Patents

Literature

218results about How to "Realize automatic crawling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

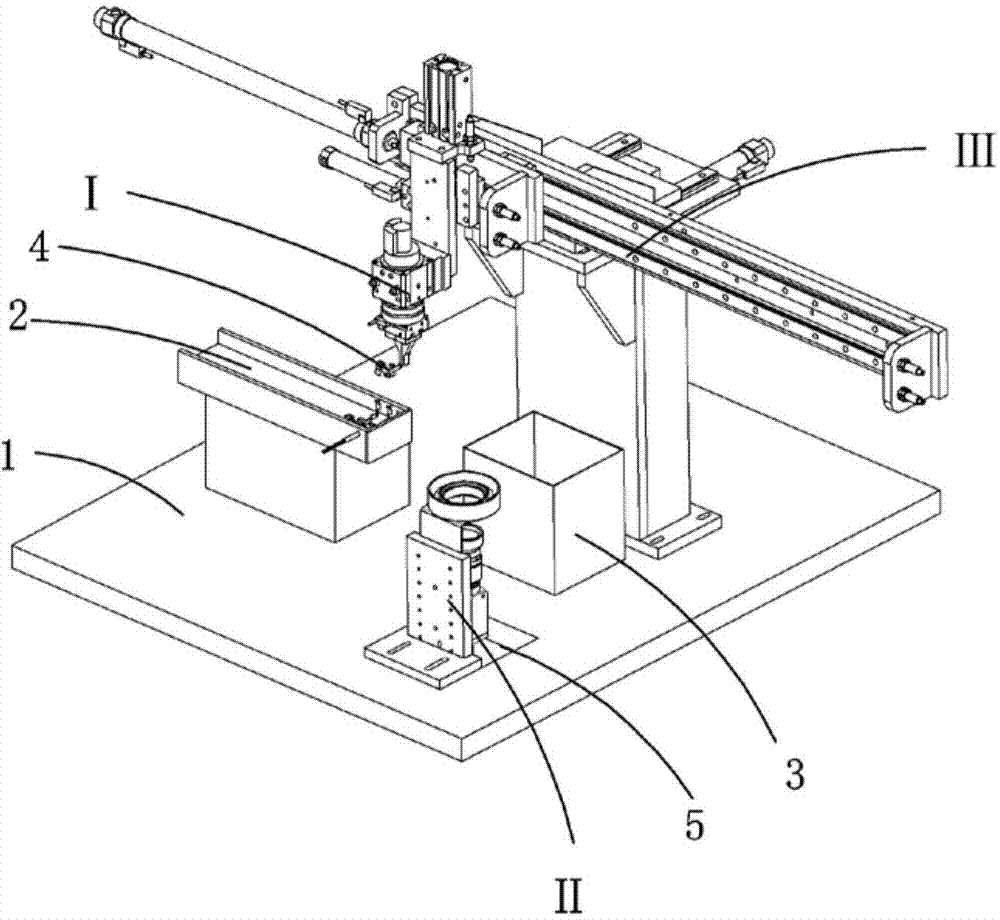

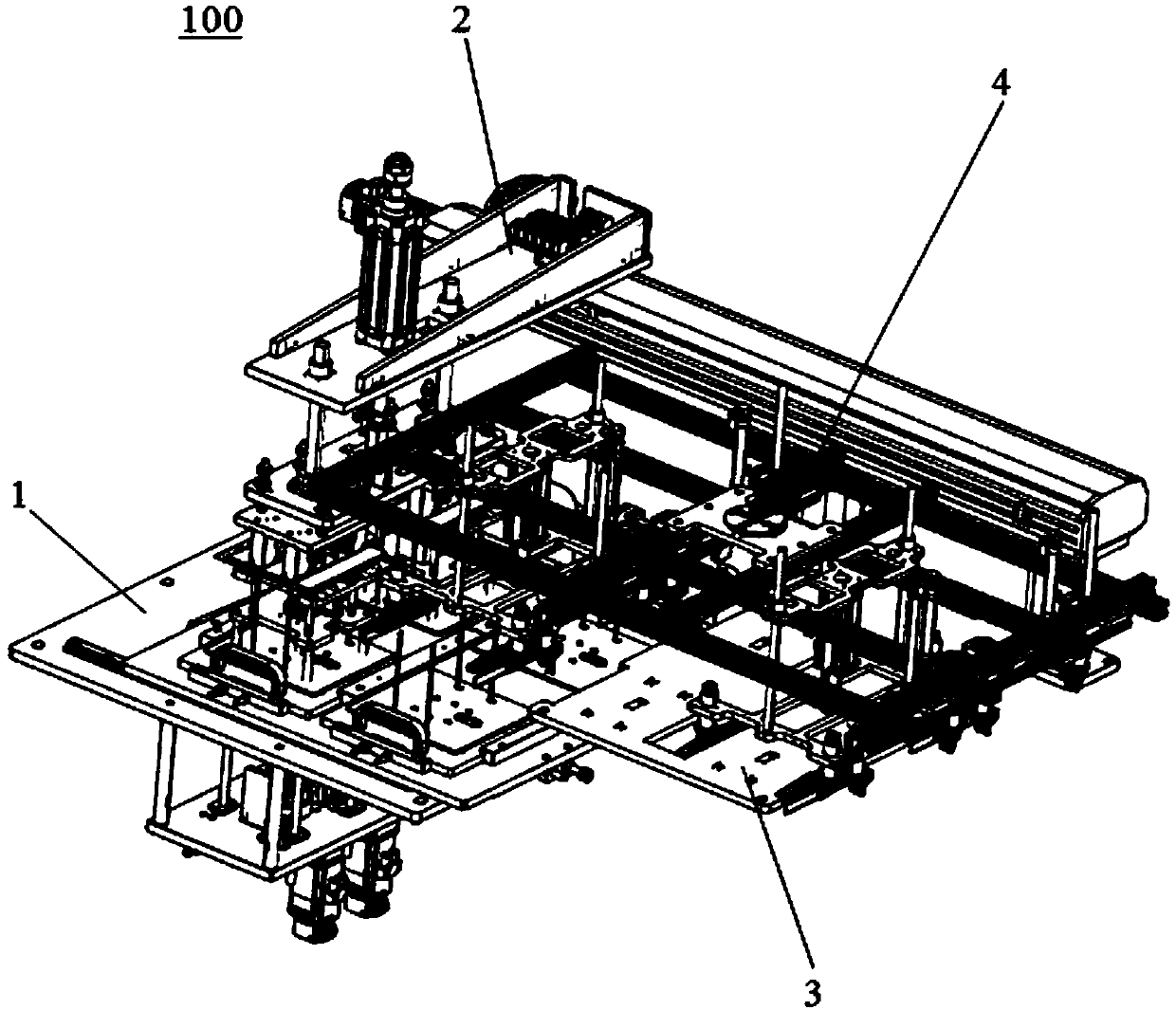

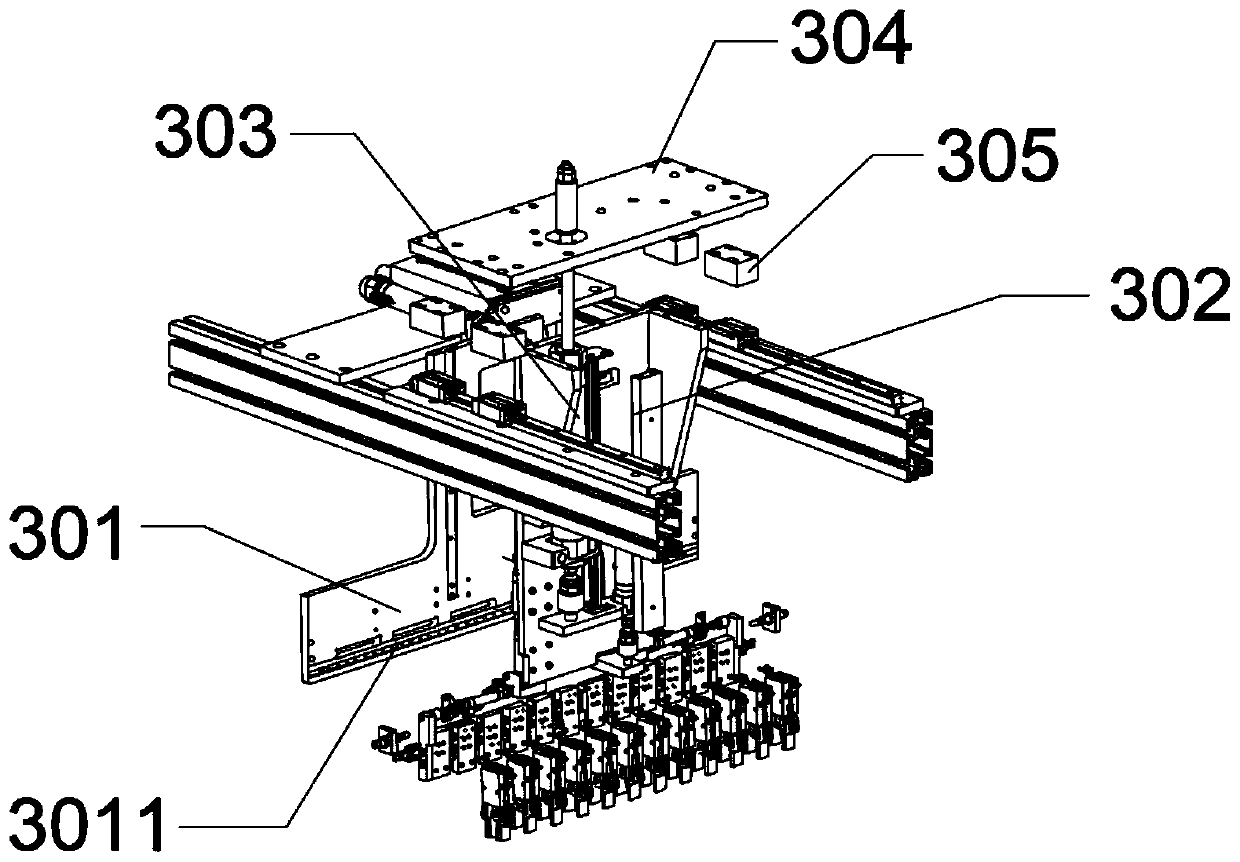

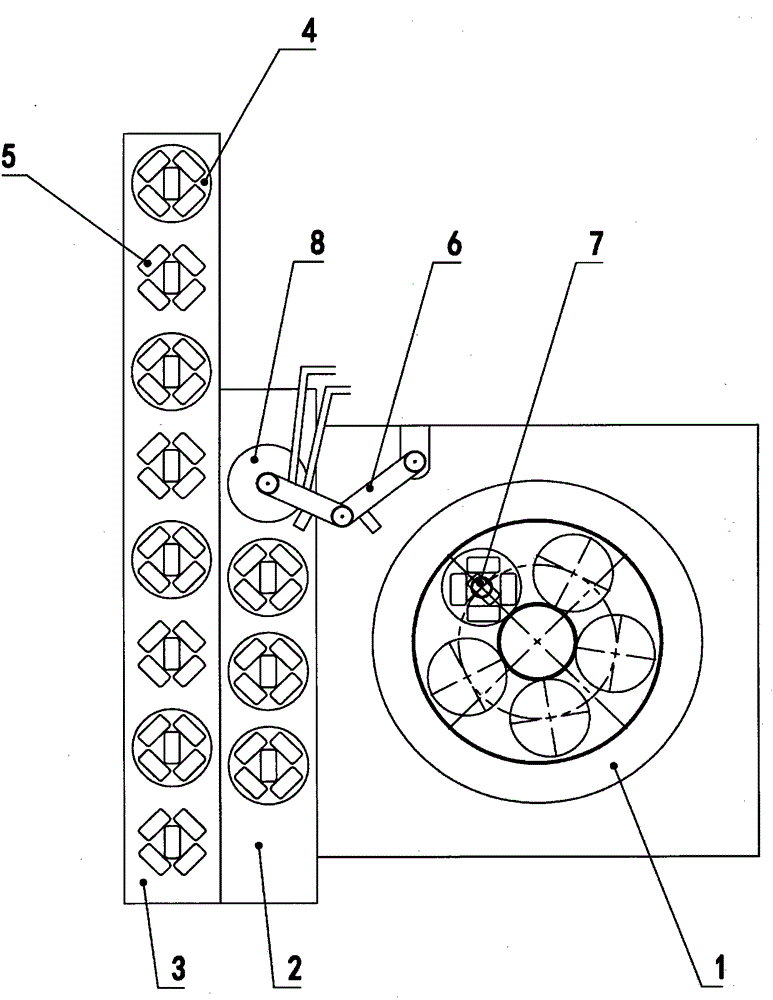

Grabbing and detecting mechanism for parts

ActiveCN103787081AAchieve absorptionRealize automatic crawlingConveyor partsMachiningIndustrial engineering

The invention relates to a grabbing and detecting mechanism for parts. The grabbing and detecting mechanism comprises a bottom plate, a grabbing mechanism, a detecting mechanism, a carrying mechanism, a part bin and an unqualified product bin. The part bin and the unqualified product bin are fixed to the bottom plate. The parts are arrayed in order in the part bin; a square groove hole is formed in the bottom plate, the detecting mechanism is installed on the bottom plate and located on the square groove hole, and the detecting mechanism is used for detecting the appearance and sizes of the grabbed parts; the carrying mechanism is installed on the bottom plate, the grabbing mechanism is installed on the carrying mechanism, the grabbing mechanism is used for grabbing the parts arrayed in order in the part bin, and the carrying mechanism is used for achieving shifting of part grabbing and detecting action; the unqualified product bin is used for storing unqualified products, and the unqualified products detected through the detecting mechanism are put in the unqualified product bin under the driving of the carrying mechanism. Through the arrangement of all the mechanisms, the parts can be automatically grabbed and detected, the detected unqualified products are conveyed to the unqualified product bin, and the grabbing and detecting mechanism is simple in structure and suitable for various machining environments.

Owner:BOZHON PRECISION IND TECH CO LTD

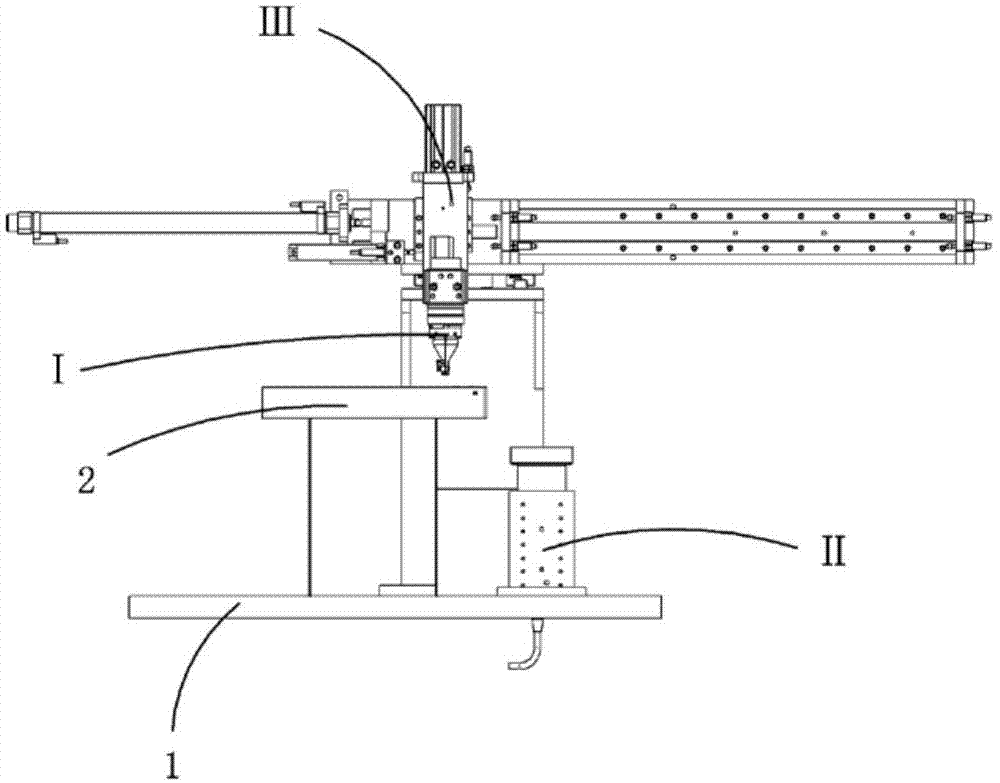

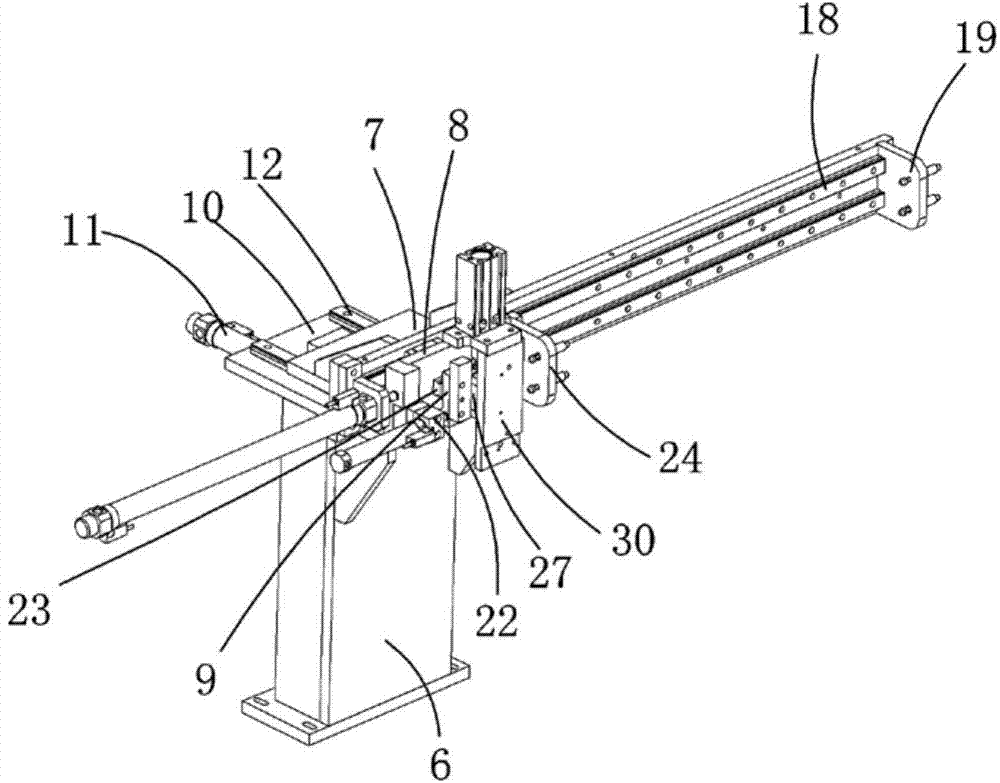

Device and method for automatic feeding and discharging of stone slabs

ActiveCN104176498ARealize automatic crawlingAchieve horizontal movementGrinding machine componentsConveyor partsMechanical engineeringTransverse beam

Owner:RIZHAO HEIN SAW

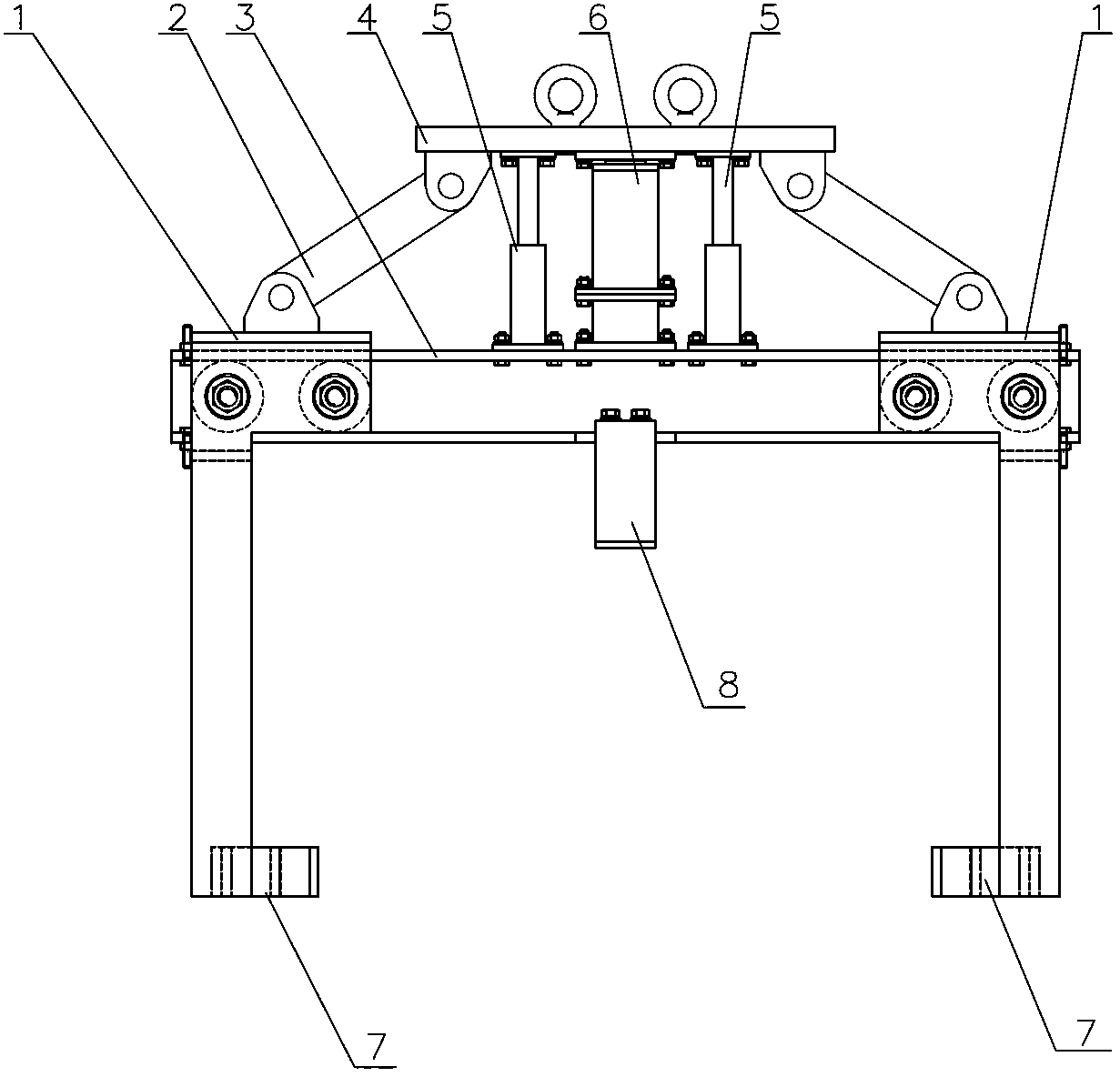

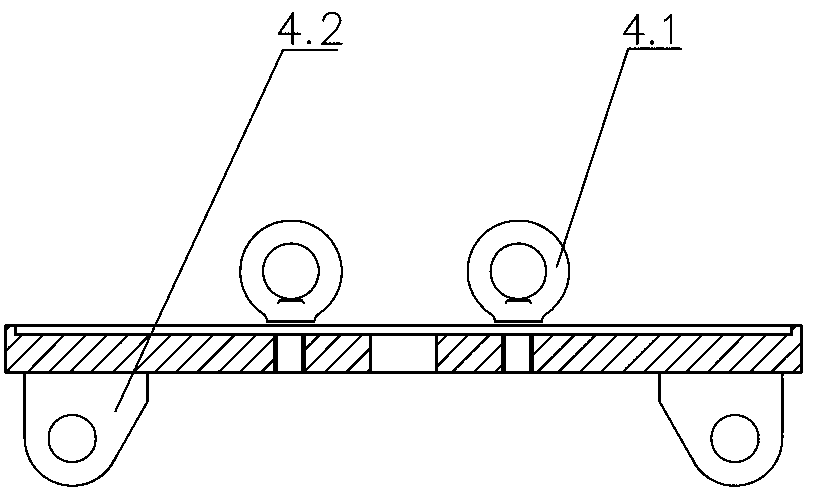

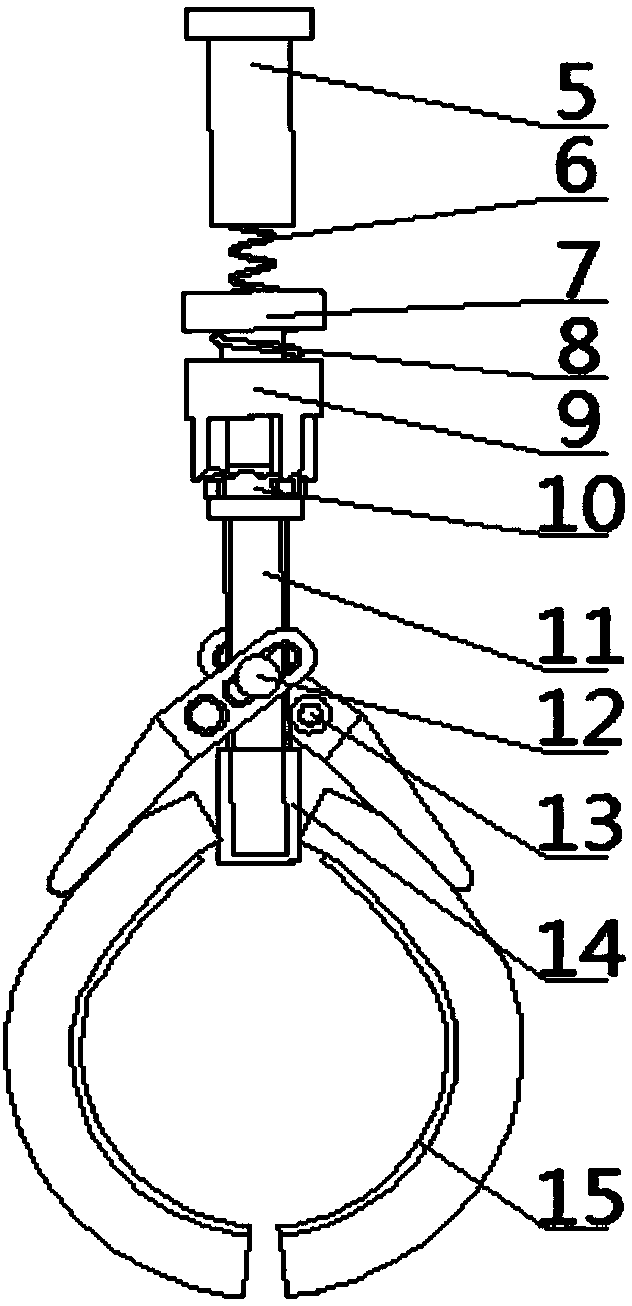

Machine lifting tool for automatically grabbing and releasing goods

ActiveCN103253592AEven by forceAvoid mechanical failureLoad-engaging elementsEngineeringSelf locking

The invention discloses a machine lifting tool for automatically grabbing and releasing goods. The machine lifting tool comprises horizontal guide rails, wherein the two ends of the horizontal guide rail are provided with flexible trolleys, the bottom parts of the flexible trolleys are provided with embracing arms for grabbing the goods, and the top parts of the flexible trolleys are provided with hinged supports; a counterweight disc is arranged above the horizontal guide rail, the top of the counterweight disc is provided with lifting rings, the two sides arranged below the counterweight disc are provided with lifting lugs, and the lifting lugs and one of the hinged supports corresponding to the lifting lug are respectively hinged with the two ends of connecting rods; and a limiting device is also arranged among the horizontal guide rails and the counterweight disc, the limiting device is mainly composed of parts such as a rotating rod, a tooth form sleeve sleeved on the rotating rod, a wedge-shaped block nested on the rotating rod, a middle shell, an arc-like block arranged in the middle shell as well as return springs. Labour and an external power device are not needed, the limiting device only depends on the self gravity control so as to carry out self locking and unlock, namely, the goods are automatically grabbed and released, the machine lifting tool is particularly suitable for operators which can not achieve harsh environments such as high temperature, high wet and radiation and narrow places of the lifting spaces.

Owner:WUHAN HAIWANG MECHANICAL & ELECTRICAL ENGTECH

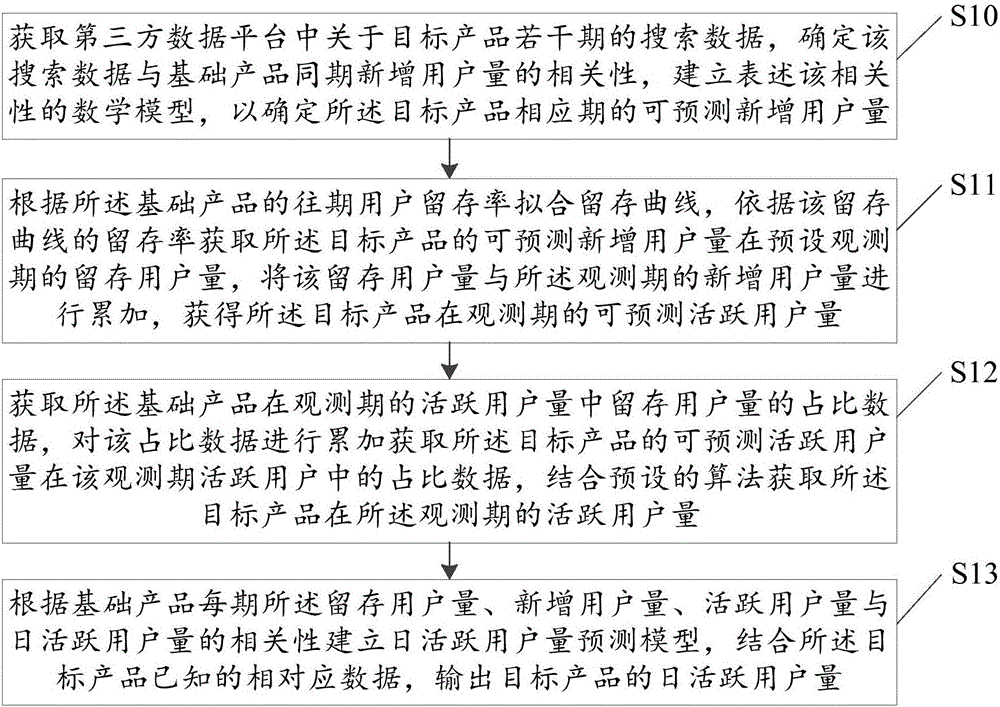

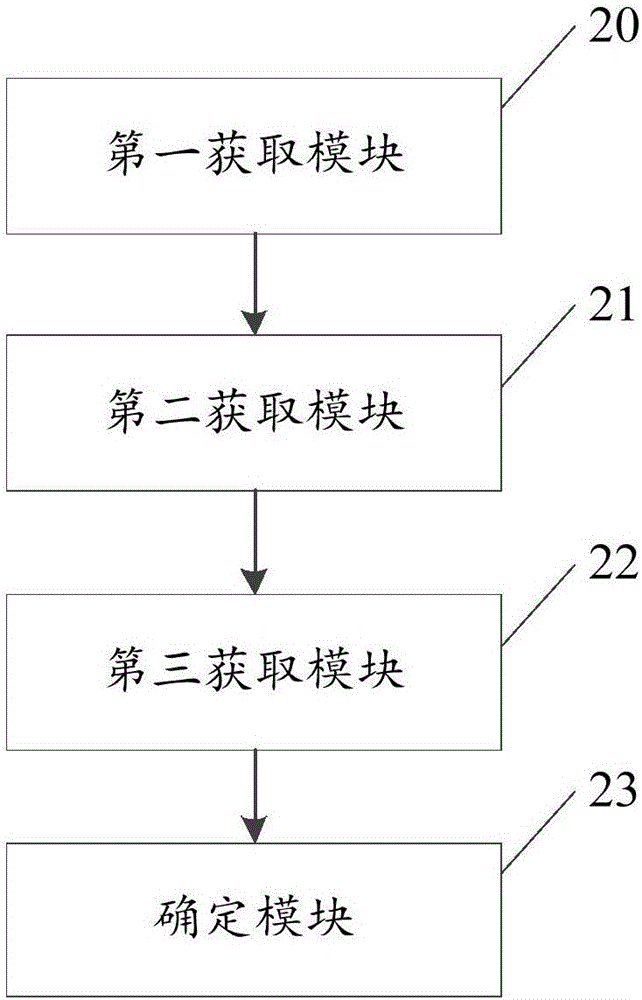

Method and apparatus for obtaining active user data of target product

ActiveCN106600344ARealize quantifiable monitoringAchieving predictabilityMarket predictionsMarket data gatheringThird partyData platform

The invention discloses a method and apparatus for obtaining active user data of target product. The method comprises: obtaining the search data in a plurality of periods of a target product in a third-party data platform; determining the correlation between the search data and the newly increased user number in the same period of a basic product so as to determine the predicted newly increased user number in the same period of the target product; according to the user remaining rate of the basic product in previous periods, fitting a remaining curve; based on the remaining curve and the newly increased user number in the observation period, obtaining the predicted active user number of the target product in the observation period; combining a preset algorithm, obtaining the active user number of the target product in the observation period; based on the correlation among the remaining user number, the newly increased user number, the active user number and the daily active user number, creating a daily active user number prediction model; and combining the already known corresponding data of the target product to output the daily active user number of the target product so as to realize the quantified monitoring on the daily active user number. With the method proposed by the invention, it is possible to realize the quantified monitoring on the daily active user number.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

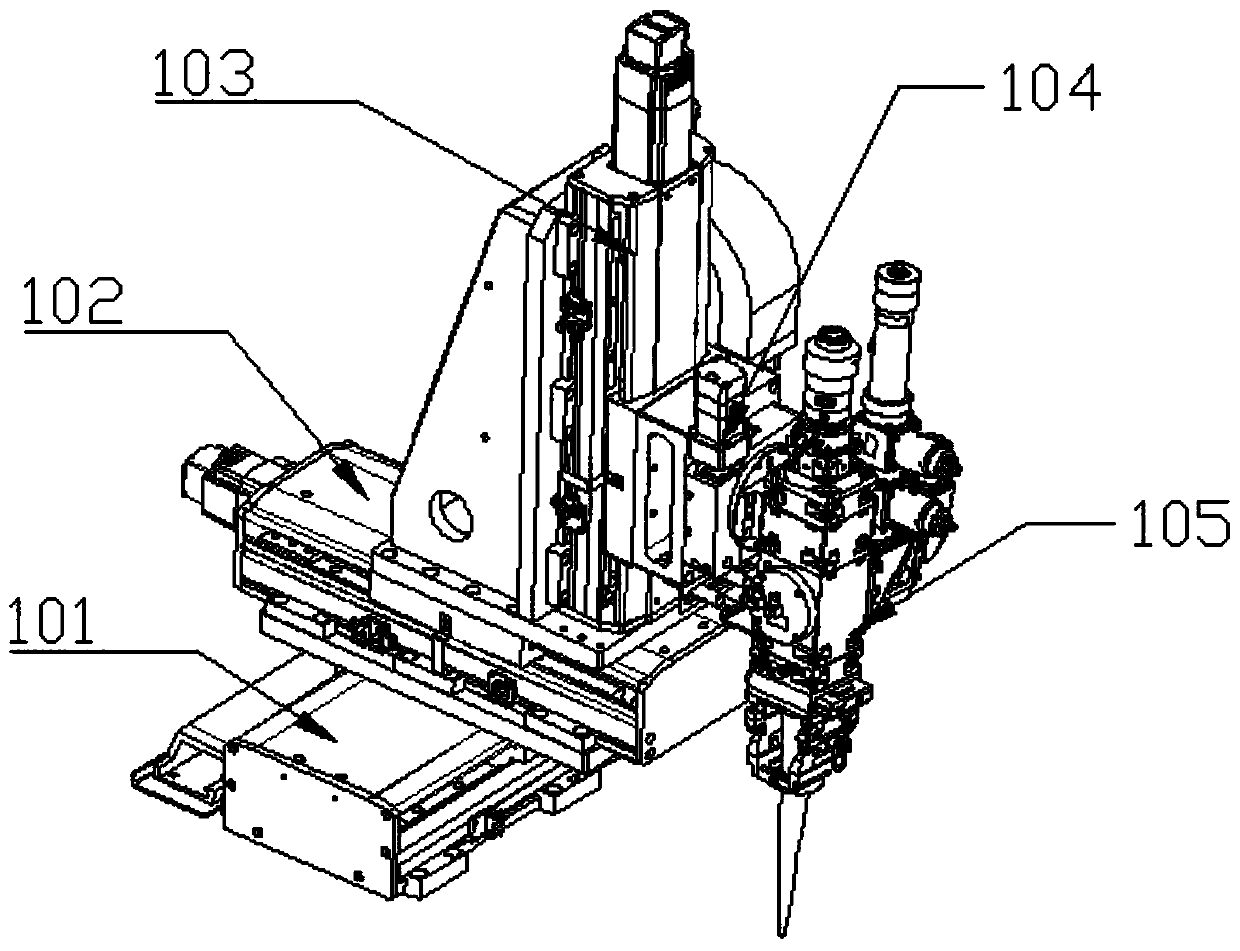

Gripping device and keyboard mouse test machine with gripping machine

InactiveCN103105552ARealize automatic crawlingAutomate operationElectrical measurement instrument detailsGripping headsEngineeringMechanical engineering

The invention discloses gripping machine which comprises a bearing piece. The bearing piece is provided with a first adjusting piece, a second adjusting piece, an adjusting piece driving mechanism and at least one sucker. The absorption plane of the sucker is arranged downward. The first adjusting piece and the second adjusting piece are arranged oppositely. The adjusting piece driving mechanism is used for driving the first adjusting piece and the second adjusting piece to be far away from each other mutually or to be close to each other mutually. The lower end of the first adjusting piece is provided with at least two first clamping pieces. The lower end of the second adjusting piece is provided with at least two second clamping pieces. The lower ends of the first adjusting piece and the lower ends of the second adjusting piece are buckled mutually. According to a keyboard mouse test machine with the gripping machine, automatic gripping to a keyboard and a mouse are achieved through the gripping device, and the keyboard and a mouse can be sent to preset positions by using arms of a robot. The gripping device and the keyboard mouse test machine with the gripping machine can not only achieve automated operation, but also save working hours and reduce labor cost.

Owner:SHENZHEN RAPOO TECH

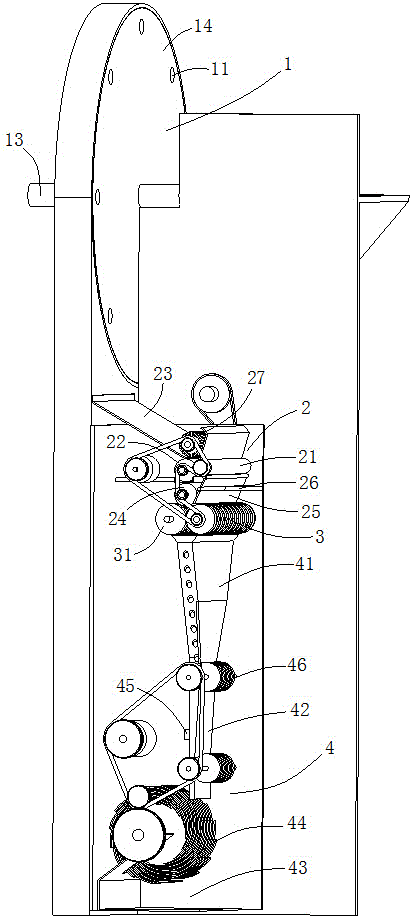

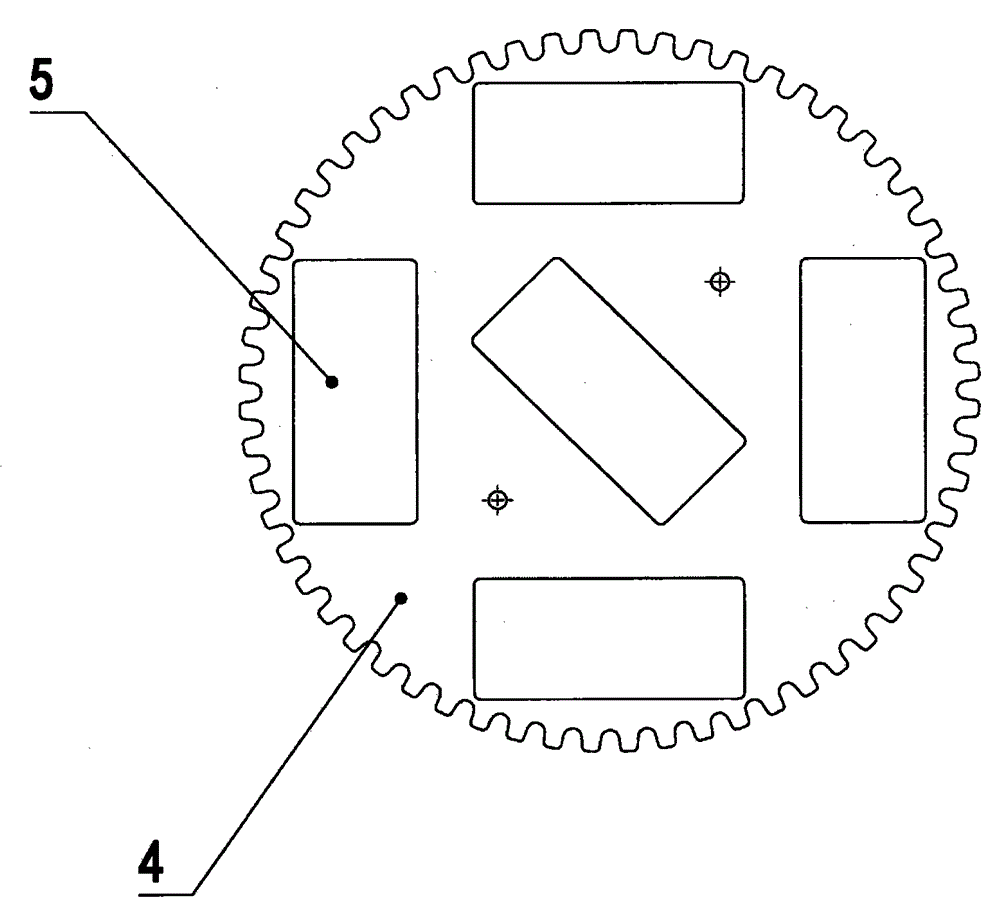

Full-automatic rotor measuring machine

ActiveCN103471542ARealize automatic crawlingRealize group storageMeasurement devicesGroove widthEngineering

The invention relates to a full-automatic rotor measuring machine, in particular to a measuring machine which can achieve measuring and grouping workpieces of the same specification in the same position and different groups in the production process of a rotor of an automobile steering vane pump according to the thicknesses and the groove widths, and the measuring machine has the functions of automatically achieving measuring and grouping of the workpieces. The measuring machine comprises a rack, a feeding stepping mechanism, a feeding stepping rotary material disc, feeding rods, a feeding mechanical arm, a material moving mechanism, a rotating positioning mechanism, a groove width measuring mechanism, a thickness measuring mechanism, an optical fiber sensor, a discharging station, an alarm light, an operation box, a servo motor movable grouping mechanism, a discharging mechanical arm, a gravity material channel, a alarm switch for the full state of material and an electronic control cabinet. The feeding stepping rotary material disc is arranged on the left portion of the rack, and the multiple feeding rods are connected to the feeding stepping rotary material disc. The full-automatic rotor measuring machine achieves automatic grabbing, automatic material moving, automatic recognizing and automatic storing in groups of the workpieces and automatically achieves measuring and grouping of the workpieces.

Owner:WUXI MEASURE MACHINE MFR

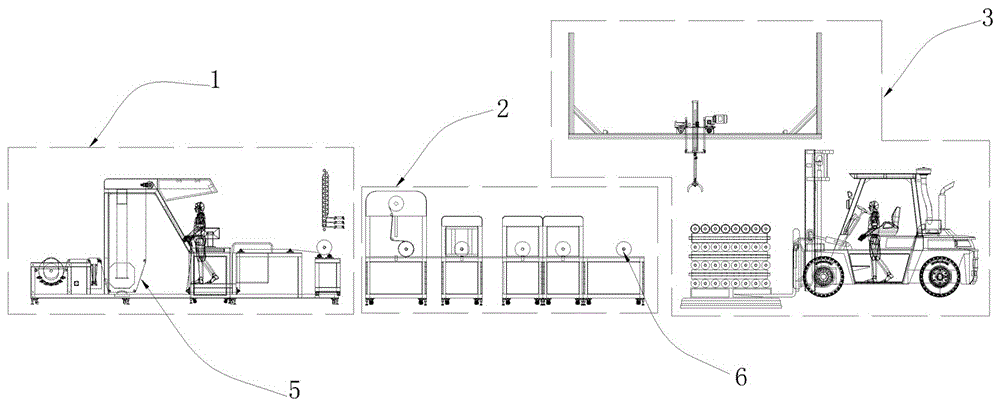

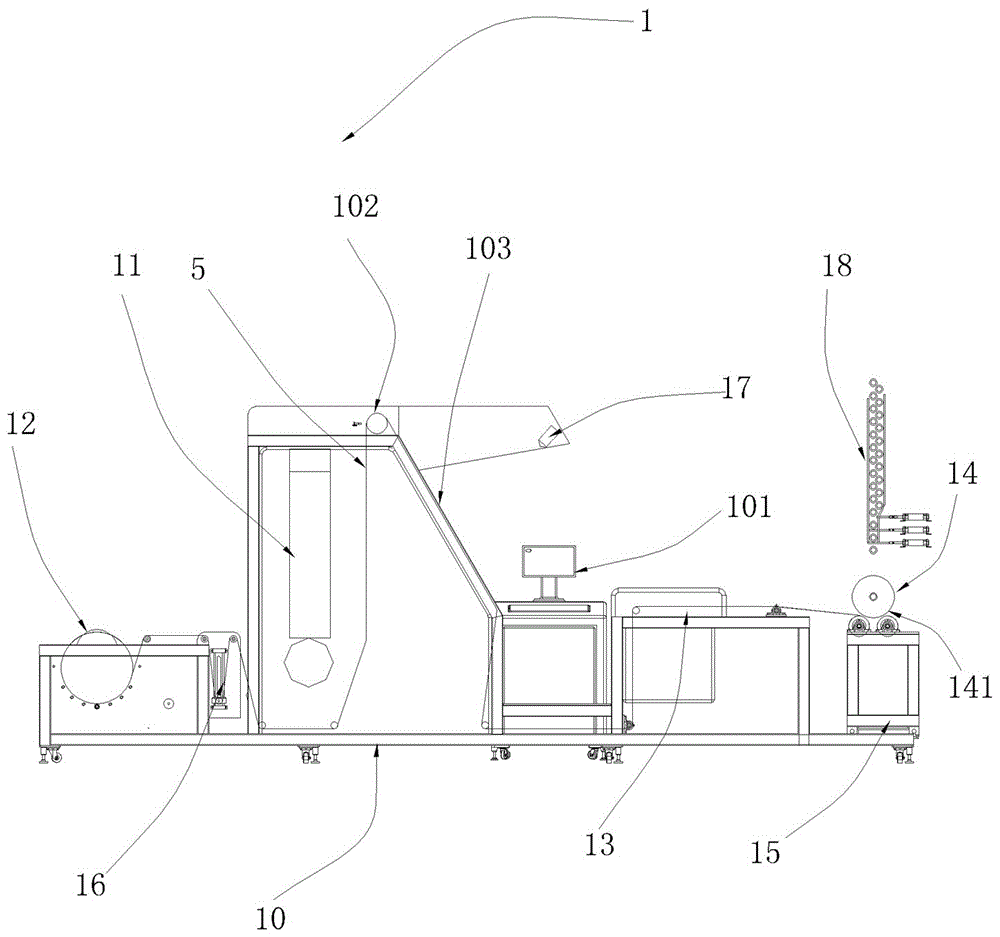

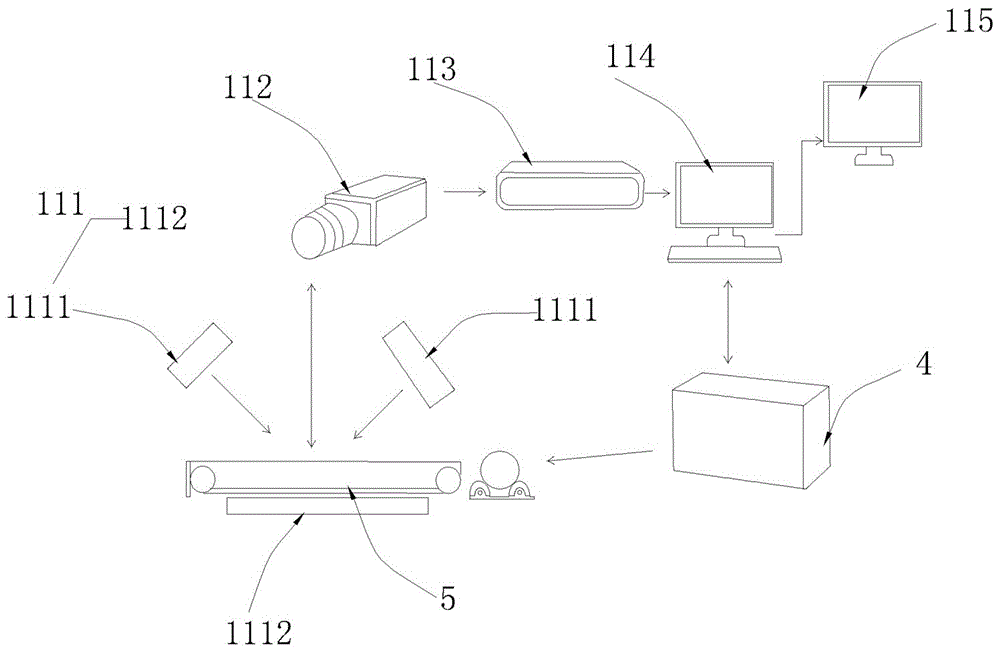

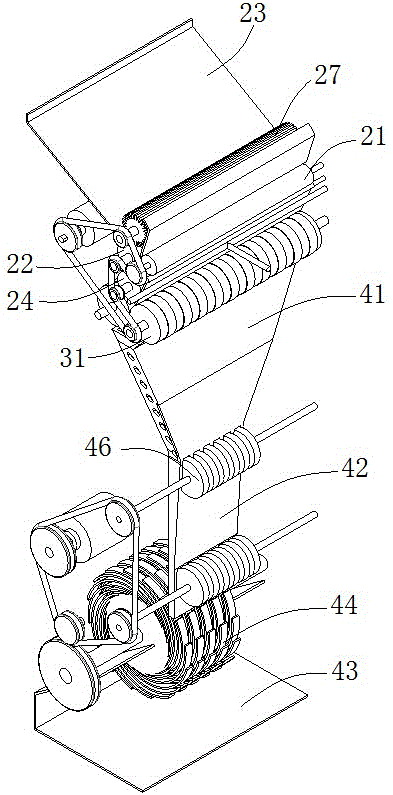

Intelligent cloth inspecting machine and cloth inspecting method thereof

ActiveCN105699392AImprove detection efficiencyImprove efficiencyMaterial analysis by optical meansEngineeringMechanical engineering

The invention discloses an intelligent cloth inspecting machine and a cloth inspecting method thereof.The intelligent cloth inspecting machine comprises a defect inspection device used for conducting defect inspection on cloth, a shrink-packaging device used for conducting hot shrinkage forming on cloth rolls which have been detected and formed, and a stacking and transporting device used for stacking and transporting the cloth rolls which have been subjected to hot shrinkage forming.The defect detection device, the shrink-packaging device and the stacking and transporting device are sequentially connected.By means of the intelligent cloth inspecting machine and the cloth inspecting method, automatic defect detection is achieved, the labor intensity is lowered, and the omission ratio and false inspection rate are decreased.The precision of cloth defect detection is improved.An automatic winding mechanism, an automatic edge cutting mechanism and the shrink-packaging device can be used in cooperation for winding the detected cloth, the cloth automatically enters the shrink-packaging device to be subjected to hot shrinkage forming after being wound, and therefore automatic cloth cutting, winding and automatic packaging are achieved when a roll of cloth is wound.

Owner:SHENZHEN MAIKESITAI CO LTD

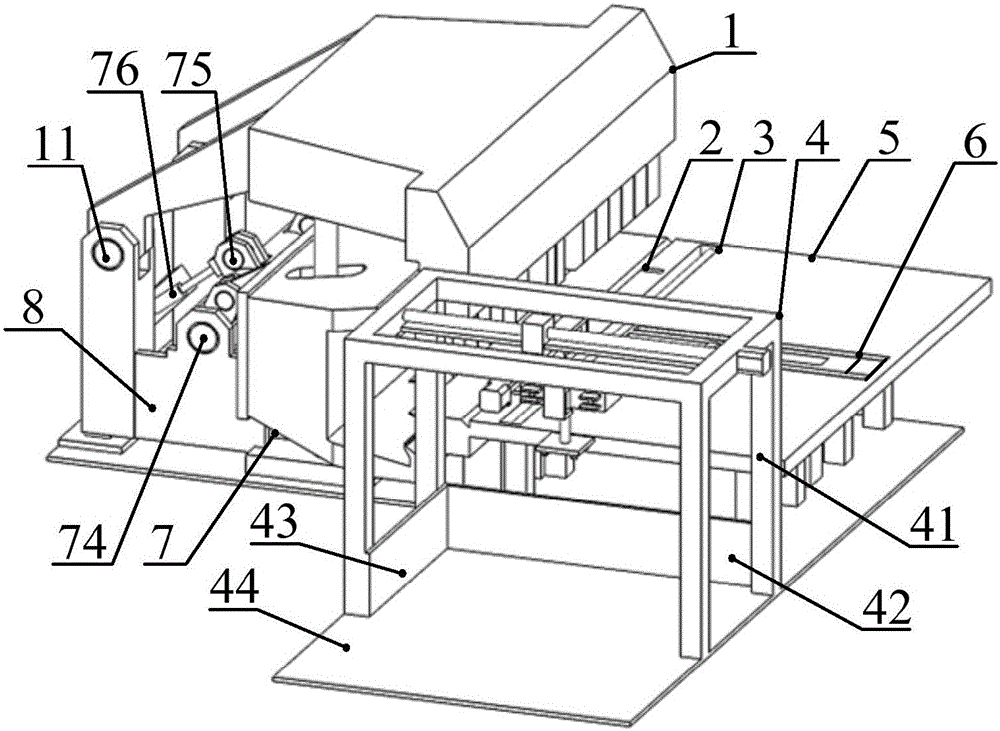

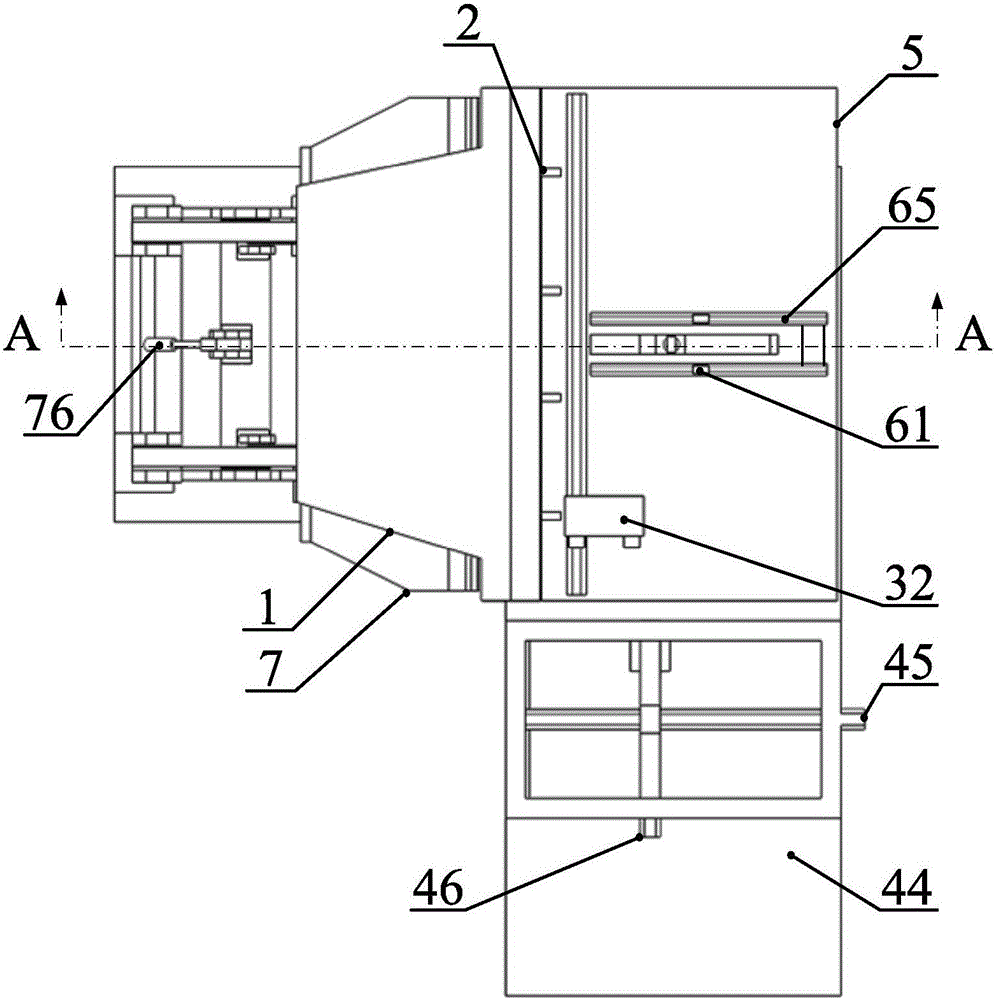

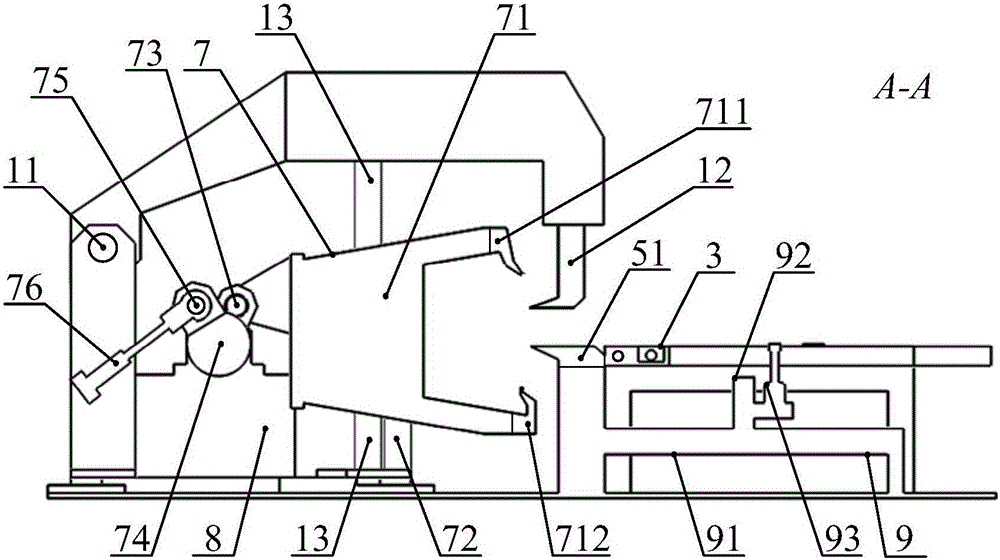

Plate bending method for intelligent numerical control bending machine

ActiveCN106077168ARealize automatic crawlingNo human intervention requiredMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention discloses a plate bending method for an intelligent numerical control bending machine and belongs to the technical field of bending machines. The machine comprises a rack, a worktable, a bending device and a base. The rack and the bending device are arranged on the base. The machine further comprises a material blocking device, a discharging device, a feeding device, a positioning device, a material conveying device and a numerical control system. A machined piece is conveyed to the worktable through the feeding device and clamped by the discharging device to move on the worktable, and the machined piece can be positioned in the X-axis direction. The material blocking device and the positioning device are matched to position the machined piece in the Y-axis direction. The material conveying device conveys the machined piece to a machining station for bending machining and controls the machined piece to rotate to be subjected to multi-edge bending, and the machined piece is pushed to get away from the worktable through the discharging device after machining is completed; and the numerical control system is used for completing automatic control over the whole bending process. The intelligent numerical control bending machine is high in work efficiency and automation degree, full-automatic multi-edge forward and reverse bending can be achieved on the machined piece, use is convenient, and the labor force can be sufficiently liberated.

Owner:JIANGSU HAIJIAN

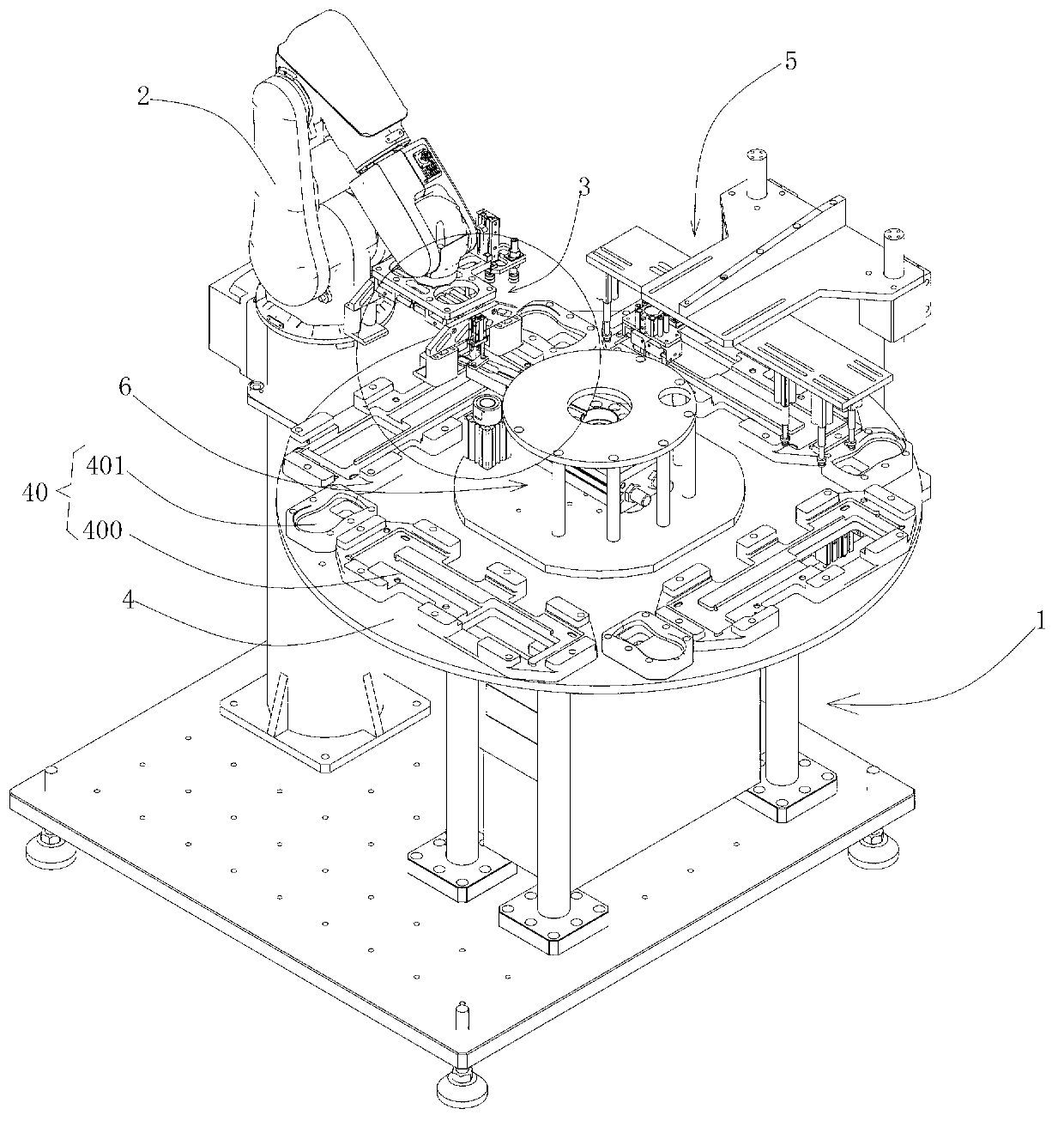

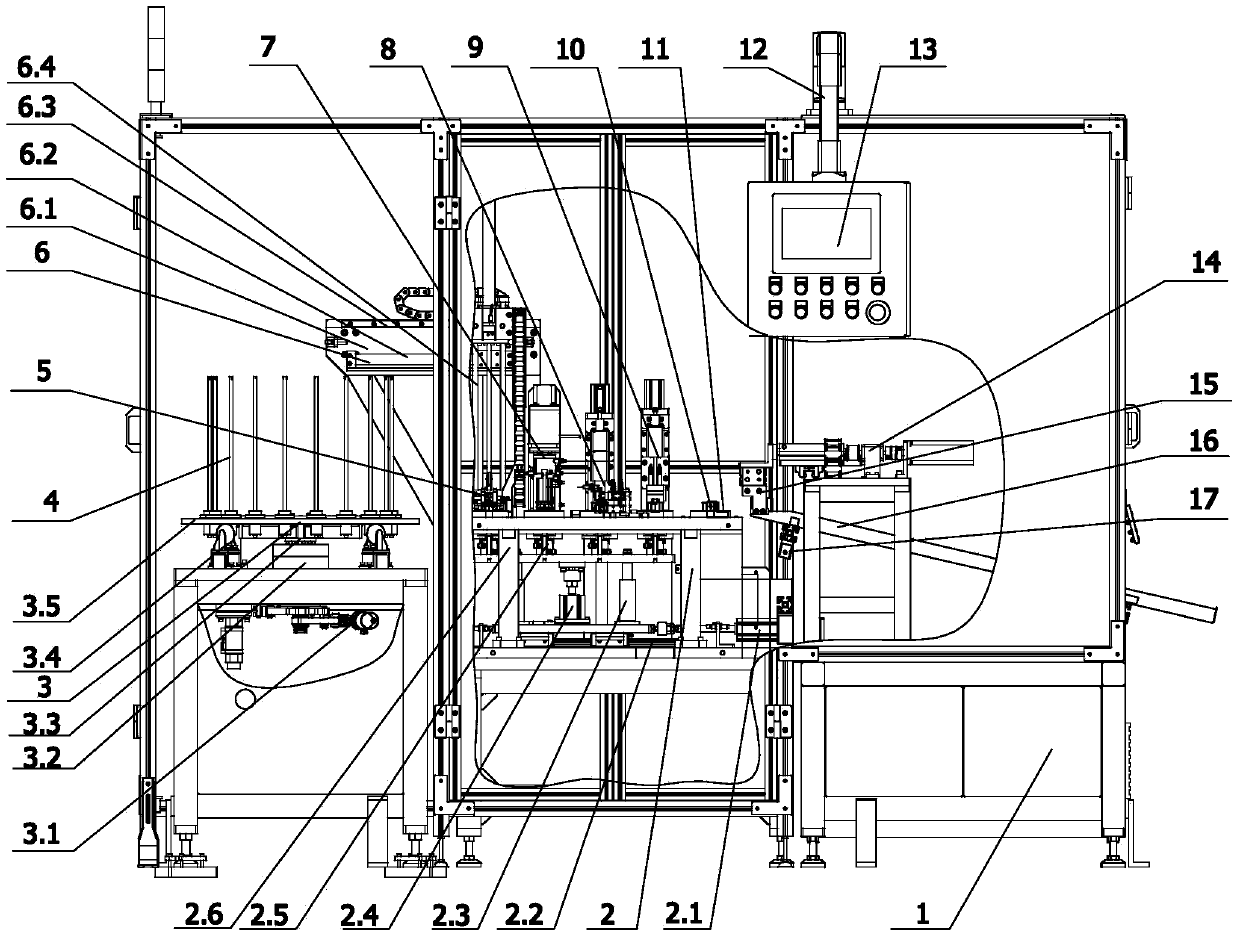

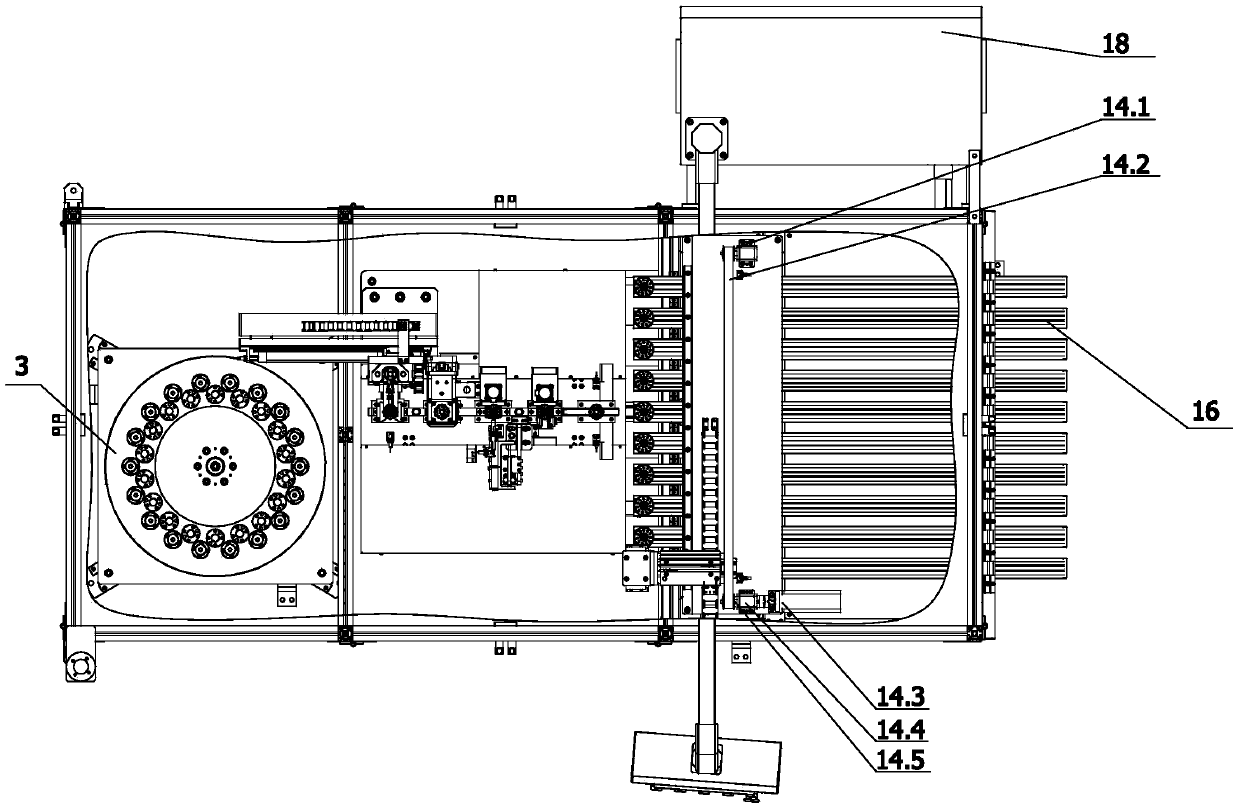

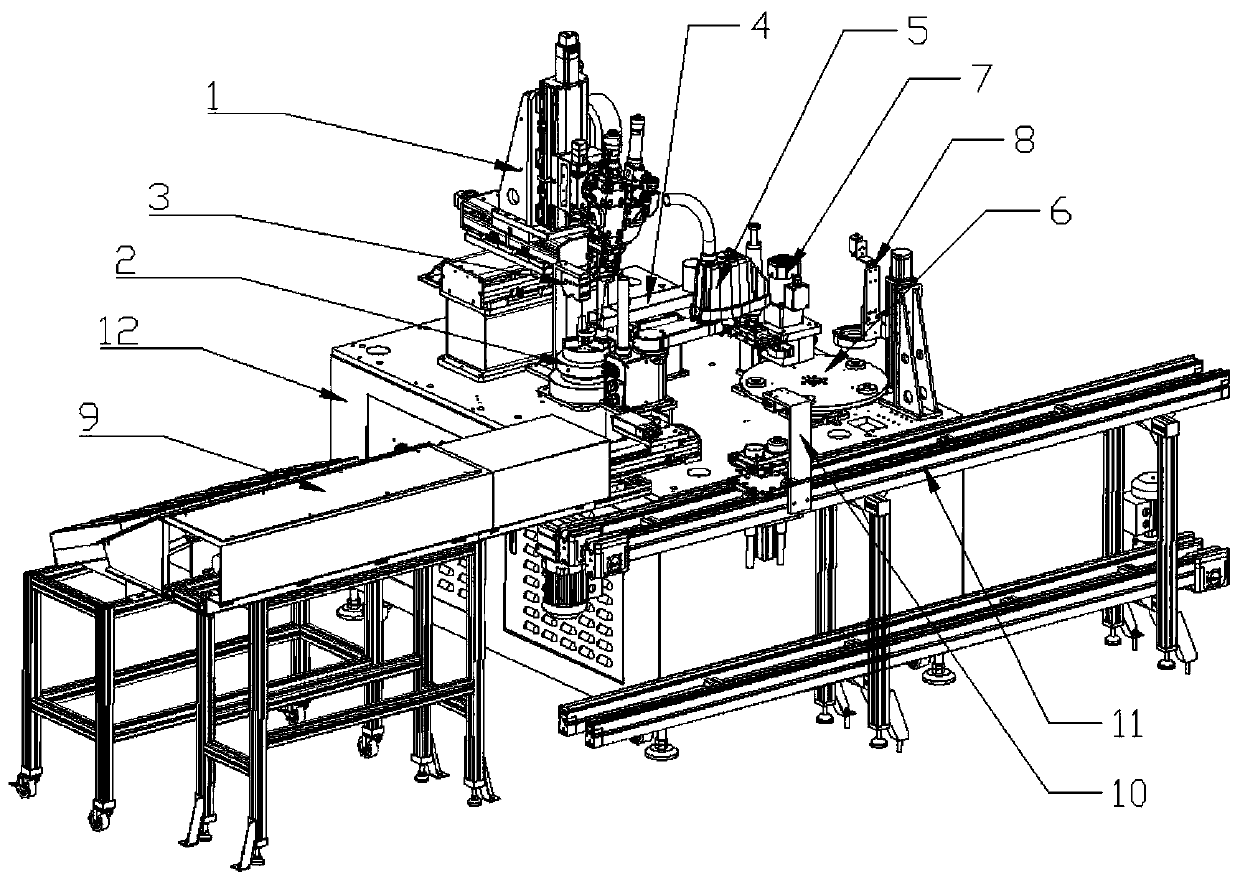

Automatic laser welding system

ActiveCN109822217AAdjustable angleAchieve precision clampingLaser beam welding apparatusThree dimensional shapeEngineering

The invention provides an automatic laser welding system. The automatic laser welding system comprises a machine table, a laser welding head drive device, a tool clamp, a 3D detecting device, a smoke-extraction and dust-removal device, a mechanical hand loading and unloading device, a material rotary disc device, a wiping device, a 2D detecting device, a sorting device, a workpiece conveyor line and a code scanning device, wherein the welding head drive device drives the laser welding head to move or deflect; the tool clamp realizes clamping and rotating of the workpiece; the 3D detecting device detects a three-dimensional shape of a welding seam; the mechanical hand loading and unloading device is used for grabbing the workpiece to realize loading and unloading; the material rotary disc device is used for sequentially rotating the welded workpiece to a wiping station, a detecting station and an unloading station; the 2D detecting device is used for detecting a quality state of the surface of the welding seam; and the code scanning device is used for reading bar codes or two-dimensional codes which are matched with welding parameters to store. The automatic laser welding system hasthe characteristics of being capable of performing circumferential welding on the welding seam workpiece, automatically loading and unloading, welding, 3D / 2D detecting, sorting and the like, does notneed manual operation, is high in efficiency, and enables welding parameters to be corresponding to bar codes.

Owner:深圳市华天世纪激光科技有限公司

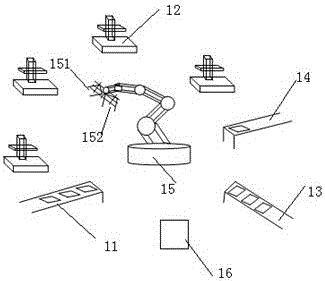

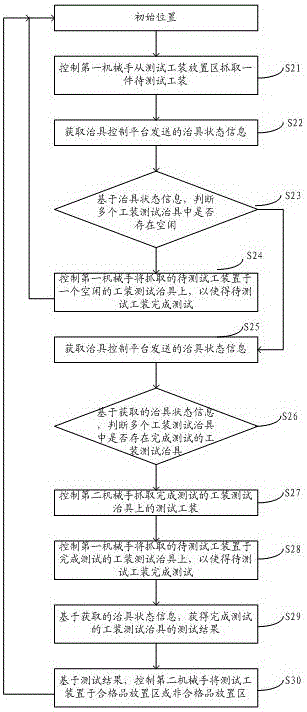

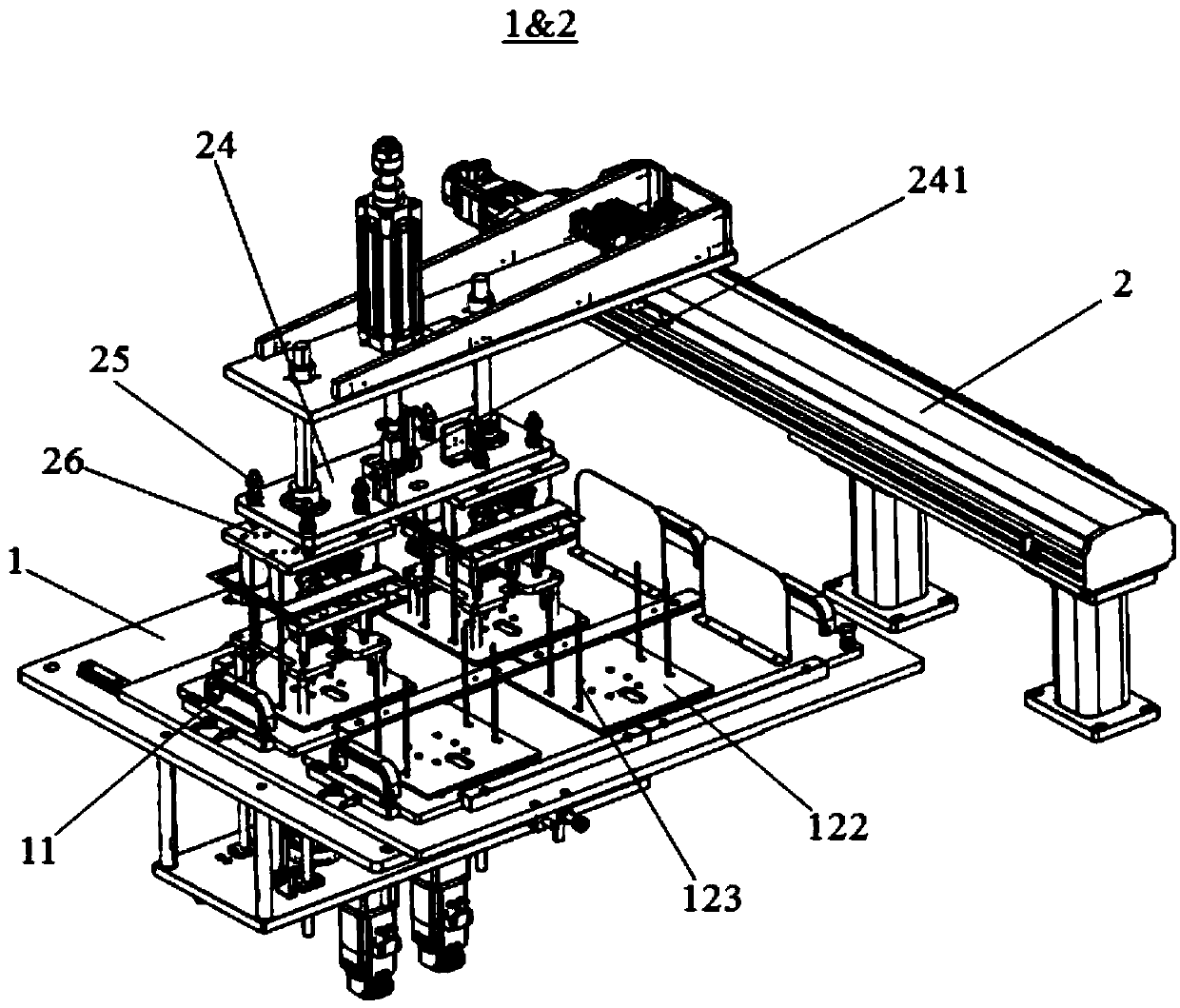

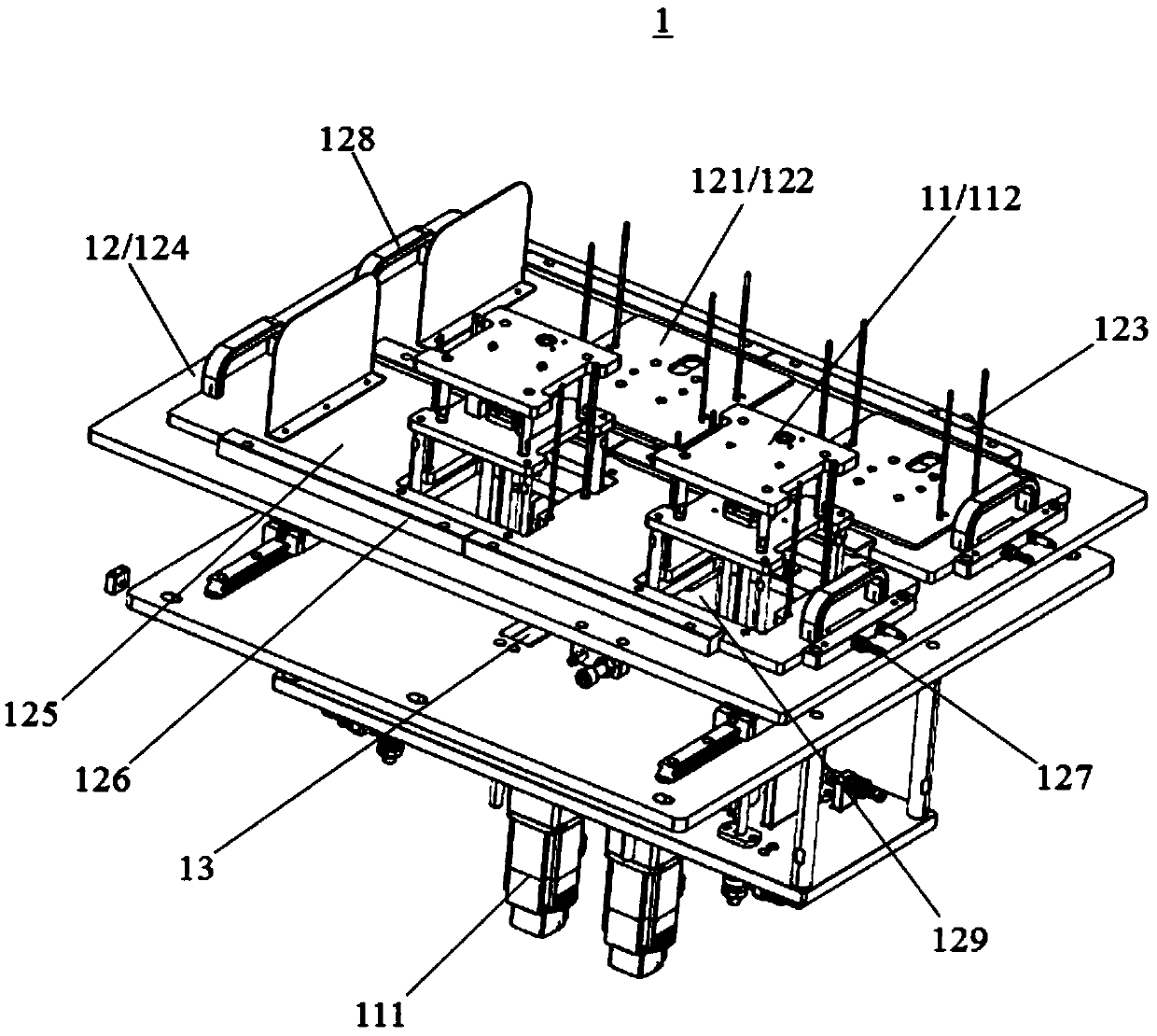

Tooling test system and tooling test control method

InactiveCN106546903AMeet the requirements of rapid productionRealize automatic crawlingPrinted circuit testingEngineeringManipulator

The invention discloses a tooling test system and a tooling test control method which solve a technical problem that existing tooling testing consumes manpower and results in man-made defective products. Tooling test system comprises a test tooling placement area, a plurality of tooling testing jigs, a qualified tooling placement area, an unqualified tooling placement area, a gripper robot and a jig control platform, and is characterized in that the gripper robot comprises a first manipulator and a second manipulator; the first manipulator grabs test tooling to be tested from the test tooling placement area and places the grabbed test tooling on a spare tooling testing jig; and the second manipulator grabs tested test tooling from the tooling testing jigs, and places the tested test tooling in the qualified tooling placement area or the unqualified tooling placement area based on jig state information sent by the jig control platform. Automatic detection and classification of the test tooling on the jigs are realized through reasonably configuring the operating sequence of the first manipulator and the second manipulator, so that manual operations are saved, and errors existing in the manual operations are avoided.

Owner:GEER TECH CO LTD

Cable duct cover plate construction device

InactiveCN105398975AImprove work efficiencyQuick turnLoad-engaging elementsCranesEngineeringInfrared probe

The invention discloses a cable duct cover plate construction device which comprises an electric flat car and a trolley. The electric flat car and the trolley are detachably connected through a hanging buckle. A first infrared probe capable of sensing whether a cover plate exists in front or not is installed at the front end of the electric flat car. A hoisting mechanism is arranged in the middle of the electric flat car and provided with a cover plate grasping assembly. The cover plate grasping assembly comprises a fixing plate, a left jack catch, a right jack catch and a double-rod cylinder. The left jack catch and the right jack catch perform a closure grasping action under the action of the double-rod cylinder. A grasping device is provided with a second infrared probe used for sensing the cover plate. Four guide devices are arranged on the two sides of the electric fat car symmetrically. The device can lay or detach the cover plate by one person, labor intensity is relieved, the automatic grasping, rotating and automatic stacking functions are achieved, and the use requirements can be met.

Owner:STATE GRID SHANDONG SHANGHE POWER SUPPLY +1

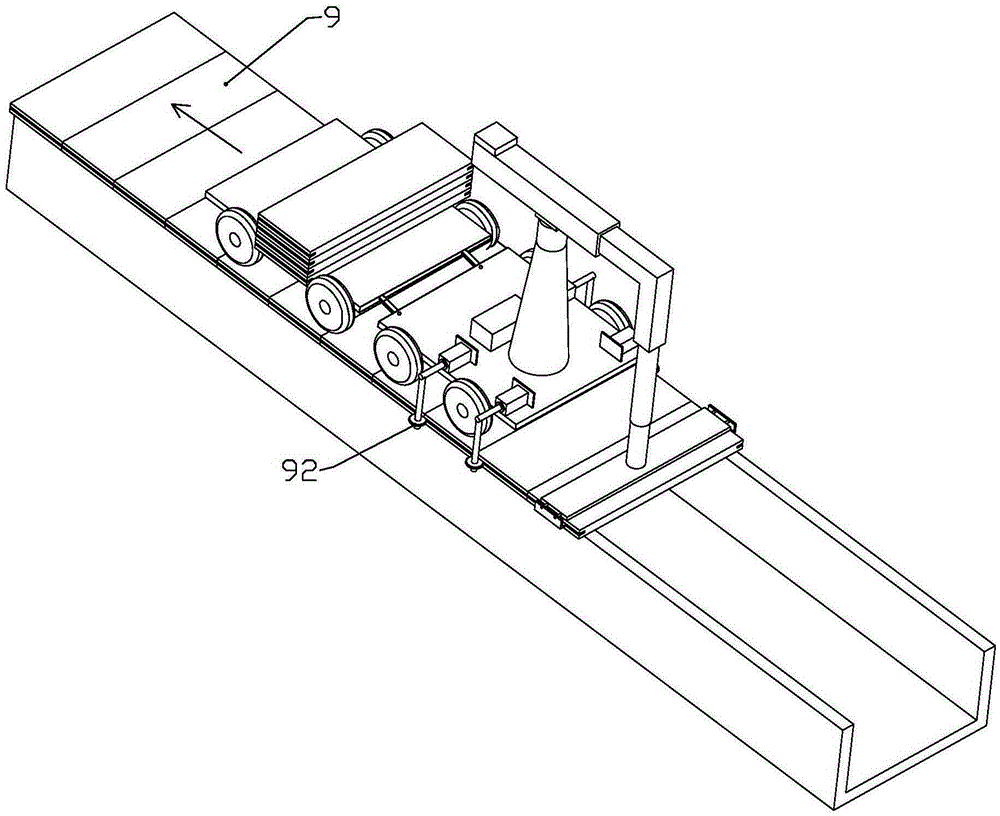

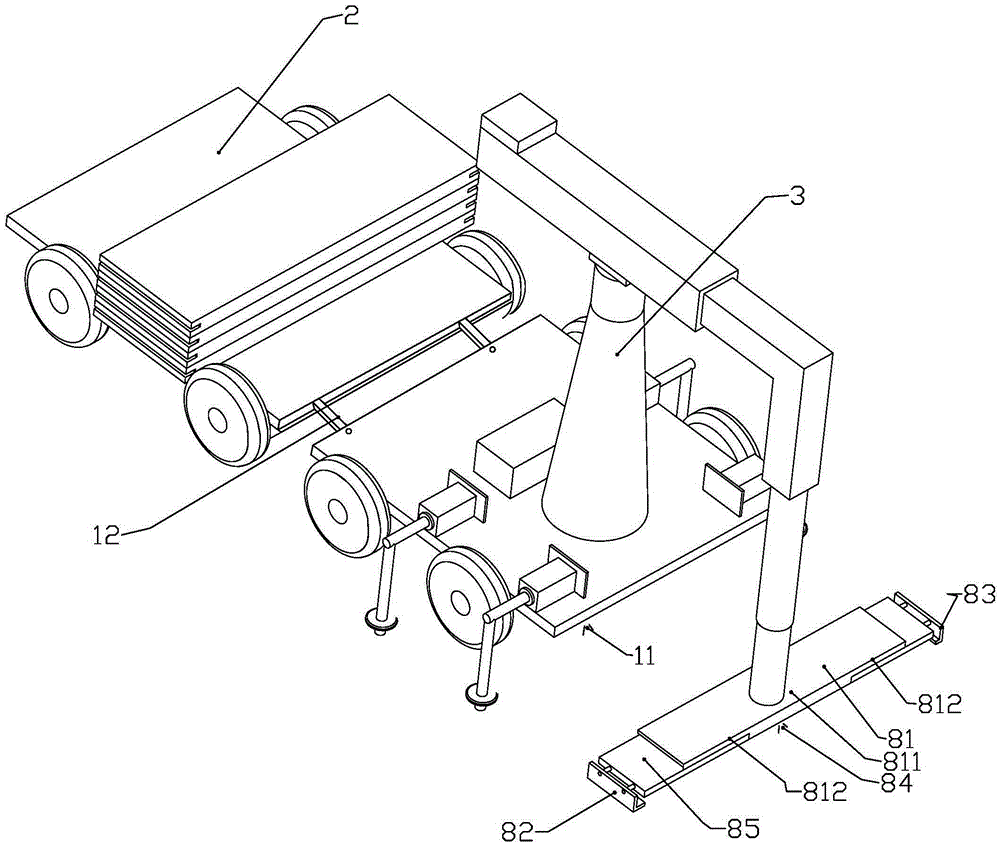

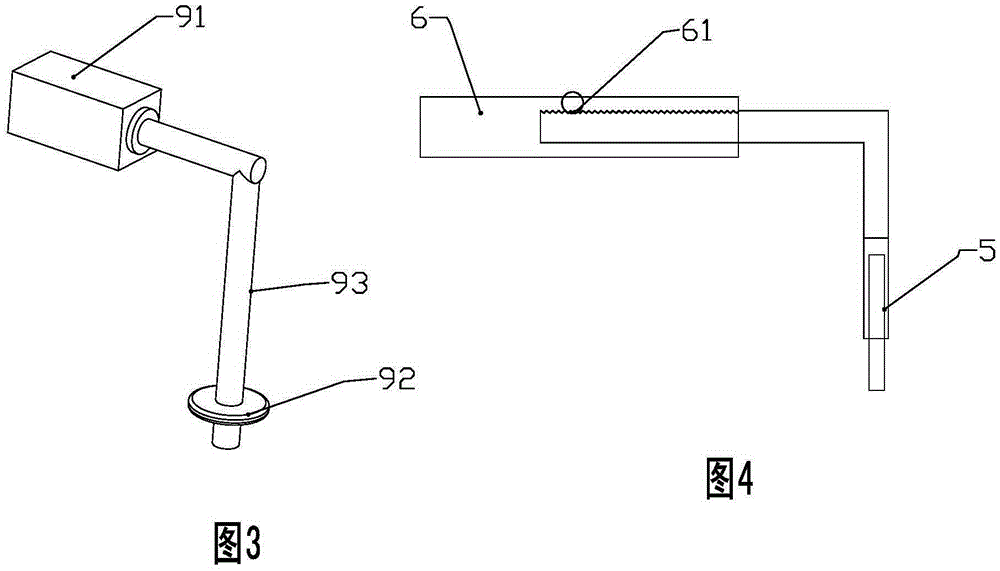

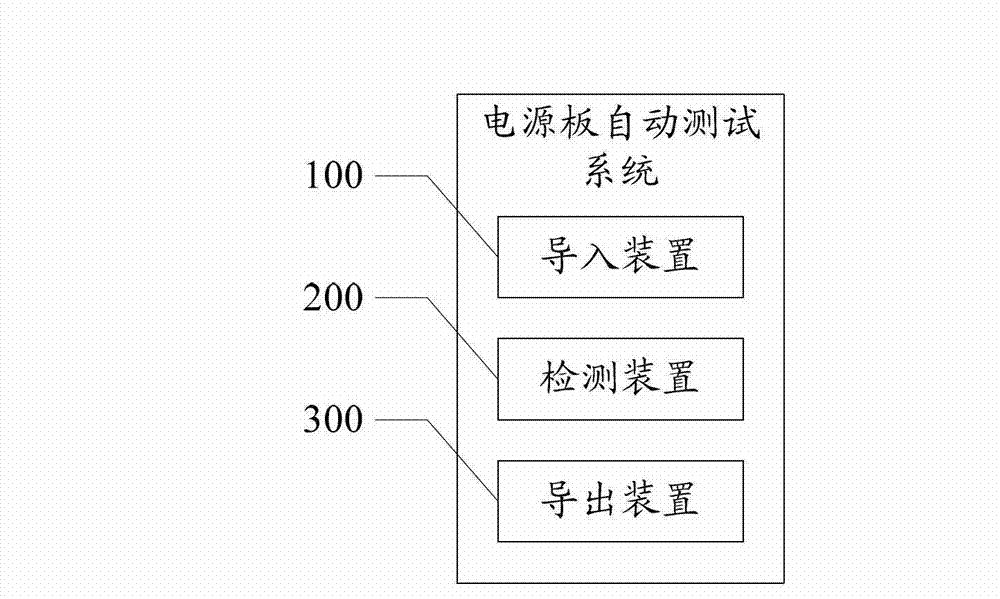

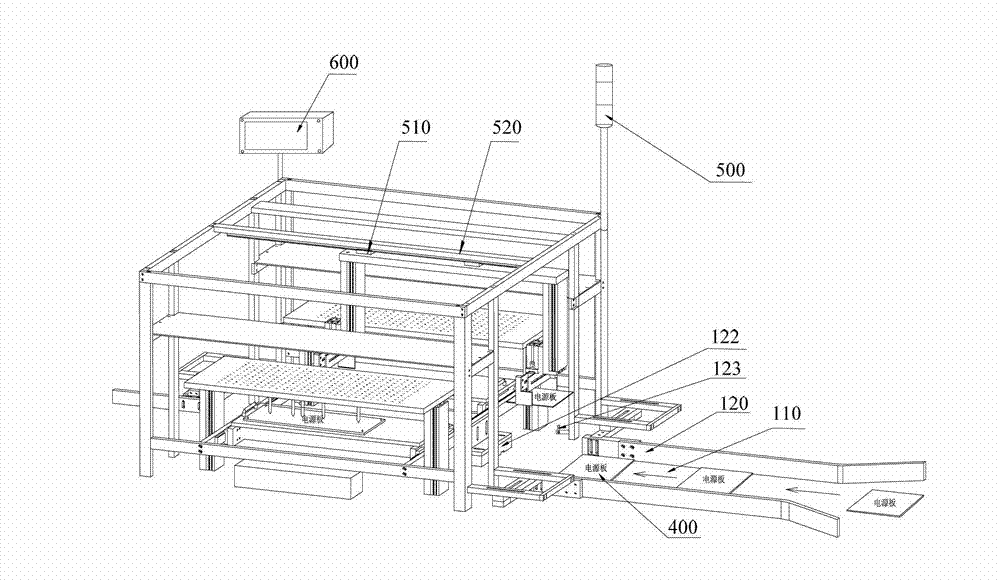

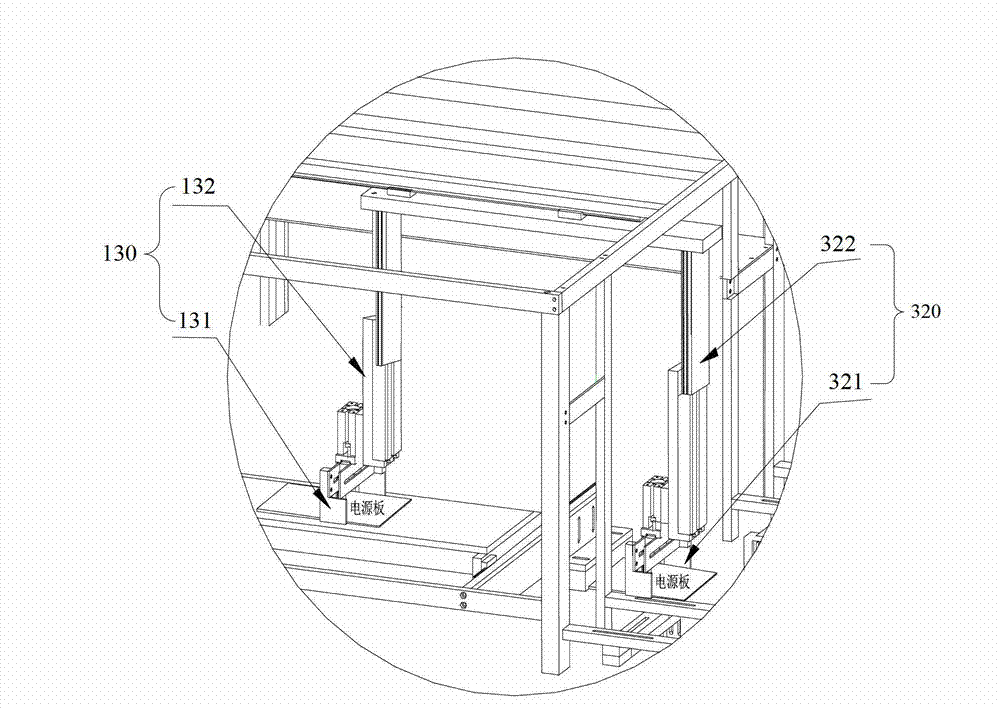

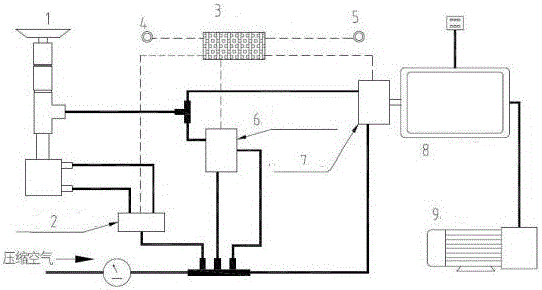

Automatic test system of power panel

InactiveCN102759715ARealize automatic crawlingReduce inconveniencePower supply testingHigh pressureAutomatic testing

The invention discloses an automatic test system of a power panel, which comprises a lead-in device, a detection device and a lead-out device, wherein the lead-in device is used for leading the power panel to the detection device; the detection device is used for carrying out high-voltage test and primary test on the power panel; and the lead-out device is used for taking out the power panel which is completely tested from the detection device, and intercepts the unqualified power panel. According to the automatic test system, the dual tests of high-voltage test and primary test of the power panel are automatically switched in the same test system; moreover, the power panel can be automatically grabbed, the whole process is finished through adopting electromechnical equipment, so inconvenience which is brought to operators is reduced; and the automatic test system is simple to debug, and has fast test speed, so the production efficiency and production quality are greatly improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Disassembling and assembling apparatus for cable trench cover plate

InactiveCN105390974AImprove work efficiencyQuick turnCable installation apparatusEngineeringInfrared probe

The present invention discloses a disassembling and assembling apparatus for a cable trench cover plate, comprising an electric flat car and a handcart, wherein the electric flat car and the handcart are dismountably connected through a hanging fastener, the front end of the electric flat car is provided with a first infrared probe for sensing whether there is a cover plate in the front, the electric flat car is provided with a set of lifting mechanism, the lifting mechanism is provided with a cover plate grabbing device, left and right claws can execute a grabbing operation under the effect of a cylinder; and the grabbing device is provided with a second infrared probe for sensing the cover plate. The disassembling and assembling apparatus of the present invention can be used for laying or dismounting the cover plate by one person, thus the labor intensity is reduced, the functions of automatic grabbing, rotation and automatic stacking can be achieved, and use requirements can be satisfied.

Owner:STATE GRID SHANDONG SHANGHE POWER SUPPLY +1

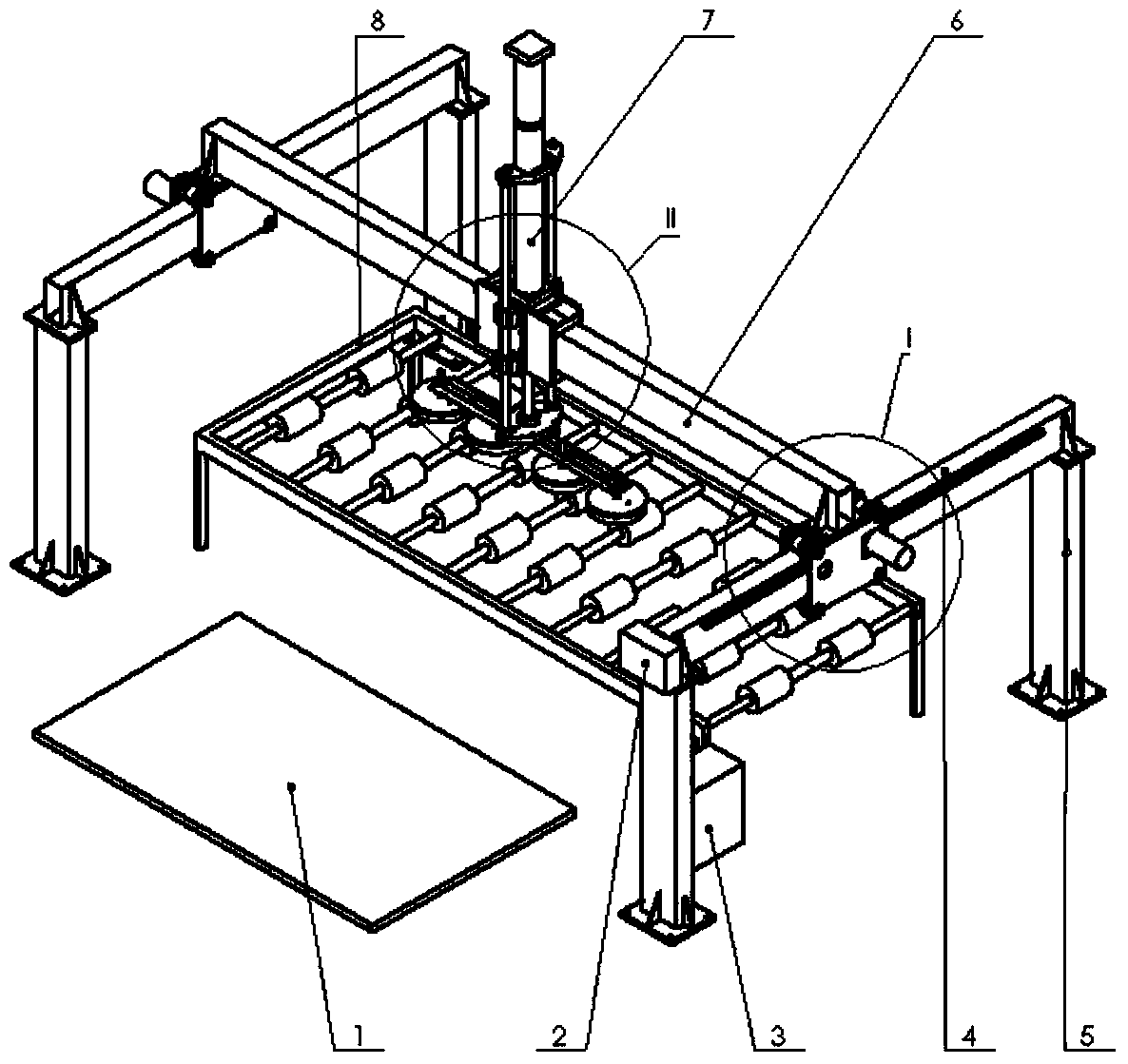

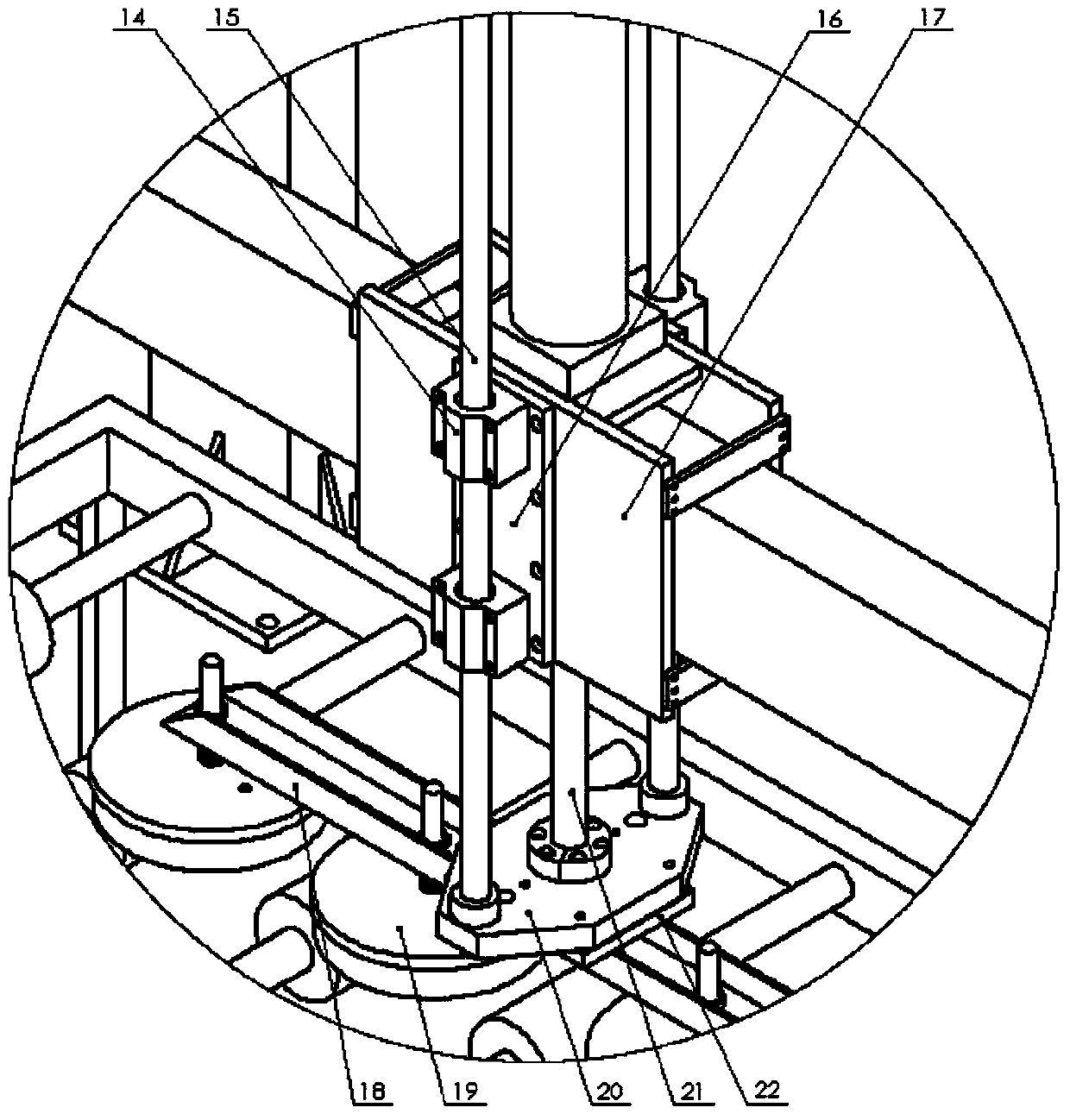

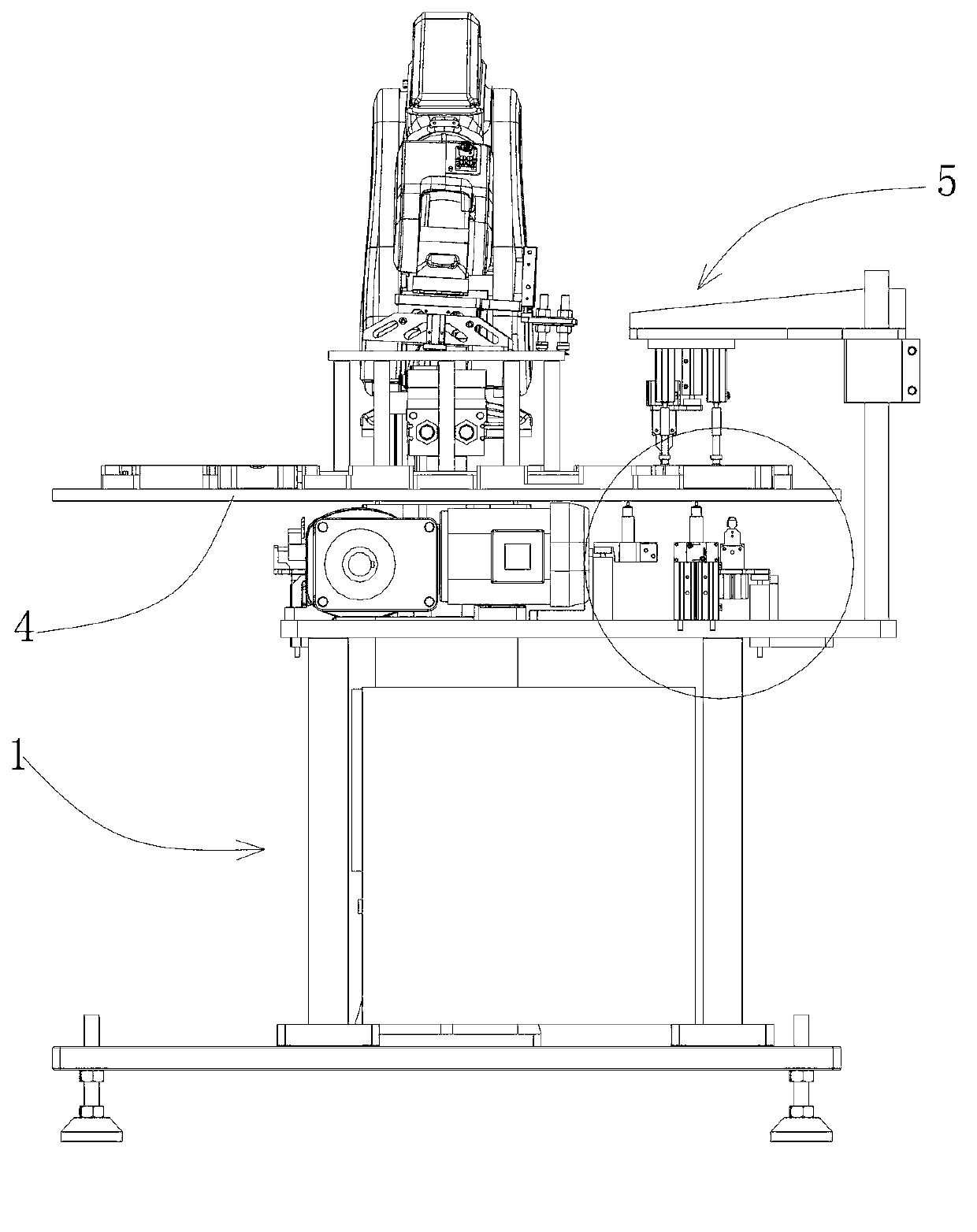

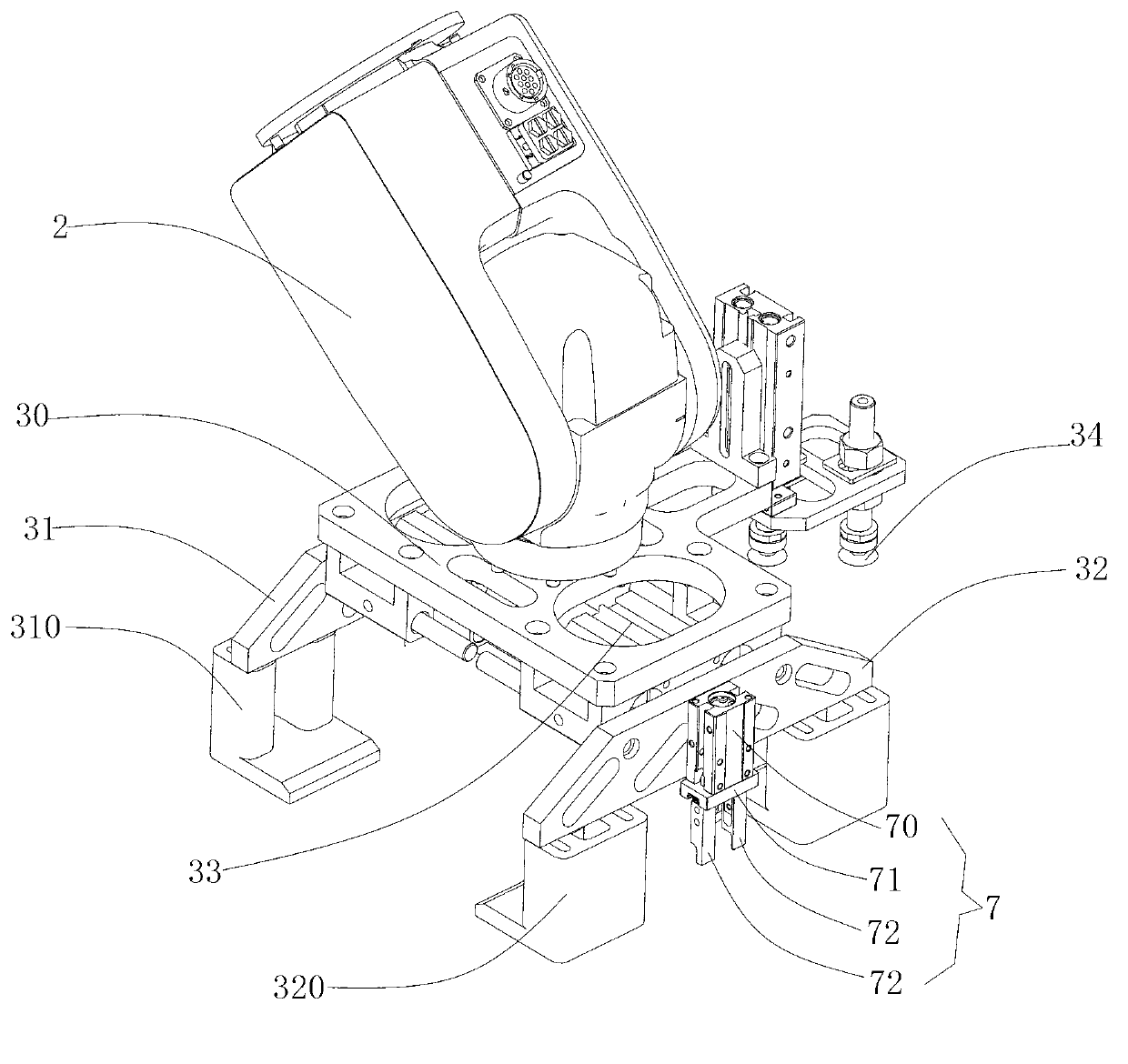

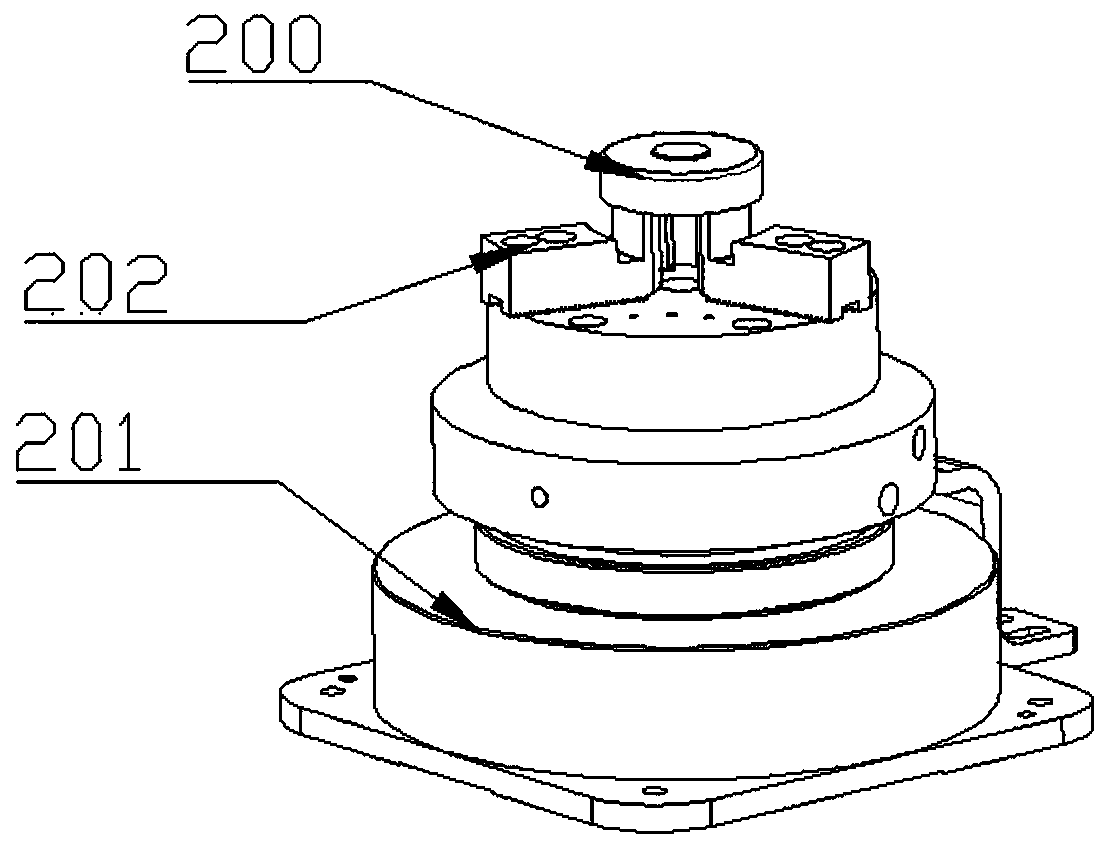

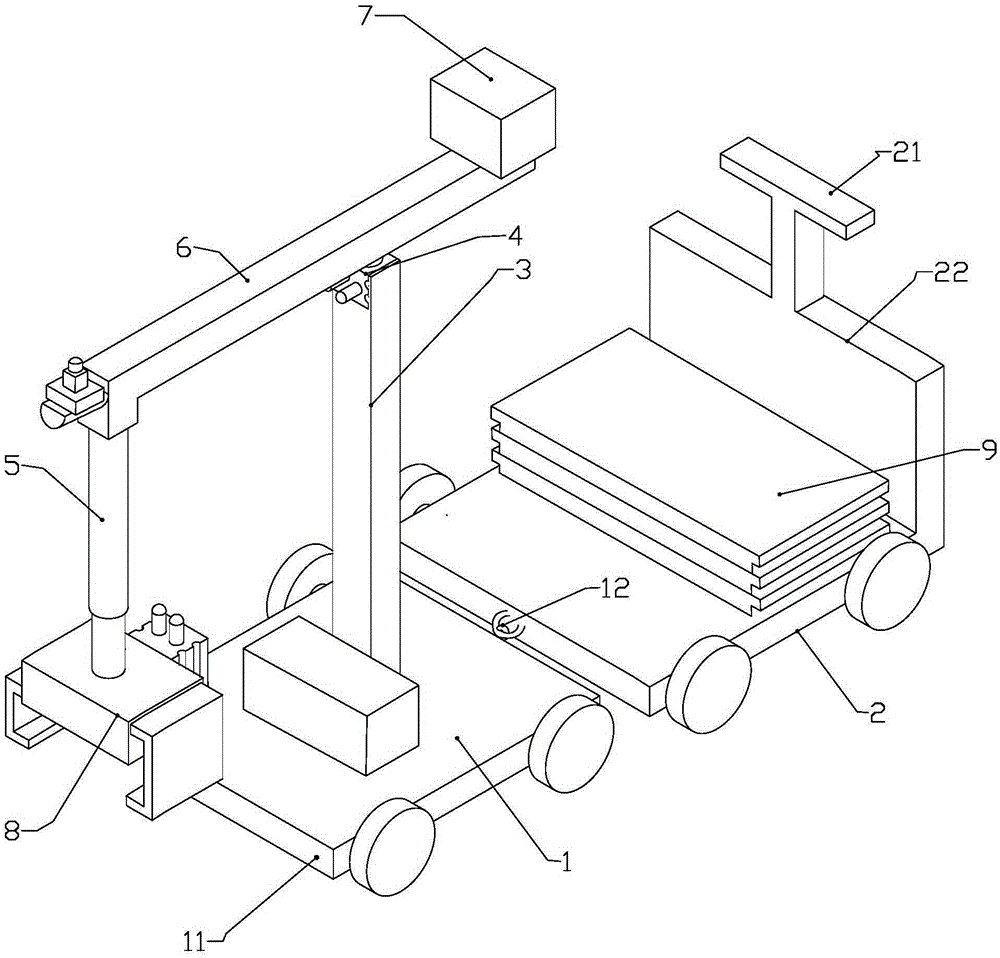

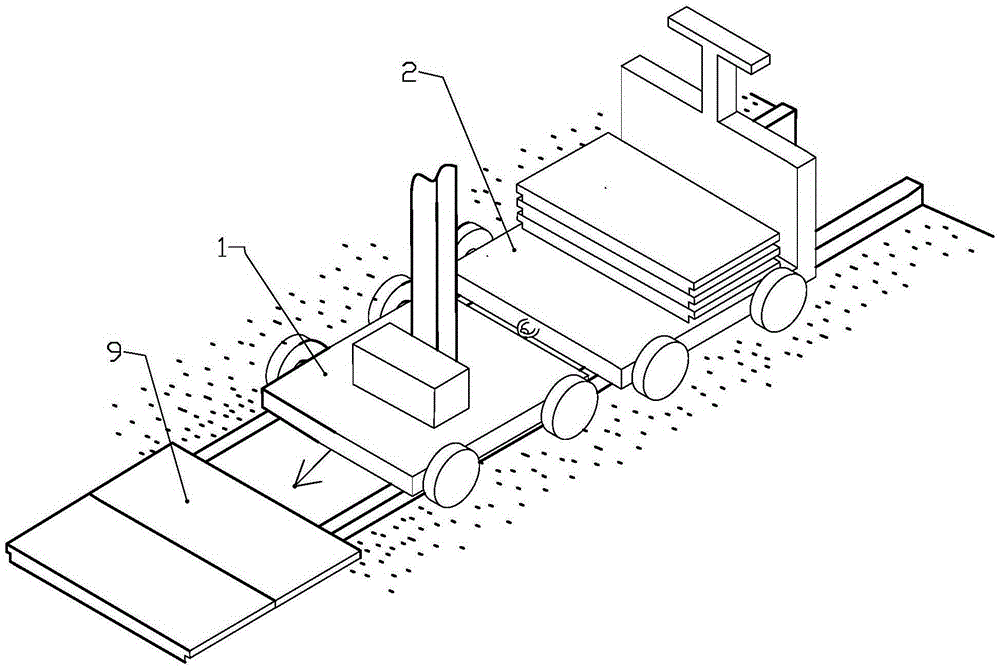

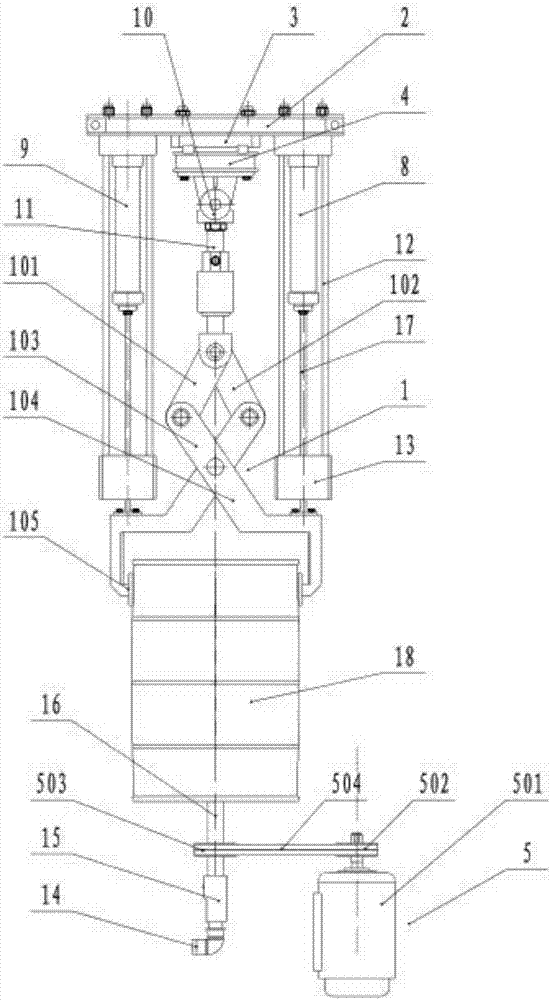

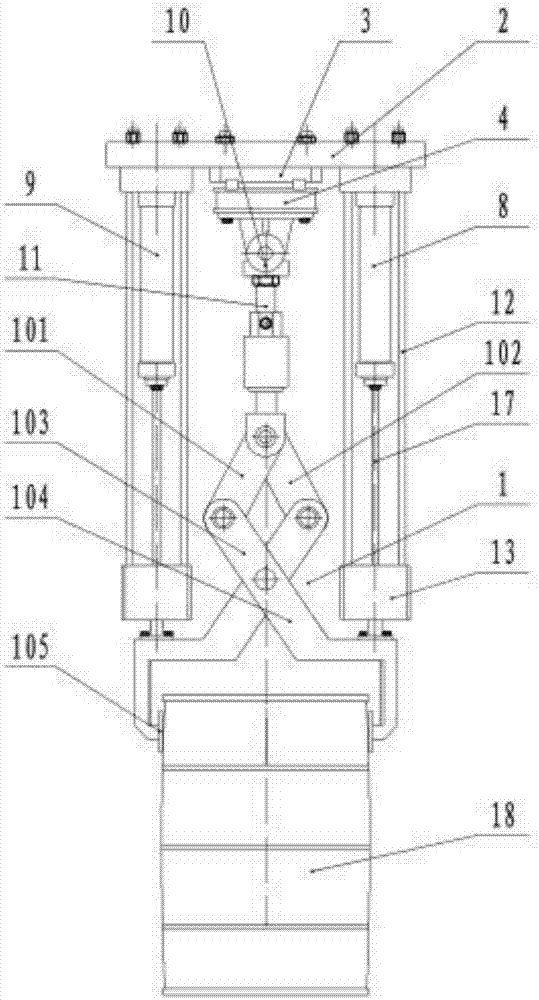

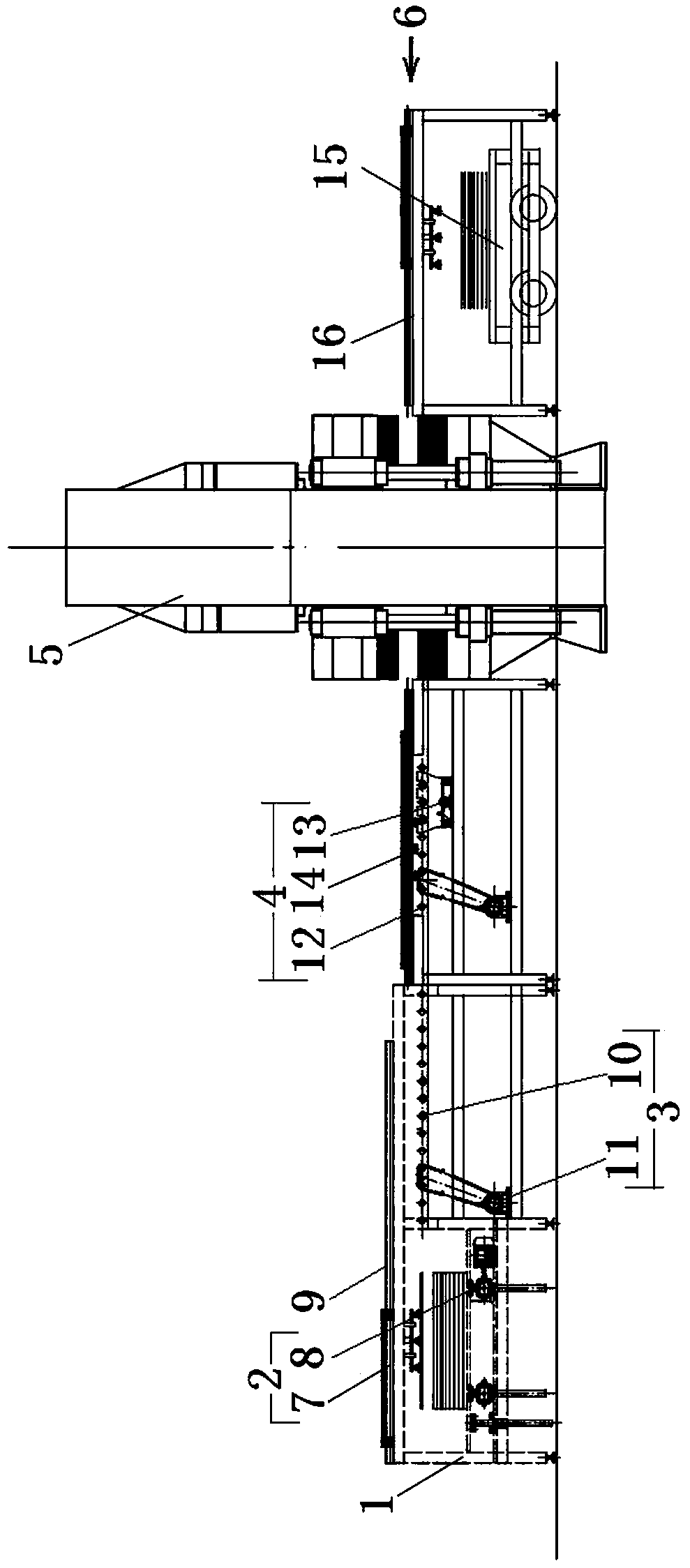

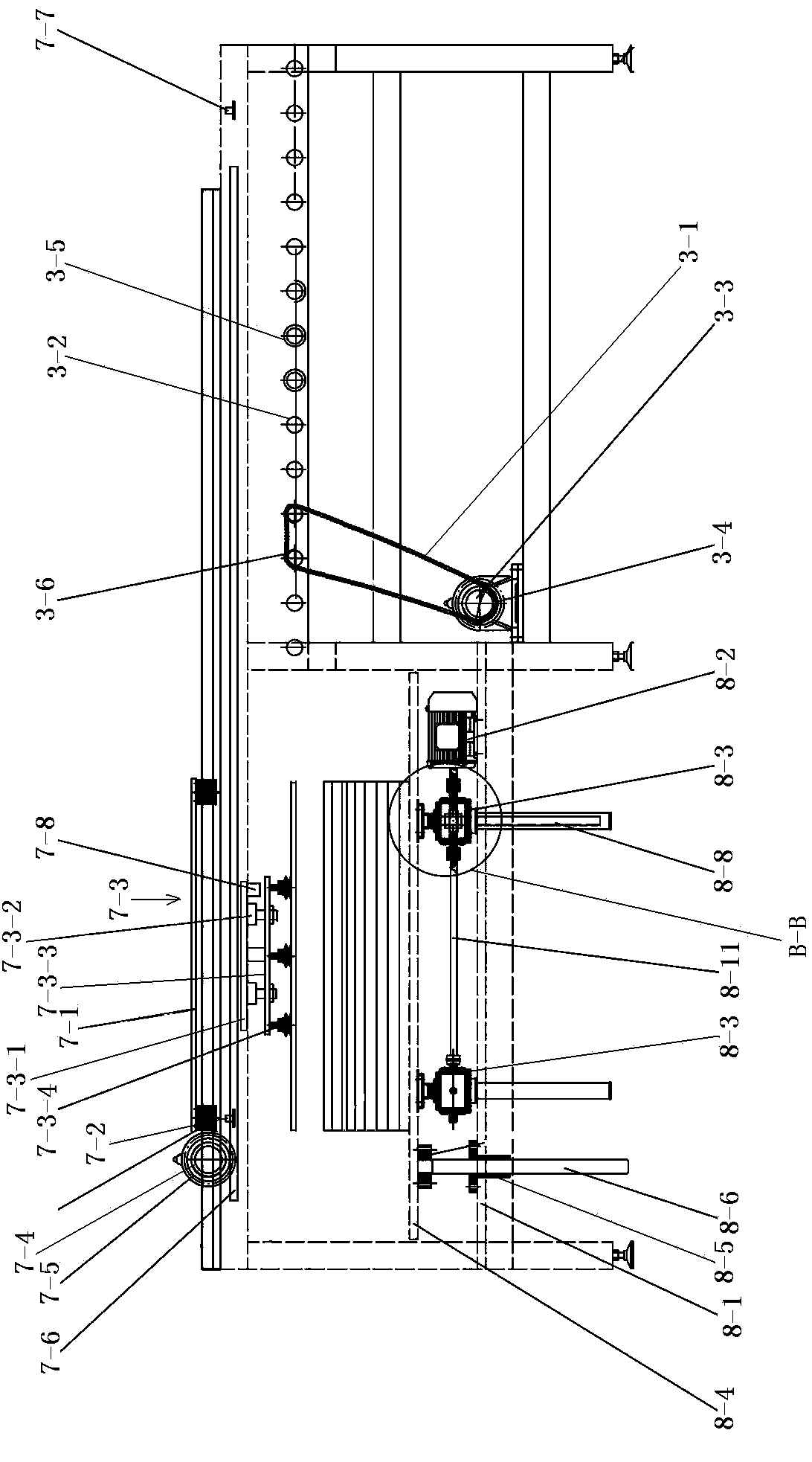

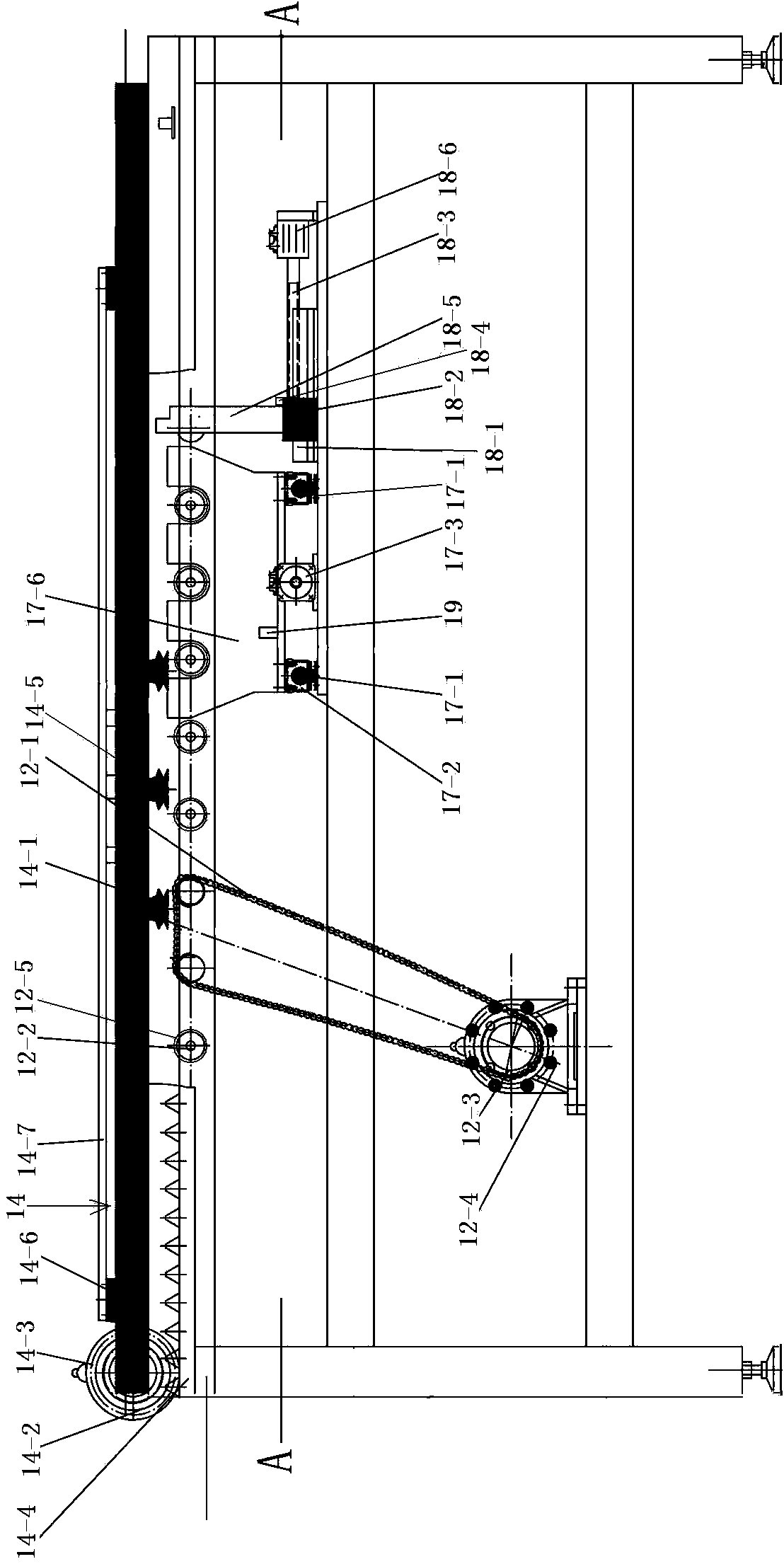

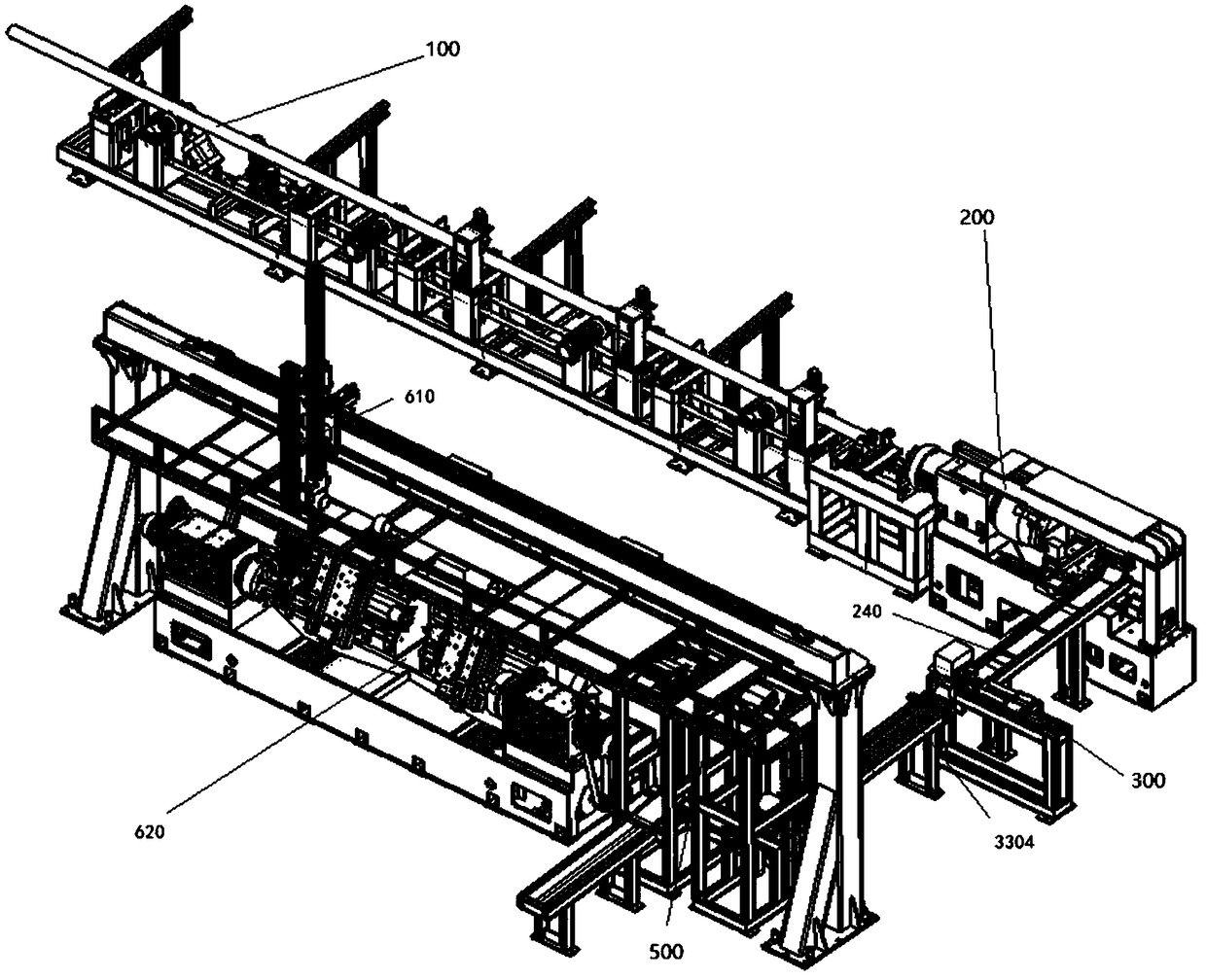

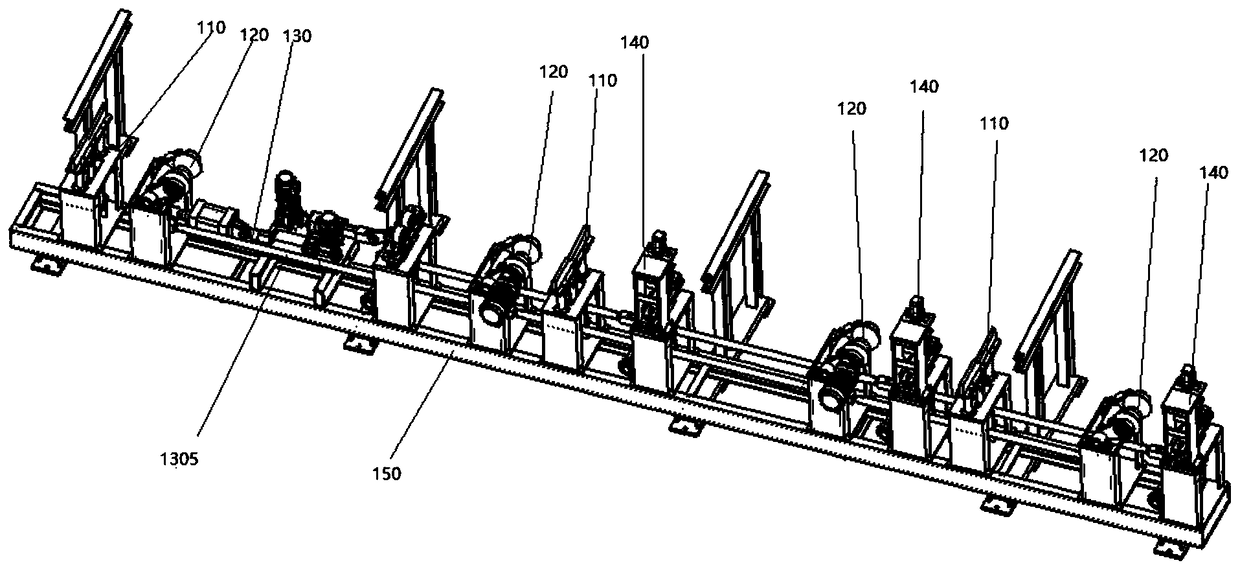

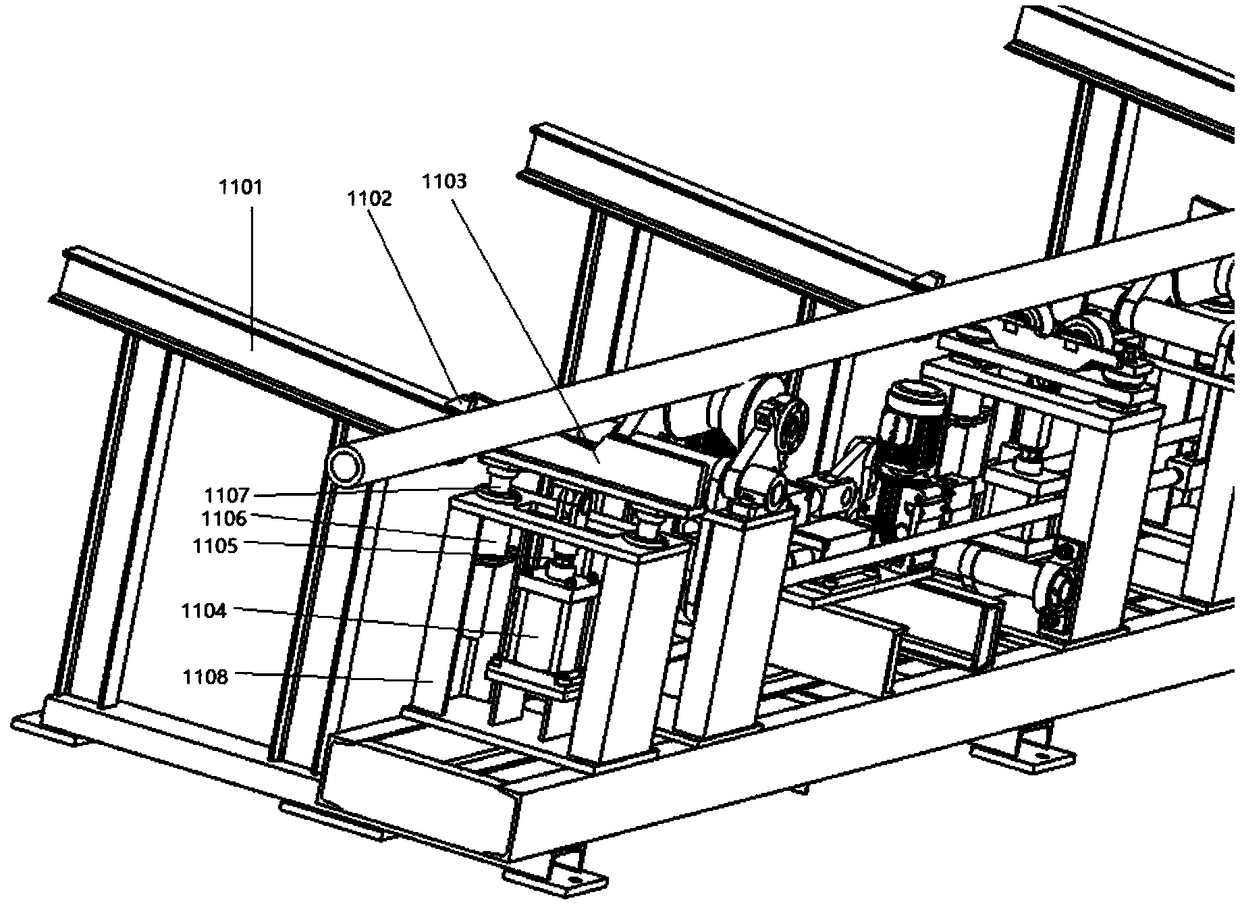

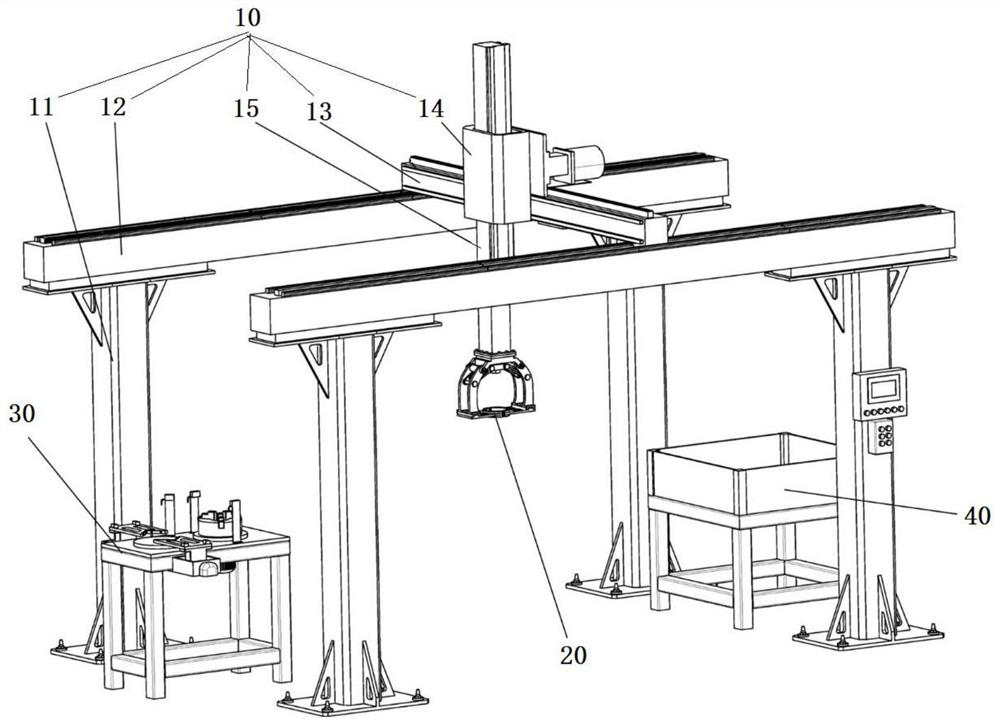

Fully automatic line-unloading transfer system for excavator engine

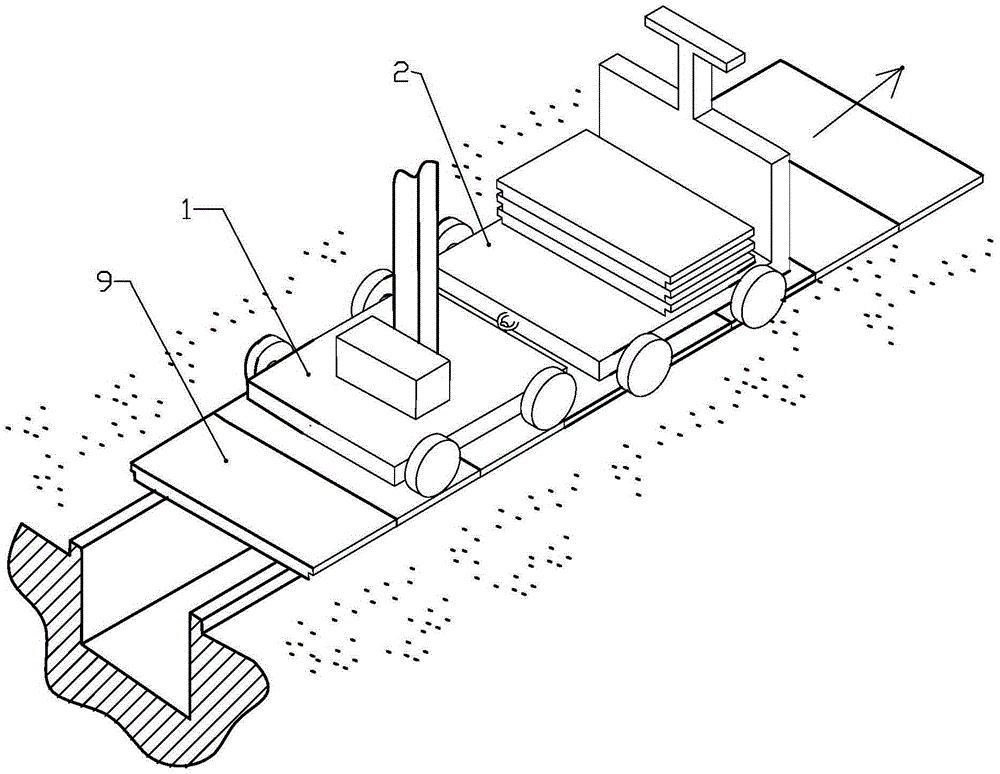

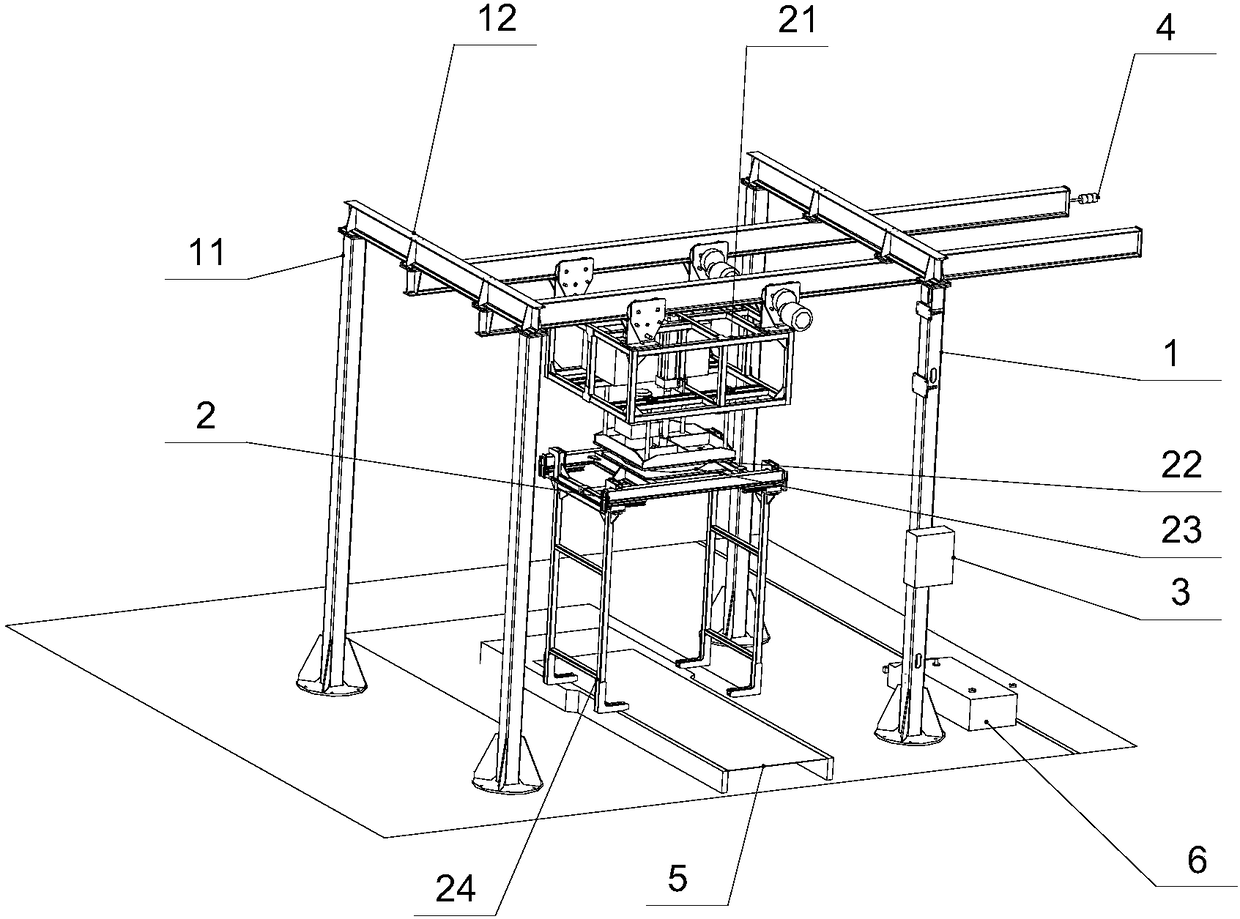

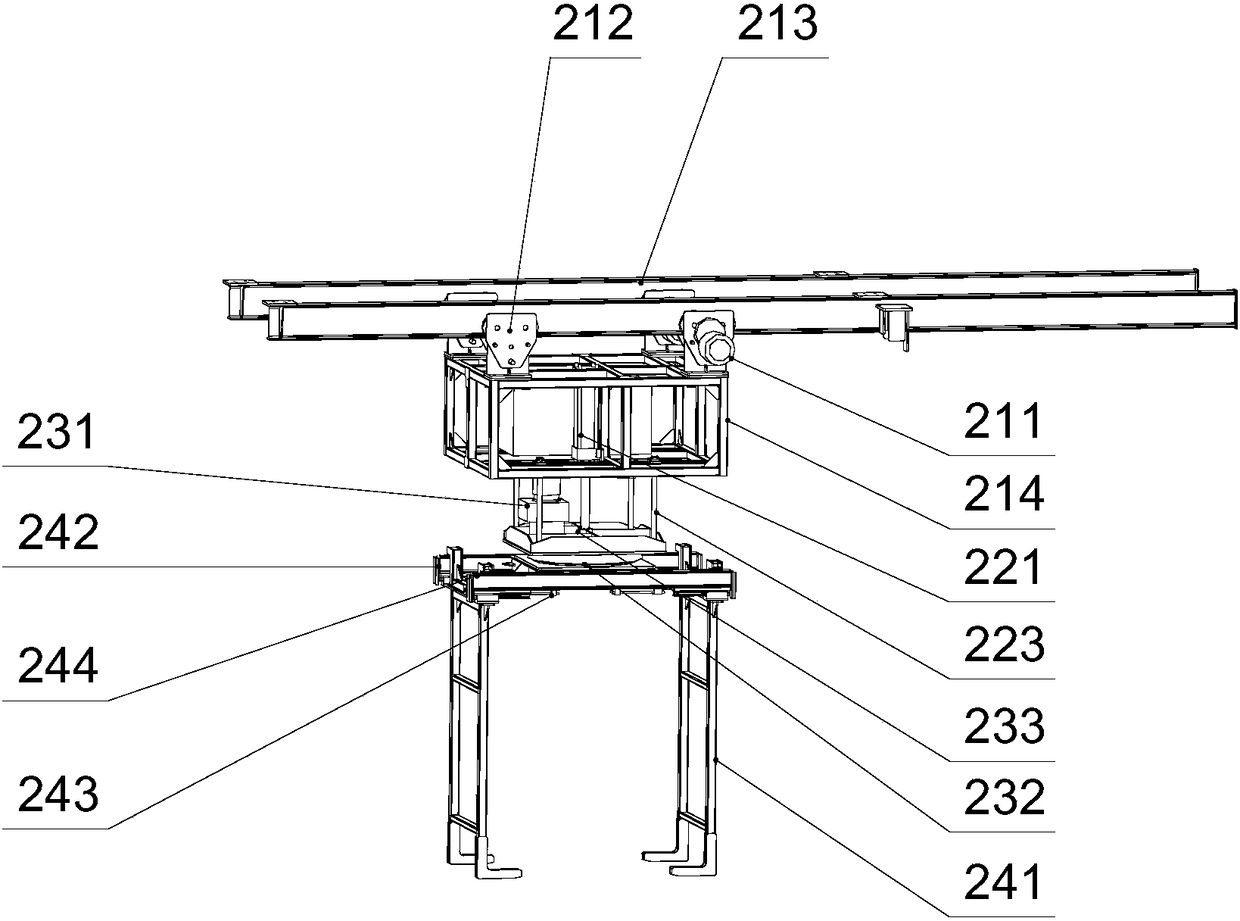

PendingCN108483272ARealize automatic crawlingAchieve translationTrolley cranesTravelling gearTransfer systemEngineering

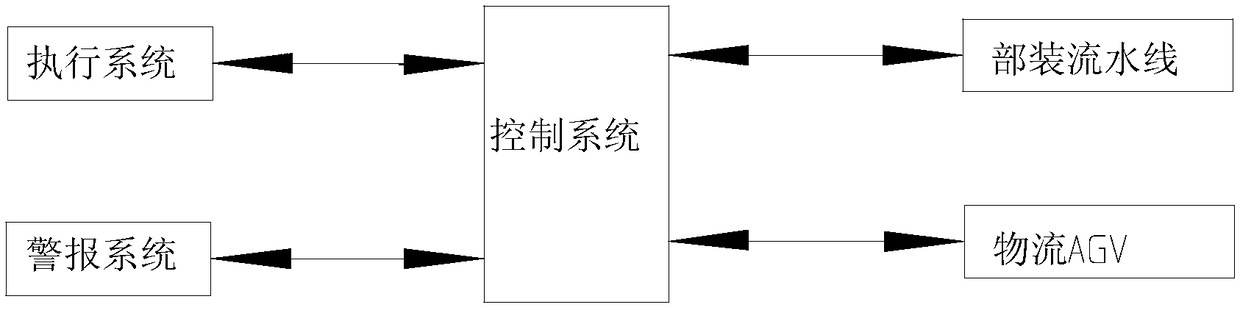

The invention discloses a fully automatic line-unloading transfer system for an excavator engine and belongs to the field of engineering machine parts production. The fully automatic line-unloading transfer system comprises a rack, an executive system, a control system, a part assembly line and a logistics AGV. The rack comprises stand columns and a beam type gantry framework. The executive systemcomprises a traveling device, a lifting device, a rotating device and a clamping device. The traveling device is fixedly arranged on the beam type gantry framework and the clamping device is connected under the traveling device by the lifting device and the rotating device. The part assembly line is arranged at the bottom of the rack. The logistics AGV is arranged at the bottom of the side edge of the rack. The control system is correspondingly connected to the executive system, the part assembly line and the logistics AGV. Automatic grab, translation, lifting and line-unloading of an engineare realized. The use of a crane is omitted, safety accidents are avoided, manpower is liberated and production efficiency is improved.

Owner:SHANDONG LINGONG CONSTR MACHINERY

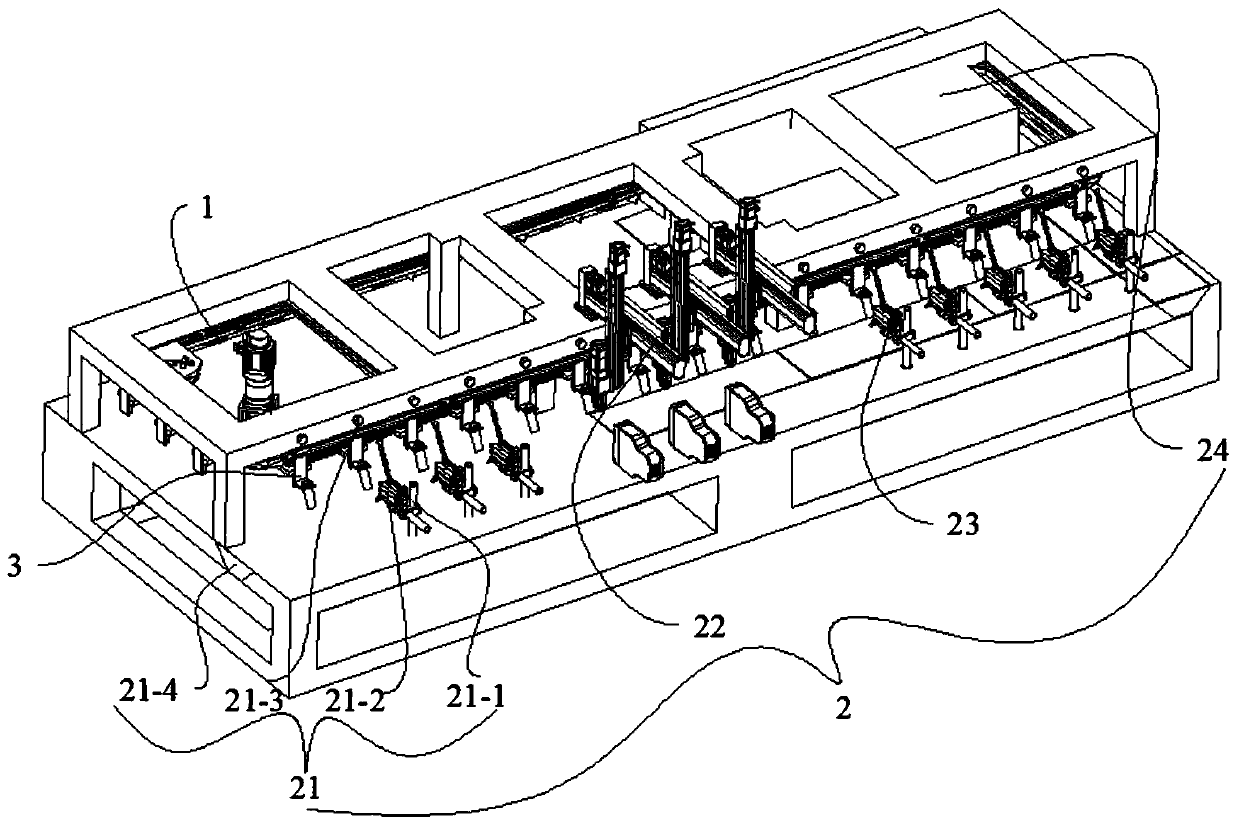

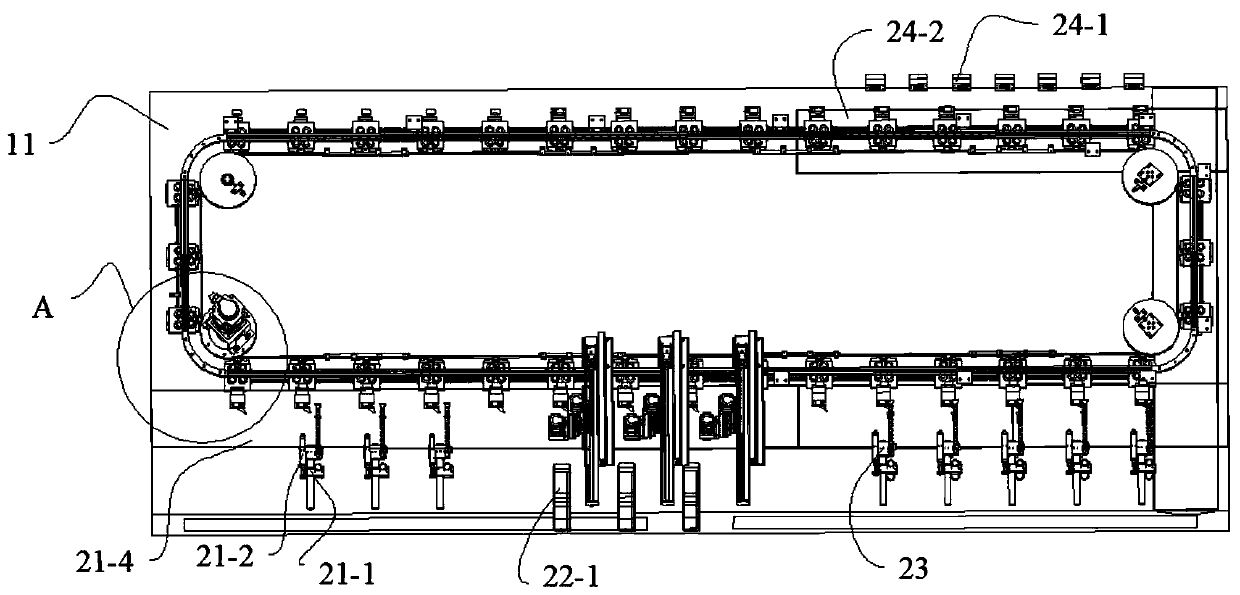

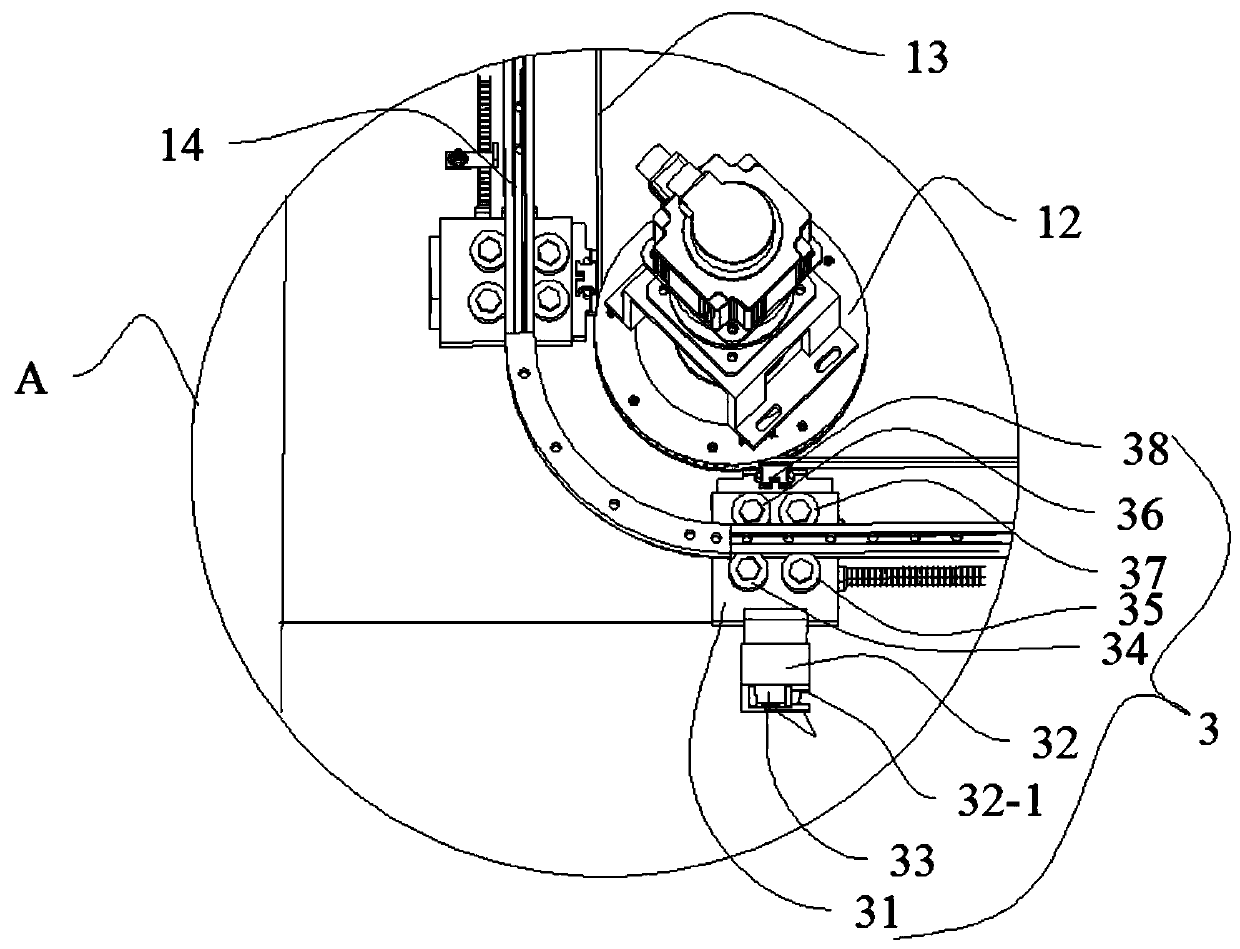

Assembly line type full-automatic blade three-dimensional detection system

ActiveCN110102530AFully automatedAutomate the processDrying solid materials with heatMeasurement apparatus componentsDrive wheelThree dimensional measurement

The invention provides an assembly line type full-automatic blade three-dimensional detection system. Blade are clamped by clamping parts, the clamping parts are conveyed circularly by an annular conveying assembly, developer spraying, scanning, cleaning or air drying treatment are conducted on the blades by a detection workpiece, full automation of spraying, scanning, cleaning and air drying of the blades can be achieved, and manual work can be replaced to complete the measuring process of the multiple blades. A conveying belt is arranged to convey the clamping parts, the multiple clamping parts can be arranged on the conveying belt, the conveying belt and a driving wheel form an automatic and circular conveying line, and manual work can be replaced to convey the blades to stations of spraying, automatic grabbing, rotary three-dimensional measurement, cleaning and drying treatment. The detection workpiece is arranged and comprises a spraying assembly, an automatic image capturing assembly, a cleaning assembly and an air drying assembly, and the whole automatic process of three-dimensional measurement of the blades can be achieved.

Owner:WUHAN POWER3D TECH

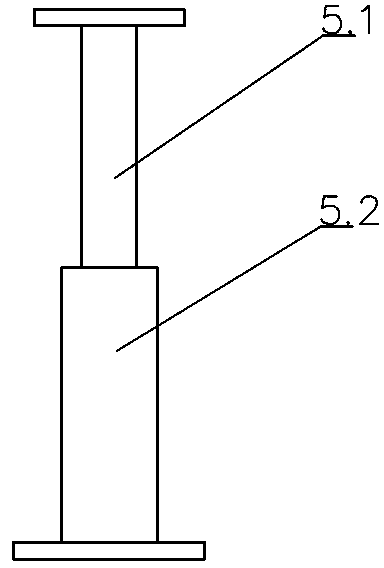

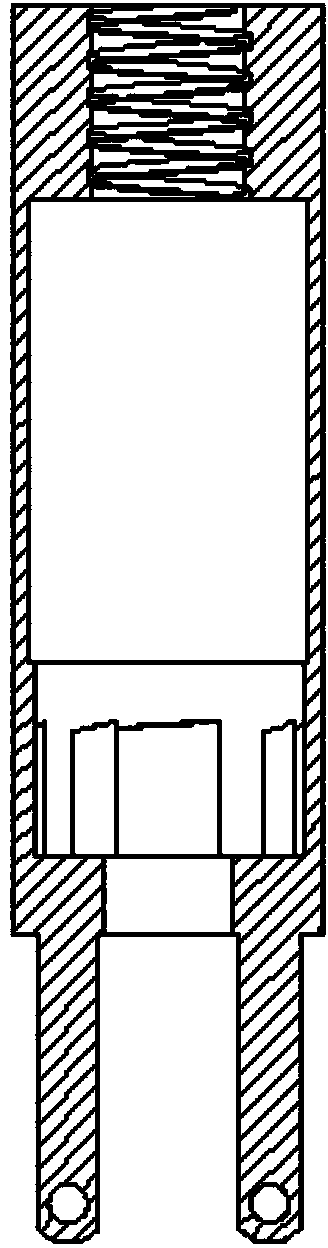

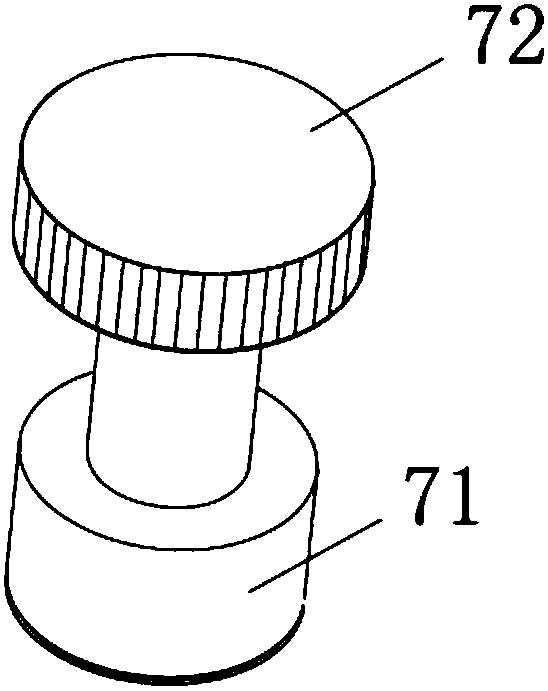

Mechanical automatic clamping grip

ActiveCN103950029ARealize automatic crawlingRealize letting goProgramme-controlled manipulatorGripping headsEngineeringCopper

The invention discloses a mechanical automatic clamping grip, and belongs to the technical field of mechanical automatic carrying. The automatic clamping grip comprises a retainer, a sliding drum, a paw, a snap ring, a connecting rod, a retractable spring, a copper sleeve, a compression spring, a sliding claw rotating drum, a sliding claw sleeve, a core shaft and a copper top sleeve, wherein the lower end of the connecting rod is connected with the retainer; the copper sleeve is fixedly connected with the upper end of the core shaft; the core shaft is sleeved with the compression spring, the sliding claw rotating drum, the sliding claw sleeve and the sliding sleeve from top to bottom; the paw is linked to the extending arm of the sliding drum and the lower end of the core shaft respectively through a bolt and a rotating hinge pin; the snap ring is fixedly connected with the paw 3; a rubber pad is arranged on the inner surface of the snap ring; the bottom of the core shaft is fixedly sleeved with the copper top sleeve. The automatic clamping grip provided by the invention can realize the carrying of automatically grasping and laying down workpieces, and is particularly suitable for workpieces, such as I-shaped steel, wire coils, and the like, which have large both ends and a small middle part, have larger quality and are difficult to achieve the automatic grasping and laying down.

Owner:ANHUI HISEED ROBOT CO LTD

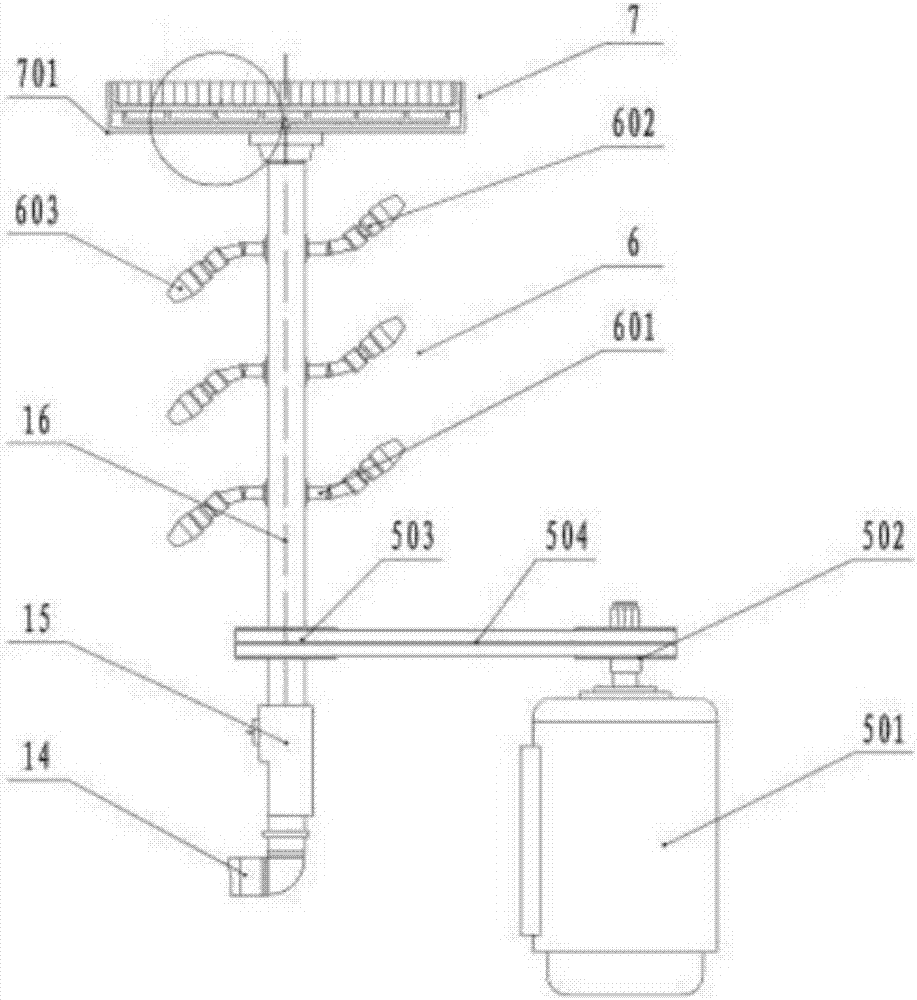

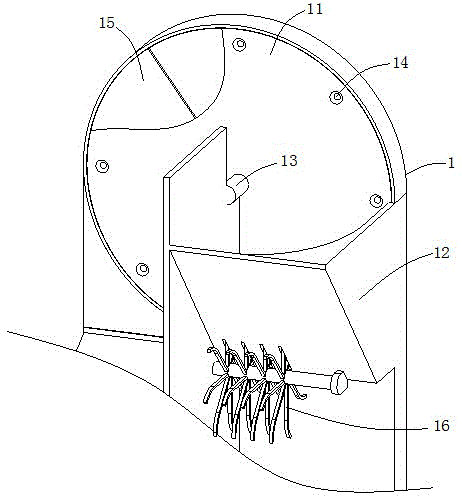

Cleaning device of draft beer barrel

ActiveCN106925580ARealize automatic crawlingAchieve cleaningHollow article cleaningChemicalsWater useStress concentration

The invention relates to a cleaning device of a draft beer barrel, and belongs to the technical field of cleaning equipment. The cleaning device comprises a pedestal, a mounting seat, a buffer, a support, a connection rod, a cylinder I, a cylinder II, a supporting rod, a movable block, a catching device, a water feeding pipe, a rotatable joint, a central pipe, a driving device, a cleaning device and a disk brush. The cleaning device of the draft beer barrel is simple in structure and convenient to maintain; automatic catching and cleaning of the draft beer barrel can be realized, the automation degree is greatly increased, the labor cost is reduced, and the safety and the cleaning efficiency are improved; meanwhile, a more advanced cavitating jet technology is used, and the water use amount is extremely small; and after bubbles formed by water flow are broken, locally high impact pressure and stress are concentrated, and the cleaning effect is extremely good.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

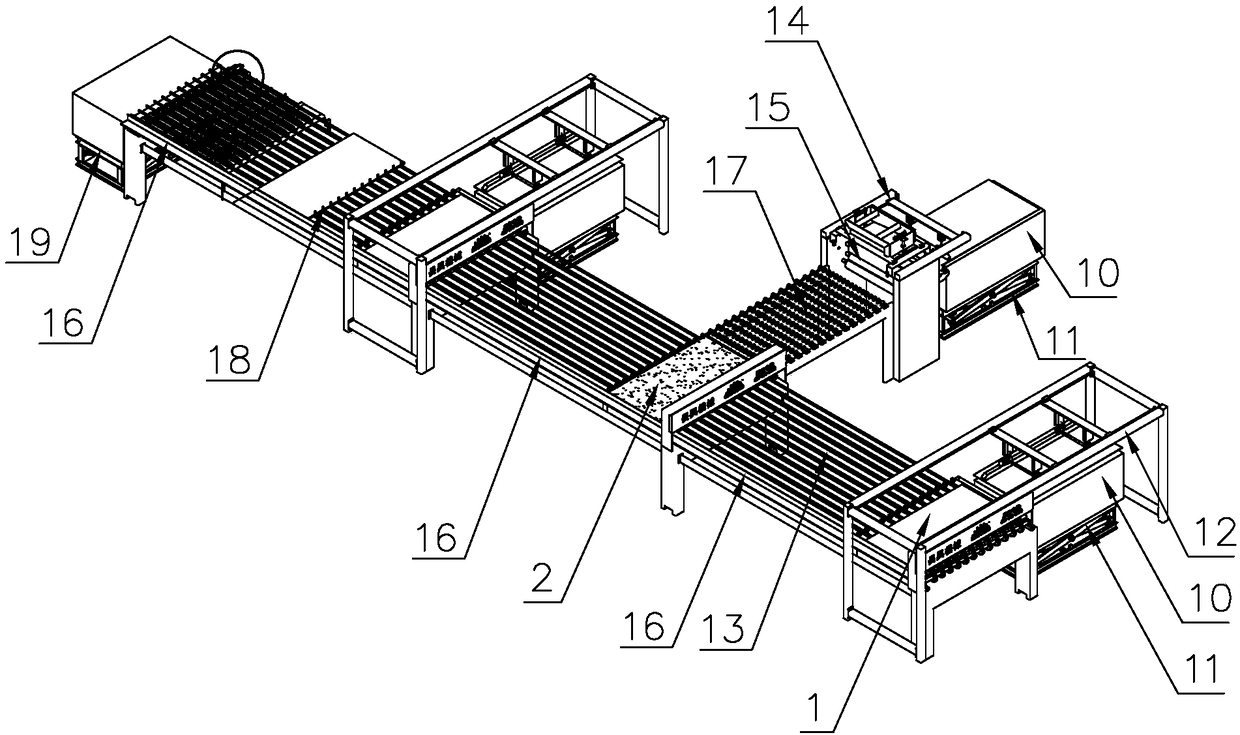

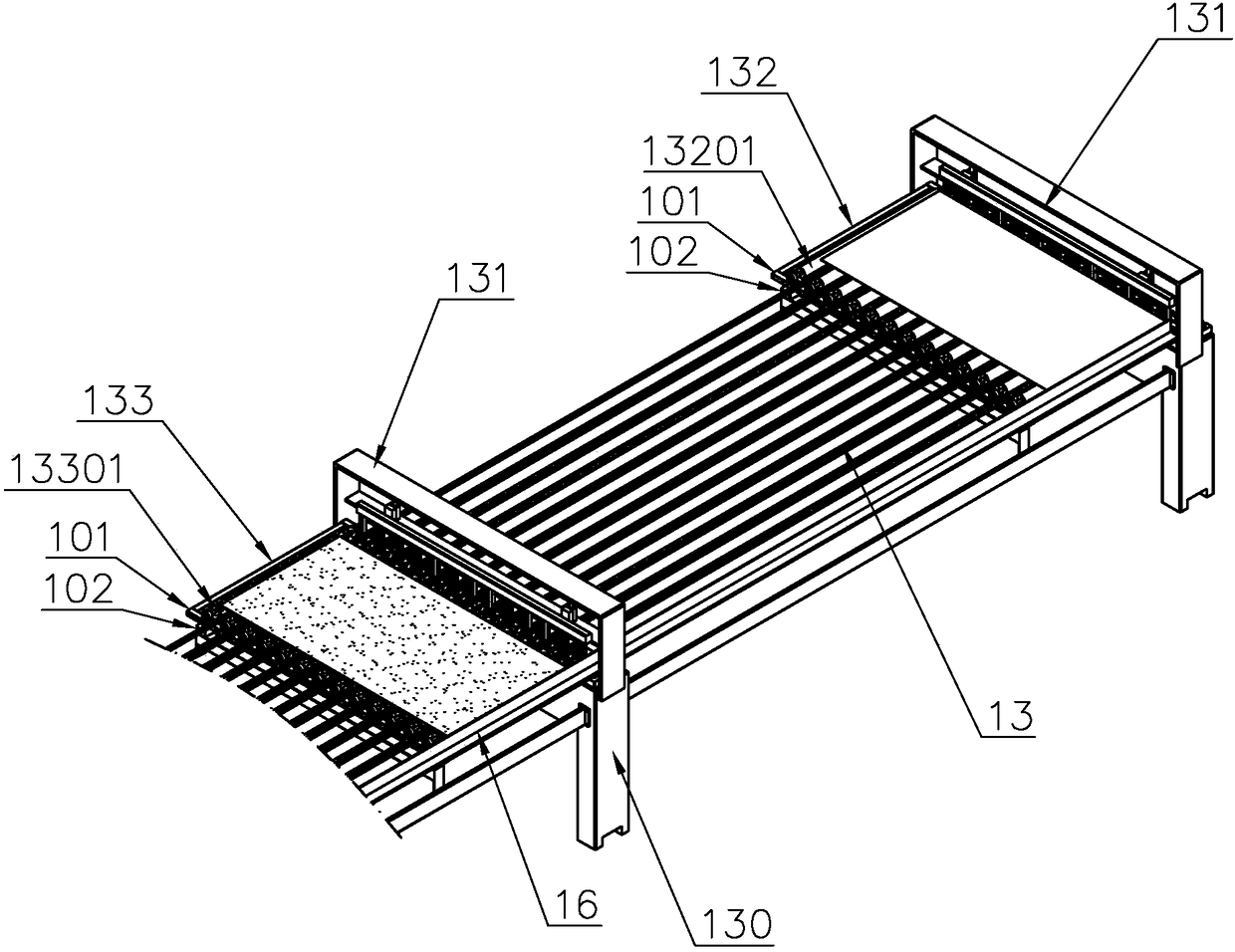

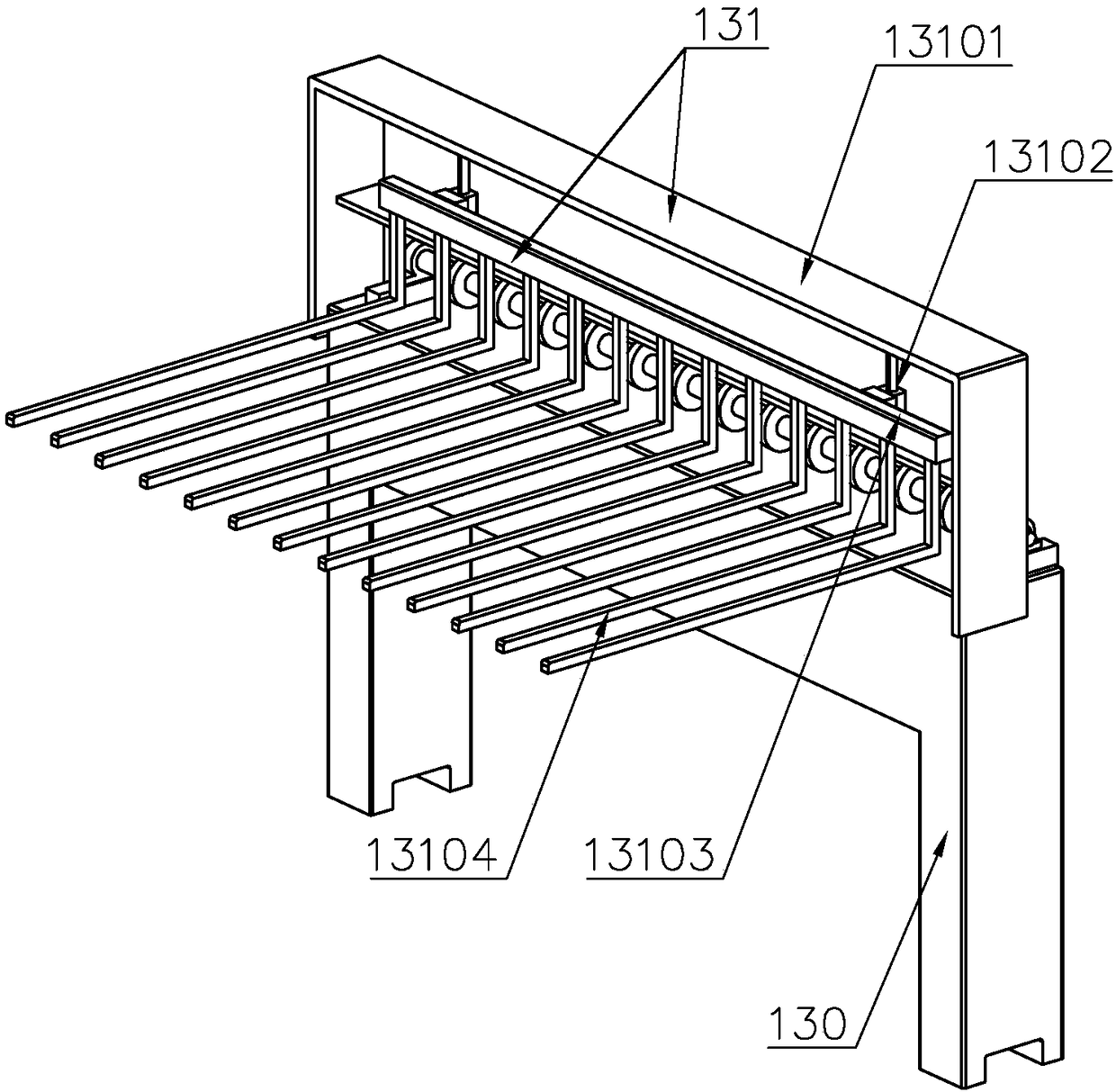

Multilayer plywood fully-automatic production line

PendingCN108082880ARealize automatic crawlingImprove work efficiencyMechanical conveyorsProduction lineStack machine

The invention discloses a multilayer plywood fully-automatic production line. The multilayer plywood fully-automatic production line comprises a fully-automatic lifting table, a horizontal feeding machine, a single sheet conveying line, a vertical feeding machine, an automatic glue applicator, a top guiding rule, a plywood conveying line, a horizontal movement guiding rule and an automatic stacking machine, wherein the conveying chains of the single sheet conveying line are provided with the horizontal movement guiding rule; the upper portion of one edge of the frame of the single sheet conveying line is provided with the top guiding rule, and the horizontal movement guiding rule and the top guiding rule achieves a positioning right angle of assembly single sheets; the frame of the singlesheet conveying line is provided with a plurality of lifting roller groups I and lifting roller groups II, which are arranged in an alternate mode, and one side of the upper portion of every lifting roller group is provided with a lifting rack. The multilayer plywood fully-automatic production line can achieve automatic single sheet gripping, automatic gluing, automatic alignment, automatic compounding, automatic stacking and fully automatic production, thereby improving the working efficiency and save a large amount of labor.

Owner:山东昶兴智能科技有限公司

Feeding device and method for heat exchanger sheet forming

PendingCN108772502AFully automatedChange the way of productionMetal-working feeding devicesHeat exchange apparatusHigh volume manufacturingWork in process

The invention discloses a feeding device and method for heat exchanger sheet forming. The device comprises a PLC installed on an electric control cabinet near a machine frame, and an automatic feedingmechanical hand system, a conveying mechanism, a conveying positioning system, a sheet stretching die, an automatic taking stacking system which are installed on the machine frame in sequence from left to right. The automatic feeding mechanical hand system is used for sucking heat exchanger sheet semi-finished products and transferring the semi-finished products to the conveying mechanism, the conveying mechanism is used for transferring the heat exchanger sheet semi-finished products to the conveying positioning system, the conveying positioning system is used for aligning the heat exchangersheet semi-finished products and transferring the semi-finished products to the sheet stretching die, and the sheet stretching die is used for stretching the heat exchanger sheet semi-finished products. The feeding device and method have the advantages that automation of the feeding work procedure, the conveying work procedure, the positioning work procedure, the stacking work procedure and the like for the plate type heat exchanger stainless steel sheet semi-finished products is achieved, production efficiency is improved, the traditional labor intensive production way is changed, and a guarantee is provided for large-batch production and industrial production.

Owner:辽宁光阳换热设备制造有限公司

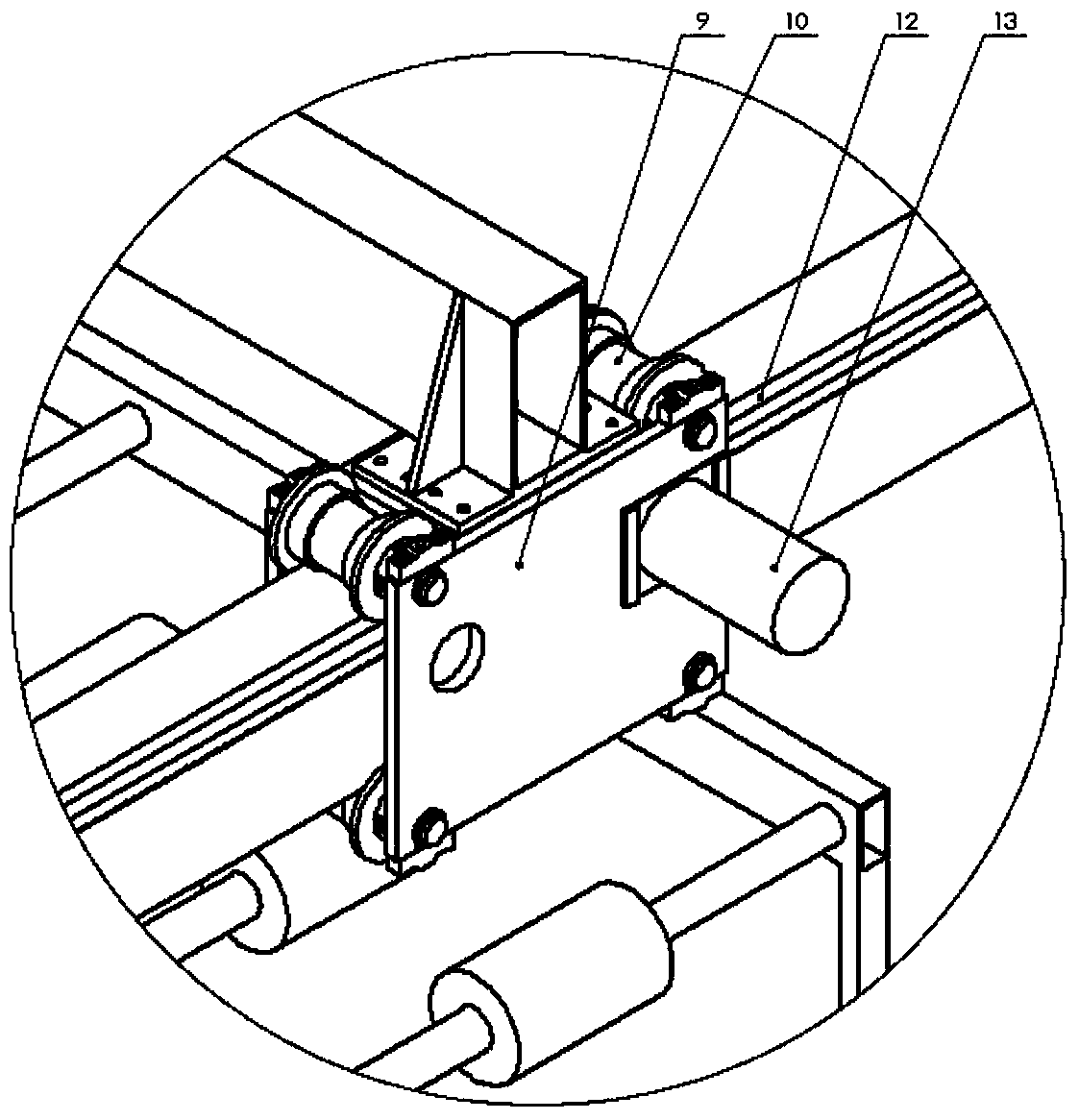

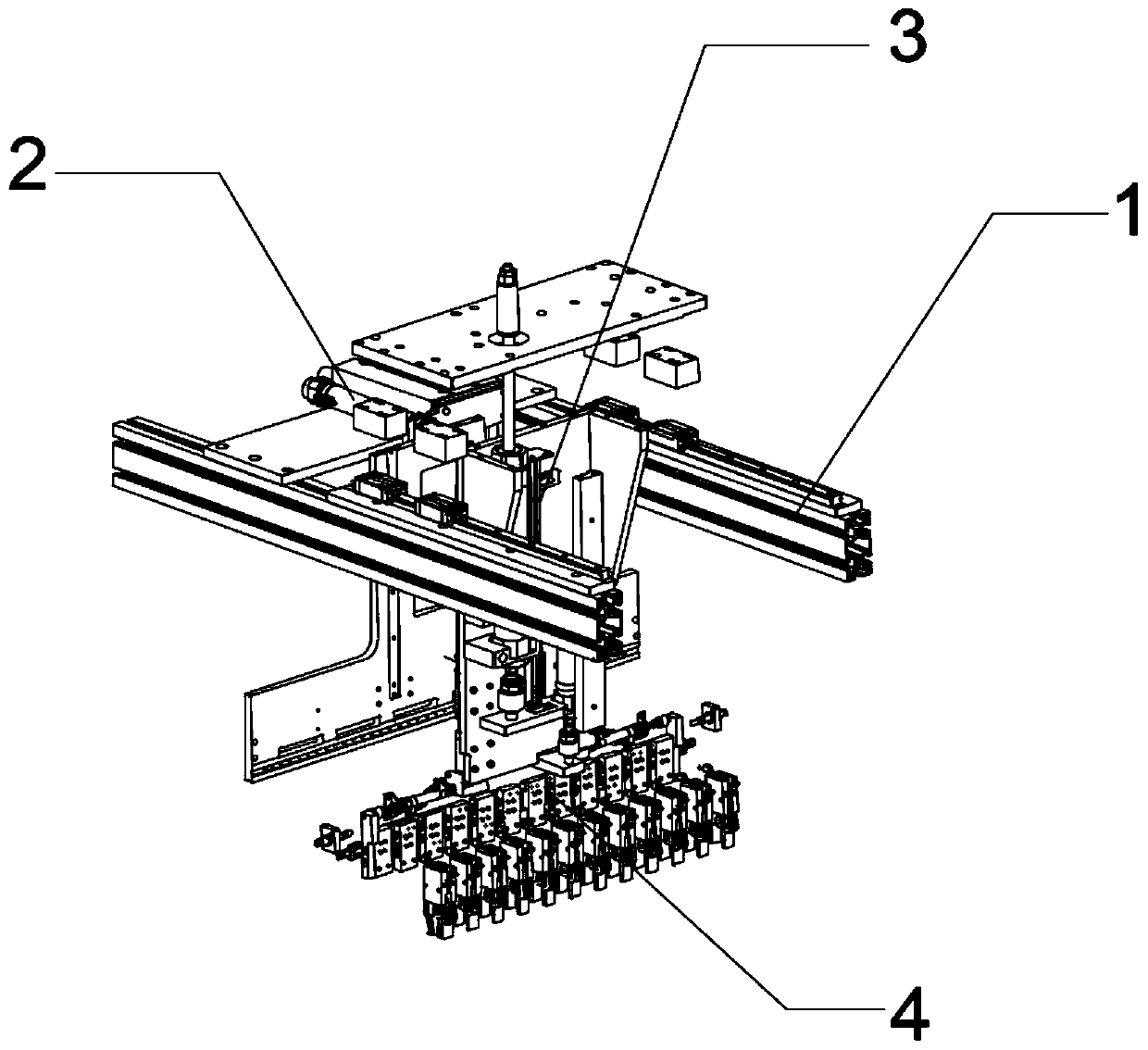

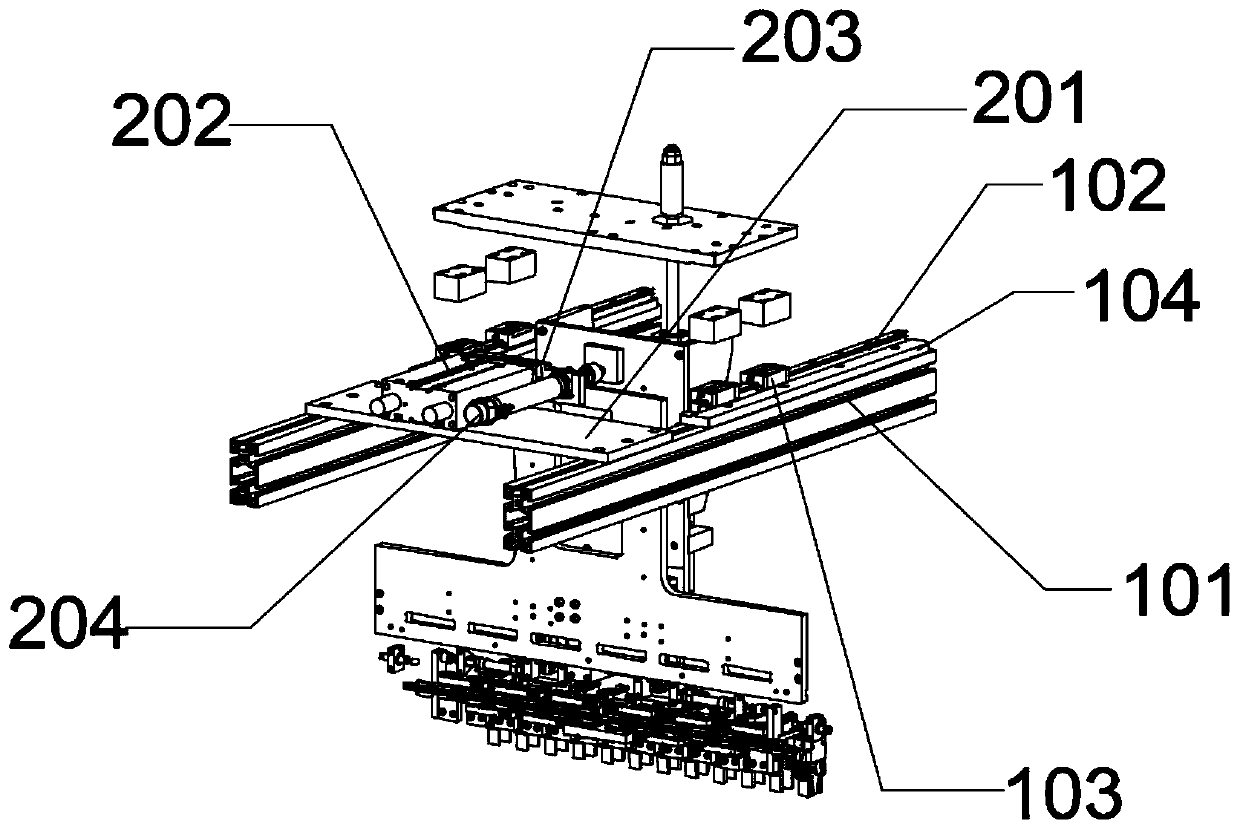

Automatic feeding, grabbing and installing integration device for screen cloth

ActiveCN107826818ARealize automatic feeding processRealize automatic crawlingArticle feedersArticle separationEngineeringTextile

The invention discloses an automatic feeding, grabbing and installing integration device for screen cloth. The automatic feeding, grabbing and installing integration device comprises a screen cloth automatic feeding unit, a screen cloth floating grabbing unit, a screen cloth transfer carrying unit and a screen cloth mesh enclosure installing clamping jaw unit, wherein the screen cloth automatic feeding unit is provided with material bins and jacking devices; the screen cloth floating grabbing unit comprises a first connecting plate and a floating structure which is connected with the first connecting plate and matched with the jacking devices to grab the screen cloth, and the floating structure comprises inserted pins obliquely inserted into the screen cloth; the screen cloth transfer carrying unit comprises transfer planes with the same amount of the material bins, and first through openings allowing the clamping jaws to enter are formed in the two sides of the transfer planes; and the screen cloth mesh enclosure installing clamping jaw unit comprises screen cloth clamping units, mesh enclosure clamping units located beside the screen cloth clamping units and mesh enclosure pressing units arranged beside the mesh enclosure clamping units. The automatic feeding, grabbing and installing integration device can precisely and effectively grab single-layer screen cloth from a screencloth pile, realizes automatic feeding, grabbing and installing of the screen cloth and greatly improves the production efficiency.

Owner:昆山墨佳工业设备有限公司

Tightness-adjustable automatic operation device

ActiveCN108159656AIncrease crawl speedImprove work efficiencyProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a tightness-adjustable automatic operation device. For the tightness-adjustable automatic operation device, linear displacement spherosyns are arranged in guide rails, readingheads are arranged in sliding sleeves, the tightness-adjustable automatic operation device further comprises at least two manipulators and a main motor, the main motor is fixedly mounted on a bottom plate of the operation device, an output shaft of the main motor is in linkage with the sliding sleeves through a reduction gearbox and a lead screw, each manipulator is composed of a pair of mechanical arms capable of rotating in an opposite way, each mechanical arm is composed of a plurality of sections of movable joints, the movable joints are rotatably connected through rotation shafts, at least two grooves are axially symmetrically formed in each rotation shaft, a guide rod is telescopically arranged in each groove, a first contrate gear is horizontally arranged at the upper end of each guide rod, a first drive mechanism is slidingly arranged at the upper end of each mechanism arm, a second contrate gear is telescopically arranged at the upper end of each first drive mechanism, and each second contrate gear is in selective linkage with the corresponding first contrate gear. With the tightness-adjustable automatic operation device, the technical problem that the mechanical arms on the existing grabbing and climbing devices are fixed in form, consequently, the application range is limited, is solved.

Owner:宁波顺凯新材料科技有限公司

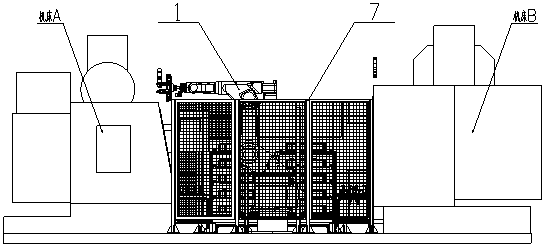

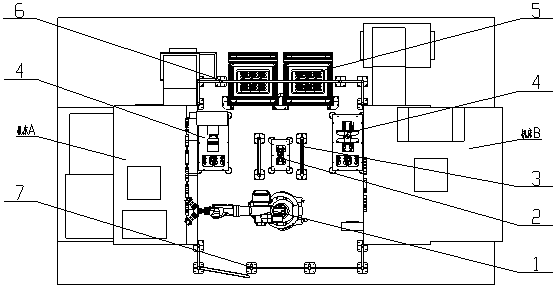

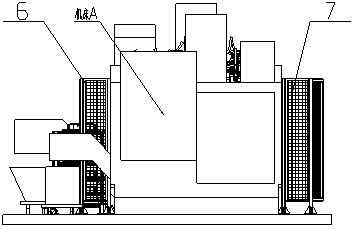

Machine tool automated feeding and discharging integrated system by robot

PendingCN107584316ARealize automatic crawlingCompact structureGripping headsMetal working apparatusNumerical controlDigital control

The invention relates to a machine tool automated feeding and discharging integrated system by a robot. The machine tool automated feeding and discharging integrated system comprises a machine tool automated feeding and discharging integrated system body, the machine tool automated feeding and discharging integrated system body comprises a robot mounting component, the robot mounting component isarranged in the middle of two machine tools, a first fast switching platform is arranged in the middle of one side of the robot mounting component, and protective fences are arranged at the two sidesof the first fast switching platform; second fast switching platforms are arranged at the two sides of the protective fences, a material cart is arranged at one side of the first fast switching platform, right side safety fences are arranged at the sides of the material cart, and left side safety fences are arranged at the opposite sides of the right side safety fences. According to the automaticfeeding and discharging integrated system by the robot, the integration of the automated feeding and discharging robot and the digital control machine tool is achieved, a vision system is adopted forworkpiece locating, all processes of automatic crawling, feeding, discharging, clamping, machining and the like can be achieved, the manpower cost can be greatly saved, and the production efficiency is improved. The machine tool automated feeding and discharging integrated system by the robot is particularly applicable to machining large-scale and miniature parts.

Owner:SHANGHAI LANZHONG AUTOMATION EQUIP CO LTD

Rubbing-separation type banknote automatic flattening device

InactiveCN105551136ARelieve pressureReduce frictionPaper-money handling devicesEngineeringUltimate tensile strength

The invention discloses a rubbing-separation type banknote automatic flattening device, comprising a rack, a material feeding mechanism installed on the rack and a rubbing-separation mechanism; the rubbing-separation mechanism comprises a first rubbing-separation roller and a second rubbing-separation roller which are installed on the rack and are parallel to each other; the gap between the first rubbing-separation roller and the second rubbing-separation roller is smaller than the total thickness of the two banknote; the gap is big enough to allow a single banknote to pass through; the rubbing-separation mechanism also comprises a material guiding plate which is extended obliquely and downwardly to the part between the first rubbing-separation roller and the second rubbing-separation roller; and the material guiding plate is positioned under the material feeding mechanism. The invention can automatically grab the banknote to feed, can rub the banknotes for separation and flatten the banknote, and can collect and count the banknote. Besides, the rubbing-separation effect is good, the reliability is high and counting is accurate. The invention can reduce the labor intense and improve the working efficiency.

Owner:CHONGQING UNIV OF TECH

Petroleum casing collar automatic production line

PendingCN109454467AGuaranteed stabilityConsistent positionOther manufacturing equipments/toolsProduction lineElectrical control

The invention discloses a petroleum casing collar automatic production line. The petroleum casing collar automatic production line comprises a long casing conveying device, a long casing cutting device, a marking device, a collar blank conveying device, a lifting device, a mechanical hand structure, a machining device and other multiple process devices; and the long casting cutting device, the marking device, the collar blank conveying device and the lifting device are connected through connection conveying plates. According to the petroleum casing collar automatic production line provided bythe invention, the mechanical devices cooperates with electrical control, the process that taking and conveying of a long casting, turning of the end surface and the outer circle of the long casting,cutting off of the long casing, marking of a collar blank, conveying of the collar blank between planes different in height, mechanical hand grabbing and machine tool machining are automatically and efficiently conducted is achieved, manpower is saved, and the production efficiency is improved.

Owner:SHANGHAI JIANGAO CNC MACHINE TOOLS

Field planting cup loading device

PendingCN110002227ARealize automatic crawlingPick up accuratelyConveyorsAgriculture gas emission reductionEngineering

The invention relates to the technological field of field planting, in particular to a field planting cup loading device. The field planting cup loading device comprises a proximate matter bracket, ahorizontal driving mechanism, a downward pressing mechanism and a field planting cup grasping mechanism fixed at the output end of the downward pressing mechanism; the horizontal driving mechanism andthe downward pressing mechanism are arranged on the proximate matter bracket, the output end of the horizontal driving mechanism is connected to the downward pressing mechanism to move horizontally along the proximate matter bracket, and the field planting cup grasping mechanism is provided with a plurality of mechanical clamping jaws and guiding devices for adjusting the gaps between the adjacent mechanical clamping jaws. According to the field planting cup loading device, the horizontal driving mechanism enables the downward pressing mechanism to move to arrange field planting cups, the downward pressing mechanism is used for downwards pushing the field planting cup grasping mechanism to enable the field planting cup grasping mechanism to touch the field planting cups, and automatic grasping of the field planting cups is achieved; and the guiding devices on the field planting cup grasping mechanism arranges the field planting cups equidistantly according to the requirements, then the downward pressing mechanism is used for achieving accurate filling of field planting, the field planting cups can be stably clamped, and the field planting cups can be arranged equidistantly and beaccurately placed on a field planting plate.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

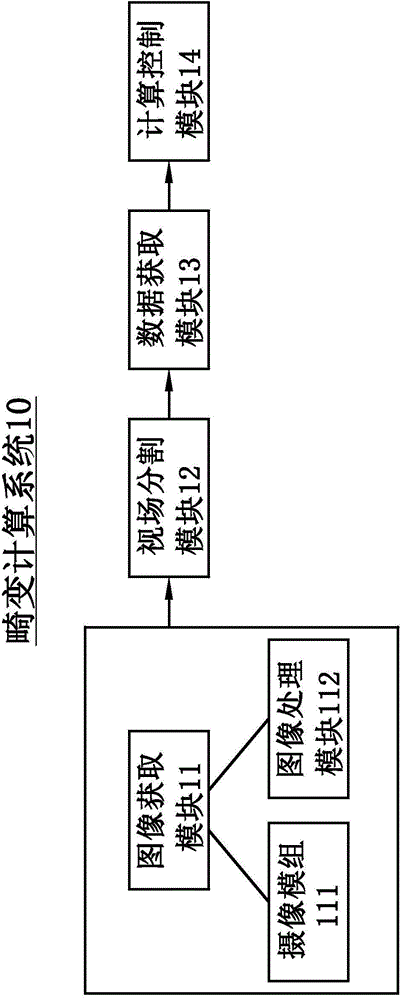

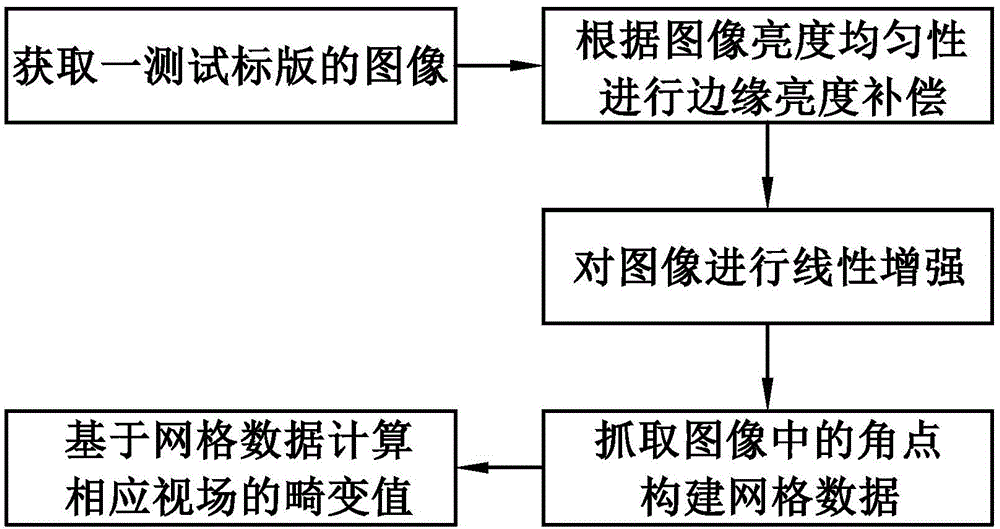

Method for computing lens distortion of photographing module

InactiveCN105791655ACalculation speedRealize real-time computingTelevision system detailsImage enhancementCamera lensAngular point

The invention discloses a method for computing lens distortion of a photographing module. The method comprises following steps of (a), utilizing the photographing module to obtain a test chart image; (b), capturing angular points in the image; forming grid data; and (c), computing the lens distortion value of the photographing module based on the grid data.

Owner:NINGBO SUNNY OPOTECH CO LTD

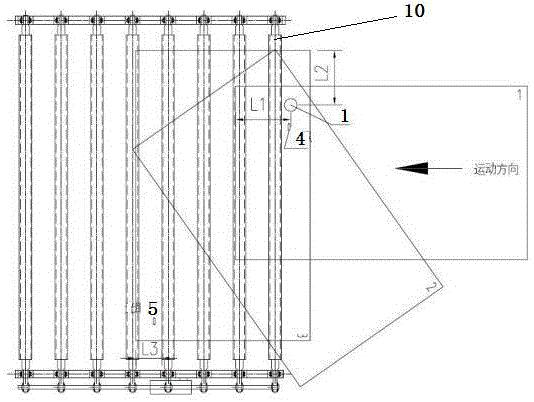

Flat plate glass conveying automatic steering device and automatic steering method

ActiveCN106494888ARealize automatic crawlingReasonable structureConveyorsControl devices for conveyorsFlat glassAutomatic steering

The invention belongs to the technical field of flat plate glass deep processing production, and provides a glass conveying automatic steering device and an automatic steering method. The glass conveying automatic steering device provided by the invention is provided with a first light hole (4) formed in the front part of a conveying steering roller; a suction disc (1) is arranged above the first light hole (4); a second light hole (5) is also formed in the automatic steering device; an air suction electromagnetic valve (7) and an air blowing electromagnetic valve (6) are also arranged in a way of corresponding to the suction disc (1); the air blowing electromagnetic valve (6) and the air suction electromagnetic valve (7) respectively communicate with a vacuum pump (9) through a vacuum tank (8); an ascending and descending electromagnetic valve (2) is also arranged in a way of corresponding to the suction disc (1); the first light hole (4), the second light hole (5), the ascending and descending electromagnetic valve (5), the air blowing electromagnetic valve (6) and the air suction electromagnetic valve (7) communicate with a PLC (programmable logic controller) (3). The device and the method provided by the invention achieve the goal of enabling the glass to realize automatic steering, and have the characteristics that the structure is reasonable; the installation is convenient; the operation and control are simple; the cost is low.

Owner:海南海控特玻科技有限公司 +1

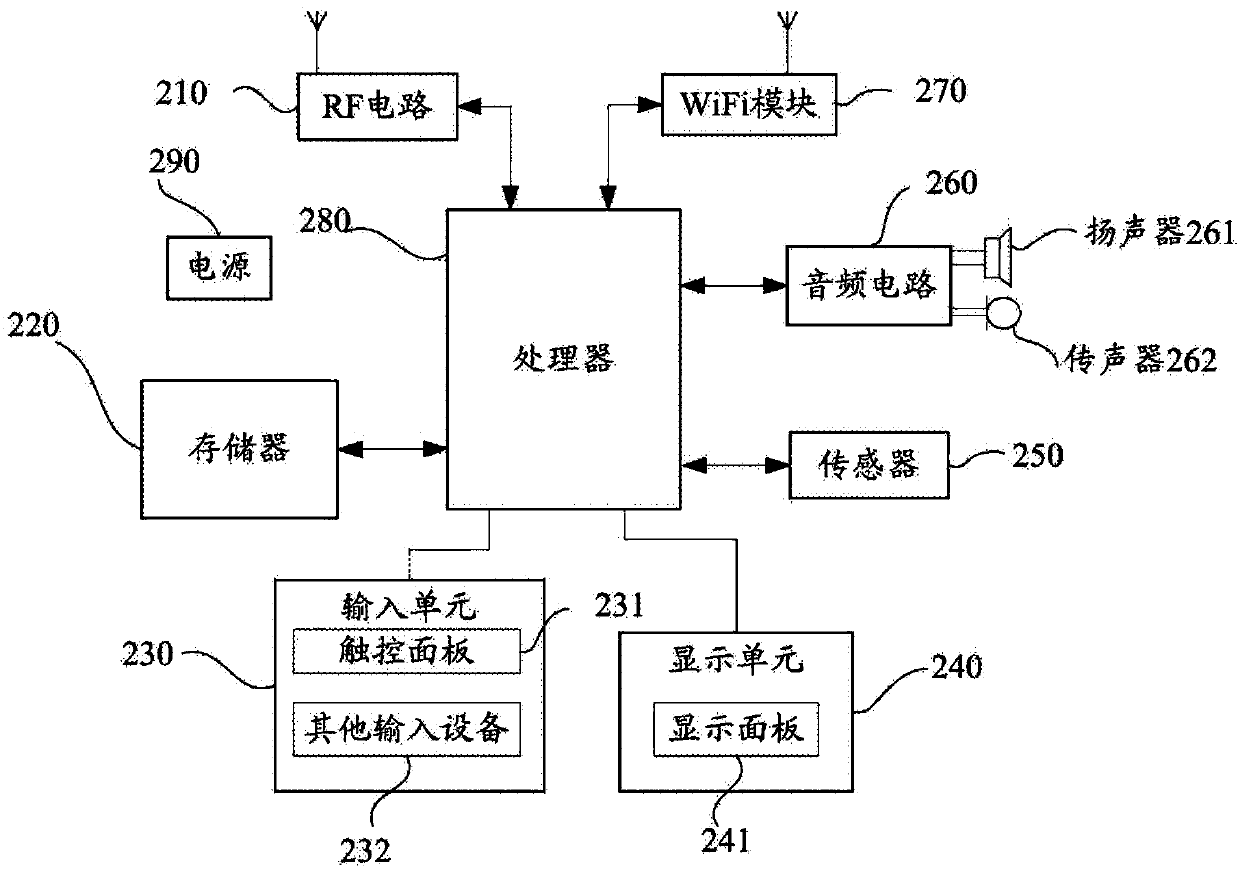

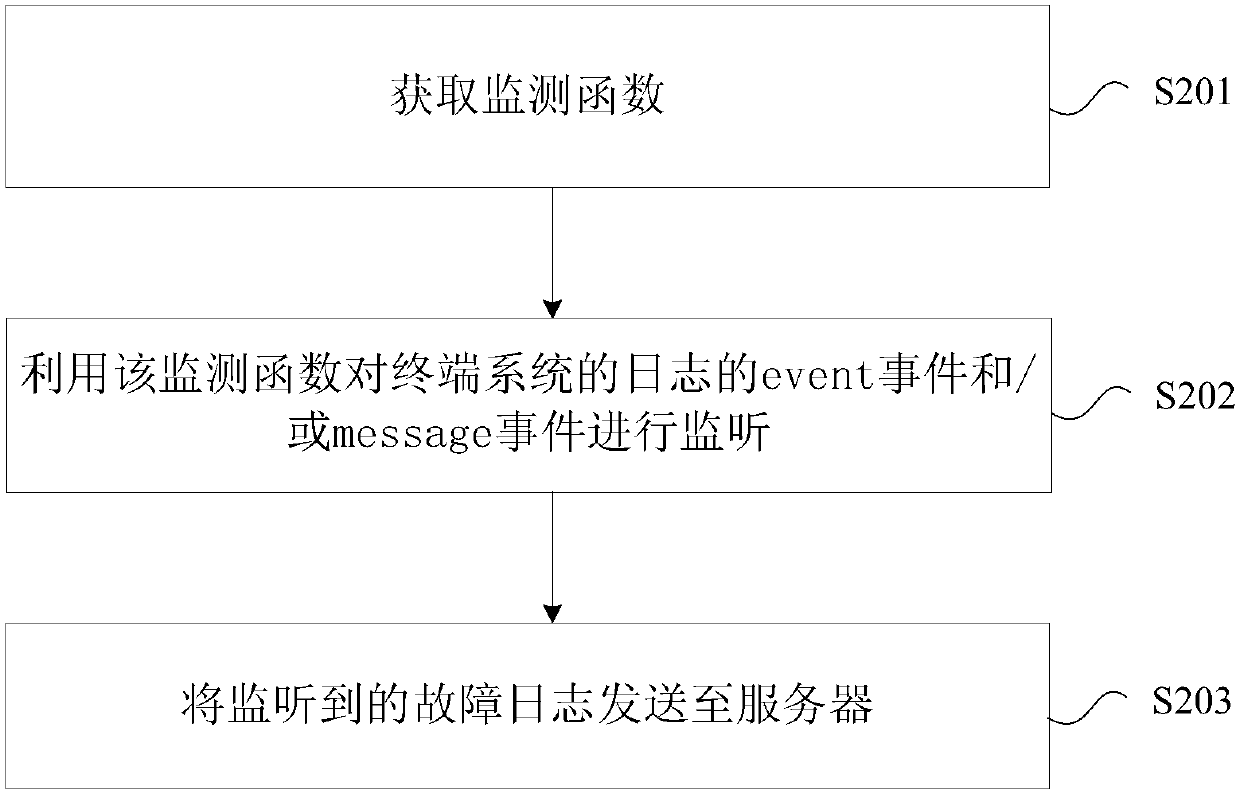

Terminal log grabbing method and device and terminal log analysis method and device

InactiveCN108021491ARealize automatic crawlingImprove accuracyHardware monitoringComputer terminalWorkload

The invention provides a terminal log grabbing method and device, a terminal log analysis method and device, a terminal, a server and a computer readable storage medium. The terminal log analysis method includes the steps of acquiring a monitoring function; using the monitoring function to monitor event events and / or message events of logs of a terminal system; sending monitored fault logs to theserver. According to the terminal log grabbing method and device, the terminal log analysis method and device, the terminal, the server and the computer readable storage medium, the problems that in the prior art, fault logs in the terminal system can only be manually grabbed by technicians, the workload of personnel is increased, and the work efficiency of system monitoring is reduced are solved,automatic grabbing of the fault logs by the terminal is achieved, the manpower is saved, and the accuracy of grabbing the fault logs is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

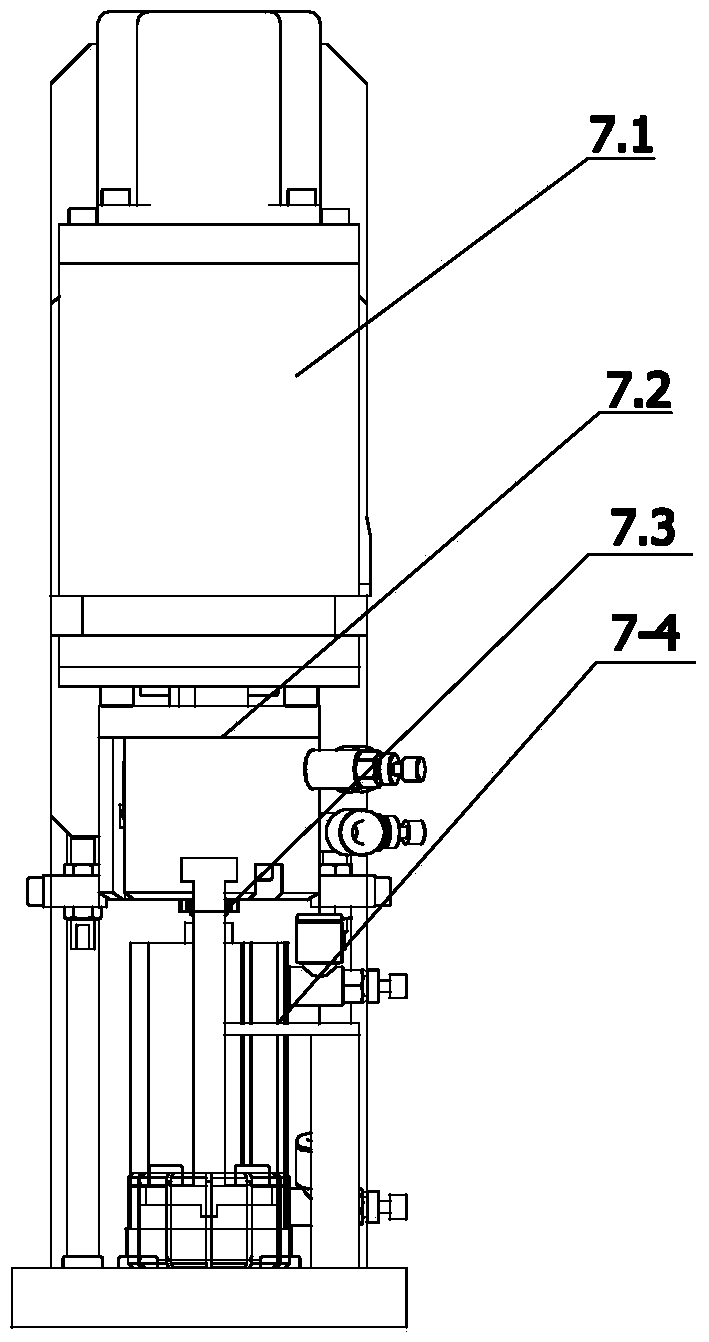

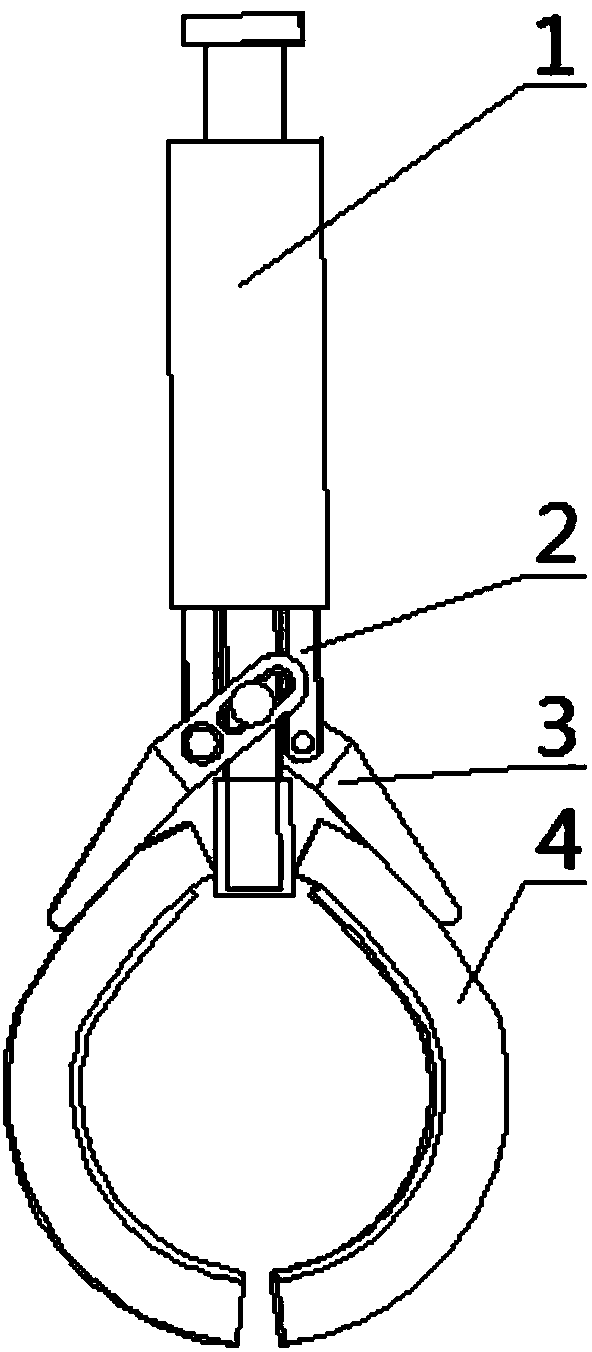

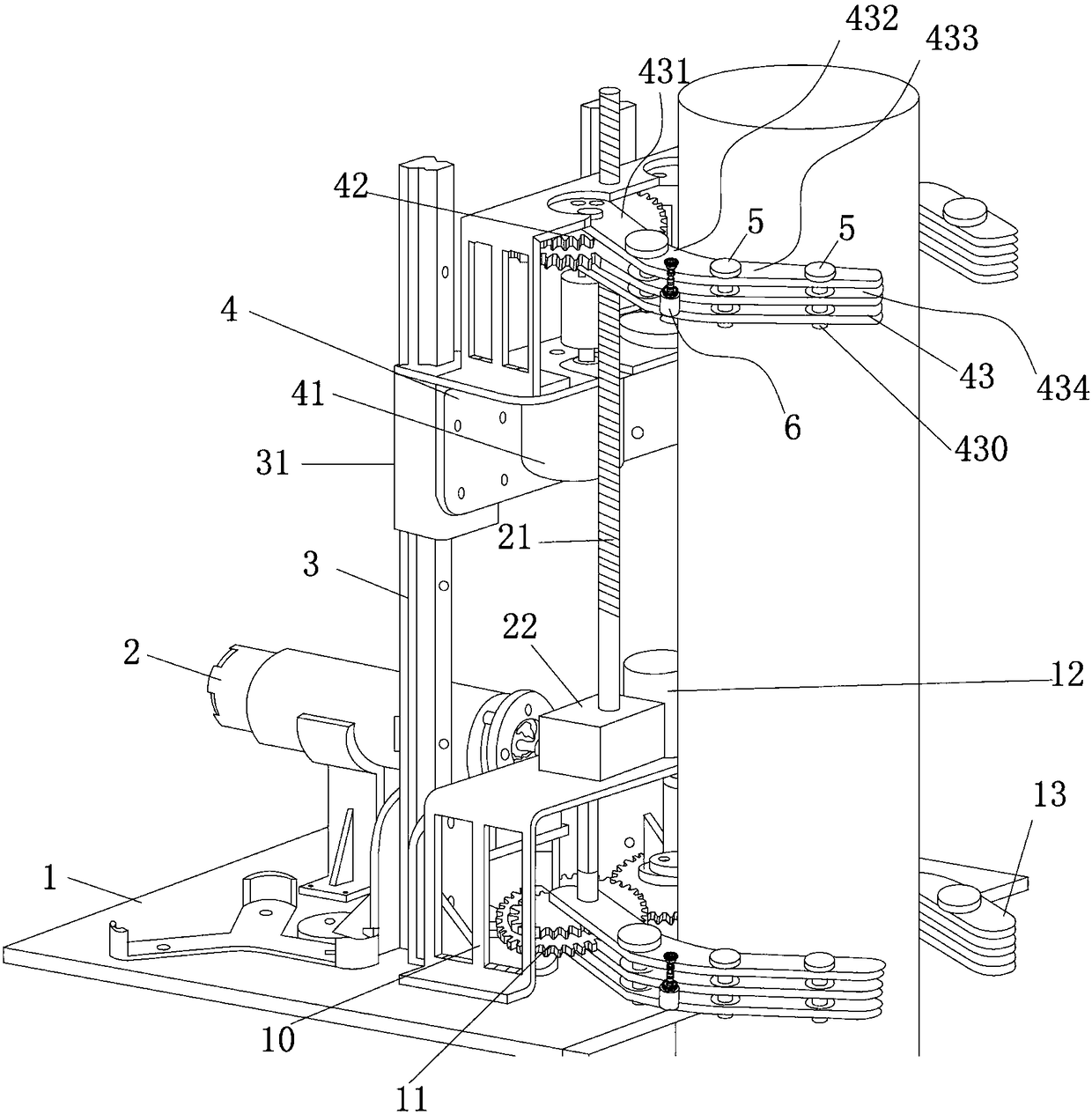

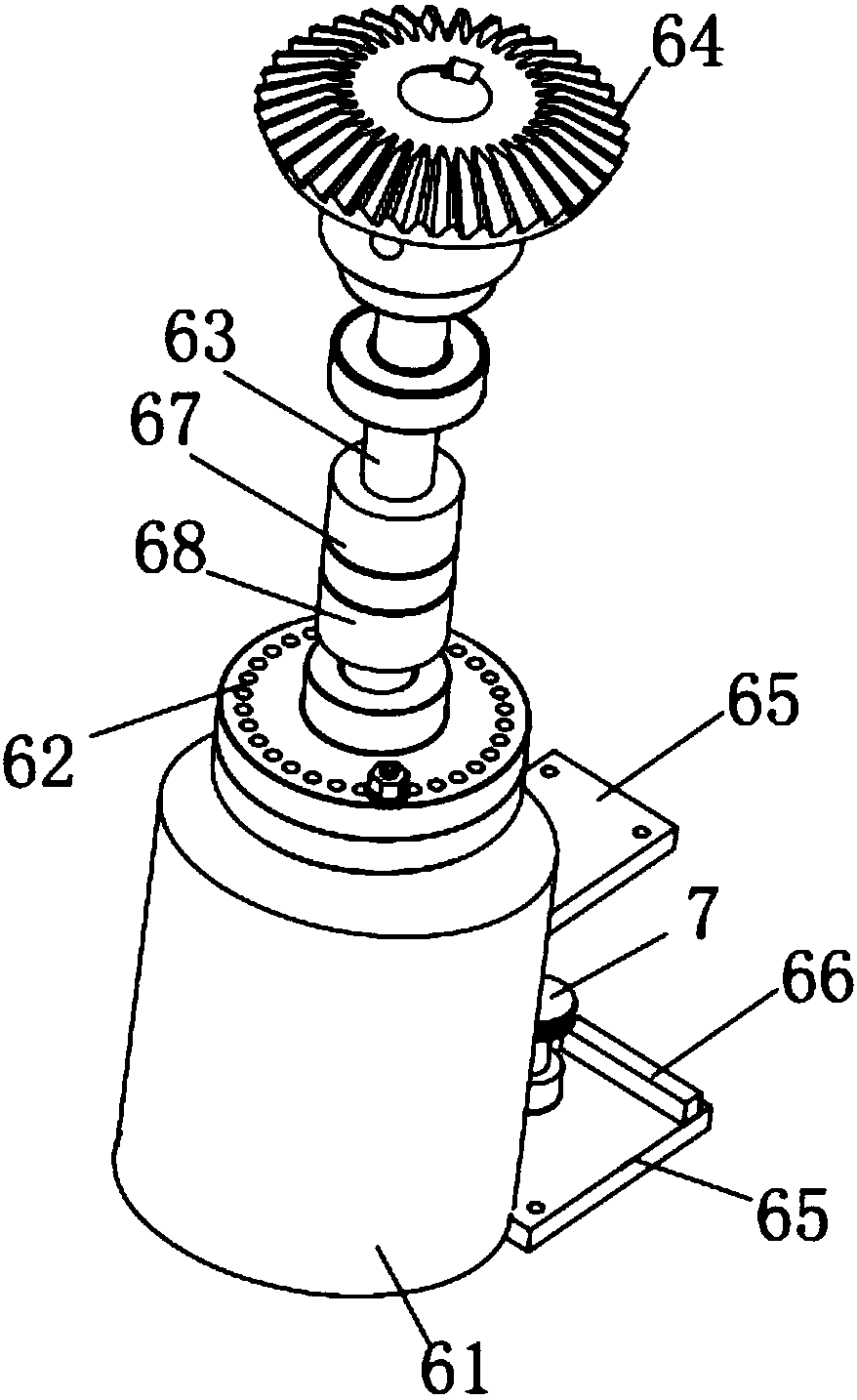

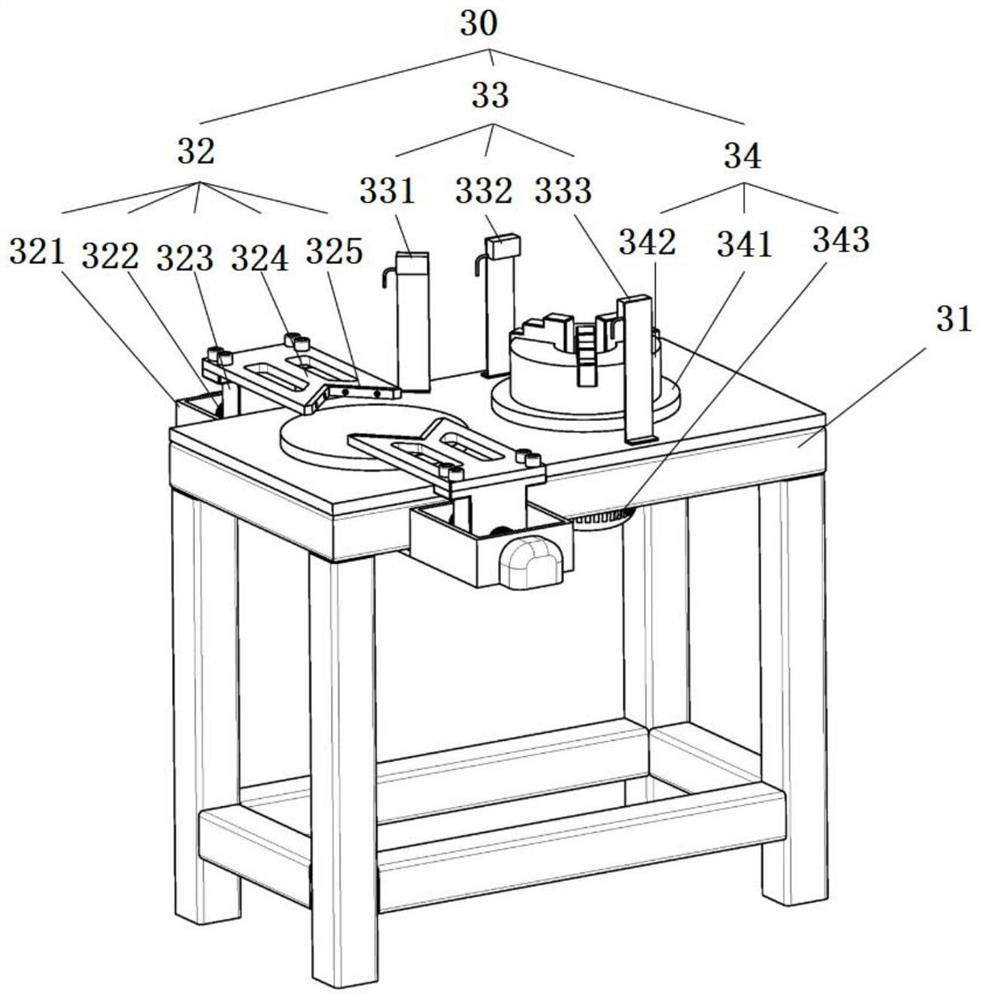

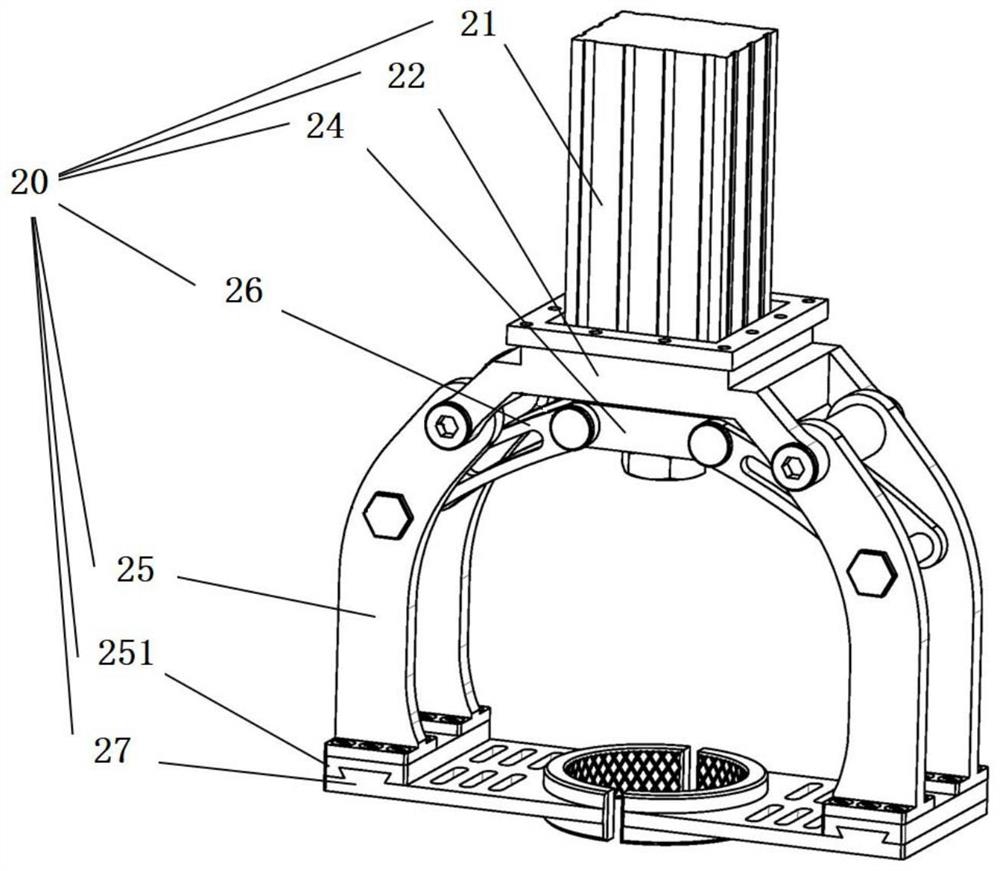

Truss type loading and unloading system and method suitable for multi-specification mining drill bits

ActiveCN112743516ASimple structureLarge range of supportProgramme-controlled manipulatorGripping headsStructural engineeringPiston rod

The invention discloses a truss type loading and unloading system and method suitable for multi-specification mining drill bits. The truss type loading and unloading system comprises a truss type mechanical arm, a flexible gripper installed on the truss type mechanical arm, a loading and positioning device arranged below the truss type mechanical arm and a unloading tray. The flexible gripper comprises an air cylinder, a fixing base arranged on the lower portion of the air cylinder, a lifting base connected to the lower portion of the fixing base and connected with the lower portion of a piston rod of the air cylinder, two sets of arc-shaped supporting plates hinged to two ends of the fixing base, connecting plates hinged to the lifting base and the supporting plates respectively, and quick-change clamping jaws detachably arranged at the lower ends of the supporting plates. The loading and positioning device comprises a loading worktable, a pre-positioning mechanism arranged on the loading worktable, a laser positioning mechanism and a rotary displacement mechanism. The flexible gripper can accurately grab the drill bits, the quick-change clamping jaw is convenient to replace, and the drill bits of different specifications can be automatically grabbed; A locating and positioning device solves the problems that it is hard to position a blade of the drill bit and the grabbing position is inaccurate as the heights of the drill bits are inconsistent and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

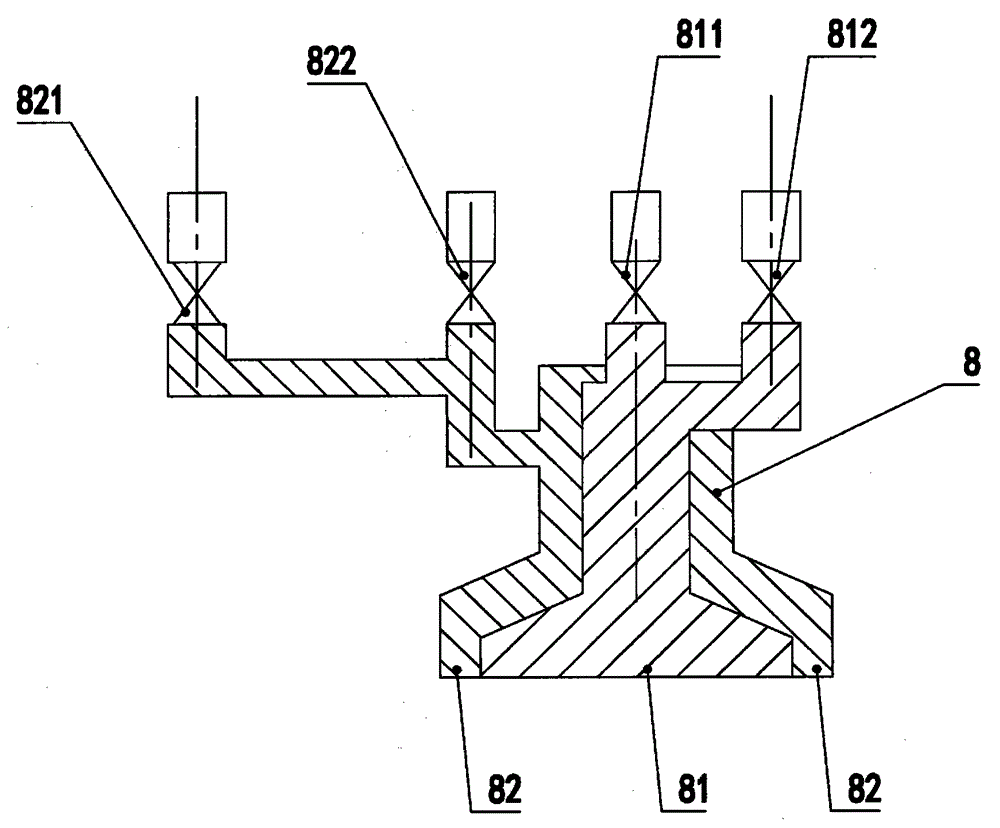

Automatic grab mechanism, automatic grab method and polishing machine provided with automatic grab mechanism

InactiveCN106276241ARealize automatic crawlingHigh degree of automationConveyor partsEngineeringManipulator

The invention provides an automatic grab mechanism, comprising a manipulator and an extracting tray connected with the manipulator, wherein the extracting tray is an airflow distributor which is provided with a main cavity and an auxiliary cavity, the main cavity is connected with a main cavity positive valve and a main cavity negative valve through pipelines, and the auxiliary cavity is connected with an auxiliary cavity positive valve and an auxiliary cavity negative valve through pipelines. The invention also provides an automatic grab method. The invention also provides a polishing machine provided with the automatic grab mechanism. The automatic grab mechanism has the beneficial effects that automatic grab of glass is achieved, the automation degree is high, the efficiency is high, and the precision is high.

Owner:深圳市恒凤祥机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com