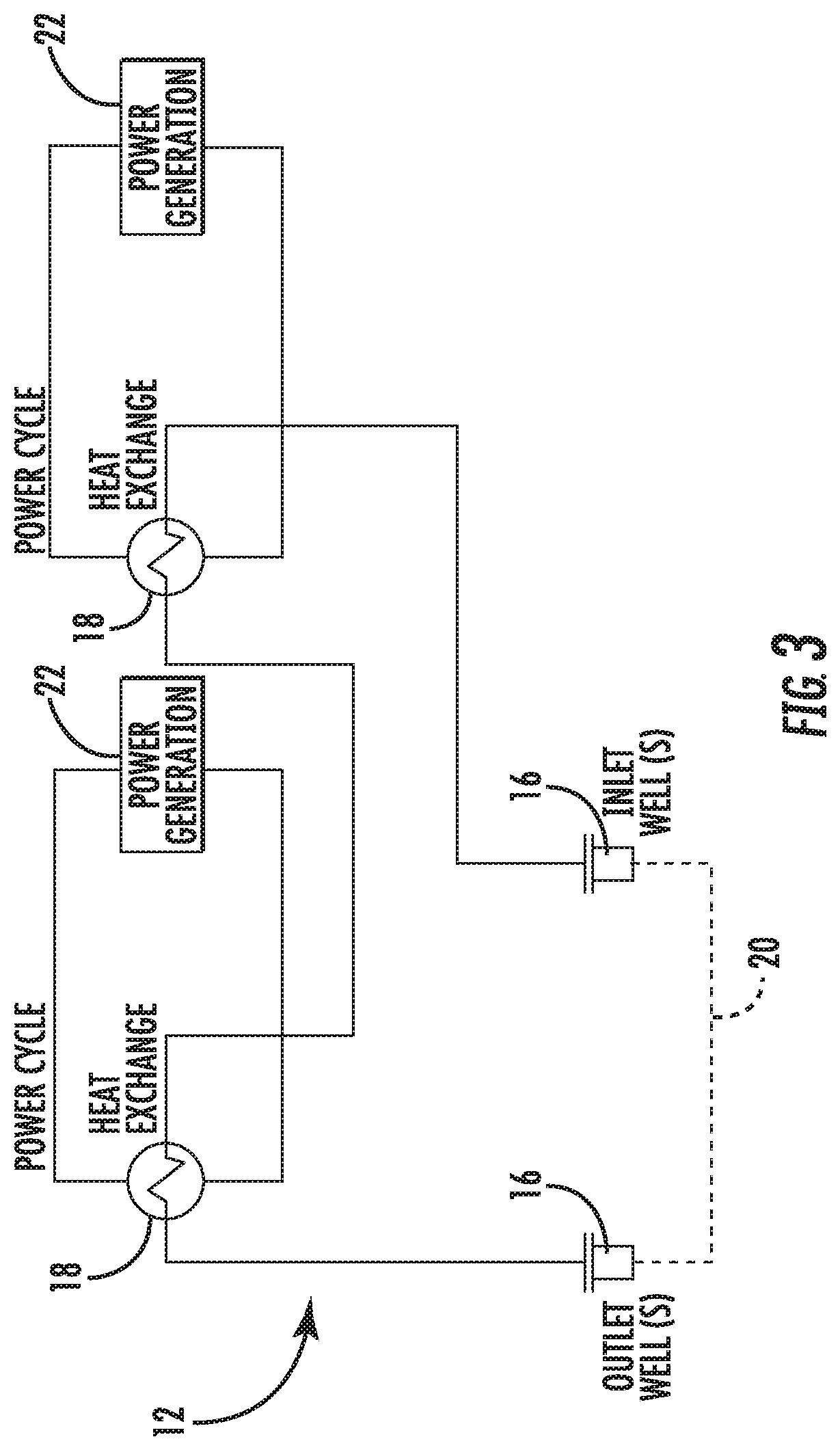

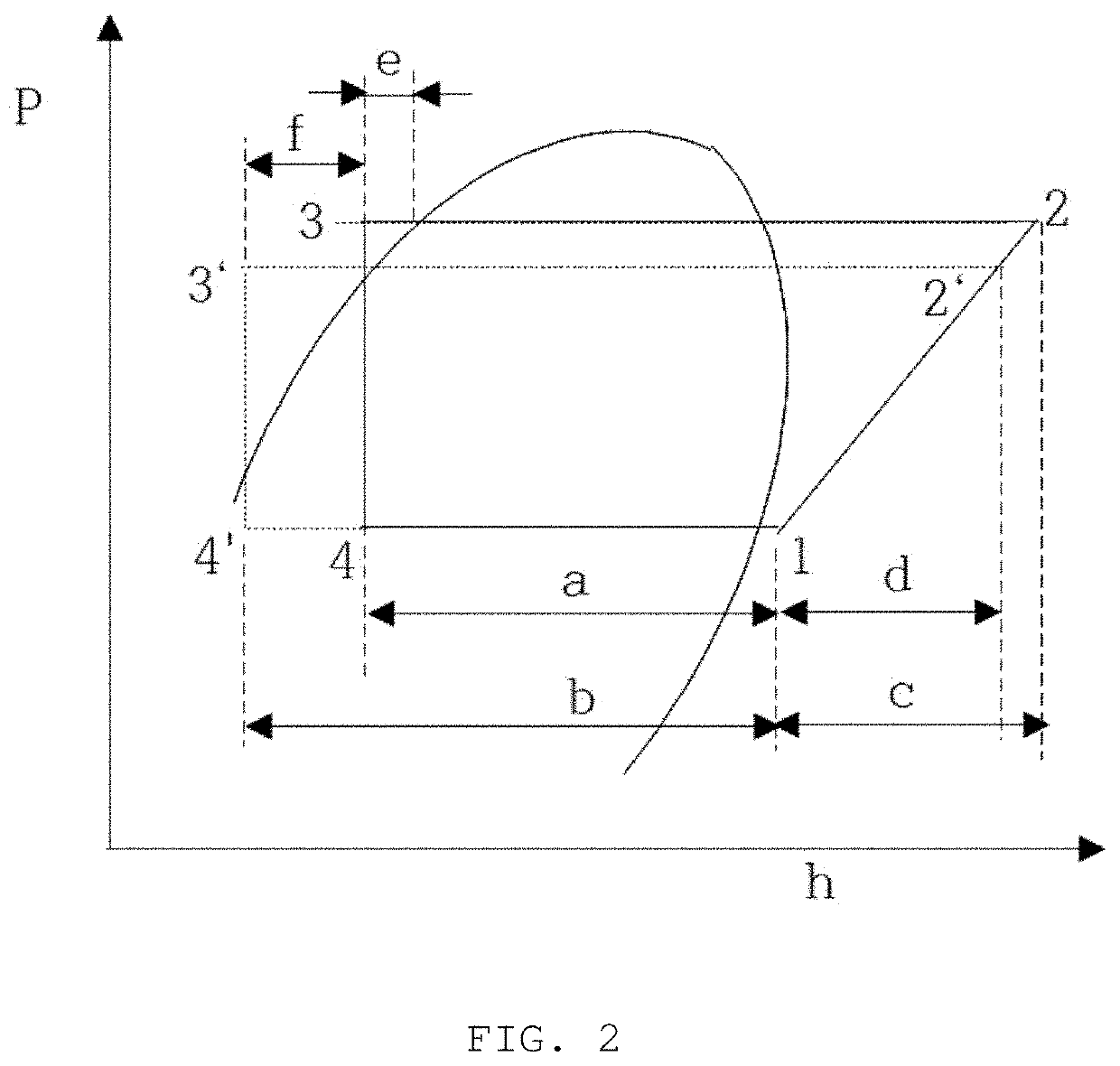

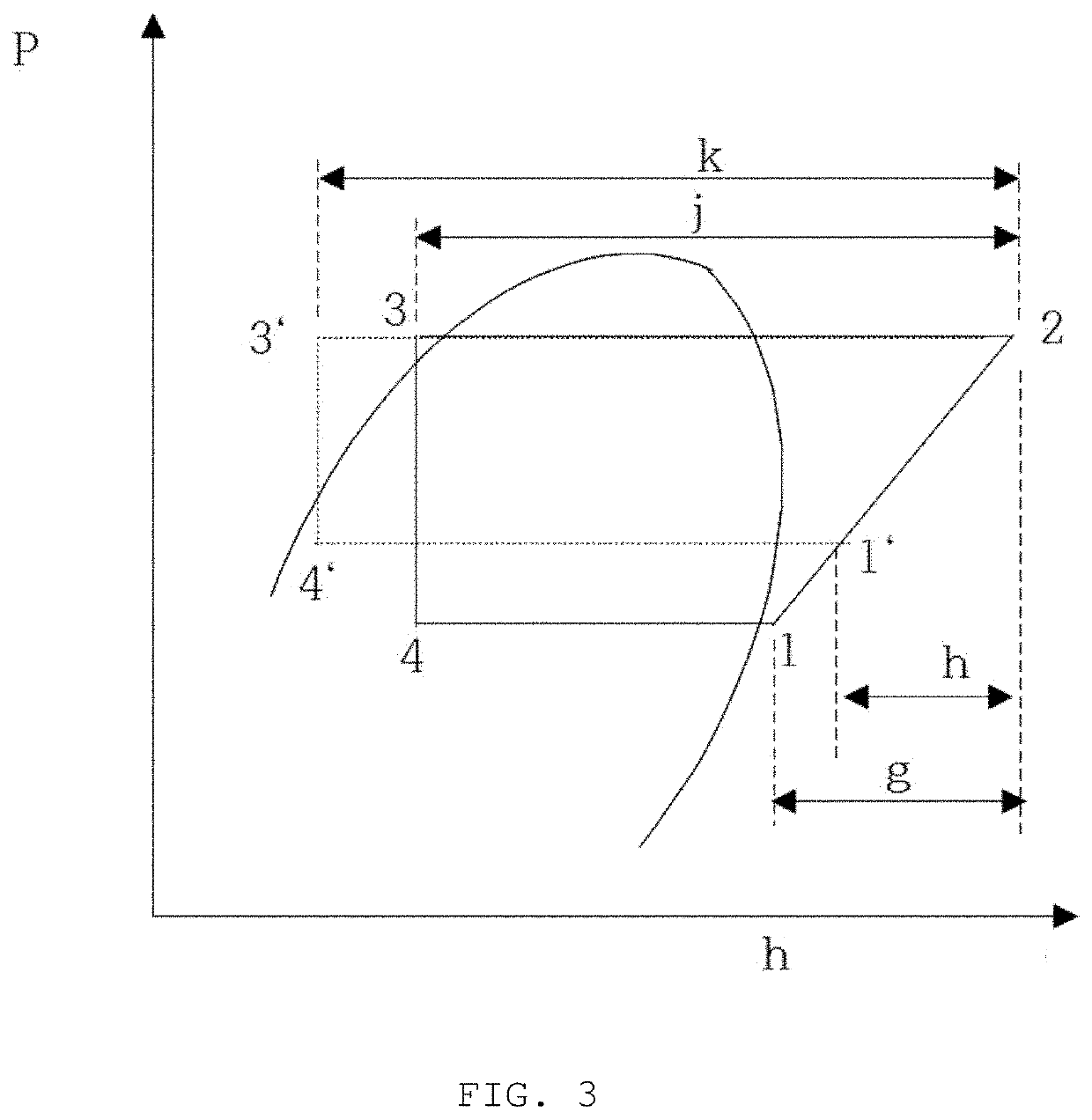

Fluid for use in power production environments

ActiveUS20190346181A1Wide applicabilityMaximize temperatureCollector components/accessoriesLighting and heating apparatusElectricityClosed loop

Fluid classes for use in energy recovery in well and geothermal environments for power production are disclosed. The fluids fall into the classes of fluids being capable of increasing thermodynamic efficiency of electricity and / or heat generation from a closed-loop geothermal system. Numerous methods are disclosed which exploit the thermodynamics of the fluids for optimum energy recovery.

Owner:EAVOR TECH INC

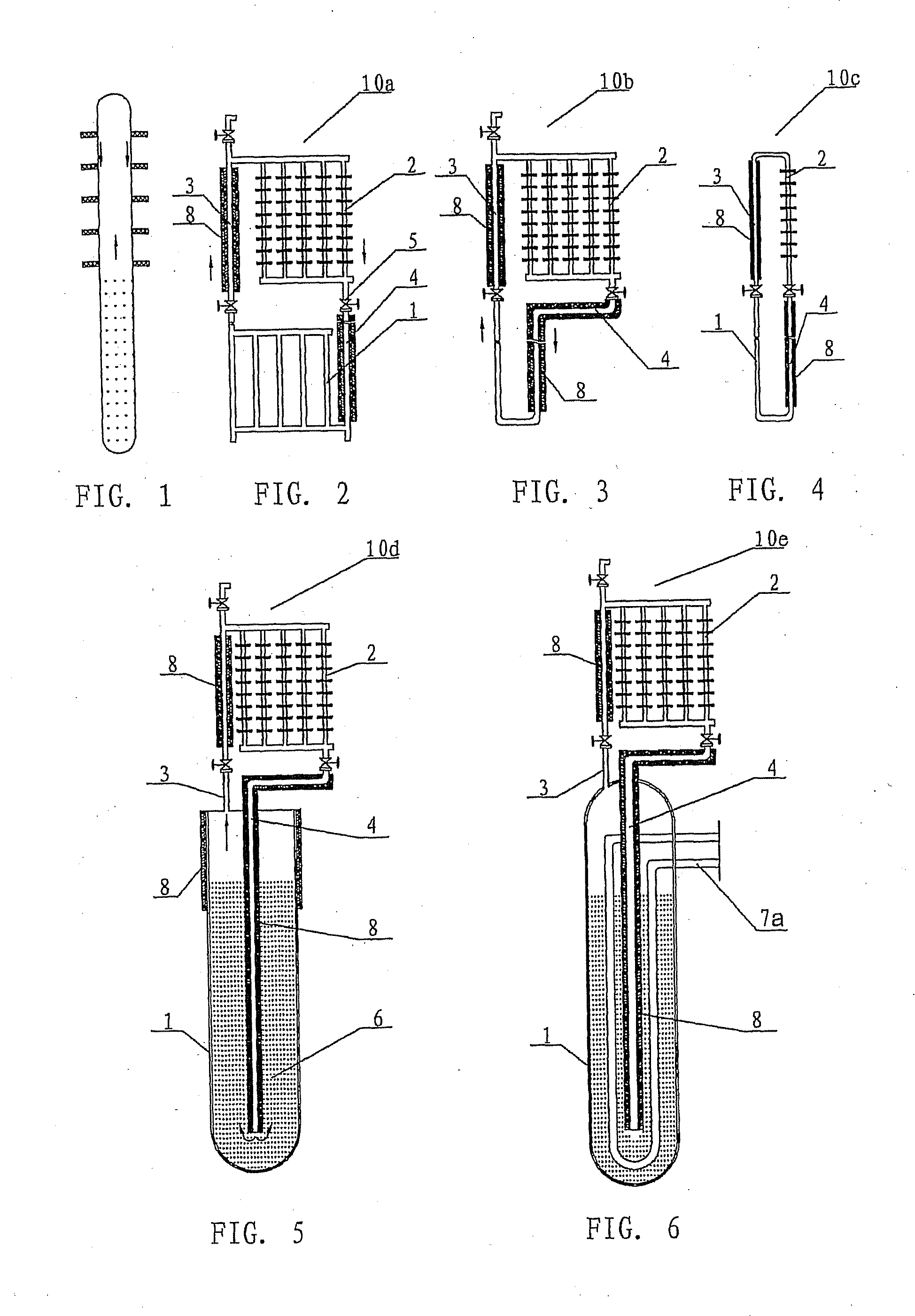

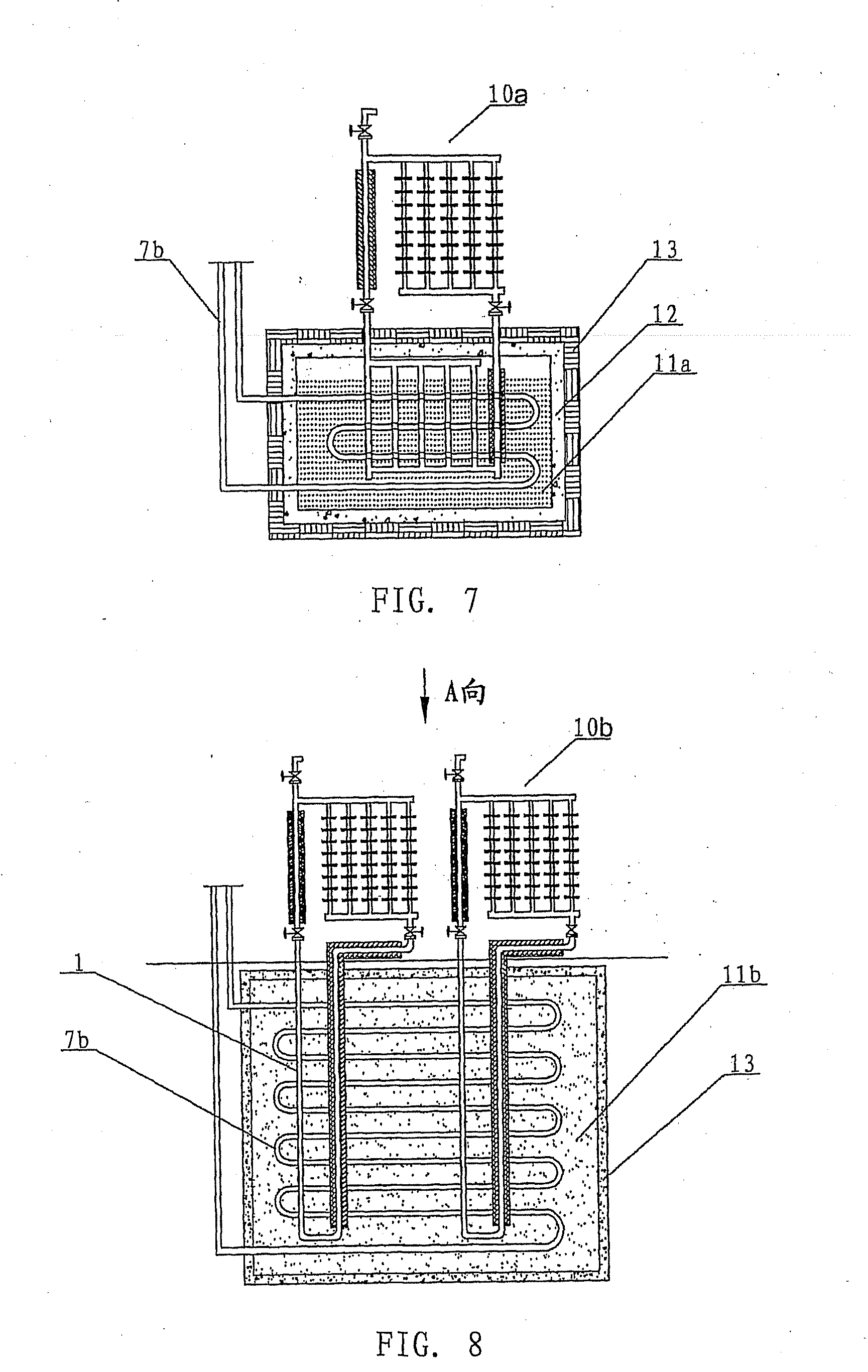

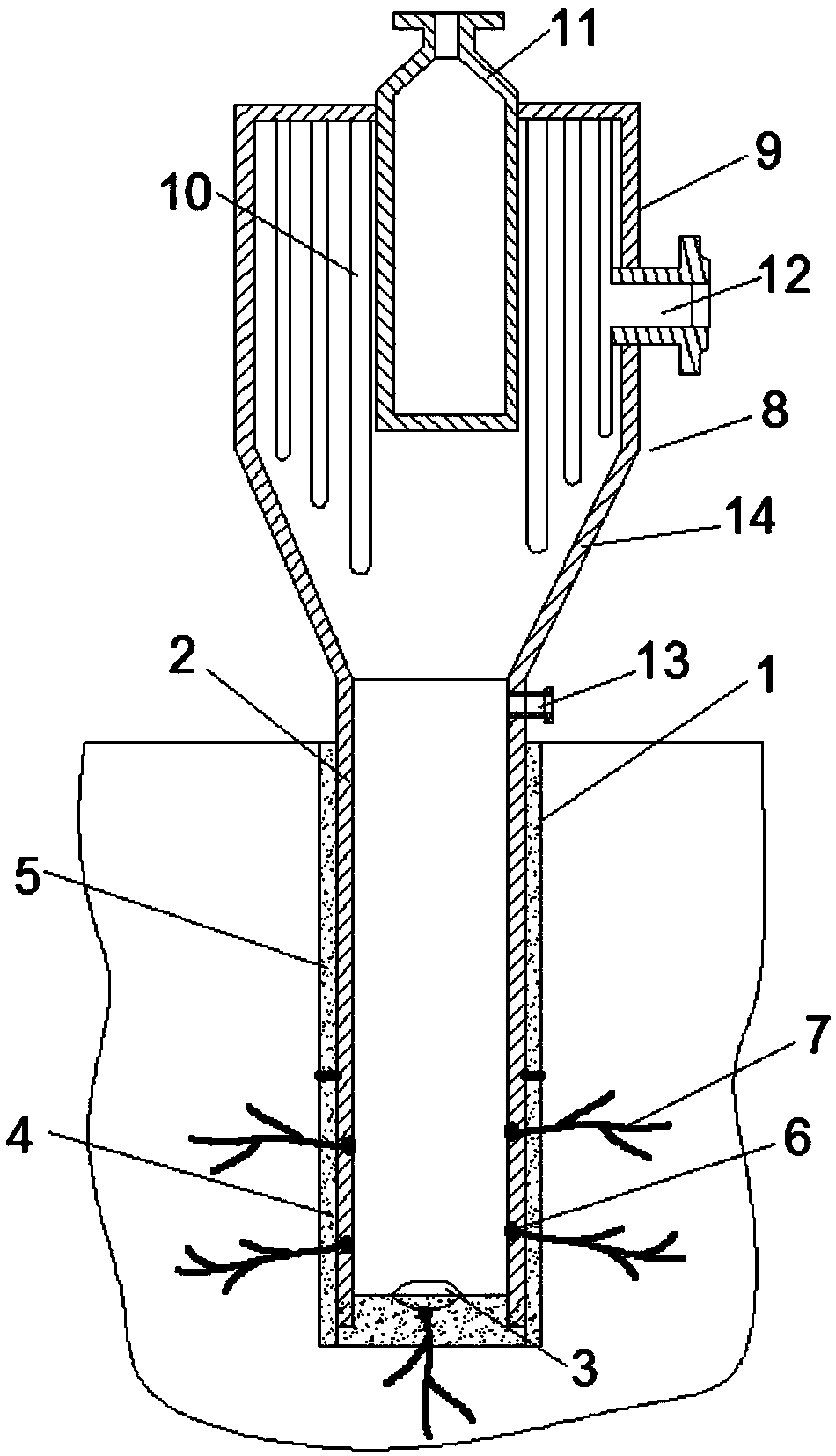

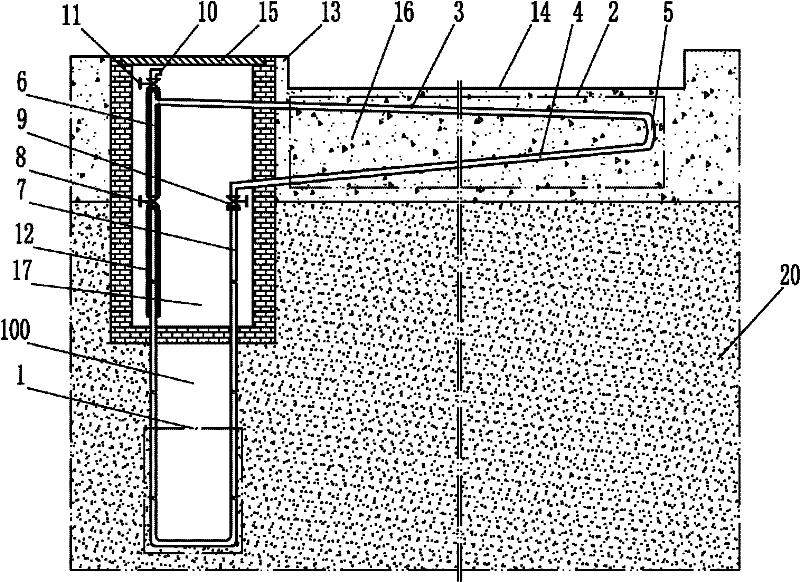

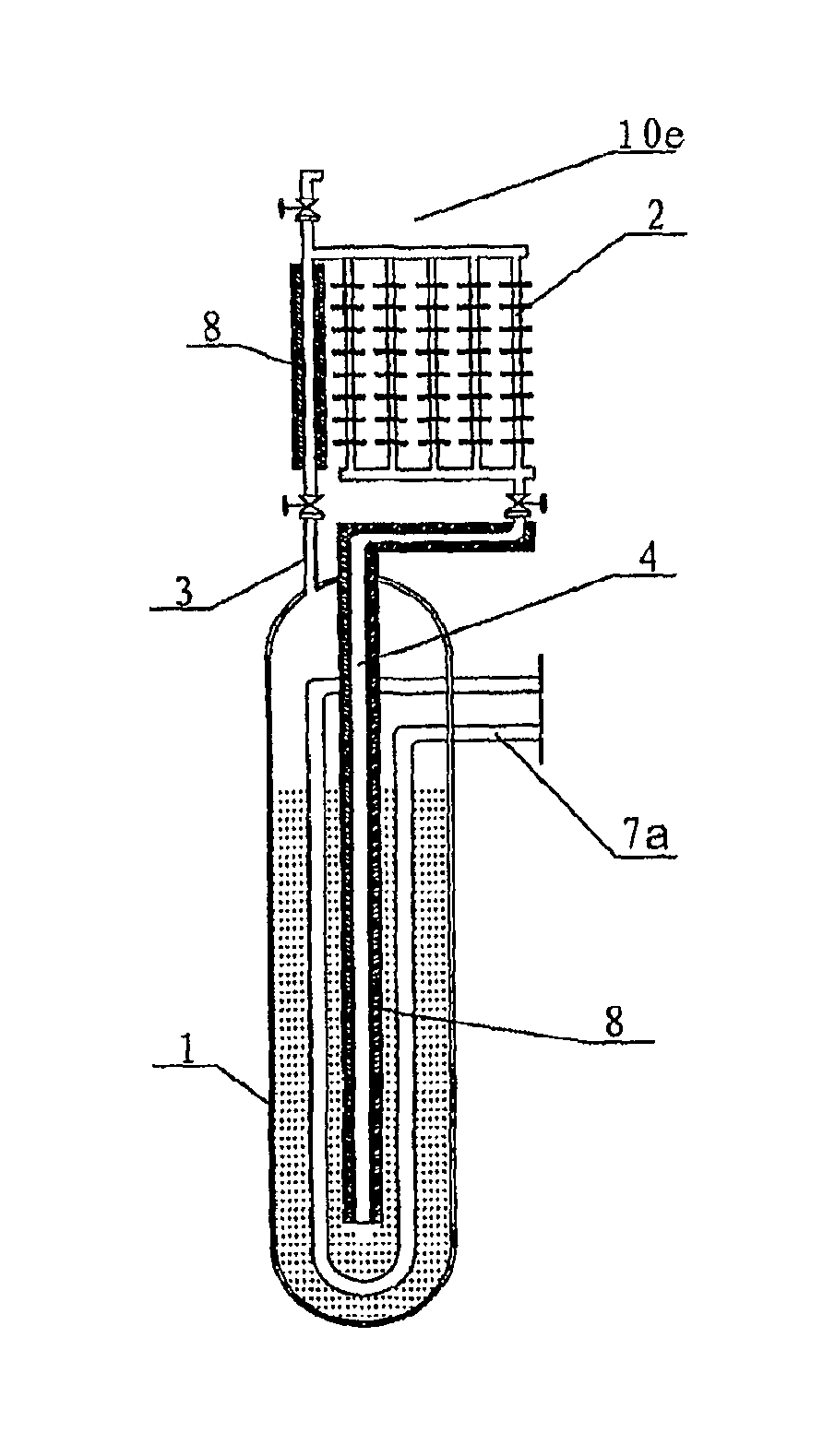

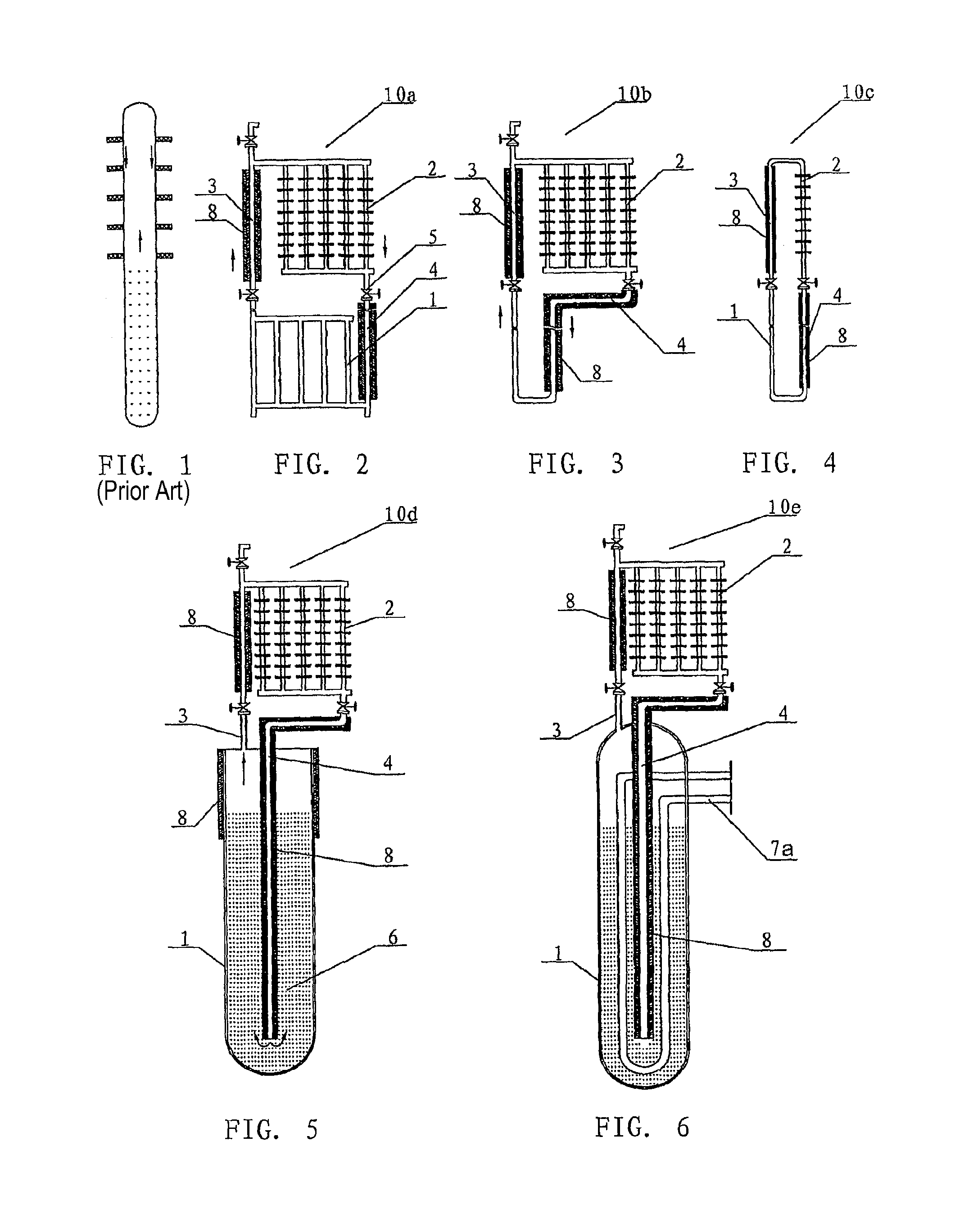

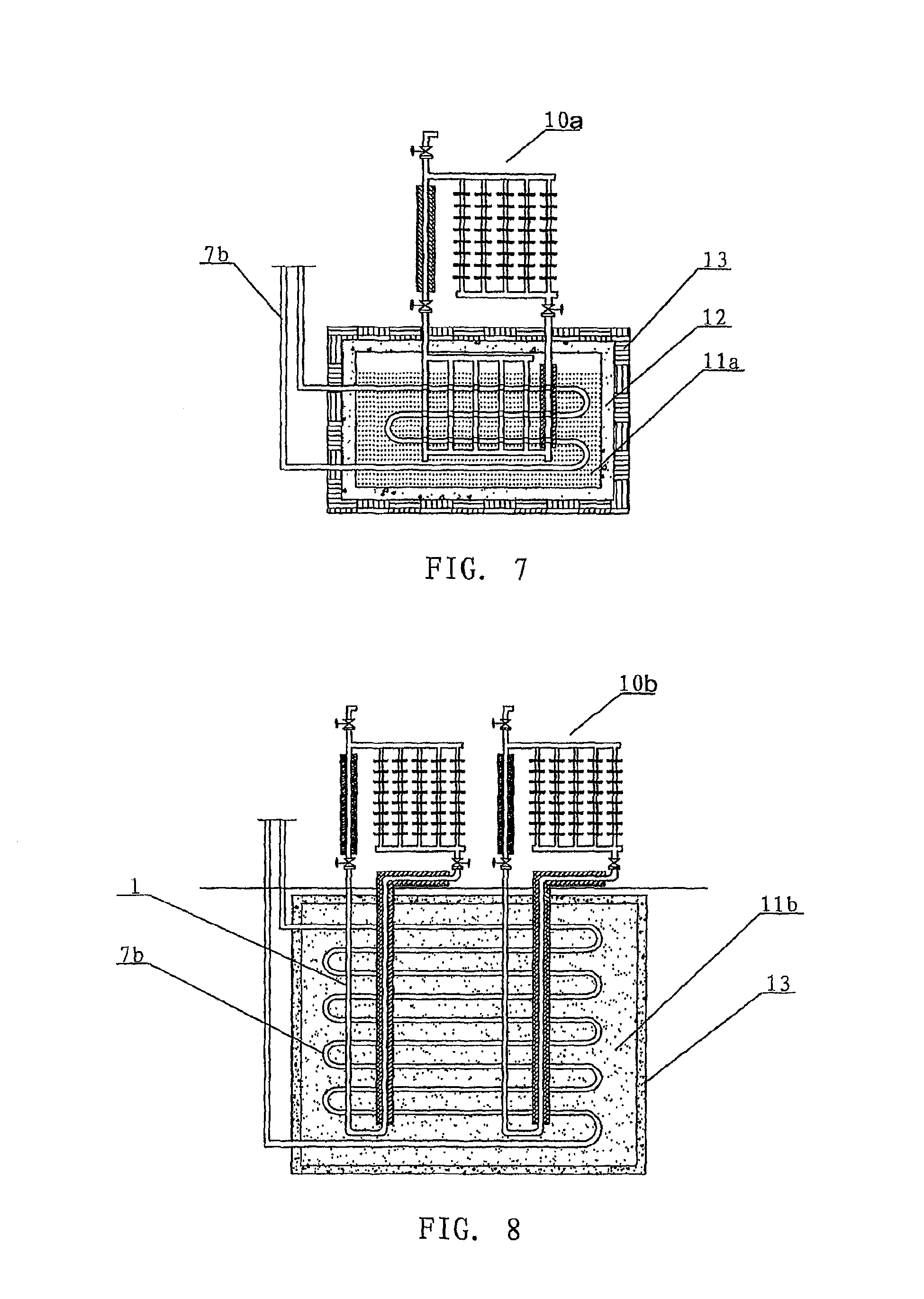

Ground temperature regulation and snow melting device using natural geothermal heat and its application

ActiveCN102277819AInhibition retentionPrevent freezingOther heat production devicesGeothermal energy generationThermal energyWorking fluid

The invention relates to a ground temperature-regulating snow-melting device utilizing natural geothermal energy and its application, belonging to a geothermal utilization system, in particular to a snow-melting device for snow and ice removal. It includes a heat collection part and a heat dissipation part. The heat collection part is connected with the heat dissipation part through the output pipe and the return pipe to form a closed circuit. The characteristic is that the circuit is equipped with a low boiling point working fluid. The cooling tube is connected with the collecting tube through the return part, the collecting tube is located under the cooling tube, the two ends of the cooling tube are respectively connected with the output tube and the return part, and the two ends of the collecting tube are respectively connected with the return part and the return part. The upper ends of the pipes are connected, and the collecting pipe is continuously inclined downward from the return part to the return pipe, and the inclination is less than 1:10. The invention utilizes the heat medium with a low boiling point in the heat collector to absorb underground heat energy, and the heat medium after absorbing heat and gasification directly transmits heat to the radiator installed under the ground or road surface, so as to prevent frost and snow from remaining on the ground or road surface Or the effect of melting frost and snow, it does not consume extra energy, is environmentally friendly and economical, and can ensure the smooth flow of roads.

Owner:尹学军 +1

Vapor-lift pump heat transport apparatus

InactiveUS20070089861A1Small resistanceLarge capacityOther heat production devicesGeothermal energy generationVapor liquidHeat resistance

A vapor-lift pump heat transport apparatus having a small heat resistance and a large heat transport capacity. A heat exchange circulating solution container has a first space and a second space communicating with the first space through a communication opening and contains a heat exchange circulating solution, and vapor thereof, in each space. A circulating solution transport passage includes a pipe connected to the solution outlet of the container and provided with a sensible heat releasing heat exchanger, a pipe disposed in the container, and a pipe connected to a vapor-liquid two-phase fluid inlet and provided with a heating heat exchanger. A vapor-liquid two-phase fluid flows into only the first space through the vapor-liquid two-phase fluid inlet. When the entrance of the vapor-liquid two-phase fluid has caused a pressure difference between the first and second spaces, a difference occurs between the positions of the vapor-liquid interfaces in the first and second spaces.

Owner:MITSUBISHI ELECTRIC CORP

Operational protocol for harvesting a thermally productive formation

PendingUS20210003320A1Effective recoveryAlleviate challengeCollector components/accessoriesConstructionsThermodynamicsWell drilling

Owner:EAVOR TECH INC

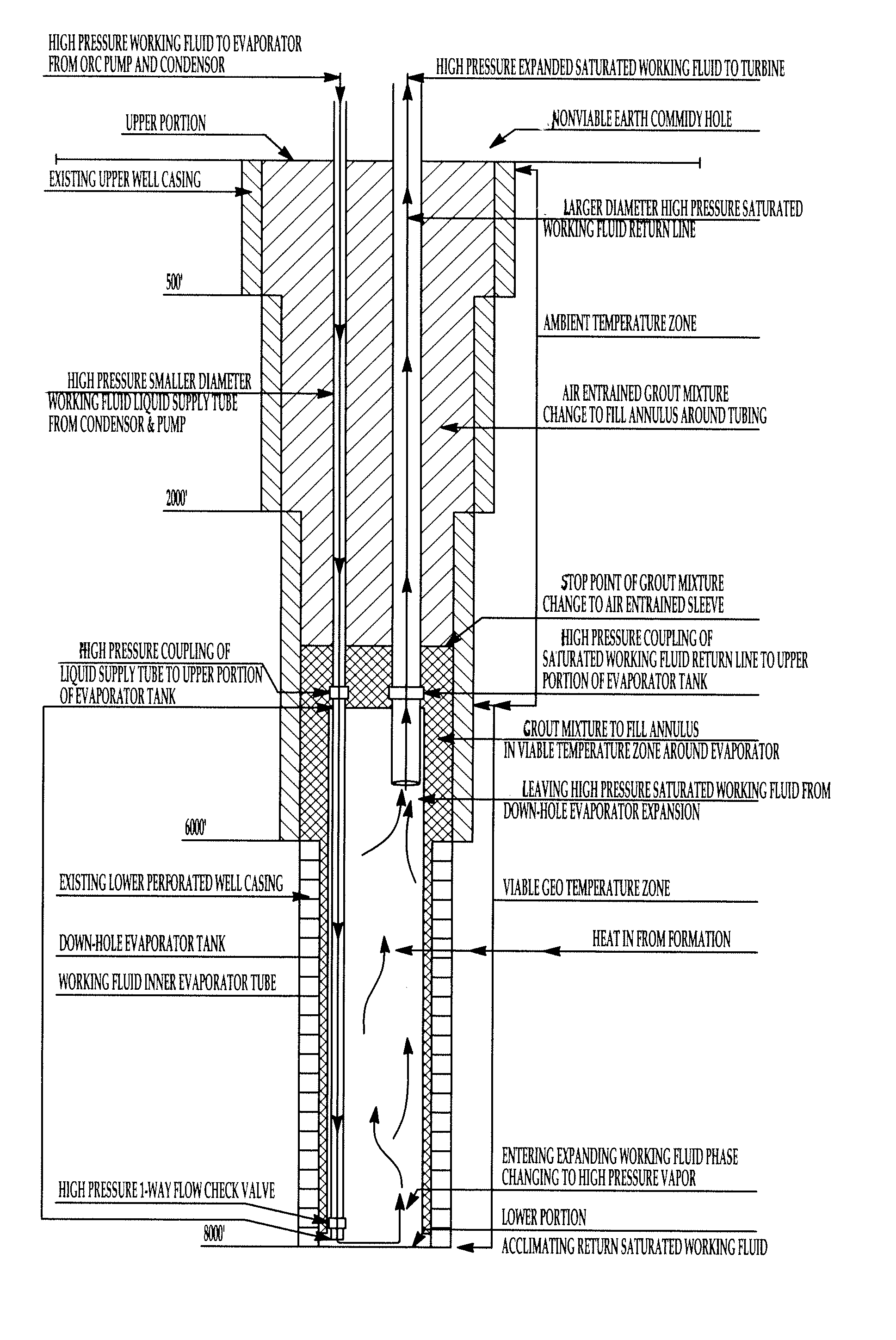

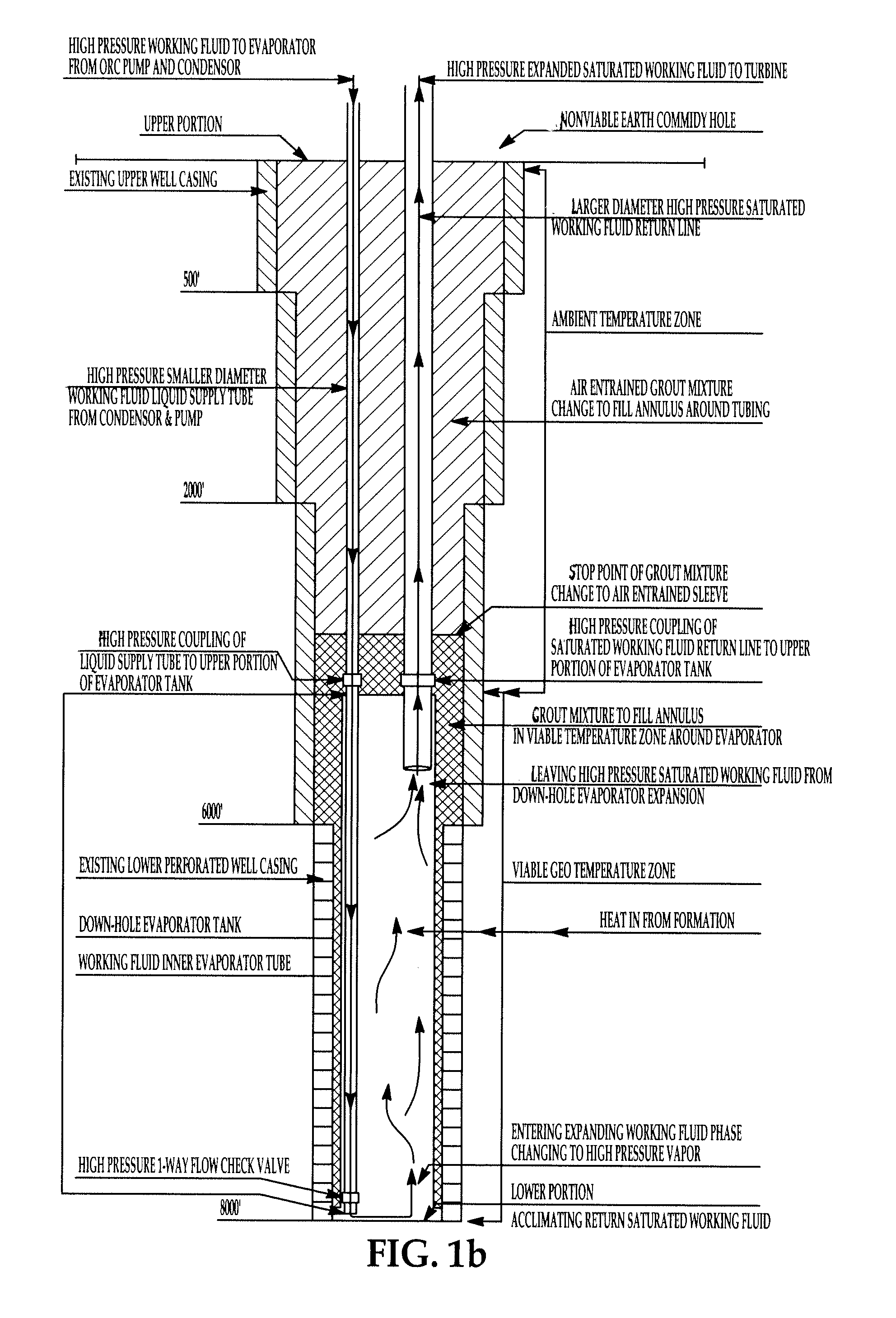

Methods and systems for hole reclamation for power generation via geo-saturation of secondary working fluids

InactiveUS20090321040A1Premium priced powerEase premium power pricesOther heat production devicesGeothermal energy generationWorking fluidFilling materials

This invention relates to systems and methods for using a hole to generate power via geo-saturation of secondary working fluids. One system includes a plurality of conduits / tubulars / exchangers, a thermal hydraulic engine, power generation equipment, organic compound secondary working fluid, thermally conditioned fill material, a condenser, a cooling apparatus, and a fluid pump.

Owner:POITRAS JOSHUA J

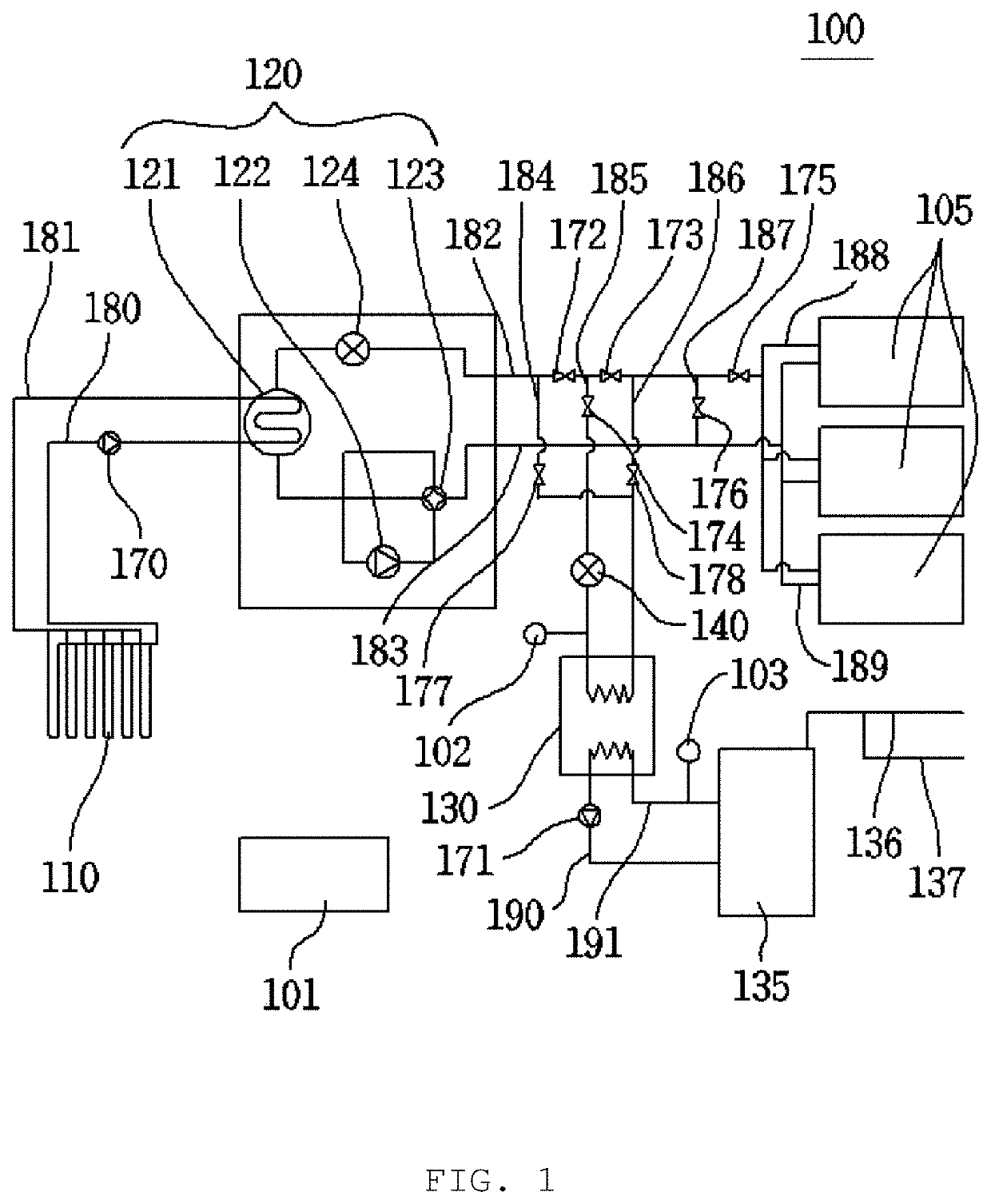

Intelligent heat pump system having dual heat exchanger structure

ActiveUS20200278135A1Reduce power consumptionEasy to operateMechanical apparatusHeat pumpsEngineeringRefrigerant

An intelligent heat pump system having a dual heat exchanger structure includes a heat source side heat exchange member, a heat pump, an external expansion valve, a refrigerant-water heat exchanger, a heat storage tank, and a target side end unit. A refrigerant flows through the heat pump, the refrigerant-water heat exchanger, and the target side end unit, and in a non-air-conditioning state for the target site, circulates between the heat pump and the refrigerant-water heat exchanger, so that cooled or heated water is stored in the heat storage tank. In an air-conditioning state for the target site, the heat pump and the heat storage tank supply cooling and heating to the target site, so that the power consumption for normal operation is reduced in order to improve the operation efficiency of the intelligent heat pump system.

Owner:J&G CO LTD

Geothermal heating system and method

PendingCN111237847AReduce condensation lossIncrease productionGeothermal energy generationIndirect heat exchangersGeothermal heatingWater vapor

The invention discloses a geothermal heating system and method. The geothermal heating system comprises equipment of a heat pipe, a vapor compressor, a heat exchanger and the like, through a heat pipestructure deeply buried in the ground by 50 m or below, under a required pressure environment, working medium liquid water in the heat pipe is evaporated by absorbing deep geothermal energy, obtainedwater vapor enters a vapor compressor to be heated and pressurized, and then releases latent heat through the heat exchanger to be condensed, thus the purpose of supplying the heat to a user side isrealized, and then saturated liquid water generated through condensation is returned into the heat pipe to be recycled. The geothermal heating system and method recycle free geothermal resources to the greatest extent, has the advantages of being less in vapor loss, high in heat-exchanging efficiency, good in heating performance, low in operating cost, simple in operation process and the like, andis suitable for the fields of life, industrial heat supply, refrigeration and the like.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

Direct exchange geothermal refrigerant power advanced generating system

ActiveUS8650875B2Improve heat transfer efficiencyReduce operating costsLighting and heating apparatusGeothermal energy generationWorking fluidClosed loop

A single closed loop direct exchange geothermal power production system that utilizes a refrigerant working fluid in at least one of three primary designs to generate electrical power from deep wells: with a first version of a direct exchange geothermal power generating system operating primarily on refrigerant vapor pressure; with a second version of a direct exchange geothermal power generating system operating primarily on liquid refrigerant gravitational pressure; and with a third version of a direct exchange geothermal power generating system operating primarily on both liquid refrigerant gravitational pressure and refrigerant phase change / expansion from a liquid to a vapor state.

Owner:DEEP WELL POWER

Heat tube device utilizing cold energy and application thereof

An energy storage device that stores hot and / or cold energy includes an evaporating part and a condensing part. According to one aspect, the evaporating part includes a heat tube in a U shape or a thimble shape and further includes one or more power cycle tubes. A working substance within the evaporating part evaporates after absorbing heat and condenses in the condensing part after releasing heat.

Owner:YIN XUEJUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com