Patents

Literature

42results about How to "No breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367AImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

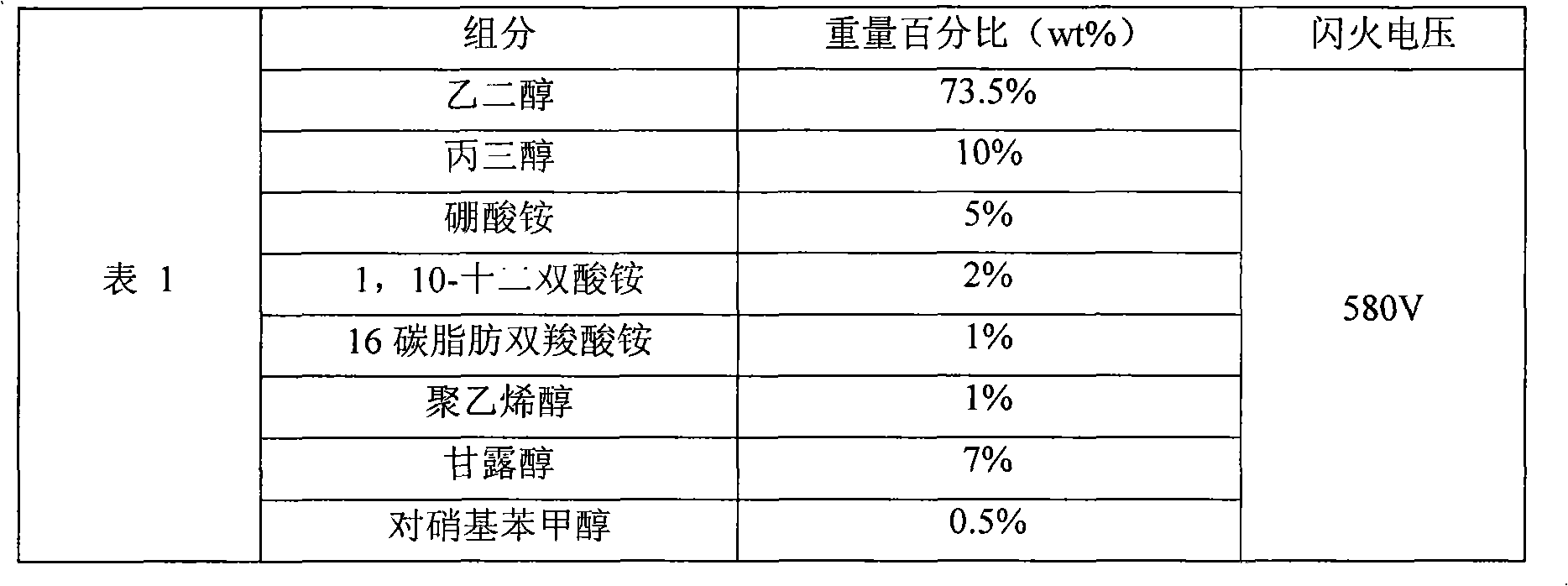

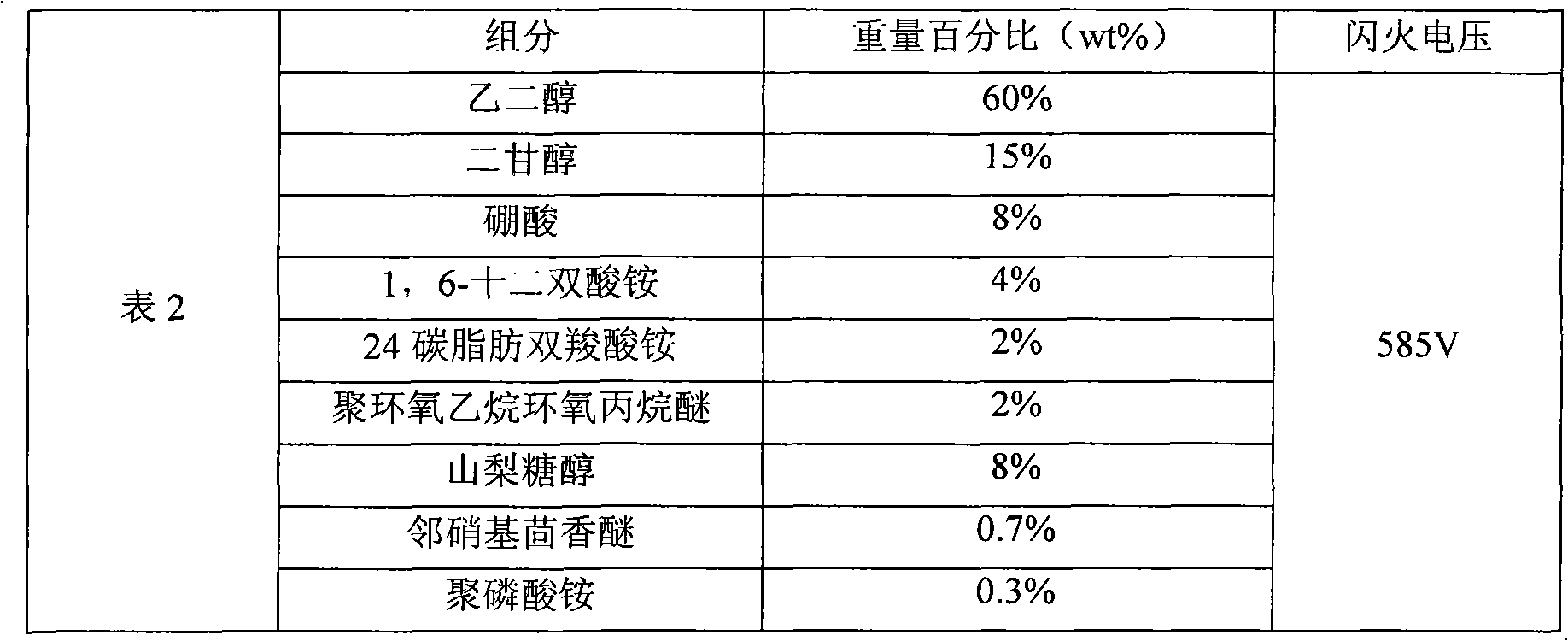

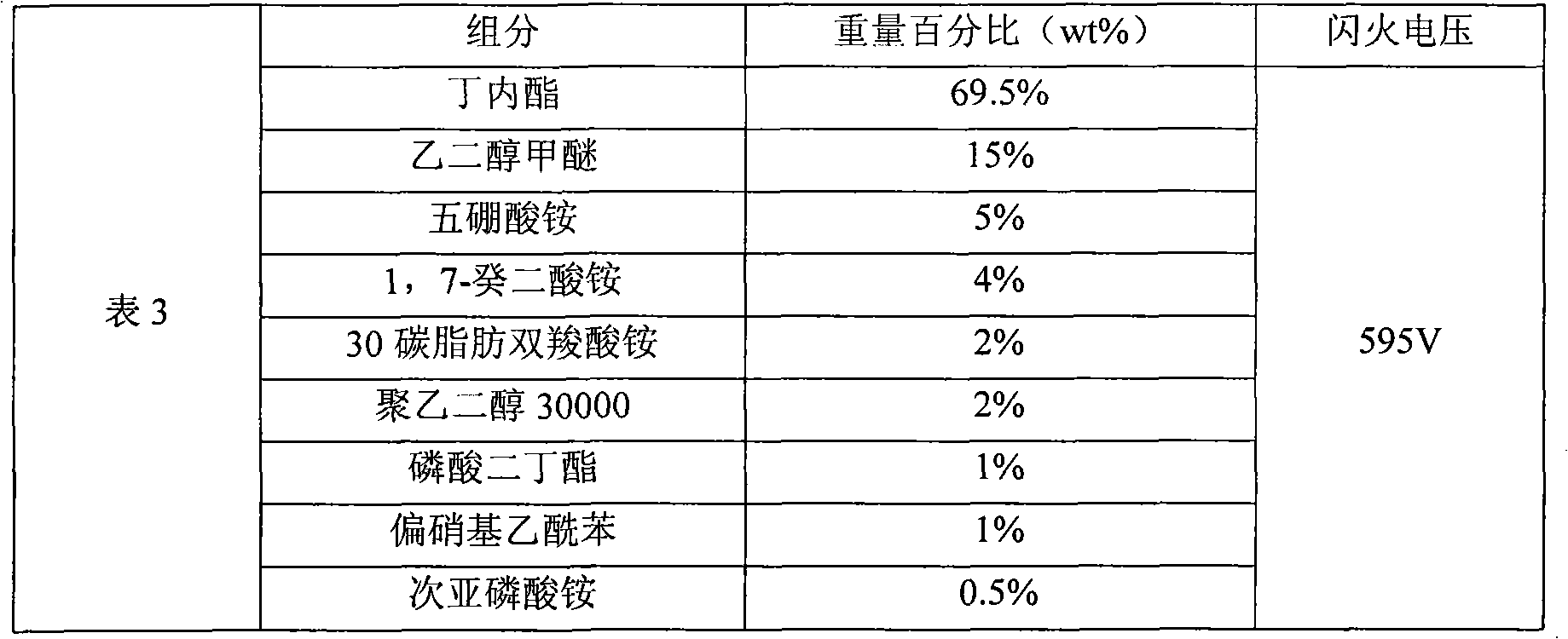

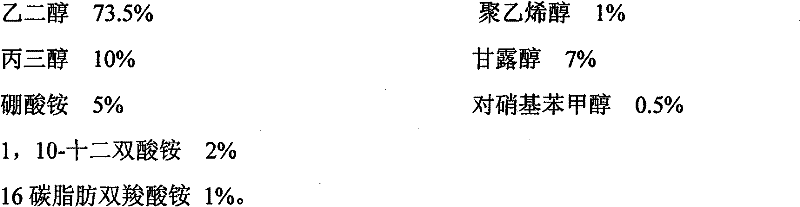

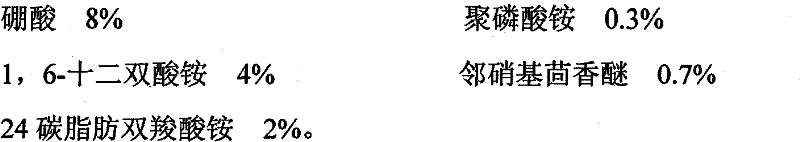

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Failure analysis method for gate oxide defect original appearance

ActiveCN104078343ANo breakdownKnow what happened before breakdownSemiconductor/solid-state device testing/measurementSemiconductor devicesSemiconductor structureEngineering

The invention relates to the technical field of semiconductor defect analysis, in particular to a failure analysis method for a gate oxide defect original appearance. The method includes the steps that firstly, a semiconductor structure to be tested is screened out under the preset voltage condition, wherein the semiconductor structure to be tested has a gate oxide defect; secondly, the semiconductor structure to be tested is operated, the semiconductor structure has the gate oxide defect, a metal interconnection layer is ground off, a scanning electron microscope voltage comparison method is used for determining the position of the gate oxide defect, an interconnection line, a dielectric layer and a gate are removed in sequence, a contrast layer having the high contrast ratio with the transmission electron microscope contrast ratio of the gate oxide is deposited on the rest of the gate oxide, a transmission electron microscope sample is manufactured on a defective gate area, and finally analysis is conducted through a transmission electron microscope. According to the failure analysis method for the gate oxide defect original appearance, the gate oxide defect original appearance can be clearly observed, and a forceful basis and a forceful direction can be provided for finding the processing technology defect of the gate oxide.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

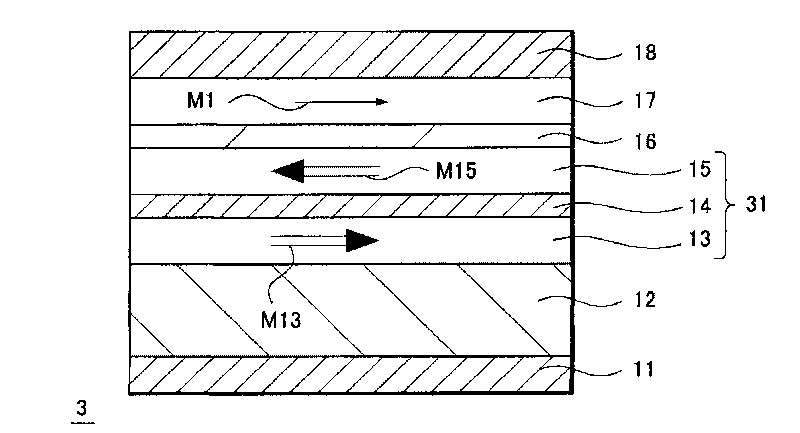

Storage element and memory

InactiveCN101743634AImprove coercive forceImprove thermal stabilityNanomagnetismNanoinformaticsInsulation layerMagnetization

A memory in which thermal stability is improved without increasing the writing current. The memory is provided with a storage element (3) having a storage layer (17) for holding information by the magnetization state of a magnetic body. A magnetization fixation layer (31) is provided on the storage layer (17) through an intermediate layer (16). The intermediate layer (16) consists of an insulator. Direction of magnetization M1 of the storage layer (17) is changed by injecting electrons subjected to spin polarization in the laminating direction, and information is recorded on the storage layer (17). Strain is applied to the storage layer (17)from an insulation layer on the periphery of the storage layer (17) having a smaller coefficient of thermal expansion as compared with the storage layer (17). The memory is also provided with wiring for supplying a current in the laminating direction of the storage element (3).

Owner:SONY CORP

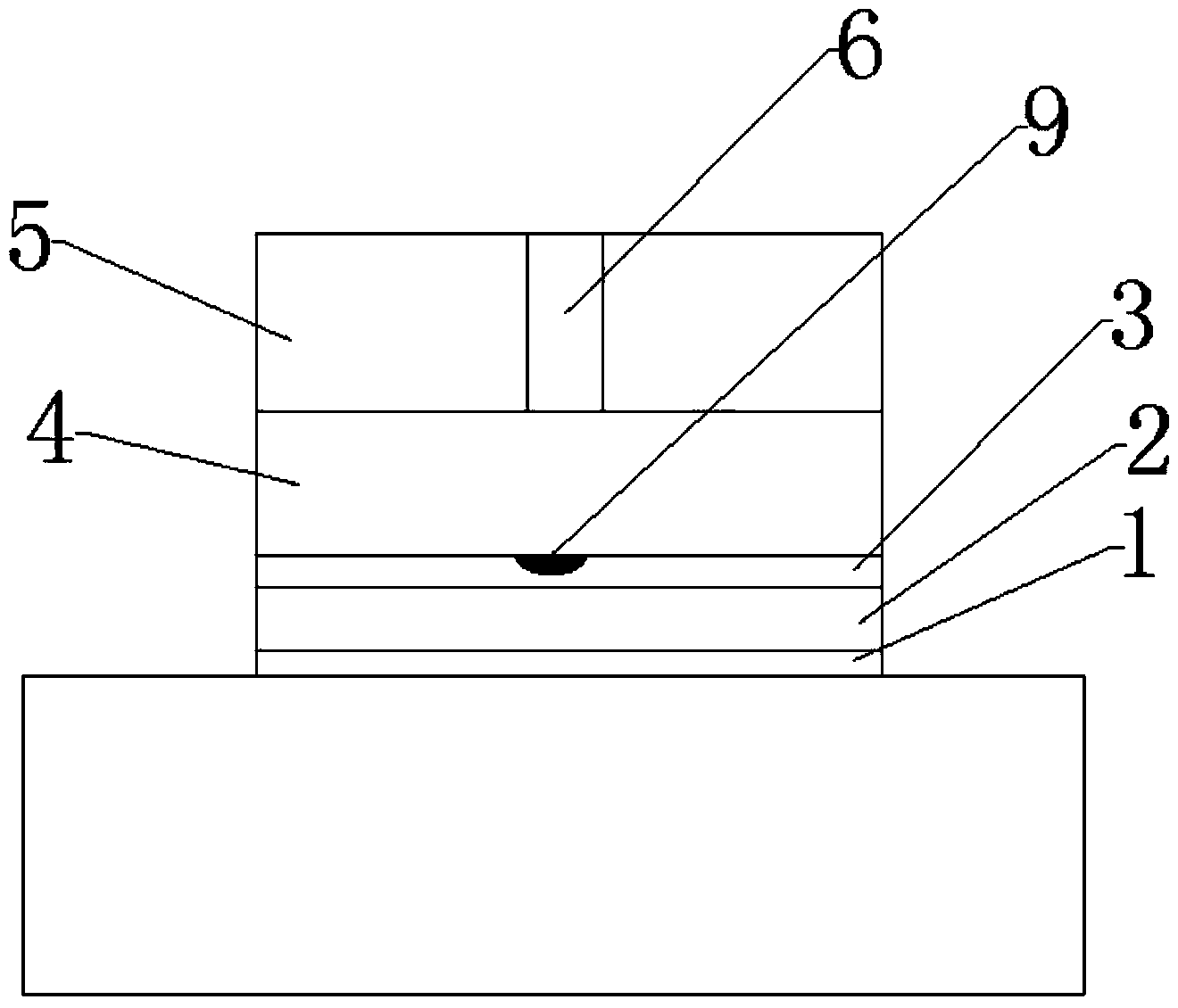

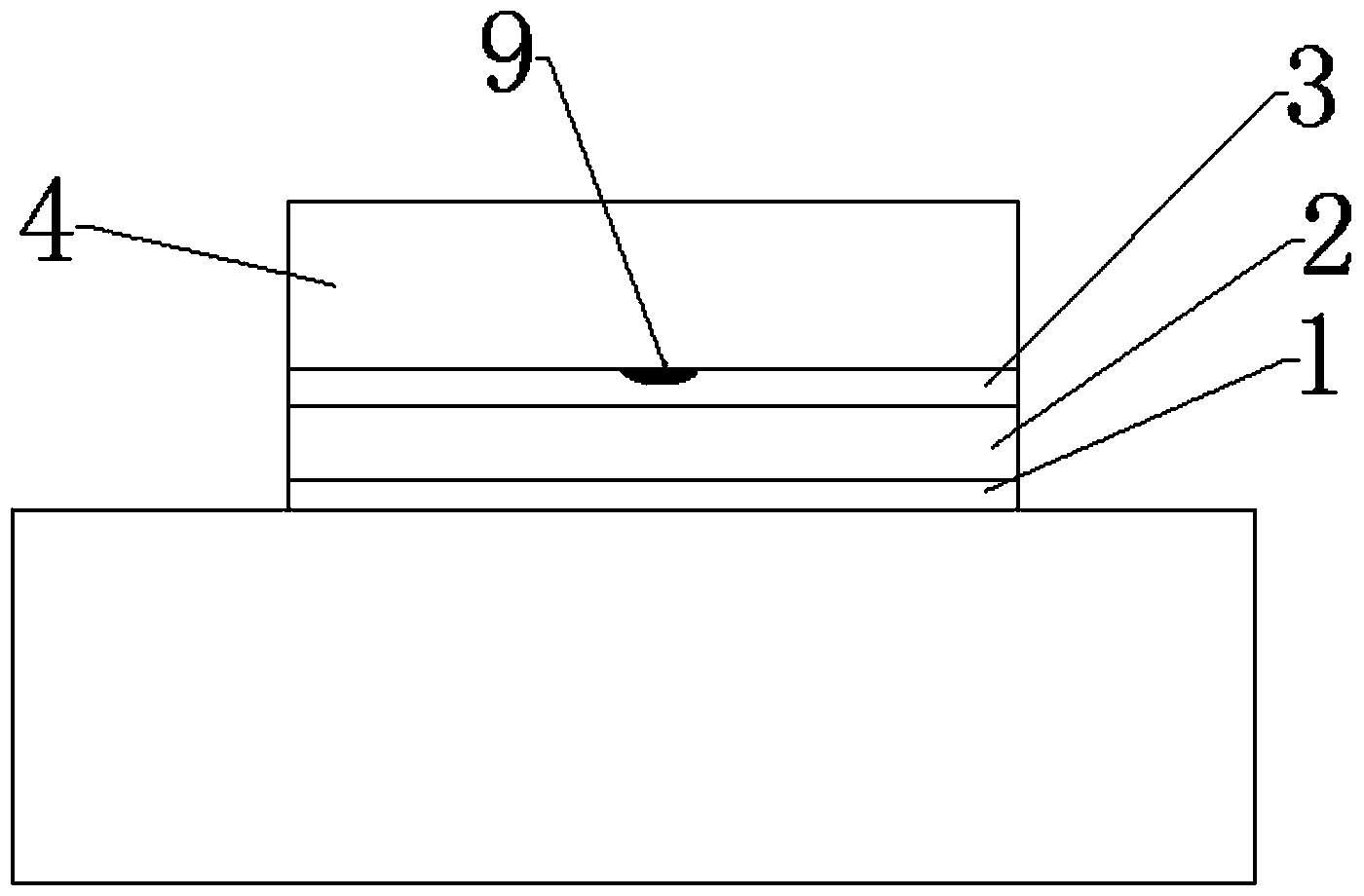

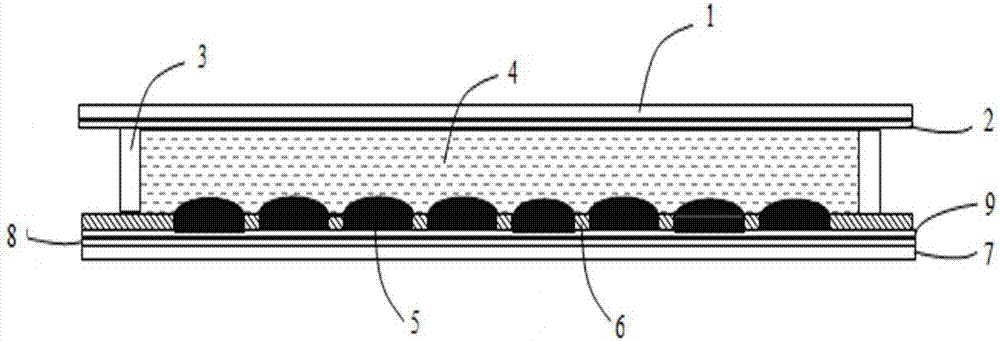

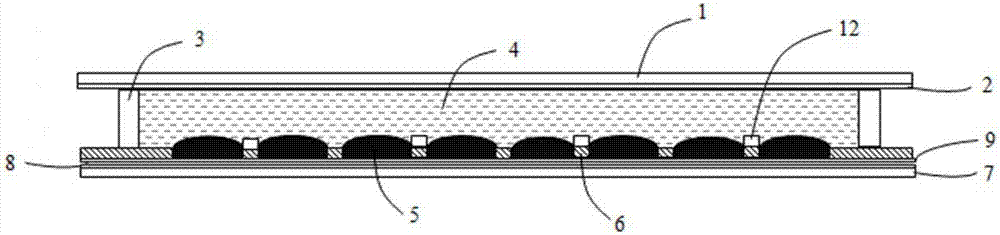

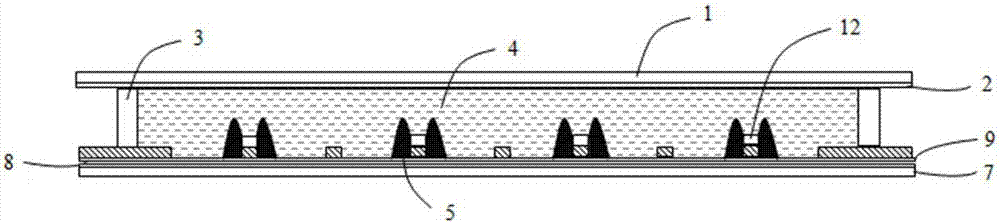

Electrowetting display device capable of controlling ink movement and preparation method thereof

InactiveCN106932894AAvoid accumulationAvoid microspheres and microrodsIdentification meansOptical elementsElectricityControl manner

The invention, which relates to the technical field of an electrowetting display device, discloses an electrowetting display device capable of controlling ink movement and a preparation method thereof. The display device comprises an upper substrate and a lower substrate. The upper substrate consists of an upper support plate, a first electrode, and a sealant; and the lower substrate includes a lower support plate, a second electrode, a hydrophobic insulating layer and pixel walls and ink control posts are arranged at the pixel walls. In addition, the invention also discloses a preparation method for the electrowetting display device. Because of the ink control posts arranged at the pixel walls, a reliable control way is provided for ink movement. When ink is opened, the ink control posts are compatible with the ink and are repellent to water, so that ink in four pixel grids around the posts is collected towards the posts to realize oriented movement of ink under pressurization and thus the ink movement direction can be controlled. Meanwhile, ink in the pixel grids is reduced because the ink is collected to the posts during the pressurization process, so that the aperture opening ratio of the pixel grid increases.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

Highly aqueous and high-stability electrolyte used for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469990AGood electrochemical propertiesHigh impedanceElectrolytic capacitorsElectrolytic agentPhosphoric acid

The present invention relates to the technical field of electrolytes, in particular to a highly aqueous and high-stability electrolyte used for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 10-14 parts of ammonium adipate, 6-10 parts of a water-proofing agent, 4.5-7 parts of ammonia, 3-5 parts of ammonium formate, 1-2 parts of p-nitrobenzoic acid, 0.5-1 part of phosphoric acid, 6-10 parts of glycol and 50-70 parts of deionized water. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 102 V and the conductivity rate of the prepared electrolyte can reach 100 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high frequency, low impedance and high stability, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Large and permanent magnet wind turbine generator scatteredly embedded winding stator insulation mechanism

InactiveCN103427523ANo coronaStrong anti-stunning abilityWindings insulation shape/form/constructionSynthetic resin layered productsSlot insulationDielectric loss

The invention relates to a large and permanent magnet wind turbine generator scatteredly embedded winding stator insulation mechanism which comprises a slot inside insulation component and an end part insulation component. The slot inside insulation component comprises a slot wedge, a slot insulation, a slot bottom filler strip, a middle insulation and a scatteredly embedded wire winding. The slot wedge is arranged on one end of the scatteredly embedded wire winding. The scatteredly embedded wire winding is composed of an upper winding and a lower winding. The middle insulation is arranged between the upper winding and the lower winding. The slot insulation is arranged on the outer side of the scatteredly embedded wire winding. The slot bottom filler strip is arranged at the lower part of the slot insulation. The end part insulation component comprises end part insulation pieces between phases, end part insulations, lashing ropes, soft end bands and a winding end part sealing piece. The end part insulation pieces between phases are arranged between windings at the end parts of a generator. The end part insulations wrap the outer sides of the windings. The winding end part sealing piece is arranged on the non wire outlet end of the scatteredly embedded wire winding. The soft end bands are lashed on the outer side of an end part insulation through the lashing ropes. Compared with the prior art, the mechanism provided by the invention has the advantages of strong anti halo ability, good insulation performance, less dielectric loss, good dielectric strength performance and the like.

Owner:SHANGHAI WANDE WIND POWER

Electrolyte for high-conductance and long-life aluminum electrolytic capacitor and preparation method thereof

ActiveCN105575665ASimple processEasy to operate and controlElectrolytic capacitor manufactureElectrolysisPolyethylene glycol

The invention relates to the technical field of electrolytes and particularly relates to an electrolyte for a high-conductance and long-life aluminum electrolytic capacitor and a preparation method thereof. The electrolyte is composed of the following raw materials in weight part: 8-12 parts of ammonium benzoate, 6-10 parts of ammonium adipate, 4-6 parts of polyethylene glycol, 1.5-2.5 parts of mannitol, 2-3 parts of boric acid, 2.5-3.5 parts of ammonium sebacate, 0.2-0.4 part of ammonium hypophosphite, 0.6-1.0 part of p nitrophenol, 3-5 parts of ammoniacal liquor, 0.1-0.3 part of EDTA and 55-75 parts of glycol. According to the technical scheme of the invention, based on the interaction of the above-described materials, the weight proportion of all the raw materials is strictly controlled, and the scintillation voltage of the prepared electrolyte is up to 380V. The conductivity of the prepared electrolyte is up to 5.5ms / cm. meanwhile, the electrolyte is good in electrochemistry characteristics, high in conductivity and long in service life, thus being applied to the manufacture of aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

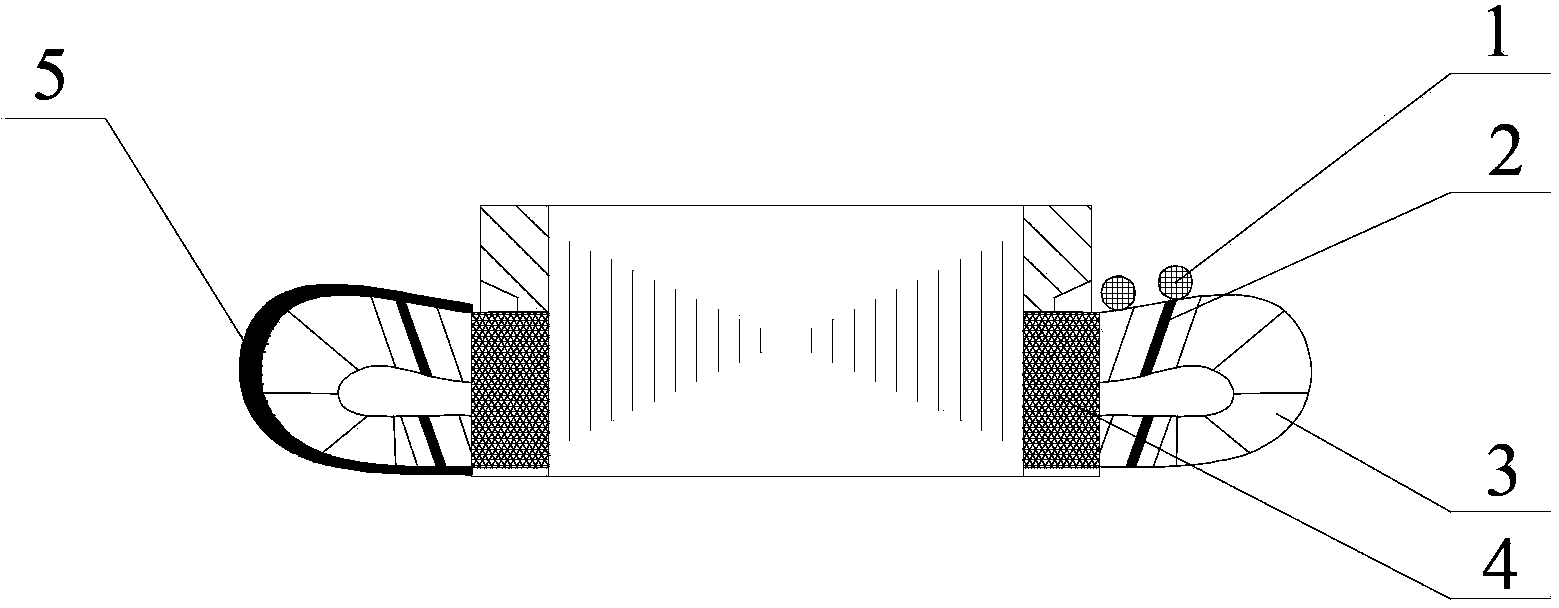

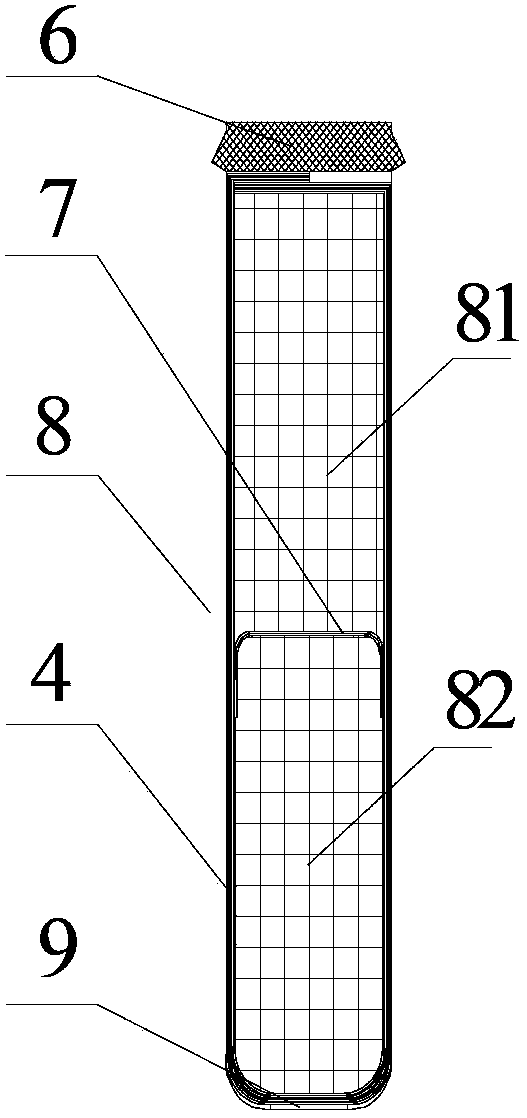

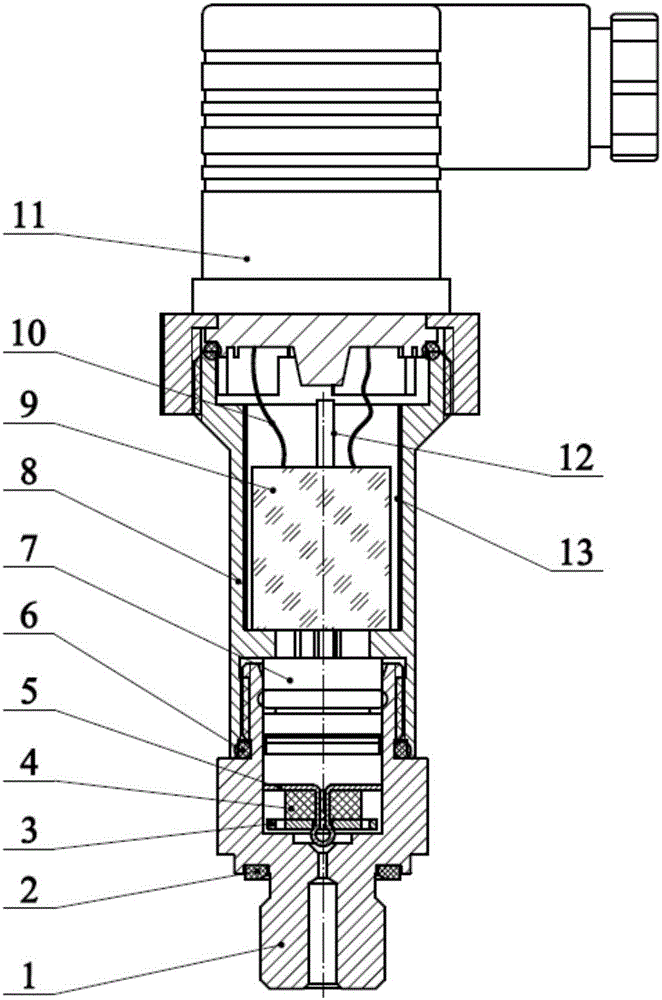

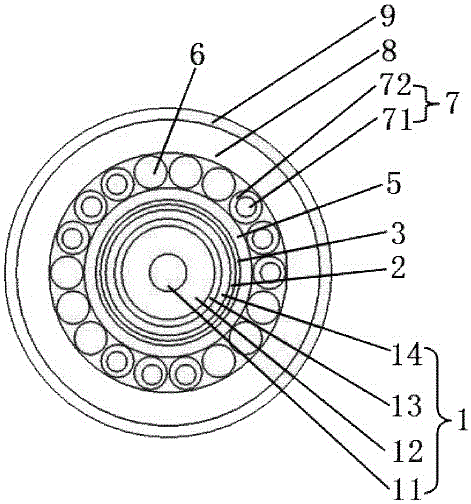

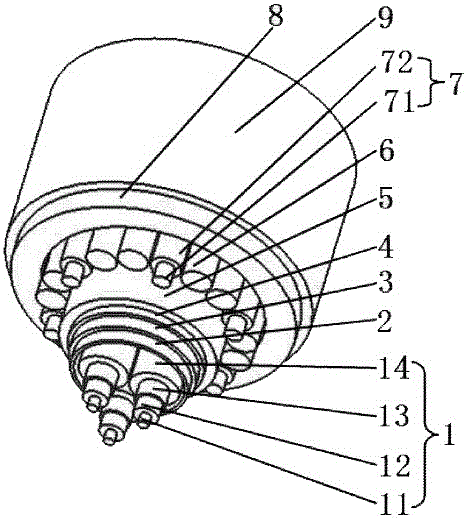

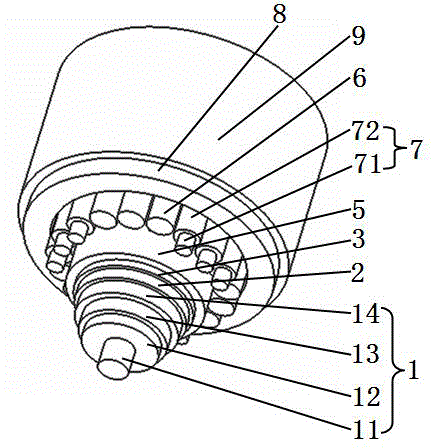

Special pressure transmitter for water pump

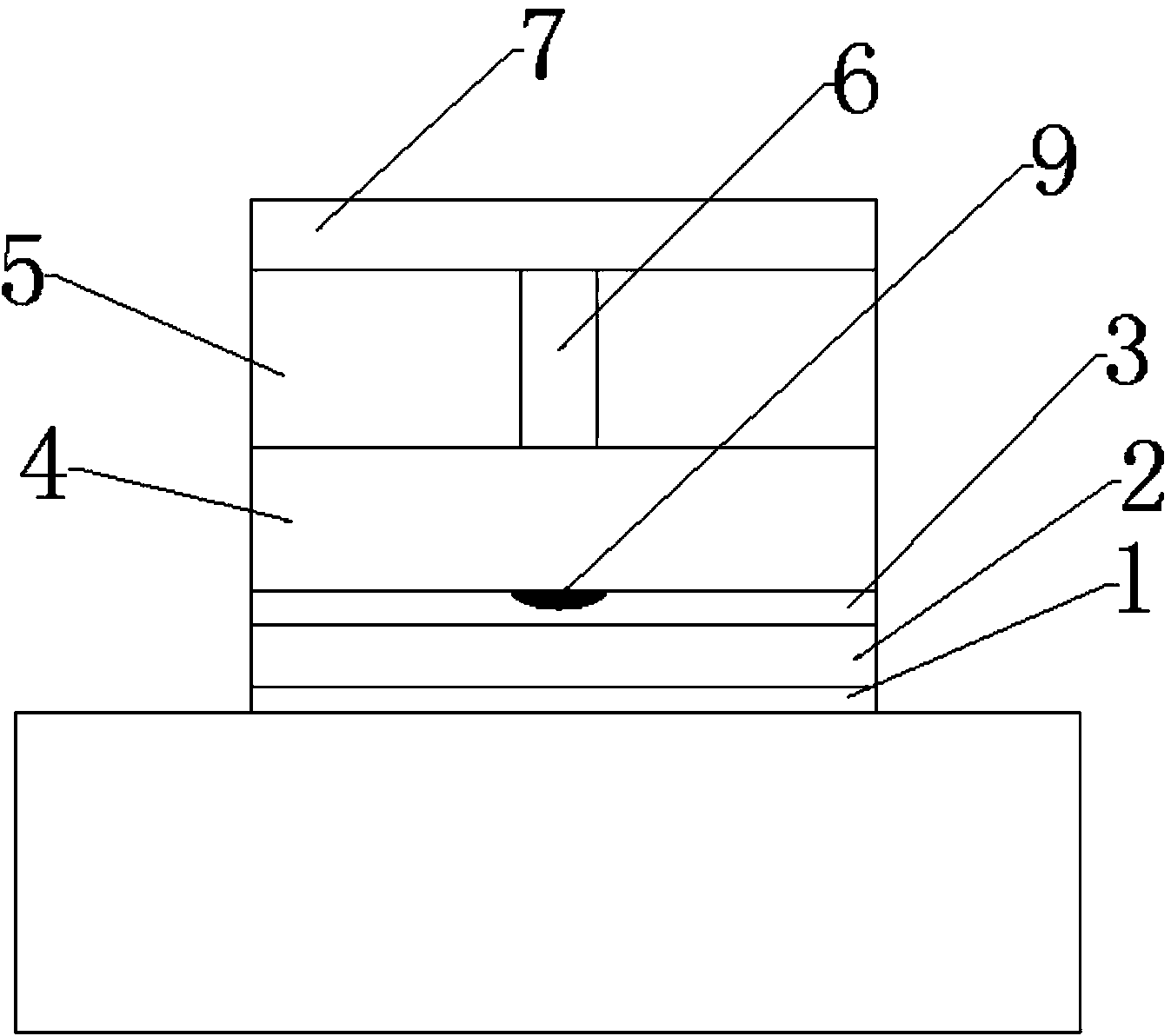

The invention relates to a special pressure transmitter for a water pump. The special pressure transmitter for the water pump comprises a base, a buffering sheet, foam cotton, a steel wire, an O-shaped seal ring, a sensor, a shell, a circuit board, a silicone wire, a Hirschmann joint, an air guide tube and an insulation sleeve, wherein a groove used for accommodating the O-shaped seal ring is formed in the outer circle of the sensor; the O-shaped seal ring is clamped with the sensor via the groove; a metal tube is arranged at the top of the sensor; the air guide tube is in inserted connection with the metal tube; a cavity with an open top is formed in the base; the sensor is arranged inside the cavity; the buffering sheet is arranged between the bottom of the cavity of the base and the bottom of the sensor; the foam cotton is arranged between the buffering sheet and the bottom of the sensor; the buffering sheet is clamped with the foam cotton via the steel wire; the circuit board is fixedly arranged in the insulation sleeve; the insulation sleeve is fixedly arranged in the shell; the circuit board is connected to the Hirschmann joint via the silicone wire; the top of the base is connected to one end of the shell; the other end of the shell is connected to the Hirschmann joint.

Owner:西安森瑟斯传感器有限责任公司

High-sparking and anti-lightning electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469992ASimple processEasy to operate and controlElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

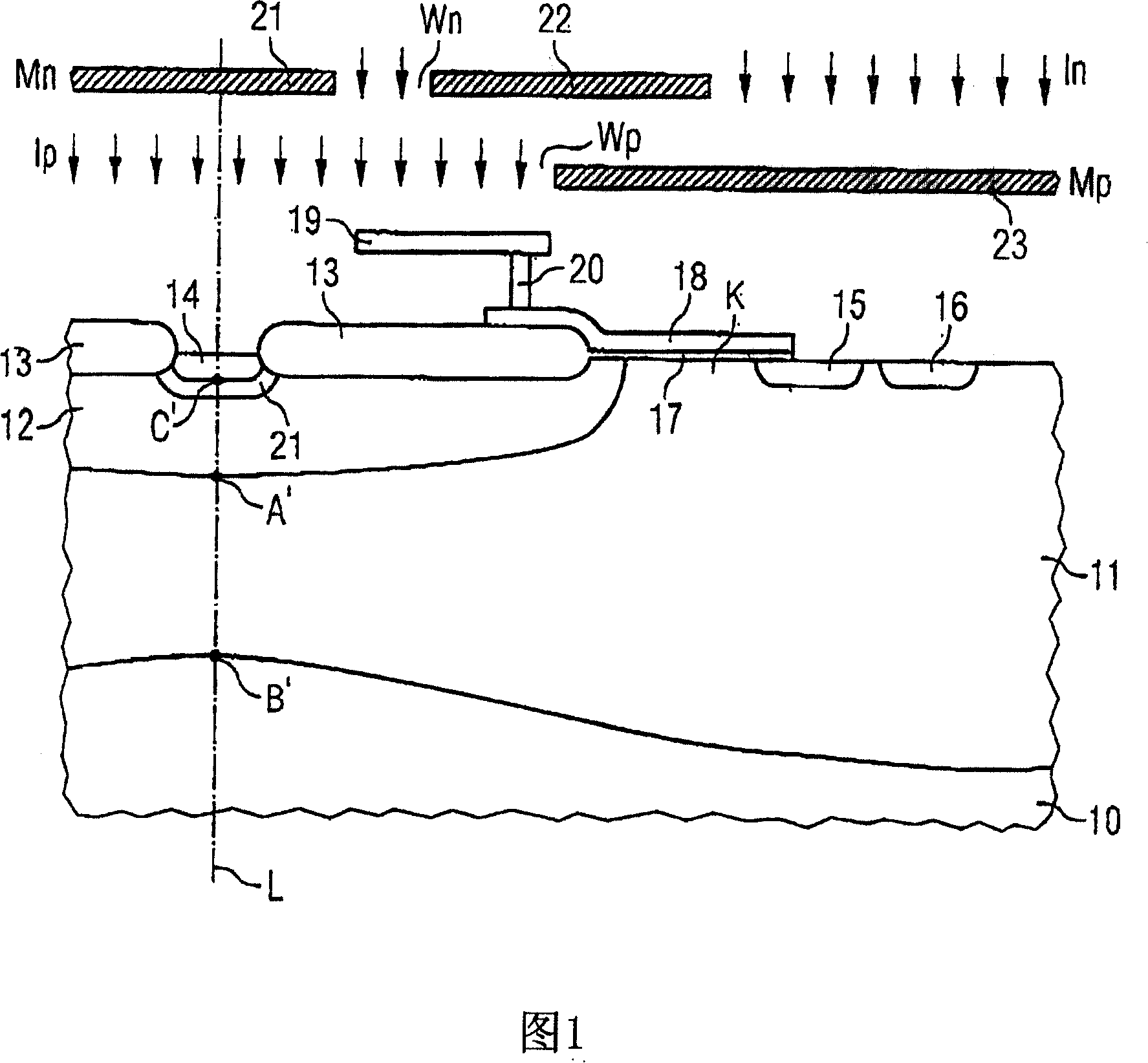

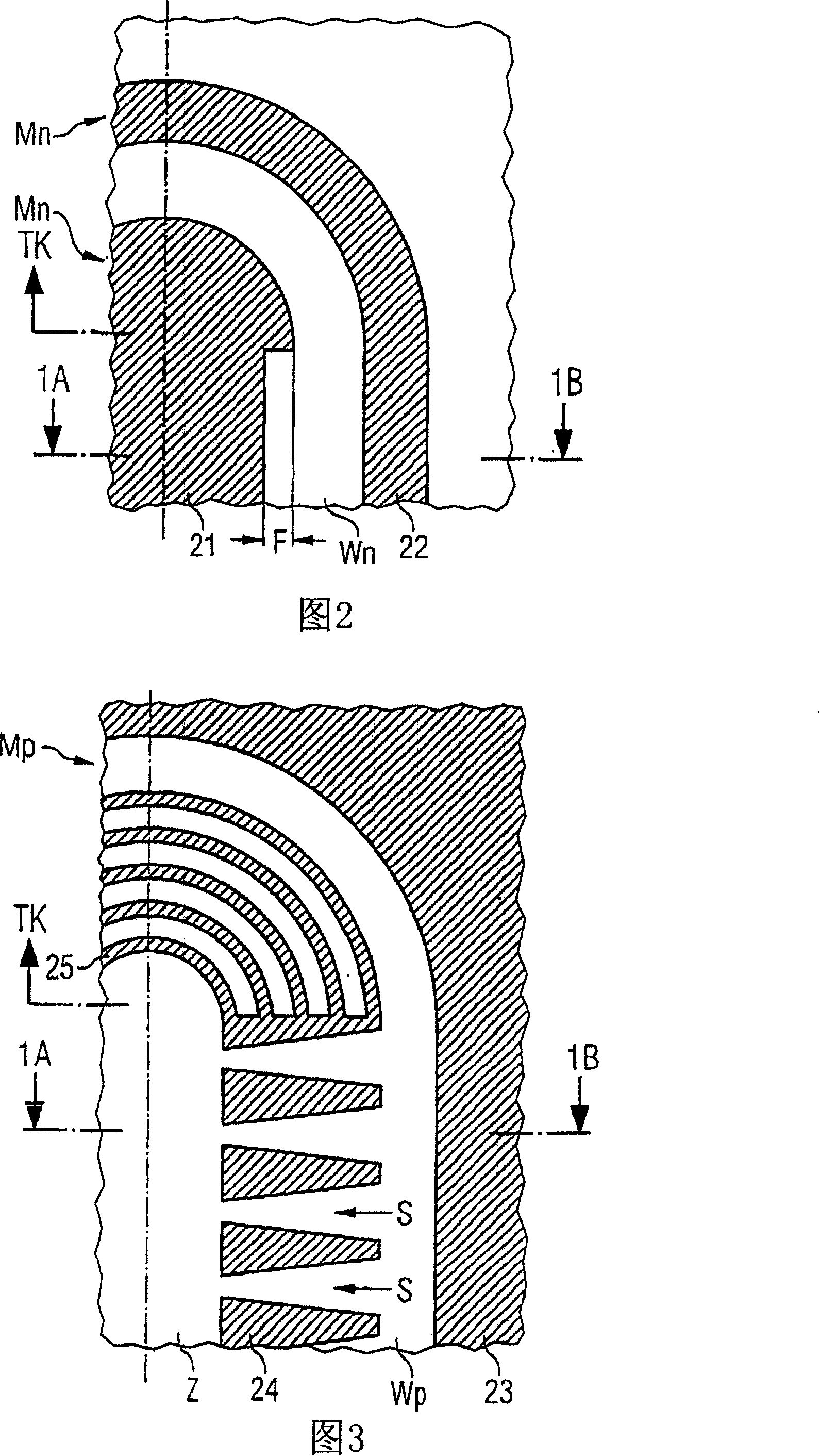

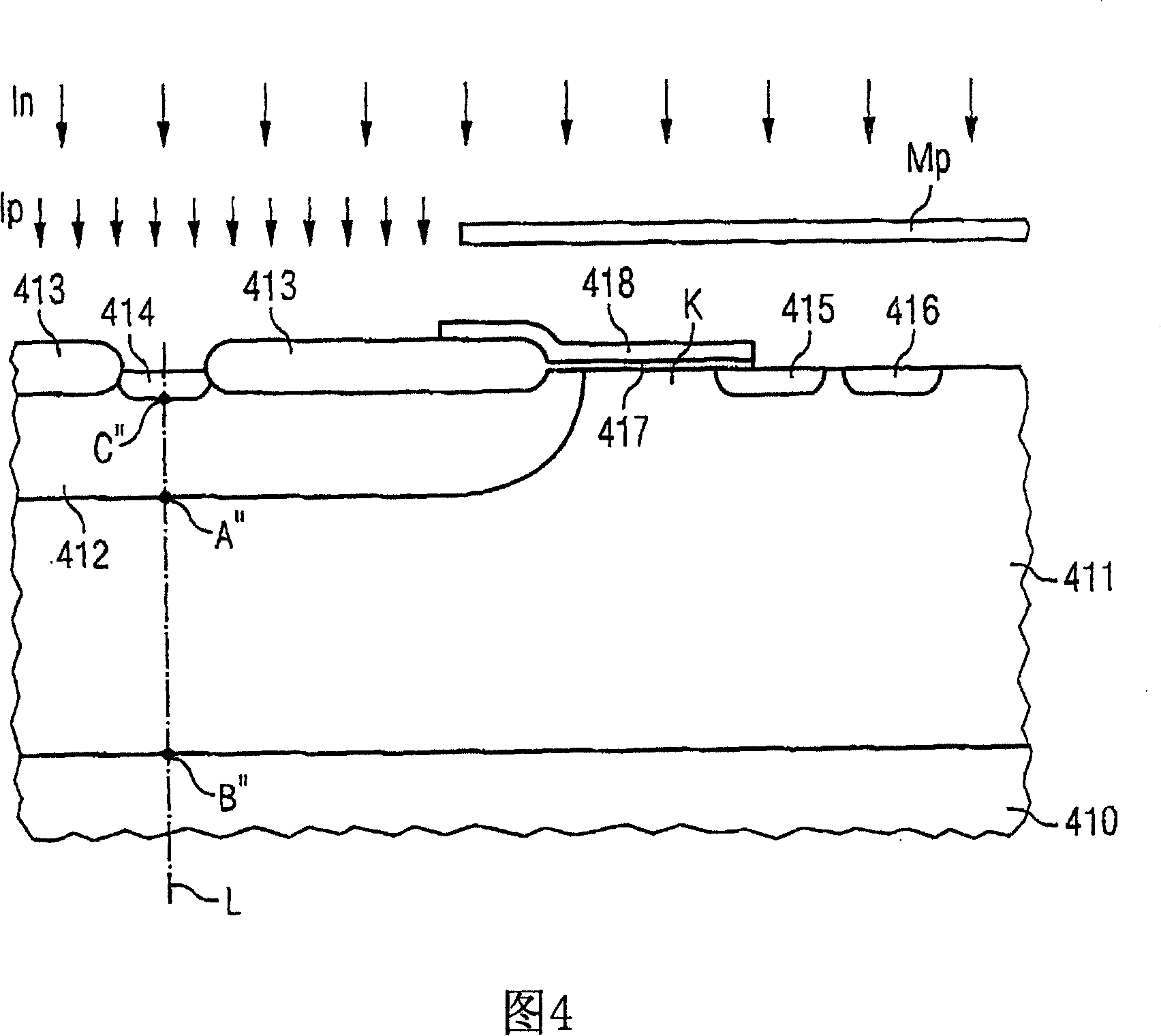

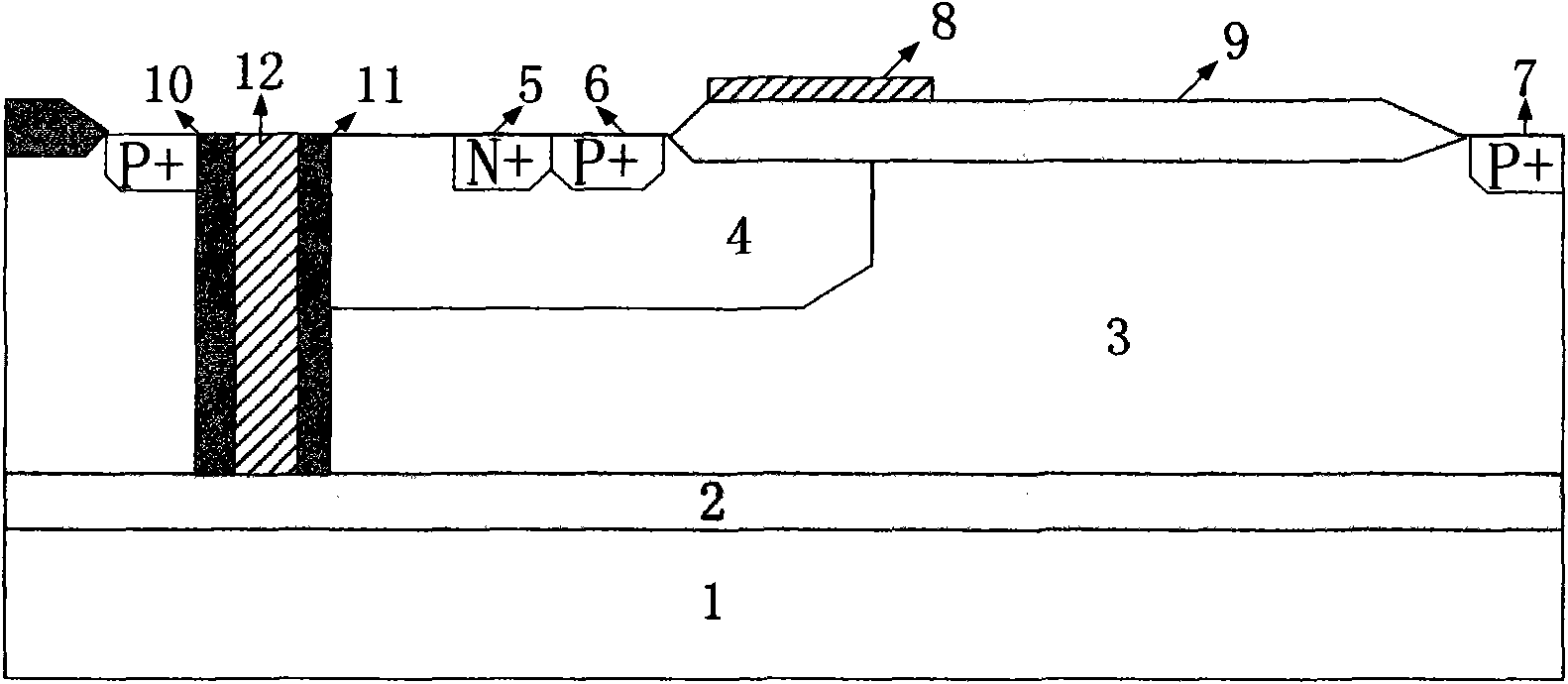

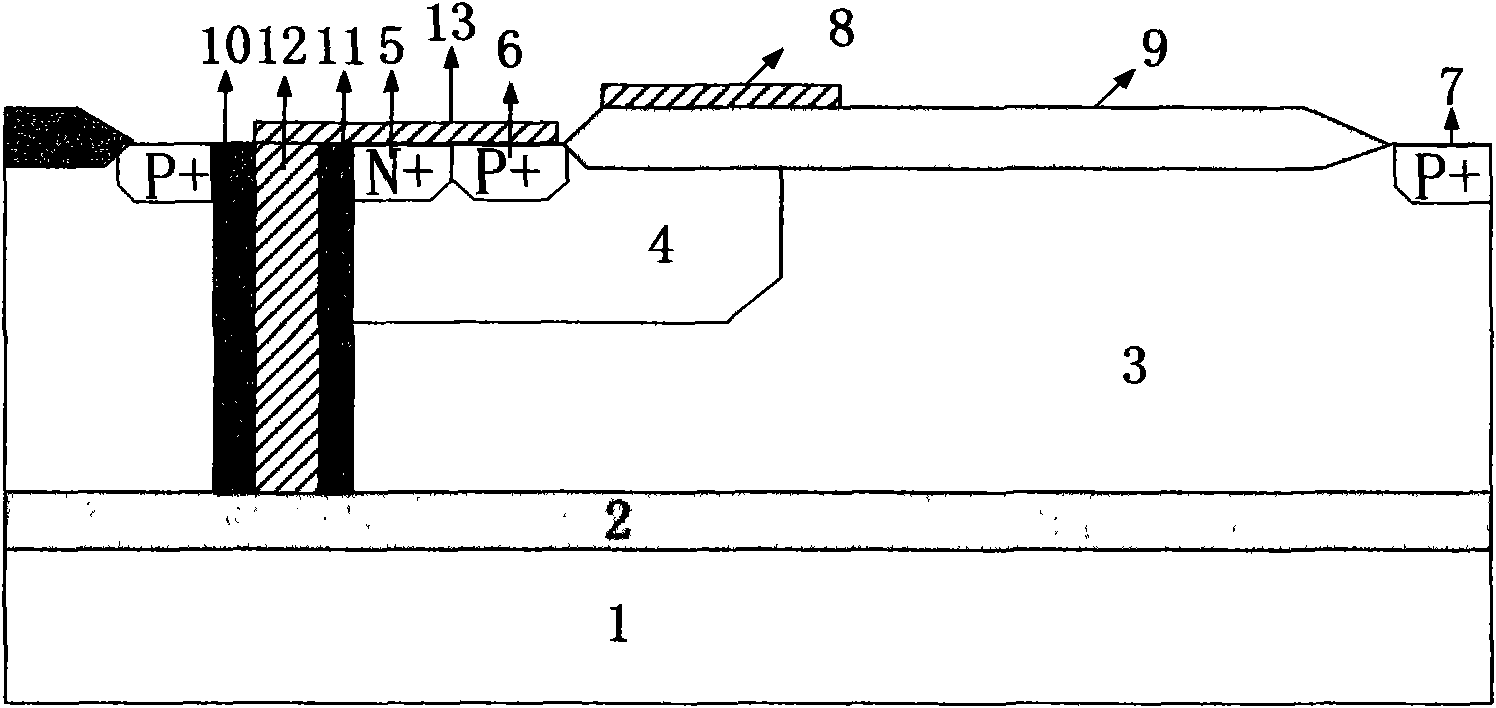

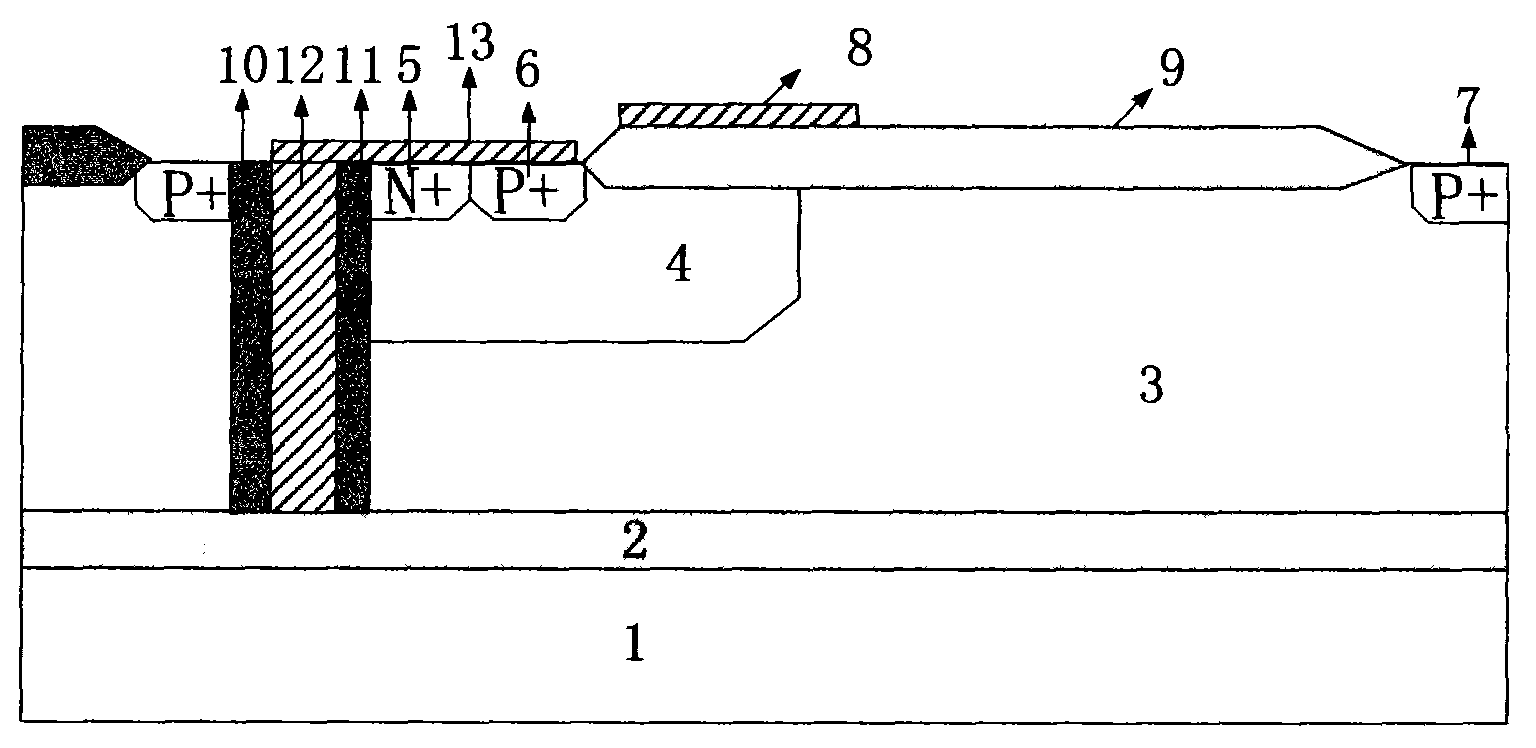

High voltage pmos transistor

ActiveCN101124680AIncrease working voltageImprove high voltage characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesHigh voltage transistorsEngineering

Owner:AUSTRIAMICROSYSTEMS AG

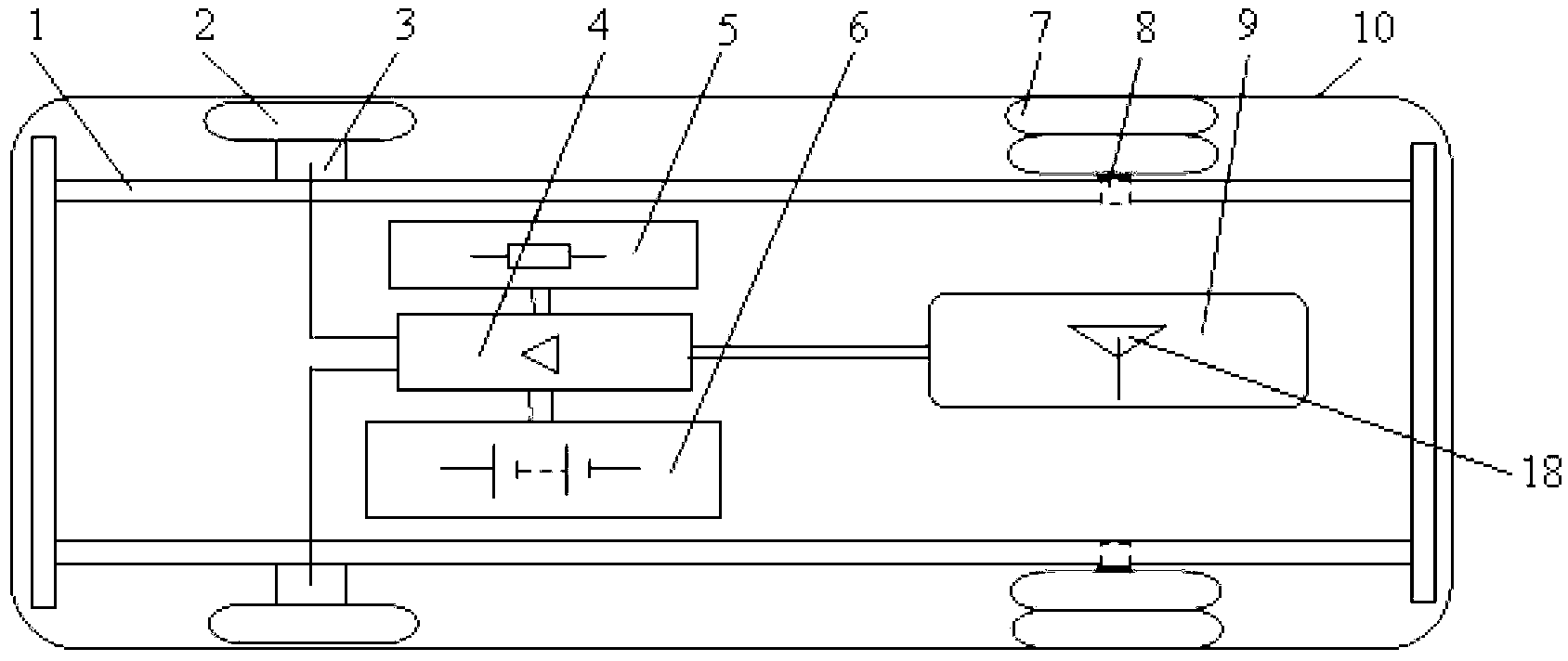

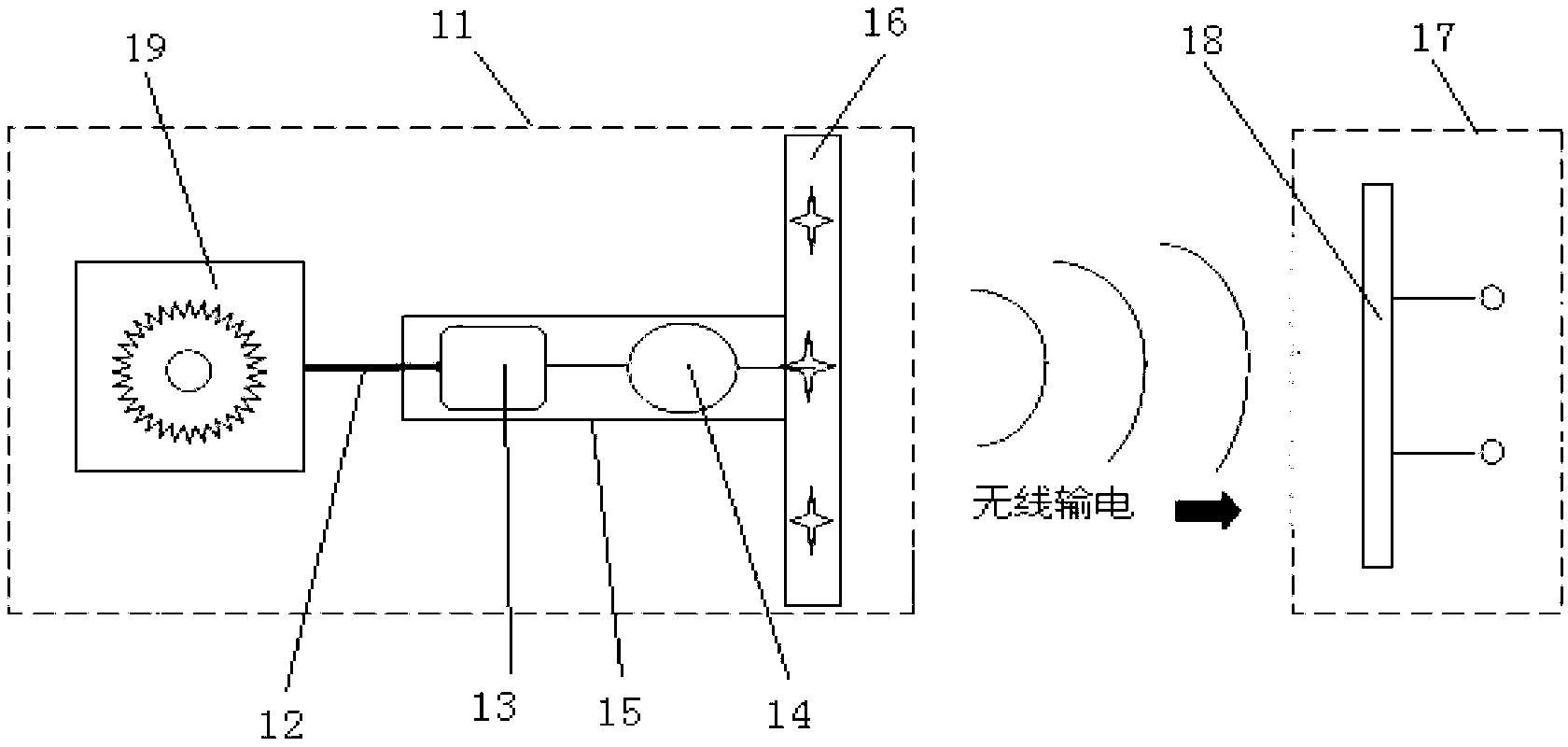

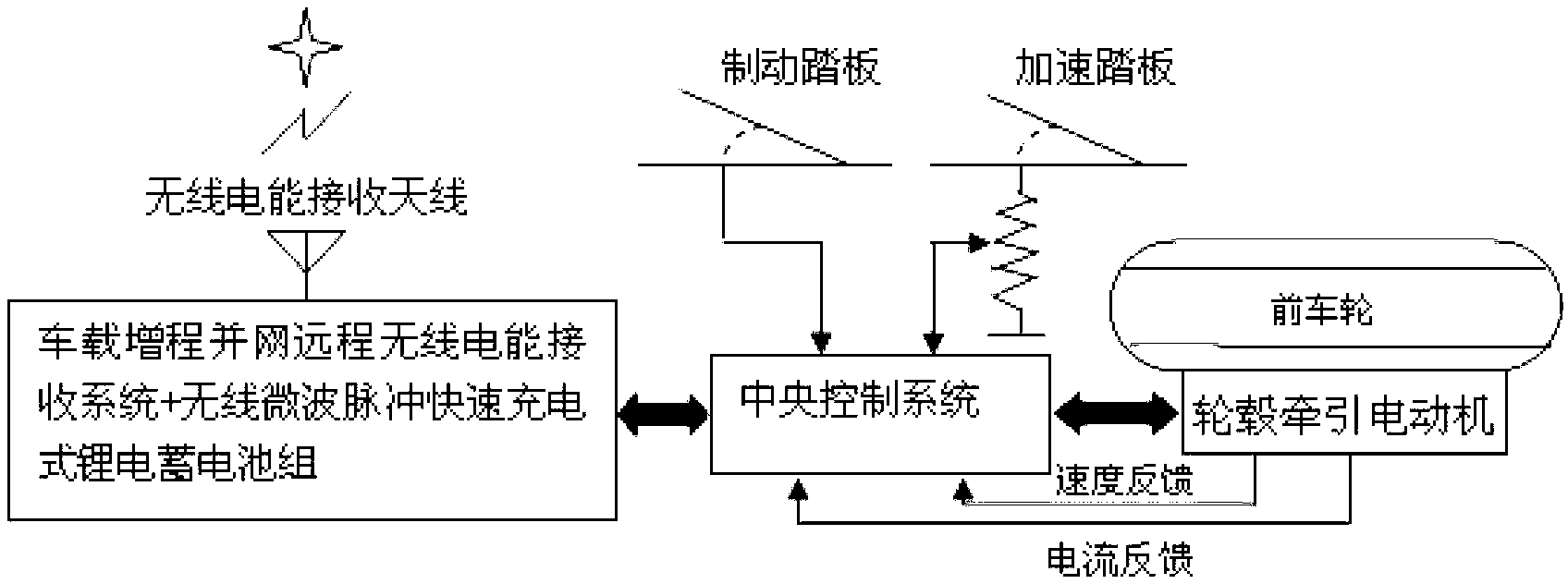

Remote wireless power transmission type mileage-increasing electric automobile

InactiveCN103287283AAchieve conversionIncrease mileageElectric vehicle charging technologyVehicular energy storagePulse fastCharging station

The invention provides a remote wireless power transmission type mileage-increasing electric automobile. A hub traction motor is mounted on each front wheel. Rear wheels are connected with a rear wheel axle. An automobile housing is fixed on an automobile girder. The hub traction motors and the rear wheel axle are fixed on the automobile girder to form an automobile body. A vehicular mileage-increasing grid-connected wireless electric power receiving system is mounted on the automobile girder. An input end of the vehicular mileage-increasing grid-connected wireless electric power receiving system is connected with a wireless electric power receiving antenna. An output end of the vehicular mileage-increasing grid-connected wireless electric power receiving system is connected with a central control system to input power. The central control system is further connected with a wireless microwave pulse fast-charging lithium storage battery pack, the hub traction motors and other electric loads in the automobile. By the remote wireless power transmission type mileage-increasing electric automobile, 'zero fuel consumption, zero emission and mileage increasing' are achieved, and power supply from charging stations is not necessary. In addition, the remote wireless power transmission type mileage-increasing electric automobile is powered by national wireless microwave power grids and is capable of realizing limitless mileage increasing in a range covered by microwave electric power.

Owner:CHANGAN UNIV

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367BImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

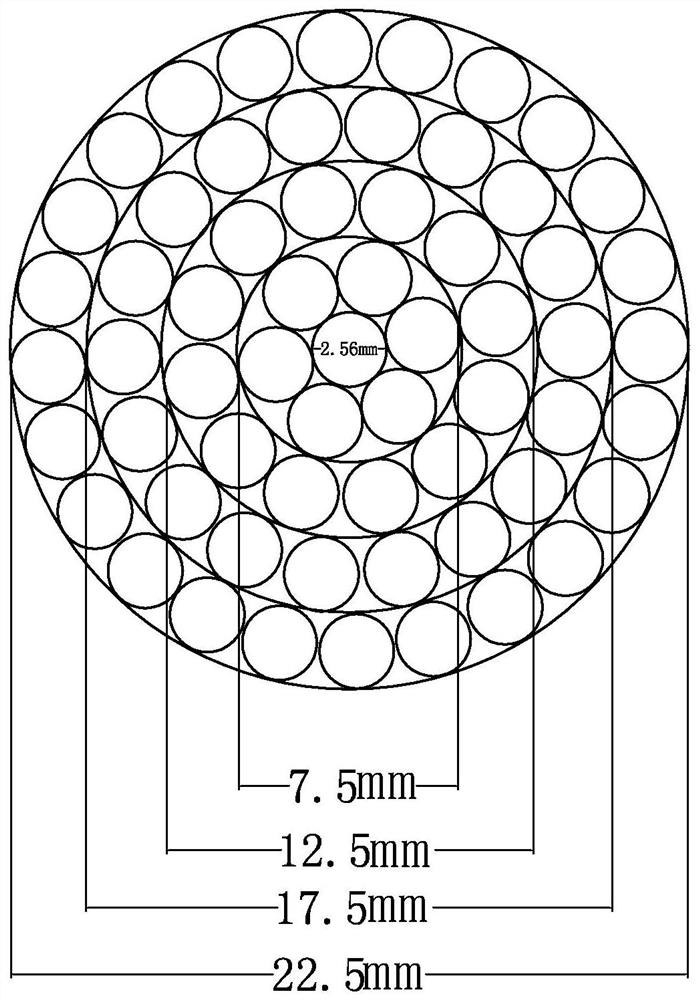

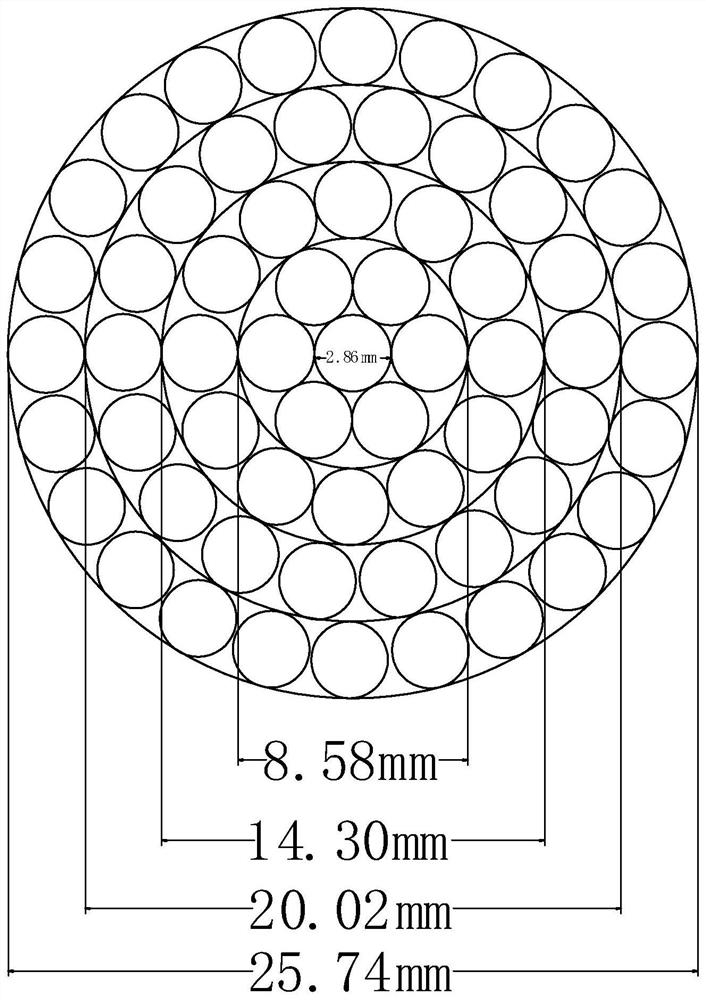

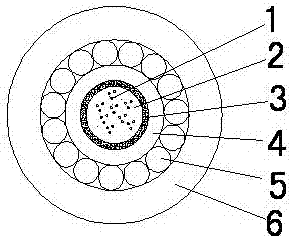

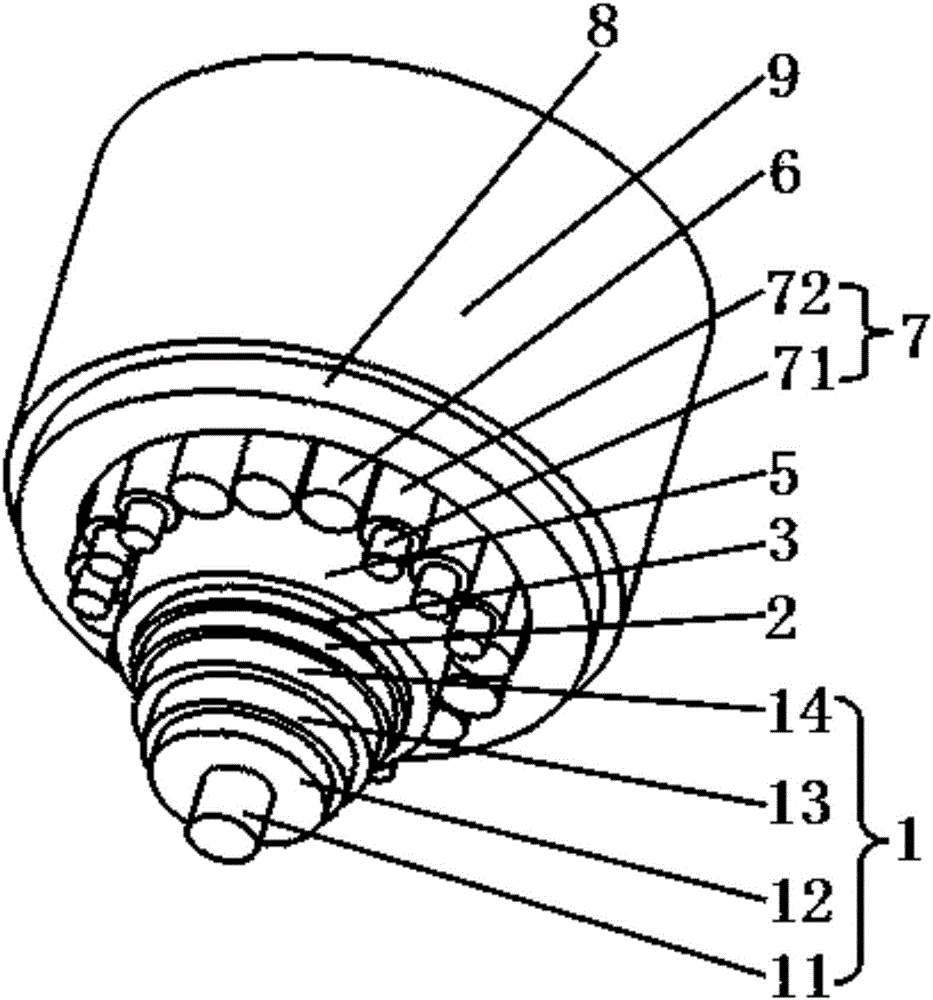

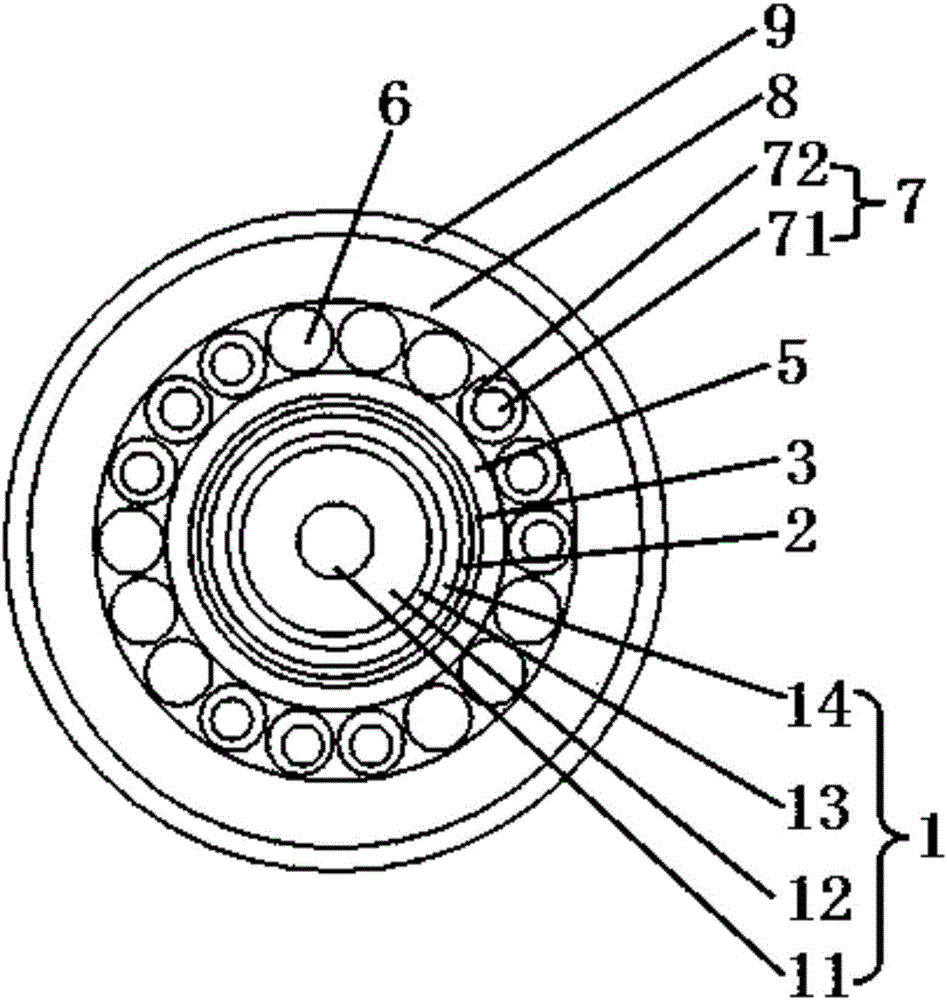

Submarine high voltage cable and manufacturing method thereof

ActiveCN104376904ASave resourcesImprove wear resistancePlastic/resin/waxes insulatorsClimate change adaptationInsulation layerElectrical conductor

The invention belongs to the technical field of cables and particularly relates to a submarine high voltage cable which is formed by a conducting unit, a metal shielding layer, a water-resistant layer, an inner sheath, an armoring layer, an outer sheath and an outer sheath protective layer which are arranged sequentially from inside to outside. The conducting unit is formed by a conductor, an insulation layer, an insulation shielding layer and a conductor protective layer. On one of any cross sections, the circle center of the conductor coincides with the circular center of the insulation layer, the diameter of the insulation layer is 1.5 to 5 times that of the conductor, and the minimum value of the thickness of the insulation layer is 1.5mm. Filling rope groups and reinforcing part groups are distributed outside the inner sheath in an alternating mode and cling to the inner sheath. The outer sheath protective layer is made of polyamide. The insulation layer is made of organosilane crosslinked polyethylene or special materials. The invention further discloses a manufacturing method of the submarine high voltage cable. The submarine high voltage cable mainly has the following advantages of being proper in mechanical performance redundancy, capable of saving resources, high in abrasion resistance, water seepage resistance, sea water resistance and shielding performance and good in high voltage transmission.

Owner:海悦电缆制造有限公司

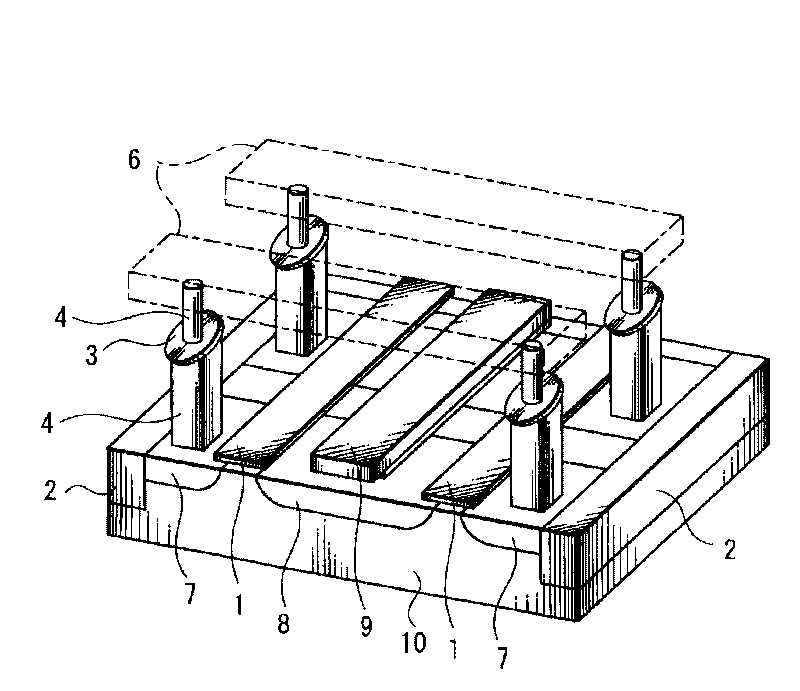

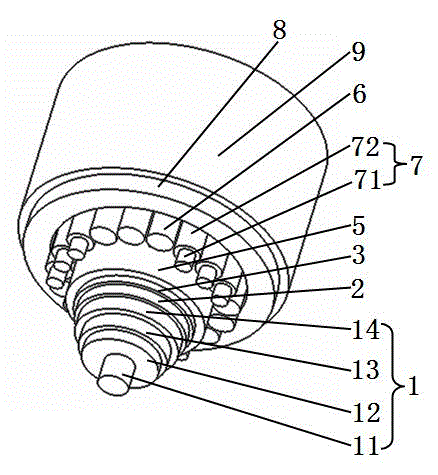

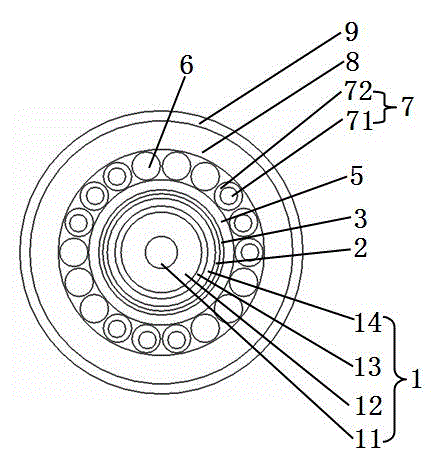

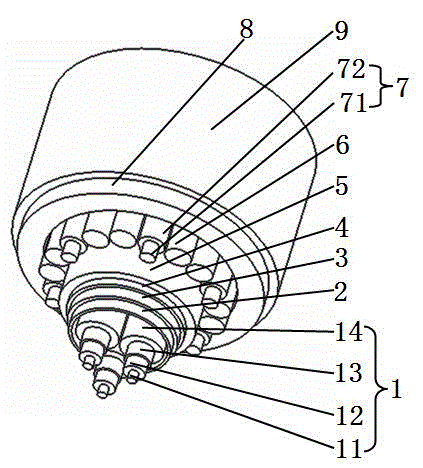

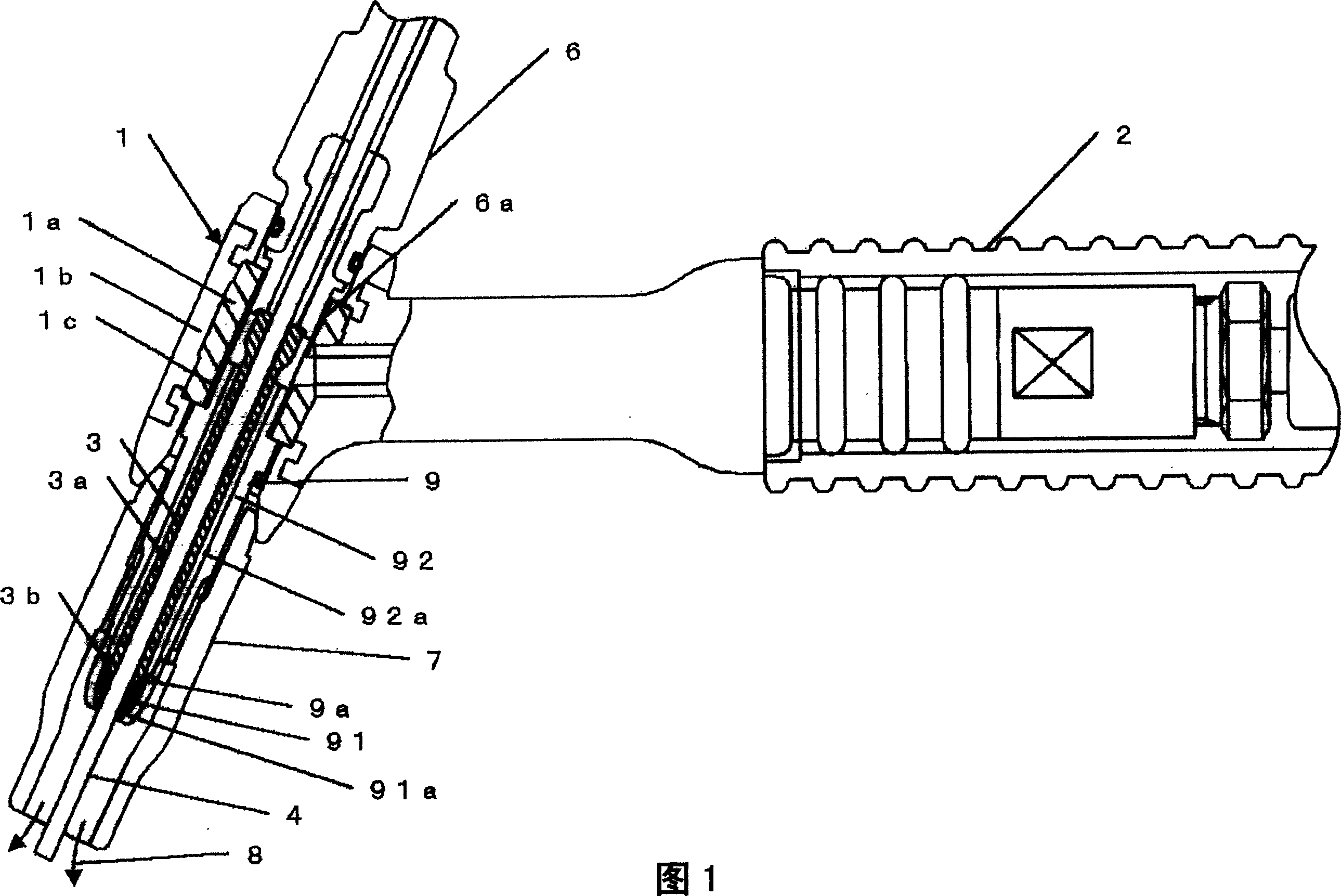

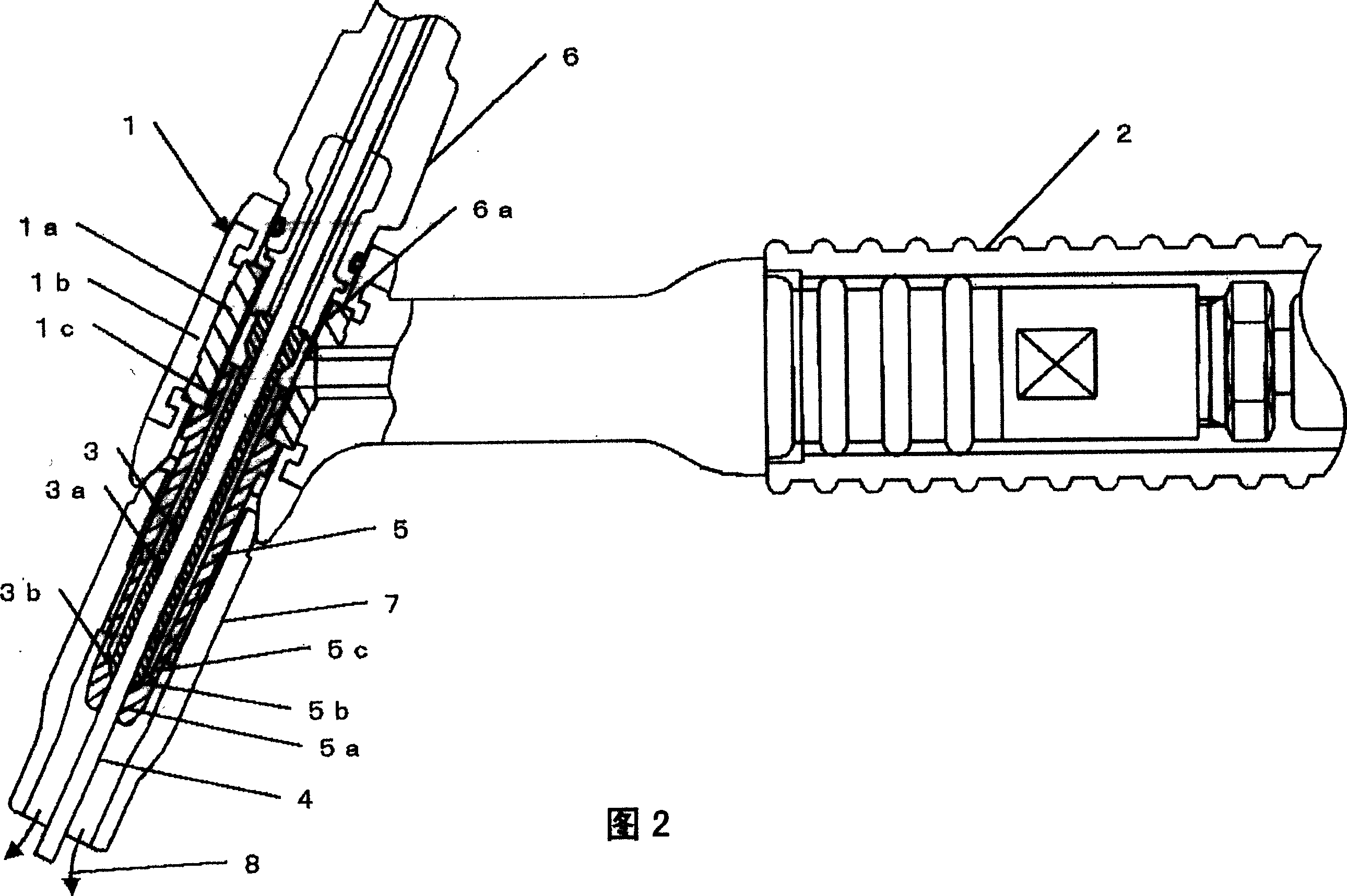

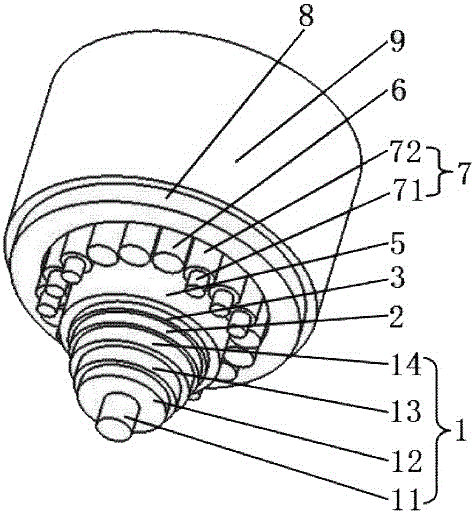

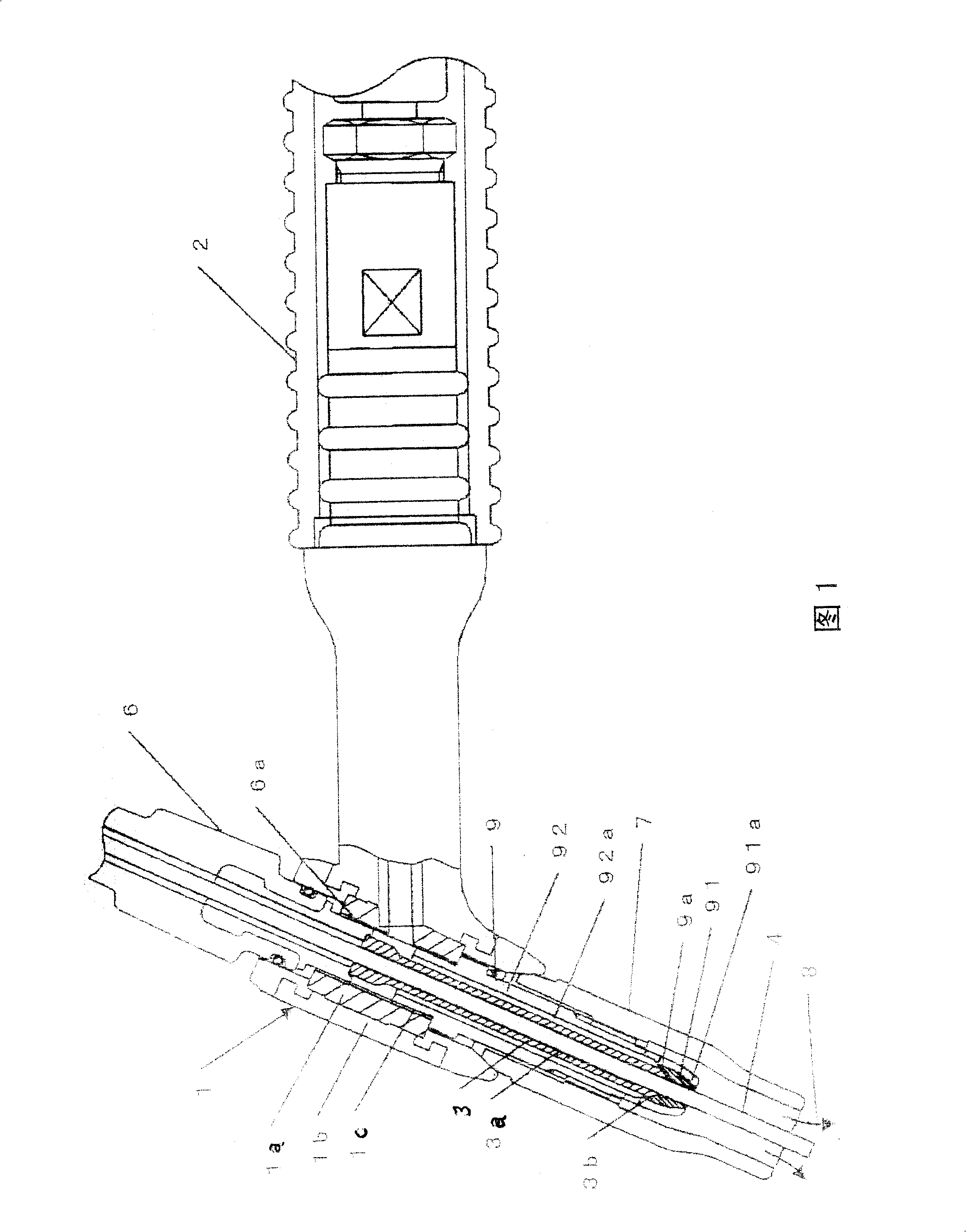

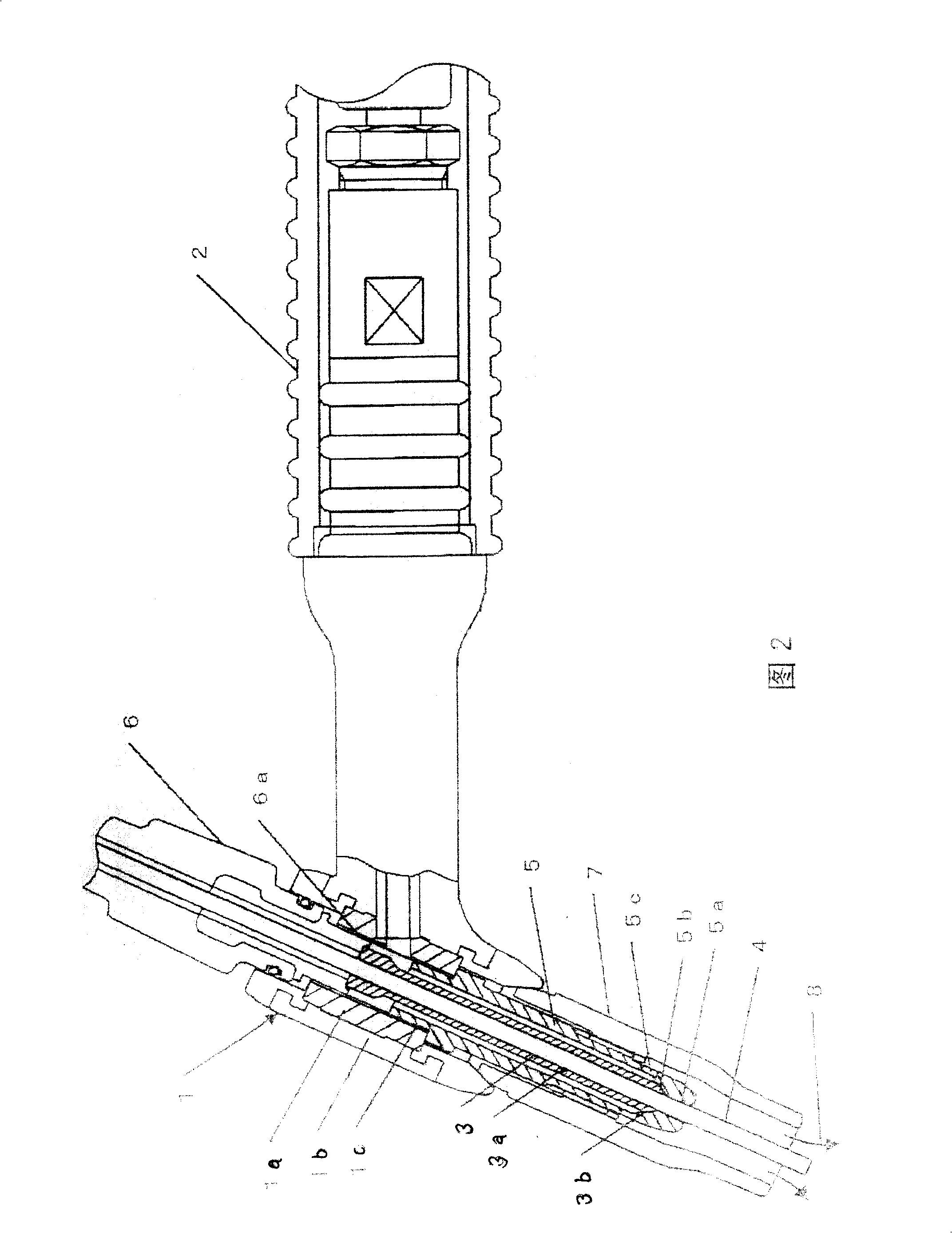

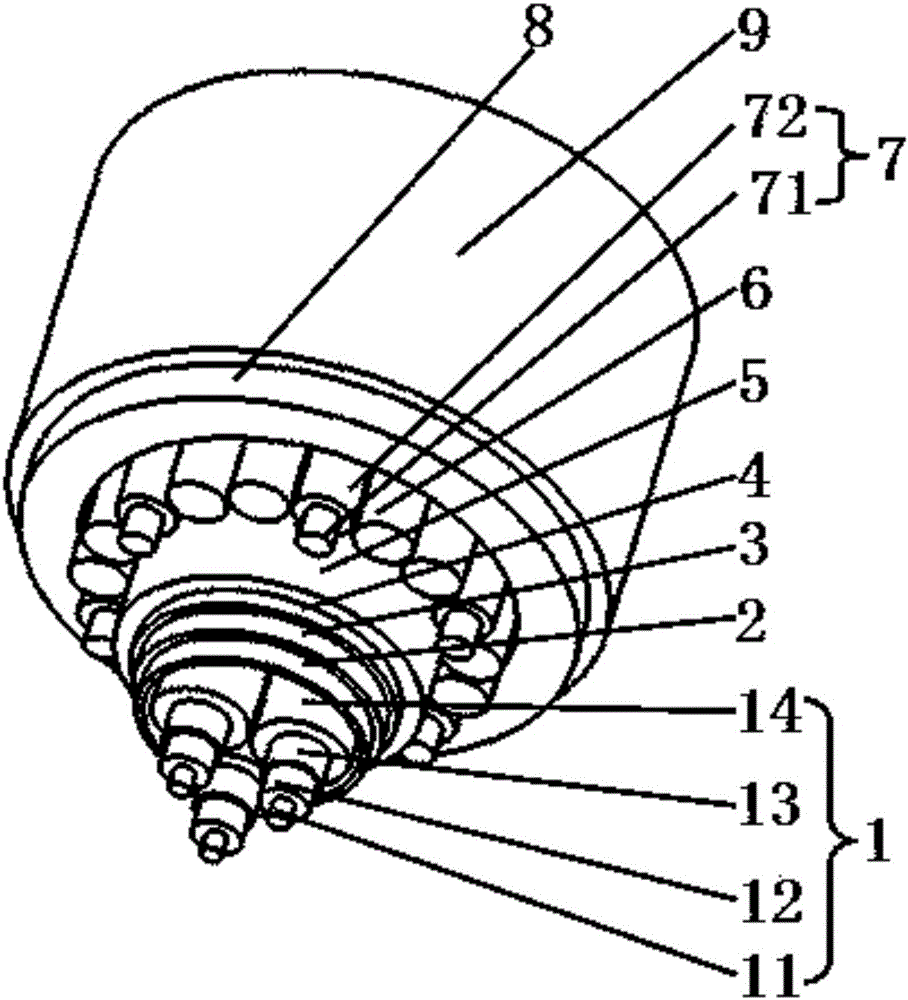

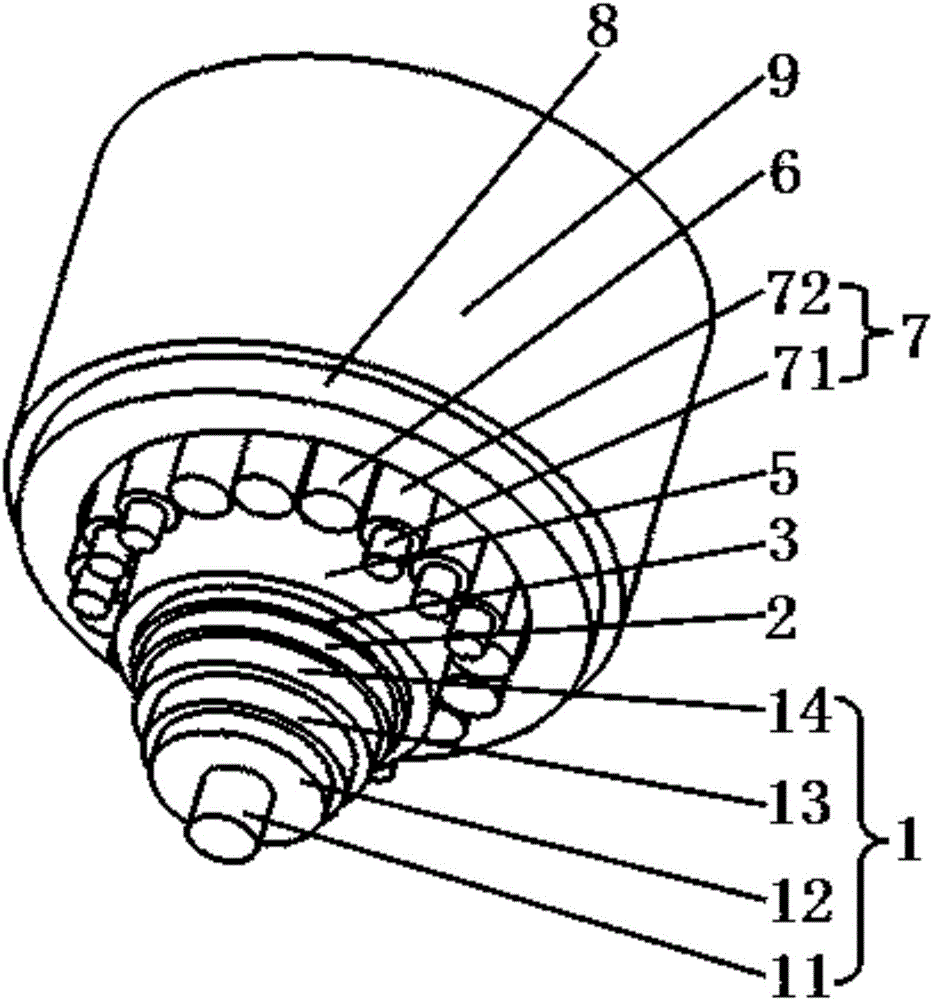

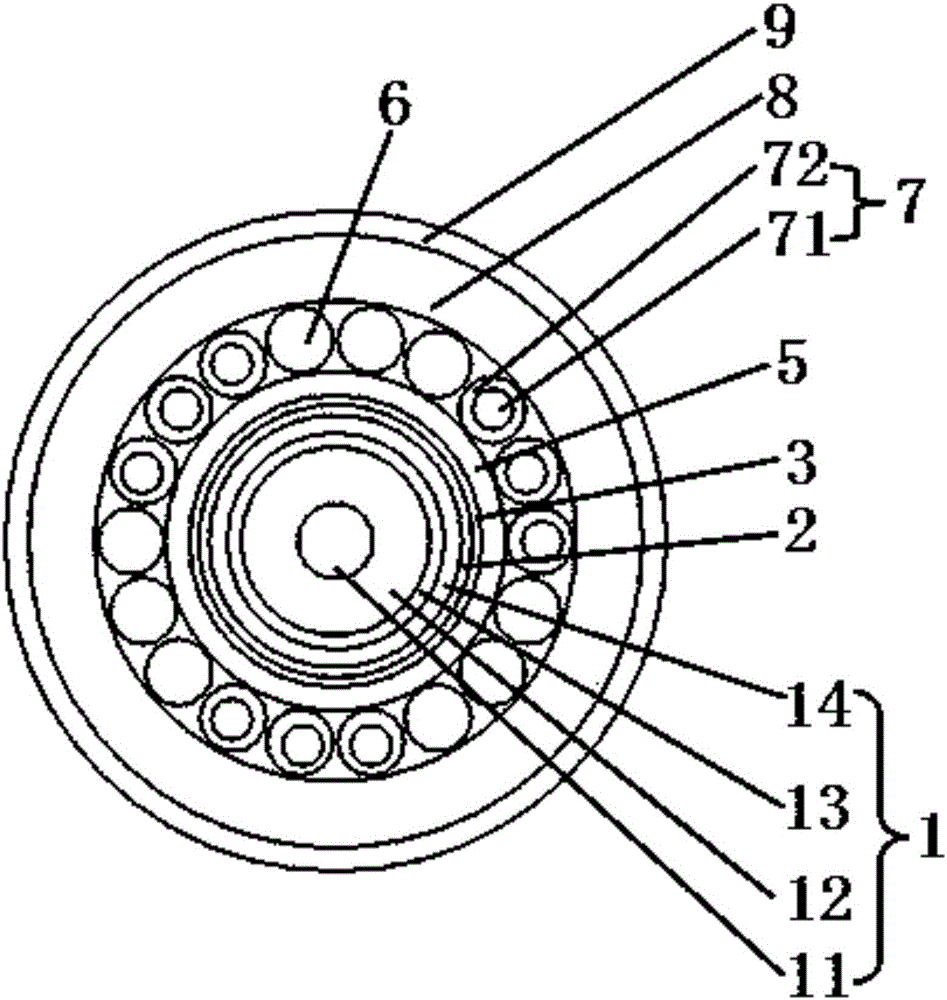

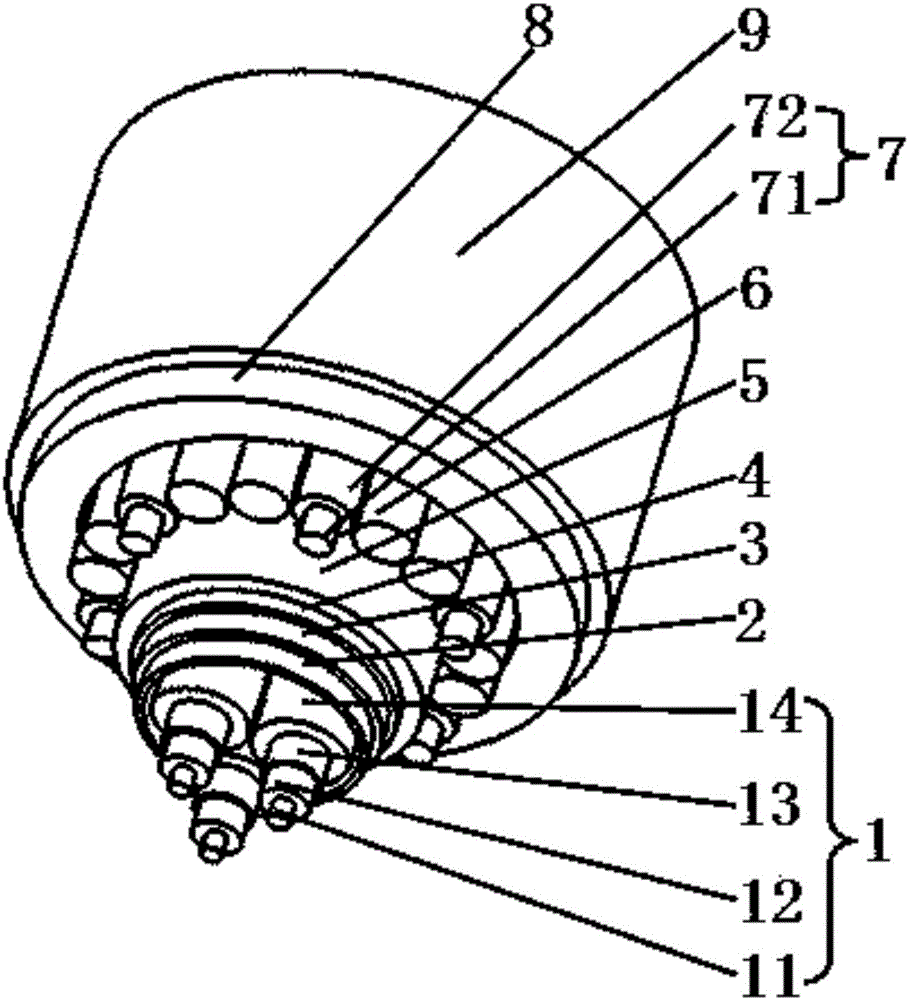

Welding torch for milling head sleeve and tungsten-pole inert gas protection welding

ActiveCN1640605AAvoid transmissionLower resistanceSupport devices with shieldingEngineeringWear resistance

To provide a TIG (inert gas shielded tungsten arc) welding torch in which the seizure in the contact faces between a collet and a collet body is prevented to facilitate the exchange of an electrode, the phenomenon that arc heat conducts from the electrode to a torch body via the collet body is suppressed and large welding current can be made to flow, and whose using rate can be increased. The TIG welding torch is provided with a torch body, a collet supporting an electrode located at the center of the torch body, and a collet body supported by a metallic member in contact with the inside thereof and supporting the collet in contact therewith. The collet body is composed of a cylindrical insert member fitted to the tip part of the collet body and having a receiving hole of the electrode at an axial core part, and the balance collet body shell having an inserting hole of the collet. The insert member is formed of an electrically conductive metal having high electrical conductivity and having impact resistance and wear resistance. The collet body shell is formed of an electrically conductive metal having low thermal conductivity.

Owner:DAIHEN CORP

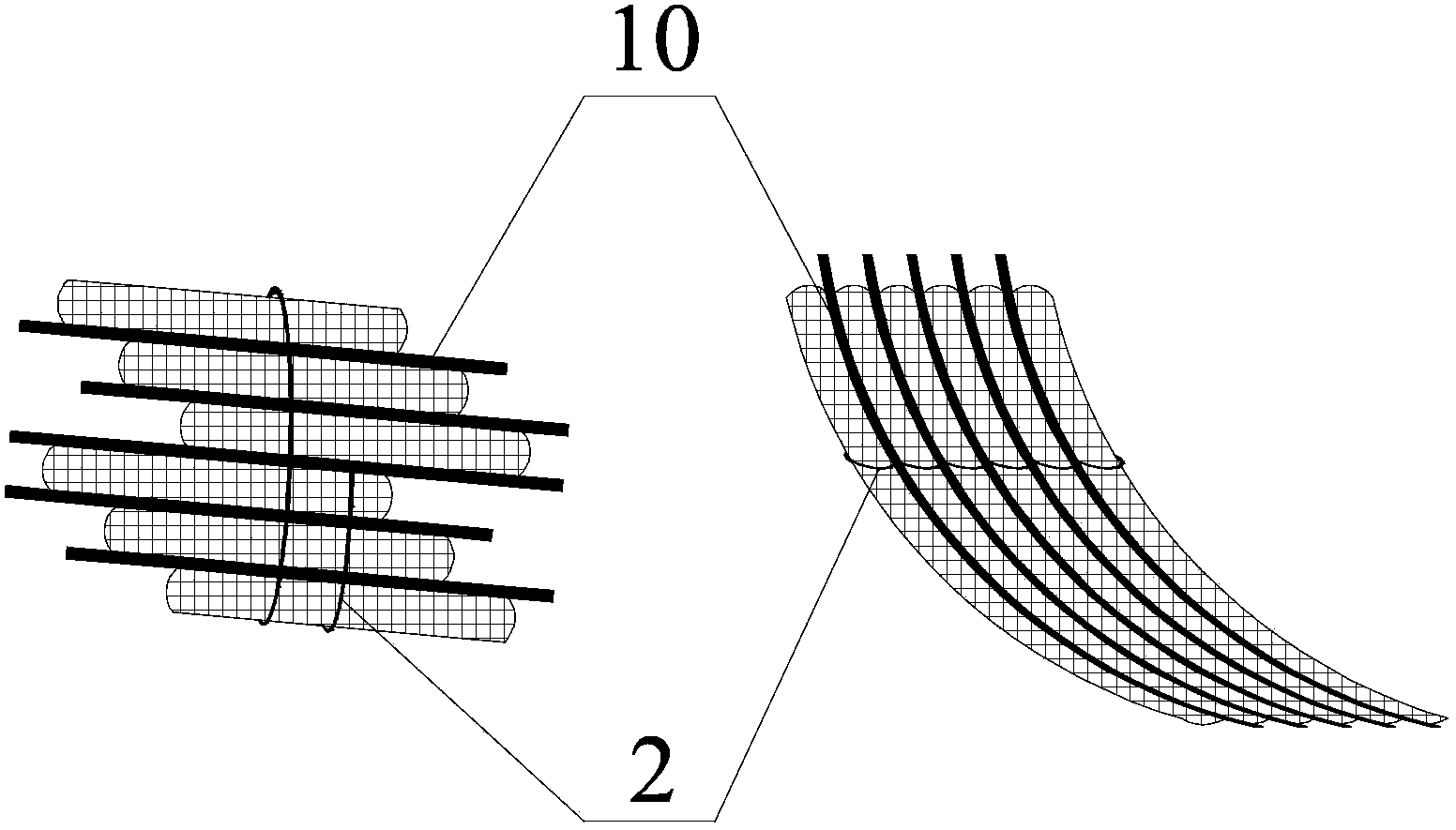

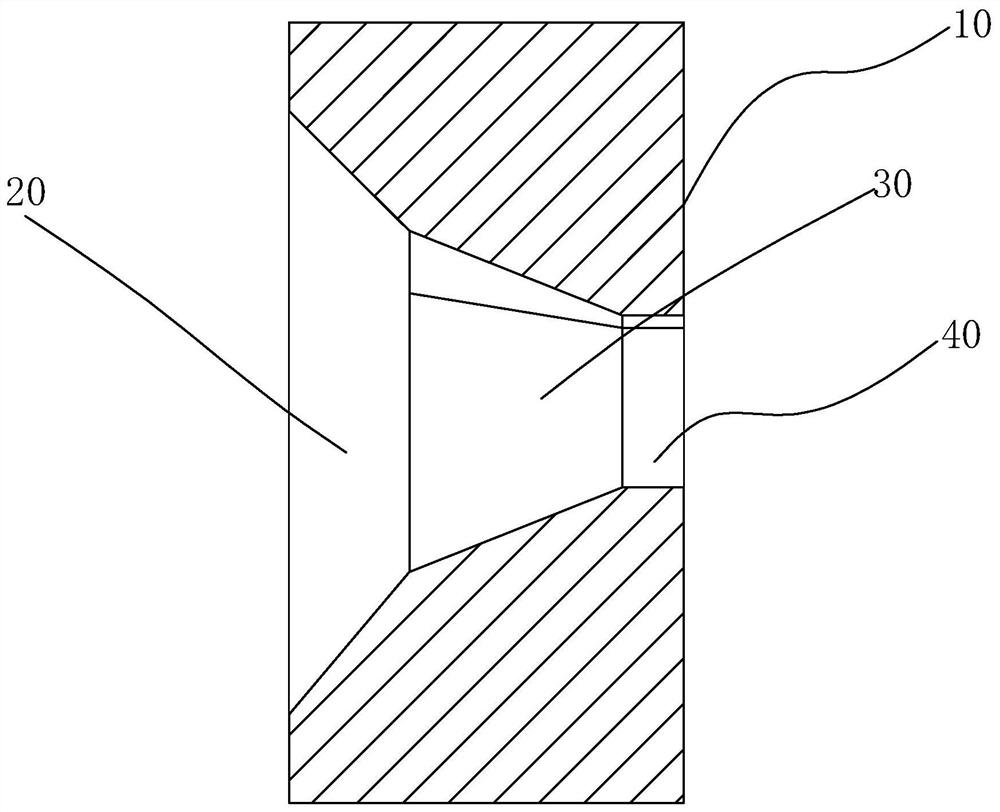

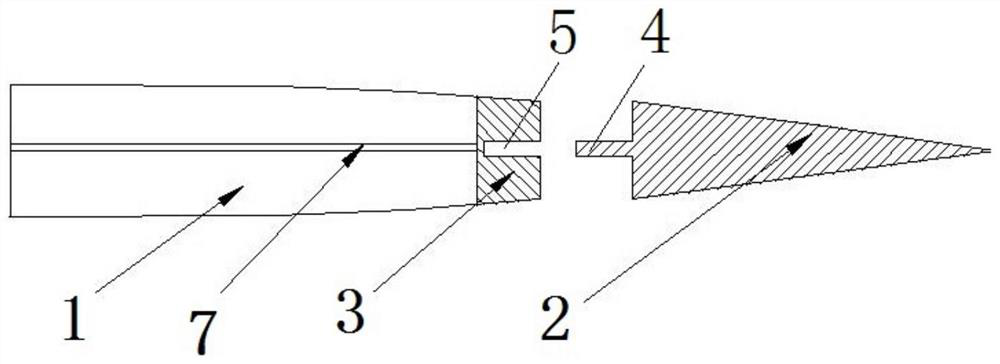

Pressing-like special-shaped wire stranded conductor single-wire drawing die, conductor and processing method

PendingCN112768145AAvoid disconnectionDisconnection is not easy to occurDrawing diesCable/conductor manufactureElectrical conductorCopper wire

The invention relates to a pressing-like special-shaped wire stranded conductor single-wire drawing die, a conductor and a processing method. The die comprises a die body, the die body is a cylinder structure, and a fan-shaped through hole is formed in the middle of the die body; the fan-shaped through hole comprises an inlet section, a compression section and a sizing section; and an included angle between the junction of the compression section and the sizing section and the horizontal direction is 30-31.5 degrees. The included angle formed by the junction of the compression section and the sizing section and the horizontal direction ranges from 30 degrees to 31.5 degrees, the copper wire can be well prevented from being broken in the drawing process, the production efficiency is improved, the four end corners, close to the compression section, of the sizing section are provided with fillets, the situation that the appearance is smooth without burrs when a conductor is stranded is avoided, cable insulation does not have a skin effect to cause breakdown, the stranded conductor obtained by drawing is less in material consumption, wire breakage is not easy to occur in the drawing process, and the production efficiency is not influenced.

Owner:深圳市金环宇电线电缆有限公司

High-sparking and long-service-life electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469991AGood electrochemical propertiesIncrease the flash voltageLiquid electrolytic capacitorsCapacitor manufactureElectrolysisPhosphate

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and long-service-life electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 3-5 parts of ammonium sebate, 1-2 parts of ammonium pentaborate, 1-2 parts of sorbitol, 1.5-2.5 parts of ammonium dodecanedioate, 8-12 parts of a sparking boosting agent, 4-6 parts of branch-chain organic acid, 0.05-0.15 part of organic phosphate, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of p-nitrophenol, 5-7 parts of ethylene glycol nano silica sol, 4-6 parts of Y-butyrolactone and 55-75 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials; the sparking voltage of the prepared electrolyte can reach 535 V and the conductivity rate of the prepared electrolyte can reach 1.8 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage and long service life, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

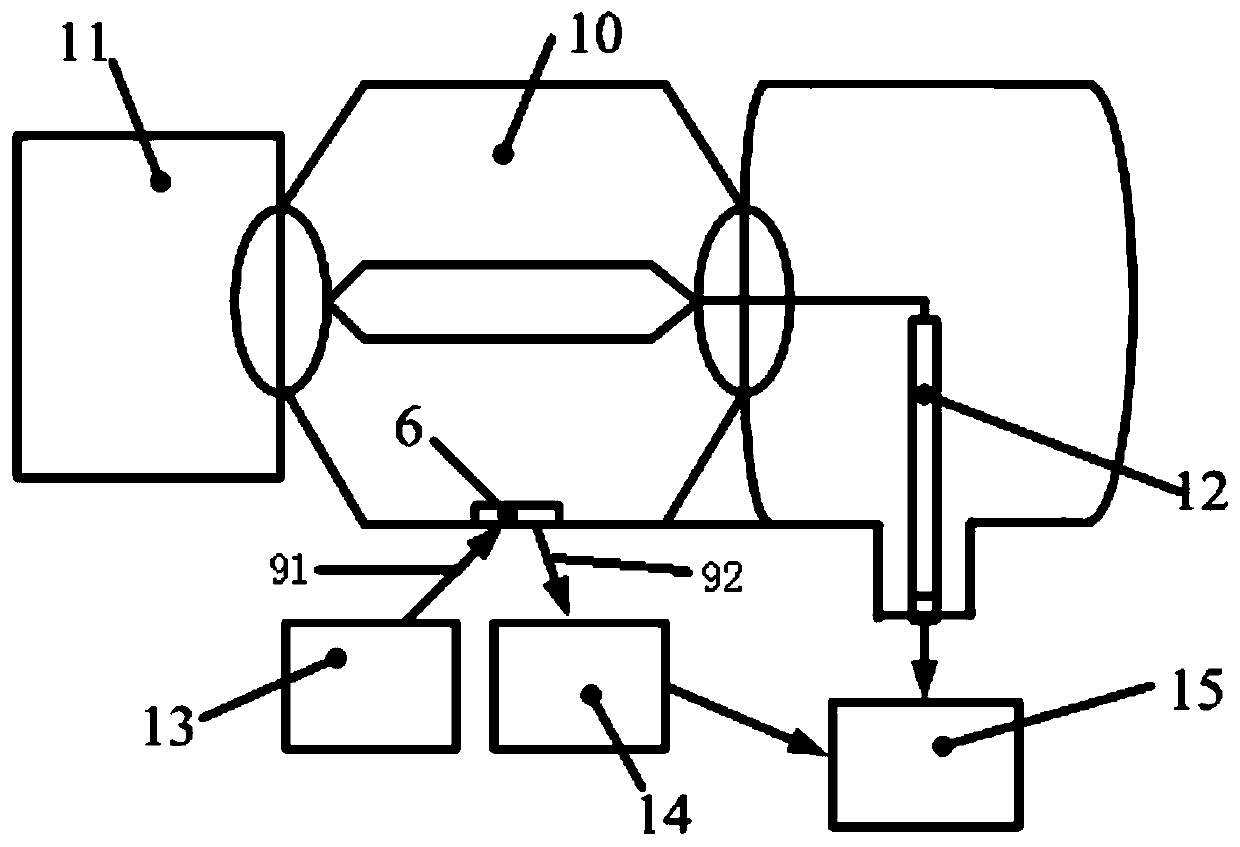

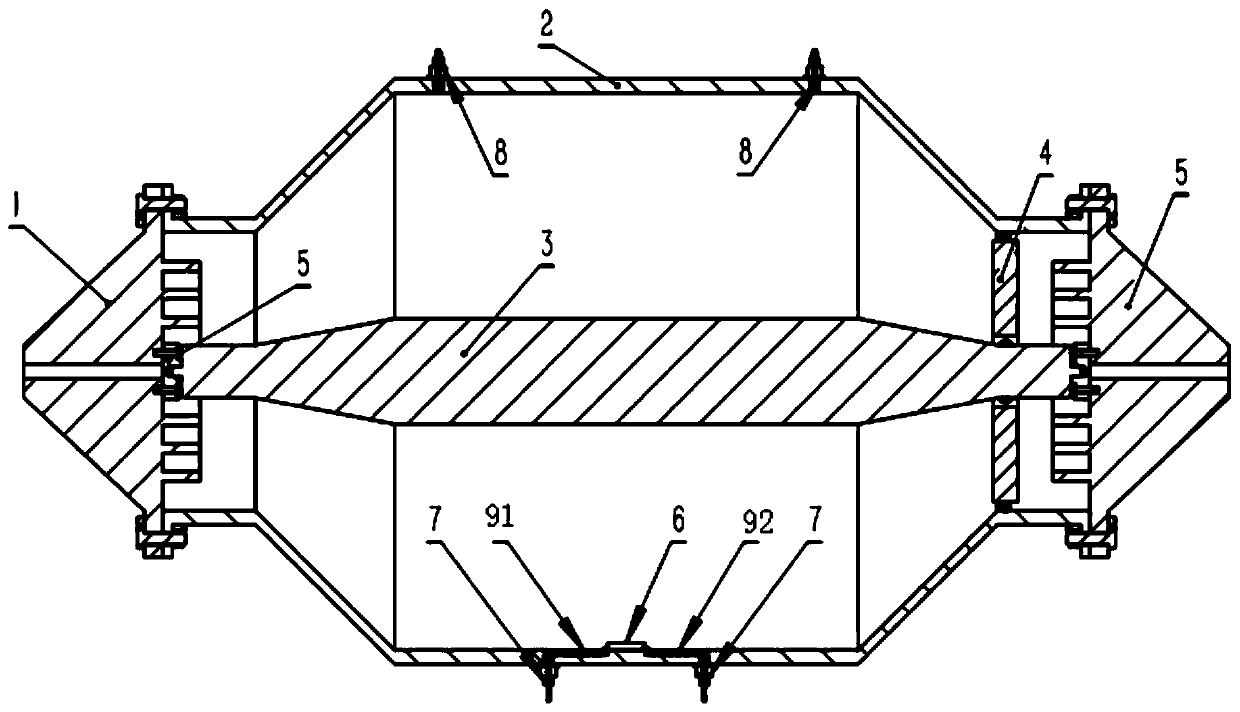

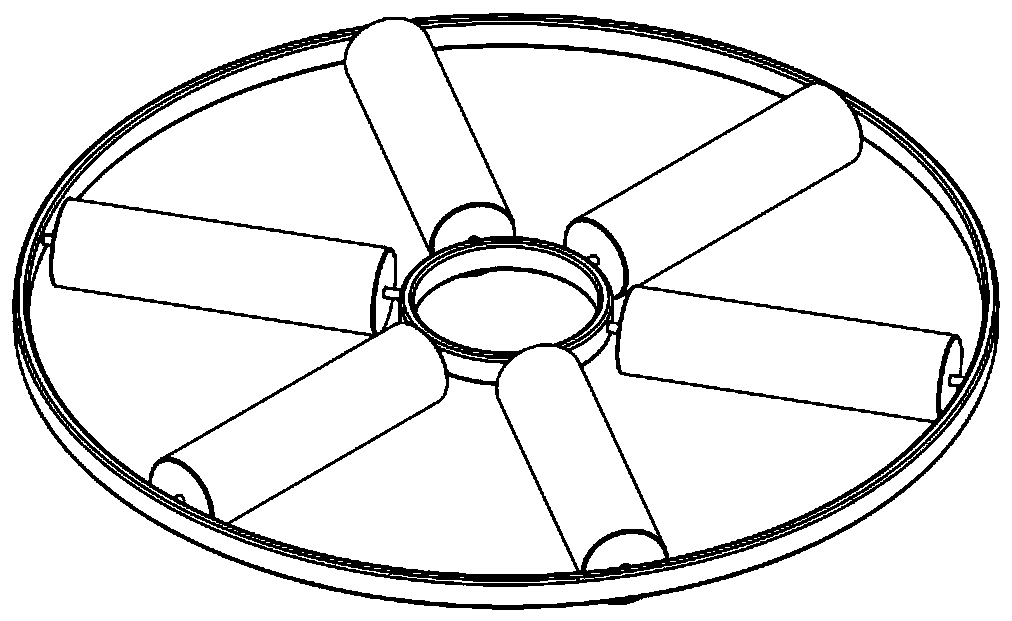

Full-range calibration device and method of high voltage nanosecond pulse voltage divider calibration factors

ActiveCN110031789AReduce equivalent inductanceLight weightElectrical measurementsPhysicsElectric field

The invention provides a full-range calibration device and method of high voltage nanosecond pulse voltage divider calibration factors to reduce the measurement deviation of nanosecond pulse voltage in a pulse power technology. According to the full-range calibration device and method, the characteristic that the calibration coefficient of a nanosecond pulse electric field measuring probe can be calibrated by devices such as a GTEM cell or a TEM cell in a large amplitude range is utilized, by correlating the nanosecond pulse voltage and the nanosecond pulse electric field, the present situation of a nanosecond pulse voltage non-standard measurement system under a high-voltage level is skillfully avoided, the calibration of the calibration coefficient of the nanosecond pulse divider under hundreds of kilovolts voltage level is achieved, and the traceability problem of hundreds of kilovolts voltage measurement in the pulse power technology is solved.

Owner:NORTHWEST INST OF NUCLEAR TECH

High dielectric constant stress control material

InactiveCN1901102AChange the potential distributionUniform electric fieldRubber insulatorsPower cables with screens/conductive layersMass compositionStearic acid

This invention relates to a high dielectric constant stress control material characterizing that its mass composition includes: raw rubber: 100, stearic acid: 0.5-1.2, nm-ZnO: 5-10, TiO2: 6-10, olefin oil: 15-25, carbon black: 20-30, coupler: 2-3, sulfur: 2-3, dioxide DIPB: 3-4, accelerant TMTD: 2-3, and mixing and injection molding technics are applied to process it, which is advantaged that it can be prepared to a resistance-capacitance stress tube to control the stress of the cut place of shield of the cable to alter the potential distribution of the cable insulation surface so as to uniform the electric field and the break through phenomenon will not happen since field strength of this place is uniformly distributed.

Owner:江苏宇诚业基电气设备有限公司

Seabed high-voltage power cable and manufacture method for same

InactiveCN105825928ASave resourcesImprove wear resistancePlastic/resin/waxes insulatorsClimate change adaptationElectrical conductorWater leakage

The invention belongs to the technical field of cables and especially relates to a seabed high-voltage power cable. The cable is composed of an electric conduction unit, a metal shielding layer, a waterproof layer, an inner sheath, an armor layer, an outer sheath and an outer sheath protective layer which are disposed successively from inside to outside, wherein the electric conduction unit is composed of a conductor, an insulating layer, an insulation shielding layer and a conductor protective layer, the circle center of the conductor and the circle center of the insulating layer coincide, the diameter of the insulating layer is 1.5-5 times of the diameter of the conductor, and the minimum thickness of the insulating layer is 1.5 mm; a filling rope group and a reinforcing part group are distributed outside the inner sheath alternately, and both the filling rope group and the reinforcing part group are tightly adhered to the inner sheath; the outer sheath protective layer is made of polyamide; and the insulating layer is made of silane cross-linking polyethylene; and the insulating layer is made of silane cross-linking polyethylene or a special material. The invention also discloses a manufacture method for the cable. The cable provided by the invention mainly has the beneficial effects that redundancy of mechanical performance is more proper; consumption of resources is reduced; the cable has higher wear resistance; the cable can be protected from water leakage and seawater; shielding performance is better; and the cable can even transmit high voltages.

Owner:沈群华

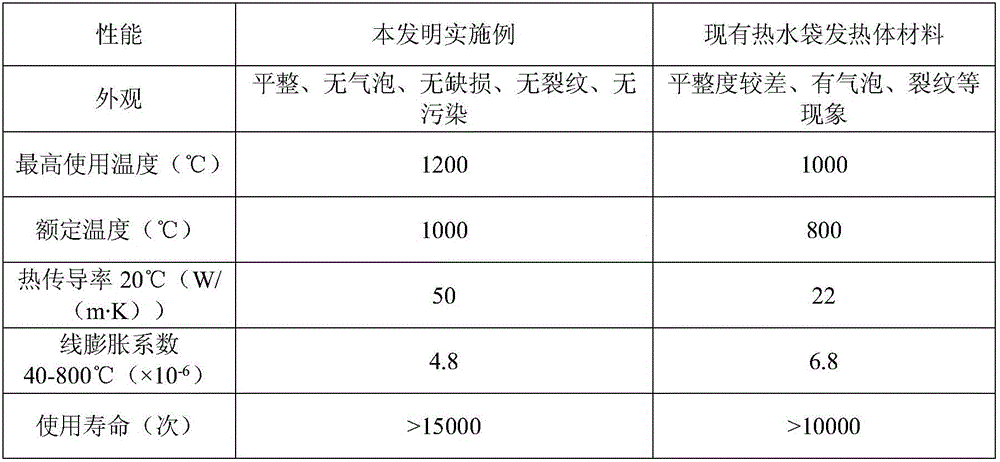

Electric hot-water bottle heat-generating body material formula

InactiveCN106255237AHeating up fastWide temperature rangeHeating element materialsIridiumNon toxicity

The invention discloses an electric hot-water bottle heat-generating body material formula which comprises the following ingredients, by weight, 70 to 90 parts of ceramic powders, 5 to 10 parts of adhesives, 0.2 to 6 parts of reinforcing agents, 3 to 8 parts of polyvinyl alcohols, 5 to 15 parts of tungsten, 2 to 5 parts of palladium, 3 to 8 parts of iridium, 1 to 3 parts of ruthenium, and 1 to 5 parts of sintering aids. The invention belongs to the field of electric hot-water bottle heat-generating body materials and concretely provides a hot-water bottle heat-generating body material formula with the advantages of a simple process, good heat resistance performance, high heat conductivity, energy saving and consumption reduction, safety and non-toxicity, and a long service life.

Owner:广东聚荣塑胶制品有限公司

Submarine high-voltage cable and production method for same

InactiveCN104700936ASave resourcesImprove wear resistancePlastic/resin/waxes insulatorsClimate change adaptationInsulation layerElectrical conductor

The invention belongs to the technical field of cables and particularly relates to a submarine high-voltage cable. The cable comprises a conductive unit, a metal shielding layer, a waterproof layer, an inner sheath, an armor layer, an outer sheath and an outer sheath protection layer. The conductive unit comprises a conductor, an insulation layer, an insulation shielding layer and a conductor protection layer. On any one cross section, the circular center of the conductor and the circular center of the insulation layer coincide, the diameter of the insulation layer is 1.5 times to 5 times of that of the conductor, and the minimum insulation layer thickness is 1.5mm. Filling rope layers and reinforcing elements are distributed on the outside of the inner sheath alternately and are attached to the inner sheath. The outer sheath protection layer is made of polyamides, and the insulation layer is made of silane crosslinked polyethylene or special materials. The invention further discloses a production method for the cable. The cable and the production method have the advantages of being appropriate in mechanical performance redundancy is, capable of saving resources, anti-abrasion, anti-water-seepage, anti-seawater, good in shielding performance and capable of transmission high voltages.

Owner:沈群华

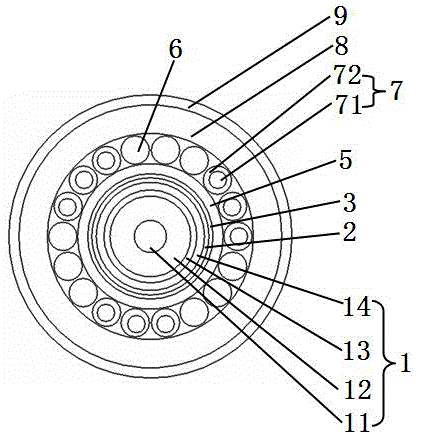

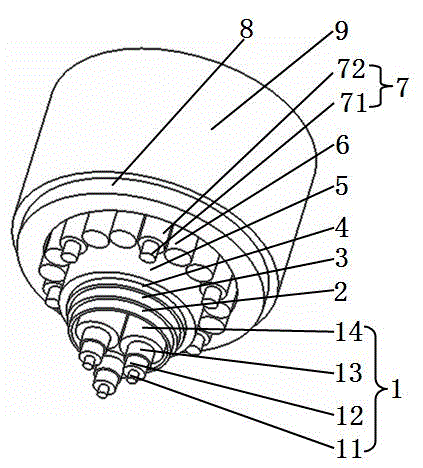

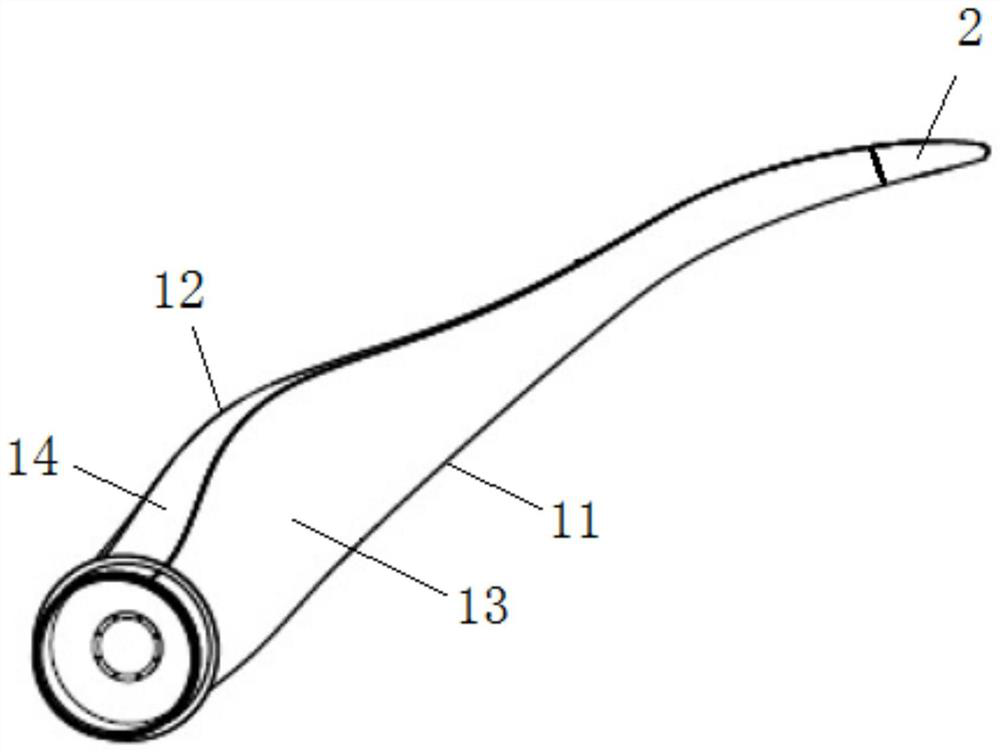

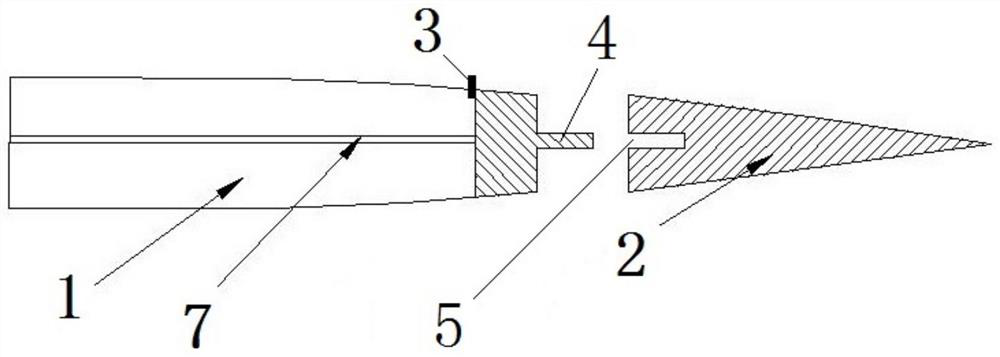

Megawatt wind power blade, assembling and manufacturing method thereof and blade tip manufacturing method

InactiveCN111637002AAdequate dielectric strengthHigh implementabilityFinal product manufactureMachines/enginesStructural engineeringMechanical engineering

The invention provides a megawatt wind power blade, an assembling and manufacturing method thereof and a blade tip manufacturing method, and belongs to the technical field of wind power equipment. Themegawatt wind power blade comprises a blade body and a blade tip, wherein the top end of the blade body is provided with an installing structure for connecting the blade tip, the blade tip is detachably connected to the top end of the blade body through an installing structure, all the blade tip is made of insulating materials, the thickness of the blade tip is 10 cm-40 cm, and smooth transitionis adopted at the top end of the blade tip. According to the megawatt wind power blade, no lightning arrester is arranged at the top end of the blade tip, all the blade tip is made of insulating materials, no conductive or semi-conductive substances are contained in the blade tip, smooth transition is designed at the top end of the blade tip, accordingly, the insulating intensity of the blade tipis improved, the phenomena of breakdown and slipping lightning cannot happen in the blade tip thunder and lightning current arc climbing process, and blade tip lightning protection actionability and reliability are greatly improved.

Owner:SINOMATECH WIND POWER BLADE

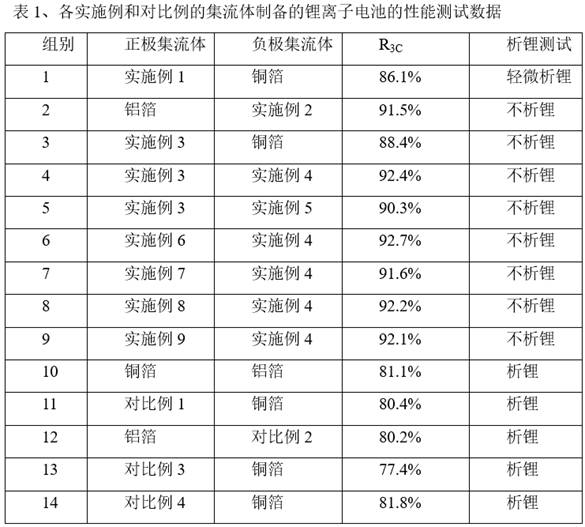

A current collector, a pole piece and a lithium ion battery with a pore-forming functional coating

ActiveCN114464816BImprove dynamic performanceImprove pore structureElectrode thermal treatmentElectrode carriers/collectorsPhysical chemistryEngineering

The invention provides a current collector with a pore-forming functional coating, a pole piece and a lithium ion battery, and the current collector with a pore-forming functional coating, comprising a conductive base layer and a functional coating coated on at least one surface of the base layer layer, the functional coating contains a gas-generating compound whose decomposition temperature is below 250°C and can generate gas. The functional layer of the current collector of the present invention is coated with a compound with gas-generating and decomposing properties, which can produce through-holes through the coating by decomposing the gas-generating compound at the bottom of the active coating without affecting the existing coating process. , thereby improving the dynamic performance of battery products. The method is simple, easy to implement, low in cost, suitable for promotion and has high application value.

Owner:REPT BATTERO ENERGY CO LTD +1

Laser spot welding method for metal panel components

ActiveCN103358024BFirmly connectedNo breakdownWelding/cutting auxillary devicesAuxillary welding devicesOptoelectronicsPre treatment

The invention relates to a laser spot welding method for metal panel components. The method comprises the following steps: selecting a laser welding machine; carrying out pre-treatment on a to-be-spot-welded lower layer metal panel with thickness of 0.8 mm to 1 mm and a to-be-spot-welded upper layer metal panel with thickness of 1 mm to 1.2 mm; carrying out fit fixation on the to-be-spot-welded lower layer metal panel and the to-be-spot-welded upper layer metal panel; carrying out laser electric welding on two layers of to-be-welded metal panels by adopting a laser spot welding manner. The laser spot welding method for metal panel components is characterized in that technological parameters of laser spot welding are as follows: laser power is 2.3 KW to 3.0 KW, spot welding time is 180 ms to 220 ms, welding speed is 12 mm / s to 16 mm / s, focal length of lens is Phi 50 *120 to Phi 50*150 mm, off-focus value: is 0 to 1 mm, and light extraction frequency is 6 Hz to 10 Hz; the laser power is enabled to rise to 100% of total power within the first 0.5 ms and kept for 8.5 ms to 9 ms, the laser spot welding work is completed, and then the laser power is fallen to zero from 100% of total power within 0.4 ms. The laser spot welding method for metal panel components has the advantages that the flat surface, small deformation, non-oxidation and no other traces of the welded metal panels can be guaranteed, and the welded metal panels are connected fixedly and reliably without punctures.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

High pressure P-shaped metal oxide semiconductor tube of silicon-on-insulator

InactiveCN101692454BNo breakdownAvoid burnsSolid-state devicesSemiconductor/solid-state device manufacturingHigh pressureSemiconductor

The invention provides a high pressure P-shaped metal oxide semiconductor tube which is used for silicon-on-insulator, comprising a semiconductor substrate, wherein a buried oxide layer is arranged on the semiconductor substrate; the buried oxide layer is provided with an isolation deep groove which is constituted by a left oxide layer, a right oxide layer and a polysilicon layer which is arranged between the left oxide layer and the right oxide layer; the left and right sides of the isolation deep groove are both high pressure P-shaped metal oxide semiconductor tubes of silicon-on-insulator with common structures; an N-shaped contact area of the transistors at the right side of the deep groove is connected with the polysilicon layer in the middle of the deep groove through a layer of polysilicon on the surface; and the right oxide layer of the deep groove clings closely with the N-shaped contact area of the transistors at the right side of the deep groove. The isolation groove structure not only can effectively prevent the overburning of the high pressure P-shaped metal oxide semiconductor tube of silicon-on-insulator at the right side of the deep groove under the condition of breakdown, but also can effectively reduce chip area and improve integration level.

Owner:SUZHOU POWERON IC DESIGN

Equipotential optical fiber unit for high-voltage photoelectric composite cable and preparation method thereof

ActiveCN104297875BExtended service lifeNo breakdownFibre mechanical structuresPower cables including optical transmission elementsPower cablePotential difference

The invention discloses an equipotential optical fiber unit for a high-voltage photoelectric composite cable. Tube, semi-conductive plastic reinforcement, wire armor and semi-conductive plastic outer sheath. Each protective layer protects the electrical connection through metal and non-metallic materials, and each protective layer is equipotential. Under the action of the electric field of the power cable, there will be no potential difference between the metal and non-metallic protective layers, and the optical unit as a whole and other structures of the photoelectric composite cable also form an equipotential body, and other structures using the optical unit and the cable do not exist Potential difference, so that not only the optical unit itself will not cause breakdown due to excessive induced voltage, but also prevent breakdown between the optical unit and the high-voltage cable core, which ensures the safety of the optical unit and the cable body, and improves the safety of the cable. service life.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Welding torch for milling head sleeve and tungsten-pole inert gas protection welding

ActiveCN100429031CAvoid transmissionLower resistanceSupport devices with shieldingEngineeringWear resistance

To provide a TIG (inert gas shielded tungsten arc) welding torch in which the seizure in the contact faces between a collet and a collet body is prevented to facilitate the exchange of an electrode, the phenomenon that arc heat conducts from the electrode to a torch body via the collet body is suppressed and large welding current can be made to flow, and whose using rate can be increased. The TIG welding torch is provided with a torch body, a collet supporting an electrode located at the center of the torch body, and a collet body supported by a metallic member in contact with the inside thereof and supporting the collet in contact therewith. The collet body is composed of a cylindrical insert member fitted to the tip part of the collet body and having a receiving hole of the electrode at an axial core part, and the balance collet body shell having an inserting hole of the collet. The insert member is formed of an electrically conductive metal having high electrical conductivity and having impact resistance and wear resistance. The collet body shell is formed of an electrically conductive metal having low thermal conductivity.

Owner:DAIHEN CORP

Submarine high-voltage cable

InactiveCN105913907ASave resourcesImprove wear resistanceClimate change adaptationPower cables with screens/conductive layersElectrical conductorSilanes

Owner:周杰

Wide temperature range high voltage aluminum electrolysis capacitor working electrolyte and preparation thereof

The invention relates to a working electrolyte of a wide-temperature and high-pressure aluminum electrolytic capacitor, which comprises solvents glycol and r-butyrolactone, solutes 1,6-Dodecanedioic acid (1,6-DDA), dimethylamine and additive phosphoric acid, and pure water, and the weight percentages of the components are respectively 10 to 37 percent : 50 to 68 percent : 8 to 12 percent : 3 to 5 percent : 0.1 to 0.6 percent : 2 to 4 percent. The preparation of the working electrolyte comprises the following steps: (1), 1,6-DDA is poured into a mixed solvent of glycol and r-butyrolactone and stirred and mixed, and then dimethylamine liquefied gas is pumped in; and the mixture is continuously stirred; (2), the electrolyte already reacted in step (1) and on the whole clarified is continuously heated to a temperature of 65 to 80 DEG C; then additive phosphoric acid is added; and finally, pure water is added, and the electrolyte is naturally cooled. Materials utilized in the working electrolyte has the advantages of low cost, good solubility and better freezing resistance performance, thereby causing the working electrolyte to be provided with good forming ability and high temperature stability.

Owner:湖北海成电子有限公司

Submarine high-pressure cable good in shielding performance

InactiveCN105825954ASave resourcesImprove wear resistanceInsulated cablesInsulated conductorsElectrical conductorPolyamide

The invention belongs to the technical field of cables and particularly relates to a submarine high-pressure cable. The submarine high-pressure cable is composed of a conductive unit, a metal shielding layer, a water retention layer, an inner protecting bush, an armor layer, an outer protecting bush and an outer protecting bush protection layer; the conductive unit is composed of a conductor, an insulating layer, an insulation shielding layer and a conductor protecting layer, on any cross section, the circle center of the conductor coincides with the circle center of the insulating layer, the diameter of the insulating layer is 1.5-5 times that of the conductor, and the minimum value of the insulating layer thickness is 1.5 mm; filling rope groups and reinforcing piece groups are distributed outside the inner protecting bush in an alternate mode, and both the filling rope groups and the reinforcing piece groups are tightly attached to the inner protecting bush; the outer protecting bush protection layer is made of polyamide; the insulating layer is made of organosilane crosslinked polyethylene or a special material. The invention further discloses a manufacturing method of the submarine high-pressure cable. The submarine high-pressure cable and the preparation method thereof have the advantages that mechanical property redundancy is more proper, more resources are saved, wear resistance is better, water seepage performance is better, seawater resistance is better, shielding performance is better, and high voltage can be transmitted better.

Owner:周杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com