Technology for improving heat production capacity of geothermal wells

A technology for heat production capacity and geothermal wells, applied in the direction of boreholes/well components, heat collectors that operate without external energy, and production fluids, etc., can solve problems such as increased risk of land subsidence, poor heat transfer capacity, and increased engineering volume , to avoid heat loss, eliminate adverse effects, and accelerate heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

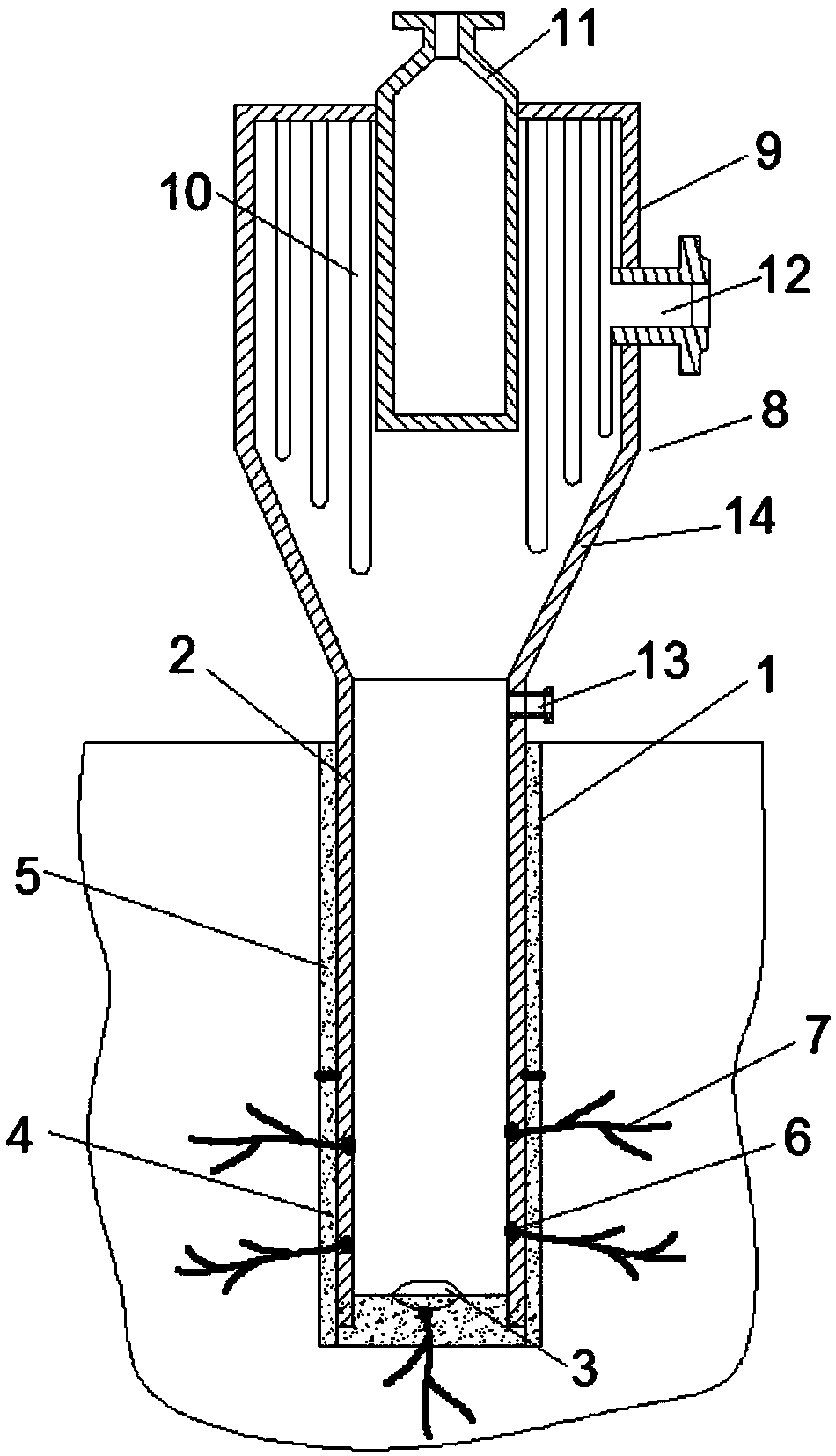

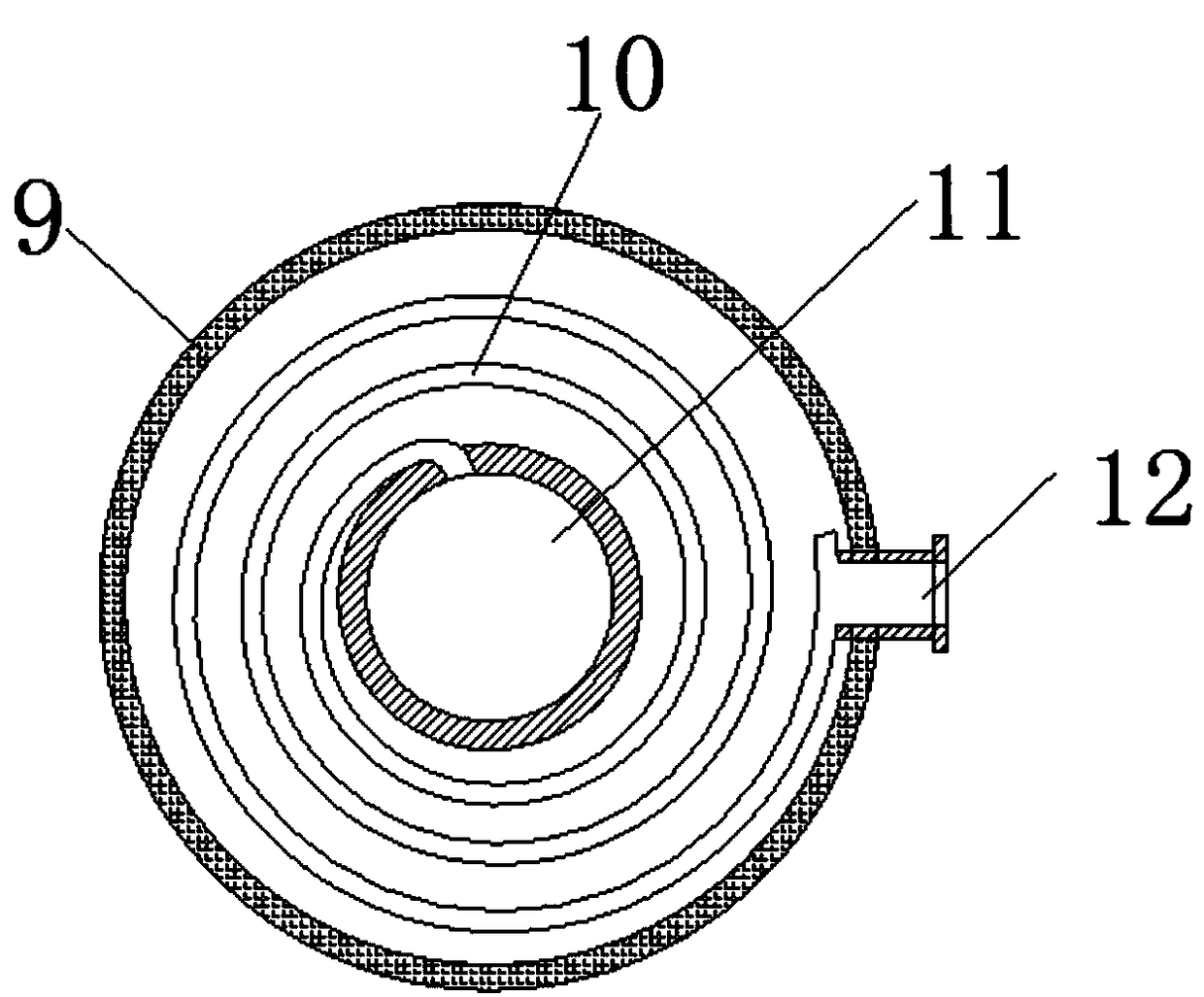

[0031] The process of improving the heat production capacity of geothermal wells, through heat conduction cementing technology and augmentation fracturing technology to improve the ability of geothermal energy in rock formations to import geothermal wells, and then complete efficient heat extraction and heat exchange through gravity heat pipe heat exchangers in the spiral plate condensation section A new geothermal well technology is used; the specific process is as follows: after completion of geothermal well drilling and casing running, heat conduction cementing is performed, that is, heat-insulating cement slurry is injected into the low-temperature section of the formation, and heat-conductive cement slurry is injected into the high-temperature section of the formation to complete the well cementing ; After the heat-insulating cement slurry and heat-conducting cement slurry of the well cementing are solidified, perform segmental perforation and fracturing in the casing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com