Patents

Literature

8320results about How to "No manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

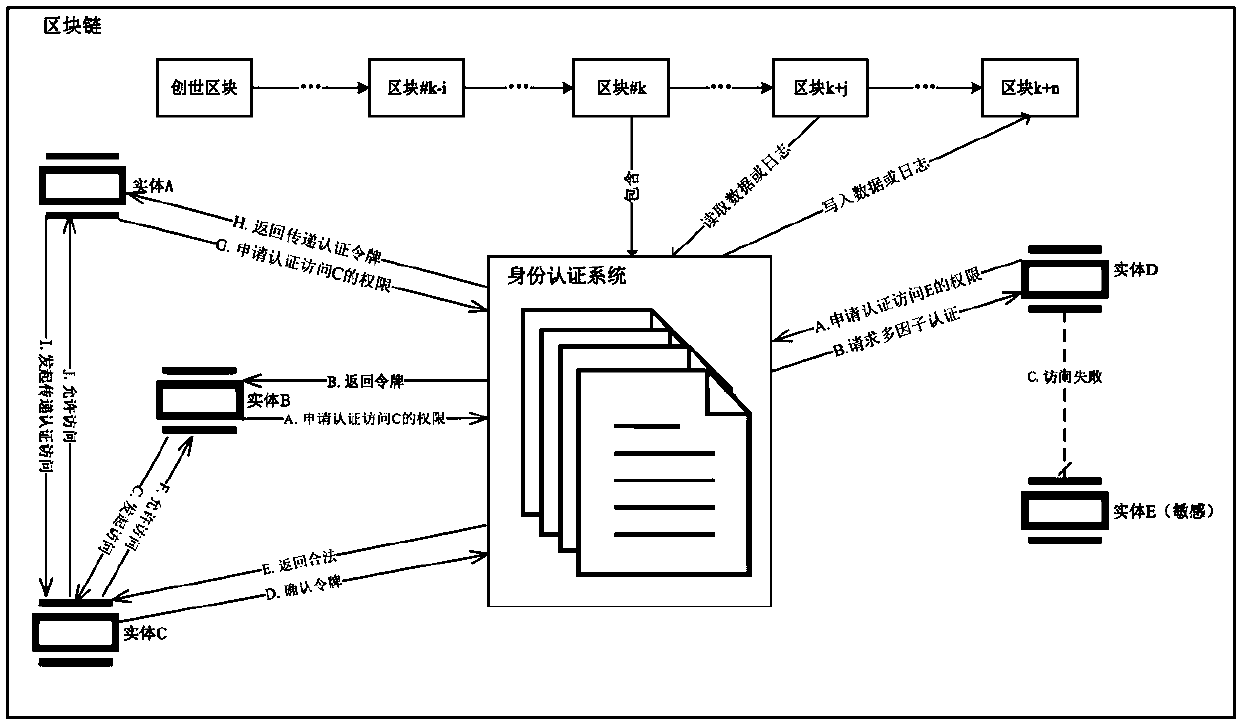

Internet of Things identity authentication method based on blockchain

The invention belongs to the technical field of identity authentication, and specifically provides an Internet of Things identity authentication method based on a blockchain. The basic steps of the Internet of Things identity authentication method provided by the invention are as follows: an entity calls an intelligent contract by means of an own key to accomplish the registration in an identity authentication system; each entity can call the intelligent contract to set an access strategy so as to limit the access of other entities to the entity and to form a trust network of the Internet of Things; when one entity accesses the data of the other entity, the entity needs to apply for a token from the intelligent contract to obtain the access qualification, and the intelligent contract checks whether the entity initiating the access has the access qualification according to the access strategy set by the accessed entity in the trust network between the entities, and if yes, the intelligent contract generates the token and returns the token to the entity initiating the access; or otherwise, the intelligent contract returns token application failure information. By adoption of the method provided by the invention, a centralized authority mechanism in an identity authentication process is removed, malicious tampering of records of identity authentication and data access is prevented, a strategy execution result is not manually manipulated, and a fair, transparent and credible execution environment is provided for the identity authentication of the entities in the Internet of Things.

Owner:FUDAN UNIV

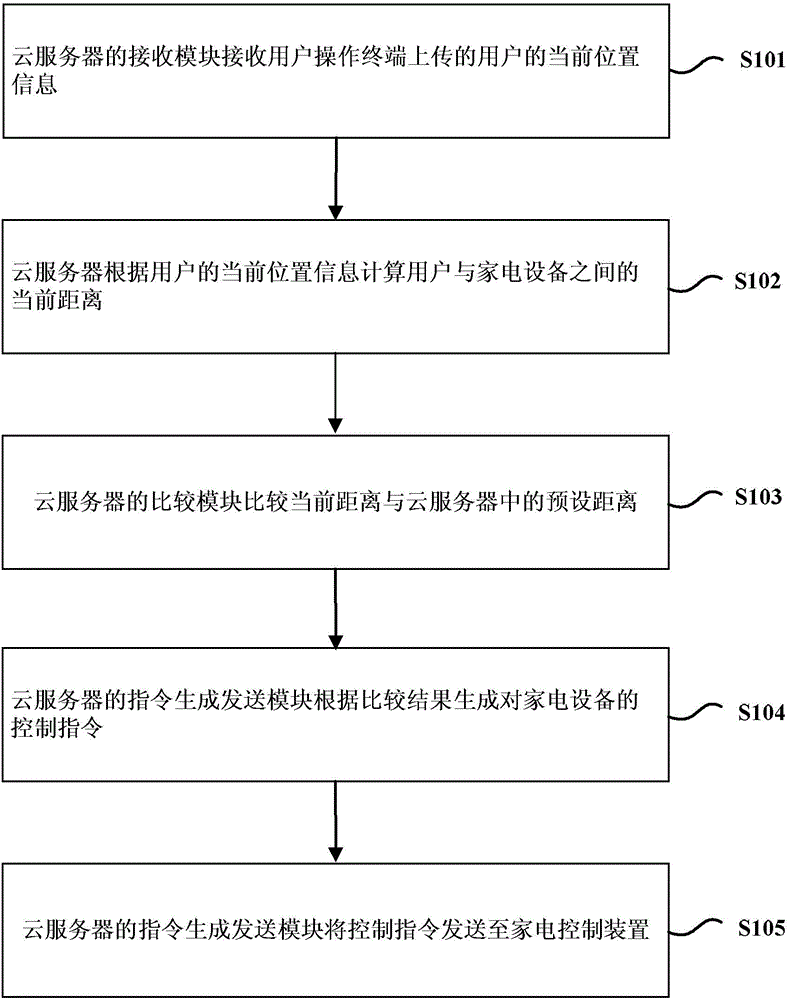

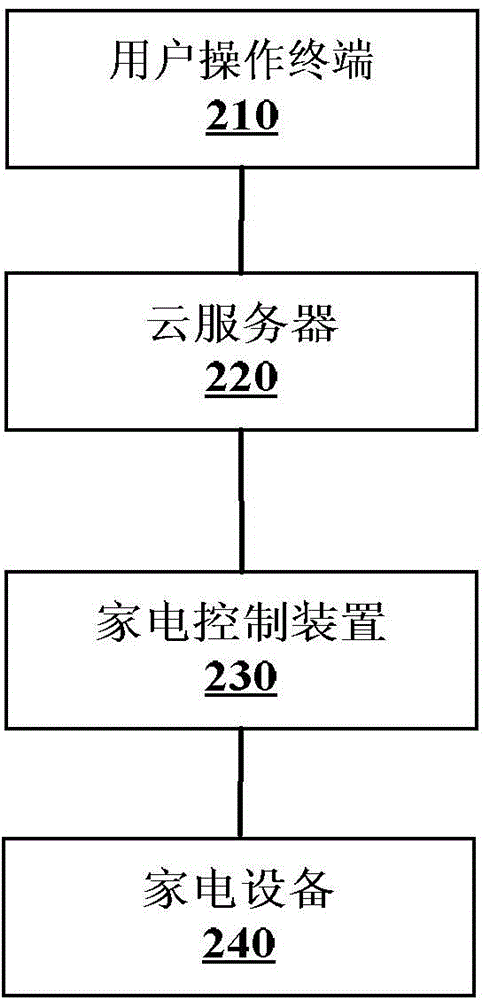

Method and system for controlling domestic equipment according to position of user

InactiveCN103914038AIntelligent controlIncrease the scope of applicationProgramme total factory controlEmbedded systemUser Friendly

The invention provides a method and system for controlling domestic equipment according to the position of a user. The method includes the steps that current user position information uploaded by a user operation terminal is received; the current distance between the user and the domestic equipment is worked out according to the current position information of the user; the current distance is compared with a preset distance in a cloud server, and an instruction of control over the domestic equipment is generated according to comparison results; the control instruction is sent to a domestic equipment control device to enable the domestic equipment to execute corresponding operation according to the control instruction. Due to the adoption of the method and system, domestic equipment remote operation control is more intelligent, the application range is wider, and a more user-friendly effect can be achieved.

Owner:HAIER GRP CORP +1

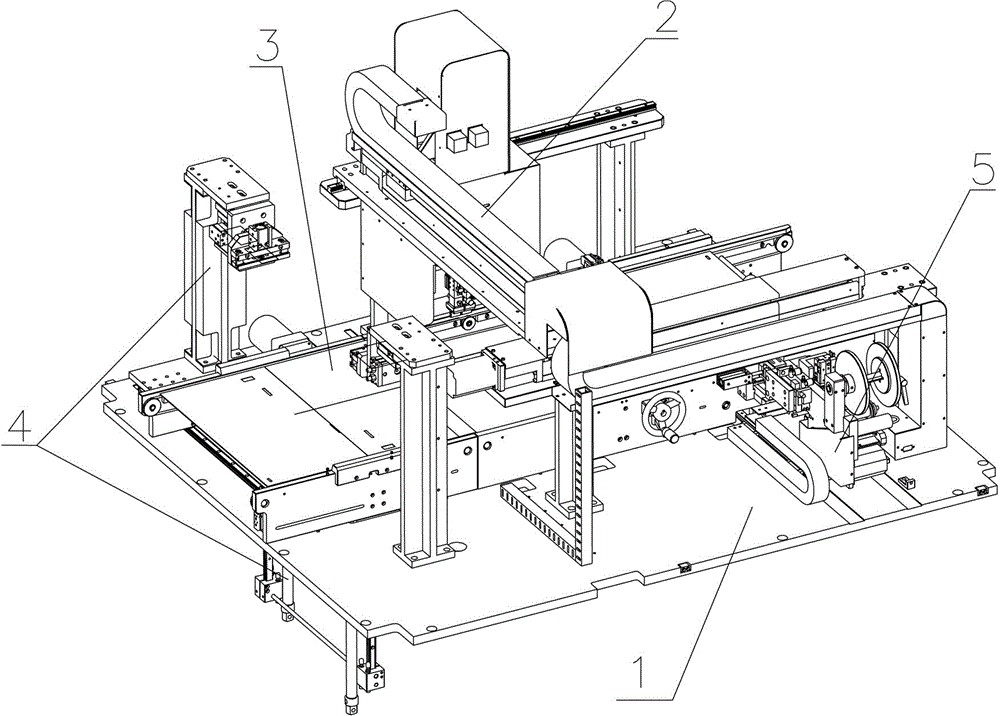

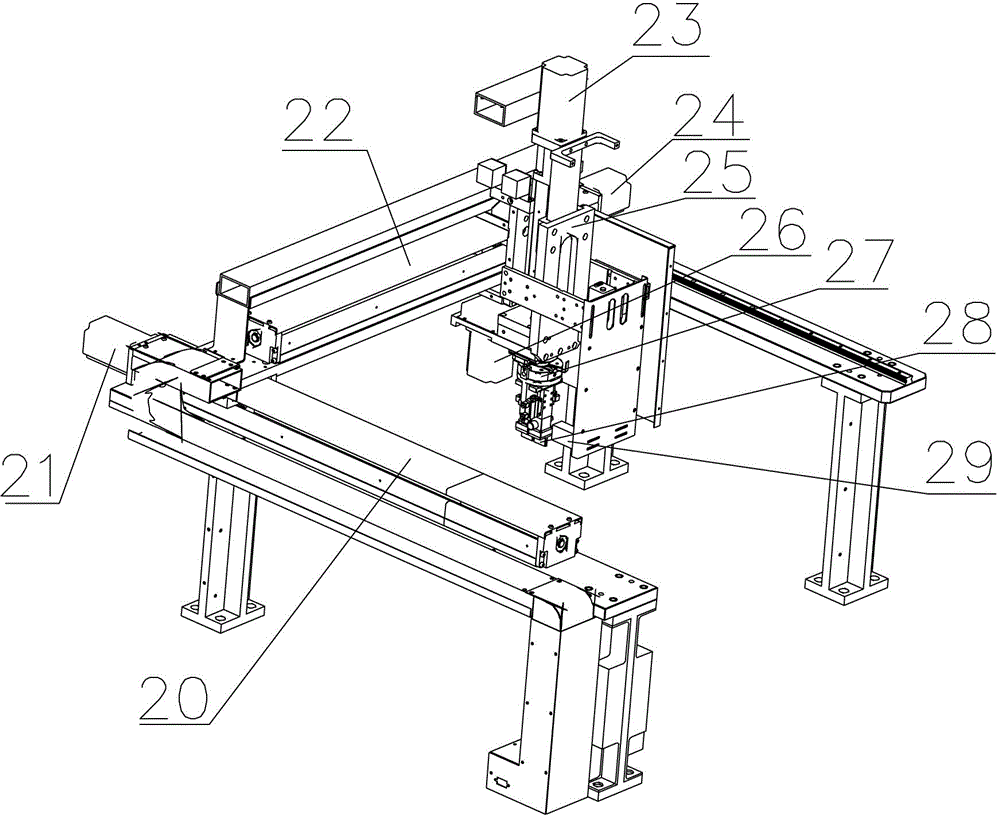

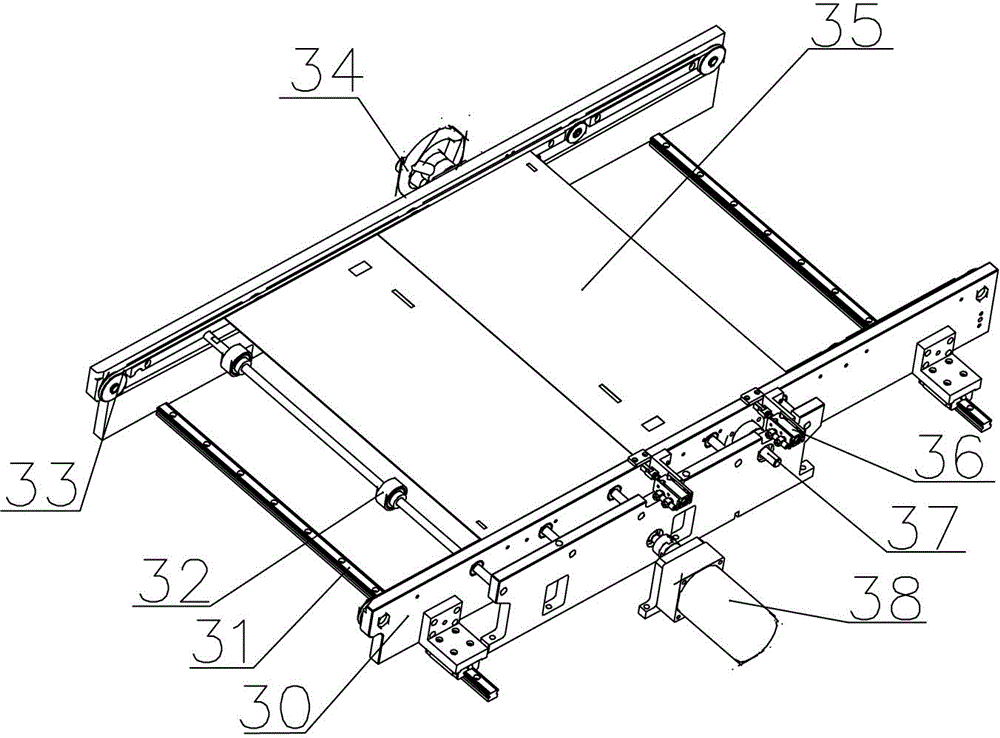

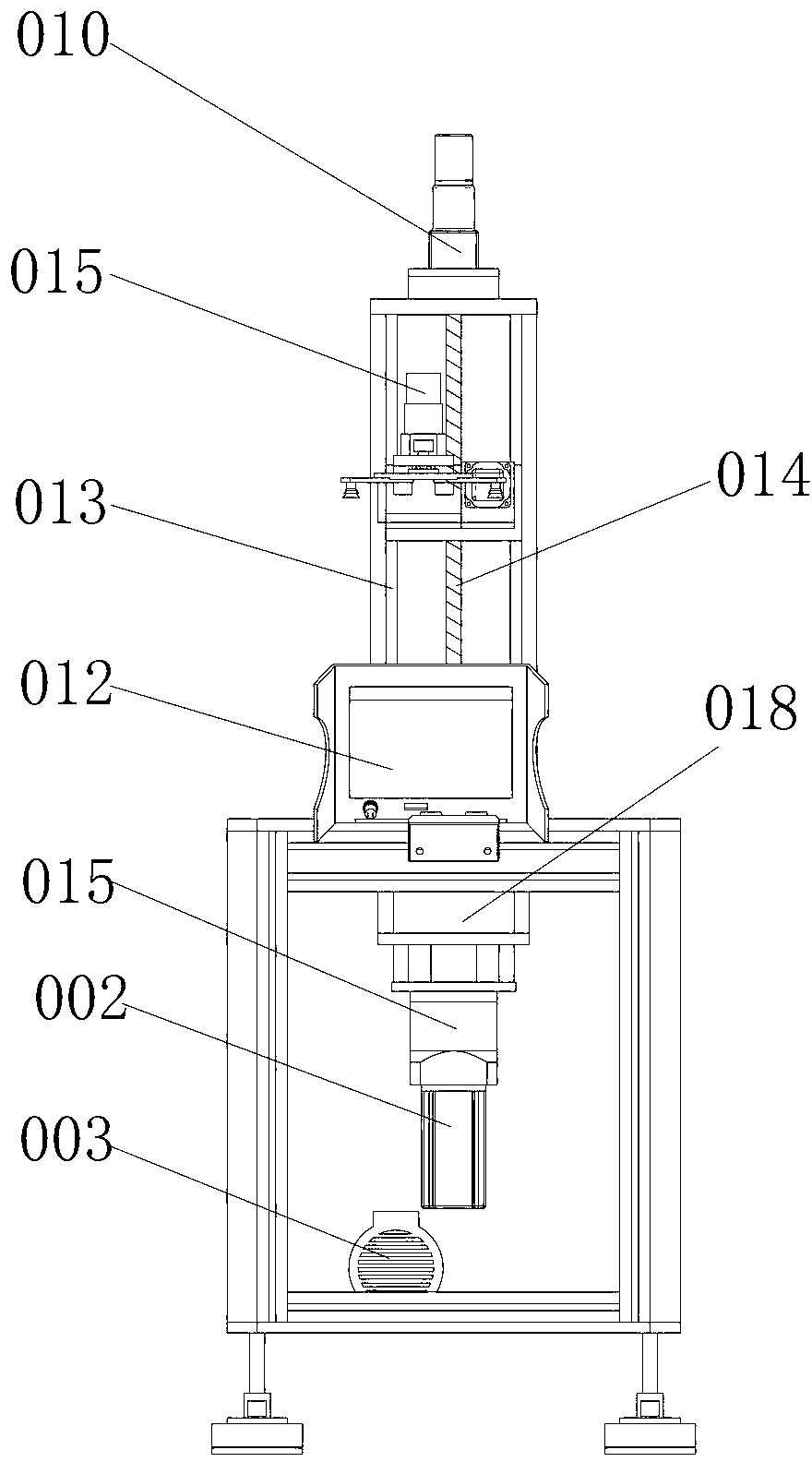

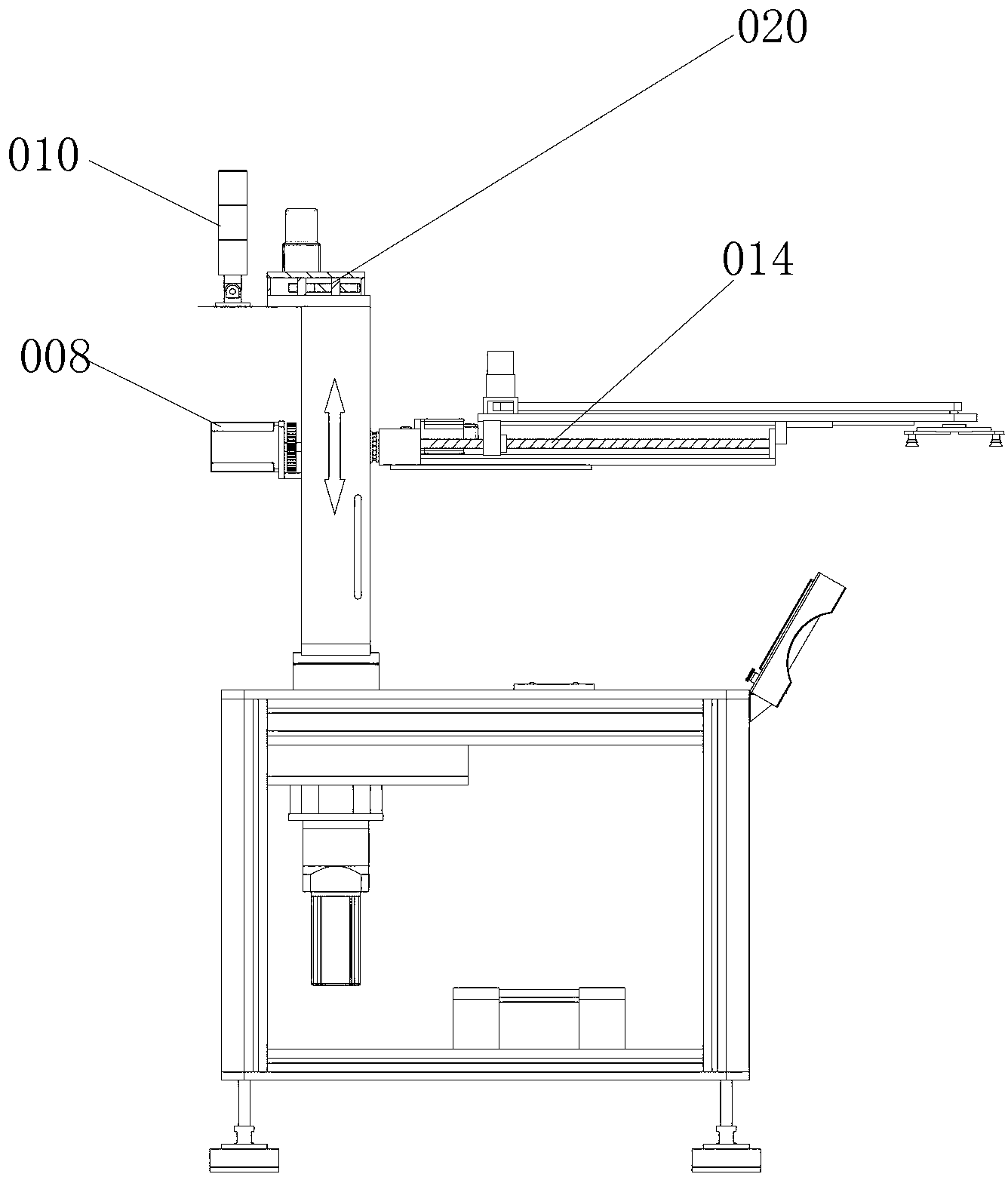

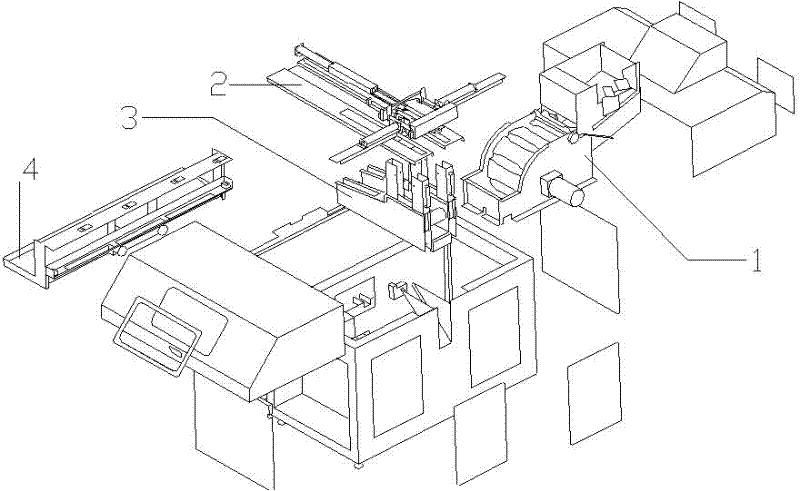

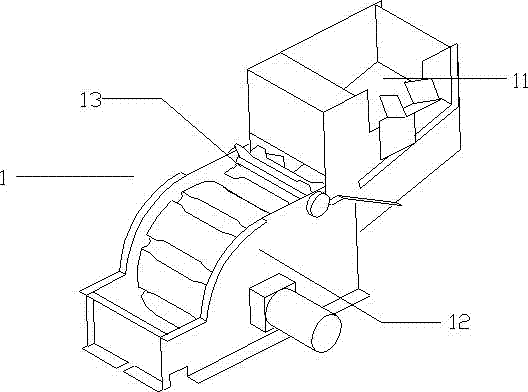

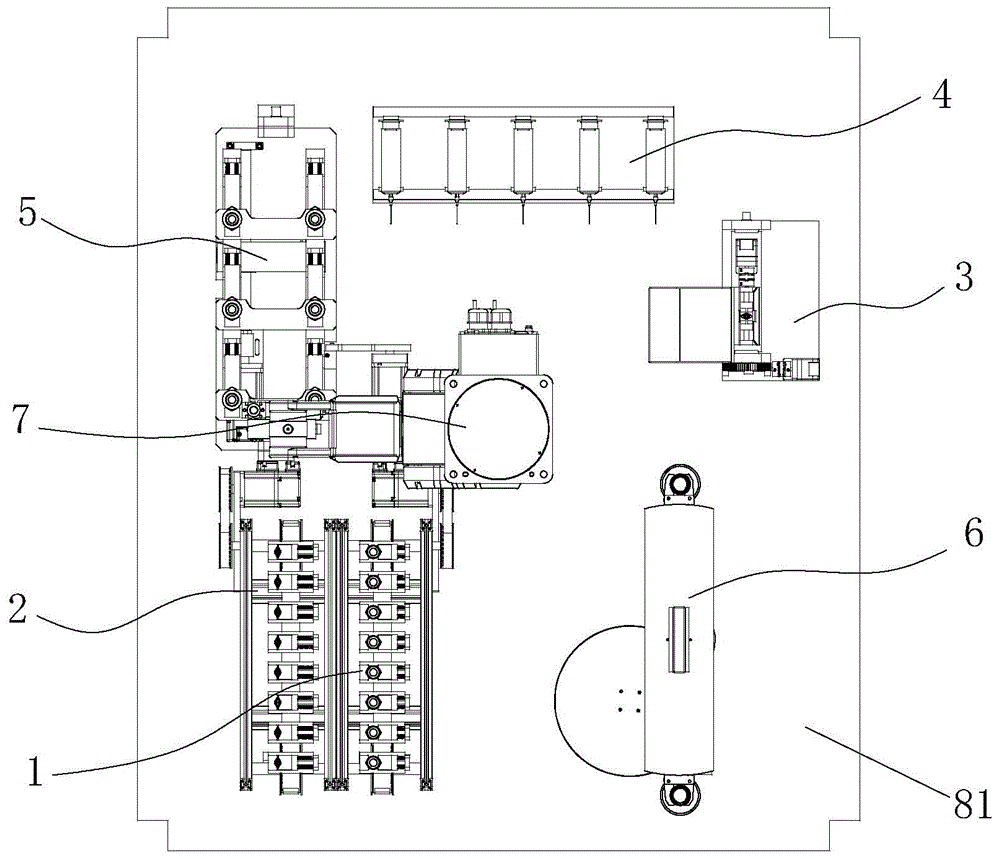

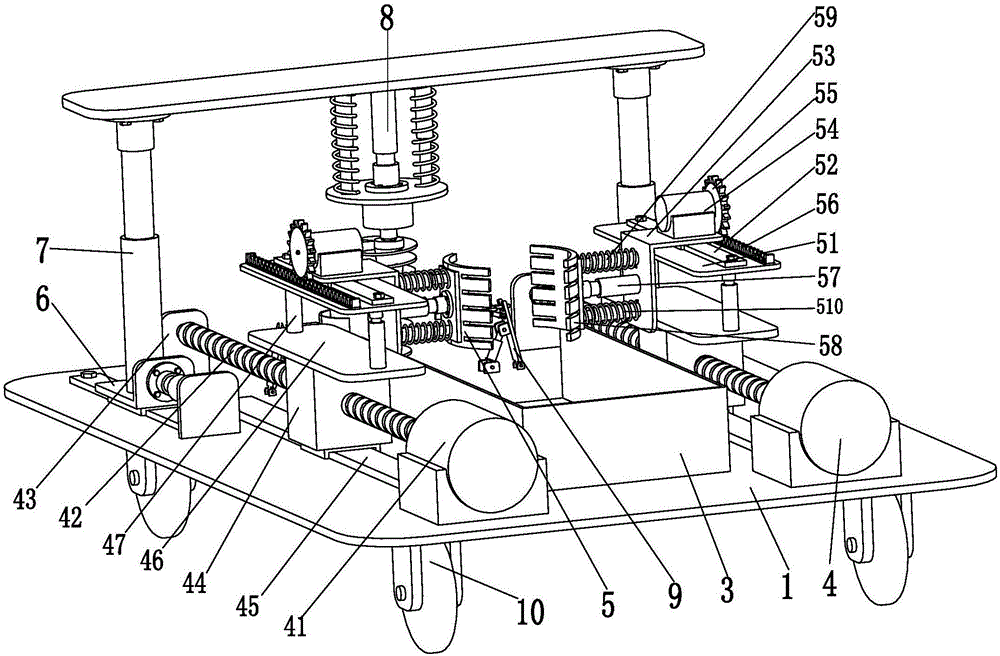

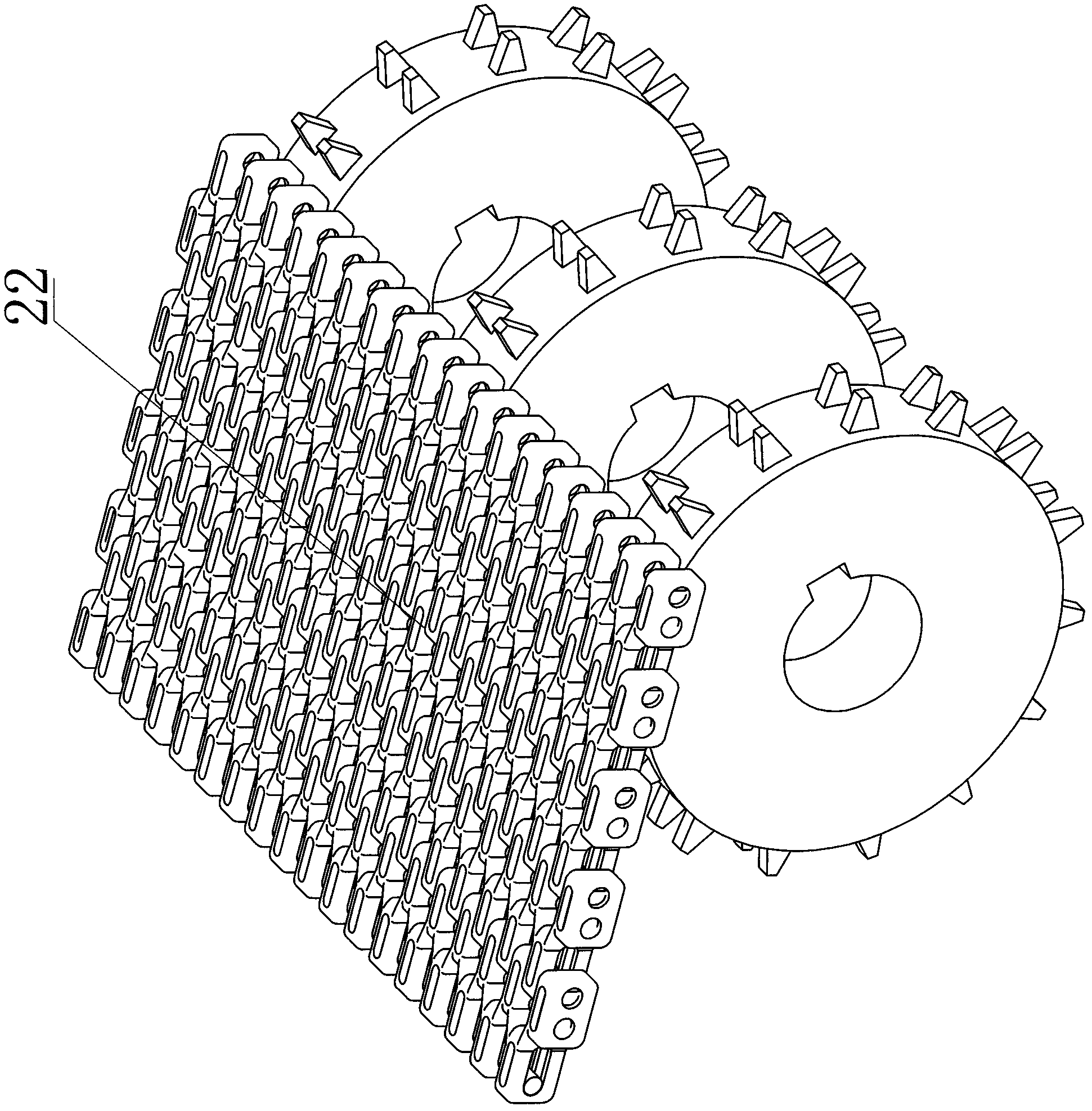

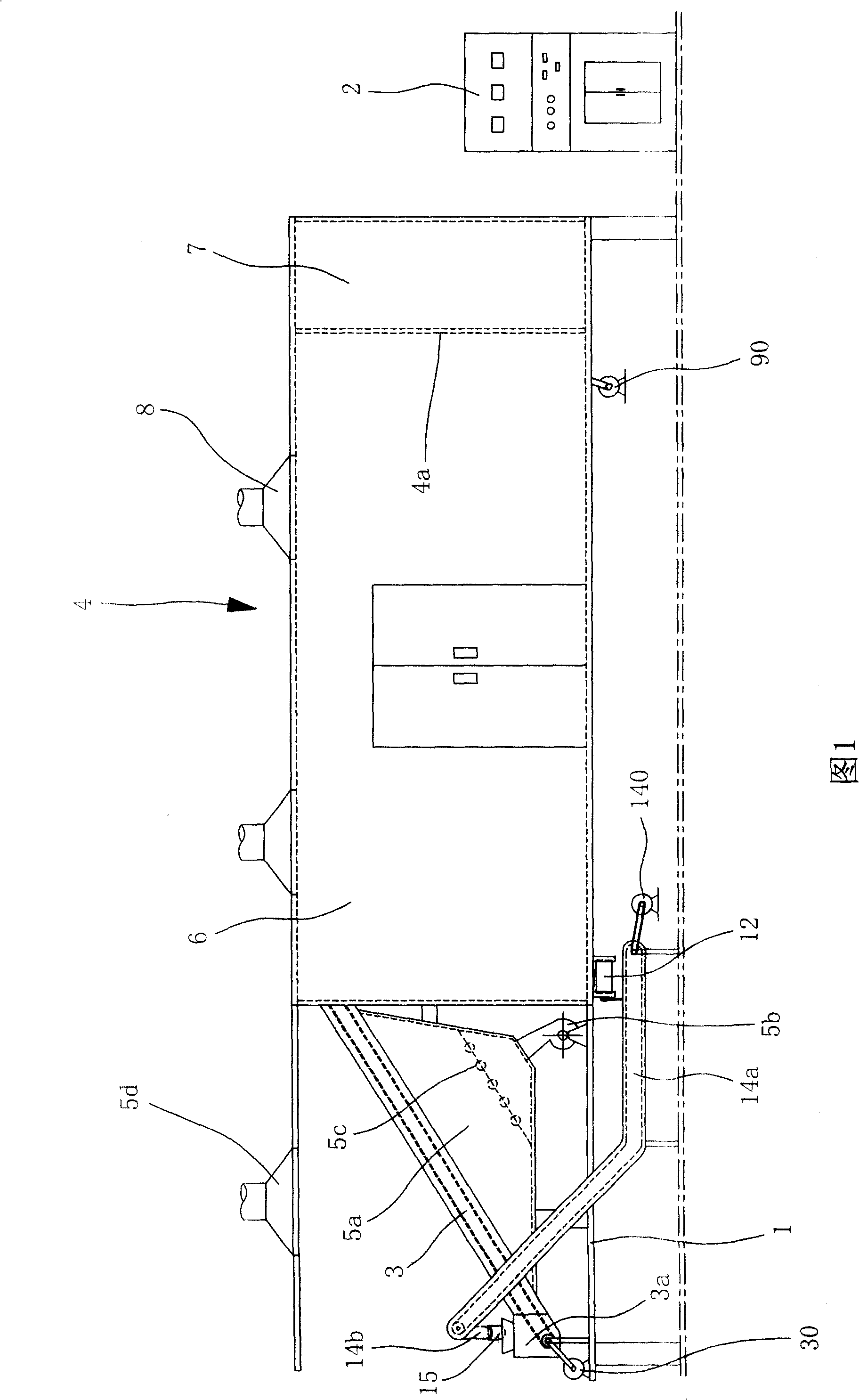

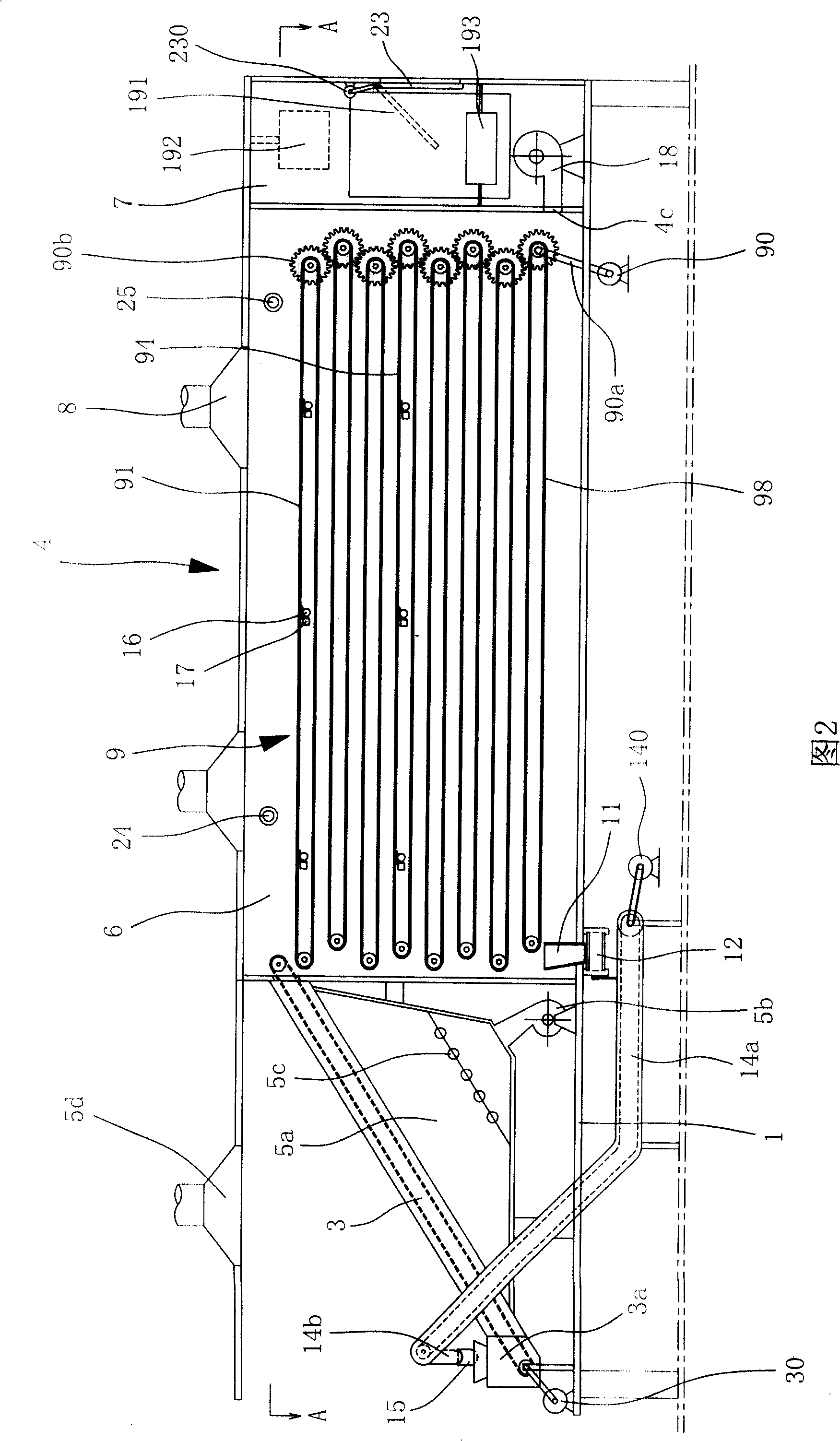

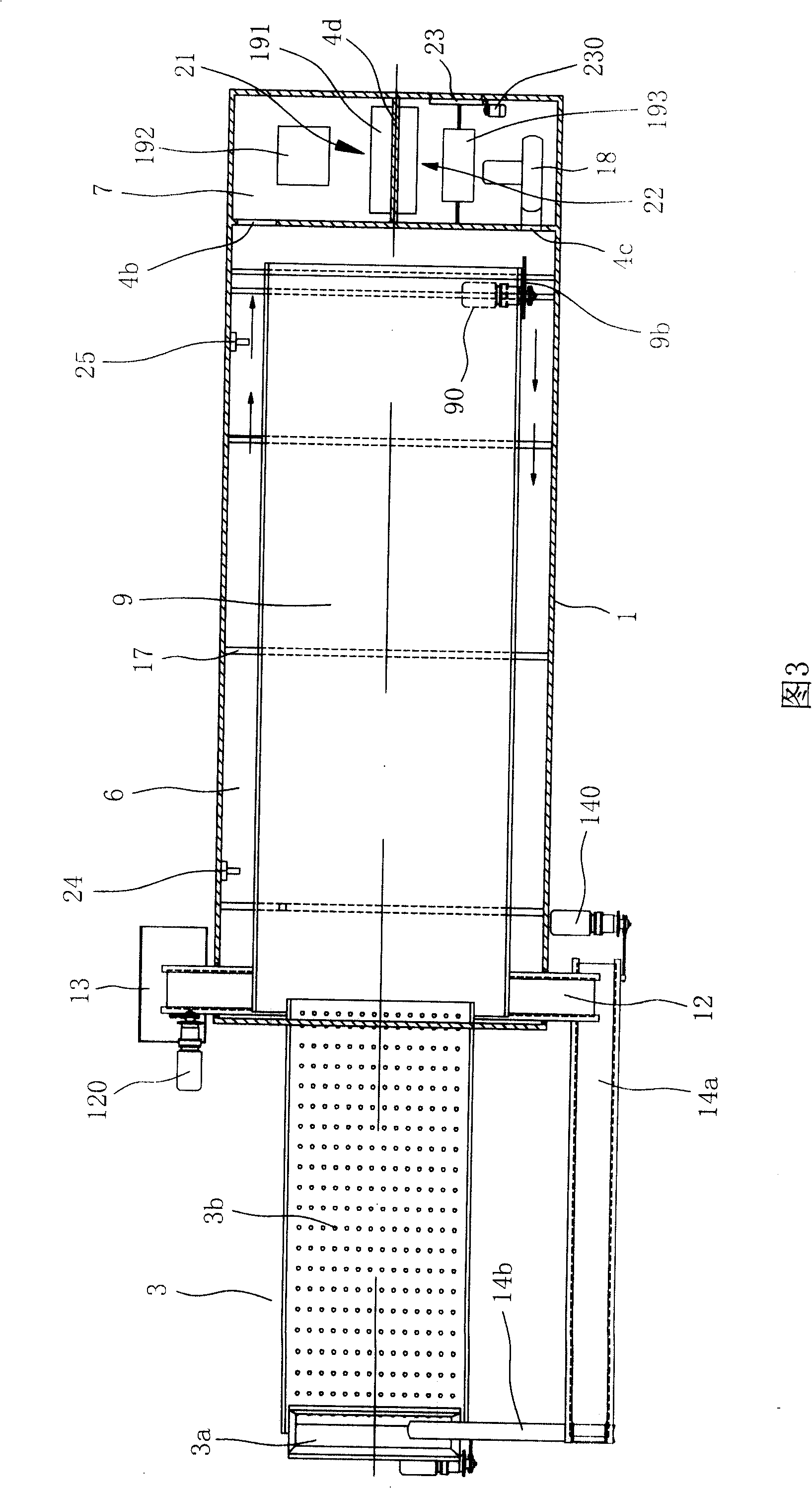

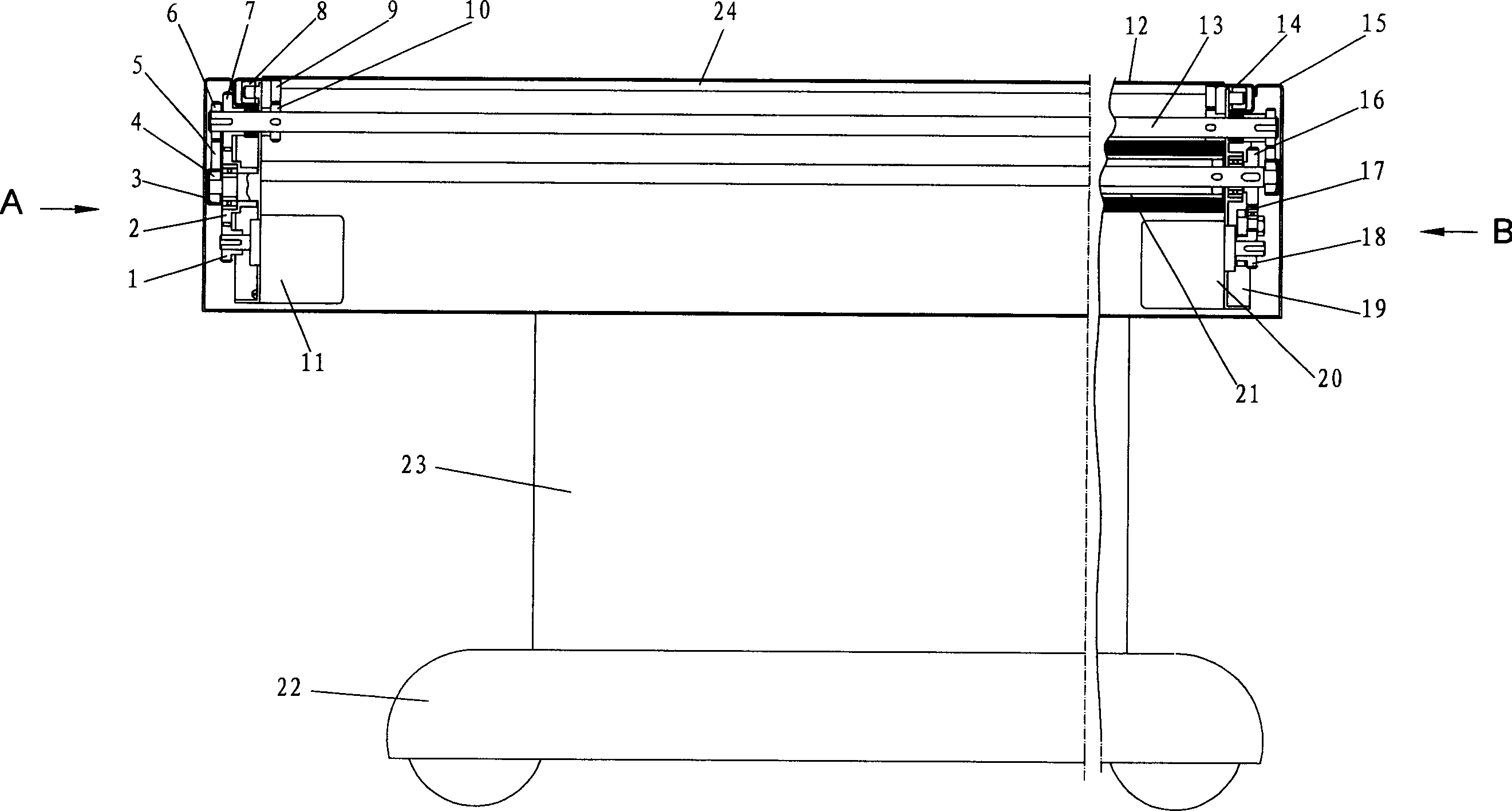

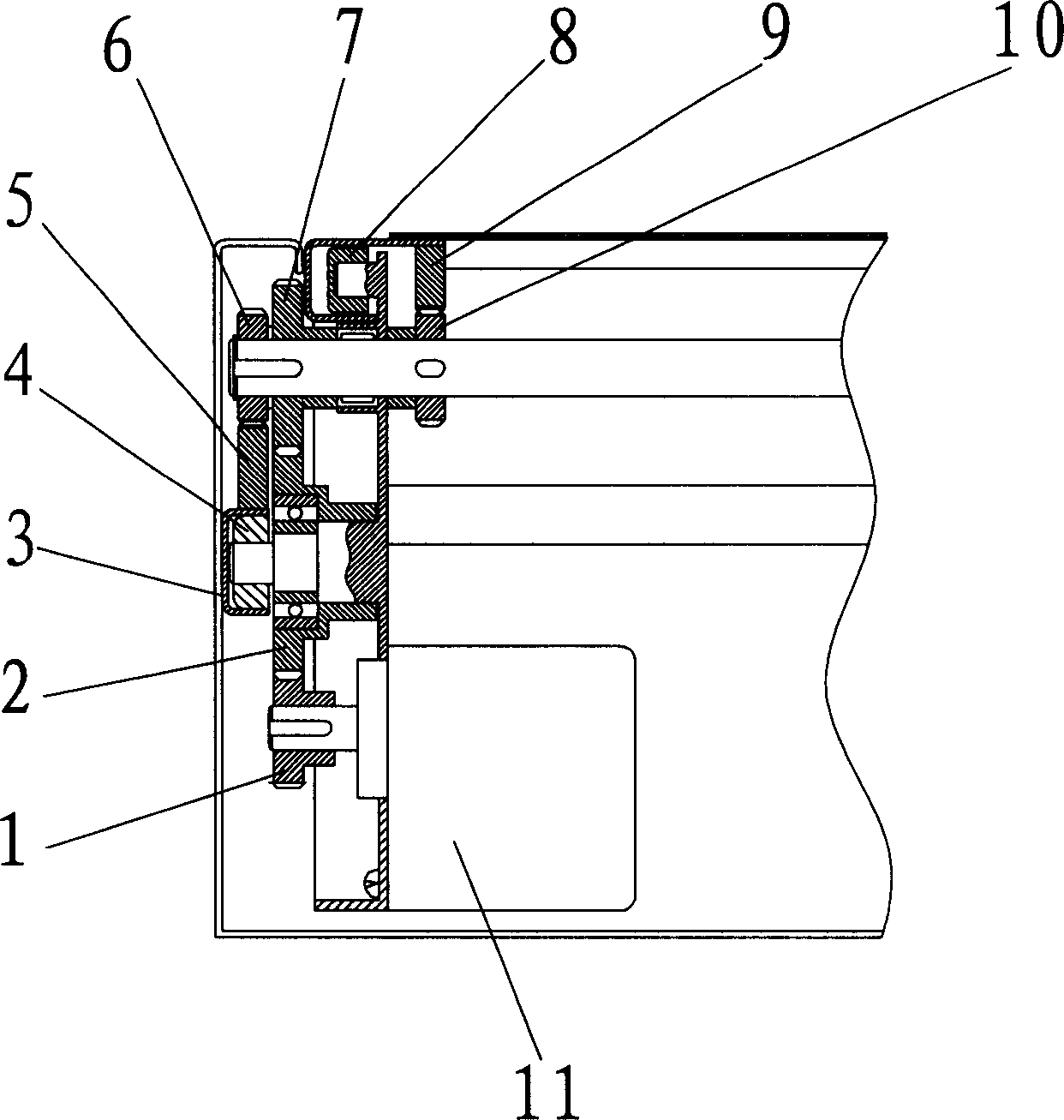

Full-automatic PCB labeling machine and implementation method thereof

The invention relates to the field of labeling equipment and in particular relates to a full-automatic PCB labeling machine and an implementation method thereof. The full-automatic PCB labeling machine comprises a frame, wherein a runner mechanism used for conveying PCBs is arranged in the frame; a label supply mechanism used for supplying label strips and stripping to-be-attached labels in the label strips is arranged at a position, which is positioned on the runner mechanism, in the frame; a labeling manipulator mechanism used for transferring and attaching the to-be-attached labels to the corresponding positions on the PCB is arranged at a position, which is positioned at the output end of the label supply mechanism, on the runner mechanism; and a labeling induction camera used for identifying position information of the to-be-attached labels of the PCB and label information is arranged on the labeling manipulator mechanism. According to the labeling machine disclosed by the invention, the on-line synchronization between production site information and an internal or external system information network can be realized by virtue of a network communication module in a control cabinet, the labels are attached to the surfaces of the PCBs or components with different angles, the labeling application range is wide, and the universality is high; and moreover, different materials can be adhered, the integration is high, the automation is high, the manual operation is not required, and the labeling sequence, labeling strength and frequency can be changed according to needs.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

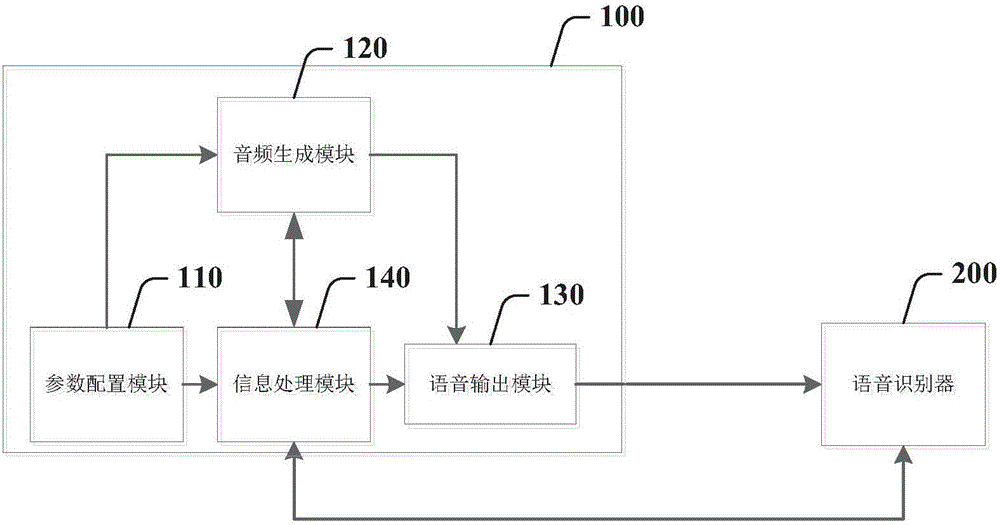

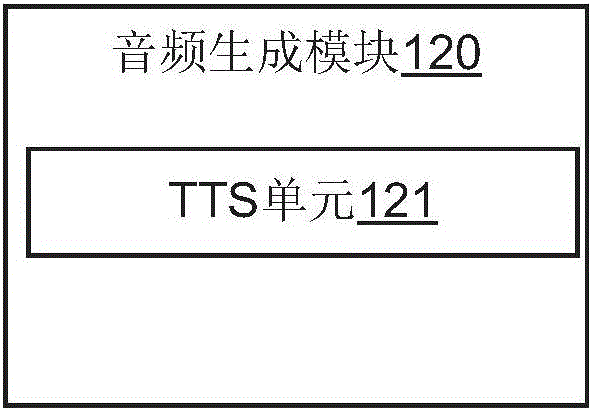

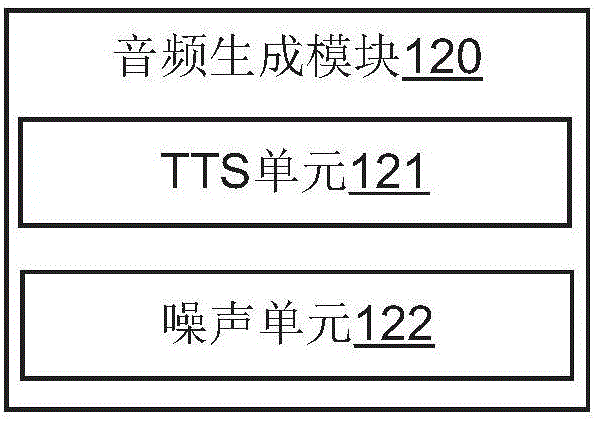

Voice recognition testing system and method

InactiveCN106548772AIntuitive access to speech recognitionEnable large-scale testingSpeech recognitionSpeech synthesisInformation processingSpeech identification

The invention discloses a voice recognition testing system comprising an audio frequency generation module, a voice output module and an information processing module, wherein the audio frequency generation module is used for generating an audio file from a test text based on testing parameters, the voice output module is used for playing the audio file so as to provide voice input for a voice recognizer to be tested, the information processing module is used for processing voice recognizing results from the voice recognizer so as to obtain a testing report form on the voice recognizer, and the testing report form comprises recognition performance parameters of the voice recognizer under different conditions relevant to the testing parameters.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

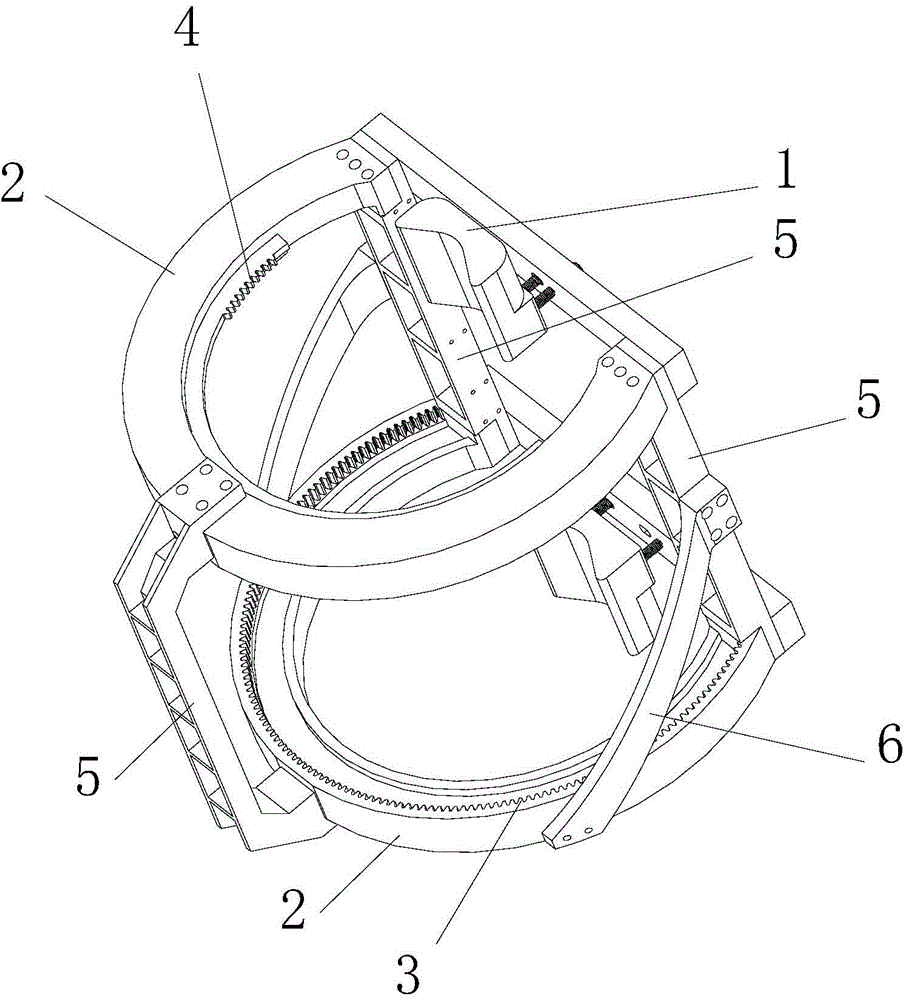

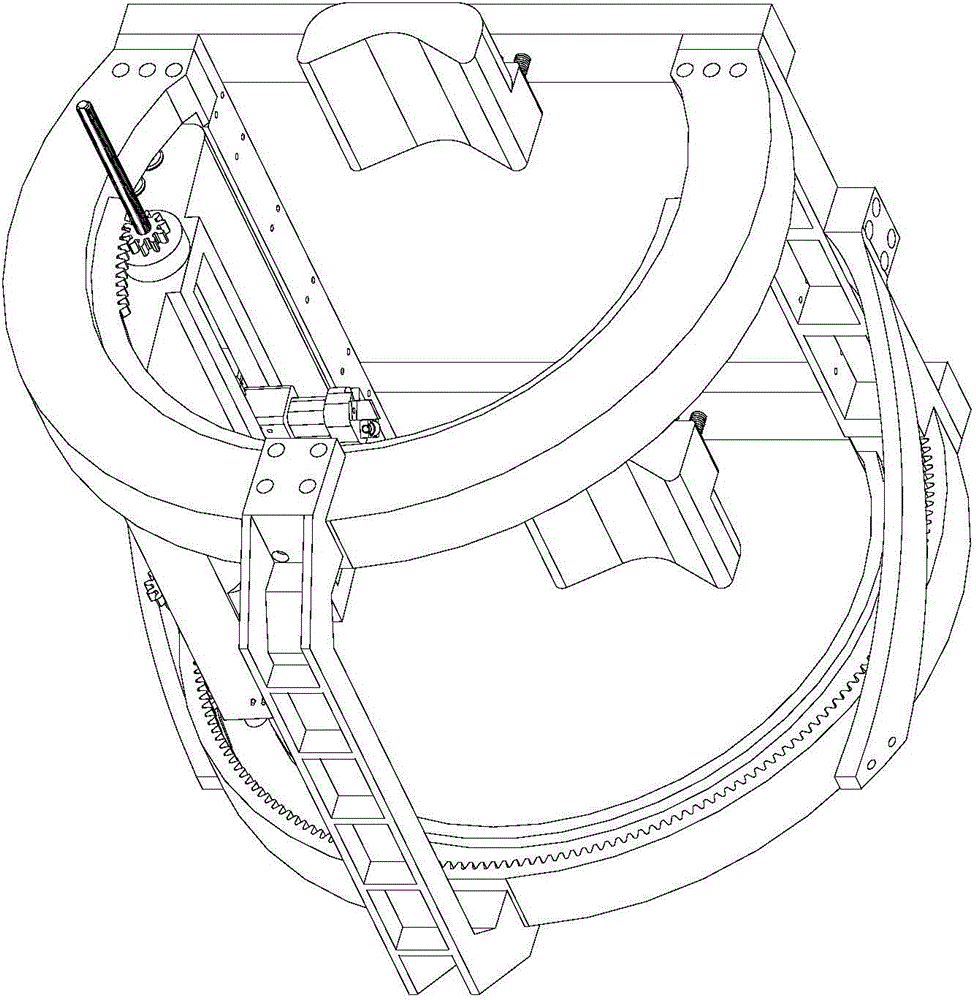

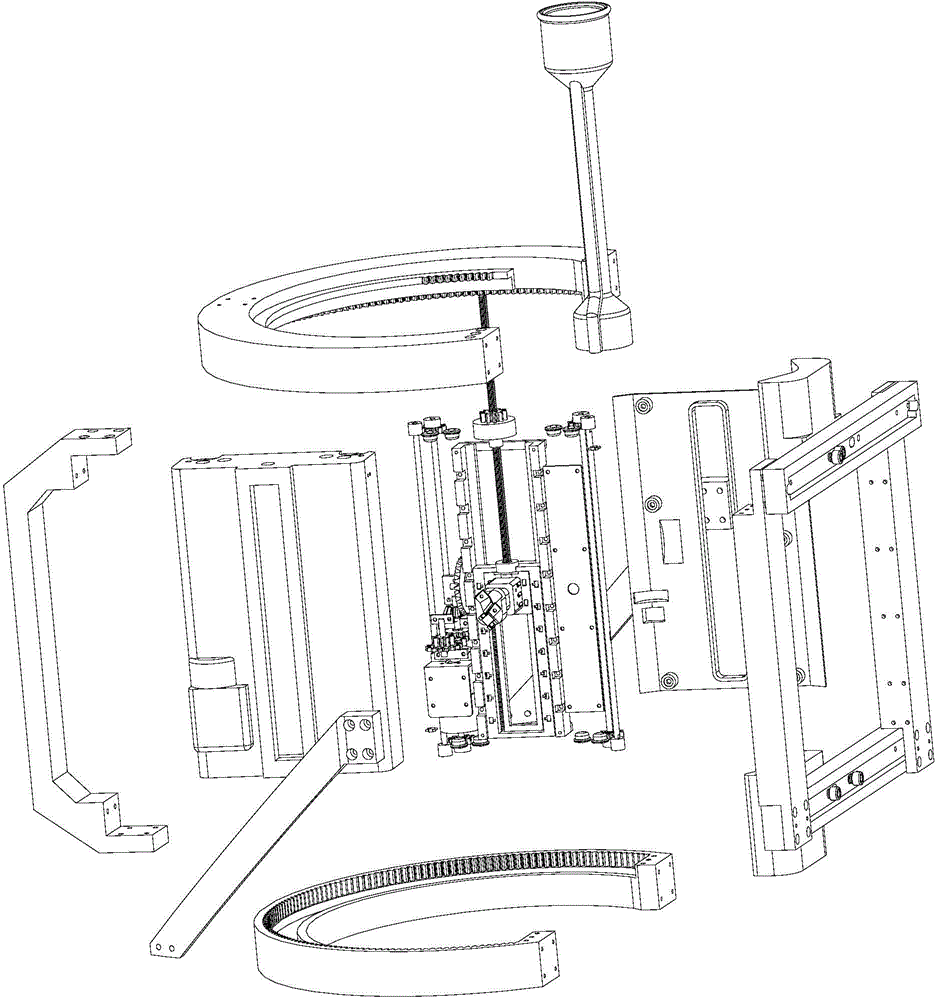

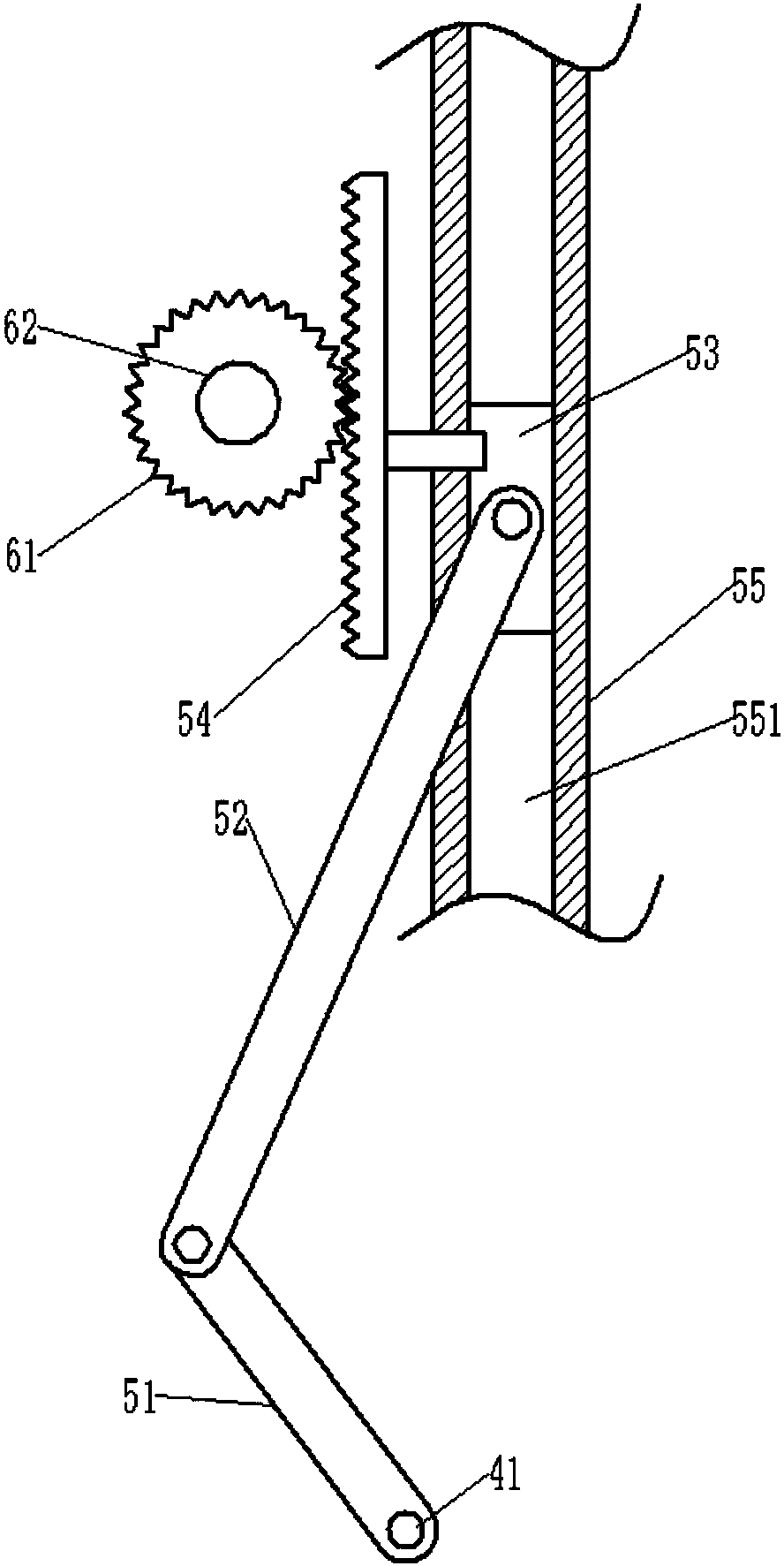

Rubber tapping machine

ActiveCN104429813ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryAutomatic controlControl system

The invention discloses a rubber tapping machine. The rubber tapping machine comprises a tree binding fixing frame and two annular planetary gear outer shells installed at the upper end and the lower end of the tree binding fixing frame respectively. A vector movement knife rest assembly is arranged between the two annular planetary gear outer shells. A gear shaft is arranged on the vector movement knife rest assembly, a motor and a rubber tapping knife rest with a gear rack are arranged in the vector movement knife rest assembly, a rubber tapping knife assembly is arranged in the rubber tapping knife rest, a lead screw is connected to the top end of the rubber tapping assembly, and the rubber tapping knife assembly can vertically move in the rubber tapping knife rest by rotating the lead screw. By means of the rubber tapping machine, manual operation is not needed, and starting, stopping, forward rotating and backward rotating of the motor and starting, stopping, the spraying time and the spraying amount of a catalyst spraying assembly can be controlled by an automatic control system according to a set program. In addition, the automatic control system can be in communication with the exterior through an input-output module, receive a command of an upper computer, update internal program setting and transmit various working states of the rubber tapping machine outwards at any time.

Owner:NINGBO CIHEVEA TECH CO LTD

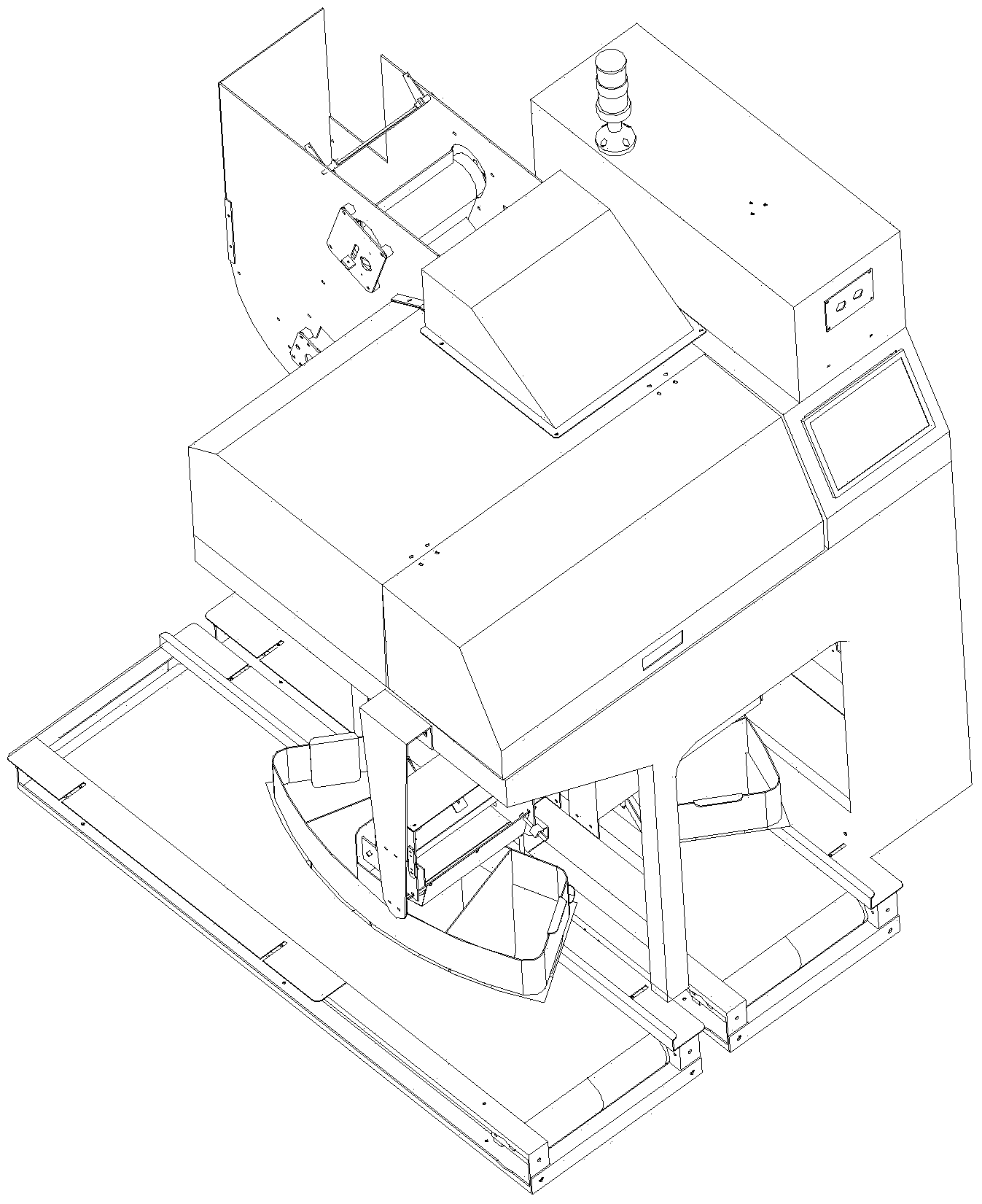

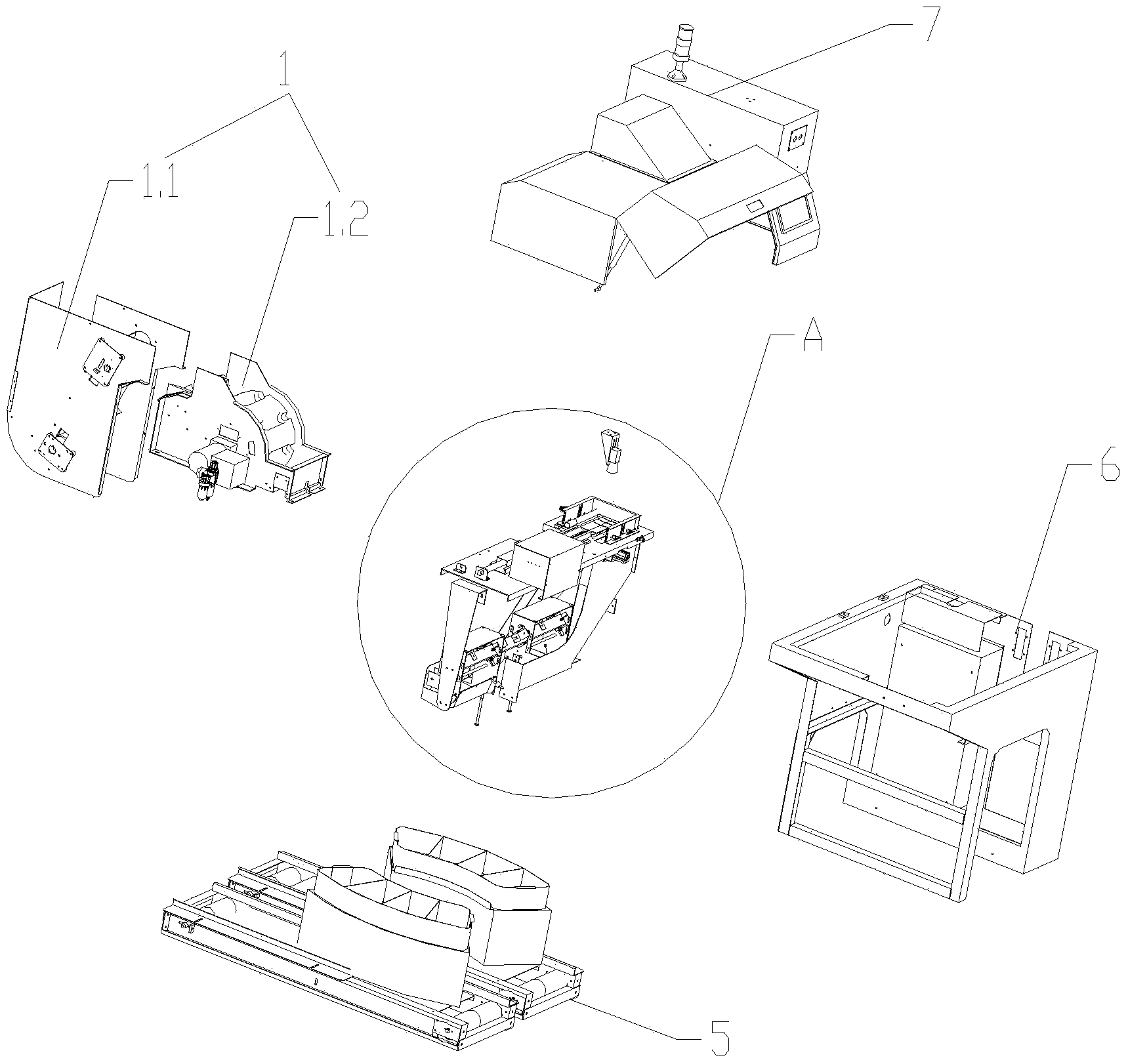

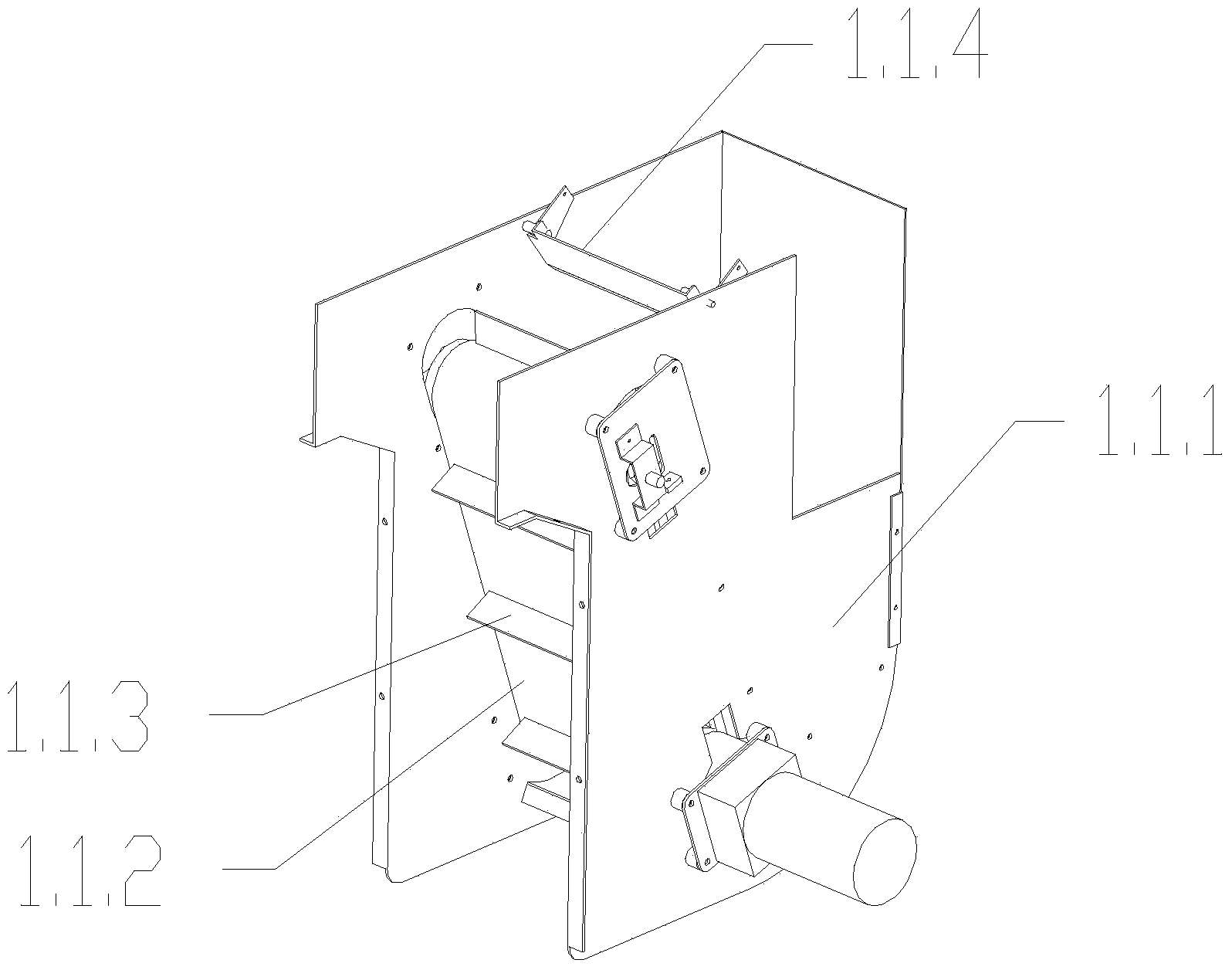

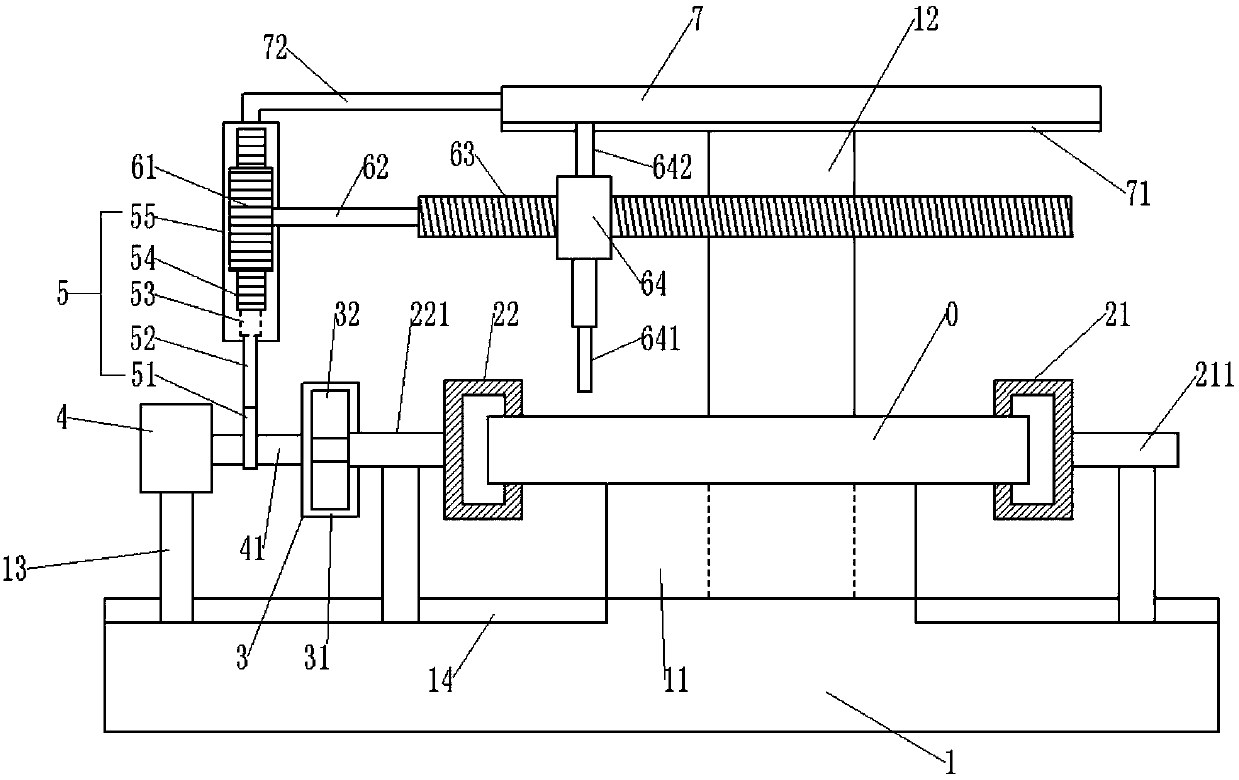

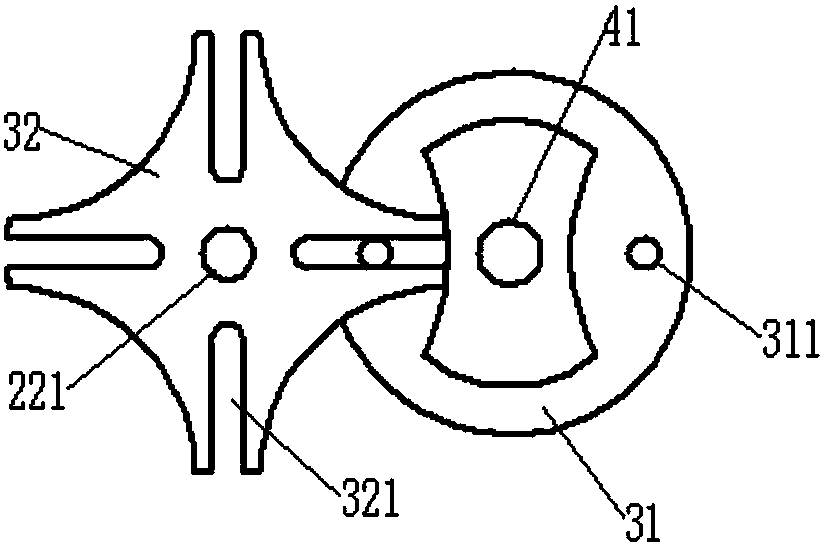

Bobbin burying machine

The invention relates to a bobbin burying machine. The bobbin burying machine is characterized by comprising a bobbin storage mechanism (1), a bobbin separating mechanism (2), a bobbin falling mechanism (3), a bobbin connecting buffer mechanism (4), a bobbin connecting mechanism (5), a rack (6) and an outer shell (7). The bobbin storage mechanism (1), the bobbin separating mechanism (2), the bobbin falling mechanism (3) and the bobbin connecting buffer mechanism (4) are arranged on the rack (6), the outer shell (7) covers the top of the rack (6), and the bobbin connecting mechanism (5) is arranged below the bobbin connecting buffer mechanism (4). According to the bobbin burying machine, whether bobbins contain yarn or not can be distinguished, the colors of empty bobbins are distinguished, the big ends and the small ends of the bobbins without the yarn are straightened out, automation is achieved in the whole process, the manual operation is not needed, the manual operation difficulty of workers is greatly relieved, the number of employees of enterprises can be effectively saved, the employment pressure of the enterprises can be effectively relieved, and the bobbin burying machine has the advantages of improving work efficiency, and being high in automation degree and capable of being applied to arc-shaped recycle cases.

Owner:江阴市凯业纺织机械制造有限公司

Workpiece stamping intelligent control process and intelligent control manipulator

InactiveCN103252770AImprove work efficiencyImprove securityProgramme-controlled manipulatorMetal-working feeding devicesAutomatic controlMachining process

The invention discloses a workpiece stamping intelligent control process. The workpiece stamping intelligent control process controls automatically and satisfies all actions to be operated coherently to effectively improve working efficiency, no manual work is needed, safety is improved and cost is effectively saved. Product quality is guaranteed to enable products to meet market demands. The invention further provides an intelligent control manipulator implementing the process. Through an efficient, accurate, flexible, safe operation mode flexible in design, the intelligent control manipulator is convenient to operate, production efficiency is greatly improved, structural design is reasonable, design mode is flexible, effects are obvious, process persistence is high, raw materials are saved and energy consumption is quite low; a regulation and control type industrial control process satisfies different demands, the structural design enhances smoothness, swing precision is guaranteed, and machining process is guaranteed to be completed automatically, continuously and effectively; and conventional manual or semi-automatic machining modes are replaced, and resources are saved.

Owner:FOSHAN DINGFENG ROBOT

Plastic spraying device

InactiveCN107899799ARealize all-round plastic sprayingSimple structureSpraying apparatusEngineeringAutomation

The invention relates to the technical field of plastic spraying equipment for guardrail production and particularly discloses a plastic spraying device which comprises a motor, a clamping mechanism,a groove wheel mechanism, a slider-crank mechanism, a plastic spraying mechanism and a supporting base. The groove wheel mechanism and the slider-crank mechanism are connected with the motor. The plastic spraying mechanism is located above the clamping mechanism. The supporting base is used for supporting the motor, the clamping mechanism, the slider-crank mechanism and the plastic spraying mechanism. The supporting base is provided with a supporting table used for storing a guardrail. The clamping mechanism comprises two clamps located on the two sides of the supporting table. One clamp is connected with the groove wheel mechanism. The plastic spraying mechanism comprises a lead screw, a nut and a plastic spraying gun. The slider-crank mechanism can drive the plastic spraying gun to movein a reciprocating manner. The groove wheel mechanism can drive the guardrail to rotate intermittently. The plastic spraying device is adopted for carrying out plastic spraying on the guardrail, all-dimensional automatic plastic spraying can be carried out on the guardrail, the automation degree is high, the operation cost is low, and the plastic spraying efficiency is high.

Owner:重庆立帆金属结构有限公司

Grabbing and detecting mechanism for parts

ActiveCN103787081AAchieve absorptionRealize automatic crawlingConveyor partsMachiningIndustrial engineering

The invention relates to a grabbing and detecting mechanism for parts. The grabbing and detecting mechanism comprises a bottom plate, a grabbing mechanism, a detecting mechanism, a carrying mechanism, a part bin and an unqualified product bin. The part bin and the unqualified product bin are fixed to the bottom plate. The parts are arrayed in order in the part bin; a square groove hole is formed in the bottom plate, the detecting mechanism is installed on the bottom plate and located on the square groove hole, and the detecting mechanism is used for detecting the appearance and sizes of the grabbed parts; the carrying mechanism is installed on the bottom plate, the grabbing mechanism is installed on the carrying mechanism, the grabbing mechanism is used for grabbing the parts arrayed in order in the part bin, and the carrying mechanism is used for achieving shifting of part grabbing and detecting action; the unqualified product bin is used for storing unqualified products, and the unqualified products detected through the detecting mechanism are put in the unqualified product bin under the driving of the carrying mechanism. Through the arrangement of all the mechanisms, the parts can be automatically grabbed and detected, the detected unqualified products are conveyed to the unqualified product bin, and the grabbing and detecting mechanism is simple in structure and suitable for various machining environments.

Owner:BOZHON PRECISION IND TECH CO LTD

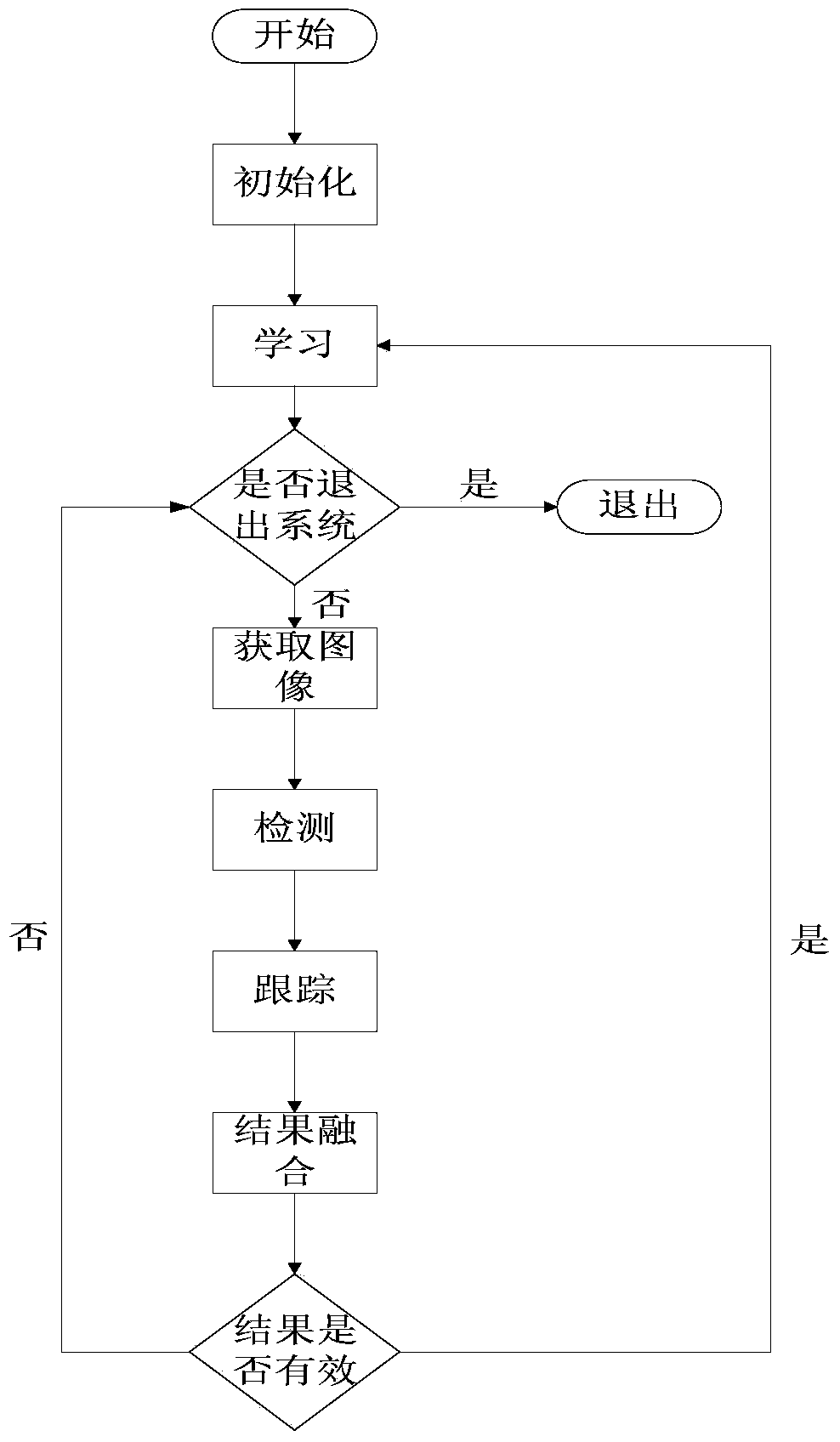

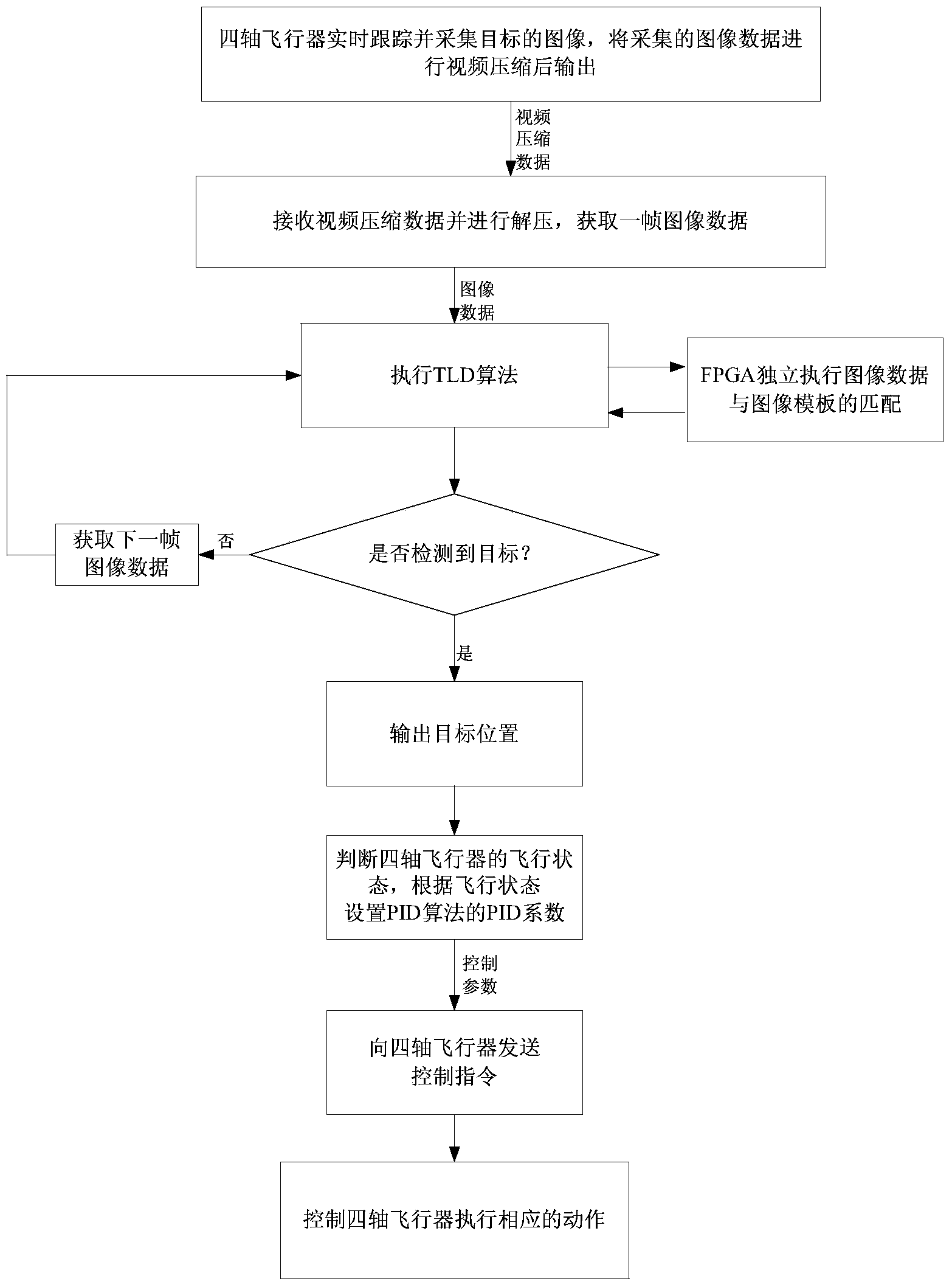

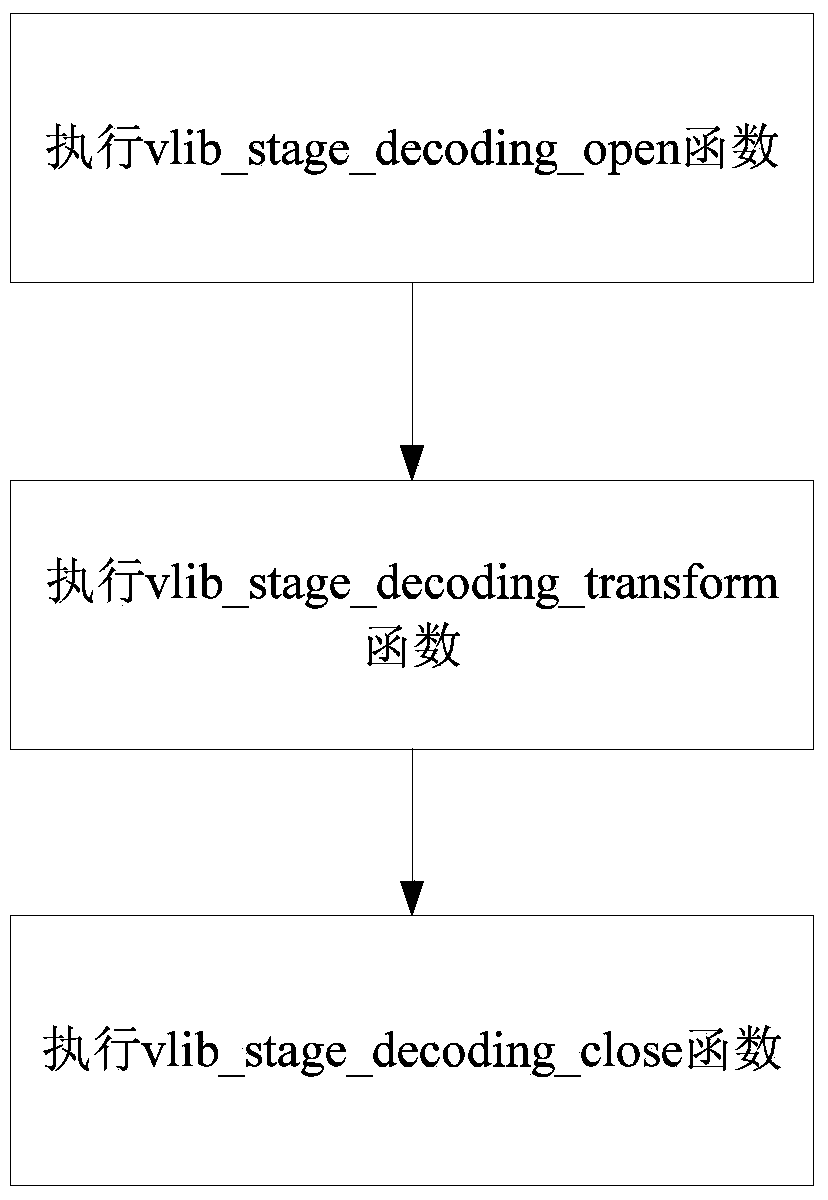

Portable target tracking method and system based on four-axis air vehicle

ActiveCN103838244ASimplified filtersFast executionTarget-seeking controlAdaptive controlTemplate matchingComputer science

The invention discloses a portable target tracking method and system based on a four-axis air vehicle. The method includes the steps that (1) the four-axis air vehicle tracks and collects a target image in real time, and the image is output after being compressed; (2) video compression data are received, decompression is performed, target detecting and tracking are conducted through a TLD algorithm according to the decompressed image data, template matching is executed independently, and when a target is detected, the detected target location is output; (3) a control parameter is obtained through calculation by using a PID algorithm according to the target location, a PID coefficient in the PID algorithm is set according to the flight state, and the movement of the four-axis air vehicle is controlled. The device comprises the four-axis air vehicle, a target detecting and tracking module and a flight control unit, wherein the four-axis air vehicle is used for tracking and collecting the target image in real time, the target detecting and tracking module is used for conducting target detecting and tracking, and the flight control unit is used for calculating the control parameter. The device has the advantages of being high in execution speed, high in tracking accuracy and capable of achieving the purpose of automatic searching and tracking.

Owner:湖南爱守护智能科技有限公司

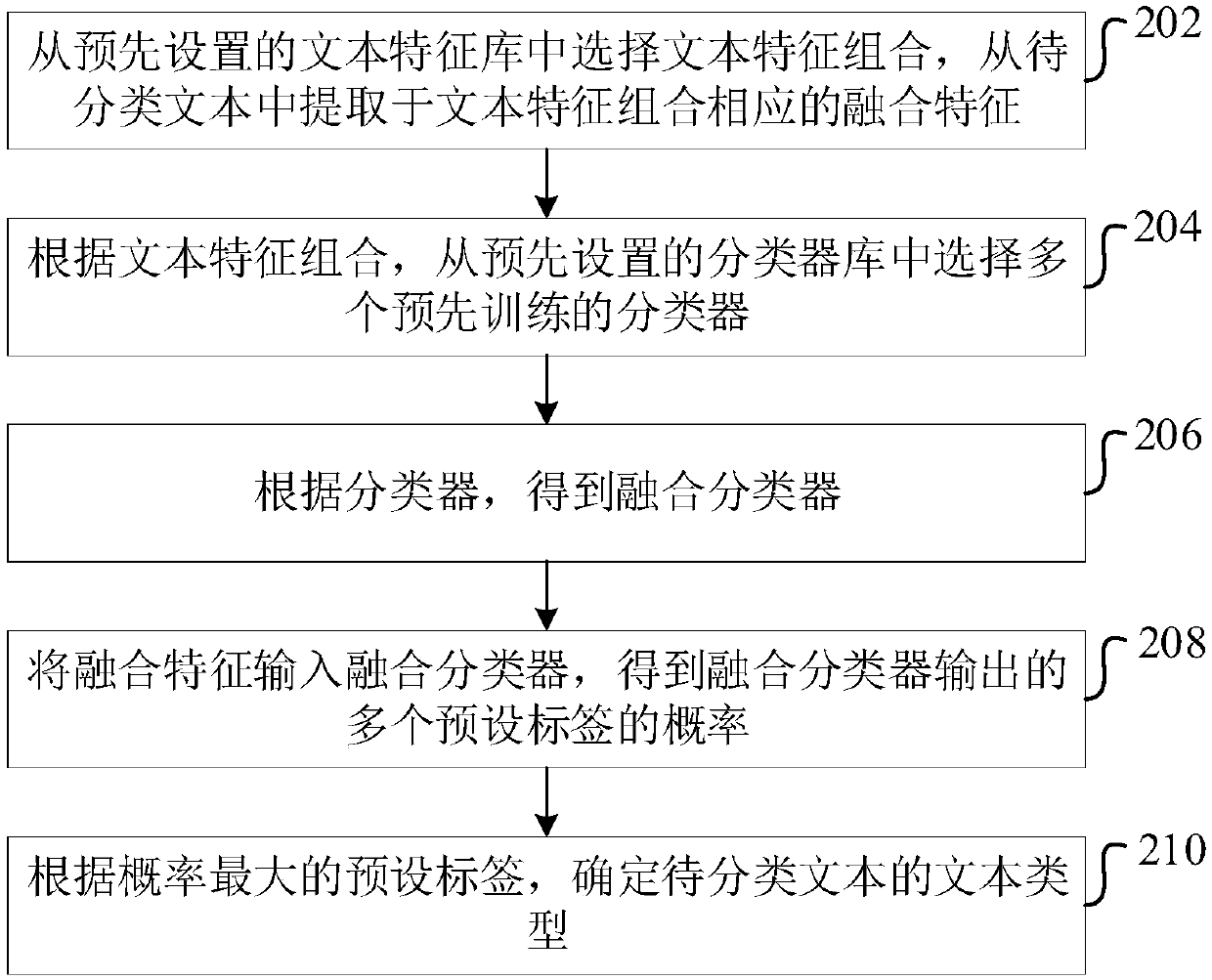

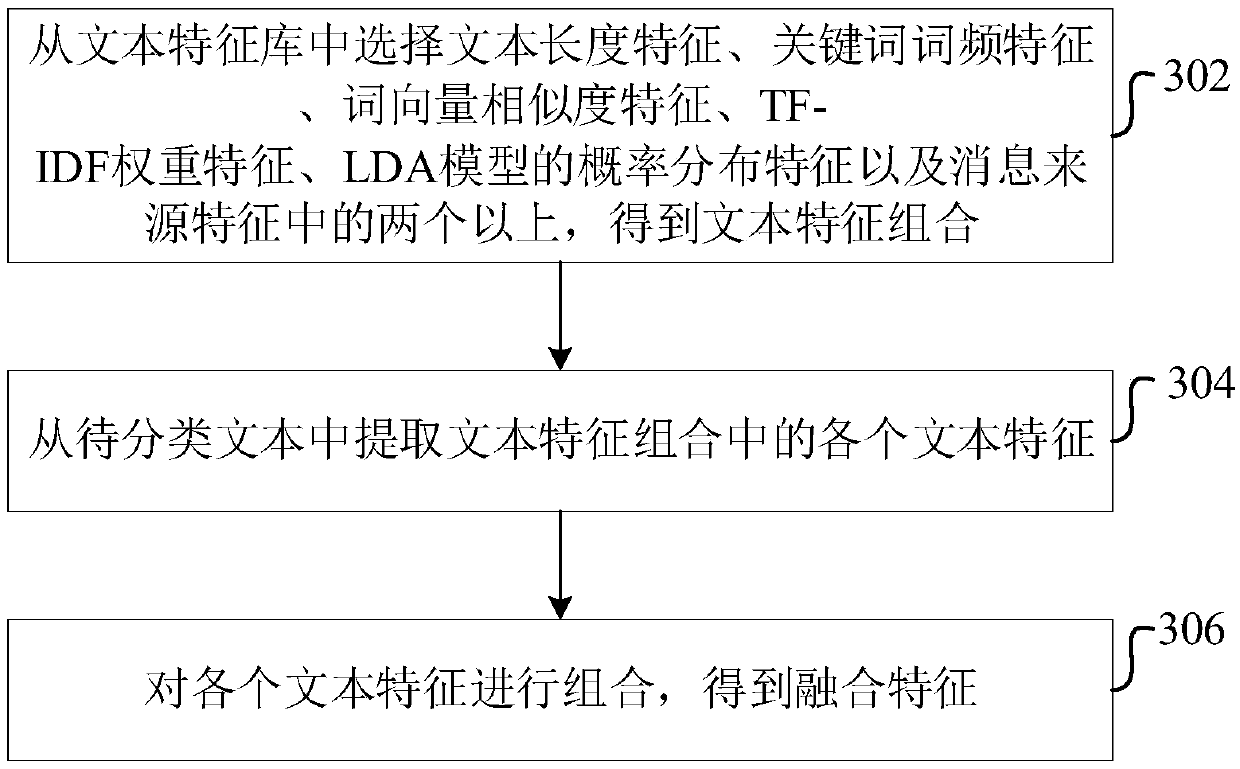

Text classification method and apparatus, computer device, and storage medium

PendingCN109543032AAccurate Classification PredictionImprove accuracyNatural language data processingSpecial data processing applicationsText categorizationClassification methods

The present application relates to a text classification method and apparatus based on a classification model, a computer device anda storage medium. The method comprises: selecting a text feature combination from a preset text feature library, extracting a corresponding fusion feature from the text to be classified from the text feature combination; according to text feature combination, selecting a plurality of pre-trained classifiers from a preset classifier library; According to the classifier, the fusion classifier is obtained, the fusion feature is input to the fusion classifier, and the probability of a plurality of preset labels output by the fusion classifier is obtained. The preset labels correspond to a text type, and the text type of the text to be classified is determined according to the preset labels with the greatest probability. The method can improve the accuracy of text classification.

Owner:PING AN TECH (SHENZHEN) CO LTD

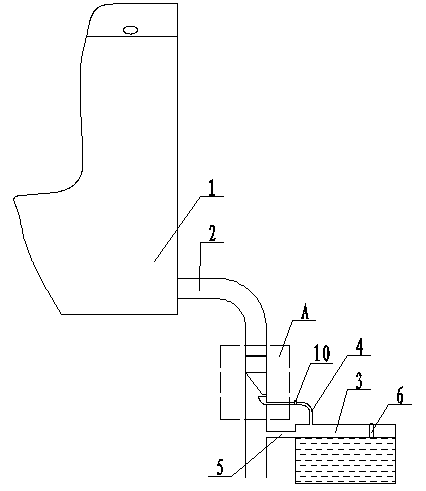

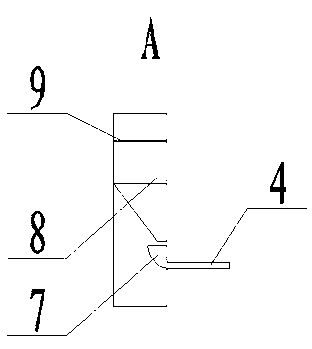

Urine separation and collection device

The invention discloses a urine separation and collection device, which comprises a urine collection pool arranged on a drain pipe on the bottom of a urinal, wherein an alarming device is arranged in the urine collection pool, the side face of the urine collection pool is connected with the drain pipe through an overflow pipe, a small-flow liquid guide pipe is arranged above the urine collection pool, a valve is arranged on the small-flow liquid guide pipe, and the small-flow liquid guide pipe is further arranged on the drain pipe; a connecting funnel is arranged on the inlet end of the small-flow liquid guide pipe, a bundling funnel is arranged above the collecting funnel, and a filter screen is arranged avove the bundling funnel. The urine separation and collection device has the advantages of simple structure, convenience in assembly, simplicity in maintenance, long service life, and greatly lower production cost compared with current similar products; and the device is environment-friendly and hygienic, the problems of strong odor, poor environmental and hygienic condition and the like caused by a primitive urine collection method are prevented, the separate and sealing type collection of urine enables pollution of flushing water to be low, and subsequent purification treatment and circulated recycling are facilitated.

Owner:郅西敬

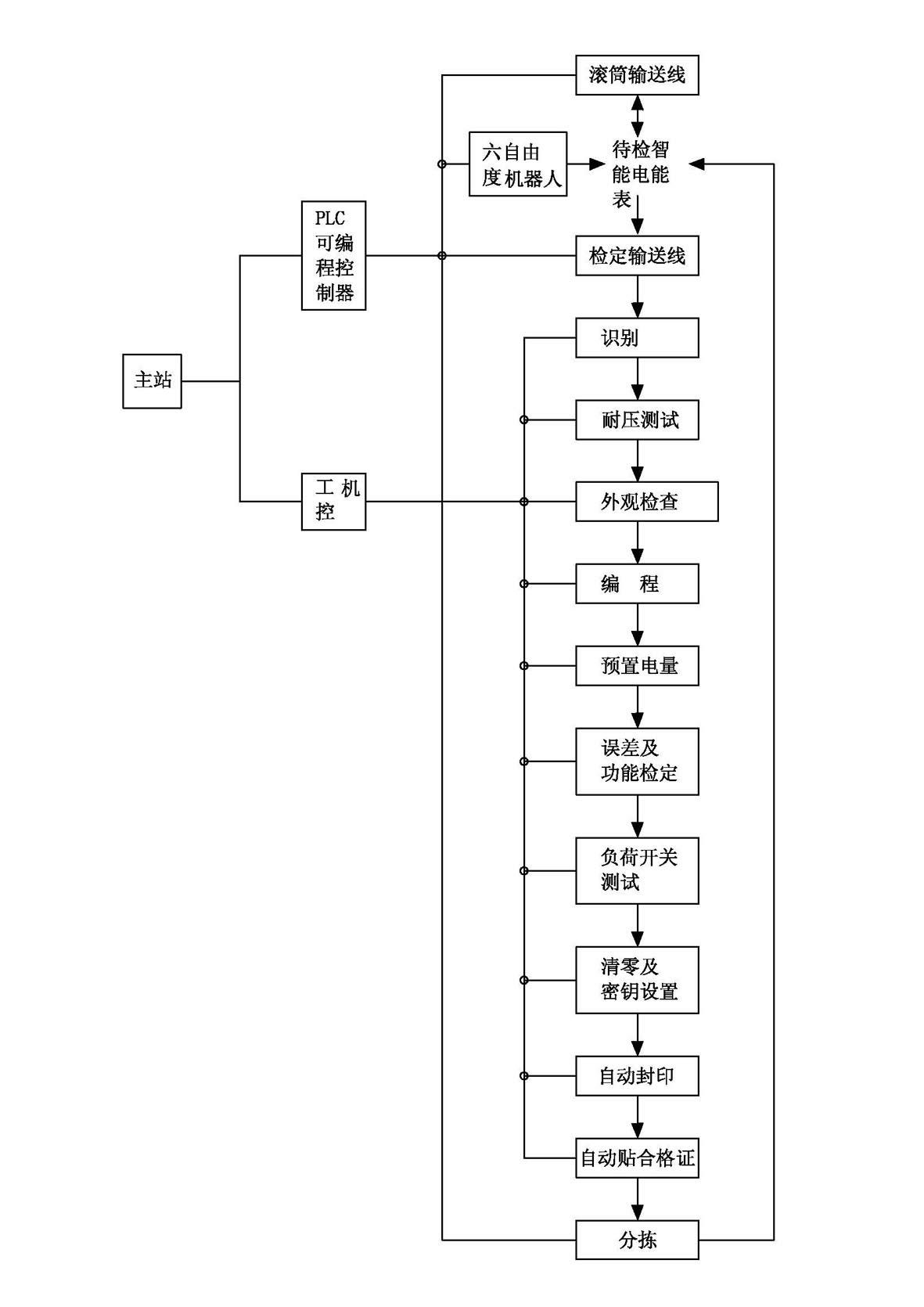

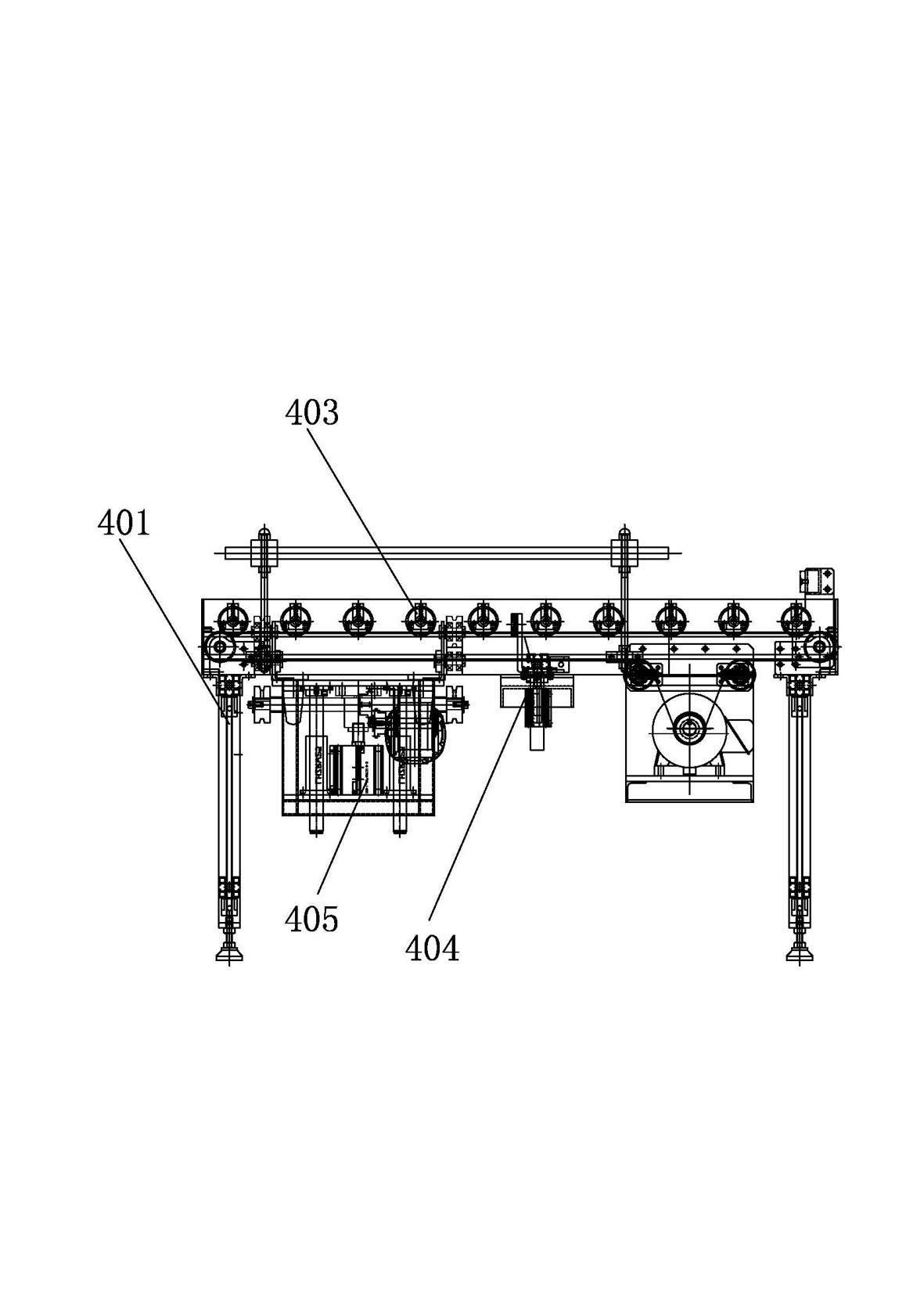

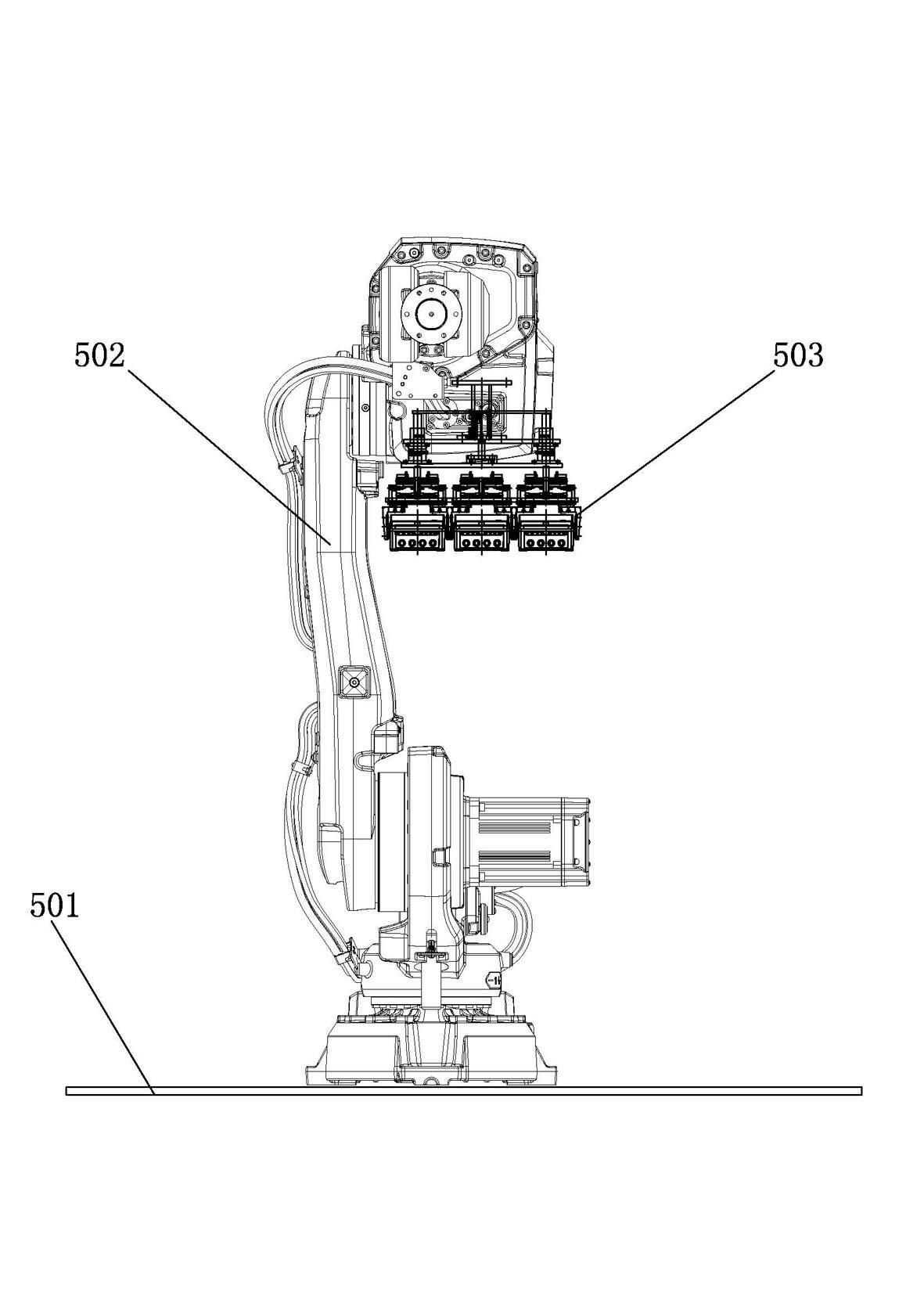

Automatic verification system and method for single-phase intelligent watt-hour meter

InactiveCN102565747ANo manual operationImprove work efficiencyElectrical measurementsProgrammable logic controllerMaster station

The invention discloses an automatic verification system and method for a single-phase intelligent watt-hour meter. The verification system comprises a master station, an industrial personal computer, a programmable logic controller (PLC), a roller conveying line, a six-degree-of-freedom robot, a verification conveying line, recognition equipment, pressure-resistant test equipment, appearance inspection equipment, programming equipment, power presetting equipment, error and function verification equipment, load-switch test equipment, reset-key setting equipment, seal equipment, certificate sticking equipment and sorting equipment. The verification method sequentially comprises the following steps of: conveying, meter taking, conveying, recognition, pressure-resistant test, appearance inspection, programming, power presetting, error and function verification, load-switch test, reset-key setting, seal, certificate sticking and sorting. The verification system and the method have high verification efficiency and small labor strength, and the phenomenon of missing detection is not easily generated.

Owner:SHENZHEN CLOU ELECTRONICS

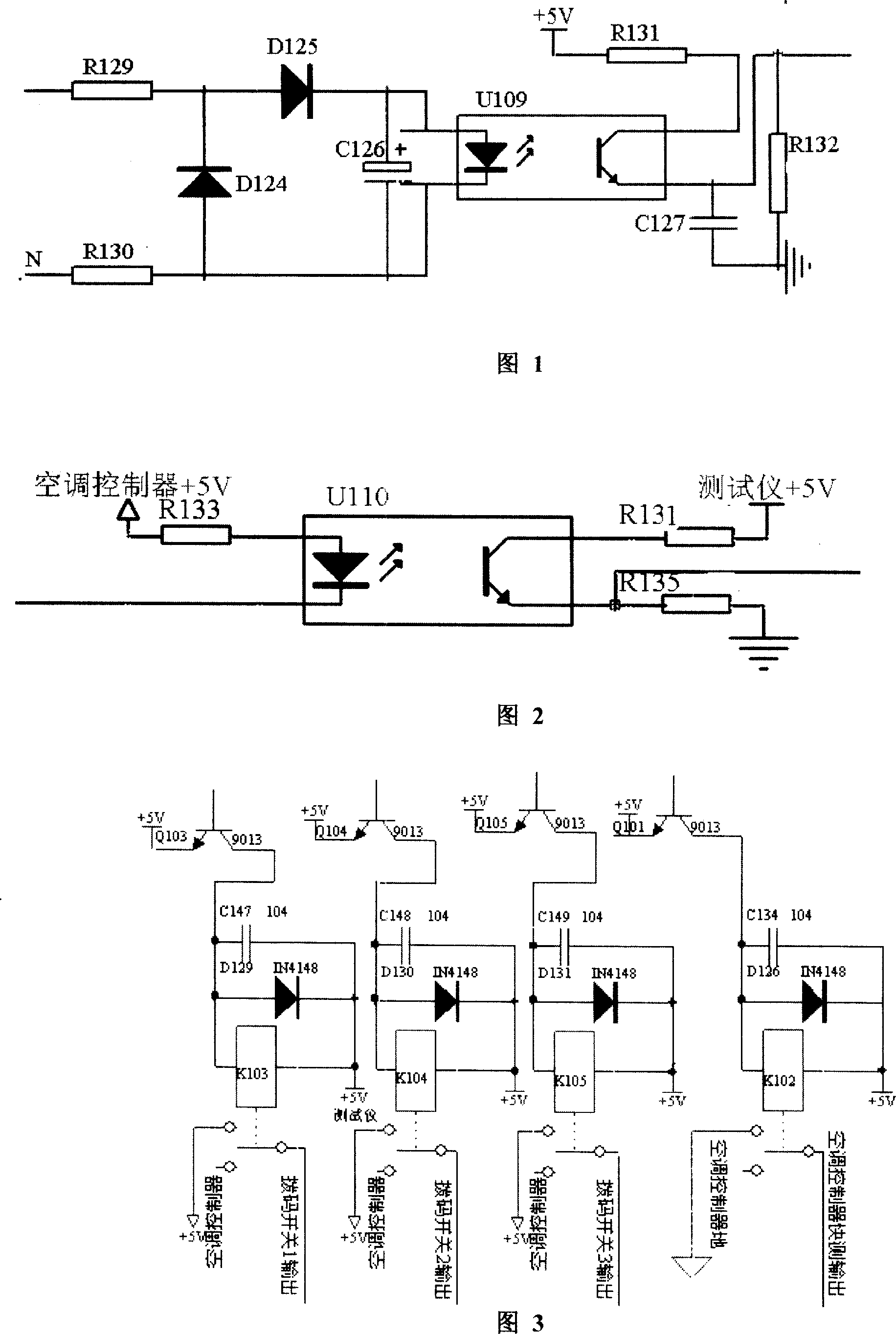

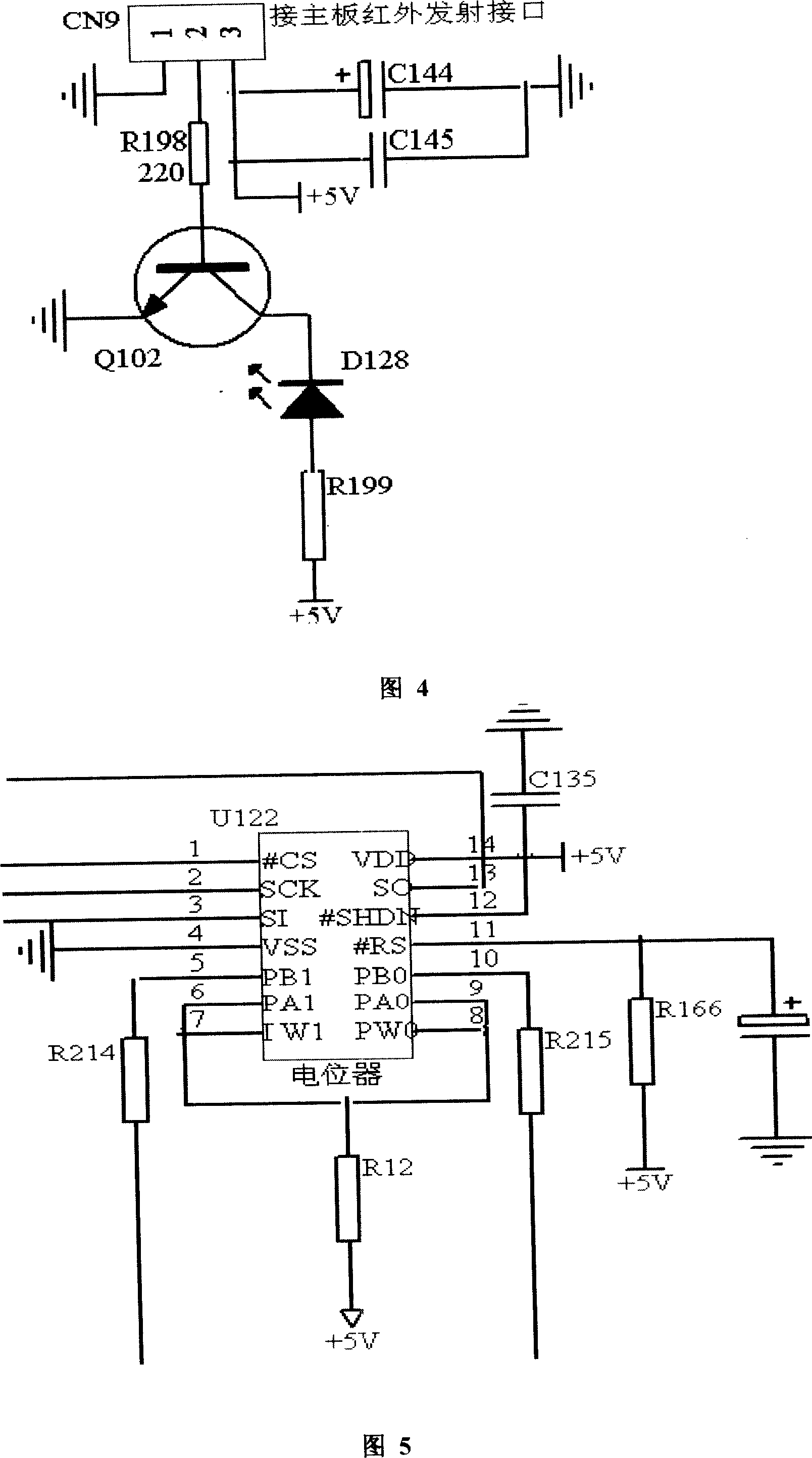

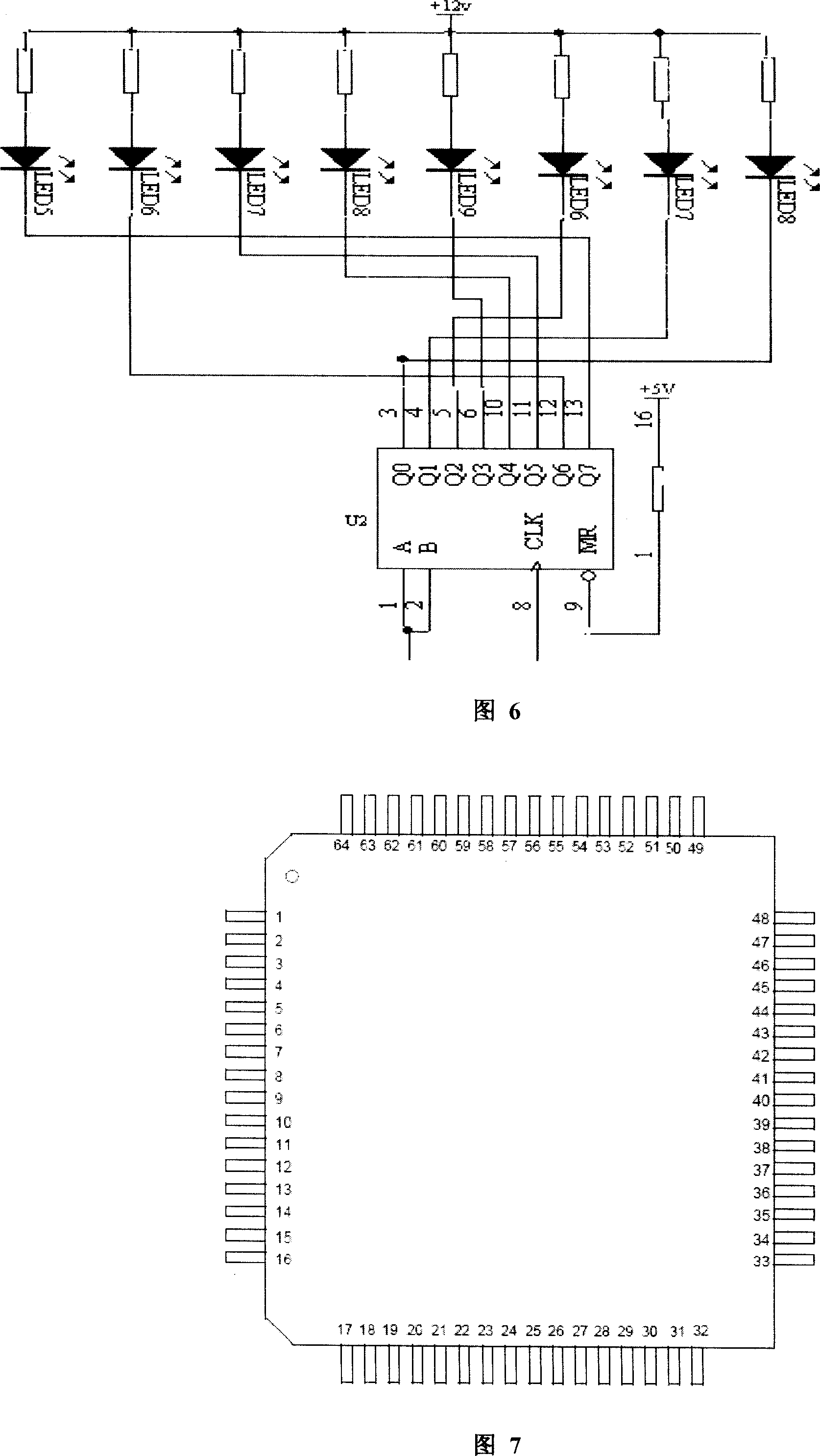

Air conditioner controller automatic test equipment and test method thereof

InactiveCN101113942AImplement automated testingNo manual operationSpace heating and ventilation safety systemsLighting and heating apparatusMicrocontrollerSignal processing circuits

The invention provides an air conditioning controller automatic test device and method which employs single-chip computer technology. The device can carry out complete automatic test, even in one person-multi-testers automatic test way and can realize the generalization of testers, reducing the quantity of testers significantly. Diversified working conditions under which the air conditioner works can be obtained by simulating with voltage, thereby reducing the difficulty of the air conditioning controller test. The device comprises a tester, a thimble connected with a contact of a controller under test, a thimble mounting seat and a connecting lead connecting the thimble and an element of the tester circuit. The tester comprises a shell and elements of the tester circuit which comprises a main-board, a connecting board between the main-board and the thimble mounting seat and a light board. The main-board comprises an HV feedback signal processing circuit, a scavenging motor detecting circuit, a control signal output circuit, an infrared signal transmission circuit, a simulation temperature voltage signal generating circuit, a light board driving circuit and a single-chip microcomputer. The light board of the tester is provided with a display device.

Owner:GREE ELECTRIC APPLIANCES INC

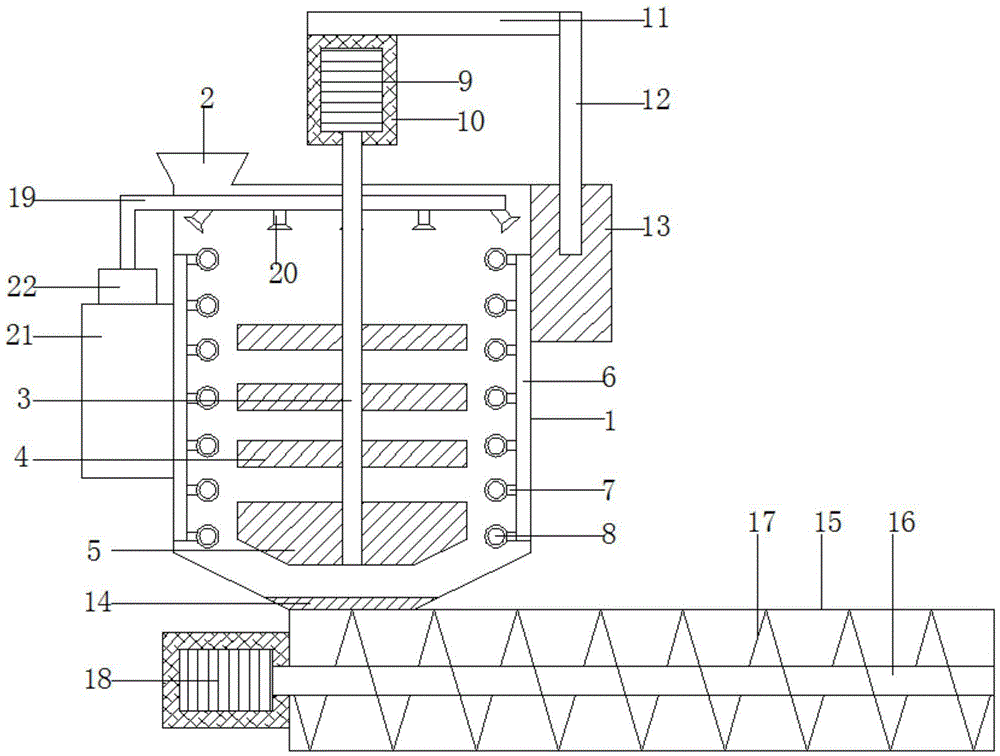

Efficient concrete mixer with water capable of being added automatically

InactiveCN104924462AQuality assuranceReduce noiseDischarging apparatusCement mixing apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete mixer with water capable of being added automatically. The efficient concrete mixer comprises a mixing drum, a screw conveying drum and spray heads. A feeding funnel is arranged at the left end of the upper side of the mixing drum, a stirring rotating shaft is vertically arranged at the axis of the inside of the mixing drum, stirring blades are arranged on the outer wall of the middle section of the stirring rotating shaft in a left-right symmetrical mode, and the bottom of the stirring rotating shaft is connected with a stirring plate. According to the concrete mixer with water capable of being added automatically, the stirring blades, the stirring plate and stirring wheels are used for stirring concrete in the horizontal direction and the vertical direction at the same time, a hydraulic cylinder is used for driving a mixing mechanism to move up and down for stirring, hence, the stirring effect and working efficiency of the mixer are greatly improved, and the concrete quality is guaranteed; moreover, automatic discharging is achieved through a screw conveying mechanism, the concrete can be stirred continuously in the discharging process, and the working efficiency of the mixer is improved; in addition, noise of the mixer in the working process is small, and automatic water adding and cleaning can be achieved.

Owner:苏晓玲

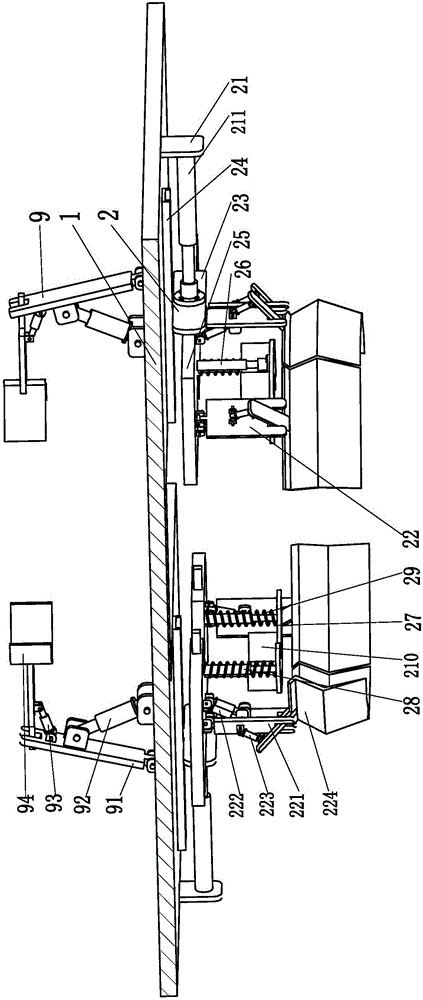

Tube managing machine

The invention relates to a tube managing machine which comprises a case. The tube managing machine is characterized in that the case is internally provided with a tube storing mechanism (1), a tube sorting mechanism (2) and a tube turning mechanism (3). The tube sorting mechanism (2) is connected with a PLC (Programmable Logic Controller) through multiple photoelectric sensors and color sensors to control a main driving cylinder (23), a downward turning cylinder (28) and branch cylinders (29) for distinguishing the existence of yarns and colors of various yarns; a small head of a bobbin is enabled to point downwards through the tube turning mechanism (3) and is transmitted into a cart through a conveying belt (34). The tube managing machine disclosed by the invention can be used for identifying bobbins with or without yarns, and distinguishing the colors of the bobbins, straightening out big and small heads of the bobbins without yarns, and realizes automation of the whole process without manual operation, thus manual operating intensity of workers is greatly reduced and employment number of enterprises and ease employment pressure of enterprises can be effectively decreased.

Owner:江阴市凯业纺织机械制造有限公司

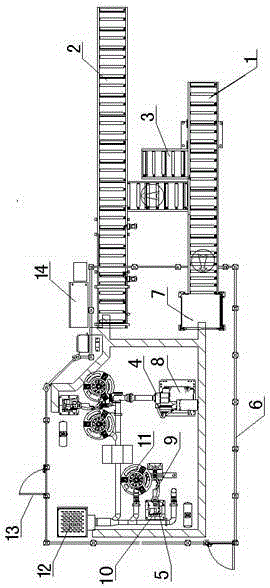

Automatic fluid preparation system and automatic fluid preparation machine used for preparing intravenous fluids

ActiveCN104436354AAvoid cross infectionNo manual operationInfusion devicesPharmaceutical containersSterile environmentShake up

The invention relates to an automatic fluid preparation system and an automatic fluid preparation machine used for preparing intravenous fluids. The automatic fluid preparation system comprises an ampoule bottle conveying device, a penicillin bottle conveying device, an ampoule bottle breaking device, an injector arrangement device, a shaking up device, an infusion bottle conveying device and a multifunctional manipulator. Through the organic combination of the above devices, the fluid preparation is automatically completed in class 100 clean sterile environment without manual operations, so that safety and convenience are increased. In addition, after medical staff inputs an instruction sheet for fluid preparation, the automatic fluid preparation system can automatically check the types of configured medicine bottles, if differences occur, a dispensing action is stopped and an alarm is generated. The automatic fluid preparation system carries out a dispensing program after the medicine staff arranges the medicine which needs to be prepared, the whole process is carried out in a clean environment, so that manual intervention is reduced and the purpose of clean and safe production is achieved.

Owner:DONGGUAN CHANGYUAN SPRAYING TECH

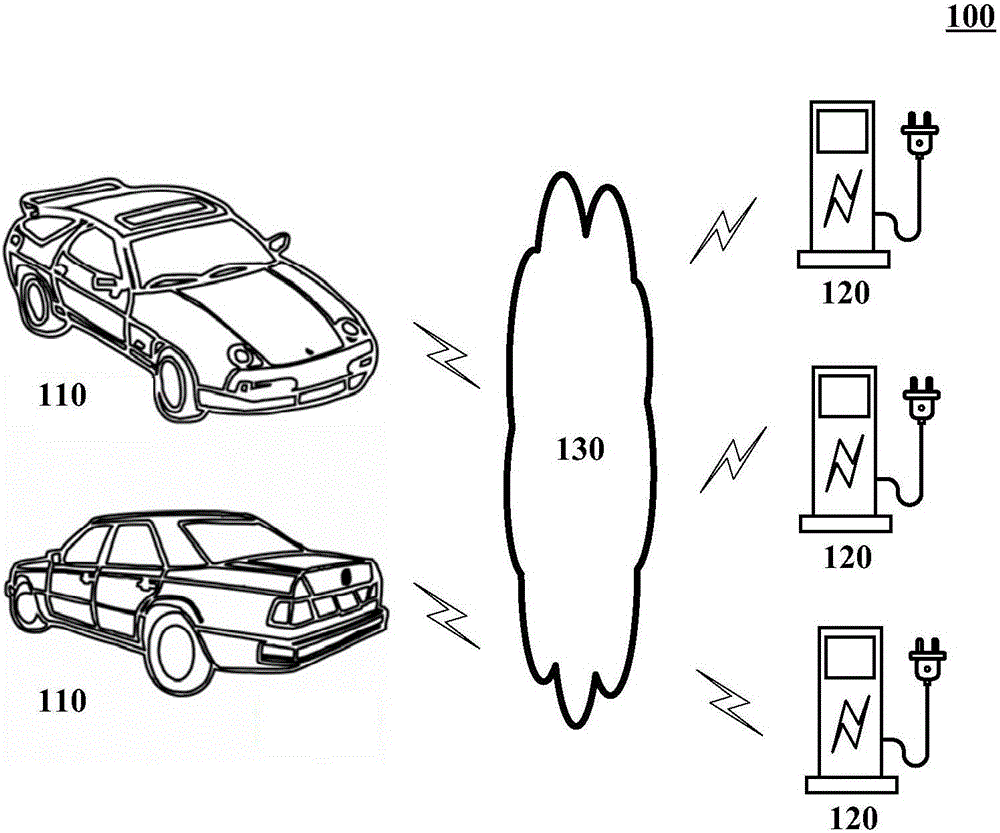

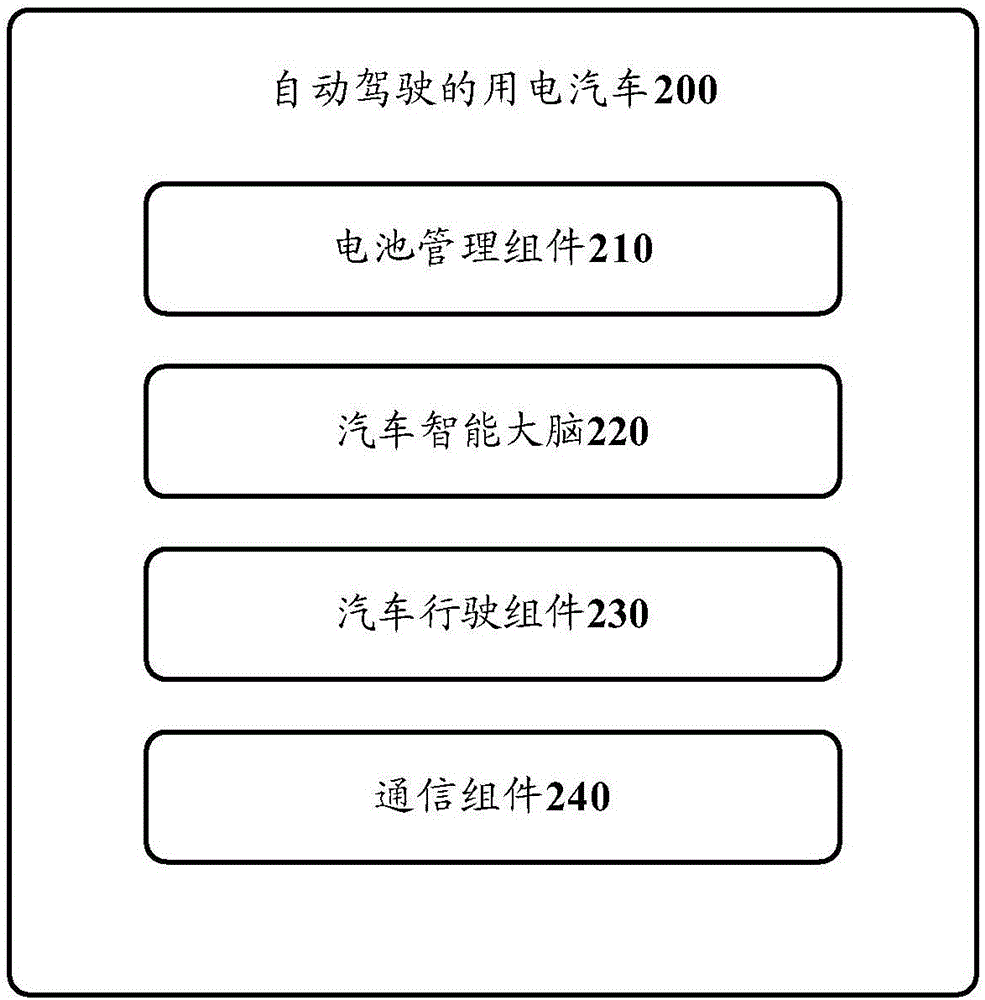

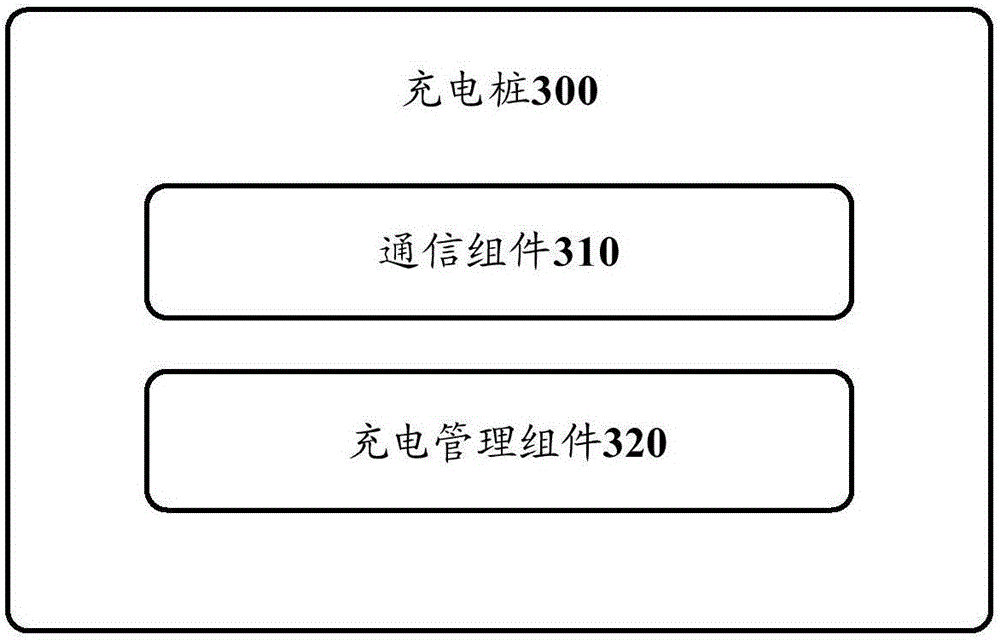

Unmanned electric vehicle, charging pile and charging method for unmanned electric vehicle

ActiveCN105811513ANo manual operationImprove charging efficiencyBatteries circuit arrangementsCharging stationsEngineeringElectric vehicle

The invention discloses an unmanned electric vehicle, a charging pile and a charging method for the unmanned electric vehicle. According to a specific implementation way, the method comprises the steps as follows: in response to that the electric quantity of a battery is lower than a predefined threshold, charging pile information is searched to obtain a charging pile information list, wherein the charging pile information at least comprises position information of the charging pile; on the basis of the position information of the charging pile, target charging pile information is determined from the charging pile information list; the unmanned electric vehicle is controlled to drive to a target charging pile according to the position information of the target charging pile; a charging request is transmitted to the target charging pile; the charging request comprises an evidence for qualification authentication and preset charging amount; and in response to that the charging amount from the target charging pile reaches the preset charging amount, a charging stopping request is transmitted to the target charging pile. According to the implementation way, the automatic charging process of the unmanned electric vehicle is achieved; a manual operation is not needed; and the charging efficiency is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

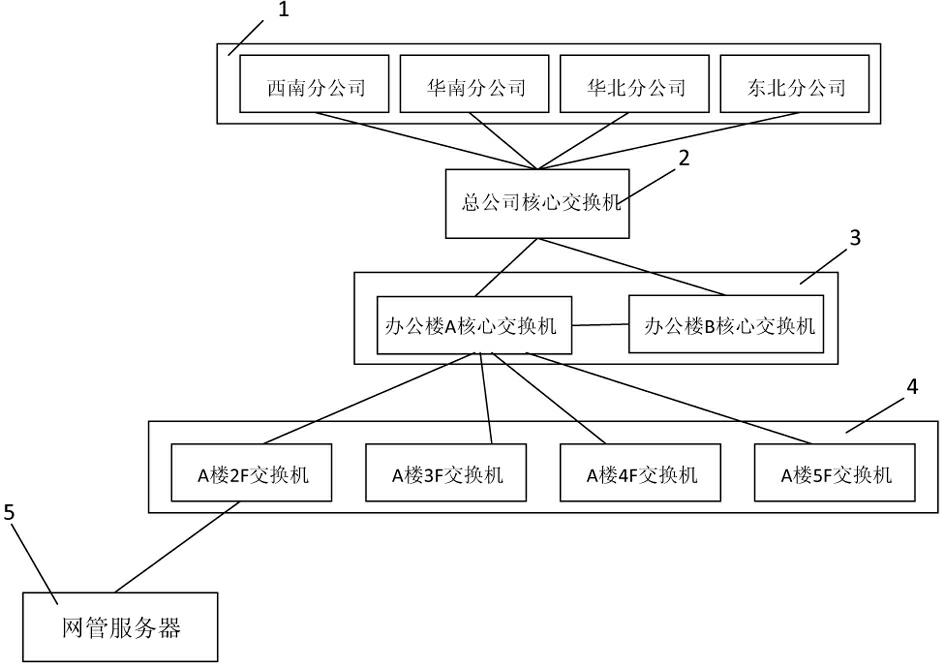

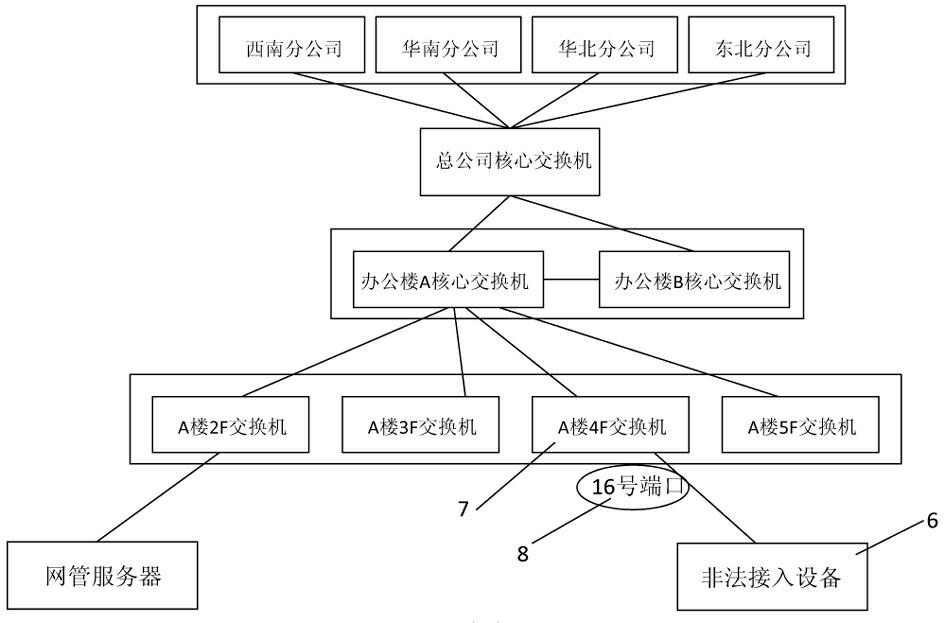

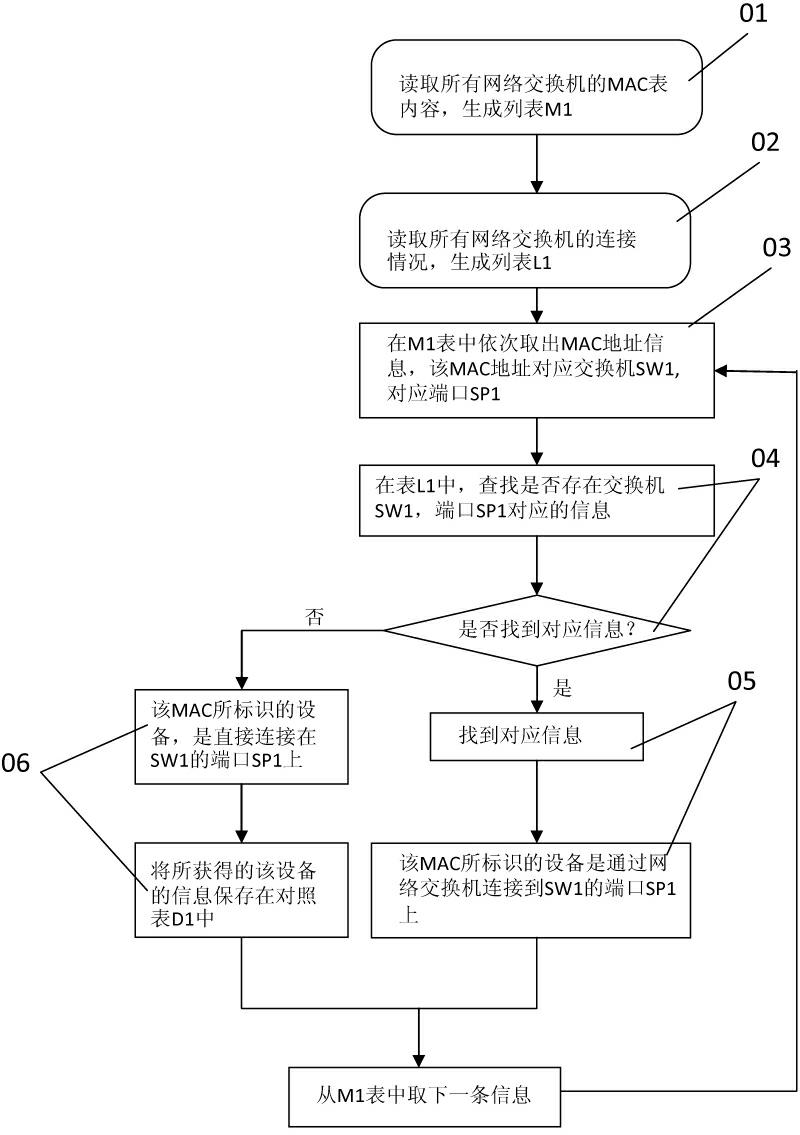

Method for discovering illegally-accessed equipment

ActiveCN102118271ALearn about real deploymentsNo manual operationData switching networksAddress Resolution ProtocolIp address

The invention discloses a method for discovering illegally-accessed equipment. According to the method, two defense lines are adopted. The first defense line comprises the following steps: utilizing a topological physical graph of network management software to display all equipment in a controlled local network onto the topological physical graph; obtaining all PC client side information connected with switches in the local network through an SNMP (Simple Network Management Protocol), an ARP (Address Resolution Protocol), and an Netbios (Network Basic Input / Output System Protocol); adopting an MAC address discrimination method to establish a standard comparison table containing the content of legal equipment in the local network; carrying out binding operations on IP addresses of PC client sides, MAC and port numbers of the switches according to the standard comparison table. The second defense line comprises the following steps: randomly adopting the MAC address discrimination method to obtain port information of the switches connected with the all PC client sides, comparing the port information with that of the comparison table, and determining the client sides which do not exist as new-emerging ones and as illegally-accessed equipment and blocking. The method provides double safety.

Owner:上海北塔软件股份有限公司

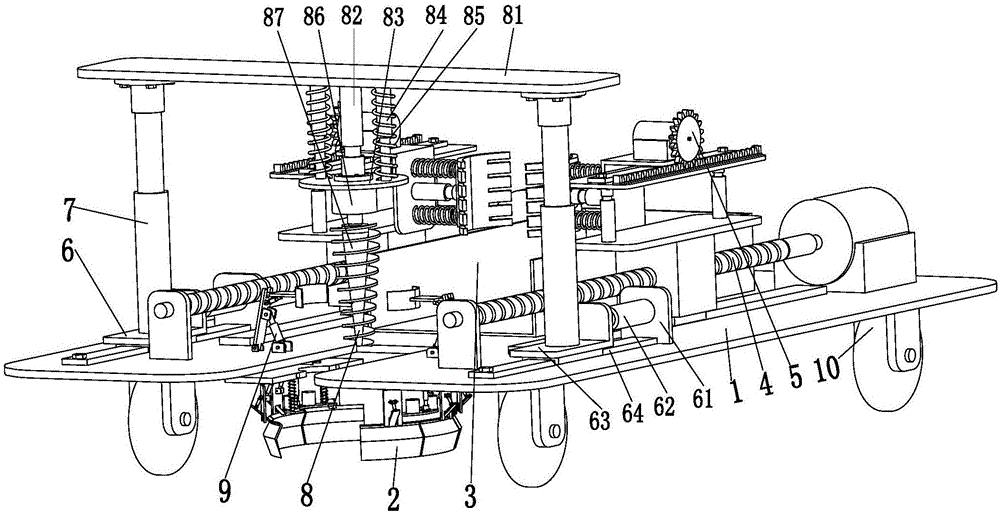

Special automatic digging and planting machine for tree seedlings in urban green belt construction

InactiveCN106665270AClamp evenlyNo manual operationPlantingFurrow making/coveringEngineeringUltimate tensile strength

The invention relates to a special automatic digging and planting machine for tree seedlings in urban green belt construction. The special automatic digging and planting machine comprises a bottom plate, wherein four universal wheels are symmetrically arranged at the lower end of the bottom plate; an opening structure is arranged at the left end of the bottom plate; a placing frame is arranged in the middle of the bottom plate; two horizontal feeding mechanisms are symmetrically arranged at the front side and the rear side of the bottom plate and are respectively provided with a movable clamping mechanism; two pushing mechanism are symmetrically arranged at the left end of the bottom plate and are respectively provided with an electric pushing rod; the two electric pushing rods are arranged on an earth digging mechanism by two flanges; two opposite earth burying mechanisms are arranged at the lower side of the left end of the bottom plate. The special automatic digging and planting machine has the advantages that the difficulties of separated operation for digging and planting, complex operation, high labor intensity of workers and low planting efficiency and the like in the semiautomatic tree seedling planting mode adopted in the existing municipal park and garden construction can be solved, and the full-automatic integrated digging and planting function for the tree seedlings can be realized.

Owner:高雅

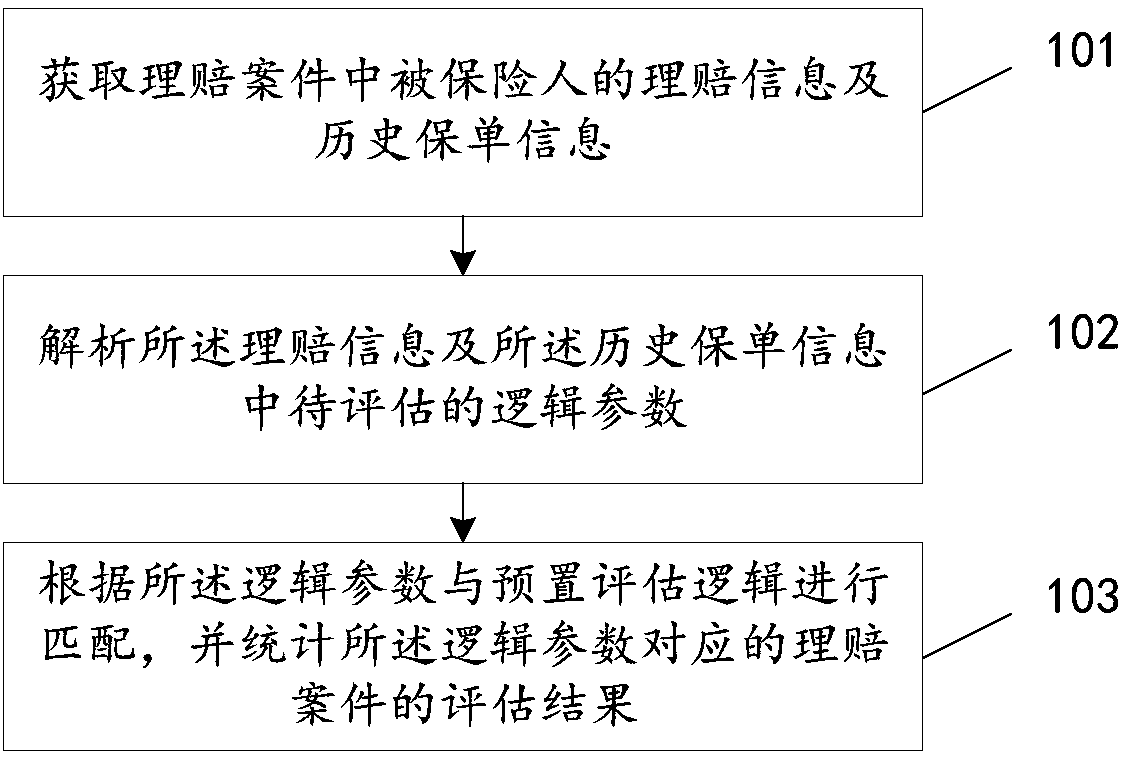

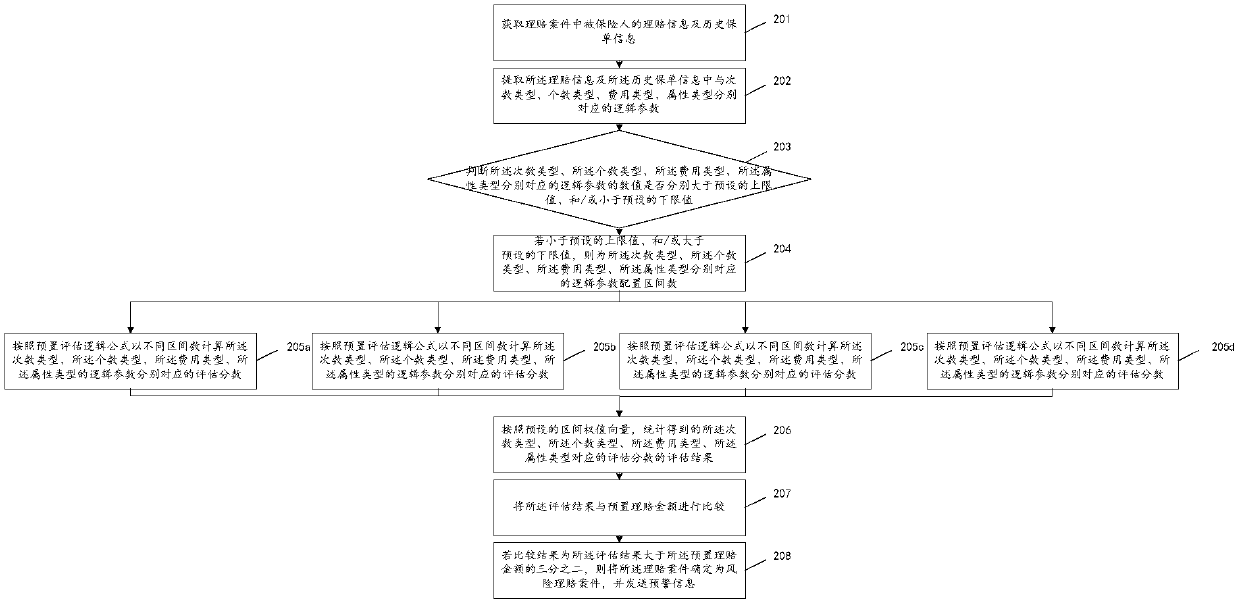

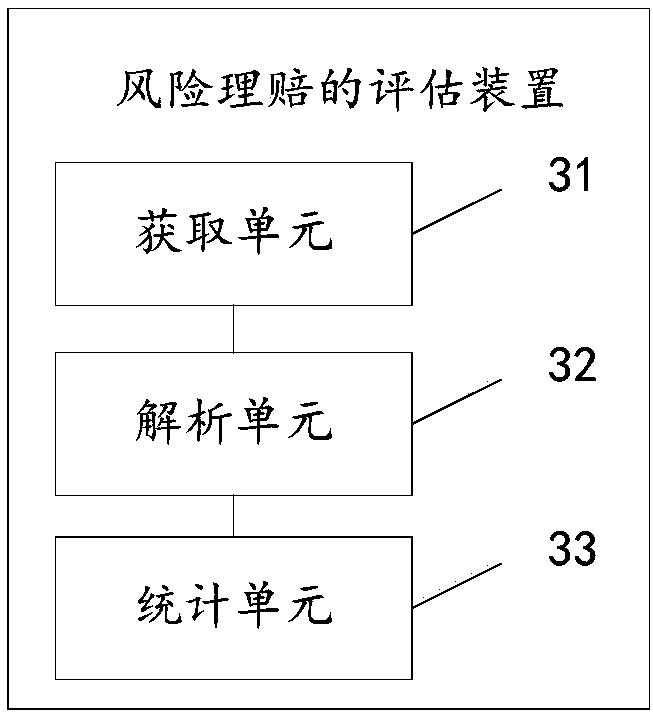

Method and device for evaluating risk claim settlement

InactiveCN107871284AImprove evaluation efficiencyRealize automatic calculationFinanceEvaluation resultComputer science

The invention discloses a method and a device for evaluating a risk claim settlement, relates to the technical field of data processing and mainly solves the problem that the economic loss is broughtto an insurance company when existing loss-evaluating personnel checks a claim settlement case and easily misses high-risk cases through manual check. A main technical scheme of the method comprises the steps of acquiring claim settlement information and historical insurance policy information of an insured in the claim settlement case; analyzing to-be-evaluated logic parameters in the claim settlement information and the historical insurance policy information, wherein the logic parameters are used for reflecting the situation that the insured participates in medical programs in the claim settlement case; and matching the logic parameters and preset evaluation logics, counting an evaluation result of the claim settlement case corresponding to the logic parameters, wherein the preset evaluation logics are used for reflecting a relation between different logic parameters and different evaluation scores. The method and the device are mainly used for evaluating the risk claim settlement.

Owner:PING AN TECH (SHENZHEN) CO LTD

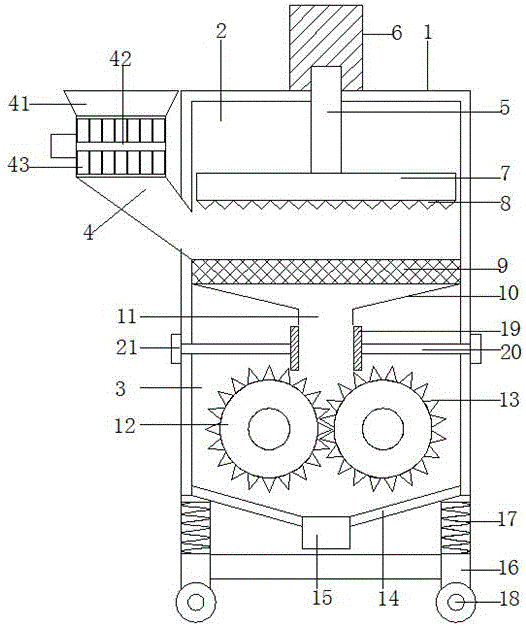

Crushing device for chemical industry production

InactiveCN106733113AQuality assuranceImprove work efficiencyGrain treatmentsChemical industryHydraulic cylinder

The invention discloses a crushing device for chemical industry production. The crushing device for chemical industry production comprises a crushing machine body. The crushing machine body is divided into a crushing cavity and a smashing cavity in an upper-lower mode. The bottom end of the left side of the crushing cavity is connected with a feeding pipe, a feeding hopper is arranged on the upper side of the feeding pipe, and an iron removing rotary shaft is horizontally arranged in the center in the feeding hopper. Permanent magnet sheets are arranged on the outer wall of the iron removing rotary shaft in a vertically symmetrical mode. A telescopic column is vertically arranged in the center in the crushing cavity, the top end of the telescopic column stretches out of the crushing cavity and is connected with a hydraulic cylinder fixed on the outer wall of the upper side of the crushing machine body, and the bottom end of the telescopic column is connected with a crushing hammer arranged horizontally. The crushing device for chemical industry production can conduct iron removing on materials twice, thereby being good in iron removing effect and sufficient in iron removing; two crushing mechanisms arranged up and down are adopted for sufficiently crushing materials, gears are engaged to conduct crushing, and thus the crushing effect is good, and crushing is sufficient; and besides, effective shock absorption can be achieved, and the service life of the machine body is prolonged.

Owner:GUANGXI UNIV

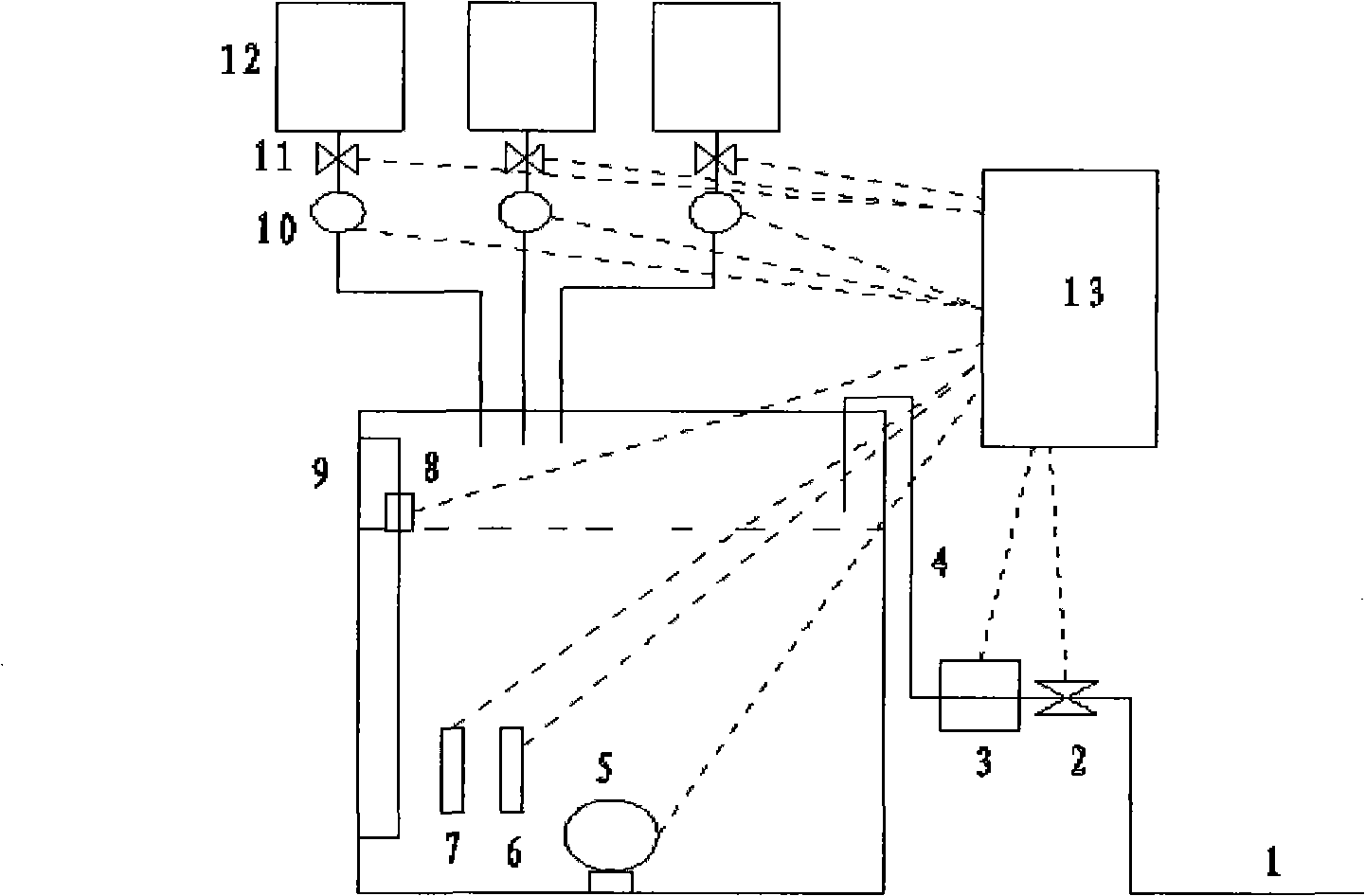

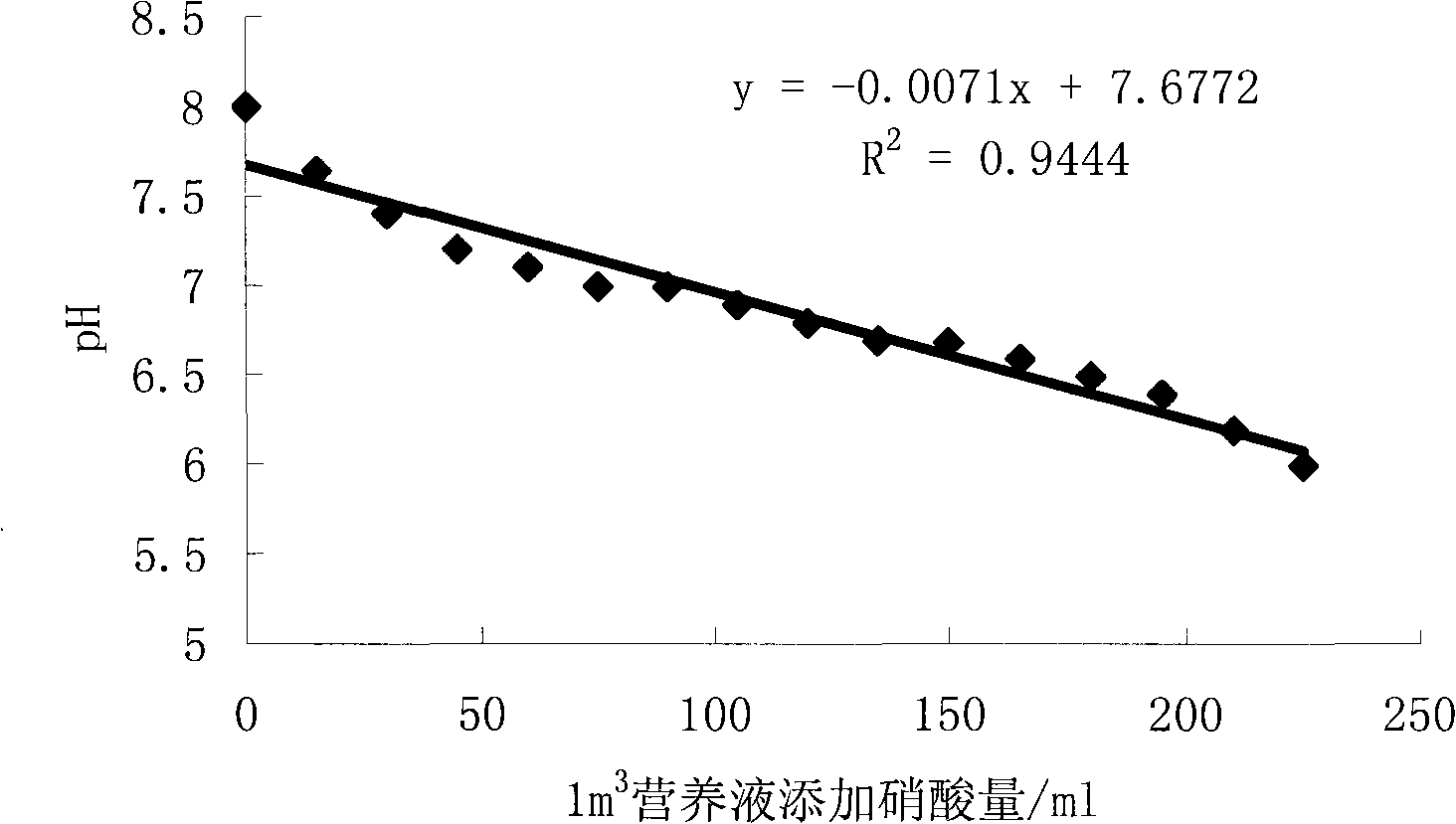

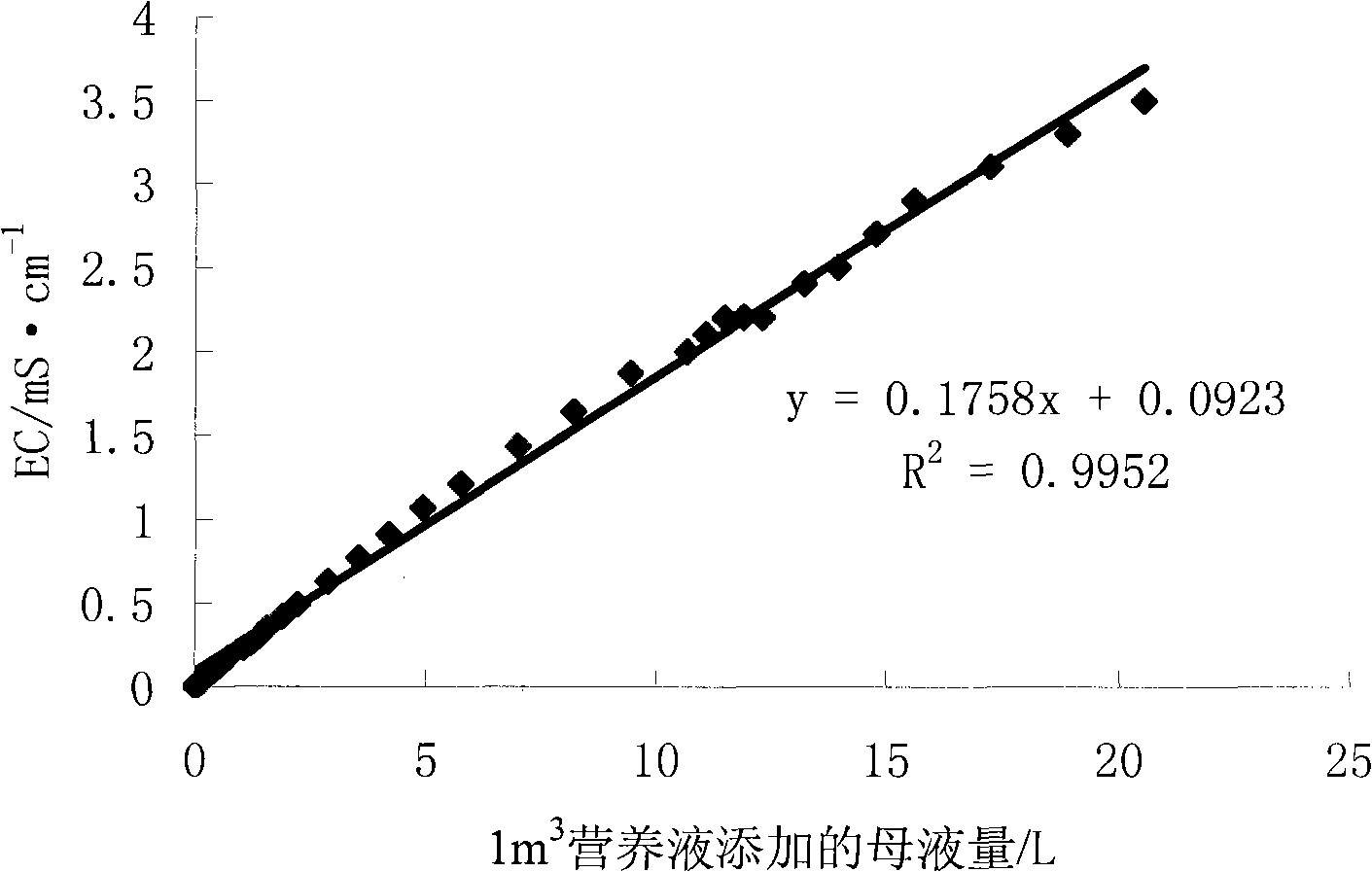

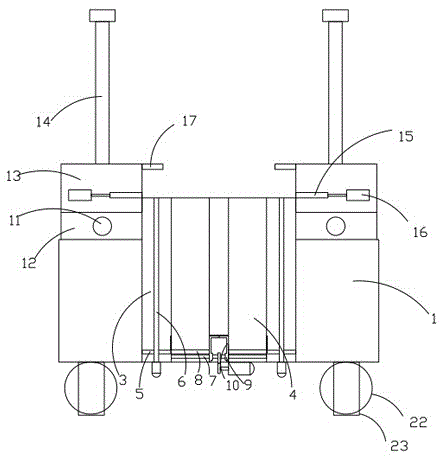

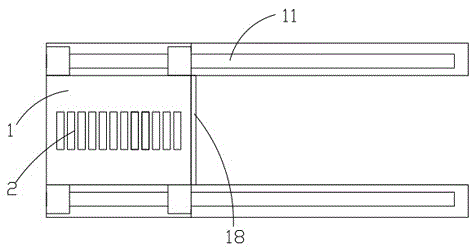

Nutrient solution replenishing and adjusting device and method

InactiveCN101491206AGuaranteed demandLow costAgriculture gas emission reductionCultivating equipmentsWater sourceEngineering

The invention discloses a nutrient solution supply and adjusting device in the field of soilless culture and a method thereof. The device comprises a water source, a water supply electromagnetic valve, an electronic water meter, a water supply pipeline, a liquid mixing pump, an EC sensor, a pH sensor, a liquid level sensor, a nutrient solution bath, a metering pump, a fertilizer supply electromagnetic valve, a mother liquor reservoir and a control device. Through the real-time monitoring of the nutrient solution reserves, the EC value and pH value variation, the device takes corresponding fertilizer, acid and water supply measures so as to realize the adjustment and supply of the nutrient solution during the soilless culture and ensure the normal supply of the nutrient solution. The method and the device have the advantages of simplicity, low cost, practicability, easy realization and good effects.

Owner:CHINA AGRI UNIV

Automatic large flange stacking and loading machine

ActiveCN105460642AOvercoming uneven connectionsNo manual operationConveyorsStacking articlesEngineeringFlange

The invention provides an automatic large flange stacking and loading machine. The automatic large flange stacking and loading machine comprises a flange conveying frame, a flange conveying track connected with a loading vehicle, and an automatic flange stacking device arranged in the loading vehicle. The automatic flange stacking device comprises a conveying track and a stacking device. The conveying track comprises a transverse rack body and a plurality of longitudinal track bodies. The stacking device comprises a machine frame, and a cushion strip storing and conveying device is arranged in the machine frame and comprises cushion strip storing and conveying units arranged on two sides of the machine frame. Each cushion storing and conveying unit comprises a cushion strip lifting passage, a cushion strip storing passage, a cushion strip lifting mechanism and a pushing mechanism. Cushion strip outlets communicated with the cushion strip lifting passages on two sides are formed in the work surface of the machine frame. Stacking mechanisms used for automatically stacking cushion strips and flanges are arranged on the left and right sides of the machine frame respectively. The automatic large flange stacking and loading machine can automatically stack large flanges, is low in labor intensity and is high in efficiency.

Owner:JIANGYIN HENGRUN RING FORGING

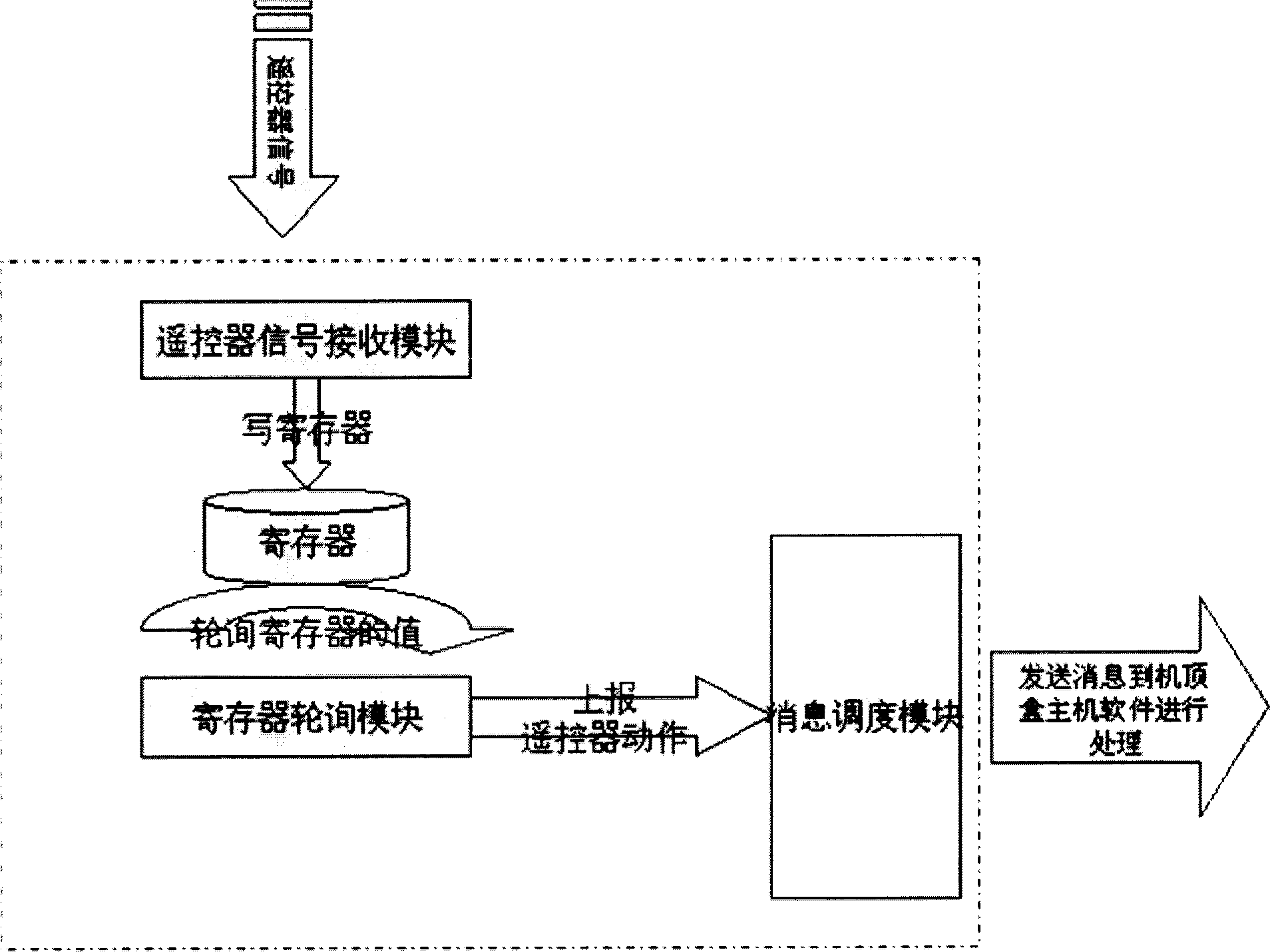

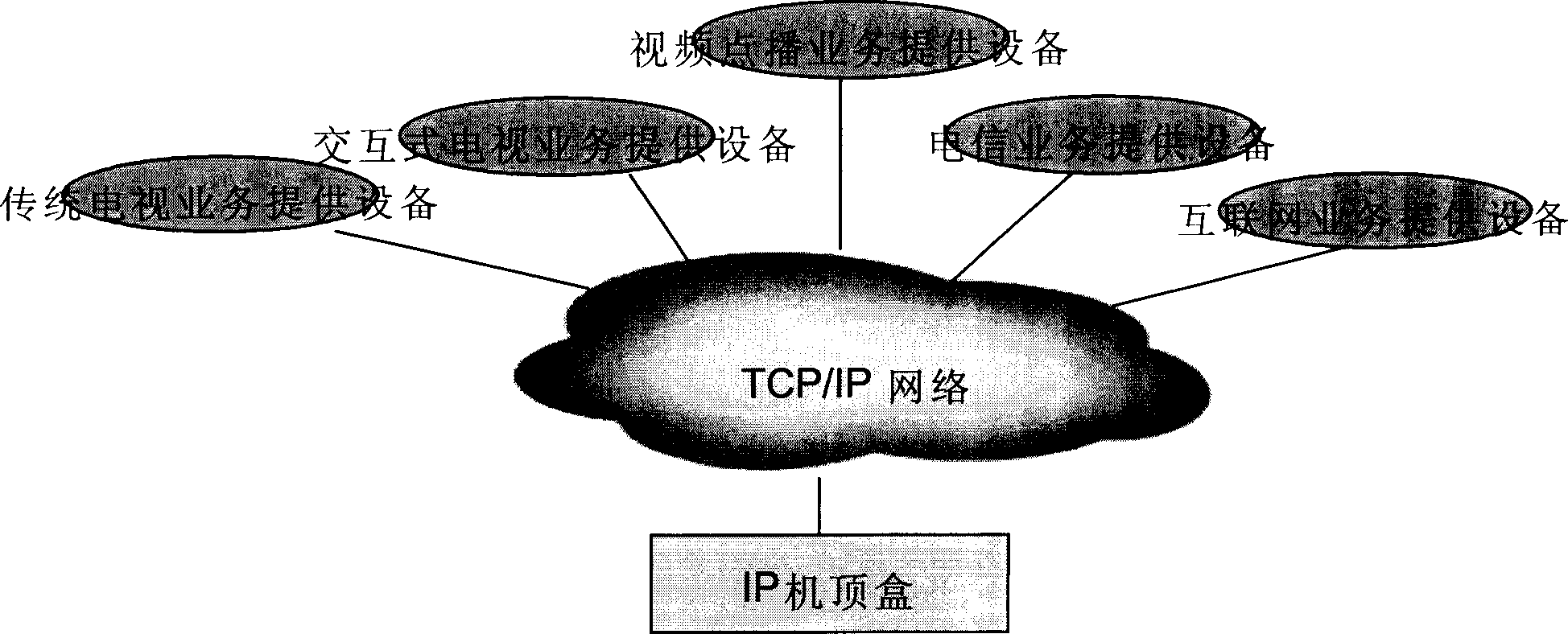

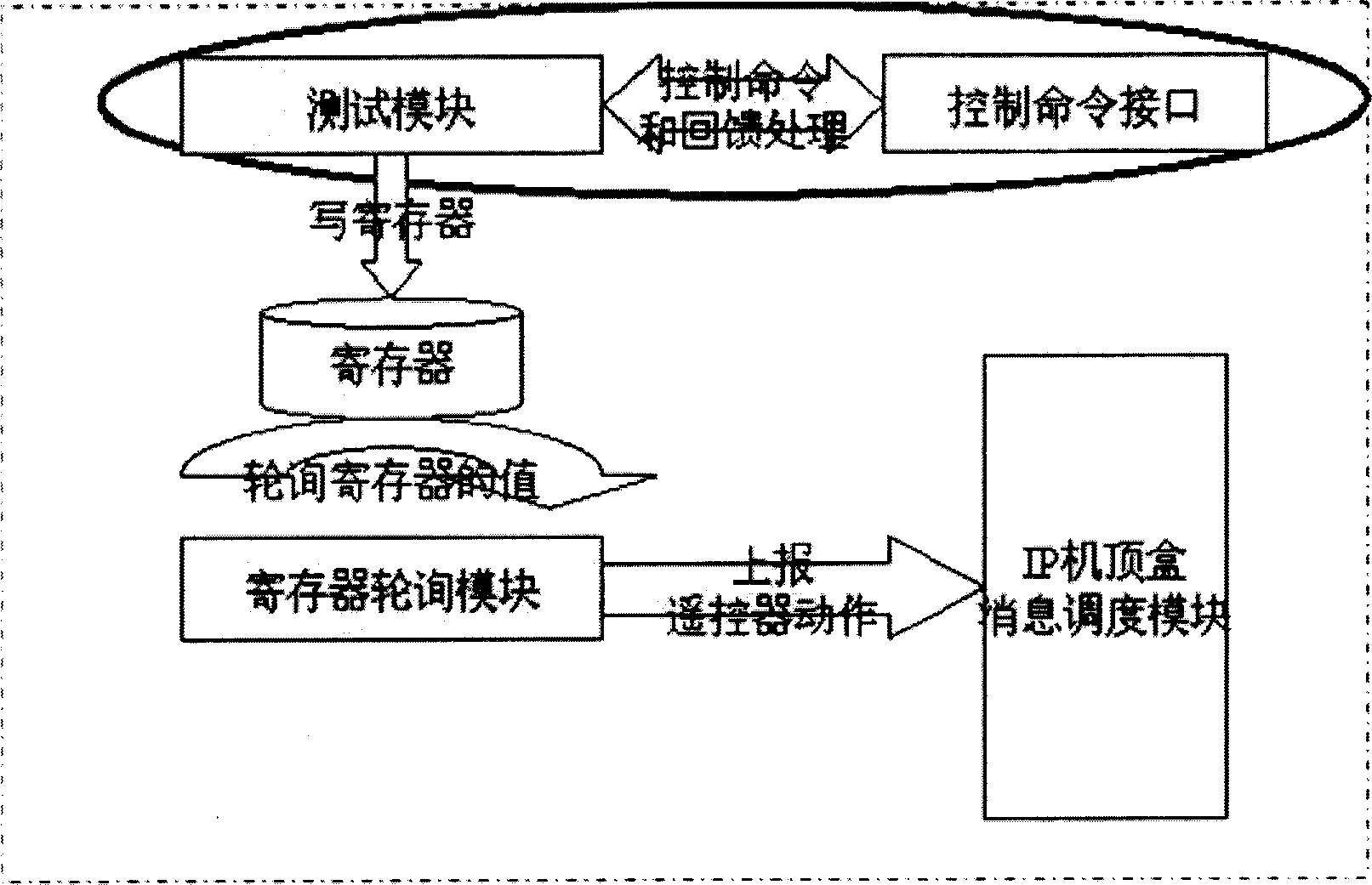

Detecting system for IP set-top tox and realizing method

InactiveCN1859581AImplement automated testingNo manual operationTelevision systemsSet top boxTest case

The present invention provides IP set-top box test system and implementation method. System includes remote controller signal reception module, message scheduler module, and test module and control command interface set in set-top box; wherein control command interface converting command as instruction and transmitting to test module, test module processing and transmitting to message scheduler module to make processing; through analyzing some operation flow message interactive process, then according to analytical result compiling test case making script, finally executing script i.e. according to script test. Said system or method can customize test condition and scene, to realize set-top box automatization testing.

Owner:HUAWEI TECH CO LTD

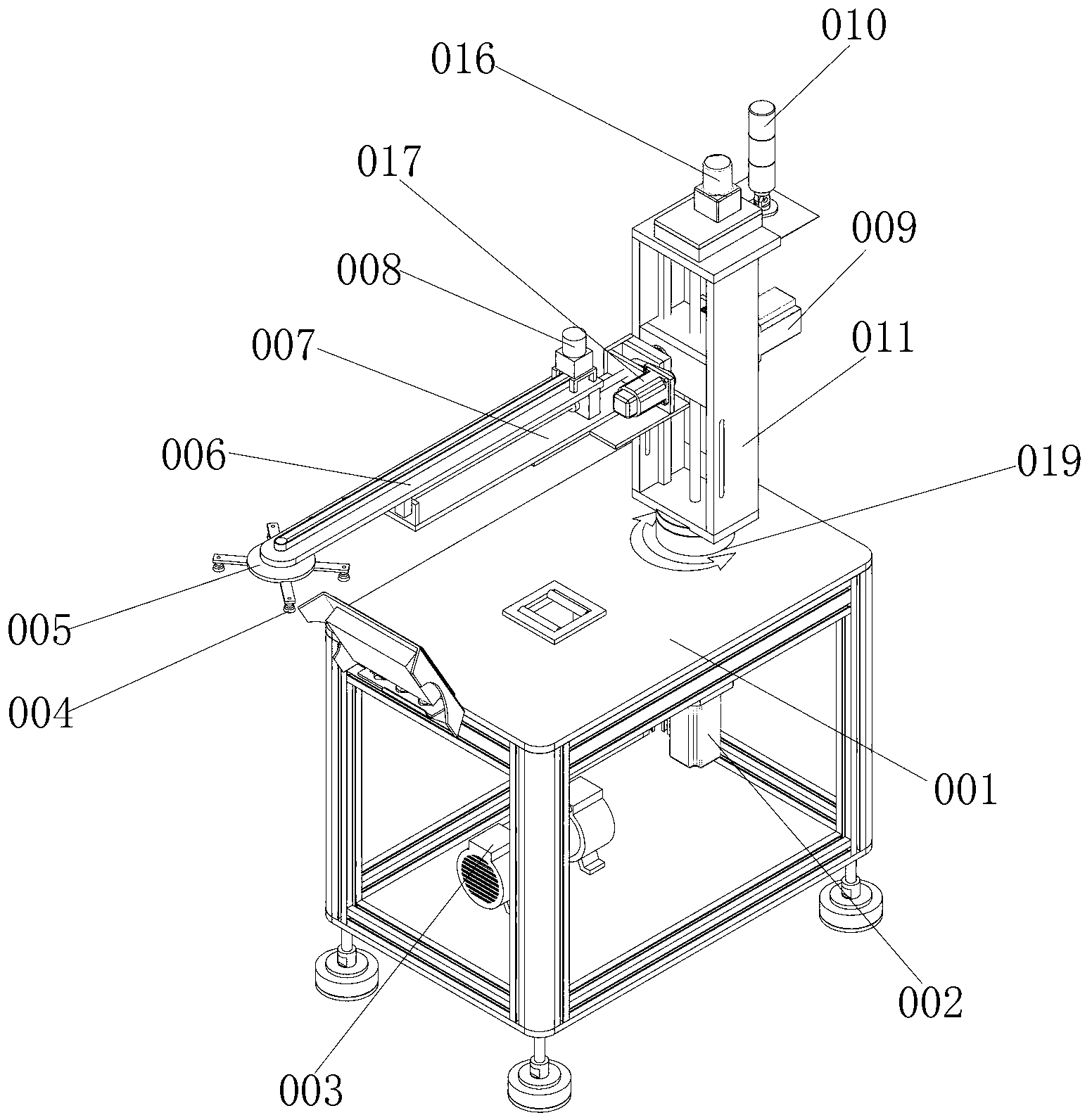

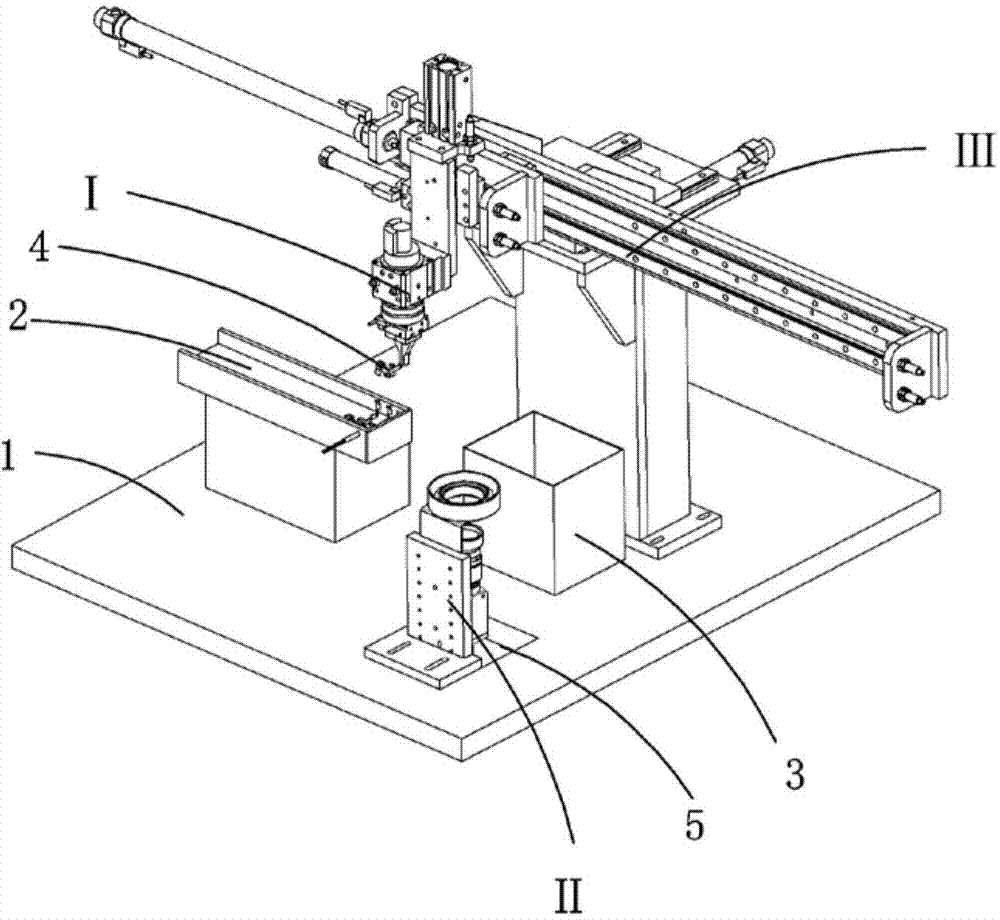

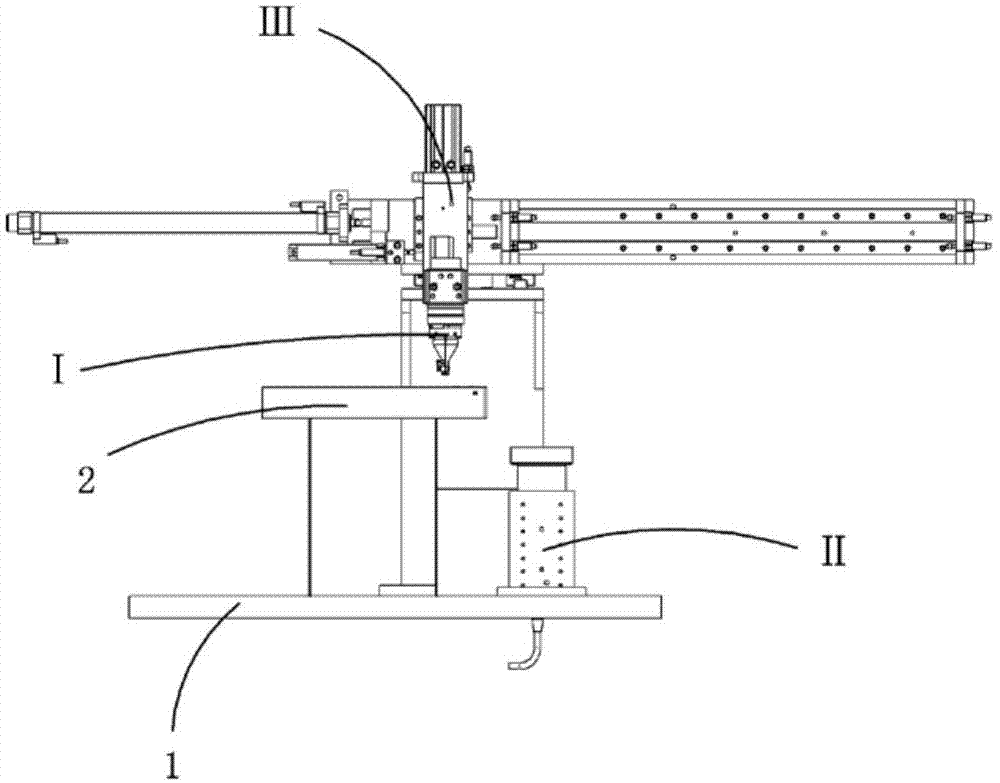

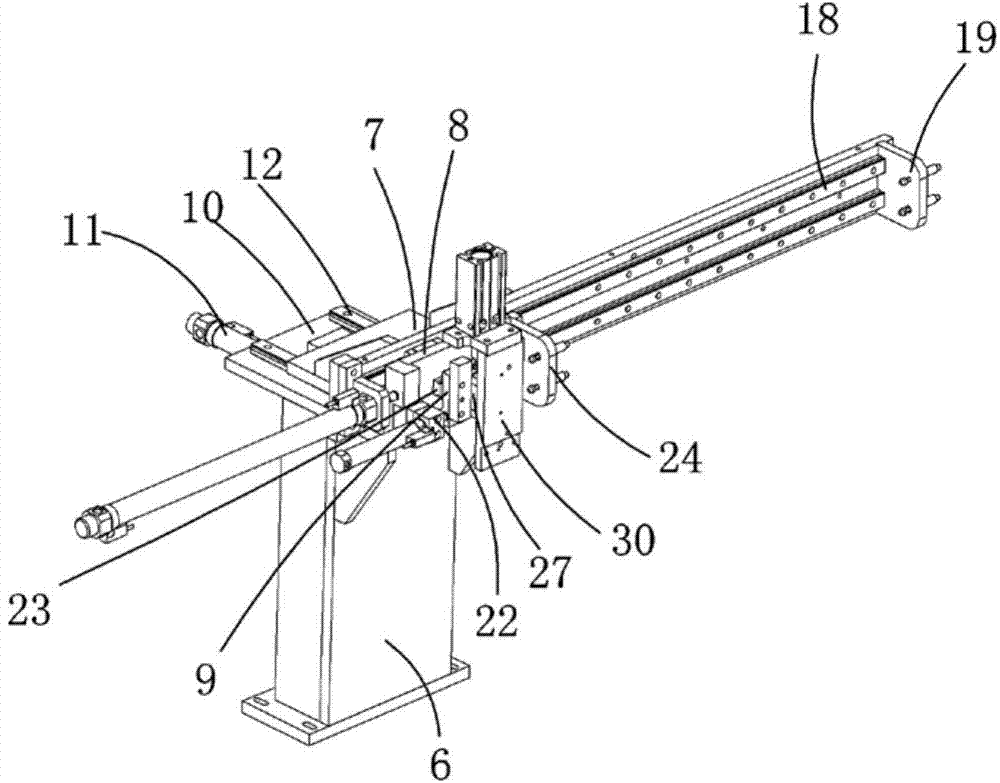

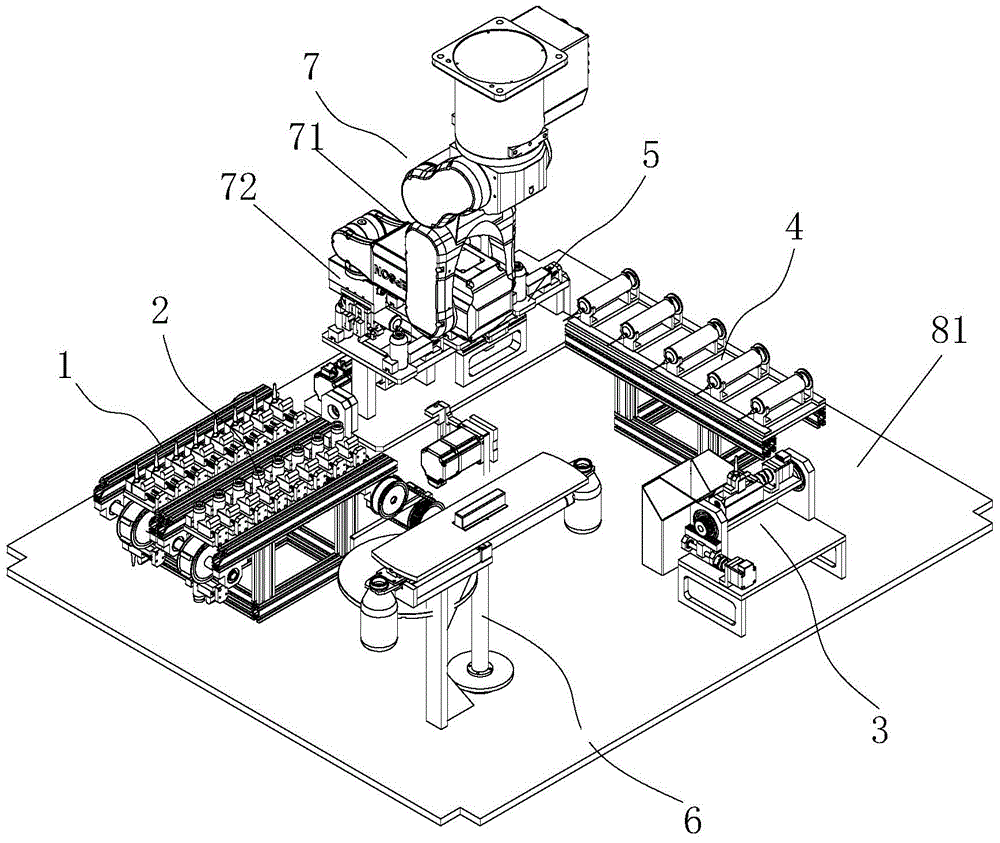

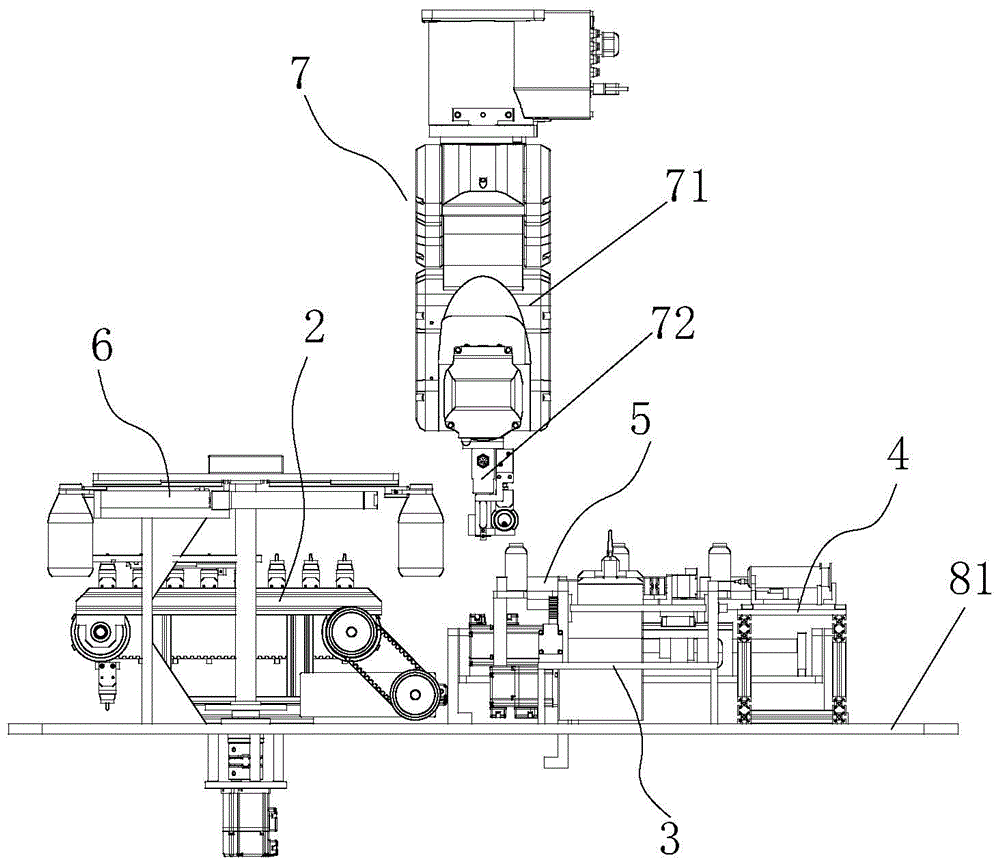

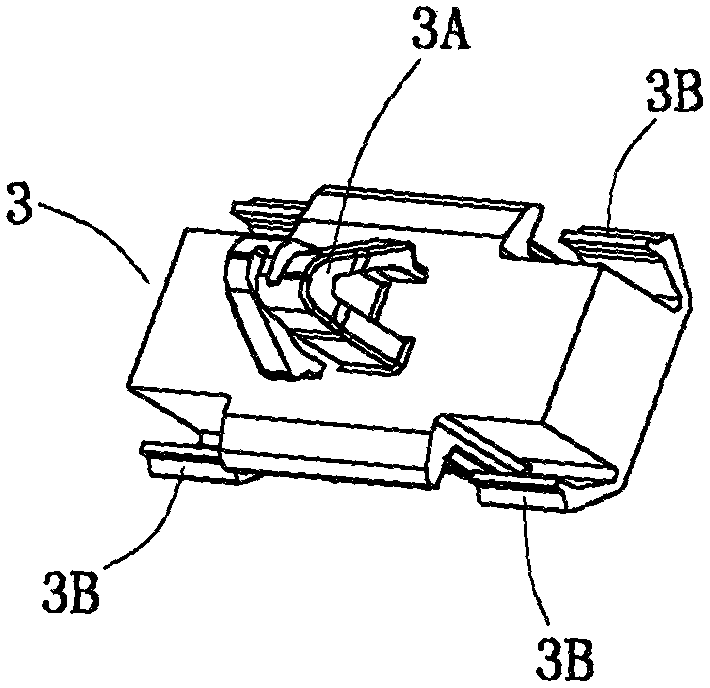

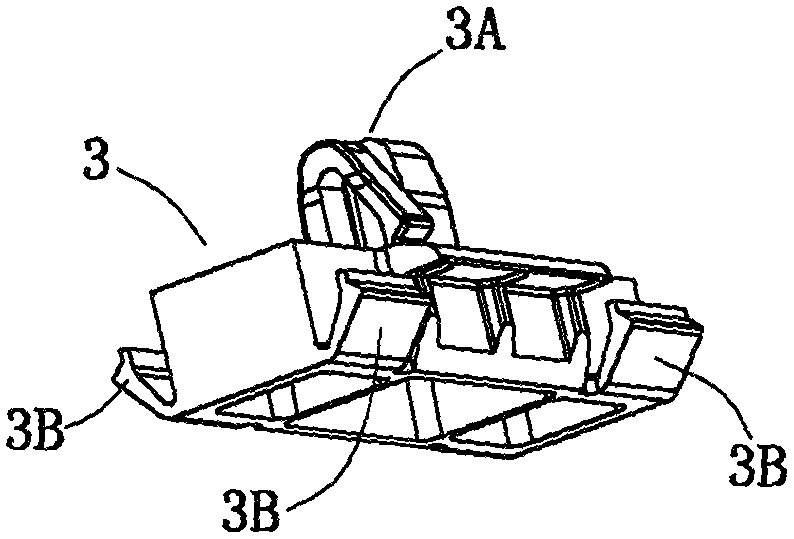

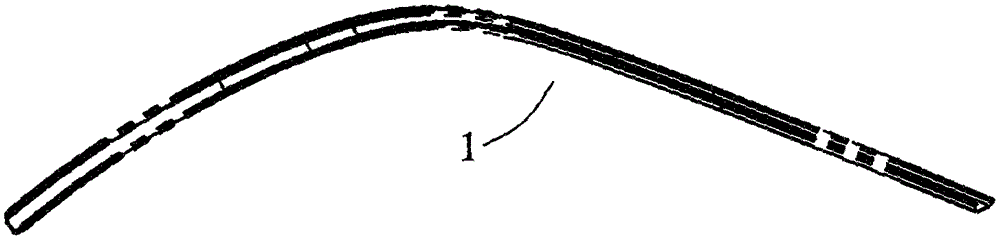

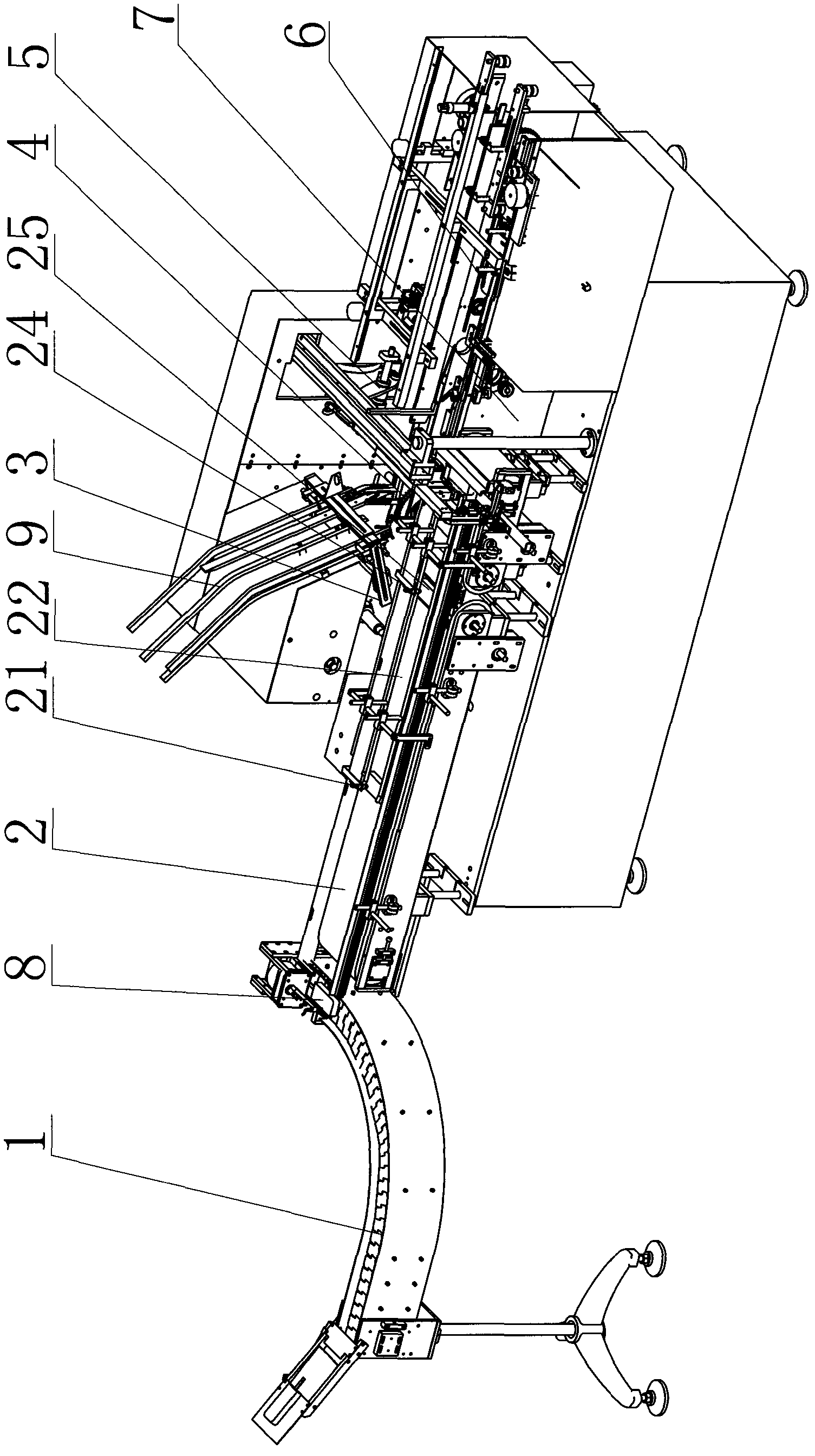

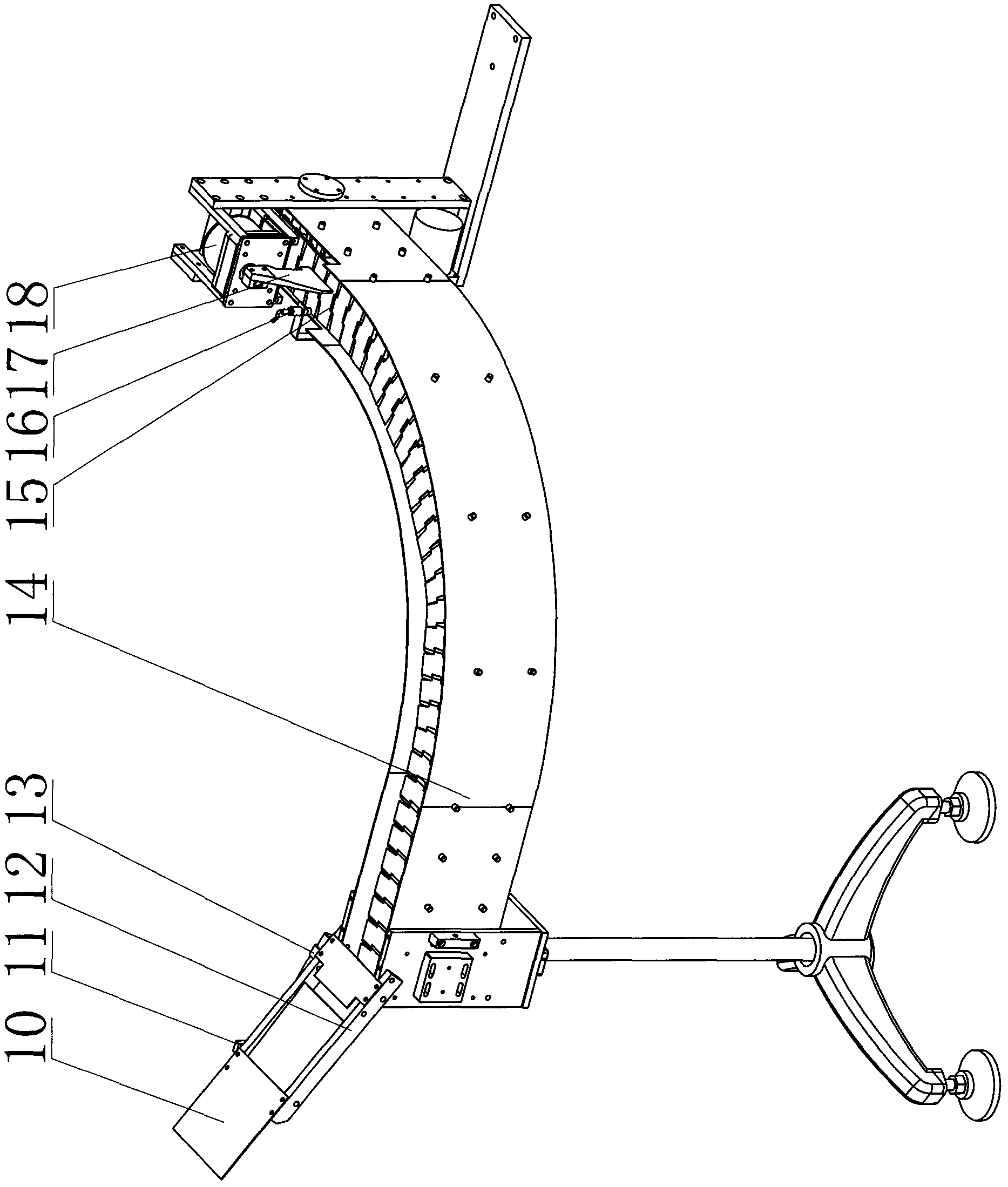

Automatic decoration strip and buckle mounting device and method

ActiveCN105269300AImprove installation work efficiencyHigh degree of automationVehicle componentsMetal working apparatusEngineeringAutomation

The invention provides an automatic decoration strip and buckle mounting device and method. The device comprises a workpiece carrying table (2), a robot (4) and a buckle vibrating disk (5), wherein the workpiece carrying table (2) is used for carrying decoration strip workpieces (1); the robot (4) is used for grabbing and mounting buckles (3) onto the decoration strip workpieces (1); the buckle vibrating disk (5) is used for automatically providing the buckles (3). The workpiece carrying table (2) comprises a table board (6). Workpiece carrying blocks (7) are arranged on the table board (6). A workpiece carrying groove (7A) matched with each decoration strip workpiece (1) in shape is formed in the upper surface of each workpiece carrying block (7). A plurality of workpiece hold-down mechanisms (8) are arranged at intervals beside the workpiece carrying blocks (7) in the extending direction of the workpiece carrying blocks (7). The two ends of each workpiece carrying block (7) are provided with extending direction workpiece positioning mechanisms. The end of a movable arm of the robot (4) is provided with a rotary disk (9). A plurality of buckle clamp holders (10) are evenly arranged in the circumferential direction of the rotary disk (9). The automatic decoration strip and buckle mounting device is high in automation degree and operating efficiency and good in product uniformity; the operation of mounting a plurality of buckles onto a decoration strip is completed in one step without midway manual operation and completed automatically and entirely by the device.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

ice cream cartoning machine

ActiveCN102285467ANo manual operationImprove efficiencyPackaging automatic controlCartoning machineEngineering

The invention discloses a box packing machine of ice cream. The box packing machine is characterized by comprising a machine body (7), a feeding mechanism (1), a delivery mechanism (2), a box sucking mechanism (3), a box feeding mechanism (4), a material pushing mechanism (5), a box sealing mechanism (6) and a transmission mechanism, wherein the material pushing mechanism is arranged at the end part of the delivery mechanism; the delivery belt of the delivery mechanism is a net chain; the box feeding mechanism is composed of a conveying chain and shifting forks (40); the shifting forks are arranged on the conveying chain; and a groove matched with the box is formed between the shifting forks; the conveying chain is arranged on the side of the net chain, and is parallel to the net chain; the material pushing mechanism comprises a pushing rod (50) and a reciprocating mobile device; the pushing rod is connected to the reciprocating mobile device, and the pushing rod is arranged vertically to the conveying chain. The box packing machine with the structure can automatically convey and pack cold food such as ice cream and the like into paper boxes, and has the characteristics of high speed and environmental protection.

Owner:上海宏海食品有限公司

Tea leaf withering process plant

InactiveCN101243817ATimely withering treatmentEvenly dryPre-extraction tea treatmentControl systemAir treatment

The invention provides a tea withering machine, comprising a frame, an electric cabinet and a case on the rear part of the frame. A feeding and conveying belt for delivering tealeaves into the case is arranged on the frame in front of the case; small vent holes are densely arranged on the conveying belt, and a heating and cooling air supplying device is positioned under the conveying belt; the case is divided into a tealeaves treating chamber and an air treatment chamber by a separating plate with respective air inlets and outlets at both sides; the air treatment chamber is provided with a temperature and humidity treatment device for recirculation air, and a blower; the blower is connected with the air outlets of the separating plate; the tealeaves treating chamber is provided with an air exhausting device and a multi-layer tealeaves distributing and conveying belt; the tealeaves distributing and conveying belt is used to support the tealeaves on the feeding and conveying belt, and deliver downward the tealeaves layer-by-layer; a conveying belt for the discharge tealeaves is arranged at the lower part of a discharge port of the lowest tealeaves distributing and conveying belt; a circulating and back-feeding device for delivering the tealeaves to a hopper is arranged between one end of the conveying belt for the discharge tealeaves and the hopper; a receiving chute is positioned below the other end of the conveying belt for the discharge tealeaves; a temperature and humidity sensor connected with an input end of a control system is arranged in the tealeaves treatment chamber. The tea withering machine has the advantages of saved space and excellent withering effects.

Owner:林清矫

Operating table capable of automatically fetching patient

InactiveCN1813648ASolve the problem of insufficient reachImprove stabilityOperating tablesNursing bedsEngineeringOperating table

The present invention relates to an operating table capable of automatically moving patient. Said operating table is composed of the following several portions: operating table frame, upper table surface, table surface frame, supporting structure, traveling drive device, conveyer belt, driving rollers and rollers drive device. Said invention also provides its concrete operation method.

Owner:吉林省天惠医药科技有限公司

Automatic deburring production line for hub robot

InactiveCN105171551AProtect healthNo manual operationEdge grinding machinesGrinding feedersProduction lineControl system

The invention discloses an automatic deburring production line for a hub robot. The automatic deburring production line consists of a loading and unloading mechanism, a deburring robot and a control system. The automatic deburring production line is characterized in that the loading and unloading mechanism, the deburring robot and the control system are enclosed into a sealed system by virtue of an enclosure (6), wherein a robot I (4) grabs a hub and carries the hub to a position above a hub clamp rotary table (11) and turns over the hub; the robot I (4) carries out charging operation on four hub clamp rotary tables in turn; a hub grinding claw (9) of a robot II (5) completes deburring and grinding operations on a hub window; the robot I (4) grabs the hub from the hub clamp rotary table (11) and then puts the hub into an upper-layer finished product discharging roller way (2) or a lower-layer waste discharging roller way (3), thereby completing a cycle. The automatic deburring production line does not need manual operation in the whole process; and a system can automatically position, identify, debur, grind and discharge a workpiece.

Owner:江苏天宏智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com