Patents

Literature

1049results about "Heavy duty vehicle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

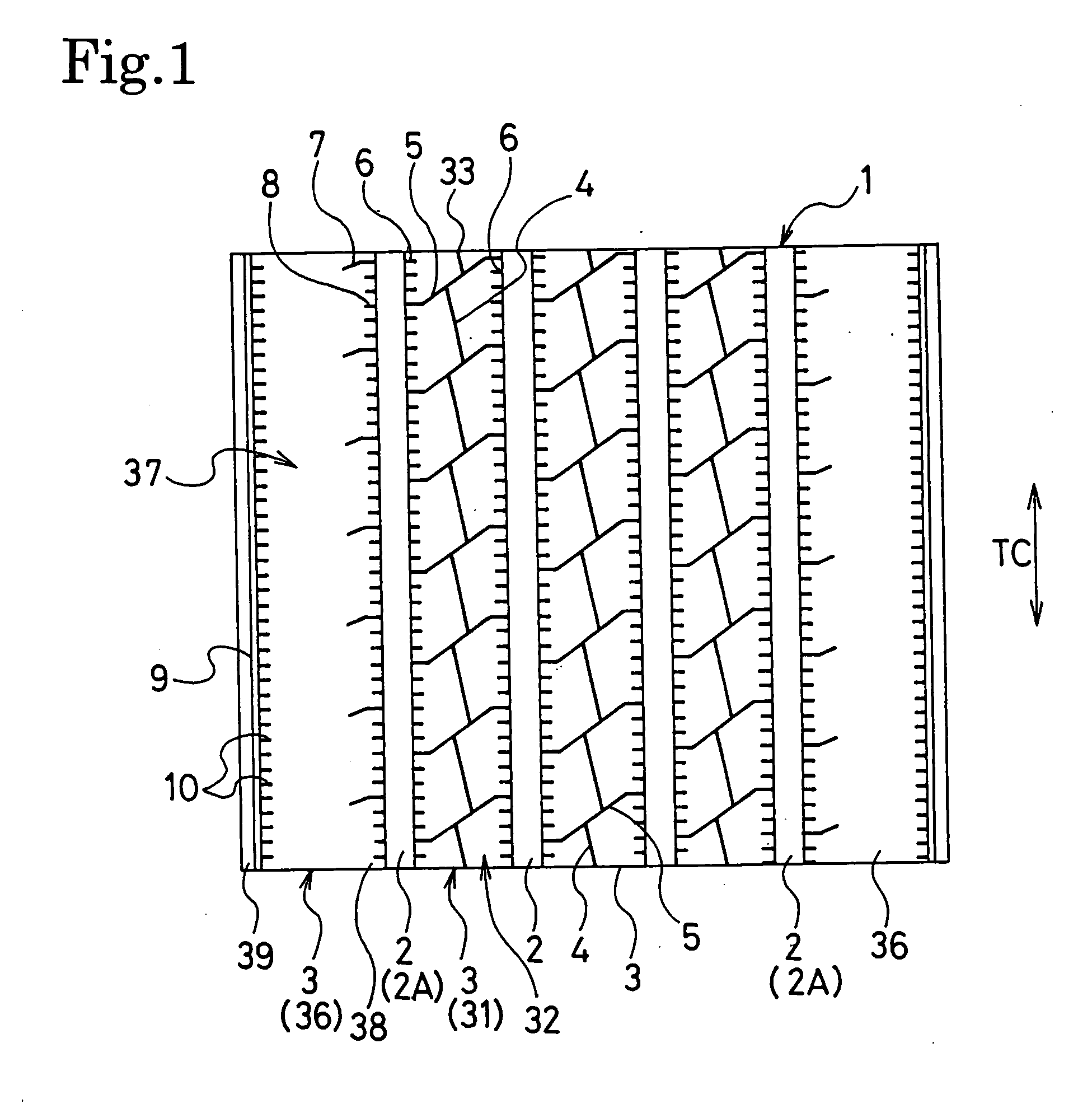

Tire tread with groove reinforcement

A tire has an axis of rotation. The tire includes two sidewalls extending radially outward and a tread disposed radially outward of the two sidewalls and interconnecting the two sidewalls. The tread includes a main portion comprising a first compound and a reinforcing structure comprising a second compound having reinforcing short fibers oriented between −20 degrees to +20 degrees to a circumferential direction of the tread. The main portion of the tread includes at least one circumferential groove separating circumferential ribs. Each circumferential groove has two sides and a base therebetween. The reinforcing structure includes a layer of the second compound secured to the sides of each circumferential groove.

Owner:THE GOODYEAR TIRE & RUBBER CO

Heavy-duty tire

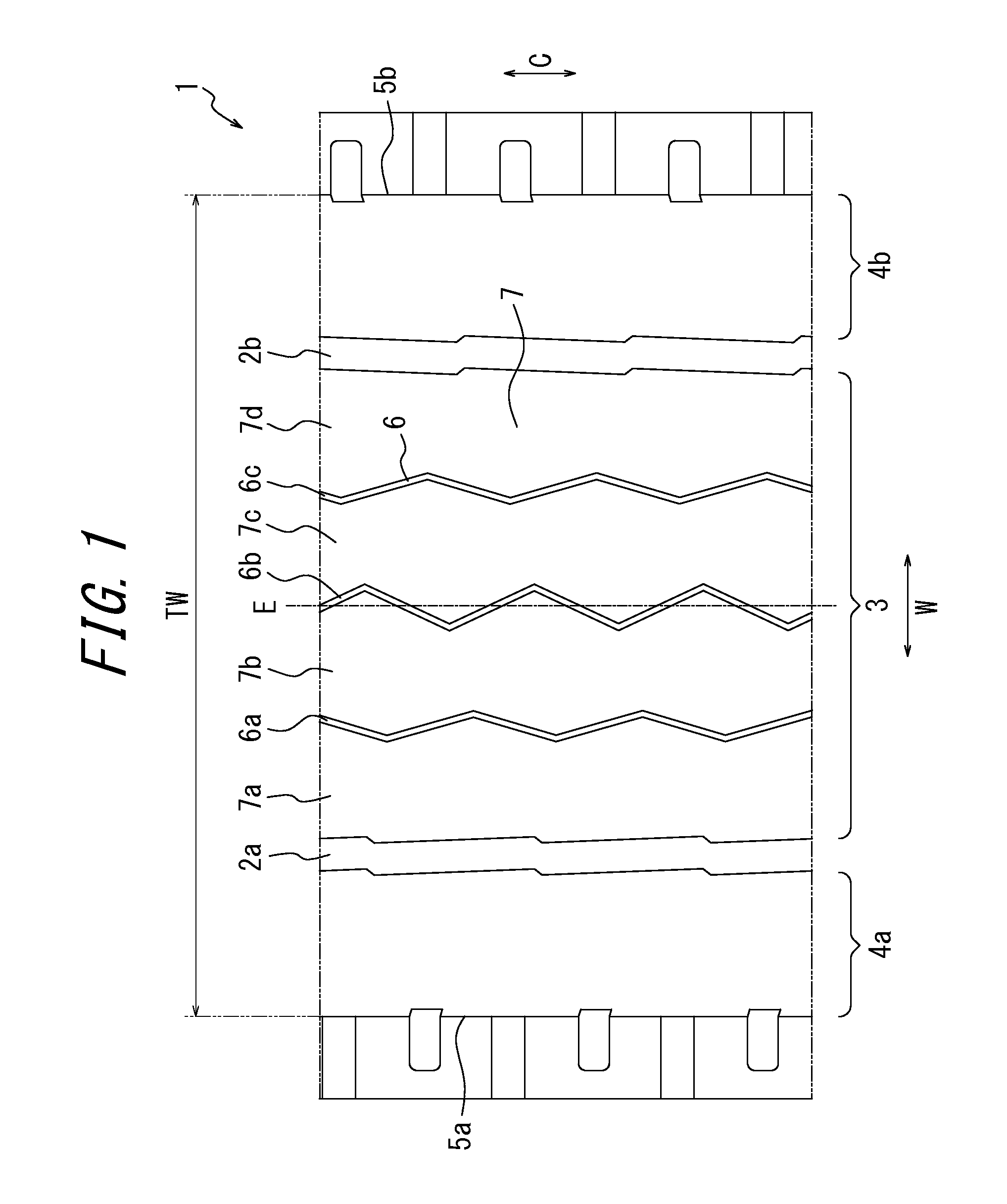

InactiveUS20070151646A1Increase stiffnessReduce ground pressureHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

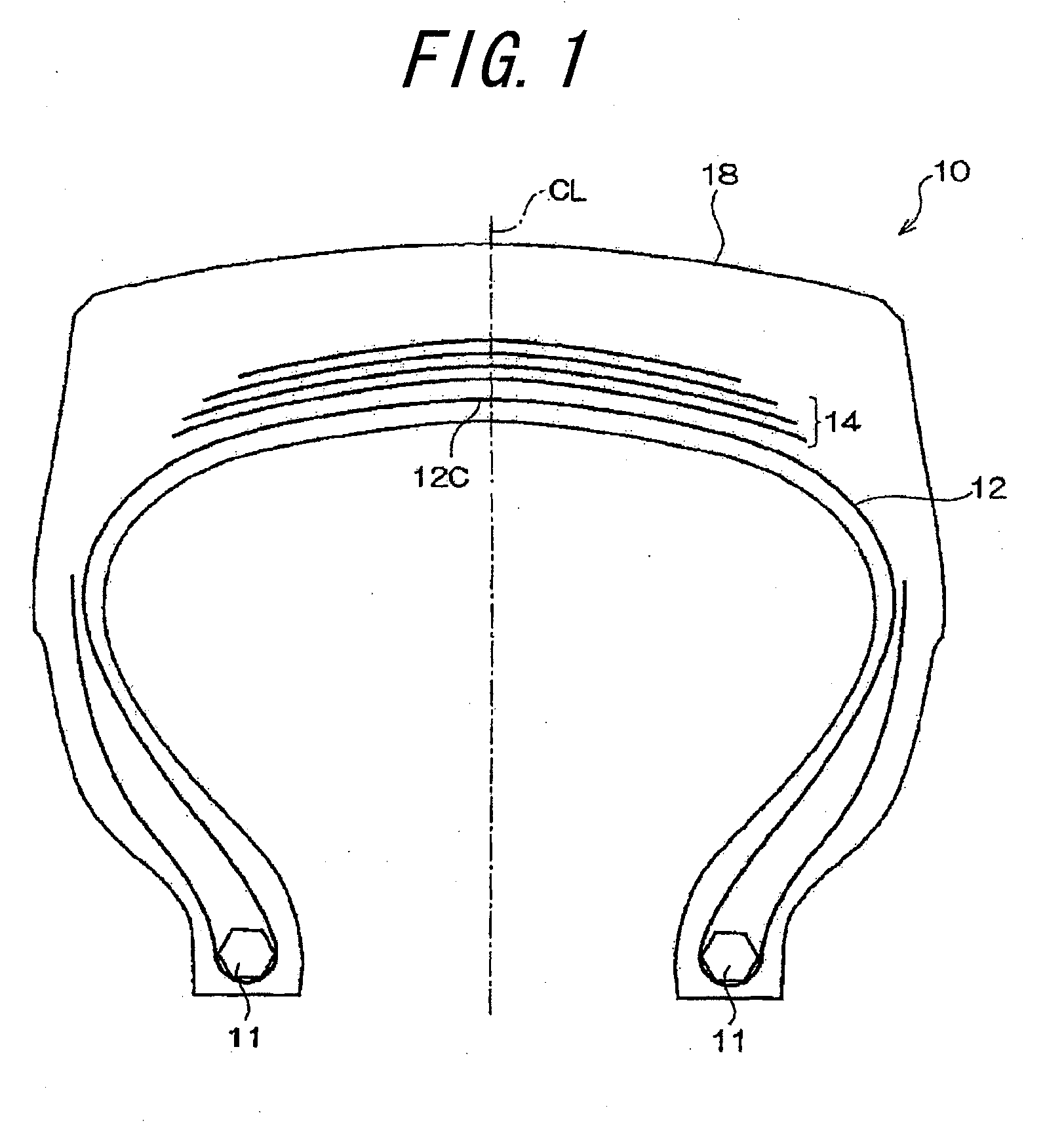

Pneumatic tire

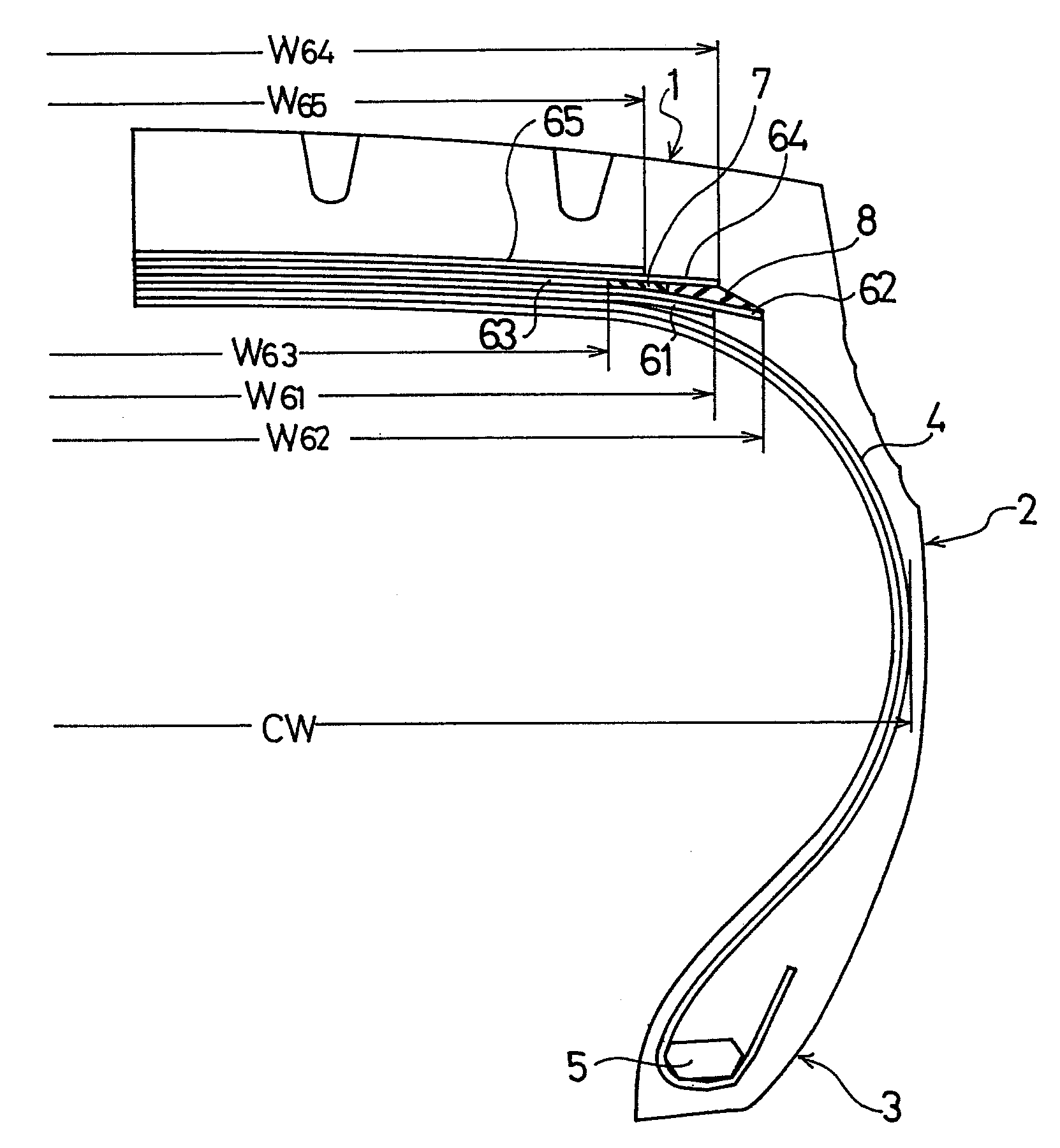

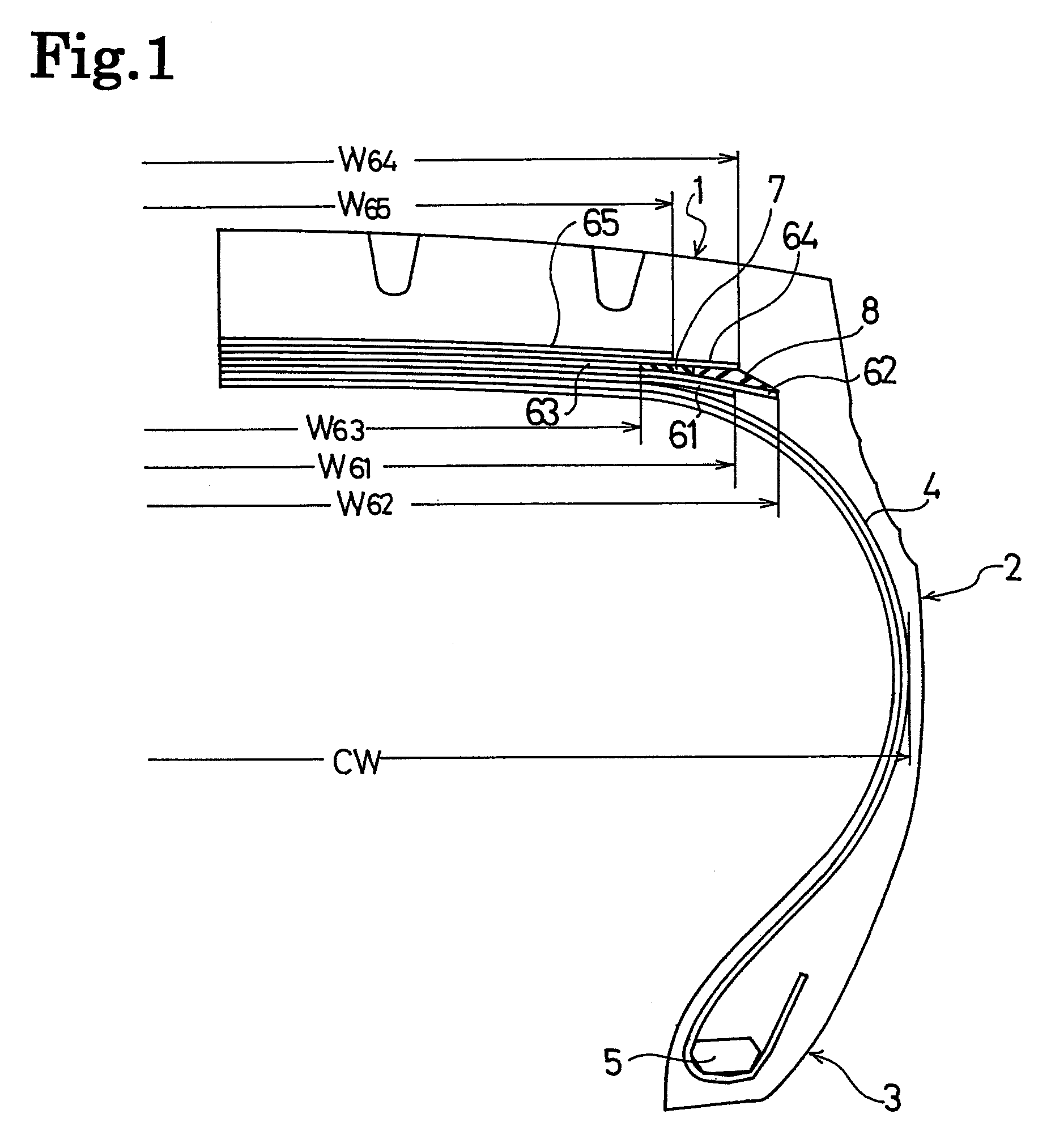

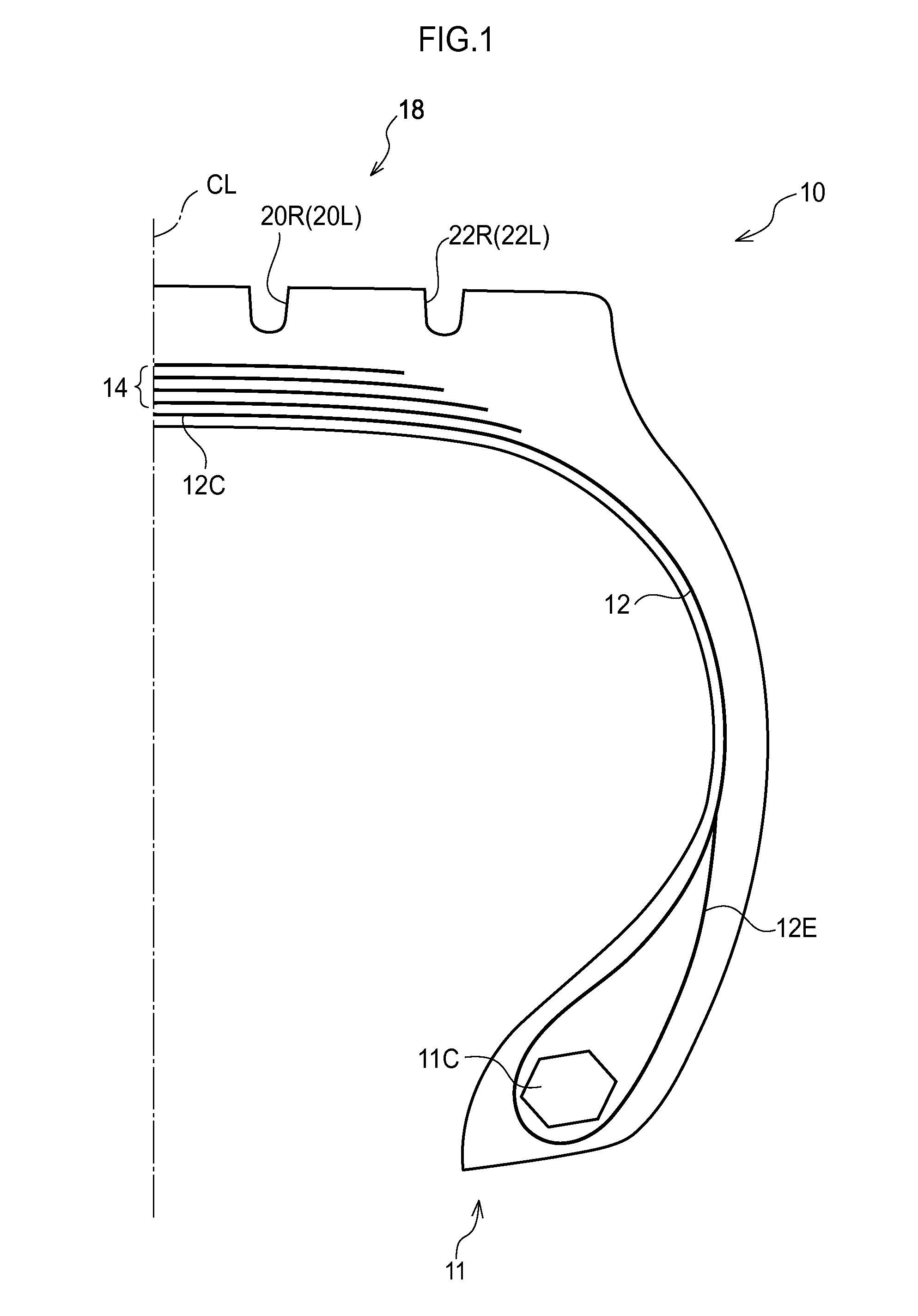

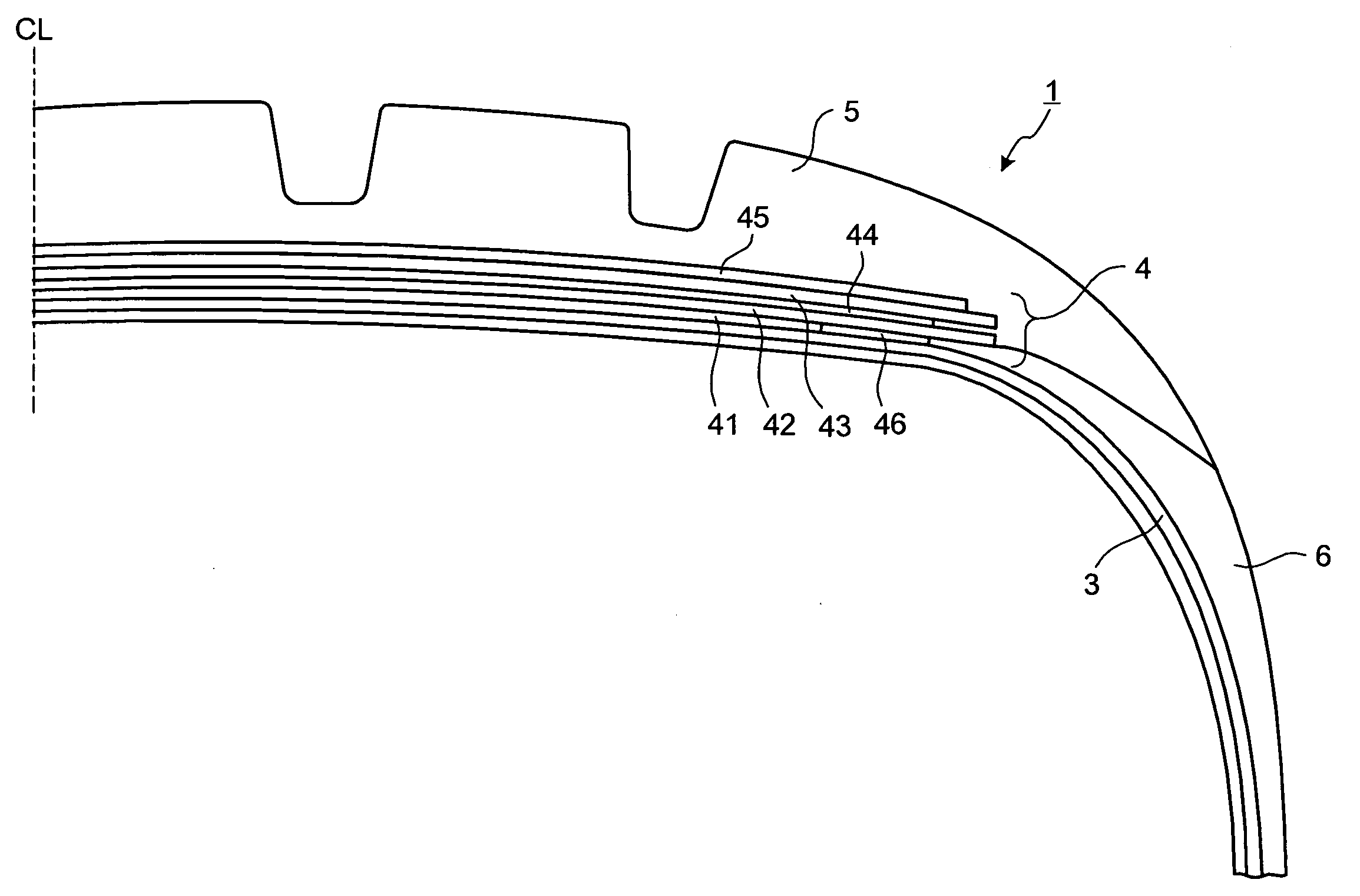

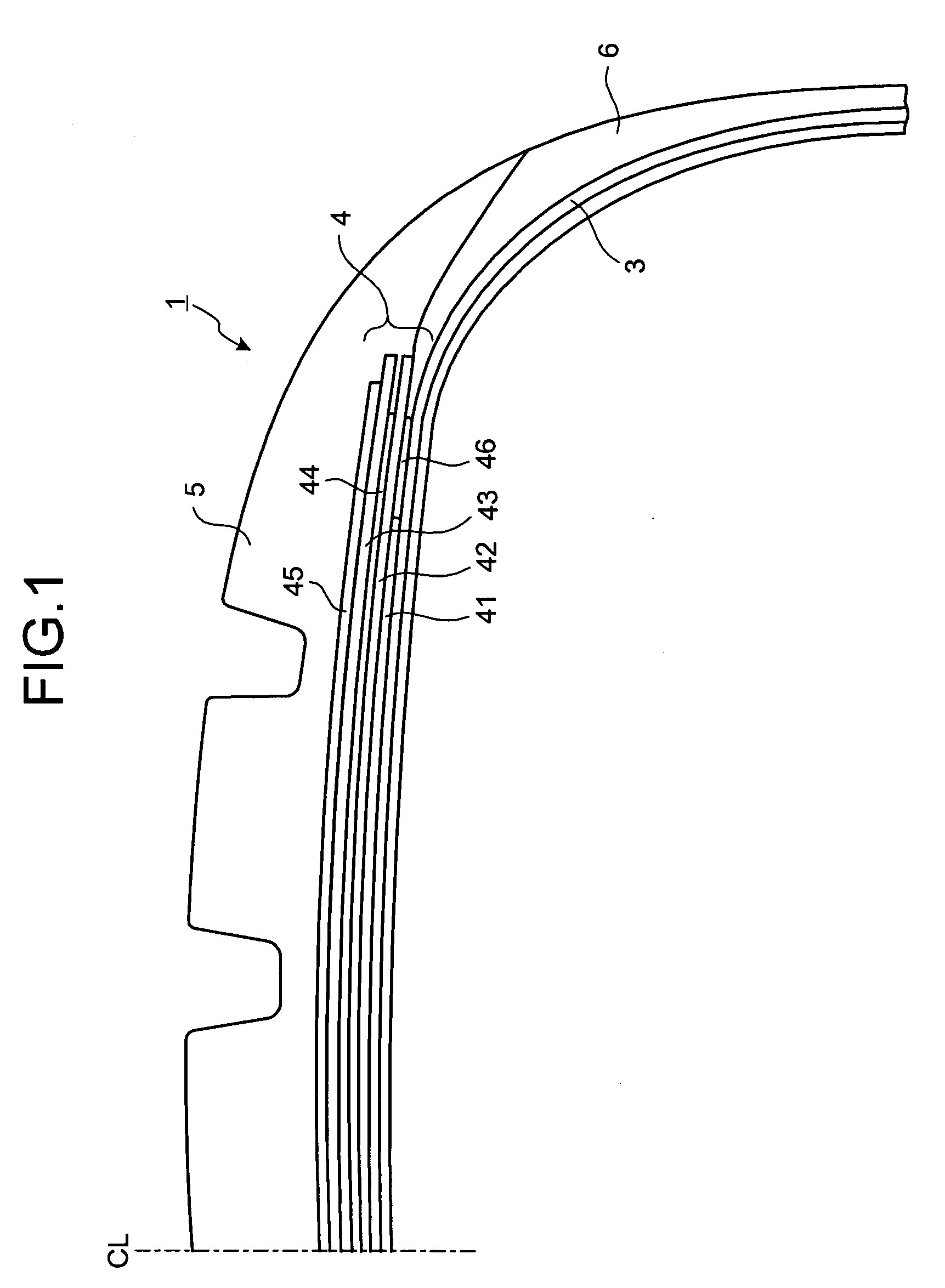

ActiveUS20090277557A1Avoid fatigue fractureIncrease widthHeavy duty tyresHeavy duty vehicleEngineeringStress relaxation

The present invention provides a pneumatic tire that inhibits any fatigue rupture at an edge portion of a circumferential-direction reinforcing belt layer and also inhibits any separation at an edge portion of crossed belt layers. In the pneumatic tire, at least two crossed belt layers are disposed on the outer circumferential side of a carcass layer in a tread portion. At least one circumferential-direction reinforcing belt layer with a width smaller than those of the crossed belt layers is disposed between the crossed belt layers. Moreover, a stress relaxation layer of a rubber composition having a fixed thickness is disposed between the crossed belt layers while lying adjacent to an edge portion of and outside, in the width directions of, the circumferential-direction reinforcing belt layer.

Owner:THE YOKOHAMA RUBBER CO LTD

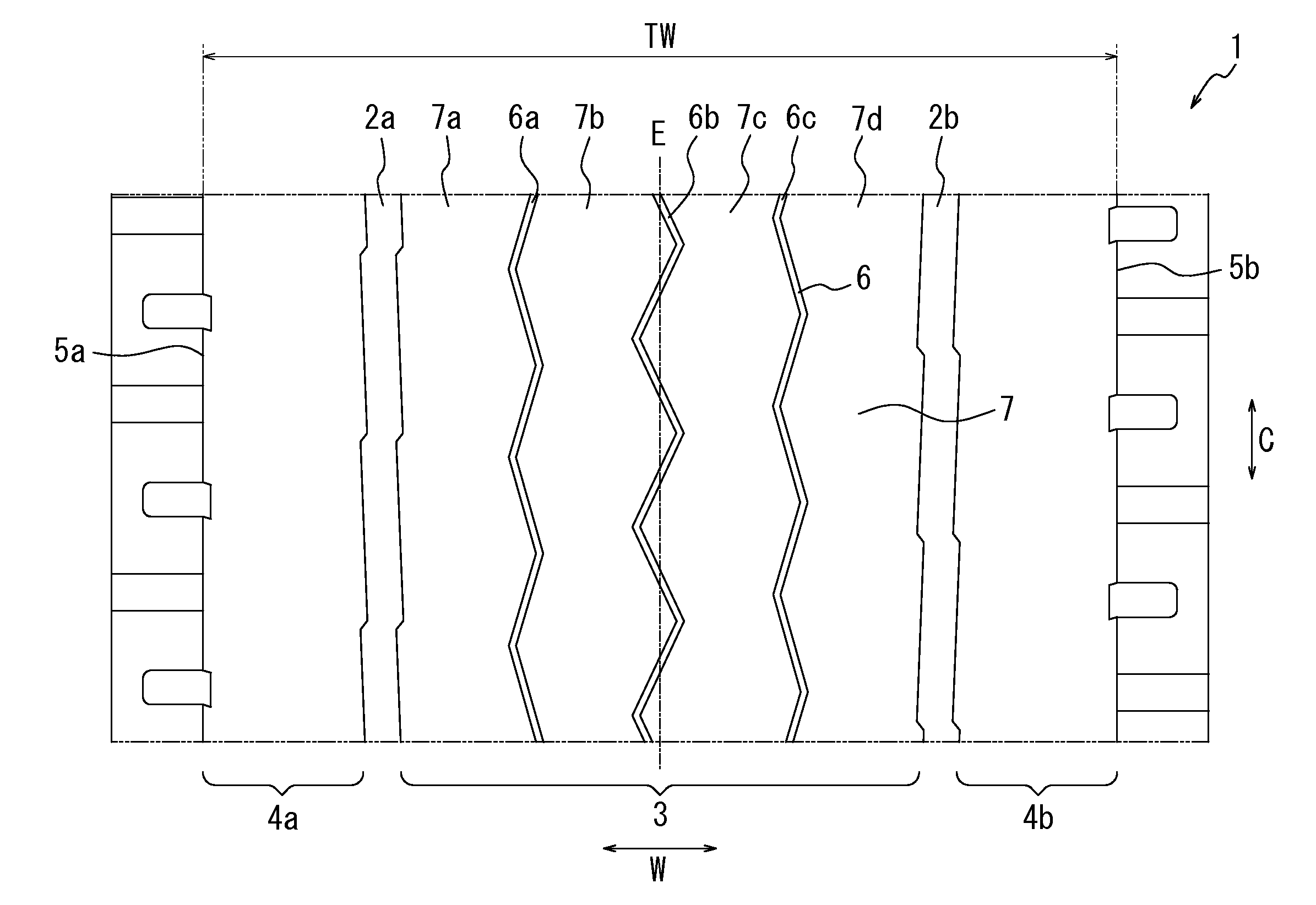

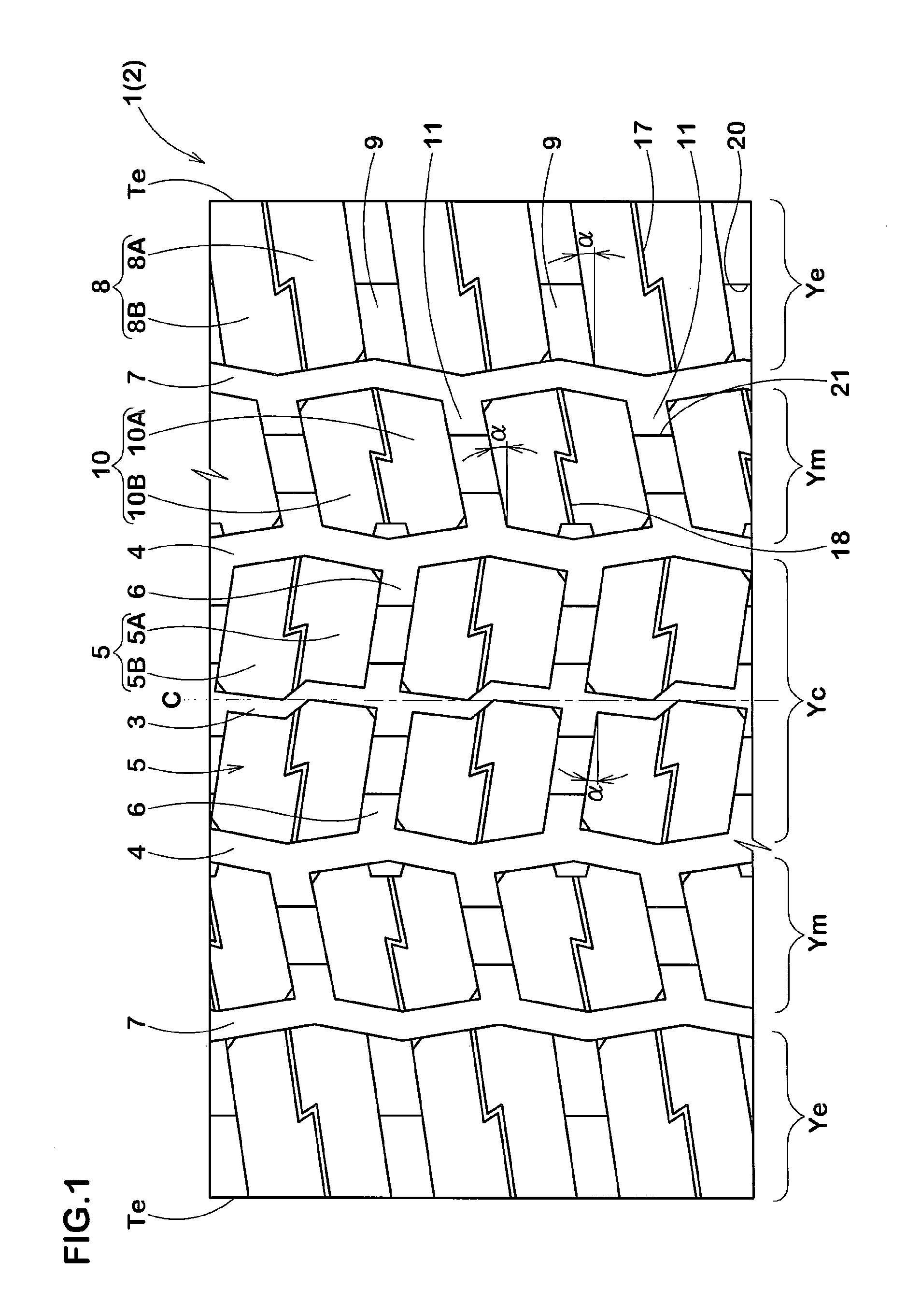

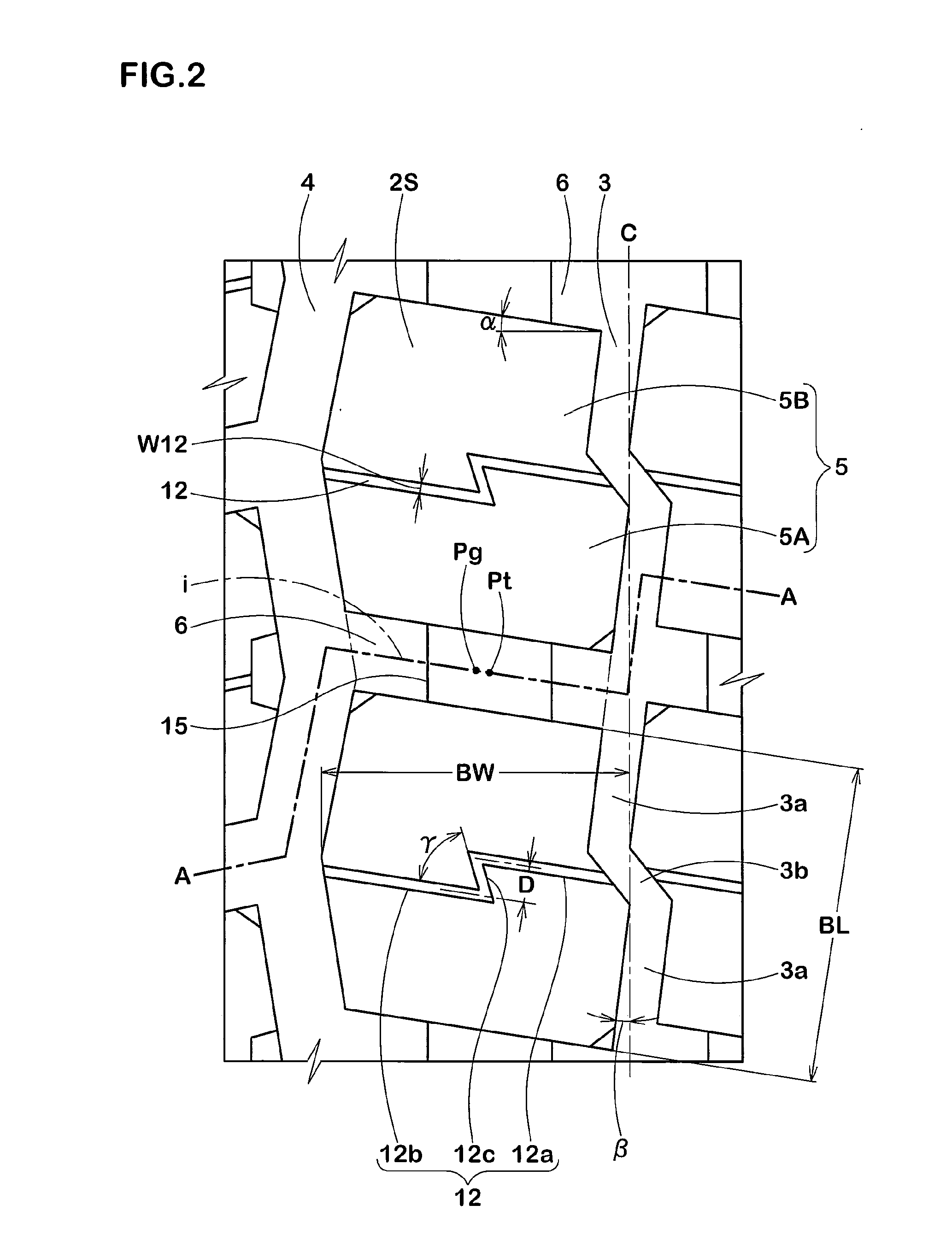

Pneumatic vehicle tire

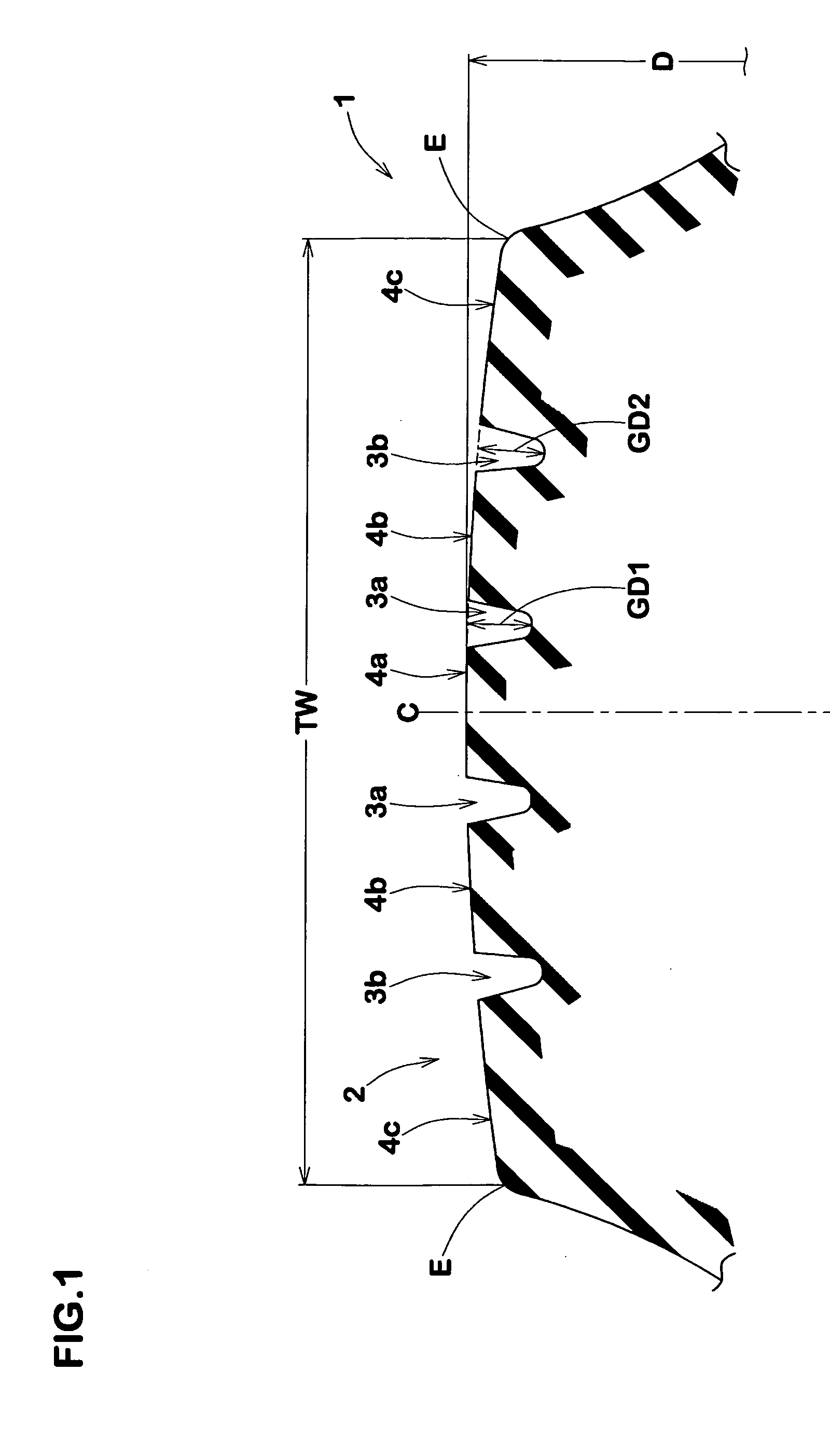

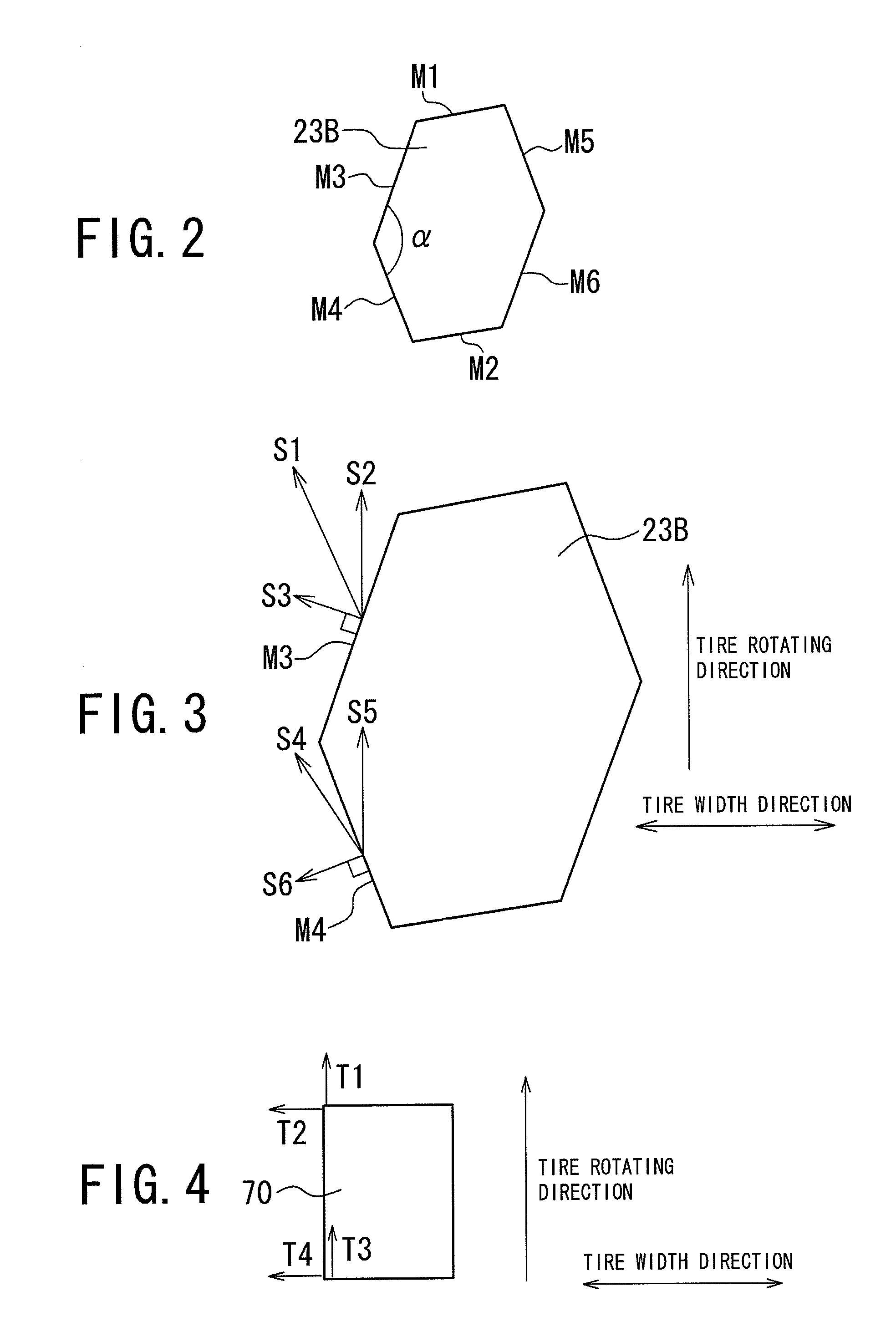

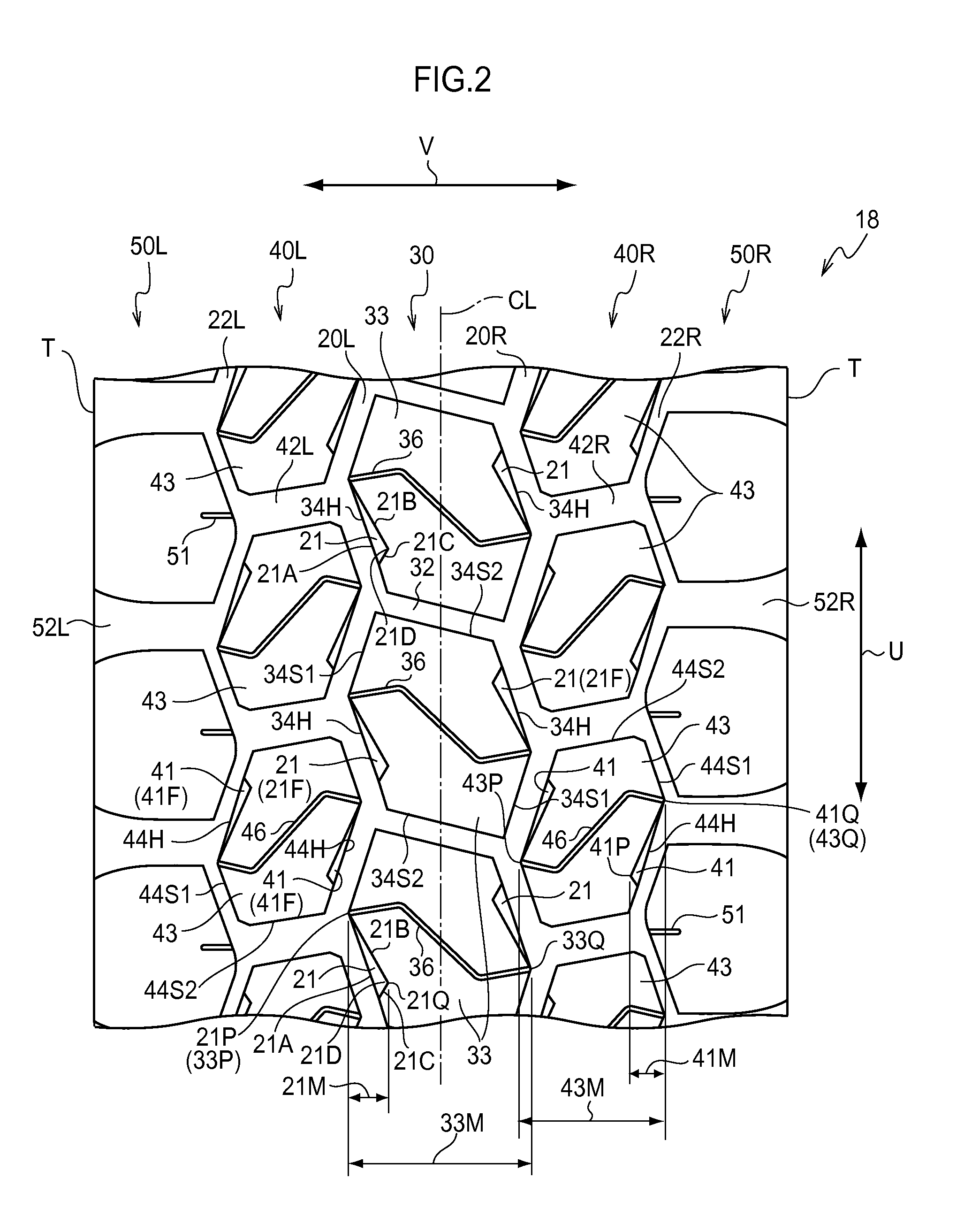

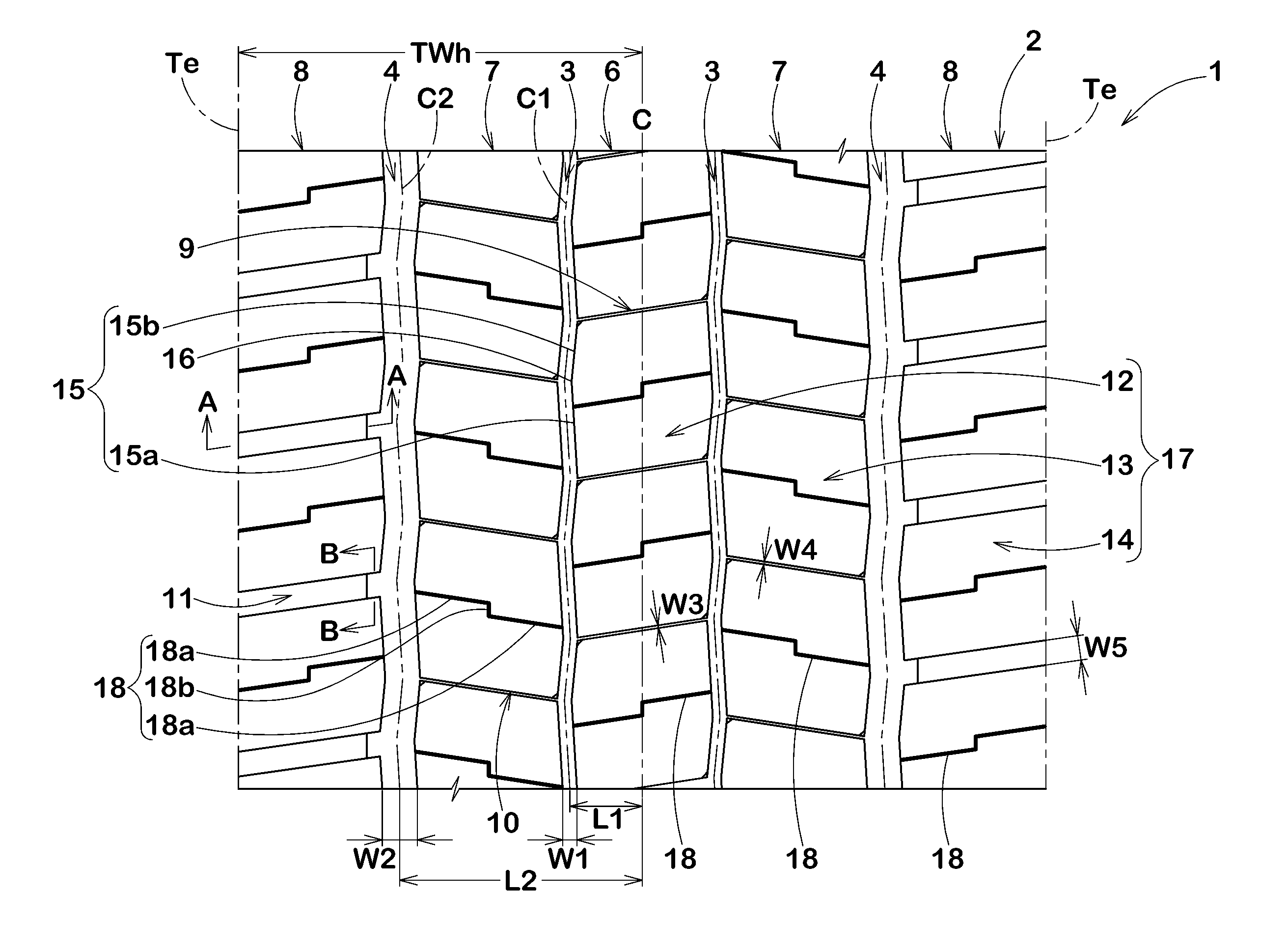

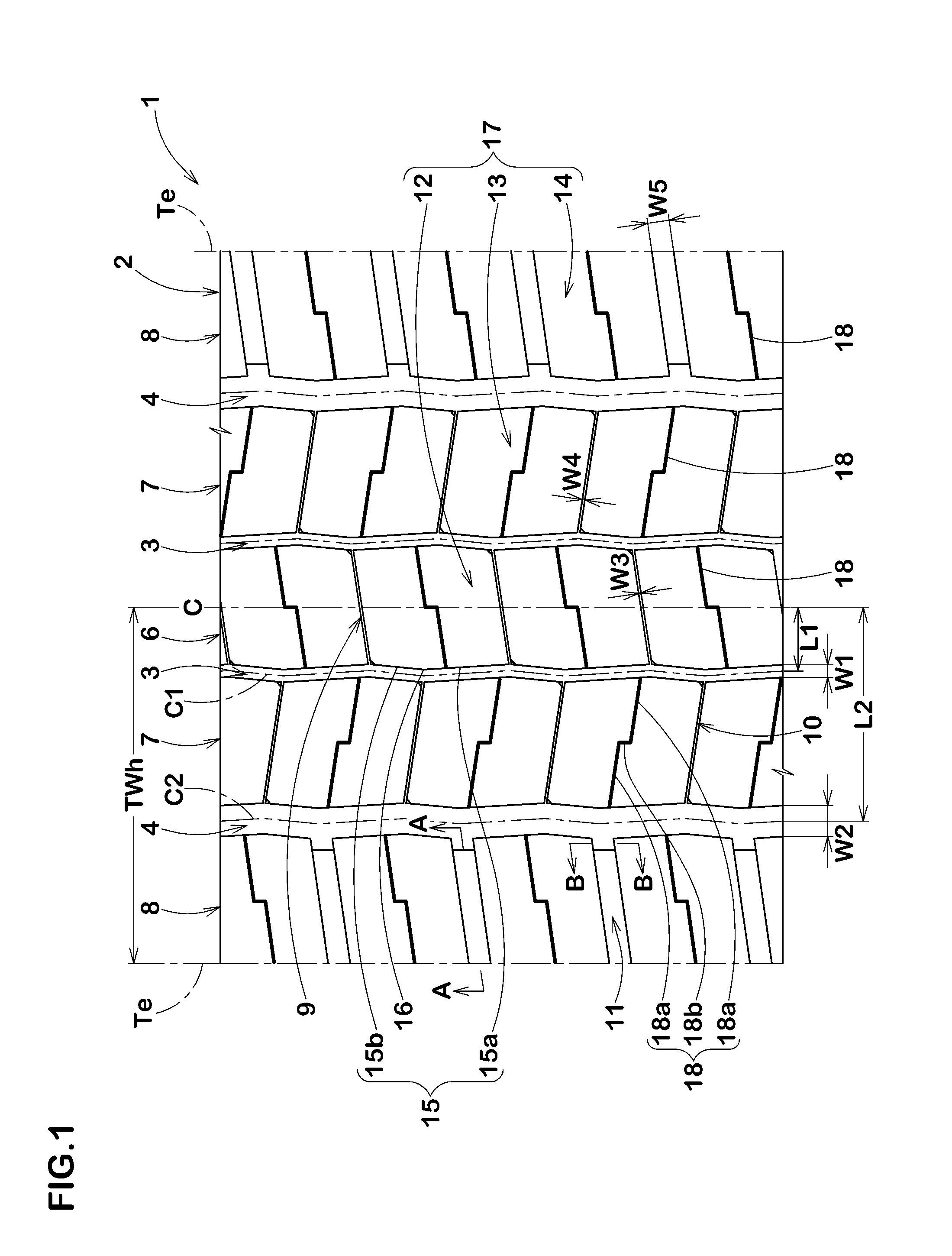

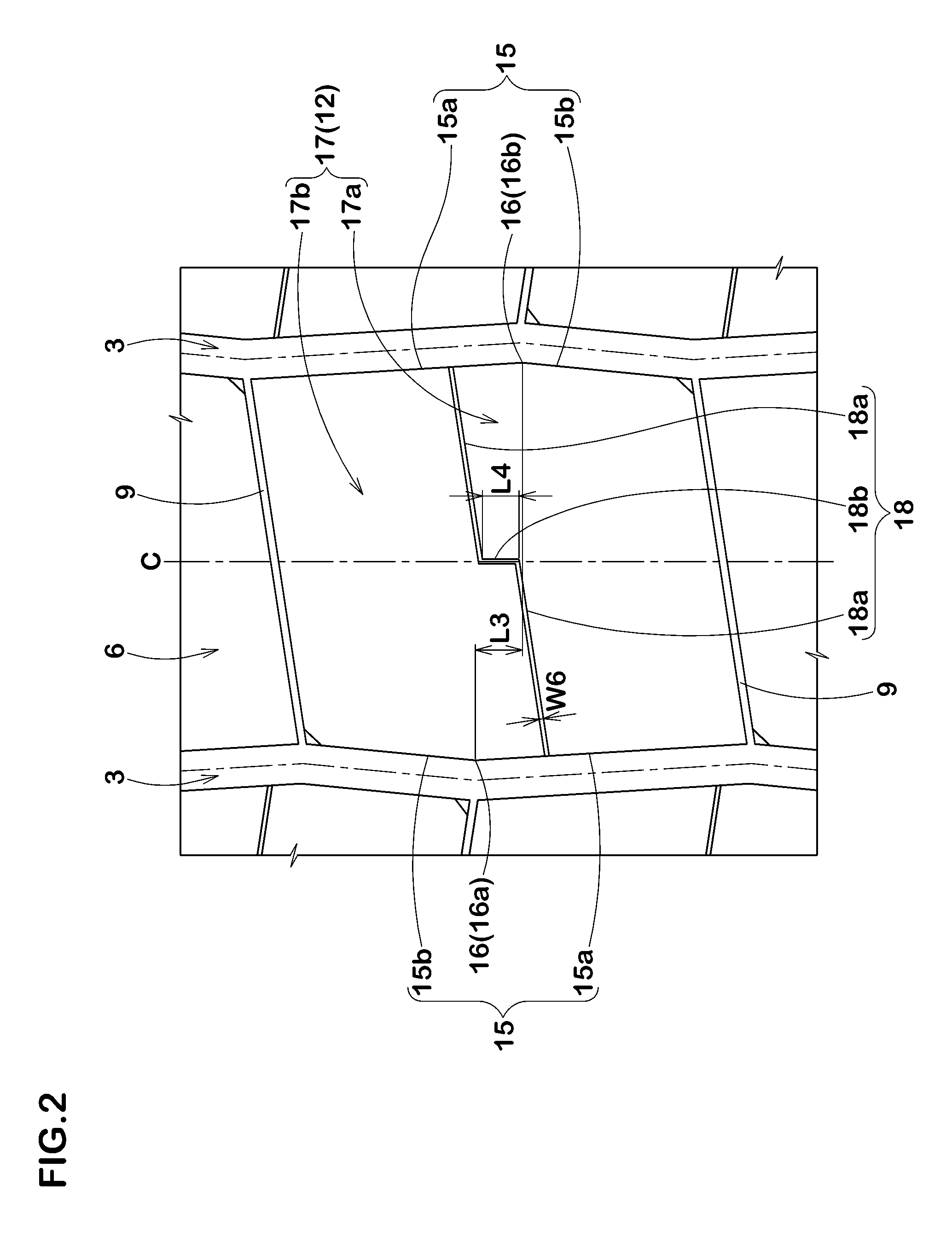

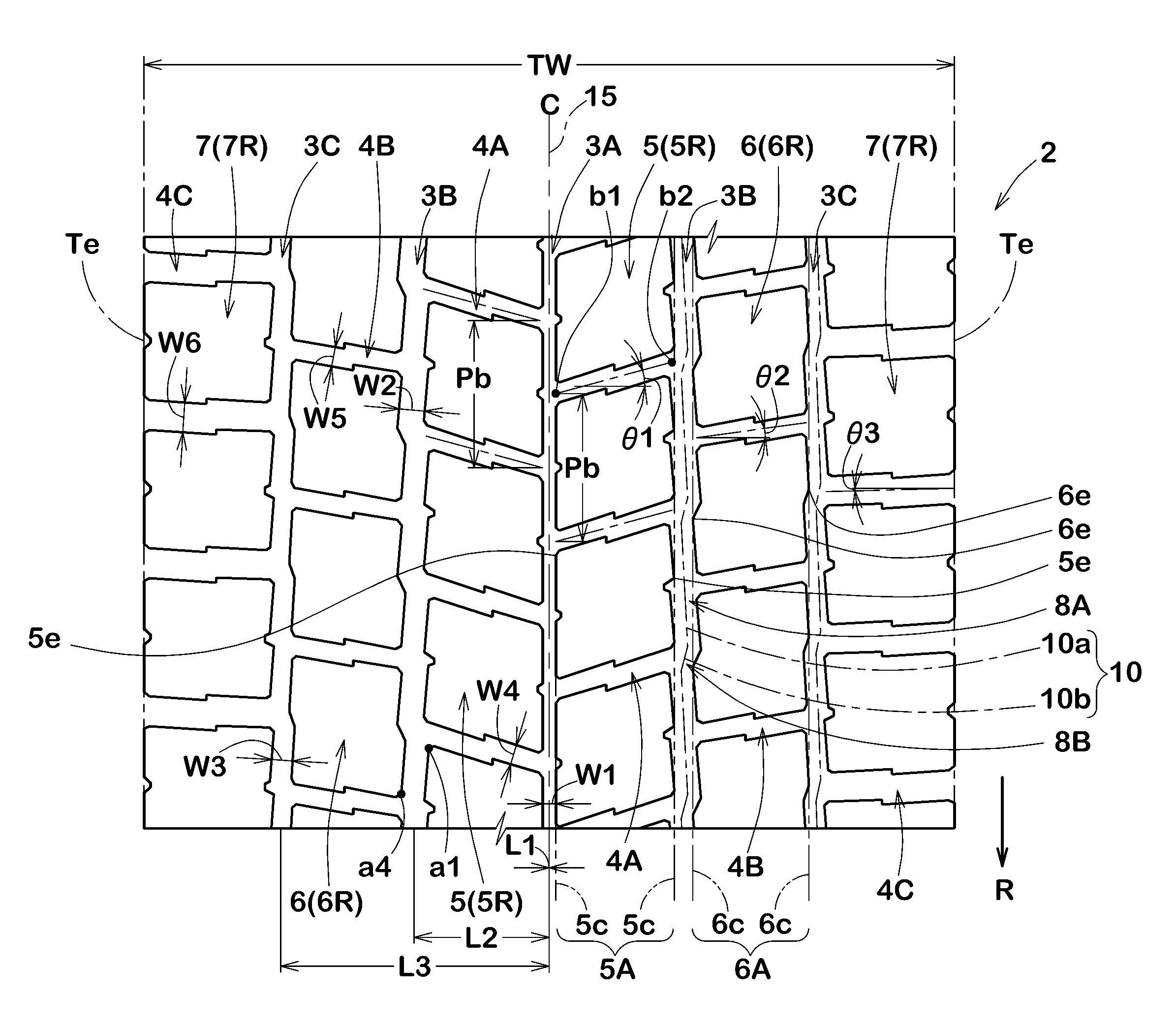

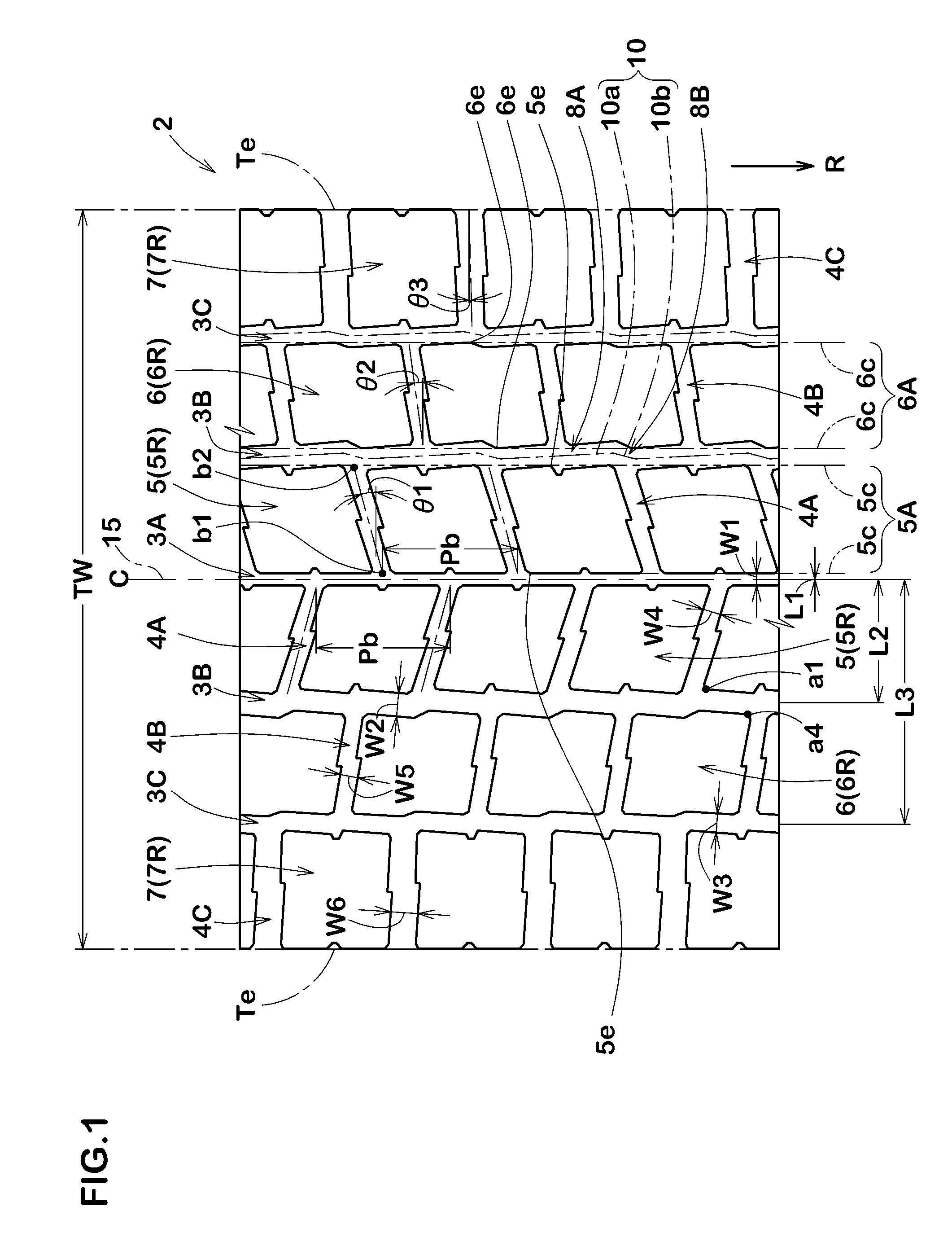

ActiveUS20150251500A1Improve featuresGreat tractionHeavy duty tyresHeavy duty vehicleTransverse grooveEngineering

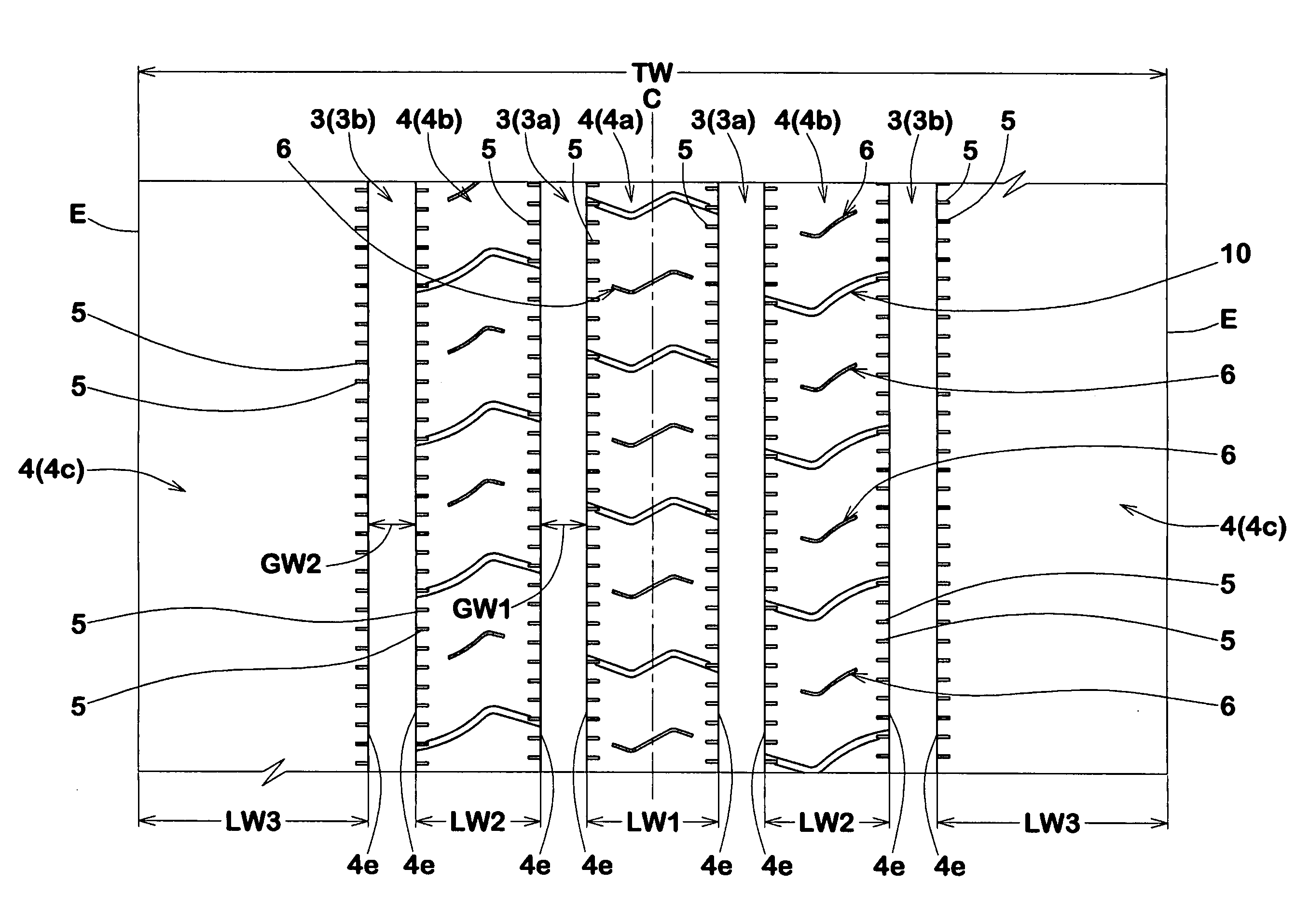

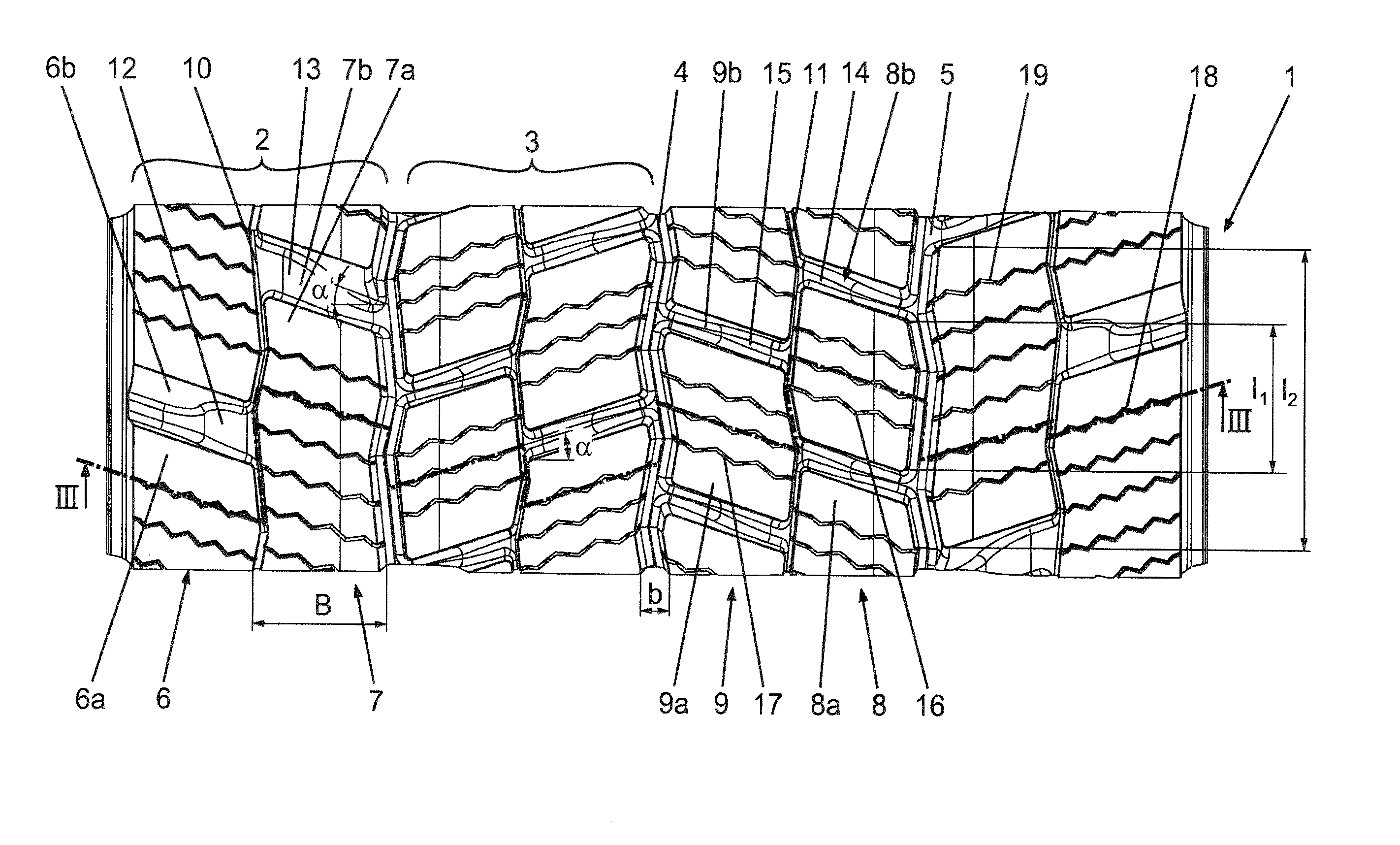

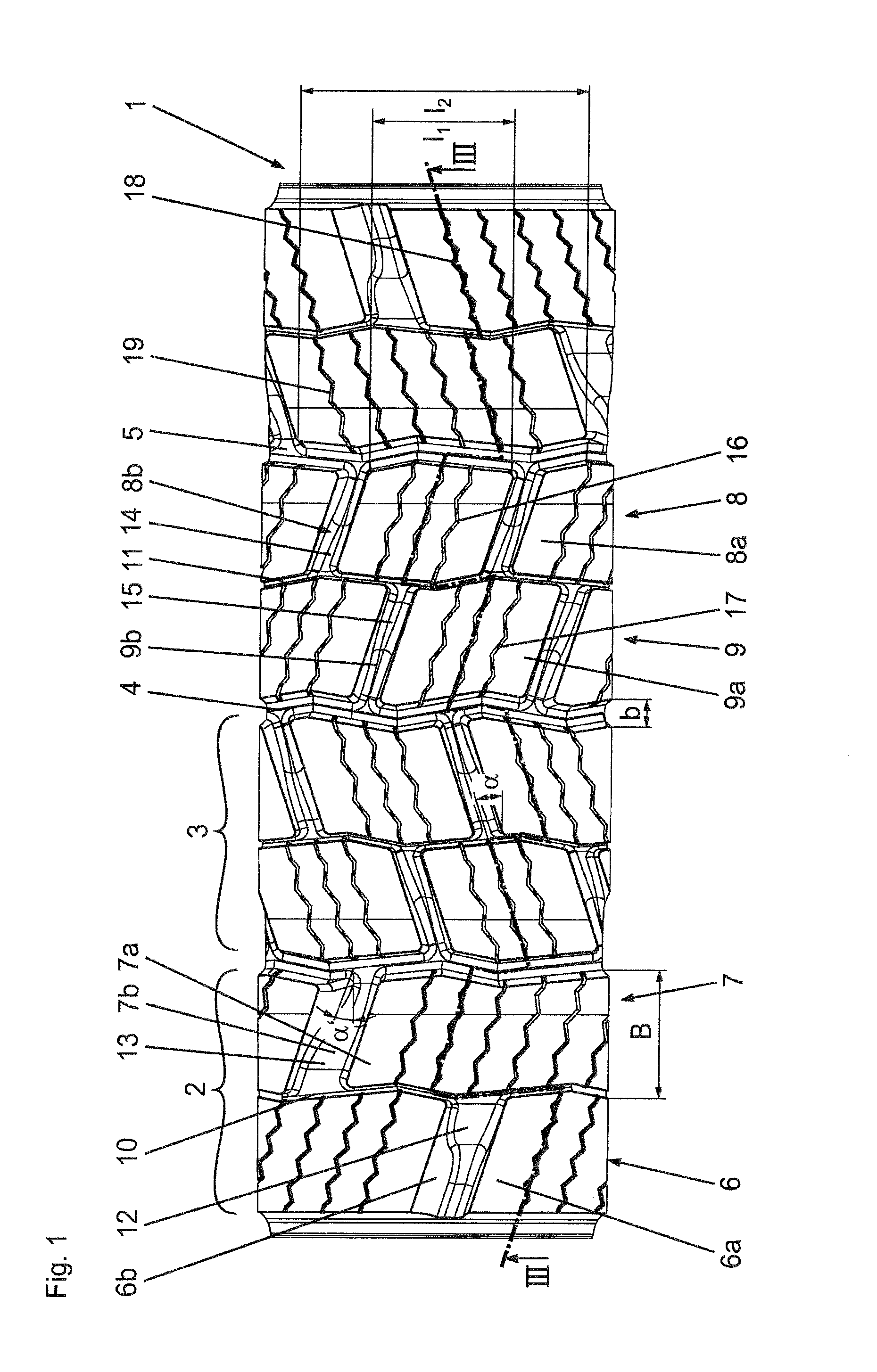

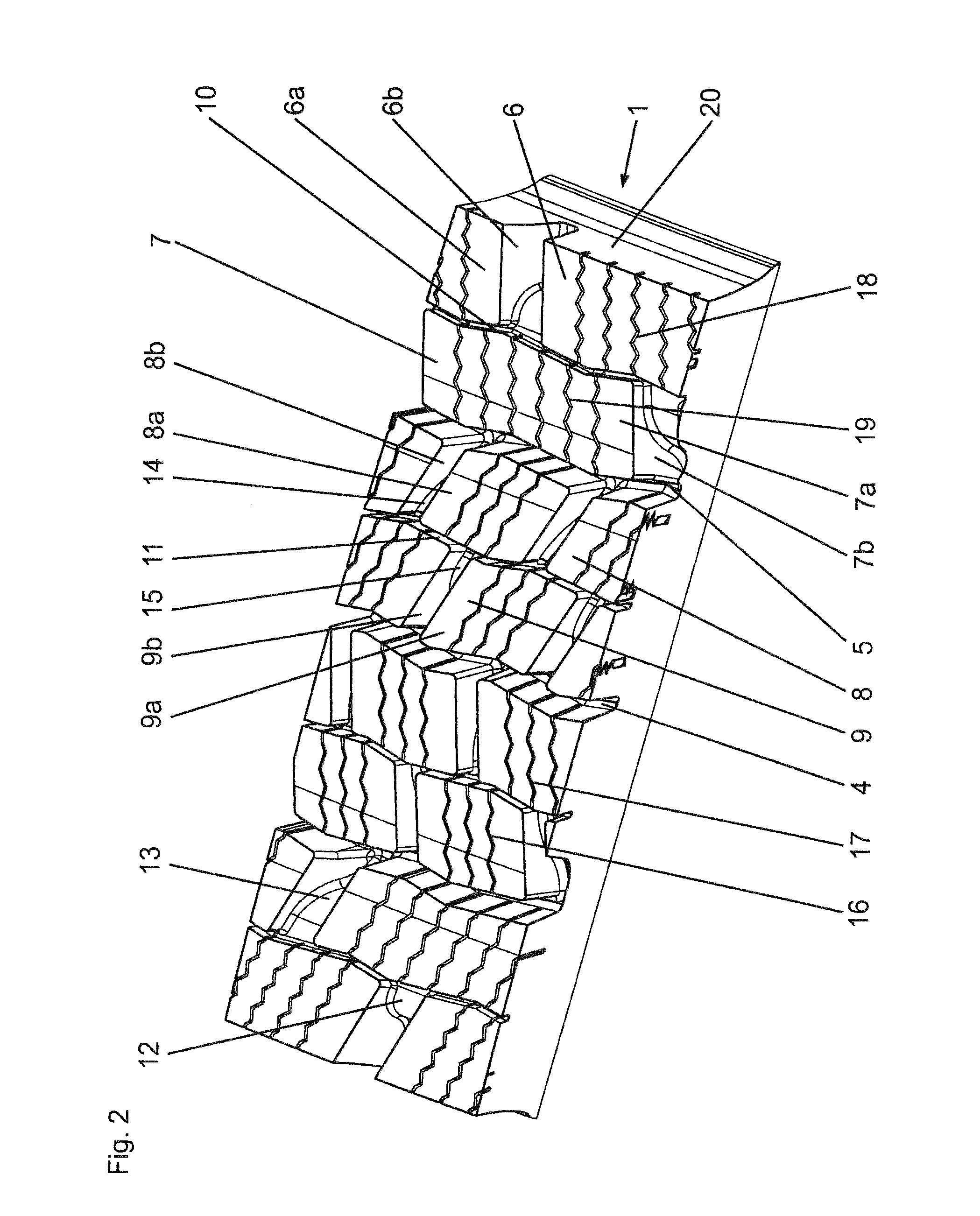

A vehicle tire has outer shoulders and two tread halves. The vehicle tire includes a tire tread having six block rows and a plurality of circumferential grooves. Mutually adjacent ones of the block rows are separated from each other by a corresponding one of the plurality of circumferential grooves. Each of the block rows has a plurality of individual blocks and the individual blocks of each of the block rows are separated from each other by mutually parallel essentially straight transverse grooves running at an angle to the axial direction of the tire. The circumferential grooves includes first circumferential grooves having a maximum profile depth and second circumferential grooves. The block rows are arranged such that each tread profile half has two pairs of block rows. The pairs of block rows of each tread profile half are separated from each other by a corresponding one of the first circumferential grooves. The block rows of each of the pairs of block rows are separated from each other by a corresponding one of the second circumferential grooves. The second circumferential grooves have a second profile depth less than the maximum profile depth. A first portion of the transverse grooves defines first outlet locations to the first circumferential grooves and a second portion of the transverse grooves has first outlet locations to the outer shoulders. The transverse grooves have a depth approximately corresponding to the maximum profile depth at the first outlet locations. The transverse grooves define second outlet locations to a corresponding one of the second circumferential grooves. The transverse grooves have a depth corresponding to the second profile depth at the second outlet locations.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

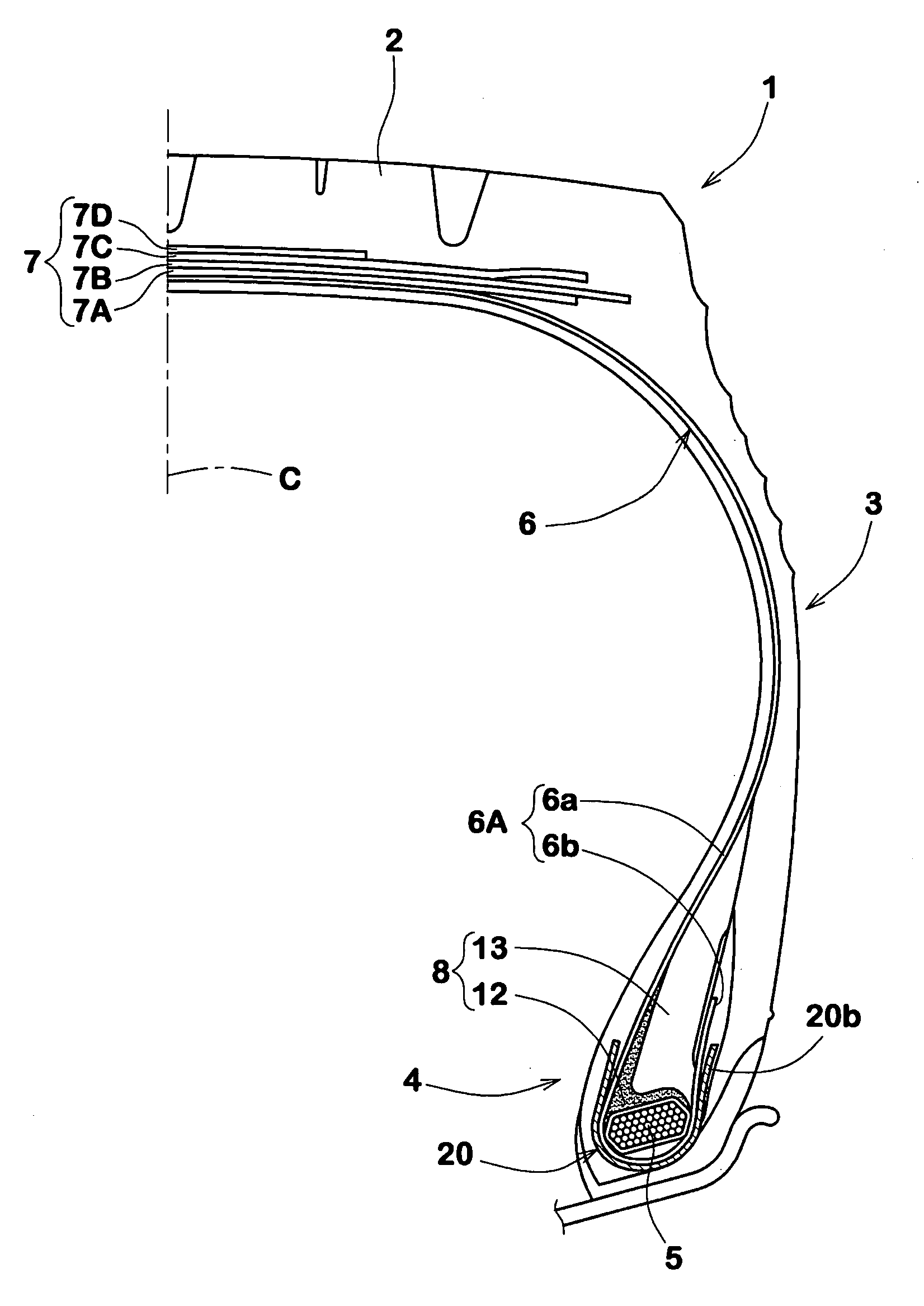

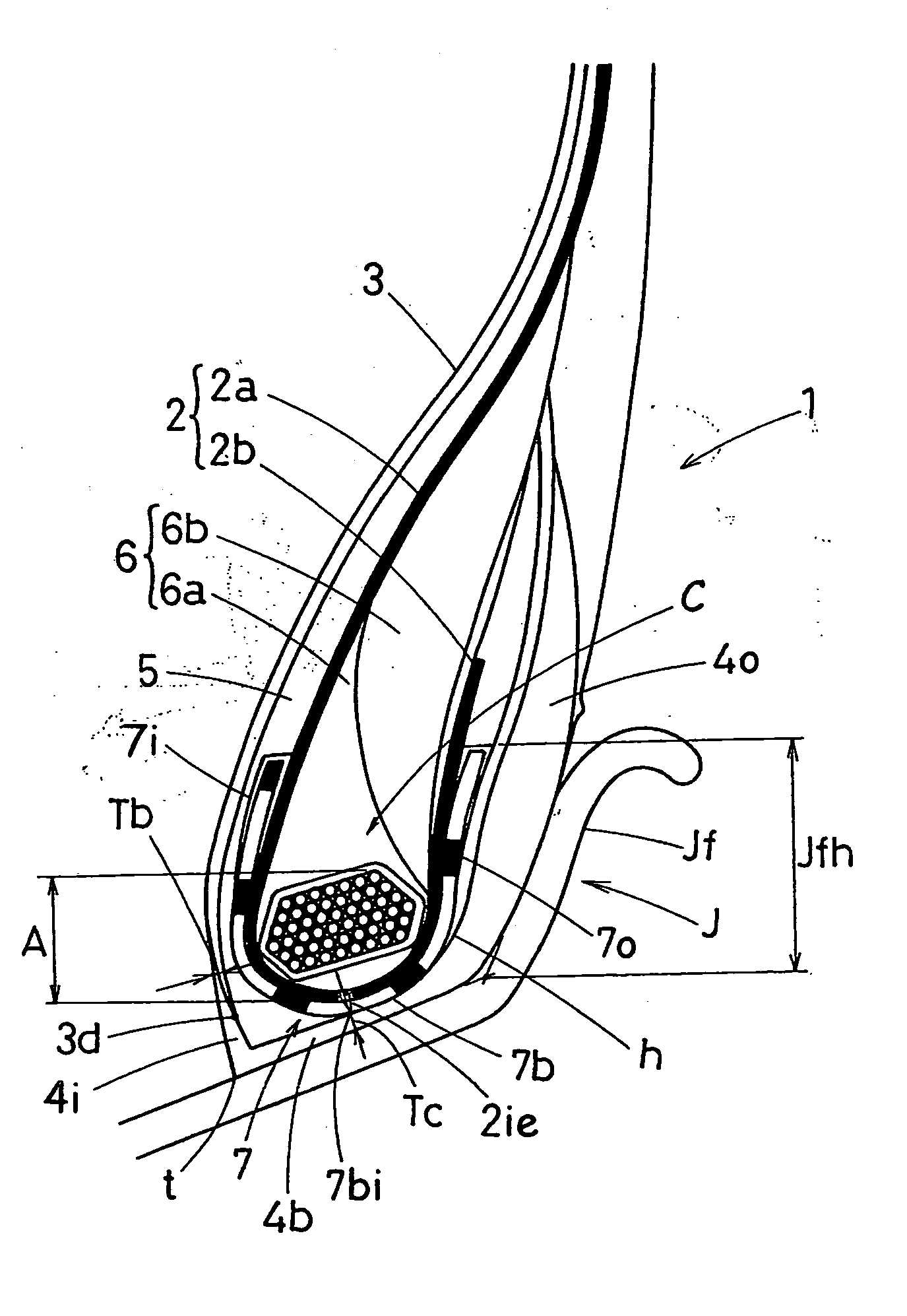

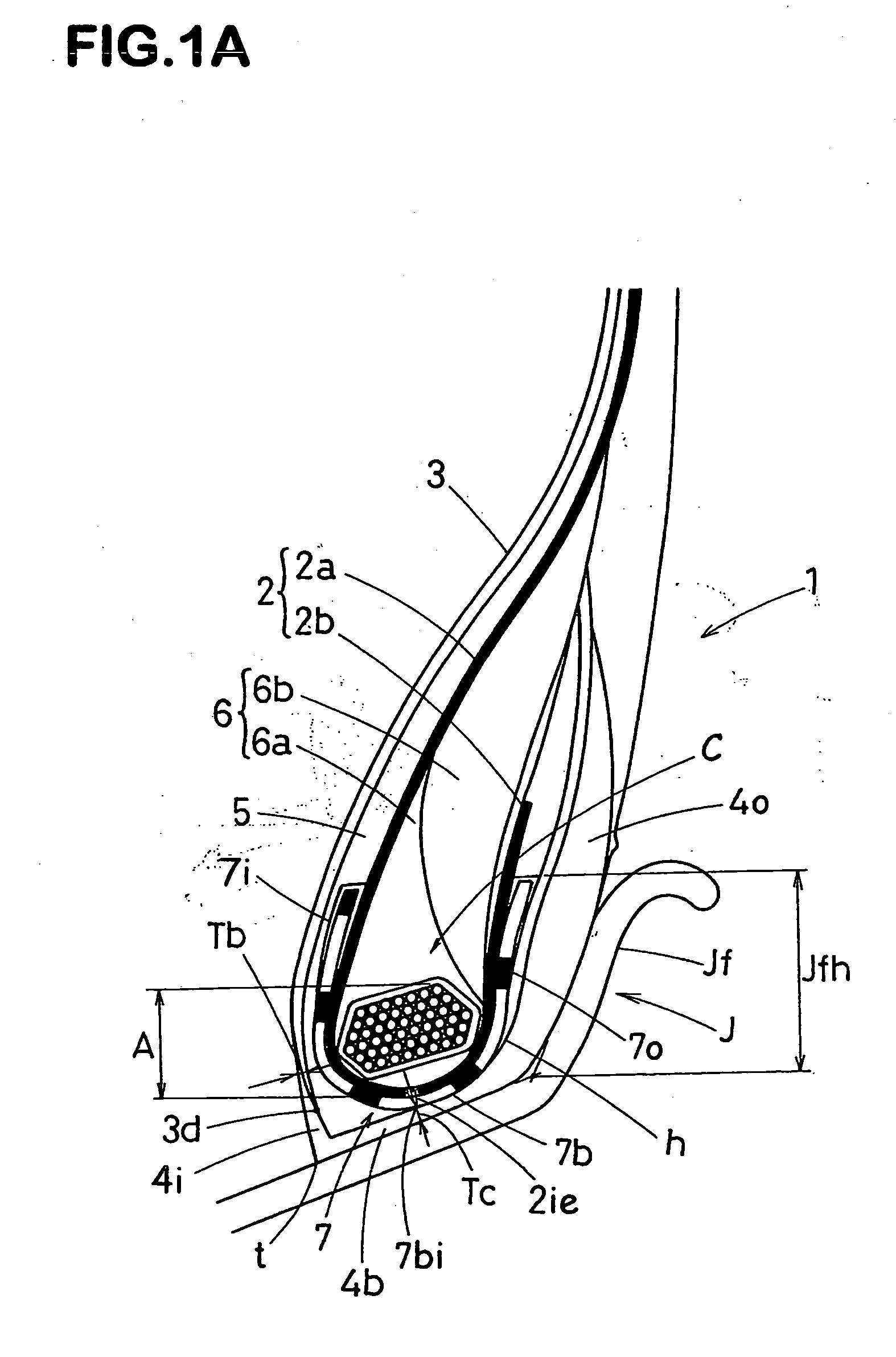

Heavy duty tire

InactiveUS20050045260A1Improve bead durabilityEffectively restrict occurrenceHeavy duty tyresHeavy duty vehicleTire beadHeavy duty

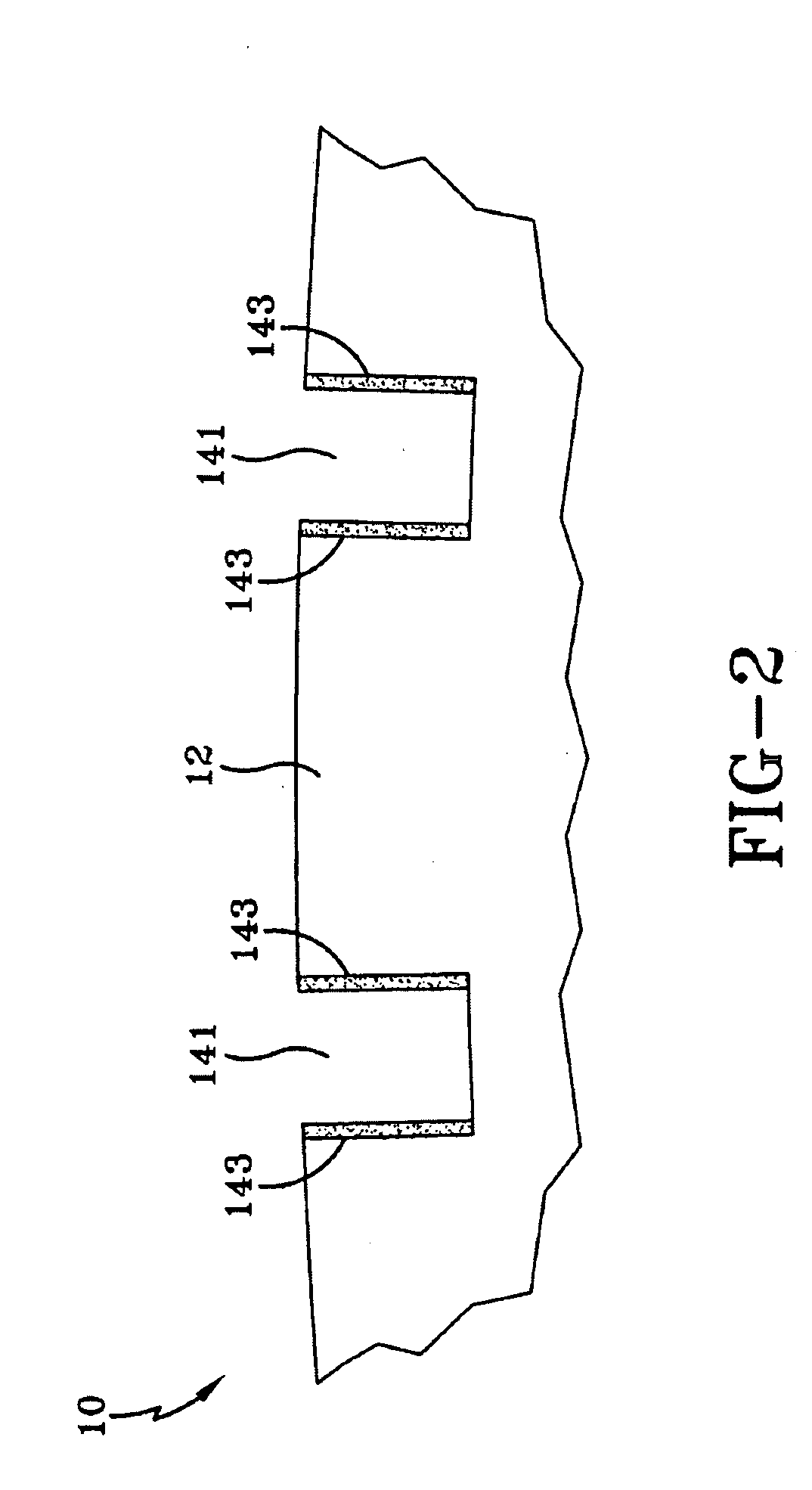

It is a subject to restrict occurrence of deficient moldings and to improve the bead durability without harming the advantages provided through a bead wind structure, and for this purpose, a ply turn-up portion of a carcass comprises a winding portion, which continues from a main portion that is bent along a bead core, which extends while being spaced from the bead core, and which inclines at an angle θ that is smaller than 90°. A height of a tip end of the winding portion from an outer surface of the bead core is 3 to 15 mm. A cushion rubber having a complex elastic modulus E1* at 70° C. of 2 to 25 MPa is disposed in a region surrounded by a ply main body portion of the carcass, the bead core and the winding portion.

Owner:SUMITOMO RUBBER IND LTD

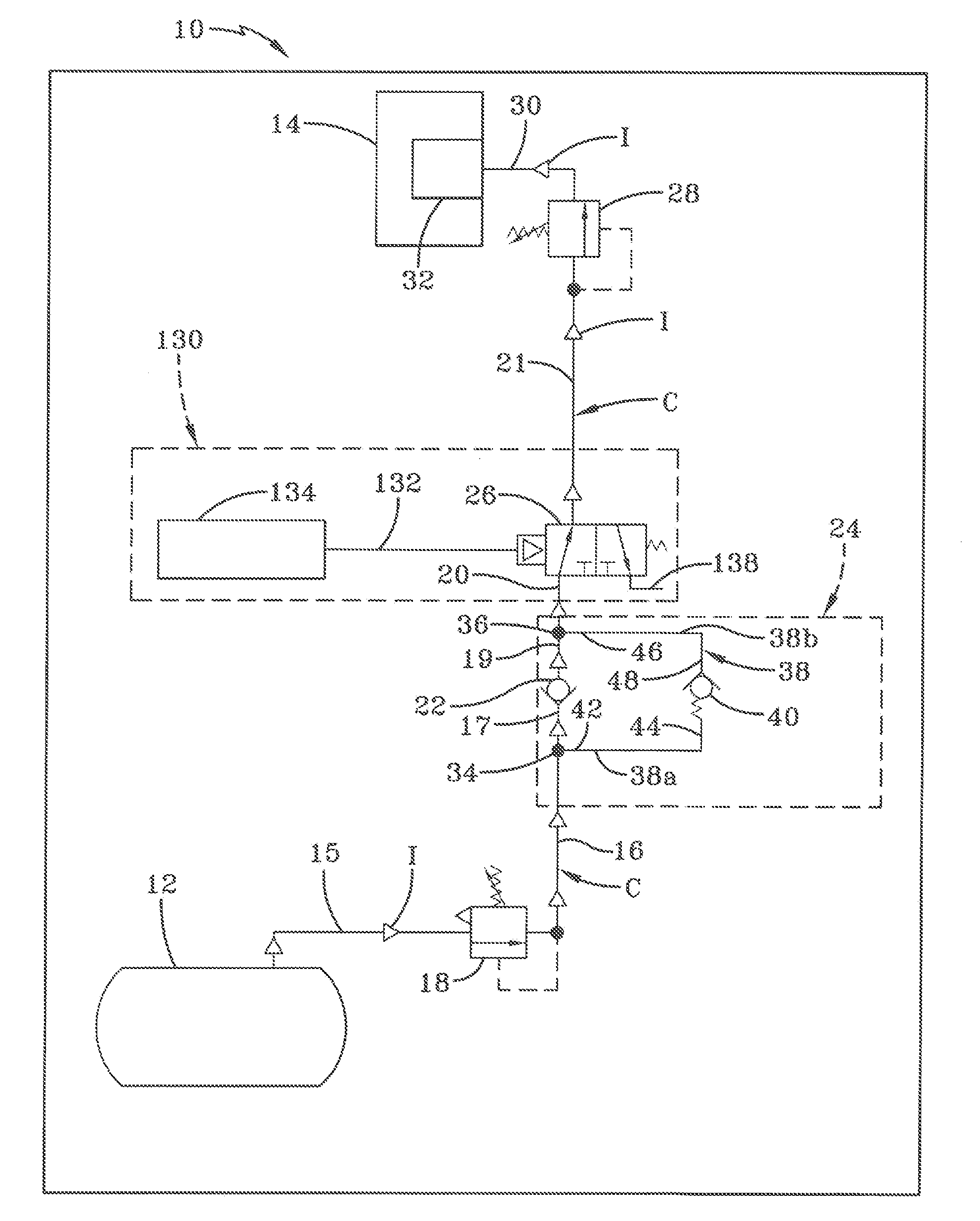

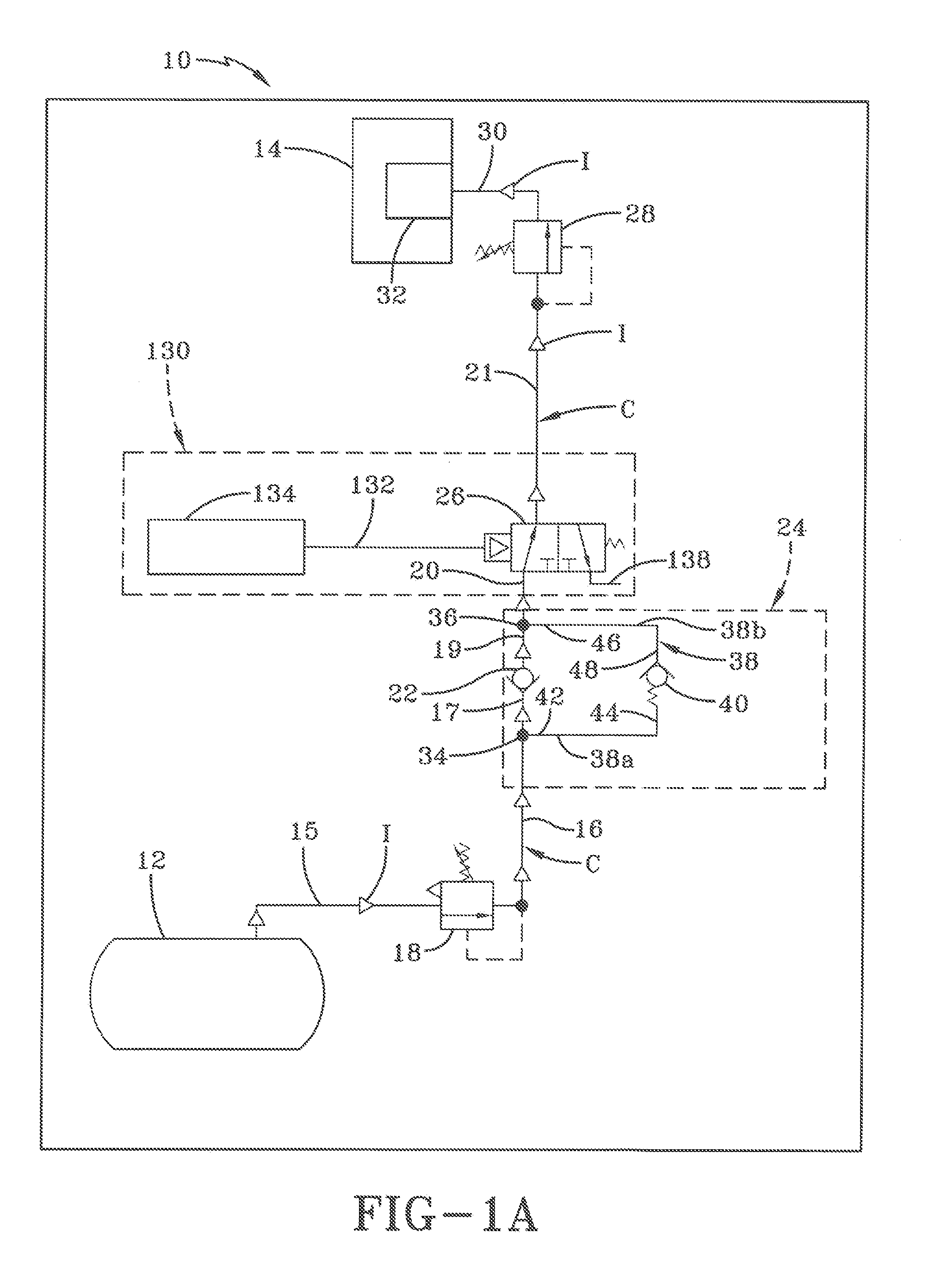

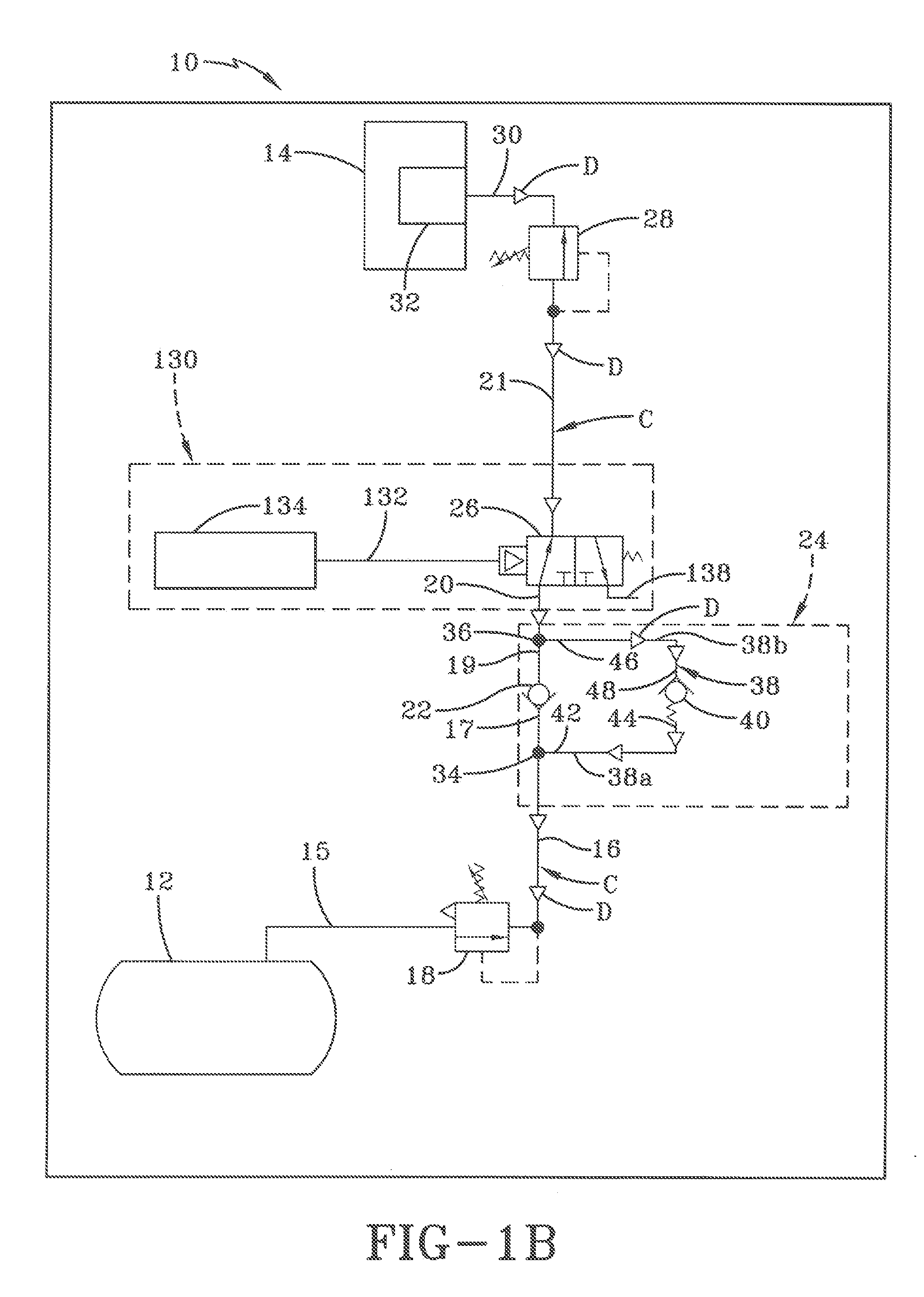

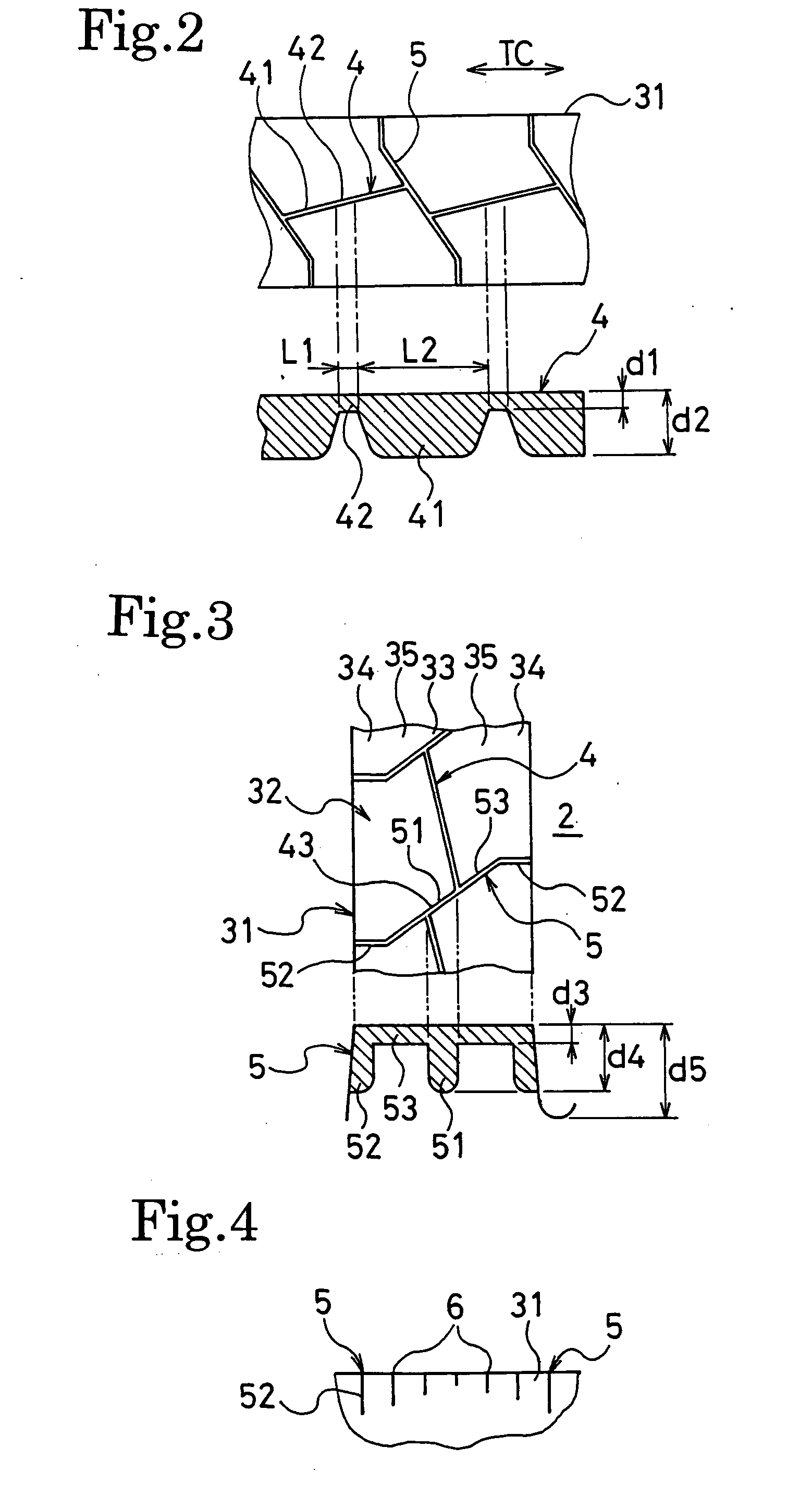

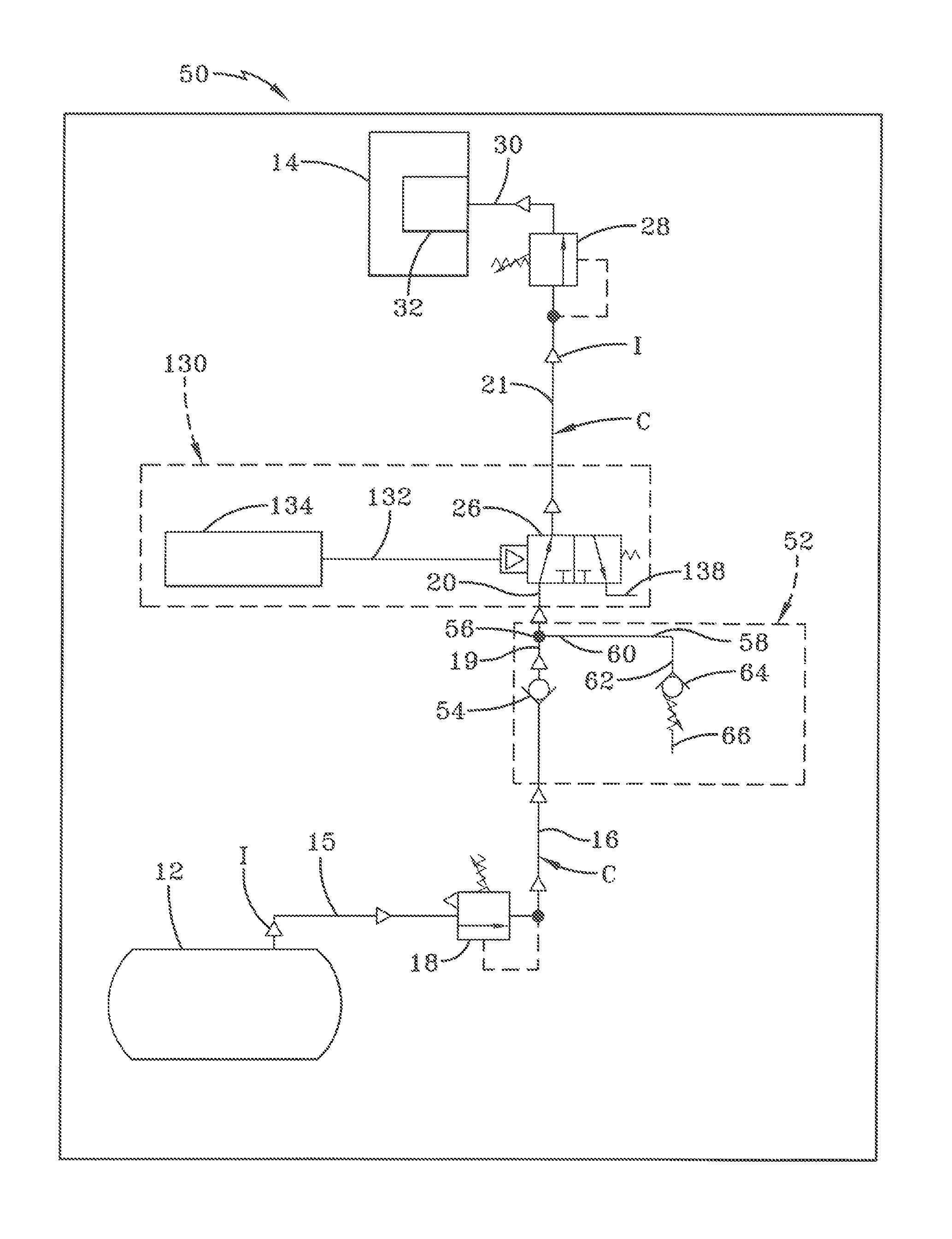

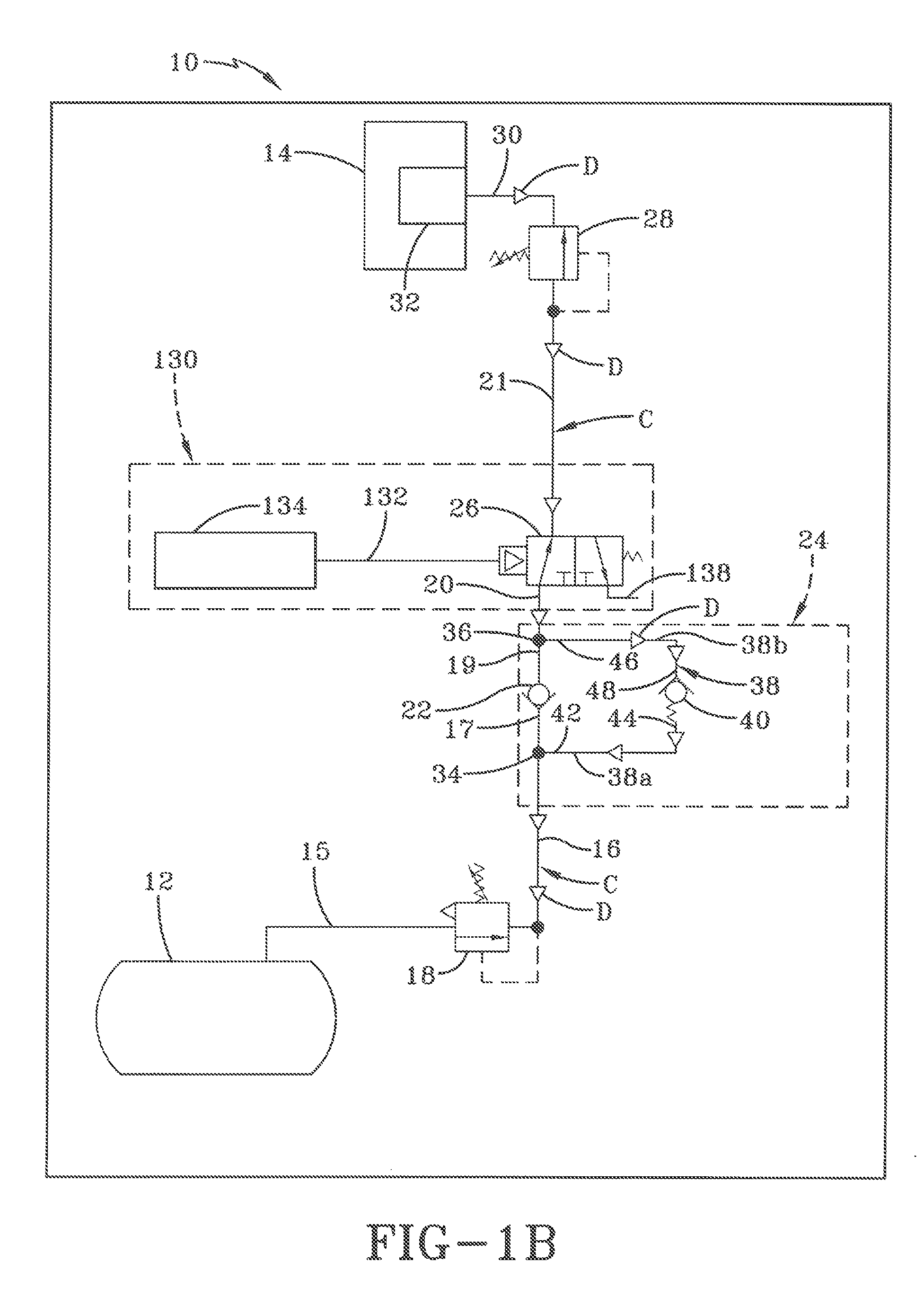

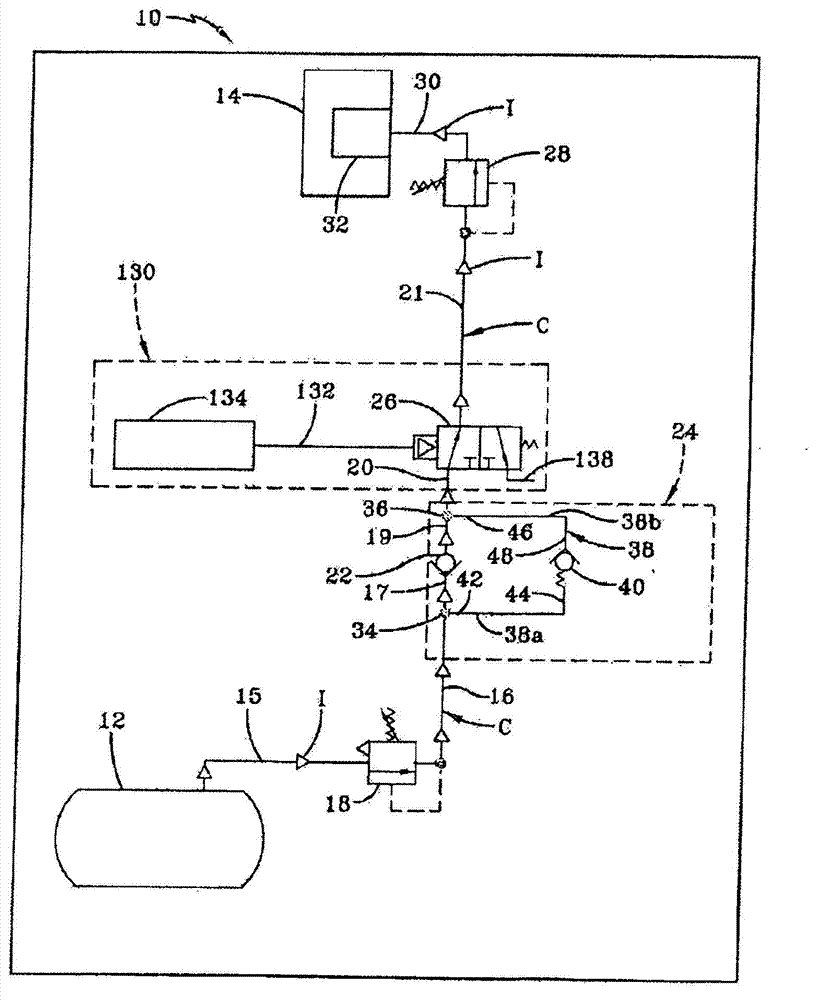

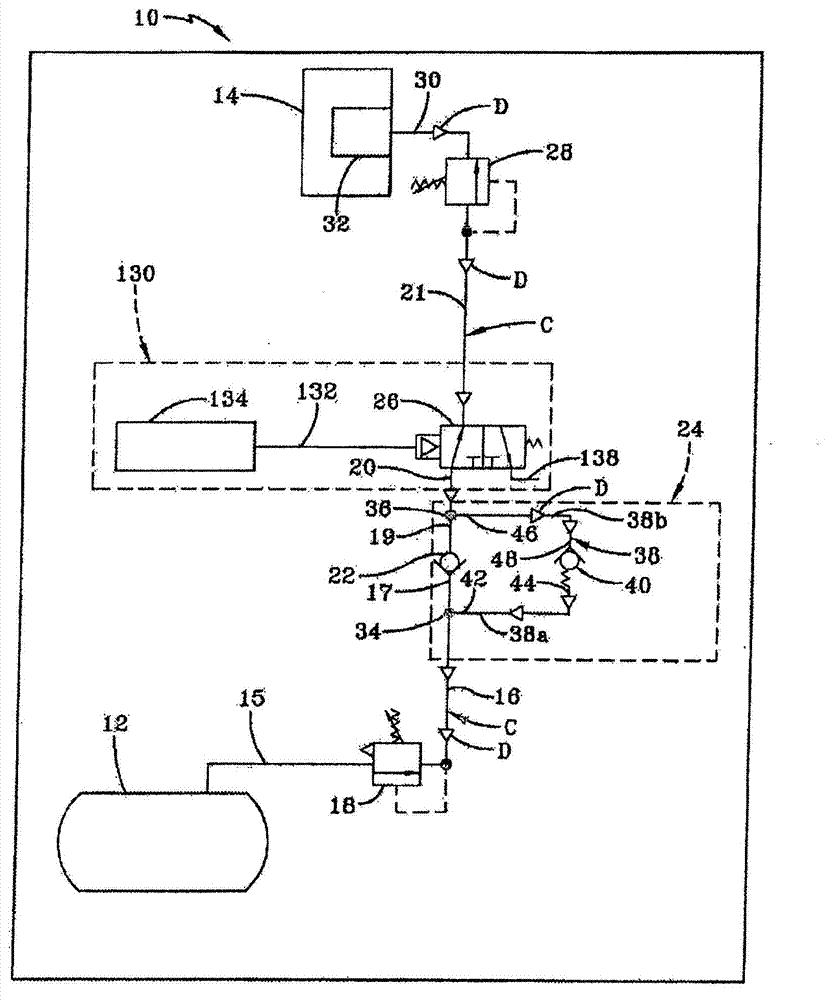

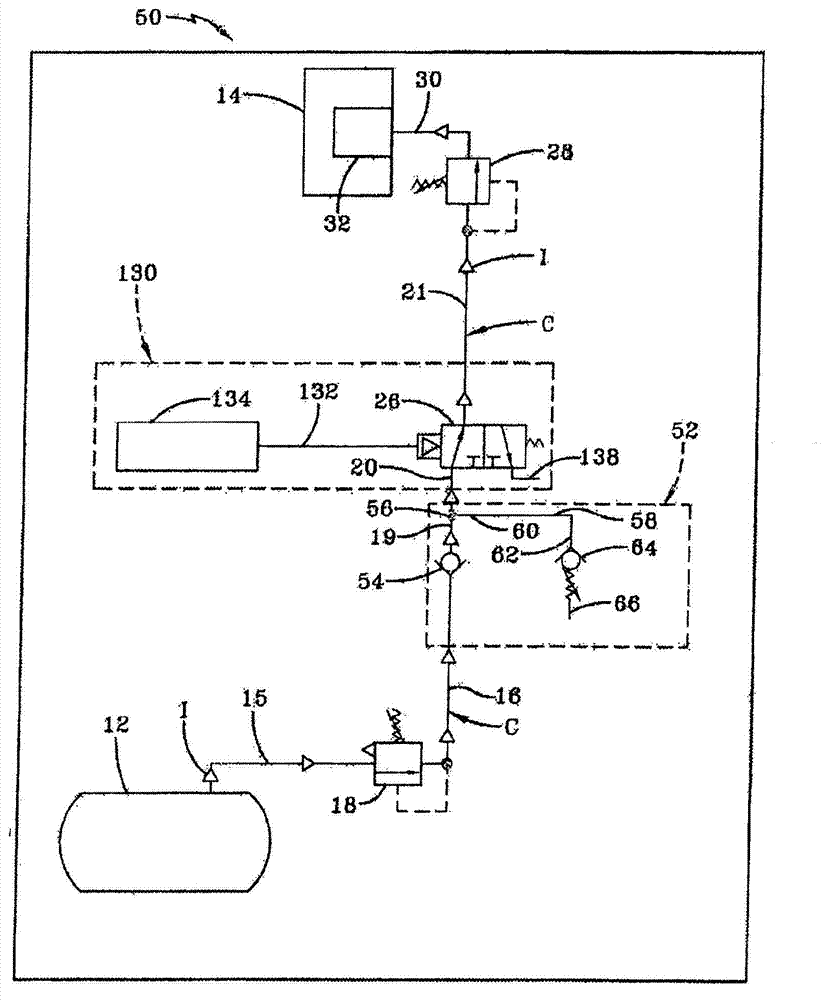

Tire inflation system with discrete deflation circuit

ActiveUS20120059546A1More dependableMore efficientVehicle testingHeavy duty tyresPneumatic circuitIncrease pressure

A vehicle tire inflation system includes an air supply source in fluid communication with multiple tires of the vehicle. A pneumatic conduit extends between and is in fluid communication with the air supply source and the tires. Means are fluidly connected to the pneumatic conduit for enabling selective inflation and deflation of the tires. The means include a first pneumatic circuit for inflation of the tires, and a second pneumatic circuit for deflation of the tires. The second pneumatic circuit is discrete from the first pneumatic circuit and is common to more than one of the tires. The means provides controlled deflation of the tires in the second pneumatic circuit based upon a predetermined condition, preventing deflation of the tires until the vehicle is parked, or limiting the deflation of the tires, which in turn enables the tire inflation system to accommodate a desirable increased pressure in the tires.

Owner:HENDRICKSON USA L L C

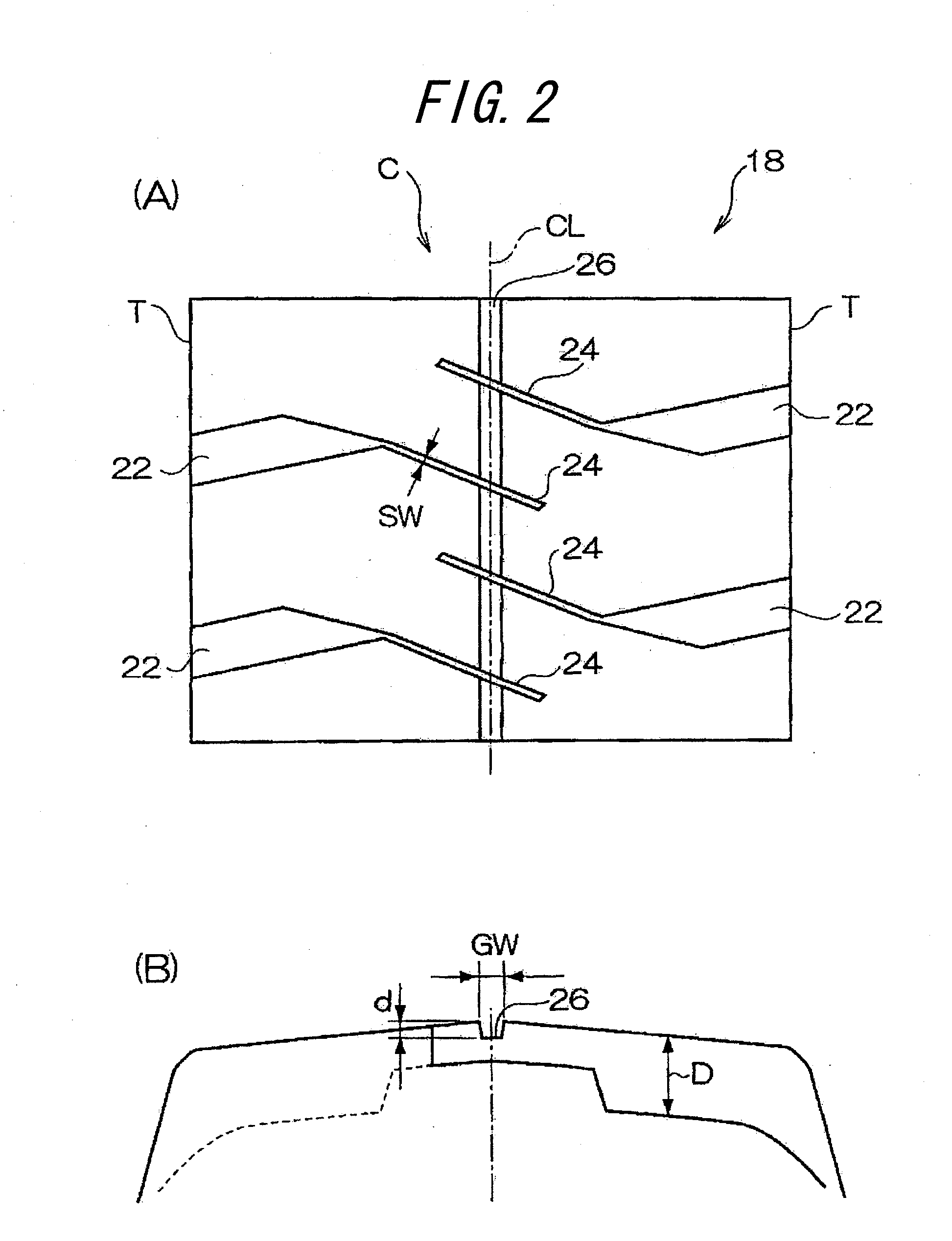

tire

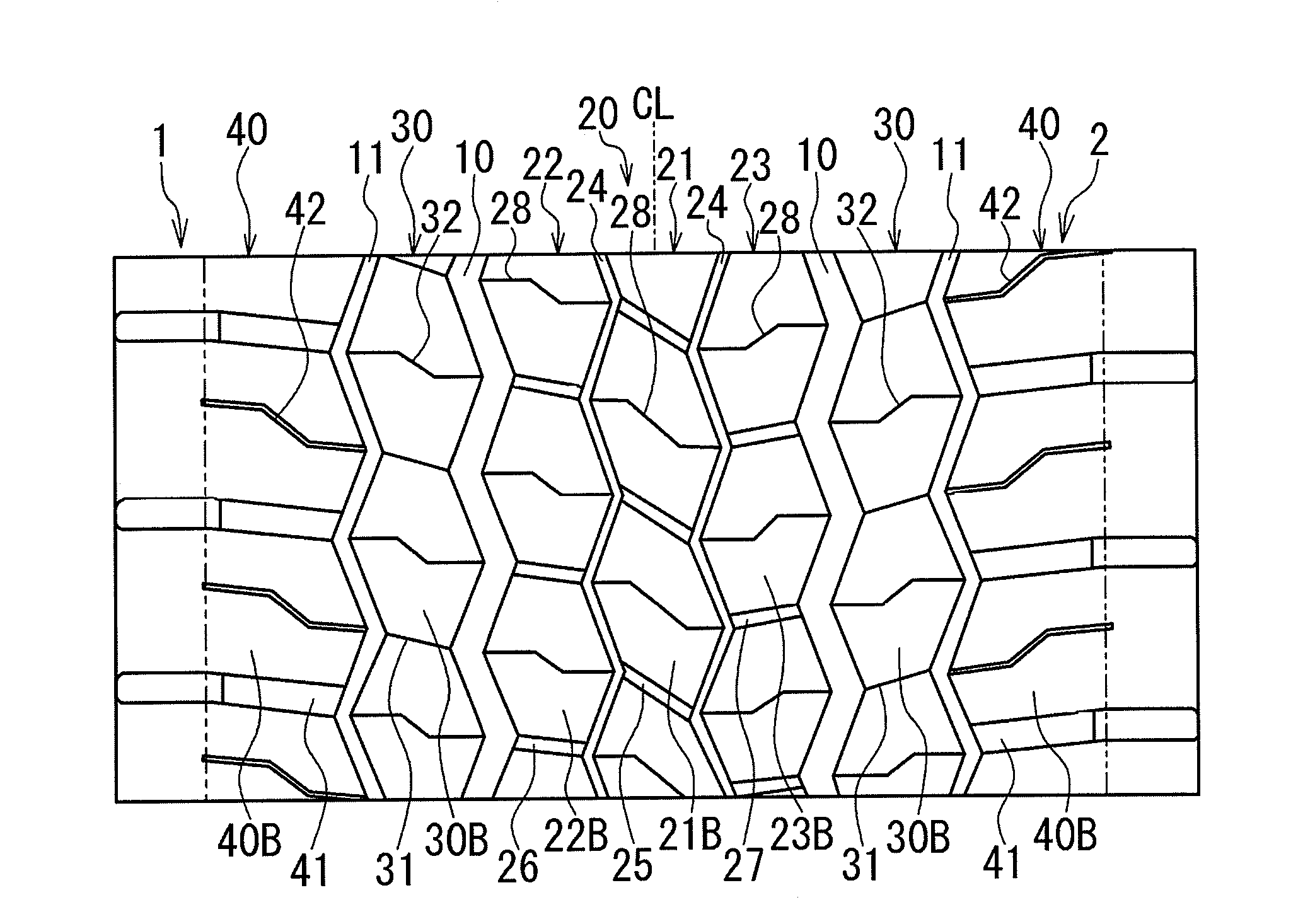

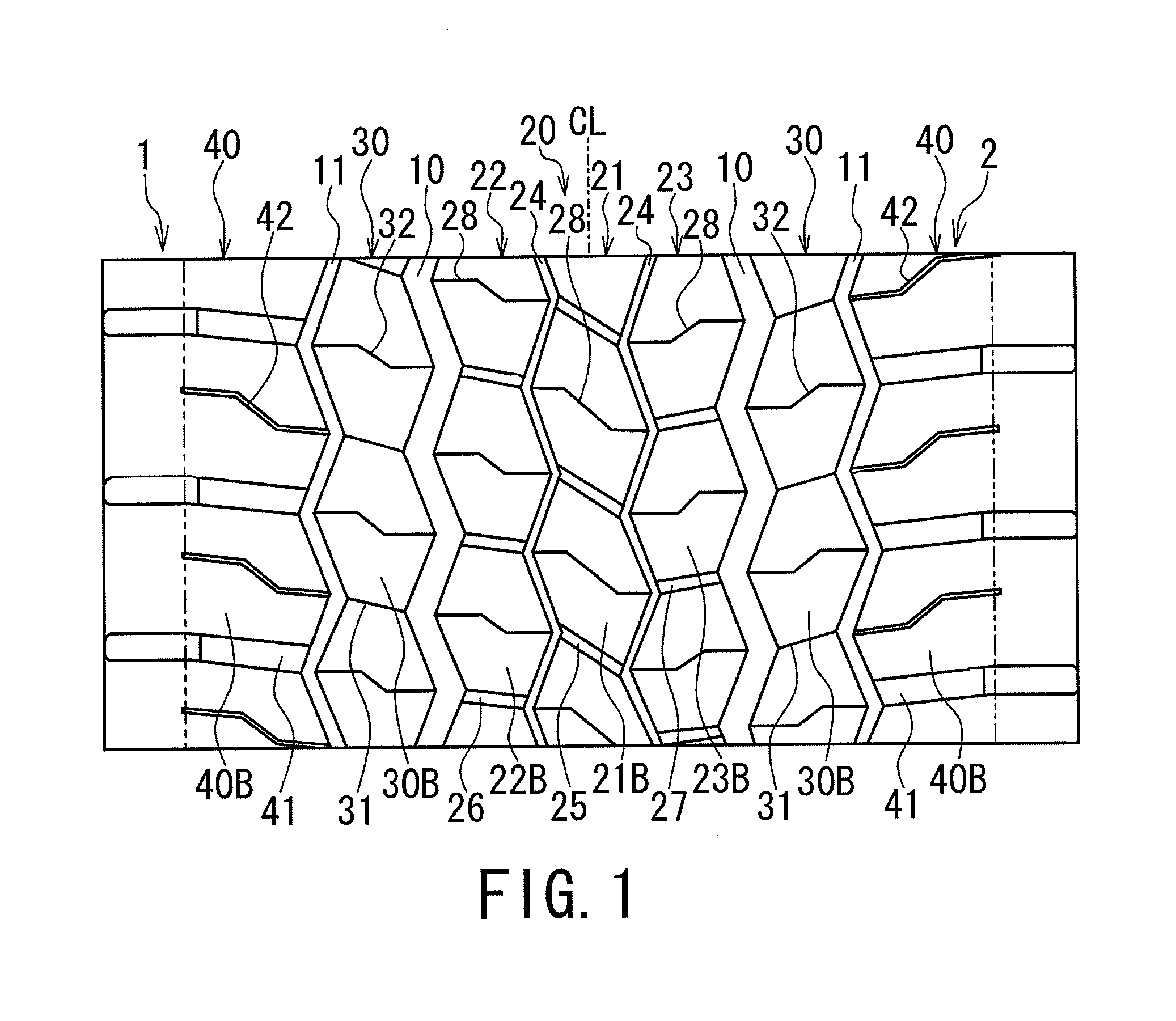

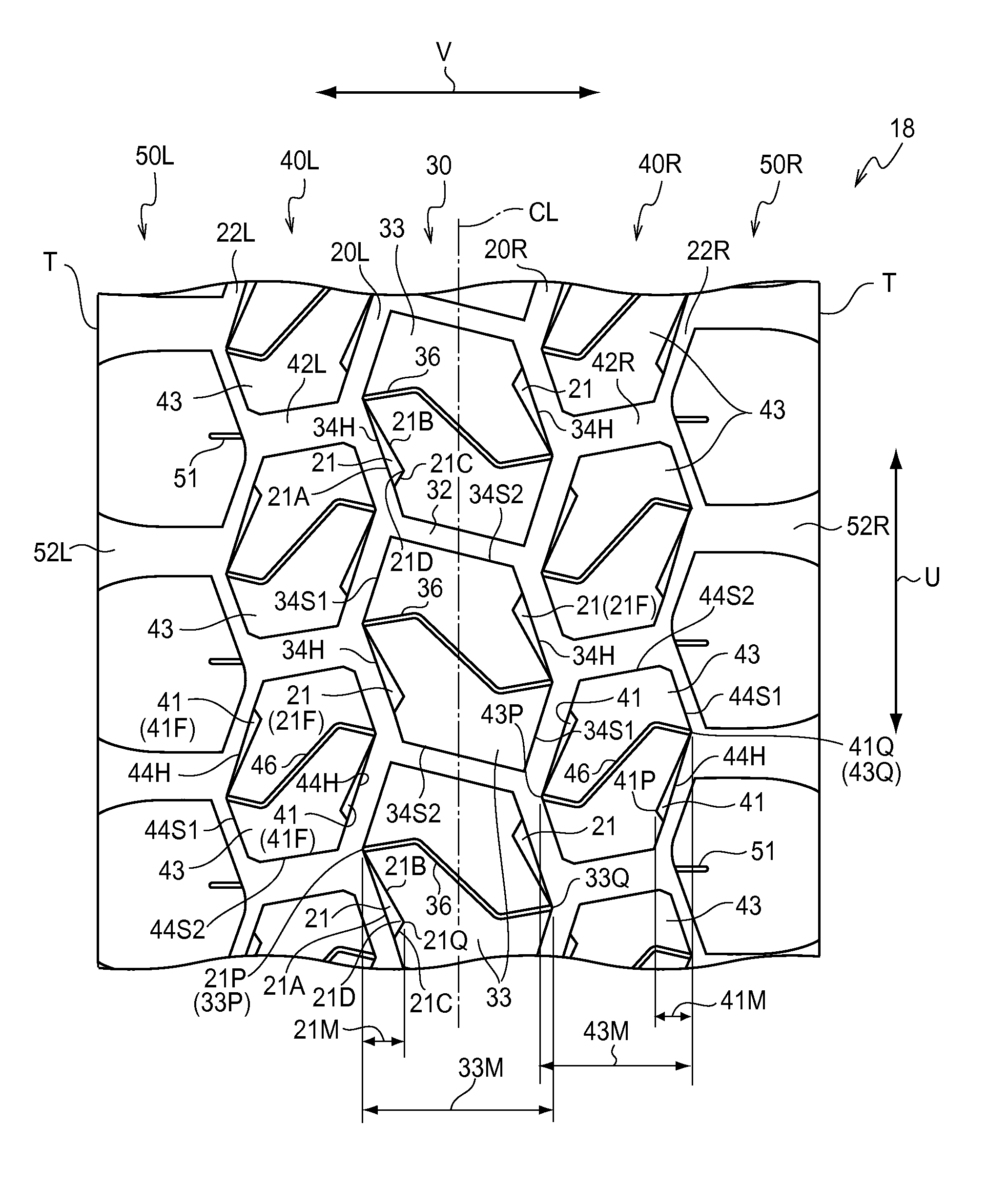

ActiveUS20120216931A1Improve partial wearReduce noiseHeavy duty tyresHeavy duty vehicleGround contactEngineering

Wet performance and partial wear resistance of a tire are improved, and a noise generated during running of the tire is reduced.At a tread portion 2, a plurality of land portions 20, 30, and 40 is defined by circumferential main grooves 10 and 11 extending in a zig-zag manner in a tire circumferential direction. In the center land portion 20 and the second land portion 30, a plurality of hexagonal blocks 21B, 22B, 23B, and 30B is provided, each gradually expanding to the both sides in the tire width direction from the both end portions in the tire circumferential direction toward the center. In the center land portion 20, the plurality of hexagonal blocks 21B, 22B, and 23B is arranged so as to be brought close to each other in the tire width direction while sandwiching a circumferential thin groove 24 extending in a zig-zag manner in the tire circumferential direction and to be defined by lug grooves 25, 26, and 27 in the tire circumferential direction. In the second land portion 30, the plurality of hexagonal blocks 30B is arranged so as to continue in the tire circumferential direction while sandwiching a sipe 31, and formed in a rib shape continuous in a ground-contacting surface.

Owner:BRIDGESTONE CORP

Heavy duty tire

InactiveUS20080035261A1Increasing weightIncreasing volumeHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

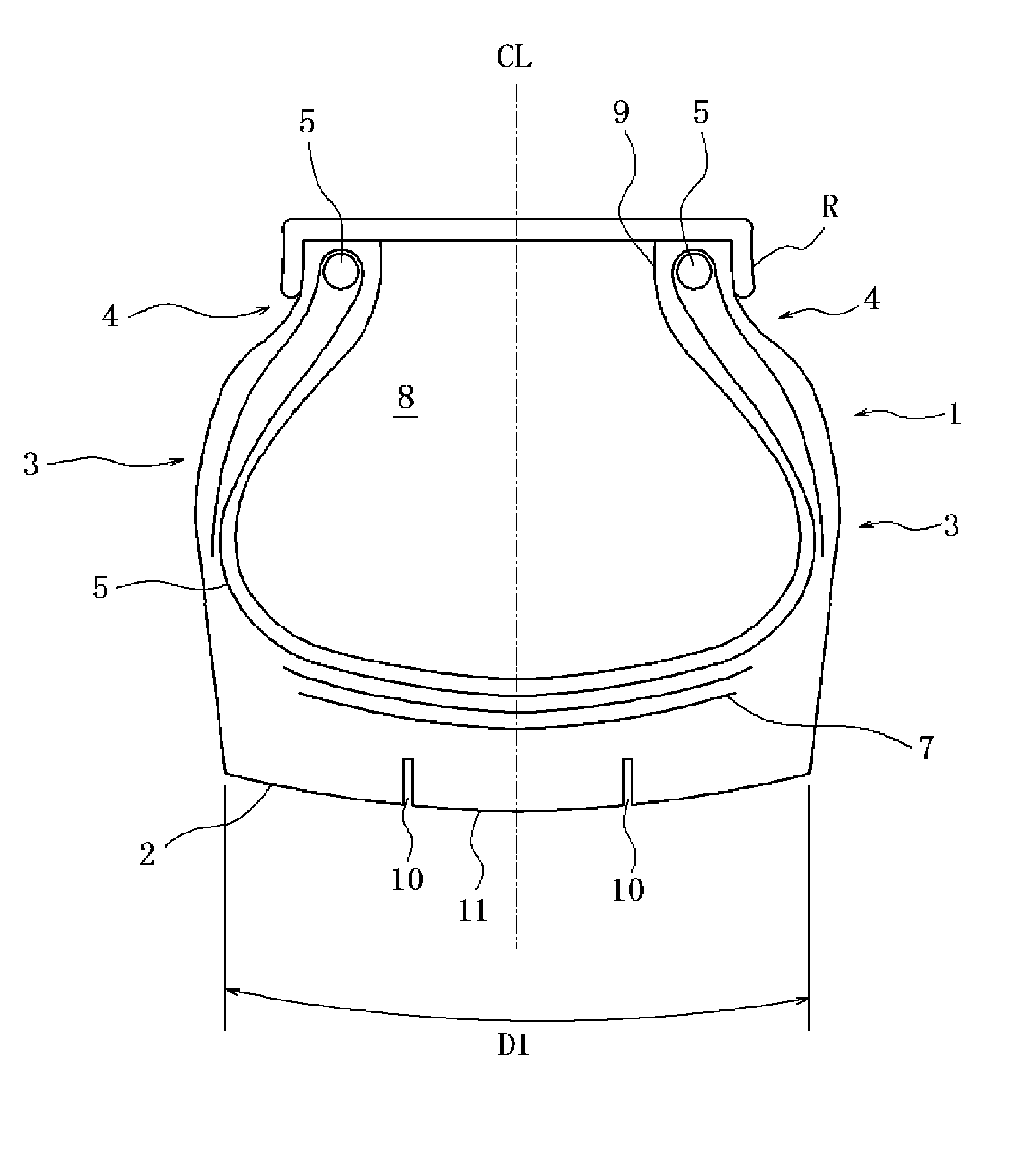

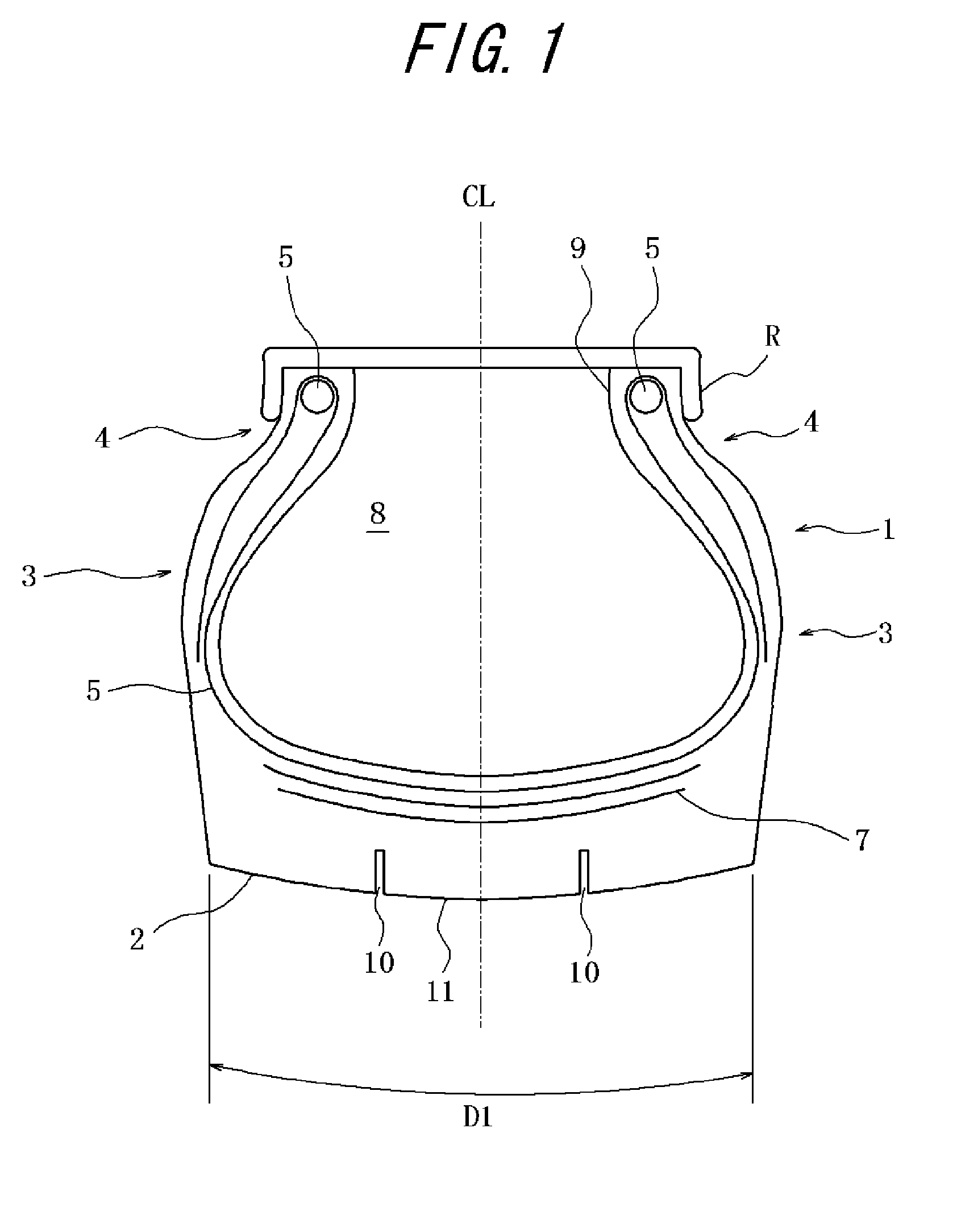

Pneumatic tire

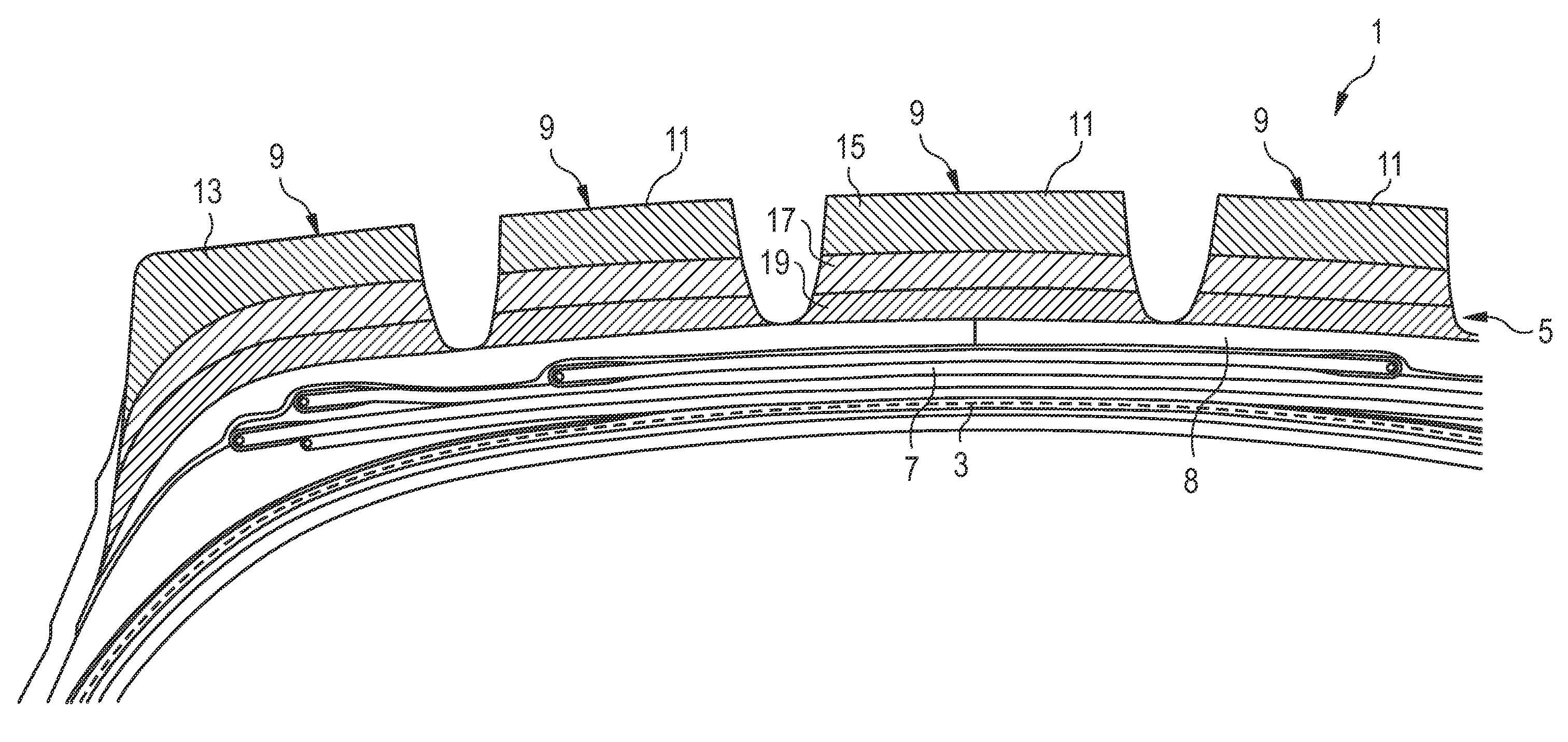

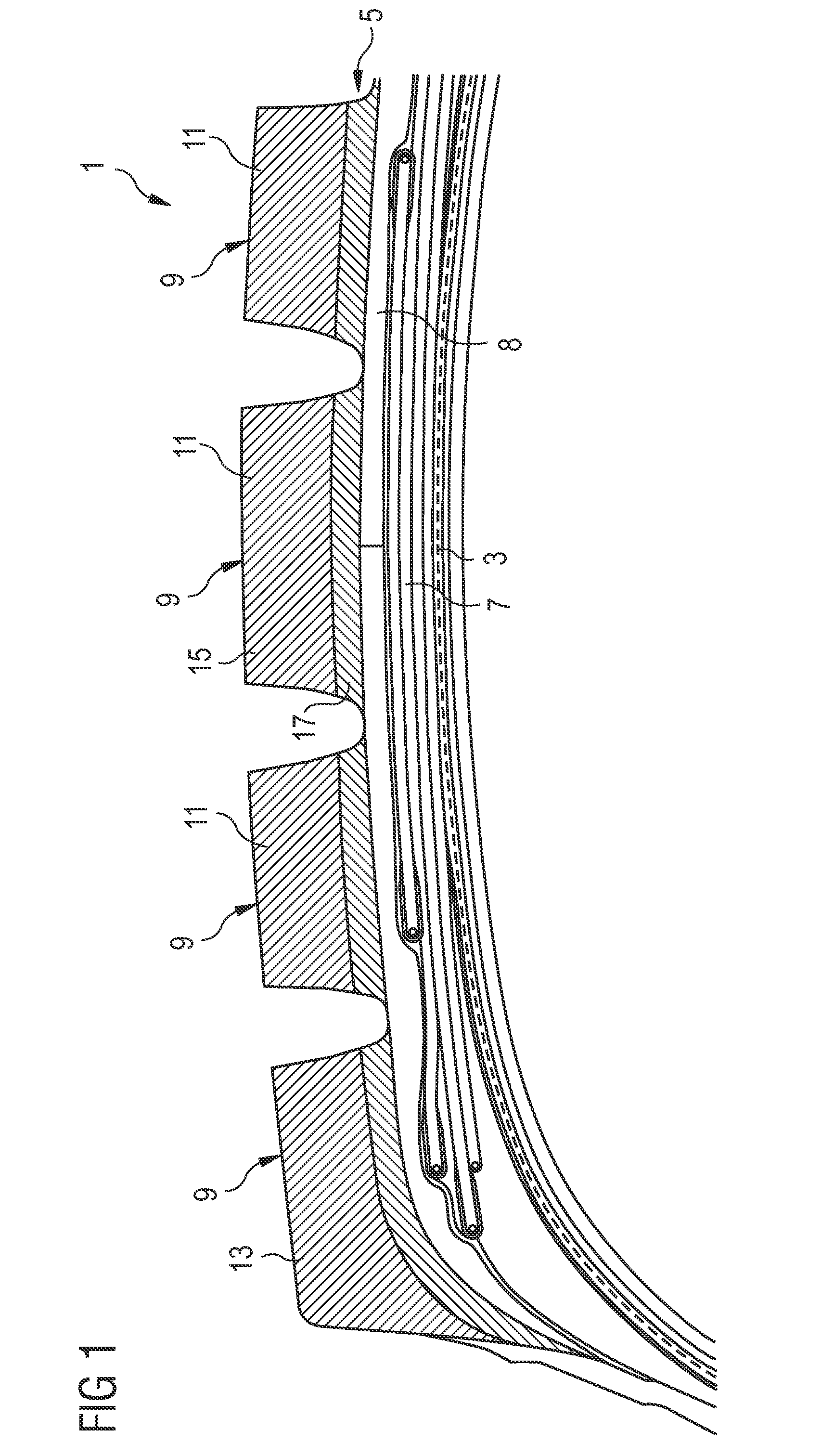

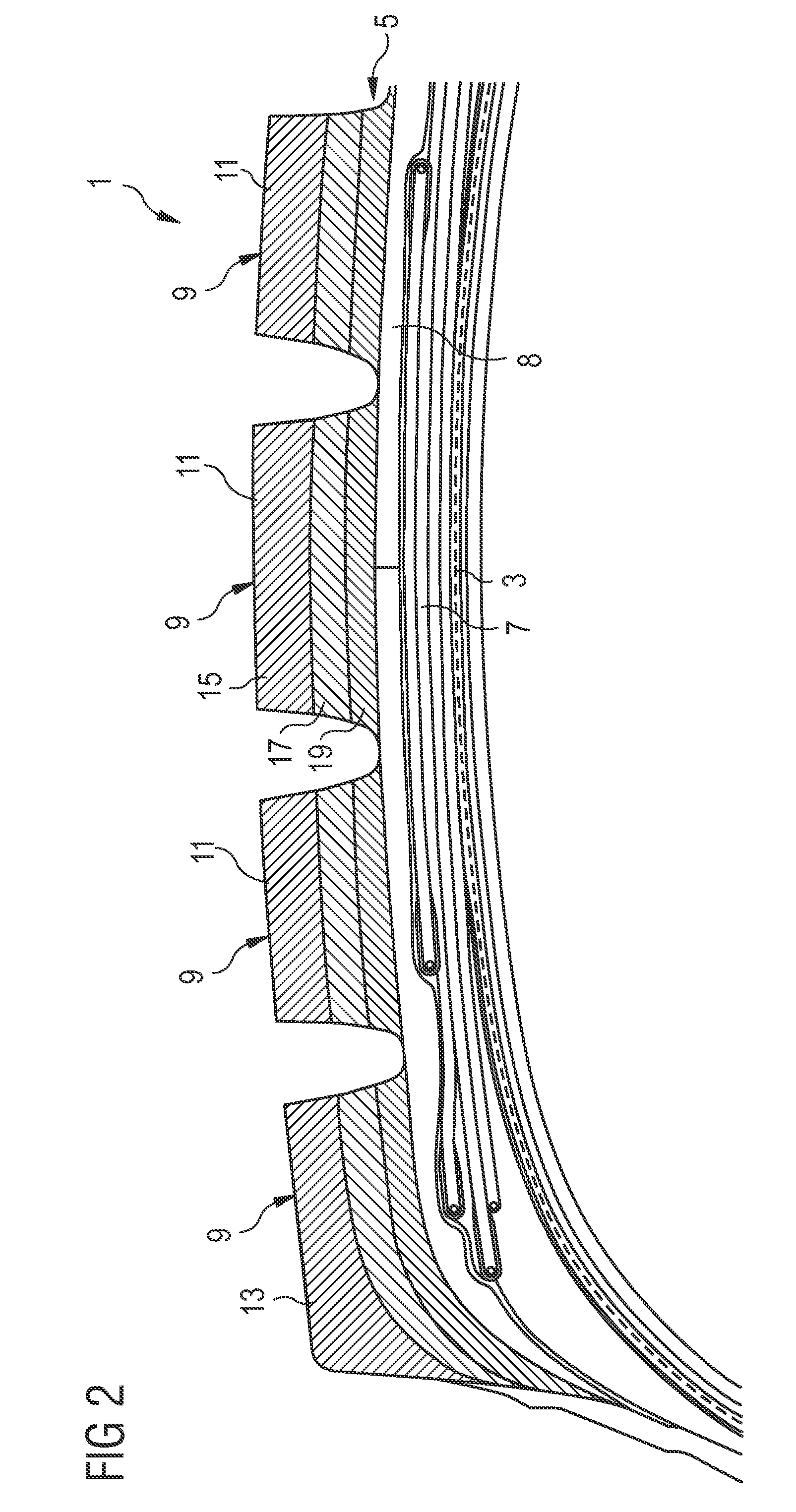

ActiveUS20120132331A1Easy to adjustStable and controllable performanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

The present invention is directed to a pneumatic tire 1 comprising at least one pair of parallel annular beads; at least one carcass ply 3 wrapped around said beads; a tread 5; and first and second sidewalls disposed between said tread and one of said at least one pair of beads; as well as a belt portion 7 between the carcass ply 3 and the tread 5. In accordance with the invention, the tread 5 comprises a tread base layer 8 and a plurality of tread blocks 9, wherein the tread blocks 9 comprise at least two different rubber layers 15, 17, 19 arranged radially above each other, whereas the rubber layers 15, 17, 19 of different tread blocks are axially separate from each other.

Owner:THE GOODYEAR TIRE & RUBBER CO

Pneumatic tire for heavy load

InactiveUS20140238568A1Good performance in both fuel efficiencyGood drainageHeavy duty tyresHeavy duty vehicleGround contactFuel efficiency

An object of the present invention is to provide a tire for heavy load, which exhibits good performances in both fuel efficiency and drainage. One example of the pneumatic tire comprising a tread portion and a pair of circumferential main grooves formed in a ground contact surface of the tread portion to section the ground contact surface of the tread portion into the central region and respective side regions, wherein the tire further comprises three circumferential narrow grooves formed in the central region to demarcate four rib-like center land portions in the central region; and the central region has a structure in which openings of the circumferential narrow grooves are closed so that the rib-like center land portions adjacent to each other with the circumferential narrow grooves therebetween are in contact with and thus supported by each other when the tire is in contact with the ground.

Owner:BRIDGESTONE CORP

Tire

ActiveUS20120006456A1Enhanced wet weather performanceMaintain resistanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

Owner:BRIDGESTONE CORP

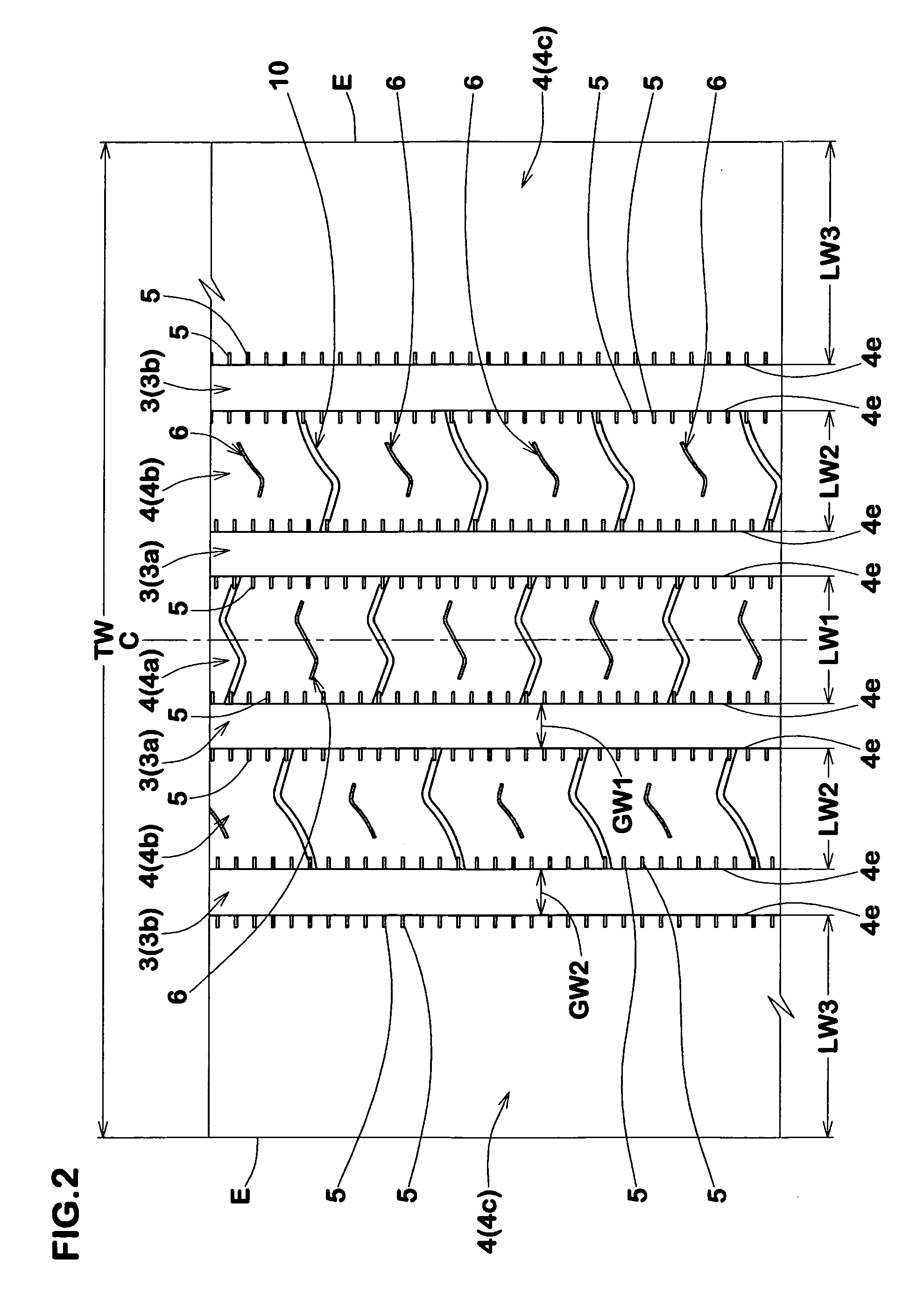

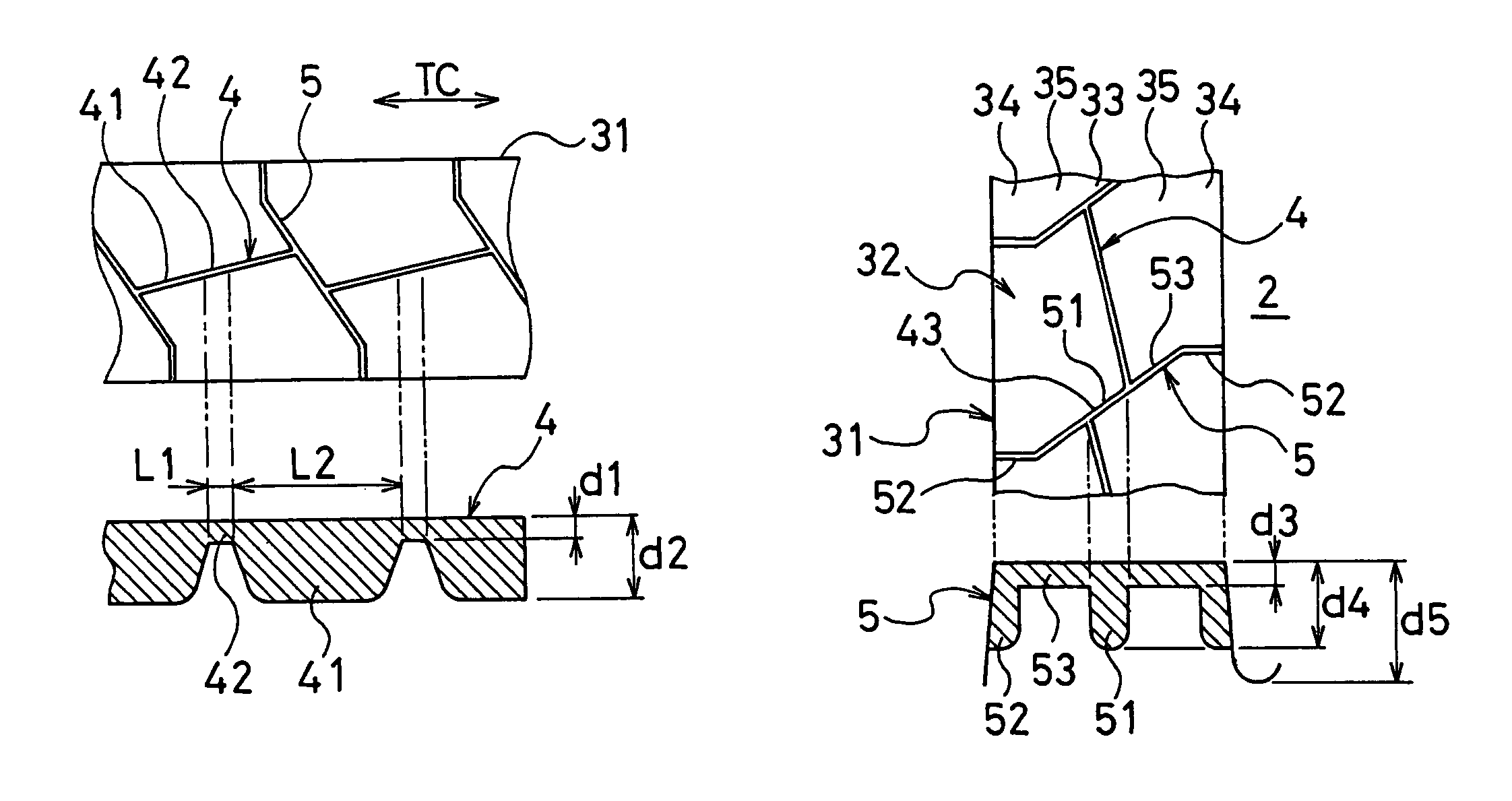

Pneumatic tire with rib having widthwise sipes and circumferential sipe

ActiveUS7836926B2Improve uneven wear resistanceImprove wettabilityHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

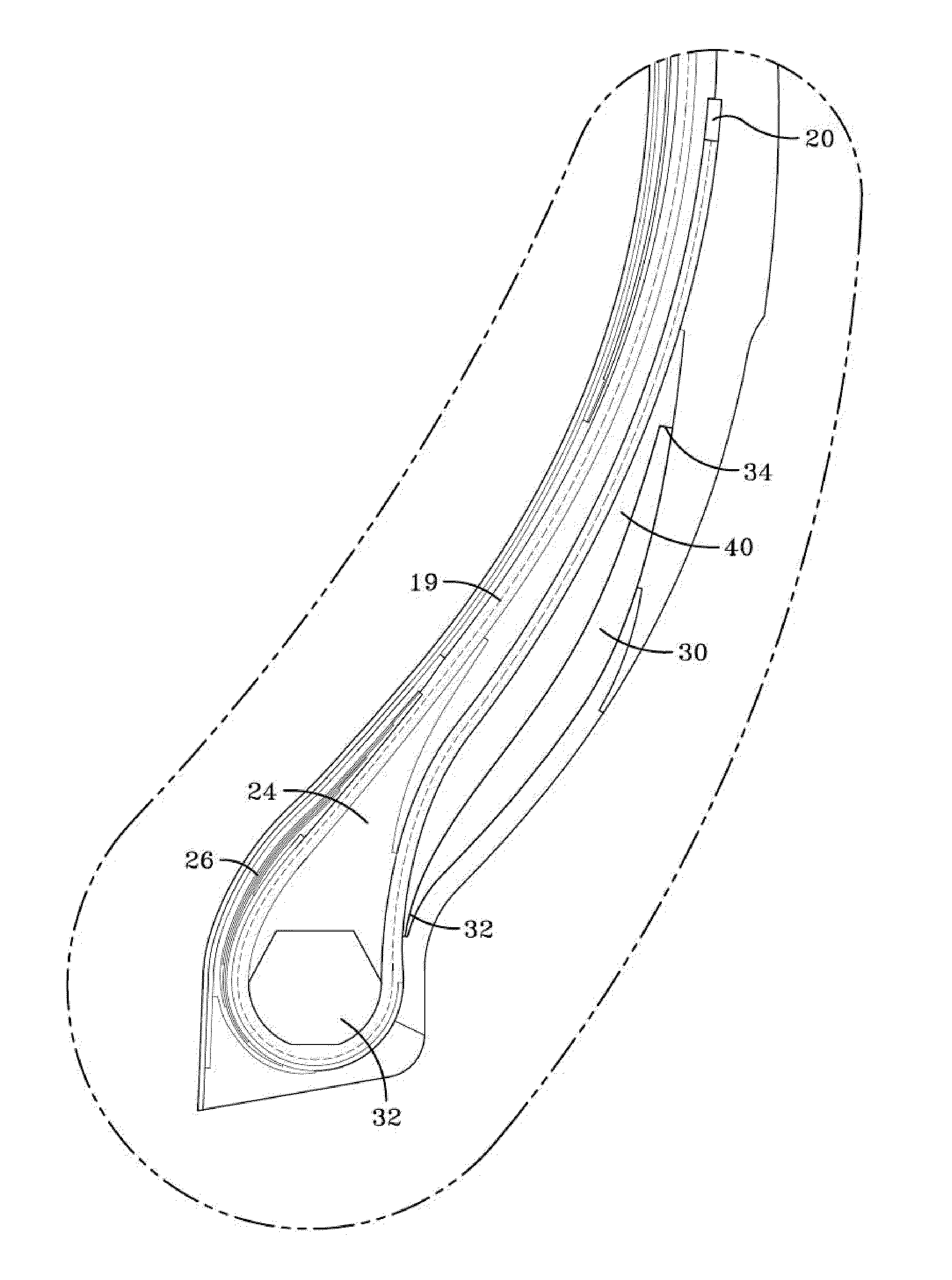

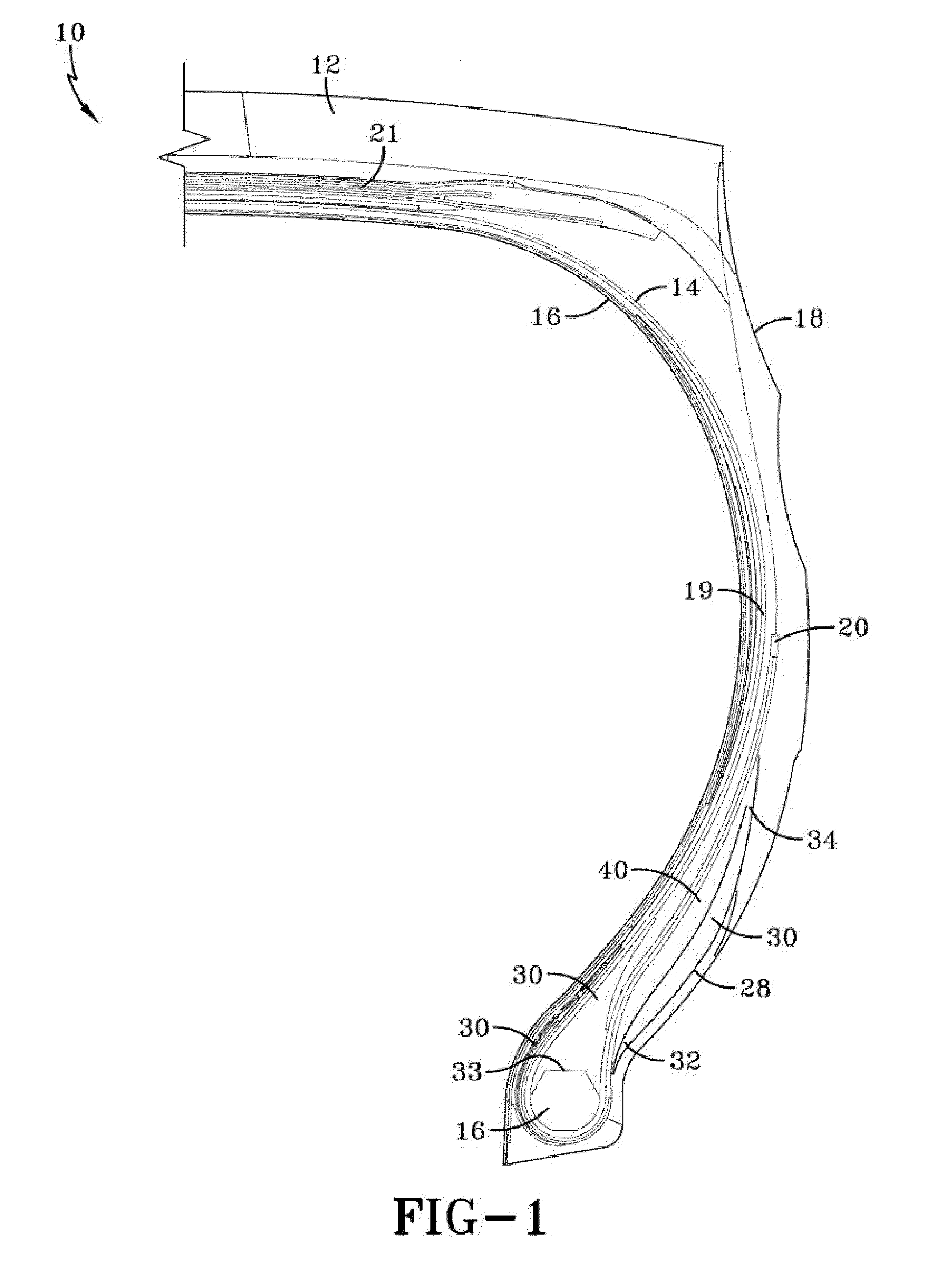

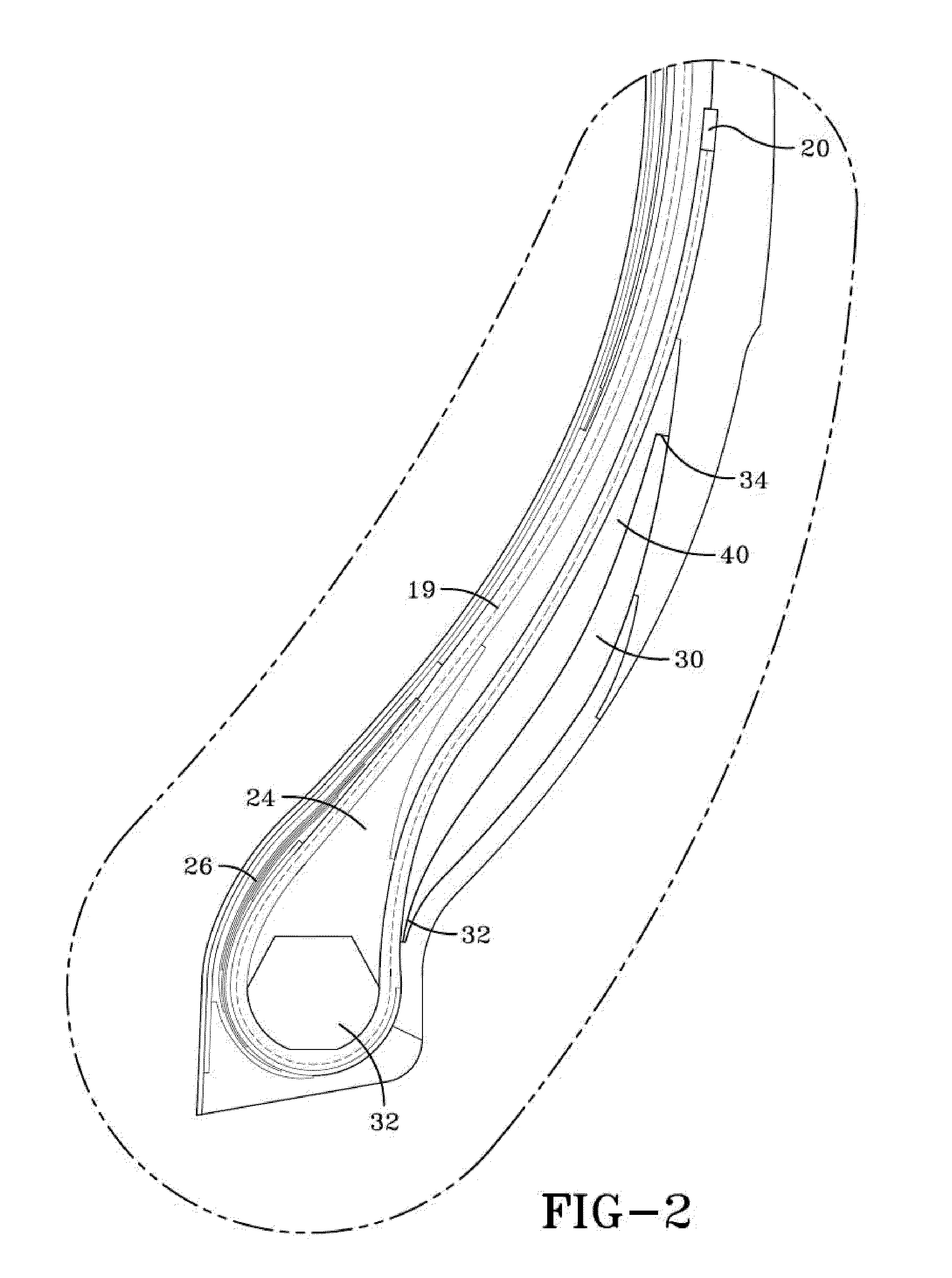

Heavy duty tire

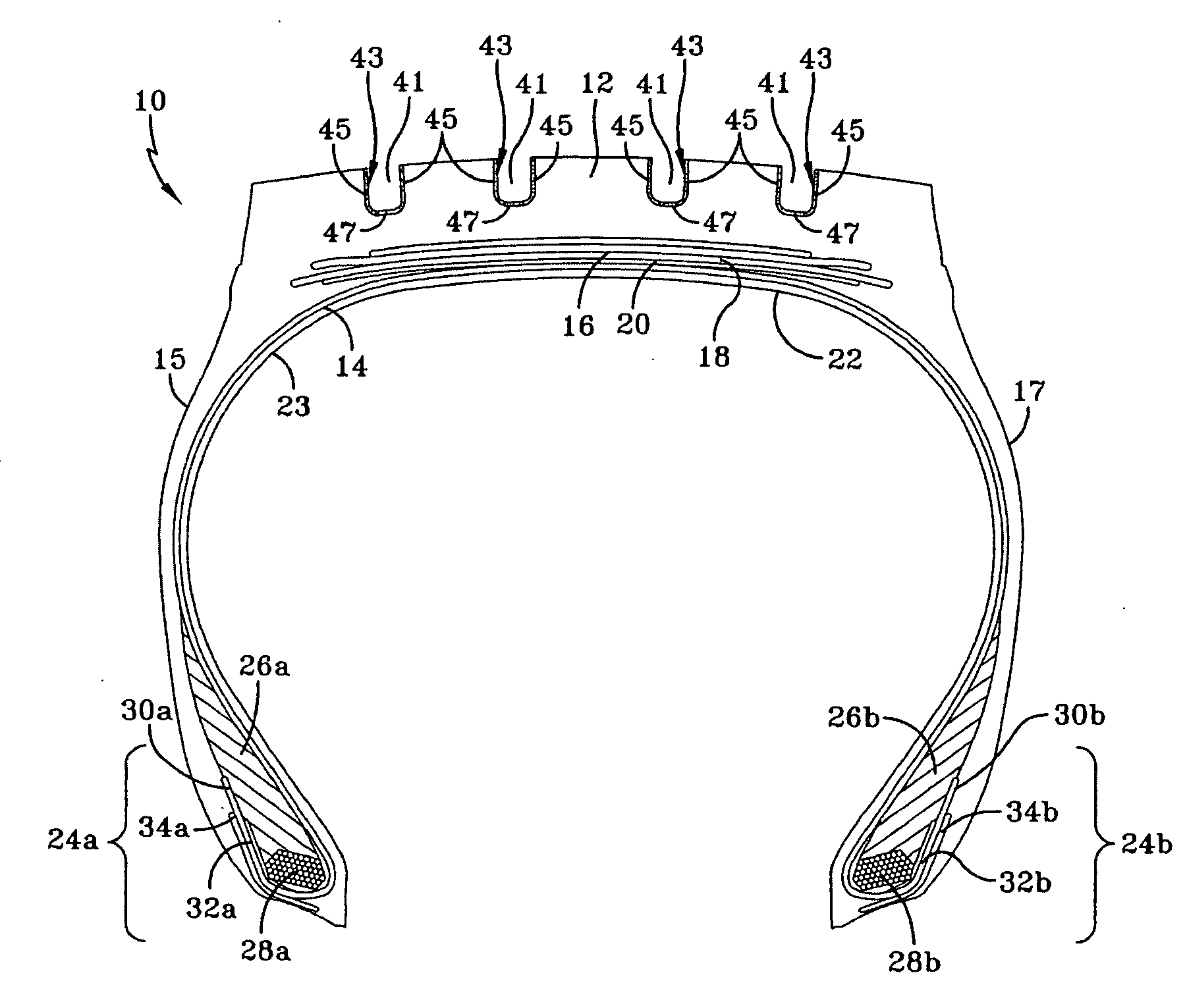

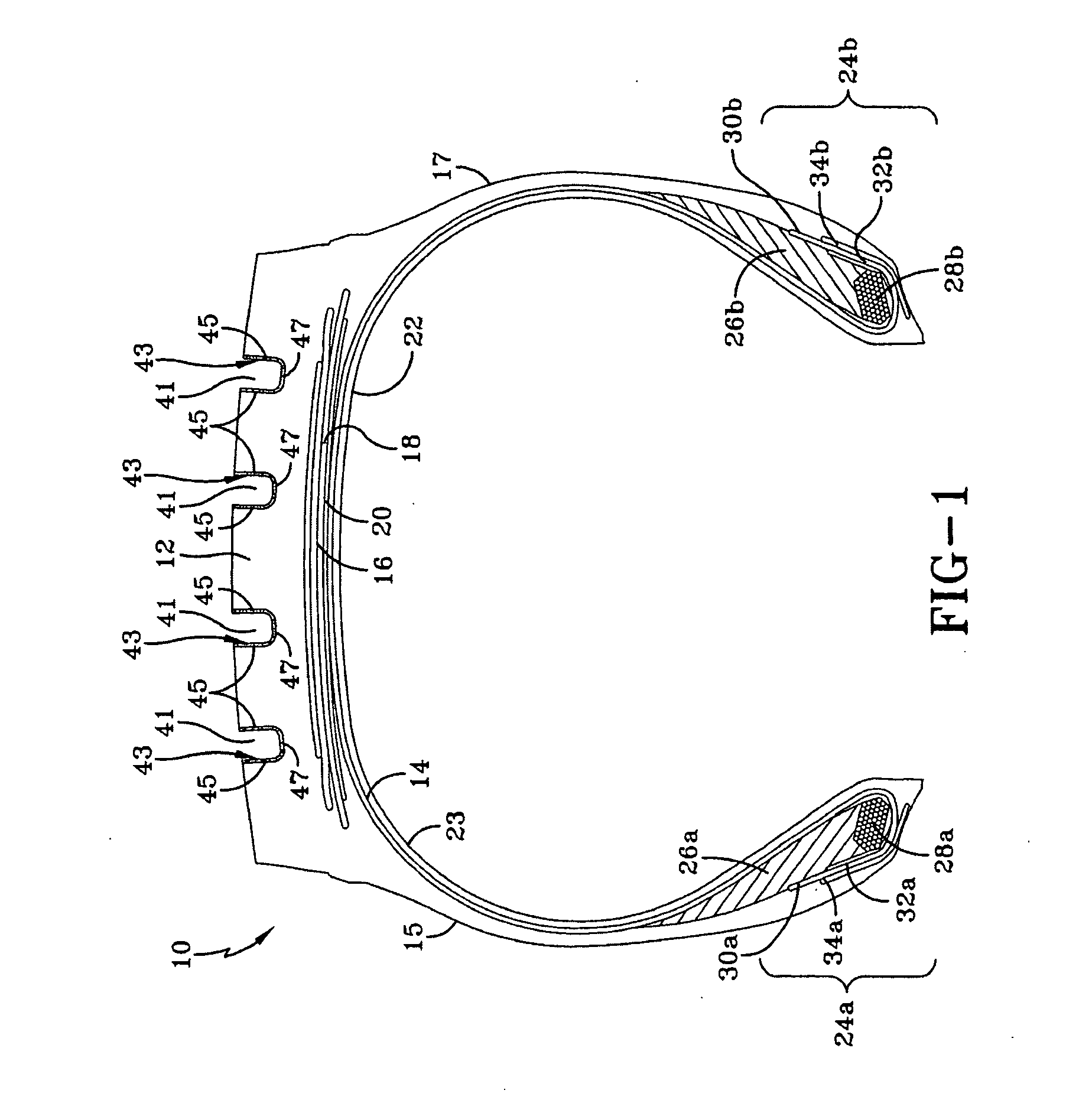

A pneumatic tire construction is described suitable for severe loading conditions. The tire includes a bead portion further having an apex which extends radially outward of the bead core, and a first turnup pad located adjacent said chafer, and a second turnup pad located adjacent said first turnup pad, wherein the first turnup pad has a G′ less than the G′ of the second turnup pad. Alternatively, the first turnup pad may be located adjacent to the rim flange and the second turnup pad may be located axially inward of the first pad. The second turnup pad is preferably thicker and longer than the first turnup pad.

Owner:VENKATARAMANI GAYATHRI +2

Heavy duty pneumatic tire

InactiveUS20120241061A1Improve the level ofEasy to wearHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

Pneumatic radial tire

InactiveUS20120318427A1Increased durabilityAvoid separationHeavy duty tyresHeavy duty vehicleTire beadPolymer science

A pneumatic radial tire has a rubber filler includes a lower filler and an upper filler. The lower filler surrounds a bead core and has a round cross sectional shape. The upper filler has a lower rubber hardness than the lower filler. A chafer is wound up around the bead core outside of a carcass ply and includes a metal cord. A wound-up end of the carcass ply is arranged radially outside of an upper end of the lower filler and a wound-up end of the chafer. A rubber pad has a higher rubber hardness than the upper filler and sandwiches the wound-up end of the carcass ply. The rubber pad extends to radially inside of the upper end of the lower filler and contacts with an inside of a wound-up portion of the carcass ply.

Owner:TOYO TIRE & RUBBER CO LTD

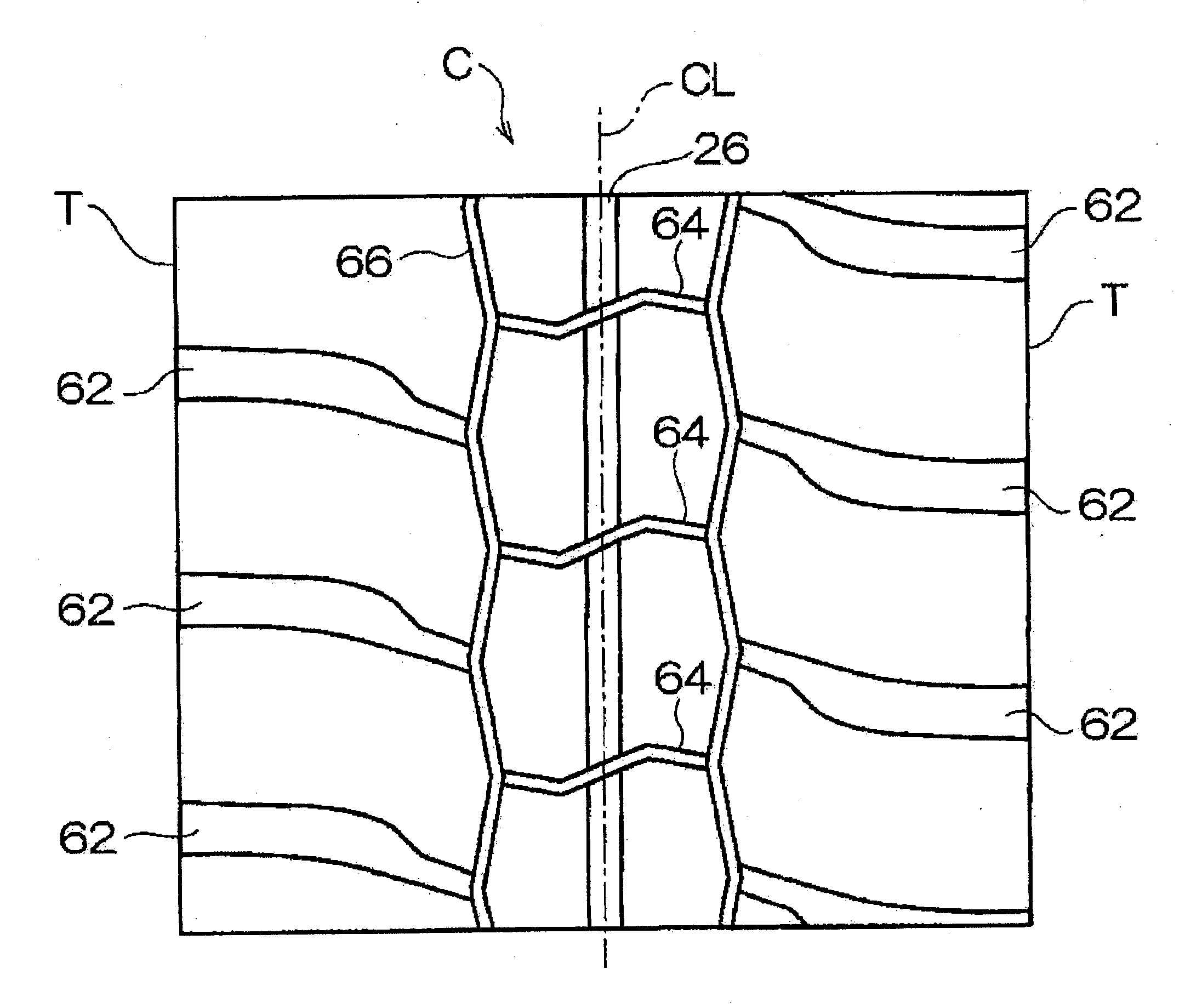

Tire for construction vehicle

InactiveUS20090032157A1Curb troubleImprove featuresHeavy duty tyresHeavy duty vehicleShoulder regionThermal radiation

An object of the present invention is to provide a tire for a construction vehicle which suppresses a trouble of the tire by enhancing a heat-radiation characteristic of a tire center portion.A tire for a construction vehicle according to the present invention is provided with a plurality of lug grooves 22 in tread shoulder regions located at the both sides in the width direction of the tire. A plurality of widthwise-extending narrow grooves 24 extending generally along the width direction of the tire and having an end in the width direction of the tire terminated in the tread are disposed in a tire center portion C. This may improve the wear resistance characteristic and to enhance the heat-radiation characteristic by suppressing the decrease of the rigidity of the land portion. In addition, an equatorial shallow groove 26 extending in the circumferential direction of the tire is disposed on the tire equator CL. This allows the compressive stress acting on the tire center portion to be relaxed and the area for hear-radiation to be increased.

Owner:BRIDGESTONE CORP

Heavy duty tire

ActiveUS20130098519A1Improve fuel efficiencySmall overall deformationHeavy duty tyresHeavy duty vehicleGroove widthEngineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20070284026A1Moderate shear strainUneven wearHeavy duty tyresHeavy duty vehicleEngineeringTread

A circumferential sipe extends continuously in the circumferential direction of the tire in the center region of the tread surface section of a rib defined between circumferential grooves. Widthwise sipes are disposed at prescribed intervals in the circumferential direction of the tire in the tread surface section, the widthwise sipes extending in the widthwise direction of the tire in crossing relationship to the circumferential sipe, the widthwise sipes each having opposing terminal ends open to the circumferential grooves. The circumferential sipe changes in depth periodically in such a manner that the circumferential sipe is shallow between adjacent widthwise sipes. The widthwise sipes changes in depth in such a manner that they are greater in depth in the center region and end regions of the tread surface section.

Owner:THE YOKOHAMA RUBBER CO LTD

Tire inflation system with discrete deflation circuit

ActiveUS8973633B2More dependableMore efficientVehicle testingHeavy duty tyresPneumatic circuitEngineering

A vehicle tire inflation system includes an air supply source in fluid communication with multiple tires of the vehicle. A pneumatic conduit extends between and is in fluid communication with the air supply source and the tires. Means are fluidly connected to the pneumatic conduit for enabling selective inflation and deflation of the tires. The means include a first pneumatic circuit for inflation of the tires, and a second pneumatic circuit for deflation of the tires. The second pneumatic circuit is discrete from the first pneumatic circuit and is common to more than one of the tires. The means provides controlled deflation of the tires in the second pneumatic circuit based upon a predetermined condition, preventing deflation of the tires until the vehicle is parked, or limiting the deflation of the tires, which in turn enables the tire inflation system to accommodate a desirable increased pressure in the tires.

Owner:HENDRICKSON USA L L C

Heavy duty pneumatic tire

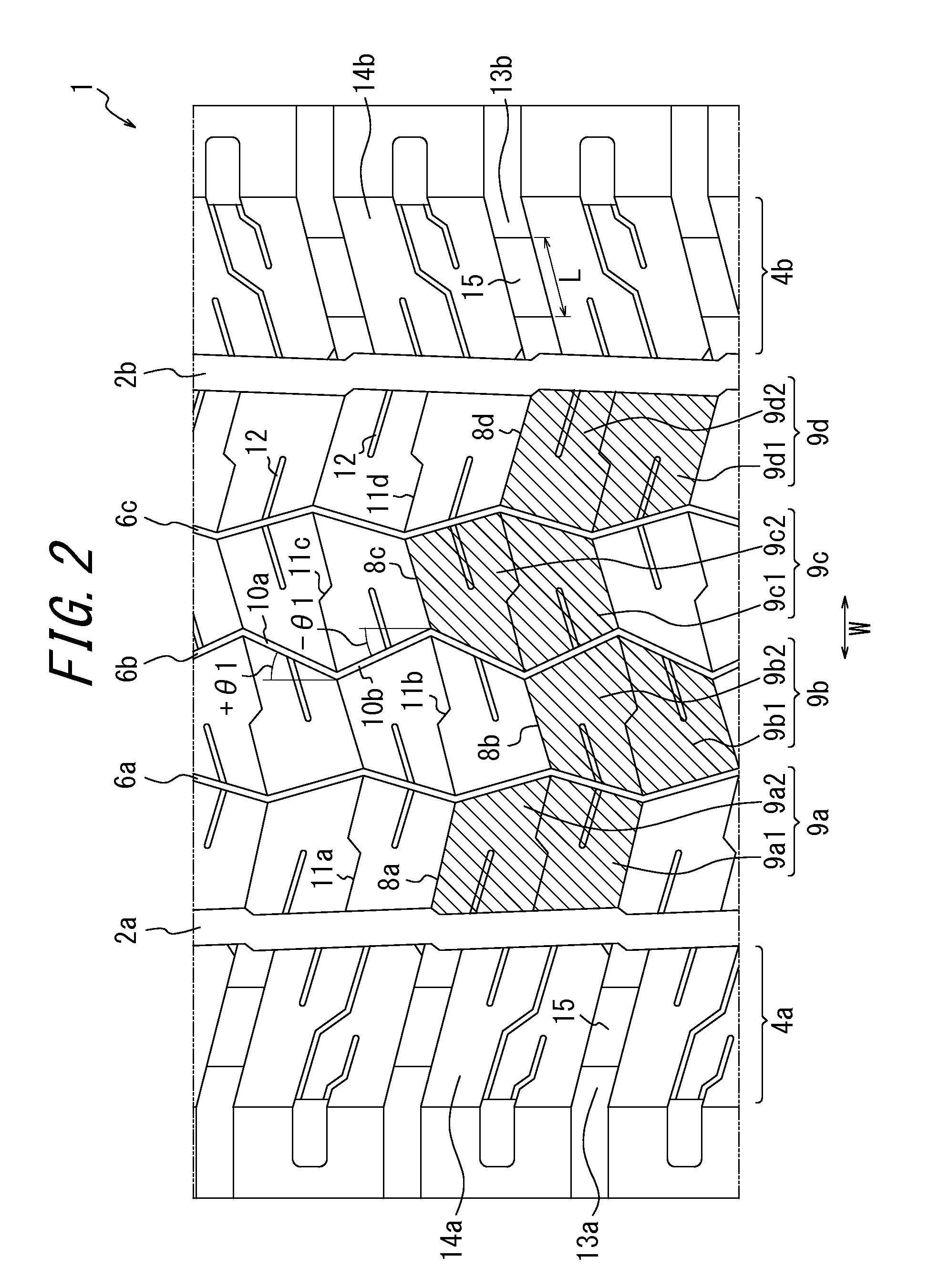

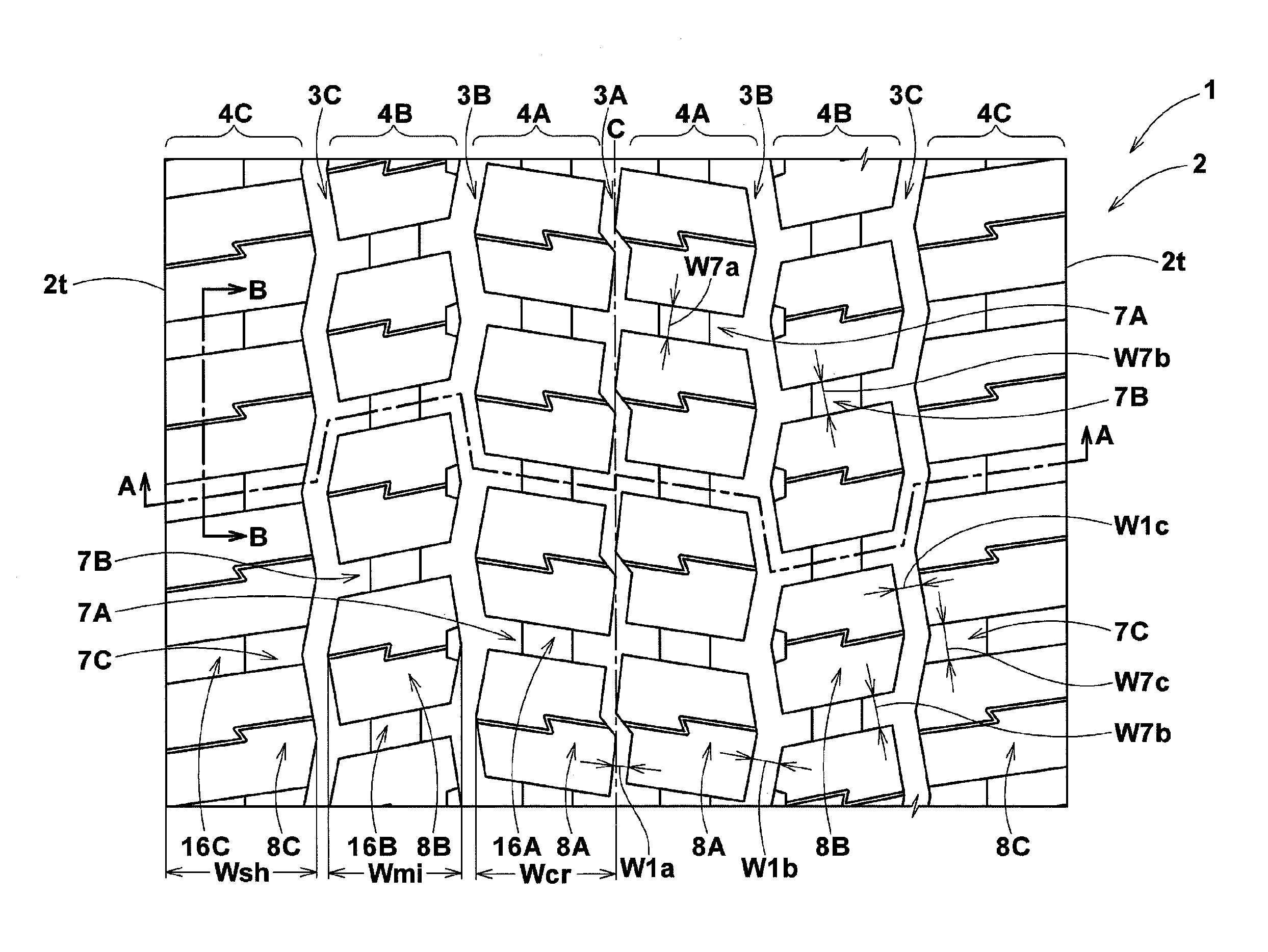

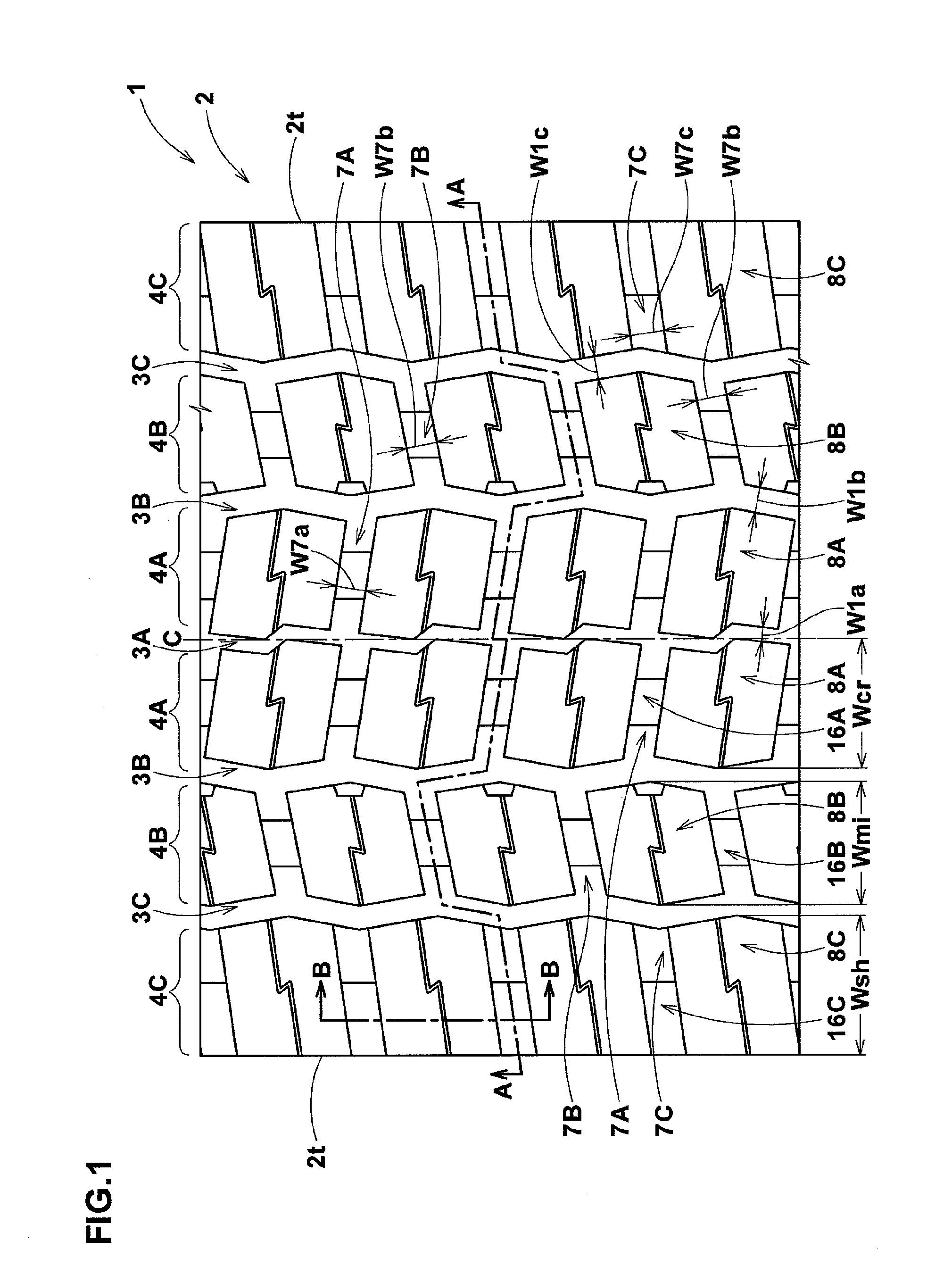

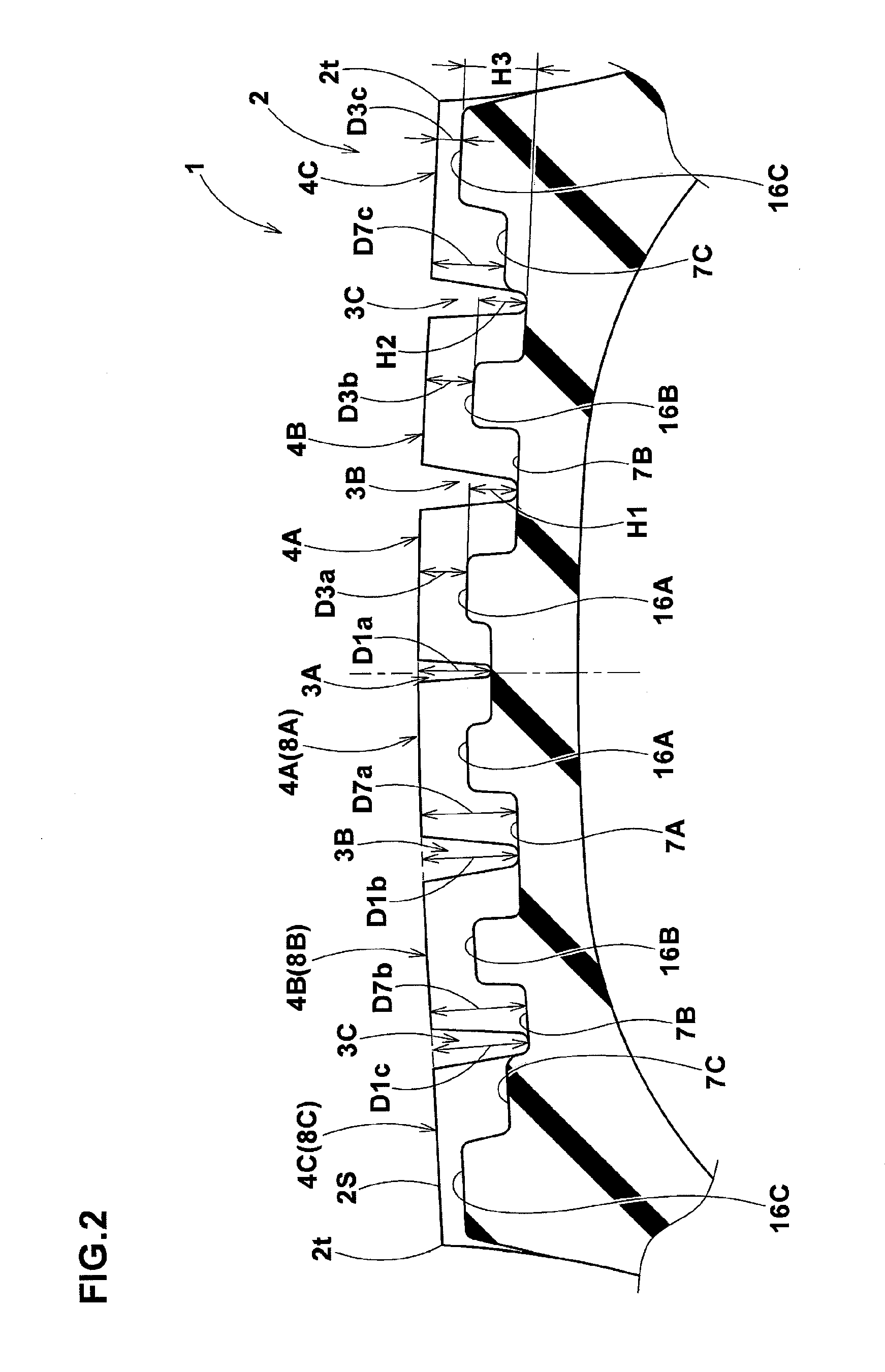

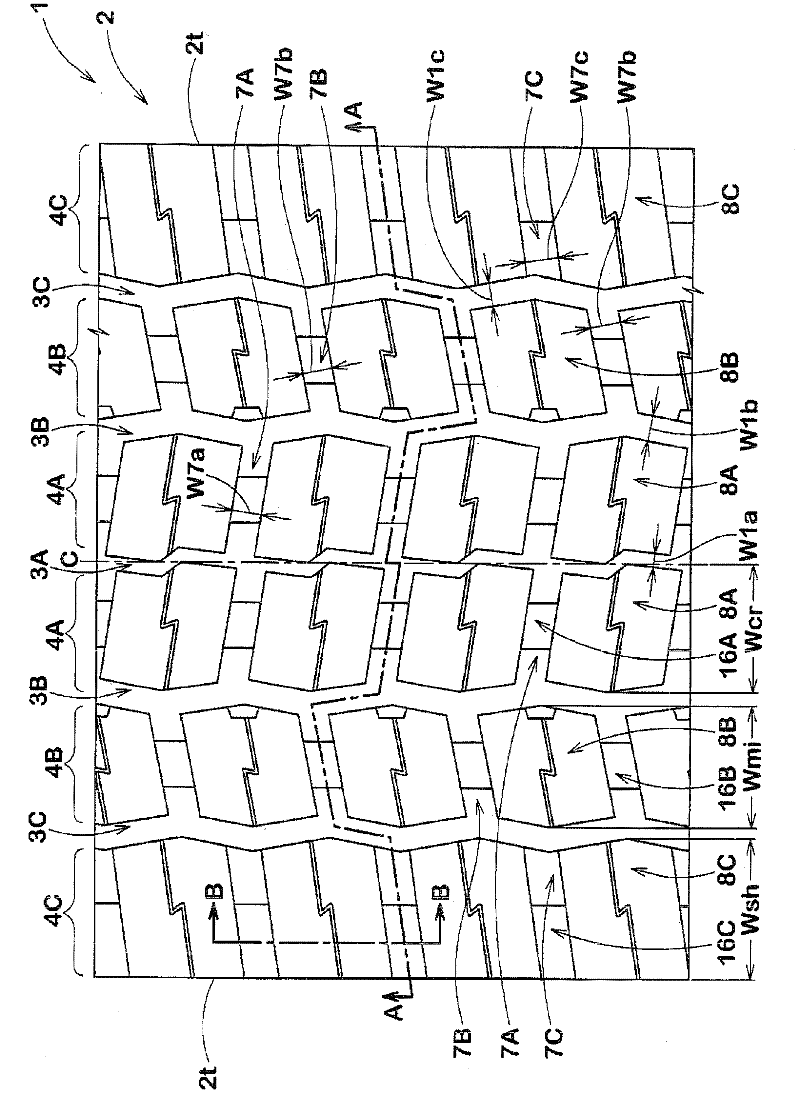

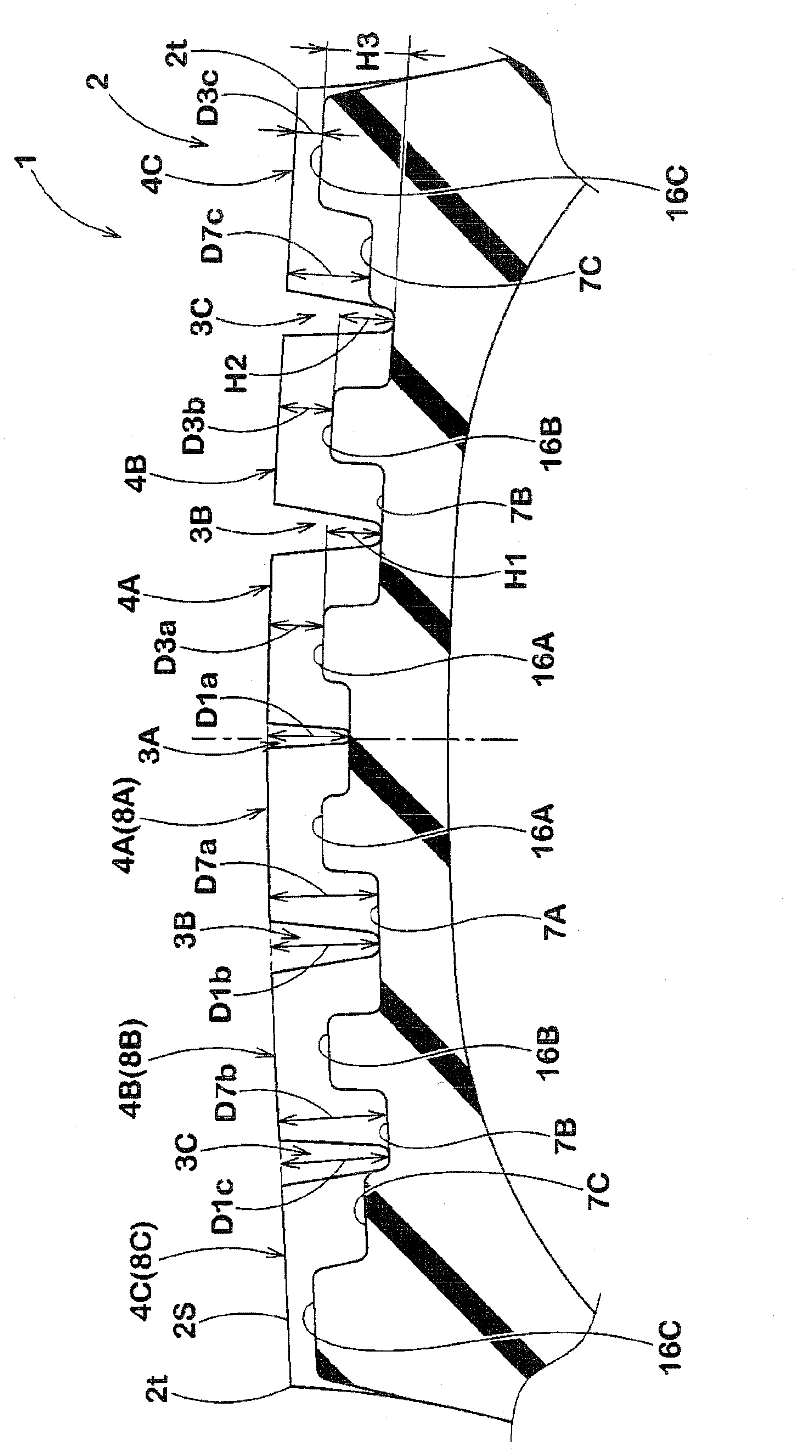

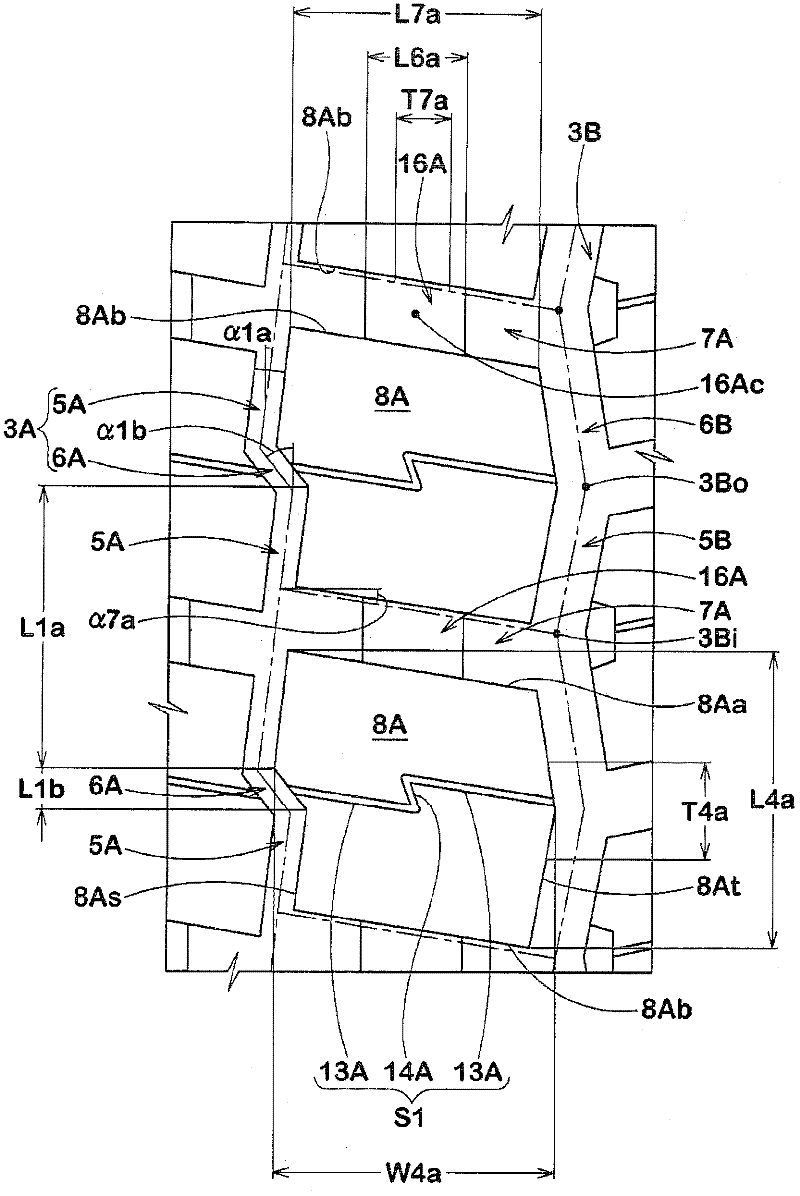

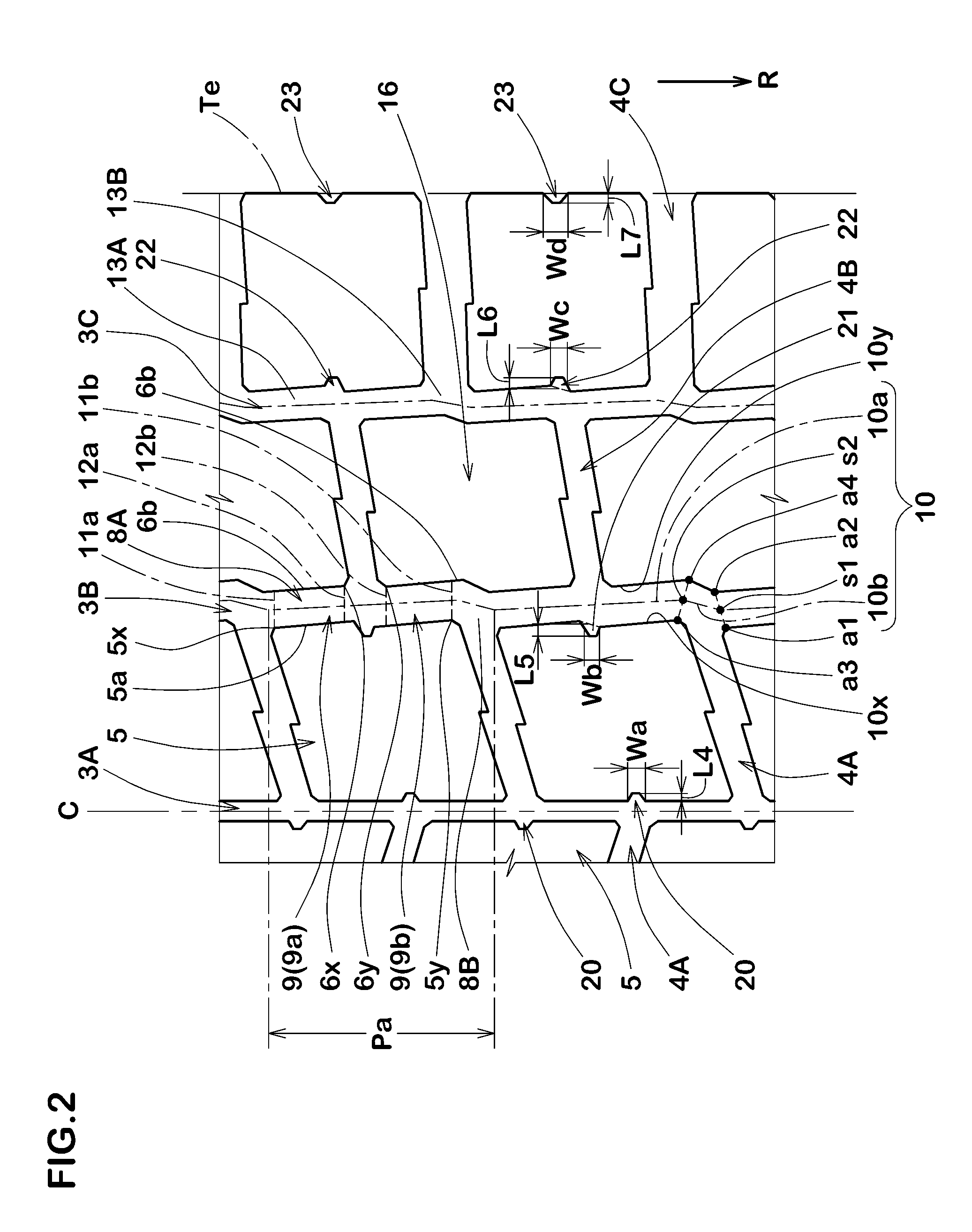

ActiveCN102689568AImprove traction performanceEasy to wearHeavy duty tyresHeavy duty vehicleHeel-and-toeEngineering

The invention discloses a heavy duty pneumatic tire. Both of the center wear and heel-and-toe wear can be improved to high levels. A tread portion 2 is divided into a pair of crown land portions 4A, a pair of middle land portions 4B and a pair of shoulder land portions 4C by center main grooves 3A, middle main grooves 3B, and shoulder main grooves 3C. The crown land portions 4A, the middle land portions 4B and the shoulder land portions 4C are divided into crown blocks 8A, middle blocks 8B and shoulder blocks 8C by crown axial grooves 7A, middle axial grooves 7B and shoulder axial grooves 7C. The crown axial groove 7A, the middle axial groove 7B and the shoulder axial groove 7C are provided with a crown tie bar 16A, a middle tie bar 16B and a shoulder tie bar 16C, respectively. The maximum width Wcr of the crown land portion, the maximum width Wmi of the middle land portion, and the maximum width Wsh of the shoulder land portion are set in the preset range.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveUS20070056673A1Improve bead durabilityNot easy to rotateHeavy duty tyresHeavy duty vehicleElastic modulusEngineering

Owner:SUMITOMO RUBBER IND LTD

Heavy duty tire

InactiveUS20110259494A1Wet performance decreaseAvoid damageHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

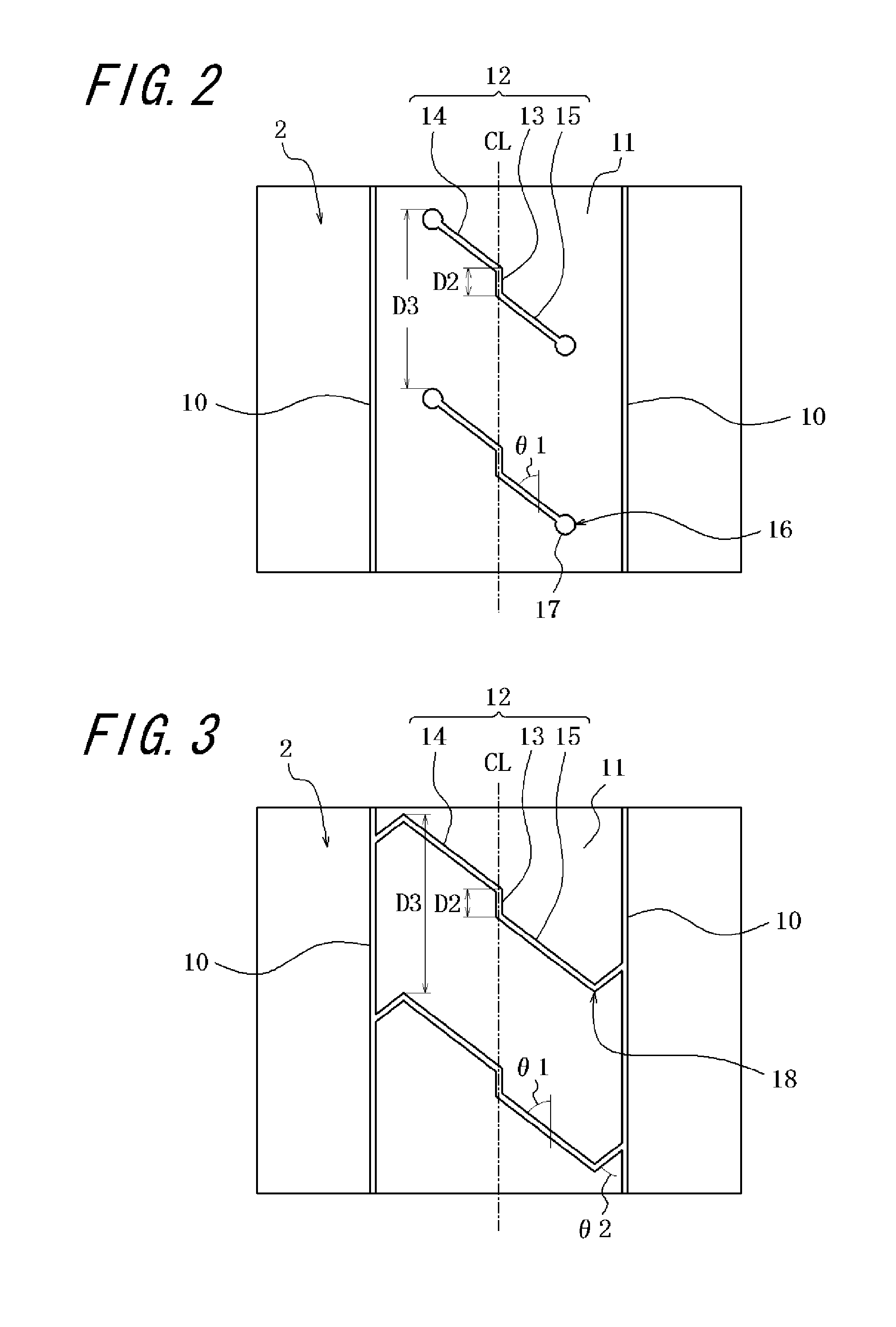

ActiveUS20110005652A1Improve partial wear resistanceIncrease resistanceHeavy duty tyresHeavy duty vehicleEngineeringWear resistance

A pneumatic tire has a tread pattern designed to provide improved heat dissipation properties, wear resistance, and uneven wear resistance. The tire has arranged in a tread (2) two circumferential fine grooves (10) disposed on opposite sides of the equatorial surface (CL) of the tire and extending in the circumferential direction of the tire, and the circumferential fine grooves (10) define a center land section (11). In the center land section (11) are formed oblique fine grooves (12) each having a first small groove (13) extending in the tire's circumferential direction, a second small groove (14) extending obliquely relative to the circumferential direction from one end of the first small groove (13) toward one circumferential fine groove, and a third small groove (15) extending obliquely relative to the circumferential direction from the other end of the first small groove (13) toward the other circumferential fine groove.

Owner:BRIDGESTONE CORP

Pneumatic Tire

InactiveUS20080156410A1Suppresses breakageSuppresses wearHeavy duty tyresHeavy duty vehicleMechanical engineeringEngineering

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20140130949A1Improve wear resistanceGood mannersHeavy duty tyresHeavy duty vehicleEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

A pneumatic tire comprises a tread portion, a pair of sidewall portions, a pair of bead portions, a bead core disposed in each bead portion, a carcass comprising a ply of carcass cords extending between the bead portions through the tread portion and sidewall portions and turned up around the bead core in each bead portion, and an inner liner made of air-impermeable rubber extending on the tire cavity side of the carcass from one of the bead portions to the other. The radially inner end of the inner liner is located radially inside the radially innermost end of the carcass. In a radial region between the radially innermost end of the carcass and the radially outermost end of the bead core, the thickness of the inner liner is not less than 0.15 time but not more than 4.0 times the cross section diameter of the carcass cord.

Owner:UEYOKO KIYOSHI +2

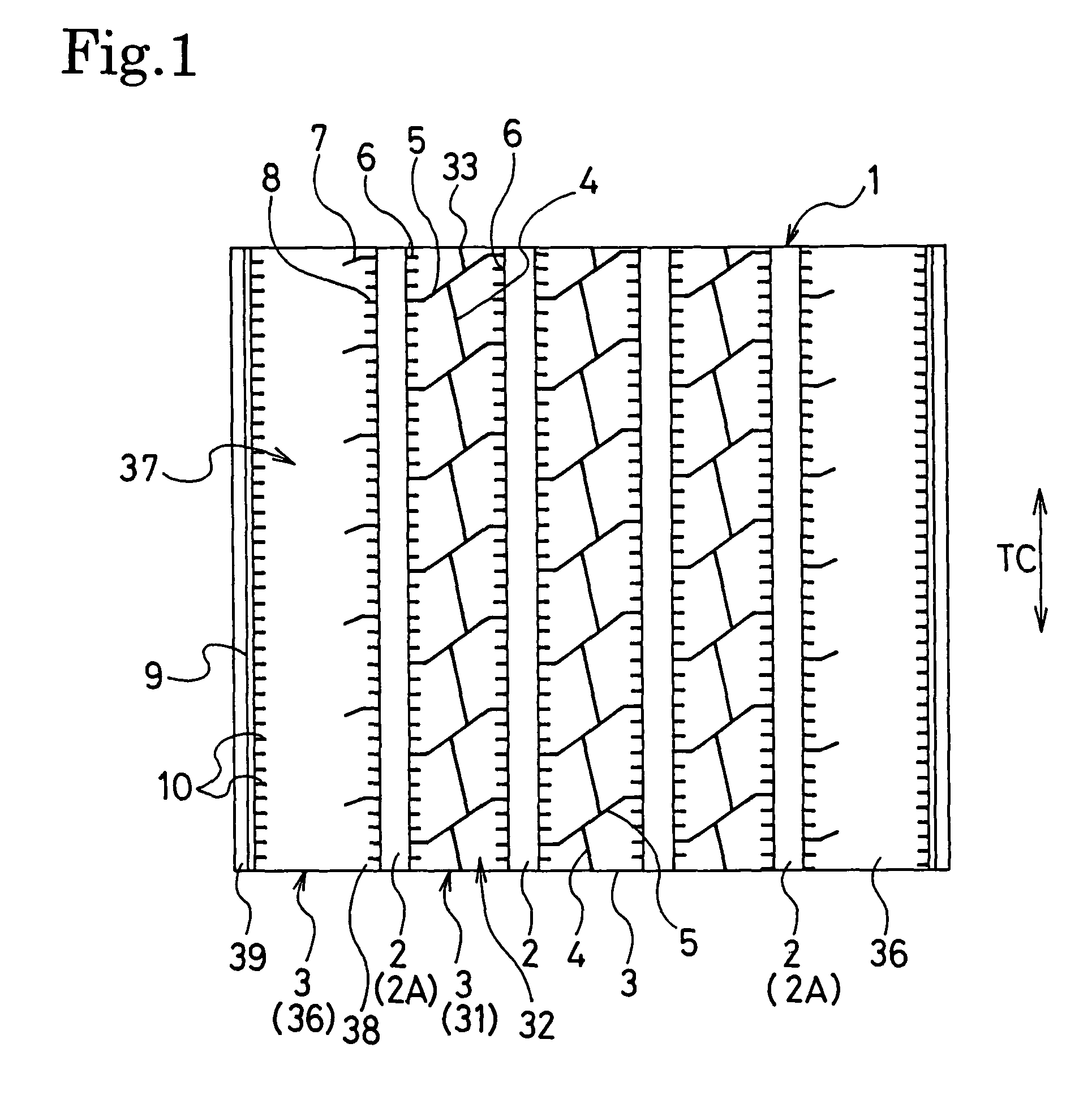

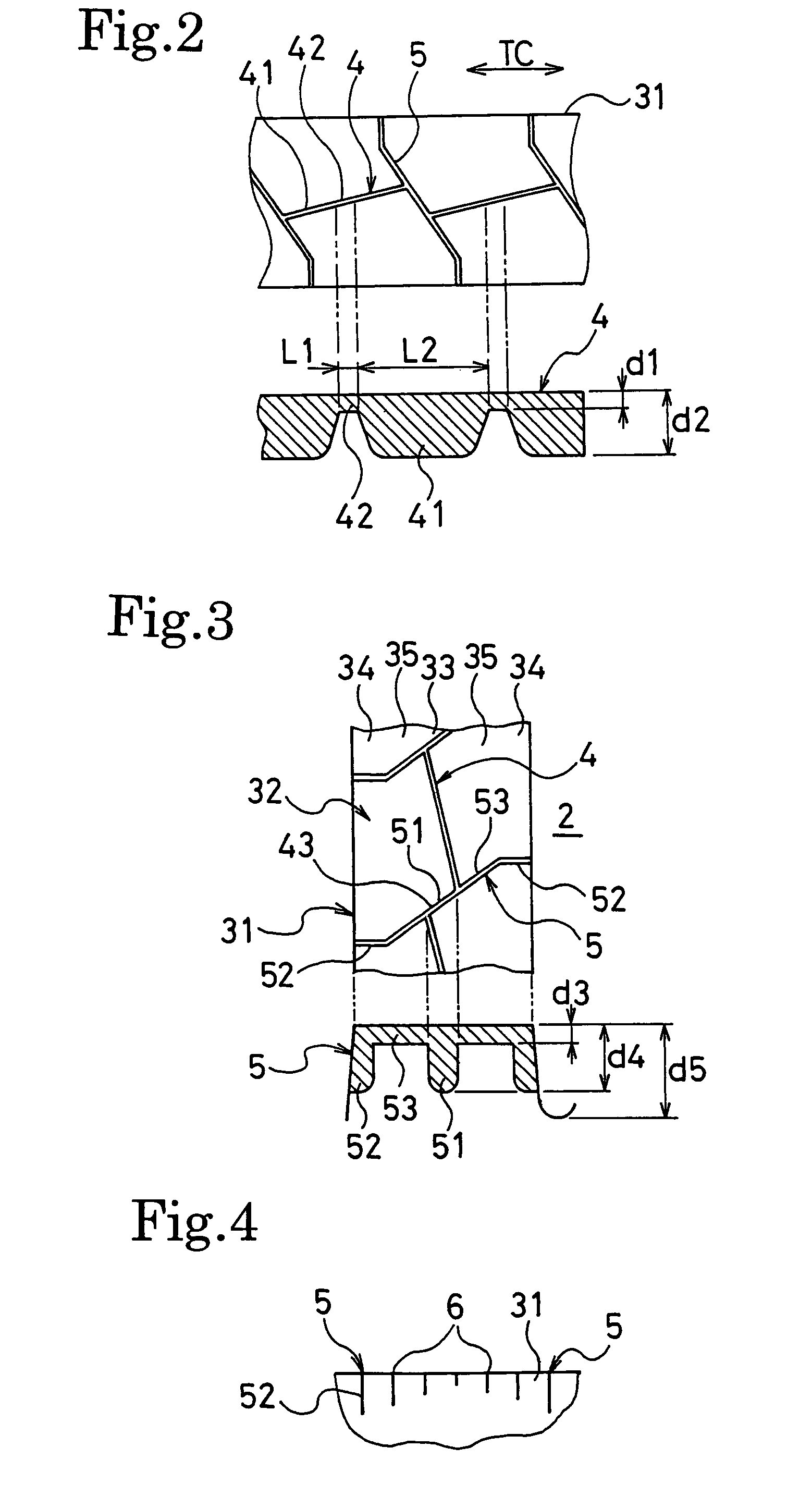

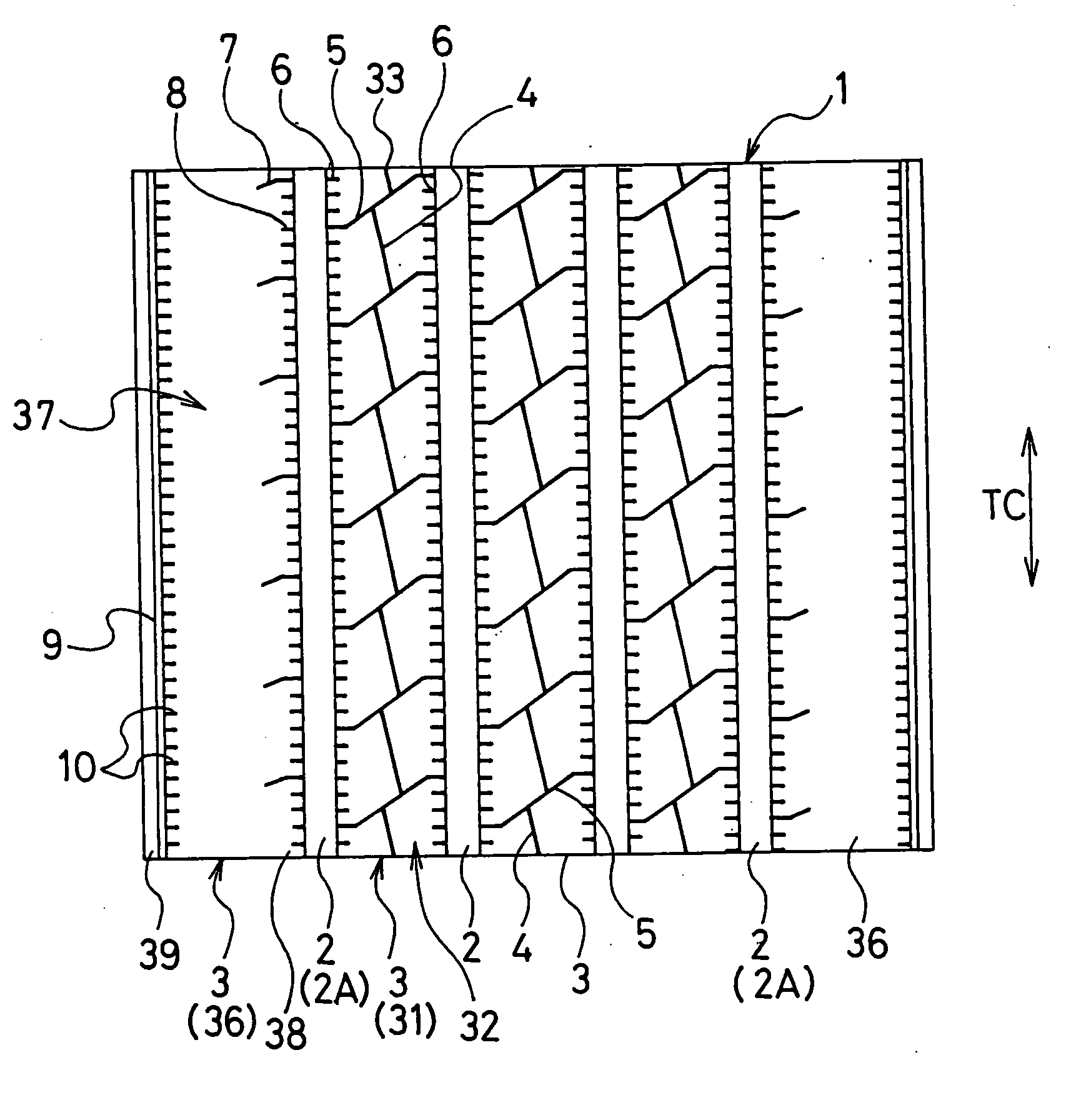

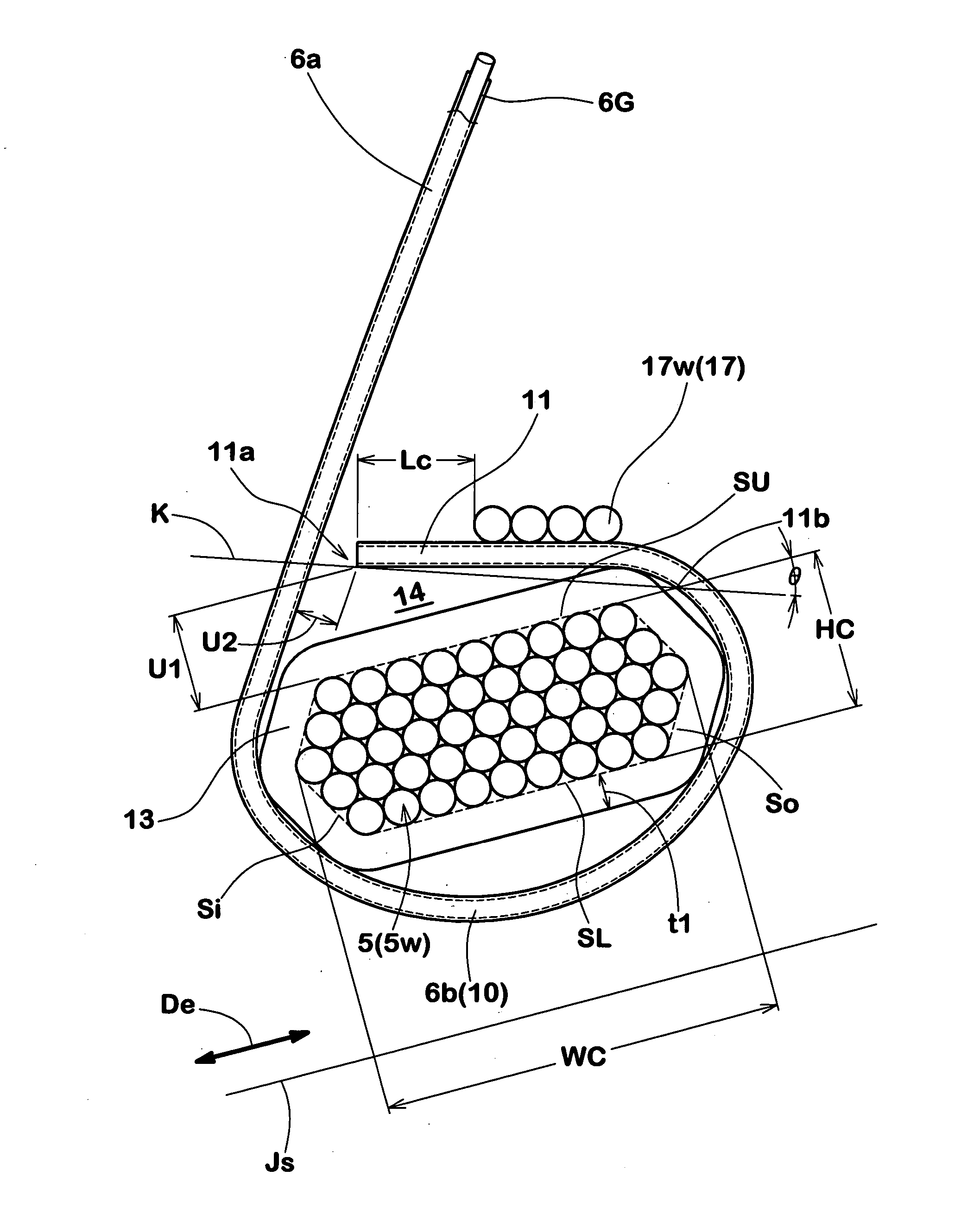

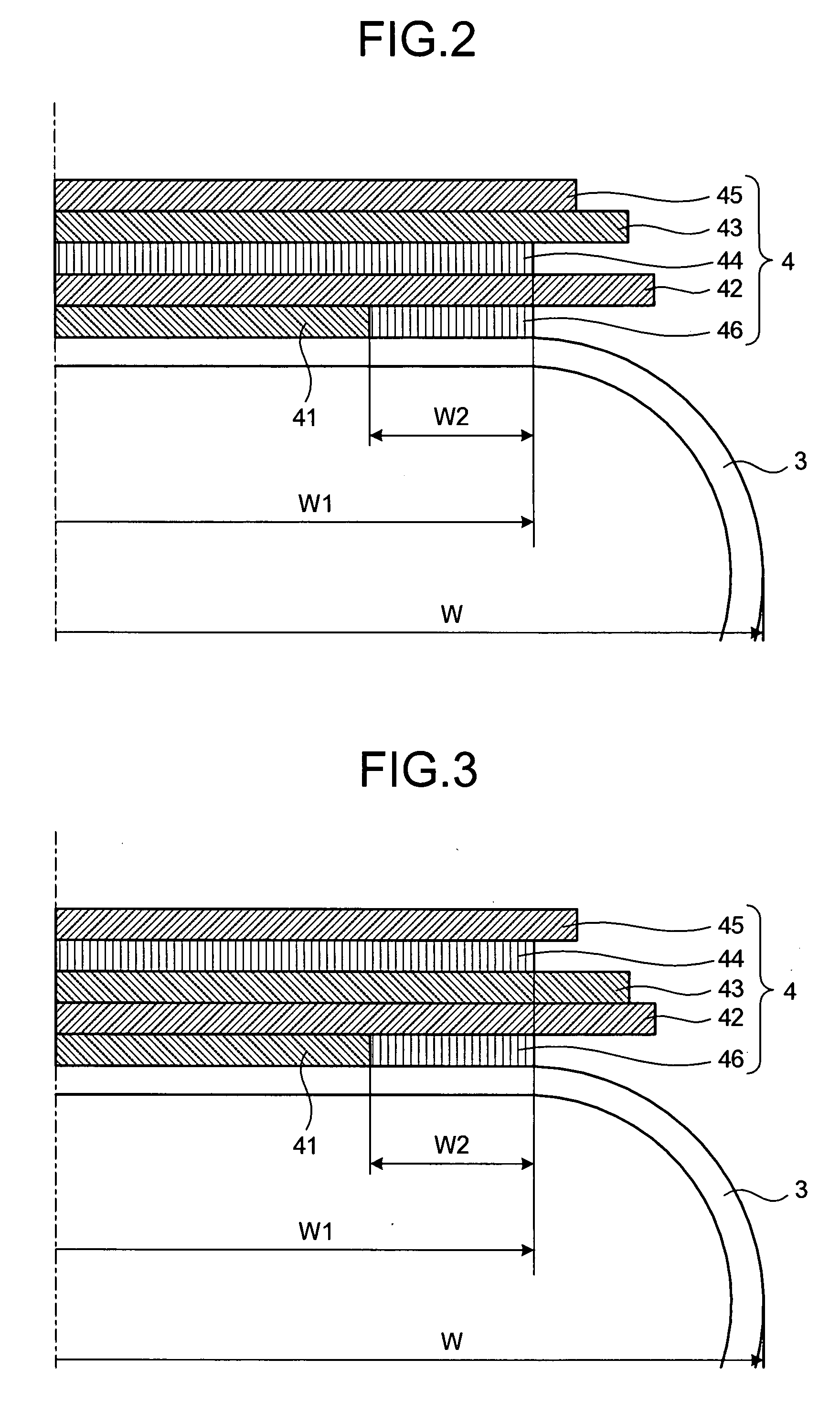

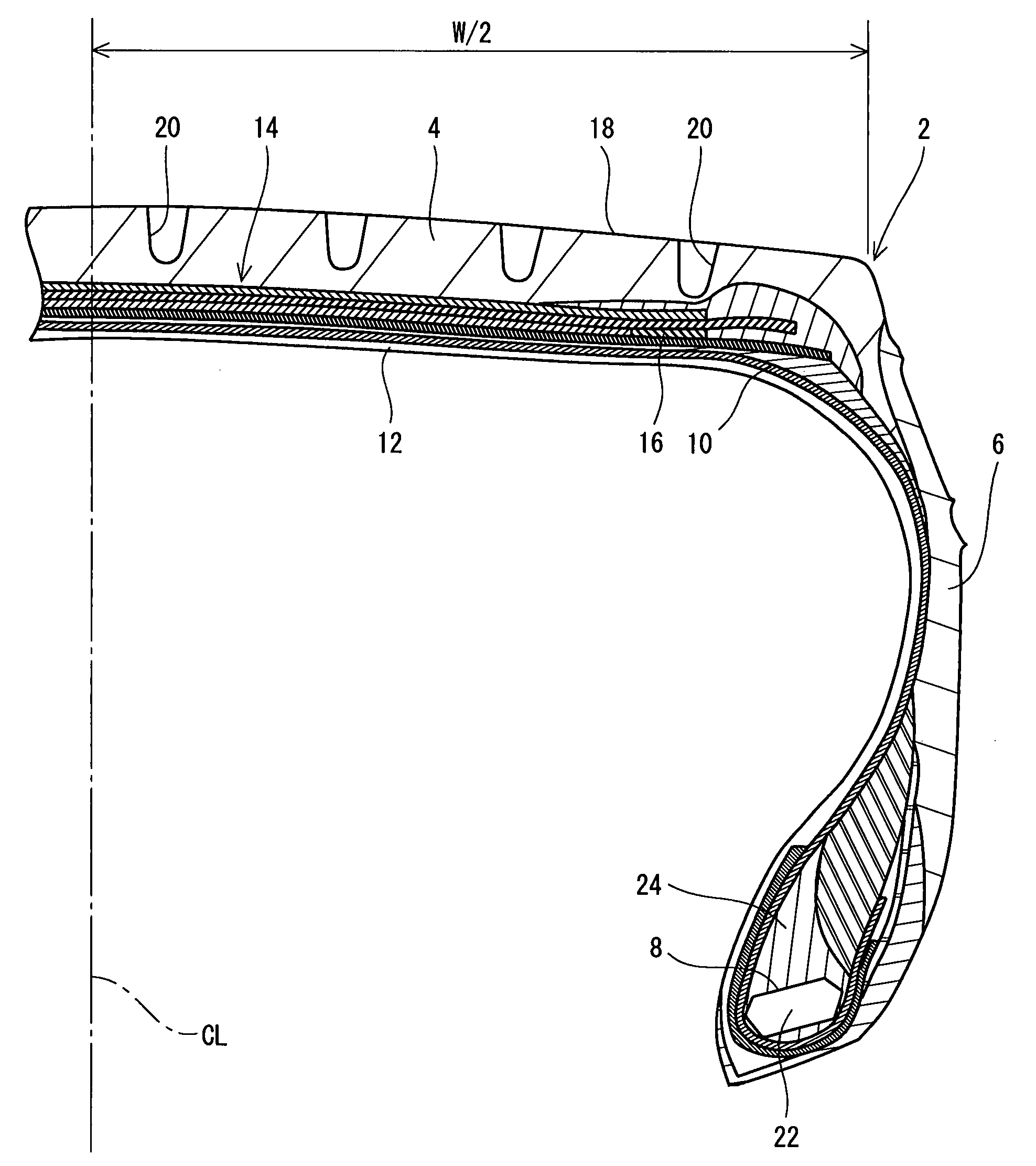

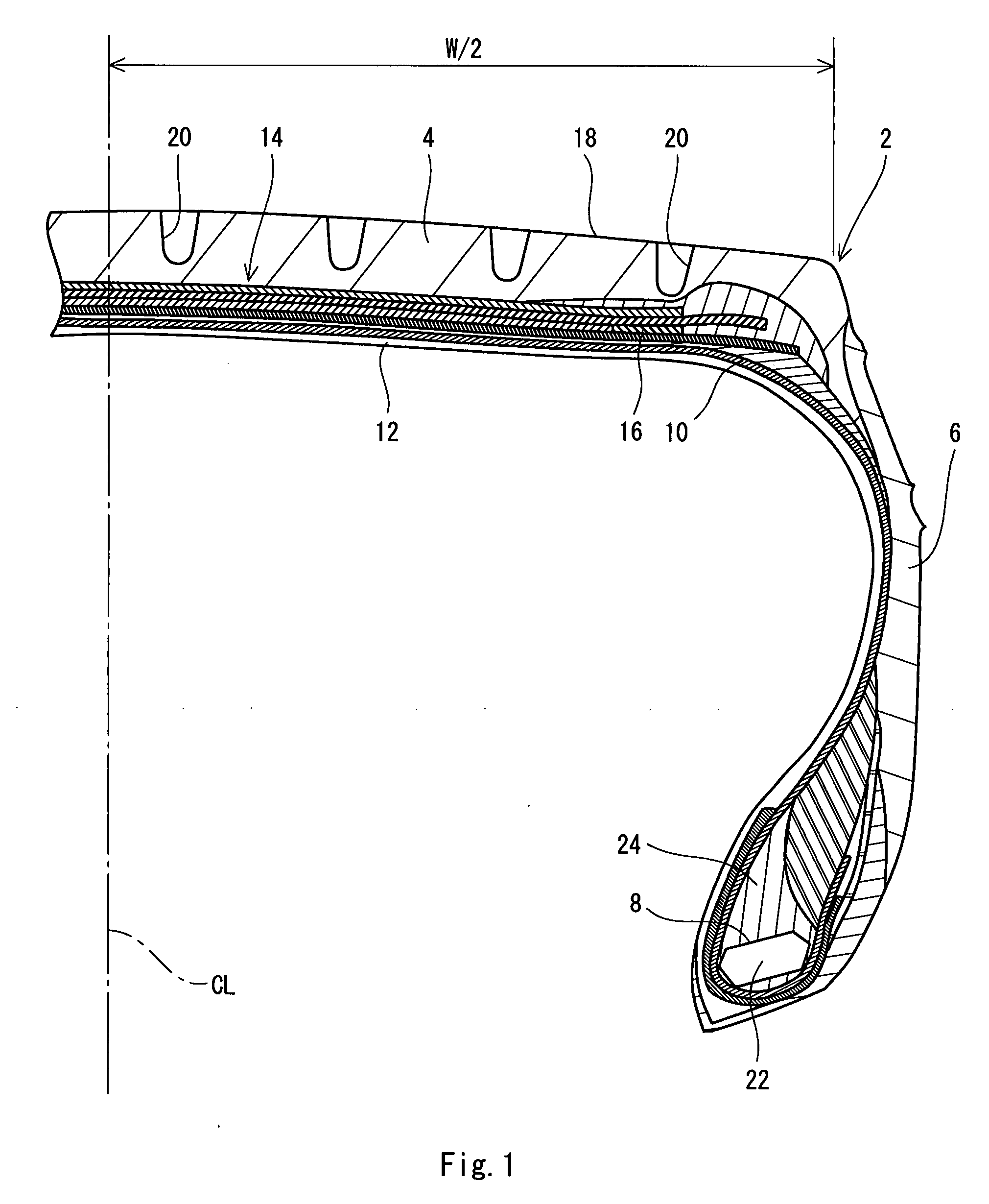

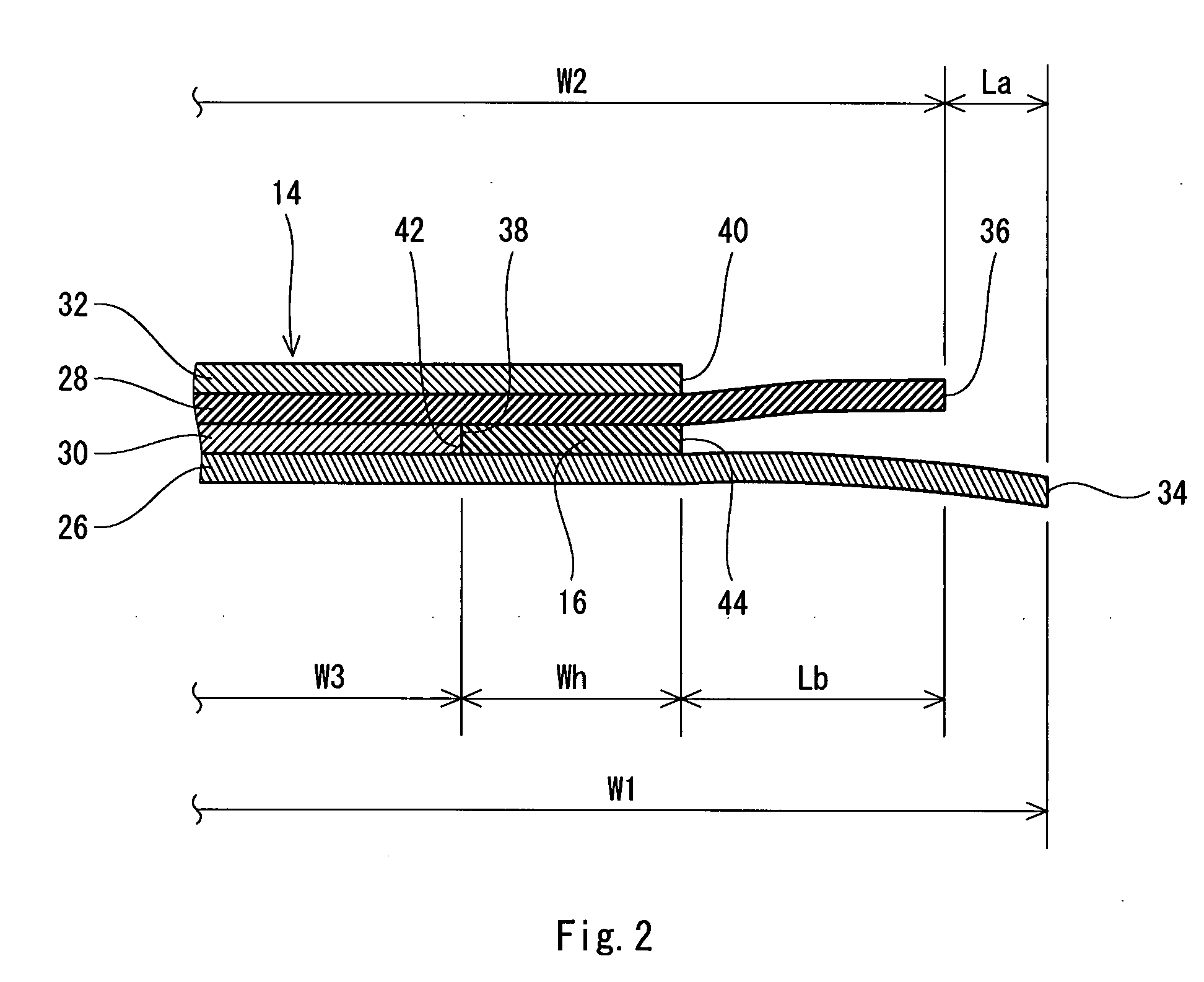

Heavy duty pneumatic tire

InactiveUS20080000566A1Add dimensionNot easily causedHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

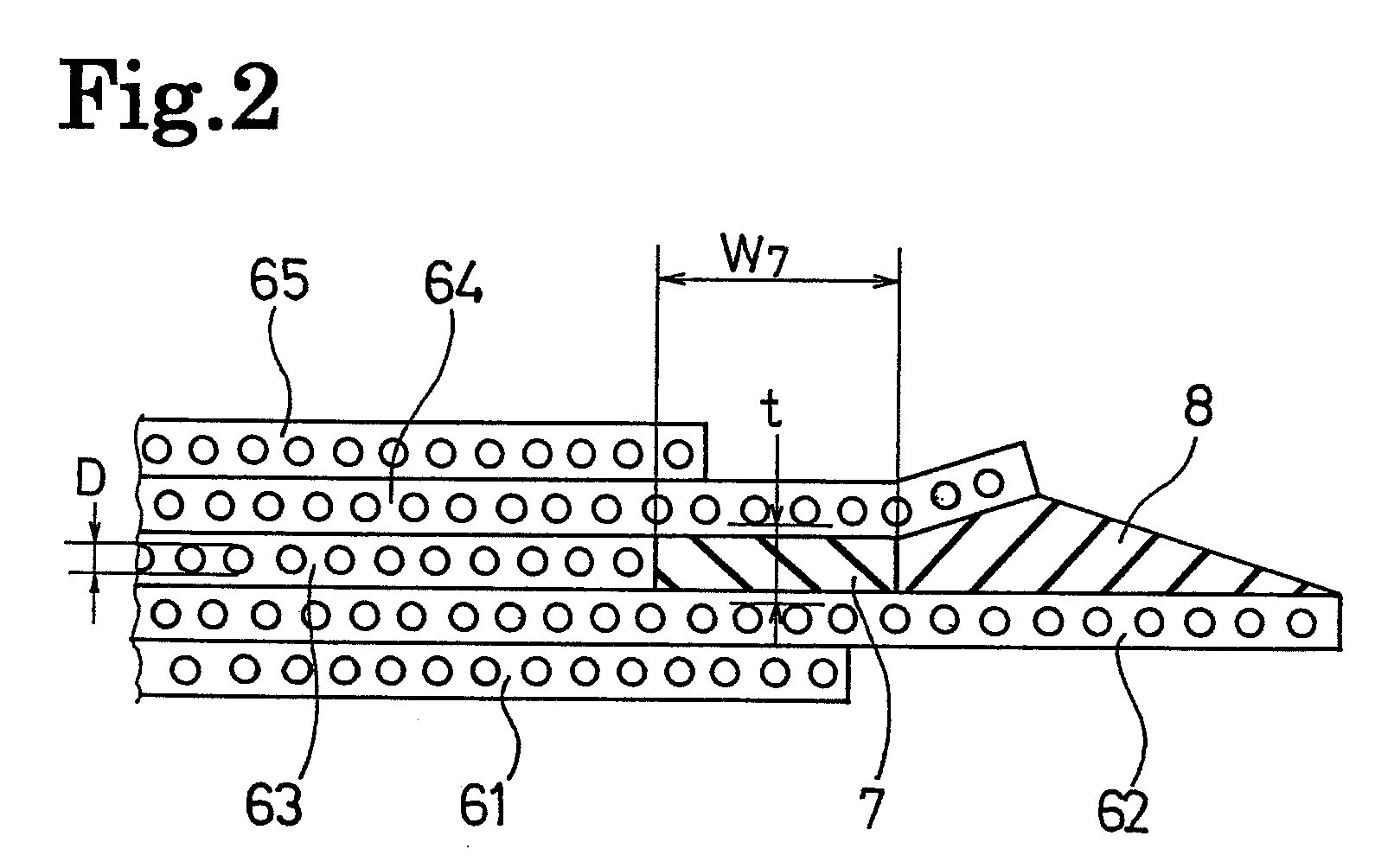

A tire 2 has a belt 14 and a hard rubber layer 16. The belt 14 has a first ply 26, a second ply 28, a third ply 30 and a fourth ply 32. A width W3 of the third ply 30 is smaller than a width W1 of the first ply 26 and a width W2 of the second ply 28, and 75% of a width of a tread. Each of the plies 26, 28, 30, 32 has a steel cord. The first ply 26 and the second ply 28 construct a cross-ply structure. A cord of the third ply 30 is wound spirally. The third ply 30 has what is referred to as a jointless structure. The hard rubber layer 16 is positioned between the first ply 26 and the second ply 28, and outward of the third ply 30 in an axial direction. A complex elastic modulus of the hard rubber layer 16 is equal to or greater than 30 MPa.

Owner:SUMITOMO RUBBER IND LTD

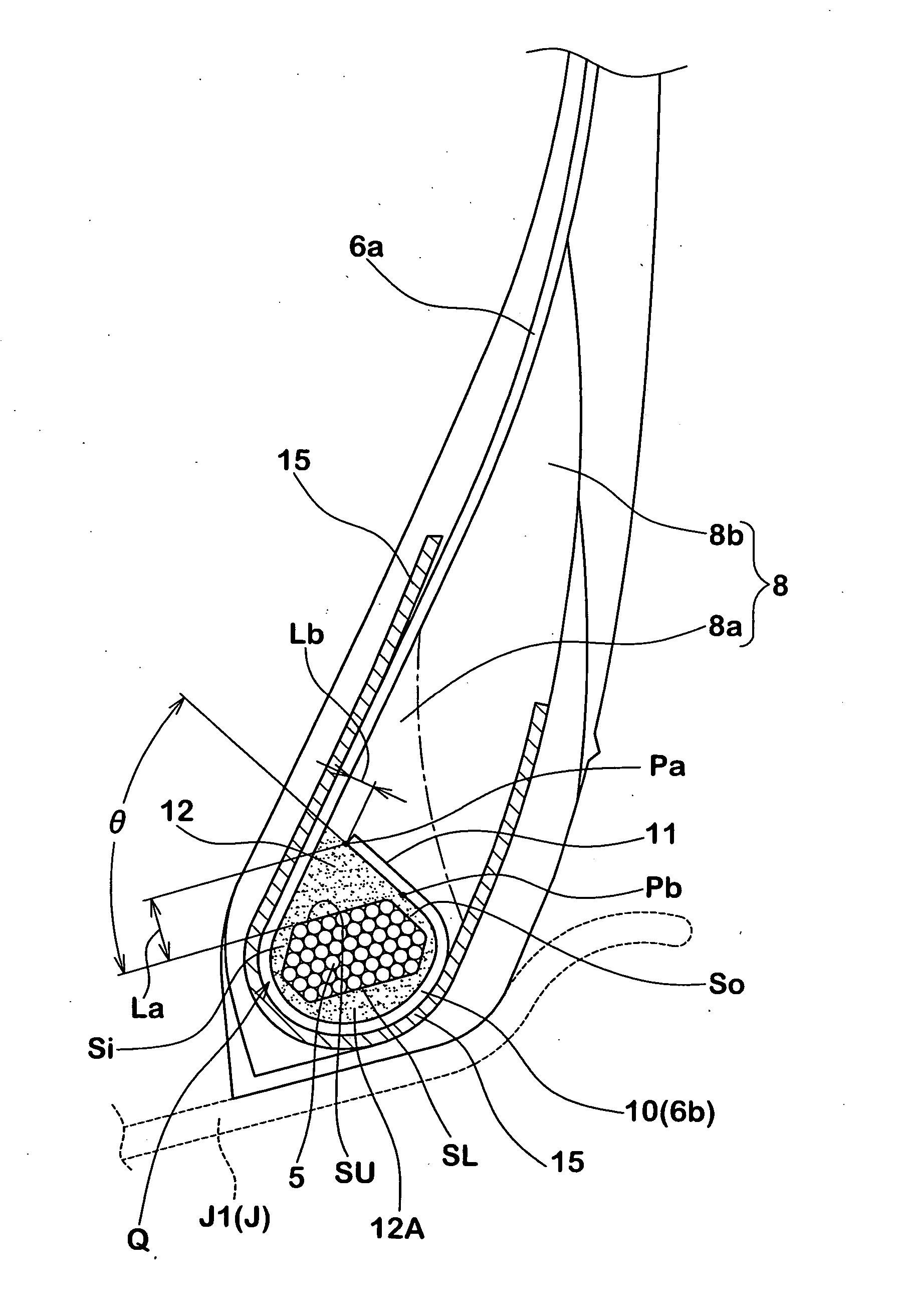

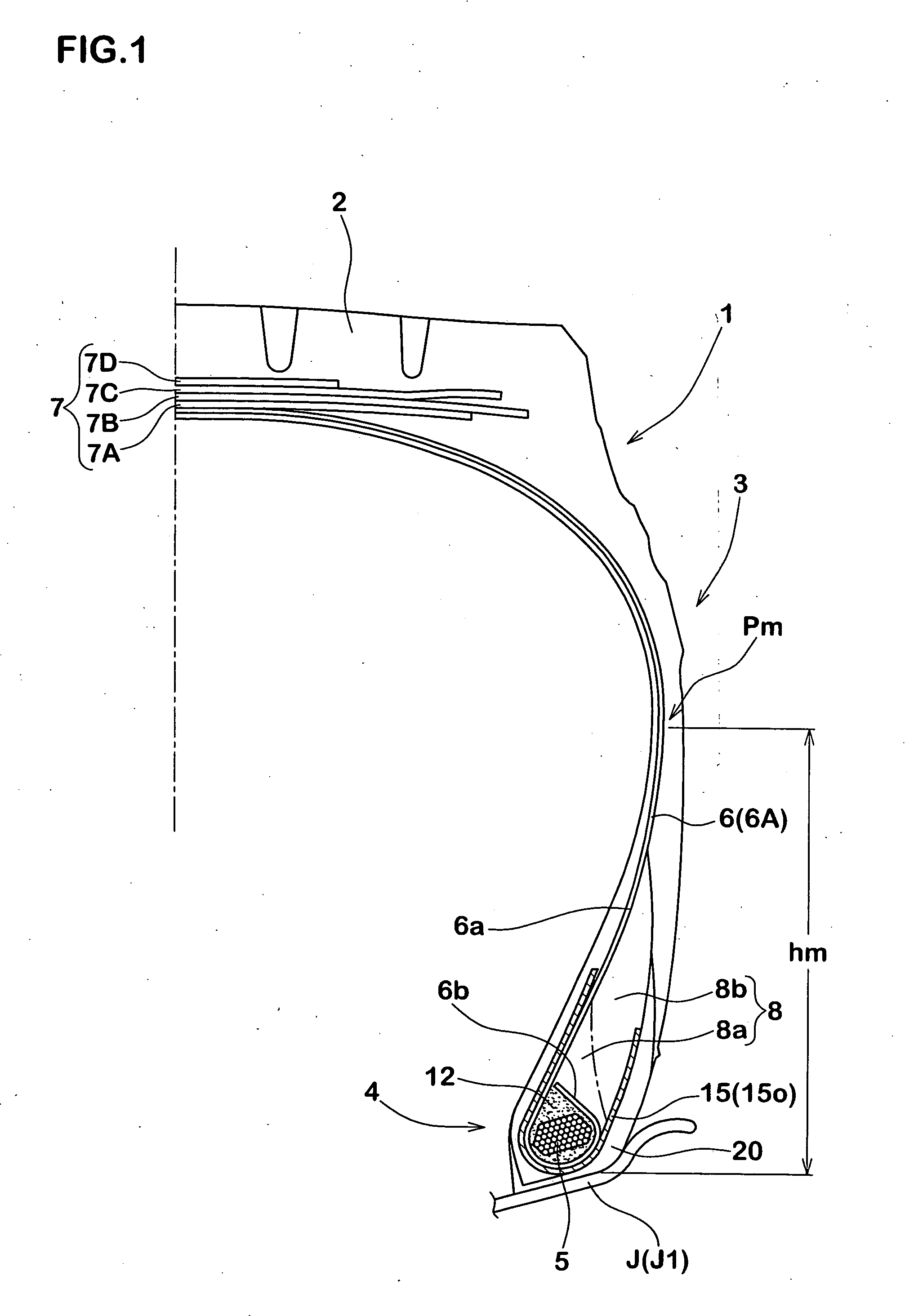

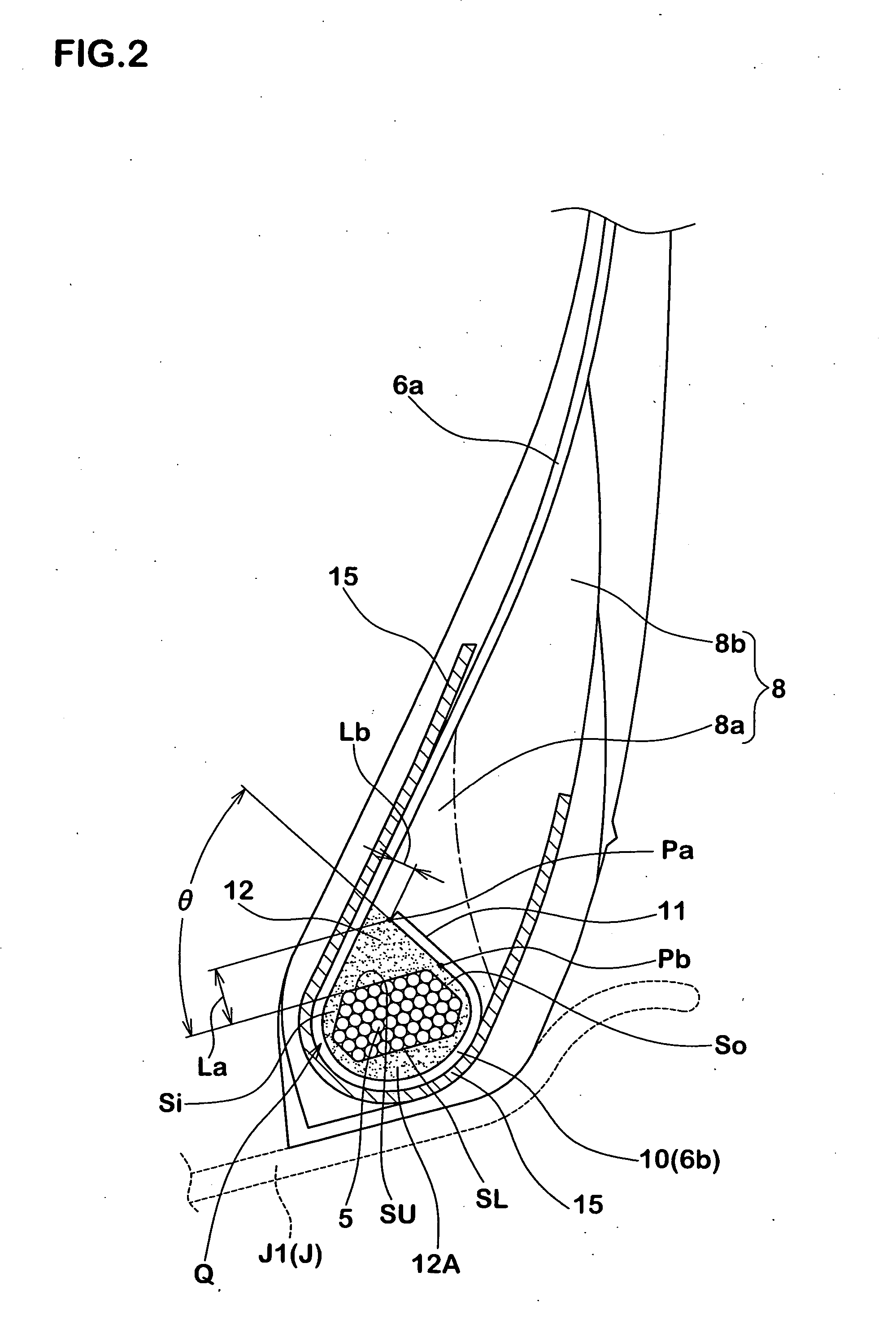

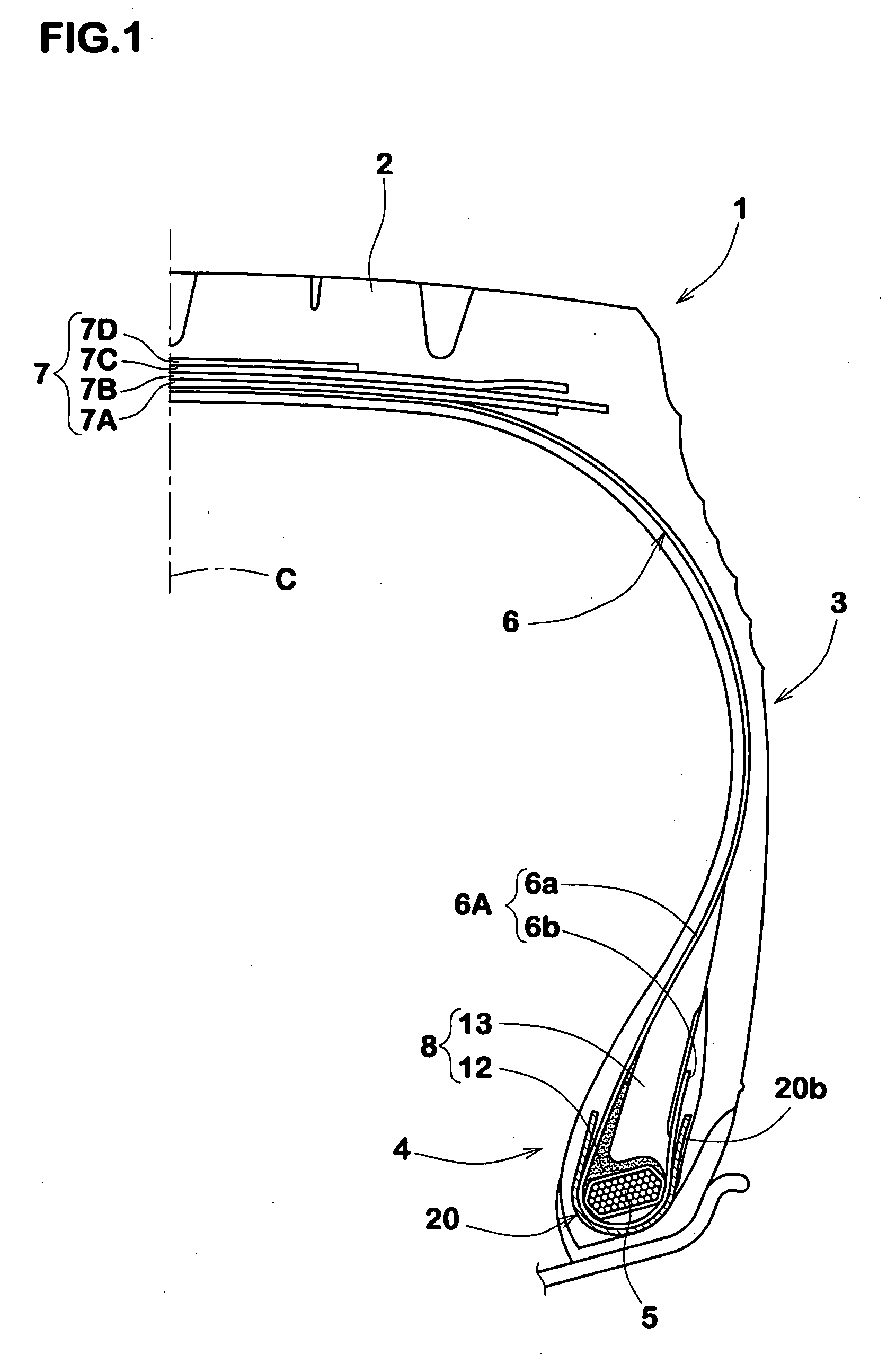

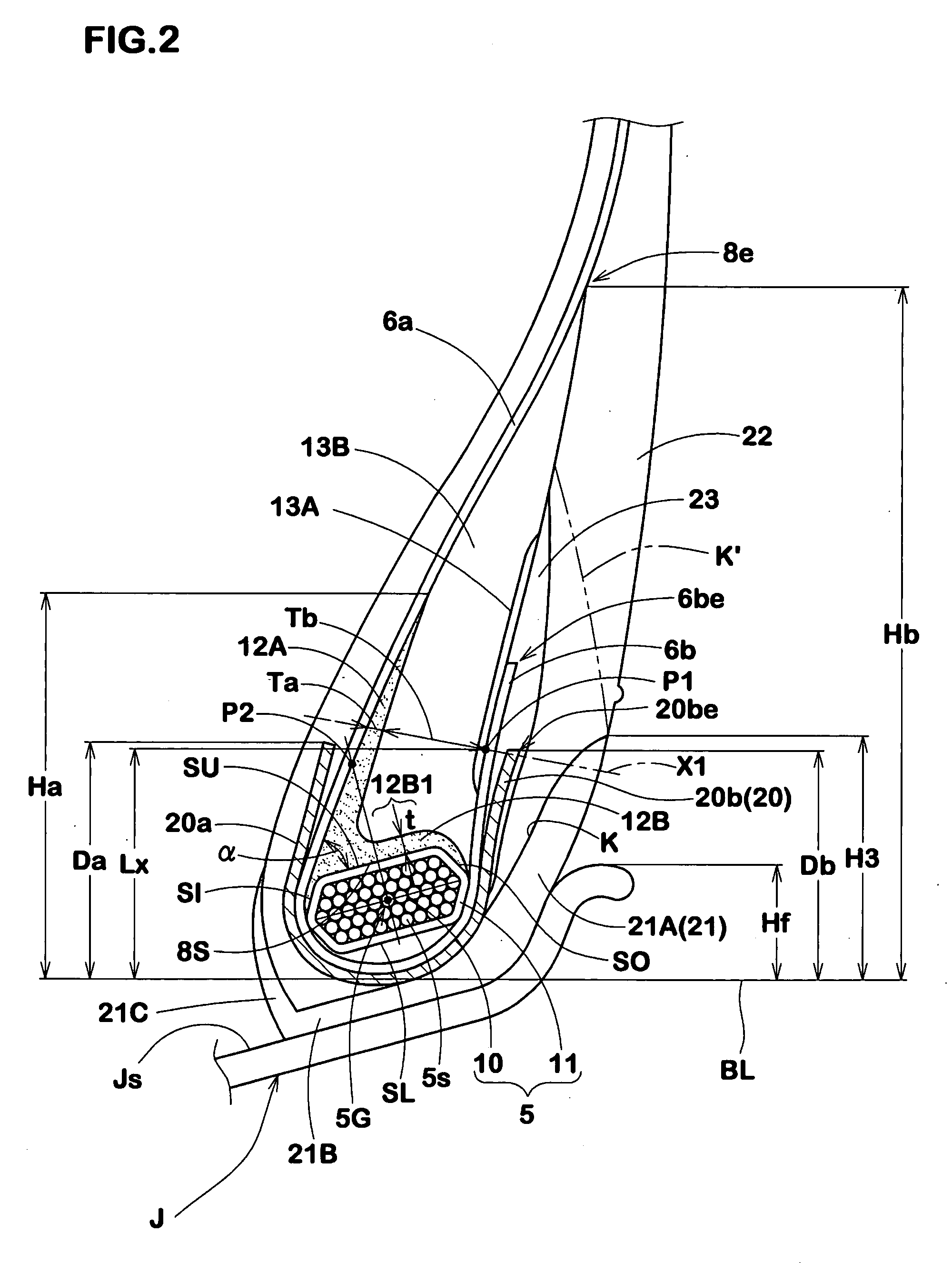

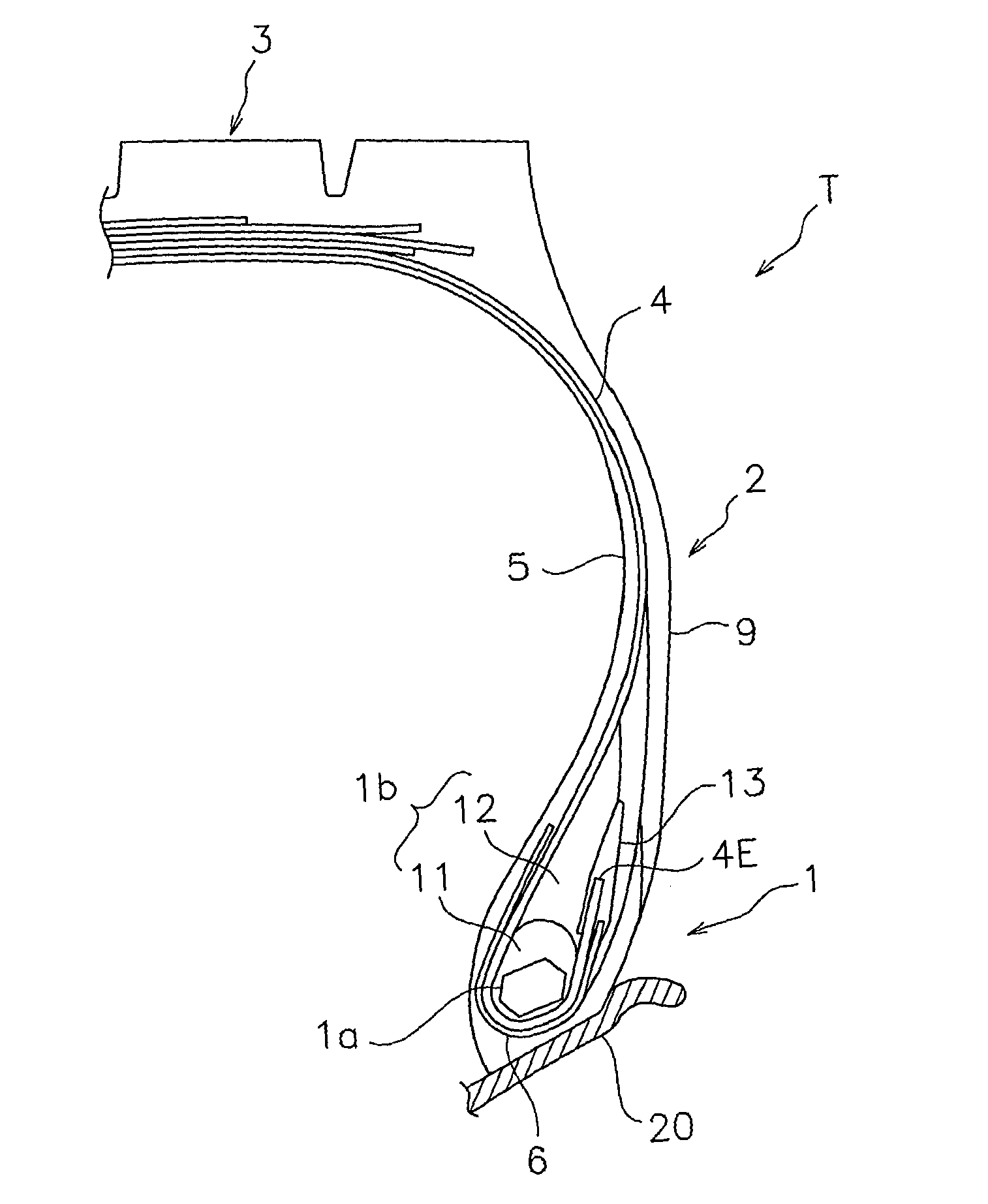

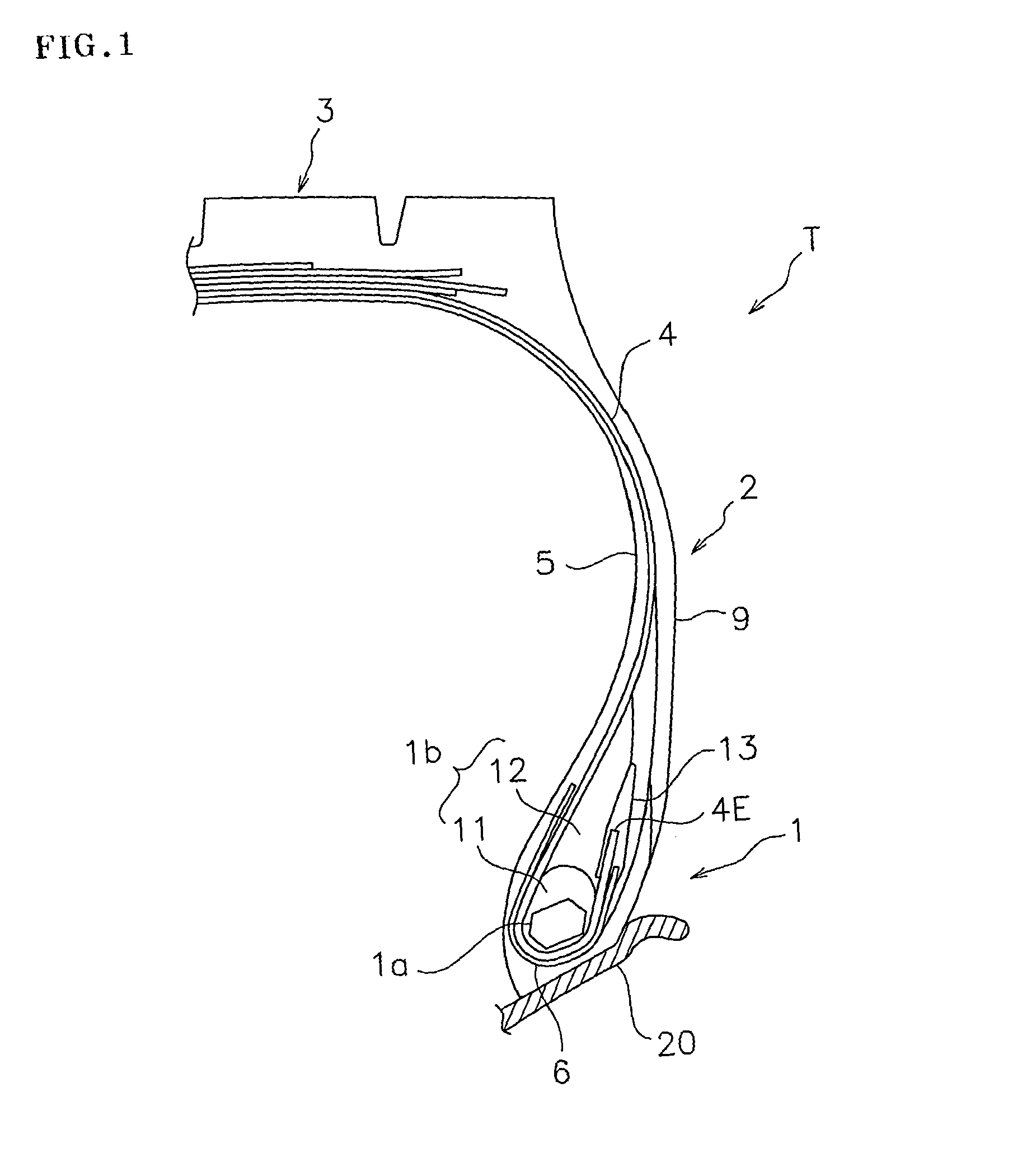

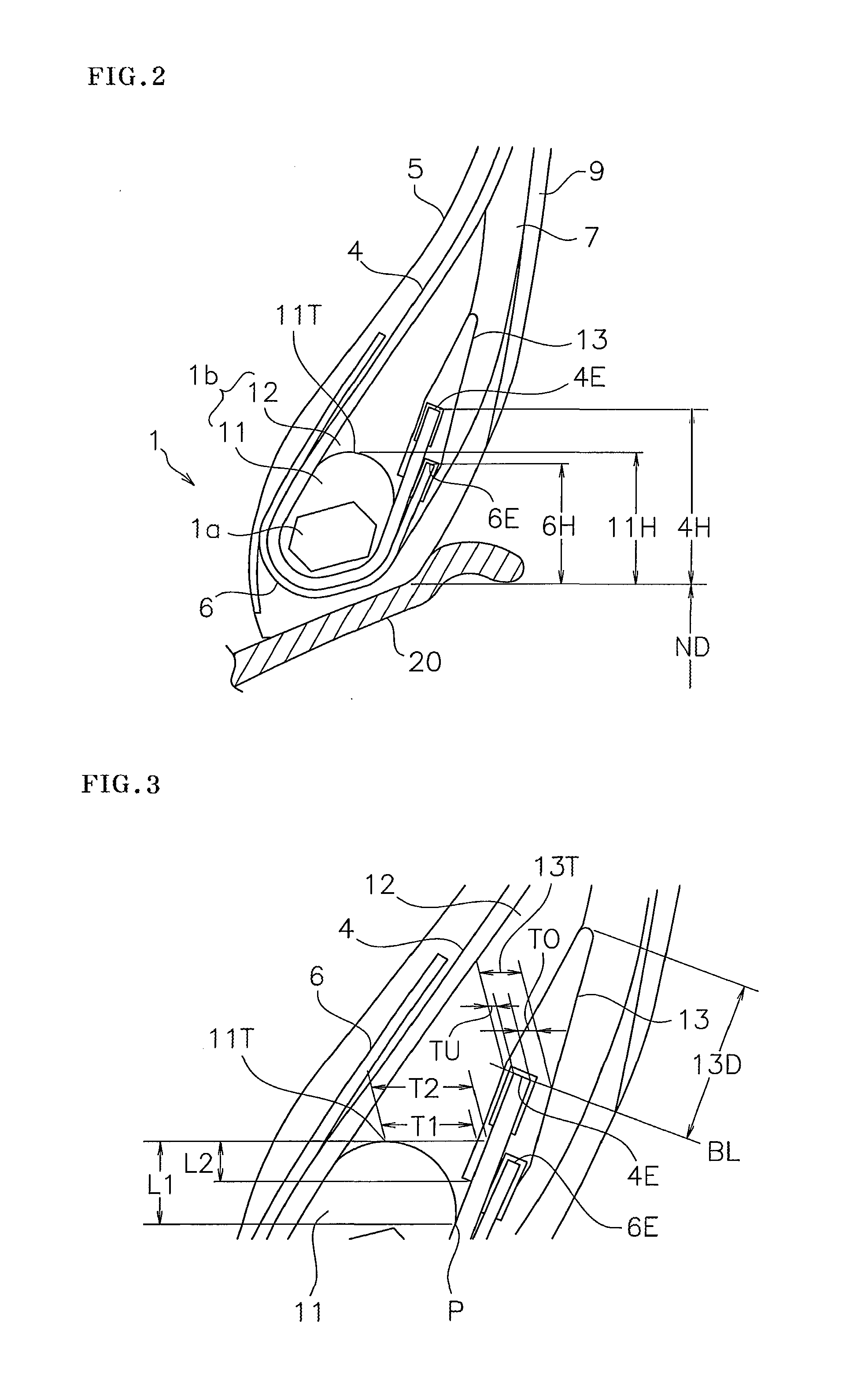

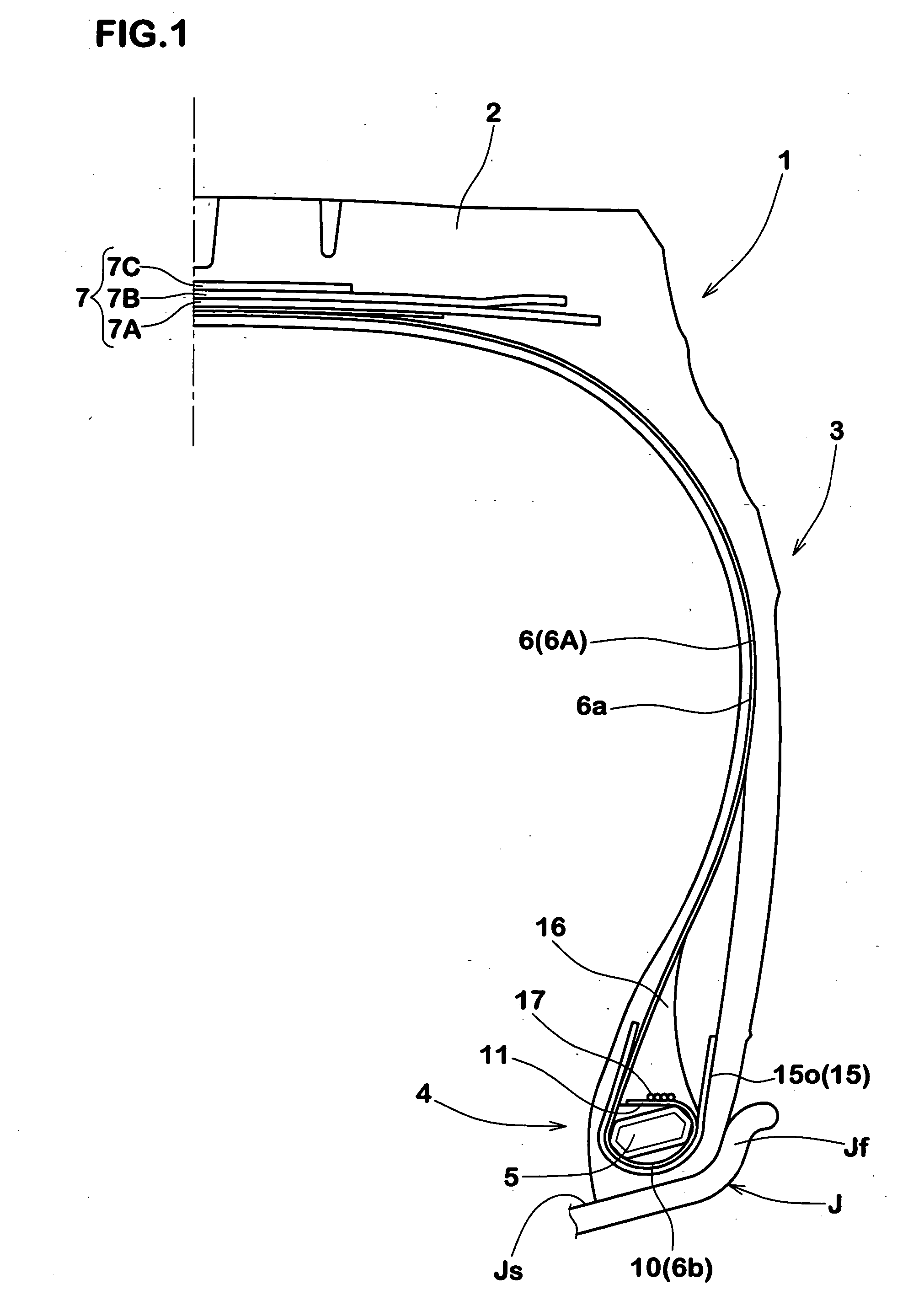

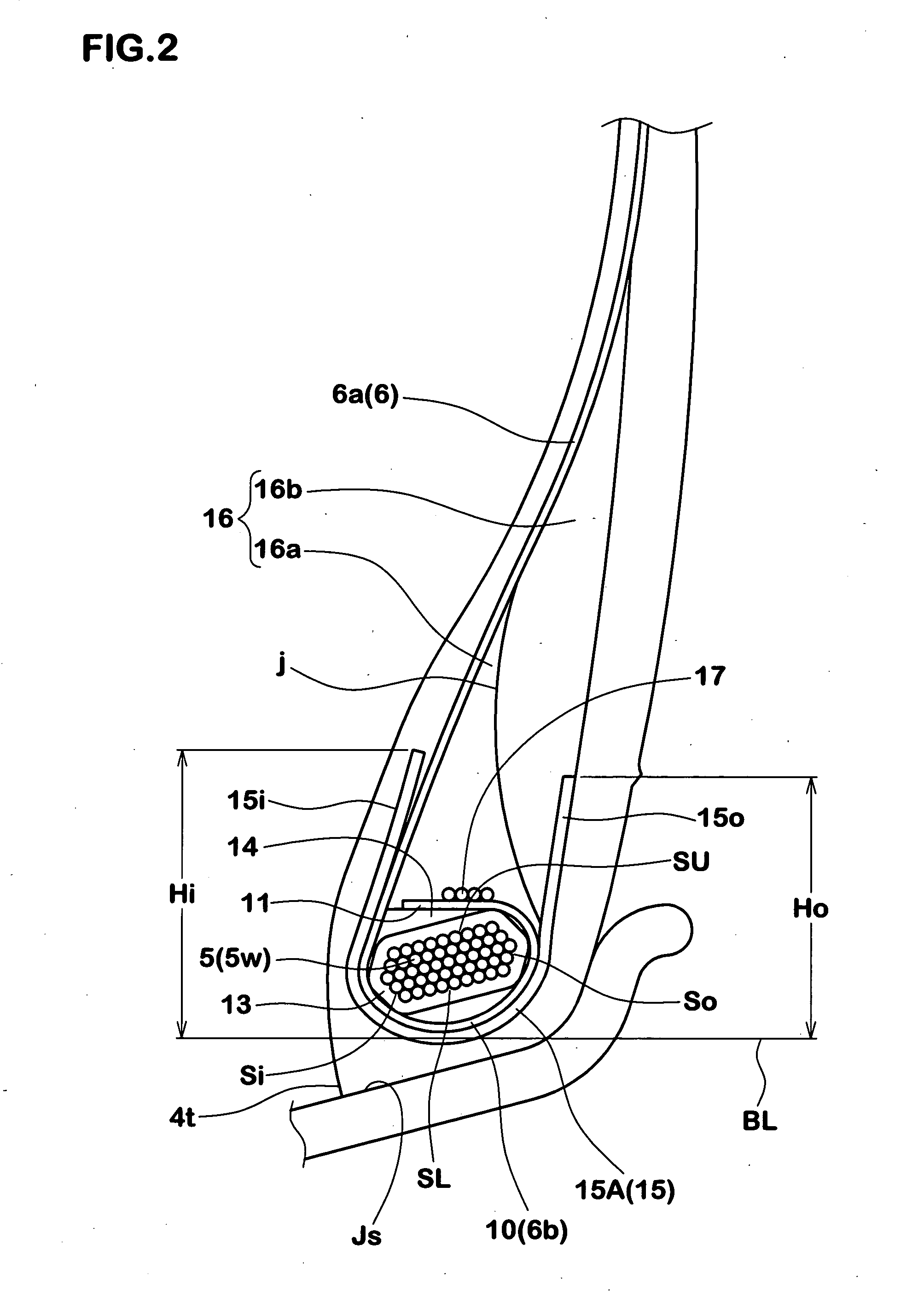

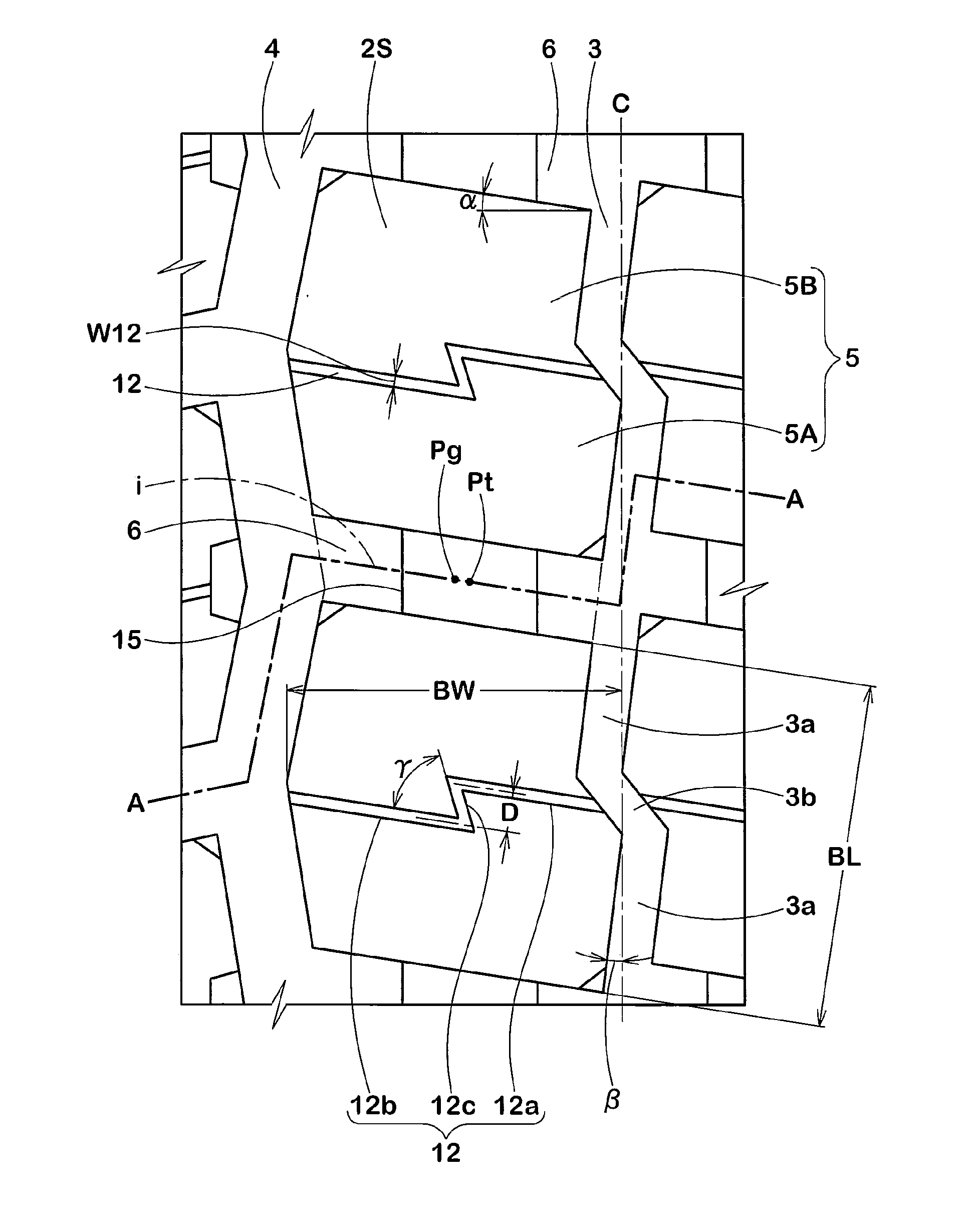

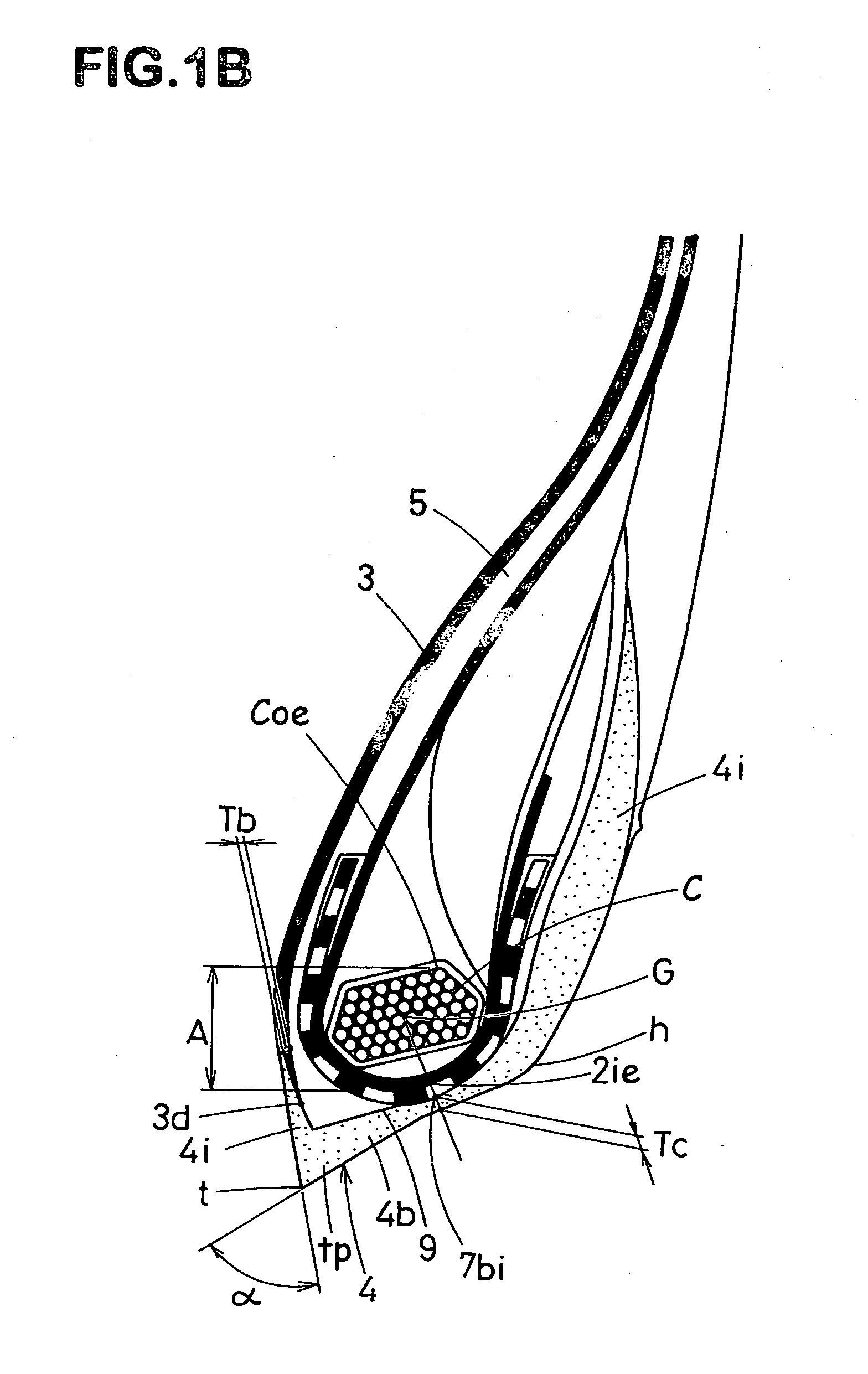

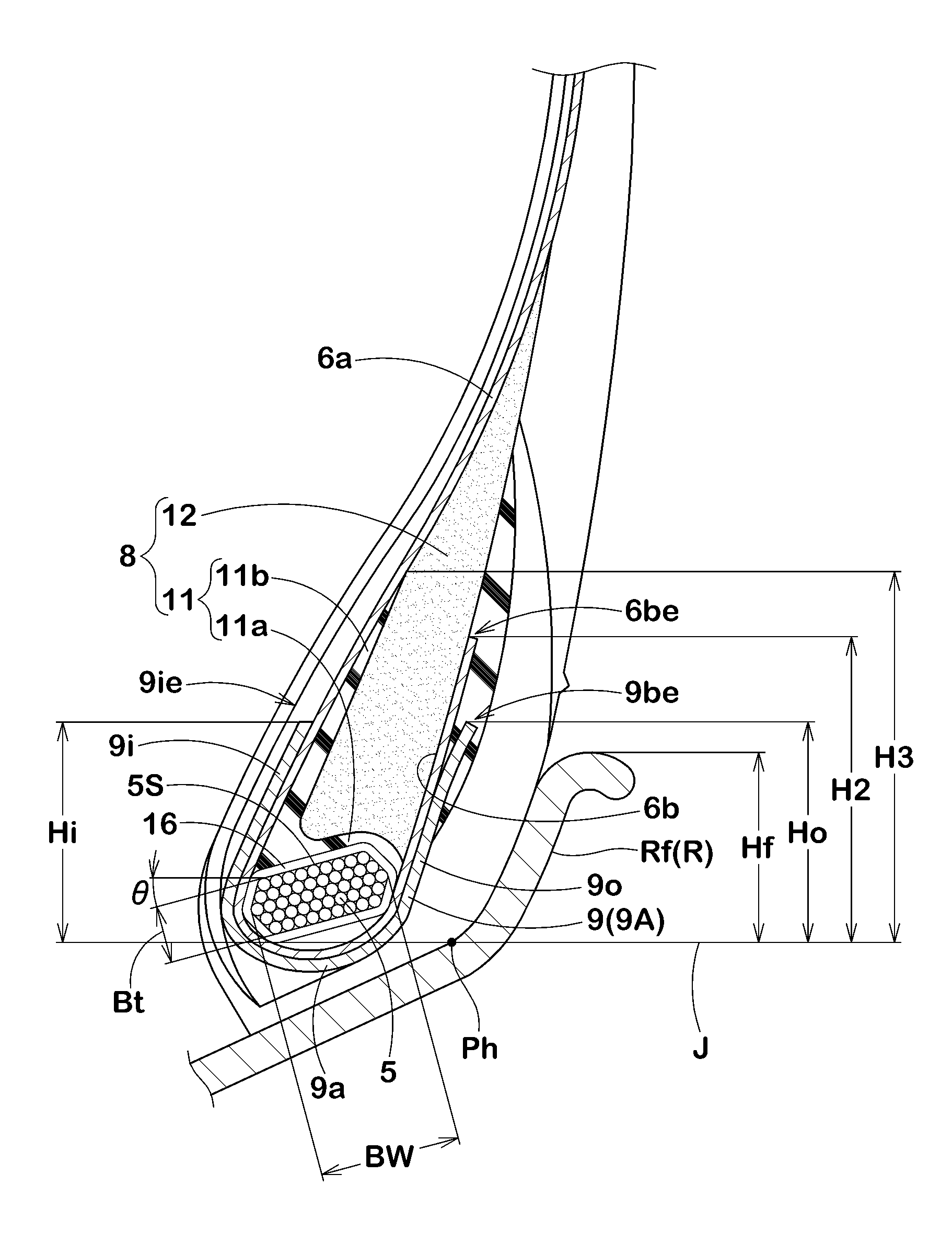

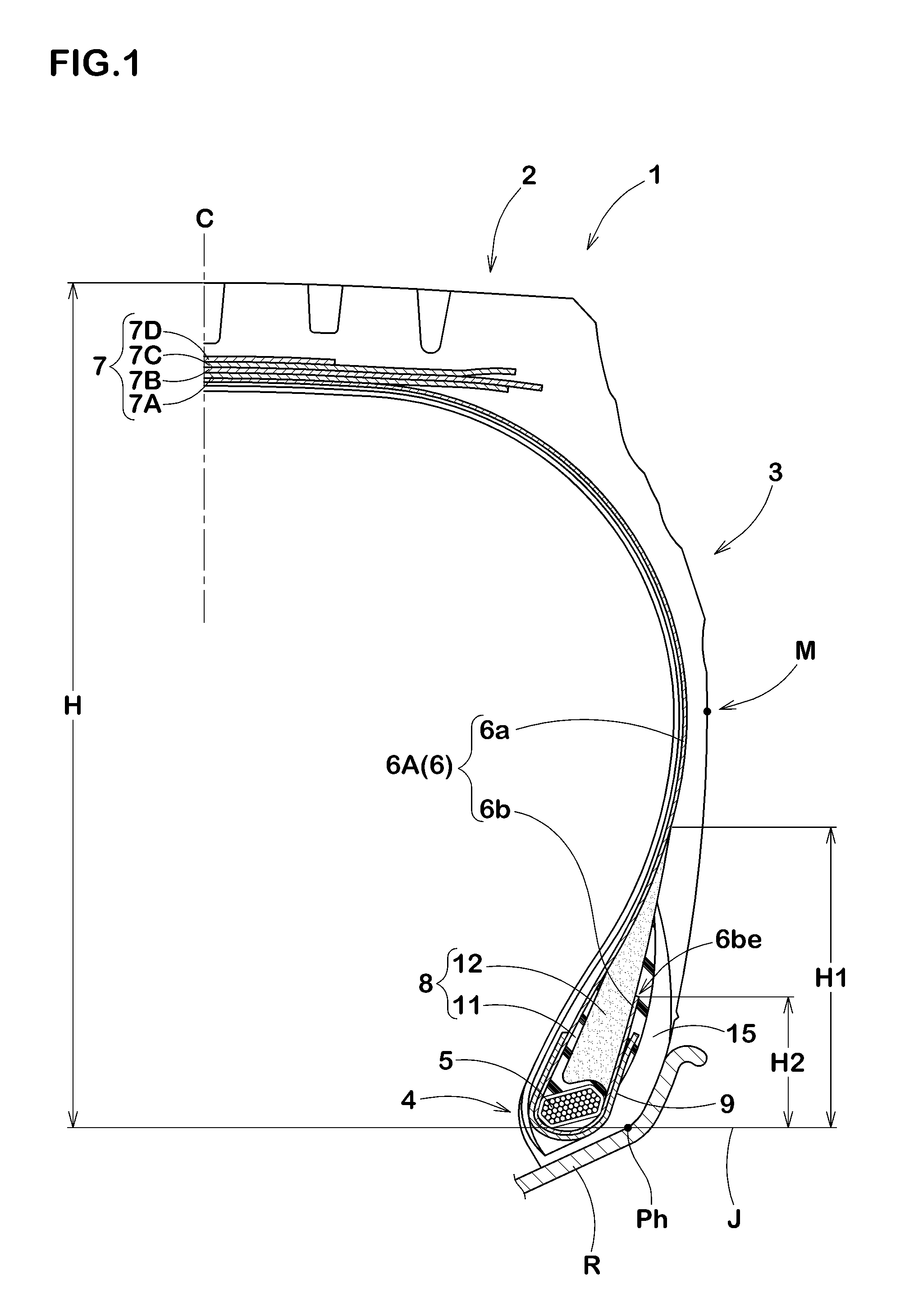

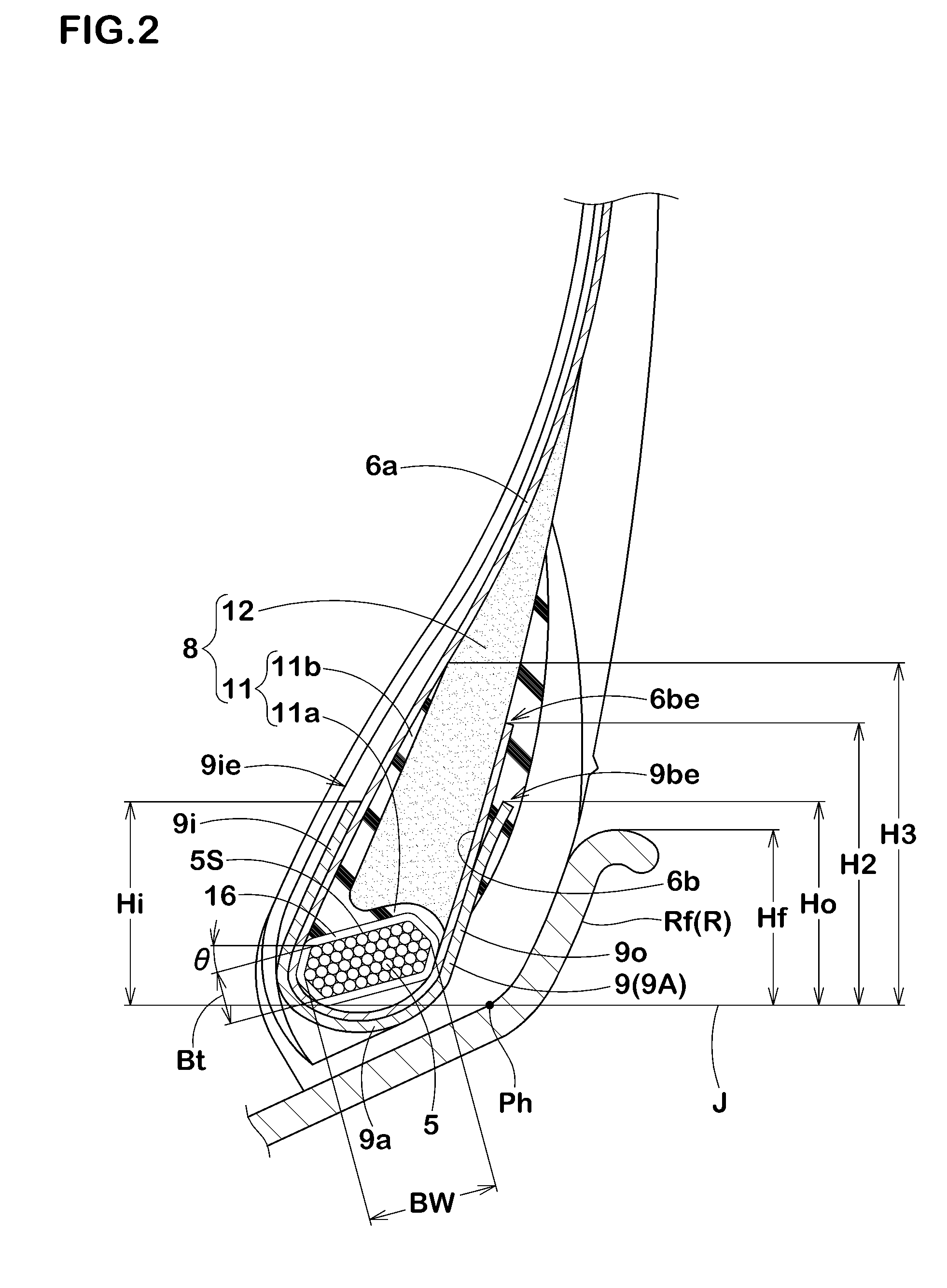

Heavy-load radial tire

InactiveUS20100224300A1Avoid deformationEffectively inhibit cord looseningHeavy duty tyresHeavy duty vehicleRadial tireHeavy load

A heavy-load radial tire includes a bead apex rubber 8 composed of a high-elastic lower apex portion 11 and a low-elastic upper apex portion 12. The lower apex portion 11 has an L-shaped cross section composed of a bottom piece portion 11a disposed along the radially outer surface of a bead core 5 and a standing piece portion 11b standing from the axially inner end of the bottom piece portion 11a and radially outwardly extending along a ply main portion 6a of a carcass 6. At an outer end position P1 of a ply turnup portion 6b, the upper apex portion 12 has a thickness T1s of 0.50 to 0.75 times a core width Bw of the bead core 5. At an outer end position P2 of an outer wound-up portion 9o of a bead reinforcing cord layer 9, the upper apex portion 12 has a thickness T2s of 0.57 to 0.90 times the core width Bw. The core width Bw is 0.68 to 0.80 times a bead bottom width BL. A distance W1 oriented in parallel to an outer surface 5S of the bead core 5 and ranging from a bead heal point Ph to an axially innermost end 5e of the bead core 5 is 0.92 to 1.08 times the bead bottom width BL.

Owner:SUMITOMO RUBBER IND LTD

Tire inflation system with discrete deflation circuit

ActiveCN103025546AMinimize pneumatic pressure lossHeavy duty tyresHeavy duty vehiclePneumatic circuitIncrease pressure

A vehicle tire inflation system includes an air supply source in fluid communication with multiple tires of the vehicle. A pneumatic conduit extends between and is in fluid communication with the air supply source and the tires. Means are fluidly connected to the pneumatic conduit for enabling selective inflation and deflation of the tires. The means include a first pneumatic circuit for inflation of the tires, and a second pneumatic circuit for deflation of the tires. The second pneumatic circuit is discrete from the first pneumatic circuit and is common to more than one of the tires. The means provides controlled deflation of the tires in the second pneumatic circuit based upon a predetermined condition, preventing deflation of the tires until the vehicle is parked, or limiting the deflation of the tires, which in turn enables the tire inflation system to accommodate a desirable increased pressure in the tires.

Owner:HENDRICKSON USA L L C

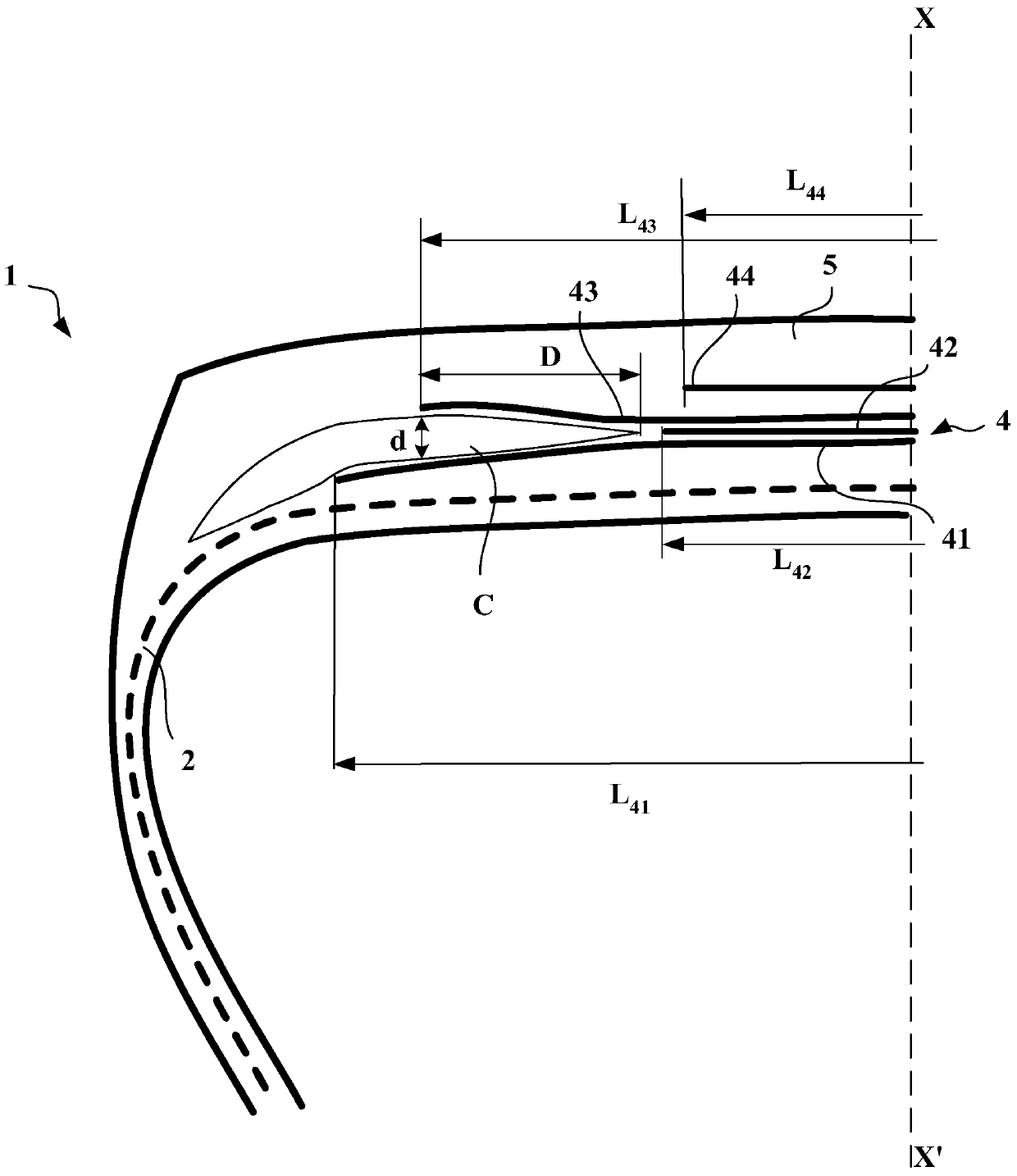

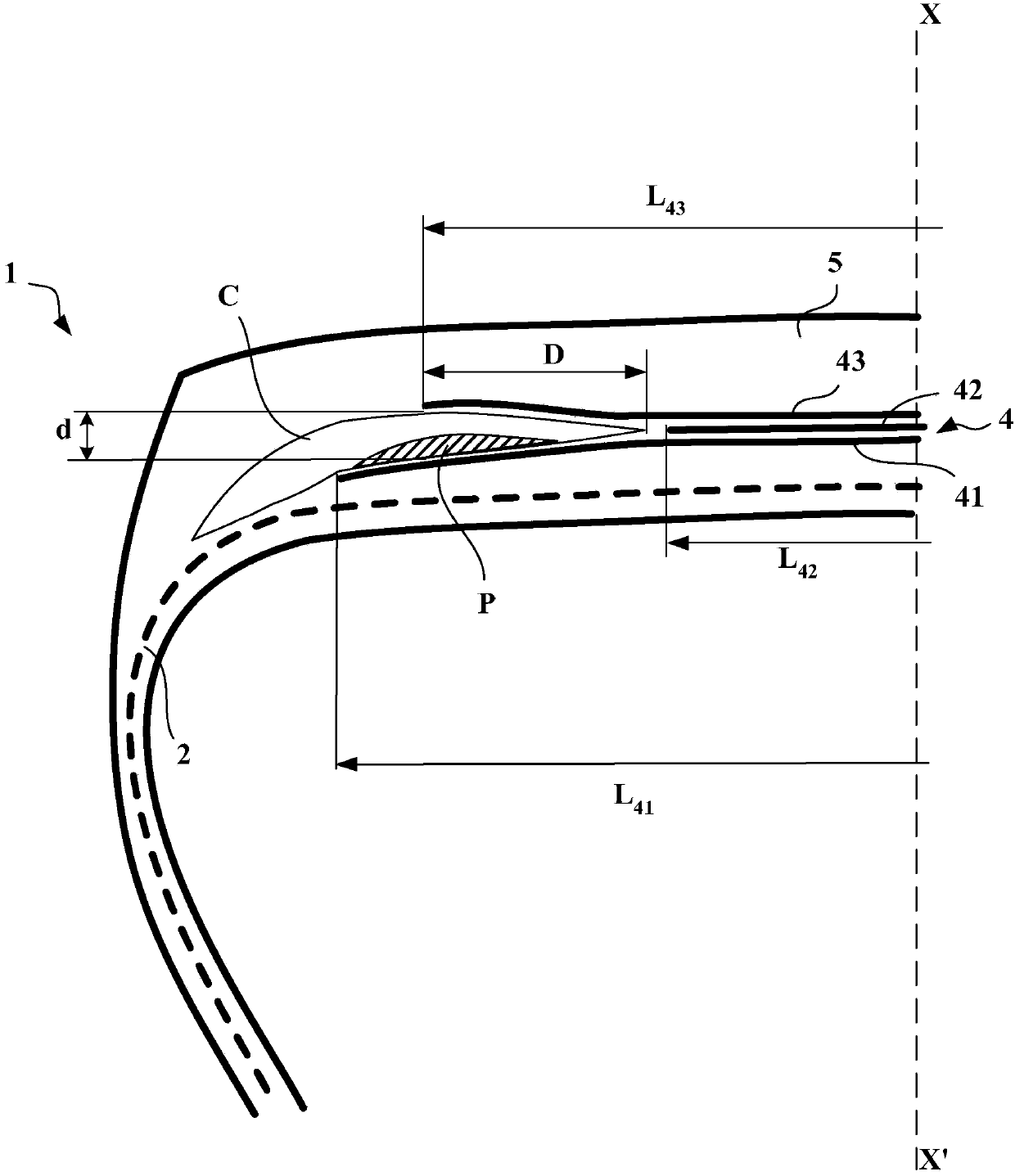

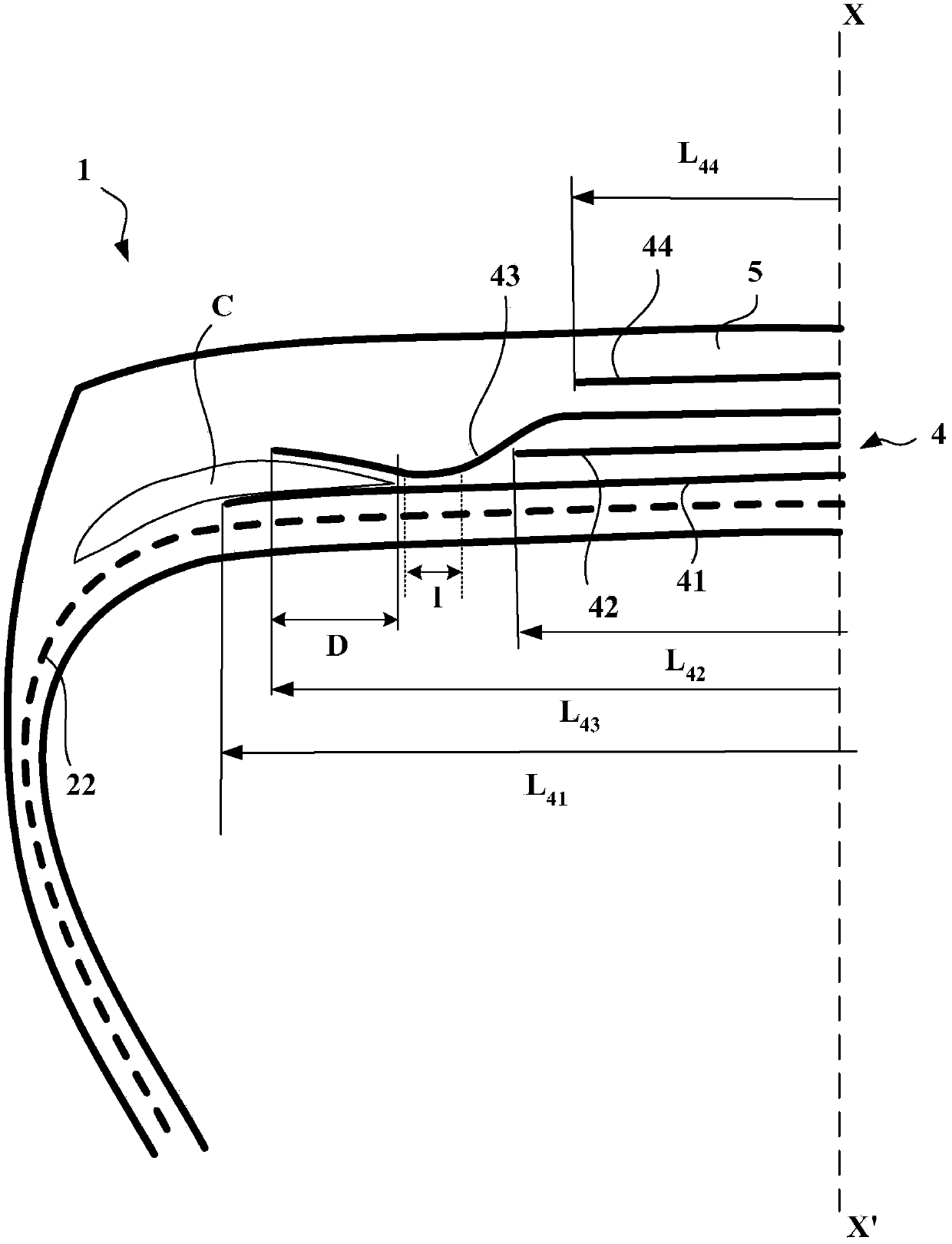

Tyre comprising a layer of circumferential reinforcing elements

ActiveCN103874588ALow modulus of elasticityHeavy duty tyresHeavy duty vehicleTensile strainEngineering

The invention relates to a tyre comprising a crown reinforcement formed of at least two working crown layers of reinforcing elements, a first layer C of rubber compound being positioned between at least the ends of said at least two working crown layers, and the crown reinforcement comprising at least one layer of metal circumferential reinforcing elements. According to the invention, the elastic modulus at 10% tensile strain of the first layer C is less than 8 MPa and the maximum value of tan(delta), denoted tan(delta) max, of the first layer C is less than 0.100.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com