Patents

Literature

175results about How to "Improve capacity play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

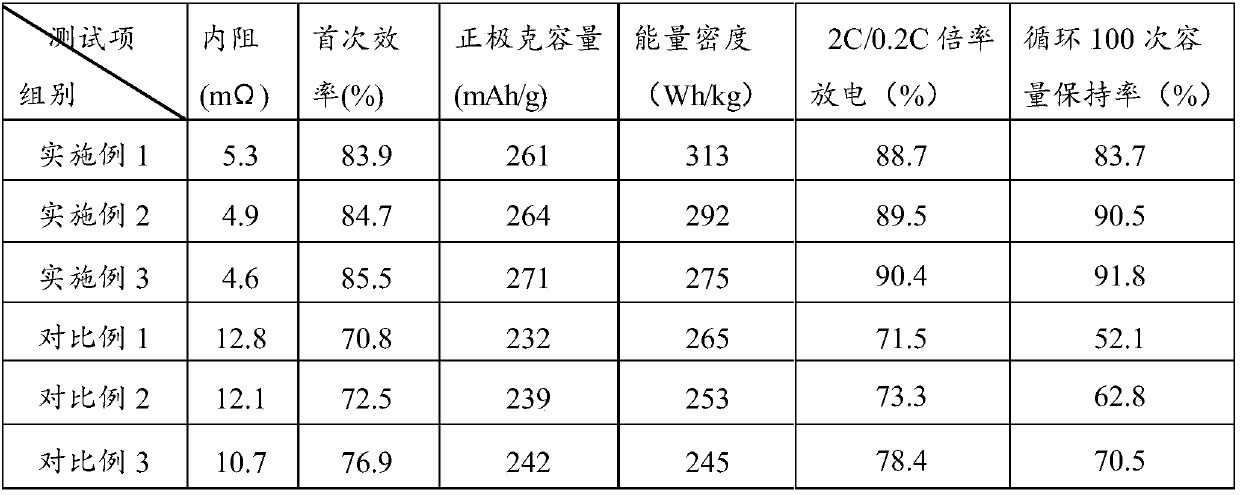

Modified composite material containing silicon-base material, preparation method thereof, and application thereof in lithium ion battery

PendingCN109301184AImprove performanceEasy to crushMaterial nanotechnologyCell electrodesStructural stabilitySide reaction

The invention discloses a modified composite material containing silicon-base material, a preparation method thereof, and an application thereof in a lithium ion battery. The composite material includes a silicon-base core and a modifying layer covering same. The modifying layer includes a polymer covering film and a nano-conductive material embedded therein. The modified composite material not only can isolate an electrolyte to inhibit side reactions of the electrolyte on the surface of the material, thus improving overall performance of the battery, but also can improve electric conductivityand improve structural stability due to the unique structure by embedding the nano-conductive material in the polymer. Tension is absorbed by means of deformation, so that problems of breaking and pulverization and stripping of the electrode during processing and use of the silicon-base negative material are solved. The problems of pulverization and stripping of the electrode due to large expansion during charge / discharge processes of the silicon-base material are solved, thus stabilizing the structure of the electrode and improving cycle performance of the cell.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

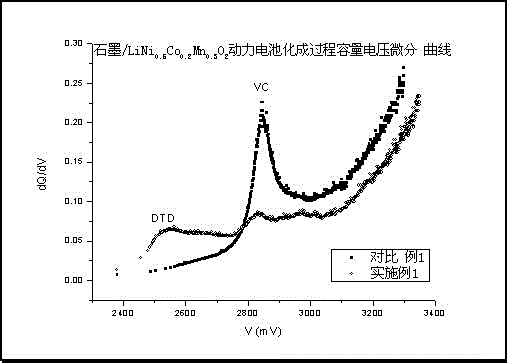

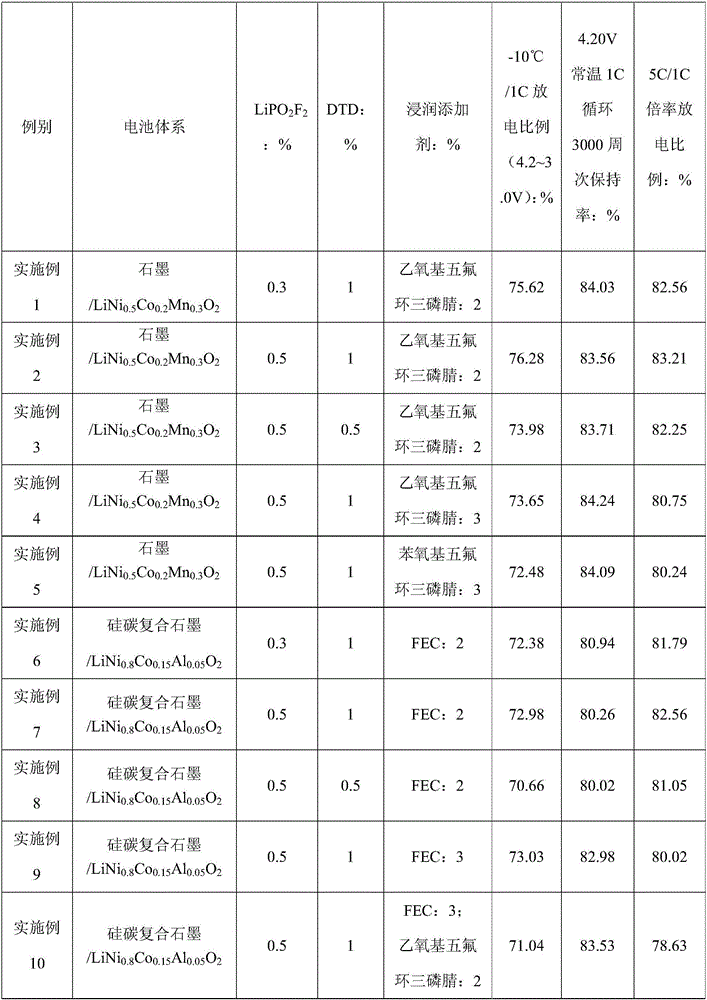

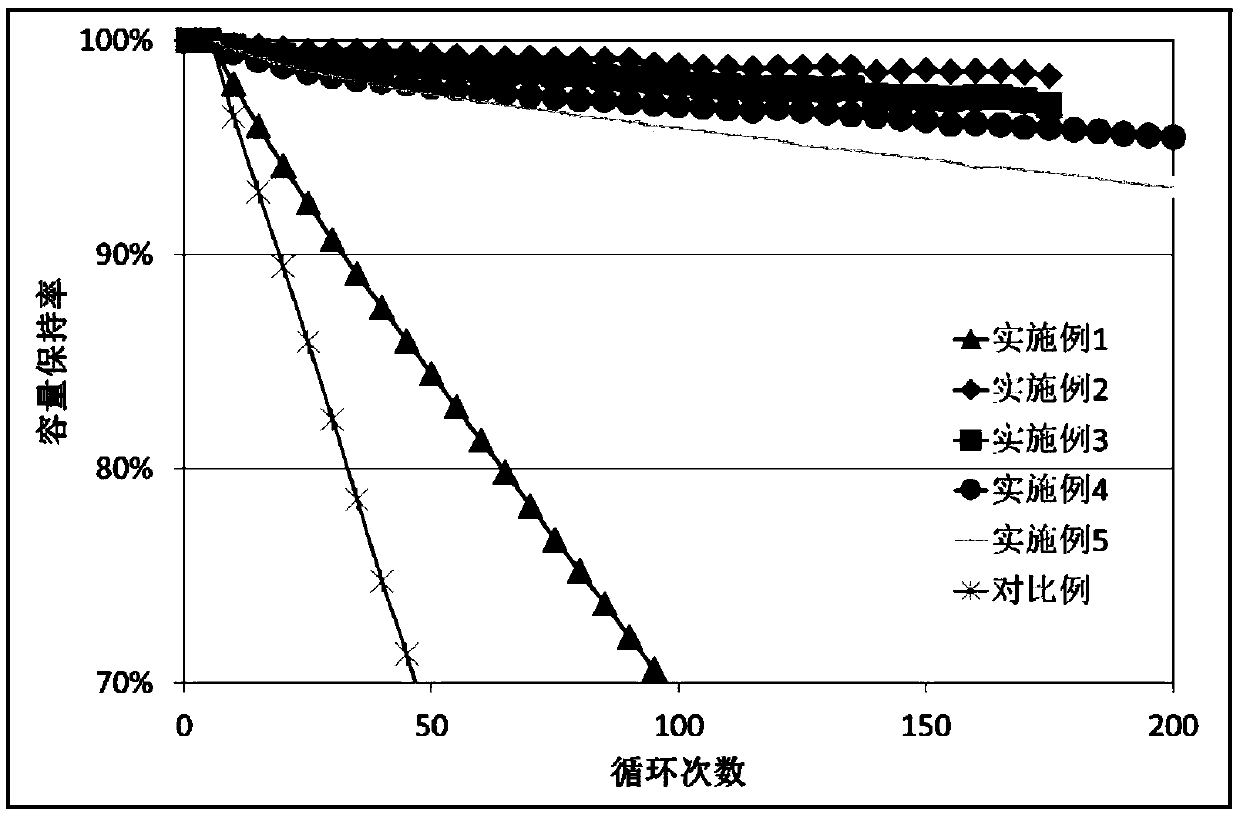

High-nickel ternary lithium ion power battery electrolyte and high-nickel ternary lithium ion power battery

InactiveCN106058316AImprove transmission characteristicsImprove dynamic propertiesSecondary cellsBatteriesDifluorophosphatePower battery

The invention discloses a high-nickel ternary lithium ion power battery electrolyte and a high-nickel ternary lithium ion power battery. The electrolyte includes a non-aqueous organic solvent, a lithium salt, a conductive additive, a film forming additive and an infiltration additive, wherein the conductive additive is lithium difluorophosphate, the film forming additive is ethylene sulfate, and the infiltration additive is at least one of fluorophosphazene and fluoroethylene carbonate; and synergism and mutual promotion of the three additives makes an excellent SEI film be formed on the surface of an electrode and effectively promotes all dynamic processes in the lithium ion battery. The power battery electrolyte has the advantages of good lithium ion transmission characteristic, good oxidation resistance, guaranteeing of high power characteristic and good cycle performances of the power battery, and high safety.

Owner:GUANGZHOU TINCI MATERIALS TECH

Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

InactiveCN109103441AImprove overall performanceStable electrode structureNegative electrodesSecondary cellsSolventCharge and discharge

The invention discloses a modified composite material containing a silicon base material, which comprises a silicon base core and a polymer cladding layer covering the surface of the core, and a preparation method and use thereof in a lithium ion battery. The method comprises the steps of : 1) adding a polymer into a liquid solvent and dispersing to obtain a slurry; 2) adding a silicon-based material or a mixture of that silicon-based material and the carbon material into the slurry and mixing the solid and liquid; 3) removing the solvent to obtain a modified composite material containing a silicon-based material. As the polymer coat layer is introduced on the surface of the silicon base core, so that the electrolyte can be isolated and the side reaction of the electrolyte on the surface of the silicon base core can be prevented; the method can also improve the crushing, electrode pulverization and peeling of the silicon-based negative electrode material in the process of processing and using, and reduce the electrode crushing and peeling caused by the huge volume expansion of the silicon-based material in the process of charging and discharging, so as to achieve the purpose of stabilizing the electrode structure and improving the cell cycle performance.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

Battery positive electrode and preparation method thereof, and lithium ion secondary battery

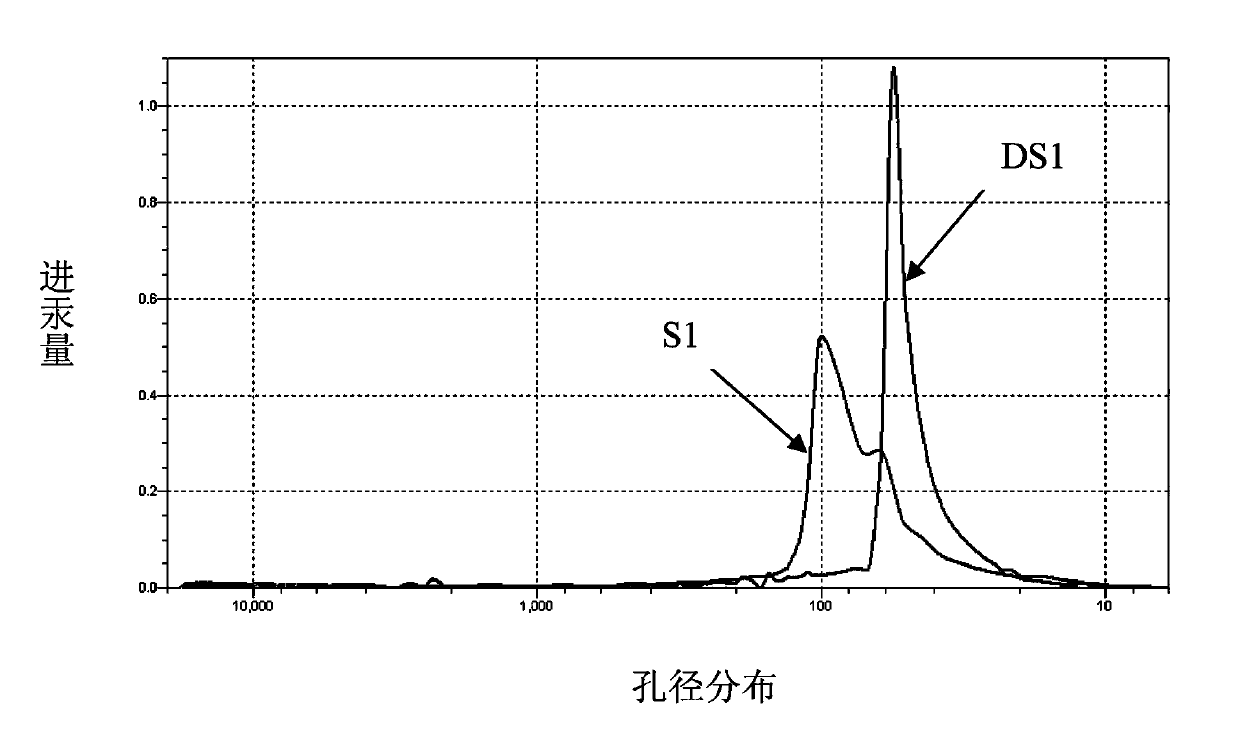

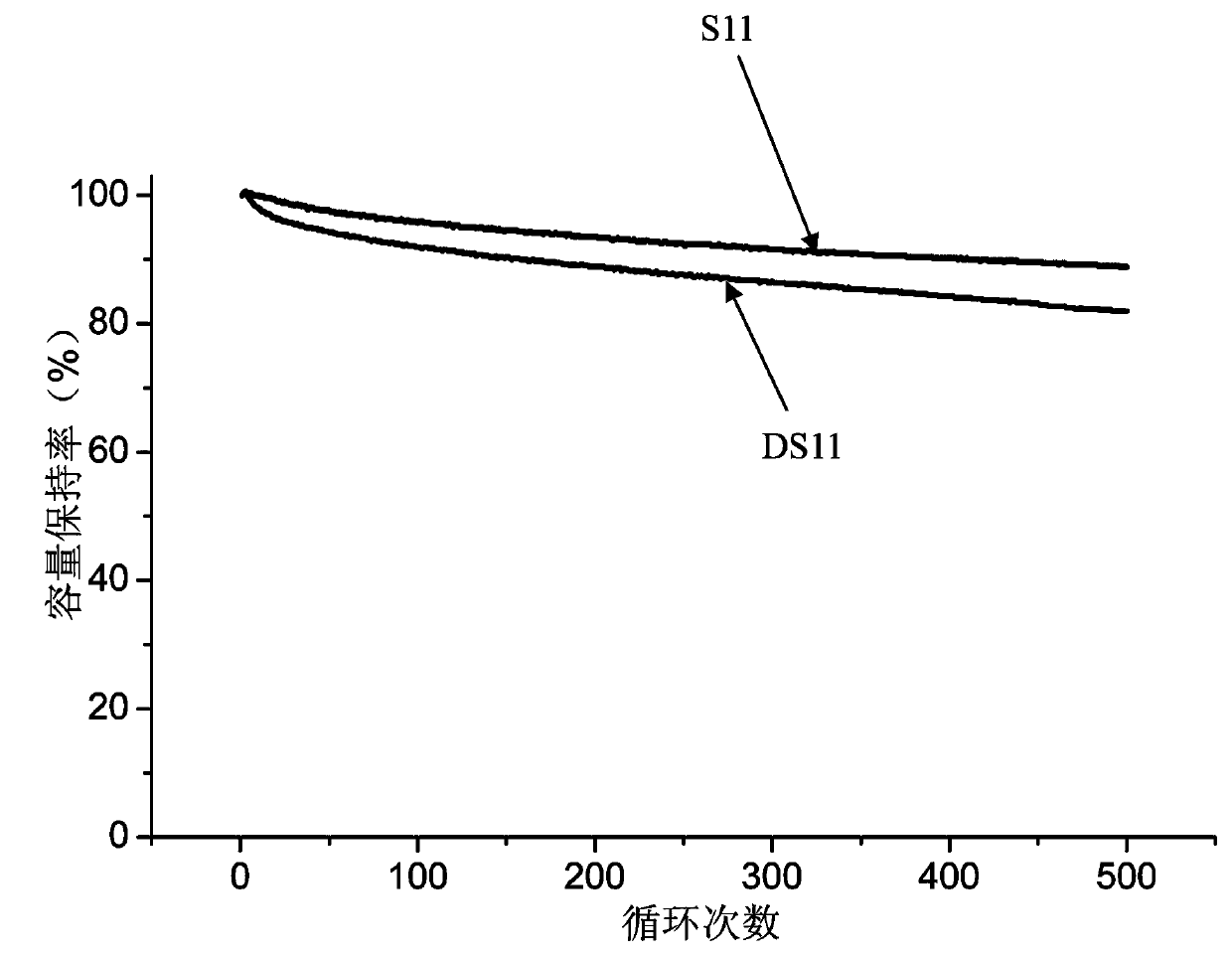

ActiveCN103633289AIncrease energy densityHigh Aperture RatioSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh temperature storageLithium

The present invention provides a battery positive electrode and a preparation method thereof, and a lithium ion secondary battery. The positive electrode comprises a conductive substrate and a material layer coated on the conductive substrate surface, wherein the material layer comprises a first conductive material layer attached on the conductive substrate, a first active material layer attached on the first conductive material layer, a second conductive material layer attached on the first active material layer, and a second active material layer attached on the second conductive material layer, and the compact density of the second active material layer is lower than the compact density of the first active material layer. According to the present invention, characteristics of excellent pore size distribution, good electrolyte infiltration and material shedding resistance are provided, and the prepared battery has characteristics of good cycle performance, low internal resistance, excellent rate capability, excellent high temperature storage performance and high energy density.

Owner:BYD CO LTD

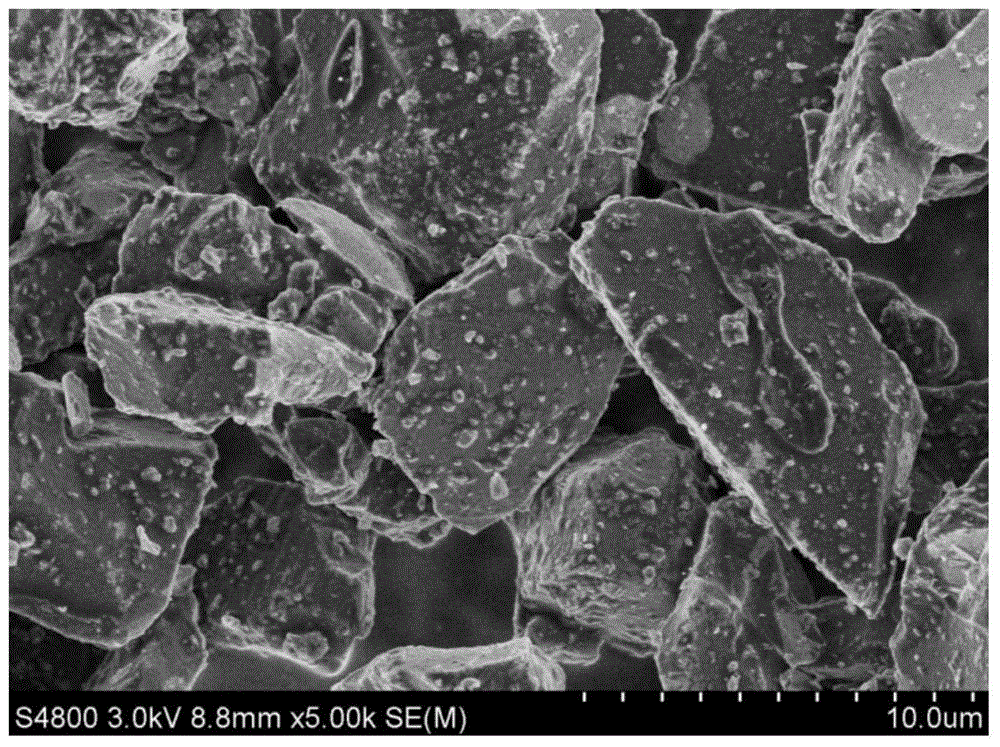

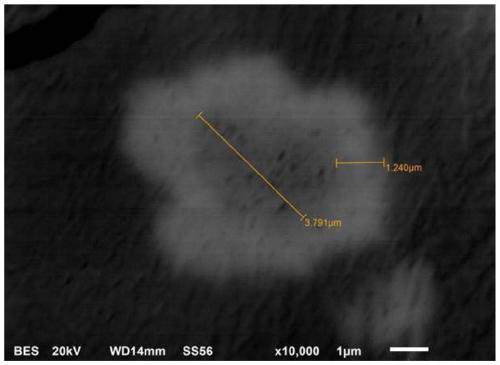

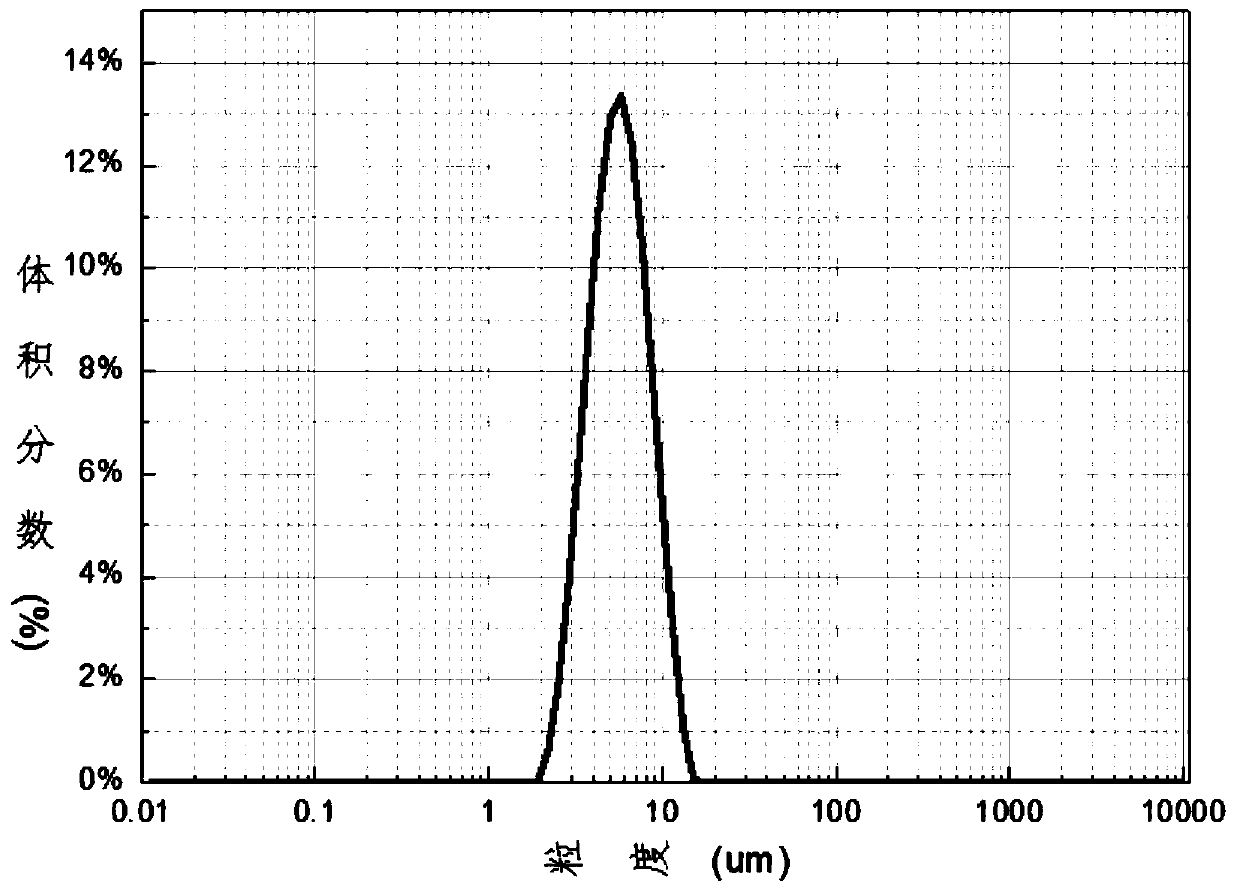

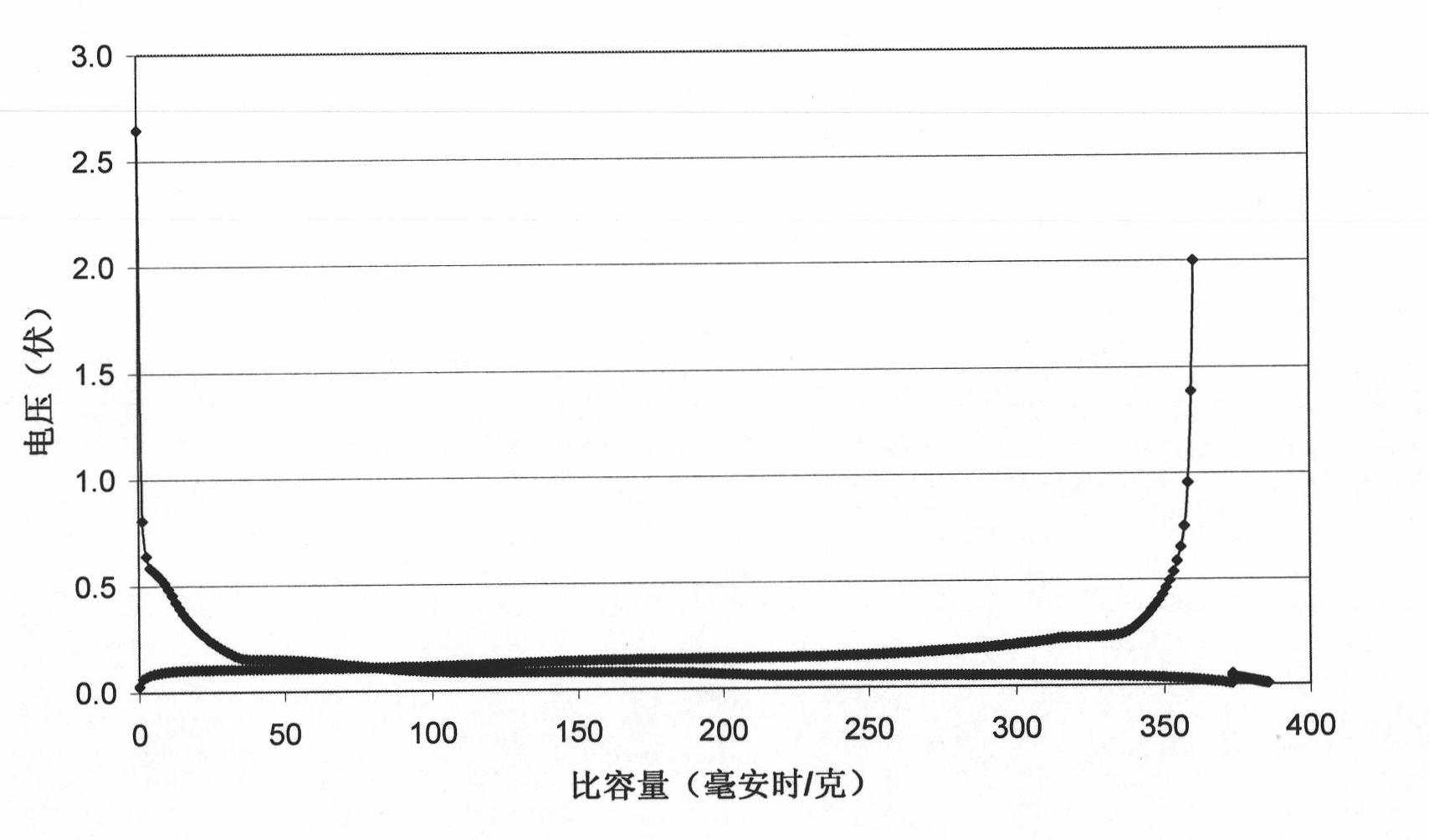

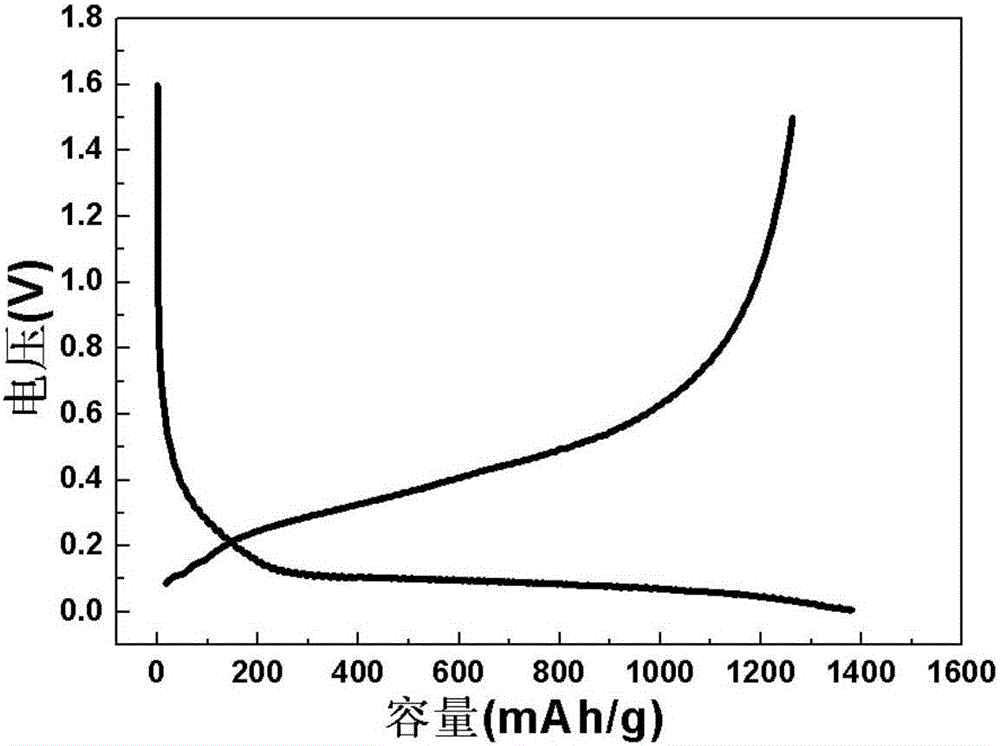

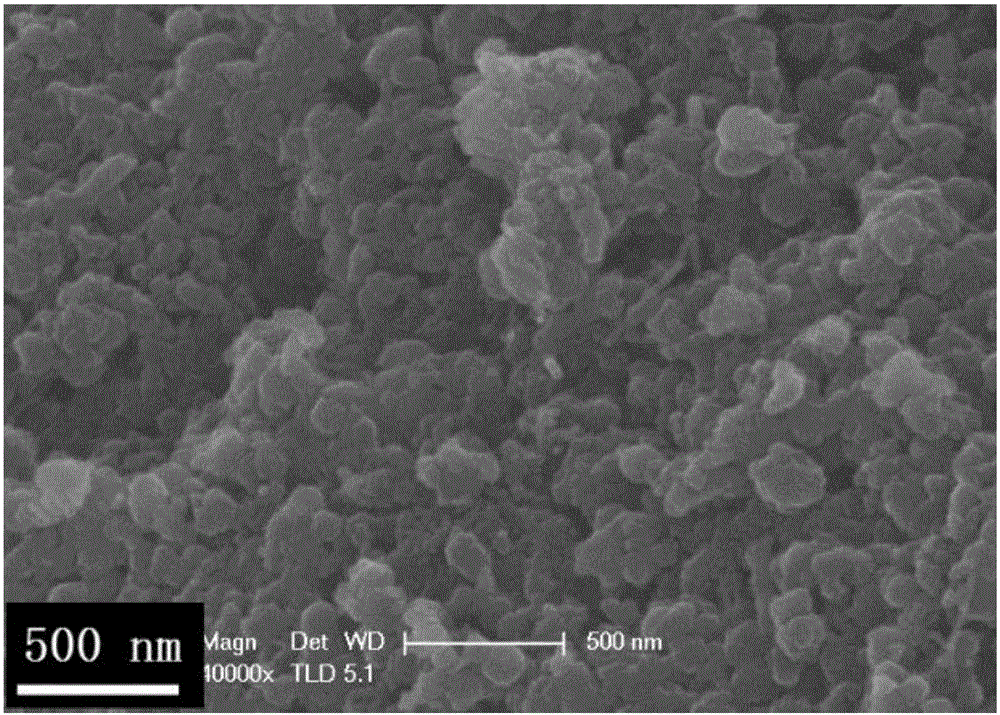

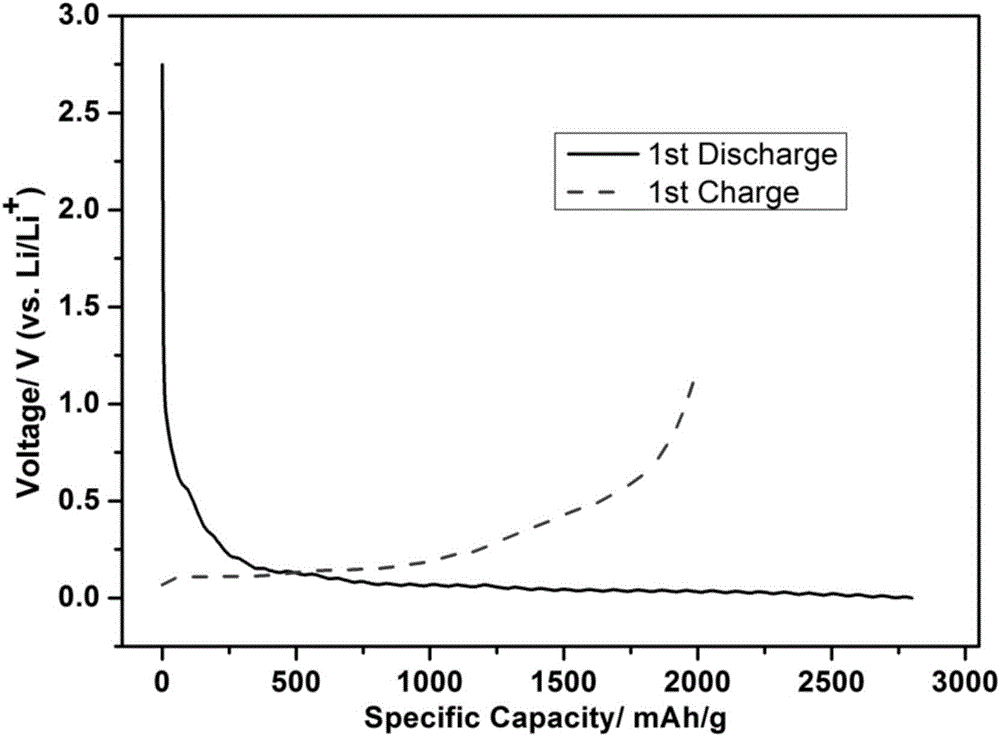

Lithium ion battery SiO composite material as well as preparation method and application thereof

ActiveCN104638237AImprove the first Coulombic efficiencyImprove capacity playCell electrodesSecondary cellsCarbon coatingHigh rate

The invention relates to a lithium ion battery SiO composite material which comprises powder and a conductive carbon coating layer, wherein the chemical formula of the powder is SiOx; x is greater than 0.9 and less than 1.1; the volume of powder with particle diameters below 1.0mu m accounts for less than 15.0% of that of all the SiOx powder; D90 / D10 is greater than 3.0 and less than 15.0; D90 is less than 25.0mu m; Dmax is less than 50.0mu m; and the median particle diameterD50 of the SiOx changes within 0.5-2.0mu m before and after carbon coating. When the composite material charges and discharges at 0-1.5V as a lithium ion battery cathode material, the reversible specific capacity is high (over 1,650mAh / g), the initial coulomb efficiency is up to a theoretical value (over 79.0%), and meanwhile the composite material has excellent cycle performance, excellent conductive performance and low volume expansion, is suitable for high-rate charge and discharge, and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD

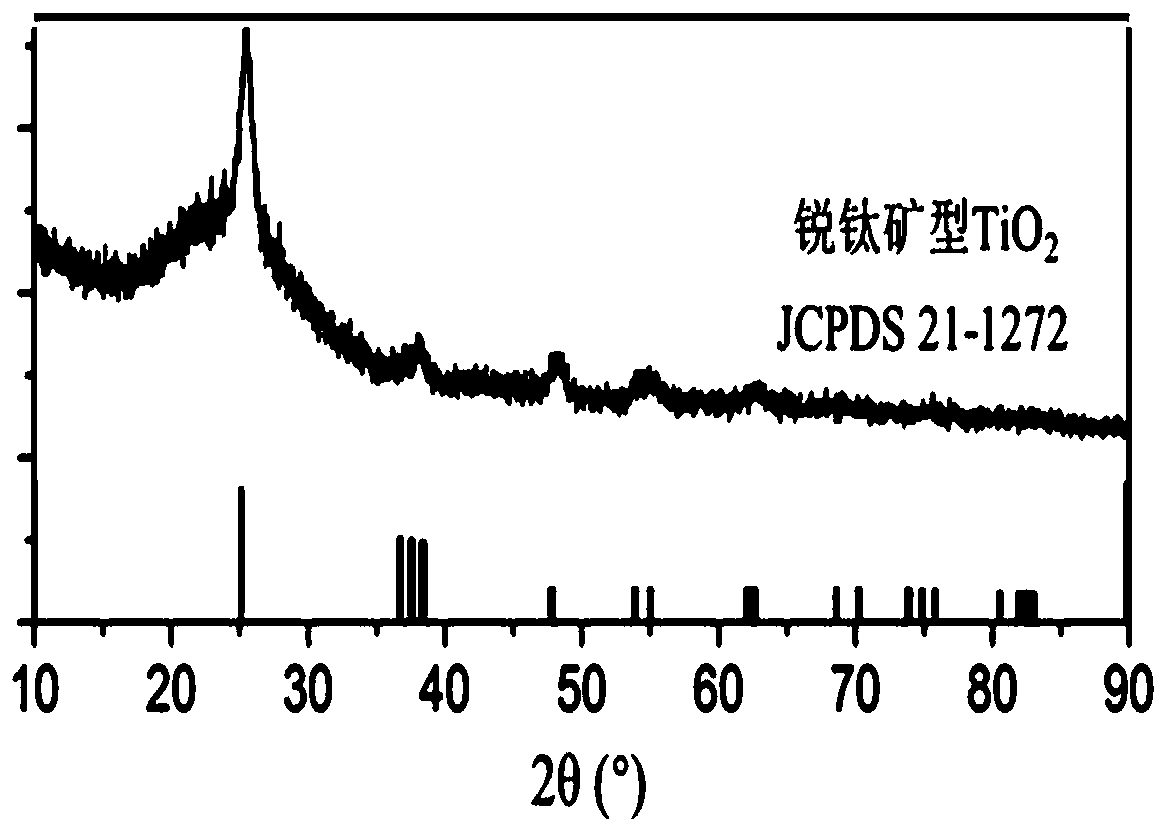

Organic-inorganic composite solid electrolyte, preparation method and application of electrolyte in solid lithium battery

ActiveCN108232293AFlexibleStretchableSolid electrolytesLi-accumulatorsSolid state electrolyteElectrical conductor

The invention discloses an organic-inorganic composite solid electrolyte. The solid electrolyte is characterized by being prepared from an acrylate material, lithium salt, a crosslinking agent, an initiator, a plasticizer, a fast ionic conductor and a porous rigid support material. The preparation method of the inorganic composite solid electrolyte is characterized by comprising steps as follows:mixing the acrylate material with the lithium salt to completely dissolve the lithium salt in acrylate; adding the crosslinking agent and the plasticizer to the mixed solution, and stirring the mixture evenly; adding the fast ionic conductor to the mixed solution, and performing ultrasonic treatment or stirring to disperse the conductor uniformly; adding the initiator to the mixed solution, and performing stirring uniformly; uniformly pouring the mixed solution on the porous rigid support material; performing heating initiation at 60-100 DEG C to enable the acrylate material to be copolymerized with the crosslinking agent to obtain the organic-inorganic composite solid electrolyte. The solid electrolyte has the advantages that the preparation method is simple, the production efficiency ishigh, and the assembled solid lithium battery has lower impedance and higher capacity.

Owner:QINGTAO KUNSHAN ENERGY DEV CO LTD

Lithium ion battery and formation method thereof

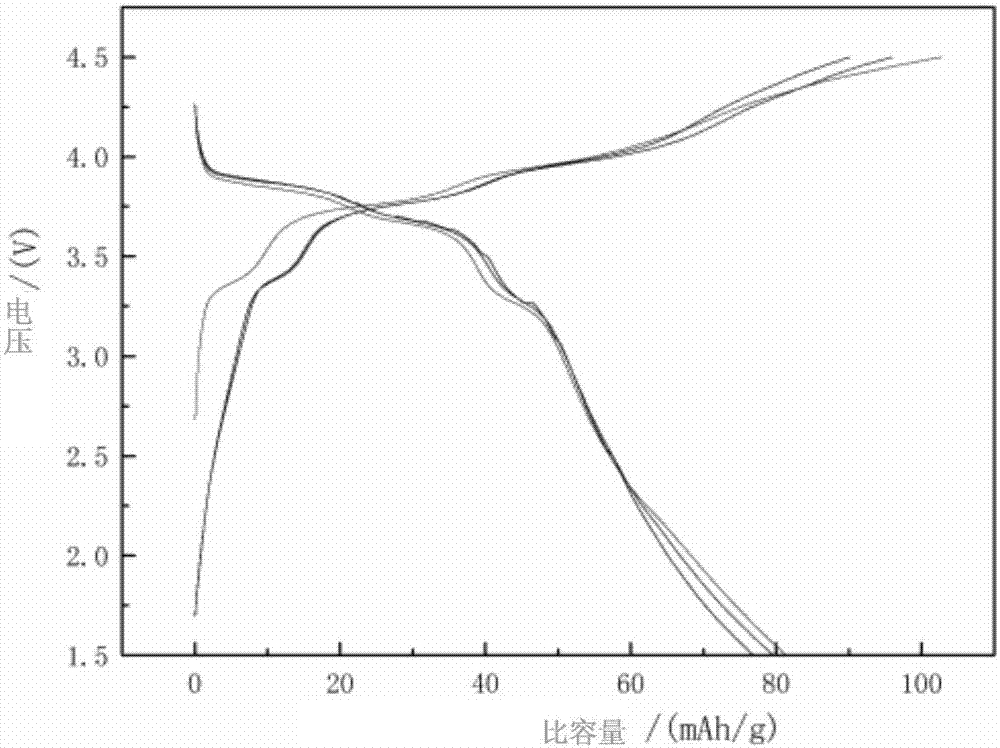

ActiveCN107959071AImprove structural stabilityImprove capacity playSecondary cells charging/dischargingLow voltageManganese

The invention discloses a lithium ion battery formation method. A negative electrode active substance of a lithium ion battery comprises a lithium-rich manganese-based positive electrode material. Theformation method includes at least three times of charge-discharge cycles; in the two former charge-discharge cycles, charge cut-off voltage is lower than 4.4V, discharge current is higher than charge current, and the second-time charge current is higher than the first-time charge current; in the last charge-discharge cycle, the charge cut-off voltage is not lower than 4.4V, and the charge current is not lower than the second-time charge current. By the step voltage charge-discharge formation method, a stable SEI film can be formed on the surface of a negative electrode in repeated low-voltage charge-discharge processes while a stable CEI film is formed on the surface of a positive electrode, side reaction between electrolyte and an electrode piece can be inhibited, gas generation is reduced, and accordingly the problem of battery swelling is solved. In addition, by the method, structural stability and capacity exertion of the lithium-rich manganese-based positive electrode material under a high voltage can be improved, and the cycle performance and the energy density of the battery are improved as well.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

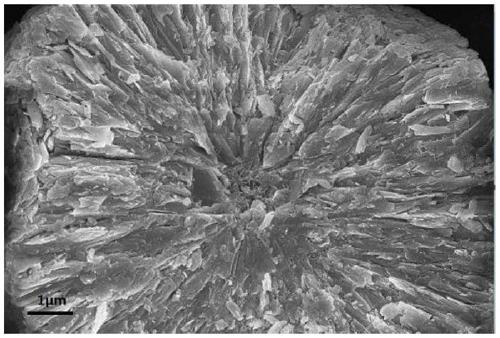

Preparation method of high-capacity monocrystalline type ternary cathode material

ActiveCN110002515AAccelerates the infiltration processEasy to storeCell electrodesSecondary cellsManganeseIncrease ph

A preparation method of a high-capacity monocrystalline type ternary cathode material comprises steps as follows: S1, a nickel cobalt manganese hydroxide precursor of a core-shell structure is prepared with a coprecipitation method, a loose and porous core is prepared by intermittently introducing a certain quantity of bicarbonate at the initial stage of core making, after core making ends, and loose flaky shells are prepared by substantially reducing the rotation speed and increasing pH; meanwhile, at the core-shell transition stage, a dispersant is added to effectively prevent agglomerationof the shells due to decrease of the rotation speed; S2, the prepared precursor and lithium salt are mixed and calcined once in the oxygen-rich atmosphere at the high temperature, and the monocrystalline type ternary cathode material is obtained. A battery is prepared from the ternary cathode material and has high capacity and good safety performance due to high lithium ion transport efficiency and reduced anisotropy in crystals. The problem of poor capacity of the material because of low lithium ion transport efficiency of monocrystalline type ternary materials is effectively solved. Besides,the monocrystalline type ternary cathode material is prepared through one-time sintering, the preparation procedure is simple, and the production cost is low.

Owner:南通金通储能动力新材料有限公司

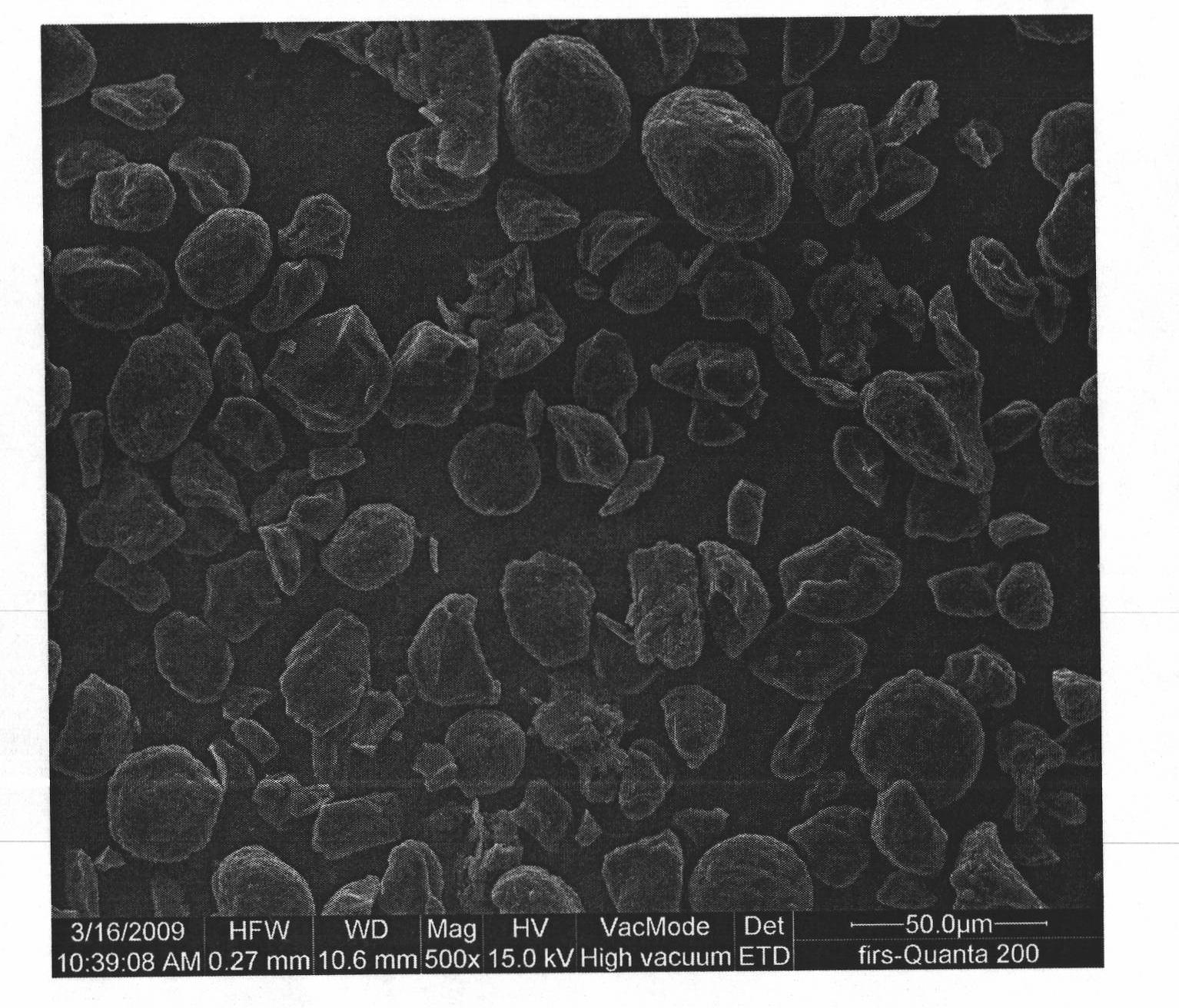

Graphite material at negative pole of lithium ion battery and preparation method thereof

ActiveCN102110813AImprove adaptabilityImprove performanceCell electrodesMicroballoon preparationMass ratioGraphite

The invention discloses a graphite material at the negative pole of a lithium ion battery, which comprises interphase graphite and artificial graphite in mass ratio of 90:10 to 20:80. The graphite material has the advantages of highly compacted density, small specific surface area, high discharge capacity, long circulating life, high charge-discharge efficiency and high product performance-price ratio. The invention also provides a method for preparing the graphite material, which has the advantages of simple, convenient and feasible technology, wide raw material sources and lower cost.

Owner:福建杉杉科技有限公司

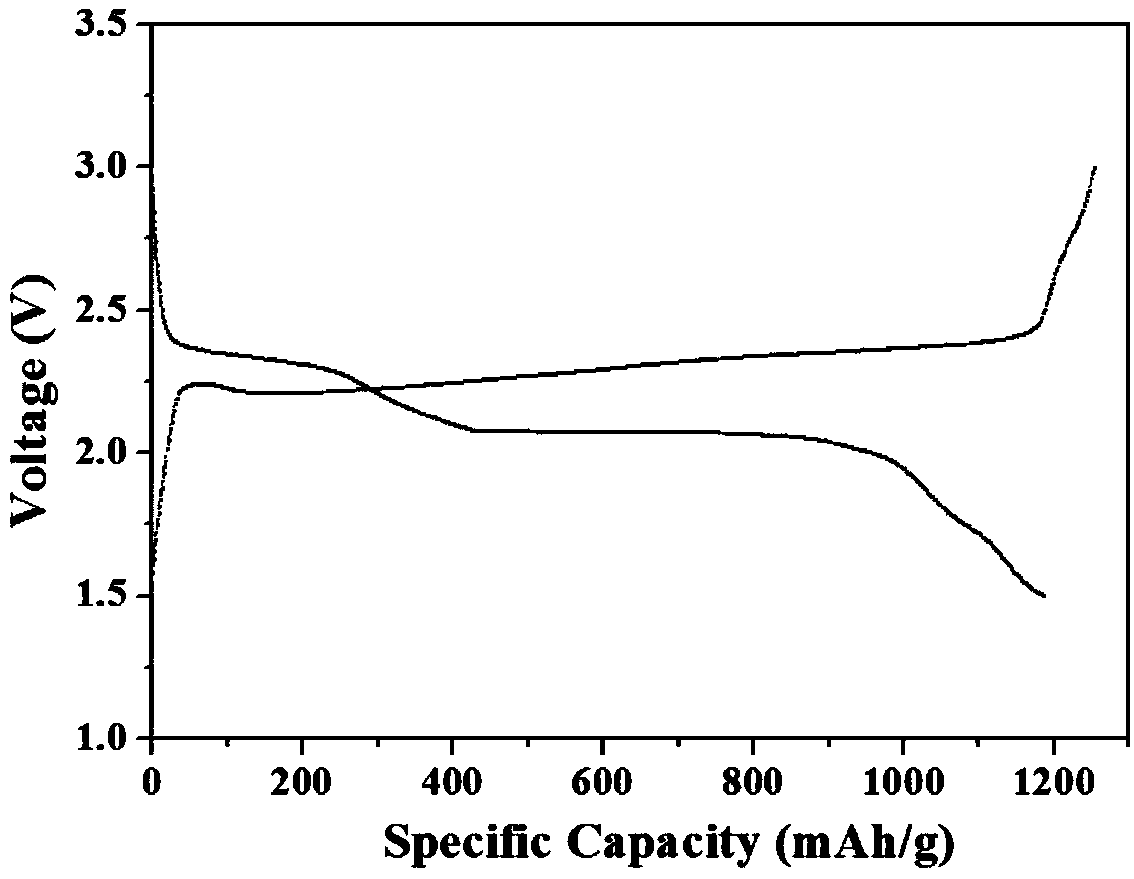

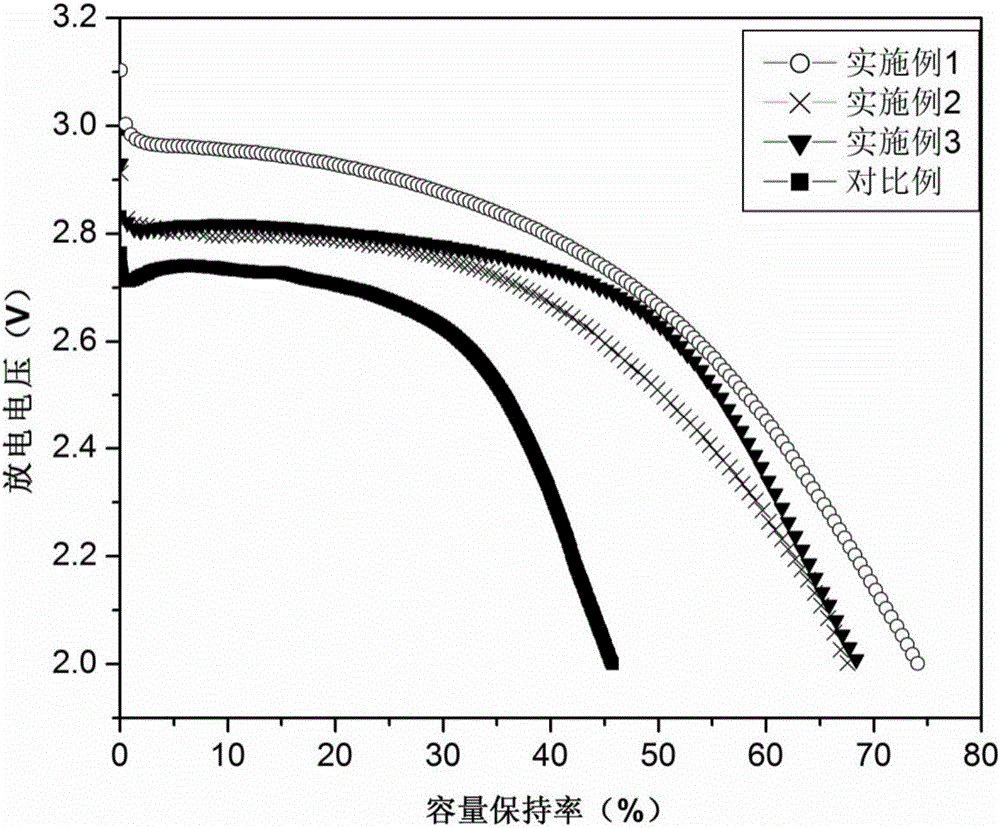

Positive electrode material for lithium sulphur battery and preparation method thereof, and lithium sulphur battery

ActiveCN109713282AImprove capacity playImprove cycle stabilityCell electrodesLi-accumulatorsElectrochemical responseMetallic sulfide

A positive electrode material for a lithium sulphur battery and a preparation method thereof, and the lithium sulphur battery are disclosed. The positive electrode material comprises activated carbon,carbon black, transition metal or a transition metal compound, and sublimed sulfur; and the transition metal compound is metal carbide, metal boride, metal nitride, metal phosphide, metal oxide or metal sulfide. The activated carbon is utilized as a main body of sulfur carrying; the carbon black can carry sulfur and can also strengthen the conductivity of the positive electrode material; and thetransition metal or the transition metal compound can play a fixation role in lithium polysulfide produced in an electrochemical reaction, inhibits the shuttle effect of polysulfide ions, and enablesthe cycle performance of the lithium sulphur battery to be improved. The positive electrode material for the lithium sulphur battery disclosed by the invention has the advantages of being simple and easy to obtain, easy to be prepared on a large scale, and the like, and the lithium sulphur battery with long circulation, high specific capacity and high specific energy can be obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

Cathode material of lithium ion battery and preparation method and lithium ion battery

PendingCN110993933AIncrease energy densityImprove capacity playElectrode manufacturing processesFinal product manufactureCapacity lossLithium-ion battery

The invention provides a cathode material of a lithium ion battery. The cathode material comprises a high-capacity cathode active material, a lithium supplementing material, a conductive agent and a binder, wherein the mass percentage ratio of the high-capacity cathode active material to the lithium supplementing material to the conductive agent to the binder is (77-97%):(1-15%):(0.1-3%):(1-5%); the chemical formula of the lithium supplementing material is LixMyNz, x is larger than or equal to 1 and smaller than or equal to 8, y is larger than or equal to 1 and smaller than or equal to 6, z islarger than or equal to 1 and smaller than or equal to 6, M is one or more metal elements of Fe, Cu, Mn, Zr, Mg and Al, and N is one or more non-metal elements of O, N, F, B and S. The invention alsoprovides a preparation method of the cathode material of the lithium ion battery and the lithium ion battery. According to the cathode material of the lithium ion battery, the preparation method andthe lithium ion battery provided by the invention, the capacity exertion of the cathode active material can be improved, the active lithium consumed by the first irreversible capacity loss is well compensated, and the energy density of the lithium ion battery is further improved.

Owner:湖州鑫远电池系统技术有限公司

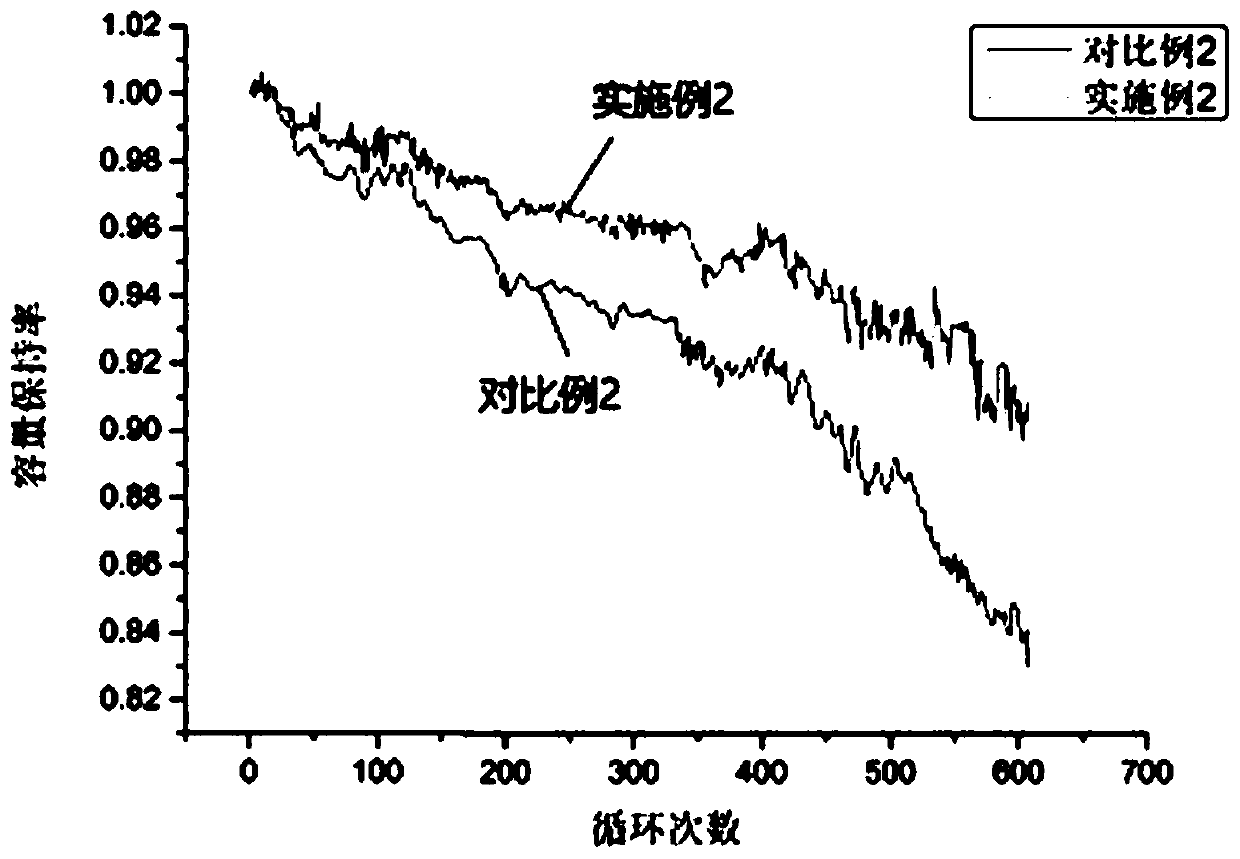

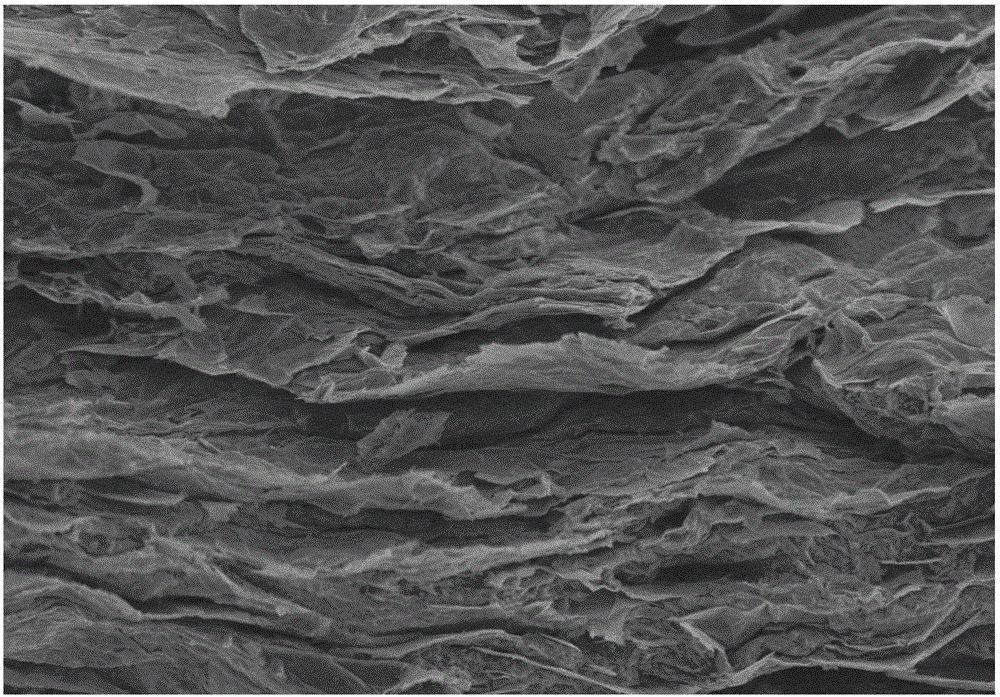

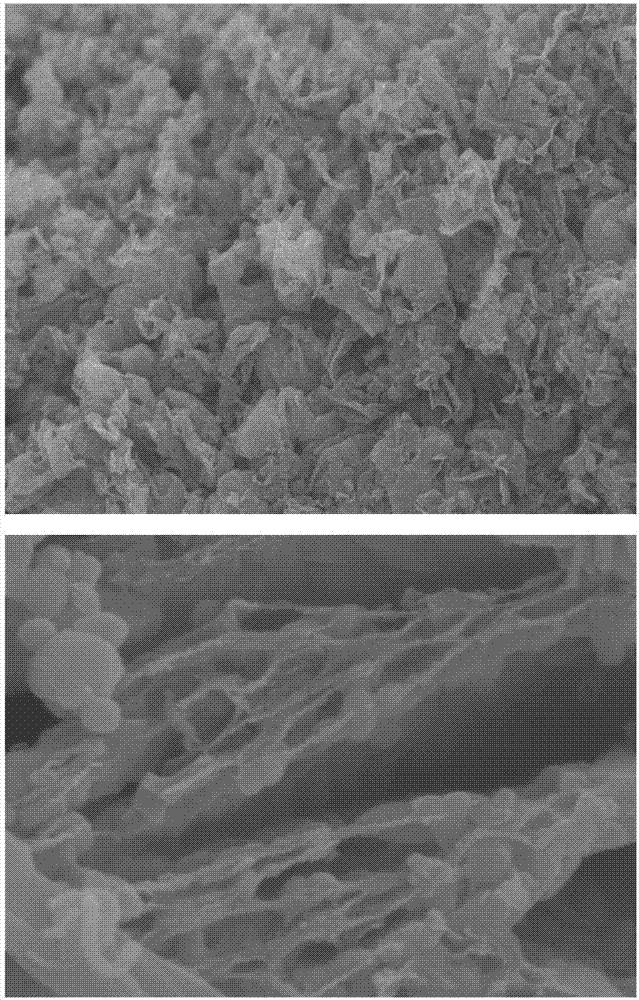

Negative electrode active material, preparation method thereof, and lithium ion battery

ActiveCN105336923AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsCarbon layerState of art

The invention provides a negative electrode active material to solve the problems of poor cycle performances and poor rate performance of negative electrode active materials in the prior art. The negative electrode active material comprises an inner layer material and an outer layer material covered on the surface of the inner layer material; the inner layer material comprises multilayer graphene and silicon particles, a plurality of superposed lamellae are arranged in the multilayer graphene, and a spacing between adjacent lamellae is 20-500nm; the silicon particles are positioned among the lamellae in the multilayer graphene; and the outer layer material is a carbon layer. The invention also discloses a preparation method of the negative electrode active material, and a lithium ion battery. The negative electrode active material has the advantages of high conductivity, high capacity, low expansion, excellent cycle performances and excellent rate performance.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

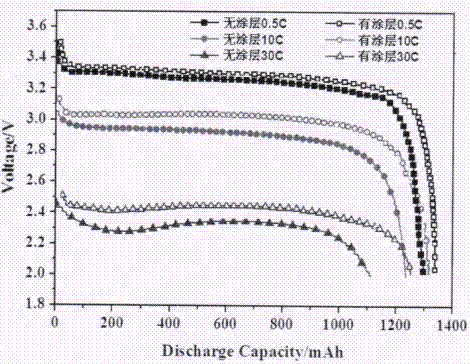

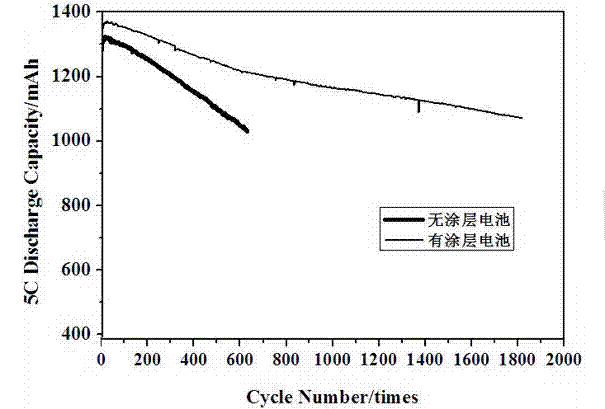

Lithium ion battery anode functional coating and preparation method thereof

ActiveCN102757700AReduce the presence of air bubblesEasy to processCell electrodesElectrically-conductive paintsLow speedSlurry

The invention provides a lithium ion battery anode functional coating and a preparation method thereof. A dispersing agent NMP (N-methyl-pyrrolidone) is stirred by a planetary stirrer at a high speed till the temperature reaches 40 to 50 DEG C; a certain proportion of a binding agent PVDF (Polyvinylidene Fluoride) is added to enable the solid content of a binding agent solution to be 1.2 to 3.5 percent; low-speed revolution is performed and then high-speed rotation is started; cold circulating water is received to control the temperature of the slurry below 50 DEG C; stirring is preformed for 2 to 6 h; a carbon black conductive agent (conductive carbon) is added to enable the solid contend of the slurry to be 20 to 30 percent; stirring is performed for 2 to 4 h; the slurry is transferred into a high-efficiency dynaflow ultrasonic slurry mixer to be subjected to ultrasonic dispersion for 1 to 2 h; after the preparation is finished, the slurry passes through a 200-mesh screen stencil and is sprayed through a spraying machine, wherein the spraying thickness is controlled within 3 to 5 Mum; and after the spraying is finished, a coated pole piece is baked for 12 to 14 h at 110 plus or minus 3 DEG C, wherein dry nitrogen is filled for replacement once each two hours, so as to obtain the lithium ion battery anode functional coating. The replacement of a current collector with an anode aluminium foil material by a current collector with the functional coating can greatly improve the electrochemical properties of lithium ion batteries.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

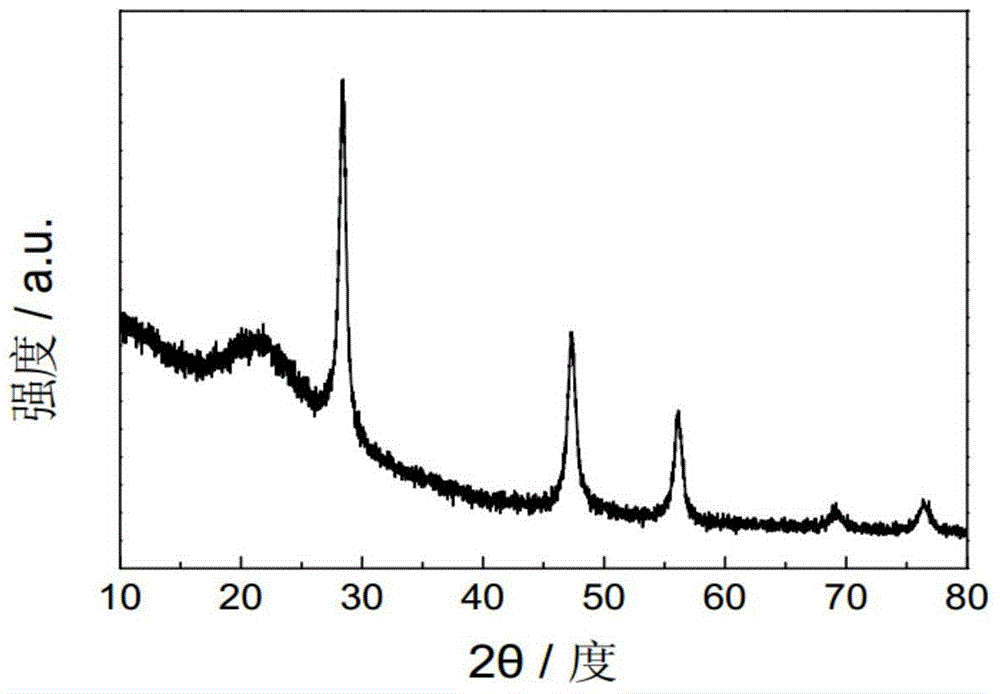

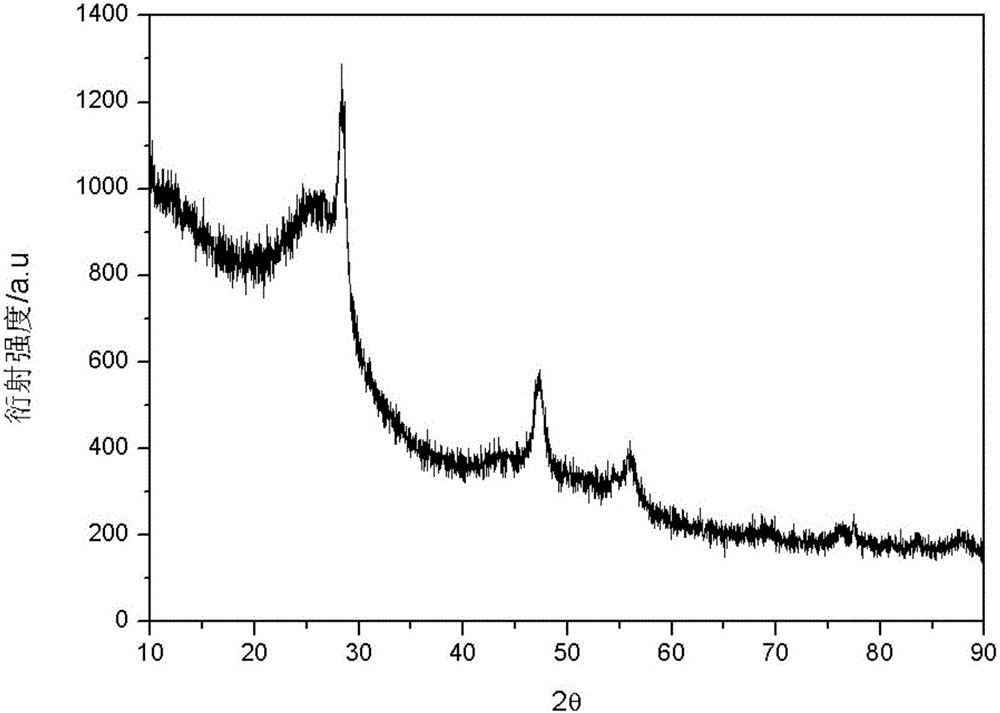

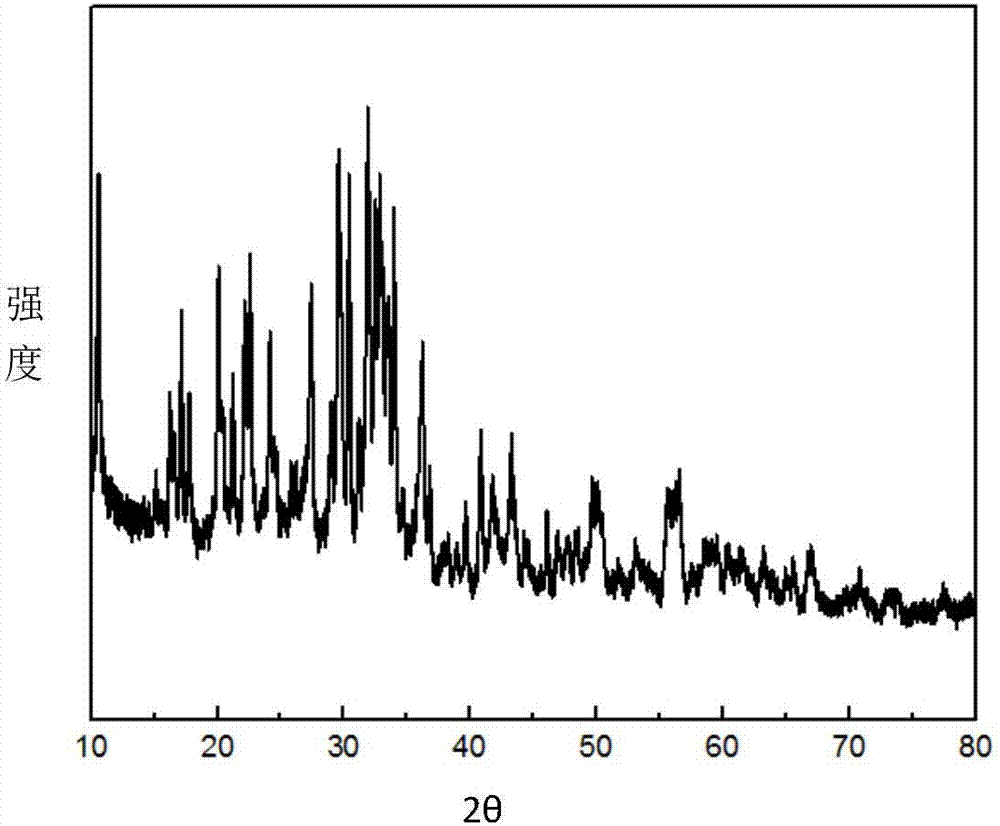

Carbon coated sodium manganese pyrophosphate@graphene oxide composite material with sandwich structure, as well as preparation method and application thereof

ActiveCN107017395AImprove thermal stabilityGood chemical stabilityCell electrodesSecondary cellsFreeze-dryingOxide composite

The invention discloses a carbon coated sodium manganese pyrophosphate@graphene oxide composite material with a sandwich structure, as well as a preparation method and application thereof. The composite material is formed by stacking graphene oxide sheets, wherein carbon coated sodium manganese pyrophosphate particles are uniformly distributed on the surfaces of the graphene oxide sheets. The preparation method comprises the following steps: adding the graphene oxide into an aqueous solution in which a phosphorus source, a sodium source, a manganese source and a complexing agent are dissolved, and performing ultrasonic treatment, liquid nitrogen freezing and freeze drying sequentially to obtain a precursor; putting the precursor under protective atmosphere and performing heat treatment to obtain the carbon coated sodium manganese pyrophosphate@graphene oxide composite material with the sandwich structure. The carbon coated sodium manganese pyrophosphate@graphene oxide composite material serving as a sodium ion battery positive electrode material has excellent electrochemical property; the 'Na-Mn-P-O' system resource is rich, and the cost is low; the preparation method is simple to operate, and the commercial application prospect is wide.

Owner:湖南钠邦新能源有限公司

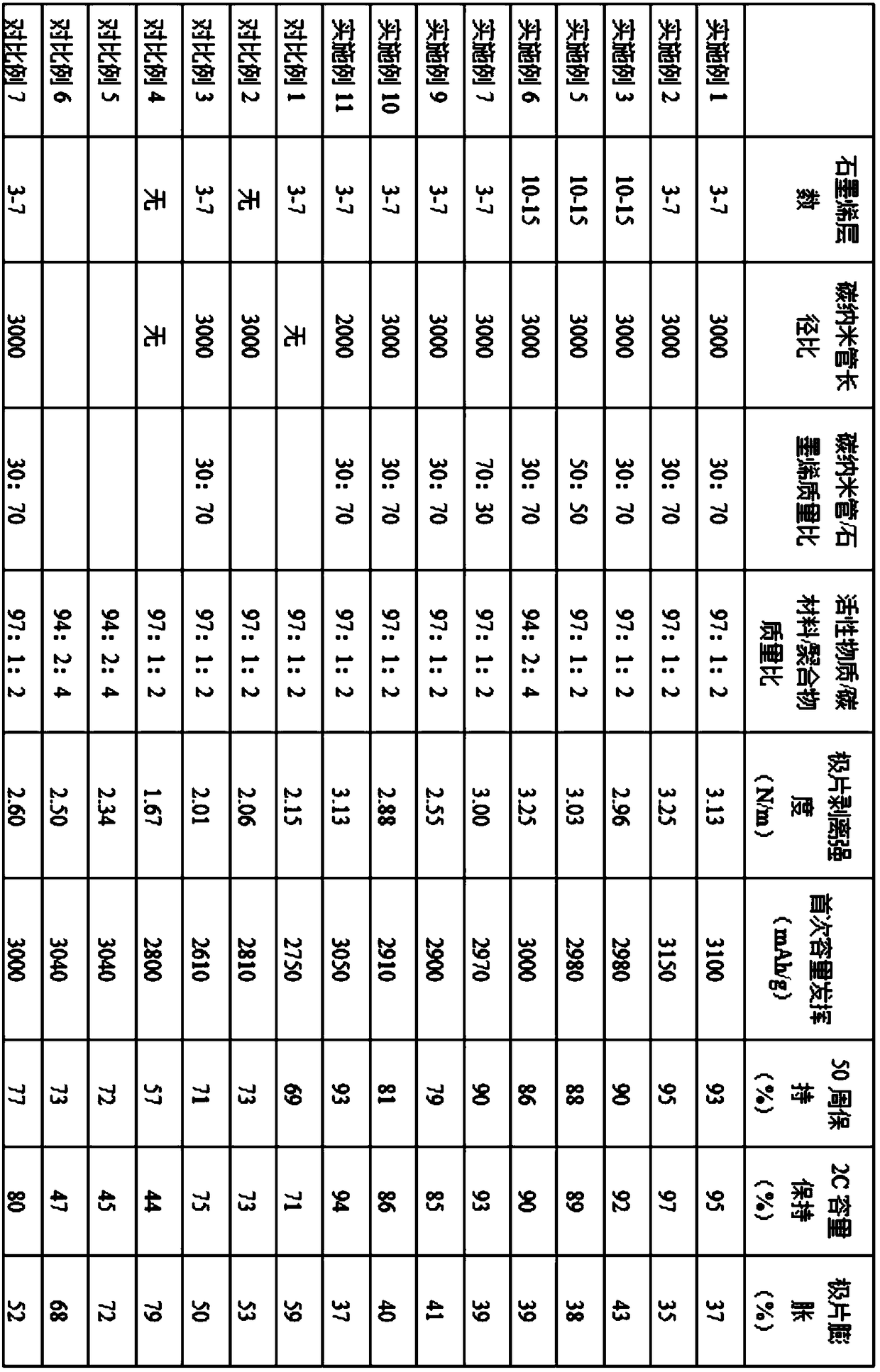

Three-dimensional mixed conductive adhesive used for lithium battery, and battery containing adhesive

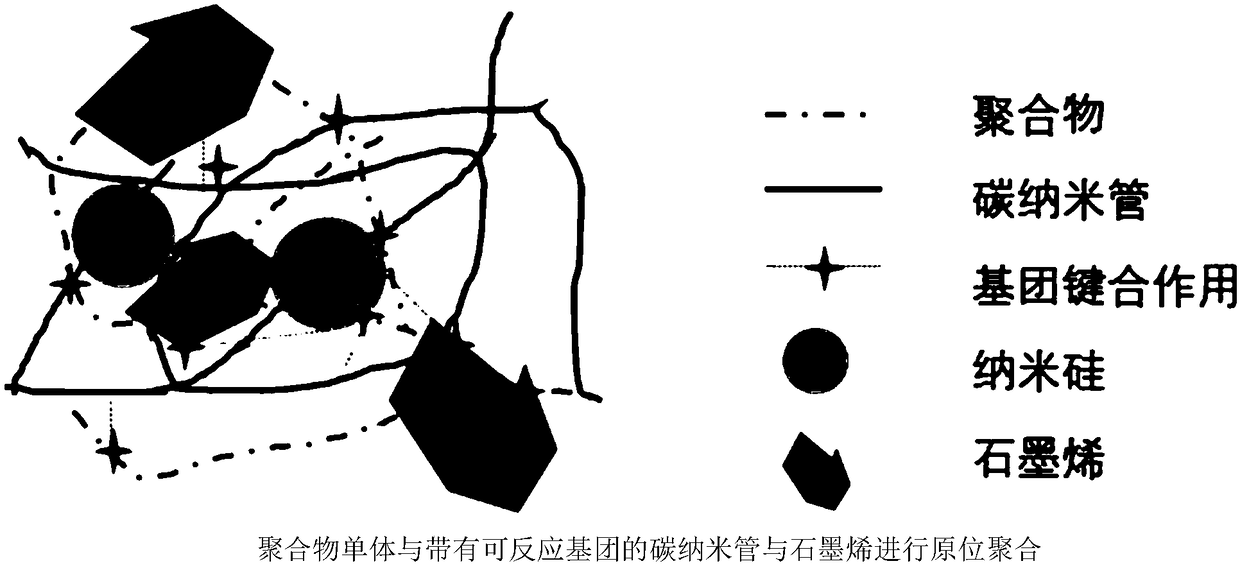

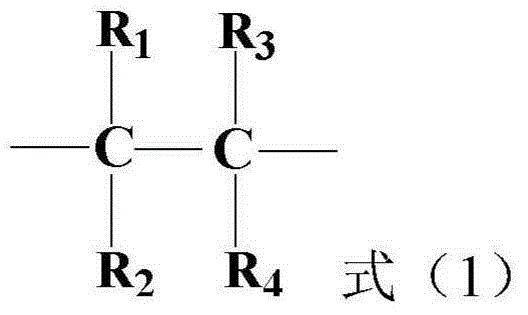

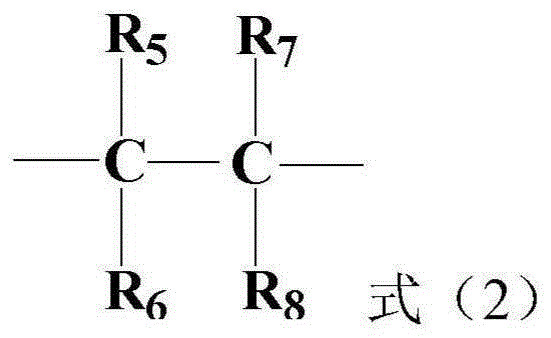

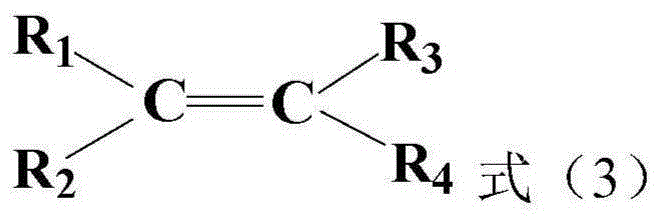

ActiveCN109461937AAdaptableStrong mechanical propertiesCell electrodesFinal product manufactureChemical LinkageAdhesive

The invention provides a three-dimensional mixed conductive adhesive used for lithium battery, and a battery containing the adhesive. The adhesive contains a carbon nanotube, a graphene and a polymerhaving a chemical bonding effect with the carbon nanotube and the graphene. The carbon nanotube and the graphene in the adhesive are mixed according to a certain proportion to form a three-dimensionalconductive network; polymer groups and groups on the graphene carbon nanotube are effectively combined to improve the intensity of the compound; and the compound is perfectly dispersed when the electrode slurry is prepared. During the charging-discharging process, the three-dimensional compound conductive adhesive is capable of better controlling the expansion and the shrinkage of the active material of the electrode plate, and effectively improves the cycling stability and the rate capability of high-capacity high-volume-change type electrode material, such as the silicon-based cathode material, the tin-based cathode material, and the high-volume-change type electrode material that can be expanded into the new battery system in the future.

Owner:SHENZHEN EUBO NEW MATERIAL TECH +1

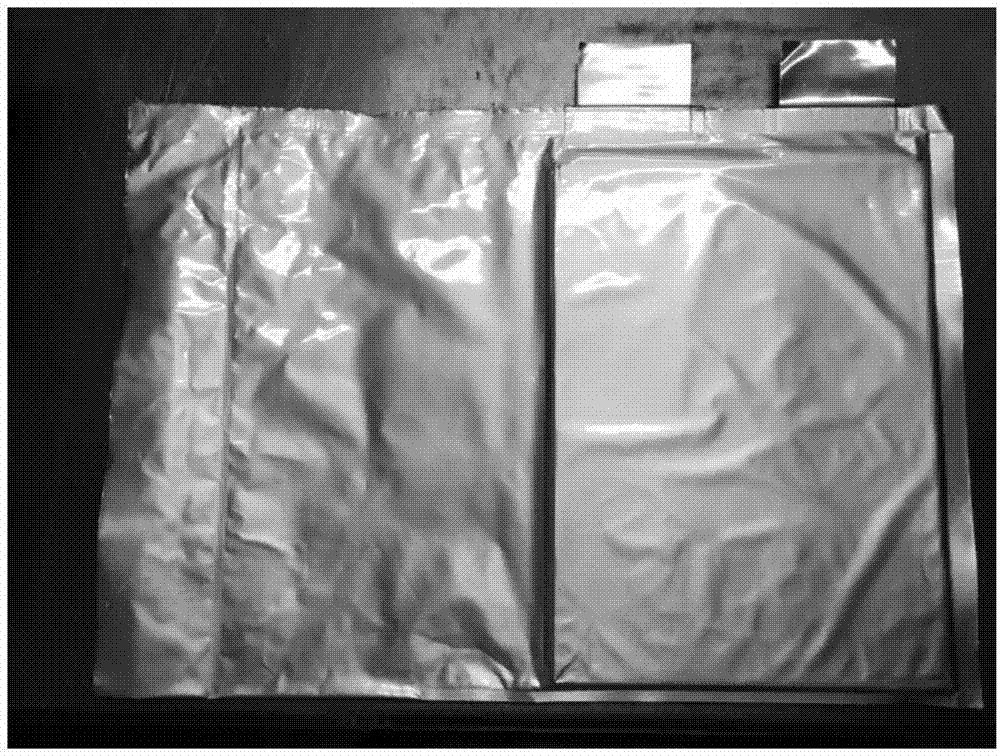

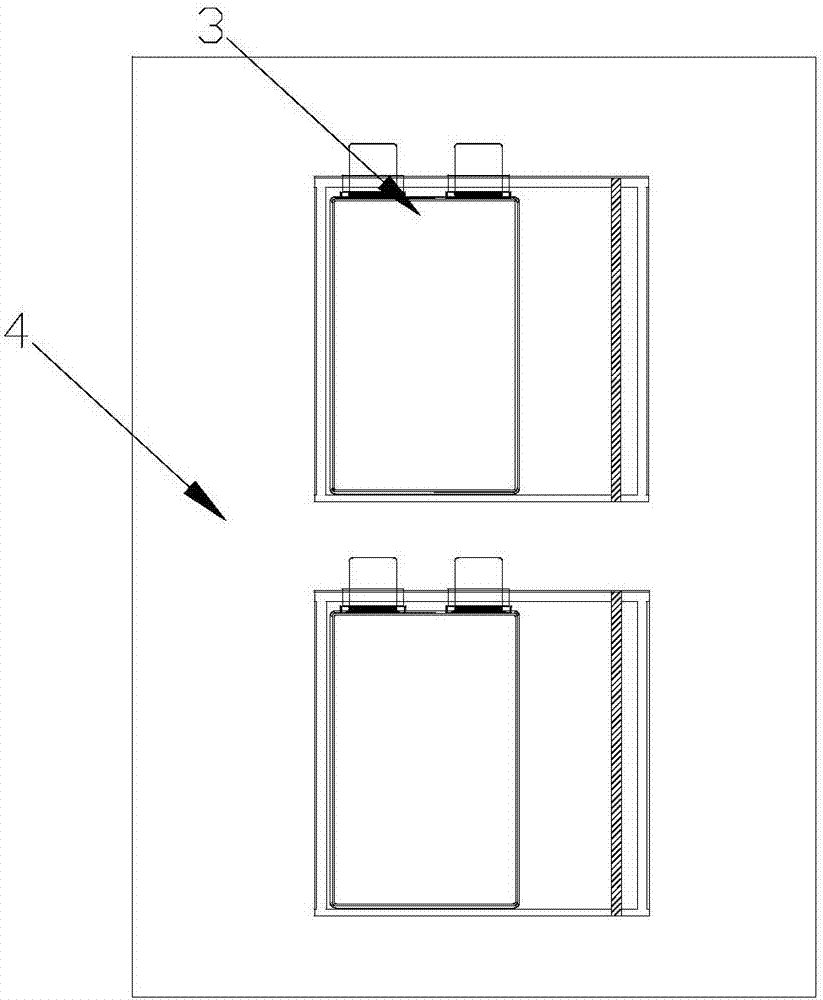

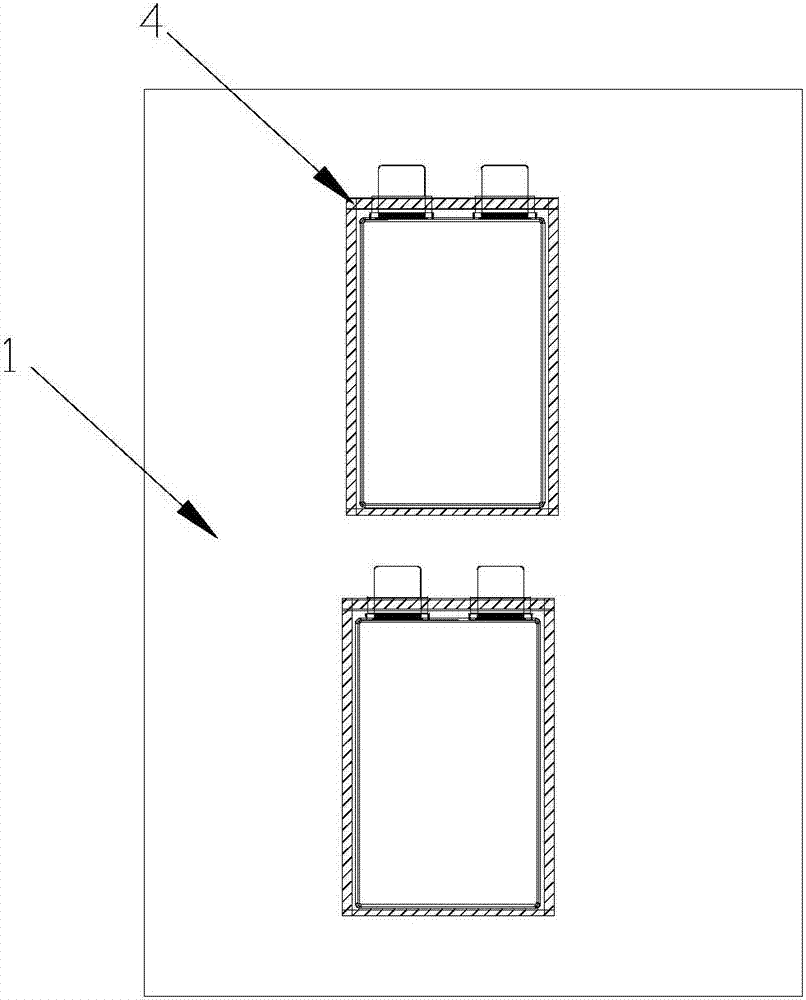

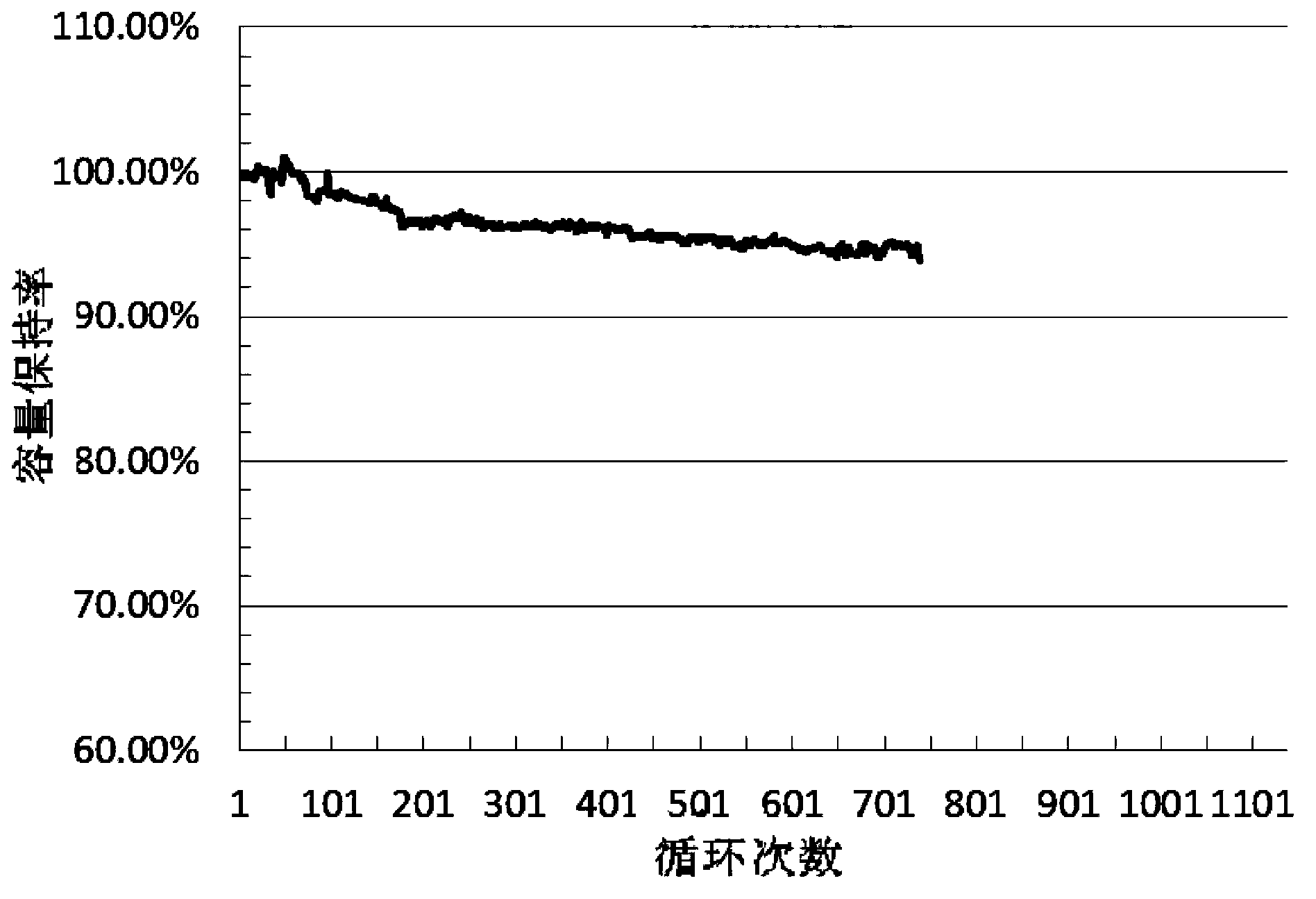

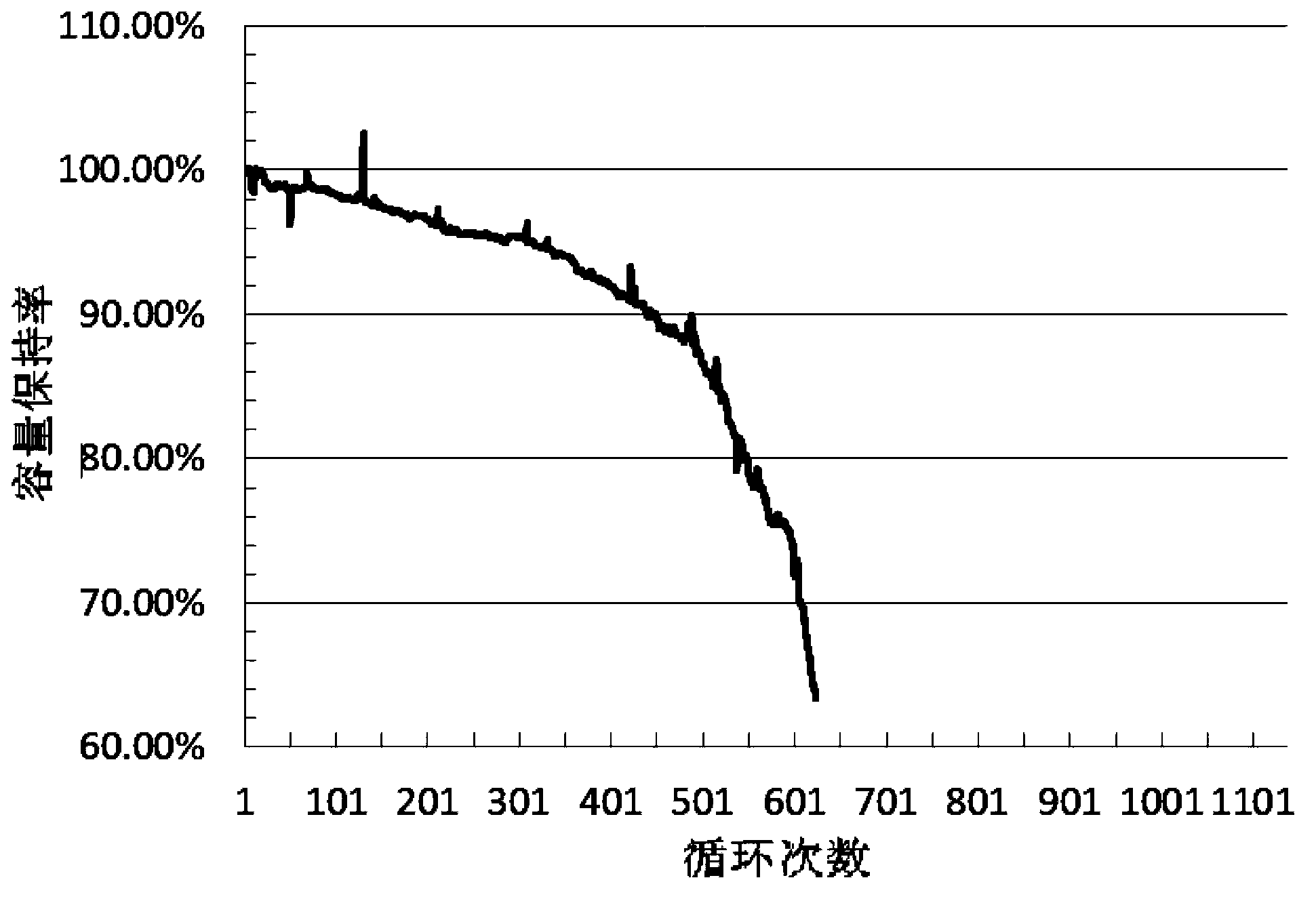

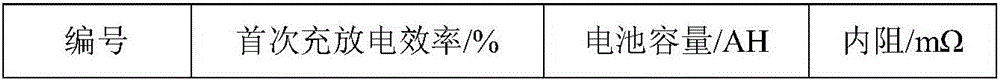

Formation and lamination method for flexible package lithium ion power battery

ActiveCN107403945ALarge fluid lossAvoid lostFinal product manufactureSecondary cells manufactureInternal resistancePre-charge

The invention relates to the technical field of lithium ion batteries and discloses a formation and lamination method for a flexible package lithium ion power battery. The method comprises the following steps: (a) carrying out hot pressing on a battery before pre-charging; (b) carrying out cold pressing on the battery before pre-charging; (c) pre-charging; (d) carrying out hot pressing on the battery after pre-charging; (e) carrying out cold pressing on the battery after pre-charging; (f) carrying out capacity grading; and (g) carrying out cold pressing on the battery after the capacity grading. The liquid maintaining amount of electrolyte processed by virtue of the formation and lamination method is high, the battery is rarely polarized, and the direct current internal resistance of the battery is low; and meanwhile, an anode group and a cathode group in the battery are in tight contact, so that the production of lithium dendrites in charging and discharging processes is avoided, the safety risk of the battery is reduced, meanwhile, the capacity expression of the battery is improved, and the cycle life of the battery is effectively prolonged.

Owner:WANXIANG 123 CO LTD

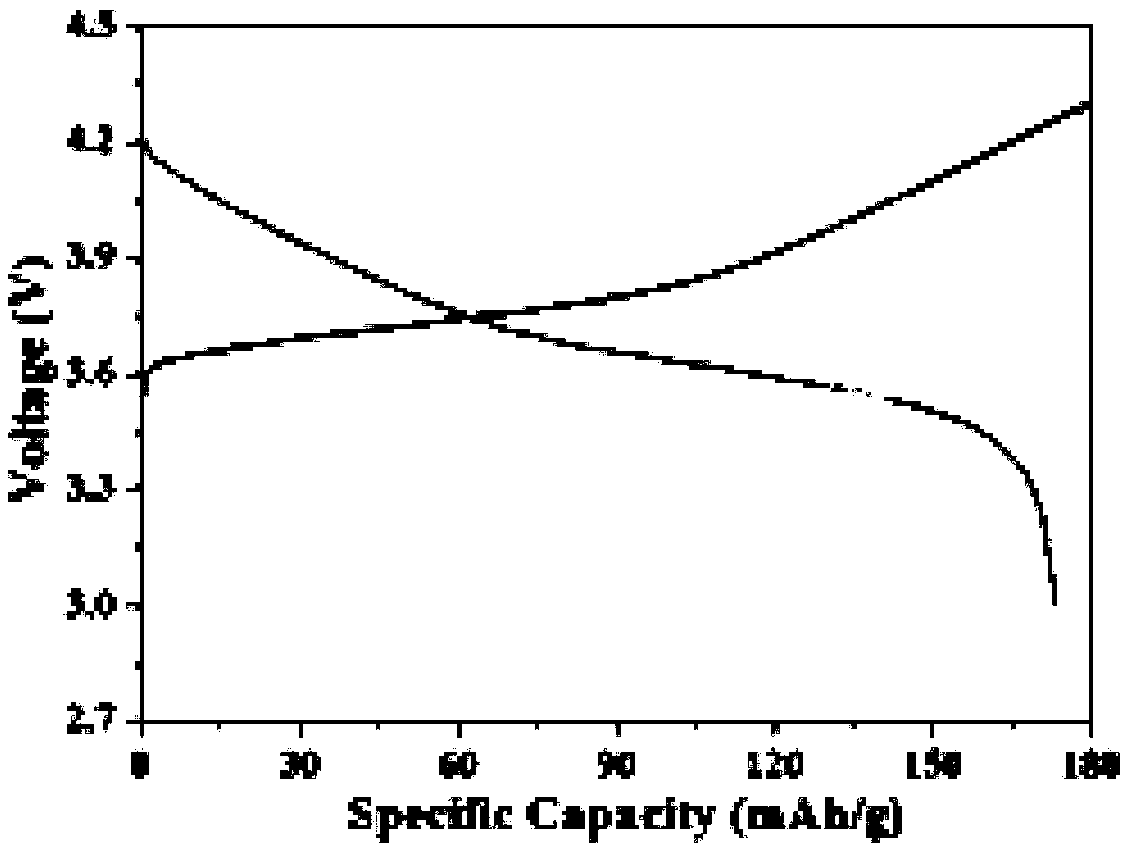

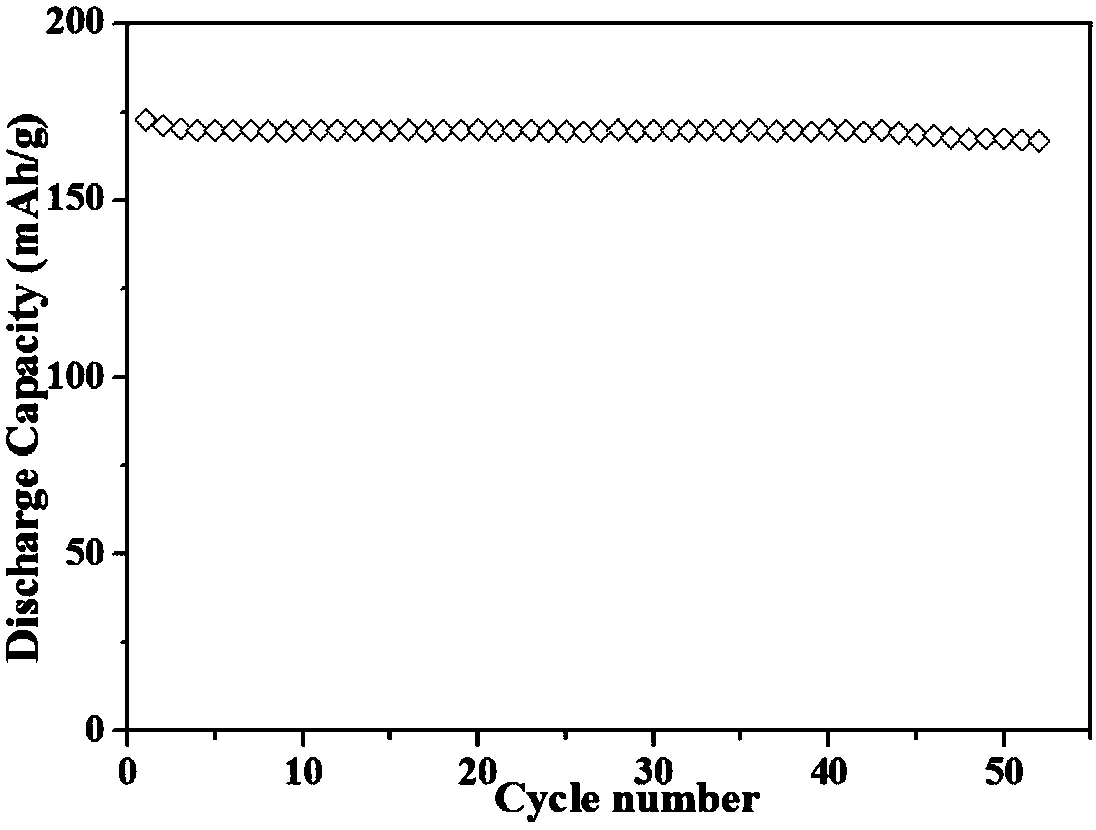

Mixed cathode material for lithium ion batteries and preparation method thereof

The invention relates to the field of batteries, and in particular relates to a long-life, high-energy density and low-cost mixed cathode material for lithium ion secondary batteries and a preparation method thereof. The mixed cathode material for the lithium ion batteries, provided by the invention, comprises the following raw components in percentage by weight: 20-60% of doped lithium-manganese spinel composite oxide and 40-80% of doped lithium-nickel-cobalt-manganese composite oxide. According to the mixed cathode material for the lithium ion batteries, provided by the invention, proper doping is carried out on lithium-manganese spinel to ensure that the lattice imperfection can be effectively reduced, the crystal structure is stabilized, the lattice distortion is restrained, the manganese dissolution is reduced, the cycle life is prolonged, the large current charge-discharge property and safety performance can be improved so as to satisfy the important requirements on the lithium ion batteries for EV (Electric Vehicles) and HEV (Hybrid Electric Vehicles); for the lithium-nickel-cobalt-manganese composite oxide of a layered structure, the doping has the same effect and the cycle performance, the rate performance and the safety performance can be better improved.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

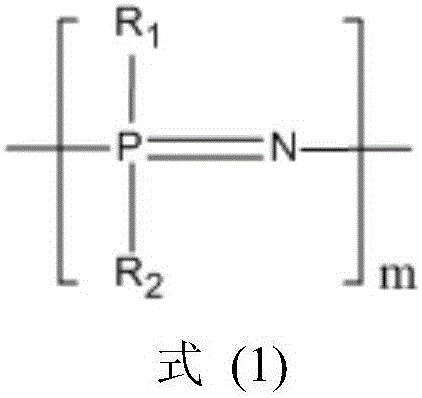

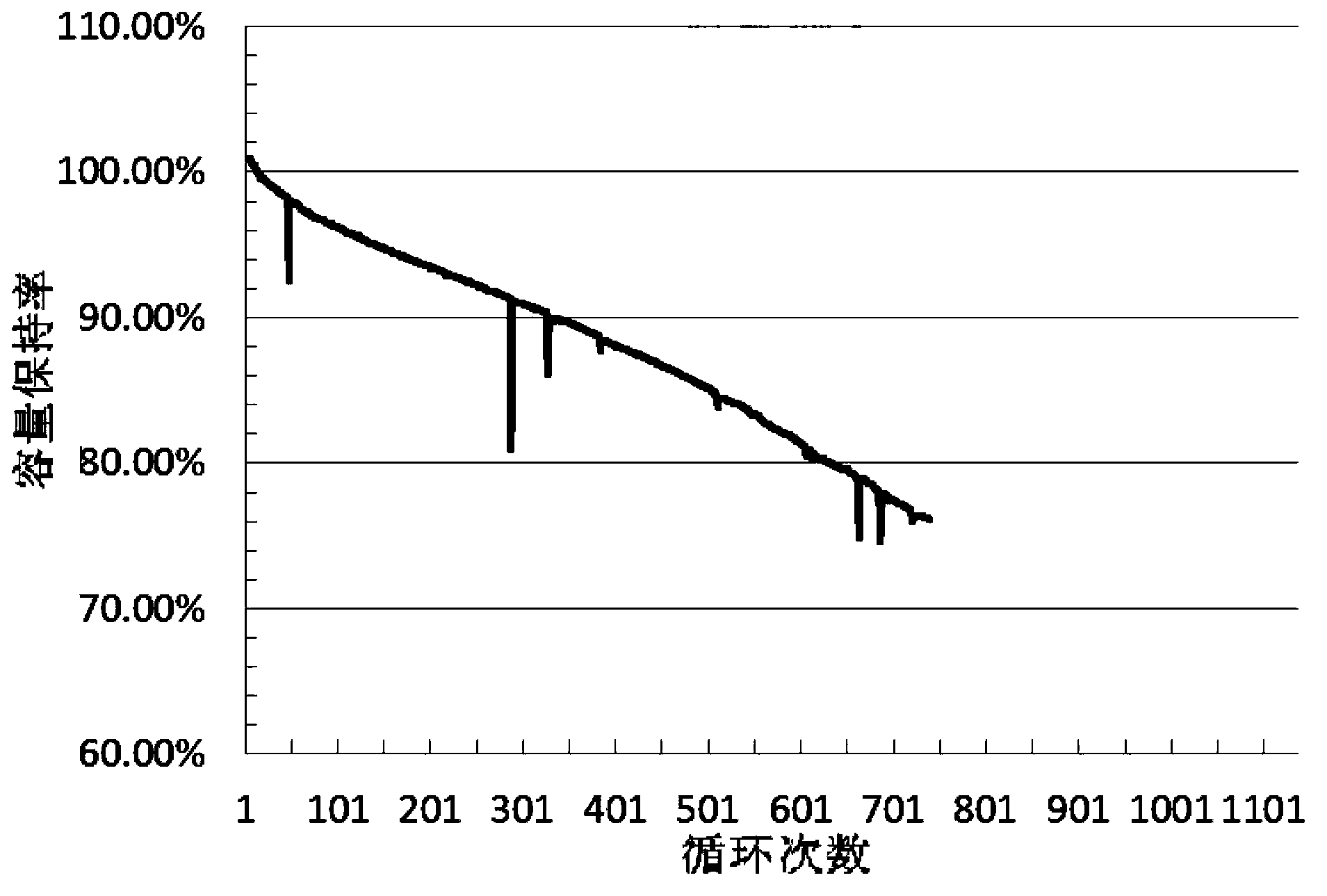

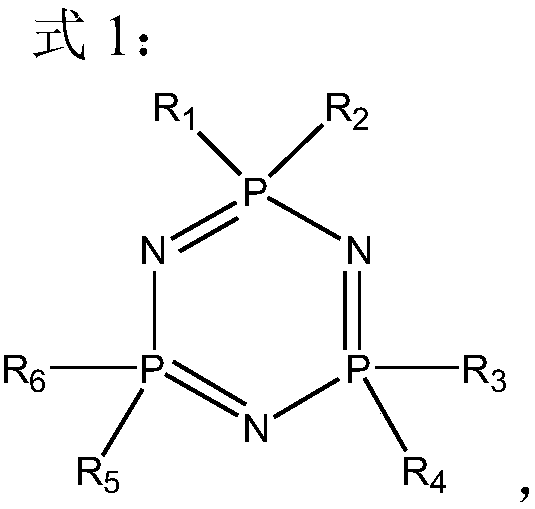

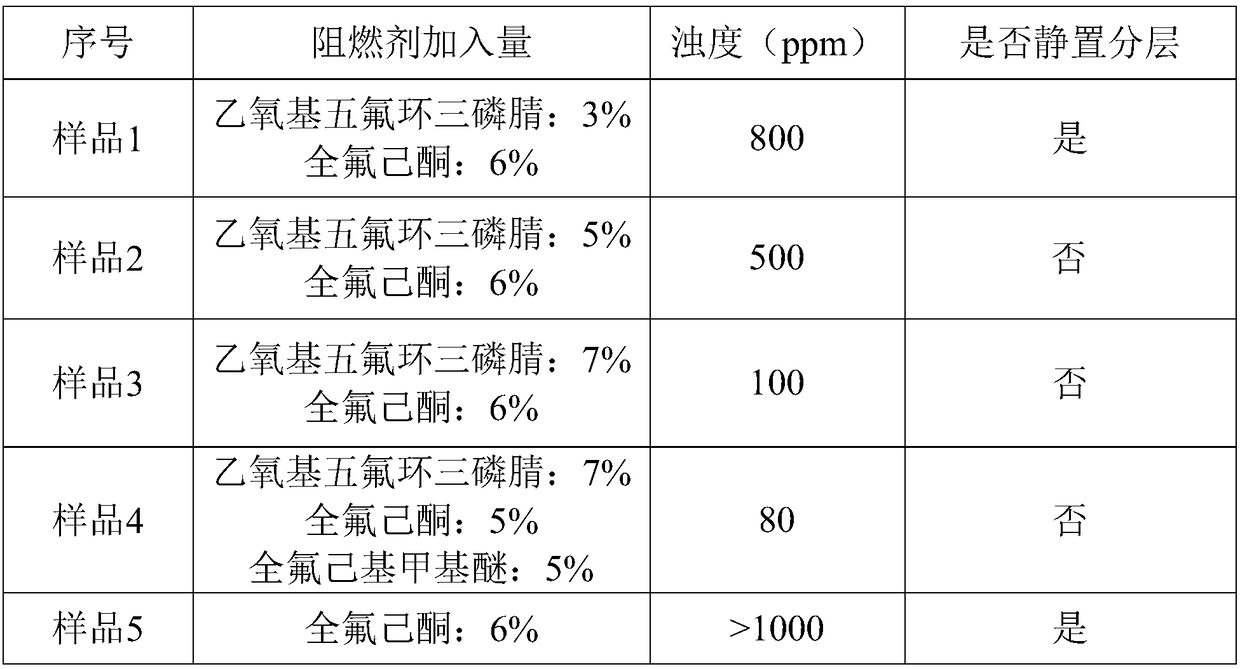

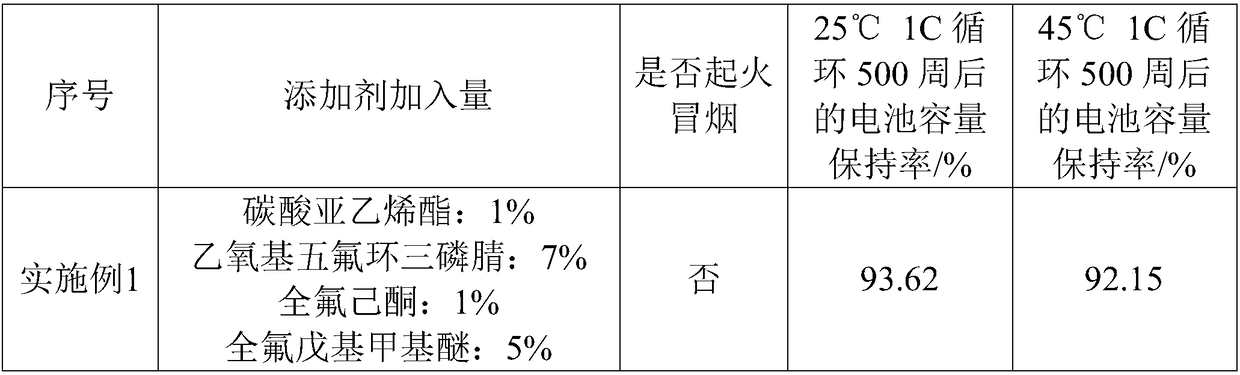

Flame retardant electrolyte for lithium ion battery

ActiveCN108923066ALow viscosityImprove capacity playSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

In order to solve the problem that electrolyte in the prior art difficultly takes into account the electrochemical properties of flame retardant properties, circulation and the like, the invention relates to electrolyte with flame retardant functions and capability of improving cyclic properties for a lithium ion battery. The electrolyte is prepared from a non-aqueous organic solvent, lithium saltand an additive; the additive is prepared from a phosphonitrile compound, perfluorinated hexanone and a perfluoroalkyl ether compound. By using the electrolyte for the lithium ion battery, disclosedby the invention, the lithium ion battery has the advantages of superior normal temperature and high temperature cycle performance, no inflation under high temperature storage conditions, small internal resistance change and capability of realizing the aims of improving the circulation and taking the flame retardant effect into account.

Owner:NANTONG CAPCHEM ELECTRONICS MATERIALS CO LTD

Aqueous binder, preparing method thereof and electrode slice, isolating membrane and cell using aqueous binder

ActiveCN104953128AImprove charge and discharge kineticsImprove ionic conductivityCell seperators/membranes/diaphragms/spacersCell electrodesEmulsionPre treatment

The invention relates to an aqueous binder. The aqueous binder is characterized in that the aqueous binder is emulsion contains emulsion particles of a core-shell structure, the core of each emulsion particle of the core-shell structure contains fluorine-containing polymer A and fluoride-free oleophylic polar polymer B, a shell of each emulsion particle of the core-shell structure contains hydrophilic polymer M, and the solid content of the emulsion particles of the core-shell structure in the emulsion is 5-50 wt%. An electrode slice prepared with the aqueous binder is applied to a lithium ion battery, the capacity of the lithium ion battery can be highly brought into play, the adhering performance of an interface between the electrode slice and an isolating membrane is good, and the cycle life of the cell is long; the isolating membrane treated with the aqueous binder is high in ionic conductivity and can be firmly adhere to the electrode slice.

Owner:CONTEMPORARY AMPEREX TECH CO

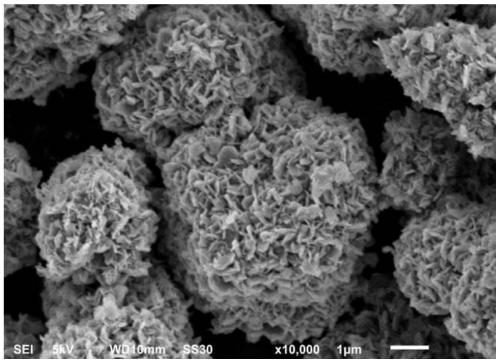

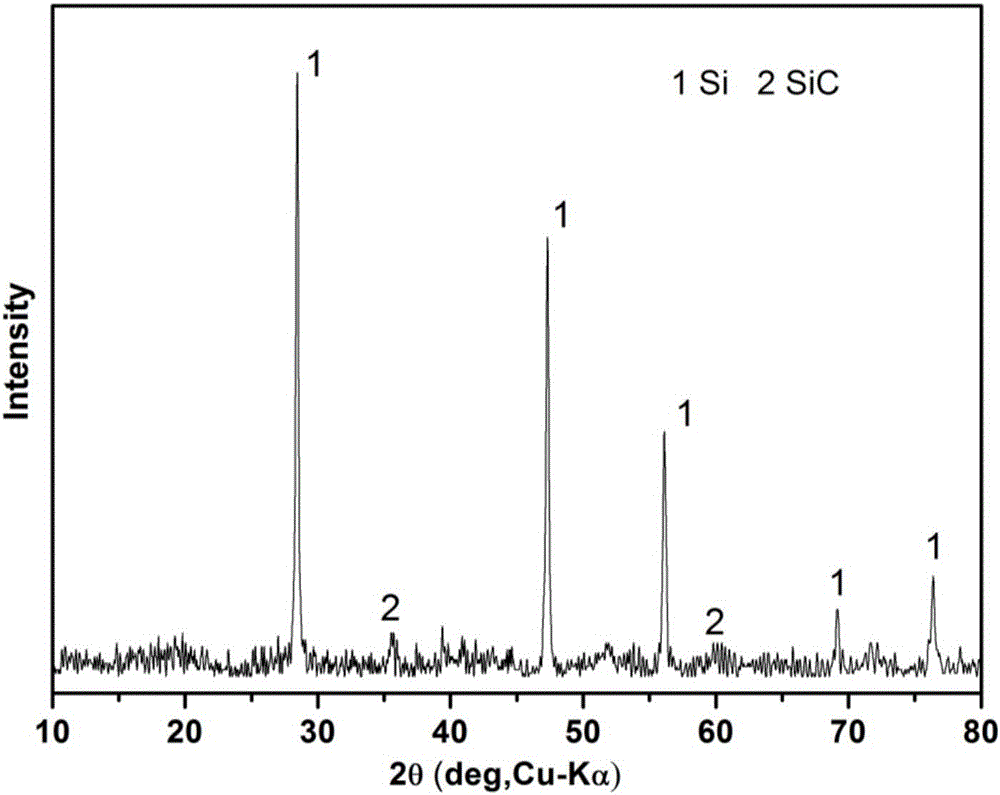

Preparation method of silicon-carbon composite material

InactiveCN106848273AImprove capacity playRapid de-embeddingElectrode thermal treatmentFinal product manufactureCarbon compositesMass ratio

The invention relates to a preparation method of a silicon-carbon composite material. The preparation method comprises the following steps of: S1, preparing a carbon-coated nano silicon-based oxide, namely separately weighing silicon particles and a carbon source aqueous solution and uniformly mixing the two in a silicon-carbon molar ratio of (5-15) to 1 to form a suspension; transferring the suspension to a container, cooling the container to room temperature and taking the container out after a hydrothermal reaction at a first predetermined temperature for a first predetermined time, and washing and drying the suspension in vacuum to obtain the carbon-coated nano silicon-based oxide; and S2, preparing the silicon-carbon composite material, namely grinding and mixing the carbon-coated nano silicon-based oxide obtained in the S1 with metal magnesium powder in a mass ratio of 1 to (0.6-1.6) to form a mixture, and then mixing the mixture in an inorganic salt; filling the container with the mixed mixture and the inorganic container, putting the container in inert gas, raising the temperature to a second predetermined temperature at a predetermined temperature raising rate, keeping the second predetermined temperature for a second predetermined time, cooling the mixture, cleaning impurities, and then drying the mixture in vacuum to obtain the silicon-carbon composite material.

Owner:OPTIMUM BATTERY CO LTD

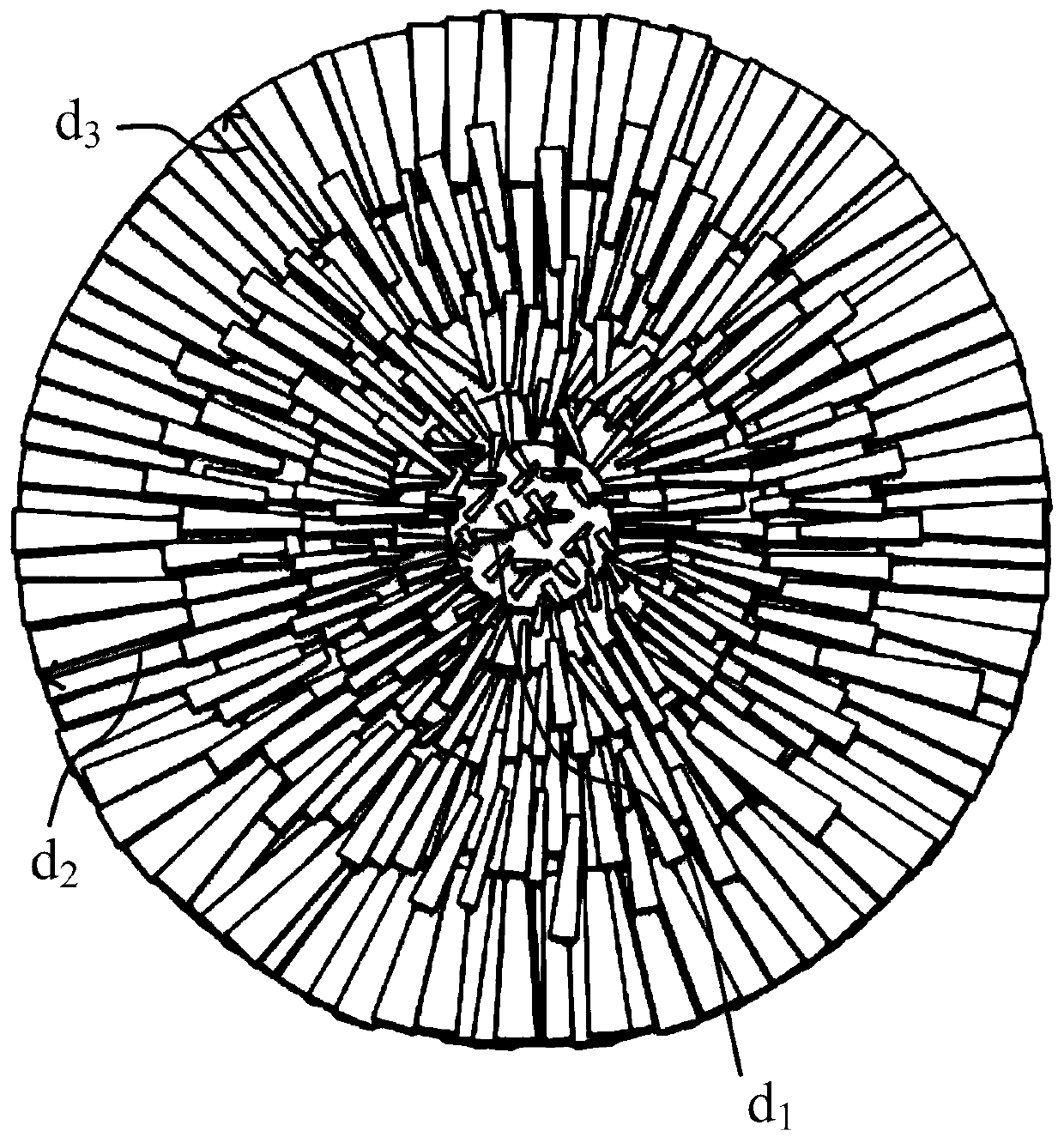

Positive electrode active material precursor and preparation method thereof, and positive electrode active material

InactiveCN111370679AHigh densityImprove cycle performanceCell electrodesSecondary cellsChemical engineeringBattery cell

The invention discloses a positive electrode active material precursor and a preparation method thereof, and a positive electrode active material. The positive electrode active material precursor comprises secondary particles formed by aggregation of a plurality of primary particles, each secondary particle comprises an internal area and an external area coating the external side of the internal area, the density of the internal area is smaller than that of the external area, and the density of the external area is gradually increased from inside to outside. According to the positive electrodeactive material precursor of the invention, the positive electrode active material adopting the positive electrode active material precursor has high initial charge specific capacity, initial discharge specific capacity, initial coulombic efficiency and cycle performance, so that the lithium ion secondary battery can have high initial charge specific capacity, initial discharge specific capacity,initial coulombic efficiency and cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

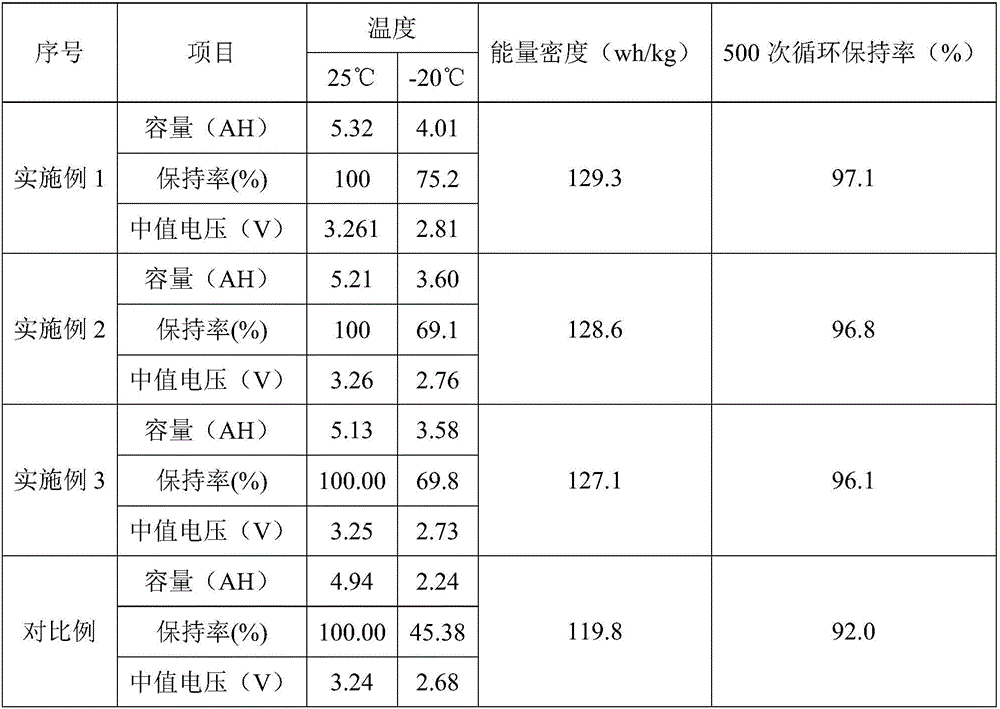

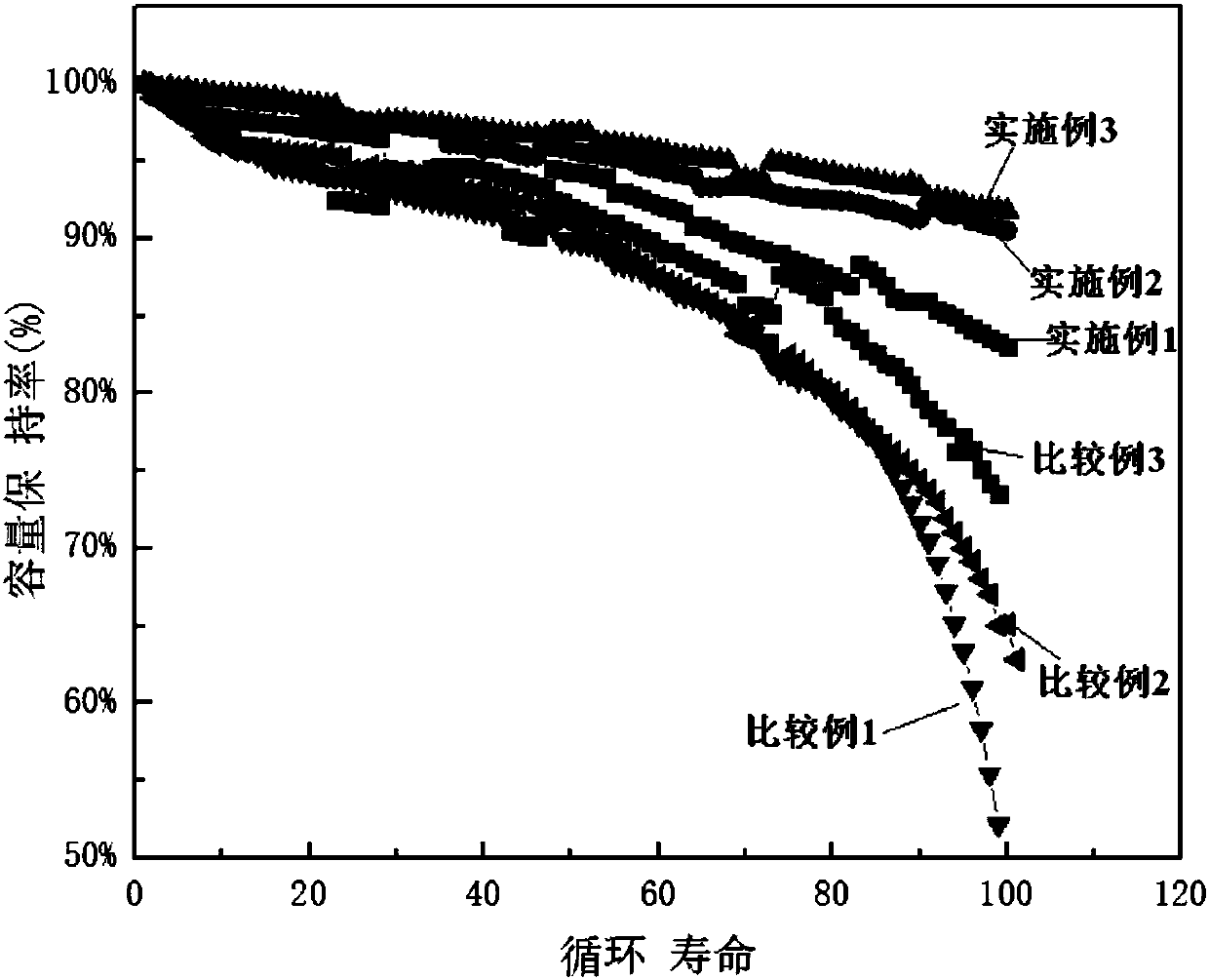

Formation method for lithium ion battery

InactiveCN105870508AImprove capacity playLower internal resistanceFinal product manufactureElectrolyte accumulators manufactureIonBatch production

The invention discloses a formation method for a lithium ion battery. The method comprises the steps of carrying out formation on the lithium ion battery, after the lithium ion battery is filled with an electrolyte and is subjected to standing, at a temperature of 35-55 DEG C by 0.01-0.5C charging current under a vacuum-pumping condition. The method adopts high-temperature negative pressure for realizing formation; the exhaust gas generated from the internal of the battery in the formation process is exhausted in time; a uniform and stable SEI film is formed on the negative electrode of the lithium ion battery at a high-temperature environment; the battery processed by the formation method has the advantages of high capacity volatilization of active materials, low internal resistance, low expansion rate, long cycle life and long storage life, so that the product quality is improved, and the service life of the battery is prolonged; and meanwhile, the method has the advantages of short formation time, high equipment utilization ratio and low energy consumption, so that the method is an efficient formation method suitable for batch production of the lithium ion batteries.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

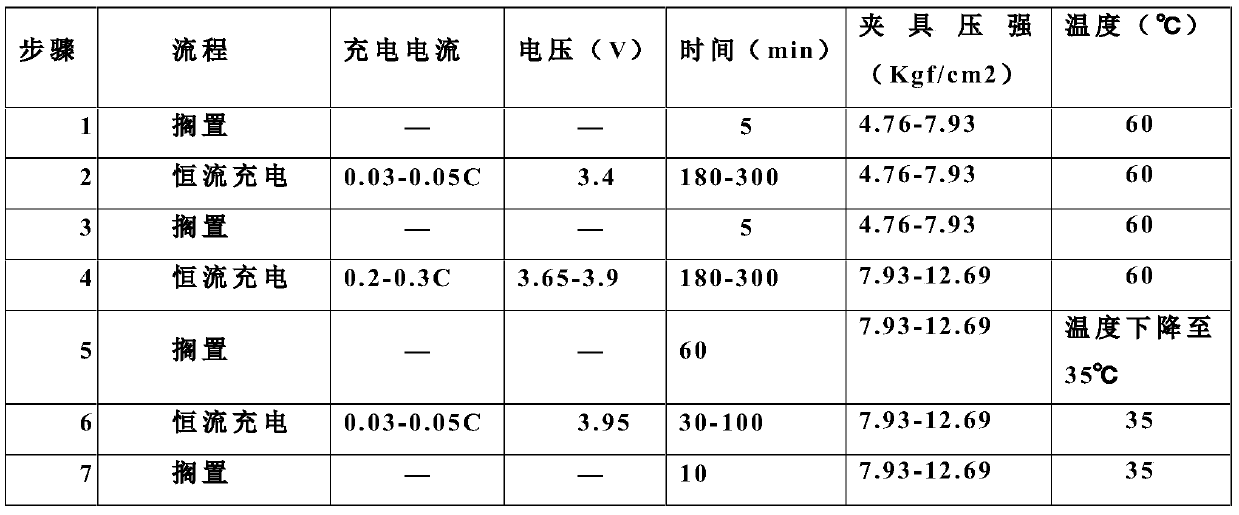

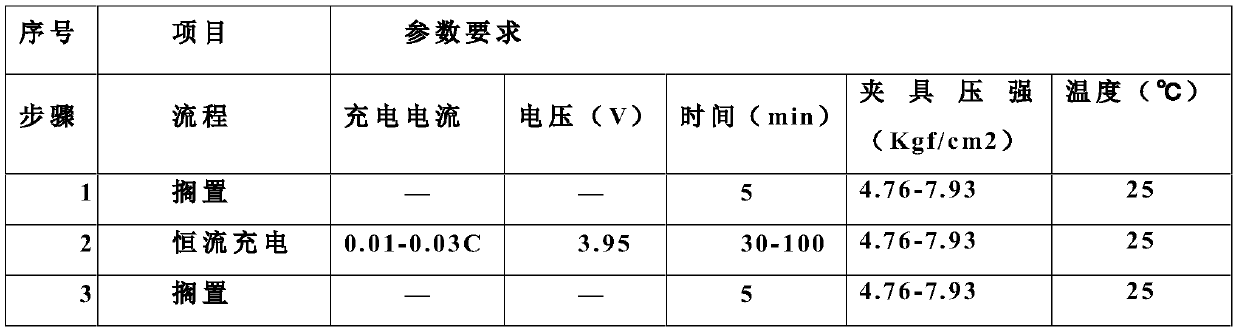

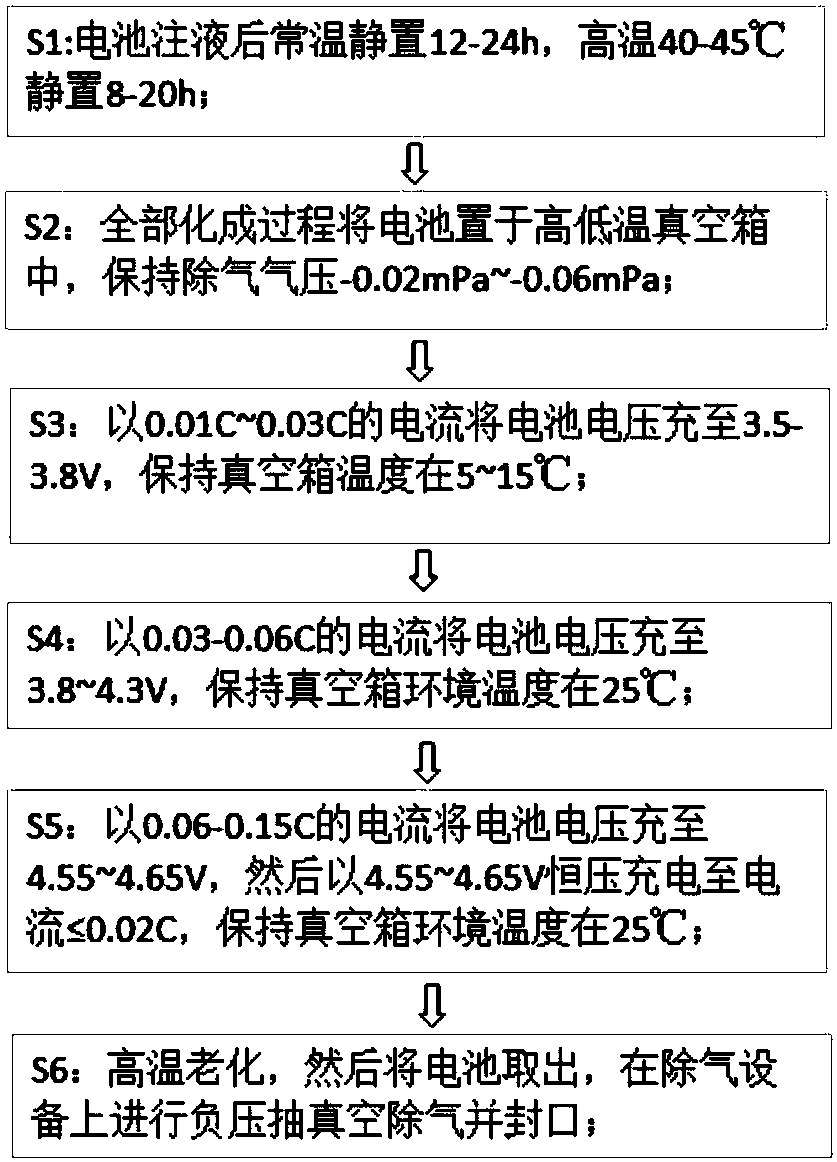

Formation method for flexibly-packaged power lithium-ion battery

ActiveCN109755680AImprove full wettabilityImprove wettabilityFinal product manufactureSecondary cells charging/dischargingElectrochemical responseCharge current

The invention protects a formation process for a high-energy-density flexibly-packaged power lithium-ion battery. The process comprises the steps that liquid is injected into a cell, the cell stands,pre-edge-sealing is performed, and the cell is vertically placed into a pressure fixture; the surface of the cell is pressurized, a certain temperature is set, primary charging is performed on the cell, and pressure, temperature and charging currents are set in a stepped mode; after charging is completed, primary second-sealing is performed, and meanwhile air is pumped while a certain vacuum degree is maintained; and standing, secondary pressurization, normal-temperature charging and secondary second-sealing are performed. According to the formation process, the high-temperature pressurizationformation process is adopted, and compared with normal-temperature normal-pressure formation, sufficient wettability of an electrolyte and an anode / cathode active material is improved, and an electrochemical reaction is benefited; in the last step of primary formation, formation pressure is raised, formation temperature is lowered, the uniformity, compactness and stability of an SEI film generated on the surface of a cathode are improved, generation of a thick interface film is avoided, and internal resistance is lowered; and capacity performance of the cell is enhanced.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

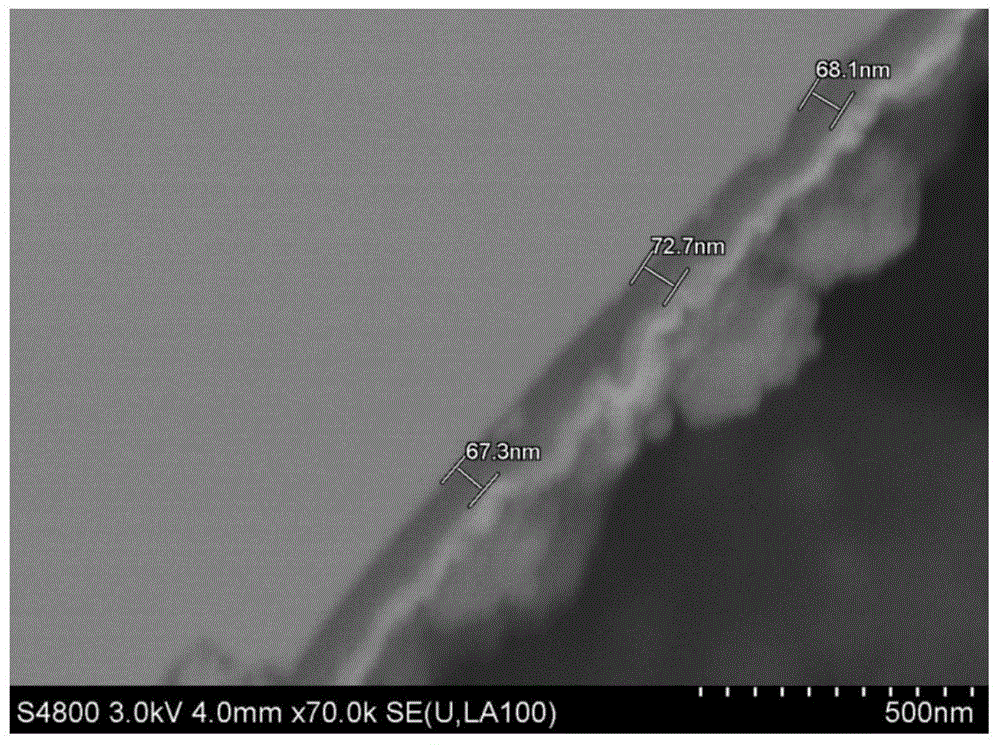

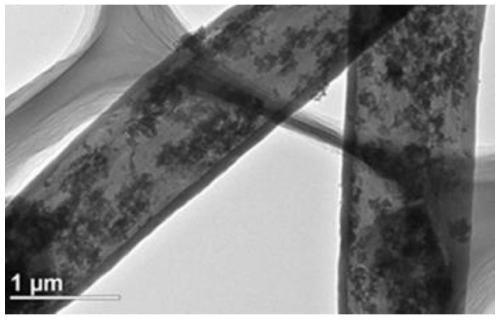

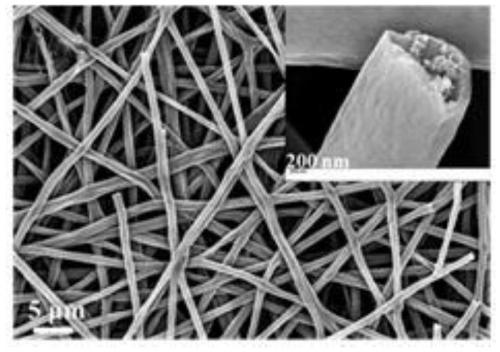

Nanoparticle-filled hollow carbon fiber composite material as well as preparation method and application thereof

ActiveCN111092203AEvenly distributedGood electrical contactCell electrodesLi-accumulatorsSpinningElectrospinning

The embodiment of the invention discloses a nanoparticle-filled hollow carbon fiber composite material and a preparation method and an application thereof. The nanoparticle-filled hollow carbon fibercomposite material comprises hollow carbon fibers and nanoparticles filled in the hollow carbon fibers. The method is advantaged in that a coaxial electrostatic spinning method is utilized, polyacrylonitrile solution with a high carbon forming rate is used as shell solution, polymer solution with a low carbon yield is used as core solution, and nanoparticles are dispersed in the core solution, a composite fiber with a core-shell structure is formed after coaxial electrostatic spinning, subsequent oxidation carbonization treatment is carried out to obtain the nanoparticle-filled hollow carbon fiber. The method is simple, environment-friendly and high in operability, and the formed hollow carbon fiber composite material can be used as a sulfur positive electrode carrier in a lithium-sulfur battery and shows high capacity and long cycle stability.

Owner:深圳石墨烯创新中心有限公司

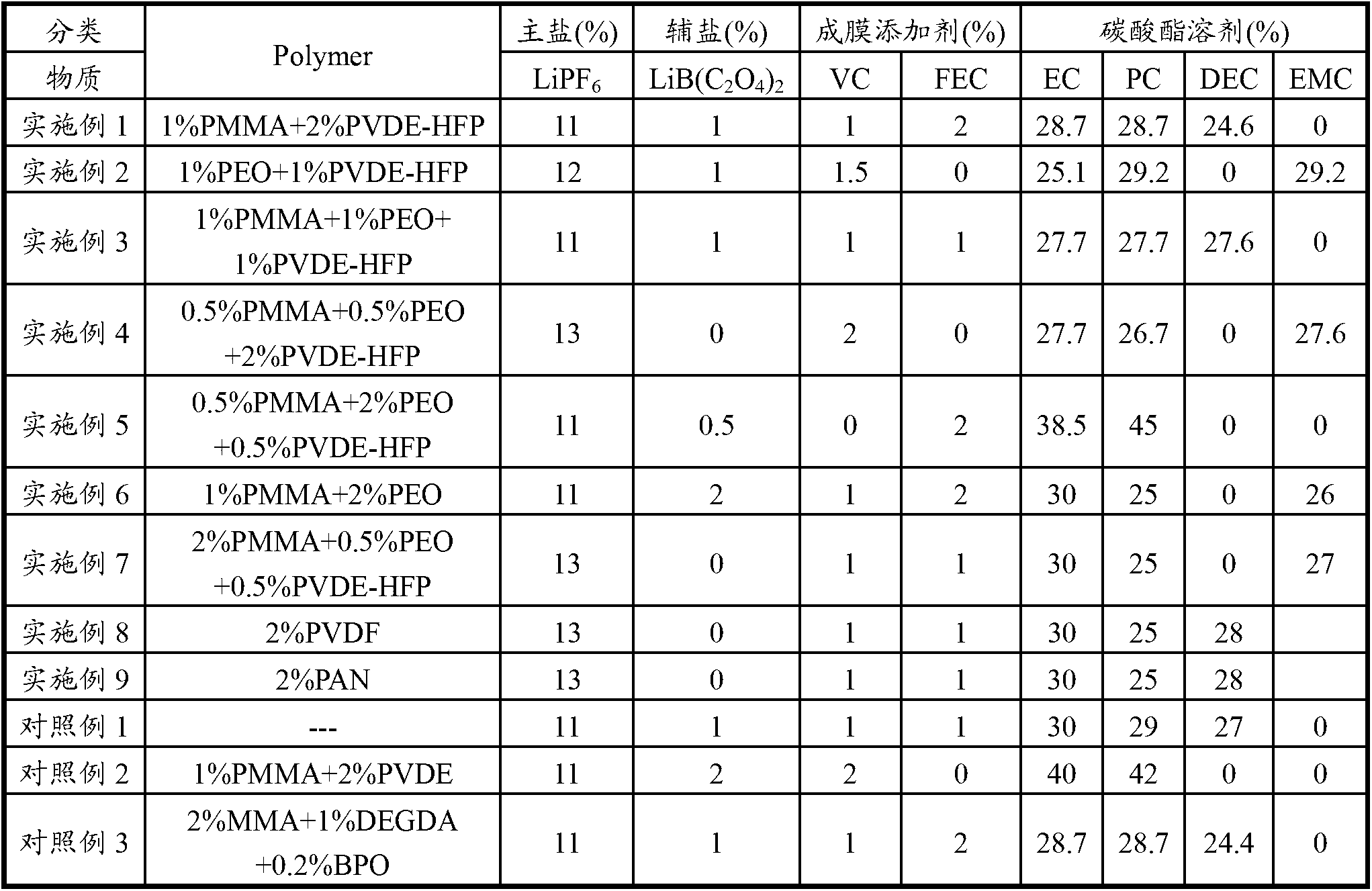

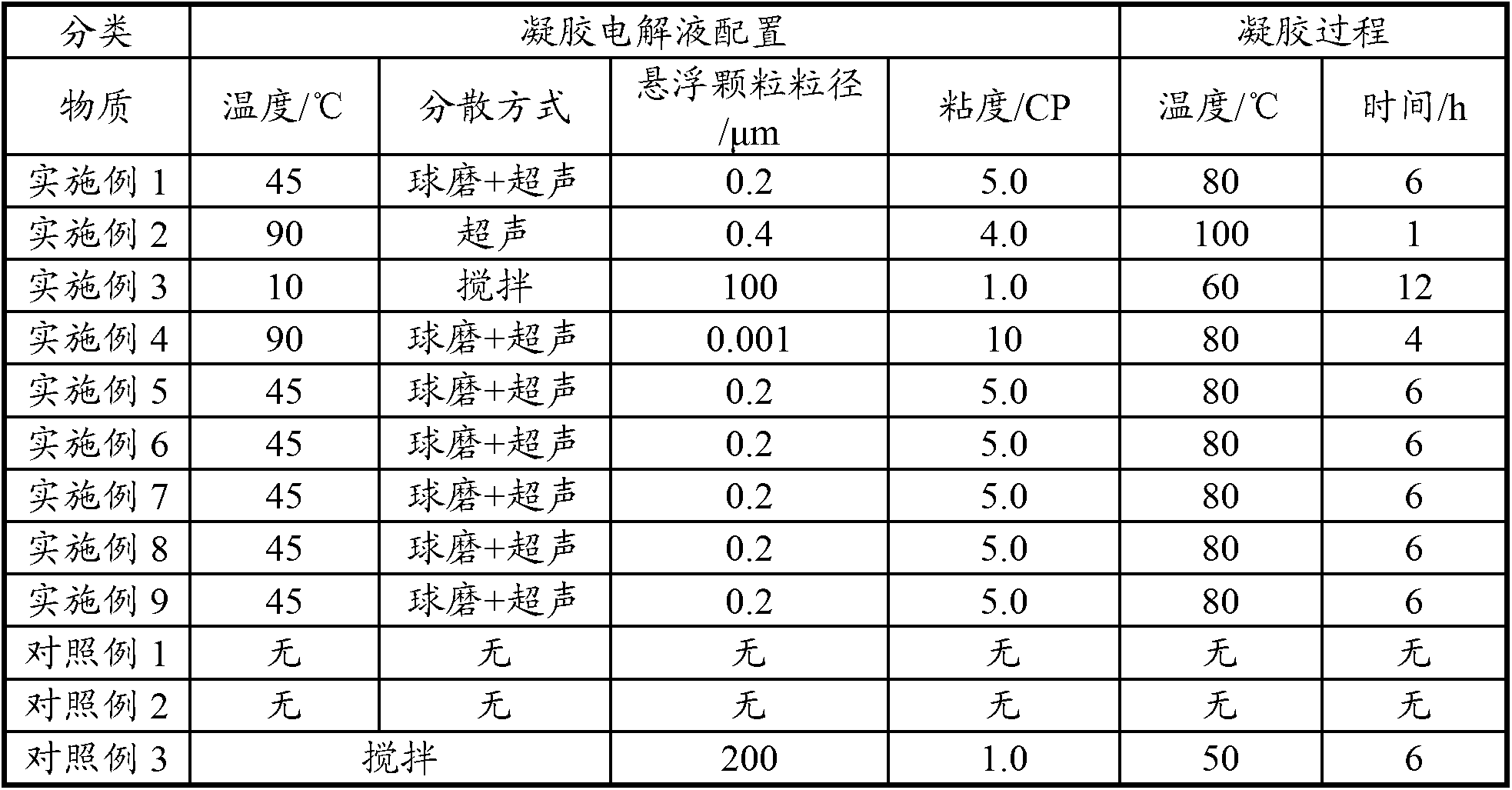

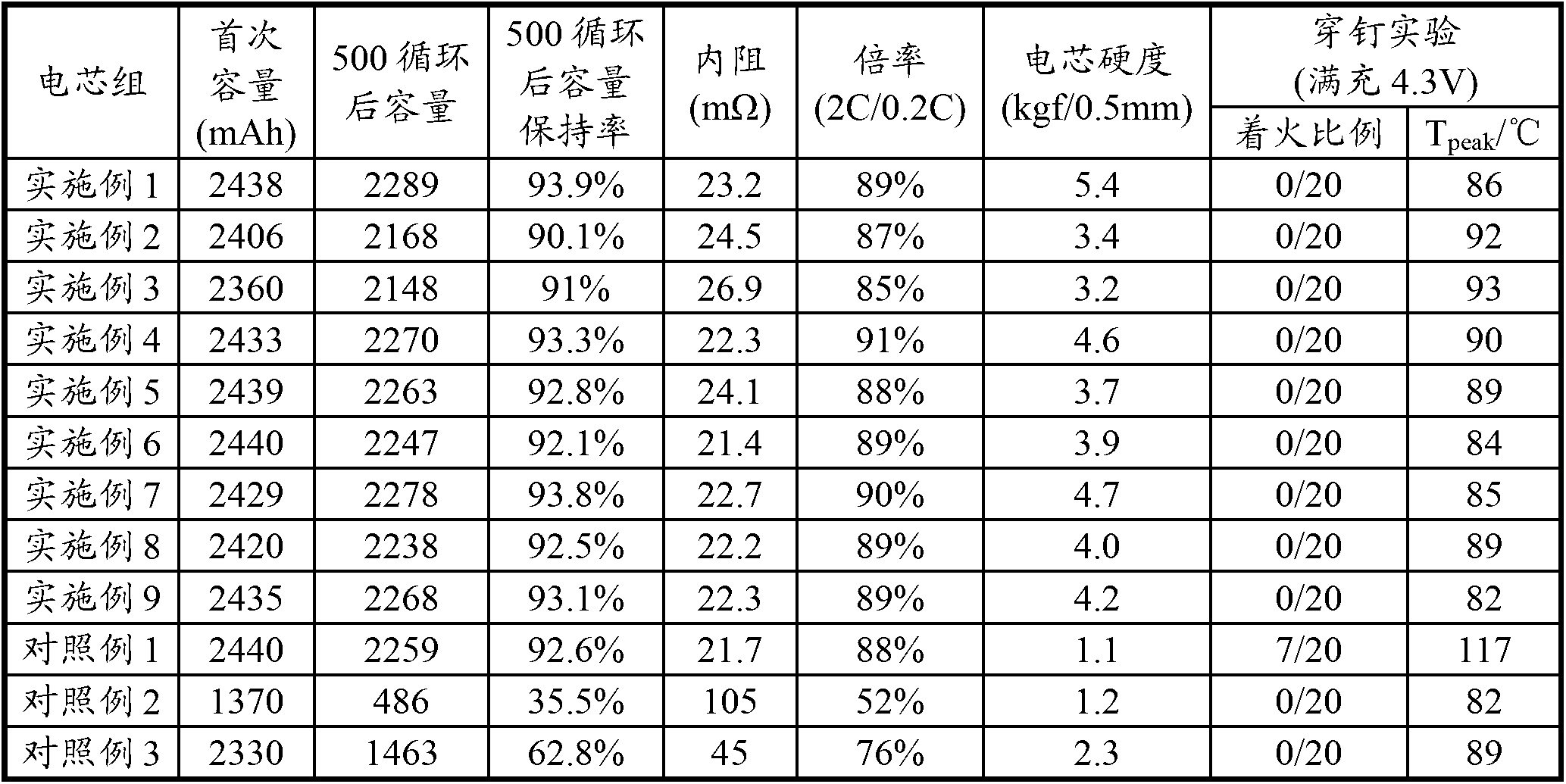

Method for preparing polymer gel electrolyte cell

ActiveCN103178303AHigh purityImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureLithiumPolymer science

The invention discloses a method for preparing a polymer gel electrolyte cell. The method comprises the following steps of: (1) polymer powder pretreatment: performing high-speed ball-milling on a polymer powder body, and thus obtaining powder with the granularity less than 1 mu m; (2) polymer powder dispersion: mixing the polymer powder which is obtained by ball-milling in the step (1) with a non-aqueous solvent, lithium salt and an additive to prepare sub-micron-sized polymer suspended dispersion liquid; and (3) electrolyte gelatinization: injecting the polymer suspended dispersion liquid which is prepared in the step (2) into a lithium ion cell for full immersion, gelatinizing at high temperature for 1 to 12 hours, and cooling to obtain the polymer gel electrolyte cell. Compared with the prior art, the polymer gel electrolyte cell prepared by using the method is high in ionic conductivity, low in battery internal resistance, long in cycle life, high in high-temperature performance, high in safety performance and free from liquid leakage risk. The polymer gel electrolyte cell is obviously superior to an electrolyte cell prepared by using a conventional preparation method in terms of comprehensive performance.

Owner:DONGGUAN AMPEREX TECH

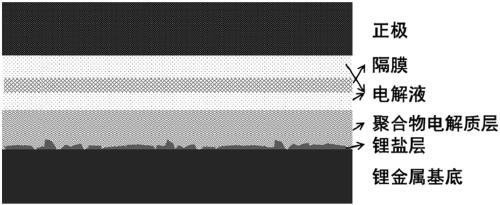

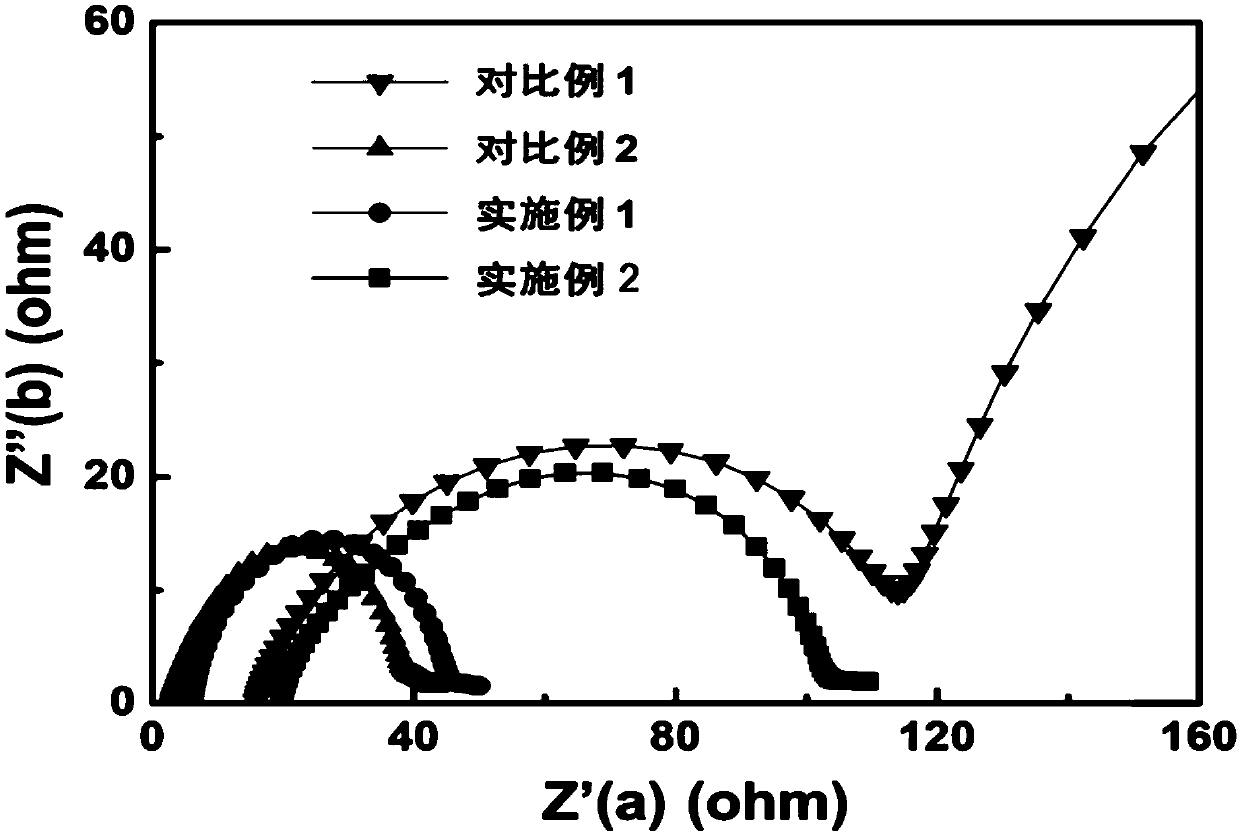

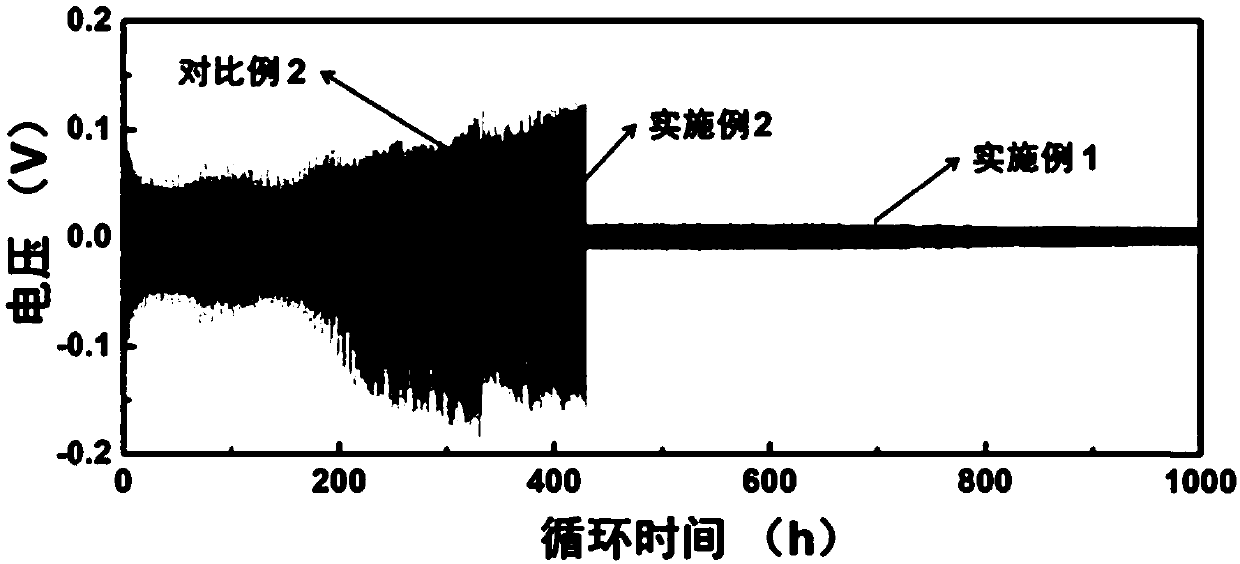

Lithium metal negative electrode, preparation thereof and application of lithium metal negative electrode

ActiveCN111293287ALow concentration of lithium ionsLow viscosityNegative electrodesLi-accumulatorsSolid state electrolytePolymer electrolytes

The invention relates to a lithium metal negative electrode, a preparation thereof and application of the lithium metal negative electrode. According to the lithium metal negative electrode, lithium metal is taken as a substrate; the surface, facing a positive electrode, of the substrate is sequentially coated with a solid lithium salt layer and a polymer electrolyte layer. When the lithium metalnegative electrode is applied to a lithium metal battery, an electrolyte system in which lithium ion concentration from a positive electrode to the negative electrode is in low-to-high gradient distribution can be formed. With the electrolyte with lithium ions in gradient distribution adopted, the problems of low ionic conductivity and high interface contact impedance in a solid electrolyte can beeffectively solved, and the problem of poor stability of an SEI film in a liquid electrolyte can be also solved; lithium dendritic crystal growth can be inhibited; and the cycling stability of a lithium battery can be improved. The electrolyte has important practical application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Composite cathode material of low-temperature lithium ion battery, cathode plate of low-temperature lithium ion battery, preparation method thereof, and lithium ion battery

ActiveCN105914394AImprove low temperature performanceImprove cycle performanceCell electrodesSecondary cellsDischarge efficiencyPolypropylene composites

The invention discloses a composite cathode material of a low-temperature lithium ion battery, a cathode plate of the low-temperature lithium ion battery, a preparation method thereof, and a lithium ion battery. The composite cathode material is composed of lithium iron phosphate, a carbon nano tube / polypropylene composite material, carbon nanofibres and a lithium containing compound, wherein the mass ratio of lithium iron phosphate, the carbon nano tube / polypropylene composite material, carbon nanofibres to the lithium containing compound is (90-94):(1-2):(1-2):(0.5-1). The composite cathode material of the low-temperature lithium ion battery provided by the invention is capable of effectively supplying lithium ions consumed for formation of an SEI film in a process of charging and discharging the lithium ion battery, and providing more lithium ions for the lithium ion battery in a low-temperature charging, discharging and cycling process; the low-temperature performance and the cycle performance of the lithium ion battery are improved; due to the composite cathode material of the low-temperature lithium ion battery provided by the invention, the first-time discharging efficiency of the lithium ion battery can be increased; capacity playing of active substances is promoted; and thus, the energy density of the lithium ion battery is increased.

Owner:LUOYANG LIRONG NEW ENERGY TECH

Formation method of lithium-ion battery

ActiveCN107565170AReasonable N/P designImprove capacity playFinal product manufactureElectrolyte accumulators manufactureInternal resistanceLithium-ion battery

The invention provides a formation method of a lithium-ion battery. The formation method comprises the following steps of (A) carrying out liquid injection of the lithium-ion battery, standing at roomtemperature for 12-24h and then standing at 40-45 DEG C for 8-20h; (B) charging the battery at the current of 0.01-0.03C until the voltage is 3.5-3.8V, and keeping the environment temperature at 5-15DEG C; (C) charging the battery at the current of 0.03-0.06C until the voltage is 3.8-4.35V and keeping the environment temperature at 20-30 DEG C; (D) charging the battery at the current of 0.06-0.15C until the voltage is 4.55-4.65V, charging the battery at constant voltage of 4.55-4.65V until the current is smaller than or equal to 0.02C and keeping the environment temperature at 20-30 DEG C; and (E) carrying out high-temperature ageing. According to the formation method of the lithium-ion battery, the internal resistance of the battery can be effectively reduced, the cycle performance of the battery is improved and the energy density of the battery is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

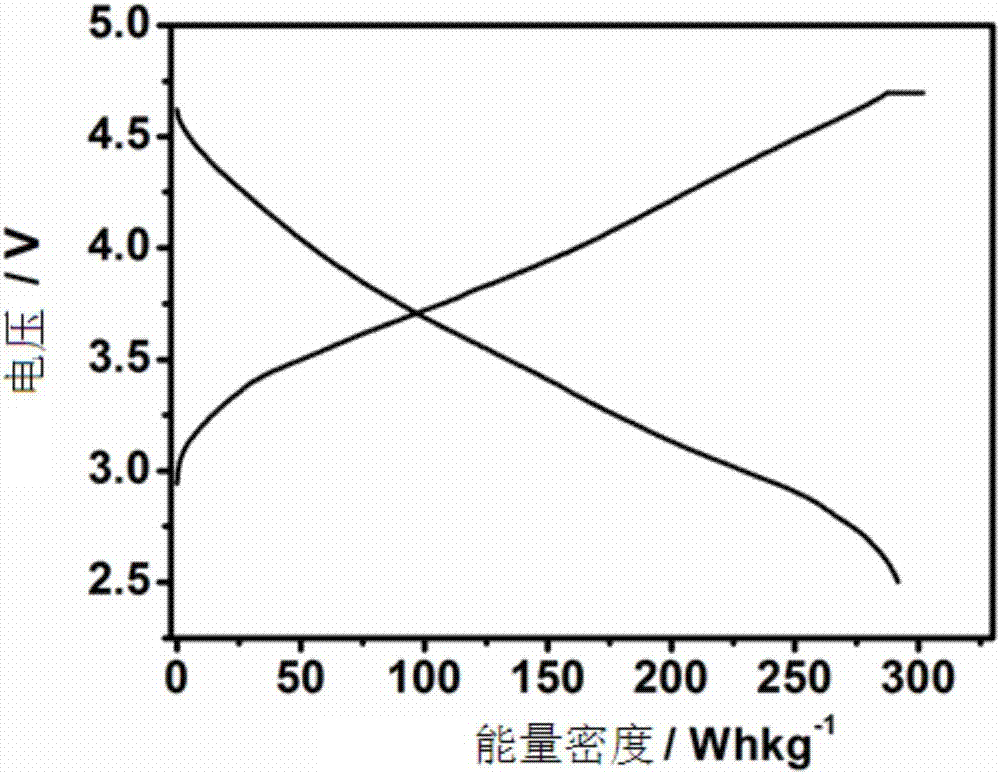

Graphene-coated titanium niobium oxide composite electrode material, lithium primary battery and preparation method thereof

InactiveCN109167049AEasy to prepareLow costNon-aqueous electrolyte cellsPositive electrodesHigh energyLithium-ion battery

A lithium primary battery comprise TiNbxO2 (2 +2. 5x) core and graphene coating layer, lithium primary battery and preparation method thereof, wherein that mass fraction of the graphene coating layeris 0.01%-5% wt%, where x is 1.8-2.3. A manufacture method comprises mix a titanium source and a niobium source, and sintering to obtain a TiNbxO2 (2 +2.5 x) material; TiNbxO (2 + 2.5 x) was mixed withgraphene or graphene precursor and sintered to obtain graphene-coated titanium niobium oxide composite electrode material. The primary lithium battery uses the graphene-coated titanium niobium oxidecomposite electrode material as the positive electrode active material and the lithium as the negative electrode active material. The TiNbxO_(2 +2.5 x) composite electrode material utilizes the high lithium storage capacity of TiNbxO (2 +2.5 x) and the good conductivity of graphene, and adopts the graphene-coated TiNbxO (2 +2.5 x) material, which greatly improves the gram capacity exertion and magnification performance of the material. The preparation method is simple and the cost is low. The lithium primary battery has high energy density, high safety and reliability, and has the characteristics of large current pulse.

Owner:天津普兰能源科技有限公司

Special graphene conductive agent for lithium battery

InactiveCN103474668AEasy to prepareEasy to operateCell electrodesNon-conductive material with dispersed conductive materialAcrylic resinCarbon nanotube

The invention discloses a special graphene conductive agent for a lithium battery, which comprises the following components in parts by weight: 5-20 parts of graphene, 10-30 parts of resin, 20-50 parts of solvent, and 10-15 parts of auxiliary agent, wherein the resin is formed by one or two of acrylic resin and alkyd resin; the solvent is formed by mixing one or several of water, ethanol and acetone; the auxiliary agent comprises a dispersing agent and a diluent. According to the invention, the preparation steps are simple, convenient and easy to operate; the obtained special graphene conductive agent for the lithium battery is superior in performance, has the composite indicator superior to that of carbon nano tubes and carbon nanofibres, can remarkably increase the volume of electrode materials, reduces the battery internal resistance, and prolongs the battery cycle life, thereby being a new partner for the high-performance lithium battery.

Owner:SUZHOU AITESI FURTHER MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com