Preparation method for aqueous binder used for lithium ion battery

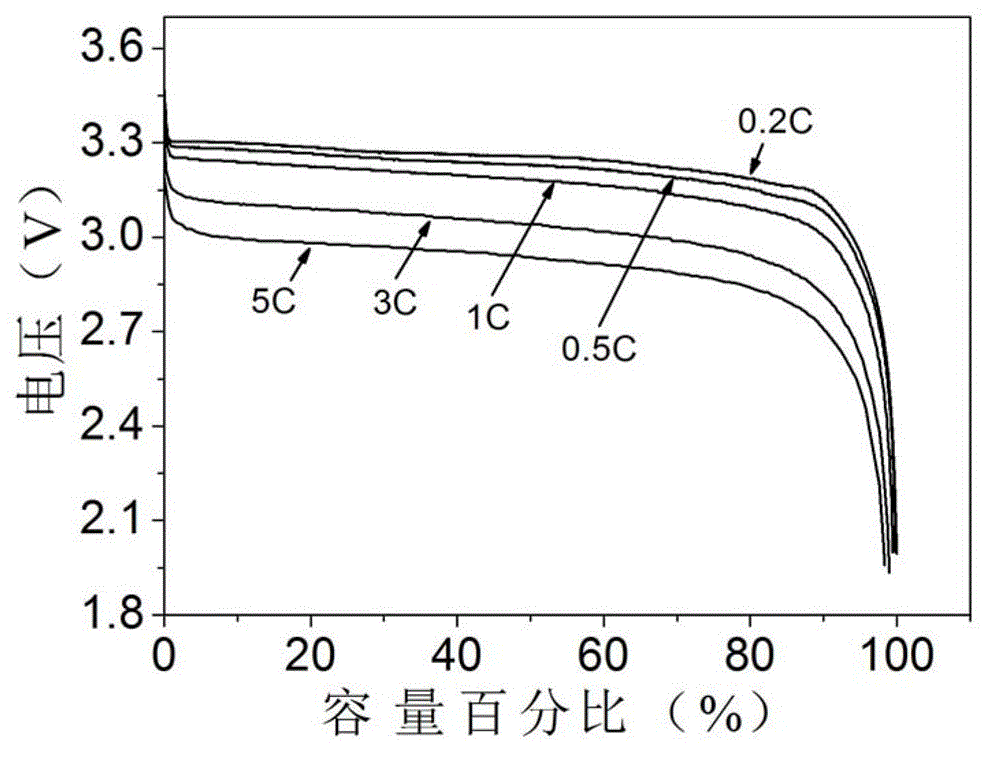

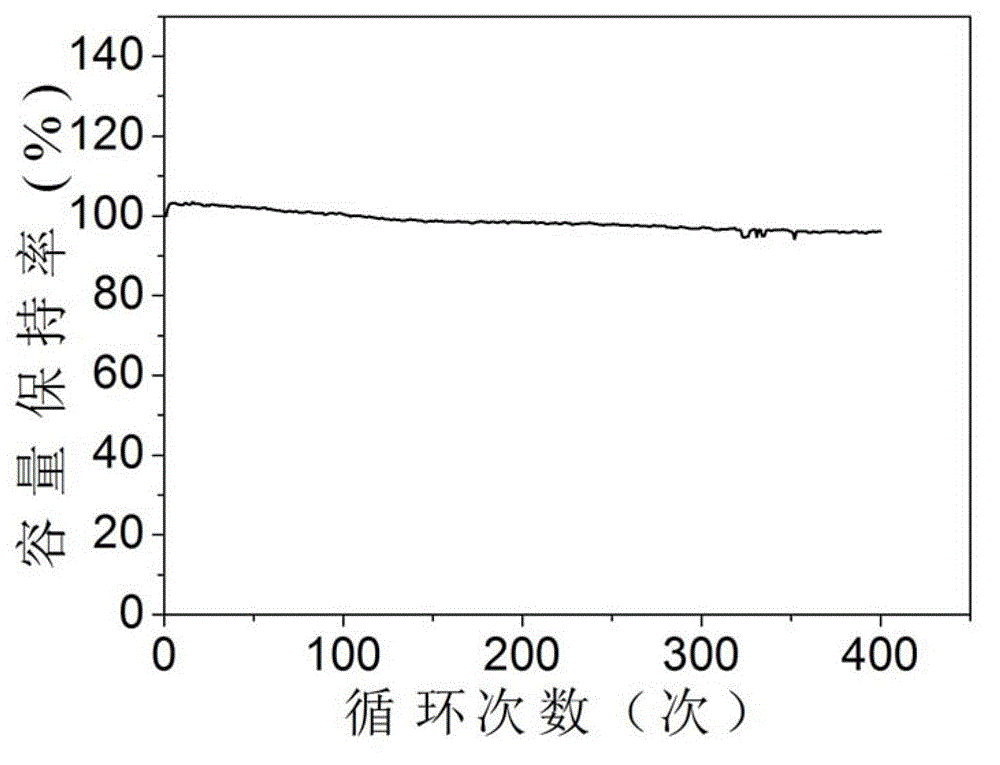

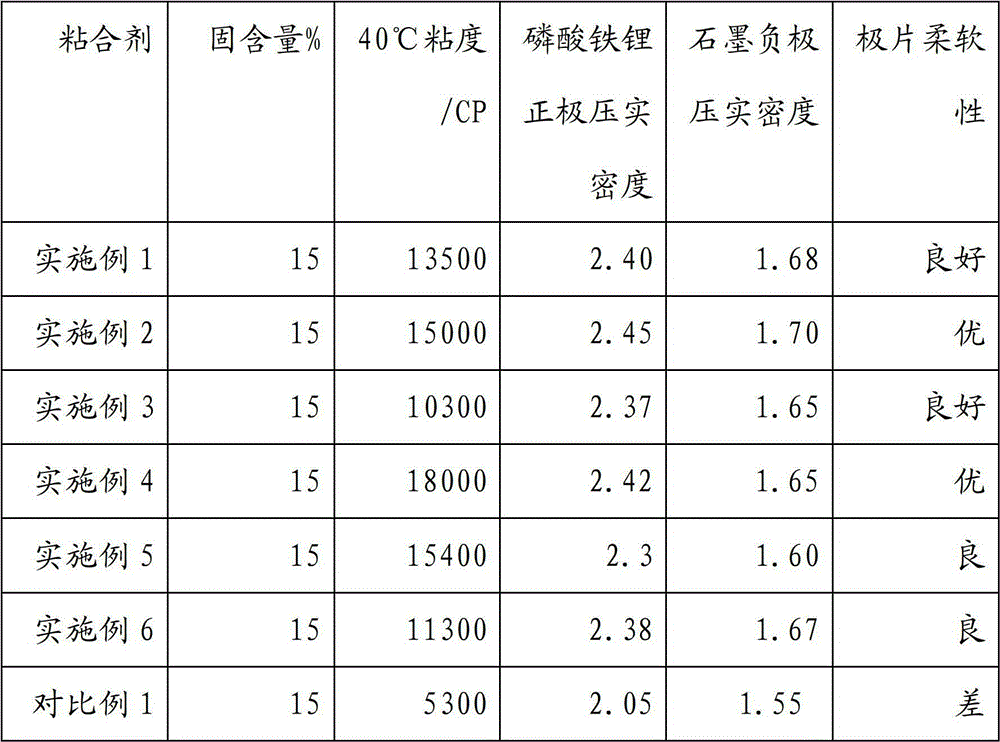

A water-based adhesive, lithium-ion battery technology, applied in the direction of acid copolymer adhesive, adhesive type, amide/imide polymer adhesive, etc., can solve the problem of reducing battery yield and compaction density Low cost, high price and other problems, to achieve the effect of good cycle performance and rate performance, low production cost and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of lithium-ion battery aqueous adhesive, comprises the steps:

[0023] (1) Weigh the raw materials according to the weight ratio of unsaturated hydrophilic monomer and unsaturated lipophilic monomer to 0.81~8:1, and then weigh the proportion of unsaturated hydrophilic monomer and unsaturated lipophilic monomer 0.3 to 4% of the total weight of additives;

[0024](2) Dissolve the above-mentioned weighed unsaturated hydrophilic monomer in distilled water to obtain an aqueous solution of unsaturated hydrophilic monomer, mix the aqueous solution of unsaturated hydrophilic monomer with unsaturated lipophilic monomer and additives Stir and mix evenly, the stirring speed is 20-360 rpm, the stirring time is 0.1-20 hours, and the weight ratio of unsaturated hydrophilic monomer to distilled water is 0.05-9:1;

[0025] (3) Adjust the pH value to 5-13 with an alkaline solution, and feed high-purity N 2 Exhaust oxygen for 0.5-3 ho...

Embodiment 1

[0040] In this embodiment, hydrophilic monomers acrylic acid (AA), acrylamide (AM) and lipophilic monomer vinyl acetate (VAc) are copolymerized in aqueous solution to generate a water-based adhesive for lithium ion batteries. Its comonomer composition is AA:AM:VAc=4:6:5 (mass ratio), the solid content of the copolymer is about 15%, and its appearance is emulsion-like.

[0041] The preparation method of the water-based adhesive for the above-mentioned lithium ion battery is: 6 parts of acrylic acid and 14 parts of acrylamide are dissolved in 70 parts and 90 parts of distilled water respectively, with 10 parts of vinyl acetate and 0.4 part of OP-10 emulsifier, in Stir and mix evenly in the reaction kettle, the stirring speed is 50 rpm, and the stirring time is 0.5 hours. Use 200g / L sodium hydroxide solution to adjust PH=9, feed nitrogen to drive oxygen for 2 hours, and the nitrogen flow rate is 30mL / min. Heating to 60°C and keeping the temperature constant for 1 hour, then addin...

Embodiment 2

[0044] The preparation method and operating conditions of the adhesive in this embodiment are basically the same as in Example 1. 8 parts of methacrylic acid and 14 parts of methacrylamide are dissolved in 70 parts and 90 parts of distilled water respectively, and mixed with 8 parts of styrene and 0.5 part of 2-octylphenol polyoxyethylene ether additive, stir and mix evenly in the reaction kettle, the stirring speed is 50 rpm, the stirring time is 3 hours, adjust the pH to 9 with 25% ammonia water, and pass in nitrogen Oxygen was driven for 2 hours, the nitrogen flow rate was 30mL / min, heated to 60°C and kept at a constant temperature for 1 hour, then 0.8 parts of sodium persulfate was added, and after 8 hours of reaction, the aqueous adhesive for lithium-ion batteries could be prepared. The solid content of the copolymer is about 15%, and the appearance of the product is emulsion.

[0045]Lithium-ion battery water-based binder performance detection is the same as in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com