Flat plate glass conveying automatic steering device and automatic steering method

An automatic steering and glass technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of large equipment investment and floor space, and achieve the effects of reasonable structure, convenient installation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described with reference to the drawings and specific embodiments:

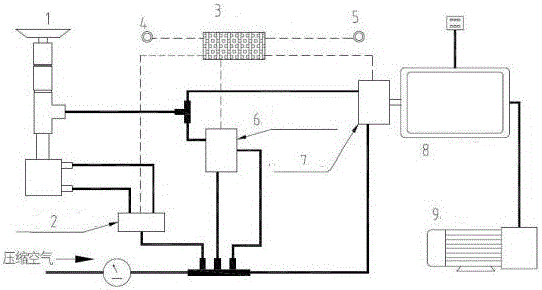

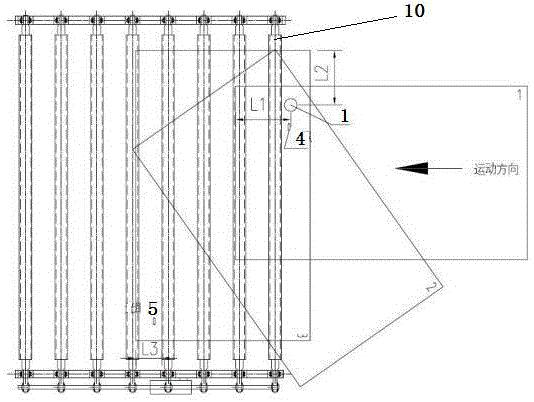

[0014] Such as figure 1 As shown, an automatic steering device for glass conveying. The automatic steering device has a light eye I4 arranged in front of the conveying steering roller; above the light eye I4 is provided a suction cup 1 for adsorbing glass and turning it. The suction cup 1 is located below the glass, and the distance from the side of the glass is L2, L2=100mm; the automatic steering device is also provided with a light eye Ⅱ 5; the light eye Ⅱ 5 is located in the lower part of the glass adjacent to two conveying rollers In the gap between, the distance between the light eye II and the light eye I along the parallel direction of the conveying roller is: glass width -100mm to ensure that the glass is aligned after turning; a suction solenoid valve 7 is provided corresponding to the suction cup 1 And the blowing solenoid valve 6; the blowing solenoid valve 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com