Metal surface oil and rust removal agent

A metal surface and rust remover technology, applied in the field of cleaning agents, can solve the problems of increasing costs, affecting the health of operators, and easily forming acid mist, etc., and achieves the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

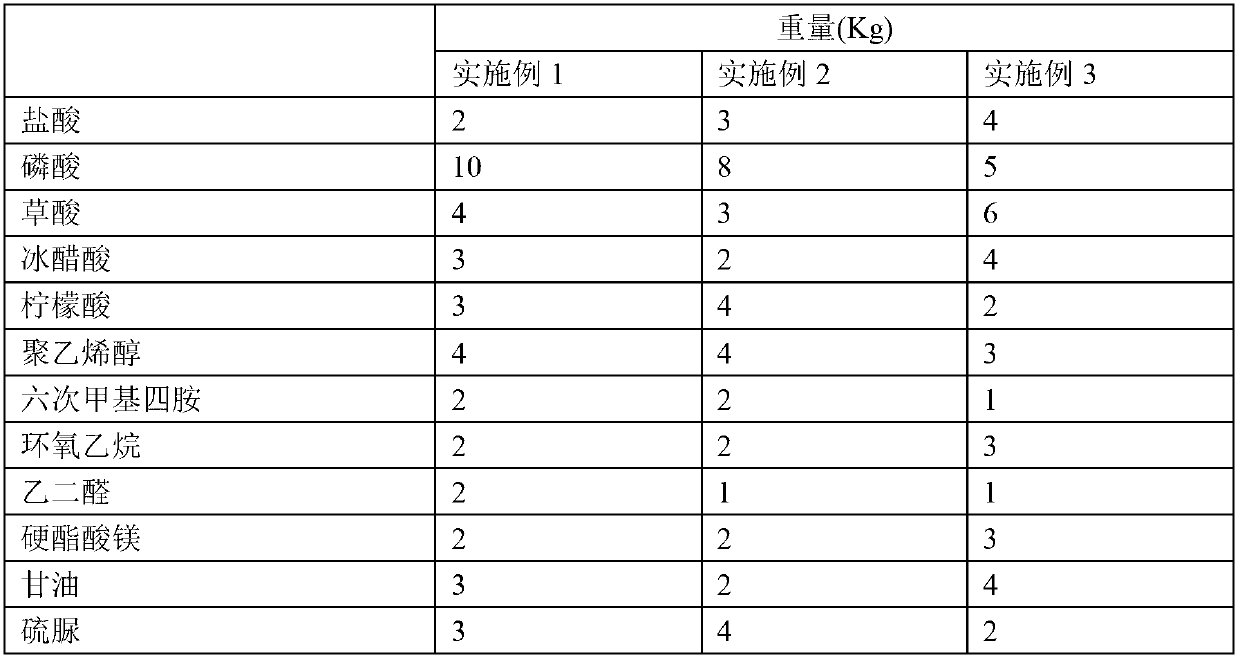

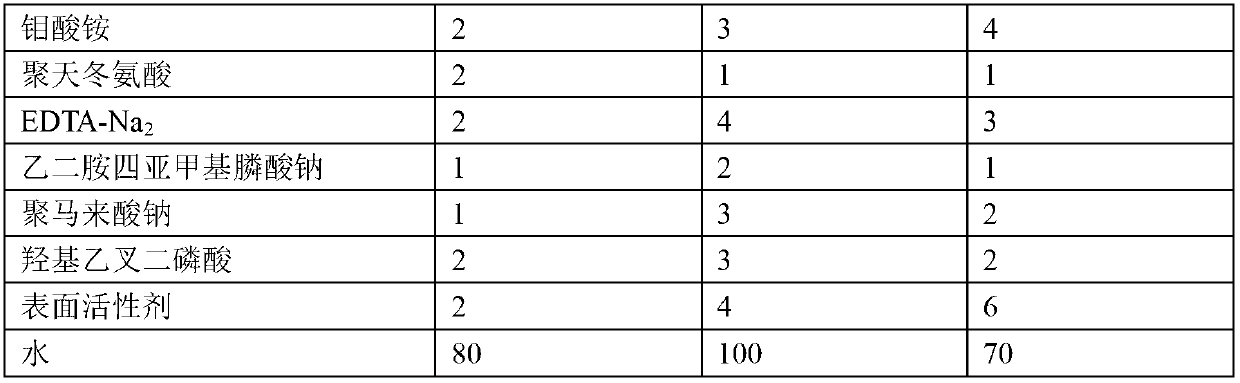

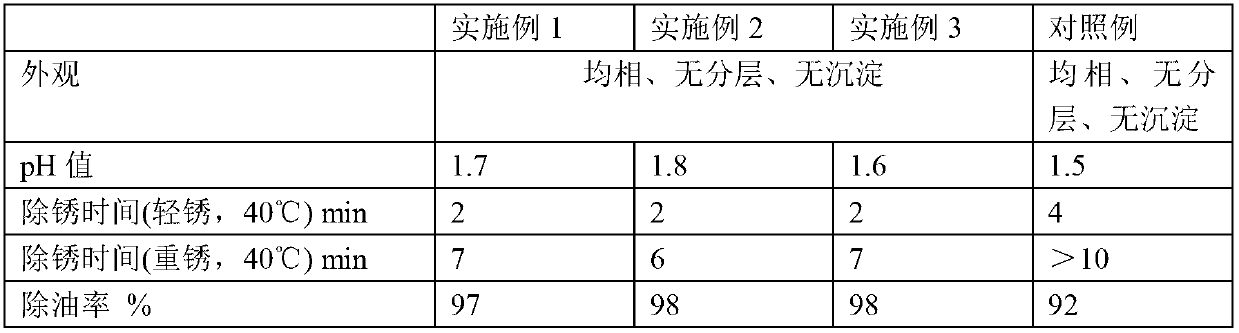

[0013] The components were prepared in the weight ratios shown in Table 1.

[0014] The weight proportion of table 1 embodiment 1~embodiment 3

[0015]

[0016]

[0017] Above-mentioned tensio-active agent adopts fatty alcohol polyoxyethylene ether sodium sulfate.

[0018] The above-mentioned polyvinyl alcohol has a molecular weight of 10,000 to 30,000.

[0019] The preparation method is:

[0020] S1: Add water, hydrochloric acid, phosphoric acid, oxalic acid, glacial acetic acid, citric acid, EDTA-Na 2 , Sodium ethylenediamine tetramethylene phosphonate, sodium polymaleate, and hydroxyethylidene diphosphoric acid, then slowly heat up to about 40°C, keep warm for 30-60 minutes, and let cool;

[0021] S2: Add polyvinyl alcohol and hexamethylenetetramine to the mixture obtained in S1 while stirring to fully dissolve it;

[0022] S3: Add ethylene oxide, glyoxal, magnesium stearate, glycerin, thiourea, ammonium molybdate, polyaspartic acid, and surfactant to the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com