Patents

Literature

327results about How to "Improve high pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367AImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

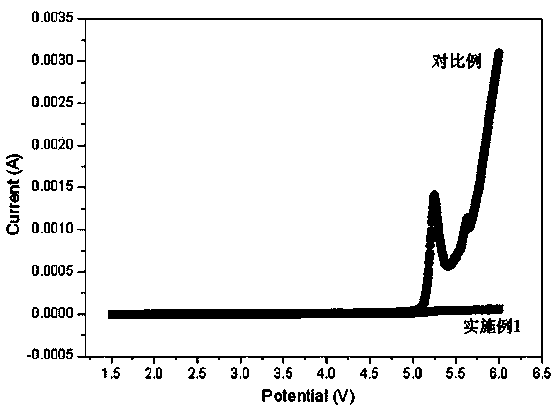

High-voltage lithium ion battery electrolyte

ActiveCN103401020AIncrease oxidation potentialSolve severe flatulenceSecondary cellsElectrolytic agentInternal resistance

The invention specifically relates to a high-voltage lithium ion battery electrolyte, which belongs to the technical field of lithium ion battery electrolytes. The high-voltage lithium ion battery electrolyte provided by the invention comprises a non-aqueous solvent, a lithium salt and an additive, wherein the additive comprises a mixture of a fluoro-ether additive and an alkyl dinitrile additive. A lithium ion battery using the high-voltage lithium ion battery electrolyte has stable cycle performance at normal temperature, no gas generation at a high temperature condition and small changes of internal resistance. A preparation process for the high-voltage lithium ion battery electrolyte is simple and easy to implement and has good market prospects.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Non-water electrolyte for high-voltage lithium ion battery and preparation method

The invention relates to non-water electrolyte for a high-voltage lithium ion battery and a preparation method. The non-water electrolyte is characterized in that: respectively purifying sulphone compound, halogenated cyclic carbonic ester and carbonic ester through rectification and molecular sieving under the protection of argon or nitrogen; mixing the sulphone compound, the halogenated cyclic carbonic ester and the carbonic ester in the weight ratio of 1:1:2 to obtain a non-water mixed solvent from which impurities and water are removed; dissolving 10 to 18 percent of mixed lithium salt in 80 to 87 percent of non-water mixed solvent to obtain the electrolyte; adding 2 to 5 percent of additive into the electrolyte; and uniformly mixing at the temperature of 40 DEG C to obtain the non-water electrolyte for a 4.8 Vvs.Li+ / Li lithium ion battery. The electrolyte has higher compatibility with a cathode material under high voltage and can form a stable solid electrolyte interface (SEI) film on the surfaces of a positive electrode and a negative electrode. Besides, the invention has the advantages that: the preparation process is simple, and the method is easy to implement and suitable for industrialized production.

Owner:XIANGHE KUNLUN NEW ENERGY MATERIALS CO LTD

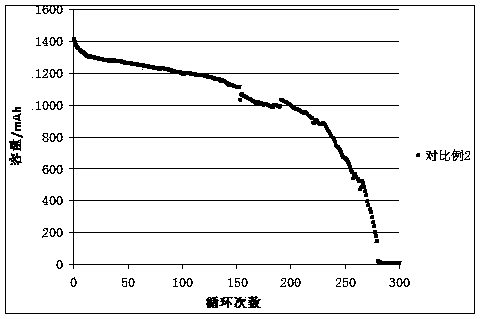

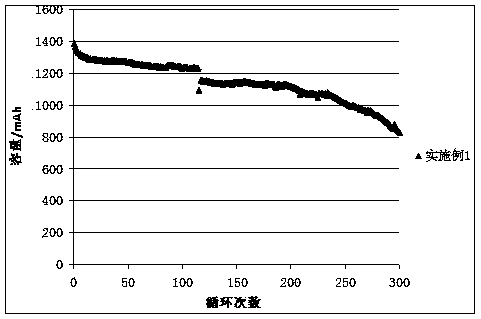

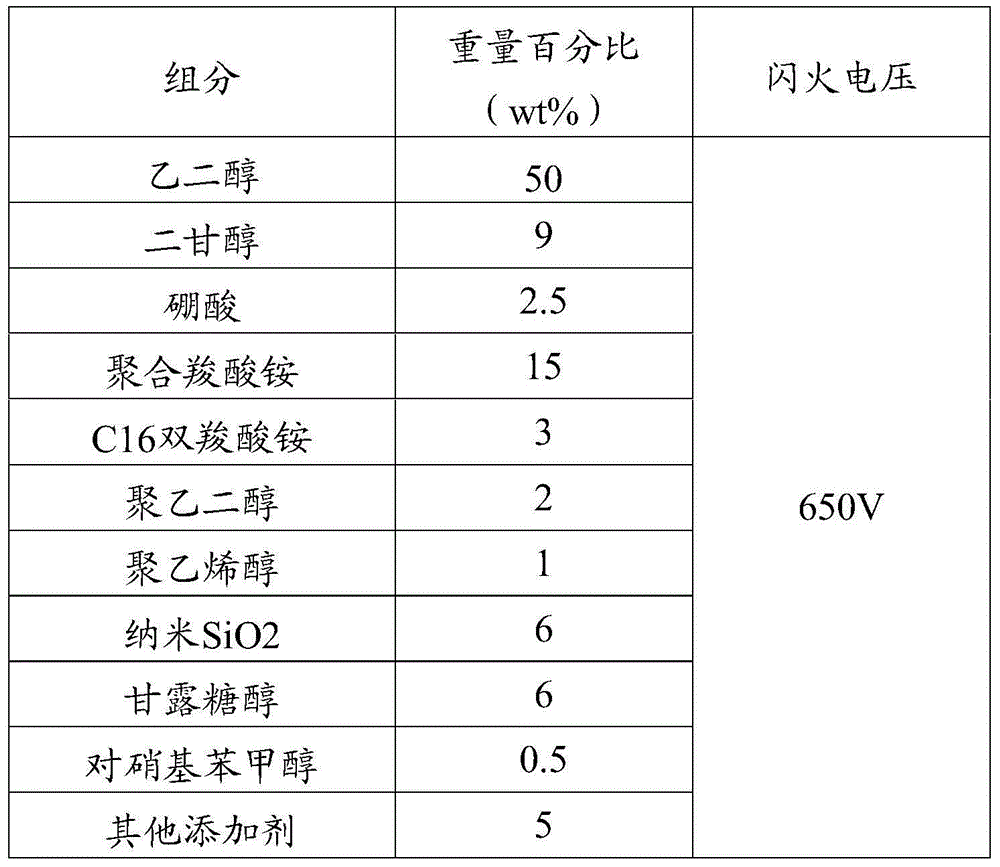

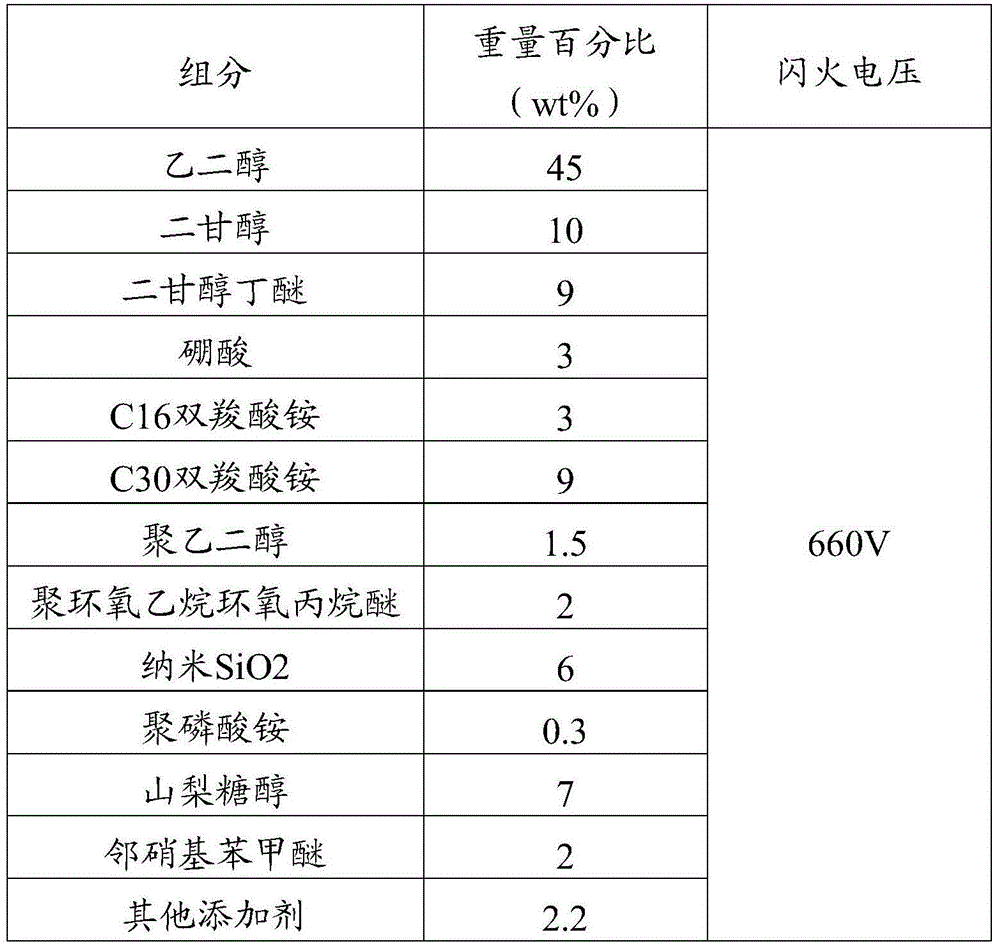

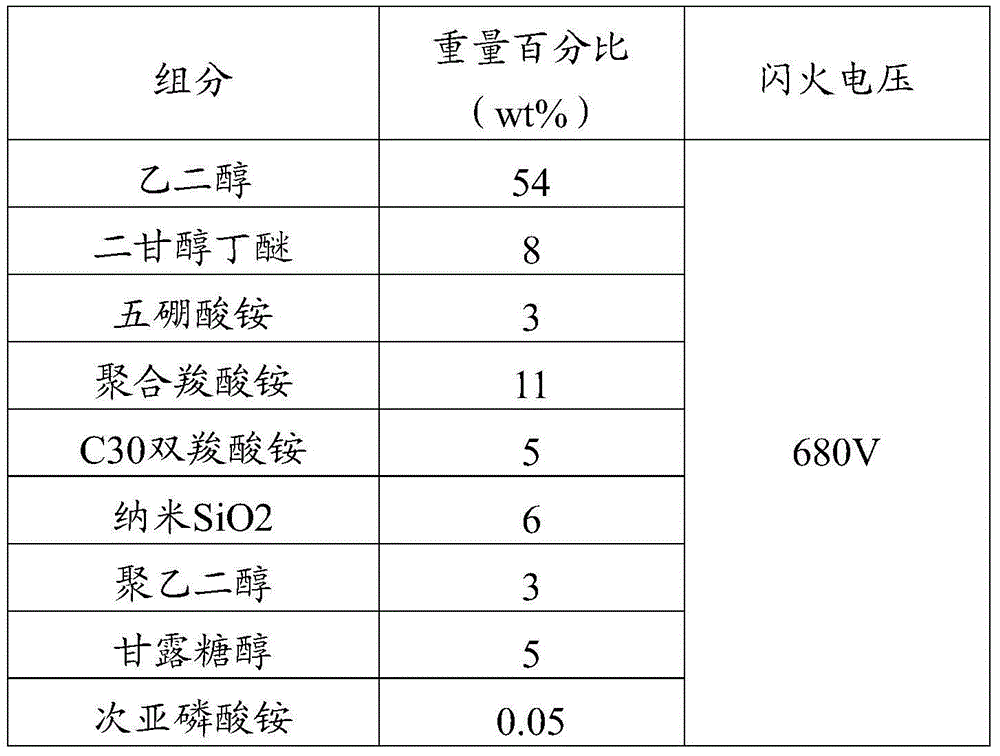

650V-700V extra-high-voltage aluminum electrolytic capacitor, working electrolyte and preparation method thereof

InactiveCN103915258AImprove high pressure resistanceImprove high temperature resistanceElectrolytic capacitorsHydrogenBreakdown phenomenon

The invention discloses working electrolyte of a 650V-700V extra-high-voltage aluminum electrolytic capacitor. The working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor comprises, by weight, 45-65% of primary solvents, 5-20.5% of secondary solvents, 10-20% of solutes, 8-25% of spark voltage improvers, 5-10% of stabilizers, 0.2-3% of hydrogen absorbents, and 2-5% of other additives. The invention further discloses a preparation method of the working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor and the 650V-700V extra-high-voltage aluminum electrolytic capacitor. According to the 650V-700V extra-high-voltage aluminum electrolytic capacitor, the working electrolyte and the preparation method of the working electrolyte, the spark voltage improvers and the stabilizers within the reasonable ranges are used, the high-voltage resistance and high-temperature resistance of the electrolyte are improved, and meanwhile the working electrolyte has low gas production performance. When the aluminum electrolytic capacitor with the electrolyte is subjected to a ripple current life test at 85 DEG C for 2000 hours, the aluminum electrolytic capacitor can resist the voltage of 650-700V and even higher voltage, and a breakdown phenomenon caused by unstable spark voltage of the electrolyte is avoided.

Owner:深圳市智胜新电子技术有限公司

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

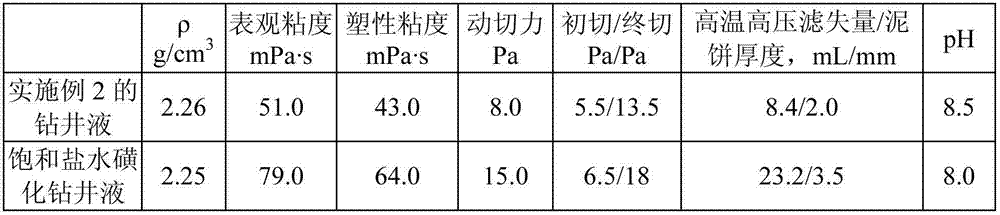

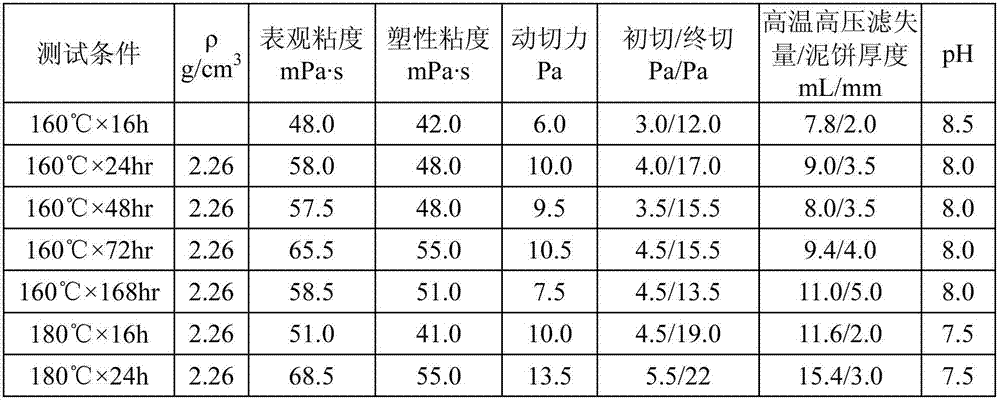

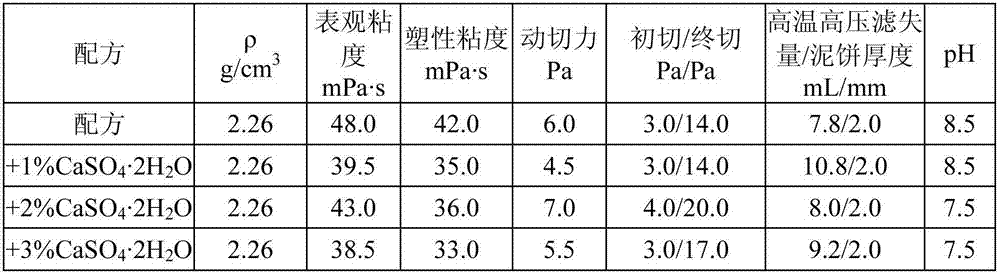

High-temperature-resistant high-density formate polysulfonate drilling fluid and preparation method thereof

ActiveCN102766446AGood thermal stabilityImprove salt resistanceDrilling compositionChemistryPotassium hydroxide

The invention relates to high-temperature-resistant high-density formate polysulfonate drilling fluid and a preparation method thereof. The high-temperature-resistant high-density formate polysulfonate drilling fluid comprises, by weight, 100 parts of water, 2-5 parts of bentonite, 0.1-10 parts of high-temperature-resistant sulphate polymer, 20-100 parts of formate, 0.6-2.0 parts of potassium hydroxide, 8-20 parts of sulfonating agent, 2-6 parts of blocking agent, 0.5-3.0 parts of emulsifier, 0.2-3.0 parts of pH regulator, and 120-270 parts of barite powder. The invention further provides the preparation method of the high-temperature-resistant high-density formate polysulfonate drilling fluid. The high-temperature-resistant high-density formate polysulfonate drilling fluid is applicable to petroleum drilling of deep wells and extra-deep wells, especially wells in high-thickness salt bed, is capable of resisting the temperature up to 180 DEG C under the density of 1.8-2.5g / cm<3>, tolerating salt to saturation and resisting calcium at 800-1000ppm, and is drilling fluid which is fine in performance and resistant to high temperature, high pressure and hypersalinity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

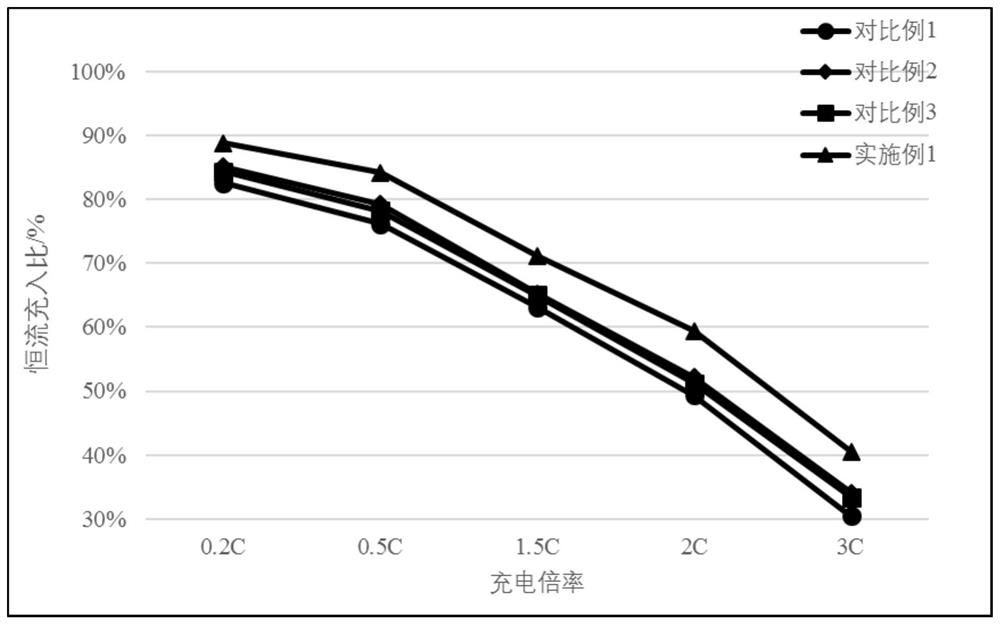

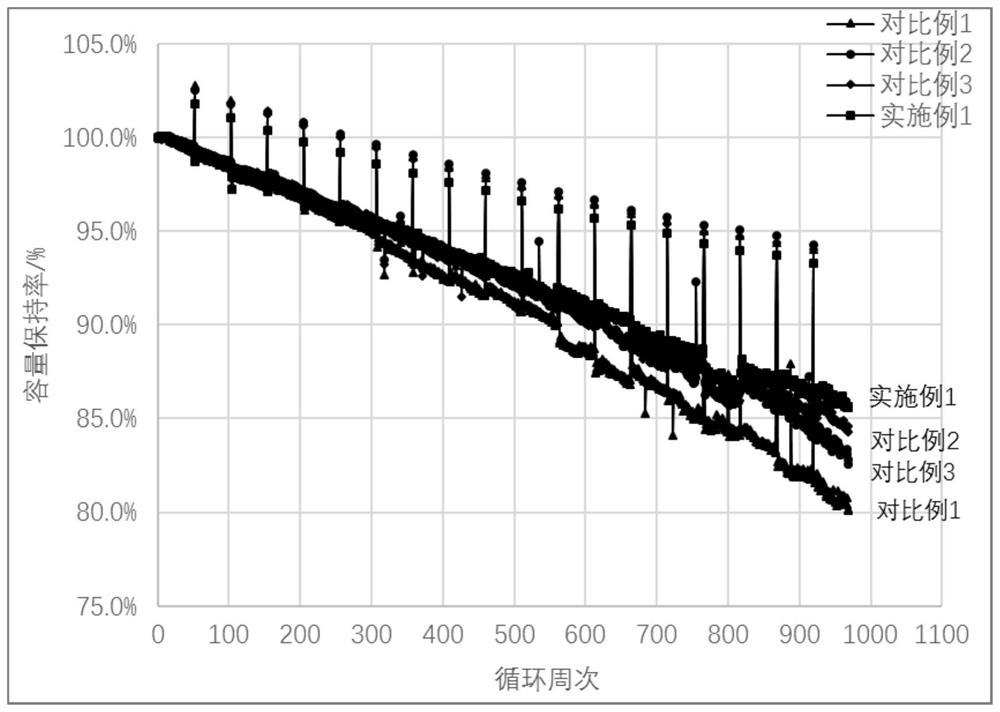

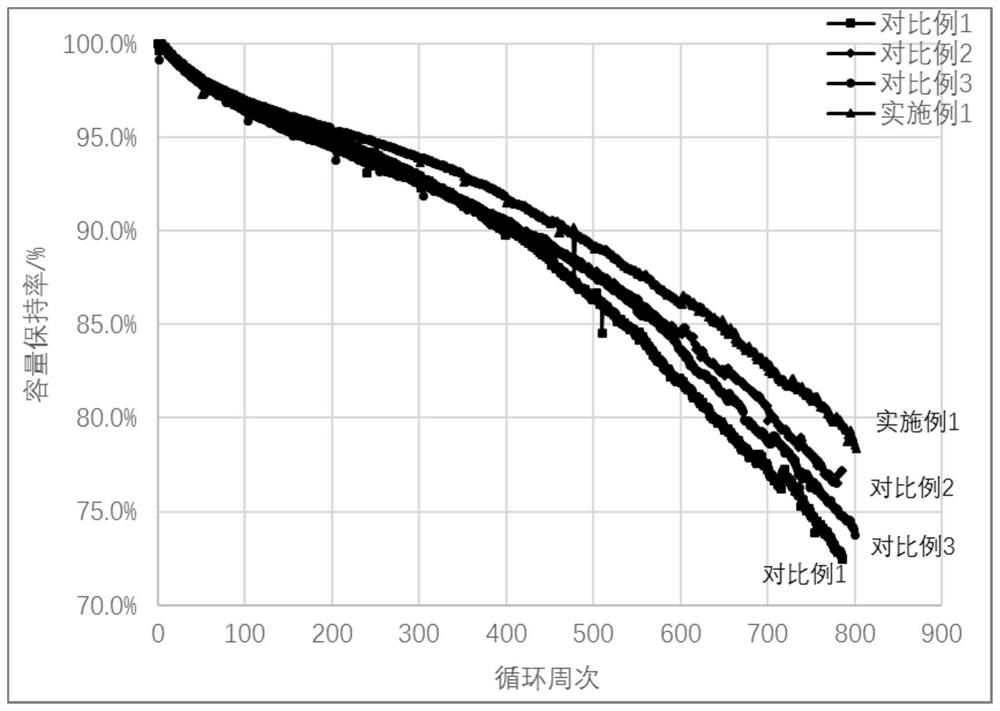

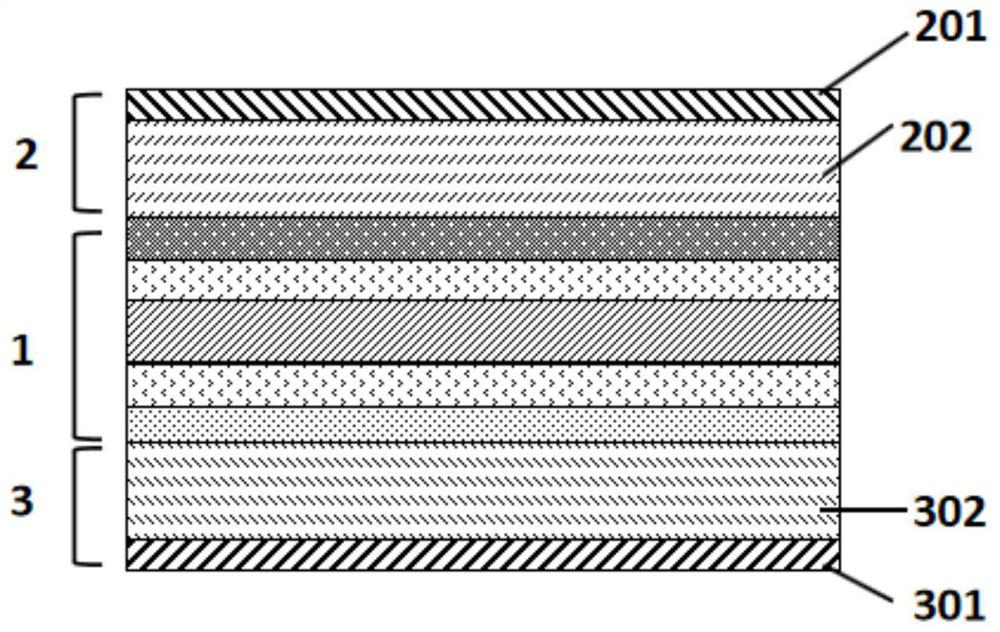

Positive plate and lithium ion battery comprising positive plate

InactiveCN111916665ALower internal resistanceImprove fast charge cycle performancePositive electrodesSecondary cells charging/dischargingInternal resistanceFast charging

The invention provides a positive plate and a lithium ion battery comprising the positive plate. The positive plate comprises a positive current collector, a first positive active material layer and asecond positive active material layer, wherein the first positive active material layer is arranged on the first surface of the positive current collector, and the second positive active material layer is arranged on the surface of the first positive active material layer; the first positive electrode active material layer comprises a first positive electrode active material, the second positiveelectrode active material layer comprises a second positive electrode active material, the first positive electrode active material is a positive electrode active material doped and / or coated with anMg element and an Al element, and the second positive electrode active material is a positive electrode active material doped and / or coated with an Al element. According to the positive plate, on theone hand, the high-temperature resistance and high-voltage resistance of positive active material particles on the surface of the positive plate can be ensured; on the other hand, the internal resistance of the positive plate is reduced, so the polarization in a quick charging process is reduced, and the quick charging cycle performance of the lithium ion battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

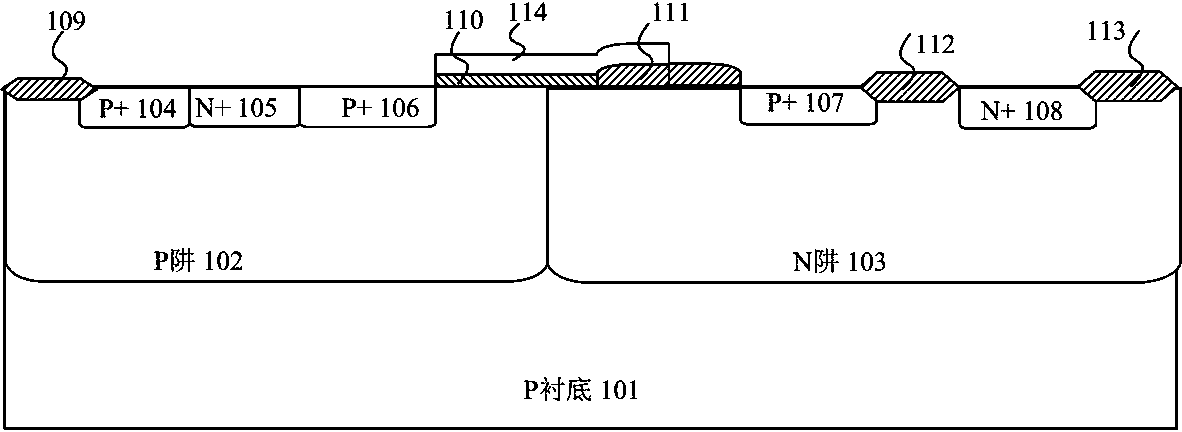

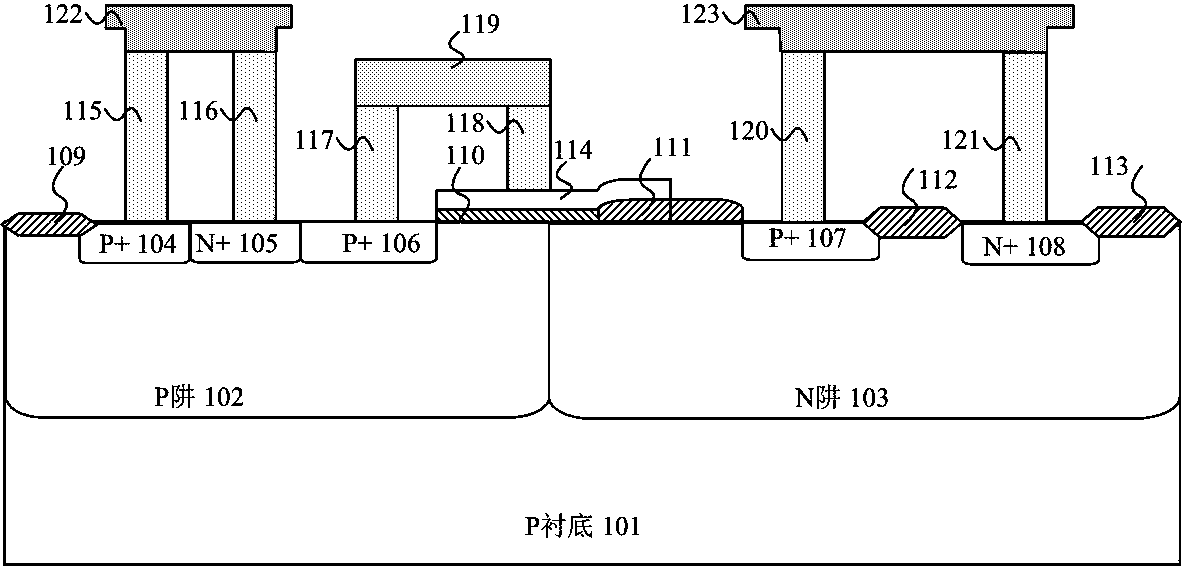

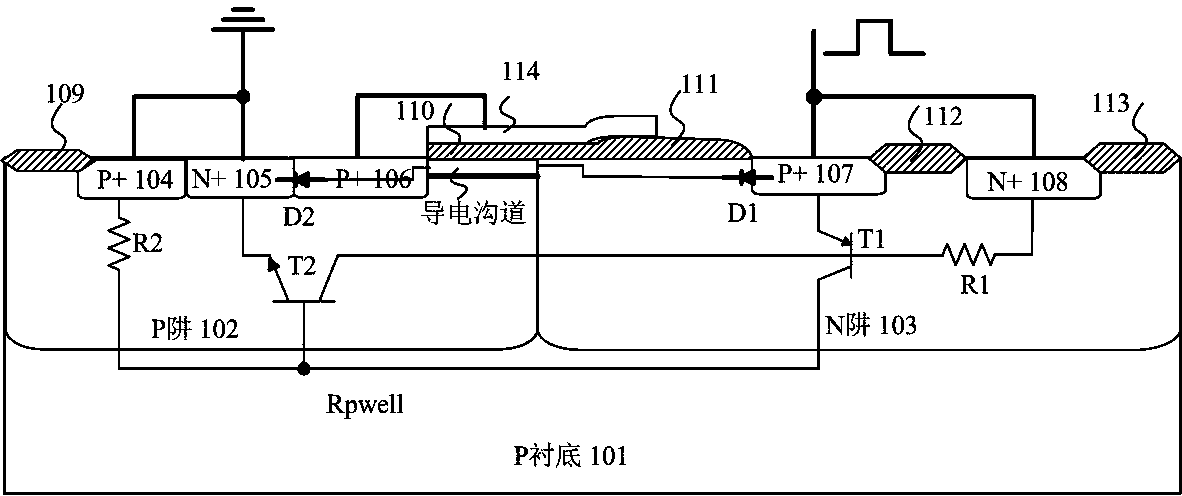

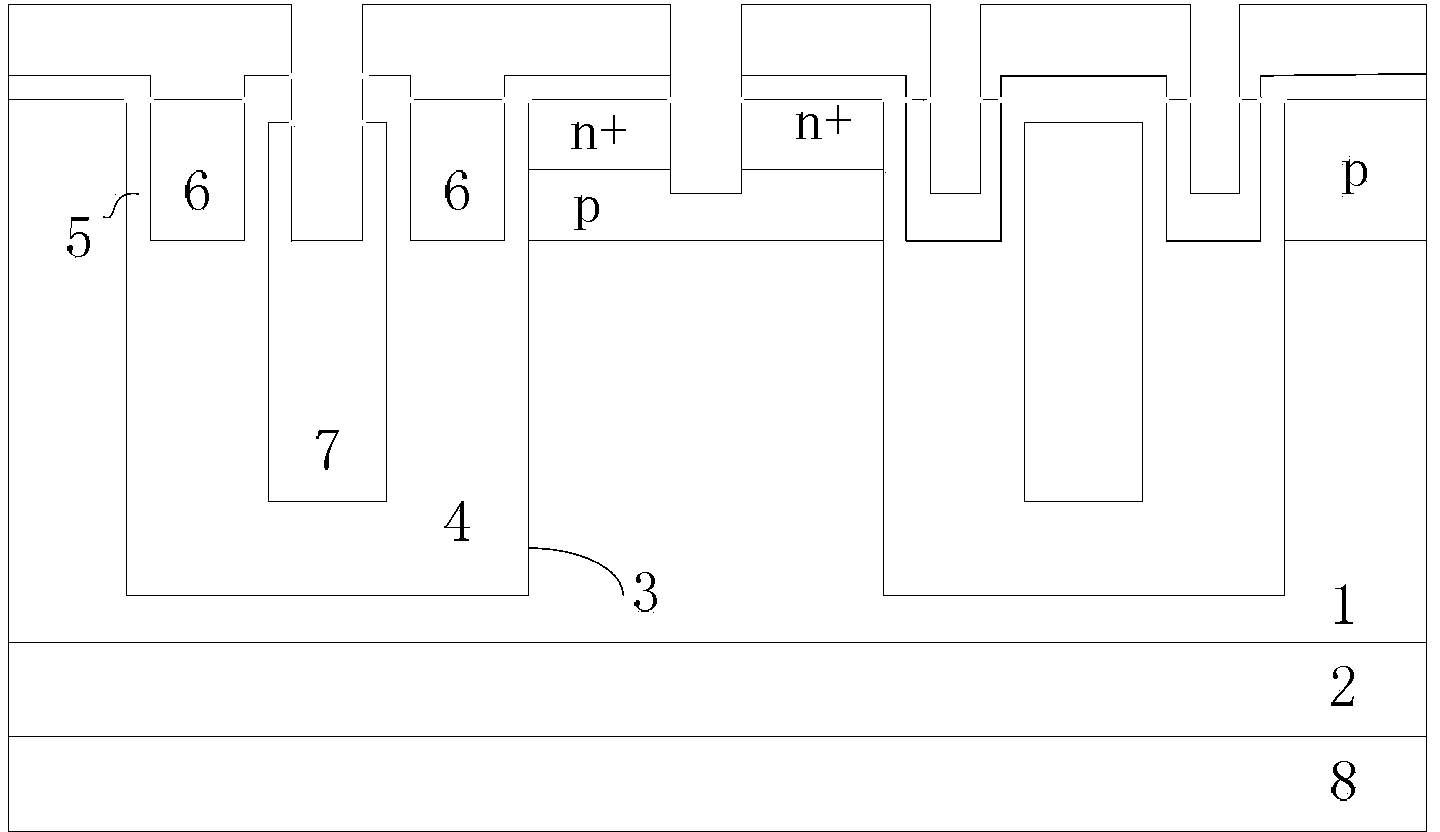

ESD self-protection device with LDMOS-SCR structure and high in holding current and robustness

ActiveCN103730462AImprove high pressure resistanceIncrease the secondary failure currentSolid-state devicesSemiconductor devicesPhysicsPolycrystalline silicon

An ESD self-protection device with an LDMOS-SCR structure and high in holding current and robustness can be used for an on-chip IC high-voltage ESD self-protection circuit. The ESD self-protection device is mainly formed by a P substrate, a P trap, an N trap, a first P+ injection region, a first N+ injection region, a second P+ injection region, a third P+ injection region, a second N+ injection region, a first field oxide isolation region, a thin gate oxide layer, a second field oxide isolation region, a third field oxide isolation region, a fourth field oxide isolation region and a polysilicon gate. According to the ESD self-protection device with the LDMOS-SCR structure, the parasitic LDMOS-SCR structure and an ESD current discharging path with two diodes connected with an LDMOS conducting channel can be formed respectively under the high-voltage ESD pulse effect, an ESD current is discharged rapidly, the holding current and a failure current after device trigger hysteresis are improved, the ESD robustness of the device is enhanced, and the ESD self-protection device is suitable for ESD self-protection of the high-voltage circuit.

Owner:JIANGNAN UNIV

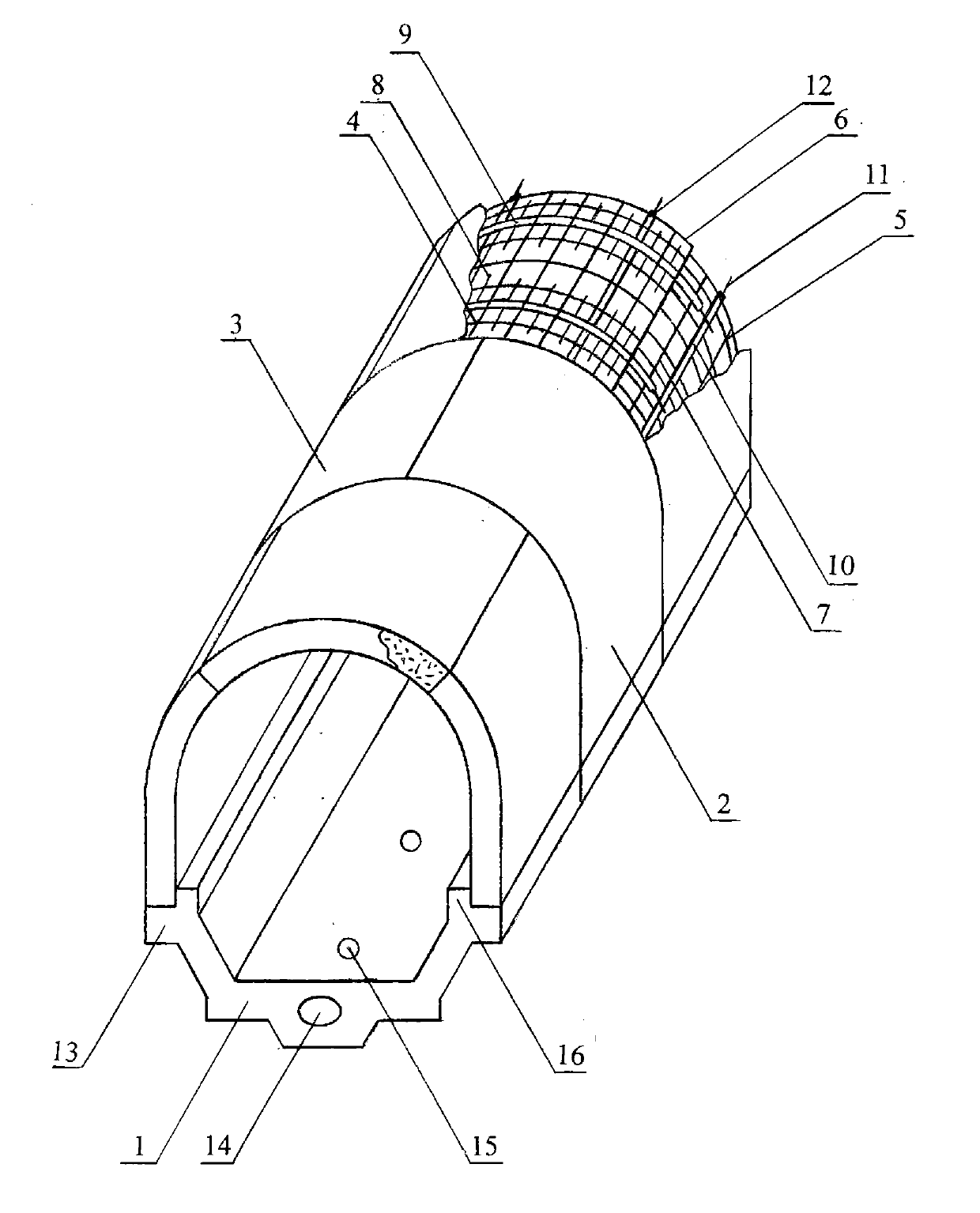

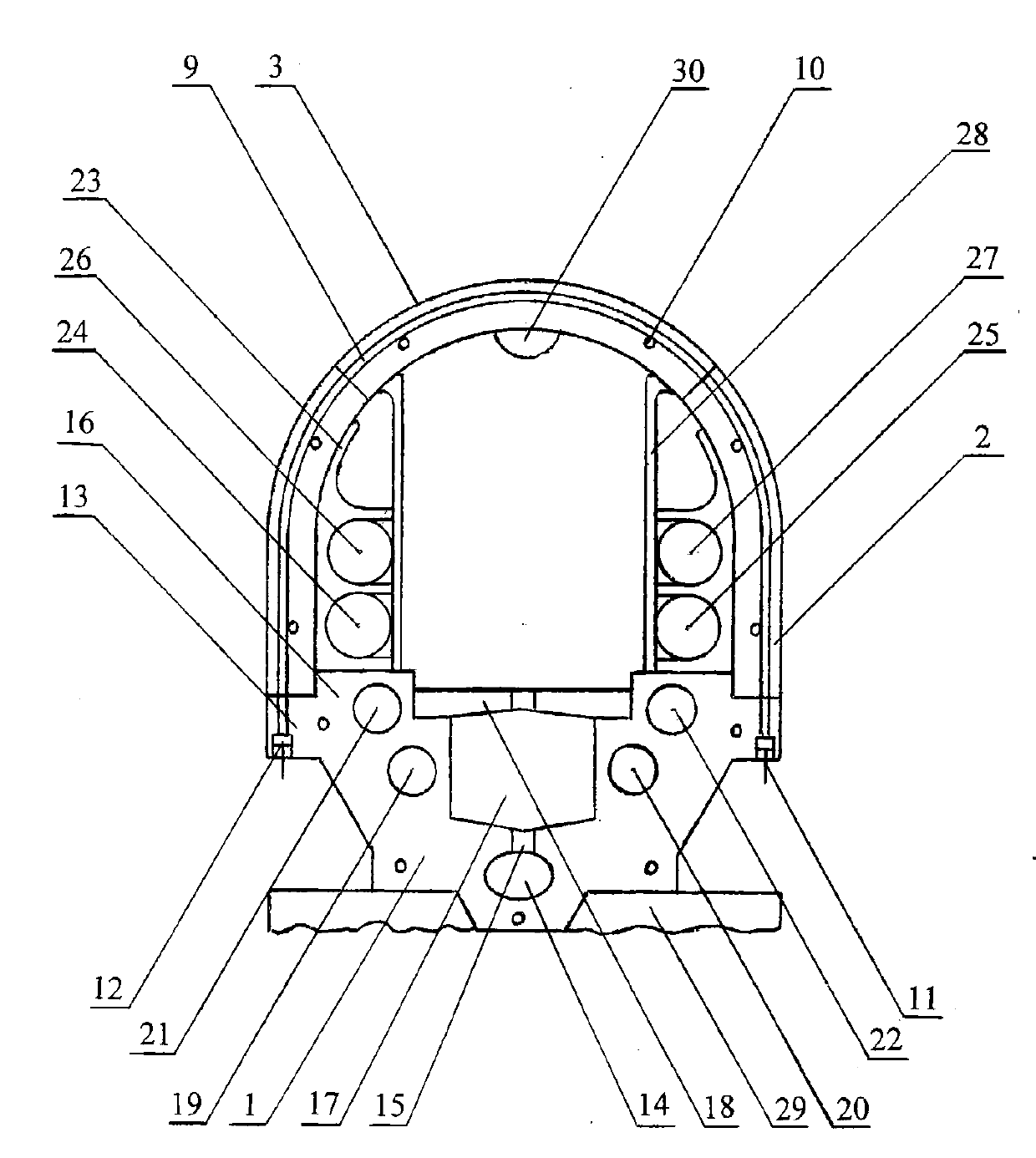

Multifunctional arched combined prestress underground pipe gallery for cisty and preparation process thereof

InactiveCN102995660AImprove shear resistanceImprove high pressure resistanceArtificial islandsUnderwater structuresHigh standardHigh pressure

The invention discloses a multifunctional arched combined prestress underground pipe gallery for a city, and a preparation process thereof. The multifunctional arched combined prestress underground pipe gallery consists of a concrete pipe sheet seat and an arched pipe body, wherein the arched pipe body is arranged on the pipe sheet seat and consists of the tube sheet. The pipe sheet seat and the pipe sheet are utilized, the underground pipe gallery is combined according to a structural mode of the arched pipe body to meet a high standard requirement on high pressure resistance, sedimentation resistance, torsion resistance, displacement resistance and earthquake resistance, so that the construction level of the city is improved. According to the topography of a town, a drainage network with a self-flow function is arranged, so that a design target of the functional pipe gallery and the safe pipe gallery is fulfilled.

Owner:张双里

Unsaturated polyester glass fiber reinforced molding compound and application thereof

InactiveCN102504509AHigh mechanical strengthImprove high pressure resistancePlastic/resin/waxes insulatorsGlass fiberLow voltage

The invention relates to an unsaturated polyester glass fiber reinforced molding compound, which is characterized in that the unsaturated polyester glass fiber reinforced molding compound comprises the following components by weight: 26-39 parts of unsaturated polyester resin, 0.5-0.8 parts of releasing agent, 1.5-5 parts of thickener, 0.2-1 parts of initiator, 0.3-1 parts of light stabilizer, 28-38 parts of aluminum hydroxide powder, 3-8 parts of talcum powder and 25-30 parts of reinforcing material. And the invention also provides application of the unsaturated polyester glass fiber reinforced molding compound in the low-voltage apparatus field. An insulator processed by the formulation provided by the invention has high mechanical strength, heat resistance, high-voltage resistance, insulation resistance and flame resistance, and has outstanding ageing resistance from the points of the whole performance and comprehensive performance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

High voltage electrolyte for lithium ion batteries

ActiveCN104282939AImprove solubilityAvoid structural changesSecondary cellsSolubilityHydrofluoroether

The invention discloses a high voltage electrolyte for lithium ion batteries, the high voltage electrolyte is composed of an organic solvent, electrolyte lithium salt and a cathode film-forming additive, wherein the organic solvent is a mixed solvent of fluorinated ethylene carbonate, trifluorinated propylene carbonate and hydrofluoroether, the electrolyte lithium salt mixed is lithium salt of lithium hexafluorophosphate and lithium bis(oxalate)borate. The high voltage electrolyte effectively solves the problems that fluorinated solvents are high in viscosity and the electrolyte lithium salt is poor in solubility in fluorinated organic solvents, so that the fluorinated organic solvents can be directly used as the organic solvents in lithium ion battery electrolyte, the high voltage electrolyte has wide electrochemical window and good oxidation resistance and high voltage resistant characteristics, has high electric conductivity, can guarantee the high magnification and power characteristics of a power battery, is high in safety, and can greatly improve the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

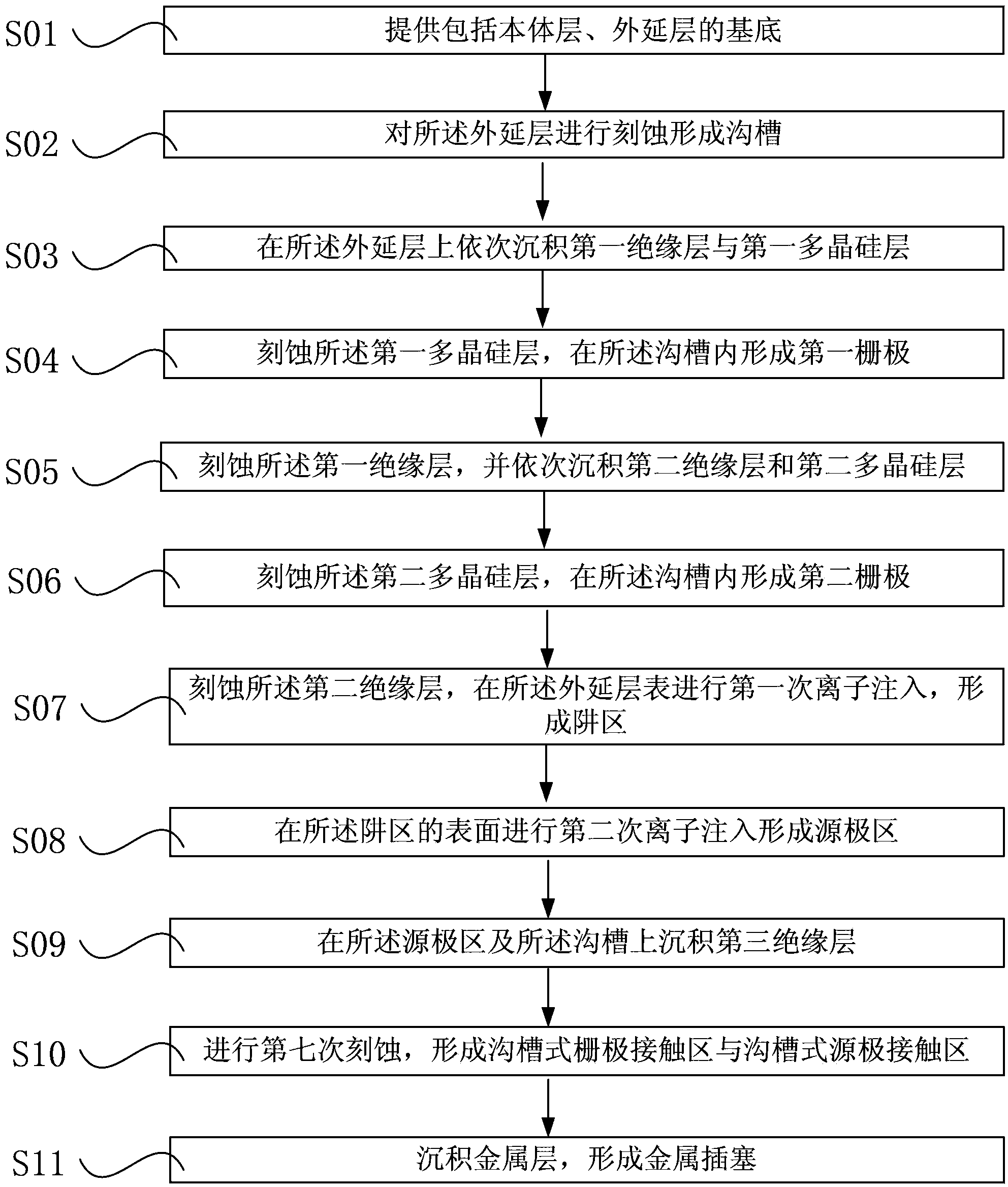

Groove MOSFET device and manufacturing method thereof

ActiveCN103413765ALower threshold voltageLow switching currentSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetIon implantation

The invention provides a groove MOSFET device and a manufacturing method thereof. The manufacturing method includes the steps that a substrate with an epitaxy layer is provided; a groove is formed in the epitaxy layer; a first insulating layer, a first gate electrode, a second insulating layer and a second gate electrode are sequentially formed in the groove through deposition and etching; ions are ejected into the two sides of the groove to form a well region and a source electrode region; groove type contact regions and a metal connector are formed. By means of the manufacturing method, the first gate electrode and the second gate electrode are separated, the thickness of the first insulating layer between the lower portion of the first gate electrode and the epitaxy layer is large, the thickness of the second insulating layer between the second gate electrode and the well region and between the second gate electrode and the source electrode region is small, and the two separated gate electrodes are connected through the metal connector, so that the device is good in high voltage resistance while the threshold voltage of the device is low. The device is stable in performance, simple in preparing method and low in preparing cost.

Owner:HANGZHOU SILICON-MAGIC SEMICON TECH CO LTD

Composite soft magnetic metal powder, preparation method and integrally-formed inductor

InactiveCN110181036AImprove conductivityImprove high pressure resistanceTransportation and packagingMetal-working apparatusRare earthInductor

The invention discloses composite soft magnetic metal powder, a preparation method and an integrally-formed inductor. The preparation method of the composite soft magnetic metal powder comprises the following steps of performing passivation treatment, preparing a coating agent, coating the soft magnetic metal powder, granulating, and adding a lubricant. The preparation method of the composite softmagnetic metal powder has the advantages that the high pressure impact resistance of the soft magnetic composite metal powder is greatly improved by adding rare earth oxide into the soft magnetic composite metal powder, so that the performance of the integrally-formed inductor is improved.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

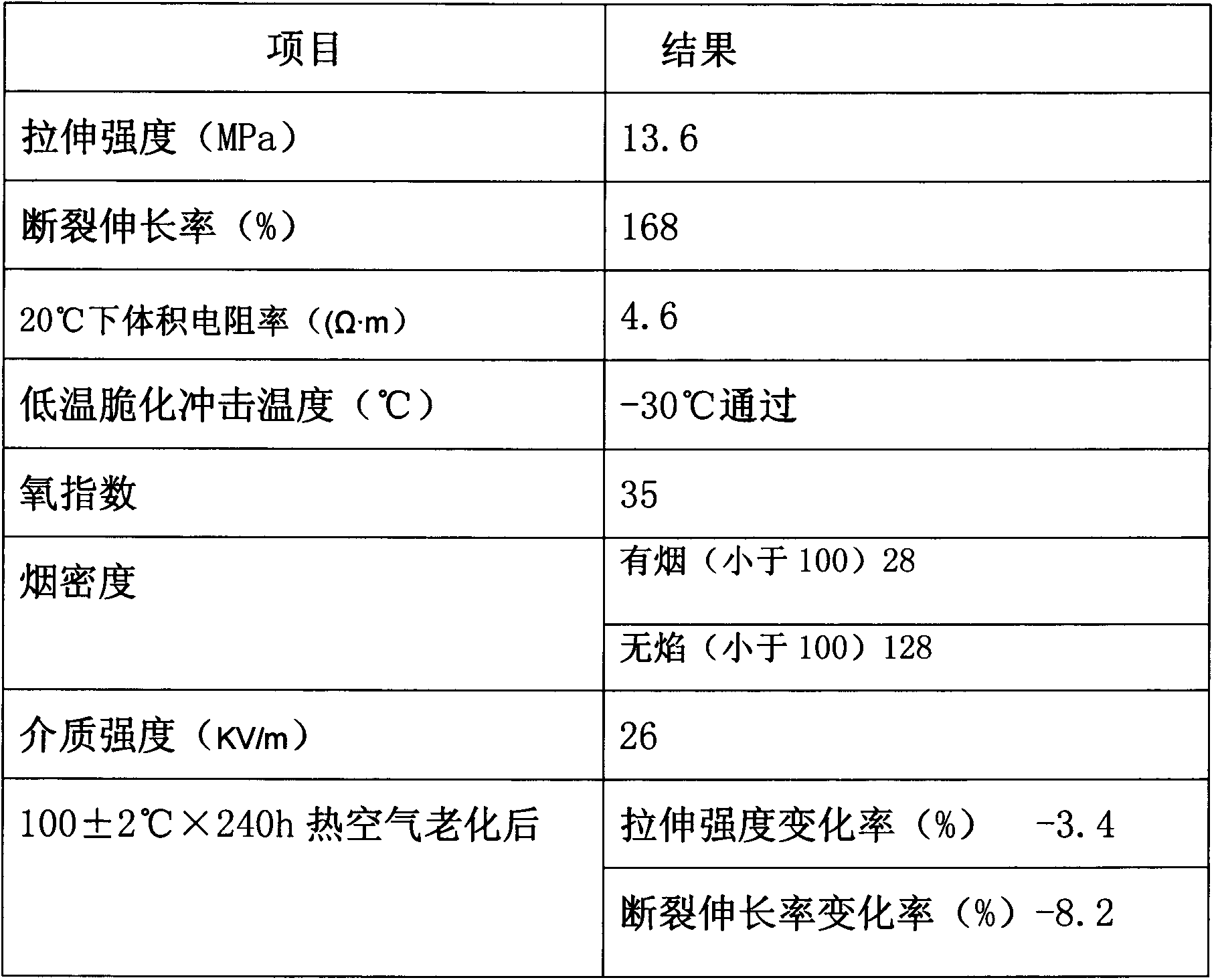

Novel low-smoke zero halogen flame-retardant cable material

InactiveCN104341676AGood weather resistanceGood flexibilityPlastic/resin/waxes insulatorsStearic acidSmoke

The invention discloses a novel low-smoke zero halogen flame-retardant cable material which comprises the following raw materials in parts by weight: 30-50 parts of EVA resin, 30-60 parts of silane coupling agent modified magnesium hydrate fire retardant, 5-6 parts of nanometer silicon carbide, 0.2-0.4 parts of nanometer aluminum nitride powder, 1-2 parts of cross-linking agents, 1-2 parts of calcium stearate, 0.5-1.0 part of stearic acid, 0.2-0.4 part of ultraviolet light absorber UV-531, 8-15 parts of smoke suppression agents, 20-40 parts of compatilizer, 1-4 parts of antioxygen, 7-10 parts of processing agents, 3-6 parts of antioxygen and 1-3 parts of termite resistances. The novel low-smoke zero halogen flame-retardant cable material has excellent fire resistance and non-delay flammability; during a burning process, the smoke volume is less, no toxic gas is generated and no corrosive gas is generated; the low temperature resistance and the uvioresistant property are excellent.

Owner:ANHUI TIANYUAN CABLE

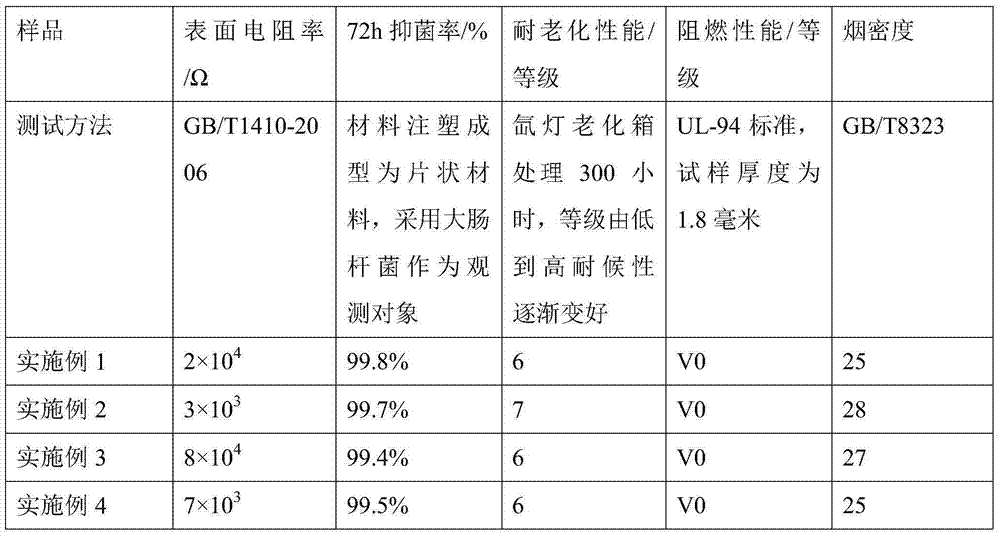

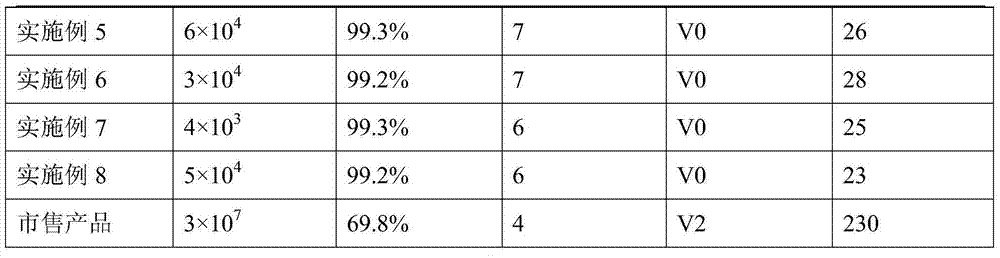

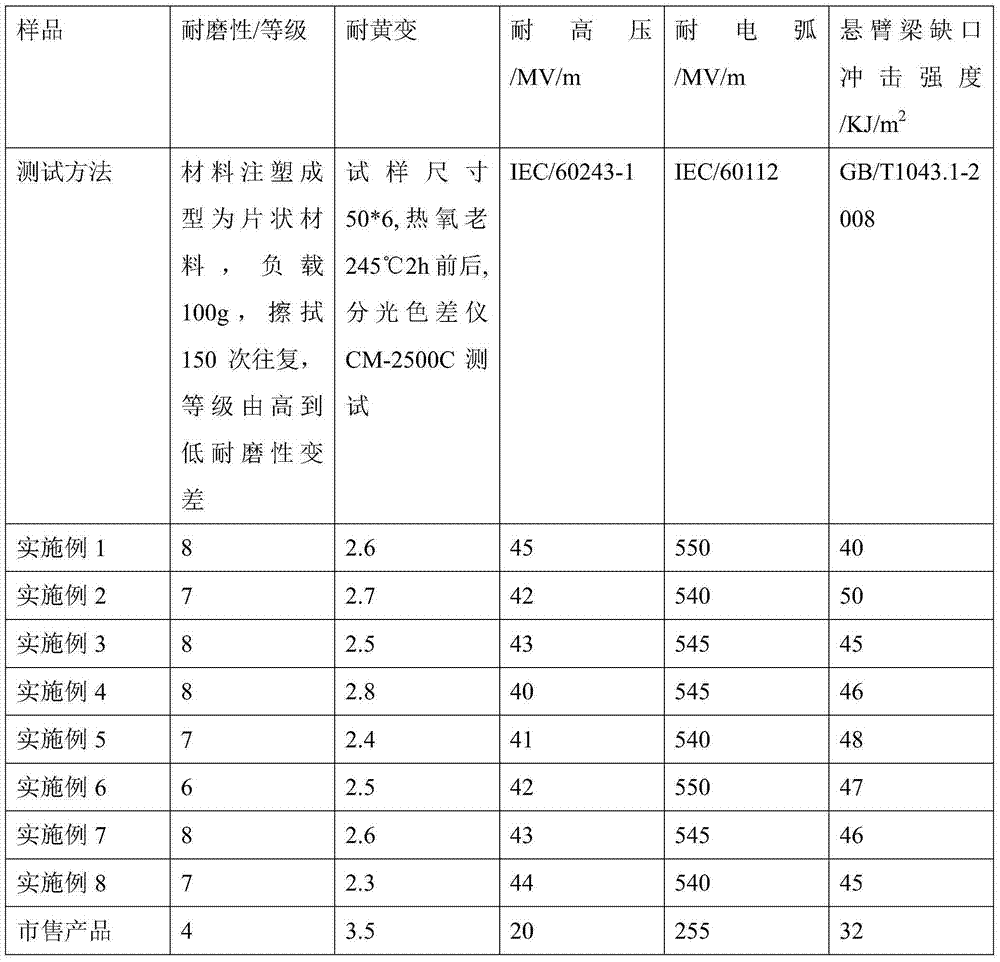

Antistatic antibacterial PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene copolymer) composite material

The invention discloses an antistatic antibacterial PC (polycarbonate) / ABS (acrylonitrile-butadiene-styrene copolymer) composite material comprising the following components by weight: 63-93 parts of polycarbonate, 57-65 parts of ABS, 33-47 parts of a flame retardant agent, 29-44 parts of a nano antibacterial agent, 41-47 parts of an antiaging agent, 24-32 parts of an antistatic agent, 24-32 parts of a compatibility agent, 22-26 parts of a lubricant, 19-23 parts of a toughening agent, 15-20 parts of a synergistic agent, 10-16 parts of an insulation agent, 10-16 parts of a yellowing resistant agent and 17-24 parts of a wear-resisting agent. The antistatic antibacterial PC / ABS composite material has excellent antistatic performance, avoids the deleterious effects of electrostatic, and also has antibacterial properties, more than 99% bacteriostasis rate can be maintained for a long term, the composite material has good anti-aging properties, is flame retardant, simultaneously reduces the combustion smoke density, has excellent characteristics of wear resistance, yellowing resistance, high voltage resistance and electric arc resistance, and is suitable for different use requirements.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

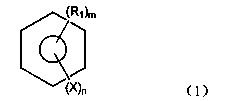

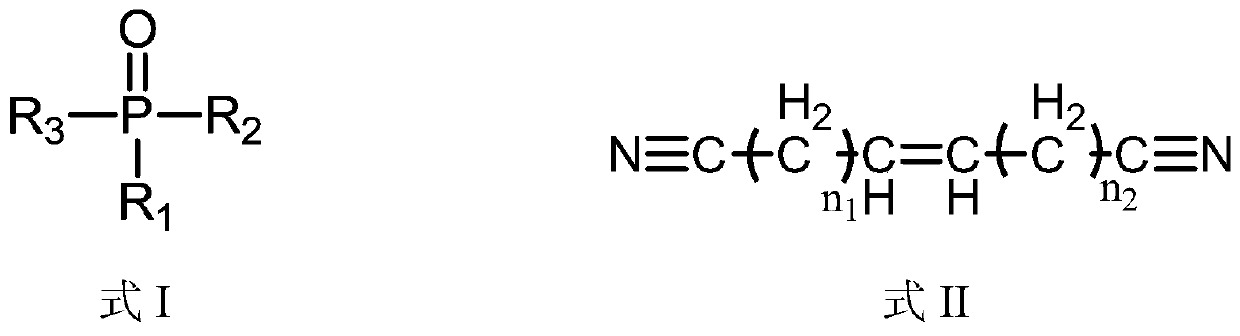

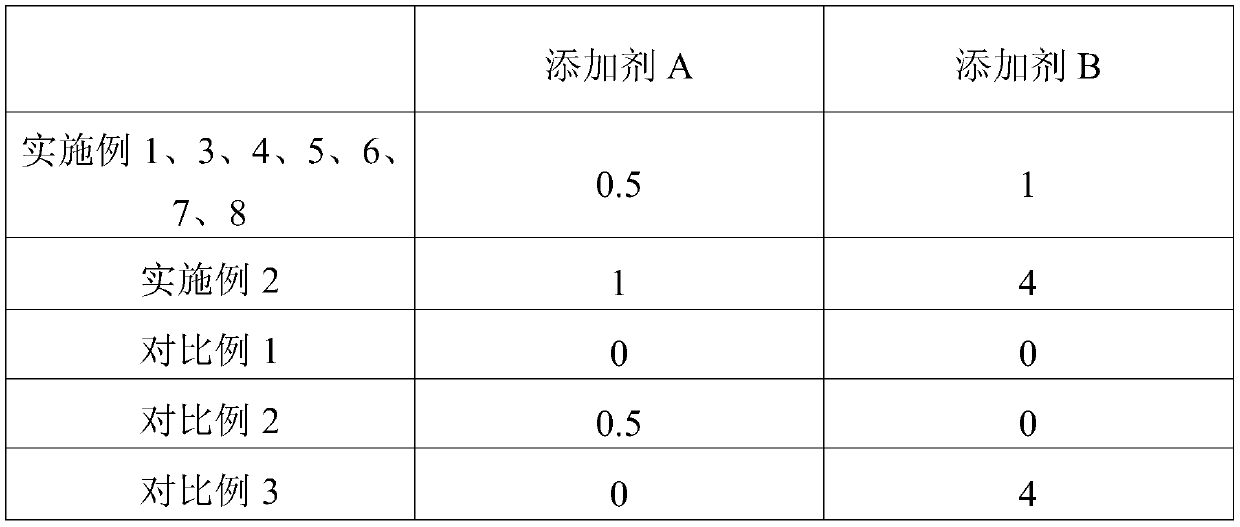

Soft package lithium ion silicon carbon battery electrolyte and lithium ion battery

ActiveCN110048164AImprove permeabilityAvoid decompositionSecondary cellsOrganic electrolytesHigh temperature storageElectrolysis

The invention provides a soft package lithium ion silicon carbon battery electrolyte and a lithium ion battery. The electrolyte comprises an additive A and an additive B, the structure of the additiveA is shown as a formula I, and the structure of the additive B is shown as a formula II. The electrolyte forms a protective film on the positive electrode and the negative electrode, so that the positive electrode and the negative electrode of the battery have better high-voltage resistance, the expansion rate of the silicon carbon negative electrode is reduced, the side reaction loss of the electrolyte is effectively reduced, the cycle life of the battery is prolonged, the high-temperature storage performance of the battery is improved, and the low-temperature charging and discharging performance of the battery is not influenced.

Owner:东莞维科电池有限公司

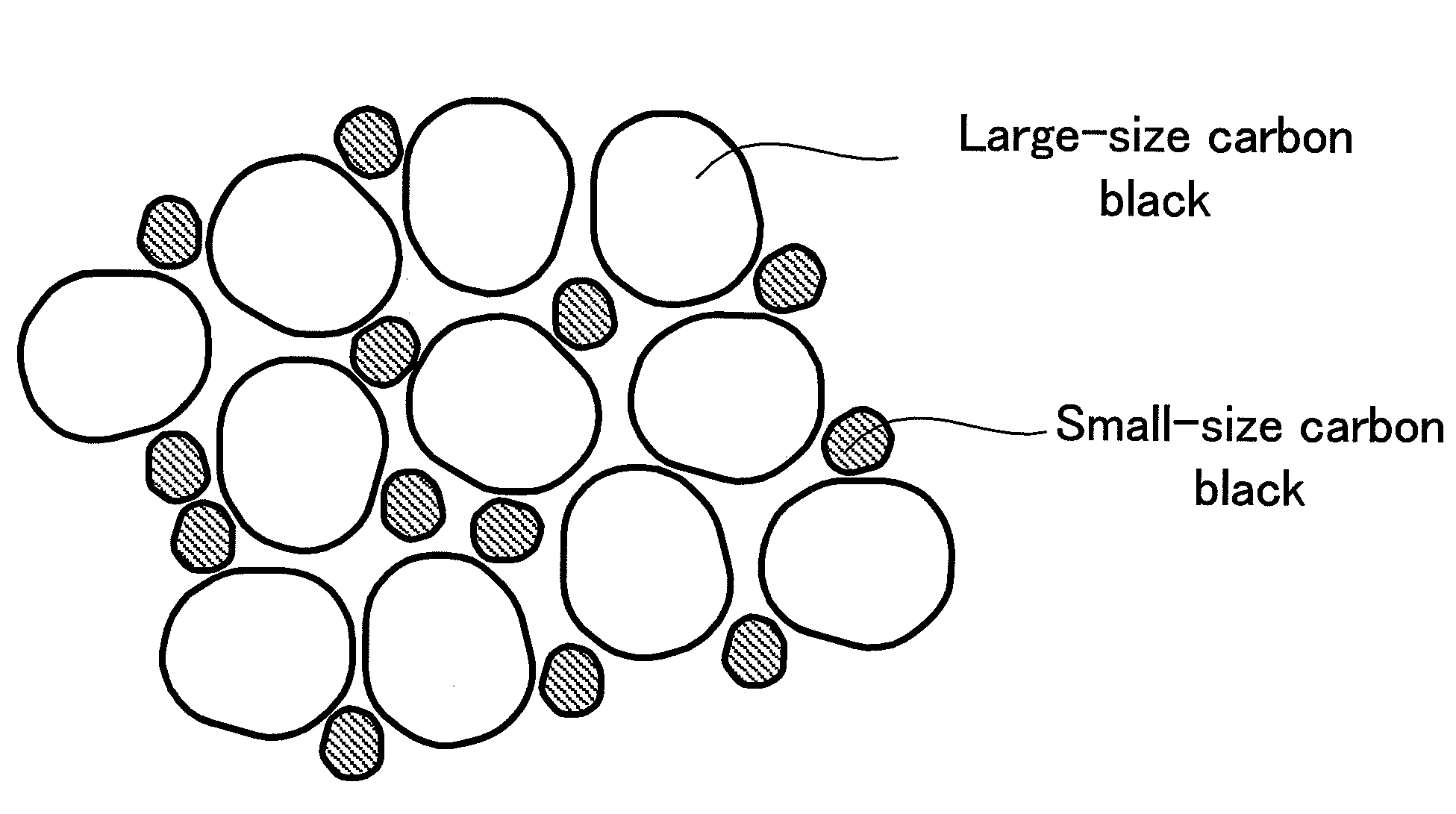

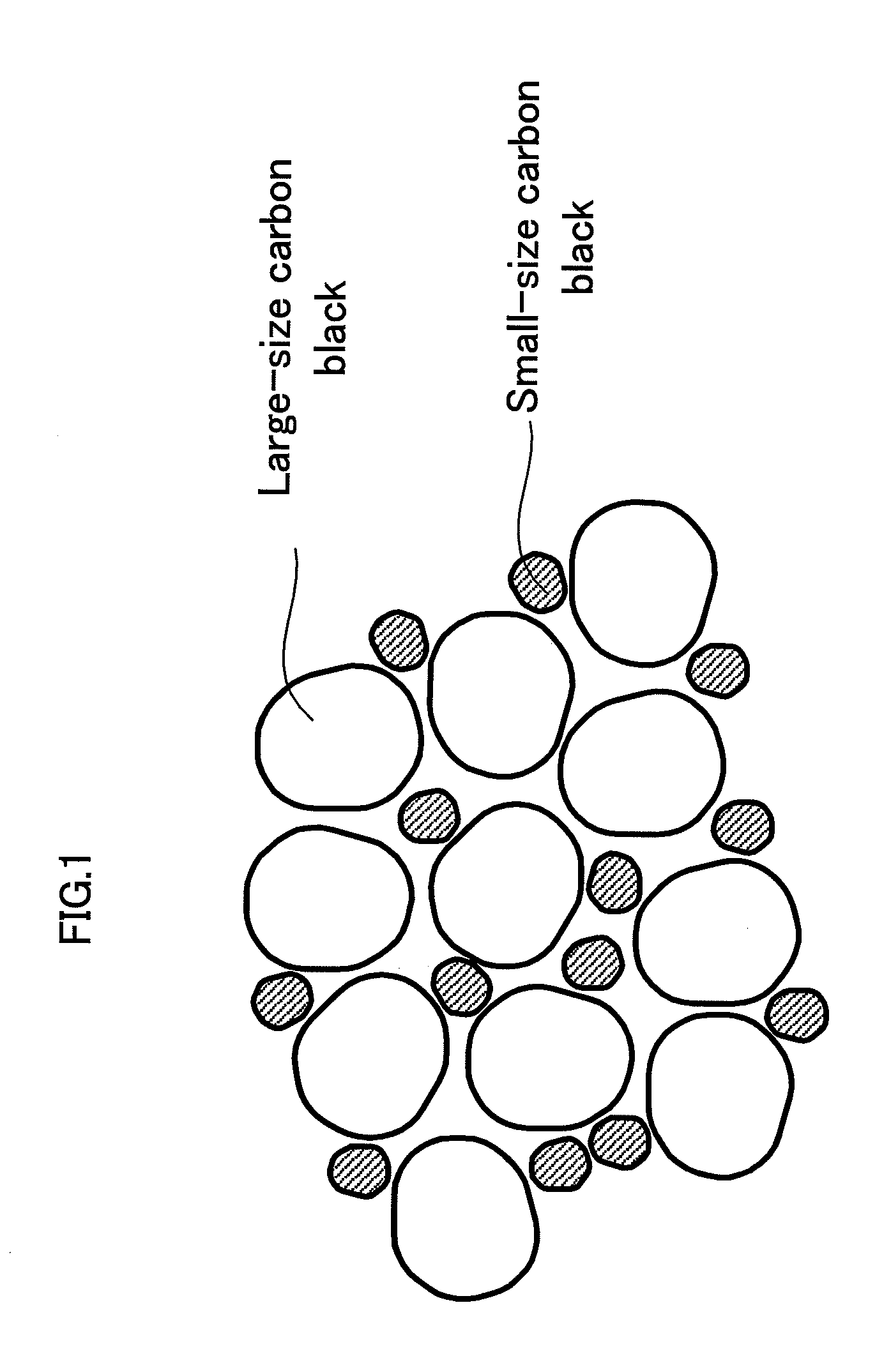

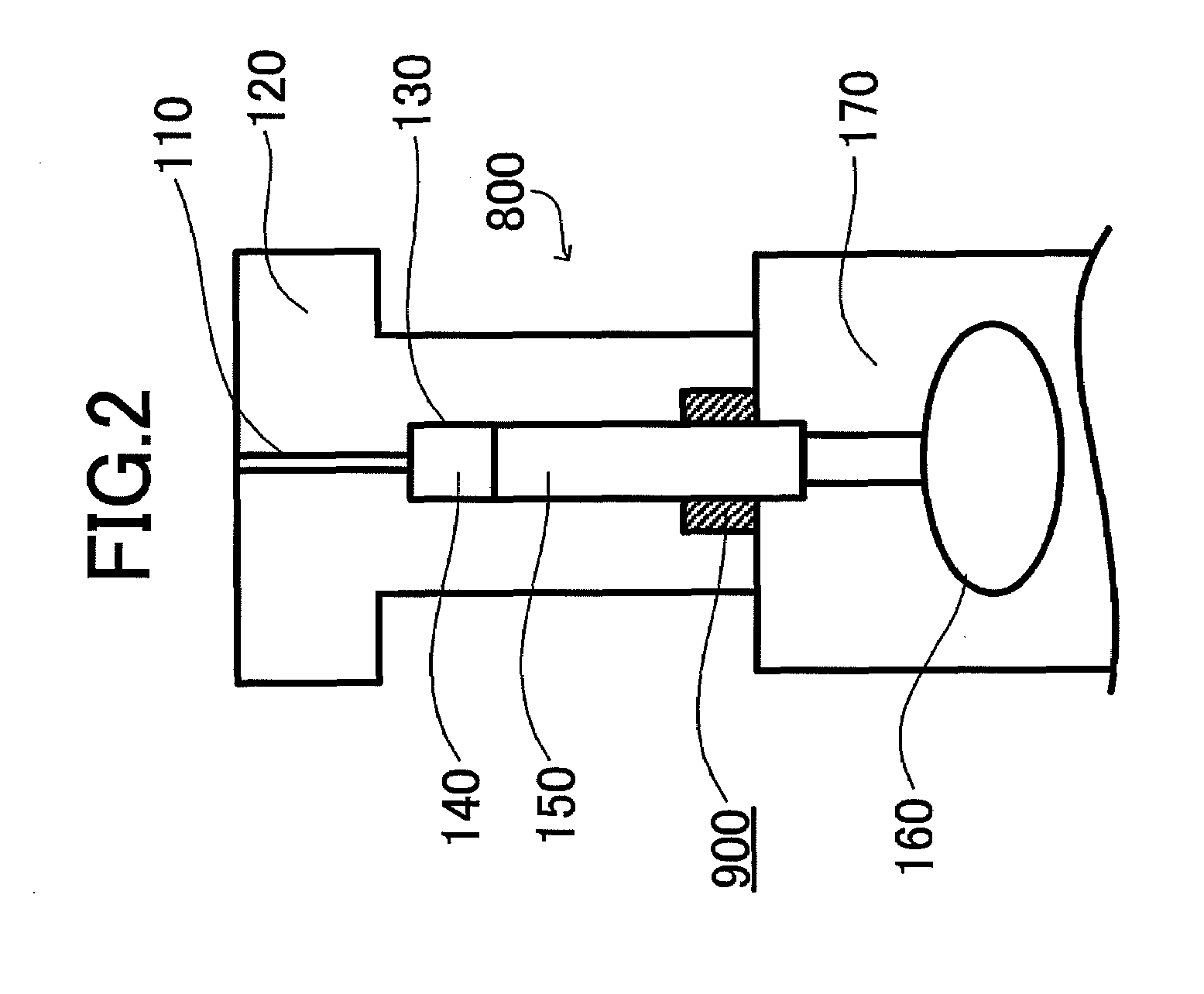

Rubber composition and a sealing member using thereof

InactiveUS20100029811A1Increase resistanceLower resistanceGroup 4/14 element organic compoundsPlastic/resin/waxes insulatorsPolymer scienceCarbon black

Owner:FUJIKURA COMPOSITES INC +1

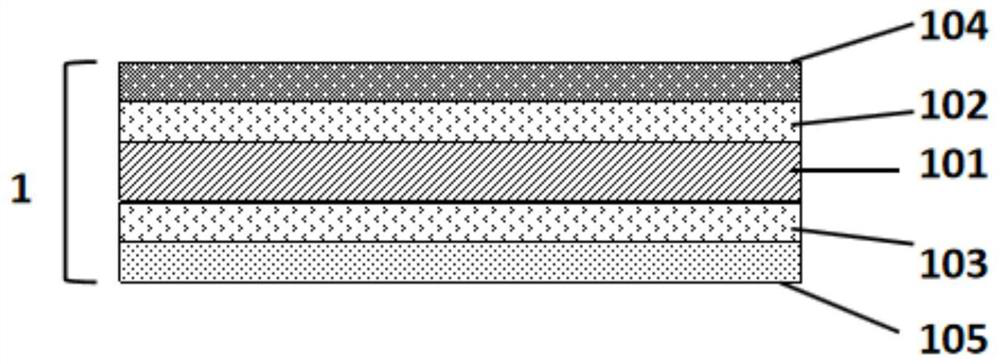

Composite diaphragm with lithium supplementing effect, and preparation method thereof and lithium ion battery

PendingCN112599928AImprove electrochemical performanceGood chemical propertiesElectrolyte/reactants regenerationCell component detailsHigh diaphragmCeramic coating

The invention provides a composite diaphragm with a lithium supplementing effect. The composite diaphragm comprises a base membrane, a first ceramic coating and a second ceramic coating which are respectively positioned on the upper surface and the lower surface of the base membrane, a lithium supplementing gel coating positioned on the upper surface of the first ceramic coating, and a gel coatingpositioned on the lower surface of the second ceramic coating. According to the invention, with the ceramic coating in the diaphragm, the temperature resistance of the diaphragm is improved, the thermal shrinkage of the diaphragm is improved, explosion caused by short circuit due to direct contact between a positive electrode and a negative electrode due to diaphragm deformation caused by thermalcontraction of the diaphragm at a high temperature is prevented, the lithium supplementing gel coating can realize uniform and accurate lithium supplementing of a silicon-carbon negative electrode sheet, a silicon-carbon negative electrode is prevented from being excessively lithiated to cause lithium precipitation, after lithium supplementing is finished, the gel coating and the electrode sheethave higher bonding force under the action of hot-pressing shaping, and the lithium ion good conductor powder remained in the lithium supplementing coating has good ionic conductivity, so that the conduction of lithium ions is promoted.

Owner:TIANJIN ENERGIES

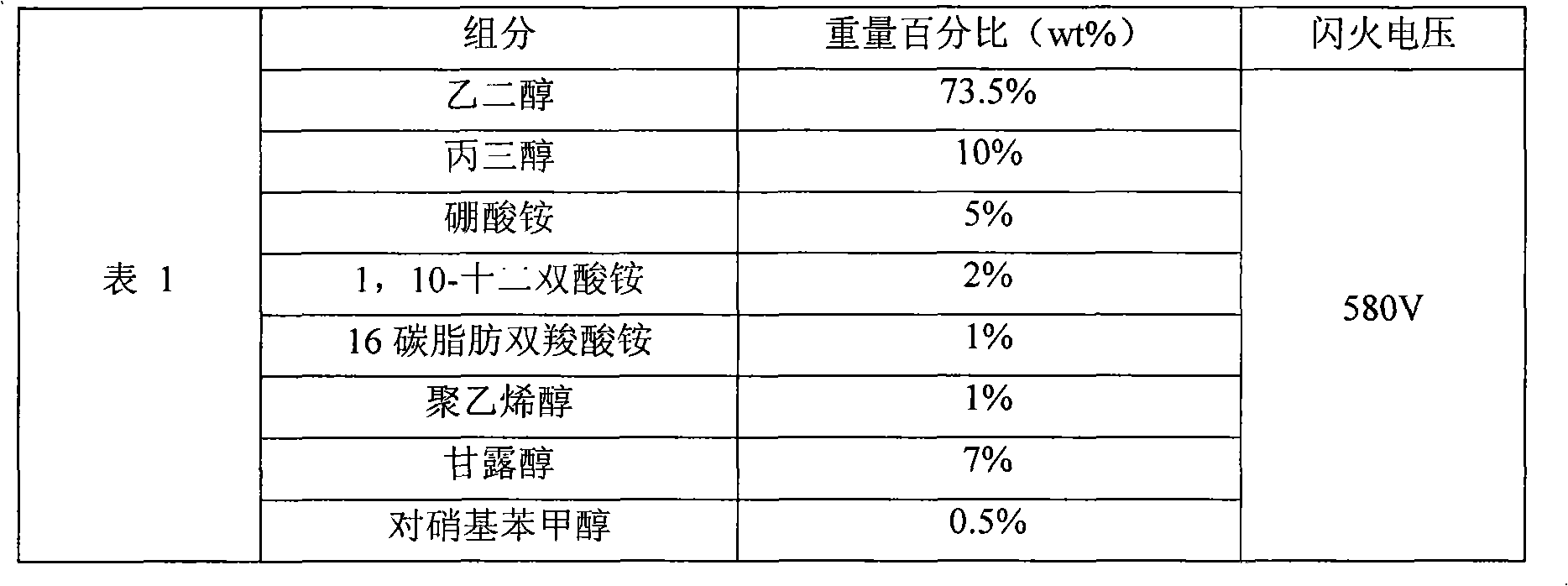

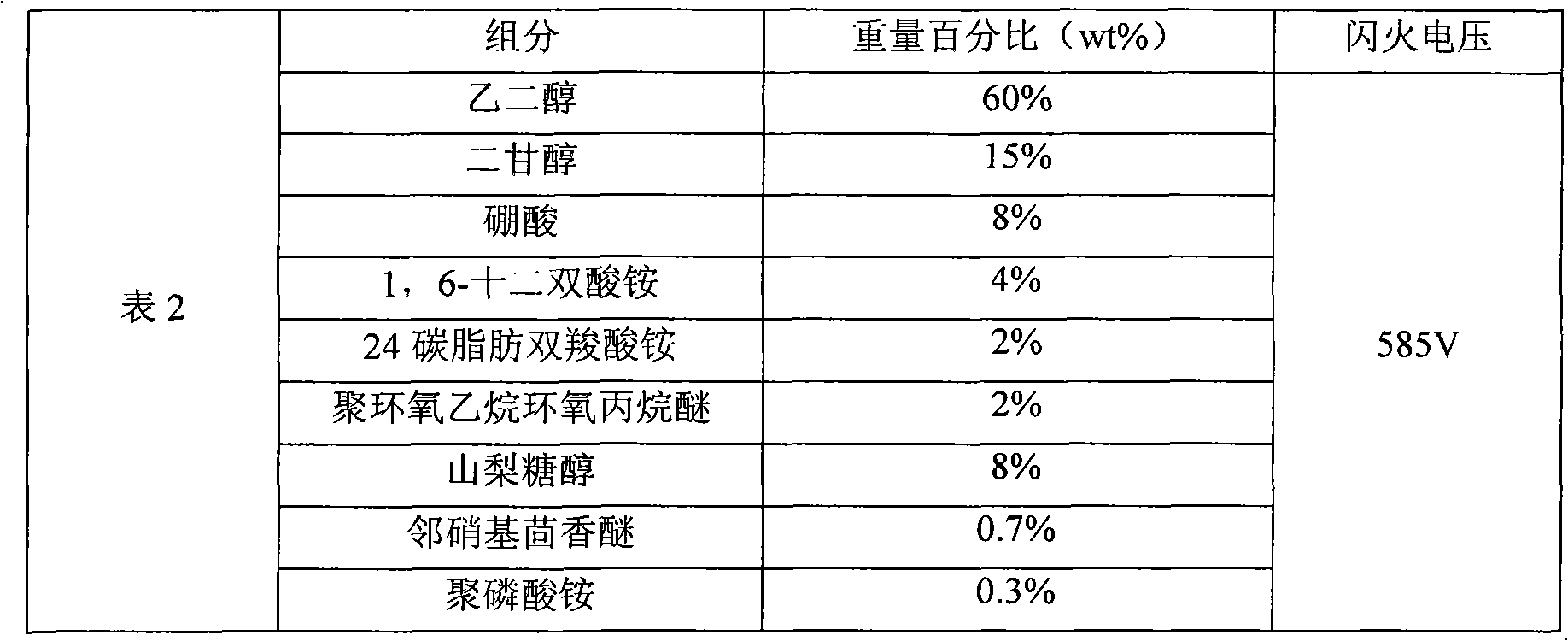

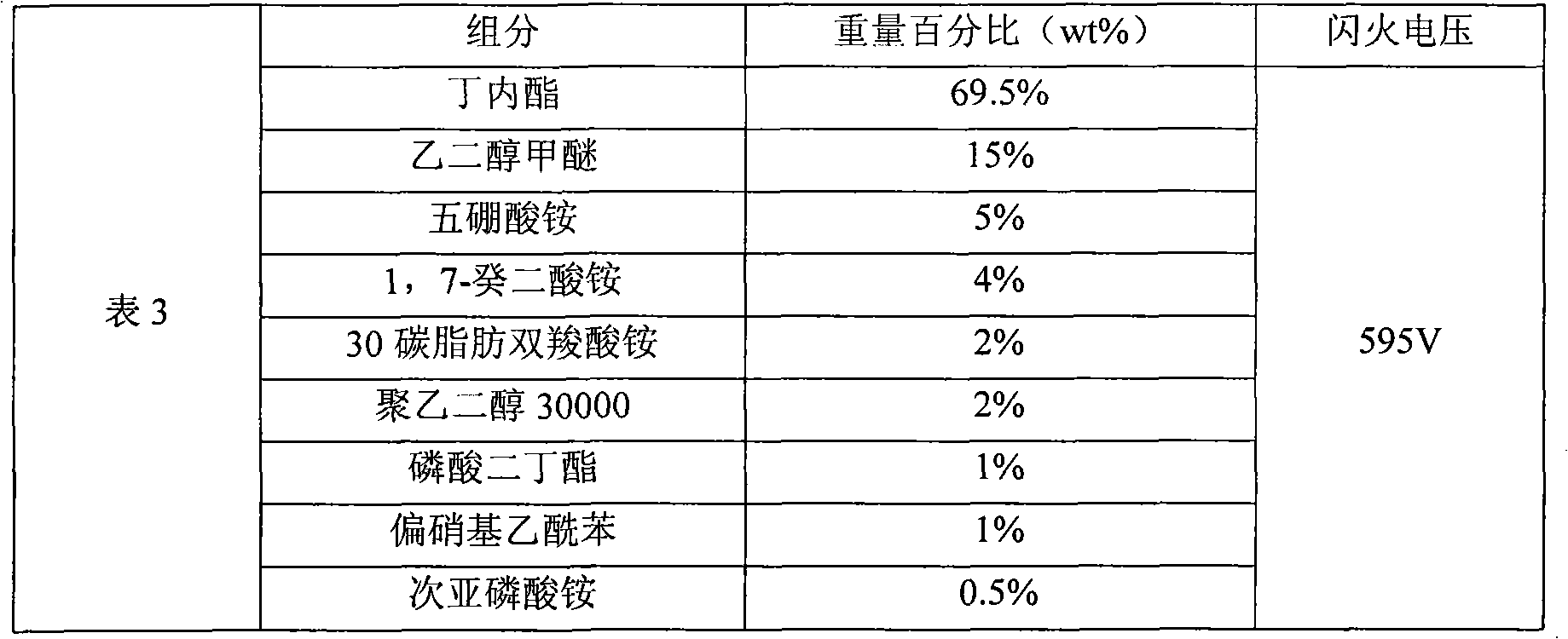

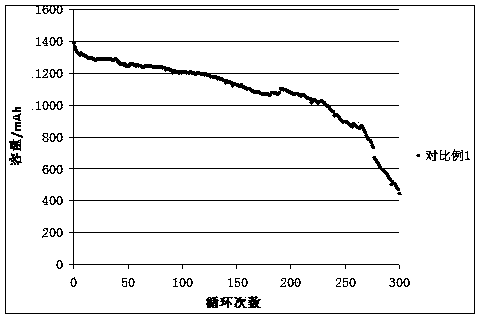

Electrolytic capacitor working electrolyte capable of improving high-temperature resistance and prolonging service life of electrolytic capacitor

InactiveCN102789900AImprove high pressure resistanceExtended service lifeElectrolytic capacitorsElectrical and Electronics engineeringMaterials science

The invention provides electrolytic capacitor working electrolyte capable of improving high-temperature resistance and prolonging service life of an electrolytic capacitor. The electrolytic capacitor working electrolyte comprises, by weight, 5-15% of electrolyte, 1.8-5% of auxiliary electrolyte, 60-85% of solvent, 4-11% of flash fire voltage enhancing agent, 4-8% of stabilizer and 0.2-1% of hydrogen eliminating agent. The electrolytic capacitor working electrolyte is applied to the electrolytic capacitor, can well improve high-pressure resistance and high-temperature resistance of the electrolytic capacitor, and simultaneously the service life of the electrolytic capacitor is well prolonged.

Owner:NANJING YIPIN MACHINERY ELECTRONICS

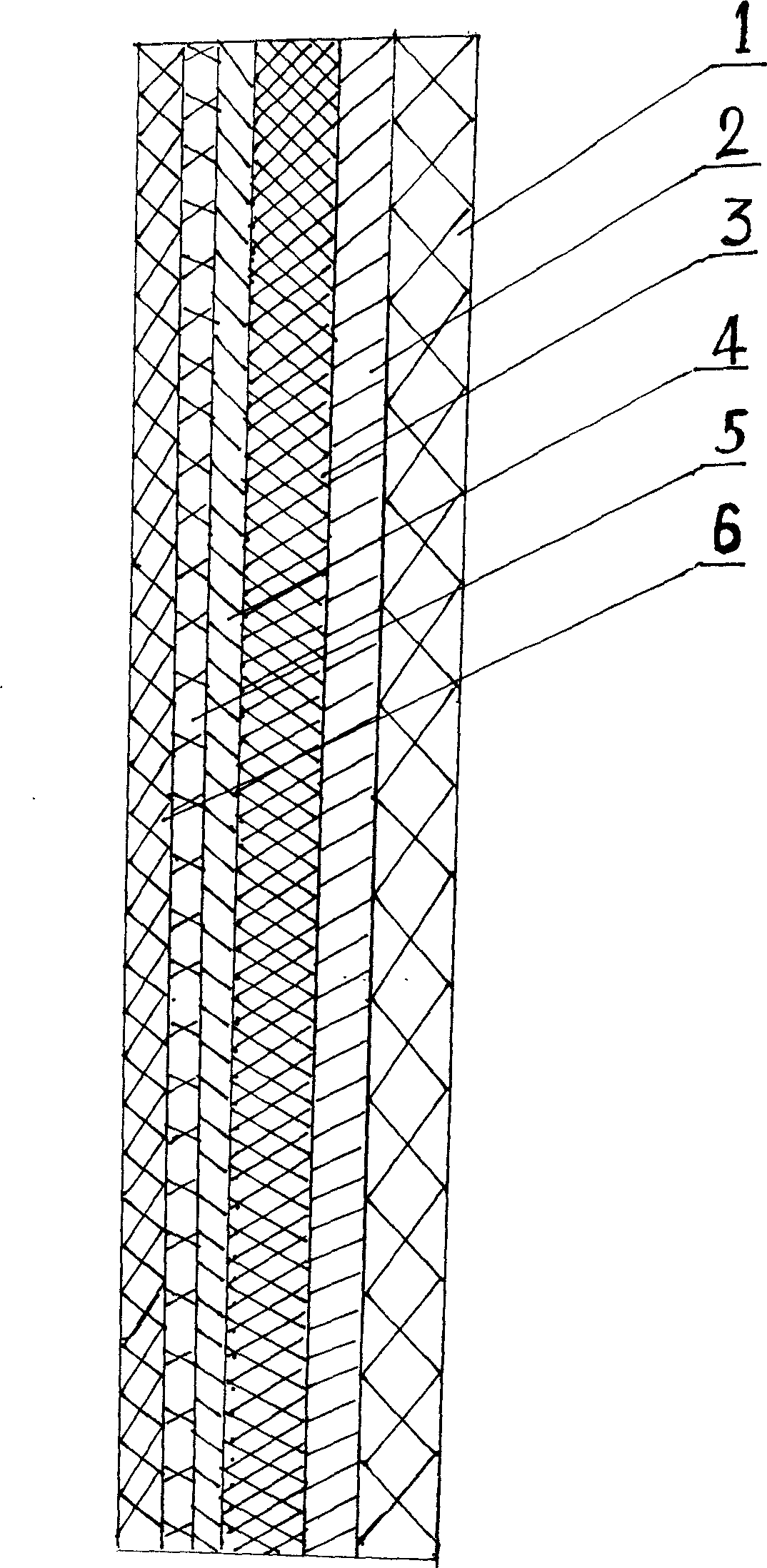

Continuous fiber reinforced thermoplastic composite tube and forming method thereof

The invention discloses a continuous fiber reinforced thermoplastic composite tube and a forming method thereof. The continuous fiber reinforced thermoplastic composite tube comprises an SFT extruding layer and an CFRT winding reinforcing layer, which are alternatively wound, and are extruded and wound on a winding mould. With the adoption of the scheme, the manufactured tube structurally changes a three-layer structure of a lining layer, a reinforcing layer and a protective layer of a conventional reinforcing tube, and a production mode is changed into a one-step process from a conventional three-section process, so that the biggest advantages are that the efficiency is improved and energy consumption is reduced; and extruding and winding are performed through one step, so that the tube has designability and meets requirements of different application fields. The tube is wide in applicability, can be used for manufacturing small-caliber tubes and also can be used for manufacturing large-caliber tubes; compared with energy consumption of a conventional winding tube, energy consumption of the large-caliber tubes is reduced by 30%-50%; and manufactured products and generated leftover materials can be recycled and utilized again, so that the forming method belongs to the green product technology.

Owner:山东极威新材料科技有限公司

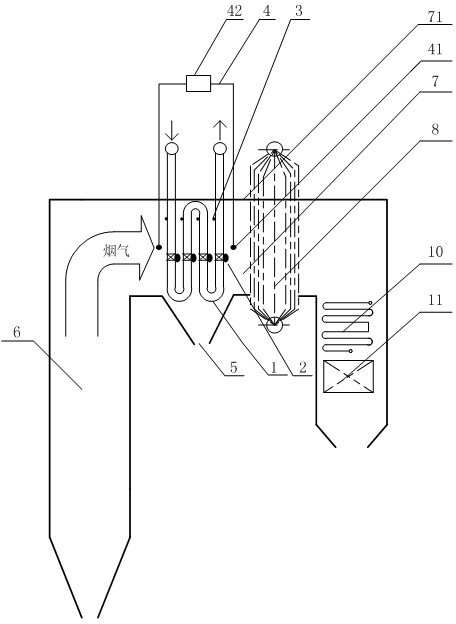

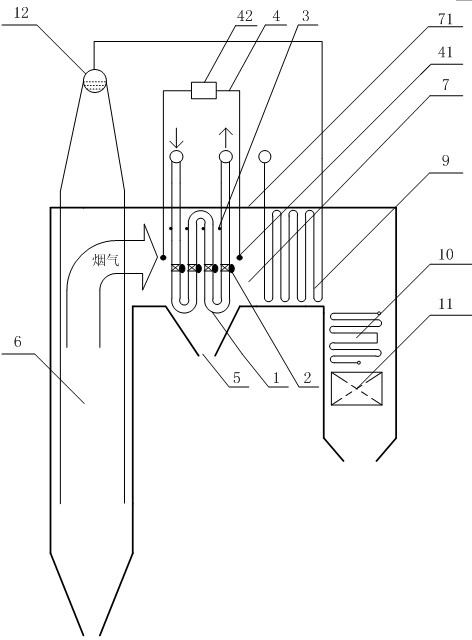

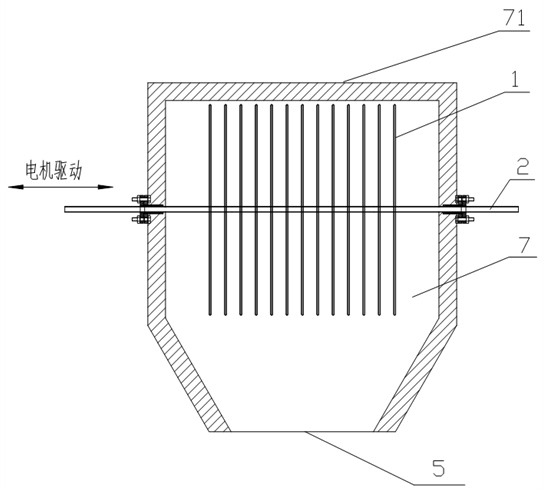

Deashing device and method for waste incineration boiler and biomass boiler

The invention provides a deashing device and method for a waste incineration boiler and a biomass boiler. The deashing device is characterized by comprising a metal hose (1), a push rod (2), a temperature measuring device (3), a differential pressure measuring device (4) and an ash discharge port (5); and a horizontal flue (7) at the exit of a boiler furnace (6) is surrounded by a horizontal flue furnace wall (71) and is hollow. The method comprises the following steps: flue gas leaves the furnace (6) and flows through the metal hose (1) arranged in the horizontal flue (7) so that ash deposition in the flue gas can be blocked by the metal hose (1); when the drop changes of the temperature and the resistance measured by the temperature measuring device (3) and the differential pressure measuring device (4) exceed threshold values, the push rod (2) starts to do reciprocating motion and drives the metal hose (1) to deform, so that the ash deposition deposited on the surface of the metal hose (1) can fall off from the surface due to the deformation and can be discharged from the ash discharge port (5). The deashing device provided by the invention has a simple structure; in addition, the deashing device and method have the advantages of high deashing efficiency, low cost and wide application range.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

Fireproof and thermal insulating nylon hose and method for production thereof

InactiveCN1865743AExtended service lifeSmall bending radiusSynthetic resin layered productsLaminationFiberCombustion

The invention discloses a fireproof thermal-insulated nylon tube, which comprises a tube chamber and a tube body. It is characterized in that: form inner to outer, the tube body comprises a nylon layer (1), a metallic wire winded layer (2), a thermal-insulated fireproof layer (3), a metal woven layer (4), a fireproof fiber cloth layer (5), and a polyurethane combustion inhibitor layer (6). The invention is resistant to abrasion, heat, corrosion, etc, while it can prolong the service life of tube; and it uses fireproof thermal-insulated material, to reduce the thickness of tube.

Owner:杨世奉 +1

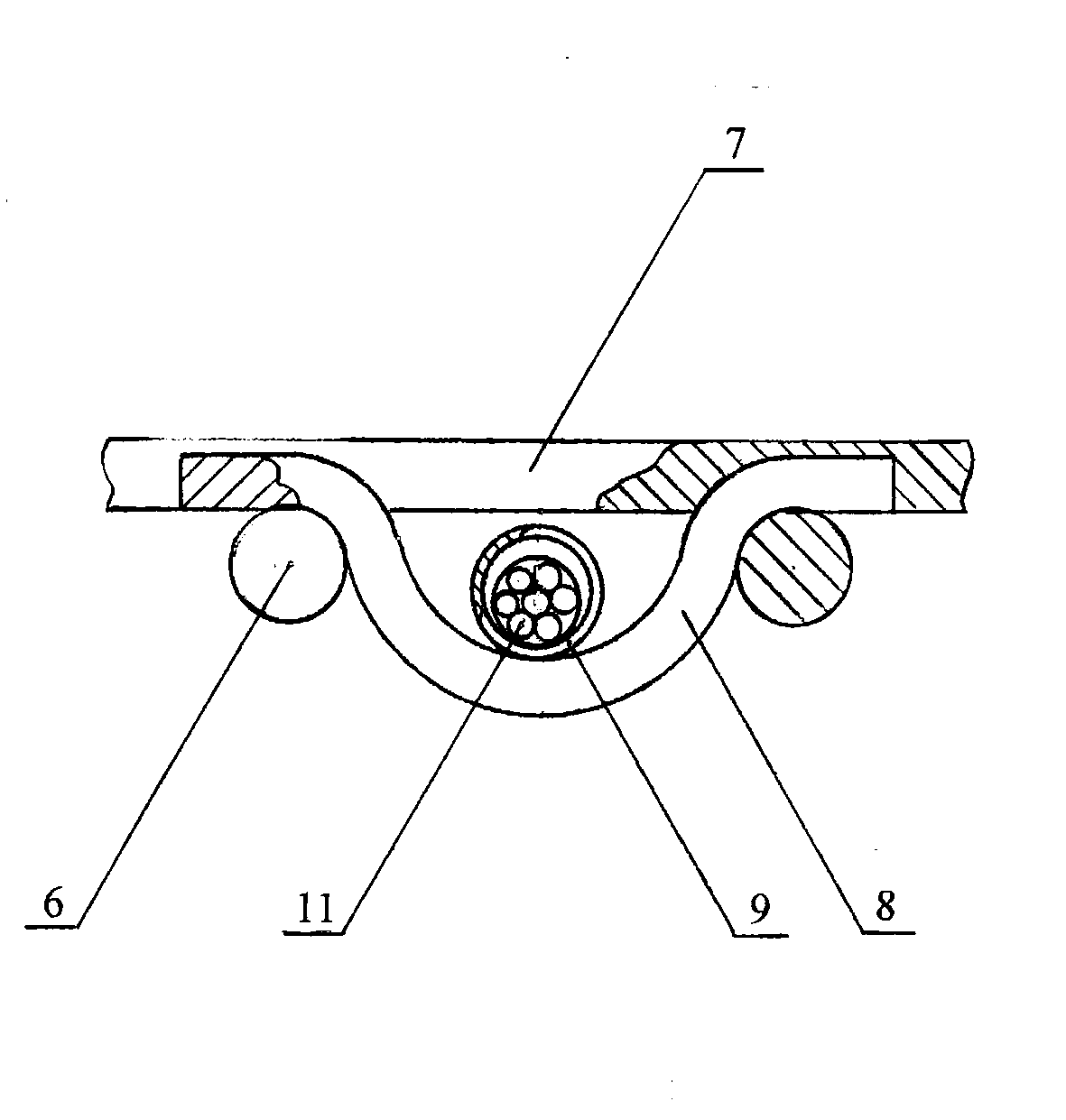

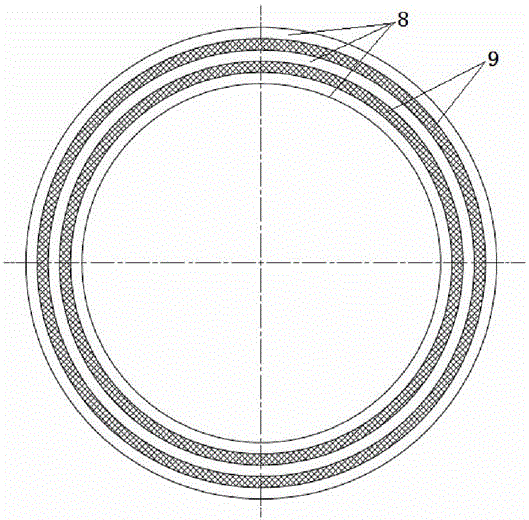

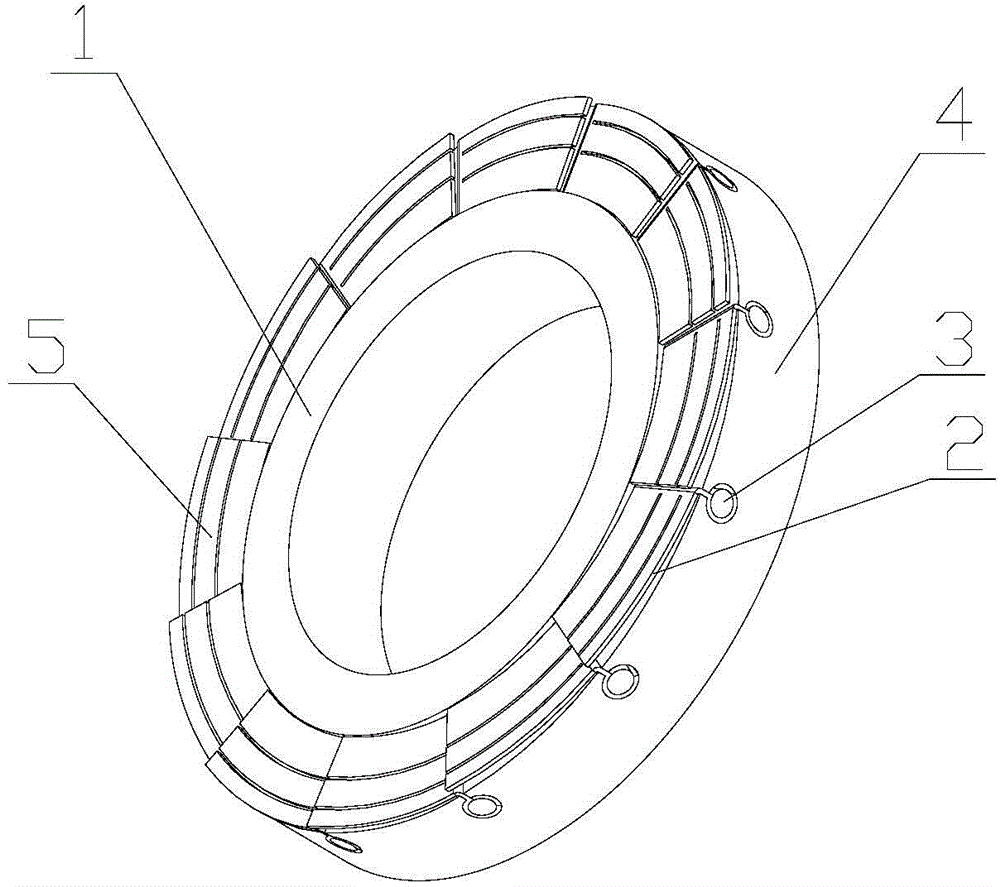

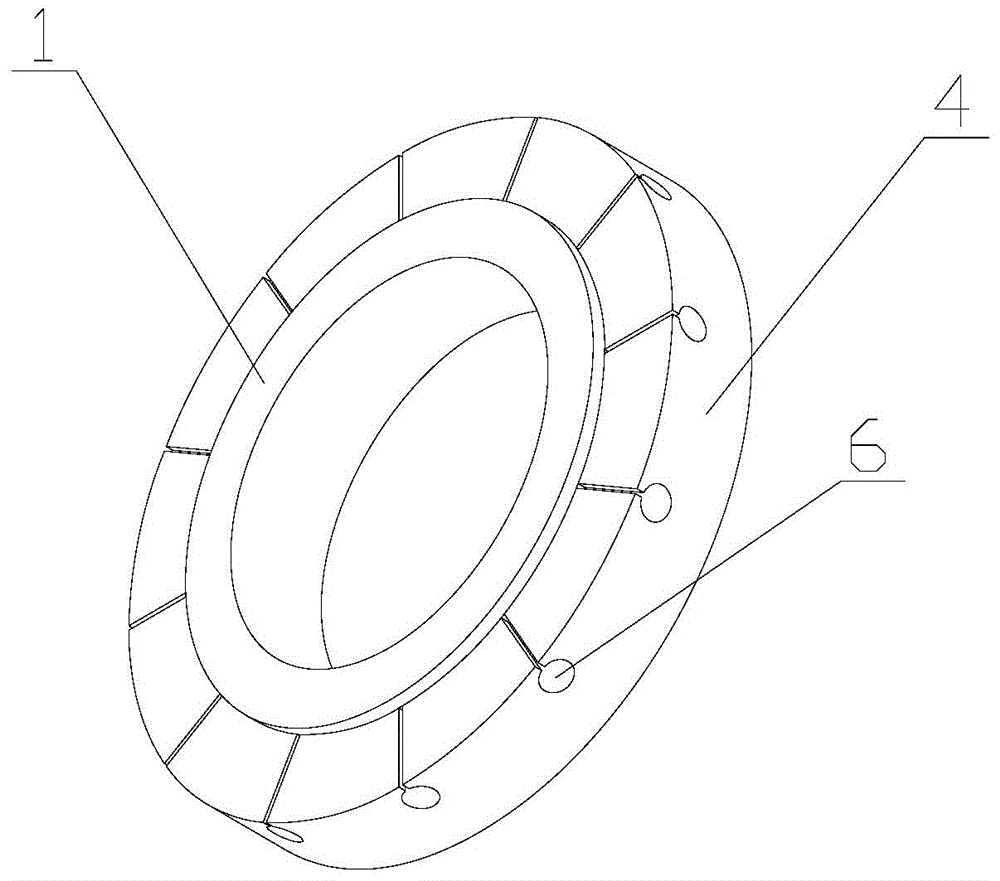

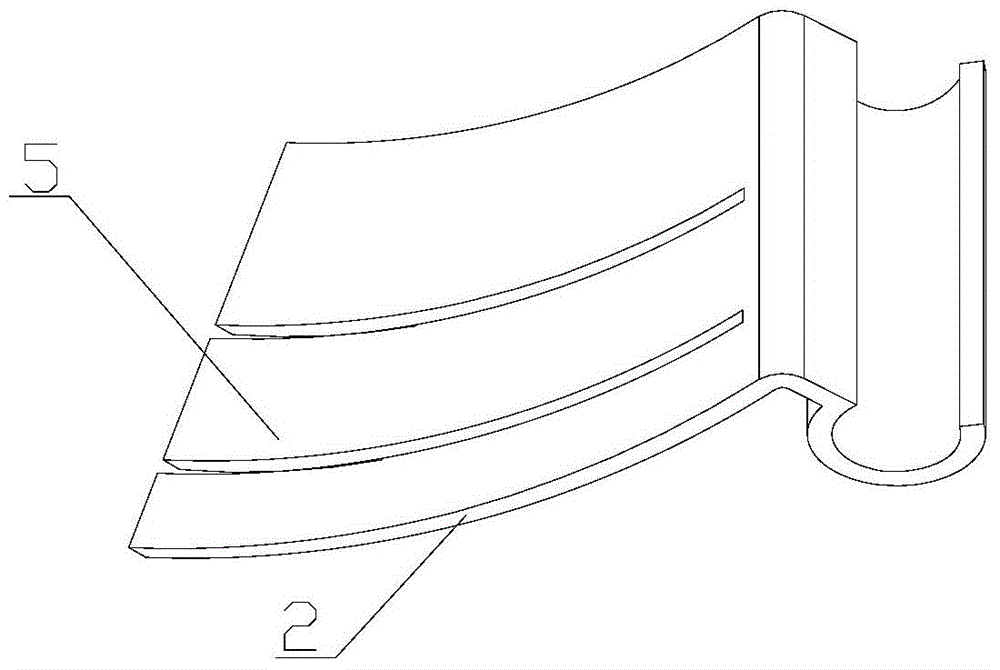

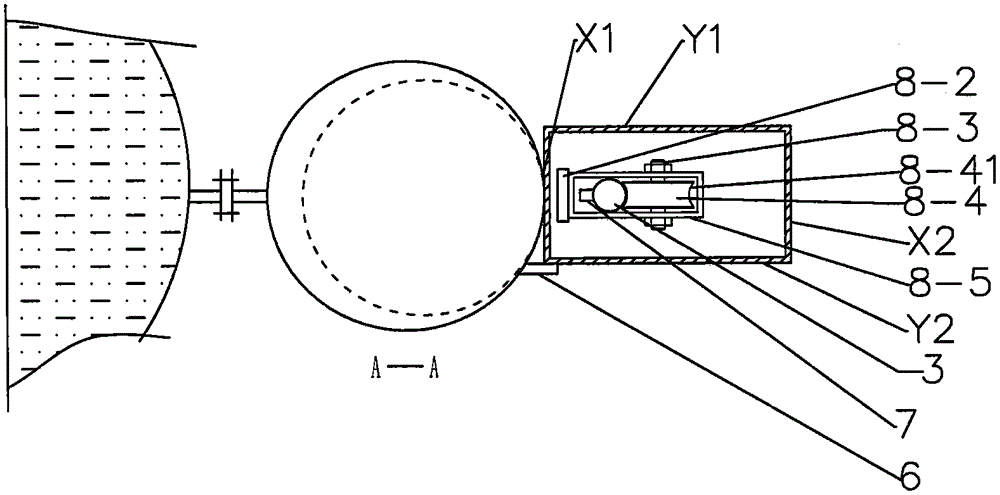

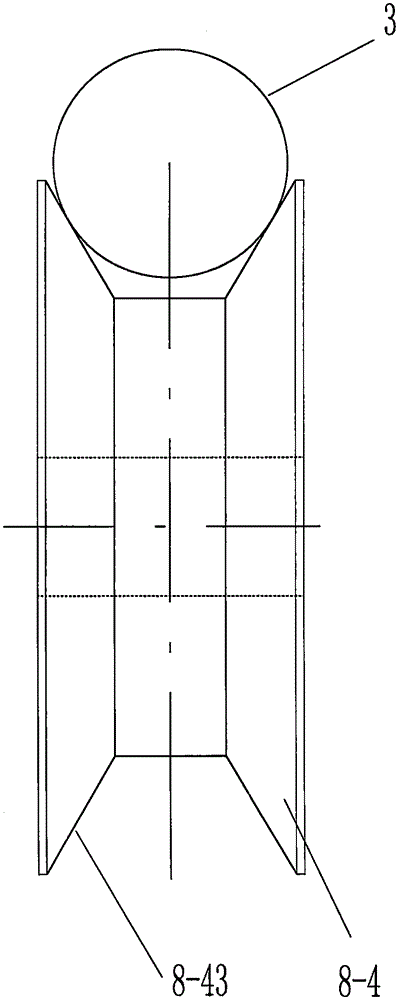

Gas film face seal structure for cantilever-type foils

The invention discloses a gas film face seal structure for cantilever-type foils. The gas film face seal structure comprises a dynamic ring and a static ring which are in gas film face seal; the seal face of at least one seal ring of the dynamic ring or the static ring is a cantilever-type foil face; the cantilever-type foil face comprises a circular ring-shaped ring body, a plurality of foils and dowels, wherein each foil is made of an elastic material; the inner side of the ring body is bulged to form a circular ring step; a seal dam is formed on the upper surface of the circular ring step; the foils are laid on the circular ring concave surface of the outer side of the seal dam end to end; the foils are evenly distributed along the circumference in a fan shape; one end of each foil is fixed to the ring body, and the other end of each foil is free; the free end of each of the foils is hung above the fixed end of the previous foil; the upper surface of the free end of each foil is flush with the plane of the seal dam and is higher than the upper surface of the fixed end; the peripheral directions from the fixed ends to the free ends of the foils are respectively consistent with the circumferential direction of airflow; each foil is divided into a plurality of small pieces along the radial direction from the free end to the fixed end, wherein the small pieces at the inner side are wider than the small pieces at the outer side. The gas film face seal structure disclosed by the invention has the characteristics that the stability is high, the abrasion is small, the service life is long, the reliability is high, high temperature can be resisted, the rotation speed is high, and the adaptivity is strong.

Owner:ZHEJIANG UNIV OF TECH

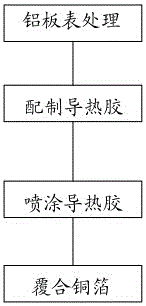

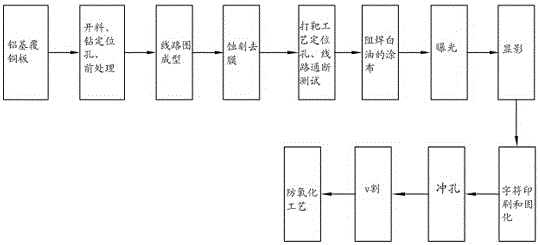

Production process of electric and light source integrated light emitting diode (LED) aluminum-based circuit board

ActiveCN105813389ASpray evenlySave ink or glueNon-macromolecular adhesive additivesPrinted circuit manufacturePunchingHigh volume manufacturing

The invention relates to a production process for an electric and light source integrated light emitting diode (LED) aluminum-based circuit board. A finished product is obtained according to the following steps of surface processing on an aluminum plate, head conduction adhesive fabrication, coating, composite copper foil lamination, cutting, positioning hole drilling, pre-processing, circuit pattern forming, etching and film removal, positioning hole by a target process, circuit on / off test, solder resistant white oil coating, exposure, development, character printing and curing, punching, v-shaped cutting and anti-oxidation process, wherein in the step of coating, the heat conduction adhesive is sprayed by a curtain formed by a spraying cutter. By the process, an aluminum-based circuit integrated with a light source and an electric source can be produced at a large scale, and the fabricated LED and the electric source both have favorable heat dissipation performance.

Owner:ZHEJIANG LEUCHTEK ELECTRONICS

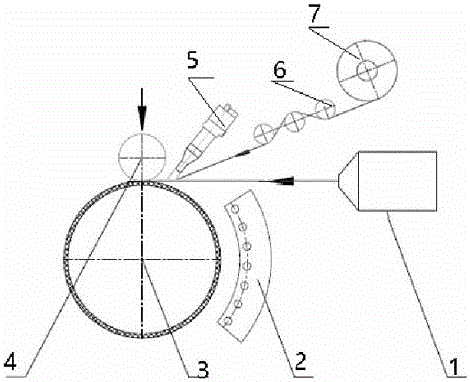

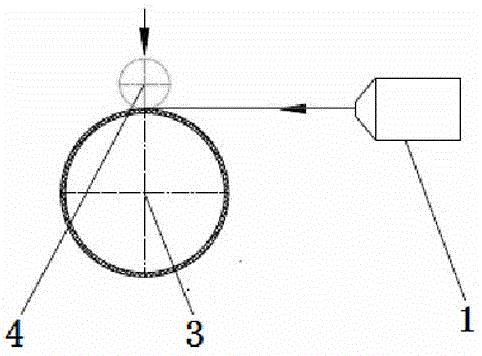

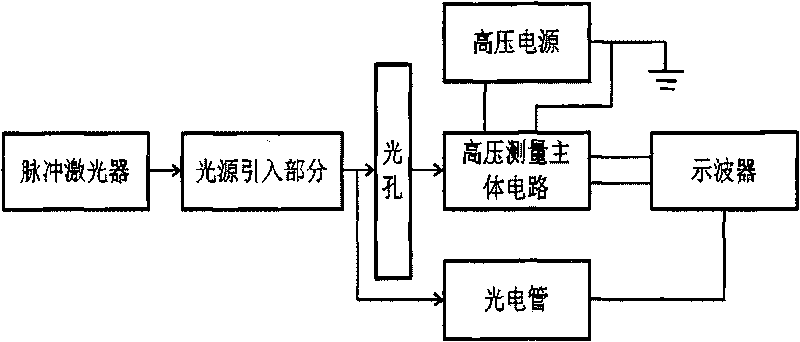

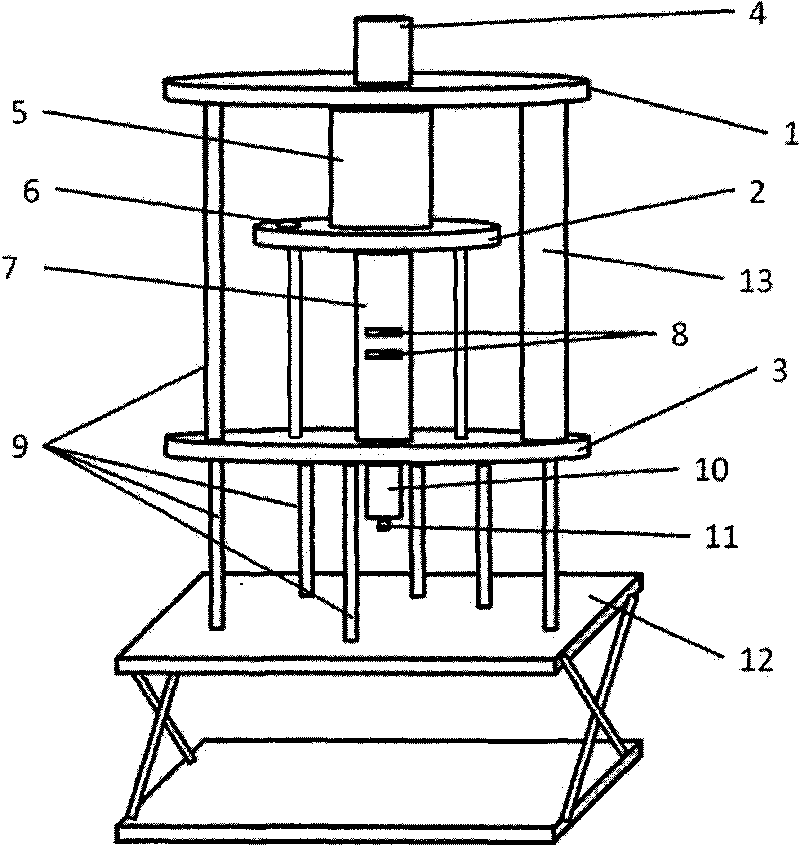

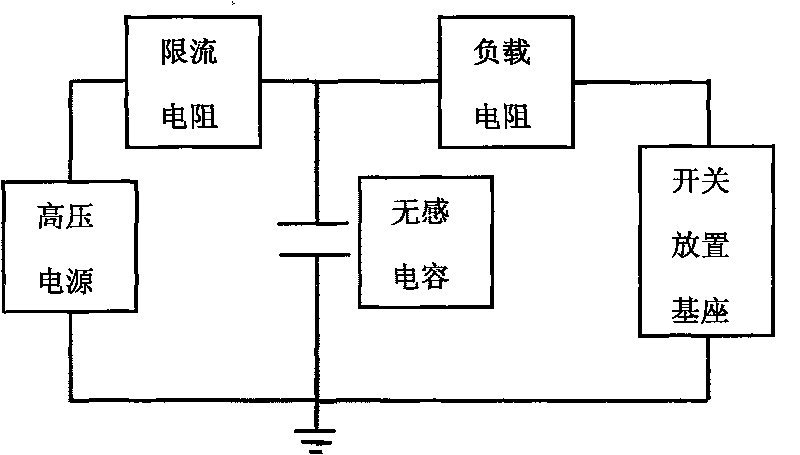

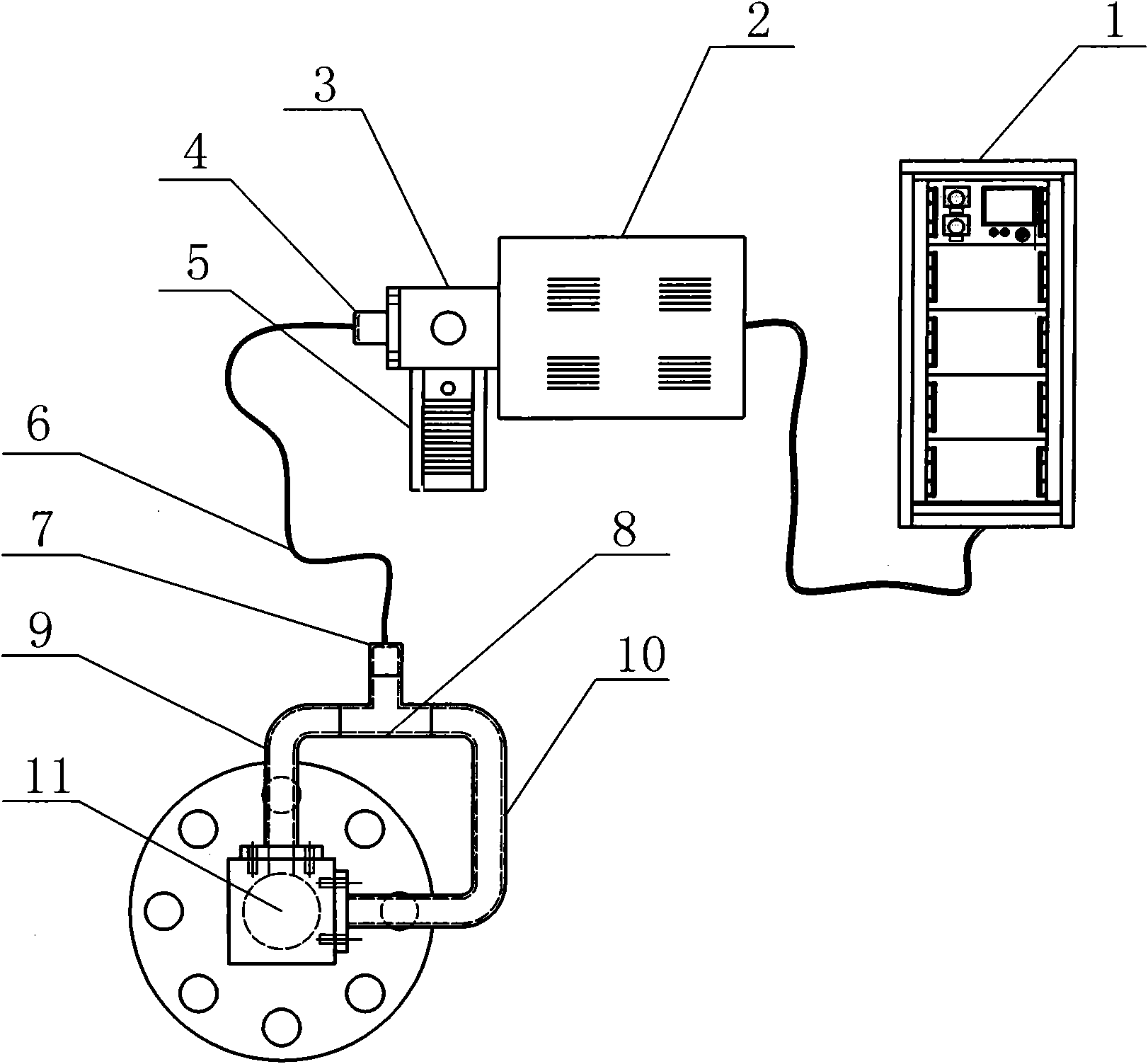

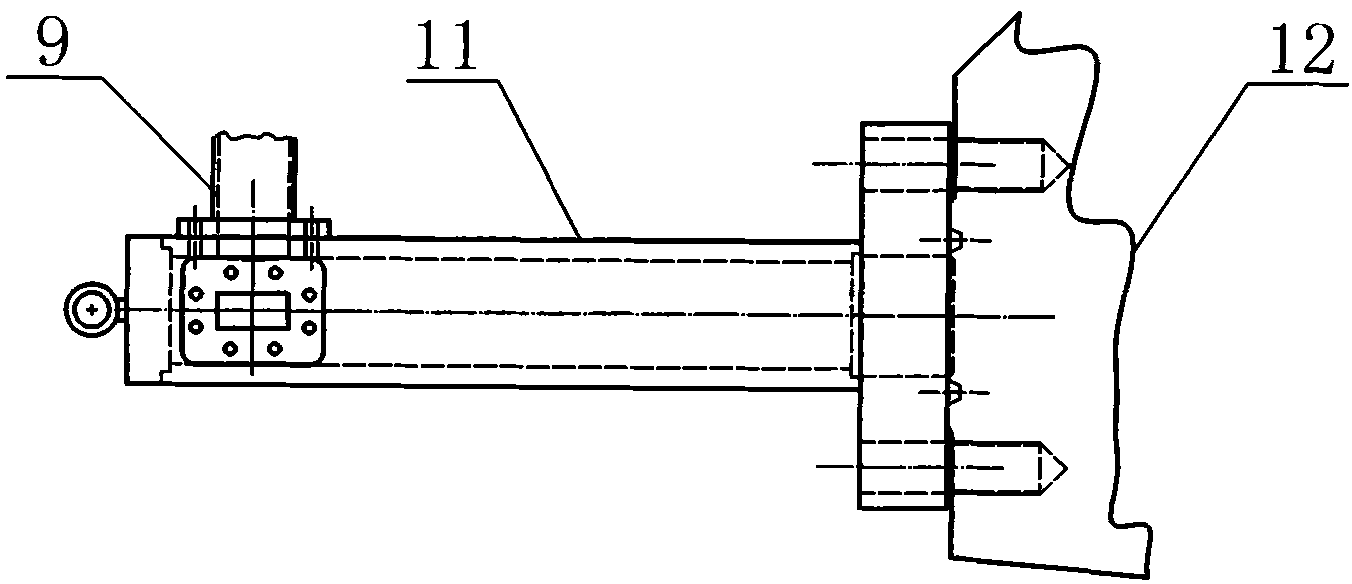

High-power photoconductivity switch test device and application thereof

ActiveCN101762784APrecise alignmentCompact structureElectrical measurement instrument detailsCircuit interrupters testingLight spotHigh pressure

The invention relates to a high-power photoconductivity switch test device and application thereof. The test device comprises a pulse laser, a light source leading-in part, a light hole, a high-voltage measurement main circuit, a high-voltage power supply, an oscilloscope and a phototube, wherein the laser pulse generated by the pulse laser is received by the light source leading-in part to form light spots, and the light source leading-in part adjusts the light path and controls the light intensity of the light spots at unit area; the light spots are divided into measurement light spots and reference light spots by a spectroscope arranged in the light source leading-in part; the light hole receives the measurement light spots and adjusts the light intensity of the measurement light spots; the phototube receives and converts the reference light spots into electrical signals and transmits the electrical signals to the oscilloscope; the high-voltage measurement main circuit outputs electrical signals generated by the irradiation of the measurement light spots of a photoconductivity switch to be tested; the high-voltage power supply applies voltage to the high-voltage measurement main circuit; and the oscilloscope analyzes and displays the electrical signals from the high-voltage measurement main circuit.

Owner:江苏先进无机材料研究院

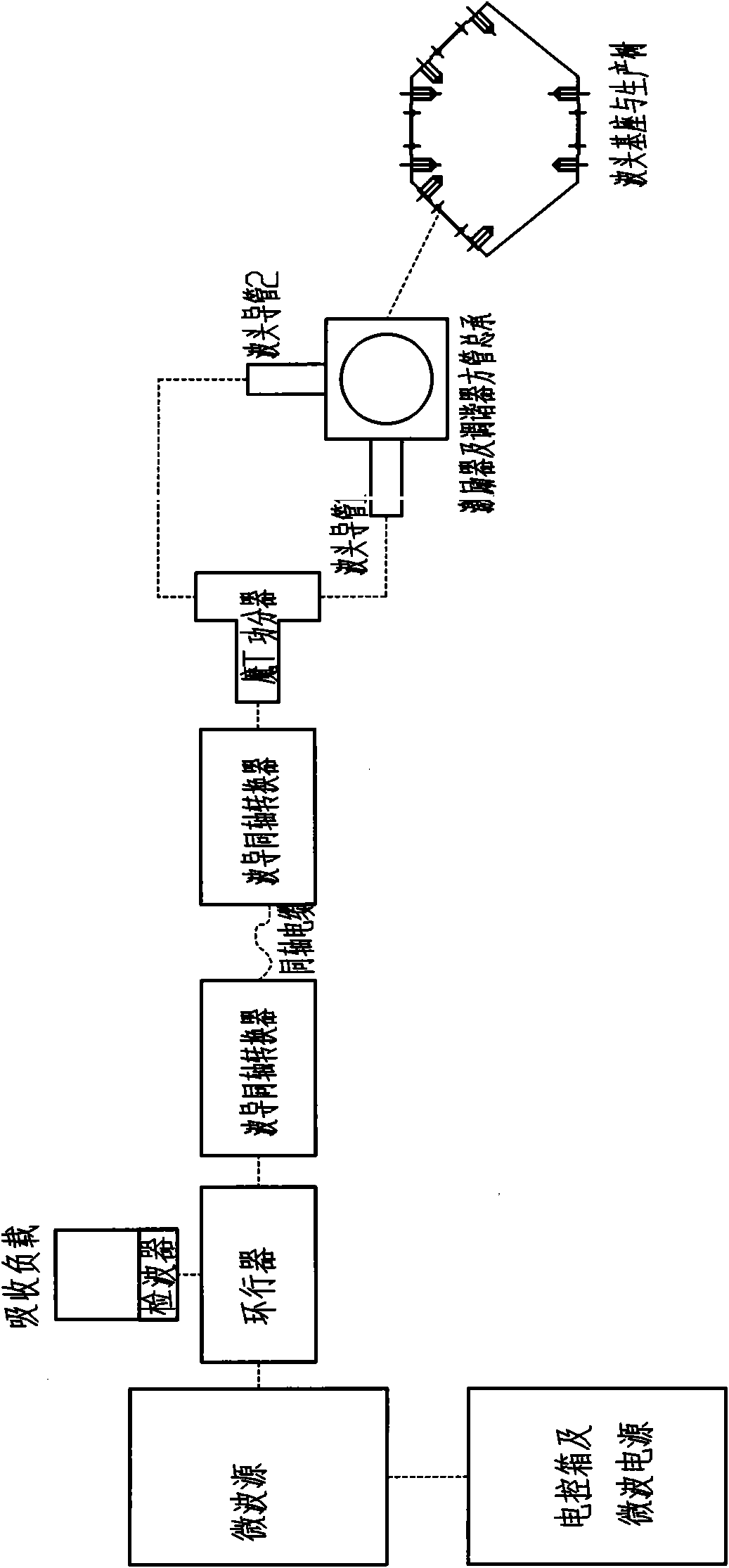

Blockage removal method and device for microwave hydrate for gas well

The invention discloses a blockage removal method and a blockage removal device for a microwave hydrate for a gas well. The deicing technology adopted by the conventional natural gas wells and carbon dioxide gas wells is that: 1, a well mouth or a gas pipeline is heated by adopting a water jacket furnace; 2, methanol and other inhibitors are added into the gas wells; 3, the carbon dioxide gas is heated by means of terrestrial heat of the stratum; and 4, an oil pipe gas recovery mode is changed into a sleeve gas recovery mode. The deicing technology has the disadvantages of severe environmental contamination, complex technology, high labor intensity and strict technical requirement. The blockage removal method is that: a high-frequency microwave power source is adopted and is guided into a well tube through a wave head pipeline, and a waveguide channel is formed by the well wall tube; and microwave electromagnetic waves are transmitted to a hydrate freezing blockage point in an enclosing way, so that the freezing blockage point is irradiated by the high-frequency electromagnetic waves, gets energy, raises the temperature and is dissolved. Therefore, the freezing blockage problem of the hydrate is solved. The blockage removal method is used for unfreezing the gas wells.

Owner:大庆市新中瑞环保有限公司

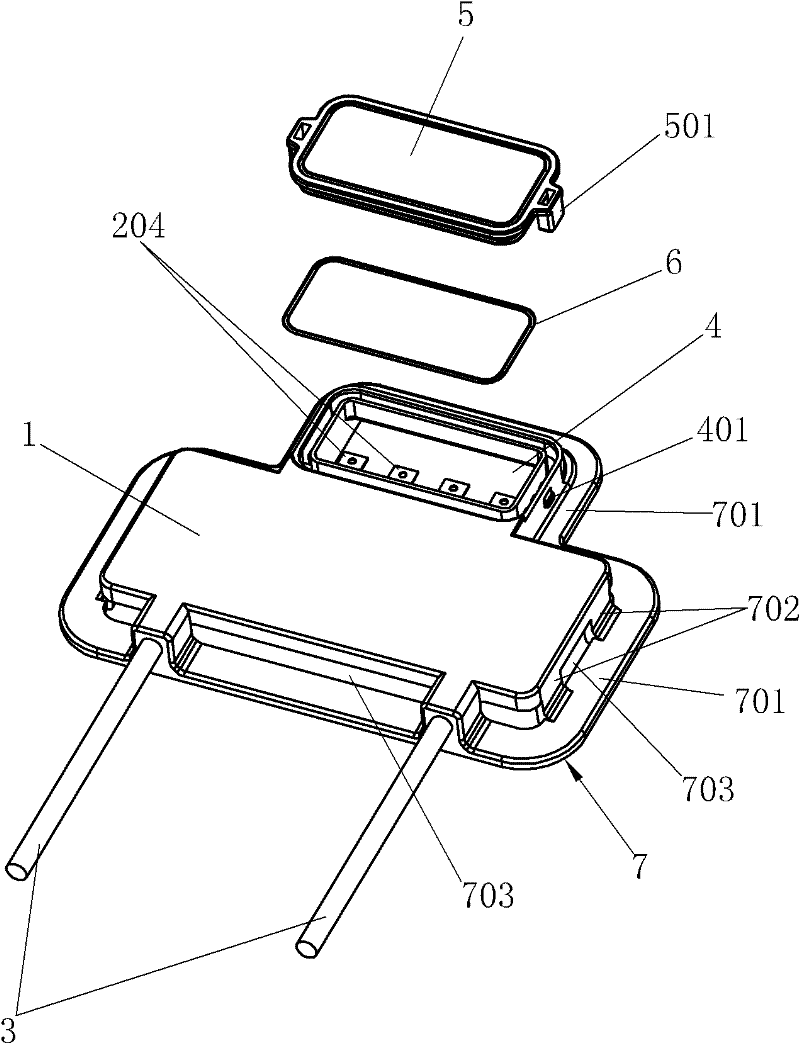

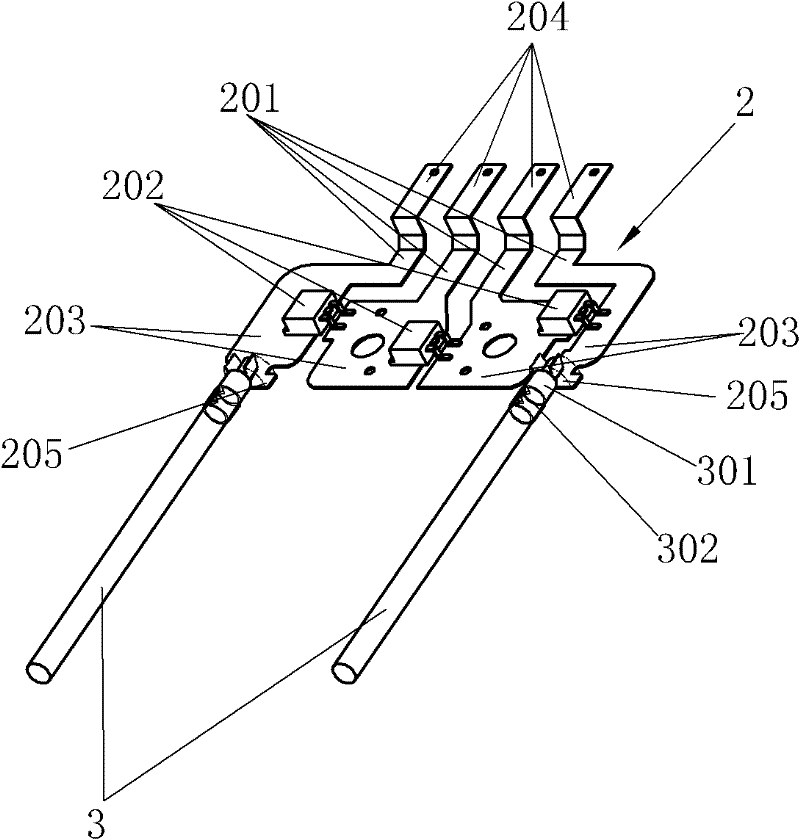

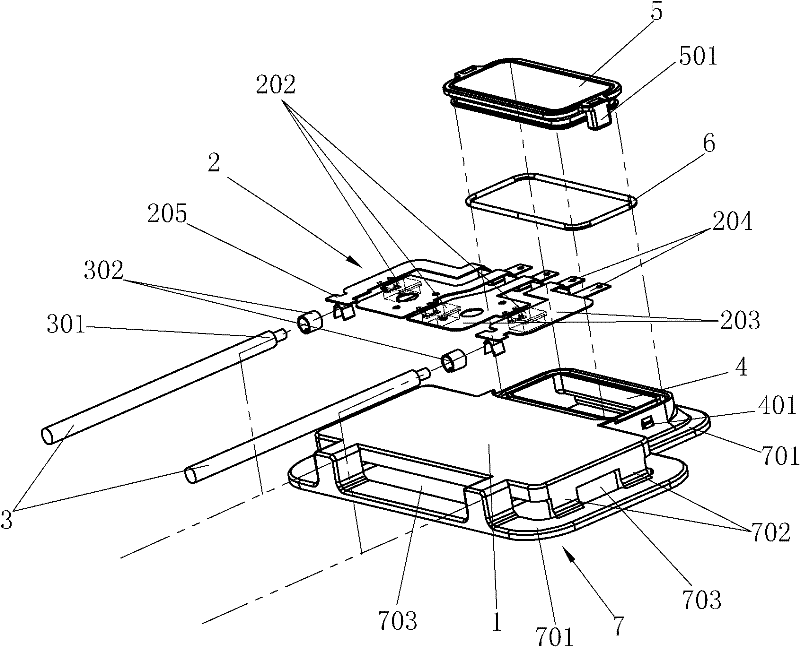

Junction box of solar photovoltaic module

InactiveCN102263148ASimple processLow manufacturing costClimate change adaptationPhotovoltaicsPower flowMetal

The invention relates to a junction box of a solar photovoltaic module, which is characterized by comprising an electrical part, wherein the electrical part comprises a group of metal sheets and diodes which are connected among the metal sheets; a cable conductor is connected with the electrical part; the electrical part and one connecting end of the cable conductor are packaged in a body plastically; the front side of the body is provided with a connecting line cavity body which is provided with a sealed cover, and a seal ring is arranged between the sealed cover and the connecting line cavity body; a radiating cavity body is arranged below the body and formed by a mounting edge and a lateral bar, and the lateral bar is connected with the mounting edge and the body; and the front ends of the metal sheets extend out of the body to stretch into the connecting line cavity body so as to form lead ends, and the mounting edge is arranged below the connecting line cavity body in an extended mode. The body, the electrical part, the connecting line cavity body and the radiating cavity body are subjected to the integral injection molding to form an integral body. The technology is simple, the manufacturing cost is low, the volume is small, the radiating performance is good, the current bearing capacity is strong, the waterproof and dustproof performance is good, and the service life is long.

Owner:崔鹏 +1

Propping agent prepared by using boron rocks and iron ores and preparation method thereof

ActiveCN103145402AFlat surfaceHigh compressive strengthFluid removalCeramic materials productionSoft clayExpanded clay aggregate

The invention relates to a propping agent. The propping agent is prepared from the following raw preparation materials: boron rock tailings, iron ore tailings and soft clay. The preparation method of the propping agent comprises the following steps: firstly, carrying out light roasting treatment on the boron rock tailings, and grinding the boron rock tailings by using a ball mill; respectively carrying out dry treatment on the iron ore tailings and the soft clay, and then respectively grinding the iron ore tailings and the soft clay by using the ball mill; weighting raw materials in proportion, and uniformly mixing the raw materials so as to obtain a premix; carrying out granulation and screening on the premix; placing the premix into a rotary kiln, burning the obtained product, and carrying out heat preservation on the obtained product; carrying out screening on the burned ceramsites so as to obtain the propping agent. The propping agent disclosed by the invention has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance, high strength, high flow conductivity, low breakage rate, and the like; and the preparation method is small in energy consumption and large in productivity.

Owner:杨松

Proppant prepared from magnesium ore tailings, iron ore tailings and boron sludge

The invention relates to a proppant. The raw materials for preparing the proppant comprise magnesium ore tailings, boron sludge, silica and soft clay, or magnesium ore tailings, iron ore tailings and soft clay, or iron ore tailings, boron sludge and soft clay, or boron sludge, silica and soft clay. The preparation method of the proppant comprises the following steps: respectively carrying out soft burning on the magnesium ore tailings, iron ore tailings, boron sludge and silica, and respectively milling by a ball mill; drying the soft clay, and milling by a ball mill; proportionally weighing the raw materials, and uniformly mixing to obtain a premix; granulating and screening the premix; sending into a rotary kiln, firing, and keeping the temperature; and screening the fired haydite to obtain the proppant. The proppant provided by the invention has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance, high strength, high flow conductivity, low breaking ratio and the like; and the preparation method has the characteristics of low energy consumption and high productivity.

Owner:杨松

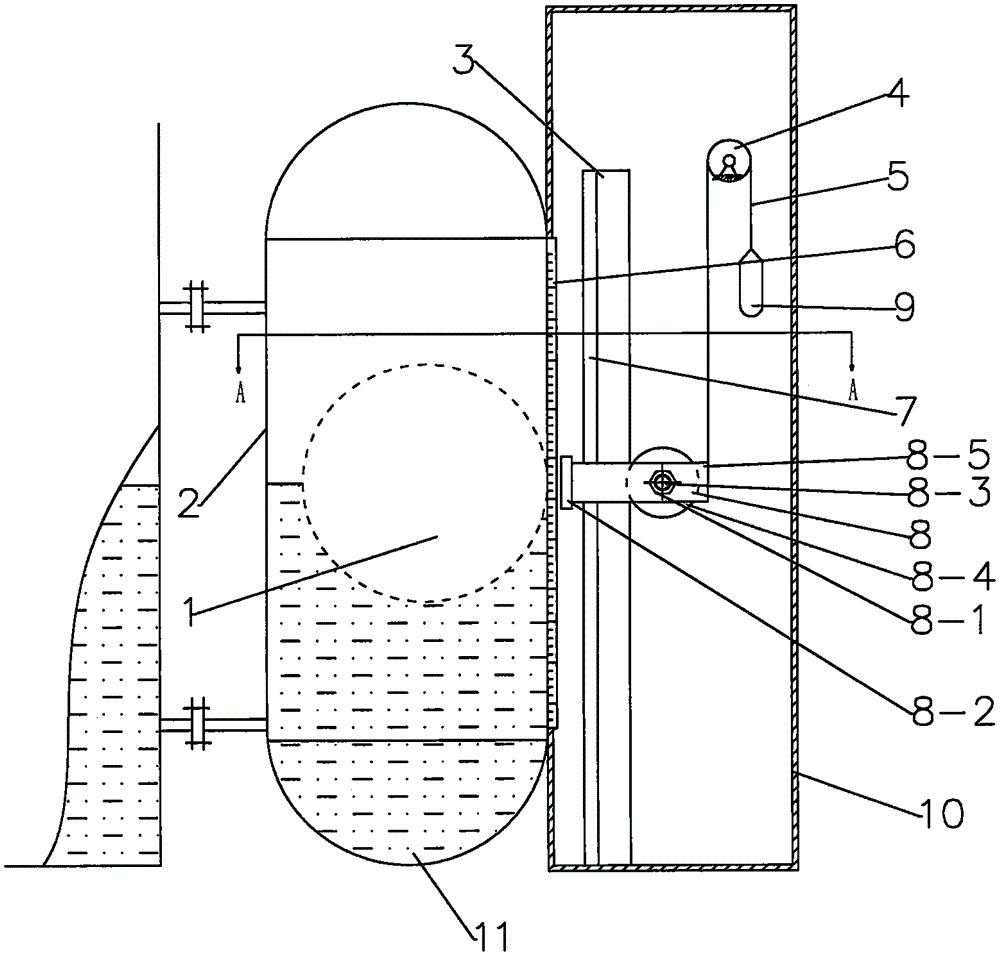

Ball float type liquidometer with vernier display

ActiveCN105277258AIncrease stiffnessGuaranteed measurement accuracyLevel indicators by floatsFloat chamberRolling-element bearing

The invention relates to a ball float type liquidometer with vernier display. The ball float type liquidometer comprises a ball float chamber and a ferromagnetic spherical floating ball arranged therein, a vernier outside the ball float chamber, a calibrated scale and a vernier guide rail. The vernier comprises magnetic steel, a frame and a rolling system which is horizontally fixed and sleeved in the frame; the rolling system comprises rolling wheels which are provided with radial grooves along a circumferential surface, rolling bearings and shafts; the magnetic steel is disposed between the ball float chamber and the frame and is fixed outside one side surface close to the ball float chamber on the frame, and the magnetic pole of the magnetic steel is right oriented towards the floating ball; the vernier guide rail is sleeved in the frame and is disposed between the magnetic steel and the rolling system; and the rolling system enables the rolling wheels to roll vertically along the vernier guide rail at groove positions through a magnetic coupling force between the magnetic steel and the floating ball. The ball float type liquidometer is simple and scientific in structure, reliable in application performance, easy to manufacture and low in cost, reduces defects in the prior art and effectively meets needs in correlation fields.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com