Surface processing device with rust remover convenient to completely remove rust for drill stem

A surface treatment device and a thorough cleaning technology, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of low efficiency and high cost of iron filings on the outer wall of drill pipes, and meet the sealing requirements , easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

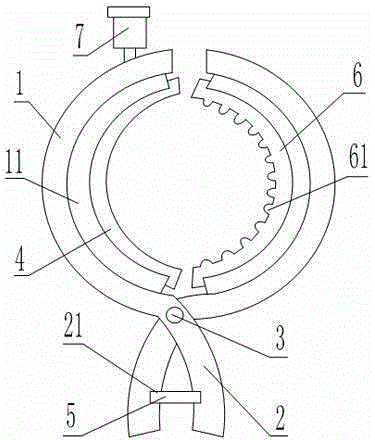

[0018] Such as figure 1 As shown, the surface treatment device for drill pipes with a rust remover is convenient for completely removing rust, including a cylinder that matches the outer wall of the drill pipe. The cylinder is composed of two semi-arc-shaped clamping blocks 1 that cooperate with each other. The end is provided with a movable plate 2 that cooperates with each other. The movable plate 2 is an arc-shaped plate that bends inward. The opposite side of the movable plate 2 is provided with a through groove 21. A clamping plate 5 is arranged between the two through grooves 21. The ends of the holding block 1 are connected by the rotating shaft 3, the inner side of the holding block 1 is provided with fixed pieces 11 at both ends in the axial direction, and the opposite side of the two fixed pieces 11 on the same holding block 1 is provided with concave holes. Groove, the scouring pad 4 is fixed on the inside of one clamping block 1 through the cooperation of protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com