Battery case for vehicle

A battery and vehicle technology, applied in the direction of batteries, vehicle parts, battery pack parts, etc., can solve the problems of increasing cost and increasing the overall weight of the battery case, and achieve the effect of reducing weight, reducing the number of parts and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

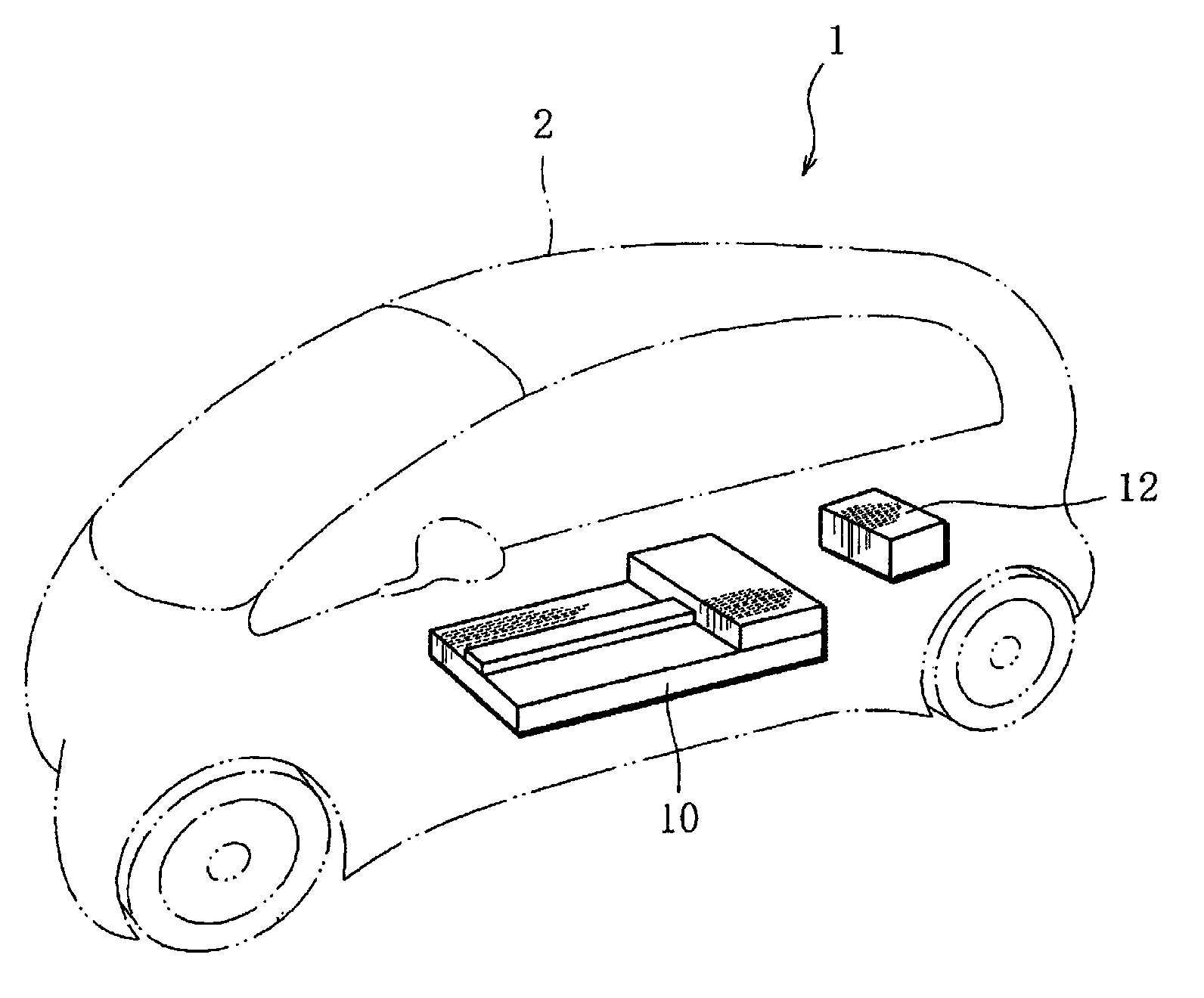

[0053] figure 1 It is a perspective view of an electric vehicle equipped with a battery case of the present invention.

[0054] Such as figure 1 As shown, the electric vehicle 1 has a battery case 10 placed under the floor of the vehicle body 2, and an external charging path (not shown), and a charger 12 for receiving power supply from the charging path and charging is arranged on the vehicle body. 2, the battery case 10 is connected to a charger 12 to store electricity.

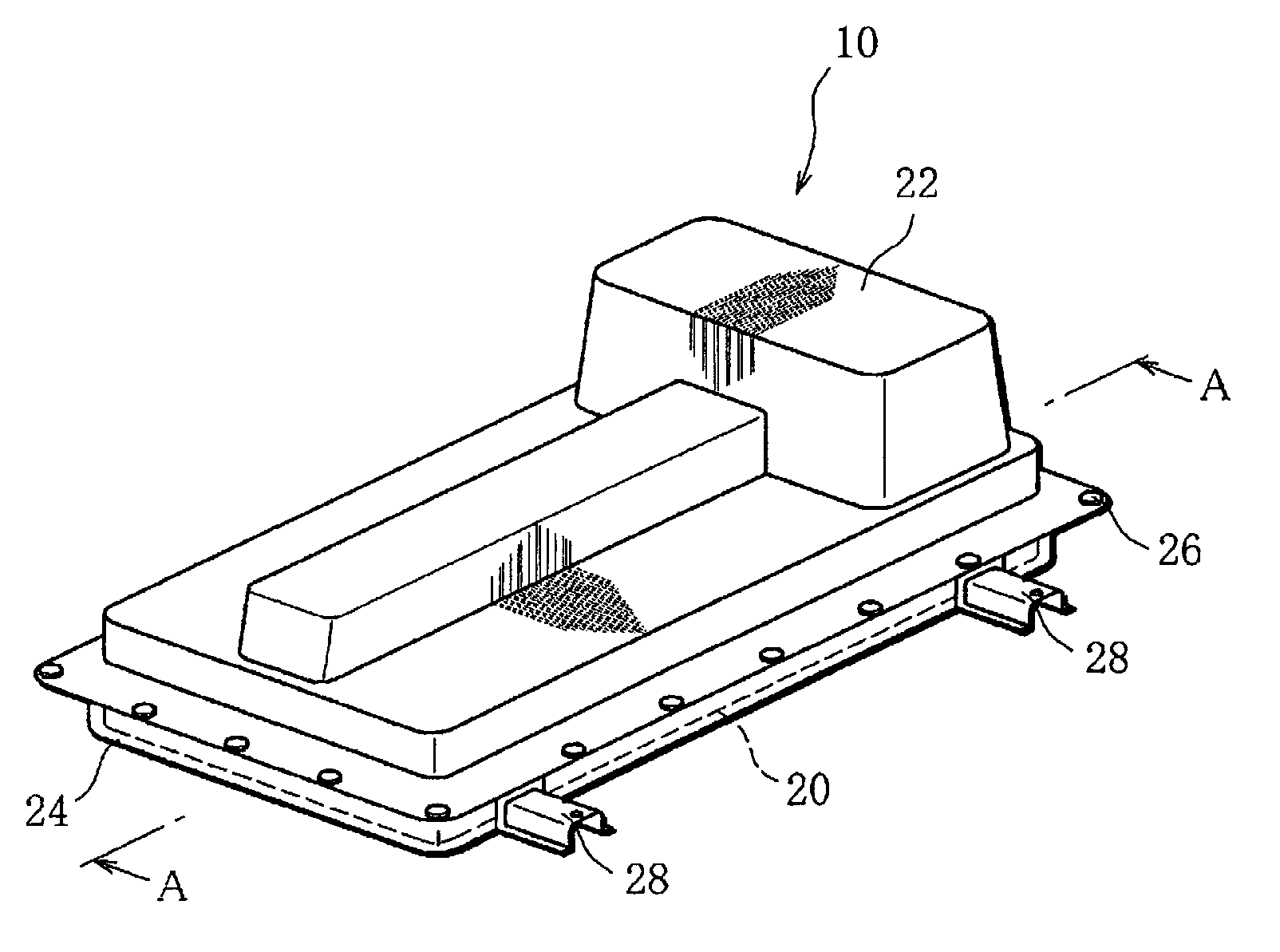

[0055] figure 2 A schematic configuration diagram of the battery case 10 is shown.

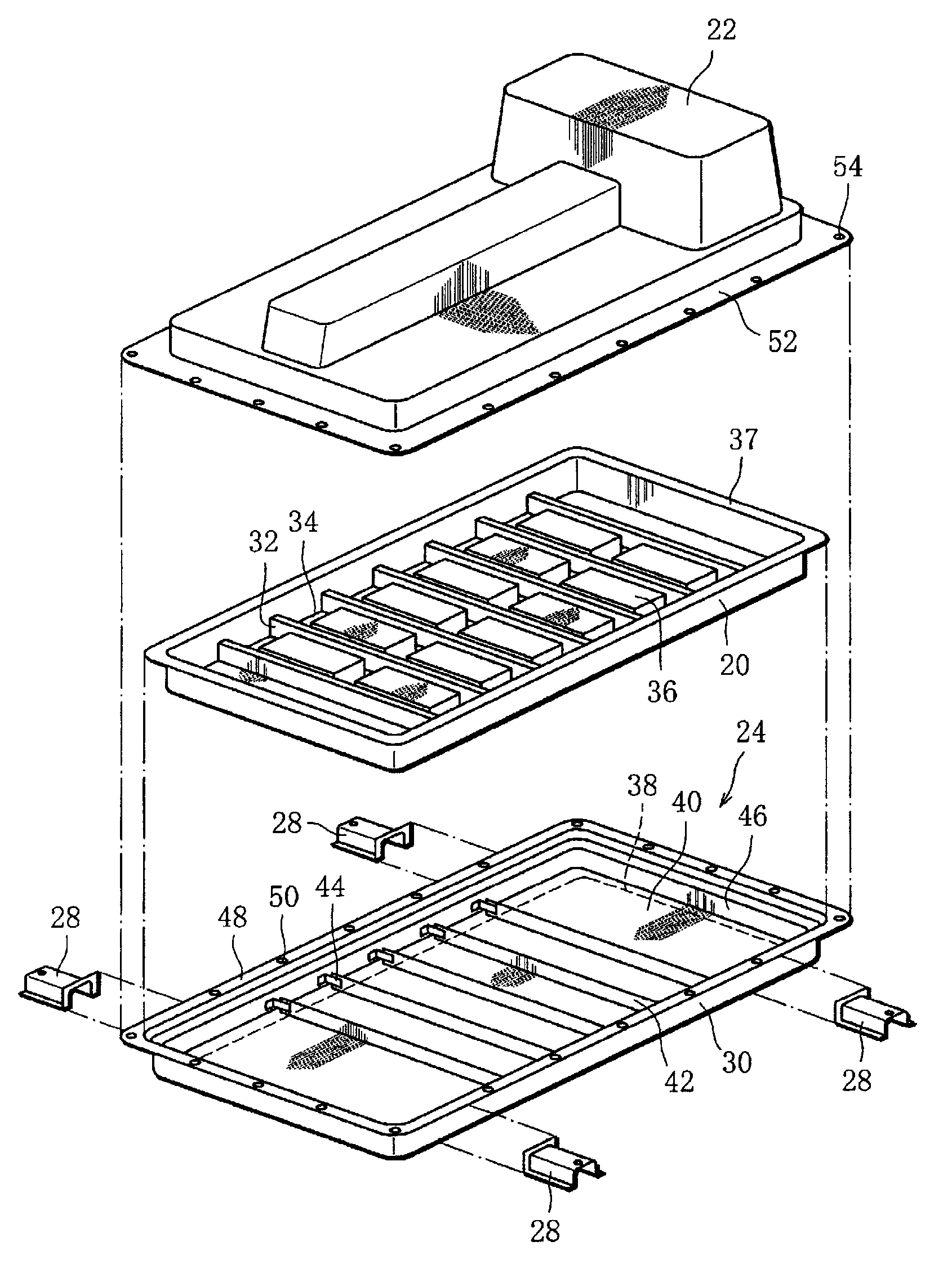

[0056] The battery case 10 includes: a resin tray (tray part) 20; a case (case part) 22; a frame (reinforcing tray part, frame part) 24 covering the outer periphery of the resin tray 20; and a mounting bracket 28 for mounting the battery case 10 on the vehicle body 2 .

[0057] The resin tray 20 and the case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com