Staged stirring head for thick plate stirring friction welding

A friction stir welding and graded technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of increasing the fluidity of bottom materials, holes and grooves, etc., to avoid complicated processes and increase production Effect of increasing heat and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

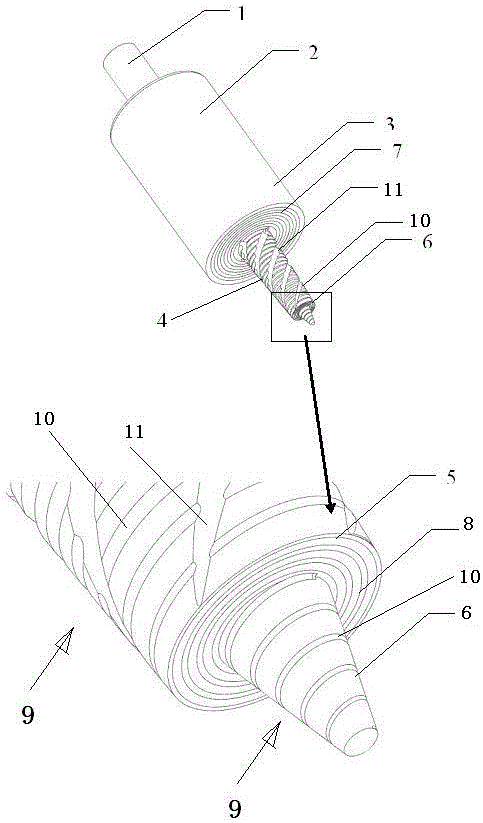

[0017] Such as figure 1 shown.

[0018] A staged stirring head for friction stir welding of thick plates, which consists of a clamping handle 1, a support body 2 and at least two stages of stirring components 9, each stage of stirring components 9 is composed of a shaft shoulder and a stirring needle, such as figure 1 Shown is a schematic structural diagram of a stirring head with two-stage stirring assembly 9. The structure of more than two stages can be designed by analogy. Since the sizes of the shaft shoulders and stirring needles of each stage are gradually reduced, the material should be considered in the specific design. The strength, try to choose the material with high strength and good fracture resistance as the material of the mixing head. figure 1 The graded stirring head of the two-stage stirring assembly structure in the middle is compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com