Laser spot welding method for metal panel components

A metal panel, laser spot welding technology, used in laser welding equipment, metal processing equipment, welding equipment and other directions, to achieve the effect of small deformation, firm connection and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

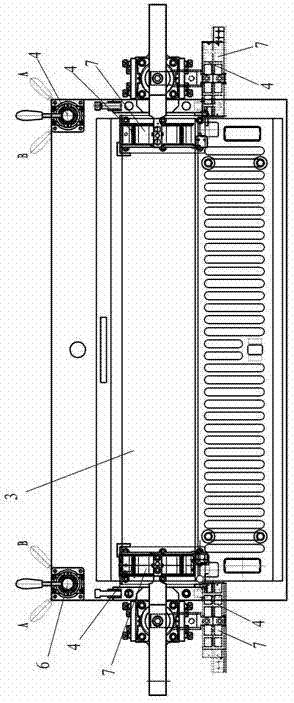

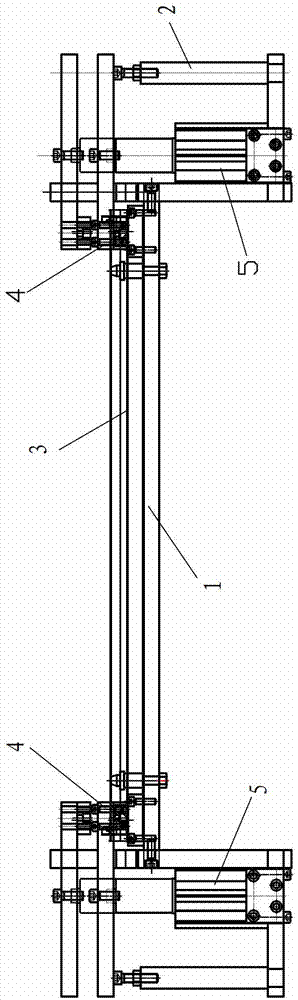

Image

Examples

Embodiment 1

[0035] In the laser spot welding method for metal panel parts provided in this embodiment, a PB series optical fiber transmission laser welding machine is first selected, and then the lower stainless steel panel with a thickness of 0.8mm and the upper stainless steel panel with a thickness of 1mm to be spot welded are pretreated. , the pretreatment mainly removes the stains on the stainless steel panel, attaches and fixes the upper stainless steel panel and the lower stainless steel panel to be welded, and finally adopts the laser spot welding method to carry out the laser electric welding step on the two-layer stainless steel panel parts to be welded, in which the laser spot The welding process parameters are:

[0036] Laser power: choose a parameter value from 2.0KW to 3.0KW, and the laser power in this embodiment is 2.8KW;

[0037] Spot welding time: choose a parameter value from 180 to 220ms, and the spot welding time in this embodiment is 200ms;

[0038] Welding speed: cho...

Embodiment 2

[0052] Different from Embodiment 1, the thickness of the lower stainless steel panel to be spot welded is 1mm, and the thickness of the upper stainless steel panel is 1.2mm, wherein the process parameters during laser spot welding are:

[0053] The laser power is 3.0KW;

[0054] The spot welding time is 215ms;

[0055] Welding speed: 15mm / s;

[0056] Lens focal length: the same choice of φ50×150mm;

[0057] Defocus amount: choose a parameter value from 0 to 1mm, and the defocus amount in this embodiment is 0.7mm;

[0058] Light output frequency: 6HZ;

[0059] The remaining parameters and fixtures are consistent with the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com