A current collector, a pole piece and a lithium ion battery with a pore-forming functional coating

A technology for lithium ion batteries and current collectors, applied in the field of pole pieces, lithium ion batteries and current collectors, can solve the problems that the pores cannot be guaranteed to penetrate to the bottom of the active material coating, the uneven distribution of active materials in the membrane surface pits, and the high cost. , to improve cycle stability and power performance, enhance adhesion and electronic conductivity, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

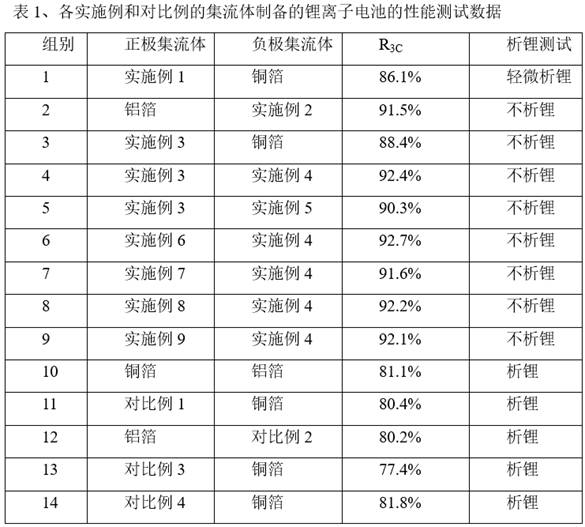

Examples

Embodiment 1

[0031] Dissolve and disperse ammonium bicarbonate in NMP to form a functional coating slurry with a solid content (that is, mass concentration) of 10%. Use a coating machine to transfer the slurry to the surface of the aluminum foil, and then dry the coating at 30 °C to form a tape. Current collectors with functional coatings. The surface density of ammonium bicarbonate after double-sided coating and drying is 35g / m 2 .

Embodiment 2

[0033] Dissolve and disperse ammonium bicarbonate in deionized water to form a functional coating slurry with a solid content of 10%. Use a coating machine to transfer the slurry to the surface of the copper foil, and then dry the coating at 30 °C to form a functional coating. layer of current collectors. The surface density of ammonium bicarbonate after double-sided coating and drying is 20g / m2 2 .

Embodiment 3

[0035] Dissolve and disperse ammonium bicarbonate and PVDF in NMP at a mass ratio of 100:1 to form a functional coating slurry with a solid content of 10.1%. Use a coating machine to transfer the slurry to the surface of the aluminum foil, and then dry and coat at 30 °C. The layers form current collectors with functional coatings. The surface density of ammonium bicarbonate after double-sided coating and drying is 35g / m 2 , the PVDF areal density is 0.35g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com