Polishing belt and preparation method and application thereof

A technology of polishing belt and abrasive belt machine, which is applied in the field of polishing, and can solve problems such as lack of application range, limited polishing effect, and complicated polishing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

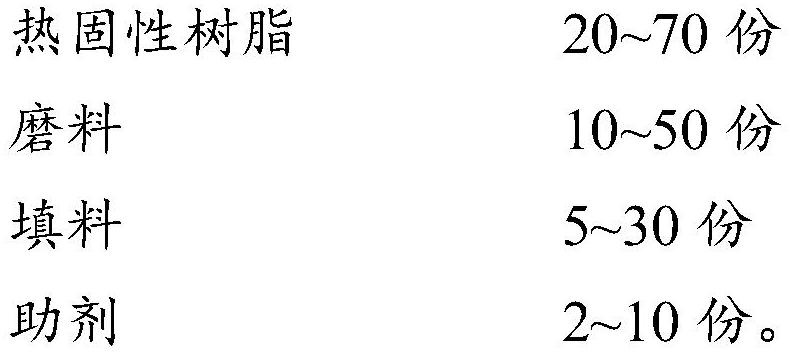

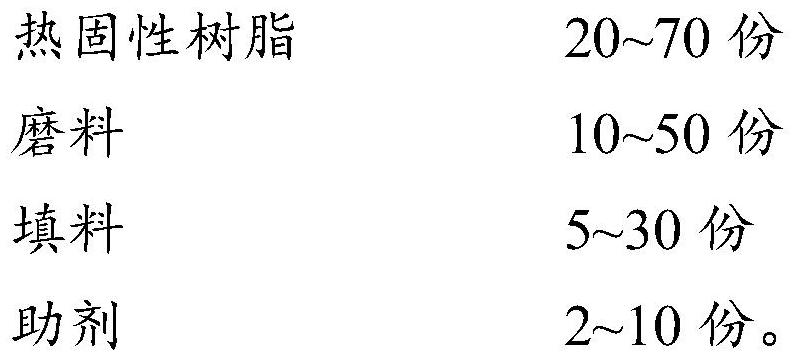

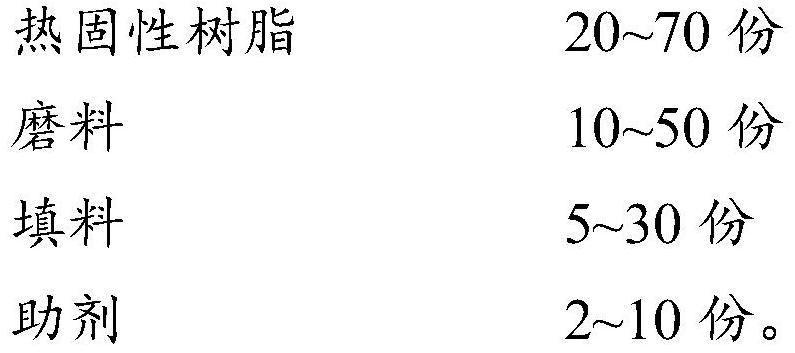

[0046] The present invention also provides a preparation method for the polishing tape described in the above technical solution, comprising the following steps:

[0047] Mix thermosetting resin, abrasives, fillers and additives to obtain a working layer mixture;

[0048] The working layer mixture is sequentially heat-cured and demolded on the surface of the base layer to obtain the polishing tape.

[0049] The invention mixes thermosetting resin, abrasive material, filler and auxiliary agent to obtain the working layer mixture. In the present invention, there is no special limitation on the order of mixing, and the order of mixing known to those skilled in the art can be used for mixing. In the present invention, the mixing is preferably carried out under the condition of stirring; the present invention does not have any special limitation on the stirring, and the stirring can be carried out by a process well known to those skilled in the art.

[0050] After the working lay...

Embodiment 1

[0059] Base layer: Gram weight is 450g / m 2 the canvas;

[0060] Working layer: by weight: 36 parts of bisphenol A epoxy resin, 9 parts of polyetheramine curing agent, 20 parts of polycrystalline diamond (3000 mesh), 5 parts of silicon carbide (3000 mesh), calcium carbonate (3000 mesh) 10 parts, 10 parts of copper (3000 mesh), 5 parts of chopped carbon fiber (length 1000 μm, diameter 7 μm), 3 parts of silane coupling agent γ-aminopropyltriethoxysilane, defoamer XP1036P high-purity silicon 2 parts polyether.

[0061] Under the condition of stirring, mix according to the components and proportions of the above-mentioned working layer to obtain the working layer mixture;

[0062] A mold is fixed on the surface of the base layer, and the working layer mixture is placed on the mold, followed by thermal curing and demoulding, the thermal curing includes first curing and second curing; the temperature of the first curing The temperature is 30° C., the pressure is 2 MPa, and the tim...

Embodiment 2

[0065] Base layer: Gram weight is 420g / m 2 nylon cloth;

[0066] Working layer: by weight: 40 parts of phenolic resin, 25 parts of polycrystalline diamond (4000 mesh), 5 parts of boron nitride (4000 mesh), 10 parts of hollow silica (5000 mesh), aluminum hydroxide (4000 mesh ) 5 parts, talc powder (5000 mesh) 7 parts, titanate coupling agent propyl dioleate acyloxy (dioctyl phosphate acyloxy) titanate 3 parts.

[0067] Under the condition of stirring, mix according to the components and proportions of the above-mentioned working layer to obtain the working layer mixture;

[0068] Fixing a mold on the surface of the base layer, and placing the working layer mixture on the mold, performing thermal curing in a hot press, and demolding, the thermal curing includes first curing and second curing; The temperature of the first curing is 120°C, the pressure is 2MPa, and the time is 10min; the temperature of the second curing is 140min, the pressure is 1MPa, and the time is 30min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com