Patents

Literature

1504results about How to "Avoid deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

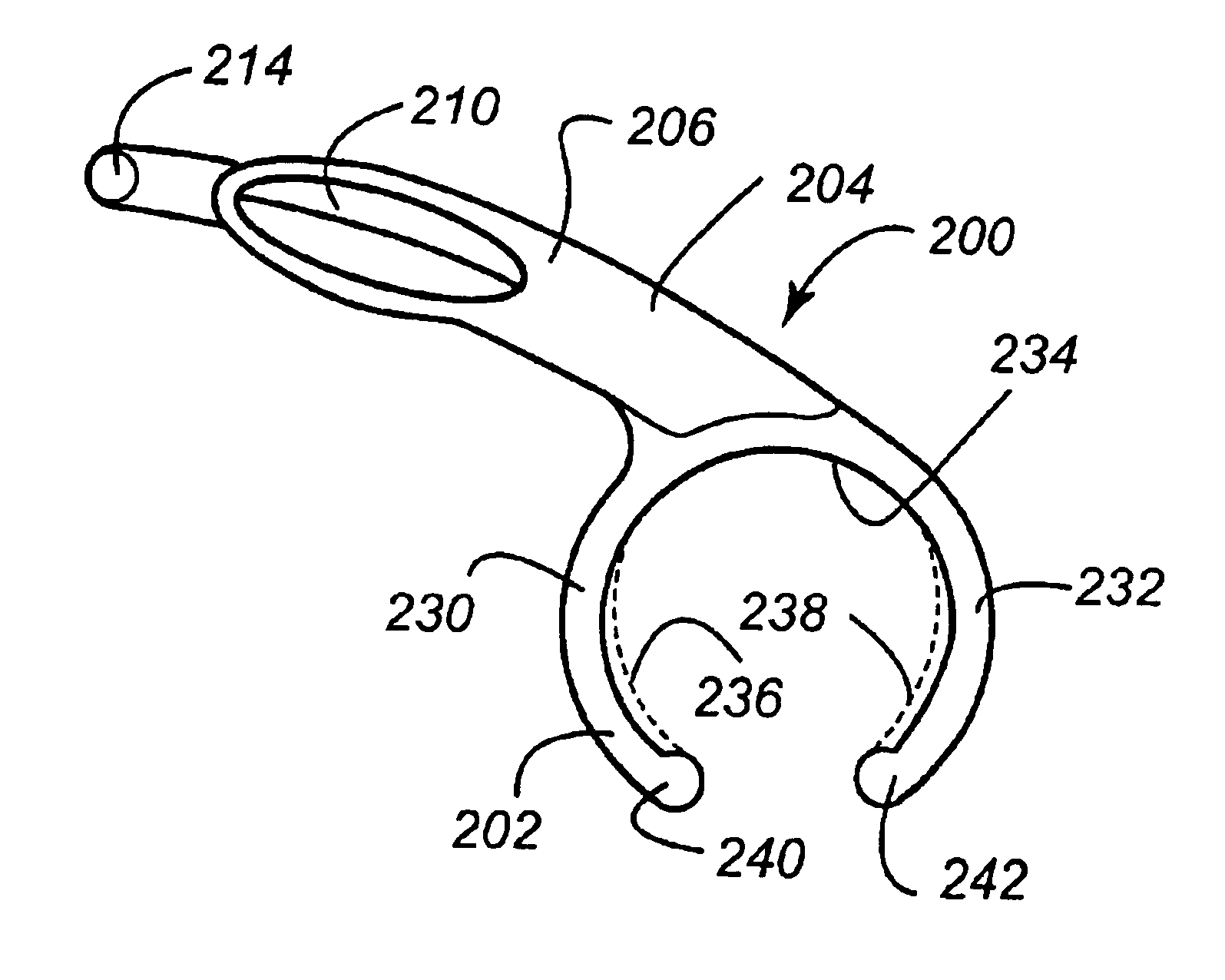

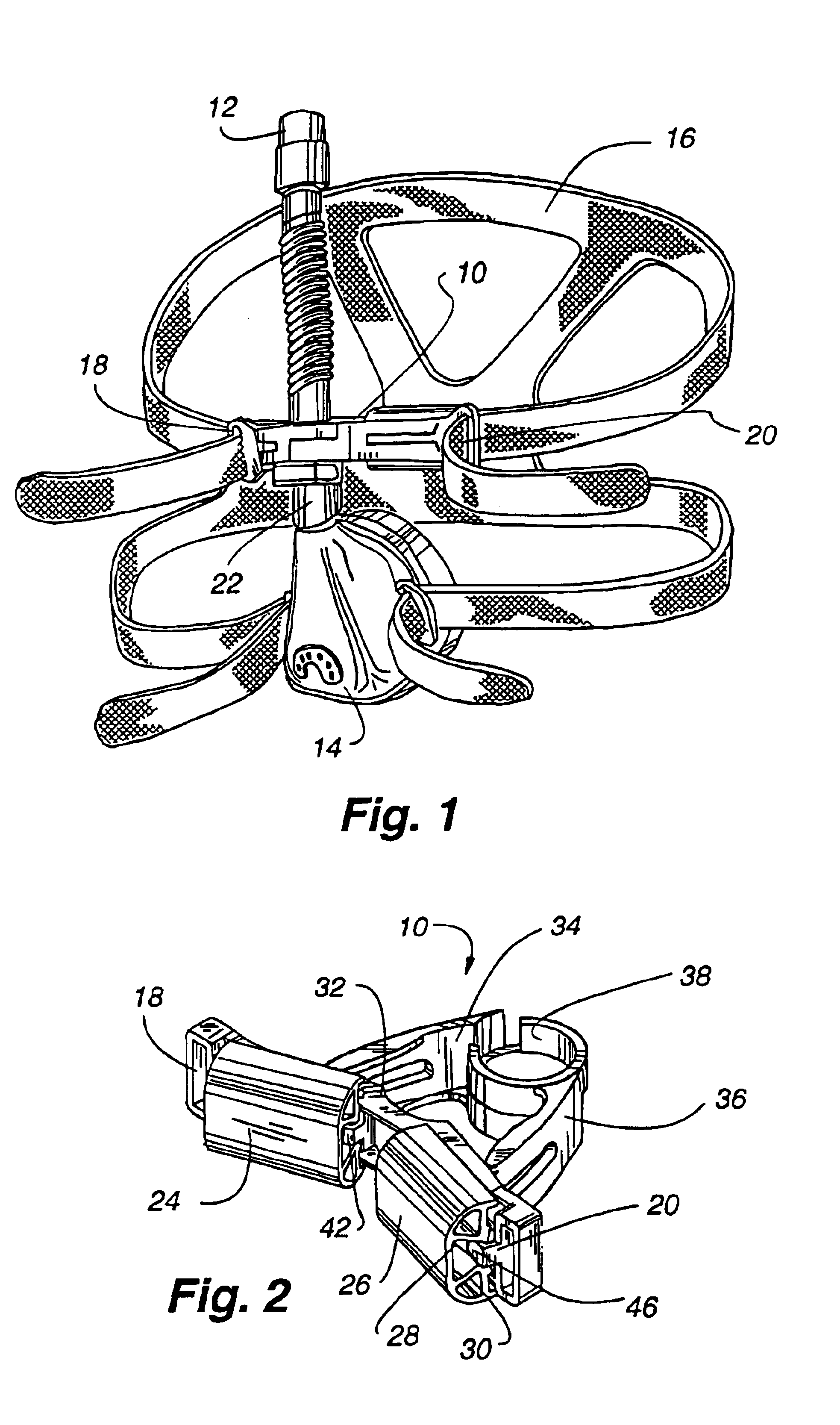

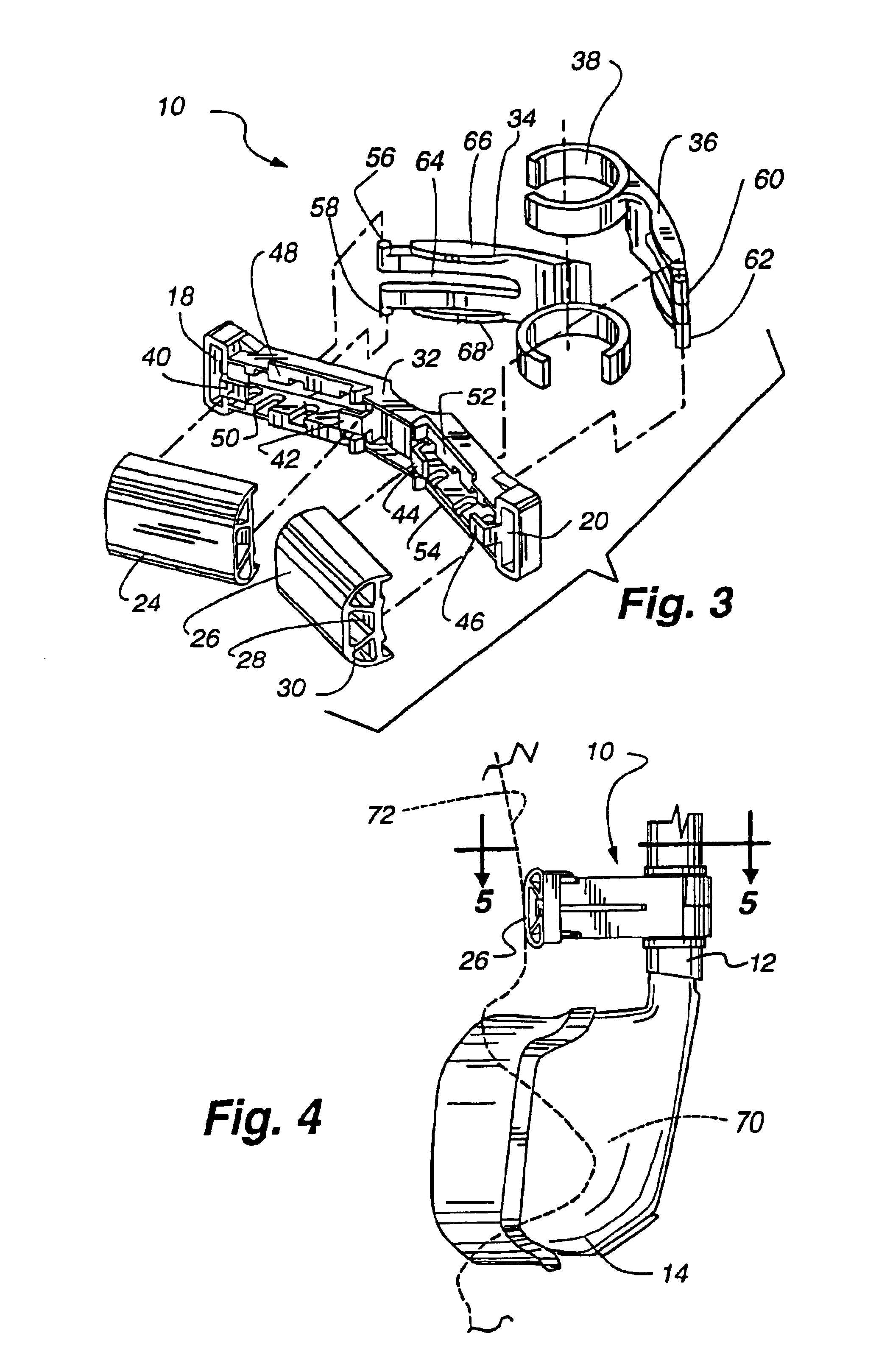

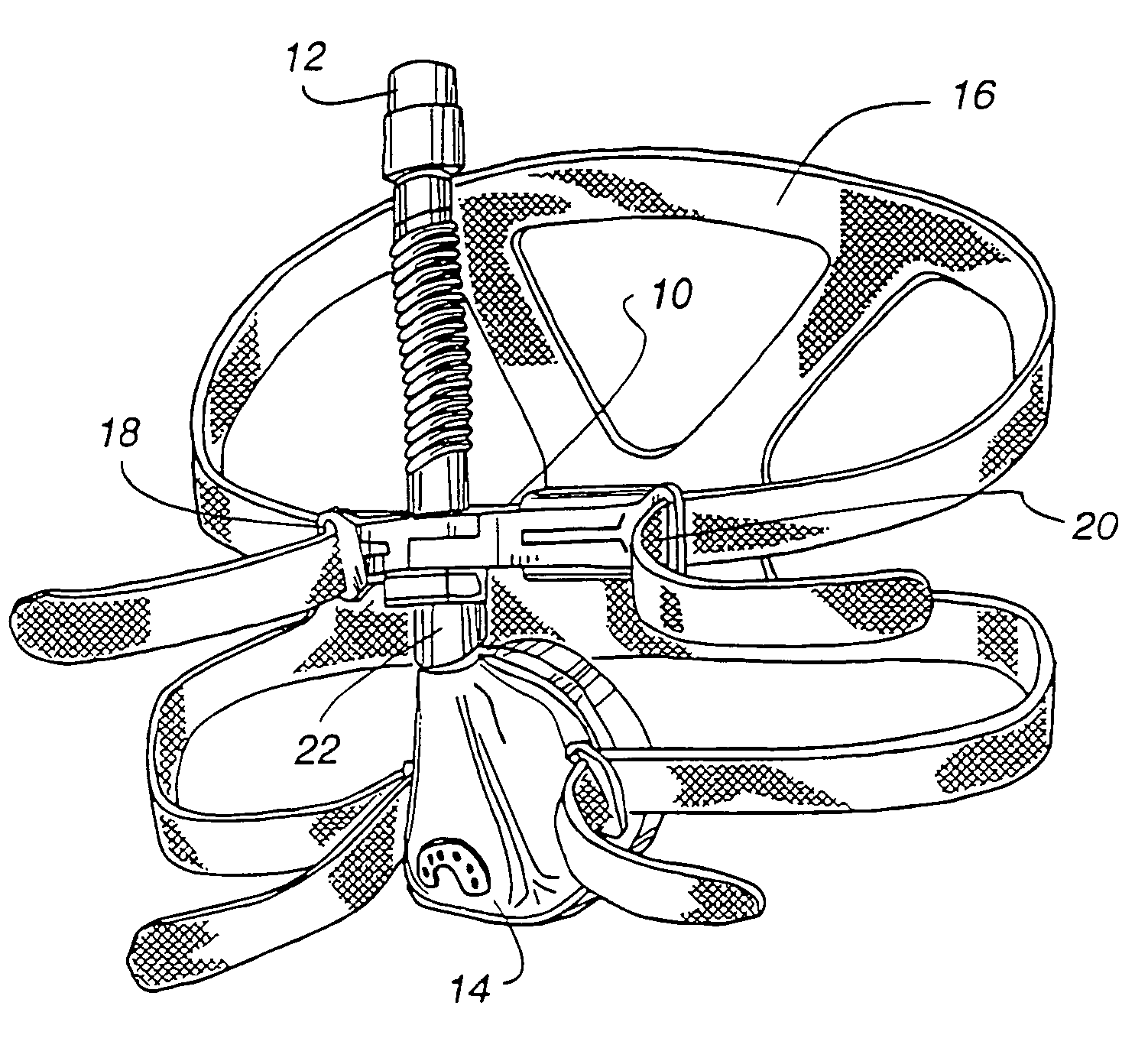

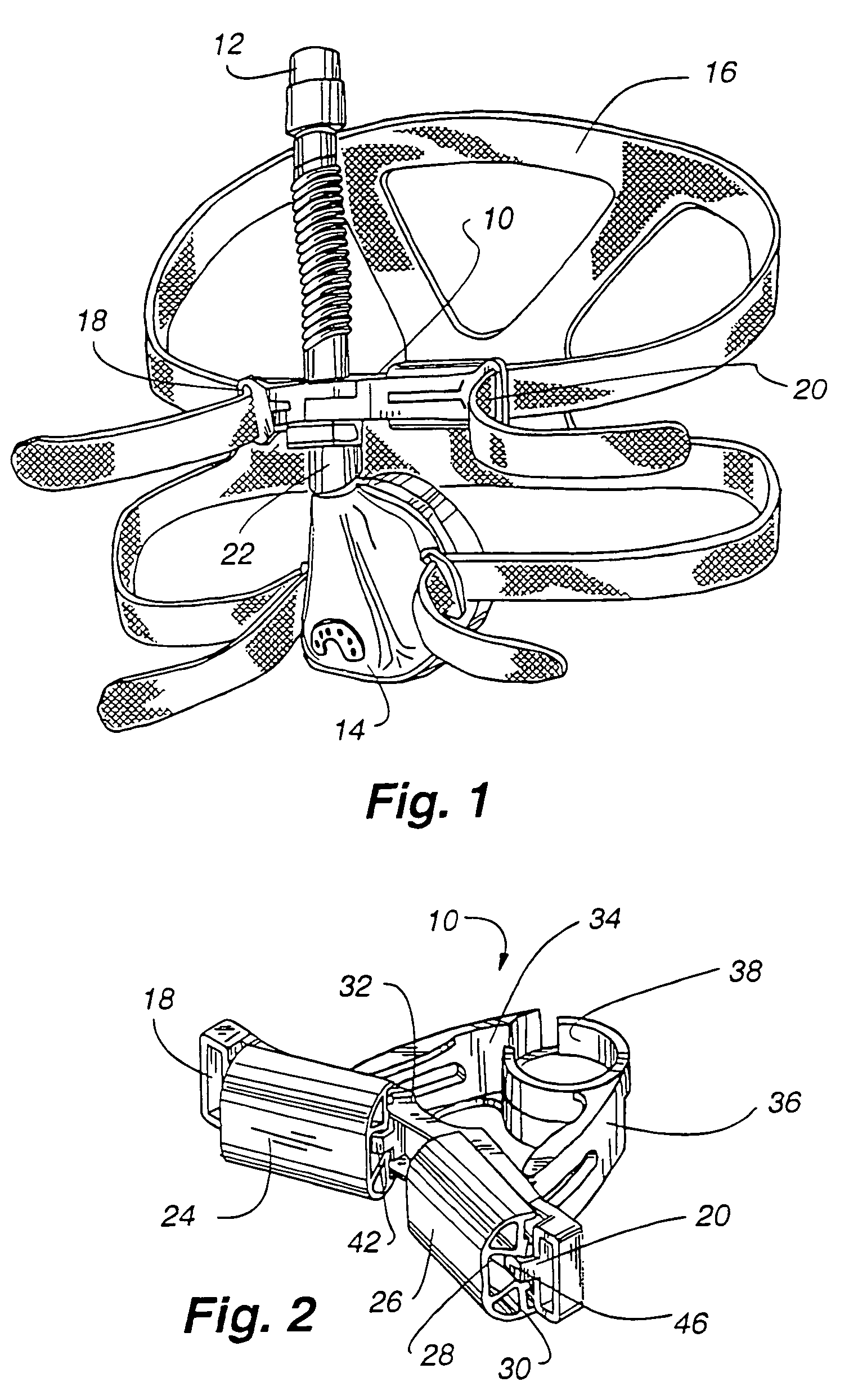

Forehead support for facial mask

The present invention discloses an adjustable forehead support for a nasal or full-face mask wherein the forehead support may be adjusted for the different shapes and sizes of a facial profile. The forehead support utilizes a dual-arm system that adjusts the position of the forehead support vis-á-vis the mask and / or airflow tube. The angle of the mask to the face may be adjusted with the present invention.

Owner:RESMED LTD

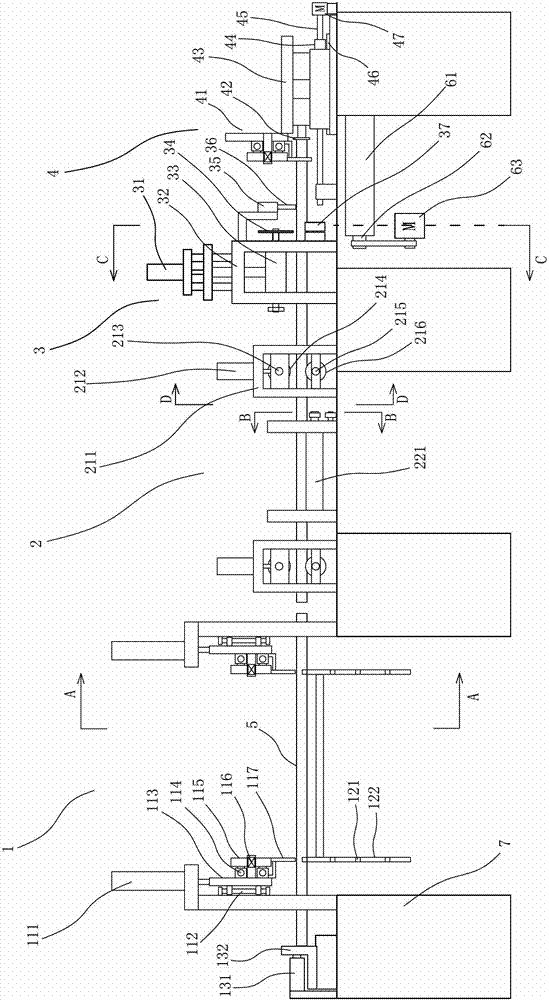

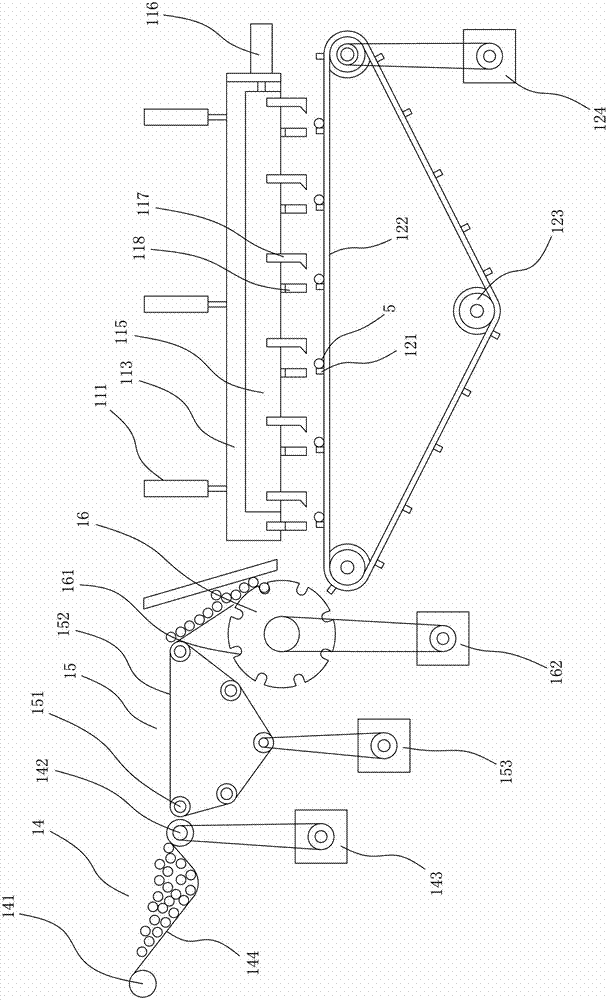

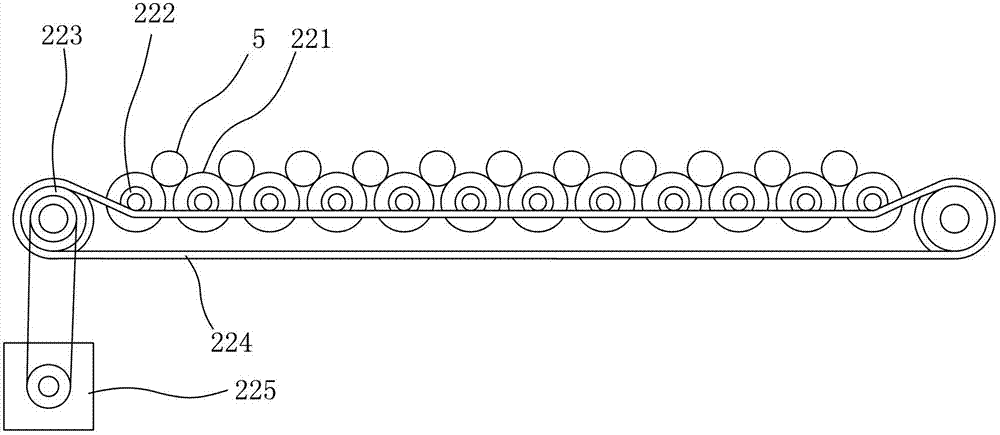

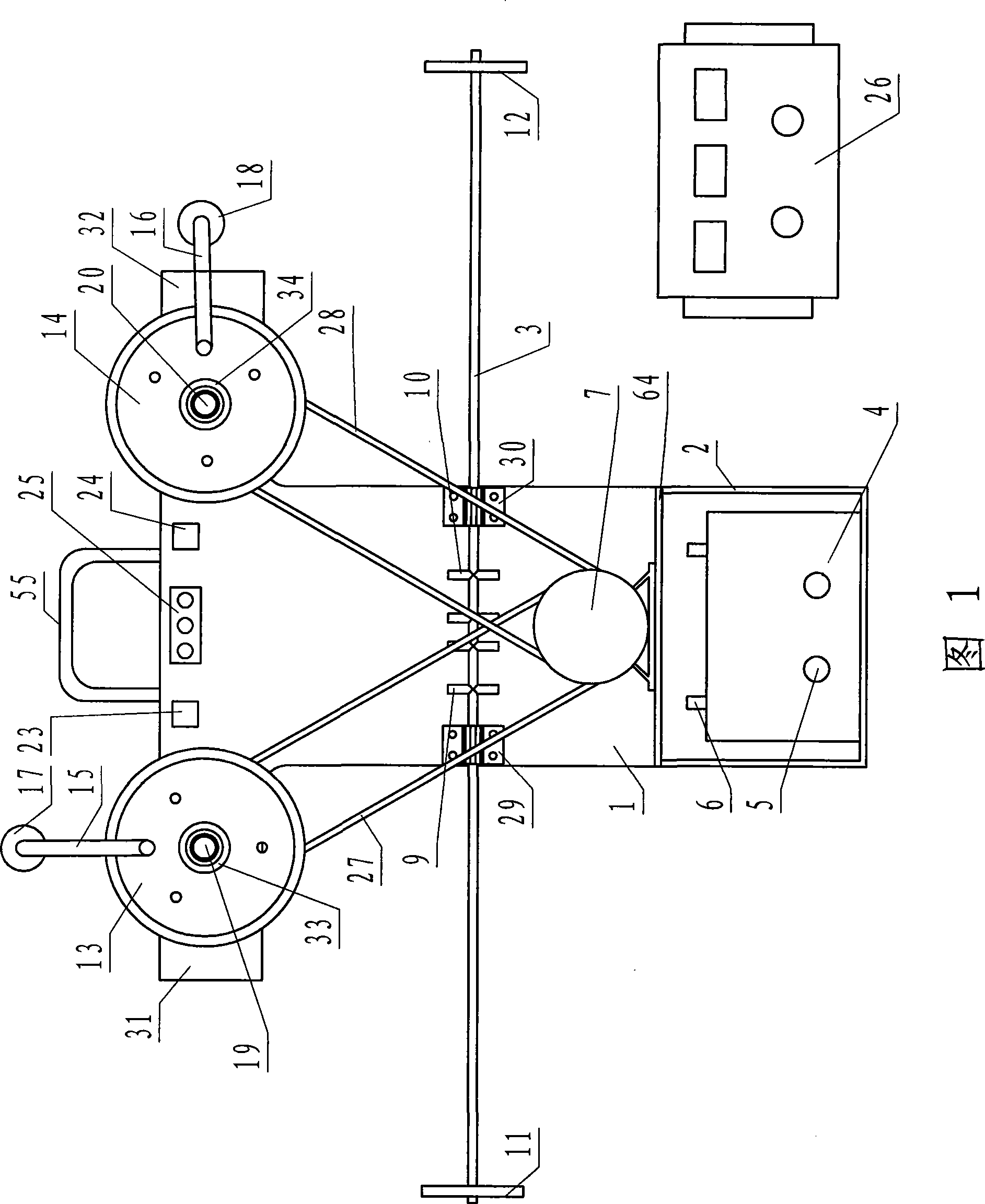

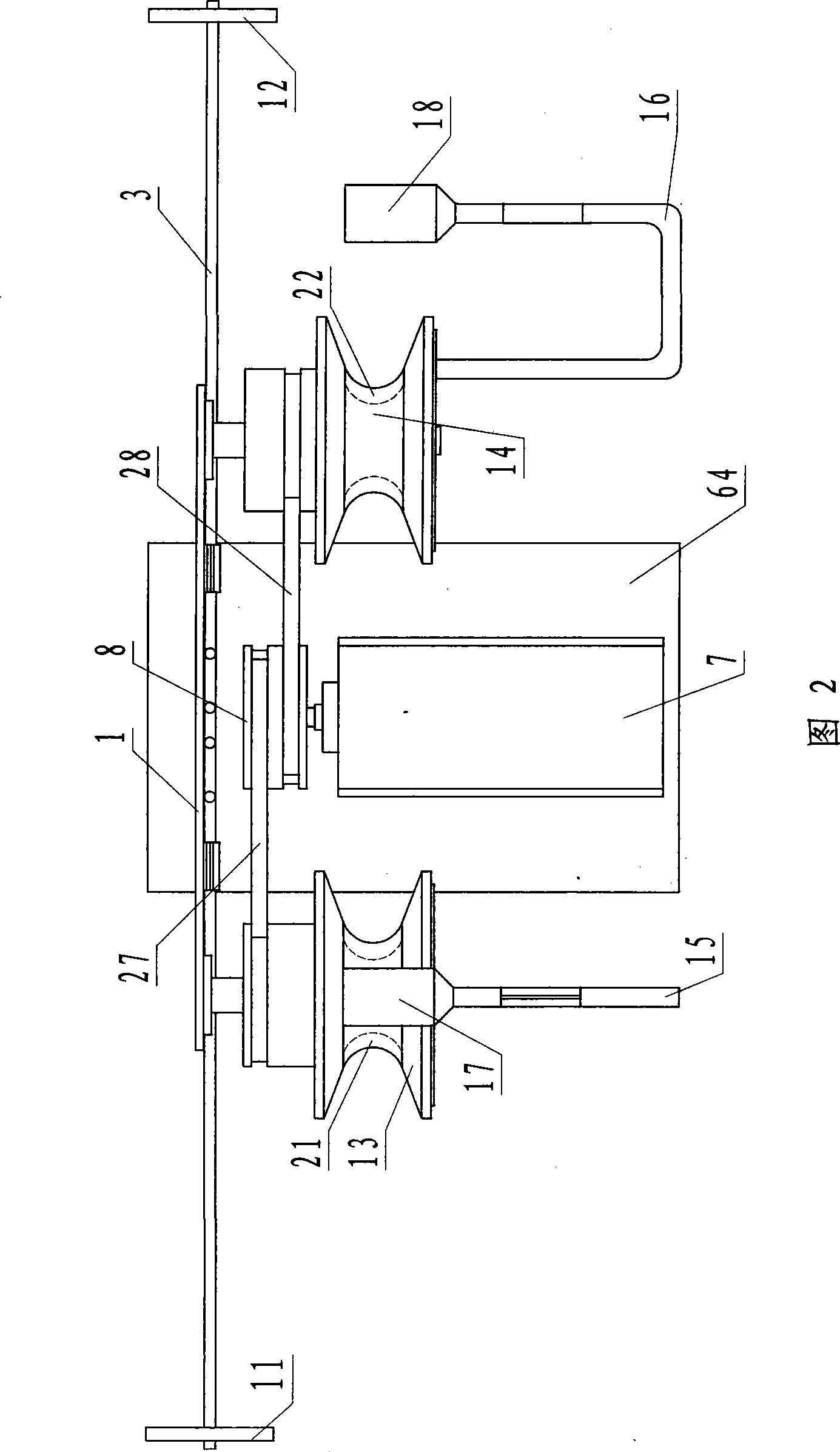

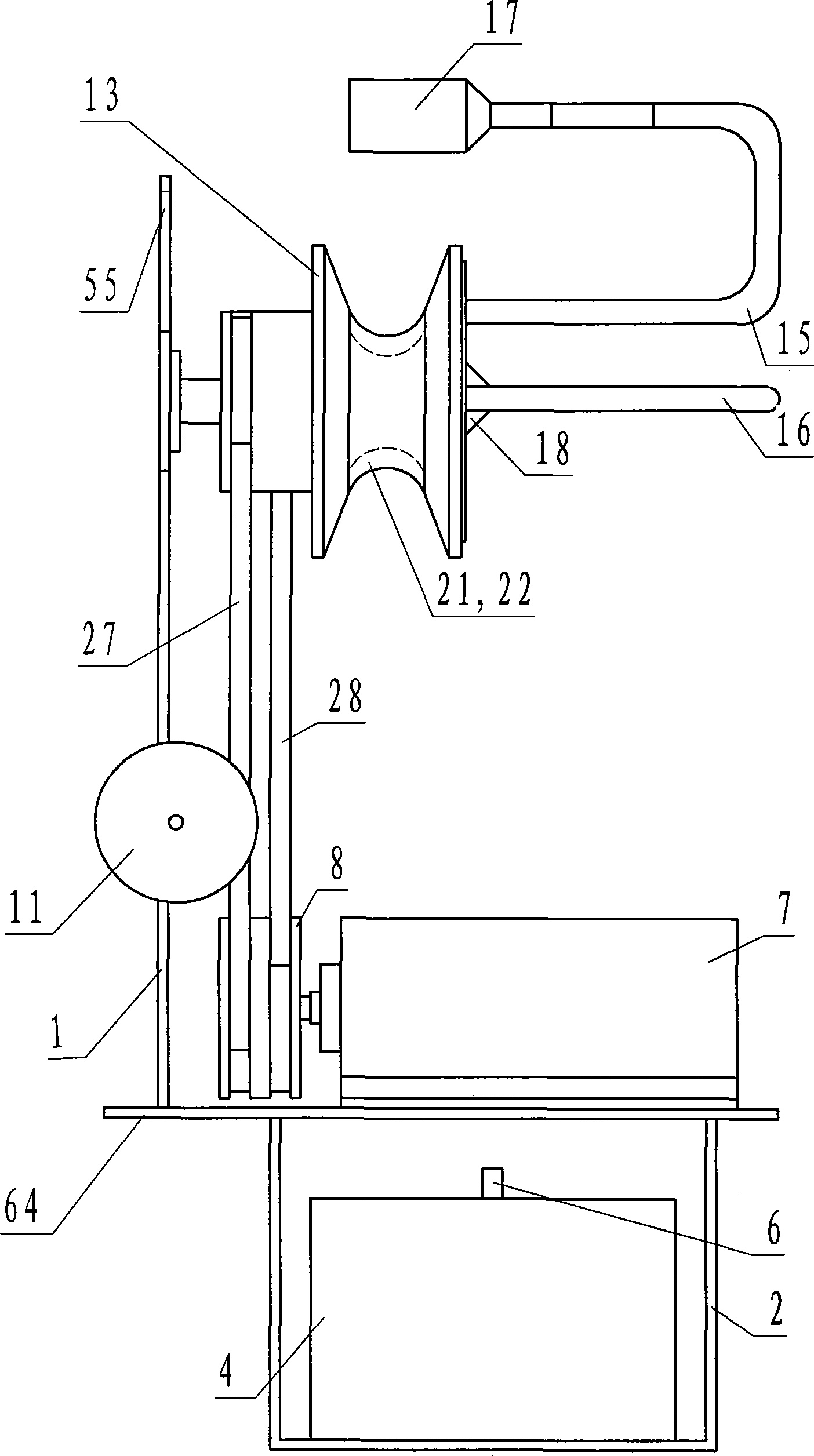

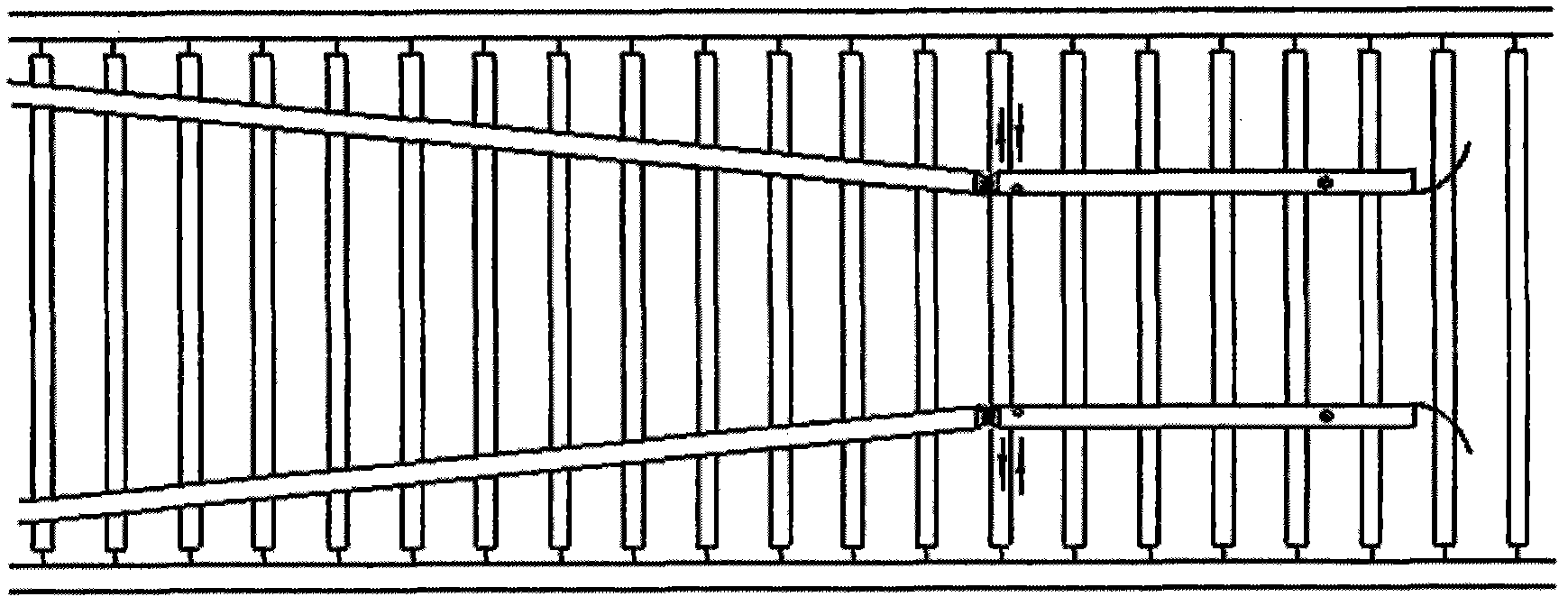

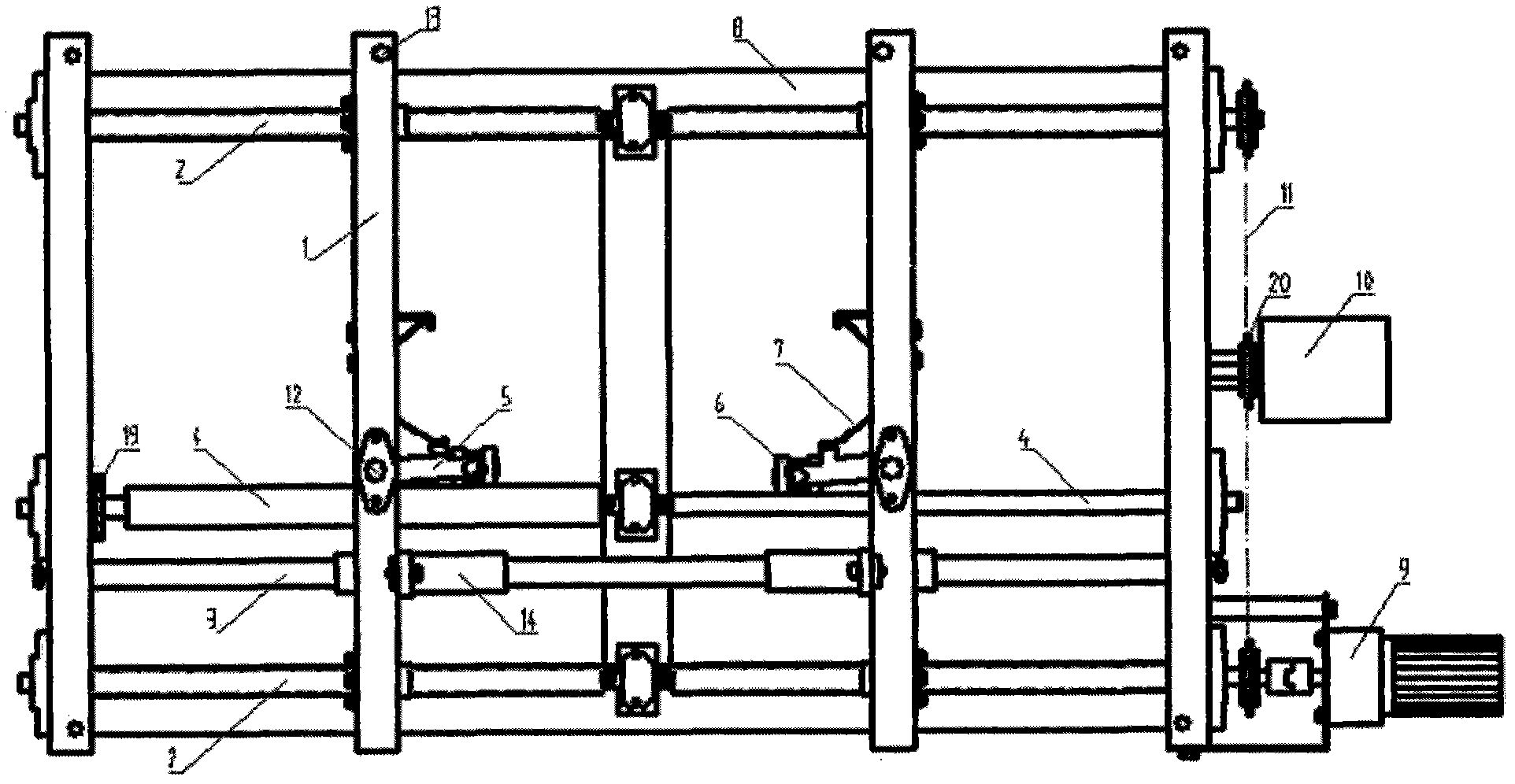

Full-automatic pipe cutting machine

ActiveCN102814547ARealize automatic controlPrecise deliveryMetal sawing devicesCircular sawEngineering

The invention provides a full-automatic pipe cutting machine comprising a frame, and a charging device, a feeding device, a cutting device, a measuring device and a control device which are sequentially arranged on the frame horizontally; the cutting device comprises a cutter holder which is arranged on the frame, a plurality of first motors which are lined horizontally along a longitudinal direction and can be arranged on the cutter holder by moving up and down, a first cylinder which is connected with and drives each first motor to move up and down synchronously, a circular saw blade which is arranged on the output shaft of each first motor, a second motor which is in transmission connection with the input shaft of each first motor through a first transmission mechanism, and a bearing piece which is arranged on the tool rest below each circular saw blade and is used for bearing a pipe at a cut part; and the measuring device comprises a guide rail which is horizontally arranged on the frame, a slide frame which is movably arranged on the guide rail, a driving mechanism which is connected with and drives the slide frame to move along the guide rail, a pipe baffle which is arranged on the slide frame and a first pipe clamping mechanism which is horizontally arranged on the slide frame along the longitudinal direction. According to the full-automatic pipe cutting machine, more than one pipe can be cut at one time, and the machine has the advantages of high cutting efficiency, good cutting quality and the like.

Owner:冠达星股份有限公司

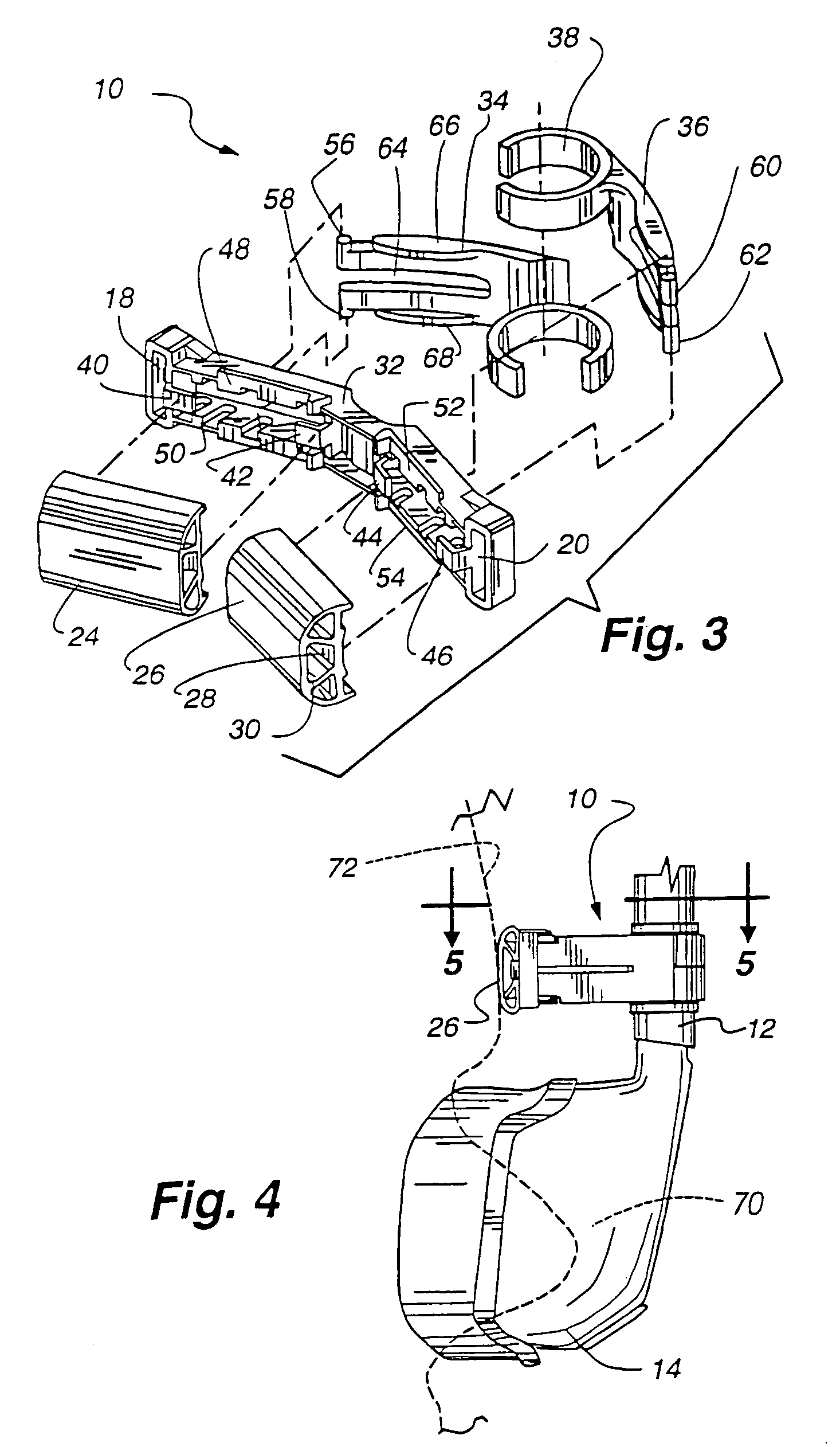

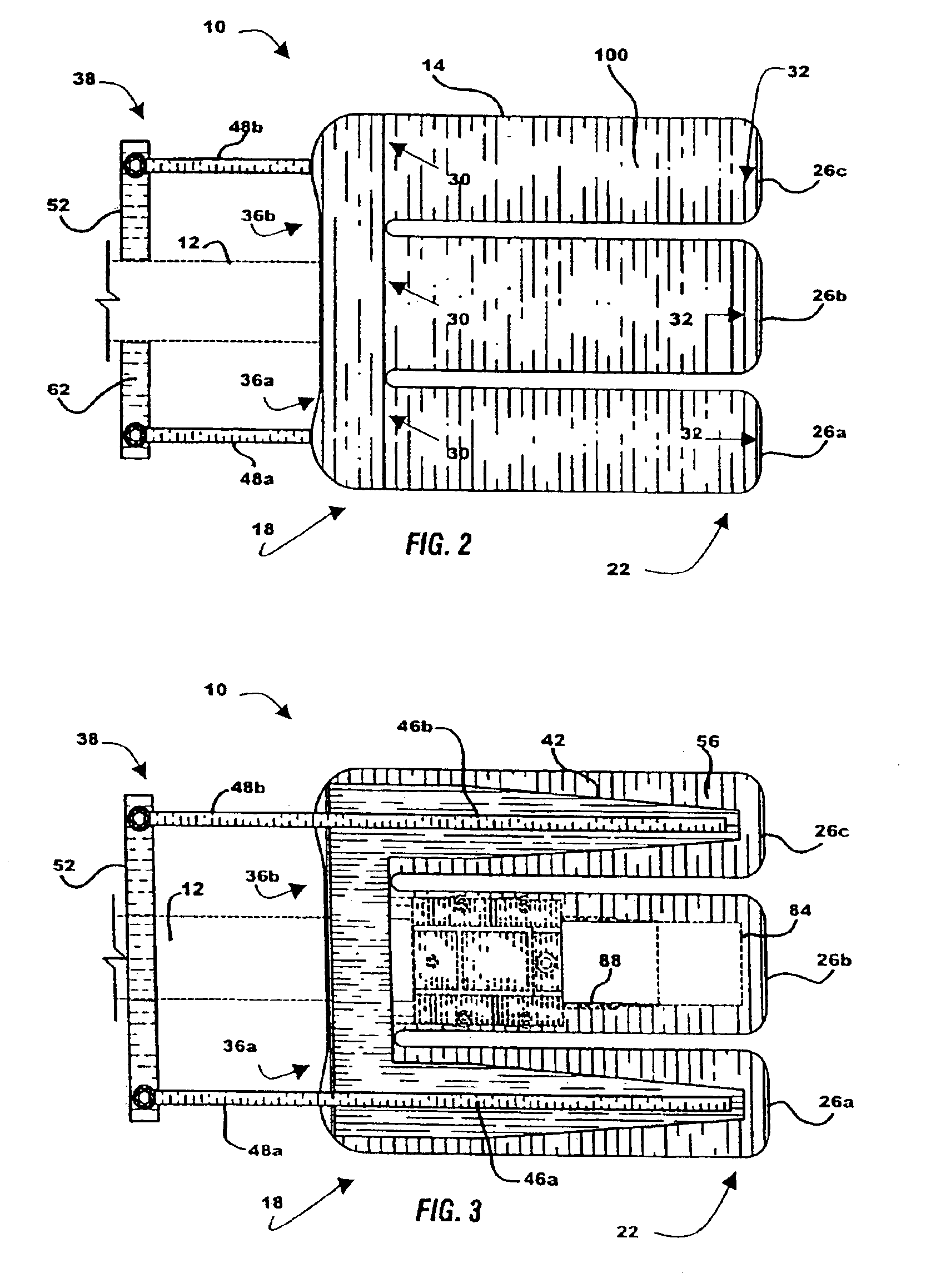

Forehead support for facial mask

InactiveUS7614400B2Easily be compressed togetherCompress more easilyRespiratory masksBreathing masksNoseForehead

The present invention discloses an adjustable forehead support for a nasal or full-face mask wherein the forehead support may be adjusted for the different shapes and sizes of a facial profile. The forehead support utilizes a dual-arm system that adjusts the position of the forehead support vis-á-vis the mask and / or airflow tube. The angle of the mask to the face may be adjusted with the present invention.

Owner:RESMED LTD

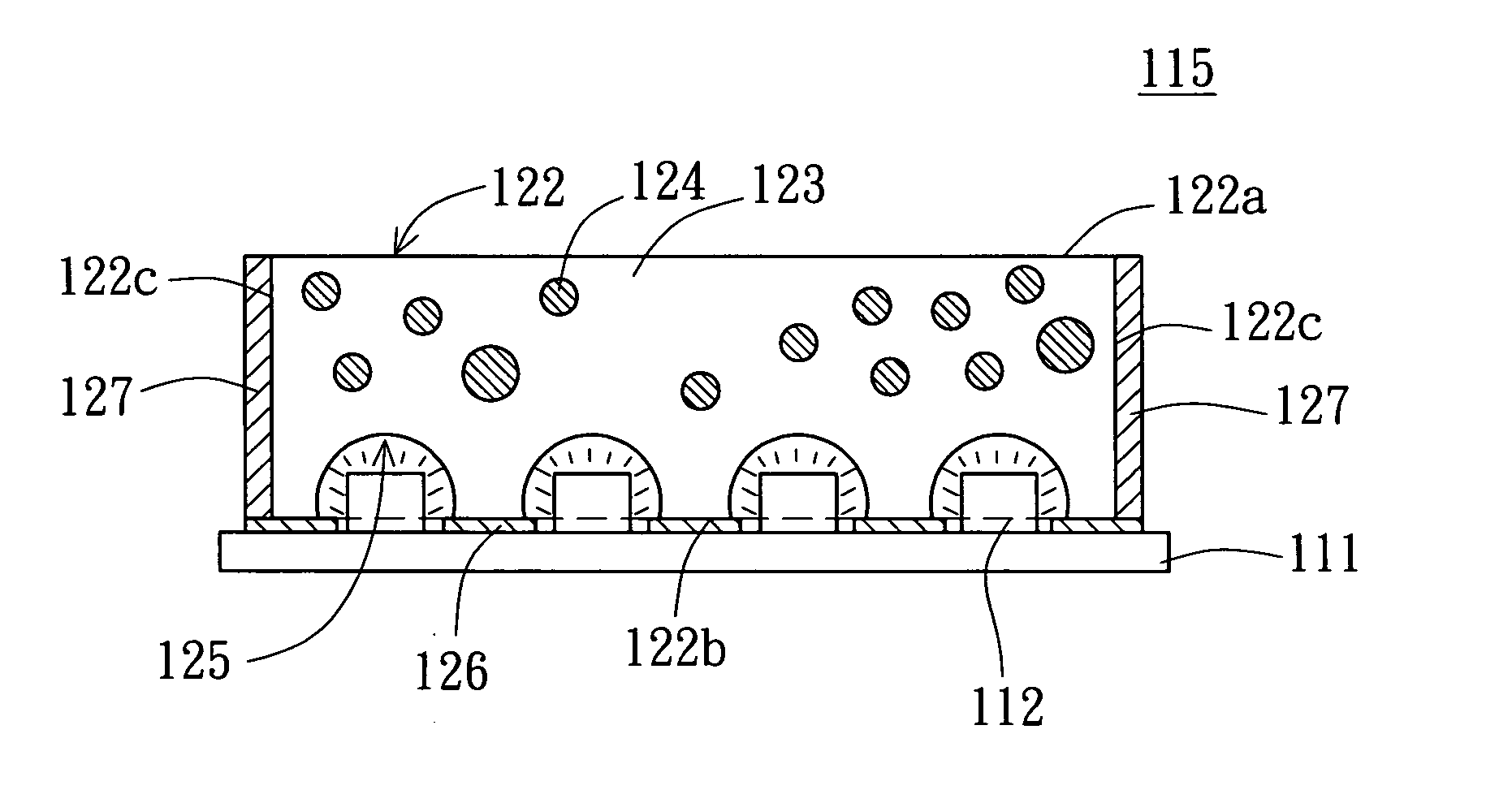

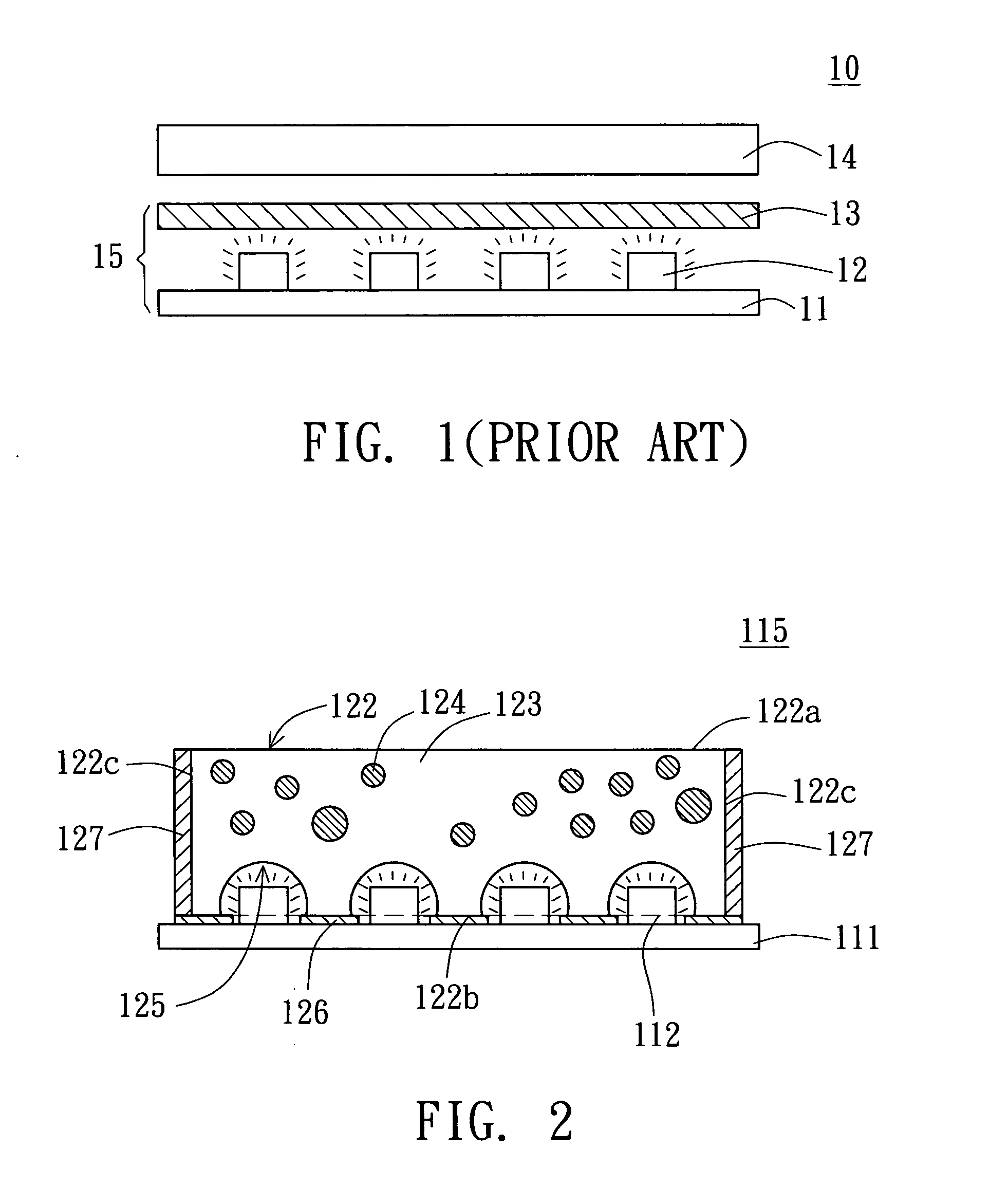

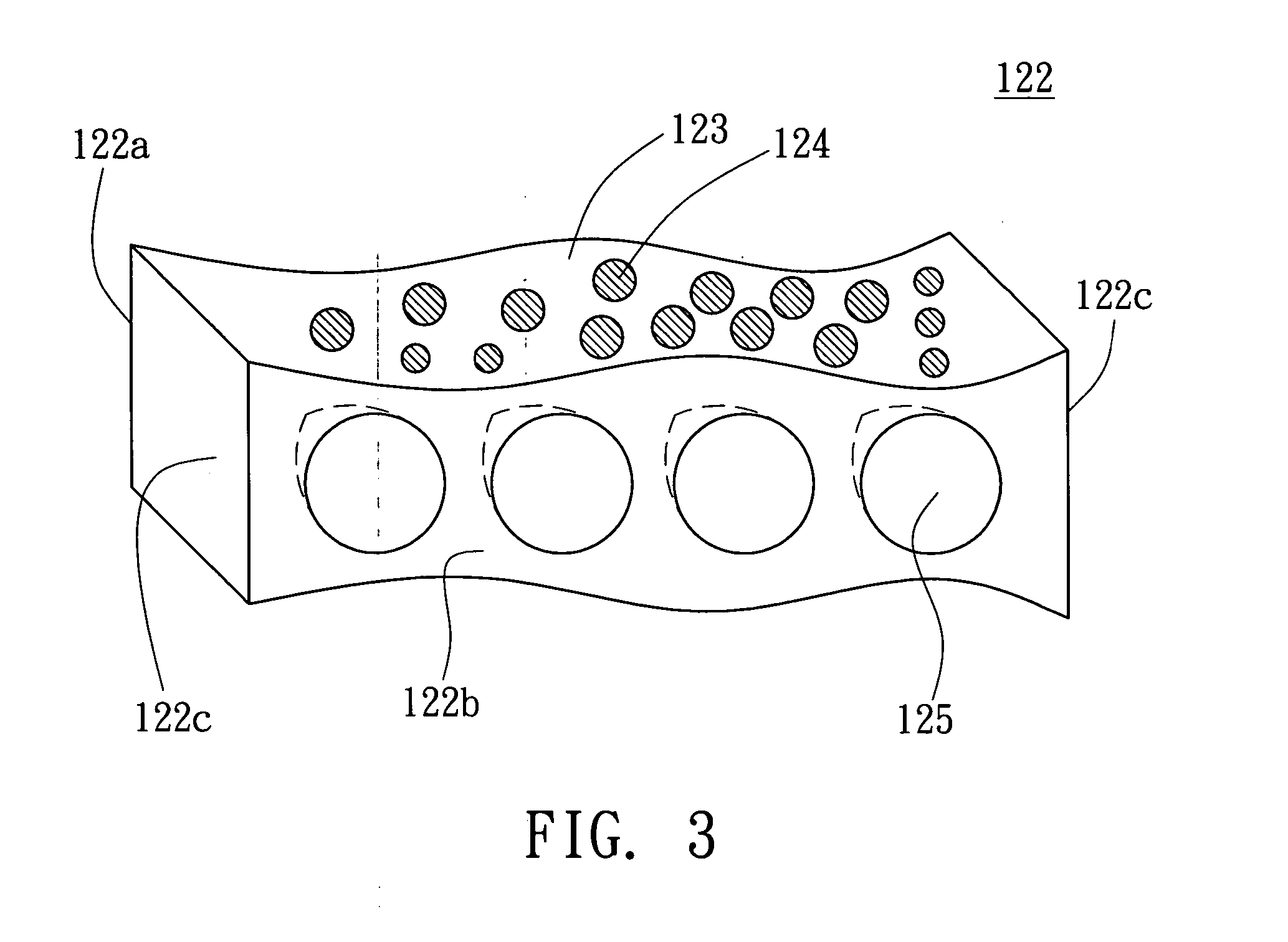

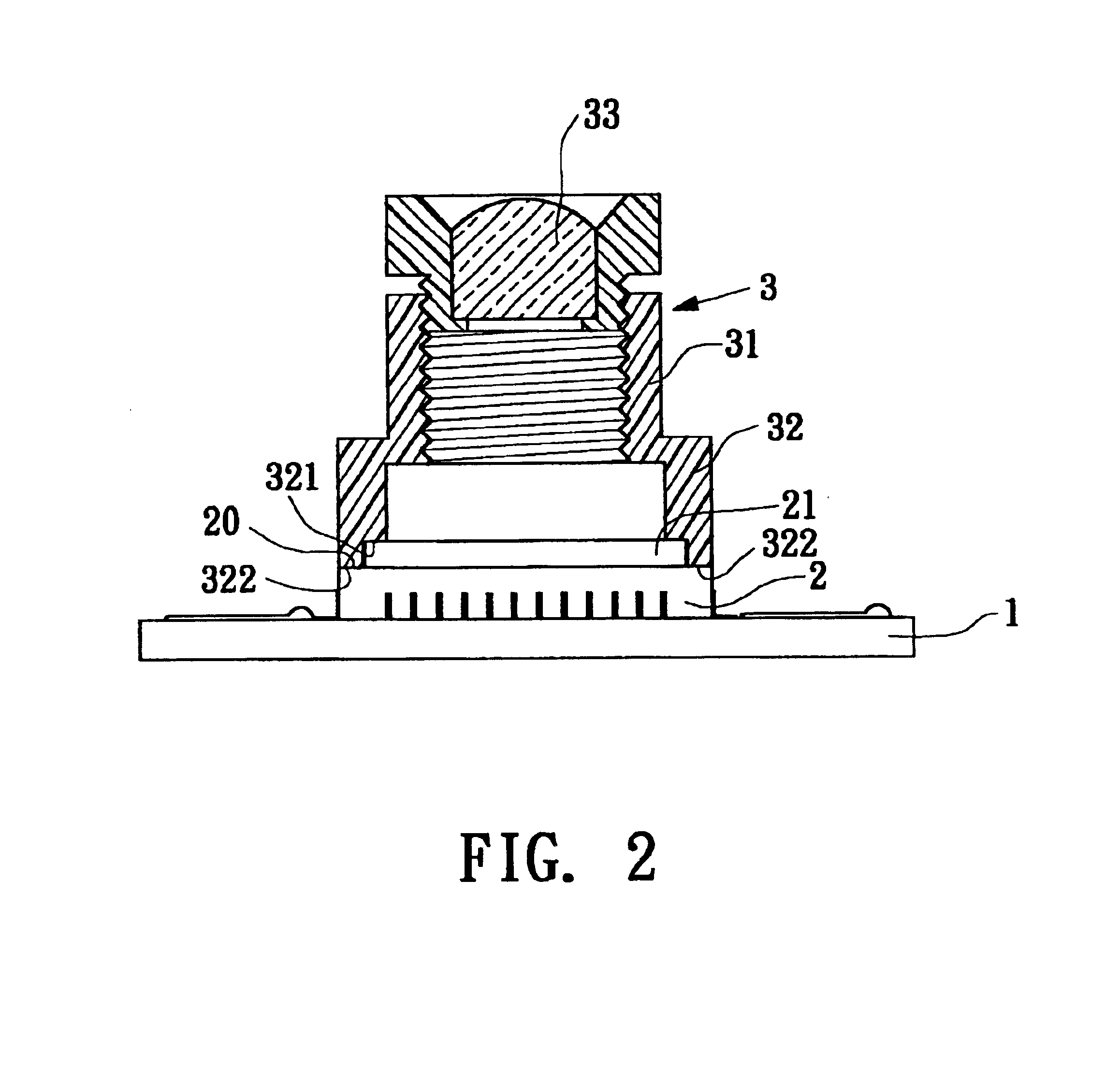

Light emitting apparatus

InactiveUS20050045897A1Improve light mixing effectAvoid deflectionSolid-state devicesSemiconductor devicesEngineeringWhite light

A light emitting apparatus at least includes a circuit board, several light emitting diodes (LEDs), a first reflective substance, and a diffusion structure. The LEDs, including red (R), green (G), and blue (B) LEDs, are disposed on the circuit board and connected therewith, and the first reflective substance is disposed on the circuit board and having a plurality of cavities for the LEDs. The diffusion structure is disposed on the circuit board and covering the LEDs. The diffusion structure includes several indentations, a transparent main body and several diffusion beads. The indentations are formed on a bottom surface of the diffusion structure and face the LEDs to accommodate the LEDs. The diffusion beads are dispersed in the transparent main body and diffuse light emitted from the LEDs so that light emitted from R / G / B LEDs can be mixed into white light more sufficiently through the diffusion structure.

Owner:AU OPTRONICS CORP

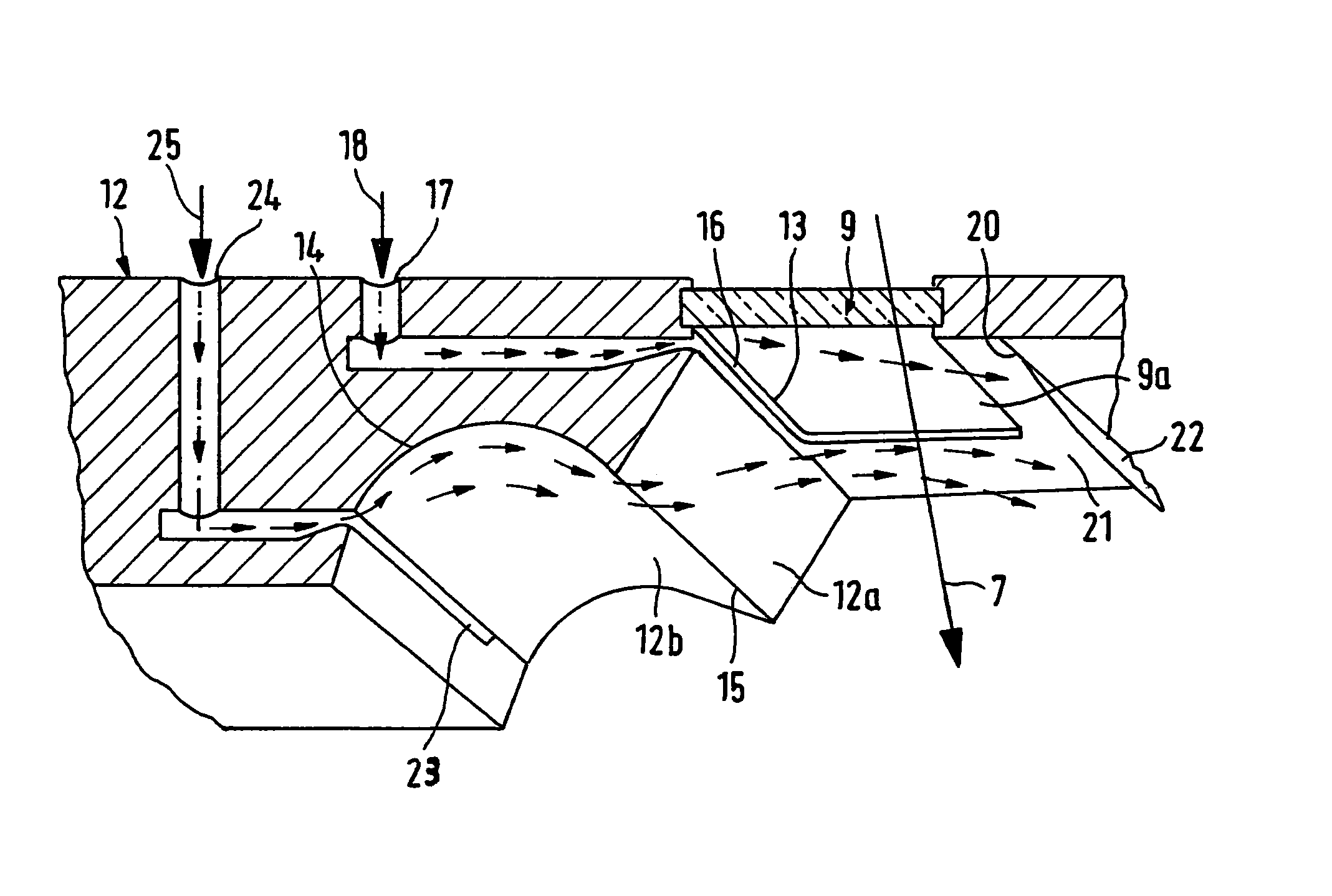

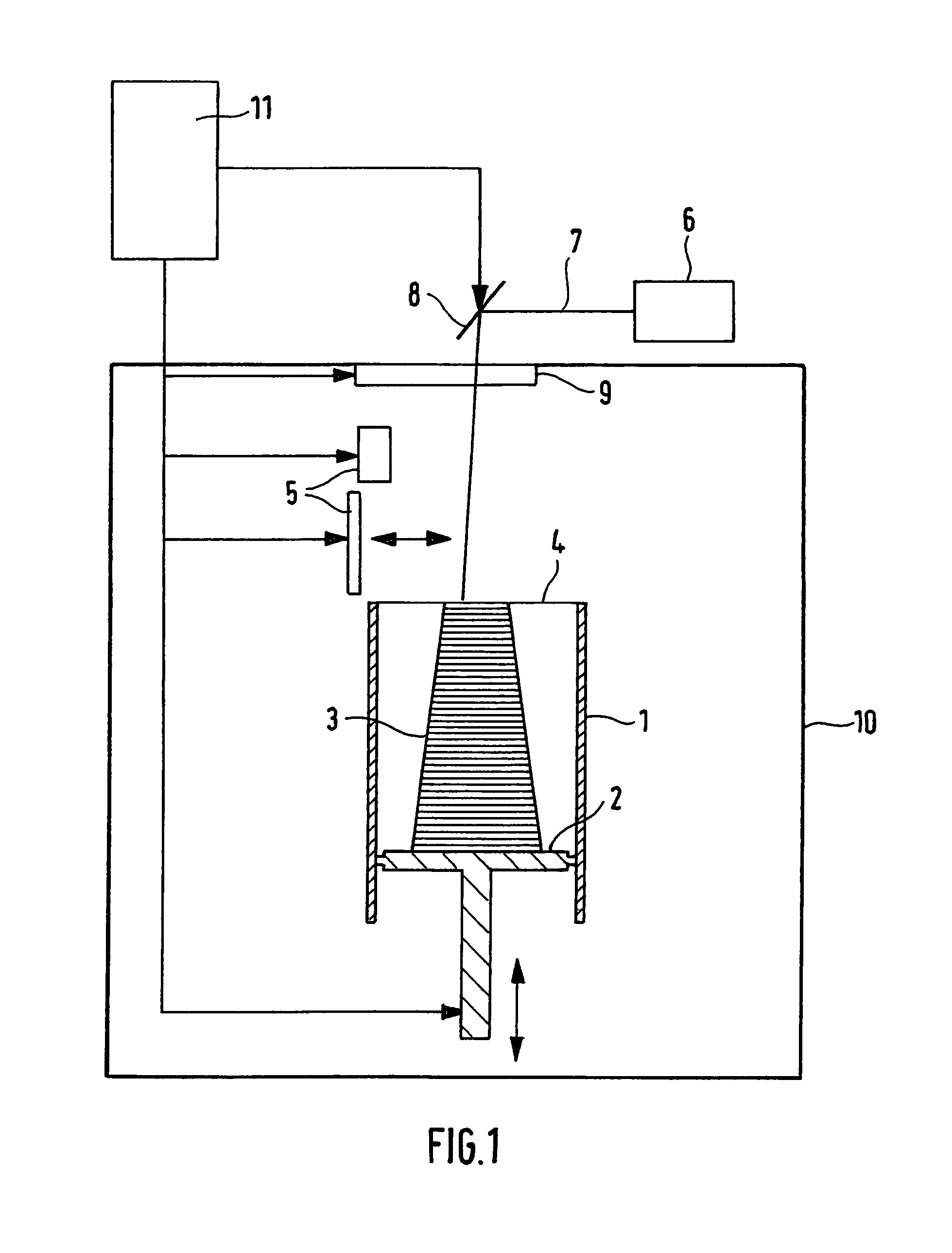

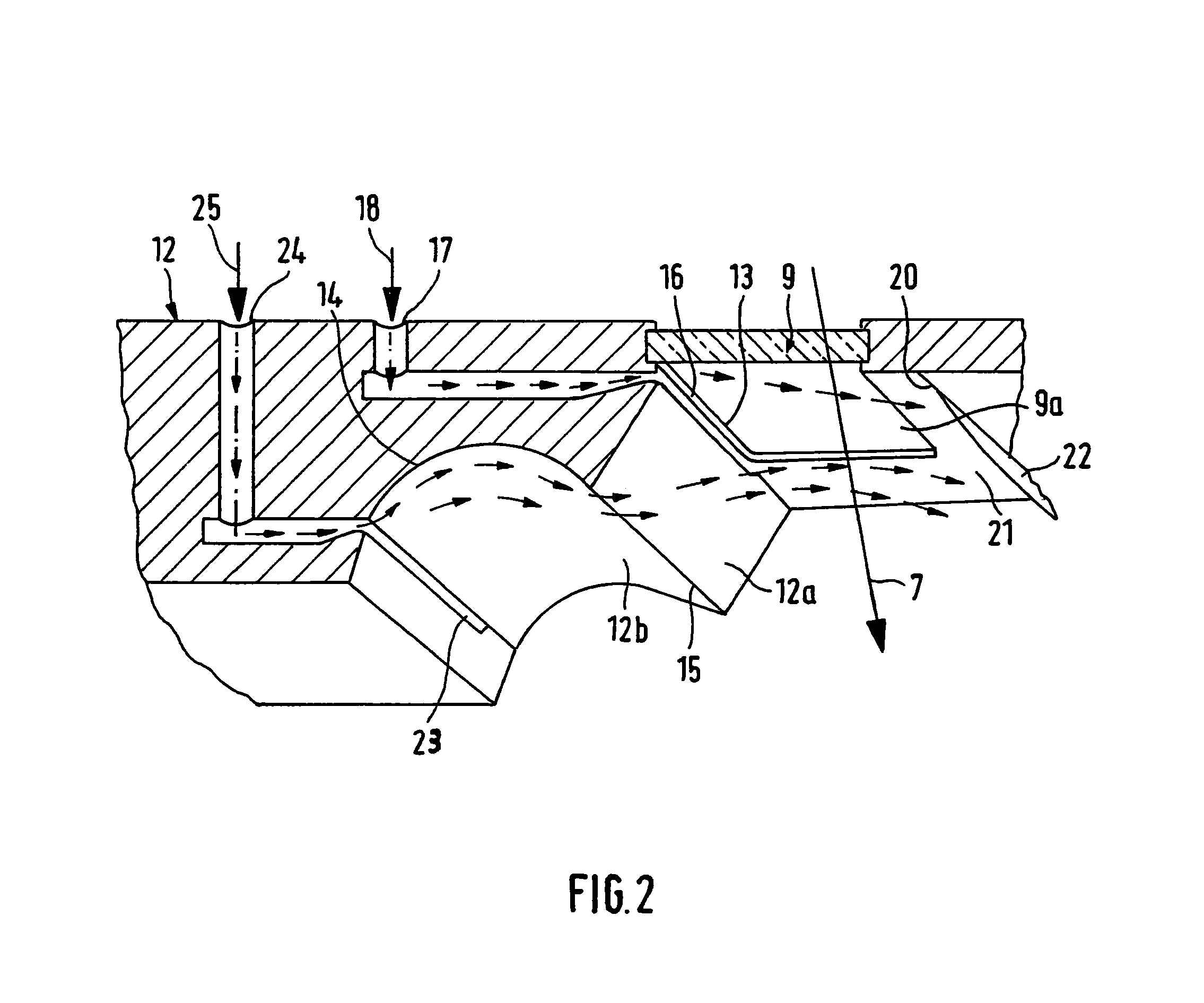

Process chamber and method for processing a material by a directed beam of electromagnetic radiation, in particular for a laser sintering device

ActiveUS8895893B2Avoid deflectionLow gas flowAdditive manufacturing apparatusIncreasing energy efficiencyAirflowElectromagnetic radiation

A process chamber for a processing of a material by means of a directed beam of electromagnetic radiation is provided, which comprises an optical element (9) for coupling the beam (7) into the process chamber (10), wherein the optical element has a surface (9a) facing the inside of the process chamber, a wall section (12) surrounding the optical element (9), a first inlet (16) for a gas that is arranged at one side of the optical element (9) and designed such that an escaping first gas flow (18) strokes substantially tangentially over the surface (9a) of the optical element (9), a second inlet (23) for a gas, which is designed and arranged such that an escaping second gas flow (25) flows at a distance to the surface (9a) in substantially the same direction as the first gas flow (18).

Owner:EOS ELECTRO OPTICAL SYST

Optical element package

InactiveUS20080205066A1Improve wrinklesIncrease deflectionWrappers shrinkageLamination ancillary operationsPhysicsLight source

An optical packaged body capable of preventing generation of a wrinkle, deflection, and warpage, capable of being thinned is provided. The optical package body includes a support medium and a packaging film that covers the support medium in a state of being applied with shrinkage force. The packaging film has an optical function section that acts on light from a light source in at least one of a first region into which the light from the light source enters and a second region from which the light from the light source is emitted after passing through the optical packaged body when the light source is arranged on one face side of the optical packaged body.

Owner:SONY CORP

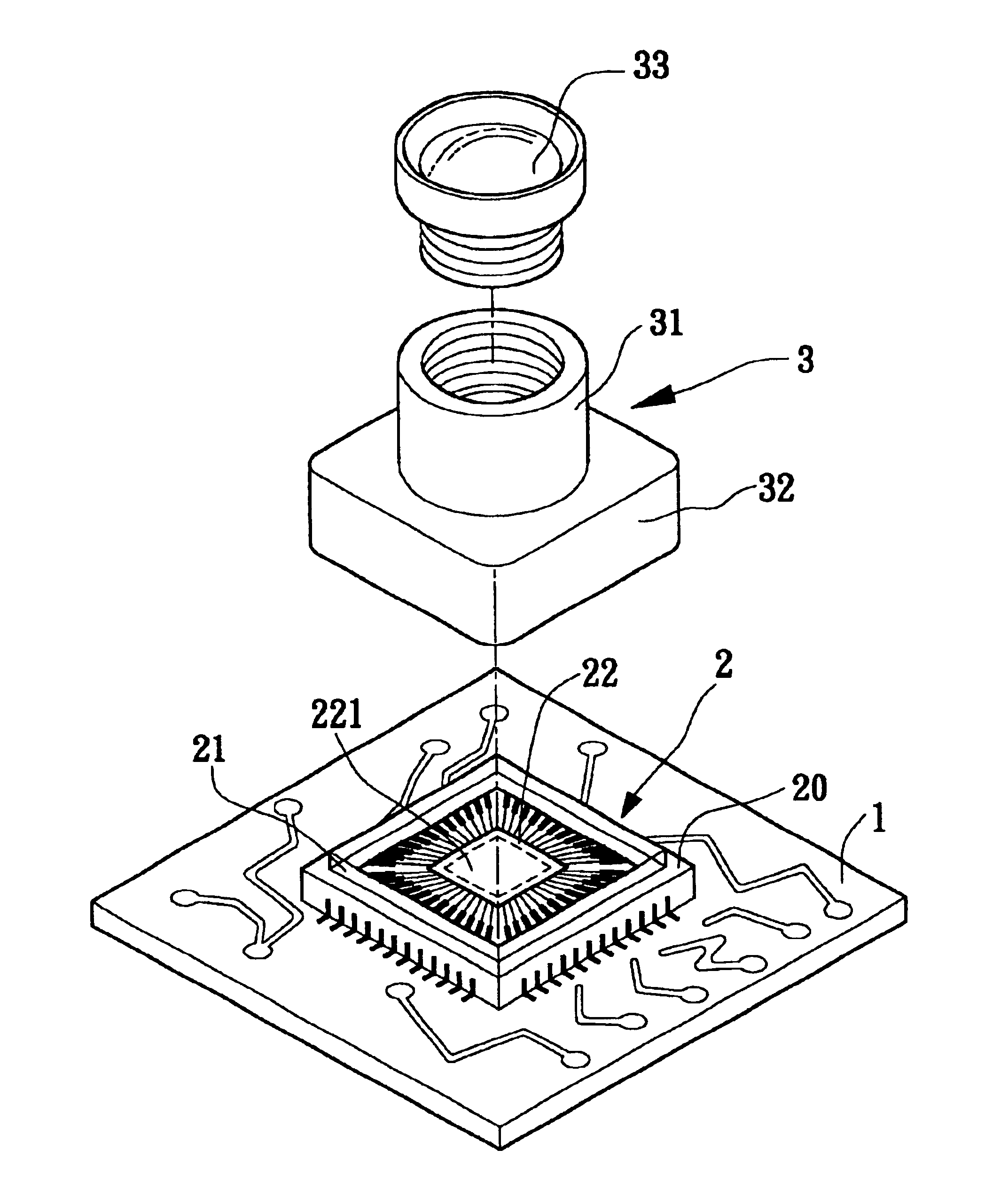

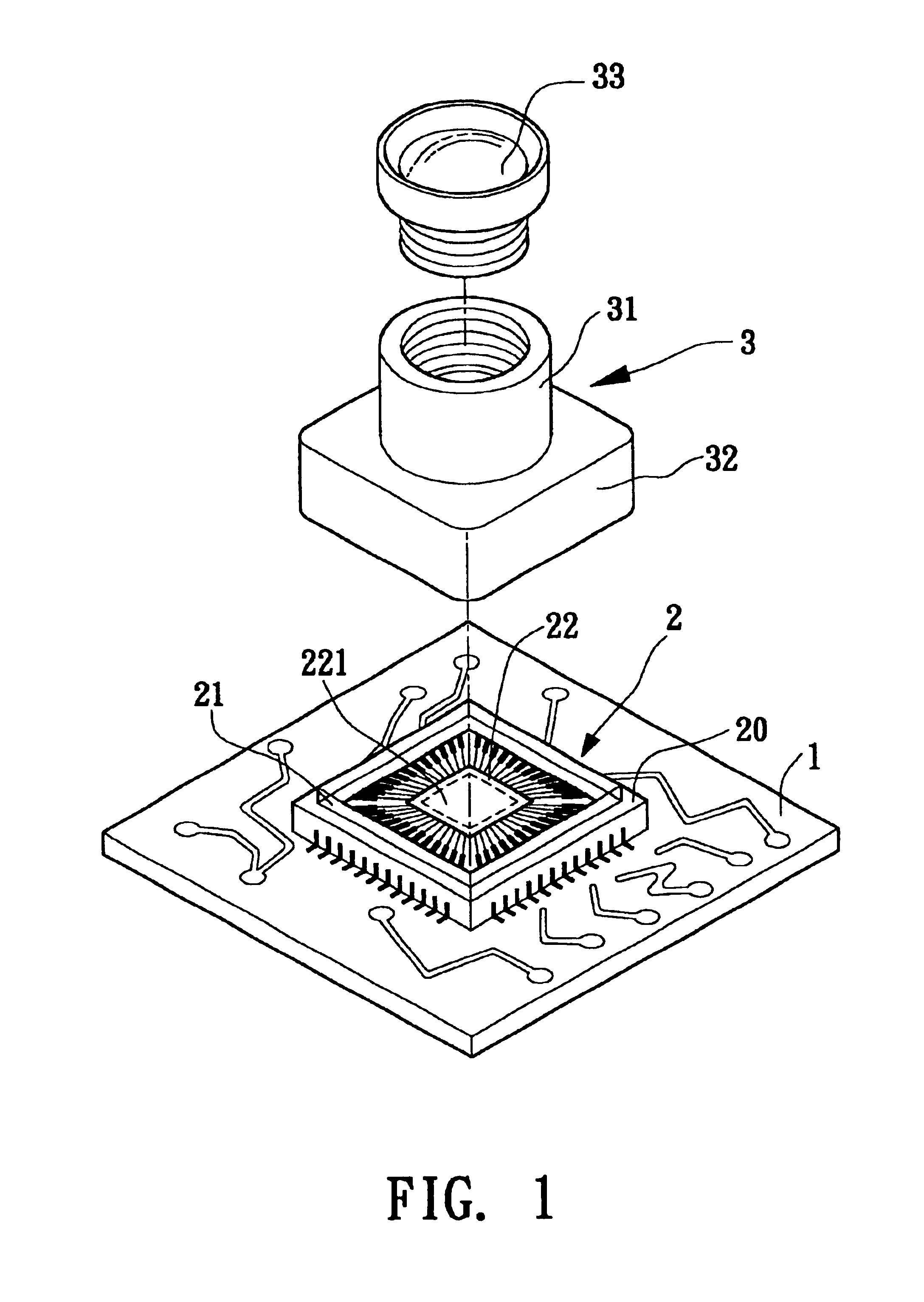

Image pickup module

InactiveUS6900913B2Avoid deflectionLower the volumeTelevision system detailsTelevision system scanning detailsCMOSSoftware engineering

A CCD and CMOS image pickup module including a circuit main board on which an image sensor (CMOS, CCD) and relevant electronic elements are laid. A lens seat is disposed on an upper edge of a package of the image sensor. The lens seat has an image pickup cylinder correspondingly positioned above a coupling transistor of the image sensor. The lens seat covers and encloses the image sensor with the connecting section of the bottom of the image pickup cylinder sealedly attaching to the periphery of the top face of the package of the image sensor. With the profile of the outer periphery of the package of the image sensor serving as a normal standard for the axis of the lens, the axis of the lens being projected onto the sensor center of the coupling transistor.

Owner:CHEN WEN CHING

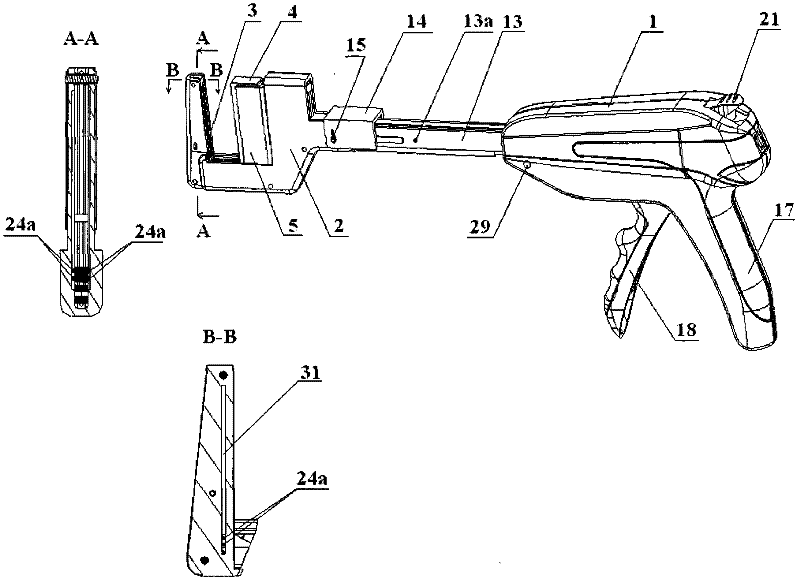

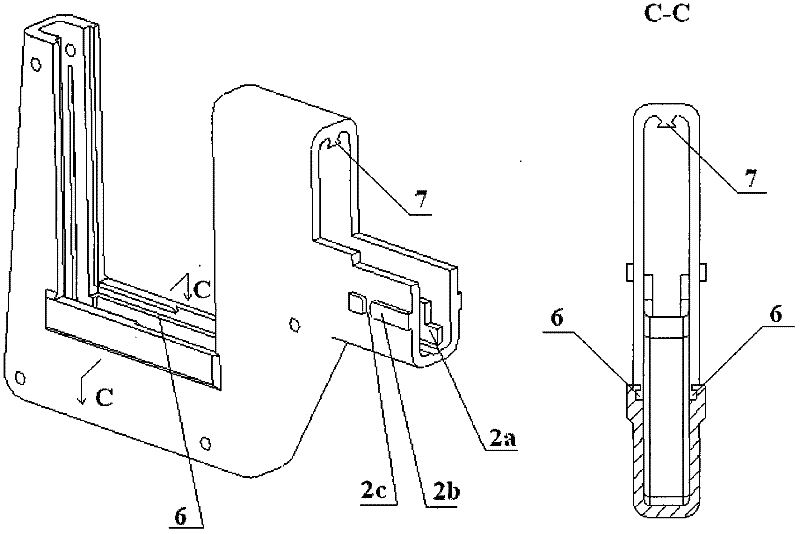

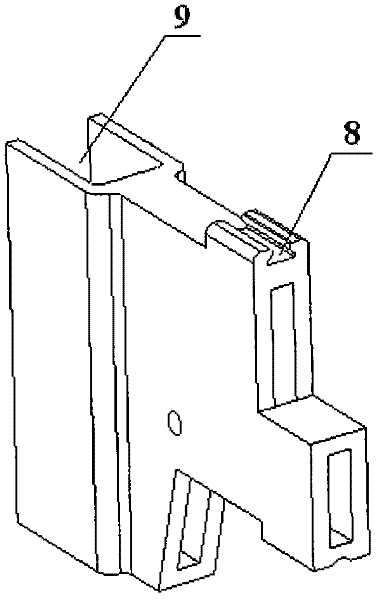

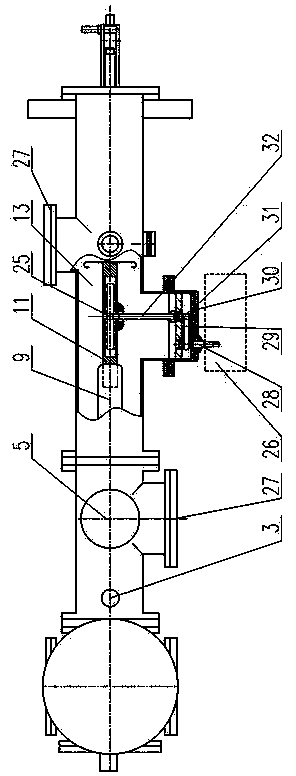

Forceps opening assembly with guiding structure and stitching instrument adopting forceps opening assembly

The invention relates to a forceps opening assembly with a guiding structure and a stitching instrument adopting the forceps opening assembly. The forceps opening assembly comprises a nail pressing seat bracket 2, a nail pressing seat 3, a nail cabin bracket 5 and a nail cabin 4; a first chute 6 is formed at the middle lower part of the nail pressing seat bracket 2; a dovetail slide rail 7 is arranged at the upper part of the rear end of the nail pressing seat bracket 2; a second chute 8 is formed at the top part of the rear end of the nail cabinet bracket 5; the lower end of the nail cabinet 4 is arranged in the first chute 6 in a sliding manner; and the slide rail 7 is arranged in the second chute 8 in a sliding manner. The stitching instrument further comprises a cutting device. In the invention, the forceps assembly with the guiding structure can effectively prevent the nail cabinet from running out in the closing process of the forceps assembly; the adopted cutting device can easily realize full separation of tissues; meanwhile, the removable forceps assembly can satisfy the requirements of the stitching instruments with different suture lengths in a same operation, such that manufacturing cost and operation cost of the stitching instrument can be saved.

Owner:B J ZH F PANTHER MEDICAL EQUIP

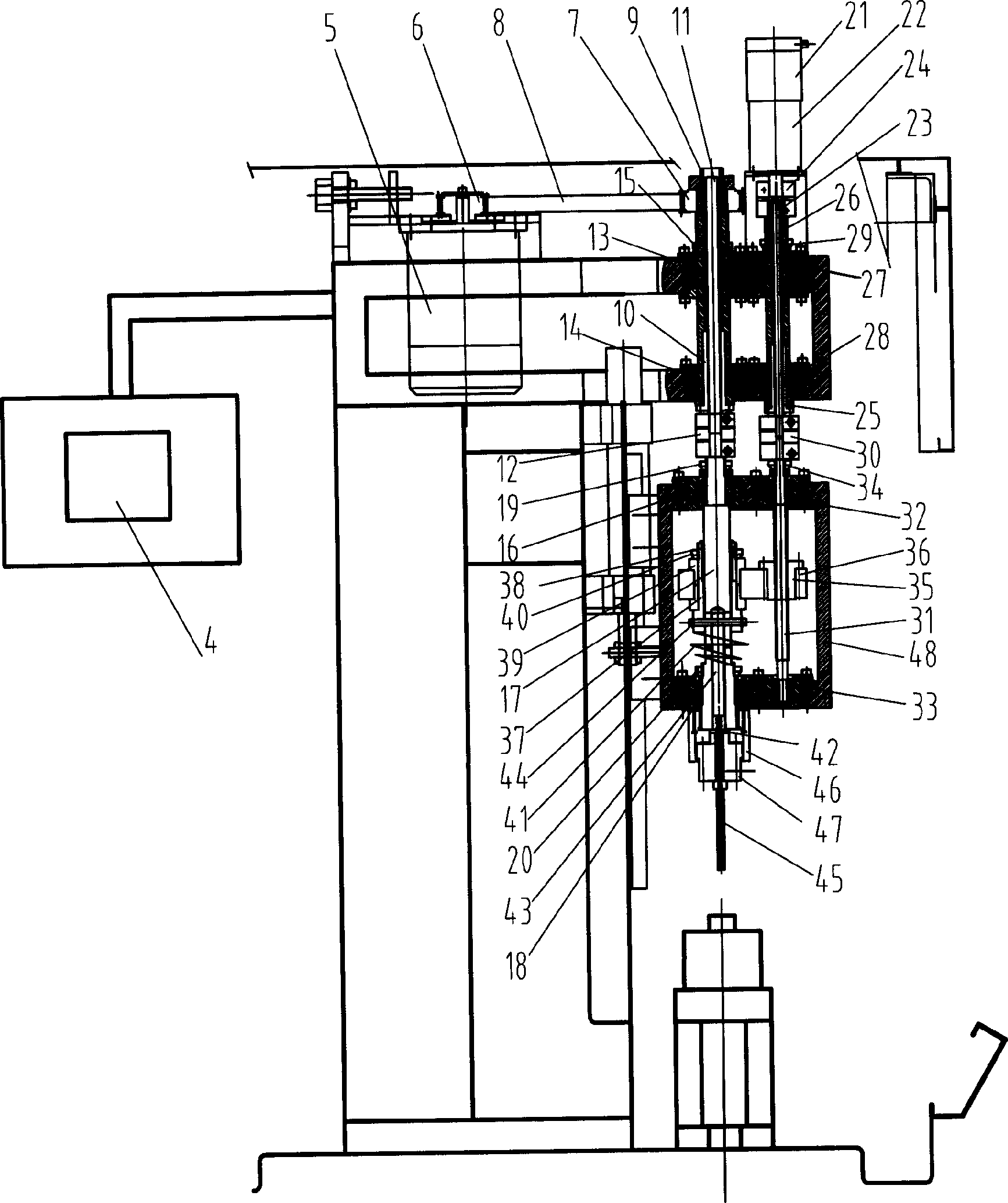

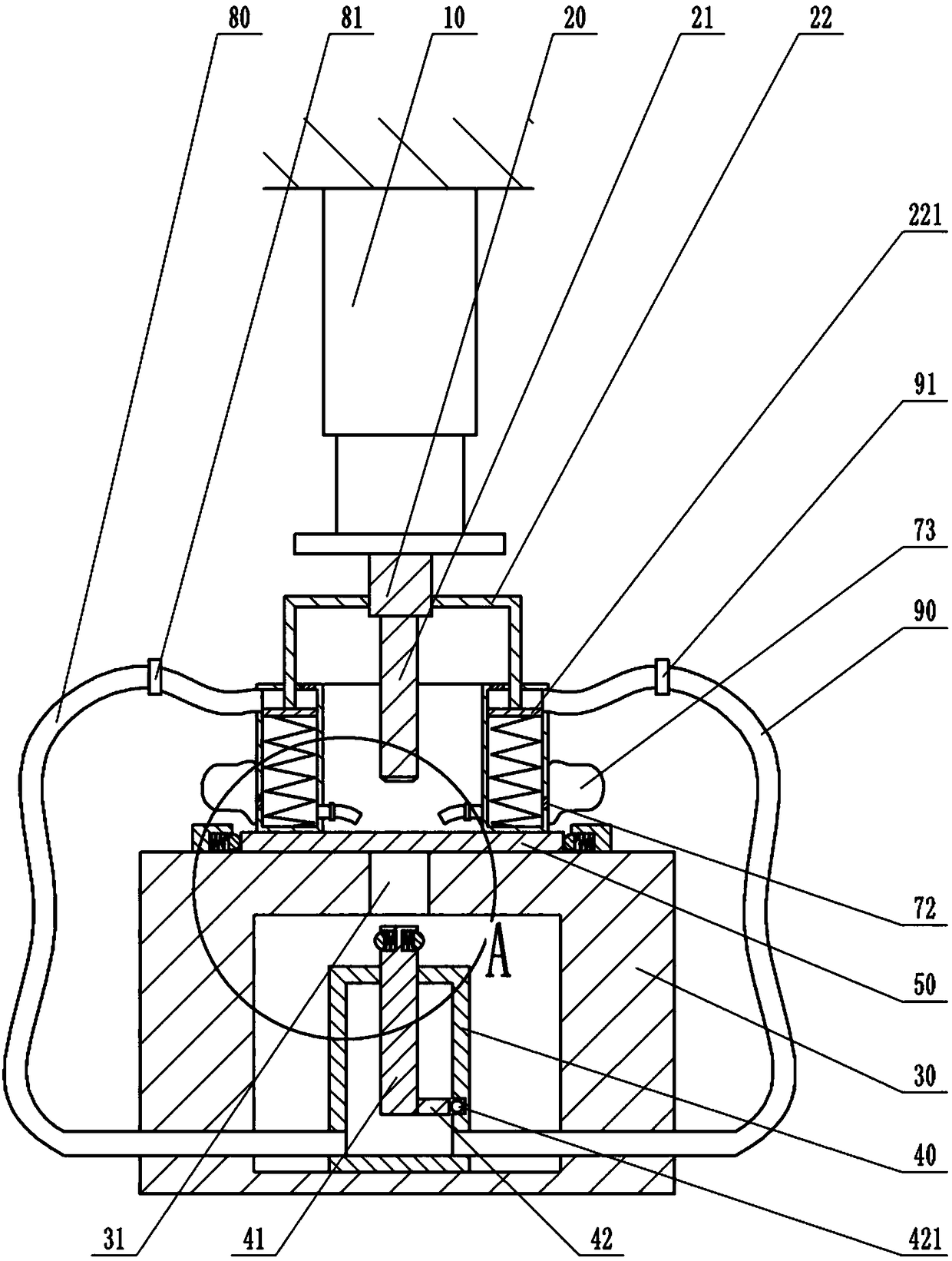

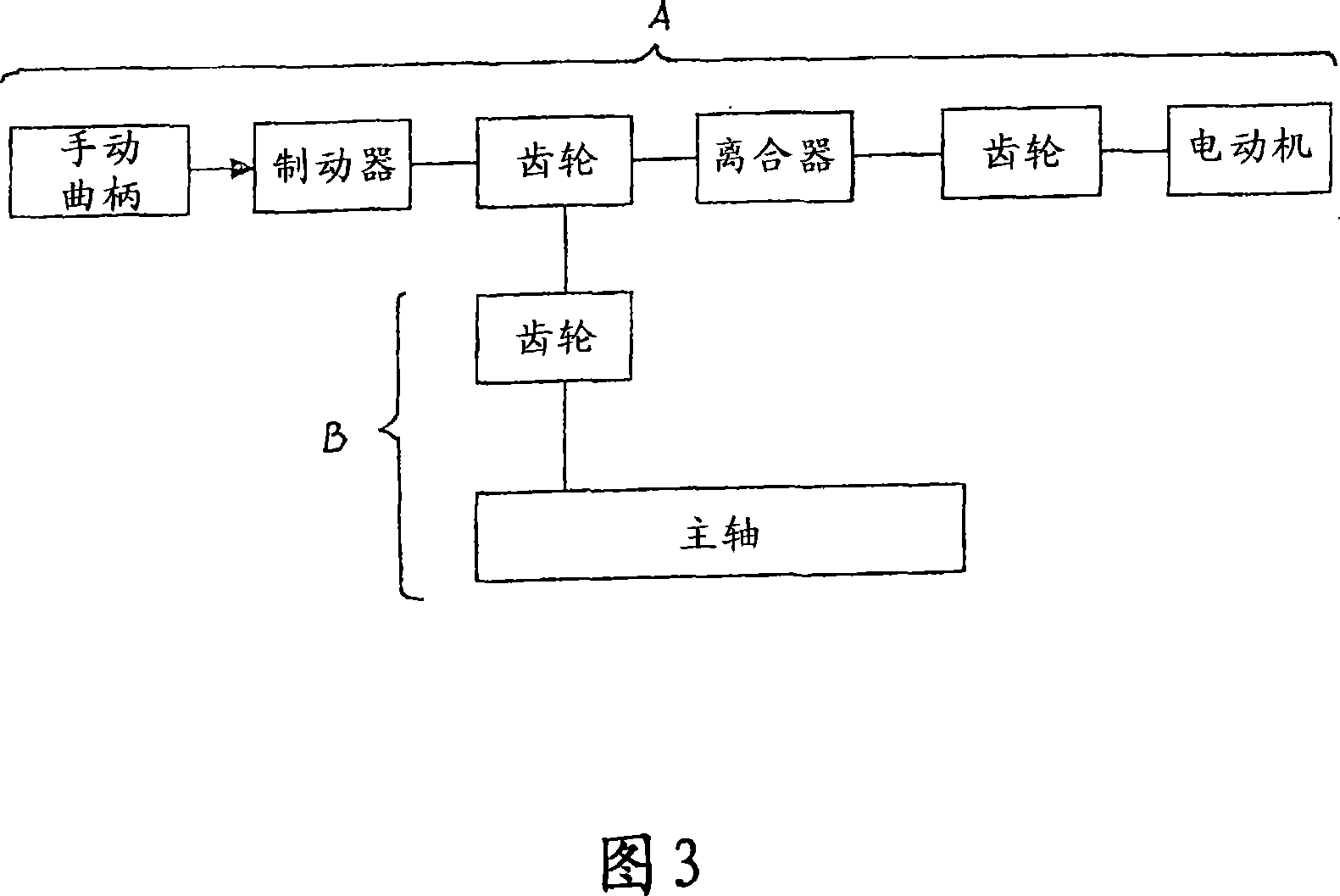

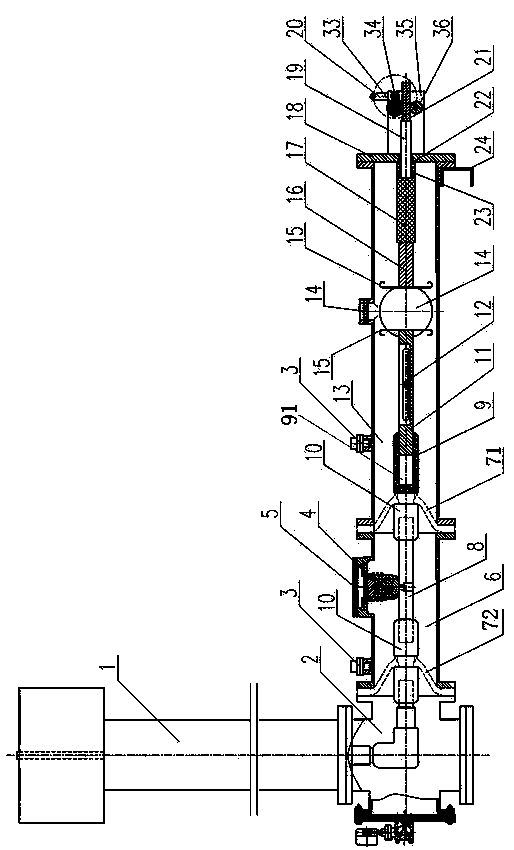

Digital control vertical high precision honing machine

InactiveCN1654167AConvenient real-time operation and monitoringEasy to operateAutomatic grinding controlHoning machinesProcessing accuracyReciprocating motion

The numerically controlled vertical high precision honing machine in the field of mechanical technology includes main shaft driving mechanism of vertical honing head, radial micro feeding mechanism of honing strip, high speed smooth honing head reciprocating mechanism, and digital control system. The connection mode includes vertical setting of the main shaft driving mechanism of vertical honing head and the radial micro feeding mechanism of honing strip on the honing machine bed, connection between the main shaft driving mechanism of vertical honing head and the radial micro feeding mechanism of honing strip via the feeding sleeve, and the connection of the high speed smooth honing head reciprocating mechanism to the main shaft driving mechanism of vertical honing head and the radial micro feeding mechanism of honing strip via bearing. The present invention has the advantages of simple structure, reasonable layout, high stability and reliability, etc.

Owner:SHANGHAI JIAO TONG UNIV +1

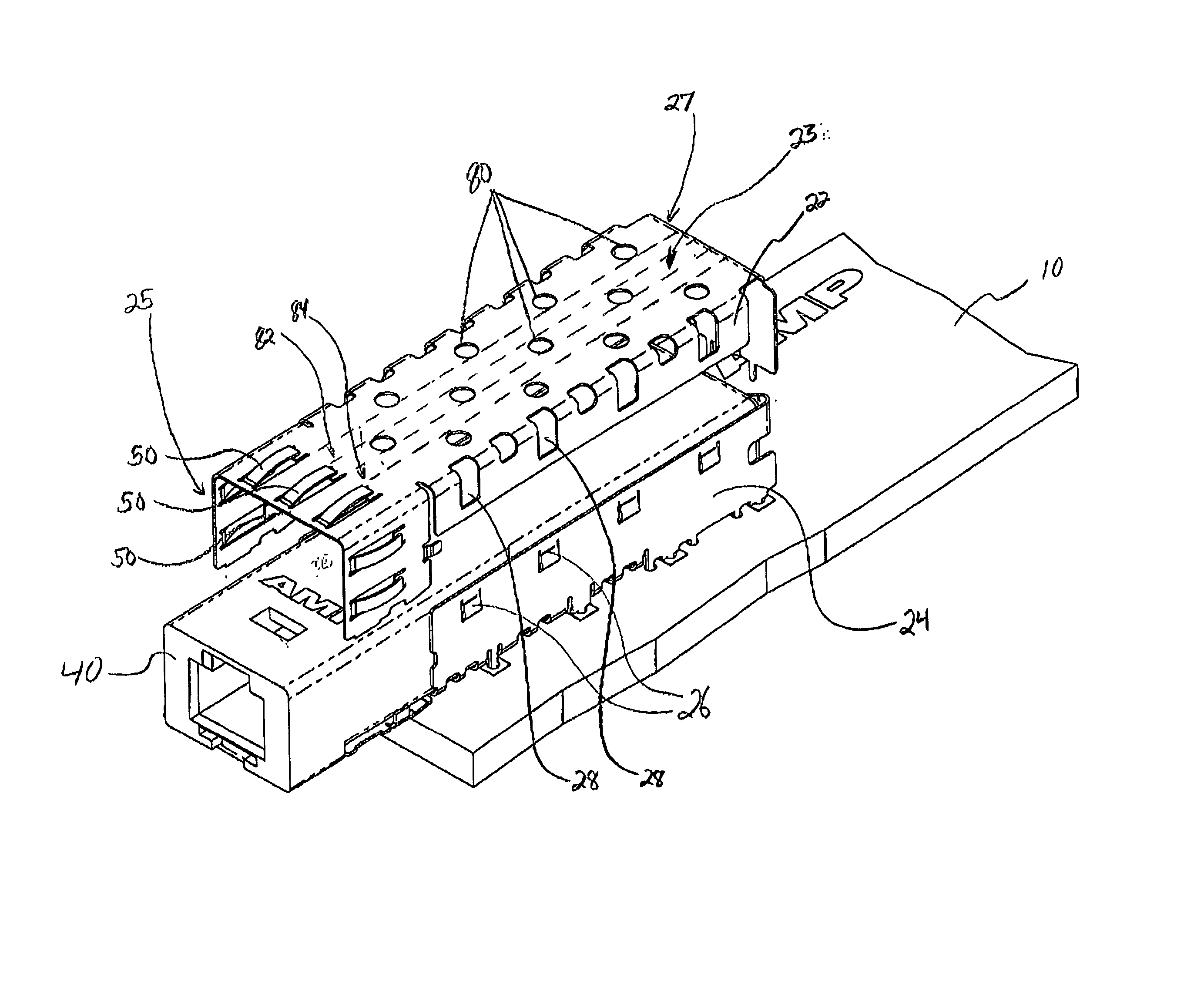

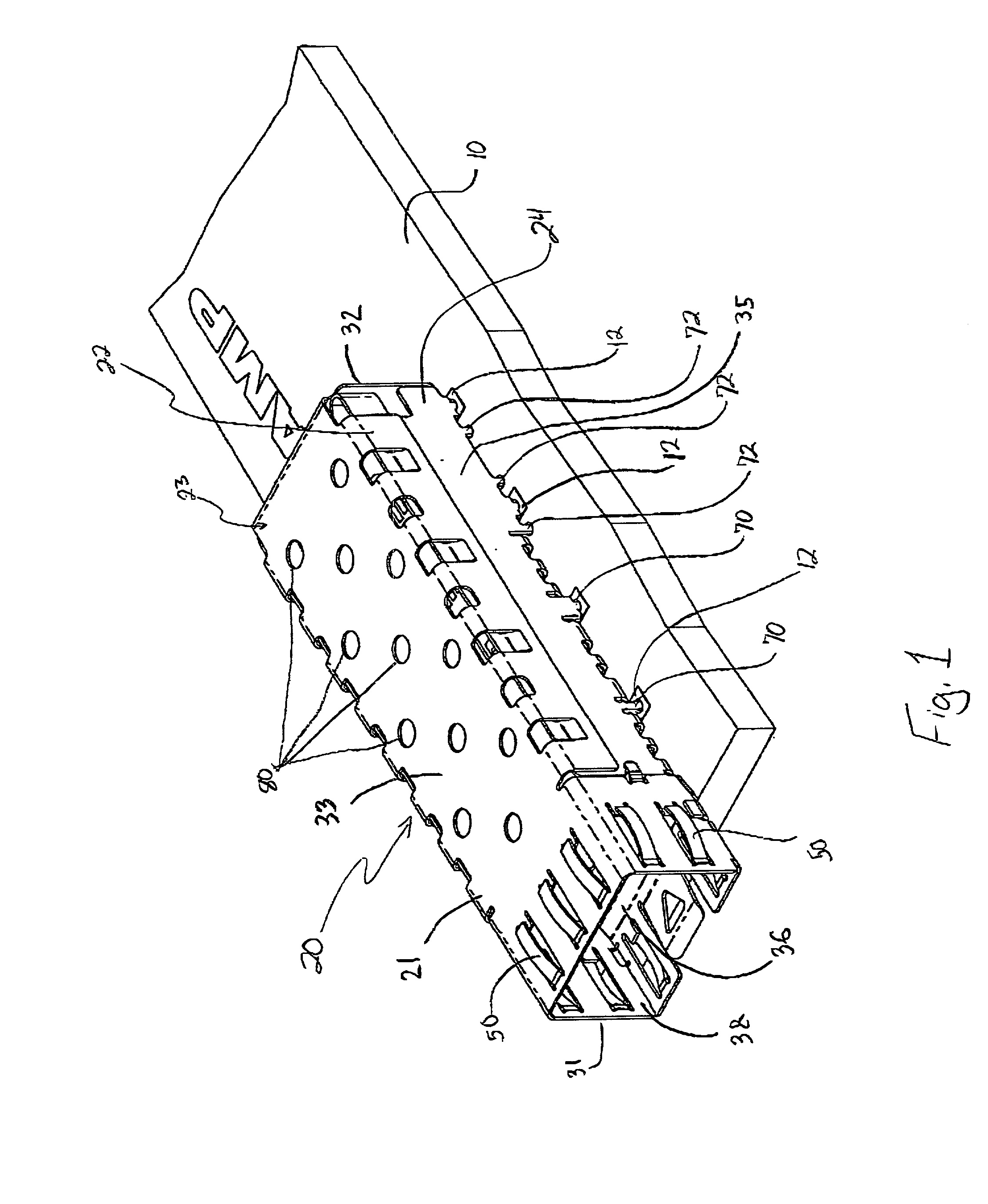

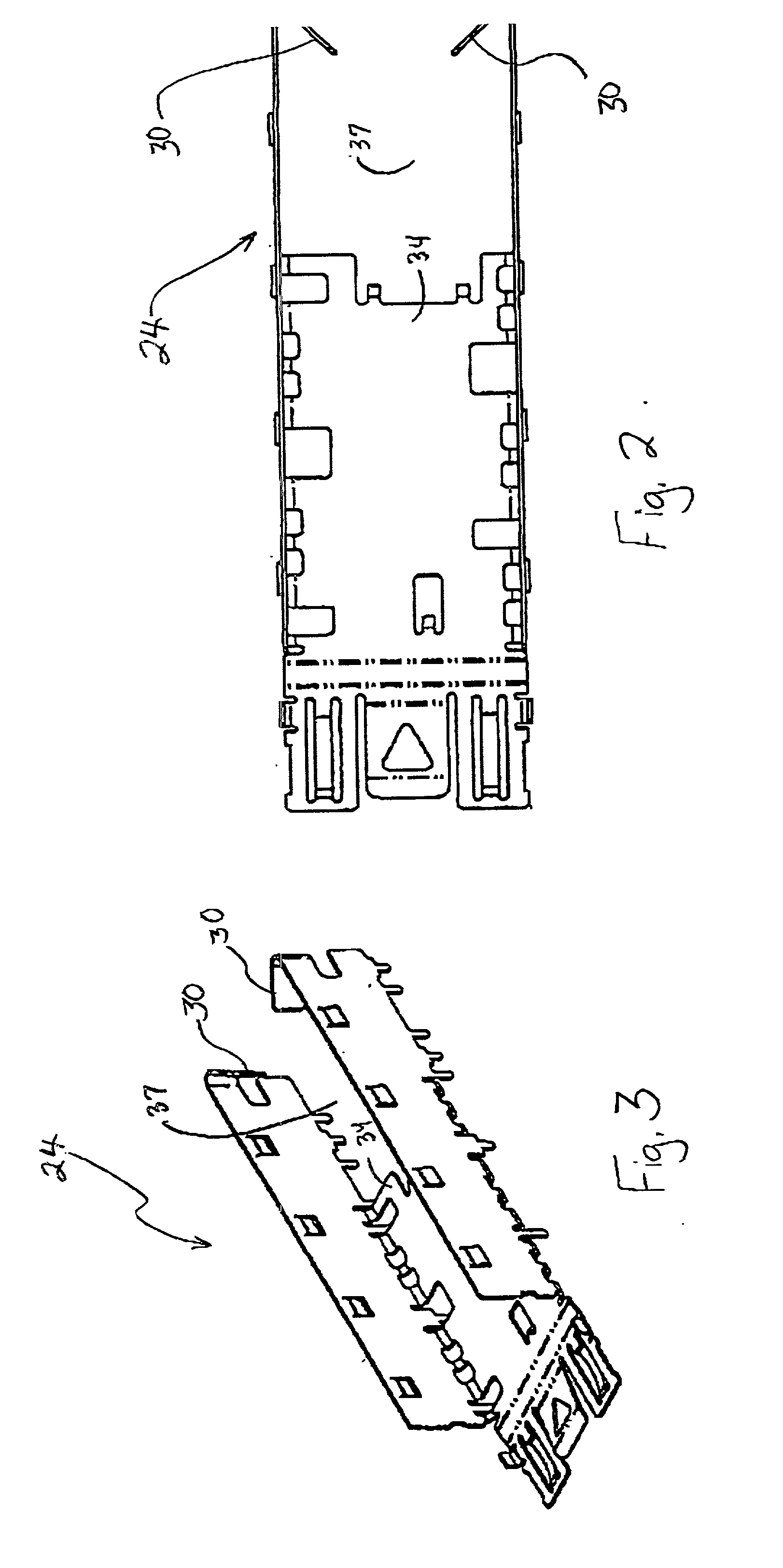

Pluggable module and receptacle

InactiveUS20020068481A1High frequencyHighly miniaturizedMagnetic/electric field screeningContact members penetrating/cutting insulation/cable strandsElectrical connectionConductive materials

A receptacle for a pluggable module includes a housing having a front, a back wall, a top wall, a bottom wall, and side walls and defining a cavity for receiving a module. The bottom wall has a bottom opening to receive a receptacle connector, and the front has a front opening to receive the module. The walls of the housing are made from a conductive material. A plurality of elongated members extend down from the housing past the bottom wall. The elongated members are adapted for electrical connection to a host circuit board such that the walls of the housing are electrically connected to the host circuit board.

Owner:TE CONNECTIVITY CORP

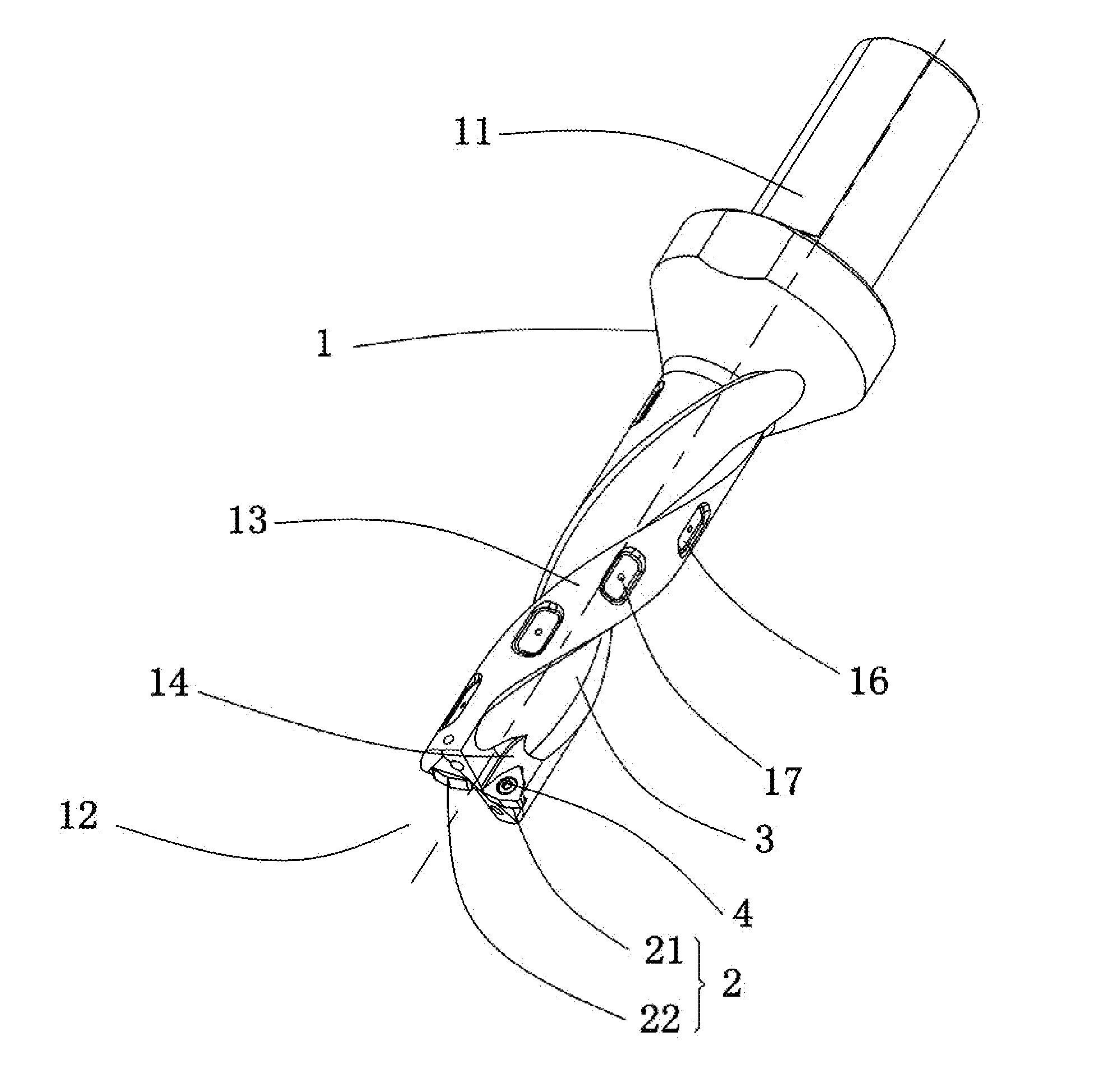

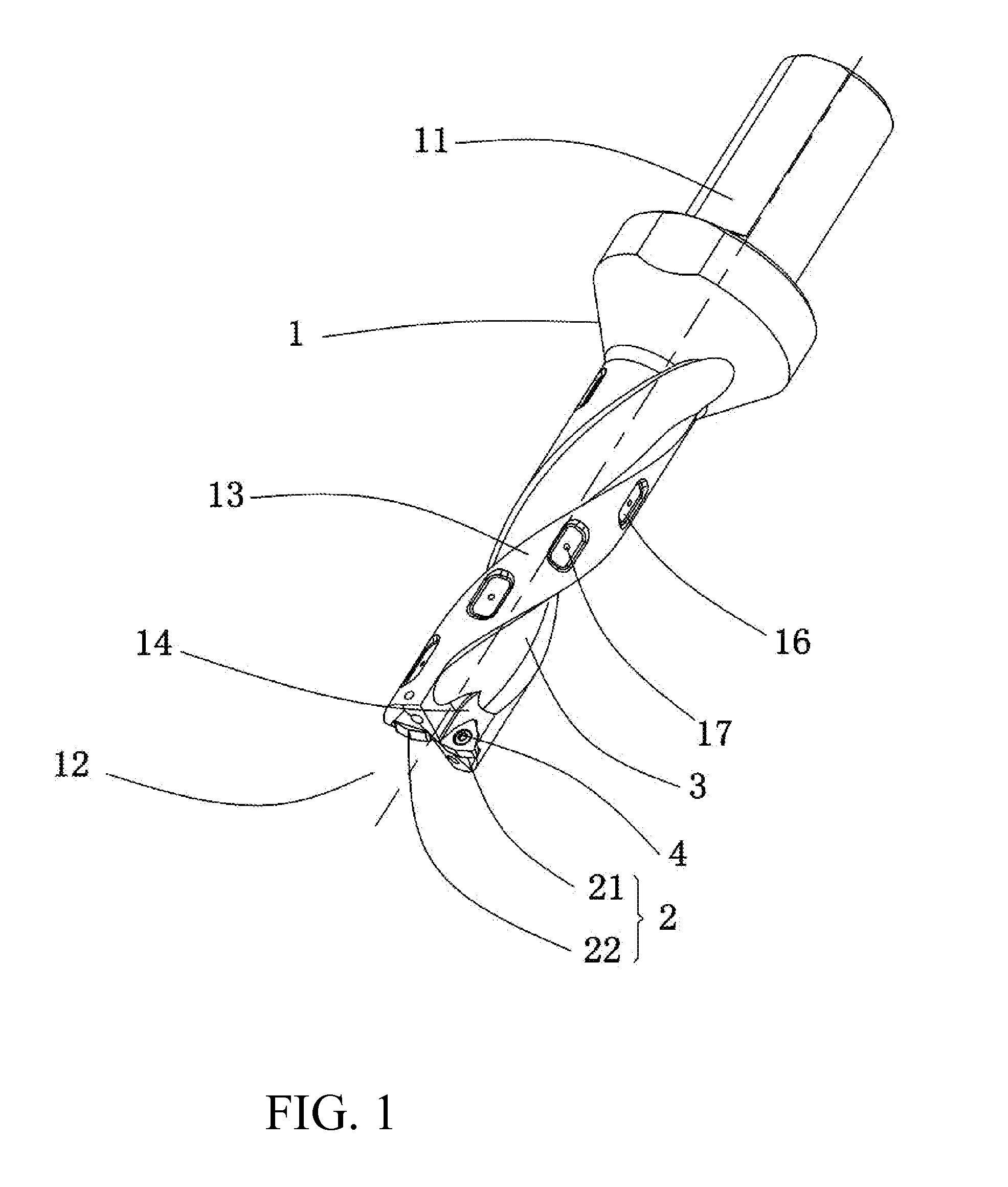

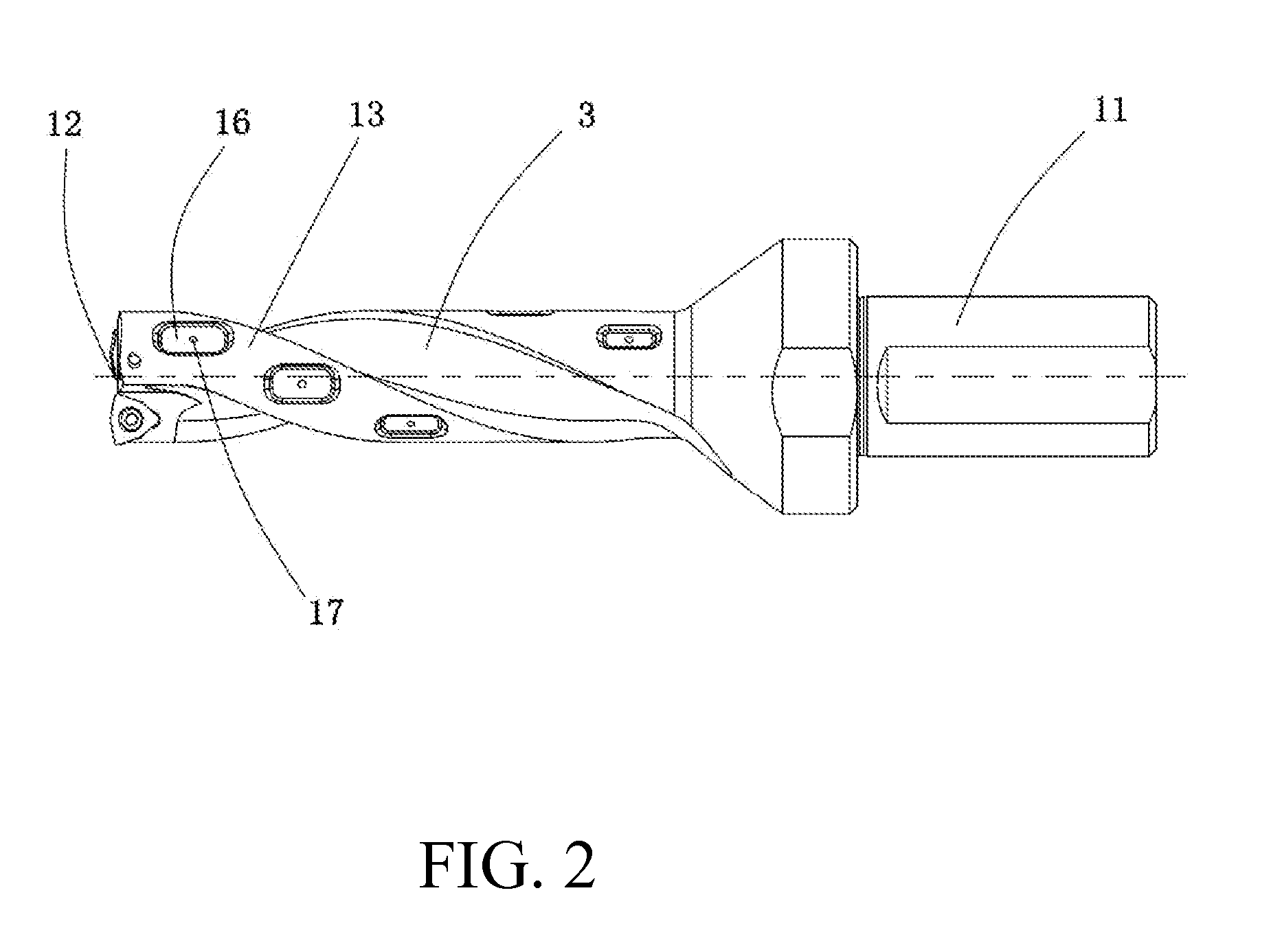

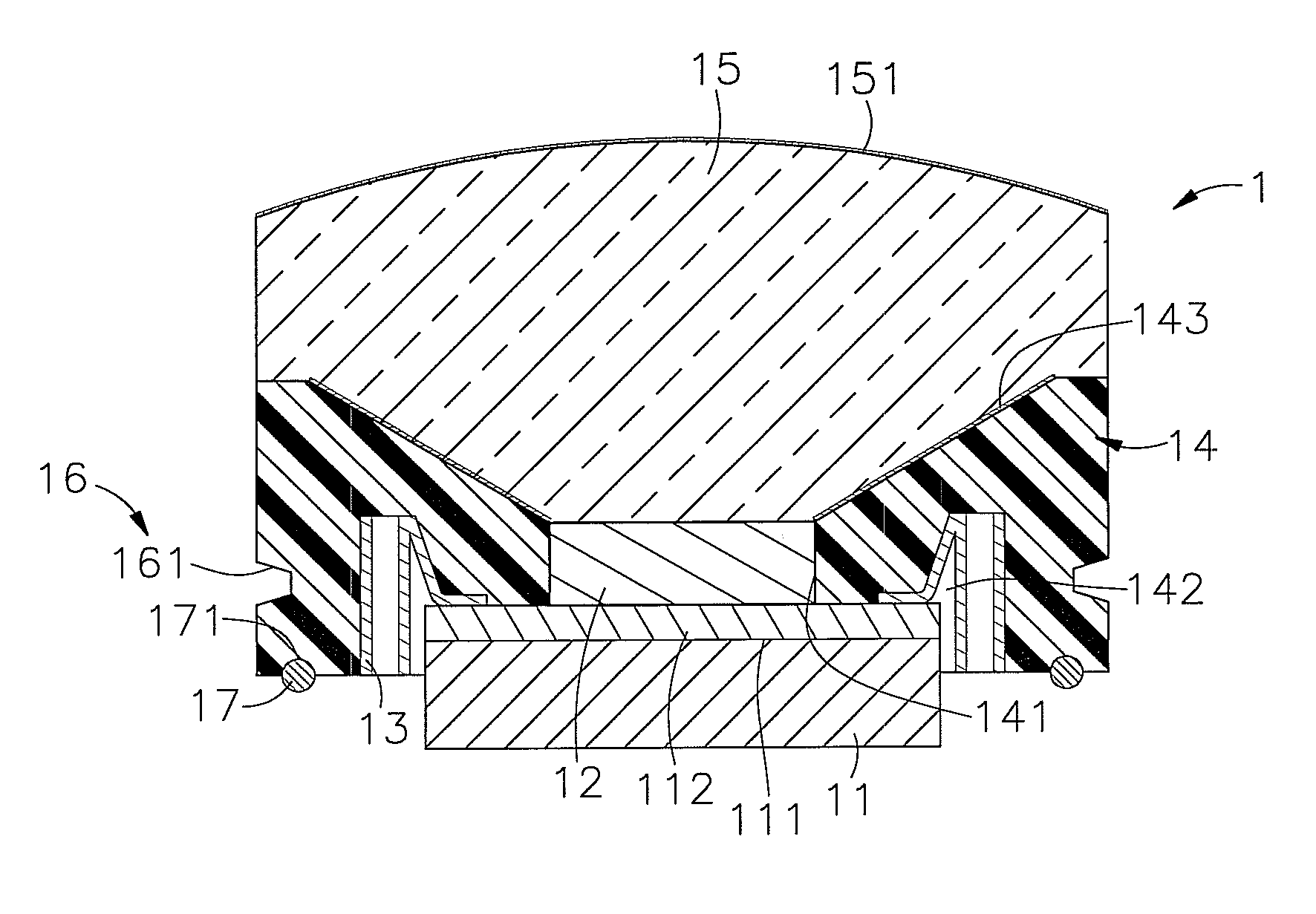

Boring Cutter

InactiveUS20150328696A1Minimize tool deflectionMinimize drilling vibrationTransportation and packagingMulti-purpose machinesFluteEngineering

A boring cutter includes a tool body and a cutting insert. The tool body includes a shaft handle and a cutting end, and defines a circumferential face extended between the shaft handle and the cutting end. The tool body further has an insert pocket extended to the cutting end to secure the cutting insert at the insert pocket, and a flute formed on the circumferential face to communicate with the insert pocket. The tool body further has a cooling channel extended through the shaft handle to the cutting end, and a plurality of discharging chambers spacedly formed on the circumferential face to communicate with the cooling channel. During a drilling process, cooling fluid is released to the discharging chambers from the cooling channel to create a pressure between the tool body and an inner wall of a hole of a workpiece to prevent the tool deflection and drilling vibration.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

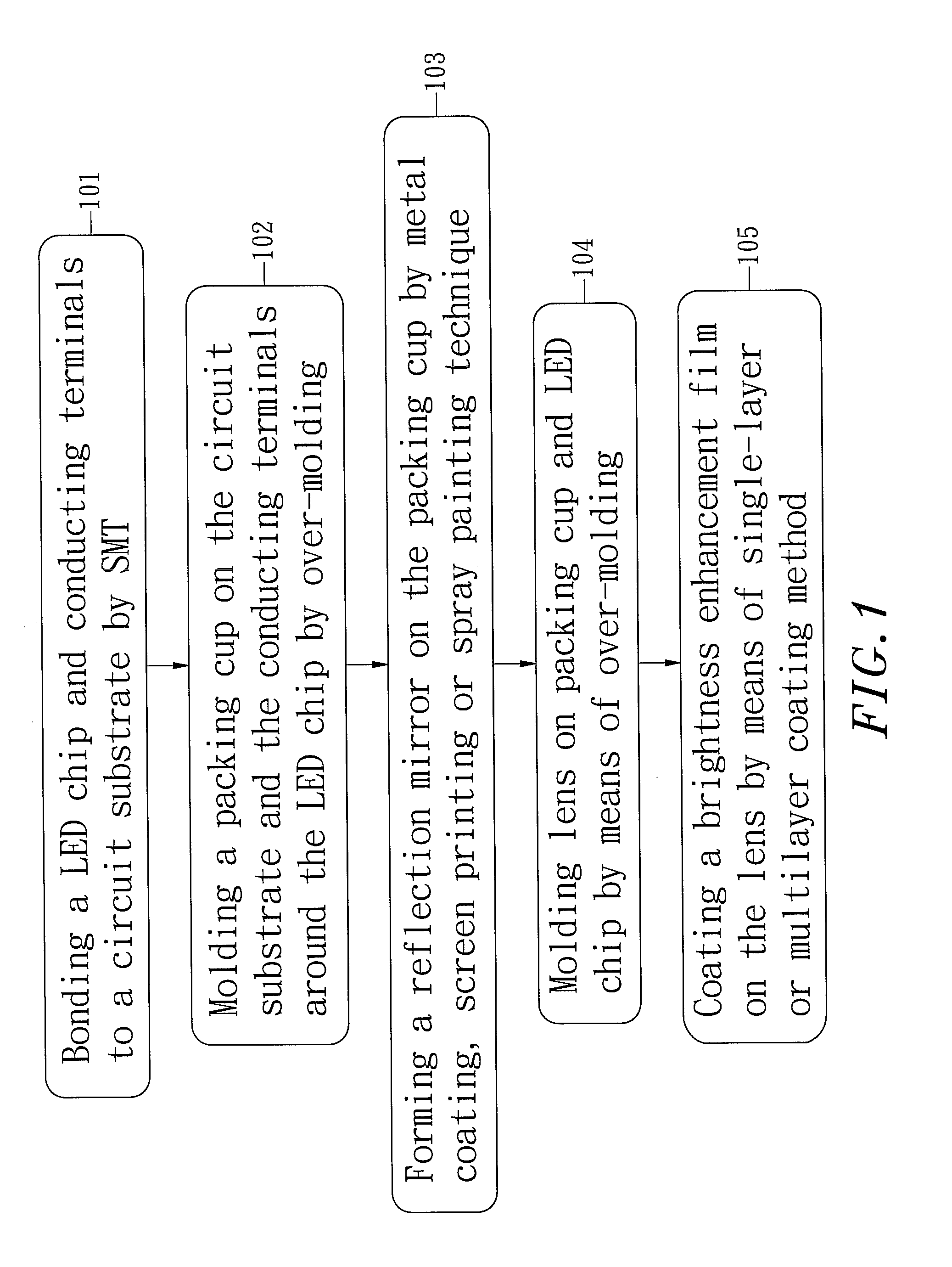

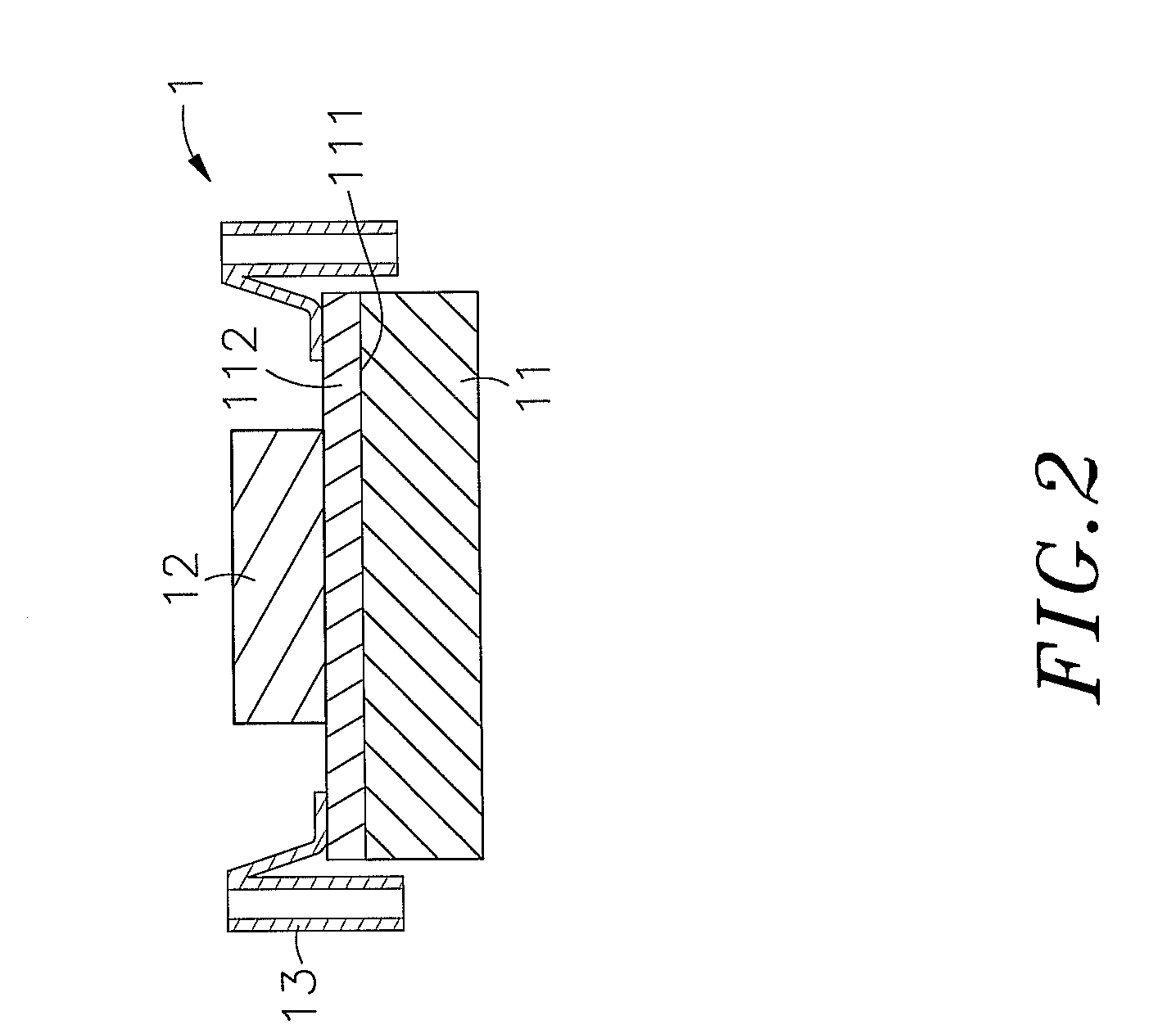

LED module fabrication method

InactiveUS20100311193A1Eliminates deflection and total reflection and light attenuationAssures uniform distributionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBrightness perception

A method of fabricating a LED module by: bonding one or multiple LED chips and multiple conducting terminals to a circuit substrate, and then molding a packing cup on the circuit substrate over by over molding for enabling the LED chip(s) and the conducting terminals to be exposed to the outside of the packing cup, and then molding a lens on the packing cup and the LED chip(s) by over-molding. By means of directly molding the lens on the packing cup and the LED chip(s), no any gap is left in the lens, avoiding deflection, total reflection or light attenuation and enhancing luminous brightness and assuring uniform distribution of output light.

Owner:KWO GER METAL TECH

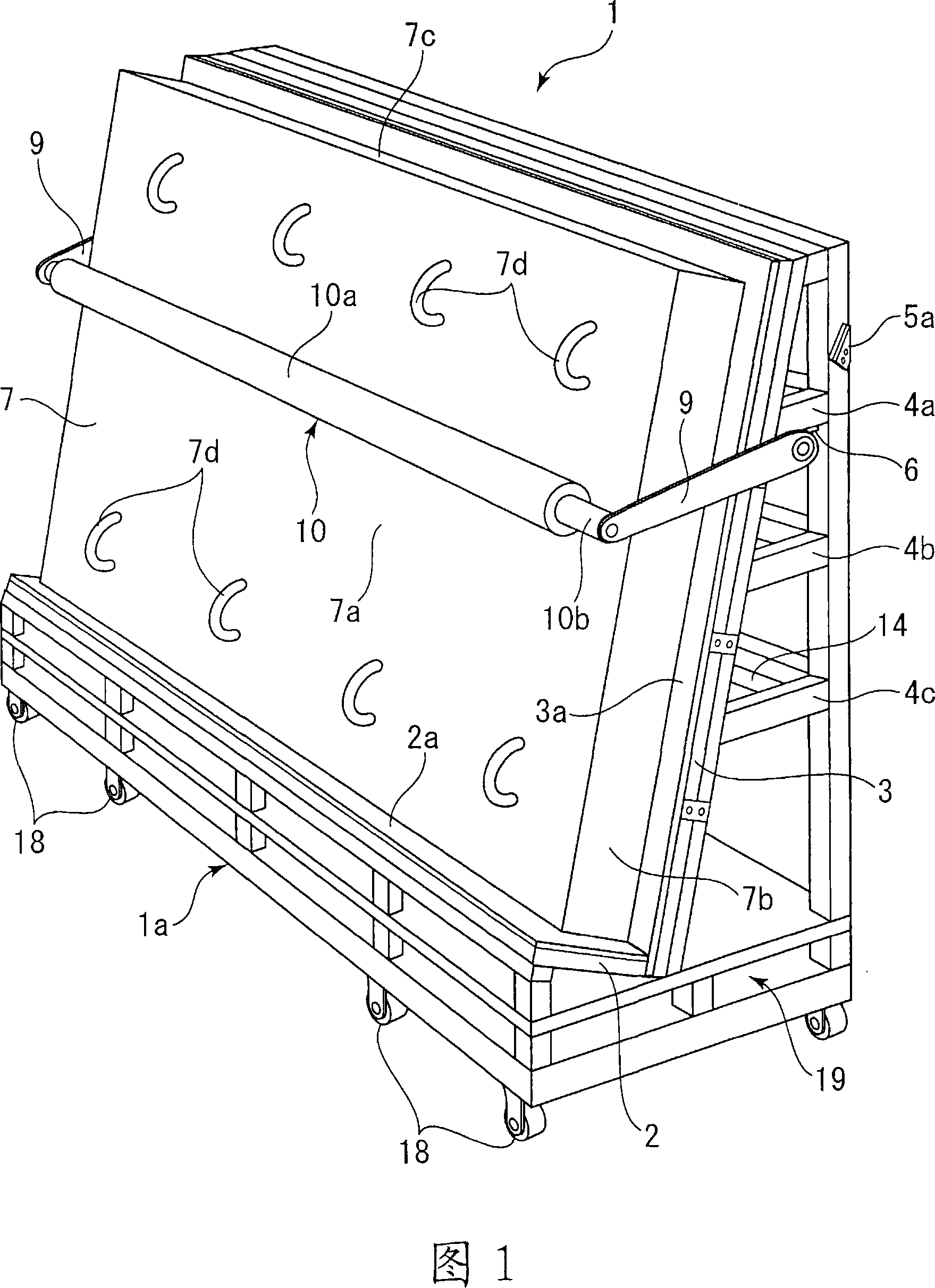

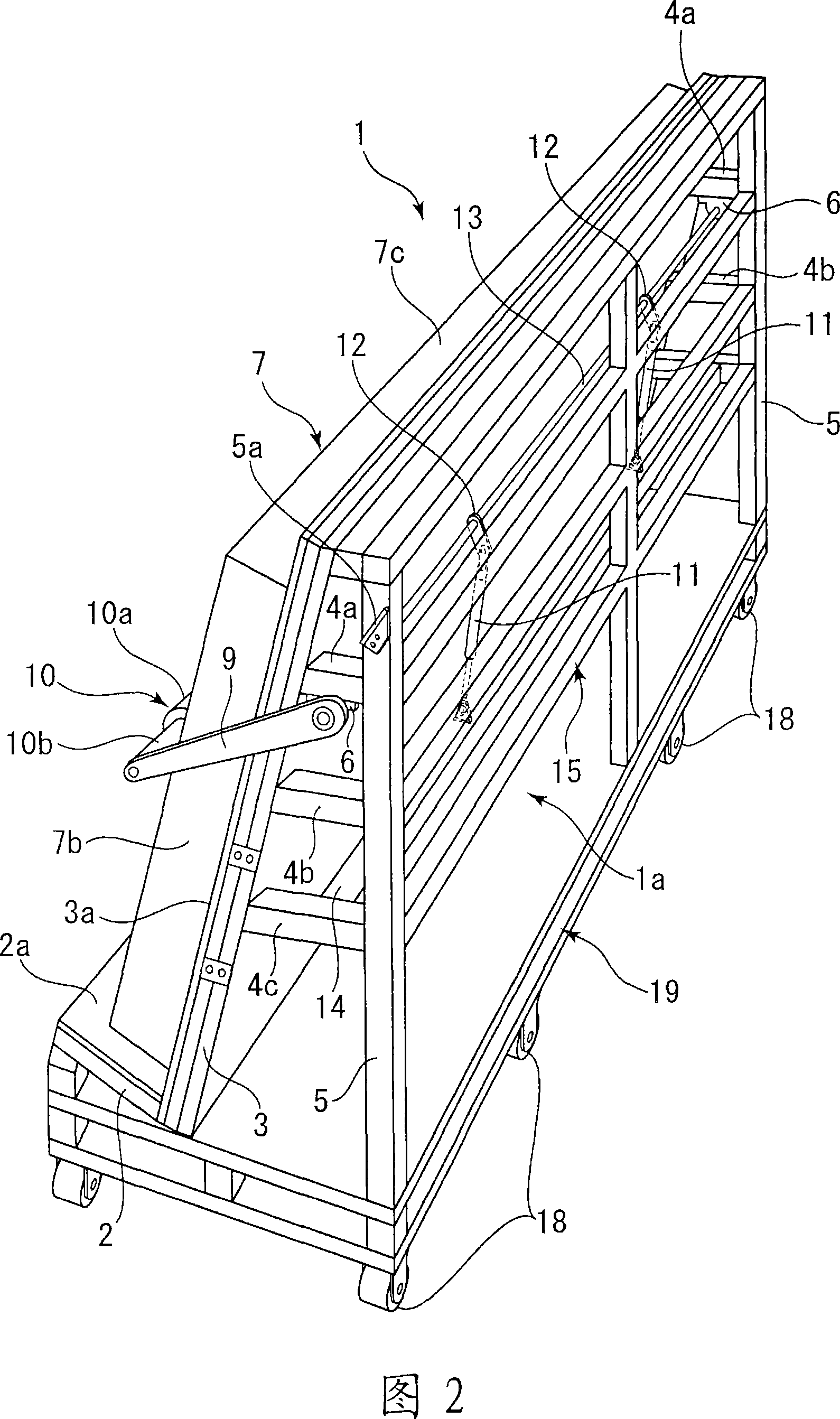

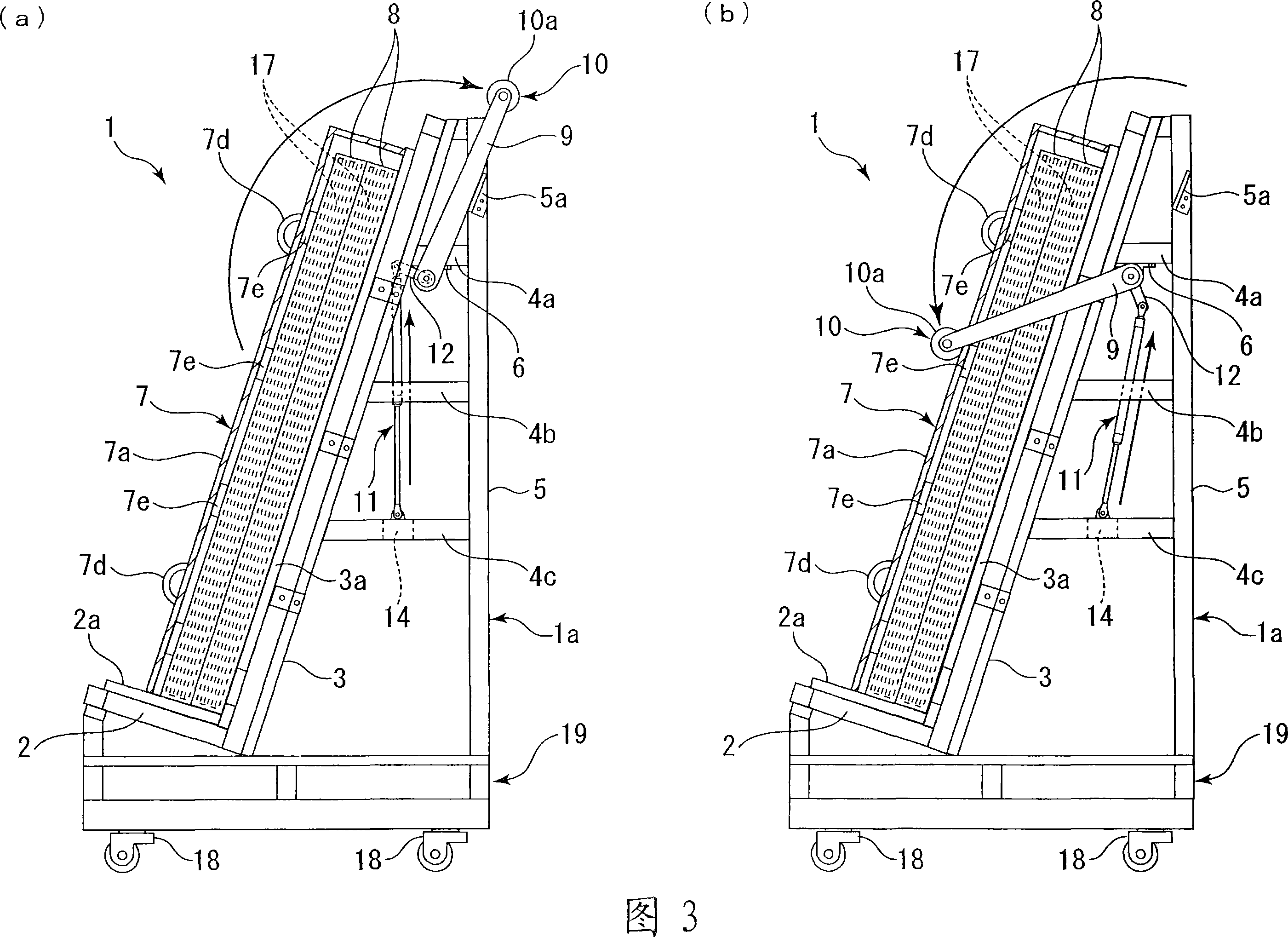

Glass plate conveyance pallet

ActiveCN101160249ASafe and reliable transferAvoid deflectionSledge wheelsRigid containersCover glassPallet

A glass plate conveyance pallet with good operability, where, even when glass plates are vertically layered on the conveyance pallet, no sag occurs about the center of the glass plates and sliding between the glass plates does not occur even in movement. Because a center bar (10) is made to be in contact with the vicinity of a central section (17a) of a cover body (7) covering glass plates (17) that are vertically layered, sag in the vicinity of the central section (17a) of the individual glass plates (17) that are layered and supported can be suppressed by the center bar (10). As a result, even during transfer of the conveyance pallet (1), movement of the layered and supported glass plates (17) is reliably prevented to prevent breakage of the glass plates (17). Further, the fixation and release of the layered and supported glass plates (17) by the center bar (10) can be made by swing motion of a support arm (9), so that operation is easy and, even if the number of layers of the glass plates (17) is increased or decreased, such a change can be easily coped with by changing the swing radius of the center bar (10).

Owner:ASAHI GLASS CO LTD

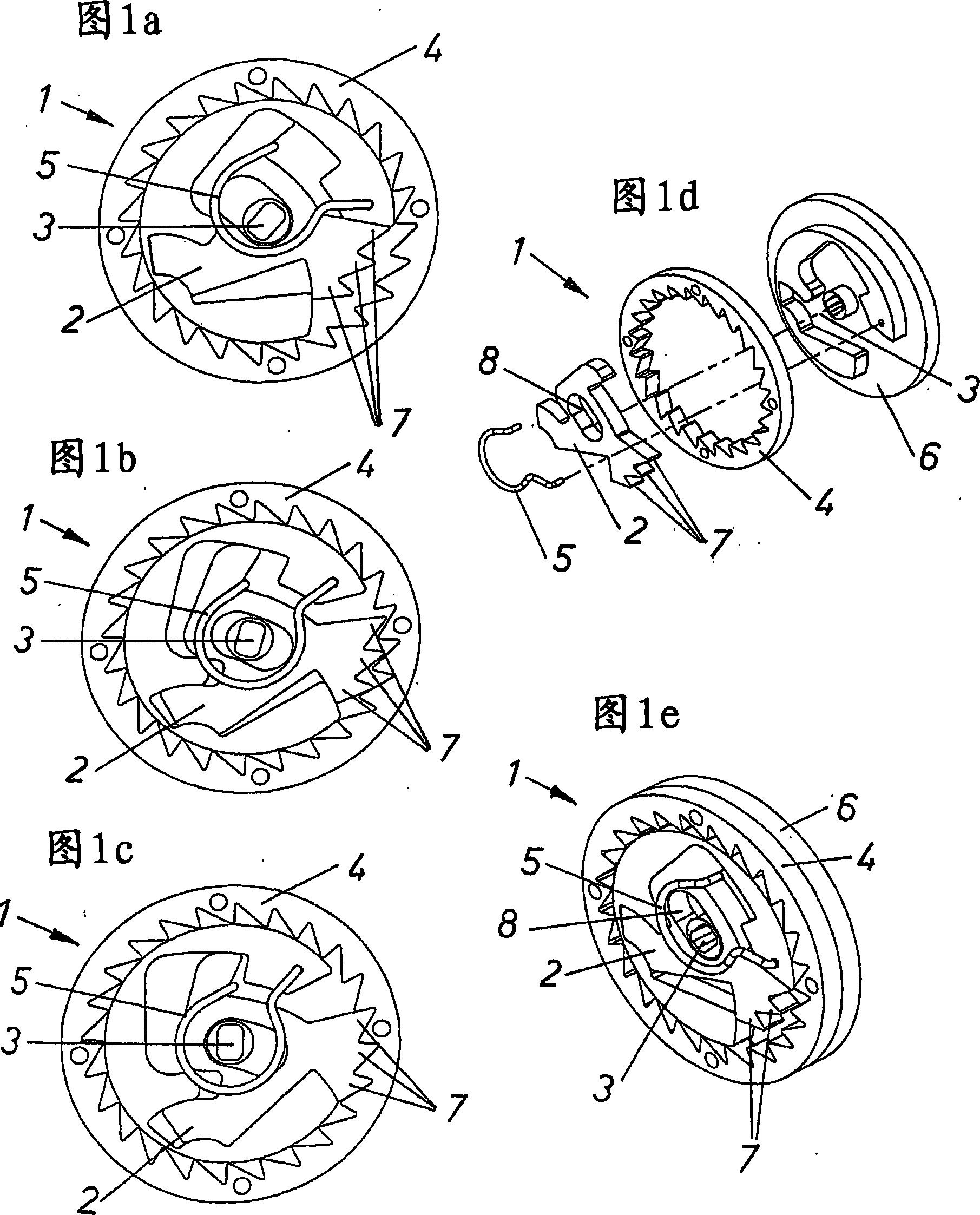

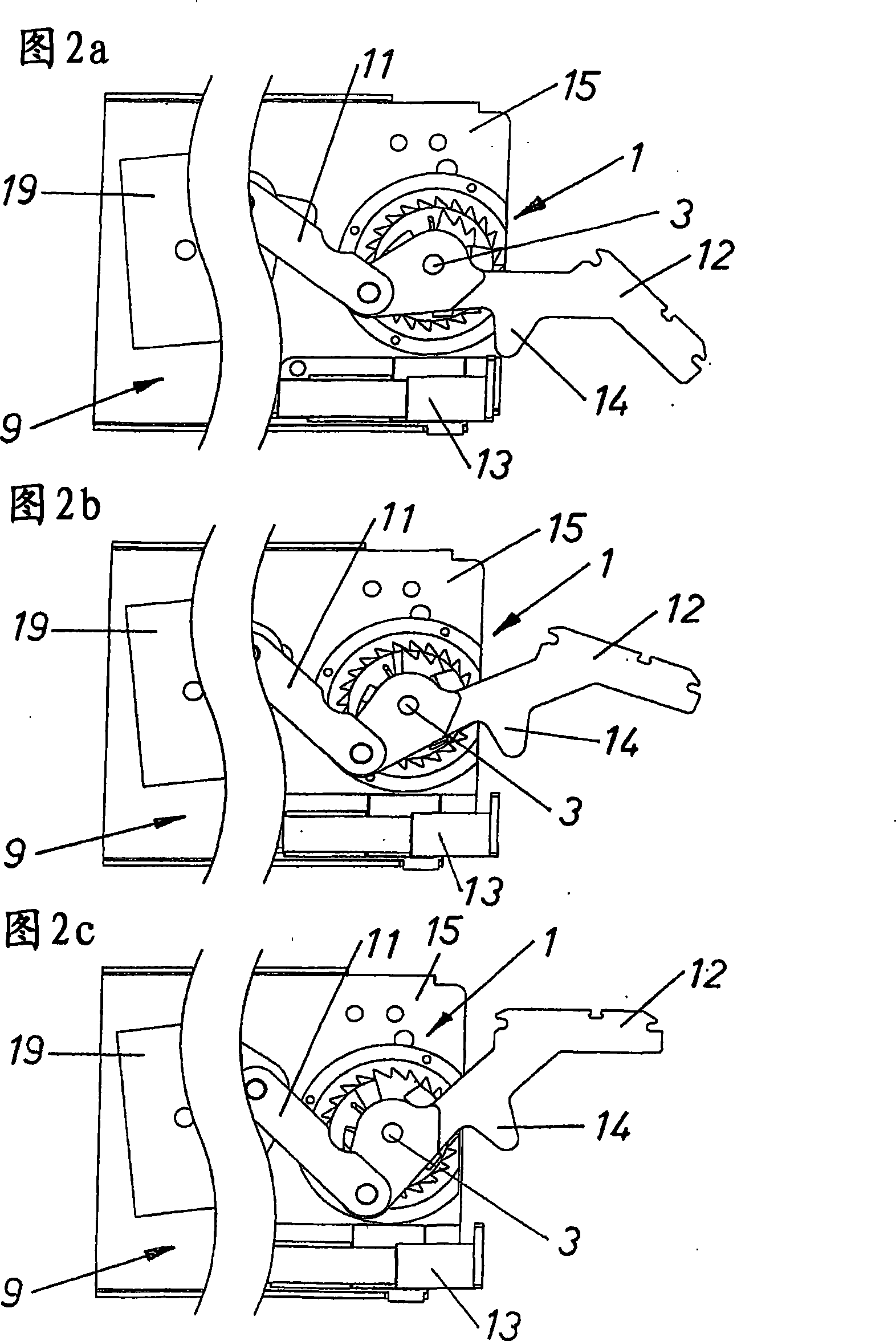

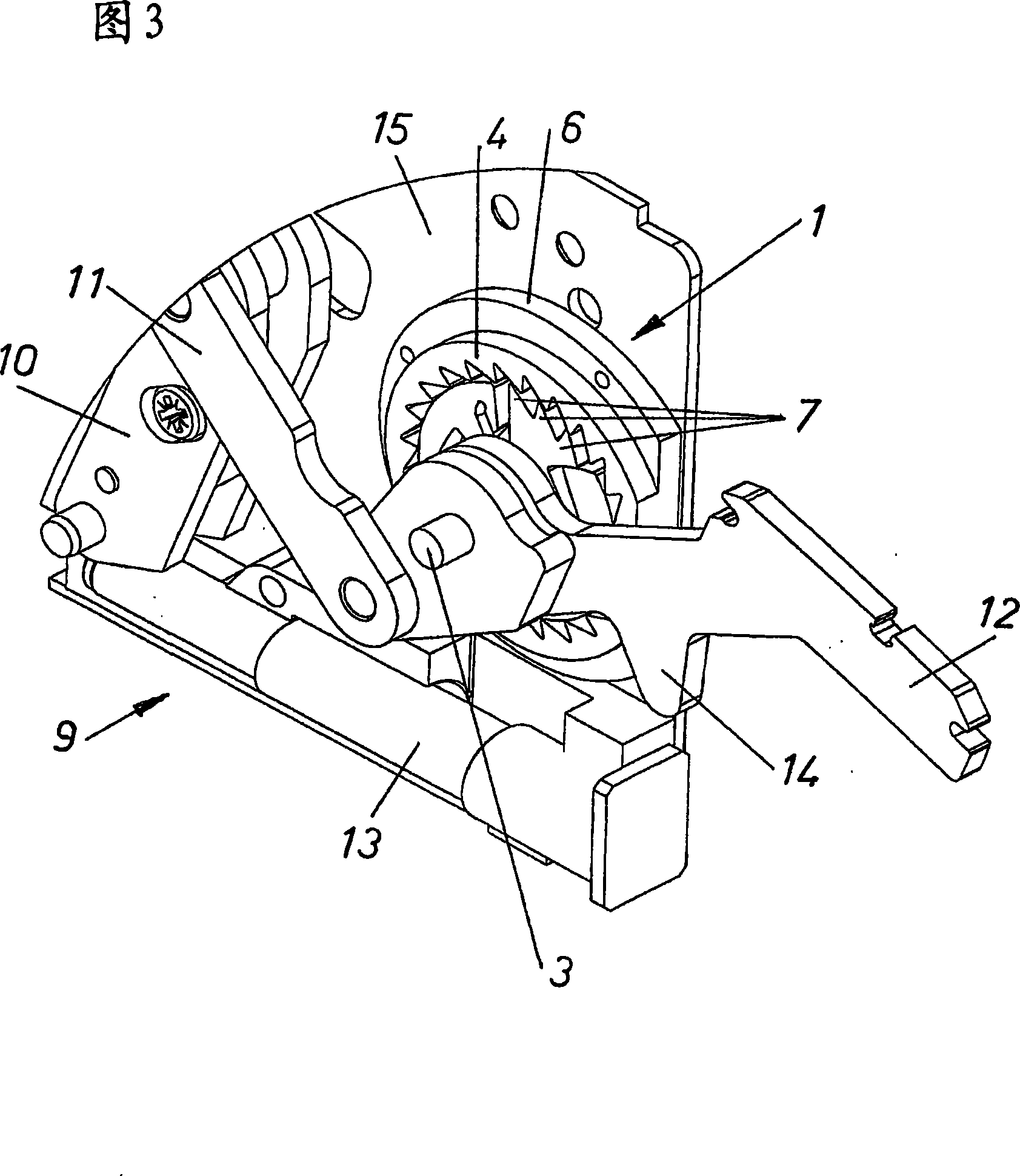

Control mechanism provided with at least one adjusting arm

ActiveCN101091034APrevent openingAvoid deflectionBuilding braking devicesWing openersMechanical engineeringEngineering

The invention relates to an actuating device for moving a flap of a piece of furniture, including at least one actuating arm for moving the flap, a base member on which the actuating arm is pivotally arranged, and a spring device able to act upon the actuating arm. An assembly securing device for the vacant actuating arm, which has not yet been fitted with a flap, includes a braking device which limits the opening speed of the vacant actuating arm.

Owner:JULIUS BLUM GMBH

Knocking type deicer for power transmission line

InactiveCN101420110AImprove efficiencyAvoid deflectionOverhead installationMotor driveRemote control

The invention relates to a knocking type ice removal for a transmission cable, which mainly consists of a main board, a transverse plate, a battery case, a battery jar, a direct current motor, a belt pulley, a probe reversing bar, a reversing touch disc, road wheels, a knocking arm, a knocking hammer, a belt, magnets, a sensor, a remote control transmitter, a remote control receiver, a fire balloon and a lead wire, and adopts 24V direct current power supply and a 150W direct current motor, wherein, in each road wheel, each magnet is attached on the transmission cable to prevent beating; the direct current motor drives a left road wheel and a right road wheel to walk left and right; the knocking hammer alternately and circularly knocks ice slush on the transmission cable with the frequency of 3 times / s; the sensor receives ice removing information; the remote control transmitter dictates to complete knocking action; the ice removal adopts a wired controllable fire balloon to be hung and dropped straightly. The device has the advantages of reasonable design, compact structure, safety, stability, reliability, energy conservation, good ice removal effect and high efficiency. By knocking to-and-fro, the ice removing ratio of the ice removal can reach 98 percent, the work efficiency is improved by 2 to 3 times than ice removing by milling, and energy can be saved by 500 times compared with ice removing by transforming voltage heat.

Owner:TAIYUAN UNIV OF TECH

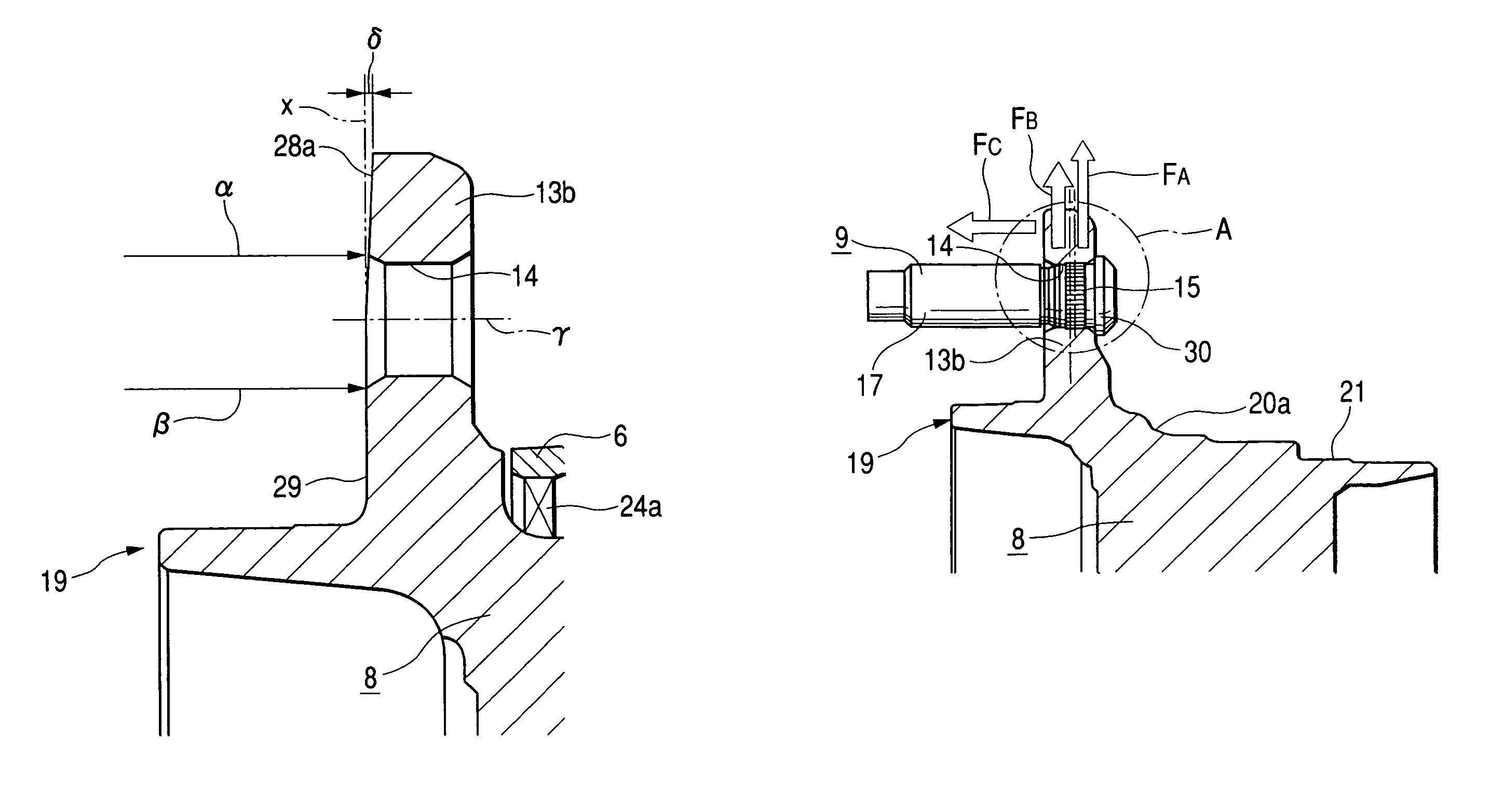

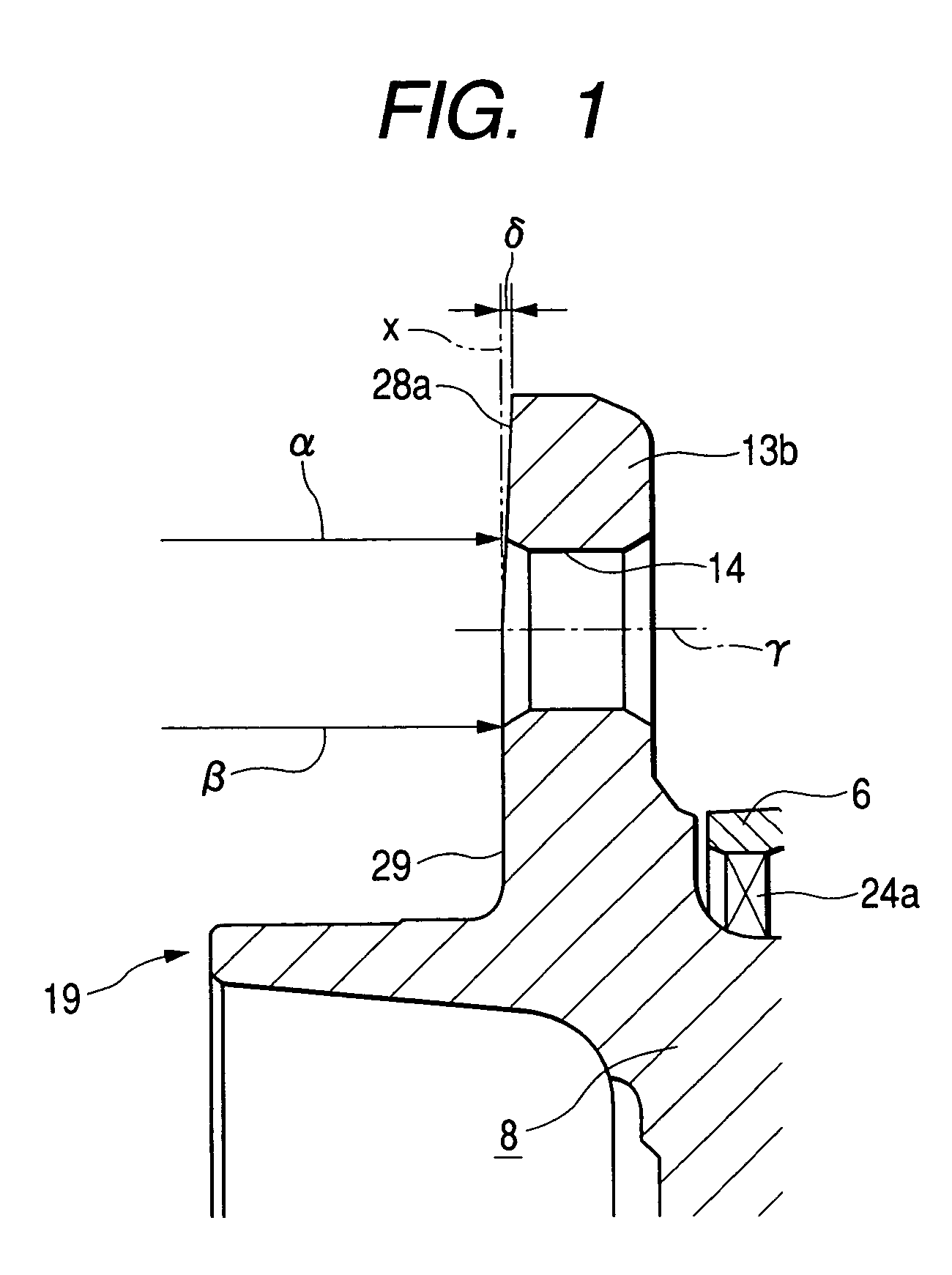

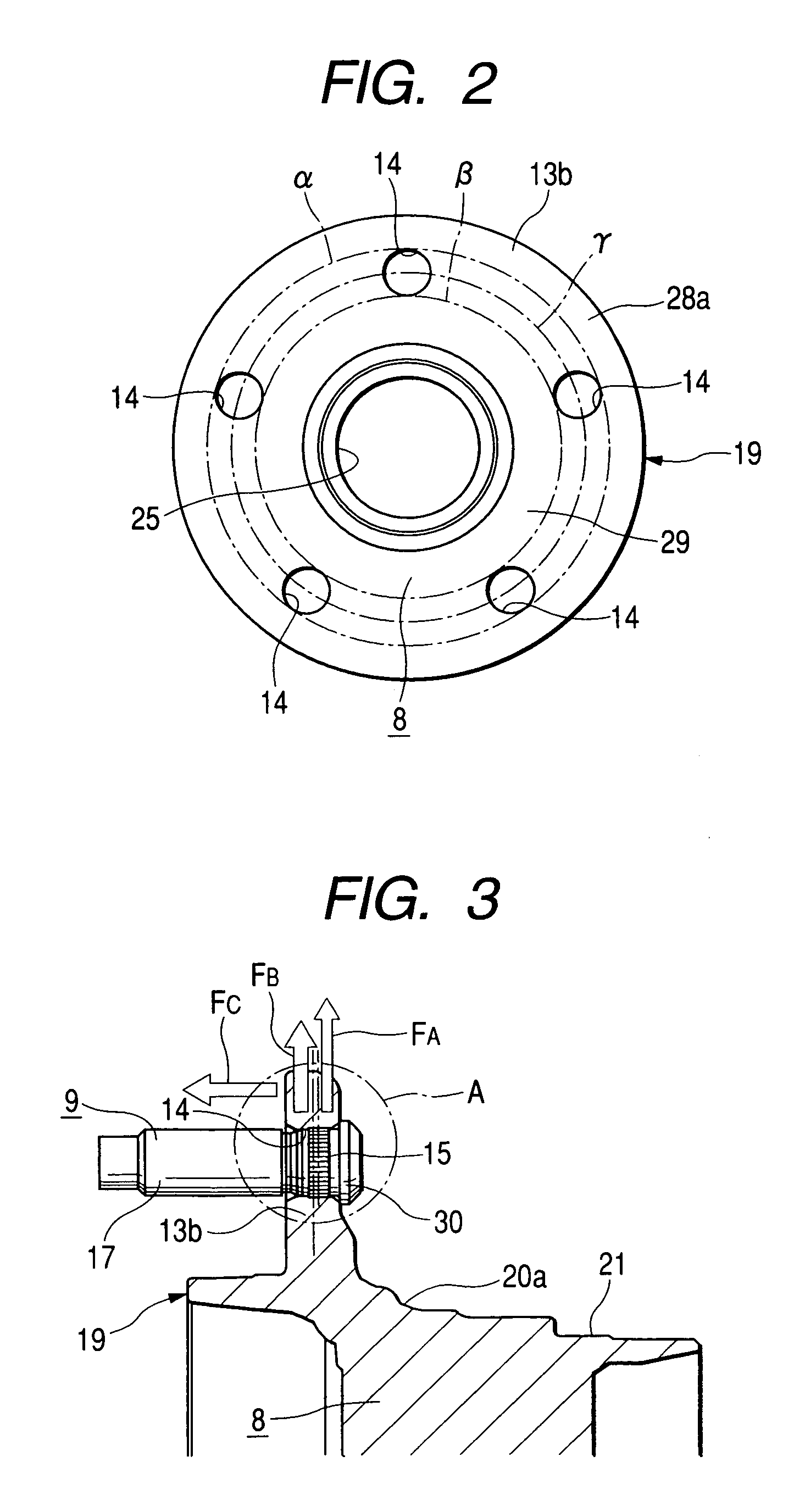

Wheel supporting roller bearing unit and manufacturing method of the same

ActiveUS7044563B2Avoid deformationSimple working processBraking element arrangementsRolling contact bearingsEngineeringFlange

The serrated portions of the studs are fitted in those portions of the mounting holes 14 close to the other side face of the mounting flange 13b. Accordingly, the radially outer portion of the mounting flange 13b is deformed to the one side face. At the radially outer portion of the one side face and throughout the circumference, there is formed a taper face 28a, which is inclined the closer to the other side face as it goes the closer to the radially outer side. As a result, the aforementioned problem can be solved because the radially outer potion of the one side face does not protrude from a flat face 29 formed at the radially inner portion of the one side face even with that deformation. Moreover, the taper face 28a can be formed at a low cost by a lathe-turning.

Owner:NSK CORPORATION

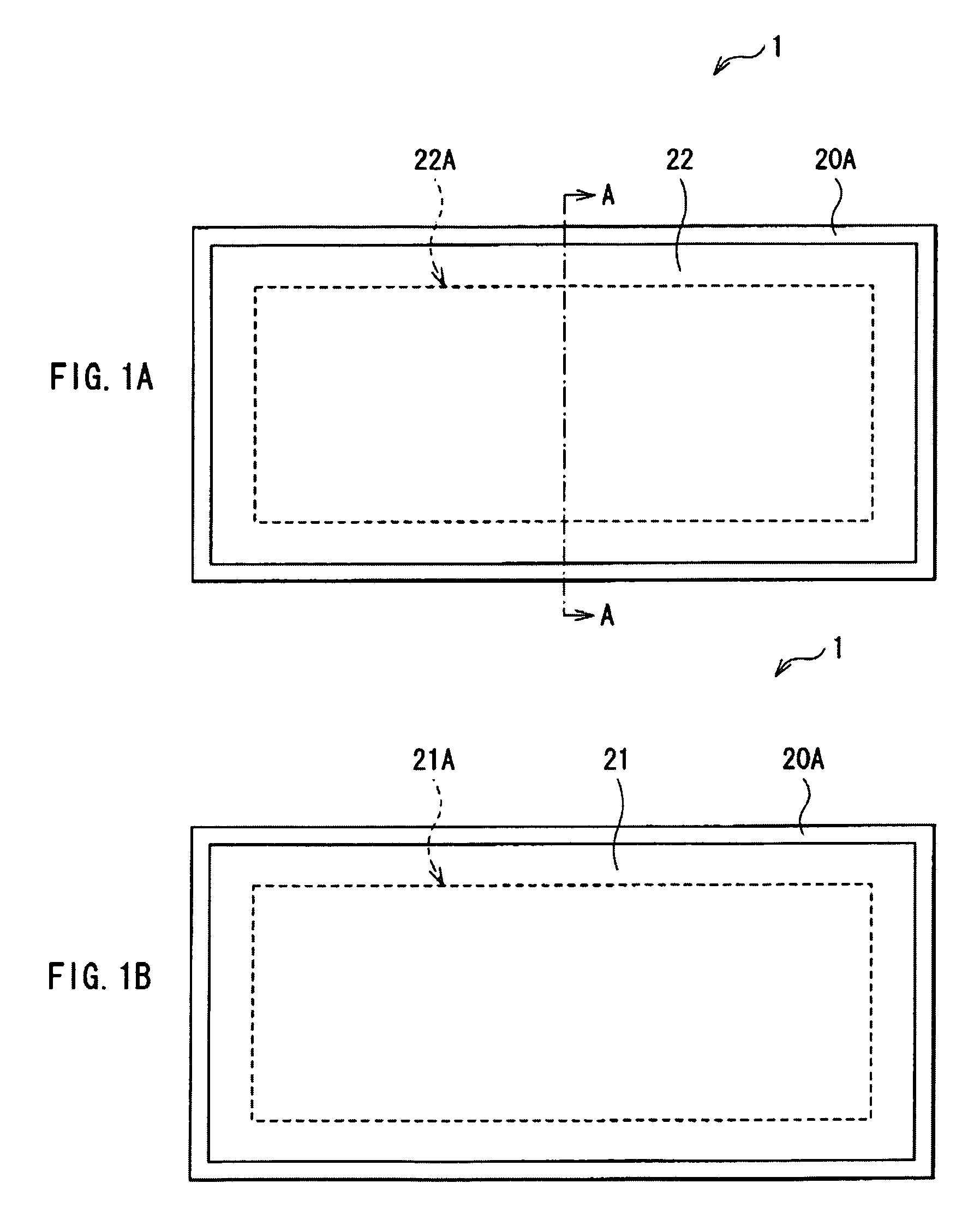

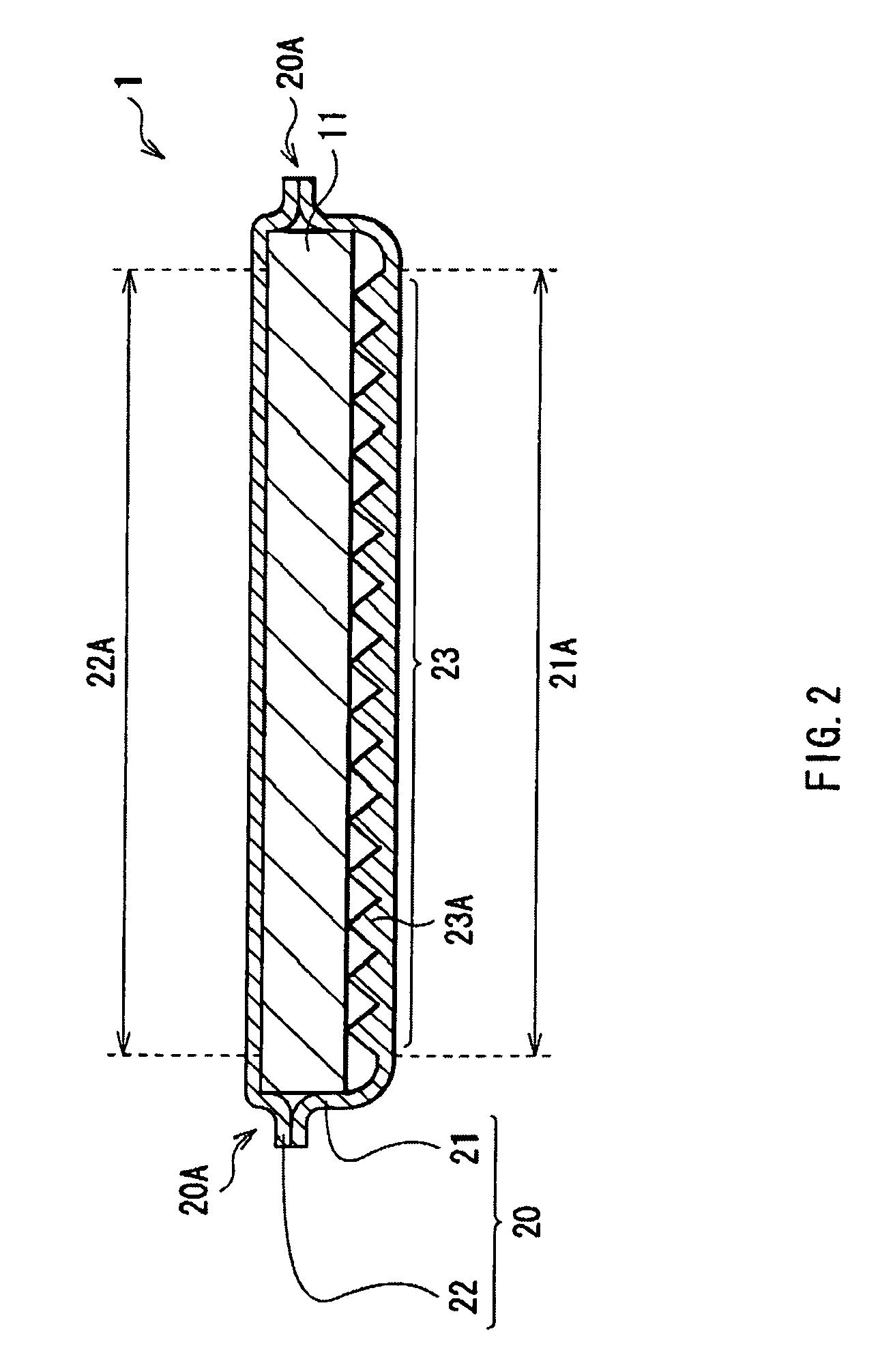

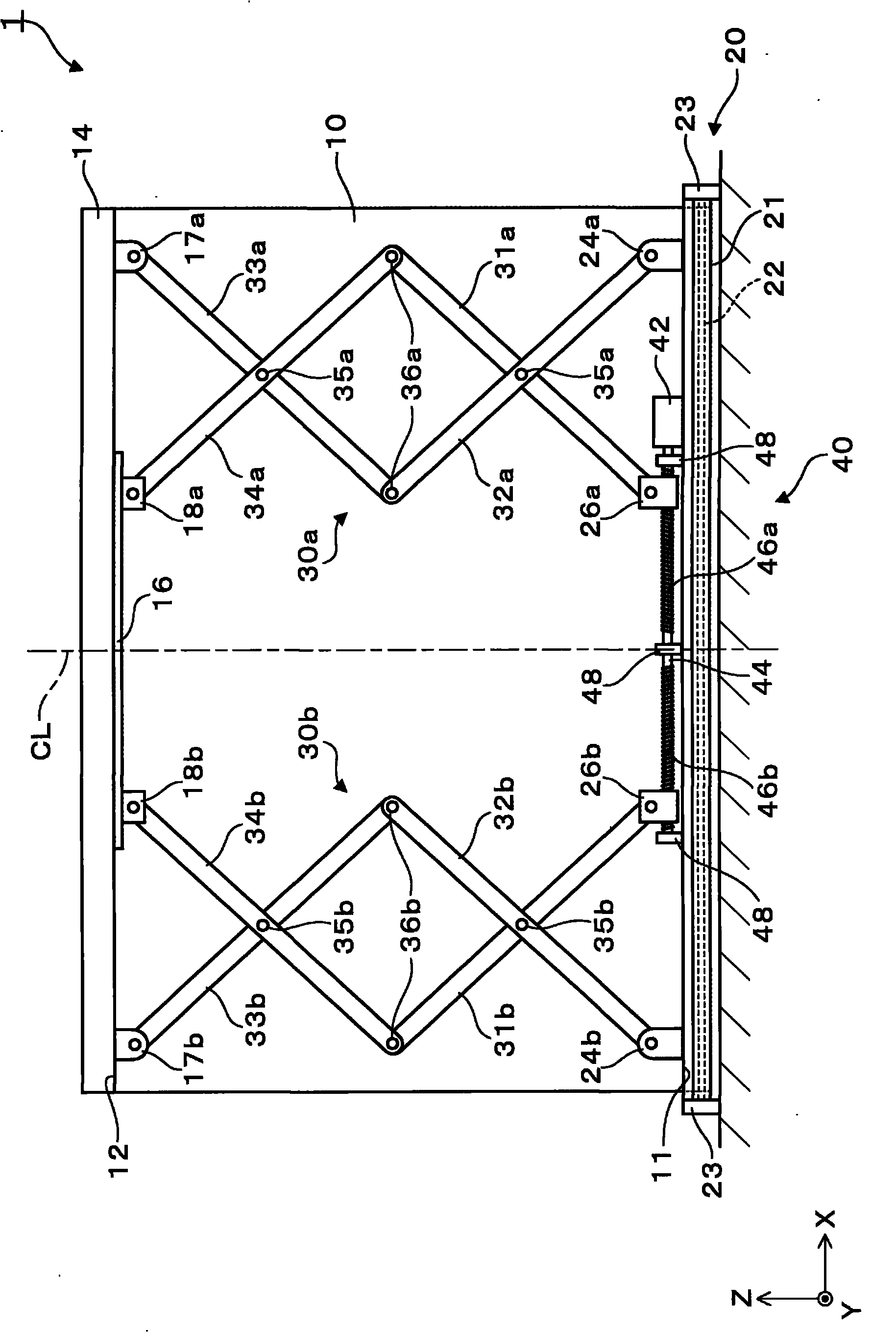

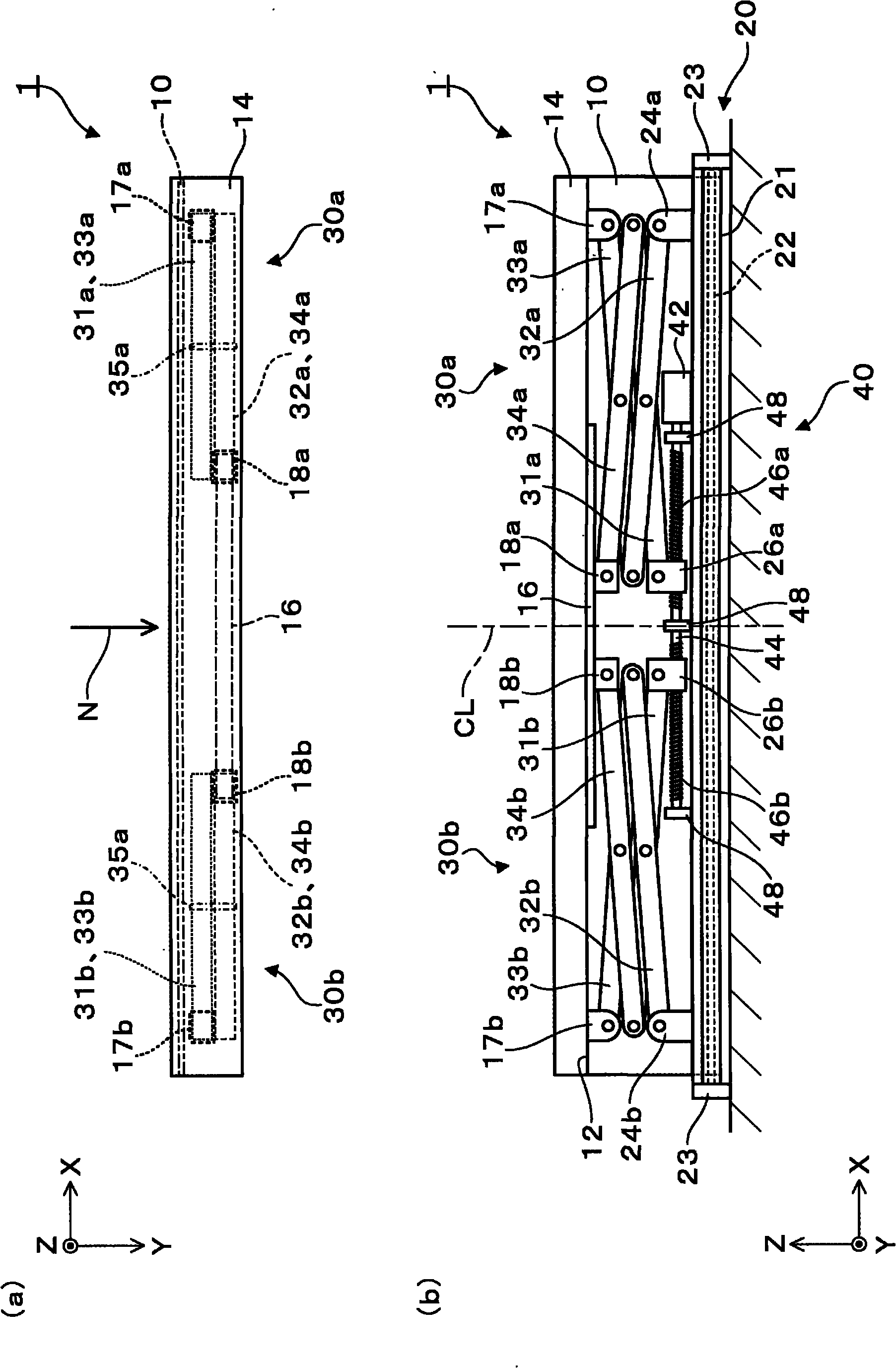

Screen unit

Owner:SEIKO EPSON CORP

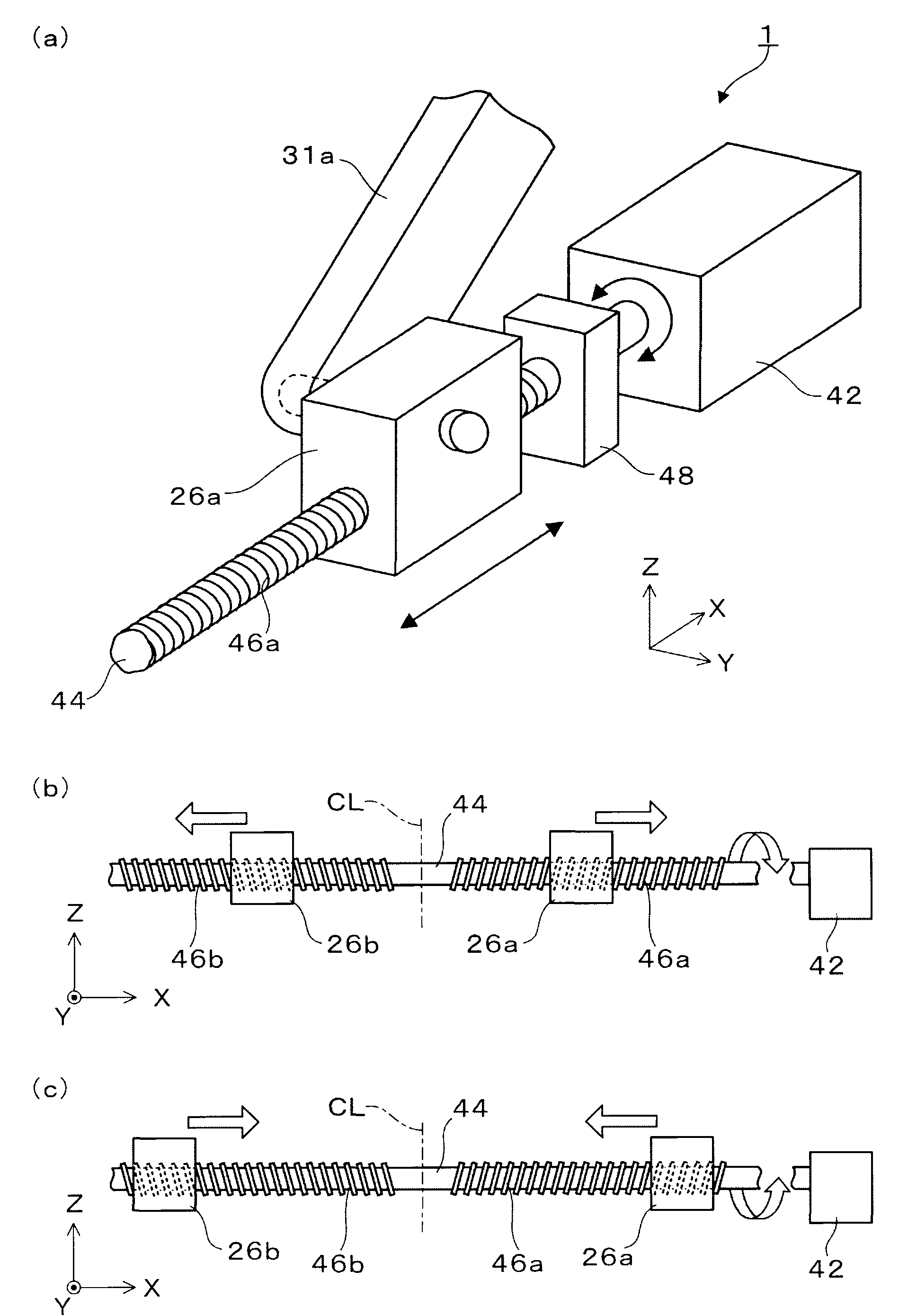

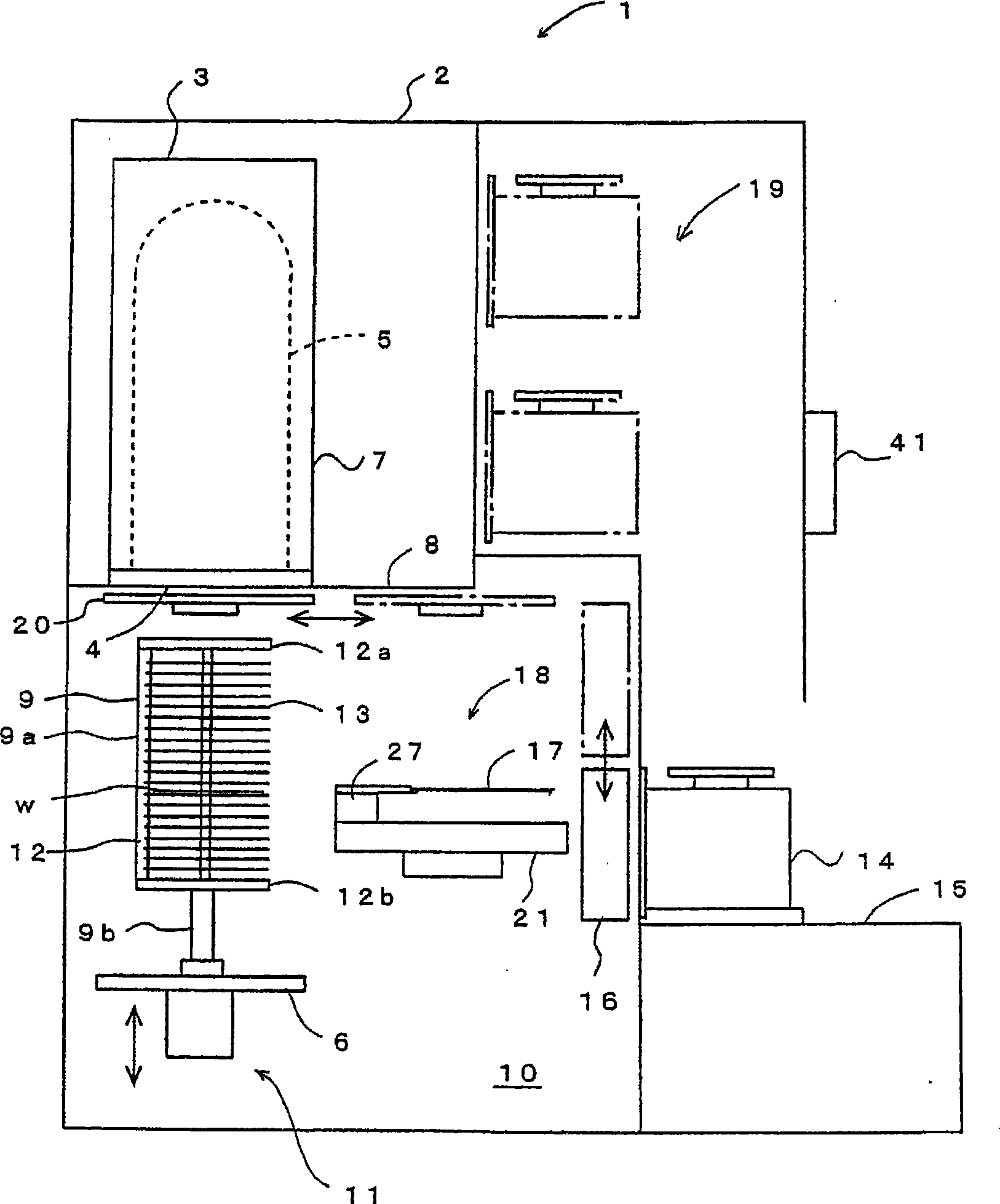

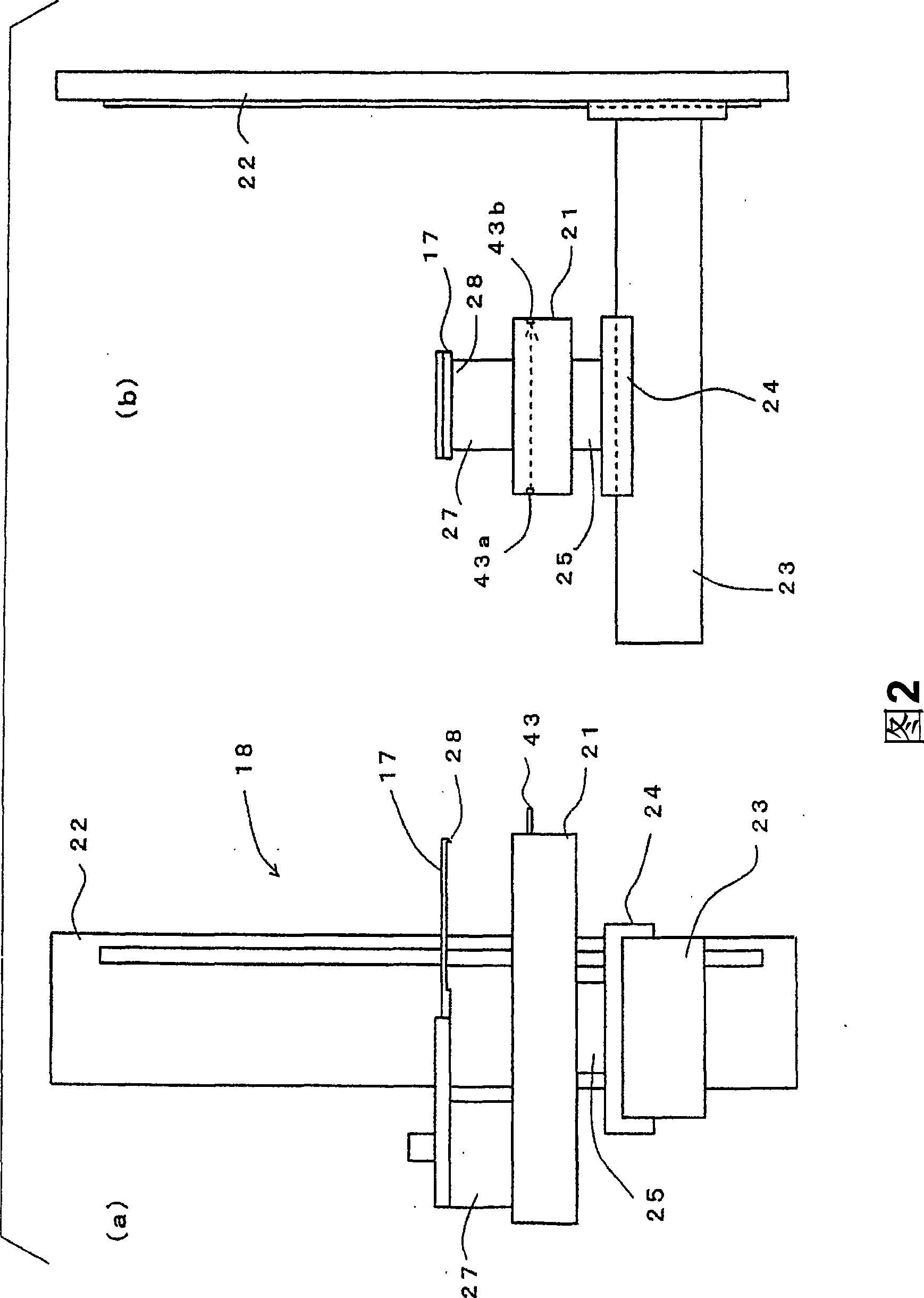

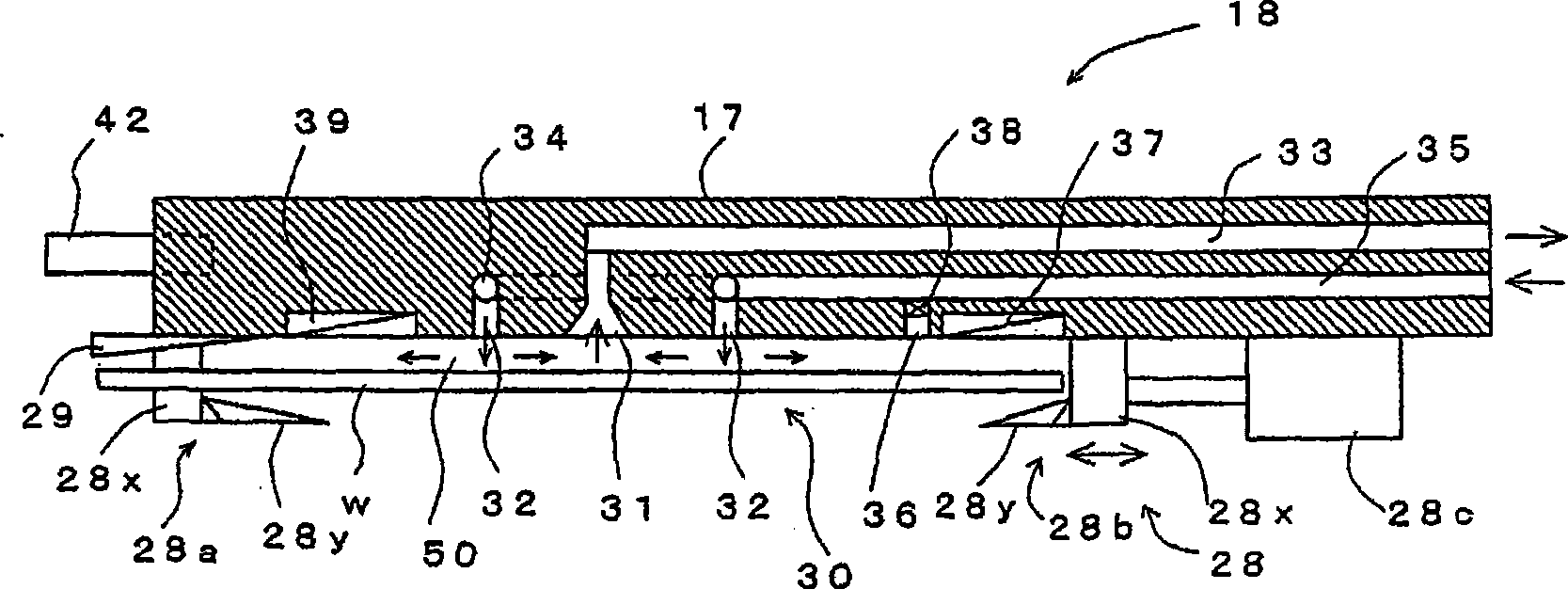

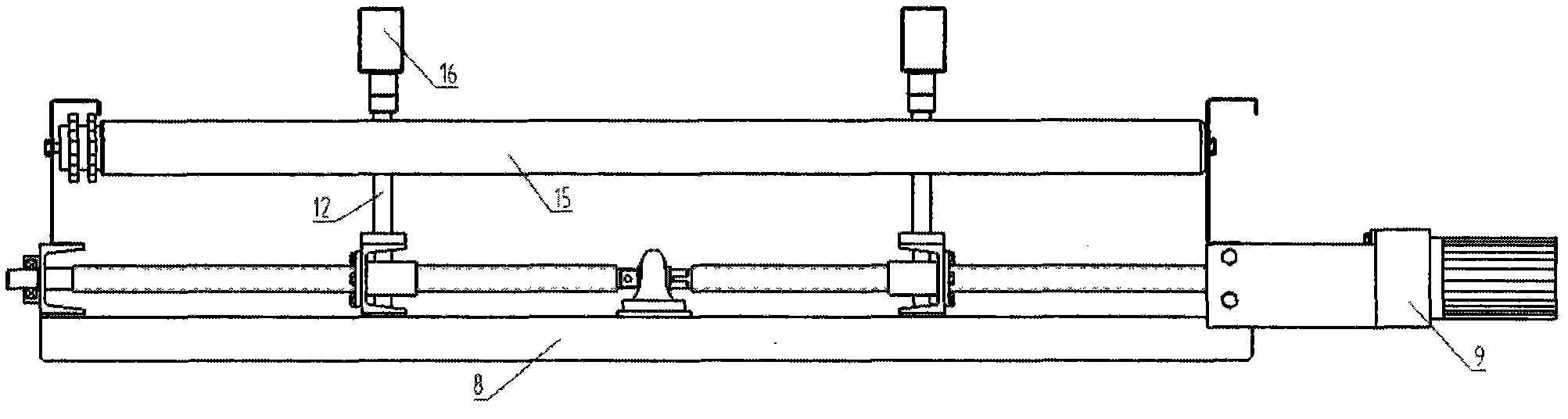

Substrate conveyance device and vertical heat treatment equipment

InactiveCN101443899AReduce stressReduce precisionSemiconductor/solid-state device manufacturingConveyor partsEngineeringHeat treated

Warping of a substrate during conveyance in the central portion thereof due to its own weight is suppressed as a substrate of super large diameter is employed. A substrate conveyance device (18) comprises a supporting section (17) which is moved to above a large diameter substrate (w), and an upper catching mechanism provided at the supporting section (17) and supporting the substrate (w) while catching the peripheral portion thereof from above. The supporting section (17) is provided with a noncontact suction holding portion consisting of a suction hole and a blowing hole. The noncontact suction holding portion blows gas against the central portion of the upper surface of the substrate (w) and forms an air layer so that the central portion of the substrate (w) is not bent thus suction holding the substrate (w) by noncontact.

Owner:TOKYO ELECTRON LTD

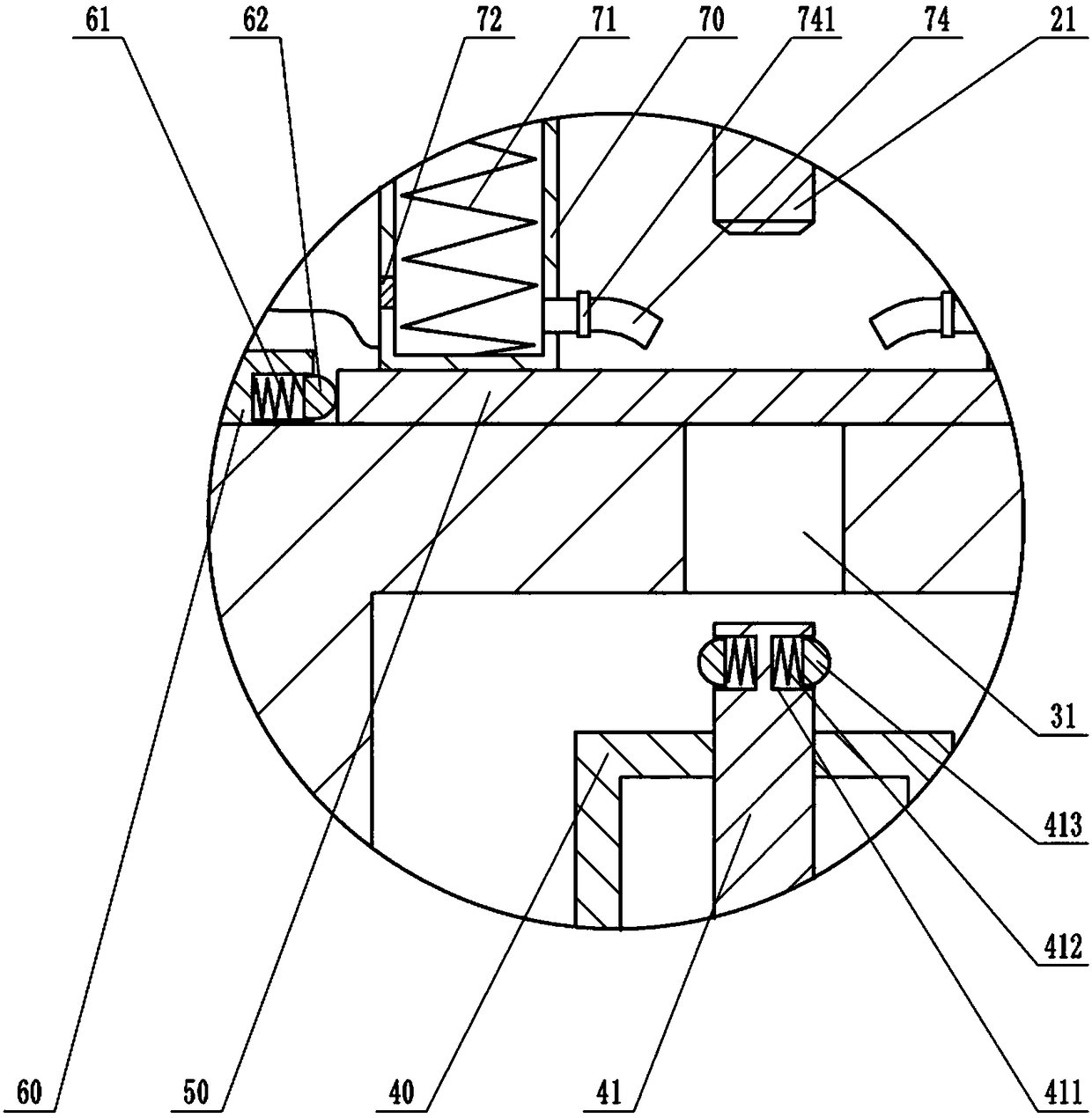

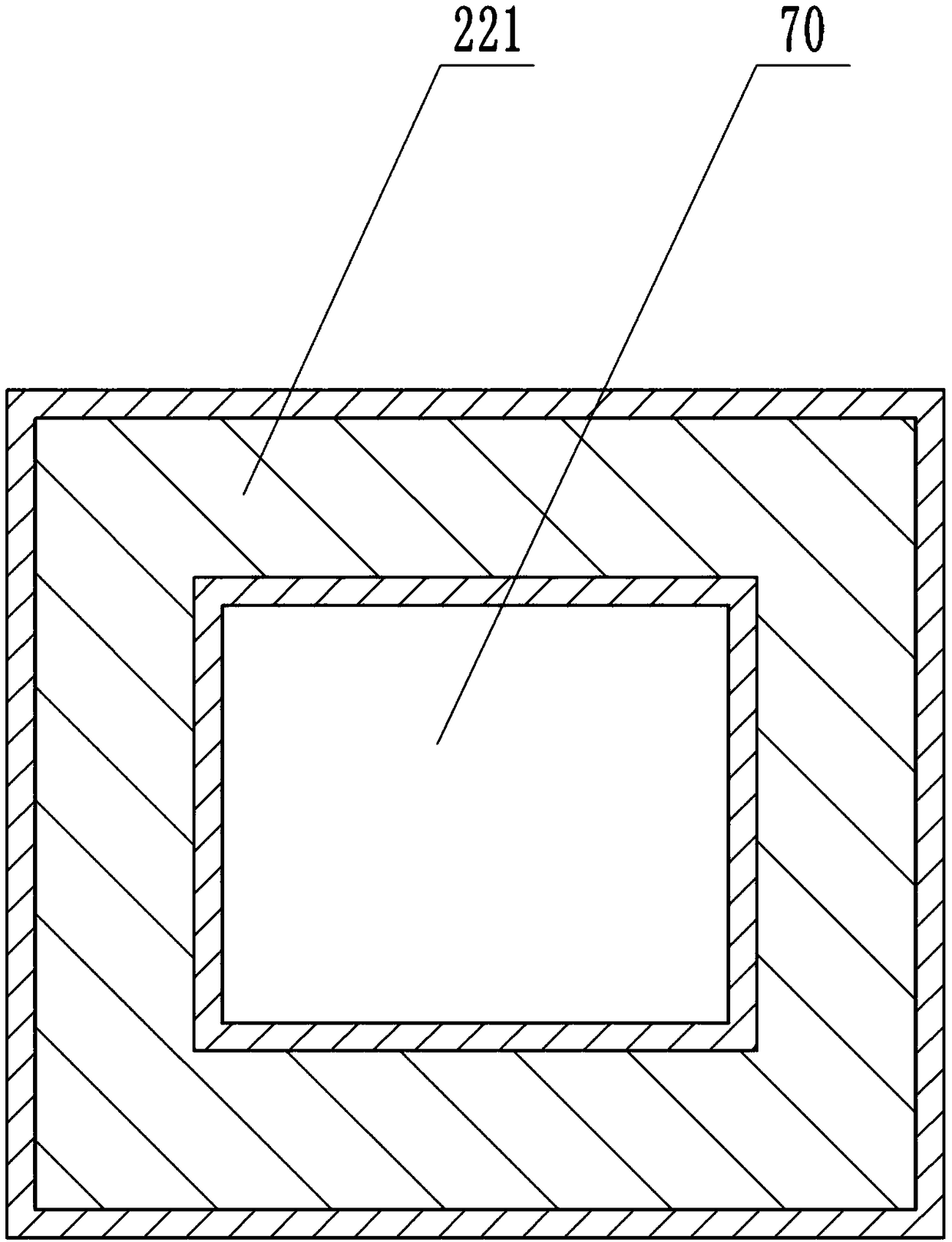

Stamping device with polishing function

The invention belongs to the technical field of machining, and particularly discloses a stamping device with a polishing function. The stamping device comprises a workbench, an annular press block, amounting base and a power mechanism. The mounting base is provided with a punch and push rods, a through hole is formed in the workbench, a fixed cylinder is arranged in the workbench, a spiral grooveis formed in the inner wall of the fixed cylinder, the fixed cylinder is in sliding connection with a push column, and the push column is provided with an upper clamping rod. Concave cavities are formed in the sidewall of the upper portion of the push column, the interiors of the concave cavities are in sliding connection with polishing bulges, and first springs are connected between the polishing bulges and the concave cavities. A cavity is formed in the annular press block, the interior of the cavity is in sliding connection with a piston, and a second spring is connected between the pistonand the annular press block. The sidewall of the lower portion of the annular press block is provided with filter bags and air suction pipes, the sidewall of the upper portion of the annular press block is connected with an air inlet pipe and an air outlet pipe, the air inlet pipe is provided with a first one-way valve, and the air outlet pipe is provided with a second one-way valve. By using thedevice, the inner wall punched out of the through hole can be polished after punching, and the processing efficiency is improved.

Owner:重庆伟福机械有限公司

Cargo deviation correction device for roller conveyor

The invention relates to a cargo deviation correction device for a roller conveyor, which consists of two parts, i.e. a deviation correction system and a passage width regulation system, wherein the deviation correction system consists of a transmission mechanism, an elliptical shaft, a leaned wheel assembly and a rocker arm assembly; and the passage width regulation system consists of a motor, a control box, positive and negative threaded screw rods, a guide shaft, a translation frame and a positioning shaft. The cargo deviation correction device is characterized in that the error correction system rotates by the elliptical shaft and the force is transferred to a railing by a related mechanical device so as to ensure the railing to carry out the periodic pulsation; and the passage width regulation system positively or negatively operates by the motor so as to drive a related mechanical device to move the railing, thereby achieving the effect of regulating the width of a passage. According to the cargo deviation correction device, deviated cargoes on the conveyor can be continuously and automatically corrected to the center and be neatly arranged; the width of the passage is remotely regulated to adapt to cargo cartons with different sizes without shutting down the cargo deviation correction device; and when the cargo deviation correction device is applied to a cargo conveying line below a beam of an electron accelerator, the uniformity of the irradiation dose and the efficiency can be obviously improved. The cargo deviation correction device for the roller conveyor is applicable to various production equipment with specific requirements on cargo positions on the conveyor.

Owner:ZHOUSHAN LEIDA ELECTRICAL TECH

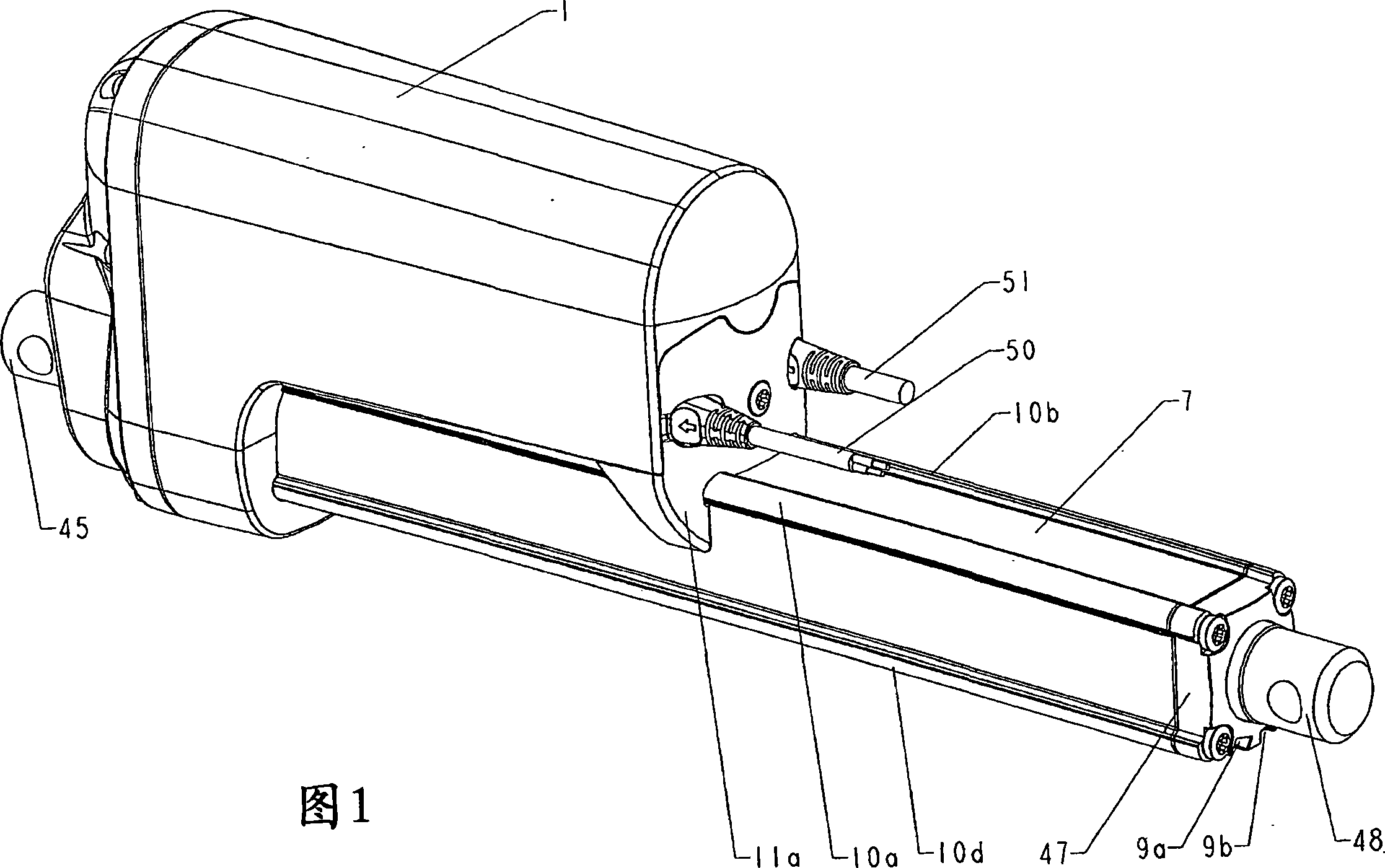

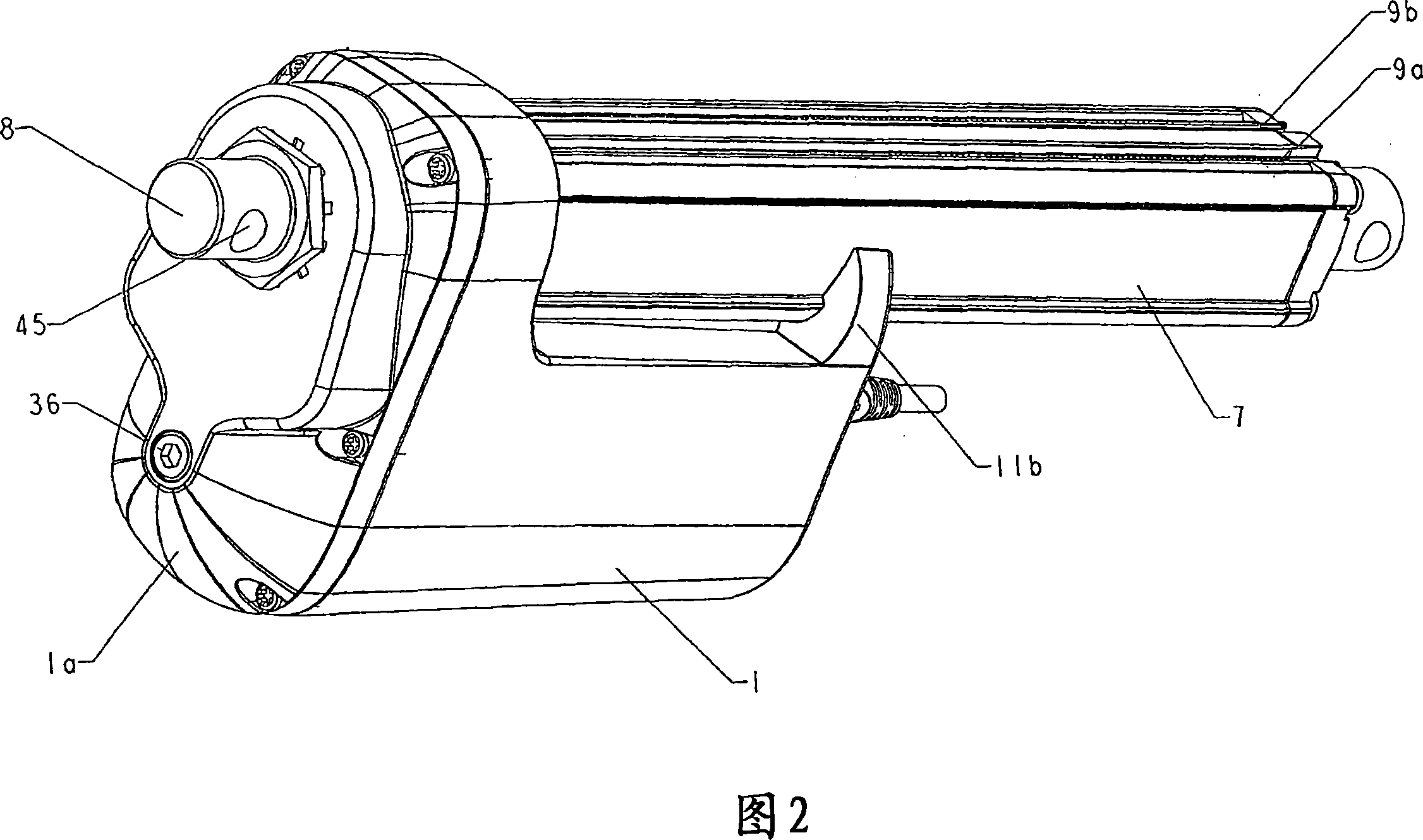

A linear actuator comprising an overload clutch

Owner:LINAK AS

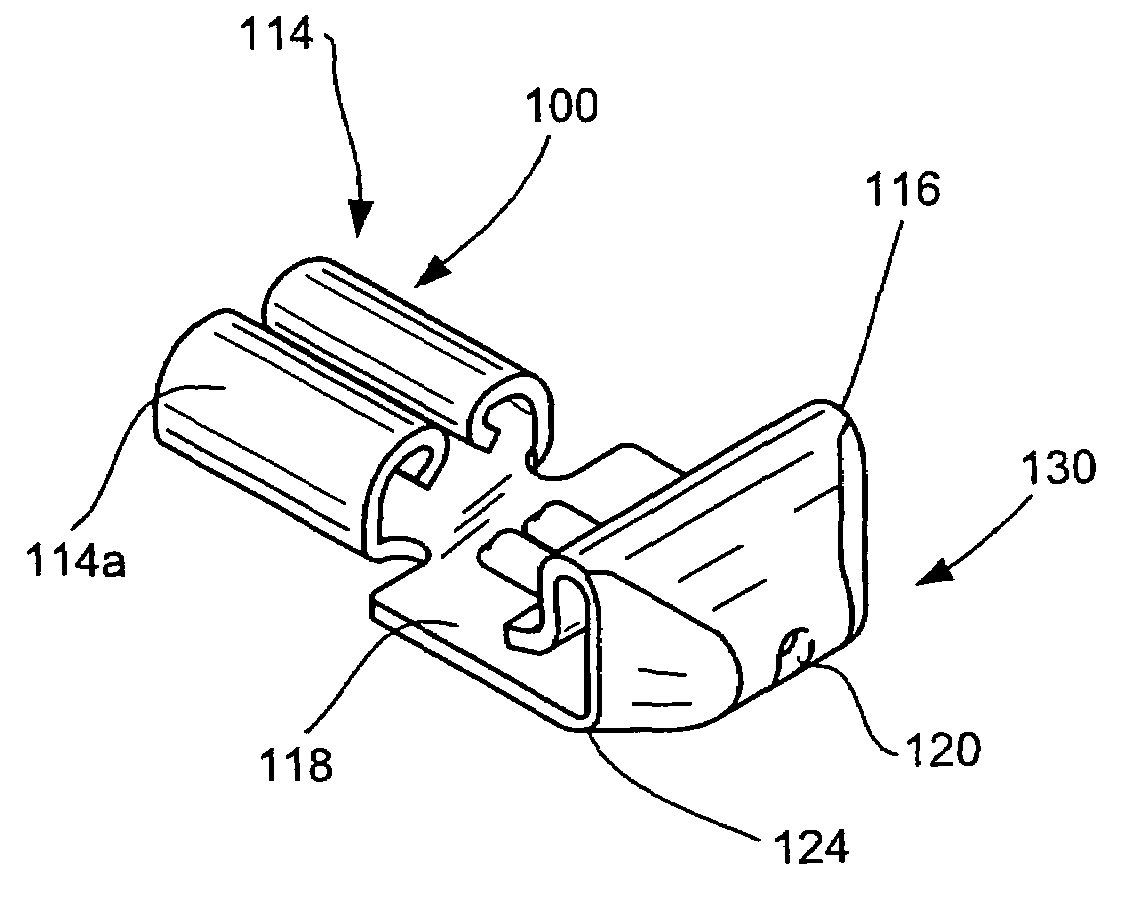

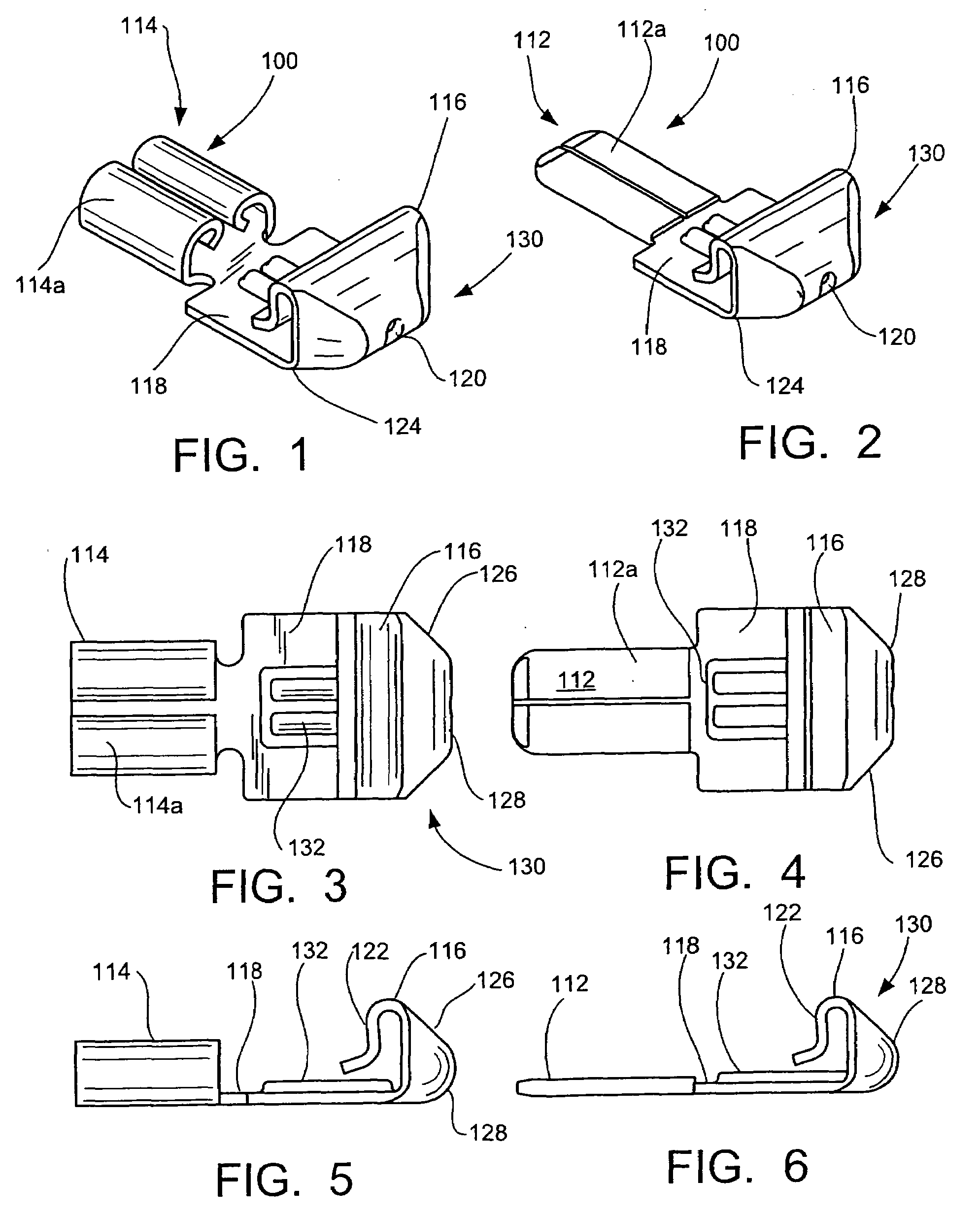

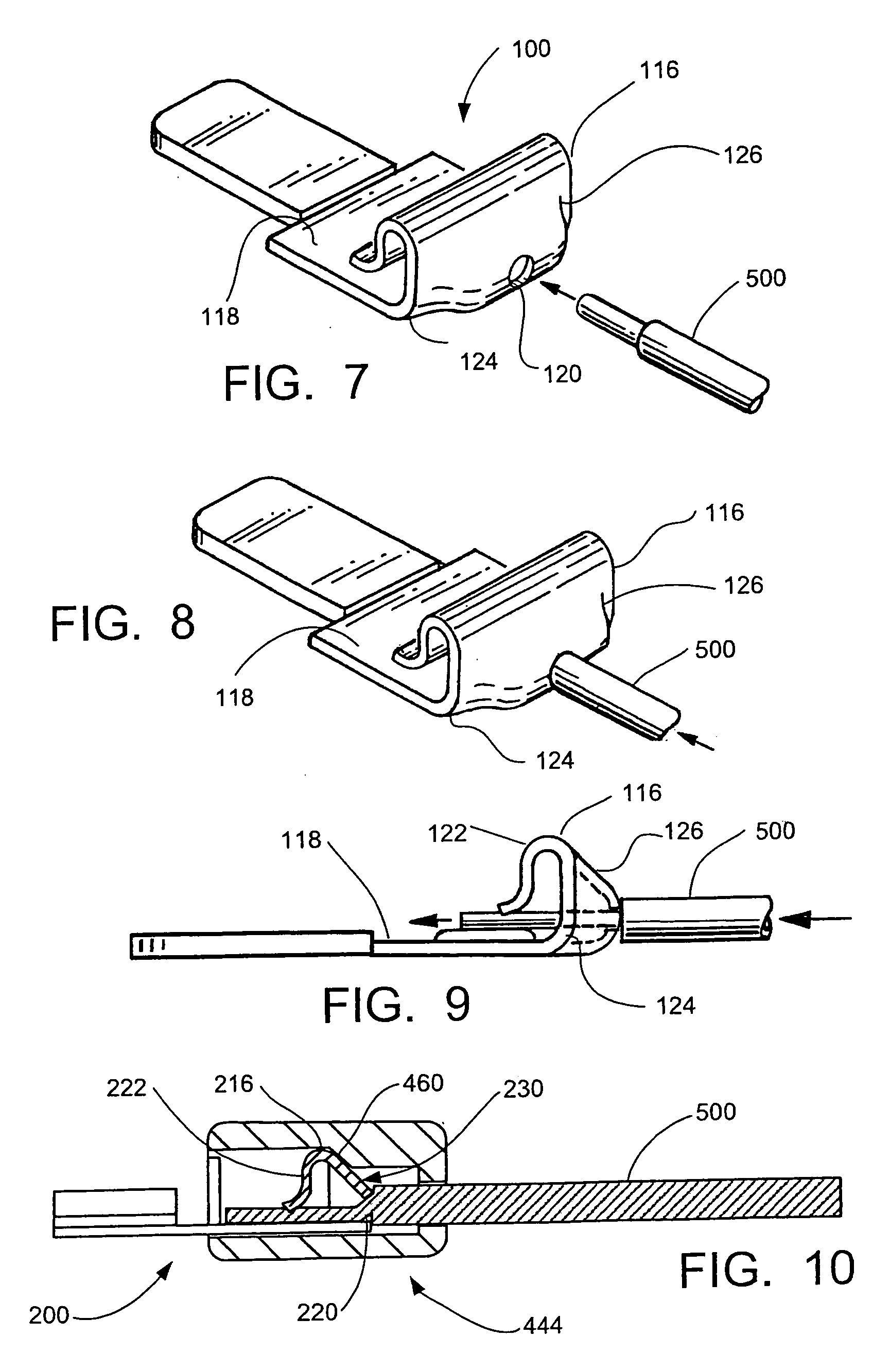

Electrical connector components

ActiveUS20070249215A1Low resistanceEasy to implementElectric connection basesContact members penetrating/cutting insulation/cable strandsCantileverElectrical and Electronics engineering

Owner:THOMAS & BETTS INT INC

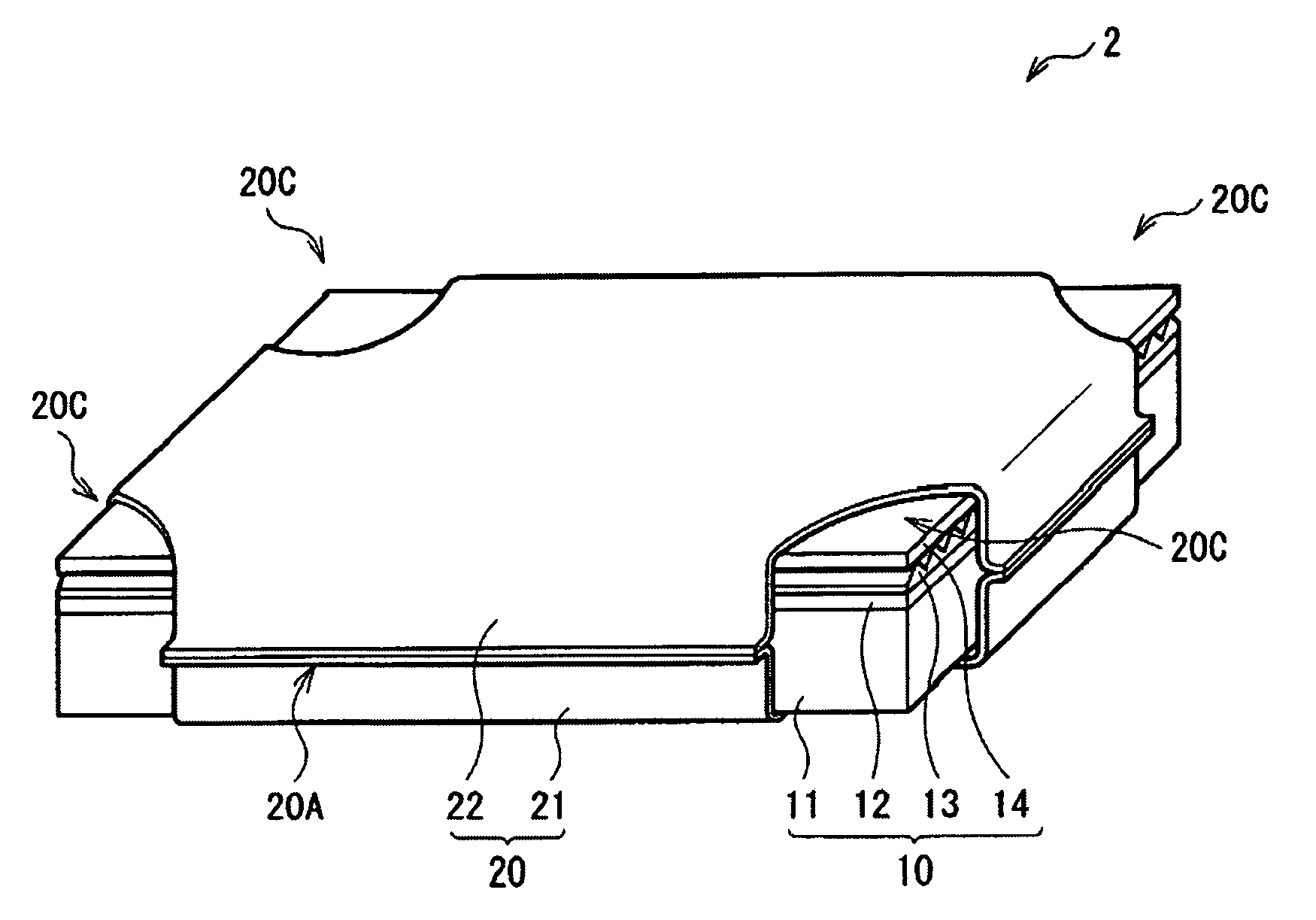

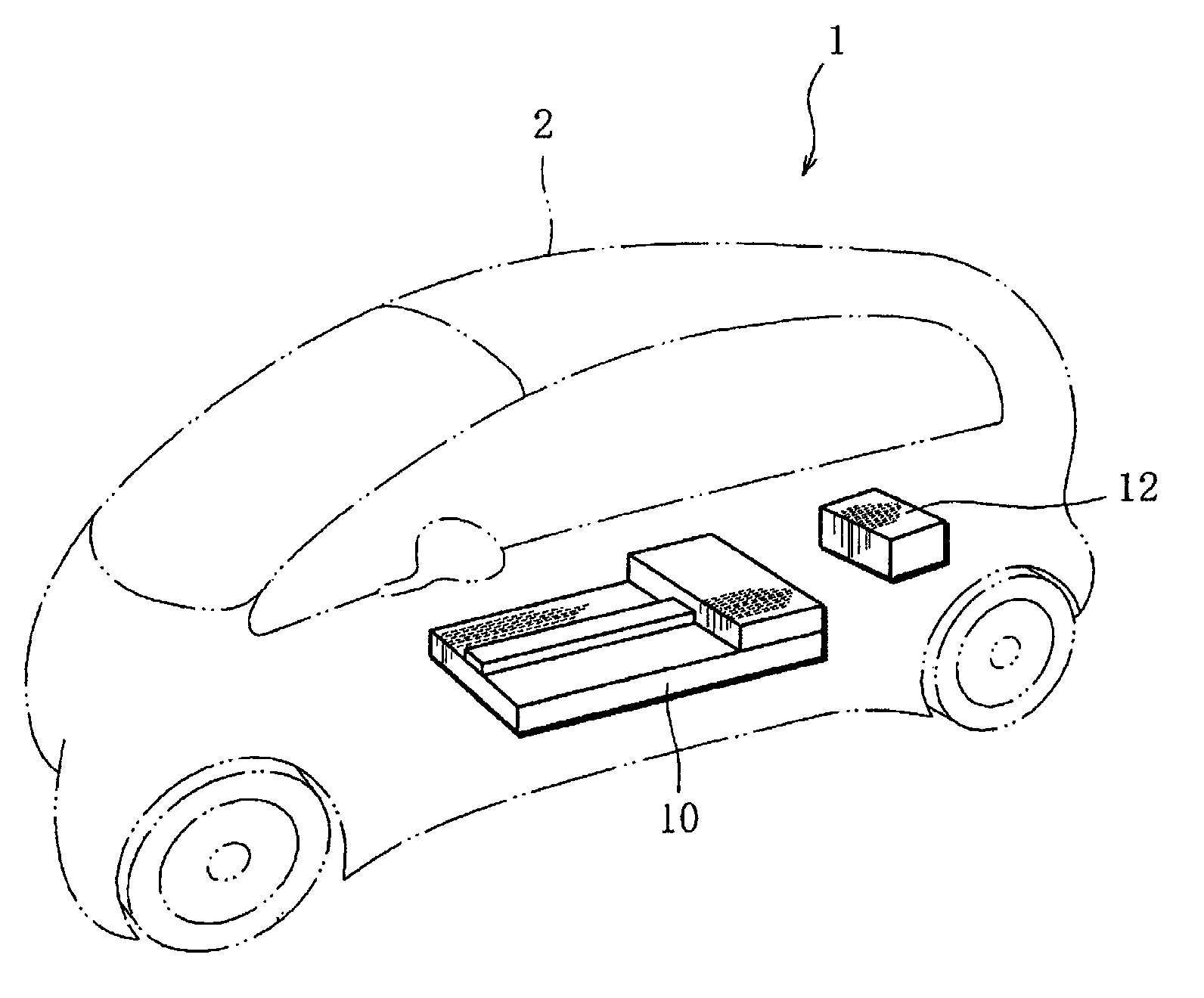

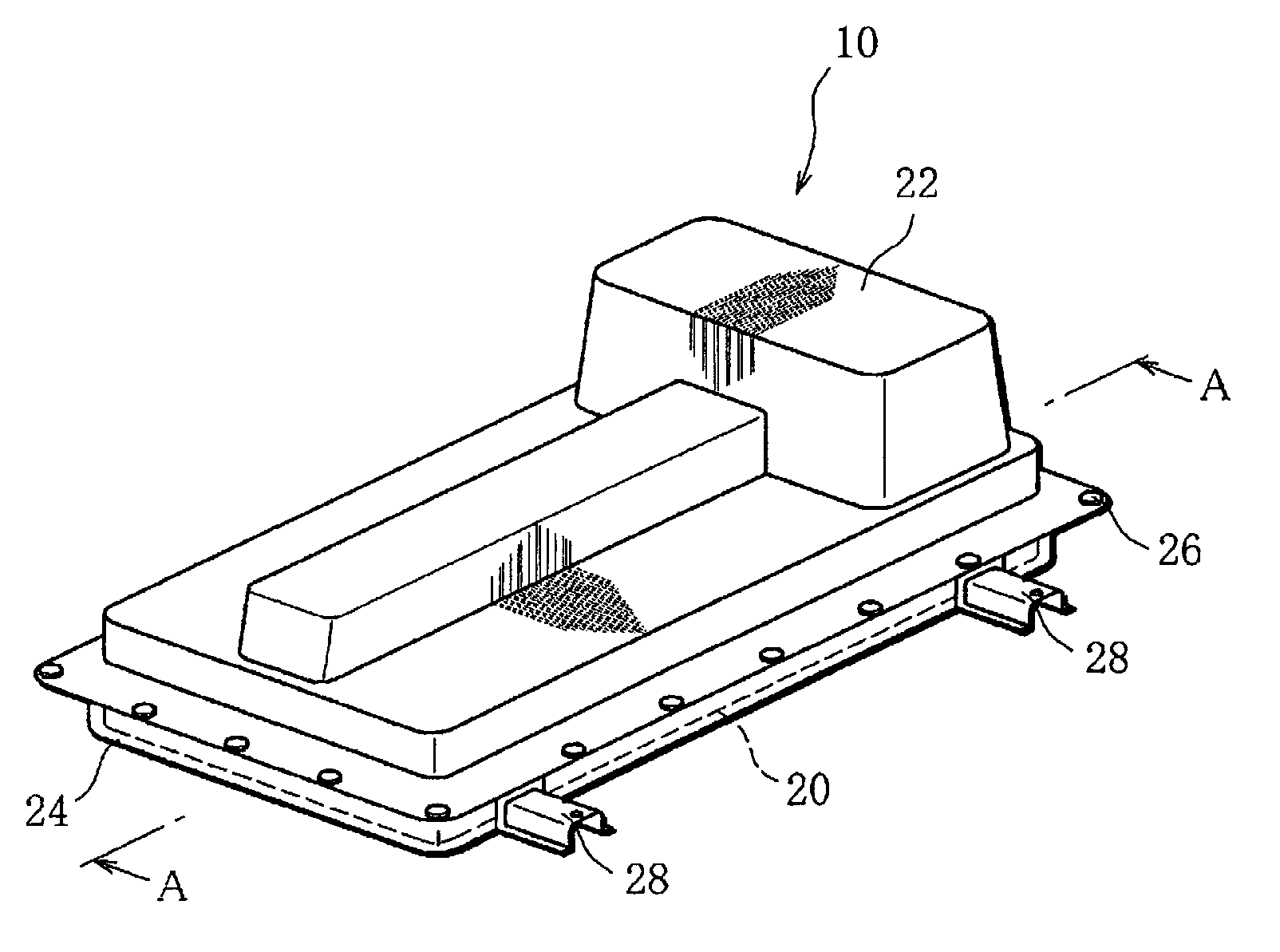

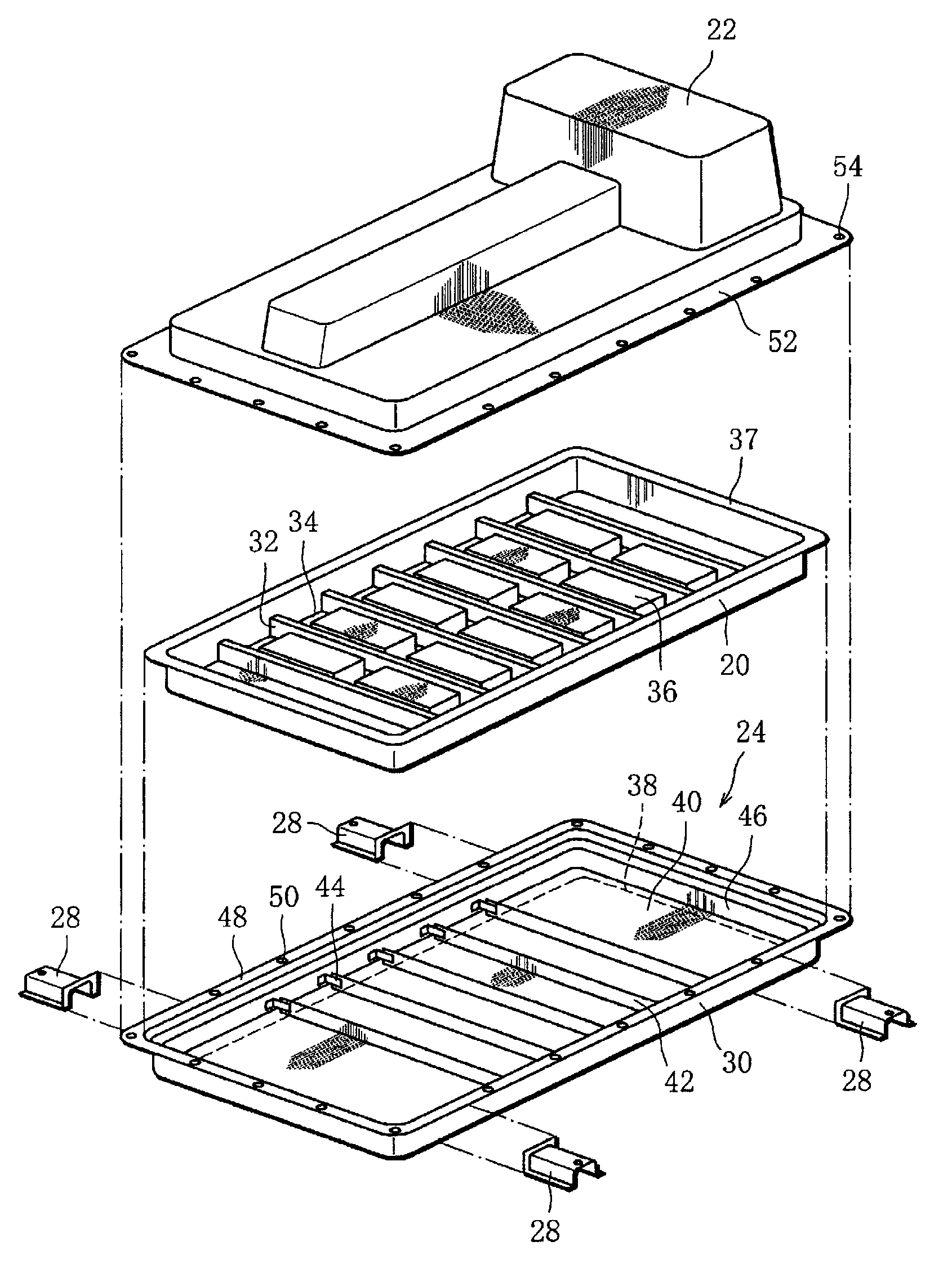

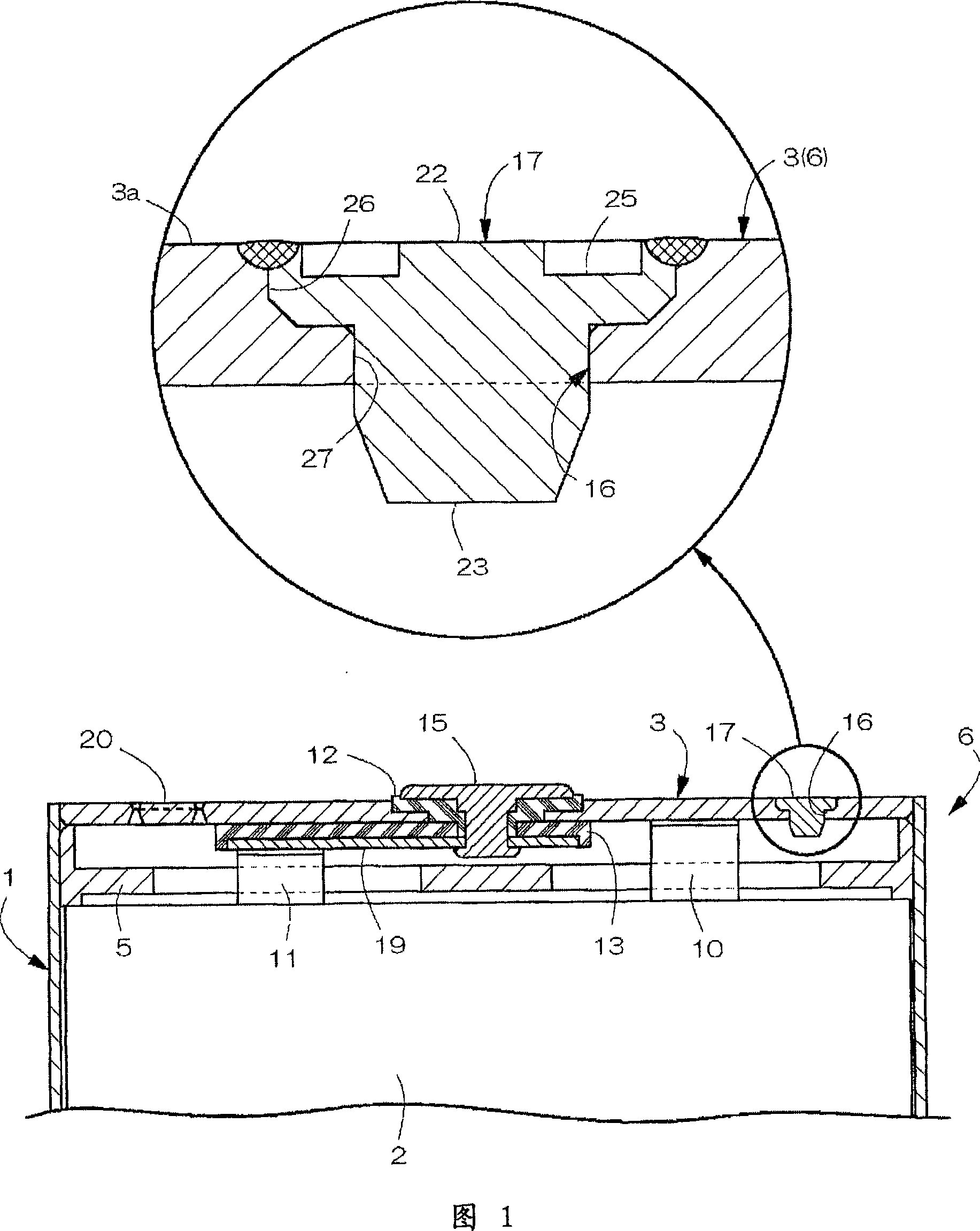

Battery case for vehicle

ActiveCN102714287AGuaranteed rigidityAvoid deflectionElectric propulsion mountingCell component detailsMetalElectrical and Electronics engineering

Disclosed is a battery case for a vehicle, which is provided with: a resin tray member (20), which holds a battery (36), and which has a plurality of protruding sections (32) formed on the bottom portion (34); and a reinforcing tray member, which is disposed on the outer surface of the tray member, and which has at least one reinforcing member (42), which is configured of a metal plate that is provided upright on the side that faces the tray member. On the outer surface of each of the protruding sections, a recessed section (56) is formed, corresponding to at least the reinforcing member, and the reinforcing member is fitted in the recessed section.

Owner:MITSUBISHI MOTORS CORP

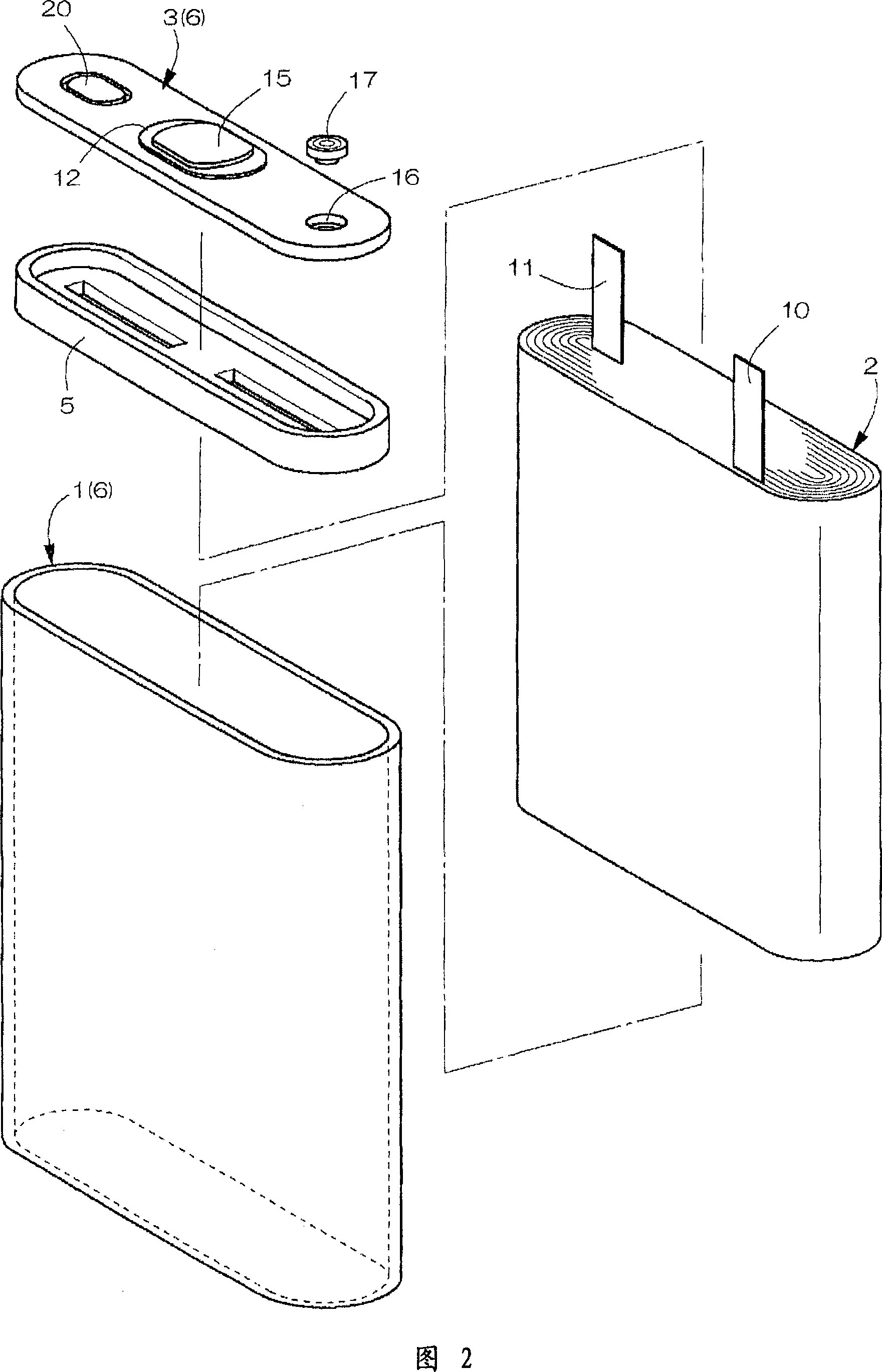

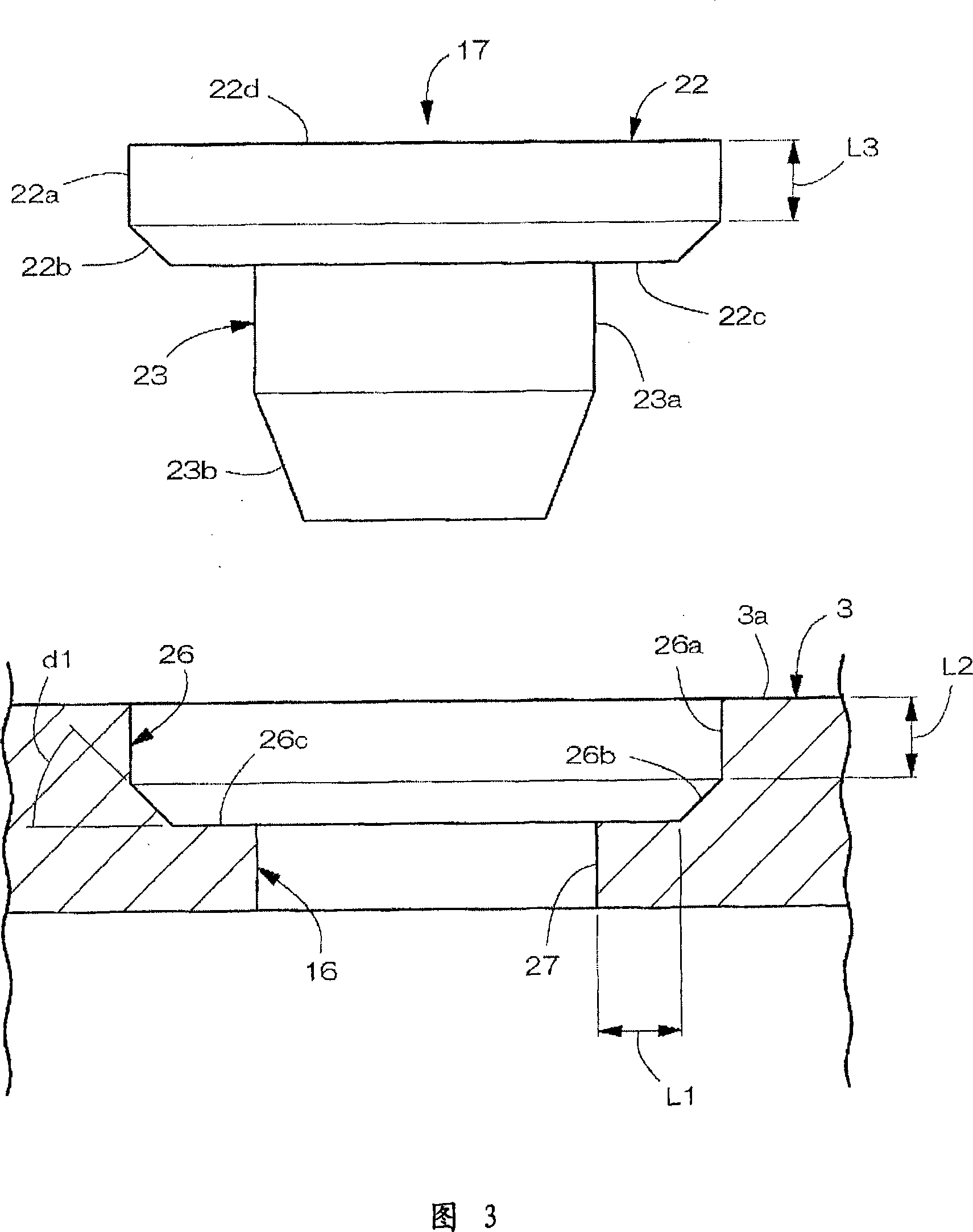

Sealed battery

ActiveCN101083310AReduce areaReliable leak tightnessNon-aqueous electrolyte accumulatorsCell component detailsEngineeringBearing surface

The present invention provides a sealing battery, which prevents electrolyte from remaining in the injecting hole and joints a sealing bolt and injecting hole. After injecting electrolyte into the battery box through the injecting hole, to joint the sealing bolt on the injecting hole to seal the injecting hole. The sealing bolt is arranged with a head and a axis extending from the lower surface of the head. The injecting hole is arranged with a chimeric concave part to table the head of the sealing bolt and a chimeric part of the axis part which is pressed into the sealing bolt. The chimeric part of the injecting hole includes: vertical inner surface part; taper inner surface part with taper surface shaped which turns narrow downwards; and bearing surface part to support the lower surfaceof the head of the sealing bolt. The head of the sealing bolt includes: lower surface; vertical outer surface part which is opposite to the vertical inner surface part of the injecting hole; and taper outer surface part with taper surface shaped which is opposite to the taper inner surface part of the injecting hole and turns narrow downwards.

Owner:MAXELL HLDG LTD

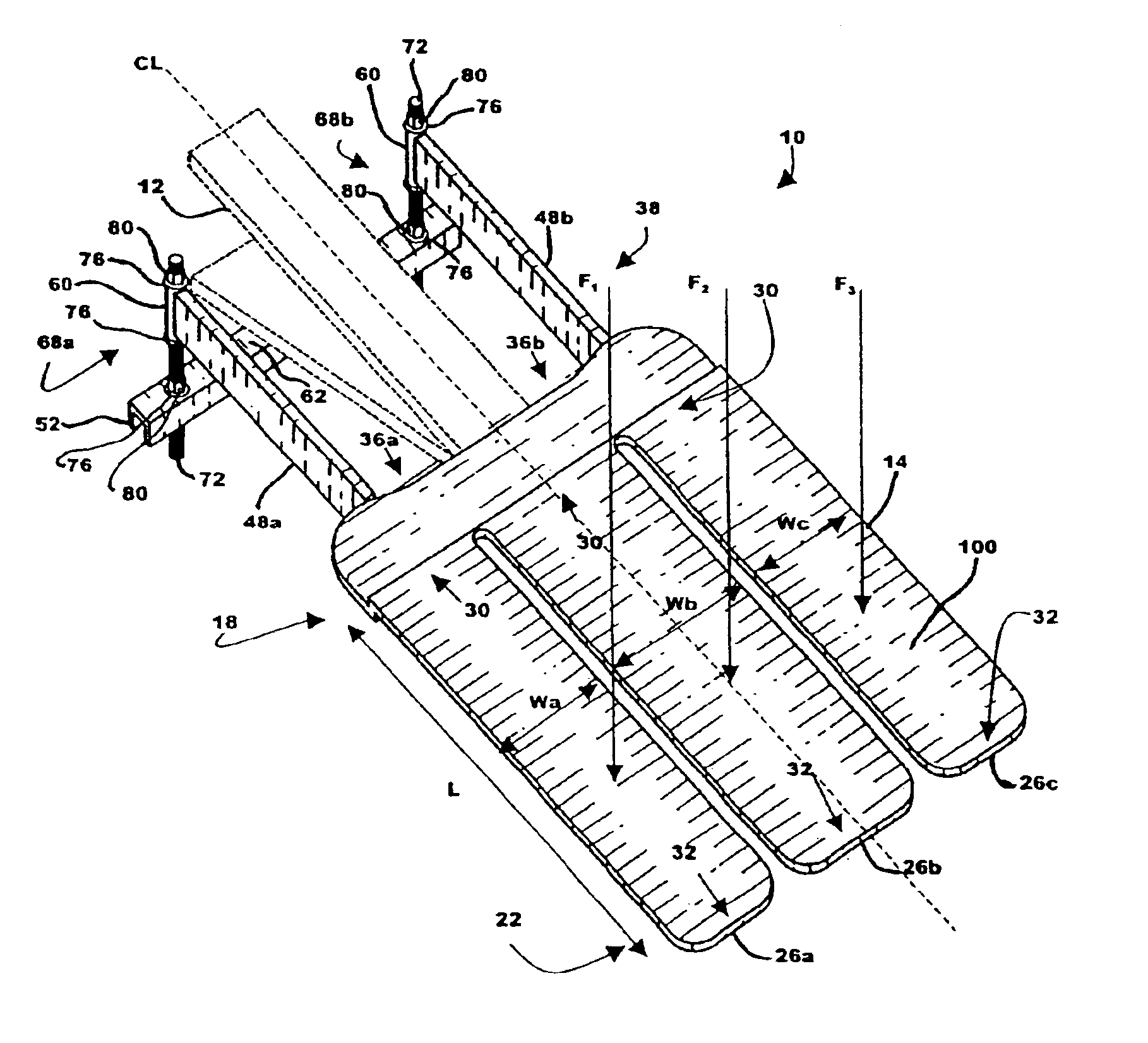

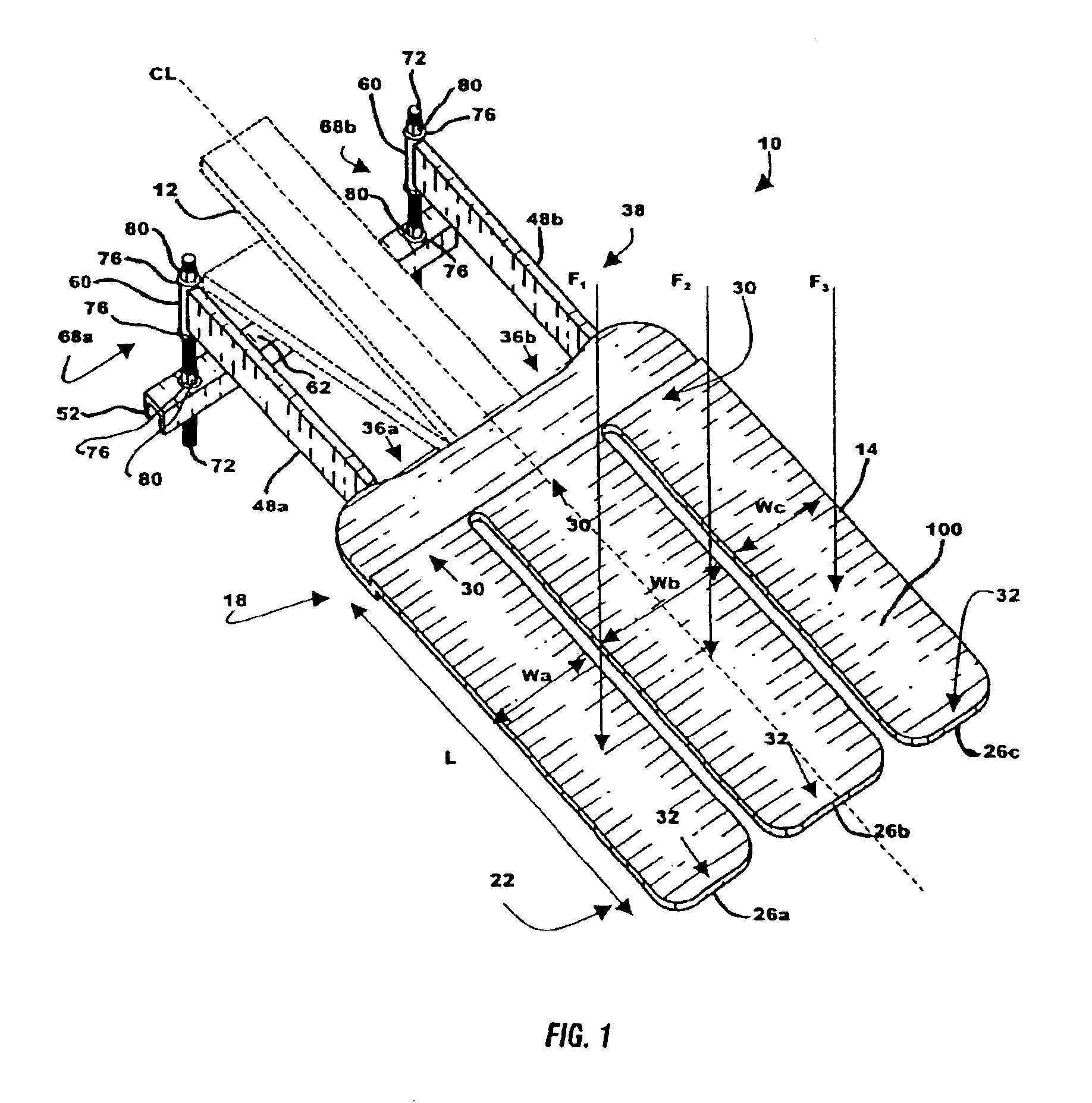

Multi-use pallet with torsion control for a printing machine

InactiveUS6910419B2Resists deflectionAvoid deflectionLiquid surface applicatorsPlaten pressesEngineeringPrinting press

A pallet (10) for use with a screen printing apparatus having arms (12) extending outwardly from the printing machine supports an article against a printing force supplied by the screen printing machine. A base portion (14) of the pallet (10) is attachable to the arm (12) of the printing machine and includes a support structure extending therefrom to stabilize and reduce deflection against the printing force.

Owner:M&R PRINTING EQUIP

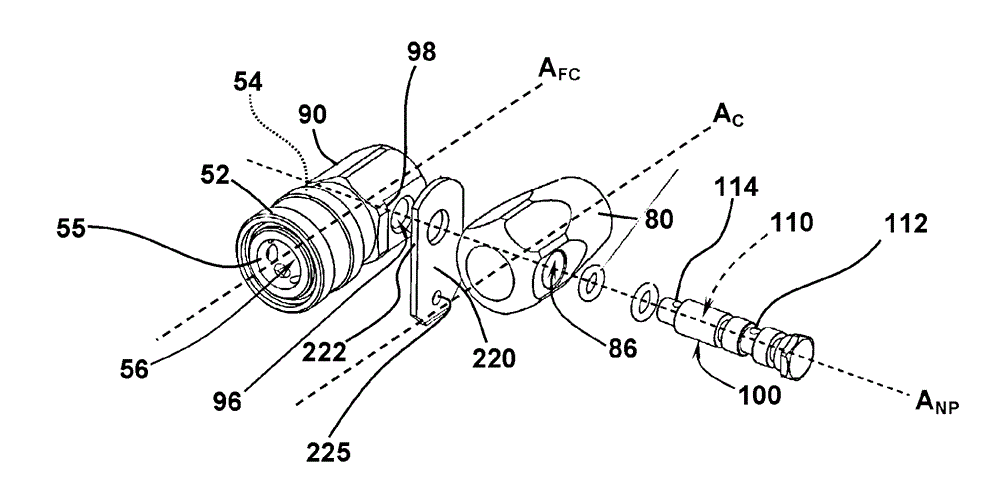

Sprayer with remotely pivotable and selectively lockable nozzle

A fluid sprayer includes a rigid fluid conduit with a conduit side wall extending along a conduit axis between open first and second conduit ends. The conduit side wall defines a fluid passage extending between the open first and second ends. A spray nozzle with a fluid-expulsion bore is connected to the second conduit end such that it can pivot about a nozzle-pivot axis that extends orthogonally to the conduit axis and such that fluid introduced into the first conduit end is expelled through the fluid-expulsion bore. A nozzle actuator is attached to the conduit for bi-directional rotation about an actuator-rotation axis having a component of spatial extension perpendicular to the conduit axis. The nozzle actuator and nozzle are mechanically linked so that rotation of the actuator causes the nozzle to pivot with respect to the conduit axis. A spray-angle selector rotates in tandem with the nozzle actuator and includes an angle-selection surface. A selector stop, with a base portion fixed relative to the fluid conduit, cooperatively engages the angle-selection surface to define a plurality of angular nozzle positions and provide resistance opposing pivotal movement out of each angular nozzle position.

Owner:HYDE TOOLS

Test research device used for electrical performance research on mixed gas of high-voltage electrical equipment

ActiveCN104133162AMeet Electrical Performance StudiesPrecise control of axial movement positionTesting dielectric strengthEngineeringElectrical performance

The invention relates to the field of high-voltage power transmission technology, and particularly relates to a test research device used for electrical performance research on mixed gas of high-voltage electrical equipment. The device comprises a lead terminal gas room connected with a high-voltage casing; the lead terminal gas room is connected with a horizontally-arranged barrel body; the barrel body is isolated by a basin-type insulator into a first test gas room and a second gas room; the first test gas room is adjacent to the lead terminal gas room; the barrel body of the first test gas room is provided with a mounting port; a flange used for mounting a test-used post insulator and a cover plate used for covering the mounting port are arranged at the mounting port; two guide rods coaxial in the horizontal direction and arranged at intervals are arranged in the second test gas room; the guide rod is provided with opposite end parts for removing an assembly contact or an arc contact or a shielding cover; and at least one of the two guide rods is in transmission connection with a driving mechanism used for driving the corresponding guide rod to move along the axial direction of itself so as to adjust the gap between the opposite end parts of the two guide rods. By adopting the device of the invention, dynamic and static tests can be carried out.

Owner:STATE GRID CORP OF CHINA +3

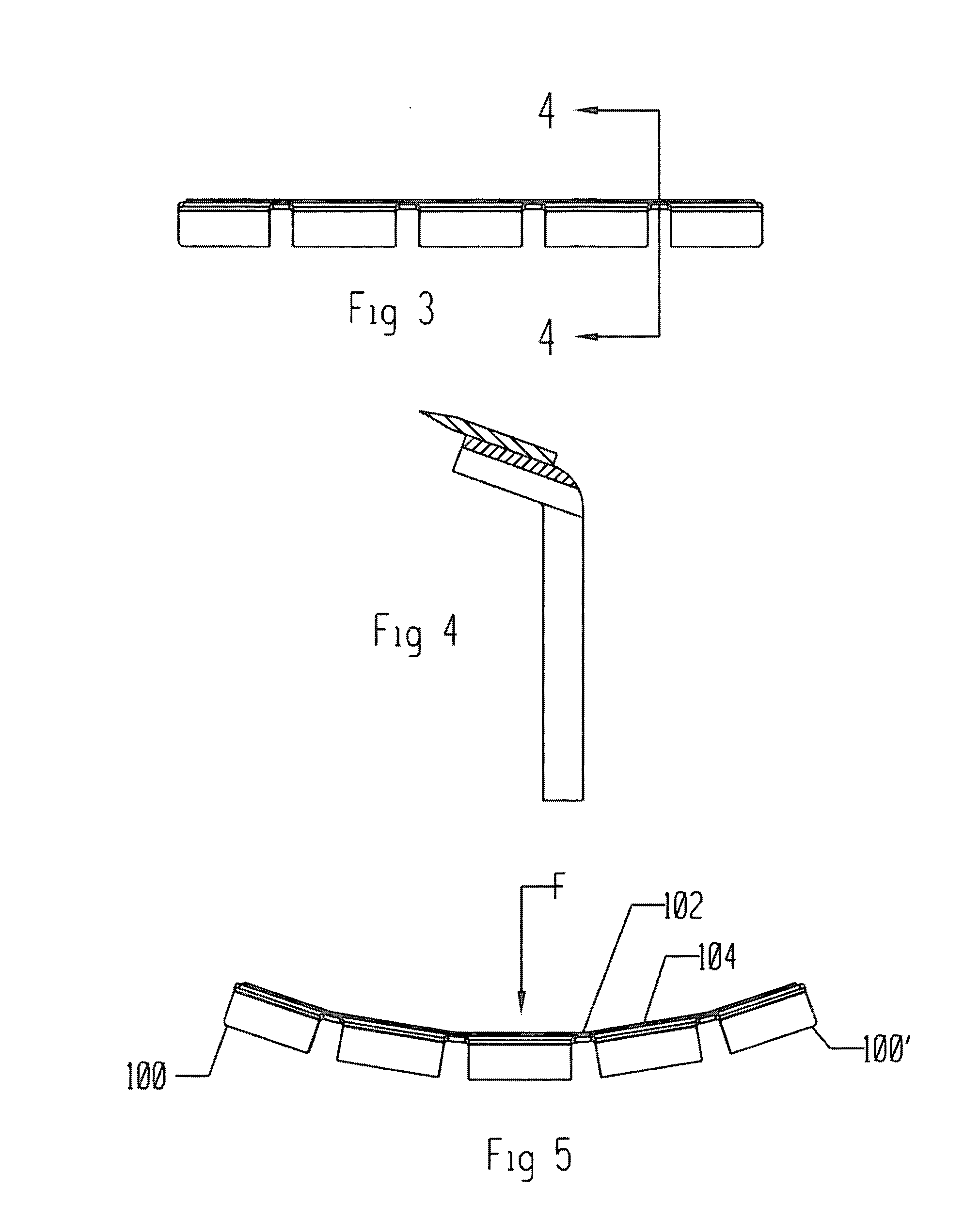

Razor blade and support assembly

ActiveUS20060248726A1Lower elastic modulusControl deflectionMetal working apparatusEngineeringKnife blades

A razor blade and support assembly is provided which flexes in response to shaving forces near slots in the blade support. A razor cartridge includes one or more of the aforementioned razor blade and support assemblies positioned in a housing. The razor cartridge may be permanently or removably coupled to a handle to provide a shaving razor.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

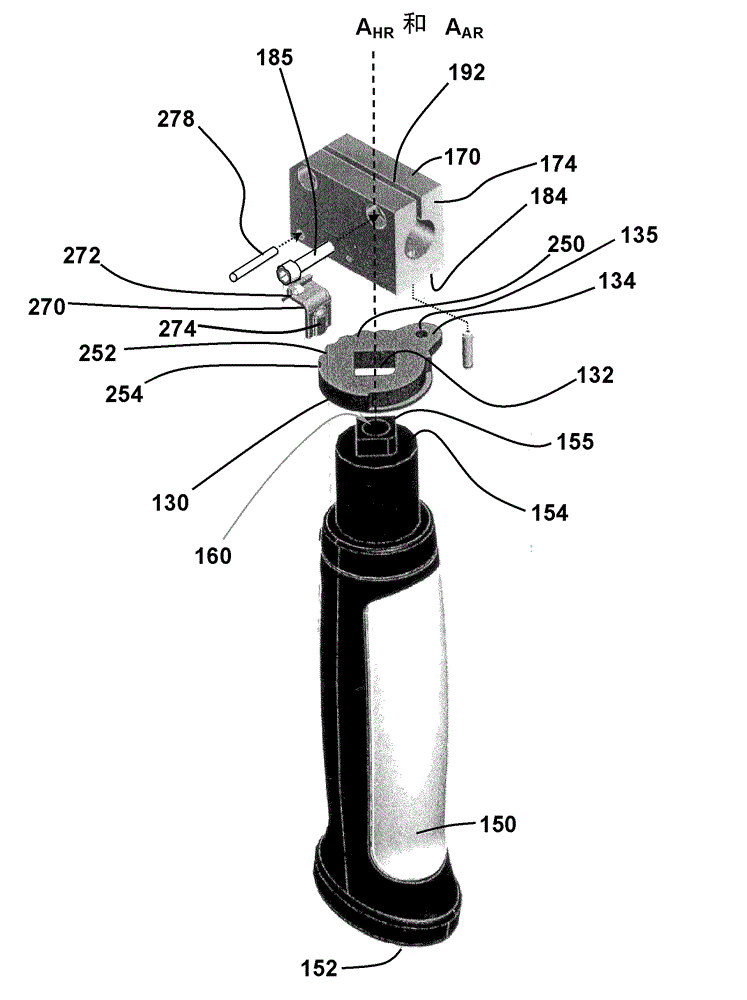

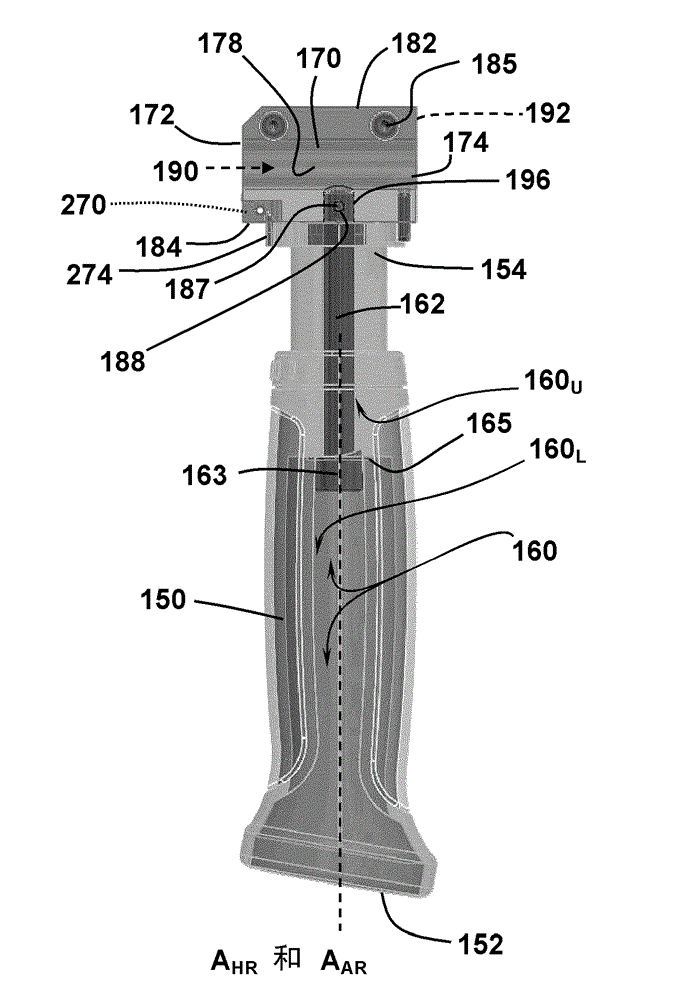

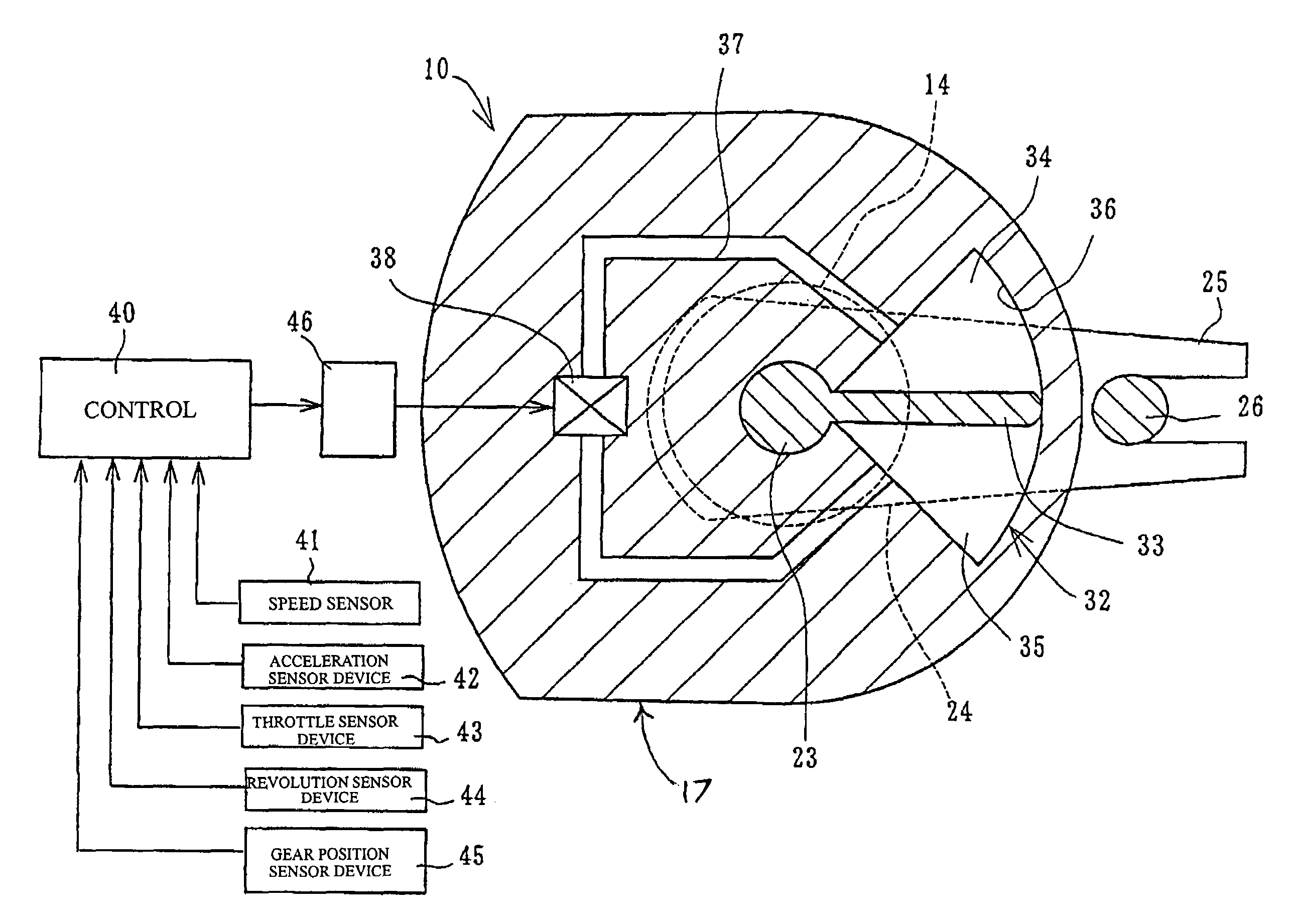

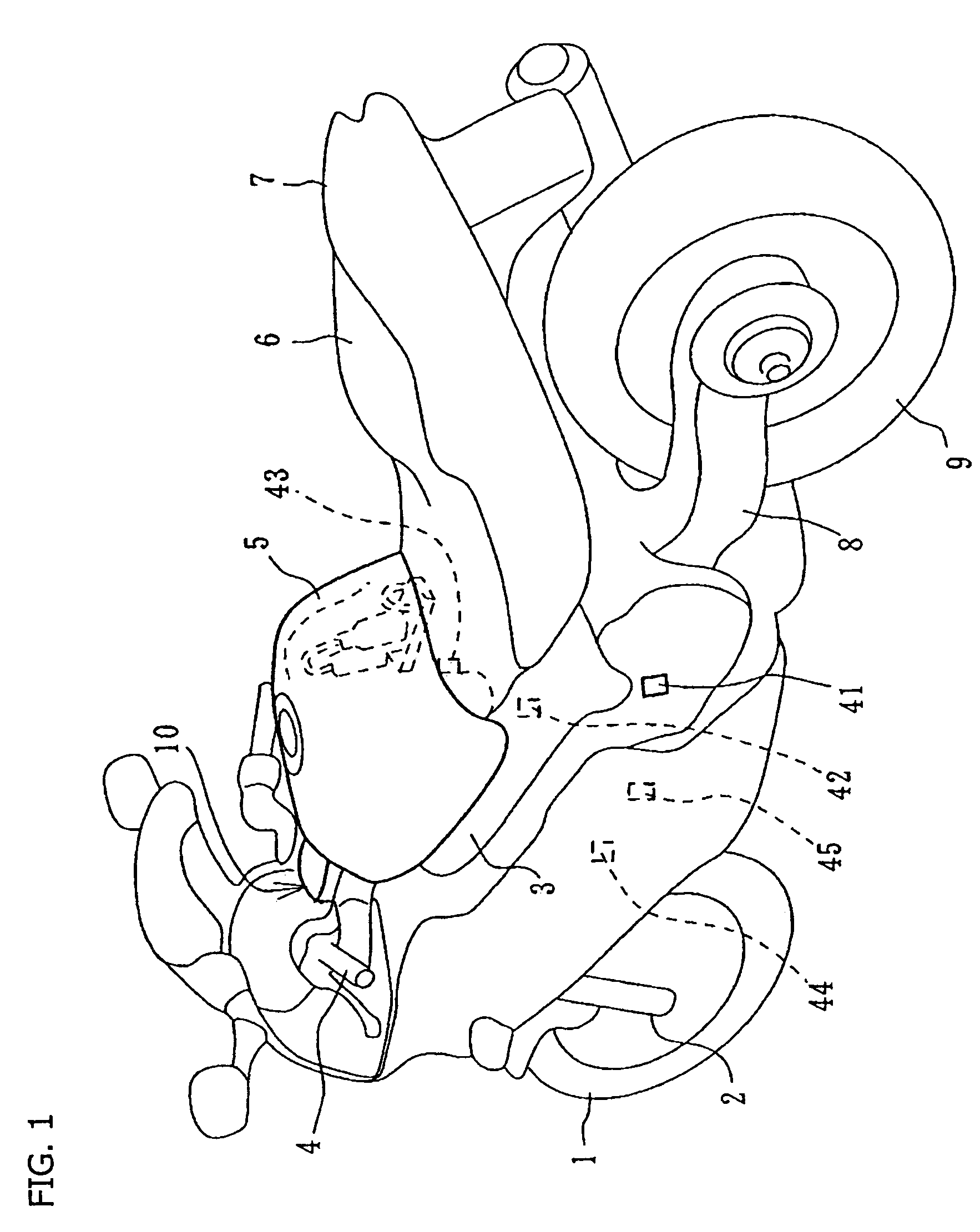

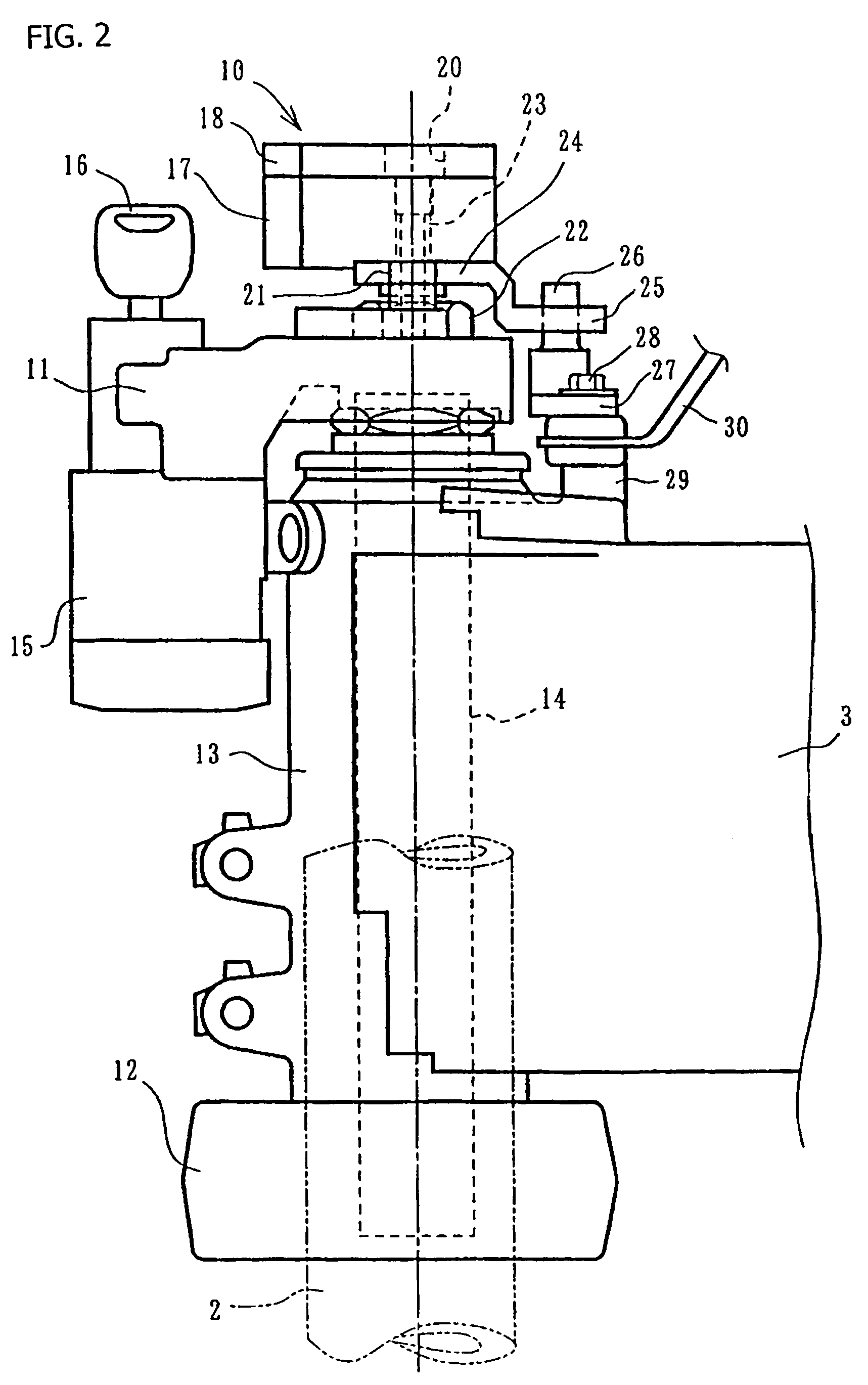

Steering damper apparatus, and method of using same

ActiveUS7377533B2Minimize steering damp apparatus-induced loadImprove mobilityWheel based transmissionFrictional rollers based transmissionSnubberControl theory

A steering damper is provided coaxially with a steering shaft, and a handlebar load is provided by causing a variable valve to generate damping force, using rotation of the steering shaft. The damping force is variably controlled in response to vehicle speed. The damping force is fixed to a minimum value C1 for vehicle speeds equal to or below first reference speed V1, fixed to a maximum value C2 for vehicle speeds equal to or above second reference speed V2, and variably controlled in response to vehicle speed and acceleration in an intermediate speed range. Fine maneuverability of a vehicle body is achieved by reducing a load on a handlebar at low vehicle speeds, and a stable movement of the vehicle body is maintained at high vehicle speed by increasing the load on the handlebar and thereby suppressing deflection of the handlebar.

Owner:HONDA MOTOR CO LTD

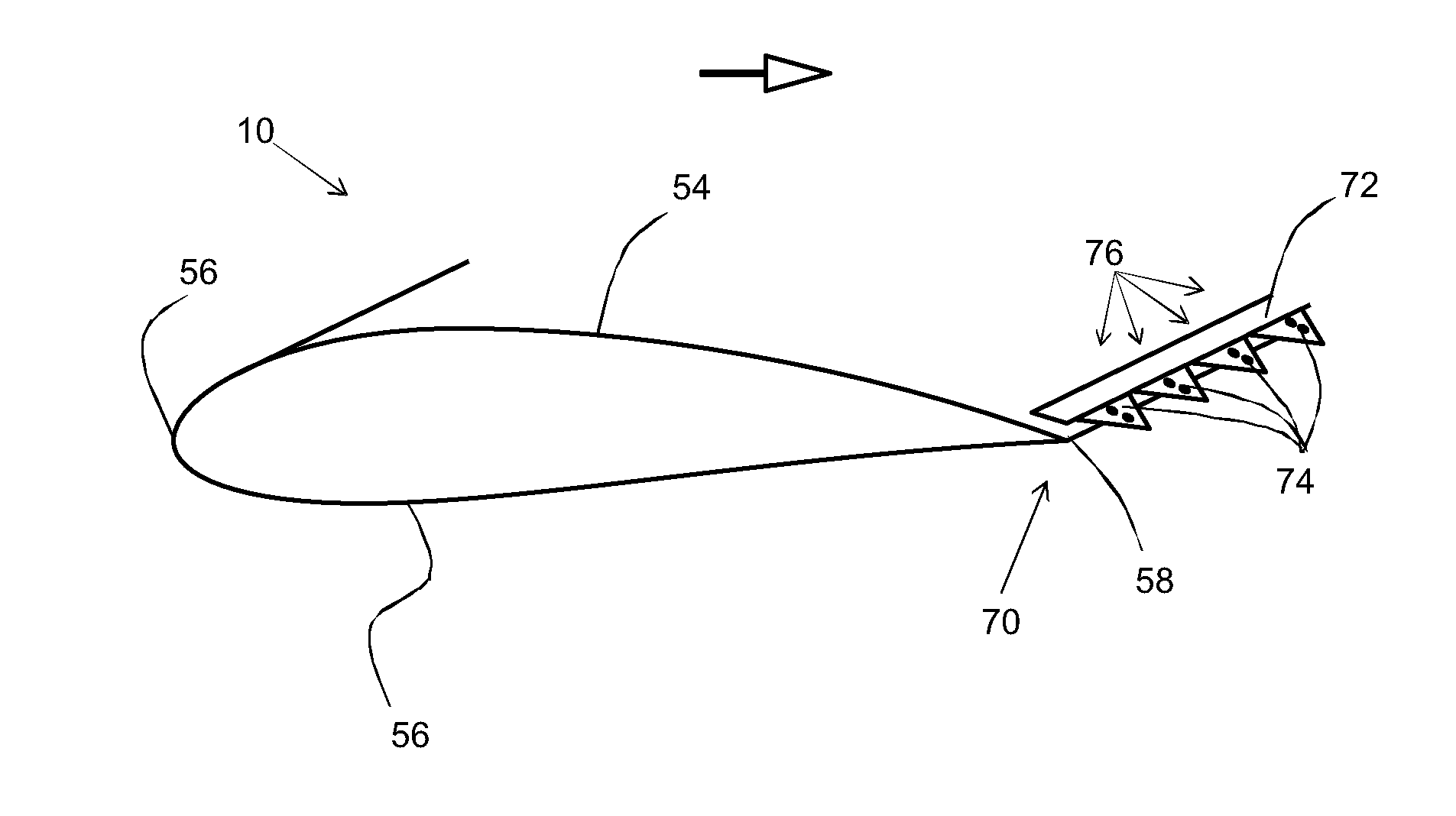

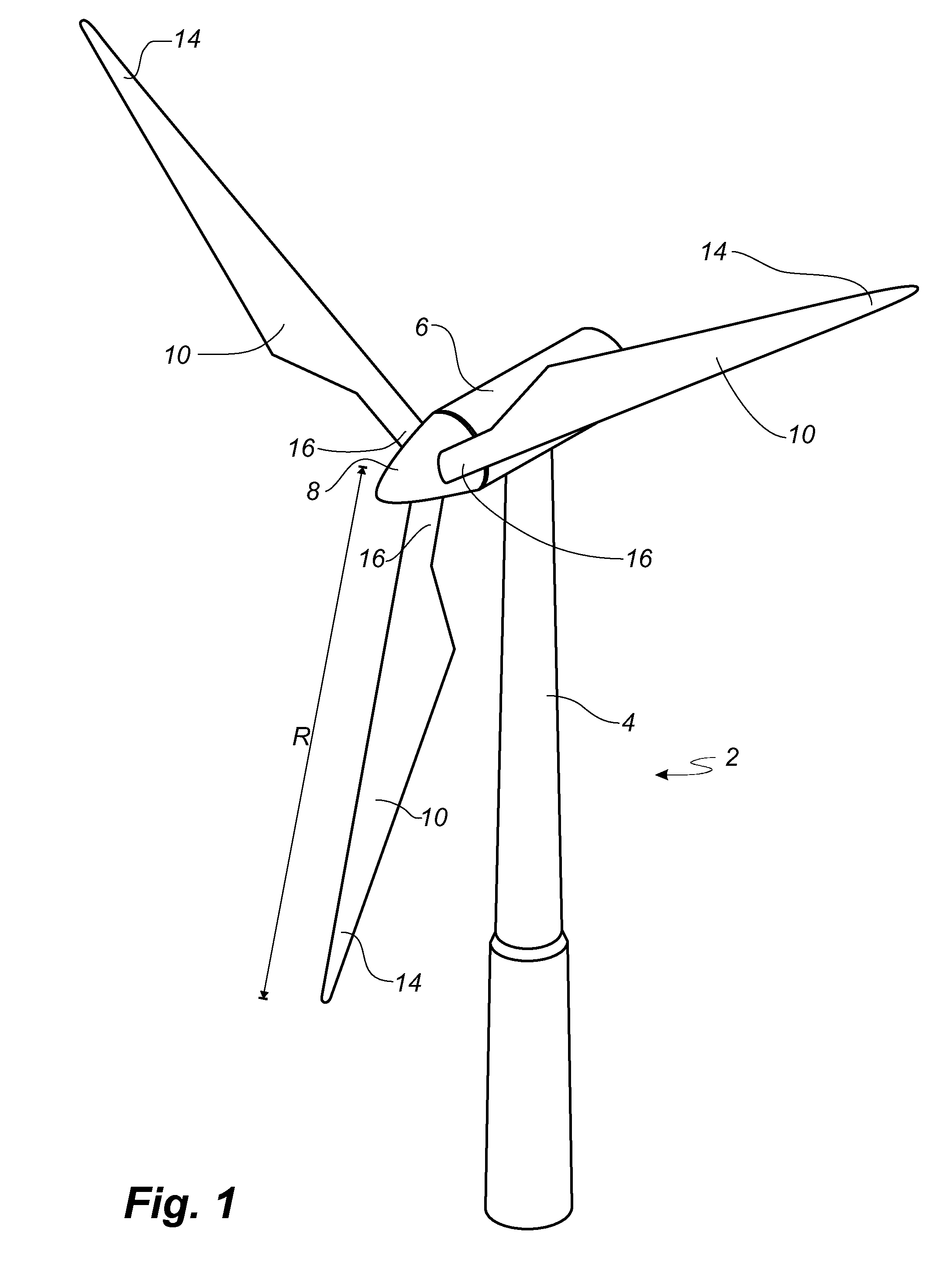

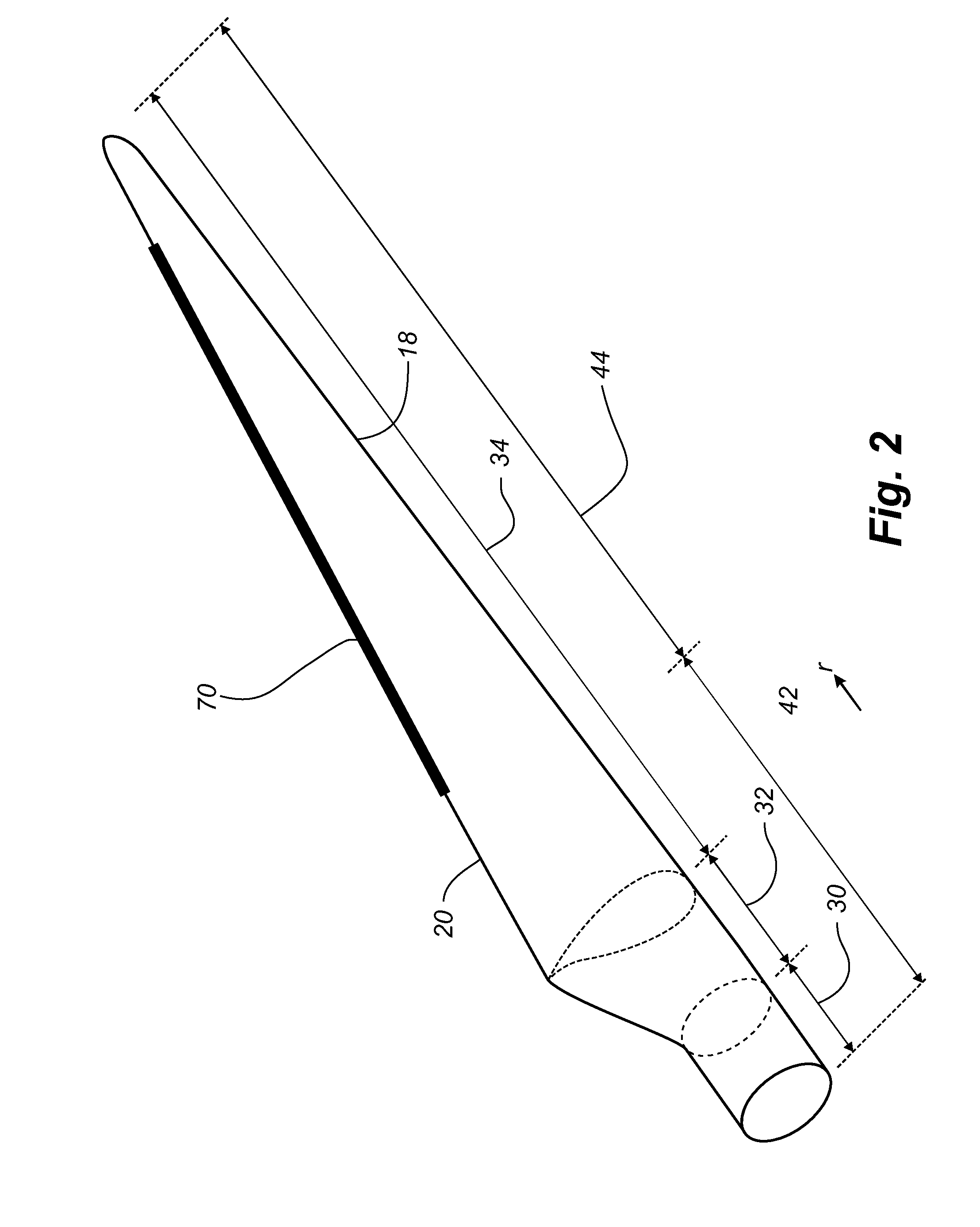

Wind turbine blade

ActiveUS20140286784A1Reduce stepsAvoid deflectionEngine fuctionsReaction enginesSuction stressTurbine blade

A wind turbine blade is described having noise reduction features. The blade has a plurality of projecting serrations provided at the blade trailing edge to reduce the scattering noise produced during operation of the blade, wherein the serrations have a plurality of through-going apertures defined in the serration body. The apertures act to provide a pressure equalisation effect at the serrations between the suction and pressure sides. This pressure equalisation provides for improved noise reduction performance, as well as a reduction in mechanical stresses and strains which may be experienced by the serrations, increasing serration lifetime.

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com