Novel intelligent crust breaking cylinder

A cracking cylinder, intelligent technology, applied in the field of cracking cylinder and its control air circuit, can solve the problems of cylinder leakage, unable to detect whether the working process is over, increase the driving load quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

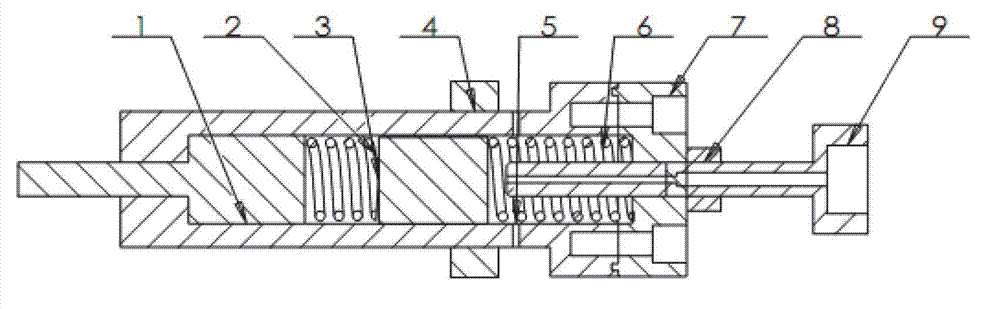

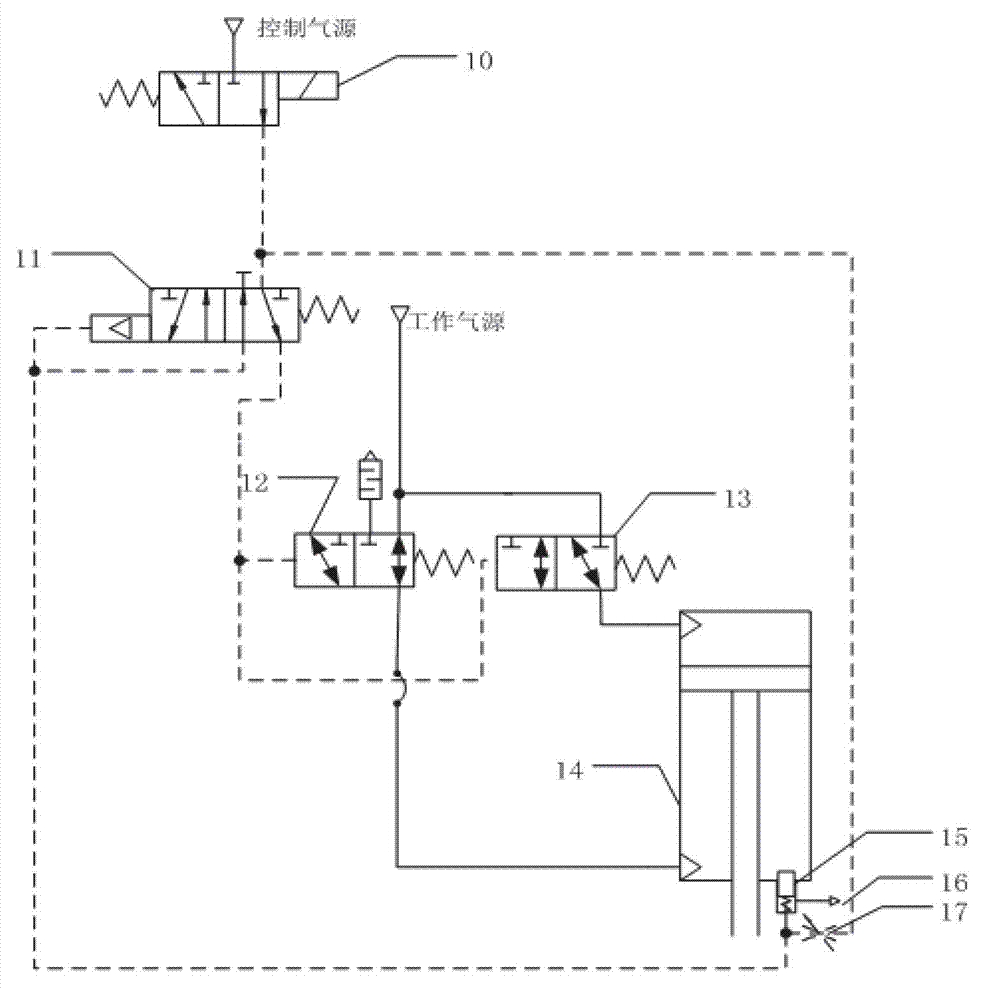

[0017] When the solenoid valve (10) at the control end is opened, the control air source drives the two-position three-way single air control valve (12, 13) to reversing through the two-position five-way single-air control valve (11), so that the working air source will flow into The cylinder performs shelling work; at the same time, the control gas source gas flows into the mechanical position detection device (15) through the throttle valve (17) and the air inlet (9), and is discharged through the exhaust port (16). The control port of the valve (11) is connected to the downstream interface of the throttle valve (13). Due to the damping effect of the throttle valve (13), the gas pressure drops sharply, which is not enough to drive the two-position five-way valve for reversing, so that the opening The working process of the shell cylinder is successfully completed. When the piston moves to the bottom of the front end cover, the cylinder piston will push the spool (1) of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com