Method for preparing polymer gel electrolyte cell

A gel electrolyte and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problem of low gel electrolyte production efficiency, poor rate performance and cycle performance, and low initial capacity/efficiency of cells and other problems, to achieve the effect of good comprehensive electrochemical performance, good rate discharge performance and excellent safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of polymer suspension dispersion: in the glove box, the weight percent was 11% LiPF 6 and 1% LiB(C 2 o 4 ) 2 Add the mixed solvent EC:PC:DEC:VC:FEC to 28.7%:28.7%:24.6%:1%:2%, stir and dissolve at room temperature (25°C), cool to room temperature for later use; high-speed ball mill the pre-dispersed 1 The PMMA of % weight and the weight PVDF of 2% are added in the above-mentioned solution, after high-speed stirring 10min, seal with Para-film and take out from glove box, put into SK8200HP ultrasonic cleaner (Shanghai Kedao production, maximum ultrasonic power 500W, In the working frequency 53KHz), the temperature of the water bath is controlled between 45-50°C, and ultrasonic is used for 15 minutes to obtain a colorless and transparent polymer suspension dispersion with a viscosity not exceeding 5.0CP, which is sealed and placed in a glove box for use.

[0031] Preparation of lithium-ion batteries: 2865B3 square empty batteries packaged in aluminum and pla...

Embodiment 2-9

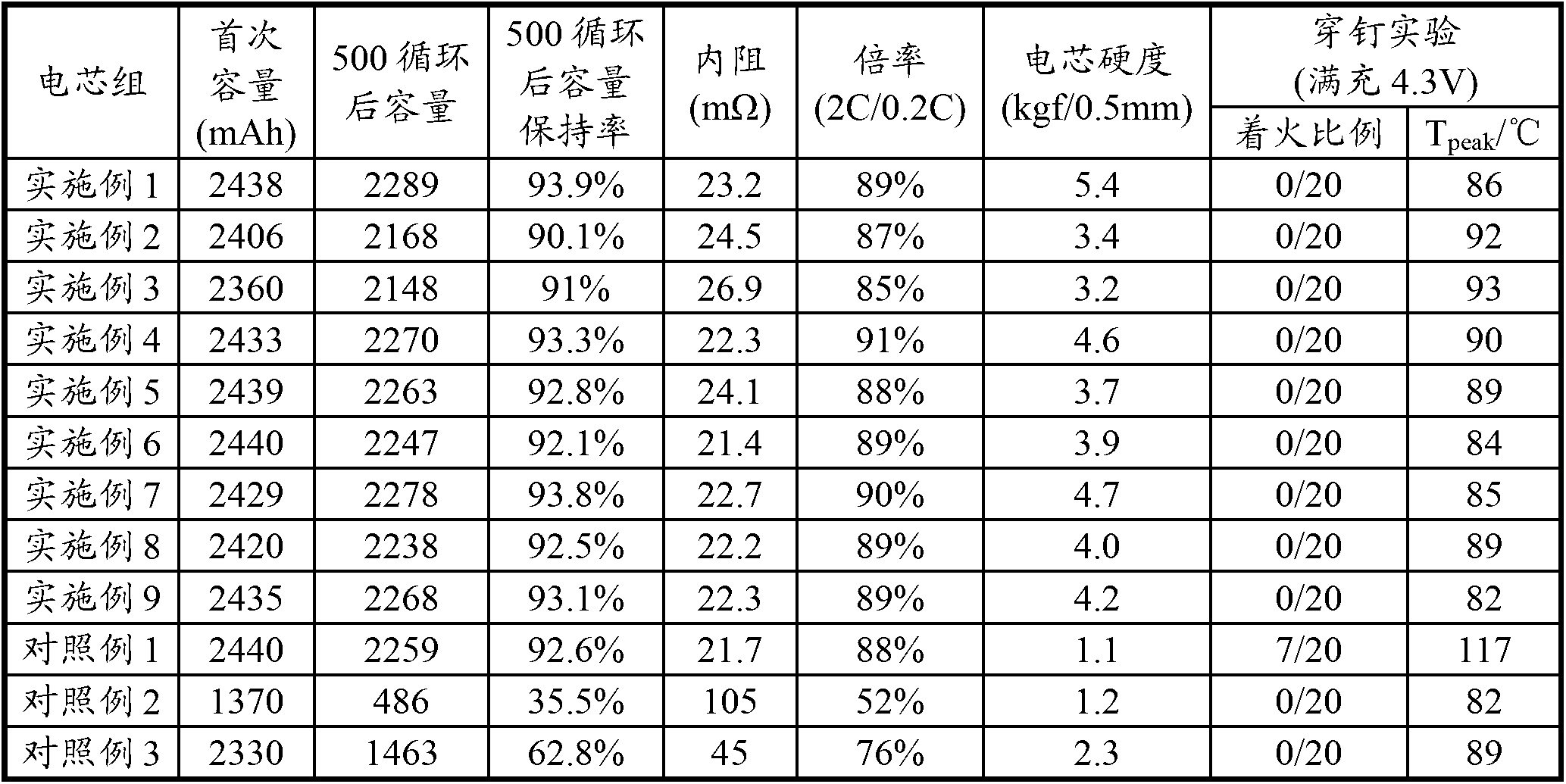

[0033] Examples 2-9: See Table 1 for the types and amounts of polymers added in each example, and see Table 2 for process parameters.

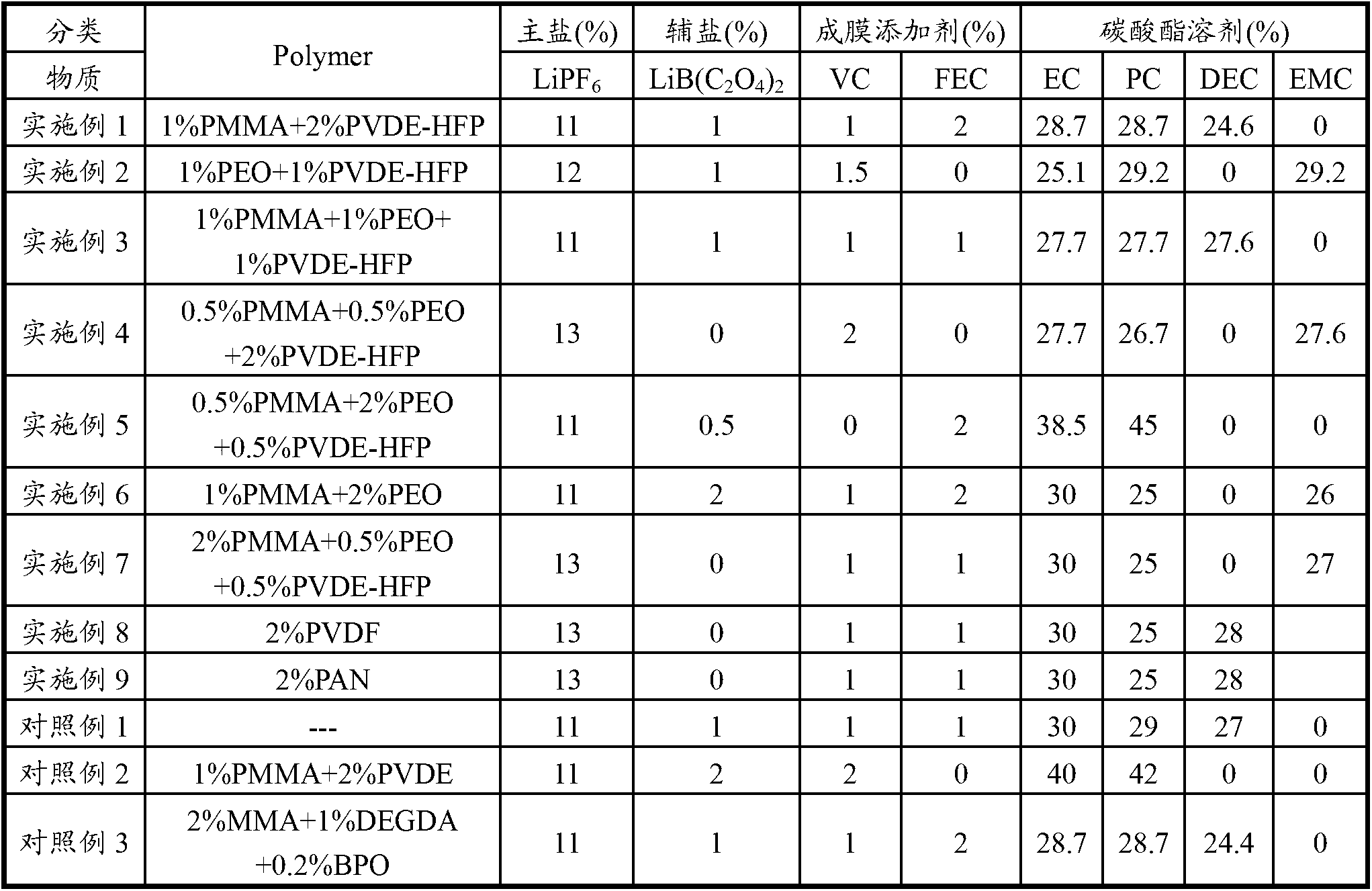

[0034] Table 1, the electrolyte formula table (%) of each embodiment and comparative example

[0035]

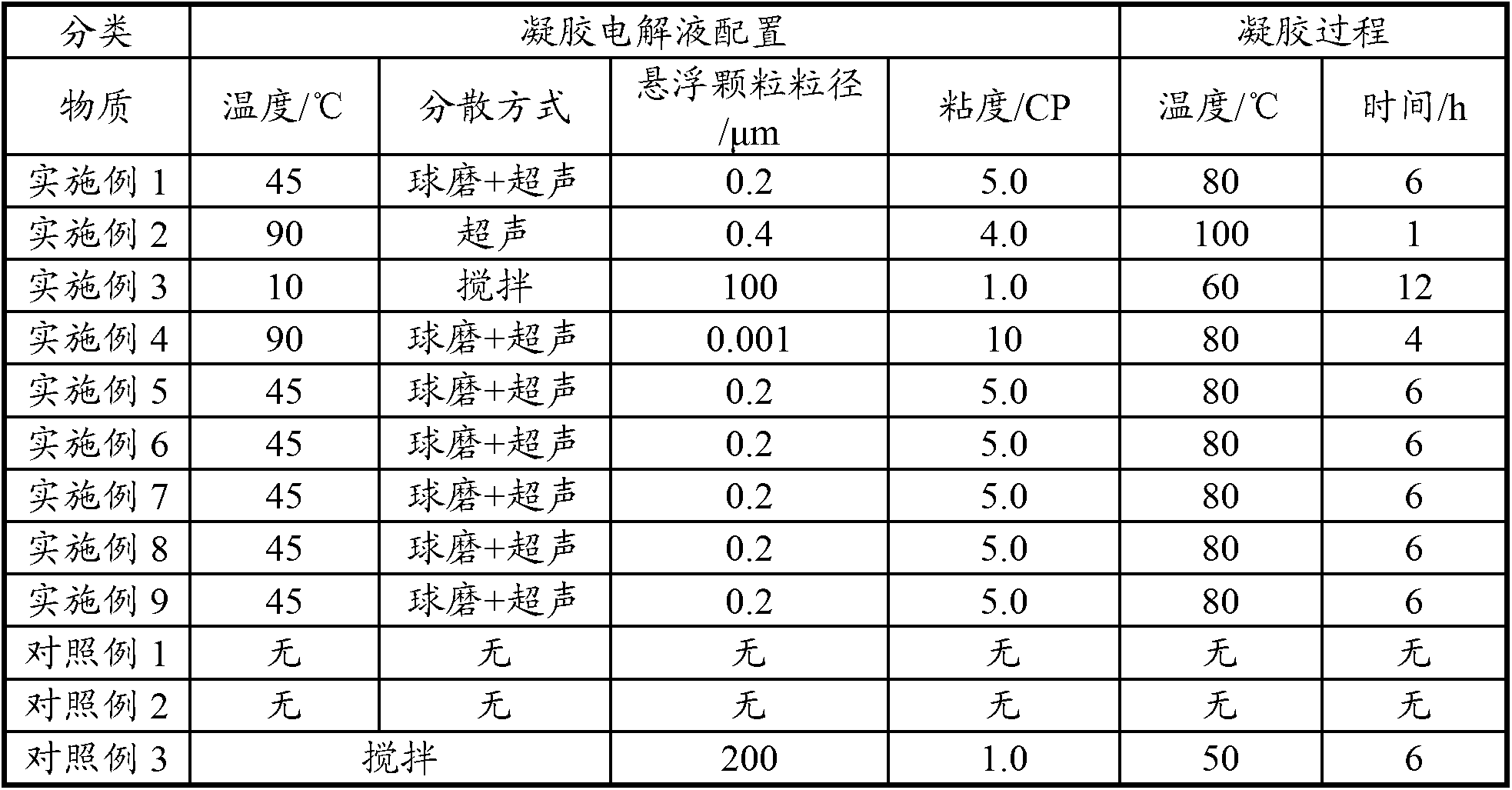

[0036] Table 2, the technological parameter table of each embodiment and comparative example

[0037]

[0038] Carefully disassemble the cells of Examples 1-9 in a dry room with a relative humidity of less than 0.5%, and find that there is no free liquid electrolyte at the anode / diaphragm / cathode interface, the edge of the bare cell, and the inner surface of the aluminum-plastic packaging bag Both can be found light yellow transparent gel, the gel is slightly viscous, and no liquid electrolyte is released when pressed by fingers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com