Patents

Literature

153results about How to "Increase heat production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical induced intracellular hyperthermia

InactiveUS7635722B1Increase intracellular heatIncrease free radicalBiocidePeptide/protein ingredientsCancer cellUncoupling Agents

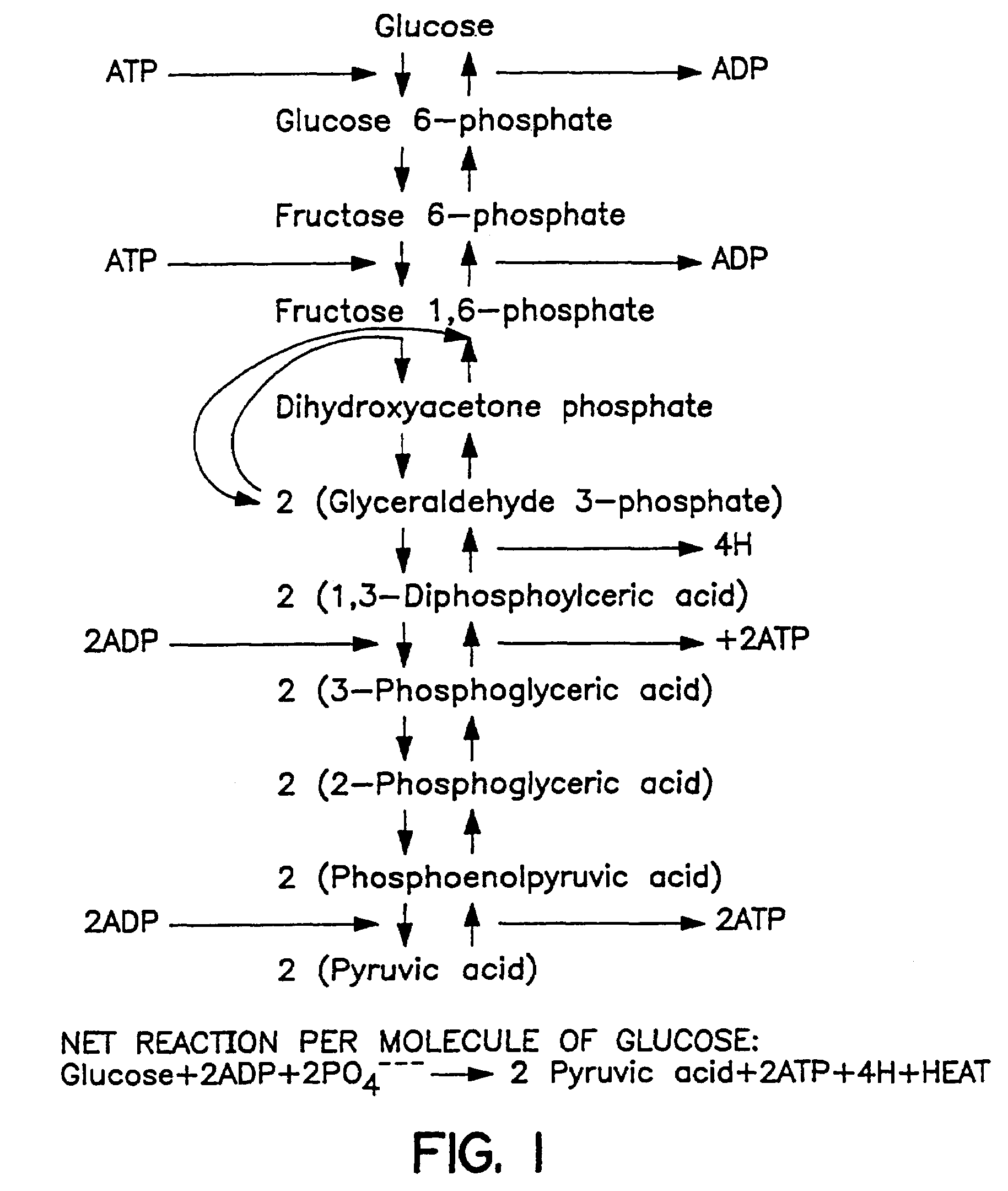

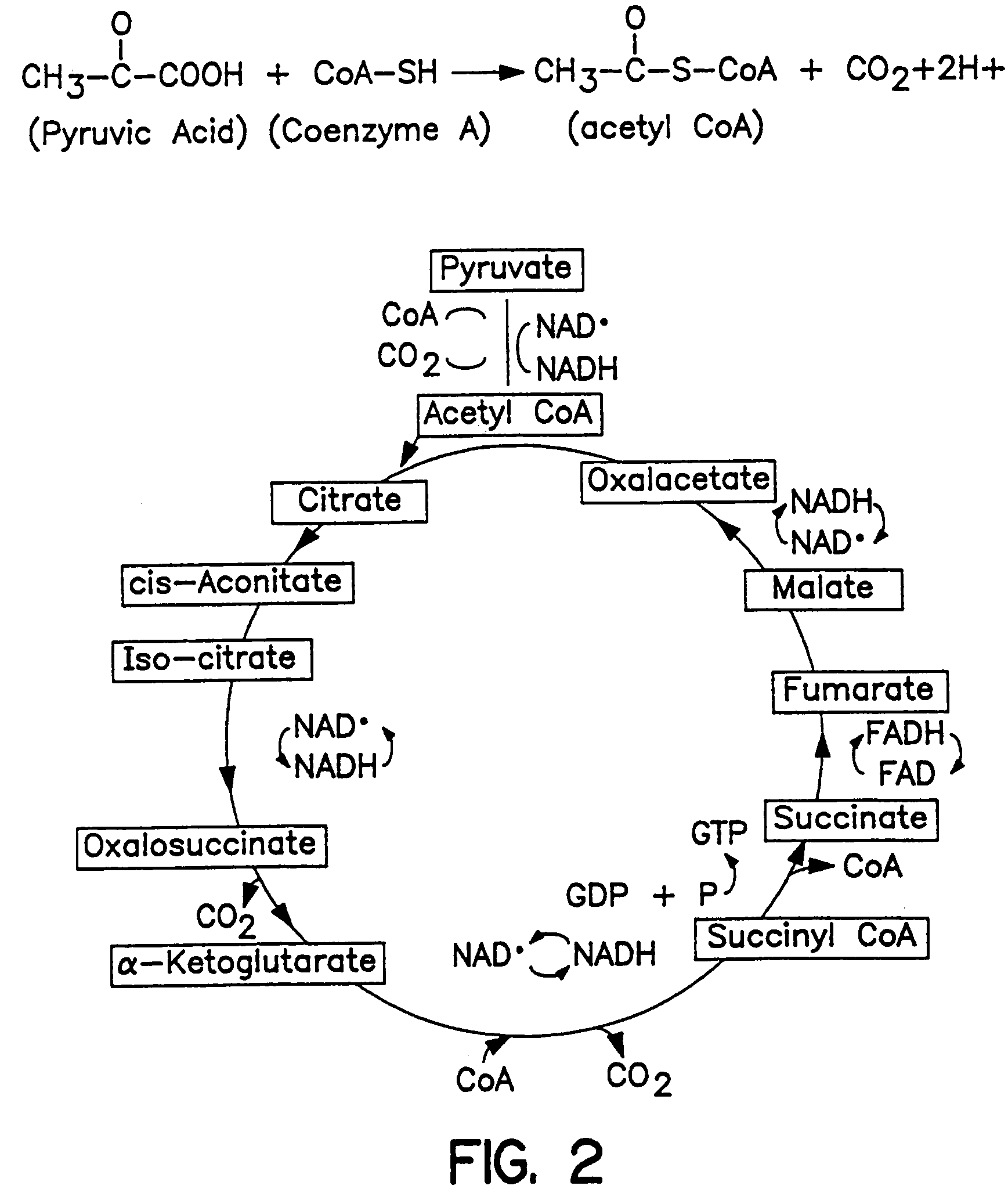

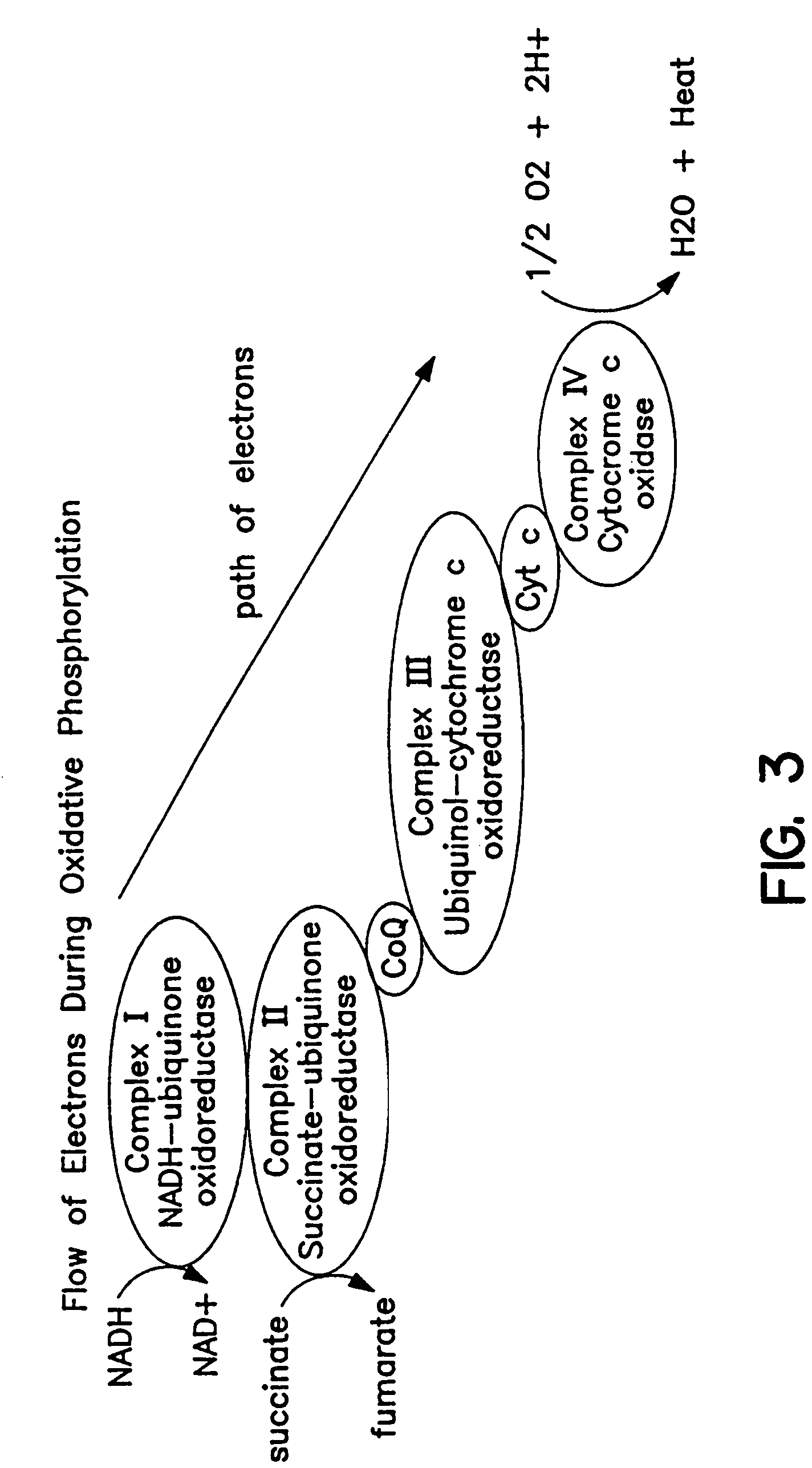

An invention relating to therapeutic pharmacological agents and methods to chemically induce intracellular hyperthermia and / or free radicals for the diagnosis and treatment of infections, malignancy and other medical conditions. The invention relates to a process and composition for the diagnosis or killing of cancer cells and inactivation of susceptible bacterial, parasitic, fungal, and viral pathogens by chemically generating heat, and / or free radicals and / or hyperthermia-inducible immunogenic determinants by using mitochondrial uncoupling agents, especially 2,4 dinitrophenol and, their conjugates, either alone or in combination with other drugs, hormones, cytokines and radiation.

Owner:TEXAS PHARMA

Thyromimetics for the Treatment of Fatty Liver Diseases

InactiveUS20090232879A1Low in fatPreventing and treating and ameliorating fatty liver diseaseBiocideMetabolism disorderSteatosisReceptor

The present invention is directed toward the use of thyromimetic compounds that are thyroid receptor ligands, pharmaceutically acceptable salts thereof, and to prodrugs of these compounds for preventing, treating, or ameliorating fatty liver diseases such as steatosis, non-alcoholic fatty liver disease, and non-alcoholic steatohepatitis.

Owner:METABASIS THERAPEUTICS INC

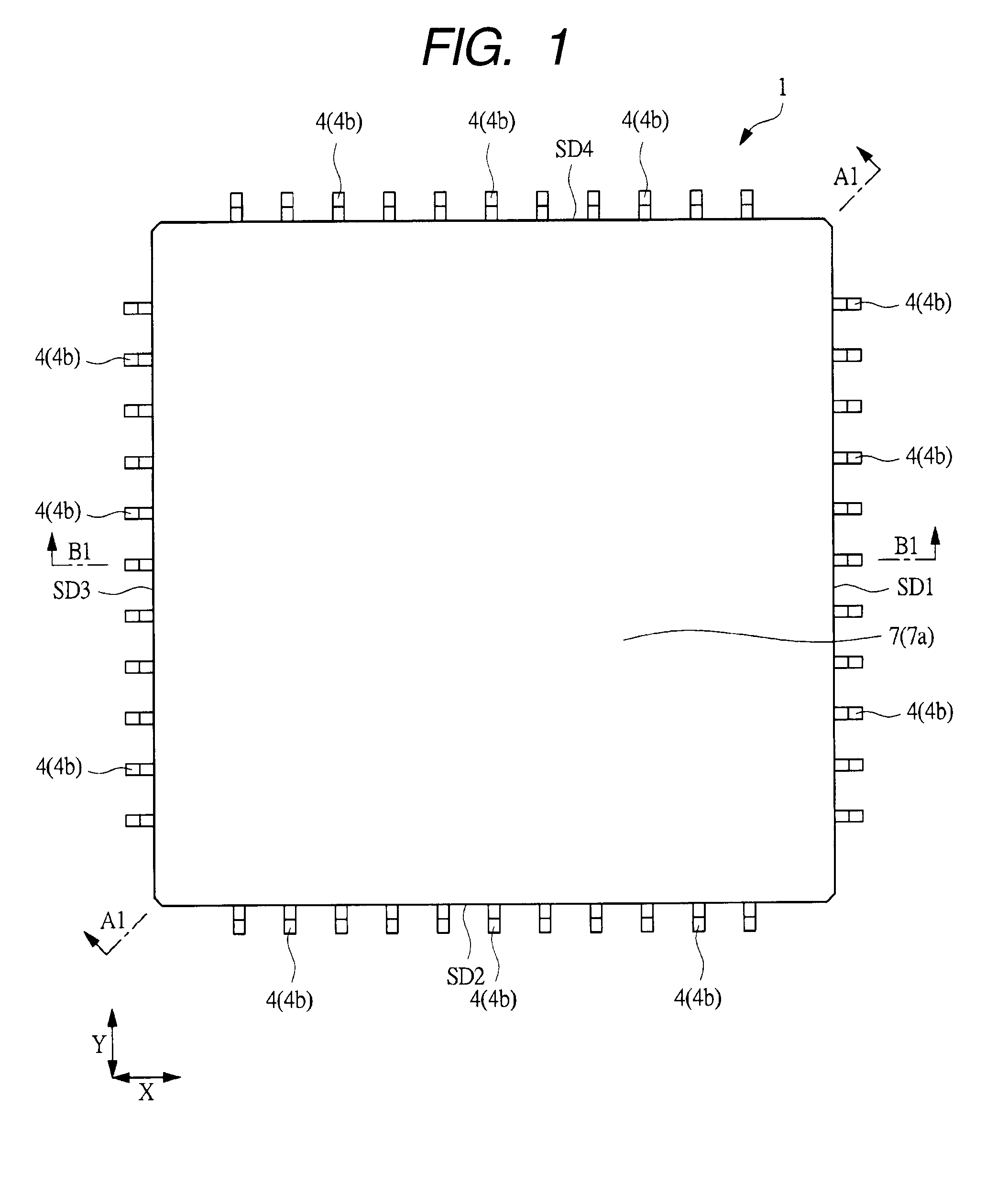

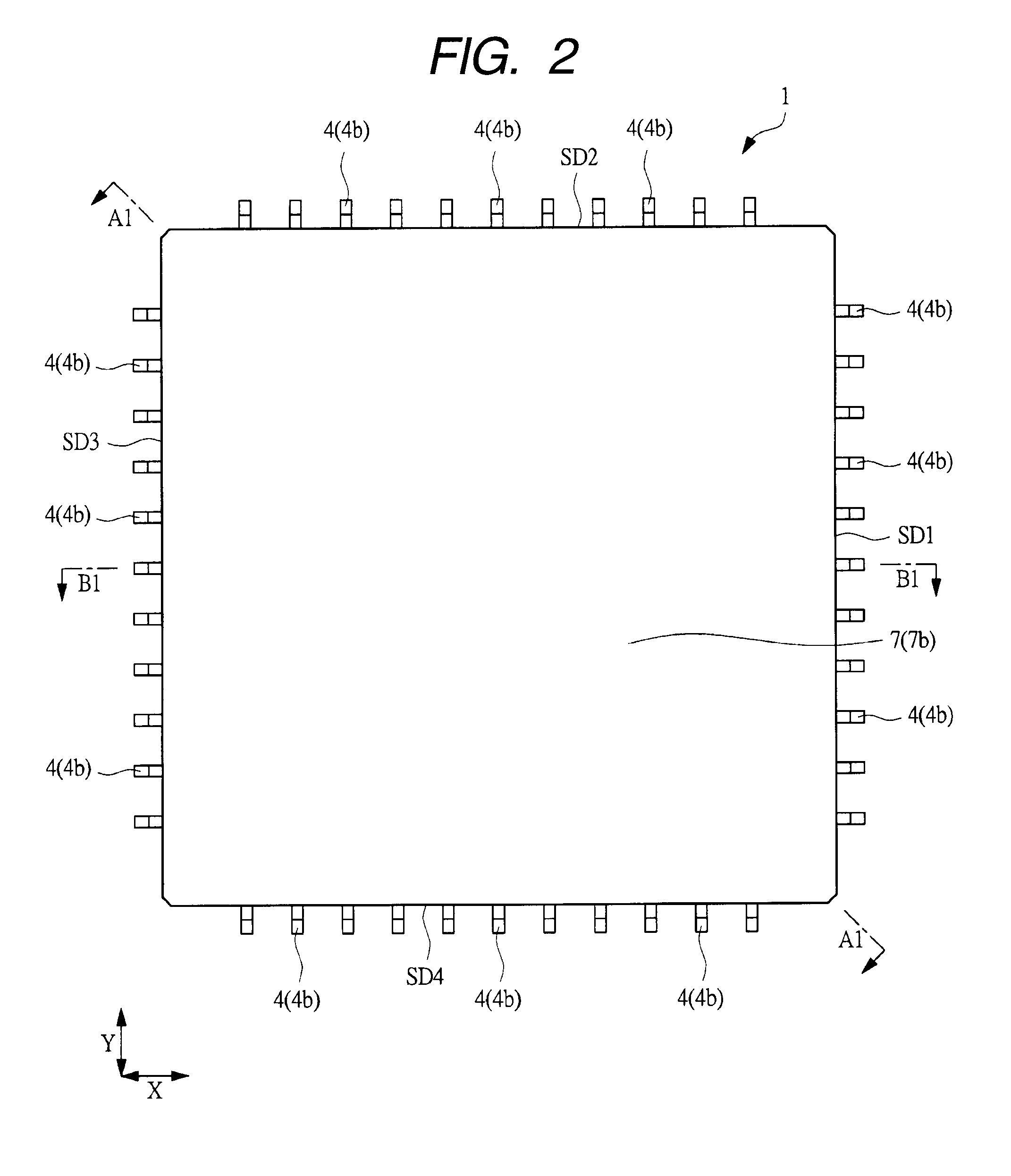

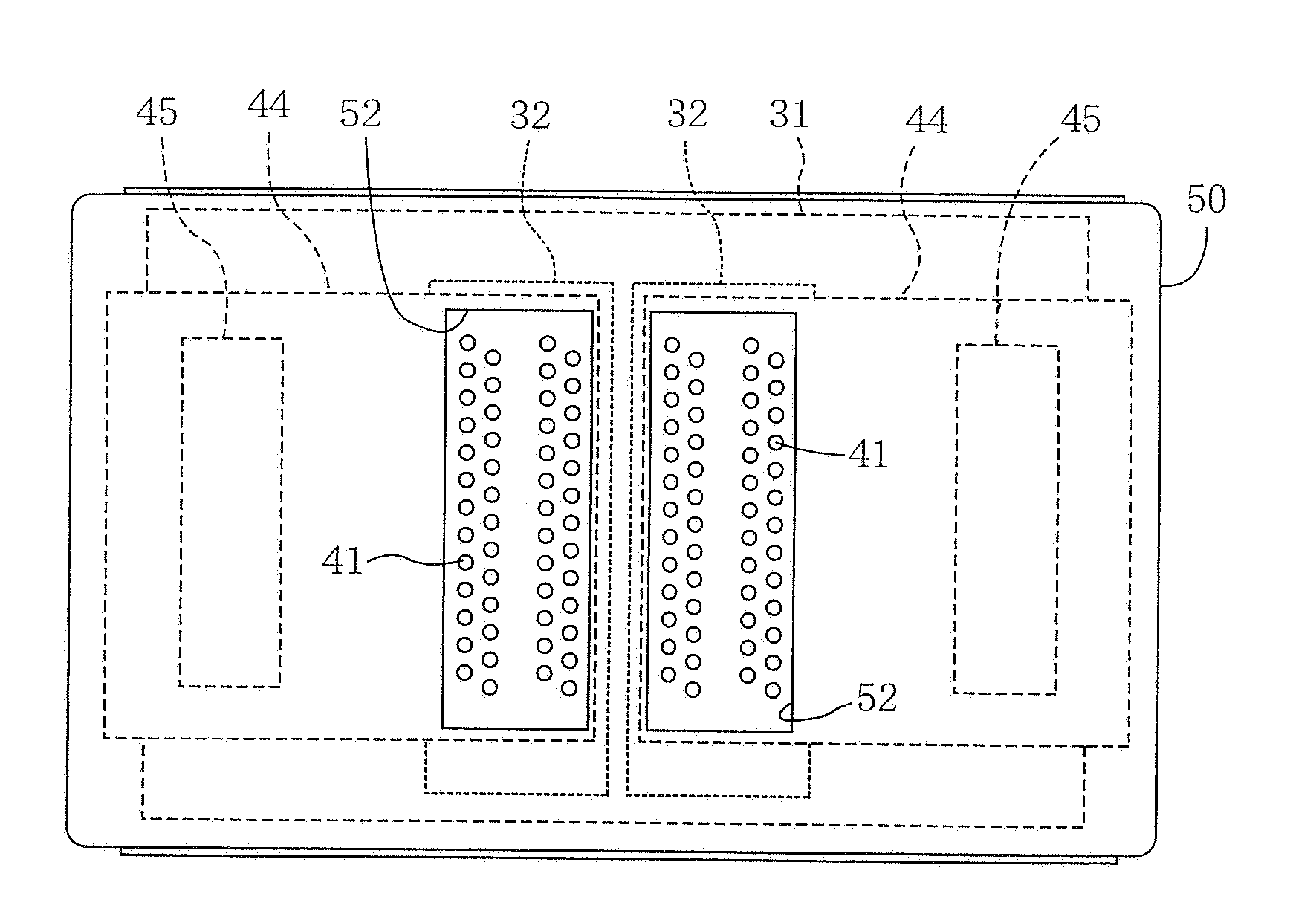

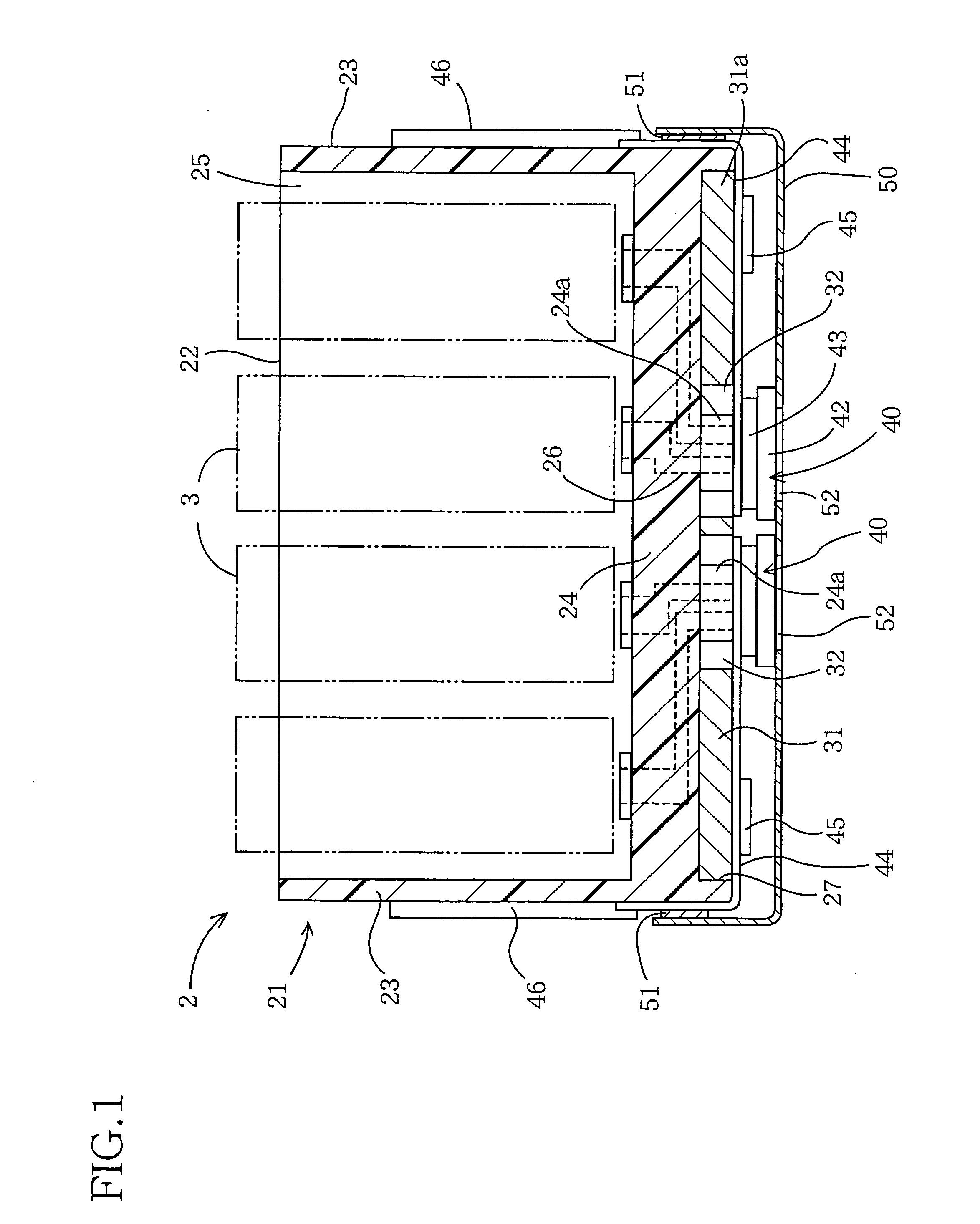

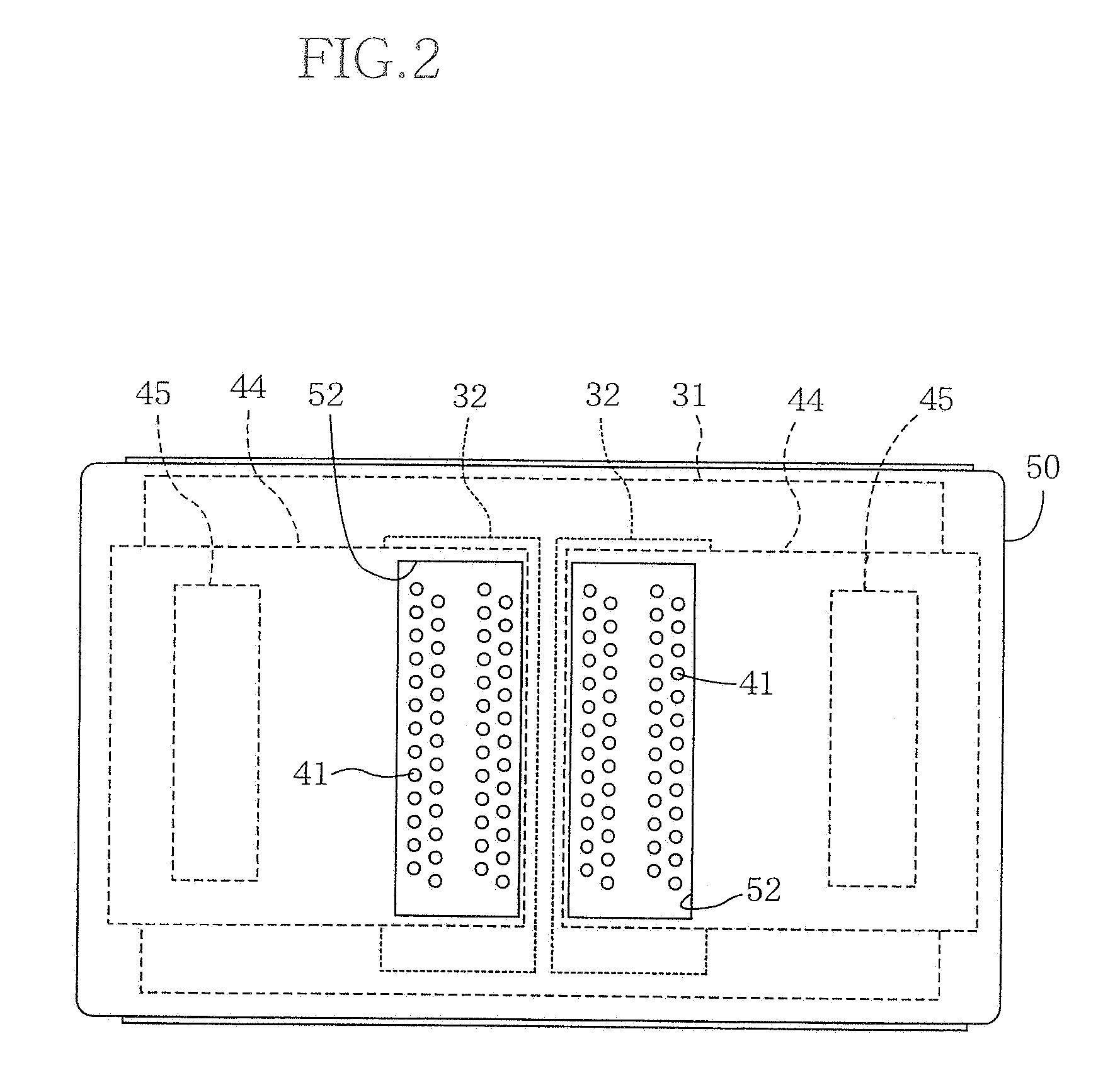

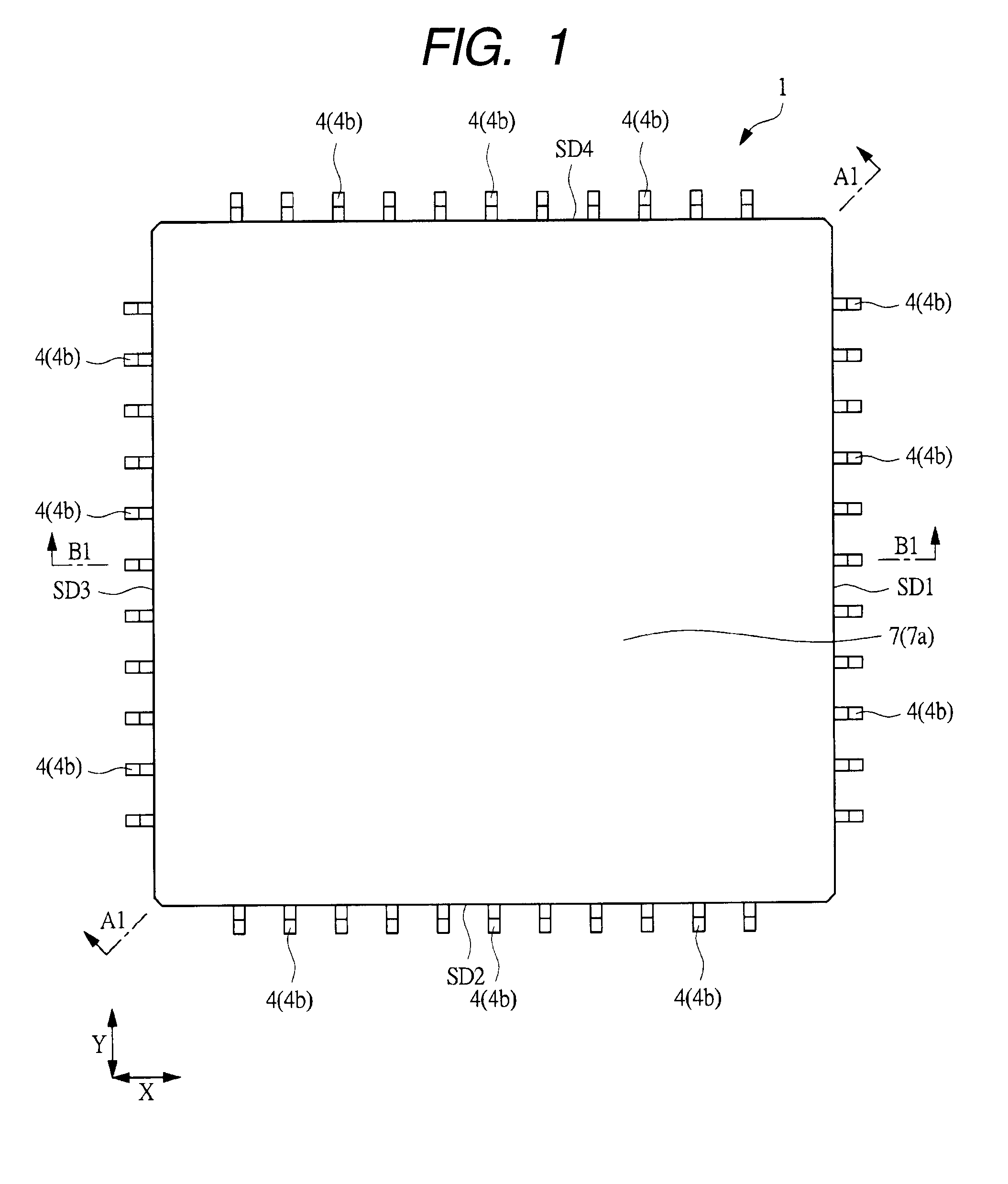

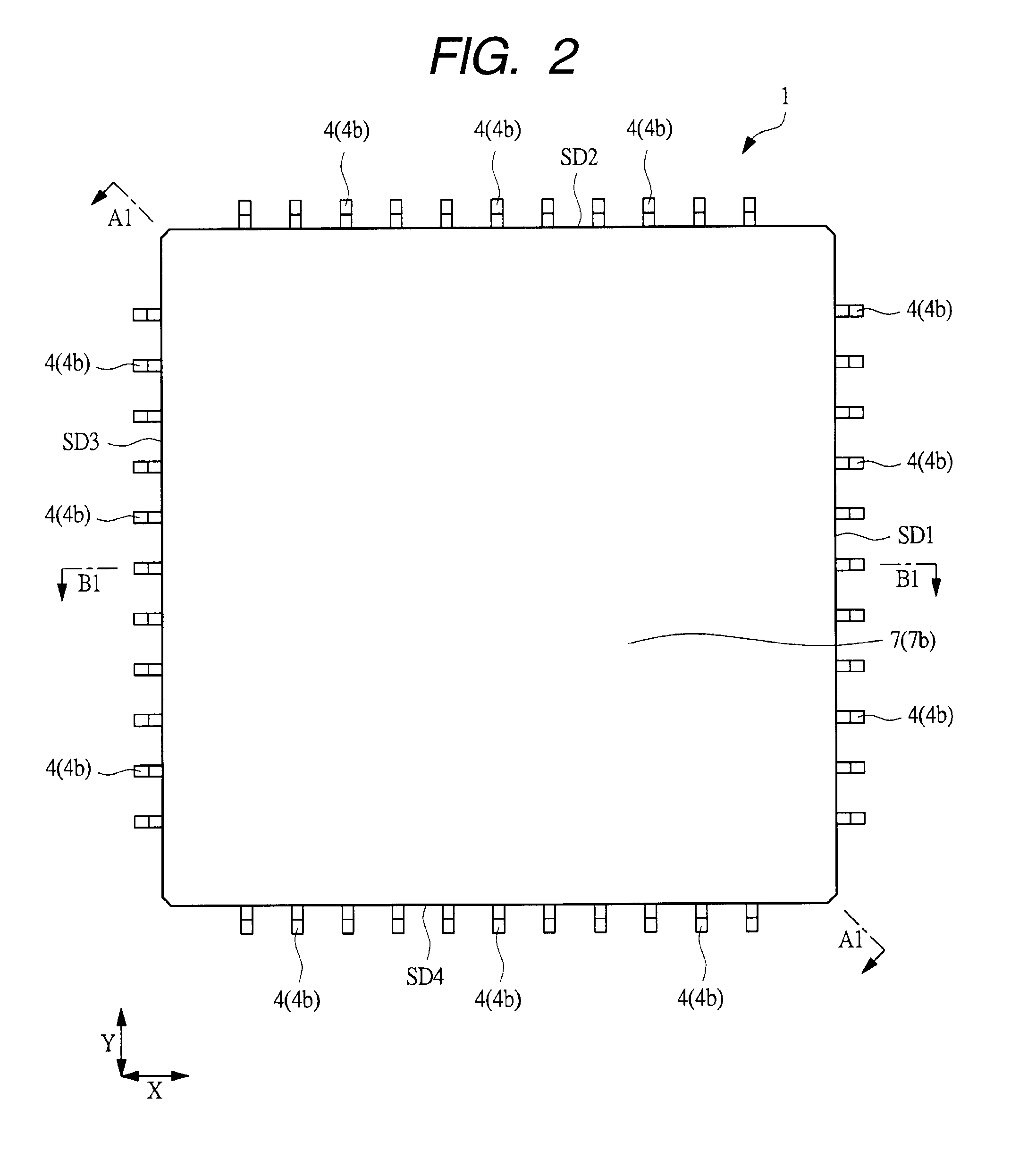

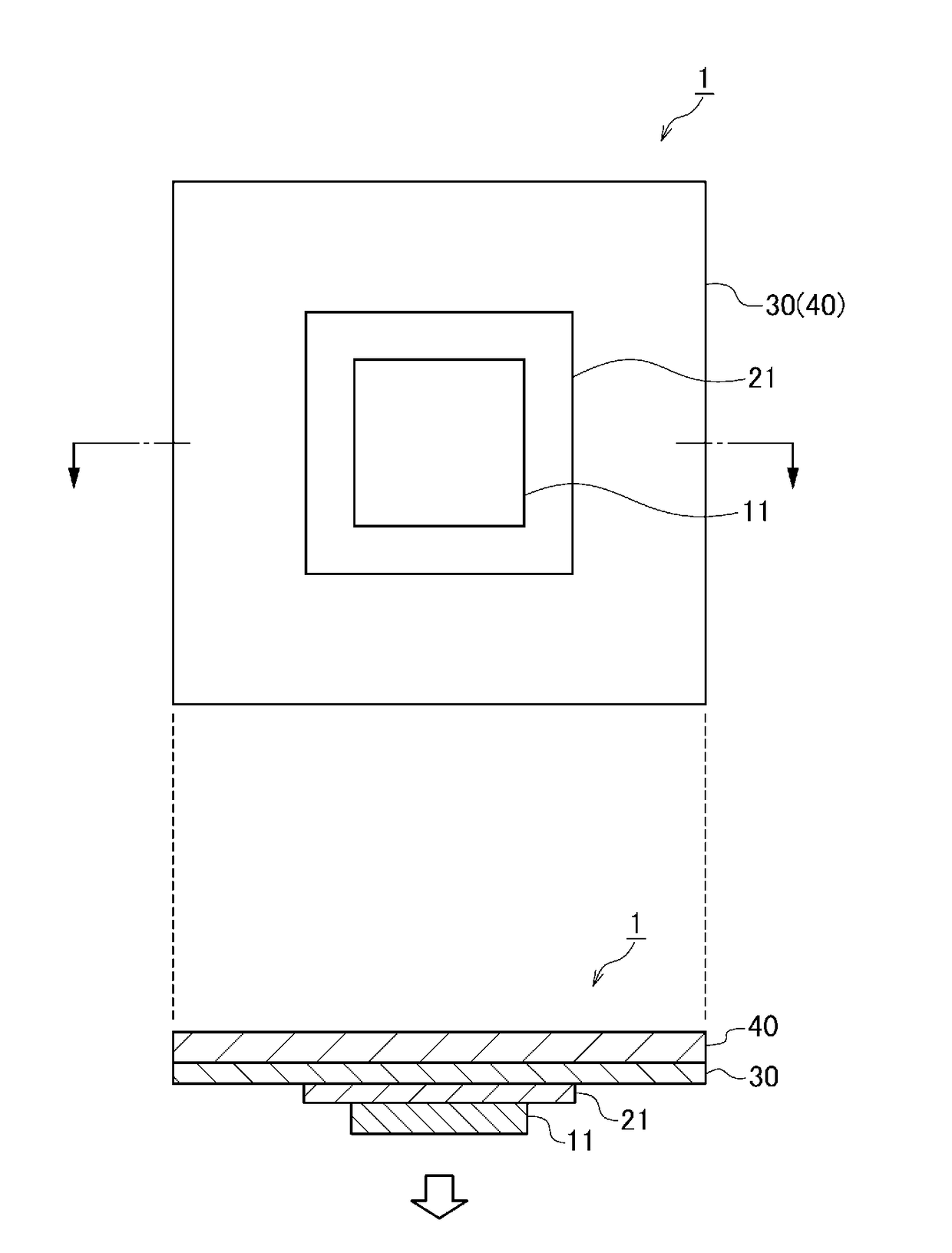

Semiconductor device and method of manufacturing same

InactiveUS20100244214A1Good heat dissipationHigh speedSemiconductor/solid-state device detailsSolid-state devicesSilver pasteDevice material

To improve the heat dissipation characteristics of a semiconductor device.The semiconductor device has a die pad, a heat dissipating plate in the form of a frame arranged between the die pad and a plurality of leads so as to surround the die pad, a plurality of members that connect the die pad and the inner edge of the heat dissipating plate, and a suspension lead linked to the outer extension of the heat dissipating plate, wherein a semiconductor chip the outer shape of which is larger than the die pad is mounted over the die pad and the members. The top surface of the die pad and the top surface of the members at the part in opposition to the back surface of the semiconductor chip are bonded to the back surface of the semiconductor chip in their entire surfaces with a silver paste. Heat in the semiconductor chip is conducted from the back surface of the semiconductor chip to the heat dissipating plate via the silver paste, the die pad, and the member, and dissipated to the outside of the semiconductor device therefrom via the lead.

Owner:RENESAS ELECTRONICS CORP

Method for making fermenting bed for ecological pig breeding by using composite strain culture

InactiveCN101565684AShort degradation cycleStrong bacterial activityFungiBacteriaMicroorganismStart time

The invention discloses a method for making a fermenting bed for ecological pig breeding by using composite strain culture, in particular relates to a method for making the fermenting bed by using a plurality of microorganisms. The invention comprises the steps of preparing the culture and making the fermenting bed. In the invention, the culture is mainly prepared by microzyme, lactobacillus, actinomycetes, photosynthetic bacterium and mycelial fungus according to proportion. The culture after being activated is stirred uniformly with organic padding pro rata, piled, fermented, prepared into the fermenting bed, and then can be used for breeding live pigs. The method solves the problems of long fermenting starting time of the organic padding, unstable microbial inoculum, strict requirements on the fermenting conditions and materials as well as short service life in the existing ecological pig breeding method. The method uses the composite strain culture to build ecological colony house; the fermenting starting time of the organic padding is short, which can be 1 to 2 days in summer and 3 to 5 days in winter; the strain activity is strong; the decomposing process can be finished in 1 to 3 days; the effect lasts for long; and the fermenting bed can be continuously used for 5 to 8 years. Moreover, the method is green and environmental friendly.

Owner:千智伟

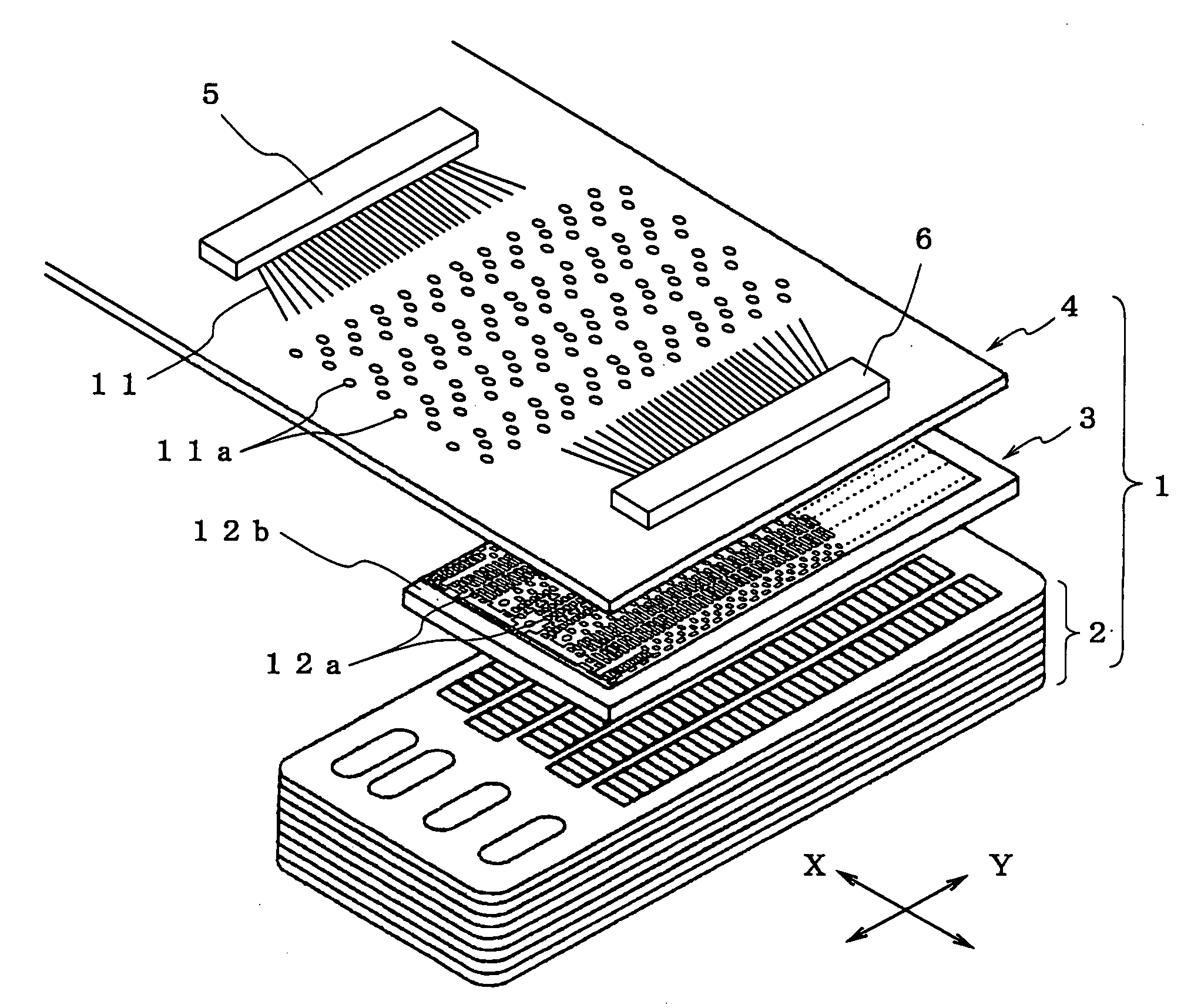

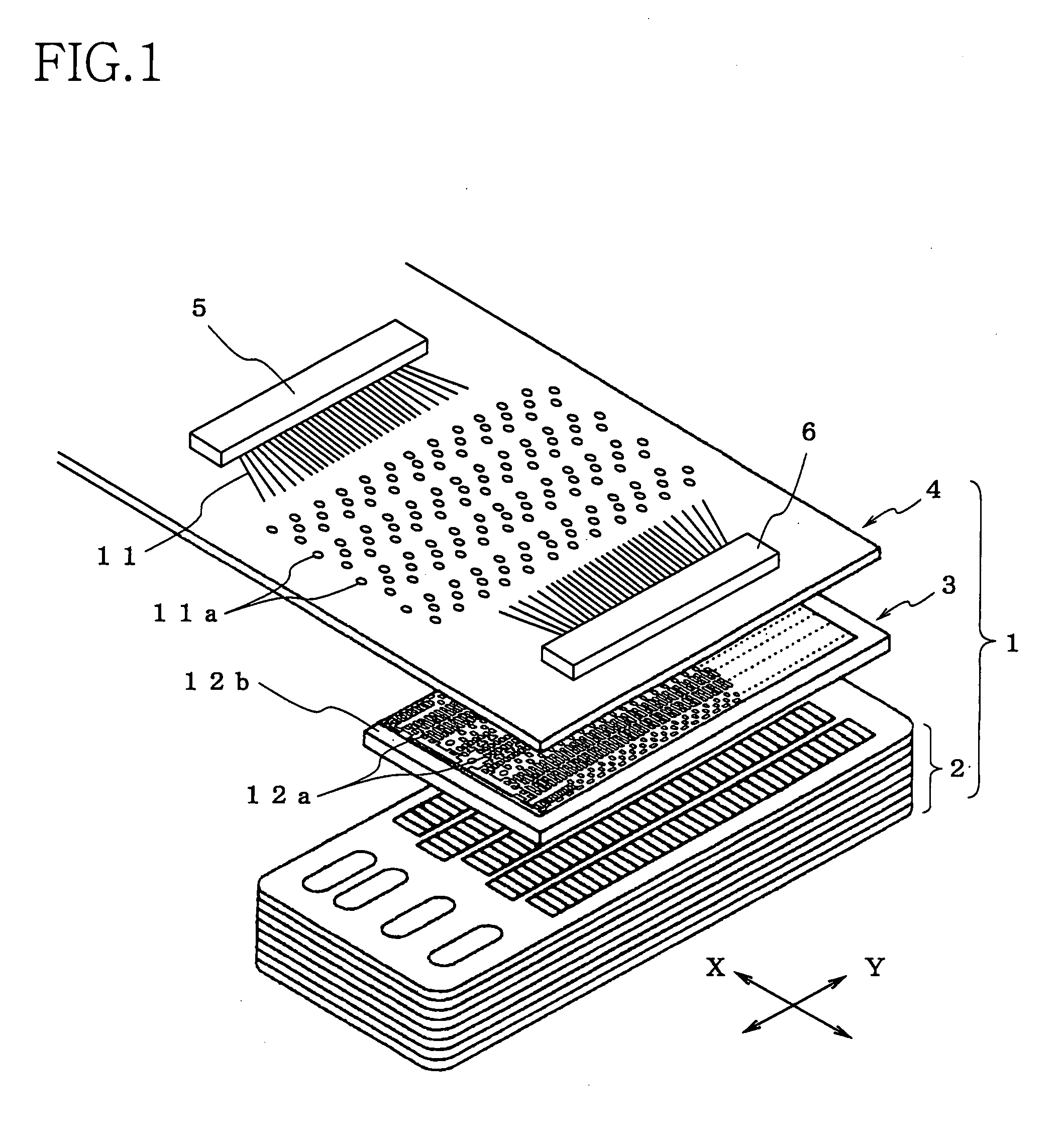

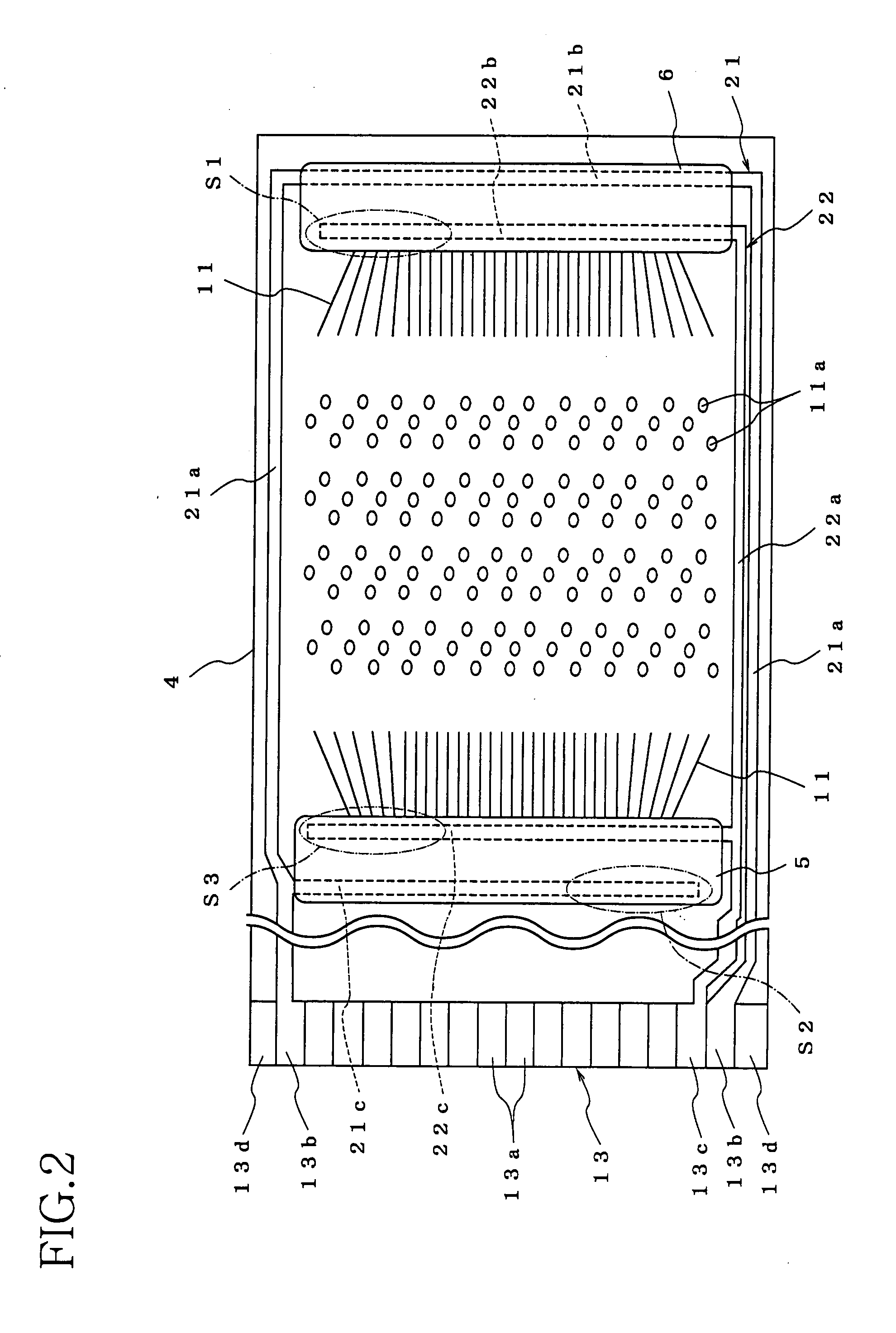

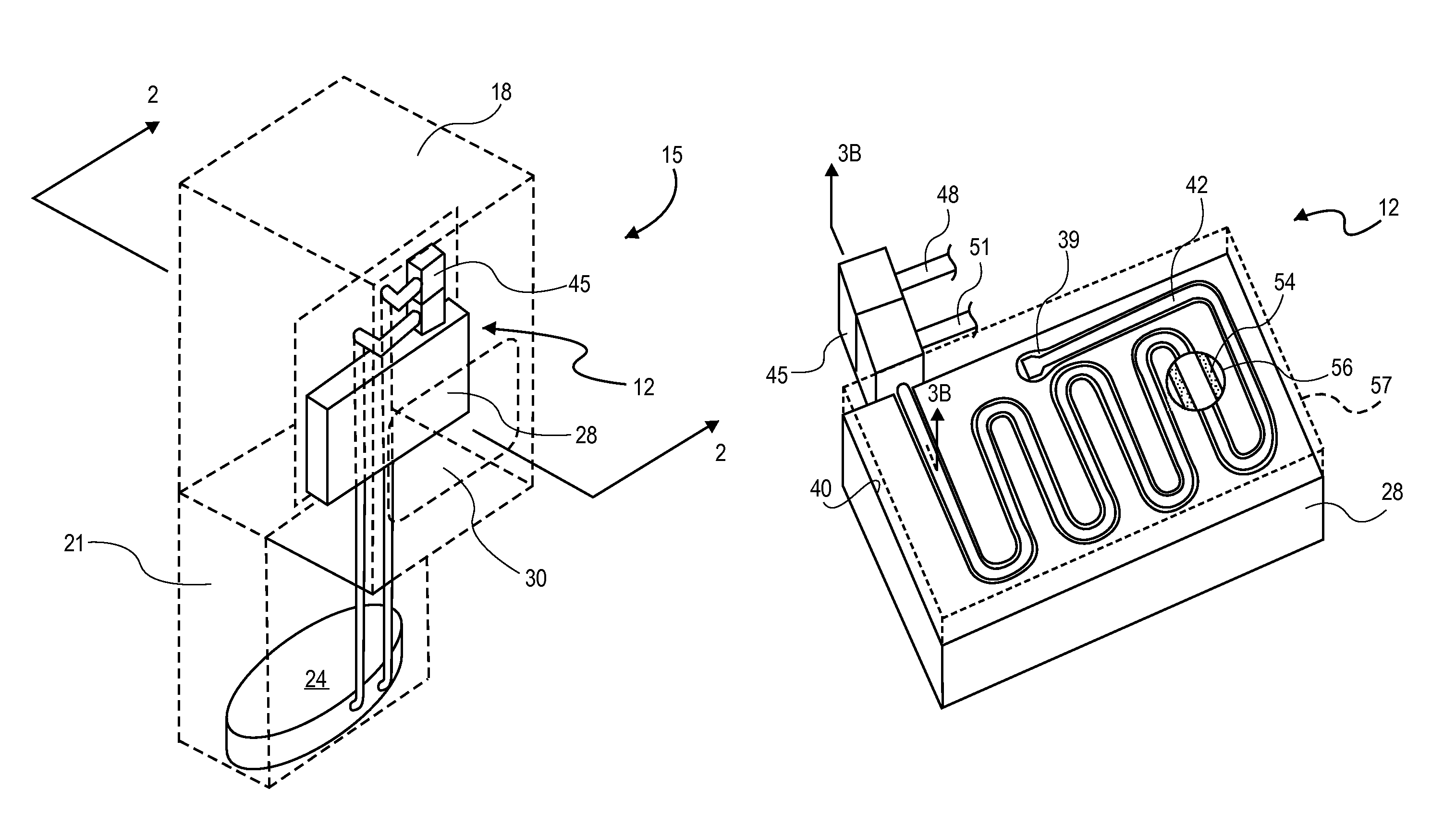

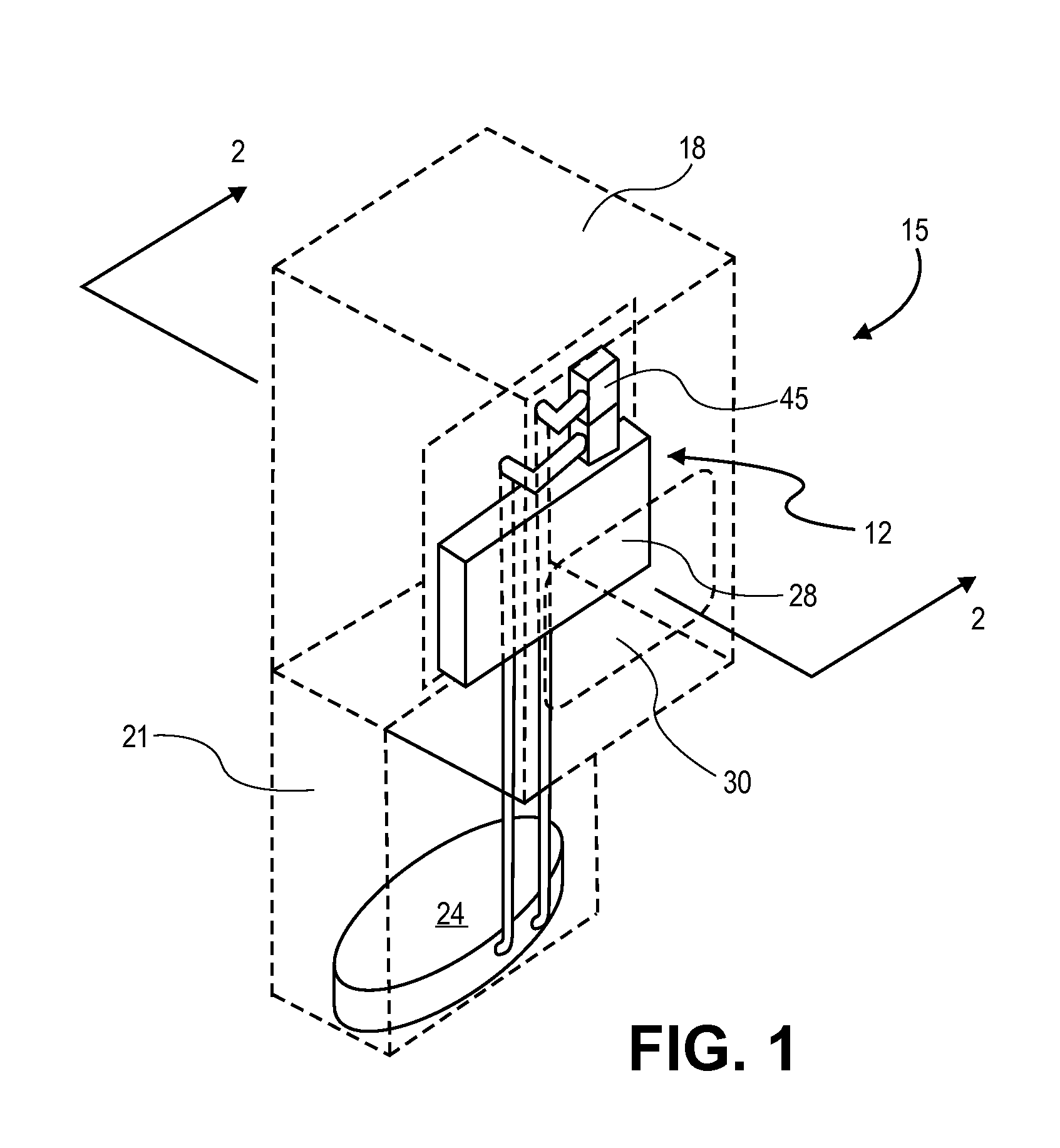

Recording apparatus equipped with heatsink

A recording apparatus having: (a) a head unit including an actuator which generates energy required for recording predetermined patterns of image on a recording medium; (b) a circuit board including a driver element which drives the actuator of the head unit; and (c) a heatsink disposed in thermally conductive communication with the driver element. The heatsink has a void portion which is opposed to the head unit.

Owner:BROTHER KOGYO KK

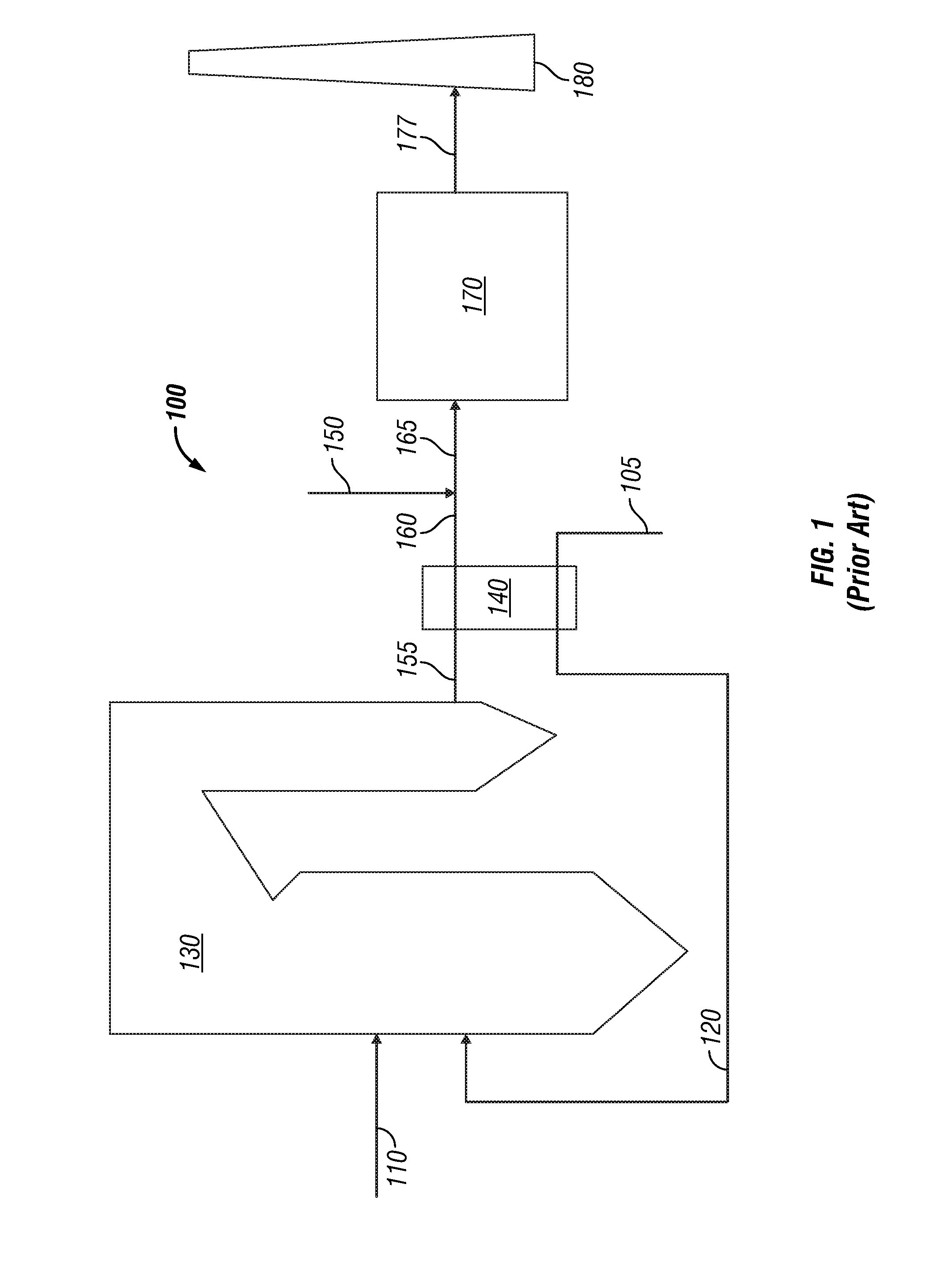

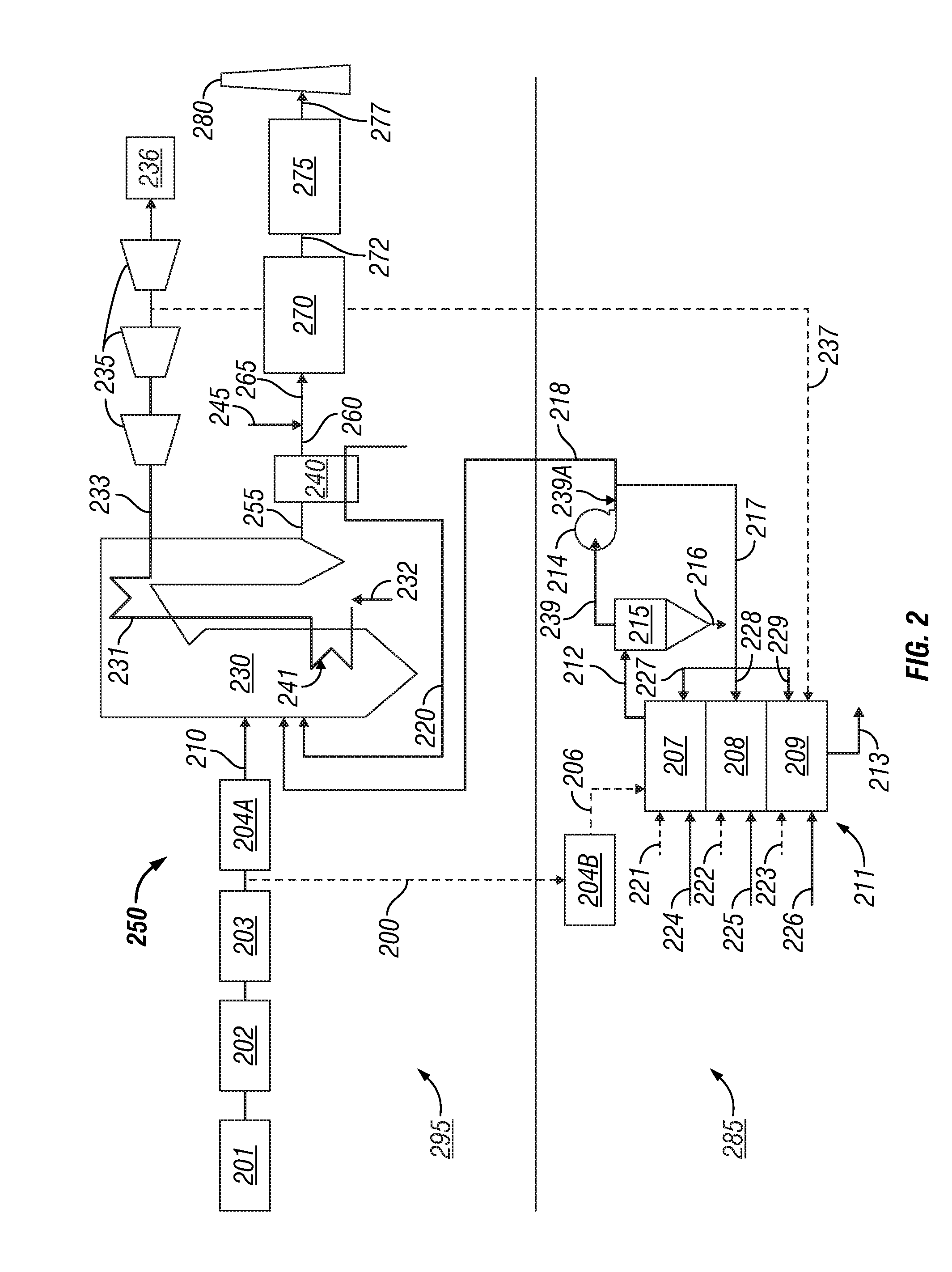

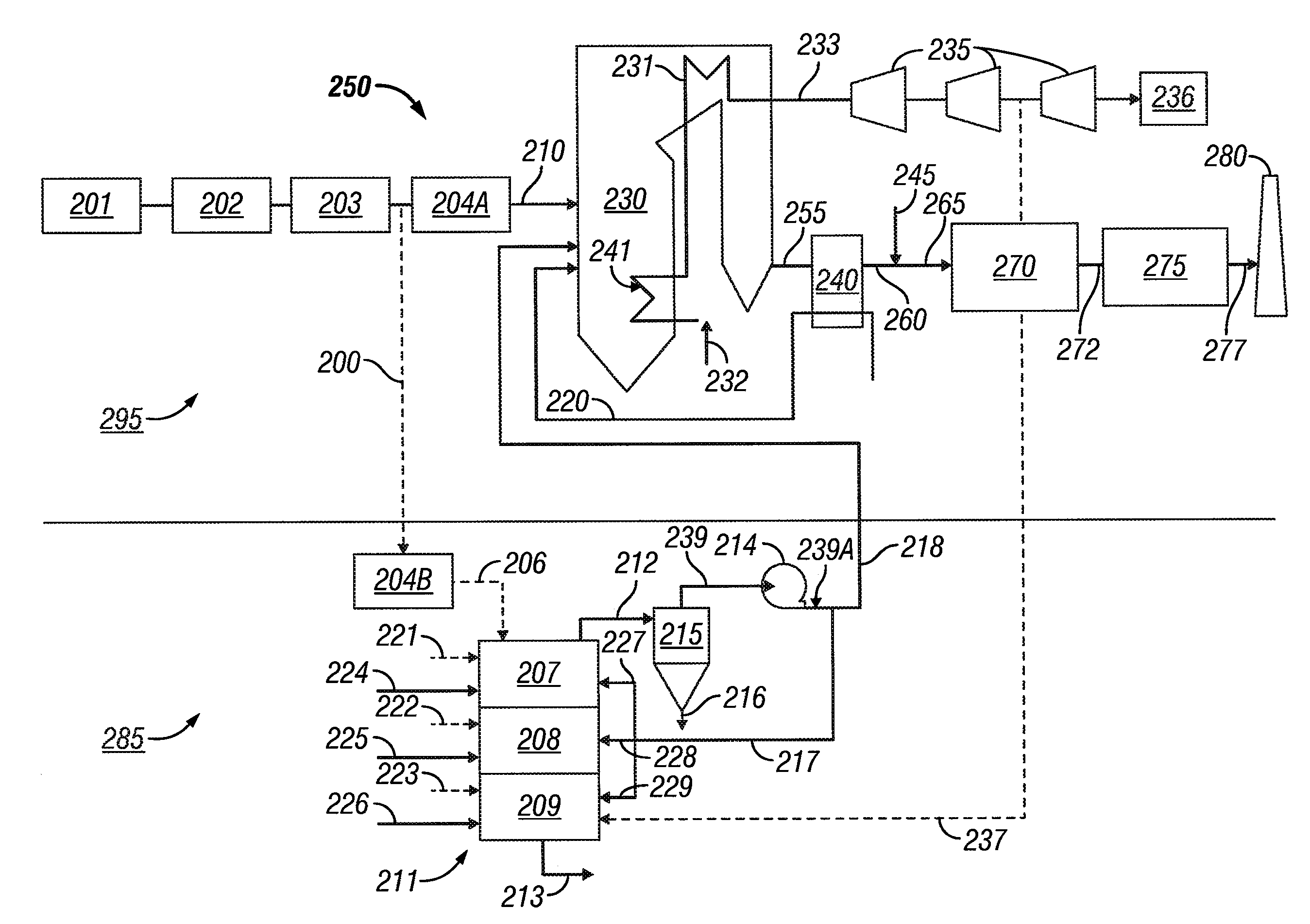

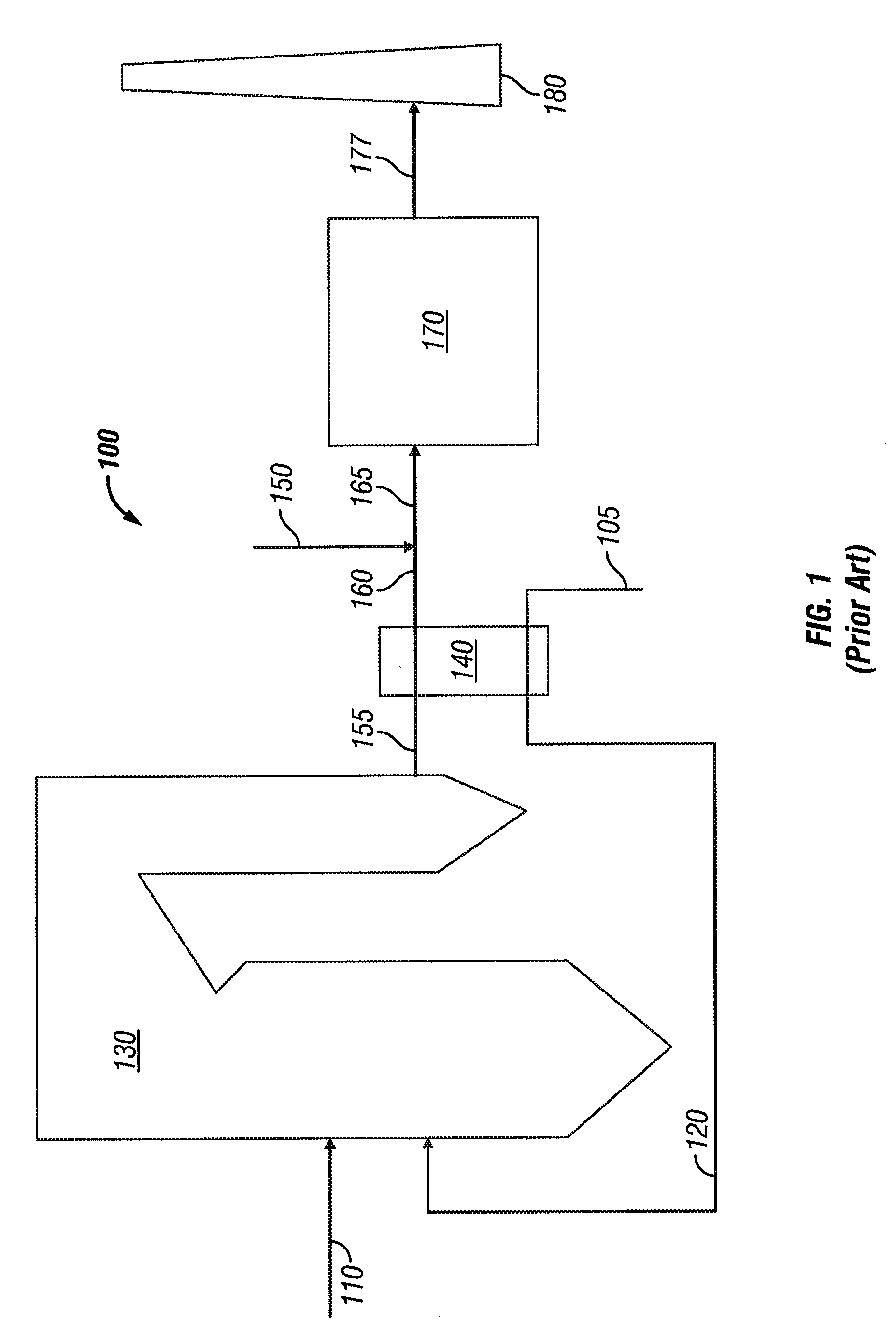

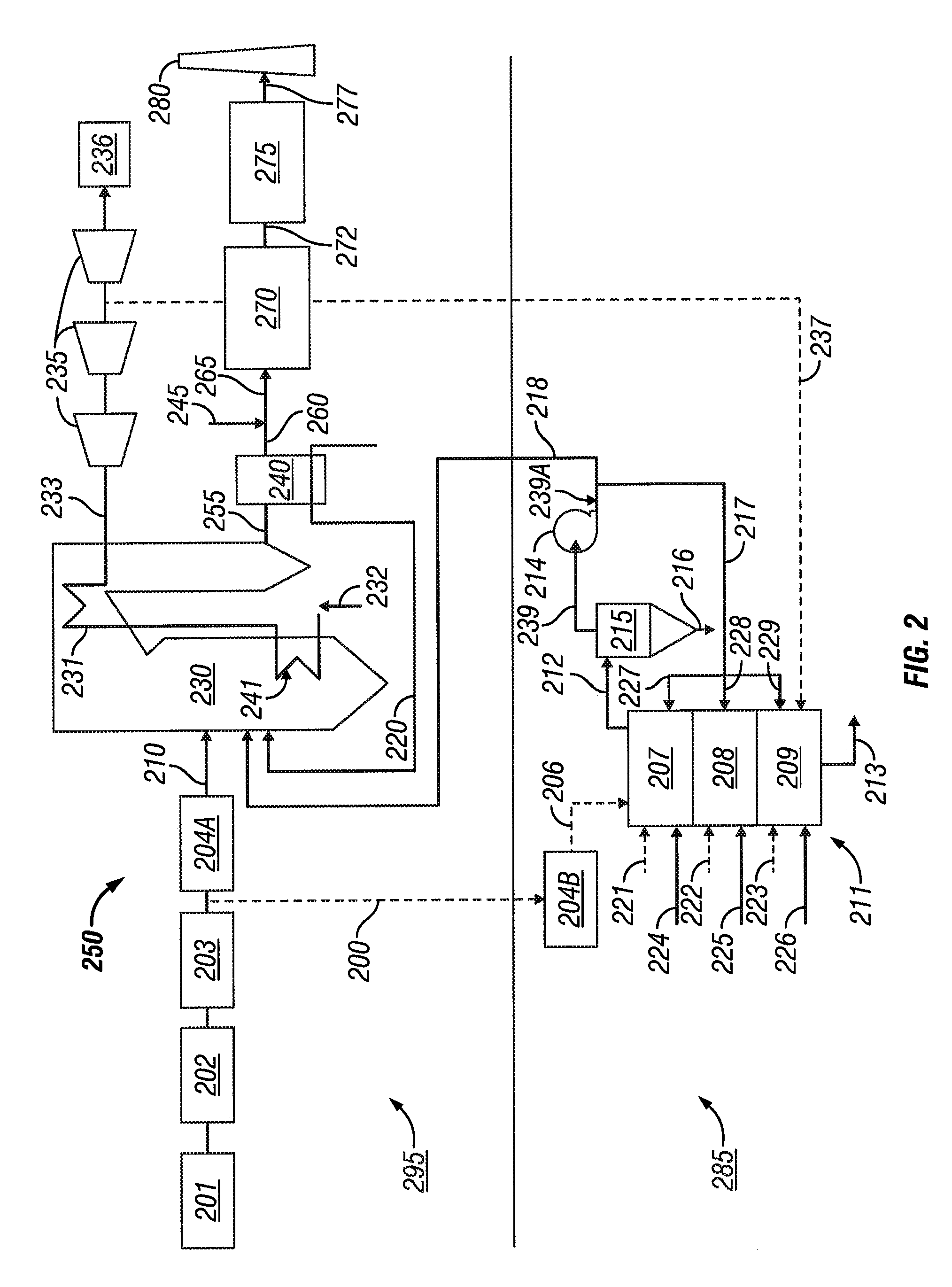

System and method for coproduction of activated carbon and steam/electricity

InactiveUS7981835B2Increase heat productionNo accumulationPigmenting treatmentSteam generation heating methodsCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

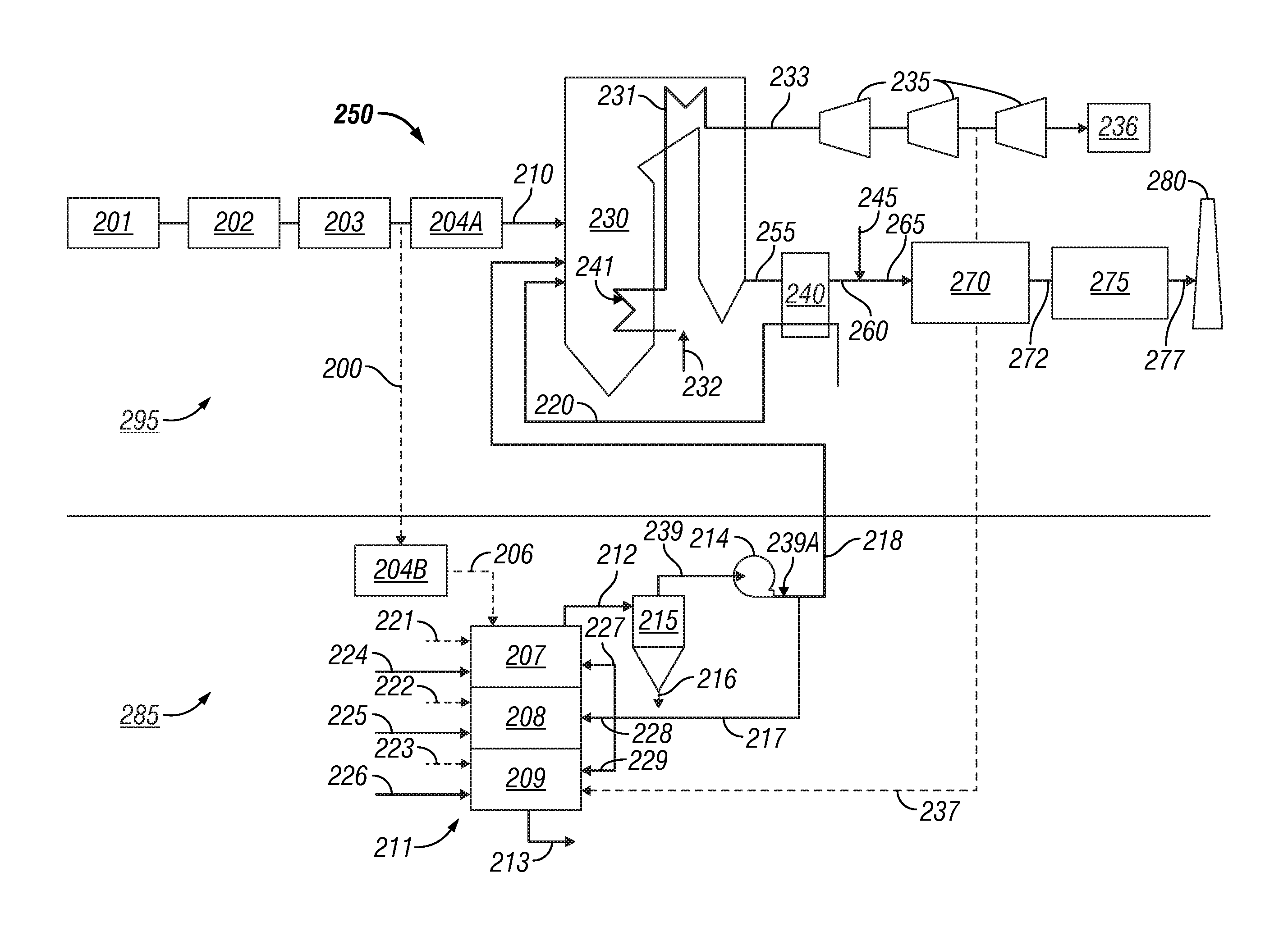

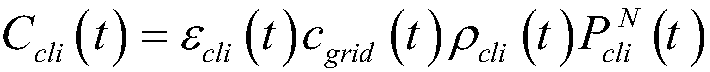

CCHP type multi-time scale optimal scheduling method and system for micro grids

ActiveCN109617142AIncrease heat productionAchieve economical operationPower network operation systems integrationSingle network parallel feeding arrangementsLithium bromideMicro grid

The invention discloses a CCHP type multi-time scale optimal scheduling method and system for micro grids. The multi-time scale optimal scheduling method comprises the steps of: firstly determining agrid compensation cost according to a switchable load and an adjustable load parameter from demand side response; respectively establishing operation gains according to a CCHP unit parameter, a lithium bromide absorption refrigeration unit and a phase-change energy storage device parameter, so as to establish a triple generation system operation gain; and finally establishing a system operation cost and a gain function, and carrying out optimal scheduling on a CCHP micro grid by adoption of a multi-time scale optimal scheduling strategy to ensure that the total cost is minimum. By adoption ofthe multi-time scale optimal scheduling method and system provided by the invention, electric vacancy can be effectively relieved, the reliability can be improved and the maximum utilization of renewable energy sources can be achieved.

Owner:YANSHAN UNIV

Chemical composition and method for enhancing metabolism

InactiveUS6932987B1Improve healthIncrease thermogenic activity and metabolismBiocideUnknown materialsChemical combinationChemistry

An innovative and synergistic chemical composition is developed for enhancing a person's metabolism. Specifically, the chemical composition aids in increasing the thermogenic activity of the body, which encourages the metabolic conversion of the foods consumed by the person. This results in a loss of body fat and weight, without adversely affecting the person's nervous or circulatory systems. In addition, a method is presented wherein the person ingests a recommended dosage of the chemical composition prior to engaging in physical exercise, thereby allowing the chemical composition to be readily utilized by many of the people who may benefit from its effects.

Owner:DIAZ JOSE A +1

Recording-head driving device for driving recording head

A recording-head driving device for driving a recording head including a plurality of actuator sections each provided for recording on a recording medium, the recording-head driving device including: a wiring board elongated in a longitudinal direction to be connected, at a connected portion near to one of longitudinally opposite ends thereof, to the plurality of actuator sections of the recording head; two drive-circuit units mounted on respective portions of the wiring board such that the connected portion of the wiring board is interposed between the mount portions, in the longitudinal direction, and wherein the wiring board includes: (a) a plurality of wires a part of which connects one of the two drive-circuit units and a part of the plurality of actuator sections, and the rest of which connects the other of the two drive-circuit units and the rest of the plurality of actuator sections; and (b) a plurality of input terminals electrically connected to the two drive-circuit units and provided on the other of the longitudinally opposite ends of the wiring board.

Owner:BROTHER KOGYO KK

System and method for coproduction of activated carbon and steam/electricity

InactiveUS20100113267A1Increase heat productionNo accumulationCarbon compoundsSteam useCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:SRINIVASACHAR SRIVATS +3

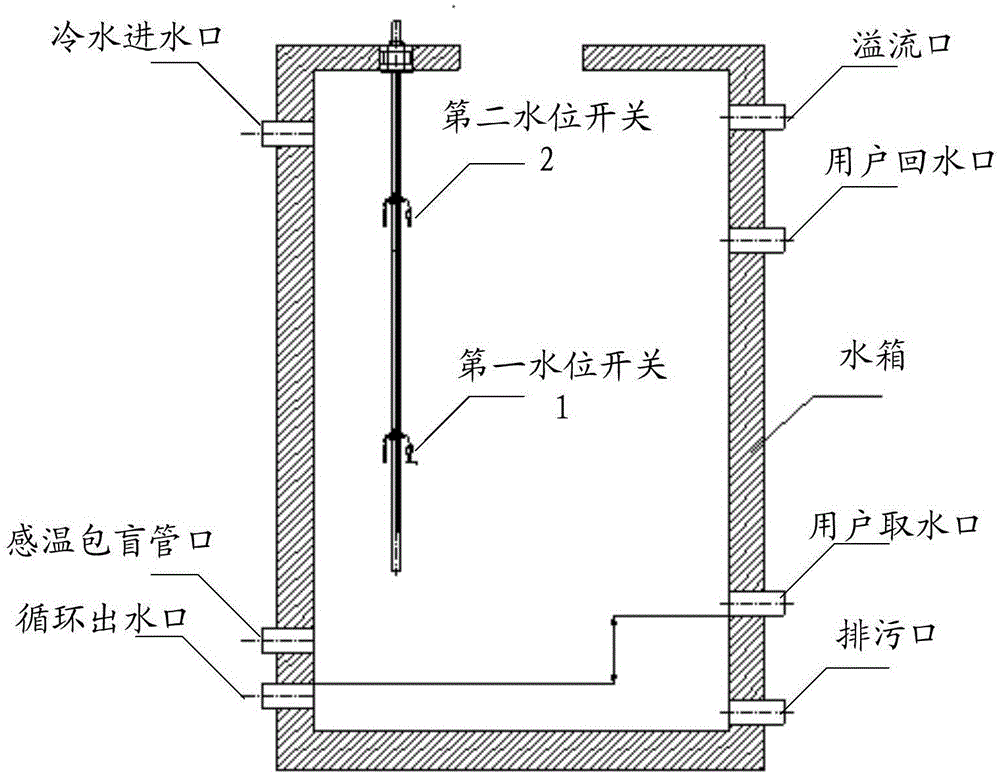

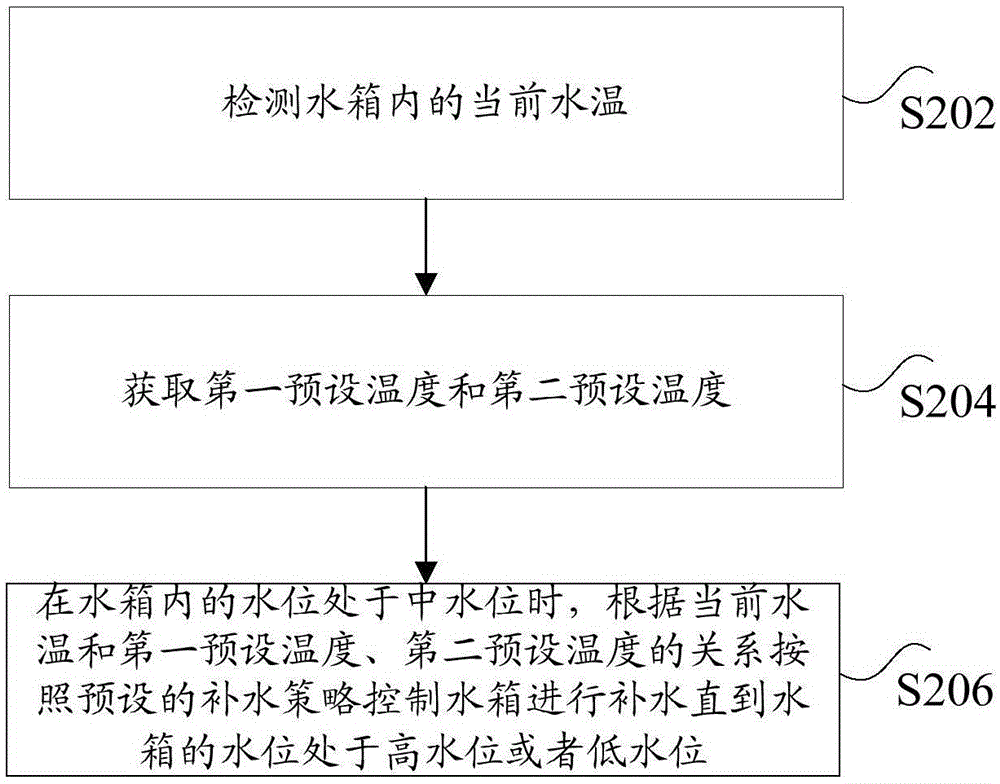

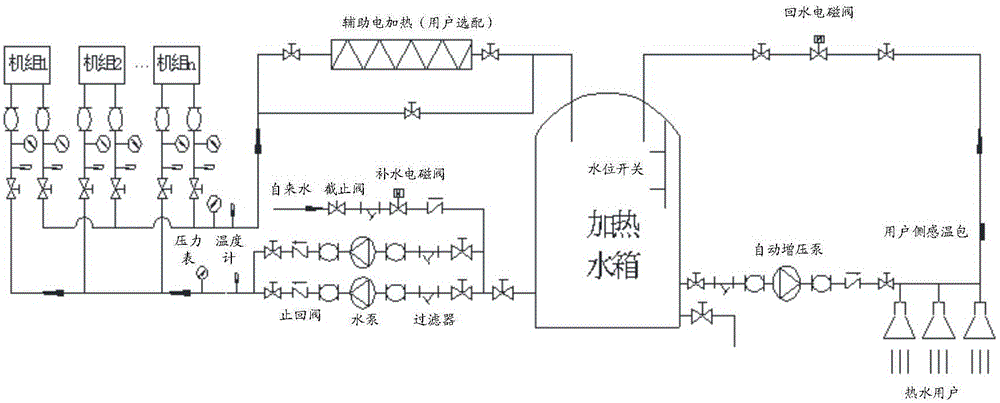

Water replenishment control method and device and water heater

The invention discloses a water replenishment control method and device and a water heater. The water replenishment control method comprises the steps that the current water temperature of a water tank is detected; a first preset temperature and a second preset temperature are obtained, wherein the first preset temperature is lower than the second preset temperature; when water in the water tank is in the medium water level, according to the relation among the current water temperature, the first preset temperature and the second preset temperature, water replenishment is controlled to be carried out on the water tank based on a preset water replenishment strategy till the water in the water tank is in the high or low water level. By means of the water replenishment control method and device, the technical problem that an existing water heater cannot stably supply hot water is solved.

Owner:GREE ELECTRIC APPLIANCES INC

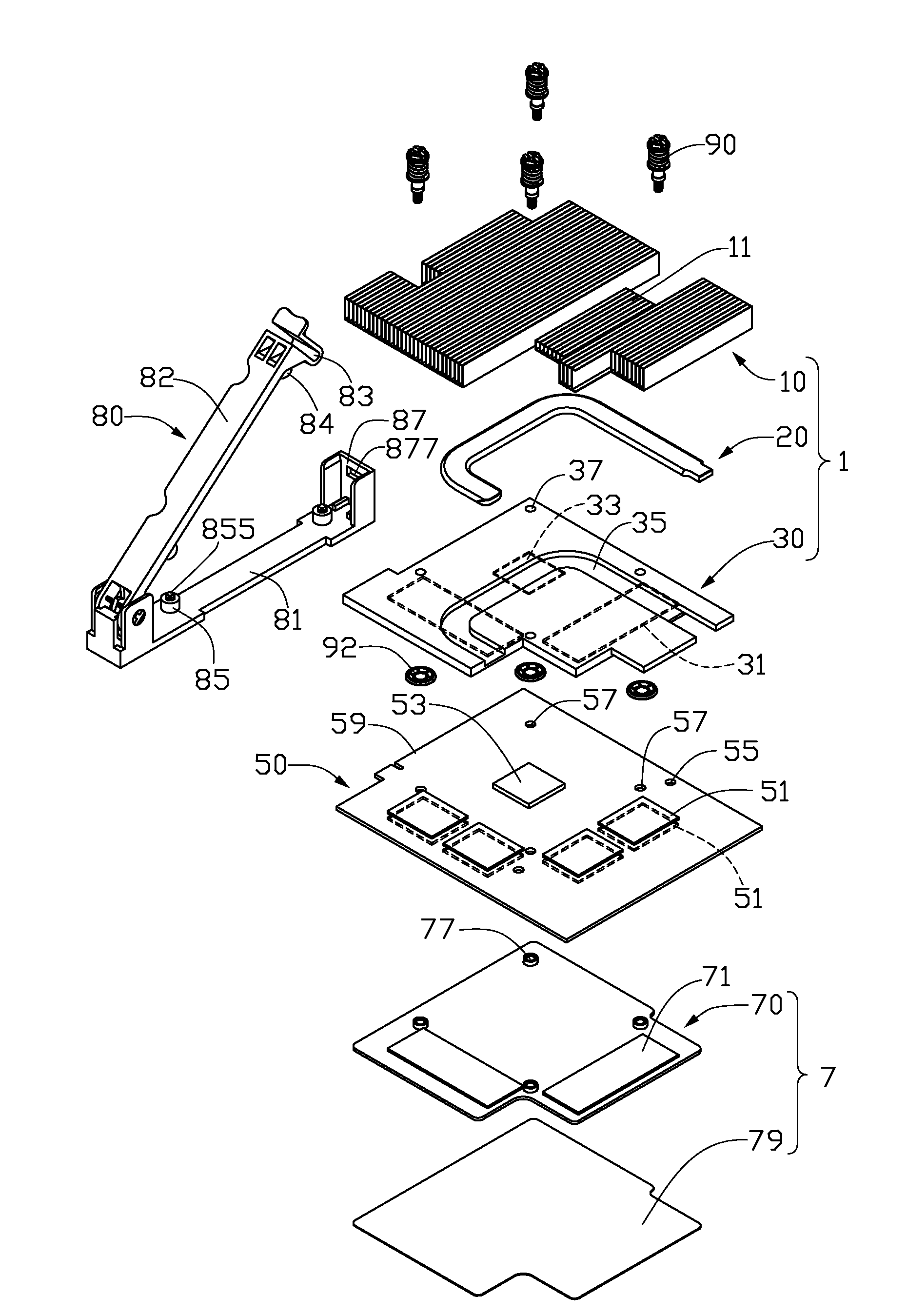

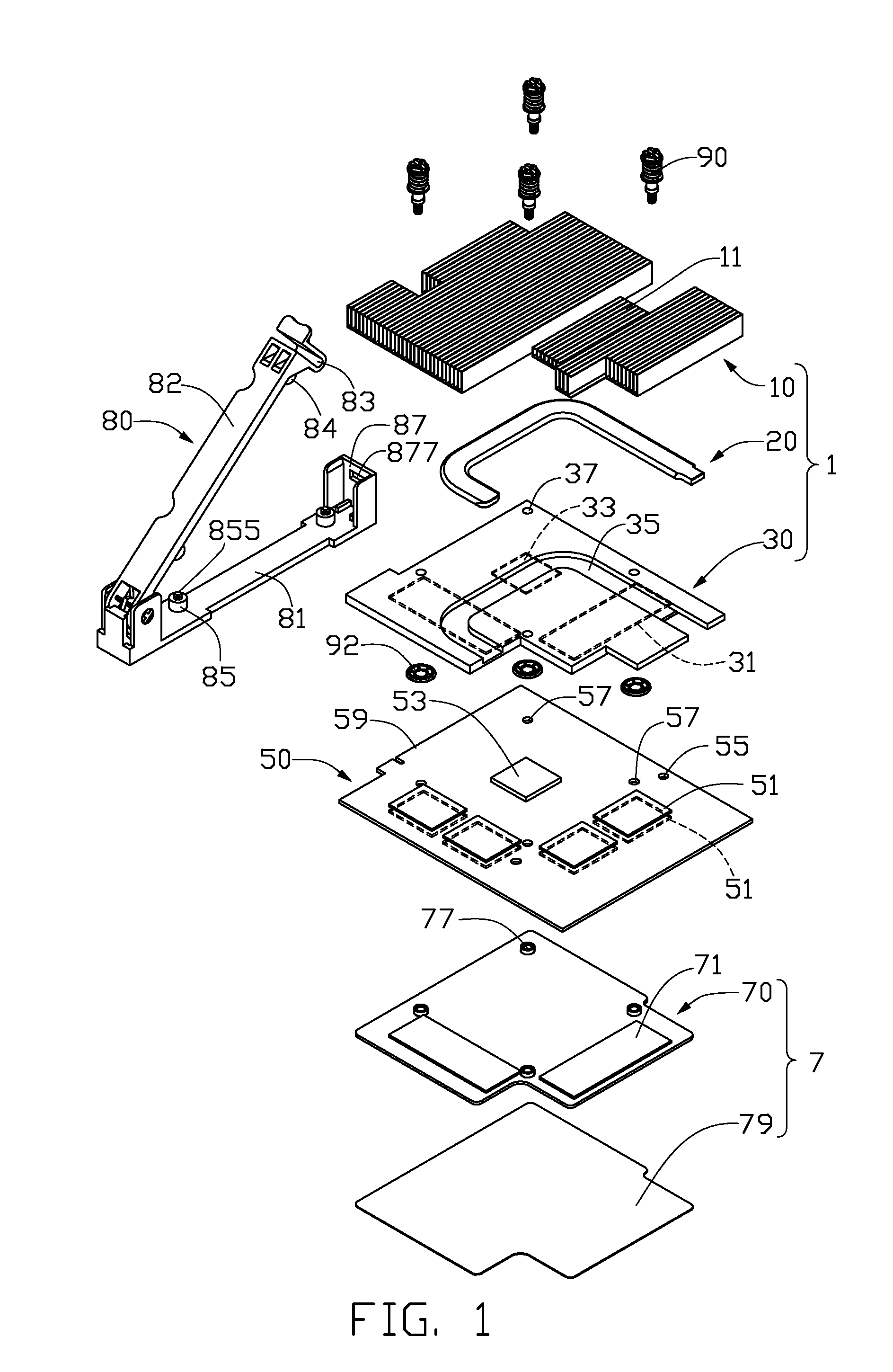

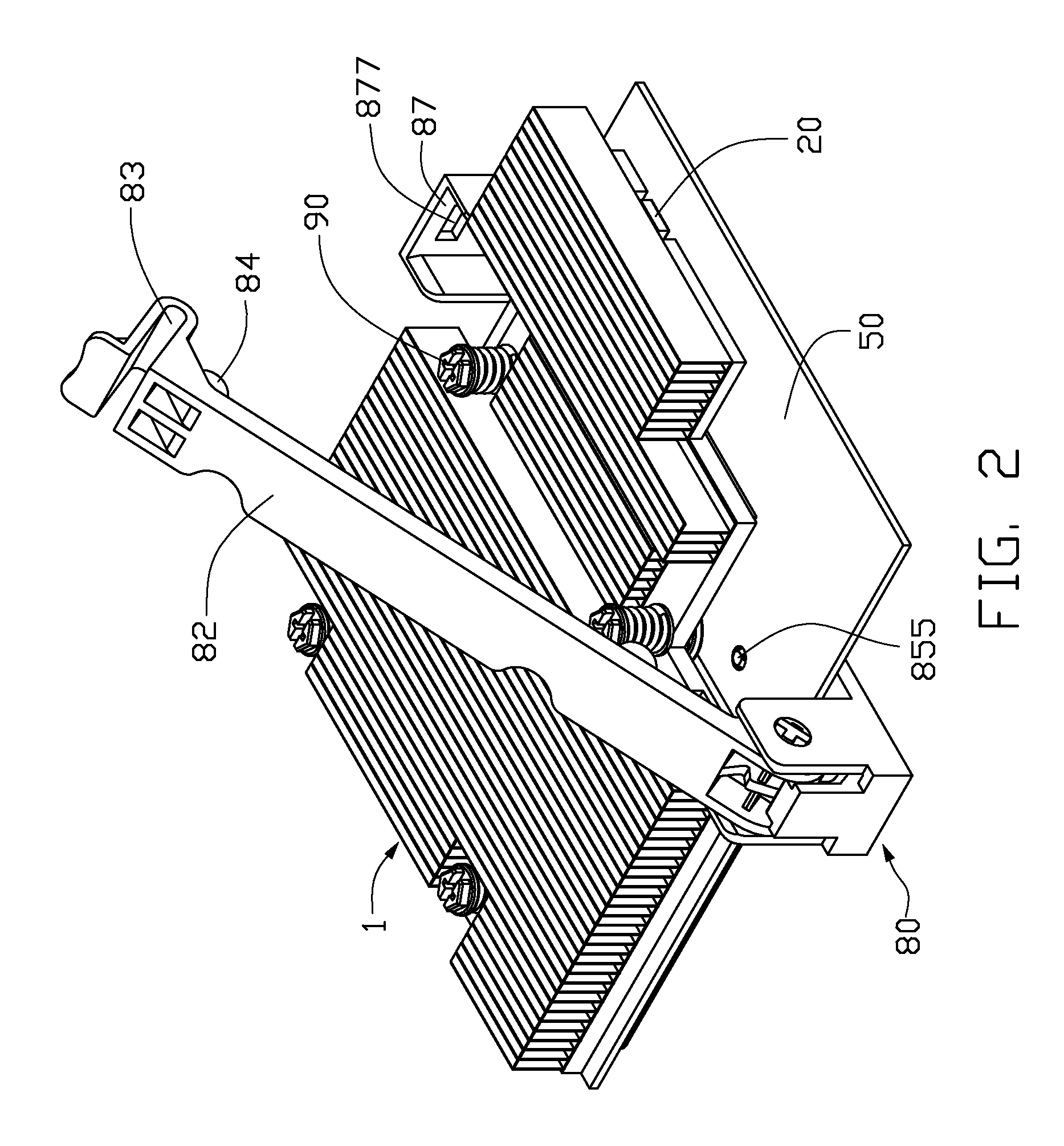

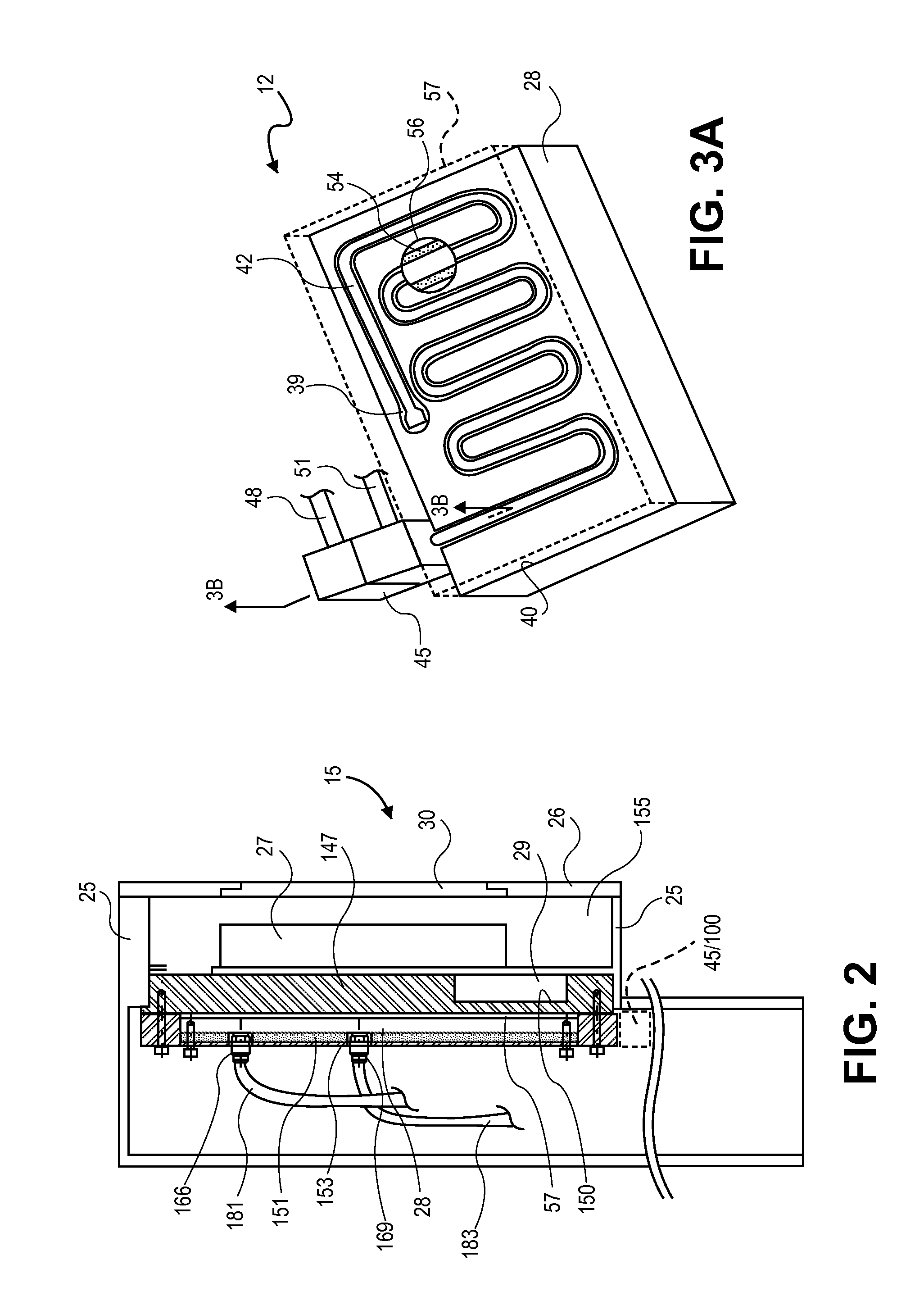

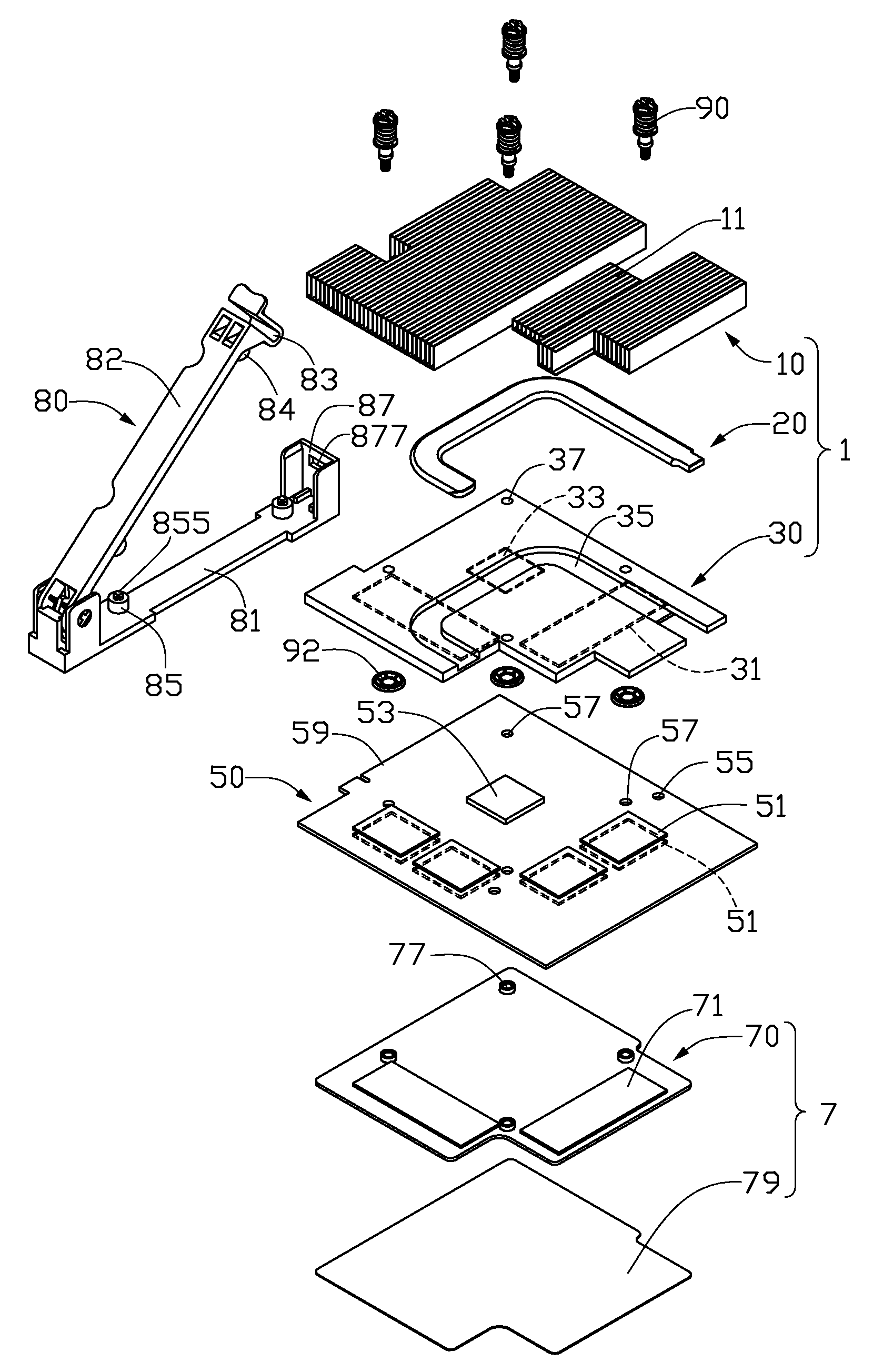

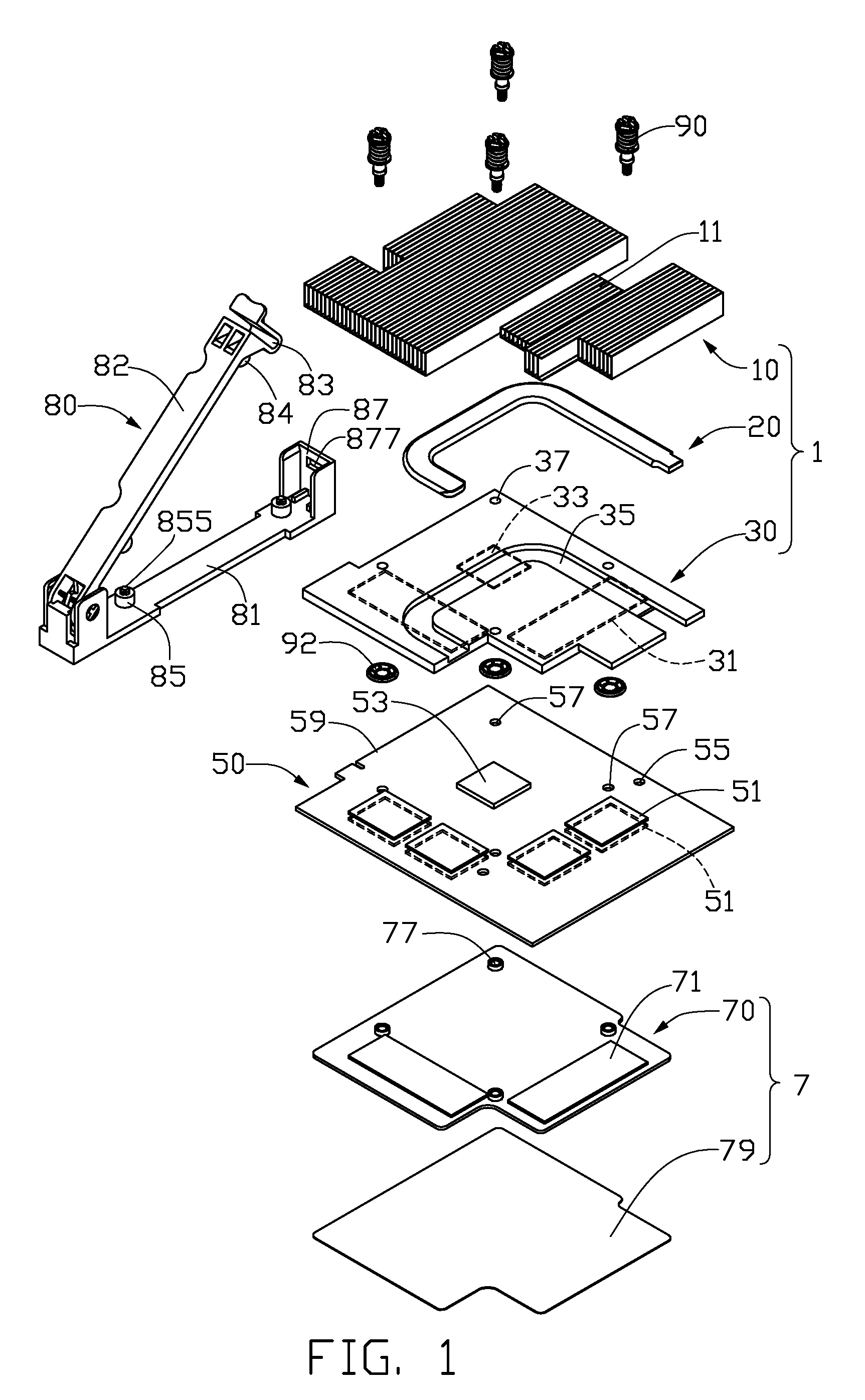

Heat dissipation assembly for graphics card and blade server using the same

InactiveUS20090122480A1Increase heat productionImprove performanceDigital data processing detailsSemiconductor/solid-state device detailsGraphicsMemory chip

A heat dissipation assembly mounted to a main board in a blade server includes a graphics card, a heat sink, and a thermal board. The graphics card includes a GPU and a plurality of first graphics memory chips mounted on a top thereof, and a plurality of second graphics memory chips mounted on a bottom thereof. The heat sink for cooling the GPU and the first graphics memory chips, includes a base attached to the top of the graphics card, a finned part fixed to a top of the base, and a heat pipe sandwiched between the base and the finned part. A pathway of the heat pipe passes over the GPU and at least part of the first graphics memory chips of the graphics card. The thermal board is mounted to the bottom of the graphics card for cooling the second graphics memory chips.

Owner:HON HAI PRECISION IND CO LTD

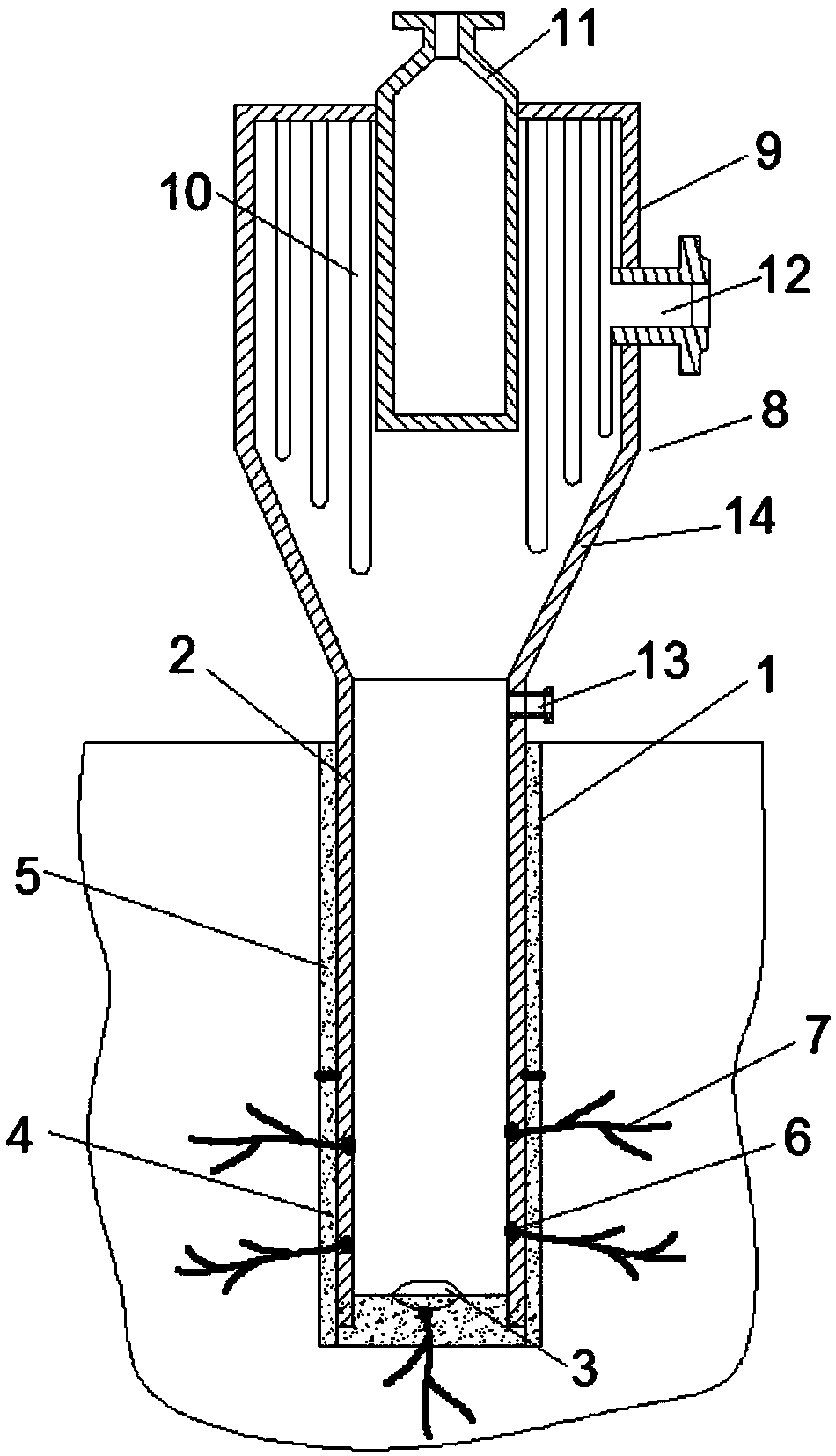

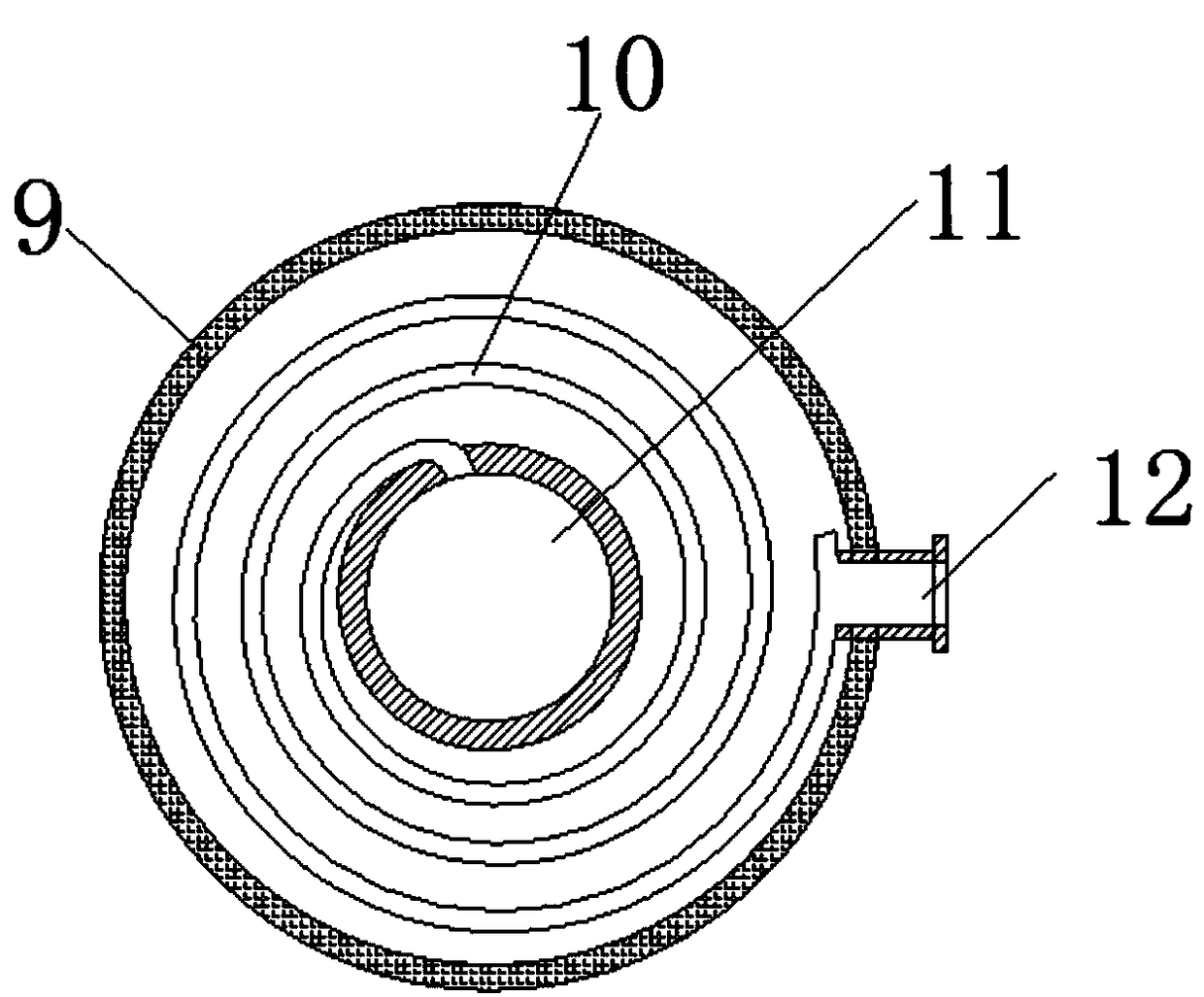

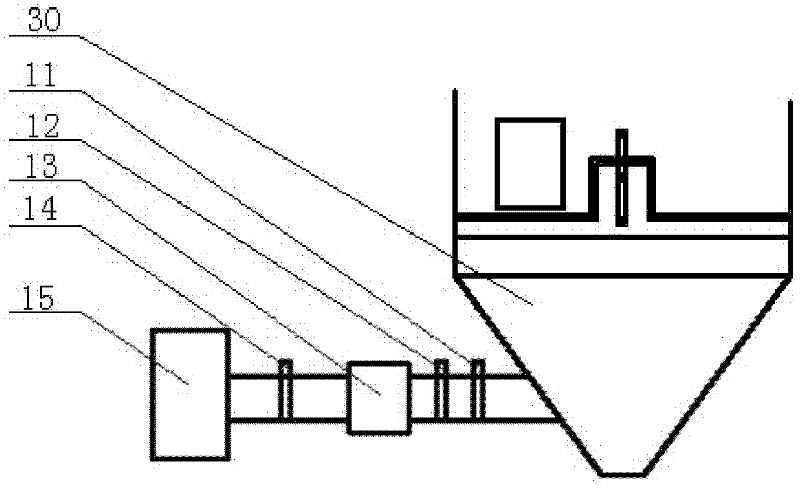

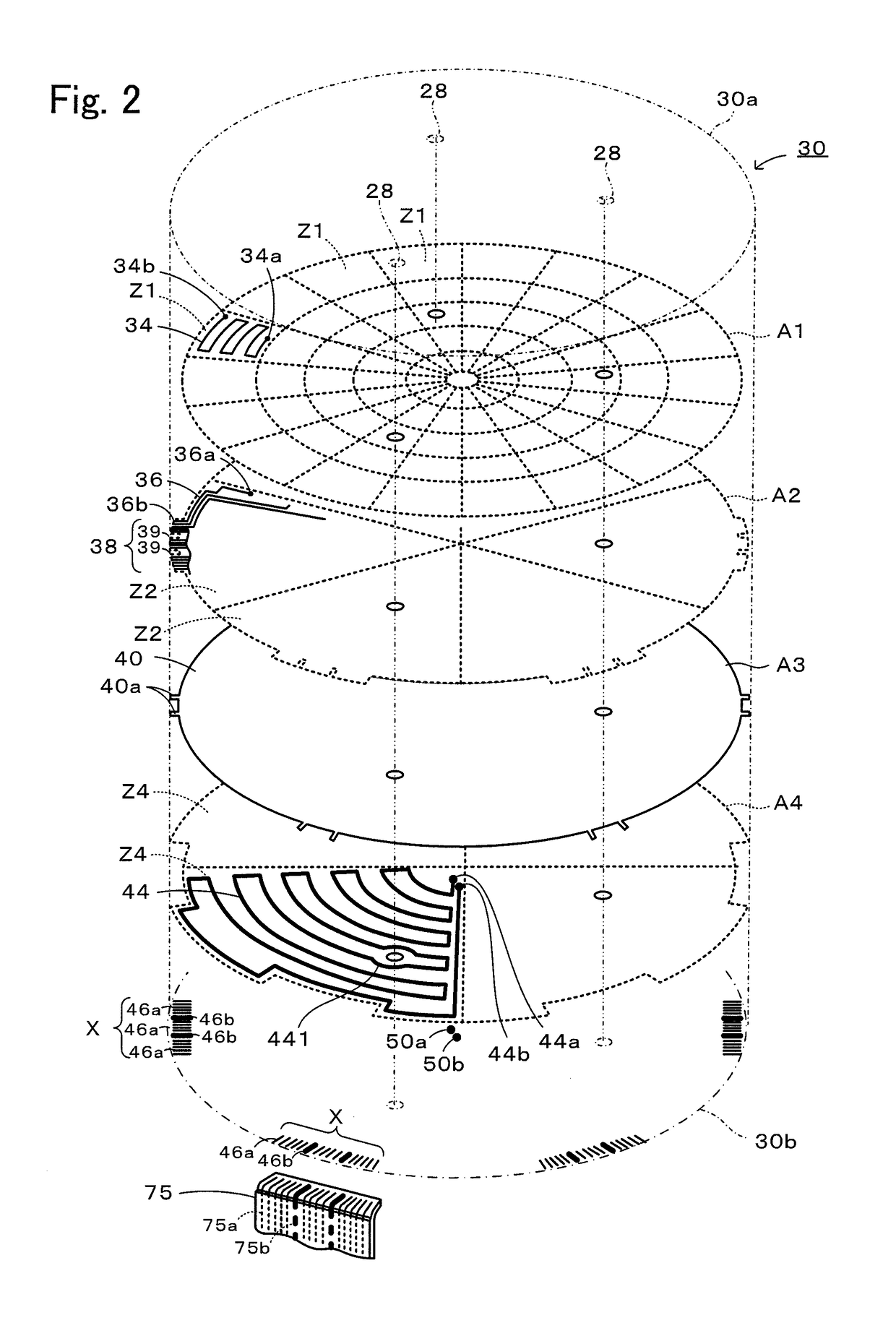

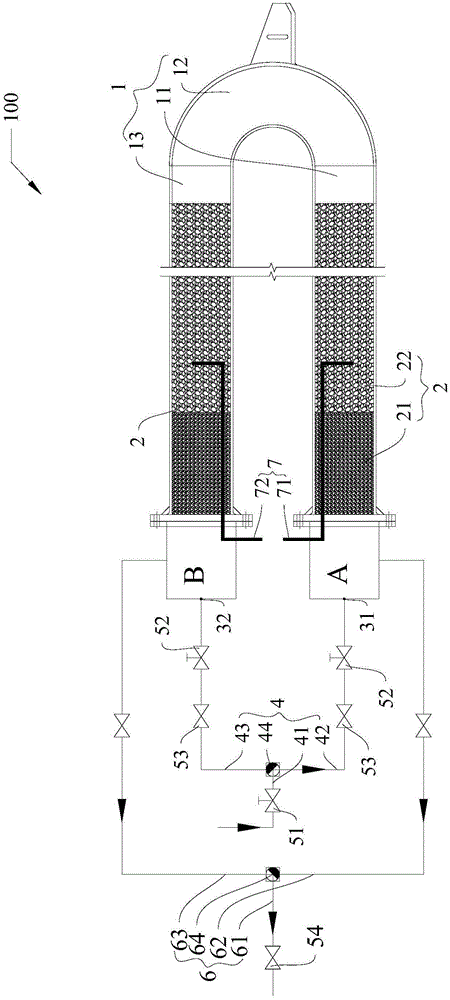

Technology for improving heat production capacity of geothermal wells

ActiveCN109403917AImprove efficiencyIncrease heat productionGeothermal energy generationFluid removalThermal insulationWell cementing

The invention relates to the technical field of geothermal energy development, in particular to a geothermal well novel technology. The technology improves the ability of leading geothermal energy inrock strata into geothermal wells through a heat conduction well cementing technology and a enhanced conductivity fracturing technology, and achieves high efficiency heat taking and heat transferringusing through spiral plate type condensing section gravity heat pipe heat exchanger. The technology comprises the following concrete process that after completing drilling a geothermal well and casinga sleeve pipe, the heat conduction well cementing is carried out, that is, thermal insulation cement slurry is injected in the low temperature section of the formation, and heat conduction cement slurry is injected into a stratum high temperature section to complete well cementing; after solidification of the heat insulation cement slurry and the heat conduction cement slurry of the well cementing, subsection perforation fracturing is carried out in the sleeve pipe of the stratum high temperature section, cracks are produced in high temperature strata, and heat conduction material is filled into the cracks to form a heat guiding belt extending from the sleeve pipe to the stratum; and finally, the condensing section of gravity heat pipe heat exchanger connected with the sleeve pipe is installed on the ground to form a high-yield geothermal well system in which rapid heat transfer in the stratum and high efficiency heat transfer in a well cylinder finally.

Owner:田振林

Cooling system for an electronic display

InactiveUS7319589B1Smooth connectionImprove heat transfer performanceModifications for display panelsStationary tubular conduit assembliesGas phaseCollector device

A cooling system for an electronic display may include a heat collector plate with internal gas and liquid phase lines. The cooling plate may be thermally isolated together with electronic components of the display within an enclosure of the display, while external lines carry liquid and gas phase refrigerant outside the enclosure to and from the heat collector plate. The external lines may be similar in size to each other and may be connected to the heat collector outside the heat collector plate by a manifold. The heat collector plate contacts a base plate of the electronic display in a thermally conductive relation to transfer heat from electronic components within the display to the gas phase refrigerant. Fans may be included for additional convective heat transfer. A single compressor may be fluidly connected to multiple heat collector plates in respective electronic displays.

Owner:HEADY GREGORY S

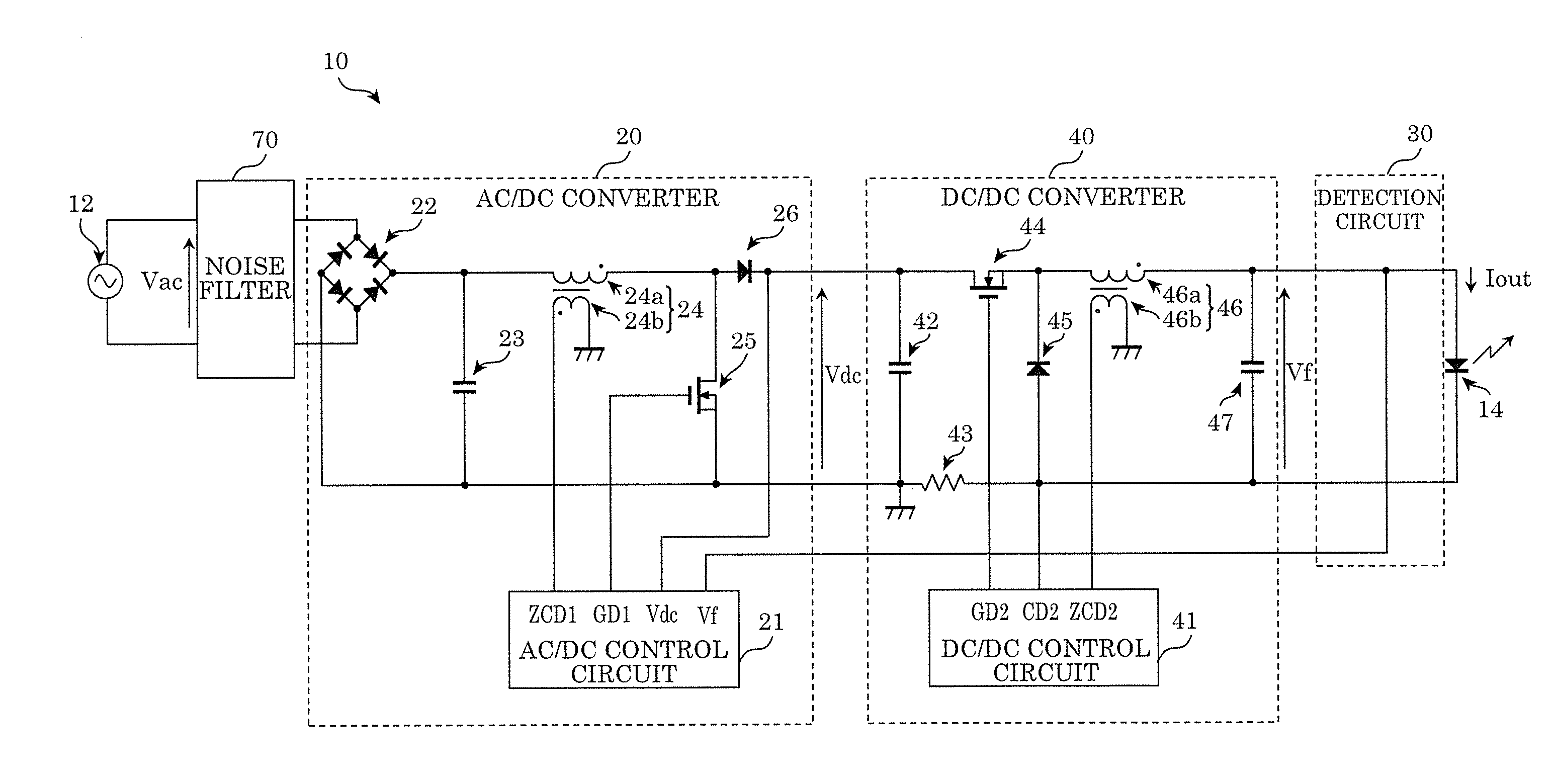

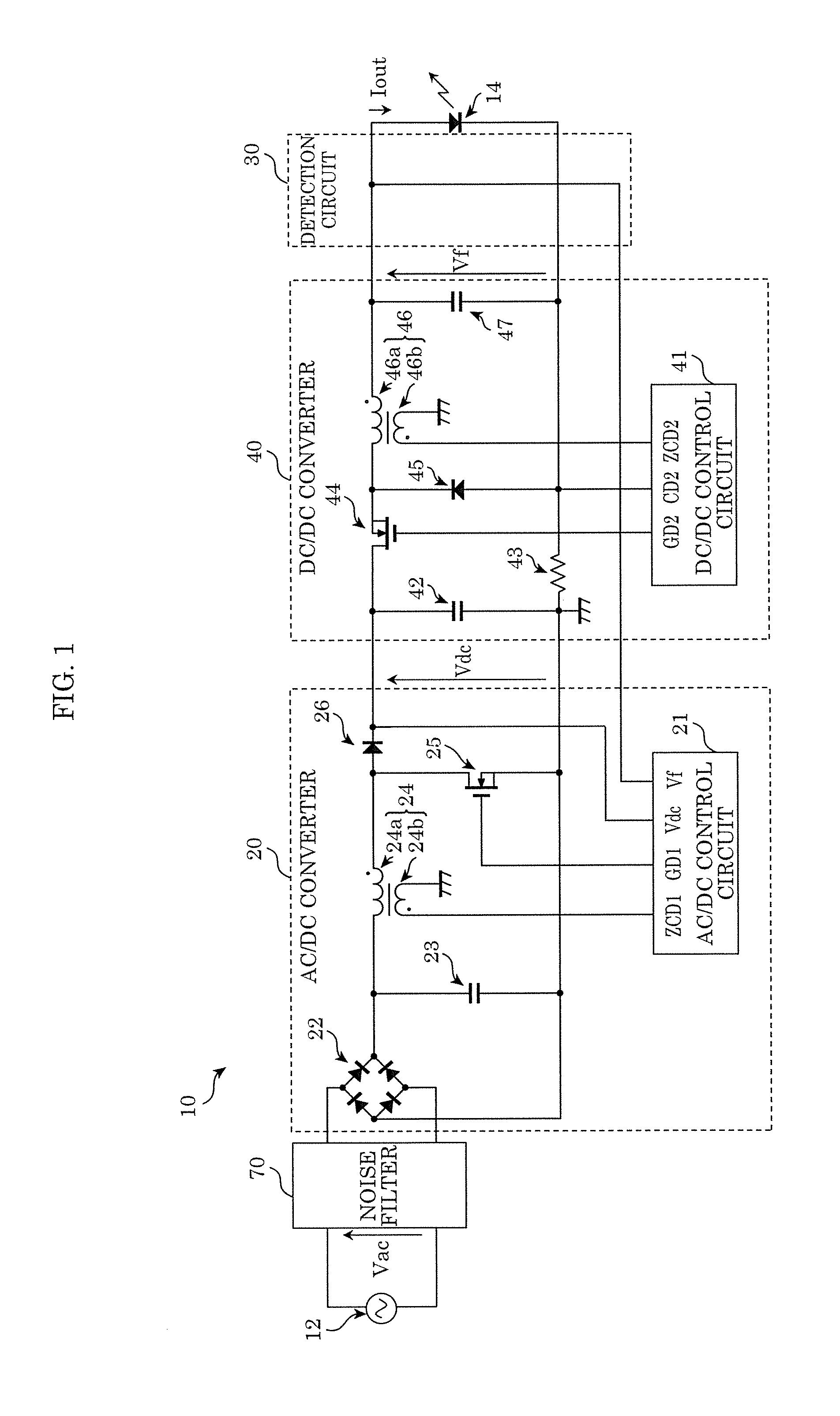

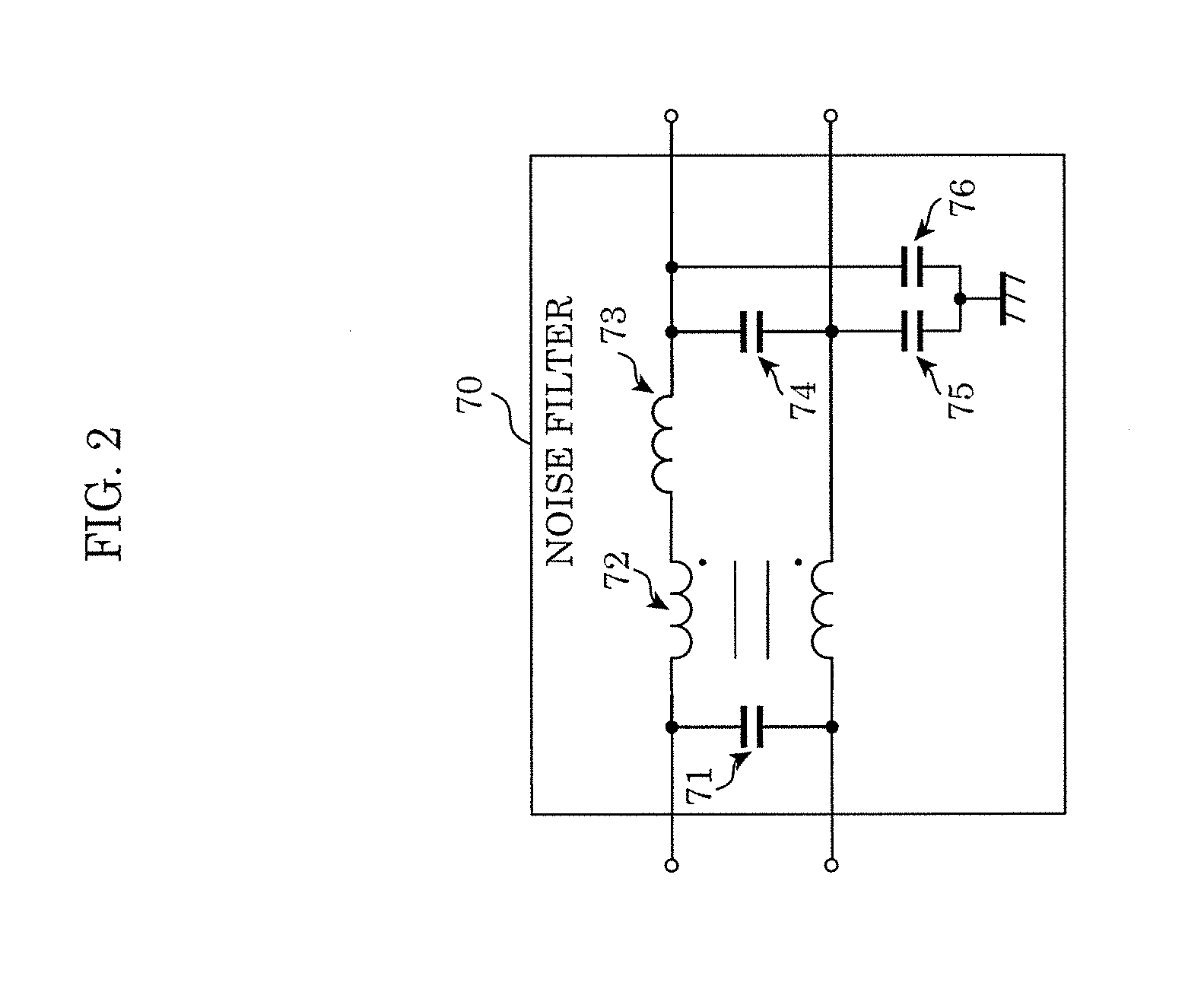

Lighting apparatus and luminaire

InactiveUS20160066375A1Increase the switching frequencySuppress noiseElectroluminescent light sourcesDc-dc conversionPower flowLight equipment

Lighting apparatus which supplies a current to solid-state light-emitting device (LED) includes: DC power supply circuit (AC / DC converter); and DC / DC converter that converts an output voltage of DC power supply circuit and applies, to solid-state light-emitting device, the output voltage converted. DC / DC converter includes: switching element; and DC / DC control circuit that performs a control of repeatedly turning ON and OFF switching element in a boundary conduction mode, and DC power supply circuit adjusts the output voltage to make a switching frequency of switching element higher than a first frequency, based on a forward voltage to be applied to solid-state light-emitting device.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Heat dissipation assembly for graphics card and blade server using the same

InactiveUS7580262B2Increase heat productionImprove performanceDigital data processing detailsSemiconductor/solid-state device detailsGraphicsMemory chip

A heat dissipation assembly mounted to a main board in a blade server includes a graphics card, a heat sink, and a thermal board. The graphics card includes a GPU and a plurality of first graphics memory chips mounted on a top thereof, and a plurality of second graphics memory chips mounted on a bottom thereof. The heat sink for cooling the GPU and the first graphics memory chips, includes a base attached to the top of the graphics card, a finned part fixed to a top of the base, and a heat pipe sandwiched between the base and the finned part. A pathway of the heat pipe passes over the GPU and at least part of the first graphics memory chips of the graphics card. The thermal board is mounted to the bottom of the graphics card for cooling the second graphics memory chips.

Owner:HON HAI PRECISION IND CO LTD

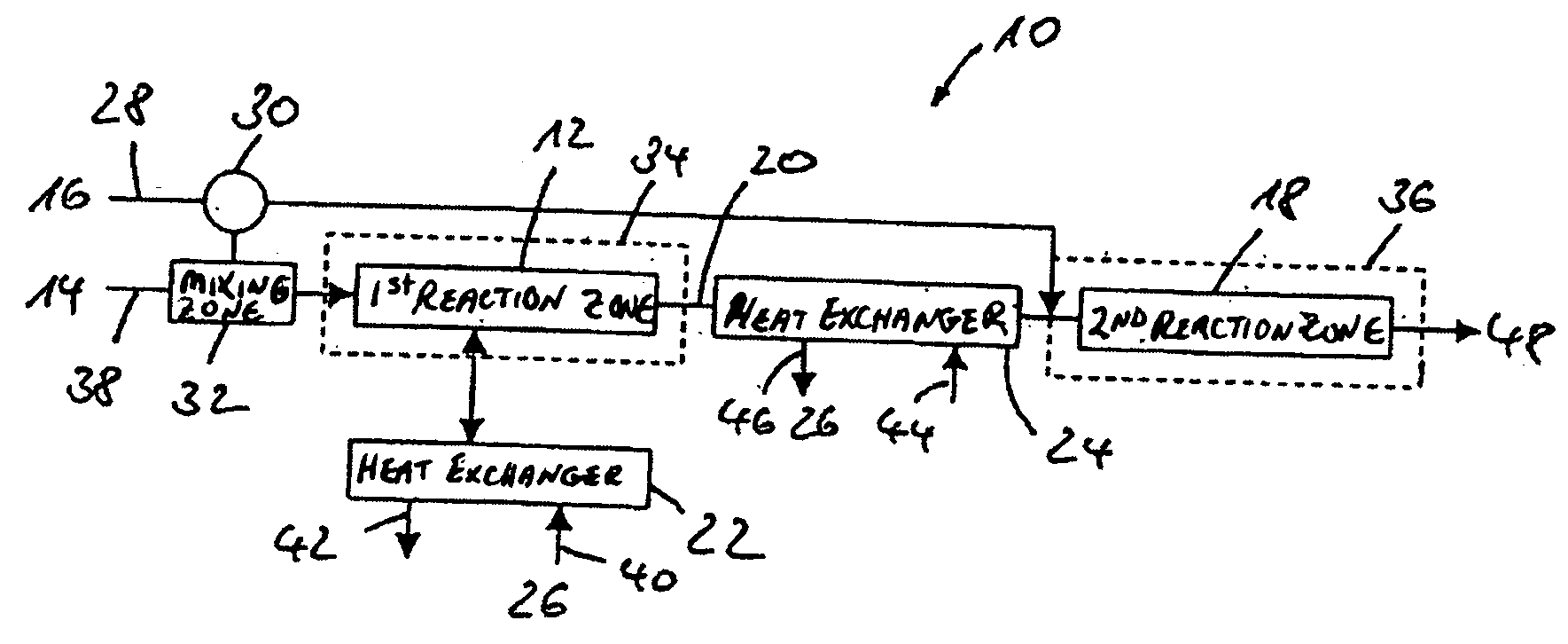

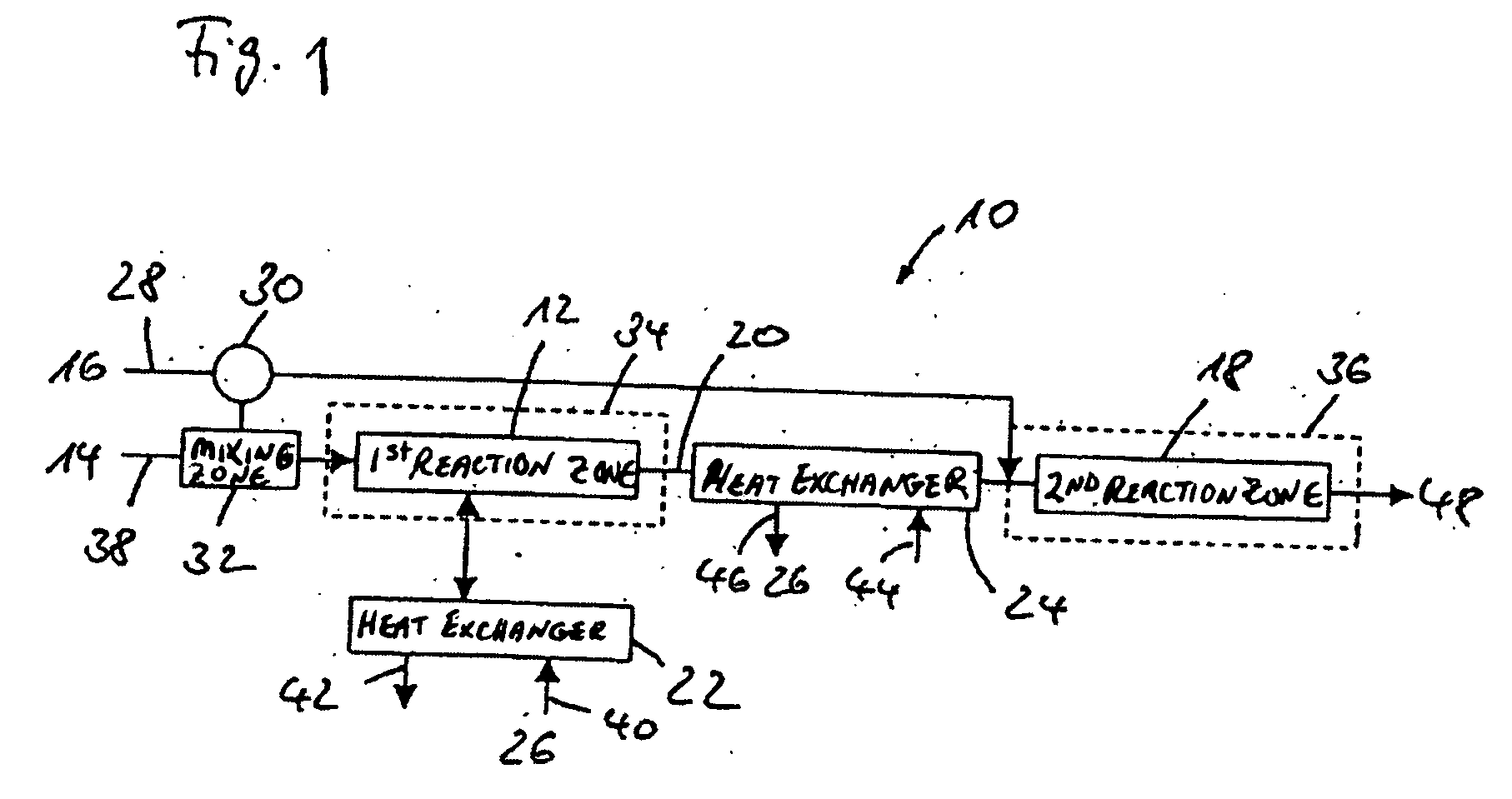

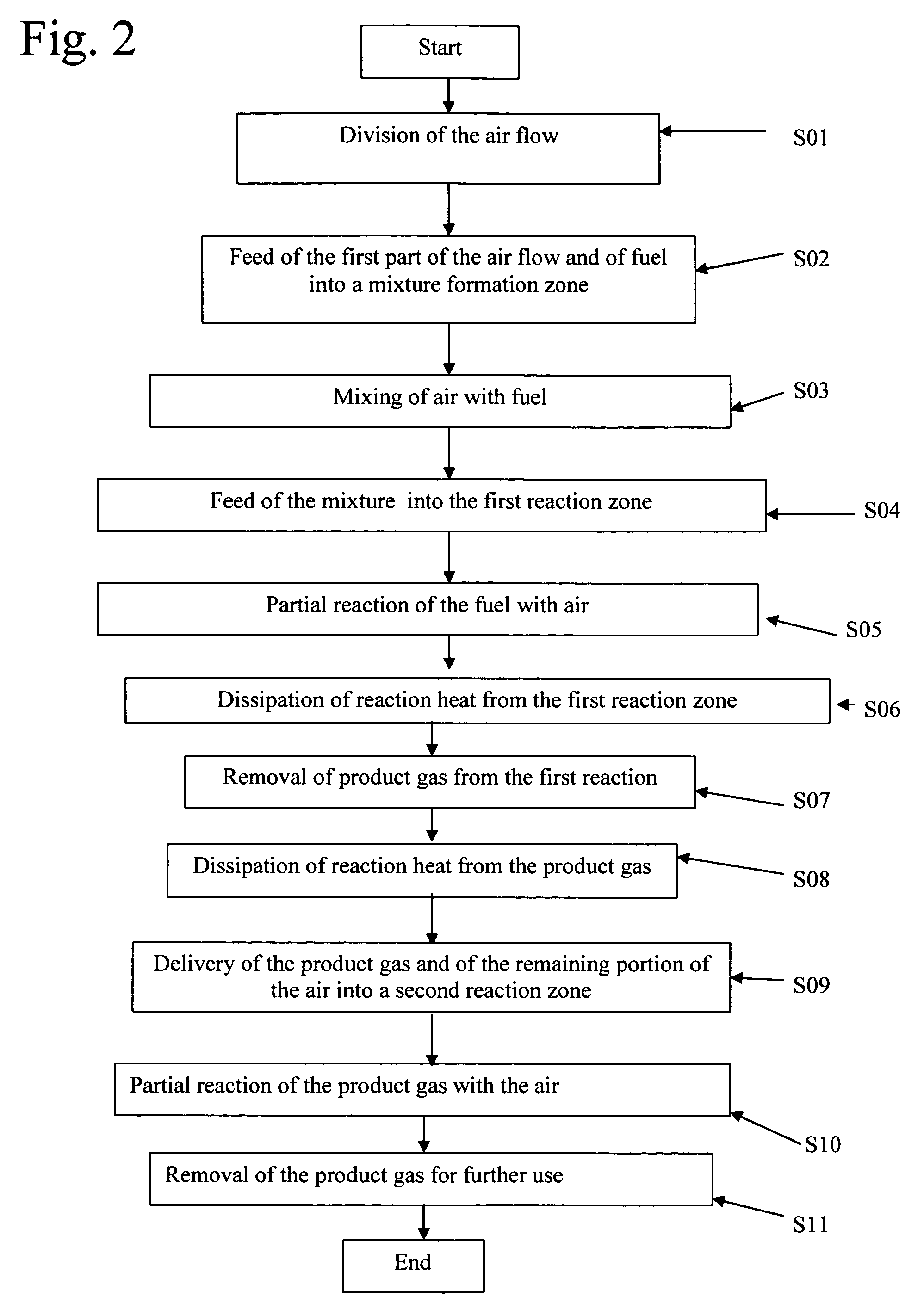

System and process for reacting fuel and oxidizer into reformate

InactiveUS20050126076A1Minimize dangerDangerous damageHydrogenFuel cell heat exchangeReaction zoneProduct gas

A system for reacting fuel and oxidizer into reformate employing a reformer having a first reaction zone to which the fuel and oxidizer are supplied, and a second reaction zone to which the product gas emerging from the first reaction zone and an oxidizer are supplied. The reformer further includes on or more heat dissipators for removing reaction heat produced in the first reaction zone before entry of the product gas into the second reaction zone.

Owner:EHNERDEJ GMBKH

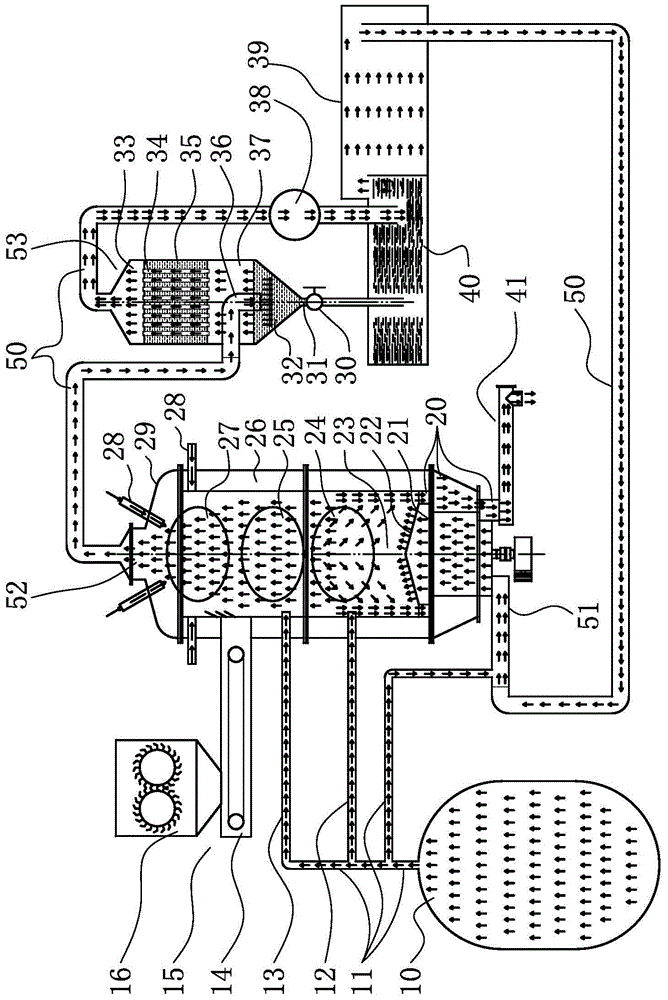

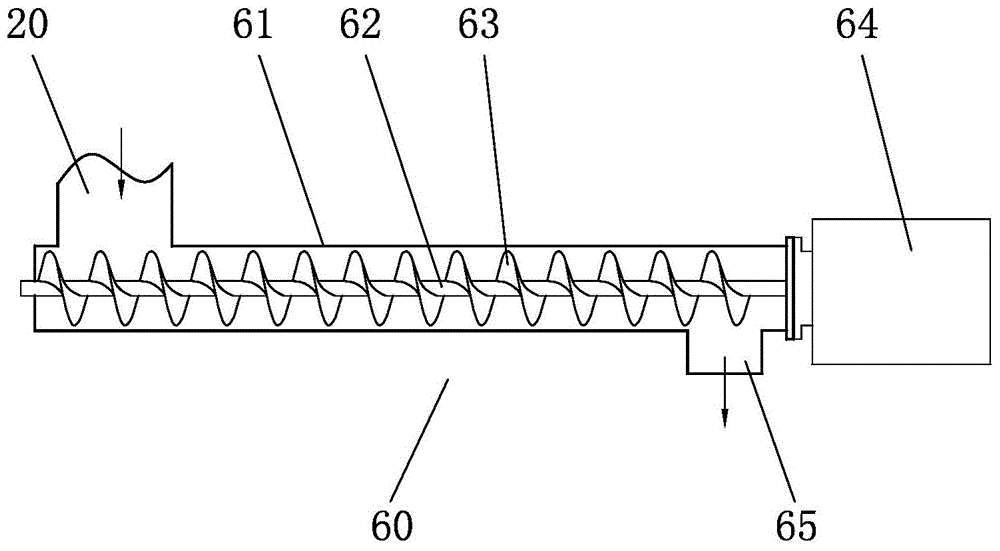

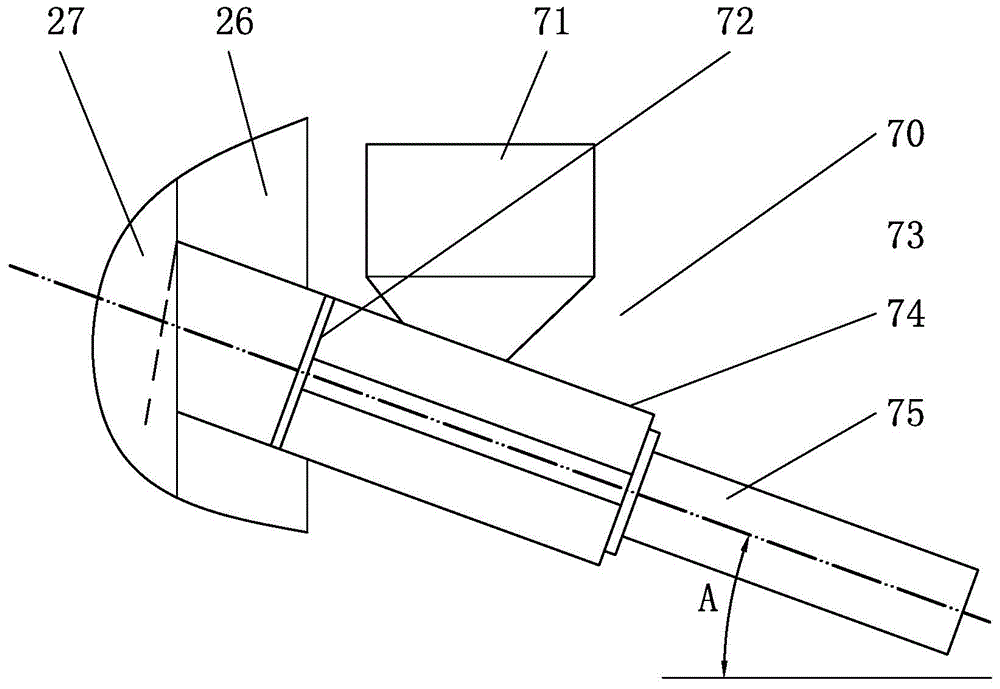

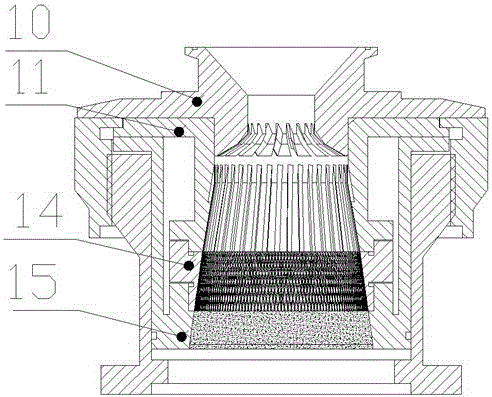

Totally-enclosed type multifunctional high-speed incinerating device and production process thereof

ActiveCN105157034AOutstanding and Beneficial Technical EffectsReduce consumptionIncinerator apparatusHazardous substanceEnvironmental engineering

The invention belongs to the technical field of refuse treatment, and relates to a totally-enclosed type multifunctional high-speed incinerating device and a production process thereof. The device is characterized in that an incinerator sequentially communicates with a purifying condensing device, an exhaust fan, a totally-enclosed cooling tank and a totally-enclosed ecological purifying area through conduits; an oxygen output tube of an oxygen generator correspondingly communicates with a first oxygen supplementing tube, a second supplementing tube and an air inlet tube. The production process is that oxygen is supplemented to an inner chamber of the incinerator, and connected wastes fed into the incinerator is incinerated once through the oxygen, and the waste gas is incinerated and pyrolysed at high temperature twice and then cooled and decoked; the decoked waste gas is purified and condensed through the purifying condensing device, then fed into the totally-enclosed cooling tank to be cooled and finally subjected to biodegradation in the ecological purifying area; the waste gas containing the rest toxic and harmful substances is introduced into the incinerator again through the air inlet tube to be pyrolysed at high temperature. Therefore, the totally-enclosed type circular treatment mode of the waste is achieved. The device and the production process have the advantages that the wastes can be treated without leakage and with zero emission.

Owner:洪知瑜

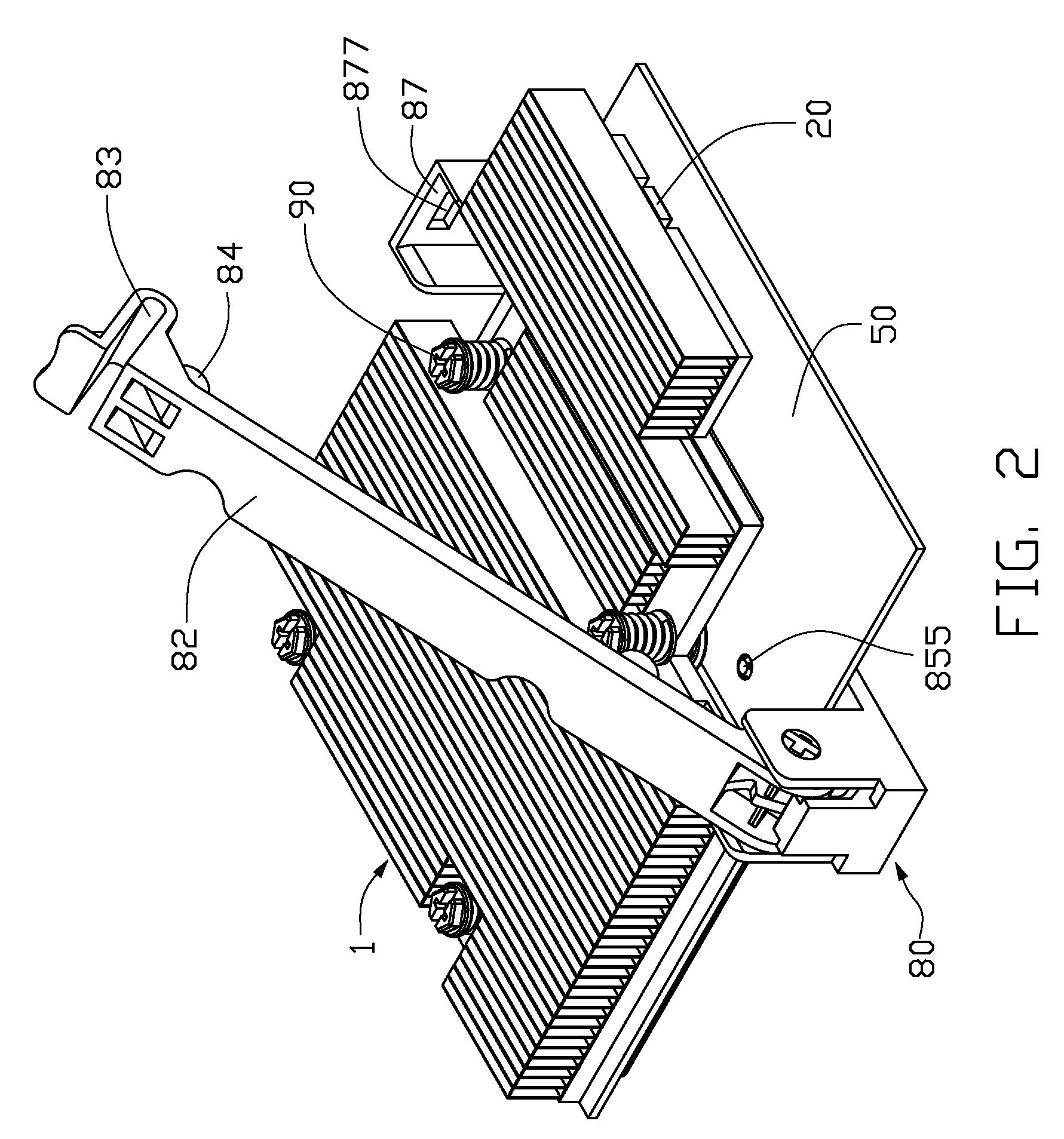

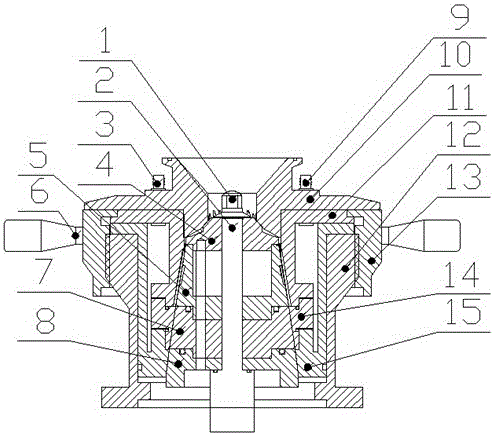

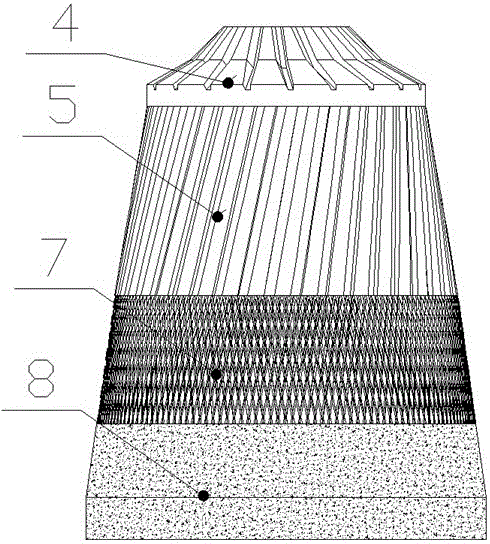

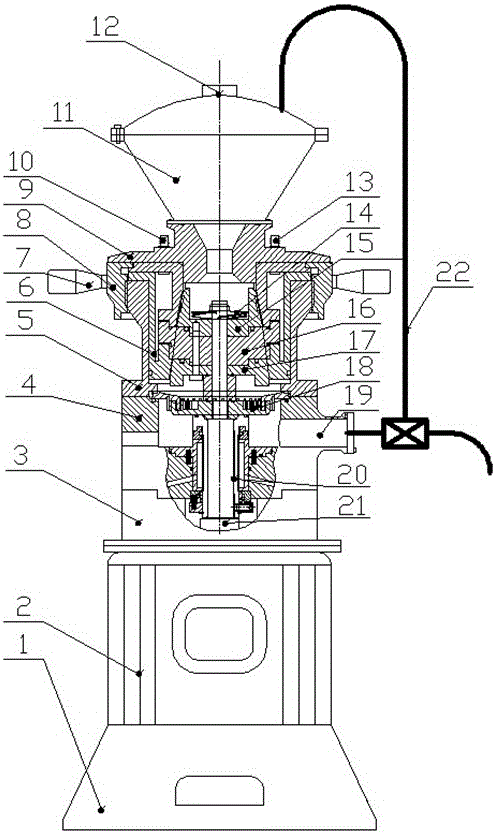

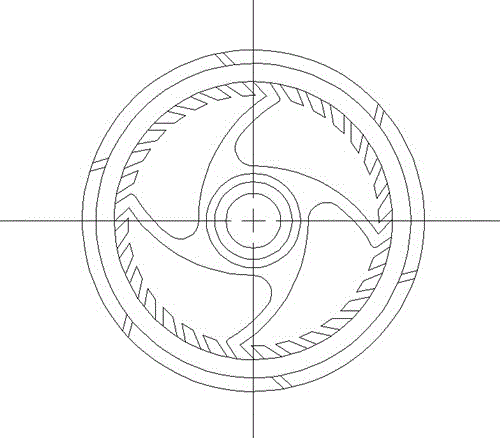

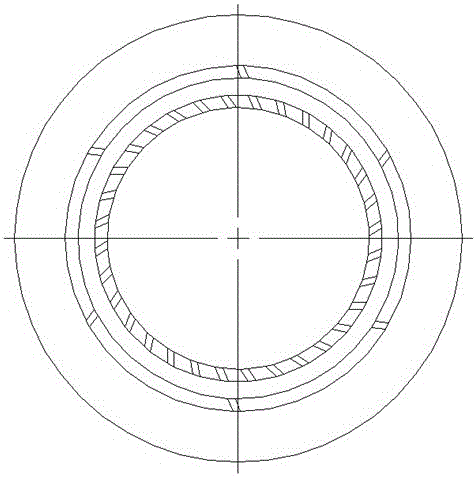

Grinding device

The invention discloses a grinding device mainly used as a grinding dispersion machine or a colloid mill. The grinding device is simple in structure, low in cost, convenient to machine and install, good in heat dissipation, suitable for high rotating speed and the like. The grinding device comprises a main shaft, three stages of static grinding bodies, a top cover, four stages of movable grinding bodies, a shell, an adjusting disk, a handle, a lock nut, a cooling liquid pipe inlet connector, a cooling liquid pipe outlet connector and the like. The movable grinding bodies are provided with four stages of sawtooth protrusions and grooves, the four stages of sawtooth protrusions and grooves become thin from thick, the fourth stage adopts a metal coating, and the distance between the three stages of static grinding bodies and the four stages of movable grinding bodies and the distance between the top cover and the four stages of movable grinding bodies can be adjusted; by means of a fineness-degree-increased grinding head rotating at a high speed, finally, micro-nano-level material particles are obtained; the four stages of movable grinding bodies are fixed to the main shaft and locked through the lock nut at the front end of the main shaft; the adjusting disk is arranged above the shell, the handle is installed on the adjusting disk, and the handle adjusts the adjusting disk so that the processing precision of materials in a cavity can be increased; and the top cover is arranged on the adjusting disk, the top cover is provided with the cooling liquid pipe inlet connector and the cooling liquid pipe outlet connector, the cooling liquid pipe inlet connector is connected with an annular cooling liquid channel, cooling liquid is added at any time, the adjusting disk, the materials and a grinding disk are protected, and the situation that the using performance is affected by the too-high temperature is avoided.

Owner:HARBIN UNIV OF SCI & TECH

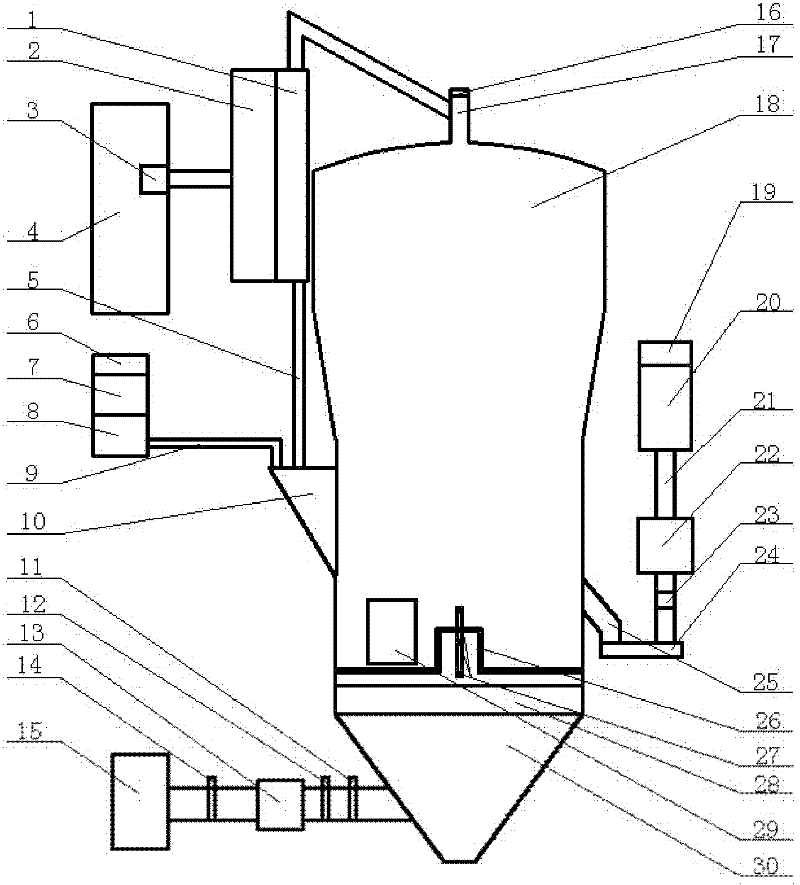

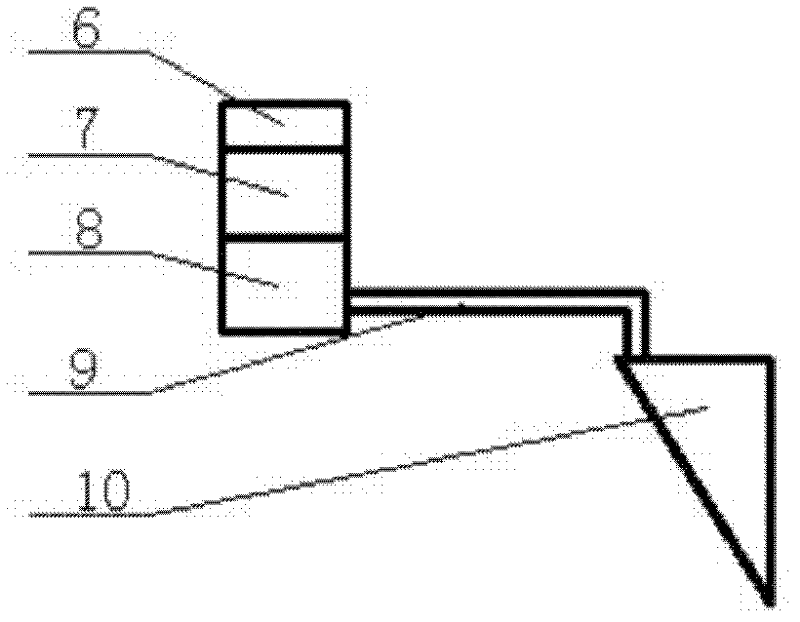

Fluidized bed furnace device for circularly roasting molybdenum concentrates and method for using same

InactiveCN102653821AFully roasted oxidation reactionIncrease heat productionFluidised-bed furnacesFluidized bedFlue gas

The invention discloses a fluidized bed furnace device for circularly roasting molybdenum concentrates, which comprises a fluidized bed furnace, a dust collection system, a flue gas recycling system, an air supply system, a feeding system and a discharged-material packing automation system, wherein the discharged-material packing automation system is connected to a discharge outlet of the fluidized bed furnace; the dust collection system and the feeding system are both connected to a feed inlet of the fluidized bed furnace; the air supply system is connected to an air chamber of the fluidized bed furnace, and is composed of a Roots blower, a heating facility and a facility capable of indicating and controlling the pressure and air inflow volume in the air chamber; and the feeding system can uniformly and continuously feed molybdenum concentrates with sizes of 20-200 meshes into the fluidized bed furnace according to a given amount. The invention also discloses a method for using the fluidized bed furnace device for circularly roasting molybdenum concentrates, through which molybdenum concentrates are in full contact with enough oxygen, so that an effect of supplying heat without using an external heat source in the roasting process of molybdenum concentrates is achieved, and high-dissolubility molybdenum oxides of which the soluble molybdenum content is greater than 98% can be efficiently produced, therefore, the method is storing in production capacity; and the concentration of SO2 in roasting in flue gas can reach 4%.

Owner:CHINA MOLYBDENUM

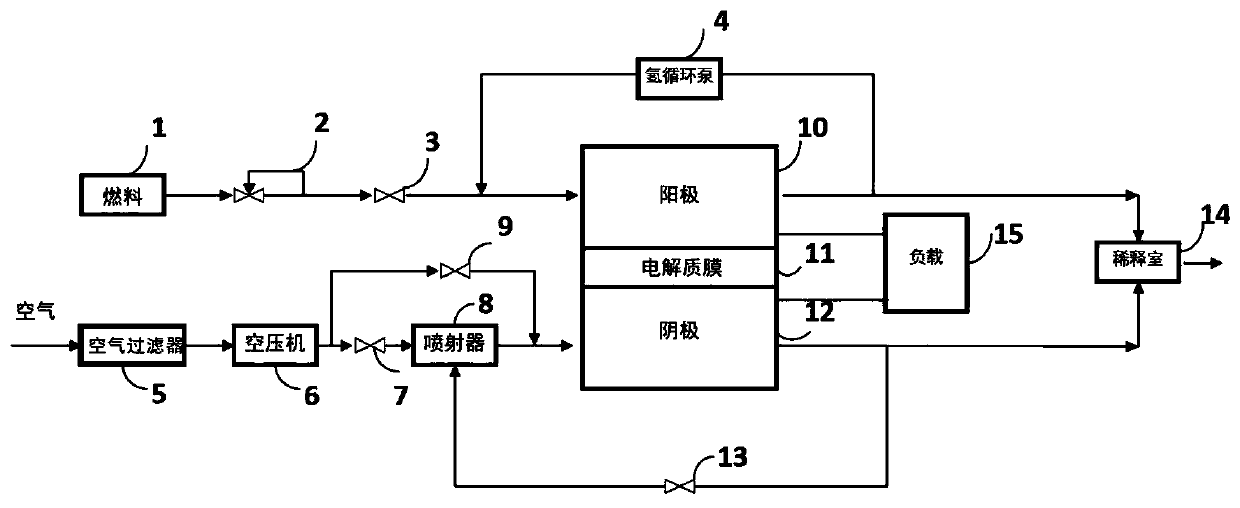

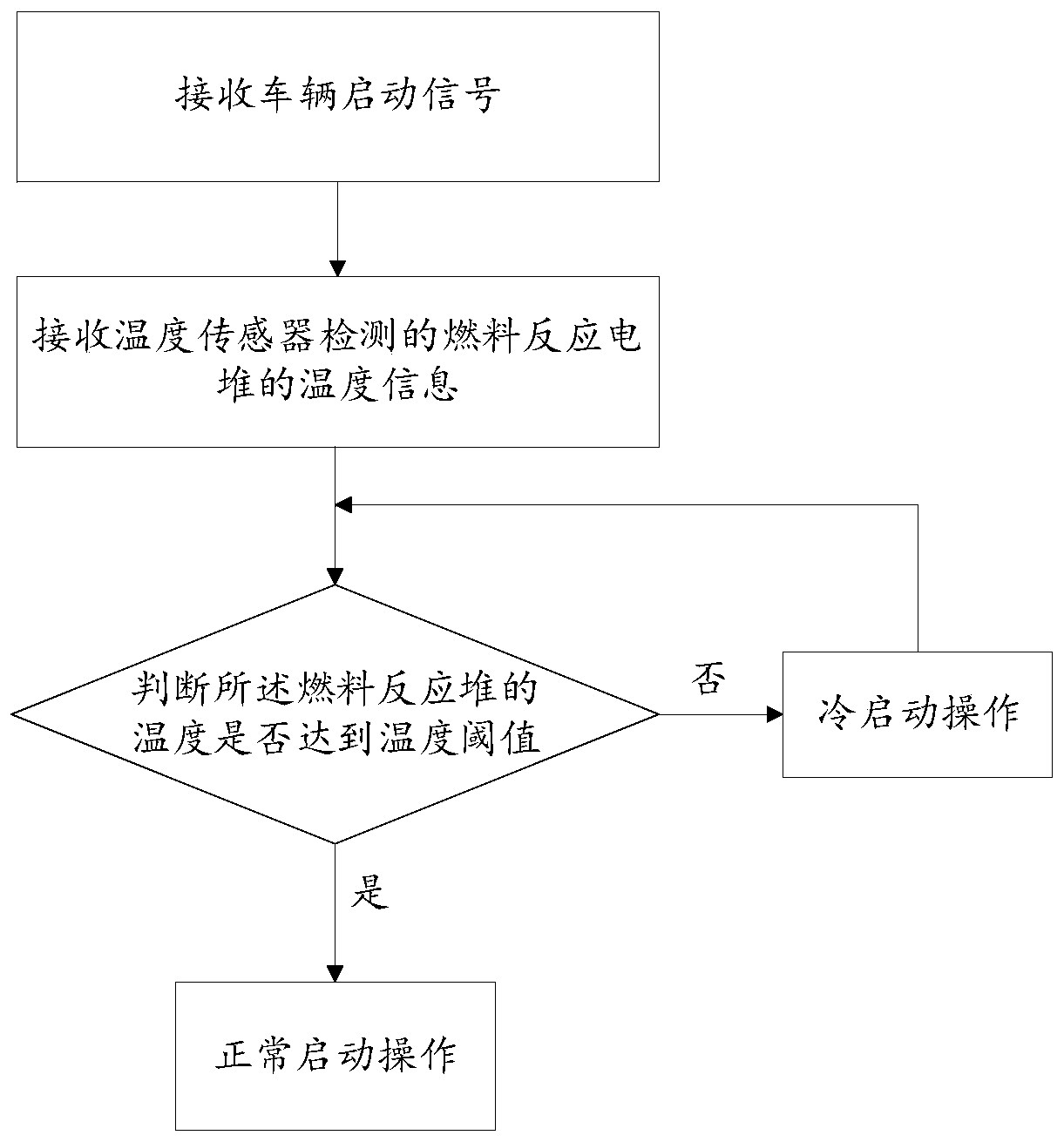

Cold starting system and control method thereof

ActiveCN109950578AIncrease concentration lossIncrease heat productionFinal product manufactureElectric vehicle charging technologyFuel cellsFuel efficiency

The invention discloses a cold starting system which comprises a fuel reaction electric pile, a fuel supply pipeline, an oxidant supply pipeline, a temperature sensor and a controller. The fuel supplypipeline is used for conveying fuel to the anode of the fuel reaction electric pile; the oxidant supply line is used for conveying an oxidant to the cathode of the fuel reaction electric pile, and comprises an injector for injecting the oxidant to the cathode of the fuel reaction electric pile in a cold start; the temperature sensor is used for detecting temperature information of the fuel reaction electric pile and transmitting the temperature information to the controller; the injector and the temperature sensor are in communication connection with the controller. The invention further provides a method for implementing a cold starting system, and the system reduces the fuel cell efficiency by reducing the concentration of the oxidizing agent, thereby increasing the heat production amount, improving the uniformity of the oxidizing agent in the electric pile, and improving the overall performance of a vehicle.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

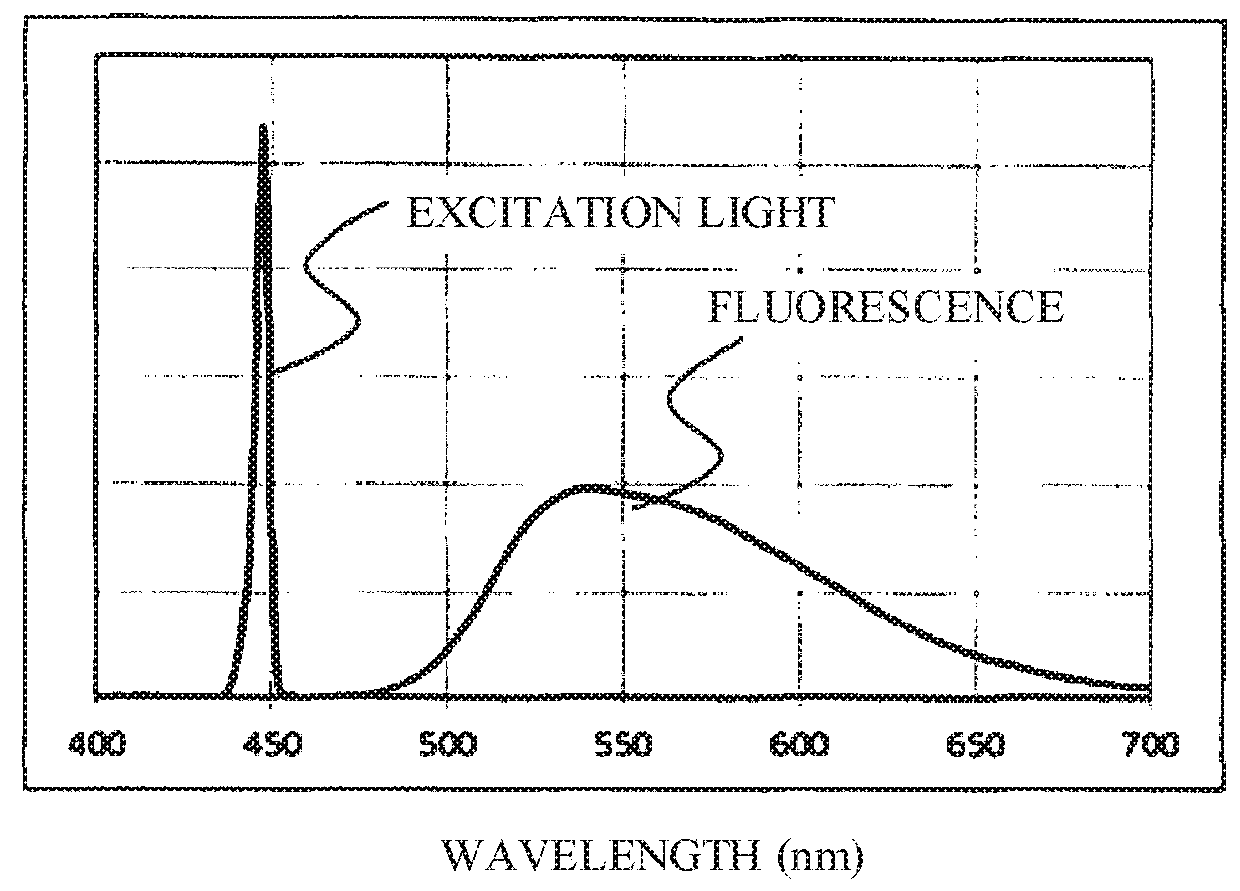

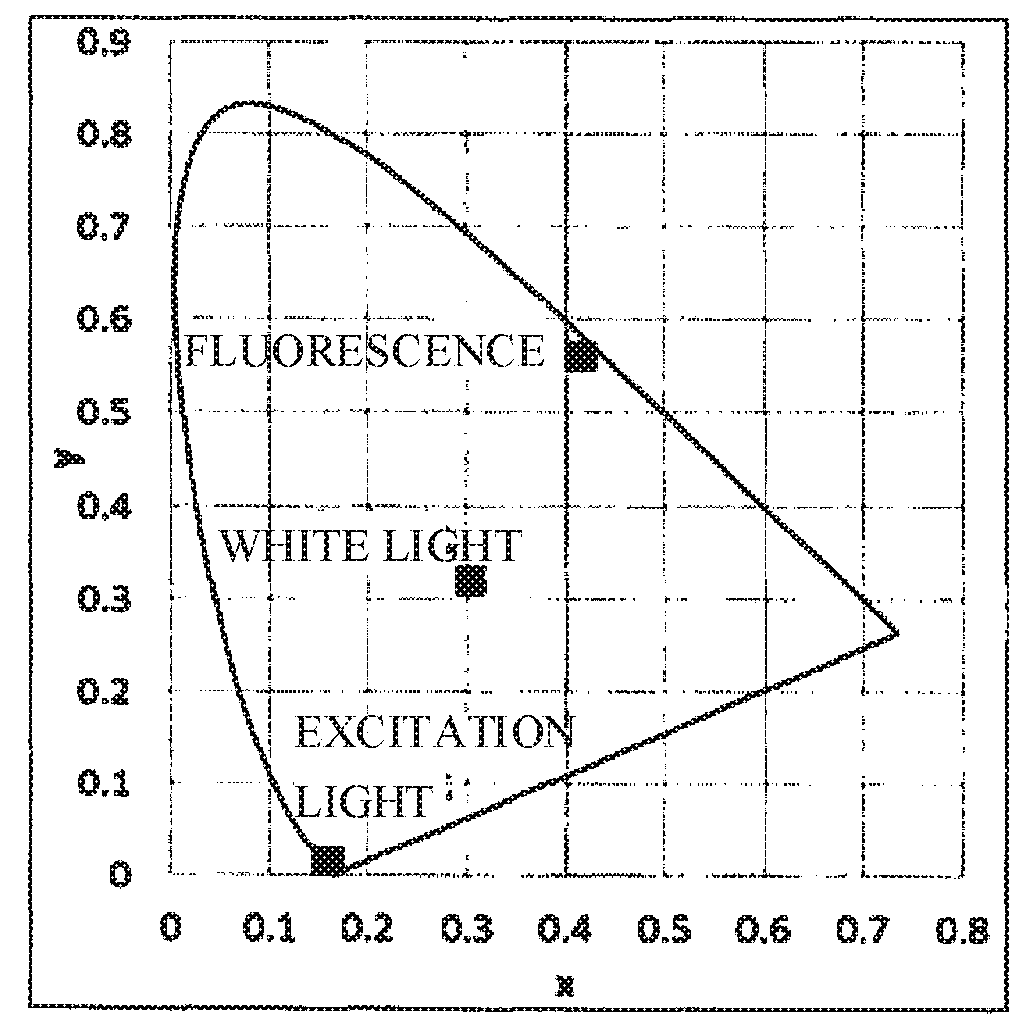

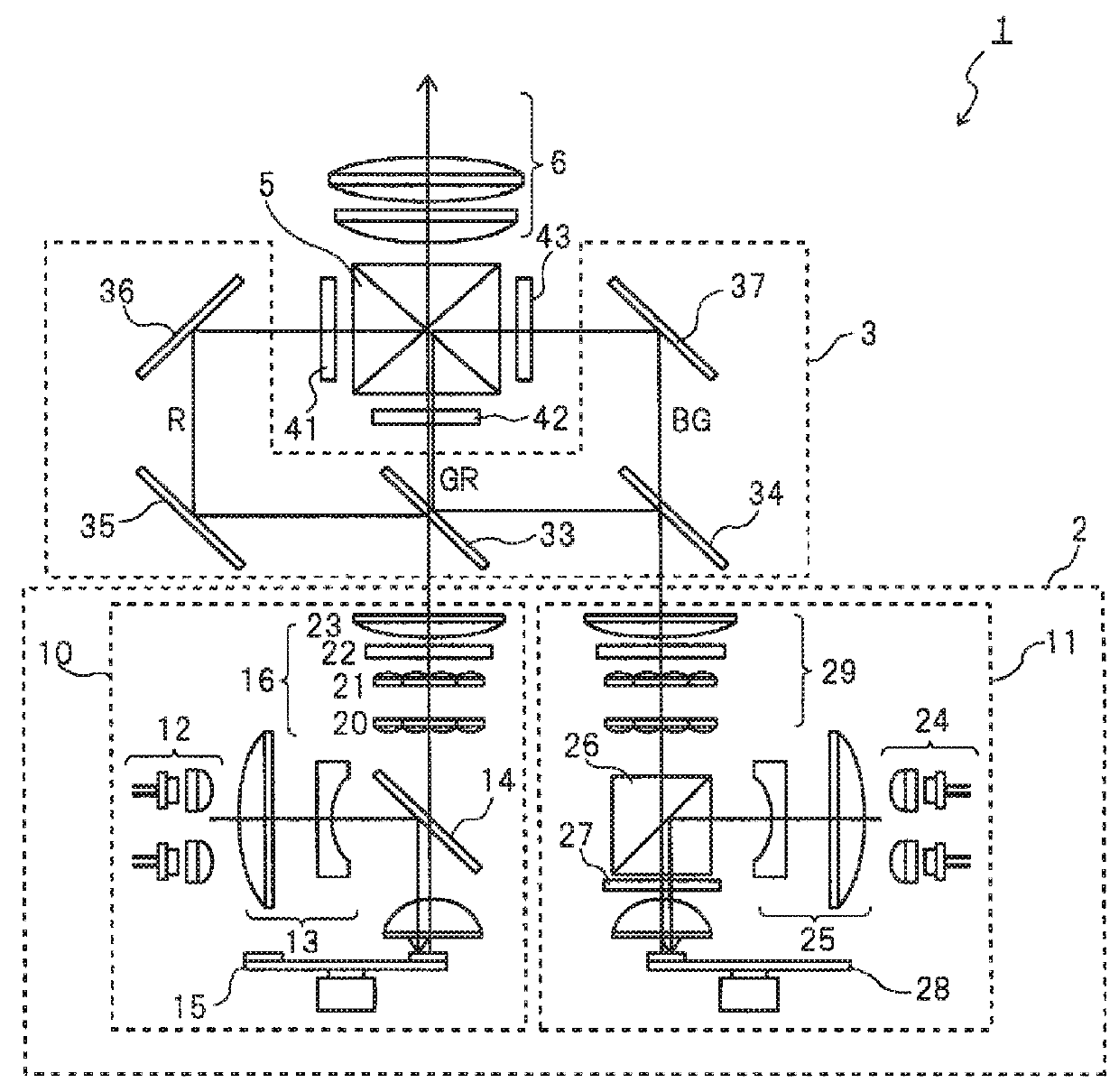

Projector and image display method

ActiveUS20180095353A1Increase heat productionLow efficiencyProjectorsColor photographyFluorescenceOptoelectronics

The present invention provides a projector with high brightness, the projector including: a first light source that outputs a first light containing a first fluorescence generated in a first fluorescence region; a second light source that outputs a second light containing a second fluorescence generated in a second fluorescence region; first to third image display elements; a light separation optical system that generates an illumination light illuminating the first to third image display elements with colors different from each other from the input first light and second light and radiates the illumination light to the first to third image display elements; and a controller that causes the first to third image display elements to display an image according to an input video signal and colors of the illumination light radiated to the first to third image display elements.

Owner:SHARP NEC DISPLAY SOLUTIONS LTD

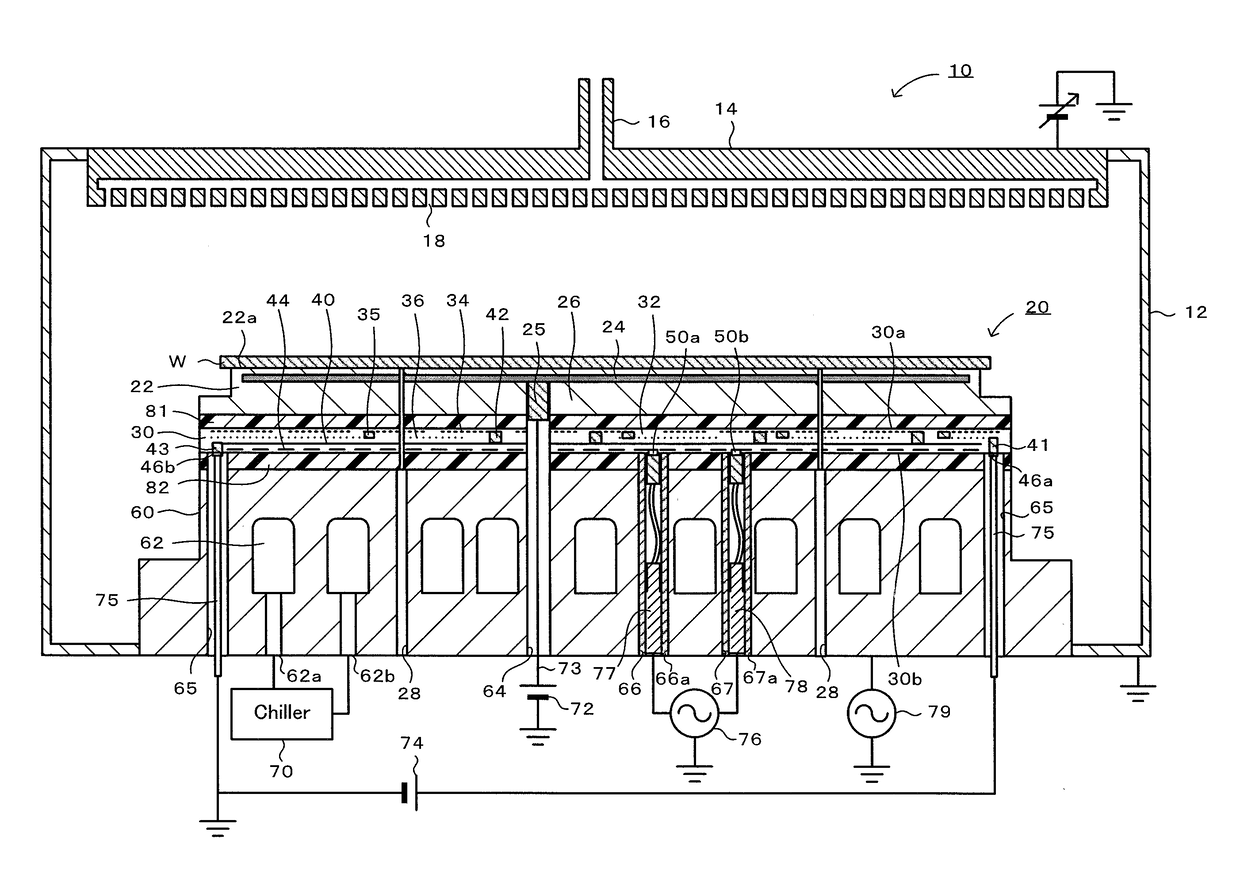

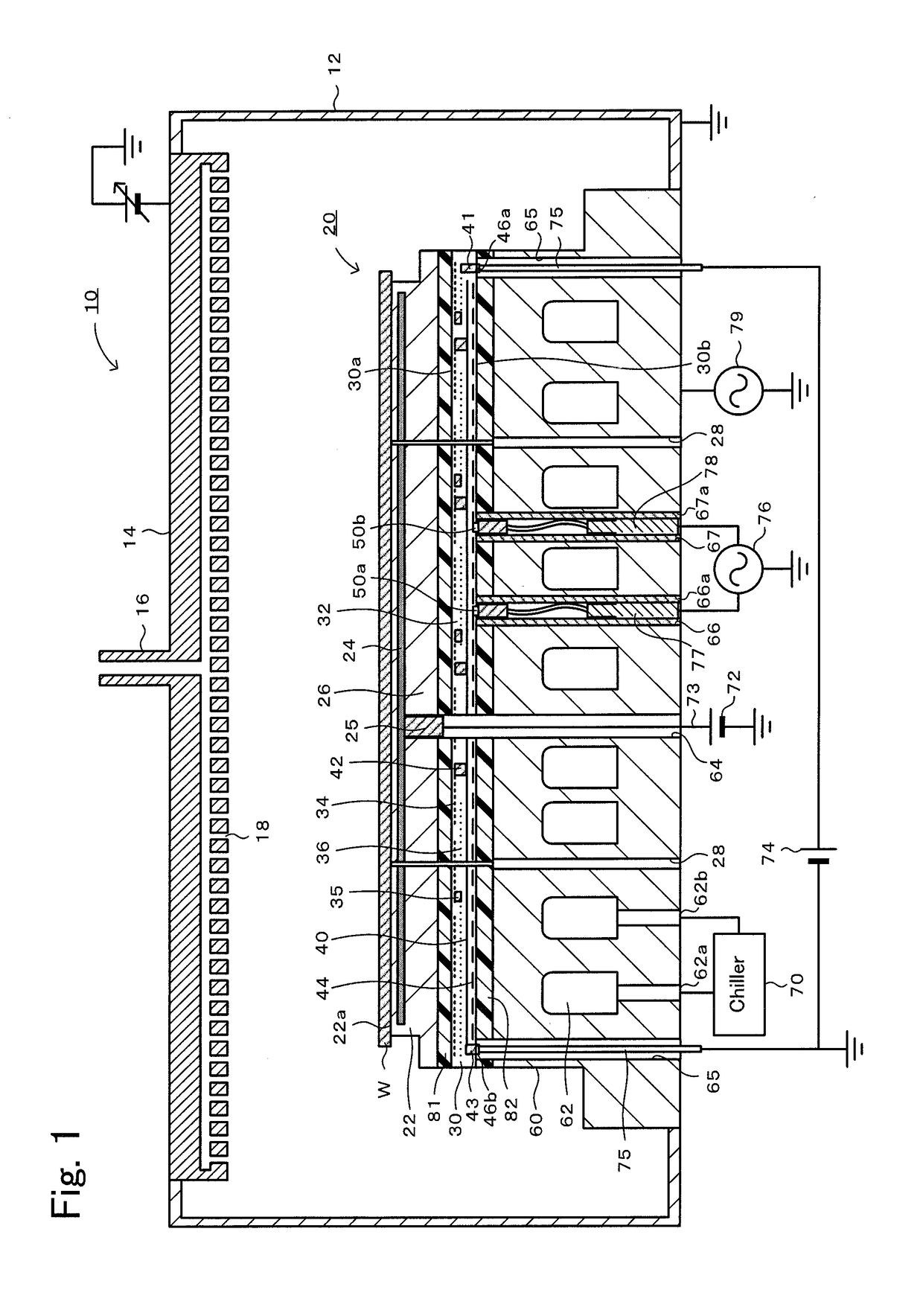

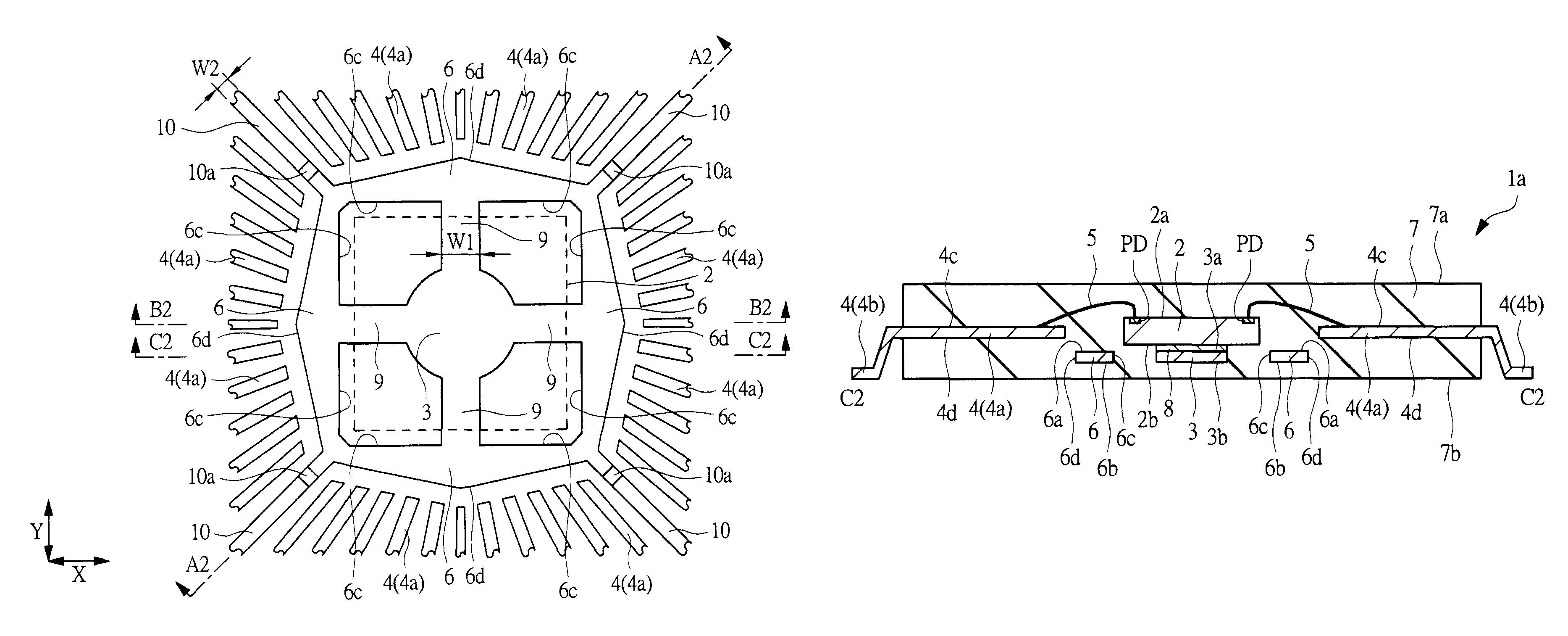

Electrostatic chuck heater

ActiveUS20180190529A1Ensure marginSmall amount of heatOhmic-resistance electrodesElectric discharge tubesElectrical resistance and conductanceExecution control

An electrostatic chuck heater includes an electrostatic chuck in which an electrostatic electrode is embedded in a ceramic sintered body; a small-zone formation region including a plurality of small zones in which small heater electrodes are wired; a power source to which the plurality of small heater electrodes are connected in parallel; and a small-zone control apparatus that performs control such that desired electric power is supplied to each of the small heater electrodes, wherein among the plurality of small heater electrodes, a small heater electrode that is wired in a small zone including a cool spot has a resistance that is set to a smaller value than that of the other small heater electrodes.

Owner:NGK INSULATORS LTD

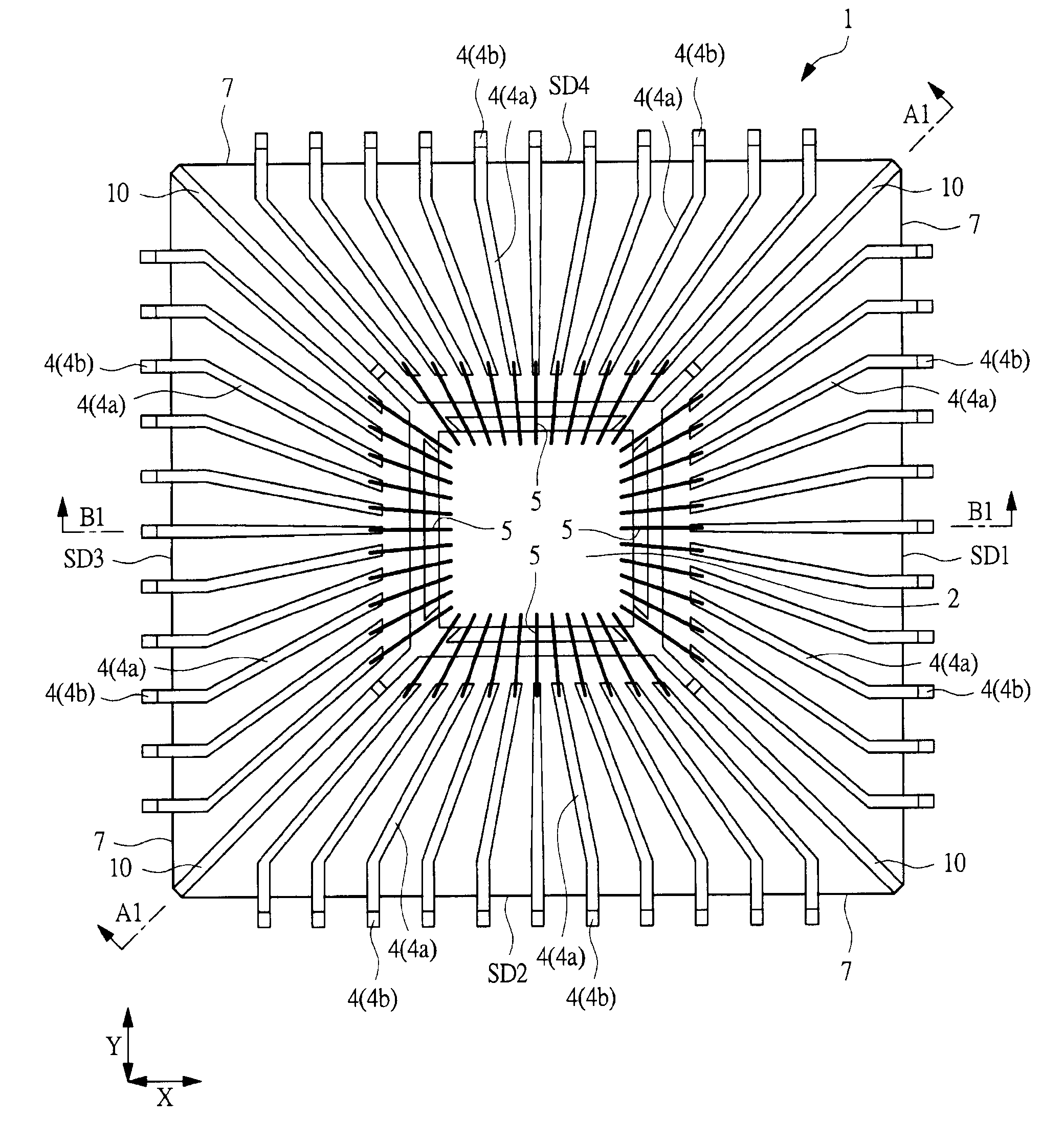

Semiconductor device and method of manufacturing same

InactiveUS8188583B2High speedIncreased power consumptionSemiconductor/solid-state device detailsSolid-state devicesSilver pasteThumb opposition

To improve the heat dissipation characteristics of a semiconductor device.The semiconductor device has a die pad, a heat dissipating plate in the form of a frame arranged between the die pad and a plurality of leads so as to surround the die pad, a plurality of members that connect the die pad and the inner edge of the heat dissipating plate, and a suspension lead linked to the outer extension of the heat dissipating plate, wherein a semiconductor chip the outer shape of which is larger than the die pad is mounted over the die pad and the members. The top surface of the die pad and the top surface of the members at the part in opposition to the back surface of the semiconductor chip are bonded to the back surface of the semiconductor chip in their entire surfaces with a silver paste. Heat in the semiconductor chip is conducted from the back surface of the semiconductor chip to the heat dissipating plate via the silver paste, the die pad, and the member, and dissipated to the outside of the semiconductor device therefrom via the lead.

Owner:RENESAS ELECTRONICS CORP

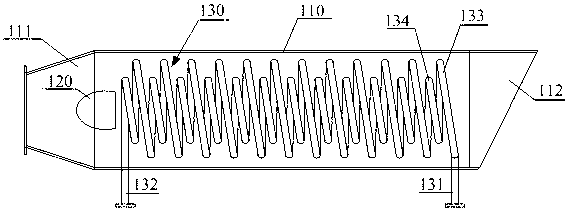

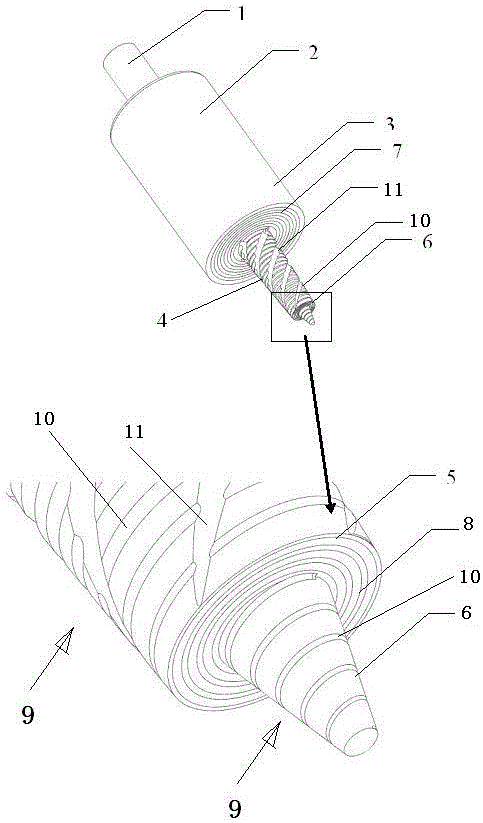

Waste heat recovery heat exchanger for drilling platform

InactiveCN102937388AFast heat productionIncrease heat productionInternal combustion piston enginesRecuperative heat exchangersFlue gasProcess engineering

A waste heat recovery heat exchanger for a drilling platform comprises a casing, a deflector and a double-helical suspension type coil, wherein the casing is a cavity with a flue gas inlet at one end and a flue gas outlet at the other end, and the flue gas inlet is connected with an exhaust port of a diesel engine; the deflector is arranged in the casing and close to the flue gas inlet of the casing; and the double-helical suspension type coil is arranged in the casing and used for transporting heated fluid media. The heat exchanger for flue gas recovery for the diesel engine of the drilling platform is high in heat exchange efficiency, small in resistance, large in heat exchange area, rapid in heat generation, controllable in temperature, superior in fixing performance and clean.

Owner:杨永利

Porous-medium radiation tube

ActiveCN104456560AExtended service lifeIncrease surface temperatureGaseous fuel burnerPorous mediumProduct gas

The invention discloses a porous-medium radiation tube. The porous-medium radiation tube comprises a tube body, a gas supply tube component, an ignitor and a smoke discharge tube component. The tube body comprises a first part, a second part and a third part, and porous media are filled in the first part and the third part respectively. The gas supply tube component is communicated with the first part and the third part respectively and supplies mixed gas to the first part and the third part alternatively. The smoke discharge tube component is communicated with the first part and the third part respectively. When the gas supply tube component supplies the mixed gas to one of the first part and the third part, smoke generated can be partially discharged from the other one of the first part and the third part not communicated with the smoke discharge tube component. According to the porous-medium radiation tube, pollutants can be reduced, heat utilization efficiency of fuel burning is improved, non-uniformity of surface temperature of the tube body is reduced, service life of the porous-medium radiation tube is prolonged, electrodeless and continuous adjustability of heat load is realized, and the porous-medium radiation tube can be suitable for low heat.

Owner:SHENWU TECH GRP CO LTD

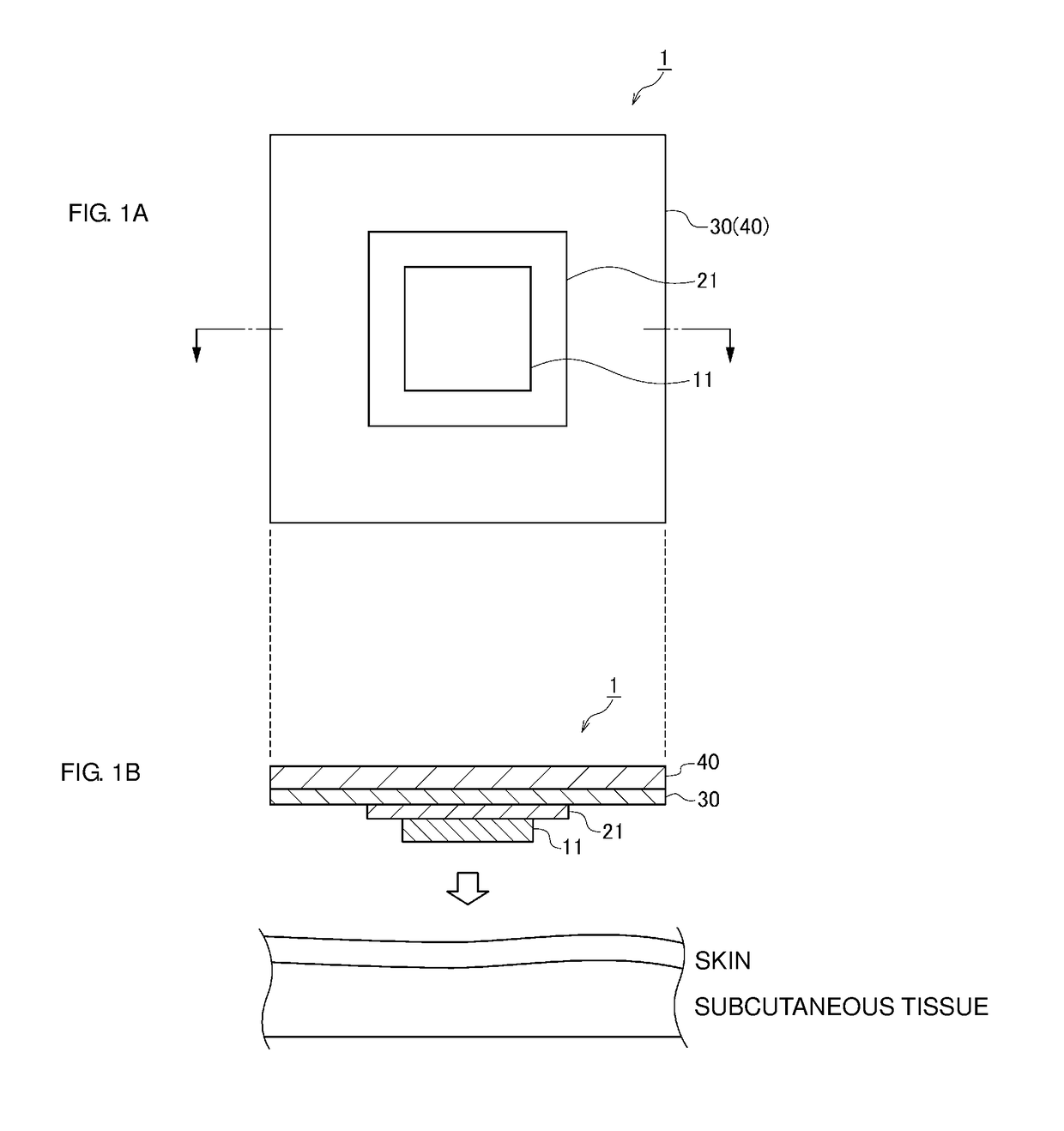

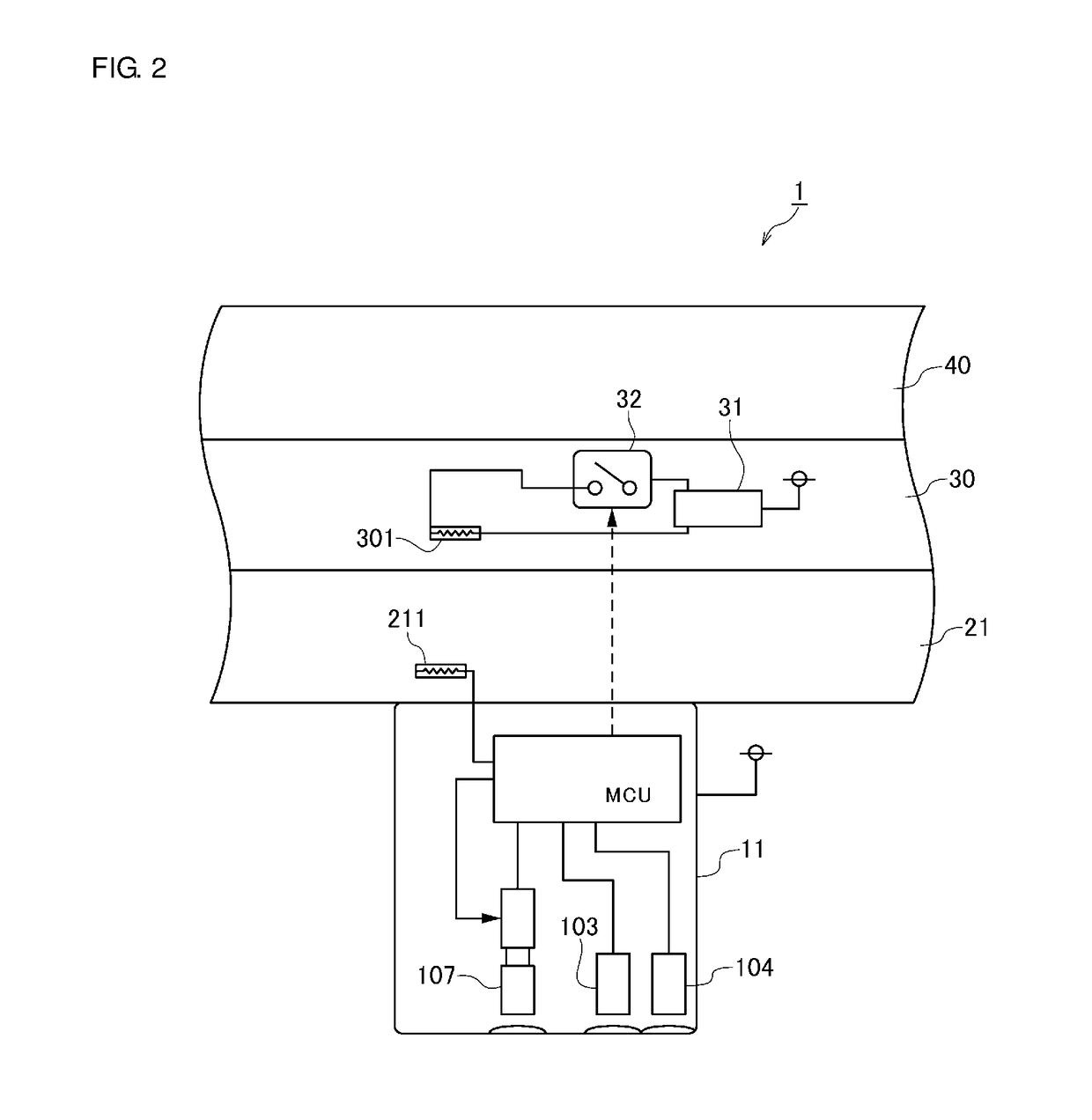

Heating oximeter

ActiveUS20180199872A1High measurement accuracyAccurate measurementSensorsMeasuring/recording heart/pulse rateThermodynamicsLiving body

A heating oximeter includes a heat insulation portion, a heat generation portion including a resistor generating heat by energization, a first temperature detector including a first temperature sensor detecting a temperature of the heat generation portion, an oxygen saturation acquisition assembly including light emitting elements and a light receiving element, and acquiring oxygen saturation in blood optically, and a third temperature detector including a third temperature sensor detecting a temperature of a living body. The heating oximeter is provided by stacking the third temperature detector, the oxygen saturation acquisition assembly, the first temperature detector, the heat generation portion, and the heat insulation portion in this order.

Owner:MURATA MFG CO LTD

Circulating colloid grinding and homogenizing machine

The invention relates to colloid grinding and homogenizing equipment mainly used in the fields of novel materials such as daily chemical industry, food processing, medical industry, construction industry, plastic industry, textile industry, papermaking industry, coal flotation agents, rare earth, nanometer materials and war industry. The main components include a motor, a stand, a machine body, a rotating blade, a three-stage grinder, homogenizing disks, a circulating body, a mechanical seal water cooling joint, a mechanical seal device and the like; the stand is provided with the machine body and the motor; and a closed hopper which is a conoid stainless steel product is arranged on a top cover of the machine body. Due to relatively high rotating speed and heat yield, the colloid grinding and homogenizing equipment is sealed by a mechanical seal group and is cooled by using liquid circulating water; a circulating colloid grinding and homogenizing machine provides a high-quality solution for fields such as mixing, dispersing, homogenizing, suspending, emulsifying, wet grinding as well as power and liquid mixing, the fineness of a material processed by the equipment can reach the nanoscale; and by using the colloid grinding and homogenizing machine, the generated particles are very uniform.

Owner:HARBIN UNIV OF SCI & TECH

Staged stirring head for thick plate stirring friction welding

InactiveCN106271030AIncrease heat productionQuality improvementNon-electric welding apparatusThick plateEngineering

The invention discloses a staged stirring head for thick plate stirring friction welding. The staged stirring head for the thick plate stirring friction welding is characterized by consisting of a clamping handle (1), a supporting body (2) and at least two stages of stirring assemblies (9); each stage of the stirring assembly (9) consists of a shaft shoulder and a stirring needle; each stage of the stirring assembly (9) and the supporting body (2) are mounted coaxially; a groove structure (7) used for increasing friction is arranged on each stage of the stirring assembly; the diameters of the shaft shoulders of all stages are gradually reduced; the sizes of the stirring needles of all stages are also gradually reduced. According to the stirring head for the stirring friction welding disclosed by the invention, the heat production quantity of a material at the bottom of a thick plate is increased; the problem that defects, such as holes and grooves, are easily formed in a bottom area of a plate material in a stirring friction welding process of the thick plate is solved; the quality of joint of the thick plate stirring friction welding is improved; meanwhile, the stirring head disclosed by the invention avoids additional investment and multifarious process of equipment, reduces the production cost, and improves the production efficiency.

Owner:JIANGXI UNIV OF SCI & TECH

Method of producing and using heat shock proteins

InactiveUS20050221421A1Improve stateIncrease heat productionPeptide preparation methodsDepsipeptidesTissue heatingRoom temperature

The present invention relates to a method of manufacturing and using heat shock proteins containing a step of initiating a coagulative necrotic process in a tissue. In particular, a method of manufacturing and using heat shock proteins comprises the steps of heating a tissue to initiate the coagulative necrotic process for a period of time, cooling the tissue, incubating the tissue in an appropriate growth medium, and collecting the supernatant from the tissue. In a preferred embodiment, the coagulative necrotic process is initiated by heating the tissue to 60°; or more. The tissue is then cooled to room temperature before incubating the tissue in growth media for 48 hours or less. Heat shock proteins produced in accordance with this method may be complexed to peptides or antigens to produce autologous vaccines in the prevention and treatment of various diseases. Furthermore, heat shock proteins may be used in diagnostic assays for various autoimmune and inflammatory diseases. Heat shock proteins produced in accordance with this method may also be used to quantify antibody levels that serve as disease markers.

Owner:UNIV OF MEDICINE & DENTISTRY OF NEW JERSEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com