Machine tool automated feeding and discharging integrated system by robot

An integrated system and robot technology, which is applied in the field of automatic loading and unloading of machine tools by robots, can solve the problems of unfavorable product structure, large area of special machine, insufficient flexibility, etc., and achieves stable and stable clamping response speed and clamping response speed. The effect of fast and saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

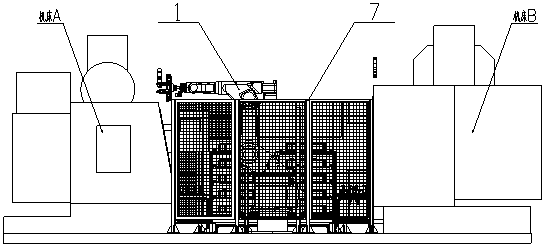

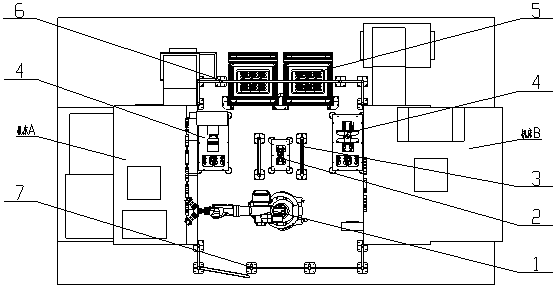

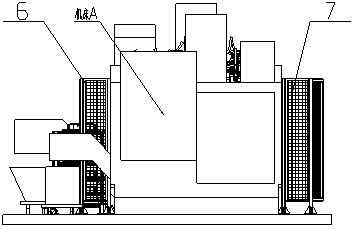

[0054] Such as Figure 1-32 As shown, the present invention provides an integrated system for automatic loading and unloading of machine tools by robots, including an integrated system for automatic loading and unloading of machine tools. One side of the middle position is equipped with a quick change table 1, and the two sides of the quick change table 2 are provided with a guardrail 3; Material trolley 5, material trolley 5 sides are provided with right safety fence 6, and the opposite side of right safety fence 6 is provided with left safety fence 7.

[0055]The robot mounting assembly 1 includes a robot base 8 on which a robot 9 is fixed, and a main clamping device 10 is provided at the flange end of the robot 9 .

[0056] The main clamping device 10 comprises a connecting flange one 11, and the camera 13 is fixed on the connecting flange one 11 through a mounting plate 12, and the middle position of the mounting plate 12 is provided with a connecting flange two 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com