Patents

Literature

383results about How to "Good grounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

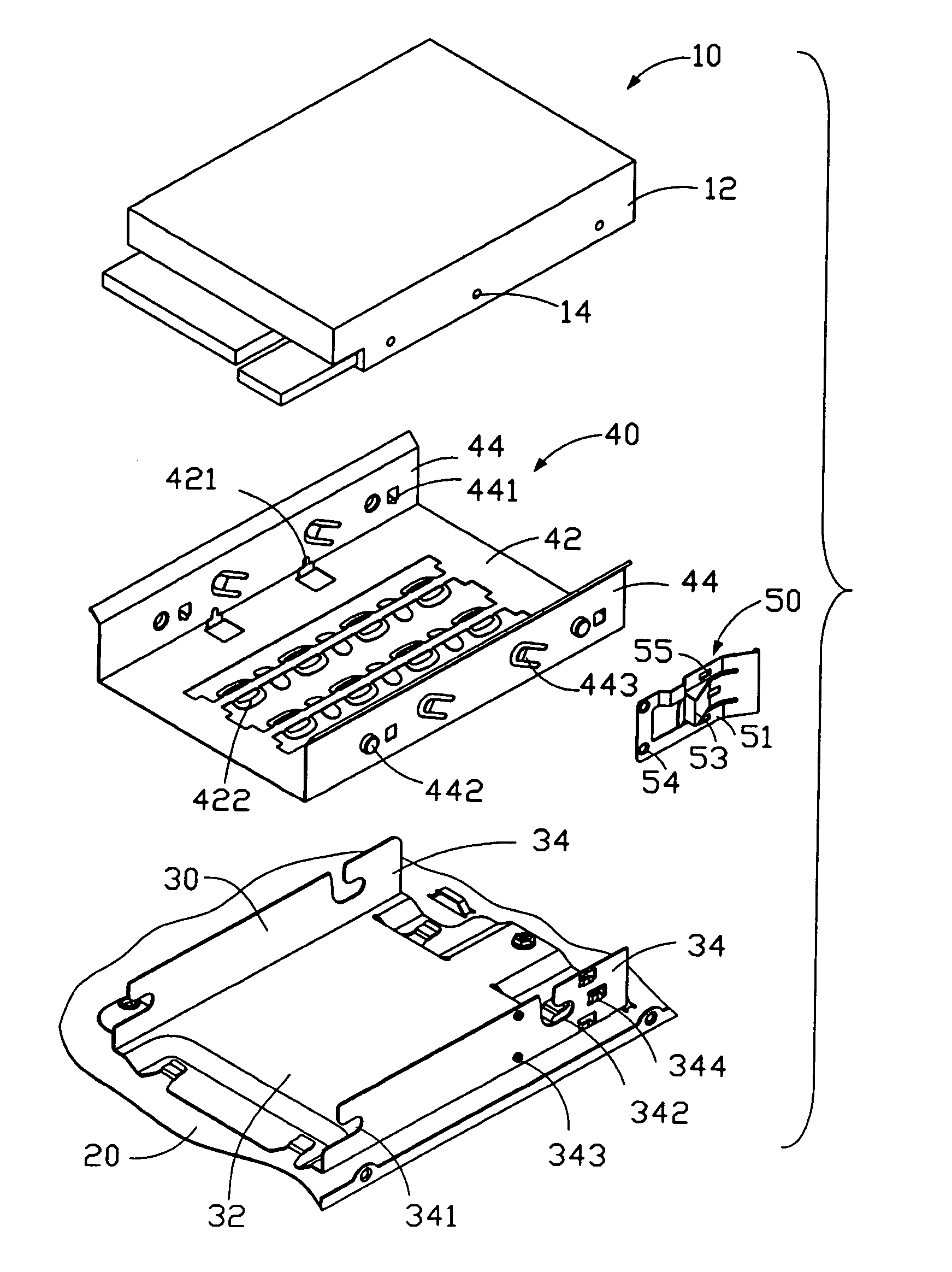

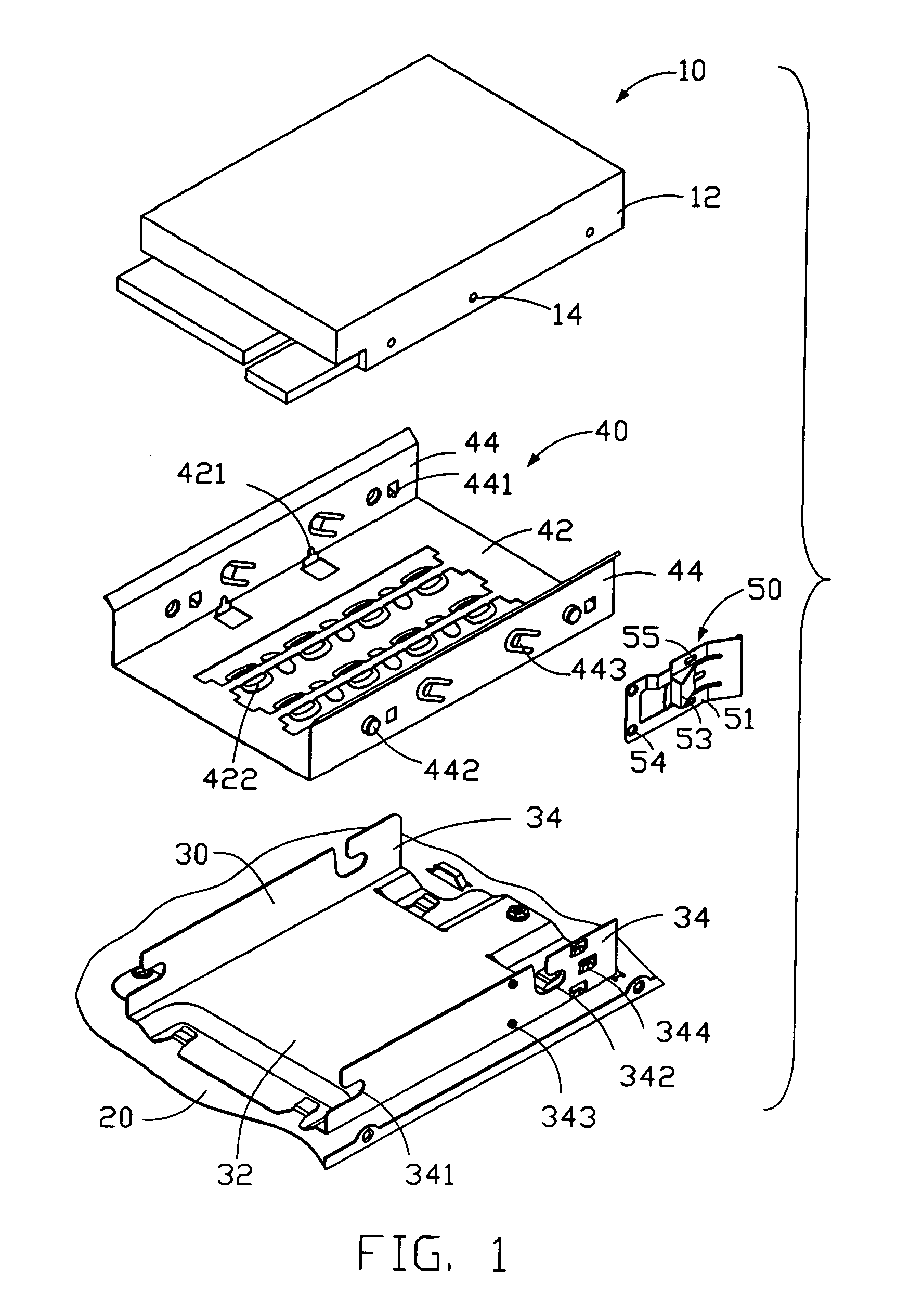

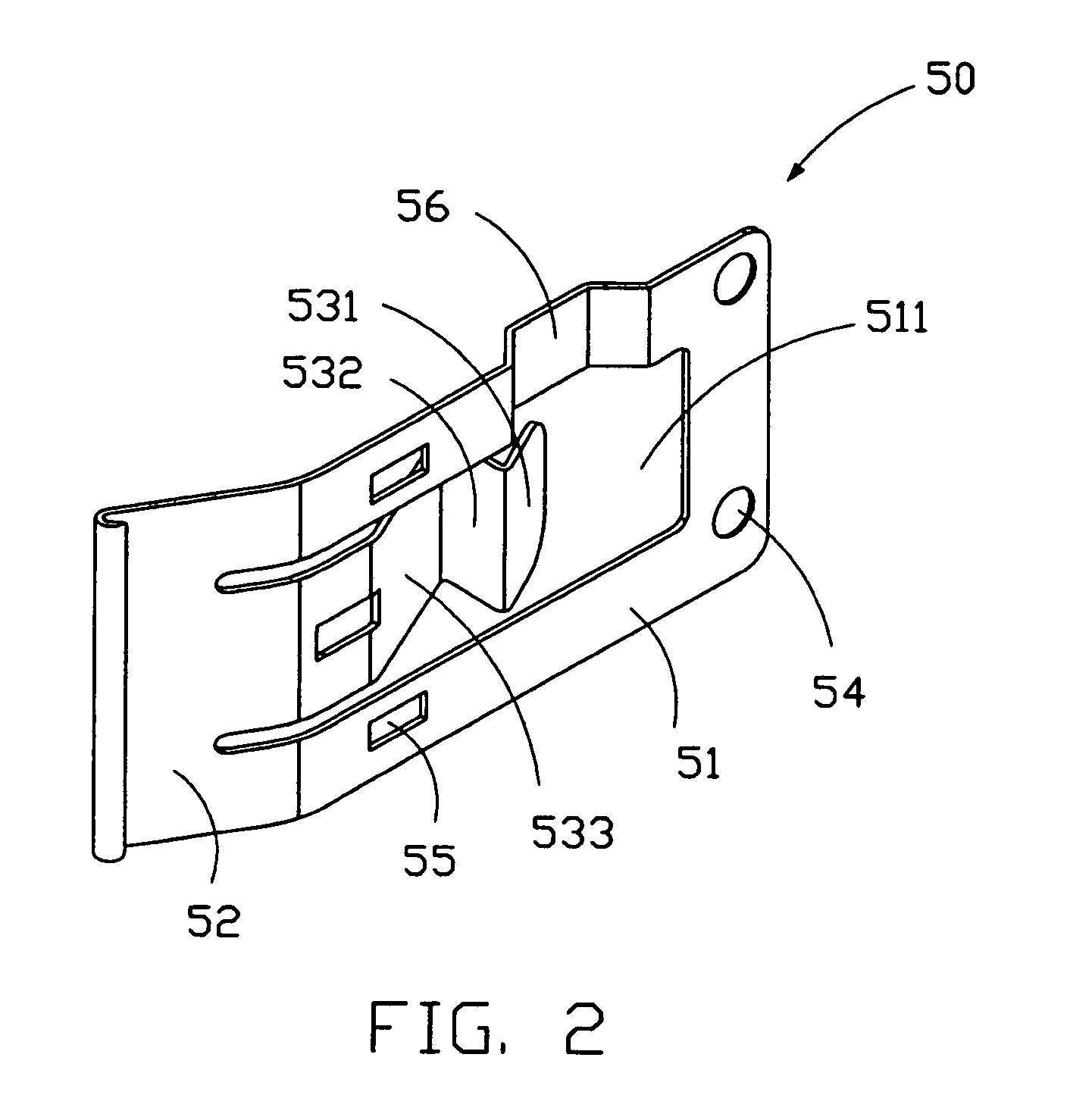

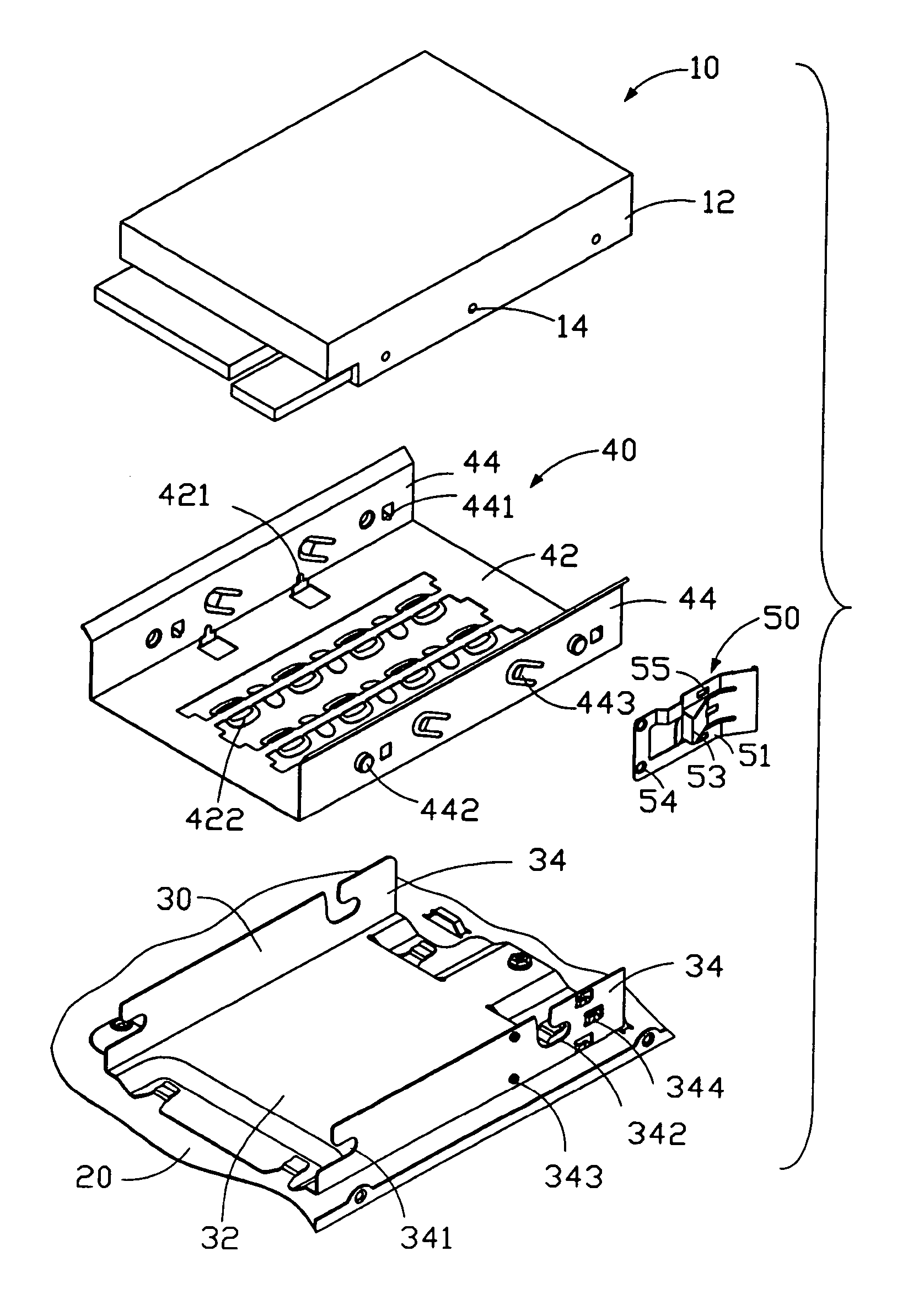

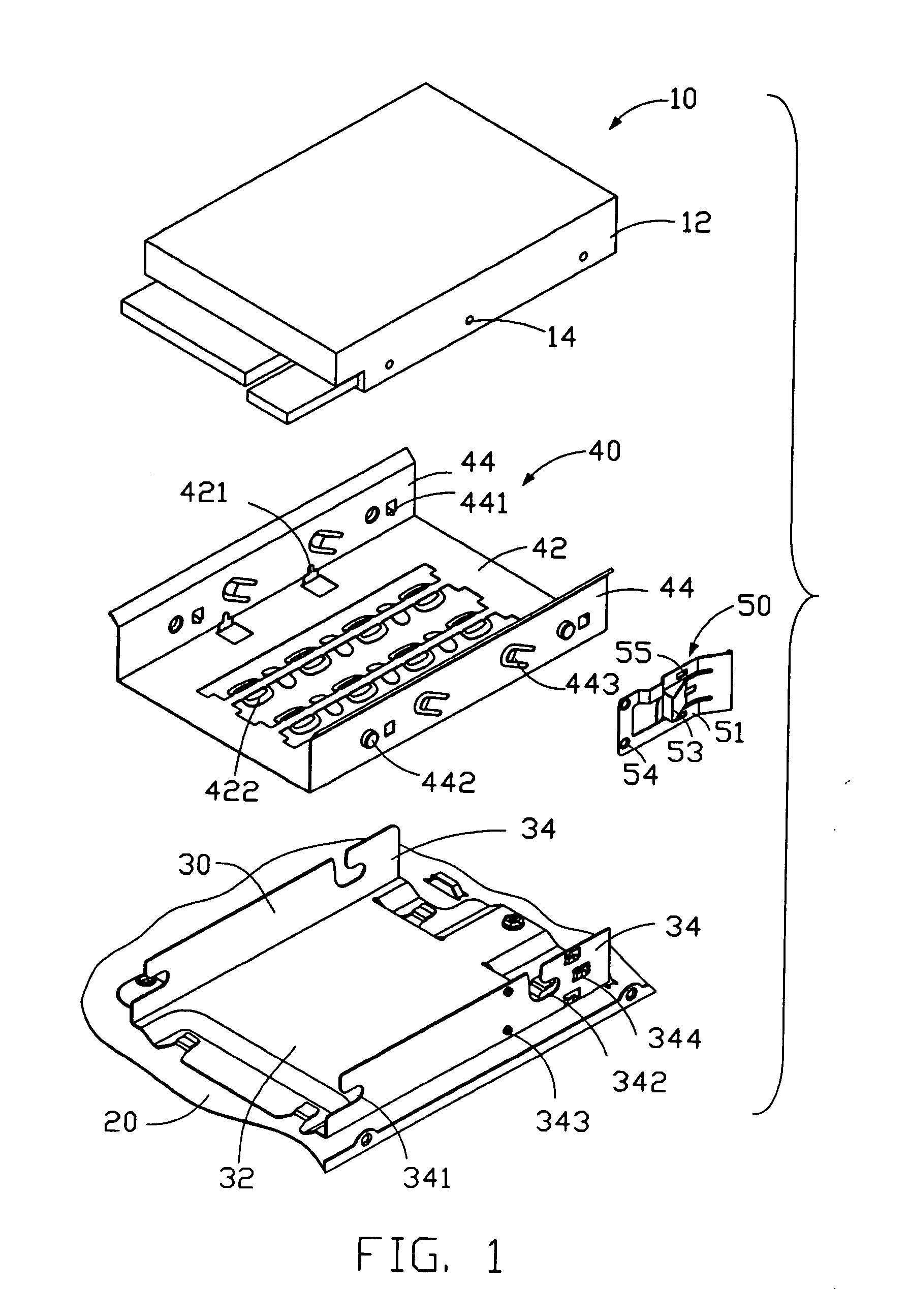

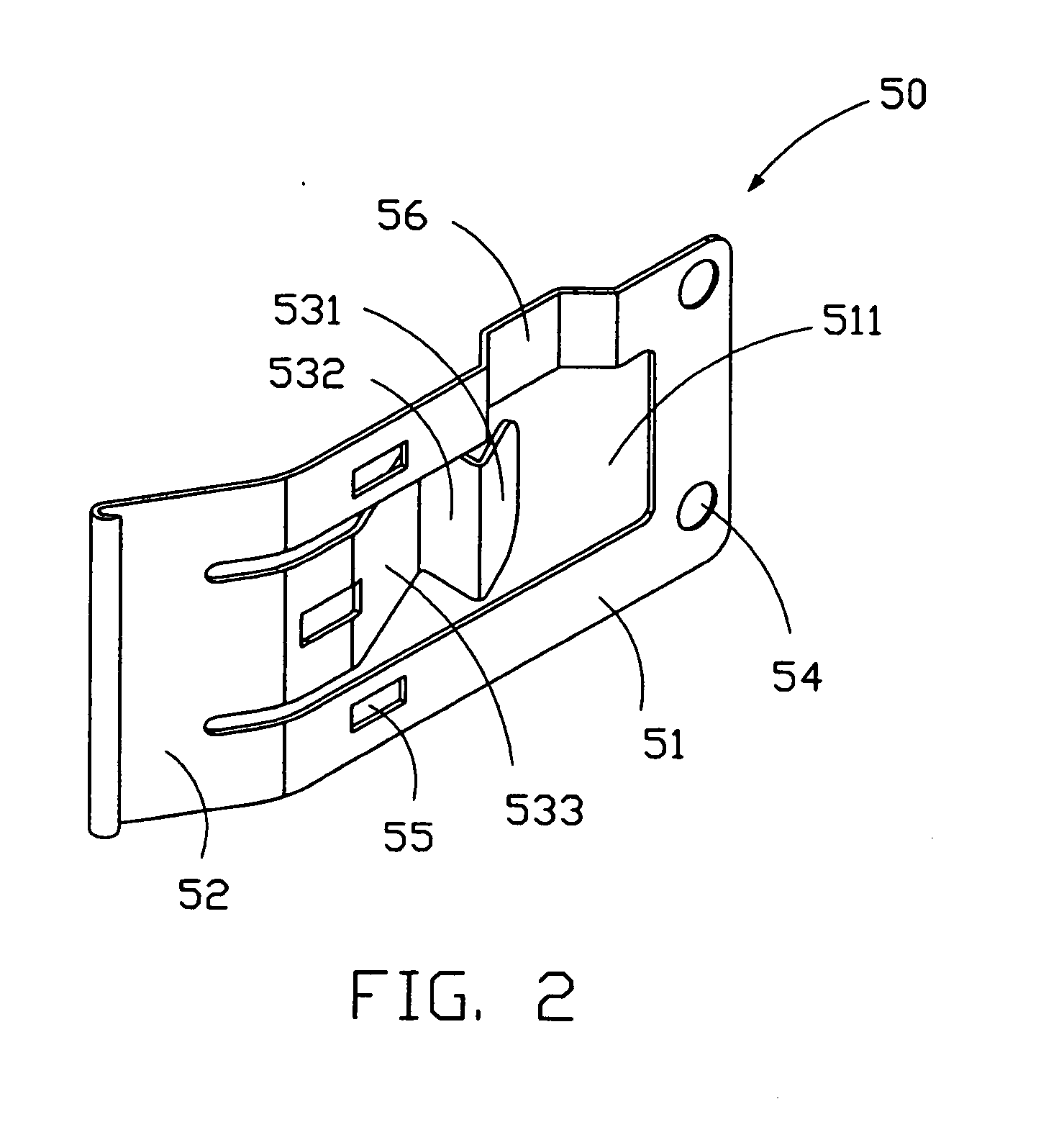

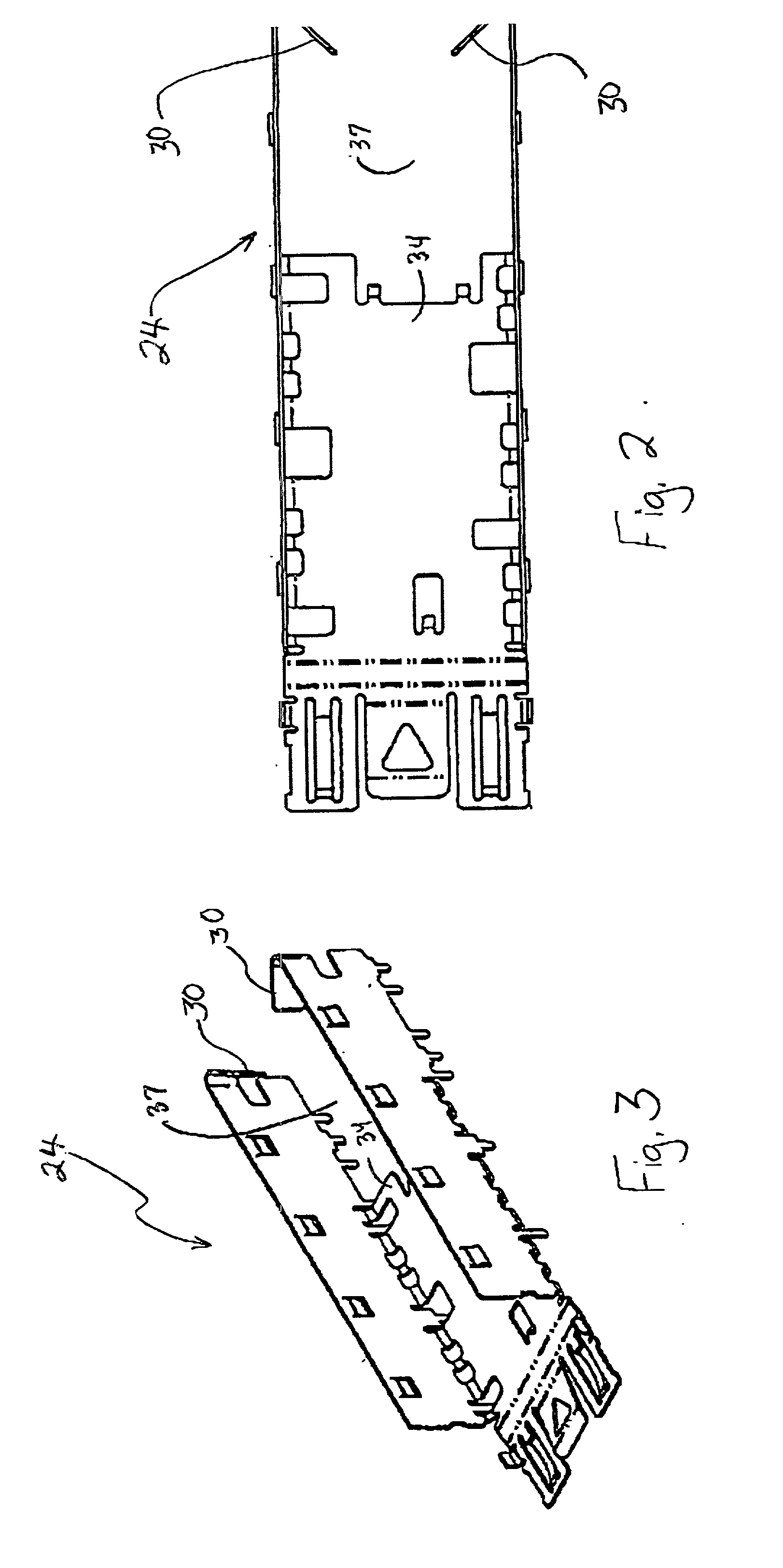

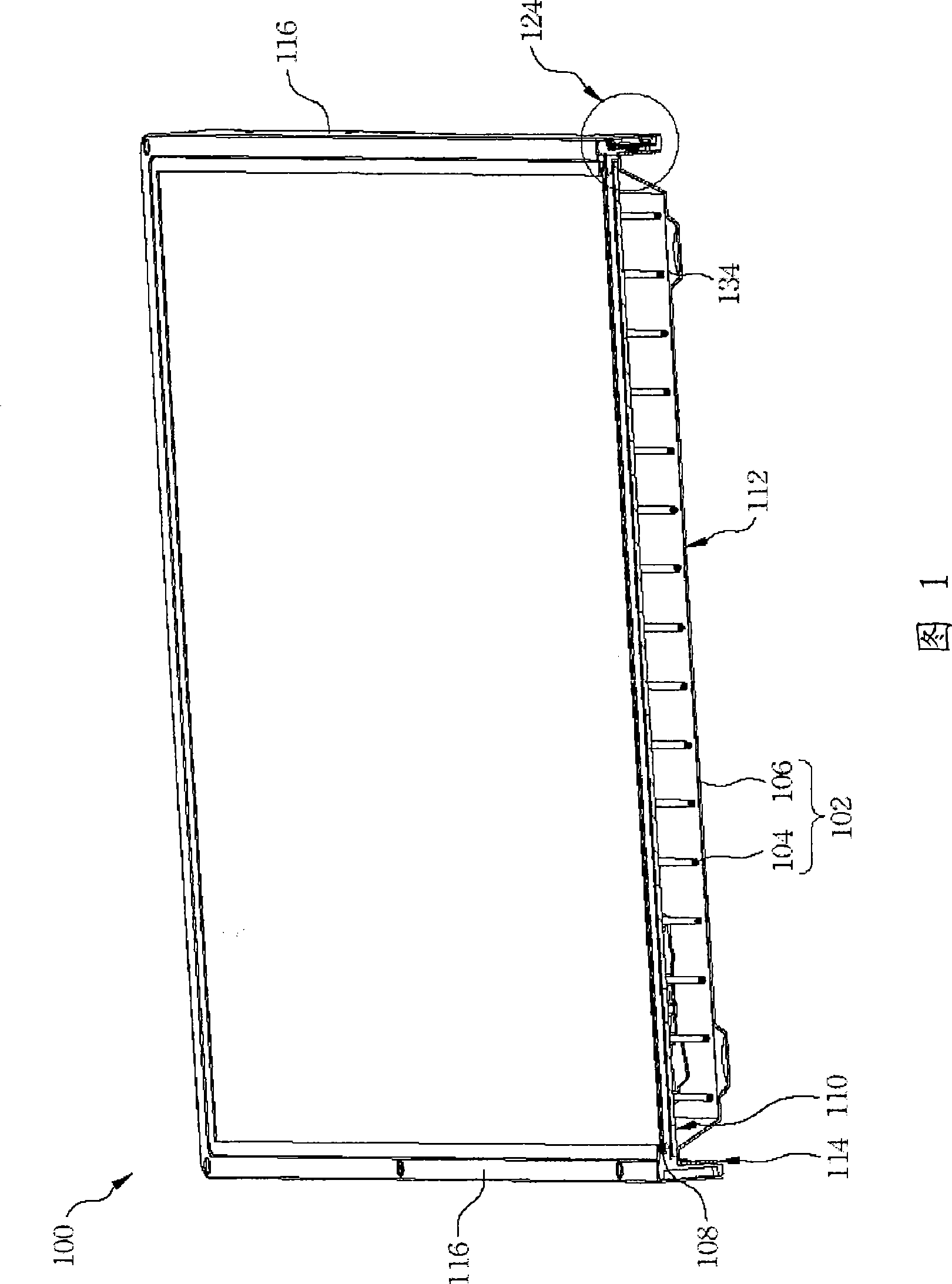

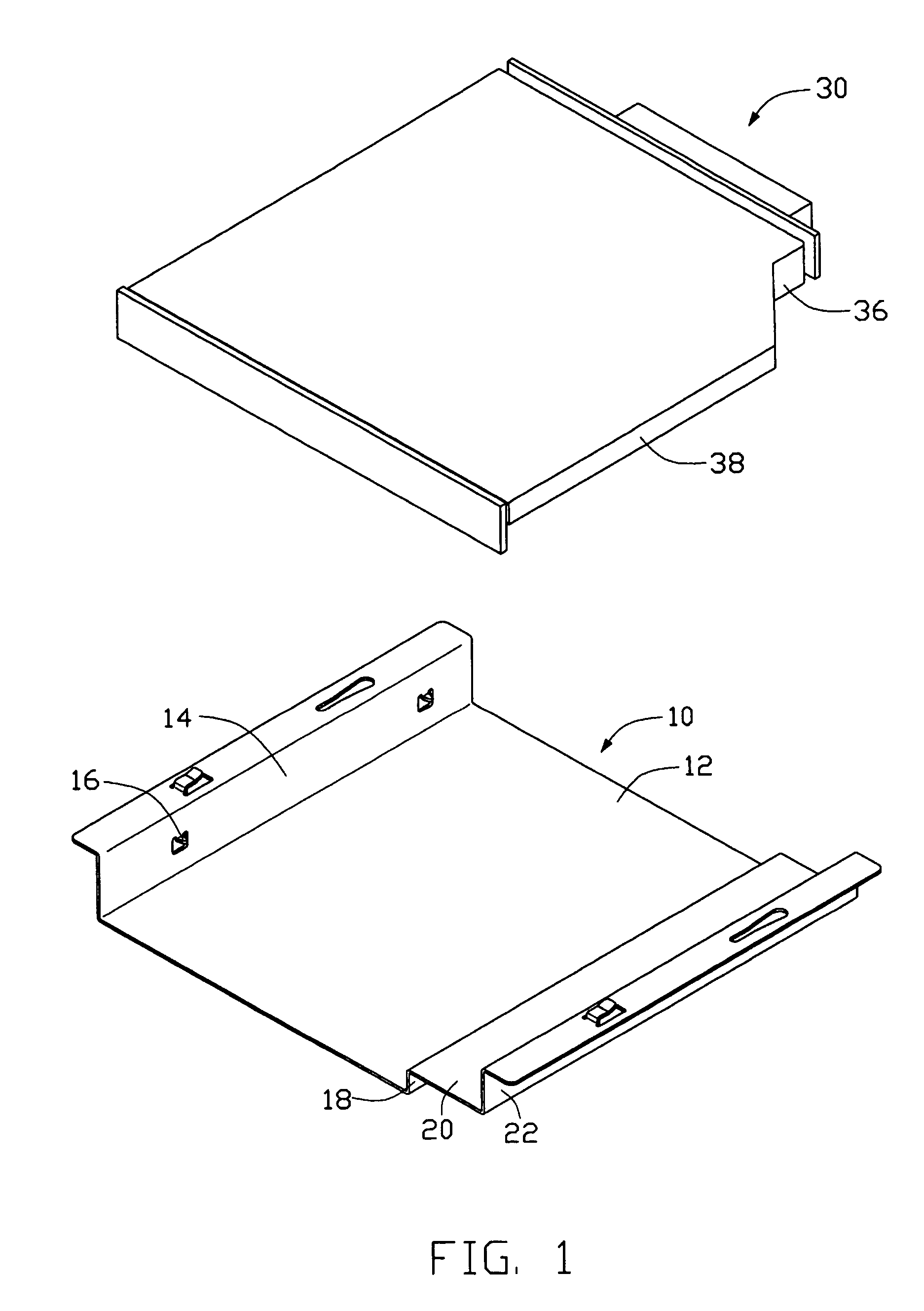

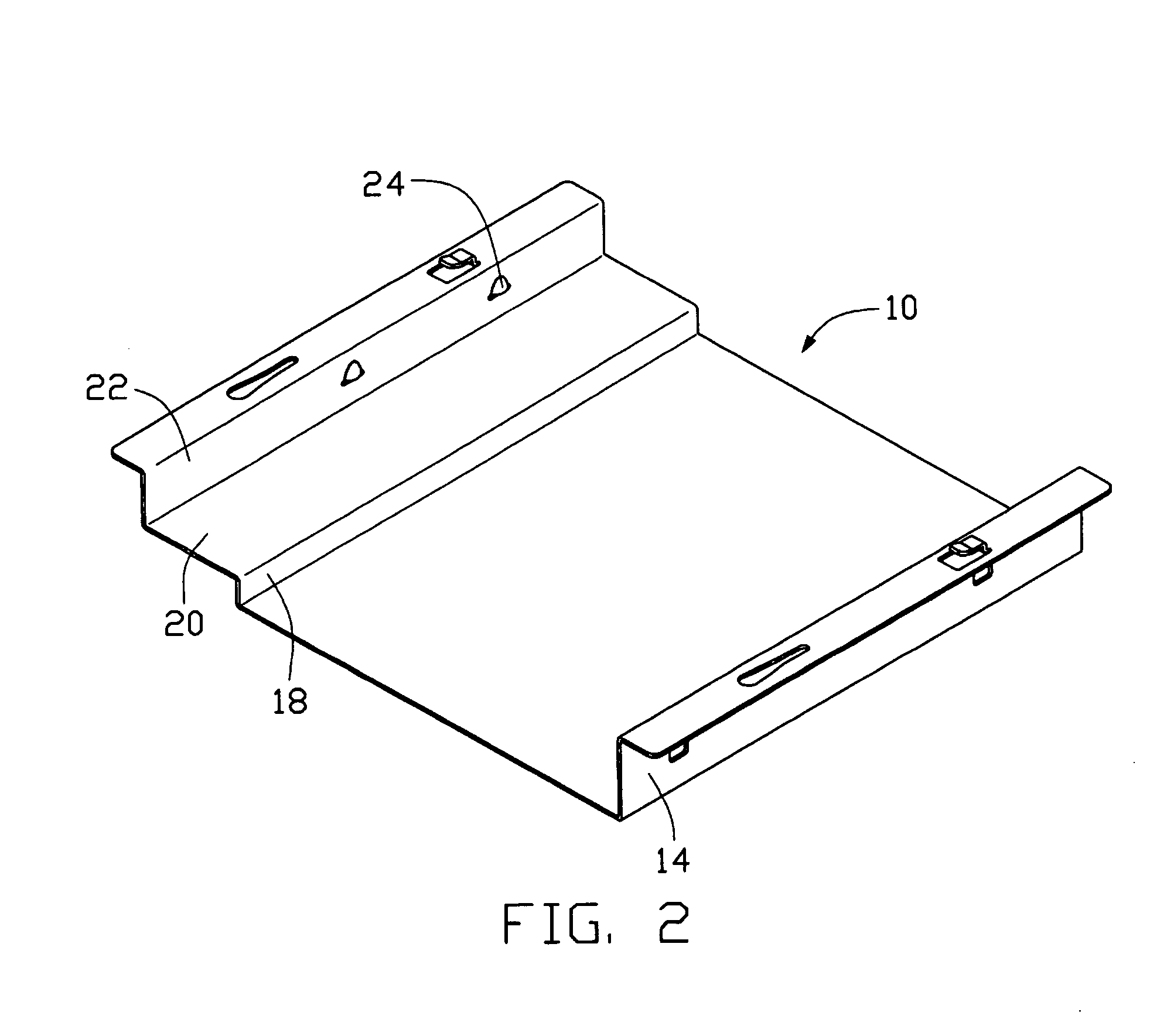

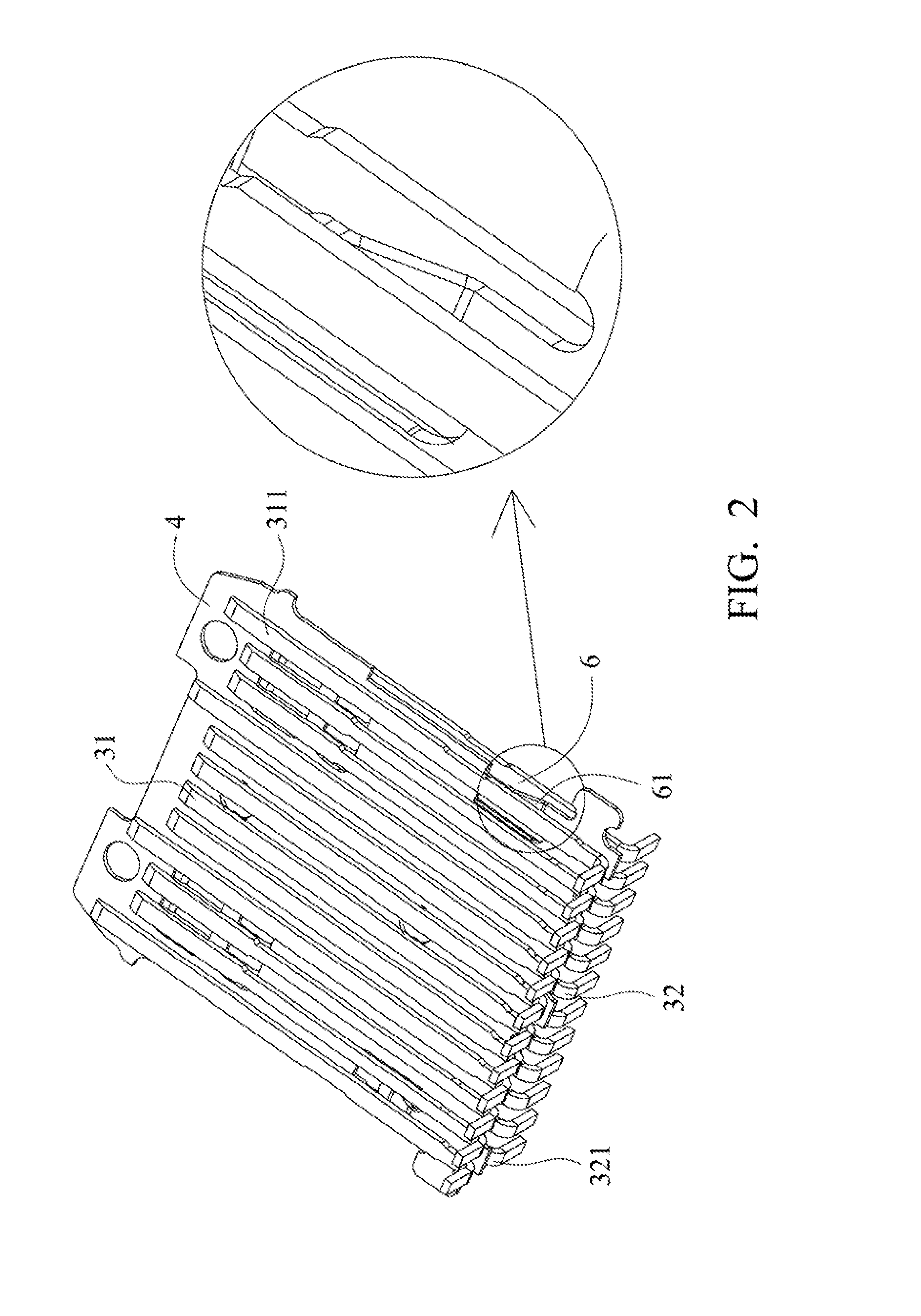

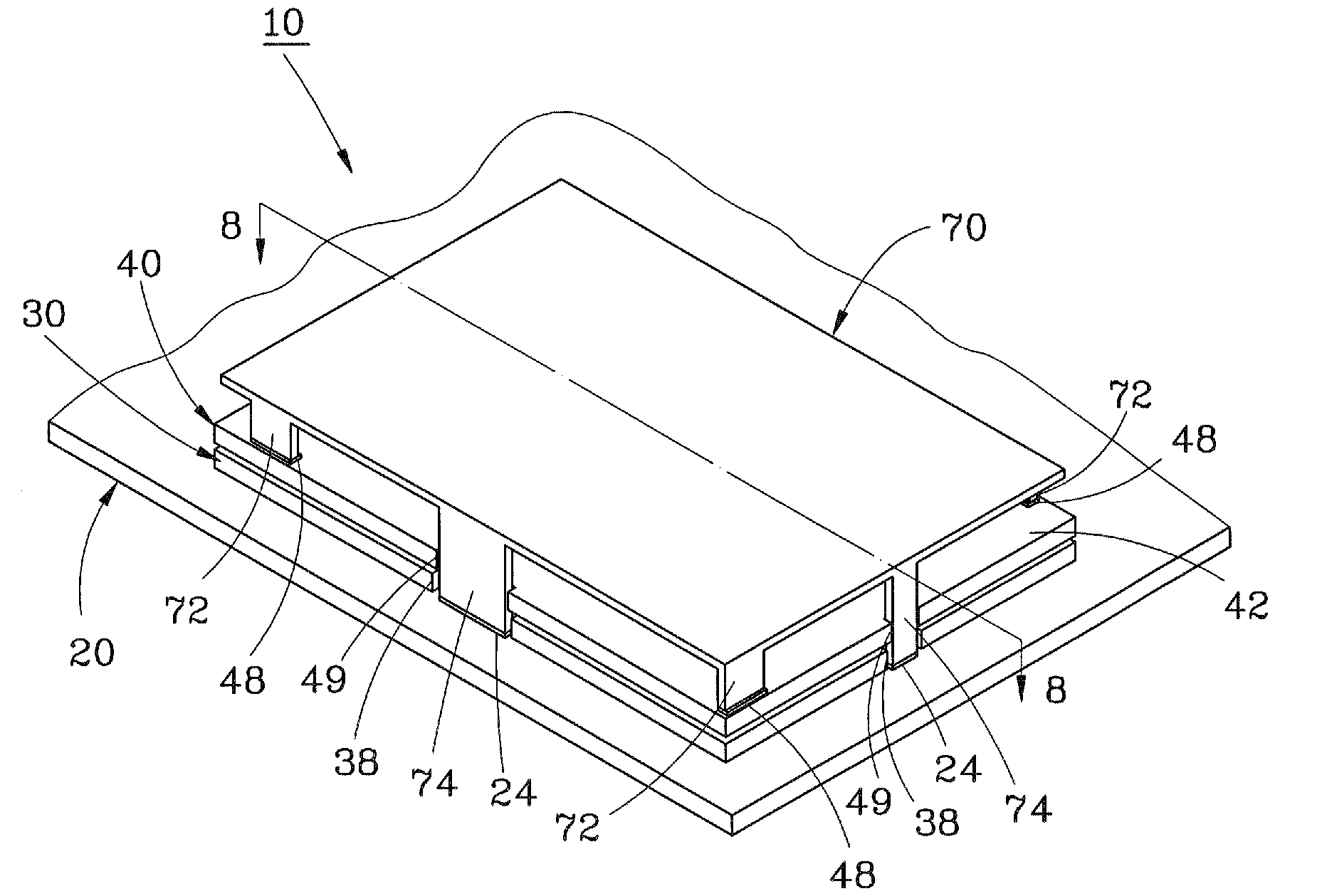

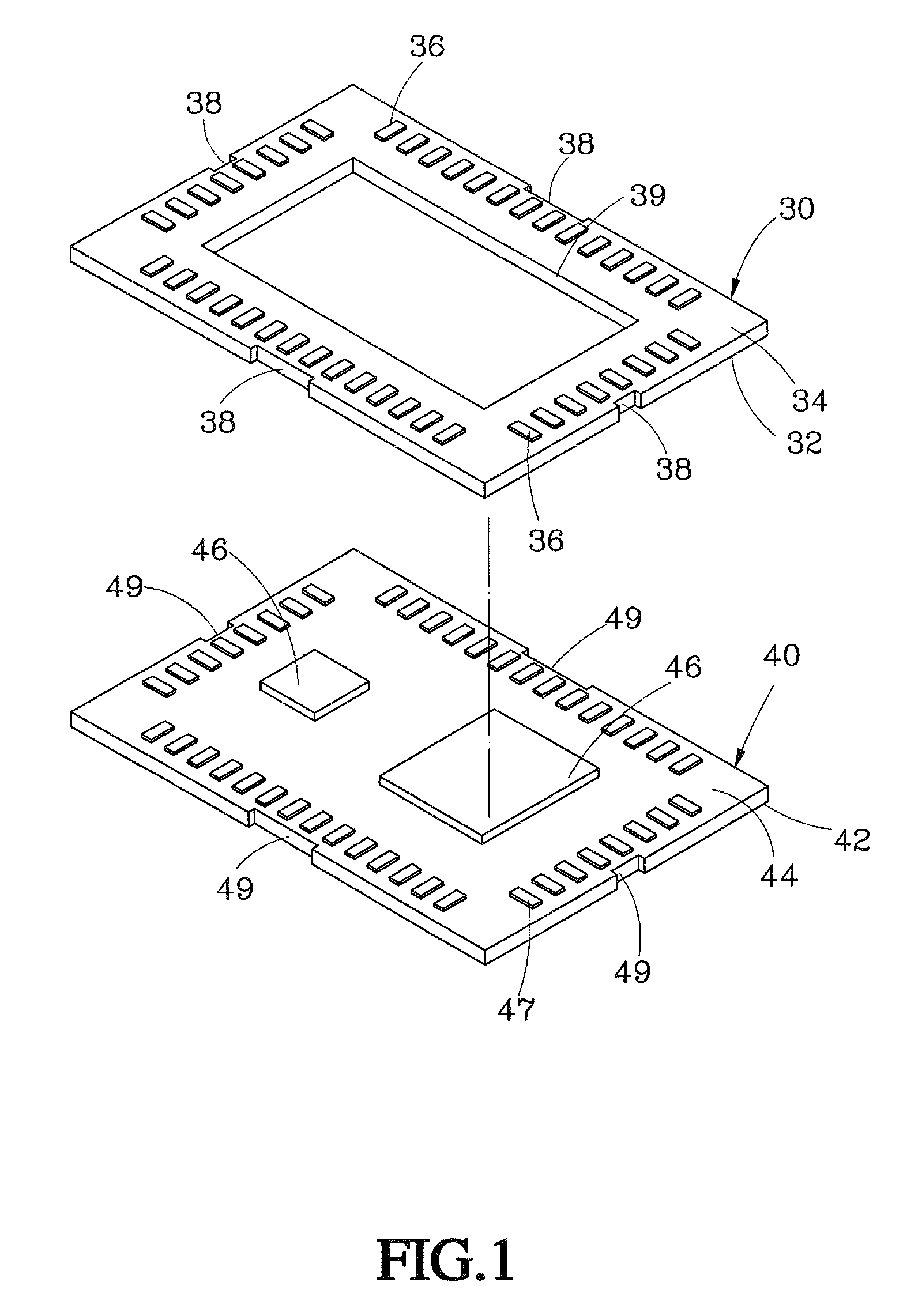

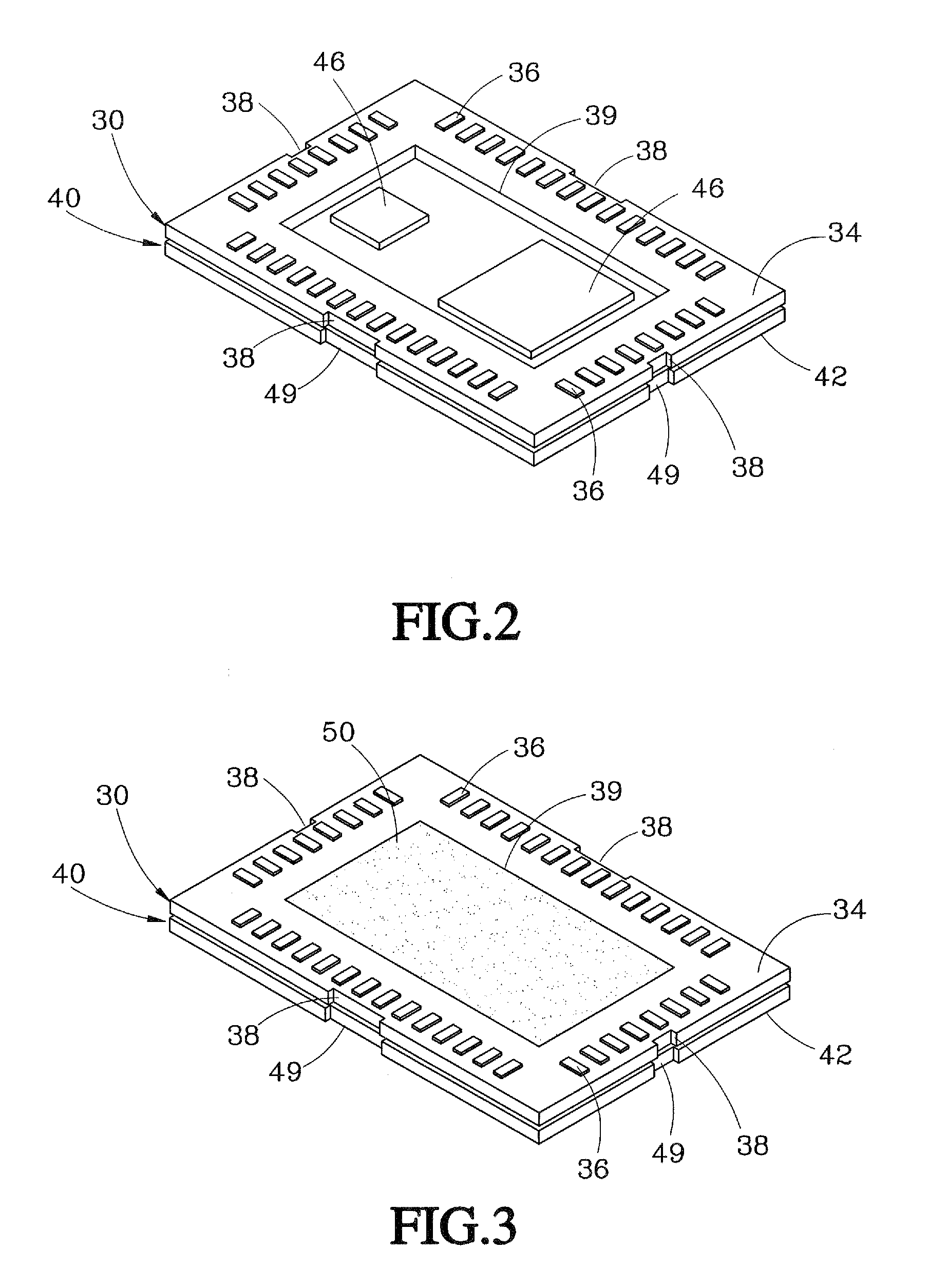

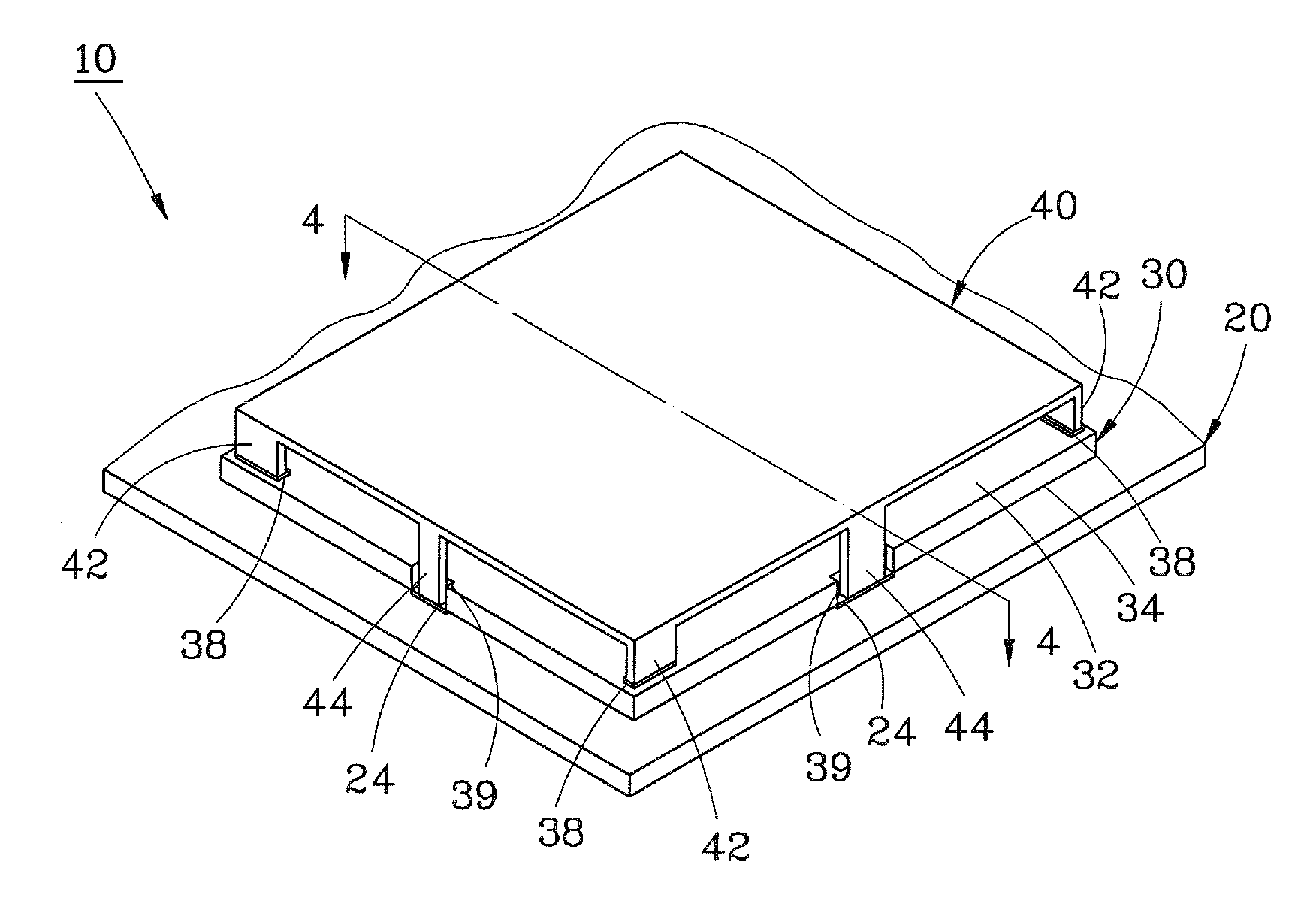

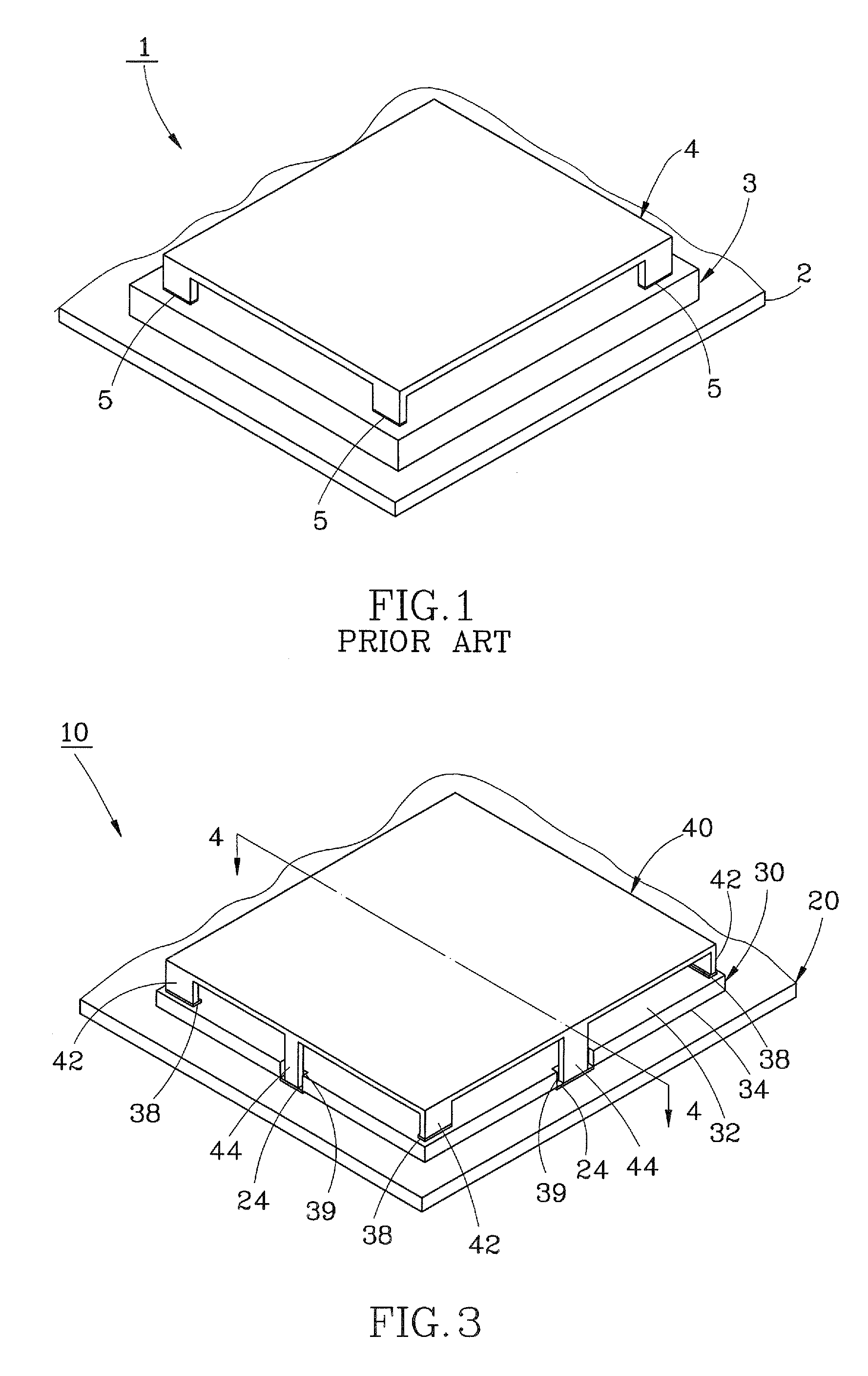

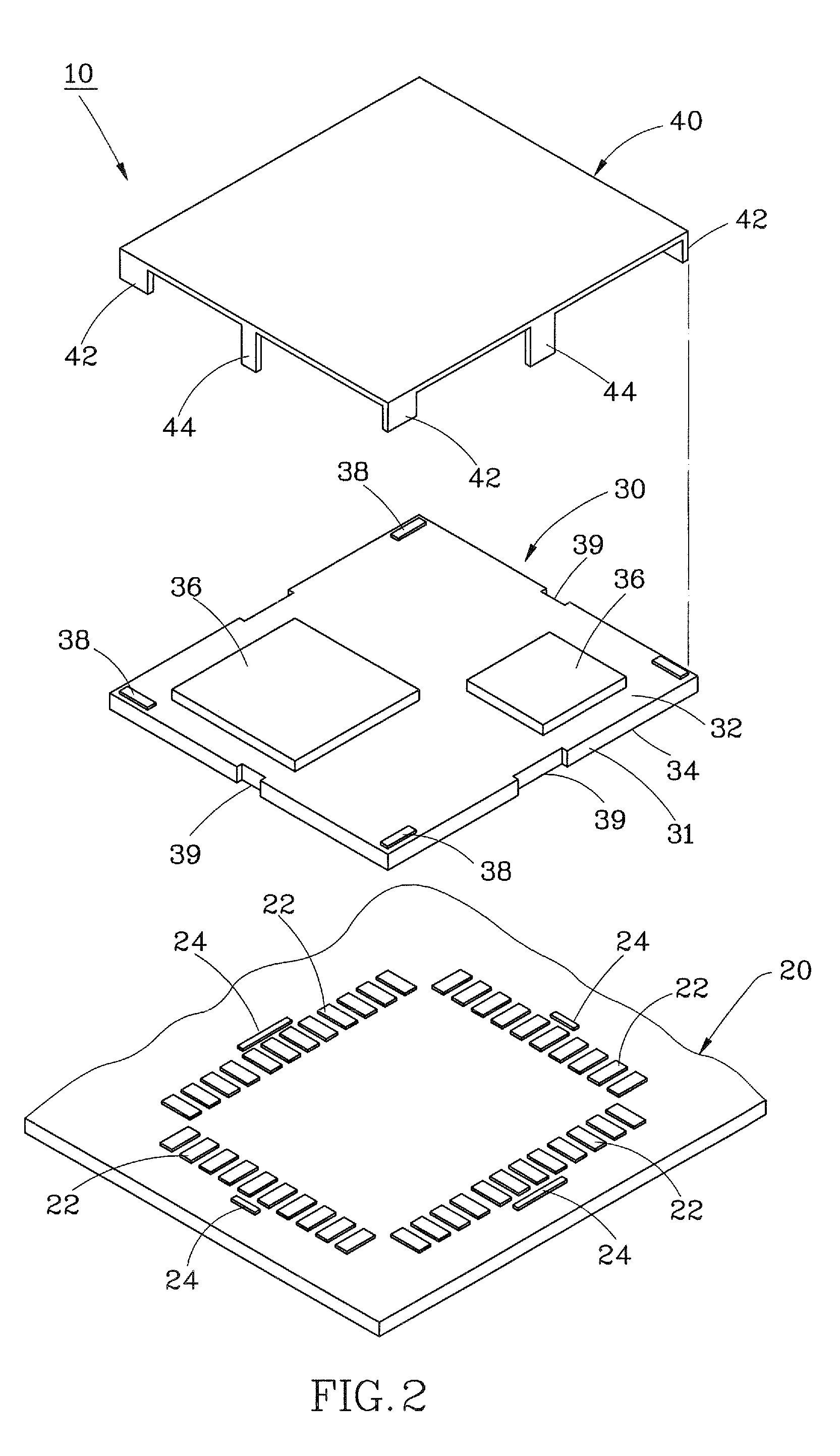

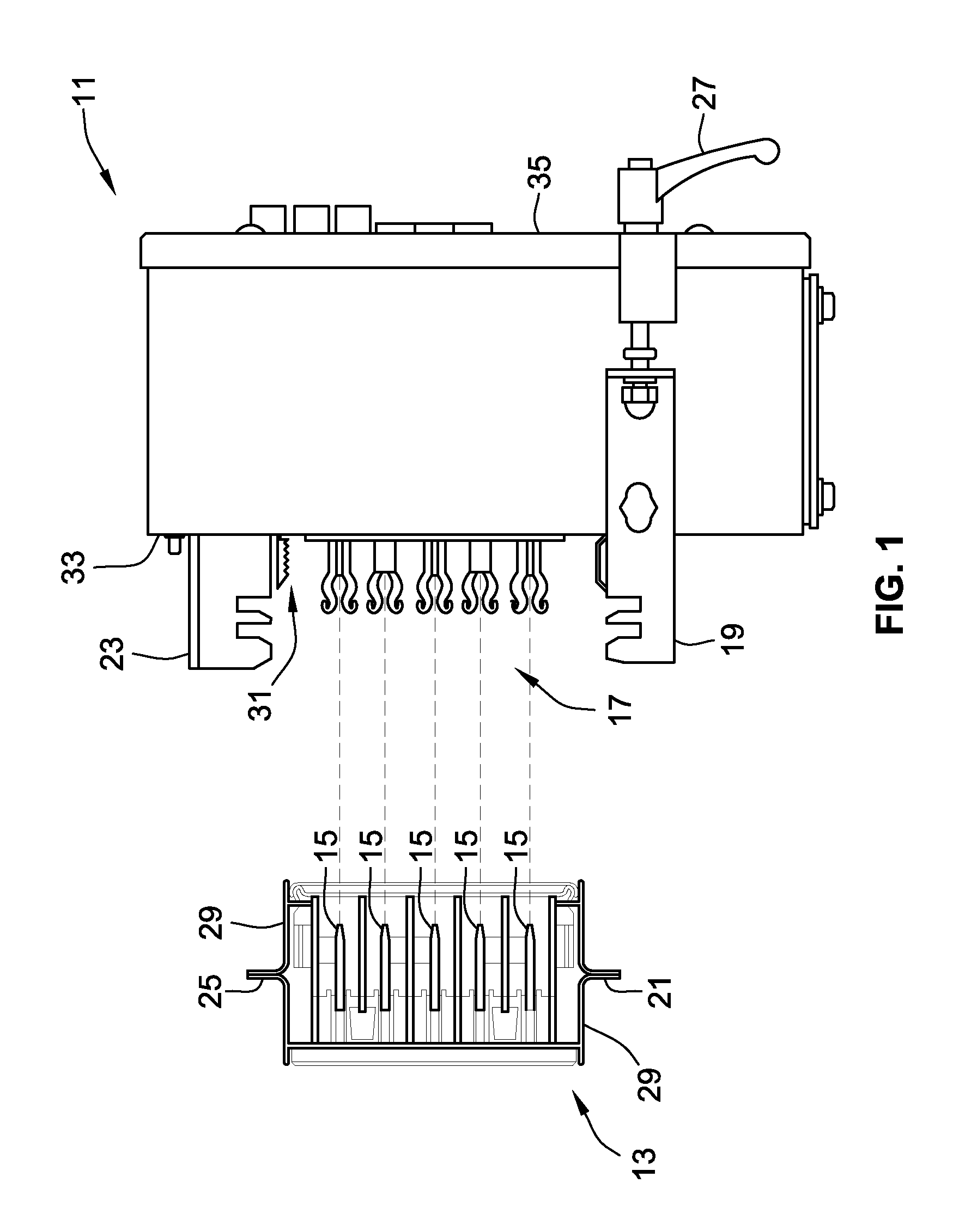

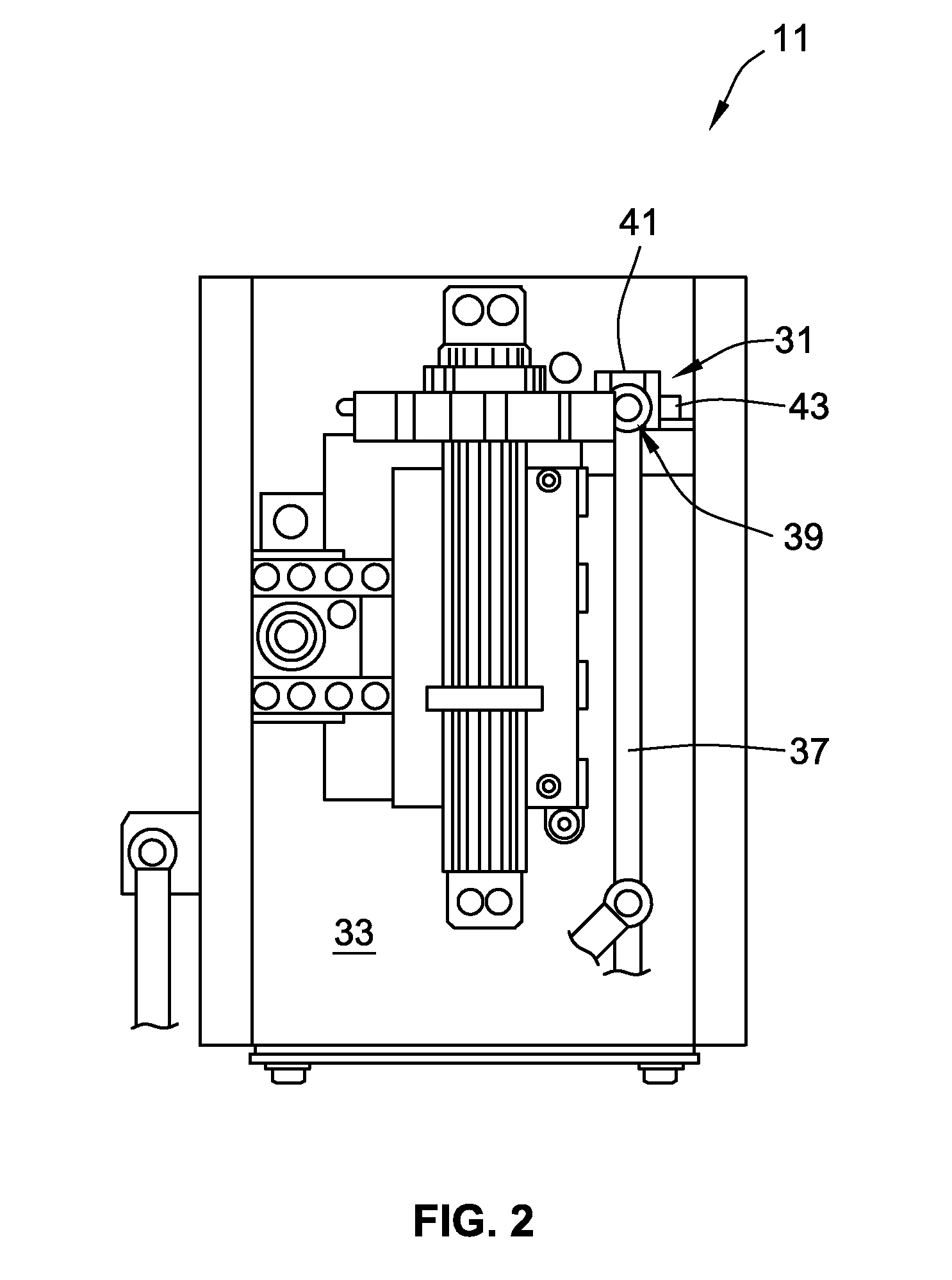

Mounting apparatus for data storage device

InactiveUS7031150B2Simple structureGood adhesionCoupling device connectionsElectric discharge tubesEngineeringMechanical engineering

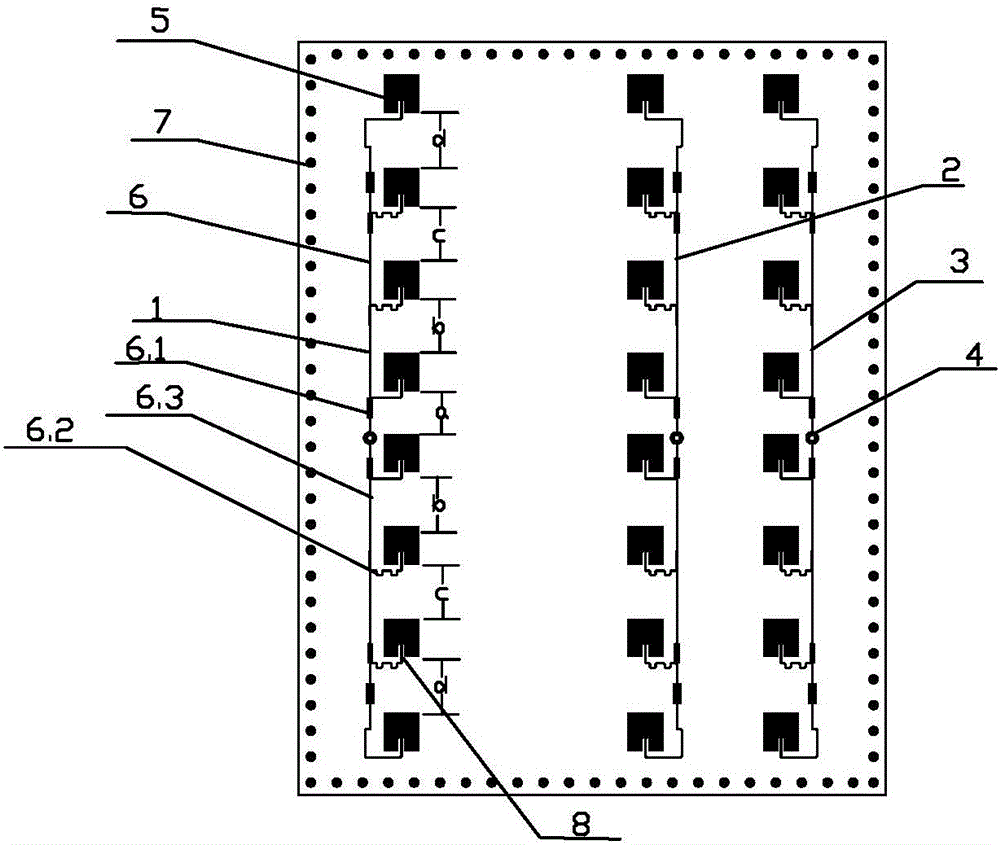

A mounting apparatus for mounting a data storage device (10) to a chassis (20), includes a drive bracket (30), a support bracket (40) received in the drive bracket and a latch (50) attached to a side wall (34) of the drive bracket. A plurality of slots (341, 342) is defined in both side walls of the drive bracket. Each slot communicates with an upper edge of the side wall via an entry. The support bracket includes a base (42) and a pair of side plates (44) for receiving the data storage device therebetween. A plurality of pins (442) extends outwardly from the side plates for slideably engaging in the slots of the drive bracket. The latch has a main body (51) and a resilient fastening portion (53). The fastening portion removably engages with the corresponding pin therefore securing the data storage device in the drive bracket.

Owner:HON HAI PRECISION IND CO LTD

Mounting apparatus for data storage device

InactiveUS20050057895A1Simple structureGood adhesionCoupling device connectionsElectric discharge tubesEngineeringChassis

A mounting apparatus for mounting a data storage device (10) to a chassis (20), includes a drive bracket (30), a support bracket (40) received in the drive bracket and a latch (50) attached to a side wall (34) of the drive bracket. A plurality of slots (341, 342) is defined in both side walls of the drive bracket. Each slot communicates with an upper edge of the side wall via an entry. The support bracket includes a base (42) and a pair of side plates (44) for receiving the data storage device therebetween. A plurality of pins (442) extends outwardly from the side plates for slideably engaging in the slots of the drive bracket. The latch has a main body (51) and a resilient fastening portion (53). The fastening portion removably engages with the corresponding pin therefore securing the data storage device in the drive bracket.

Owner:HON HAI PRECISION IND CO LTD

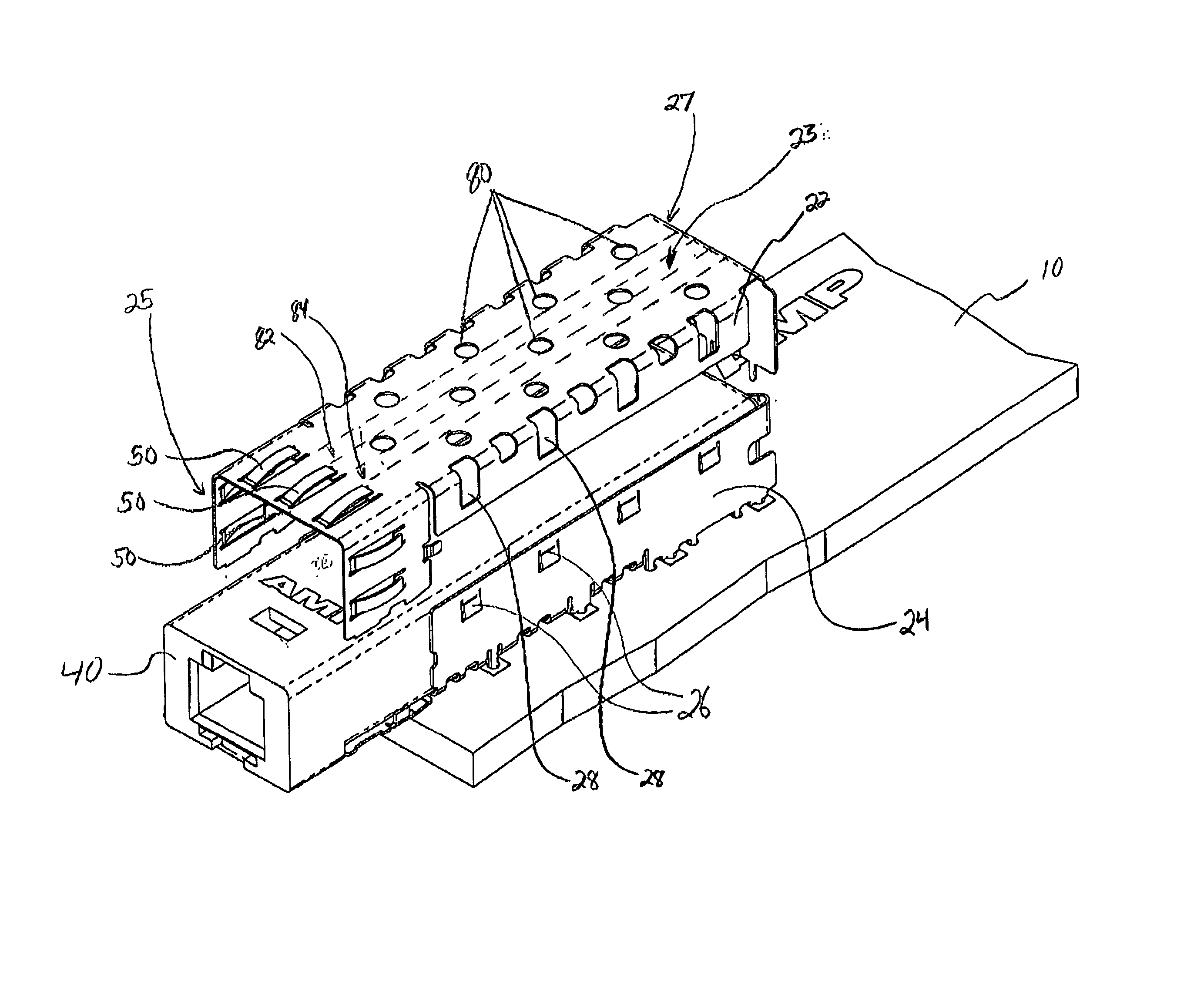

Pluggable module and receptacle

InactiveUS20020068481A1High frequencyHighly miniaturizedMagnetic/electric field screeningContact members penetrating/cutting insulation/cable strandsElectrical connectionConductive materials

A receptacle for a pluggable module includes a housing having a front, a back wall, a top wall, a bottom wall, and side walls and defining a cavity for receiving a module. The bottom wall has a bottom opening to receive a receptacle connector, and the front has a front opening to receive the module. The walls of the housing are made from a conductive material. A plurality of elongated members extend down from the housing past the bottom wall. The elongated members are adapted for electrical connection to a host circuit board such that the walls of the housing are electrically connected to the host circuit board.

Owner:TE CONNECTIVITY CORP

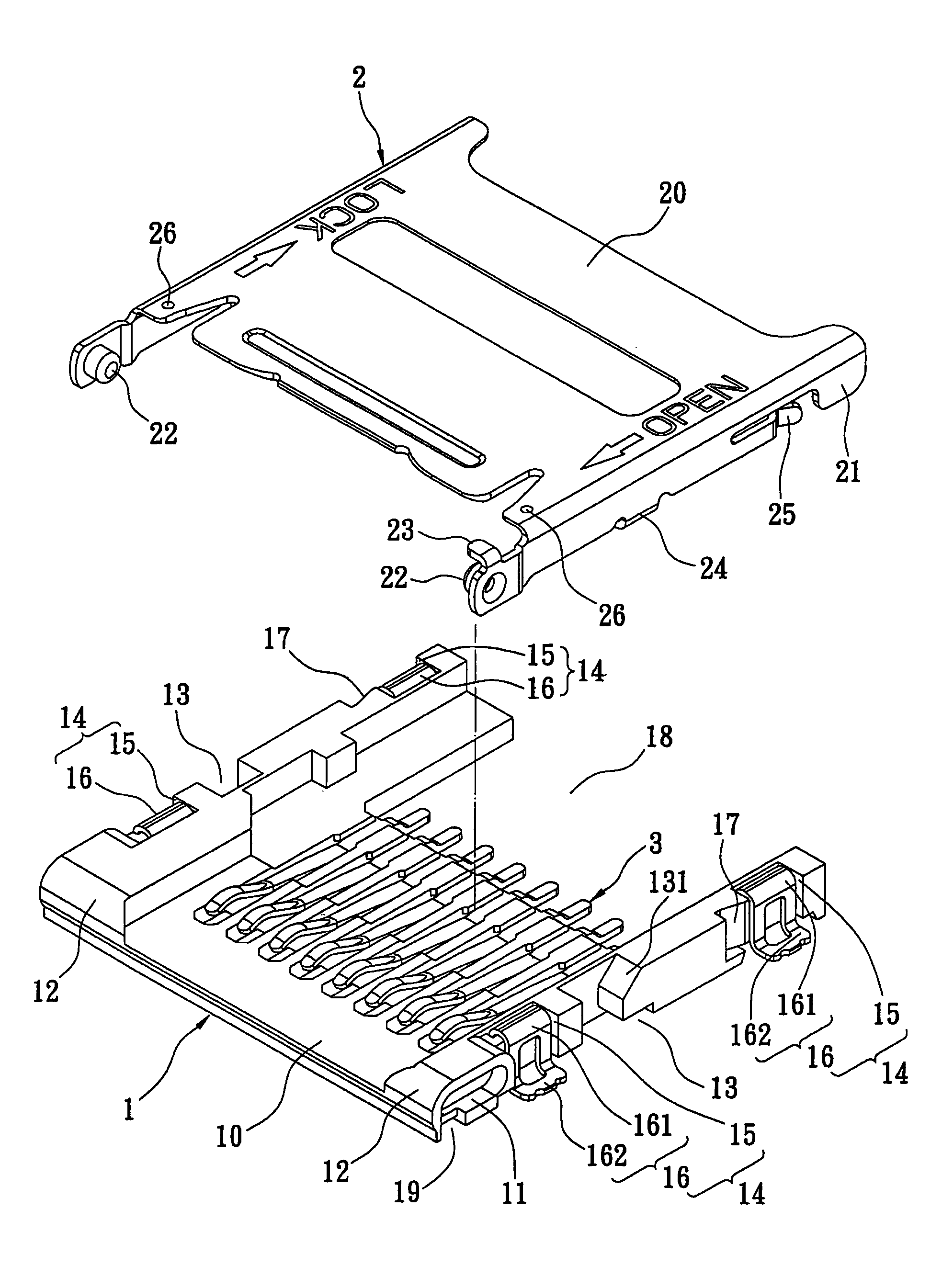

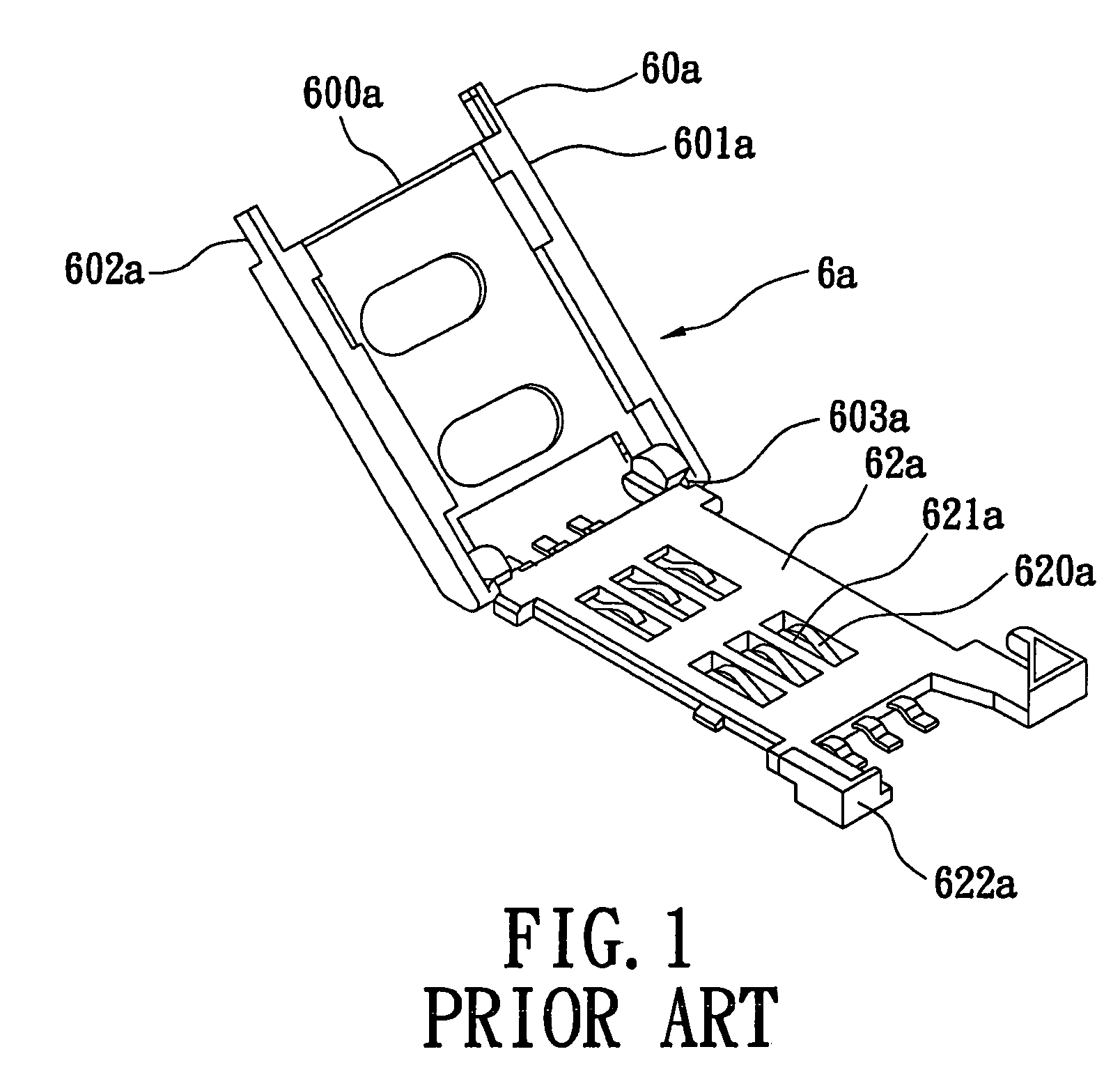

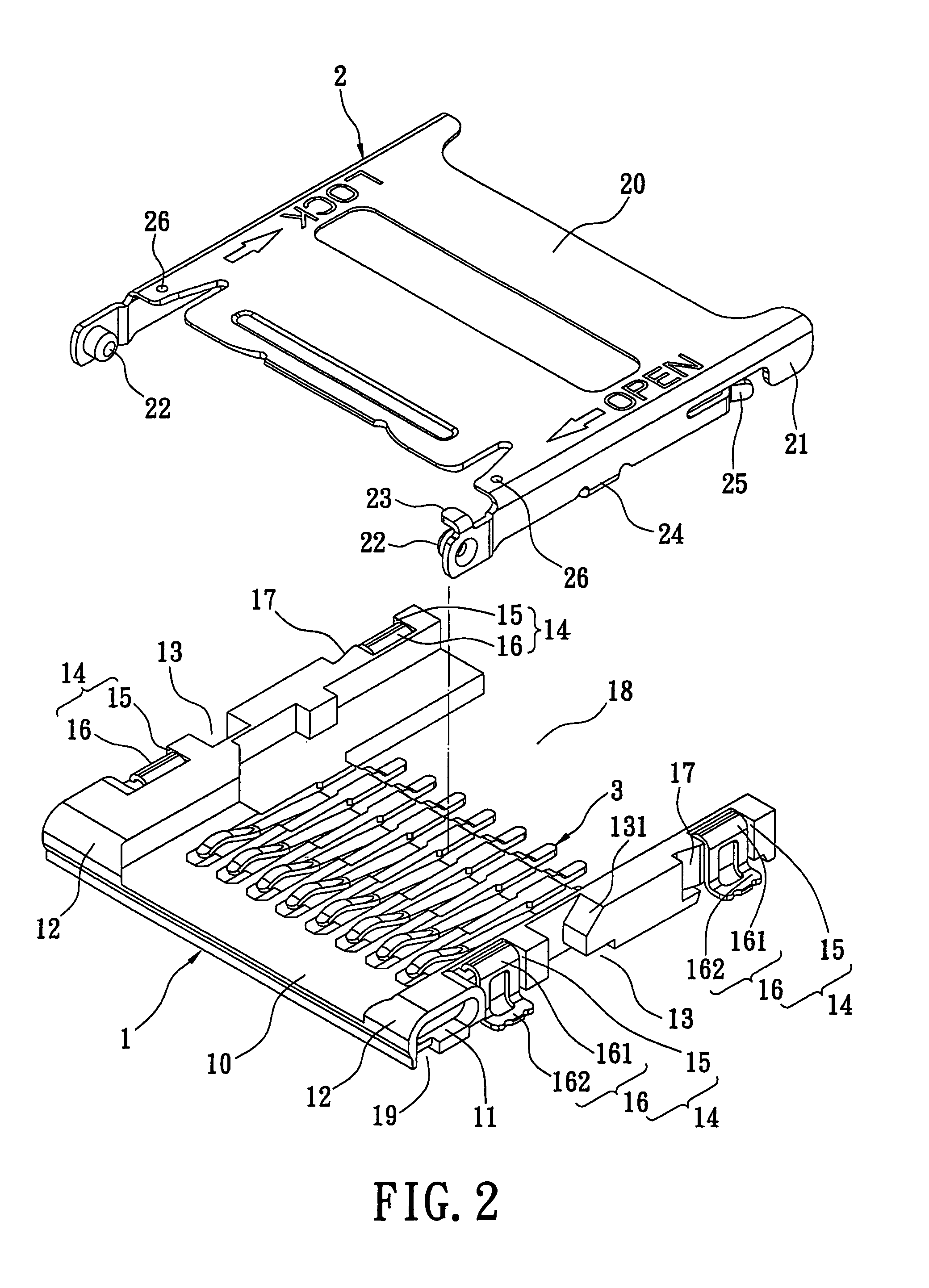

Electrical card connector including a locking mechanism

InactiveUS7270559B1Reliable lockingGood groundingEngagement/disengagement of coupling partsConveying record carriersEngineeringElectrical connector

An electrical connector includes an insulating body, and a shell body. The insulating body includes a body, pivoting concave ditches located at two sides of end of the body and formed along horizontal directions, and circular rotating angles located at the top rim of the two sides of the end of the body. The body receives a plurality of conducting pins. The shell body includes a top wall, side walls, pivoting convex columns, and a blocking element. The pivoting convex column is located in the pivoting concave ditch. By moving the pivoting convex column in the pivoting concave ditch, the shell body moves. By contacting the blocking element with the arc of the circular rotating angle, when the shell body rotates to a specified angle with the insulting body, the shell body moves along the side wall of the shell body.

Owner:JESS-LINK PRODUCTS

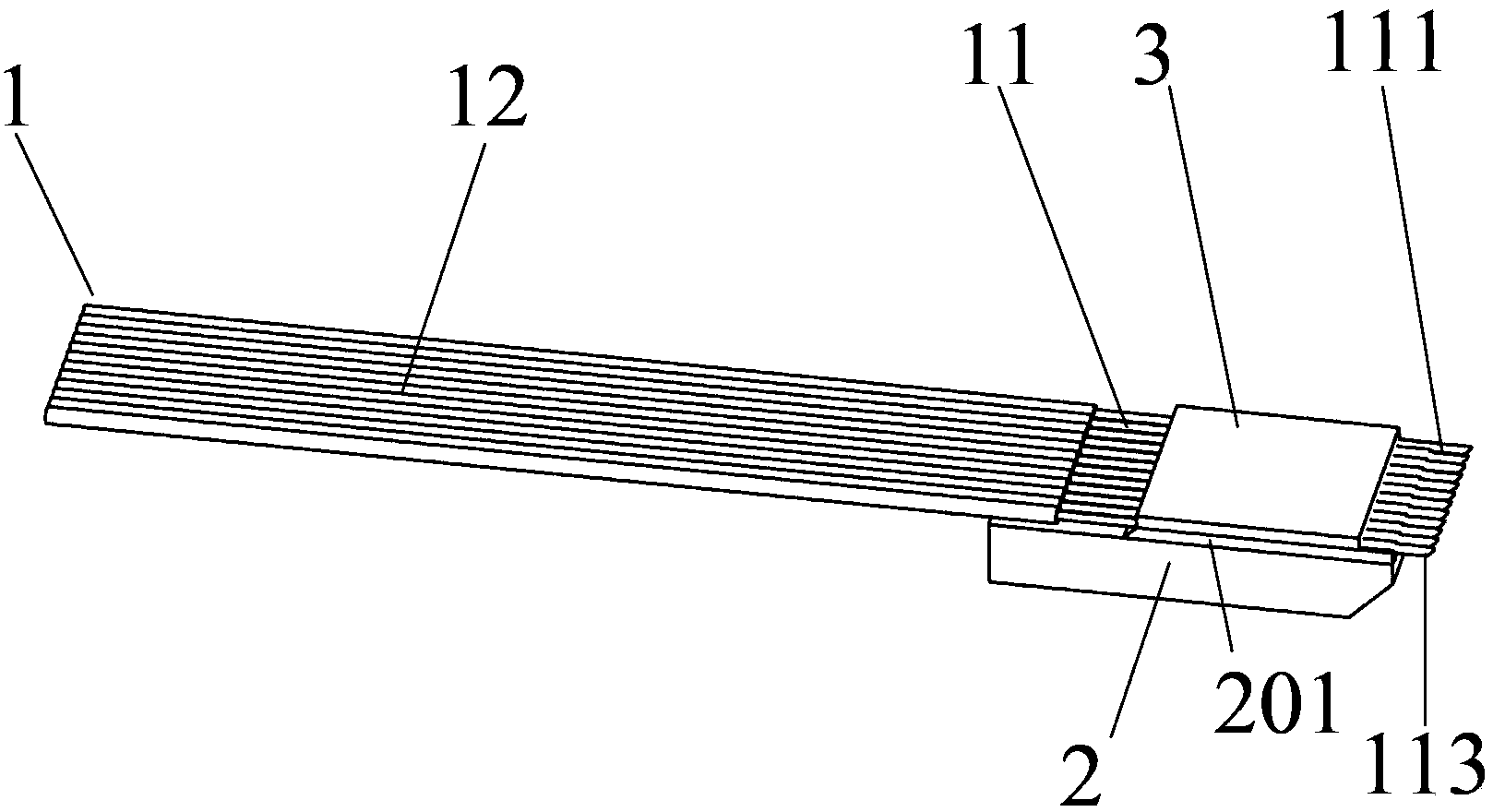

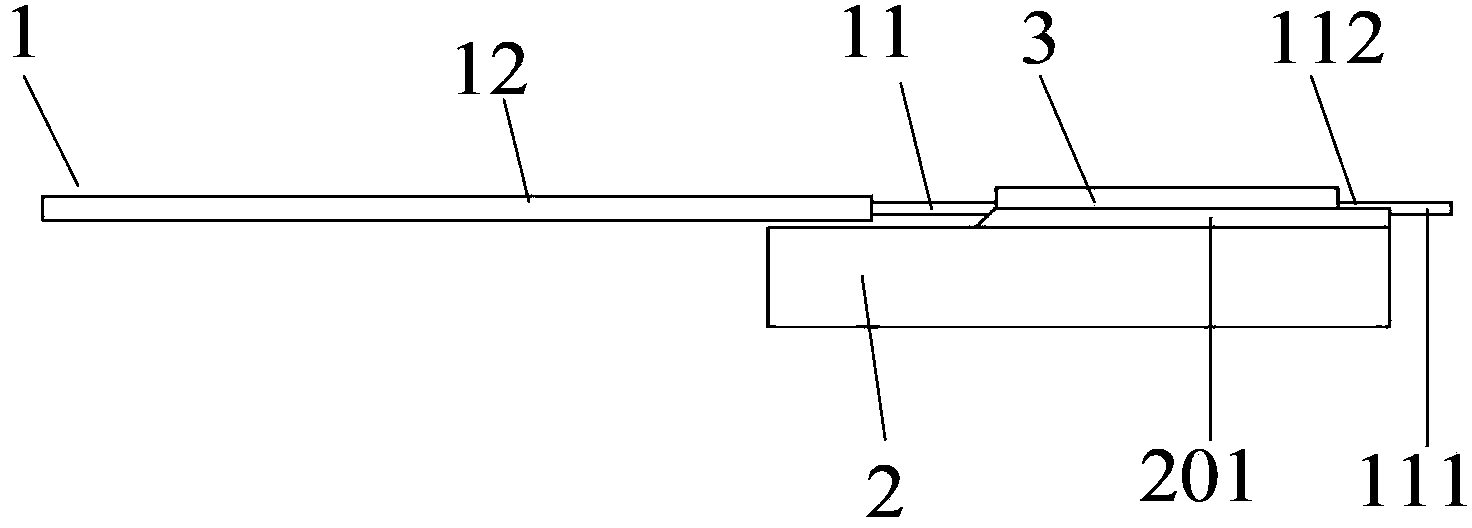

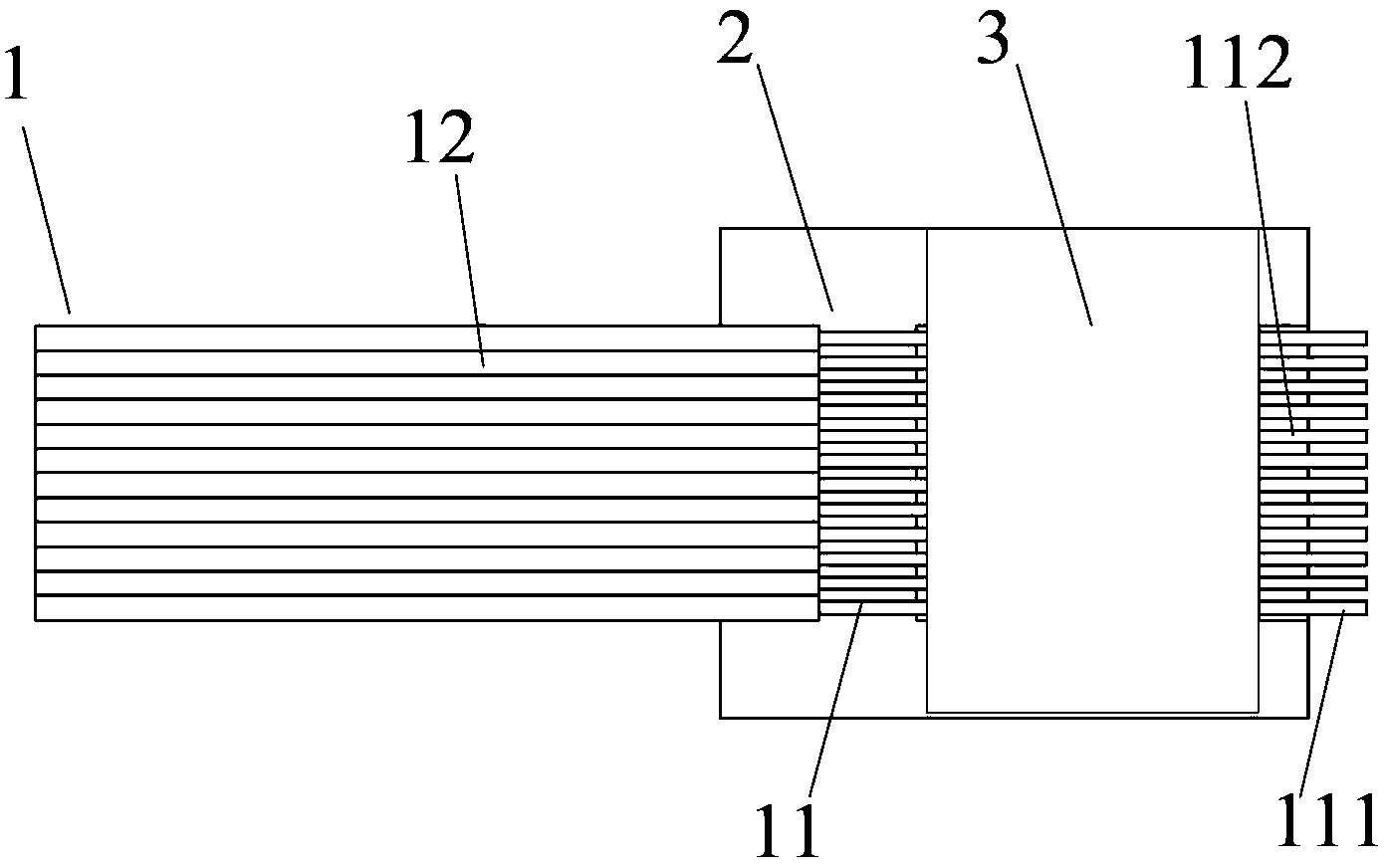

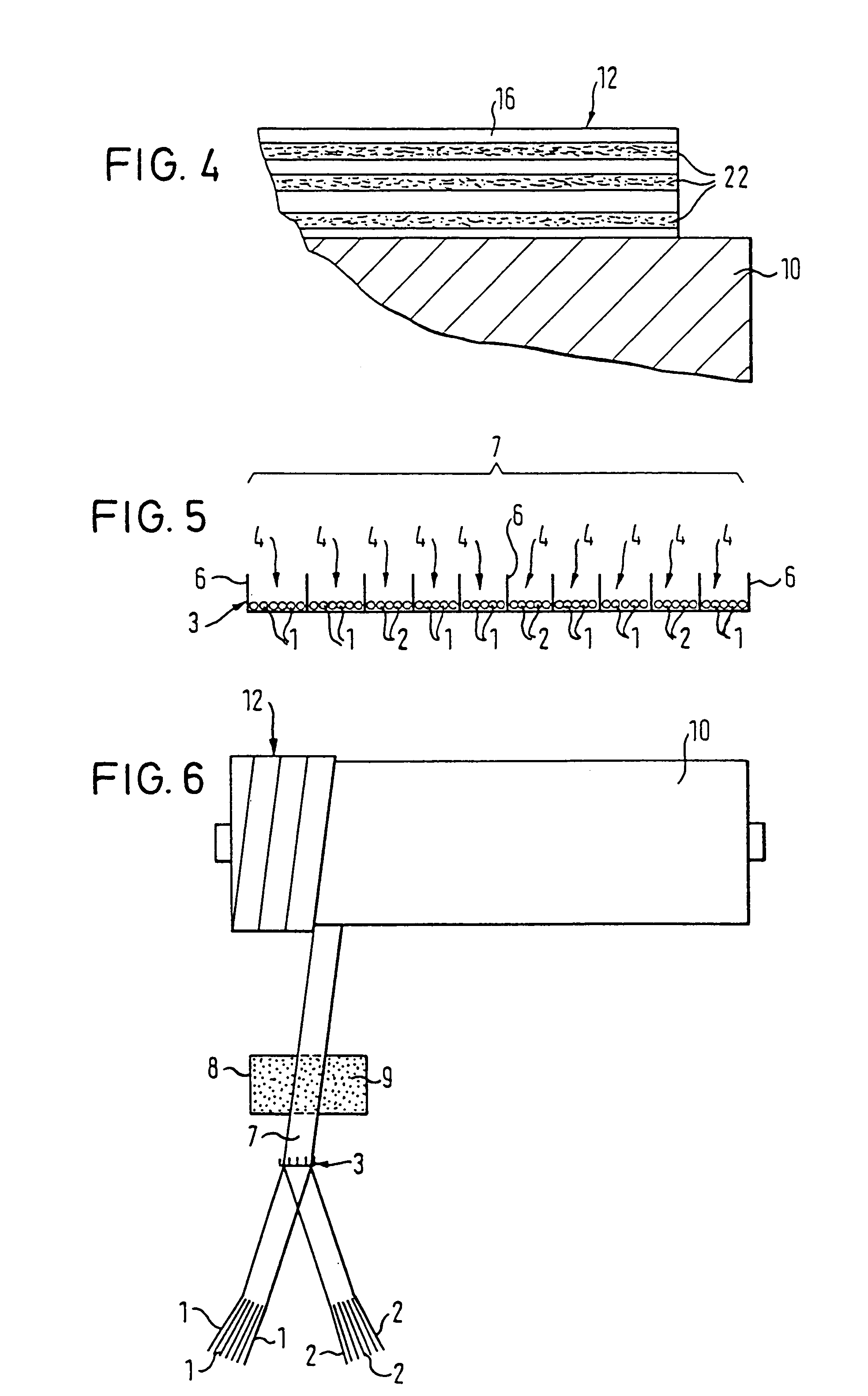

Fiber array coupled with VSCEL or PIN array and manufacturing method of fiber array

ActiveCN103383482AEfficient couplingAvoiding Adjustment Coupling Distance IssuesCoupling light guidesFiberCoupling

The invention relates to a fiber array coupled with a VSCEL or PIN array and a manufacturing method of the fiber array. The fiber array comprises a cover slip, a carving groove substrate and a fiber micro-strip, the fiber micro-strip comprises an exposed fiber micro-strip portion without a fiber coating, a V-shaped carving groove for holding the exposed fiber micro-strip portion is formed in the carving groove substrate, the cover slip presses the groove of the exposed fiber micro-strip portion, the carving groove substrate, the cover slip and the exposed fiber micro-strip portion are fixedly connected through binding agents, the cover slip is shorter than the V-shaped carving groove, the end face of the exposed fiber micro-strip portion is an optical plane with a 45-degree oblique angle, and the optical plane faces the carving groove substrate. The coupling distance between the 45-degree optical plane of the exposed fiber micro-strip portion and the VSCEL or PIN array is controlled by the aid of the cover slip of the fiber array, the thickness of the cover slip can be customized, and high-efficiency coupling is realized. The method for manufacturing the fiber array is simple, easy to implement and low in cost.

Owner:WUHAN POWERISE OPTOELECTRONICSAL TECH

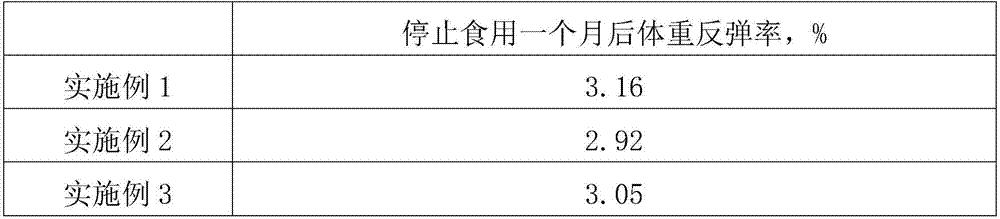

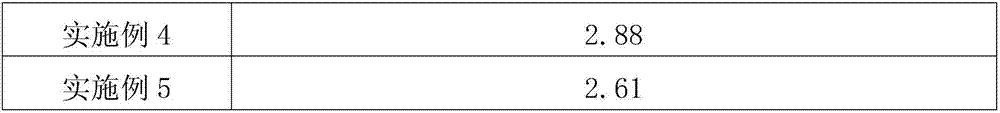

Cereal diet meal replacement powder and making method thereof

PendingCN106889521AKeep the tasteRetain nutrientsFood mechanical treatmentFood dryingMeal replacementRed bean

The invention discloses cereal diet meal replacement powder and a making method thereof. The cereal diet meal replacement powder includes raw materials yam, red dates, Chinese wolfberry fruits, oats, red beans, black beans, black sesame, walnut kernels, dried apples, chia seeds, quinoa and probiotics. The cereal diet meal replacement powder has the effects of moderating, nourishing and tonifying qi, nourishing the kidney, nourishing the blood, nourishing the intestines and detoxifying the intestines and expelling toxin, is suitable for all people, is homological in medicine and food, natural and health-care and can replace the three meals.

Owner:北京幸福人生健康科技发展有限公司

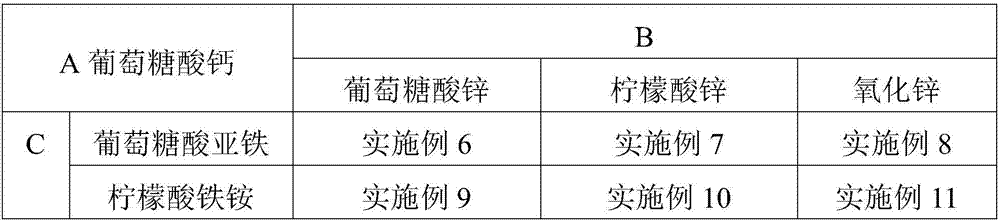

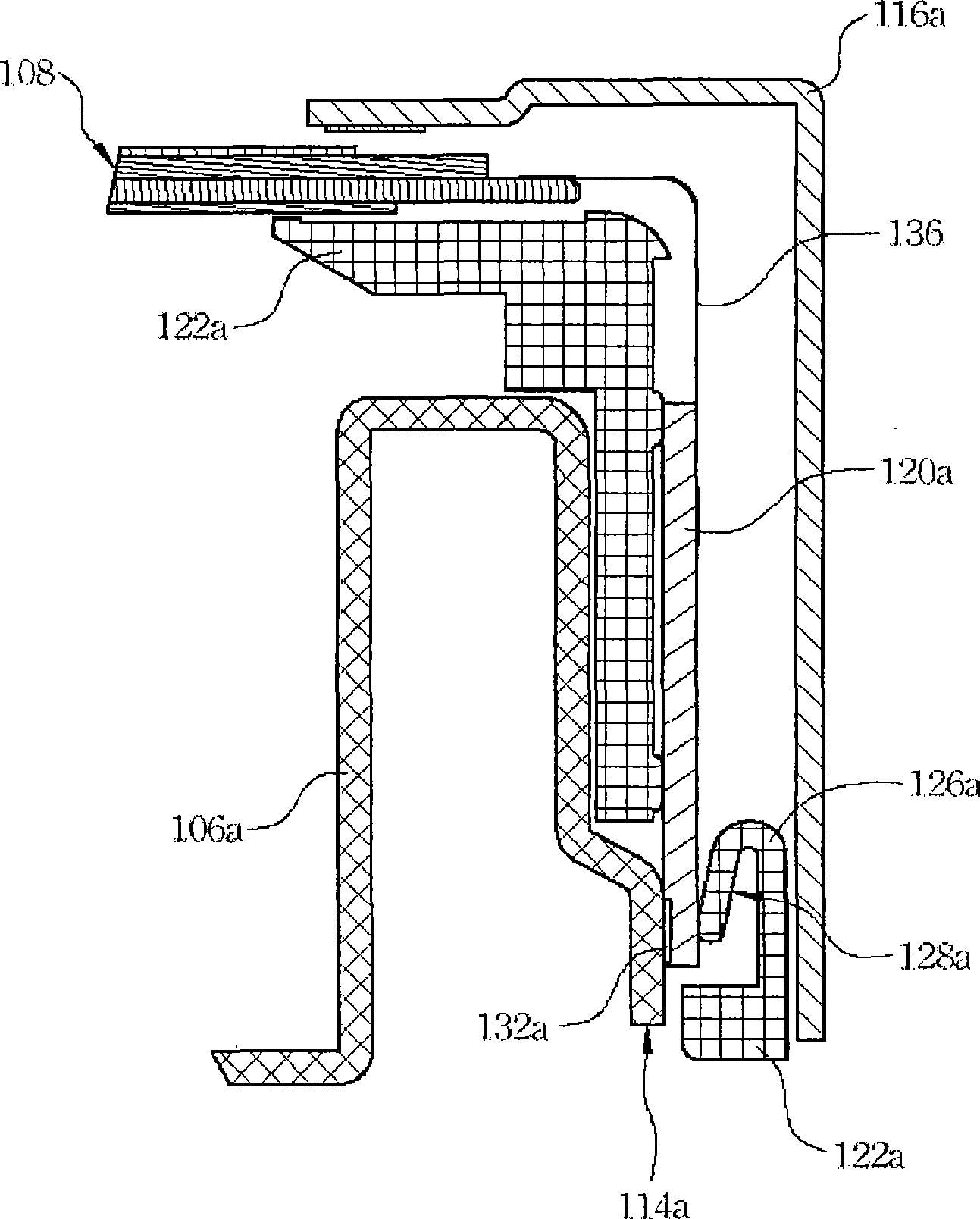

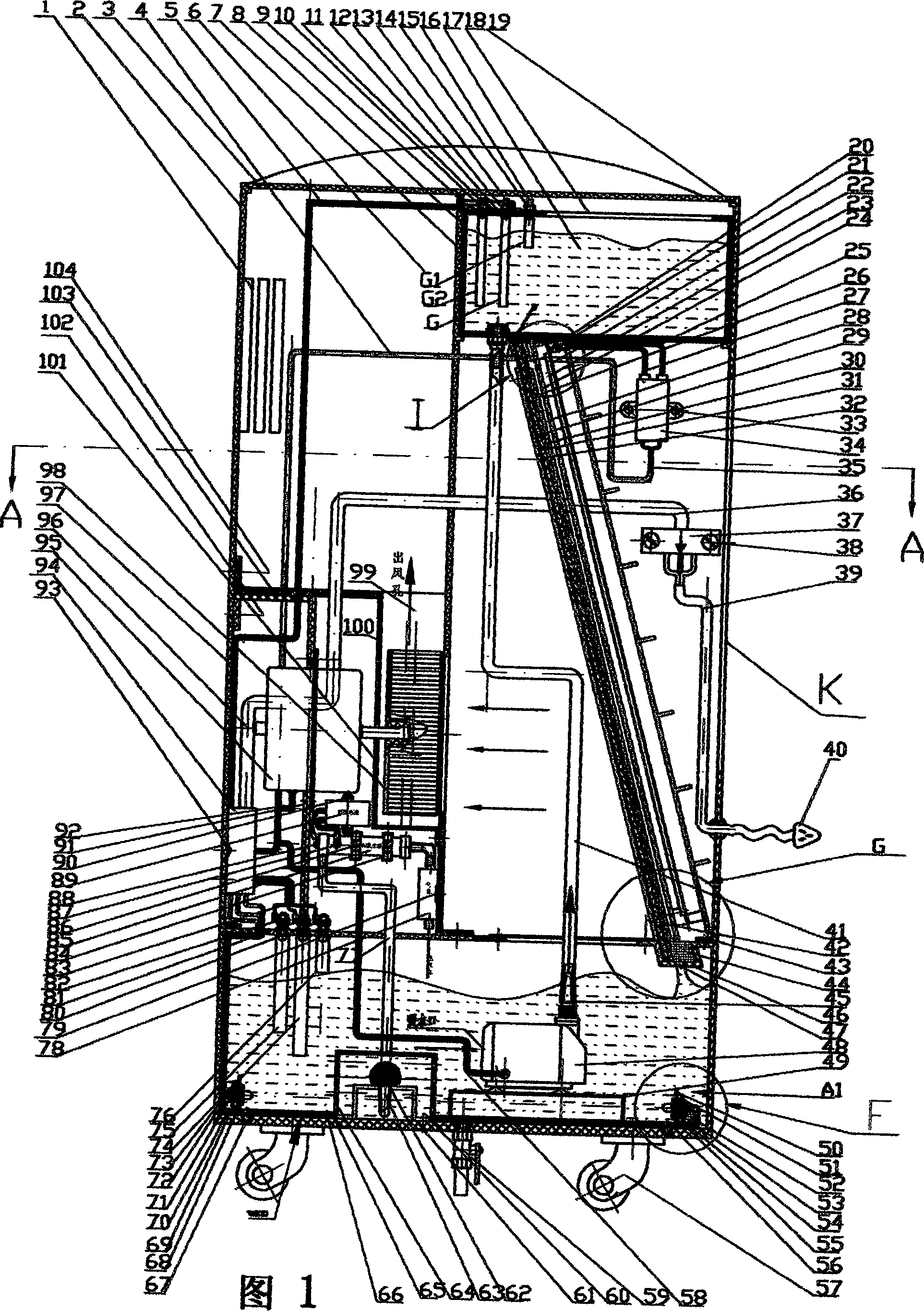

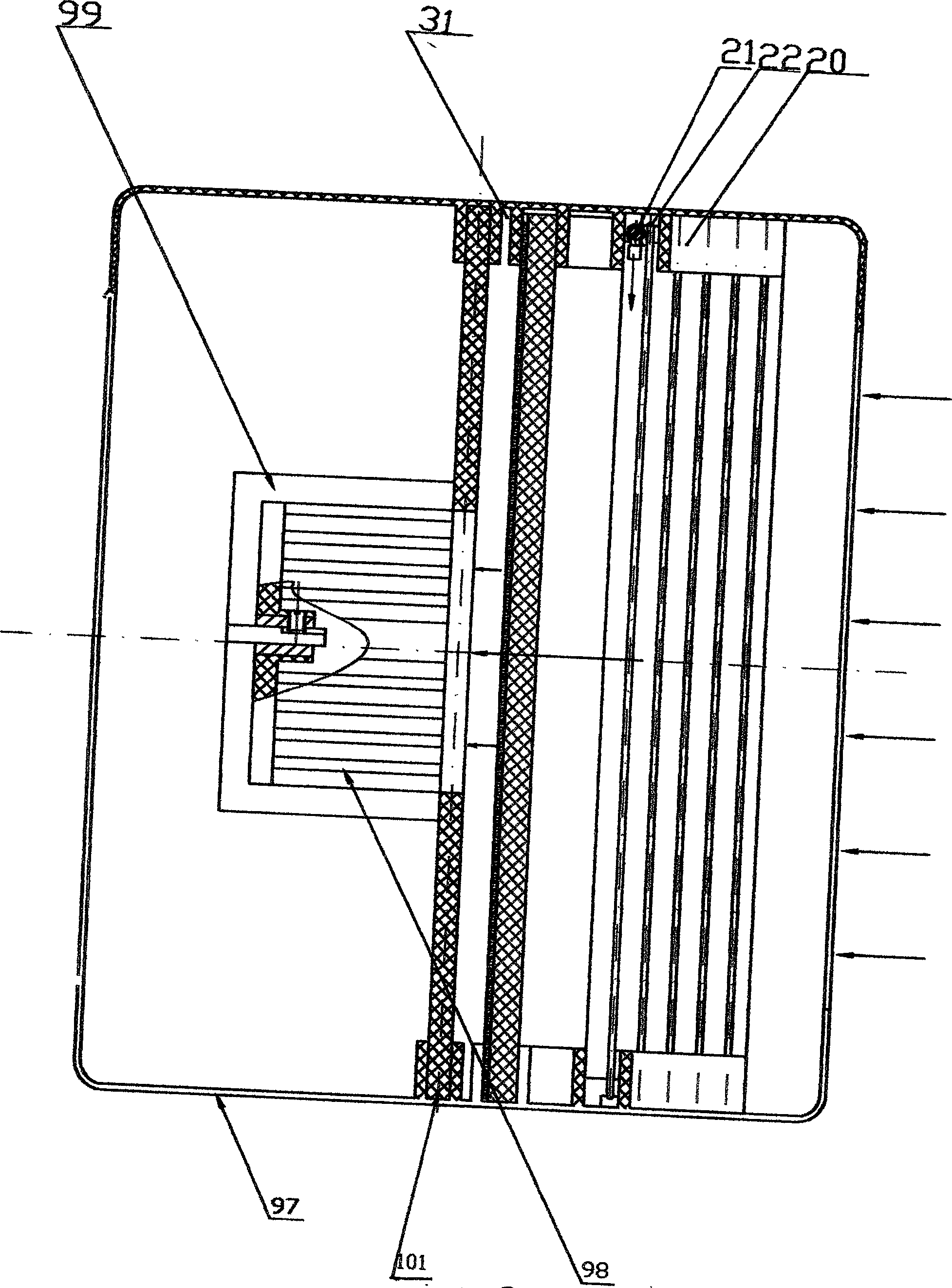

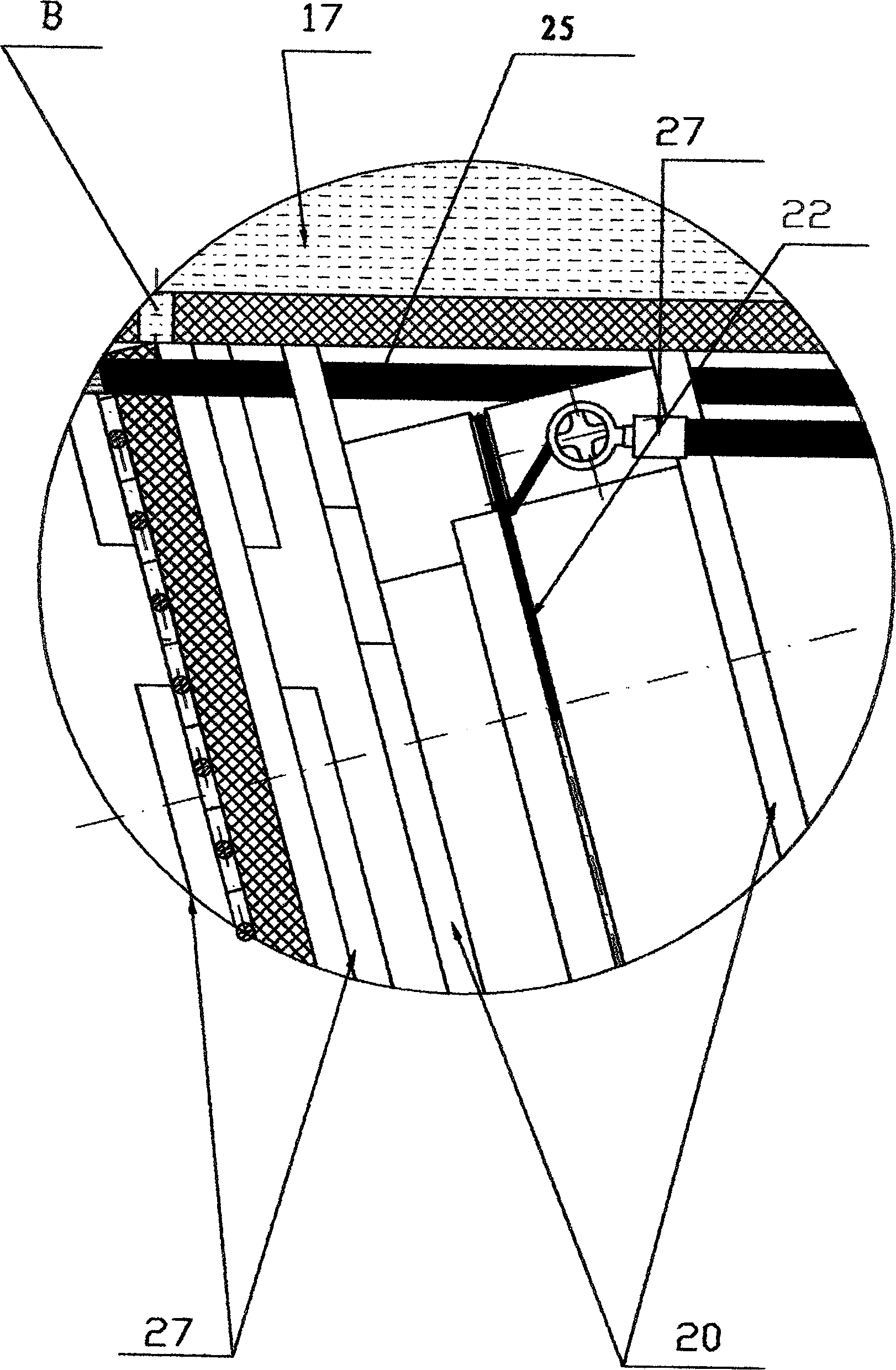

LCD device

ActiveCN101373287AFirm clampingGood grounding effectStatic indicating devicesInstrument housingMetal backedLiquid-crystal display

The invention discloses an LCD (liquid-crystal display) at least including a backlight module, a light source group, a rubber frame, an LCD panel module and a PCB (printed-circuit board). The backlight module at least includes a metal back plate, wherein the metal back plate at least includes a bottom plate and a side plate; the light source group is arranged in the metal back plate; the rubber frame is arranged on the outer edge of the metal back plate and attached to the outer side surface of the side plate of the metal back plate, wherein the rubber frame at least include a spring pressingpiece; the LCD panel module is arranged on the backlight module; and the PCB is electrically connected with the LCD panel module and arranged on the outer side of the backlight module, wherein the PCB at least includes a grounding area, and the spring pressing piece correspondingly presses the PCB for enabling the grounding area to be in direct contact with the metal back plate.

Owner:INNOLUX CORP

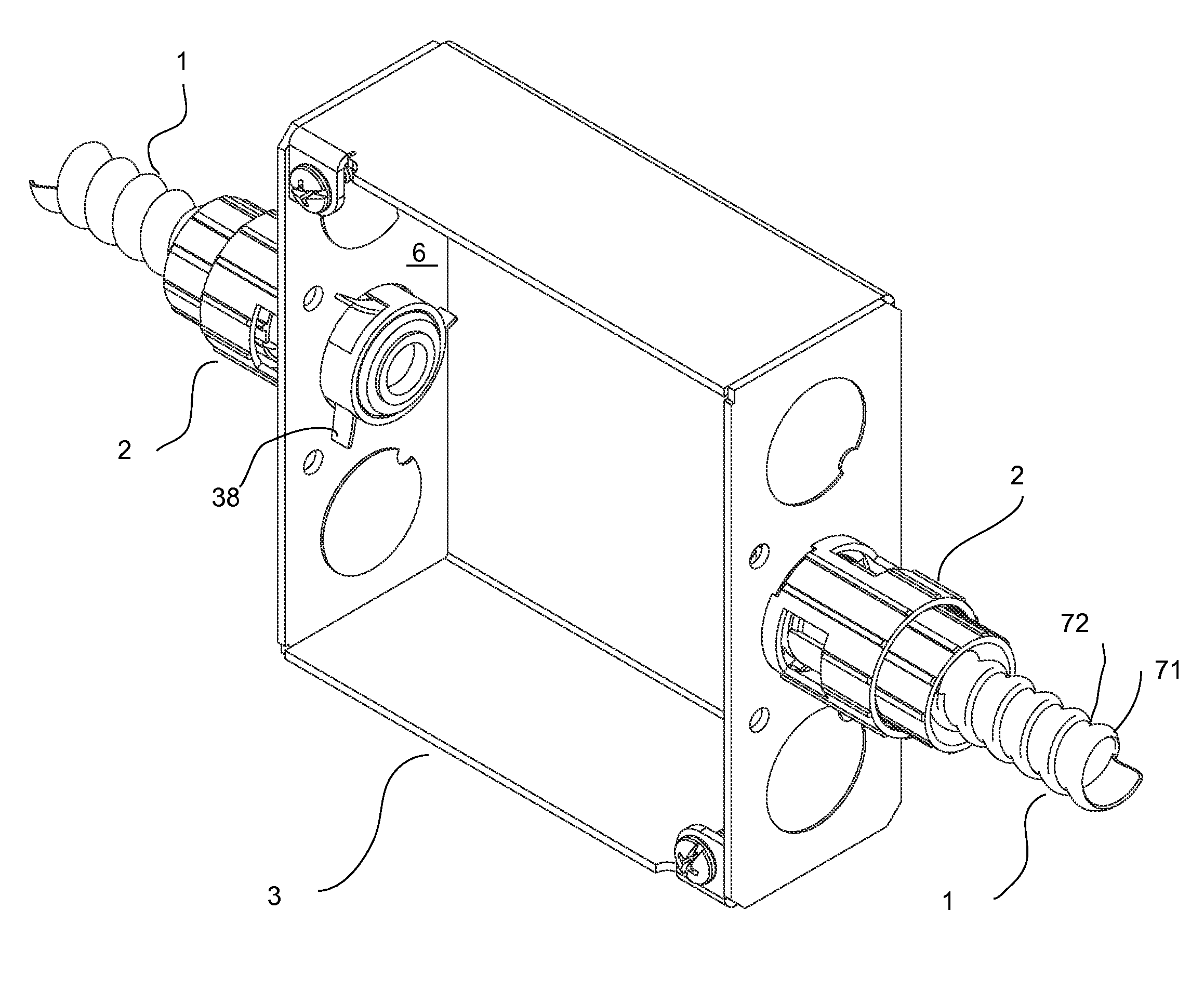

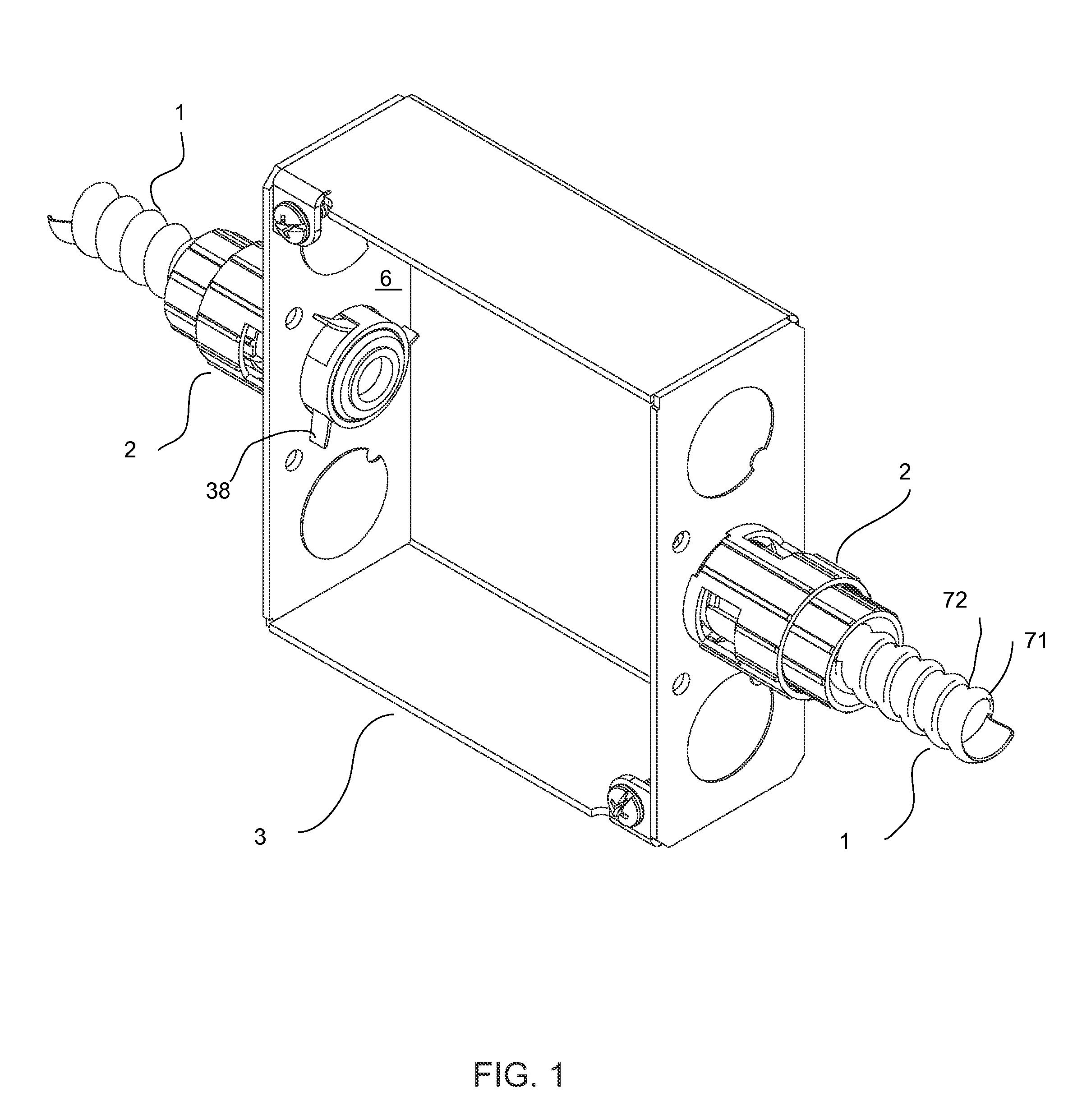

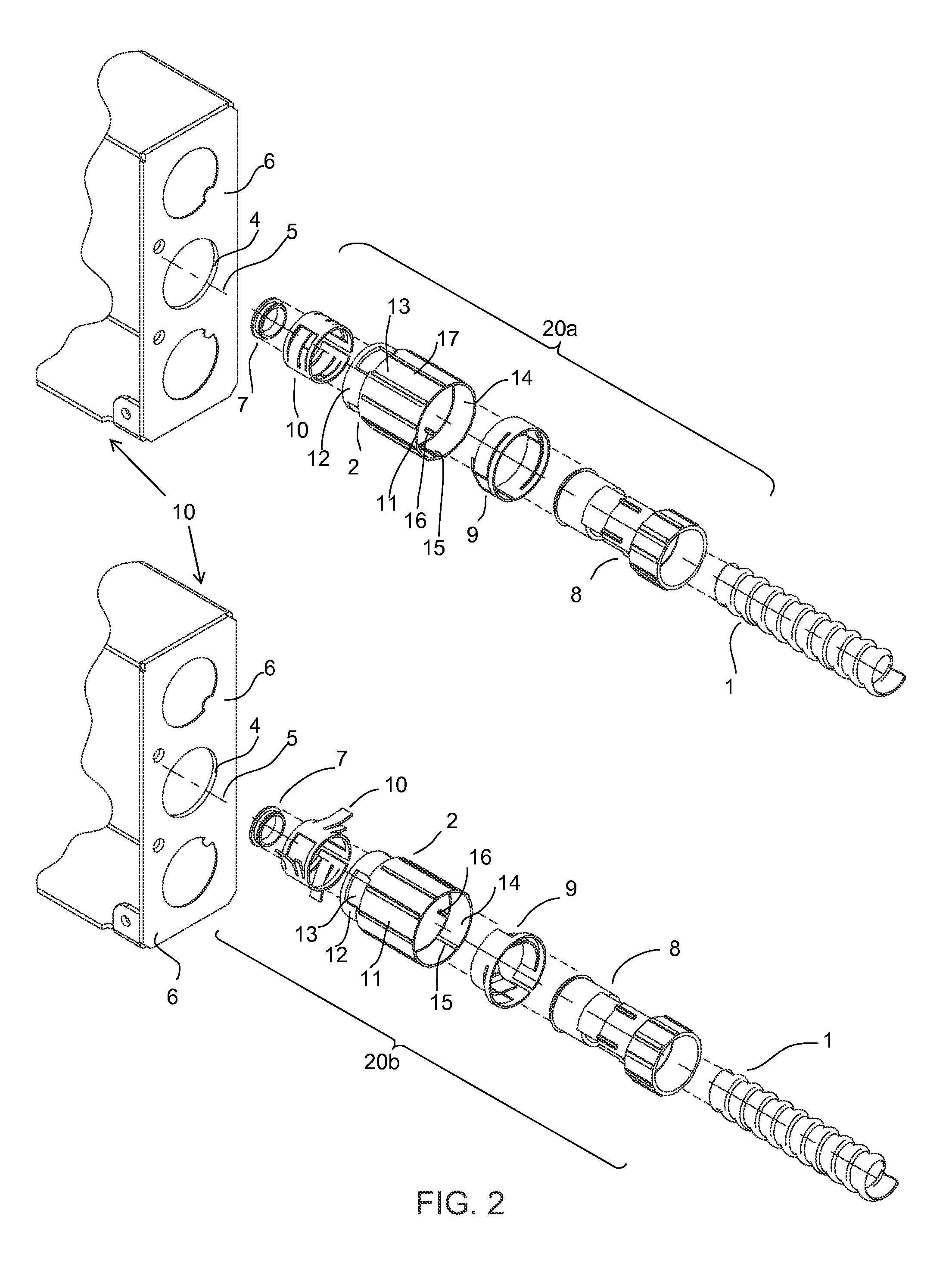

Spring lock electrical fitting

InactiveUS8791377B2Improve continuityMinimal of effortElectrical apparatusEngineeringElectrical equipment

A fitting that anchors electrical wiring to a junction box or electrical panel includes gripping members which can releasably hold electrical wiring, in or out of armored conduit, and interference members which allow the fitting to be inserted through knock out apertures and, when in place, extend to prevent withdrawal from the aperture. Optionally a rotatable collar actuates the mechanisms and abuts the wall of the box or panel, eliminating any lateral movement when the interference members are engaged.

Owner:KEEMEYA LLC DBA NEEKSON

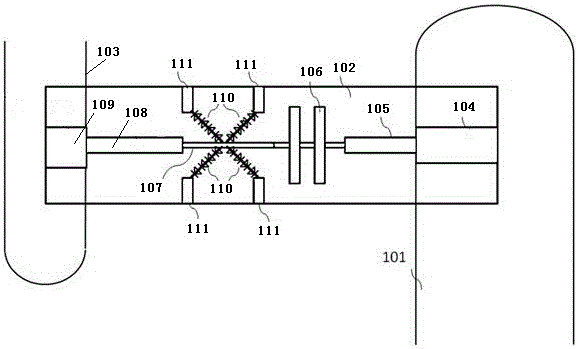

Terahertz double frequency unbalanced circuit with high power capacity

ActiveCN106026927ASimple structureIncrease the number ofOscillations generatorsCoupling devicesLow-pass filterDouble frequency

This invention discloses a terahertz double frequency unbalanced circuit with high power capacity, which relates to the terahertz circuit technology field. The circuit comprises a radio frequency input waveguide, a quartz substrate and a radio frequency output waveguide. One end of the quartz substrate is located in the waveguide slot of the radio frequency input waveguide; the other end of the quartz substrate is located in the waveguide slot of the radio frequency output waveguide. An input transition microstrip line is located on the quartz substrate. One end of the transition microstrip line is connected with an output microstrip line successively through a first transmission microstrip line, a low pass filter, a radio frequency matching mirostrip line and a second transmission microstrip line. The anodes of four multi-junction GaAs terahertz double frequency diodes are connected with the radio frequency matching microstrip line; each outermost cathode of the mulit-junction GaAs terahertz double frequency diode is connected to a grounded quartz stripline. The circuit has a simple structure and can withstand a larger input power due to an increase in the number of Schottky diodes.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

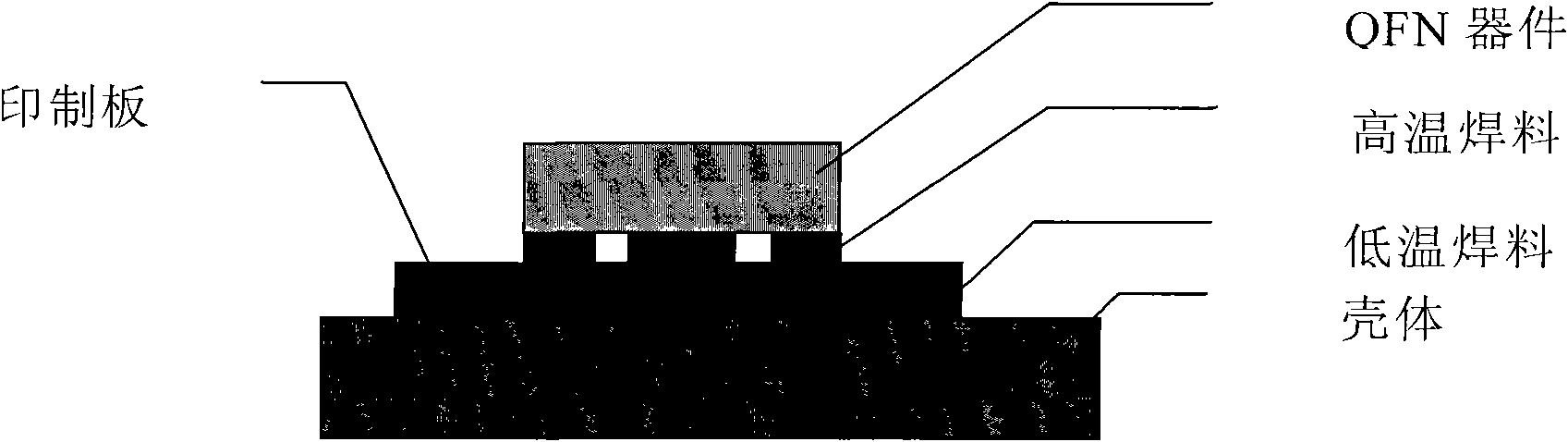

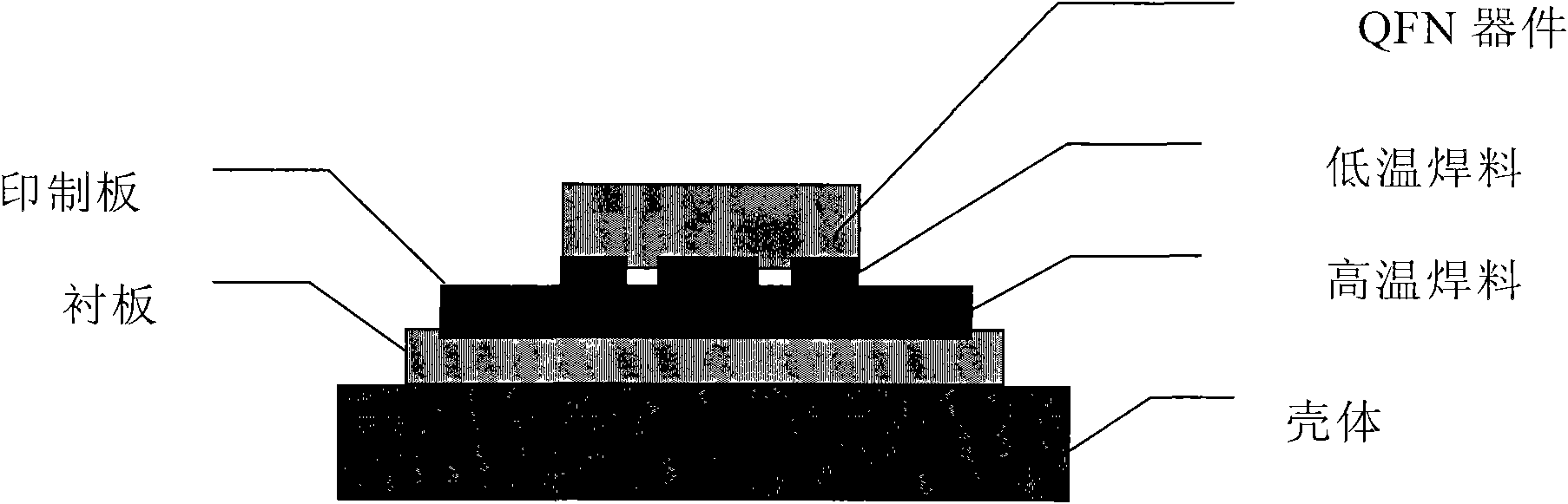

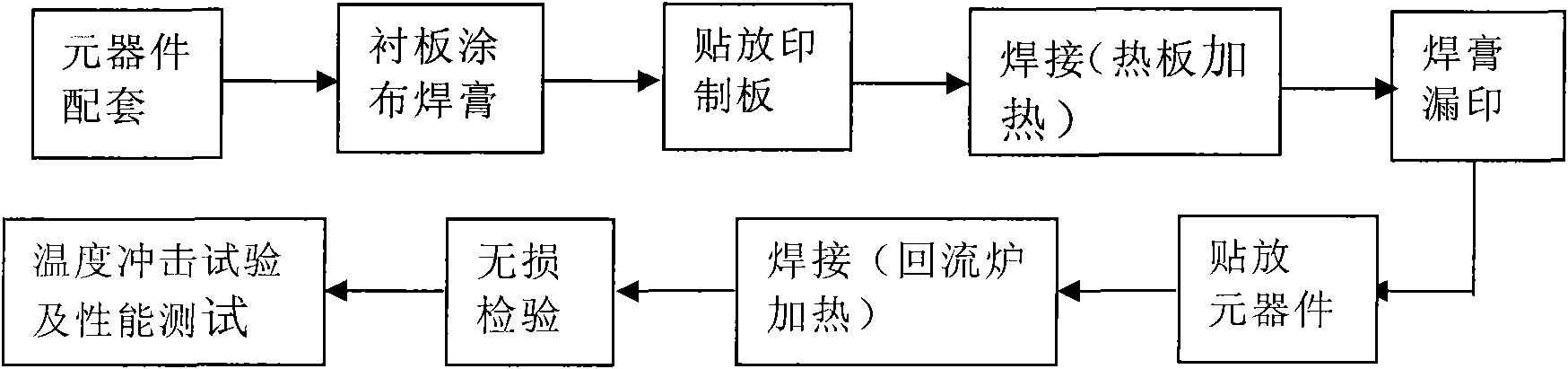

Method for enhancing welding reliability of high-frequency quad flat no lead (QFN) device

ActiveCN102083281AAvoid and reduce solder joint stressAvoid reheatingPrinted circuit assemblingElectrical and Electronics engineeringHigh frequency

The invention relates to a method for enhancing the welding reliability of a high-frequency quad flat no lead (QFN) device. The method comprises the following steps of: (1) uniformly coating a high-temperature solder with the smelting point of between 214 and 220 DEG C on a lining board and welding a printed board on the lining board; (2) coating a low-temperature solder with the smelting point of between 180 and 188 DEG C on a bonding pad of the printed board by using a bushing, sticking the QFN device and welding, wherein the opening size of the bushing is smaller than that of the bonding pad of the printed board; and (3) fastening the lining board in a shell. Through a welding method, secondary heating of the device is avoided, welding stress is reduced and good mechanical support is provided for the printed board assembly on the basis of ensuring that a printed board assembly is fully grounded; simultaneously, thermal stress produced by a component under a cold and heat exchange condition can be greatly reduced and the reliability of the QFN device is enhanced.

Owner:BEIJING RES INST OF TELEMETRY

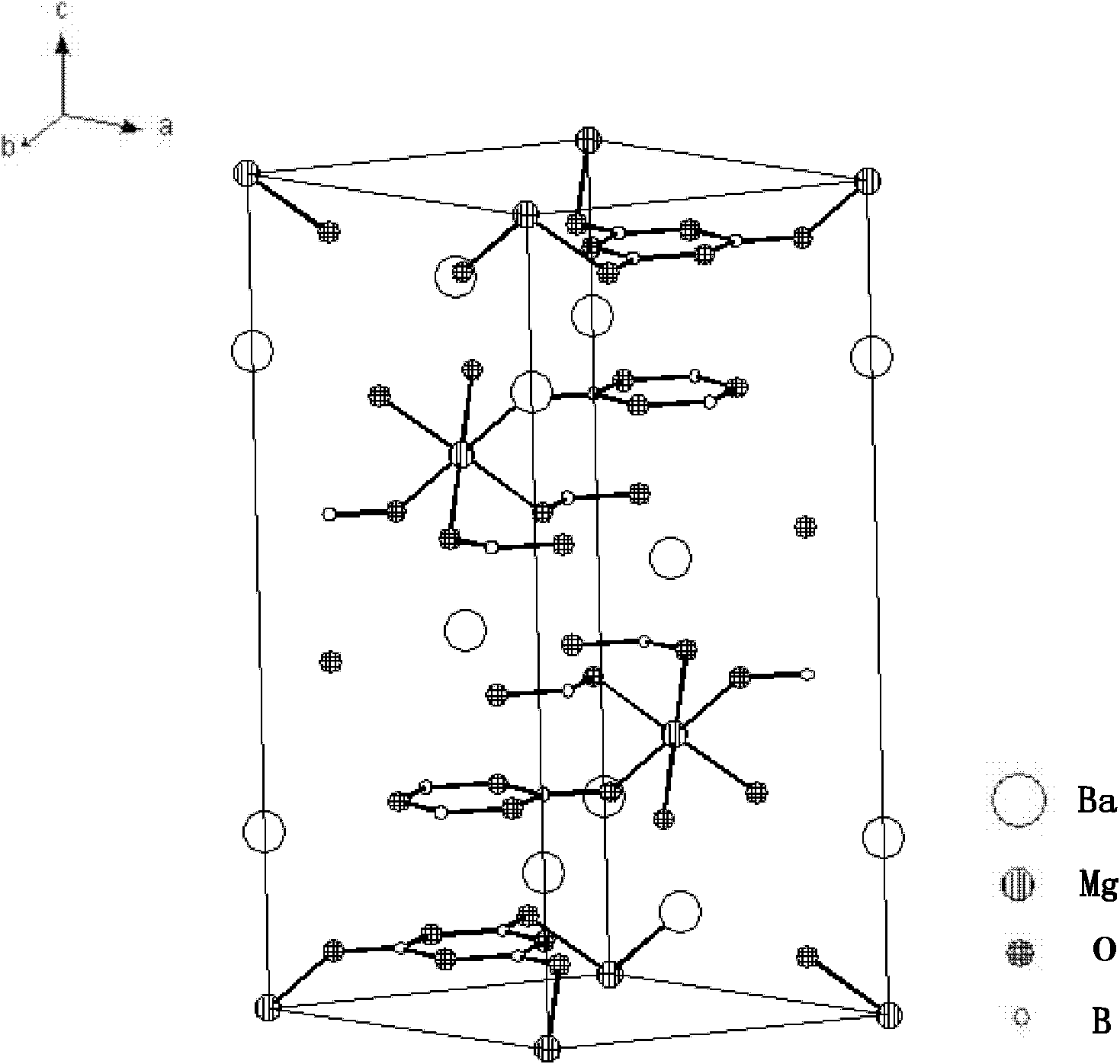

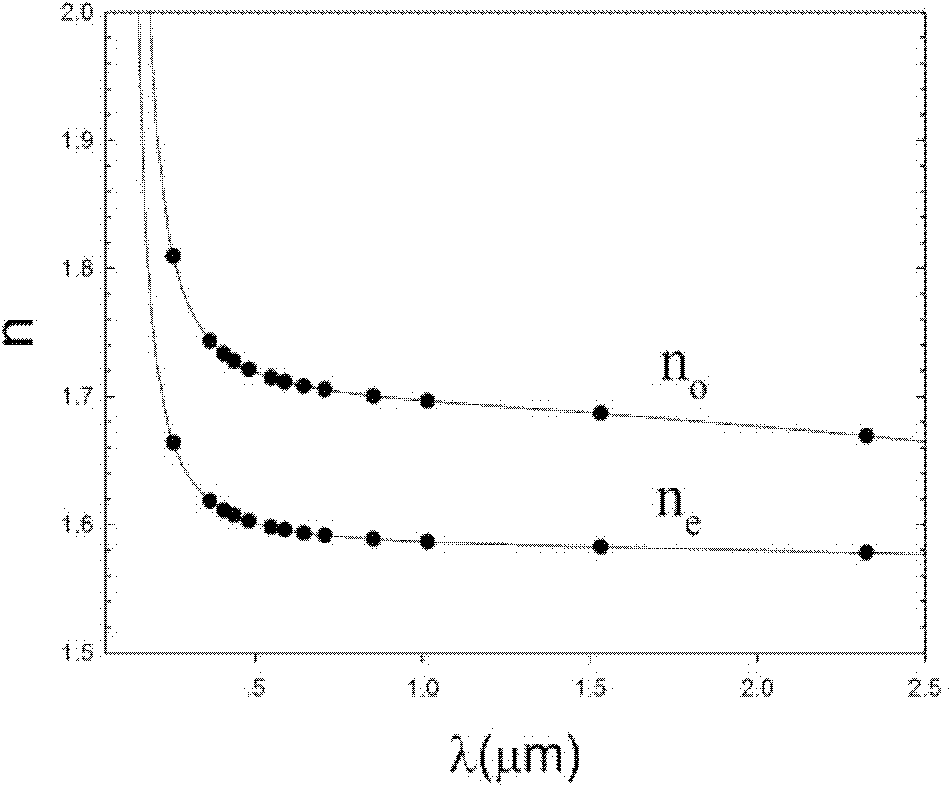

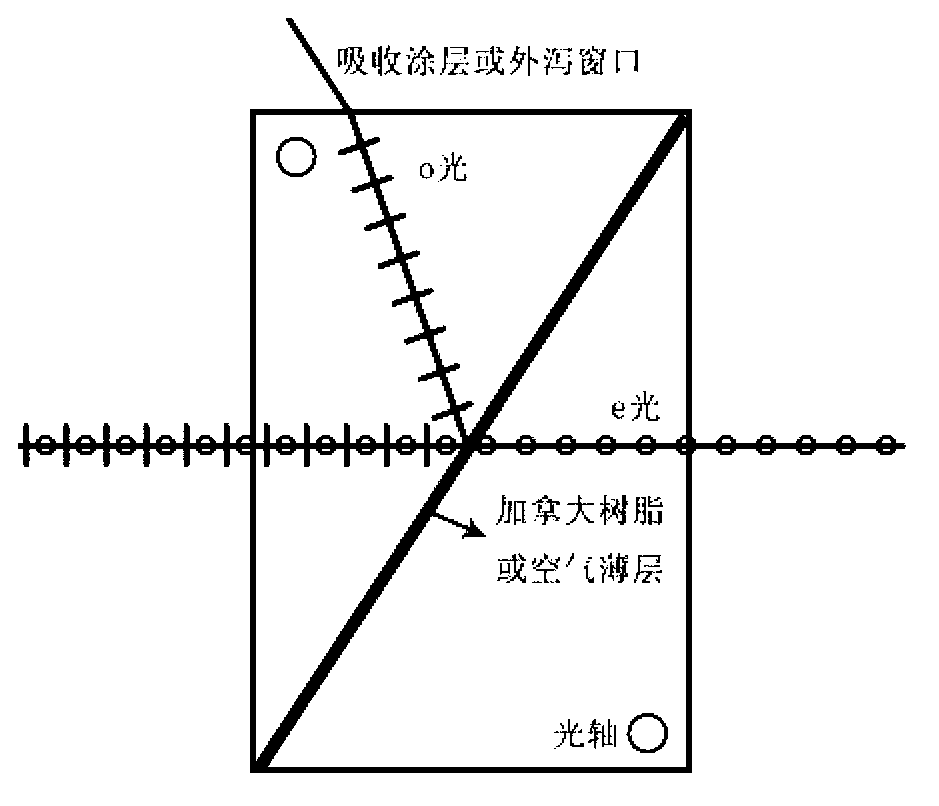

Borate birefringent crystal for ultraviolet and deep ultraviolet, and growth method and application thereof

ActiveCN102839421AGood cutGood grindingPolycrystalline material growthPolarising elementsExtreme ultravioletRefractive index

The invention relates to a borate birefringent crystal for ultraviolet and deep ultraviolet. The birefringent crystal has a chemical formula Ba2Mg (B3O6)2, belongs to trigonal system, and has a space group of R-3; and a equals to 0.70528 (3) nm, and C equals to 1.65520 (9) nm, and Z equals to 12. The barium magnesium borate birefringent crystal is an aniaxial negative crystal with ne less than no, has a transmission range of 177-3000 nm and birefringence between 0.077-0.229, and is easy for cutting, grinding, polishing and storage, stable in air, and hardly deliquesced. The barium magnesium borate birefringent crystal is subjected to a self-melt spontaneous crystallization method, a melt Czochralski method or a fluxing medium method for growth; the barium magnesium borate birefringent crystal has large birefringence (no-ne = 0.077-0.229), has important application to fields of optics and communication for the production of polarized beam splitting prism.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

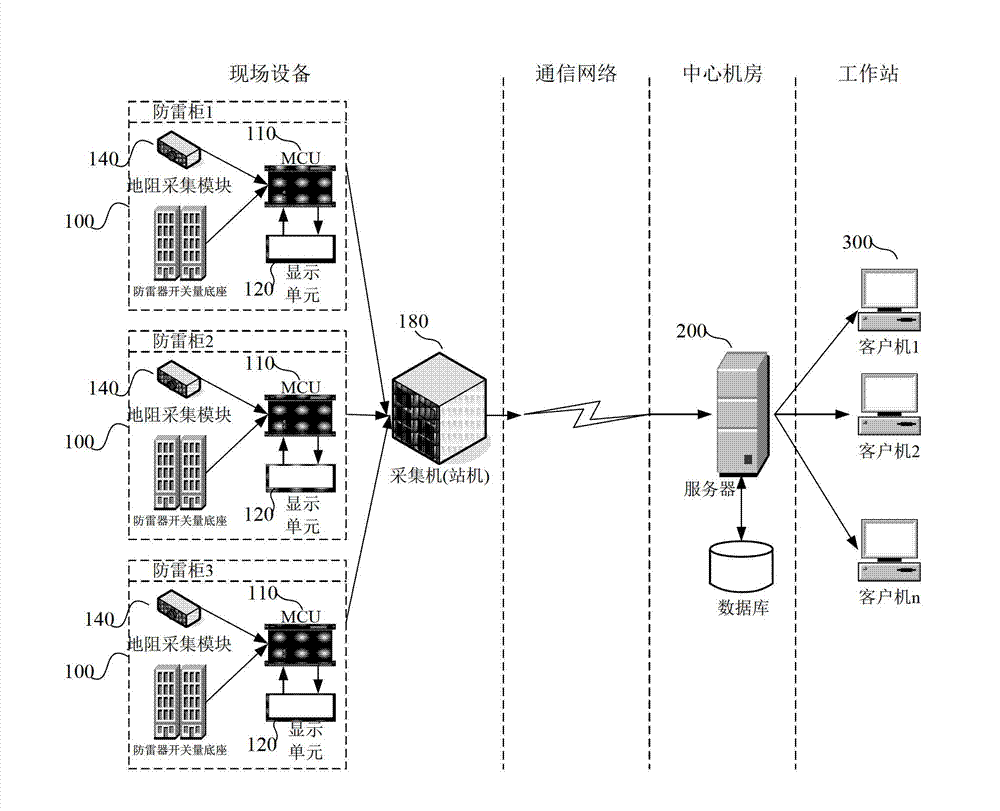

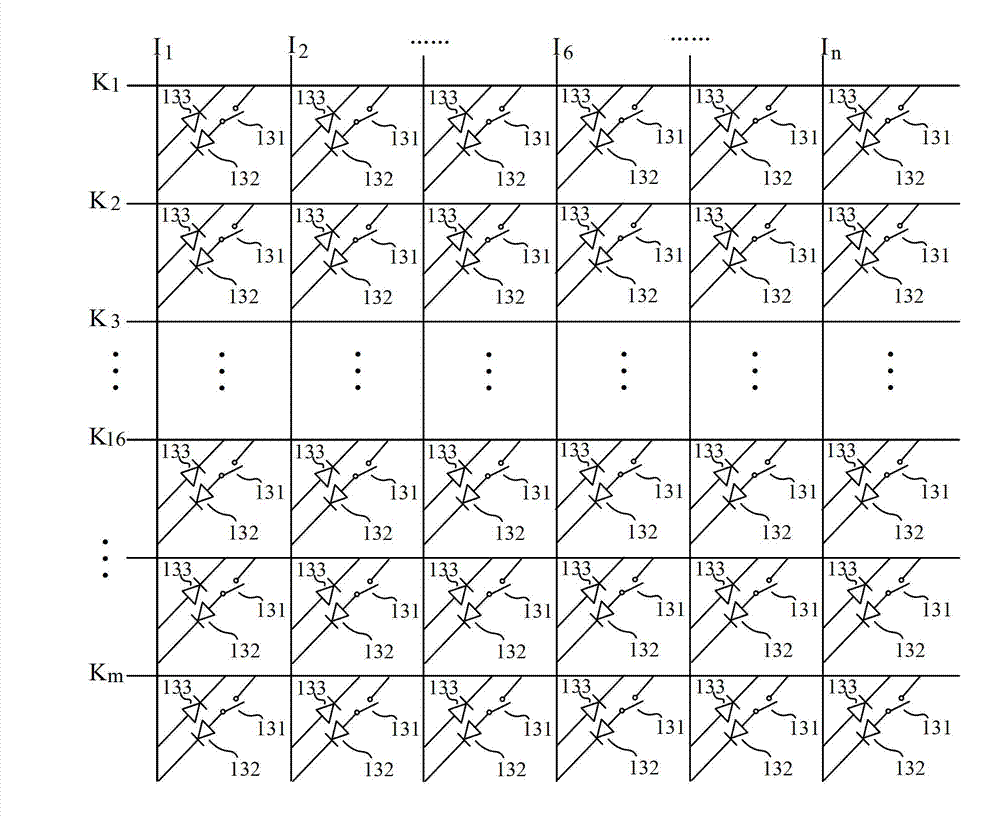

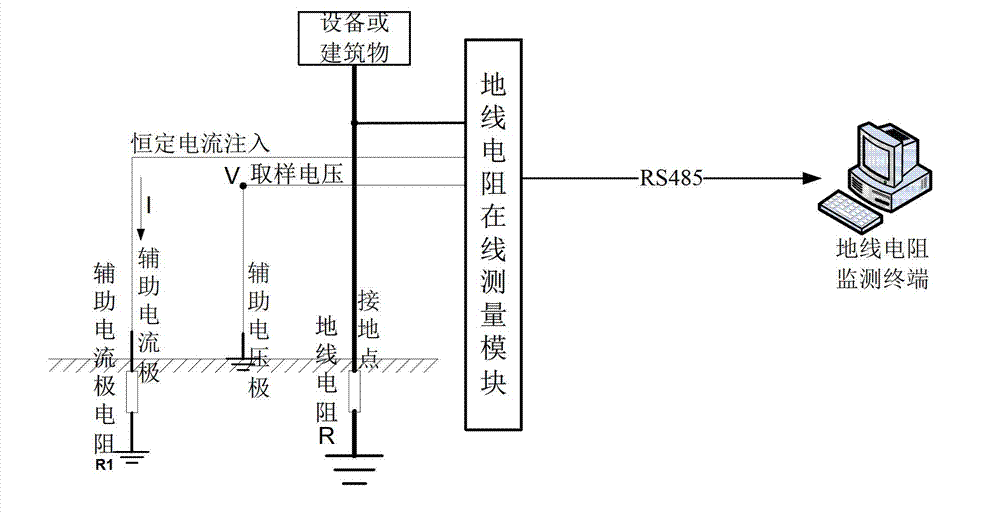

System and method for monitoring damaged on-off quantity of surge protection device and ground resistance online in real time

ActiveCN103207331AGood groundingAccurate measurementEarth resistance measurementsElectrical testingConstant current sourceSoftware modules

The invention discloses a system and method for monitoring damaged on-off quantity of a surge protection device and ground resistance online in the real time. A measuring system comprises a server, one or a plurality of remote monitoring terminals and one or a plurality of data collecting systems. The server is respectively connected with various remote monitoring terminals and all data collecting systems. Each data collecting system comprises a damaged on-off quantity data collecting module and a ground resistance collecting module. Each damaged on-off quantity data collecting module comprises m row-connecting lines and n line-connecting lines. Each ground resistance collecting module comprises a micro-processor module, a constant current source injection module, a sampling voltage reading module and a ground resistance measuring software module. The micro-processor modules are connected with the constant current injection modules, the sampling voltage reading modules and the ground resistance measuring software modules respectively. The system and method can guarantee effective judgment of damaged on-off quantity of all surge protection devices and simultaneously can measure the ground resistance in the real time precisely. The system and method is especially suitable for railway signal lightning protection.

Owner:CHINA RAILWAY SIGNAL & COMM SHANGHAI ENG BUREAU GRP

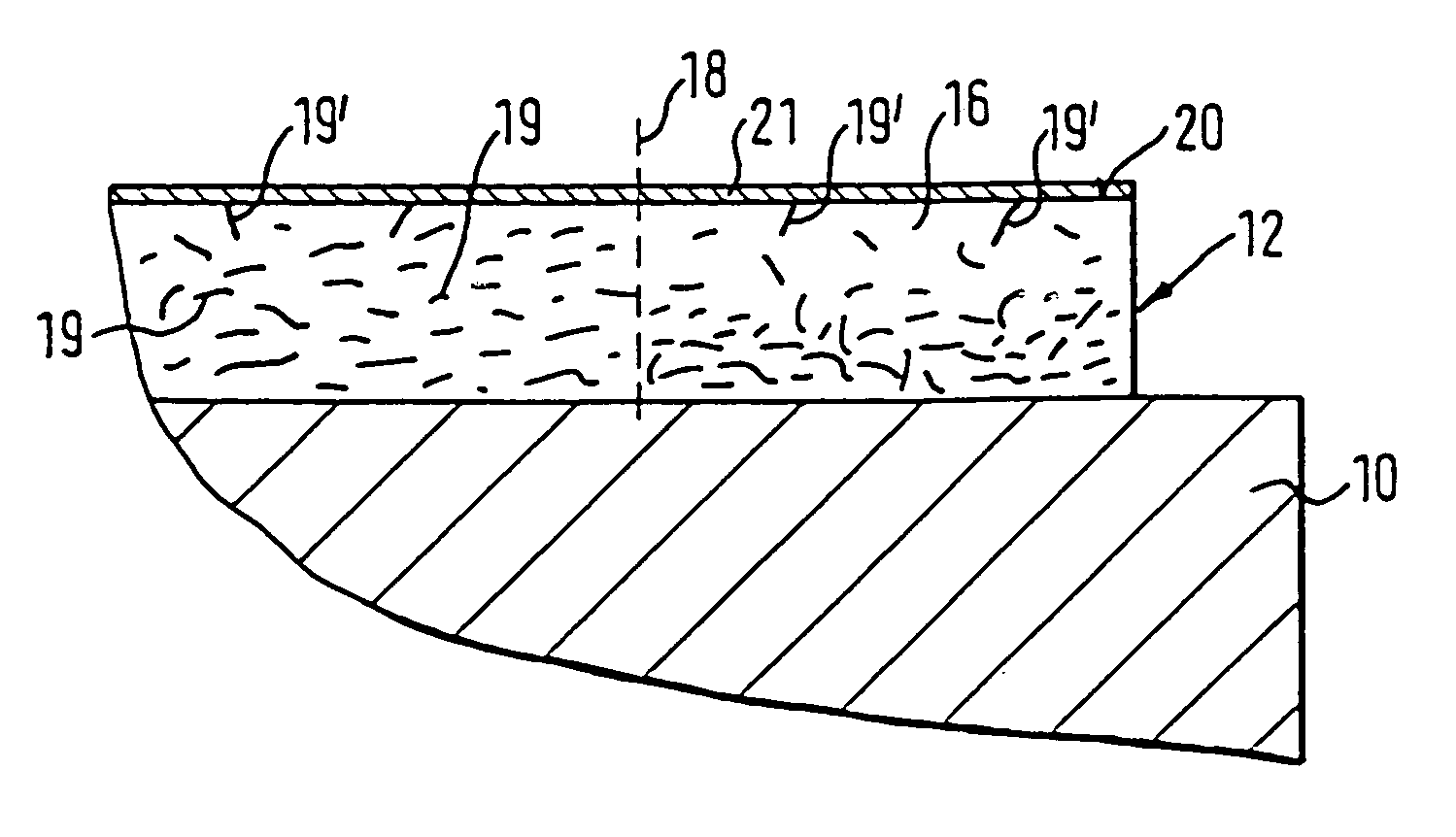

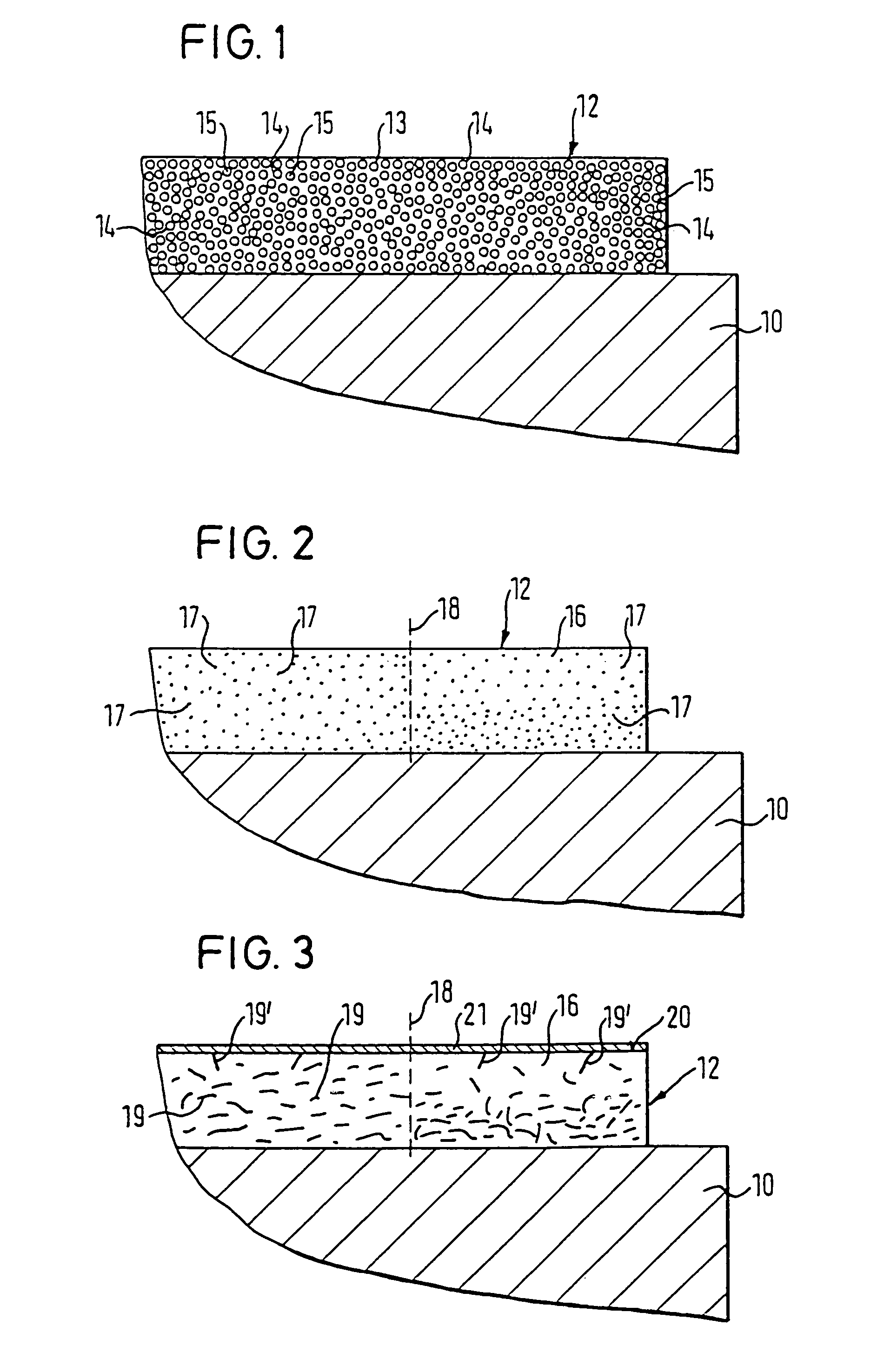

Elastic roller and process for producing same

InactiveUS6896647B1Reduce riskImprove thermal conductivityLiquid surface applicatorsShaft and bearingsElastic matrixMetallurgy

Elastic roller and process for producing elastic roller. The elastic roller includes a hard roller core and an elastic coating layer at an outer side of the hard roller core. The elastic coating layer includes an elastic matrix material and fillers imbedded in the matrix material, and at least a portion of the fillers include metallic fillers. The process includes combining at least one metallic filler into an elastic matrix material and applying the combined elastic matrix material and at least one metallic filler onto an outer side of the hard roller core to form an elastic coating layer.

Owner:VOITH PATENT GMBH

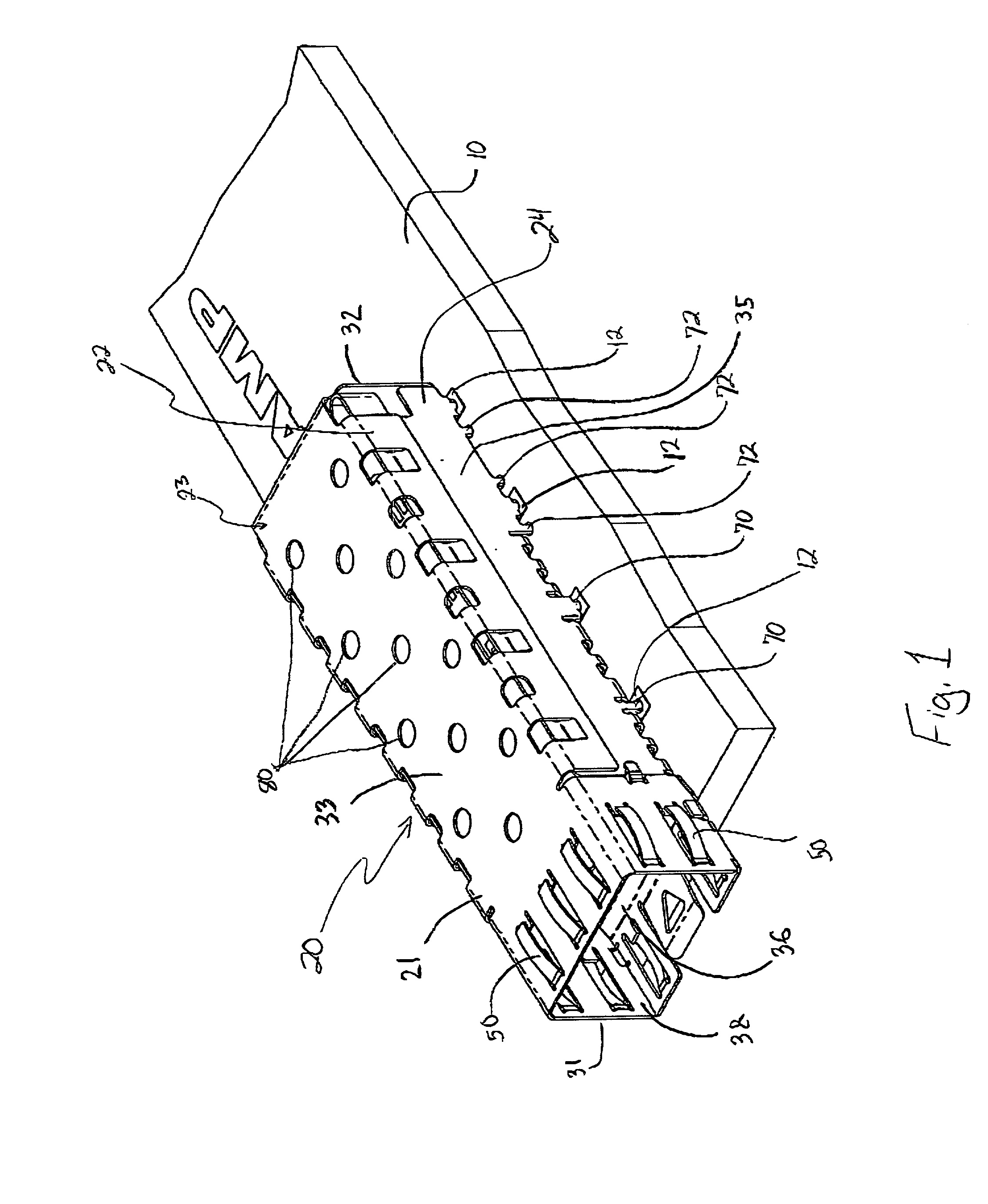

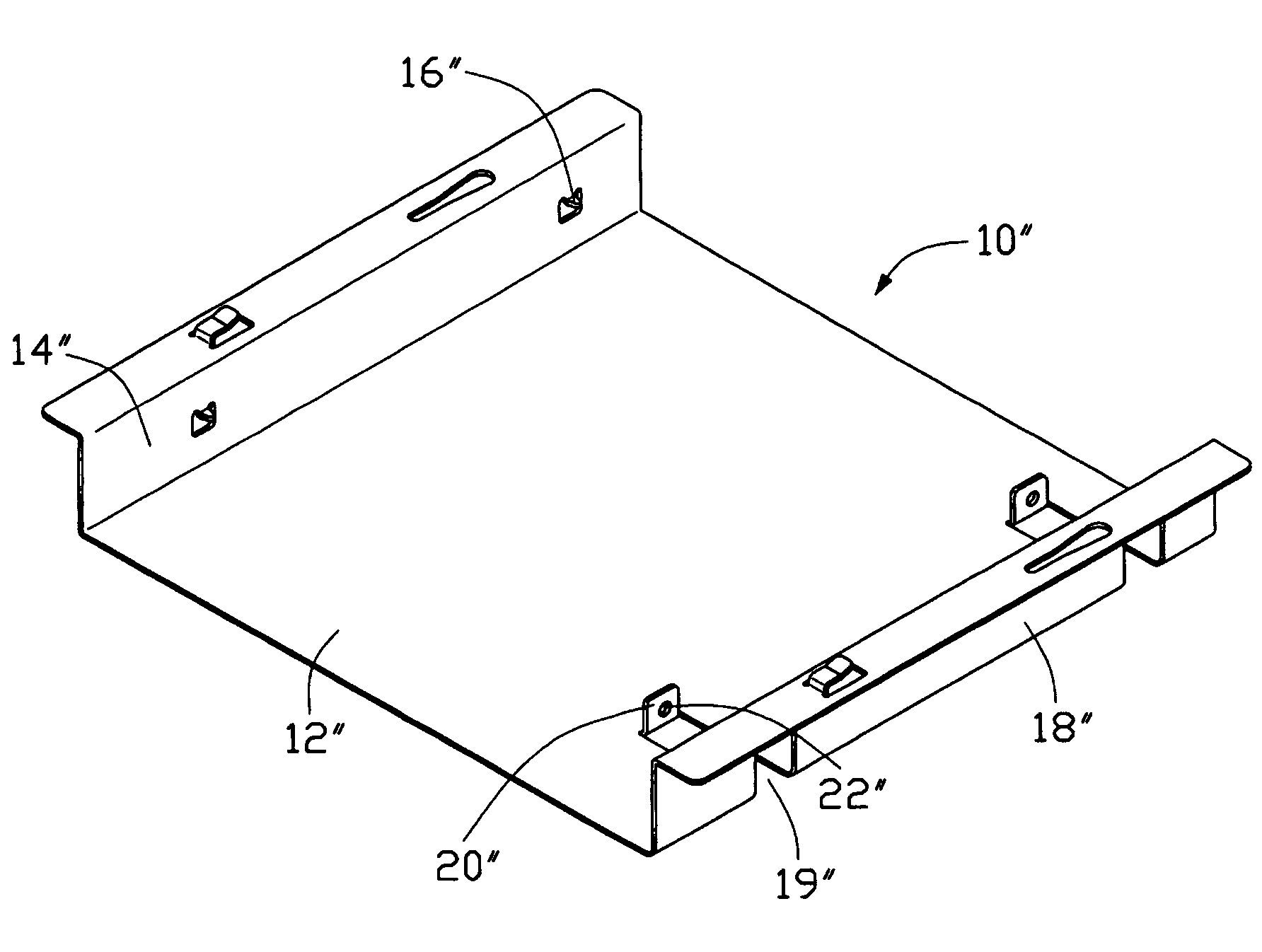

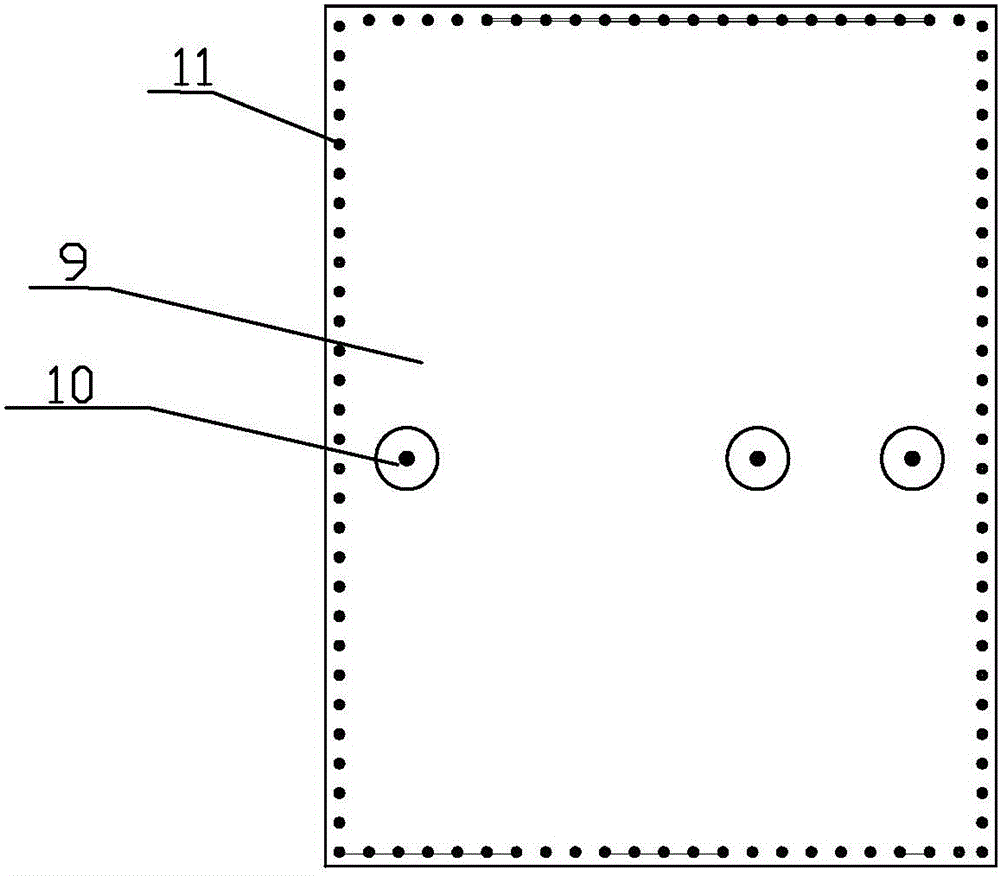

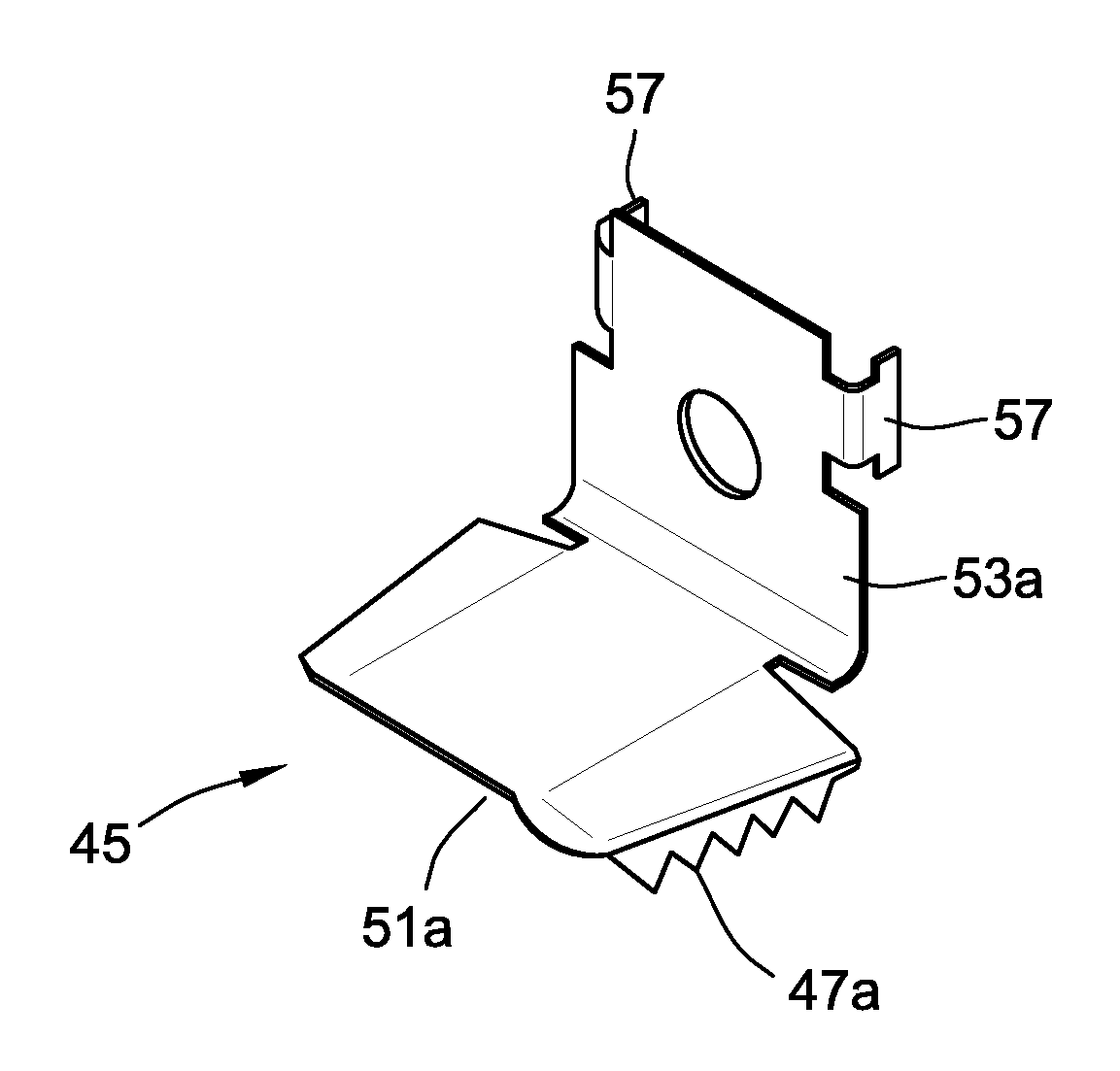

Mounting bracket for disk drive

InactiveUS7017875B2Conveniently receiveGood groundingCarrier constructional parts dispositionDigital data processing detailsEngineeringMechanical engineering

Owner:HON HAI PRECISION IND CO LTD

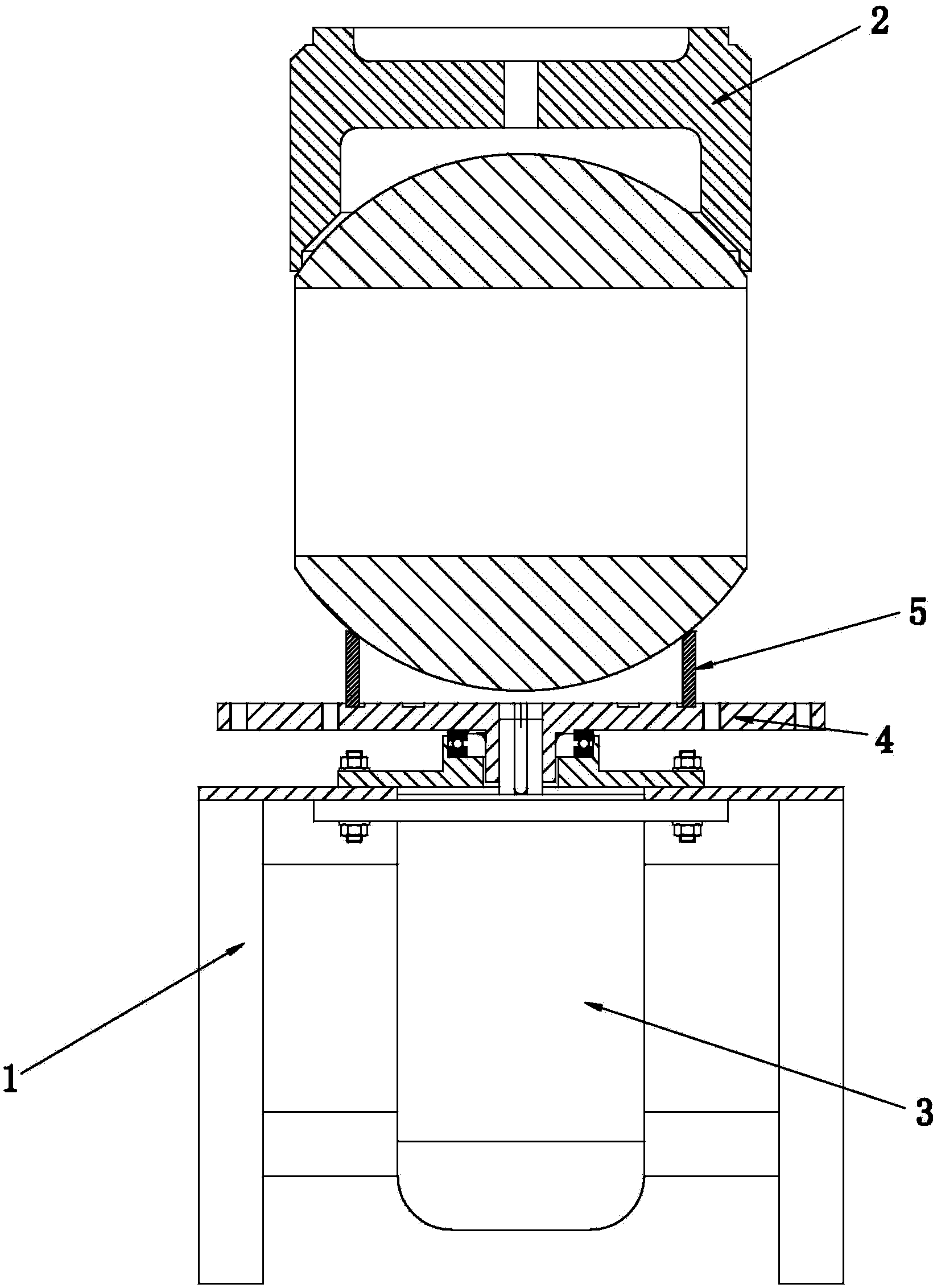

Grinding process of sealing surface of ball valve

The invention relates to a grinding process of a sealing surface of a ball valve. The grinding process comprises the steps of rough grinding, fine grinding, ultrafine grinding, and grinding and cleaning of a valve seat and a sphere, wherein a diamond paste and an engine oil mixture are adopted in the rough grinding, the particle size phi of the selected diamond paste ranges from 40mu m to 10mu m, so that the scratch removal and sphere rounding can be realized; in fine grinding, a diamond paste, kerosene and a microcrystal graphite mixture are adopted, the particle size phi of the selected diamond paste ranges from 7mu m to 5mu m, so that the primary mirror surface effect can be achieved; in the ultrafine grinding, a diamond paste and a microcrystal graphite and kerosene mixture are adopted, the particle size phi of the selected diamond paste is smaller than 5mu m, the rotating speed of the sphere is controlled to be below 5rpm to achieve the mirror surface effect, and finally the kerosene is coated on the sphere and grinding cleaning are performed to achieve a better mirror surface effect. The sphere ground and the sealing surface of the valve seat can achieve the mirror surface effect, the surface roughness can achieve Ra0.02-0.005, the operation torque is low, the service life is long, the valve seat can be adsorbed on the spherical surface of the sphere, and no leakage exists under the trial pressure of low-pressure nitrogen being 0.6Mpa.

Owner:WENZHOU ARTECH MACHINERY TECH CO LTD

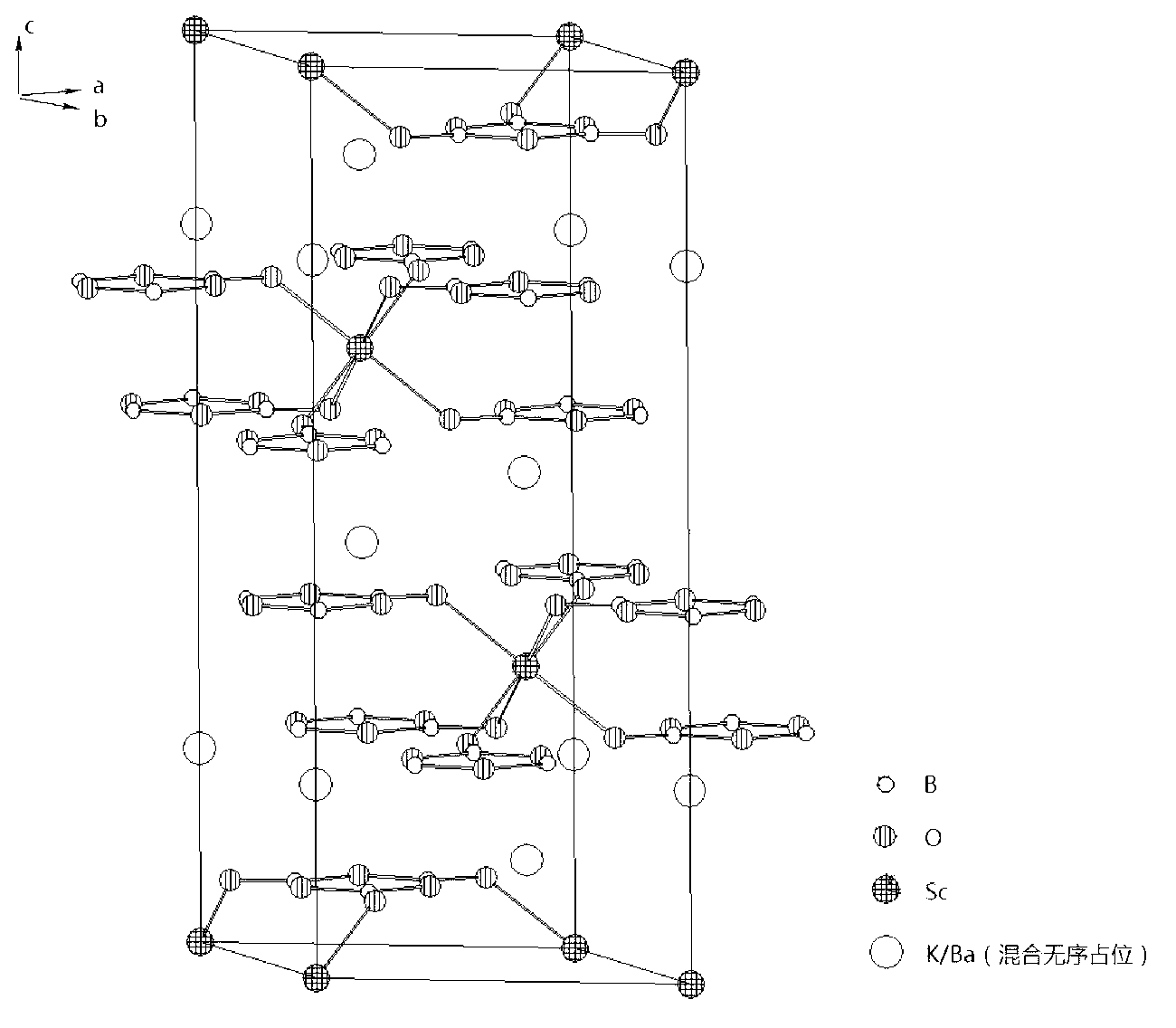

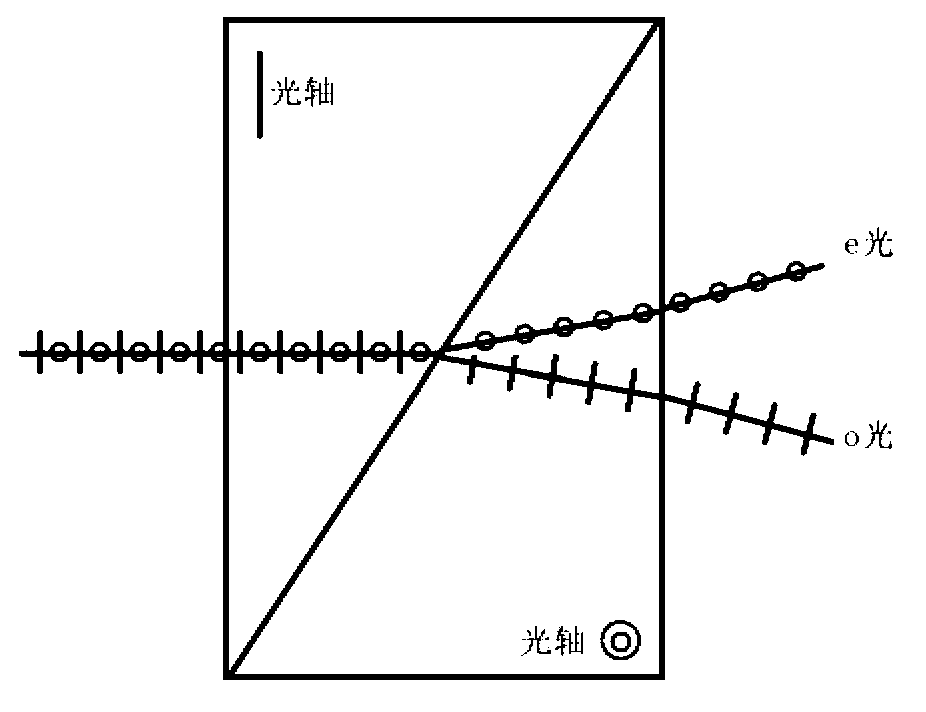

Borate birefringent crystal for ultraviolet band as well as growing method and purpose of same

InactiveCN103074684ACut wellGood groundingPolycrystalline material growthBy pulling from meltSpace groupFlux growth

The invention relates to a borate birefringent crystal for an ultraviolet band. The chemical formula of the borate birefringent crystal is KBaSc(B3O6)2 and belongs to a trigonal system; an atom K and an atom Ba in a crystal structure are in disordered mixed occupation; a space group is R-3 and a cell parameter Z is 3; the transmission range is 184-3000 nm; a calculated value n0 of the refractive index at gamma of 589 nm is 1.6168, ne is 1.5079 and delta n is 0.1089; the crystal grows by using a self-melting and spontaneous crystallization method or a flux growth method; the crystal is easy to grow, cut, grind, polish and preserve, is stable in the air, is uneasy for deliquescence and is insoluble in water; the crystal can be used for making polarization beam splitters such as Glan prisms, Wollaston prisms, Rochon prisms or beam splitting polarizers; and the crystal is importantly applied to the optical and communication fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

K-wave band microstrip patch antenna array

InactiveCN105811113AImprove anti-interference abilityHigh sensitivityAntenna arraysRadiating elements structural formsWave bandMicrostrip patch antenna array

The invention provides a K-band microstrip patch antenna array, which belongs to the field of antennas. The dielectric board is provided with three columns of antennas parallel to each other and with the same structure, which are respectively transmitting antennas, first receiving antennas and second receiving antennas; the antennas of each column There are several microstrip antenna units, several 1 / 4 wavelength microstrip feeders, power dividers and feed ports; there are several impedance converters, several microstrip transmission lines and several feeder bending lines in the power divider ; The bottom of the dielectric plate is provided with a metal grounding plate; the invention designs a K-band microstrip array antenna with stronger anti-interference ability, so that the detection of moving objects is more accurate.

Owner:GUILIN UNIV OF ELECTRONIC TECH

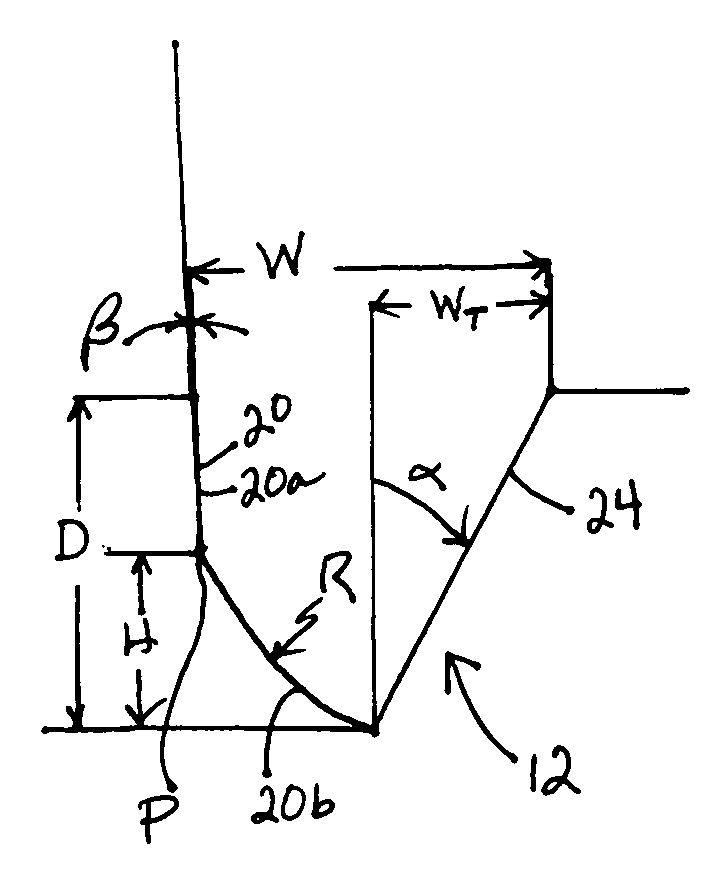

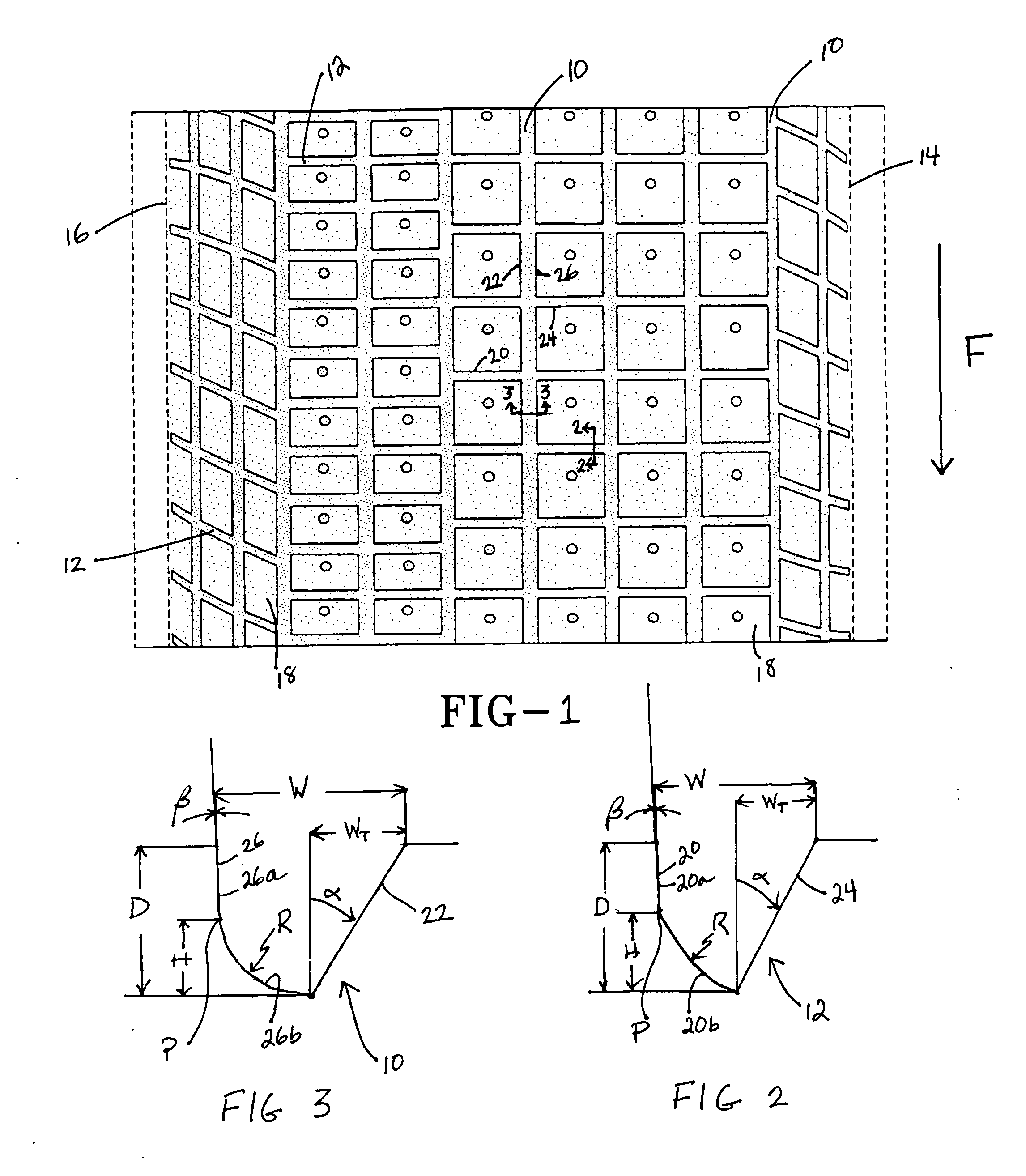

Tire tread

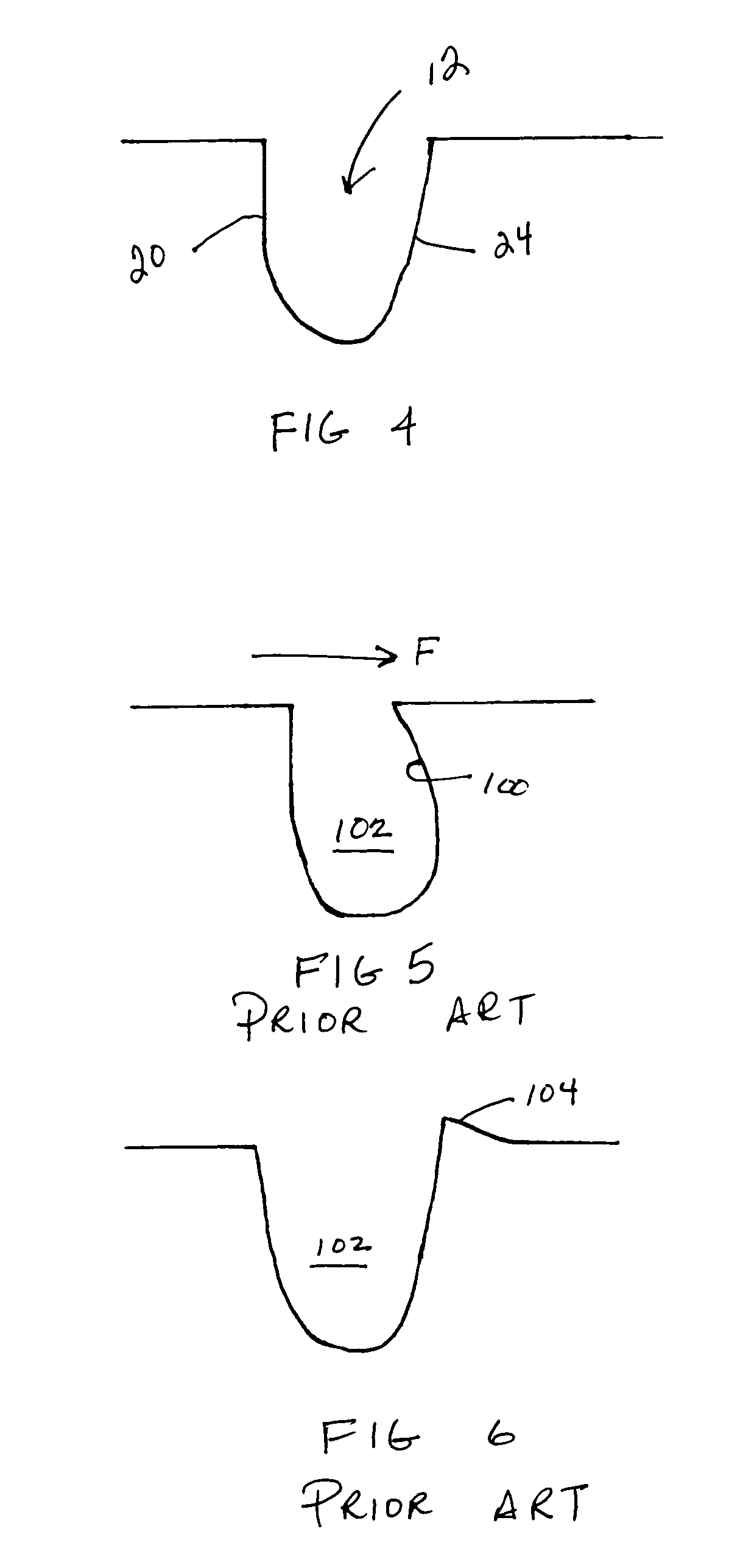

ActiveUS20060191616A1Improved uniform wear of treadGood groundingTyre tread bands/patternsNon-skid devicesLeading edgeTrailing edge

A pneumatic tire for dirt track racing comprising lateral and circumferential grooves forming blocks on the tread surface. The blocks have leading and trailing edge walls. The trailing edge walls of the blocks are buttressed by inclining the walls at an angle of 20°-60° relative to a line perpendicular to a tangent to the tread, and the edge wall extends into the groove by a distance of approximately one-half the tread width. The leading edge walls of the blocks have a radially outer portion inclined at about zero degrees and a radially inner portion have a radius of curvature of infinity or less, wherein the intersection point between the two portions is at about one-half the groove depth.

Owner:THE GOODYEAR TIRE & RUBBER CO

Water curtain type device for sanitizing and purifying air

InactiveCN1872396ALong-term useMaintenance freeLighting and heating apparatusDispersed particle separationHigh pressureOxygen

A water curtain apparatus for disinfecting and cleaning air in order to remove microbes, virus and dust from indoor air is composed of the air inlet and outlet chambers with axial-flow blower, and a disinfecting-cleaning chamber consisting of upper and lower water tanks, a netted grate for generating water curtain and connected to the negative electrode of a HF high-voltage power supply and a Mo wire mesh connected with the positive electrode of said power supply.

Owner:李长良

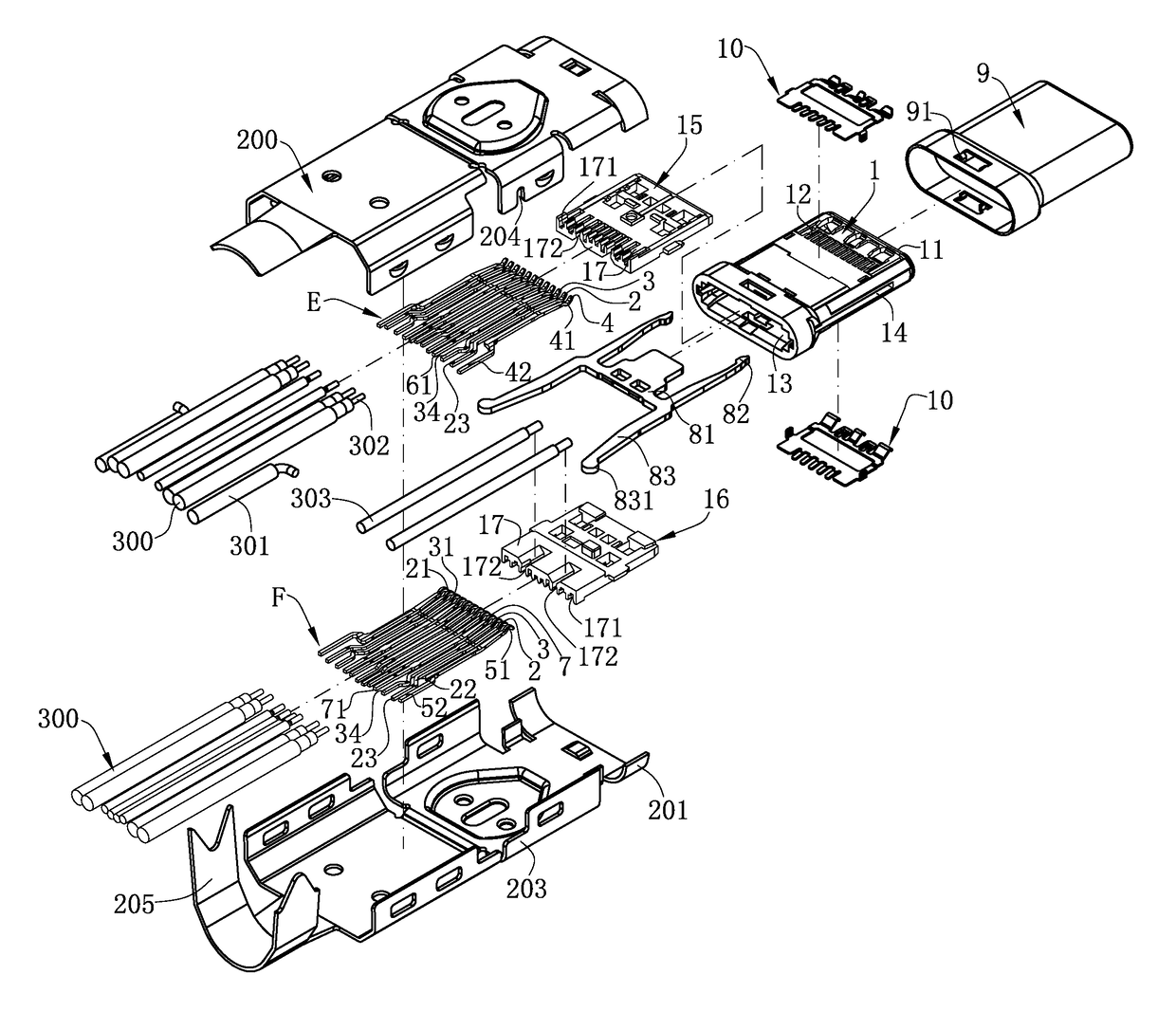

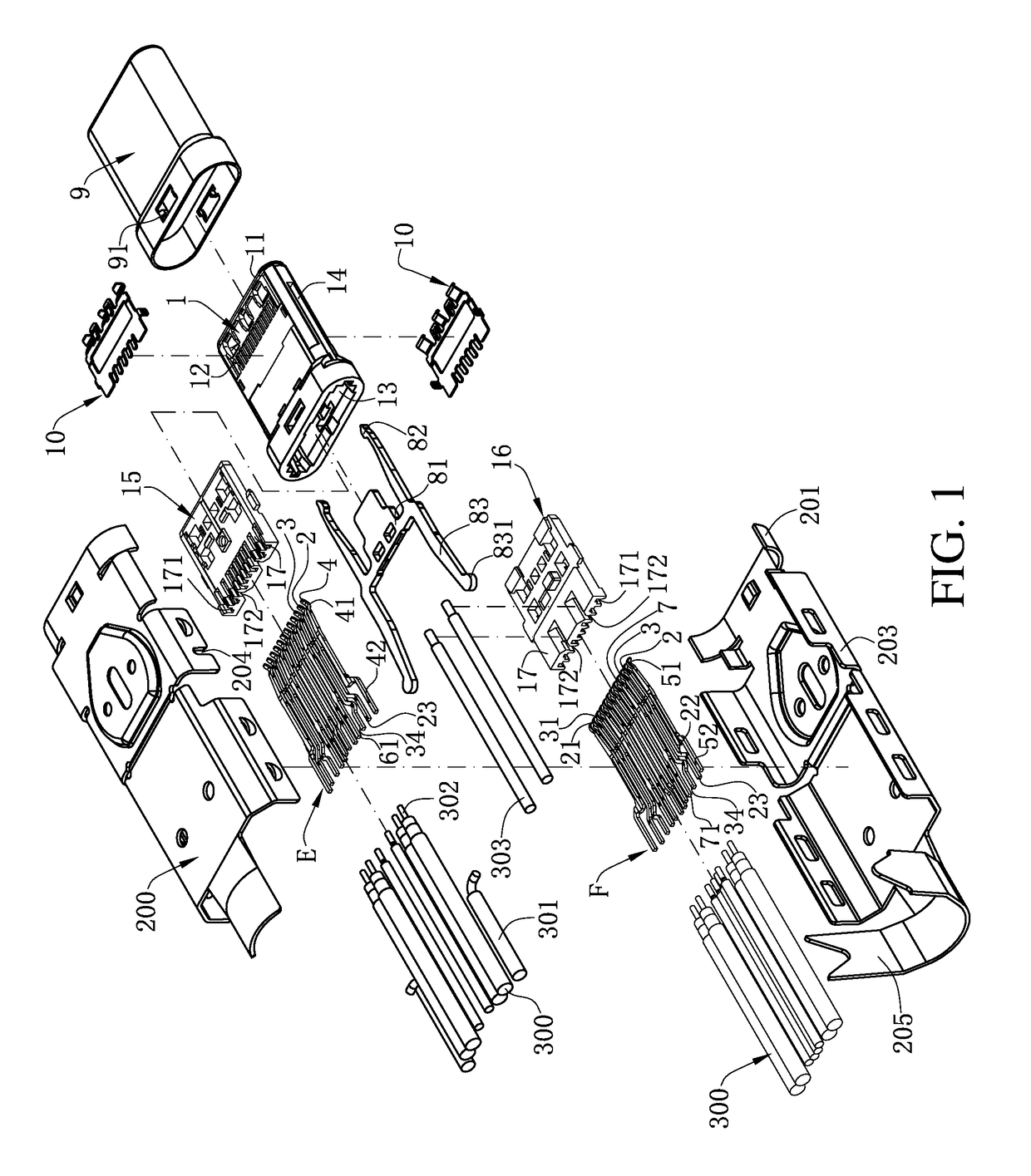

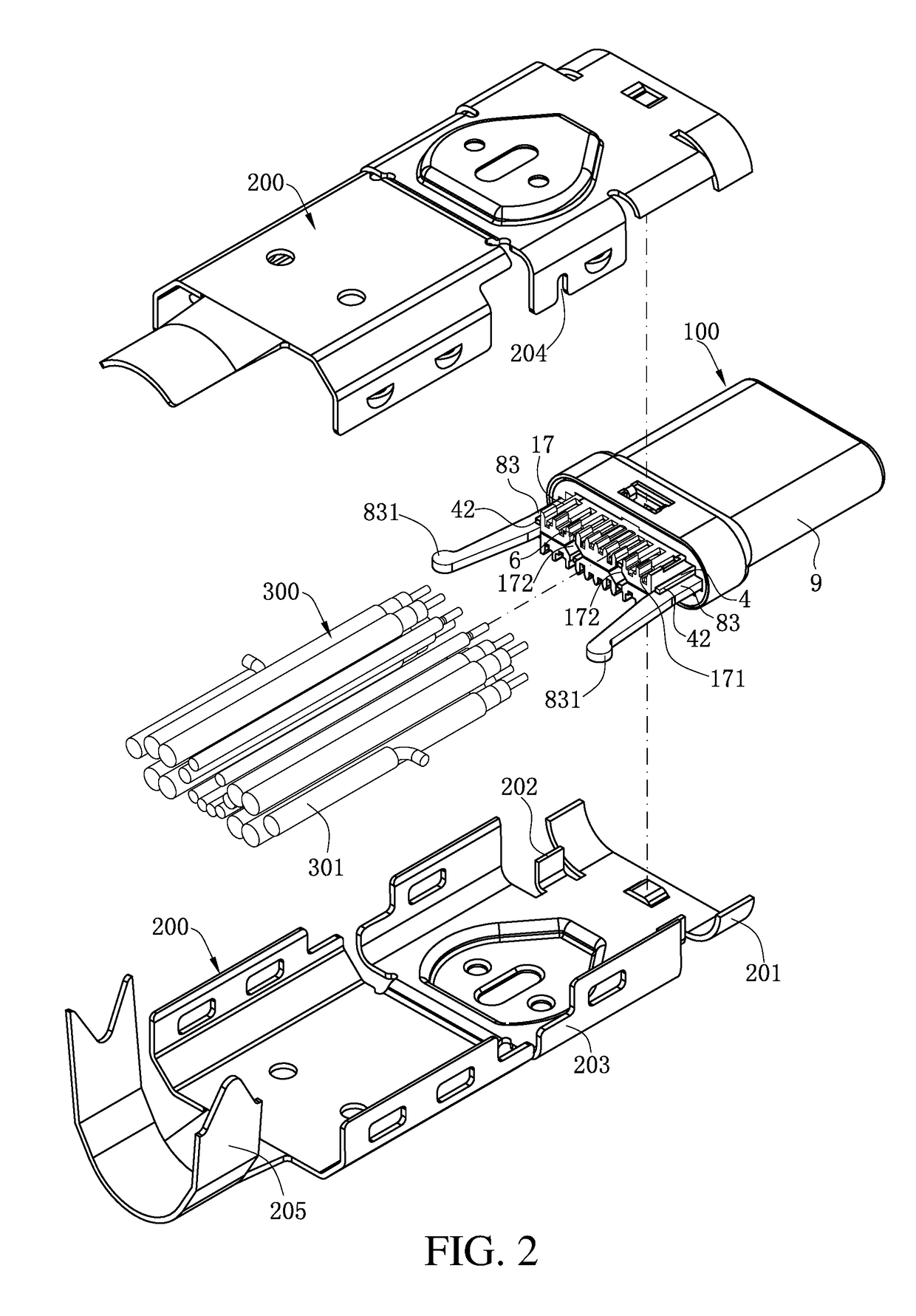

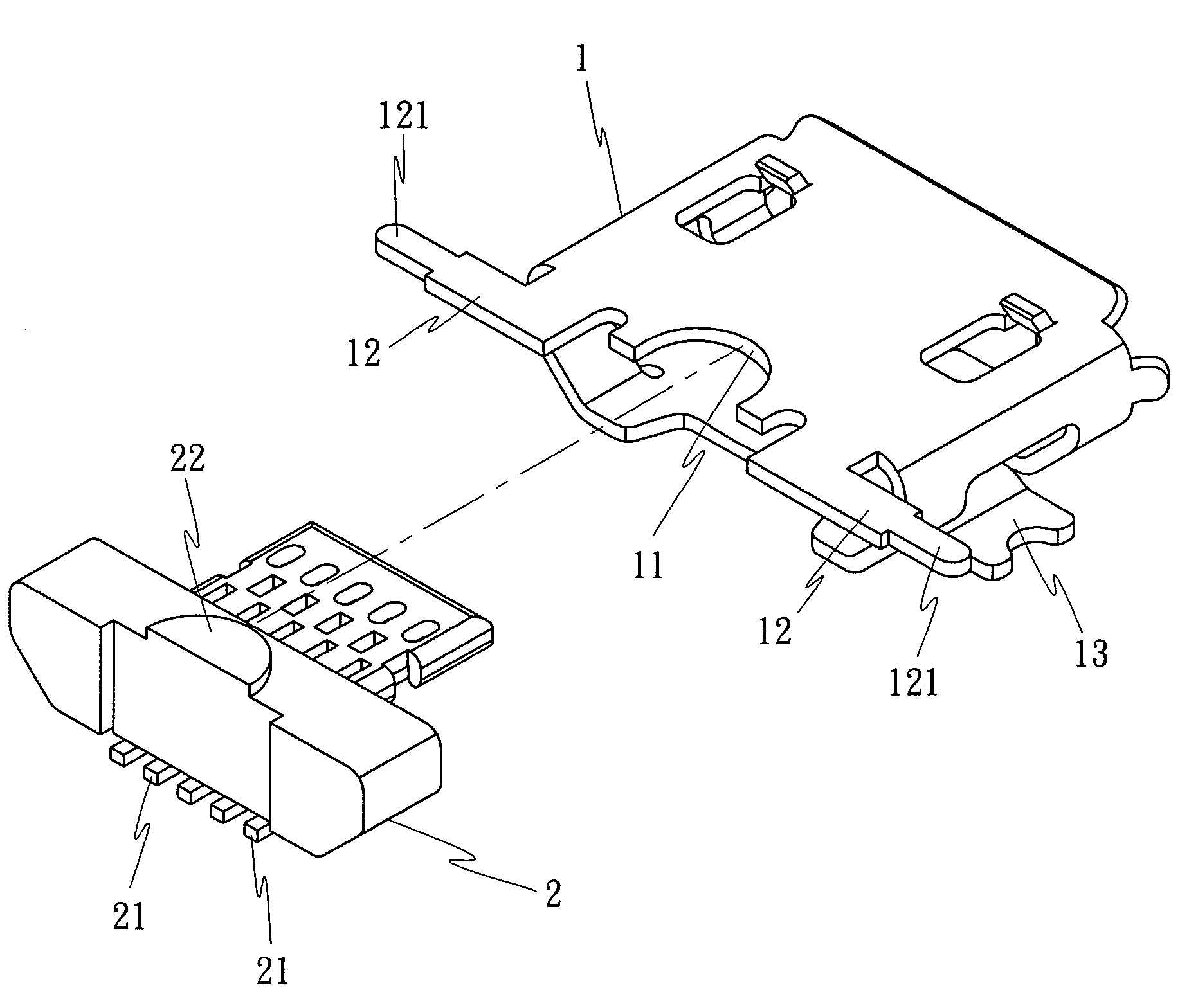

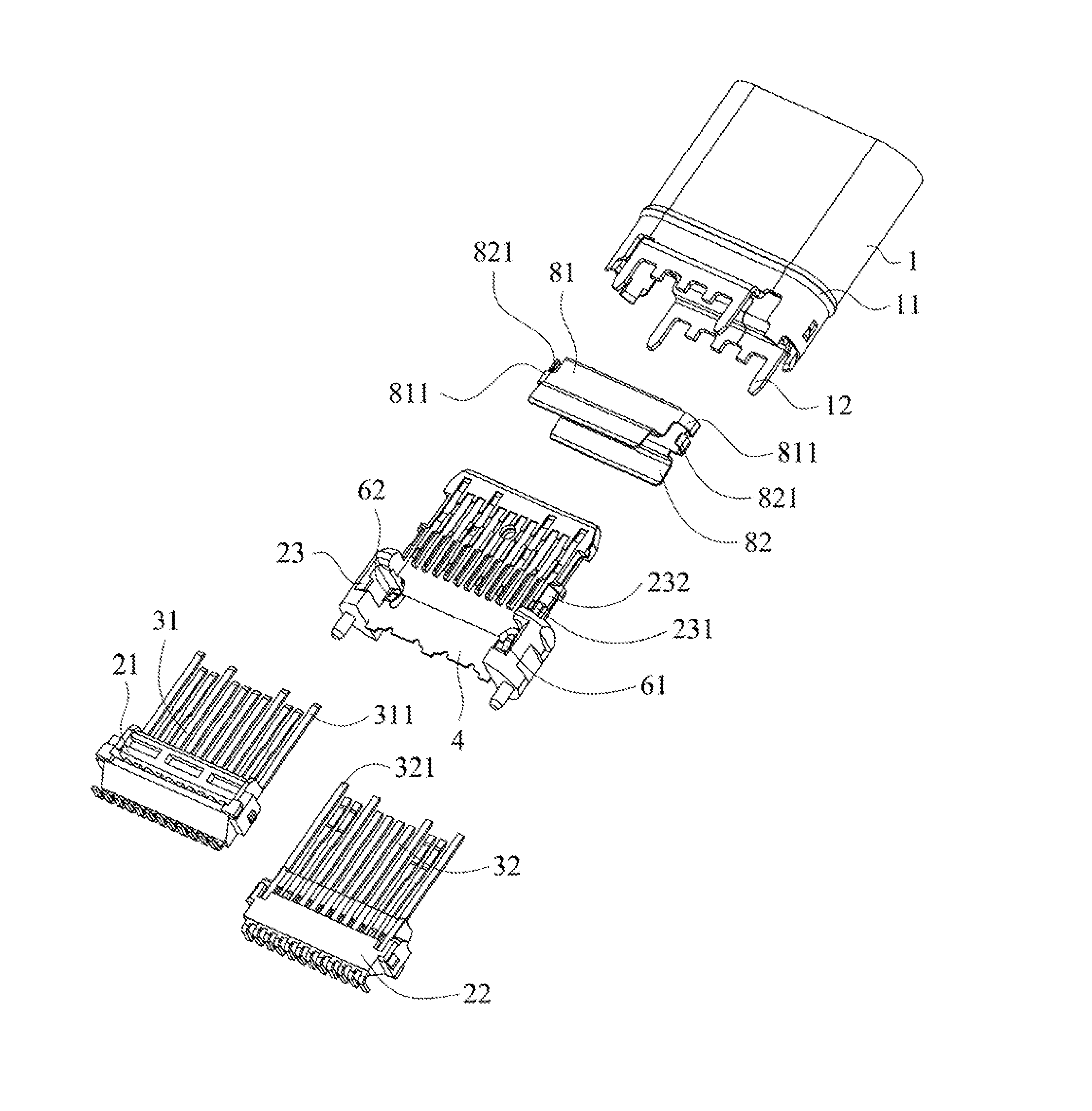

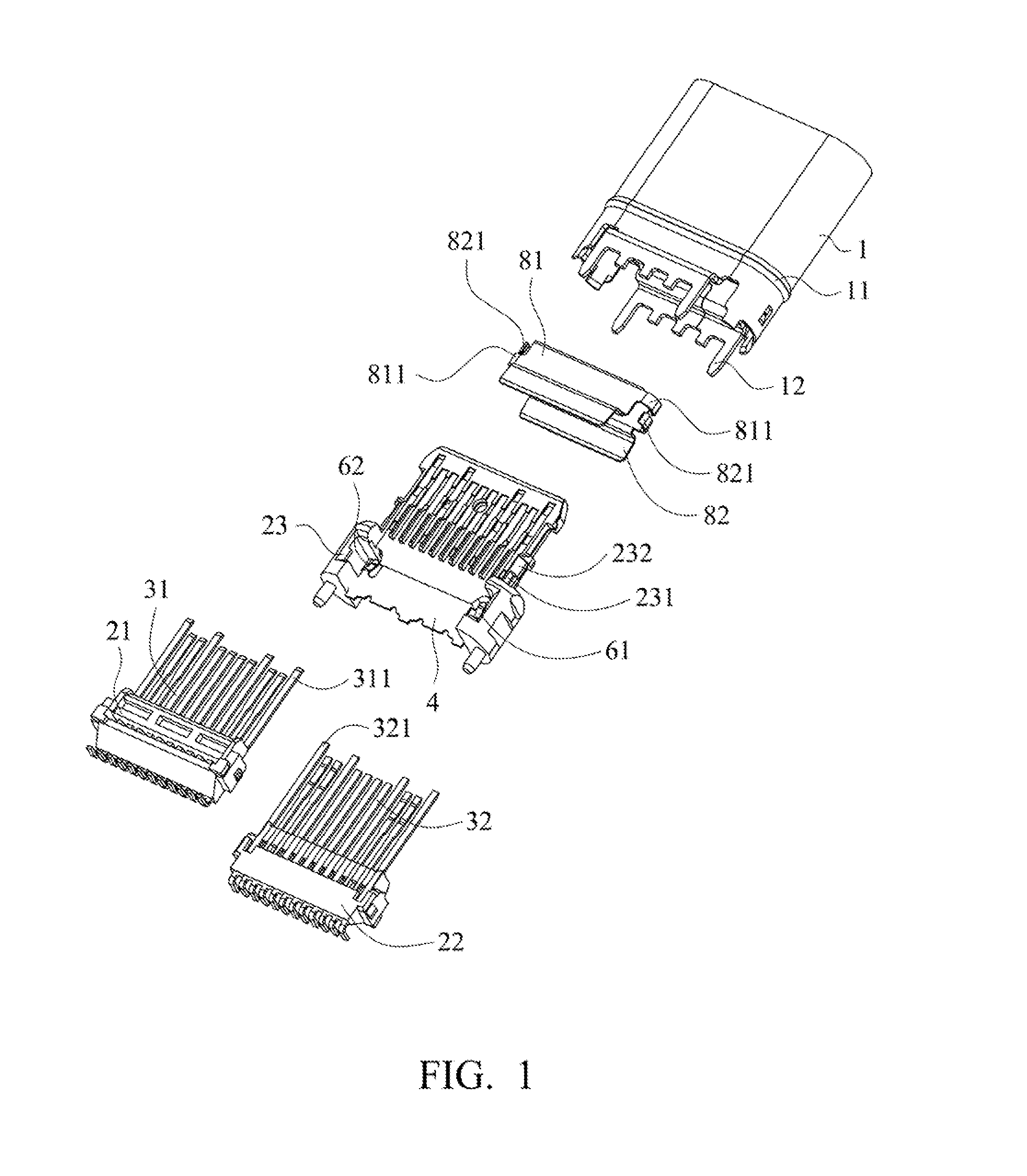

Cable connector assembly

ActiveUS10096936B2Easy to produceGood groundingSoldered/welded conductive connectionsCoupling device detailsEngineeringElectric contact

A cable connector assembly includes an electric connector having an insulating body, a first terminal group, a second terminal group, a latch member, and a first metal shell; and a second metal shell partially wrapping the periphery of a first metal shell. The first and second terminal groups have first and second ground terminals. The latch member is arranged in the insulating body and located between the first and second terminal groups. The latch member has a backward elastic arm partially protruding out of the insulating body. Both the first and second ground terminals are in electric contact with the latch member. The second metal shell has a cable-clamping portion for fixing a cable. The elastic arm elastically urges against the second metal shell.

Owner:LOTES

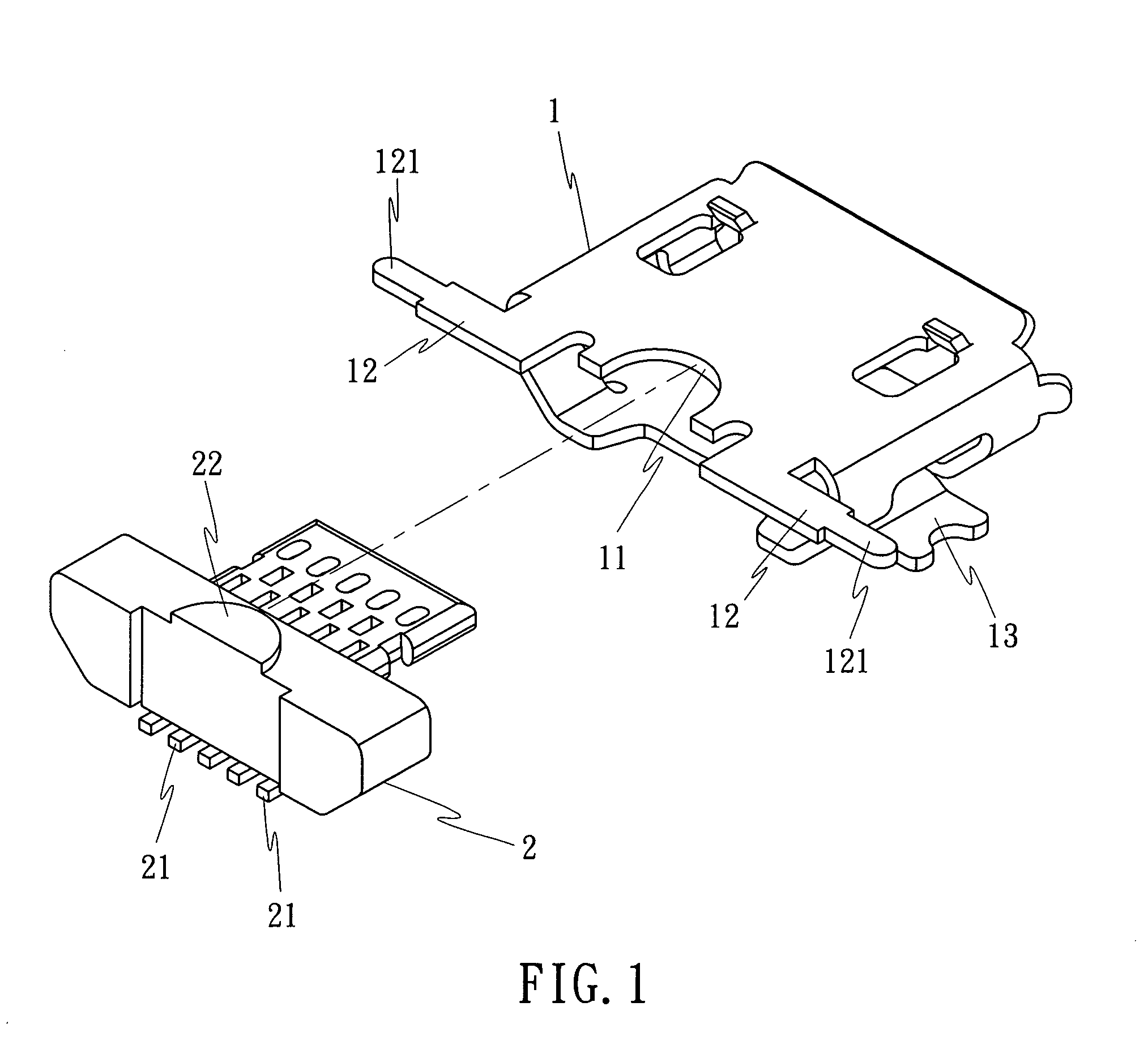

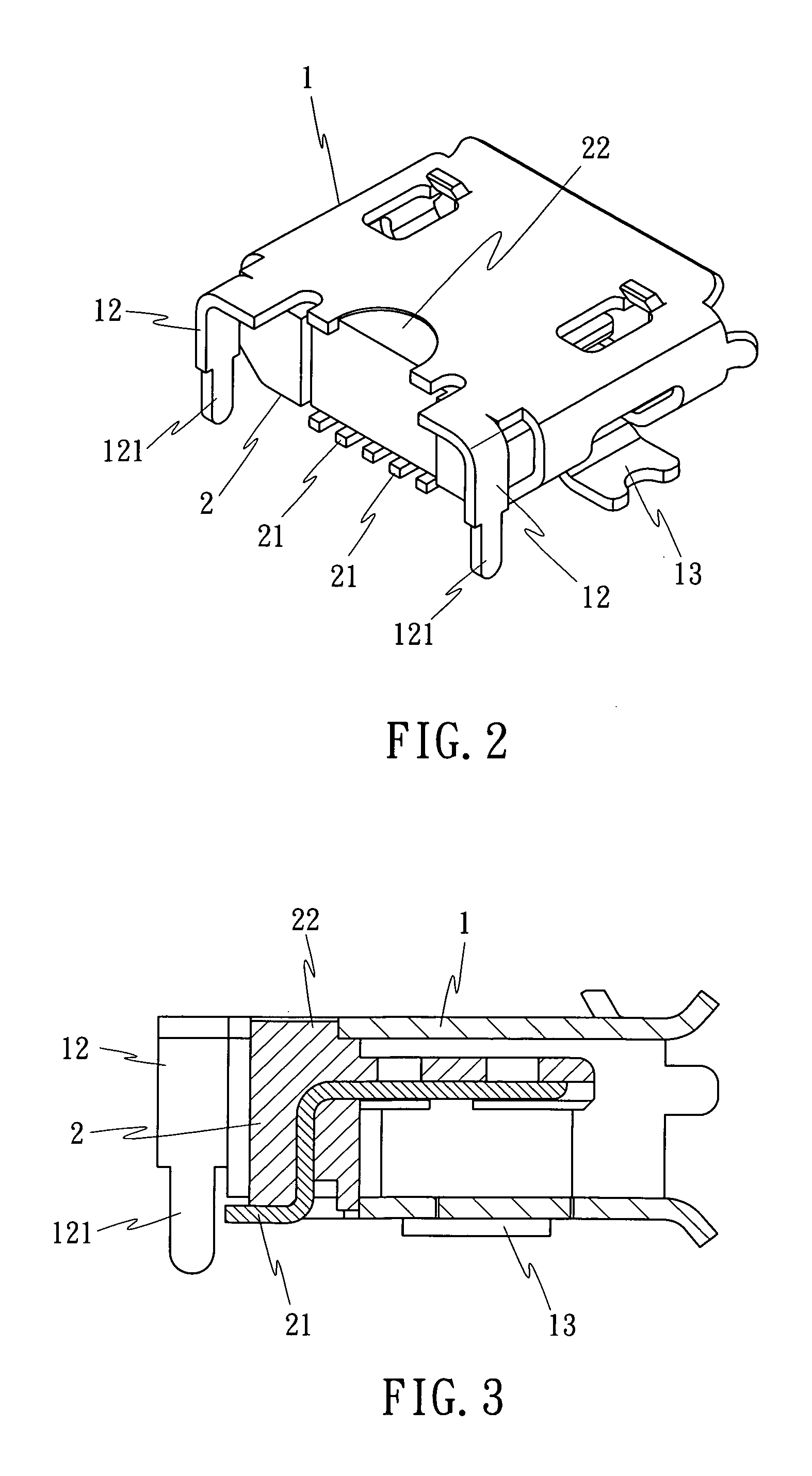

Micro USB socket connector

InactiveUS20090098746A1Good groundingRelieving strain on wire connectionContact member cases/bases manufactureEngineeringUSB

A USB socket connector includes a plastic core member, which has metal terminals embedded therein and a constraint member, for example, a raised portion, and a metal casing, which houses the plastic core member and has a constraint device, for example, notch that receives the constraint device of the plastic core member to hold the plastic core member in position upon insertion of the plastic core member into the casing, and two rear extension arms that are bent into shape and stopped against the back side of the plastic core member to hold down the plastic core member firmly in place after insertion of the plastic core member into the metal casing.

Owner:CHANT SINCERE

Female connector for high-speed transmission with grounding

ActiveUS9444199B2Good groundingImprove shielding effectTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectrical and Electronics engineeringHigh frequency

Provided is a female connector for high-speed transmission with grounding, including a case, an insulating body, and an upper terminal group and a lower terminal group disposed in the insulating body. The insulating body is disposed in the case. A shielding sheet is disposed in the insulating body. A contact part directly processed from the shielding sheet is disposed on a portion of the shielding sheet, wherein the portion corresponds to the ground terminals of the upper terminal group and the lower terminal group. The contact part is physically and electrically connected to the ground terminals. The upper terminal group and / or the lower terminal group at least includes a high frequency terminal pair, wherein the thickness of a contact portion of the high frequency terminal pair is less than the thickness of a portion adjacent to the contact portion.

Owner:BIZCONN INT CORP (SHEN ZHEN)

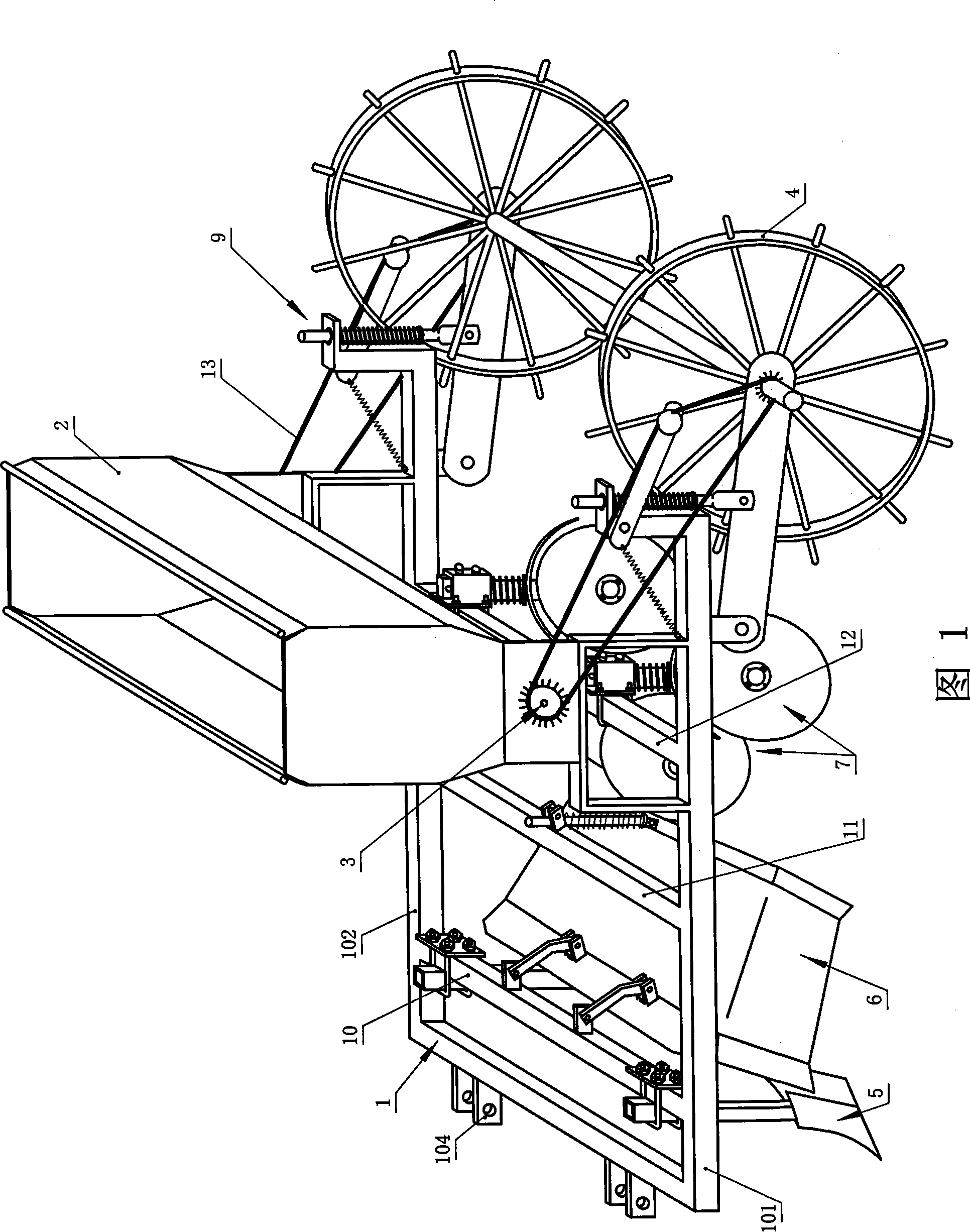

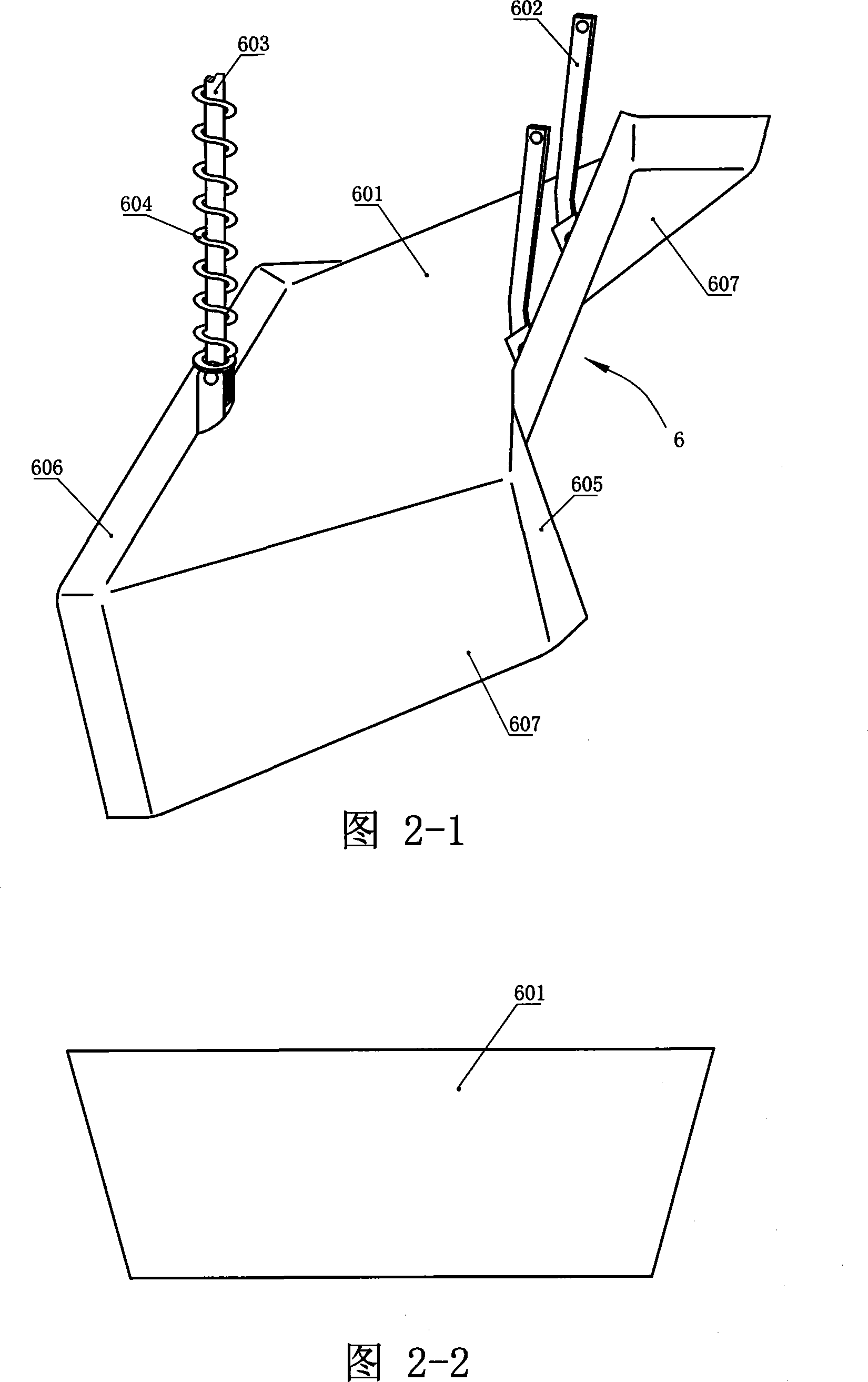

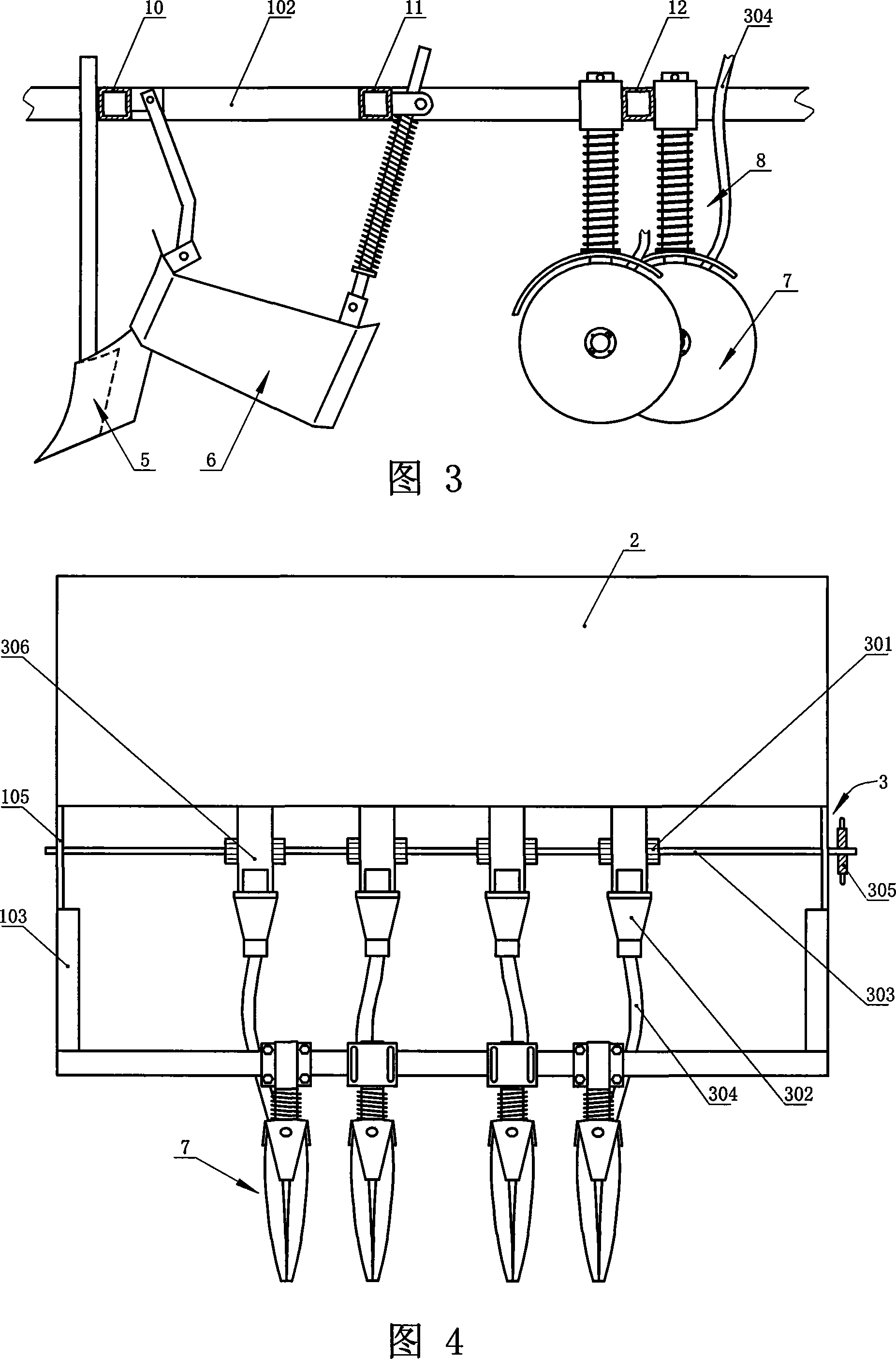

Wheat ridge-forming board and wheat ridge-forming seed-sowing machine

InactiveCN101133691AEasy to keep spacingEffective absorptionSpadesPlantingSeederAgricultural engineering

The present invention relates to a wheat ridge-forming plate and wheat ridge-forming-sowing machine. Said ridge-forming plate includes a front-face plate and two side-wing plates which are respectively connected with two sides of said front-face plate, two ends of front-face plate and two side-wing plates are respectively equipped with an upwards-flanged edge and a downwards-flanged edge. Said wheat ridge-forming-sowing machine includes the following several portions: wheat ridge-forming plate, machine frame, earthing-up plough, ridge roller, distributor and sowing wheel.

Owner:河南省农业科学院小麦研究中心

Communication module package assembly

InactiveUS20080291639A1Improve cooling effectImprove structural strengthMagnetic/electric field screeningPrinted circuit aspectsEngineeringElectrical and Electronics engineering

A communication module package assembly includes a main board having grounding pads, a communication module package electrically bonded on the main board and having notches corresponding in location to the grounding pads respectively, and a metal cover covering the communication module package and having mounting legs passing through the notches and electrically connected to the grounding pads respectively. The communication module package is of stacked structure including a carrier with an opening in which a thermal conductive layer in contact with a substrate stacked on the carrier is filled. The communication module package further includes a chip electrically bonded to the substrate, received in the opening and encapsulated by the thermal conductive layer, and a metal layer sandwiched between and in contact with the thermal conductive layer and the main board.

Owner:UNIVERSAL SCI IND CO LTD

Wireless communication nodule assembly

InactiveUS20080291654A1Good groundingMinimizing electromagnetic interferenceLocalised screeningPrinted circuit aspectsEngineeringWireless

A wireless communication module assembly includes a main board having a top surface on which a plurality of grounding pads are provided, a circuit board unit, and a metal cap. The circuit board unit has a bottom surface electrically mounted on the top surface of the main board, a top surface with a plurality of grounding pads, and a plurality of notches corresponding to the grounding pads of the main board. The metal cap covers the circuit board unit and has first mounting legs respectively and electrically connected with the grounding pads of the circuit board unit, and second mounting legs respectively passing through the notches of the circuit board unit and electrically connected with the grounding pads of the main board.

Owner:UNIVERSAL SCI IND CO LTD

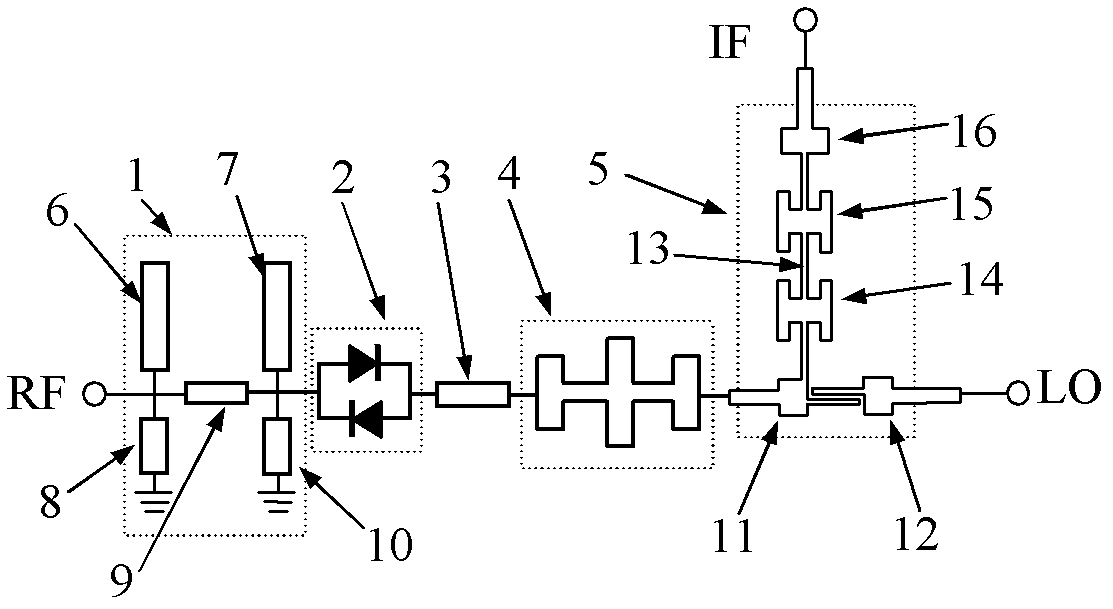

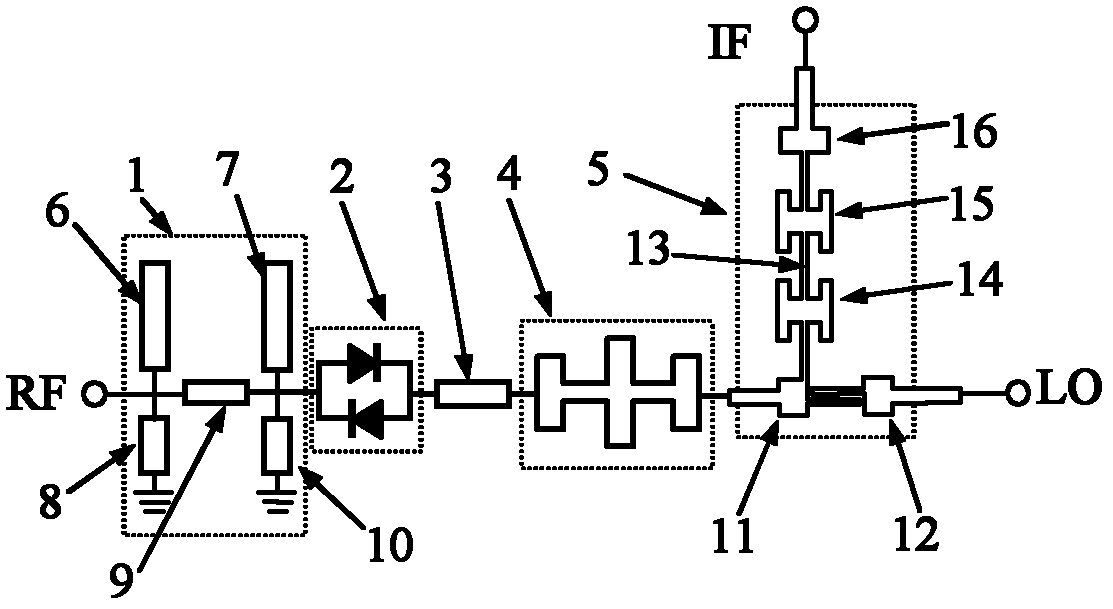

W-band even-order sub-harmonic mixer

InactiveCN102611390ARaise the cutoff frequencyImprove loss performanceMultiple-port networksModulation transference by diodesLocal oscillator signalIntermediate frequency

The invention discloses a W-band even-order sub-harmonic mixer, which comprises a radio-frequency broadband band-pass filter, an anti-parallel diode pair, a phase adjusting transmission line, a local oscillator low-pass filter and a duplexer, wherein one end of the local oscillator low-pass filter is connected with a common port of the duplexer while the other end of the local oscillator low-pass filter is connected with the phase adjusting transmission line, and the anti-parallel diode pair is bridged between the radio-frequency broadband band-pass filter and the phase adjusting transmission line. The W-band even-order sub-harmonic mixer realizes mutual isolation of radio-frequency signals, local oscillator signals and intermediate frequency signals by means of the radio-frequency broadband band-pass filter, the local oscillator low-pass filter and the duplexer, and the mixer can realize wide operation bandwidth as the radio-frequency broadband band-pass filter, the local oscillator low-pass filter and the duplexer have wide bandwidth.

Owner:SOUTHEAST UNIV

Dual Material Ground Clip For A Busway Plug In Unit

ActiveUS20140134855A1Good ground contactInhibit wearSwitchgear arrangementsTotally enclosed bus-bar installationsMaterial DesignEngineering

A ground clip for a PIU of a busway system has a two part assembly made with two different materials, a first hard material designed to remove dielectric coating on the busway section and a second highly conductive material to establish necessary electrical contact, cooperating together as the PIU is installed on the busway case to establish a reliable ground automatically and without tools.

Owner:SCHNEIDER ELECTRIC USA INC

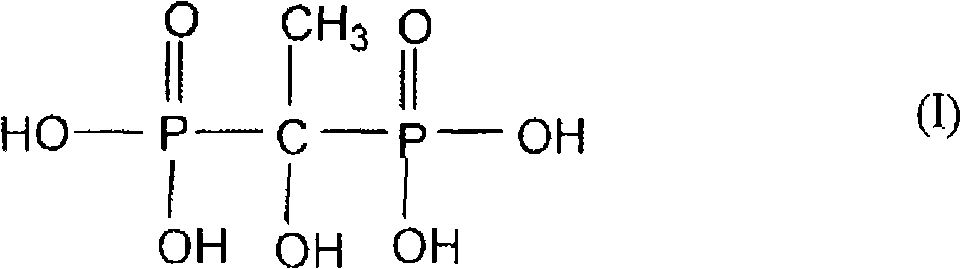

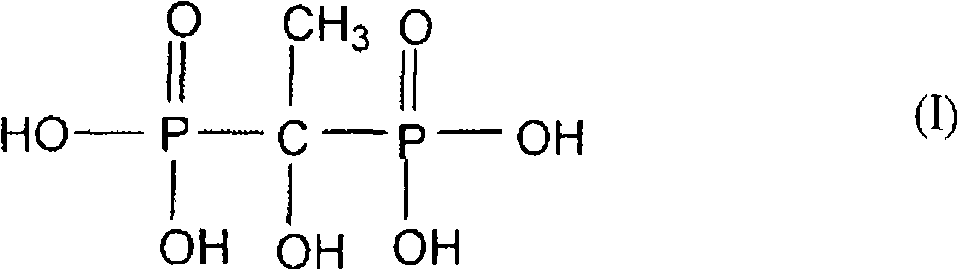

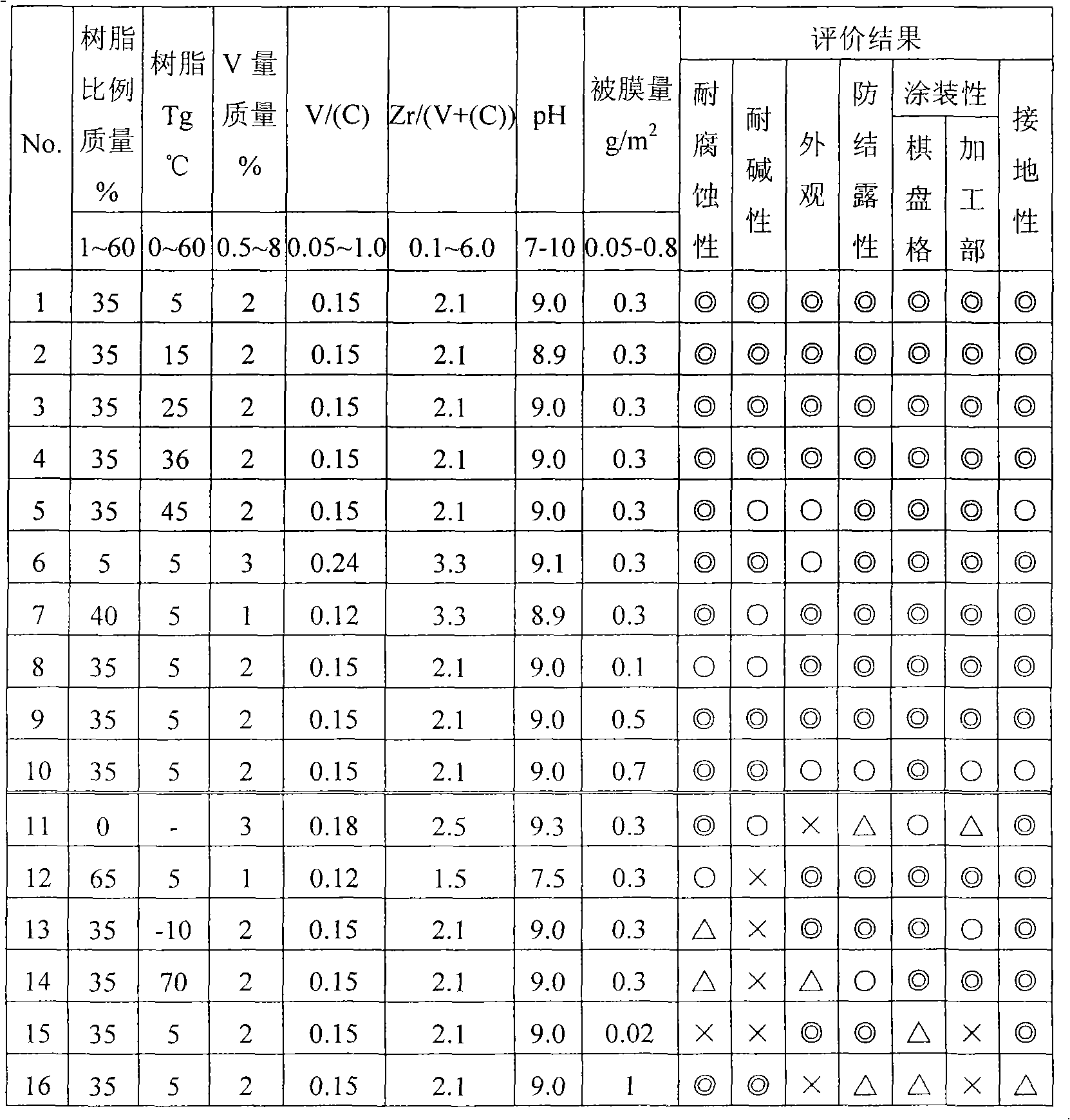

Aqueous fluid for surface treatment of zinc-plated steel sheets and zinc-plated steel sheets

InactiveCN101688309AImprove corrosion resistanceGood lookingAnti-corrosive paintsMetallic material coating processesSolid componentWater dispersible

The invention provides an aqueous fluid for surface treatment of zinc-plated steel sheets and a filmed zinc-plated steel sheets which are formed by the fluid. The aqueous fluid for treatment of zinc-plated steel sheets which comprises (A) ammonium zirconium carbonate, (B) a vanadium (IV) compound, (C) an organophosphonic acid represented by the general formula (I) or an ammonium salt thereof, (D)an anionic water-dispersible acrylic resin having a glass transition temperature (Tg) of 0 to 60 DEG C as obtained by converting the absolute temperature (K) calculated by the numerical formula (1) toCelsius temperature (DEG C), and water and which has a content of (D) of 1 to 60% by mass based on the whole solid matter, a content of (B) of 0.5 to 8% by mass in terms of V based on the whole solidmatter, a V / (C) mass ratio of 0.05 to 1.0, a Zr / (V+(C)) of 0.1 to 6.0% by mass (as calculated by converting (A) to Zr), and a pH of 7 to 10; and zinc-plated steel sheets bearing films resulting fromthe fluid on the surface. The steel sheets of the invention are excellent in corrosion resistance, alkali resistance, appearance, condensed dew resistance, coatability and groundability. The fluid canbe used in treatment equipment similar to that of temporary rust preventive chromate treatment in the manufacturing line for zinc-plated steel sheets.

Owner:NIHON PARKERIZING

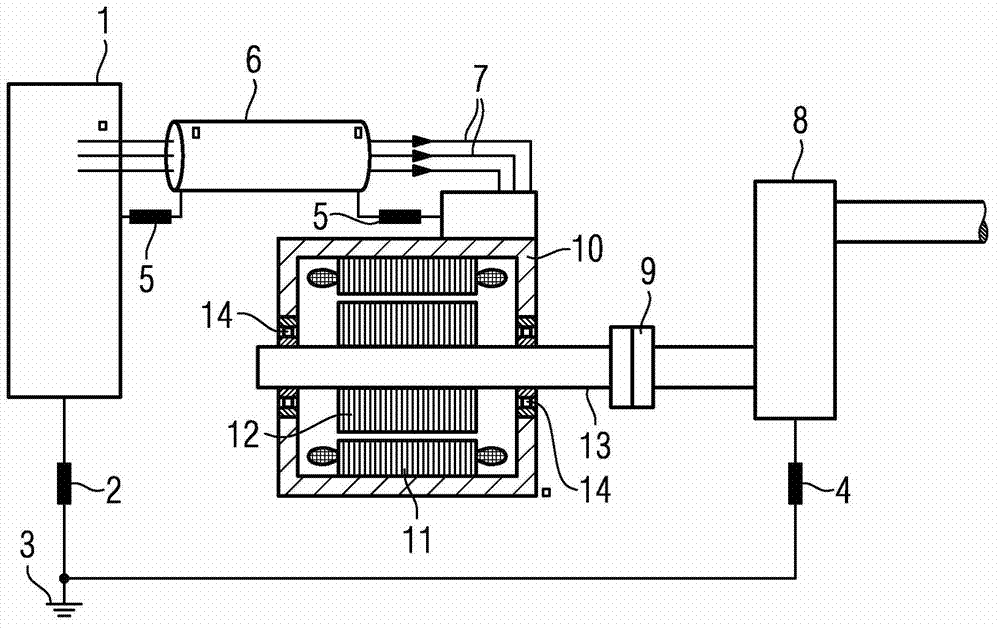

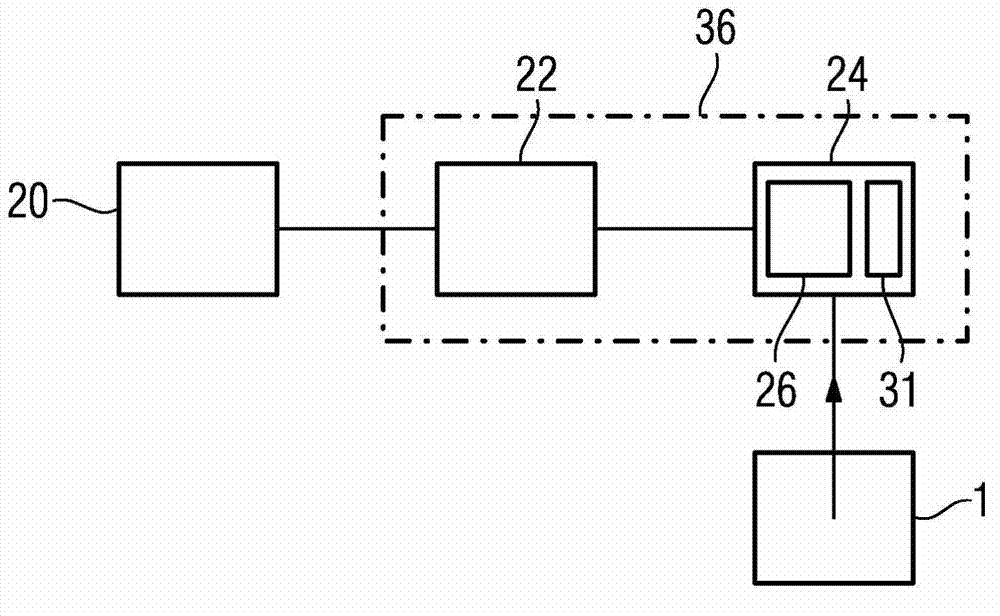

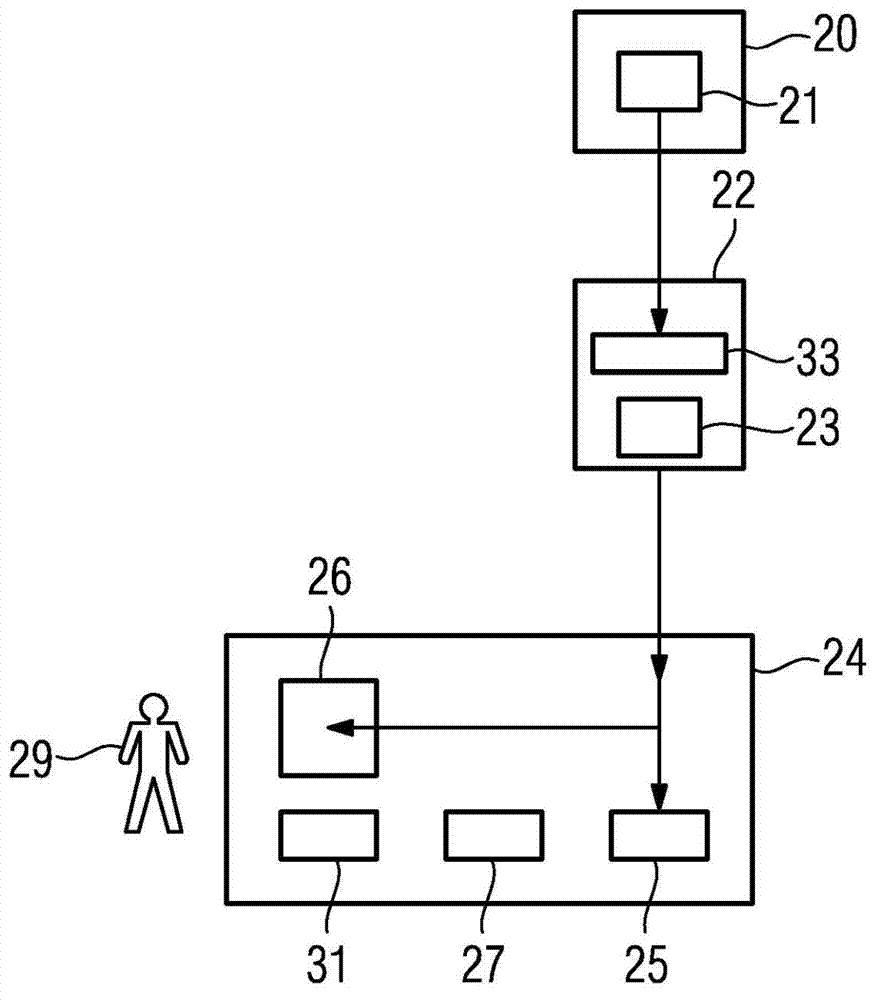

System and method for ascertaining a bearing state

In a system for ascertaining a bearing state and in a method for ascertaining a bearing state of a bearing of an electric machine, a measurement value (21) is ascertained by means of a sensor unit (20). The measurement value is transmitted to a simulation unit (22), wherein a result value (23) is ascertained by means of the simulation unit (22), wherein the result value is in particular a bearing-current value or a value that is dependent on the bearing current. The result value (23) can be transmitted to a further unit (24).

Owner:SIEMENS AG

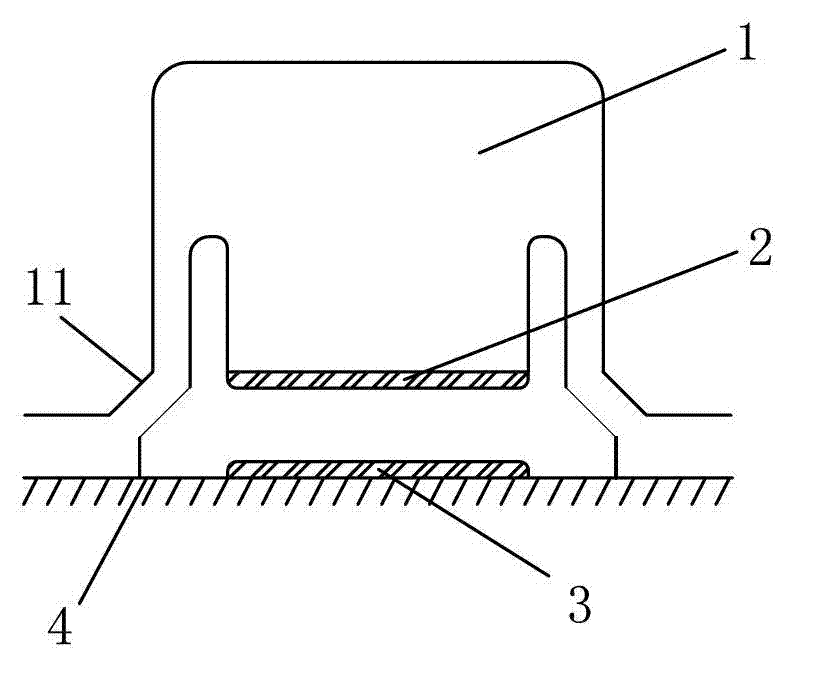

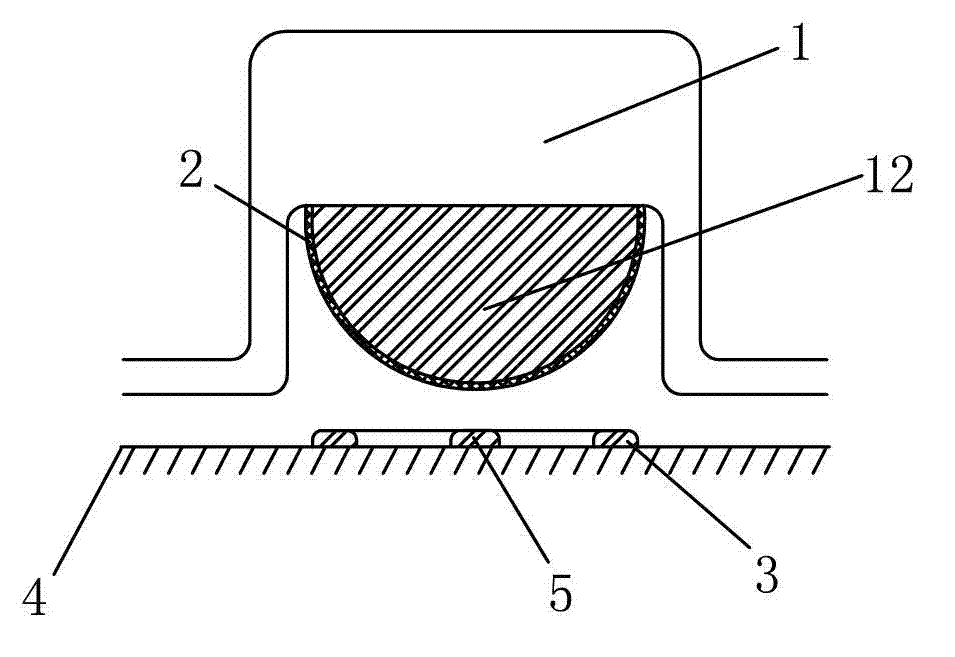

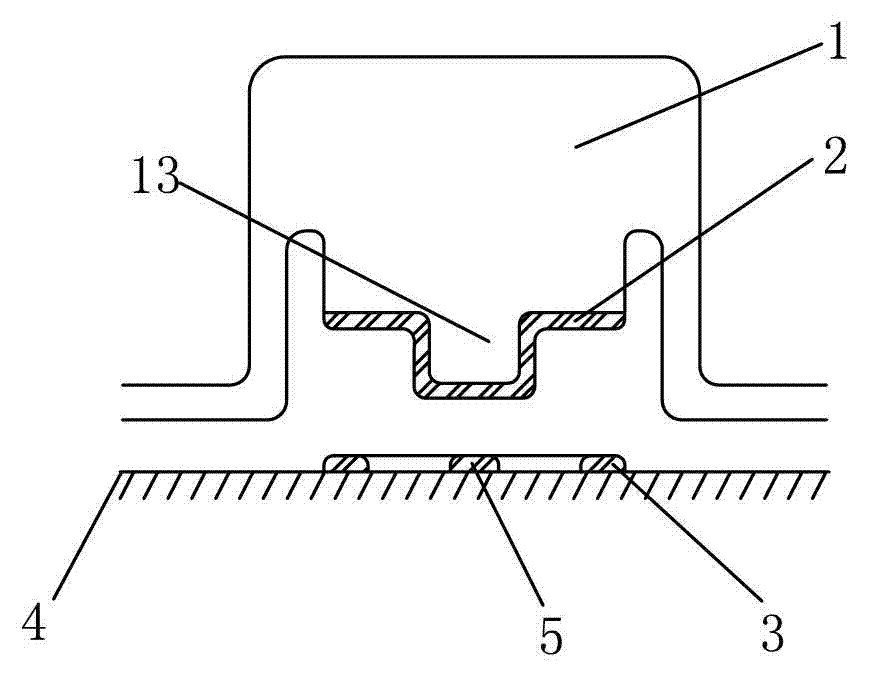

Capacitance type pressure sensing conversion device and method of achieving capacitance type pressure sensing on low-end singlechip

The invention discloses a capacitance type pressure sensing conversion device and a method of achieving capacitance type pressure sensing on a low-end singlechip. The capacitance type pressure sensing conversion device and the method of achieving capacitance type pressure sensing on the low-end singlechip comprise an elastic press key and a base plate, wherein the bottom surface of the elastic press key is coated with a conductive coating, the conductive coating is opposite to conductive copper foil on the base plate, and the conductive coating and the conductive copper foil form two poles of a capacitance. An elastic medium supporting piece is arranged between the elastic press key and the base plate, and a capacitance detection separation distance is kept between the elastic press key and the base plate. The elastic press key is pressed, and thereby the distance value of the capacitance detection separation distance is changed, and transformation output between pressing force and the capacitance change is generated. Electronic equipment of the low-end singlechip is combined with the capacitance type pressure sensing conversion device, the computer processing power of the low-end singlechip is fully utilized, the data processing efficiency is improved, and thereby the capacitance type pressure sensing conversion is achieved on an ordinary singlechip, and the ordinary singlechip has high-resolution output.

Owner:JUNSHENG TECH CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com