Patents

Literature

2763results about How to "No leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D printing cement-based material and preparation method thereof

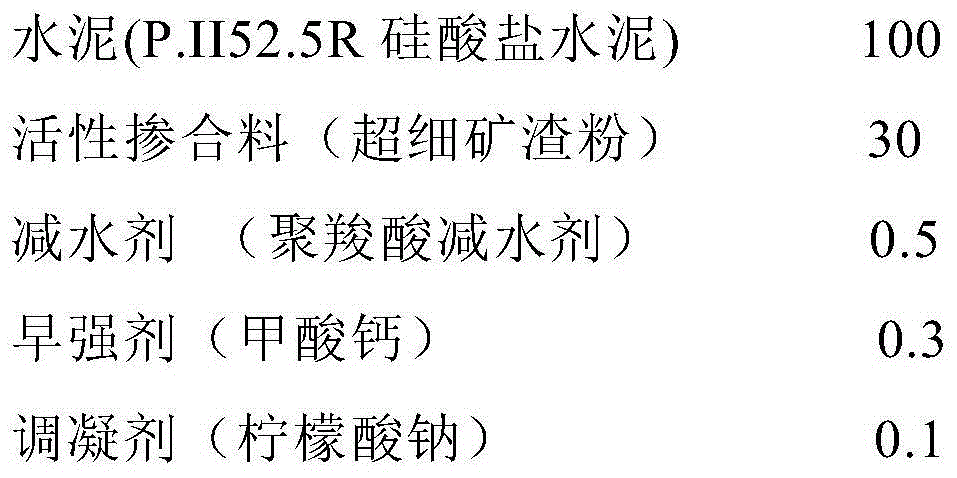

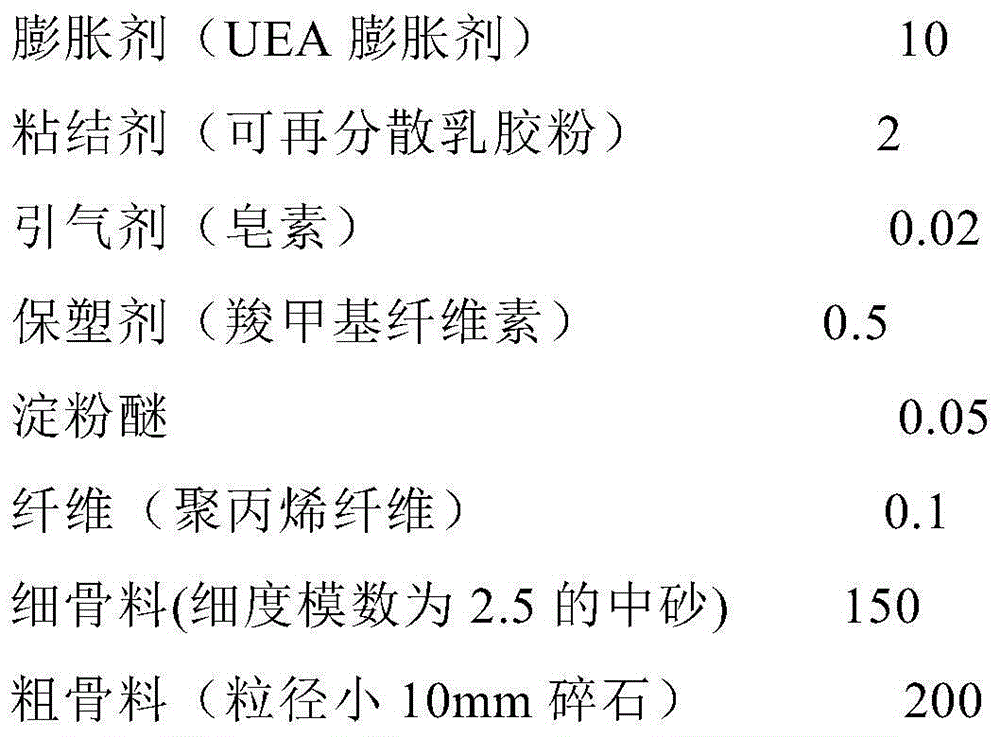

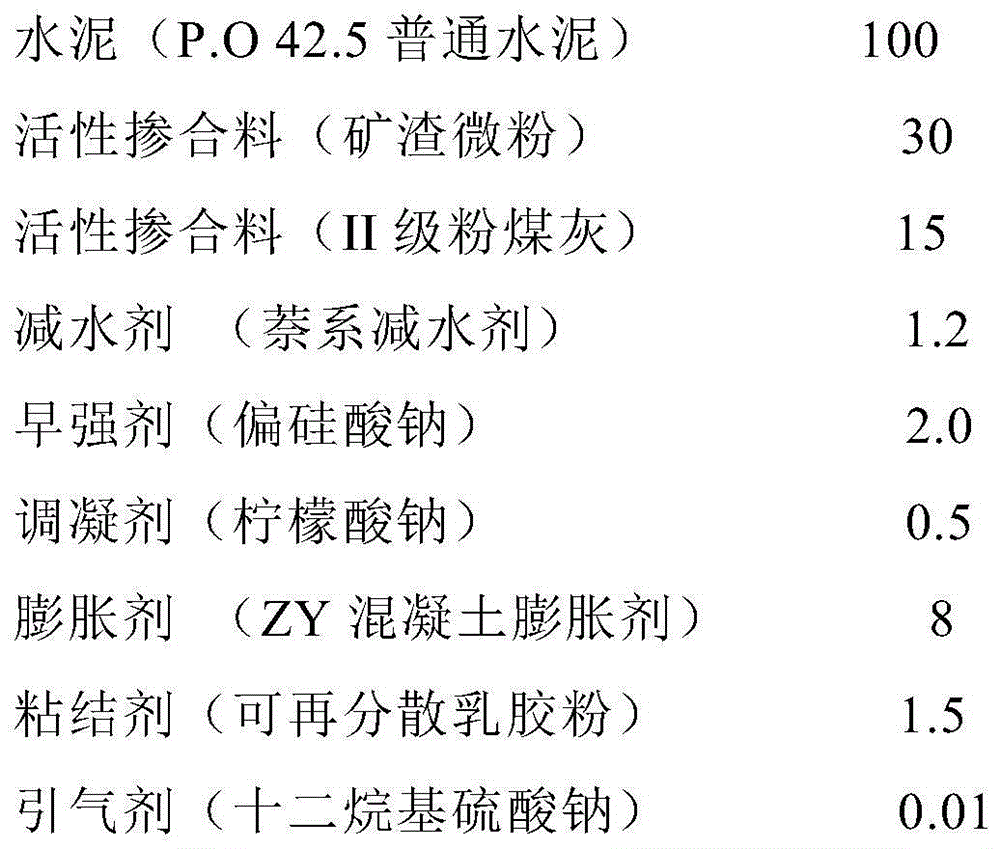

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

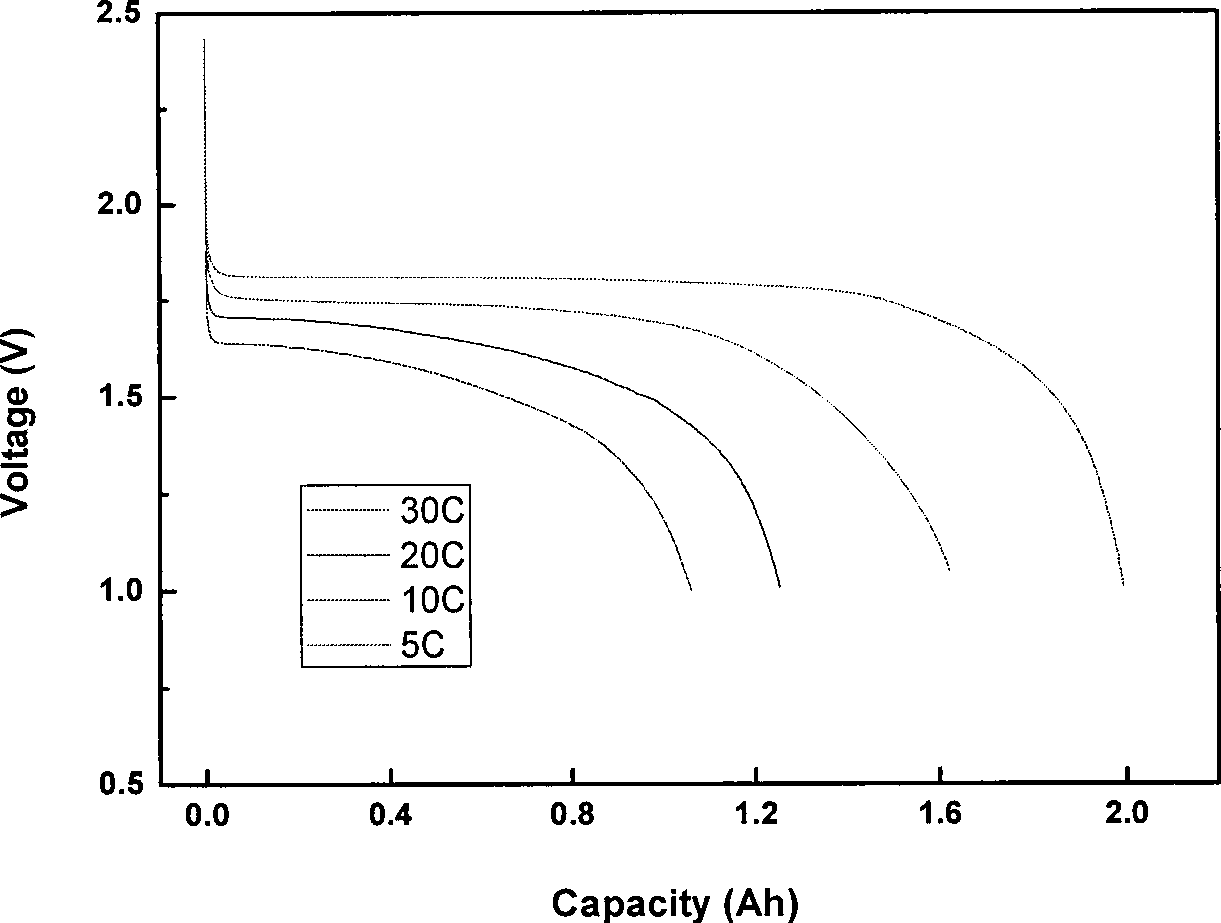

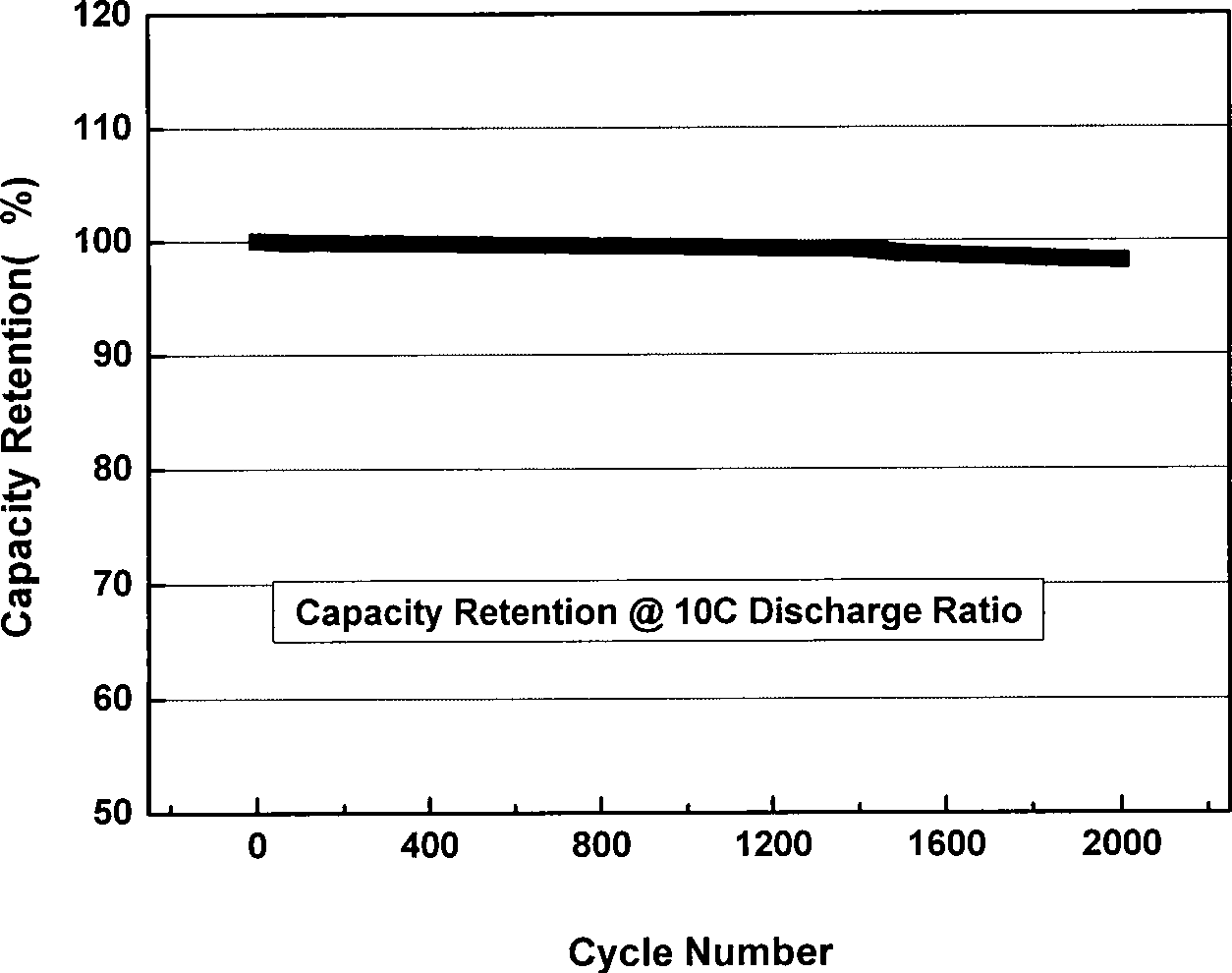

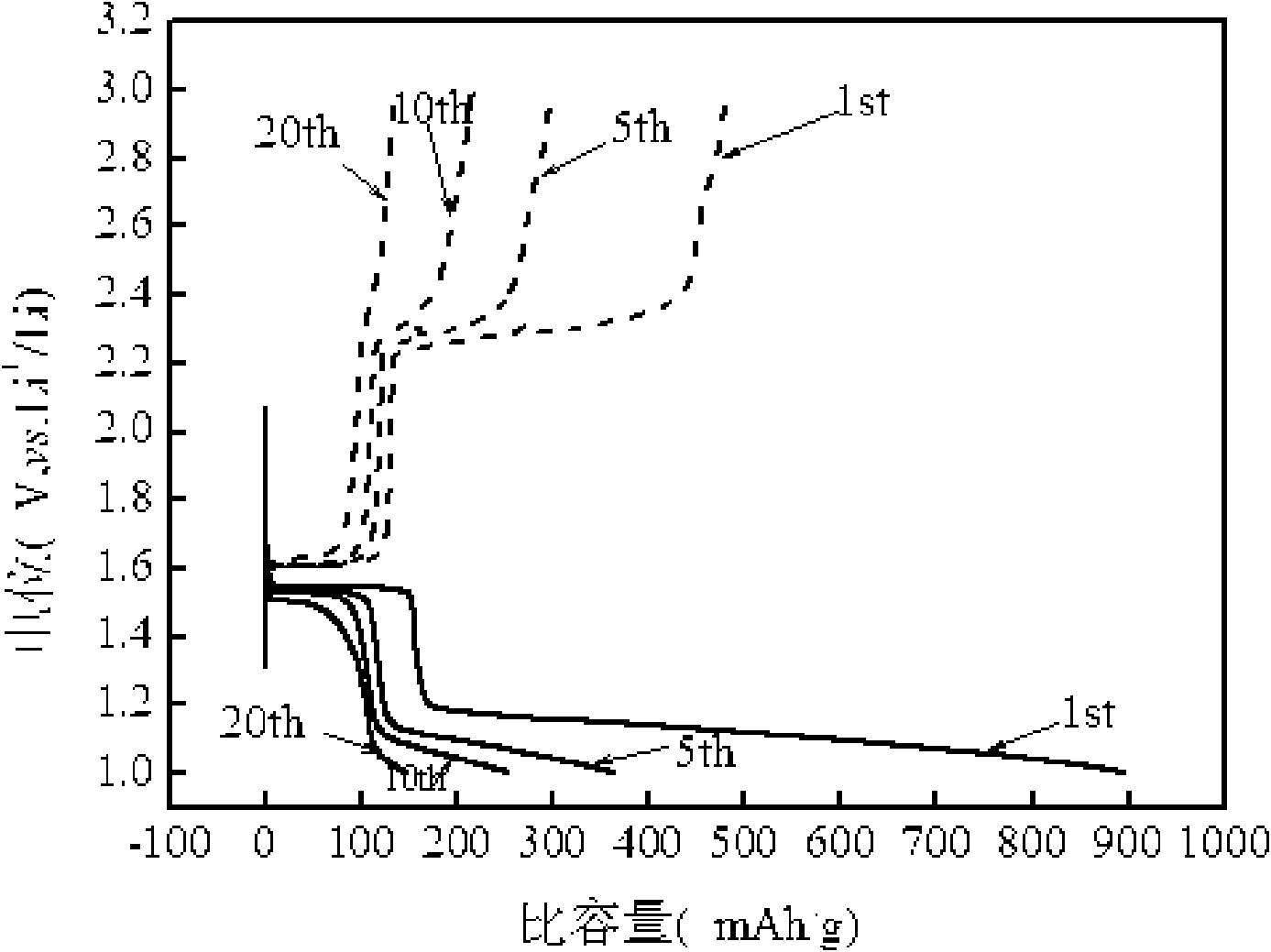

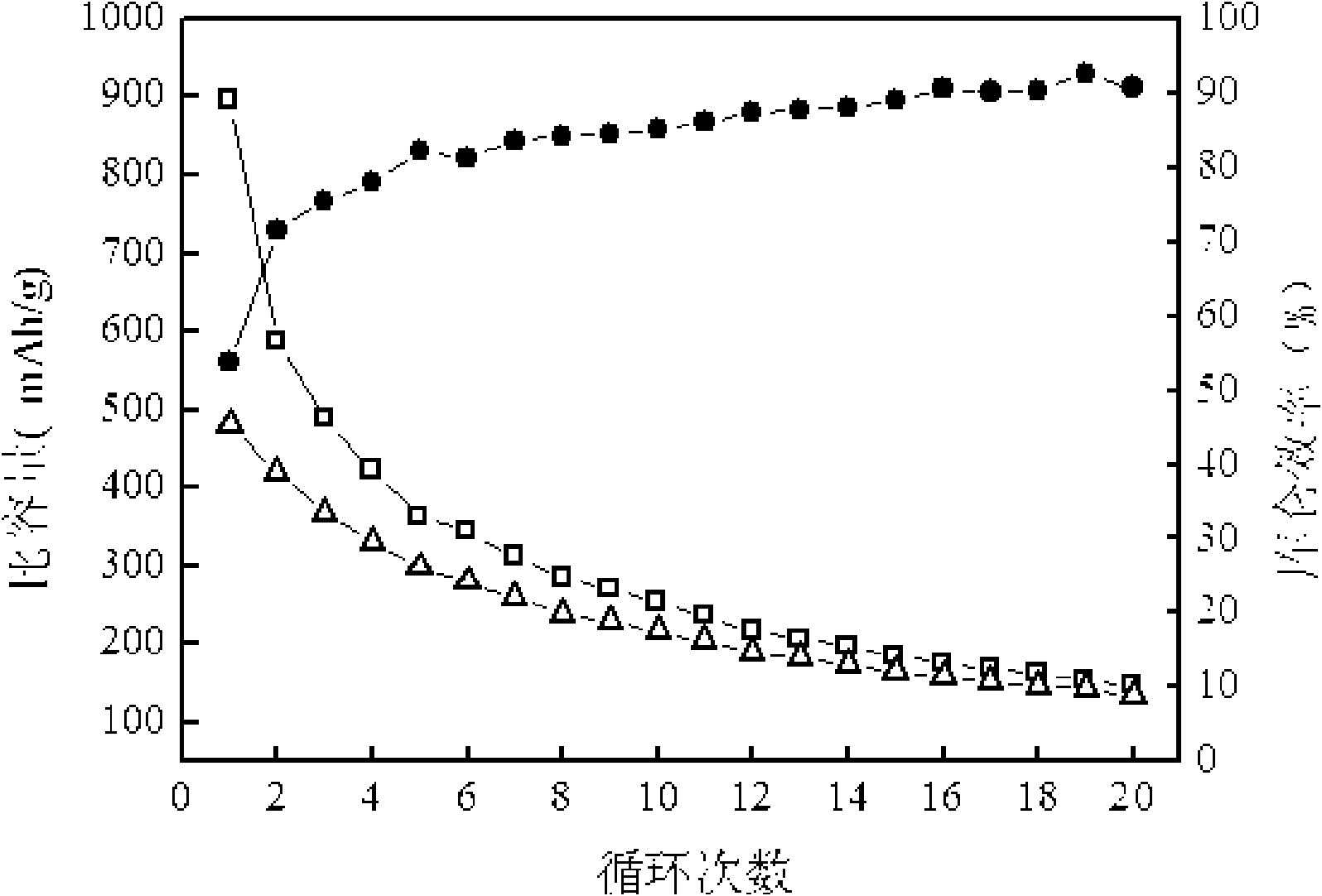

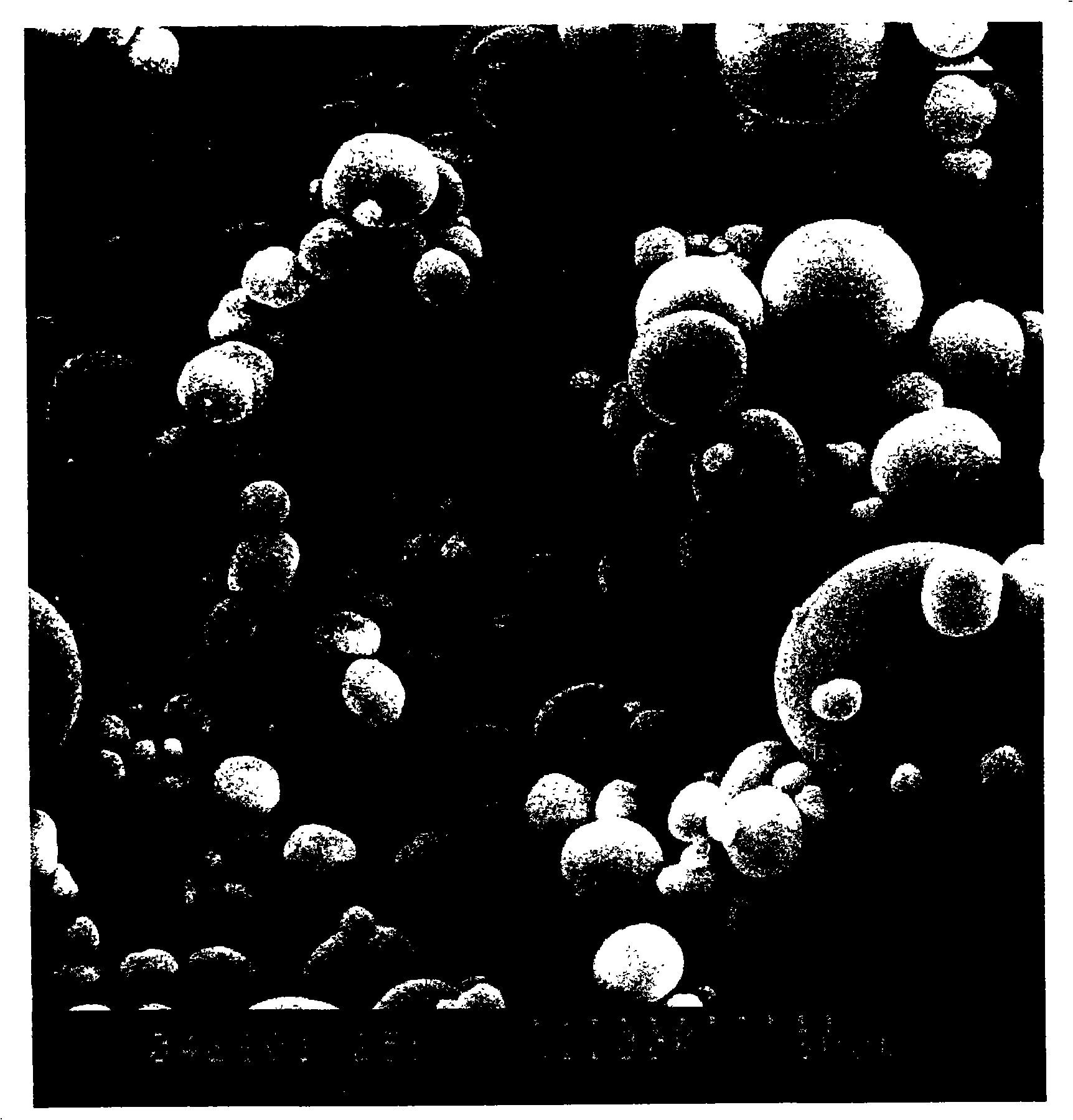

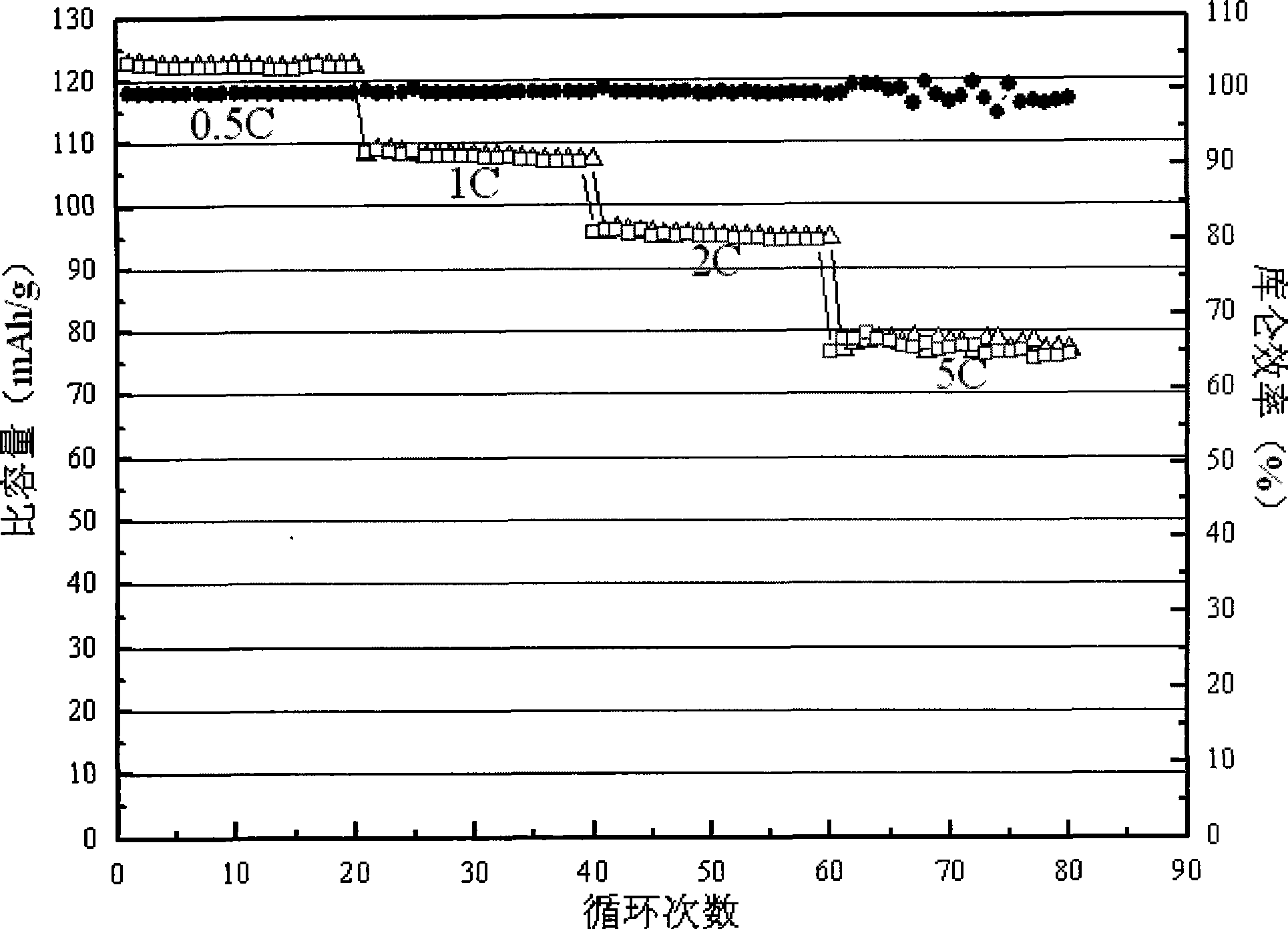

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

ActiveCN101373829AIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

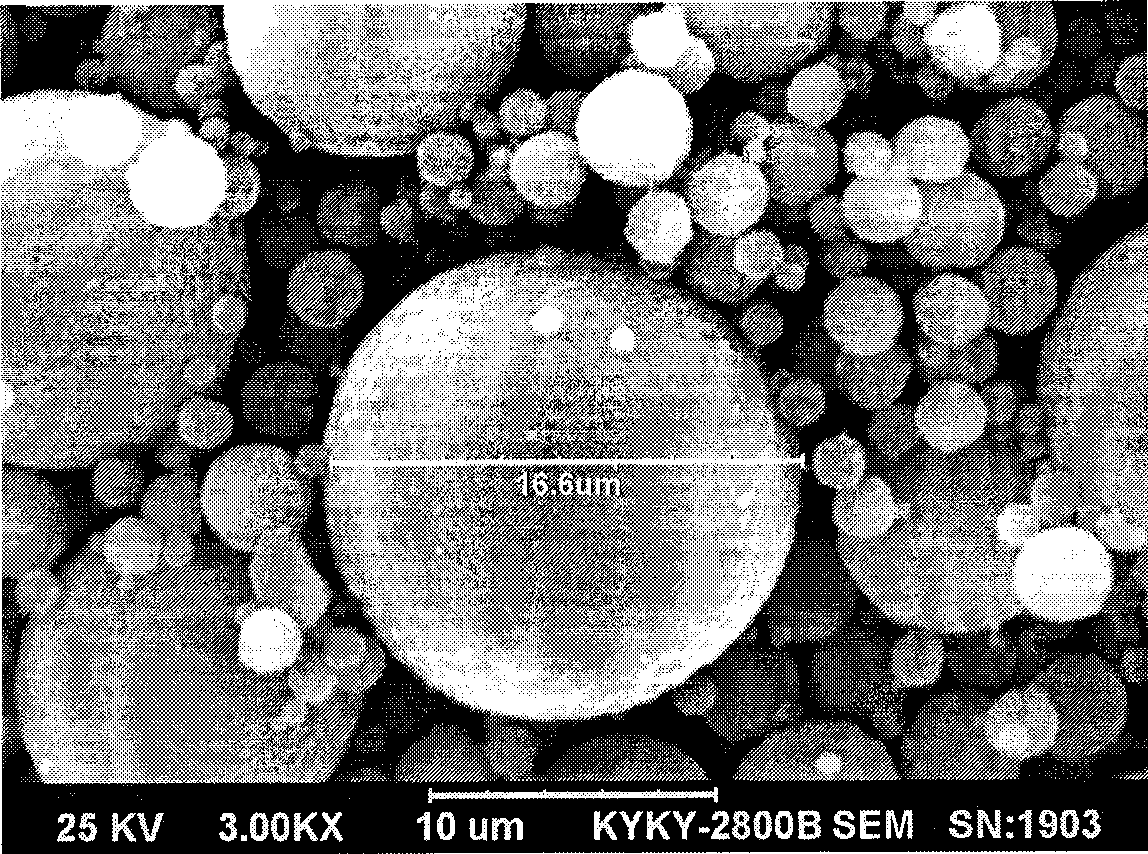

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, and aims to solve the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

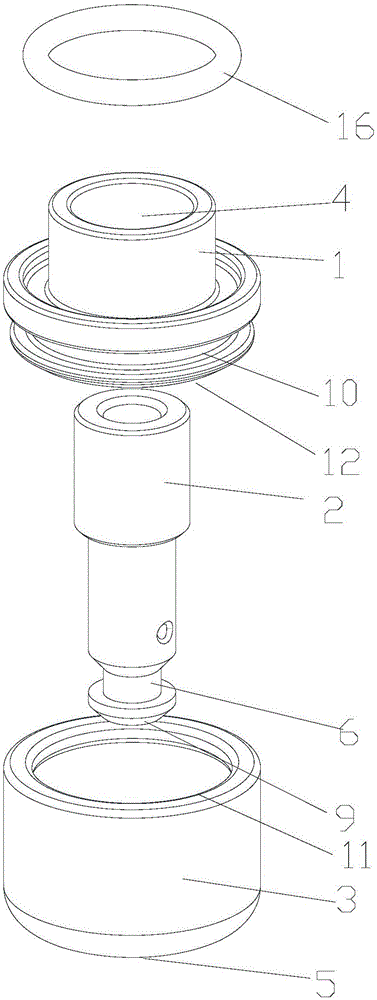

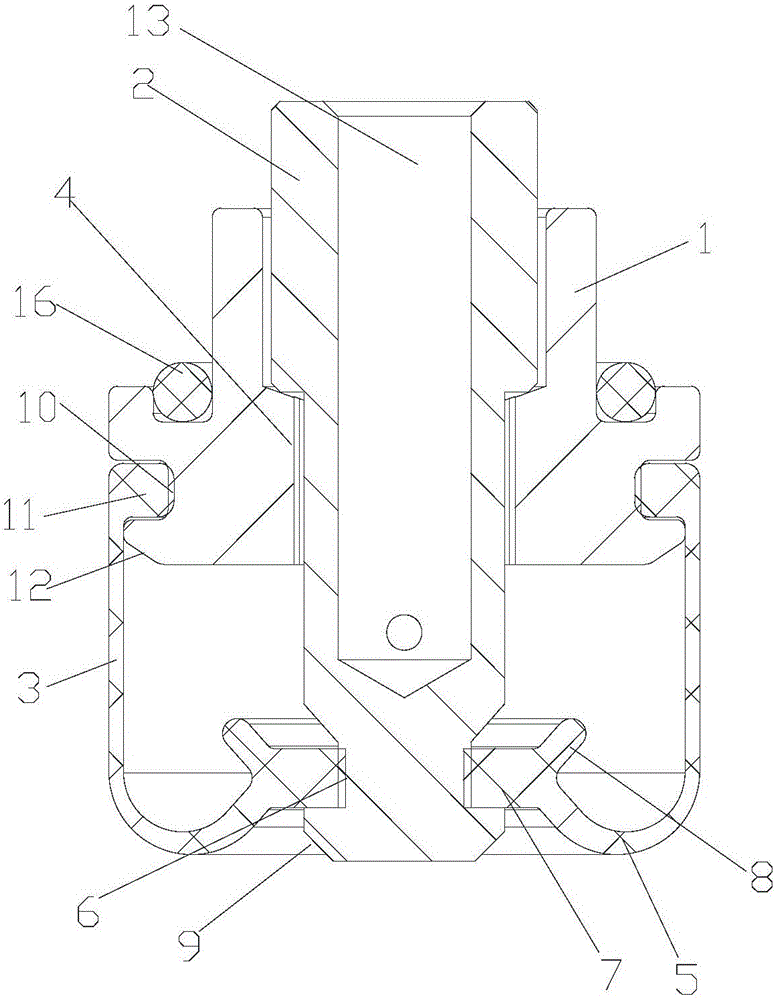

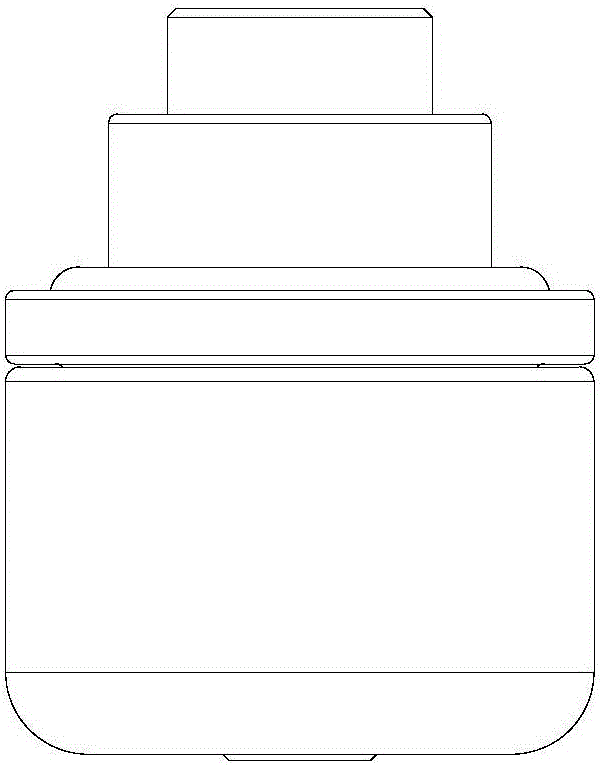

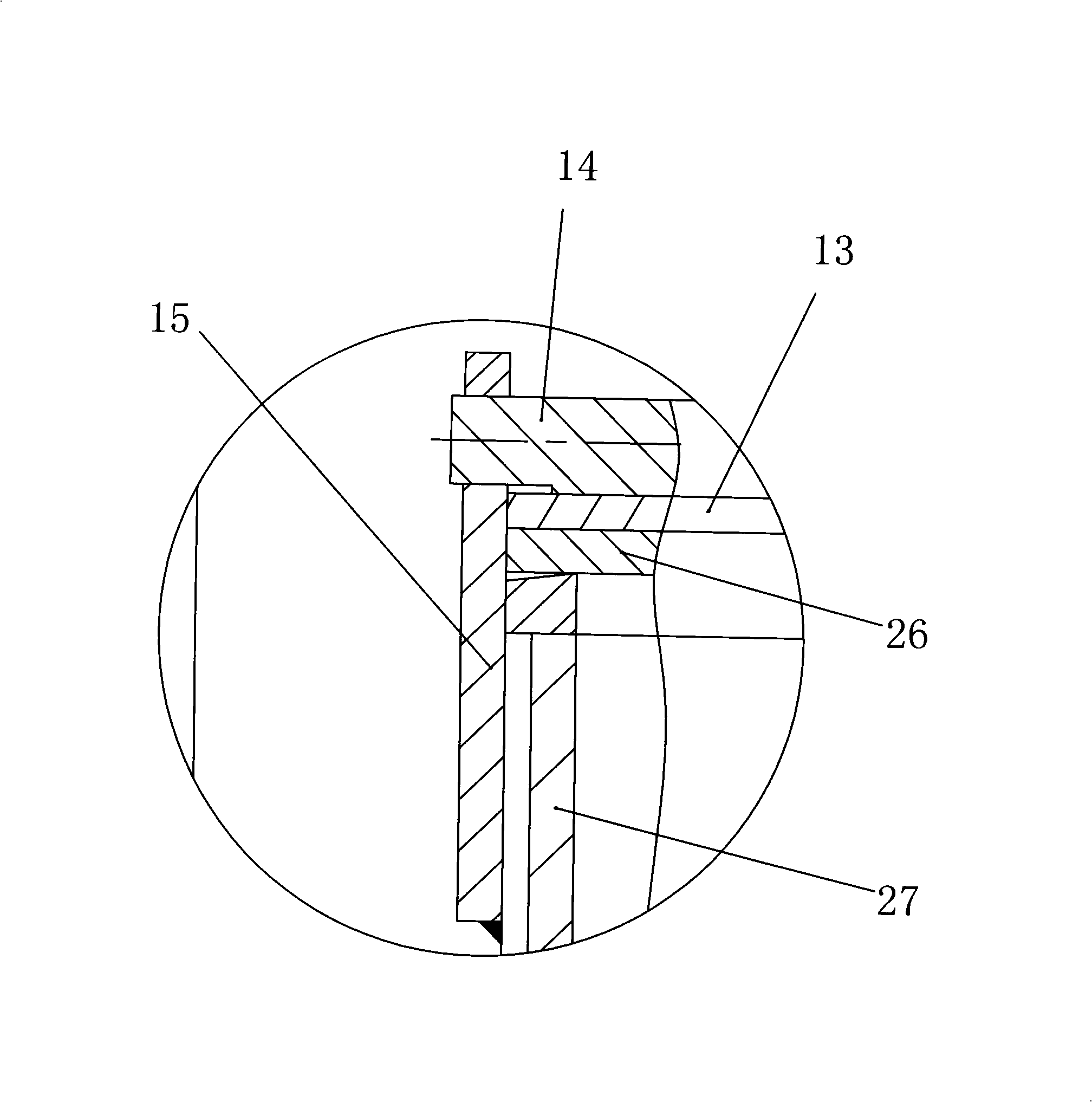

Floater valve, pot cover and pressure cooker

InactiveCN106166030ANo leakageNo problems with leaking inside the lidPressure-cookersCookerEngineering

The invention provides a float valve, a pot cover and a pressure cooker. The float valve includes a valve seat (1), a float (2) and a sealing connection part (3), the valve seat (1) is provided with a guide hole (4), and the float (2) is slidably arranged in the guide hole (4), The sealing connection part (3) is arranged on the outer side of the valve seat (1), and the sealing connection part (3) includes a movable part (5) forming a movable space with the bottom of the valve seat (1), and one end of the float (2) stops Blocking the valve seat (1), the other end is sealed and fixedly connected with the movable part (5) of the sealing connection part (3), and the movable part (5) moves together with the float (2). According to the float valve of the present invention, the problems in the prior art that the electric pressure cooker is used for a long time will cause mildew and odor inside the pot cover, and even cause the pot cover to deform.

Owner:GREE ELECTRIC APPLIANCES INC

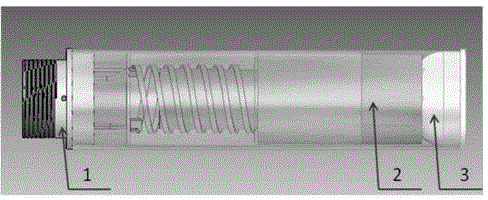

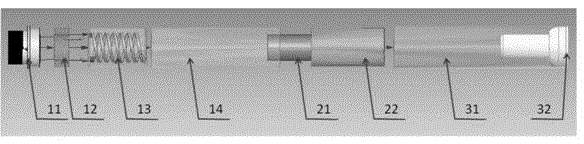

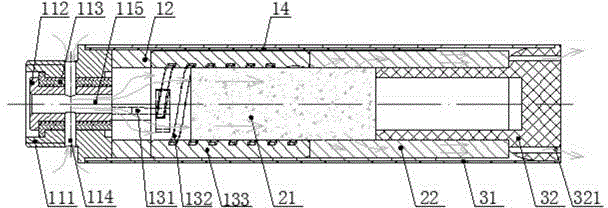

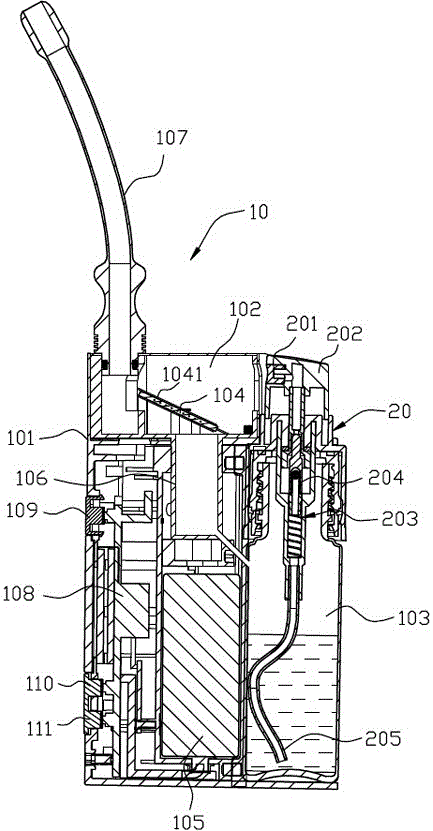

Low-temperature heating type electronic cigarette heater

A low-temperature heating type electronic cigarette heater comprises a heater component, a composite cigarette core and a cigarette holder portion. The composite cigarette core is consumable and cannot be reused, and the other portions are reusable; the composite cigarette core is composed of a core body and a filtering core in a combined manner and fills the heater component, the core body adopts natural plant fibers as the base material and is provided with tobacco aroma substances in an absorbed manner and tea polyphenol microcapsules, and the filtering core is tobacco paper filtering core compounded with bamboo fibers and is prevented from being carbonized during heating; a cigarette holder is connected to the heater component in a sleeved manner; the heater component comprises a connecting component, a supporting seat, a ceramic heating ring and a heat insulating sleeve. The composite cigarette core contacts with the ceramic heating ring in a cylindrical surface manner, the heating area is large, three ways, namely conduction, convection and radiation, of heat transfer during heating are provided, and the heating efficiency is high; the cigarette core releases contained tobacco ingredients through low-temperature heating, the taste is similar to that of a traditional cigarette, and toxics produced in the burning process can be avoided.

Owner:POWERTHINK (BEIJING) TECH CO LTD +2

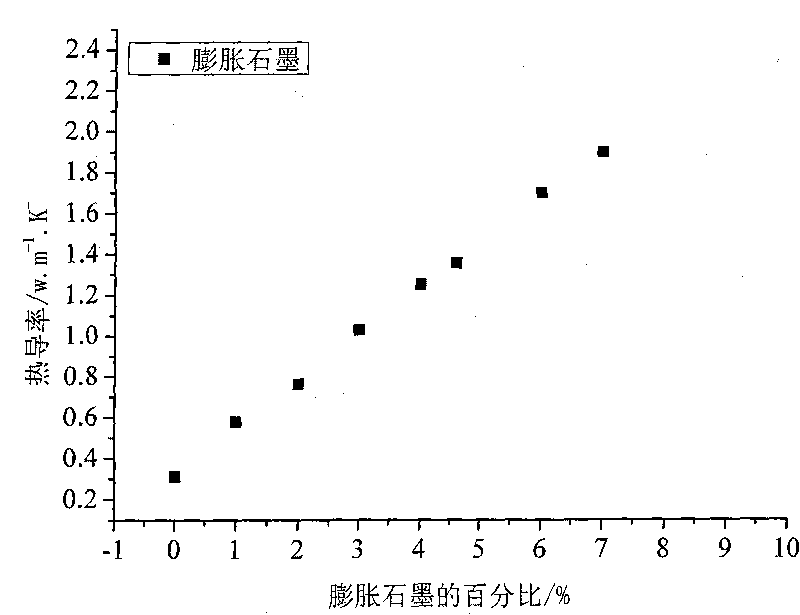

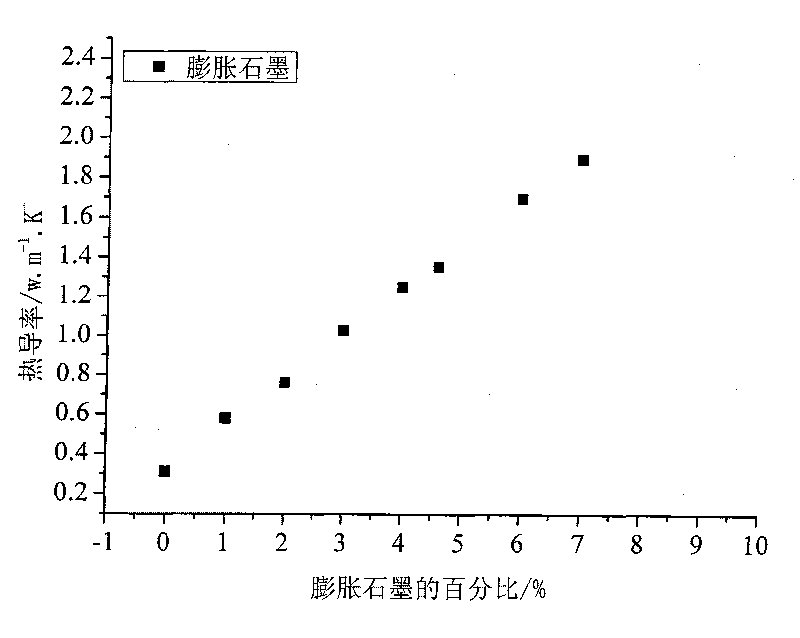

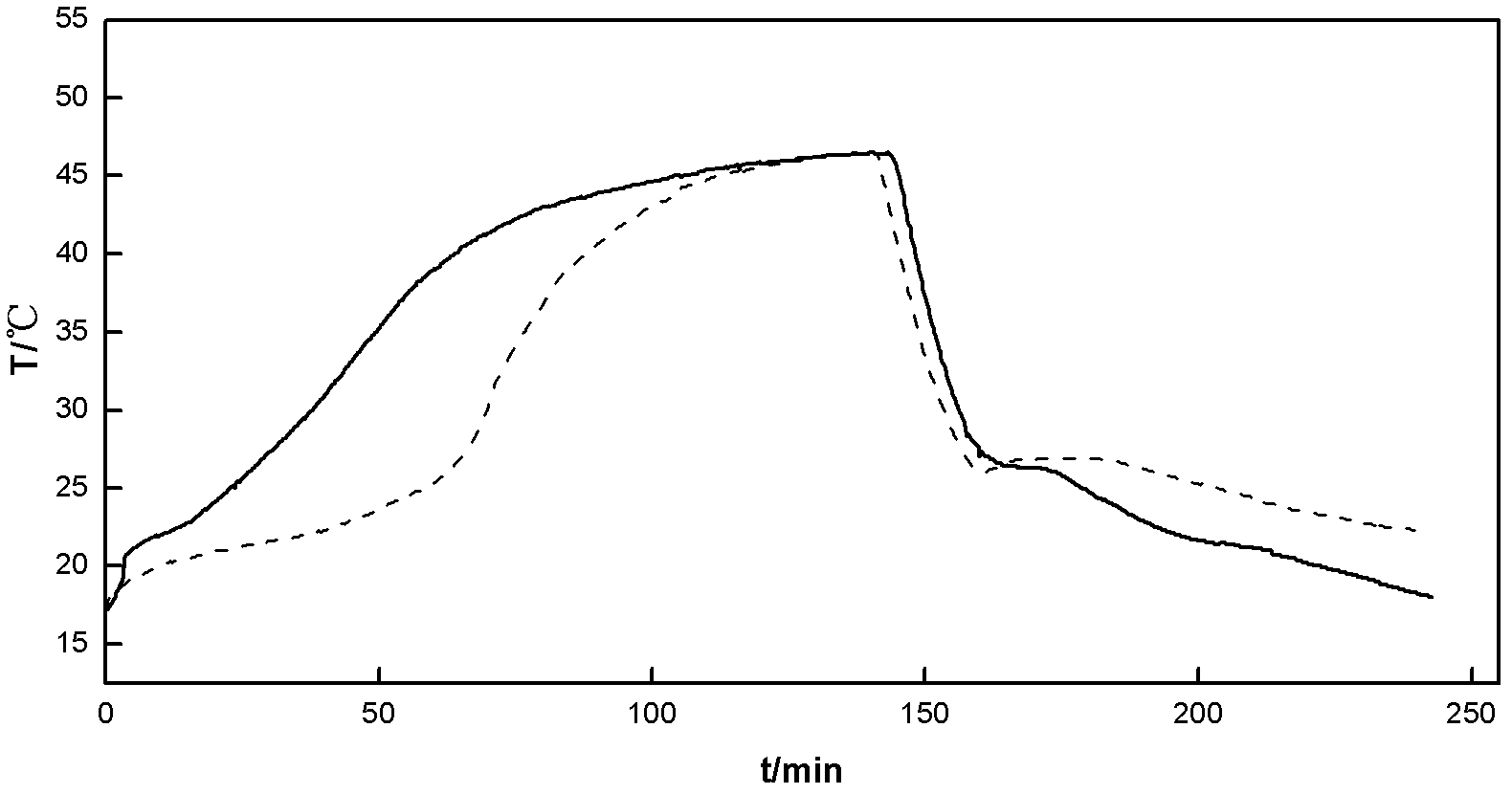

Setting phase change energy storage material with high-thermal conductivity and preparation method thereof

InactiveCN101724381AImprove thermal conductivityImprove heat transfer characteristicsHeat-exchange elementsMolten stateMaterials science

The invention relates to a setting phase change energy storage material with high-thermal conductivity and a preparation method thereof, belonging to the field of phase change heat storage materials. The setting phase change energy storage material with high-thermal conductivity is characterized by containing 65-90 percent by mass of paraffin substances as a phase-change material, 9-34 percent by mass of high-density polyethylene as a support material and 1-7 percent by mass of expanded graphite as a heat conduction intensifier; a method for adding a proper amount of expanded graphite to paraffin / high-density polyethylene in a molten state is adopted to enable the heat conductivity of the setting phase change material to be increased to 1.35W / (m.K) or higher. The method comprises the following steps of: heating to melt the paraffin substances with the mass percent of 65-90 percent, and heating to enable the temperature of the liquid paraffin to reach 120-190 DEG C; adding high-density polyethylene with the mass percent of 9-34 percent and the expanded graphite with the mass percent of 1-7 percent to the liquid paraffin, and then melting and evenly stirring in vacuum; putting the mixture in a hot mould for pressing and molding; taking the mixture from the mould after naturally cooling. The setting phase change material has high thermal conductivity, does not need to be packaged in containers and can directly contact heat-transfer media.

Owner:UNIV OF SCI & TECH OF CHINA

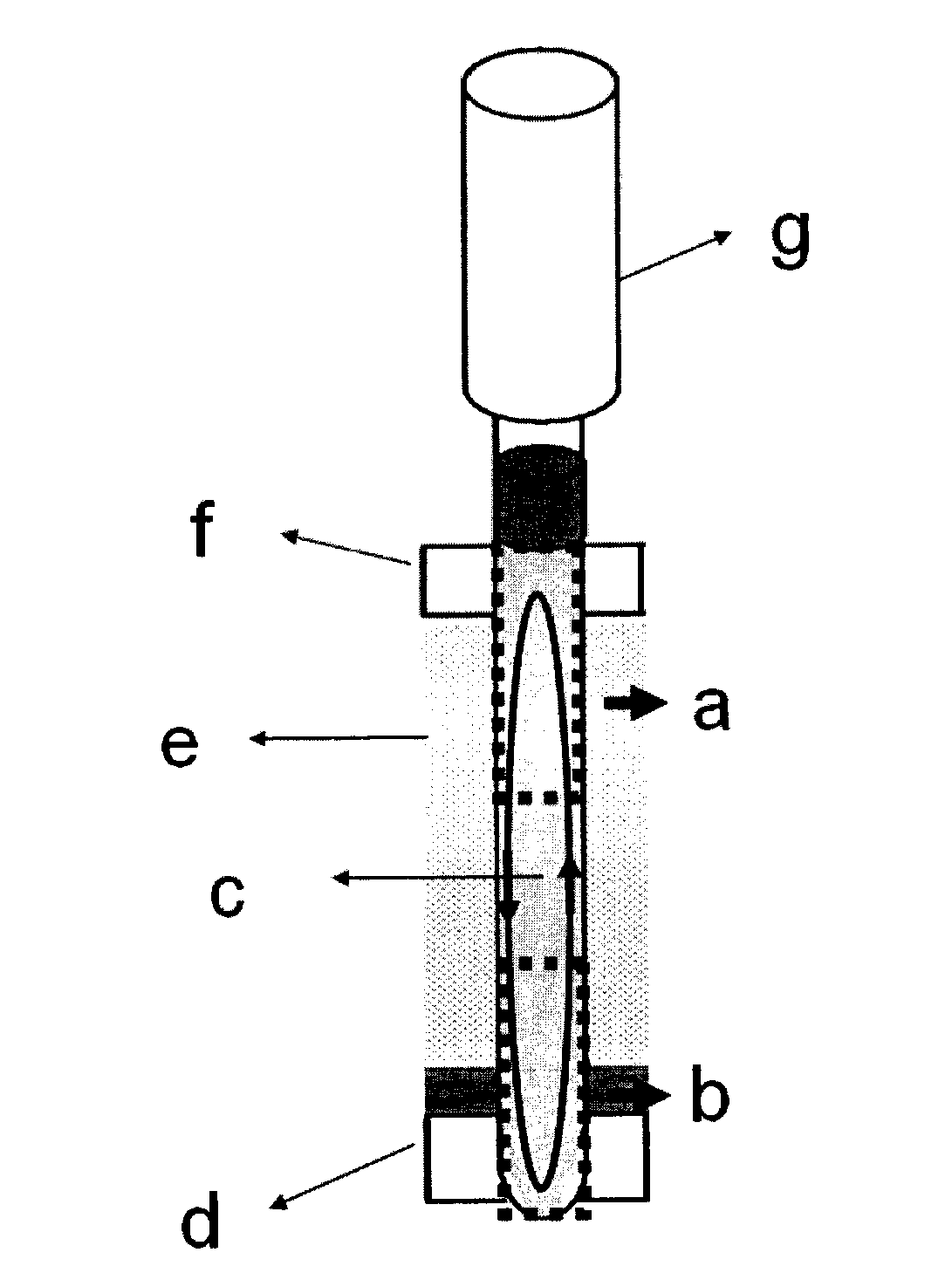

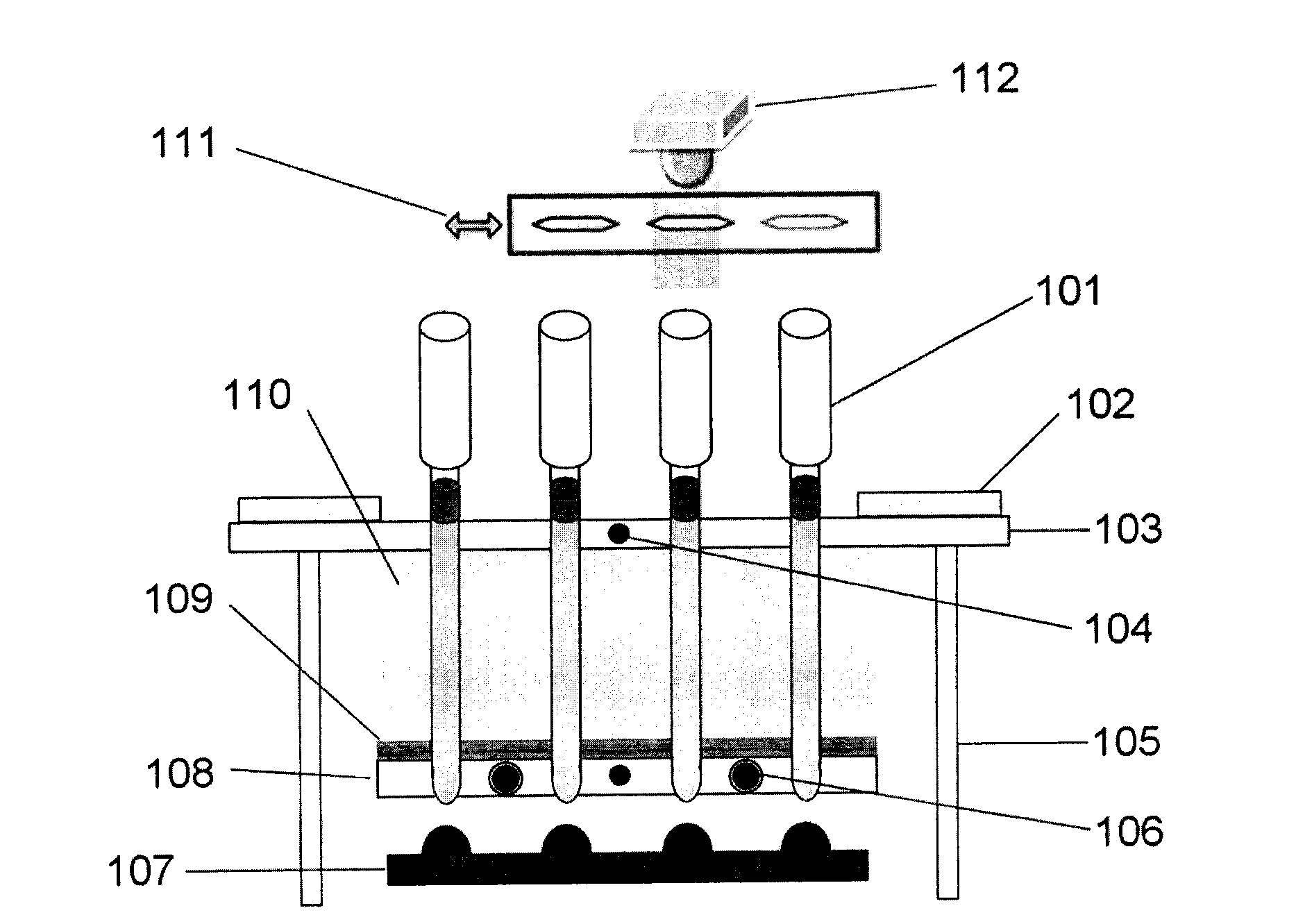

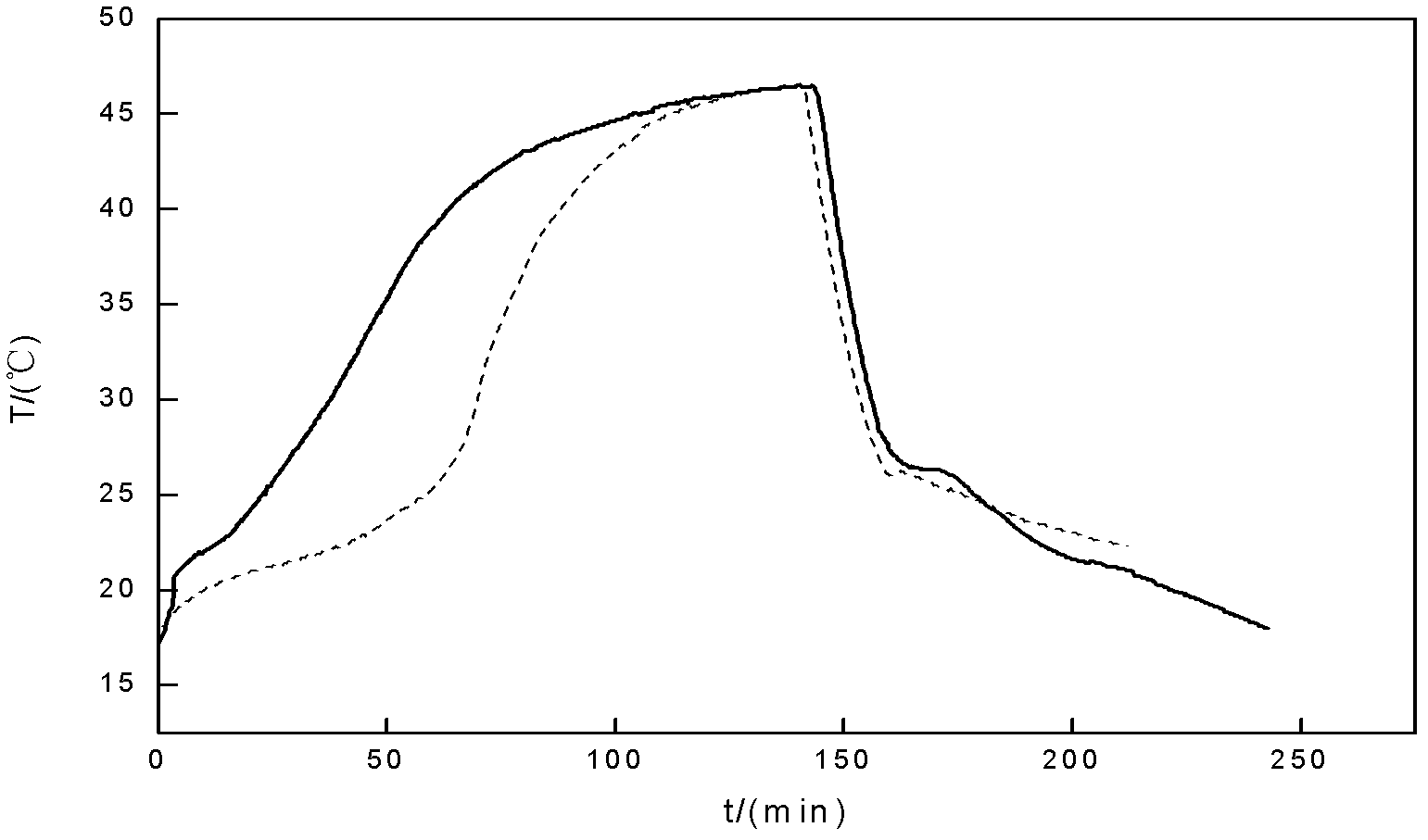

Method and device for carrying out polymerase chain reaction under constant-temperature heat source

InactiveCN103173434ASimple preparation processLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescencePhysical chemistry

The invention provides a method and device for carrying out polymerase chain reaction under a constant-temperature heat source, and specifically relates to a method for providing heat to or taking away heat from a specific area of a reaction test tube based on a Rayleigh-Benard theory to build a temperature gradient from bottom to top of reagents in the reaction tube, spontaneously carrying out convection under the condition that the reaction reagents are unevenly heated, and carrying out corresponding PCR (Polymerase Chain Reaction) amplification when the reaction reagents flow through different temperature areas. The invention also discloses a device for carrying out the reaction of the method and in-time fluorescence detection.

Owner:XIAMEN INNOVAX BIOTECH +1

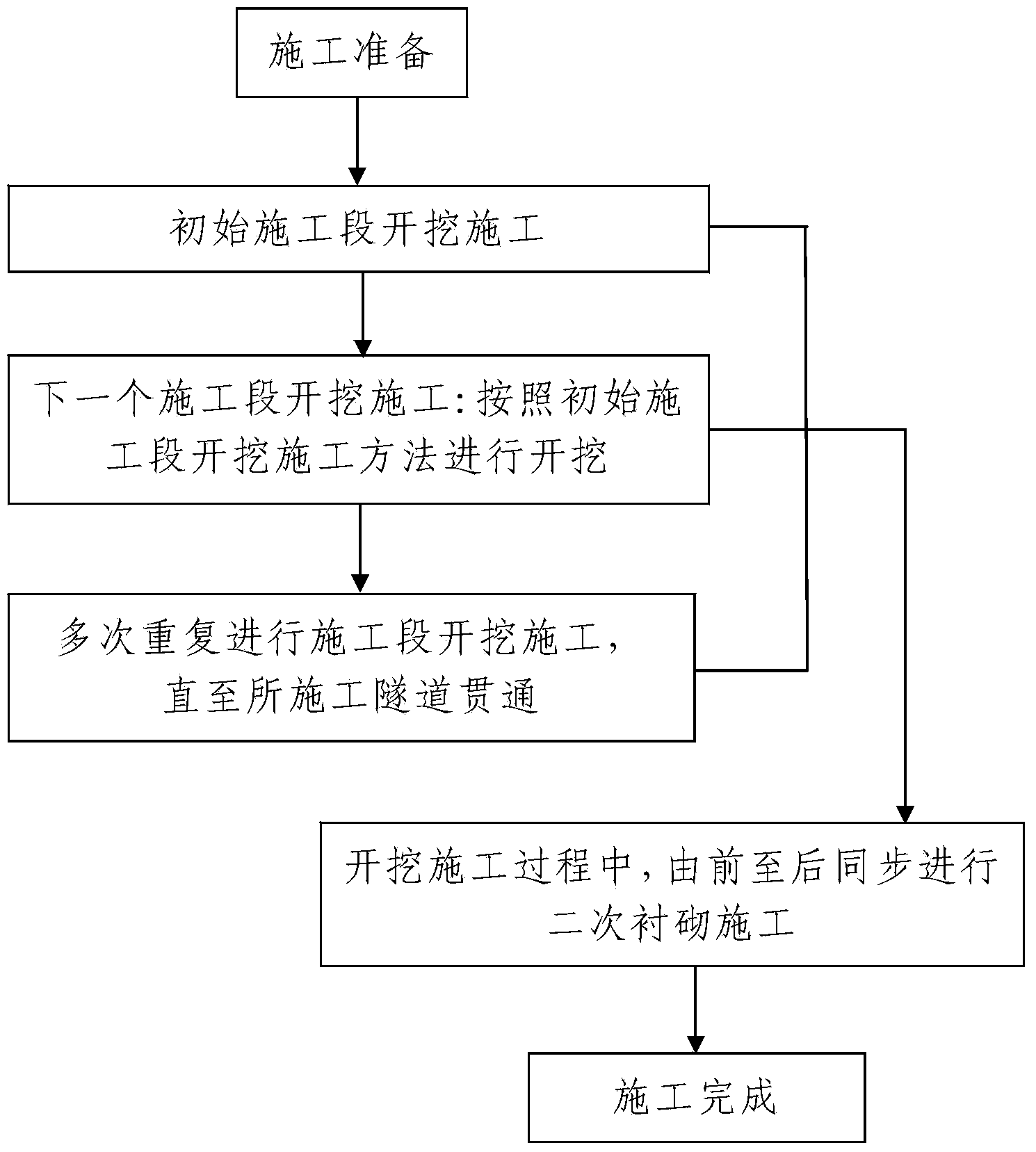

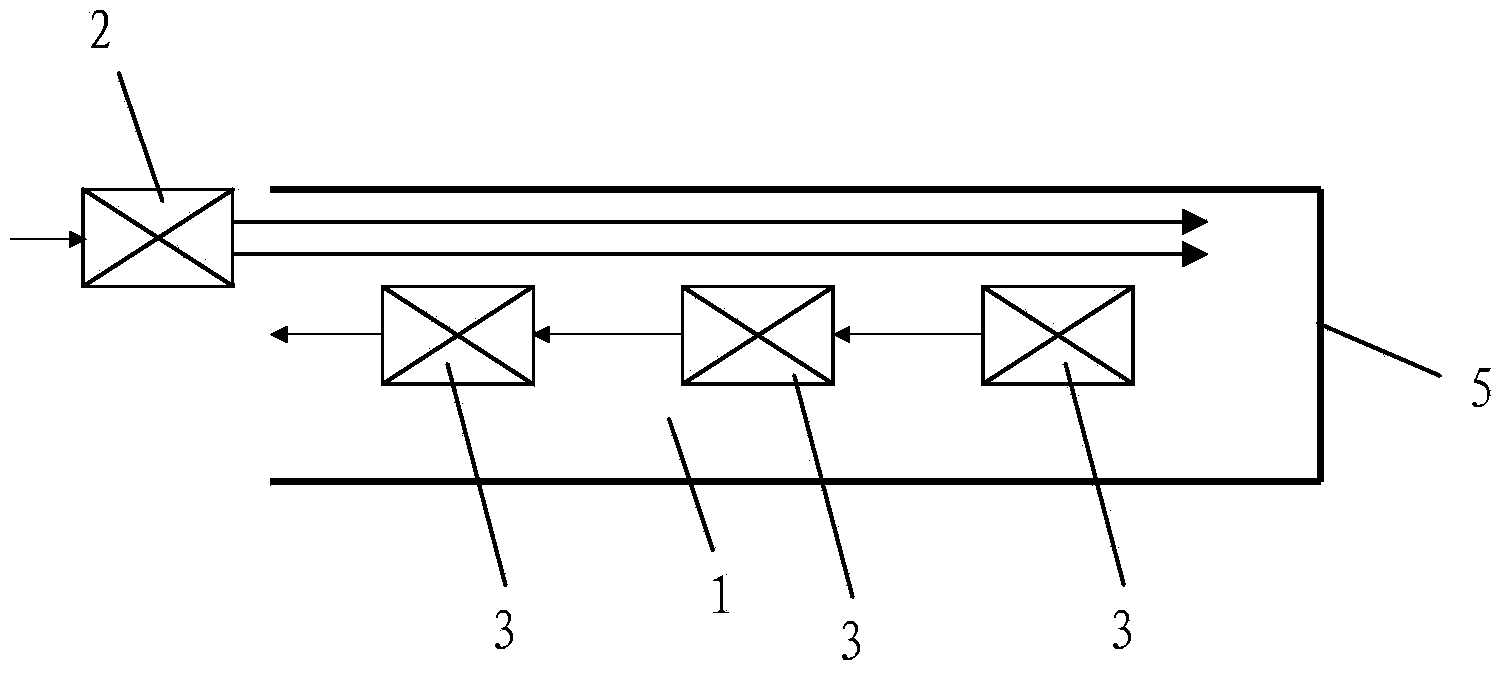

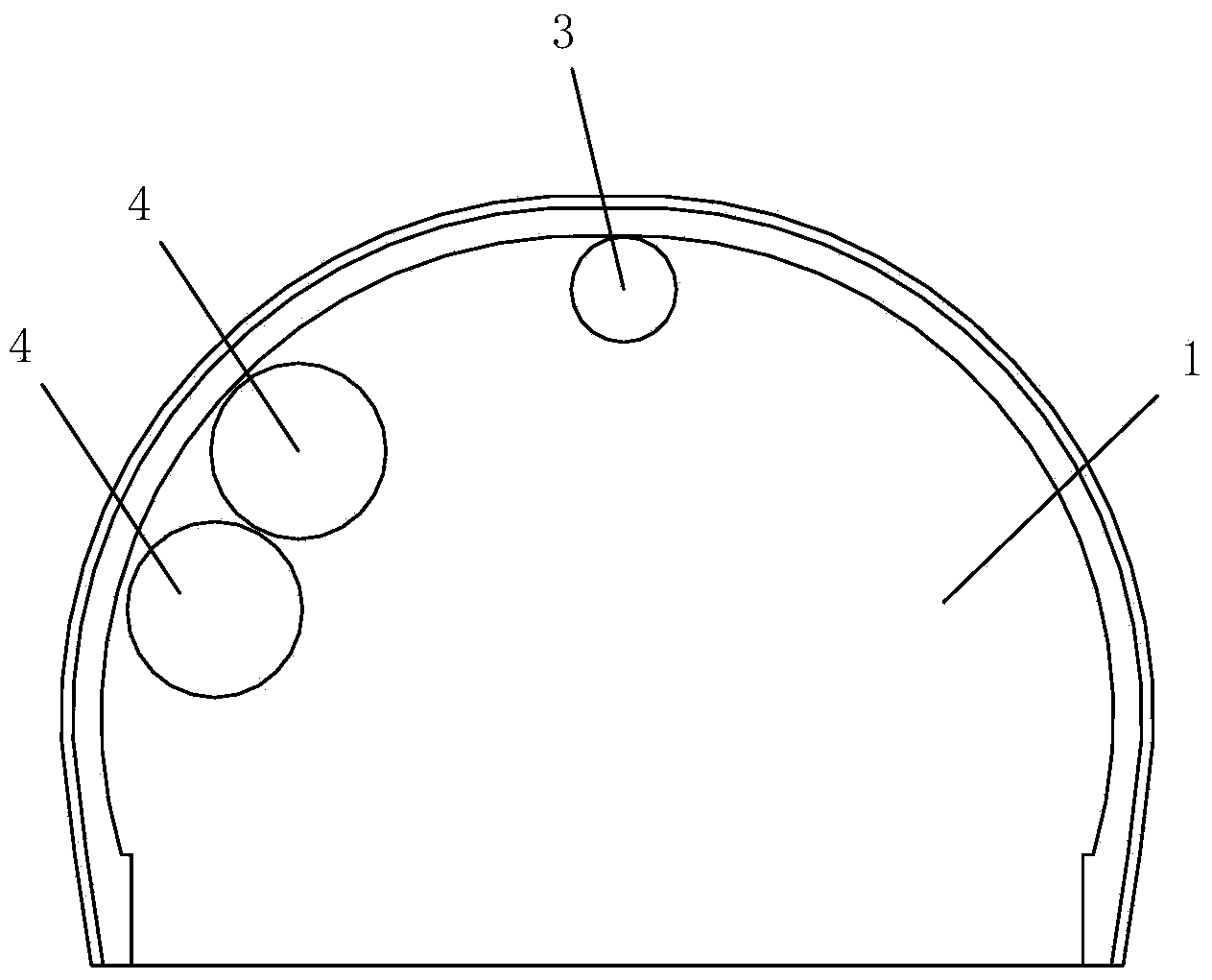

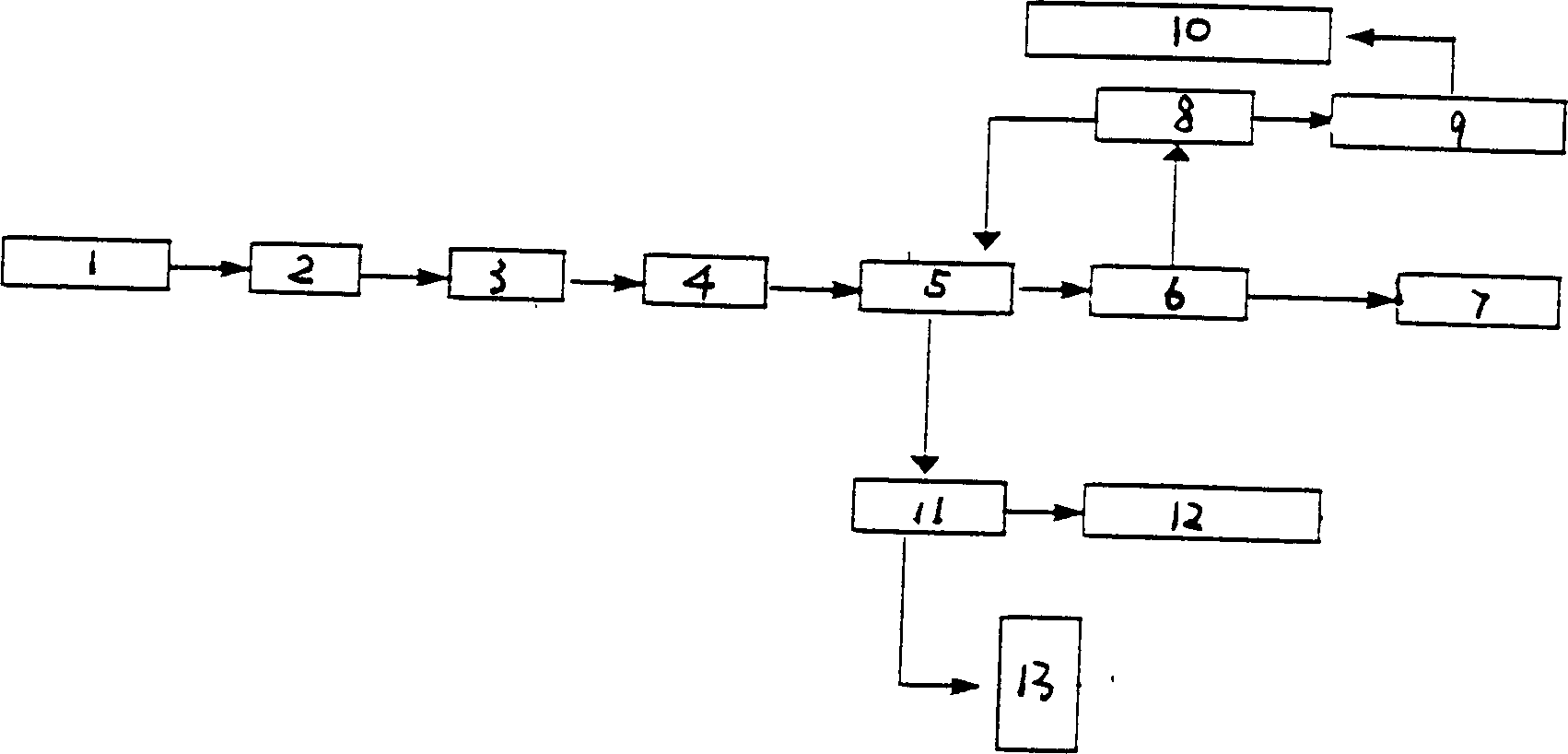

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

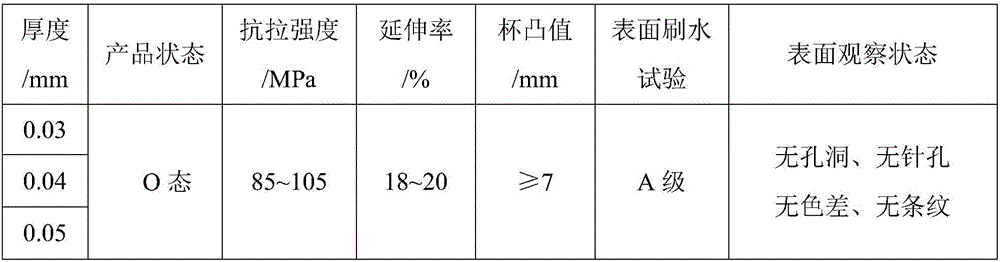

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

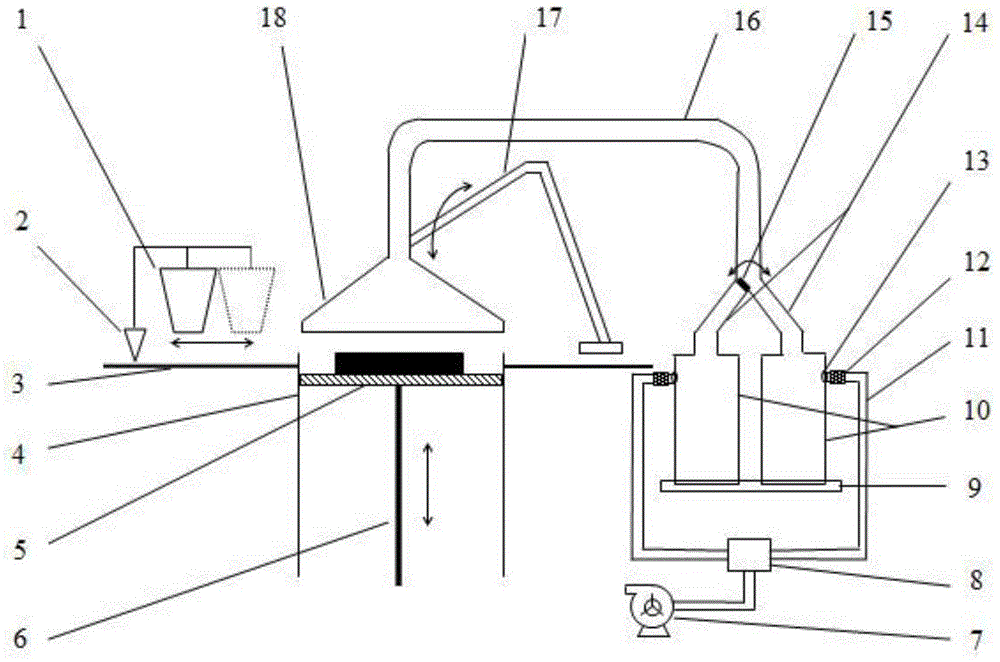

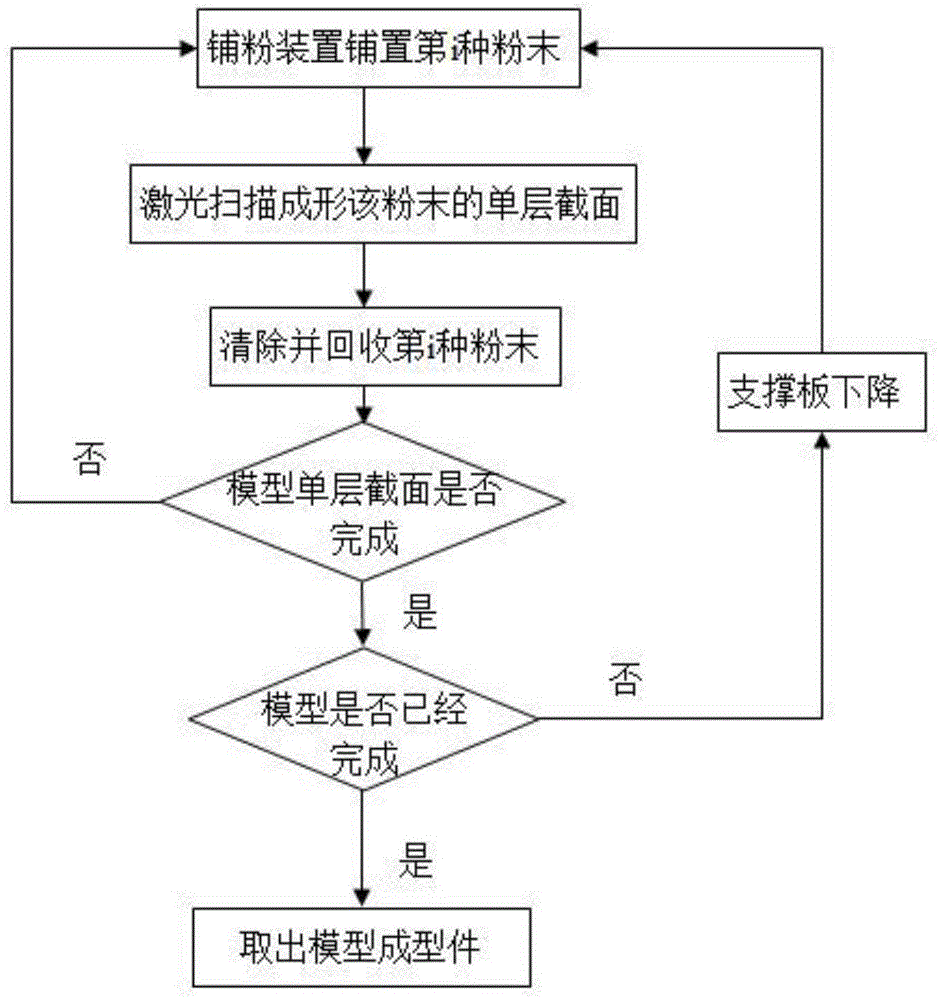

Powder laying and recovering device for selective laser melting of heterogeneous material

The invention relates to a powder laying and recovering device for selective laser melting of a heterogeneous material. The powder laying and recovering device comprises a powder laying device and a powder recovering device; a scrapper plate and a plurality of powder laying grooves are arranged on the powder laying device, wherein the scrapper plate can move in a reciprocating way along a horizontal fixed guide rail; the powder recovering device is provided with an absorbing cover; the absorbing cover can move above a molding cylinder to absorb and move away from an area above the molding cylinder to avoid interference on laser melting molding; a powder recovering pipeline is connected to the upper end of the absorbing cover; un-solidified powder can be absorbed and recovered into a specified recovery box through the control of an opening-closing baffle plate. According to the powder laying and recovering device for selective laser melting of the heterogeneous material, one material is solidified and un-solidified powder is completely removed, then another material is laid to be solidified and absorbed until the whole section of this layer is molded; materials are respectively solidified and absorbed by layers and continuously accumulated and overlapped to form a heterogeneous part. The powder laying and recovering device is applicable to selective laser melting molding of the heterogeneous part; the molding parts of a model can be combined at random.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

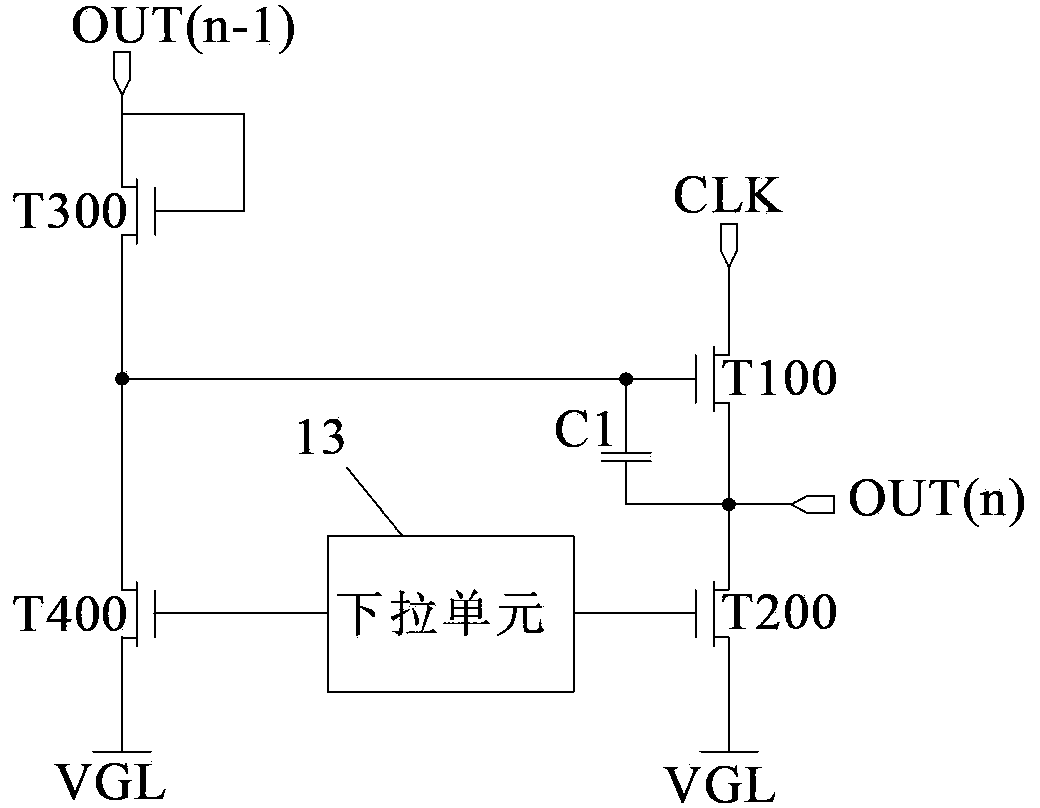

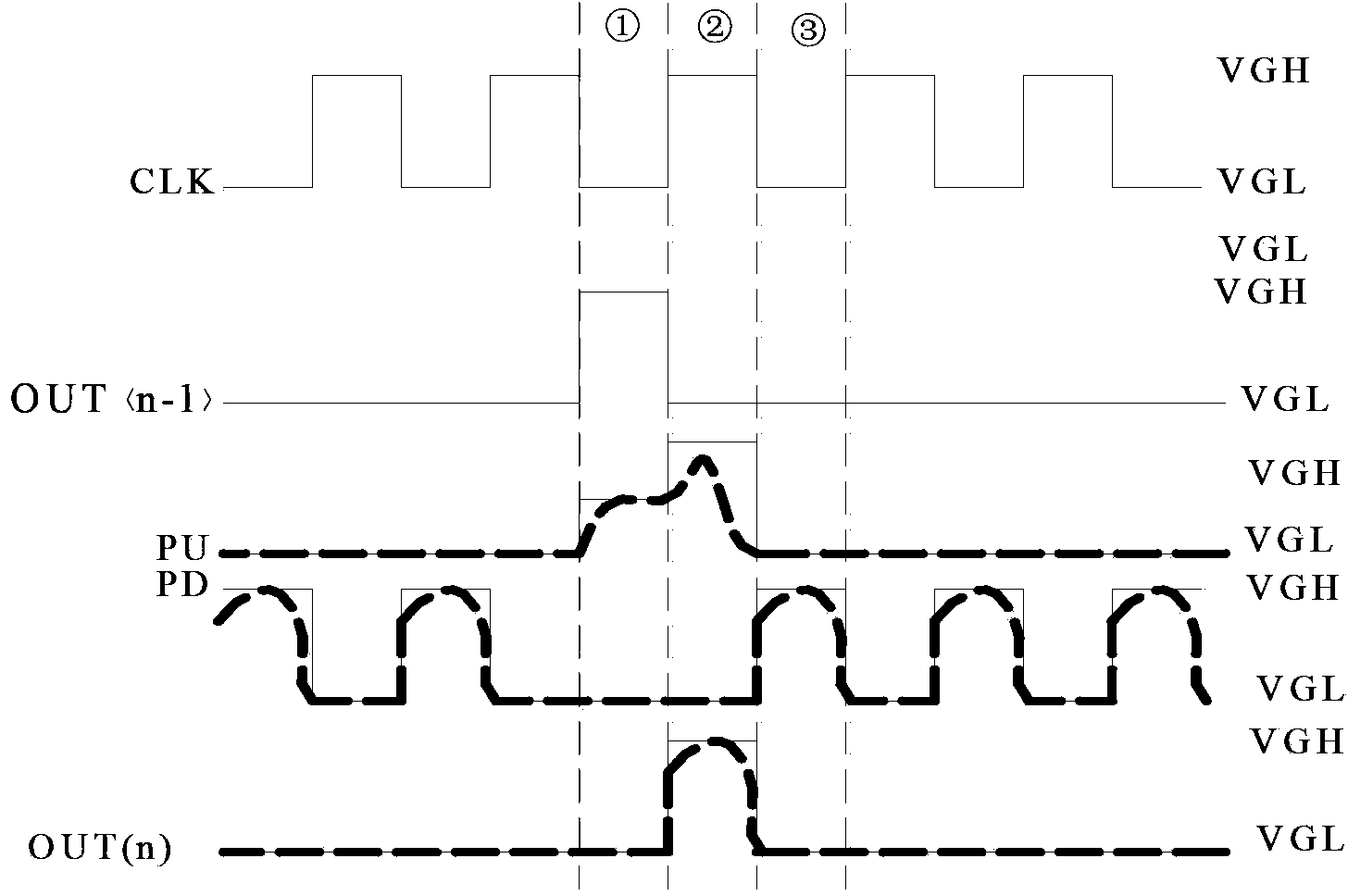

Shift registering unit, shift register and display device

InactiveCN103440839AEnhanced couplingNo leakageStatic indicating devicesDigital storageShift registerDisplay device

The invention provides a shift registering unit which comprises a first driving signal input end, a first driving signal output end, a first clock signal input end, a first pull-up transistor, a first output pull-down transistor, a switch transistor, a reset transistor and a bootstrapping capacitor. The shift registering unit further comprises a pull-down unit, wherein a first end of the pull-down unit is connected with the grid electrode of the switch transistor, a second end of the pull-down unit is connected with the grid electrode of the reset transistor, and a third end of the pull-down unit is connected with the grid electrode of first output pull-down transistor. The source electrode of the reset transistor is connected with a second low-level input end, and the source electrode of the first output pull-down transistor is connected with a third low-level input end. The invention further provides a shift register comprising the shift registering unit, a grid driver comprising the shift register, and a display device comprising the grid driver. A depletion mode transistor can be used in the shift registering unit.

Owner:BOE TECH GRP CO LTD +1

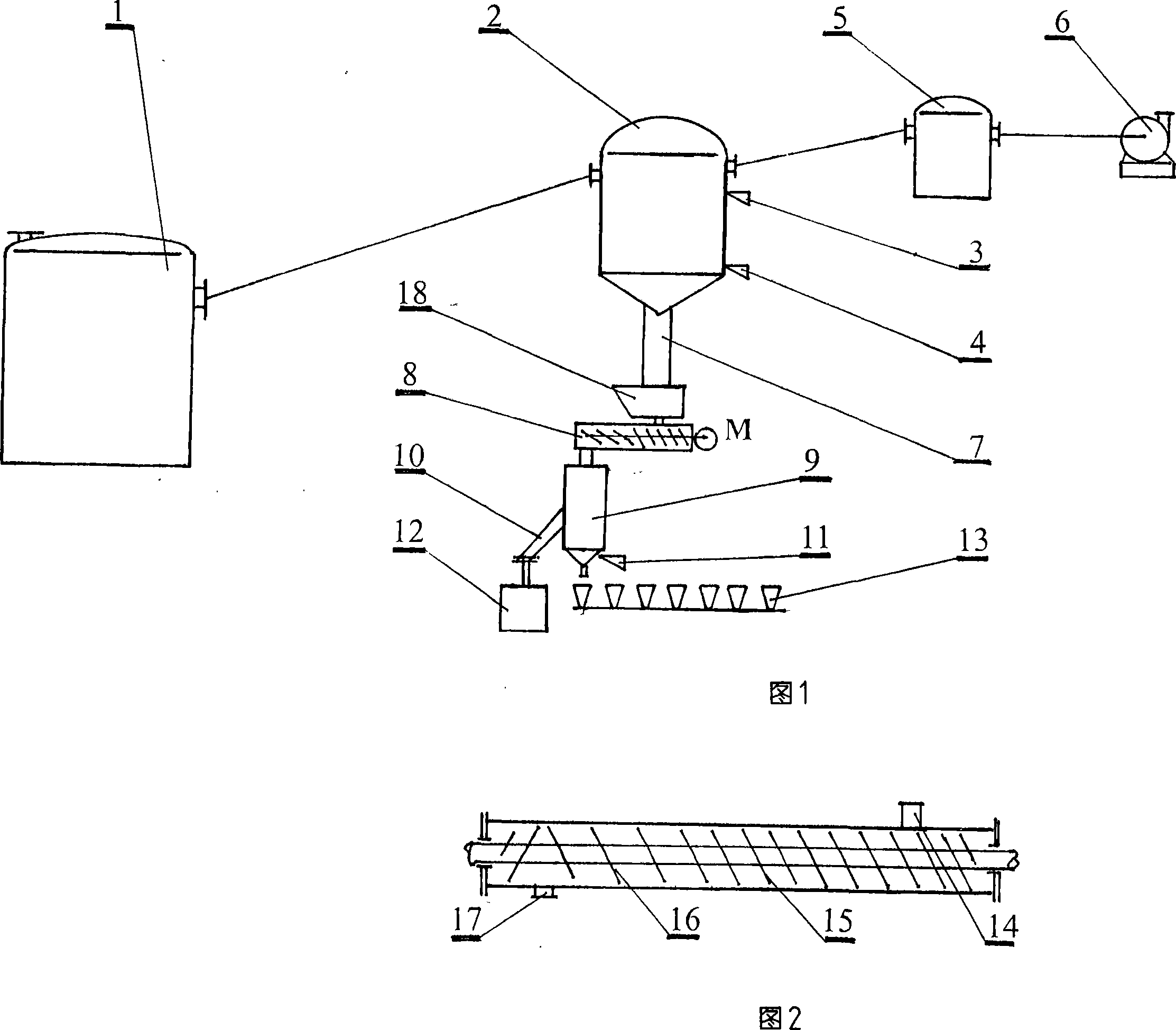

Automatic accurate weighing device for powdery material

InactiveCN101105409ANo leakageNo pollution in the processWeighing apparatus with automatic feed/dischargeMotor speedGrating

The invention discloses a powdery material accurate weighing device, which comprises a raw material tank and a weighing cup. The invention is characterized in that the feeding process is operated under vacuum, a high-level switch and a low-level switch are disposed above a vacuum intake tank, an auger conveying mechanism is disposed below the vacuum intake tank, the spiral pitch has two classes, the motor speed has two classes, a optical fiber grating pressure sensor is disposed below a weighing bunker, an automatic reverse turning bed is disposed in the weighing bunker, the signal from a material level switch and the optical fiber grating pressure sensor is transmitted to PLC, and the PLC outputs control signal to a motor of a vacuum pump, vacuum air passages and material control valves. The invention remarkably improves the weighing accuracy from above plus or minus 10 g error of the existing automatic weighing to within plus or minus 1 g error, even lower. It has the advantages of whole sealing operation under vacuum condition, no dust pollution, improved operating environment, accurate weighing, and good consistency. The invention is helpful for further improving the production quality of friction wafer product; and has high spreading and application values, and good market prospect.

Owner:李红

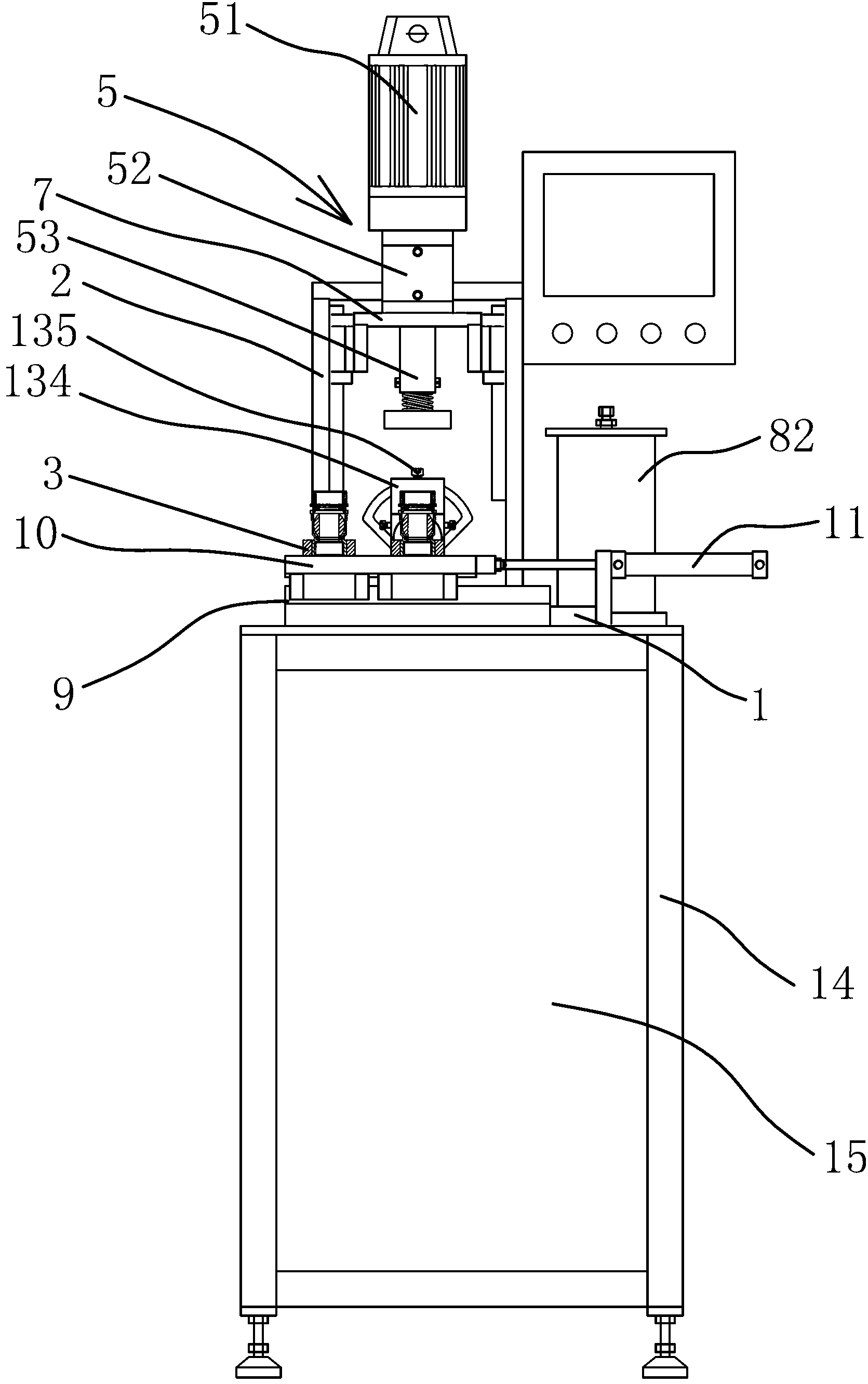

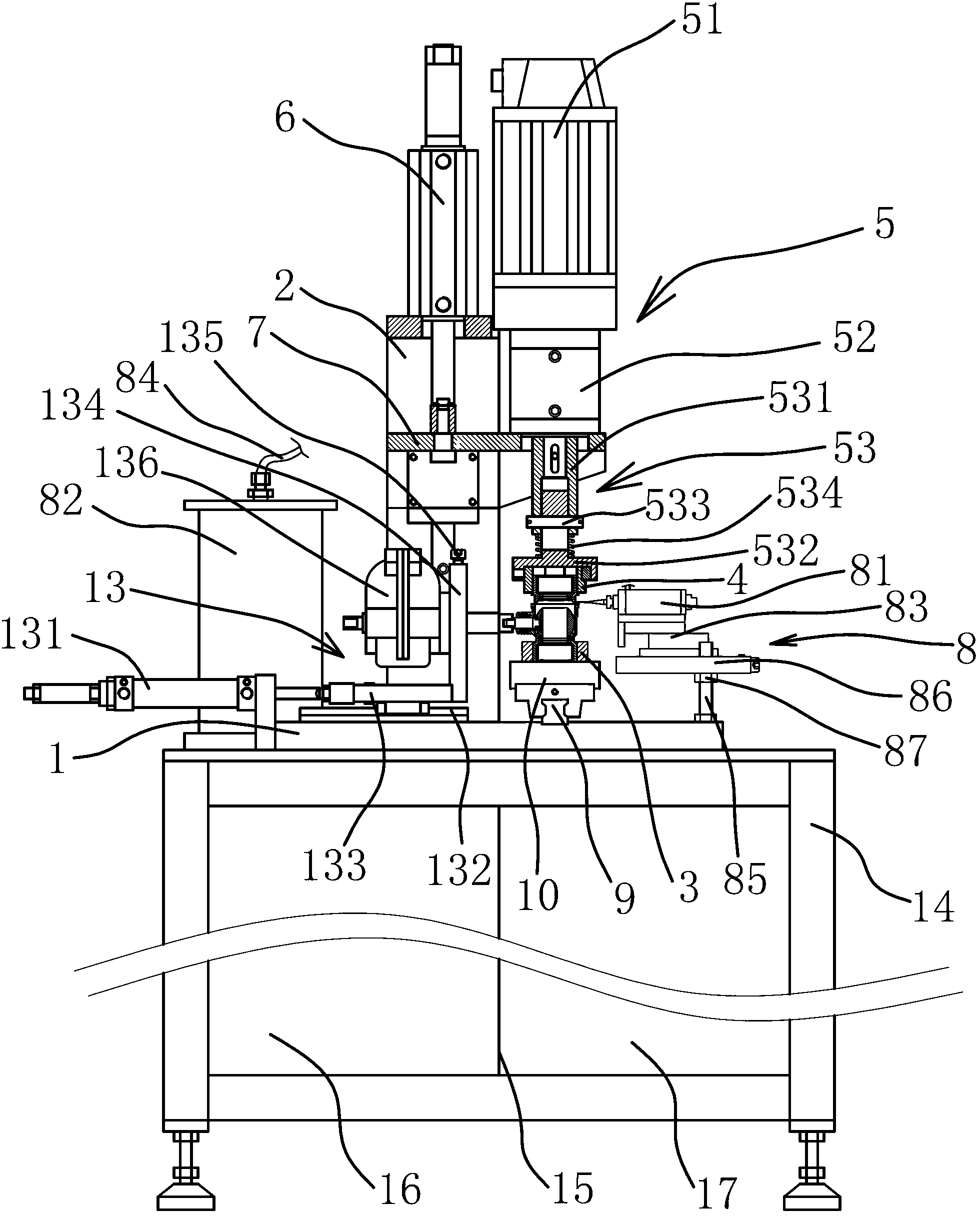

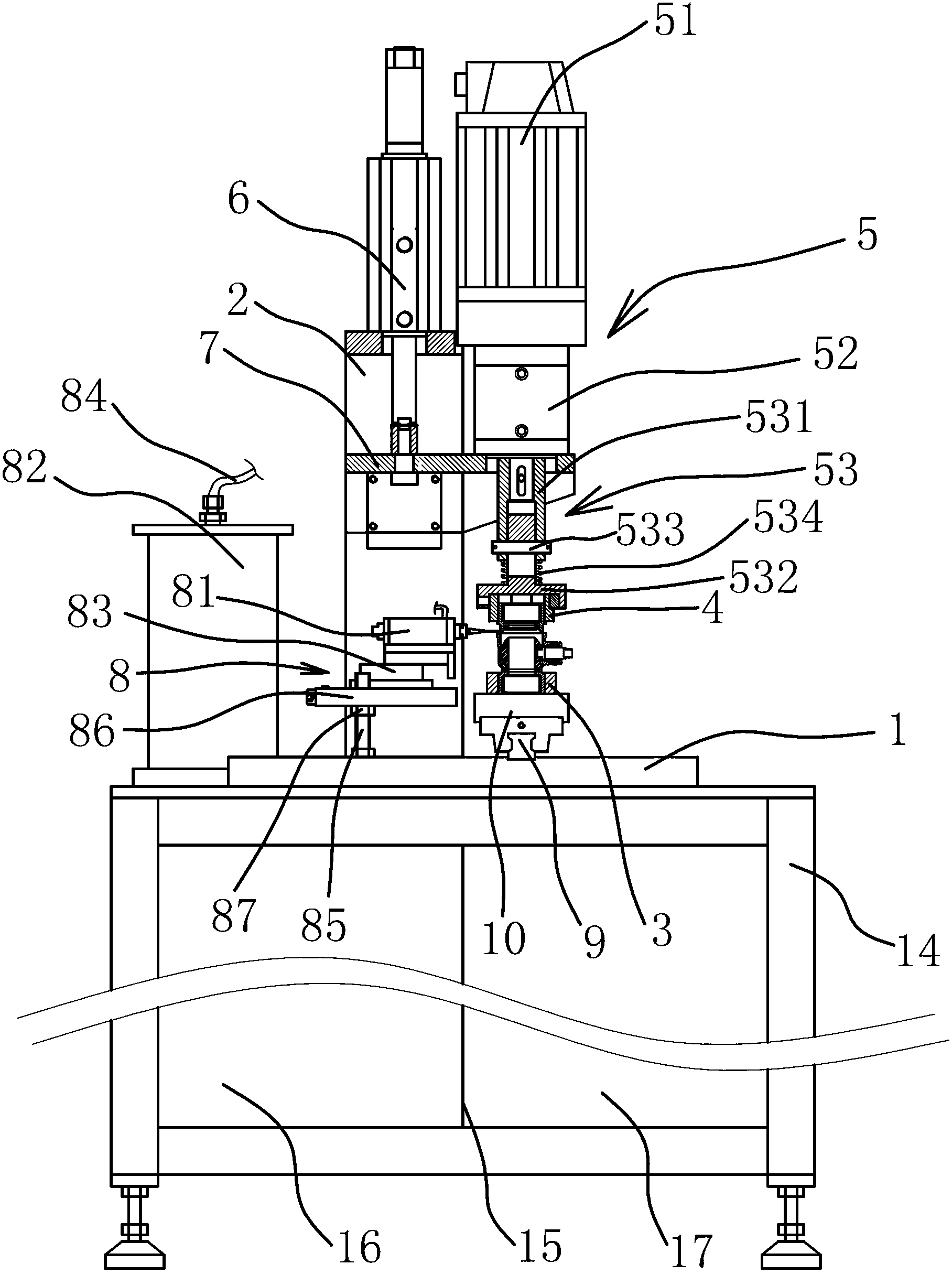

Valve body and bonnet connection torsion dispensing assembly machine

InactiveCN103231241AUniform coatingImprove the firmness of the connectionLiquid surface applicatorsAssembly machinesEngineeringPiston rod

The invention provides a valve body and bonnet connection torsion dispensing assembly machine, belongs to the technical field of valve production devices and solves problems that the existing valve body and bonnet connection assembly machine cannot achieve automatic gluing. The valve body and bonnet connection torsion dispensing assembly machine comprises a worktable and a support fixed on the worktable, wherein a lower die body is arranged on the worktable, an upper die body is arranged right above the lower die body and is fixed on the lower portion of a torsion control mechanism used for controlling rotating of the upper die body, a lifting cylinder is fixedly connected onto the support, a lifting sliding table is fixedly connected at the end of a piston rod of the lifting cylinder, the torsion control mechanism is fixed on the lifting sliding table, and a dispensing mechanism is arranged on the side portion of the lower die body. The valve body and bonnet connection torsion dispensing assembly machine has the advantages of having double functions of valve bonnet screwing and gluing, being high in automation and work efficiency and the like.

Owner:ZHEJIANG VALOGIN TECH

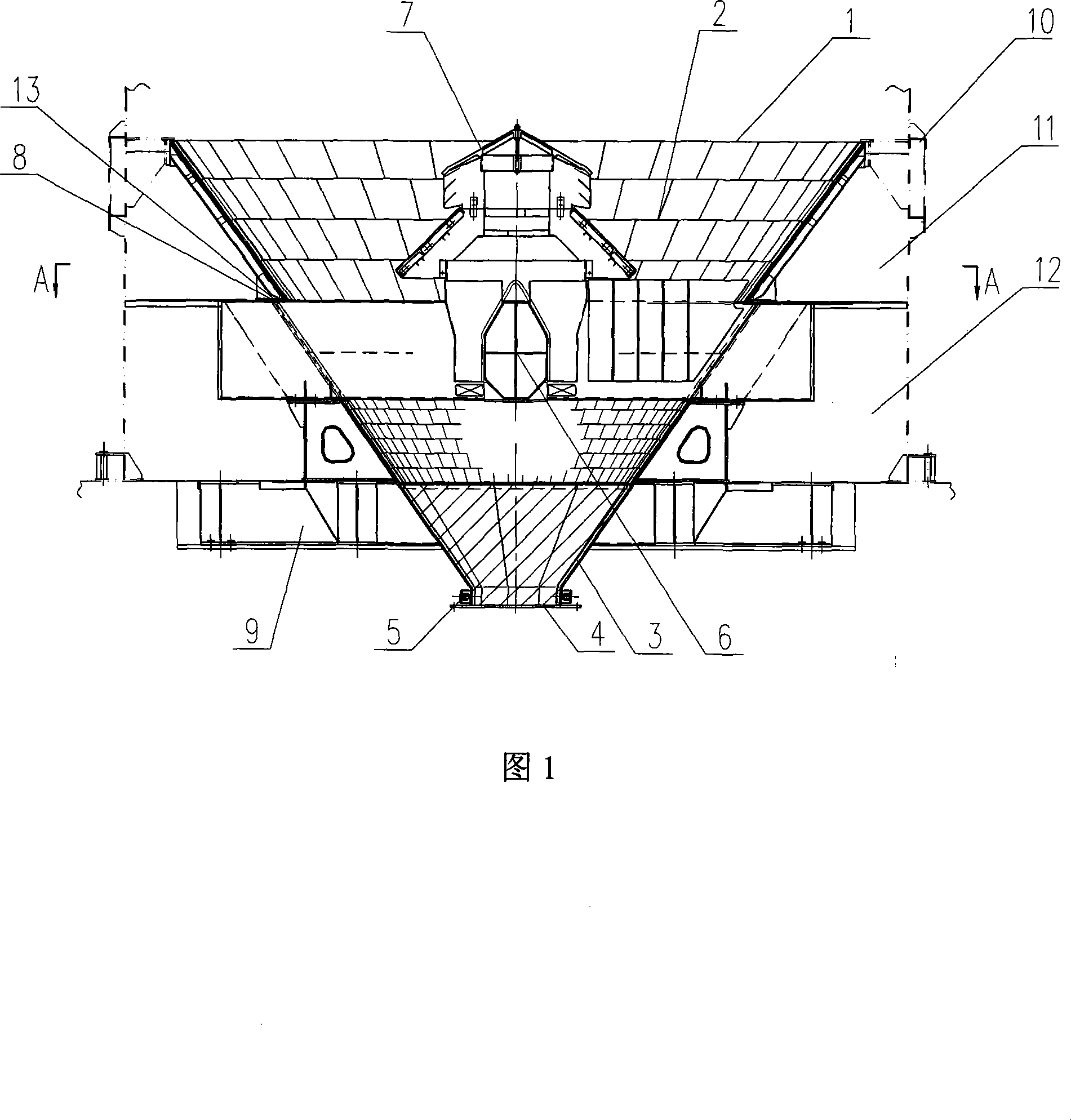

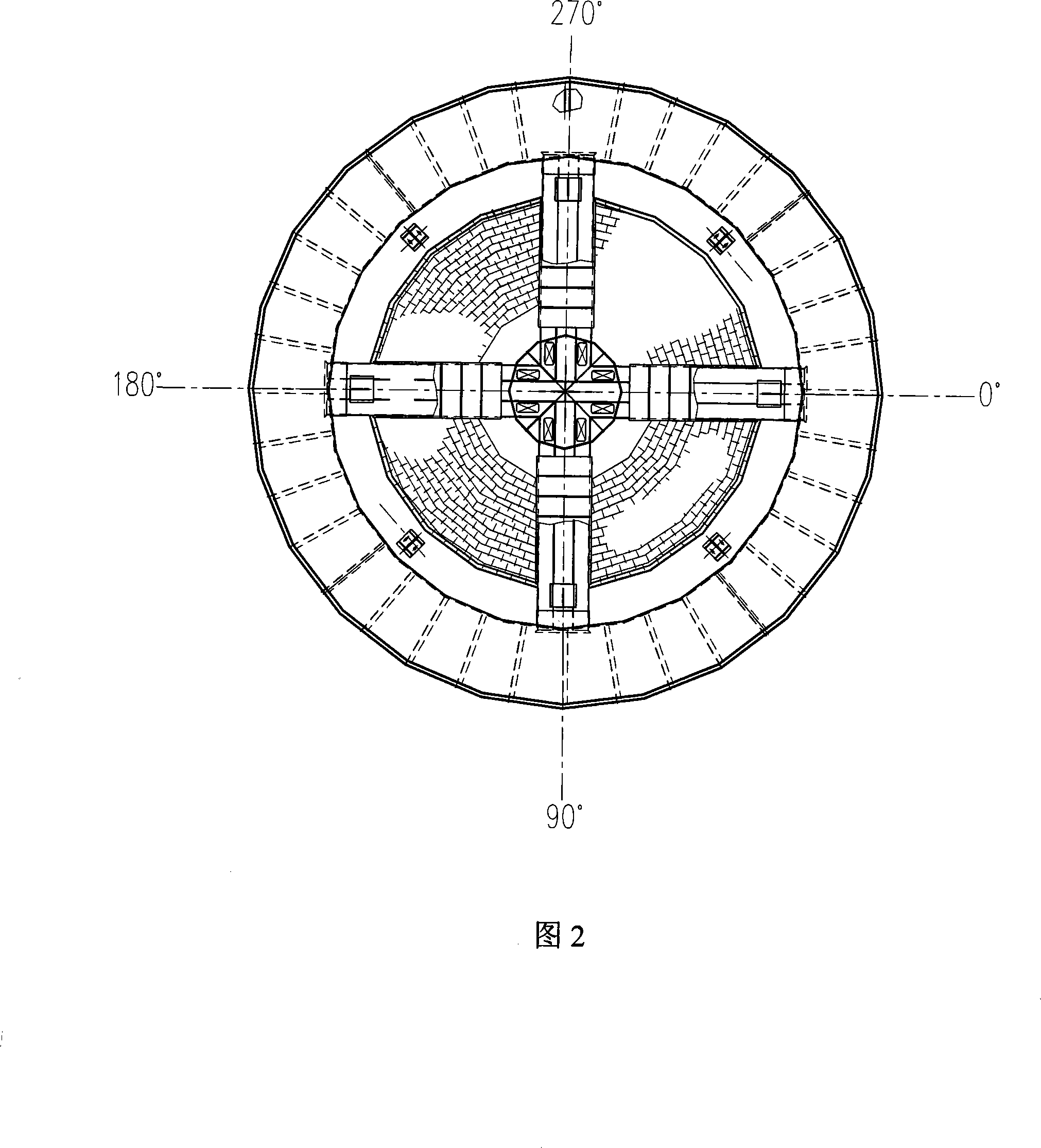

Special-purpose gas supplying device for coke dry quenching unit

The invention relates to an air supply facility specially used for a dry out furnace. The facility is composed of an upper cone funnel, a lower cone funnel, a dry out furnace casing body, a ring-shaped air channel, a cross air channel, and a central windshield, wherein the upper cone funnel and the lower cone funnel are sleeved and inserted with each other, the ring-shaped air channel is composed of an annular gap which is formed by a sleeve and inserting ledge, and the cross air channel is positioned on the upper portion of the lower cone funnel and is horizontally arranged, the centre of the cross air channel coincides with the centre of the dry out furnace and extends upwards and is communicated with the central windshield which is arranged on the cone funnel, the facility employs a combining air supply form of that peripheral air rings supply air from outside in and the central windshield supplies air from inside out on the upper portion of the furnace body. The facility can effectively resolve the problem that the cooling cycle air entering the dry out furnace is uniformly distributed in the periphery direction of the dry out furnace, which is favorable for achieving uniform cooling of the coke in the furnace, thereby improving the cooling property of the dry out furnace, increasing the cooling efficiency of the dry out furnace, and reducing the dry out time of the coke in the dry out furnace.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

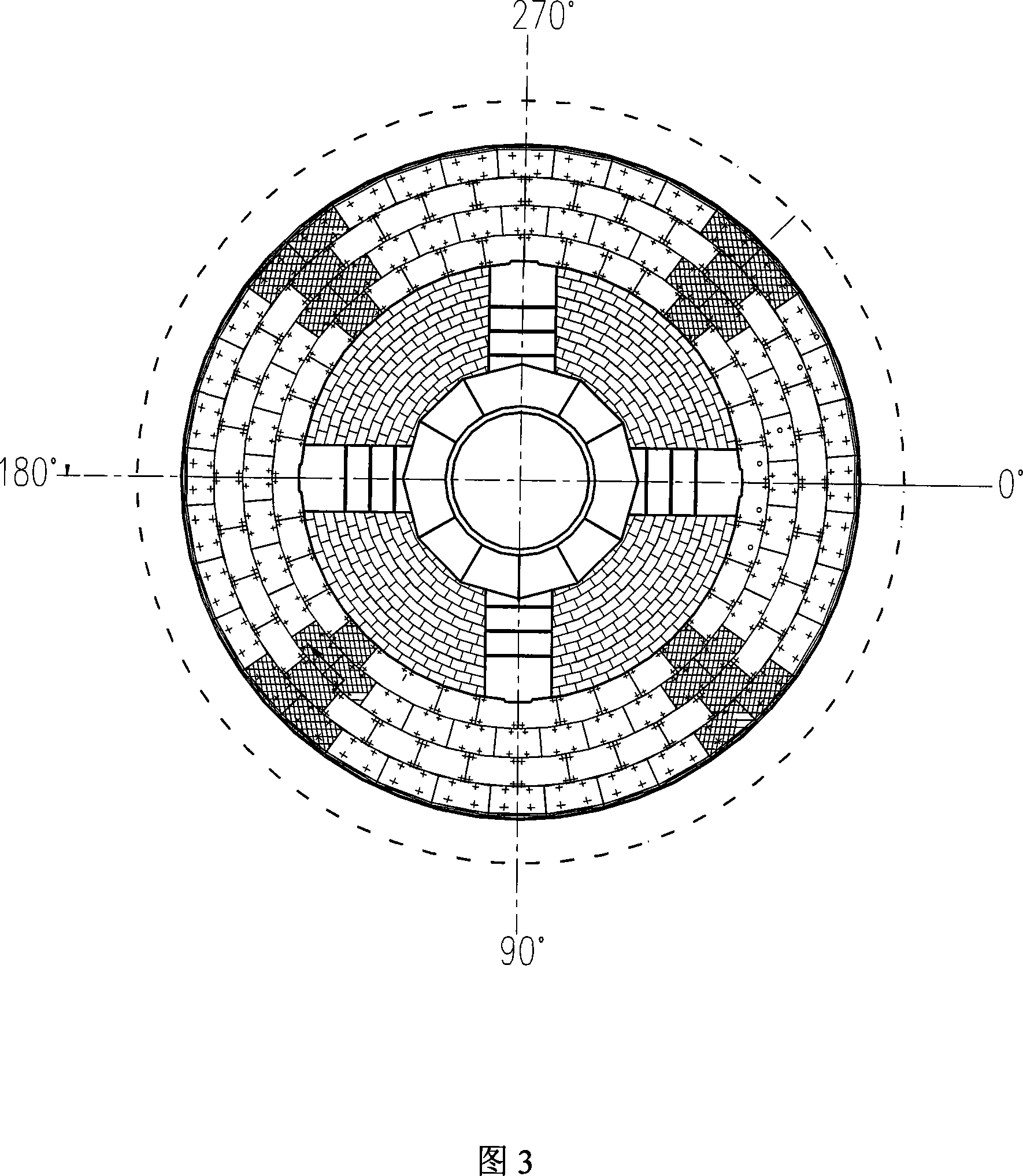

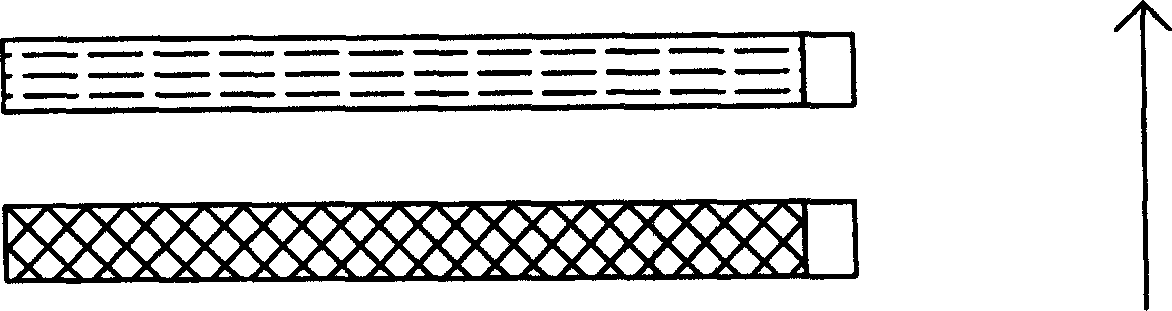

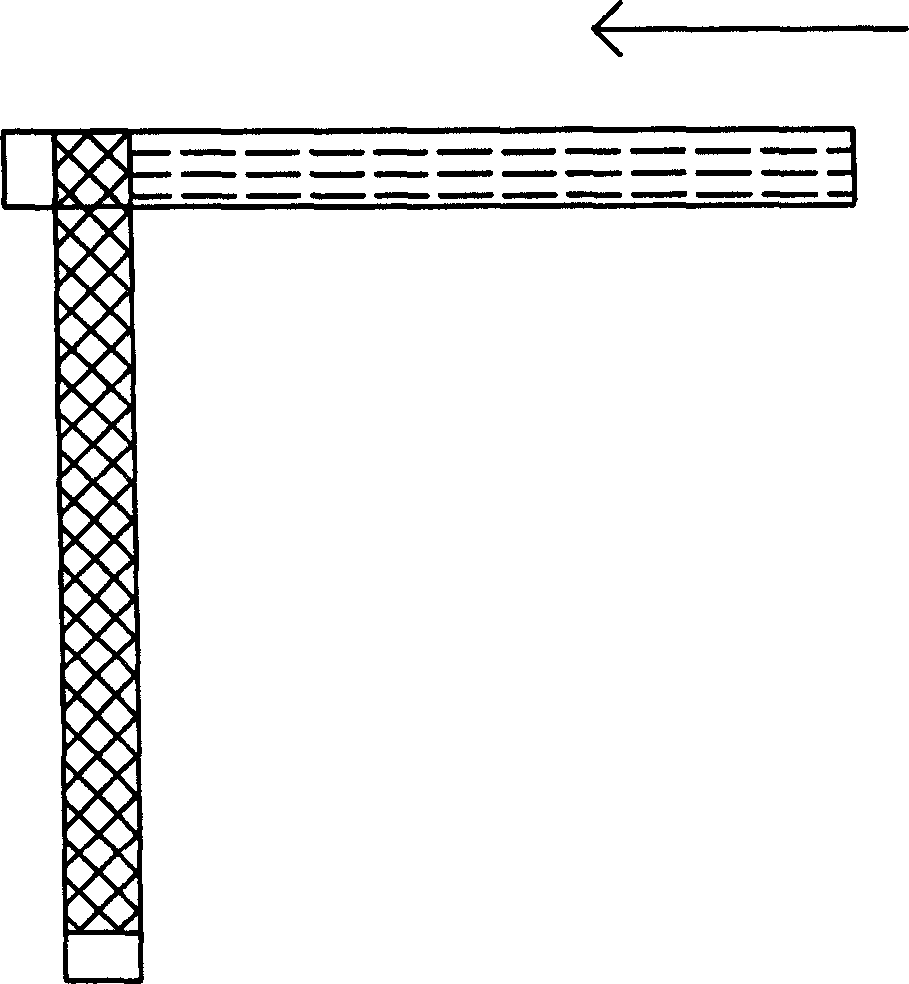

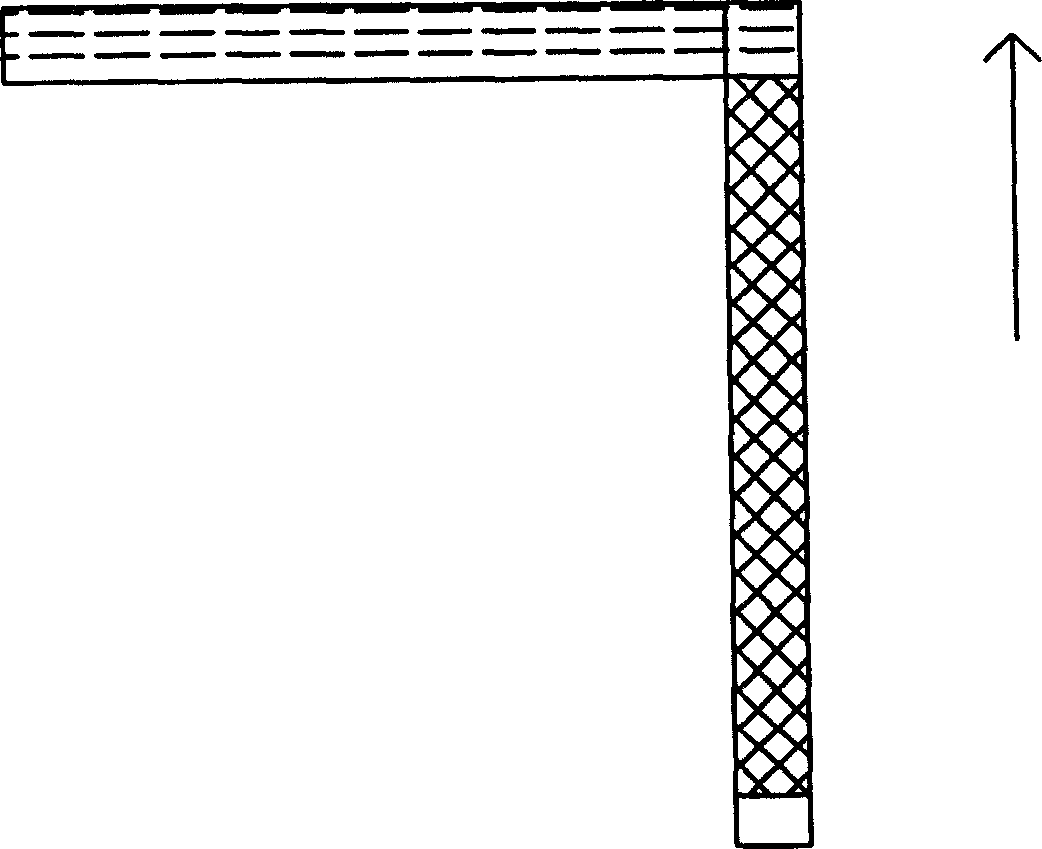

Electric core structure of lithium battery and producing method thereof

ActiveCN1610168AEvenly distributedNo leakageFinal product manufactureNon-aqueous electrolyte cellsEngineeringElectrolyte

The present invention is the structure and making process of lithium cell core. The lithium cell core includes positive pole plate, negative pole plate and diaphragm in between, and they are in the same length and width and folded into zigzag. The positive pole plates and the negative pole plates are interpenetrated and arranged alternately in the angle of 90 deg. The present invention has homogeneous electrolyte distribution, fast electrolyte adsorbing speed and may be used in producing high quality lithium cell.

Owner:EVE ENERGY CO LTD

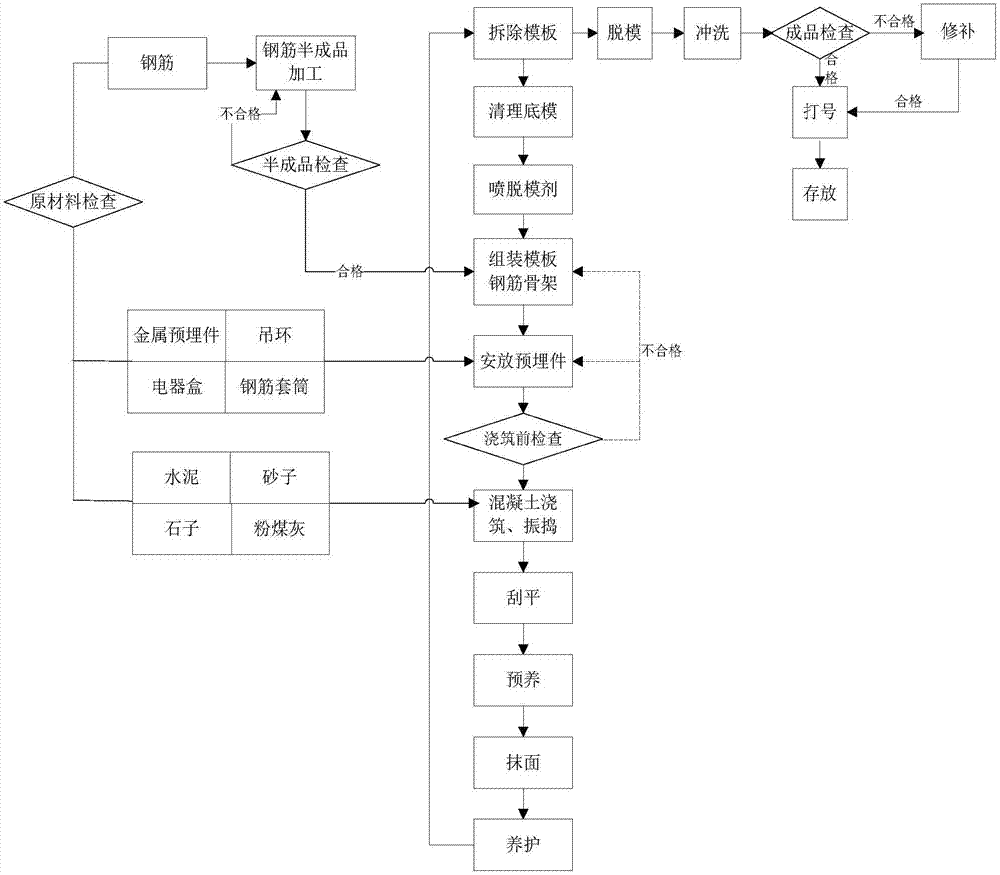

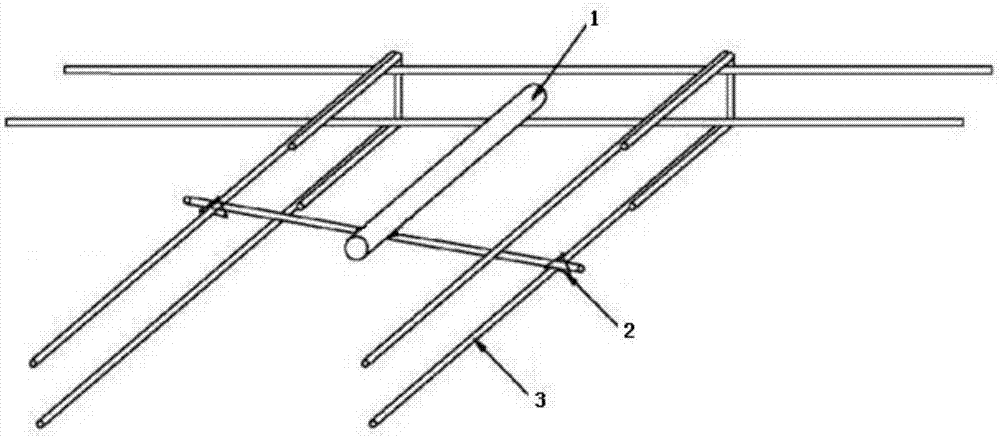

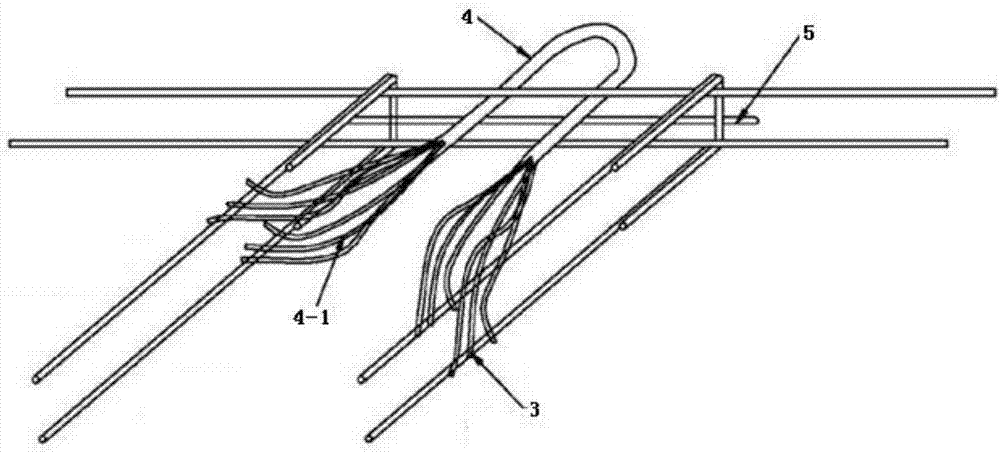

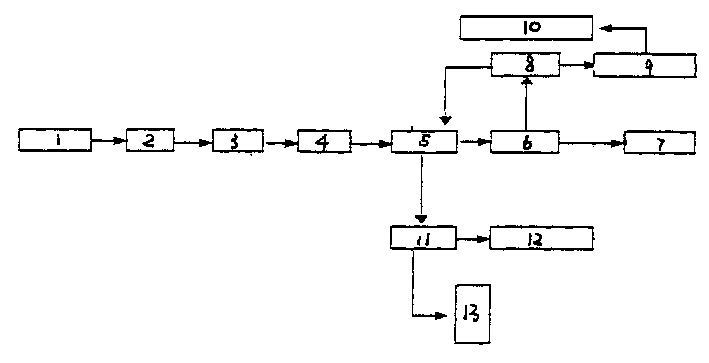

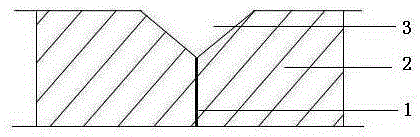

Methods for manufacturing and mounting prefabricated wall members

InactiveCN107297810ASimple processReduce generationDischarging arrangementCeramic shaping plantsHigh energyRebar

The invention discloses methods for manufacturing and mounting prefabricated wall members, and belongs to the field of technologies for constructing buildings. By the aid of the methods, the problem of low traditional building construction efficiency can be solved, and the traditional production modes with high energy consumption and severe pollution can be changed. The prefabricated wall members are internally provided with reinforcement frameworks and embedded members, and embedded reinforcement holes, grouting holes and exhaust holes are reserved in the prefabricated wall members. The method for manufacturing the prefabricated wall members includes 1), erecting formworks according to the overall dimensions of the prefabricated wall members; 2), placing the reinforcement frameworks and the embedded members in the formworks; 3), preparing and pouring concrete; 4), carrying out steam curing on the prefabricated wall members; 5), stripping the prefabricated wall members from forms; 6), laterally turning the prefabricated wall members and erecting the prefabricated wall members; 7), inserting or butting the prefabricated wall members. The methods have the advantages that buildings can be constructed by the aid of the prefabricated wall members instead of the traditional construction modes, accordingly, implementation of building industrialization can be promoted, energy consumption and garbage discharge can be reduced, the construction efficiency and the construction comprehensive quality can be improved, and collaborative management can be facilitated.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Ru-kiln celadon ware and preparation process thereof

The invention relates to a Ru-kiln celadon ware and a preparation process thereof. According to the invention, kaolin, flint clay and feldspar are adopted as blank raw materials; the blank raw materials are crushed and are subjected to wet grinding with water; quartz, feldspar, calcite, hematite, ophiolite, bone ashes, and wind cave earth calcined under 900-950 DEG C are adopted as glaze raw materials; the glaze raw materials are crushed and are subjected to wet grinding with water, until a slurry water content is regulated to 80%; a prepared blank is subjected to biscuit firing and is fetched; an obtained glaze is applied on the blank; the blank with the glaze is immediately placed in a kiln and is subjected to stepped heating and firing; after firing, heating is stopped, and the obtained ware is fetched. According to the prepared Ru-kiln ware, cracked-glaze effects with different degrees can be realized. The ware is gentle, delicate, elegant, and natural. The ware is superior among Ru-kiln wares.

Owner:王振宇

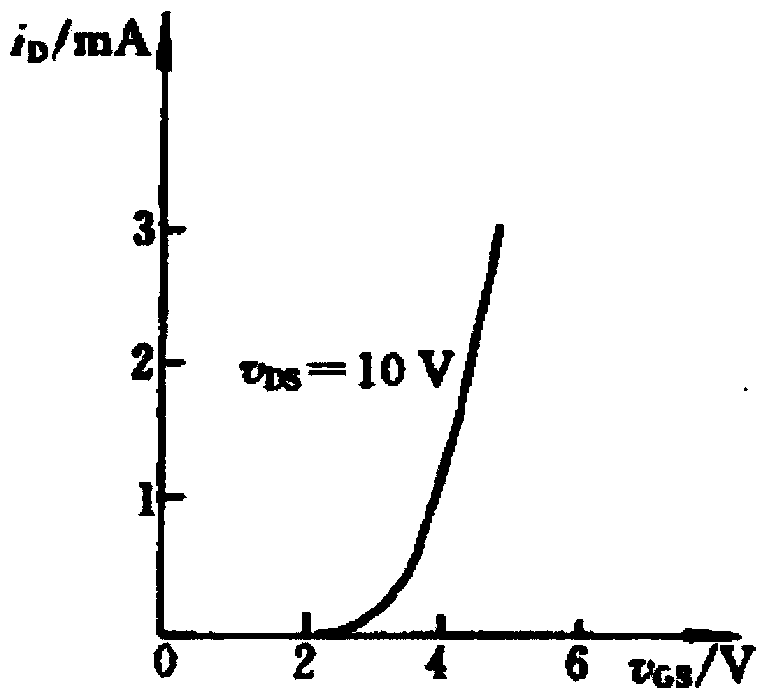

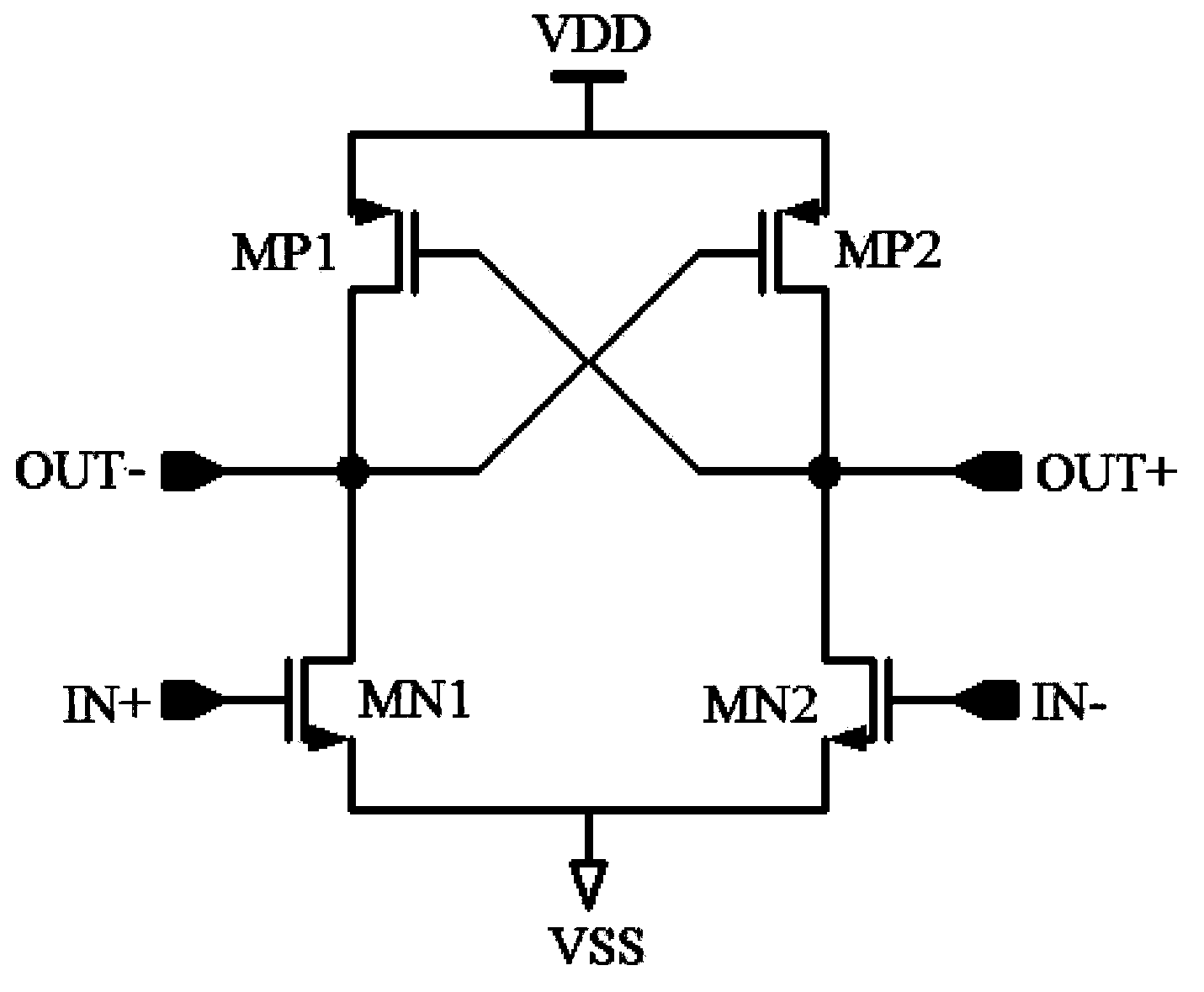

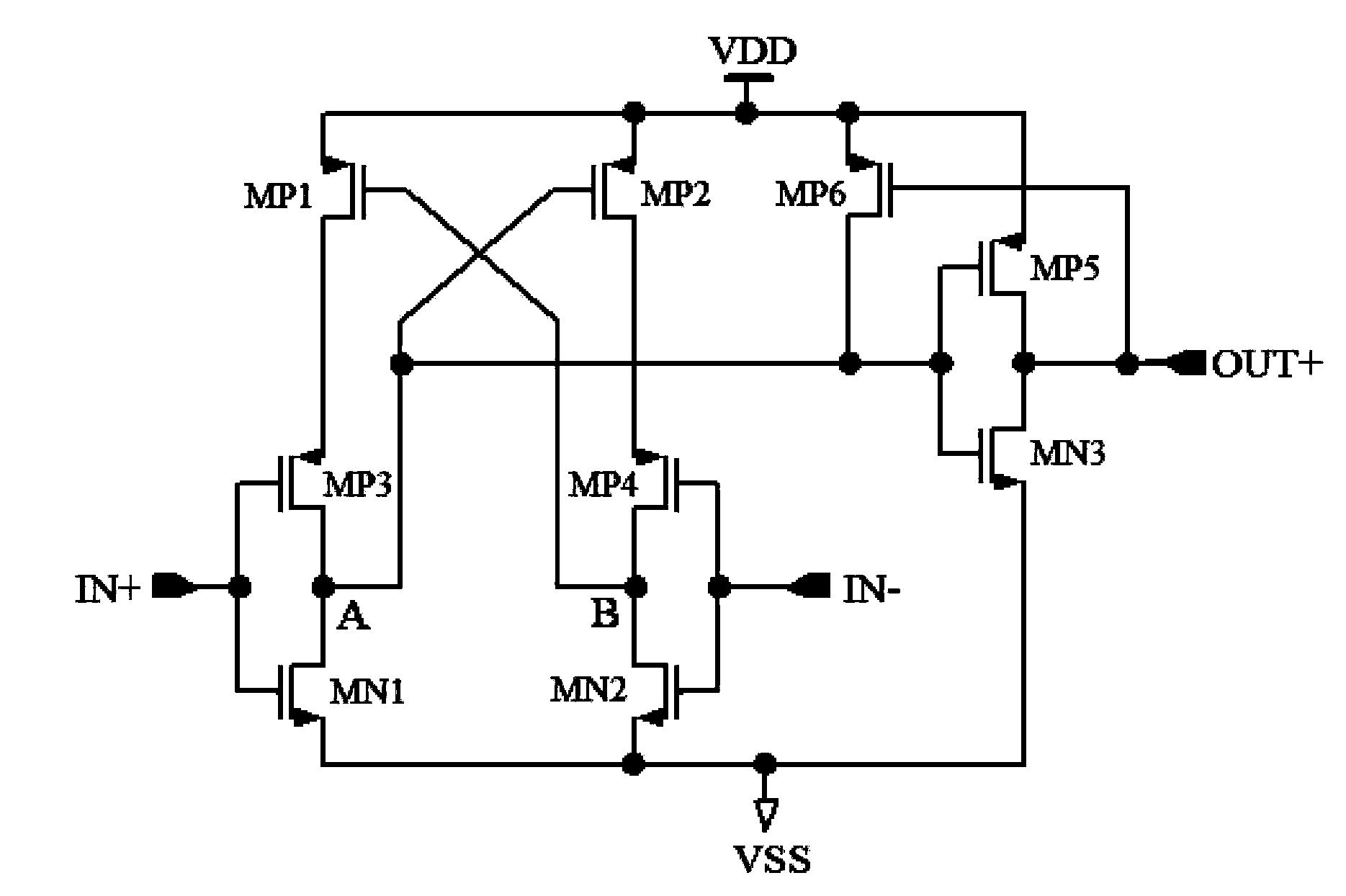

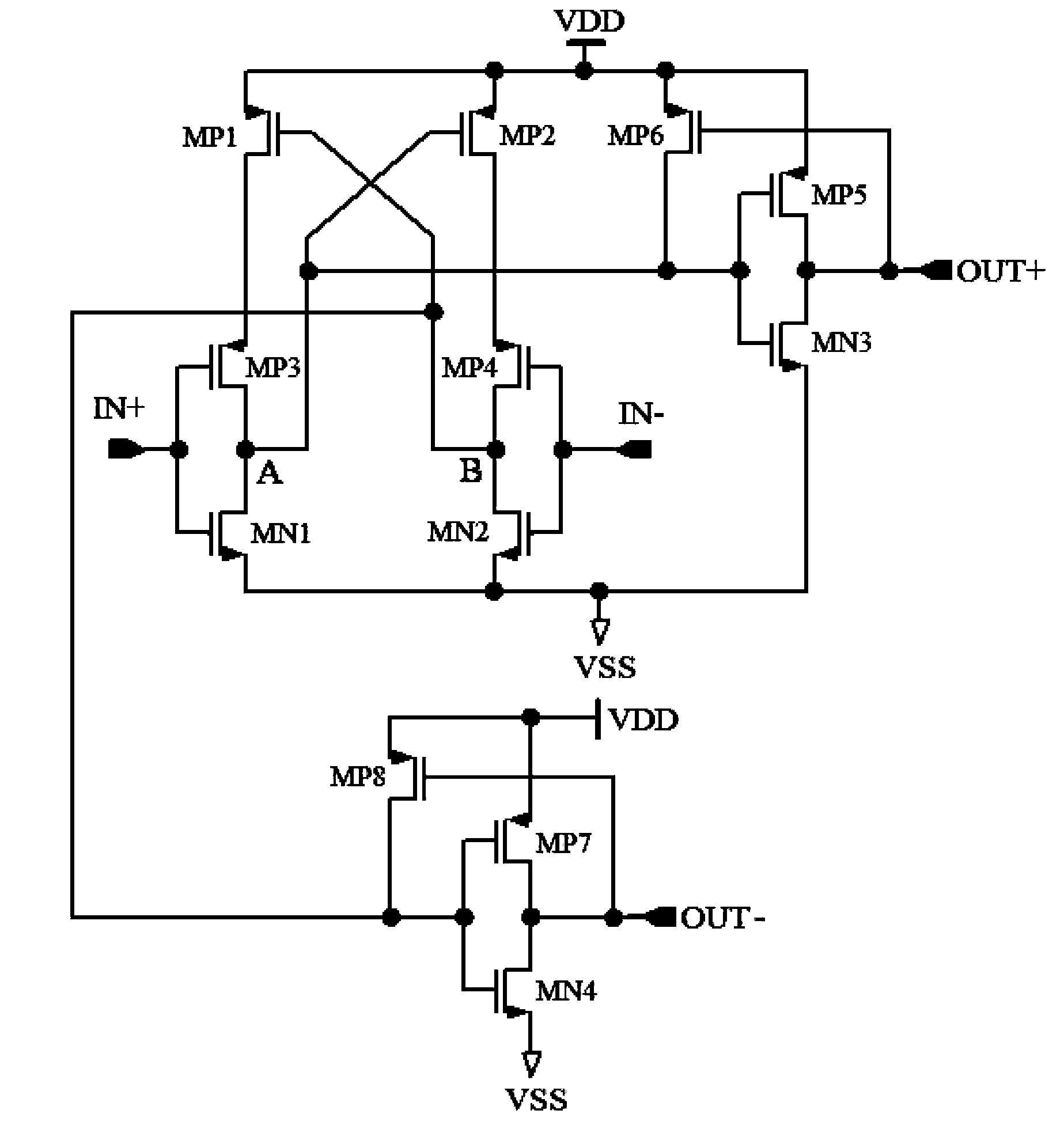

Low-to-high logic level conversion circuit

InactiveCN103856206AEliminate indefinite stateGuaranteed to workLogic circuits coupling/interface using field-effect transistorsElectricityLow voltage

The invention discloses a low-to-high logic level conversion circuit which comprises a latch, an actuator, a phase inverter and a feedback pipe. The input of the latch is a differential pair pipe which is formed by a first NMOS transistor and a second NMOS transistor, and a load of the latch is a cross coupling pair pipe which is formed by a first PMOS transistor and a second PMOS transistor. The actuator is arranged in the latch and helps the latch to be quickly turned over. The phase inverter and the feedback pipe are arranged at the output end of the latch, the feedback pipe enables a circuit output to be in a steady state when a low-voltage area is not powered, and when the low-voltage area is normally powered, normal work of the latch is not affected. By means of the low-to-high logic level conversion circuit, the probability that logic level is in an unsteady state when being converted to power level is avoided, and power consumption is reduced.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

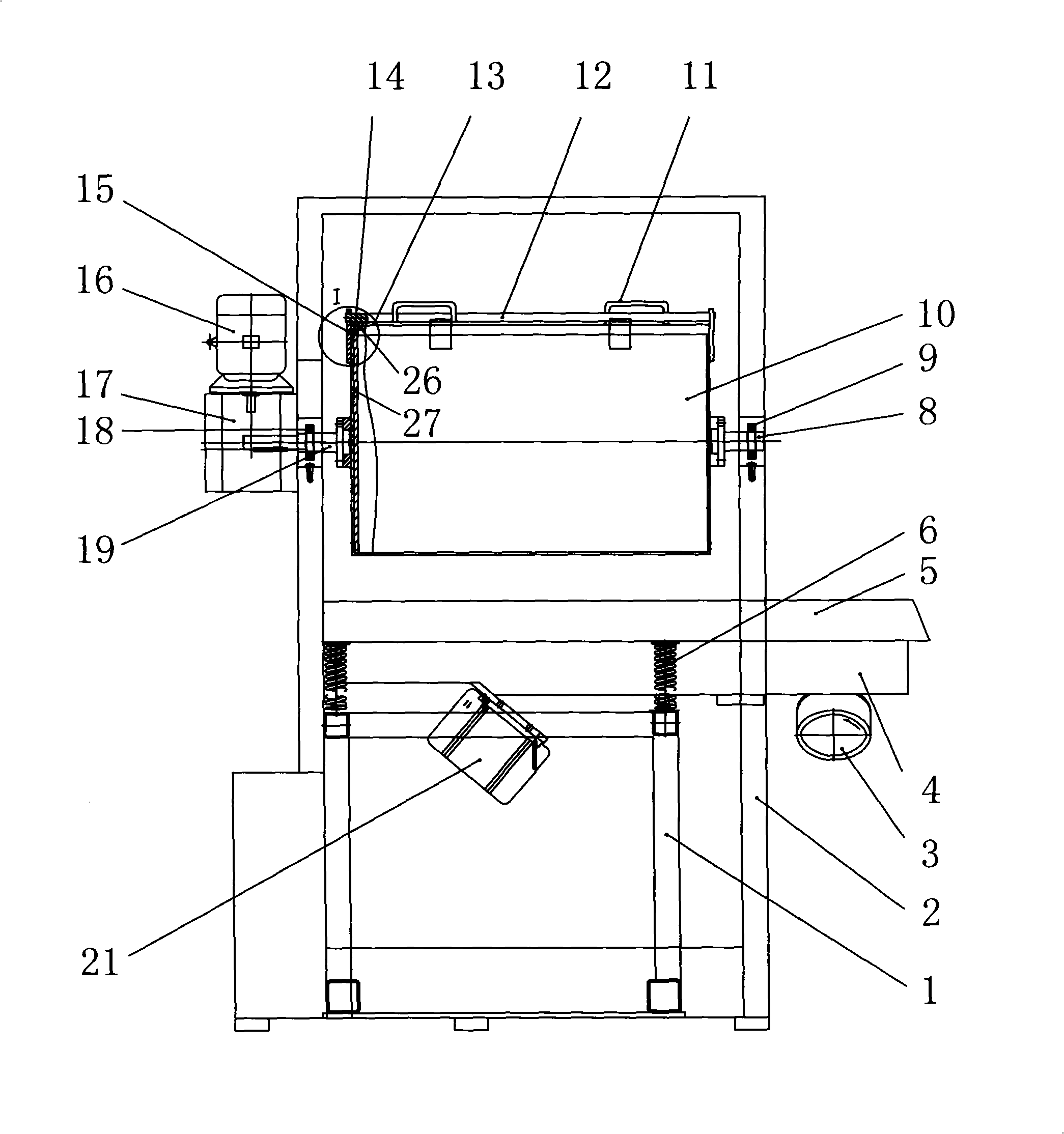

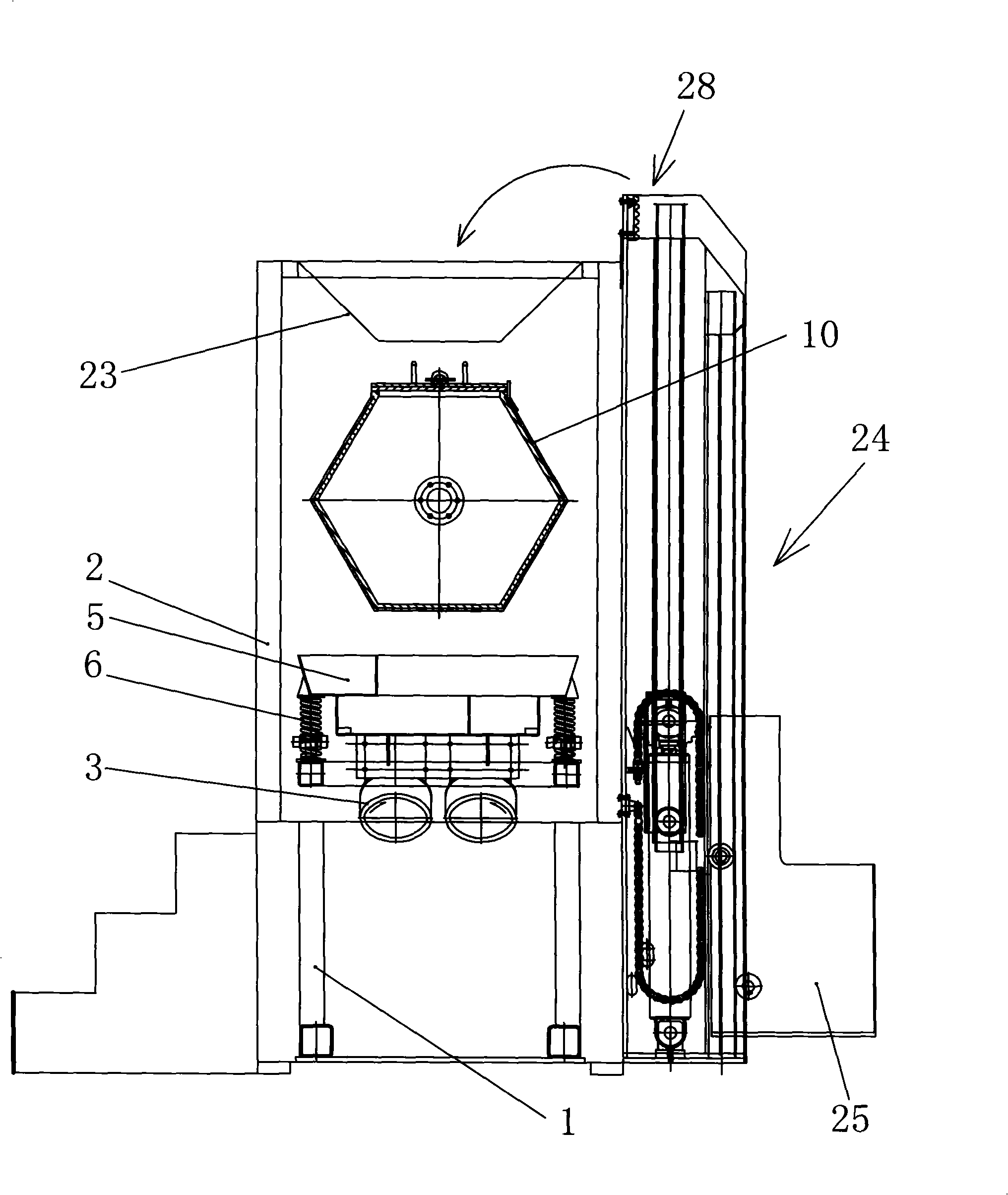

Semiautomatic revolving roll grinding miller

InactiveCN101352831AImprove work efficiencyReduce labor intensityEdge grinding machinesPolishing machinesEngineeringAutomation

The invention discloses a grinder, in particular a semi-automatic rotary drum grinder mainly used for the deburring, chamfering and polishing and the like of machined parts. The semi-automatic rotary drum grinder comprises a frame (2) on which a bearing supports a drum (10) connected with a driving device and the drum (10) is provided with a cover (13). The semi-automatic rotary drum grinder is characterized in that: one side of the frame (2) is provided with a hoister (24) and a discharge end (28) above the hoister (24) is corresponding to a cutting hopper (23) above the drum (10) on the frame (2). The semi-automatic rotary drum grinder has the advantages of less labor and time, low labor intensity, high operation efficiency and high automation level.

Owner:大连隆正光饰机制造有限公司

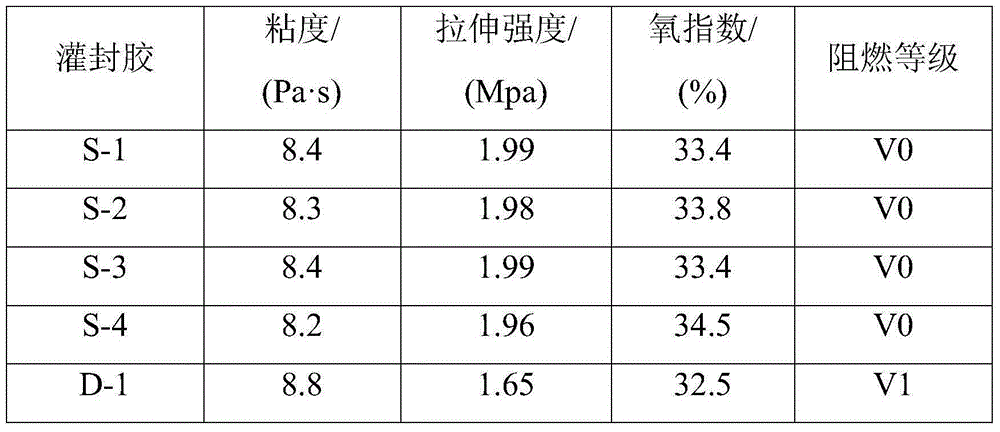

Flame-retardant microcapsule as well as preparation method and application thereof

InactiveCN105218714AColorless, odorless, low boiling pointLow boiling pointNon-macromolecular adhesive additivesMicroballoon preparationInternal pressureLiquid core

The invention discloses a flame-retardant microcapsule as well as a preparation method and application thereof. The flame-retardant microcapsule comprises a core material and a coating layer coating at the outer side of the core material, wherein the core material is liquid heptafluoropropane or liquid hexafluoropropane; and the coating layer is a polymethacrylate polymer and is prepared by polymerization by virtue of a suspension polymerization method. The flame-retardant microcapsule can be used as a flame-retardant filler singly, and also can be used as a flame-retardant filler together with magnesium hydroxide / aluminum hydroxide for preparing an electronic-pouring sealant in combination. The flame-retardant microcapsule disclosed by the invention is high in thermal stability and good in penetration resistance, and cannot generate leakage of the core material in a normal state; and only when subjected to high-temperature combustion, the coating layer is softened and the liquid core material is vaporized at the same time so that the internal pressure is increased and results in expansion breakage of the coating layer, and then the core material is released at last to quickly retard inflaming and put out a fire, so that the flame-retardant microcapsule has a broad use prospect in the field of preparation of the electronic-pouring sealant.

Owner:浙江中天东方氟硅材料股份有限公司

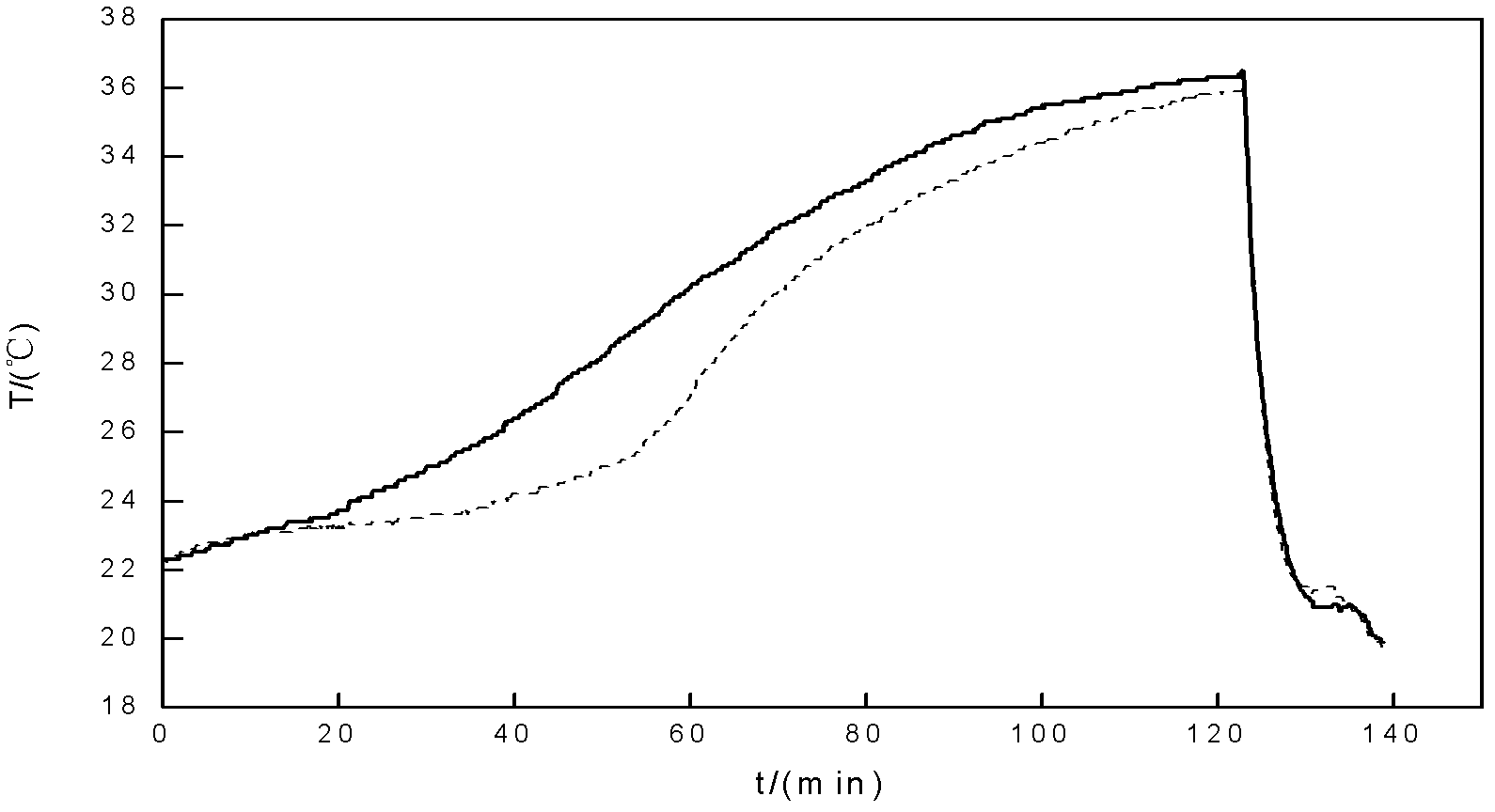

Shape-stabilized phase change energy storage material for building and preparation method thereof

InactiveCN102432258AGood thermal conductivityHigh thermal conductivityHeat-exchange elementsGypsumBuilding material

The invention relates to a shape-stabilized phase change energy storage material for building and a preparation method thereof. The material provided by the invention comprises components of: by weight, 70-85% of a composite phase change energy storage material with its melting point being 18-30 DEG C and 15-30% of gesso. The composite phase change energy storage material with its melting point being 18-30 DEG C is composed of a porous matrix and a mixed fatty acid phase change material, wherein the mass ratio of the porous matrix to the mixed fatty acid phase change material is 1:4-1:6. At the temperature of 60-80 DEG C, the porous matrix is added in the molten lauric acid-capric acid mixed fatty acid to prepare a composite phase change material. Then, gesso is mixed with the composite phase change material to prepare a shape-stabilized fatty acid phase change energy storage material with a more stable adsorption property. The prepared shape-stabilized phase change energy storage material has good thermal conductivity, good adsorption stability and good material plasticity, will not cause seepage at high temperature, is easy to mix with a building material, and has a good application prospect.

Owner:NANJING UNIV OF TECH +1

Waste tyre processing method

The waste type processing method includes three processes of tyre crushing, thermal cracking and carbon black crushing and packing. During the tyre crushing processes, waste type is first-crushed in pre-crusher and washed, and then crushed for the second time into rubber grains below 25 mm size. During the thermal cracking process, the rubber grains are thermally cracked in thermal cracking furnace at 480-700 deg.c and 0.01-0.04 MPa negative pressure, the gaseous product is condensated and cooled in washing tower to obtain fuel oil, the uncondensated light components is reused as fuel gas in the furnace and excessive inflammable gas is for heat energy conversion to provide hot water. In the carbon black crushing and packing process, the mixed material of carbon black and steel wire obtained in the thermal cracking process is magnetic separated and the carbon black is ground and packed as product.

Owner:上海绿人生态经济科技有限公司

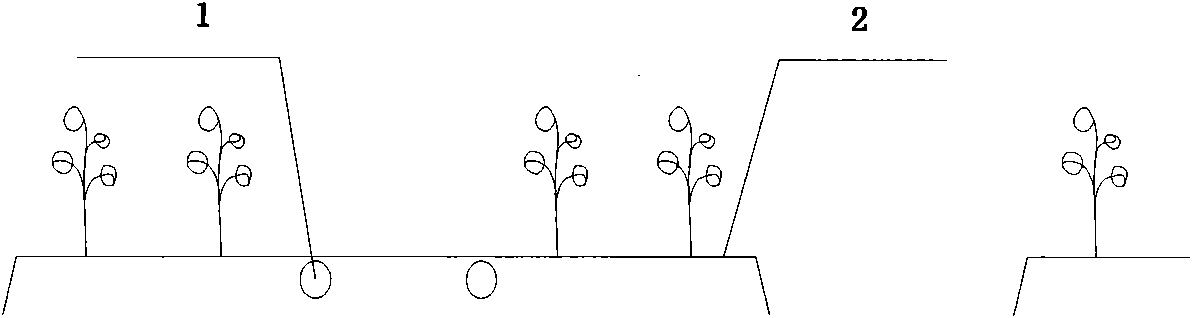

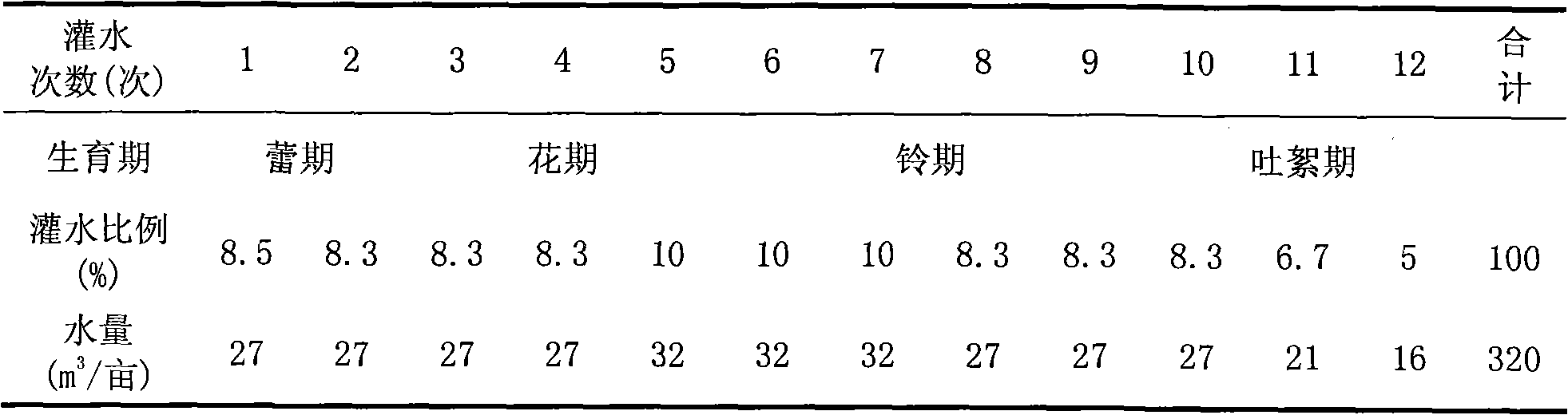

Drip Irrigation Method for Planting Cotton in Severe Saline Alkaline Land

InactiveCN102257946AReduce irrigated areaGood wetting range and wetting uniformityClimate change adaptationWatering devicesGrowth controlAgricultural science

The invention relates to a drip irrigation method for planting cotton in severe saline-alkali land. The method adopts the steps of pre-sowing preparation, capillary laying, drip irrigation, and salt control during growth period. This method does not carry out traditional submerged irrigation in autumn and winter after cotton is harvested. Before cotton is sown, pipes are laid and covered with film to drip water, and drip irrigation under film is used during the cotton growth period. It is aimed at the current situation of decreasing agricultural water consumption. A new water-saving and salt-controlling technology developed is an important supplement to the traditional method of flooding salt irrigation with large water. It has the advantages of less water consumption, good salt washing effect, and high crop emergence rate. The severely salinized areas have great potential for popularization and application.

Owner:XINJIANG AGRI UNIV

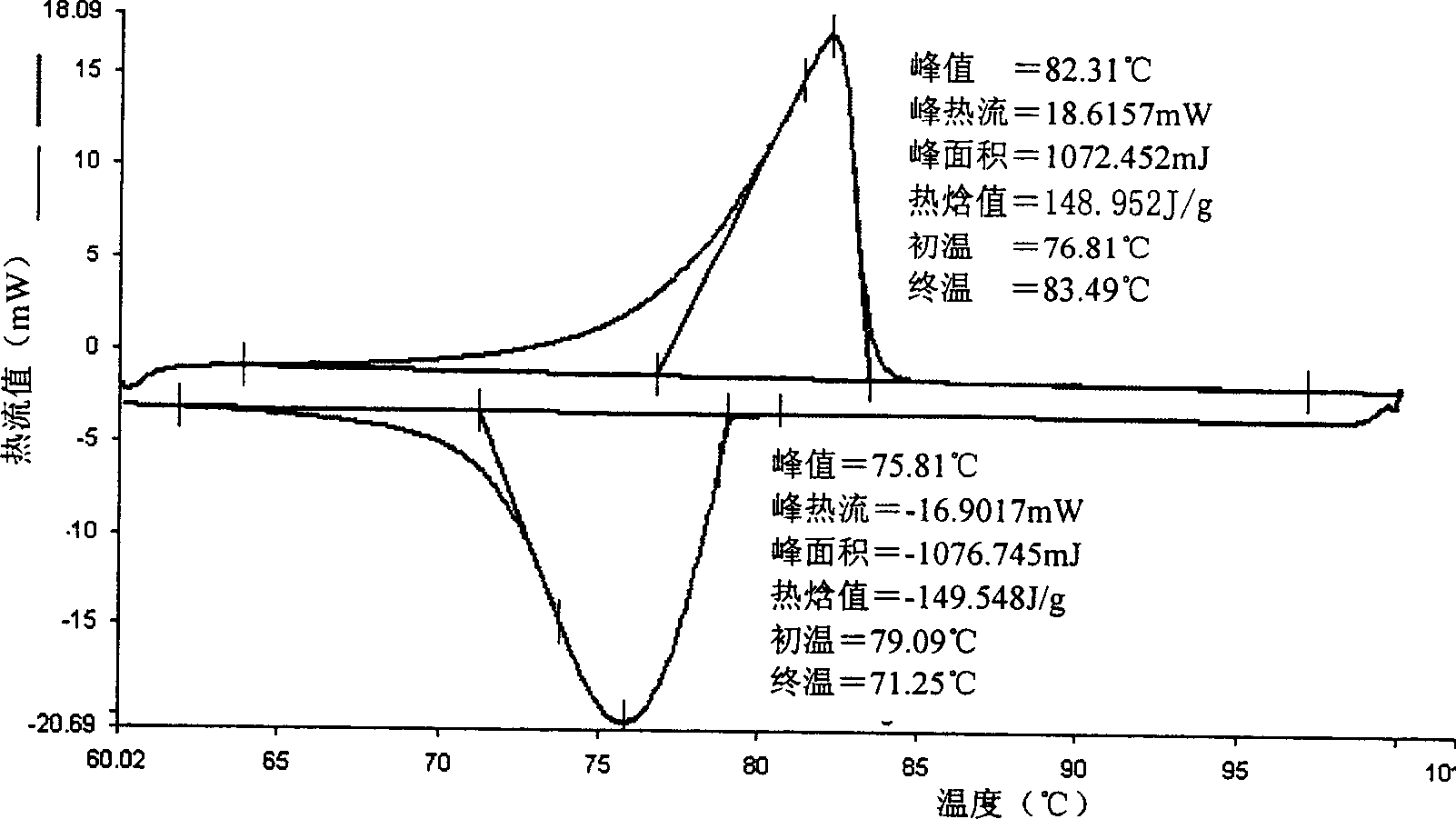

Composite fixing phase change material of 79-83 deg.c and its preparing method

InactiveCN1782018AReduce weight lossStable material performanceHeat-exchange elementsParaffin waxComposite phase change material

The composite fixed 76-83 deg C phase change material and its preparation belongs to the field of phase change heat accumulating material technology. The present invention has SEBS of smelting point 76-81.6 deg C as the packing and oil absorbing material and paraffin of phase change latent heat 200-220 kJ / kg as main energy storing material, and consists of paraffin in 66-80 wt%, high density polyethylene in 11-15 wt%, SEBS in 4-12 wt% and expanded graphite in 3-7 wt%. The composite phase change material is prepared through smelting paraffin in a reactor, adding and smelting high density polyethylene and SEBS, adding expanded graphite and mixing homogeneously, molding at 200-300 KPa pressure to form plate, cooling and demoulding. The material may be set directly inside boiler to contact water as heat transferring medium, and after soaking in hot water in temperature above the smelting point for 200 hr, it has weight loss less than 2 % and phase change latent heat change less than 10 %.

Owner:BEIJING UNIV OF TECH

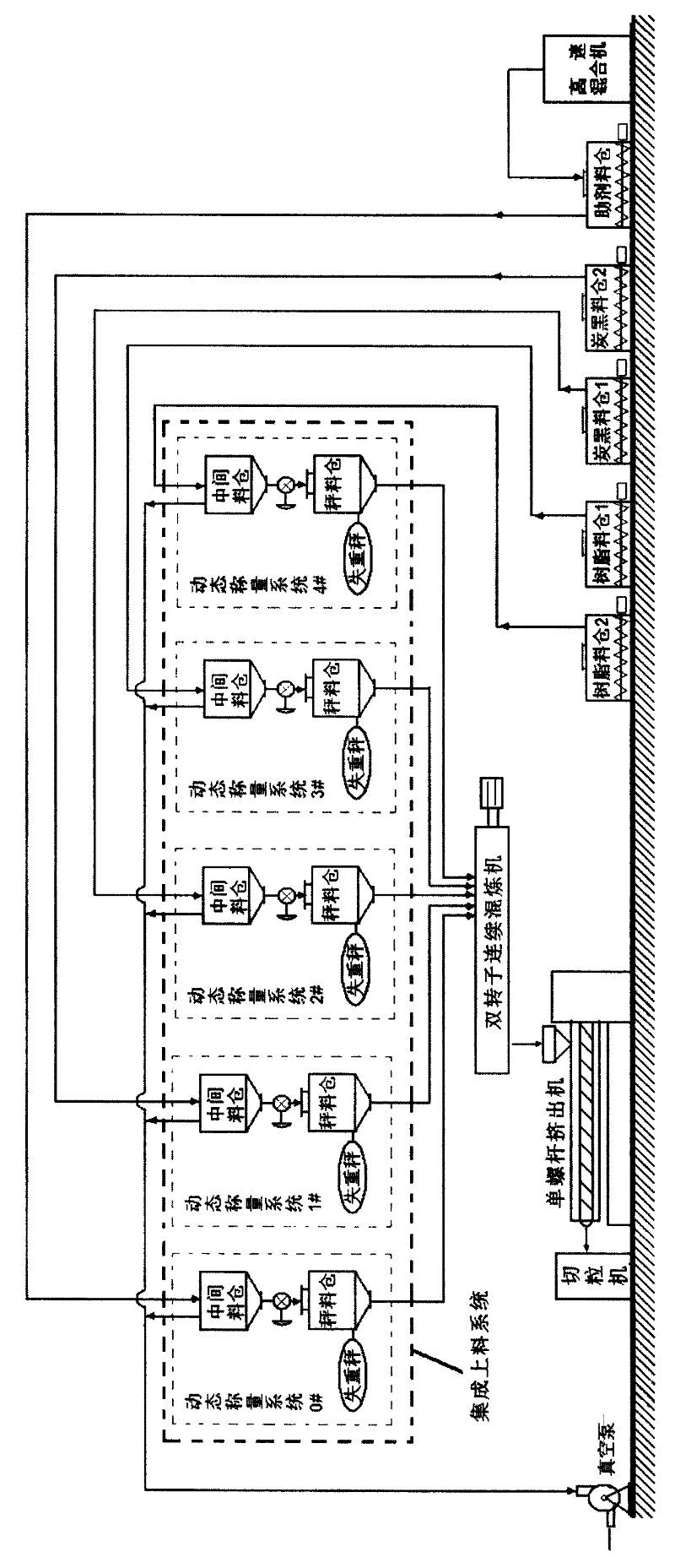

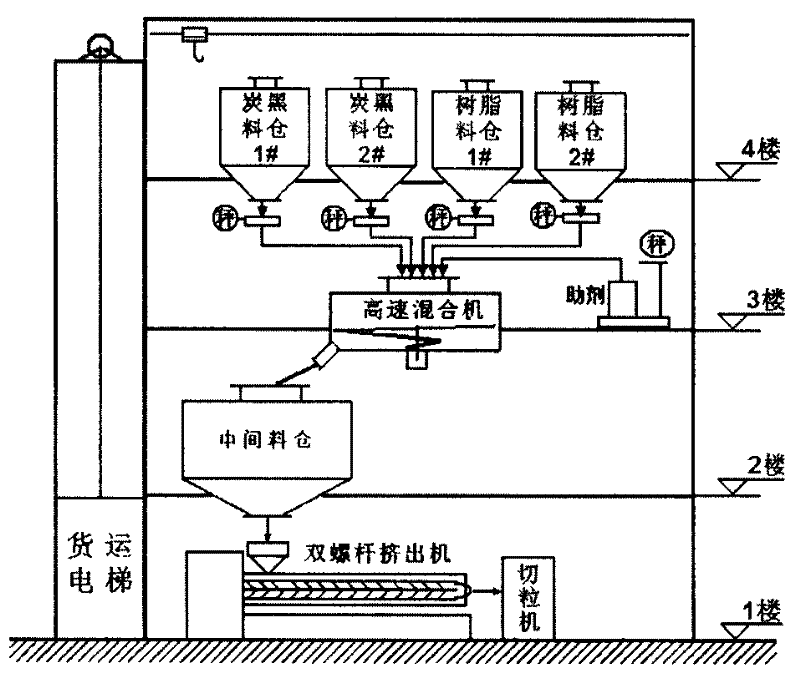

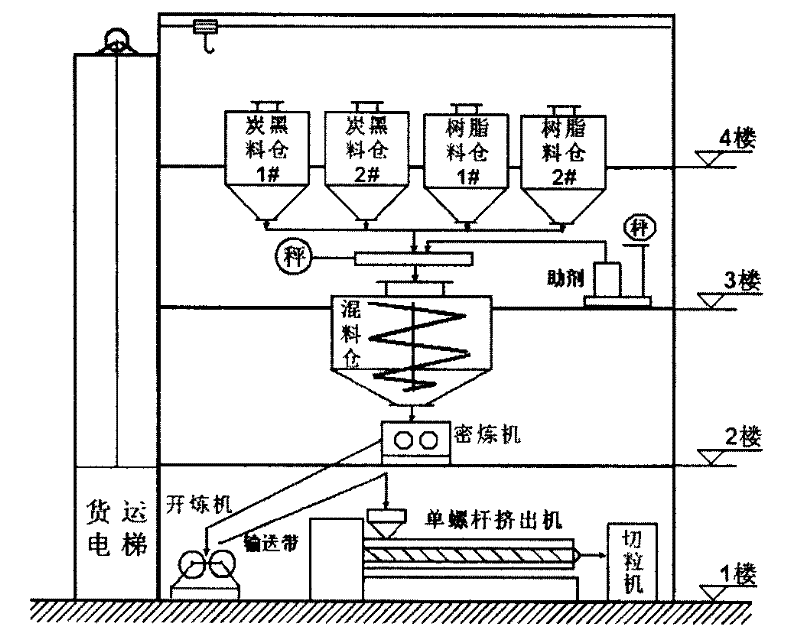

Black masterbatch with high performance, preparation system device and its preparation method

The invention discloses a black masterbatch with high performance, a preparation system device and its preparation method. The masterbatch can be taken as an ultraviolet shielding agent and a black coloring agent, which is widely applied to a polyolefin gas pipeline, a purified water delivering pipeline, conductive plastics, films and cable materials and the like. The characteristics of short production process, raw material negative pressure conveying, sealed type for formulating and feeding, continuously smelting and granulating system enable the raw materials to convey and produce in a sealed system without leakage and fly phenomenon of the carbon black, thereby the good production environment can be guaranteed. According to the invention, the black masterbatch with high performance isprepared by the following raw materials in weight proportion: 20 to 80 parts of polyolefin carrier resin, 20 to 55 parts of carbon black, 0.2 to 2 parts of dispersant, 0.1 to 0.5 parts of processing auxiliary agent and 0.1 to 1.0 parts of anti-oxidant.

Owner:NANJING UNIV OF TECH +1

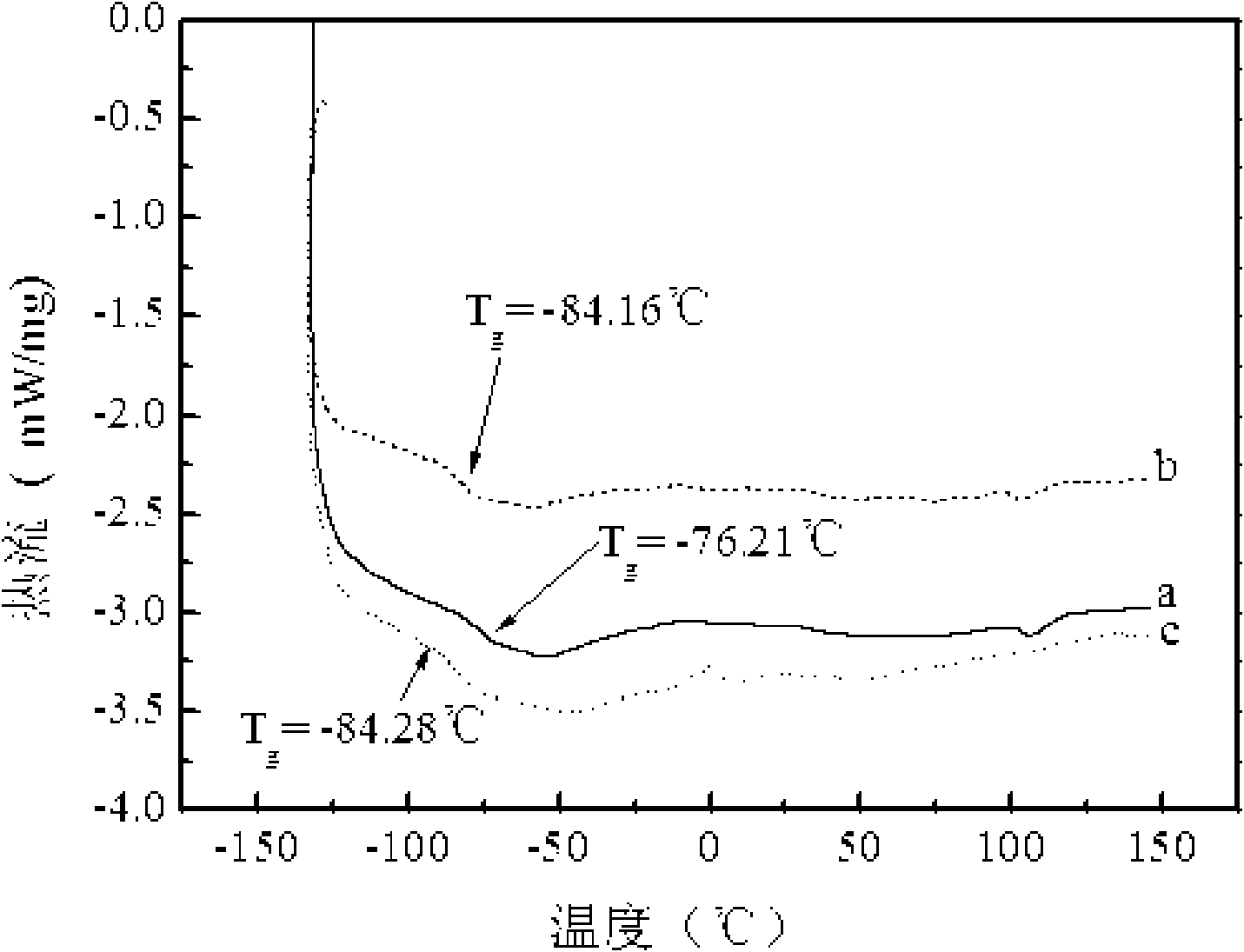

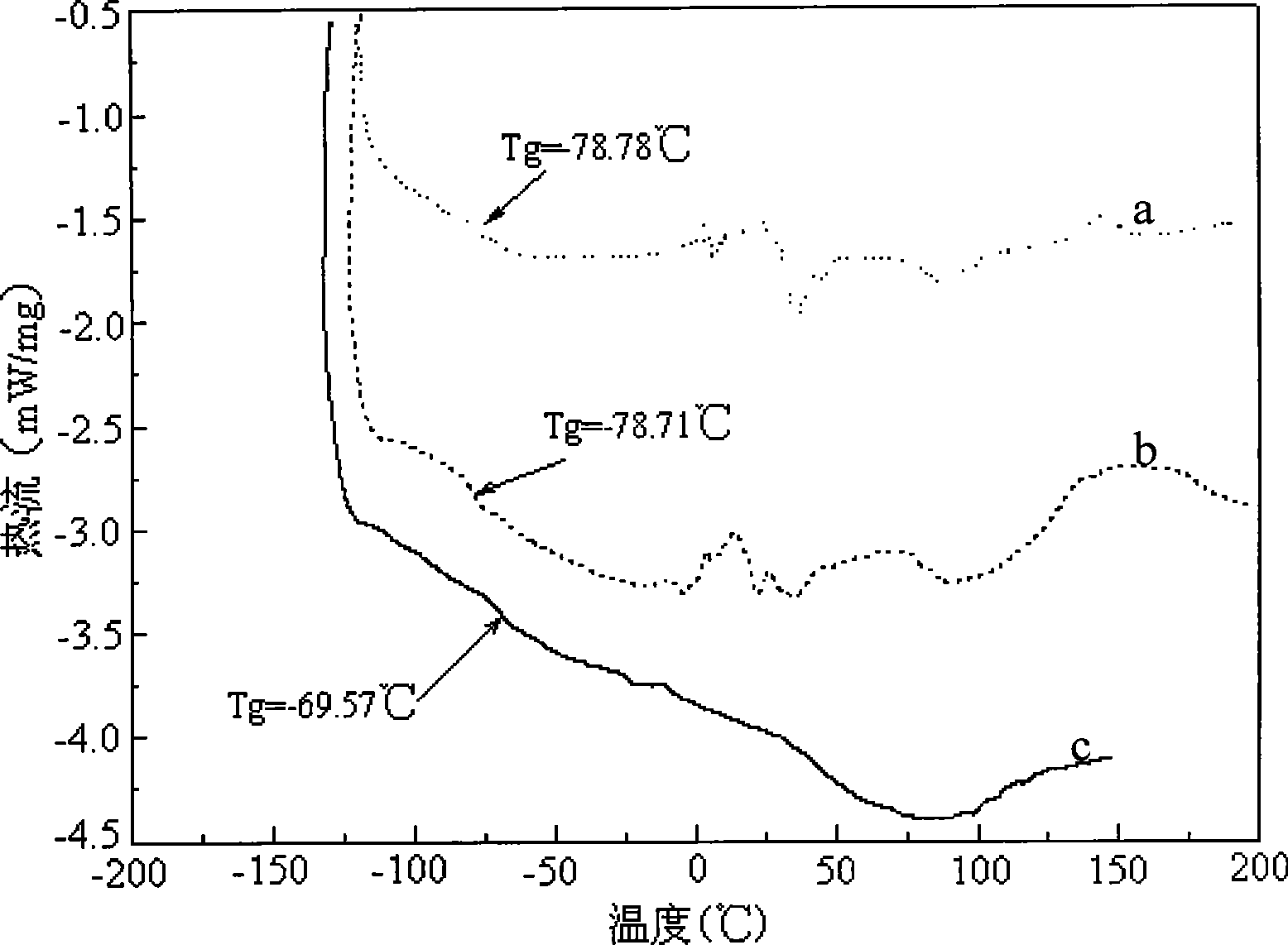

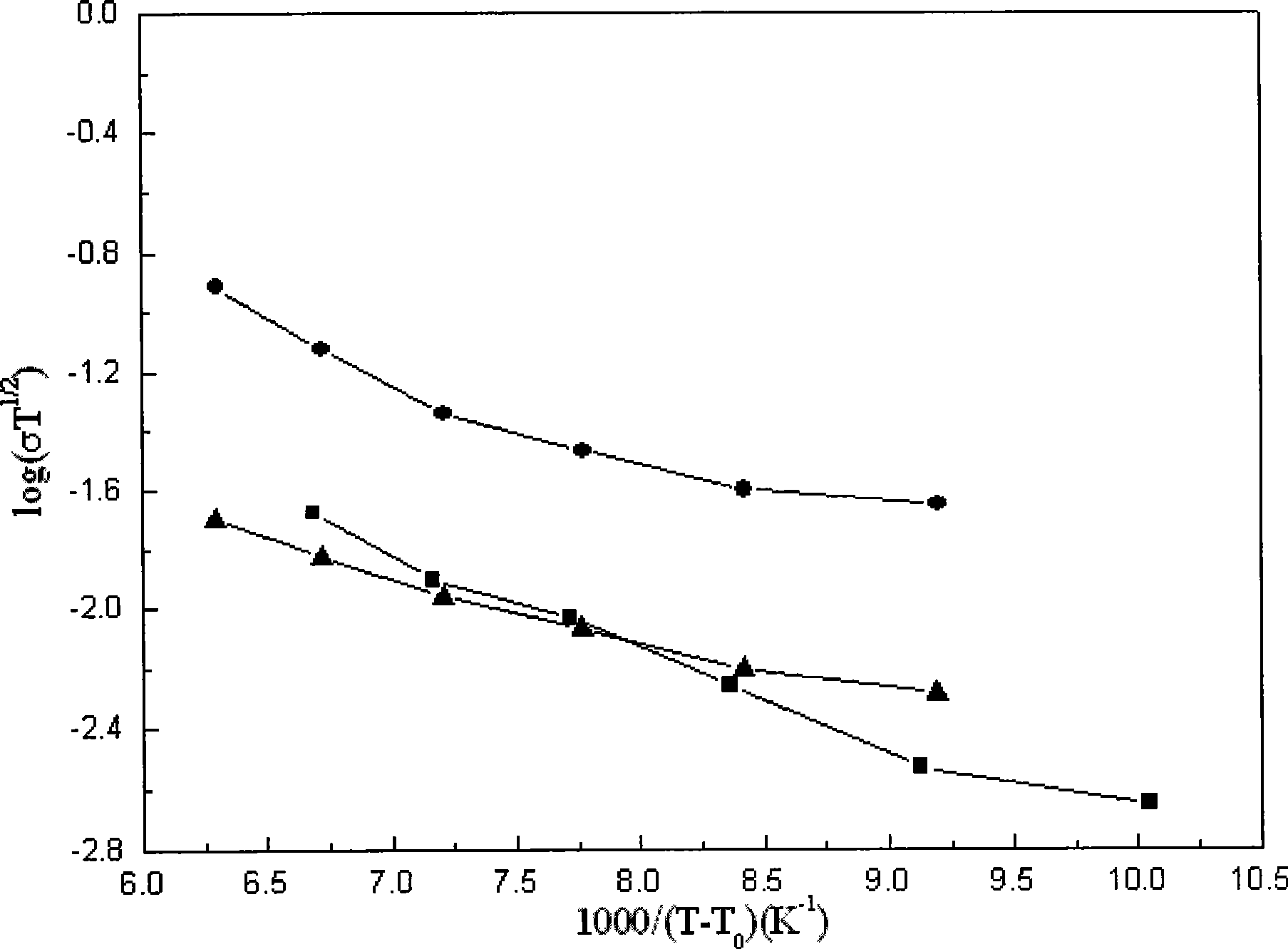

Lithium ion battery gel type ionic liquid/polymer electrolyte and preparation method thereof

InactiveCN101635380AGood thermal stabilityWide electrochemical stability windowSecondary cellsChemistryLithium electrode

The invention discloses a lithium ion battery gel type ionic liquid / polymer electrolyte and a preparation method thereof, relating to a gel type ionic liquid / polymer electrolyte and a preparation method thereof. The invention solves the problem of poor compatibility of the prior imidazole ionic liquid and a lithium ion battery cathode material. The electrolyte is made of a macromoleclar polymer, imidazole ionic liquid and lithium salt. The method comprises the following steps: 1. dissolving the macromoleclar polymer into organic solvent; 2. adding the imidazole ionic liquid and stirring till the solution is uniform; 3. adding the lithium salt to obtain gel liquid; 4. pouring the gel liquid into a die, drying in vacuum and demolding. The electrolyte has favorable compatibility with a lithium titanate cathode; a lithium ion battery made of the electrolyte has high safety, and the lithium titanate cathode presents ultrahigh specific capacity (more than a double of the theoretical specific capacity) and two charging and discharging platforms in the electrolyte. The invention has simple method and technology, low cost and convenient operation.

Owner:HARBIN INST OF TECH

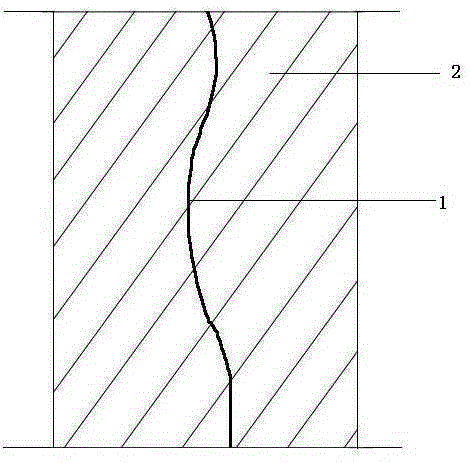

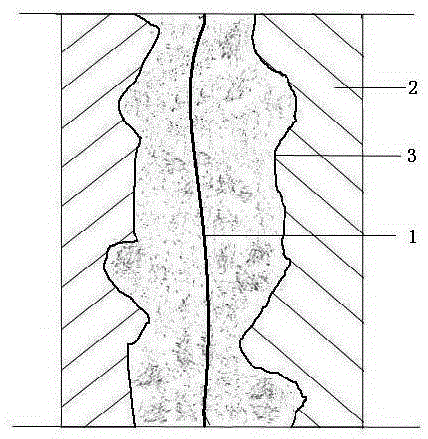

Construction process for plugging and consolidating concrete crack through chemical grouting

InactiveCN105239789ACrack works wellUniform thicknessBuilding repairsFoundation repairChemical groutingMaterials science

The invention relates to a construction process for plugging and consolidating a concrete crack through chemical grouting, which belongs to the technical field of concrete consolidation engineering and in particular relates to a concrete crack plugging and consolidating method. The construction process for plugging and consolidating the concrete crack through the chemical grouting comprises the following steps of the first step, opening a V-shaped groove, which is 20 mm wide at the upper part and at least 20mm deep, along the concrete crack; the second step, flushing the V-shaped groove; the third step, plugging the V-shaped groove; the fourth step, drilling a grouting hole; the fifth step, mounting a grouting head; the sixth step, performing grouting; and the seventh step, removing the grouting head. The construction process for plugging and consolidating the concrete crack through the chemical grouting, provided by the invention, is advantaged in that the grouting process is simple and convenient, the operation of the process is convenient, the crack is closely plugged without a gap, the plugged concrete crack is durable and fatigue-proof and not prone to crack again, the concrete crack plugging effect is good, the concrete surface is completely dry, leakage and moist are avoided, the thickness of a plugging and finishing coating on the surface of the crack is uniform, no missed brushing, no base exposure, no peeling, no swelling and no crack are achieved. And moreover, the process causes no pollution to the environment.

Owner:赵涛

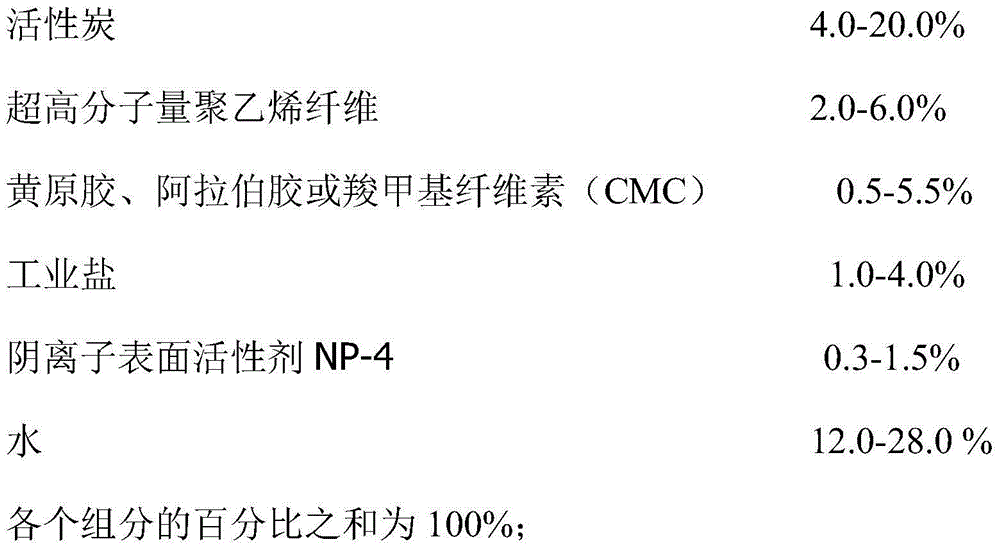

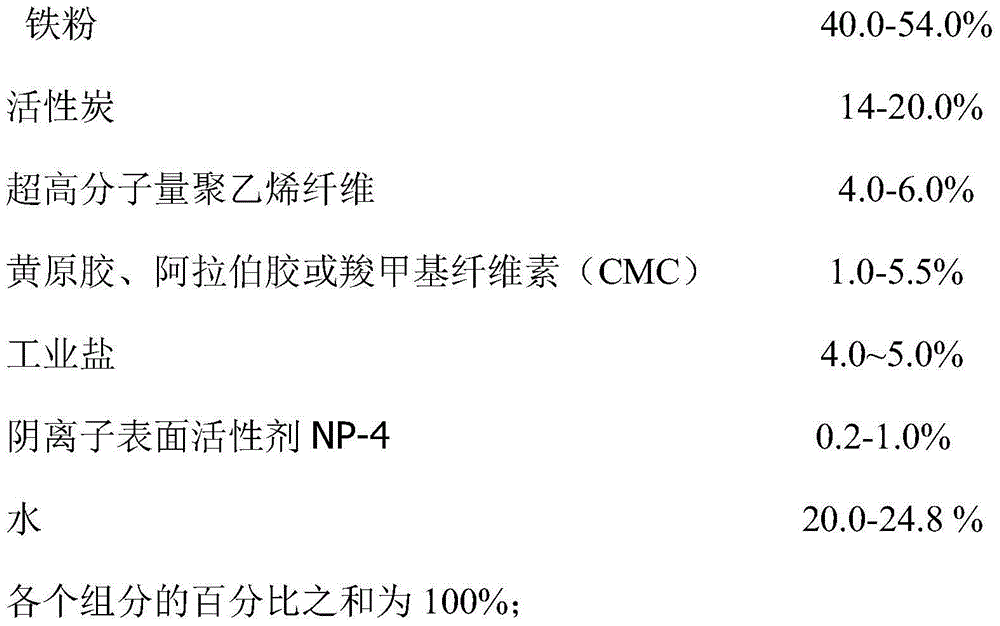

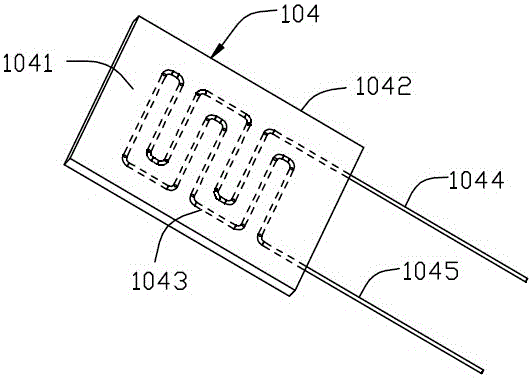

Thin-sheet-type self-heating element, preparation method and application thereof

ActiveCN104974720AImproved heating temperature stabilityNo leakageHeat-exchange elementsTherapeutic coolingFiberLumbar

The invention discloses a thin-sheet-type self-heating element, a preparation method and an application thereof. The thin-sheet-type self-heating element includes the following components, by weight, 20.0-60.0% of iron powder, 4.0-20.0% of activated carbon, 2.0-6.0% of ultrahigh-molecular-weight polyethylene fiber, 0.5-5.5% of xanthan gum, Arabic gum and carboxymethylcellulose (CMC), 1.0-4.0% of industrial salt, 0.3-1.5% of an anionic surfactant NP-4 and 12.0-28.0% of water. The self-heating element is greatly improved in heating temperature stability, can be prepared into a thin-sheet-type heating element, is free of leakage and is safe, can be widely applied in a body warming patch, a medical operation warming cushion, a medical and health-caring patch, a female menstrual-period dysmenorrhea-alleviating patch, breast caring, medical health caring of lumbar and cervical disease, instruments and meters, and digital product portable heating and the like fields.

Owner:SHANGHAI WARMYOU IND CO LTD

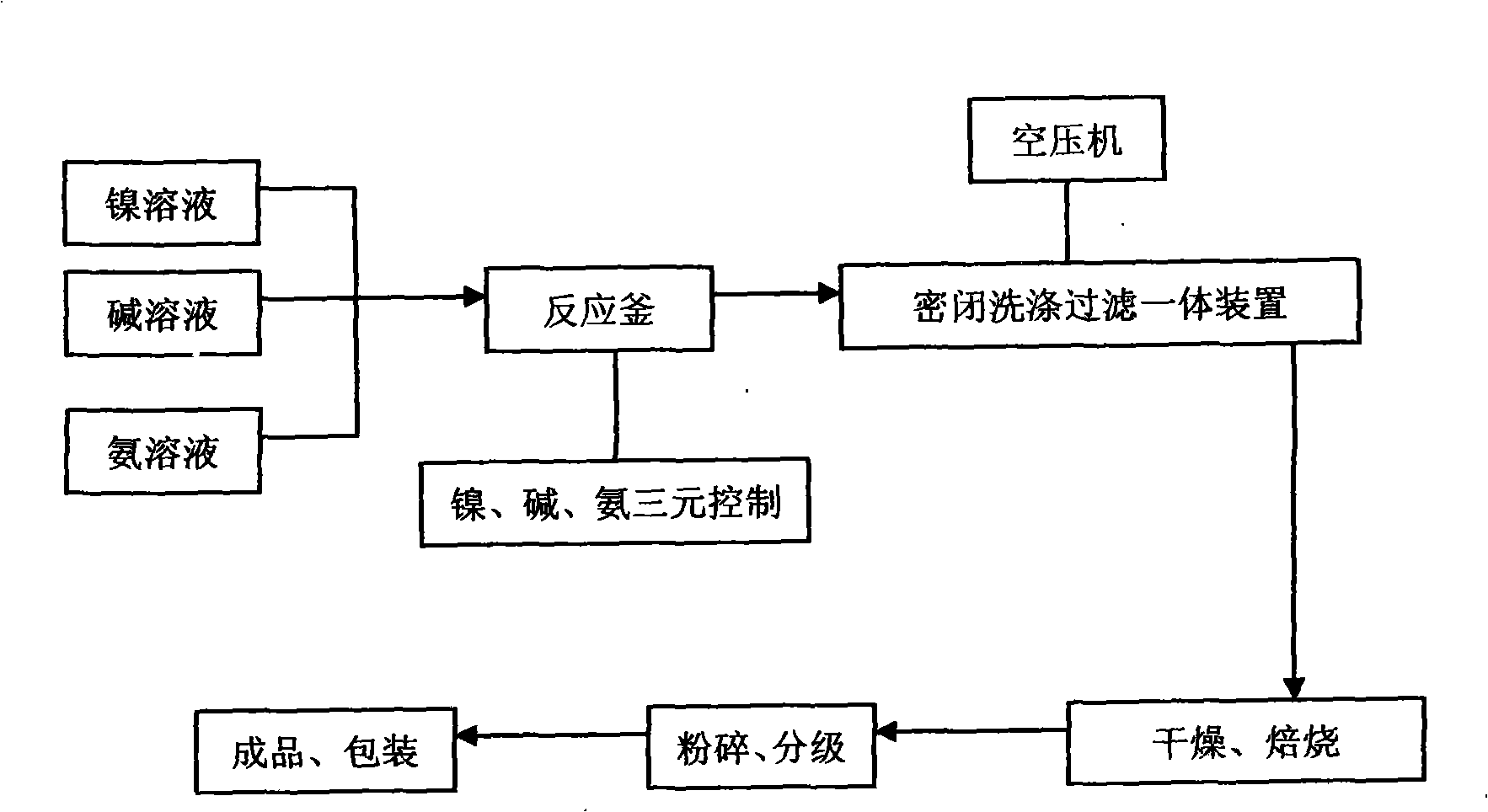

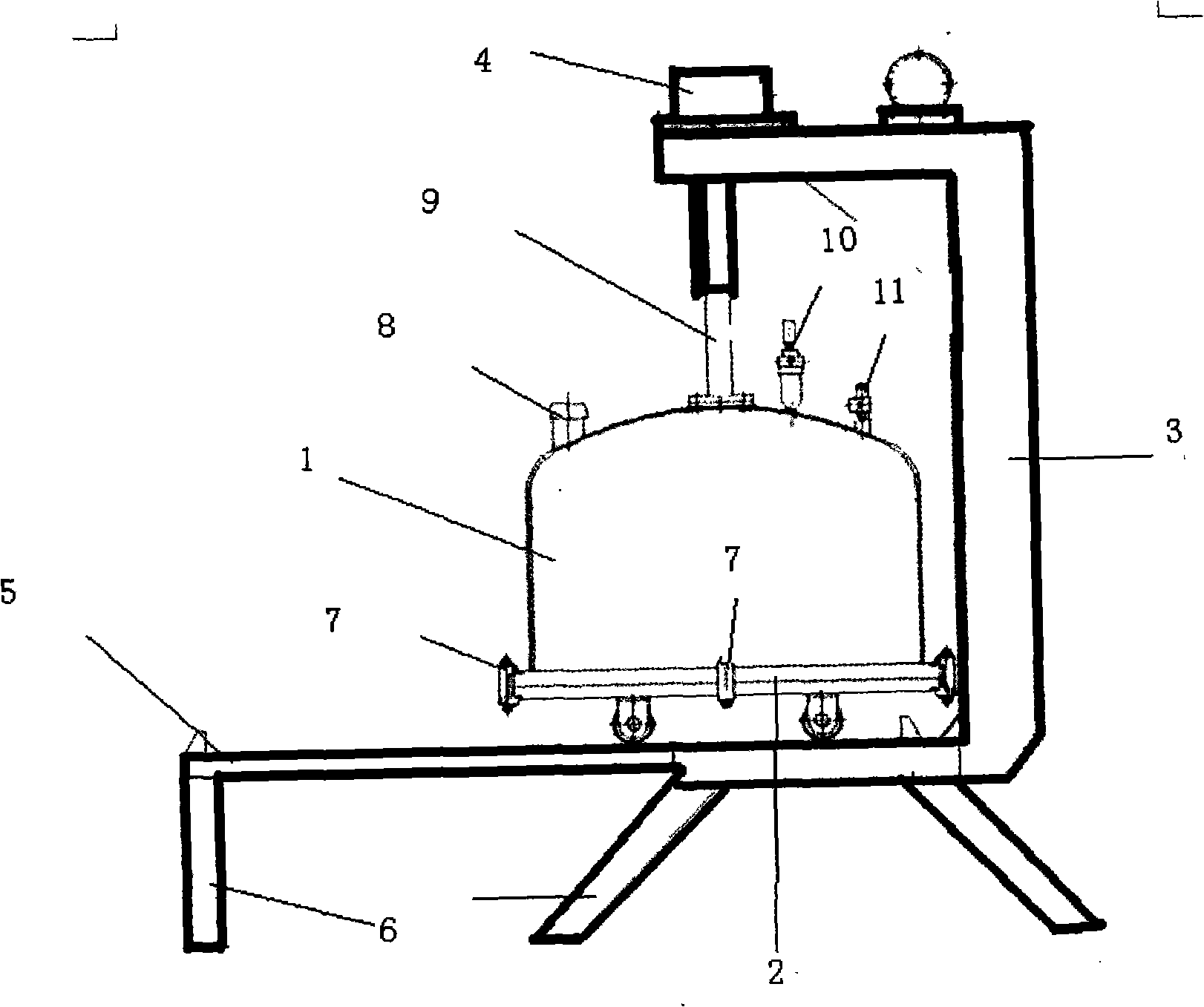

Method and device for producing high-grade nickel oxide

InactiveCN101264942ASignificant progressSignificant positive effectNickel oxides/hydroxidesFiltrationSulfate

The invention relates to a method for producing high quality nickel oxide by controlling crystal growth via nickel complex precipitation and a device thereof. The method comprises the steps of simultaneously controlling pH value, temperature, stirring speed, and the ratio of nickel salt, ammonia and sodium hydroxide; monitoring the 'ternary system' concentration (nickel sulfate (Ni<2+>), sodium hydroxide (OH<->) and ammonia (NH<+>)) in the supernatant in a reaction vessel (on-line system crystal ternary control method) and controlling the concentration range thereof to obtain high-purity sphere precursors of adjustable D50 particle diameter about 1-20 mum with uniform particles and good dispersion; and filtering, washing and calcinating under sealing to obtain high quality nickel oxide. The inventive method has the advantages of no waste gas discharge, improved working environment, ensuring operators in good health, reduced labor intensity, washing and filtering integration, saving a large amount of washing water, low energy consumption, environmental friendliness, and low time and labor consumption; and is superior to the prior washing and filtering method including centrifugation, plate-type filtration and vacuuming.

Owner:郑景宜

Lithium ionic cell gel type ion liquid / polymer electrolyte and preparation thereof

InactiveCN101440188AImprove ionic conductivityIncrease capacitySecondary cellsPolymer electrolytesOrganic solvent

The invention discloses a gel type ionic liquid / polymer electrolyte for a lithium ion battery and a preparation method thereof, and relates to a gel type ionic liquid / polymer electrolyte and a preparation method thereof. The invention solves the problem of short cycling time of the prior imidazole ionic liquid and electrode material. The electrolyte is prepared from macromolecular polymers, the imidazole ionic liquid and lithium salt. The method comprises: firstly, dissolving the macromolecular polymers into an organic solvent; secondly, adding the imidazole ionic liquid into a mixture, and stirring the mixture until the mixture is uniform; thirdly, adding the lithium salt into the mixture and obtaining a gel liquid; and fourthly, pouring the gel liquid into a die and performing vacuum drying and demolding. The electrolyte has good compatibility with a cathode of lithium titanate; the lithium ion battery prepared by the electrolyte has good safety and stable cycling performance under the condition of different multiplying factors, so as to have long cycling time; and the method has the advantages of simple technique, convenient operation and low cost.

Owner:HARBIN INST OF TECH

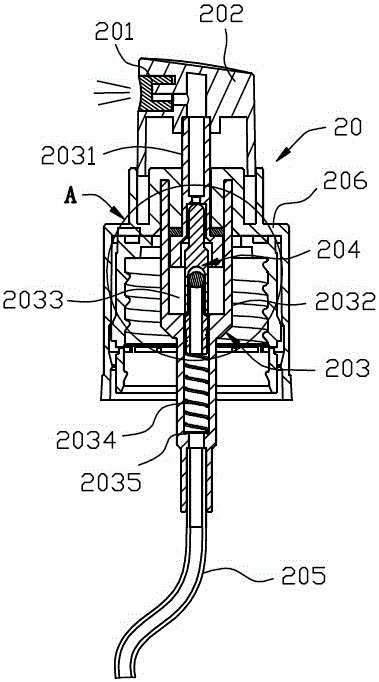

Jet-type atomization device

PendingCN105901775AImprove atomization efficiencyRealize secondary atomizationMedical devicesTobacco devicesLiquid storage tankEngineering

The invention discloses a jet-type atomization device. The jet-type atomization device comprises a shell, a liquid storage tank, a jet device, a heating element and a power supply. An atomization chamber is arranged in the shell; the liquid storage tank is used for storing cigarette liquid to be atomized; the jet device is used for jetting the cigarette liquid into the atomization chamber to form cigarette liquid particles of a certain particle size; the heating element is located in the atomization chamber and provided with a heating surface, the heating surface is used for bearing the cigarette liquid particles and heating and evaporating the cigarette liquid particles to form smoke; the power supply is arranged in the shell and used for supplying power to the heating element. Compared with the prior art, the jet-type atomization device improves the atomization efficiency, improves the smoking taste for users and improves the use experience as a jetting mode and a heating mode are adopted for dual atomization.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com