Patents

Literature

1926 results about "Polyaspartic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

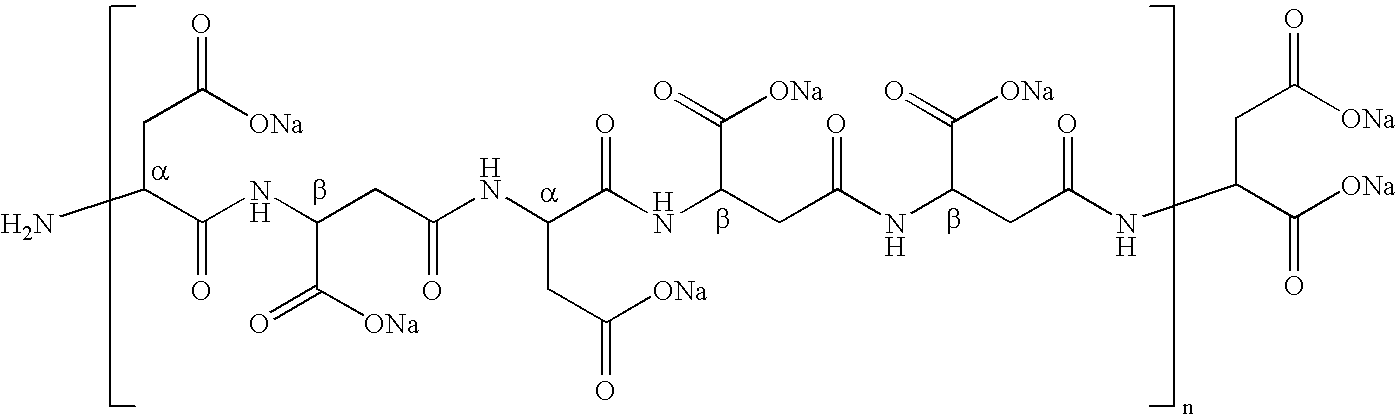

Polyaspartic acid (PASA) is a biodegradable, water-soluble polymerized amino acid. It is a biodegradable replacement for water softeners and related applications. In nature, PASA has been found in as fragments of larger proteins with length up to 50 amino acids, but as of 2004 had not been isolated as a pure homo polymeric material from any natural source. The first isolation of synthetic oligomeric sodium polyaspartate, obtained by thermal polycondensation of aspartic acid, was reported by Hugo Schiff in late 19th century. Later it was proposed that thermal polymerization process leads through polysuccinimide intermediate. Polyaspartic acid is produced industrially in both the acid form and as the sodium polyaspartate salt.

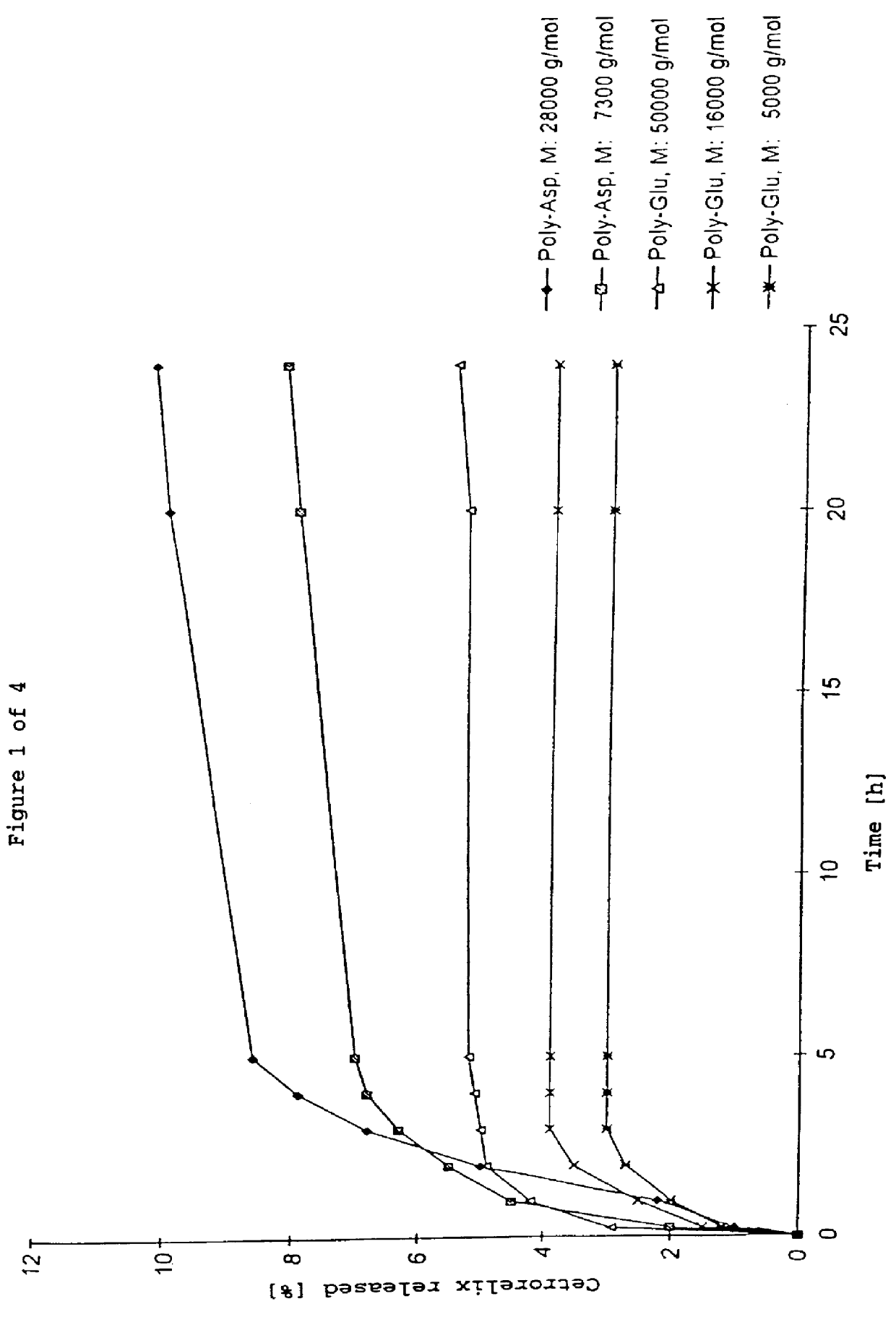

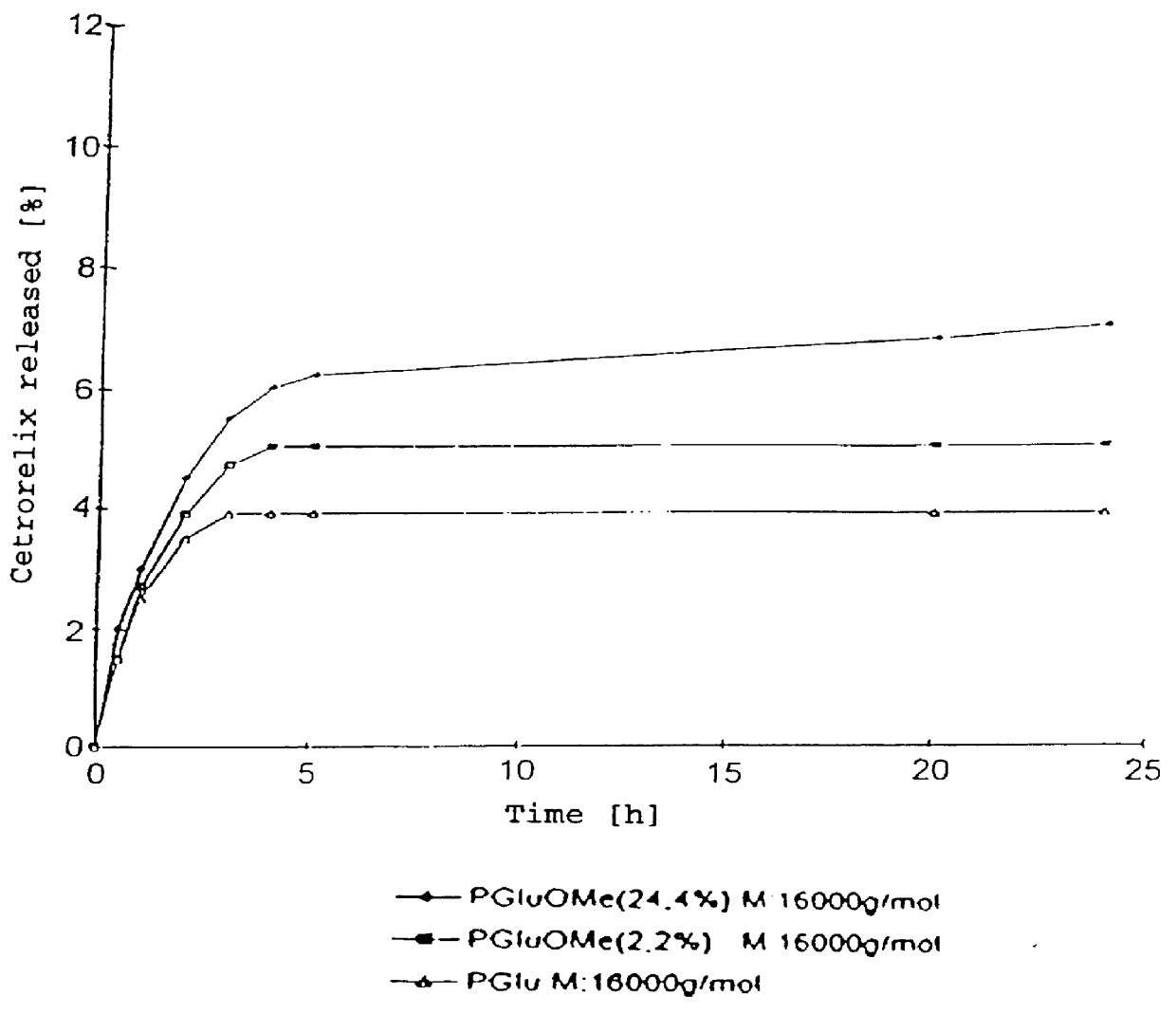

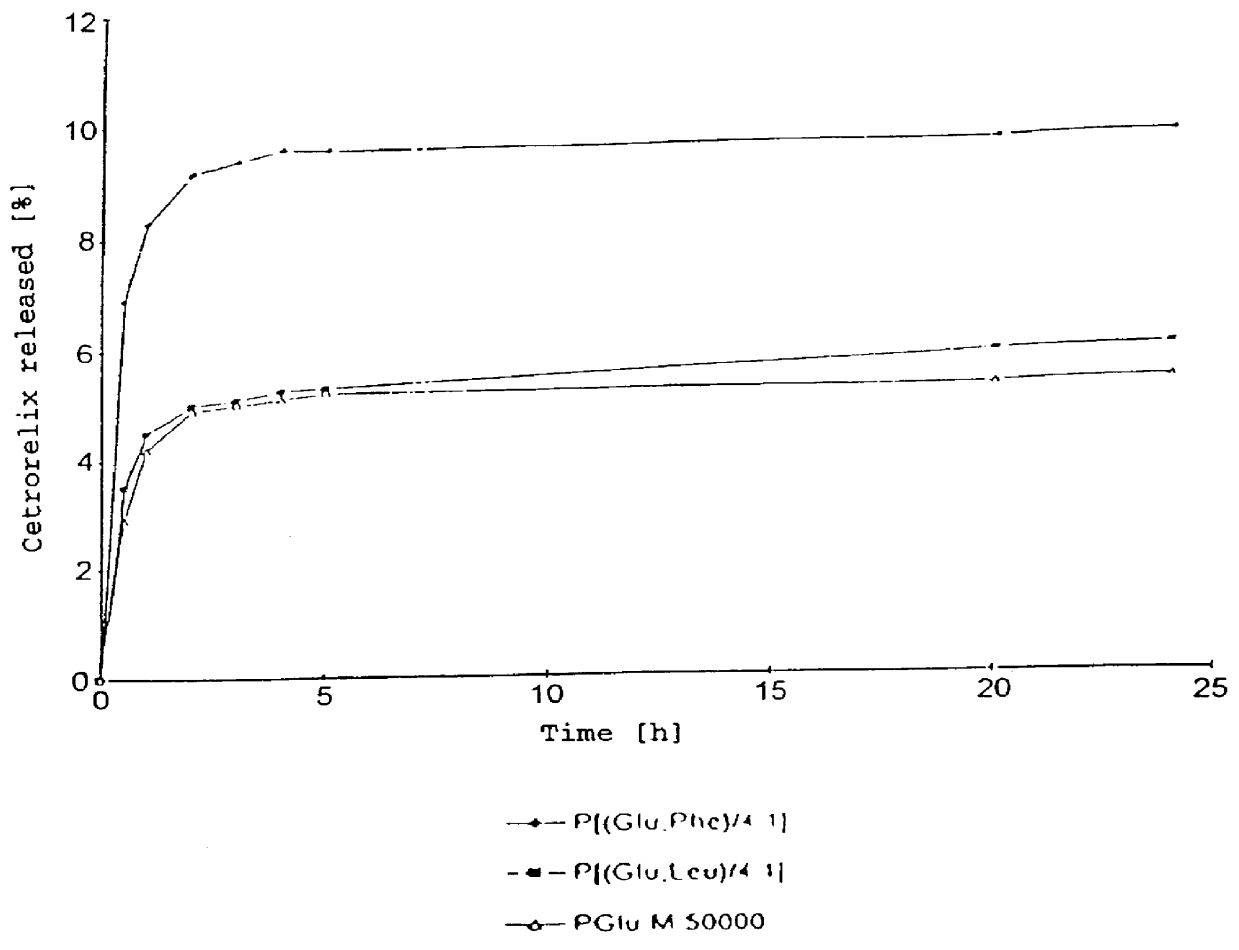

Immobilized and activity-stabilized complexes of LHRH antagonists and processes for their preparation

In this invention, a release-delaying system is to be developed for LHRH antagonists, in particular for cetrorelix, which allows the active compound to be released in a controlled manner over several weeks by complexation with suitable biophilic carriers. The acidic polyamino acids polyglutamic acid and polyaspartic acid were selected for complexation with cetrorelix. The cetrorelix polyamino acid complexes are prepared from aqueous solutions by combination of the solutions and precipitation of the complexes, which are subsequently centrifuged off and dried over P2O5 in vacuo. If complexes having a defined composition are to be obtained, lyophilization proves to be a suitable method. The cetrorelix-carboxylic acid complexes were also prepared from the aqueous solutions. In the random liberation system, the acidic polyamino acids poly-Glu and poly-Asp showed good release-delaying properties as a function of the hydrophobicity and the molecular mass of the polyamino acid. In animal experiments, it was possible to confirm the activity of the cetrorelix-polyamino acid complexes as a depot system in principle. It is thus possible by complexation of cetrorelix with polyamino acids to achieve testosterone suppression in male rats over 600 hours. The release of active compound here can be controlled by the nature and the molecular mass of the polymers.

Owner:ZENTARIS GMBH

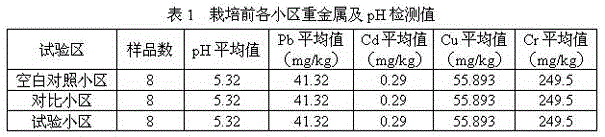

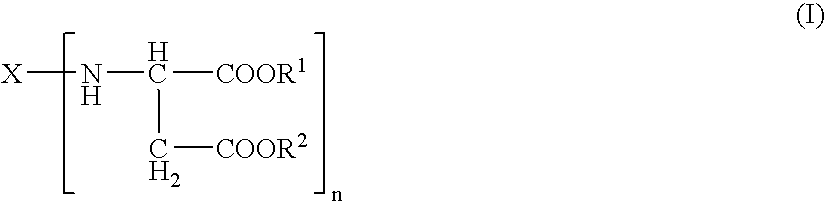

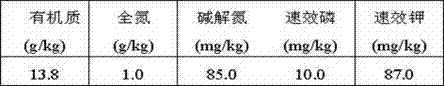

Composite soil conditioner

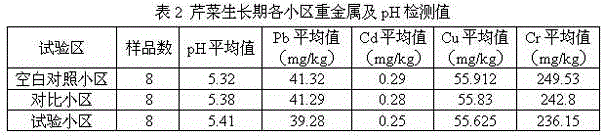

InactiveCN104788263AAdjust pHControl heavy metal contentFertilizer mixturesEcological environmentNutrition

The invention discloses a composite soil conditioner which belongs to the technical field of fertilizers, and mainly includes the following raw materials in parts by weight: 100-500 parts of humic acid with 45% of organic matter, 0.5-2 parts of ferrous sulfate, 8-100 parts of polyglutamic acid, 15-150 parts of polyaspartic acid, 1-50 parts of earthworm powder, 12-180 parts of shell powder, 10-50 parts of soybean cakes, 1-10 parts of amino-oligosaccharin, 10-30 parts of attapulgite powder and 10-20 parts of microorganism composite zymophyte. The composite soil conditioner provided by the invention can provide nutrition, adjust and balance the pH value of soil, adjust the soil microflora, improves the water retention, fertilizer maintenance and breathability of soil, degrade organic pollutants, releases phosphorus and potassium, has the antagonism function to heavy metals or can be used for precipitating heavy metals, reduces absorption of crops to heavy metals, and has the multiple conditioning functions of detoxifying the soil, building up fertility, improving the physical properties and micro-ecological environment of soil.

Owner:王龙潮 +1

Production process of cross-linked polysuccinimide resin

Owner:MITSUI CHEM INC

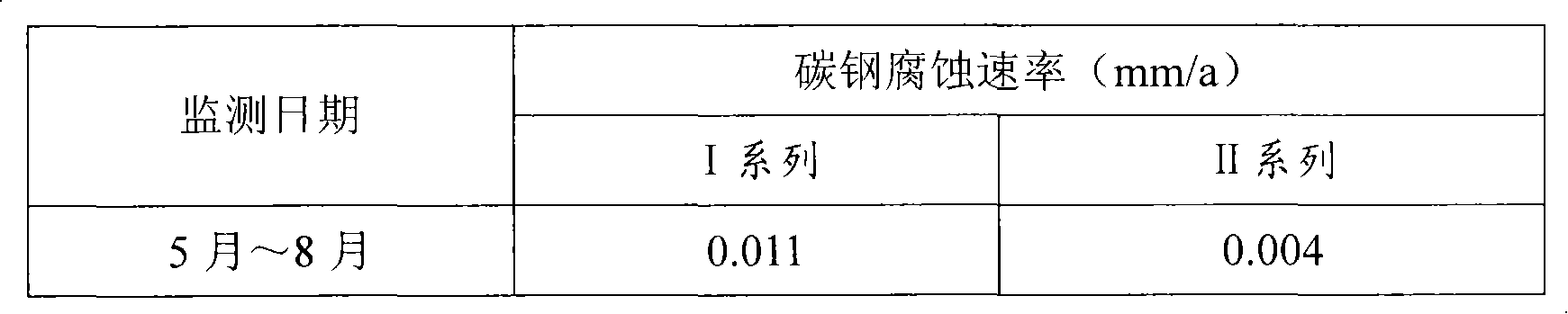

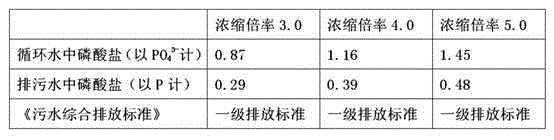

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

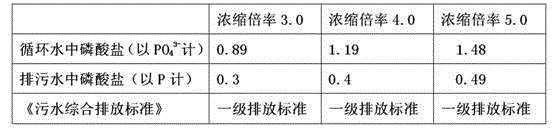

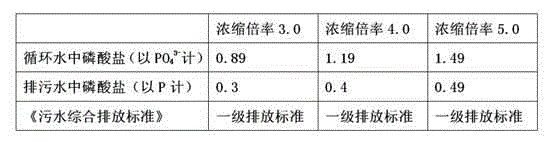

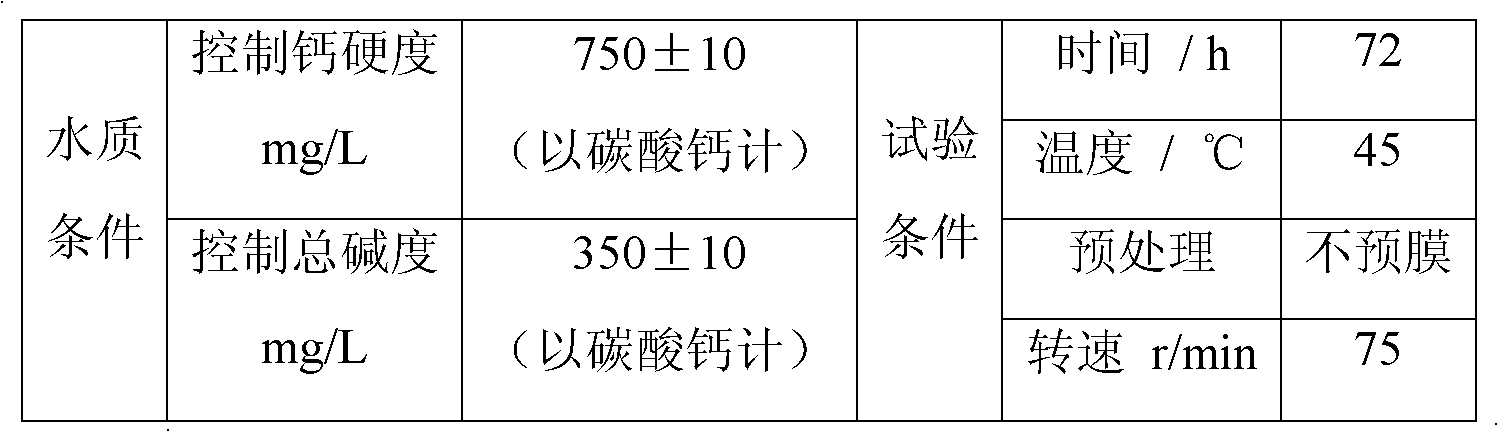

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

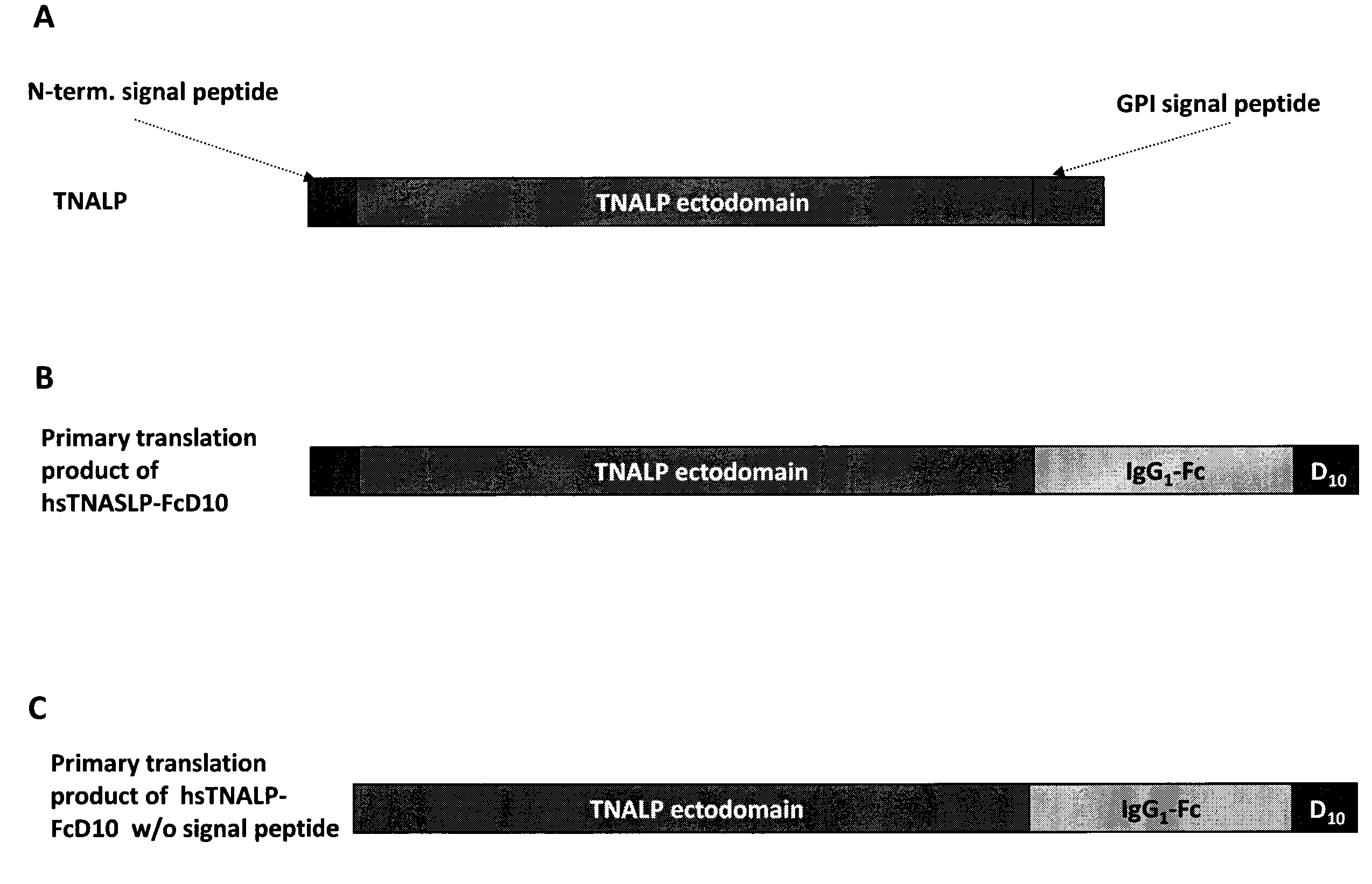

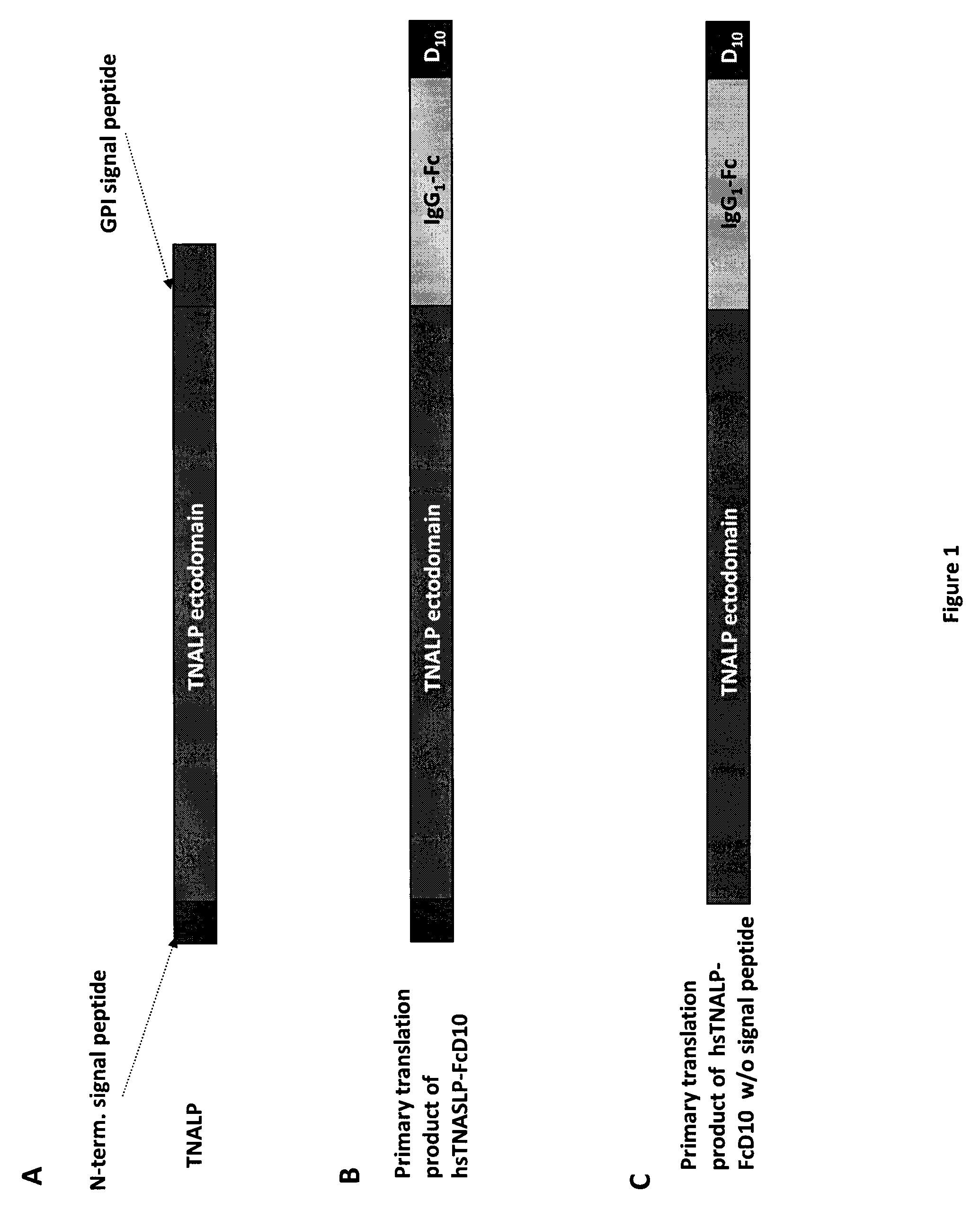

Bone targeted alkaline phosphatase, kits and methods of use thereof

InactiveUS20100297119A1Efficient foldingReduce forceVirusesSugar derivativesPolyaspartic acidExtracellular Structure

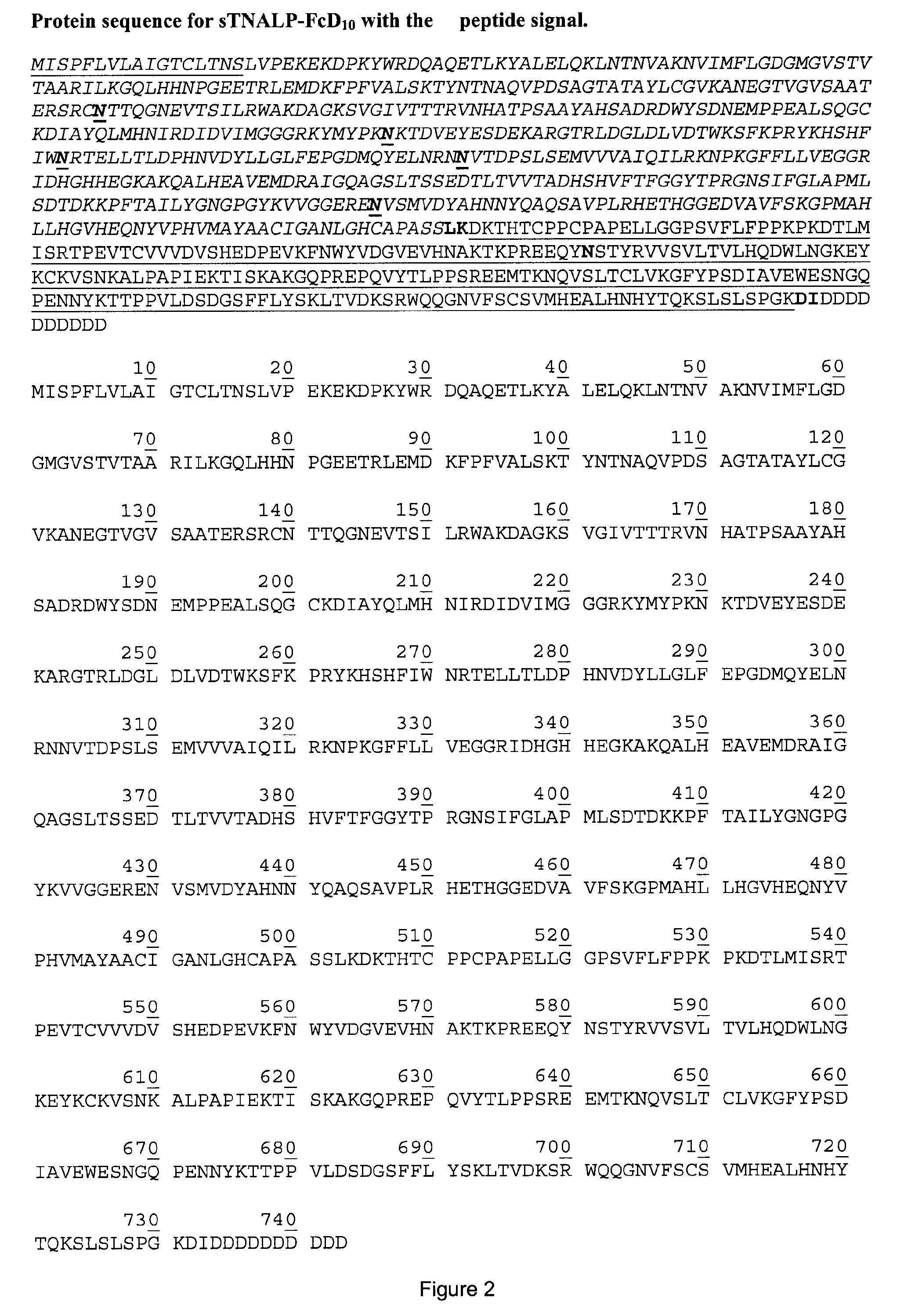

A bone targeted alkaline phosphatase comprising a polypeptide having the structure: Z-sALP-Y-spacer-X-Wn-V, wherein sALP is the extracellular domain of the alkaline phosphatase; wherein V is absent or is an amino acid sequence of at least one amino acid; X is absent or is an amino acid sequence of at least one amino acid; Y is absent or is an amino acid sequence of at least one amino acid; Z is absent or is an amino acid sequence of at least one amino acid; and Wn is a polyaspartate or a polyglutamate wherein n=10 to 16. Kits and methods of use thereof.

Owner:ALEXION PHARMA INC

Polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and preparation method thereof

The invention discloses a polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and a preparation method of the liquid chelated fertilizer. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer comprises the components by weight percent: 5-25% of urea, 5-15% of ammonium polyphosphate, 5-25% of potassium nitrate, 0.2-3% of potassium silicate, 0.8-5% of potassium chloride, 0.008-0.1% of polyaspartic acid, 0.8-5% of ammonium sulfate, 0.8-5% of ethylene diamine tetraacetic acid (EDTA) calcium, 0.2-3% of EDTA magnesium, 0.02-1.5% of EDTA boron, 0.005-0.1% of EDTA zinc, 0.005-0.1% of EDTA iron, 0.005-0.05% of EDTA copper, 0.005-0.05% of EDTA manganese, 0.001-0.01% of nickel sulfate, 0.001-0.01% of ammonium molybdate, 0.0008-0.01% of cobaltous sulfate, 0.008-0.1% of polyacrylamide and the balance of water. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer disclosed by the invention is simple in technology, scientific in proportion, balanced in fertilization, low in cost and good in effect.

Owner:张朝晖

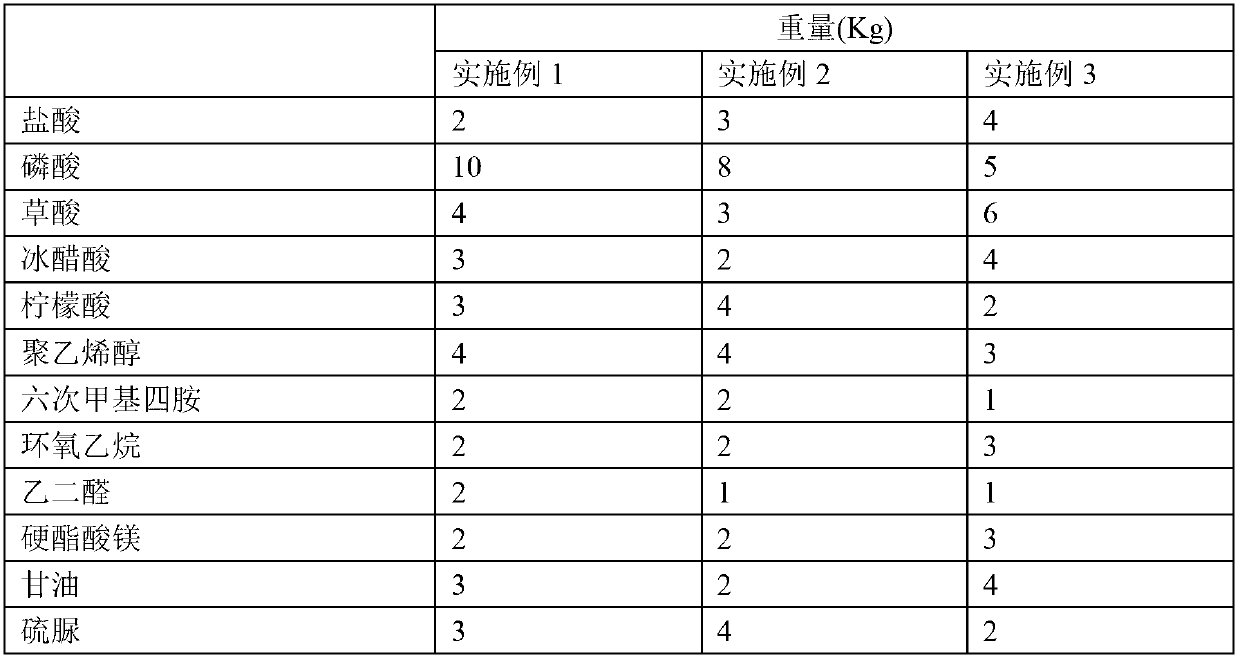

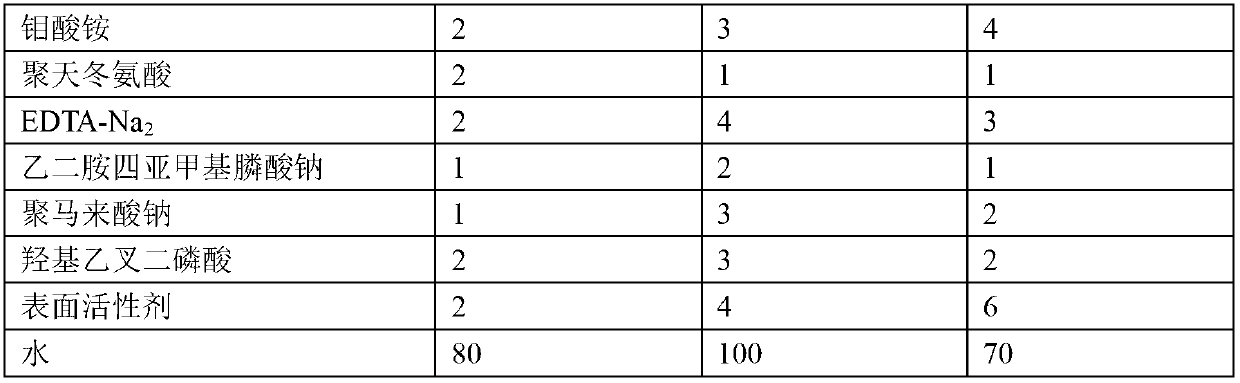

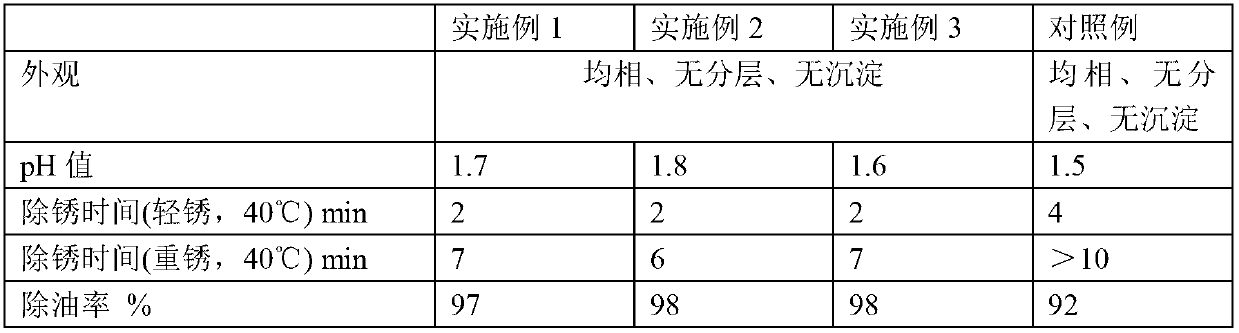

Metal surface oil and rust removal agent

The invention provides a metal surface oil and rust removal agent, and belongs to the technical field of cleaning agents. The metal surface oil and rust removal agent comprises the following components by weight: 2 to 4 parts of hydrochloric acid, 5 to 10 parts of phosphoric acid, 3 to 6 parts of oxalic acid, 3 to 5 parts of glacial acetic acid, 2 to 4 parts of citric acid, 3 to 4 parts of polyvinyl alcohol, 1 to 2 parts of hexamethylene tetramine, 2 to 3 parts of ethylene oxide, 1 to 2 parts of glyoxal, 2 to 3 parts of magnesium stearate, 2 to 4 parts of glycerol, 2 to 4 parts of thiourea, 2 to 4 parts of ammonium molybdate, 1 to 2 parts of polyaspartic acid, 2 to 4 parts of EDTA-Na2, 1 to 2 parts of ethylene diamine tetra sodium, 1 to 3 parts of poly maleic acid sodium, 2 to 3 parts of HEDPA, 2 to 6 parts of surface active agent and 70 to 100 parts of water. The metal surface oil and rust removal agent is convenient to use, and removes light rust for about 2 minutes and heavy rust for 6 to 7 minutes, and the oil removal rate can reach more than 97%.

Owner:盐城创咏新能源投资有限公司

Corrosion-inhibition scale inhibitor composition and corrosion-inhibition scale inhibitor and application thereof

ActiveCN102786158AGood corrosion inhibition effectGood anti-scaling effectScale removal and water softeningPolyaspartic acidSuccinic acid

The invention provides a corrosion-inhibition scale inhibitor composition, a corrosion-inhibition scale inhibitor and an application thereof, wherein the corrosion-inhibition scale inhibitor composition comprises water-soluble oxidizable inorganic metal salts, water-soluble inorganic zinc salts, phosphine compounds and polymers; the weight ratio of the water-soluble oxidizable inorganic metal salts, the water-soluble inorganic zinc salts, the phosphine compounds and the polymers is 0.005-0.2:0.05-1:0.1-0.75:1; the polymer is selected from one or more than one of hydrolyzed polymaleic anhydride, polyaspartic acid, polyepoxy succinic acid, and polyacrylic acid polymers. The corrosion-inhibition scale inhibitor composition and the corrosion-inhibition scale inhibitor provided by the invention has both good corrosion inhibition and scale inhibition.

Owner:CHINA PETROLEUM & CHEM CORP +1

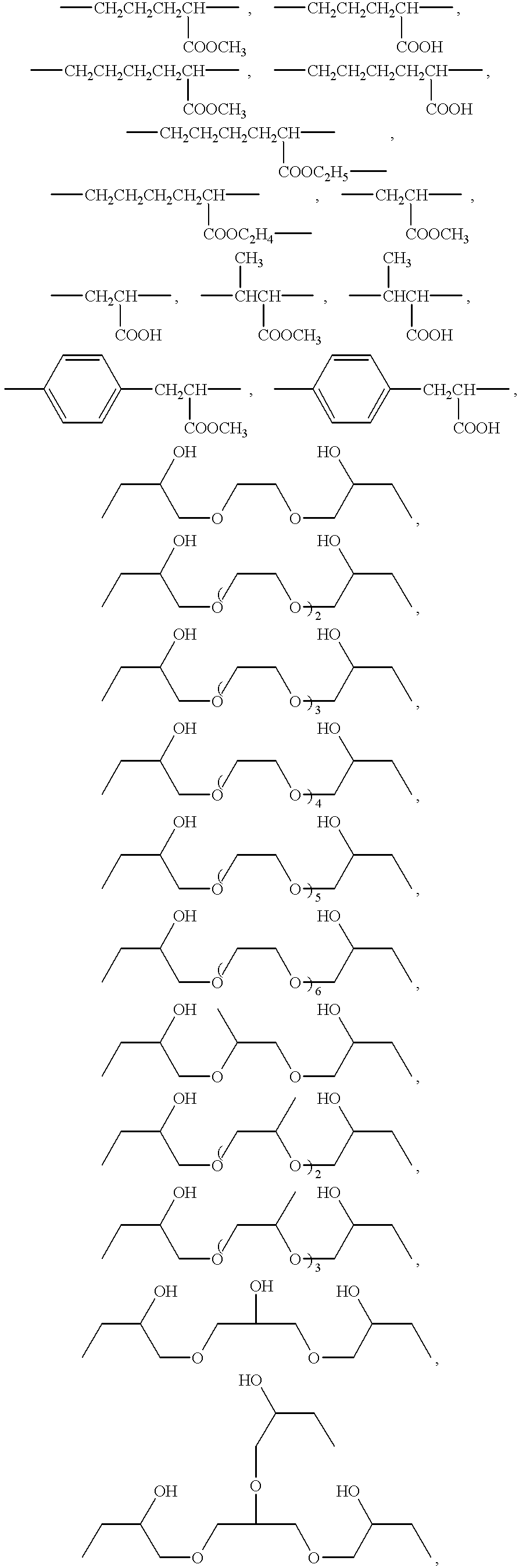

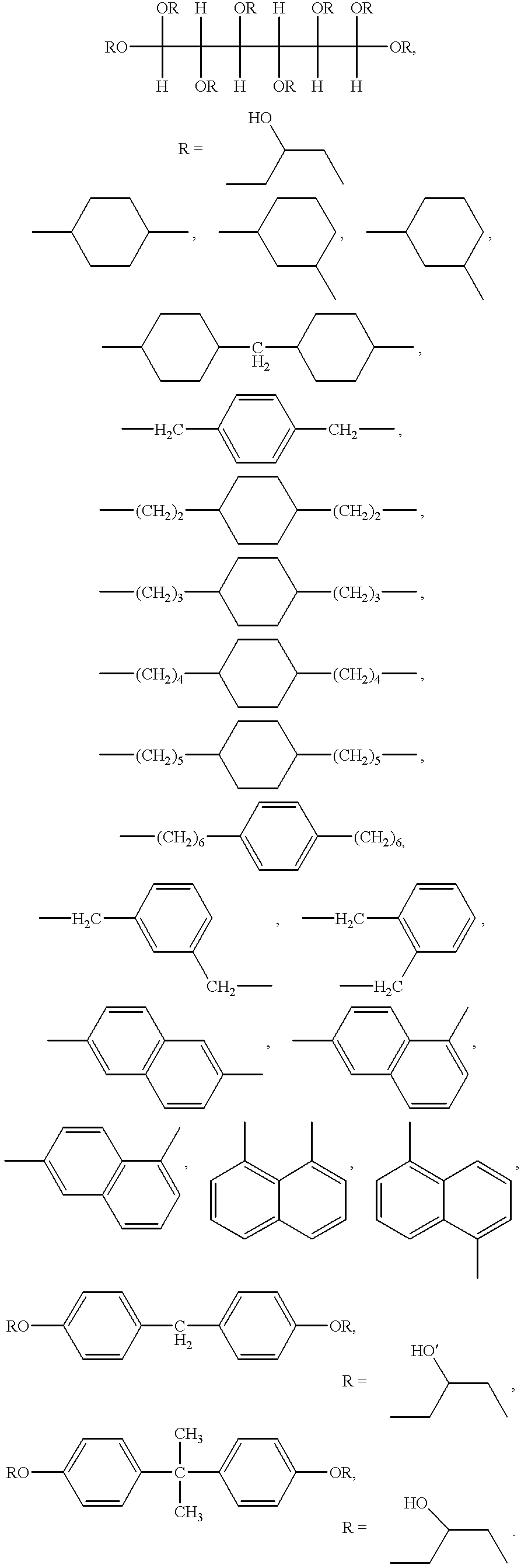

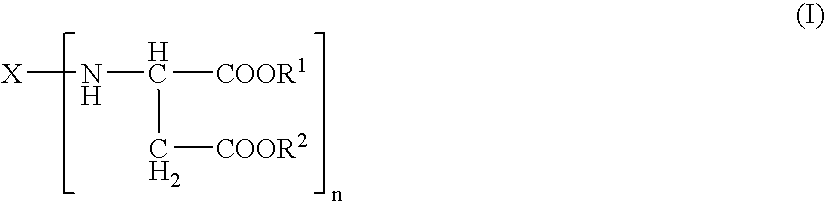

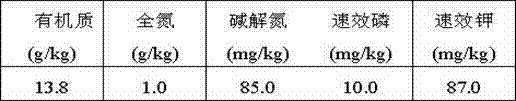

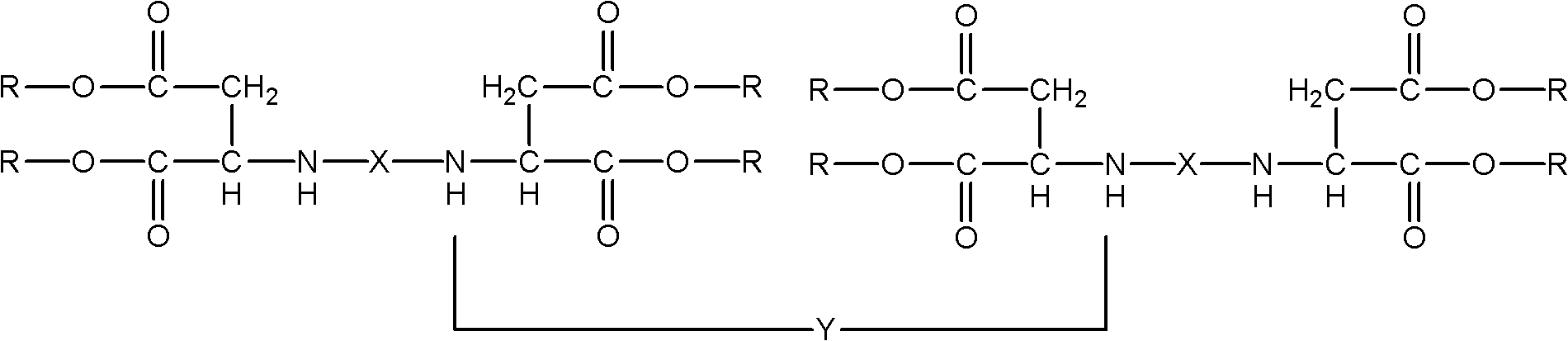

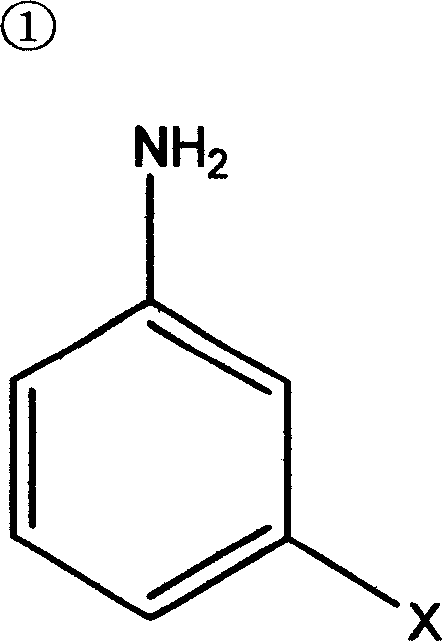

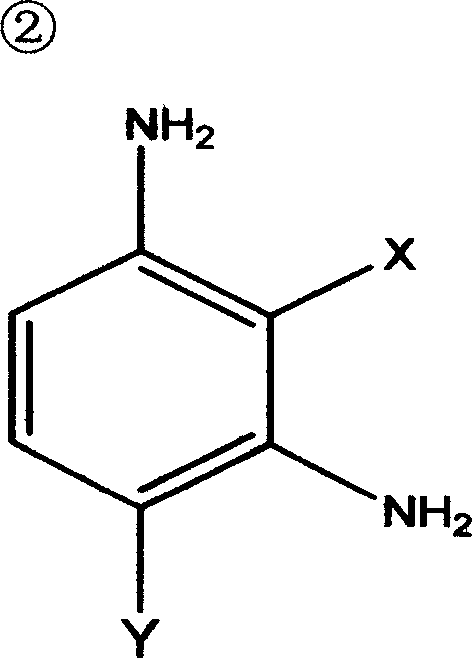

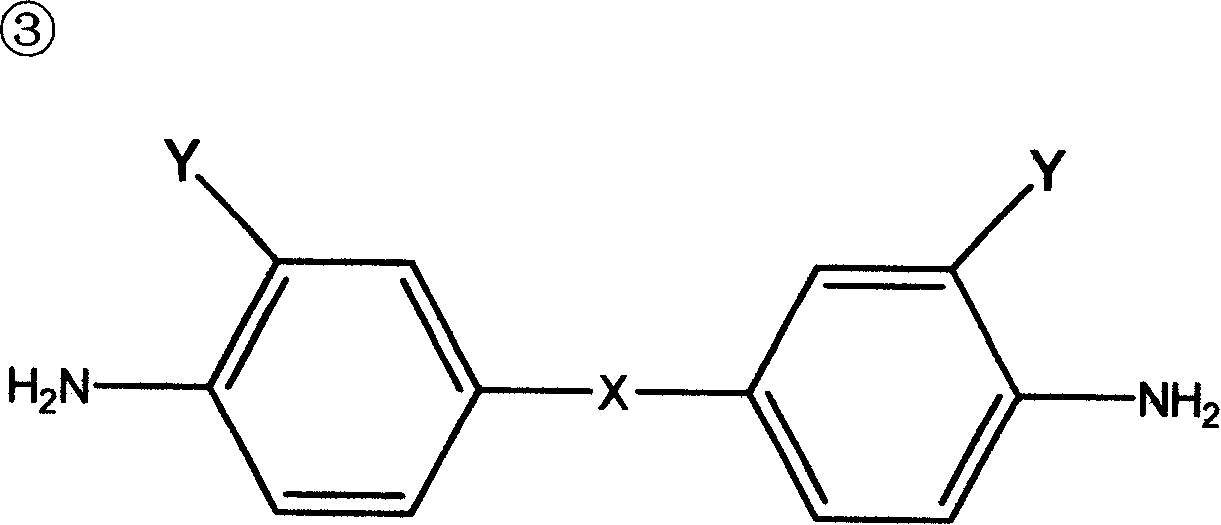

Binder mixtures of polyaspartates and sulfonate-modified polyisocyanates

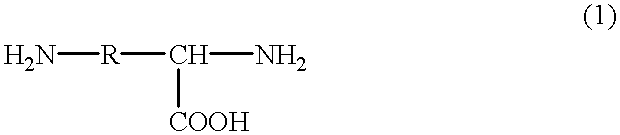

The present invention relates to two-component coating systems for the production of polyurea coatings containing A) a sulfonate group-containing polyisocyanate and B) an amino-functional polyaspartate corresponding to formula (I) wherein X represents the n-valent organic group obtained by removing the primary amino groups from an n-valent polyamine, R1, R2 represent the same or different organic groups, which are inert to isocyanate groups under the reaction conditions, and n represents an integer of at least 2. The present invention also relates to coatings obtained from these coating systems.

Owner:BAYER MATERIALSCIENCE AG

Multifunctional sewage treatment agent and preparation method thereof

ActiveCN103708631AOvercome deficienciesReduce flocculation costScale removal and water softeningWater/sewage treatment by ion-exchangeCross-linkSodium Bentonite

The invention relates to the technical field of water treatment agents and particularly relates to a multifunctional sewage treatment agent. The multifunctional sewage treatment agent comprises the following raw materials in parts by weight: 10-20 parts of sepiolite powder, 30-40 parts of bentonite, 30-40 parts of starch xanthate, 0.1-0.5 part of sodium hydroxide caustic soda, 1-5 parts of polyaspartic acid, 0.1-0.5 part of amino trimethylene phosphonic acid, 25-50 parts of cross-linked rectorite, 20-50 parts of aluminum polychlorid, 5-30 parts of chitosan and 10-30 parts of deionized water. The multifunctional sewage treatment agent provided by the invention is high in purity, free of impurity and dustless, the aqueous solution is clear, transparent, non-toxic and free of effect on operation workers, and the treated water is free of problems such as secondary pollution.

Owner:WENZHOU HONGJIAN CONSTR ENG

Selenium-iron-zinc-enriched organic-inorganic fertilizer and application method thereof

ActiveCN102503673AIncrease productionImprove qualityFertilising methodsFertilizer mixturesSelenious AcidSoil science

The invention relates to a fertilizer formula and an application method of the fertilizer. The selenium-iron-zinc-enriched organic-inorganic fertilizer for producing selenium-iron-zinc-enriched rice is prepared by granulating proportionally mixed selenite, ferrite, zinc salt, nitrogen fertilizer, phosphate fertilizer, potash fertilizer, polyaspartic acid or other salts, decomposed organic fertilizer and silicon fertilizer. The fertilizer is applied to the field as a base fertilizer or supplementary fertilizer 1-4 times. The fertilizer can simultaneously provide selenium, iron and zinc and other nutrient reinforcing substances required by growth of crops. The fertilizer is beneficial to growth of the crops, enhances the absorptivity and conversion rate of selenium, iron and zinc, and can produce selenium-iron-zinc-enriched rice satisfying the Food Standard.

Owner:广东海纳肥业有限公司 +1

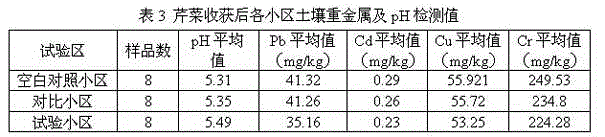

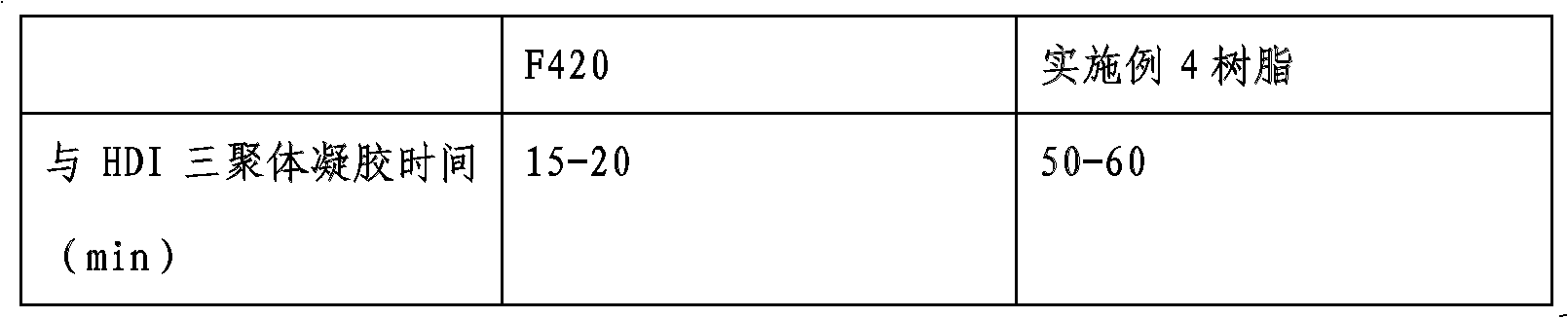

Polymerized modified polyaspartic acid ester compound and preparation method thereof

InactiveCN103030773AReduce concentrationImprove performancePolyurea/polyurethane coatingsPolyaspartic acidCarbon chain

The invention relates to a coating raw material and discloses a polymerized modified polyaspartic acid ester compound, which has the following structural general formula shown in the specification, wherein R is alkyl with at most ten carbon atoms, Y is a chain extender, and X is a straight-chain or ring-shaped carbon chain structure. The invention also discloses a preparation method of the compound. Compared with the polyurea paint prepared by the polyaspartic acid ester, the polyurea paint prepared by using the compound disclosed by the invention as the raw material has the advantages of convenience in construction, prolonged gel time, shortened surface drying time, enhanced tensile strength, enhanced elongation at break and improved elastic film coating hardness.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

Selenium and ferrum-enriched organic inorganic fertilizer and application method thereof

InactiveCN102503672AIncrease productionImprove qualityFertilising methodsFertilizer mixturesSelenious AcidSoil science

The invention relates to a formula of a fertilizer, and a using method for the fertilizer. A selenium and ferrum-enriched organic inorganic fertilizer used for producing selenium and ferrum-enriched rice is prepared by mixing selenite, ferrite, a nitrogen fertilizer, a phosphate fertilizer, a potash fertilizer, a decomposed organic fertilizer and a silicon fertilizer in a ratio, and granulating. The selenium and ferrum-enriched organic inorganic fertilizer is prepared from the following components in part by weight: 0.004 to 0.010 part of selenite, 1 to 5 parts of ferrite, 15 to 33 parts of nitrogen fertilizer, 12 to 24 parts of phosphate fertilizer, 10 to 17 parts of potash fertilizer, 0.02 to 0.08 part of sodium of polyaspartic acid or salt thereof, 30 to 50 parts of decomposed organic fertilizer and 5 to 8 parts of silicon fertilizer. The fertilizer contains selenium and ferrum, also contains other nutritional fortification substances required by growth of crops, can simultaneously provide selenium, ferrum and nutritional fortification substances required by the growth for the crops, contributes to the growth of the crops, improves the absorption rate and conversion rate of the selenium and the ferrum, and achieves an effect of producing the selenium and ferrum-enriched rice reaching the selenium and ferrum-enriched rice standard by applying a small amount of selenium and ferrum.

Owner:广东海纳农业有限公司 +1

Production process of cross-linked polyaspartic acid resin

InactiveUS6072024AMeet high volumeImprove water absorptionLiquid surface applicatorsCoatingsCross-linkProduction rate

A process is disclosed for producing with good productivity a cross-linked polyaspartic acid resin having biodegradability and high water absorbency. The process features inclusion of one of the following steps: (a) a polysuccinimide, which has been brought into a dispersed state by a dispersant, and a cross-linking agent are reacted to produce the cross-linked polyaspartic acid resin; (b) imide rings of a cross-linked polysuccinimide are subjected to a hydrolysis reaction while controlling a swelling degree of a resulting gel, whereby the cross-linked polyaspartic acid resin is produced; and (c) a gel of a cross-linked polysuccinimide, which has been obtained by reacting a cross-linking agent to a solution of a polysuccinimide in an organic solvent, is disintegrated to subject imide rings of the cross-linked polysuccinimide to a hydrolysis reaction, so that the cross-linked polyaspartic acid resin is produced. The process may also include one or both of the following steps as needed: (d) a gel of the cross-linked polyaspartic acid resin is washed with water and / or a water-miscible organic solvent; and (e) the polysuccinimide is produced using a basic amino acid as a cross-linking agent.

Owner:MITSUI CHEM INC

Efficient low-phosphorus compound water treatment agent

InactiveCN102718333AReduce manufacturing costPrevent scalingScale removal and water softeningPolyaspartic acidTricarboxylic acid

The invention provides an efficient low-phosphorus compound water treatment agent and belongs to the technical field of industrial circulating cooling water treatment. The water treatment agent consists of the following raw materials: polyaspartic acid (PESA), 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA), zinc salt, azoles, maleic acid-acrylic copolymer (MA / AA) and deionized water, wherein PESA is taken as a main scale inhibitor, PBTCA and MA / AA are taken as auxiliary scale inhibitors, a corrosion inhibitor is formed by the zinc salt, the azoles, PBTCA and PESA, and MA / AA is taken as a dispersing agent. By fully utilizing the synergistic effect of various components, a multifunctional low-phosphorus compound water treatment agent with scale and corrosion inhibition functions is formed.

Owner:SHANDONG TIANQING TECH DEV

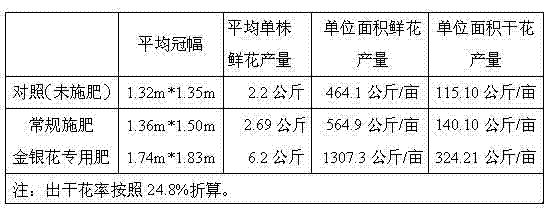

Selenium-enriched foliar fertilizer special for honeysuckle flower and preparation method thereof

InactiveCN102391050AHigh nutrient contentImprove absorption and utilizationFertilizer mixturesBrassicaAcetic acid

Owner:SHANDONG LUFENG HONEYSUCKLE PROMOTION

Non-phosphorus scale and corrosion inhibitor, and preparation method and applications thereof

InactiveCN102079584AGood dispersionImprove stabilityScale removal and water softeningPhosphinePolymer

The invention relates to a non-phosphorus scale and corrosion inhibitor for industrial circulating water and a preparation method and applications thereof, and provides a non-phosphorus (phosphine) scale and corrosion inhibitor for industrial circulating water in order to settle the technical problems. The product containing single component has the characteristics of being convenient in addition and excellent in scale and corrosion inhibiting performance. The non-phosphorus scale and corrosion inhibitor consists of the following components in parts by weight: 30 to 50 parts of dispersing scale inhibitor, 8 to 25 parts of corrosion inhibitor and 28 to 43 parts of auxiliary, wherein the dispersing scale inhibitor is acrylic acid-acrylic ester terpolymer or the mixture of the acrylic acid-acrylic ester terpolymer and at least one of the hydrolytic maleic anhydride, polyaspartic acid and sodium polystyrene sulfonate; and the corrosion inhibitor is soluble zinc salt (e.g. zinc sulfate and zinc chloride) and benzotriazole (or methyl benzotriazole). The non-phosphorus scale and corrosion inhibitor has excellent scale and corrosion inhibiting performance as well as meets and precedes the demand of GB50050-2007.

Owner:CHENGDU QIDA WATER TREATMENT ENG

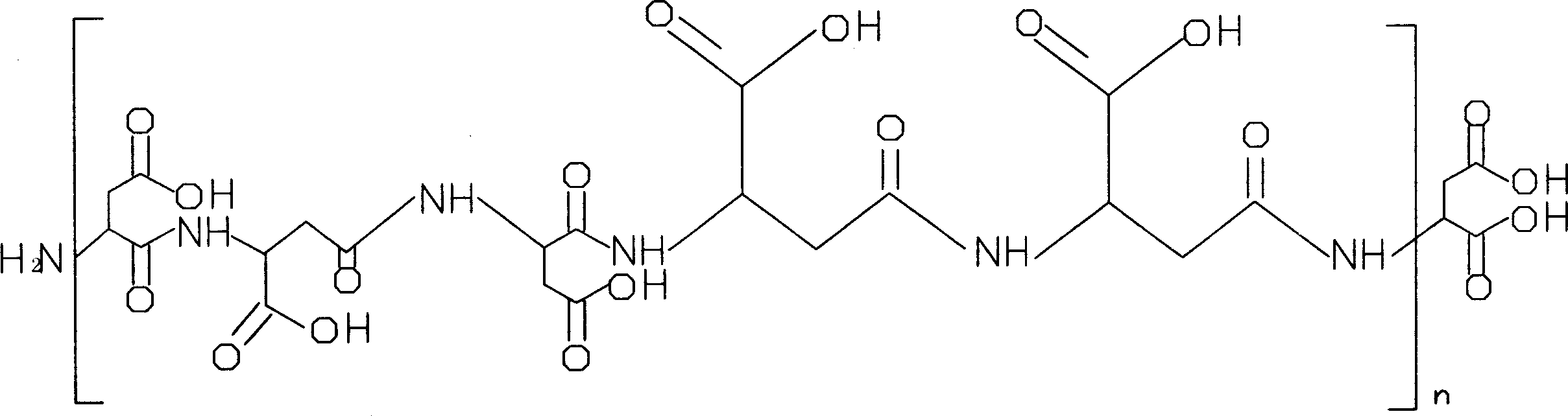

Compositions and process for recovering subterranean oil using green non-toxic biodegradable strong alkali metal salts of polymerized weak acids

InactiveUS20080312108A1Good oil recoveryEliminate needFlushingDrilling compositionPolyasparticSURFACTANT BLEND

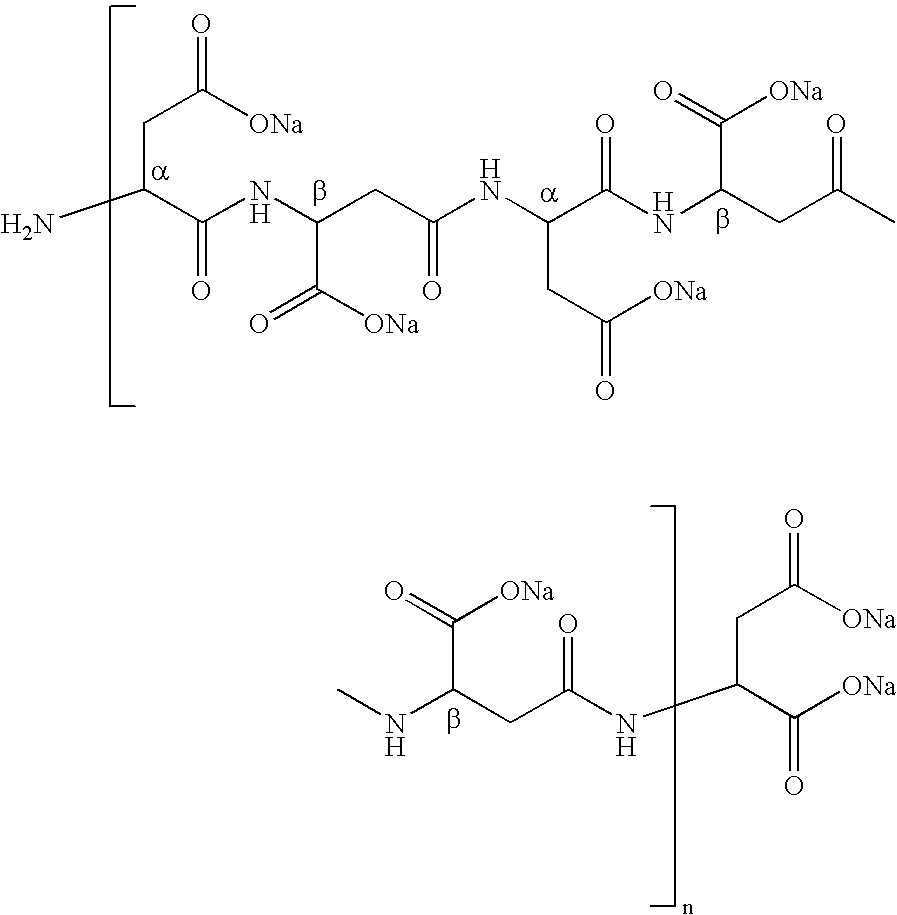

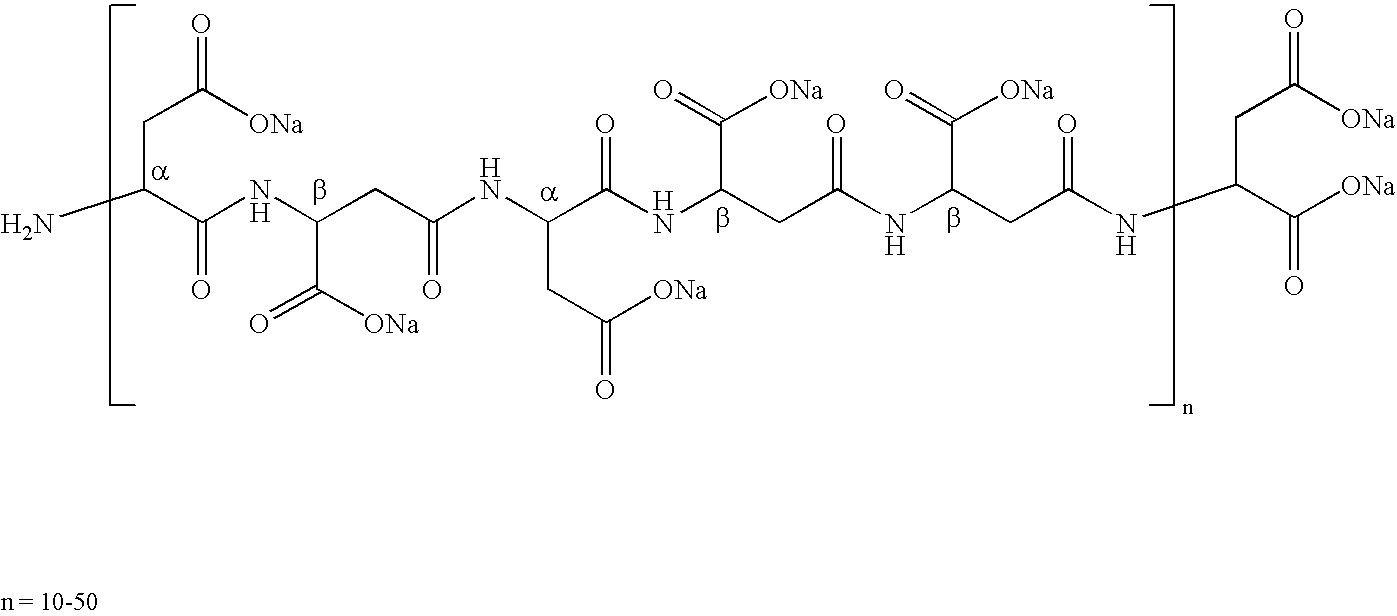

Compositions and process for recovering of oil from subterranean oil-bearing reservoirs consisting of green non-toxic biodegradable strong alkali metal salt of polymerized weak acids, one or more surfactants, an aqueous fluid, a optionally one or more mobility control agents and optionally one or more co-solvents are disclosed. Such compositions are injected into the reservoir through one or more injection wells and assist in recovering trapped oil through one or more producing wells.A preferred green non-toxic biodegradable strong alkali metal salt of polymerized weak acids is the sodium salt of polyaspartic acid shown below where n is 10 to 50.The compositions and the process of the present invention offer the advantage of improved compatibility with unsoftened waters, surfactants, and various mobility control agents. The green non-toxic, biodegradable properties of the alkali makes it particularly suitable for environmentally sensitive applications such as offshore and inland lakes.

Owner:BERGER PAUL DANIEL +1

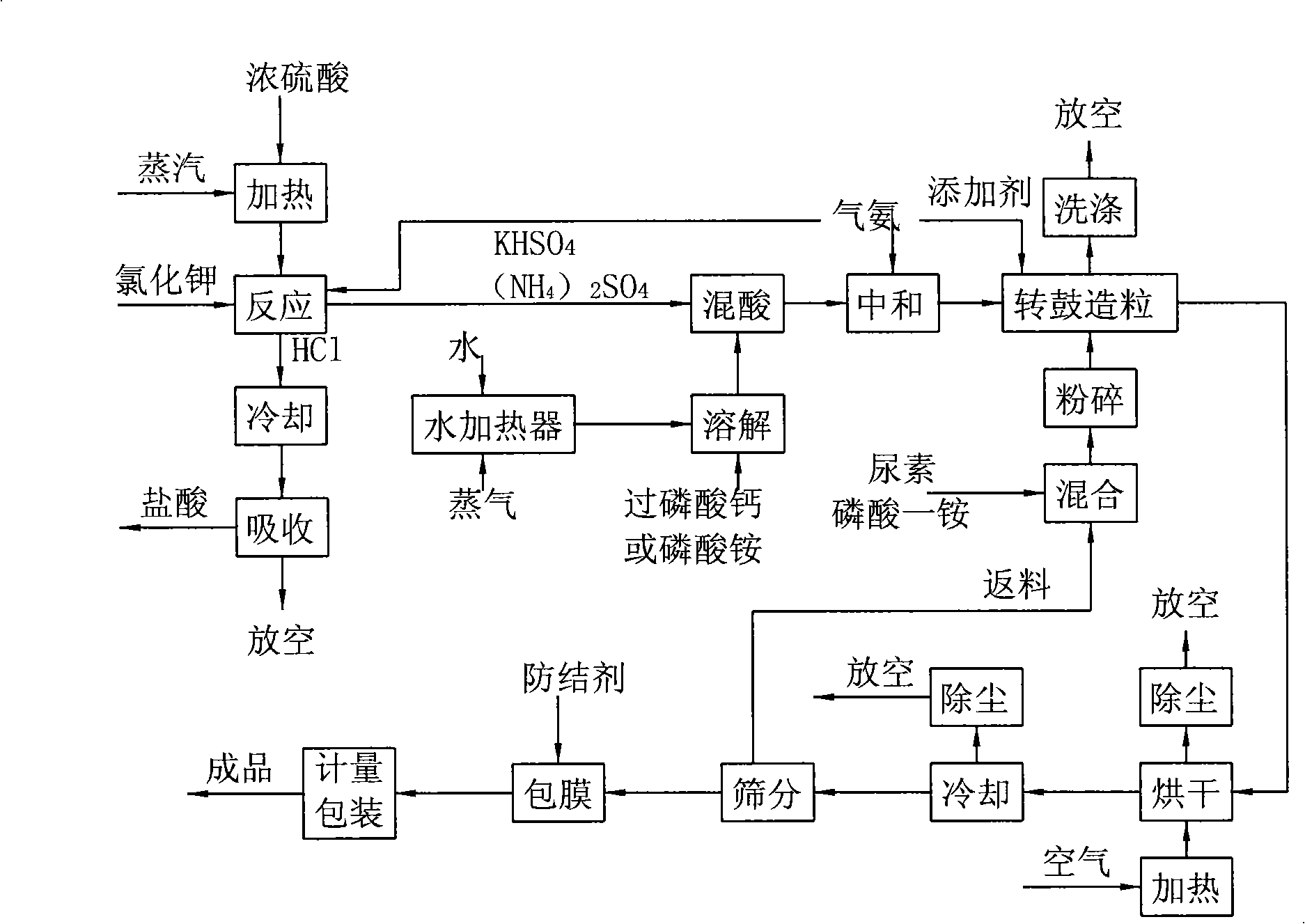

Prepn of polyasparagic acid as environment protecting scale inhibitor

InactiveCN1398799AAvoid dangerAvoid the hassle of separating organic solventsScale removal and water softeningInorganic saltsPolyaspartic acid

The present invention is polyasparagic acid as degradable environment-protection scale inhibitor and its synthesis process. The scale inhibitor is a kind of homopolymer with amido group and carboxyl group. Owing to the amino group and carboxyl group, the polyasparagic acid has excellent dispersivity to various kinds of scales. In addition, owing to the peptide linkage structure of amino acid in the structure, the scale inhibitor may be degraded into inorganic salt under the action of microbes. The polyasparagic acid is prepared through converting maleic anhydride into amine salt, polymerization and shrinkage into polysuccinylimide and hydrolysis under the presence dof alkali.

Owner:TONGJI UNIV

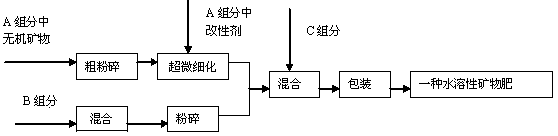

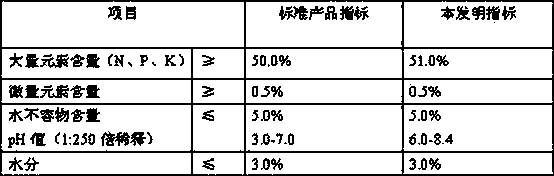

Water-soluble mineral fertilizer and preparation method thereof

InactiveCN103755498APromote growthPromote absorptionAgriculture gas emission reductionFertilizer mixturesPhosphatePyrrolidinones

The invention discloses a water-soluble mineral fertilizer, belongs to the field of crop fertilizers, and particularly relates to a water-soluble inorganic mineral fertilizer. The water-soluble mineral fertilizer is composed of an A component, a B component and a C component, wherein the A component is composed of potash feldspar, powdered rock phosphate, medical stones, kieselguhr, bentonite and a water-soluble hydrophilic grafting agent; the B component is composed of urea, biological nitrogen-fixing bacteria, a urease inhibitor, a nitrification inhibitor and carboxymethyl starch, and the C component is composed of polyaspartic acid, polyyvinylpyrrolidone and casein. A preparation method of the water-soluble mineral fertilizer takes an inorganic mineral powder body as a main raw material, the water-soluble hydrophilic grafting agent is utilized, and the inorganic mineral powder body is dissolved in the water to form a stability colloid. The water-soluble mineral fertilizer provided by the invention contains a large number of nitrogen phosphorus and potassium elements and also contains different medium / trace elements and rare earth elements required by the growth of a plant, a soil structure is improved, the growth of the plant is improved, the product quality of a crop is improved, a raw material is easily available, the price is low, the raw material is non-pollution, the production technology is simple, and a market prospect is wide.

Owner:甘肃百金惠戈壁农业科技有限公司

Phosphorus-free green composite corrosion and scale inhibitor

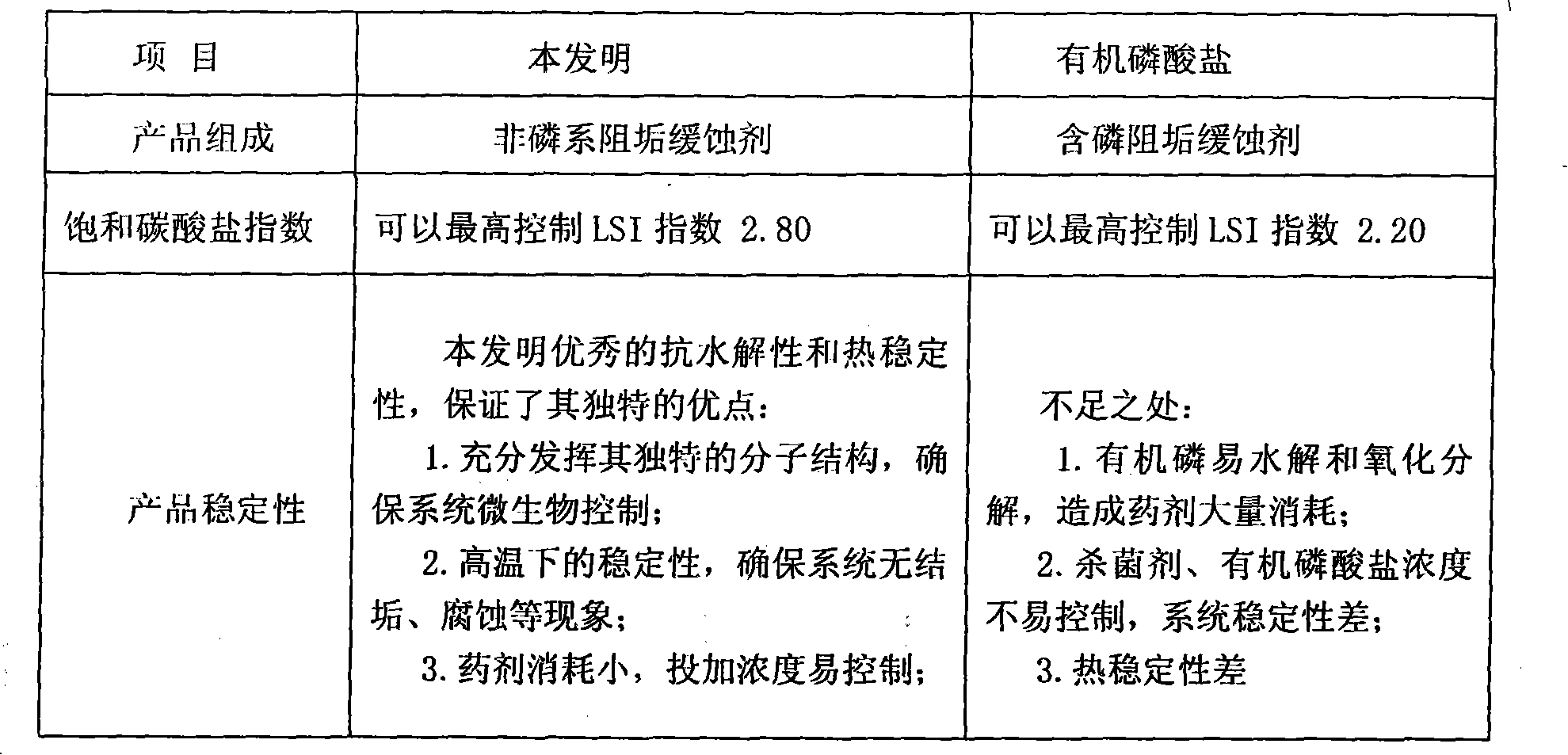

ActiveCN101805067AGood corrosion inhibitionReduce usageSpecific water treatment objectivesNature of treatment waterChemistryPolyaspartic acid

The invention discloses a phosphorus-free green composite corrosion and scale inhibitor, which comprises polyaspartic acid or polyepoxysuccinic acid, maleic acid homopolymers, acrylic copolymers, inorganic zinc salt, an ECH inhibition synergist and water. The ECH inhibition synergist is mixture of lanthanum nitrate and sodium gluconate mixed according to a mass ratio of 1:10-1:5. The phosphorus-free green composite corrosion and scale inhibitor of the invention is phosphorus-free, non-toxic and highly biodegradable, and not only can overcome the defects of water body eutrophication and high toxicity caused by water treatment agents containing phosphorus, chromium, nitrite and the like, but also can be used for treatment of corrosive water with low alkalinity and low concentration and can satisfy the requirements of circulating water with high temperature, high alkalinity, high hardness and high pH value at present. Moreover, the invention is a multifunctional security and environmental protection type water treatment agent with a function of inhibiting both corrosion and scale.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

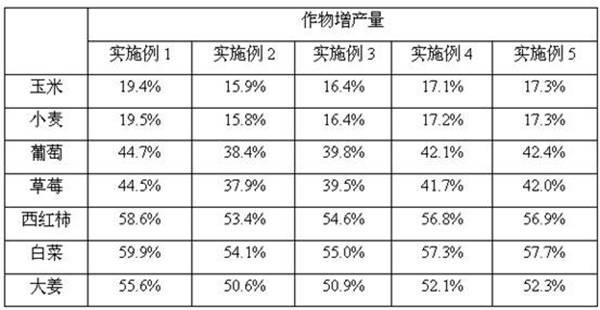

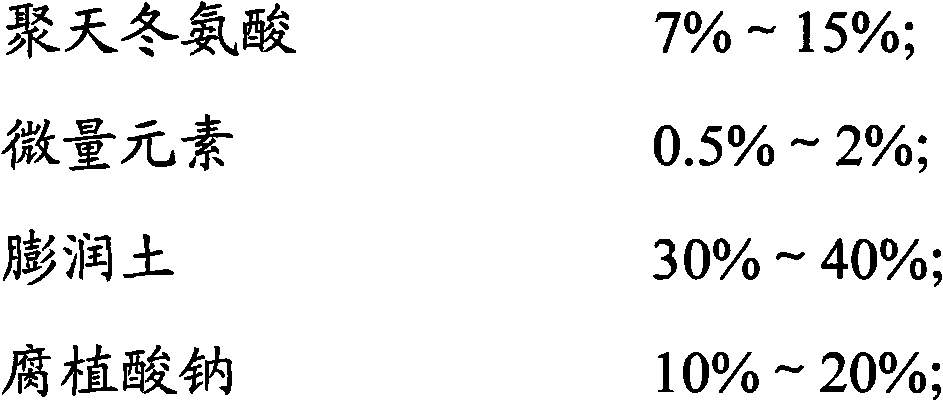

Fertilizer synergist and preparation method thereof

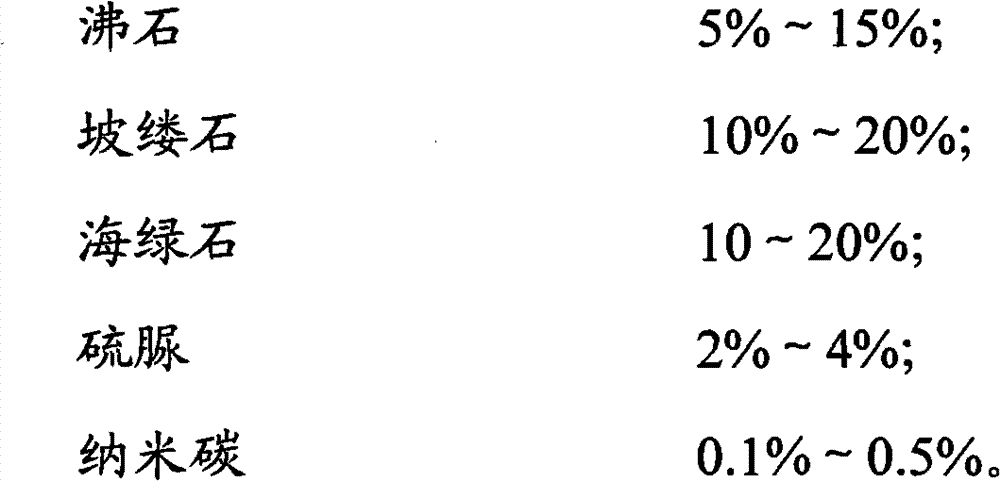

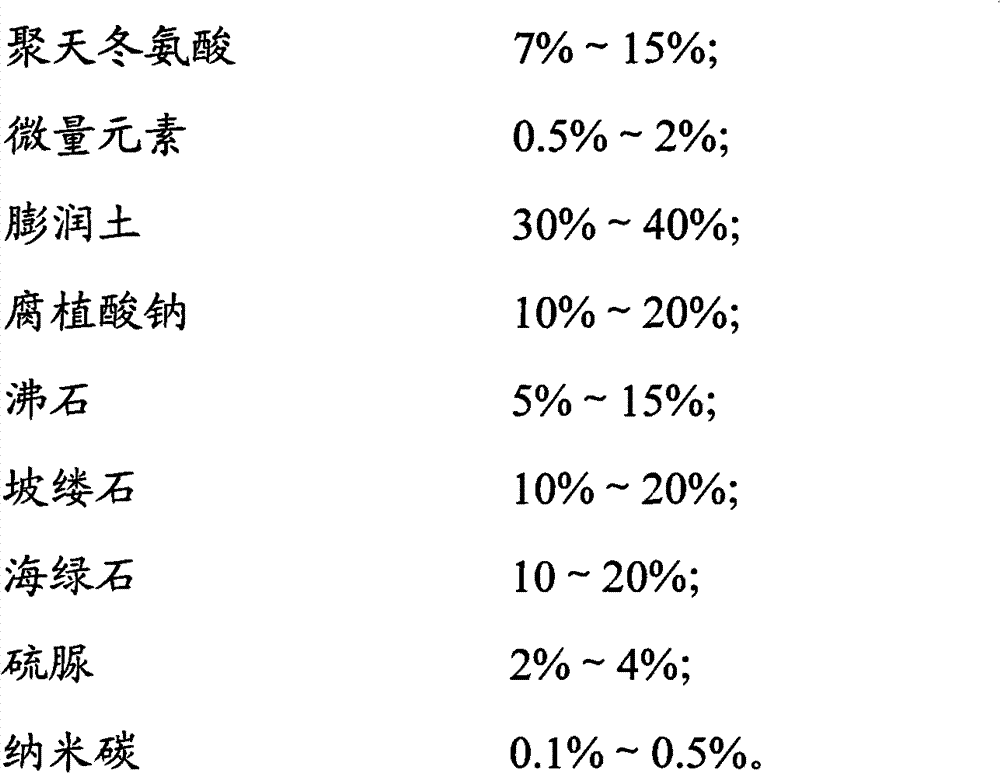

The invention provides a fertilizer synergist, which comprises the following components in parts by weight: 7%-15% of polyaspartic acid, 0.5%-2% of trace element, 30%-40% of bentonite, 10%-20% of sodium humate, 5%-15% of zeolite, 10%-20% of palygorskite, 10%-20% of glauconite, 2%-4% of thiourea and 0.1%-0.5% of nanometer carbon. The invention further provides a preparation method of the fertilizer synergist. The components of the fertilizer synergist are promoted with one another to obtain good combined effect. The fertilizer synergist does not contain any harmful chemical components and produces good effects of improving the soil and increasing the quality and yield of crops.

Owner:吴江

Green compound corrosion and scale inhibitor

InactiveCN101746902ASolve the shortcomings of low scale inhibition efficiencySolving compatibility problemsScale removal and water softeningEutrophicationPhosphate

The invention discloses a green compound corrosion and scale inhibitor used in a circulating cooling water system. The green compound corrosion and scale inhibitor comprises sodium humate, starch, polyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid or acrylic acid-acrylate-sulfonate, zinc salt (zinc sulfate or zinc chloride) and tdlyltriazole. The green compound corrosion and scale inhibitor not only solves the problems that the frequently-used organic phosphate type corrosion and scale inhibitor used in the circulating cooling water system easily causes eutrophication of surrounding waters due to the phosphorus discharge to further lead to red tide, environmental pollution and the like, but also achieves the same high scale-preventing rate and corrosion inhibiting efficiency of the organic phosphate type corrosion and scale inhibitor.

Owner:成都澳贝龙科技发展有限公司

Scale and corrosion inhibitor for treating circulating cooling water

InactiveCN102134130AReduce deliveryLow costScale removal and water softeningPolyaspartic acidWater quality

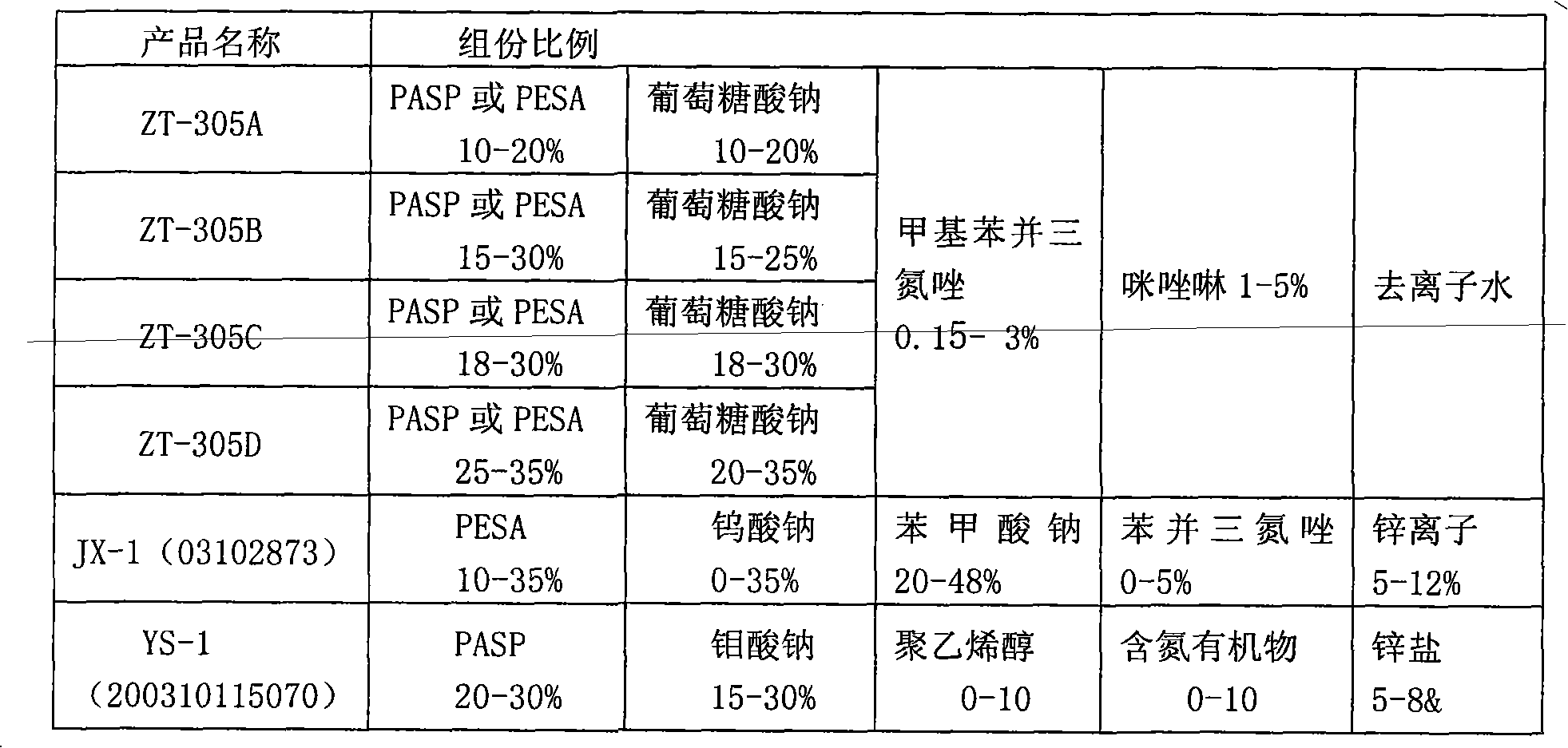

The invention relates to a scale and corrosion inhibitor for treating circulating cooling water, which is prepared from the following components in percentage by weight: 10 to 35 percent of polyaspartic acid (PASP) or polyepoxysuccinic acid, 10 to 35 percent of sodium gluconate, 0.15 to 3 percent of methyl benzotriazole, 1 to 5 percent of imidazoline and deionized water. The polyaspartic acid (PASP) or the polyepoxysuccinic acid (PESA) with biodegradability serving as a main body is compounded with the deionized water, the methyl benzotriazole, the sodium gluconate and the imidazoline to form a phosphorus-free product; the sodium gluconate has good synergy with the methyl benzotriazole and the imidazoline, so the scale and corrosion inhibiting effect is good, and scale formation, corrosion and bacteria and algae propagation of the circulating water can be effectively prevented; and when the added mass concentration is 20mg / L, the corrosion rate is 0.0561mm / a. Under the same water quality condition, the scale and corrosion inhibitor has low adding concentration, low adding quantity and low cost compared with other like products; and the scale and corrosion inhibitor is stable at a high temperature, has certain chlorine resistance and oxidation resistance, can ensure that a system has no scale or corrosion or the like, and can be adapt to the water quality of various complex severe working conditions.

Owner:HUBEI ZO TAI ENVIRONMENT TECH

Plant cultivating substrate as well as preparation method and application of same

InactiveCN102754572ALow costTake full advantage of water absorptionCultivating equipmentsAridGrowth plant

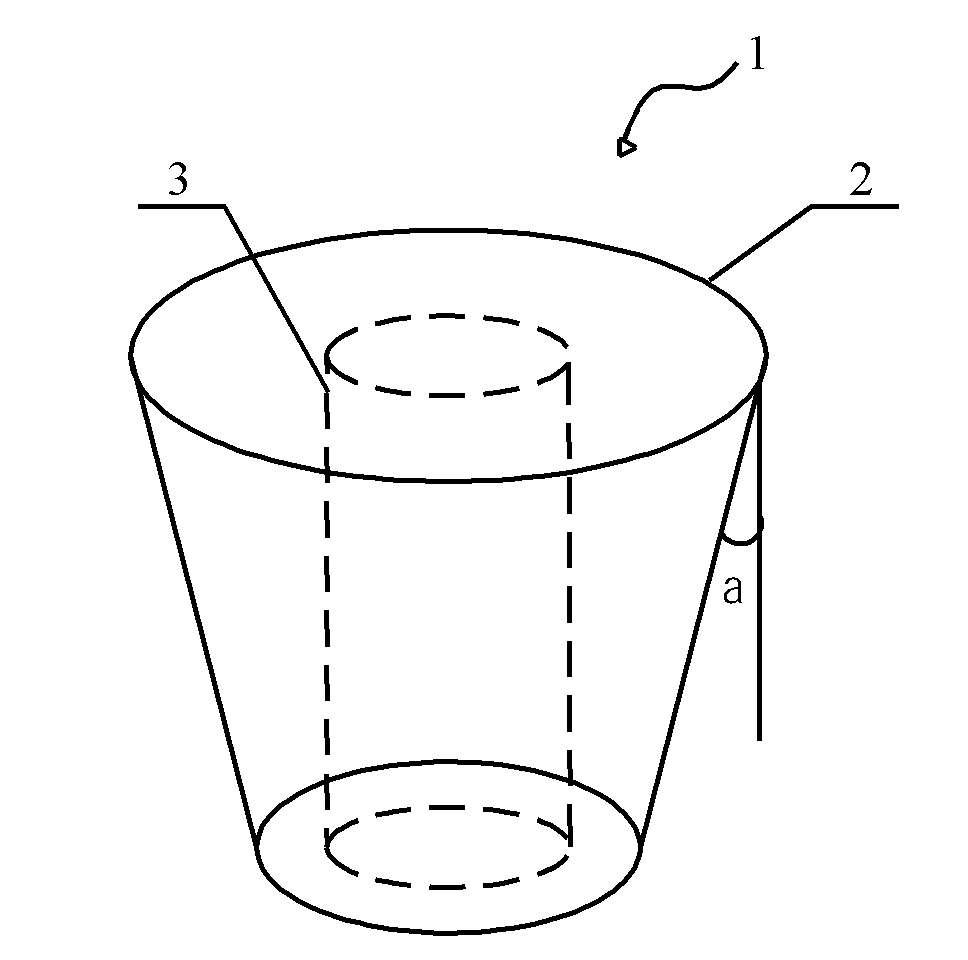

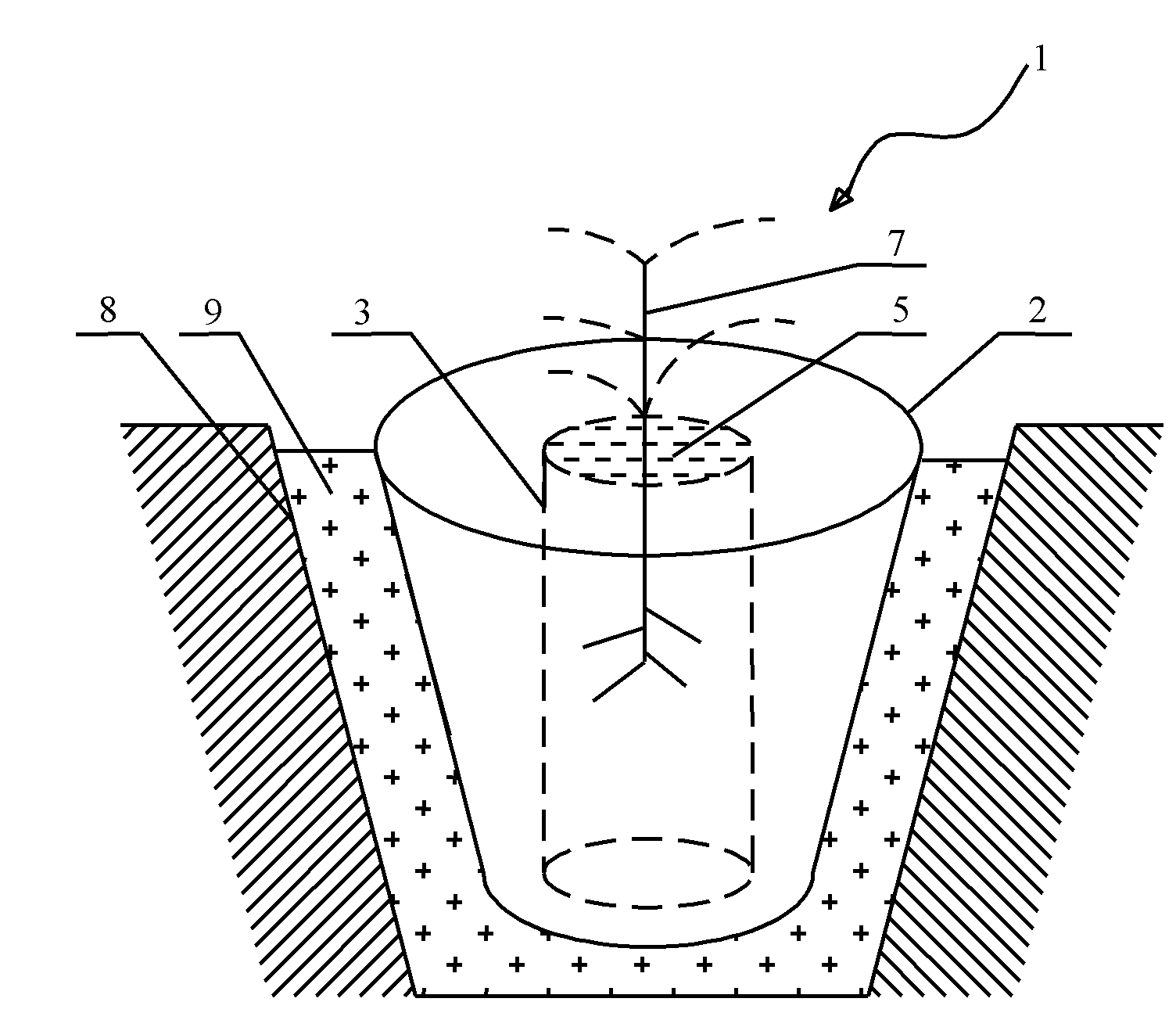

The invention relates to a plant cultivating substrate as well as a preparation method and application of the plant cultivating substrate. The plant cultivating substrate is prepared by taking polyaspartic acid water-absorbent resin as a binder, mixing sand and water, moulding and drying, is preferably a truncated cone with a longitudinal through hole formed at an axis, and can be matched with a plant cultivating medium containing polyaspartic acid fertilizer and a polyaspartic acid water-absorbent resin aquasorb for plant seed preservation and seedling cultivation. The plant cultivating substrate can effectively absorb and retain moisture, can supply moisture and nutritional elements which are necessary to plant growth in an uninterrupted way, so that a greening effect can be achieved and the balance of a local ecological environment and species is not destroyed; therefore, the plant cultivating substrate is particularly applicable to afforestation, barren hill greening and desertification control in arid areas.

Owner:BEIJING UNIV OF CHEM TECH

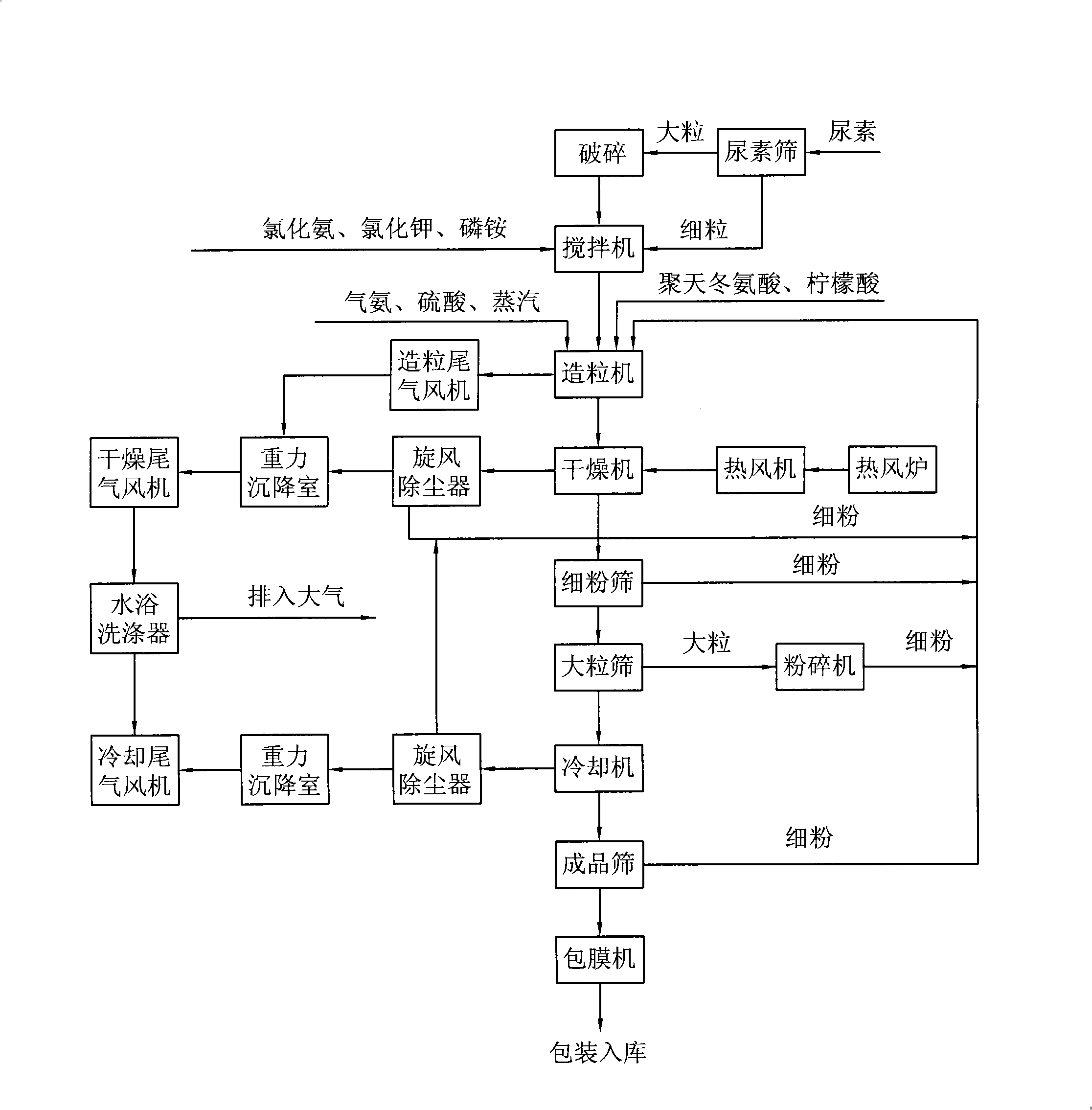

Synergistic composite fertilizer and method for preparing same

InactiveCN101289345AEnhance resilienceImprove qualityFertilizer mixturesHydroxycitric acidHumic acid

The invention discloses a synergistic compound fertilizer and a preparation method thereof. The synergistic compound fertilizer of the invention is characterized in that: poly-aspartic acid or aspartate and phosphate-dissolving agents are added into common compound fertilizer, wherein, the weight percentage of the compound fertilizer, the poly-aspartic acid or the aspartate and the phosphate agents is respectively as follows: 75.0 to 99.98 percent of the compound fertilizer, 5.0 to 0.01 percent of the poly-aspartic acid or the aspartate and 20.0 to 0.01 percent of the phosphate-dissolving agent. The phosphate-dissolving agents are the combination of one or a plurality of oxalic acid, citric acid, tartaric acid, acrylic acid, zeolite powder and humic acid. The preparation method of the synergistic compound fertilizer of the invention is that the current device and technology of producing fertilizers using the granulating method are adopted to add the poly-aspartic acid or the aspartateand the phosphate-dissolving agents into a granulator after the poly-aspartic acid or the aspartate and the phosphate-dissolving agents are measured by the measuring device arranged at the front of the granulator. The synergistic compound fertilizer can greatly facilitate the full absorption of trace elements such as nitrogen, phosphorus, potassium by crops, which can comprehensively improve fertilizer utilization ratio and the quality of crops.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

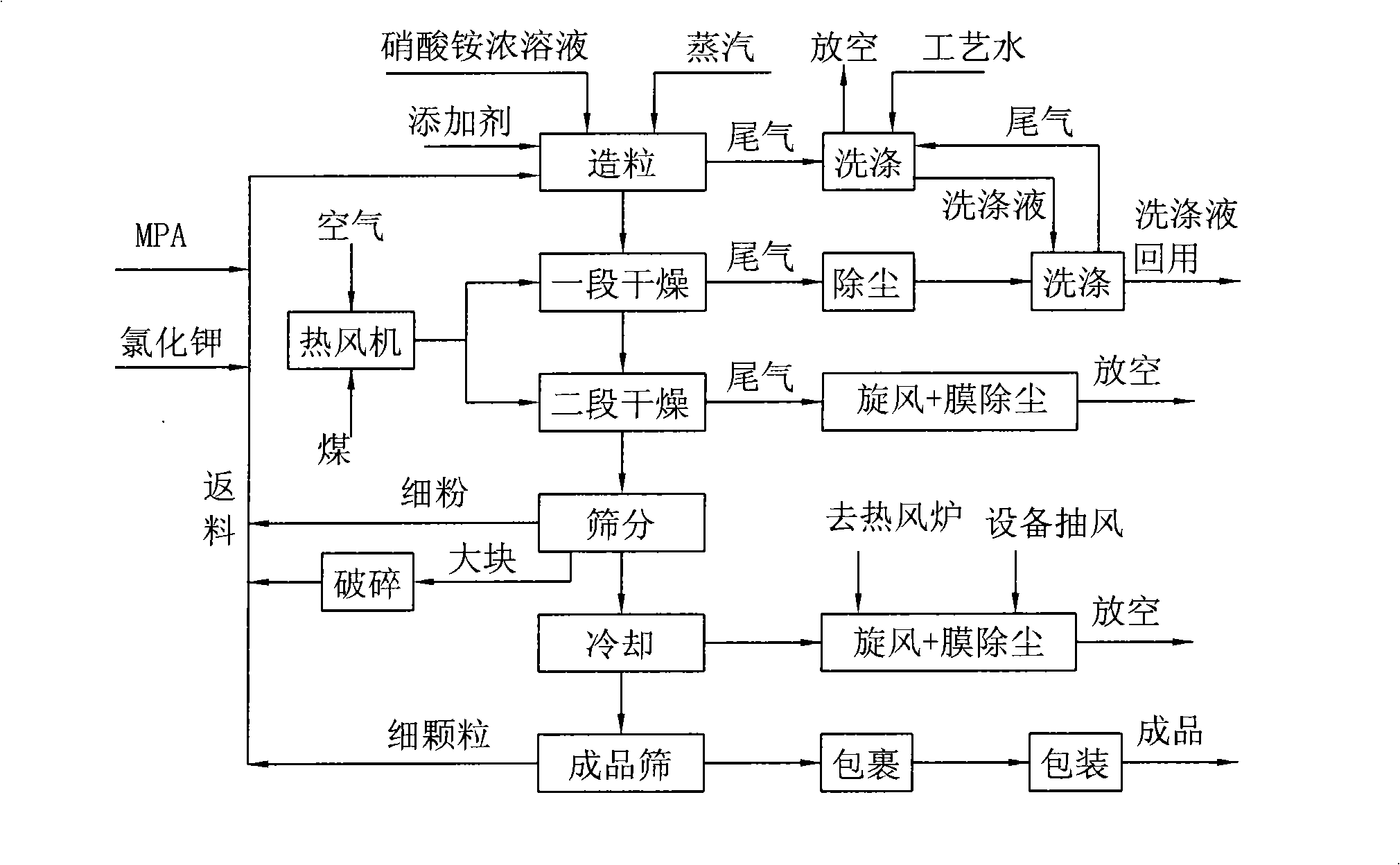

Polypeptide composite fertilizer and its production

InactiveCN101028984APrevent and delay lossIncrease profitUrea compound fertilisersPotassium fertilisersAqueous solutionChemistry

A composite polypeptite fertilizer for promoting growth, and improving crop quality and soil is prepared from a composite fertilizer and polyaminosuccinic acid or its salt through preparing composite fertilizer, preparing the aqueous solution of polyaminosuccinic acid or its salt, mixing and granulating.

Owner:SHOUGUANG LIFENG CHEM

Synthesis of polyaspartate aminoester polyether-amine containing secondary-amine group

InactiveCN101074280AShort reaction timeExtended gel timePolyurea/polyurethane coatingsPolyaspartic acidFumarate Esters

Synthesis of polyaspartic acid ester polyether ammonium containing secondary amine is carried out by taking arylamine compound as active catalyst and Micro-addition reacting for polyether ammonium and maleate or fumarate ester to obtain final product. It has shorter reactive time and delays polyurea coating gel time.

Owner:上海市涂料研究所有限公司

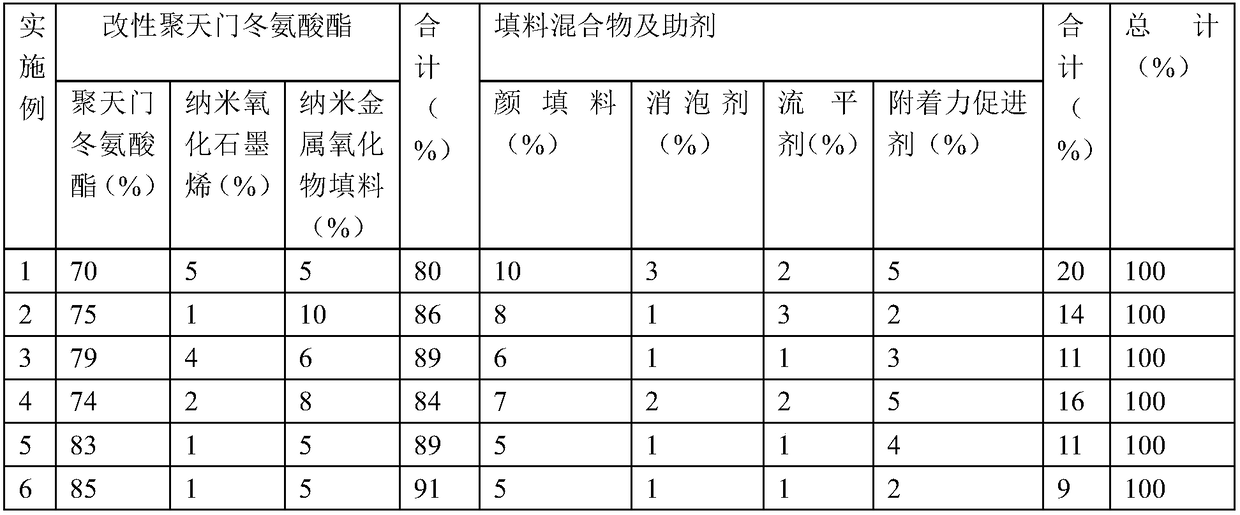

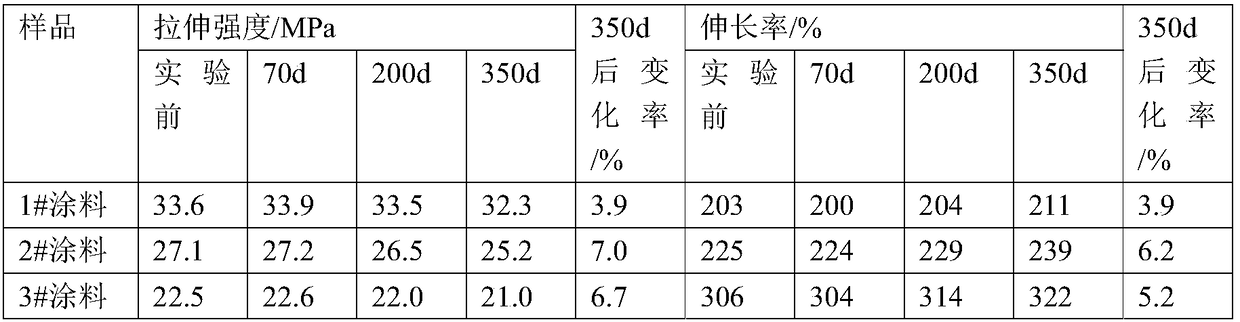

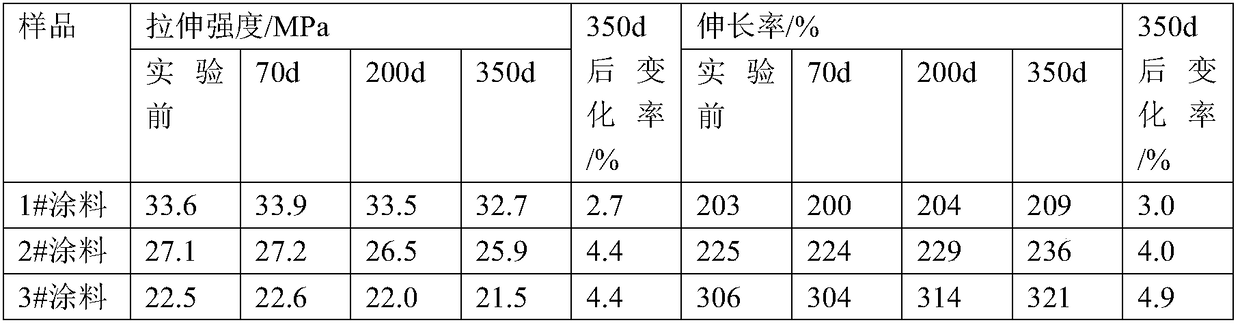

Polyaspartic acid ester polyurea protective paint with good corrosion resistance, preparation method, using method and application

InactiveCN109456684AStrong adhesionImprove mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidGraphene

The invention belongs to the technical field of spraying polyurea elastic materials, and discloses polyaspartic acid ester polyurea protective paint with good corrosion resistance. The polyaspartic acid ester polyurea protective paint with the good corrosion resistance is mainly prepared from the following raw materials: a material A and a material B, wherein a molar ratio of NCO in the material Ato NH in the material B is 1.05-1.1; the material A is mainly prepared from 20-40% of polyether glycol and 60-80% of polyisocyanate; and the material B is mainly prepared from 70-85% of polyasparticacid ester, 1-5% of nano oxidized graphene, 5-10% of nano metallic oxide filler, 5-10% of pigment and filler, 1-3% of a defoamer, 1-3% of a flatting agent and 2-5% of an adhesion promoter. The invention provides a preparation method, a using method and application of the polyaspartic acid ester polyurea protective paint. The invention has the advantages that after aging the polyaspartic acid esterpolyurea protective paint for 350 d, a change rate of tensile strength is less than 4.5%, and a change rate of elongation at break is less than 5.0%, the polyaspartic acid ester polyurea protective paint has a good mechanical property and corrosion resistance, an adhesive force is stronger, capacity of an anti-corrosion coating to resist an environmental change in practical application can be improved, and maintenance cost is reduced.

Owner:四川嘉宝莉涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com