Speed sensor-less method for estimating rotor angle and revolving speed of permanent-magnet synchronous motor

A permanent magnet synchronous motor and speed sensorless technology, which is applied in the control of generators, motor generators, electronically commutated motors, etc., can solve problems such as complex principles, unstable systems, and drops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

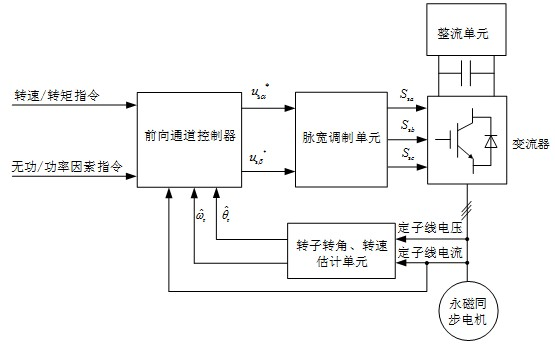

[0059] figure 1 It is a typical system block diagram of an existing speed sensor-based permanent magnet synchronous motor. The controlled object is a permanent magnet synchronous motor, and the actuator is a converter. The rectification unit rectifies the grid voltage and maintains the DC bus voltage of the converter constant, thereby ensuring the normal operation of the converter. The control system mainly includes three parts, the forward channel controller, the pulse width modulation unit and the rotor angle and speed estimation unit. The forward channel controller receives the given speed / torque command and reactive power / power factor command, and controls the stator voltage at Components in the Coordinate System . PWM unit pair Modulate to generate the switching signals required by the converter , and then drive the permanent magnet synchronous motor. The rotor angle and speed estimation unit is located on the feedback channel, extracts the rotor angle and spee...

Embodiment 2

[0096] In this embodiment, the method for estimating the rotor angle and rotational speed of a permanent magnet synchronous motor given in the present invention is applied to a direct drive wind power generation system based on a permanent magnet synchronous motor. The main parameters of the direct drive permanent magnet synchronous wind power generation system are as follows:

[0097]

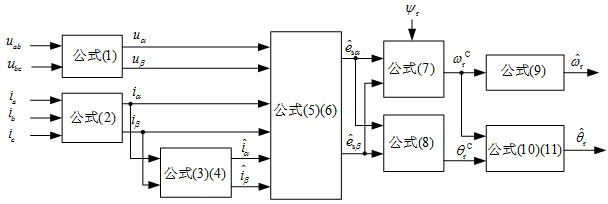

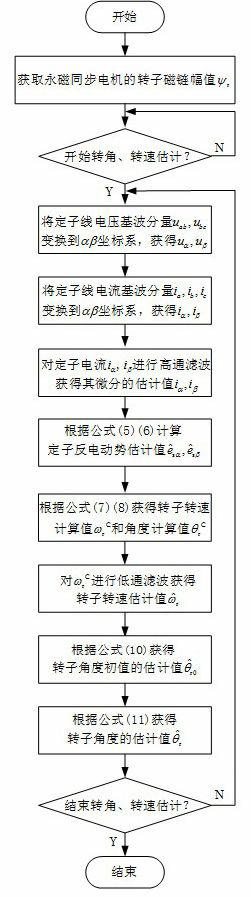

[0098] Firstly, the amplitude of the rotor flux linkage of the permanent magnet synchronous motor It can be calculated from the rated parameters: . Then, follow figure 2 The structure shown in the present invention is used to realize the method for estimating the rotor angle and rotational speed of the permanent magnet synchronous motor proposed by the present invention. Among them, the high-pass filter According to the design of the first-order high-pass filter link, the time constant is taken as ,Right now . low pass filter All are designed according to the first-order low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com