Patents

Literature

2429 results about "Aluminum electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum electrolysis inert anode

InactiveCN103757661AAvoid consumptionWith energy saving and emission reductionElectrolysisHigh entropy alloys

The invention provides an aluminum electrolysis inert anode of which the material is a high-entropy alloy. The high-entropy alloy contains 5-10 alloy elements of which the mole ratio can be identical or different; and the atomic percent of each main element is 5-35%. The high-entropy alloy inert anode has the characteristics of favorable high-temperature oxidation resistance, high aluminum electrolysis salt corrosion resistance, high electric conductivity and the like. The high-entropy alloy prepared by the smelting method has the advantages of simple technique and low cost, and is easy for connection. When being used for aluminum electrolysis, the high-entropy alloy can avoid the consumption of the carbon anode and the emission of the CO2 gas, and has the advantages of energy saving and emission reduction.

Owner:FUJIAN UNIV OF TECH

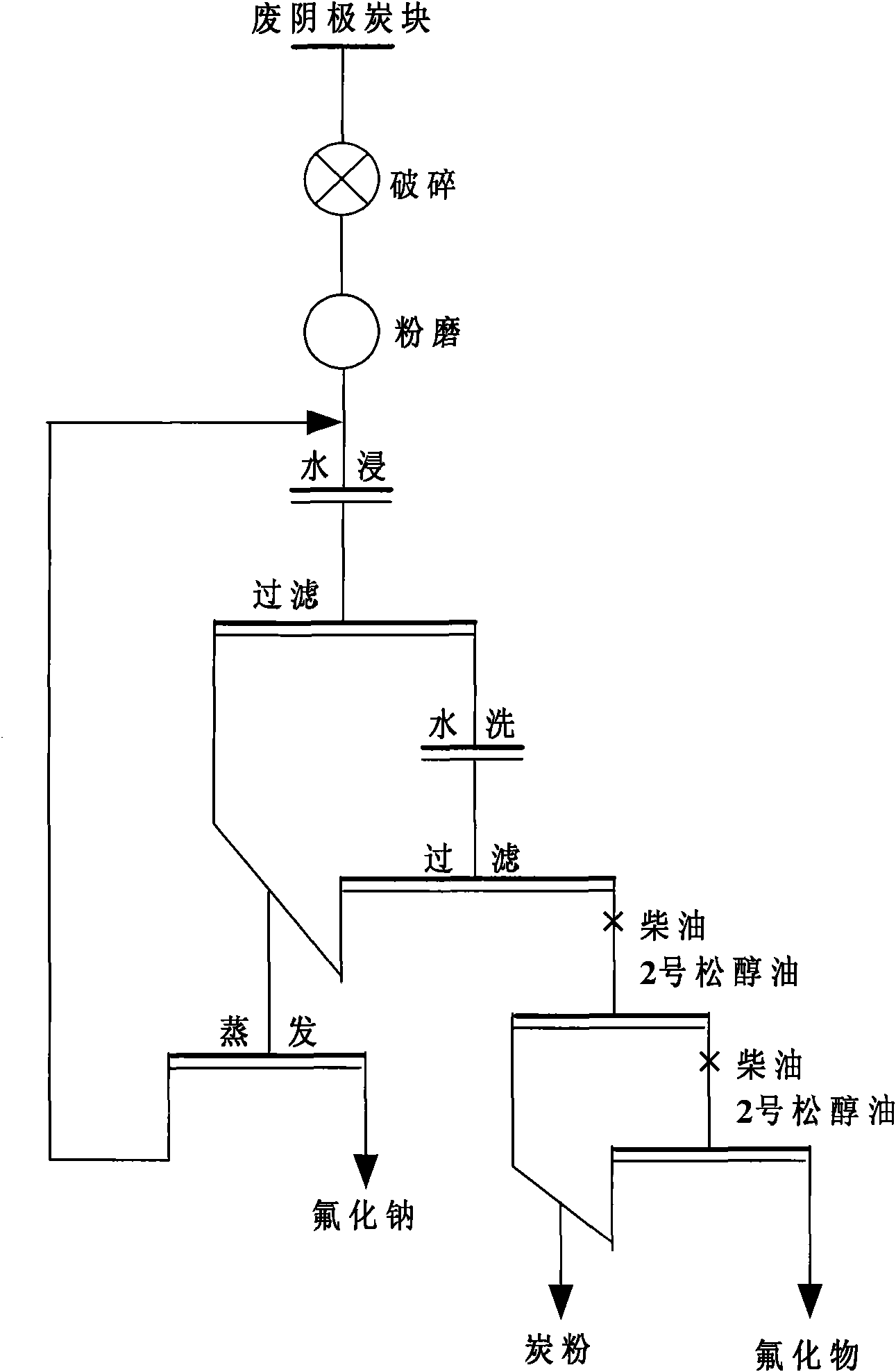

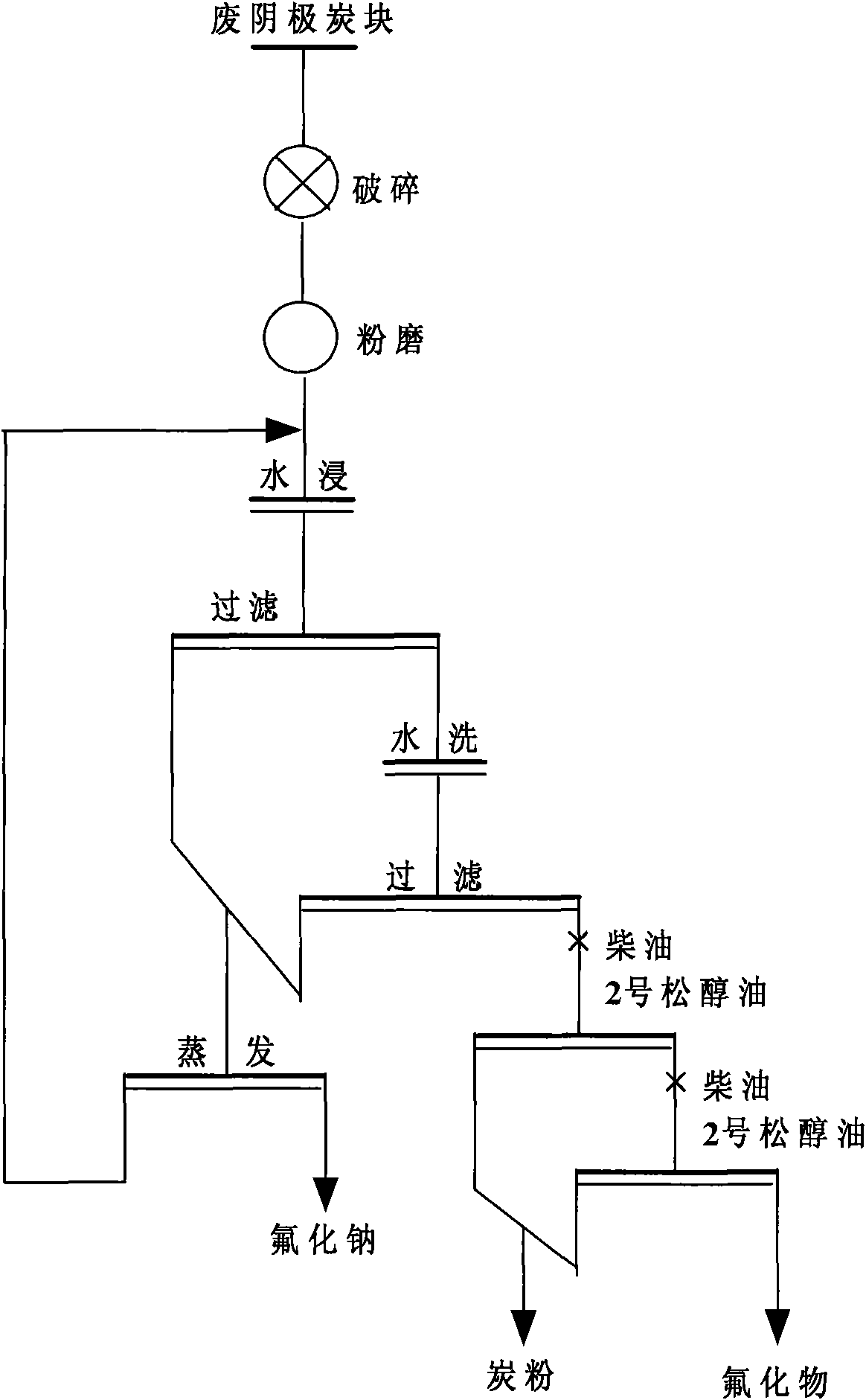

Method for recovering carbon from waste cathode carbon blocks of electrolytic aluminum

The invention discloses a method for recovering carbon from waste cathode carbon blocks of electrolytic aluminum. The method mainly comprises the following steps of: crushing, grinding, leaching in water, floating, and the like. The method has the advantages that the carbon content of recovered powdered carbon reaches higher than 70 percent, and the carbon recovery rate reaches higher than 98 percent, thus the recovered powdered carbon can be used for preparing carbon materials for aluminum electrolysis, aluminum oxide desulfurizing agents, and the like; and the method has simple process, low production cost, no secondary pollution, stable and reliable product quality and high yield, can realize continuous scale production and is beneficial to environmental protection.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for treating aluminum electrolysis waste cathode carbon block using acid and alkali combination method

A method for treating aluminum electrolytic waste cathode carbon blocks by an acid and alkali combination method is characterized by comprising the following steps: (1) aluminum electrolytic waste cathode is added to concentrated basic solution for reaction; a filtered solid phase is obtained by filtering and is added to concentrated acid for reaction; and carbon powder is obtained after filtration; (2) filtrates are mixed and dropwise added with the concentrated basic solution, the pH value thereof is adjusted to 9, the obtained mixture is kept standing and filtered to obtain cryolite; (3) the filtrate is added with saturated bleach solution, kept standing and filtered to obtain calcium fluoride; (4) the fourth filtrates is heated, evaporated and crystallized to obtain sodium chloride solid. With the purposes of waste utilization and environmental protection, the method successfully provides the process for treating aluminum electrolytic waste cathode by the acid and alkali method, which causes the waste cathode to not be the conventional waste and pollutant and to become artificial mineral resources. The method solves the problem of waste utilization in aluminum electrolysis industry, improves benefit, and improves the comprehensive level of the aluminum electrolysis industry of China.

Owner:NORTHEASTERN UNIV +1

High-temperature disposal method for spent cathodes of electrolytic aluminum

InactiveCN105642649ARealize harmless disposalImplement resourcesSolid waste disposalTransportation and packagingElectricityCyanide

The invention provides a high-temperature disposal method for spent cathodes of electrolytic aluminum. The method comprises the following steps: spent cathode carbon blocks of electrolytic aluminum are crushed into particles of 3-15 mm; then roasting is carried out by using a super high temperature furnace, fluorides in the spent cathode carbon blocks are volatilized, cyanides in the spent cathode carbon blocks are decomposed, flue gas generated during roasting is absorbed through a water spray absorption mode; then, processes such as filtering, drying and the like are carried out, the fluorides and the like are reused in aluminum electrolysis; and a cathode carbon material is discharged out of the super high temperature furnace after the material is cooled. According to the physical and chemical properties of the fluorides, the cyanides and carbon in the spent cathodes of electrolytic aluminum, the fluorides in the spent cathode carbon blocks are volatilized, the cyanides in the spent cathode carbon blocks are decomposed with the high-temperature method; however, on the condition of primary vacuum, carbon in the cathodes cannot burn, so that effective separation of carbon, the fluorides and the cyanides in the cathodes is achieved, and hazard-free disposal and resource utilization of the spent cathodes of electrolytic aluminum are achieved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

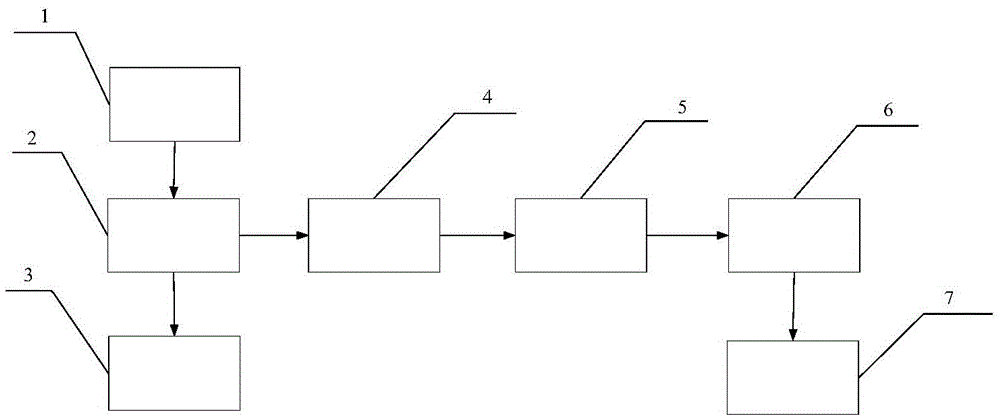

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

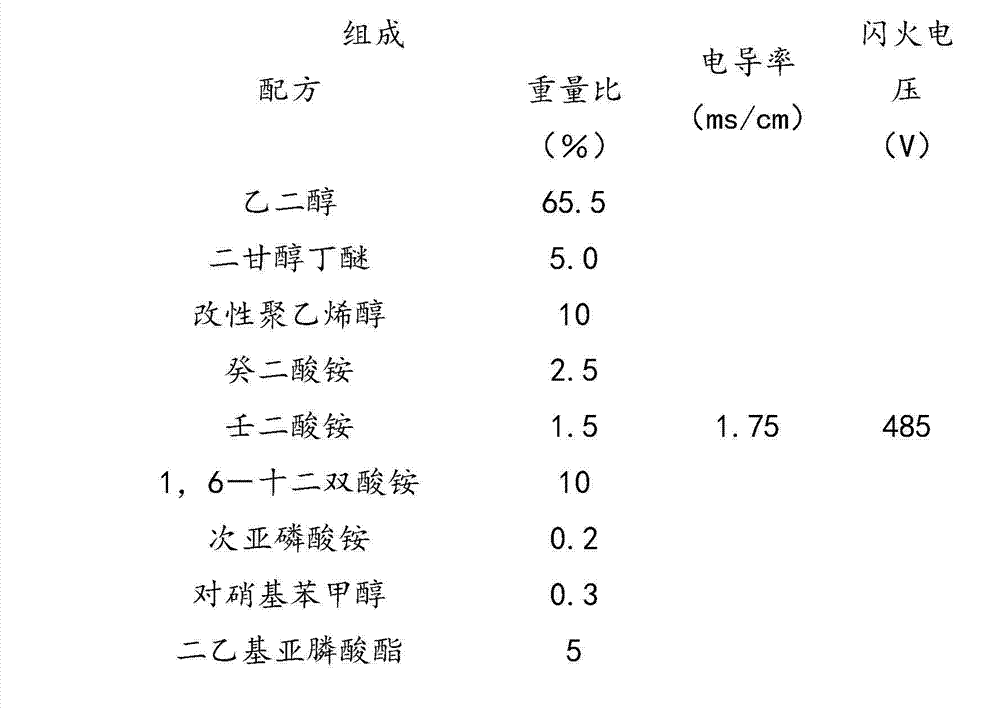

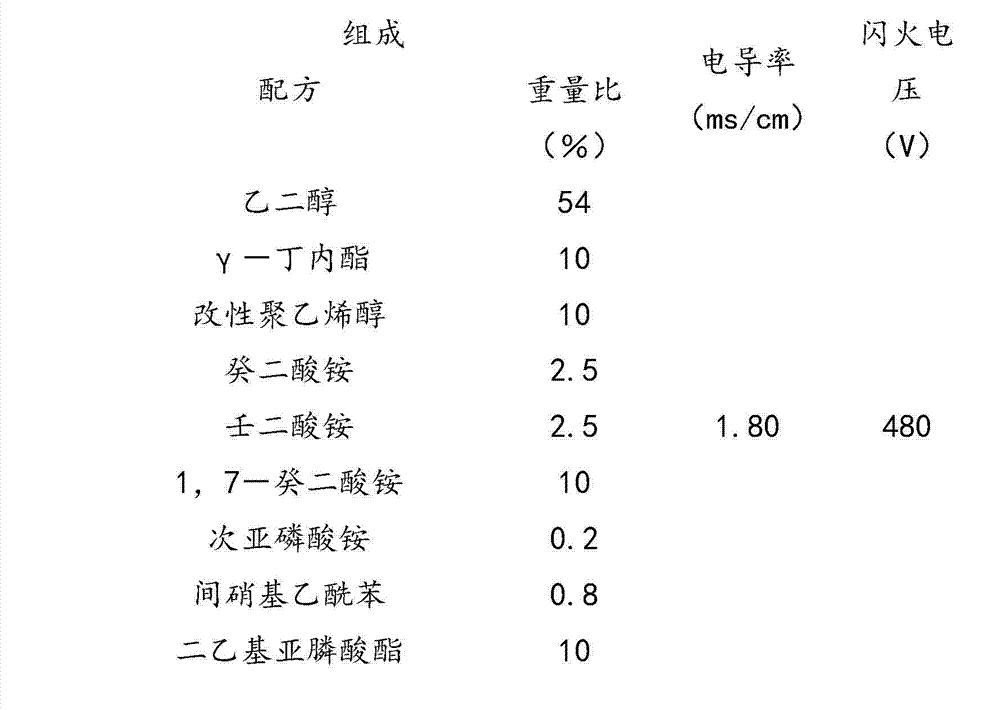

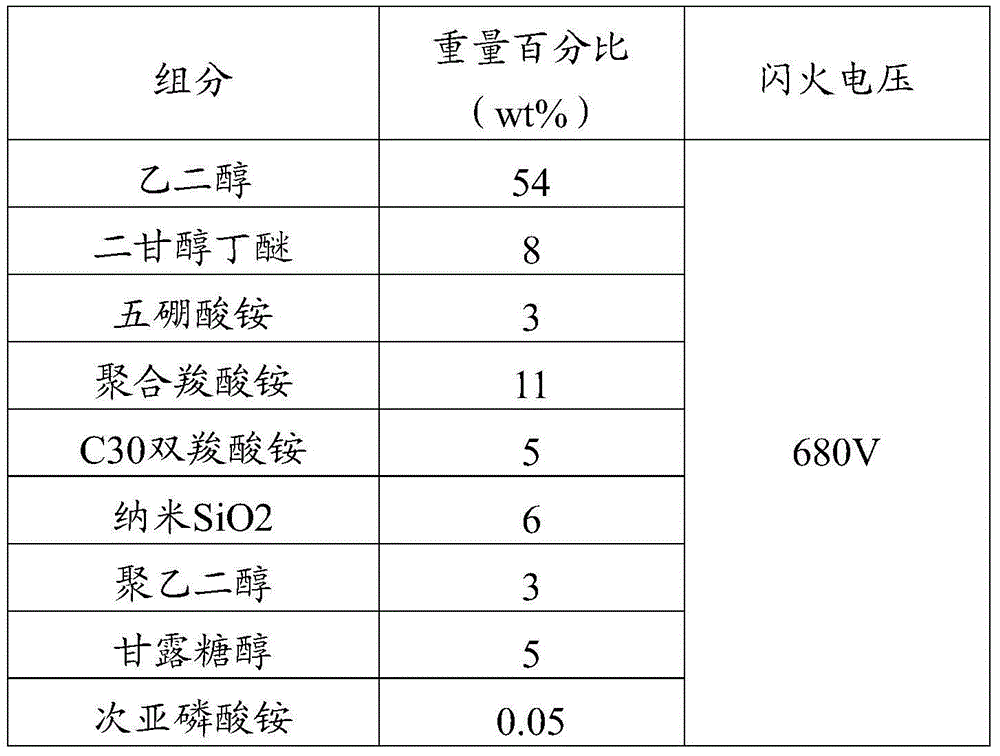

Electrolyte for flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor and preparation method thereof

ActiveCN102779644AWide temperature rangeGuaranteed stabilityElectrolytic capacitorsCapacitanceCarboxylic salt

The invention provides a working electrolyte for a flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor, which comprises the following components in percentage by weight: 45-80% of main solvent, 0.1-5% of oxidation film stabilizer, 5-15% of secondary solvent, 0.2-3% of hydrogen absorption agent, 5-10% of solute, 5-15% of flame retardant and 5-15% of spark voltage increasing agent. The invention also provides a preparation method of the electrolyte and application of the electrolyte in preparation of a high-voltage electrolytic capacitor. In the electrolyte, appropriate solvent combination is adopted, thus the wide temperature from -40 DEG C to 105 DEG C is realized; a composite solute of an organic carboxylate with a branched chain and a straight-chain carboxylate with a long carbon chain is adopted, thus the stability is ensured, and the cost is controlled; the appropriate spark voltage increasing agent, oxidation film stabilizer and hydrogen absorption agent are added, thus the spark voltage of the electrolyte is increased, and the characteristic parameters of the aluminum electrolytic capacitor are not deteriorated after the aluminum electrolytic capacitor is used for a long time; and the flame retardant is added, thus the aluminum electrolytic capacitor is difficult to burn after striking fire.

Owner:SHENZHEN ZHONGYUAN ELECTRONICS

Method for removing cyanide in waste cathode carbon in aluminum electrolysis cell

InactiveCN105772486ANo consumptionReduce energy consumptionSolid waste disposalSlagResource utilization

The invention relates to a method for removing cyanide in waste cathode carbon in an aluminum electrolysis cell, and belongs to the technical field of aluminum electrolysis solid waste resource recycling. After being levigated, an aluminum electrolysis cell waste cathode carbon block is added in water to be immersed; filtering is conducted after immersing, and first filter liquor and first filter slag are obtained; the reaction is conducted at the temperature of 30 DEG C to 70 DEG C after hydrogen peroxide, a stabilizing agent and a catalyst are added in the first filter liquor; filtering is conducted after the reaction, and second filter liquor and second filter slag are obtained; the second filter liquor is evaporated, distilled water and a crystal substance are obtained, and an oxidative product is decomposed into utilizable gas (CO2 and NH3). Treatment of the waste cathode carbon block with high efficiency and low energy consumption is achieved through the cooperative effect of the hydrogen peroxide, the proper number of the catalyst and the proper number of the stabilizing agent. The technology is simple, controllability is high, closed-loop circulation is achieved, secondary pollution is avoided, the resource utilization rate is high, and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

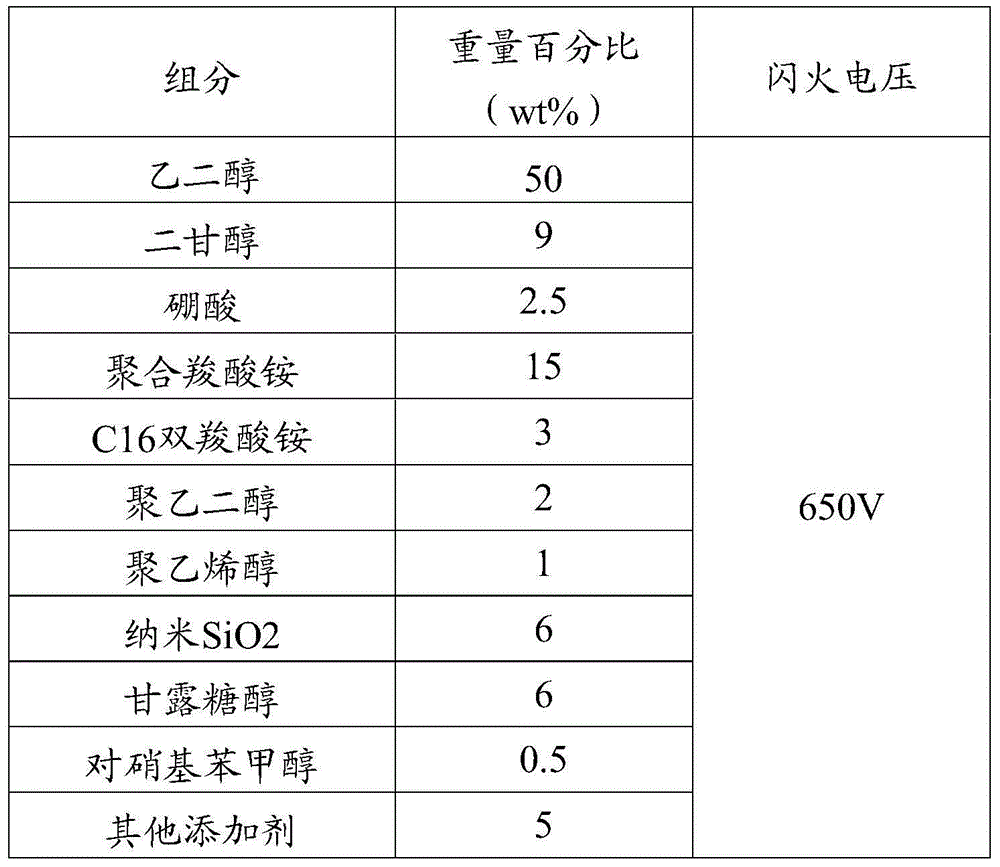

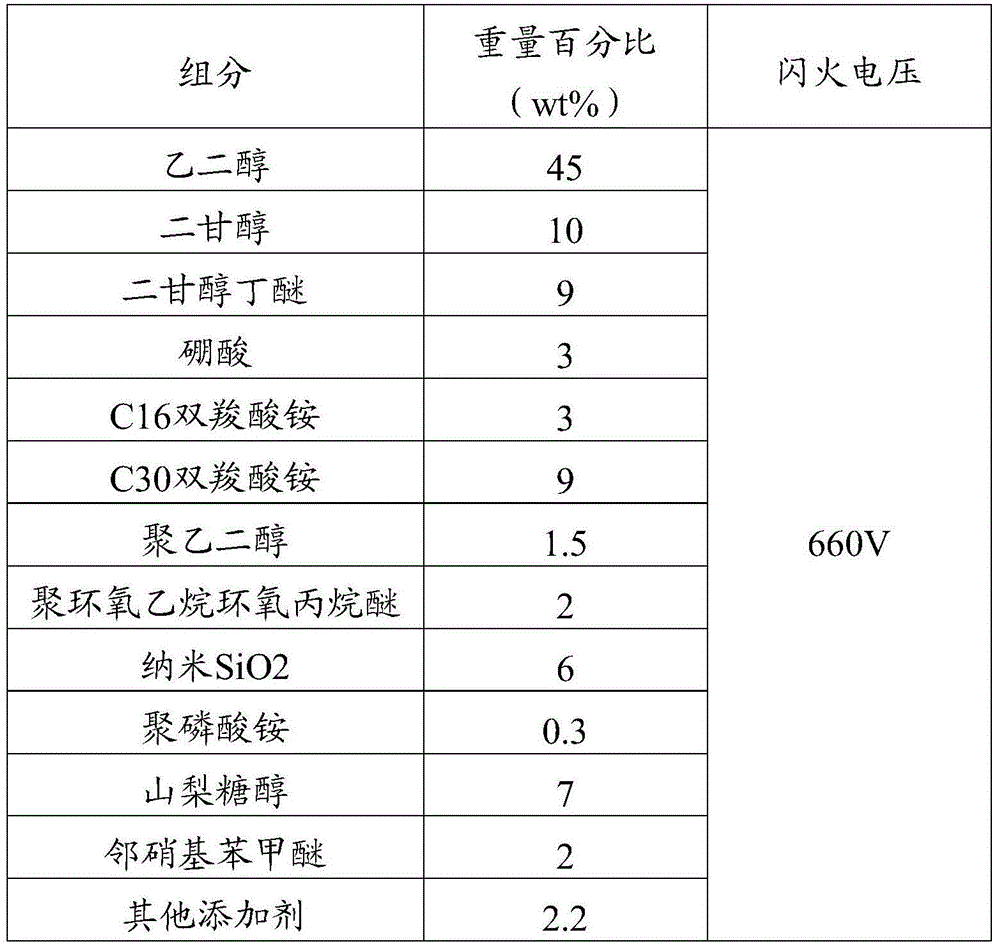

650V-700V extra-high-voltage aluminum electrolytic capacitor, working electrolyte and preparation method thereof

InactiveCN103915258AImprove high pressure resistanceImprove high temperature resistanceElectrolytic capacitorsHydrogenBreakdown phenomenon

The invention discloses working electrolyte of a 650V-700V extra-high-voltage aluminum electrolytic capacitor. The working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor comprises, by weight, 45-65% of primary solvents, 5-20.5% of secondary solvents, 10-20% of solutes, 8-25% of spark voltage improvers, 5-10% of stabilizers, 0.2-3% of hydrogen absorbents, and 2-5% of other additives. The invention further discloses a preparation method of the working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor and the 650V-700V extra-high-voltage aluminum electrolytic capacitor. According to the 650V-700V extra-high-voltage aluminum electrolytic capacitor, the working electrolyte and the preparation method of the working electrolyte, the spark voltage improvers and the stabilizers within the reasonable ranges are used, the high-voltage resistance and high-temperature resistance of the electrolyte are improved, and meanwhile the working electrolyte has low gas production performance. When the aluminum electrolytic capacitor with the electrolyte is subjected to a ripple current life test at 85 DEG C for 2000 hours, the aluminum electrolytic capacitor can resist the voltage of 650-700V and even higher voltage, and a breakdown phenomenon caused by unstable spark voltage of the electrolyte is avoided.

Owner:深圳市智胜新电子技术有限公司

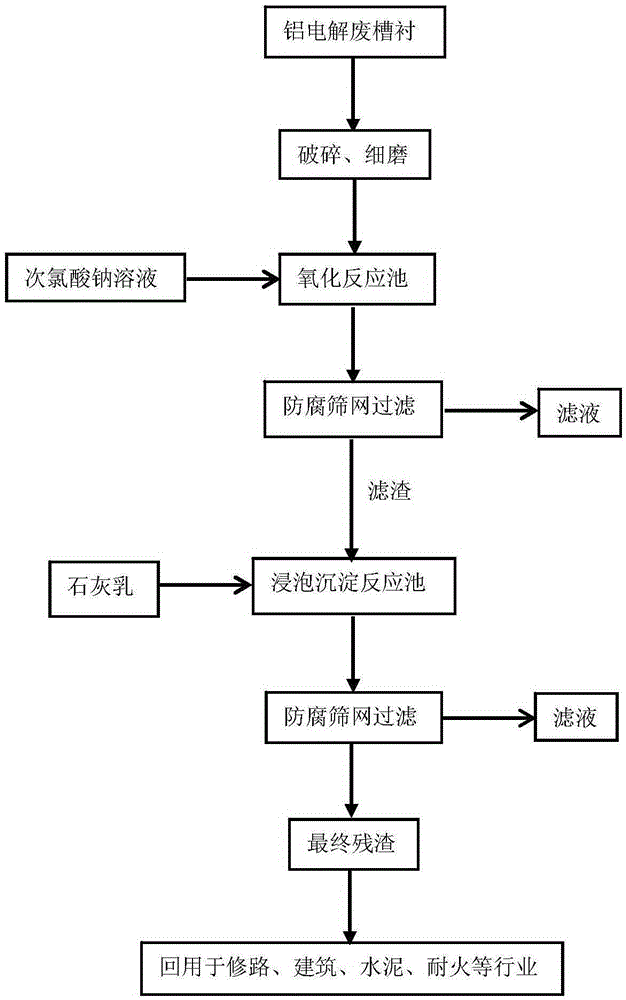

Aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction

ActiveCN105327933AReduce processing costsIncrease productivitySolid waste disposalProcessing costFire resistance

The invention discloses an aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction. A waste cell lining is crushed and ground to reach the granularity of 1-10 mm and then input into an oxidation reaction pool; a sodium hypochlorite solution is added according to the proportion 1.2-2.0 times of the theoretical value, the alkalescent pH value is controlled to be 7.0-8.5, dangerous element cyanide has a redox reaction with the sodium hypochlorite solution and then is removed, and the reaction time is 0.5-1.0 h; an anti-corrosion sieve is used for filtering out residues after the redox reaction and the residues are put into a precipitation reaction pool; whitewash with the concentration 0.8-1.0 time of the saturation concentration value is added into the precipitation reaction pool, and the residues are soaked for 1.0-1.5 h, are combined with fluoride for reaction and then generate indissolvable CaF2; the anti-corrosion sieve carries out filtering after the precipitation reaction, and obtained filtrate can serve as raw materials for the sodium carbonate industry and aluminum oxide industry; the filtered-out final residues are harmless and can serve as raw materials used for road construction, buildings, cement, fire resistance and other industries. The aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction is simple and convenient to implement, low in processing cost and high in production efficiency and does not need an incinerator or other combustion equipment.

Owner:内蒙古泓旺铝业有限责任公司

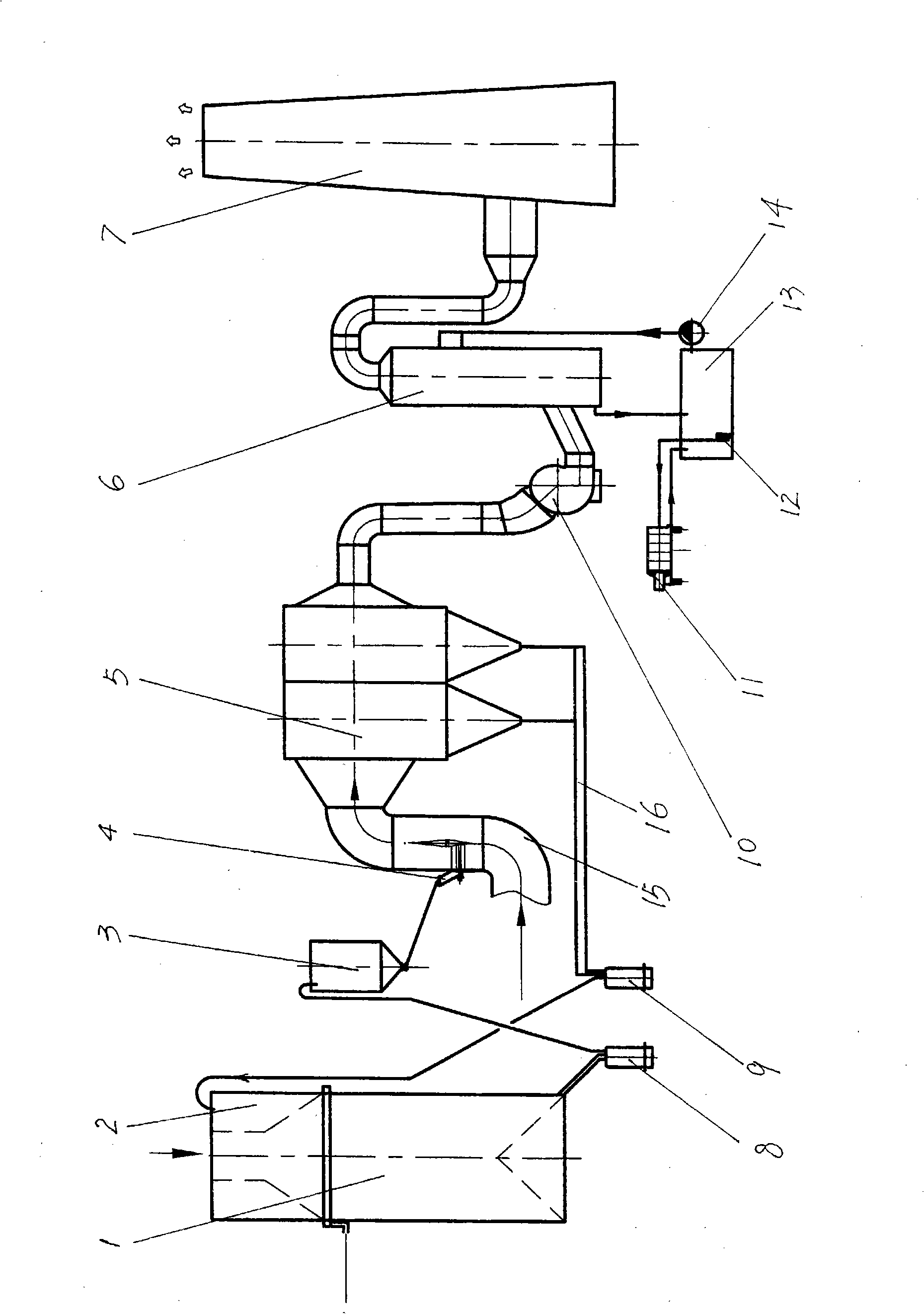

Dry and wet methods combined aluminum electrolysis flue gas deep treatment process

InactiveCN101348924ALow running costEmission reductionDispersed particle separationLiquid wastePartial oxidation

A novel process for realizing deep treatment of electrolytic aluminum flue gas through combining a dry-wet method is characterized in that flue gas of each electrolytic cell is fully contacted with fresh alumina powder inside a VIR reactor; after fluorine is absorbed, the alumina powder and the flue gas enter an electrostatic dust collector so as to remove most alumina powder and alumina powder dust; waste gas enters an absorption tower of a wet system, and is in counter current contact with an absorption liquid so as to remove alumina powder, dust, hydrogen fluoride and sulfur dioxide in the waste gas; and the purified tail gas is exhausted into the atmosphere. The novel process has the advantages that the process turns the prior dry bag-type dust removal into electrostatic dust removal, thereby substantially reducing the investment of dry dust removal and the operating cost of the entire environmental protection system; then, wet treatment is adopted so as to reach the goal of deep treatment; meanwhile, SO2 with flue gas removed is absorbed, thereby greatly reducing the emission of pollutants during aluminum electrolysis; through the organic combination of the dry-wet technology, the process ensures that fluoride inside the wet system is directly synthesized into cryolite and is reclaimed, thereby solving the problems that the prior wet purification process needs to adopt a villaumite recovery device and that villaumite liquid wastes are difficult to treat.

Owner:商丘市丰源铝电有限责任公司

Ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks

The invention relates to an ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks belongs to the technical field of aluminum electrolysis solid waste resource recovery, and comprises the following steps of smashing the aluminum electrolysis spent cathode carbon blocks, adding the aluminum electrolysis spent cathode carbon blocks into alkaline liquor for leaching, and filtering to obtain carbon powder and first filter liquor; carrying out alkaline pickling under the ultrasonic environment; leading CO2 into the first filter liquor, crystallizing out, filtering to obtain cryolite, an aluminum hydroxide mixture and second filter liquor, and recycling the second filter liquor. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks is simple in process, and convenient to operate; and through the synergistic effect of ultrasonic wave and alkaline pickling, the reaction rate is accelerated, the purity of the product carbon powder is improved, the maximum purity of the carbon powder is 97.92 percent, and the production cycle is 70min.

Owner:CENT SOUTH UNIV

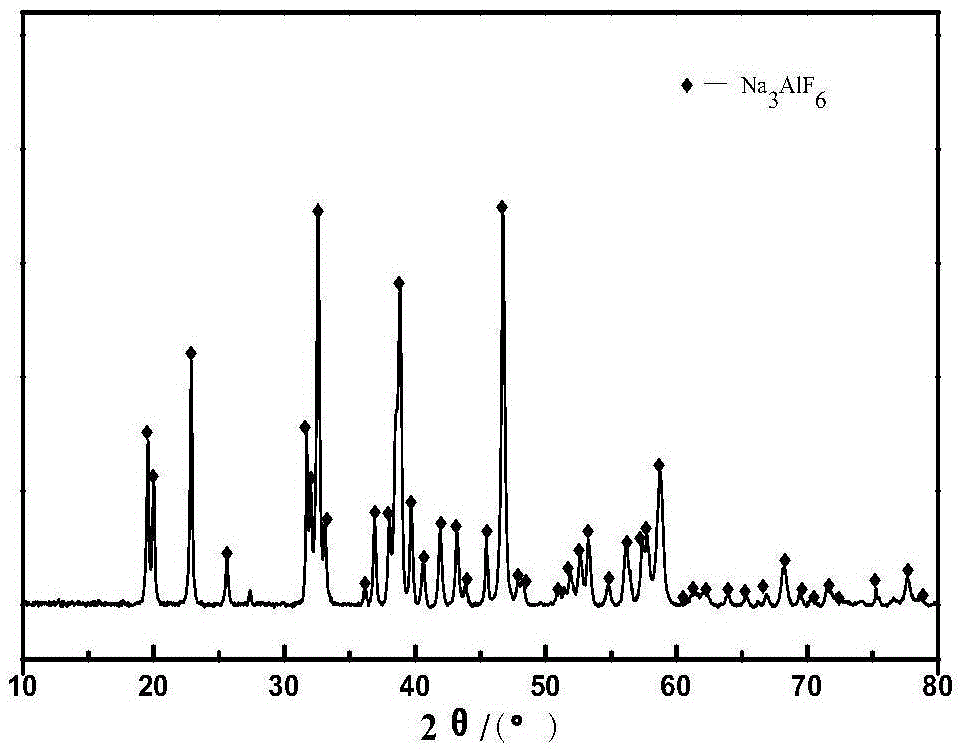

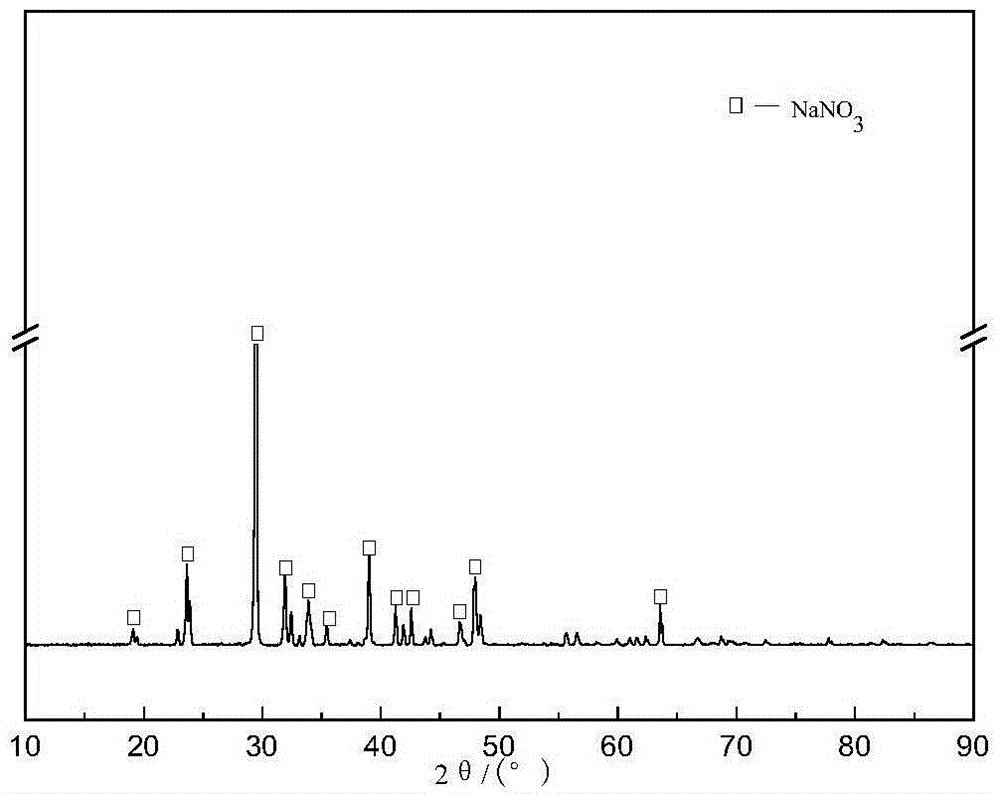

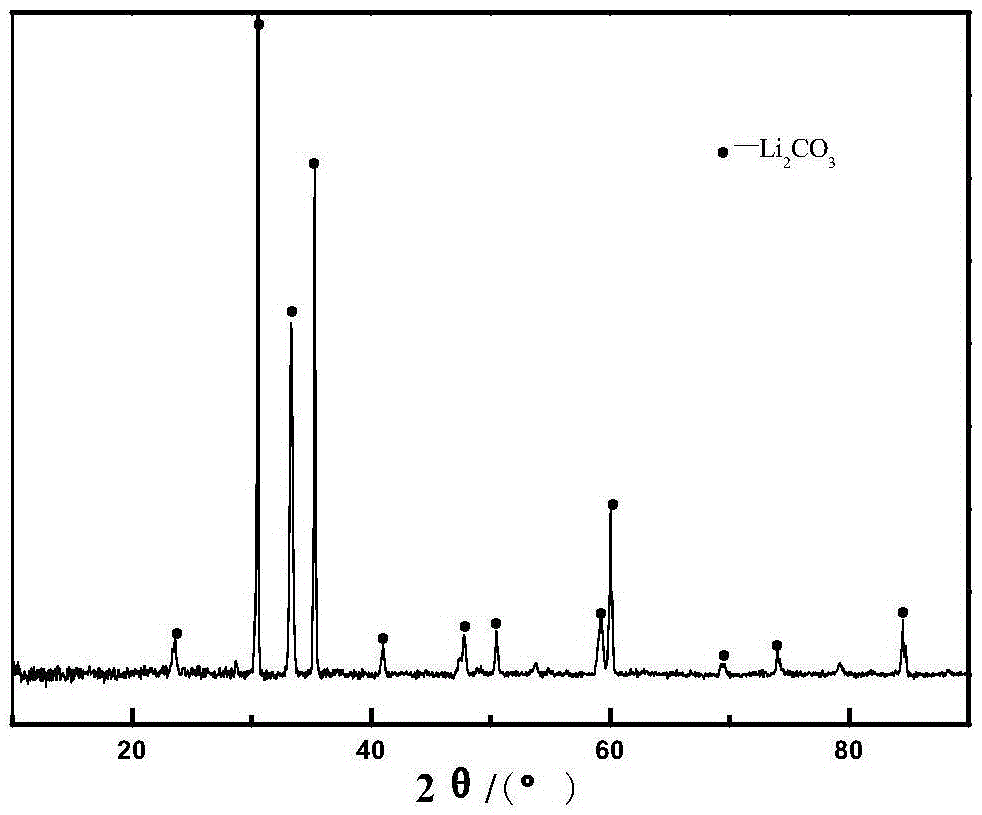

Method for extracting lithium salt from aluminum electrolyte by utilizing fluoride roasting and acid leaching

ActiveCN105543504AReduce energy consumptionEfficient extractionProcess efficiency improvementLithium soapLithium carbonate

The invention discloses a method for extracting lithium salt from aluminum electrolyte by utilizing fluoride roasting and acid leaching, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: step 1: mixing materials; and step 2: carrying out fluoride roasting; and step (3): (1) carrying out acid leaching and filtering to obtain primary filtrate and primary filtered substances; (2) respectively treating the primary filtrate and the primary filtered substances to obtain secondary filtrate and secondary filtered substances; (3) respectively treating the secondary filtrate and the secondary filtered substances to obtain tertiary filtrate and tertiary filtered substances; and (4) respectively treating the tertiary filtrate and the tertiary filtered substances. According to the method disclosed by the invention, an element lithium in the electrolyte can be effectively extracted, so that energy consumption for electrolytic aluminum production is reduced; lithium carbonate chemical raw materials with a high additional value are recycled, and the used raw materials are common raw materials in the chemical field, so that the comprehensive average extraction cost is relatively low; various substances can be separated out, and the obtained substances are relatively high in purity; and the lithium element influence problem is solved for the aluminum electrolysis industry, benefits are increased, and the comprehensive level of the aluminum electrolysis industry in China is improved.

Owner:NORTHEASTERN UNIV

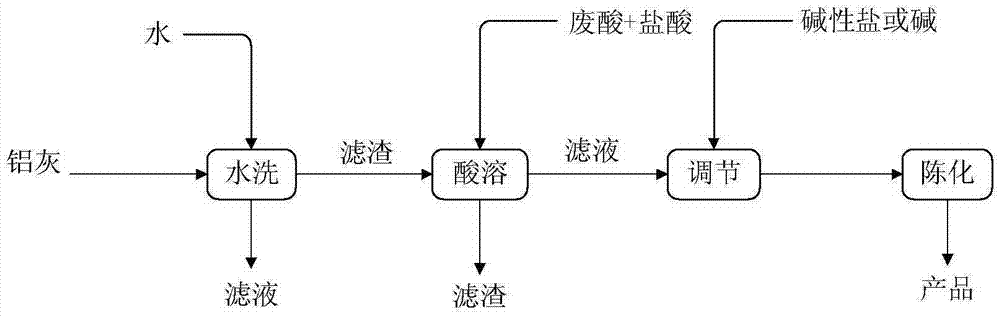

Method for producing aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash

InactiveCN106892444AQuick buildGuaranteed stabilityAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productResource utilization

The invention relates to a method for producing an aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash. The method comprises the following steps: carrying out dissolving reaction on the solid waste aluminum ash produced in an aluminum electrolysis process and waste hydrochloric acid produced in a resource utilization process of high-aluminum coal ash, so as to obtain an aluminum-containing solution; adding alkaline salt or alkali into the aluminum-containing solution, and carrying out polymerization reaction, so as to obtain a primary product; and ageing the primary product, so as to obtain an aluminum polychlorid liquid product. By utilizing the method, the problems of solid waste pollution and wastewater emission can be solved, and the aluminum polychlorid product meeting the index requirements of national standard (GB15892-2009) can be prepared; and the method has good economic and social values.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

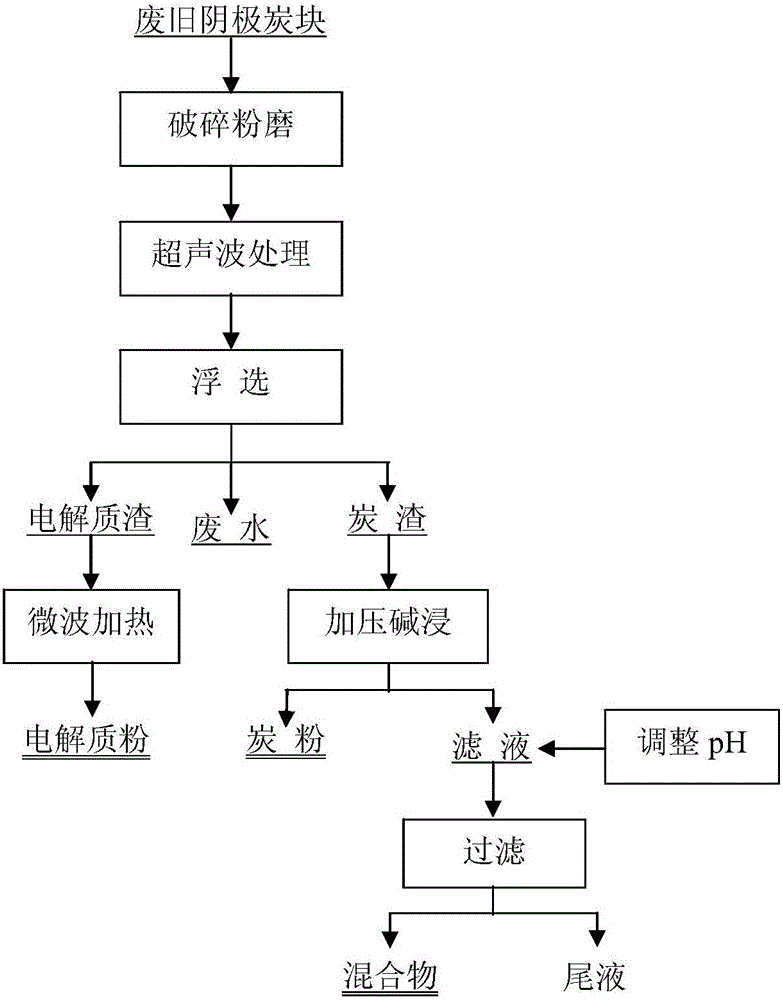

Method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching

ActiveCN106077038AReduce consumptionShorten the alkaline leaching timeSolid waste disposalFiltrationMaterials science

The invention relates to a method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching, and belongs to the technical field of comprehensive utilization of aluminum electrolysis solid waste resources. The method comprises the steps of carrying out ultrasonic pretreatment after crushing and grinding the aluminum electrolysis waste cathode carbon blocks, carrying out floatation on pretreated powder to obtain electrolyte residues and carbon residues, and reusing the wastewater of floatation; removing carbon impurities after the electrolyte residues are subjected to microwave heating to obtain electrolyte powder with high purity, and carrying out pressure alkali leaching on the carbon residues to remove solvend so as to obtain carbon powder with high purity; adjusting the pH of alkali leaching filter liquor to generate sediment, carrying out filtration to obtain electrolyte, and reusing the filter liquor. According to the method, through collaborative assistance action among the ultrasonic pretreatment technology, the microwave heating technology and the pressure alkali leaching technology, the high-efficiency comprehensive recycling of aluminum electrolysis waste cathodes is achieved. The method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching is reasonable in technological design, high in recovery rate of valuable matter, purity of obtained products and processing speed, free of secondary pollutants and applicable to industrial large-scale application.

Owner:CENT SOUTH UNIV

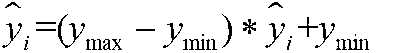

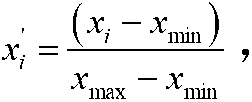

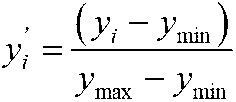

Dynamic evolution modeling method for aluminum electrolysis process electrolytic bath technology energy consumption

InactiveCN103345559AStrong tracking abilityFast convergenceSpecial data processing applicationsRate of convergenceComputer science

Provided is a dynamic evolution modeling method for aluminum electrolysis process electrolytic bath technology energy consumption. The method is characterized by including the following steps of step 1, collecting data [XN, Y], step 2, carrying out normalization processing on the collected data, step 3, carrying out modeling on the data after the normalization processing by strongly tracking a square root trackless Kalman neural network, and step 4, estimating an electrolysis process energy consumption value by applying an established model to obtain a technology energy consumption value of the electrolysis process at the moment. The method has the advantages that advantages of strong tracking filtering and square root filtering are combined, convergence rates of the model and tracking ability on electrolytic bath mutation states are improved, the algorithm is stable, accuracy is high, tracking ability on the electrolytic bath mutation states is strong, therefore, real time estimation on the aluminum electrolysis process electrolytic bath technology energy consumption is achieved, technology operations on the aluminum electrolysis process can be optimized, and the purposes of saving energy and reducing emission can be achieved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

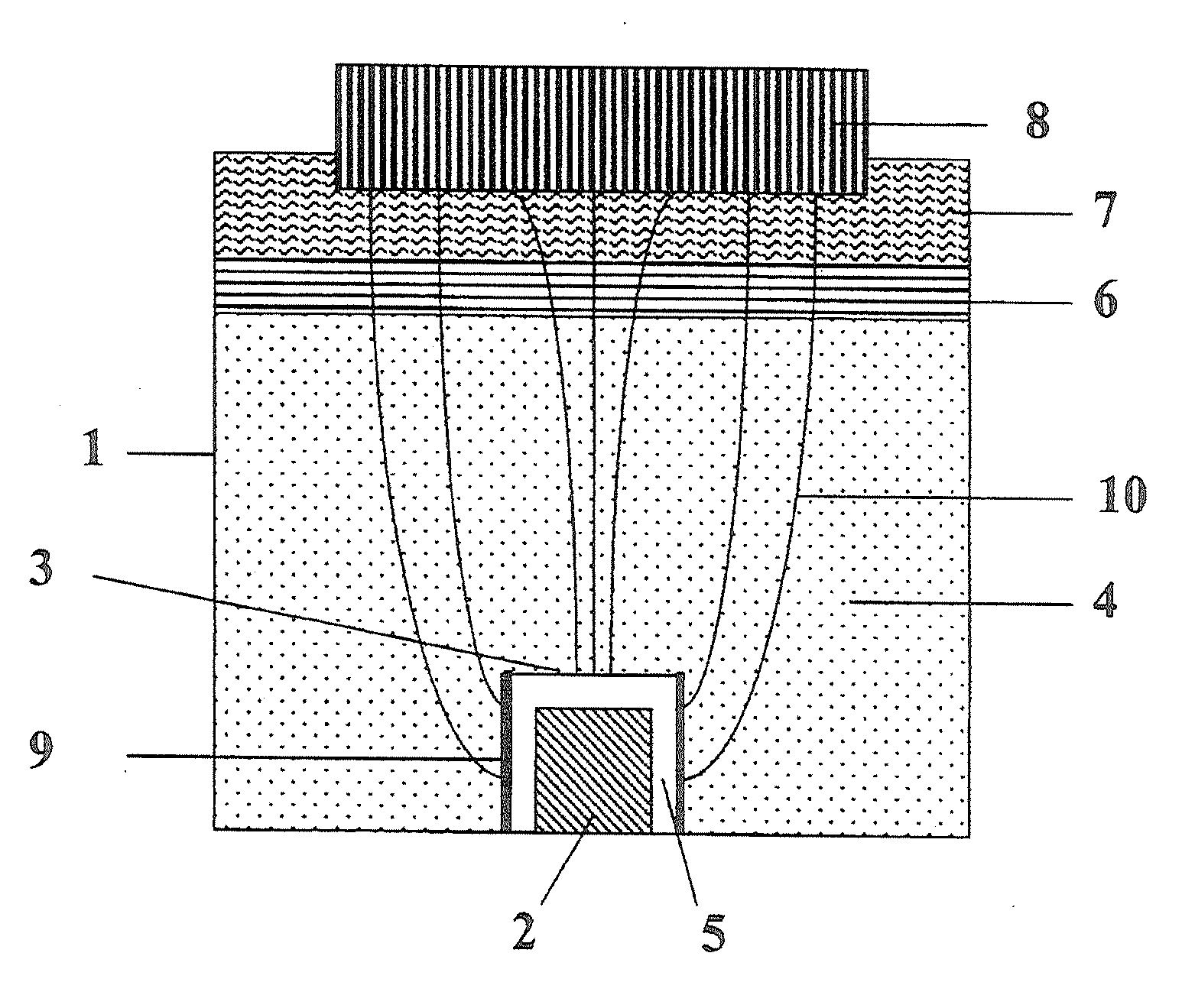

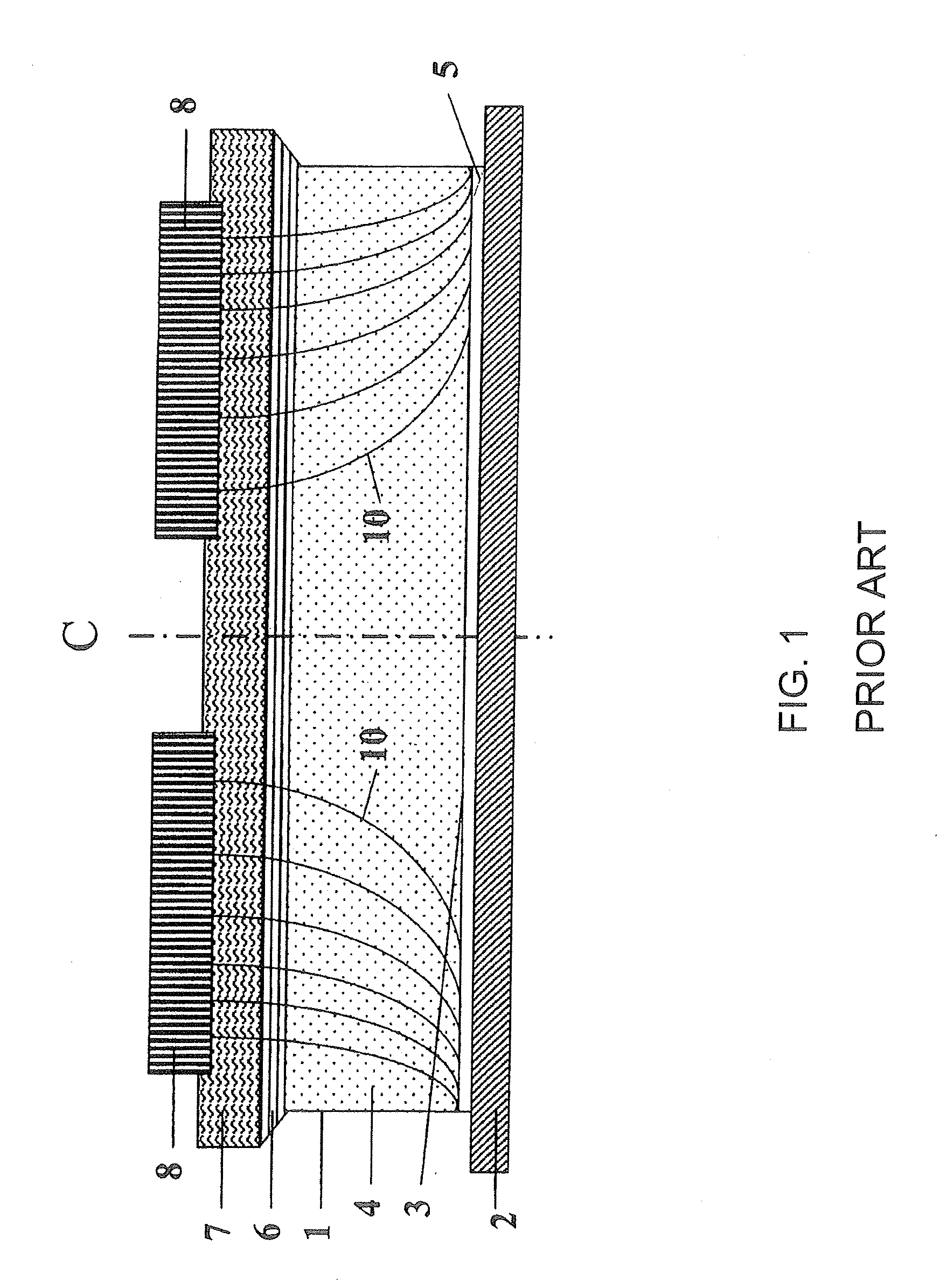

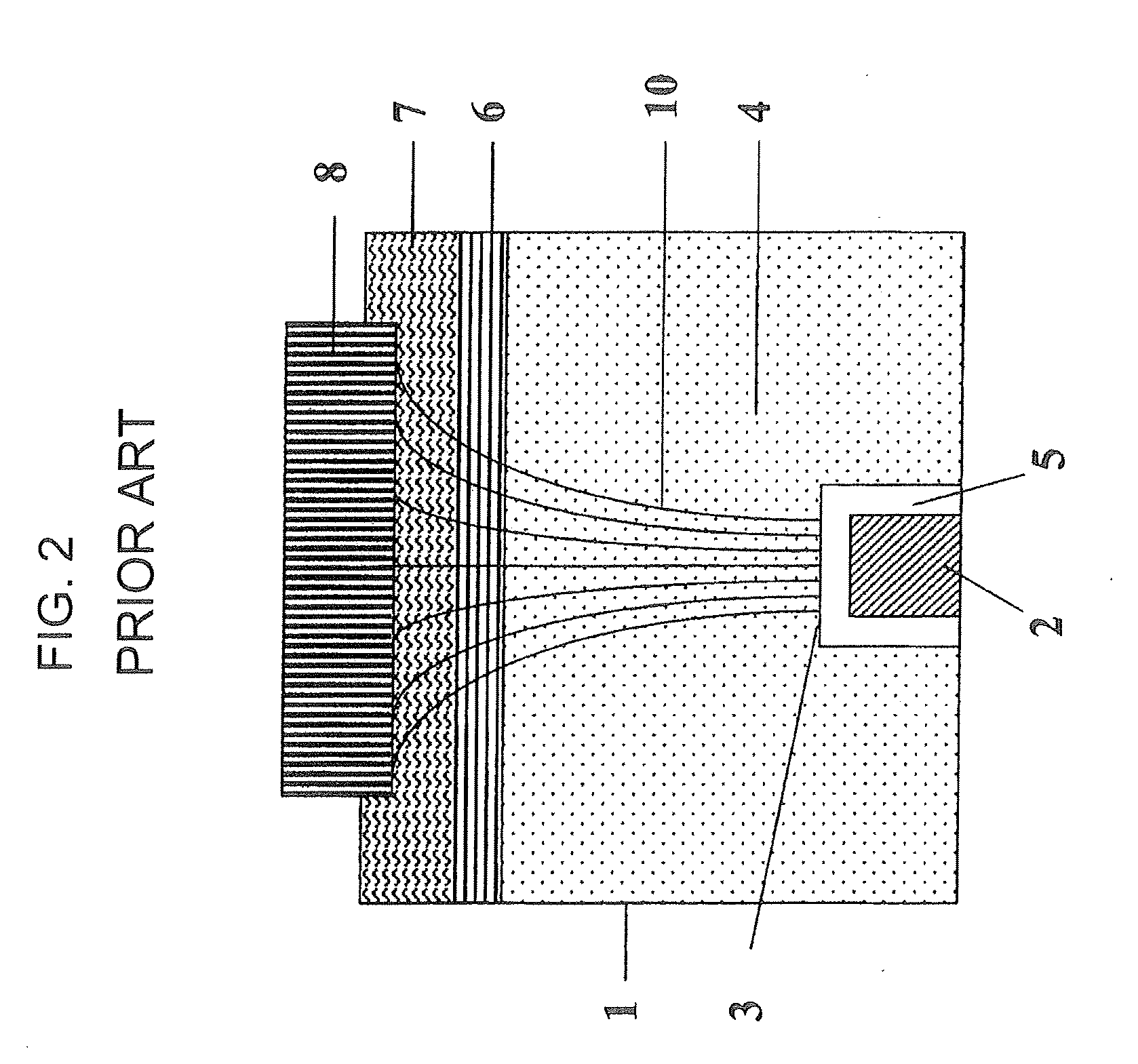

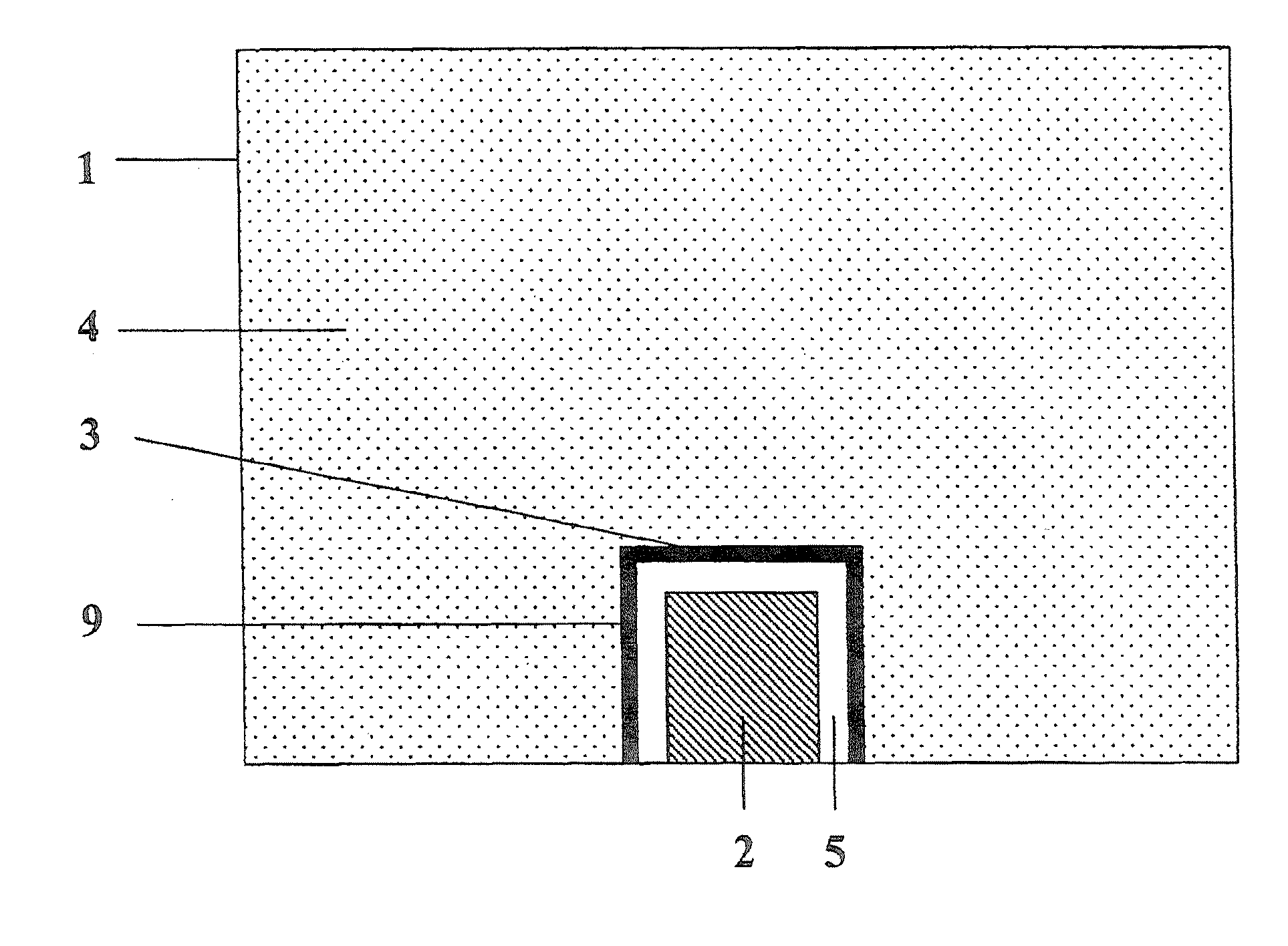

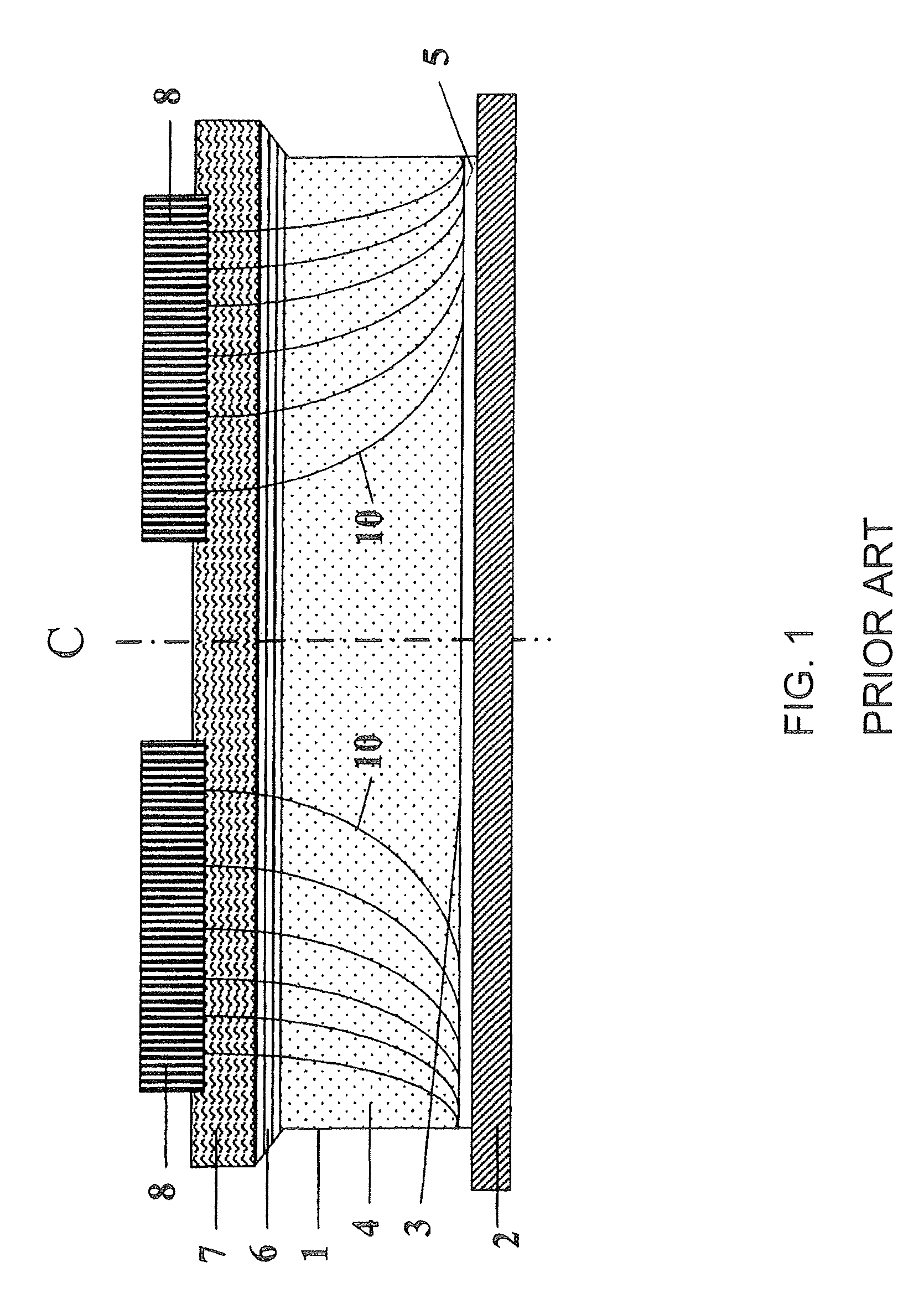

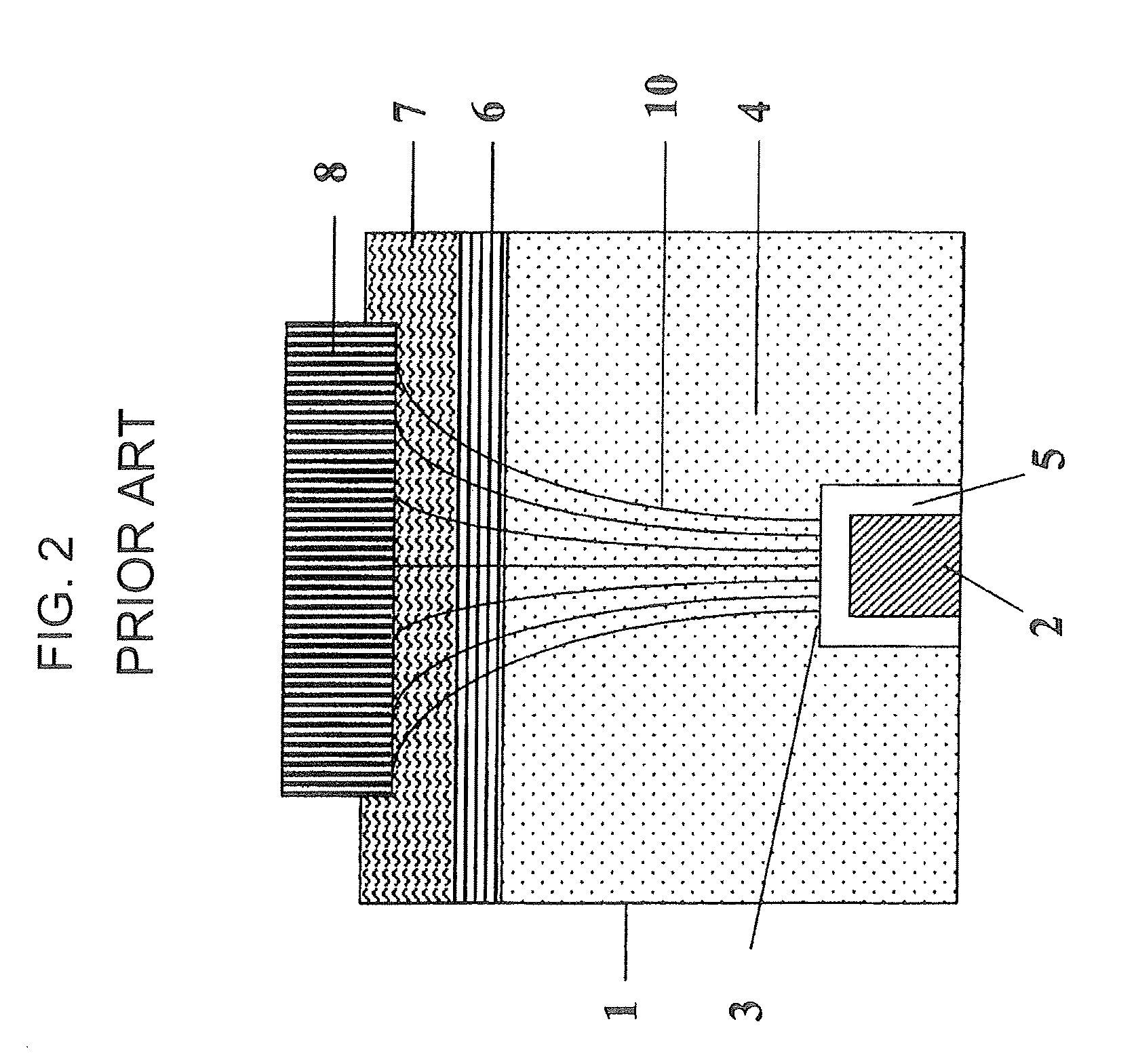

Cathodes for Aluminum Electrolysis Cell with Expanded Graphite Lining

ActiveUS20080308415A1Excellent ElectricalImprove thermal conductivityMachining electrodesLine/current collector detailsProduction rateElectrical battery

Cathodes for aluminum electrolysis cells are formed of cathode blocks and current collector bars attached to those blocks. The cathode slots receiving the collector bar are lined with expanded graphite lining thus providing longer useful lifetime of such cathodes and increased cell productivity. The expanded graphite provides a good electrical and thermal conductivity especially with its plane layer.

Owner:TOKAI COBEX GMBH

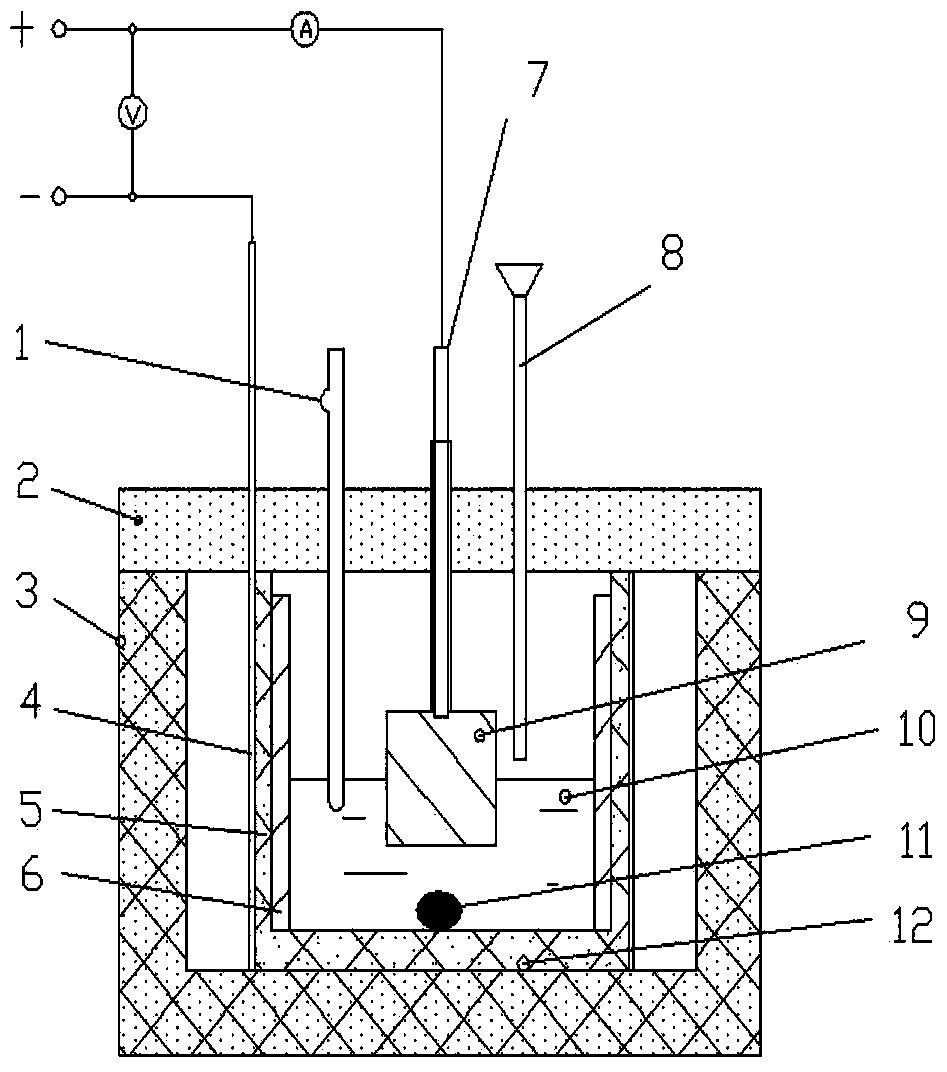

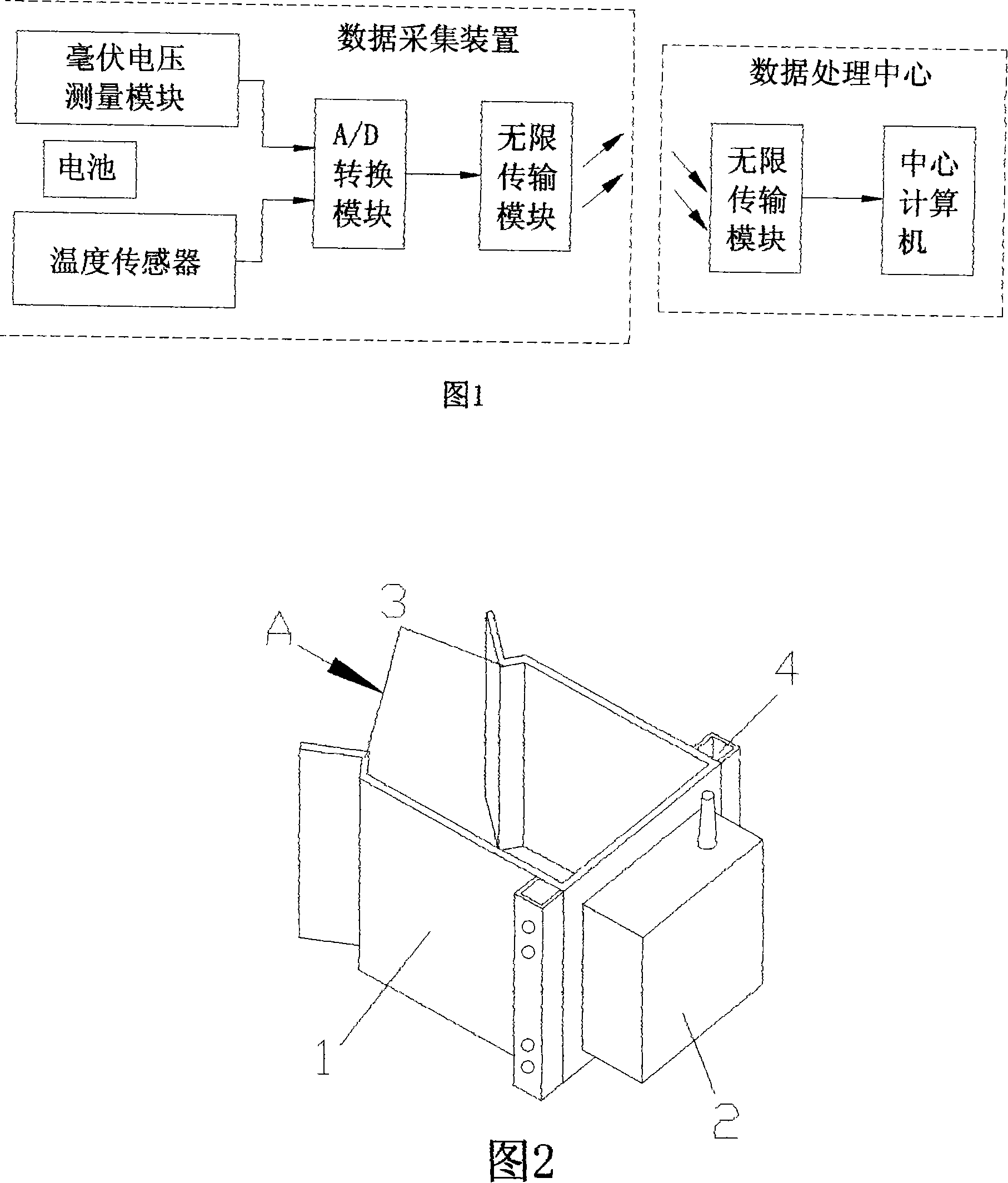

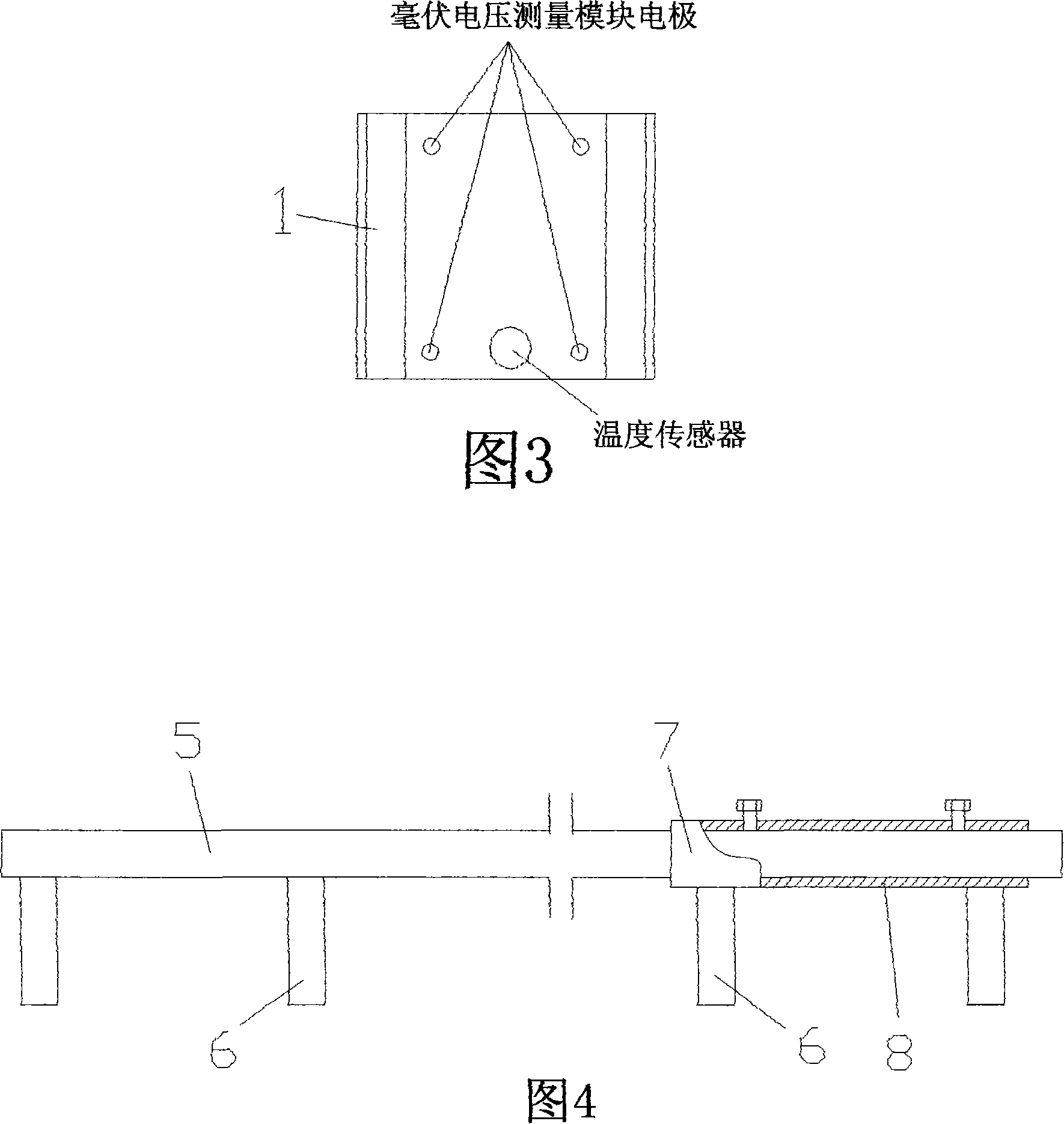

On-line testing method for aluminum cell anodic current distribution and monitoring device

InactiveCN101220489AImprove current efficiencyPrevents shedding failurePower flowCurrent distribution

The invention discloses an on-line detection method for current distribution in the anode of an aluminum reduction cell. By clamping voltage data collecting devices on all the anode guide rods in the reduction cell one by one and using the radio transmission technology, the method realizes simultaneous collecting of voltage data of all the anode guide rods in the reduction cell, thus providing timely and accurate data for analyzing the distribution and changing trend of current in the anode. The on-line monitoring method for current distribution in the anode of the aluminum reduction cell of the invention can master the distribution of the current in the anode of the reduction cell in time, provide timely and accurate data for an operator to adjust the height of the anode in time and ensure stable and isostatic distribution of the current in the anode of the reduction cell according to technology condition, avoid anode shedding caused by current convergence in the anode, specify the furnace cavity, increase current efficiency of the reduction cell, reduce anode consumption and power consumption and achieve the goal of saving electric power resource.

Owner:北京华深中色科技发展有限公司

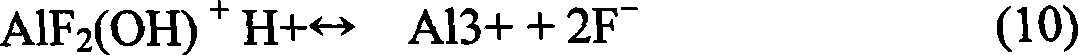

Method for recycling waste cathode carbon blocks of aluminum electrolysis cell

InactiveCN107282598ASave chemical processing raw materialsUse allSolid waste disposalAluminium sulfateAluminum fluoride

The invention discloses a method for recycling waste cathode carbon blocks of an aluminum electrolysis cell. The method comprises the following steps: 1, grinding the waste cathode carbon blocks into powder of 100-200 meshes through superfine grinding, and then winnowing the powder to separate the carbon powder from aluminum and aluminum carbide; 2, adding the fine carbon powder into water, stirring the fine carbon powder, then filtering the obtained solution, and preparing filtrate and filter residues for later use; 3, adding the filter residues in the step 2 into an aluminum sulfate solution, leaving the mixed solution to stand at normal temperature for 20-30 hours, then filtering the mixed solution, washing obtained filter residues to obtain the carbon powder with the carbon content higher than 90% and preparing filtrate for later use; 4, mixing the filtrate obtained in the step 2 and the filtrate obtained in the step 3, adjusting the pH value to be 5.5, increasing the temperature to 90 DEG C, then carrying out reaction for 3 hours to obtain flocculent hydroxyl aluminum fluoride, and carrying out filtering to obtain filter residues; and 5, calcining the filter residues obtained in the step 3 at 485 DEG C to obtain AlF3 and Na5Al3F14 and using AlF3 and Na5Al3F14 as raw materials of aluminum electrolysis. Through the method, the waste cathode carbon blocks of the aluminum electrolysis cell can be efficiently recycled.

Owner:李立安

Cathodes for aluminum electrolysis cell with expanded graphite lining

ActiveUS7776190B2Increase resistanceReduce the overall heightMachining electrodesCellsProduction rateElectrical battery

Owner:TOKAI COBEX GMBH

Low-temperature molten salt system for aluminum electrolysis and method for carrying out aluminum electrolysis by same

The invention relates to the field of molten salt electrolysis of nonferrous metal metallurgy and provides a novel molten salt electrolyte system which can be applied to the aluminum electrolysis industry. The molten salt as an electrolyte system of aluminum electrolysis can greatly reduce the electrolysis temperature, and the electrolyte system also presents a favorable dissolving performance onAl2O3 in the process of electrolysis. The novel molten salt electrolyte system comprises ternary or multivariant salt, such as KF, KCl, NaF, NaCl, AlF3, MgF2, CaF2, LiF, BaF2, Al2O3, and the like. Theelectrolyte system has a lower primary crystal temperature and the favorable dissolving performance on the Al2O3. The problems of low Al2O3 solubility and low dissolving speed brought by reducing theelectrolyte primary crystal temperature through reducing the NaF / AlF3 ratio in a sodium cryolite system are solved. In addition, the low-temperature electrolyte system is particularly suitable for adopting an inert anode of metal ceramics or metal alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Aluminum electrolysis carbon anode oxidation coating and coating method thereof

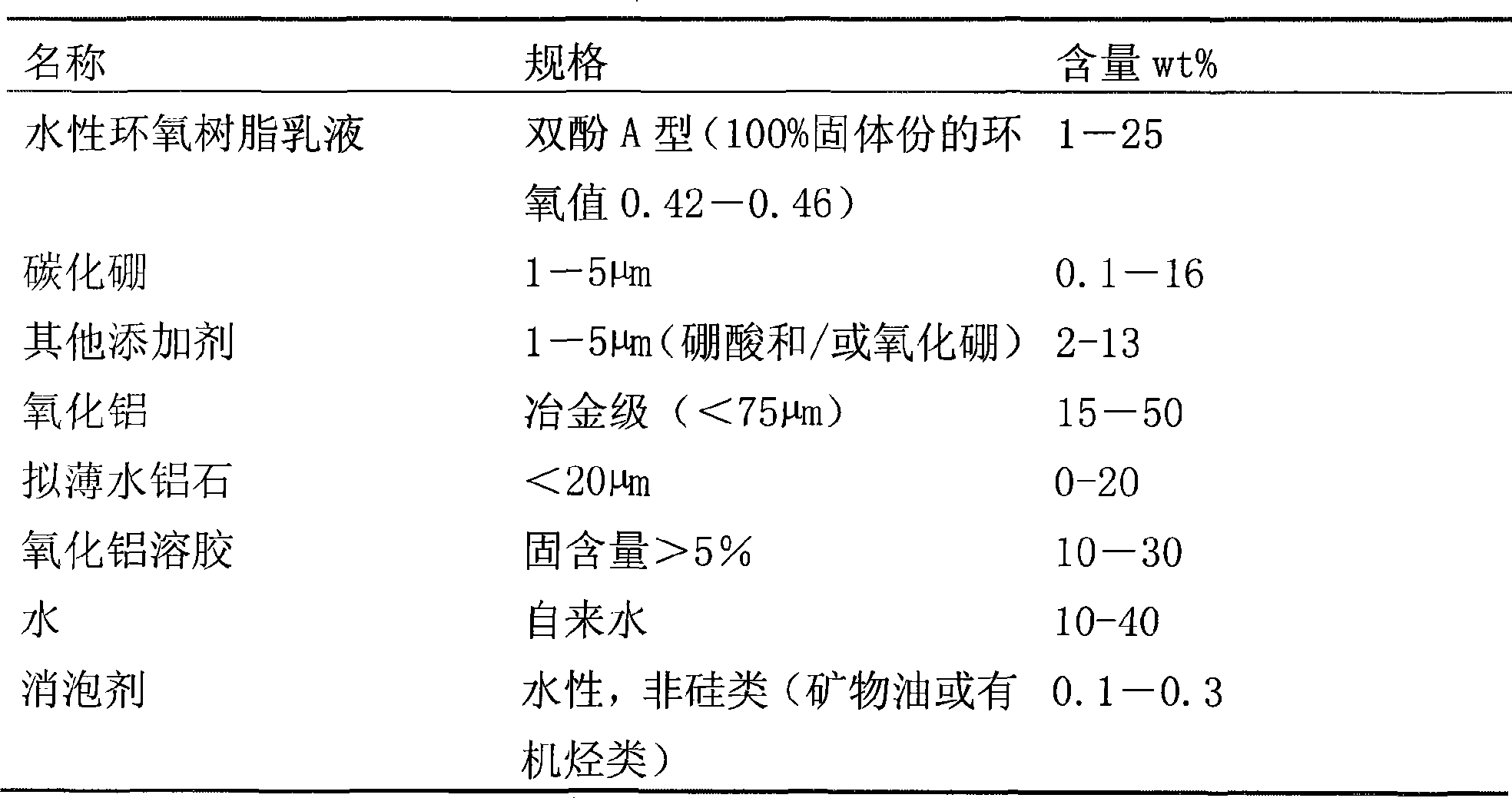

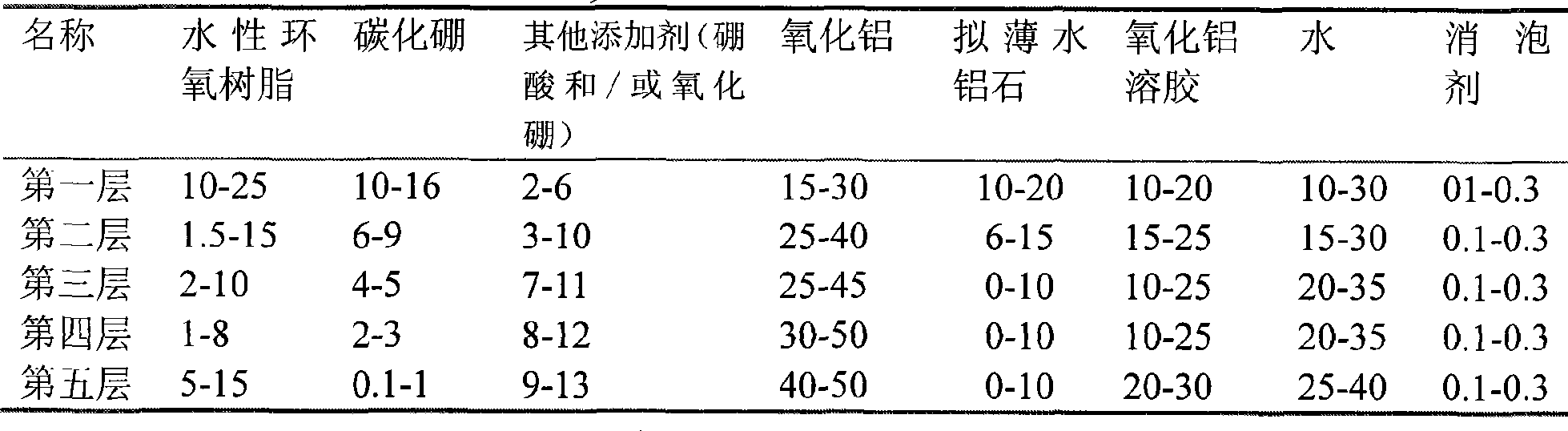

The invention relates to an oxidation resistant coating for aluminum electrolytic carbon anode and a coating method thereof. The method is characterized in that the surface of the aluminum electrolytic carbon anode is provided with an anti-oxidation coating formed by dried and mixed coat which is sprayed on the surface of the electrode, wherein the mixed coat comprises the following compositions in weight percentage: 1 to 25 percent of bisphenol A-type waterborne epoxy resin, 0.1 to 16 percent of boron carbide, 2 to 13 percent of boric acid and / or boric oxide, 15 to 50 percent of alumina, 0 to 20 percent of pseudo-boehmite, 10 to 30 percent of alumina sol, 0.1 to 0.3 percent of foam suppressor, and the balance being water. The coating and the method adopt an alumina-based gradient boron carbide oxidation resistant coating with a multilayer structure, and effectively blocks the contact of air and CO2 with carbon anode carbon, thereby avoiding or reducing excessive consumption of the carbon anode carbon. The method can realize carbon conservation by aluminum electrolytic prebaked anode by 10 to 20 kilogram / ton-Al.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

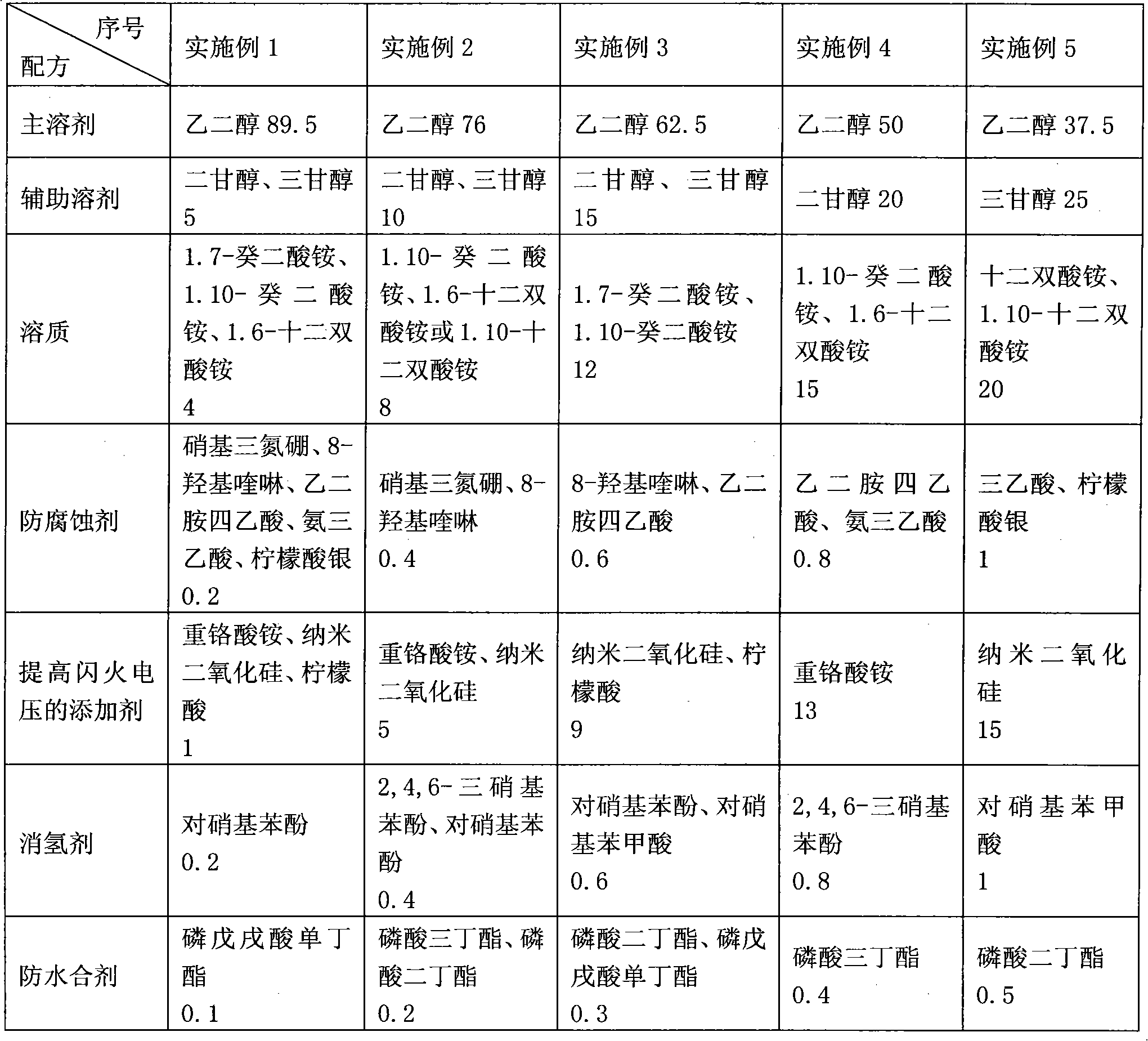

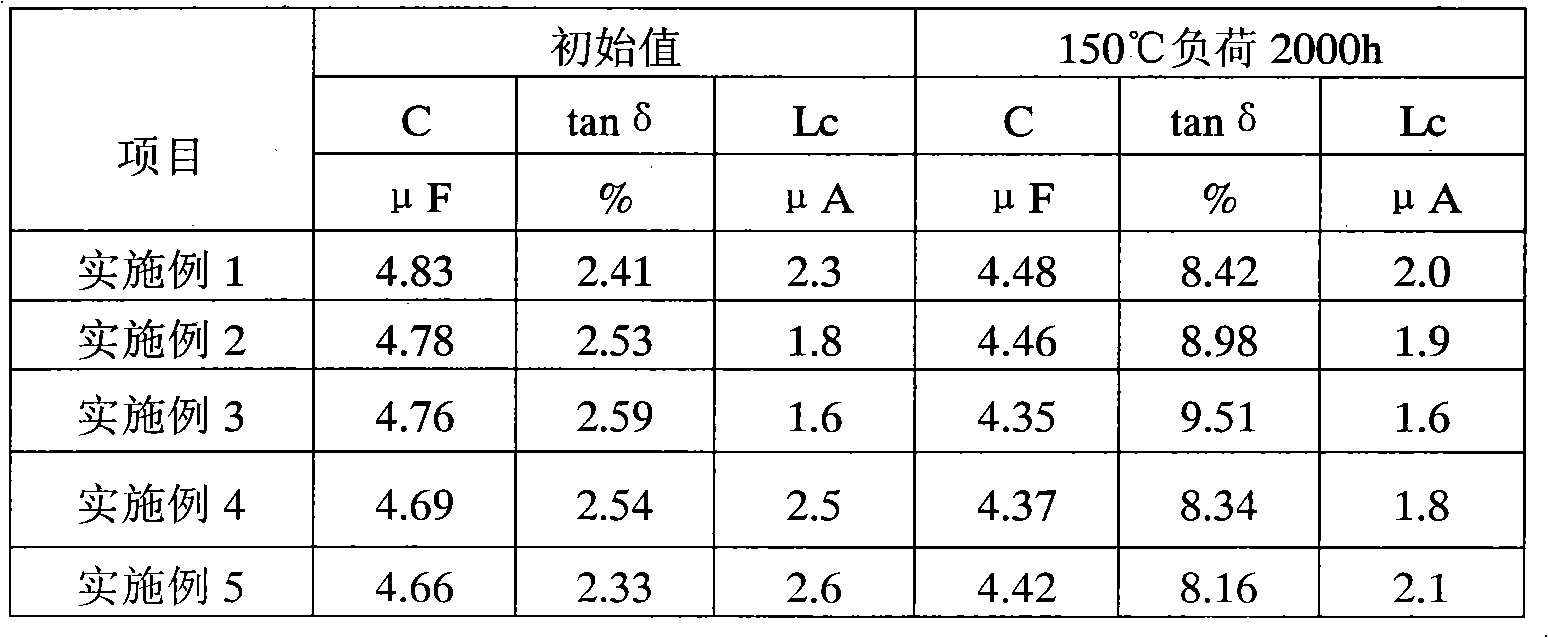

Temperature-resistant electrolyte for aluminum electrolysis and application thereof

InactiveCN101866751AIncrease the flash voltageImprove high temperature resistanceElectrolytic capacitorsElectrolysisWorking temperature

The invention discloses temperature-resistant electrolyte for aluminum electrolysis and application thereof. The electrolyte comprises the following components in percentage by mass: 37.5 to 89.5 percent of main solvent, 5 to 25 percent of auxiliary solvent, 4 to 20 percent of solute, 0.2 to 1 percent of anticorrosive agent, 1 to 15 percent of additive for increasing a breakdown voltage, 0.2 to 1 percent of hydrogen-eliminating agent and 0.1 to 0.5 percent of hydration preventing agent. The electrolyte has the characteristics of high-temperature resistance, high corrosion resistance, high breakdown voltage and the like. The upper limit working temperature of an aluminum electrolytic capacitor prepared by using the electrolyte of the invention is as high as 150 DEG C, the service life is 2,000 hours at the temperature of 150 DEG C, so that the product can completely meet the strict requirements of high-power electric energy-saving lights, automobile electrics and the like on high-temperature resistance and long service life.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Processing method for aluminum electrolysis waste cathode carbon block

ActiveCN107662913AAchieve recyclingElectrolytic realizationCalcium/strontium/barium sulfatesAluminates/aluminium-oxide/aluminium-hydroxide purificationElectrolysisAluminium hydroxide

The invention belongs to the technical field of recycling of electrolytic aluminum industrial wastes and specifically discloses a processing method for an aluminum electrolysis waste cathode carbon block. The processing method comprises the following steps: breaking the waste cathode carbon block and then adding water for ball-milling, performing decyanation treatment, leaching with hot water, leaching with concentrated sulfuric acid, washing and performing flotation, thereby acquiring a first-level carbon powder product and a second-level carbon powder product; reacting a primary acid leaching solution with a sodium hydroxide solution and filtering, thereby acquiring solid aluminum hydroxide; mixing the reaction filtrate with lime and filtering, thereby acquiring calcium sulfate; using water for absorbing the mixed gas formed by the primary washing gas and the acid leaching gas, thereby acquiring a hydrofluoric acid solution; mixing the prepared hydrofluoric acid solution with a ball-milling separating liquor and a hot water leaching separating liquor; adding aluminum hydroxide into the mixed liquor; filtering and separating the reactants; filtering, thereby acquiring the liquid phase of reusable water and the solid phase of fluorine-containing aluminum hydroxide; and roasting, thereby acquiring a fluorine-containing aluminum hydroxide product. According to the method providedby the invention, the harmless comprehensive recycling of the aluminum electrolysis waste cathode carbon block is realized.

Owner:山东绿脉铝业科技有限公司

125 DEG C high temperature long life aluminum electrolysis capacitor, production method thereof and special electrolysis liquid

InactiveCN101483101ALower impedanceSolution to short lifeLiquid electrolytic capacitorsCapacitor terminalsElectrolytic agentEngineering

The present invention relates to the manufacture field of capacitor, specifically to a high temperature (125 DEG C) long life electrolytic capacitor, its manufacturing method and its special electrolyte. The capacitor is formed by manufacturing a capacitor core package by coiling together the cathode foil, cathode foil, electrolytic paper and leading-out wires; dipping the core packages in the electrolyte; and then putting in the aluminum shell; and sealing by the plug. The electrolyte has 85-88 parts of solvent composition, 5.5-11 parts of solute, 1-1.5 parts of additives and 3-5 parts of high temperature stabilizer. The capacitor has a low impedance, high-profile current resistance, long-life (5,000 hours in durability test at 125 DEG C).

Owner:FOSHAN SANSHUI RIMING ELECTRONCS

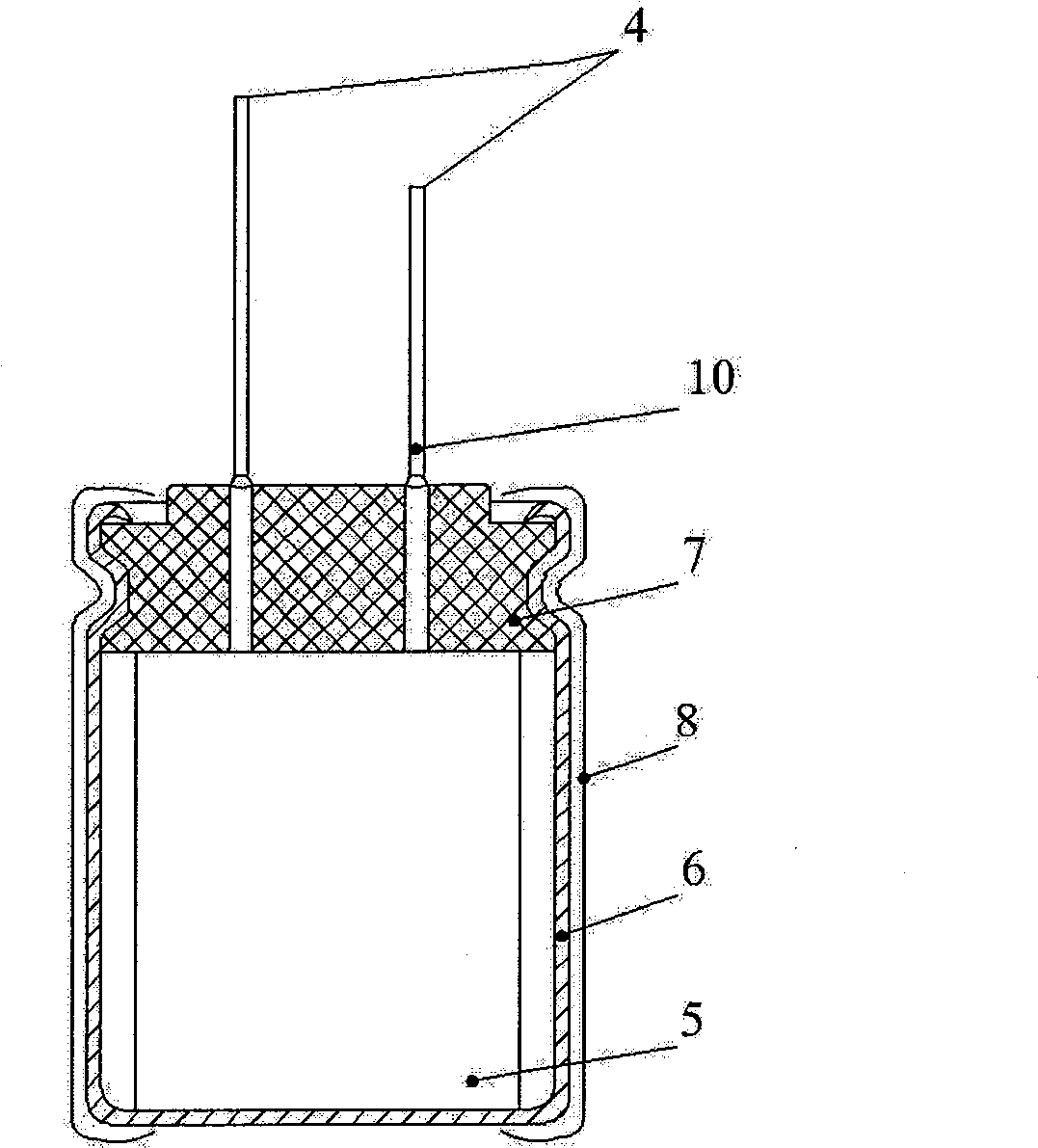

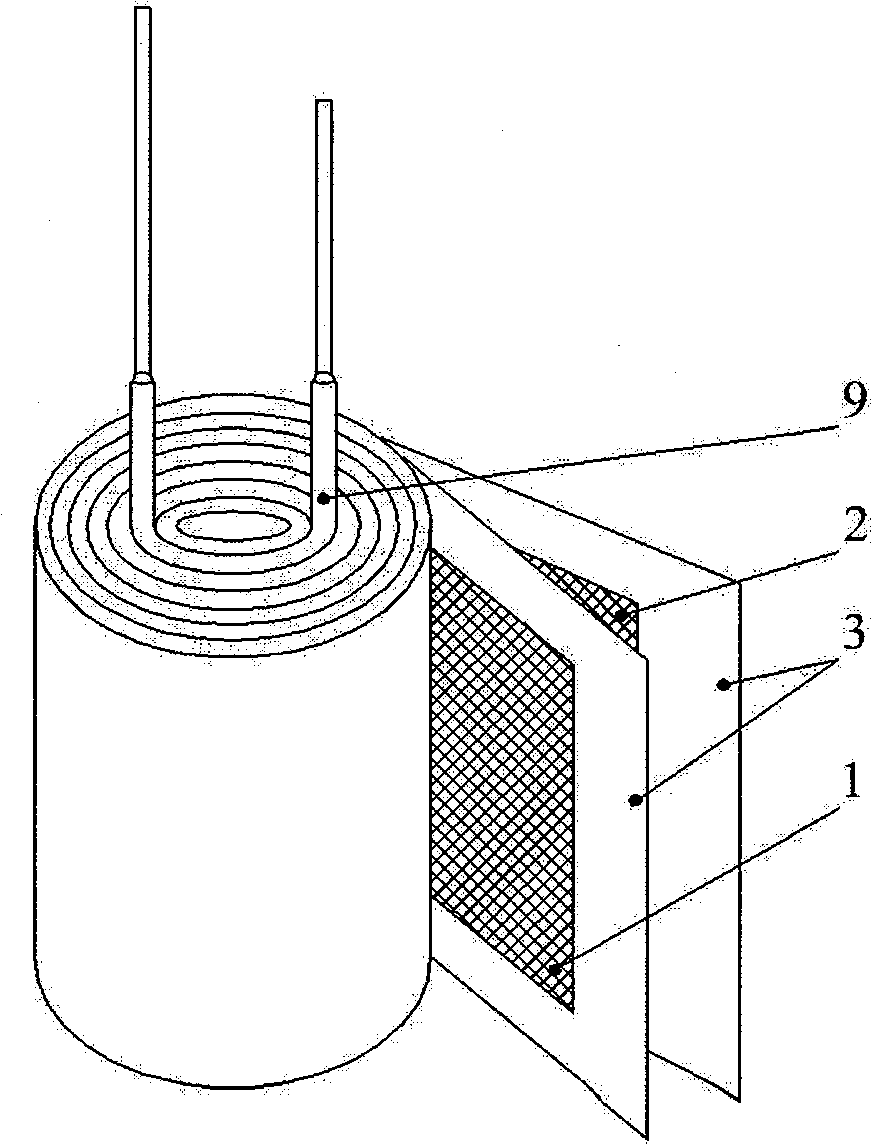

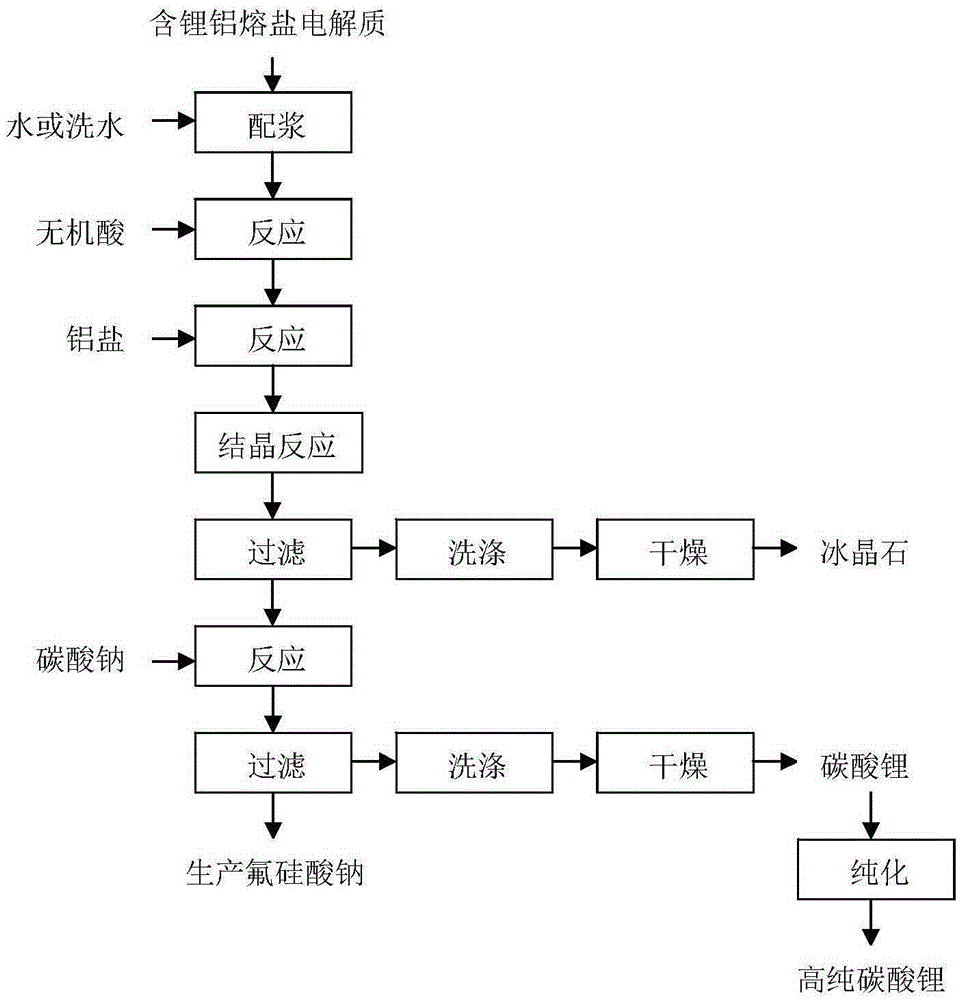

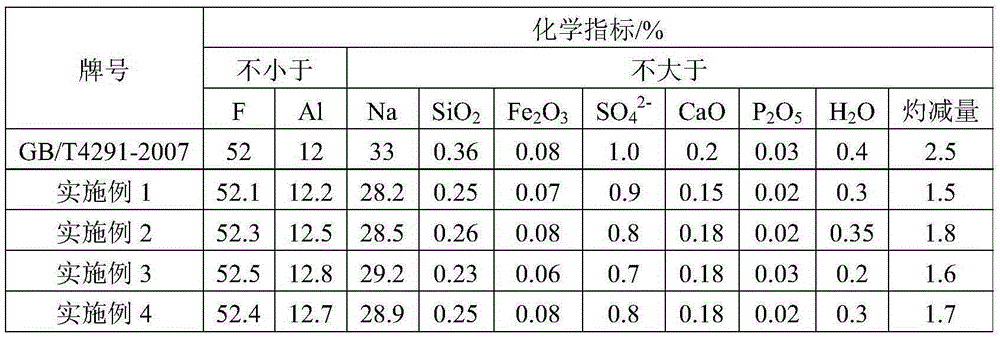

Lithium-aluminum-contained electrolyte comprehensive recycling method

ActiveCN105349786AImprove qualityRunning balance and stabilityProcess efficiency improvementLithiumSlurry

Owner:DO FLUORIDE CHEM CO LTD

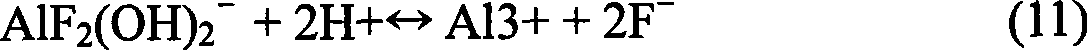

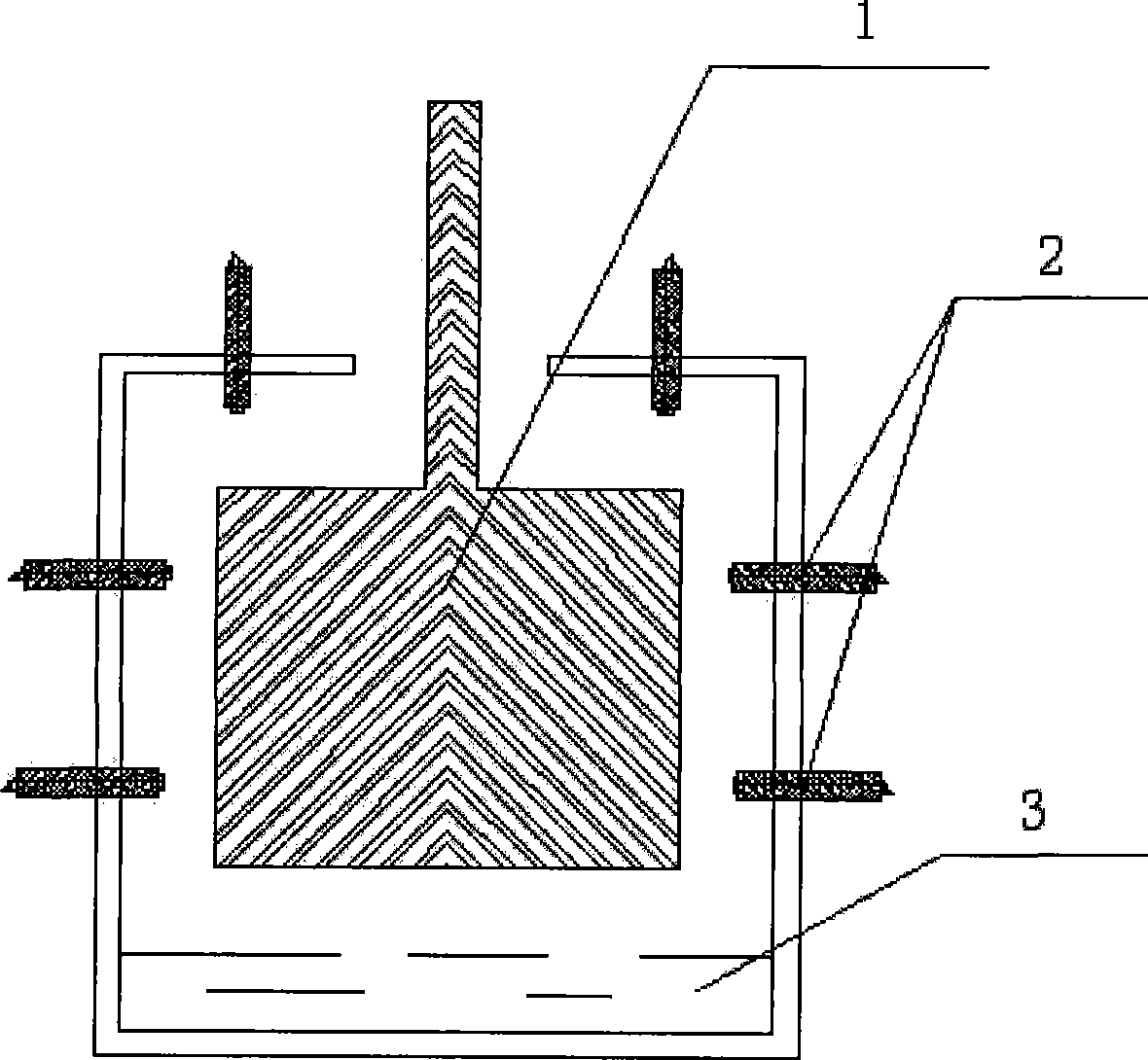

Aluminum electrolysis waste tank lining harmless treatment device and treatment method

ActiveCN107377592AImprove processing efficiencyGood effectSolid waste disposalElectrolysisFiltration

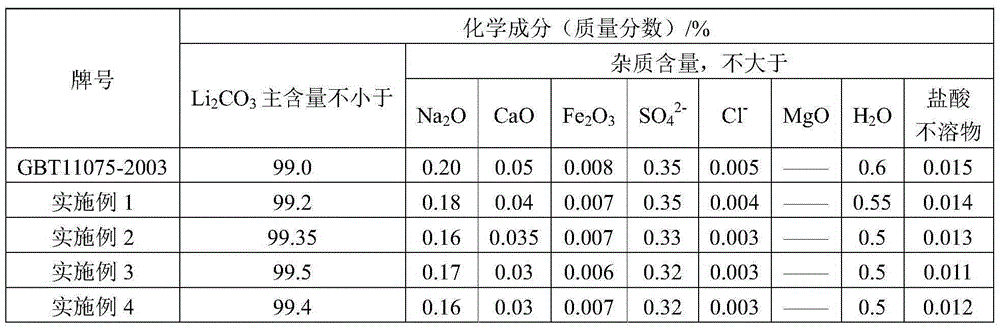

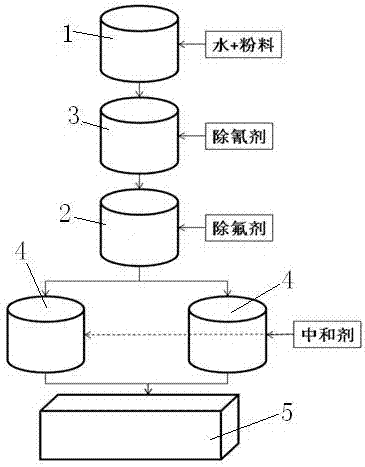

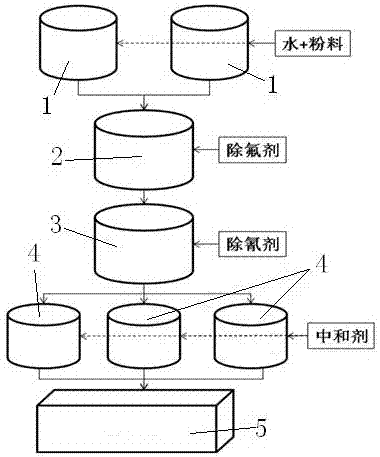

The invention relates to an aluminum electrolysis waste tank lining harmless treatment device and a treatment method. The treatment device is characterized by comprising a water adding reaction bin, a cyanogen removing agent or fluorine removing agent adding reaction bin, a fluorine removing agent or cyanogen removing agent adding reaction bin, a neutralizing agent adding reaction bin and a collecting bin connected in sequence. The treatment method comprises the following process: an aluminum electrolysis waste tank lining is crushed and milled as powder to feed in the water adding reaction bin, the cyanogen removing agent or fluorine removing agent adding reaction bin, the fluorine removing agent or cyanogen removing agent adding reaction bin, the neutralizing agent adding reaction bin and the collecting bin in sequence; charging, reaction and discharge are performed at the same time to form continuous aluminum electrolysis waste tank lining harmless treatment process; treated slurry is totally poured in the collecting bin, and is injected in a filter press by the collecting bin for pressing and filtration; harmless slag is carried out; and filtrate is recycled, so that the waste tank lining harmless treatment is realized, the treatment efficiency is high, the effect is good, and the operation is flexibility, simple and convenient.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for reclaiming electrolyte in carbon dross of aluminium electrolysis

A method for retrieving electrolyte form aluminum electrolysis carbon residue, characterized in that the aluminum electrolysis carbon residue is mixed with calcium fluoride serving as disperser with a weight of 1 to 10 wt. % of the carbon residue, and coal serving as combustion catalyst with a weight of 1 to 10 wt. % of the carbon residue, and then is roasted for 1 to 3 hours under a temperature of 650 to 850 degree C.. The method has the advantages of low process cost, high retrieving rate of electrolyte, easy implementation. The retrieved electrolyte has little impurity, and can be directly and completely returned to the electrolysis cell for use without negative effect to the quality of the electrolyte and aluminum melt.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

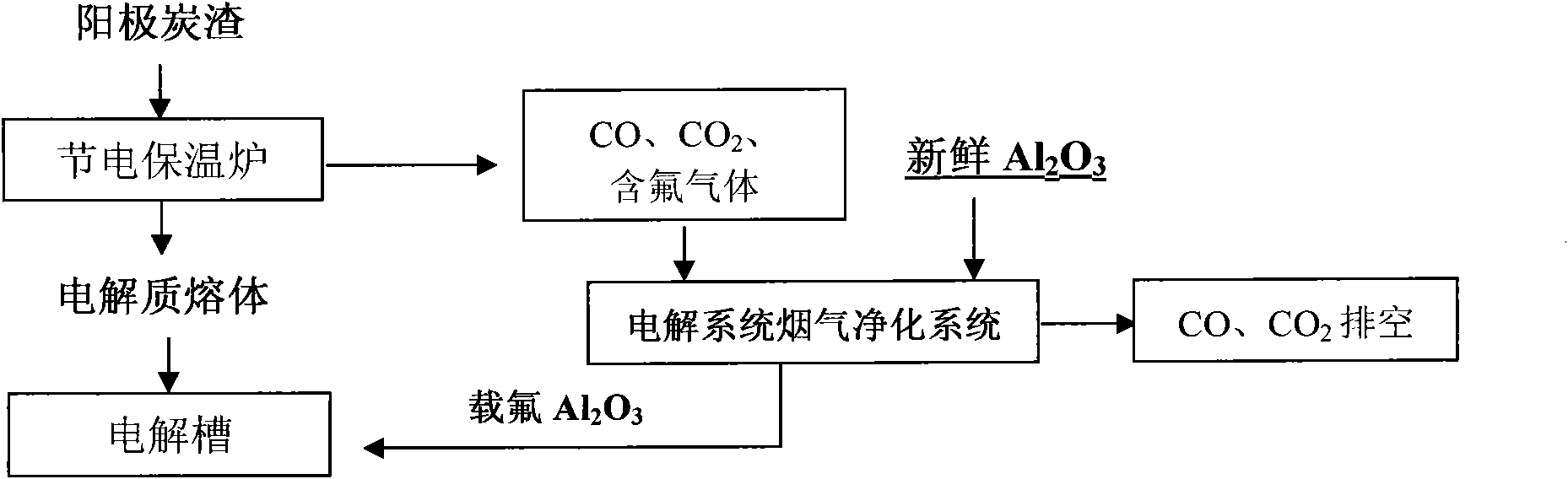

Method for innocent treatment of aluminum electrolysis anode carbon residue and recovery of electrolyte

ActiveCN102011148ARealize harmless treatmentReduce pollutionSolid waste disposalEnvironmental resistanceMaterials science

The invention discloses a method for innocent treatment of aluminum electrolysis anode carbon residue and recovery of electrolyte. The method comprises that: the anode carbon residue from an electrolytic cell is directly thrown into a power-saving holding furnace for smelting, and after a carbon material is completely combusted, the electrolyte completely forms an electrolyte melt; flue gas generated in the smelting process is introduced into an electrolysis series flue gas purification system, and fluoride gases are absorbed by alumina and returned to an electrolytic cell; the electrolyte melt directly enters the electrolytic cell for use or is cooled and ground for baking start-up of the electrolytic cell; and continuous feeding and continuous discharging are realized in the whole production process. The invention realizes innocent treatment of the anode carbon residue and comprehensive recycling of the electrolyte, and overcomes the defects that the carbon residue is needed to be crushed, ground and briquetted, various additives are needed to be added and environmentally-friendly treatment cannot be realized and the like in the prior art. The method is simple in technology, high in electrolyte recovery, low in production treatment cost and obvious in environment-friendly effects and economic benefits, and can realize harmlessness of the carbon residue after treatment.

Owner:YUNNAN YONGXIN ALUMINUM

Regeneration treatment method for waste cathode carbon blocks of aluminum electrolytic cell

The invention discloses a regeneration treatment method for waste cathode carbon blocks of an aluminum electrolytic cell and belongs to the technical field of solid waste treatment in the aluminum electrolysis industry. The main treatment process comprises the steps of crushing, screening, toxicity inhibition, batching and pressure-controlled heat treatment. After waste cathode carbon block materials of the aluminum electrolytic cell are crushed and screened, toxic inhibitors of hydrogen peroxide, potassium permanganate, hypochlorite and the like are added, then carbonaceous materials of anthracite, calcined petroleum coke, waste anode carbon blocks, anode scraps and the like are blended to serve as furnace-in raw materials, and the furnace-in raw materials are placed in a resistance furnace to be subjected to heat treatment at the ordinary pressure (1200-1800 DEG C) or the control pressure (1000-1600 DEG C and 0.01-0.5 atm). Fluoride volatilized from flue gas can be used for producingfluoride salt electrolytes after being cooled and crystallized, treated materials do not contain any contaminant, the carbon content is up to 99%, the conductivity is good, the specific surface areais large, the treated materials can be used for producing various carbon products, waste is turned into wealth, and environment-friendly resource application of overhaul of the waste cathode carbon blocks of the aluminum electrolytic cell is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Soft soil curing agent prepared by means of industrial residues

InactiveCN105236908AReduce pressure on environmental protectionSolve the shortage of resourcesSolid waste managementPortland cementSlag

The invention discloses a soft soil curing agent prepared by means of industrial residues. The curing agent is prepared from, by weight, 35-65% of steel slag, 30-50% of mineral waste residues, 10-30% of desulfurization gypsum, 2-6% of sulphoaluminate cement clinker, 2-4% of ordinary portland cement clinker, 2-5% of aluminum dregs and 0-5% of cement. The sum of the weight percentages of all the components is 100%. The soft soil curing agent is prepared by fully utilizing industrial residues of heat-engine plants, steel works and aluminum electrolysis enterprises, unconfined compression strength is high during soft soil foundation reinforcement, waste is recycled, and economic benefits and environmental protection benefits are high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com