Patents

Literature

764results about "Amide/imide polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioadhesive compositions and biomedical electrodes containing them

InactiveUS7076282B2Good bioadhesionHigh mechanical strengthElectrocardiographySurgical adhesivesWound dressingHydrophobic polymer

Owner:FIRST WATER

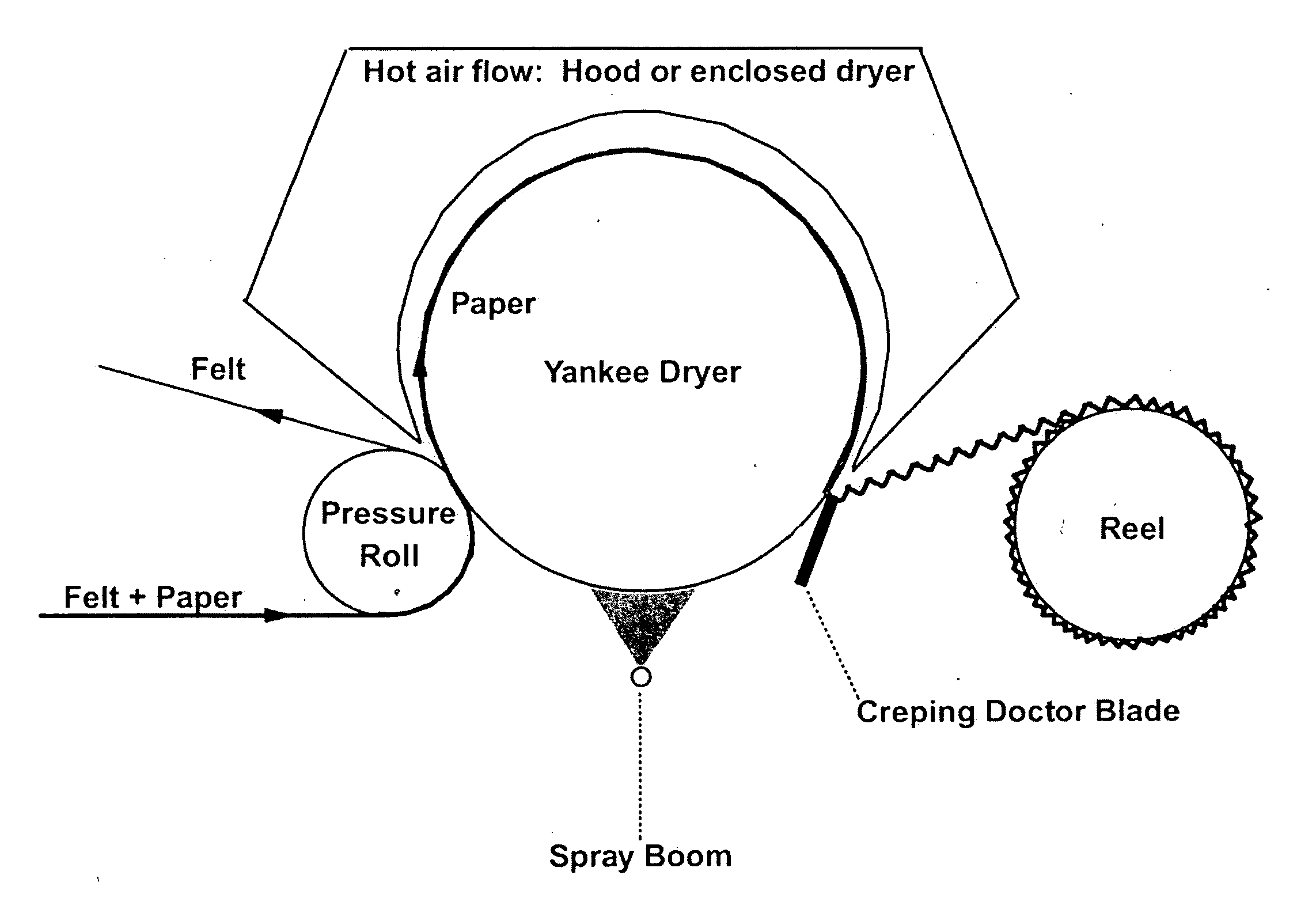

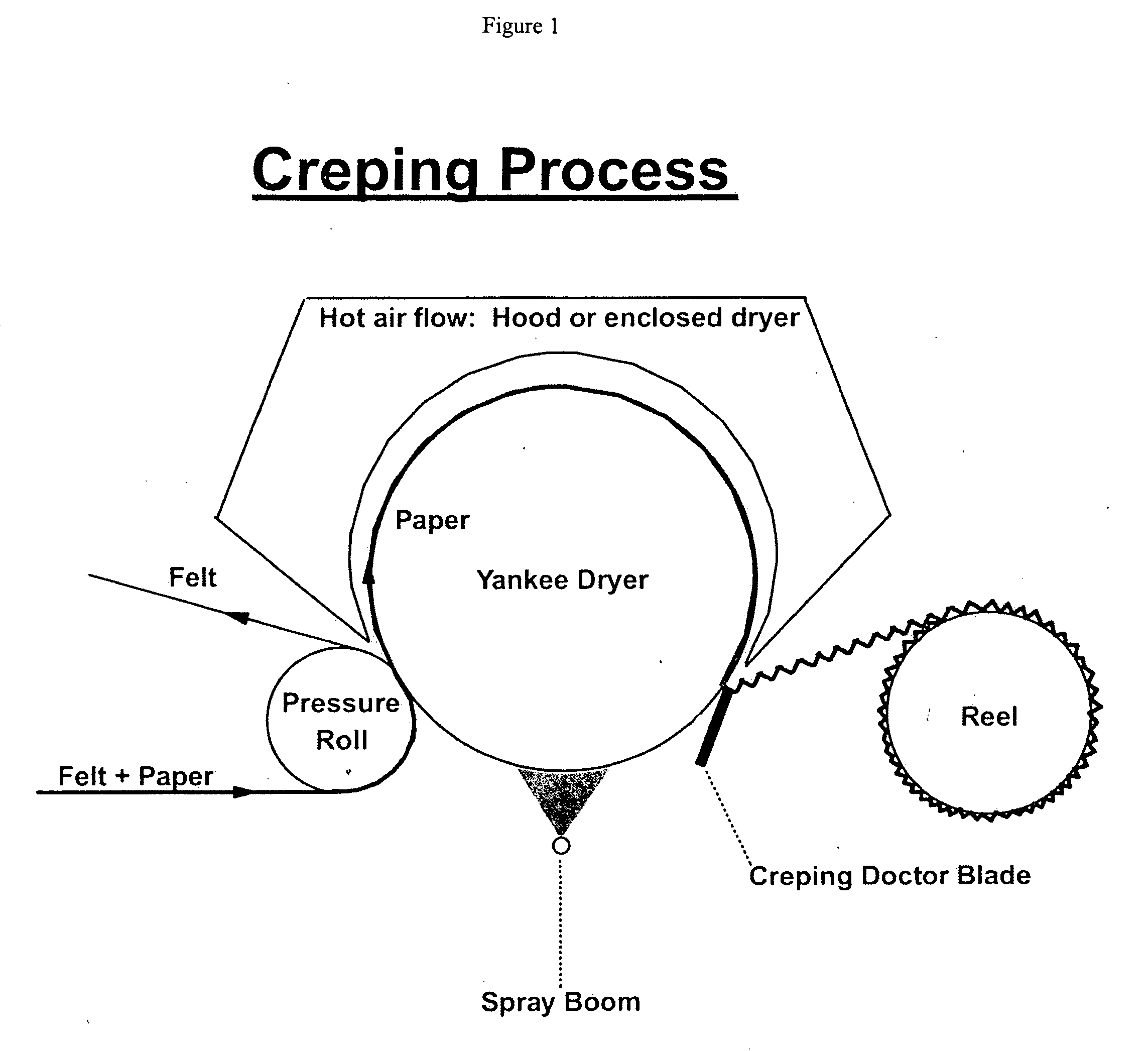

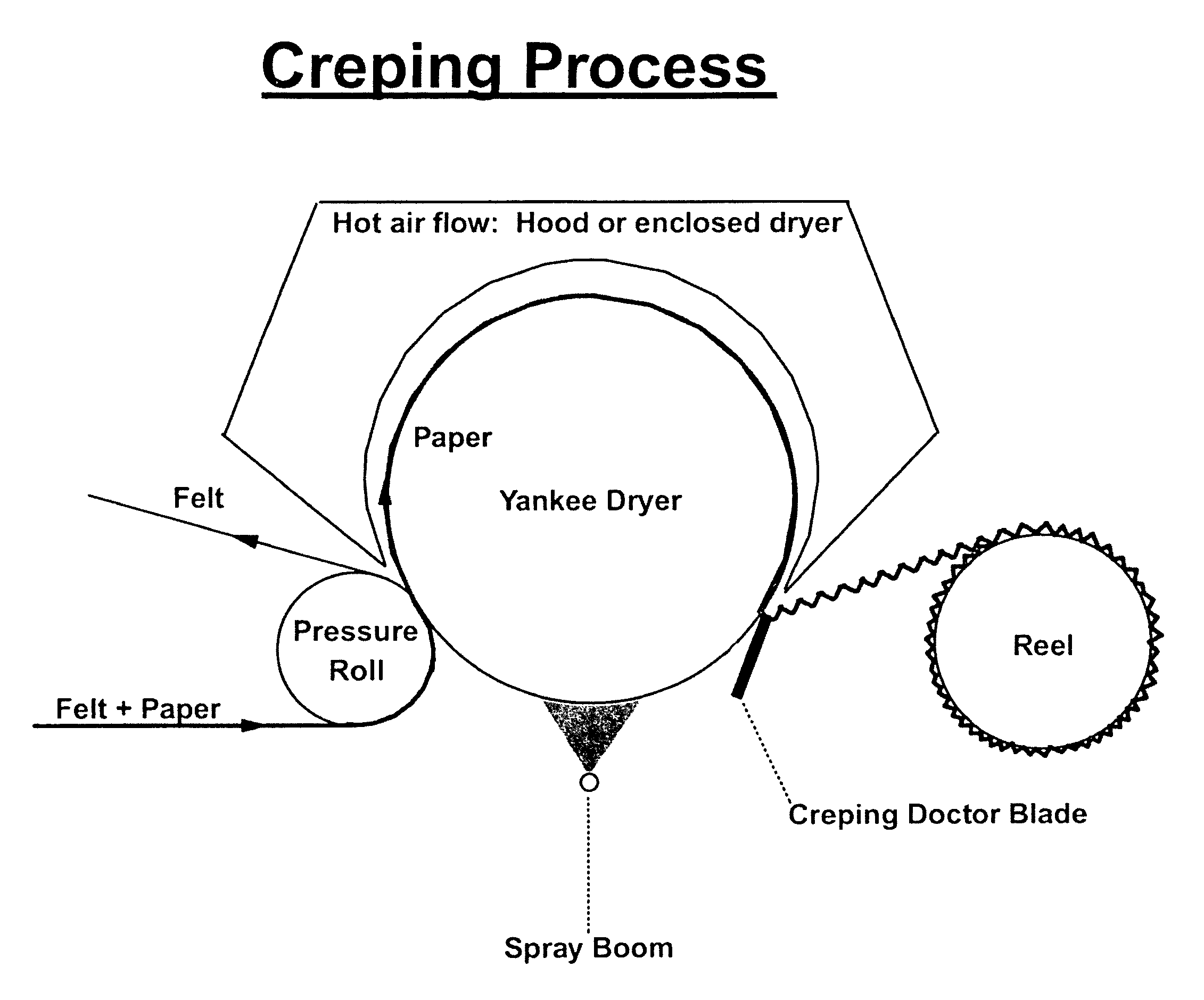

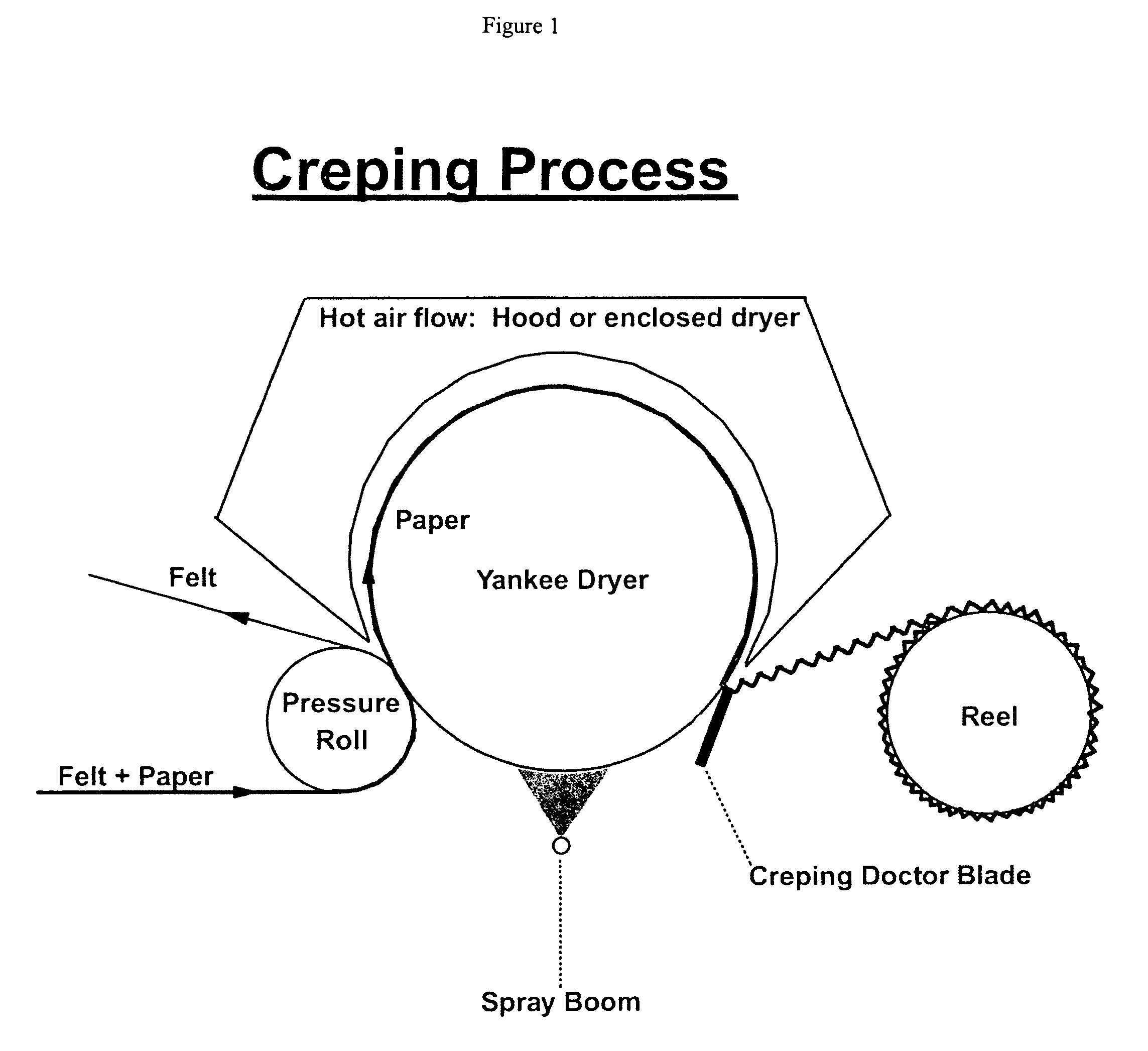

Modified creping adhesive composition and method of use thereof

ActiveUS20050245669A1Soften and plasticizeSoften and/or plasticize the creping adhesiveNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industry

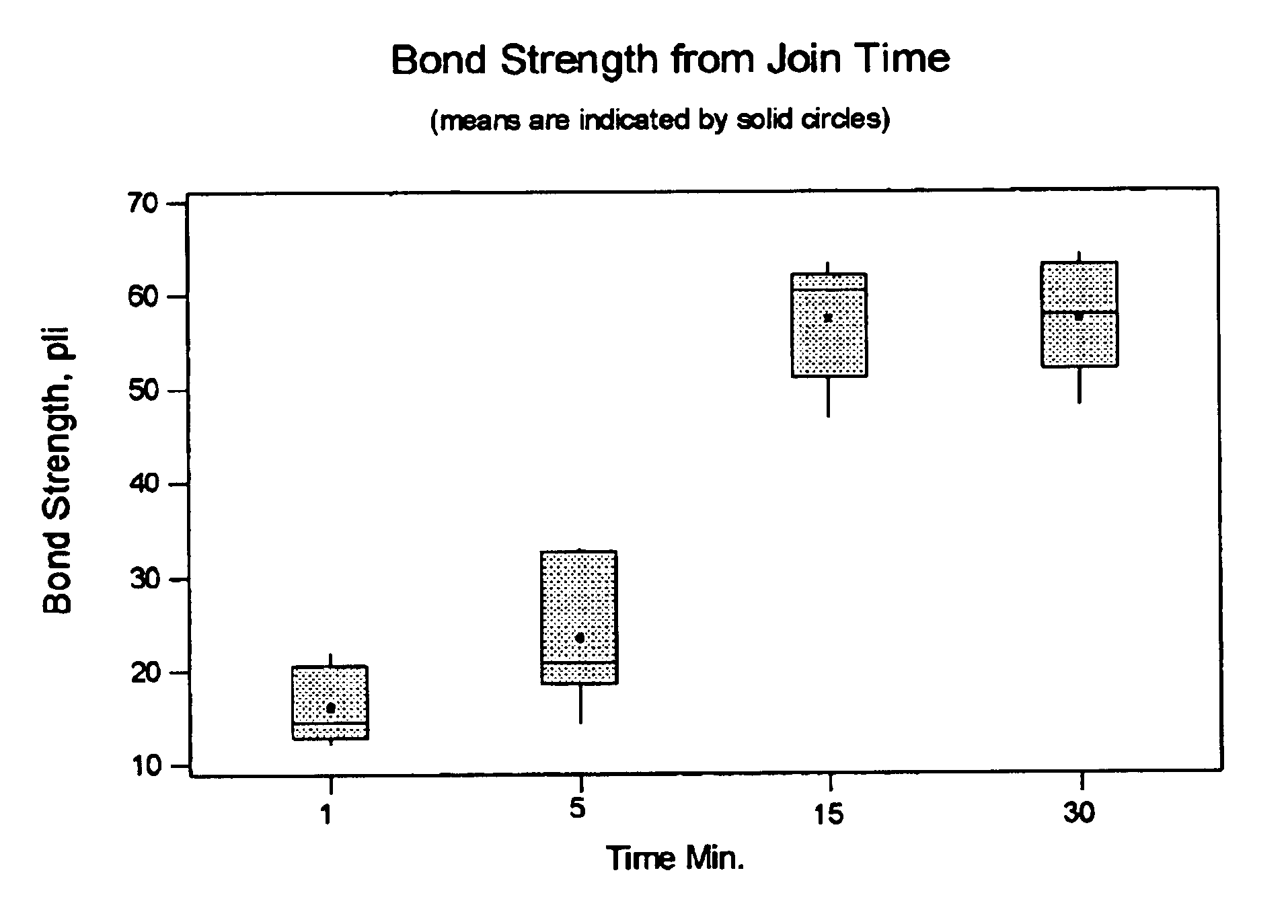

A modified creping adhesive composition, comprising an adhesive component and at least one terpene modifier, and its use in the production of creped paper products by a process which includes the steps of adhering a paper web to the surface of a drying cylinder and separating the paper web from the drying cylinder with a creping blade.

Owner:GPCP IP HLDG LLC

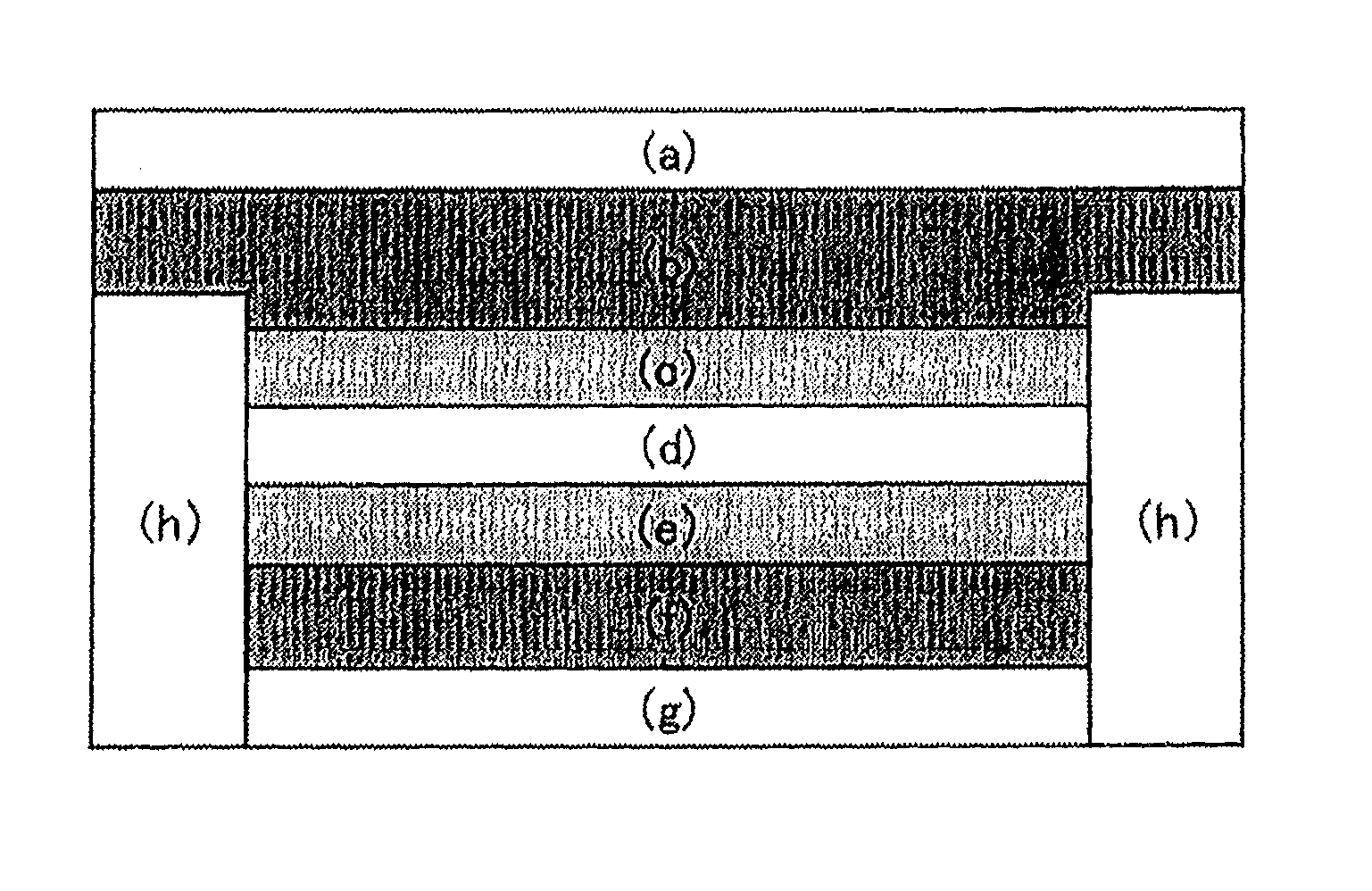

Easily Adhesive Polyester Film and Film for Protecting Back Side of Solar Cell Using the Same

InactiveUS20080050583A1Improve adhesionEasy to stickFilm/foil adhesivesSynthetic resin layered productsVitrificationPolyvinyl alcohol

An easily adhesive polyester film is provided which is used for protection of the back side of a solar cell, the adhesive polyester film comprising a polyester film and a resin film situated on a surface of the polyester film, the resin film comprising a crosslinking agent and a resin selected from the group consisting of a polyester resin having a glass transition point of 20 to 100° C., an acrylic resin having a glass transition point of 20 to 100° C., a combination of the resins and a combination of at least one of the resins and a polyvinyl alcohol having a saponification degree of 70 to 90 mol %. This film has excellent adhesion to EVA while having excellent mechanical properties, heat resistance and moisture resistance.

Owner:TEIJIN DUPONT FILMS JAPAN

Acrylic polymer for use in pressure-sensitive adhesive composition for touch screen panel

InactiveUS20130211028A1High dielectric constantHigh transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcid value

An object of the invention is to provide a pressure-sensitive adhesive sheet. Provided is an acrylic polymer for use in a pressure-sensitive adhesive composition for a touch screen panel, the acrylic polymer being obtained by copolymerizing monomer components comprising (a) a (meth)acrylic acid ester monomer having a C1-12 hydrocarbon group, (b) a hydroxy group-containing (meth)acrylic acid ester monomer, (c) an amide group-containing monomer, and (d) a vinyl ester monomer. The acrylic polymer has an acid value of 0.1 mg KOH / g or less, a weight-average molecular weight of 400,000 to 2,000,000, a Tg of −80 to 0° C., and a permittivity of 3 to 6.

Owner:DAIDOU KASEI KOGYO KK

Modified creping adhesive composition and method of use thereof

ActiveUS7404875B2Soften and/or plasticize the creping adhesiveNatural cellulose pulp/paperMechanical working/deformationPulp and paper industryPolymer science

A modified creping adhesive composition, comprising an adhesive component and at least one terpene modifier, and its use in the production of creped paper products by a process which includes the steps of adhering a paper web to the surface of a drying cylinder and separating the paper web from the drying cylinder with a creping blade.

Owner:GPCP IP HLDG LLC

Delayed-tack adhesive composition

InactiveUS6080480AIncrease stickinessImprove the immunityNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer sciencePlasticizer

PCT No. PCT / JP96 / 02685 Sec. 371 Date Mar. 25, 1998 Sec. 102(e) Date Mar. 25, 1998 PCT Filed Sep. 18, 1996 PCT Pub. No. WO97 / 12010 PCT Pub. Date Apr. 3, 1997A delayed-tack adhesive composition exhibiting a high tack strength even for adherends made of non-polar materials such as polyethylene and polypropylene, which comprises a (co)polymer prepared by the use of a radical-polymerizable monomer having a straight-chain or branched alkyl group having 9 to 18 carbon atoms and a plasticizer being solid at ordinary temperatures.

Owner:TOYO INK SC HOLD CO LTD

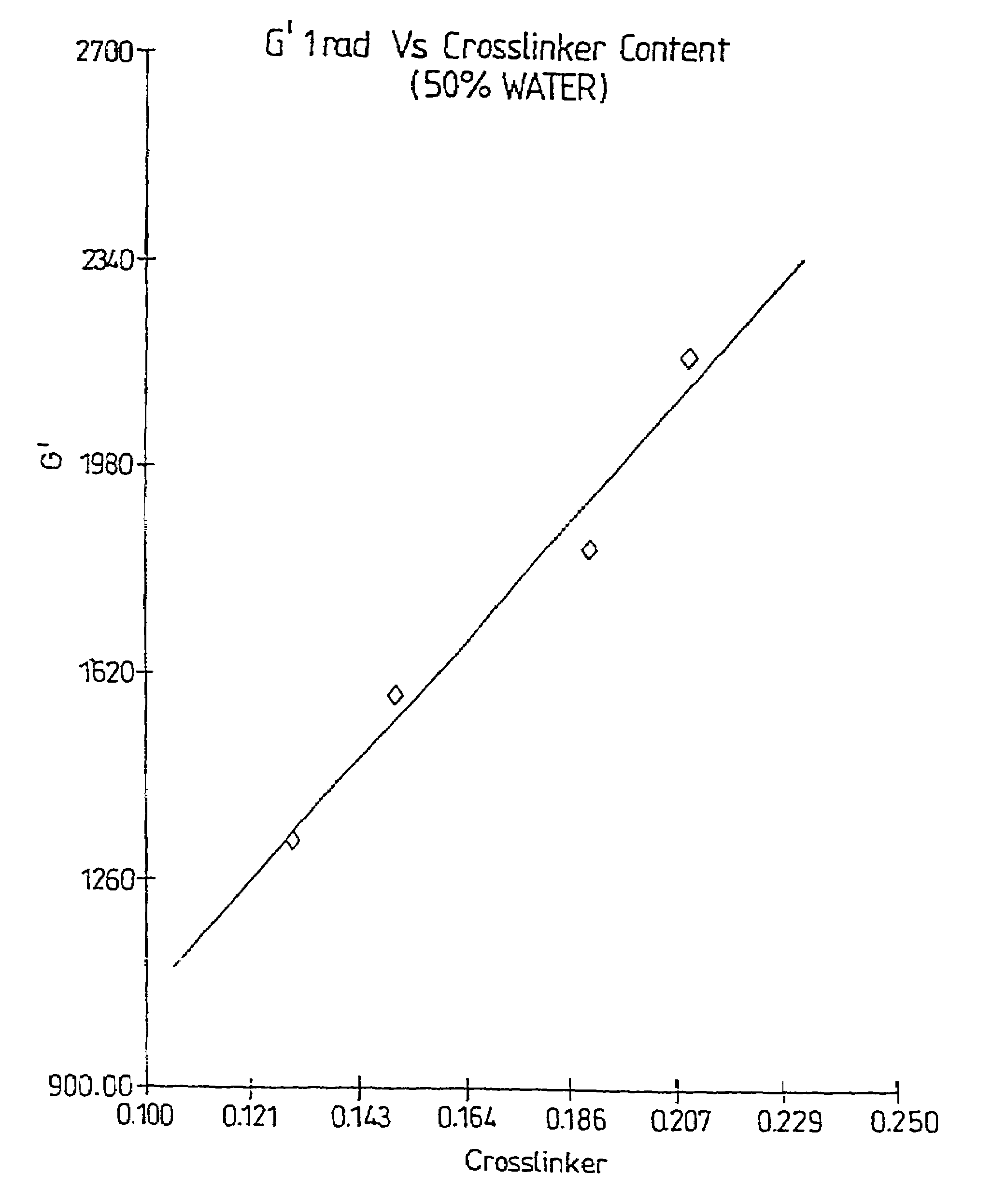

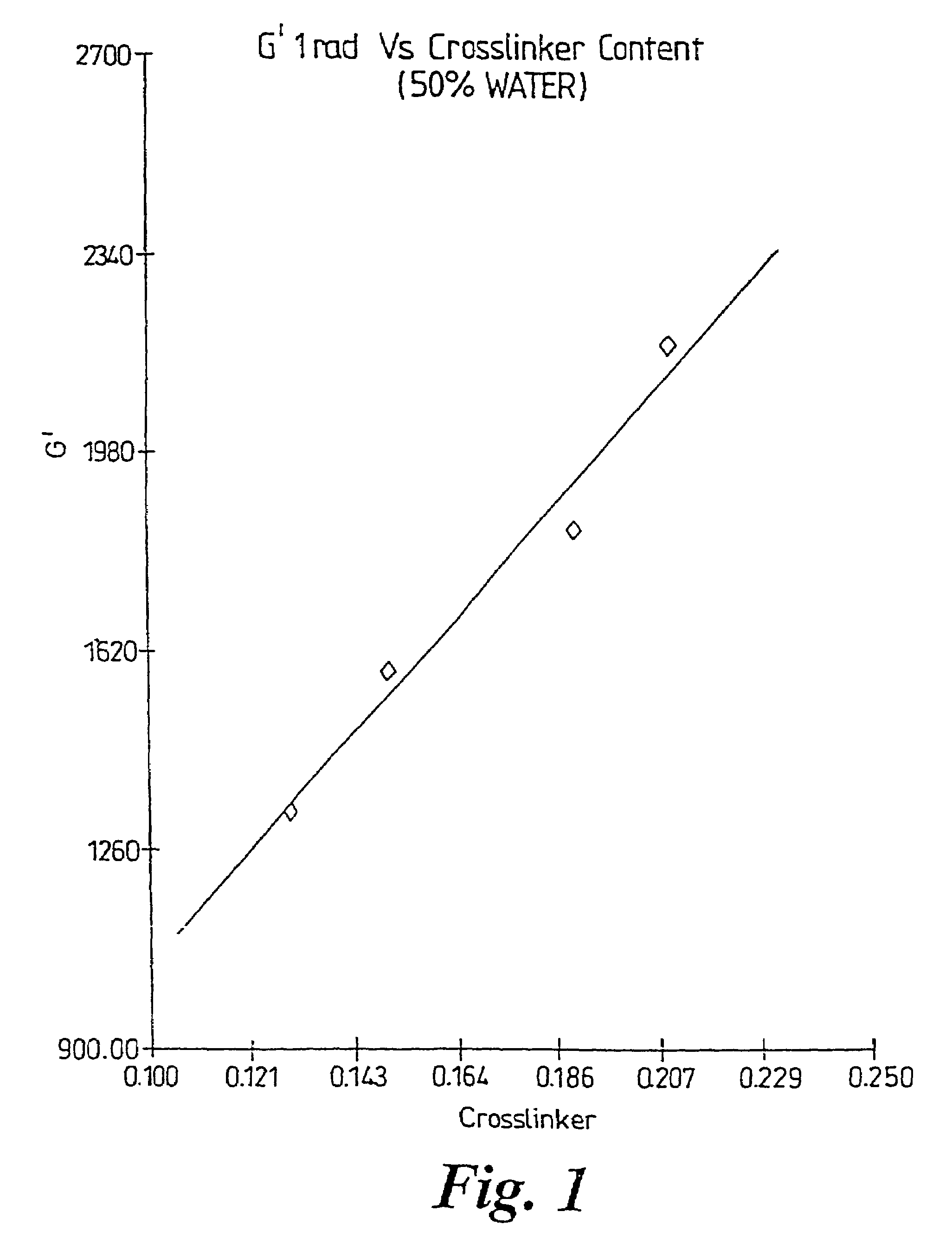

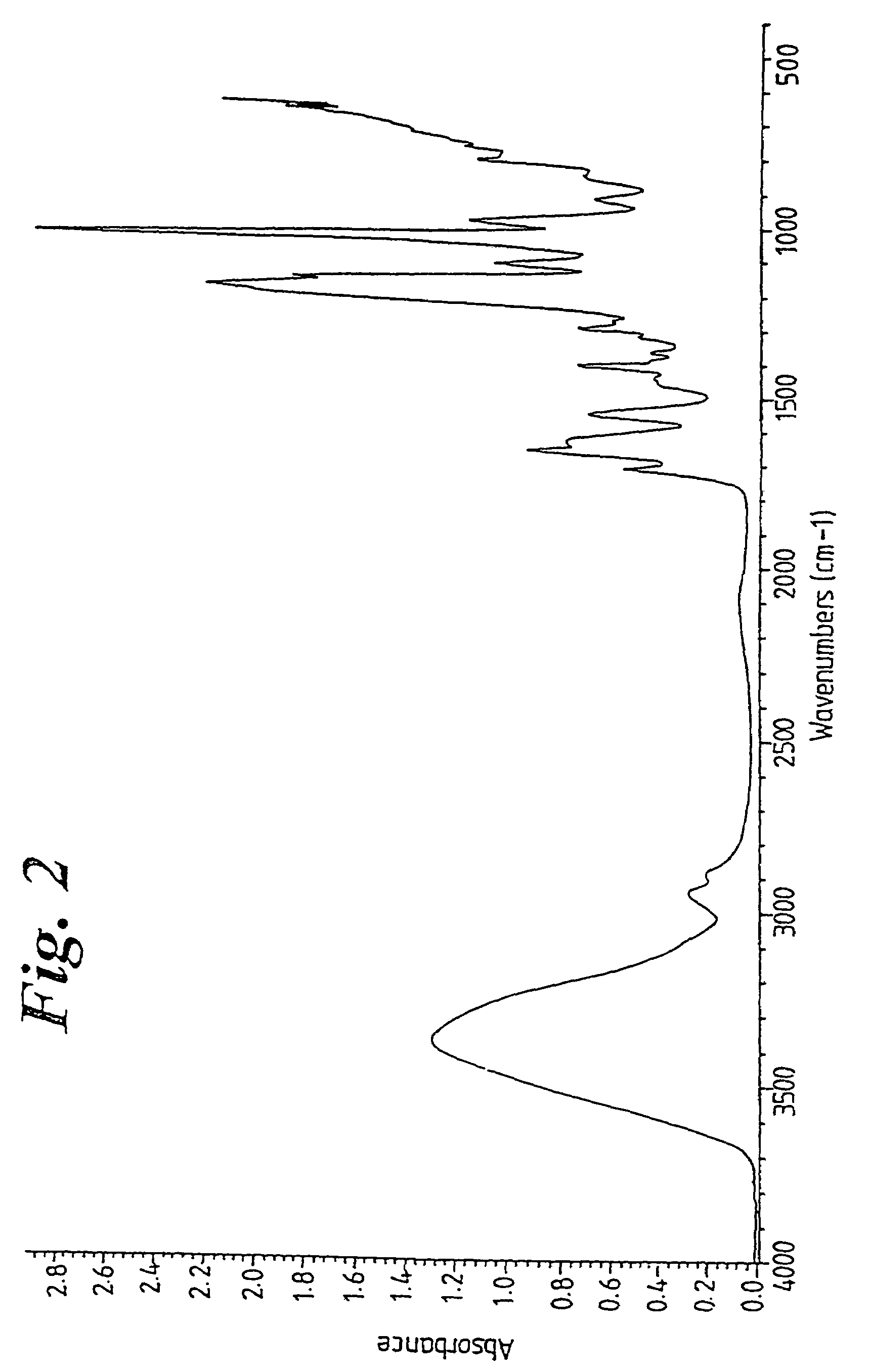

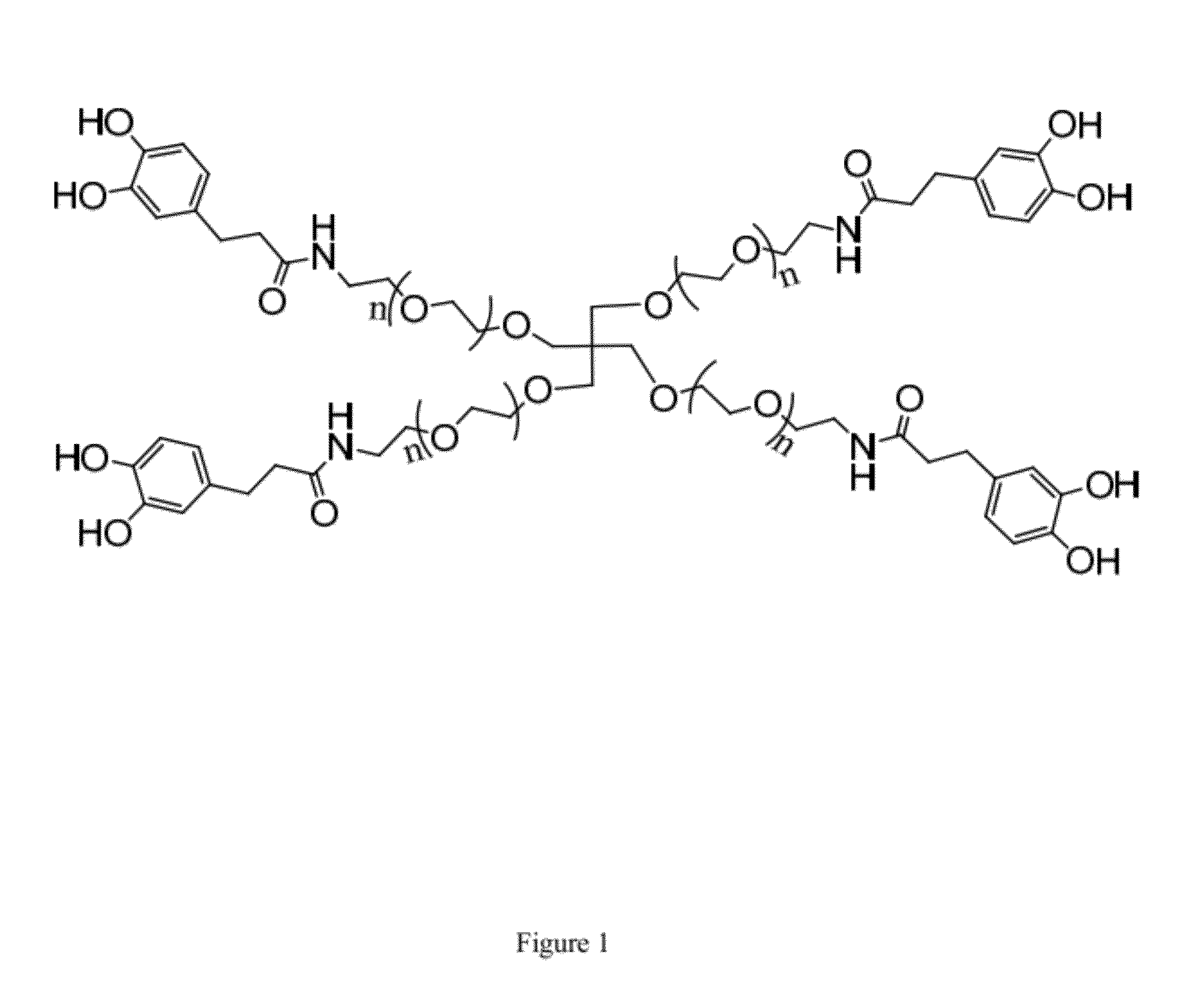

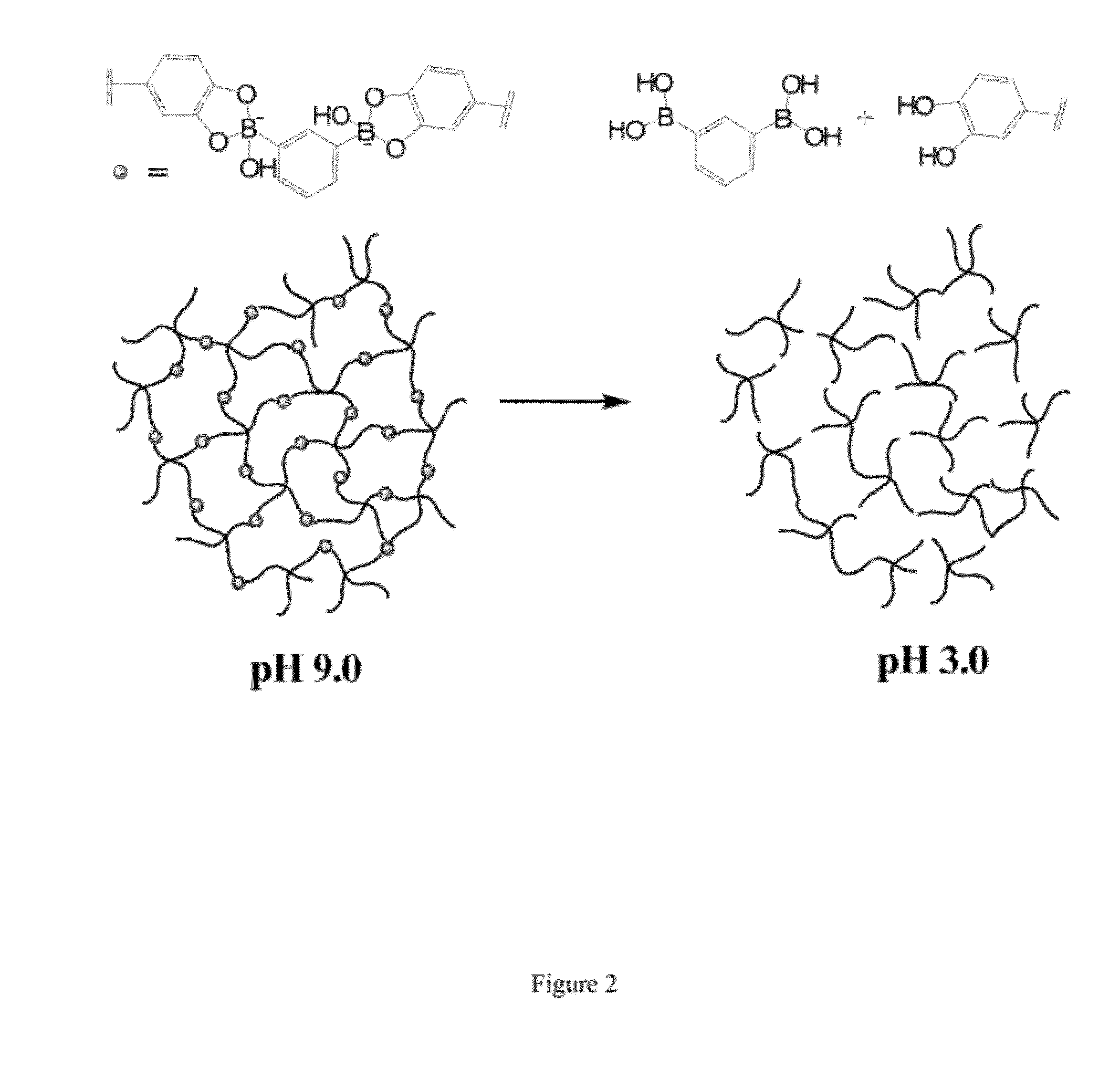

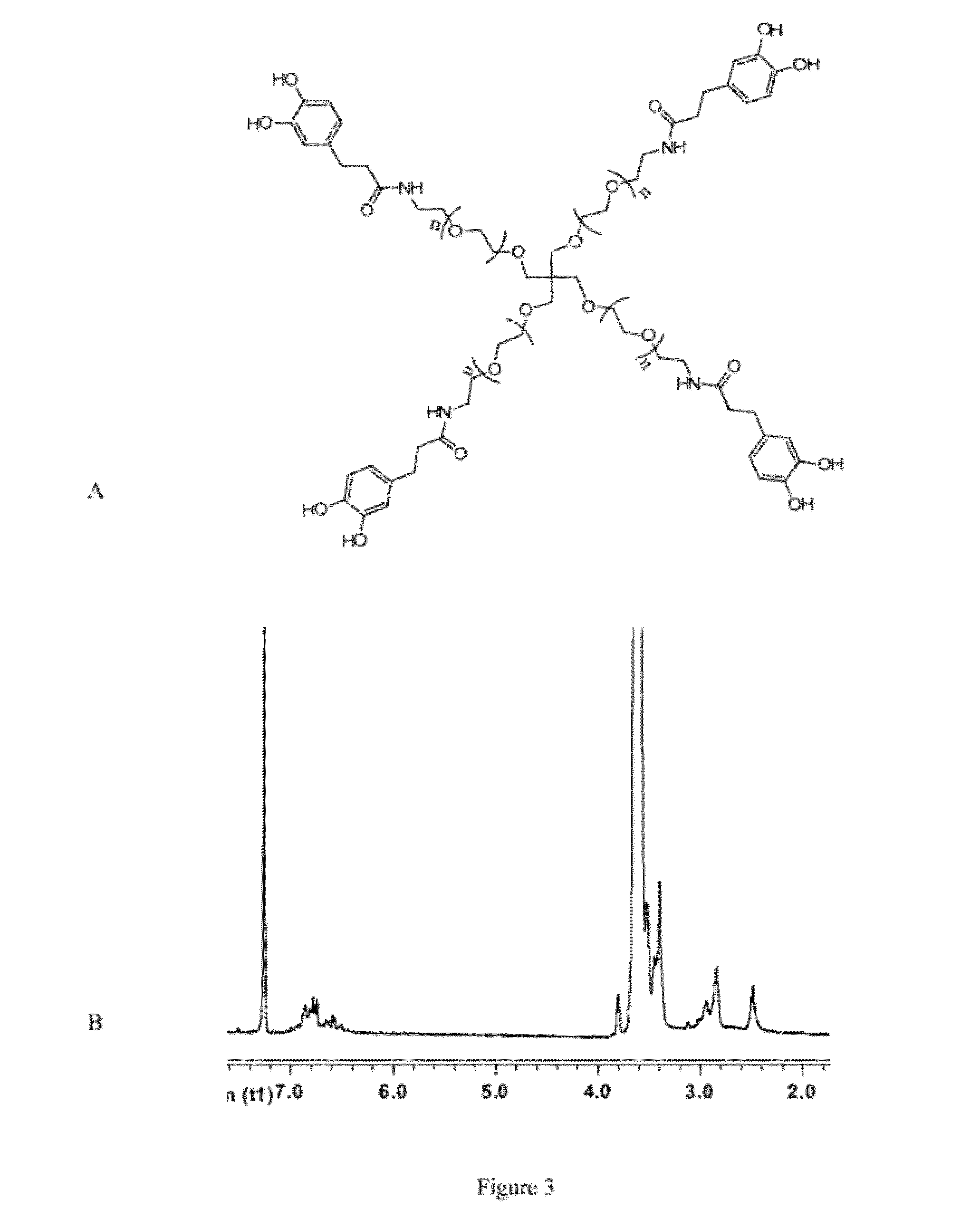

pH Responsive Self-Heating Hydrogels Formed By Boronate-Catechol Complexation

Biocompatible hydrogels made from cross-linked catechol-borate ester polymers are disclosed, along with methods of synthesizing and using such hydrogels. The hydrogels of the present invention are prepared by boronic acid-catechol complexation between catechol-containing macromonomers and boronic acid-containing cross-linkers. The resulting hydrogels are pH-responsive and self-healing, and can be used in a number of different biomedical applications, including in surgical implants, in surgical adhesives, and in drug delivery systems is data provides further evidence of the viability of using the disclosed hydrogels for in vivo in biomedical applications.

Owner:NORTHWESTERN UNIV

Optical pressure-sensitive adhesive, pressure-sensitive adhesive attached optical film, and image display

ActiveUS20090104445A1Suppress display unevennessSuppress unevennessLayered productsFilm/foil adhesivesMeth-Display device

An object of the invention is to provide an optical pressure-sensitive adhesive that is for use in pressure-sensitive adhesive attached optical films and so on, includes an acrylic copolymer and is less likely to cause display unevenness in the peripheral portion of a display screen. An optical pressure-sensitive adhesive, comprising: an acrylic copolymer containing alkyl (meth)acrylate (a1) and N-(2-hydroxyethyl)(meth)acrylamide (a2) as a monomer unit.

Owner:NITTO DENKO CORP

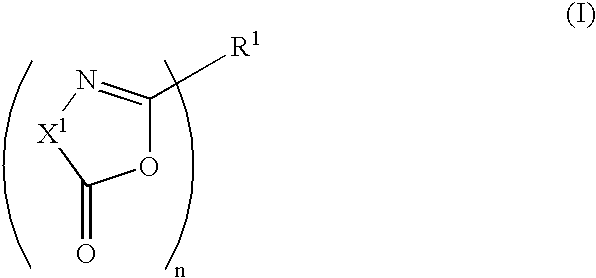

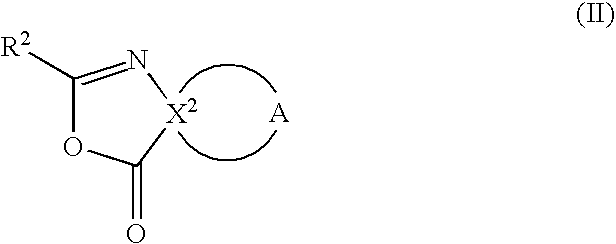

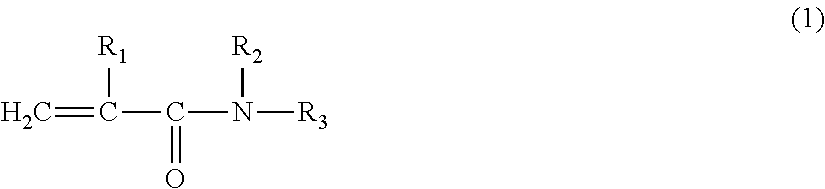

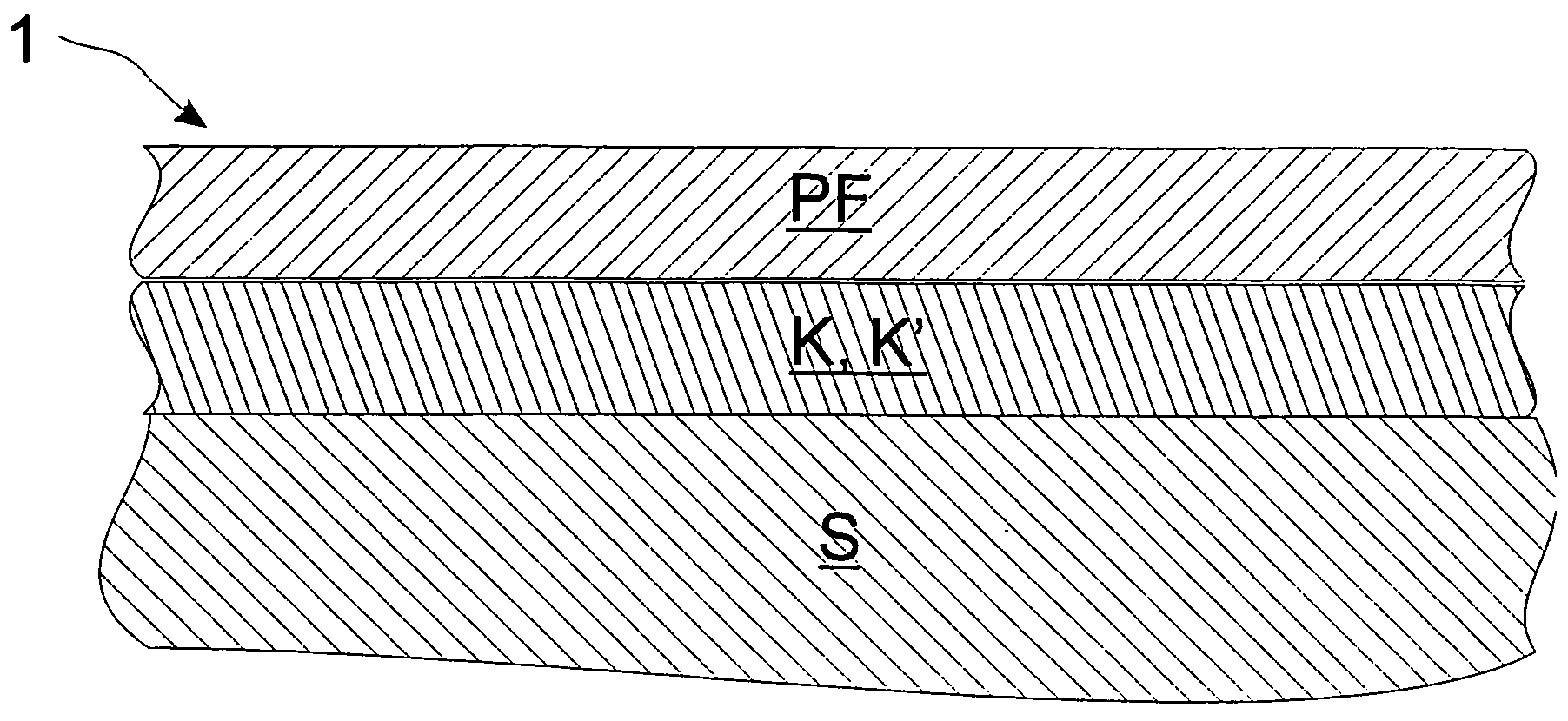

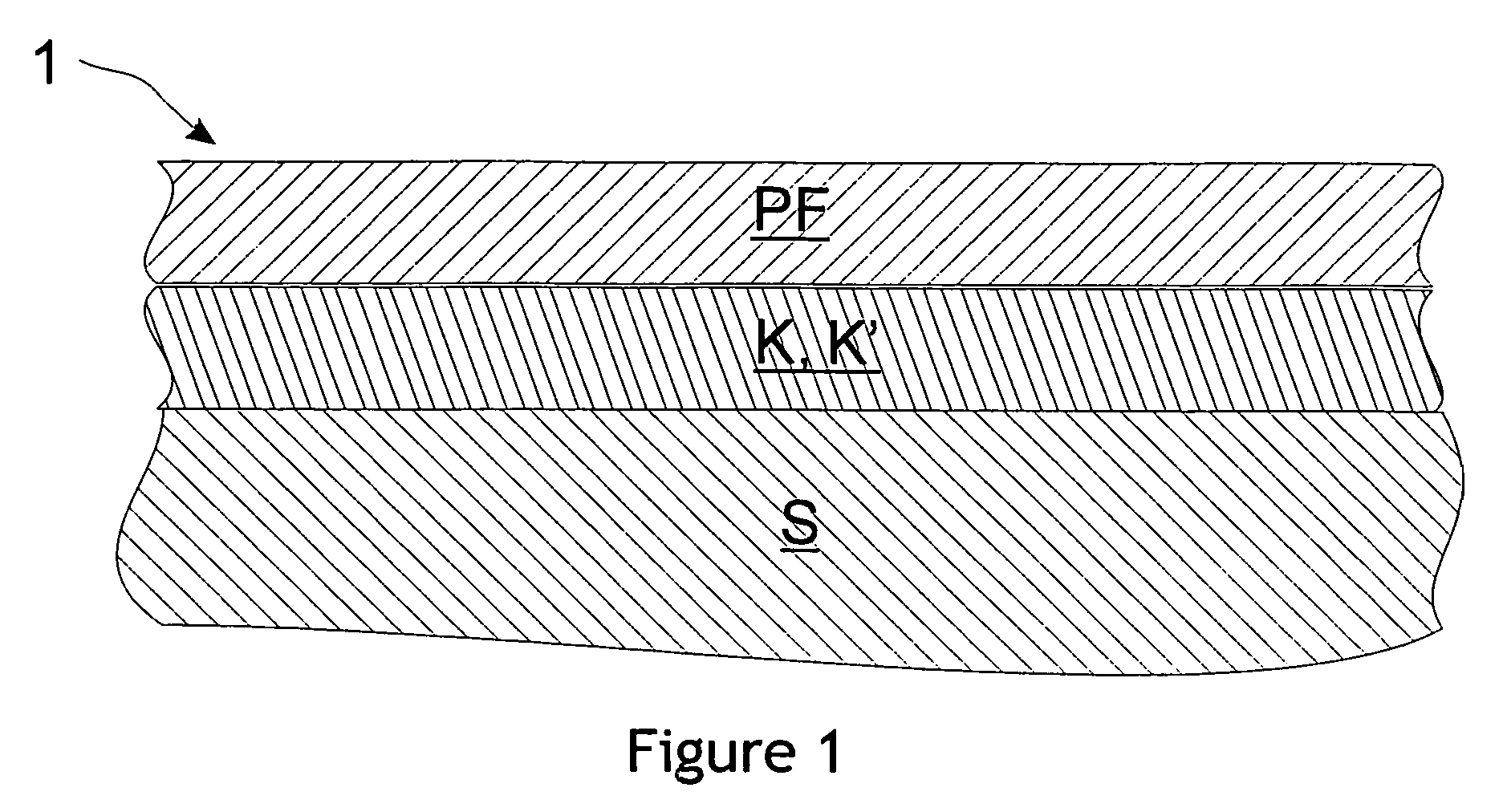

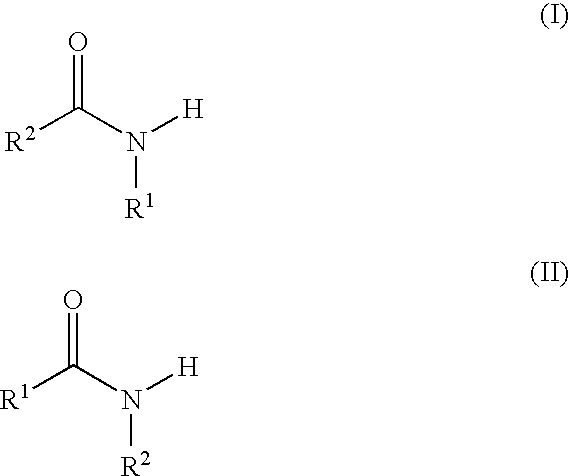

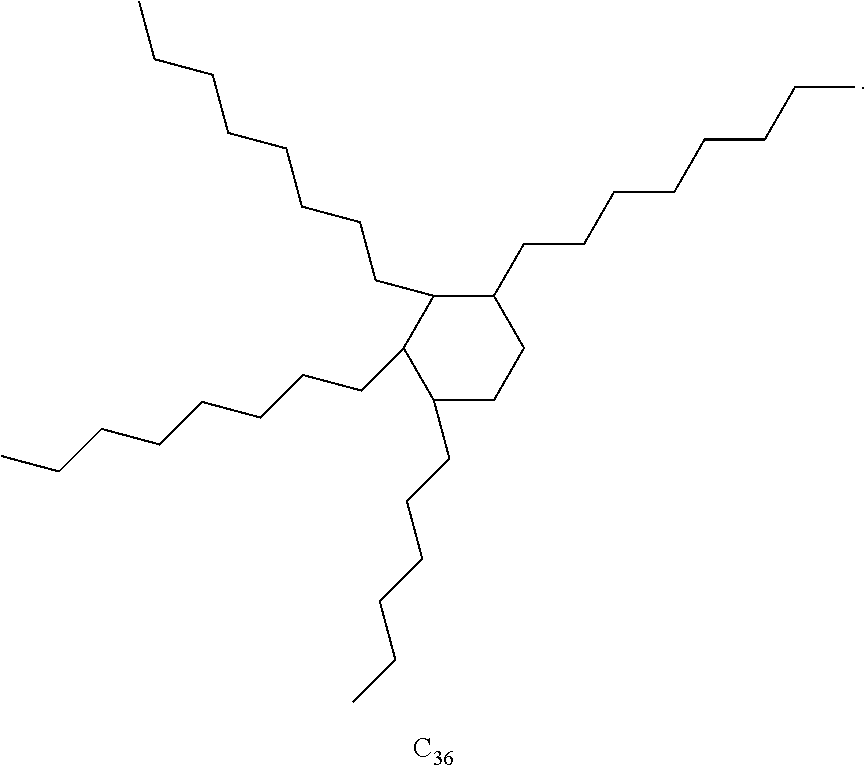

Hotmelt adhesive with good adhesion to polyolefins

InactiveUS20090142610A1Good adhesion to polyolefinsLittle and no adhesionNon-macromolecular adhesive additivesSynthetic resin layered productsPolyolefinPolymer science

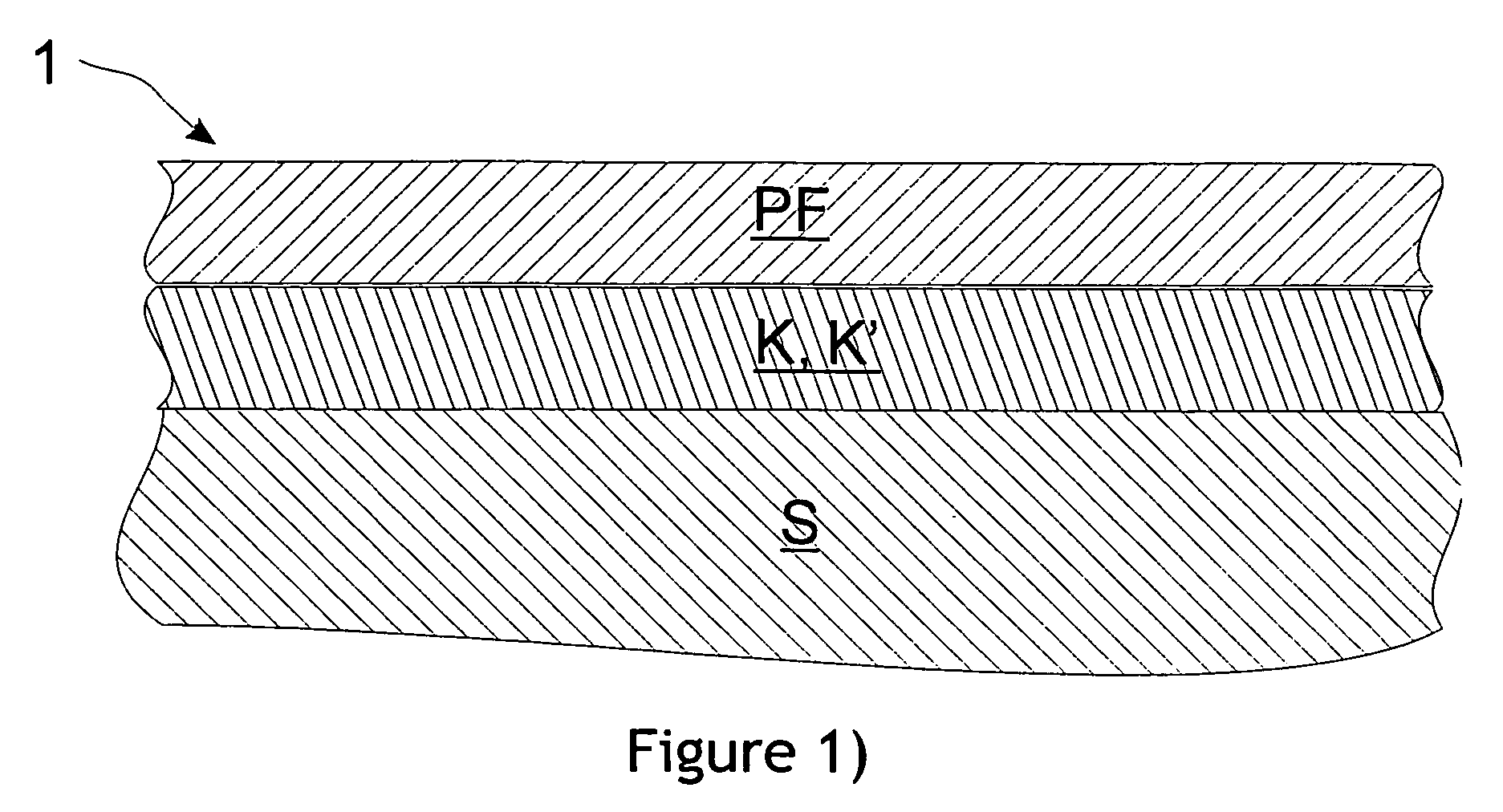

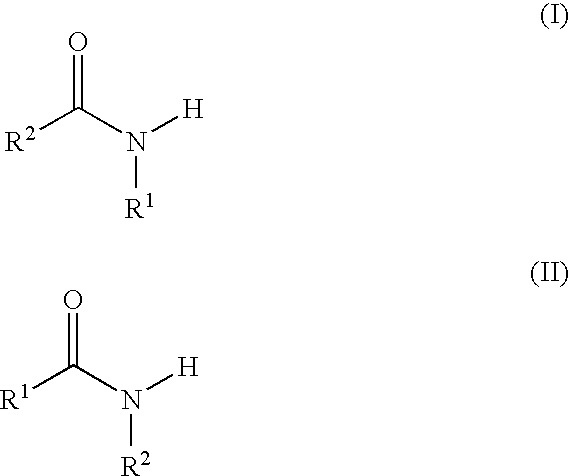

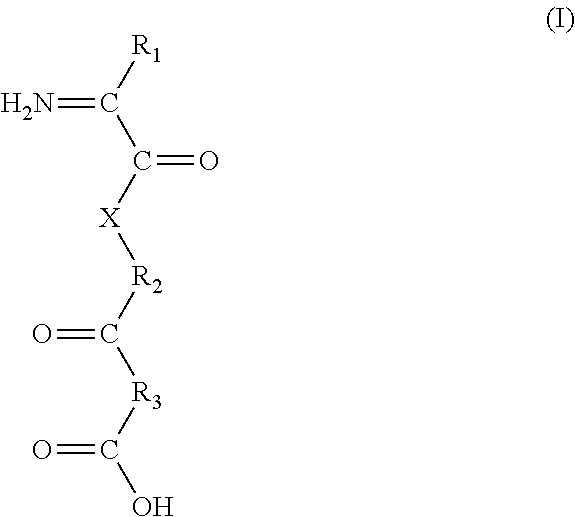

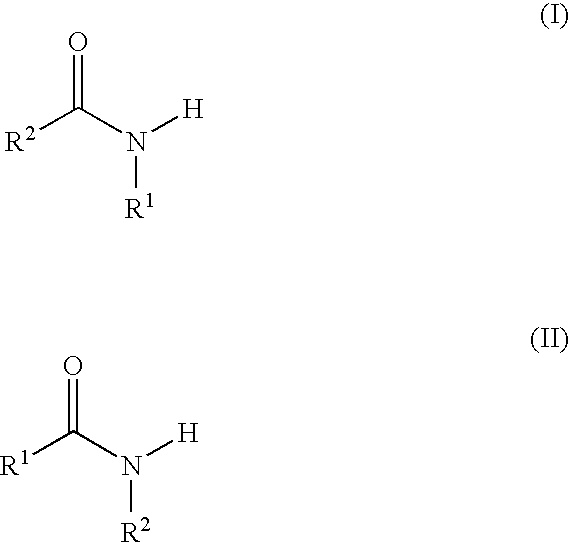

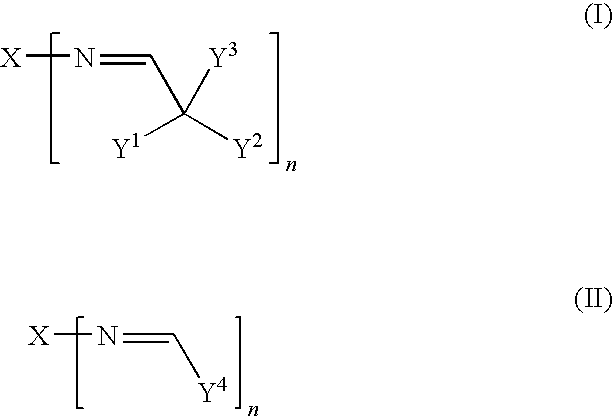

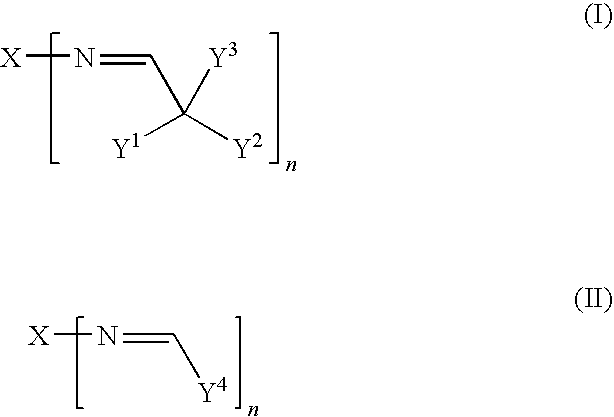

The present invention relates to hotmelt adhesive compositions which comprise at least one thermoplastic polyolefin (P) which is solid at 25° C., and also at least one amide (A) of the formula (I) or (II).These hotmelt adhesive compositions are suitable more particularly for the adhesive bonding of polyolefin films. More particularly it is possible to form assemblies of a substrate (S) and polyolefins bonded with a hotmelt adhesive.

Owner:SIKA TECH AG

Adhesive sheet

ActiveUS20070238805A1Sufficient followabilityHigh strengthImpression capsSolid-state devicesCarbon numberMeth-

An adhesive sheet includes a substrate and an energy-ray curable adhesive layer formed on the substrate. The energy-ray curable adhesive layer includes an energy-ray curable acrylic copolymer and a urethane acrylate. The energy-ray curable acrylic copolymer is formed by copolymerizing at least one of either a dialkyl(meth)acrylamide that has an alkyl group with carbon number of not more than 4, a phenol EO modified (meth)acrylate that has an ethylene glycol chain with a phenyl group bonded to the ethylene glycol chain, a (meth)acryloyl morpholine, or a (meth)acrylate that has an aceto-acetoxyl group, in total of 1 to 30 weight percent of all monomers to form the energy-ray curable acrylic copolymer. The energy-ray curable acrylic copolymer further includes a side chain with an unsaturated group.

Owner:LINTEC CORP

Acrylic Compositions Adhering to Low Surface Energy Substrates

ActiveUS20120171915A1Toxic reductionMaintain good propertiesFilm/foil adhesivesSynthetic resin layered productsSolubilityAlcohol

In general, the invention features a pressure sensitive adhesive that comprises the reaction product of:(a) from about 25 to about 95 parts by weight of at least one acrylic acid ester of a monohydric alcohol whose homopolymer has a Tg less than 0° C.,(b) from 0 to about 75 parts by weight of at least one non-polar ethylenically unsaturated monomer whose homopolymer has a solubility parameter of no greater than 10.50 and a Tg greater than 15° C.; and(c) from about 5 to about 35 parts by weight of at least one polar ethylenically unsaturated monomer whose homopolymer has a solubility parameter of greater than 10.50 and a Tg greater than 15° C.The pressure sensitive adhesives adhere to substrates having a low surface energy and / or high surface energy.

Owner:AVERY DENNISON CORP

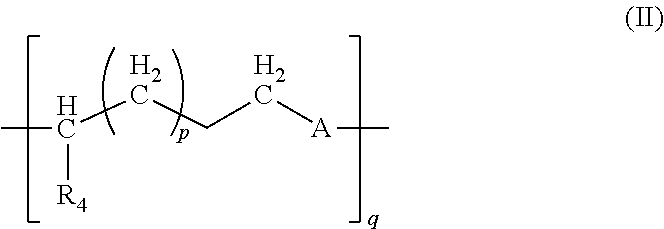

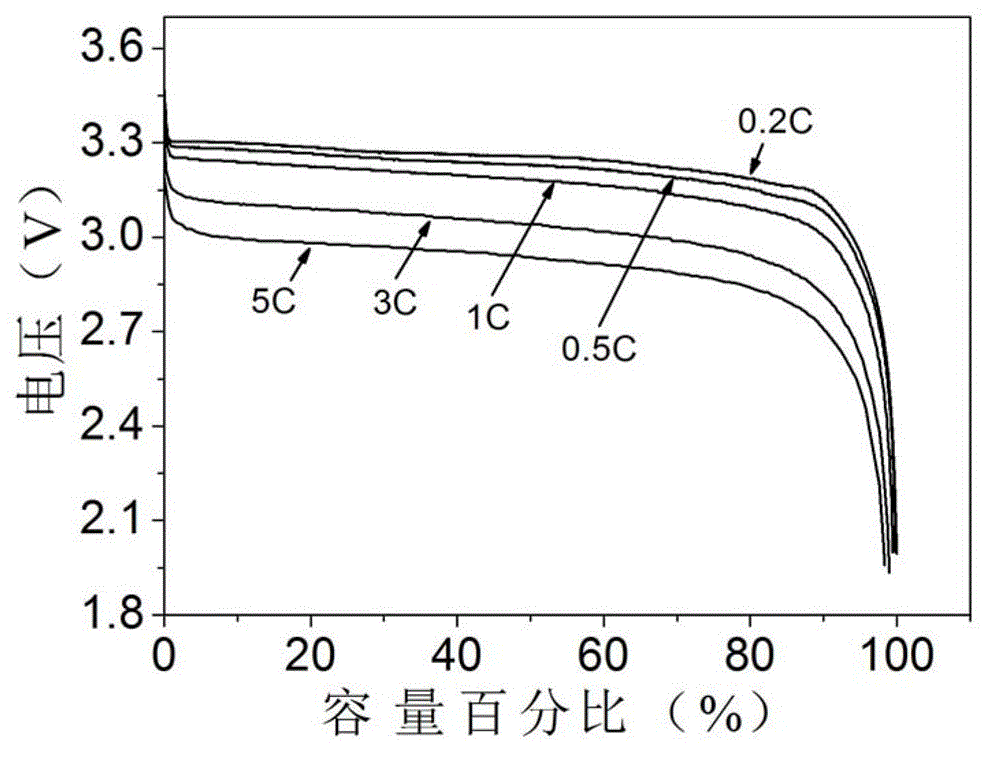

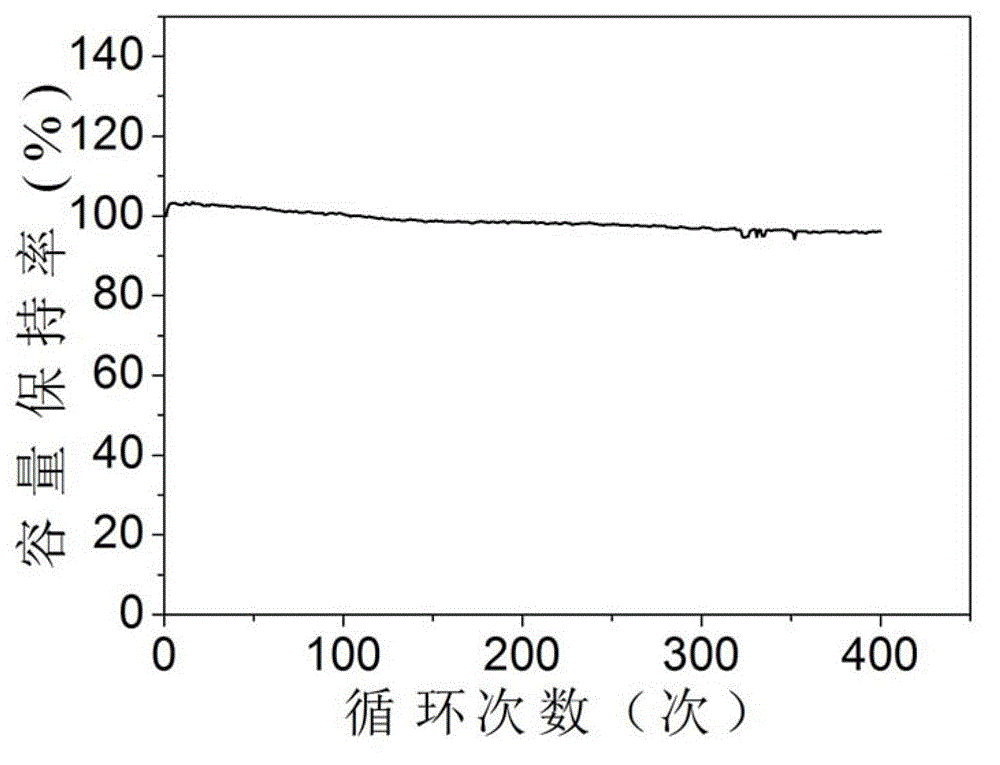

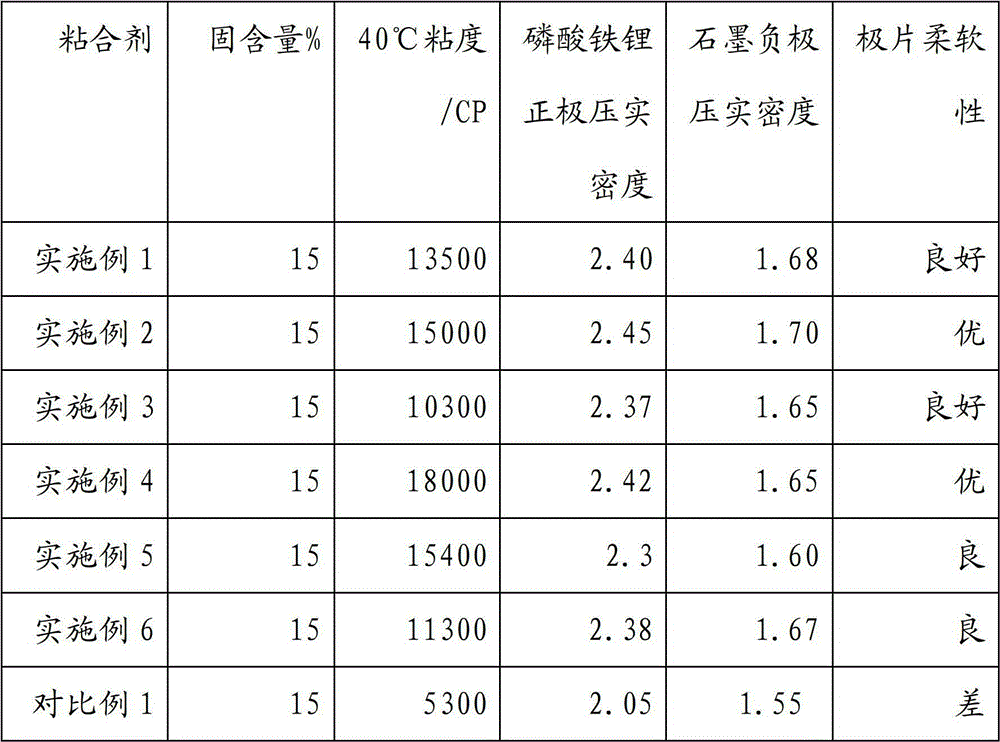

Preparation method for aqueous binder used for lithium ion battery

InactiveCN102746813AImprove cycle performanceImproved magnification performanceCell electrodesAcid polymer adhesivesHydrophilic monomerAluminium-ion battery

The invention provides a preparation method for an aqueous binder used for a lithium ion battery. The method comprises the following steps: weighing unsaturated hydrophilic monomers, unsaturated lipophilic monomers and auxiliary agents; dissolving the weighed unsaturated hydrophilic monomers in distilled water and uniform mixing the dissolved unsaturated hydrophilic monomers with the weighed unsaturated lipophilic monomers and auxiliary agents under stirring; adjusting the pH value of an obtained mixture to be 5 to 13, blowing in high purity nitrogen to remove oxygen and adjusting temperature to a constant temperature; adding an initiator for initiation of polymerization; and extracting residual monomers under vacuum so as to obtain the aqueous binder for a lithium ion battery. The aqueous binder for a lithium ion battery provided in the invention has the advantages of environment friendliness, low production cost and good bonding performance; an electrode slice prepared from the aqueous binder for a lithium ion battery has good flexibility and high compacted density and enables performance of positive and negative electrode materials of a lithium ion battery to be fully played; and a prepared lithium ion battery has good cycle performance and rate capability.

Owner:张倩

Acrylic pressure-sensitive adhesive sheet

The present invention relates to an acrylic pressure-sensitive adhesive sheet including: a viscoelastic material layer (X) containing hollow microspheres; and a pressure-sensitive adhesive layer (Y) provided on at least one face of the viscoelastic material layer (X) and formed from a monomer composition, in which the monomer composition includes the following monomers (m1), (m2) and (m3) as essential monomer components, in which a content of the monomer (m1) is 50 to 85% by weight, a content of the monomer (m2) is 0.1 to 20% by weight, and a content of the monomer (m3) is 2 to 40% by weight, based on a total amount of monomer components constituting the monomer composition,(m1) an alkyl(meth)acrylate monomer including an alkyl group having 1 to 20 carbon atoms, which is represented by the following formula (1),[Chem. 1]CH2═C(R1)COOR2 (1)in which R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group having 1 to 20 carbon atoms,(m2) an N-hydroxyalkyl(meth)acrylamide monomer having a hydroxyalkyl group having 1 to 4 carbon atoms, which is represented by the following formula (2),[Chem. 2]CH2═C(R3)CONHR4 (2)in which R3 represents a hydrogen atom or a methyl group, and R4 represents a hydroxyalkyl group having 1 to 4 carbon atoms,(m3) a vinyl monomer having a nitrogen atom in a backbone thereof, except for the monomer (m2).

Owner:NITTO DENKO CORP

Cationic binder emulsion for coating coloring, preparation method and uses

ActiveCN101289601ANo pollution in the processReduce dosageAmide/imide polymer adhesivesEster polymer adhesivesEmulsionFiltration

The invention relates to cation adhesive emulsion, a method for making the same and a use of the same. The adhesive emulsion is generated through the reaction of the following compositions: soft monomer, hard monomer, crosslinking monomer, compound emulsifier of cation and nonionic emulsifier and initiator. When made, a mixed body of the soft monomer, the hard monomer and the crosslinking monomer and an initiator aqueous solution are added in the emulsifier and distilled water to carry out reaction; and the cation adhesive emulsion is made after cooling down and filtration. The aqueous latex not only has a simple making method, but also can be used in textile fabric coating dyeing, textile fabric function finish or the gluing fixative during nano material afterfinish; moreover, the aqueous latex can be used as the film former of an aqueous coating material.

Owner:溧阳常大技术转移中心有限公司

Hotmelt adhesive with good adhesion to polyolefins

InactiveUS8084527B2Non-macromolecular adhesive additivesSynthetic resin layered productsPolymer sciencePolyolefin

The present invention relates to hotmelt adhesive compositions which comprise at least one thermoplastic polyolefin (P) which is solid at 25° C., and also at least one amide (A) of the formula (I) or (II).These hotmelt adhesive compositions are suitable more particularly for the adhesive bonding of polyolefin films. More particularly it is possible to form assemblies of a substrate (S) and polyolefins bonded with a hotmelt adhesive.

Owner:SIKA TECH AG

Adhesive agent and adhesive sheet

ActiveCN102482546AShorten the stabilization periodFull adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesCross-linkAdhesion force

Disclosed is an adhesive agent characterized by comprising an acrylic copolymer (A) and a cross-linking agent (B), wherein the acrylic copolymer (A) comprises 30 to 77 mass% of a constituent unit (a1) derived from an alkyl acrylate monomer having a C5-20 alkyl group, 20 to 60 mass% of a constituent unit (a2) derived from a (meth)acrylate monomer containing an alicyclic group, 0.01 to 5 mass% of a constituent unit (a3) derived from a monomer containing a tertiary amino group induced from (meth)acrylic acid, and 0.1 to 10 mass% of a constituent unit (a4) derived from a monomer containing a functional group (which is different from a tertiary amino group). The adhesive agent can exhibit a satisfactory adhesion force to a material to be adhered regardless of the level of polarity of the surface of the material, can achieve the smooth cross-linking reaction with the cross-linking agent, and can have a decreased stabilization period without the need of using any heavy metal that has concerns about adverse influence on the environments.

Owner:LINTEC CORP

Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

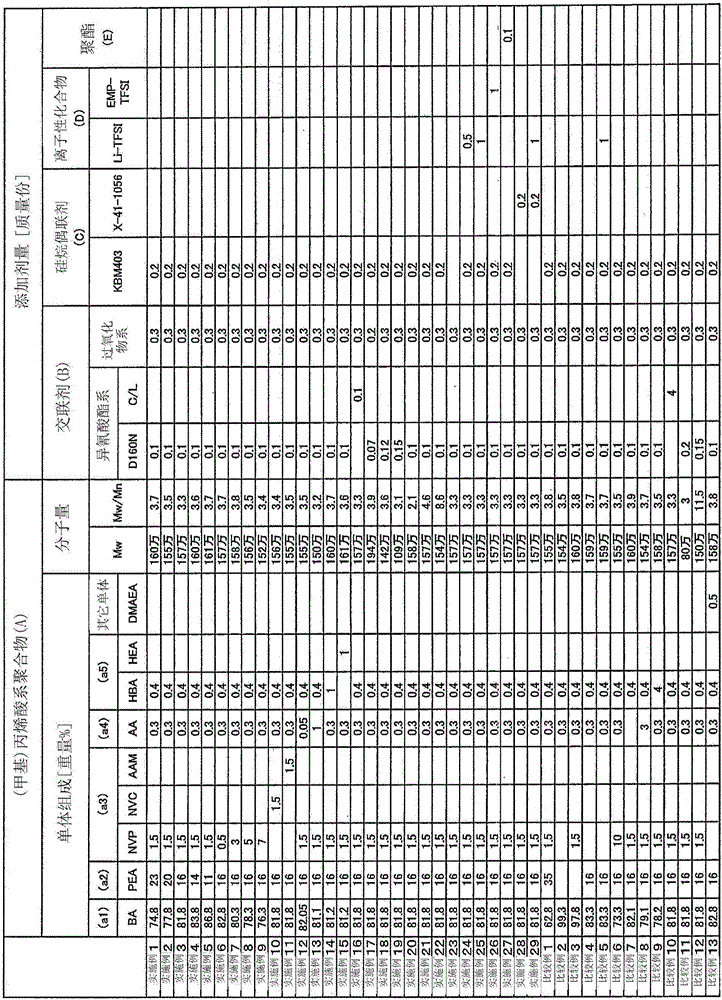

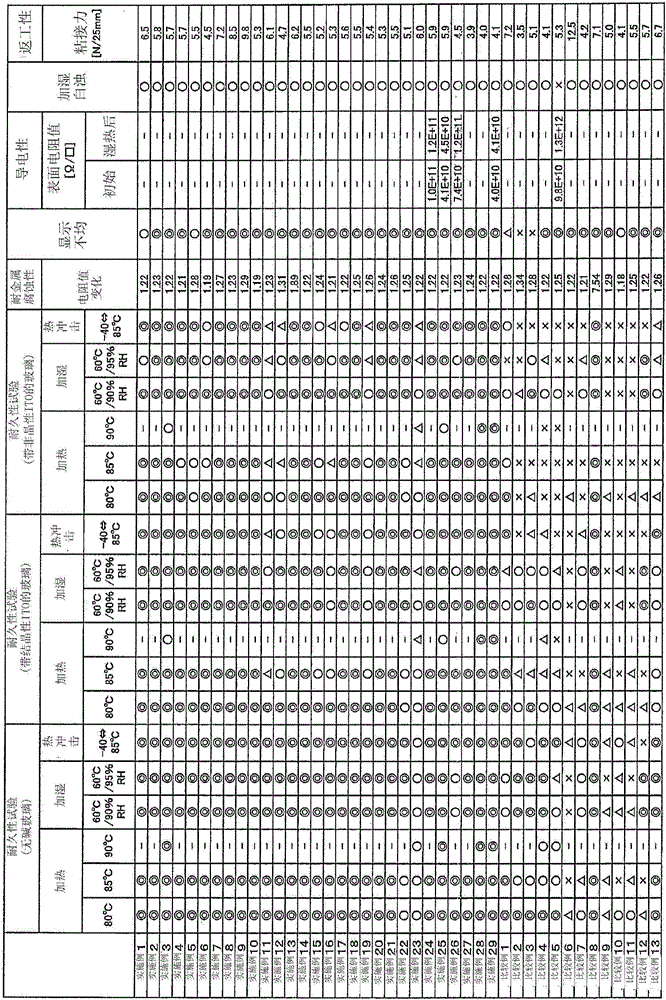

ActiveCN106133096AIncreased durabilityPrevent peelingNon-macromolecular adhesive additivesPolarising elementsPolymer scienceMeth-

An adhesive agent composition for optical films, which comprises: a (meth)acrylic polymer (A) that contains, as monomer units, 70% by weight or more of an alkyl (meth)acrylate (a1), 3 to 25% by weight of an aromatic-ring-containing (meth)acrylate (a2), 0.1 to 8% by weight of an amide-group-containing monomer (a3), 0.01 to 2% by weight of a carboxyl-group-containing monomer (a4) and 0.01 to 3% by weight of a hydroxyl-group-containing monomer (a5) and meets such requirements that the weight average molecular weight (Mw) is 1,000,000 to 2,500,000 and the Mw / (number average molecular weight (Mn)) ratio is 1.8 to 10 inclusive; and a cross-linking agent (B) in an amount of 0.01 to 3 parts by weight relative to 100 parts by weight of the (meth)acrylic polymer (A). The adhesive agent composition can be formed into an adhesive agent layer which satisfies durability to such an extent that the adhesive agent layer does not undergo foaming, is not detached or does not get clouded under humidified conditions when applied onto a glass or a transparent conductive layer, and which can prevent the occurrence of display unevenness due to leakage of light, and which has excellent metal corrosion resistance.

Owner:NITTO DENKO CORP

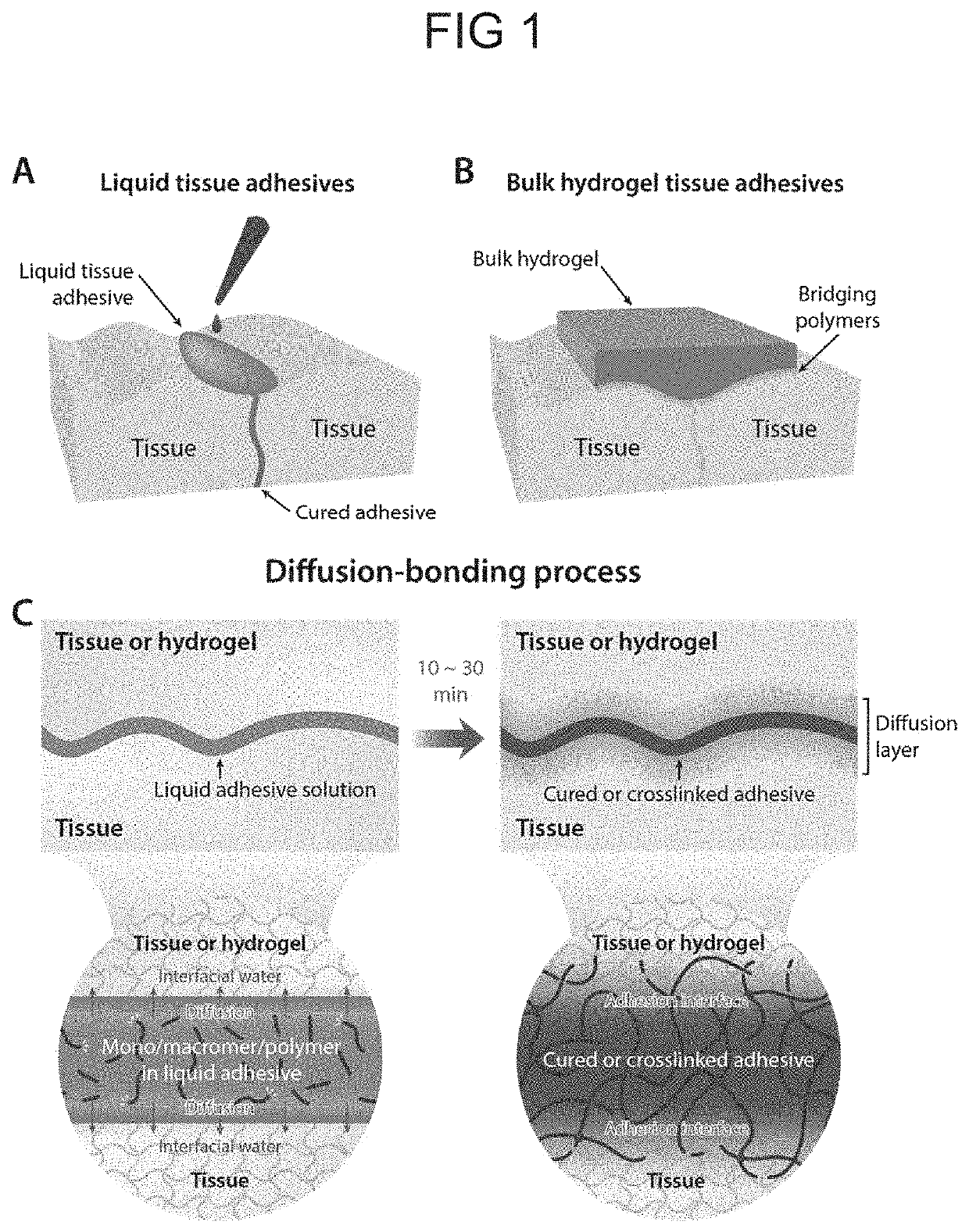

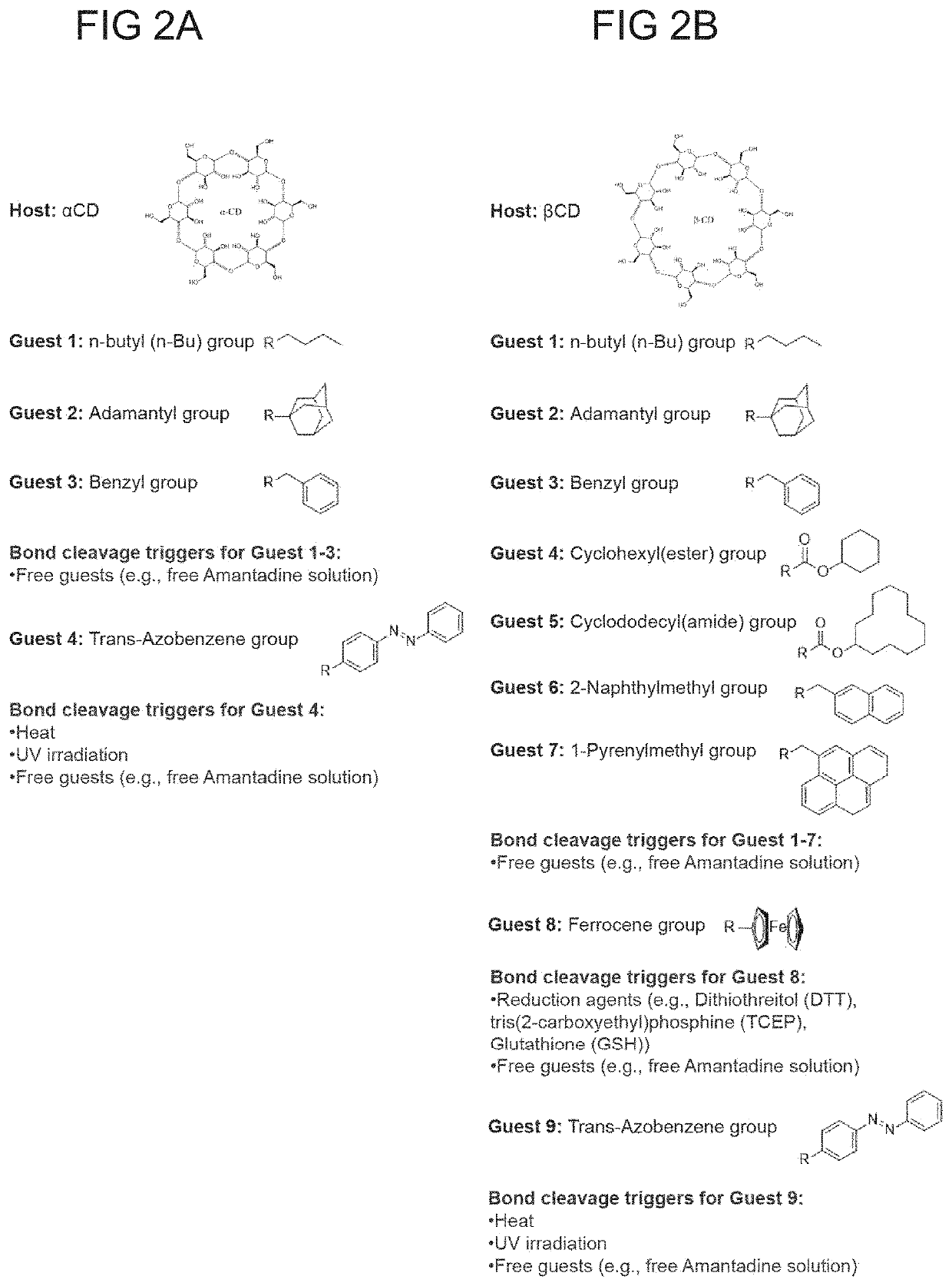

Adhesive material with triggerable on-demand detachment

An adhesive material that provides fast and robust adhesion on wet surfaces, where the adhesion formed is detachable on-demand. The adhesive material is formed of one or more hydrophilic polymers or copolymers grafted with one or more amine coupling groups via a plurality of cleavable physical bonds and / or cleavable covalent bonds and one or more cross linkers. Application of the adhesive material on a wet surface causes the adhesive material to absorb liquid to thereby swell the adhesive material to form a layer of hydrogel, resulting in the formation of temporary crosslinks followed by covalent crosslinks with the surface. Introducing a triggering agent cleaves the cleavable physical bonds and / or cleavable covalent bonds to allow for non-traumatic detachment of the adhesive material from the surface.

Owner:MASSACHUSETTS INST OF TECH

Preparation method of formaldehyde-free water-resistant protein adhesive

InactiveCN103937441ALow costIncrease crosslink densityNon-macromolecular adhesive additivesProtein adhesivesPROTEIN S HEERLENProtein activation

The invention relates to a preparation method of a formaldehyde-free water-resistant protein adhesive. The main preparation steps are as follows: 1) activating a protein raw material: adding the protein-containing raw material and absolute ethanol, stirring, further adding an alkaline solution, and heating to 45-80 DEG C for reaction; cooling to room temperature and adding a reducing agent; and adjusting to neutral, and evaporating to dryness to obtain activated protein powder; and 2) preparing the protein adhesive: adding the activated protein powder prepared in the step 1, water, an acid-adjusting reagent, an enhancer and a preservative into a reactor, reacting at the temperature of 30-50 DEG C, and reducing to room temperature to obtain the protein adhesive. The preparation method is characterized in that a special protein activation process is adopted to enable proteins to expose active groups thereof and utilize a variety of active functional groups of the proteins to the greater extent; the preparation process of the adhesive is simple and has the advantages of good reproductivity, low cost, no formaldehyde and good water resistance; and a hot pressing process is the same with an existing urea-formaldehyde resin pressure plate process, on the basis of not changing and increasing the hot pressing process and equipment, the production of formaldehyde-free artificial plates can be realized, and the market prospects are greater in comparison with the existing protein adhesive in industrial production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

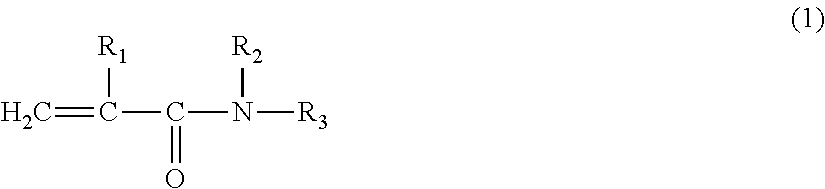

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, process for producing the pressure-sensitive adhesive layer, and optical member with pressure-sensitive adhesive

InactiveUS20090042004A1Excellent pressure-sensitive adhesive propertyIncreased durabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDisplay deviceLayer thickness

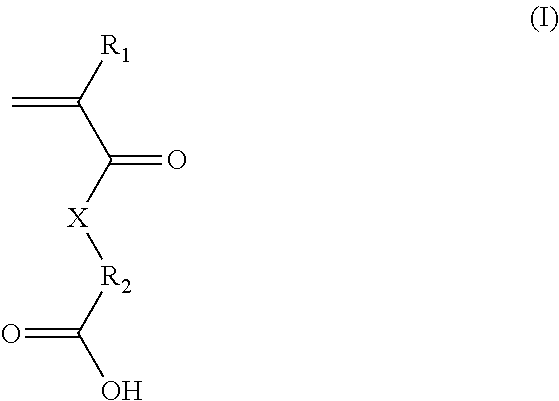

This invention provides a pressure-sensitive adhesive composition that exhibits excellent pressure-sensitive adhesive properties after crosslinking treatment, does not cause lifting or lifting upon heat treatment or treatment under high-humidity conditions particularly even in the case of a pressure-sensitive adhesive layer having a reduced layer thickness, and has excellent durability. A pressure-sensitive adhesive layer formed using the pressure-sensitive adhesive composition, and a process for producing the same are also provided. Further, an optical member with pressure-sensitive adhesive comprising the pressure-sensitive adhesive layer and an image display using the same are provided. The pressure-sensitive adhesive composition is characterized by comprising 100 parts by weight of an (meth)acrylic polymer and 0.02 to 2 parts by weight of a peroxide, and 0.02 to 2 parts by weight of an isocyanate crosslinking agent, the (meth)acrylic polymer comprising as monomer units 50 to 98% by weight of an (meth)acrylic monomer represented by general formula CH2═C(R1)COOR2, wherein R1 represents hydrogen or a methyl group and R2 represents an alkyl group having 2 to 14 carbon atoms, and 0.1 to 35% by weight of a nitrogen-containing monomer.

Owner:NITTO DENKO CORP

Acrylic pressure sensitive adhesive compositions

ActiveUS20060279922A1Improve antistatic performanceWithout whitening appearanceDigital data processing detailsAmide/imide polymer adhesivesNuclear chemistryMetal

The present invention relates to an acrylic pressure sensitive adhesive composition, specifically, an acrylic pressure sensitive adhesive composition having improved anti-static properties, comprising acrylic copolymers, chelating agent which may form a bond with metal ion; and alkali metal salts, and prevent whitening appearance under high temperature and humidity condition as well as static electricity without change of the durability, transparency, and adhesion.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

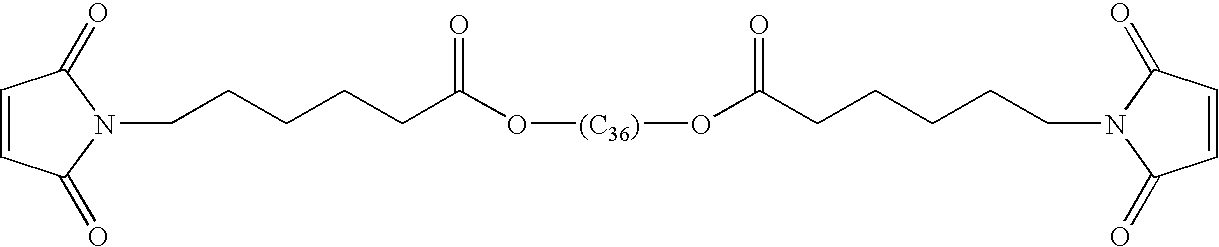

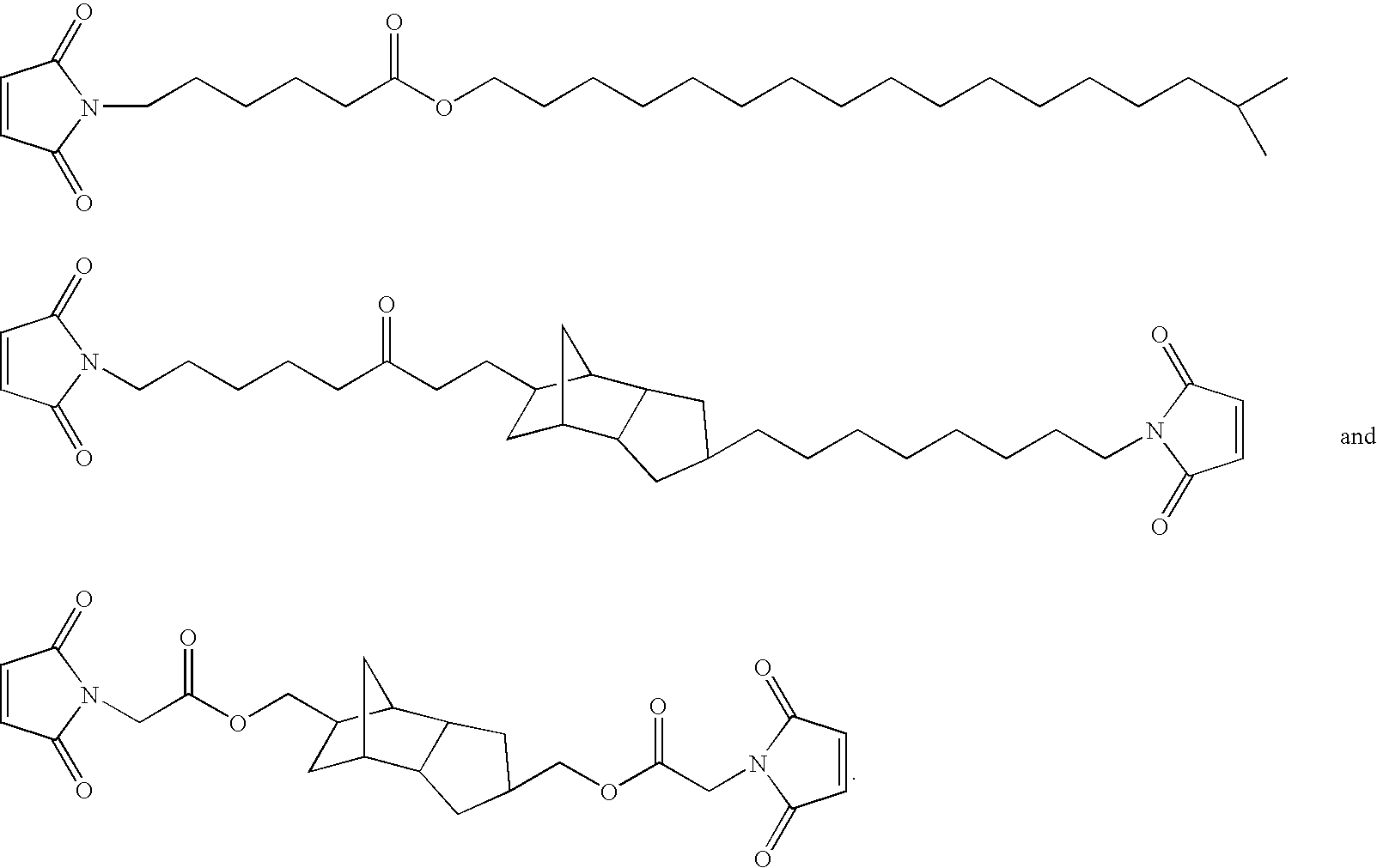

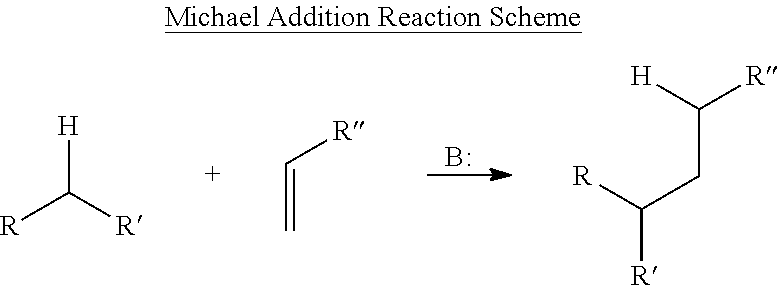

Amide-extended crosslinking compounds and methods for use thereof

ActiveUS20110152466A1Improve adhesionImprove thermal stabilitySilicon organic compoundsAmide/imide polymer adhesivesMethacrylateThermal stability

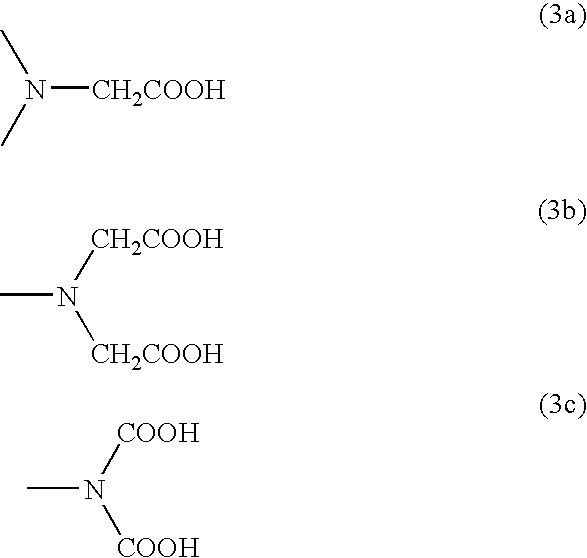

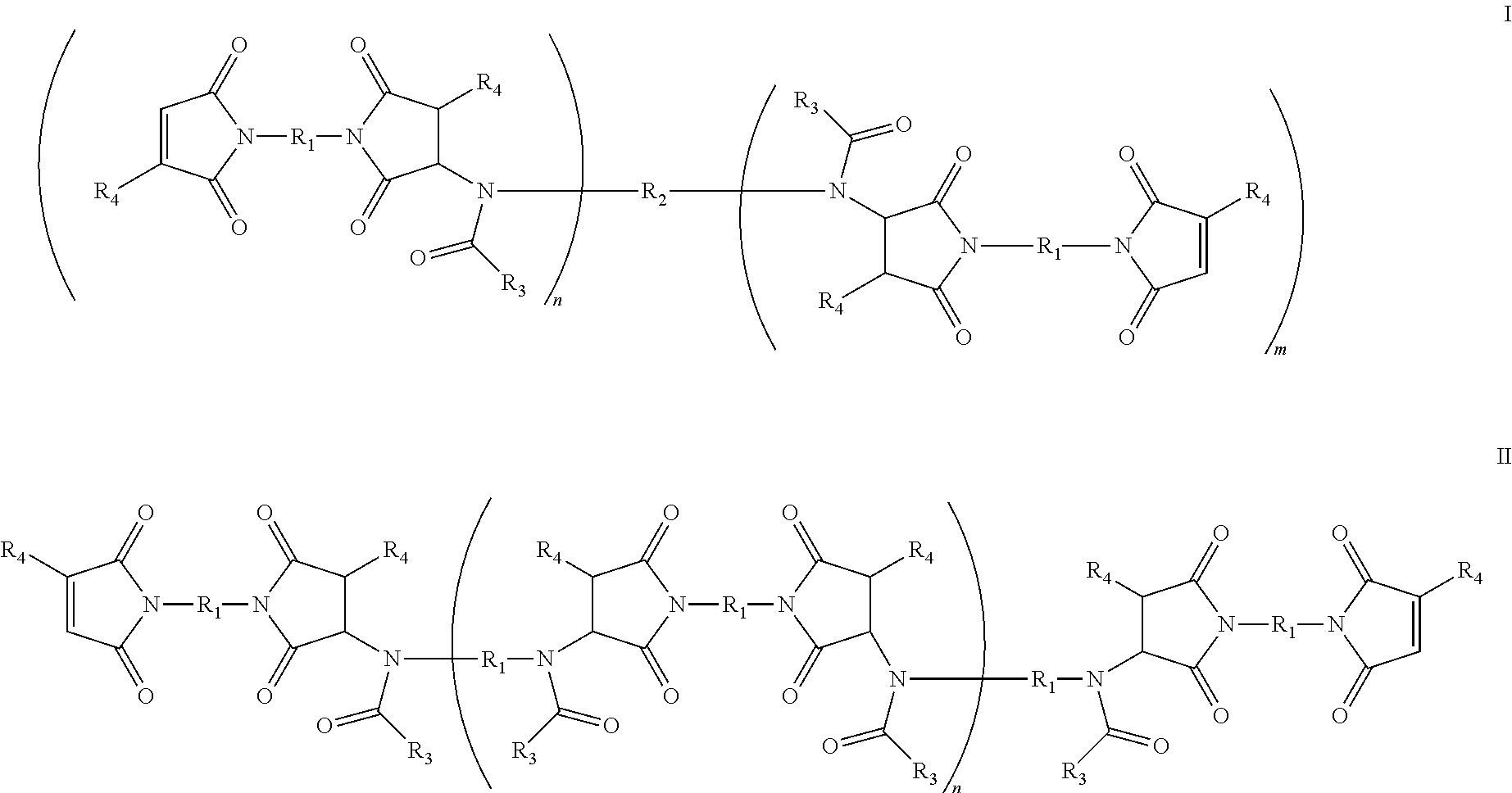

The invention is based on the discovery that a remarkable improvement in the performance of maleimide thermosets can be achieved by incorporating amide-extended maleimides into an adhesive formulation. Amide-extended maleimides described herein can be used to toughen bismaleimide thermosetting materials without sacrificing any thermal stability. Amide-extended maleimides are readily prepared by reacting a bismaleimide with an appropriate amine via the well-known Michael addition reaction. Acylation of the resulting secondary amines provides the amide-extended maleimide. The acylating agent can also be used to introduce polymerizable functional groups into the backbones of these thermoset monomers. Amide-extended acrylate and methacrylate monomers can also be prepared.

Owner:DESIGNER MOLECULES

Terpolymer compositions for coating substrates used in computer printers

InactiveUS20050027068A1Good light stabilityCosmetic preparationsHair cosmetics(Hydroxyethyl)methacrylateComputer printing

Terpolymer compositions of vinyl caprolactam (VCL), dimethylaminopropyl methacrylamide (DMAPMA) and hydroxyethyl methacrylate (HEMA) are described to coat substrates for use in computer printers, and provide advantageous print quality thereon.

Owner:ISP INVESTMENTS LLC

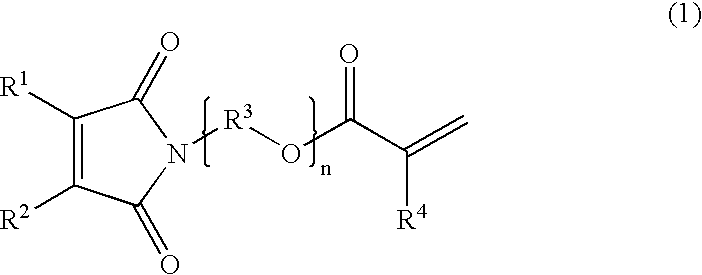

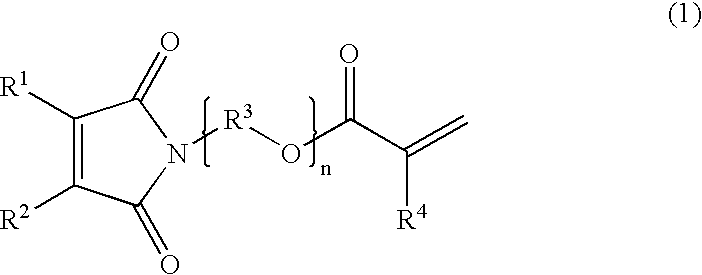

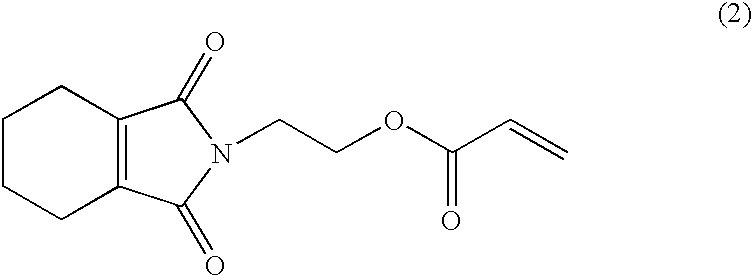

Pressure-sensitive adhesive composition curable with actinic energy ray and pressure-sensitive adhesive sheet

InactiveUS6645617B1Improve curing effectImprove performanceFilm/foil adhesivesAmide/imide polymer adhesivesImideHydrogen

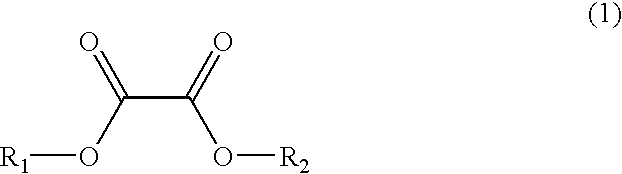

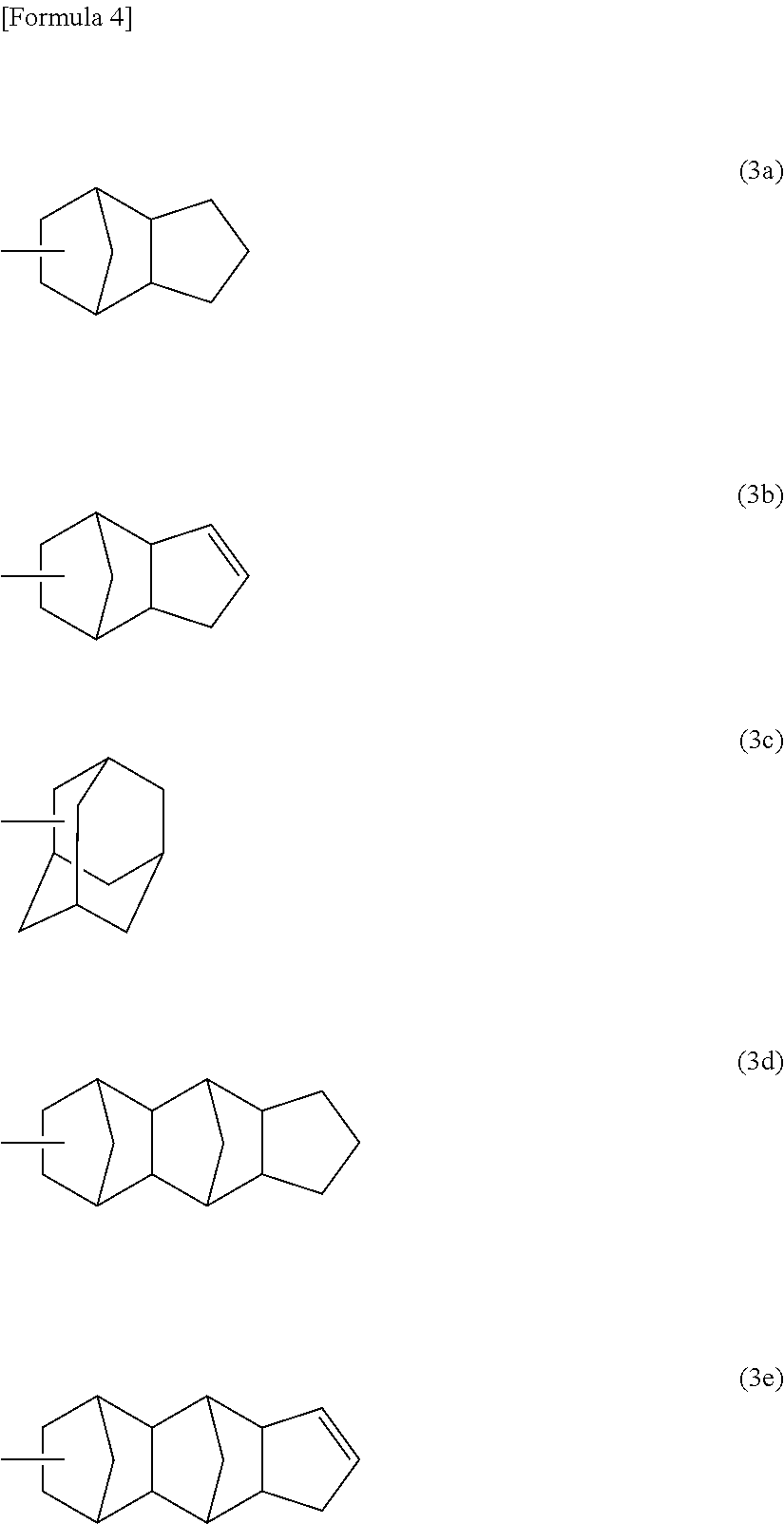

A pressure-sensitive adhesive composition curable with actinic energy rays which comprises a copolymer comprising 0.1 to 30 wt. %, preferably 0.1 to 3 wt. %, structural units derived from an imide (meth)acrylate represented by general formula (1) and 70 to 99.9 wt. %, preferably 97 to 99.9 wt. %, structural units derived from an ethylenic monomer such as an alkyl (meth)acrylate having a C4-12 alkyl group. In formula (1), R<1 >and R<2 >each independently is hydrogen or C1-4 alkyl, one of R<1 >and R<2 >is hydrogen and the other is C1-4 alkyl, or R<1 >and R<2 >are bonded to each other to form a carbon ring; R<3 >is C1-6 alkylene; R<4 >is hydrogen or methyl; and n is an integer of 1 to 6. The pressure-sensitive adhesive composition is usable as one-pack type, has excellent storage stability, and does not necessitate any step such as heating or aging when used. The cured article obtained therefrom is excellent in bonding strength and holding power, is substantially odorless, and is extremely suitable for use in pressure-sensitive adhesive sheets, etc.

Owner:TOAGOSEI CO LTD

Optical pressure-sensitive adhesive sheet, optical film and display device

ActiveUS20120100359A1Increased durabilityObscures visibilitySynthetic resin layered productsAmide/imide polymer adhesivesDynamic viscoelasticitySheet film

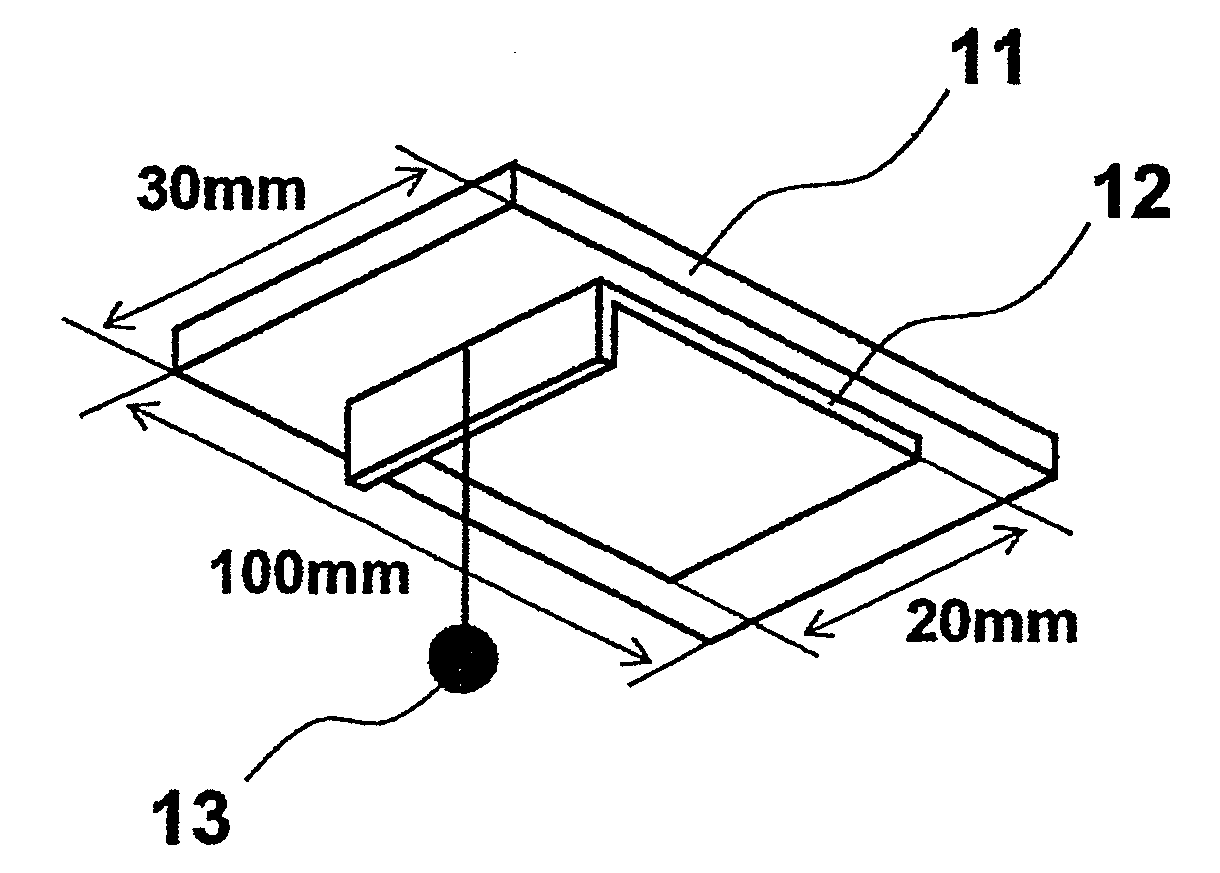

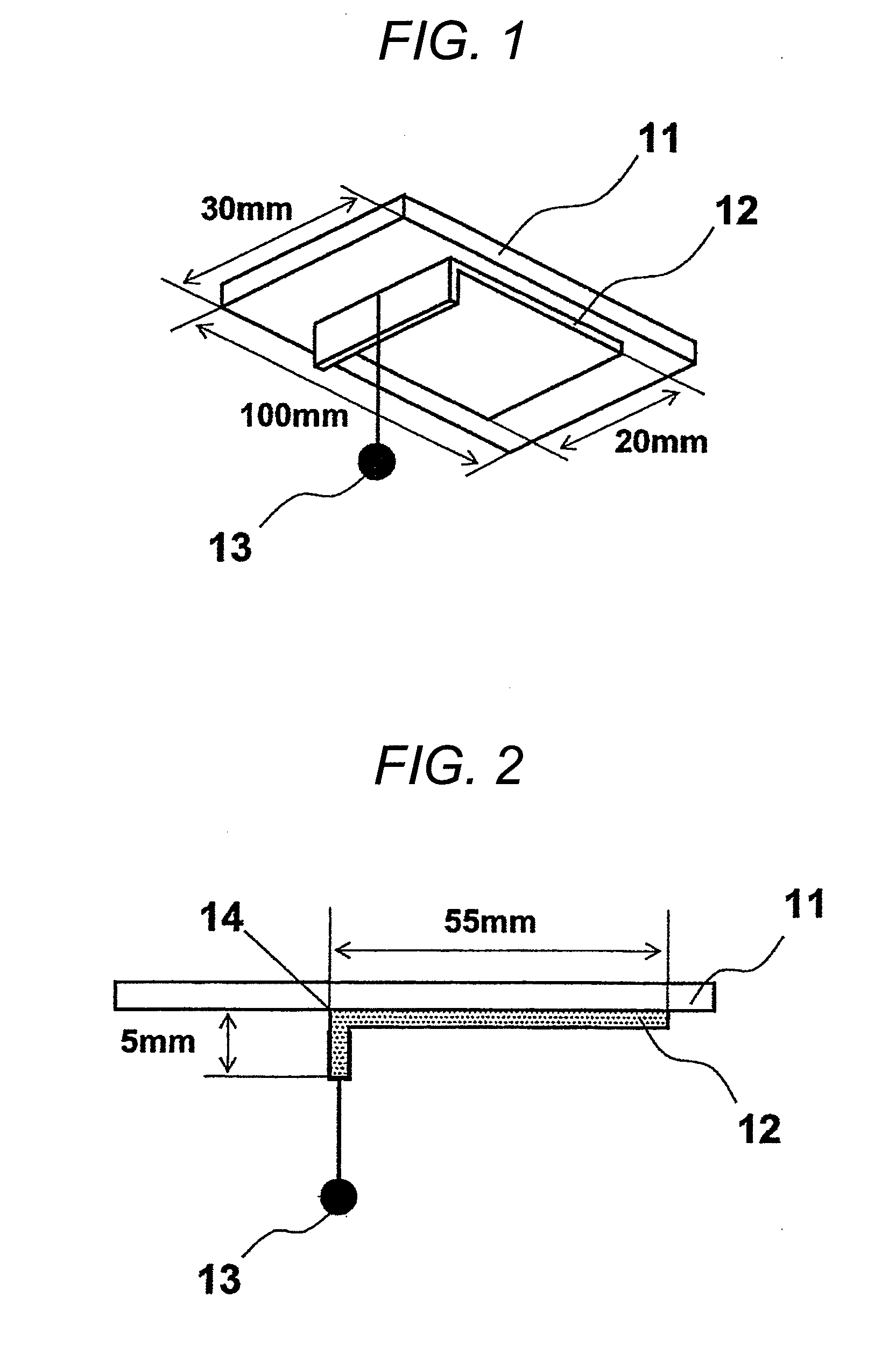

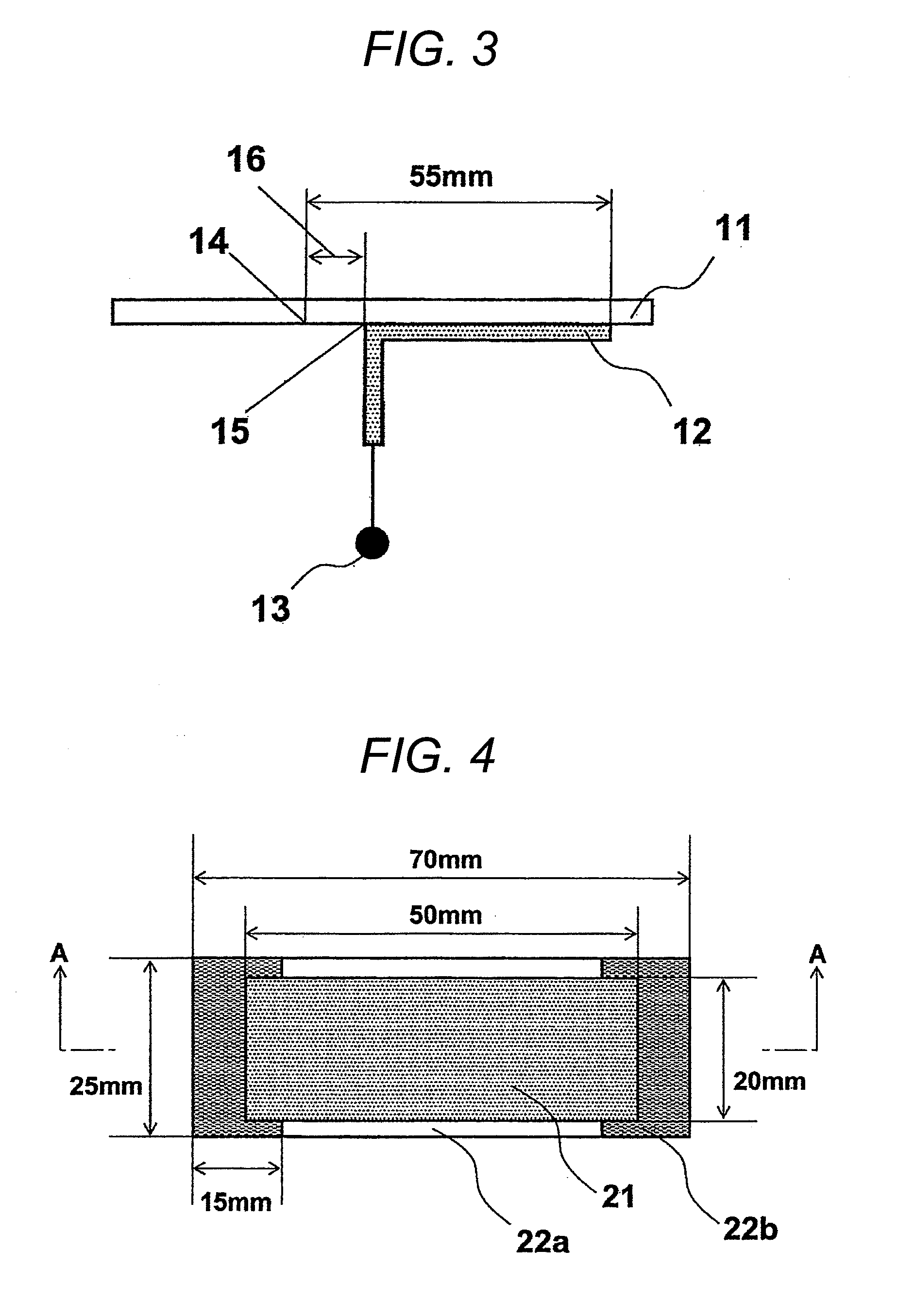

The present invention provides an optical pressure-sensitive adhesive sheet in which white turbidity is not caused by humidification and durability is excellent as well. The present invention provides an optical pressure-sensitive adhesive sheet, comprising: a pressure-sensitive adhesive layer in which a moisture ratio after storage under an environment of 60° C. and 95% RH for 120 hours is 0.65 wt % or more, and a shear storage elastic modulus at 85° C. which is measured by a dynamic viscoelastic measurement is 5.0×104 to 5.0×105 Pa, wherein a peeling distance measured by the constant-load peel test is 30 mm or less when an adherend is a polyethylene terephthalate plate, and the peeling distance measured by the following constant-load peel test is 30 mm or less when the adherend is an acrylic plate.

Owner:NITTO DENKO CORP

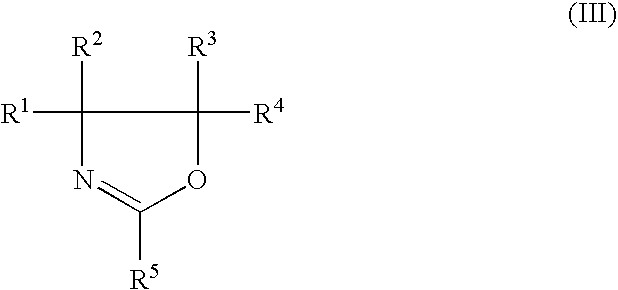

Moisture-Curing Polyurethane Composition with Good Low-Temperature Performance

InactiveUS20090202837A1Stable storageIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsMoisture cure polyurethaneSealant

The present invention relates to one-component moisture-curing compositions comprising at least one isocyanate-containing polyurethane polymer P which has a mean molecular weight of at least 4000 g / mol, and at least one polyaldimine ALD of the formula (I) or (II), where the content of isocyanate groups is at most 3.5% by weight, based on the sum of the isocyanate-containing constituents present in the composition. The compositions are suitable especially as sealants and are notable for good low-temperature performance.

Owner:SIKA TECH AG

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, and optical film

InactiveUS20140037951A1High transparencyForce is smallFilm/foil adhesivesSynthetic resin layered productsVitrificationHydrogen atom

A pressure-sensitive adhesive composition includes: 100 parts by mass of a polymer (A) having a glass transition temperature lower than 0° C.; and 0.05 parts by mass to 20 parts by mass of a (meth)acrylic polymer (B) having a weight average molecular weight (MwB) of 1000≦MwB<30000 that contains, as monomer units, both a (meth)acrylic monomer having an alicyclic structure represented by the following general formula (1) and a monomer having a polyoxyalkylene skeleton:CH2═C(R1)COOR2 (1)[wherein R1 represents a hydrogen atom or a methyl group and R2 represents an alicyclic hydrocarbon group having an alicyclic structure.]

Owner:NITTO DENKO CORP

Light-transmitting electromagnetic-shielding laminate and method for producing the same, light-transmitting radio wave absorber, and adhesive composition

InactiveUS20100147578A1High transparencyImprove visibilityMagnetic/electric field screeningShieldingElectricitySilane compounds

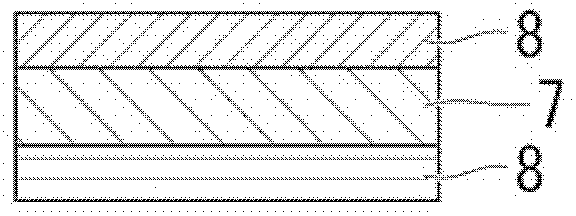

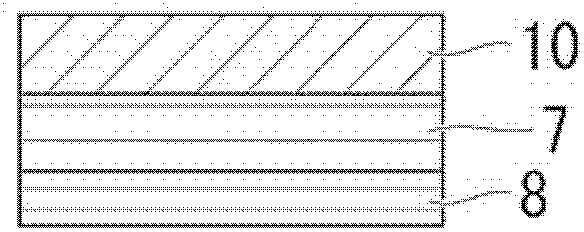

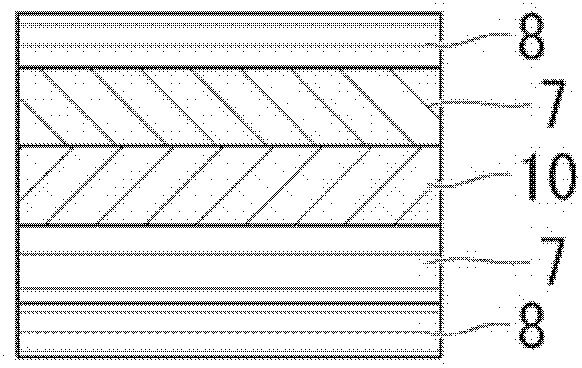

Disclosed is a light-transmitting electromagnetic-shielding laminate, which is characterized in that two or more layers including an electromagnetic-shielding layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds. Also disclosed is a light-transmitting radio wave absorber which is characterized in that a resistive layer, a dielectric spacer and a reflective layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds.

Owner:MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com