Patents

Literature

119results about How to "Full adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive agent and adhesive sheet

ActiveCN102482546AShorten the stabilization periodFull adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesCross-linkAdhesion force

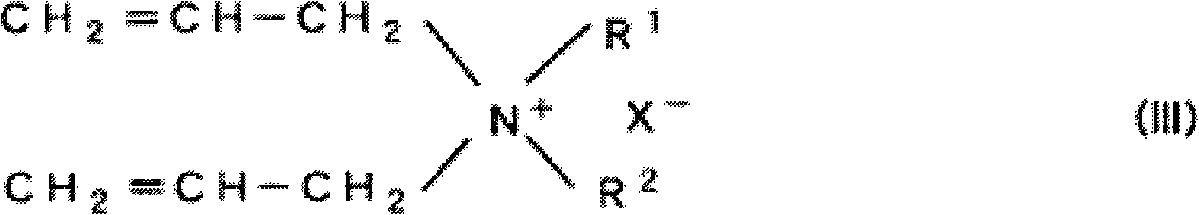

Disclosed is an adhesive agent characterized by comprising an acrylic copolymer (A) and a cross-linking agent (B), wherein the acrylic copolymer (A) comprises 30 to 77 mass% of a constituent unit (a1) derived from an alkyl acrylate monomer having a C5-20 alkyl group, 20 to 60 mass% of a constituent unit (a2) derived from a (meth)acrylate monomer containing an alicyclic group, 0.01 to 5 mass% of a constituent unit (a3) derived from a monomer containing a tertiary amino group induced from (meth)acrylic acid, and 0.1 to 10 mass% of a constituent unit (a4) derived from a monomer containing a functional group (which is different from a tertiary amino group). The adhesive agent can exhibit a satisfactory adhesion force to a material to be adhered regardless of the level of polarity of the surface of the material, can achieve the smooth cross-linking reaction with the cross-linking agent, and can have a decreased stabilization period without the need of using any heavy metal that has concerns about adverse influence on the environments.

Owner:LINTEC CORP

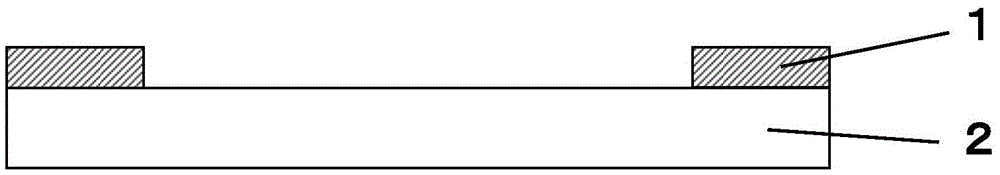

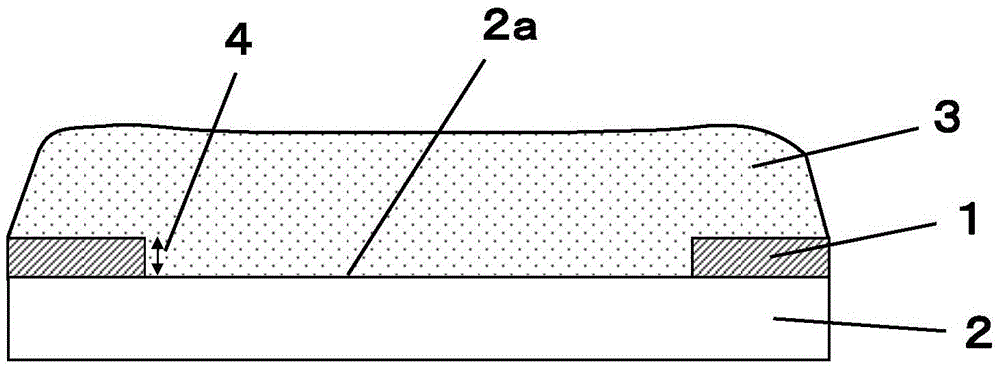

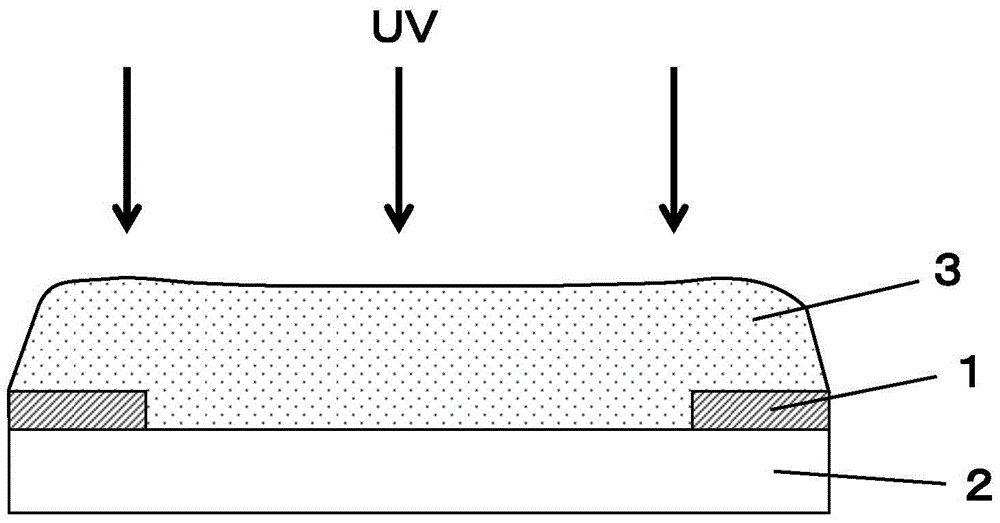

Adhesive sheet for processing semiconductor wafers and/or substrates

ActiveCN101165131APrevents troubles such as flying outFull adhesionNon-macromolecular adhesive additivesSolid-state devicesUltravioletCohesive strength

An adhesive sheet of the present invention can be to lower the adhesive strength to the optimal level during pick up or the like after irradiation with UV rays and / or radiation, while maintaining adhesion with adherends before irradiation with UV rays and / or radiation by ensuring that, regardless of the texture on the surface of adherends such as semiconductor wafers and / or substrates, the adhering surface favorably conforms to the texture with preserving enough adhesive and cohesive strength. The adhesive sheet for processing semiconductor wafers and / or substrates comprises a UV- and / or radiation-transmittable base film and an adhesive layer that undergoes a polymerization curing reaction by means of UV rays and / or radiation, wherein the adhesive layer comprises at least a tackifier and a surfactant.

Owner:NITTO DENKO CORP

Adhesive film and method for manufacturing semiconductor device using same

InactiveCN101014676AFull adhesionImpact resistantSynthetic resin layered productsSolid-state devicesDicing tapeUltimate tensile strength

Disclosed is an adhesive tape serving as a dicing tape in a dicing step which has excellent dicing properties and pick-up properties. Also disclosed is a bonding tape exhibiting excellent bonding reliability in a step for bonding a semiconductor element and a supporting member. Specifically disclosed is an adhesive film including a layer wherein an adhesive layer (A) containing an olefin polymer and another adhesive layer (B) are directly joined together. The adhesive film is characterized in that the 180 DEG peel strength between the layer (A) and the layer (B) is not more than 0.7 N / 10 mm.

Owner:MITSUI CHEM INC

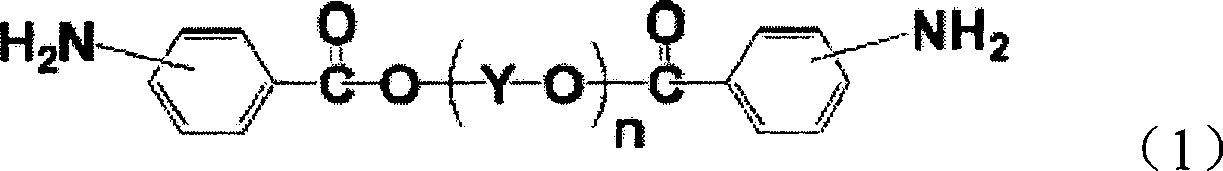

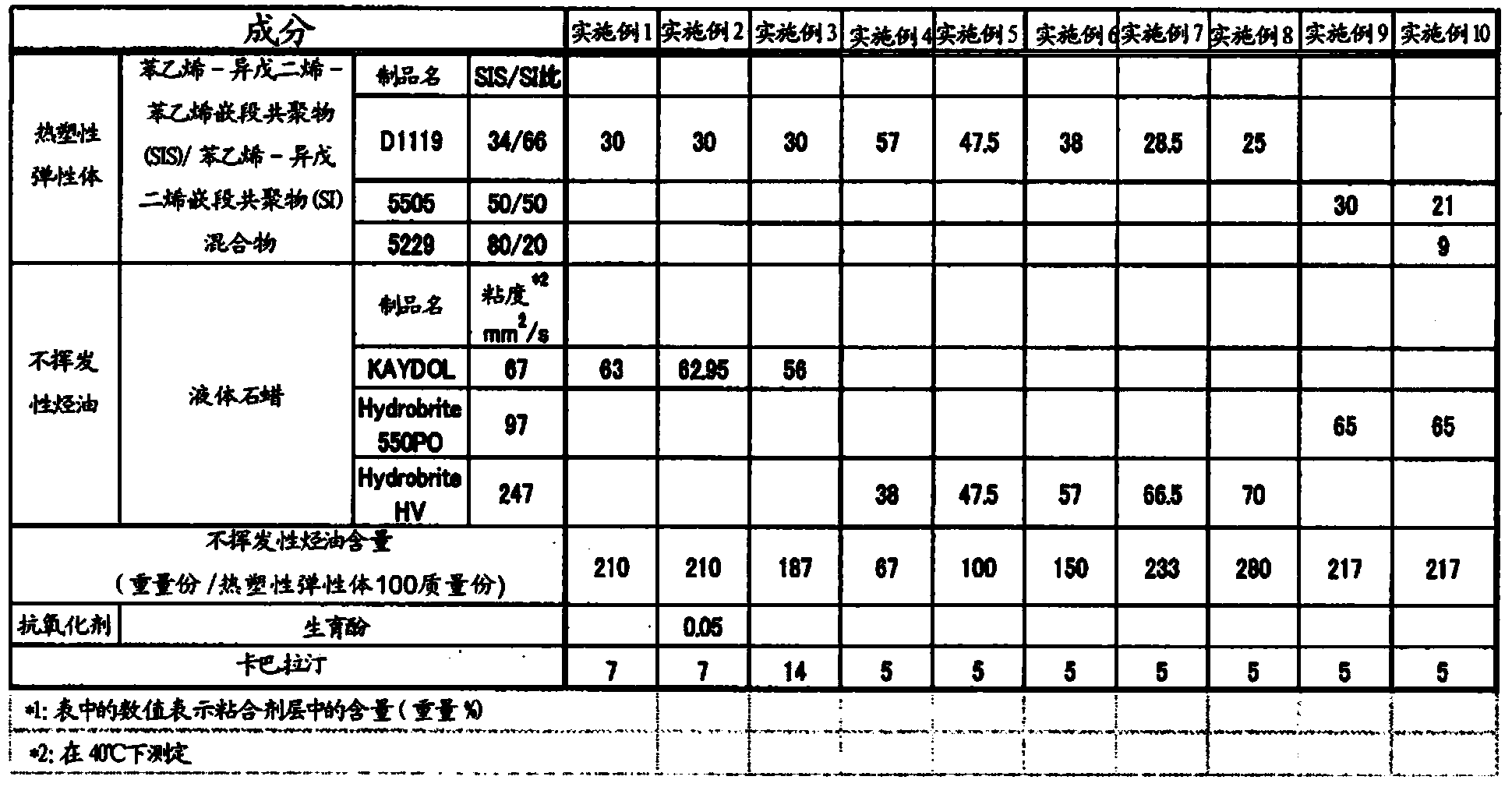

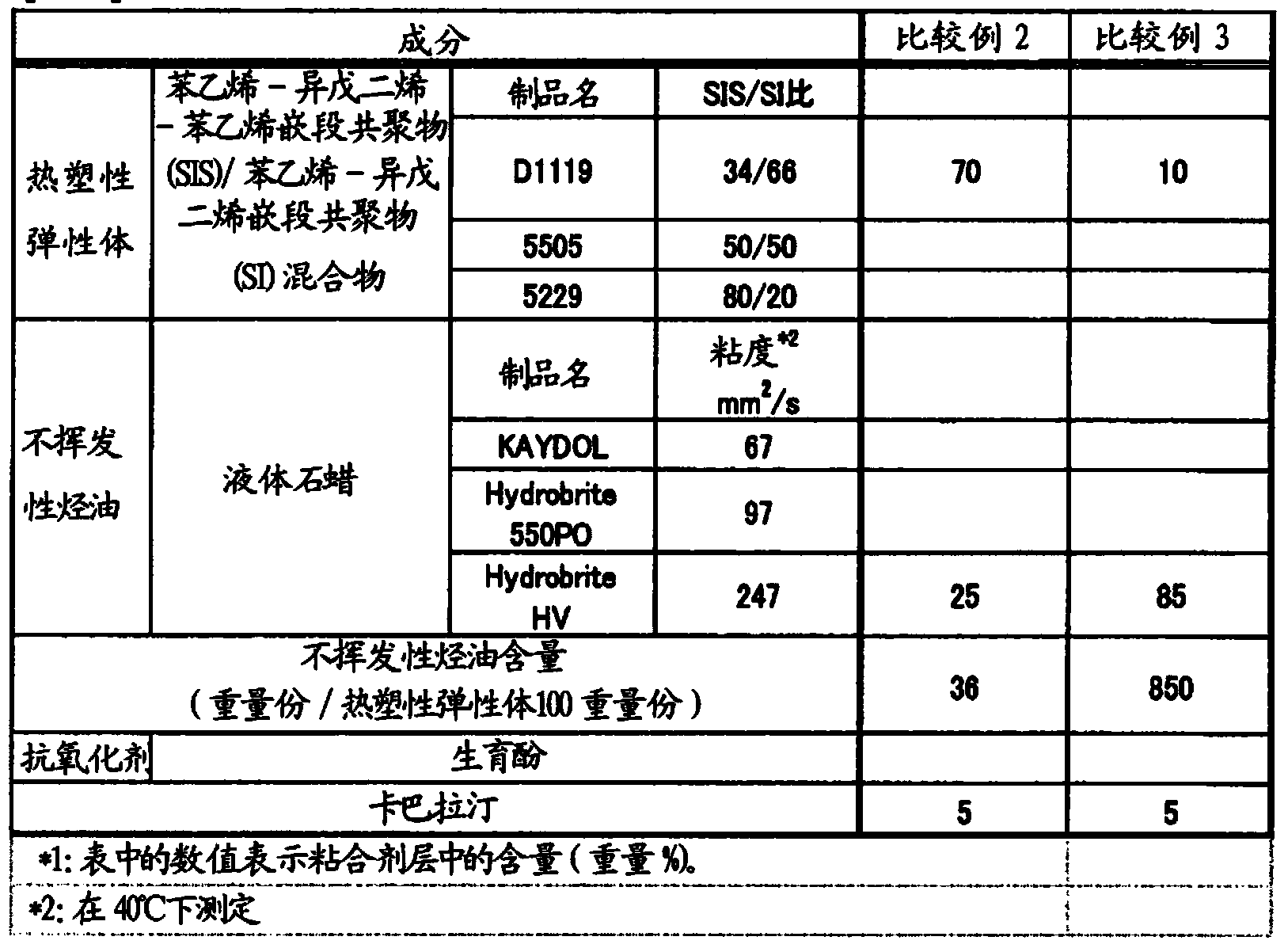

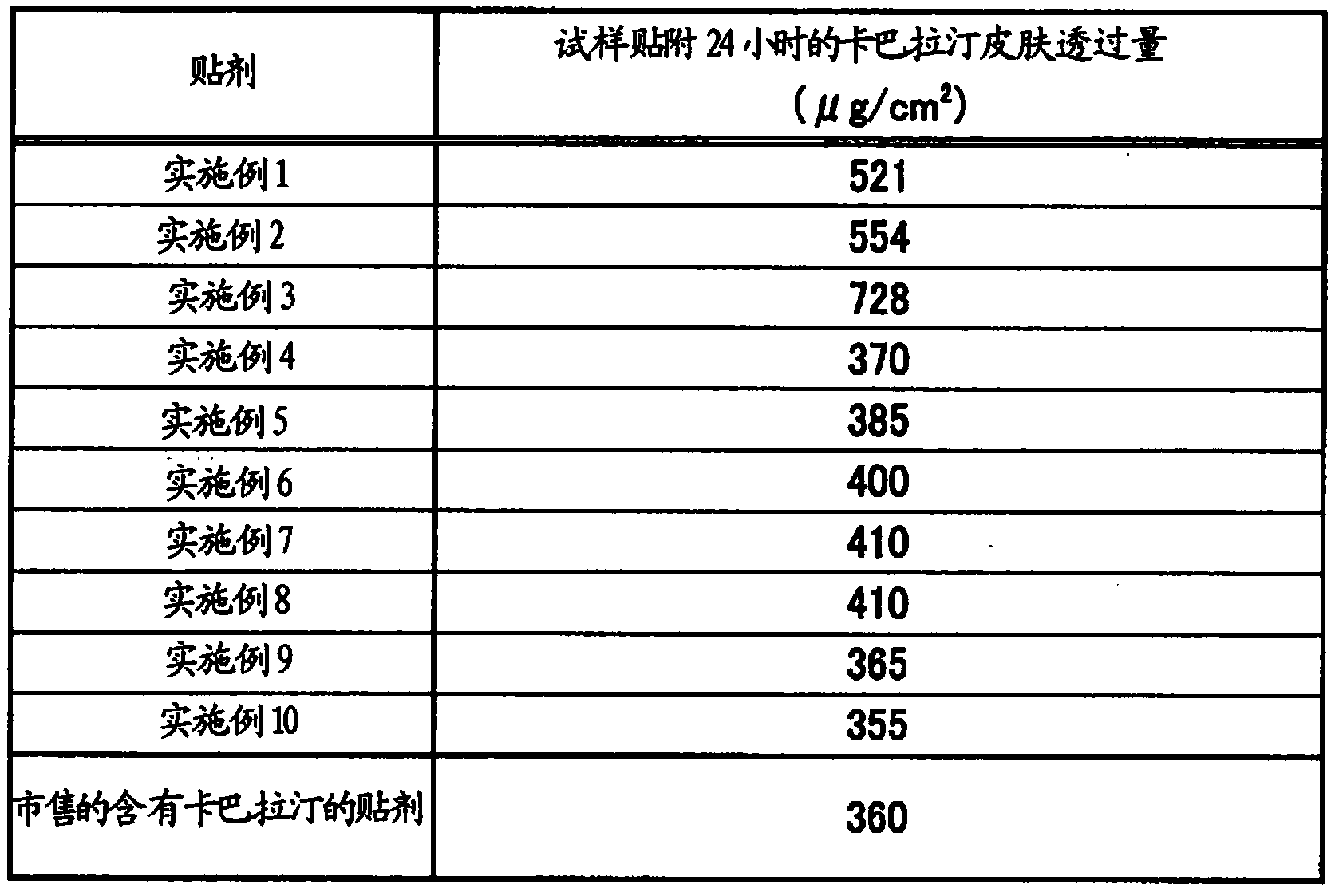

Patch

ActiveCN104114167APromote transdermal absorptionFull adhesionNervous disorderOrganic non-active ingredientsElastomerThermoplastic elastomer

Provided is a patch which is formed with an adhesive layer that retains a medicine on a support, wherein the adhesive layer contains a thermoplastic elastomer, a non-volatile hydrocarbon oil in an amount of over 50 parts by weight and 800 parts by weight or less with respect to 100 parts by weight of the elastomer, and rivastigmine or a salt thereof, and may further contain a tackifier in an amount of 10 parts by weight or less of the adhesive layer.

Owner:KM TRANSDERM LTD

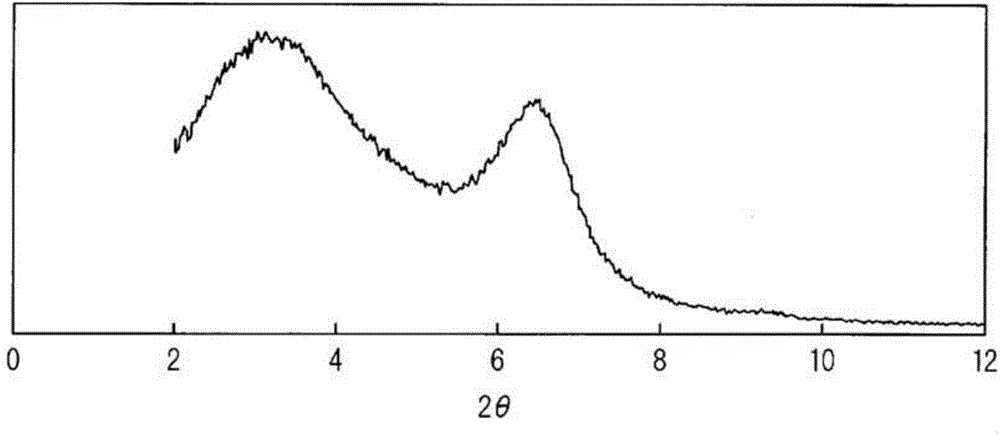

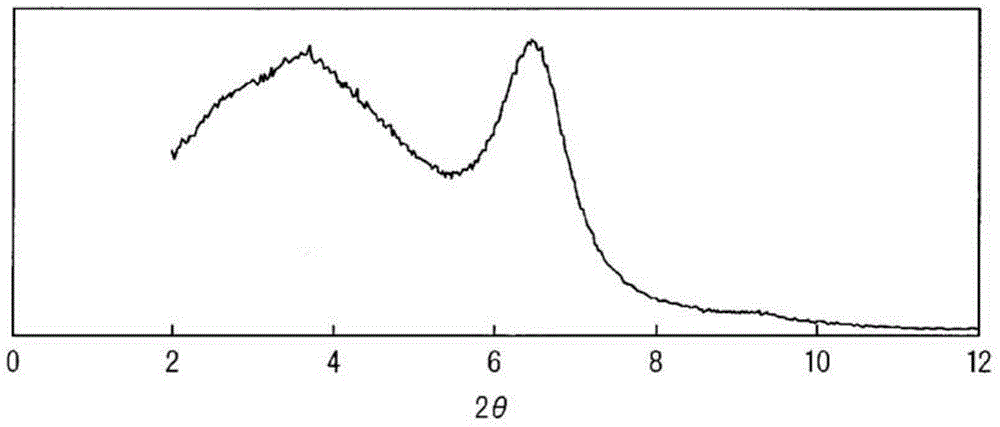

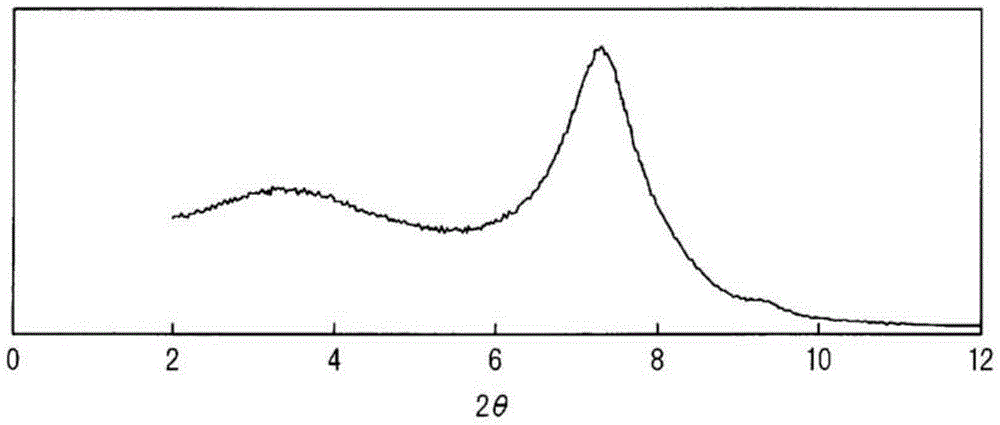

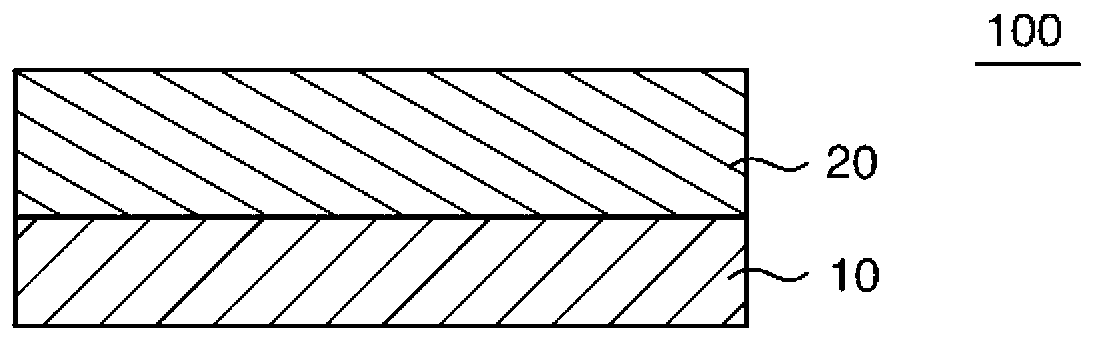

Gas barrier film

ActiveCN104136219AExcellent gas barrier performanceFull adhesionFlexible coversWrappersPlastic materialsPhysical chemistry

This gas barrier film is provided with: a substrate film comprising a plastic material; and a gas barrier coating film that is formed on one or both surfaces of the substrate film and that comprises an inorganic lamellar mineral and at least one resin component interposed between the layers of the inorganic lamellar mineral. When the x-ray diffraction spectrum of the gas barrier coating film is measured using the Cu Kalpha line in an atmosphere at 25°C and 65% RH, the x-ray diffraction spectrum exhibits a first peak top and a second peak top corresponding to the inter-layer distance of the inorganic lamellar mineral, the first peak top is derived from the inter-layer distance of a thin film consisting of the inorganic lamellar mineral, and the second peak top is derived from the inter-layer distance of the inorganic lamellar mineral having opened by means of the interposition of the resin component between the layers of the inorganic lamellar mineral, and is present at a lower position than the first peak top position in the 2theta axis.

Owner:TOPPAN PRINTING CO LTD

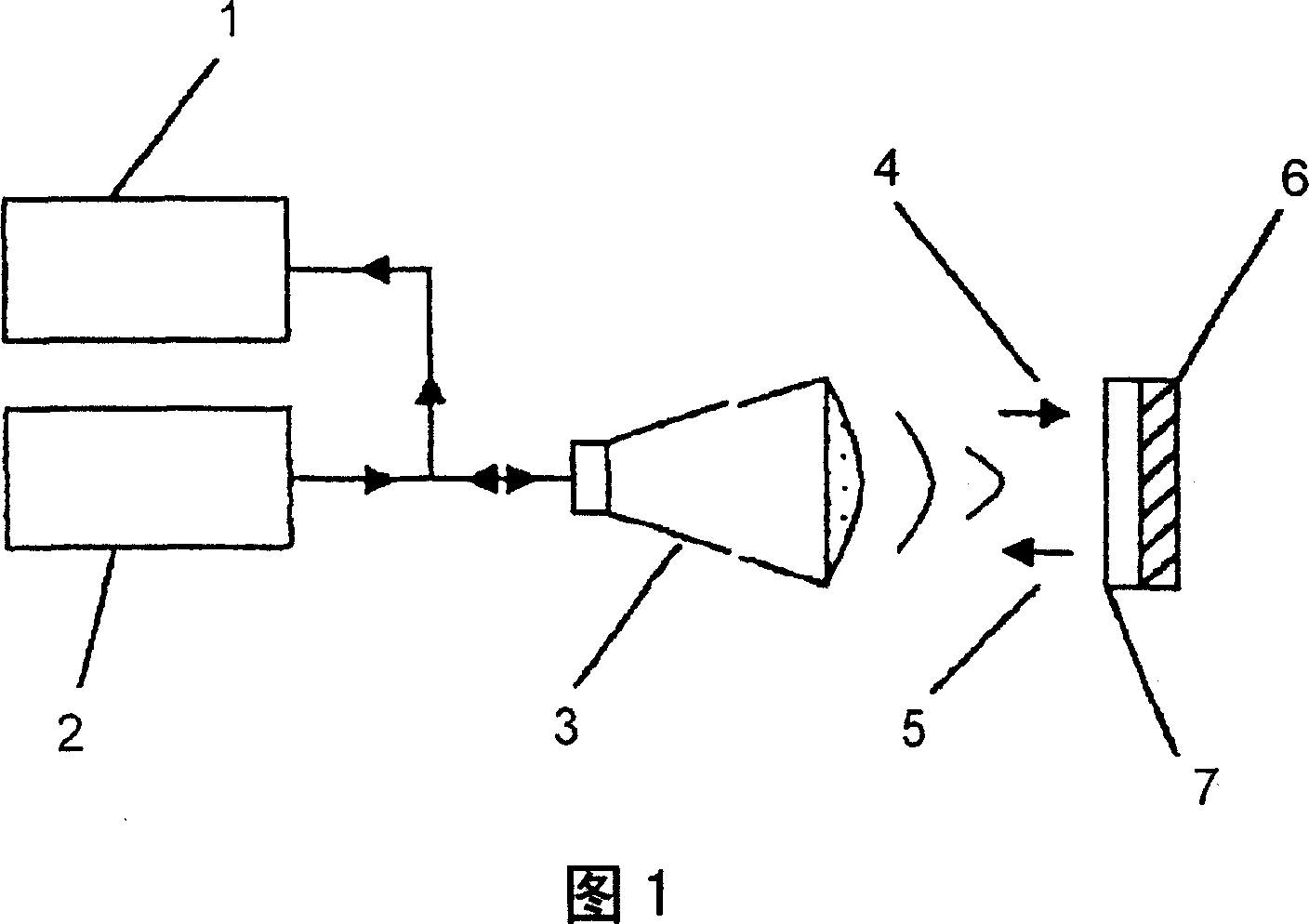

Train traction control system

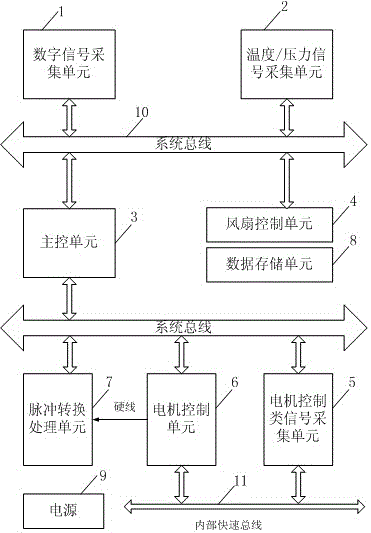

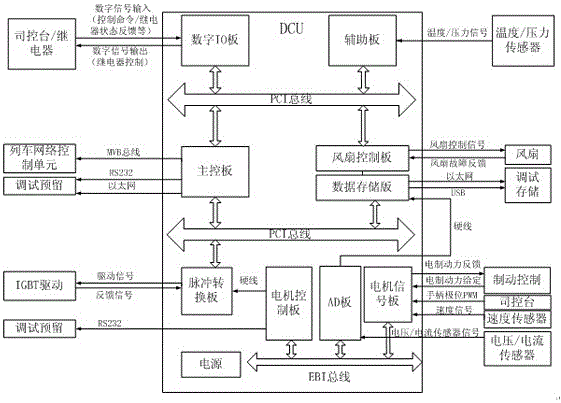

InactiveCN106054864ARich interfaceVersatileElectric testing/monitoringIdentification errorSignal acquisition

The invention discloses a train traction control system. The system comprises a digital signal acquisition unit 1, a temperature / pressure signal acquisition unit 2, a master control unit 3, a fan control unit 4, a motor control type signal acquisition unit 5, a motor control unit 6, a pulse conversion processing unit 7, a data storage unit 8, a power supply and backboard 9, a system bus 10 and an internal rapid bus 11. The train traction control system has the following technical effects: interface diversity of the train traction control system is realized, functions are rich, debugging is facilitated, control precision and control performance of the control system are quite high, the operation demand of a train can be satisfied, motor parameter identification errors are not greater than + / -10%, the moving shaft wheel rim speed and the creeping speed are both controllable, and the creeping speed is smaller than 5km / h.

Owner:CHENGDU YUNDA TECH CO LTD

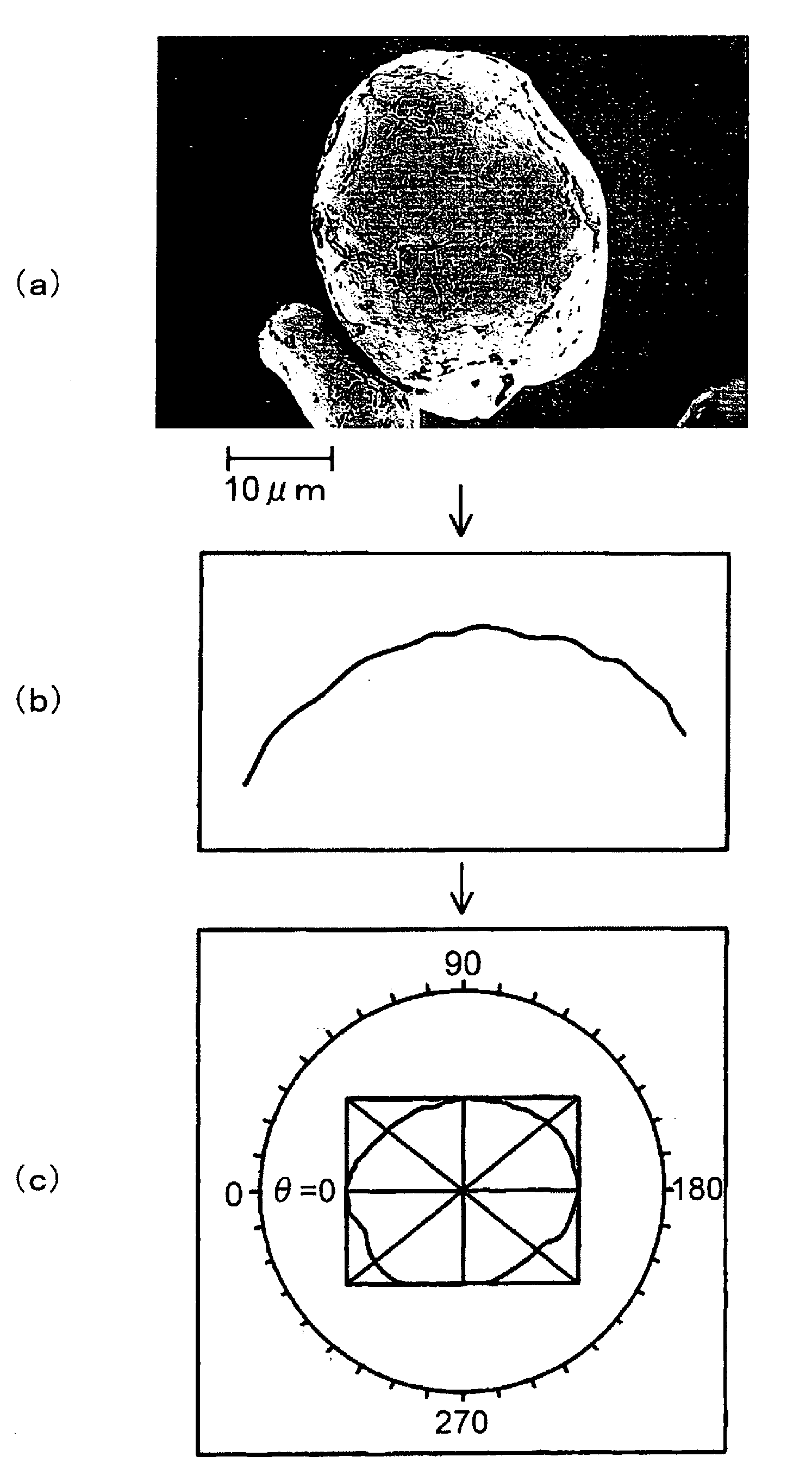

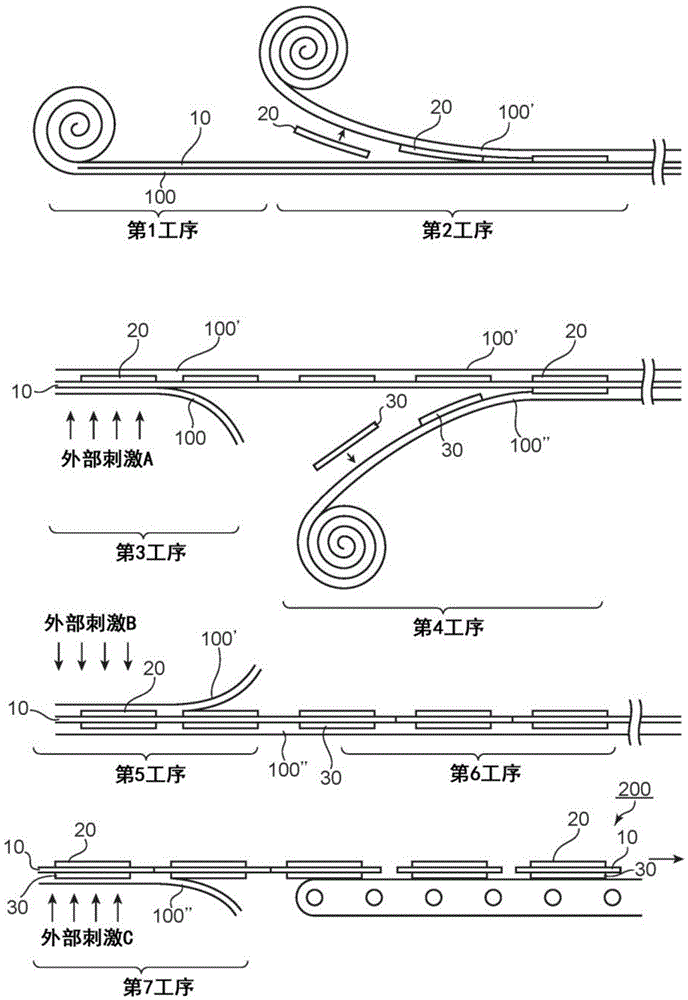

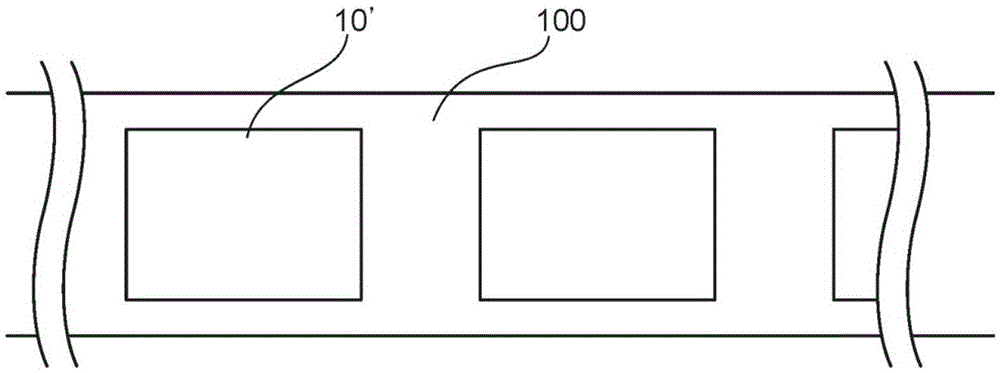

Pressure-sensitive adhesive sheet for conveying electrolyte membrane and method using said pressure-sensitive adhesive sheet to manufacture fuel-cell membrane electrode assembly

InactiveCN105612649AAvoid deformationFull adhesionFinal product manufactureSynthetic resin layered productsThermal dilatationPolymer electrolytes

This invention provides a pressure-sensitive adhesive sheet for conveying an electrolyte membrane. When processing a membrane electrode assembly (MEA), said pressure-sensitive adhesive sheet can contribute to making it easier to handle a polymer electrolyte membrane being conveyed and preventing deformation and wrinkling of said polymer electrolyte membrane. This pressure-sensitive adhesive sheet for conveying an electrolyte membrane comprises a substrate and a pressure-sensitive adhesive layer positioned on one or both surfaces of said substrate. The pressure-sensitive adhesive layer(s) partially or completely lose(s) adhesiveness upon an external stimulus. In one embodiment, the pressure-sensitive adhesive layer(s) contain(s) thermally expandable microspheres.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive tape

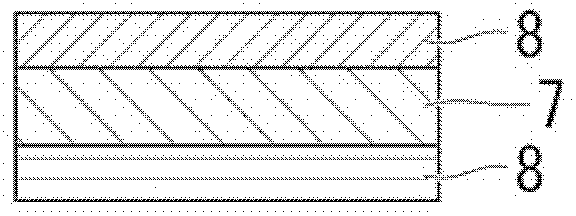

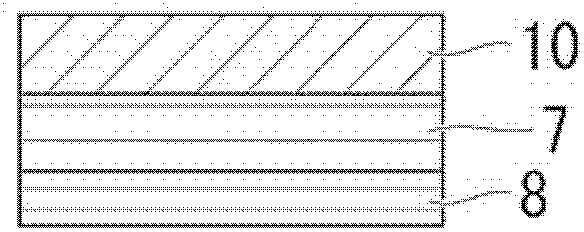

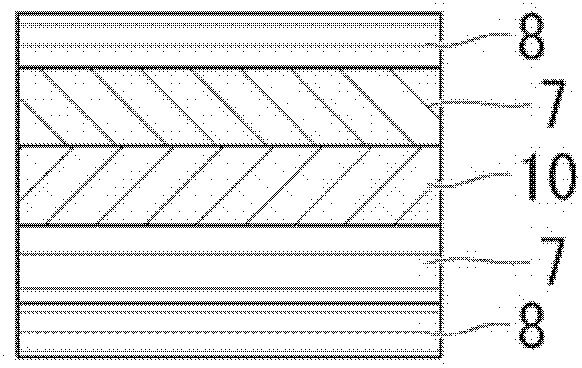

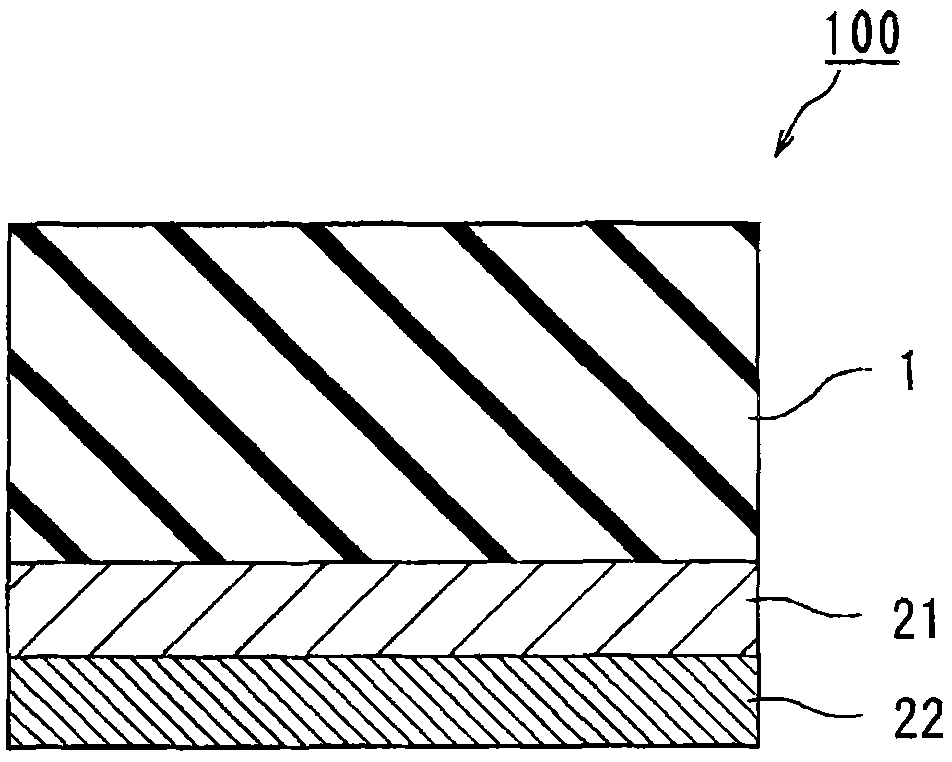

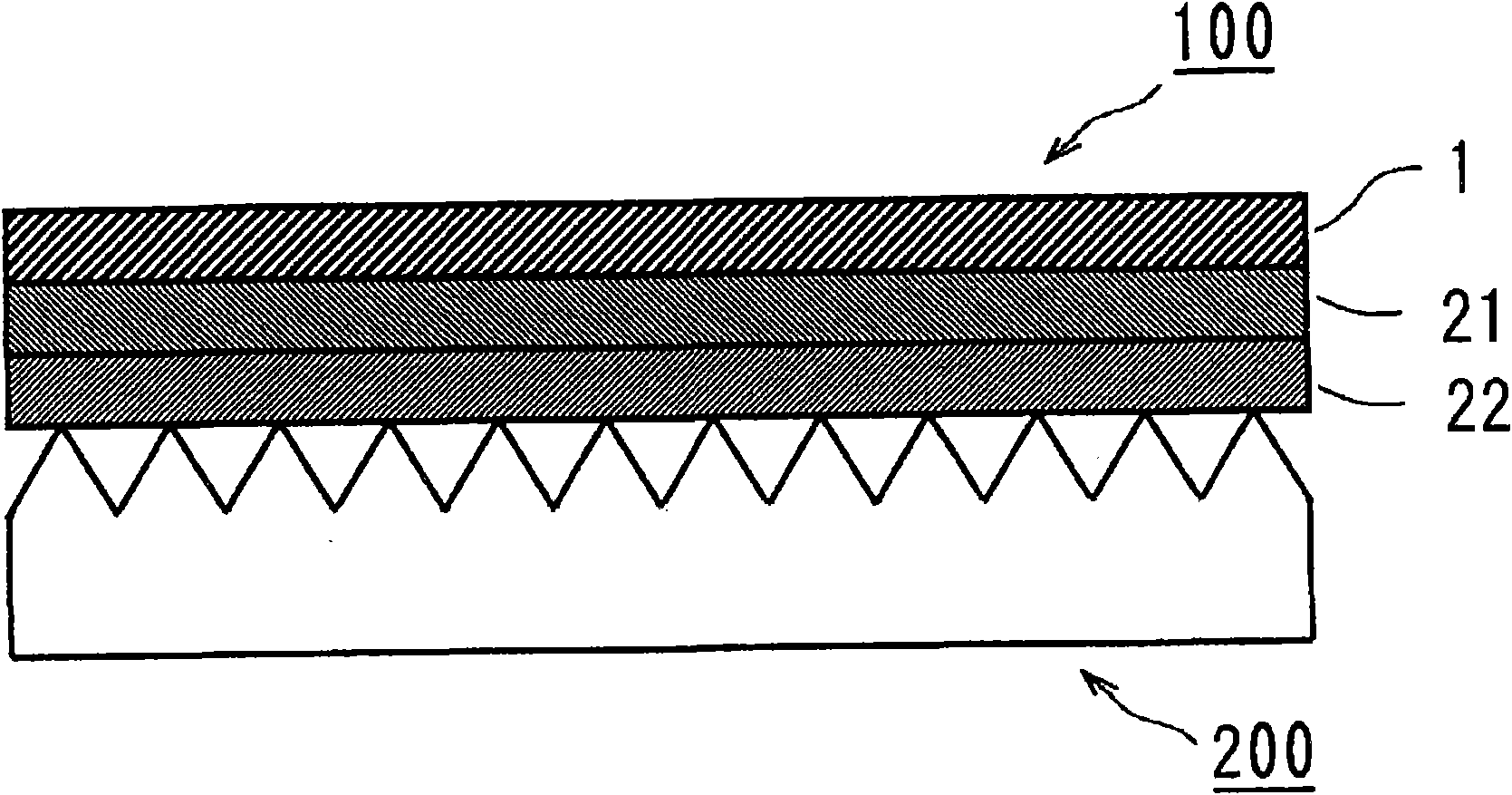

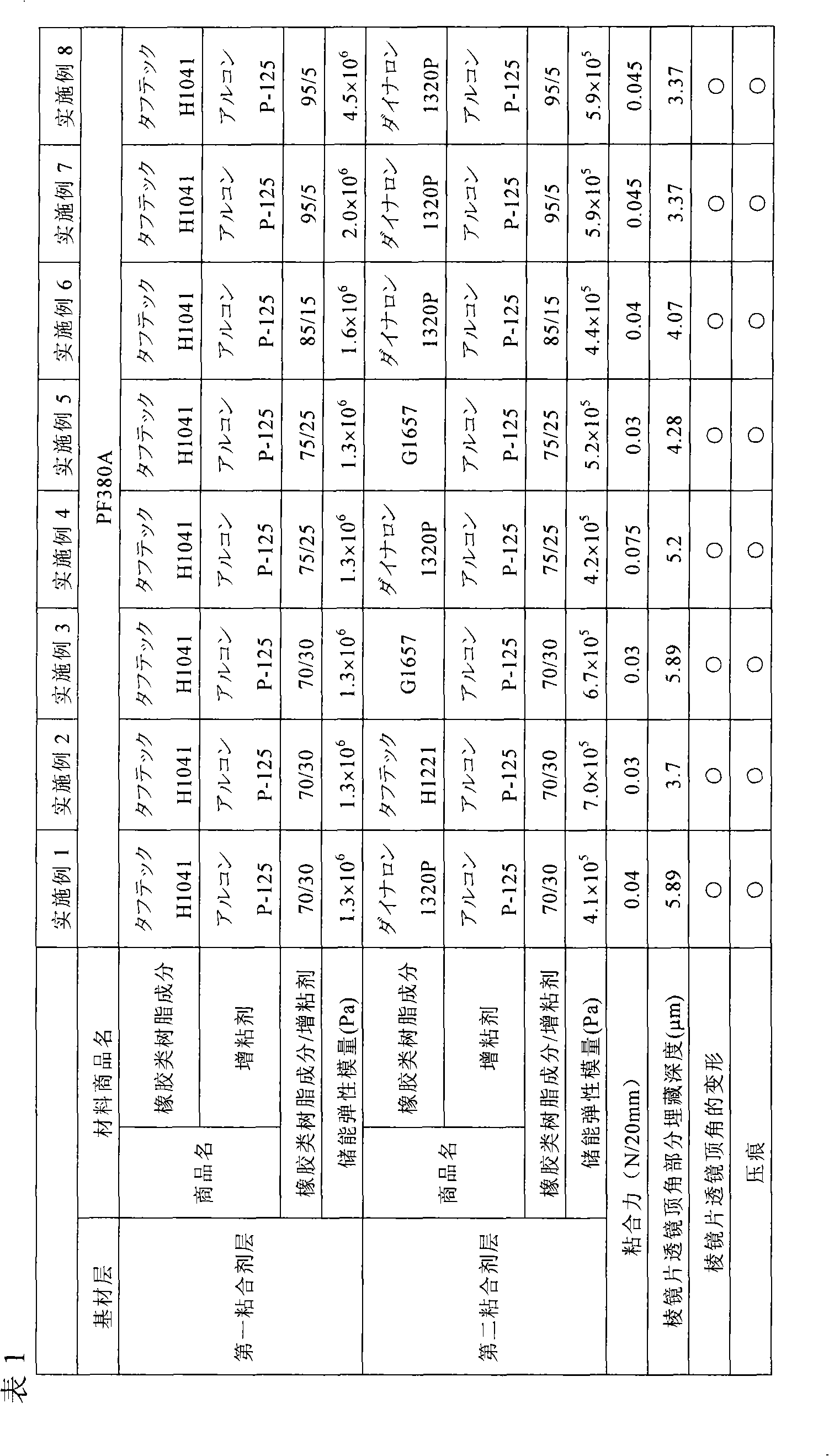

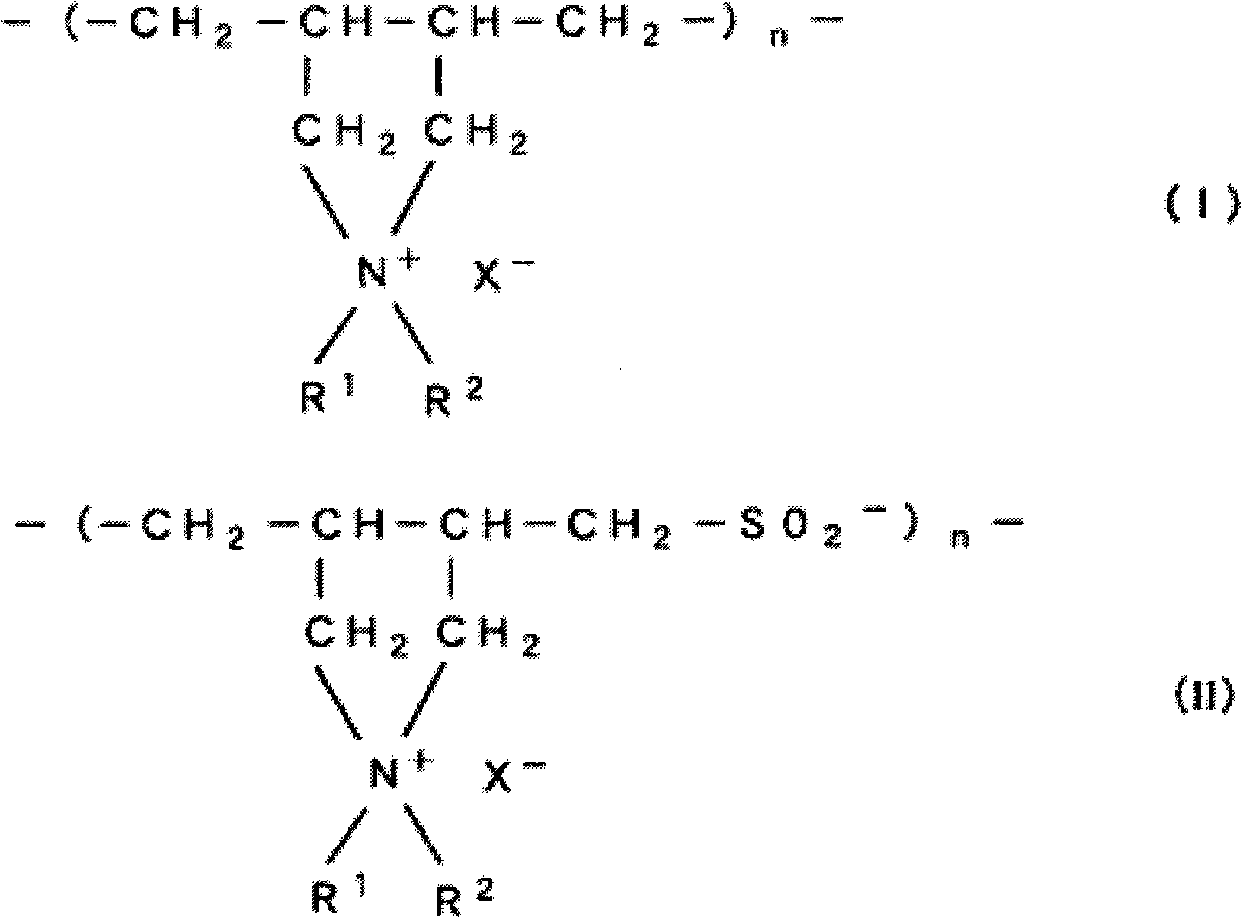

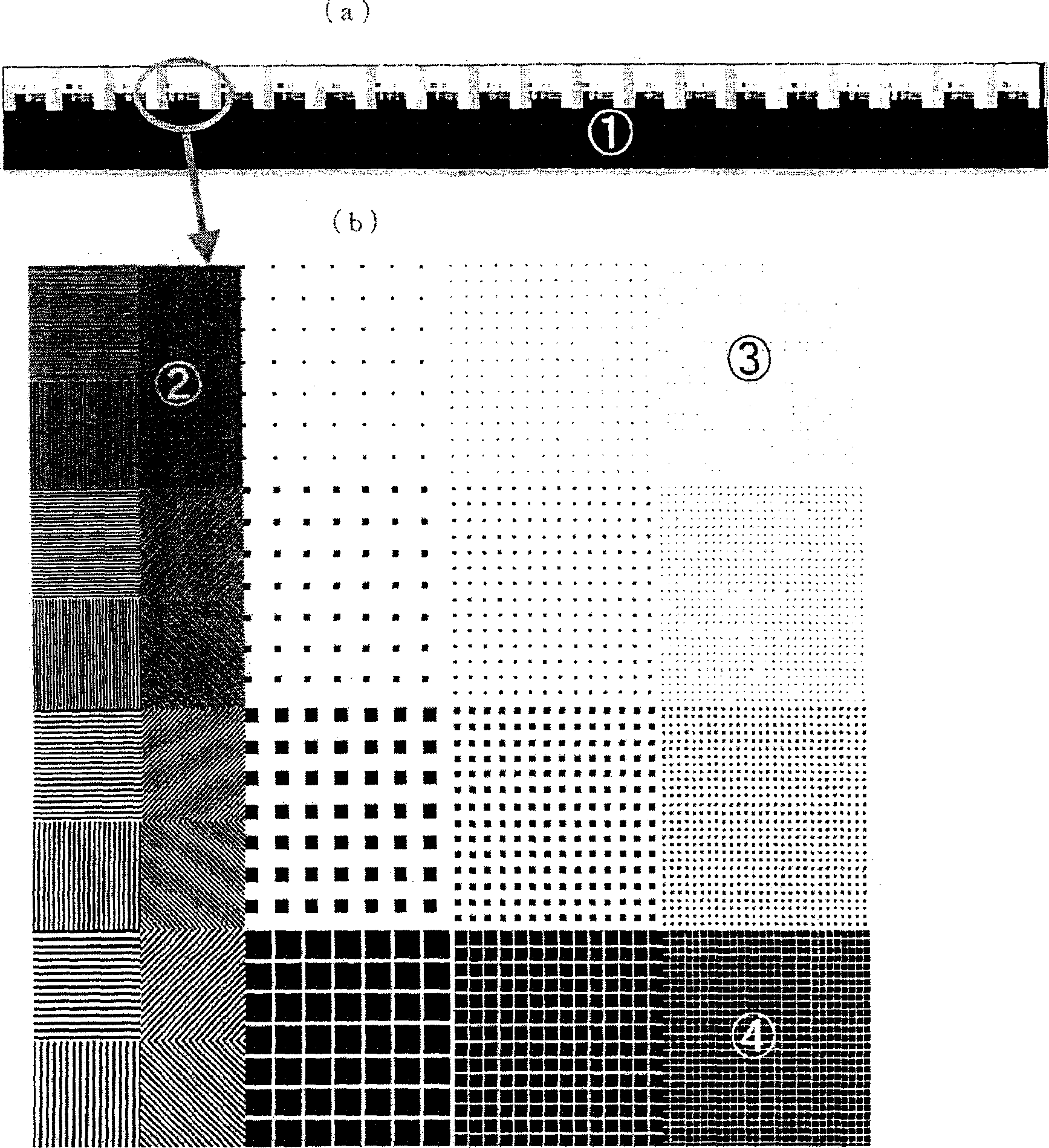

Provided is such a pressure-sensitive adhesive tape as described below, which is capable of protecting the uneven surface of a member having unevenness on its surface. The pressure-sensitive adhesive tape brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the member. In addition, even upon deformation of the member protected with the pressure-sensitive adhesive tape by, for example, lamination or continuous winding, the uneven shape does not deform and a base material layer in the pressure-sensitive adhesive tape is not damaged. Also provided is a pressure-sensitive adhesive tape useful as such a surface protective film for a prism sheet as described below, which is capable of effectively protecting, for example, a lens surface of a prism sheet having multiple triangle pole-shaped prisms fixed on its surface. The surface protective film brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the prism sheet. In addition, when the prism sheet protected with the surface protective film is brought into a state such as a laminated state or a continuously wound state, the emergence of irregularity (indentation) in the external appearance of the prism sheet to which the surface protective film is attached can be suppressed. A pressure-sensitive adhesive tape of the present invention is a pressure-sensitive adhesive tape including a base material layer, a first pressure-sensitive adhesive layer, and a second pressure-sensitive adhesive layer in the stated order, in which: the base material layer contains a thermoplastic resin; the storage modulus of the first pressure-sensitive adhesive layer is higher than the storage modulus of the second pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

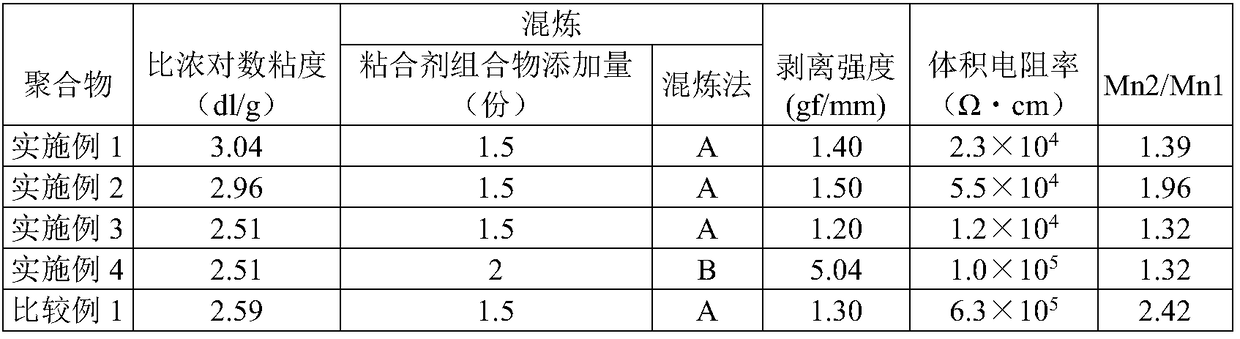

Binder composition, electrode mixture, electrode, and non-aqueous electrolyte secondary battery

ActiveCN109075343AFull adhesionGood dispersionFilm/foil adhesivesLi-accumulatorsFluoridePolymer chemistry

Provided is a binder composition that has substantial adhesiveness and that achieves excellent conductive auxiliary dispersion. This binder composition includes a vinylidene fluoride copolymer composition that includes: vinylidene fluoride; and acrylic monomers. The acrylic monomers are acrylates and / or methacrylates. The ratio (Mn2 / Mn1) of the number average molecular weight (Mn2) of the vinylidene fluoride copolymer composition after being adsorbed onto alumina to the number average molecular weight (Mn1) of the vinylidene fluoride copolymer composition before being adsorbed onto alumina isless than 2.

Owner:KUREHA KAGAKU KOGYO KK

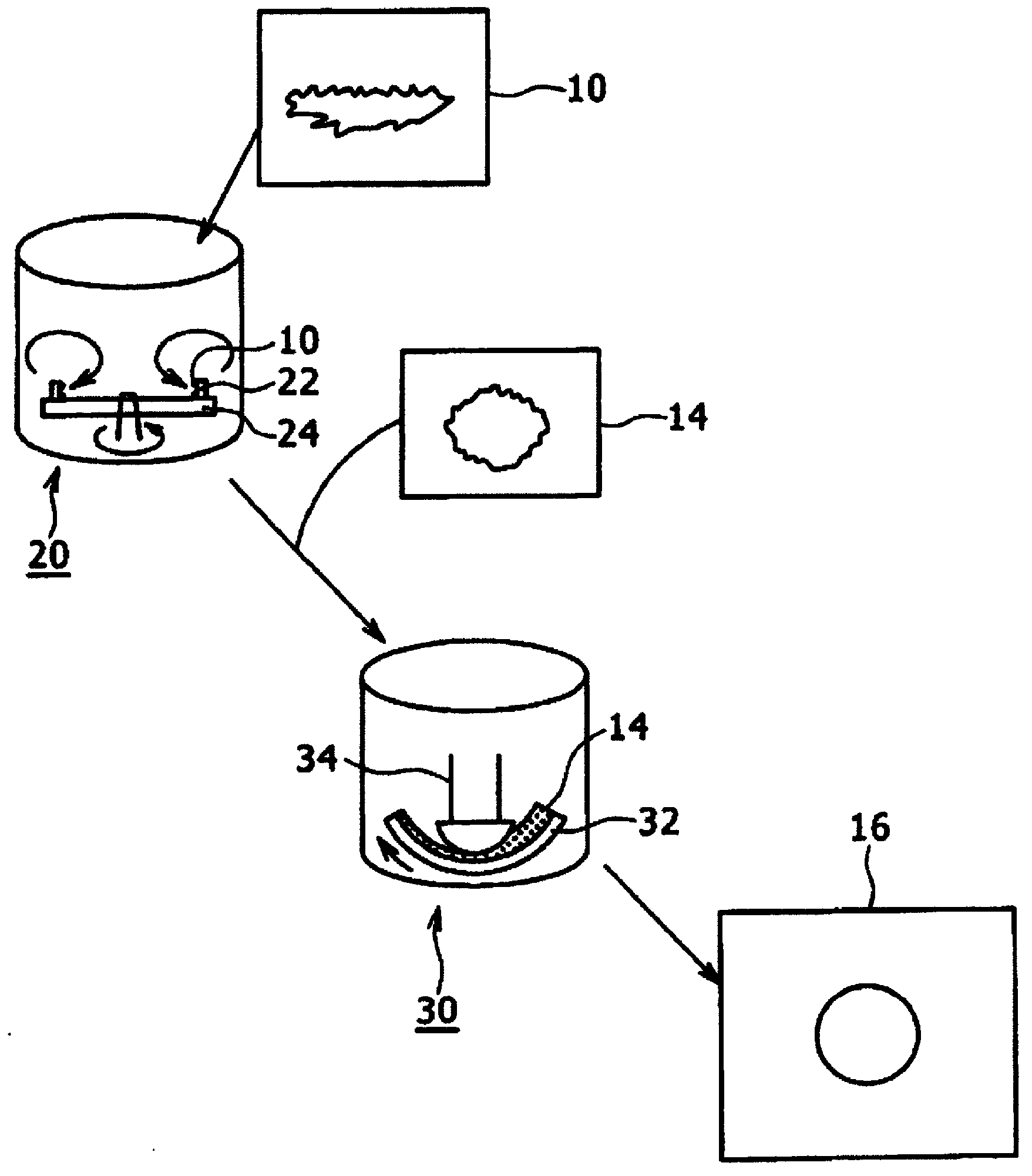

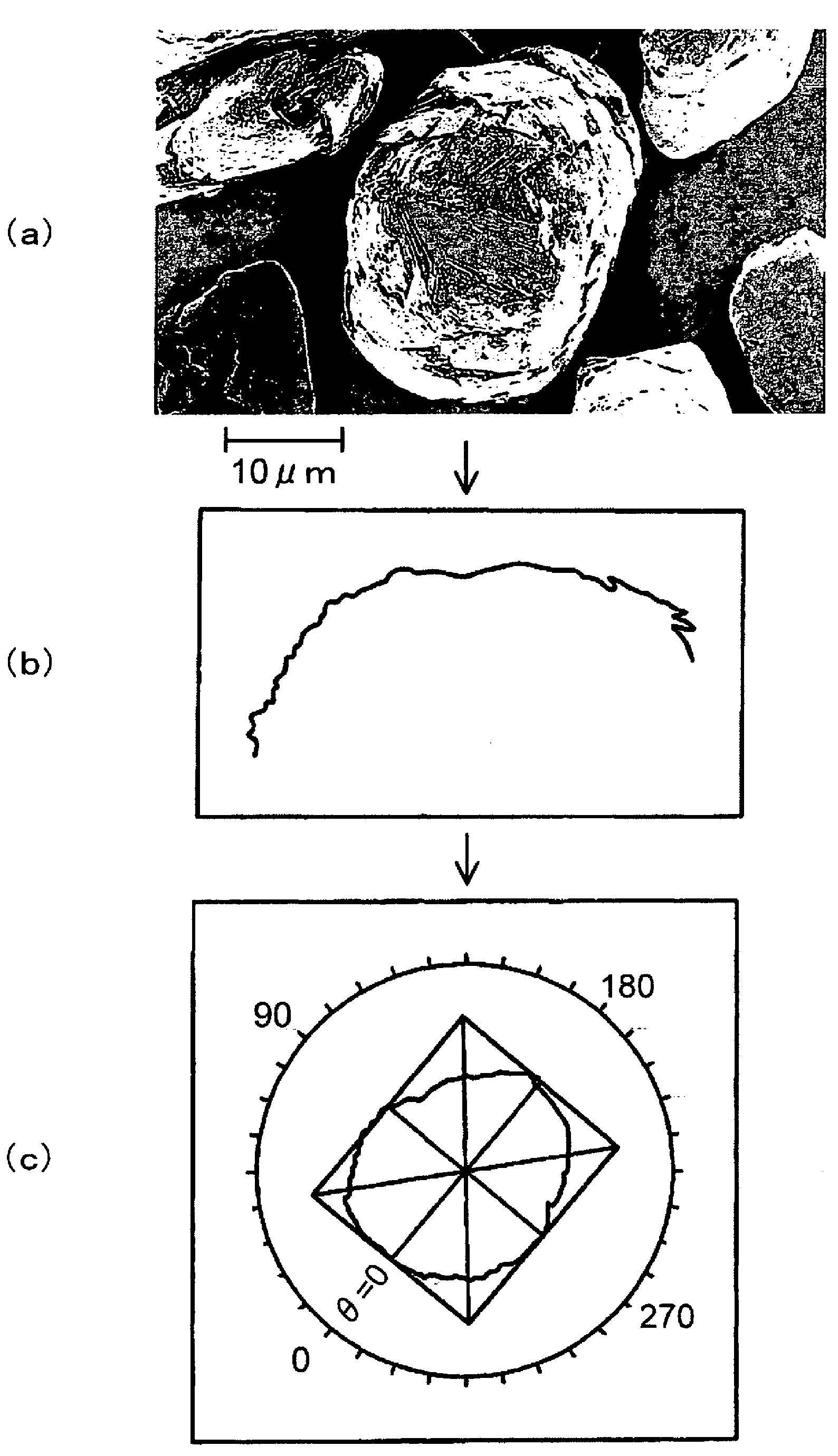

Modified natural graphite particle and method for producing same

InactiveCN102844269AIncrease packing densityFull adhesionGraphiteNegative electrodesMechanical millingSurface roughness

Disclosed is a natural graphite particle forming a negative electrode active substance for a non-aqueous electrolyte secondary battery, characterized by having a circularity of 0.93 - 1.0 and a surface roughness of 1.5% of the largest particle diameter. Also disclosed is a method for producing modified particles of natural graphite in which grinding and spheronizing are carried out by applying an impact force to the natural graphite particles and there is a process for obtaining intermediate particles with a circularity of 0.93 - 1.0 as well as a process for obtaining the modified natural graphite particles by performing surface smoothing using mechanical milling of the intermediate particles obtained.

Owner:NIPPON STEEL CORP +1

Photocurable resin composition, image display device and method for manufacturing image display device

InactiveCN105579482ASuppress floatingFull adhesionCoatingsPhotosensitive materials for photomechanical apparatusMeth-Plasticizer

Owner:RESONAC CORPORATION

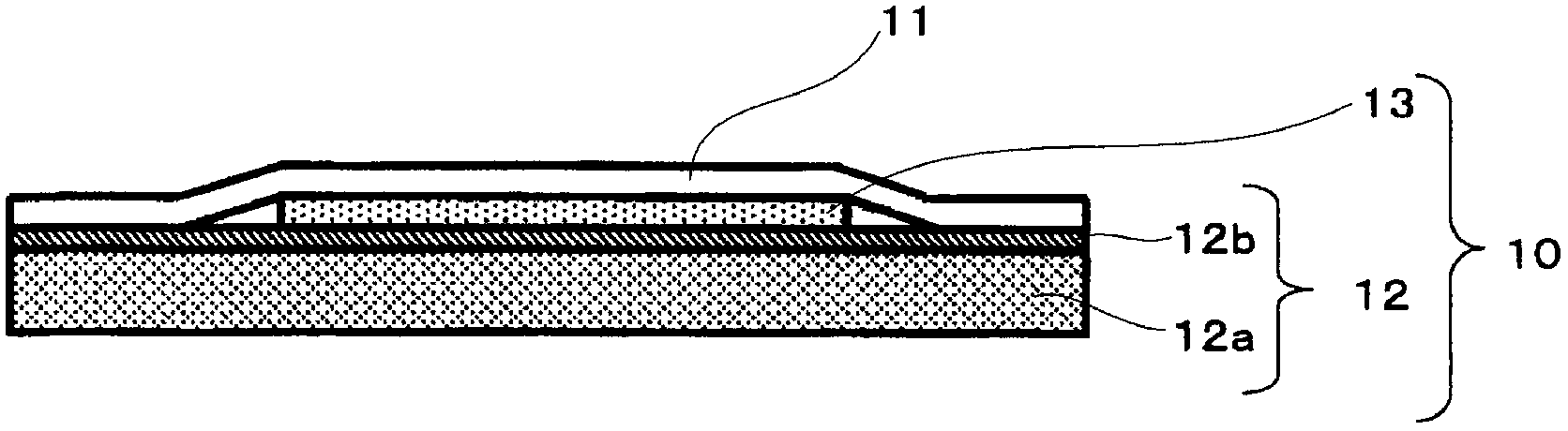

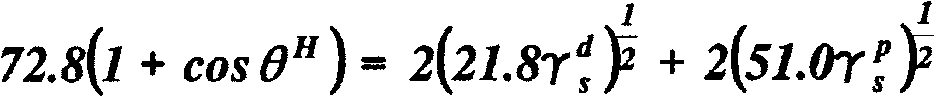

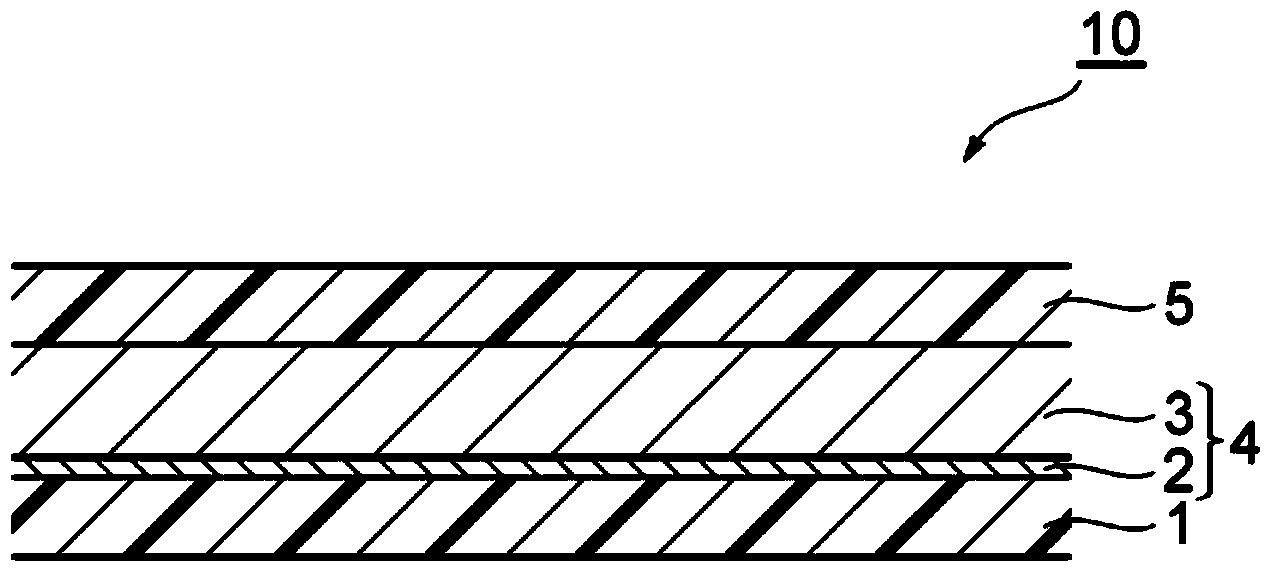

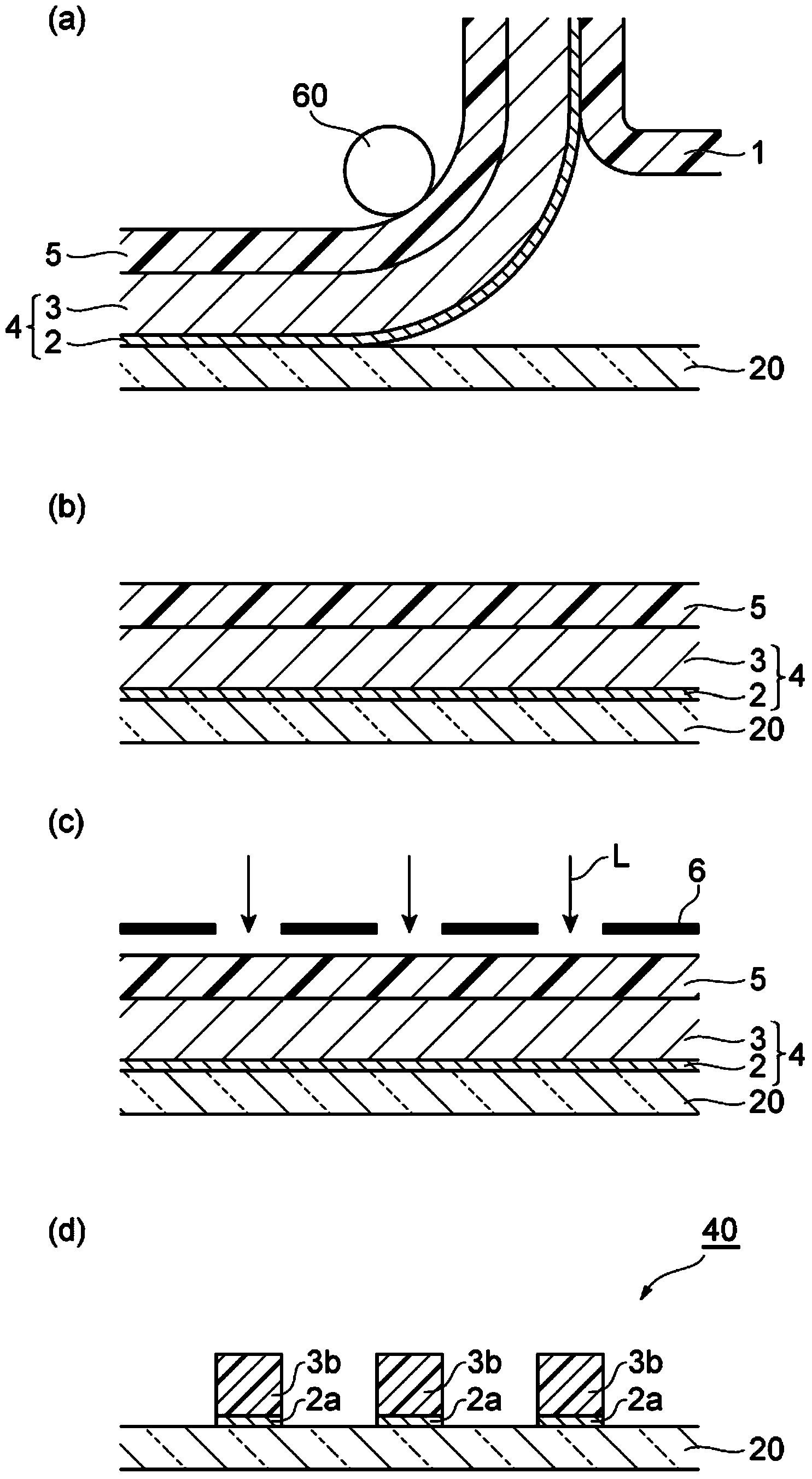

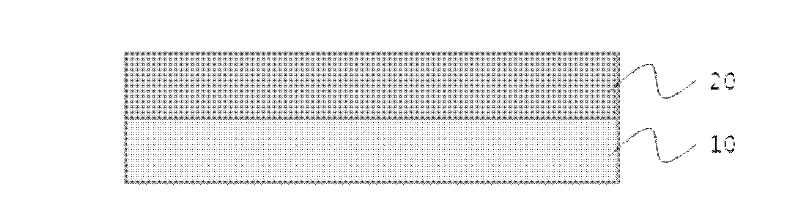

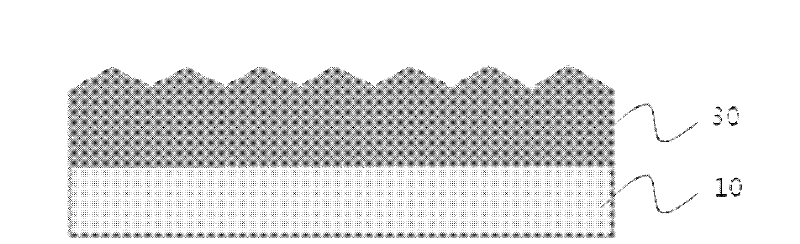

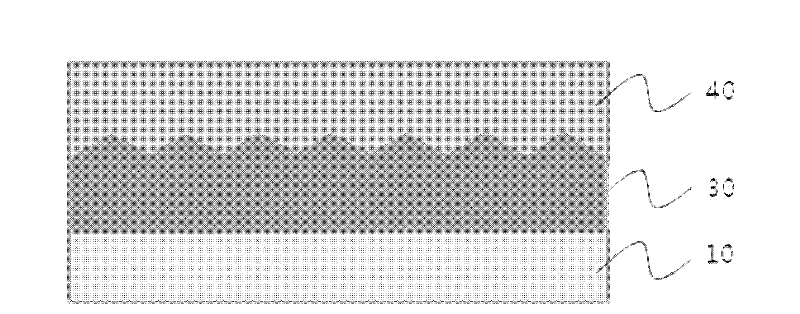

Wafer working tape

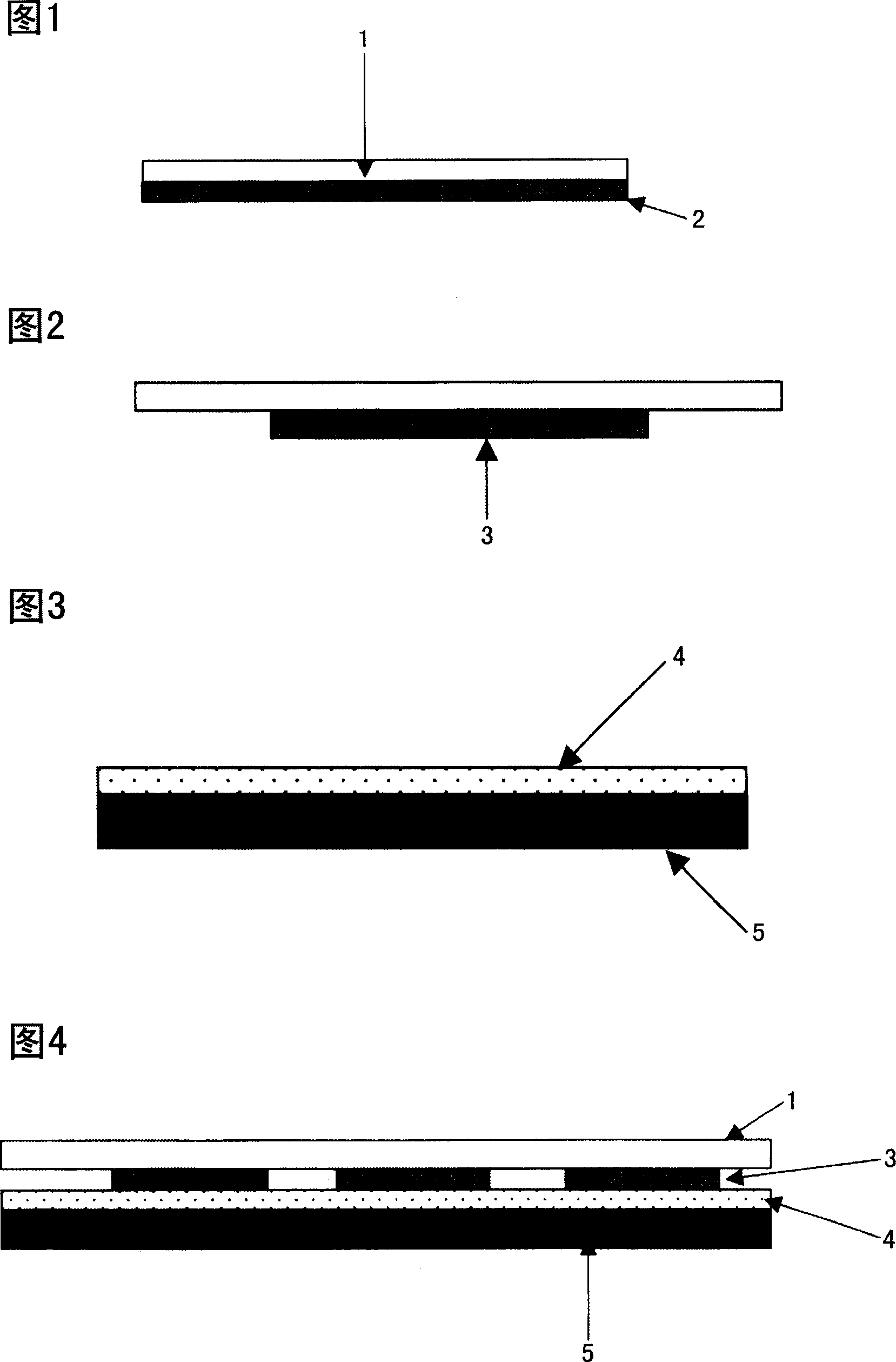

Provided is a wafer working tape wherein a support substrate, an adhesion layer, and a single binding layer are stacked in this order. The binding layer is used for pressure adhesion of a semiconductor element to either an external contact wiring member with wiring or another semiconductor element. The difference in surface free energy between the face of the binding layer which has detached from the adhesion layer and the face of the binding layer which is not in contact with the adhesion layer is 10 mJ / m2 or less.

Owner:FURUKAWA ELECTRIC CO LTD

Method for forming electroconductive pattern, and electroconductive pattern substrate

ActiveCN104170029APromote formationLower surface resistivityConductive layers on insulating-supportsLiquid conductorsFiberChemistry

This method for forming an electroconductive pattern is provided with: a lamination step for readying a photosensitive electroconductive film provided with a support film, an electroconductive layer including electroconductive fiber, and a photosensitive resin layer including a photosensitive resin, in the sequence listed, and laminating the electroconductive layer and the photosensitive resin layer so that the electroconductive layer is on a base material in intimate contact; and a patterning step for exposing and developing the photosensitive resin layer on the base material and thereby forming an electroconductive pattern.

Owner:HITACHI CHEM CO LTD

Electroless metal coatings

InactiveCN102191490AAccelerated corrosionImprove scalabilityLiquid/solution decomposition chemical coatingThin material handlingElectroless nickelElectroplating

The present invention provides a method for preparing an electroless nickel coating composition that includes (a) coating a substrate with an electroless nickel coating to provide a coated substrate; and (b) subjecting the coated substrate to a heating protocol comprising heating to a temperature in a range from about 550 DEG C. to about 700 DEG C. for a period of from about 7 to about 30 hours. An article made from the method is also provided.

Owner:GENERAL ELECTRIC CO

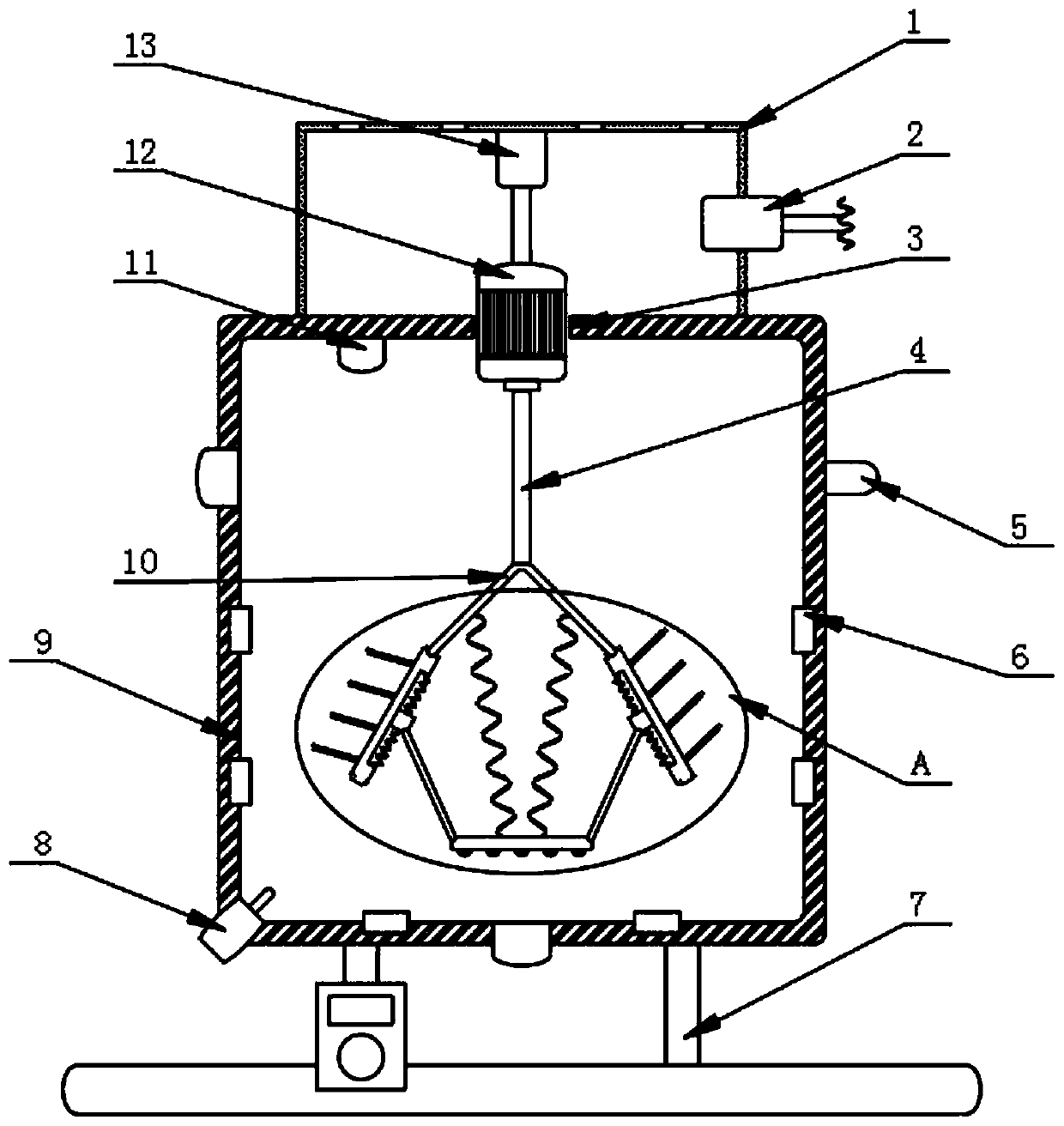

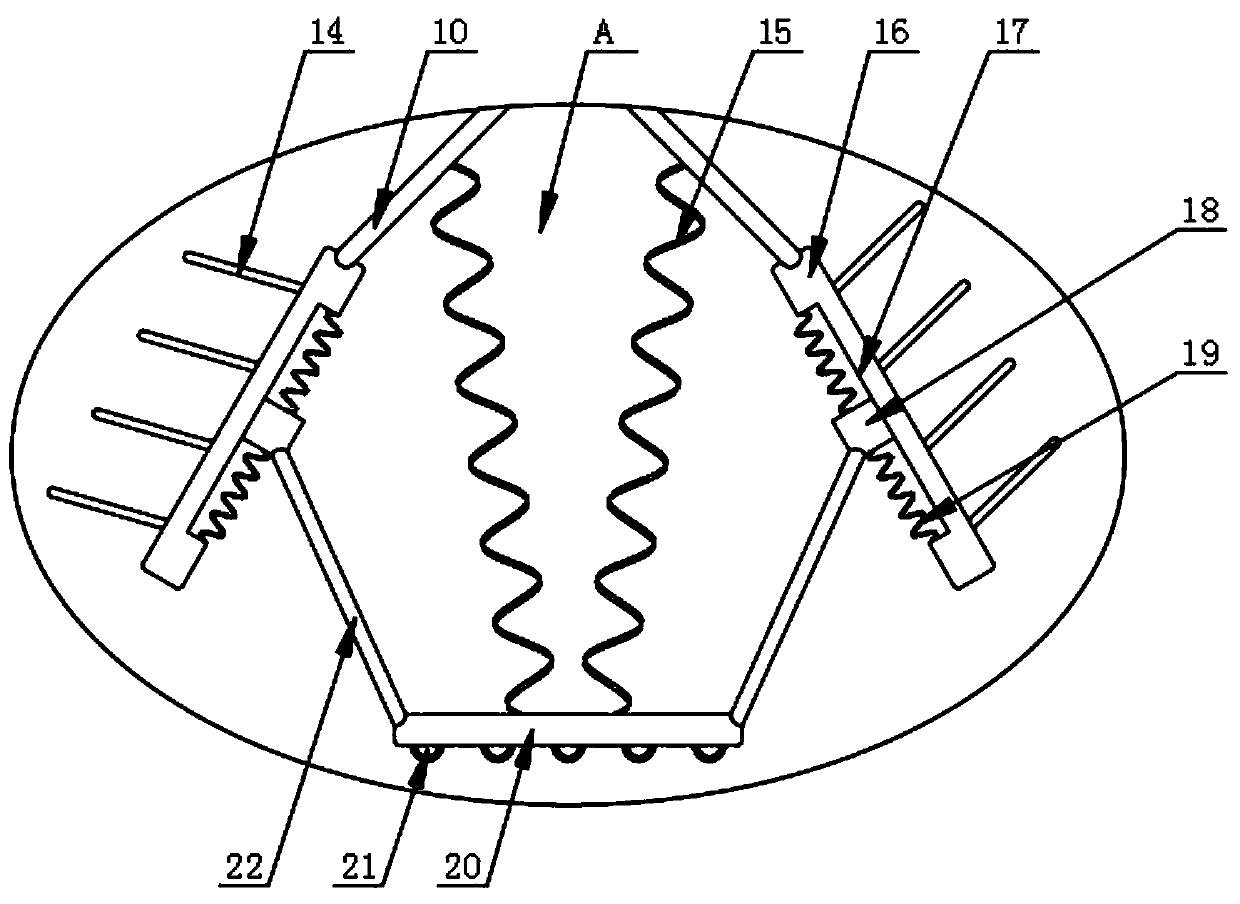

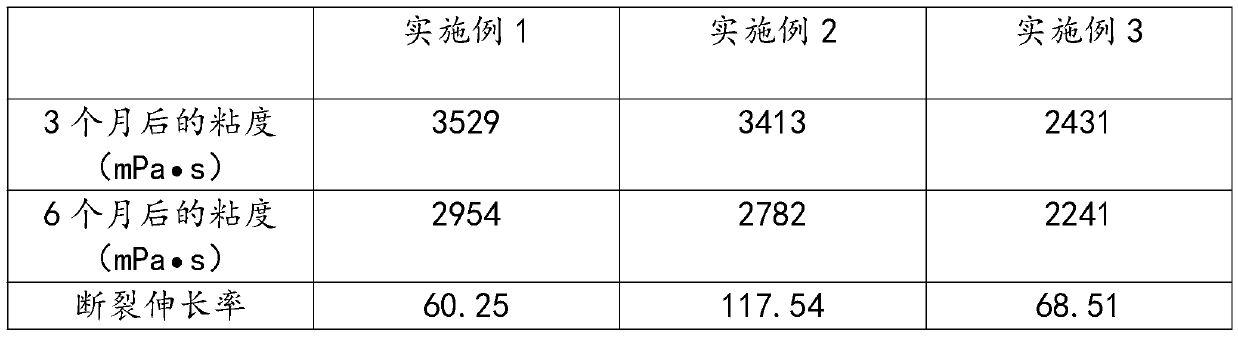

Solvent-free genuine leather laminating adhesive and preparation method thereof

ActiveCN110499133AAdd flexible segmentsPlay a space protection rolePolyureas/polyurethane adhesivesMaterial analysisXylyleneAdhesive

The invention discloses a solvent-free genuine leather laminating adhesive and a preparation method thereof. The solvent-free genuine leather laminating adhesive is formed by uniformly mixing a component A, a component B and a component C, and the component A is composed of diethylene glycol, 1,2-propylene glycol and sebacic acid according to a weight percentage ratio of 3:3:4; the component B iscomposed of xylylene diisocyanate, methylene diphenyl diisocyanate and polyether polyol according to a weight percentage ratio of 3:3:4, and the hydroxyl value of the polyether polyol is 112 mgKOH / g;the component C is composed of 2,6-di-tert-butyl-p-cresol and 3,5-dimethylpyrazole according to a weight percentage ratio of 1:1; and a weight percentage ratio of the component A to the component B tothe component C is 5:8:2. The service life of the solvent-free genuine leather laminating adhesive is greatly prolonged, so that the use effect is prevented from being greatly reduced as time goes on; an excellent adhesive effect can be achieved while ensuring the coating flexibility; and the evaporation efficiency of water is greatly improved while a mixed liquid is fully and uniformly mixed.

Owner:宿州鹏御源新材料科技有限公司

Method for manufacturing thick polyimide flexible metal-clad laminate

InactiveCN102529302AImprove adhesionSmall dimensional change ratePretreated surfacesLaminationThermal dilatationImide

The invention relates to a method for manufacturing a thick polyimide flexible metal-clad laminate. Provided is the method for manufacturing a flexible metal-clad laminate using a casting method, including: (a) forming a first polyimide layer having a coefficient of linear thermal expansion of 25 ppm / K or less above a metal layer; (b) plasma-treating a surface of the first polyimide layer; and (c) forming a second polyimide layer having a coefficient of linear thermal expansion of 25 ppm / K or lower above the first polyimide layer. The flexible metal-clad laminate according to the present invention can have excellent adhesion between the polymer film and the metal conductive layer, a low dimensional change, and a low production cost, because of superior casting workability, even though the thickness of polyimide becomes increased.

Owner:NEXFLEX CO LTD

Biaxially stretched polyester film

ActiveCN102171039AGood adhesionImprove anti-static effectSynthetic resin layered productsPolyurea/polyurethane coatingsPolyesterAntistatic agent

Owner:MITSUBISHI CHEM CORP

Affixed material for display

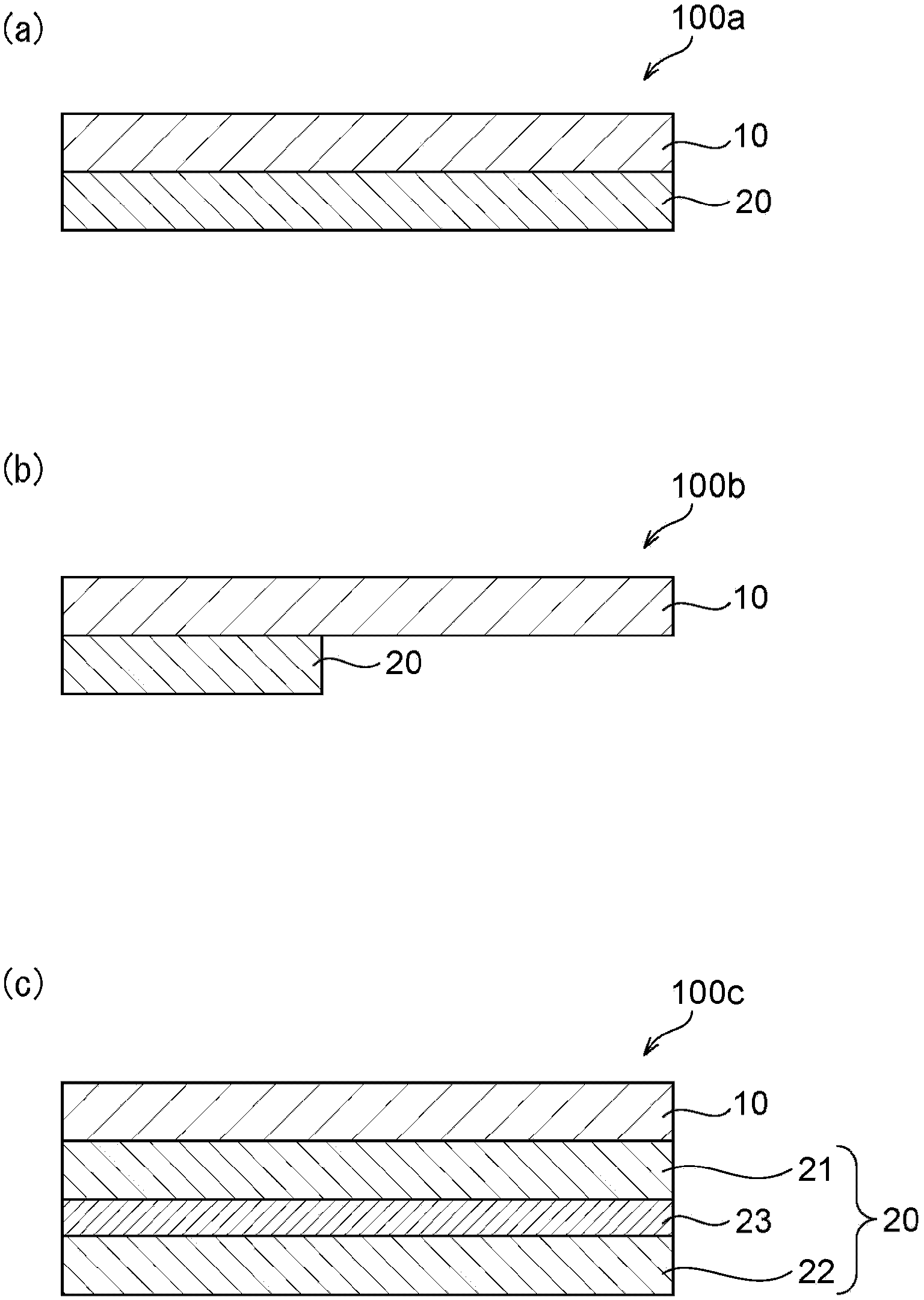

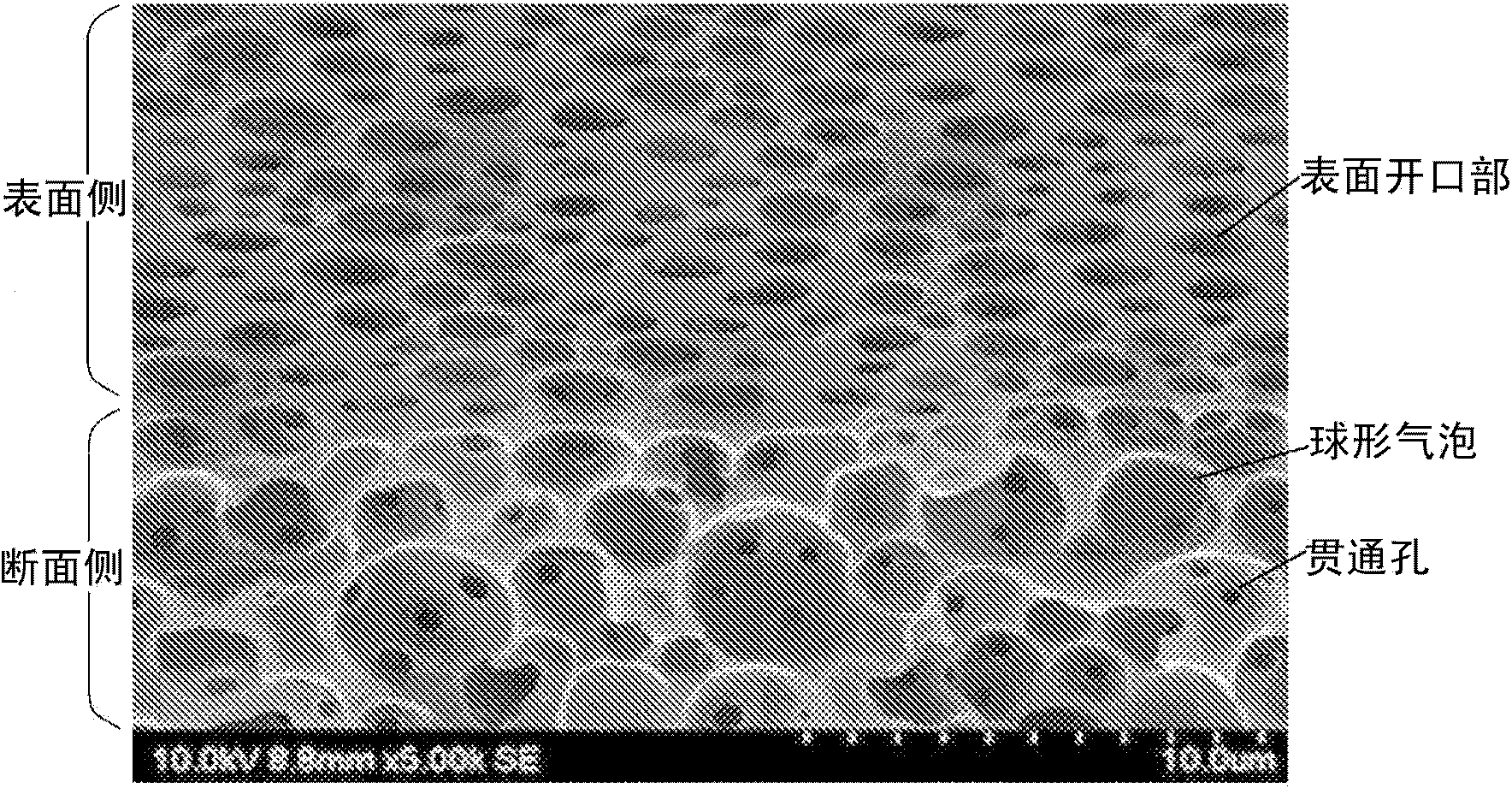

InactiveCN103999144AFull adhesionExcellent peelabilityStampsLayered productsPore diameterSpherical shaped

The present invention provides a reusable affixed material for a display which has excellent peeling properties. The affixed material for a display has a display base material and a foam layer provided on one side of the display base material which has an interconnected cell structure with through-holes connecting adjacent spherical air pockets. The average diameter of the spherical air pockets is less than 20 [mu]m, and the average diameter of the through-holes is 5 [mu]m or less. The foam layer also has surface openings with an average diameter of 20 [mu]m or less.

Owner:NITTO DENKO CORP +1

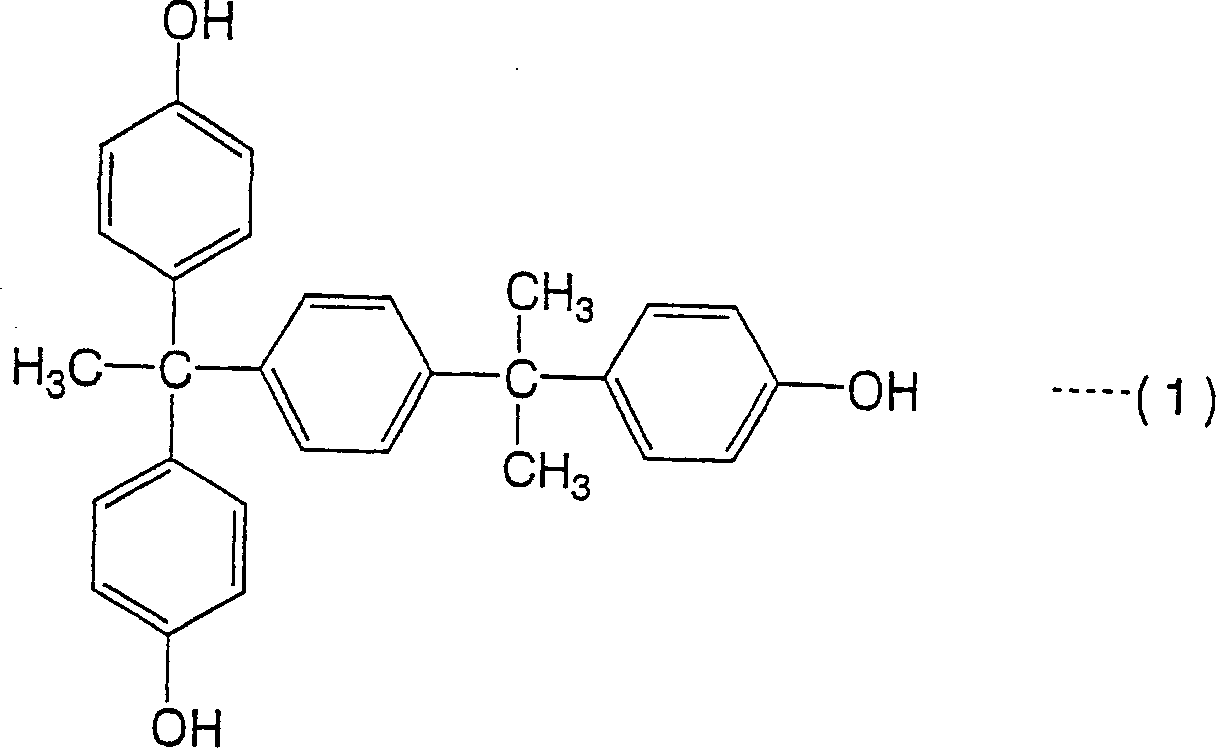

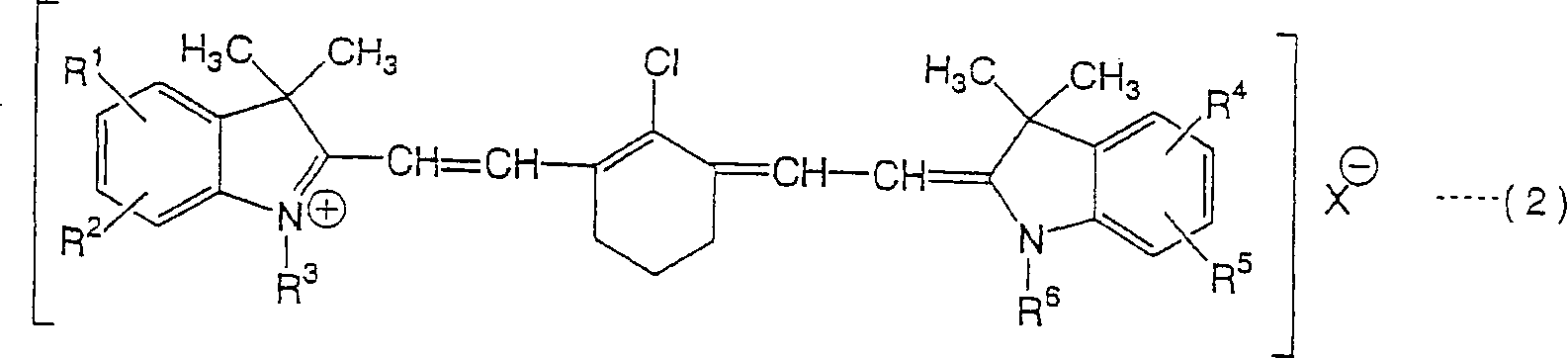

Positive type photosensitive composition

InactiveCN1791837AAdhesion is sufficientFull adhesionThermographyPhotosensitive materials for photomechanical apparatusInfraredPositive type

A positive photosensitive composition which comprises (A) an alkali-soluble organic polymer substance having a phenolic hydroxyl group, (B) a light-heat conversion substance absorbing an infrared ray of an image exposure light source and converting it to heat, (C) at least one resin selected from the group consisting of a vinyl pyrrolidone / vinyl acetate copolymer and other specific polymers or resins, and (D) a dissolution inhibiting agent. The positive photosensitive composition does not require burning, provides necessary and sufficient adhesion in an application under a condition of a humidity in a working room of 25 to 60 %, allows the development which retains high sensitivity and is free of a residue, forms an image having a sharp outline, and provides a resist film which is so hard that its resistance to flawing is improved in the handling before development.

Owner:THINK LABORATORY CO LTD

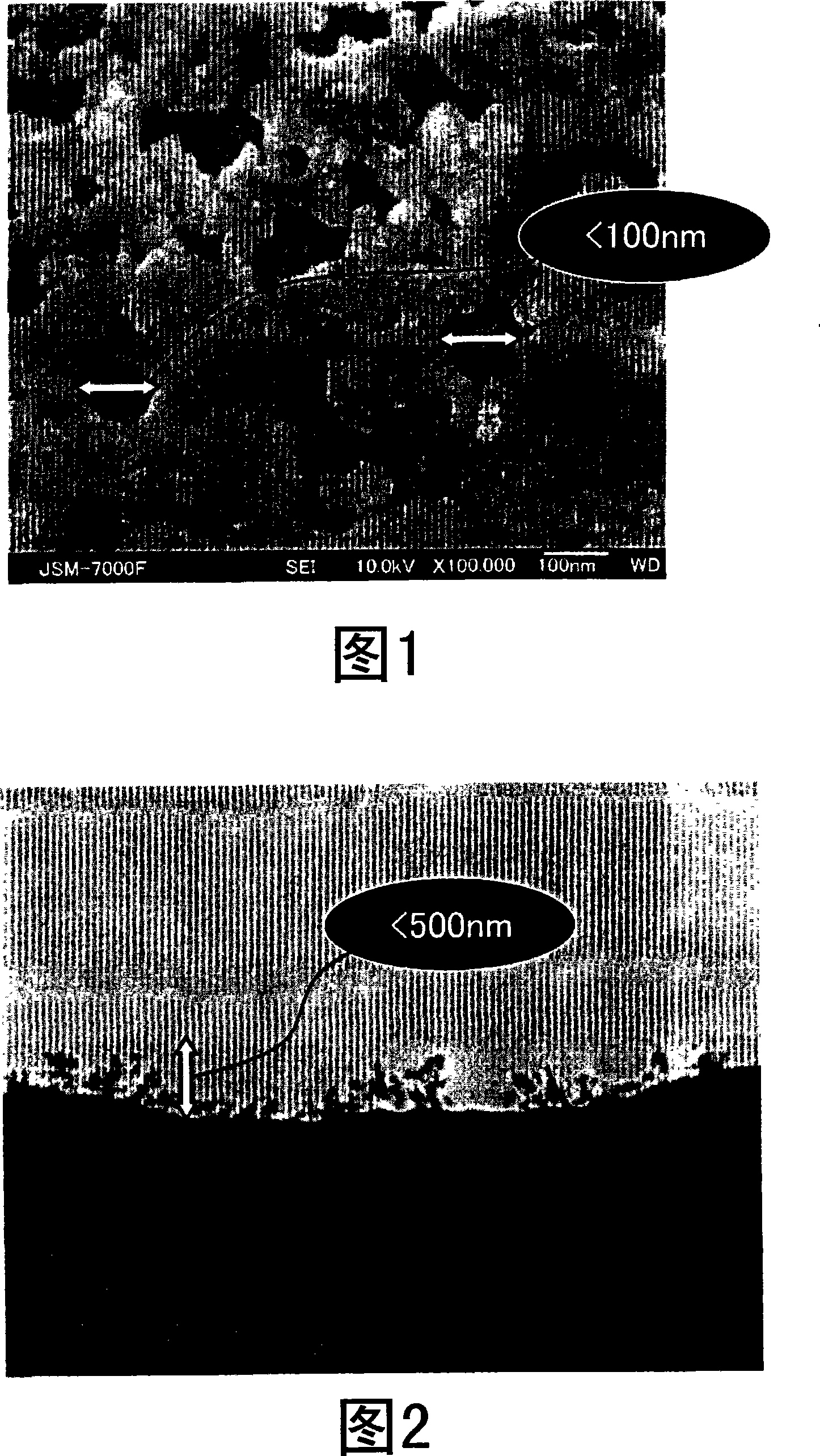

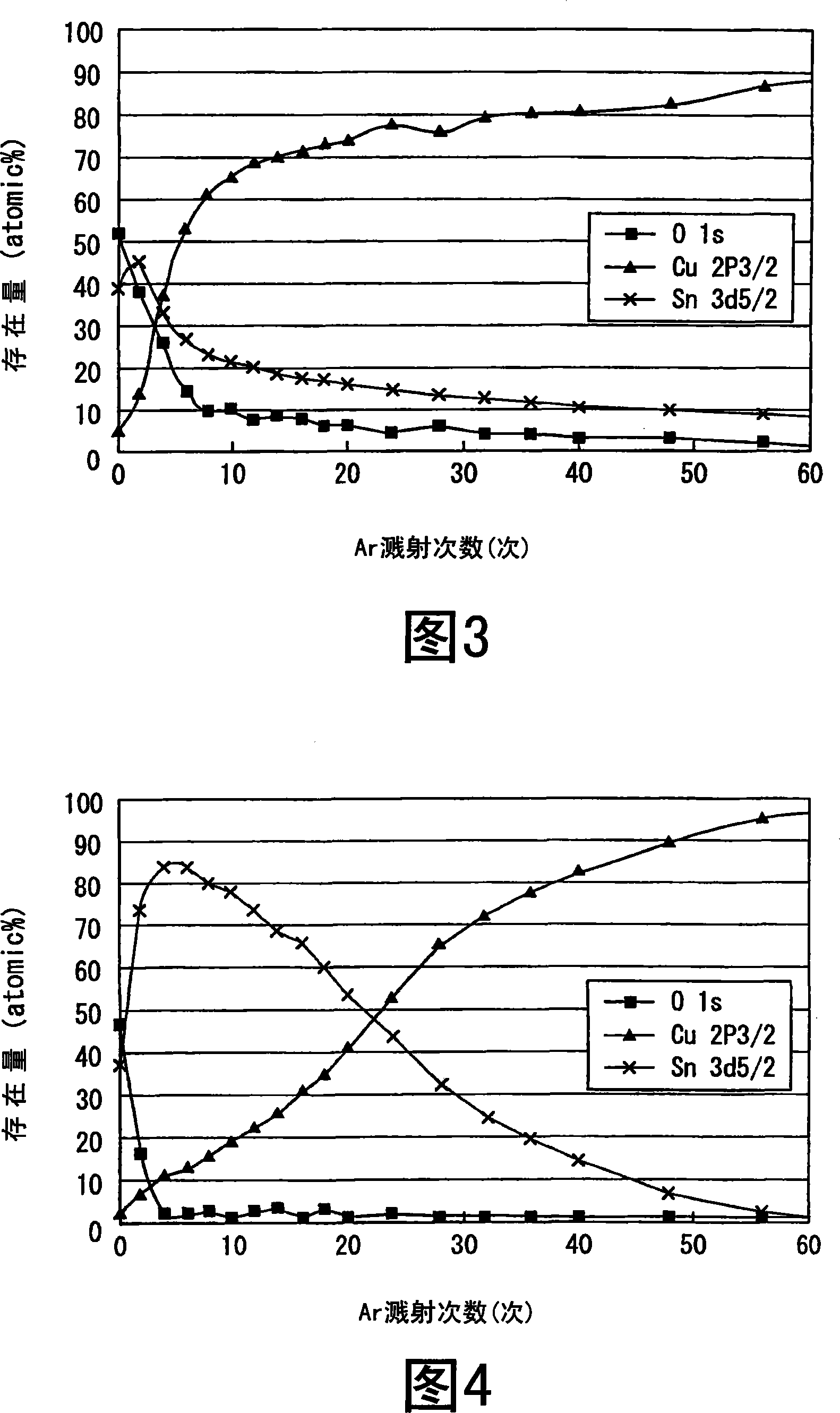

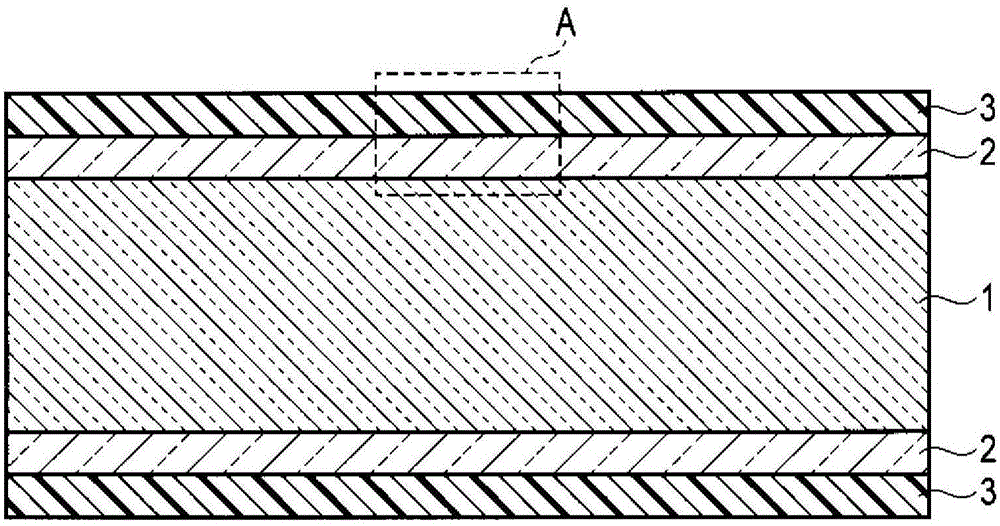

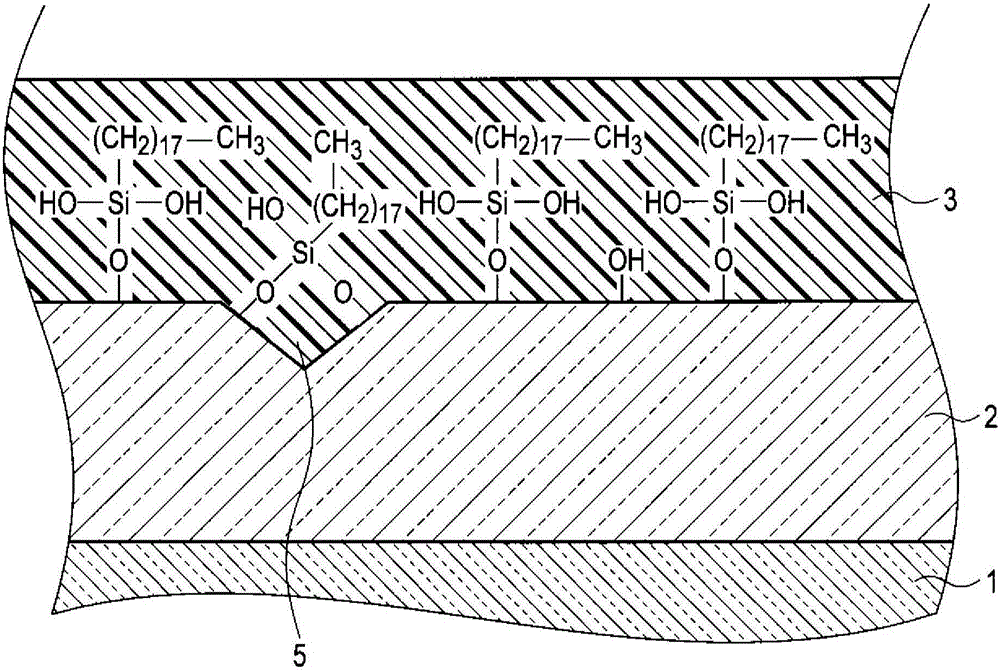

Felting laminate for resin and method for manufacturing laminated body using same

InactiveCN101157837AFull adhesionImprove adhesionPorous dielectricsNon-macromolecular adhesive additivesGlass transition pointDendrite

Owner:MEC CO LTD

Light transmission body

Provided is a light transmission body which has a good balance among excellent durability, wear resistance, lubricity and excellent adhesiveness. A light transmission body according to one embodiment of the present invention comprises a fiber strand and a covering layer. The fiber strand is configured of: a core that is formed of glass; and a cladding that covers the outer circumferential surface of the core and is formed of glass. The covering layer is composed of a plurality of alkyl groups which cover the outer circumferential surface of the cladding and are not substituted by fluorine, and each alkyl group is bonded to the cladding via a siloxane bond.

Owner:OLYMPUS CORP

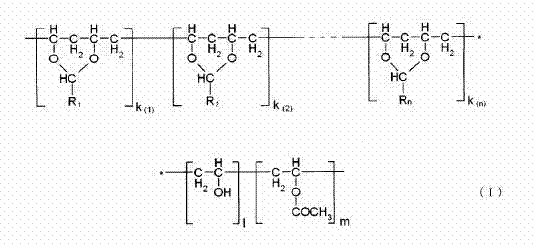

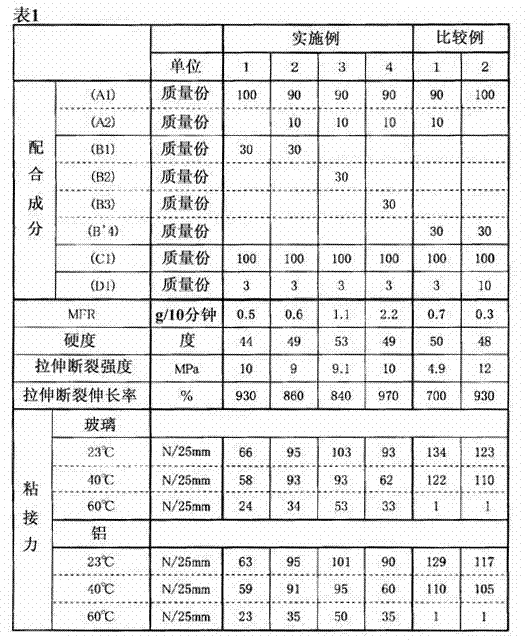

Thermoplastic polymer composition and molded article

ActiveCN103025826AGood flexibilityExcellent mechanical propertiesNon-macromolecular adhesive additivesSynthetic resin layered productsElastomerPolymer science

Provided is a thermoplastic polymer composition which has excellent flexibility, mechanical properties, and molding processability, can adhere to a ceramic, a metal, or a synthetic resin without performing a primer treatment or the like, and has high adhesiveness even if exposed to a high-temperature environment, and also provided is a molded article obtained using the thermoplastic polymer composition. Specifically, provided is a thermoplastic polymer composition comprising: 100 parts by mass of (A) a thermoplastic elastomer which is a block copolymer having a polymer block containing an aromatic vinyl compound unit and a polymer block containing a conjugated diene compound unit or a hydrogenated product thereof; 1 to 100 parts by mass of (B) a polyvinyl acetal resin having a glass transition temperature of 80 to 130 C; and 0.1 to 300 parts by mass of (C) a softener.

Owner:KURARAY CO LTD

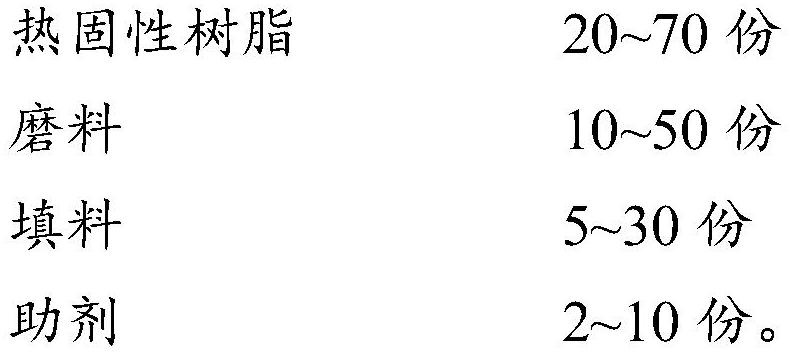

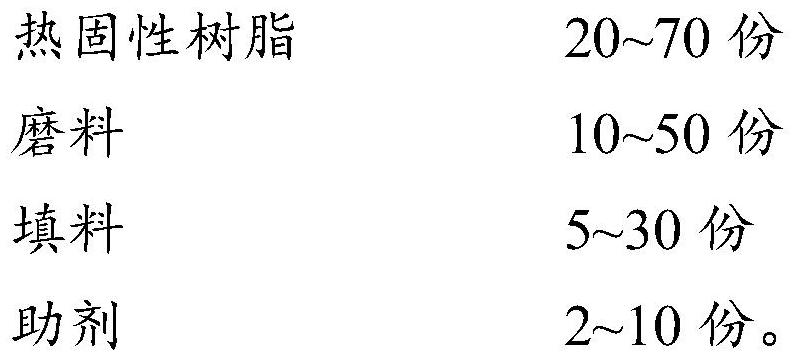

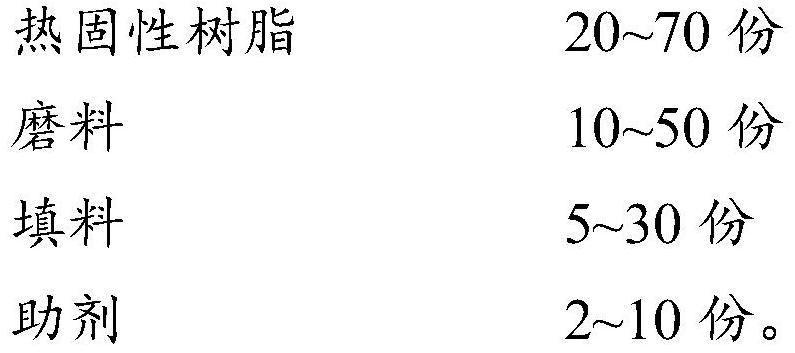

Polishing belt and preparation method and application thereof

PendingCN111843865AReduce hardnessExtended service lifeAbrasion apparatusPortable grinding machinesPolishingAbrasive

The invention relates to the technical field of polishing, in particular to a polishing belt and a preparation method and application thereof. The polishing belt comprises a base layer and a working layer located on the surface of the base layer, and the working layer comprises the following components of, in parts by weight, 20-70 parts of thermosetting resin, 10-50 parts of abrasive, 5-30 partsof filler and 2-10 parts of auxiliaries. According to the result of the embodiment, after the polishing belt is used for polishing hard material, the glossiness of the surface of the hard material canreach 90 Gu at most, and atomization is avoided.

Owner:惠安宇信金刚石工具有限公司 +1

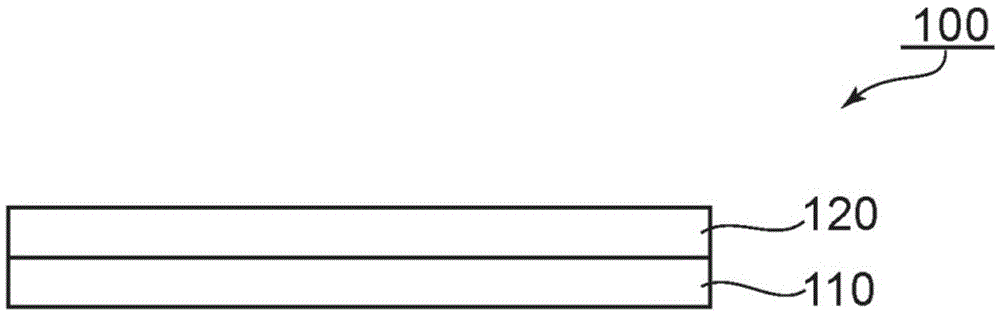

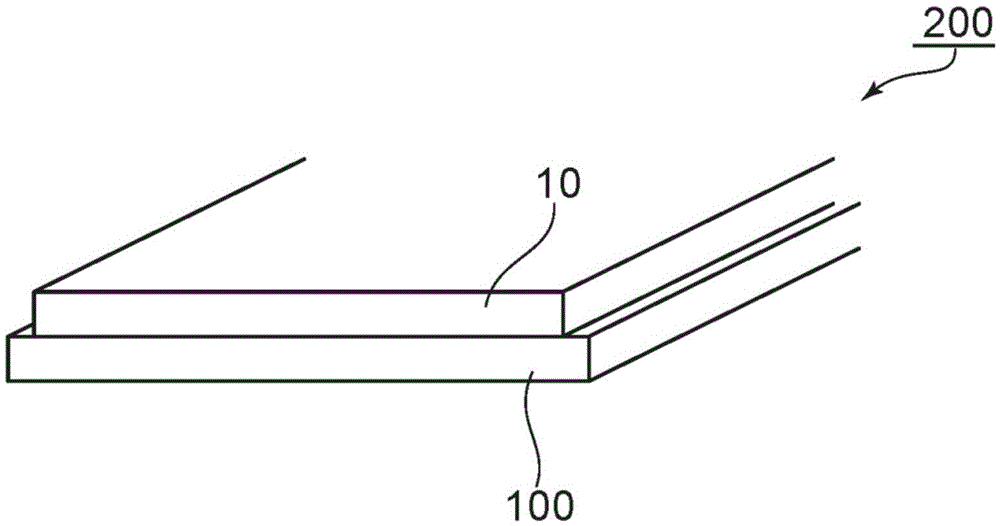

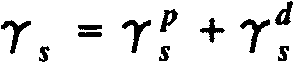

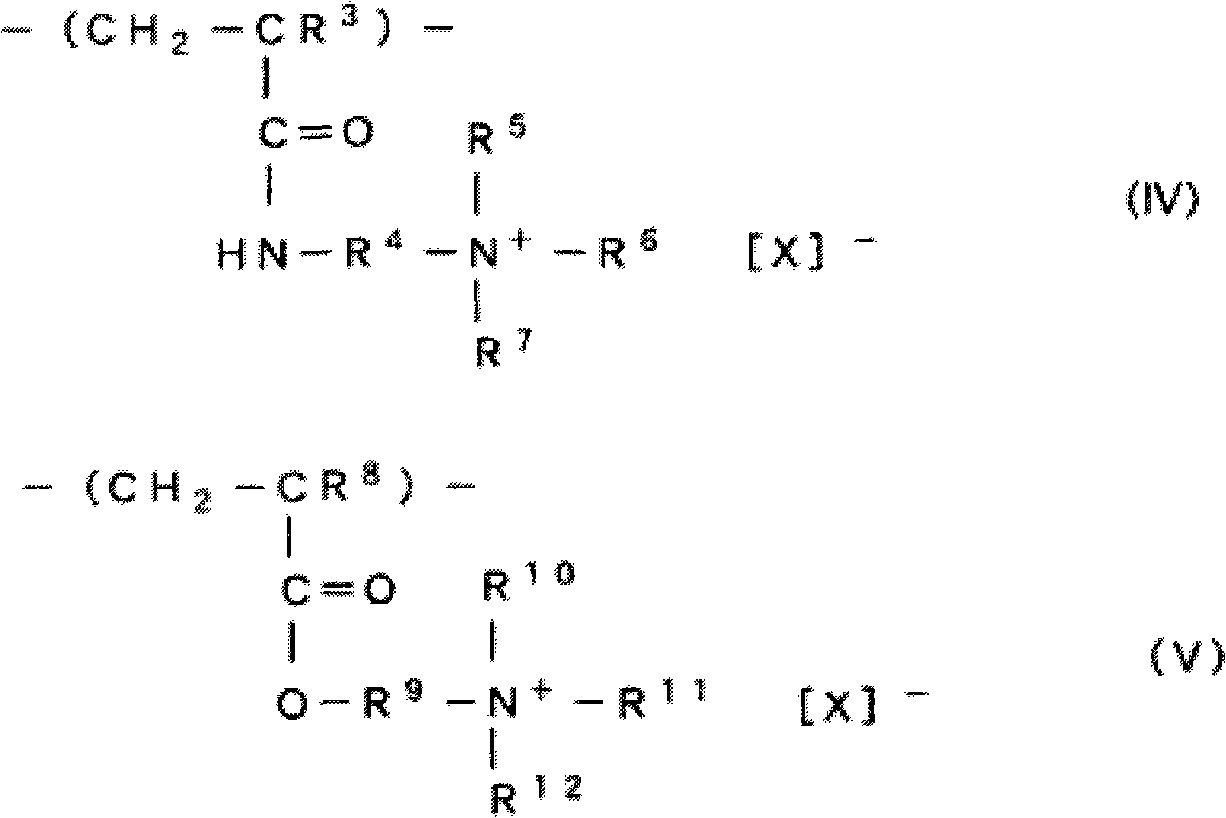

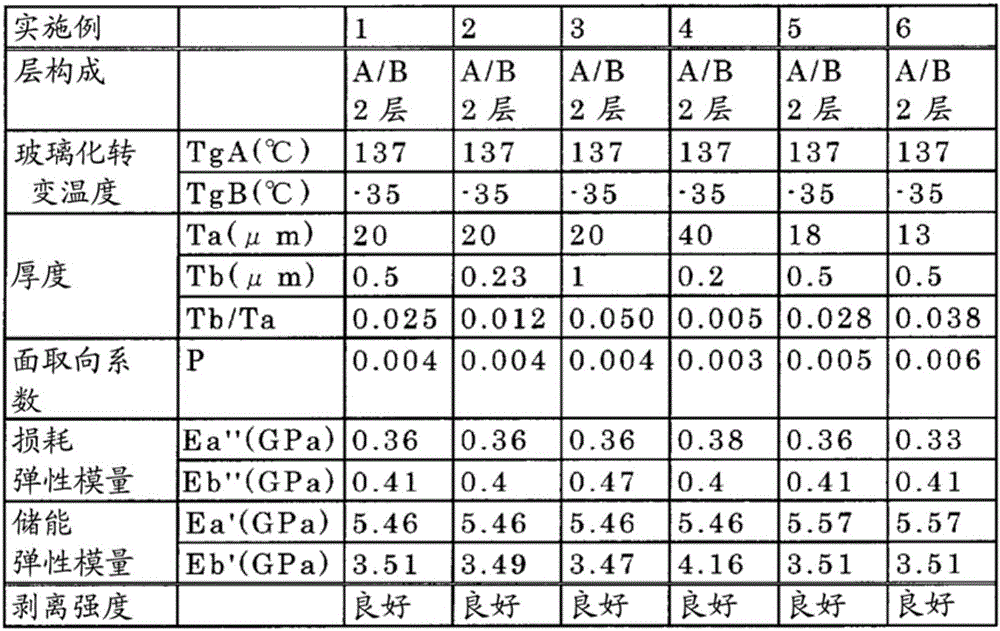

Multilayer film, polarization plate, and multilayer film production method

ActiveCN105829102AFull adhesionEfficient manufacturingSynthetic resin layered productsPretreated surfacesGlass transitionTransition temperature

The invention discloses a multilayer film, a polarization plate, and a multilayer film production method. The multilayer film is provided with a layer (A) composed of a thermoplastic resin, and a layer (B) formed on at least one surface of the layer (A), wherein the layer (B) is composed using a material (Y) that contains a polymer having a glass transition temperature of -50 DEG to 40 DEG as the main component, and formulae (1)-(4) ((1) 2.5 X 10-3<Tb / T [alpha]< 1.0 X 10-1; (2) P>1.0X10-3; (3)Eb">E[alpha]"+0.01GP[alpha]; (4)Eb'<Ea'-1GP[alpha]) are satisfied by the following: the thickness (Ta) of the layer (A); the thickness (Tb) of the layer (B); the planar orientation coefficient (P) of the layer (A); the loss elastic modulus (Ea") of the layer (A); the loss elastic modulus (Eb") of the layer (B); the storage elastic modulus (Ea') of the layer (A); and the storage elastic modulus (Eb') of the layer (B).

Owner:ZEON CORP

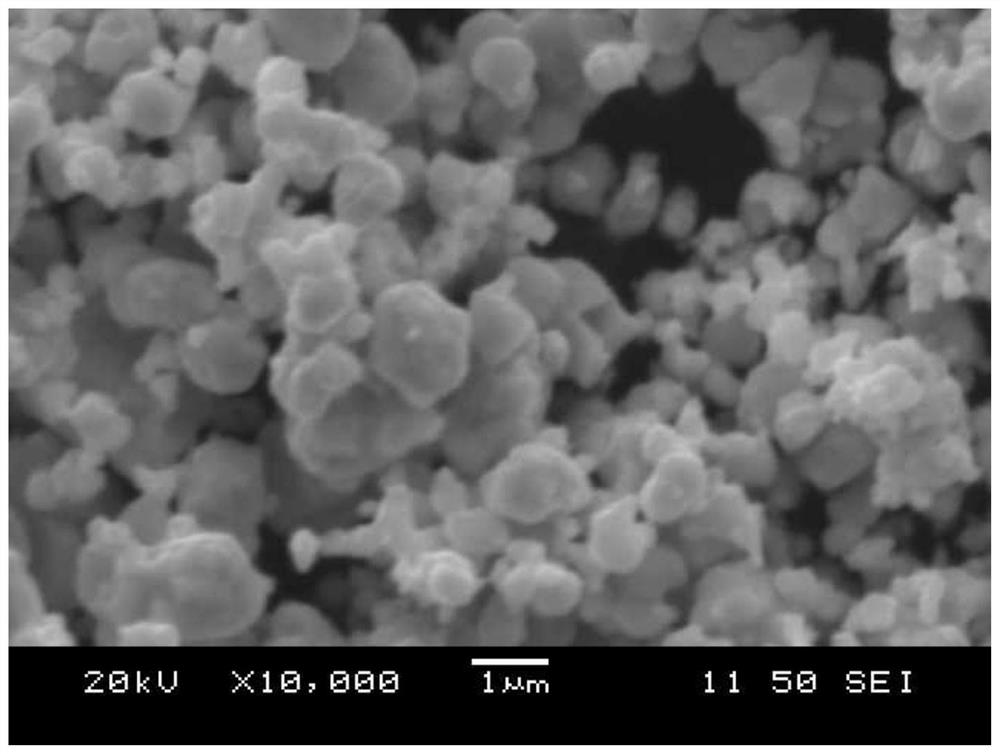

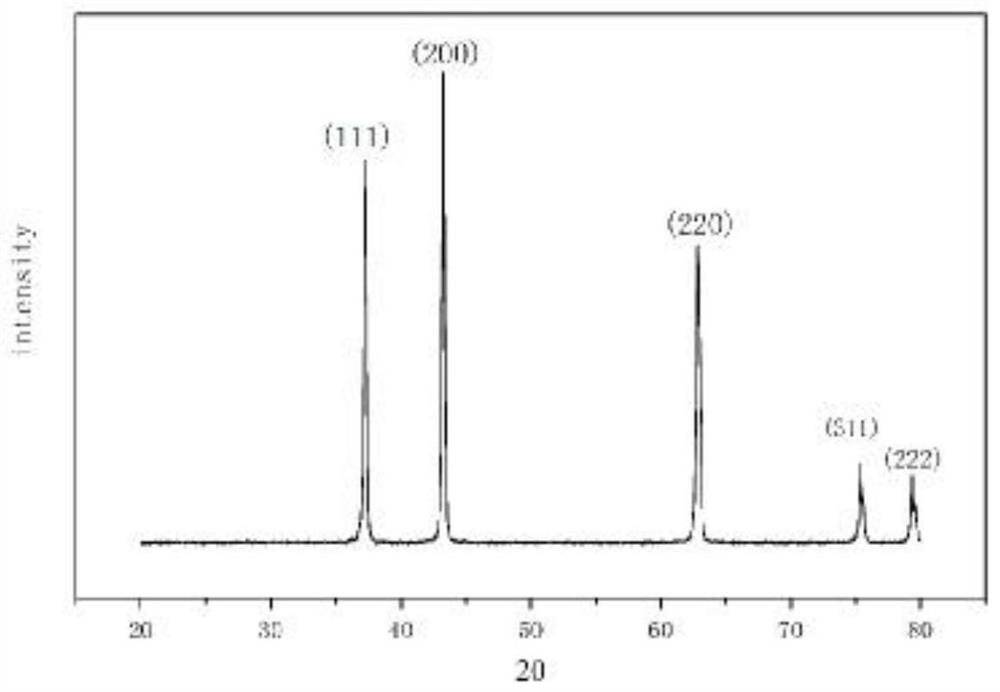

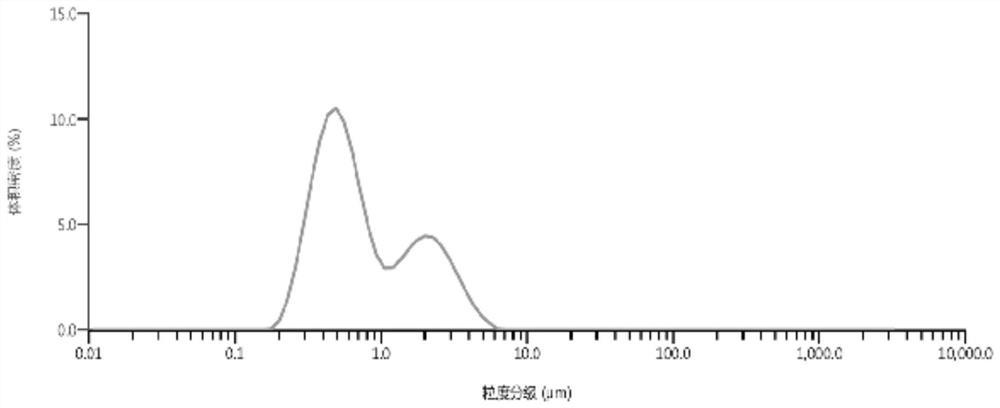

Cold isostatic pressing forming preparation method of nickel oxide-based ceramic target material

InactiveCN112456971AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedMass fraction

The invention relates to a cold isostatic pressing forming preparation method of a nickel oxide-based ceramic target material, wherein the method comprises the following steps: A, preparing raw materials: preparing mixed powder of nickel oxide powder and doped source powder, wherein the total mass fraction of doped source elements in the mixed powder is not more than 10%, wherein the doping sourceelement is selected from one or more of 0-6% of Li, 0-0.3% of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% ofV, 0-10% of W and 0-2.5% of Ti; B, carrying out spray drying; C, compacting by vibration; D, feeding a mold into a cold isostatic pressing chamber for pressing; E, degumming a biscuit; F, sintering;G, cooling after heat preservation is finished; and H, machining or not machining according to needs. The preparation method can be used for preparing the nickel oxide-based ceramic which is good in conductivity, relatively high in purity and fine in grain size.

Owner:北京航大微纳科技有限公司

Adhesive sheet

InactiveCN103289588AExcellent handlingImprove productivityFilm/foil adhesivesSemiconductor/solid-state device manufacturingEngineeringSilicon

The invention provides an adhesive sheet capable of keeping sufficient adhesive force and excellent processing properties such as paper through property and the like after an isolation film is peeled off. The adhesive sheet is provided with a matrix layer and an adhesive layer. A ball number of the adhesive layer in a roll adhesive test is smaller than 2; and an adhesive force to a silicone mirror wafer is higher than 0.3 N / 20mm. By using the adhesive sheet, the adhesive sheet taking account of the sufficient adhesive force as the adhesive sheet and the processing properties such as the paper through property and the like after an isolation film is peeled off can be obtained.

Owner:NITTO DENKO CORP

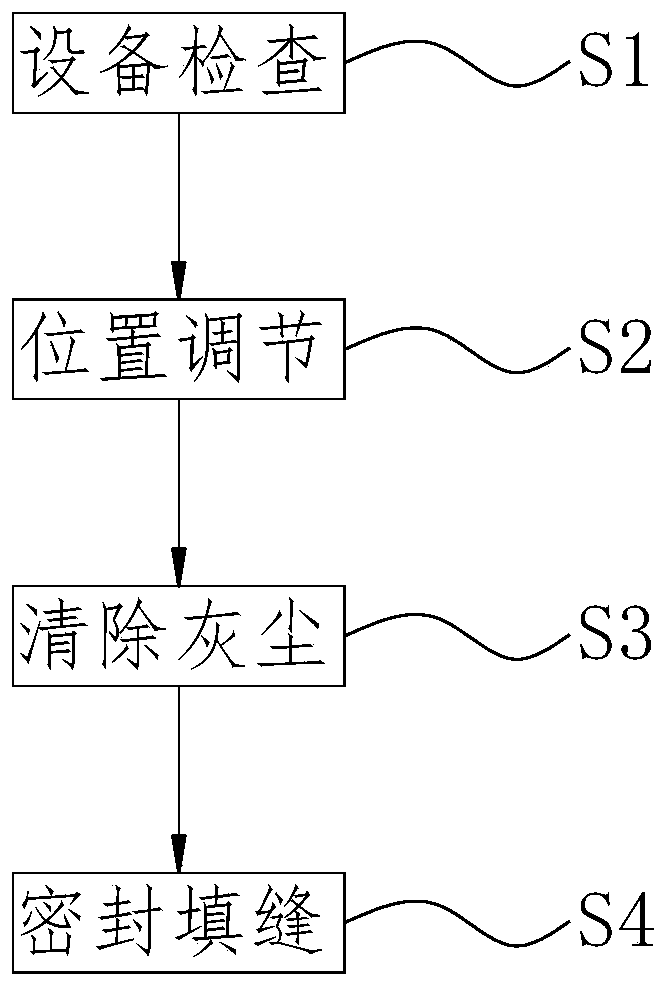

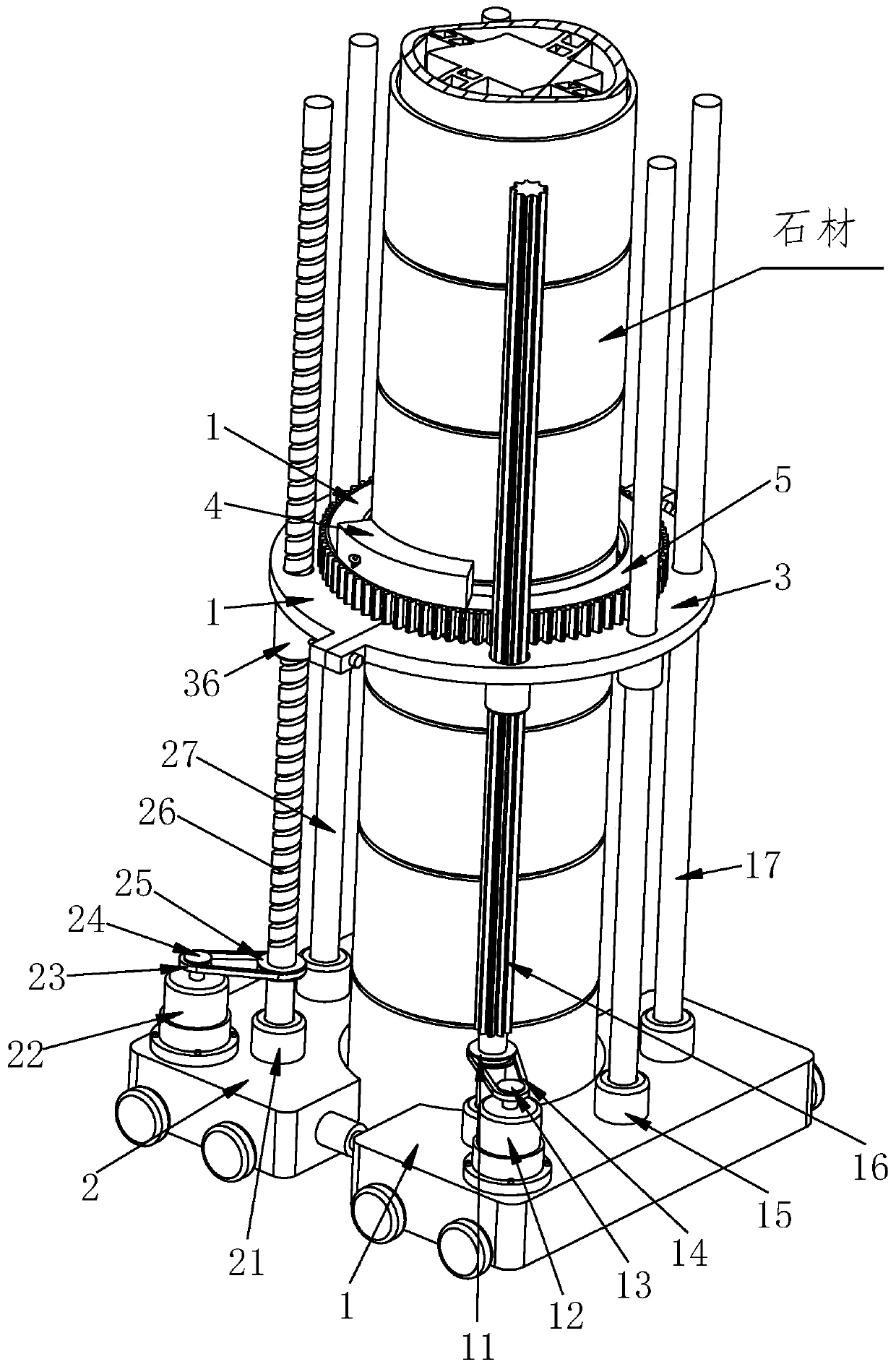

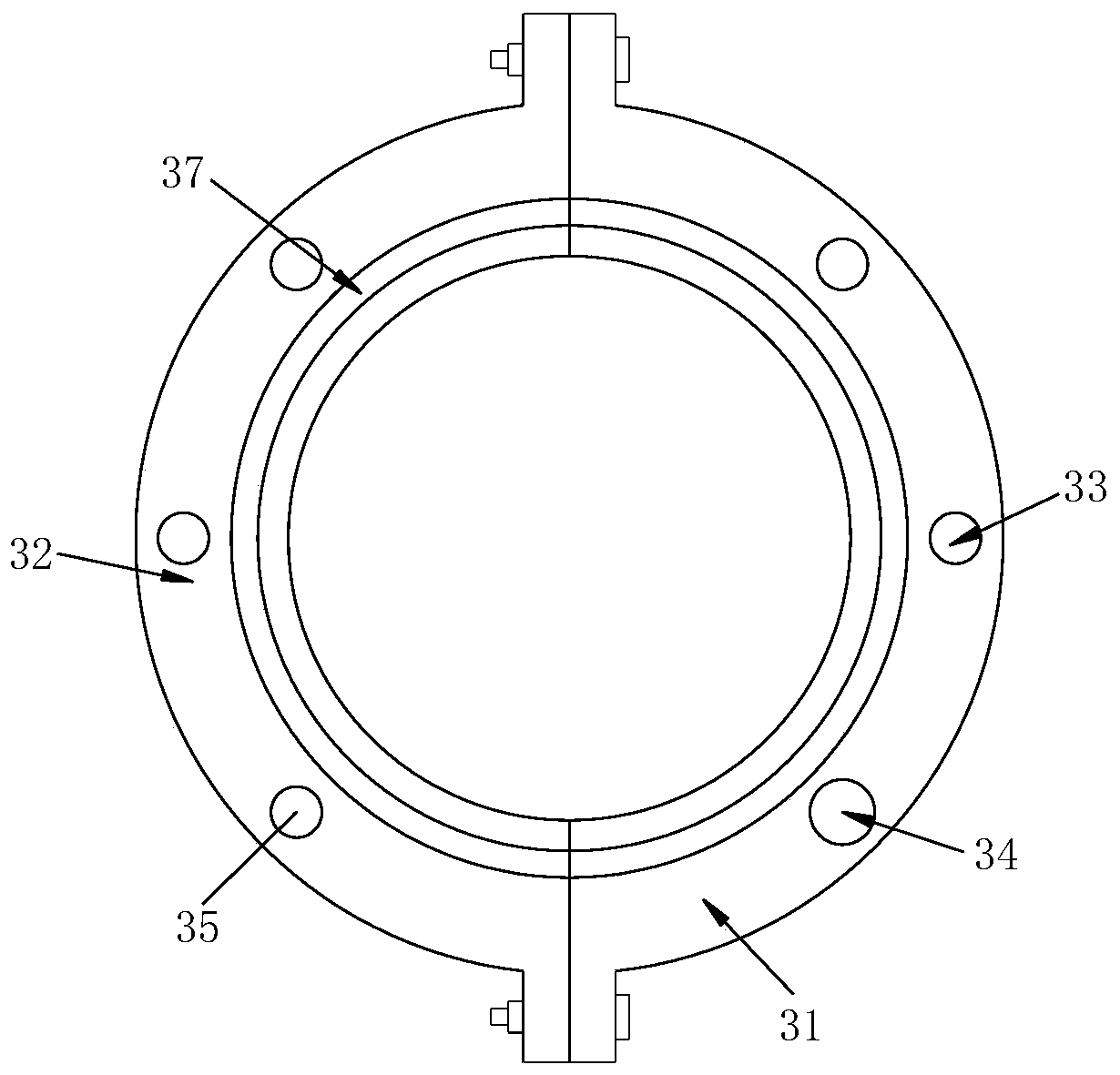

Dry-hanging, sealing and jointing treatment construction method for building wall decoration stone

ActiveCN111075168ANo need for manual visual observationReduce wasteBuilding constructionsDrive wheelArchitectural engineering

The invention relates to a dry-hanging, sealing and jointing treatment construction method for building wall decoration stone. A first support base, a second support base, a support mechanism, a dustremoval mechanism and a jointing mechanism are included, wherein one side of the first support base is connected with the second support base, the support mechanism is arranged right above the first support base and the second support base, the jointing mechanism is mounted at the upper end of the support mechanism, the dust removal mechanism is mounted on the upper end surface of the jointing mechanism, first inserting connection barrels are installed at the top of the first support base, first positioning rods and tooth groove rods are sequentially mounted in the three first inserting connection barrels, bearings A are mounted in connection positions of the first positioning rods and the tooth groove rods with the first inserting connection barrels, a first motor is mounted at the cornerof the upper end surface of the first support base, a first driving wheel is welded at an output shaft of the first motor, and a first belt is mounted on the outer side of the first driving wheel ina matched manner. The operation is simple and safe, and the sealant injection process is uniform, compact and full.

Owner:长春昆仑建设股份有限公司

Method for manufacturing fuel-cell membrane electrode assembly

InactiveCN105637050AAvoid deformationAvoid wrinklesAdhesive processesFilm/foil adhesivesPolymer electrolytesFuel cells

This invention provides a method for manufacturing a fuel-cell membrane electrode assembly. Said method makes it easy to handle a polymer electrolyte membrane, prevents deformation and wrinkling of said polymer electrolyte membrane, and allows efficient assembly of said polymer electrolyte membrane, a gas diffusion electrode, and / or a gas diffusion layer. This method for manufacturing a fuel-cell membrane electrode assembly containing a first gas diffusion electrode, a polymer electrolyte membrane, and a second gas diffusion electrode includes the following: conveying the polymer electrolyte membrane, the first gas diffusion electrode, and / or the second gas diffusion electrode by adhering same to a pressure-sensitive adhesive sheet that loses adhesiveness upon an external stimulus; and detaching the pressure-sensitive adhesive sheet by applying said external stimulus thereto so as to reduce the adhesiveness thereof.

Owner:NITTO DENKO CORP

TPE material printing method

The invention discloses a TPE material printing method. Preliminary treatment cleaning and deep cleaning are carried out on the surface of a TPE material with boiled oil-water, so oil stains and other molecules absorbed on the surface of the material are prevented from affecting the adhesion of printing ink. According to the TPE material printing method, during the deep cleaning process, the TPE material is expanded, then cotton cloth is adopted to wrap a hard object and is adhered with the boiled oil-water to wipe the surface of the TPE material, the effect of surface coarsening is achieved, the coarsening effect is more sufficient, the surface tension of the TPE material is increased, the molecular chains are broken thoroughly, the adhesive force of the TPE material and the printing ink is improved, and obvious coarsening marks are not left on the surface of the material. The TPE material is firstly expanded and extended, and is then subjected to printing ink printing, the printing ink and the TPE material are combined more sufficiently, the requirement on product printing appearance is fully guaranteed, and the investment cost is low.

Owner:天键电声股份有限公司

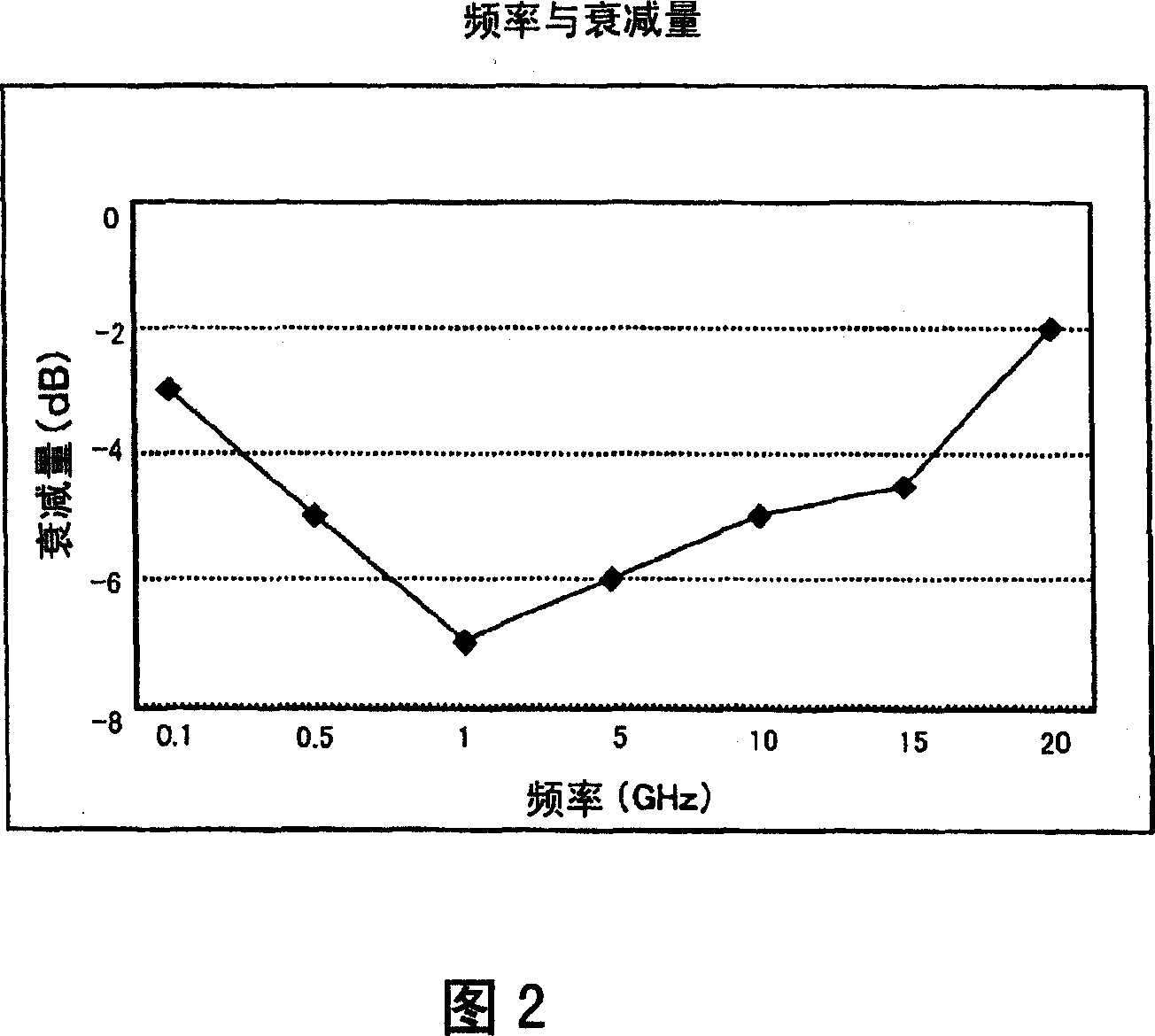

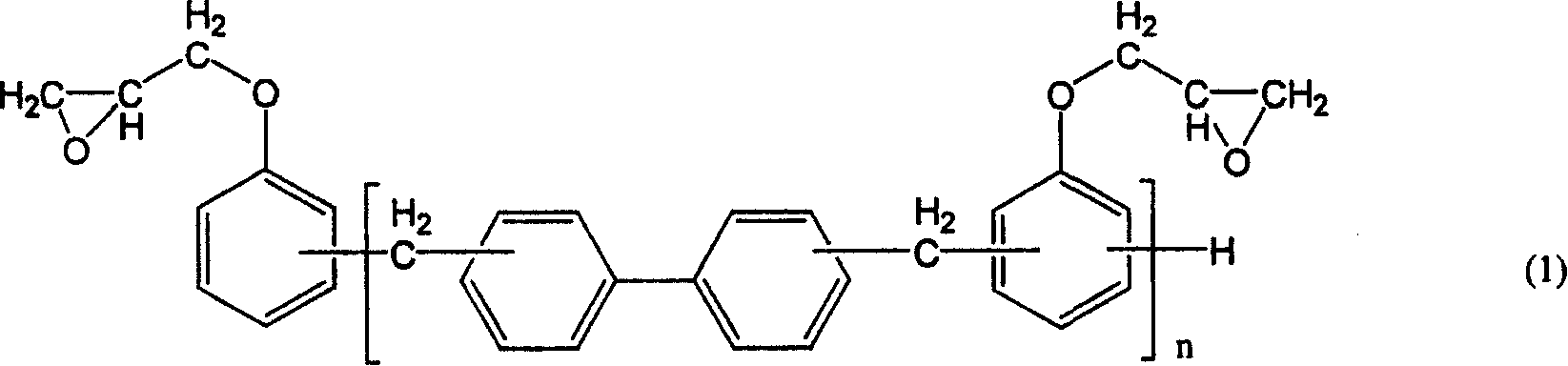

Epoxy resin composition

InactiveCN1942502ALow dielectric constantReduce lossSemiconductor/solid-state device detailsPrinted circuit aspectsEpoxyDielectric loss

To provide an epoxy resin composition which can form a cured material having low dielectric constant and low dielectric loss tangent in a radio frequency region, and a film obtained by using the epoxy resin composition. An epoxy resin composition comprising: (A) at least one epoxy resin selected from the group consisting of a novolac epoxy resin having a phenolic skeleton and a biphenyl skeleton, and a bifunctional linear epoxy resin having a weight average molecular weight of 10,000 to 200,000 and having a hydroxyl group; and (B) a modified phenolic novolac having a phenolic hydroxyl group, at least part of which is esterified with a fatty acid.

Owner:NAMICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com