Patents

Literature

124results about How to "Pick up accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

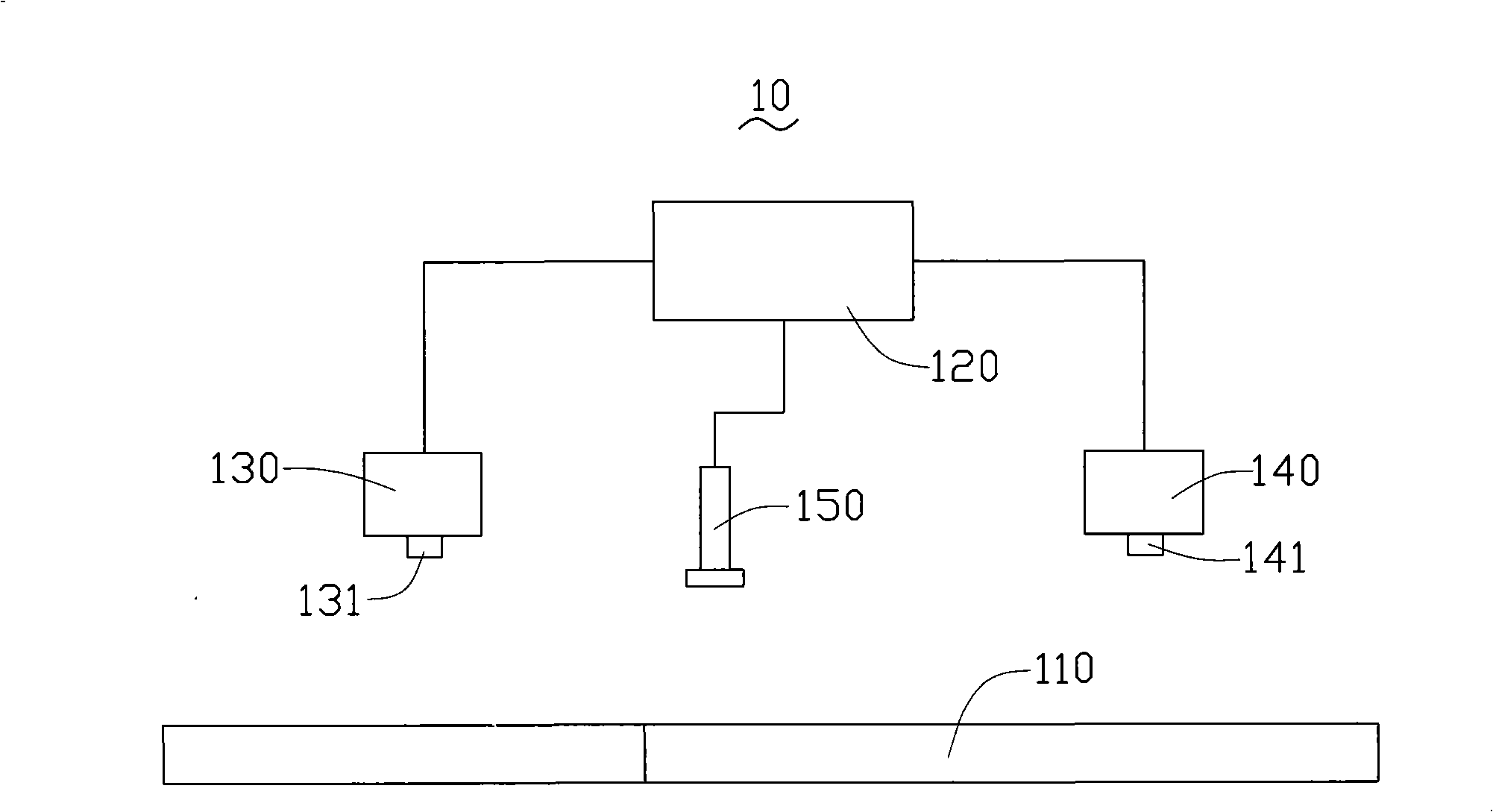

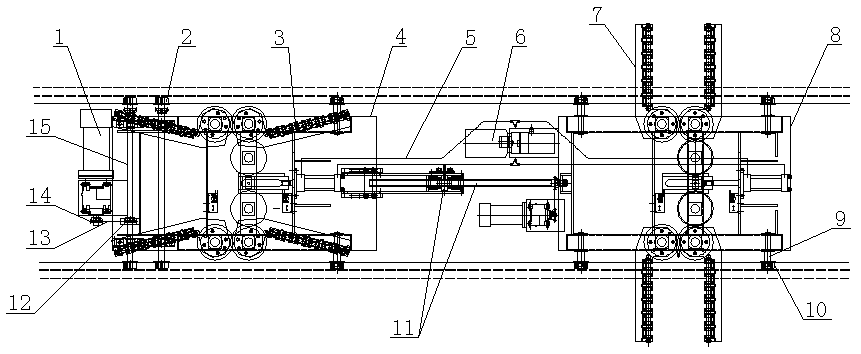

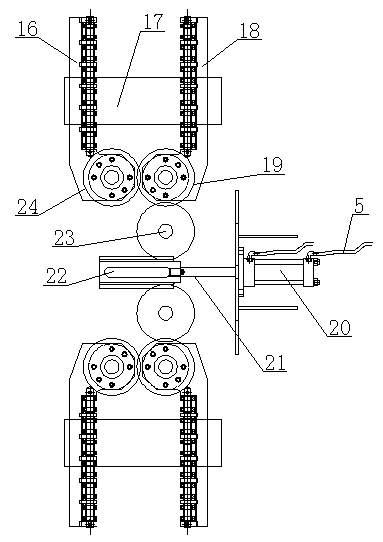

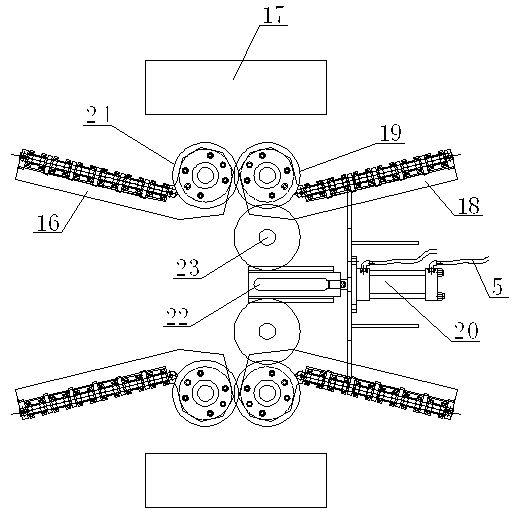

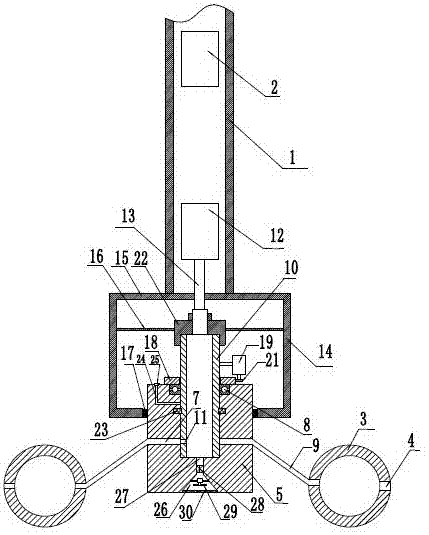

AGV (Automatic Guided Vehicle) and method

PendingCN107226310AImprove picking efficiencyImprove accuracyControl devices for conveyorsStorage devicesEngineeringTemporary storage

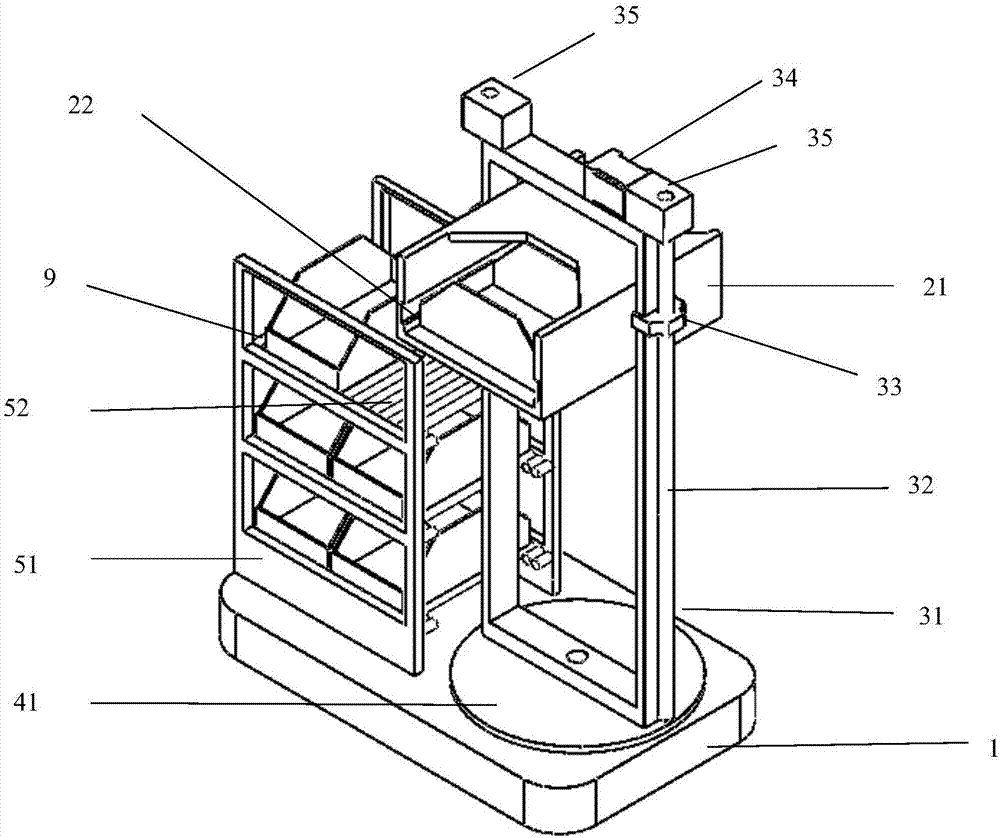

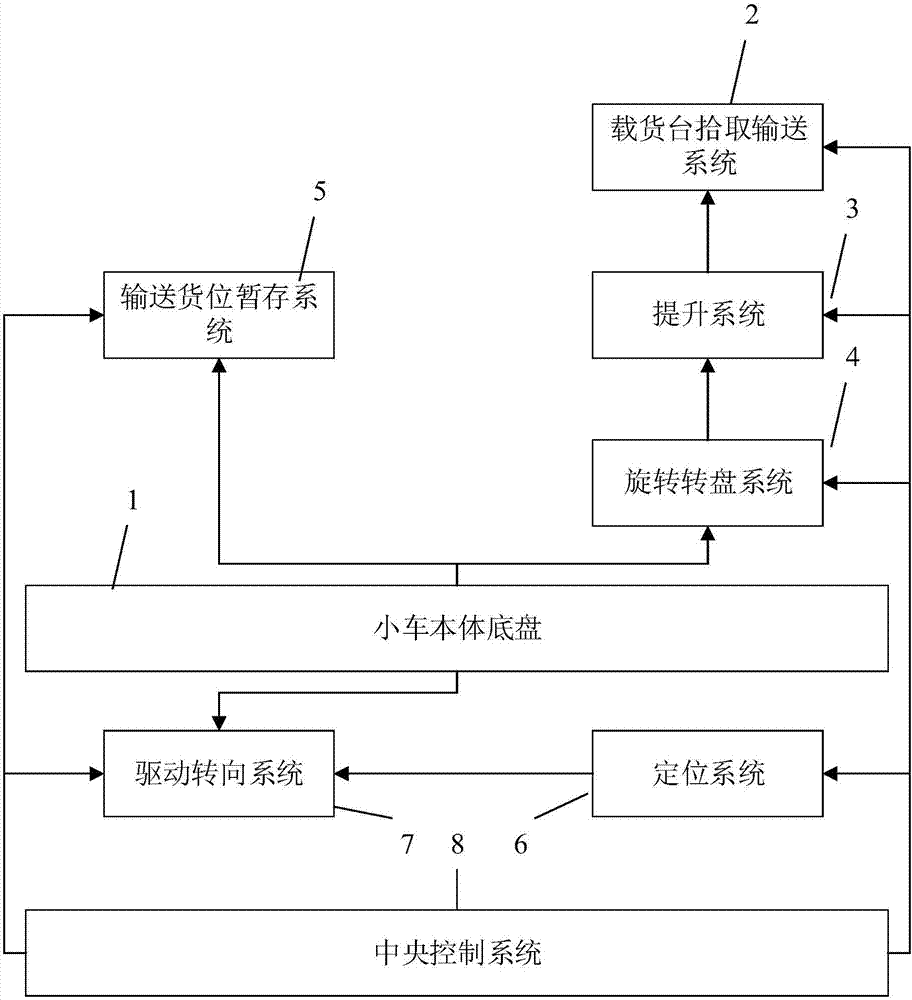

The invention discloses an AGV (Automatic Guided Vehicle) and a method. The AGV (Automatic Guided Vehicle) comprises a vehicle body chassis, a cargo bearing platform picking-up and conveying system, a lifting system, a rotary rotary-table system and a delivered cargo temporary storage system; the rotary rotary-table system and the delivered cargo temporary storage system are fixed to the two sides of the upper portion of the vehicle body chassis correspondingly; the lifting system is fixed to the upper portion of the rotary rotary-table system, and the control end of the lifting system is connected with the cargo bearing platform picking-up and conveying system; the delivered cargo temporary storage system comprises a plurality of layers of temporary storage racks, and each layer of the temporary storage racks is provided with a plurality of temporary storage cargo positions; and the lifting system is used for controlling the sliding height of the cargo bearing platform picking-up and conveying system, and the rotary rotary-table system is used for controlling the rotation angle of the lifting system. By means of the AGV (Automatic Guided Vehicle) and the method, operation of manual picking-up of workbins is omitted, manpower and time are saved, and meanwhile workbin picking-up efficiency and accuracy are also improved.

Owner:湖北九州云仓科技发展有限公司

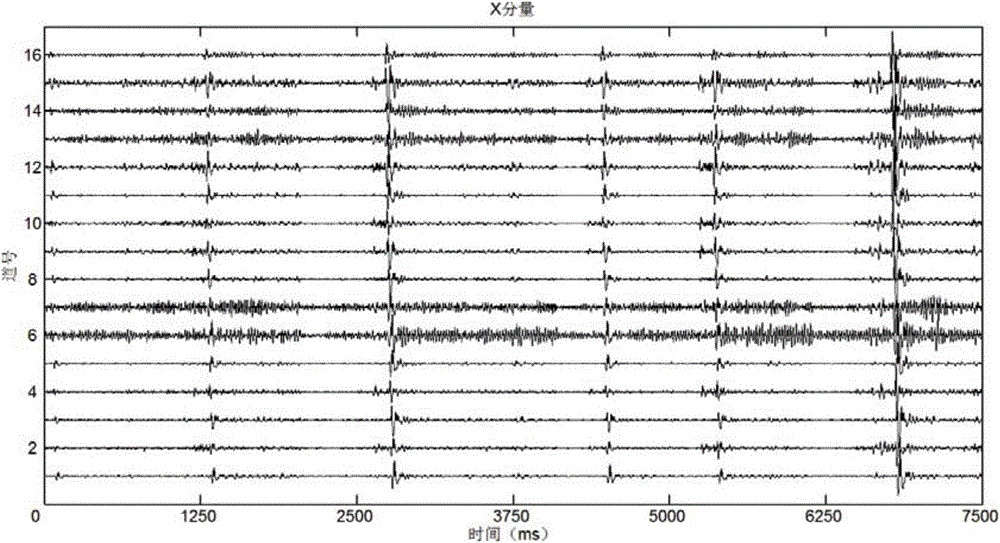

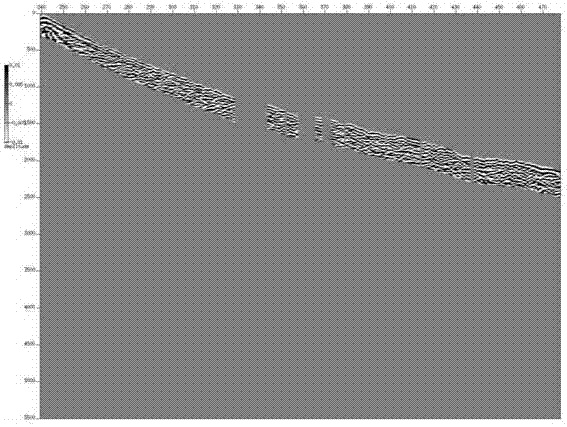

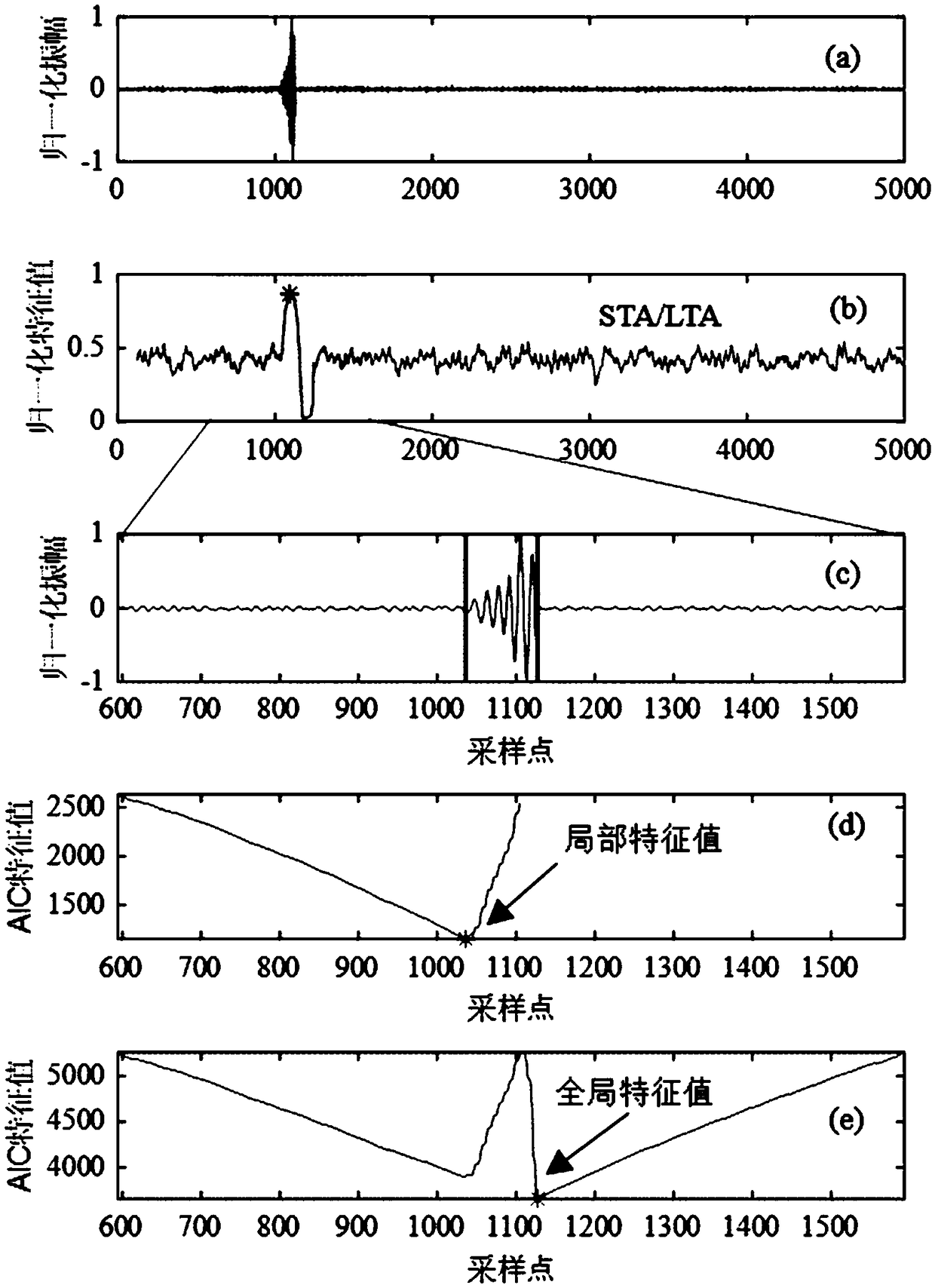

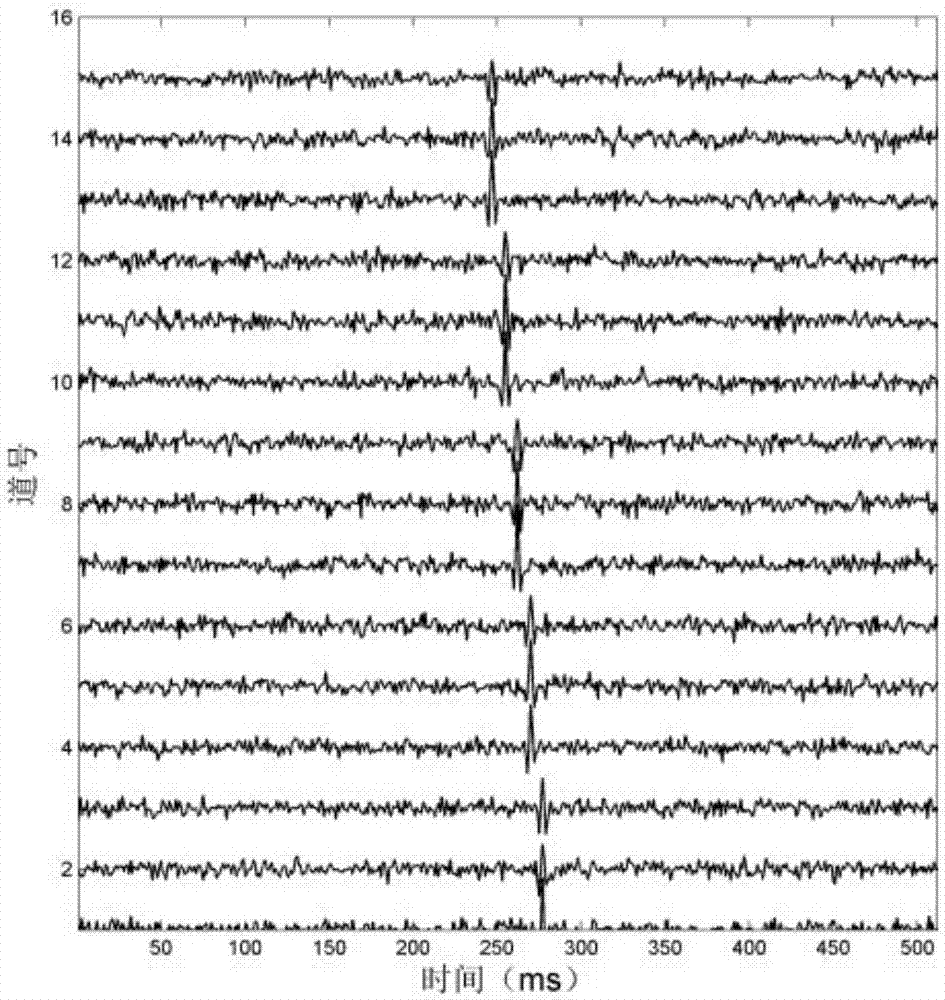

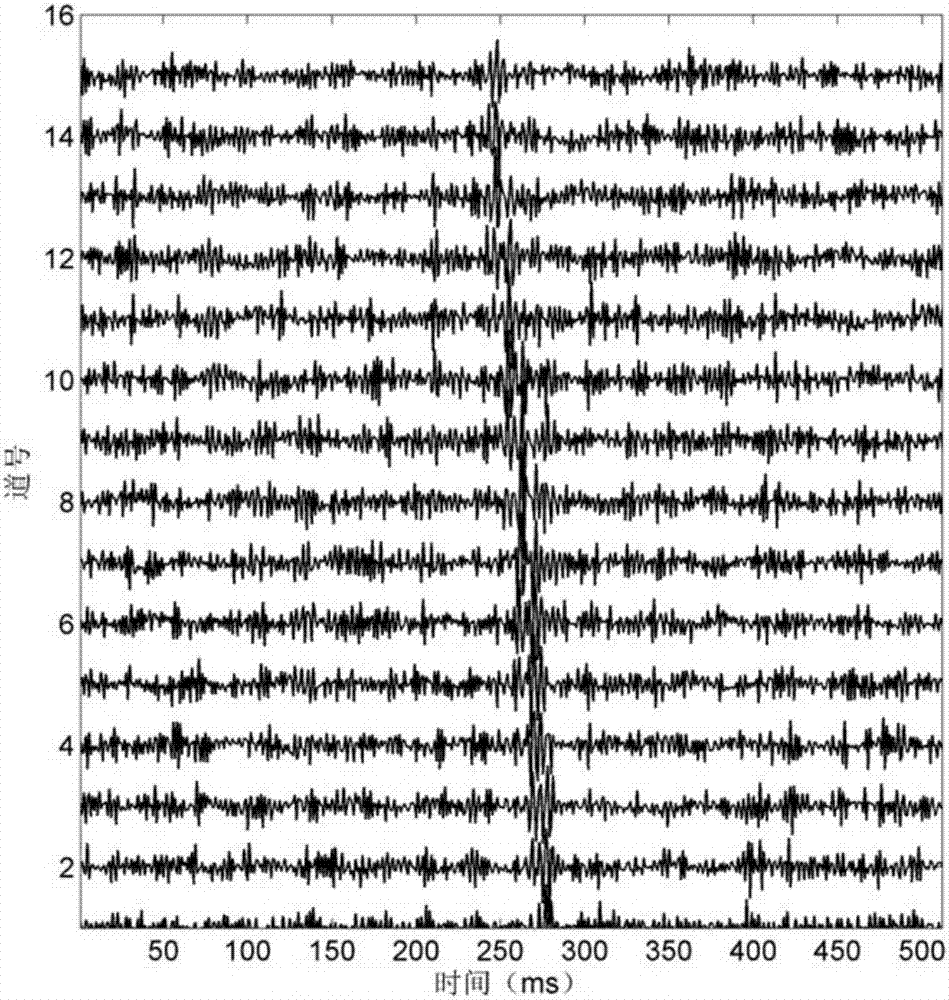

Method for recognizing and collecting microseism events in well

ActiveCN104459797ASuppress energyEliminate distractionsSeismology for water-loggingStart timePeak value

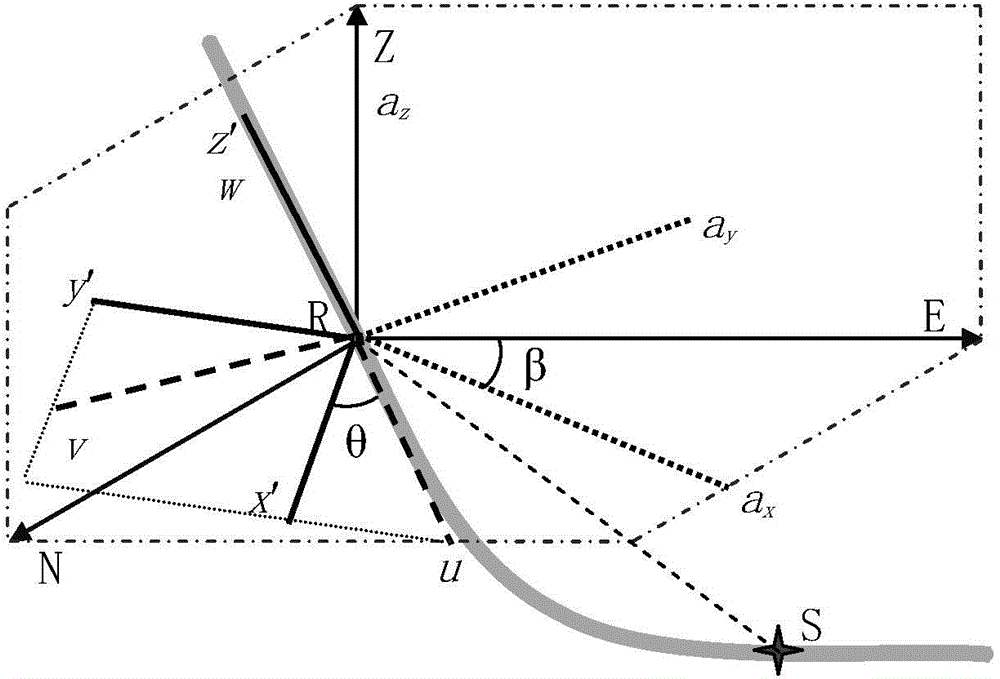

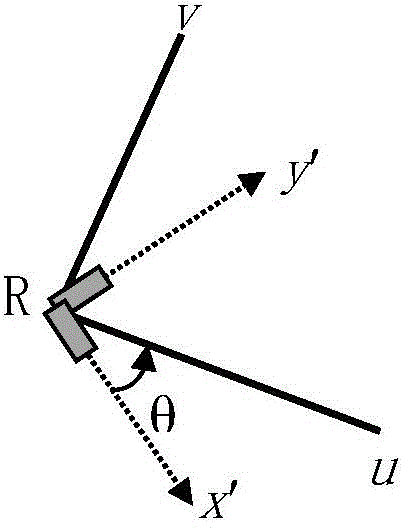

The invention provides a method for recognizing and collecting microseism events in a well and belongs to the field of microseism monitoring. The method comprises the steps that (1) orientation rotation is conducted on each receiving point recorded in the even monitoring process; (2) for records obtained after rotation is conducted, a characteristic function value CFs of each receiving point at each moment is calculated; (3) an event superposition energy function L(t) is calculated through a time difference scanning technique; (4) the seism starting time ti of events is automatically detected through self-adaptive threshold values; (5) the peak value time of S waves of a set of events is collected and checked, and the jumping time of the S waves is collected and checked; (6) for each receiving point, a characteristic function value CFp is calculated for each time point within a fixed time interval Tspmax before the jumping time of the determined set of S waves; (7) the peak value time of each receiving point of P waves of the set of events is collected and checked, and the jumping time of the P waves is collected and checked.

Owner:CHINA PETROLEUM & CHEM CORP +1

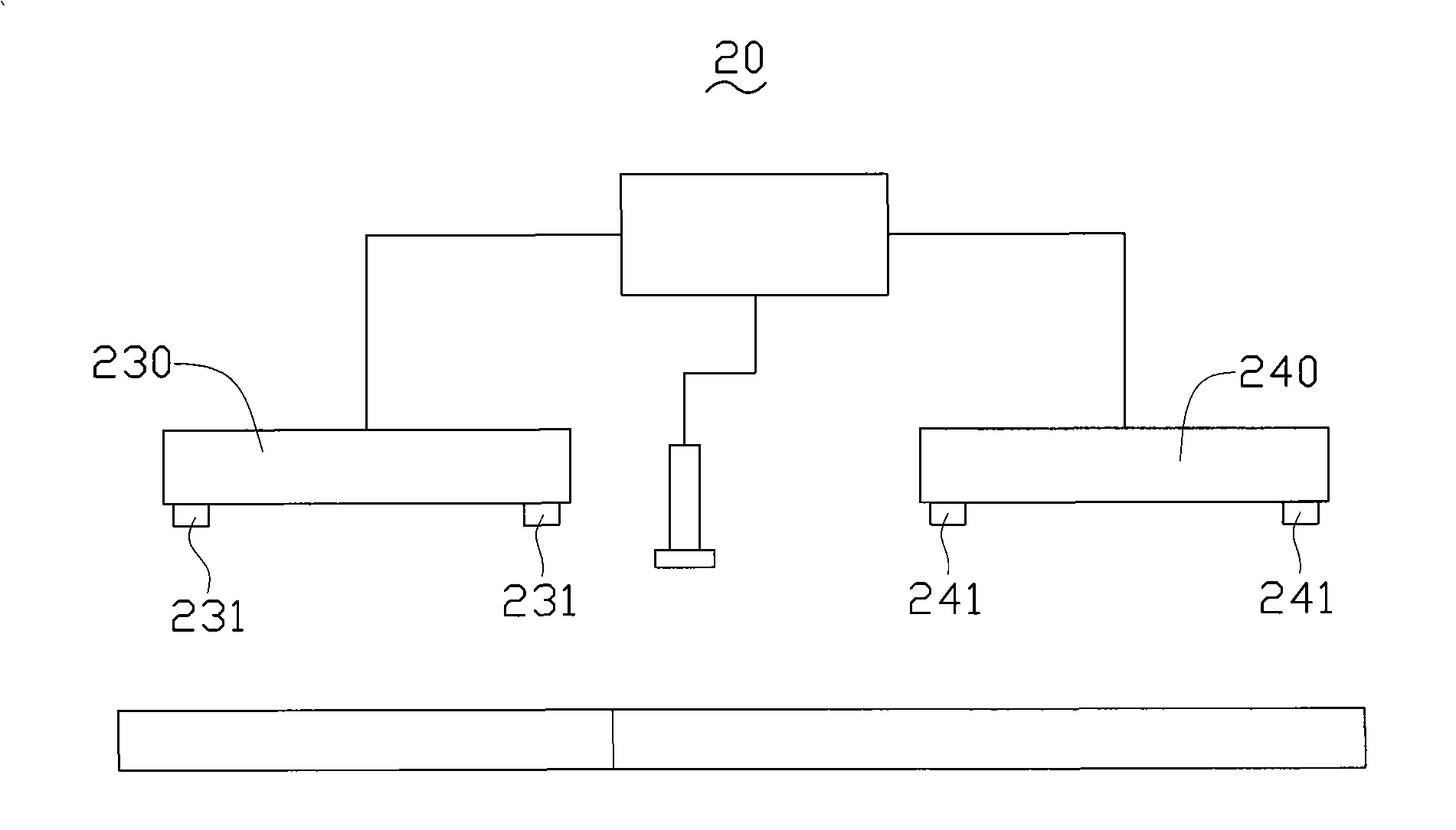

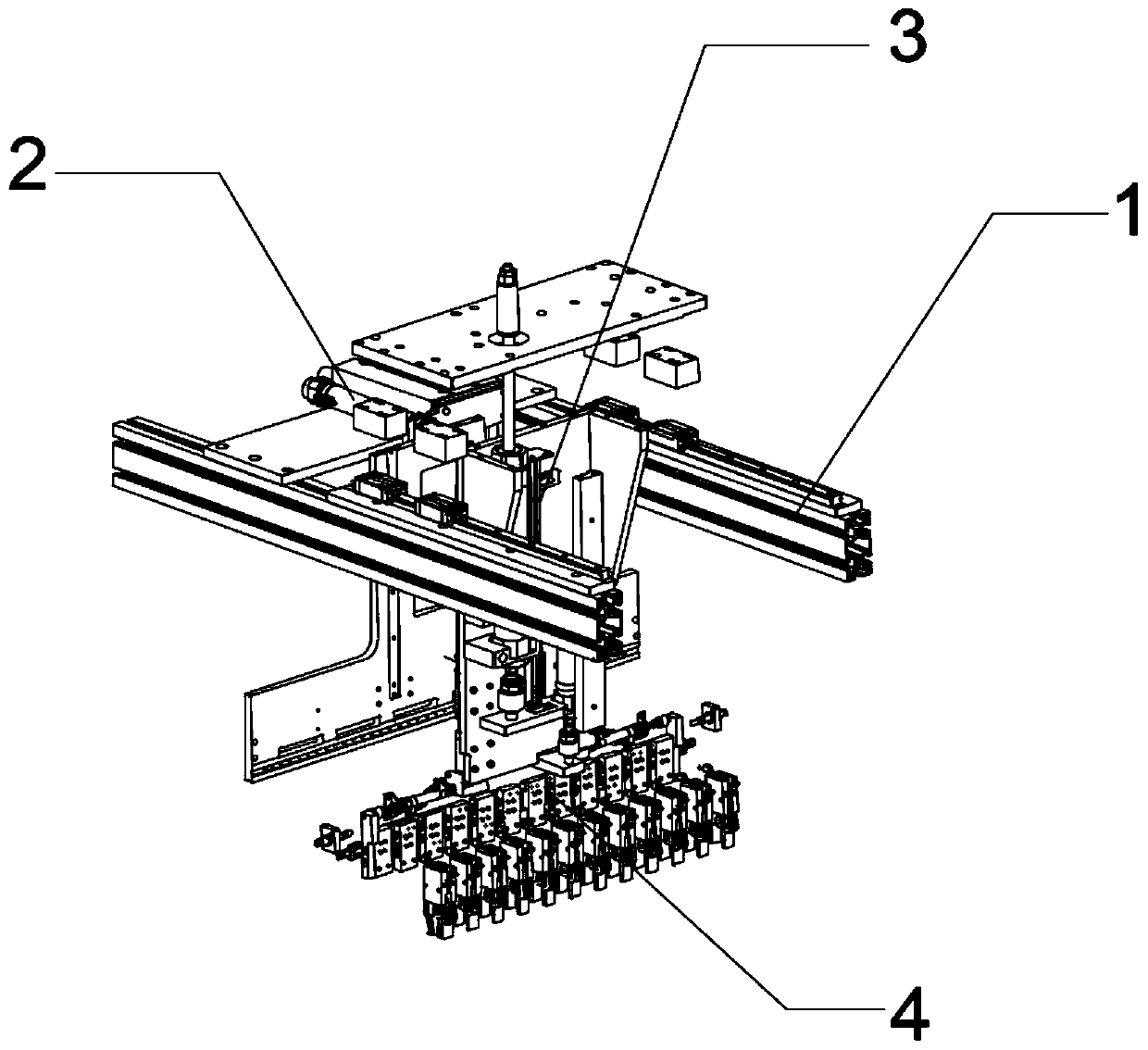

Surface-mounted contraposition apparatus and method thereof

InactiveCN101336072AOvercome the limitation of field of viewPick up accuratelyElectrical componentsComputer graphics (images)Surface mounting

The invention relates to a surface mounting contraposition method, comprising: using a first image sensing device to sense a profile image of an electronic device, and using a central control processing device to obtain geometry center coordinate of the electronic device; using a second image sensing device to sense a profile image of a pad of a printed circuit board, and using the central control processing device to obtain geometry center coordinate of the pad; moving a pickup patch device to pick up the electronic device to perform contraposition patch, thereby realizing correct automatic contraposition patch of the electronic device in large size, effectively advancing efficiency and accuracy of the surface mounting contraposition patch of the electronic device in large size. The invention also relates to a surface mounting contraposition device.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

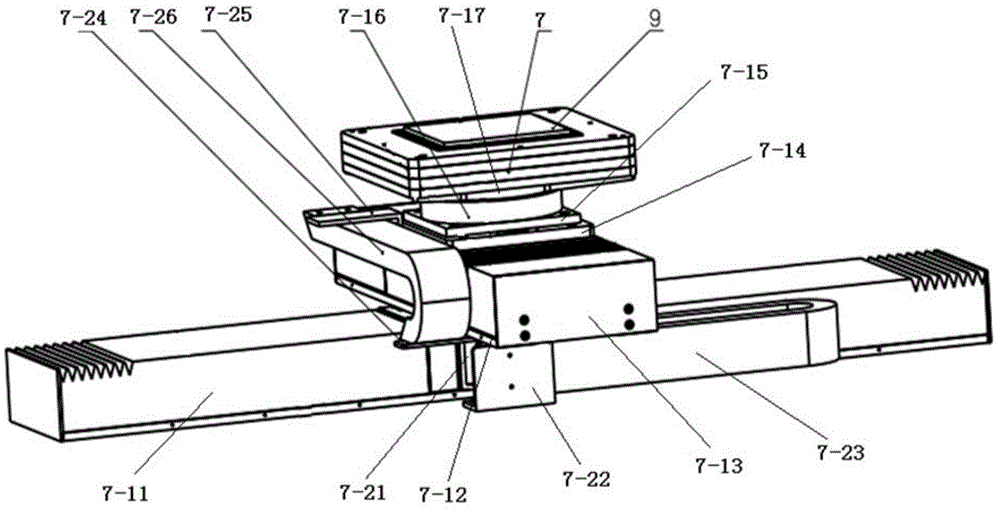

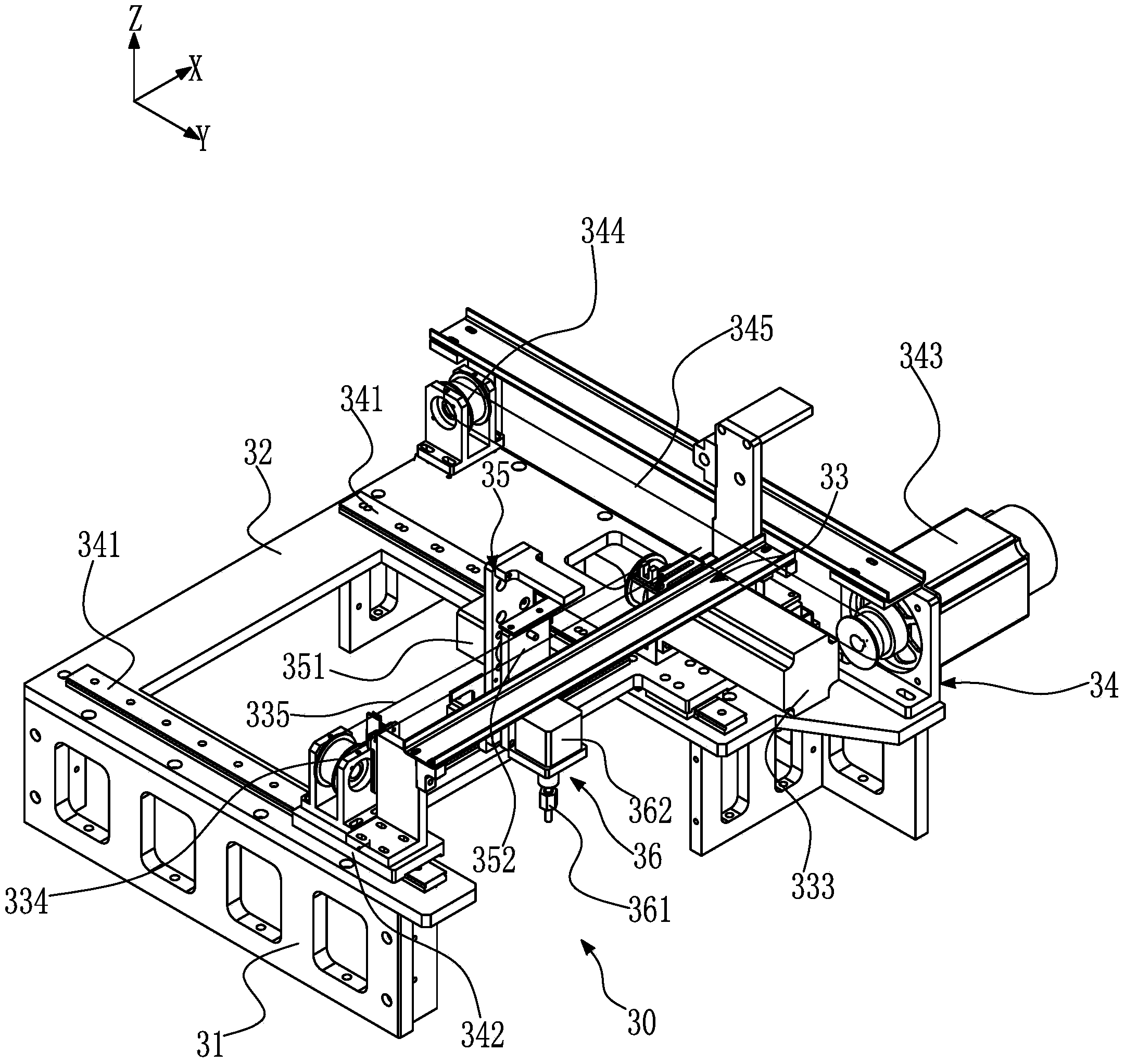

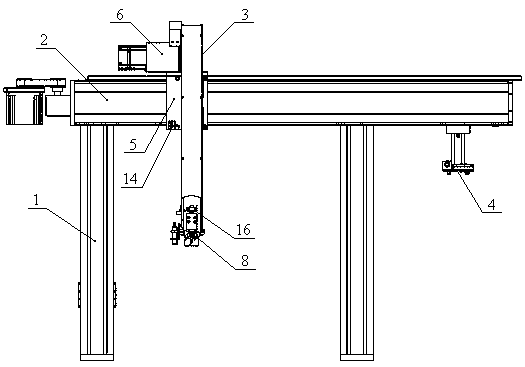

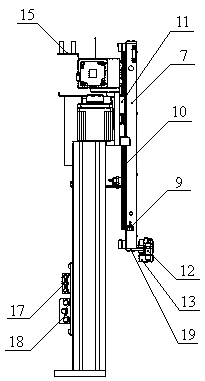

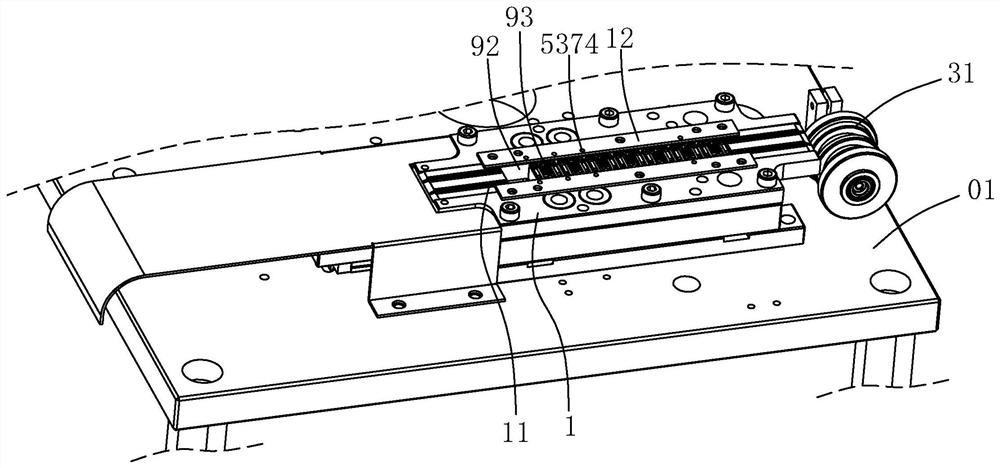

Laser cutting equipment for stainless steel chip

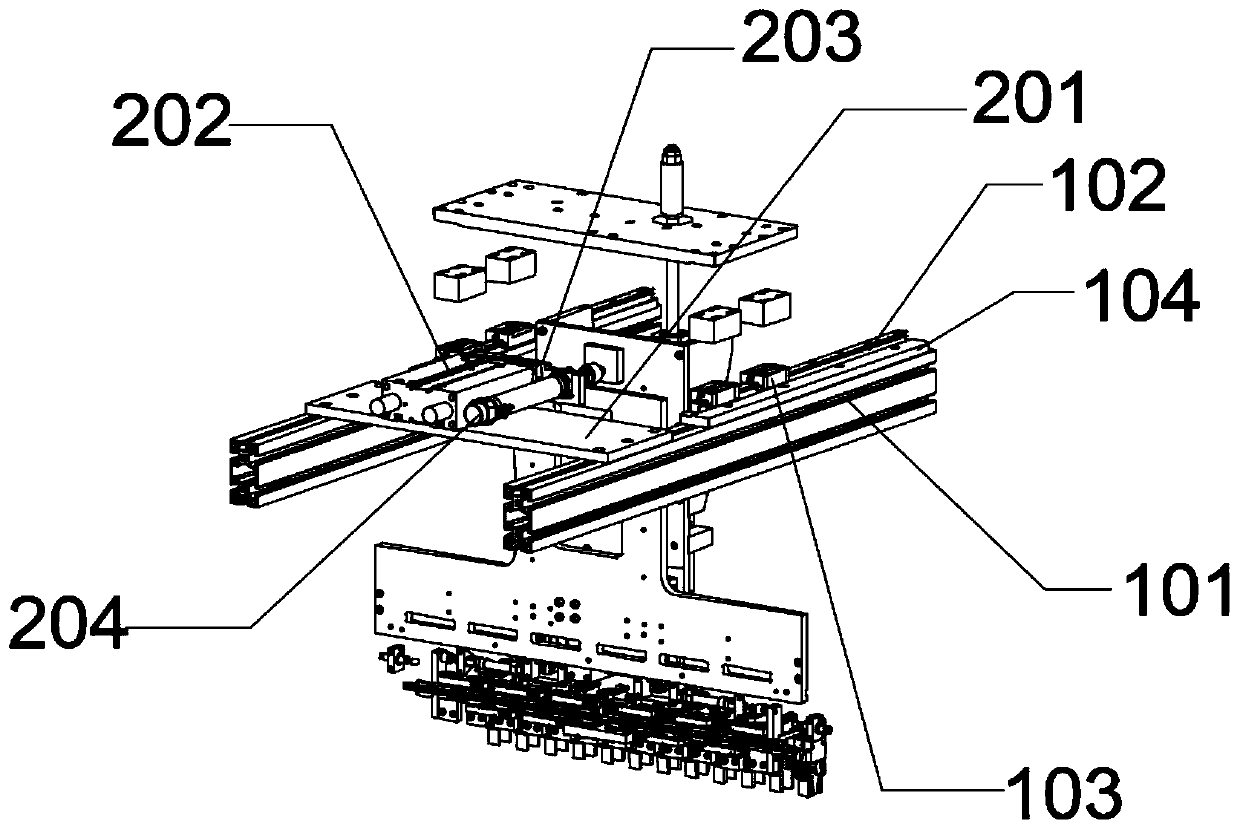

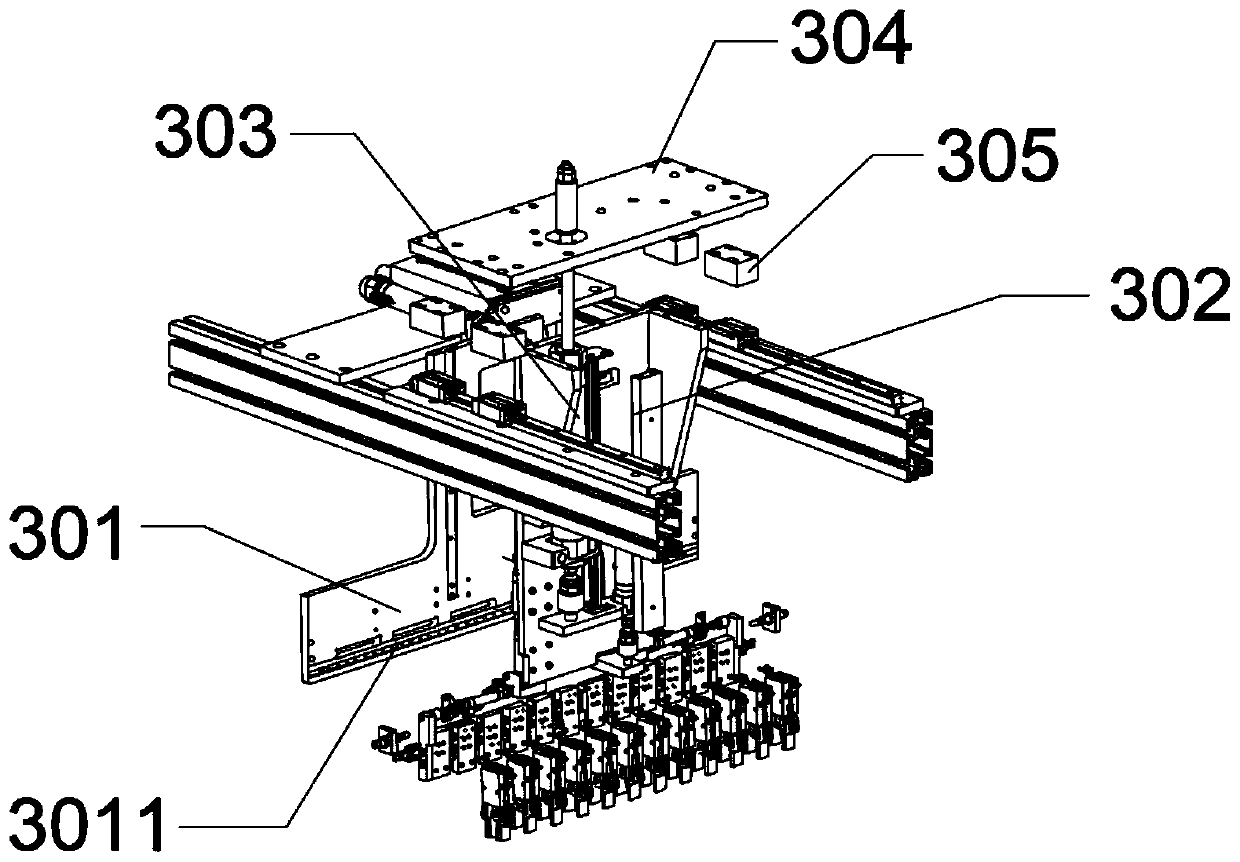

ActiveCN104084697AGuaranteed Position AccuracyPick up accuratelyMetal working apparatusLaser beam welding apparatusManipulatorLaser cutting

The invention relates to laser cutting equipment for a stainless steel chip. A loading platform device of the laser cutting equipment can carry out Y-direction straight-line motion on a platform base, and the stainless steel chip is placed on the loading platform device. A primary positioning camera is installed above the loading platform device, and used for primary positioning of the stainless steel chip. A loading mechanical hand can carry out X-direction straight-line motion and Y-direction straight-line motion on a loading base and is used for picking the stainless steel chip and placing the stainless steel chip to a suction platform. The suction platform can carry out X-direction straight-line motion, Z-direction straight-line motion and rotary motion on the platform base. A fine positioning camera is fixedly arranged above the suction platform on the platform base and used for adjusting the position of the suction platform to achieve fine positioning of the stainless steel chip. A laser cutting system and a film pasting device are fixed to the platform base and used for achieving cutting and film pasting of the stainless steel chip. The laser cutting equipment is high in integration degree, high in production efficiency, good in cutting quality and capable of well meeting the requirement for producing stainless steel chips on a large scale.

Owner:CHANGSHUN GUANGHUA MICRO ELECTRONICS EQUIP ENG CENT

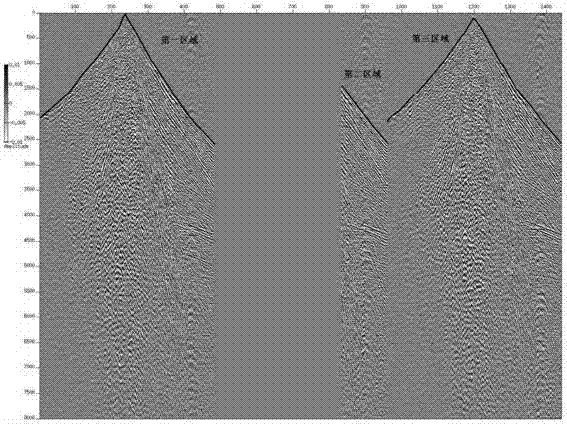

First-motion wave traveling time picking-up method and device

ActiveCN103616722AObvious takeoff timePick up accuratelySeismic signal processingCommon sourceData records

The invention provides a first-motion wave traveling time picking-up method and device. The first-motion wave traveling picking-up method comprises the steps that a calculating device processes collected earthquake data into common-source set earthquake data records; the calculation device defines an initial reference line in a partition mode in the common-source set earthquake data records, and selects a processing time window w for the initial reference line; the calculation device calculates the characteristic function value of all the sampling points in the processing time window with a sampling point on the initial reference line as a central point of earthquake channels in the common-source set earthquake data records; the calculation device extracts first-motion wave traveling time in the processing time window of the earthquake channels on the initial reference line according to the calculated characteristic function value; the calculation device processes the extracted first-motion wave traveling time in a balancing mode. The first-motion wave traveling time picking-up method and device are especially suitable for picking up the first-motion wave traveling time in areas, with complex ground surfaces, such as mountainous area, gravel areas and loess tablelands.

Owner:PETROCHINA CO LTD

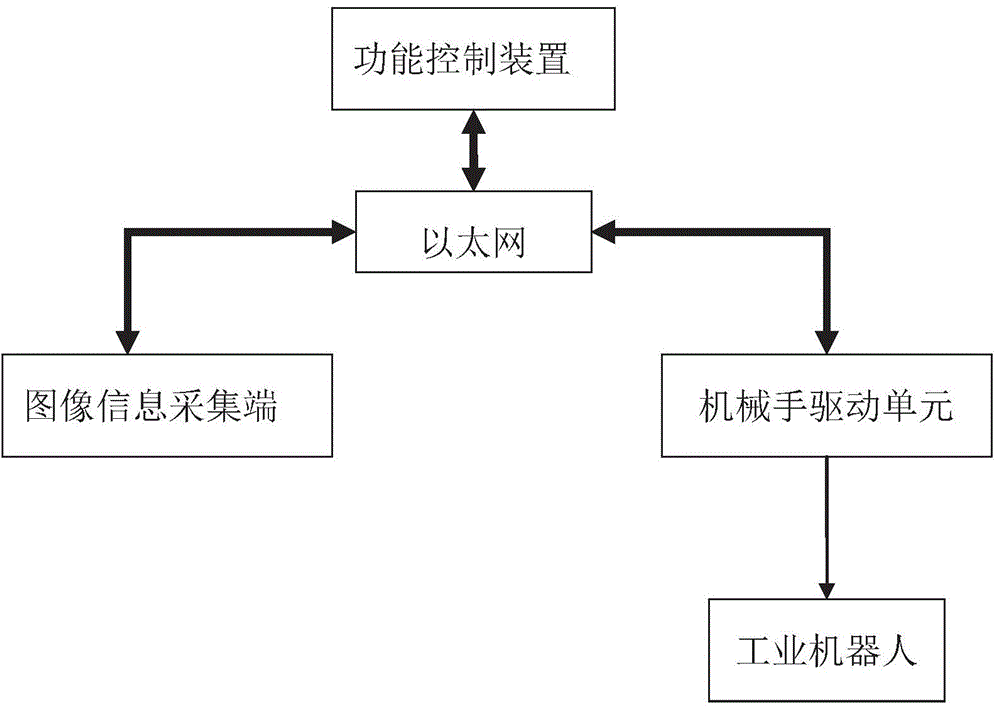

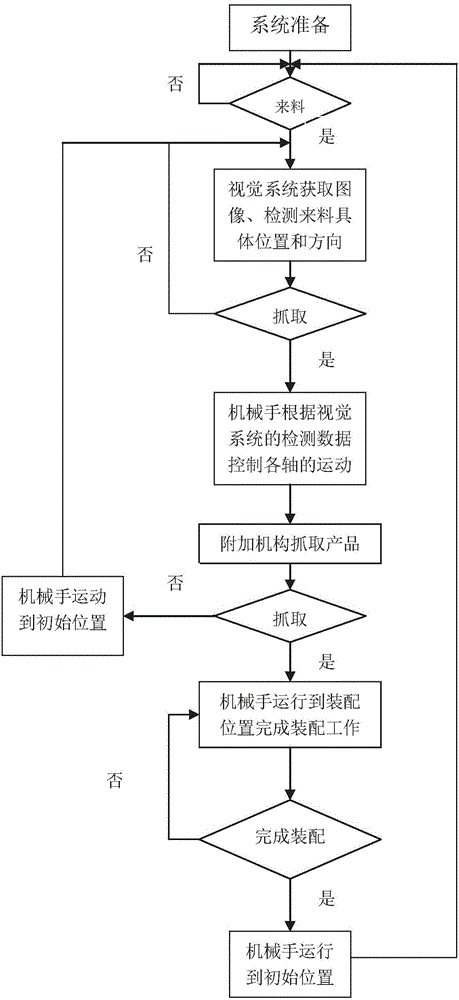

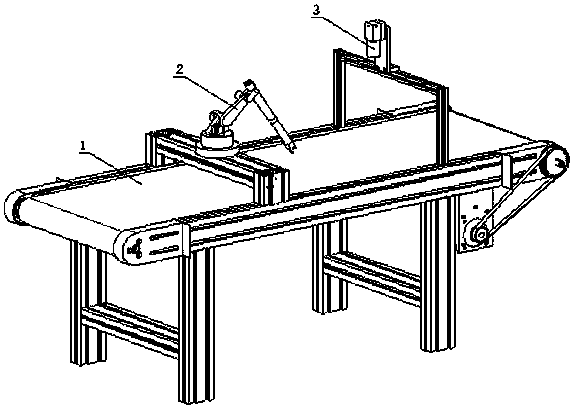

Machine vision-based intelligent control method and machine vision-based intelligent control system for industrial robot

The invention discloses a machine vision-based intelligent control method for an industrial robot. The machine vision-based intelligent control method is characterized by comprising the following steps: (1) based on GigE Vision gigabit Ethernet image transmission, installing an image information acquisition end; (2) installing a functional control device; (3) installing an EtherCAT field bus system-based industrial robot; comparing acquired image information with a preset template by the functional control device; if the grabbing condition is met, judging the position, the angle, the movement locus and the movement speed of an incoming material, and acquiring the data information of the position, the movement locus and the movement speed of the incoming material; moreover, after the data processing is performed on the data information through a central processing module, and then, sending control information to the industrial robot through the Ethernet, and driving all axes of a manipulator to move by a drive unit to enable the manipulator to move to the position of the incoming material to grab the incoming material, and after the grabbing action is finished, running to an initial position. The invention also discloses a system for implementing the method.

Owner:东莞市三瑞自动化科技有限公司

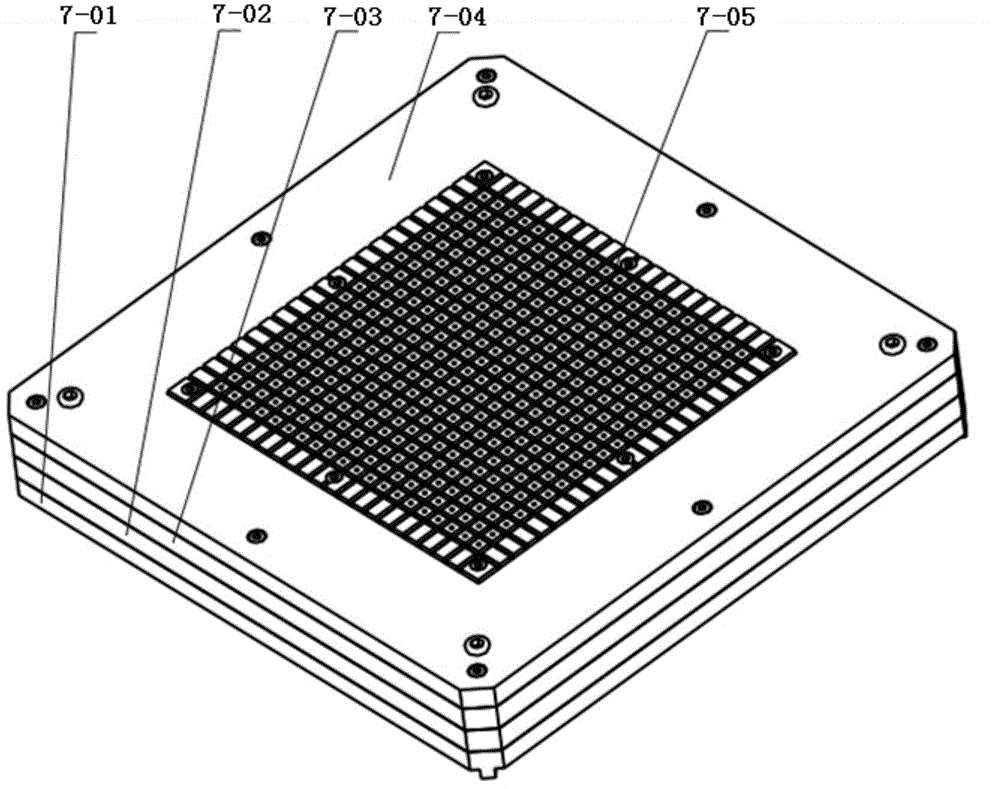

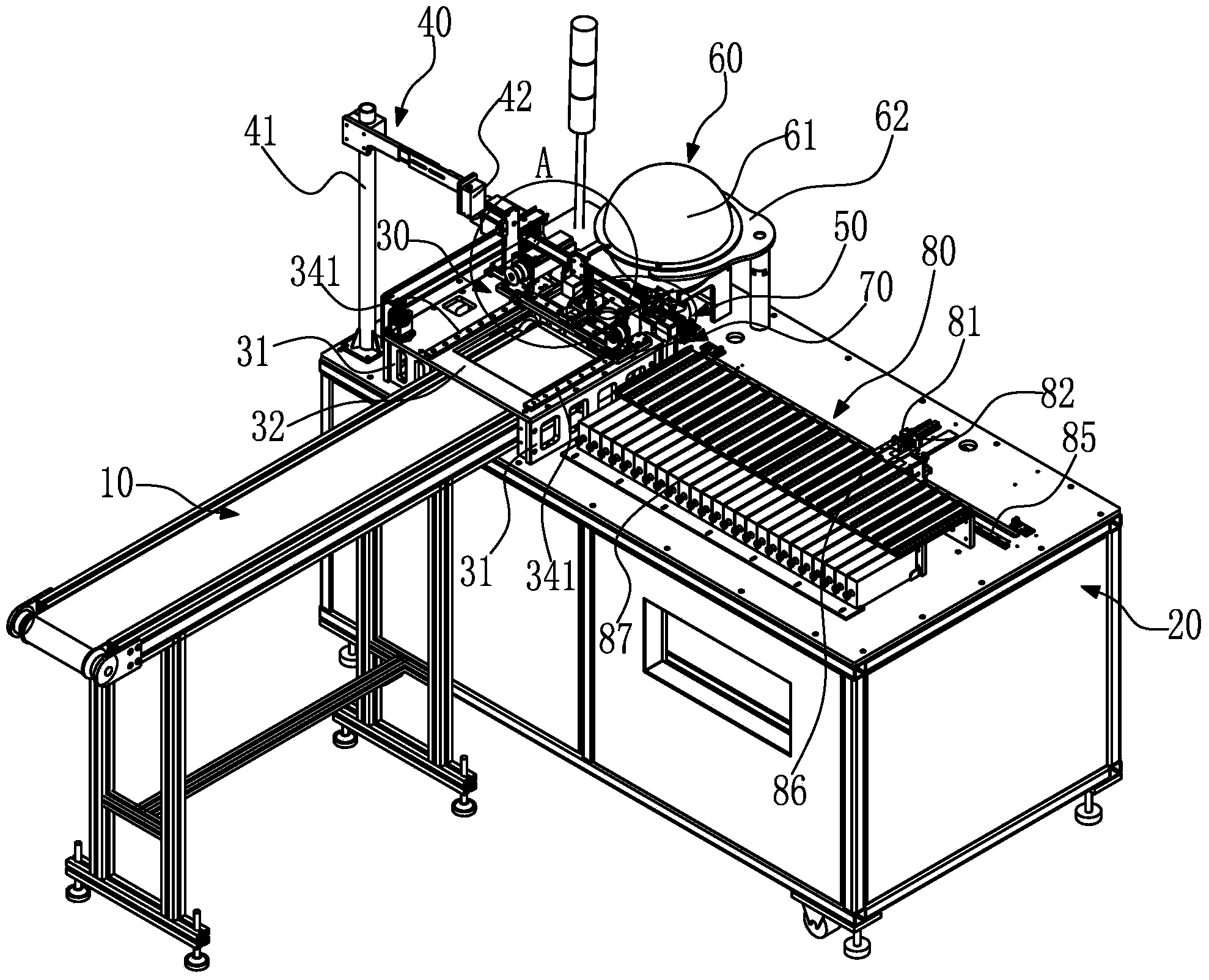

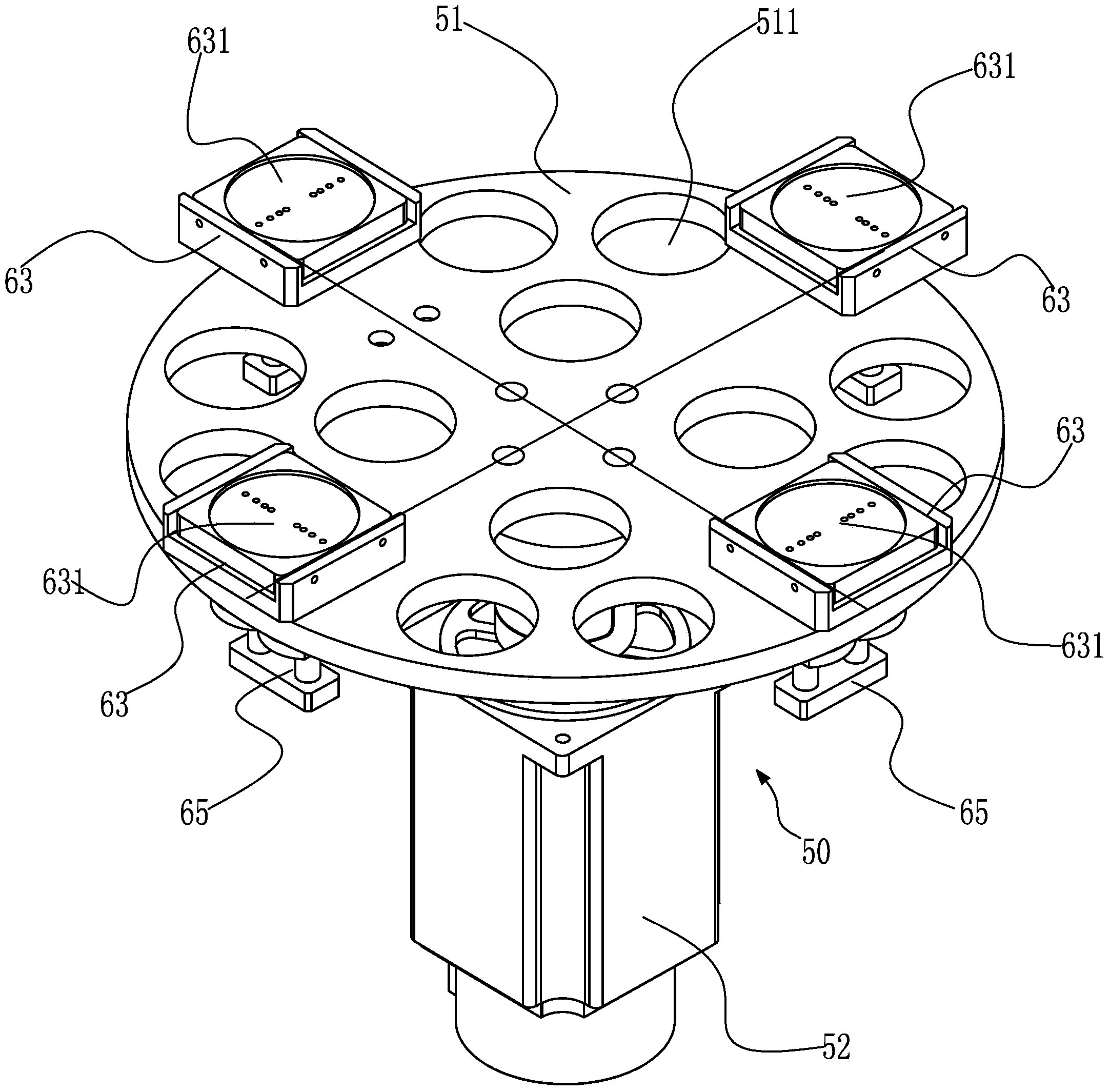

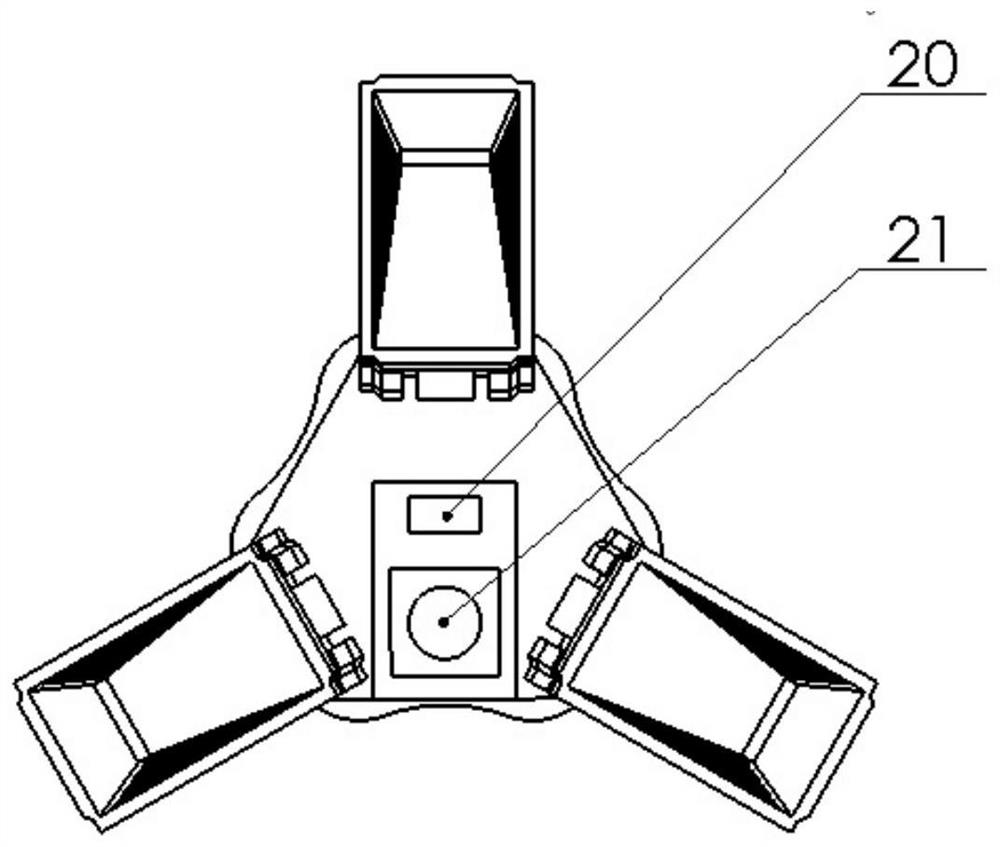

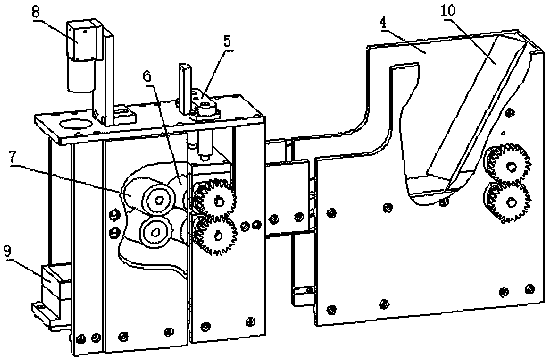

COB (chip on board) optical component automatic testing sorting machine

The invention discloses a COB (chip on board) optical component automatic testing sorting machine, comprising a cabinet, a conveyor belt, a PLC (programmable logic controller) control system, an image system, a constant-current constant-voltage source system, a spectral analysis system, a data analysis system, as well as a feeding mechanism, a testing mechanism, a discharging mechanism, a classifying and receiving mechanism and a turnplate mechanism which are respectively arranged on the cabinet. The function of the automatic testing sorting machine is to realize auto-feeding and auto-discharging, the parameters such as the wavelength, the voltage drop, the luminous flux and the chromaticity coordinates of the COB optical component can be automatically tested online by sampling the light diffusely reflected through an integrating sphere by controlling the constant-current constant-voltage source system, lighting the COB component, and starting the spectral analysis system, and the automatic classification can be realized in combination with the PLC control system, and a subsequent package mechanism can perform the classified package conveniently; the testing and the sorting of the whole COB optical component are automatically performed, the production efficiency is high, the influence from a plurality of human factor is avoided, the detection precision is high, the labor can be substituted, the labor intensity is reduced, and the labor cost is reduced.

Owner:东莞市中谱光电设备有限公司

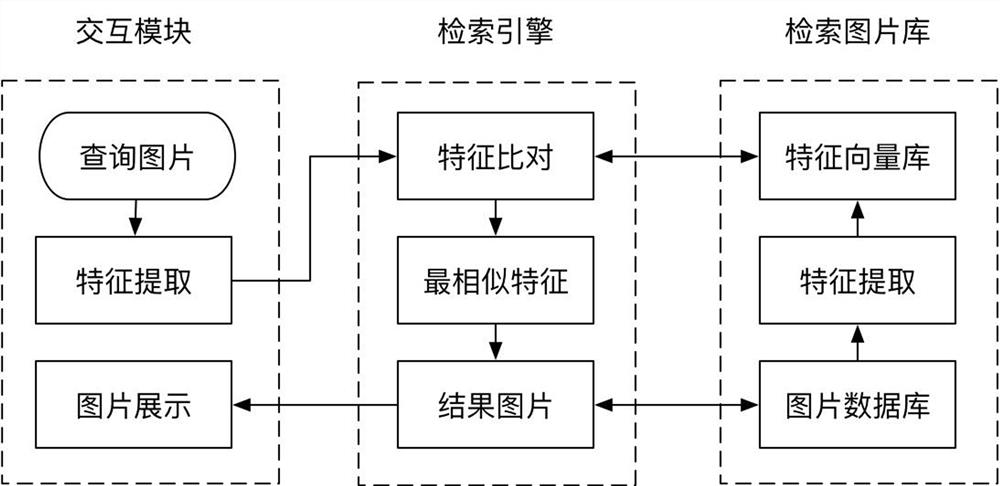

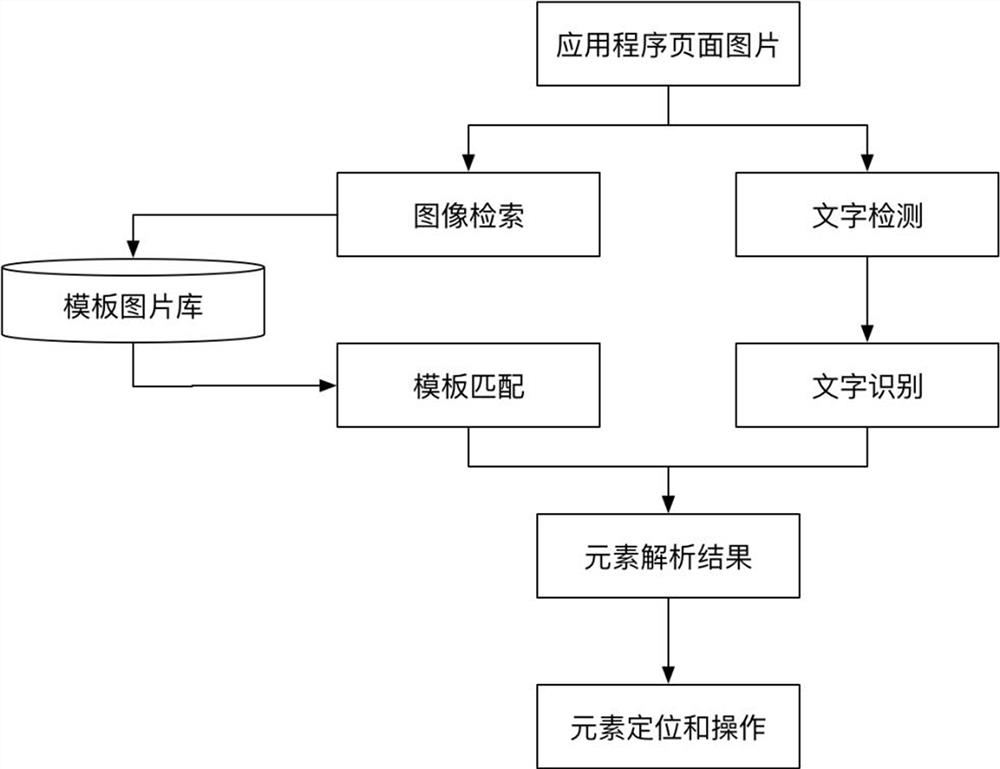

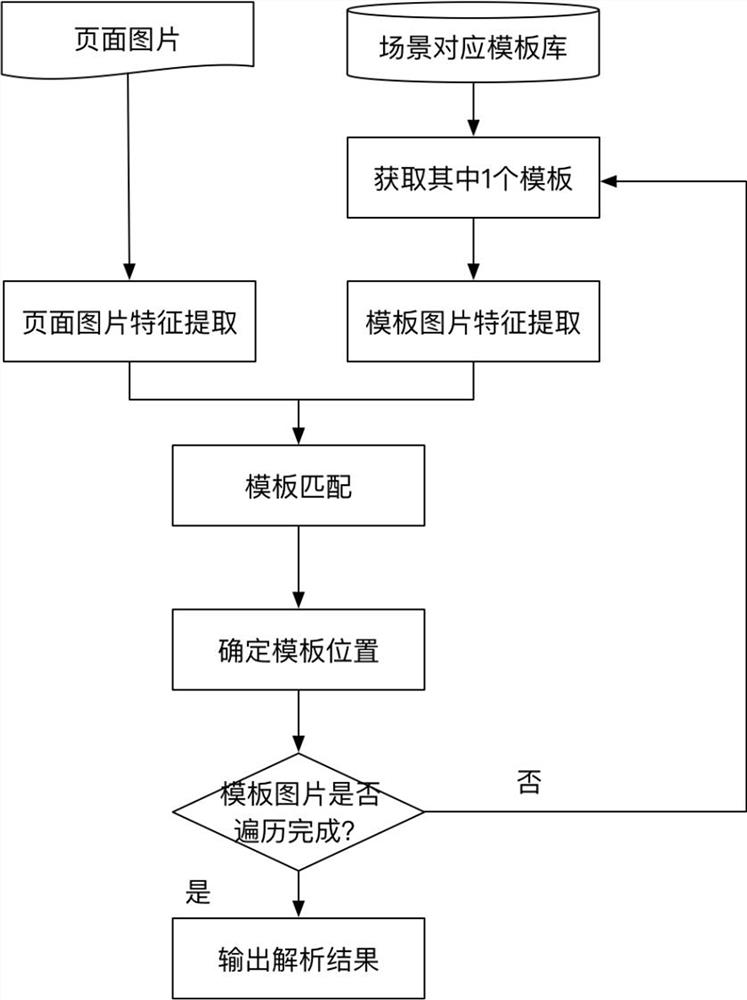

RPA robot intelligent element positioning and picking method and system

ActiveCN112101357ASolve positioningSolve operational problemsNeural architecturesNeural learning methodsVisual technologyRemote desktop

The invention discloses an RPA robot intelligent element positioning and picking method and system. According to the method, firstly a problem that a remote desktop, a virtual system and other elements cannot be positioned and operated is solved through employing a computer vision technology combining template matching, OCR and image retrieval, and a proposed new scheme can more accurately and stably locate and pick up the positions and contents of the elements on the picture; secondly, an element positioning scheme based on template matching is adopted, a large number of labeling samples arenot needed, and the scheme is more stable and controllable; thirdly, pixel point features, corner point features and convolution features of a deep neural network are fused, so that the template matching effect is more accurate and stable, and meanwhile, the OCR technology can further assist in positioning elements with text information; and finally, a template library retrieval engine is constructed by adopting an image retrieval technology, and which application the page picture to be processed belongs to can be accurately judged, so that the problem of low retrieval and matching speed caused by template library growth in multiple scenes is solved.

Owner:杭州实在智能科技有限公司

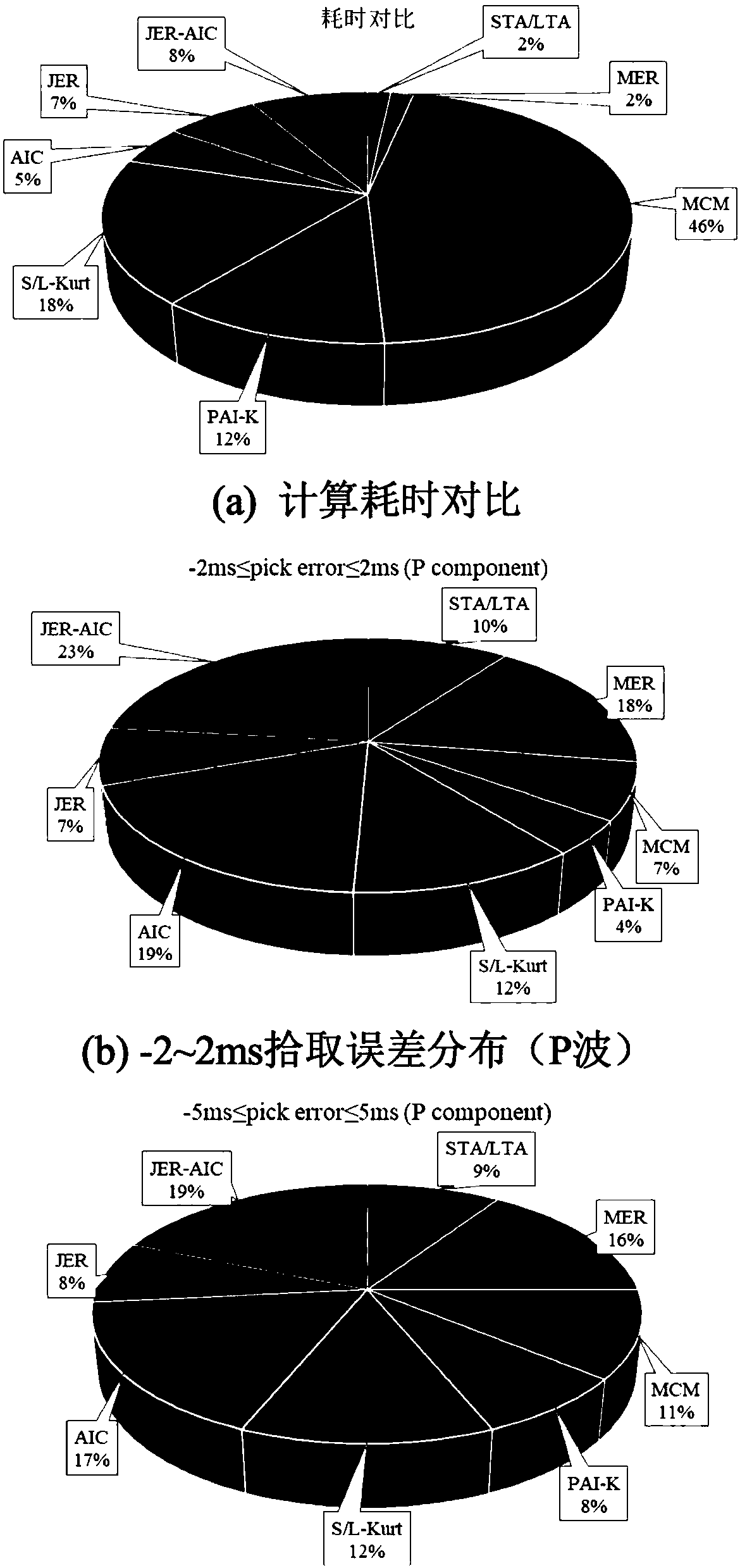

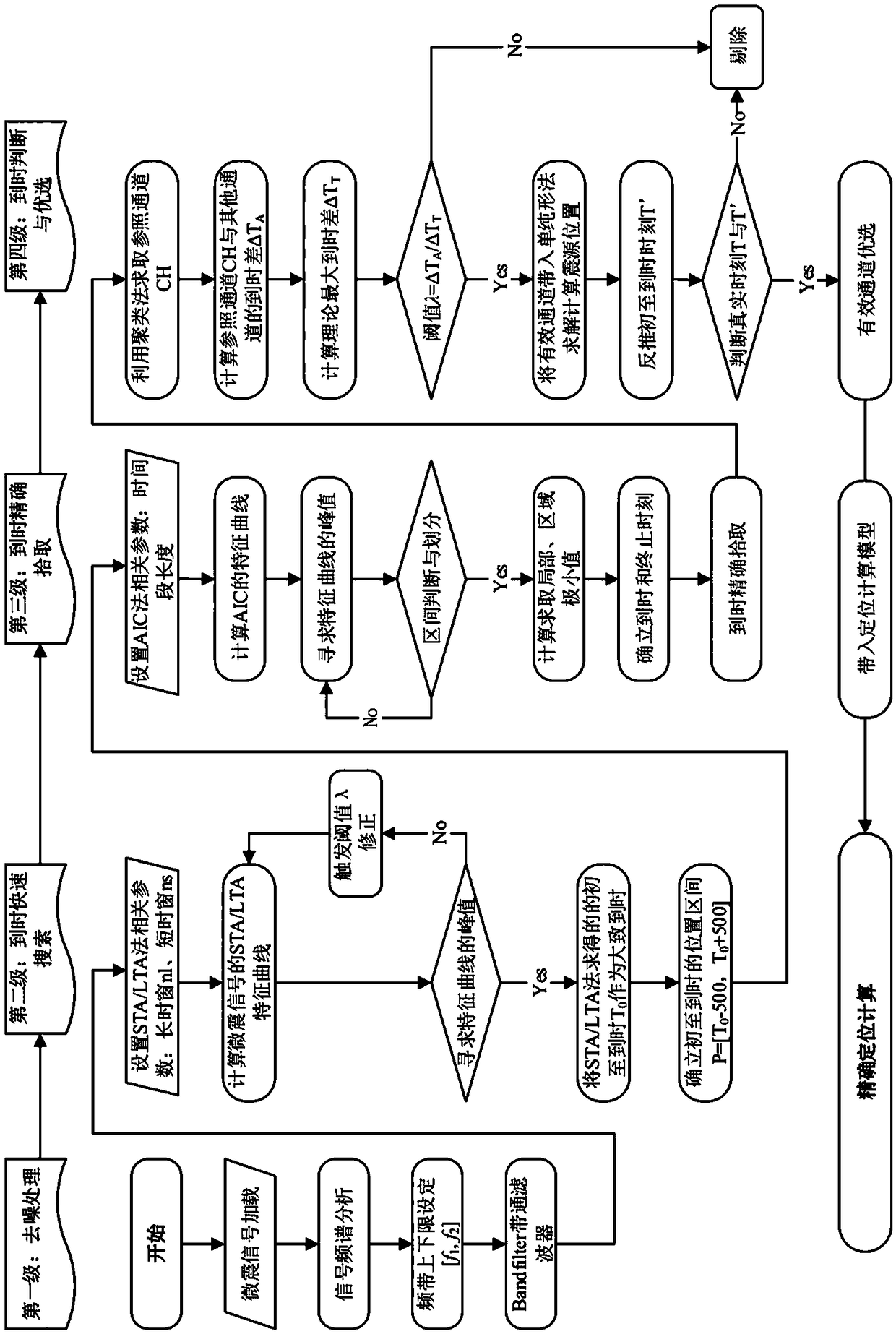

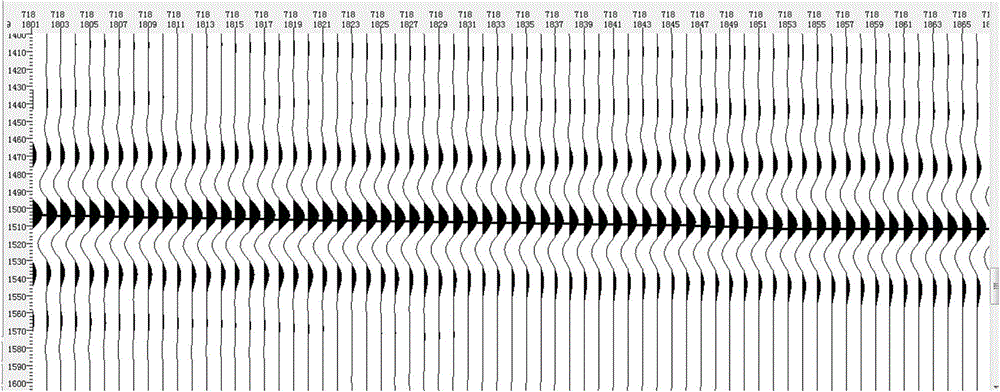

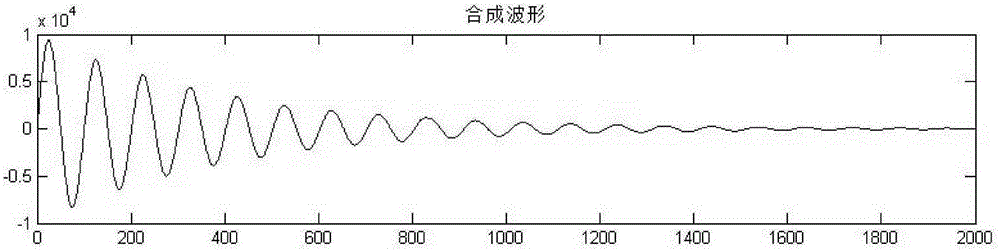

Automatic grading picking and optimizing method of micro-seismic wave shape first arrival time

The invention discloses an automatic grading picking and optimizing method of micro-seismic wave shape first arrival times. The method comprises four steps of noise reduction processing-arrival time rapid searching-arrival time accurate picking-arrival time judging and optimizing, specifically, the noise reduction processing is carried out on original signals by using a MATLAB build-in Butterworthband-pass 10-200 Hz filter; peak points in the signals are rapidly judged by using a peak judgmental method, then each 500 sampling point is pushed and moved to the left and right by using the peak points, then a first arrival time position is preliminarily established by using a STA / LTA method; first arrival time accurate picking selects two methods of AIC algorithm and MER algorithm, a first arrival time position of a micro-seismic wave shape is established; and a judging and optimizing process of an effective channel is summarized as three steps such as clustering analysis picking reference channel is carried out, time difference removing invalid channel is carried and envelope curve judging presenting error channel is carried out. The automatic grading picking and optimizing method ofthe micro-seismic wave shape first arrival time can rapidly and accurately pick the first arrival time of the micro-seismic signals, and can automatically judge and remove the channel with larger interference or error.

Owner:NORTH CHINA INST OF SCI & TECH

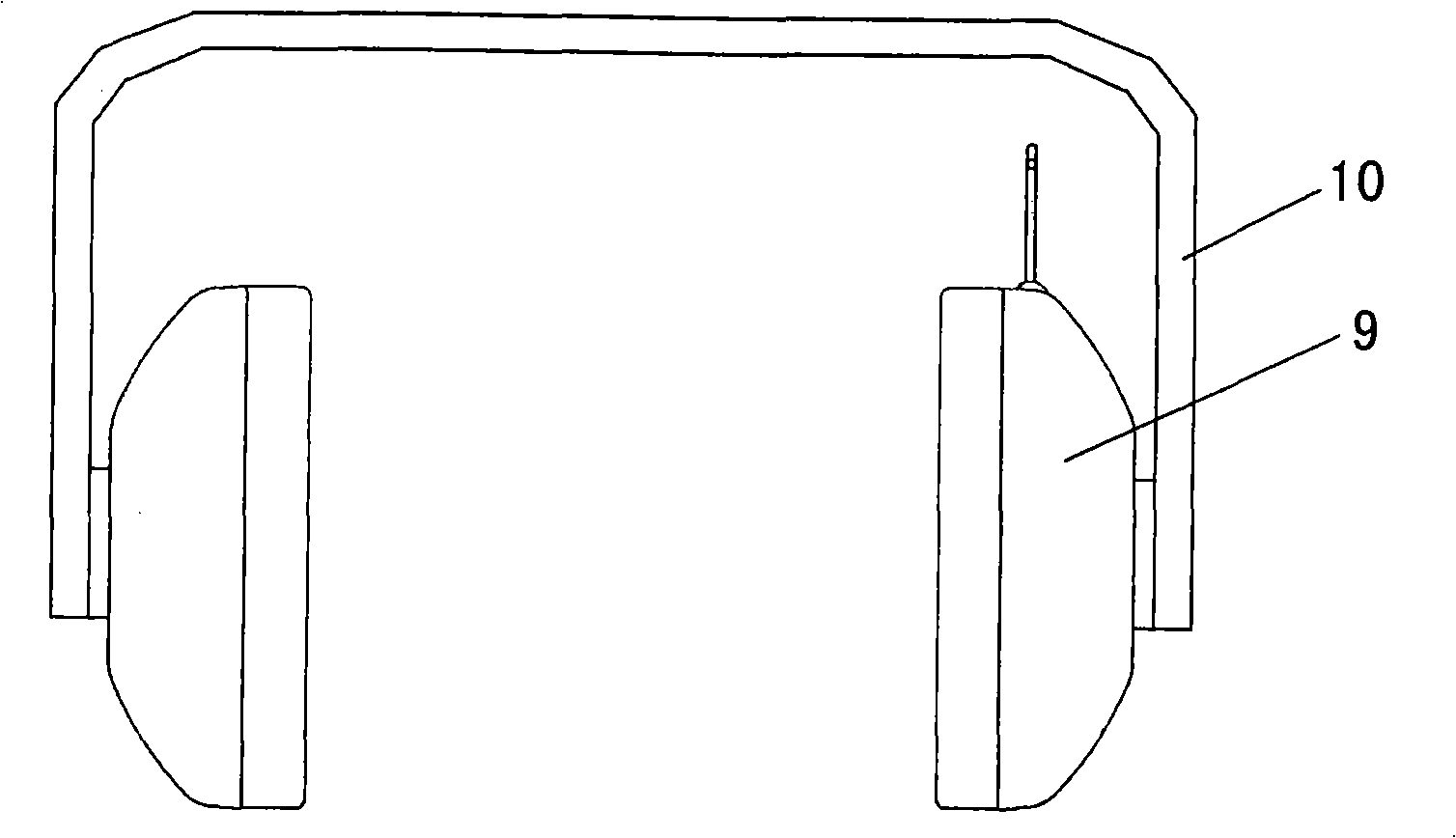

Clamp arm pickup device

ActiveCN103015766APick up accuratelyAccurately pick upParkingsControl systemProgrammable logic controller

The invention provides a clamp arm pickup device, which comprises a travelling device, a clamping device and an adjusting device. When a car is picked up, a front wheel base plate and a rear wheel base plate are driven to move through a travelling motor in the travelling device, and the position of the rear wheel base plate can be adjusted through the adjusting device according to different lengths of car bodies. When the clamp arm center of a rear clamp arm mechanism in the clamping device deviates from rear wheels, the two clamp arms for clamping the same tire are not contacted with the tire at the same time in the closing process of clamp arms, one clamp arm contacted with the tire at first receives the opposite acting force of the tire, the rear wheel base plate is pushed to move in the opposite direction under the action of the opposite acting force, a screw rod on the rear wheel base plate drives a touch rod to overcome the acting force of a spring and touch a corresponding micro-switch, and a PLC (programmable logic controller) control system is used for controlling the motor to drive the screw rod to rotate according to a received signal until the clamp arm center is aligned to the rear wheel center. The clamp arm pickup device is simple in structure and high in automation level, and can achieve the accurate positioning function.

Owner:QINGDAO QIXING IRON TOWER +1

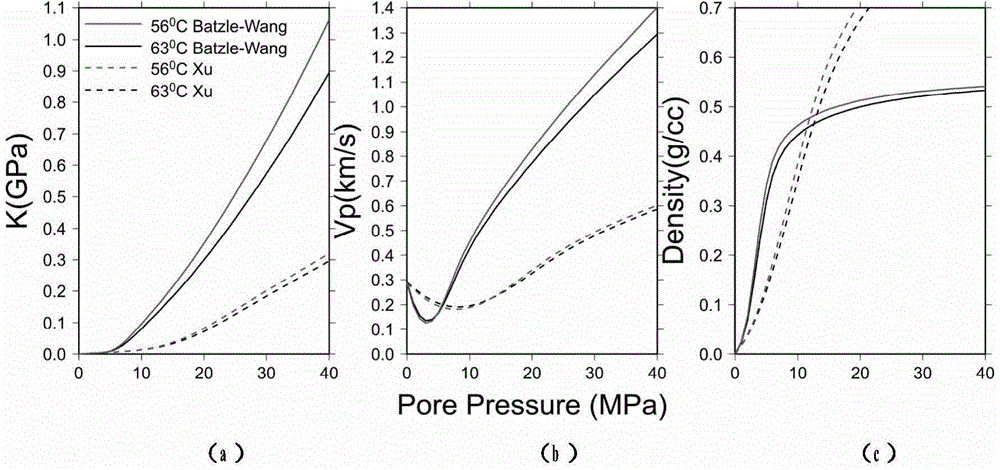

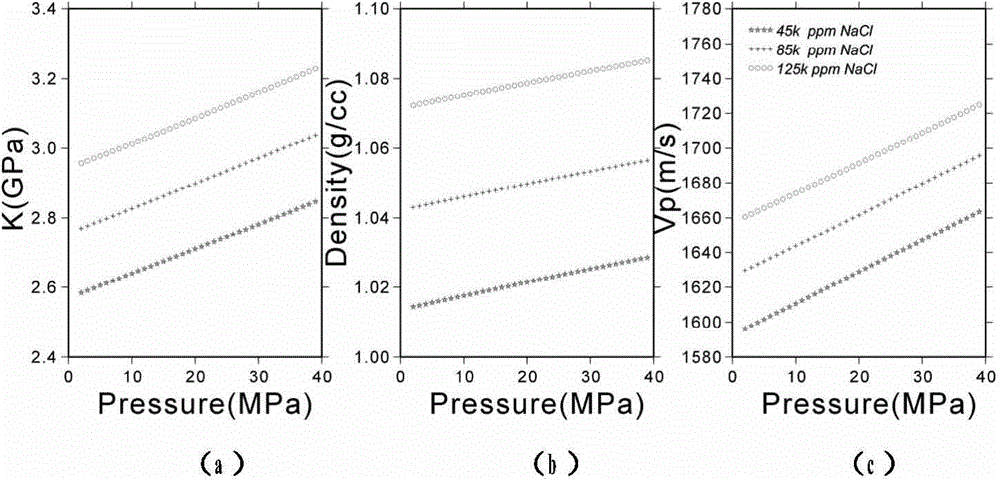

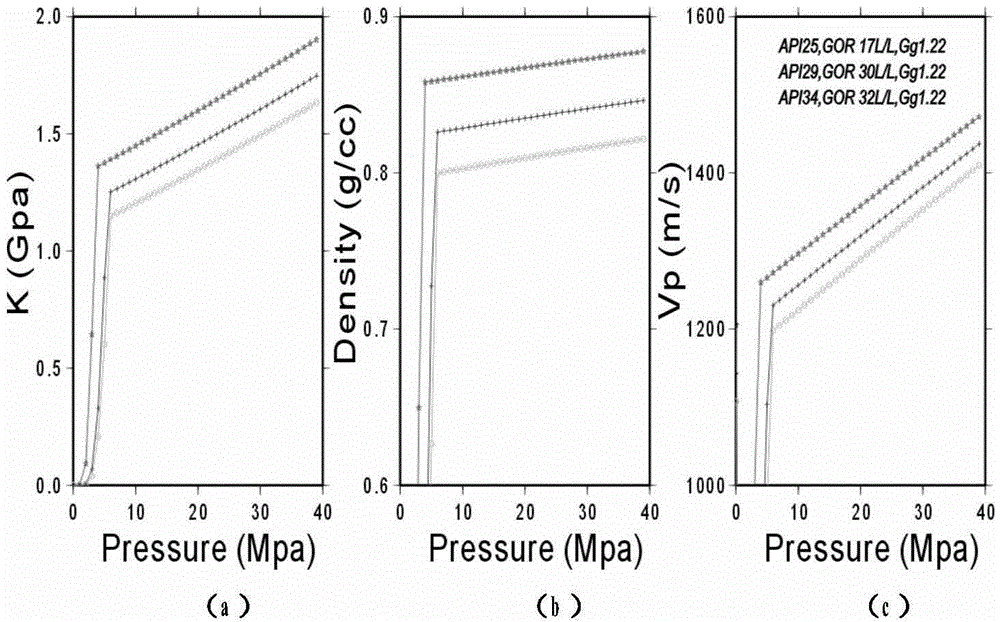

Method for predicting CO2 distribution in four-dimensional seismic data in CO2 geological sequestration

ActiveCN104678438AAccurate elastic propertiesAccurate calculationSeismic signal processingGeological sequestrationEnvironmental geology

The invention relates to a method for predicting CO2 distribution in four-dimensional seismic data in CO2 geological sequestration. The method comprises the following steps: (1) simulating fluid elasticity parameter calculation under change conditions such as different underground stratum temperatures, pressures and brine mineralization degrees; (2) establishing a relation or a formula among elasticity modulus, shear modulus and pressure of dry rock based on a rock physics test of a rock core; (3) improving a fluid replacement method based on a Gassman equation; (4) carrying out shale correction on stratums; (5) utilizing different fluid replacement methods according to different CO2 filling manners based on fluid replacement calculation of a well model filled with CO2; (6) carrying out environment correction and high-precision depth-time conversion on logging information, simultaneously, calculating ray parameter gathers or angle gathers, and manually synthesizing a seismic record; (7) establishing a gradient-intercept crossplot of CO2 saturability and pressure change, and picking up CO2 fluid identifying factors changed along with the pressure change and the saturability change; and (8) applying the CO2 fluid identifying factors to actual seismic data, so as to identify and predict the underground CO2 distribution. According to the method, the distribution of CO2 sealed underground can be identified and predicted.

Owner:NORTHWEST UNIV

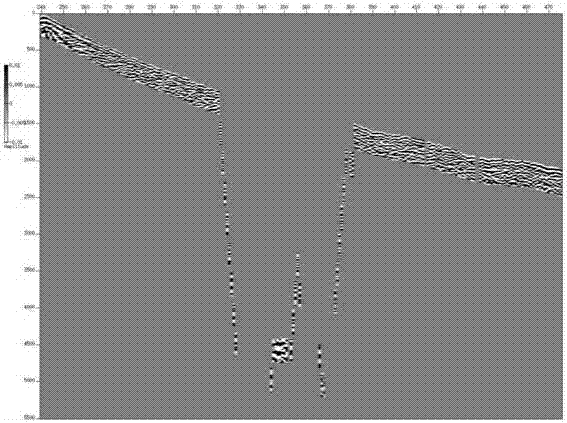

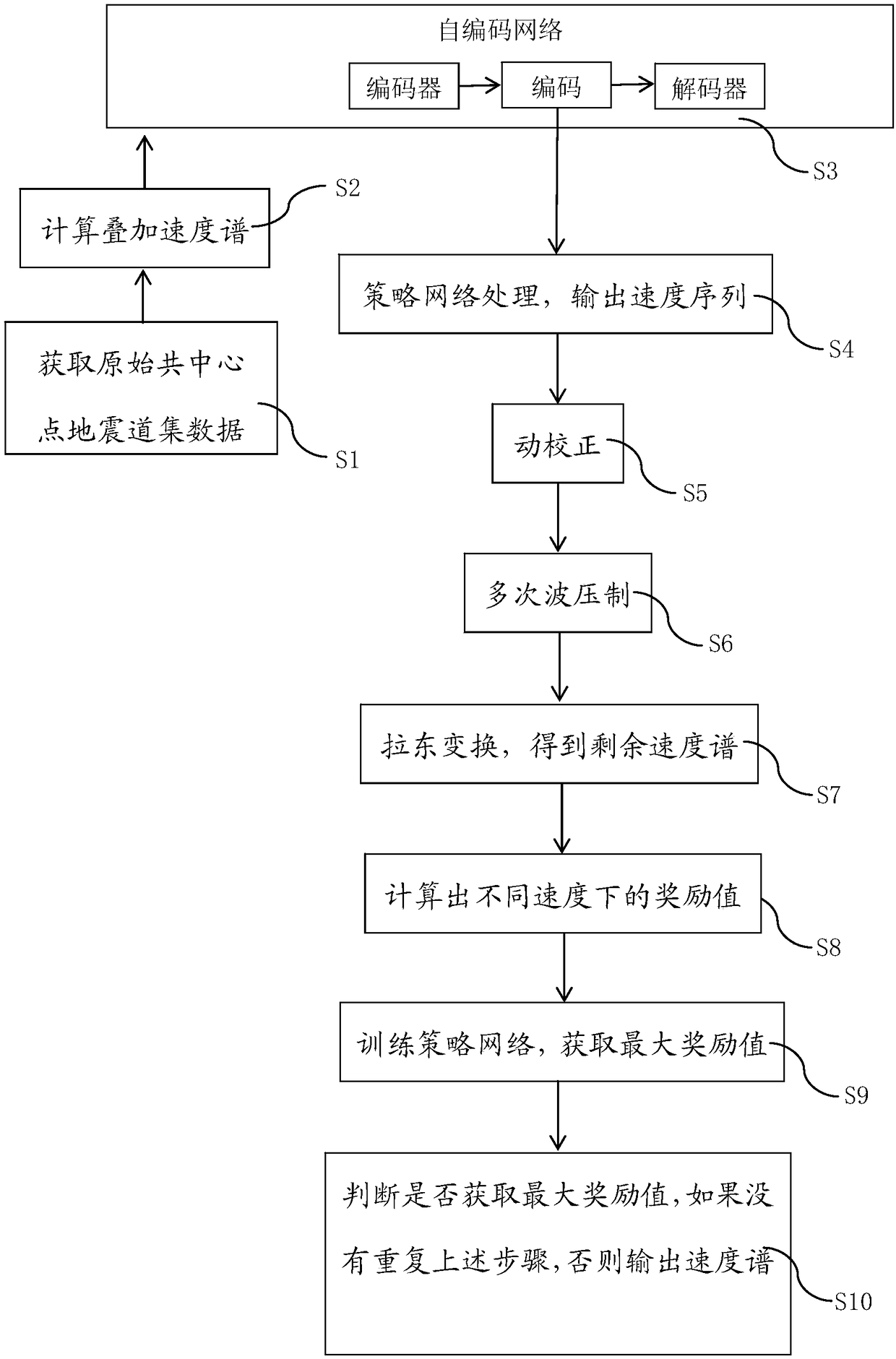

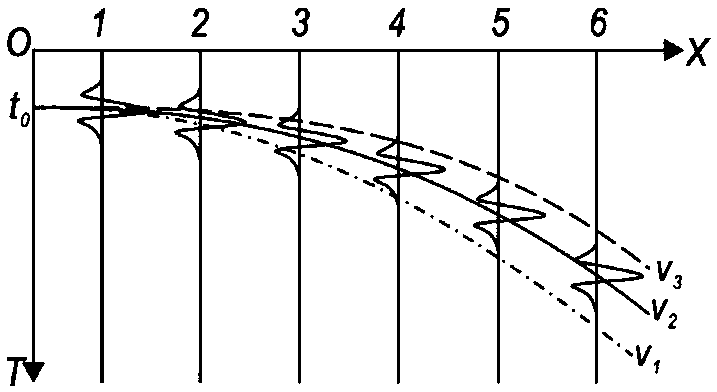

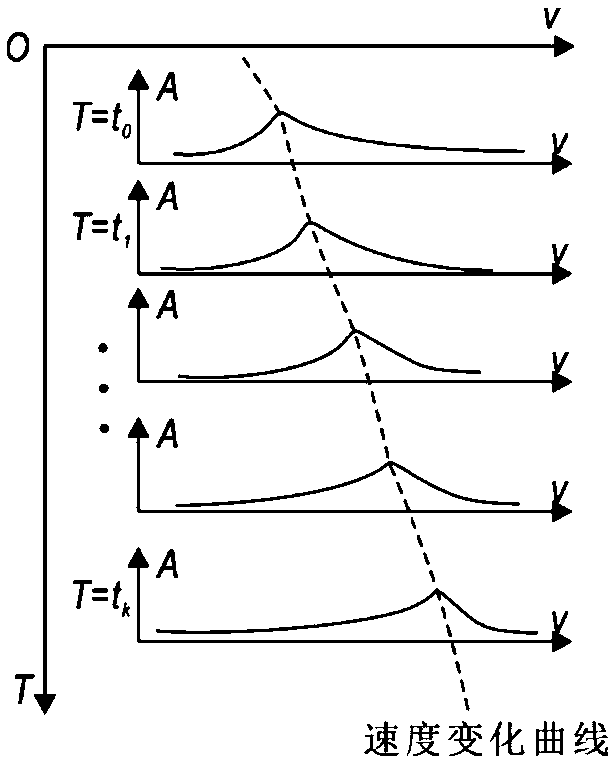

Stacking velocity spectrum pickup method based on deep reinforcement learning and processing terminal

ActiveCN109031421APick up intelligenceNo human intervention requiredSeismic signal processingVelocity spectrumComputer terminal

The invention relates to a stacking velocity spectrum pickup method based on deep reinforcement learning and a processing terminal. The method comprises the following steps of: S1, acquiring originalcommon midpoint gathers data including seismic reflection waves, and calculating a stacking velocity spectrum composed of optimal scanning speeds at various moments; S2: inputting the stacking velocity spectrum into an auto-encoding network to obtain coded high-order energy group features; S3: inputting the codes of the high-order energy group features into a policy network, picking up the optimalscanning speeds at various moments, and outputting a speed sequence; S4: evaluating the speed sequence and outputting reward values; S5: training the policy network according to the reward values; and S6: executing theS3 to the S5 iteratively until the set maximum reward value is acquired in the S4, and then outputting the optimal speed sequence. According to the stacking velocity spectrum pickupmethod based on deep reinforcement learning and the processing terminal, intelligent velocity spectrum pickup is realized without manual intervention, the interference of multiple waves can be eliminated during the pickup process, and the obtained stacking velocity curve is more accurate.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

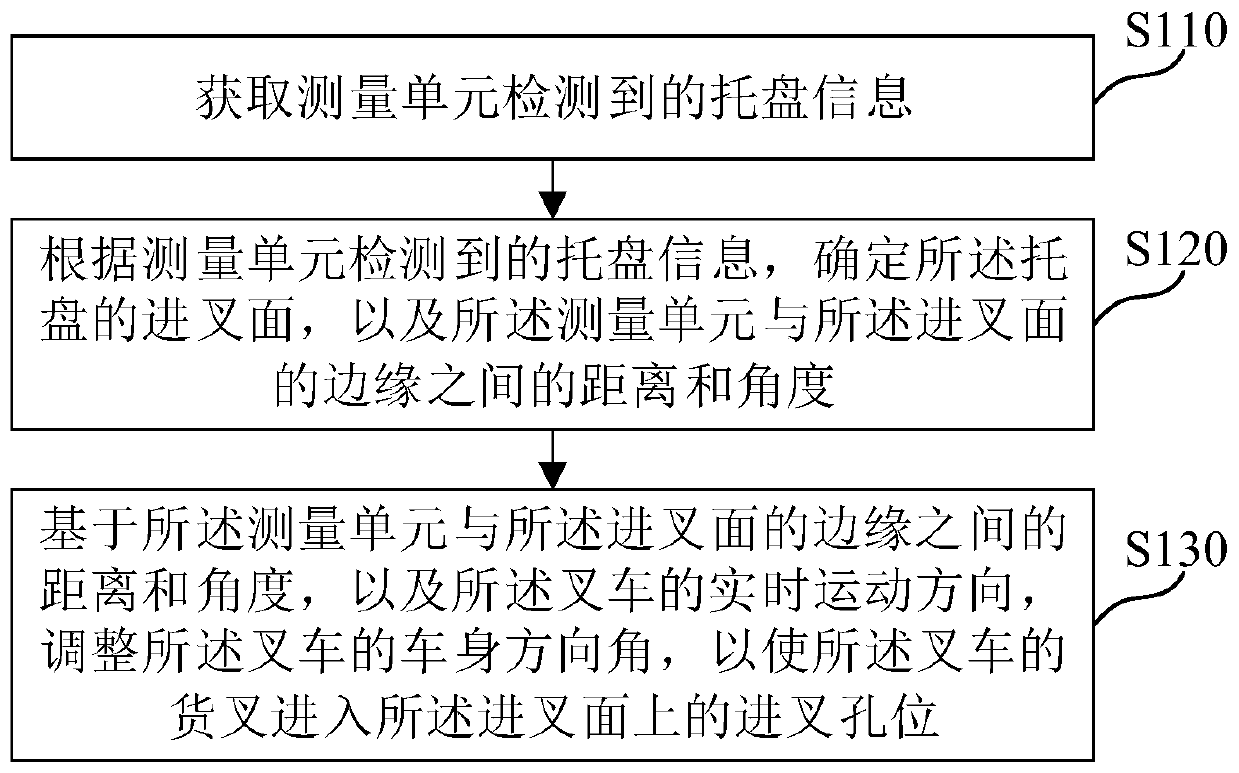

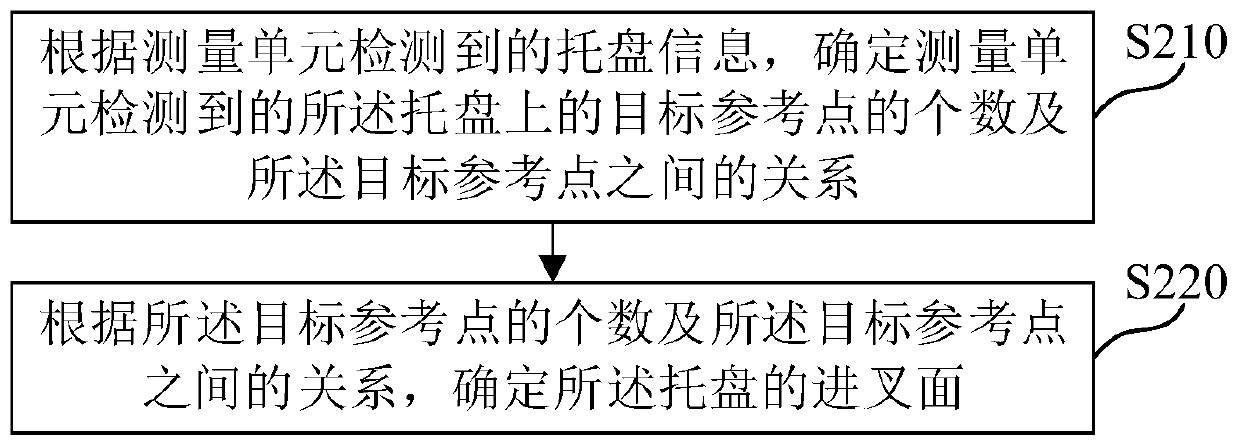

Forklift motion control method and device

ActiveCN109850810APick up accuratelyIncrease flexibilityLifting devicesReal Time KinematicEngineering

The embodiment of the invention provides a forklift motion control method and device. A forklift is provided with a measuring unit for detecting a pallet. The forklift motion control method comprisesthe following steps that the pallet information detected by the measuring unit is acquired; according to the pallet information detected by the measuring unit, the fork feeding surface of the pallet and the distance and angle between the measuring unit and the edge of the fork feeding surface are determined; and based on the distance and angle between the measuring unit and the edge of the fork feeding surface and the real-time movement direction of the forklift, the direction angle of a forklift body of the forklift is adjusted so that a fork of the forklift can enter a fork feeding hole positon in the fork feeding surface. By the adoption of the technical scheme of the forklift motion control method and device, it can be ensured that the fork of the forklift accurately enters and picks up the pallet, and the flexibility and accuracy of forklift control are improved.

Owner:NANJING SHIBANG INTELLIGENT TECH CO LTD

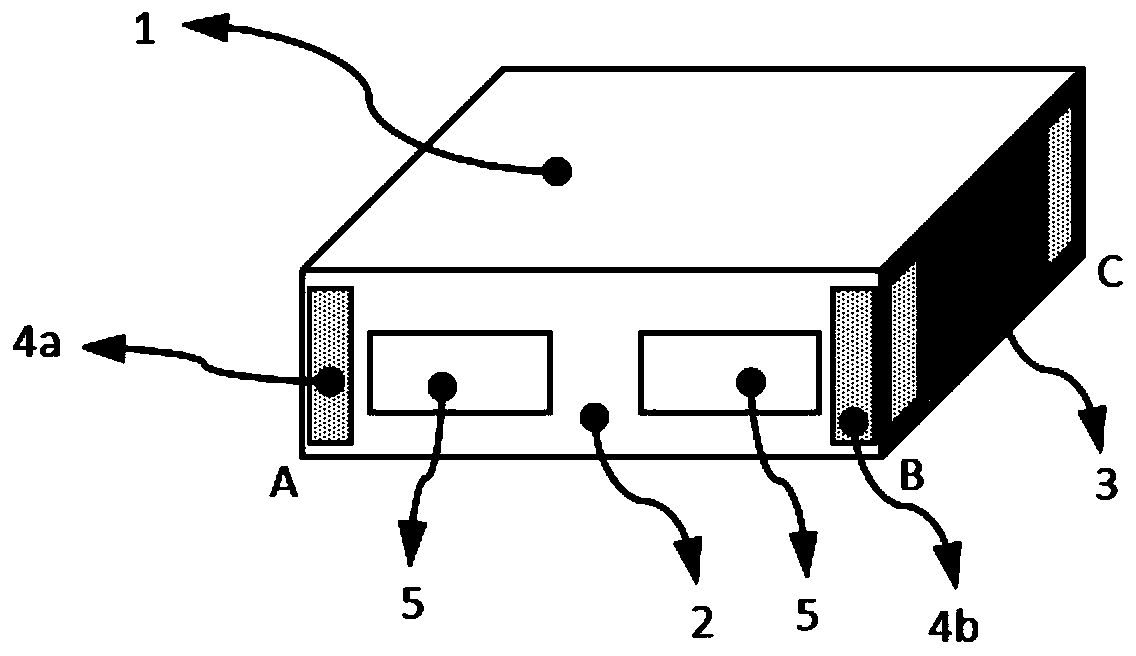

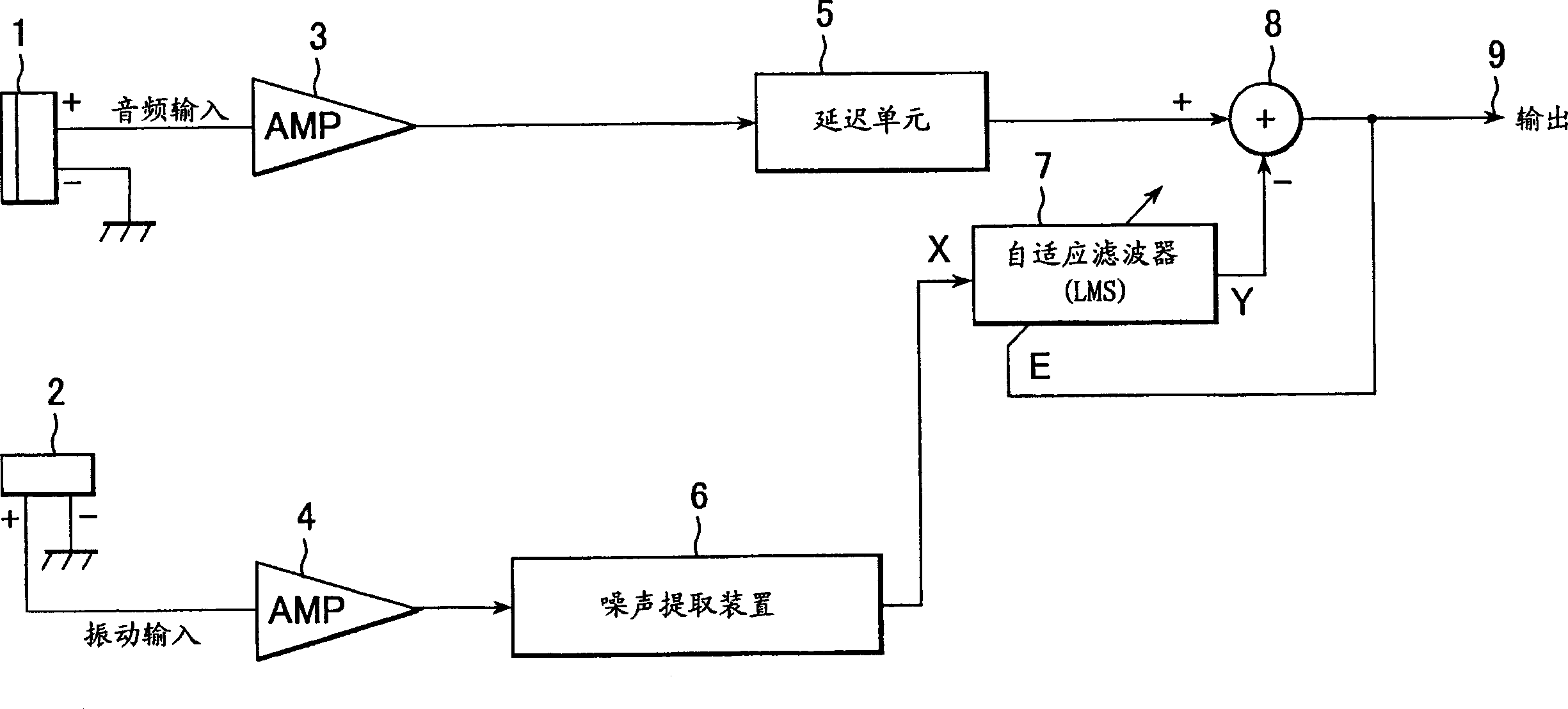

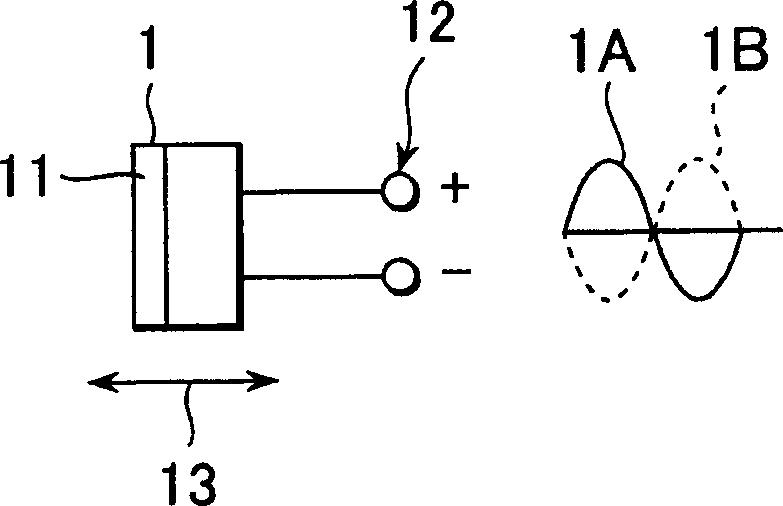

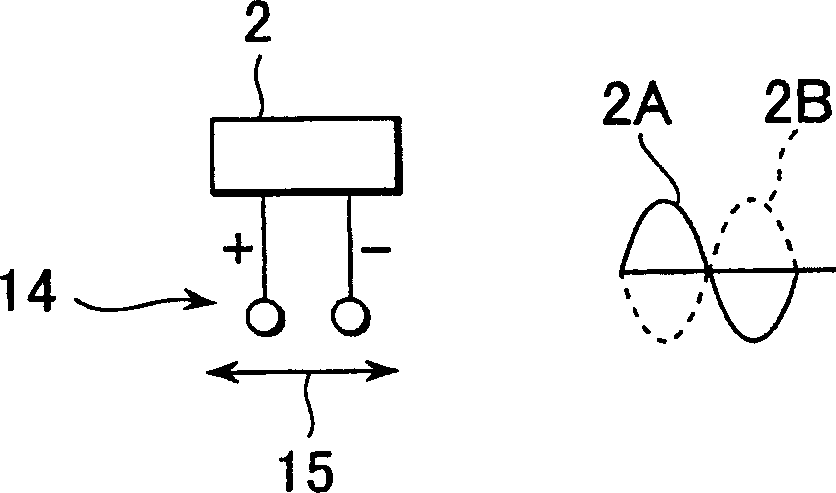

Microphone apparatus, noise reduction method and recording apparatus

InactiveCN1602116AMatch output polarityCancel noiseMicrophones signal combinationSound producing devicesNoise bandwidthAdaptive filter

The purpose of this invention is to achieve vibration-dependent noise reduction by the use of a microphone to pick up an audio signal and a vibration sensor. The microphone apparatus according to a preferred embodiment of the present invention is one having one or more microphone, one or more sensor, noise extraction means for extracting the noise bandwidth section from the output signal of the sensor, an adaptive filter coordinated with the microphone for receiving the output signal of the noise extraction means as the reference input signal, and an adder for subtracting the output signal of the adaptive filter from the output signal of the microphone, wherein the vibration detection directions of the microphone and the sensor match, and so do the output polarities of the vibration signal.

Owner:SONY CORP

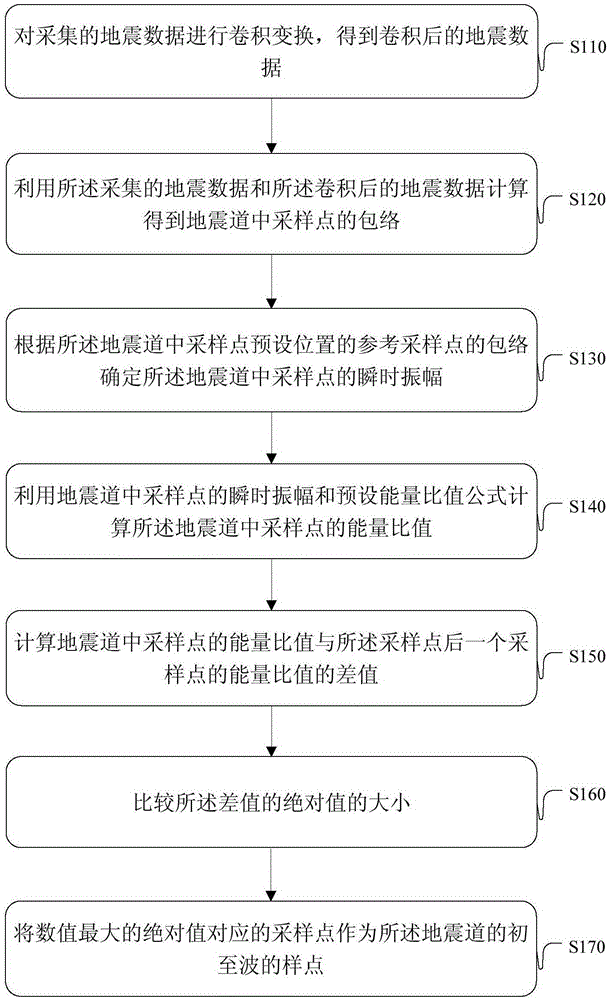

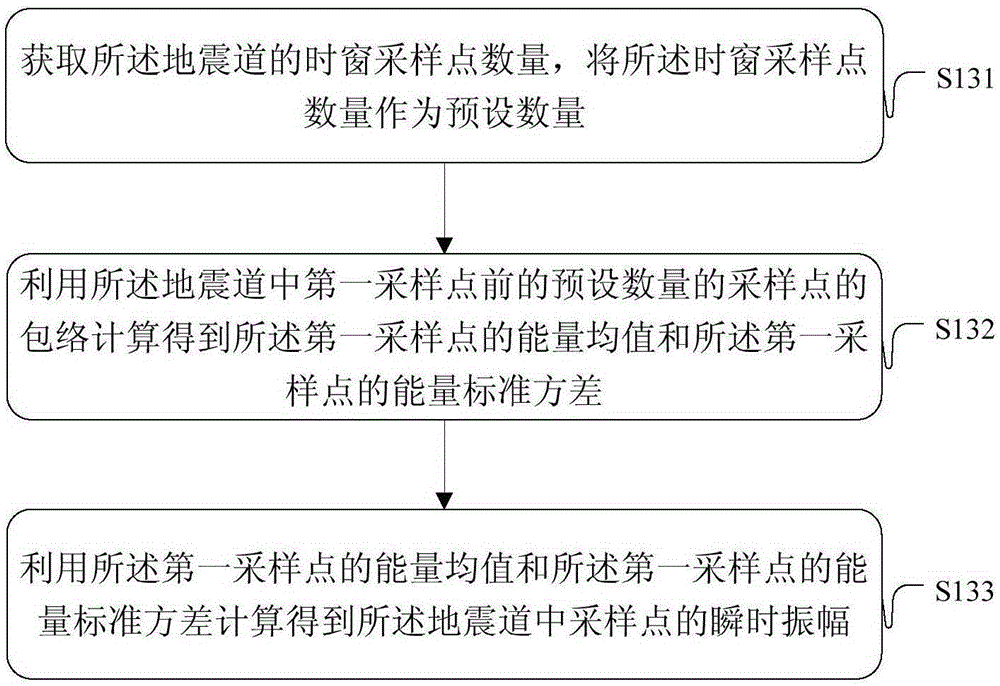

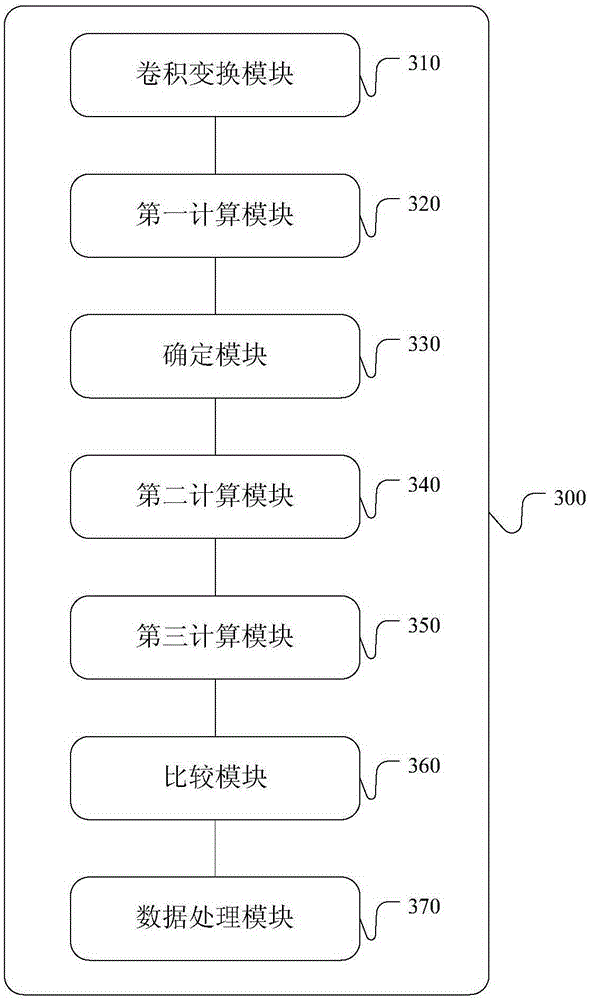

Method and device for picking up preliminary wave

ActiveCN105204065ASolve the statics problemEliminate random noiseSeismic signal processingGeophysicsConvolution

The embodiment of the invention discloses a method and device for picking up a preliminary wave. The method includes the steps that acquired seismic data are subjected to convolution transformation so that convoluted seismic data can be obtained; the acquired seismic data and the convoluted seismic data are used for obtaining envelopes of sampling points in a seismic channel through calculation; according to envelopes of reference sampling points at preset positions in the seismic channel, the instantaneous amplitude of the sampling points in the seismic channel is determined; the energy ratio of the sampling points in the seismic channel is calculated through the formula of the instantaneous amplitude of the sampling points in the seismic channel and a preset energy ratio; the difference value between the energy ratio of each sampling point in the seismic channel and the energy ratio of the next sampling point in the seismic channel is calculated; the absolute values of the difference values are compared; the sampling point corresponding to the largest absolute value serves as a sample point of the preliminary wave of the seismic channel. By means of the technical scheme, the accuracy rate of picking up the preliminary wave can be greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

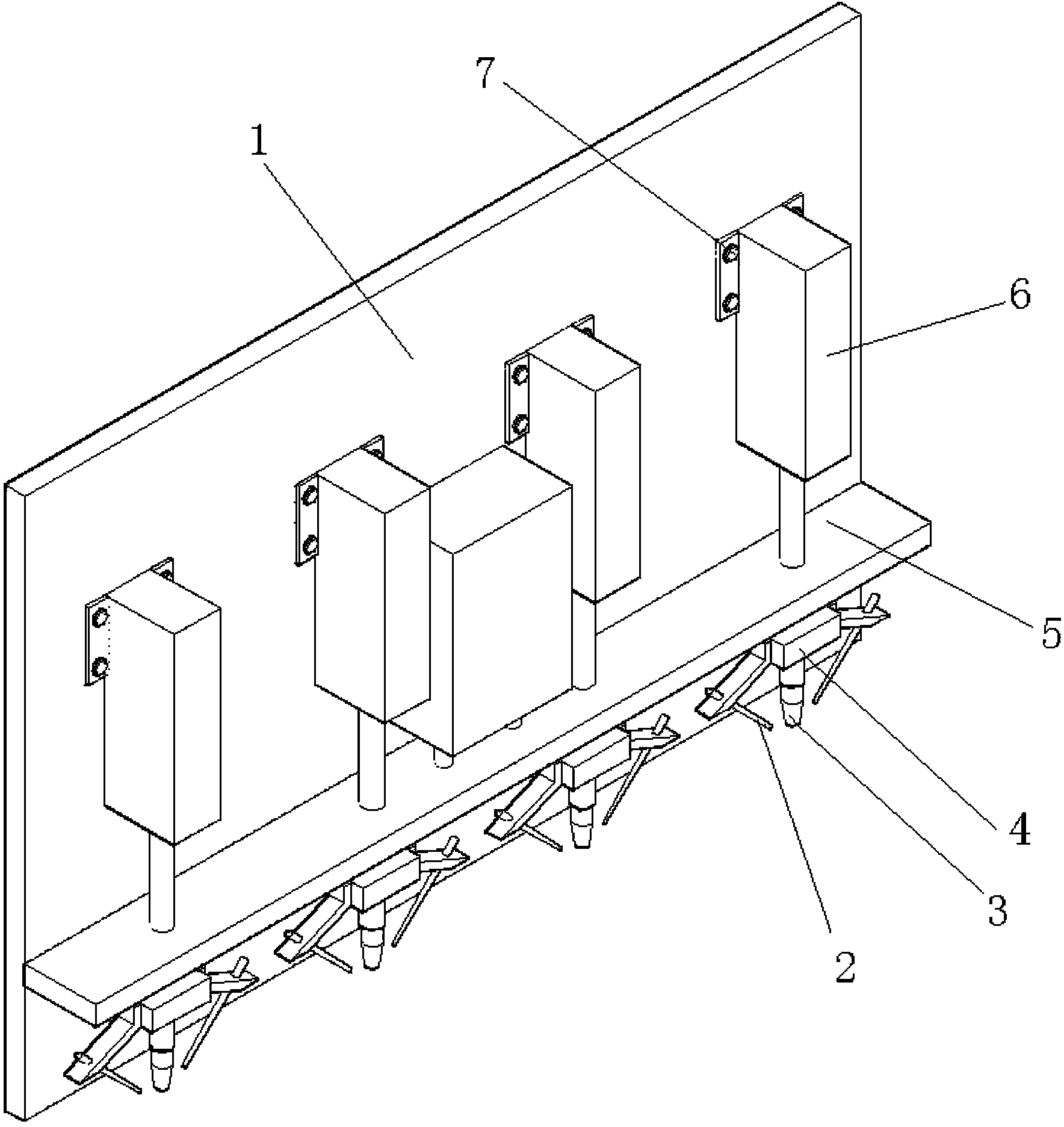

Field planting cup loading device

PendingCN110002227ARealize automatic crawlingPick up accuratelyConveyorsAgriculture gas emission reductionEngineering

The invention relates to the technological field of field planting, in particular to a field planting cup loading device. The field planting cup loading device comprises a proximate matter bracket, ahorizontal driving mechanism, a downward pressing mechanism and a field planting cup grasping mechanism fixed at the output end of the downward pressing mechanism; the horizontal driving mechanism andthe downward pressing mechanism are arranged on the proximate matter bracket, the output end of the horizontal driving mechanism is connected to the downward pressing mechanism to move horizontally along the proximate matter bracket, and the field planting cup grasping mechanism is provided with a plurality of mechanical clamping jaws and guiding devices for adjusting the gaps between the adjacent mechanical clamping jaws. According to the field planting cup loading device, the horizontal driving mechanism enables the downward pressing mechanism to move to arrange field planting cups, the downward pressing mechanism is used for downwards pushing the field planting cup grasping mechanism to enable the field planting cup grasping mechanism to touch the field planting cups, and automatic grasping of the field planting cups is achieved; and the guiding devices on the field planting cup grasping mechanism arranges the field planting cups equidistantly according to the requirements, then the downward pressing mechanism is used for achieving accurate filling of field planting, the field planting cups can be stably clamped, and the field planting cups can be arranged equidistantly and beaccurately placed on a field planting plate.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

Borehole micro-earthquake preliminary wave picking method based on shear let intra-domain kurtosis characteristic

InactiveCN107991707APick up accuratelySeismic signal processingSeismology for water-loggingTime spaceMethod of undetermined coefficients

The invention discloses a borehole micro-earthquake preliminary wave picking method based on a shear let intra-domain kurtosis characteristic. The method includes the steps of firstly, obtaining a group of two-dimensional earthquake signals to conduct discrete shear let conversion, and decomposing the two-dimensional earthquake signals into m dimensions, wherein each dimension comprises n directions; secondly, calculating related energy in all directions of adjacent high-frequency dimensions, wherein n / 2 directions with high related energy are obtained in each high-frequency dimension, and direction coefficients corresponding to the n / 2 directions are superimposed to serve as a corresponding dimension coefficient of each high-frequency dimension; thirdly, calculating the kurtosis K of thecorresponding dimension coefficient of each high-frequency dimension, obtaining the differential value maximum point of the kurtosis, and using the point with a front position as the preliminary pointof micro-earthquake preliminary waves. The related energy of all the direction coefficients on the adjacent dimensions can be calculated according to the coherent two-dimensional time-space directionality of the micro-earthquake signals, the effective signal concentration direction is determined, and the micro-earthquake preliminary waves are more accurately picked.

Owner:JILIN UNIV

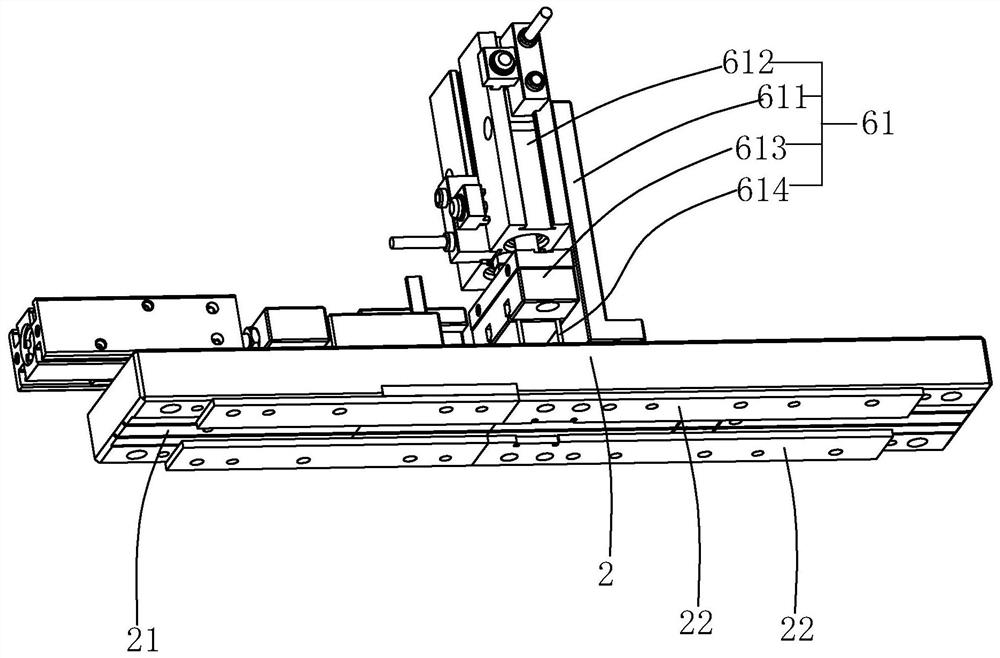

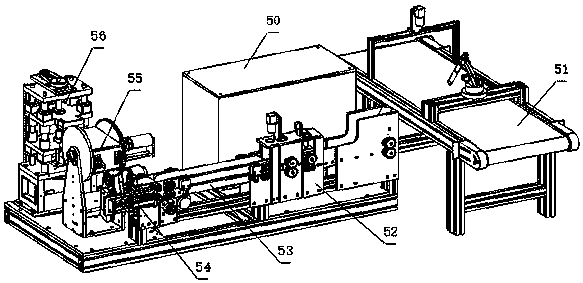

Single-shaft material taking and feeding manipulator

InactiveCN108313719ASimple structurePick up accuratelyGripping headsConveyor partsMetal machiningEngineering

The invention discloses a single-shaft material taking and feeding manipulator and belongs to the technical field of metal machining machinery. The manipulator comprises stand columns, a synchronous belt linear feeding module, a vertical material taking module and a blowing device. The vertical material taking module slides up and down to complete material taking. The synchronous belt linear feeding module drives the vertical material taking module to move left and right to complete material feeding. Through arrangement of the blowing device, the problem that the manipulator takes excessive components due to scrap iron adhesion between the components is solved. Compared with the prior art, the single-shaft material taking and feeding manipulator has the advantages of being simple in structure and high in automation degree.

Owner:临沂聚科智能设备有限公司

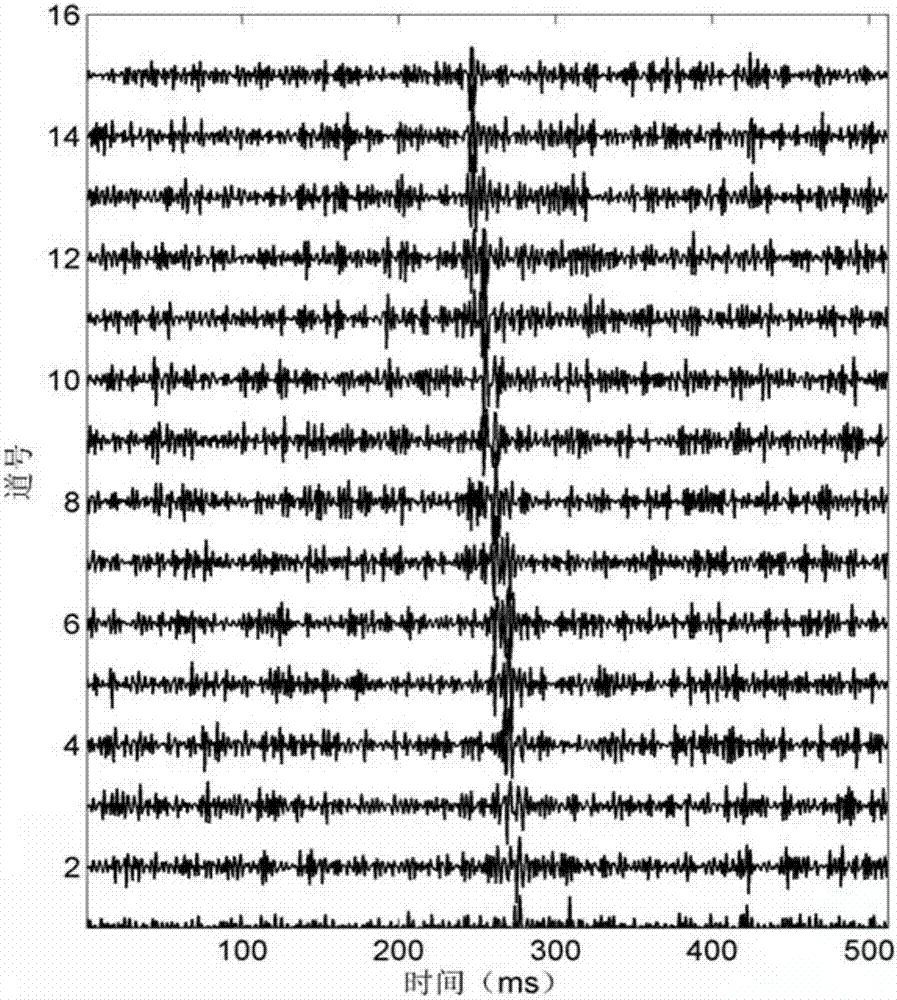

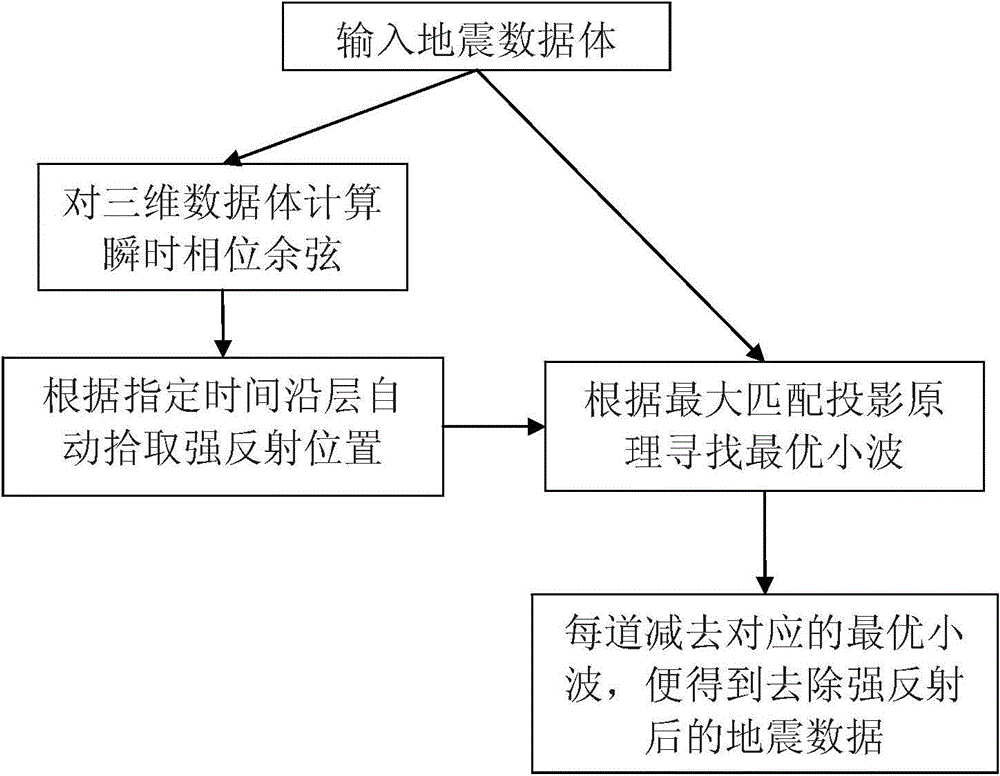

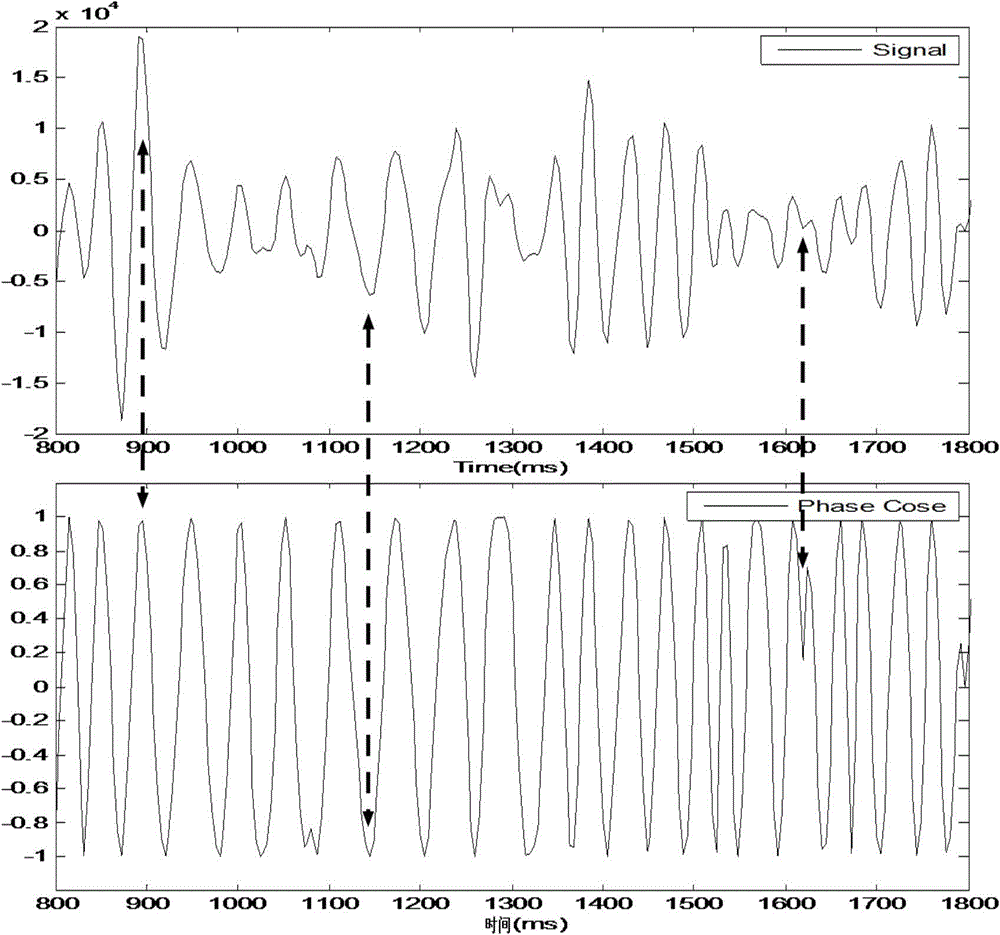

Method for self-adaptively removing strong reflection of earthquake

ActiveCN104570113ARemove strong reflectionsAvoid the effects of horizon trackingSeismic signal processingVIT signalsSelf adaptive

The invention provides a method for self-adaptively removing strong reflection of an earthquake and belongs to the field of pre-treatment of seismic data in exploration and development of oil and gas field. The method comprises the following steps: (1) inputting a three-dimensional seismic data body and calculating instantaneous phase cosine costhea(t) of each seismic signal in the whole three-dimensional seismic data body by Hilbert transform to obtain an instantaneous phase cosine data body; (2) aiming at the instantaneous phase cosine data body, automatically picking up the layer where an appointed point is by virtue of a cross-correlation method and recording the reflection time ti of each strong reflection layer, wherein the appointed point is the time of strong reflection corresponding to some channel pre-set by a user; (3) matching the optimal wavelet for input seismic data according to layer time of the channel which is automatically picked up in light of the maximum matching projection principle; then subtracting the matched optimal wavelet from the seismic data of the channel to obtain the seismic data removing appointed strong reflection of the channel.

Owner:CHINA PETROLEUM & CHEM CORP +1

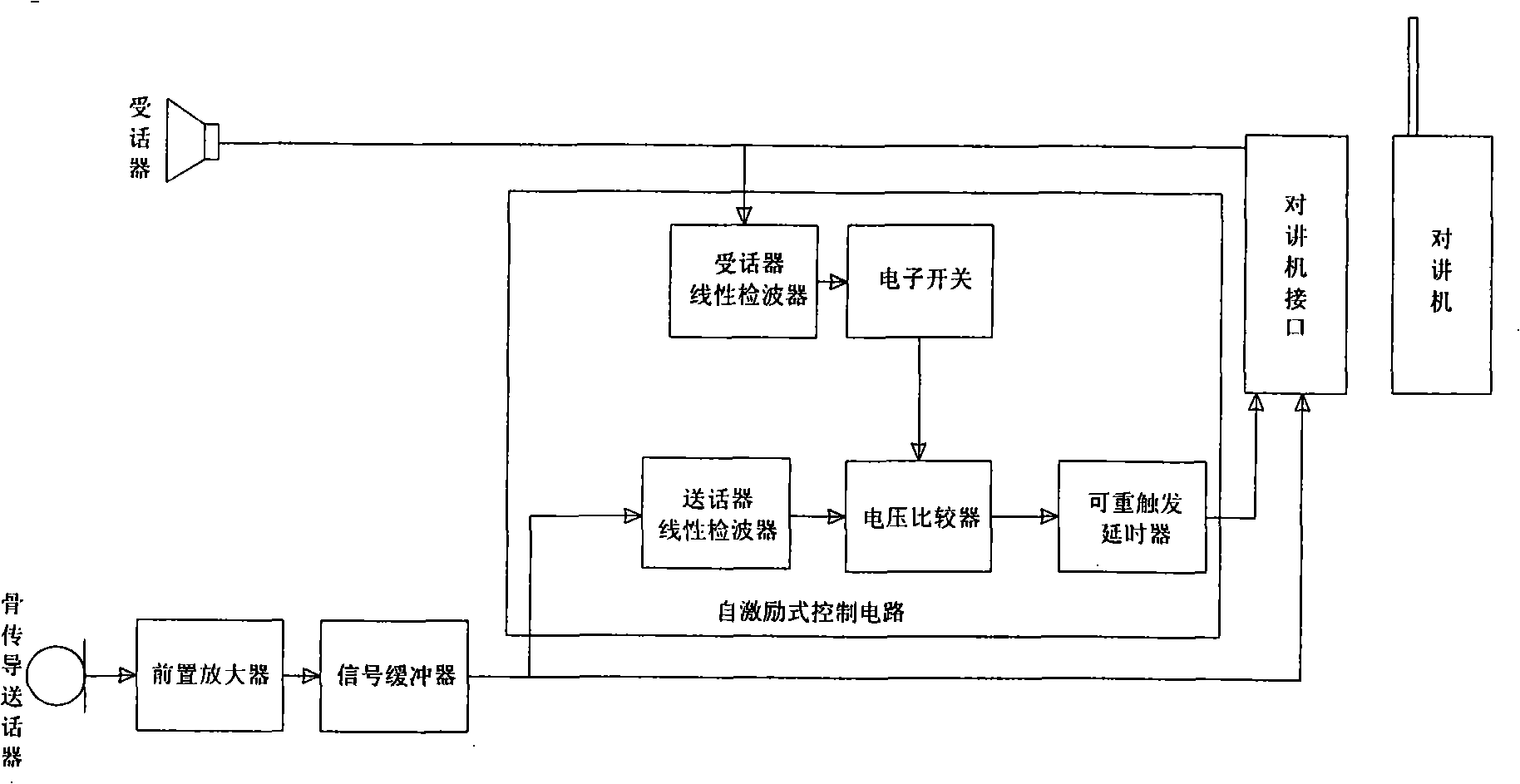

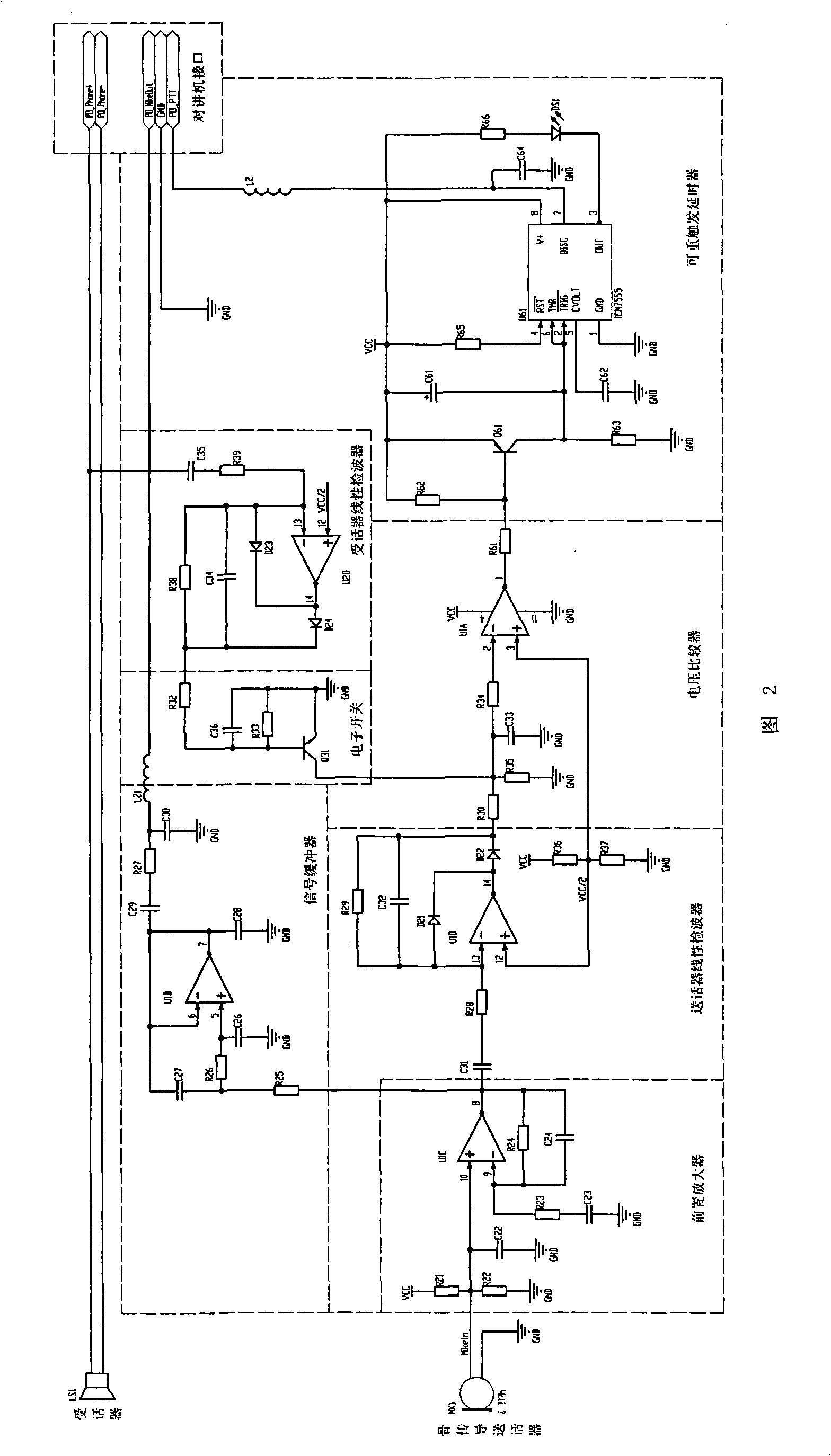

Walkie-talkie ear microphone with autoexcitation function

InactiveCN101330682AImprove call qualityNo false incentivesRadio/inductive link selection arrangementsTransmissionVoice communicationSwitching signal

The invention relates to an interphone earphone with the self-excitation function, which comprises a receiver, a transmitter, an interphone interface and a self-excitation control circuit, wherein the self-excitation control circuit comprises a transmitter linear detector for detecting output signals of the transmitter, a voltage comparer for comparing the signals detected by the transmitter linear detector with a threshold and transmitting an excitation trigger signal, a retriggerable delay for receiving the excitation trigger signal and controlling a transmitter switch of the interphone, and a talk switch interface connected with the output terminal of the retriggerable delay. The interphone earphone with the self-excitation function can achieve self-excitation to control a talk switch without pressing the talk switch of the interphone. The retriggerable delay can automatically transmit a talk switch signal of the interphone when the user starts to talk, and automatically shut off the talk switch signal in a time period (such as 0.5 second) set after stopping talking, thereby achieving continuous voice communication without influencing normal work of the user.

Owner:AEROSPACE LIFE SUPPORT IND LTD

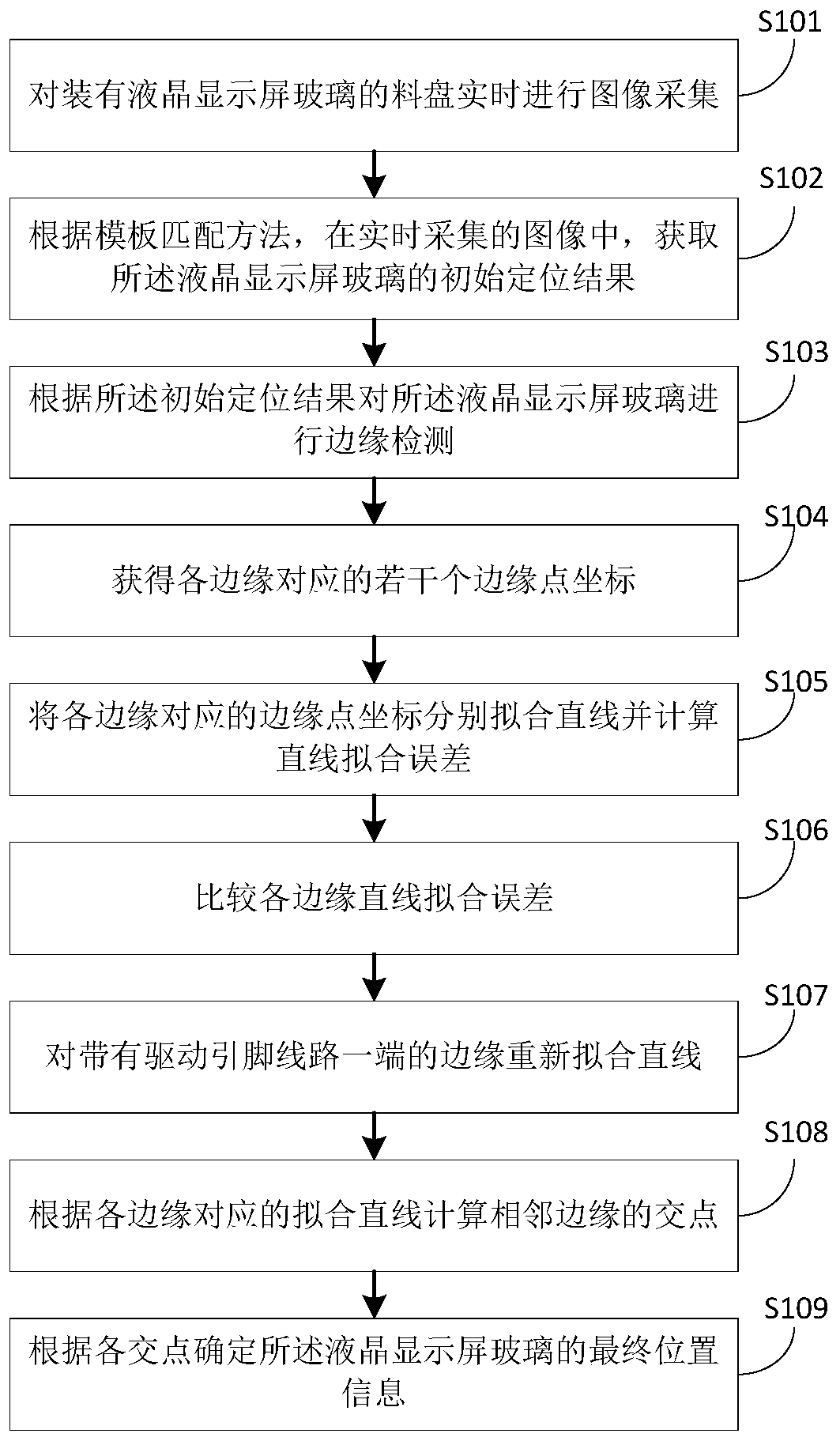

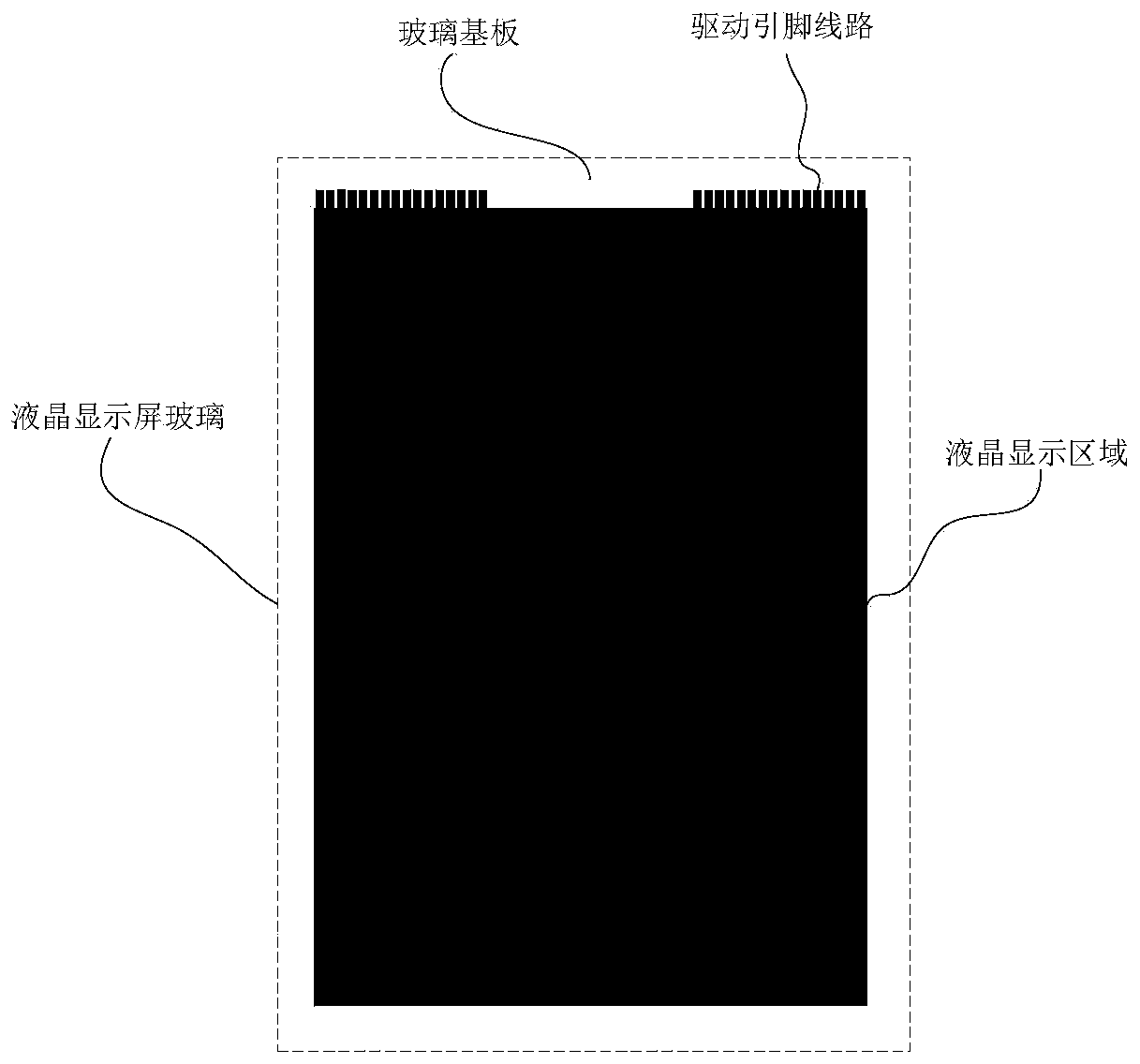

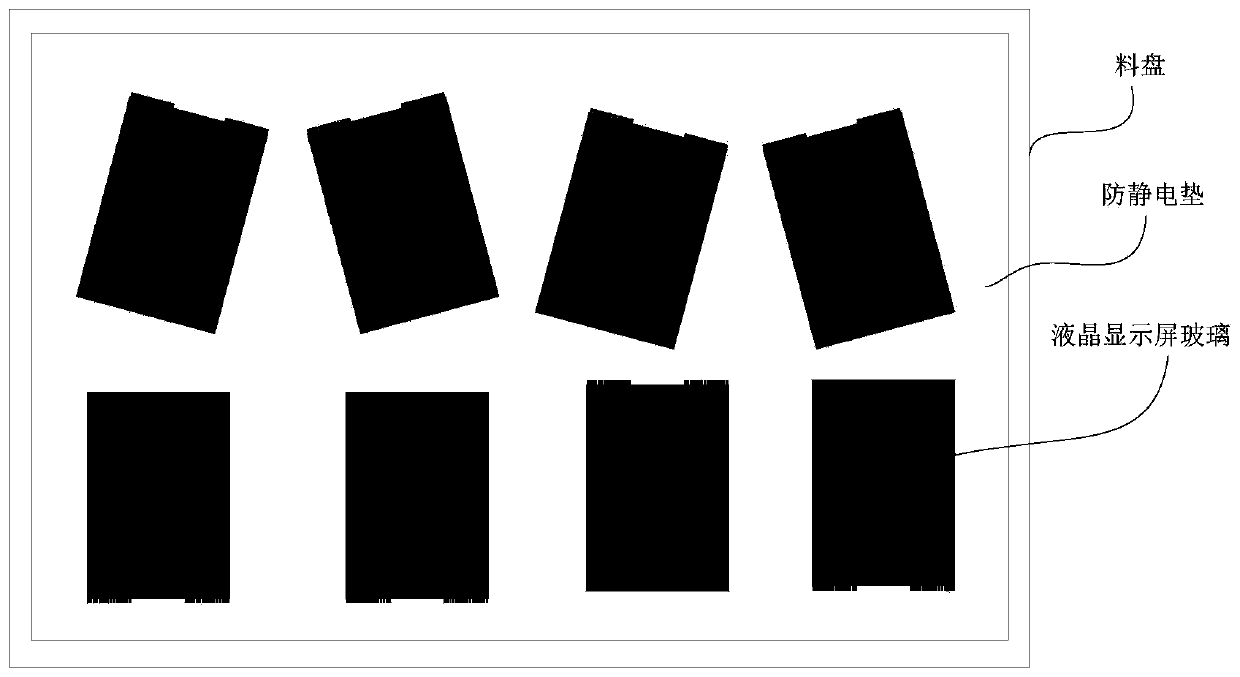

Liquid crystal display glass positioning and picking method and system and visual processing system

ActiveCN110281240AQuick pick upPick up accuratelyProgramme-controlled manipulatorImage analysisTemplate matchingLiquid-crystal display

The invention discloses a liquid crystal display glass positioning and picking method and system and a visual processing system. A robot is adopted for grabbing liquid crystal display glass; a corresponding imaging system is designed according to the characteristics of the liquid crystal display glass and a material disc; and a liquid crystal display glass image positioning method is provided according to the actual imaging characteristic of the liquid crystal display glass. Firstly, a template matching method is adopted for obtaining a liquid crystal display glass initial positioning result in an image, then the edge points on all the edges of the liquid crystal display glass are detected, and finally the position and angle of the liquid crystal display glass are calculated according to the edge points on each edge. The position and angle of the liquid crystal display glass can be fast and precisely positioned even though the liquid crystal display glass is arbitrarily placed in the material disc; then the visual processing system cooperates with a robot controller, the position and angle information for precisely positioning the liquid crystal display glass is converted into the axle position of robot picking, and therefore the robot can pick the product fast, accurately and stably.

Owner:北京博视智动技术有限公司

Unstacking method for brake discs through robot 3D visualization

ActiveCN106493731APrecise positioningPick up accuratelyProgramme-controlled manipulatorStacking articles3d cameraEngineering

The invention discloses an unstacking method for brake discs through robot 3D visualization. The method comprises the steps that an operator awaits a material frame to fall to an approximate charging position; a robot detects the two opposite corners of the material frame through a 3D camera kit, and then the approximate position of the material frame is determined; the position of the 3D camera kit is adjusted through the robot, and the 3D camera kit is made to be located over the material frame; the 3D camera kit is used for detecting the position of one brake disc in the material frame through a 3D brake disc visual identity technology, and the robot is guided to pick the brake disc up; and the robot moves the brake disc to a discharging conveying line or a clamp through a gripper. Through the method, after the material frame loading with the brake discs directly falls to the approximate charging position, the robot can achieve accurate pickup, and the brake discs do not need to be accurately positioned any more.

Owner:SHANGHAI FANUC ROBOTICS

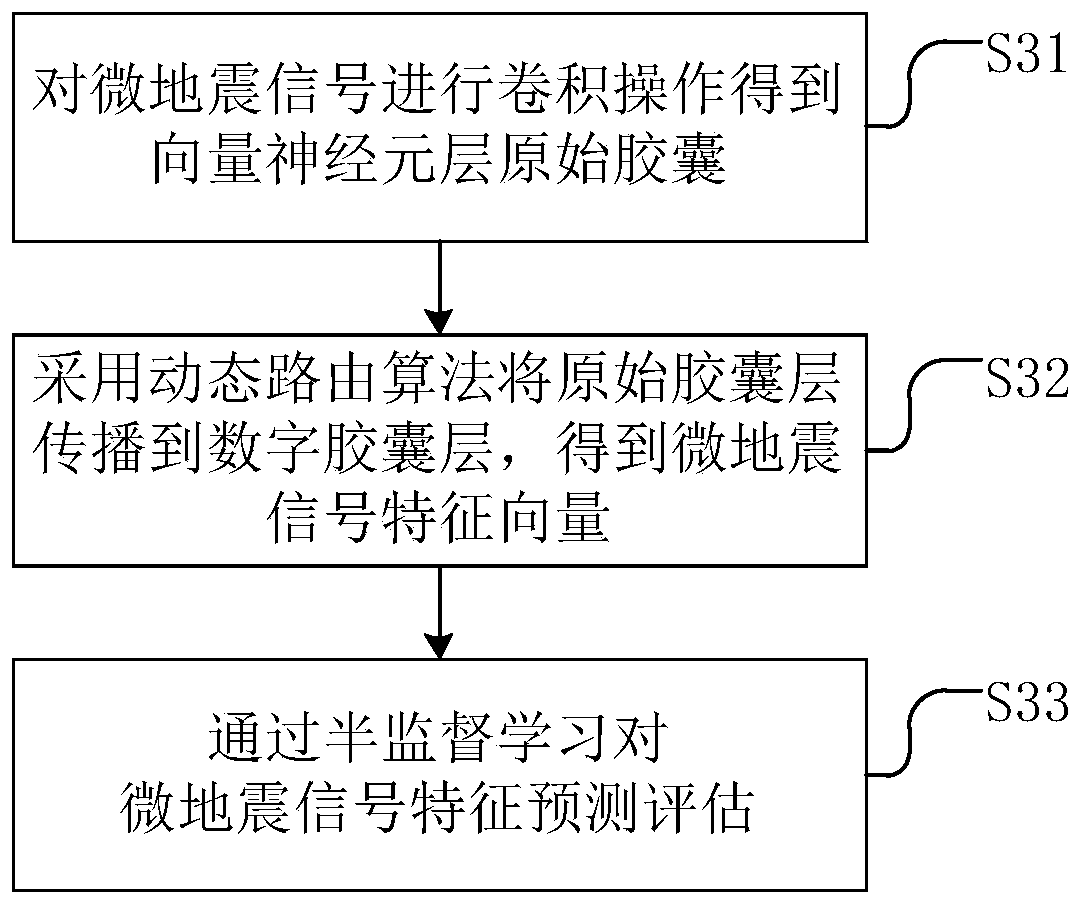

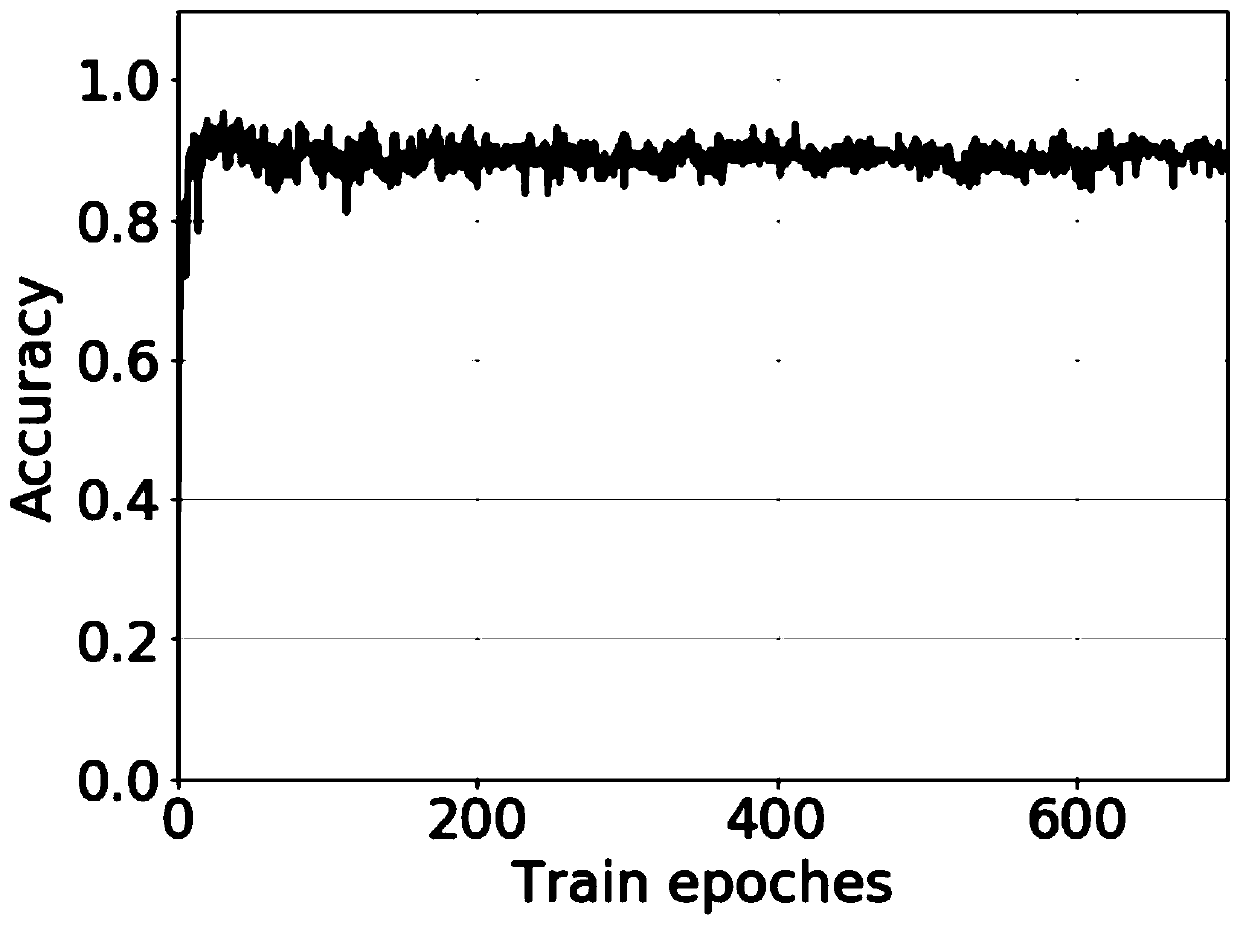

Microseism P-wave first arrival pickup method and system based on capsule neural network

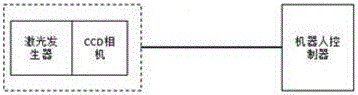

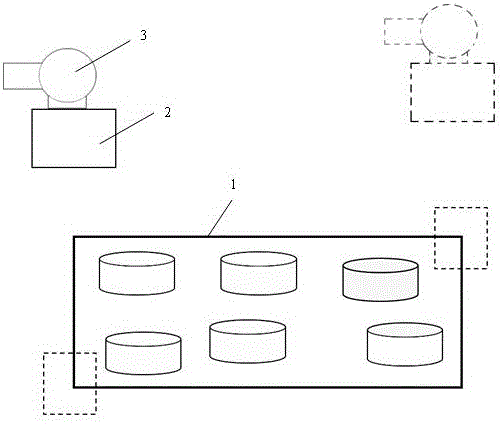

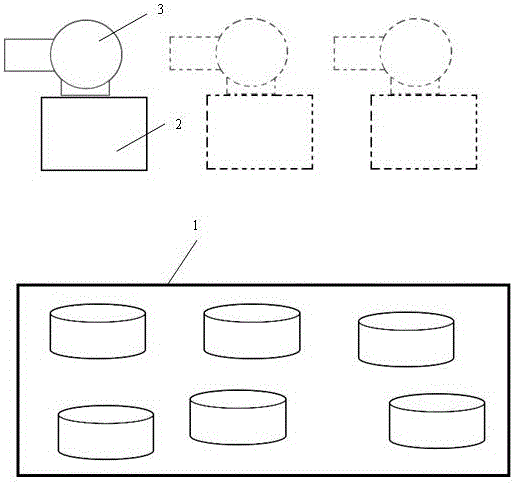

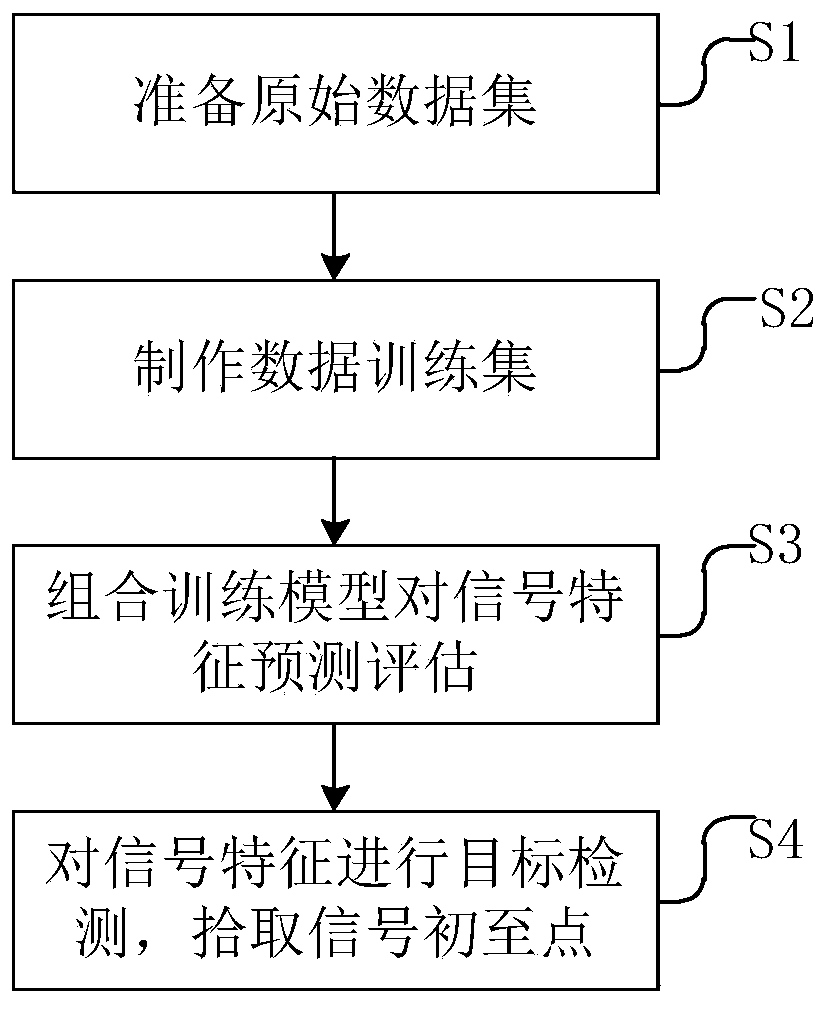

ActiveCN111505705AImplement first solstice pickingImprove accuracySeismic signal processingNeural architecturesData setOriginal data

The invention relates to the technical field of microseism data processing, in particular to a microseism P-wave first arrival pickup method and system based on a capsule neural network. The method comprises the steps of preparing an original data set, making a data training set, selecting first arrival points of a part of sample signals of the original data set, labeling the first arrival pointsto serve as a labeled part, and taking the other part of sample signals as a label-free part, inputting the data training set into a combined training model, and predicting and evaluating the characteristics of the microseism signals, carrying out target detection on the microseism signal characteristics to obtain a first arrival point of the microseism signal. The system comprises a data acquisition module, a data training set making module, a data training module and an output module. According to the embodiment of the invention, the capsule neural network and the semi-supervised learning are combined, and the RPN network is used for detecting the microseism signal, thereby achieving the pickup of the first arrival point of the microseism signal, and improving the feature extraction accuracy of the microseism signal and the accurate pickup of the P-wave first arrival point.

Owner:YANGTZE UNIVERSITY

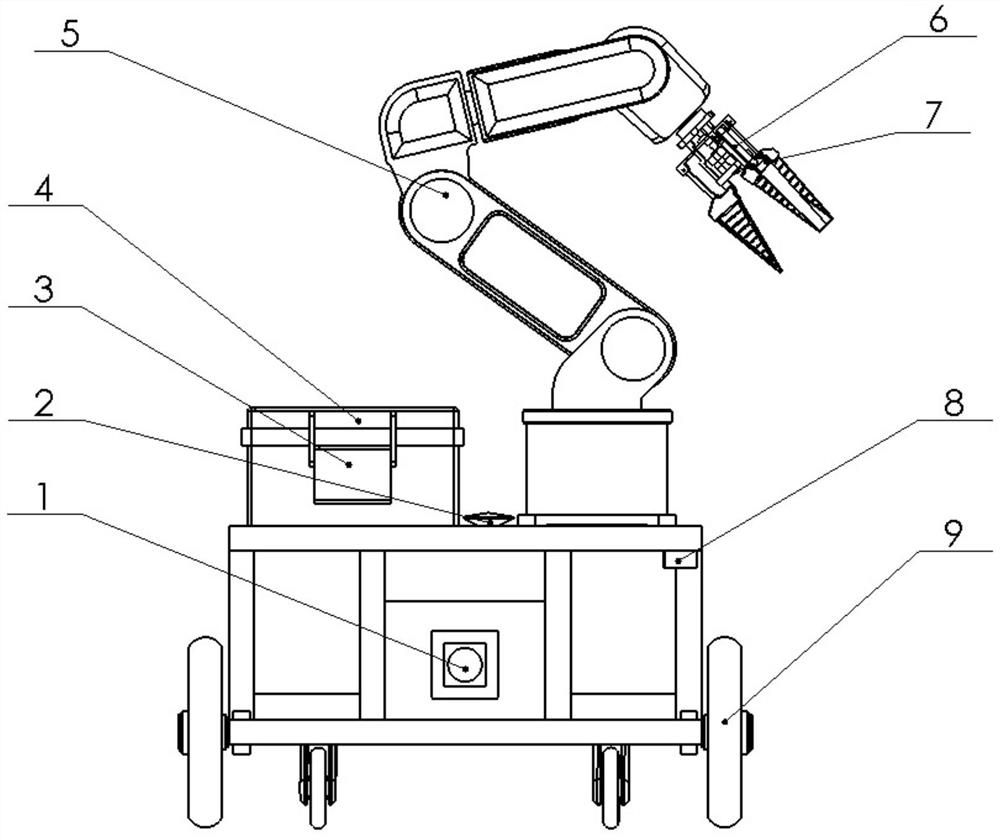

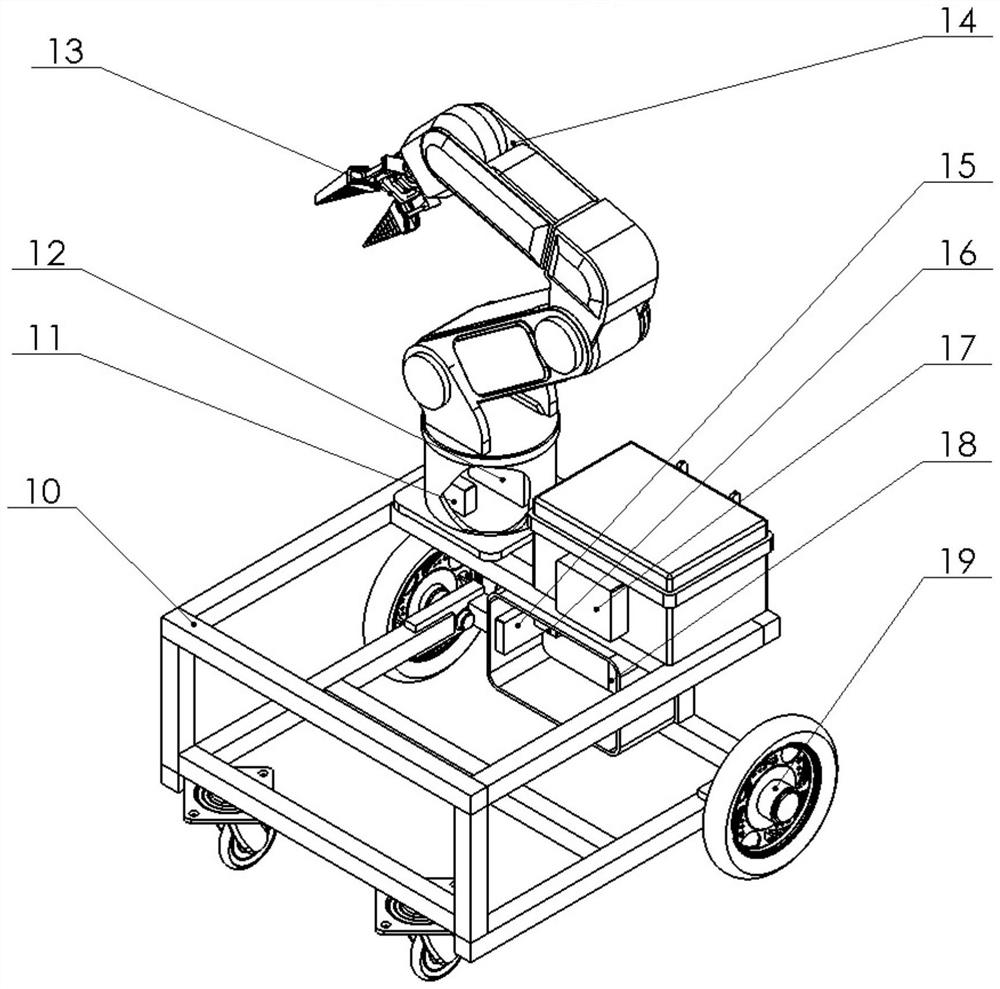

Vehicle-mounted mechanical arm type fruit picking and boxing system and method based on machine vision

PendingCN112428268AAvoid internal damagePick up automaticProgramme-controlled manipulatorIndividual articlesSocial benefitsMachine vision

The invention relates to the field of fruit post-harvest processing, and particularly relates to a vehicle-mounted mechanical arm type fruit picking and boxing system and method based on machine vision. The system comprises a self-propelled vehicle device, a machine arm device, a machine vision device and a control system, wherein the self-propelled vehicle device is used for carrying the machinearm device and related equipment and can drive the whole fruit picking and boxing system to move; the machine arm device is mounted on the self-propelled vehicle device and used for picking and boxingfruits; the machine vision device is mounted on an end effector in the machine arm device and used for recognizing and positioning the fruits; and the control system is mounted in the self-propelledvehicle device and used for analyzing data transmitted by the machine vision device and driving the machine arm device to grab the target fruits. The fruit picking and boxing efficiency is improved and the damage rate of the fruits is reduced through the advanced machine vision technology and robot technology, the fruit post-harvest processing capacity of China is greatly improved, and then huge economic benefits and social benefits are created.

Owner:NANJING AGRICULTURAL UNIVERSITY

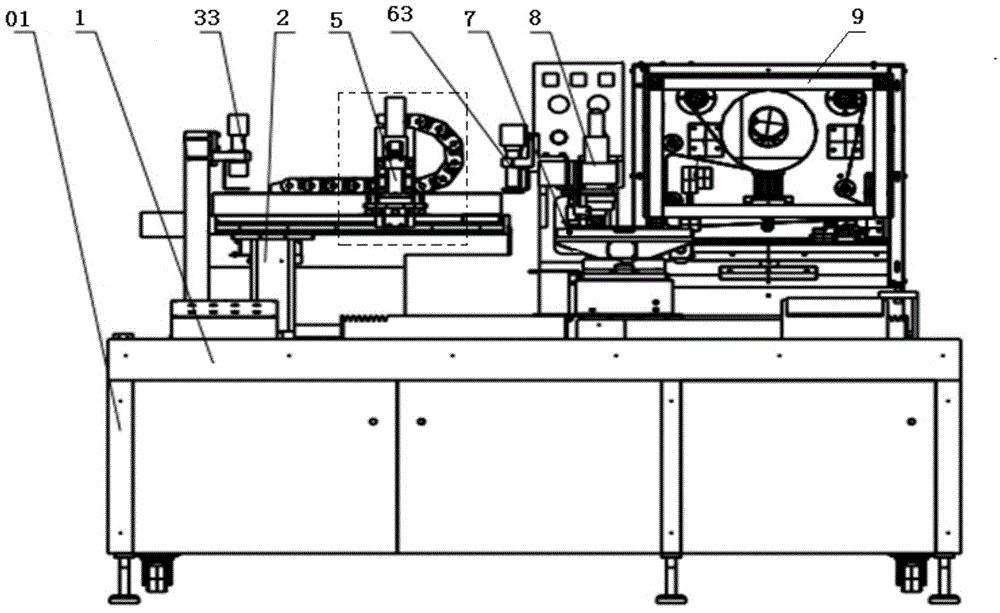

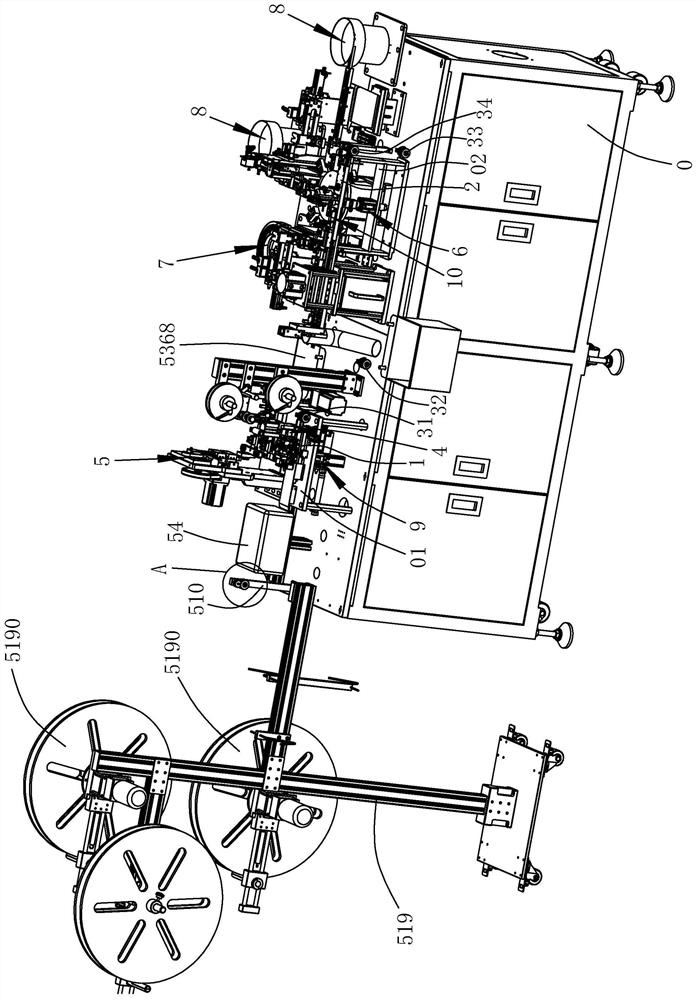

Miniature touch switch assembling machine

ActiveCN112542337AAvoid elasticImprove assembly efficiencyAssembly machinesElectric switchesAssembly machineTouch switch

The invention relates to a miniature touch switch assembling machine. The machine comprises a first guide rail, a base material belt turn-over wheel set and a second guide rail; the first guide rail is provided with a first material belt channel; the base material belt turn-over wheel set is used for turning over a base material belt; and the second guide rail is provided with a second material belt channel on the lower side. The miniature touch switch assembling machine further comprises an elastic sheet feeding device, an elastic sheet base fixing device, an upper cover base clamping device,an upper cover feeding device, and a button feeding device; the elastic sheet feeding device is arranged beside the first guide rail and used for cutting off an elastic sheet from an elastic sheet material belt and placing the elastic sheet on a base; the elastic sheet base fixing device is arranged on the first guide rail and used for fixing the elastic sheet and the base together; the upper cover base clamping device is arranged below the second guide rail. the upper cover feeding device is used for providing an upper cover for the upper cover base clamping device; the button feeding deviceis arranged beside the upper cover base clamping device and is used for providing a button for the upper cover base clamping device; the first guide rail and the second guide rail are provided with afirst material belt feeding device and a second material belt feeding device respectively, wherein the first material belt feeding device and the second material belt feeding device drive the base material belt to move along transmission paths. The assembling machine has the effects of being good in assembling quality and high in assembling efficiency.

Owner:SHENZHEN GANGYUAN MICRO KEY TECH CO LTD

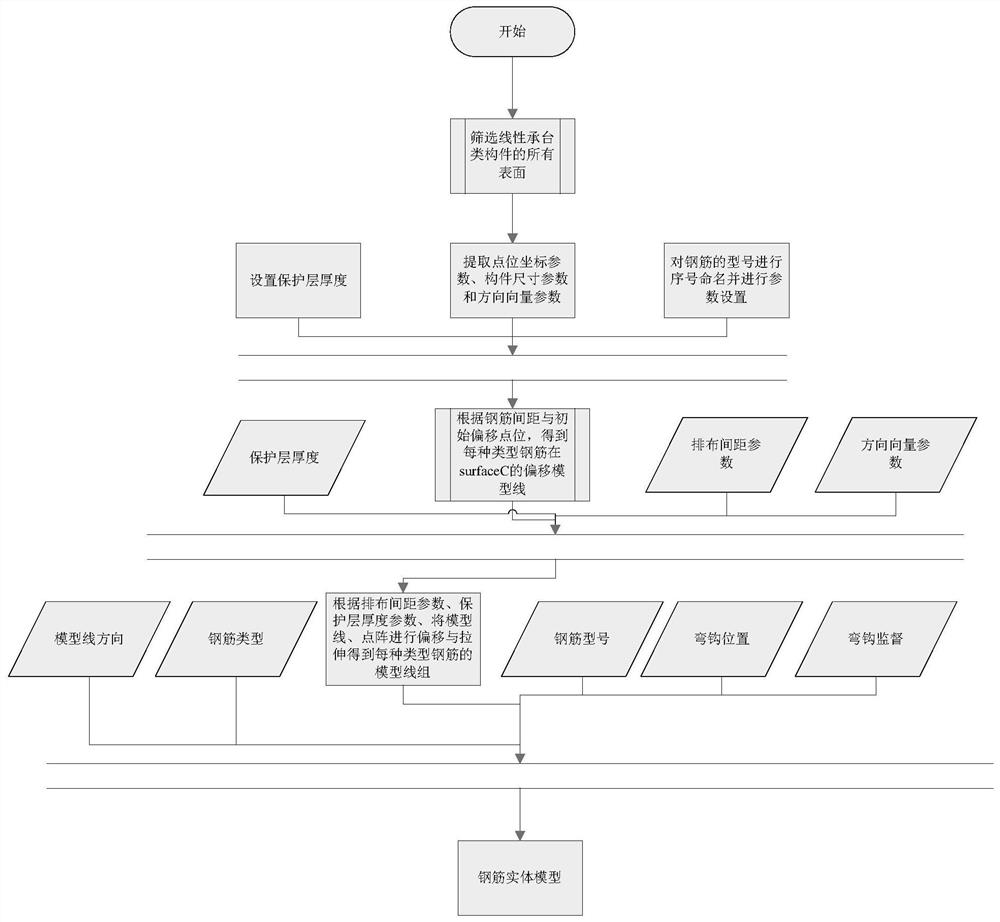

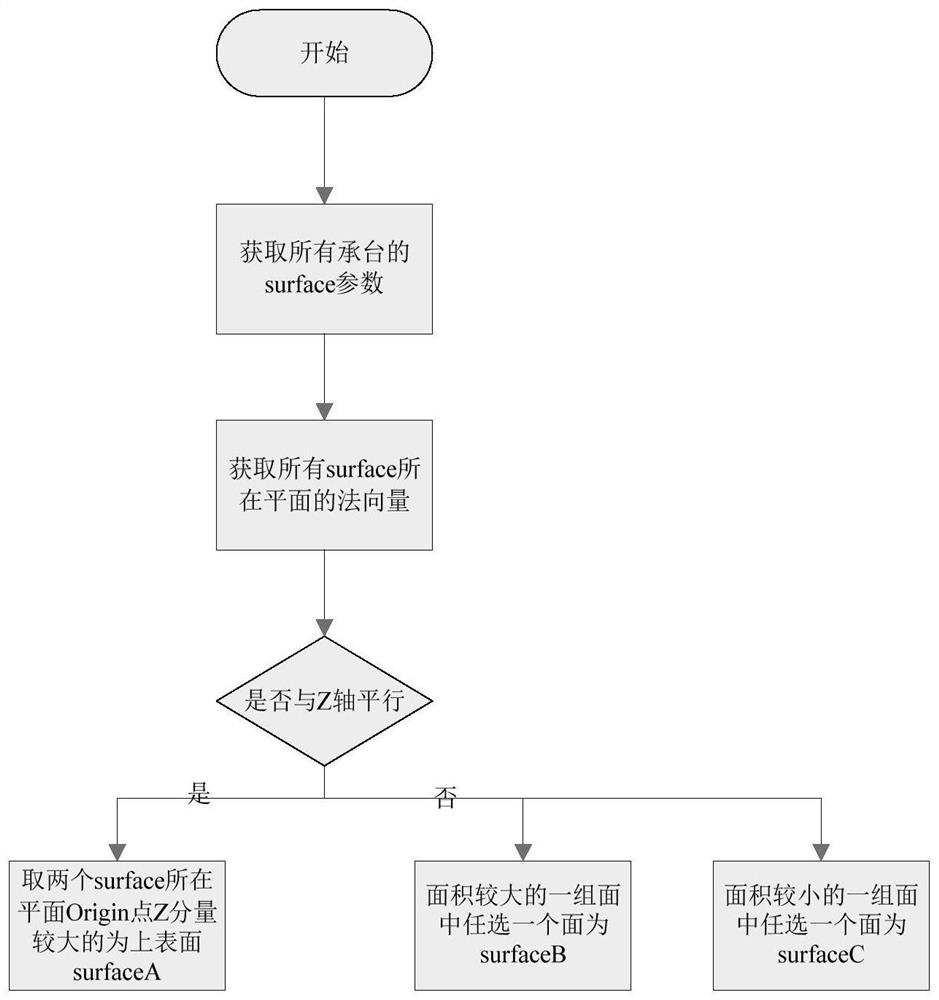

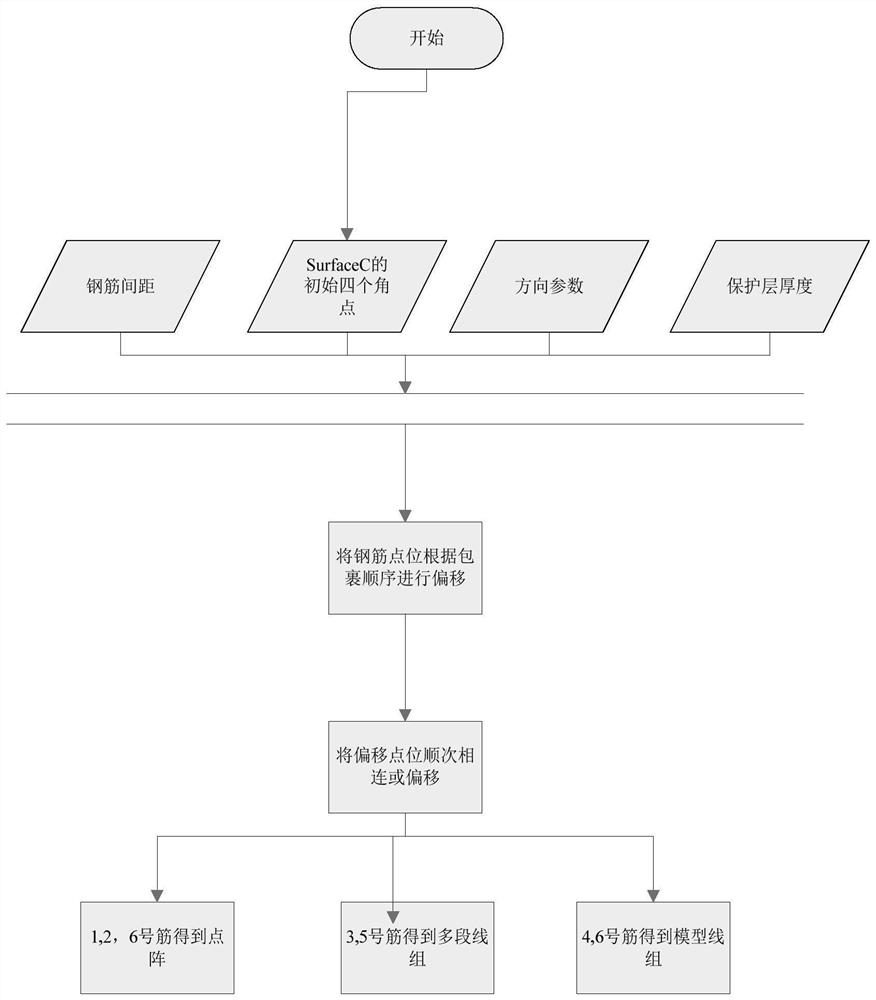

Linear bearing platform type component high-precision steel bar arrangement method

ActiveCN112116713APick up accuratelyImprove layout accuracyImage generation3D modellingDot matrixClassical mechanics

The invention relates to the technical field of building construction, and discloses a method for arranging high-precision steel bars of linear bearing platform type components based on a BIM technology. The method mainly comprises: extracting surface parameters of the linear bearing platform type component, dividing all steel bars into different types according to different space positions, and obtaining an initial dot matrix or model line on an initial offset surface according to diameter parameters, arrangement interval parameters and protective layer thickness of all types of steel bars; performing model line array offset or dot matrix offset along the longitudinal direction to obtain a steel bar model line array, and finally generating a steel bar model. According to the method, accurate positioning and self-adaptive arrangement of the steel bars in the linear bearing platform type component are achieved through computer programming, internal collision of the steel bars is avoided, and steel bar entities are rapidly generated in batches. The problems that in existing deepening design, linear bearing platform type components are low in arrangement accuracy and disordered in rule are solved. And meanwhile, the method can be used for technical disclosure of field construction and has the advantages of improving machining precision and construction efficiency and the like.

Owner:NANCHANG UNIV +2

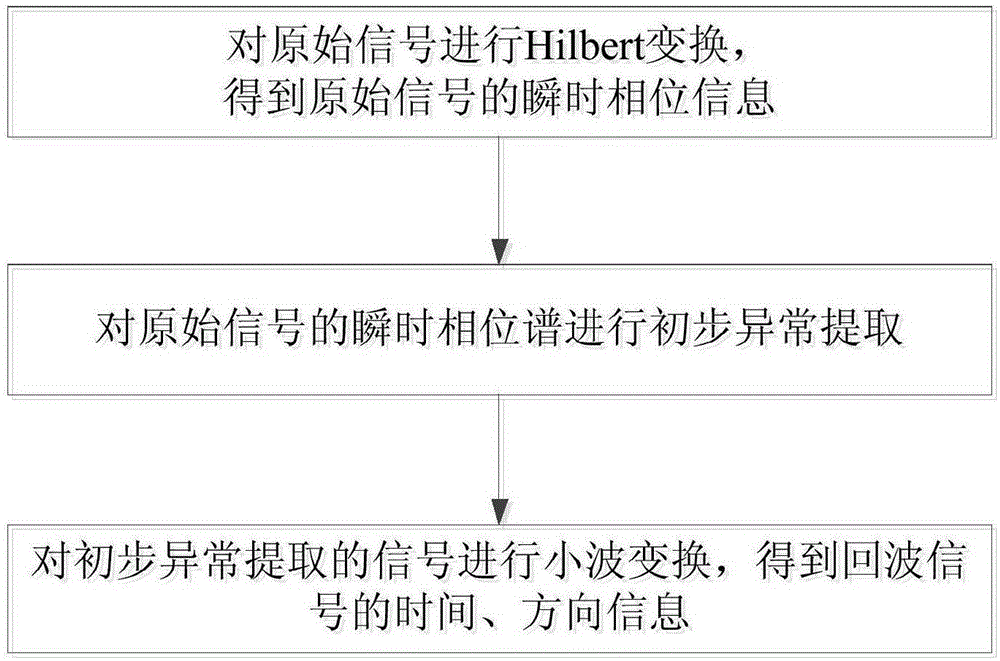

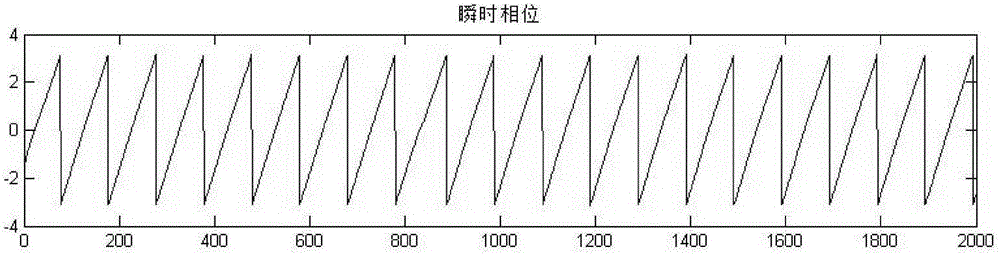

Phase-criterion-based identification and extraction method of physical detection echo signal

ActiveCN105158799APick up accuratelyAccurate separationSeismic signal processingThin layerAnalytic signal

The invention relates to a phase-criterion-based identification and extraction method of a physical detection echo signal. The method comprises: (1), carrying out Hilbert transform on an echo signal to obtain a corresponding parsing signal; (2), according to corresponding parsing, obtaining an instantaneous value of a phase theta (t); (3), carrying out phase compensation on instantaneous phase information of the signal and extracting preliminary abnormity; and (4), carrying out wavelet transform on a signal extracted by the preliminary abnormity and extracting abnormal information in an original waveform accurately. According to the method provided by the invention, echo information from the deep place of the stratum can be picked up accurately under the condition of the same source energy. Moreover, echo information of a weak reflection layer can be extracted accurately and echo information of the top surface and bottom surface of the thin layer can be separated and extracted accurately. Meanwhile, the aftershock can be suppressed effectively and the multiple influence can be reduced.

Owner:WUHAN ENG SCI & TECH RESINST

Full-automatic feather punching and shearing forming machine

ActiveCN111015819AReduce labor intensityImprove work efficiencyMetal working apparatusStamping processStructural engineering

The invention discloses a full-automatic feather punching and shearing forming machine which comprises a rack, a controller, a tidying mechanism, a conveying mechanism, a positioning and feather feeding mechanism, a rotating mechanism, a feather punching mechanism and an automatic feeding mechanism. The tidying mechanism, the conveying mechanism, the positioning and feather feeding mechanism and the automatic feeding mechanism are in signal connection with the controller and fixed to the rack. The automatic feeding mechanism is responsible for feeding materials to the tidying mechanism, the tidying mechanism is connected with the positioning and feather feeding mechanism through the conveying mechanism, the rotating mechanism corresponds to an output end of the positioning and feather feeding mechanism, and the feather punching mechanism corresponds to an output end of the rotating mechanism. By means of the structure, the processes of automatic picking, feeding, straightening, positioning conveying and stamping of feathers to be machined are automatically conducted, the forming machine reduces labor intensity, improves work efficiency, is good in accuracy and high in reliability,prevents influence on quality of to-be-processed feathers in the previous manual operation process, is simple, convenient and flexible to use, and is particularly suitable for being used in cooperation with other automatic shuttlecock processing equipment.

Owner:林先明

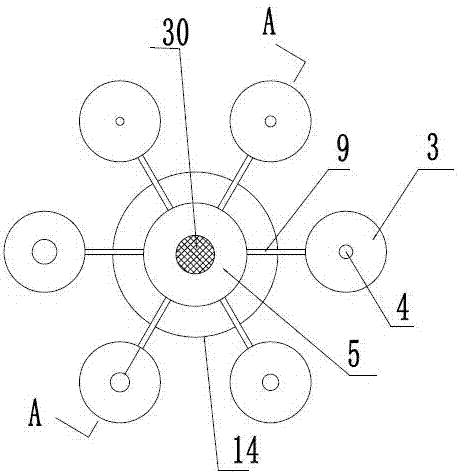

Multiple LED chip pickup device

InactiveCN103841768ASimple structureReasonable designPrinted circuit assemblingSemiconductor/solid-state device manufacturingEngineeringPiston rod

The invention discloses a multiple LED chip pickup device comprising an integrated backboard, a pickup push plate and pickup units. The pickup push plate is installed on the lower portion of the integrated backboard. The number of the pickup units is four. Each pickup unit comprises a mount cylinder, supports and a suction nozzle. The mount cylinder is vertically installed on the middle portion of the integrated backboard. The mount cylinder is located over the pickup push plate. A through hole is formed in the pickup push plate. The piston rod end of the mount cylinder passes through the through hole and is rotatably connected with the pickup push plate. The lower end of the suction nozzle has a tapered hollow columnar structure. The suction nozzle is installed on the end portion of the piston rod end of the mount cylinder. The number of the supports is two. Both of the two supports are installed on the suction nozzle. Each support is obliquely provided with an infrared sensor for detecting the LED chip position. The two infrared sensors are arranged symmetrically. According to the invention, the problem of complex pickup working process caused by the single suction nozzle automatic suction mode can be effectively solved, and at the same time, the advantage of accurate pickup can be realized.

Owner:SHAANXI ZIZHU ELECTRON

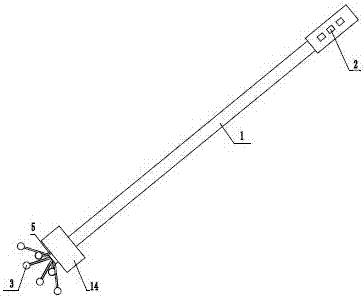

Adsorption type garbage picking-up device

The invention belongs to the technical field of environmental protection equipment, solves the technical problems existing when sanitation workers pick up sundries, and provides an adsorption type garbage picking-up device. The adsorption type garbage picking-up device comprises a picking-up head. The picking-up head is composed of multiple suction balls, each suction ball is hollow, and a suction hole is formed in each suction ball. The adsorption type garbage picking-up device also comprises a vacuum suction device and a rotary device. Different suction balls can be chosen to pick up sundries through the rotary device, and negative pressure is generated in the suction balls through the vacuum suction device. The adsorption type garbage picking-up device has the beneficial effects that the effects of convenient operation and accurate picking up can be achieved when the garbage picking up is conducted by the principle of vacuum adsorption, multiple suction balls are arranged, the suction holes with different diameters are formed in the multiple suction balls, so that the appropriate suction balls are chosen to pick up sundries according to the size of sundries, the switching of the suction holes is flexible and quick, thus the labor intensity of sanitation workers is greatly decreased, and the labor efficiency is improved.

Owner:江苏宝华环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com