Semiautomatic revolving roll grinding miller

A rotary and semi-automatic technology, which is applied in the field of grinding machines, can solve the problems of high labor intensity, high workpiece cost, and low production efficiency, and achieve the effects of overcoming time-consuming, labor-intensive, processing costs, and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

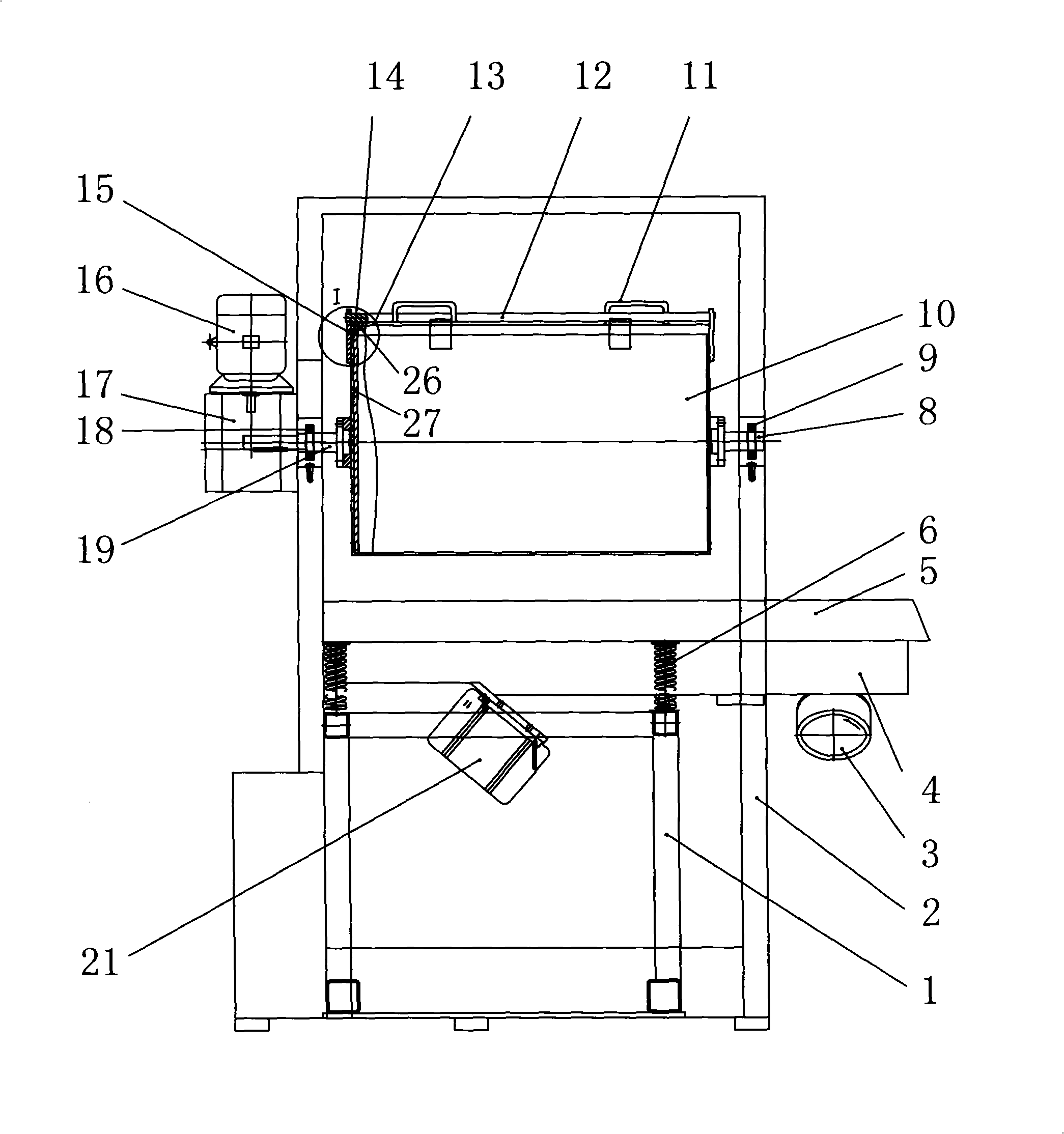

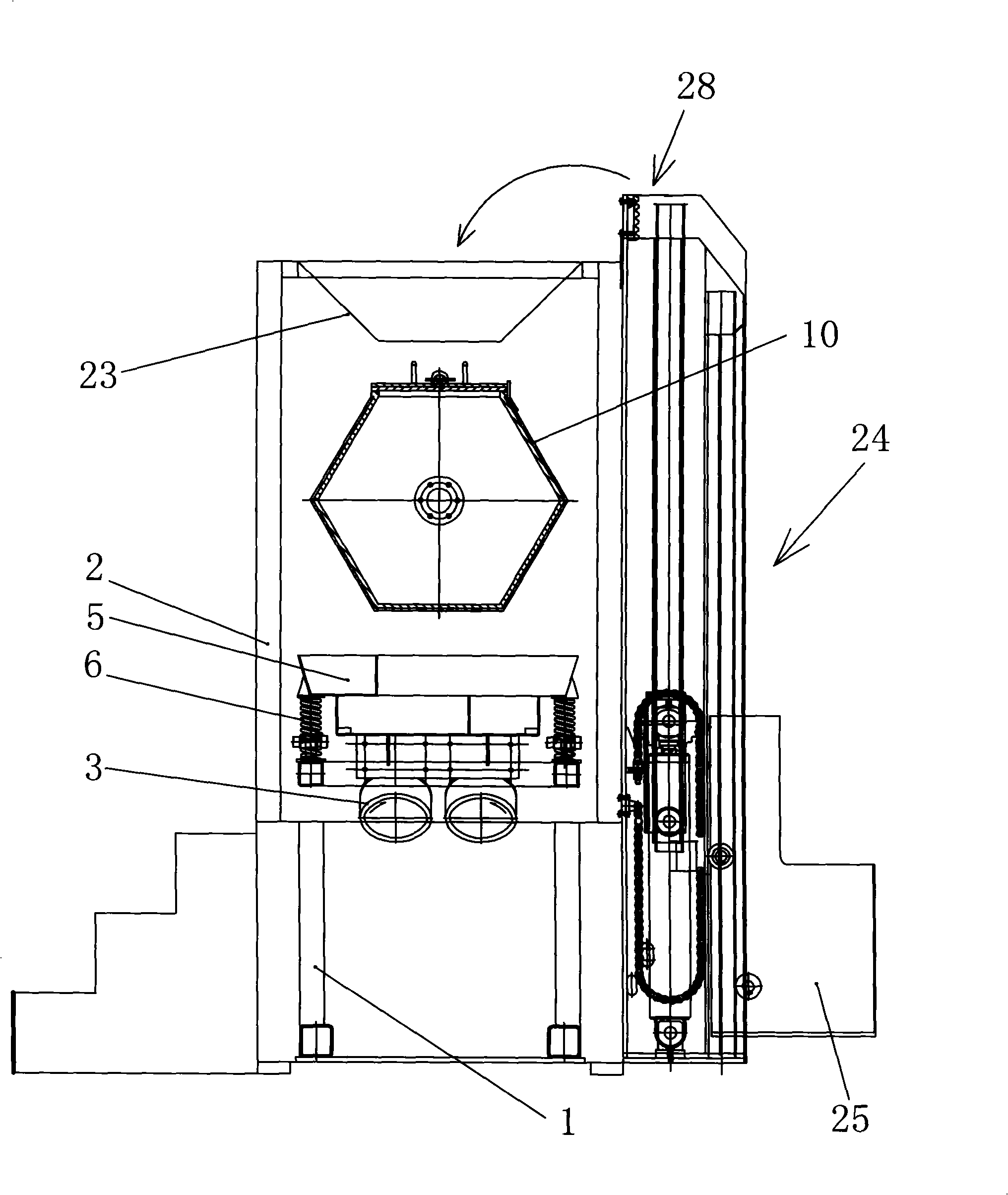

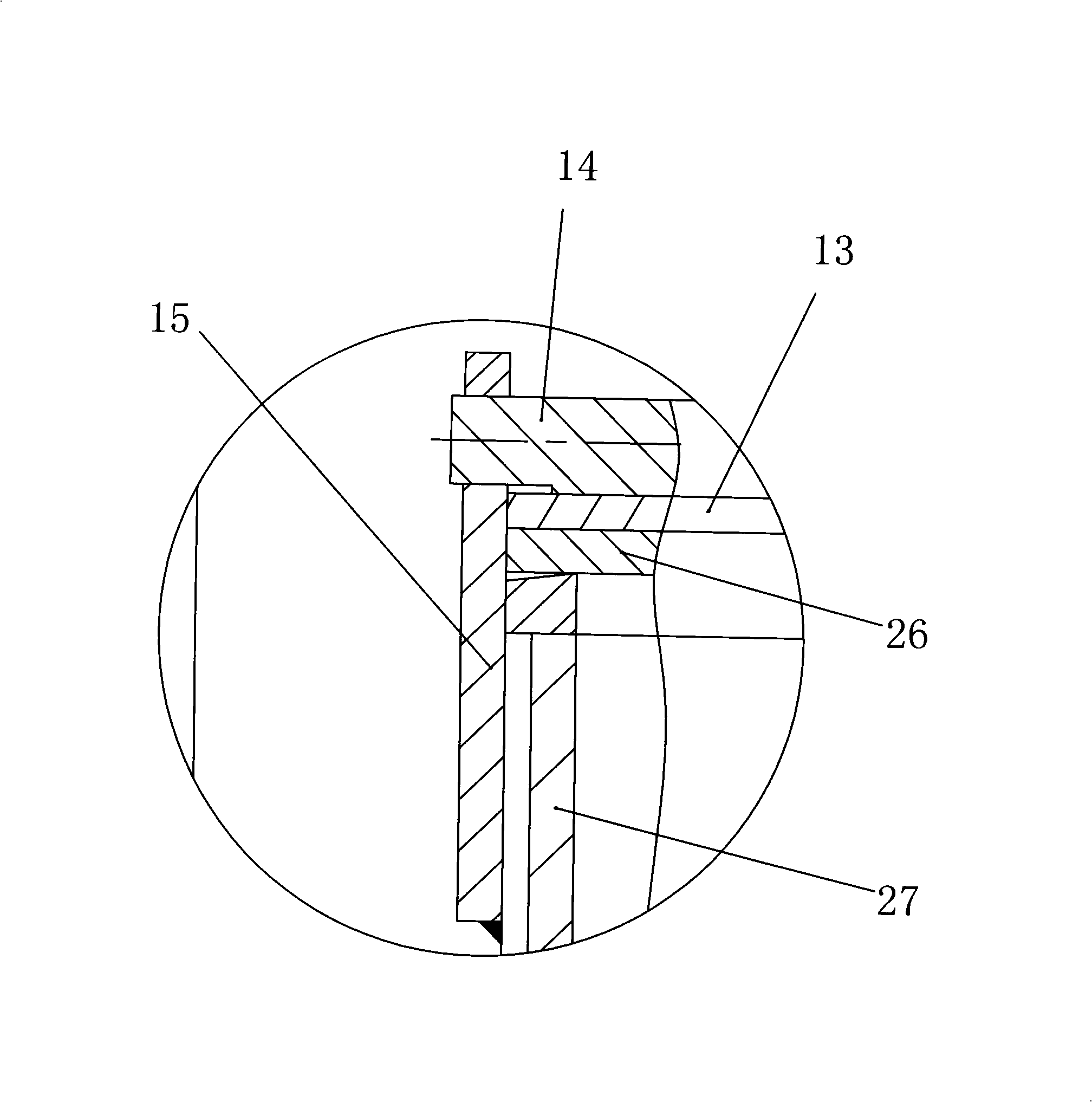

[0017] As shown in the figure: 2 is a frame, which can be made by welded section steel. 10 is a roller. End shaft 8 and end shaft 19 are bolted or welded on the two ends of cylinder 10, and cylinder 10 is supported on frame 2 with bearing 9, bearing 18 and end shaft 8, end shaft 19. The end shaft 19 is connected with the output shaft of the speed reducer 17, and the input shaft of the speed reducer 17 is connected with the motor 16, and the motor 16 and the speed reducer 17 are all bolted on the frame 2 to form the driving device of the drum 10. The drum 10 is provided with a material inlet, and a cover 13 with a handle 11 is provided at the material inlet. One side of frame 2 is provided with lifter 24, and lifter 24 is the chain type lifter that selects for use, and the discharging end 28 on the lifter 24 top is corresponding with the lower hopper 23 that is positioned at the top of cylinder 10 on the frame 2, makes The lifted material automatically falls into the lower ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com