Patents

Literature

853 results about "Residual monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

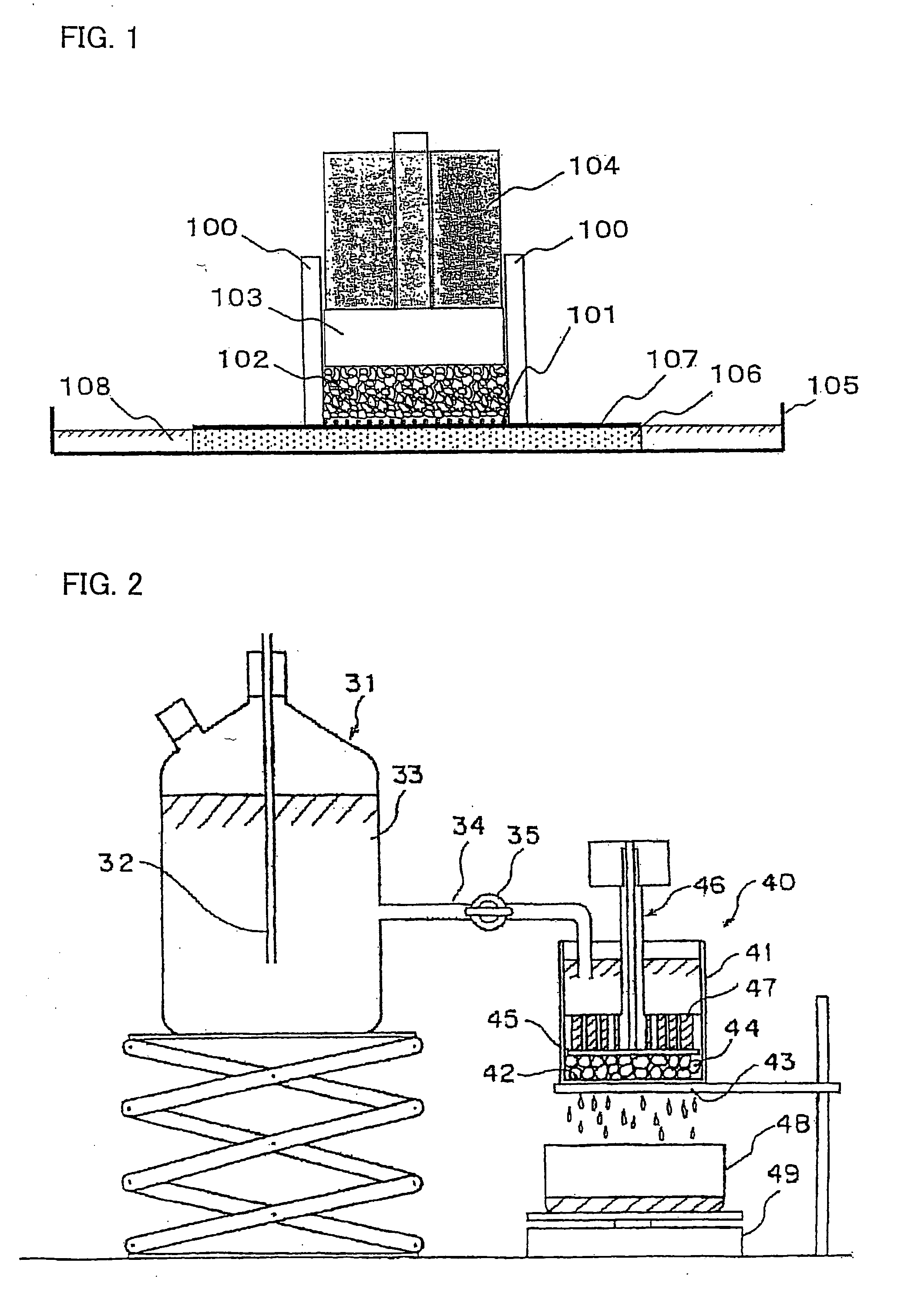

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

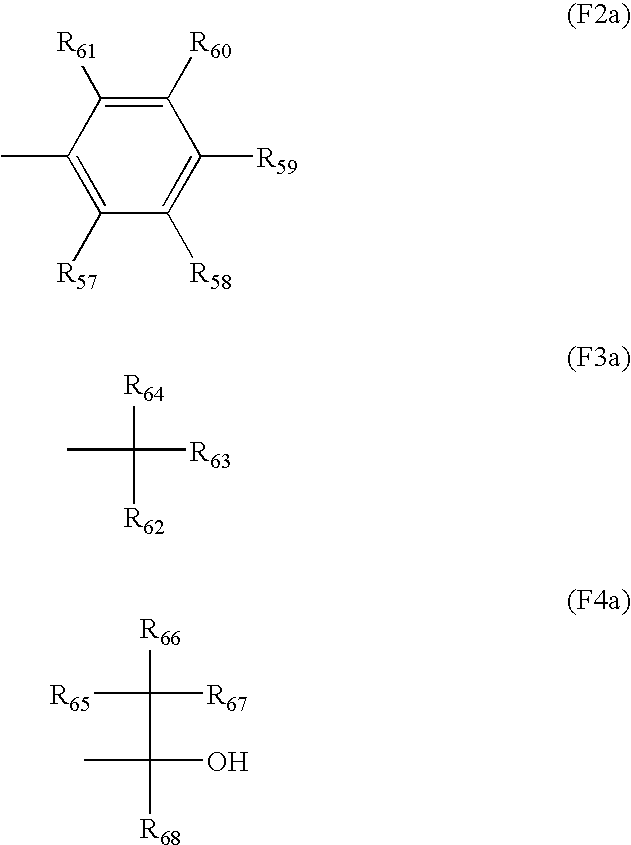

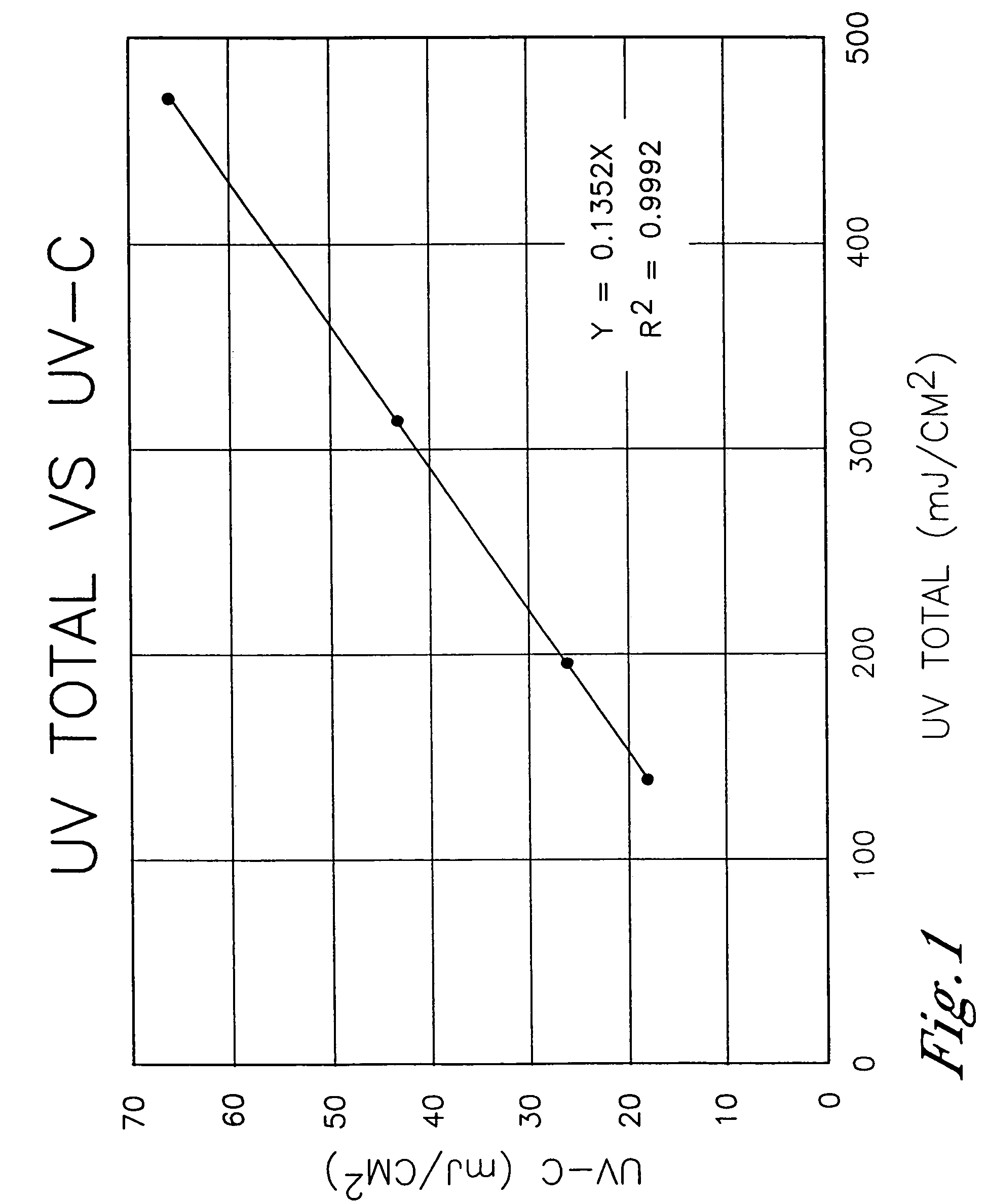

Acrylic acid composition and its production process, and process for producing water- absorbent resin using this acrylic acid composition, and water-absorbent resin

InactiveUS20040110914A1Improve productivityHigh propertyAbsorbent padsBaby linensProduction ratePolymer science

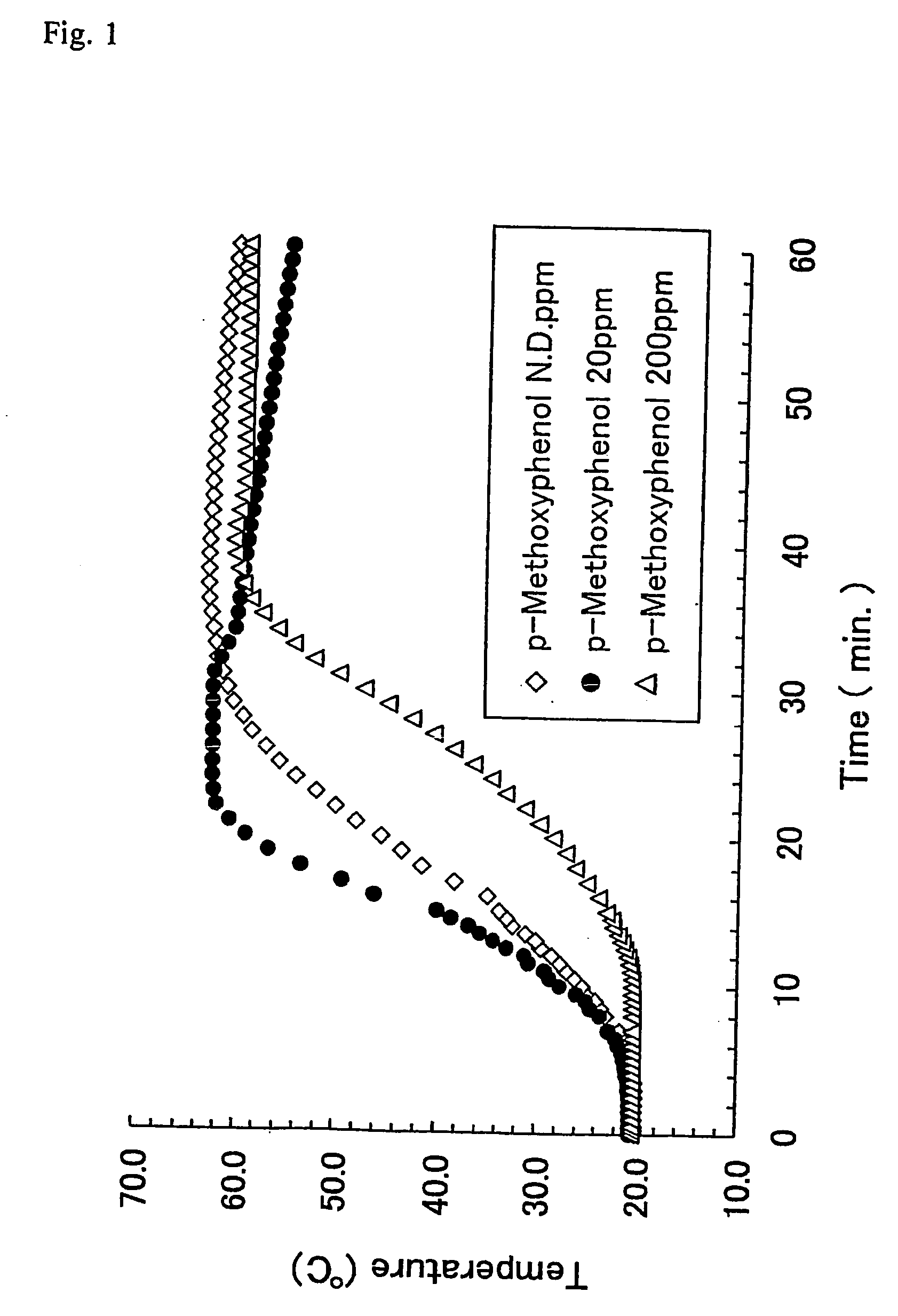

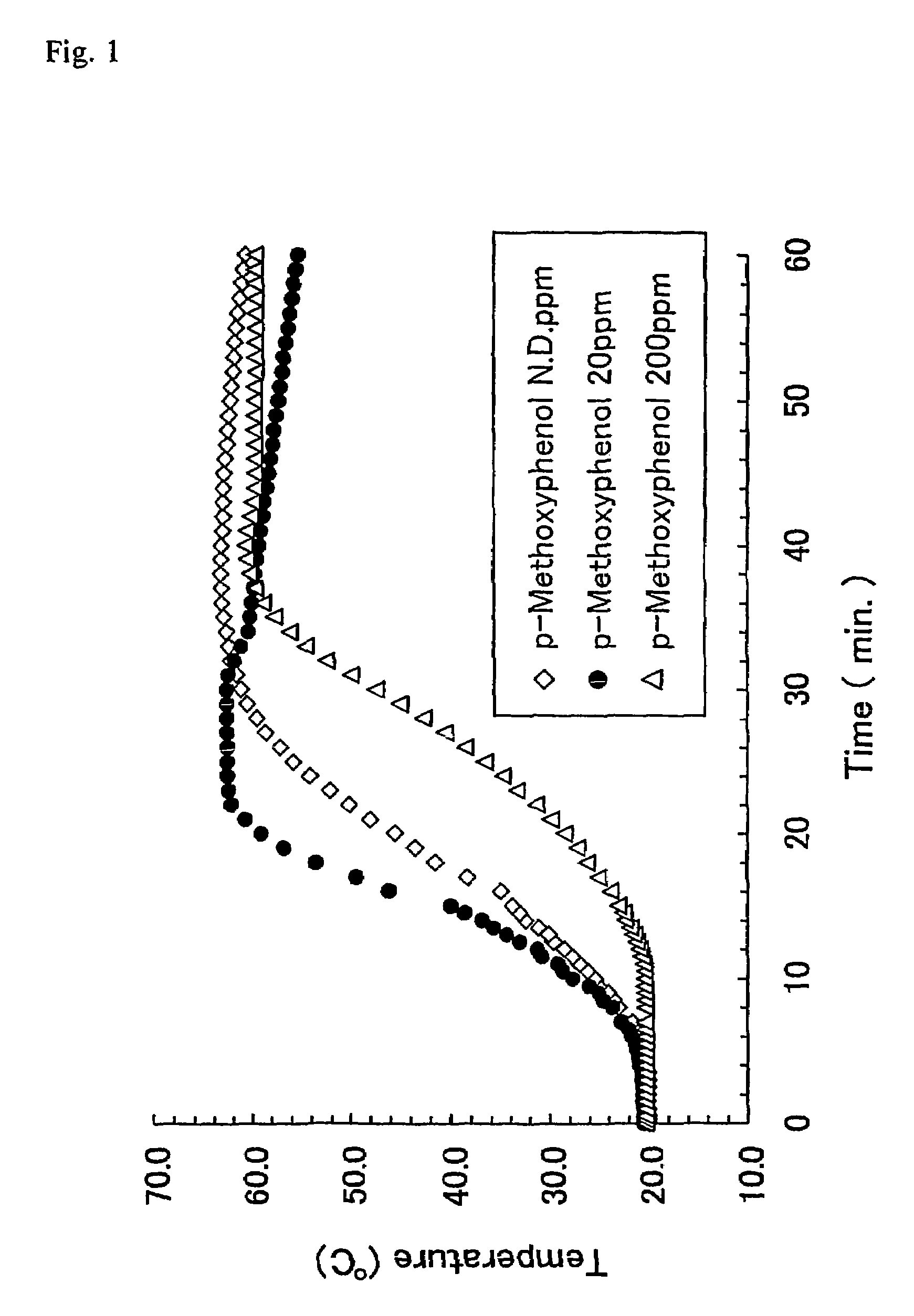

In order to produce inexpensively with high productivity a water-absorbent resin of which: the residual monomer content and the water-extractable content are both low, and the properties are high, and the colorability is low; there is provided a process for producing a water-absorbent resin, which is a process for producing a crosslinked water-absorbent resin by polymerizing a monomer component including acrylic acid and / or its salt in a major proportion wherein the acrylic acid is a product obtained by catalytic gas phase oxidation of propylene and / or propane, with the process being characterized by comprising the steps of: preparing the monomer component from an acrylic acid composition that includes the unneutralized acrylic acid and a methoxyphenol and has a methoxyphenol content of 10 to 160 ppm by weight (based on the unneutralized acrylic acid); and then carrying out radical and / or ultraviolet polymerization of the resultant monomer component.

Owner:NIPPON SHOKUBAI CO LTD

Acrylic acid composition and its production process, and process for producing water-absorbent resin using this acrylic acid composition, and water-absorbent resin

InactiveUS7049366B2Low production costHigh propertyAbsorbent padsBaby linensProduction ratePolymer science

In order to produce inexpensively with high productivity a water-absorbent resin of which: the residual monomer content and the water-extractable content are both low, and the properties are high, and the colorability is low; there is provided a process for producing a water-absorbent resin, which is a process for producing a crosslinked water-absorbent resin by polymerizing a monomer component including acrylic acid and / or its salt in a major proportion wherein the acrylic acid is a product obtained by catalytic gas phase oxidation of propylene and / or propane, with the process being characterized by comprising the steps of: preparing the monomer component from an acrylic acid composition that includes the unneutralized acrylic acid and a methoxyphenol and has a methoxyphenol content of 10 to 160 ppm by weight (based on the unneutralized acrylic acid); and then carrying out radical and / or ultraviolet polymerization of the resultant monomer component.

Owner:NIPPON SHOKUBAI CO LTD

Method for manufacturing particulate water-absorbing agent and particulate water-absorbing agent

ActiveUS20070078231A1Excellent liquid diffusibility and liquid permeabilityResidue reductionAbsorbent padsBandagesCross linkerAqueous solution

The present invention provides a method for manufacturing a particulate water-absorbing agent which has excellent liquid diffusibility and liquid permeability, and whose amount of residual monomers is reduced. The method for manufacturing the particulate water-absorbing agent of the present invention includes a step of surface-crosslinking, in the presence of an organic crosslinking agent, water-absorbing resin particles obtained through at least a step of polymerizing an aqueous solution of unsaturated monomers, and in or after the polymerizing step, a reaction system is mixed with peroxide. Thus, it is possible to obtain the particulate water-absorbing agent which has excellent liquid diffusibility and liquid permeability and whose amount of residual monomers is small, that is, it is possible to obtain the particulate water-absorbing agent which is highly functional and highly safe.

Owner:NIPPON SHOKUBAI CO LTD

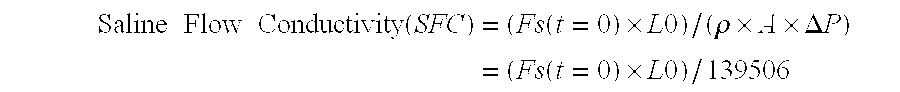

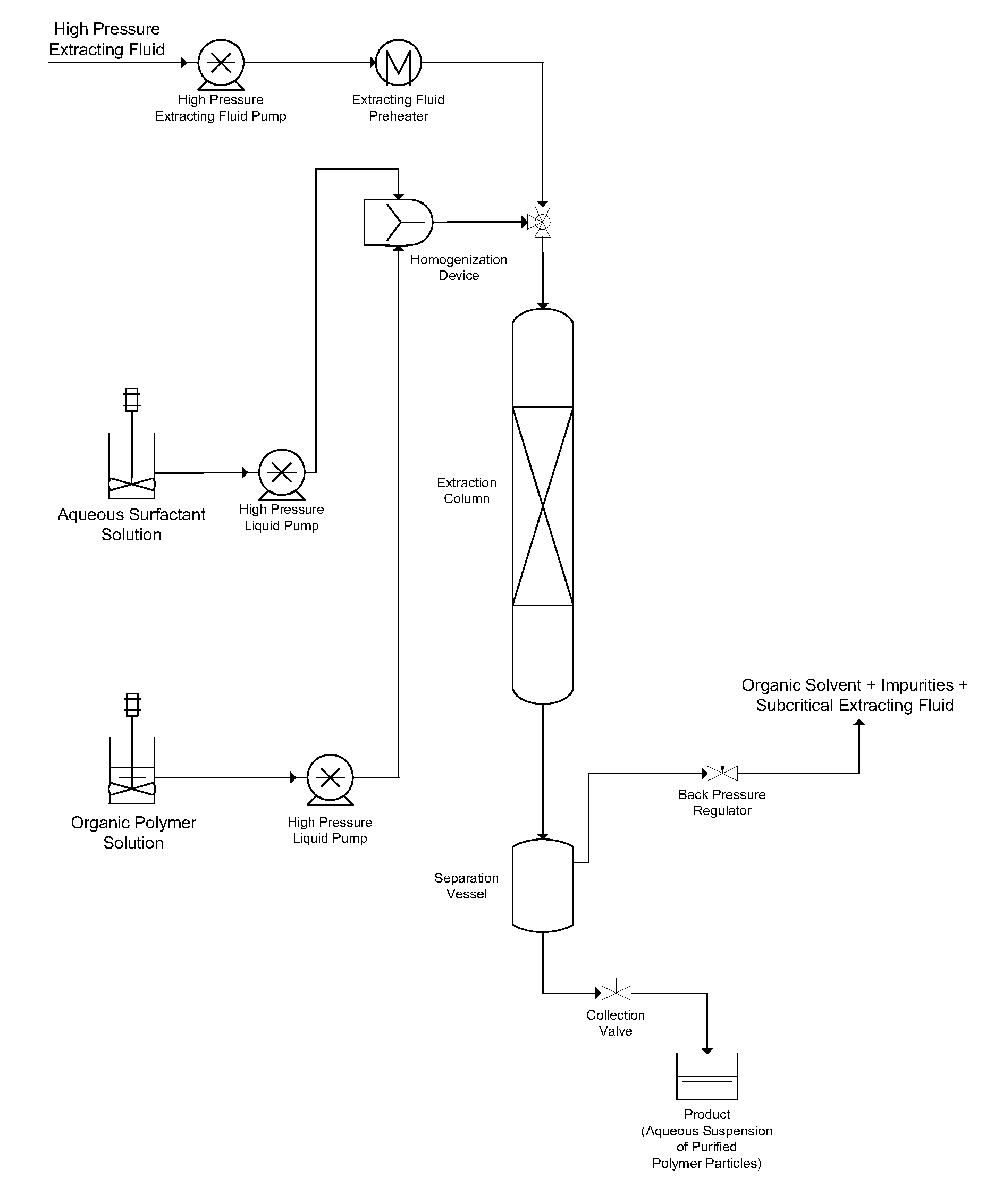

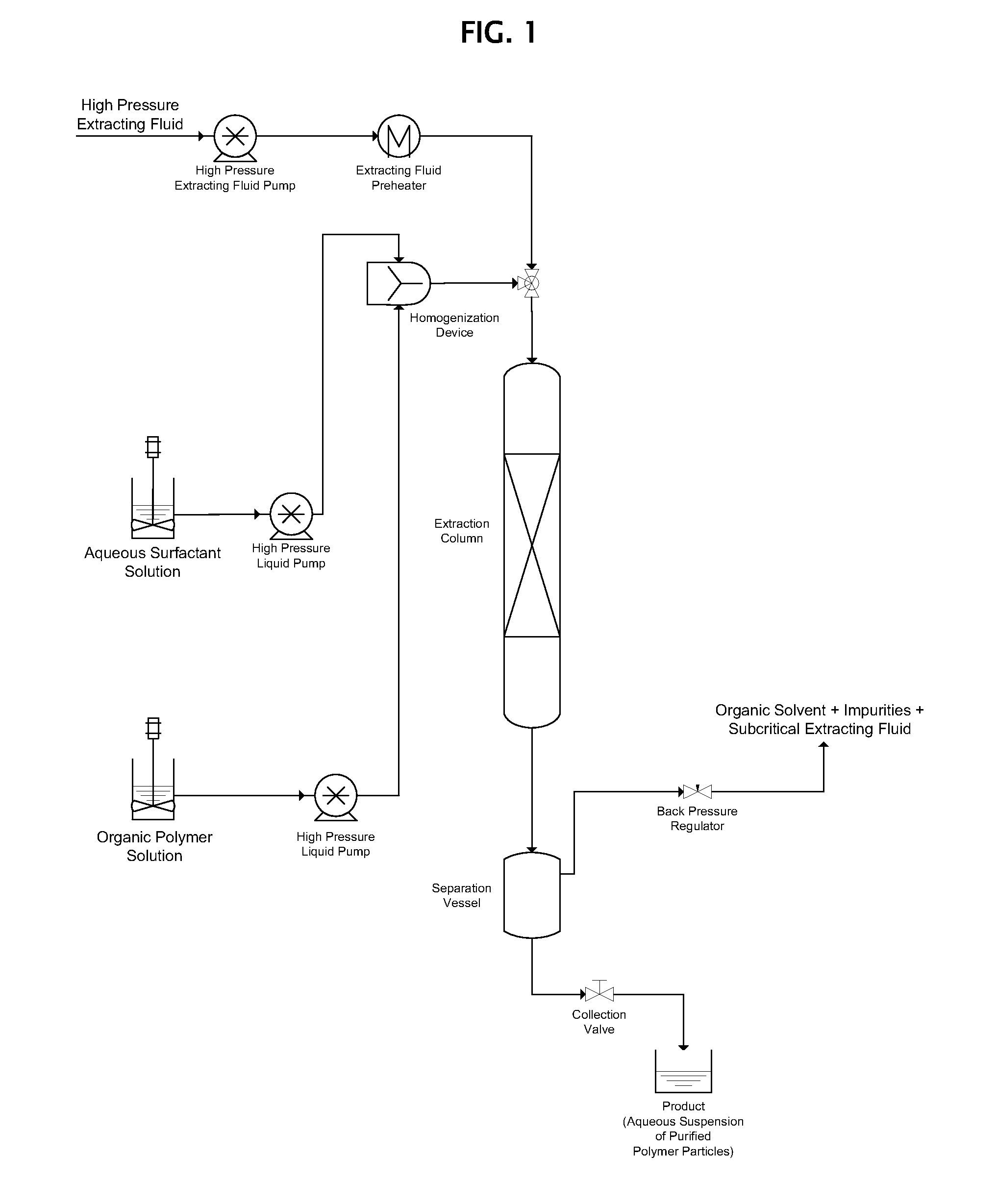

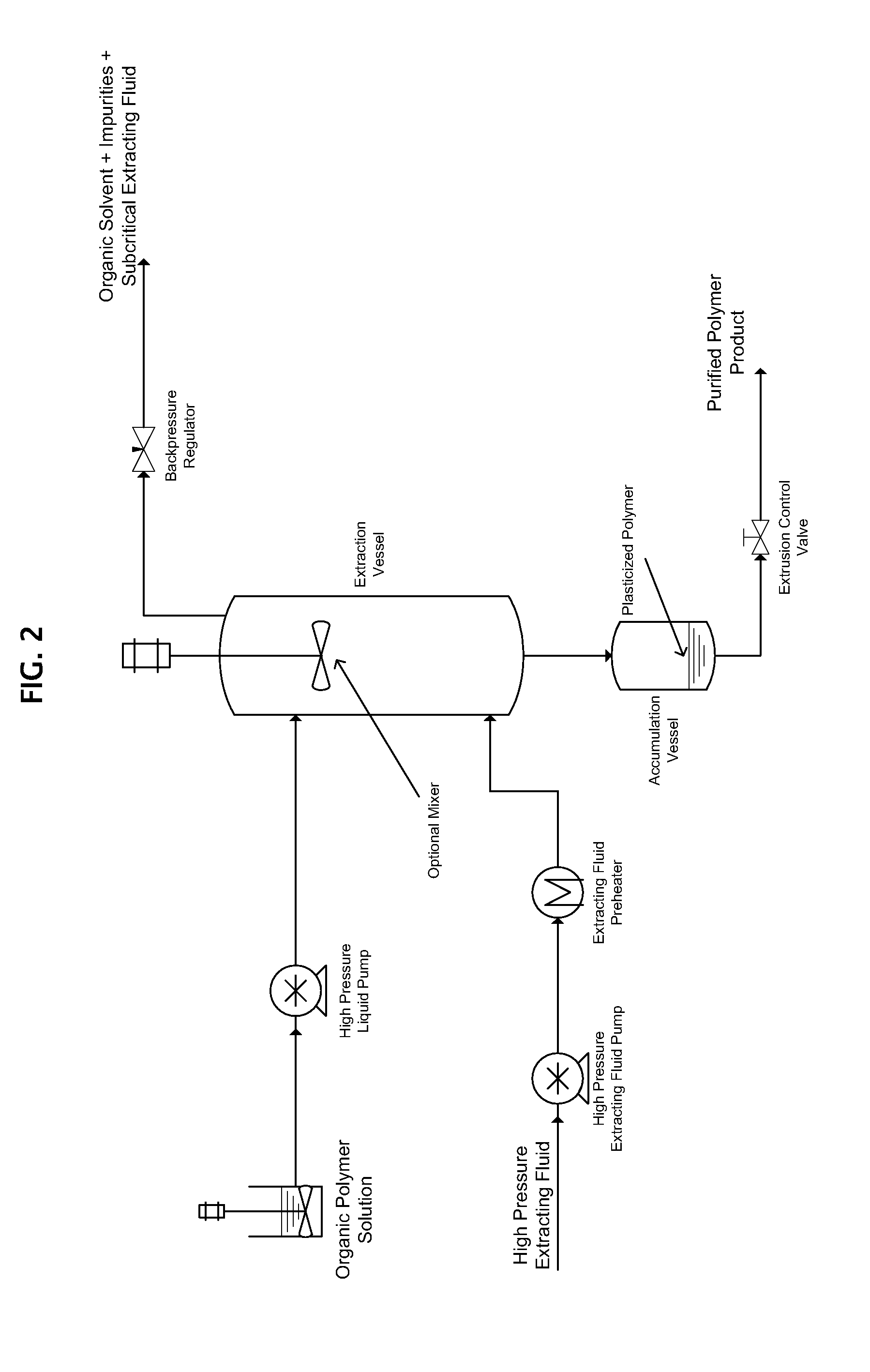

Methods for the purification of polymers

InactiveUS20080269449A1Enhanced mass transferAvoid excessive intensityBulk chemical productionOrganic solventSolvent

The present invention provides methods for purifying polymers. In each embodiment of the invention disclosed herein, a supercritical fluid is contacted with an organic solution that includes a polymer to be purified dissolved in an organic solvent. The supercritical fluid extracts the organic solvent from the organic solution. Impurities such as residual monomers and process solvents are removed with the organic solvent and supercritical fluid, thereby purifying the polymer. The methods of the invention are particularly suitable for use in the purification of biodegradable polymers for use in pharmaceutical applications.

Owner:FERRO CORP

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

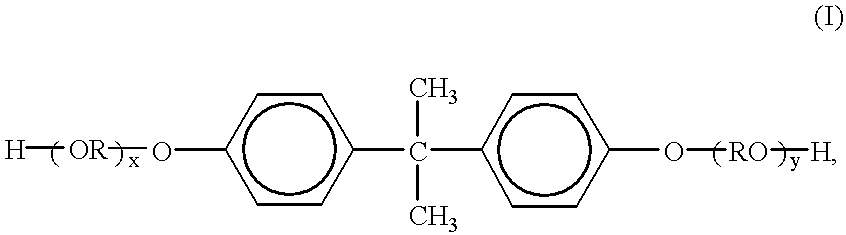

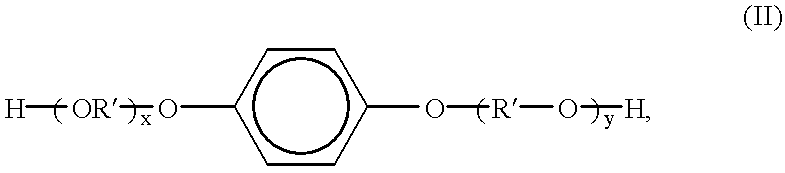

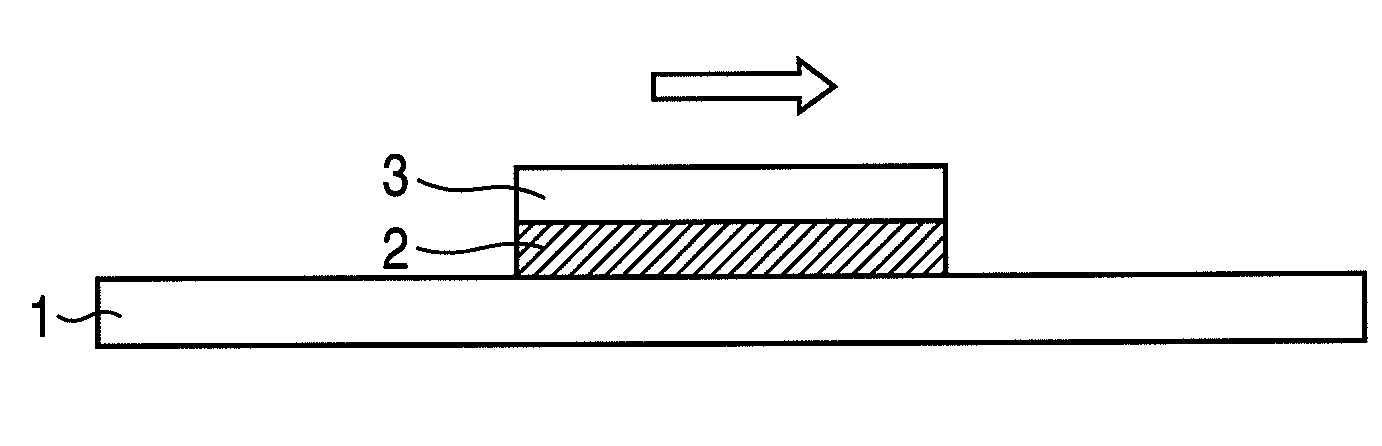

Toner and image forming method using the toner

InactiveUS6177223B1Good hue and proper glossDevelopersElectrographic process apparatusParticulatesWax

A toner suitable for use in electrophotography, etc., is composed of toner particles each containing a binder resin, a colorant and a wax component. Each toner particle has such a microtexture as to provide a cross section as observed through a transmission electron microscope (TEM) exhibiting a matrix of the binder resin, a particle of the wax enclosed with the matrix; and the binder resin dispersed in a particulate form in the wax particle, and the toner particles have a residual monomer content of at most 500 ppm by weight of the toner particles. The colorant may also be dispersed in the wax particle enclosed within the matrix of the binder resin.

Owner:CANON KK

Resin for hydrophobitizing resist surface, method for manufacturing the resin, and positive resist composition containing the resin

ActiveUS20090239176A1Prevent elutionSuppression of development defectPhotosensitive materialsRadiation applicationsResistSolid content

Owner:FUJIFILM CORP

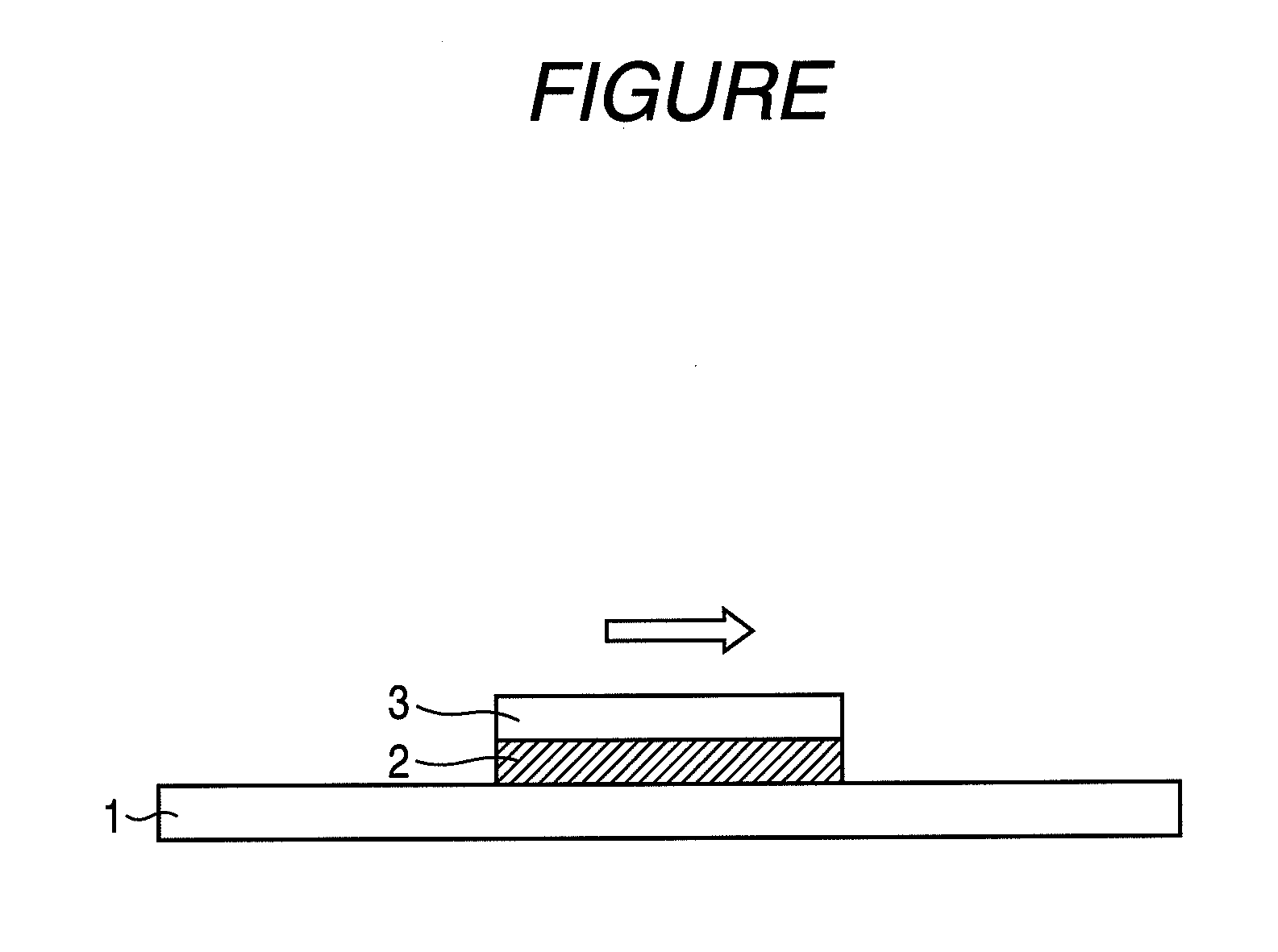

Production process for water-absorbent resin

InactiveUS6927268B2Improve water absorptionLow residual monomer contentOrganic compound preparationCarboxylic compound separation/purificationPolymer scienceGas phase

The present invention provides a process for producing a water-absorbent resin of which the residual monomer content and the extractable content are low. The process for producing a water-absorbent resin comprises the step of polymerizing at least one monomer component including acrylic acid and / or its salt as major components to produce a water-absorbent resin that is a neutralized salt, and this process is characterized in that the acrylic acid is a product obtained by catalytic gas phase oxidation of propylene and / or propane and has a protoanemonin content of not more than 10 ppm, and in that the resultant water-absorbent resin has a neutralization ratio of not less than 50 mol %.

Owner:NIPPON SHOKUBAI CO LTD

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

Aromatic/acrylate tackifier resin and acrylic polymer blends

InactiveUS20050182186A1Low residual monomer concentrationImpression capsLayered productsPolymer scienceTackifier

An adhesive composition comprising at least one tackifier resin and at least one acrylic polymer is provided wherein the tackifier resin comprises monomer repeating units from at least one aromatic monomer and at least one acrylate monomer; and wherein the tackifier resin has a low residual monomer concentration. Processes to produce the adhesive composition is also provided.

Owner:EASTMAN CHEM CO

Method for production of hydrophilic resin

Owner:NIPPON SHOKUBAI CO LTD

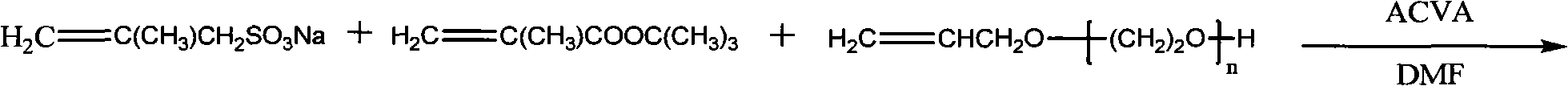

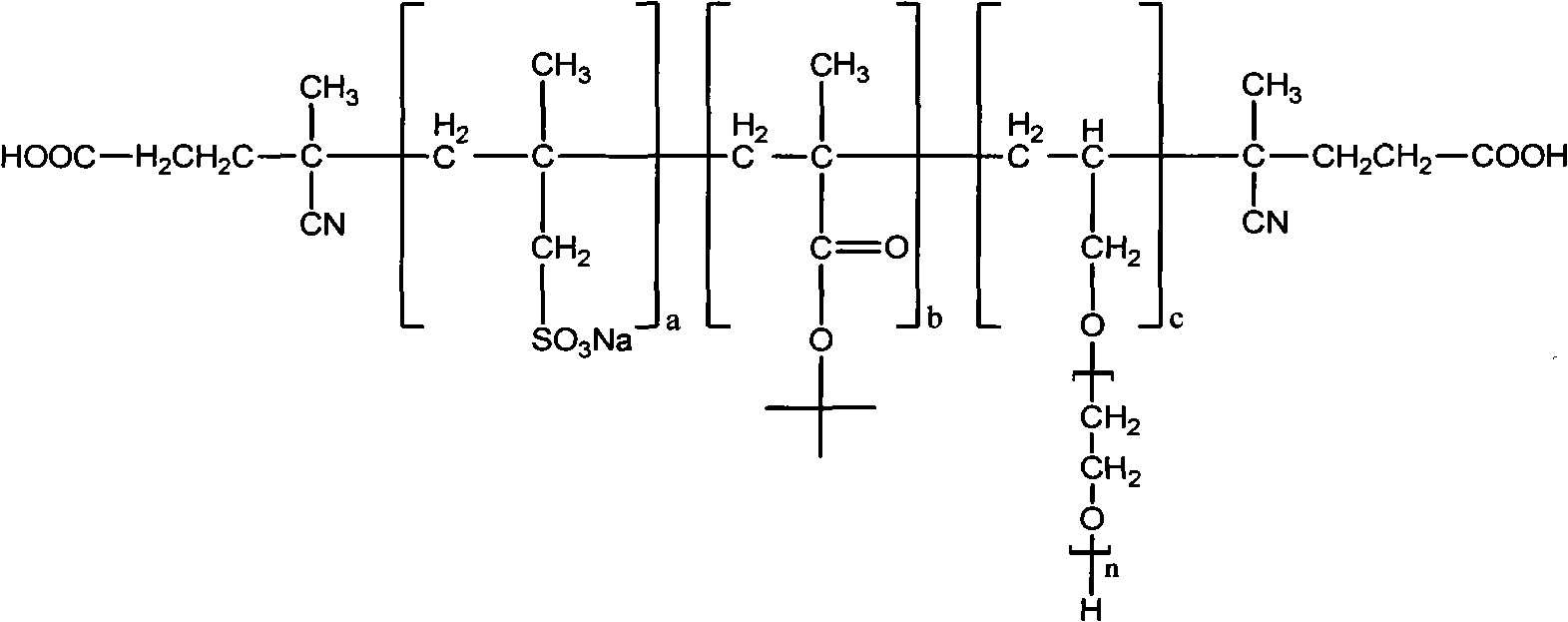

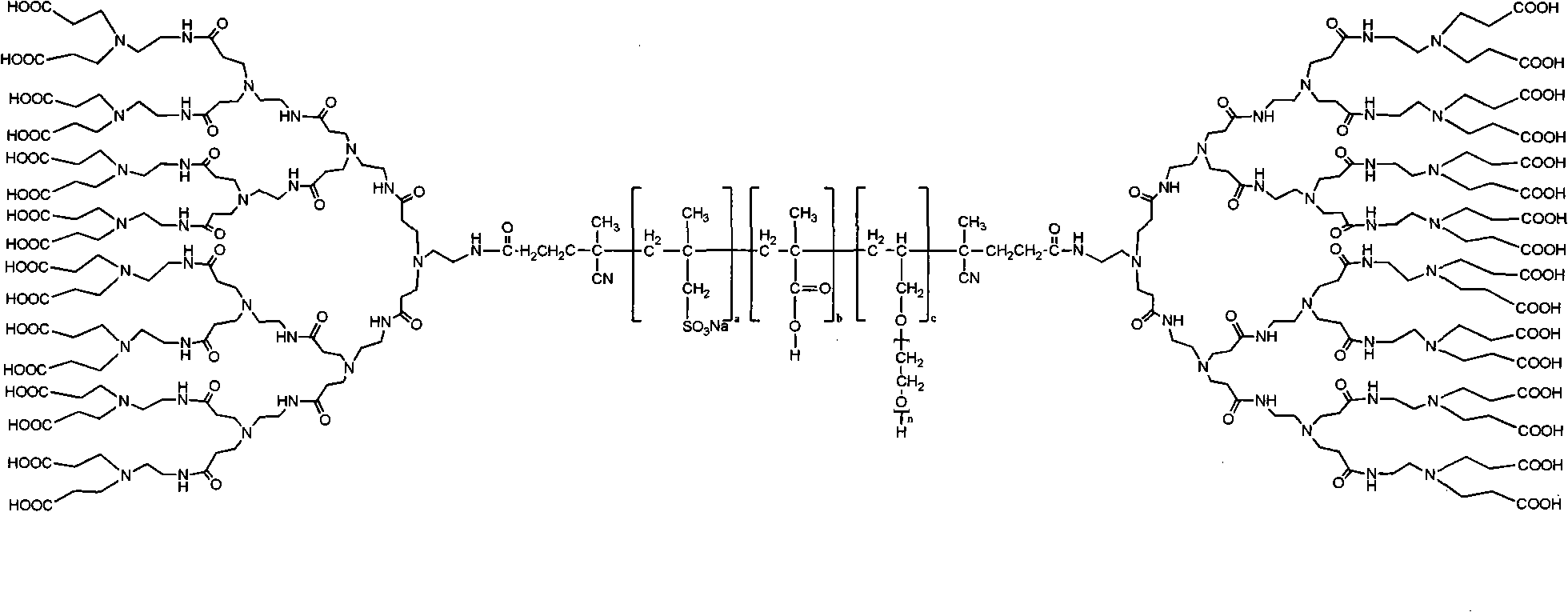

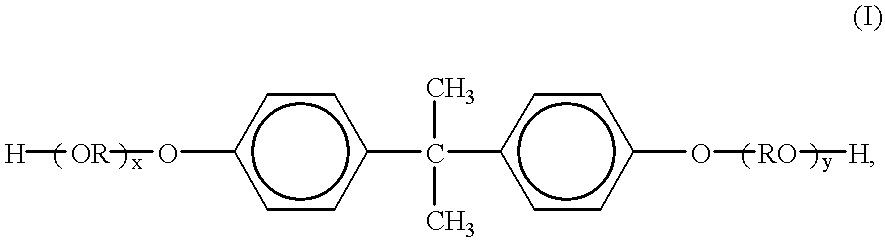

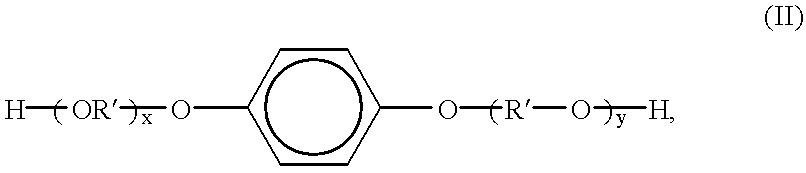

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1) preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by using N-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers and the solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent has the advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

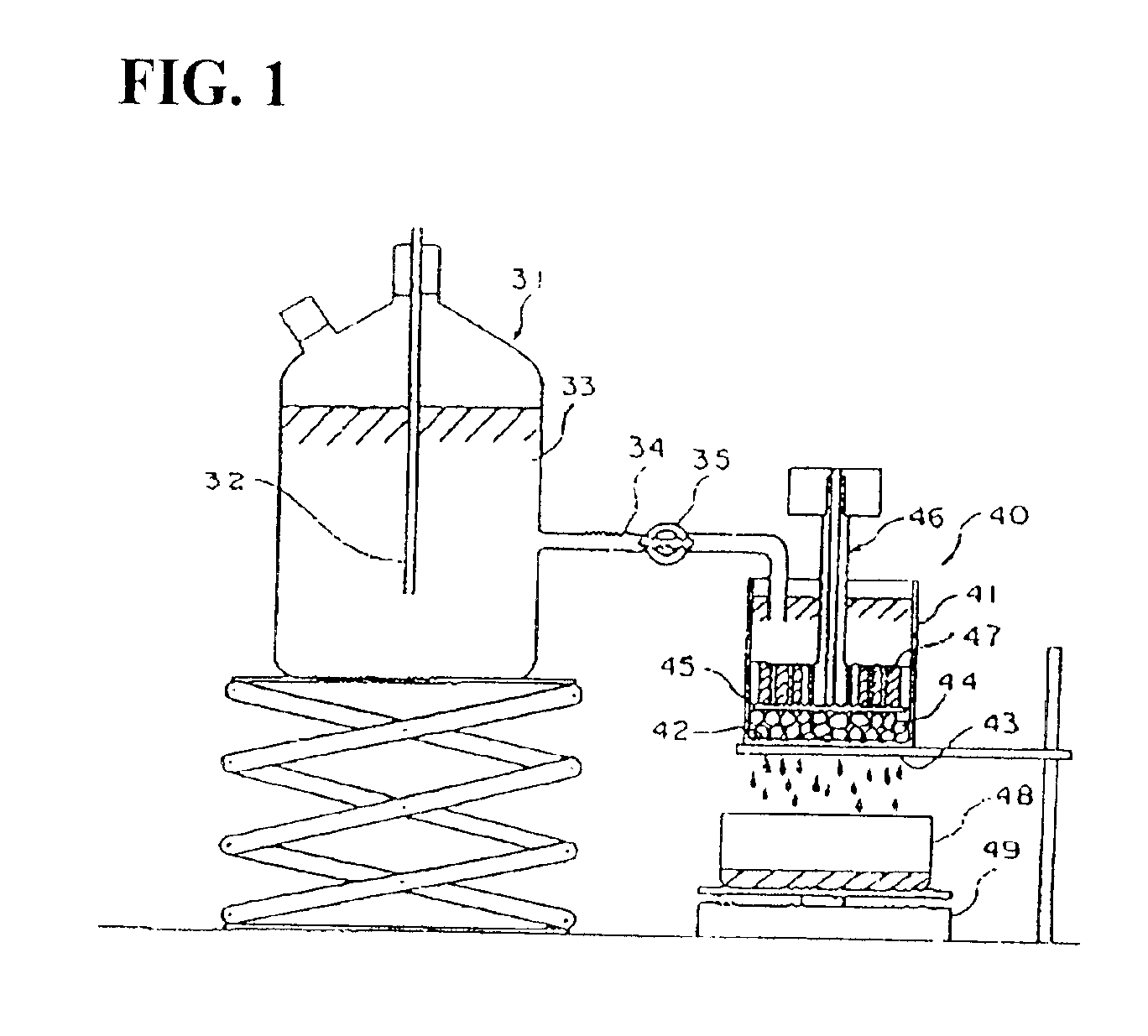

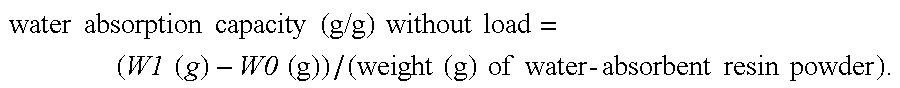

Water absorbing agent, water absorbing article and method for production of water absorbing agent

ActiveUS20100062252A1Promote absorptionReduce the amount requiredSynthetic resin layered productsCellulosic plastic layered productsCarboxylic acidEster bond

An object of the present invention is to provide a water absorbing agent having a low amount of residual monomer, small variance of the amount of residual monomer among ranges of particle size distribution and favorable absorption properties, and being sanitary; an absorbing article; and a method for the production of a water absorbing agent. The water absorbing agent of the present invention has the amount of residual monomer of not higher than 500 ppm, and a residual monomer index of not greater than 0.30. The method for the production includes a first step of obtaining a hydrogel polymer by polymerizing an aqueous solution of a monomer including an unsaturated carboxylic acid and / or a salt thereof in the presence of a crosslinking agent; a second step of obtaining a water absorbent resin precursor which is in powder form and includes particles having a particle size of 300 to 850 μm and particles having a particle size of smaller than 300 μm as main components by drying said hydrogel polymer followed by pulverization and classification to adjust the particle size distribution, a third step of obtaining a water absorbent resin by heating a mixture of said water absorbent resin precursor and a surface crosslinking agent, which can form an ester bond around the surface of said water absorbent resin precursor, a fourth step of adding by spraying an aqueous solution that includes a sulfur-containing reducing agent to said water absorbent resin, and a fifth step of subjecting the mixture of the water absorbent resin and said aqueous solution to a heat treatment under an airflow of not lower than 40° C. but not higher than 120° C.

Owner:NIPPON SHOKUBAI CO LTD

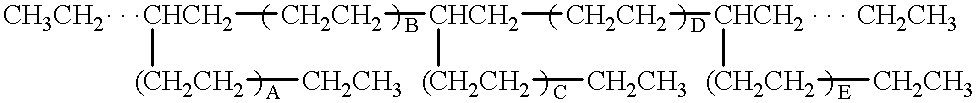

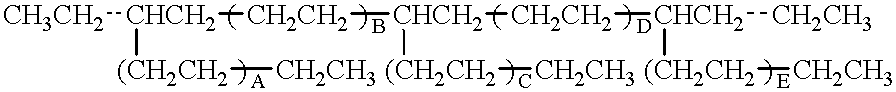

Process for production of polymer polyol, and polymer polyol

A polymer polyol comprising 25 to 60 mass % polyol (A) and 40 to 75 mass % of polymer particles (B1) formed by polymerizing ethylenically unsaturated monomer in the polyol (A), the ethylenically unsaturated monomer having the content of acrylonitrile and / or styrene is not less than 50 mass %, wherein (B1) has a particle size of not more than 100 μm and contains not less than 95 mass % of particles with the particle size of 0.01 to 10 μm; and the total content of acrylonitrile and styrene is not more than 20 ppm; and process for producing the polymer polyol. The polymer polyol exhibits a reduced residual monomer content and excellent filtration property and is useful as a raw material in the production of polyurethane or the like.

Owner:SANYO CHEM IND LTD

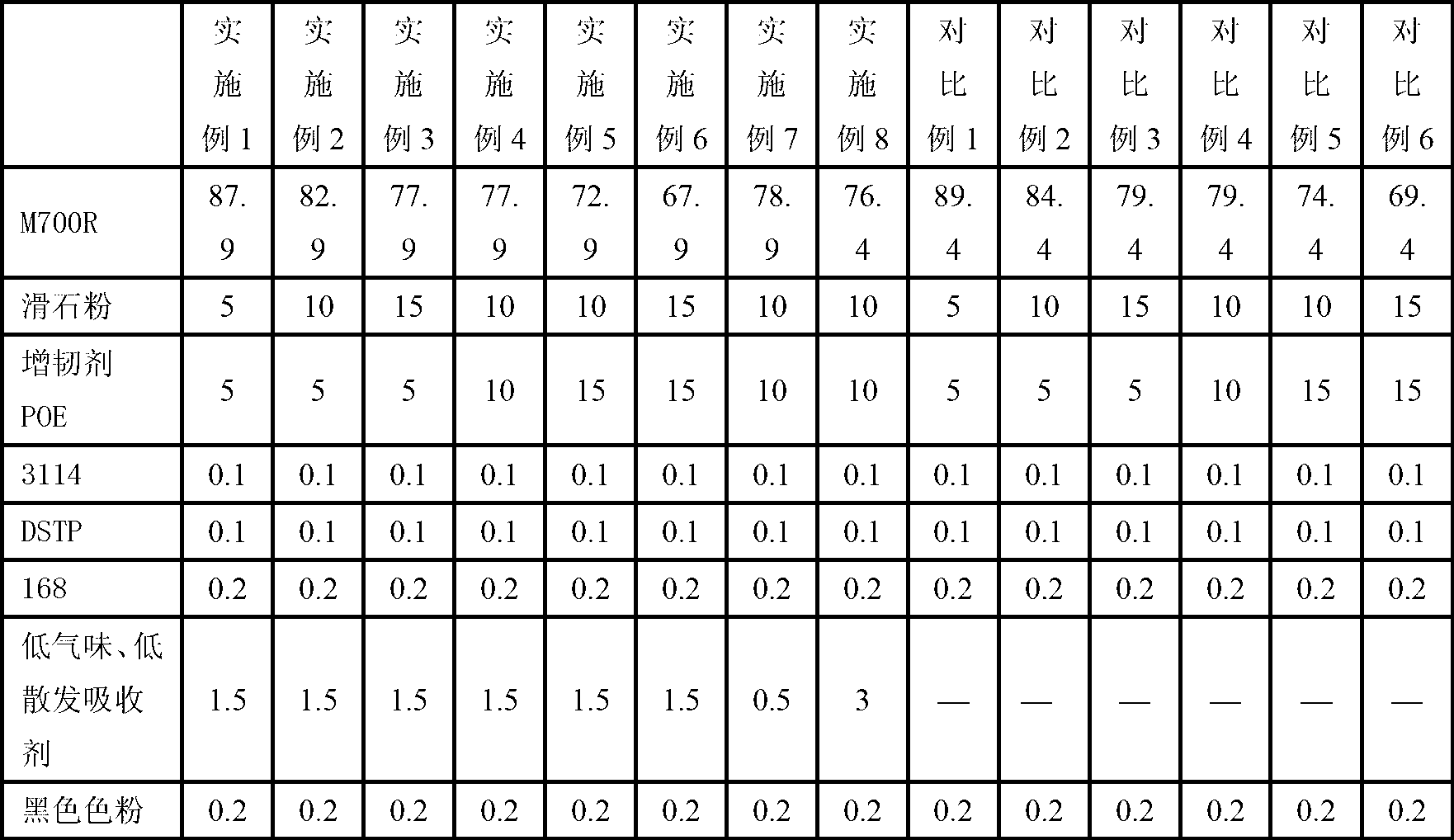

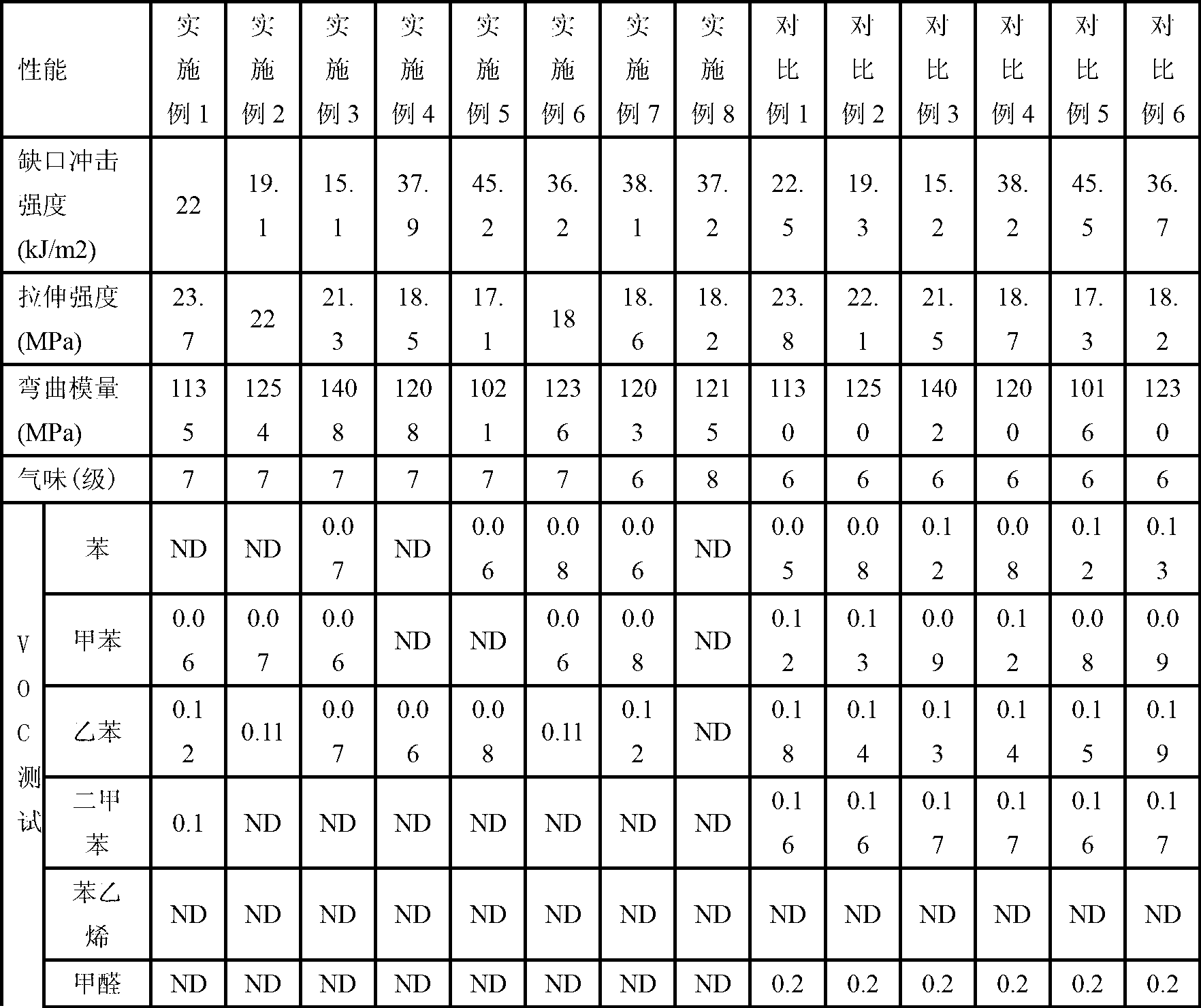

Low-odor low-volatilization modified polypropylene material and preparation method thereof

The invention discloses low-odor low-volatilization modified polypropylene material and a preparation method thereof. The low-odor low-volatilization modified polypropylene material is composed of the following raw materials by weight, polypropylene 65-89%, low-odor low-volatilization absorbent 0.5-3%, inorganic filler 5-15%, polyolefin elastomer (POE) flexibilizer 5-15% and antioxygen 0.1-2%. The low-odor low-volatilization modified polypropylene material has the advantages that nano-zinc oxide which is prepared by a microemulsion method is used for preparing nano-zinc oxide modified active carbon materials and loaded on the surface of multihole active carbon, residual monomers, decomposers and organic acid in base materials of polypropylene are effectively absorbed, obvious effect of absorbing odor is achieved, preparing process is simple, and production cost in low.

Owner:SHANGHAI PRET COMPOSITES

Preparation of expandable styrene polymers

Enhanced conversion rates are realized in a suspension polymerization process for styrene through the use of peroxide initiators having one hour half life temperatures from 101° to 111° C. are disclosed. Also disclosed are suitable initiator combinations which provide polymeric products with low residual monomer content at reduced process temperatures, polymerizable compositions containing such initiators and products produced by such processes and compositions.

Owner:ARKEMA INC

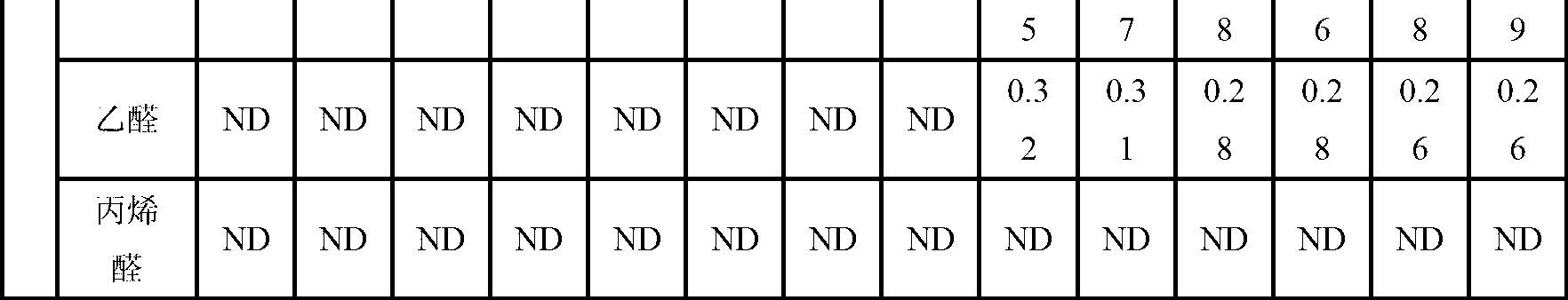

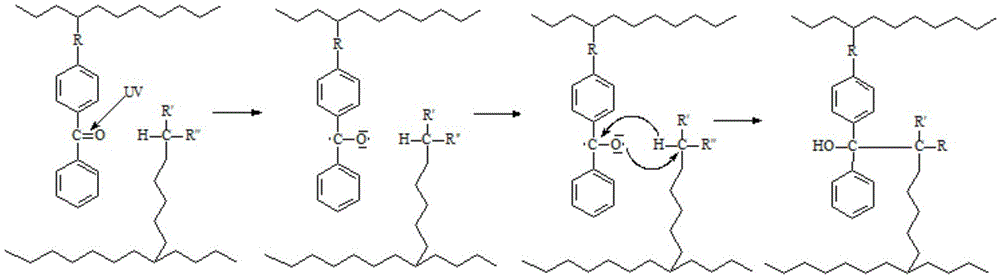

Acrylic-ester hot-melt pressure-sensitive adhesive and preparing method thereof

ActiveCN105585982AImprove adhesionExcellent storage stabilityFilm/foil adhesivesEster polymer adhesivesFunctional monomerFood contact

The invention discloses an acrylic-ester hot-melt pressure-sensitive adhesive and a preparing method thereof. The acrylic-ester hot-melt pressure-sensitive adhesive comprises, by weight, 1-10 parts of hard monomer, 70-95 parts of soft monomer, 1-5 parts of functional monomer, 1-5 parts of polymerizable UV photoinitiator, 0.2-0.5 part of free radical polymerization initiator and 0.01-0.1 part of molecular weight modifier. According to the acrylic-ester hot-melt pressure-sensitive adhesive, storage stability and weather resistance can be improved, the size shrinkage is small during cure crosslinking, coated base material adhesive force is large, adhesive shifting is not prone to occurrence, and the acrylic-ester hot-melt pressure-sensitive adhesive can be widely applied to the food contact field and the medical field. In addition, the body polymerization technology is adopted and is different from the conventional solution polymerization technology and the conventional emulsion polymerization technology, the amount of residual monomer in macromolecule prepolymers is quite small, the content of solid of a polymerization product is 100%, solvent discharging and water volatilization are avoided in the coating process of the pressure-sensitive adhesive, energy consumption is low, and the environment is protected.

Owner:KUNSHAN JIUQING PLASTIC

Modification method for using low-temperature plasma to initiate gas-phase grafting on surface of polyethylene film

ActiveCN102432905AIncrease reaction rateSuitable for large-scale continuous productionReaction rateGas phase

The invention discloses a modification method for using low-temperature plasma to initiate gas-phase grafting on the surface of a polyethylene film. The modification method comprises the following steps of: 1) adopting a low-temperature plasma treatment machine with the power being 1KW-20KW and the voltage being 380V to carry out corona treatment on the polyethylene film; 2) after mixing liquid acrylic-acid monomer and an activating agent at the weight ratio being 100: (1-20), vaporizing by a vaporizing chamber with the temperature being 120-200 DEG C, and uniformly spraying on the surface ofthe polyethylene film after corona treatment by a spraying nozzle in a gaseous form; and 3) generating ultraviolet light for irradiation by a high-voltage mercury lamp with the wavelength being 365nmand the power being 500W-5000W, sensitizing the activating agent by the ultraviolet light, initiating the grafting of the acrylic-acid monomer on the surface of the polyethylene film, blowing by hot air with the temperature being 50-80 DEG C, removing the residual monomer and obtaining the polyethylene film with the gas-phase grafted surface. The modification method is high in reaction rate of gas-phase grafting on the surface, is suitable for large-scale continuous production, is lower in cost, the surface tension permanency is improved, and the problem of quality stability of the composite packaging film can be solved.

Owner:浙江粤海包装新材料有限公司

Synthetic method of anti-compression and anti-bacterial super absorbent polymer for physiology

The invention relates to a super absorbent polymer for physiology, in particular to an anti-compression and anti-bacterial super absorbent polymer still with high water absorbency under compression and with natural anti-bacterial property. The super absorbent polymer adopts the following technical scheme: taking polyvinyl alcohol with the polymer long chain rich in hydroxy as the interpenetrating polymer network (IPN), carboxymethyl chitosan with bioactivity and natural antibacterial property as the graft polymer and acrylate as the main comonomer, being combined with a cross-linking agent with molecular chains different in length, adopting the three-stage complex initiation system and realizing interpenetrating of polyvinyl alcohol and grafting of carboxymethyl chitosan by way of aqueous solution radical copolymerization to prepare the super absorbent resins with regular granularity, uniform crosslinking and less residual monomers. The invention develops multi-component composite surface treatment solution to carry out surface treatment on the super absorbent resins, thus further reducing the residual monomers, forming gradient crosslinking on the surfaces of the super absorbent resins and finally preparing the anti-compression and anti-bacterial super absorbent polymer for physiology. The super absorbent polymer is white without yellow spots, has regular granularity, inadherent surface, good liquidity, high absorption rate and absorption, excellent filtration property and less residual monomers and is against compression and tolerant to salt and free of gel plugging.

Owner:NANTONG KEYI CHEM

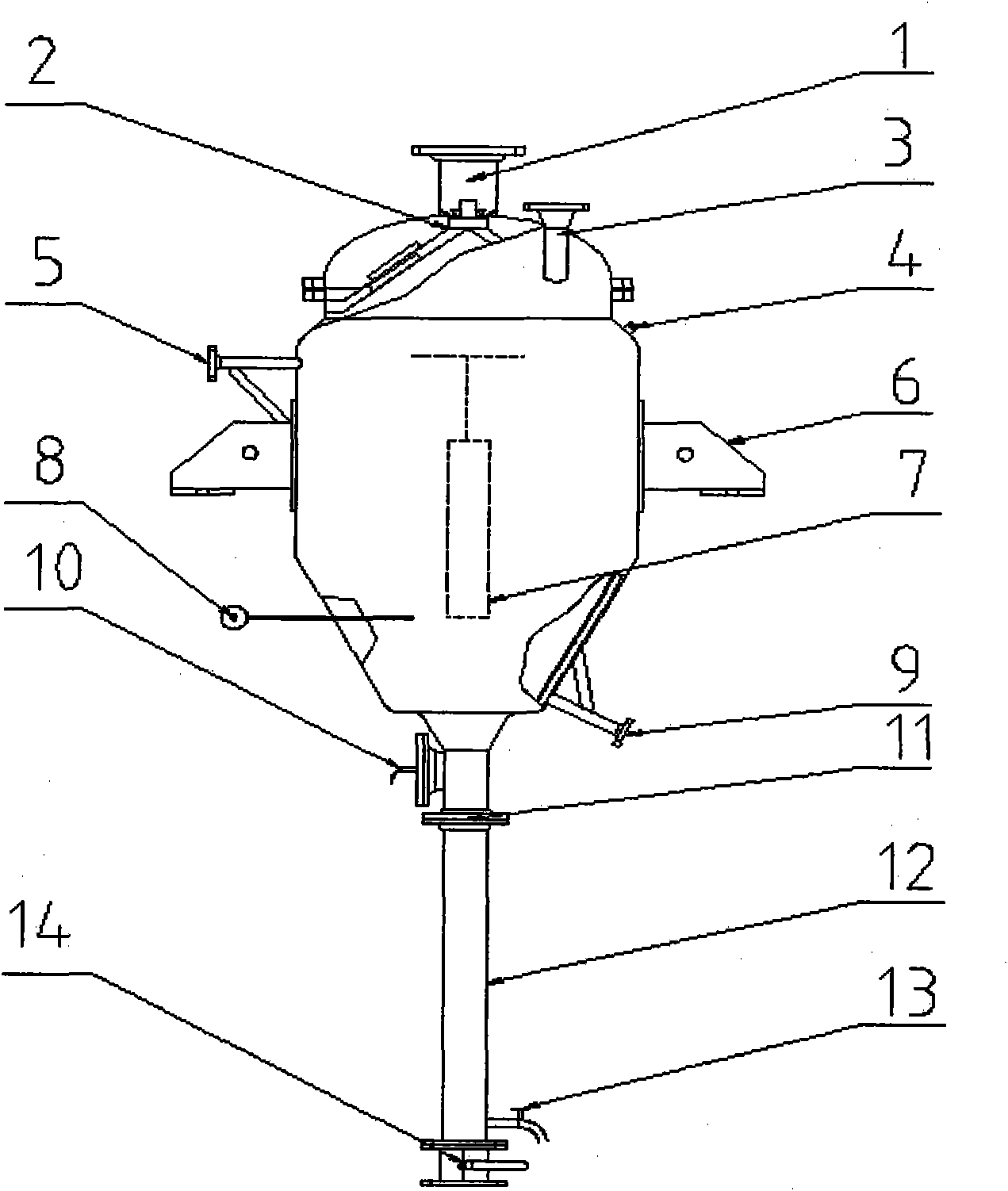

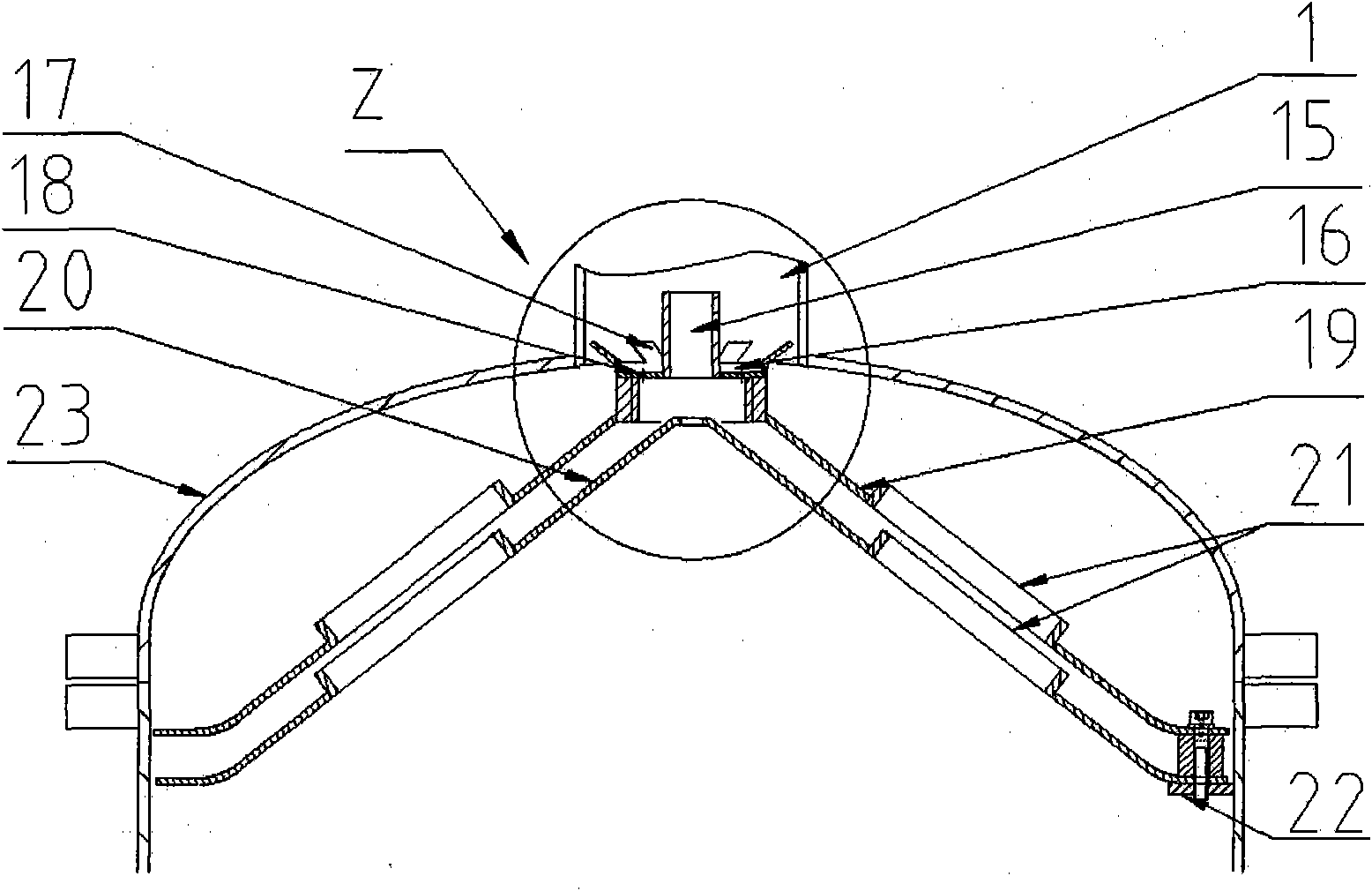

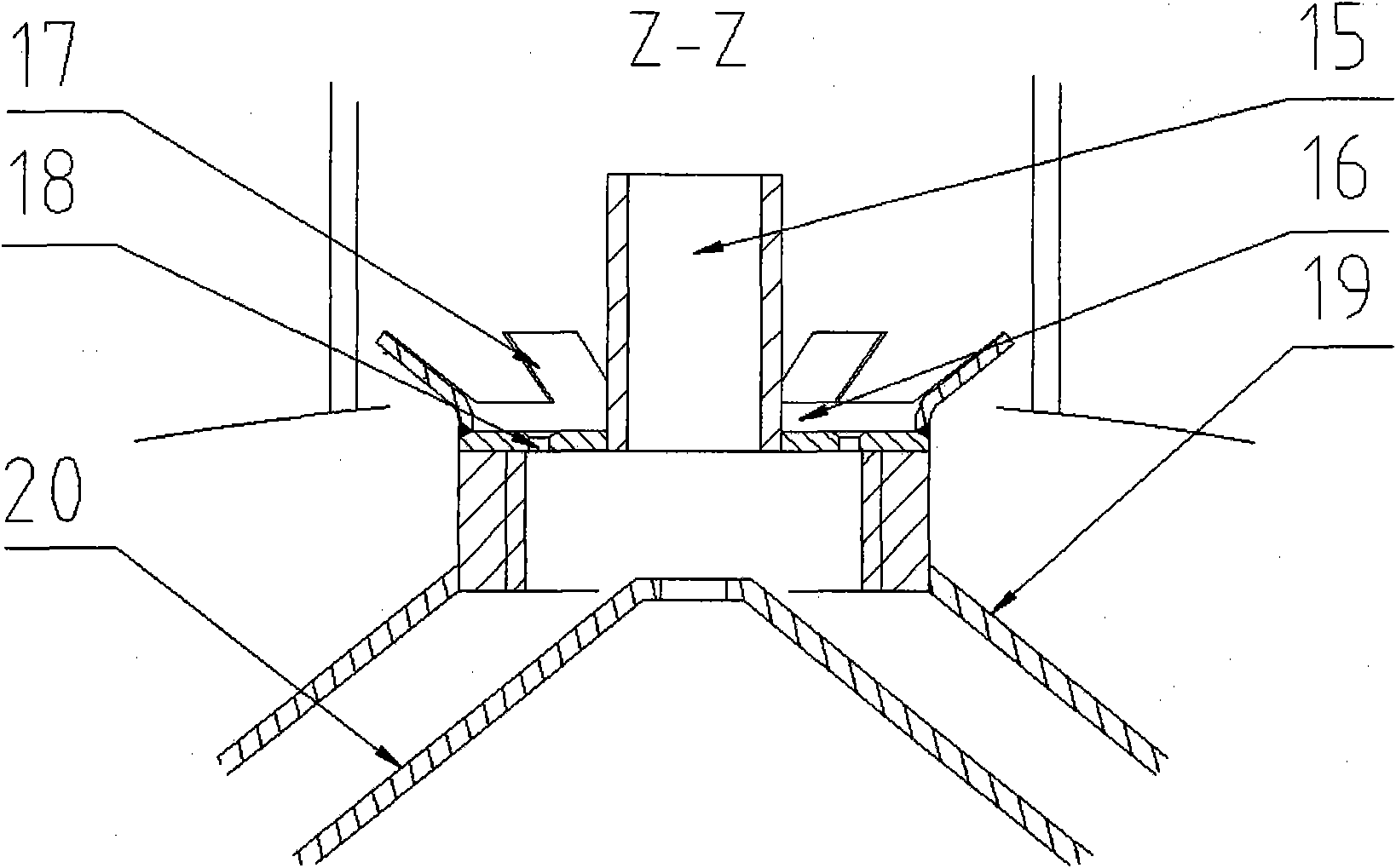

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570AContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionCarbon fibersSolvent

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm and solvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

Aromatic-acrylate tackifier resins

InactiveUS7332540B2Increase ratingsAvoid high concentrationsImpression capsLayered productsWater vaporTackifier

A tackifier resin is provided comprising monomer units from at least one aromatic monomer and at least one acrylate monomer; wherein the tackifier resin has a low residual monomer concentration. In other embodiments of the invention, the tackifier resin does not significantly decrease the moisture vapor transport rate of an adhesive composition comprising the tackifier resin, does not significantly increase fogging of an adhesive composition comprising the tackifier resin, and does not significantly exhibit skin sensitivity properties.A process to produce the tackifier resin is also provided. The process comprises contacting a tackifier resin product stream with at least one carrier at a temperature sufficient to remove a portion of at least one residual monomer from the tackifier resin product stream to produce the tackifier resin.

Owner:EASTMAN CHEM CO

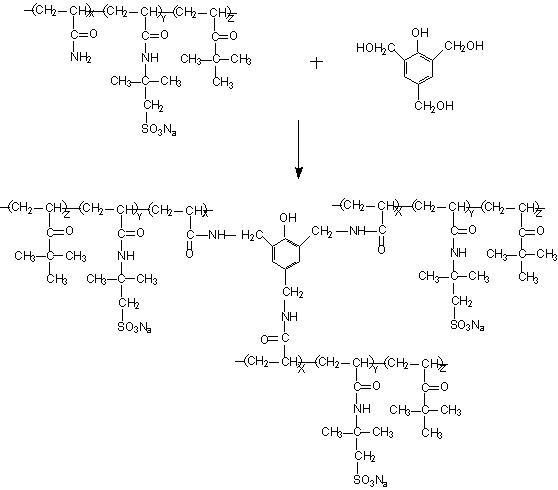

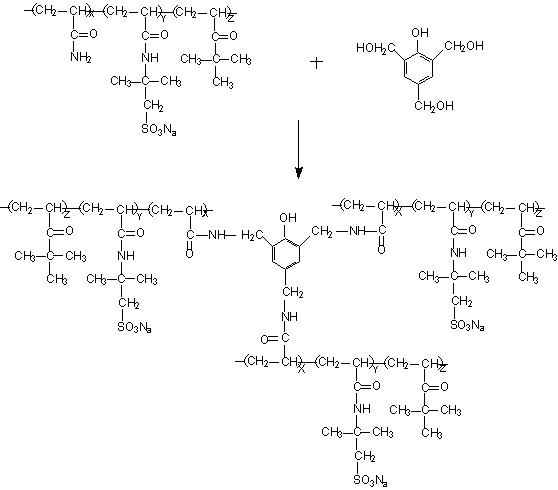

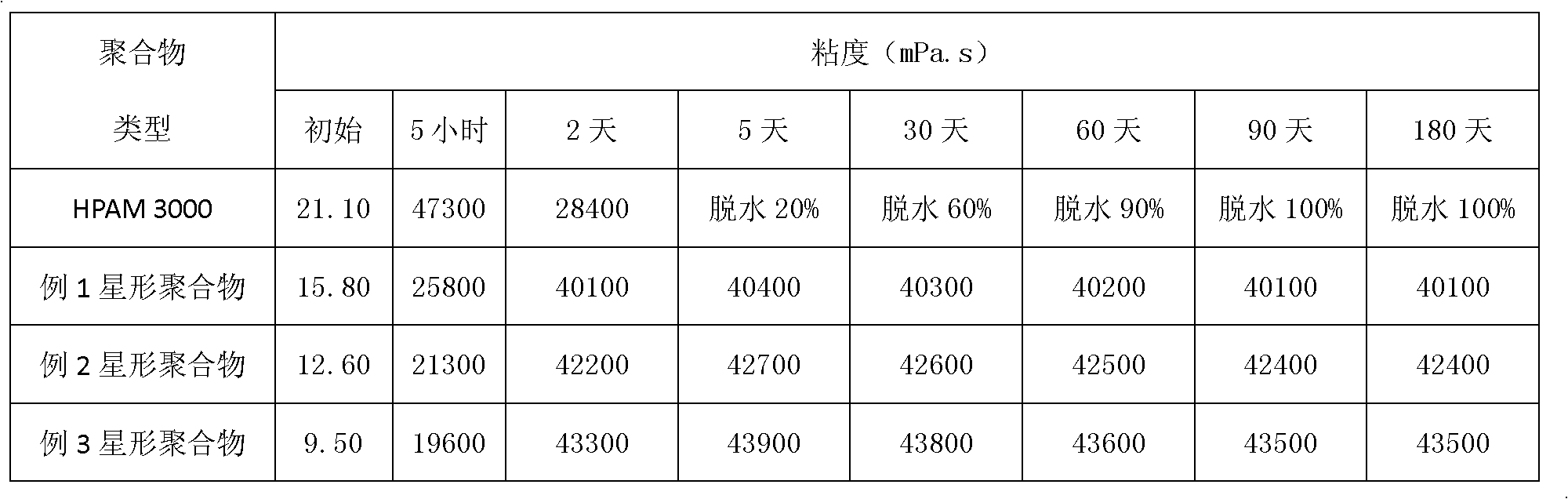

Preparation method of star polymer

ActiveCN102093505AHigh molecular weightLower the polymerization initiation temperaturePolymer scienceMeth-

The invention discloses a preparation method of a star polymer, belonging to the technical field of petroleum extraction. The method adopts a redox initiation system, and carries out water solution radical copolymerization on three water-soluble monomers, including tert-butyl acrylate, 2-acrylamido-2-methylpropane sulfonic acid and acrylamide. The redox initiation system comprises trihydroxymethyl phenol, persulfate, hydrogen peroxide, urea, sodium formaldehyde bisulfite, azoisobutyronitrile, chain transfer agent and surfactant. The molecular weight of the star polymer prepared by the method is 8-15 million; the star polymer is water-soluble; the content of the residual monomers in the product is less than or equal to 0.1 wt%; and the star polymer and a crosslinking system, which is composed of water-soluble phenolic resin and polyethylene imine, can form a movable gel system for carrying out deep profile control on a high-temperature high-salt oil reservoir of which the salinity is 117000 mg / L and the temperature is 140 DEG C.

Owner:PETROCHINA CO LTD

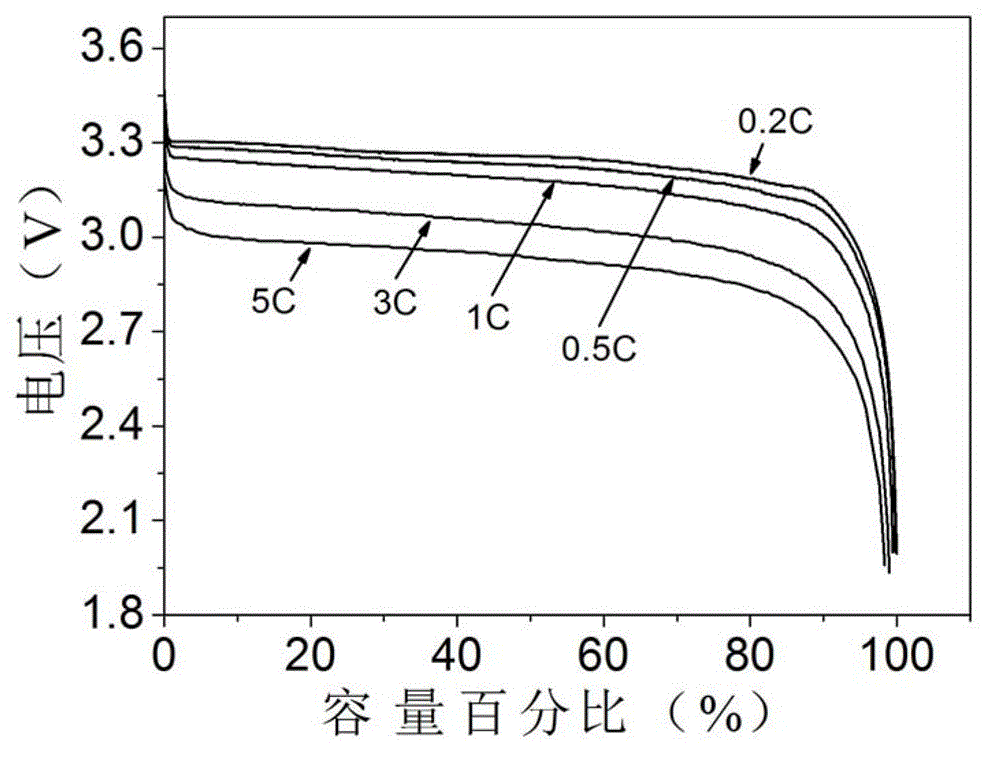

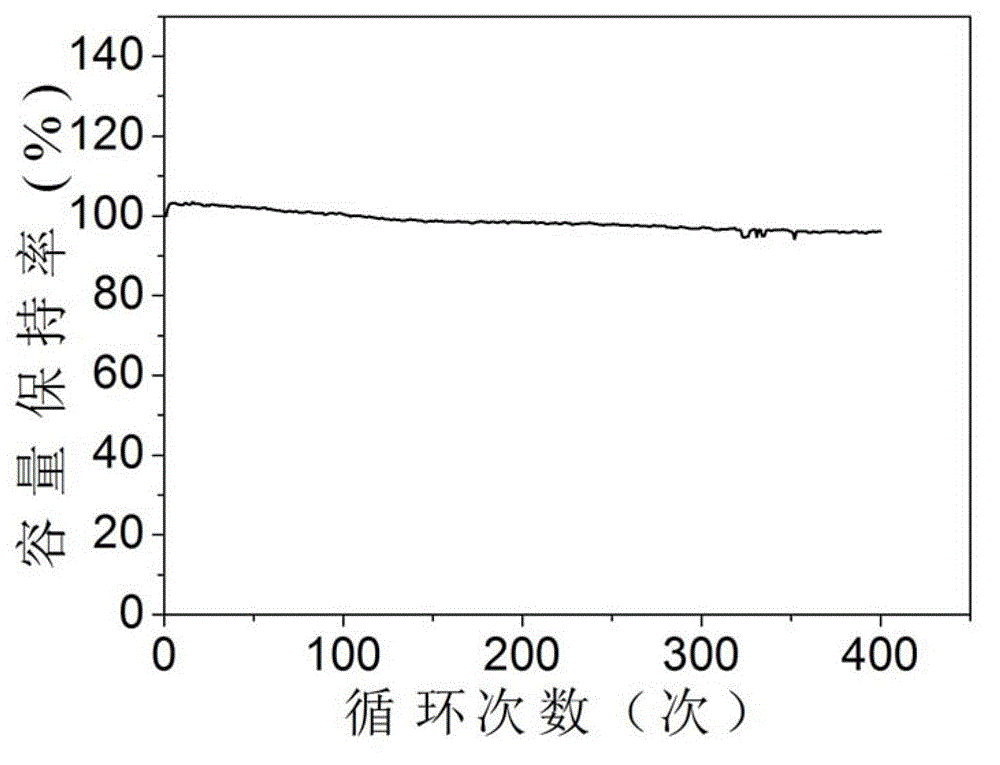

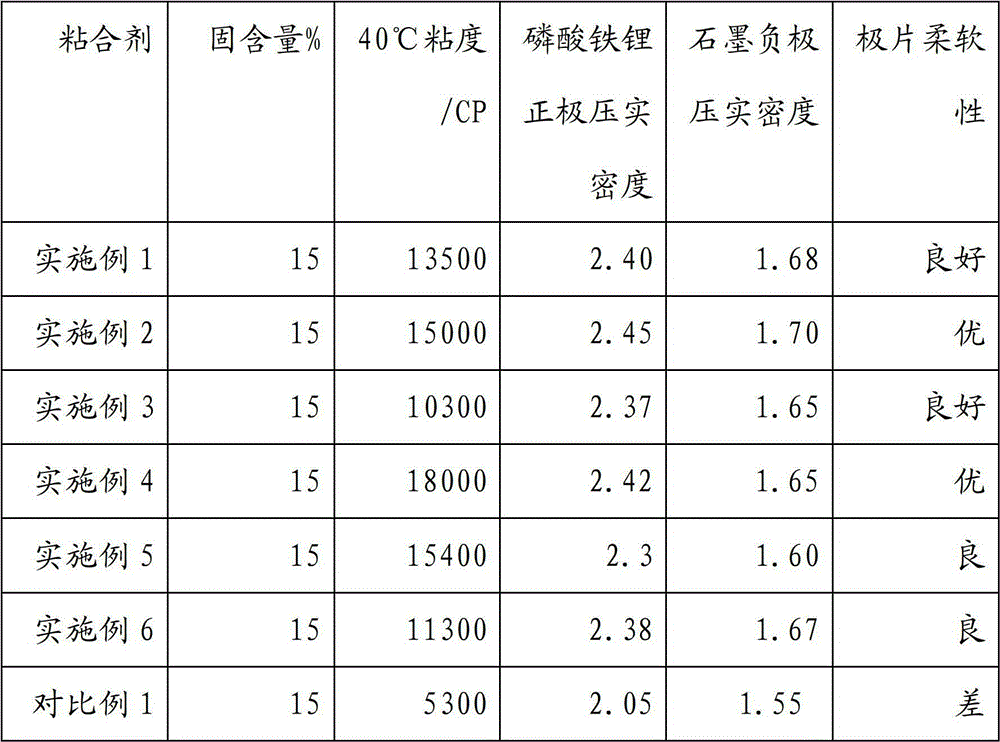

Preparation method for aqueous binder used for lithium ion battery

InactiveCN102746813AImprove cycle performanceImproved magnification performanceCell electrodesAcid polymer adhesivesHydrophilic monomerAluminium-ion battery

The invention provides a preparation method for an aqueous binder used for a lithium ion battery. The method comprises the following steps: weighing unsaturated hydrophilic monomers, unsaturated lipophilic monomers and auxiliary agents; dissolving the weighed unsaturated hydrophilic monomers in distilled water and uniform mixing the dissolved unsaturated hydrophilic monomers with the weighed unsaturated lipophilic monomers and auxiliary agents under stirring; adjusting the pH value of an obtained mixture to be 5 to 13, blowing in high purity nitrogen to remove oxygen and adjusting temperature to a constant temperature; adding an initiator for initiation of polymerization; and extracting residual monomers under vacuum so as to obtain the aqueous binder for a lithium ion battery. The aqueous binder for a lithium ion battery provided in the invention has the advantages of environment friendliness, low production cost and good bonding performance; an electrode slice prepared from the aqueous binder for a lithium ion battery has good flexibility and high compacted density and enables performance of positive and negative electrode materials of a lithium ion battery to be fully played; and a prepared lithium ion battery has good cycle performance and rate capability.

Owner:张倩

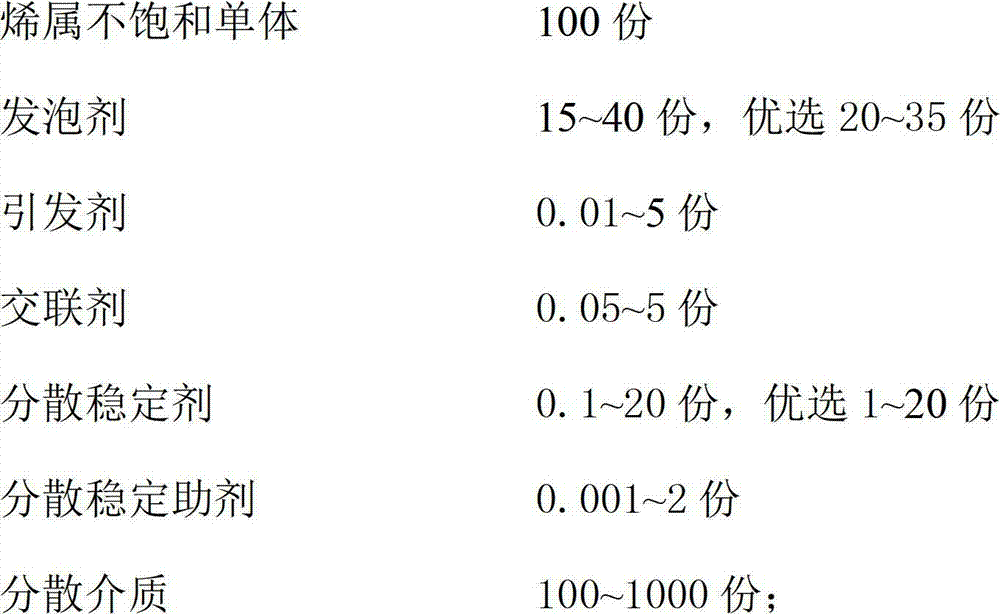

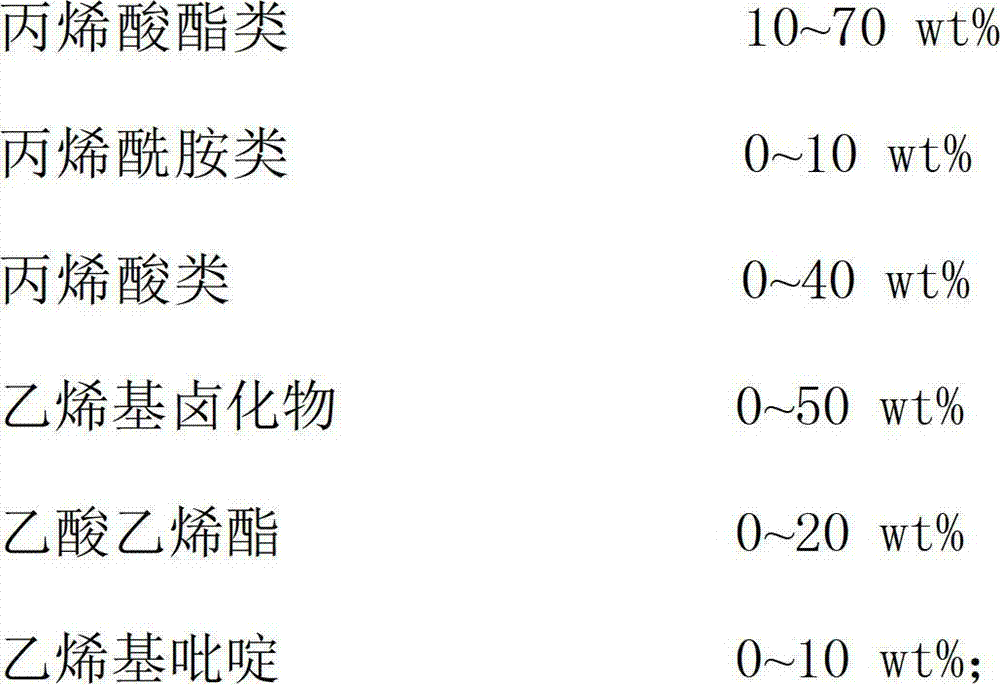

Thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of the residual monomers is an oxidation reduction initiator system. The preparation method of the thermal expansibility microsphere, provided by the invention comprises the following steps: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The technical scheme provided by the invention realizes quick reduction of the residual monomers under a low-temperature condition, is simple in production process, low in consumption and short in processing time, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium. The thermal expansibility microsphere prepared by using the method contains a little number of residual monomers and is small in pollution.

Owner:NANOSPHERE SHANGHAI

Toner and image forming method using the toner

InactiveUS6337169B1Good hue and proper glossDevelopersElectrographic process apparatusParticulatesWax

A toner suitable for use in electrophotography, etc., is composed of toner particles each containing a binder resin, a colorant and a wax component. Each toner particle has such a microtexture as to provide a cross section as observed through a transmission electron microscope (TEM) exhibiting a matrix of the binder resin, a particle of the wax enclosed with the matrix; and the binder resin dispersed in a particulate form in the wax particle, and the toner particles have a residual monomer content of at most 500 ppm by weight of the toner particles. The colorant may also be dispersed in the wax particle enclosed within the matrix of the binder resin.

Owner:CANON KK

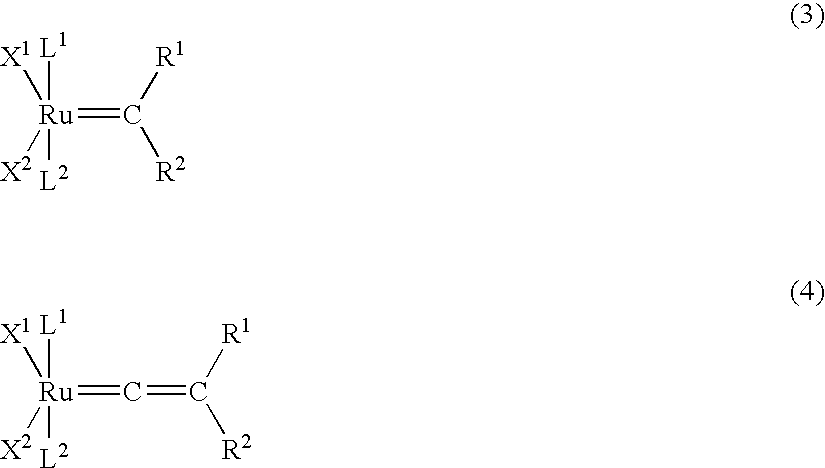

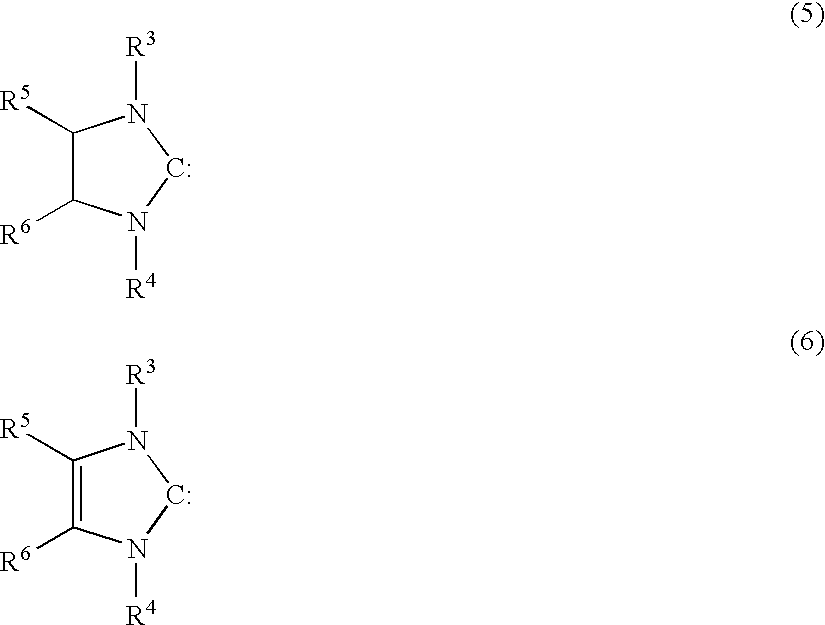

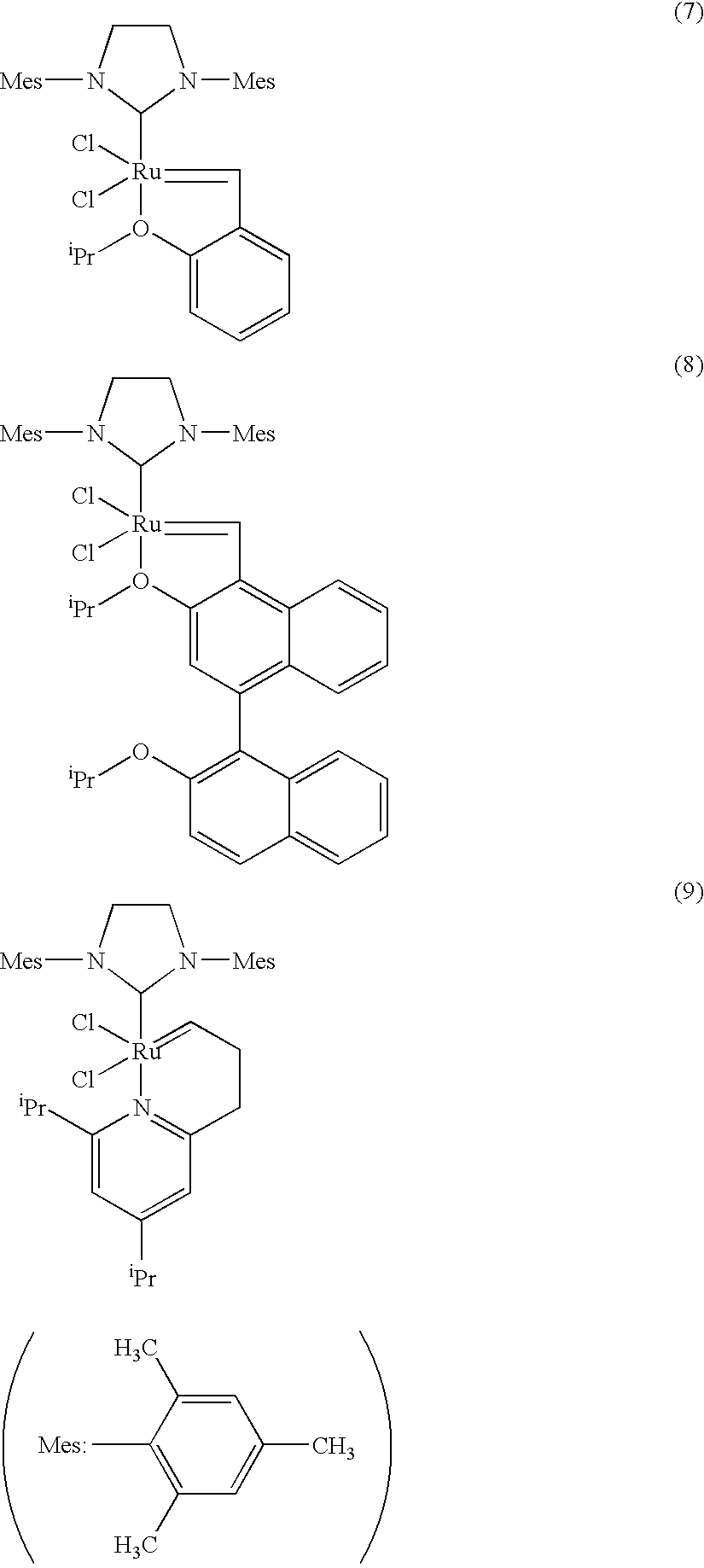

Method of manufacturing thermoplastic resin, crosslinked resin, and crosslinked resin composite material

InactiveUS20060211834A1Efficient productionAdhesive processes with surface pretreatmentSynthetic resin layered productsPolymer scienceBulk polymerization

The invention relates to a process for the production of post-crosslinkable thermoplastic resins by bulk-polymerizing a polymerizable composition (A) comprising (I) a monomer fluid containing a cyclic olefin (α) having two or more metathetical ring-opening reaction sites in the molecule in an amount 10 wt % or above based on the total amount of the monomers or a monomer fluid containing a norbornene monomer and a crosslinking agent, (II) a metathetical polymerization catalyst, and (III) a chain transfer agent; thermoplastic resins obtained by this process; and a process for producing crosslinked resins or crosslinked resin composite materials which comprises laminating such a thermoplastic resin with a substrate at need and then crosslinking the thermoplastic resin. According to the invention, thermoplastic resins which are free from odor due to residual monomers and excellent in storage stability can be efficiently obtained by a simple process of bulk-polymerizing the composition (A). The process is not only easy and simple but also applicable to continuous production, thus being industrially advantageous. The crosslinked resins and crosslinked resin composite materials obtained according to the invention are excellent in electrical insulation properties, mechanical strengths, heat resistance, dielectric characteristics and so on, thus being useful as electrical materials or the like.

Owner:ZEON CORP

High activityhydroxyl-terminated polyepichlorohydrin polyatomic alcohol and preparation thereof

The invention relates to high activity hydroxy terminated polyepichlorohydrin polylol with simple preparation technology and good color, and the preparation method thereof. The high activity hydroxy terminated polyether has the molecular structure including a large quantity of methylene lateral chloro groups and terminated by epoxy ethane or propylene oxide, and the high activity hydroxy terminated polyepichlorohydrin polylol has the average relative molecular mass of 500-9000 and the average hydroxide radical functionality of 2-3. The preparation method comprises the following steps: low molecular mass initiator and dual-metal prussiate complex compound catalyst are added in a pressure-proof reaction kettle, volatile components are removed in a vacuumed mode, part of epoxy chloropropane are added in the low molecular mass initiator and dual-metal prussiate complex compound catalyst, all the reactants are heated to 100-140 DEG to react under the nitrogen protection and the high-speed stirring, and the rest part of epoxy chloropropane is added gradually drop by drop after the activation; after the polymerization reaction is finished, the temperature is reduced to 90-120 DEG C, propylene oxide or epoxy ethane is added drop by drop for end capping, and residual monomer is removed in a vacuumed way after the reaction, thus the hydroxy terminated polyepichlorohydrin polylol is obtained.

Owner:QINGDAO UNIV OF SCI & TECH +1

Styrene acrylic emulsion for interior wall coating material, and preparation method thereof

InactiveCN102827320AIncrease crosslink densityGood scrub resistanceCoatingsSodium bicarbonateFunctional monomer

The invention provides a styrene acrylic emulsion for interior wall coating material, and a preparation method of the styrene acrylic emulsion; the preparation method comprises the following steps of: (1) mixing water, composite emulsifying agent, acrylate monomer and functional monomer, and emulsifying to obtain pre-emulsified liquid A; (2) adding reactive organic silicon into the pre-emulsified liquid A, and emulsifying to obtain pre-emulsified liquid B; (3) adding mixture of water, composite emulsifying agent, methyl alcohol and sodium bicarbonate into the pre-emulsified liquid A obtained in the step (1), and adding initiator for reaction to obtain seed emulsion C; (4) adding the pre-emulsified liquid B into the seed emulsion C obtained in the step (3), and simultaneously adding initiator water solution into the mixed solution; carrying out heat preservation after dripping, and cooling the emulsion; and (5) removing residual monomer, and adjusting the pH to be 7-8 to obtain the styrene acrylic emulsion for the interior wall coating material. The styrene acrylic emulsion can be used for preparing the interior wall coating material, and is less in adding quantity and better in scrub resistance than that of other emulsions, thus reducing the cost of coating and saving resources.

Owner:上海展辰涂料有限公司 +4

Polymer dispersions for fire prevention and firefighting

The present invention relates to water-in-oil polymer dispersions comprising of a continuous organic phase and therein finely dispersed and cross-linked, water-swellable polymerizates, where these have a residual monomer content of less than 1,000 ppm. The present invention relates further to a process for the production of polymer dispersions according to the invention. In addition, the present invention relates to devices for fire prevention and firefighting and to the use of the polymer dispersions according to the invention.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com