Patents

Literature

724 results about "Rust remover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neutral oil removal rust remover and preparation method thereof

The invention discloses a neutral oil removal rust remover, which is mainly prepared from deionized water and the following components by mass fraction: 4-8% of physical dispersing agent, 8-10% of chemical chelating agent, 4-6% of oil-removing emulsifier and 1-4% of corrosion inhibitor. The preparation method disclosed by the invention comprises the following steps: firstly, preparing the components according to the proportioning requirements; weighting the ingredients in the chemical chelating agent to put into a container; adding the deionized water to evenly agitate, so as to obtain a solution A; adding the physical dispersing agent and the corrosion inhibitor to the solution A; agitating to obtain a solution B; additionally, adding the prepared components of the oil-removing emulsifier to the container; adding the deionized water to dissolve; adding a functional additive to obtain a solution C; and evenly mixing the solution B with the solution C under the agitation condition to obtain the neutral oil removal rust remover. By adopting the product disclosed by the invention, the oil and rust removal work can be quickly and efficiently finished, and the neutral oil removal rust remover is free of damage to a substrate.

Owner:HUNAN UNIV

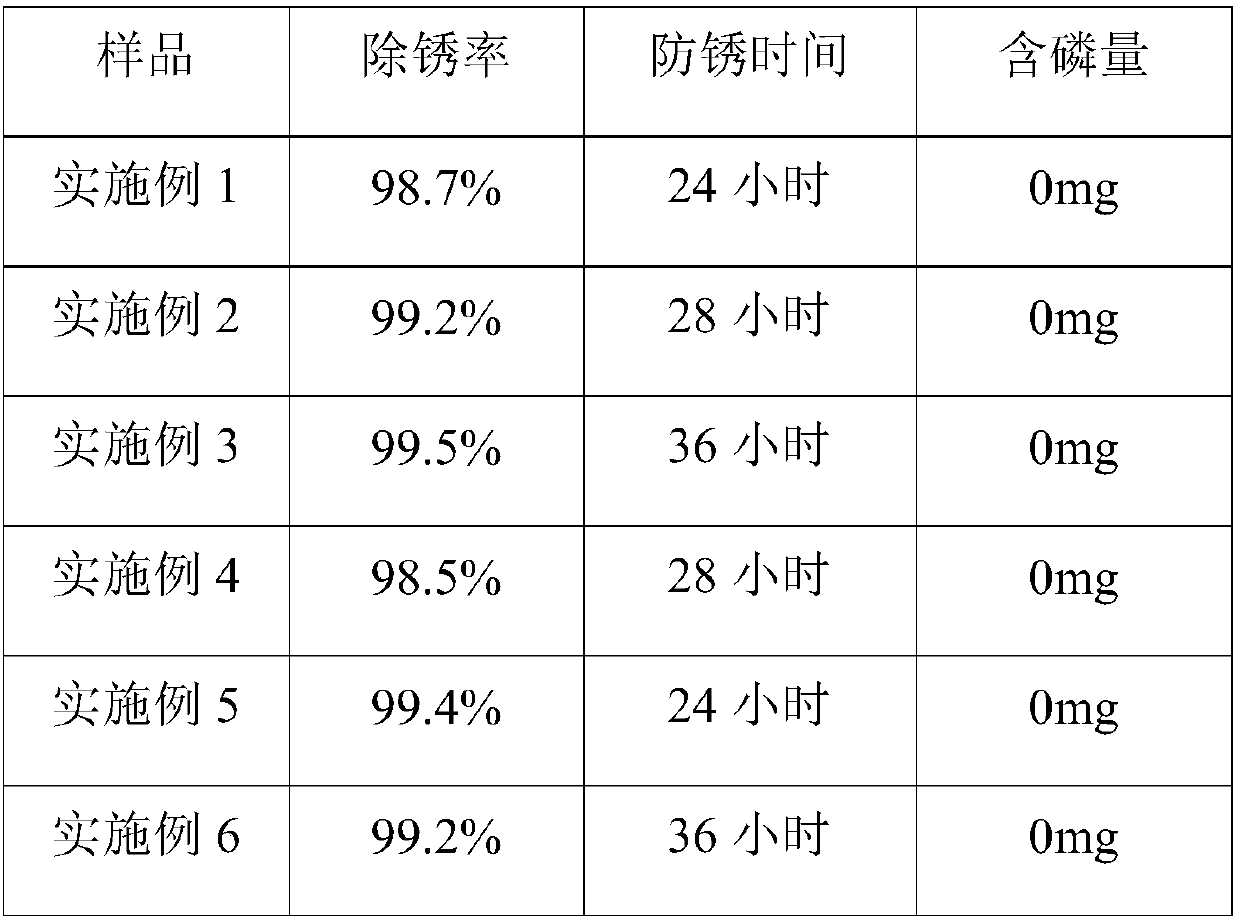

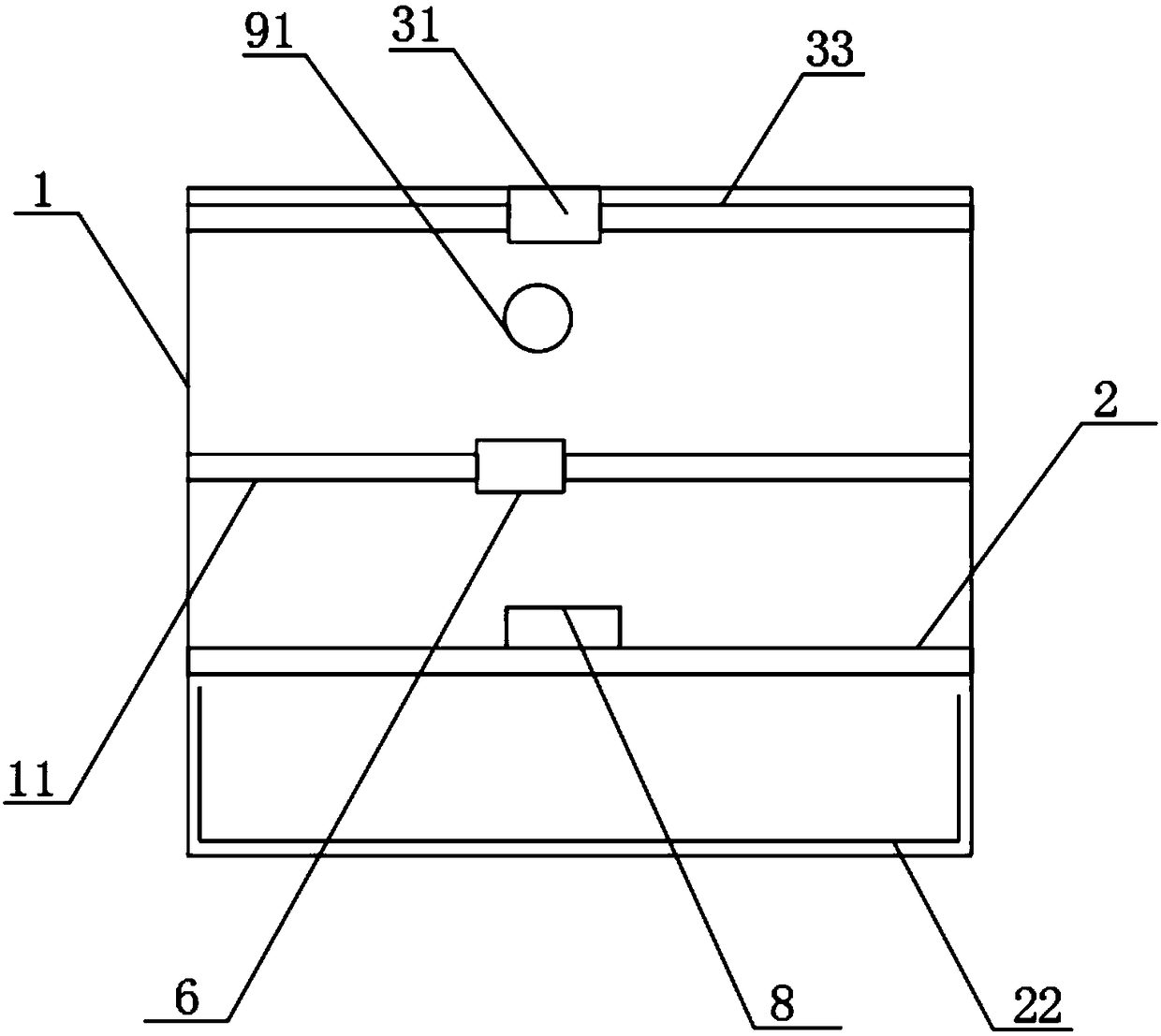

Neutral phosphorus-free rust remover used for sheet metal rust removal

The invention discloses a neutral phosphorus-free rust remover used for sheet metal rust removal. The neutral phosphorus-free rust remover is composed of, by weight: 10-35% of a complexing agent, 5-15% of an organic acid, 1-10% of a surfactant, 5-10% of an inorganic salt, 1-5% of a metal corrosion inhibitor, 3-12% of a pH regulator, and the balance deionized water. Compared with the prior art, the neutral phosphorus-free rust remover provided by the invention has the advantages of low cost, energy consumption saving in room temperature use and no environmental pollution, and can improve the workpiece's anti-rust problem caused by the workshop environment or too long process turnover time.

Owner:天津青烽永明科技发展有限公司

Environmentally friendly steel degreasing and derusting agent

InactiveCN102260875AImprove performanceImprove the working environment of degreasing and derustingSURFACTANT BLENDOxalic acid

The invention relates to a metal degreasing and rust removing agent, in particular to an environment-friendly type steel degreasing and rust removing agent, which belongs to the technical field of chemical industry. It includes hydrochloric acid, oxalic acid, surfactants, complexing agents, and corrosion inhibitors. The content of hydrochloric acid is the main factor affecting rust removal. The addition of oxalic acid can significantly reduce acid mist. Surfactants have the functions of degreasing and fog suppression. Due to the synergistic effect of each component of the formula, the process has the characteristics of normal temperature, rapidity, high efficiency, and environmental protection.

Owner:郭方全

Environment-friendly rust remover and production method thereof

The invention discloses an environment-friendly rust remover, comprising the following raw materials in parts by weight: 15-30 parts of organic acid, 5-15% of glycerin, 0.1-2 parts of dextrin, 0.5-10 parts of sodium molybdate, 0.5-2 parts of phosphoric acid, 45-70 parts of water and 0.05-0.1 part of SI-1 additive. The organic acid used in the invention is any one of citric acid, tartaric acid, malic acid, chlorogenic acid, oxalic acid, benzoic acid, salicylic acid and caffeic acid. The invention improves the traditional formula, the manufacturing process is advanced and the manufacturing method is simple, rapid and efficient. The invention overcomes the shortcoming that the existing rust removers pollute the environment, and the rust remover not only has good rust removing function, but also has excellent rust prevention function.

Owner:金福东

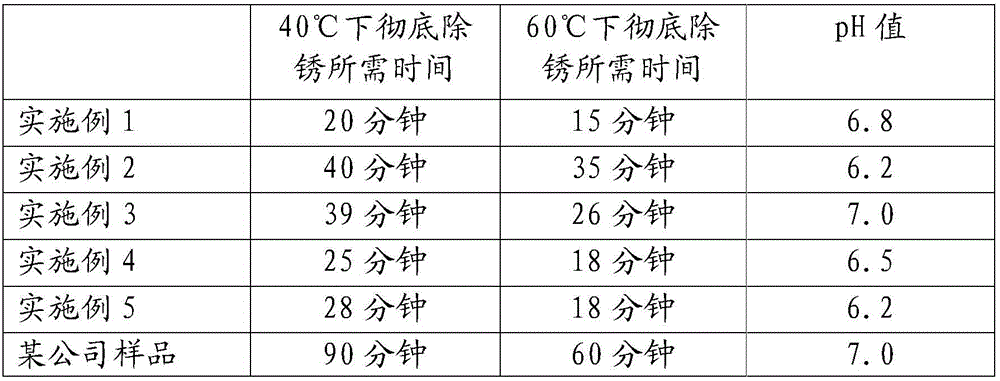

Neutral rust removal and prevention agent, preparation method and implementation process

The invention belongs to the technical field of metal surface rust removal and prevention, and particularly relates to a neutral rust removal and prevention agent, a preparation method and an implementation process. The neutral rust removal and prevention agent is prepared from, by weight, 10-20% of hydroxy ethidene diphosphate, 3-10% of a pH alkaline regulator, 0.2-1% of a complexing agent, 0.3-0.9% of a chelating agent, 0.1-0.5% of a dispersing agent, 5-10% of a rust remover and the balance water. The pH value of the neutral rust removal and prevention agent is 6-7. In general, the product preparation process is simple, preparation is easy, the raw materials are easy to obtain, the cost is low, efficient and thorough oil and rust removal work can be carried out in a neutral solution within a short time, no damage is caused to a base body, and the neutral rust removal and prevention agent has high industrial applicability and economical efficiency and has a wide application prospect in the corrosion prevention field in the medical instrument, fine workpiece, connector and bearing workpiece pretreatment and industrial equipment using process.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

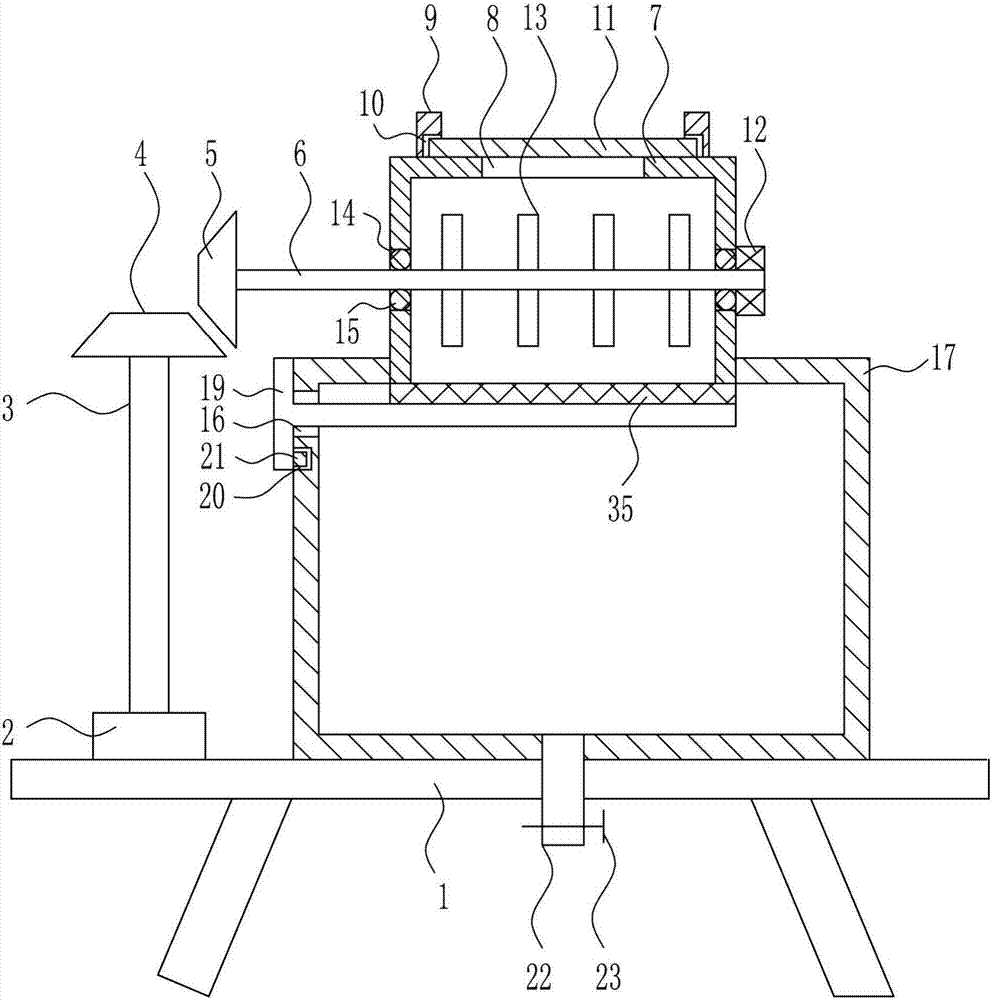

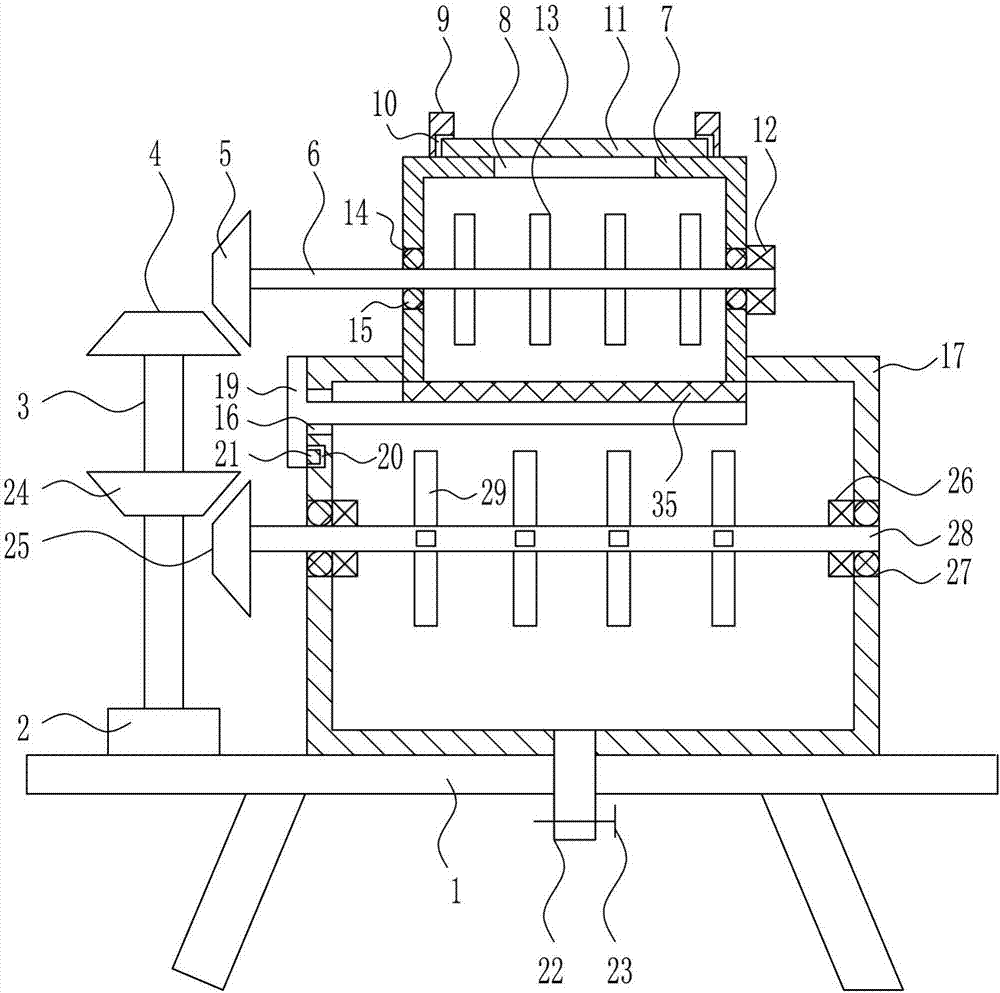

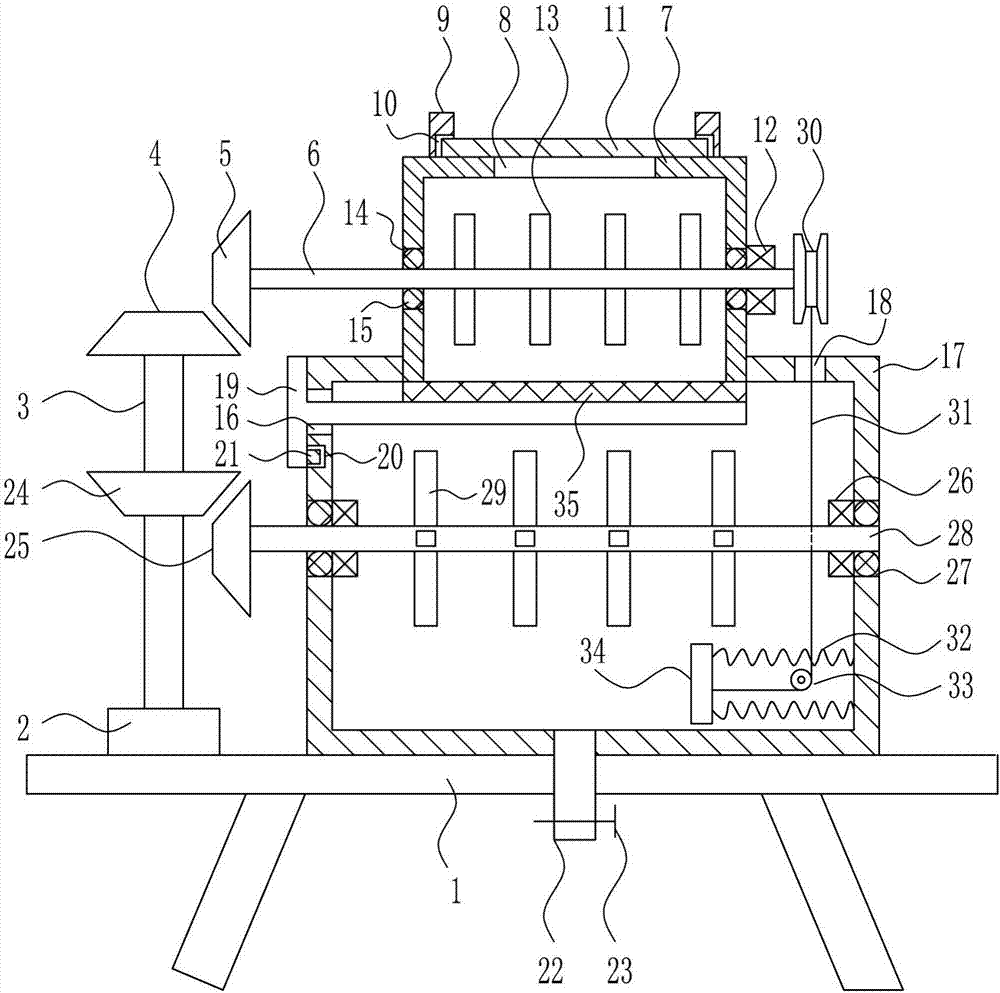

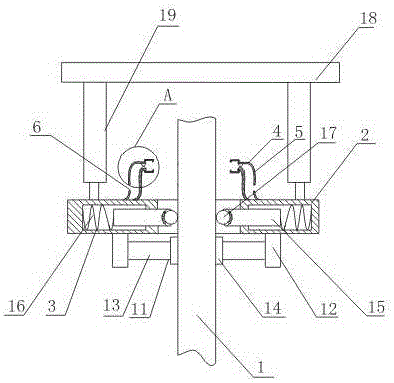

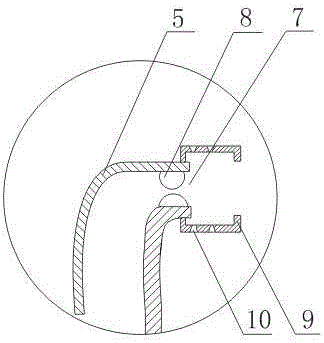

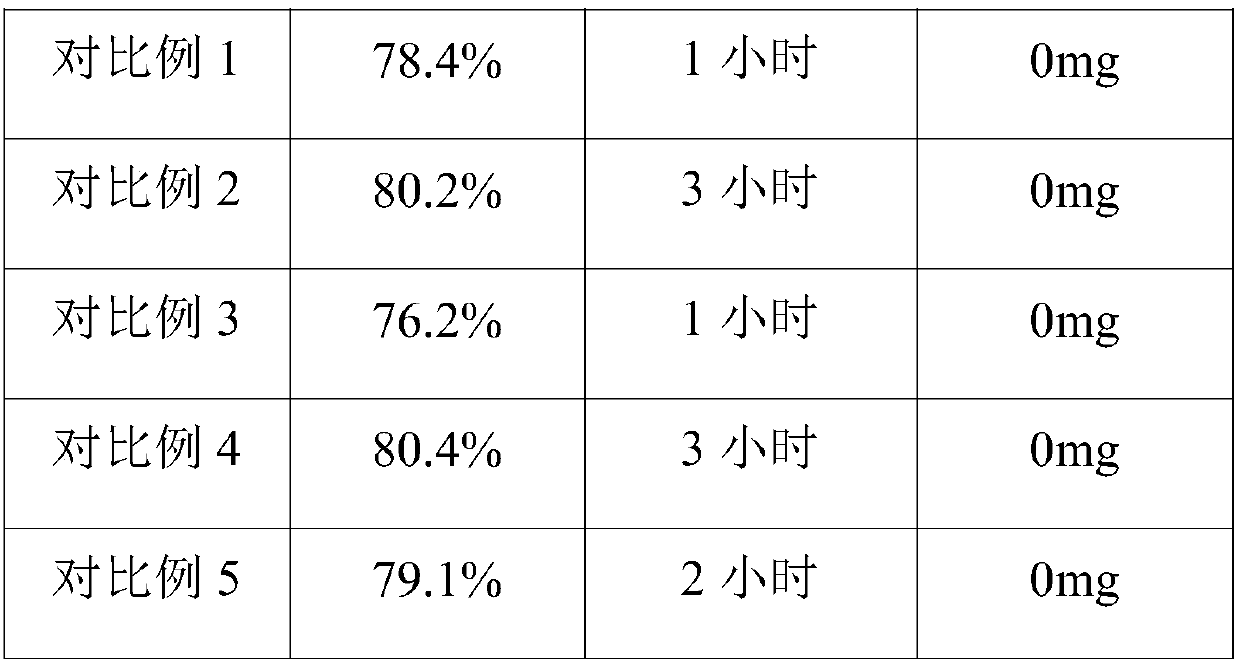

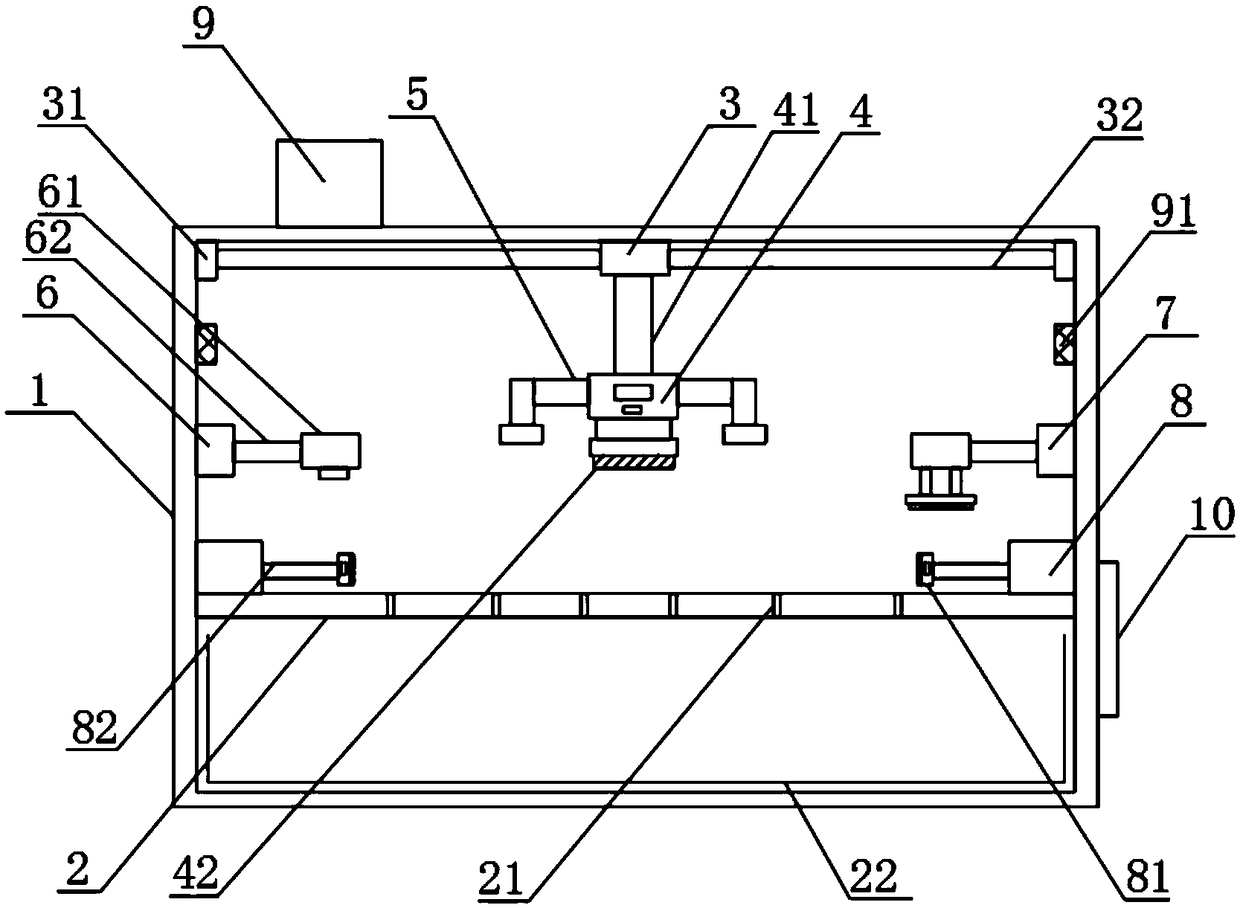

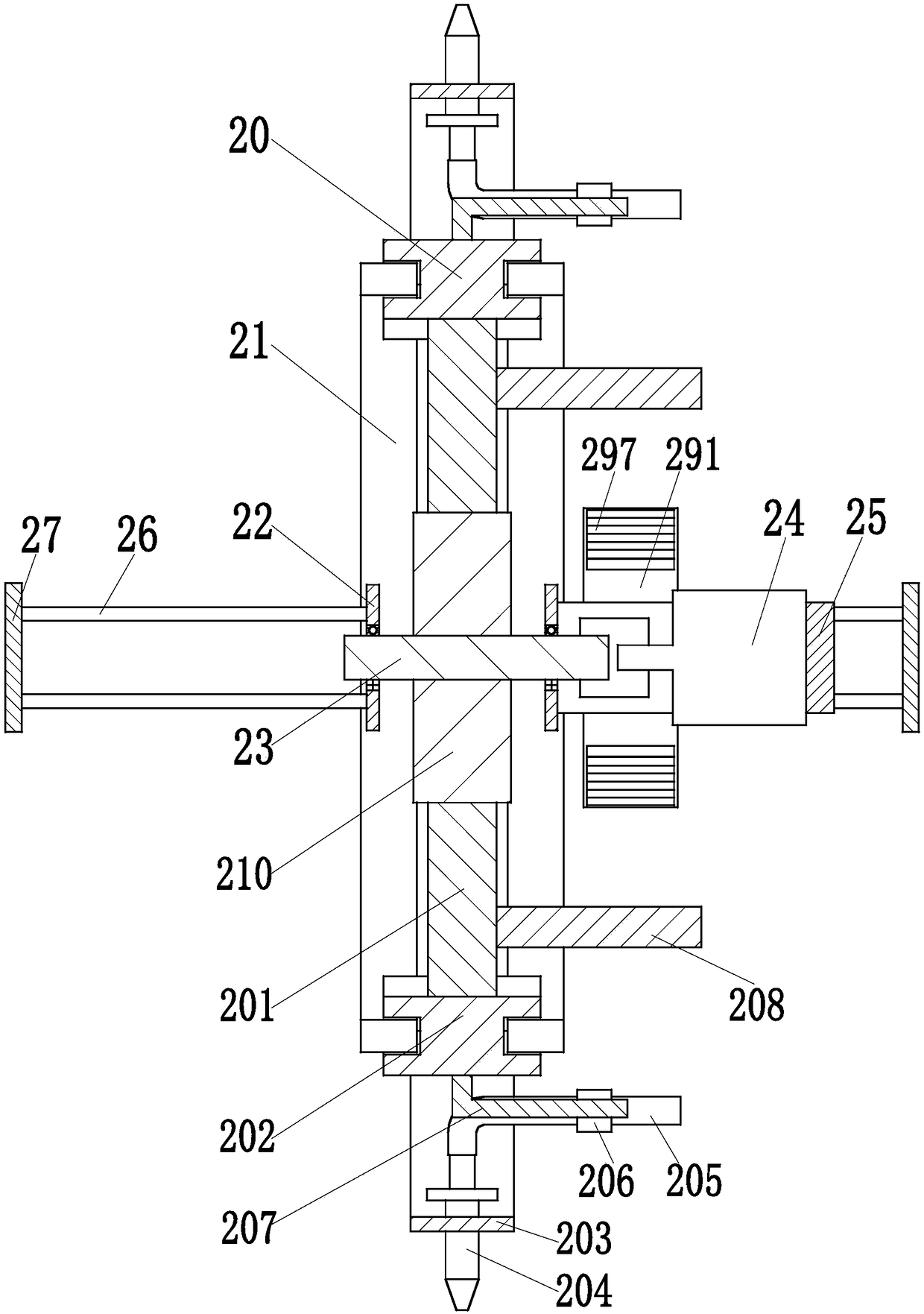

Rust removal preparation device for LED (light-emitting diode) lamp holder manufacture

InactiveCN106902694AImprove liquidityMix thoroughlyTransportation and packagingMixer accessoriesEngineeringLED lamp

The invention relates to a rust removal preparation device, in particular to a rust removal preparation device for LED (light-emitting diode) lamp holder manufacture, and aims to provide a preparation device which can achieve multistage stirring preparation and collect rust removers after rust removal. The rust removal preparation device comprises a working table, a motor, a first rotating rod, a first bevel gear, a second bevel gear, a second rotating rod, a stirring box, a supporting rod, a baffle plate, a first bearing block, a first stirring rod and the like, wherein the motor is mounted on the left side of the top of the working table, the first rotating rod is connected to the output shaft of the motor, and the first bevel gear is connected to the top end of the first rotating rod. The rust removal preparation device is further provided with a third bevel gear, a fourth bevel gear, a second bearing block, a fourth rotating rod and a second stirring rod.

Owner:宁波伍兹光电有限公司

Waterborne multifunctional coating and preparation method thereof

The invention discloses a waterborne multifunctional coating and a preparation method thereof, relating to the field of coatings. The invention provides the waterborne multifunctional coating which comprises the following components in parts by weight: 80-120 parts of water, 8-12 parts of propylene glycol, 1-2 parts of a wetting dispersant, 5-10 parts of a dispersant, 5-8 parts of a multifunctional auxiliary agent, 2-4 parts of a defoaming agent, 1-2 parts of a preservative bactericide, 150-200 parts of rutile type titanium dioxide, 30-100 parts of an antirust pigment, 500-650 parts of waterborne acrylic emulsion, 50-70 parts of a film coalescing aid, 10-20 parts of wax emulsion, 10-30 parts of a flash rust remover, 5-10 parts of a hydrophobic modified alkali swelling thickening agent and 5-10 parts of a polyurethane type thickening agent. The waterborne multifunctional coating prepared by the method disclosed by the invention has the advantages of being non-toxic, harmless, pollution-free, high in hardness and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

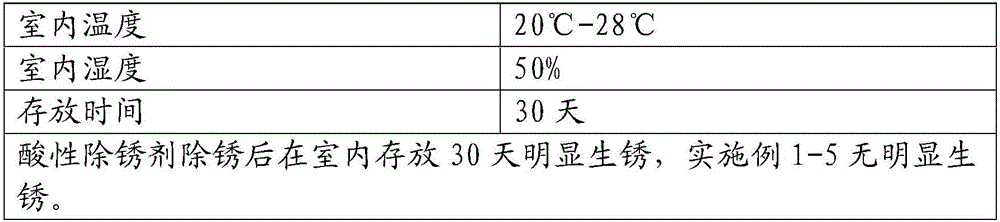

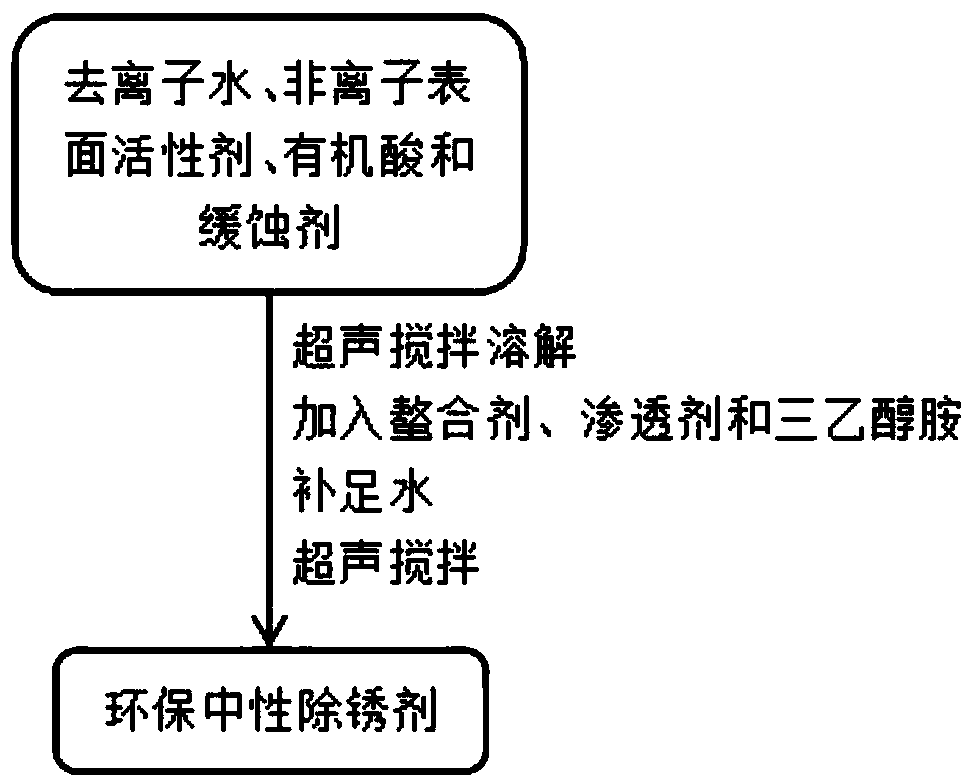

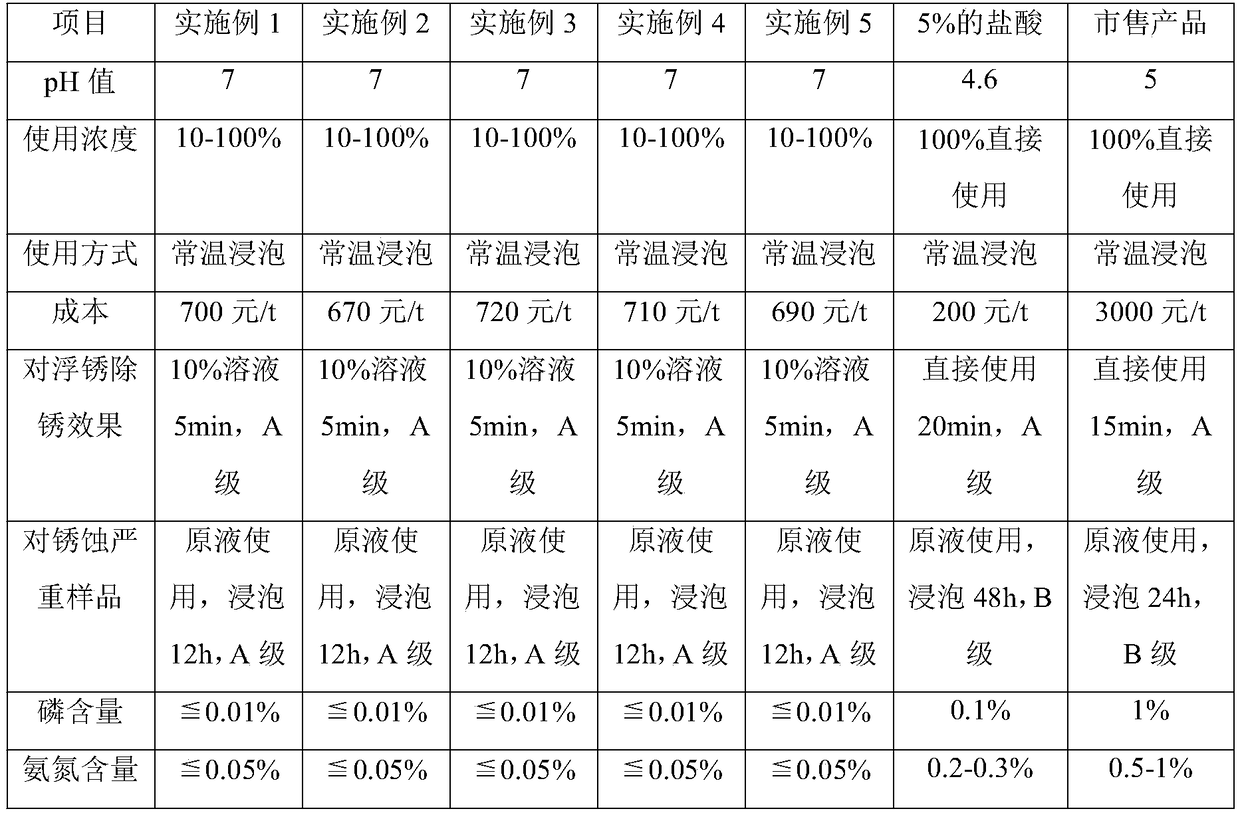

Environment-friendly neutral rust remover

InactiveCN109135945AWon't removeNot corrosiveInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOrganic acidPollutant emissions

The invention provides an environment-friendly neutral rust remover. The environment-friendly neutral rust remover is prepared by, by weight, 10-15 parts of organic acid, 20-40 parts of chelating agent, 10-30 parts of corrosion inhibitor, 30-60 parts of penetrating agent, 30-70 parts of triethanolamine, 10-20 parts of nonionic surfactant and 100-150 parts of deionized water. The environment-friendly neutral rust remover has the advantages that product precision after rust removing is increased, operation process flow is simplified, easy rust removing is achieved, harm to the health of operation staff during use is reduced, pollutant emission is reduced, energy conservation and environment protection are achieved, and fast rust removing is achieved.

Owner:VCI ANTIRUST NEW MATERIALS SHANGHAI

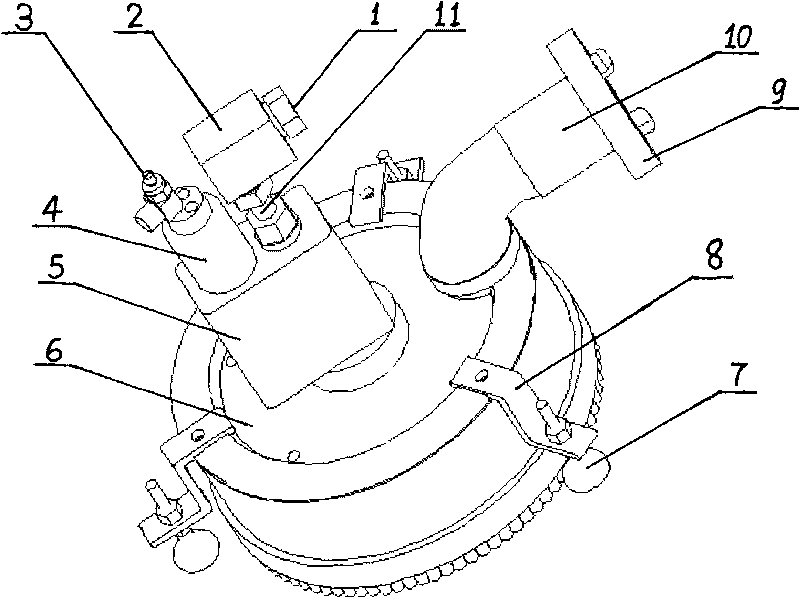

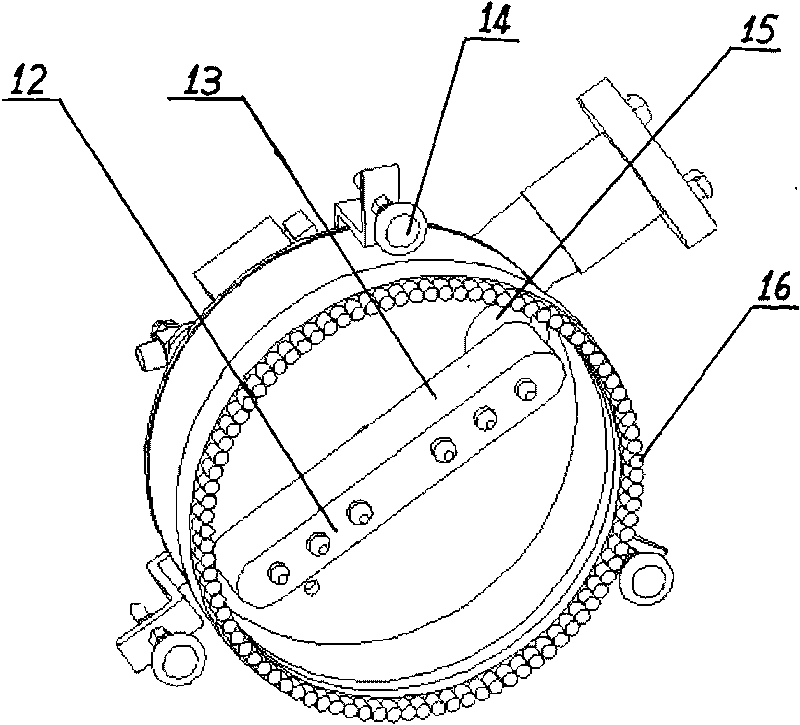

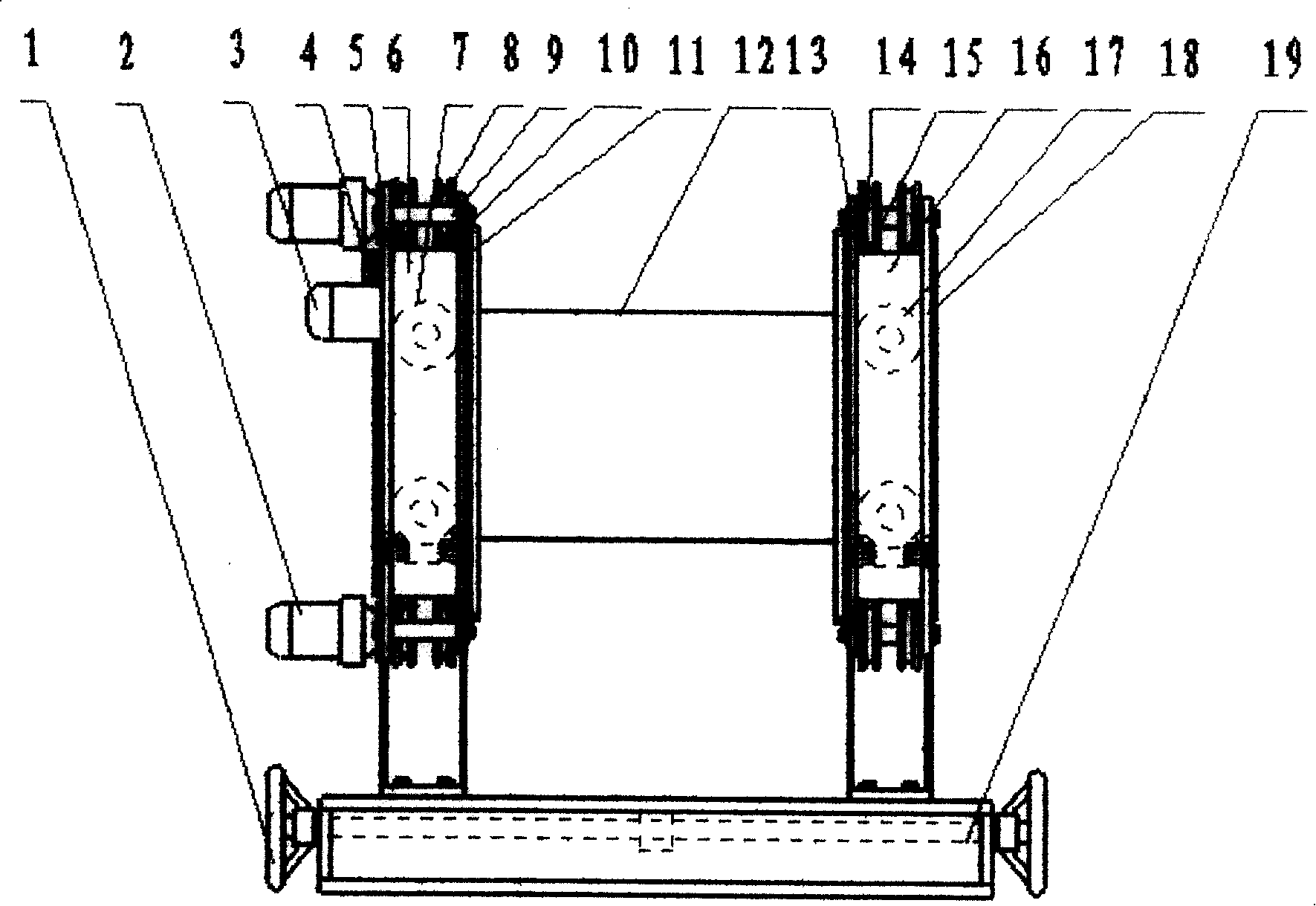

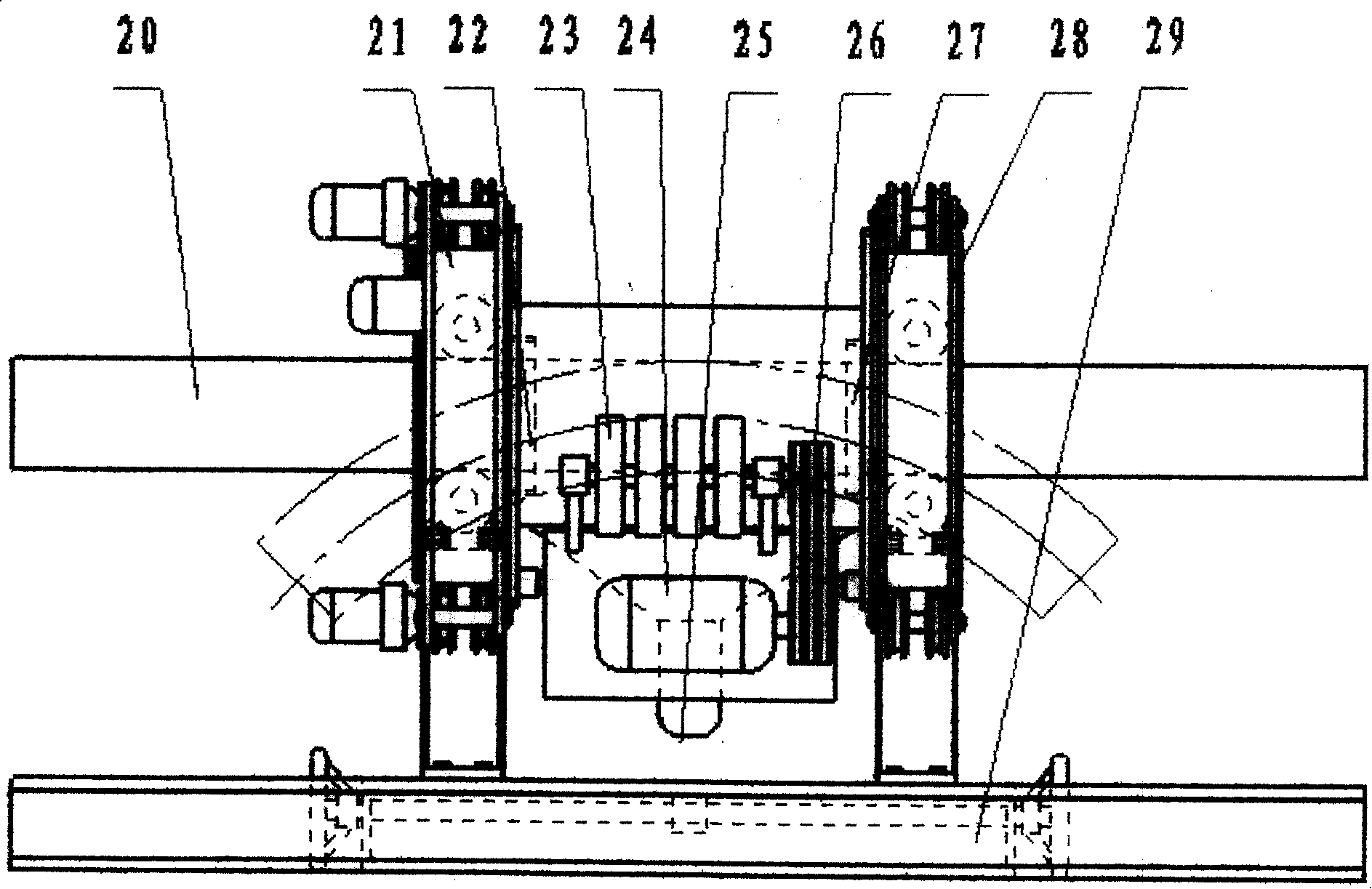

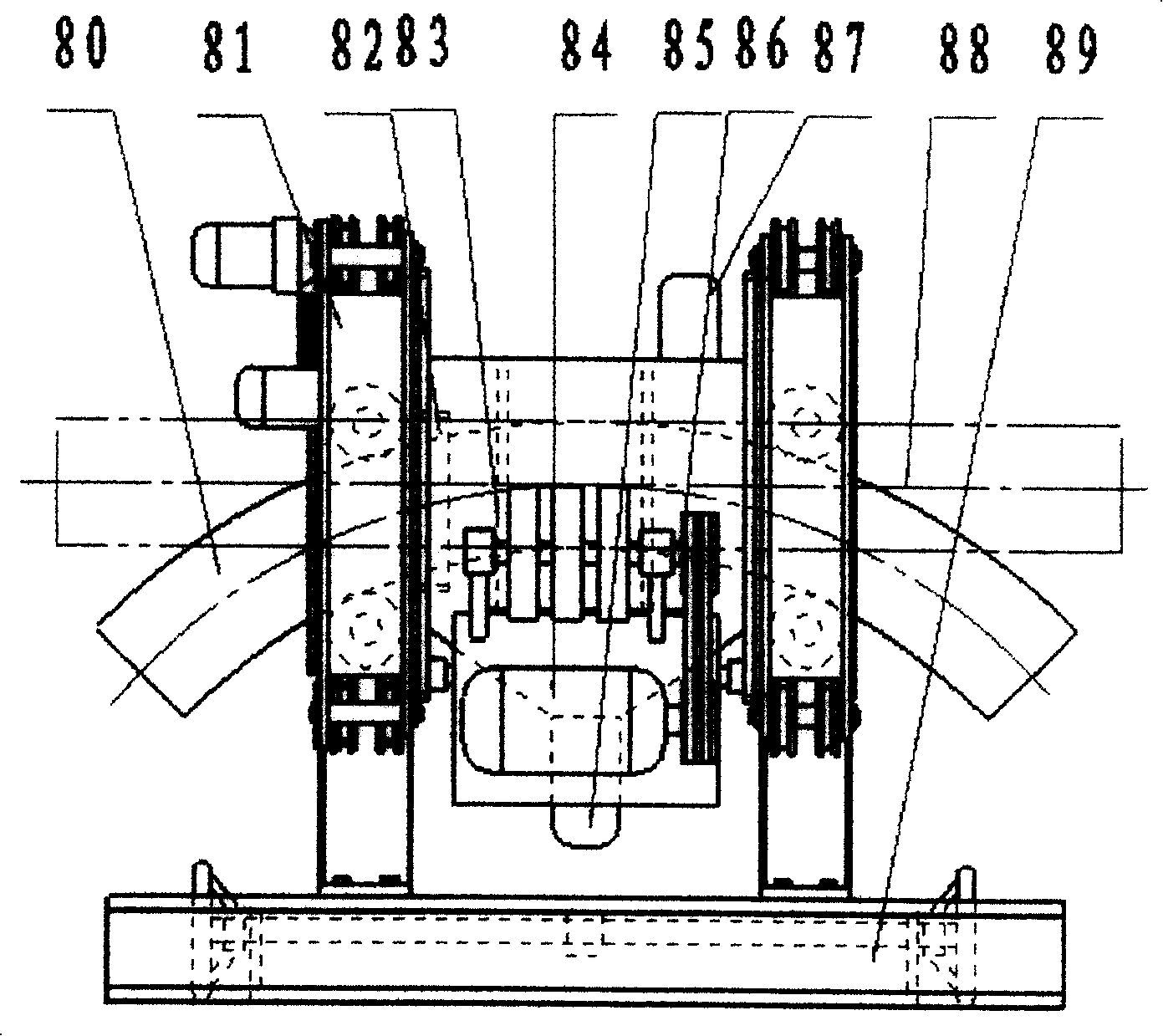

Water jet hull rust remover and operating method thereof

InactiveCN101704004AUniform derustingImprove rust removal effectCleaning using liquidsSlagEvaporation

The invention discloses a water jet hull rust remover and an operating method thereof. The rust remover comprises a high-pressure water tube interface, a high-pressure water tube interface seat, a rust removing disk, a high-pressure water tube interface seat support, a nozzle, and a nozzle rotary frame, and also comprises an air tube interface, an air tube interface seat, an air motor body, a vacuum recycling flange, a vacuum recycling tube, a vacuum recycling opening, and a high-pressure water sealing ring, wherein the vacuum recycling opening is embedded in the rust removing disk and connected with the vacuum recycling tube; the outlet end of the vacuum recycling tube is connected with the vacuum recycling flange; and the upper surface of the rust removing disk is also provided with a height adjusting support. The method comprises steps of height adjustment, rust removal and recycling. In the water jet hull rust remover, the rust removal by the superhigh pressure water jet and pumping and slag discharging by the vacuum system are compatibly designed into one body, the vacuum equipment recycles the rust, the high temperature, which is over 80 DEG C and generated by the water jet action, in the vacuum cavity can cause certain positive effects on the evaporation of water of the bulkhead, the rust removal drying is realized, and the hull is avoided from the return of rust.

Owner:DALIAN MARITIME UNIVERSITY

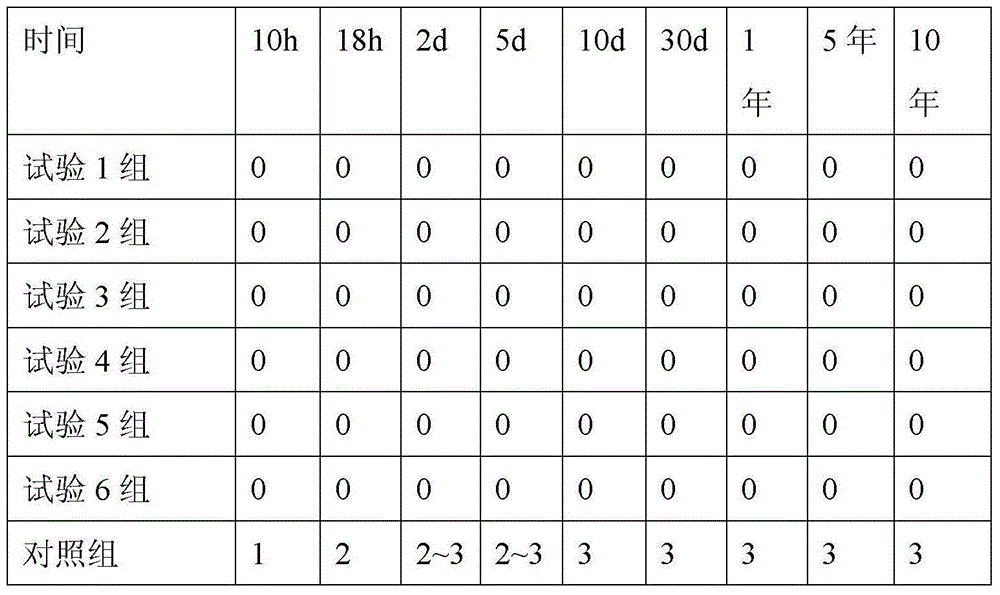

Compound rapid medical apparatus rust remover

The invention discloses a medical apparatus rust remover, and belongs to the technical field of fine chemical engineering. The rust remover is characterized in that the rust remover includes, by mass, 5-30% of an inorganic acid component, 0.5-5% of an organic acid component, 0.2-1% of a surfactant component, 0.01-0.05% of a perfume component, 0.10-0.20% of a solvent component I, and the balance solvent component II. The rust remover is a colorless, transparent, mild and weakly acidic liquid, having a pH value of 2-3, has stable performances and a mint smell, is suitable for removing floating rust, rust deposits and rusty spots of stainless steel, carbon steel, cast iron, metals of copper and the like, and alloy material apparatuses of the metals, and does not damage or corrode the materials of the above apparatuses. The components contained in the rust remover are weakly toxic to aquatic organisms, and the rust remover can be directly discharged without environmental harms.

Owner:BEI JING BAI XIANG NEW TECH

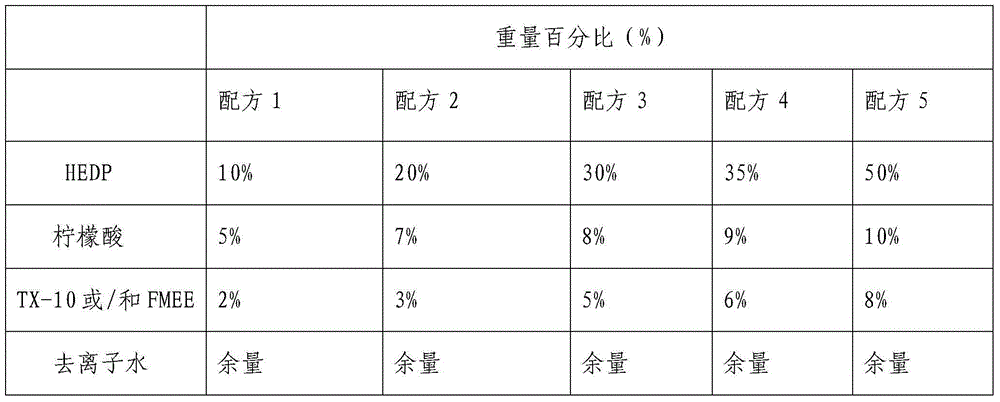

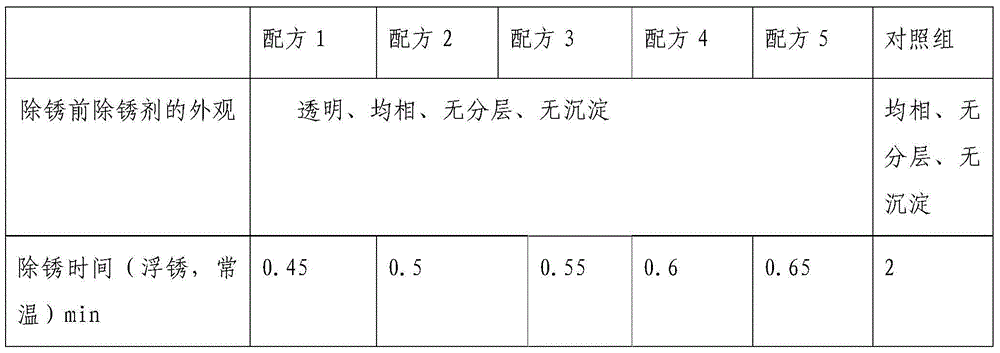

A steel environmental rust remover

The invention discloses a steel environmental rust remover. The rust remover comprises the following components by weight percentage: 10-50 % of organic phosphonic acid, 5-10 % of citric acid, and 3-5% of surfactant, with the balance being water. The surfactant is one of TX-10 and FMEE or a mixture of both. By adopting the technical solution of the invention, good rust removing effect can be achieved, the rust removing process is gentle and does not damage the surface of a steel article, and the use and manufacturing cost is low.

Owner:赵理奎

Epoxy ester dip-coating water based paint and preparation method thereof

InactiveCN106366851AImprove salt spray resistanceImprove water resistanceEpoxy resin coatingsWater basedEpoxy

The invention discloses an epoxy ester dip-coating water based paint and a preparation method thereof, and belongs to the technical field of water based paints. The epoxy ester dip-coating water based paint is prepared by proportioning a base material, an auxiliary and a pigment filler according to weight percentage, wherein the base material is prepared from 30 to 35 percent of water based epoxy ester resin and 5 to 10 percent of a water based acrylic emulsion; the auxiliary is prepared from 3 to 6 percent of a cosolvent, 0.5 to 1 percent of a dryer, 1 to 2 percent of a neutralizer, 30 to 35 percent of deionized water, 0.5 to 2 percent of a wetting dispersant, 0.1 to 0.5 percent of a defoaming agent, 1 to 2 percent of a flash rust remover, 1 to 3 percent of a thickener and 1 to 3 percent of an anti-settling agent; the pigment filler is prepared from 8 to 12 percent of heavy metal-free black pigment and 5 to 10 percent of composite zinc phosphate. The water based paint is low in carbon content and environment-friendly; the problems of low storage stability, low salt fog resistance, low water resistance and low epoxy ester paint drying speed of the existing water based dip-coating paint can be solved; meanwhile, the shortcomings that the dip-coating paint is not liable to coat, cannot be hung at corners and has sagging and pilled-in selvedge are also overcome.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Environmental-protection heavy-duty anticorrosive coating, and preparation method and coating method thereof

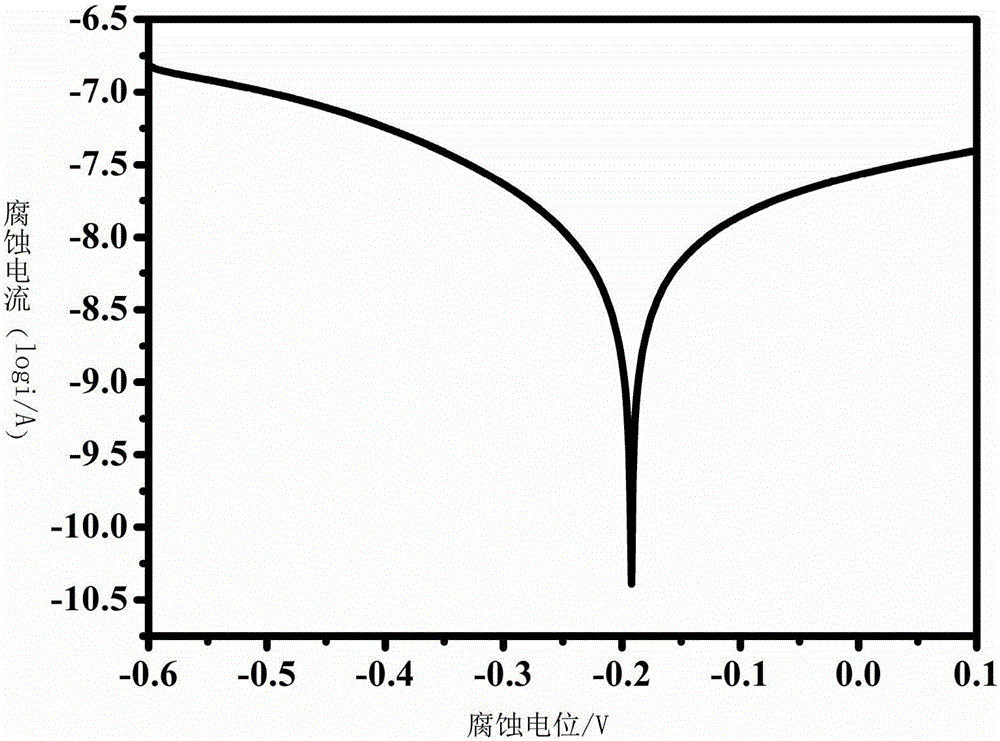

ActiveCN105131786AIncreased corrosion potentialCorrosion Prevention and MitigationAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention relates to an environmental-protection heavy-duty anticorrosive coating, and a preparation method and a coating method thereof; the anticorrosive coating includes an epoxy resin emulsion, silicon dioxide hollow microspheres, a silane coupling agent, a flash rust remover, an anti-settling agent and a curing agent, wherein the mass ratio of the epoxy resin emulsion to the silicon dioxide hollow microspheres to the silane coupling agent to the flash rust remover to the anti-settling agent to the curing agent is 100 to (1-10) to (0.5-2) to (0.1-1) to (1-5) to (10-20). The coating does not contain volatile organic small molecules, is non-toxic and environmentally friendly, and is simple in preparation process and low in cost; and an obtained anticorrosive coating layer has good physical properties and excellent corrosion resistance.

Owner:山东宝龙达新材料有限公司

Pipeline anti-scaling agent and preparation method thereof

ActiveCN104925964ASecondary Damage SuppressionRaw materials are easy to getTreatment using complexing/solubilising chemicalsMeth-Gallic acid ester

The invention relates to a pipeline anti-scaling agent and a preparation method thereof. The pipeline anti-scaling agent comprises the following components by weight percent: 5 to 15 percent of sodium phosphate, 6 to 17 percent of polyacrylamide, 7 to 15 percent of polymaleic anhydride, 4 to 11 percent of sodium dodecyl benzene sulfonate, 7 to 11 percent of hydroxyethylidene acid, 6 to 11 percent of amino trimethylene phosphonic acid, 5 to 13 percent of acrylic acid copolymer copolymer, 4 to 8 percent of gallic acid, 7 to 11 percent of phenolic derivative, 3 to 5 percent of polyepoxysuccinic acid, 2 to 6 percent of sodium stearate, 3 to 7 percent of sterilizing agent and 2 to 4 percent of rust remover. By adopting the pipeline anti-scaling agent, scale remaining in the pipeline for a long time can be effectively removed, the scale removal capacity is high, secondary harm to the pipeline is avoided, and the pipeline can have a scale-preventing function.

Owner:佛山市南海区巨人化学品制造有限公司

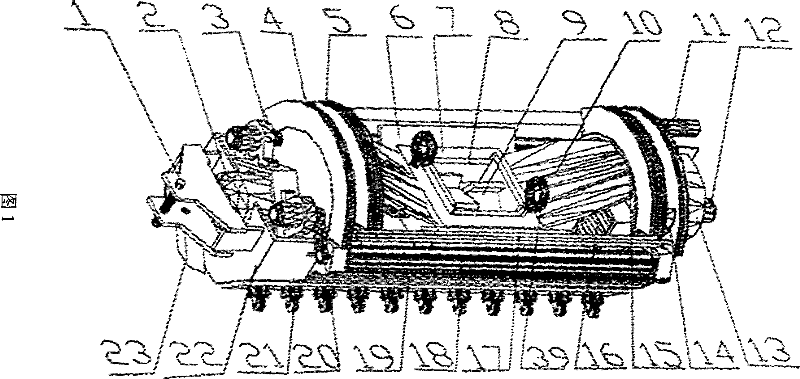

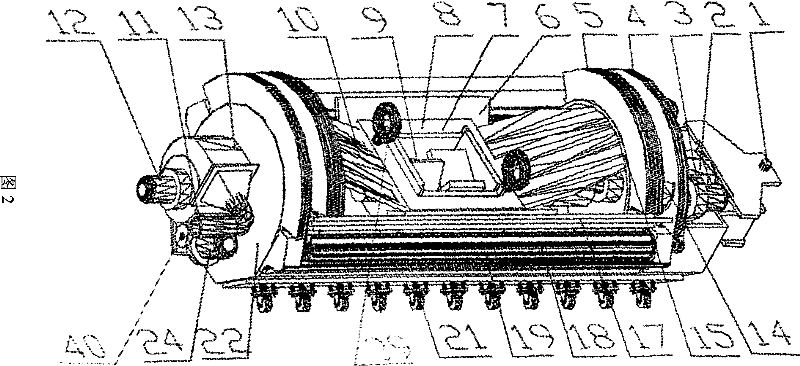

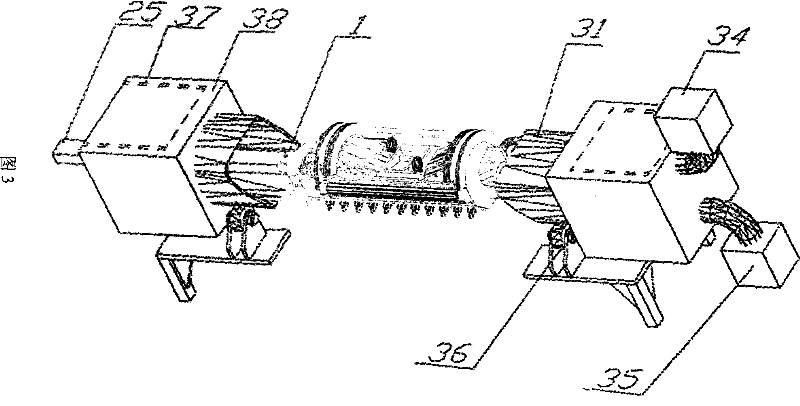

Polyethylene coating steel pipe and its producing method and production line

InactiveCN101191577AOvercoming qualityOvercome mechanical propertiesLiquid surface applicatorsCorrosion preventionEpoxyAdhesive

The invention relates to a steel pipe painted with polythene and manufacturing method and mobile production line. A drum type rust remover, a drum type threading machine, a drum type spray coater, a drum type winding machine, a drum type cooling fan, a drum type dust removing threading machine, and a drum type spray winding machine are connected in turn to form the mobile production line. At a pipe laying site, a steel pipe in turn enters the drum type rust remover, the drum type threading machine, the drum type spray coater, the drum type winding machine and the drum type cooling fan, and makes helical movement under the support of a feeding wheel and a supporting roller in a rotating drum body. The steel pipe is heated through a high-frequency induction heating method, and rust spots are removed from the external surface of the steel pipe through a mechanical method and the steel pipe is threaded also through a mechanical method, the epoxy powder spray coater is used to spray epoxy powder to the external surface of the steel pipe, the epoxy powder and a composite polythene cold adhesive tape are heated indirectly through the high-frequency induction heating method and the cold adhesive tape is turned into a composite polythene hot adhesive tape, and through a mechanical winding method, the composite polythene adhesive tape is applied onto the epoxy powder layer to produce the steel pipe painted with polythene.

Owner:陈炯

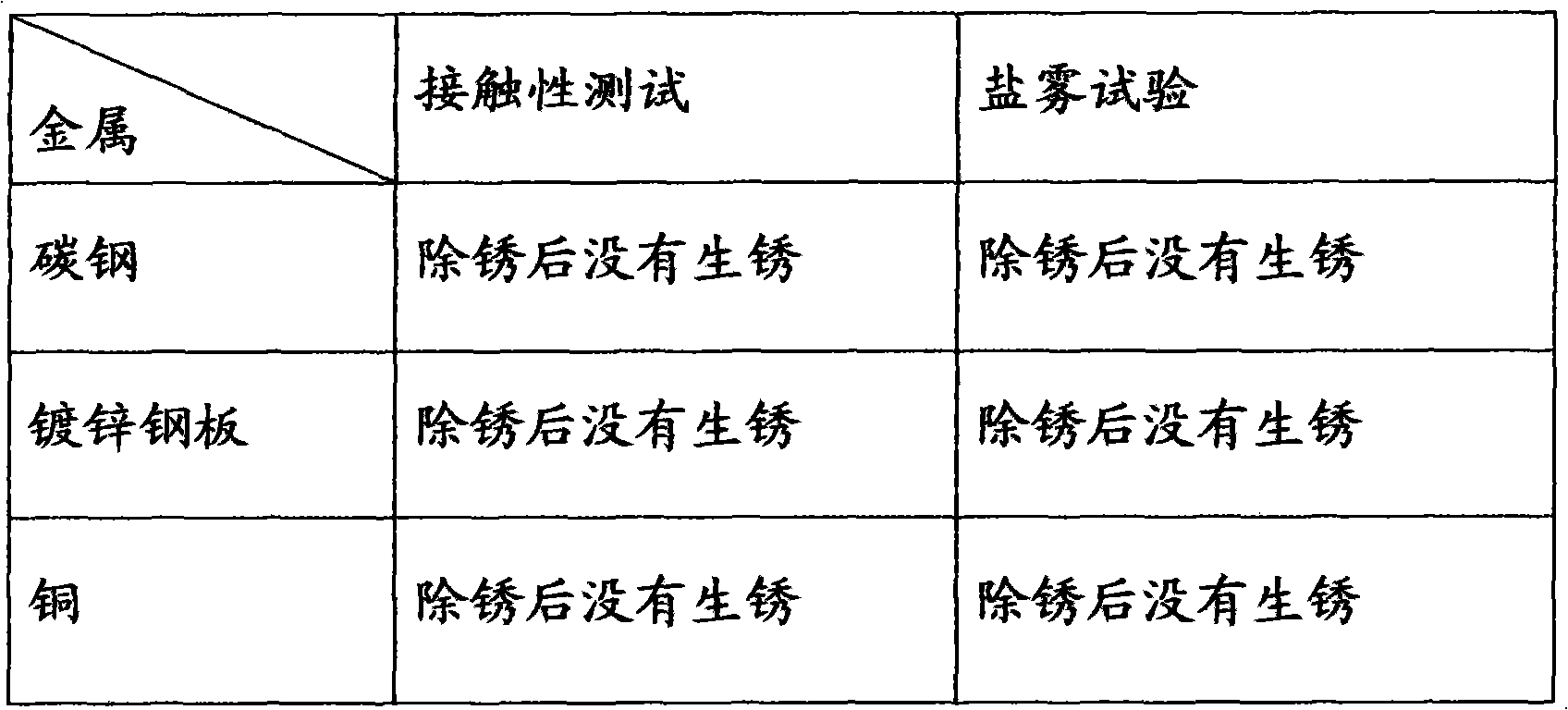

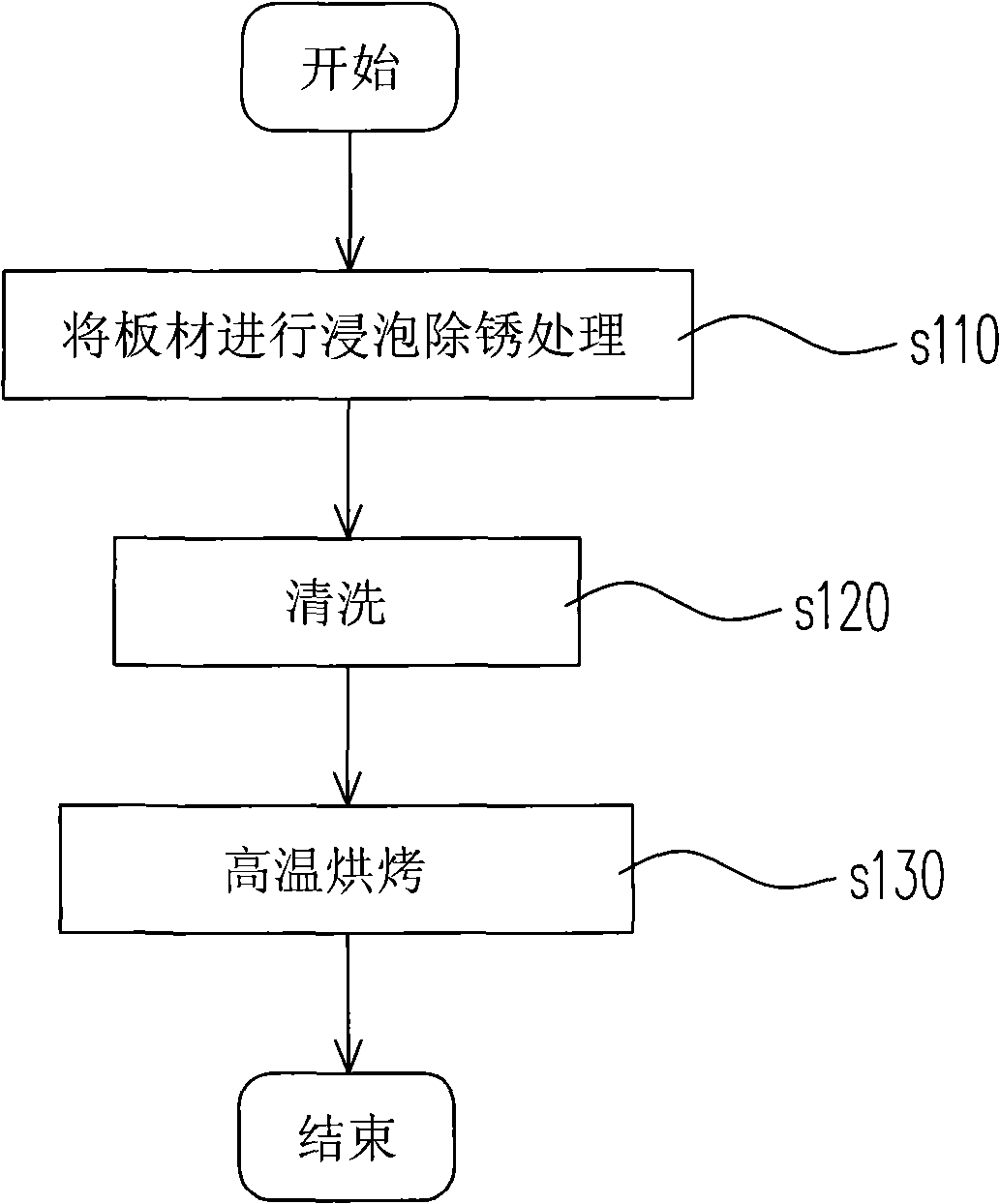

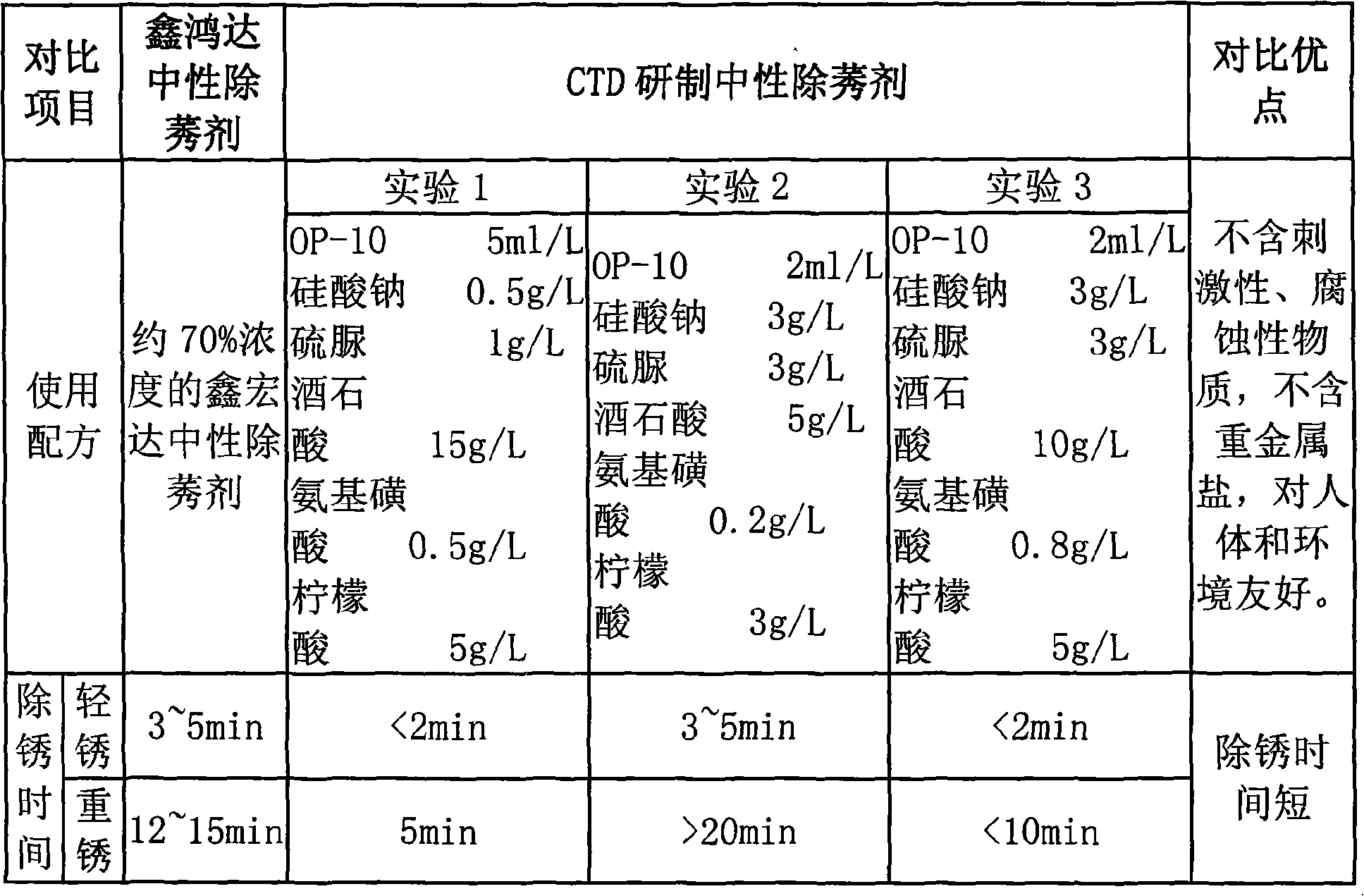

Formula and technique for neutral rust remover for rust cleaning of sheet material

The invention discloses a formula of a neutral rust remover used for rust removal of plates, and the process thereof. By utilizing the formula of the neutral rust remover, the plate is soaked for 2 to 10 min and then rust removal treatment is performed at room temperature and under the environment that PH value is 5 to 7; the neutral rust remover solution per unit volume comprises the following solutes: 0 to 20 ml / L of OP-10, 0 to 30 g / L of sodium silicate, 0 to 30 g / L of thiourea, 5 to 20 g / L of tartaric acid, 0 to 10 g / L of sulfamic acid, and 0 to 30 g / L of citric acid. The neutral rust remover has the advantages that the cost is low, the neutral rust remover can be used at normal temperature, is not easy to generate acid mist and is friendly to both the human body and the environment; furthermore, no damage is caused to the zinc layer on the surface of the plate, and the operation is simple.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

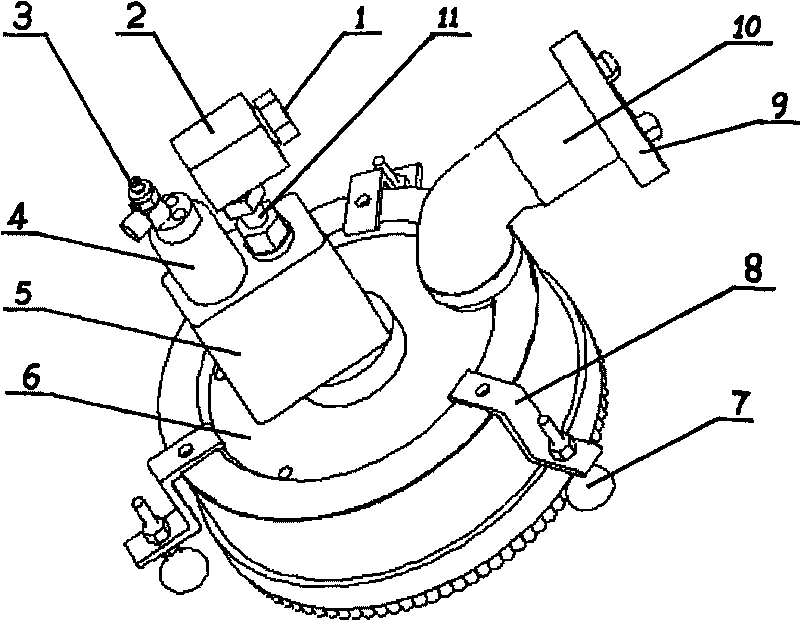

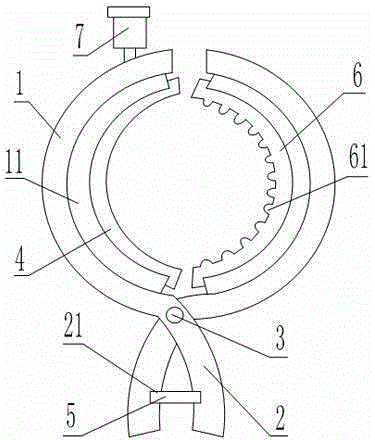

Device for cleaning petroleum drilling rod

InactiveCN105032812AExpand the spraying rangeImprove efficiencySpray nozzlesGrinding machinesRubber materialEngineering

The invention discloses a device for cleaning a petroleum drilling rod. The device comprises an annular rotating plate. The outer diameter of the petroleum drilling rod is sleeved with the annular rotating plate. An annular cavity is formed in the inner wall of the annular rotating plate. The device further comprises clamping devices evenly arranged in the annular cavity around the center of the annular rotating plate. The device further comprises a spraying device fixed to the upper surface of the annular rotating plate. The spraying device comprises a spraying head body of a cavity structure. A water inlet is formed in one side face of the spraying head body, and a water outlet A is formed in the other side face of the spraying head body. The device further comprises hemispheroids evenly arranged on the inner wall of the spraying head body around the water outlet A. The hemispheroids are made of rubber materials. The device further comprises a cover body of a cavity structure. The cover body is fixed to one end of the spraying head body. The water outlet A is formed inside the cavity structure of the cover body. Horn mouths are evenly formed in the side wall of the cover body. A water outlet B is formed in the front end face of the cover body. Due to the arrangement of the hemispheroids, the pressure of a rust remover flowing through the hemispheroids is increased, and the spraying range of the rust remover can be effectively enlarged.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

Neutral rust remover and preparation method thereof

The invention discloses a neutral rust remover and relates to the technical field of metal surface rust removal. The neutral rust remover is prepared from, by weight, 130-170 parts of hydroxy ethidenediphosphonic acid, 1-3 parts of sodium chloride and / or potassium chloride, 0.4-1.6 parts of potassium oxalate 0.4-1.6 parts of formic acid, 0.4-1.6 parts of phytic acid, 1-3 parts of citric acid, 0.4-1.6 parts of ethylenediaminetetraacetic acid and 3-7 parts of organic amine ester TPP. The invention further discloses a preparation method of the neutral rust remover. By the adoption of the neutralrust remover and the preparation method, the rust removal speed under the normal temperature is high, the rust removal effect is good, and secondary rusting time is long; meanwhile the rust remover is neutral, free of damage to a base body and free of influence on strength and ductility and malleability of metal; and all the components are environmentally-friendly, free of toxin, smoke and pungent odors, free of pollution to the environment and free of harm to the human body.

Owner:宁波际超新材料科技有限公司

Preparation and application of neutral non-phosphorus rust remover

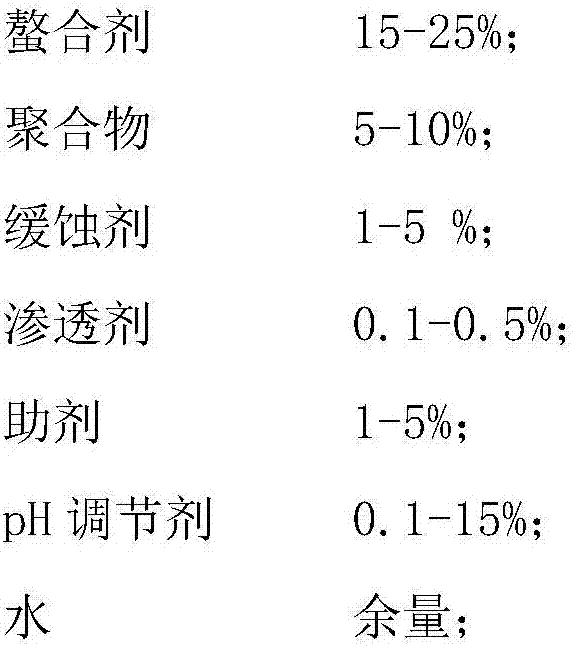

The invention discloses preparation and application of a neutral non-phosphorus rust remover. The rust remover mainly comprises a chelating agent, a polymer, a corrosion inhibitor, a penetrant, a pH regulator, water and an assistant, and can be applied to phosphorization, chromizing and silanization of coating pretreatment of steel and iron workpieces or zirconium pretreatment and rusty workpiece derusting procedure before chemical conversion coating treatment. According to the rust remover, treatment time is flexible, the rust remover is utilized at the normal temperature, does not need to be heated, can be utilized for treatment in a spraying or impregnation manner, does not contain hazardous substances like phosphorus, and is low in residues and free of scales, after rust removing, a solution is low in bubble and scale, maintenance of a bath solution is simplified, residues and scales are not liable to adhere to the workpieces and pollute the workpieces, the pH of a treating fluid is neutral, workpiece matrixes and operation equipment are not corroded and damaged, the workpieces have good corrosion inhibition and rust protection performance after treatment, and the rust protection problem of the workpieces during the transfer process is solved.

Owner:杭州五源科技实业有限公司

Electric ballasting rust remover on the inner wall of pipeline

InactiveCN101036977ALarge scope of operation managementCompact structureAbrasive blasting machinesImpellerEngineering

The invention discloses an electric impeller blasting deruster of pipe internal wall, using over all structure of electromechanical integration operating dolly type, which includes five portions of a walking system, a sealing system, an impeller blasting system, a sand sweeping system and a dedusting system, and is a special machine for automatic derusting of self sealing, self sand sweeping and self supplying sand steel tube internal wall. Comparing to prior art at home and abroad, main advantages of the deruster are that it changes the history of single establishing the derusting line for former impeller blasting deruster, and the invention can complete on-line derusting operation mating with various anti-corrosive operations, also can use alone for derusting on-scene construction, capable of realizing cycle use by adding sand at one time, with good effect and quick speed of derusting, good sealing and without environmental pollution, and the machine per se has compact structure, convenient and flexible conveying and operating, and low cost, capable of greatly reducing operation cost of derustering for steel pipe internal wall.

Owner:张景远

Rust remover for ultrasonically cleaning metal mould and preparation method thereof

InactiveCN102337545AIncrease surface tensionOptimum viscosity coefficientMetallic material coating processesO-Phosphoric AcidEthyleneglycol monobutyl ether

The invention discloses non-corroding ultrasonic cleaning equipment. A rust remover for ultrasonically cleaning a metal mould is used for rapidly and completely removing rusts on the surface of the metal mould, generating a dense and complete passivation film at the same time and avoiding a secondary oxidization. The rust remover is prepared from the following raw materials by mass percent: 8-30% of phosphoric acid, 6-25% of room-temperature steel surface conditioning agent, 1-4% of citric acid, 1-5% of tartaric acid, 1-4% of phytic acid, 1-8% of polyethylene glycol, 1-3% of penetrant JFC, 1-6% of ethylene glycol monobutyl ether and the balance of water. A preparation method of the rust remover comprises the following steps of: firstly, adding water with a calculated amount into a stainless steel reaction kettle, starting an agitator and controlling a rotary speed of the agitator to 40-60 r / min; then respectively taking the calculated amount of the phosphoric acid, the room-temperature steel surface conditioning agent, the citric acid, the tartaric acid, the phytic acid, the polyethylene glycol, the JFC and the ethylene glycol monobutyl ether and sequentially and slowly adding the materials into the reaction kettle; and adding the materials while agitating until the solution becomes a light-green transparent liquid.

Owner:DALIAN SANDAAOKE CHEM

Neutral environment-friendly rust remover and preparation method thereof

The invention discloses a neutral environment-friendly rust remover and a preparation method thereof. The neutral environment-friendly rust remover is prepared from the following raw materials in percentage by mass according to a standard that the total mass of the rust remover is 100 percent: 10 to 15 percent of organic acid, 3 to 6 percent of a chelating agent, 2 to 4 percent of a corrosion inhibitor, 0.5 to 1 percent of a penetrating agent, 5 to 20 percent of a pH adjuster and the balance of water. According to the neutral environment-friendly rust remover disclosed by the invention, by adoption of combination of the organic acid, the chelating agent, the corrosion inhibitor, the penetrating agent and the like, the obtained rust remover is neutral and does not contain phosphorus and heavy metals, and no acid mist escapes; the neutral environment-friendly rust remover cannot cause a hydrogen embrittlement phenomenon or an over etching phenomenon for equipment and workpieces; furthermore, the rust remover disclosed by the invention cannot pollute the environment and a water source, and a rust removing method is simple; the neutral environment-friendly rust remover can be used forremoving rusts and has a good anti-rust function.

Owner:广州旭淼新材料科技有限公司

Maintaining device for mold

ActiveCN108747720AConvenient grinding workImprove the efficiency of grinding and rust removalGrinding feed controlGrinding machinesEngineeringRust remover

The invention discloses a maintaining device for a mold. The maintaining device comprises a shell. A working panel is arranged in the shell, and a first sliding block is arranged at the top of the inner wall of the shell. A lifting seat is arranged at the bottom of the first sliding block, and dust blowing devices are arranged on the two sides of the lifting seat correspondingly. A side block is arranged on one side of the inner wall of the shell, and a smearing device is arranged on the other side of the inner wall of the shell. A fixing seat is arranged at the top of the working panel, and the side block and the smearing device are both arranged at the top of the fixing seat. A water storage chamber is formed in the top of the shell. By arranging the fixing seat and a pressing plate, a sixth electric push rod pushes the pressing plate to move, and thus the mold needing to be maintained can be fastened from the side face and is ground from the top conveniently; and by forming a liquidstorage chamber and the smearing device, a rust remover can be sprayed to the portion, needing to be ground, of the mold through a liquid spraying head at the bottom of the liquid storage chamber before grinding, the grinding and dust removing efficiency is improved, the mold is smeared through lubricating oil in an oil storage chamber after grinding, and the anti-oxidation effect is achieved.

Owner:ANHUI ANLAN MOLD

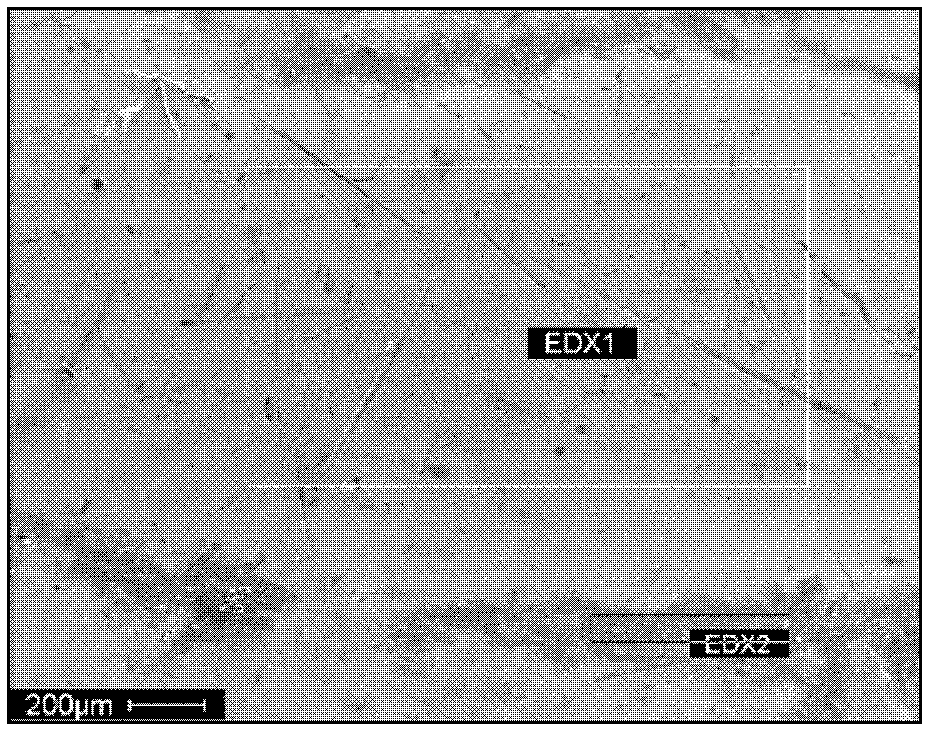

Thiourea compound rust remover and rust removal paste for protecting silverware and gilded silverware

The invention provides a thiourea compound rust remover and rust removal paste for protecting silverware and gilded silverware. The rust remover comprises of thiourea 0.9-1.1 mol / l and ferric sulfate of 0.01-0.015 mol / l and has the pH value of 1-2. The rust removal paste is prepared by adding 1.6-1.8 g of gelatin and 9-10 g of diatomite in 10 ml of rust remover with uniformly stirring and has the pH value of 2-3. The rust remover can be used in concert with the rust removal paste for removing black corrosion on the ancient silverware and gilded silverware surfaces with good effect. The rust remover and the rust removal paste accord with the protecting principles of cultural relics, such as no change of original states of cultural relics and minimal intervention, and don't cause physical damage.

Owner:中国文化遗产研究院

Rust remover for mechanical equipment and preparation method of rust remover

ActiveCN104233358AGood surface polishing performanceGood protectionPolyethylene glycolMechanical equipment

The invention discloses a rust remover for mechanical equipment and a preparation method of the rust remover. Aiming at the defects existing in an existing rust remover for mechanical equipment, the rust remover is prepared from triethylene diamine, sodium dodecyl sulfate, a cosolvent, an anionic surfactant, polyethylene glycol, an antibacterial agent, a corrosion inhibitor, a brightener, a stabilizer, an antioxidant and water according to a certain preparation method. The rust remover for the mechanical equipment disclosed by the invention has strong property of quickly removing rust from mechanical parts, and also has good surface polishing property and surface protecting property. In addition, after being cleaned, the rust remover has strong secondary antirust function, overcomes the problem of a traditional cleaning agent which causes damage or corrosion to the mechanical equipment surface, and thus the rust remover disclosed by the invention has strong practicability.

Owner:HEBEI HOFMANN NEW MATERIAL TECH CO LTD

Surface processing device with rust remover convenient to completely remove rust for drill stem

InactiveCN104624538AImprove processing efficiencyLow costCleaning using toolsEngineeringKnife blades

Owner:SICHUAN XILIN OIL SUPPLIES EQUIP

Environment-friendly steel rust remover and preparation method thereof

The invention belongs to the field of steel rust removers, and discloses an environment-friendly steel rust remover and a preparation method thereof. The environment-friendly steel rust remover and the preparation method thereof are used for solving the technical problems that an existing steel rust remover is prone to re-rusting, long in rust removal time and high in cost and pollutes the environment. The rust remover is composed of citric acid, oxalic acid, phosphoric acid, sodium alkyl benzene sulfonate, an emulsifier, a corrosion inhibitor and deionized water, or composed of citric acid, oxalic acid, phosphoric acid, sodium alkyl benzene sulfonate, an emulsifier, a corrosion inhibitor, an anti-freezing agent and deionized water. The preparation method includes the steps that 1 / 2 of water is added into a reaction still; the phosphoric acid, the citric acid, the oxalic acid, the sodium alkyl benzene sulfonate, the corrosion inhibitor and the emulsifier (or the phosphoric acid, the citric acid, the oxalic acid, the sodium alkyl benzene sulfonate, the corrosion inhibitor, the anti-freezing agent and the emulsifier) are sequentially added with stirring at the speed of 100-150 revolutions per minute; the remaining water is added; and the mixture is stirred at a constant speed till complete dissolution. The environment-friendly steel rust remover is applied to steel rust removal.

Owner:HARBIN JINSHIJIA TECH DEV CO LTD

Rust remover for steel precise components and rust removing technology

InactiveCN103911623ASimple processImprove rust removal effectMetallic material coating processesPhosphoric acidAqueous solution

The invention relates to a rust remover for steel precise components and a rust removing technology. The rust remover is composed of the following compositions in percent by weight: 15% of chromic anhydride, 15-17% of phosphoric acid, 1-1.2% of sulfuric acid and 66.8-69% of water. The rust removing technology comprises: immersing a steel precise component subjected to cleaning and oil removing into a solution of the rust remover, heating to 80-90 DEG for about 30-40 min; taking out and flushing with tap water for 1 min, and then immersing in a sodium carbonate aqueous solution with a concentration of 0.5% for about 5 min; taking out and immersing in a passivating solution composed of a sodium nitrite aqueous solution with a concentration of 10% and a sodium carbonate aqueous solution with a concentration of 0.5% according to a ratio of 50%:50%, heating to 80-90 DEG C for about 5-10 min; and taking the steel precise component out from the passivating solution, and flushing with tap water, wiping to dry and sealing with oil. The beneficial effects comprise that the technology is simple, and the rust remover has no any influence on dimension, shape, surface glossiness and precision on the steel precise component, and is good in ruse removing effect.

Owner:徐一达

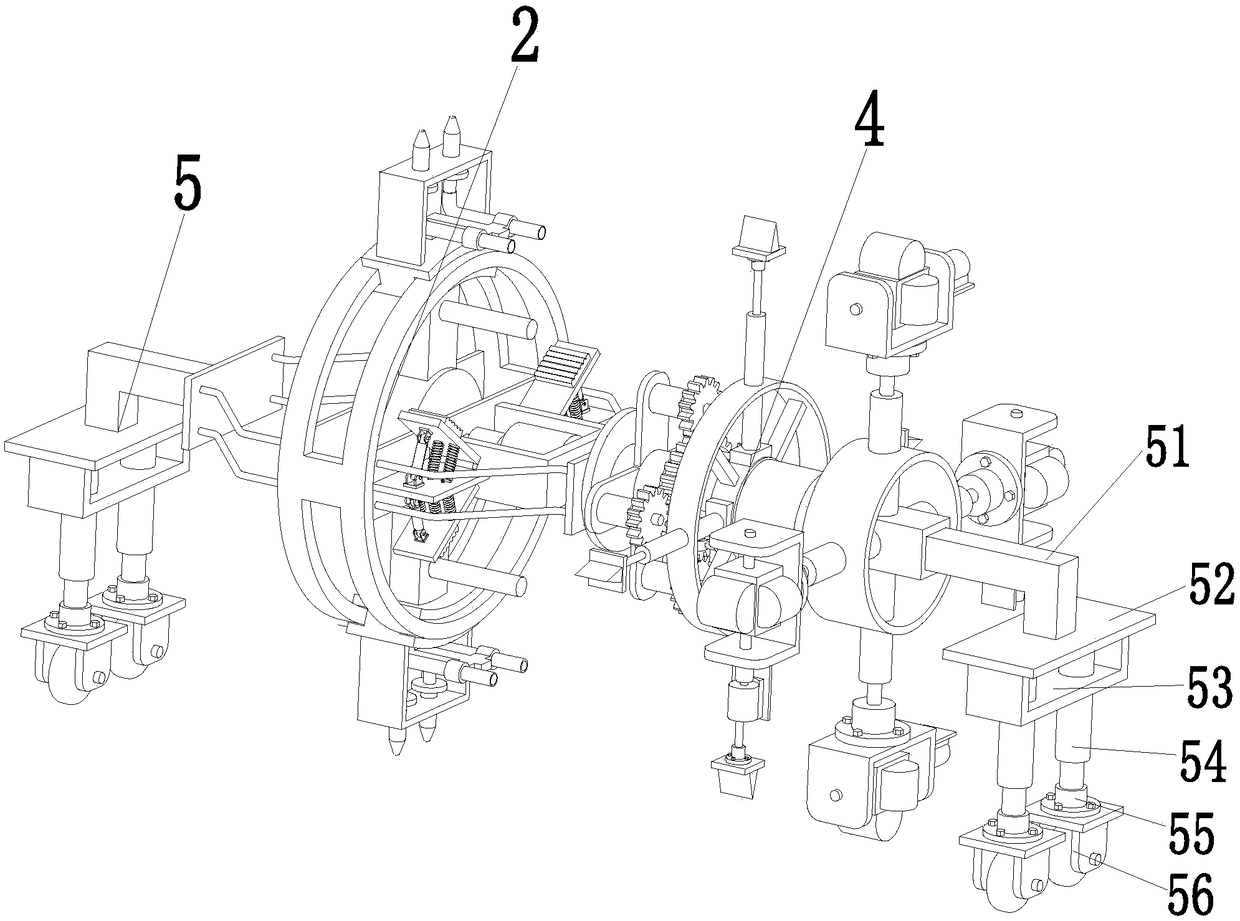

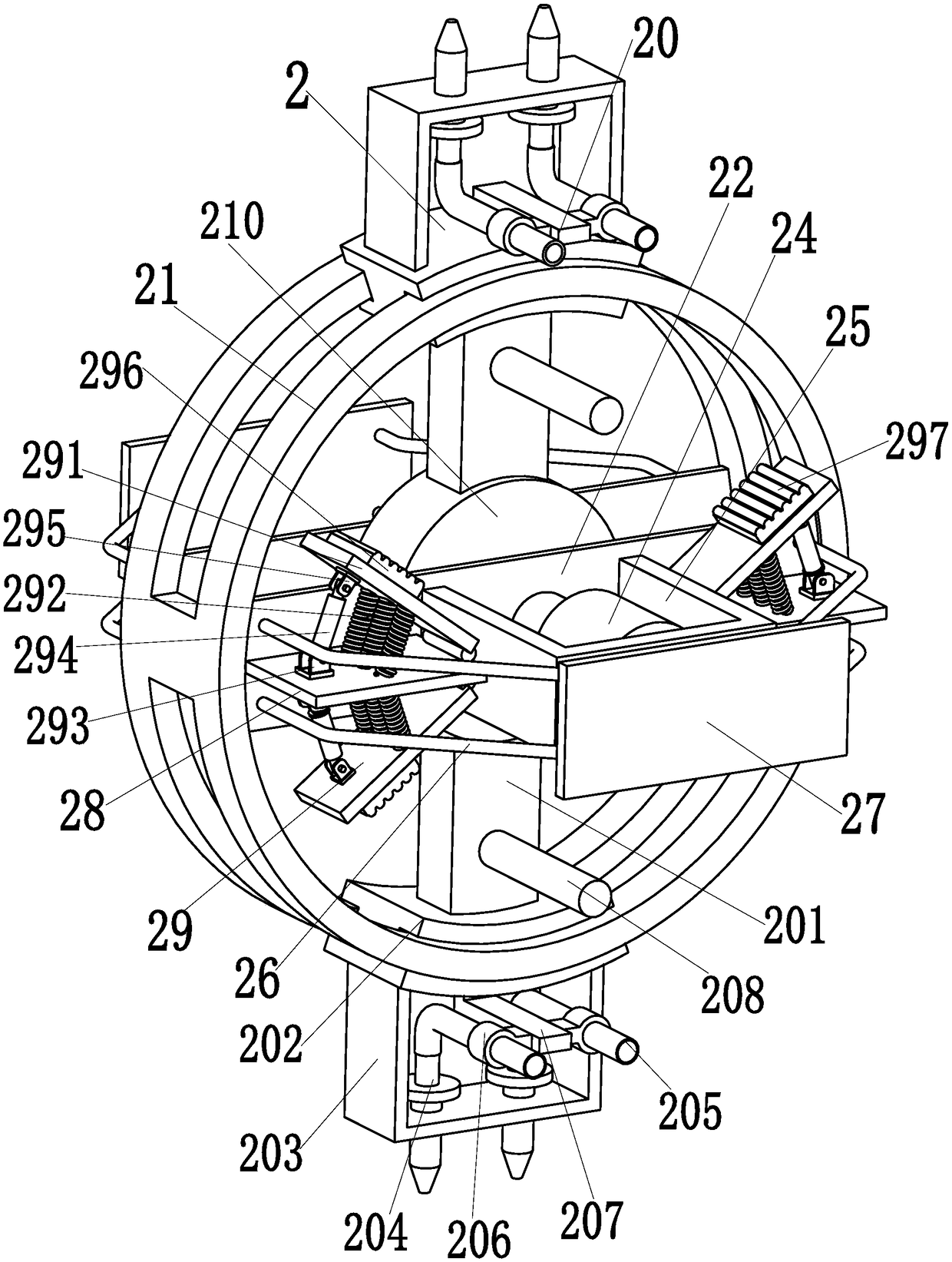

Intelligent device for machining and treating internal walls of petrochemical pipelines

ActiveCN108372453AQuick scrapeQuick functionRevolution surface grinding machinesGrinding drivesPetrochemicalHigh pressure

The invention relates to an intelligent device for machining and treating an internal wall of a petrochemical pipeline, which comprises a internal wall rotary-cleaner, wherein the internal wall rotary-cleaner can carry out a high-pressure cleaning function on the internal wall of the pipeline, partial high-pressure cleaning can be carried out according to the requirement of the internal wall of the pipeline, so the application range is wide; a cleaning angle is accurate and adjustable, the cleaning speed is high, and the cleaning efficiency is high. An internal wall rust remover is mounted atthe right side of the internal wall rotary-cleaner, the internal wall rust remover can carry out a rapid impurity scraping and rust-removing grinding function on the internal wall of the pipeline, therust-removing grinding time is short, and the rust-removing grinding effect is good. Two travelling branches are respectively welded to the left end of the internal wall rotary-cleaner and the rightend of the internal wall rust remover, and the intelligent device can travel on the internal wall of the pipeline by means of the two travelling branches. The intelligent device can continuously and stably carry out rust removal and cleaning functions on the internal wall of a petroleum pipeline, the speed of treating the internal wall of the pipeline is high, and the efficiency of treating the internal wall of the pipeline is high.

Owner:海力德工业(湛江)有限公司

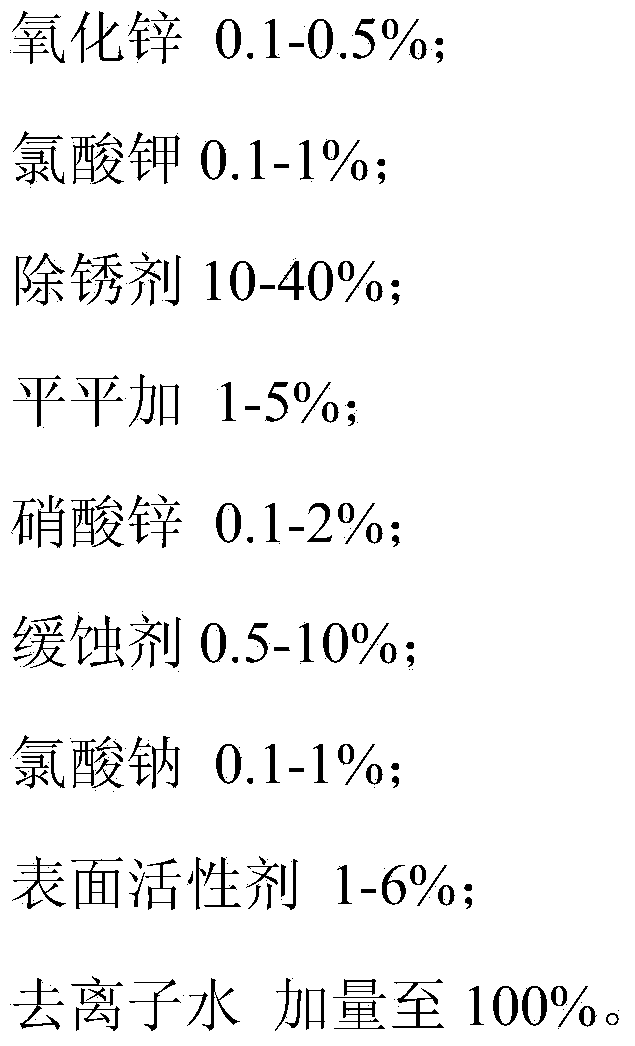

Steel surface treating agent and preparation method thereof

The invention discloses a steel surface treating agent and a preparation method thereof. The preparation method comprises the following steps: adding a rust remover, potassium chlorate, sodium chlorate, a corrosion inhibitor, a surfactant, zinc nitrate and peregal in deionized water, adding zinc oxide after mixing uniformly, and mixing uniformly again for standby application, wherein the raw materials in the steps in percentage by weight are as follows: 0.1-0.5% of zinc oxide, 0.1-1% of potassium chlorate, 10-40% of a rust remover, 1-5% of peregal, 0.1-2% of zinc nitrate, 0.5-10% of a corrosion inhibitor, 0.1-1% of sodium chlorate and 1-6% of a surfactant; the deionized water is added to 100%. The steel surface treating agent integrates the functions of oil removal, rust removal, oxide layer removal and phosphorization, is particularly suitable for the metals obtained after hot rolling process, and is simple in treating process, low in labor intensity, low in treating cost, remarkable in rust removal effect, long in holding time and pollution-free to environment.

Owner:李莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com