Tire inflation system with discrete deflation circuit

一种充气系统、气动回路的技术,应用在轮胎测量、重型轮胎、轮胎零部件等方向,能够解决不能够响应轮胎压力、降低轮胎性能、降低轮胎寿命等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

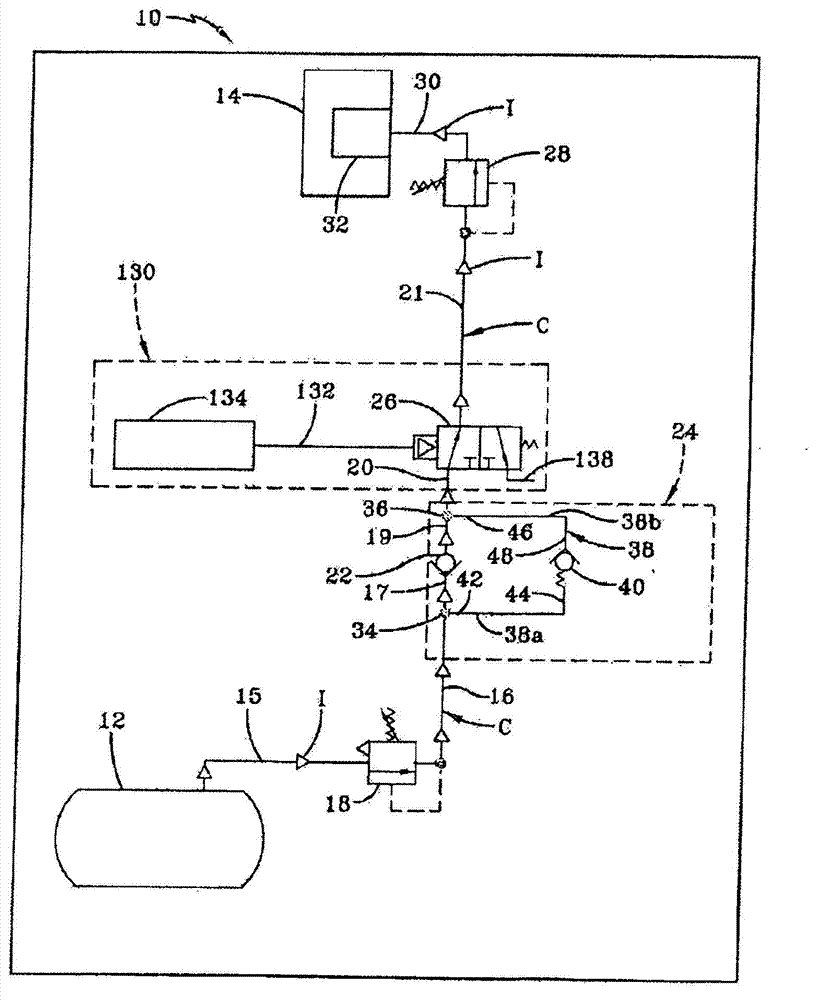

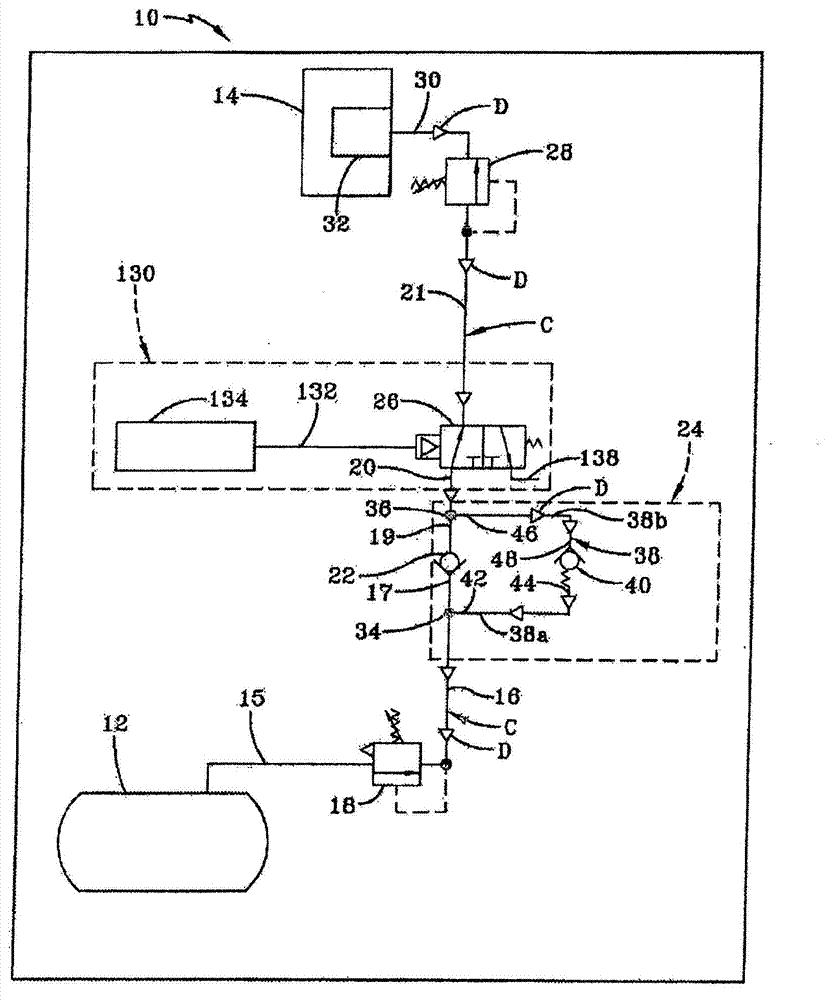

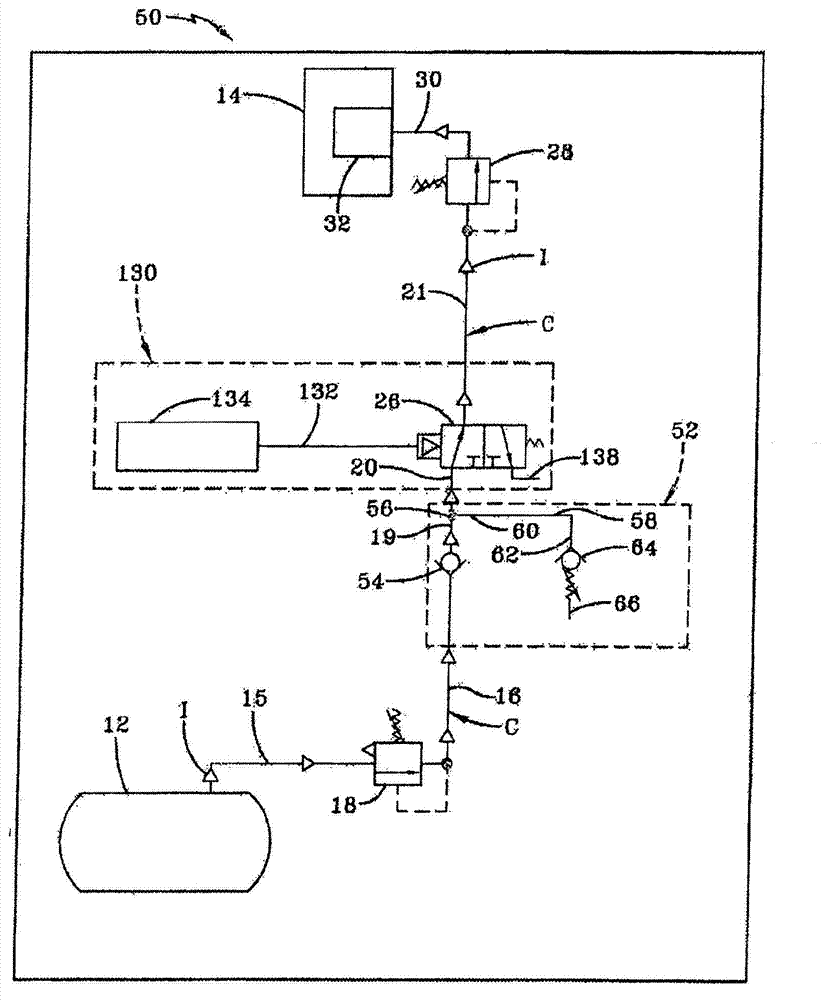

[0043] The present invention relates to a tire inflation system comprising a deflation circuit separate or separate from an inflation circuit. A separate deflation circuit is capable of controlling deflation of the tire according to specific predetermined conditions, which will be described in the exemplary embodiment of the present invention. Use these specific predetermined conditions to prevent the deflation of the tires until the vehicle is stopped, or to limit the amount of deflation of the tires, thereby preventing the tire pressure from dropping below a minimum predetermined pressure, such as set by NHTSA and / or the tire manufacturer for a specific vehicle The minimum recommended pressure for the load. It should be understood that the term target pressure referred to hereinafter refers to a desired target inflation pressure selected by the vehicle operator based on the cold inflation pressure or cold pressure of the vehicle tires.

[0044] now go to Figure 1A , a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com