Patents

Literature

437results about How to "Avoid elastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

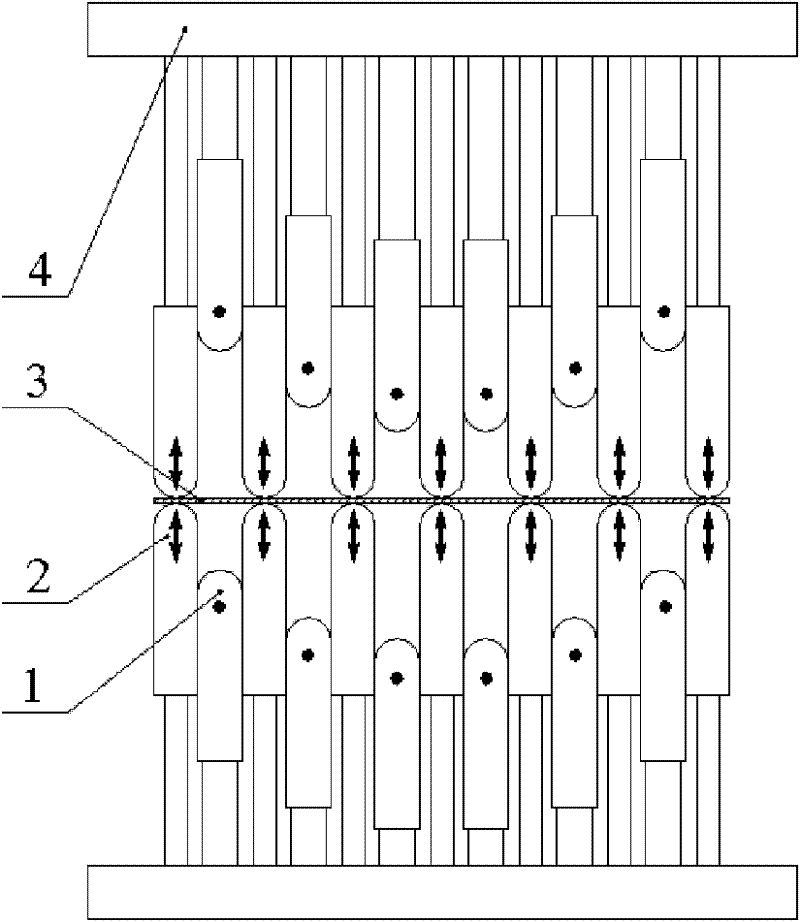

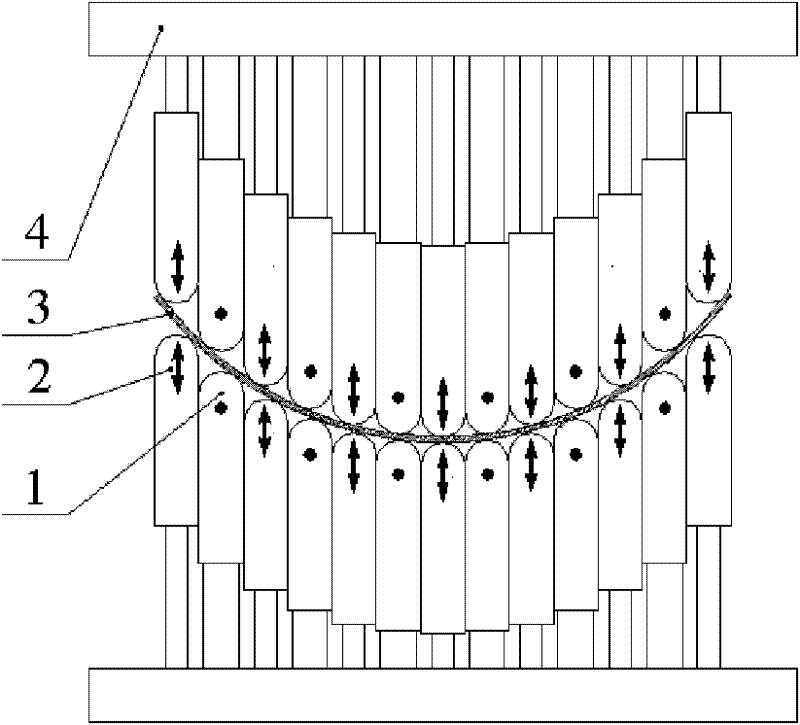

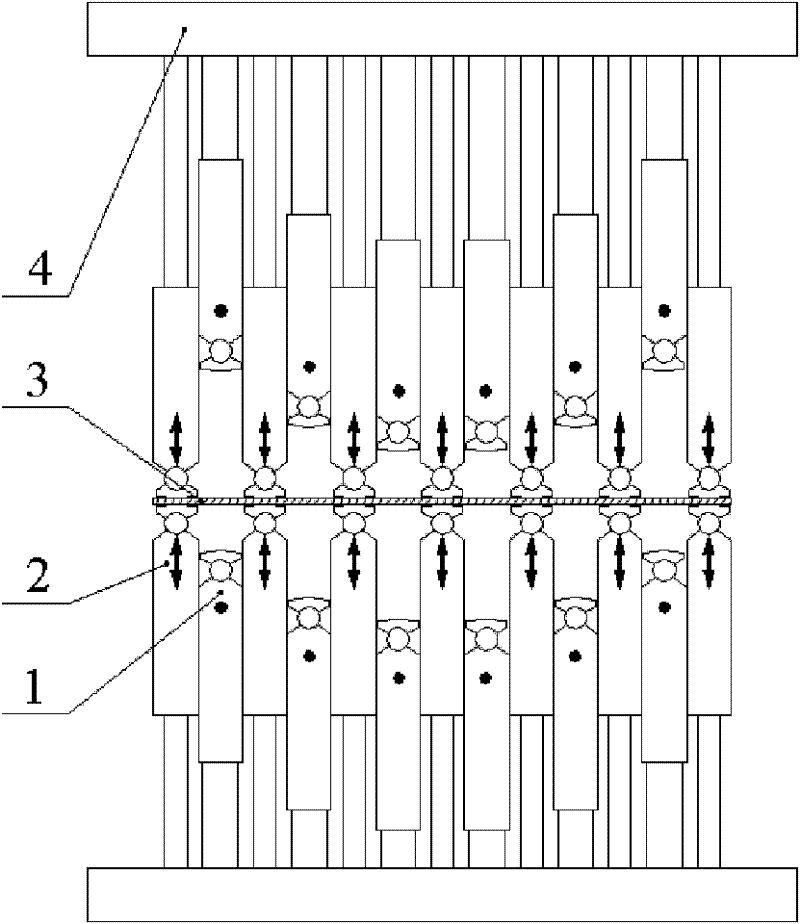

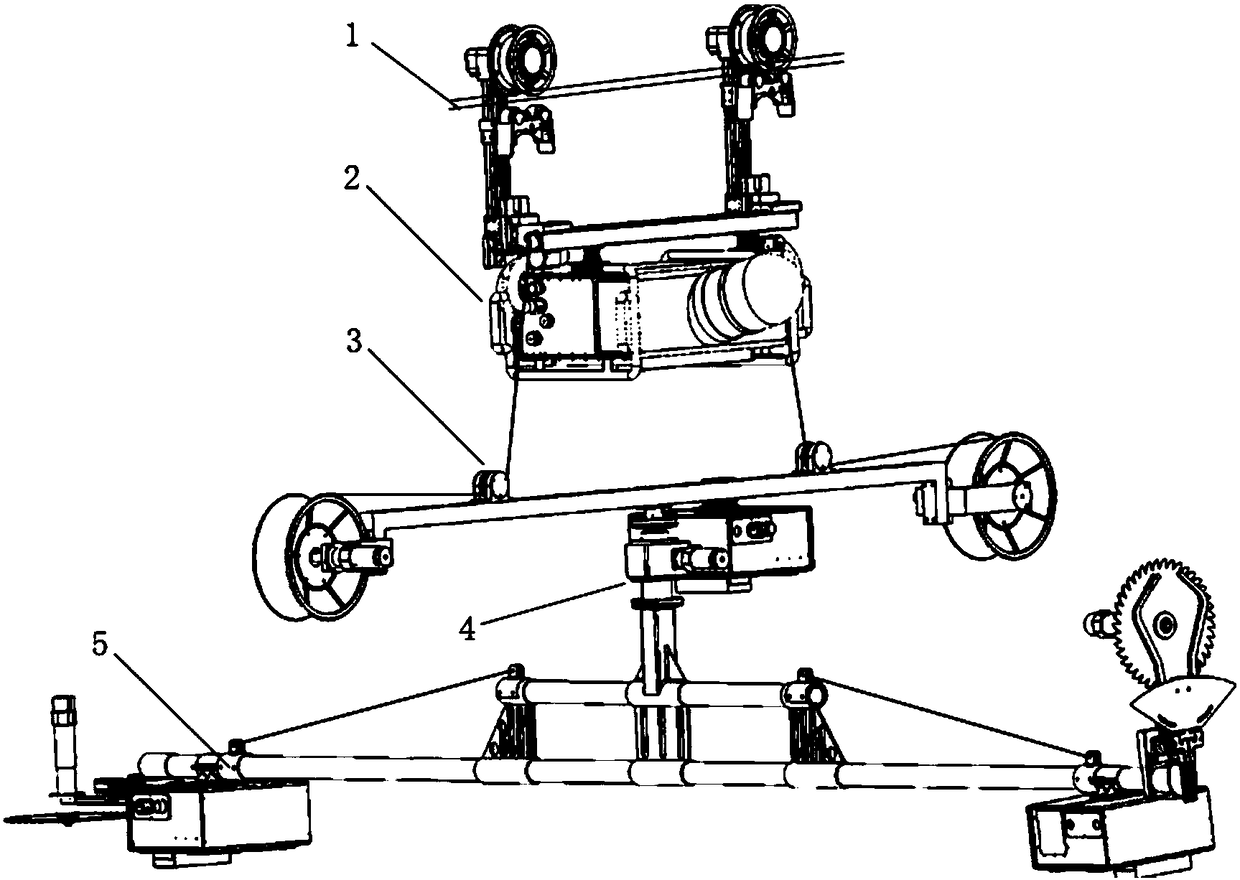

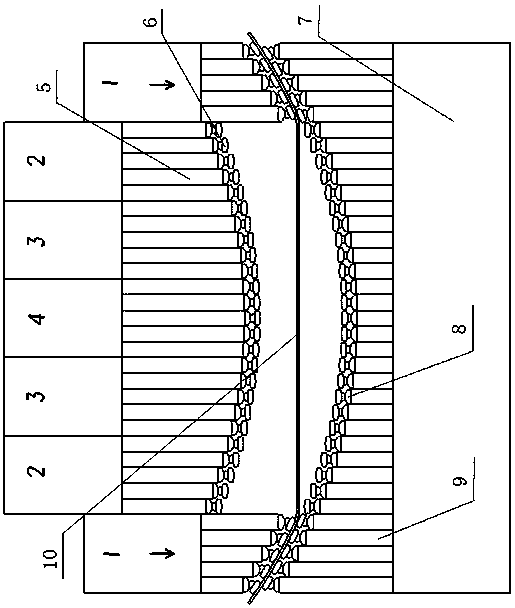

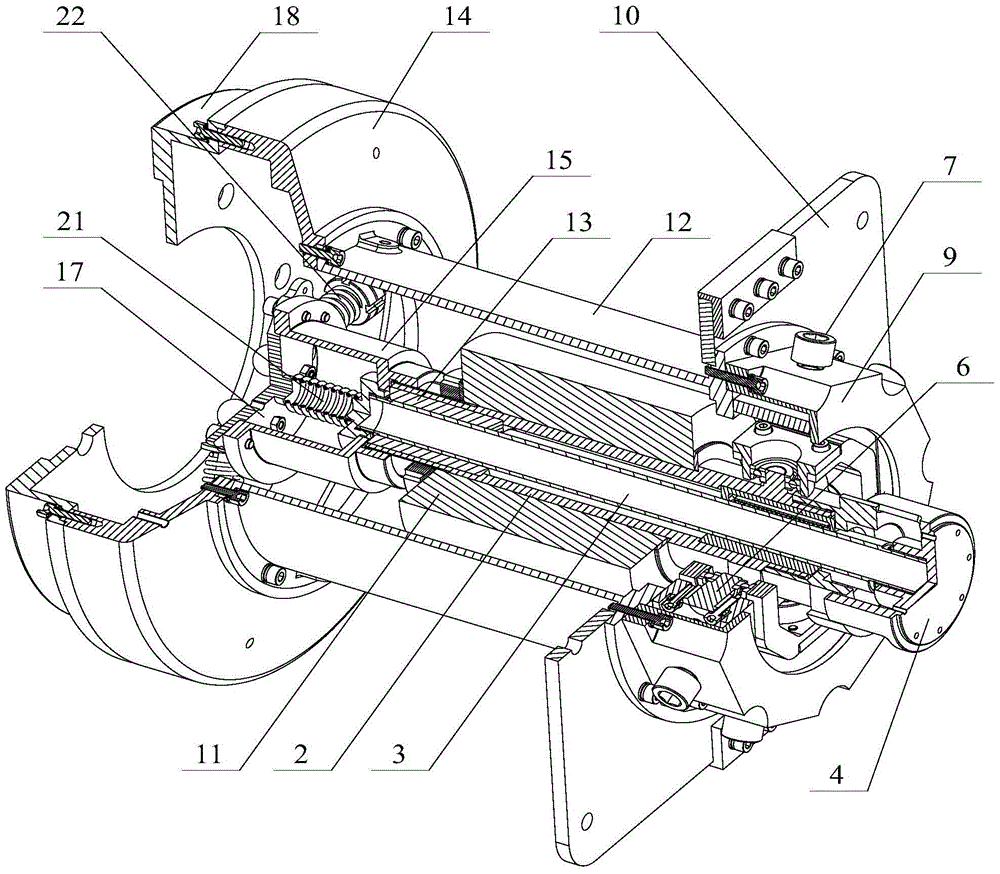

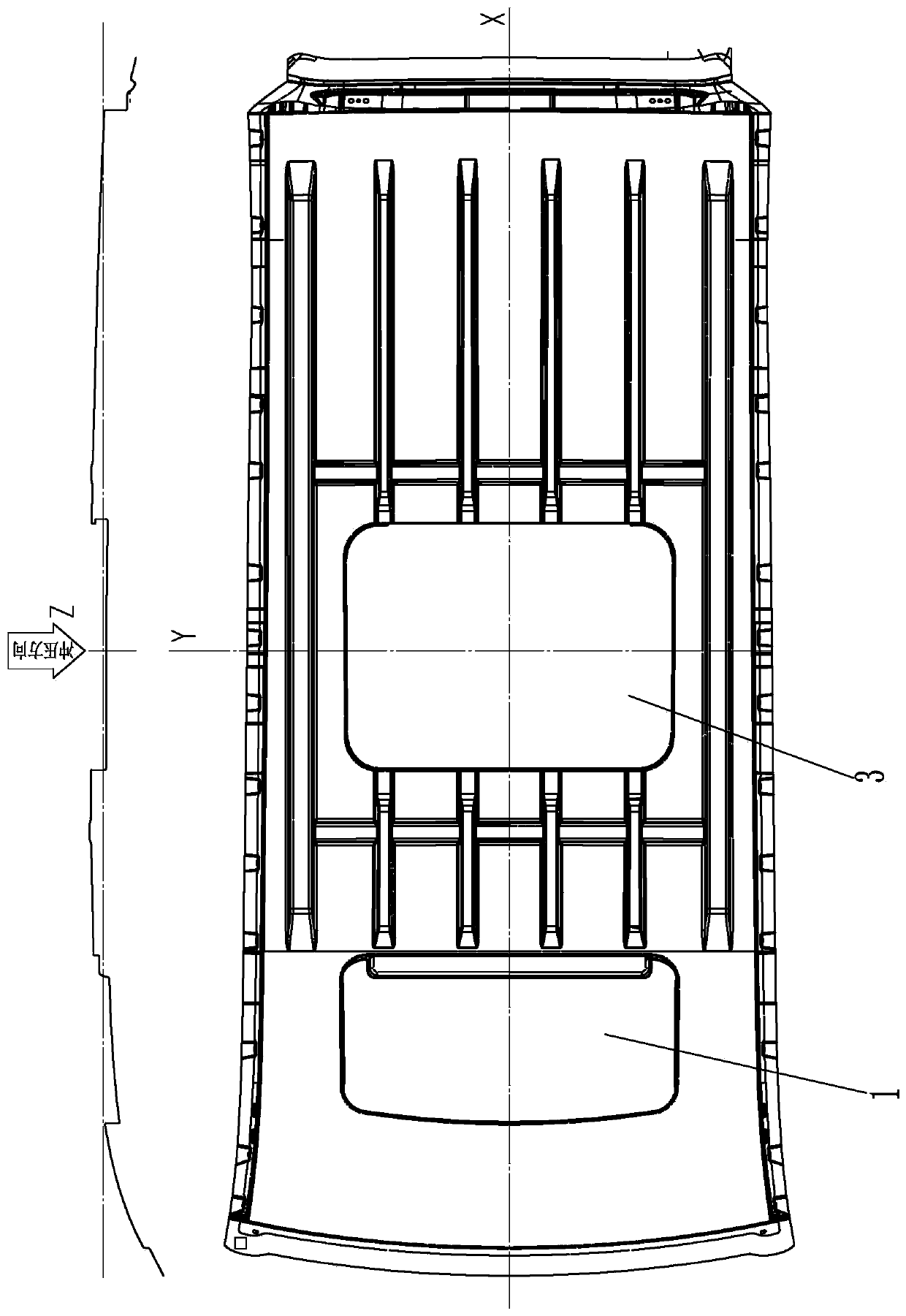

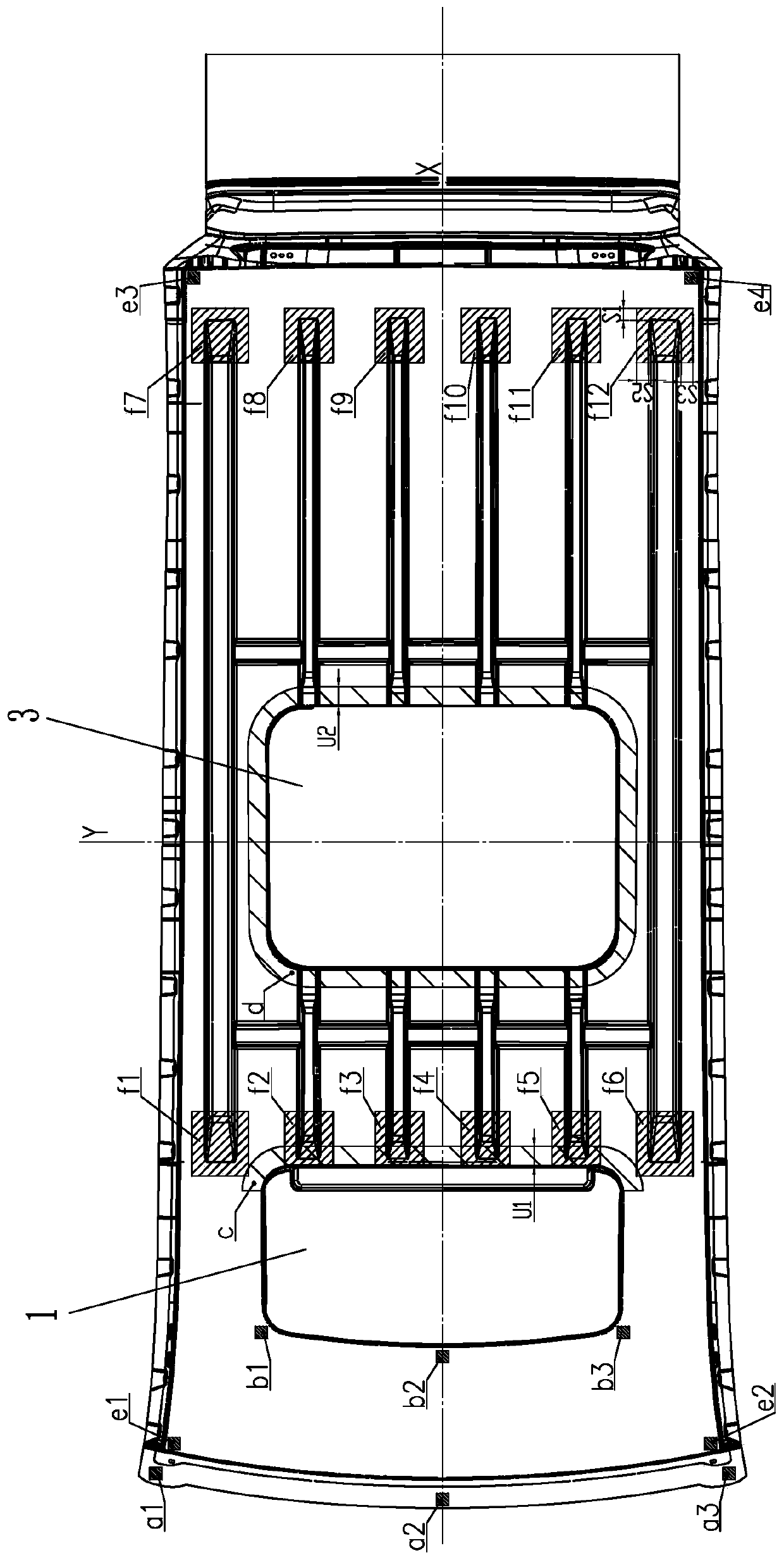

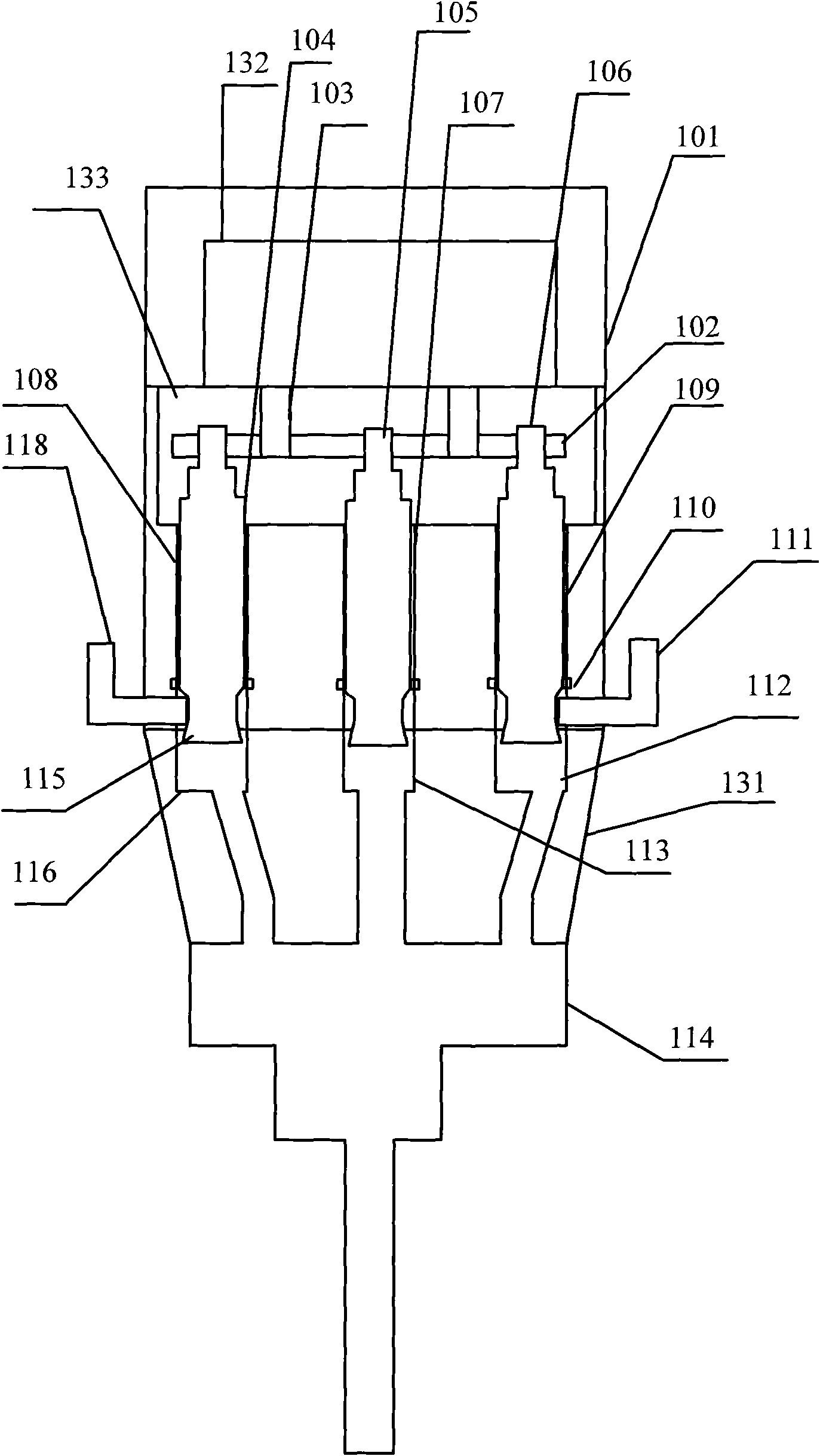

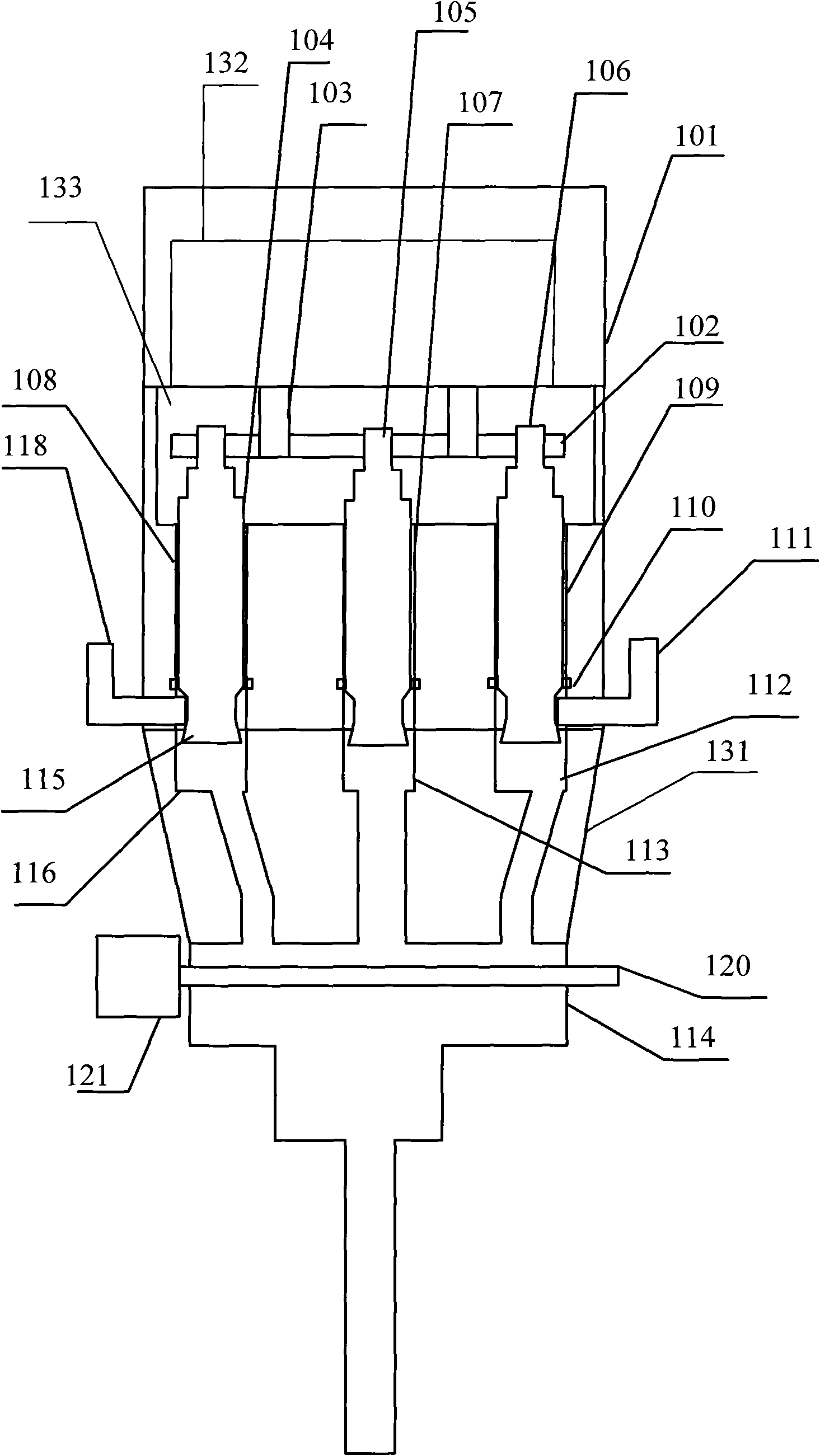

Plate multipoint forming device with crease resistant functions

ActiveCN102248053AReduce designAchieve moldless formingShaping toolsBiomedical engineeringEquipment use

The invention discloses a plate multipoint forming device with crease resistant functions, relating to plastic processing equipment used for plate curved surface forming and belonging to the field of mechanical engineering. The device mainly comprises shape-adjusting units (1), clamping units (2), a unit fixing plate (4) and a loading mechanism and is characterized in that the shape-adjusting units (1) and the clamping units (2) are arranged in a staggering manner; enveloping surface shapes of the plurality of shape-adjusting units (1) with adjustable heights can be changed through a shape-adjusting mechanism; the traditional entity die is replaced; and the plurality of clamping units (2) which are shifted passively are used for clamping a plate through back pressure effects to replace a side-pressing mechanism. The device can be used for inhibiting creases and rebound when the plate is formed and used for forming complex outline curved surface members with different sizes, therefore, the step of cutting sides after forming is omitted, and the utilization rate of the plate is improved.

Owner:JILIN UNIV

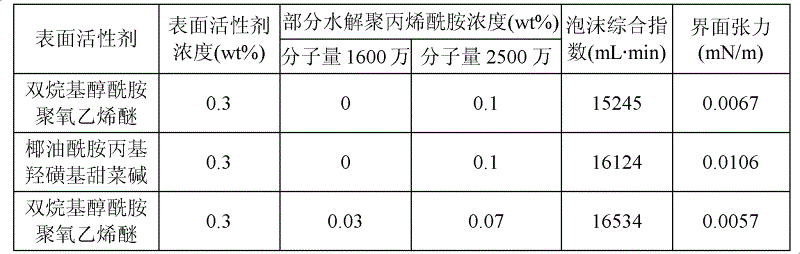

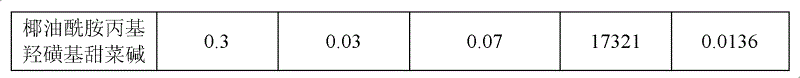

Composite foam flooding method suitable for oil field exploitation

ActiveCN102618246AImprove applicabilityMeet the use requirementsDrilling compositionInjection volumePolymer science

The invention relates to a composite foam flooding method suitable for oil field exploitation, comprising the following steps that: pretreated prepositive polymer plug is injected into the formation, and the injection volume of the polymer plug is 8-15% of the total pore volume of the formation; composite foam flooding auxiliary plug is injected into the formation, and the injection volume of the composite foam flooding auxiliary plug is 5-10% of the total pore volume of the formation; composite foam flooding main plug is injected into the formation, and the injection volume of the composite foam flooding main plug is 30-60% of the total pore volume of the formation; and follow-up protective polymer plug is injected into the formation, and the injection volume of the follow-up protective polymer plug is 10-20% of the total pore volume of the formation. With the adoption of the composite foam flooding method suitable for oil field exploitation, a good flooding effect can be obtained.

Owner:PETROCHINA CO LTD +1

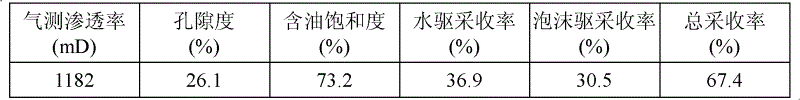

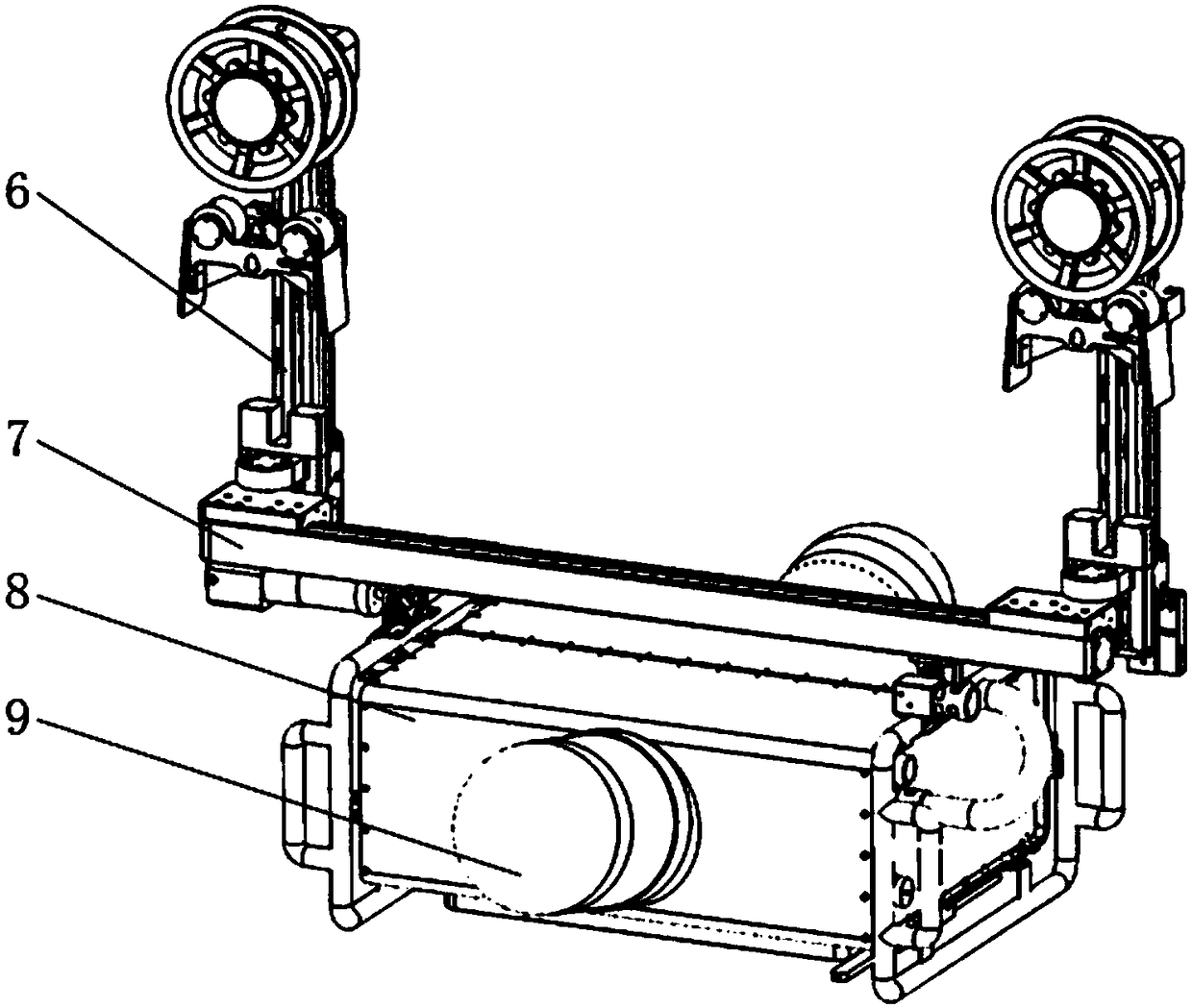

Six-traction device space debris net capture system

The invention provides a six-traction device space debris net capture system which adopts level-1 launch and mass blocks synchronization launch and concentric circles rope net folding and receiving. The system comprises a launch subsystem which is composed of a launcher, a net hold, a cushioning device and a tether tension control device; a fly net subsystem which is composed of a rope net and mass blocks; the launcher is used for pushing the mass blocks at a predetermined distance from a target at a predetermined angle and to drive the rope net be pulled from the center of the net hold while unfolding to a fully unfolded state to capture the target after reaching the target location; the mass blocks are used for dragging the rope net so that the rope net is pulled out and unfolded and the net opening is tightened up to complete capture of the target; the number of the mass blocks is at least three and six mass blocks are adopted through optimized analysis; the tether tension control device is connected with the fly net subsystem and with the target through the rope net to pull the captured target off the track; the rope net is encapsulated in the net hold in a concentric circles package and is used to form sufficient coverage to completely surround the target.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

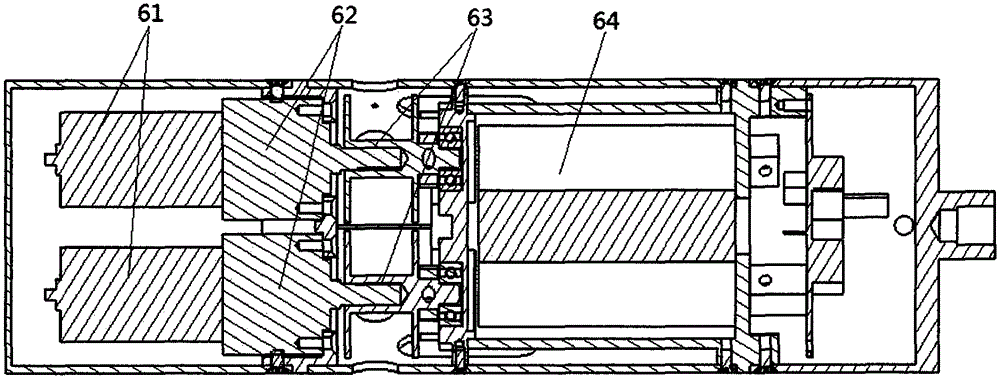

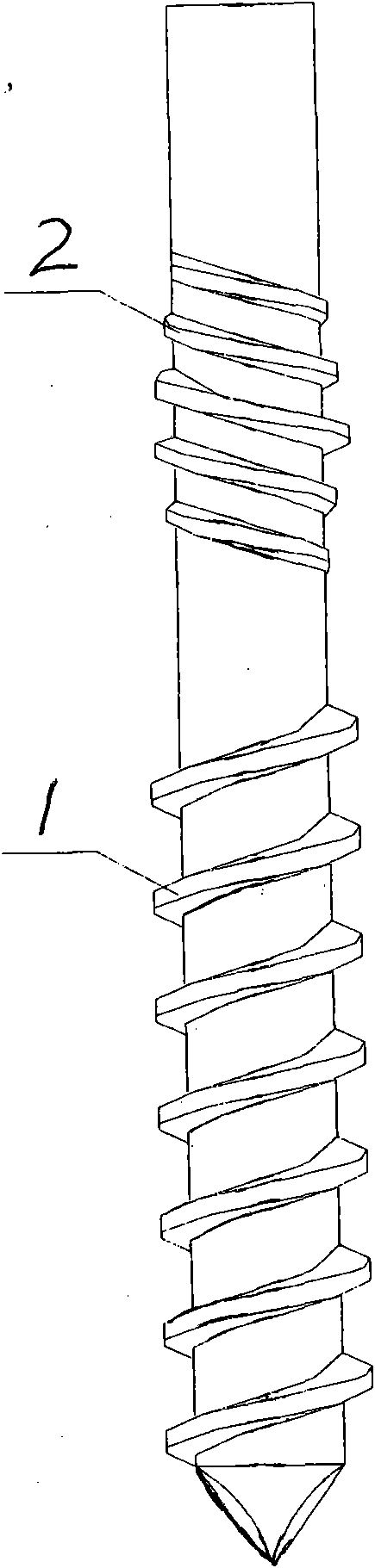

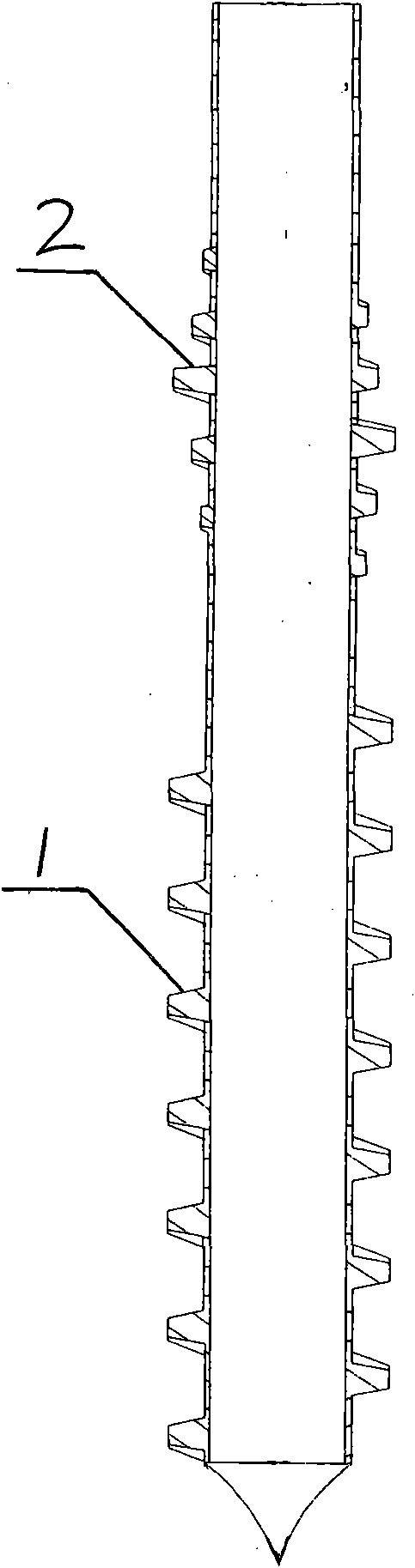

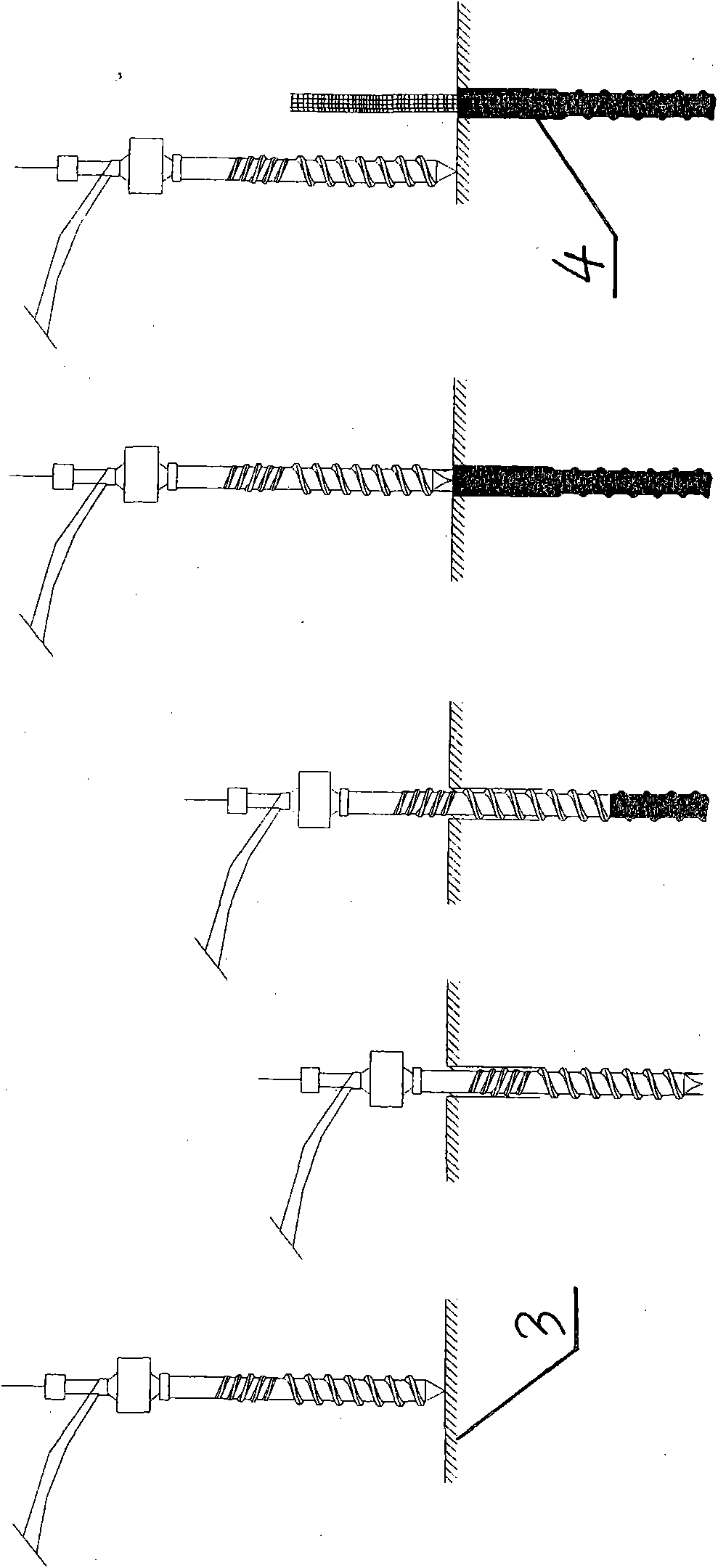

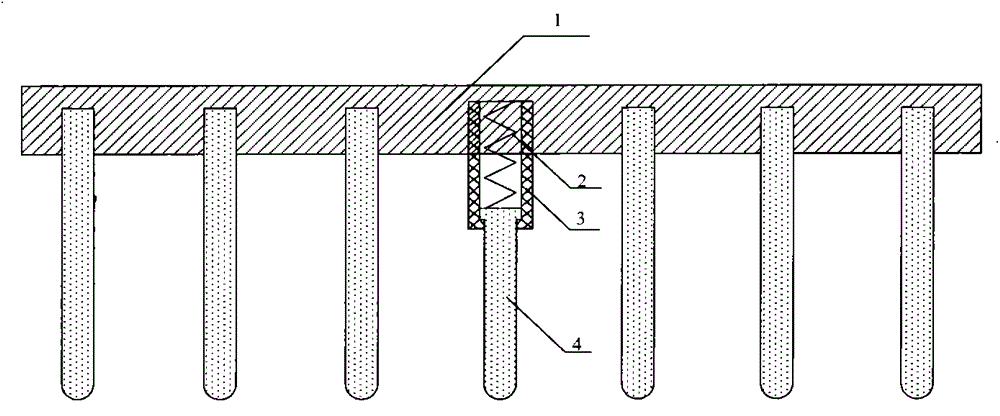

Pile-forming drilling tool for screw pile and pile-forming construction method thereof

InactiveCN101864768ASimplify the construction processSimple and fast operationDrill bitsDrilling rodsReinforced concreteRebar

The invention relates to a pile-forming drilling tool for a screw pile and a pile-forming construction method thereof, wherein forward drilling threads are arranged at the lower part of the pile-forming drilling tool, and backward sweeping threads are detachably arranged on the upper part thereof. The pile-forming construction method comprises the following steps: adopting special screw pile equipment to be assorted with the drilling tool to align with a pile position; utilizing the drilling tool to drill downwards so as to form threaded soil holes to reach the design depth of the pile, and meanwhile utilizing the sweeping threads at the upper part of the drilling tool to extrude and sweep the soil threads to form straight holes which reach the design depth of a straight lever section; lifting up the drilling tool in a rotating mode, and simultaneously concreting to form the thread section and the straight lever section of the pile; and after concreting is completed, placing a reinforcing cage to form the reinforced concrete screw pile. The drilling tool provided by the invention can effectively eliminate part of a threaded soil mass to form the straight holes by adopting forward threads and backward threads, thus achieving the effect of forming screw pile holes by boring at a time and realizing hole-forming and pile-forming of the screw pile at a time; and the pile-forming construction method has simple working procedures, faster speed, reduced construction resistance and no need of taking soil.

Owner:彭桂皎

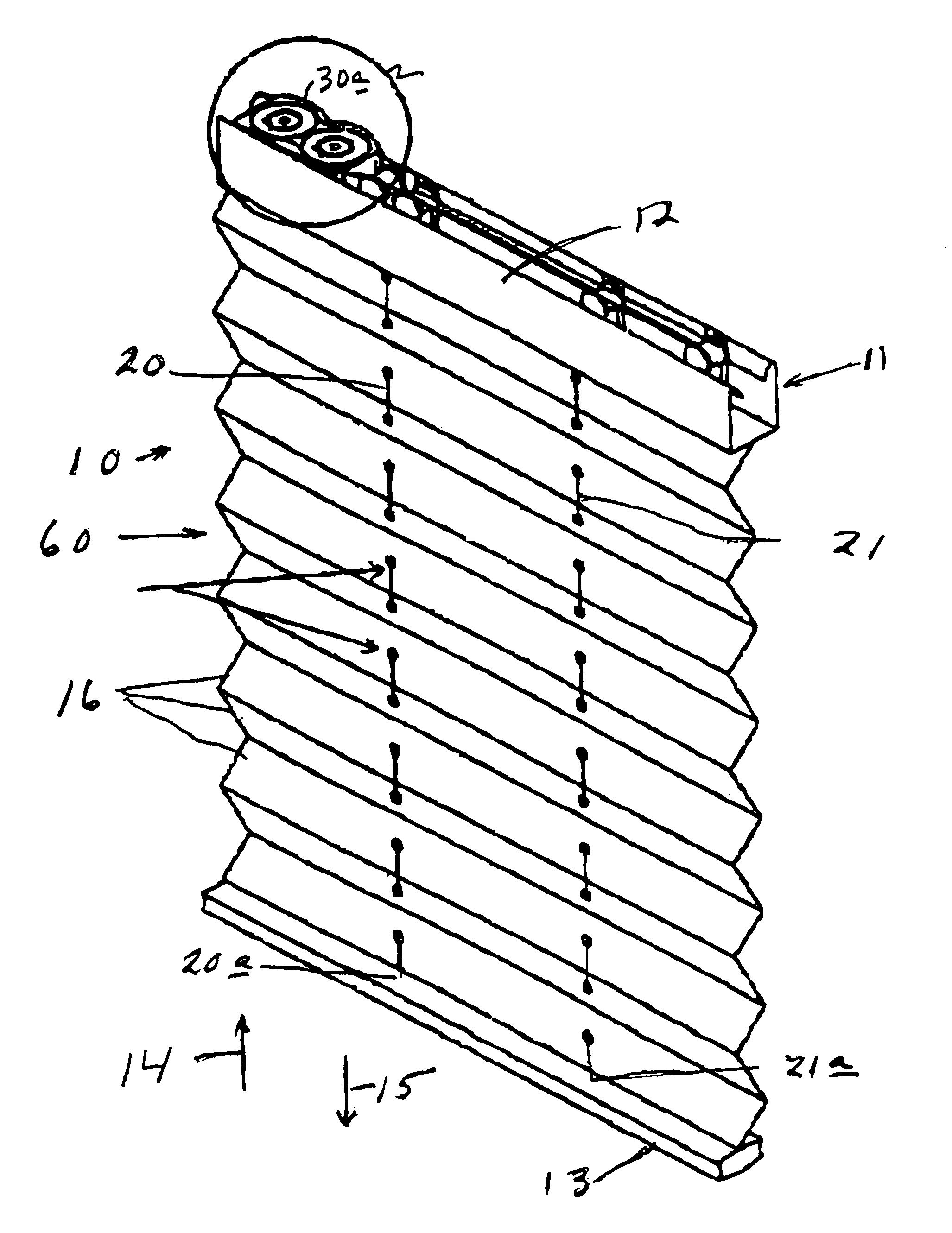

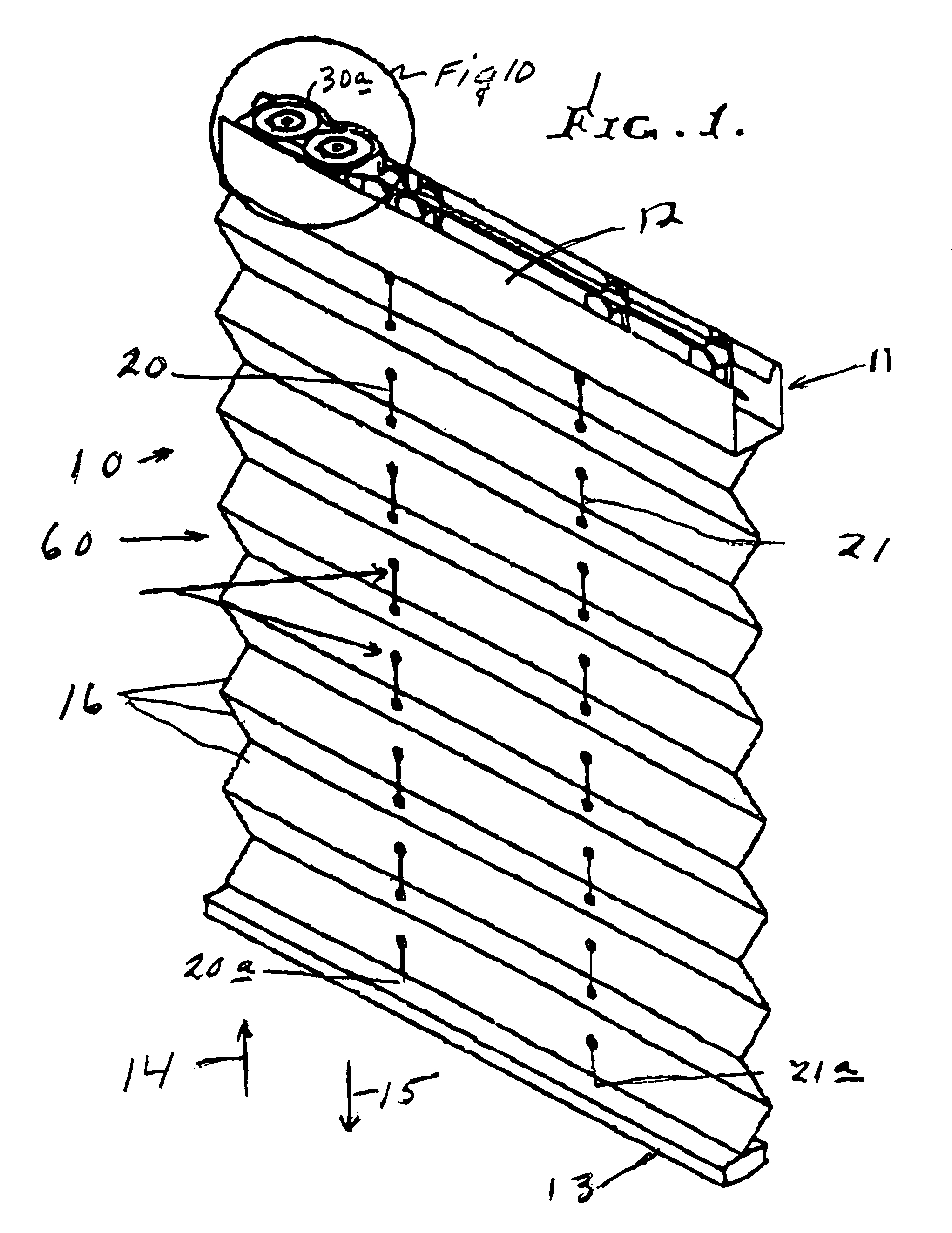

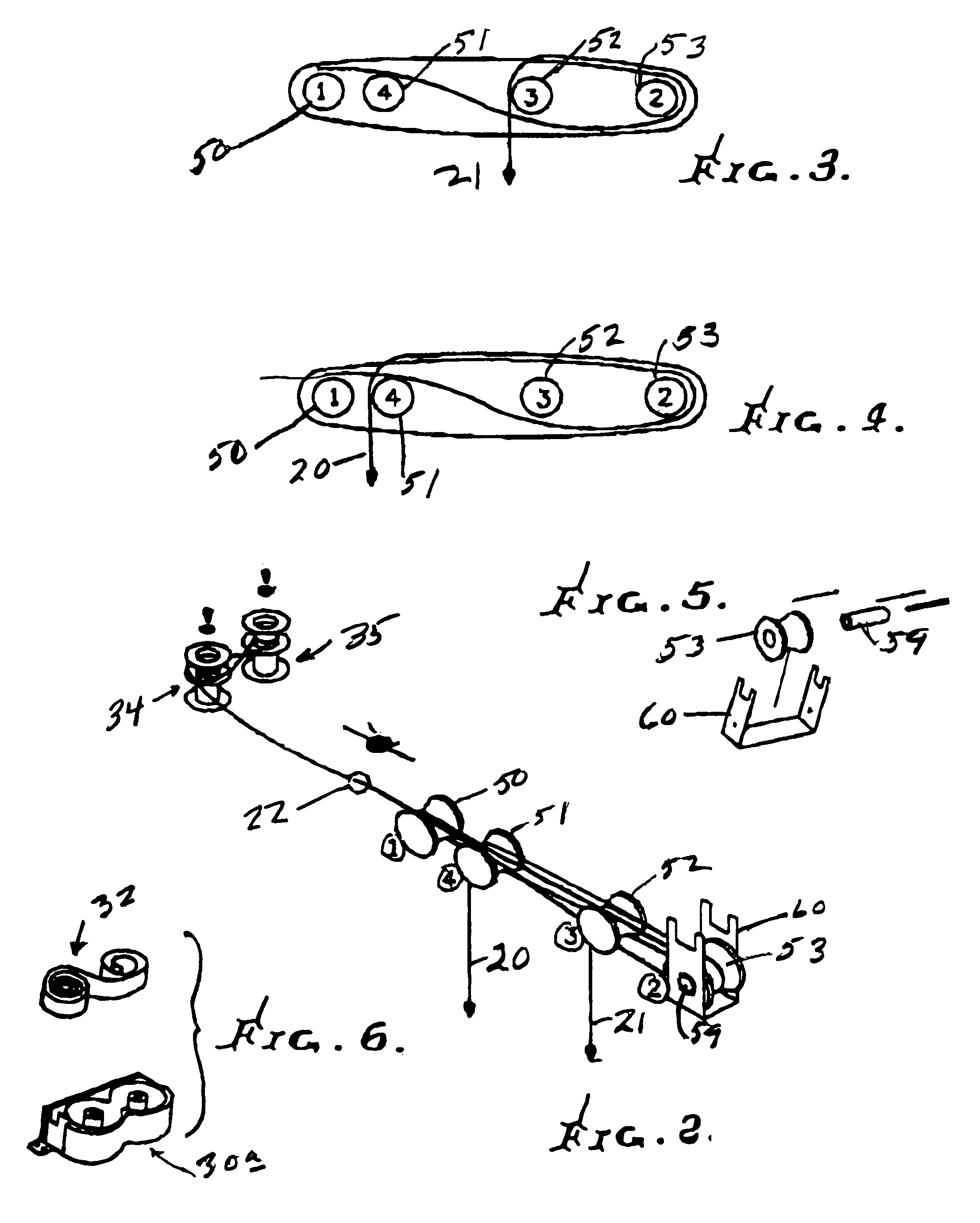

Pull down, push up, shade apparatus

InactiveUS8245756B2Easy to operateDifficult to operateExtensible doors/windowsCurtain accessoriesEngineeringPush ups

Owner:ZIPSHADE INDAL I CORP

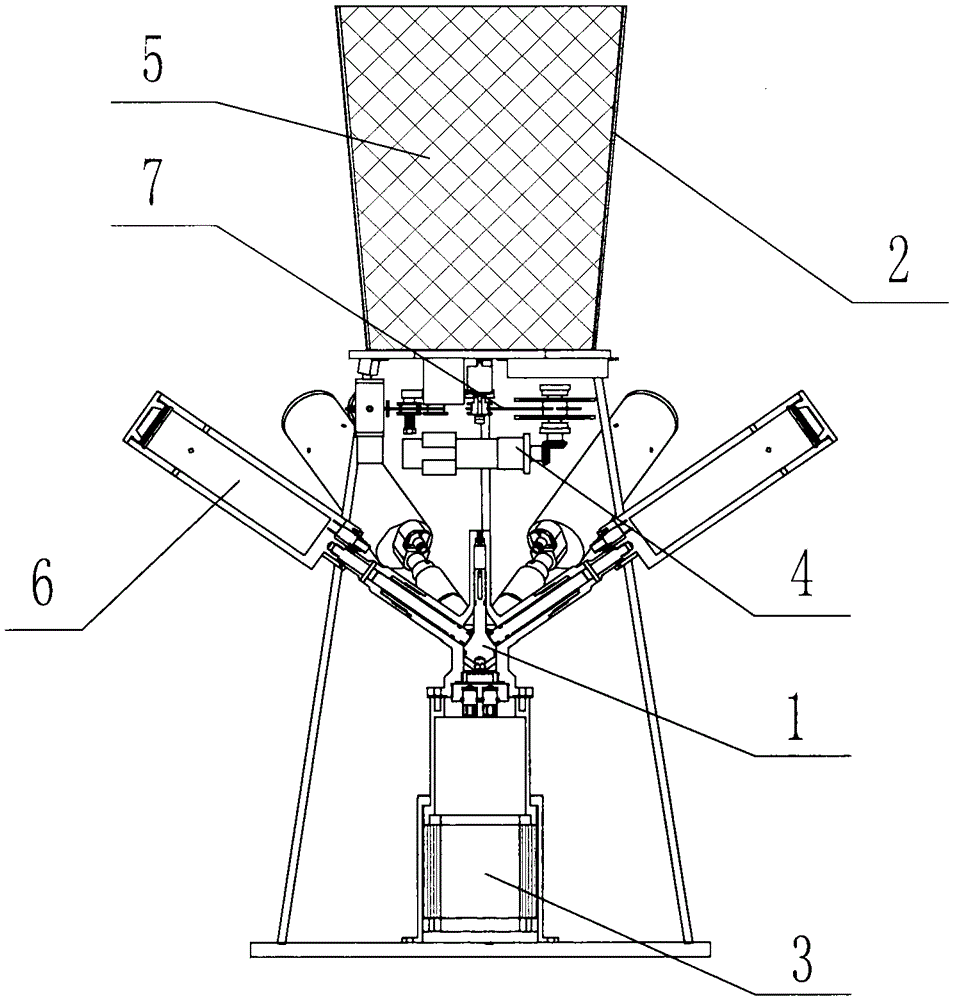

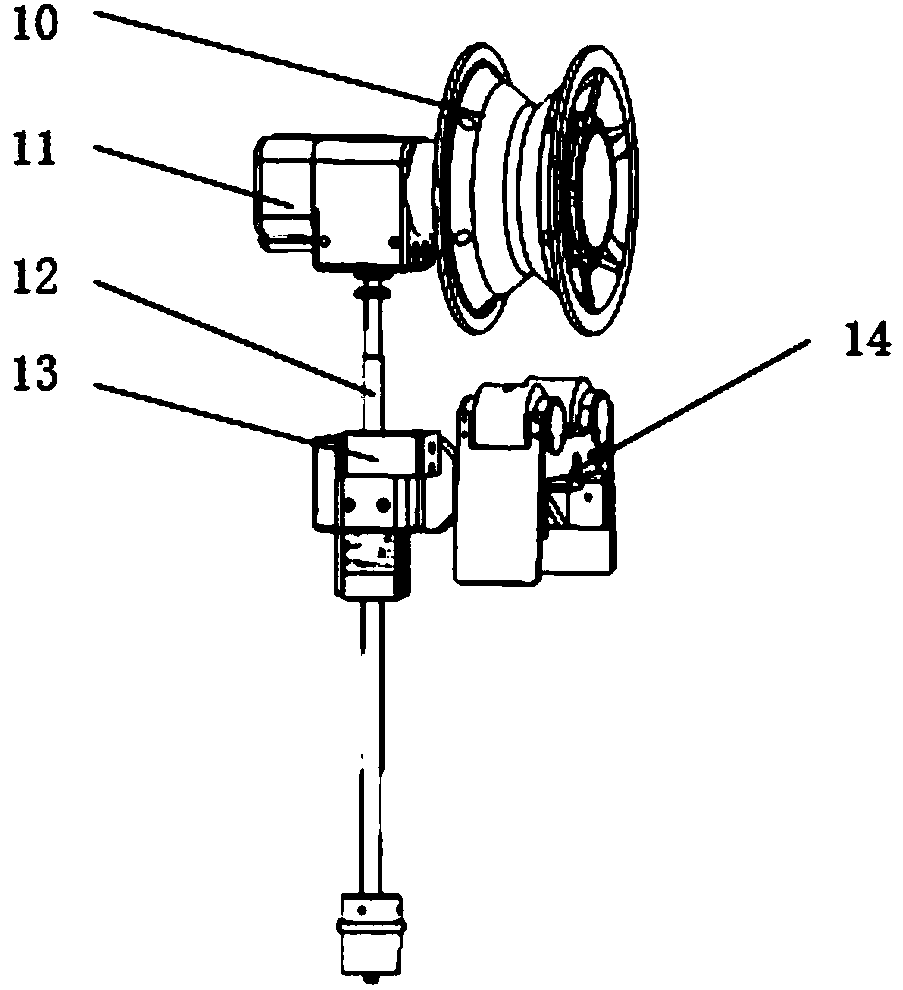

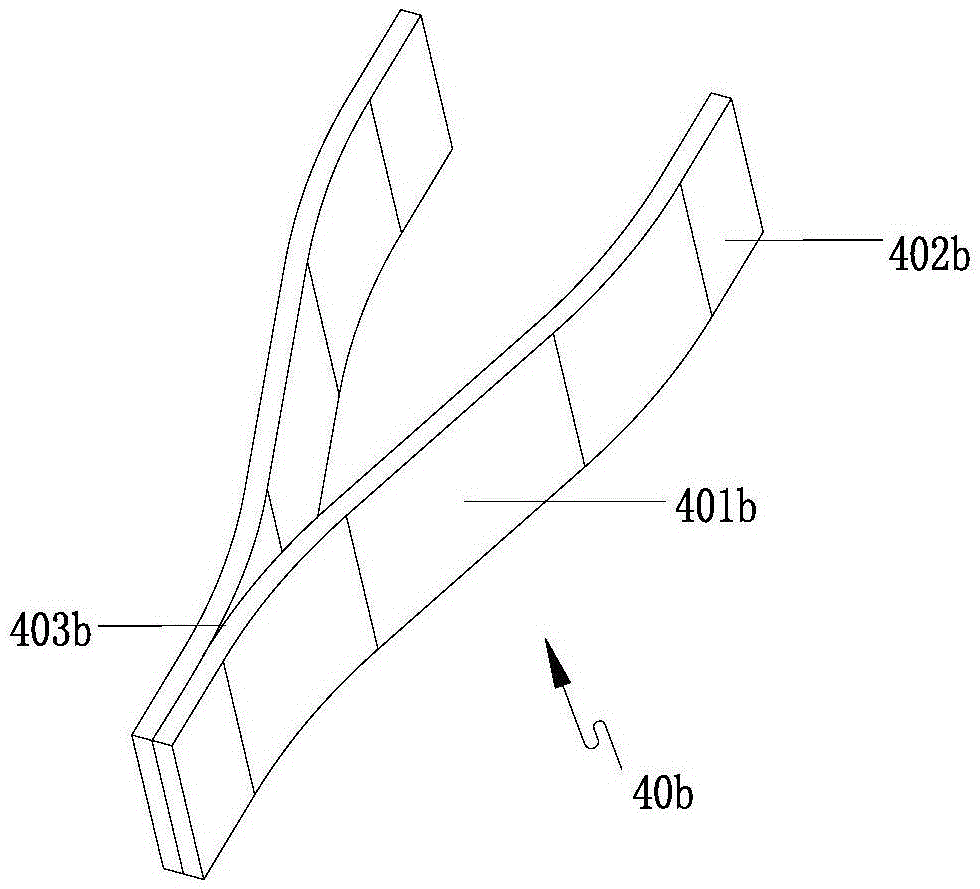

High-tension transmission line corridor branch trimming robot walking along ground wire and control method

ActiveCN108365561AAvoid elasticImprove securityLifting devicesManipulatorElectricityDistributed structure

The invention provides a high-tension transmission line corridor branch trimming robot walking along a ground wire and a control method. The robot comprises a moving robot platform, an insulating ropewinding lifting platform, a rotation mechanism and a tail end trimming mechanism, wherein the moving robot platform walks on the ground wire, the insulating rope winding lifting platform can adjust the distance between a combined insulating arm mechanism and tail end trimming mechanism in a vertical surface and a wire, thereby achieving the trimming of branches at different heights. The tail endtrimming mechanism 5 adopts a laterally symmetrical distributed structure to achieve the balance. The combined insulating arm mechanism adopts a mode of arranging two insulating pipes in parallel, thereby not only satisfying the requirement of enough insulating distance, but also more greatly reducing the weight. The high-tension transmission line corridor branch trimming robot walking along the ground wire and the control method have the advantages that the trimming of branches of a high-tension transmission line corridor is achieved, the hidden danger of 'tree electricity' of the high-tension transmission line corridor is effectively solved, thereby avoiding various disadvantages of manual branch trimming operations, the security is high, the trimming efficiency is high, and the practicability is strong.

Owner:WUHAN UNIV

Triad integration freckle-removing functional nano cream for skin external use and method for preparing same

ActiveCN101530377AReduce onset timeImprove textureCosmetic preparationsToilet preparationsSide effectTransdermal absorption

The invention relates to a triad integration freckle-removing functional nano cream for skin external use and a method for preparing the same. The three types (night use type, daytime use type and auxiliary type) freckle-removing nano creams improve and optimize a novel international passive target transdermal drug delivery system (TDDS) as a carrier, and organically combine and solubilize freckle-removing functional components with different biological efficacies, action ways and physical and chemical properties to form a good mutual aid synergic function system which has remarkable effect of controlling and relieving colored patches (such as chloasma, inflammatory pigmentation, sunburn, and the like) caused by abnormal facial metabolism of pigment. The product has the advantages of tiny particle sizes of spherical particles, obvious passive target function, excellent adaptability, homodromous property, fluidity and dispersion, strong penetrability, even texture, subtleness, lubricity and luster, is simple and convenient to use, and is comfortable without pungency and side effects; besides, the appearance is light yellow with slight opalescence, is glittering and translucent, clear and transparent, sticky but not viscous, thick but not dense, and oily but not greasy, has good stability, excellent curative effect, short industrialization cycle and high production efficiency, saves time, materials and energy sources, dose not need special devices and heat energy, and is easy for popularization and application.

Owner:董萍 +1

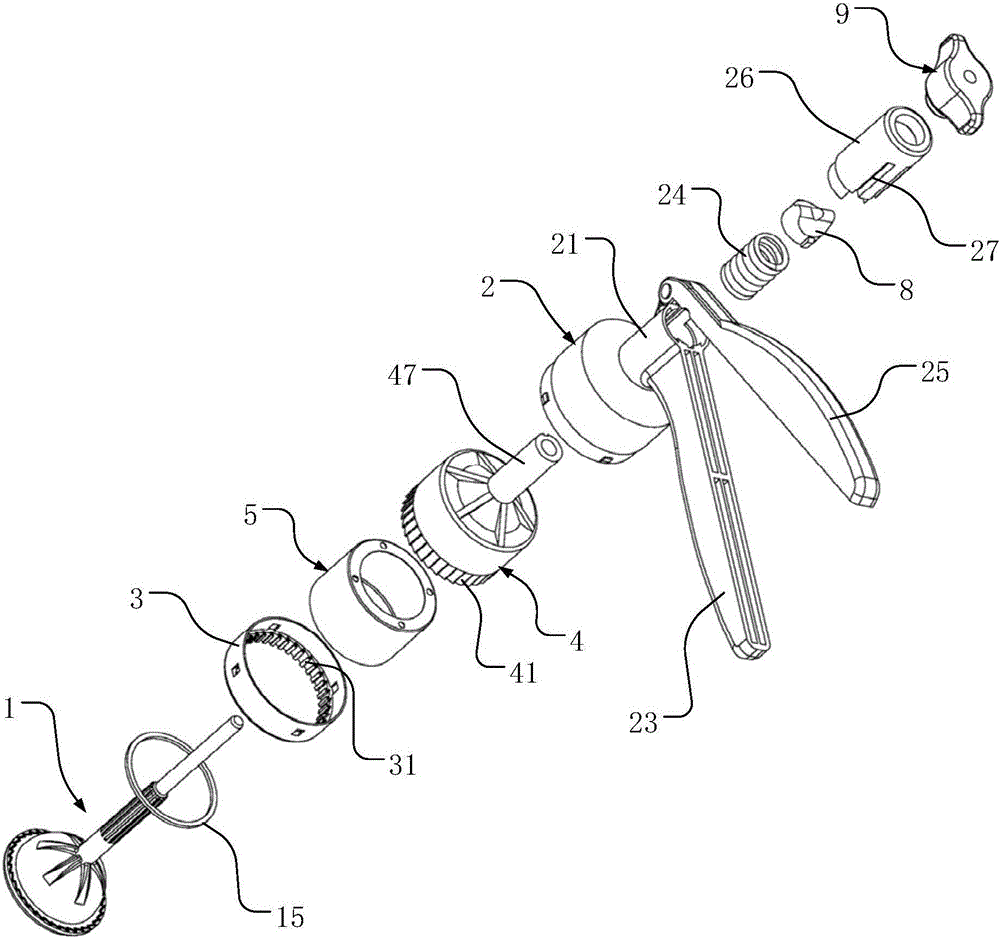

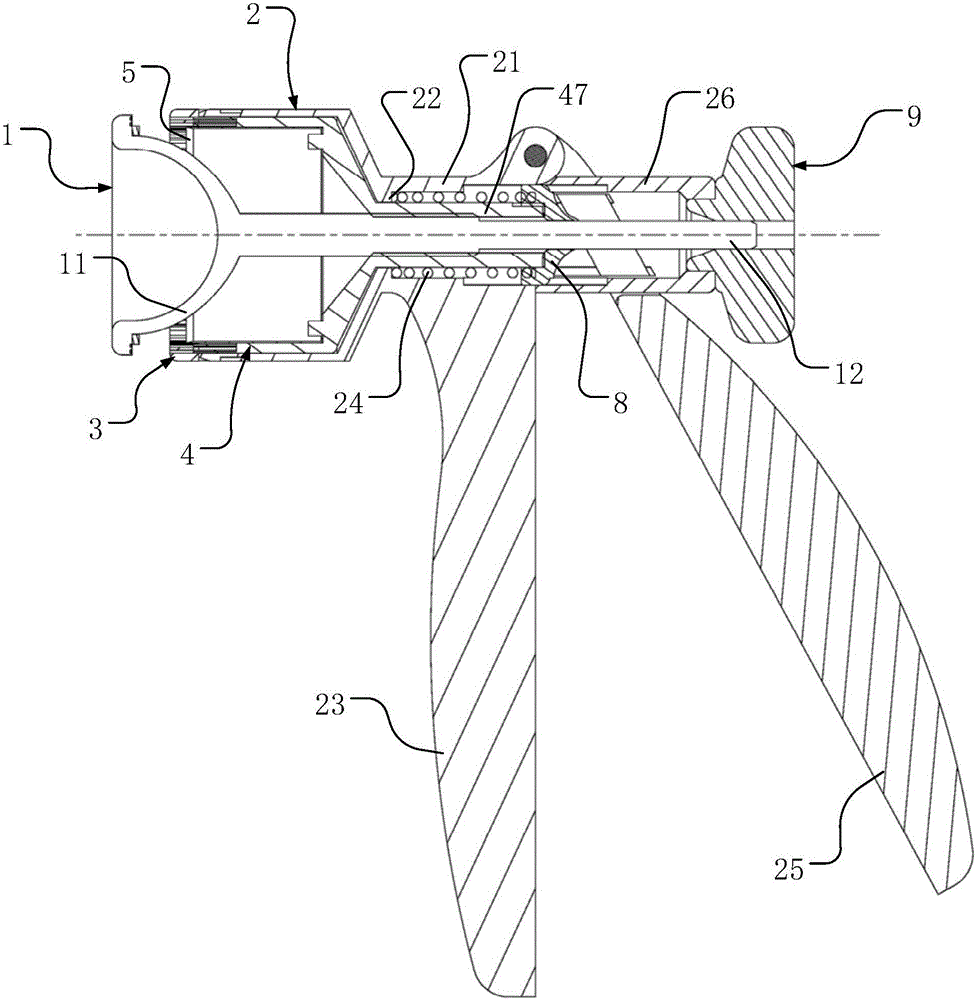

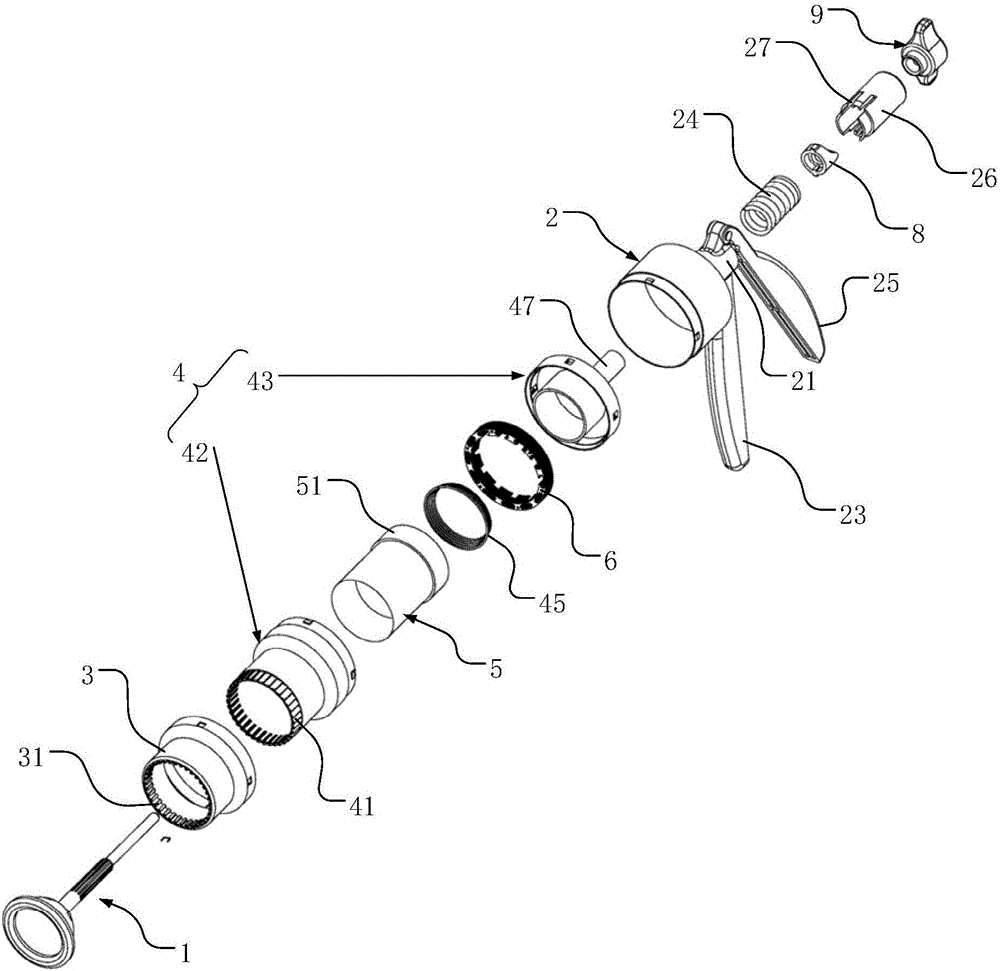

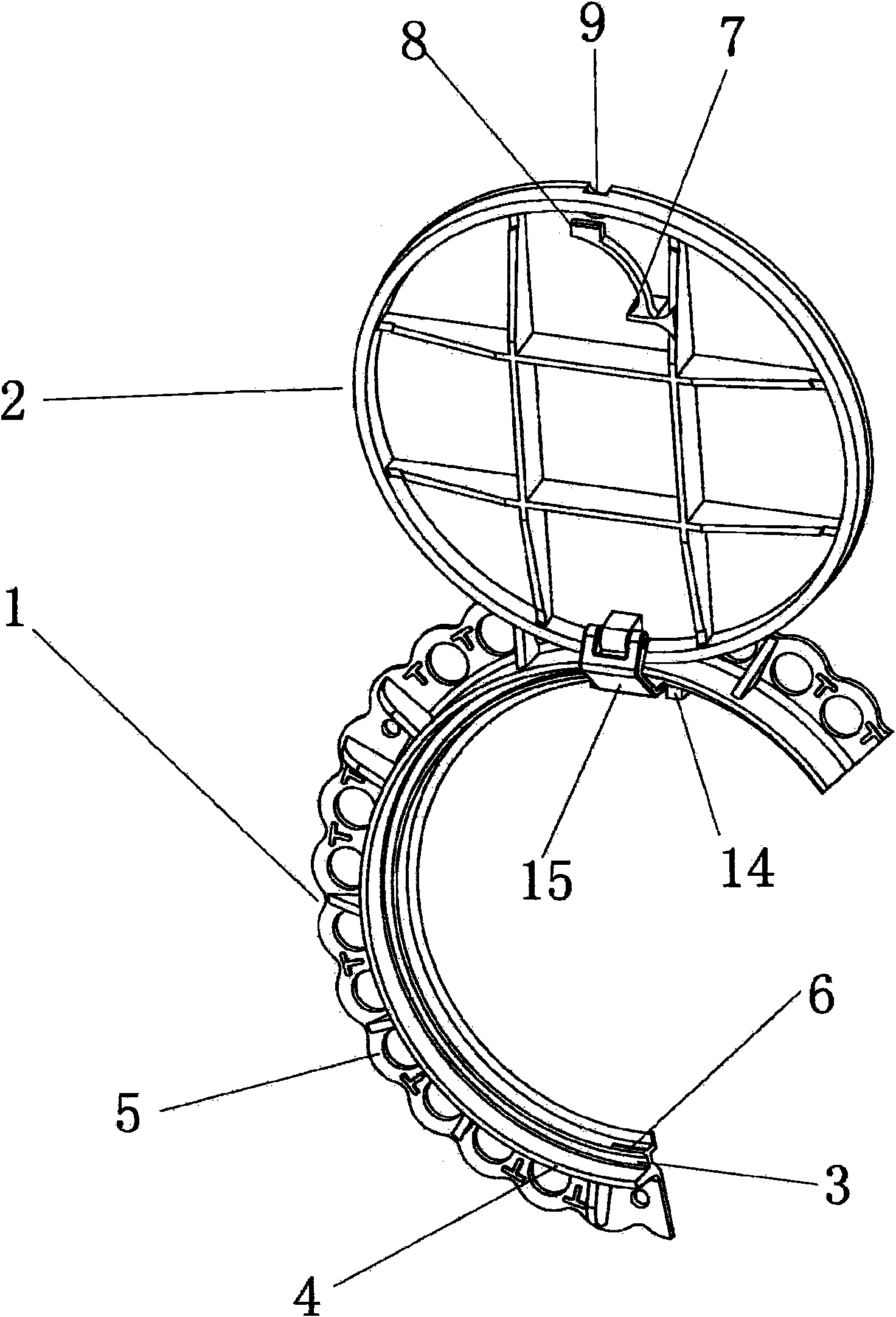

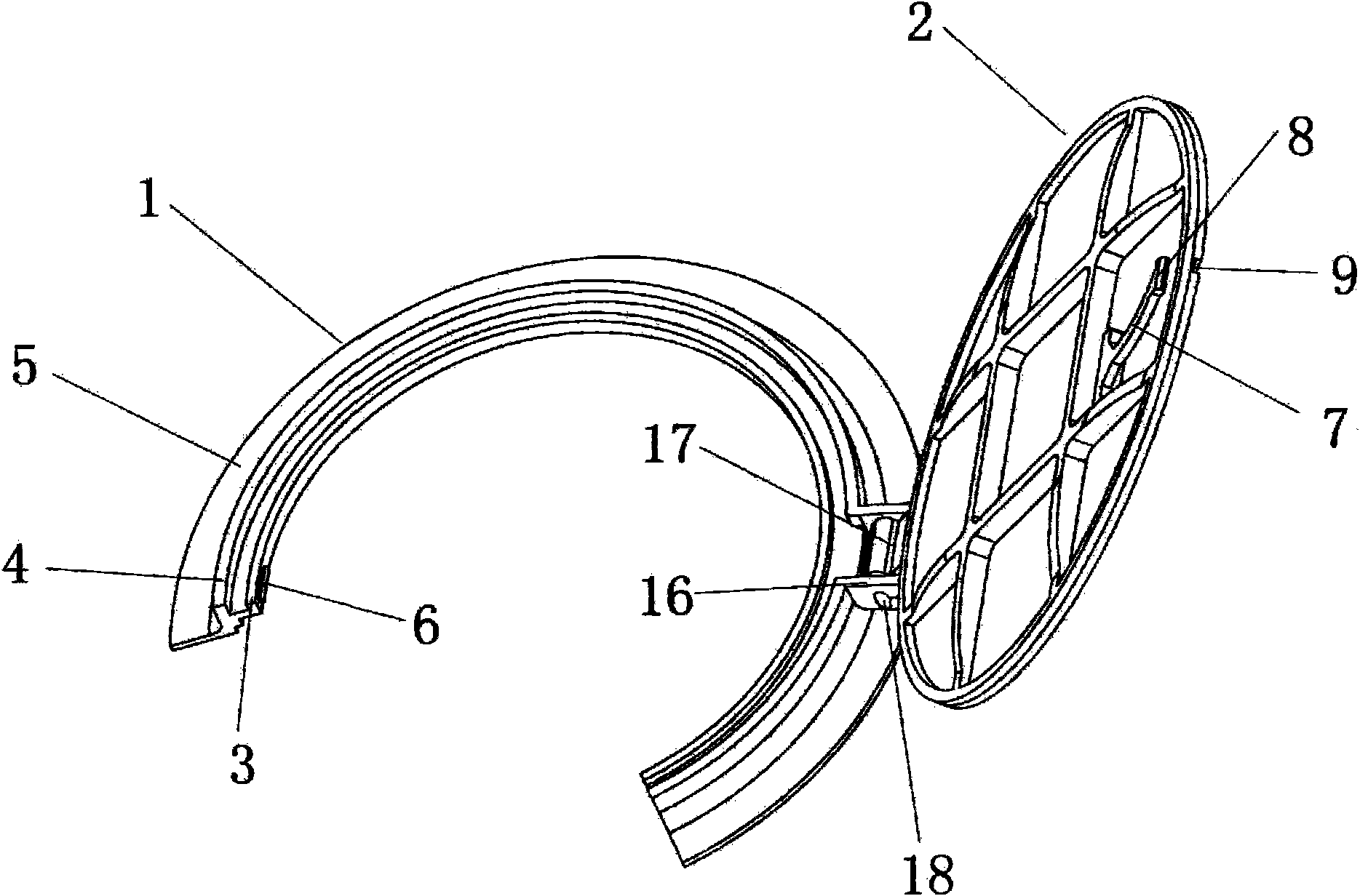

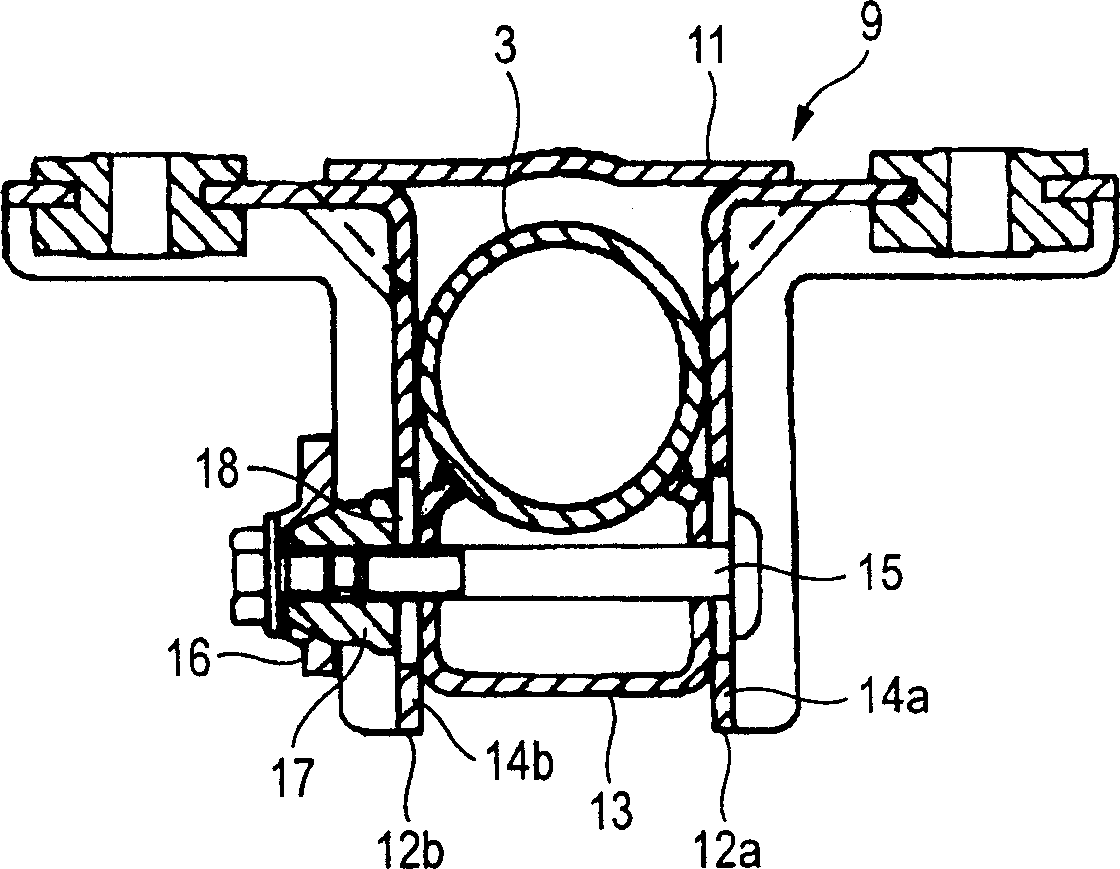

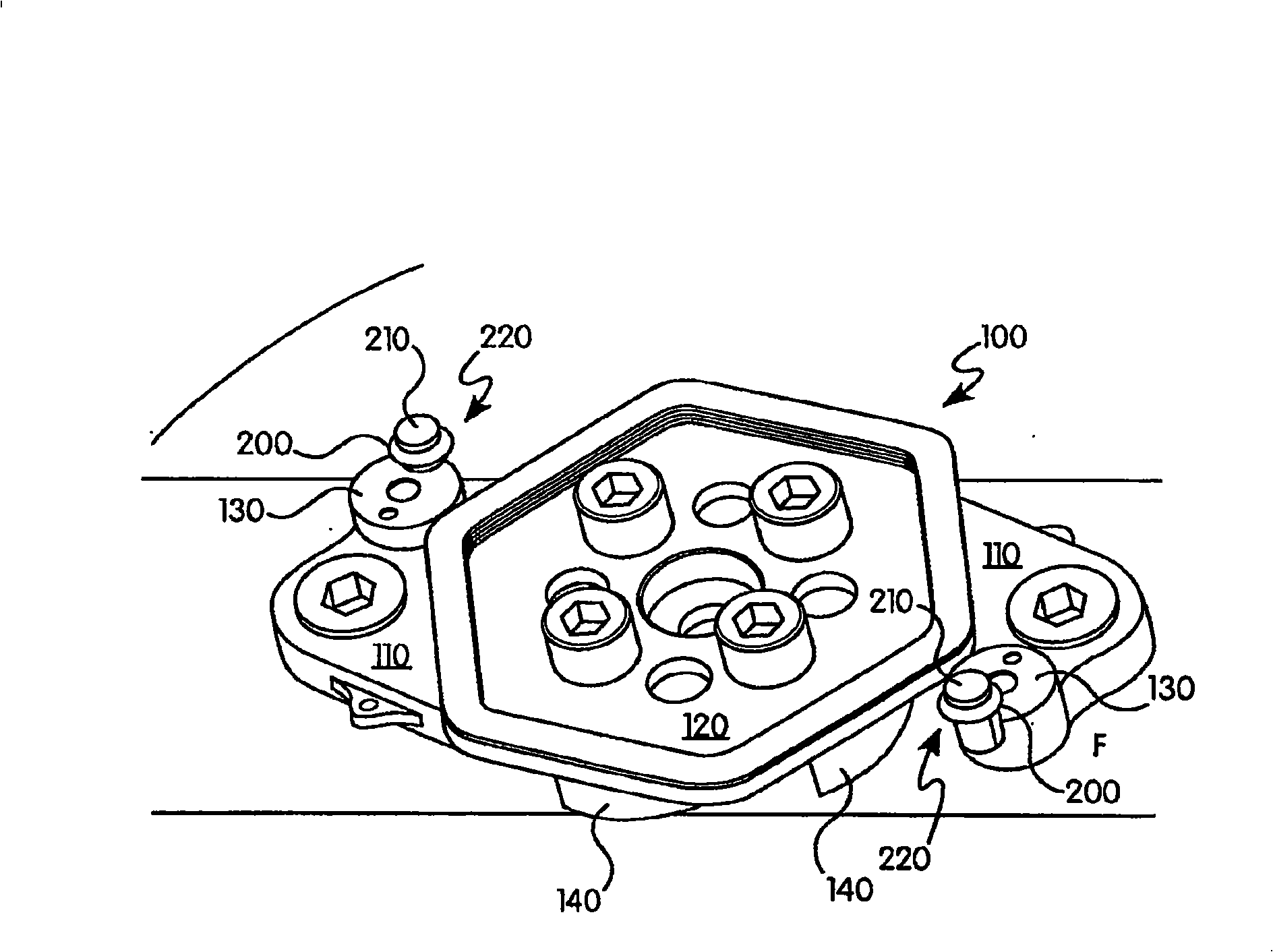

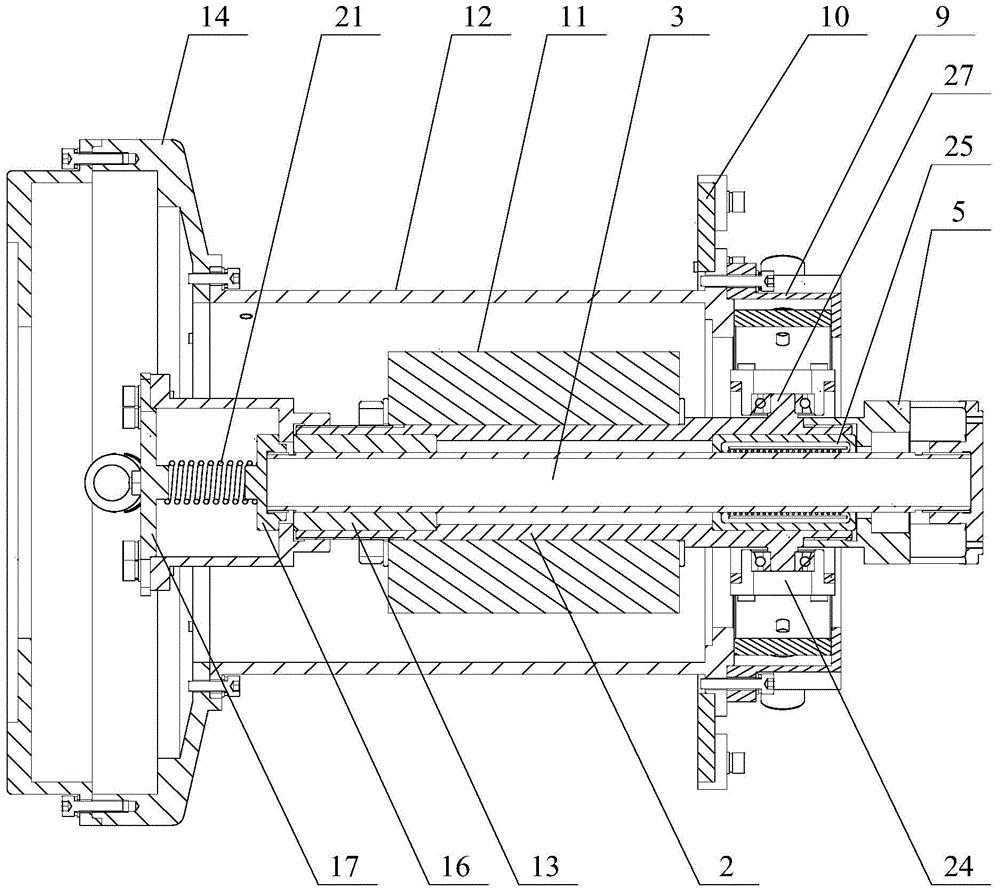

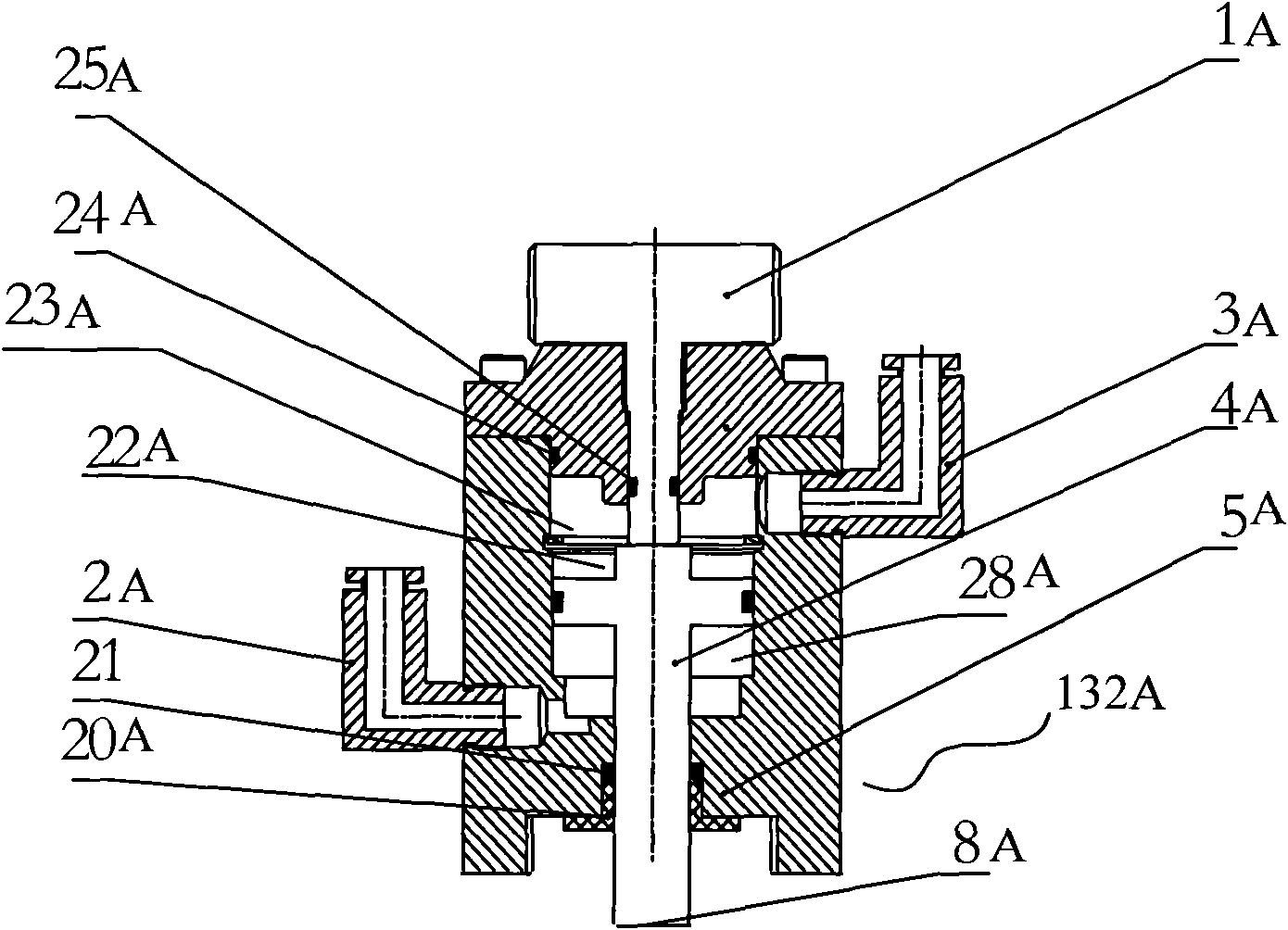

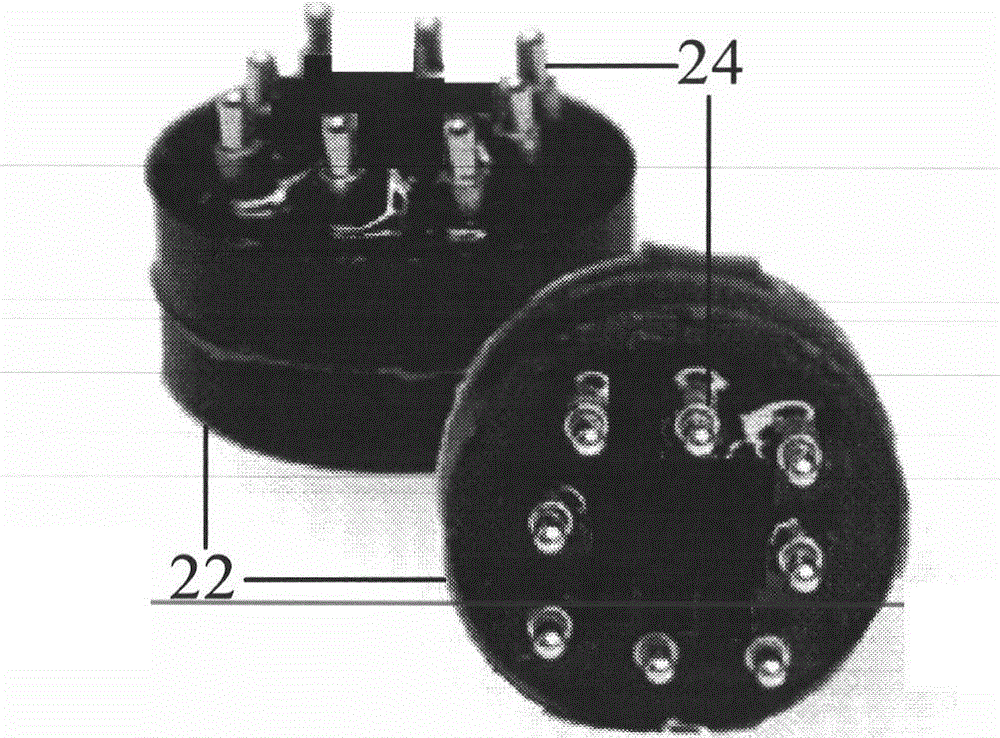

Circumcision stitching instrument

A circumcision stitching instrument includes a cylindrical main base; a circular front end cover is arranged at a front end cover of the main base; an inner side ring is projected on the inner circular wall of the front end cover in radial direction; a plurality of axial through nail bin groove holes are formed in the inner side ring in a circular array manner; the nail bin groove holes are of long kidney hole shaped structures; projections on the inner side ring in the radial direction corresponding to every two adjacent nail bin groove holes are intersected in part; the plurality of nail bin groove holes are successively arranged in an imbrication manner in the circumference direction; a U-shaped stitching nail can be arranged in each nail bin groove hole in a matching manner; a circular push body and a blade are coaxially arranged in the main base; the blade is coaxially arranged in the push body; push columns are projected at one end, corresponding to the front end cover, of the push body, wherein the number of the push columns is identical to the number of the plurality of nail bin groove holes, and the cross sections of the push columns are matched with that of the plurality of nail bin groove holes; and the plurality of push columns are inserted in the plurality of nail bin groove holes in a one-to one corresponding manner and can slide with respect to the axial direction in the nail bin groove holes.

Owner:周勇飞

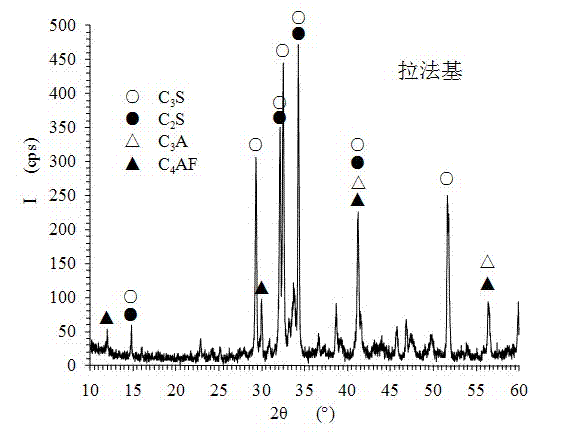

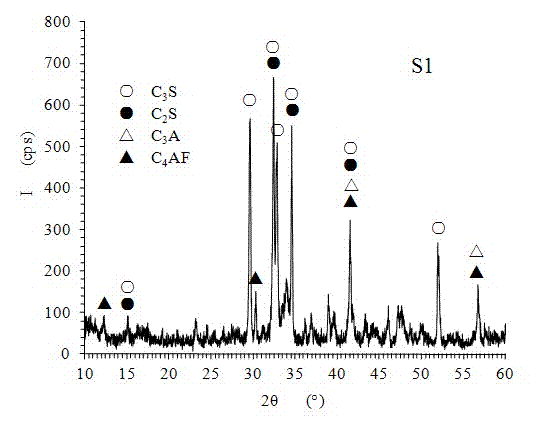

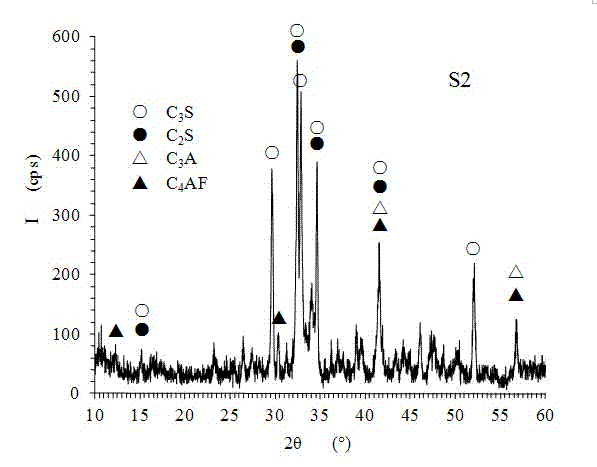

Method for preparing cement clinker by using waste concrete

InactiveCN102503196AIncrease profitImprove utilization efficiencyCement productionIron powderMaterials science

A method for preparing cement clinker by using waste concrete is disclosed, which comprises the following steps: collecting, drying and breaking waste concrete, selecting concrete particles with a particle size of 5mm-20mm, adding iron powder or sulfuric acid dregs into the concrete particles, mixing and grinding the mixture, and screening cement raw material powders by use of a square hole screen (80mum) with screen residue being 8%-16%, wherein if the iron powder is added, the mass percent of the concrete is 98.5%-99.5% and the mass percent of the iron powder is 0.5%-1.5%; and if the sulfuric acid dregs are added, the mass percent of the concrete is 95.0%-96.0% and the mass percent of the sulfuric acid dregs is 4.0%-5.0%; and finally balling, calcining and quenching the concrete so as to obtain the cement clinker. According to the method, the mass percent of the waste concrete in the cement clinker is more than 95%, the quality of the cement clinker is equivalent to that of the common cement clinker, and the cement clinker can be taken as raw material to be applied to the concrete preparation, so that a good utilization approach is found for reutilization of the waste concrete.

Owner:CHONGQING UNIV

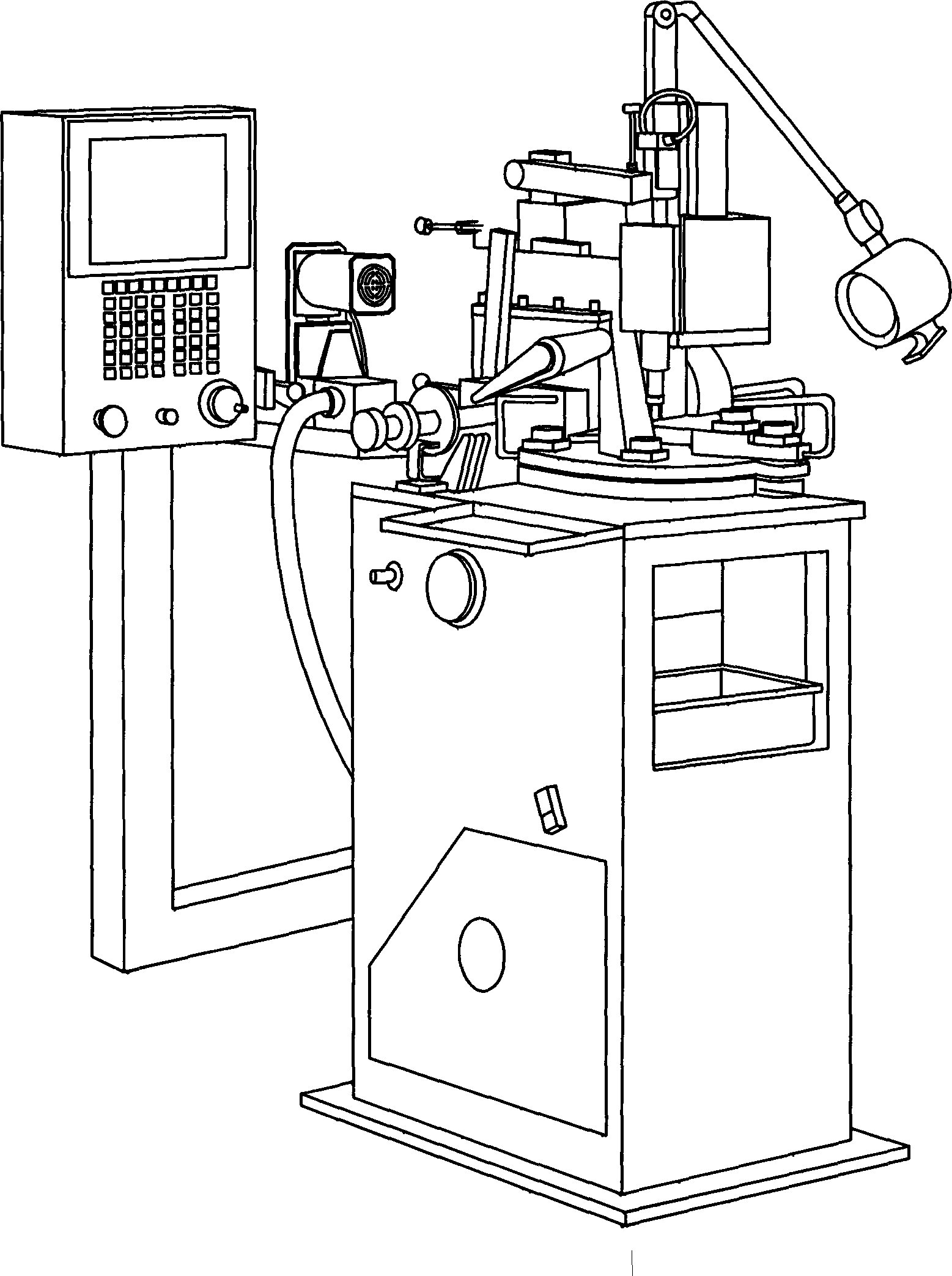

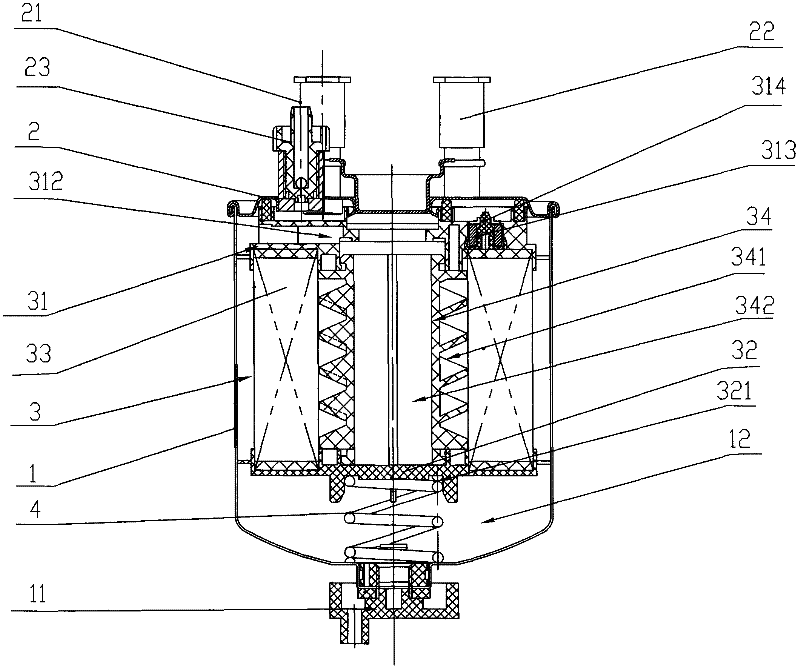

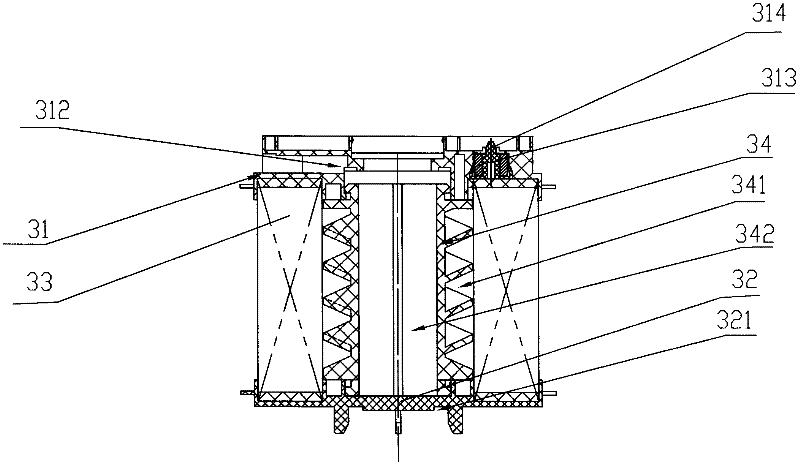

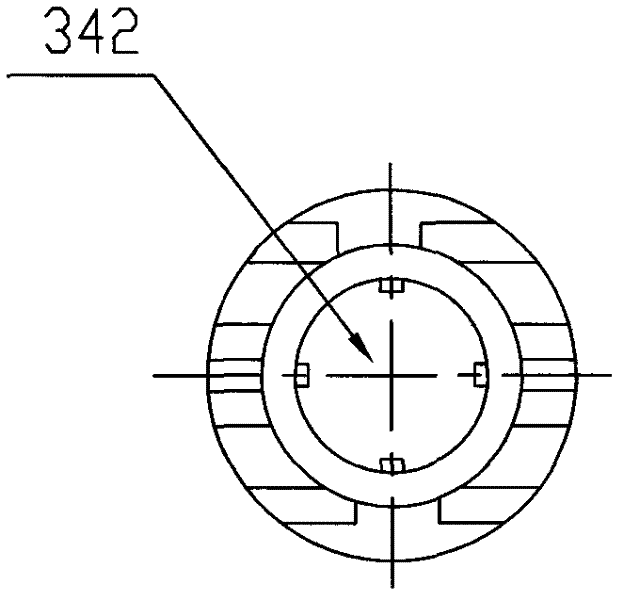

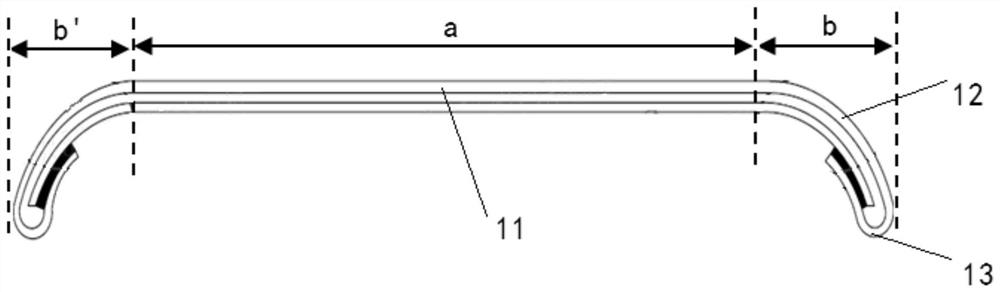

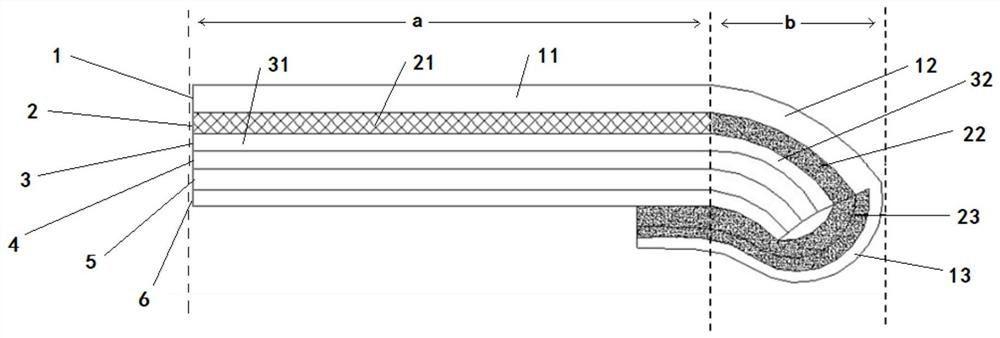

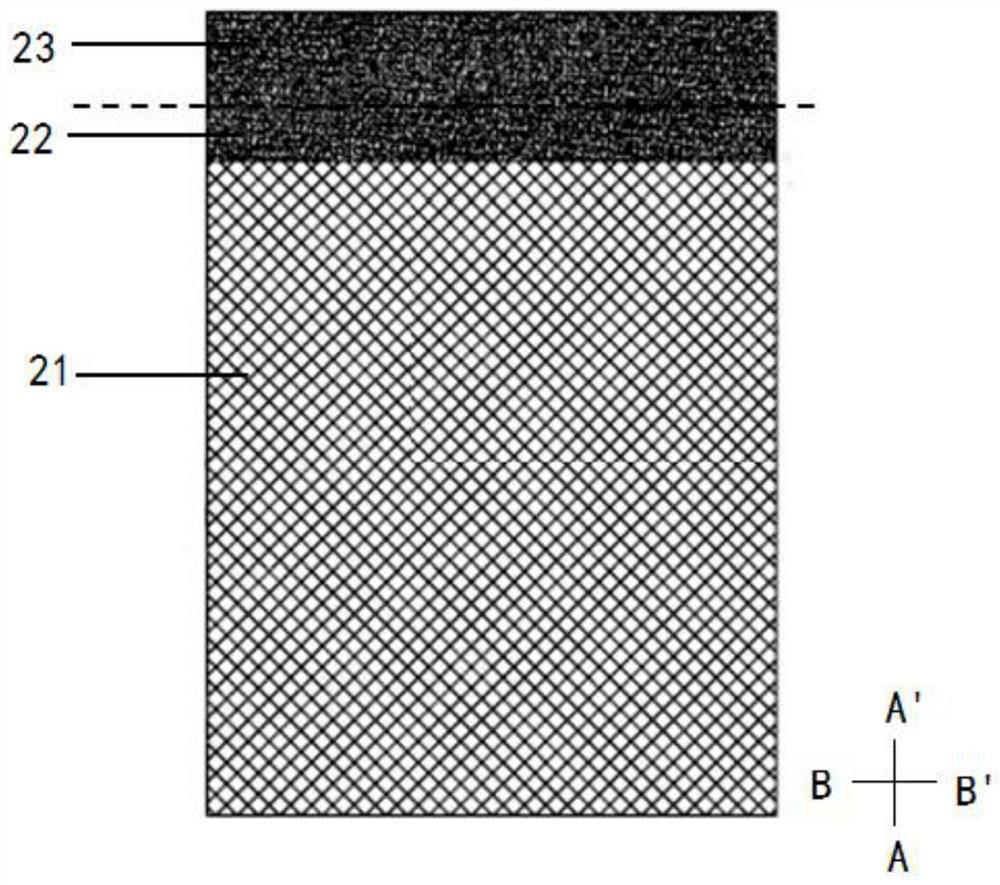

Self-bonded coil forming machine and process

InactiveCN102709047ASimple production processShort time consumptionFluid heatersCoils manufactureWork in processConductor Coil

The invention discloses a self-bonded coil forming machine and a self-bonded coil forming process. A winding mechanism is arranged on the forming machine and comprises a winding shaft and a winding chuck which can rotate along with the winding shaft; the self-bonded coil forming machine also comprises a coil heating system; and the heat spray opening of the coil heating system is opposite to a semi-finished self-bonded coil wound on the winding chuck. The coil heating system is arranged on the self-bonded coil forming machine, so that the semi-finished self-bonded coil can be heated and baked after being wound; a self-bonded layer on the outer layer of an enamelled wire is softened and formed through bonding, namely one set of equipment can be used for winding and baking; the production process is simple; a small amount of equipment is involved; the time consumption is low; the production efficiency is high; resources are saved; furthermore, the self-bonded coil is wound and baked on the same equipment, so that the self-bonded coil is not required to be transferred to an oven and heated after being wound; phenomena of rebounding and loosening of the coil during transferring are avoided; and the qualified rate of a product is increased.

Owner:昆山广辉精密五金有限公司

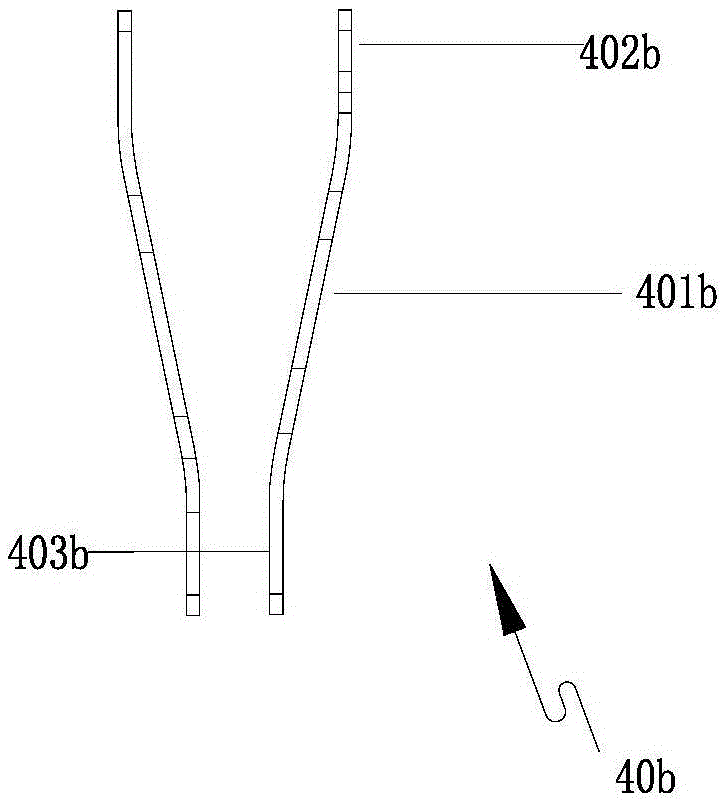

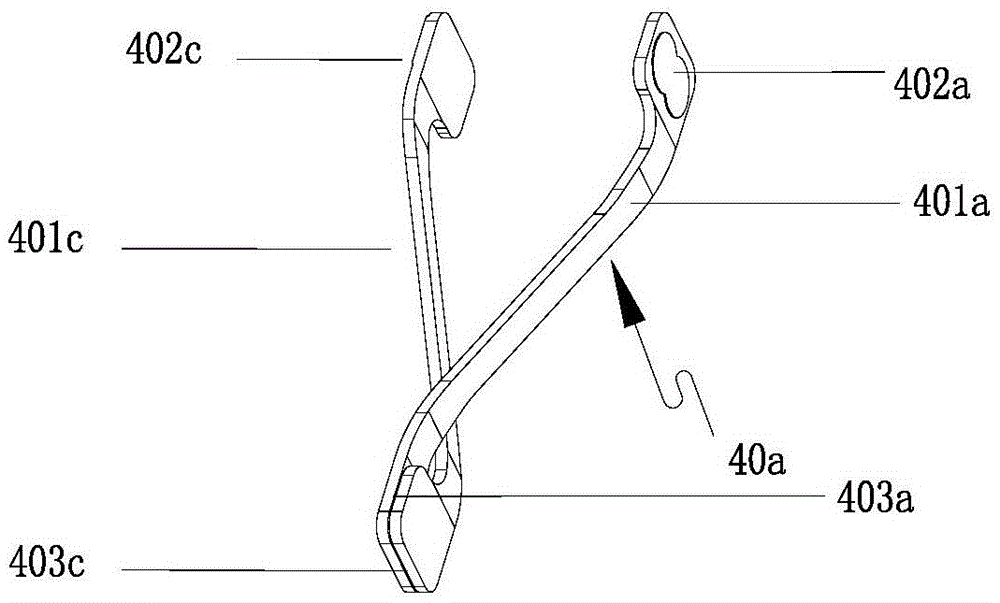

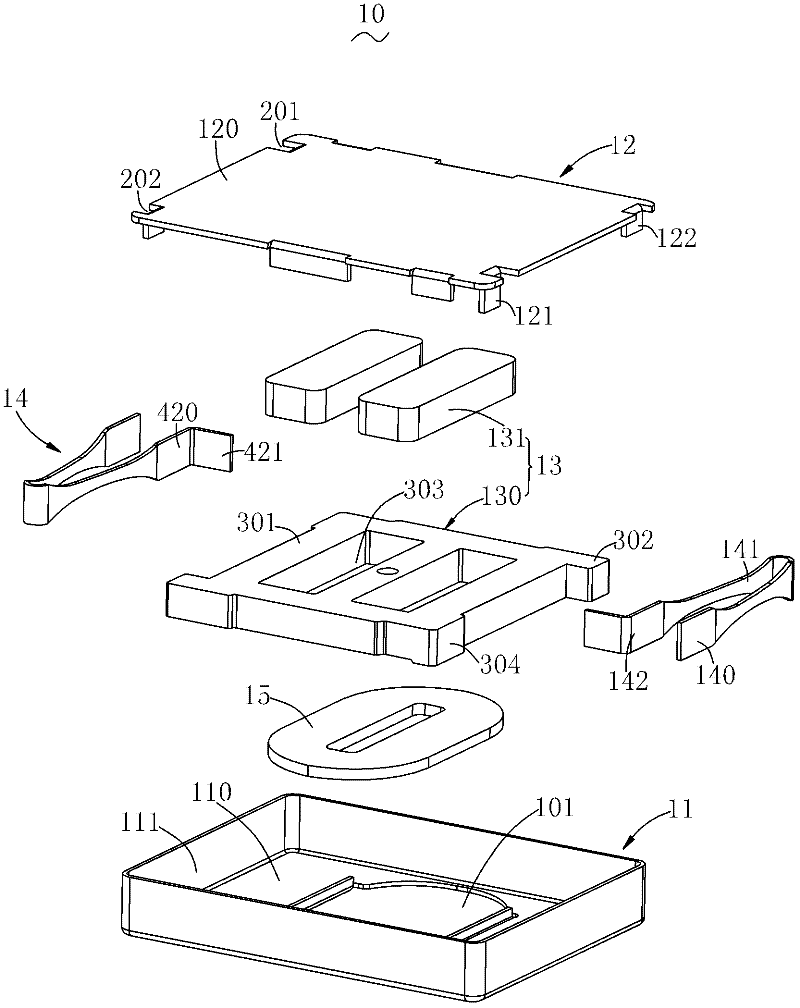

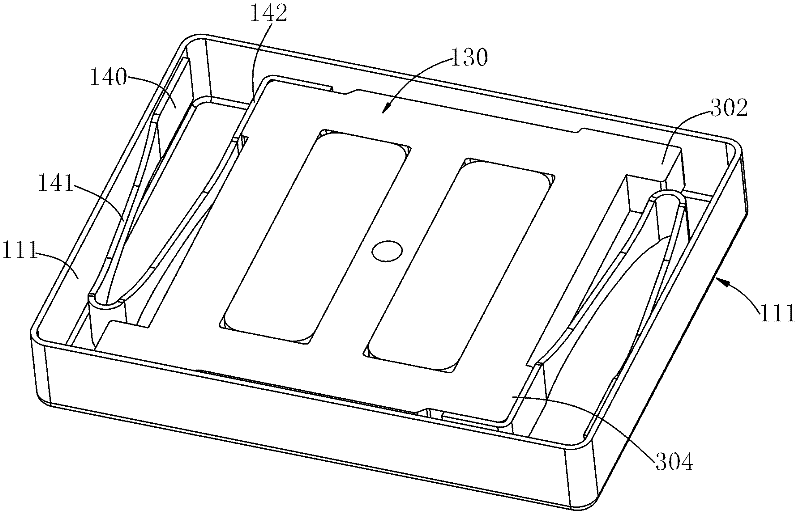

Linear vibration motor

ActiveCN105553219AImprove elastic resilienceLower resonant frequencyDynamo-electric machinesEngineeringLinear vibration

The invention discloses a linear vibration motor, and relates to the technical field of miniature motors. The linear vibration motor comprises a shell, a stator, a vibrator and elastic support elements, wherein the elastic support elements are located at two ends of the vibrator and provide elastic restoring force; each elastic support element comprises two elastic arms; connection parts are arranged at two ends of the same side of each elastic arm respectively; two connection parts at one end of every two elastic arms are combined with each other; two elastic arms extend towards the corresponding directions of respective connection parts to form a transverse crossover structure in the transverse direction respectively; and two connection parts at the other ends of every two elastic arms are combined with the vibration and the shell respectively. A vibration space, occupied by the elastic support elements in the linear vibration motor, of the vibrator is relatively small; and an enough space is left for increase of the weight and the volume of a vibrator mass block, so that the resonant frequency of the vibration motor can be effectively reduced; the low-frequency performance of the vibration motor is improved; and the overall performance of the vibration motor is relatively high.

Owner:GOERTEK INC

Multi-preventing well cover

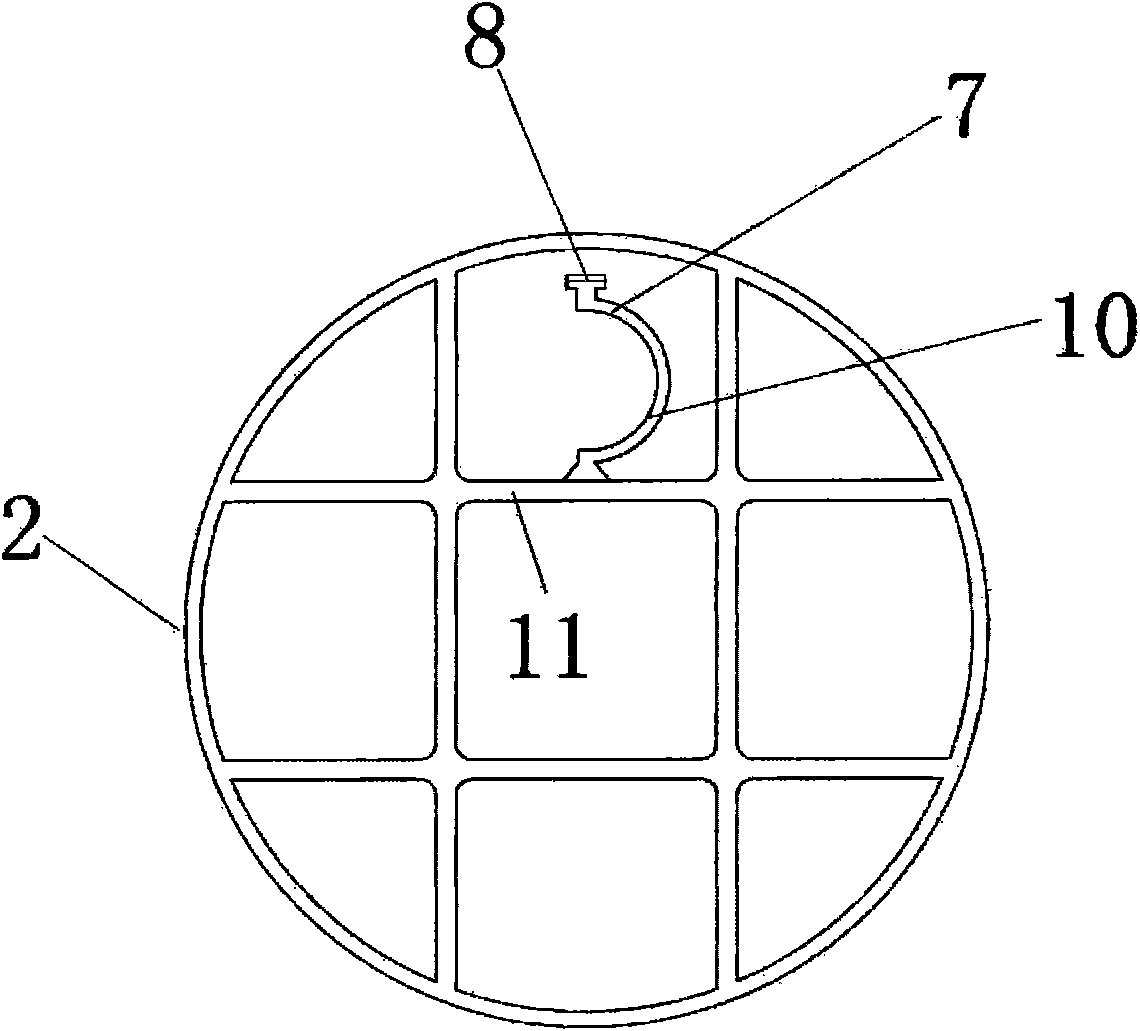

InactiveCN101555694APrevent rotationAvoid elasticArtificial islandsUnderwater structuresEngineeringDislocation

The invention discloses a multi-preventing well cover, which comprises a ring support (1) and a cover plate (2) which are rotatably connected together; the internal edge of a cover plate supporting platform (3) is provided with a buckle (6), and a bolt (8) is arranged below the cover plate (2). The bolt (8) slides into the lower part of the buckle (6) when the cover plate (2) is furiously closed and the ring support (1) and the cover plate (2) are caused to be locked together, thus not only effectively preventing the well cover from stealing, but also being capable of preventing the cover plate from bouncing. The cover plate supporting platform (3) is provided with an elastic pad piece which can prevent sound and rupture caused by the collision between the cover plate (2) and the ring support (1) due to applied external forces. Convex patterns on the surface of the cover plate (2) have skid resistance function. The well cover has multiple effects such as theft preventing, sound preventing, bouncing preventing, moving preventing, dislocation preventing, drop preventing, skid preventing and the like.

Owner:梁林华 +1

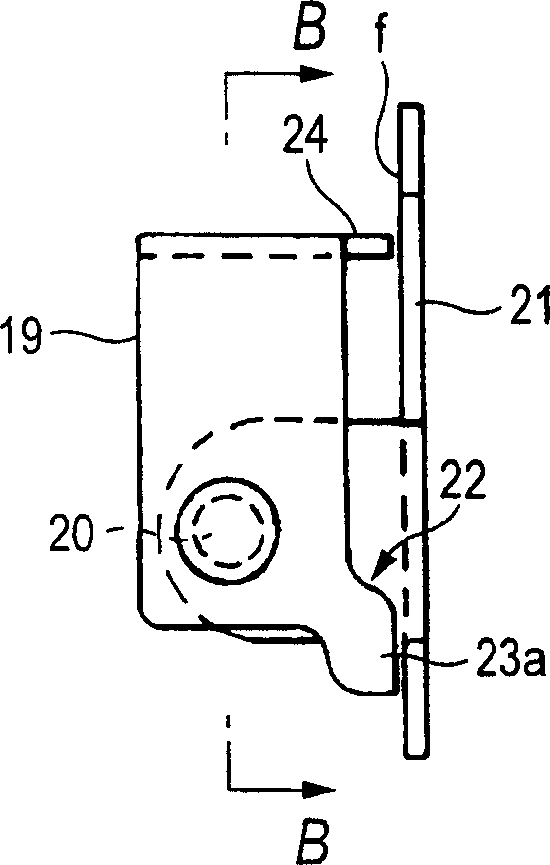

Ear muff allotting device

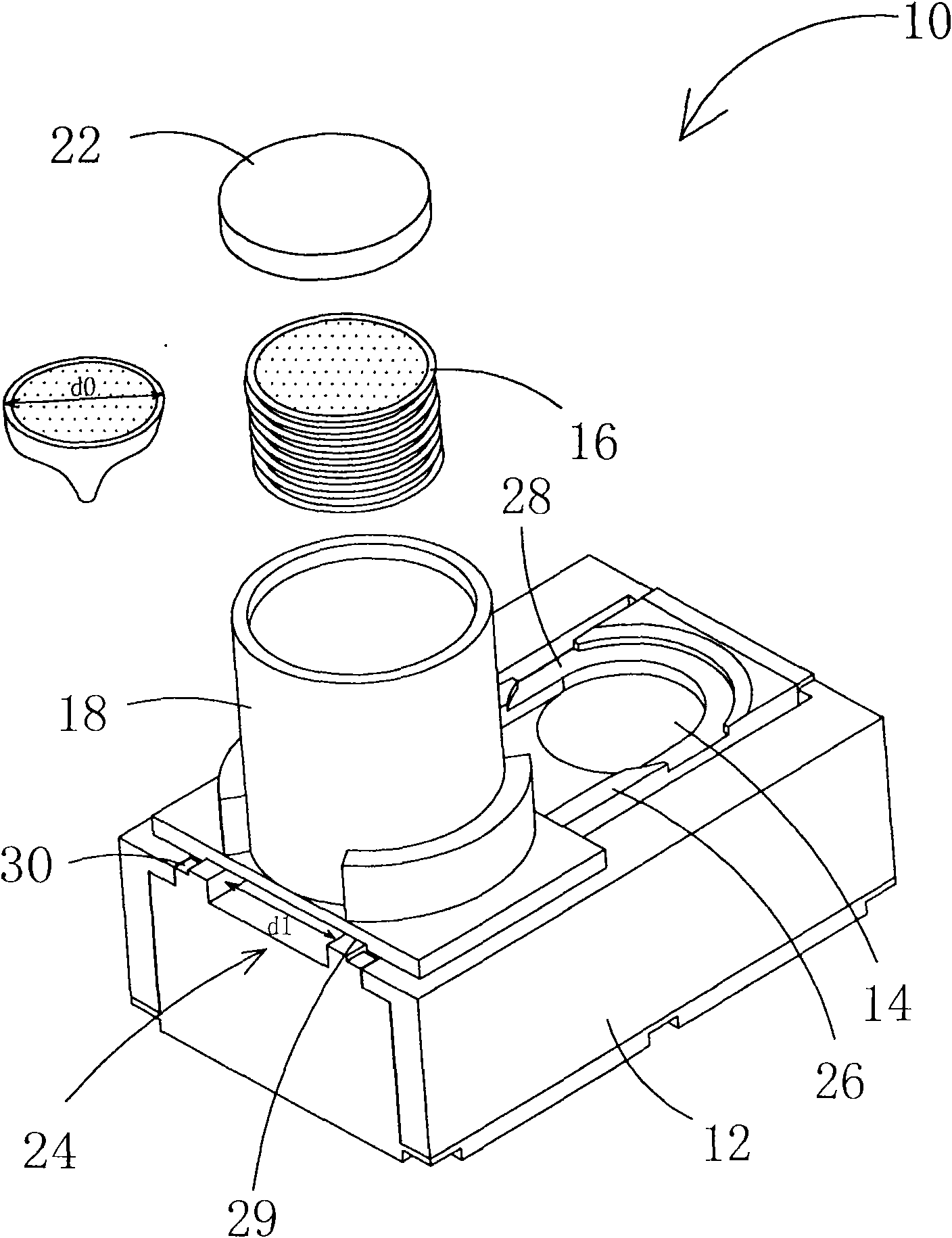

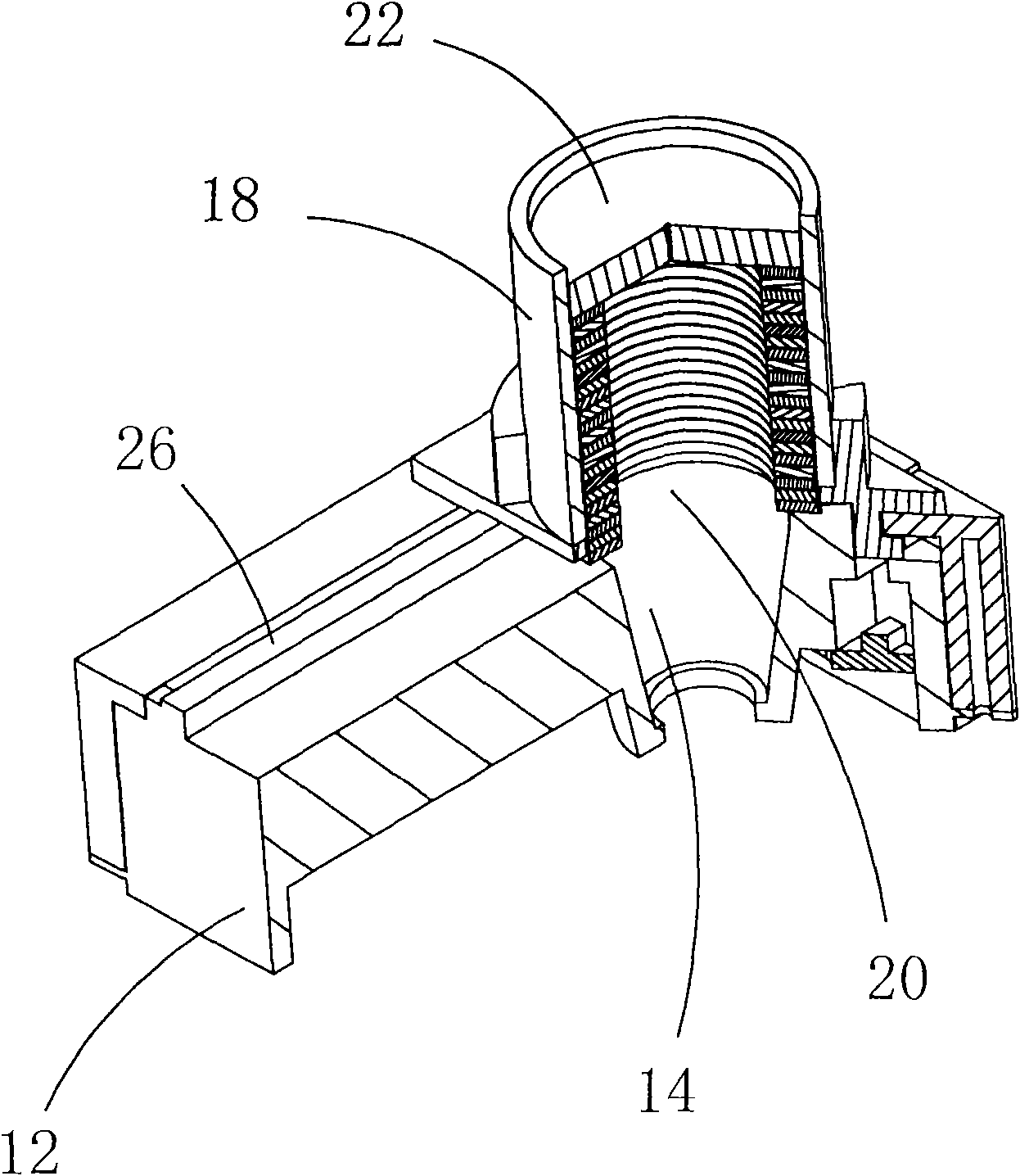

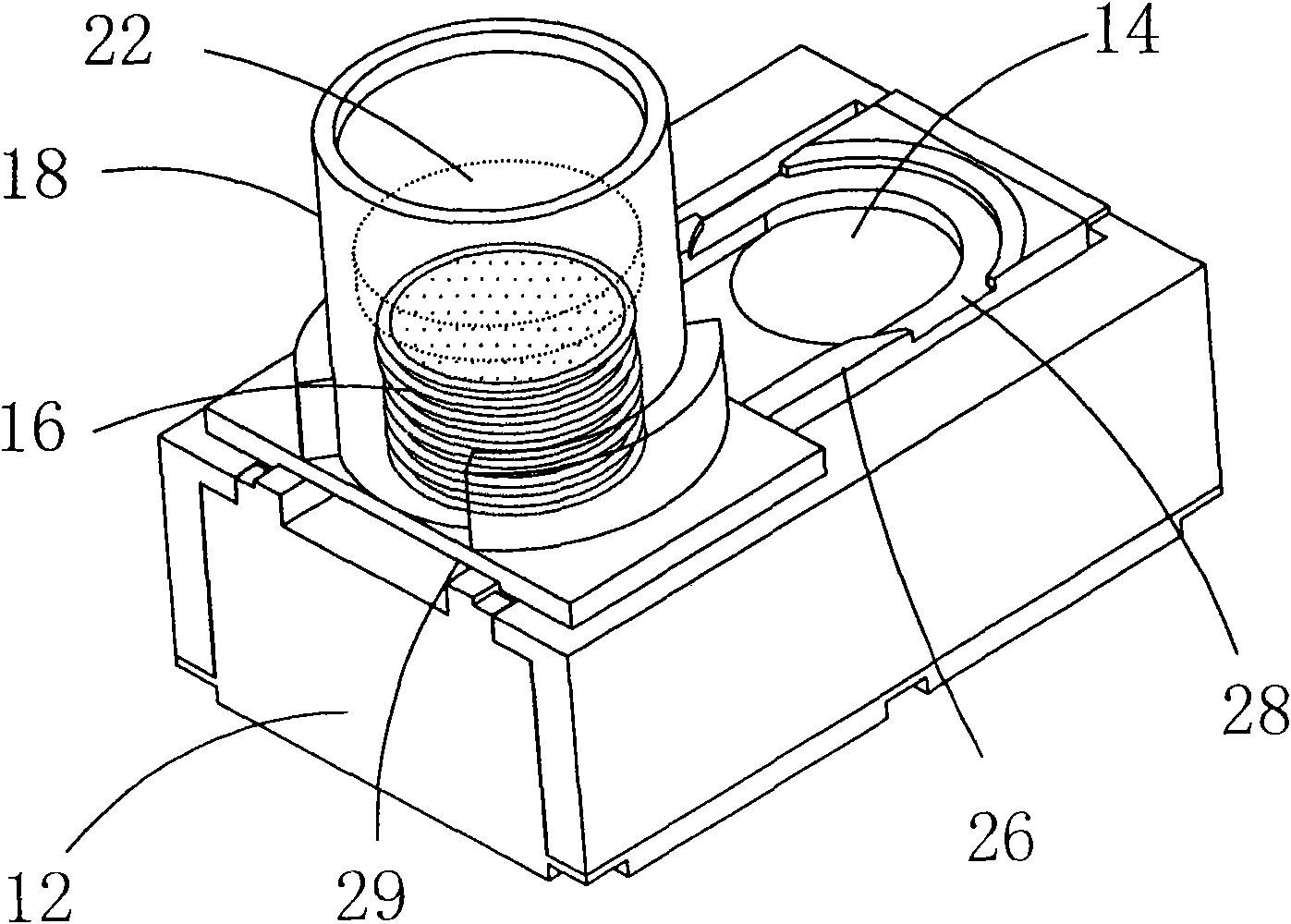

ActiveCN101584579AEasy to installReduce pollutionRadiation pyrometryDiagnostic recording/measuringEngineeringEar thermometers

The invention provides an ear muff allotting device, mainly comprising a base having an ear muff notch, an ear muff accommodating groove for accommodating the ear muff, a gravity piece for applying proper gravity to the ear muff in the ear muff accommodating groove and an impelling piece between the base and ear muff accommodating groove for pushing the ear muff fallen by the gravity in the ear muff accommodating groove to the ear muff notch to insert the probe of an ear thermometer in the ear muff, therefore the user does not need to touch the ear muff by hands to install the ear thermometer in the ear muff to effectively reduce the contamination and bacterial infection of the ear muff.

Owner:RADIANT INNOVATION INC

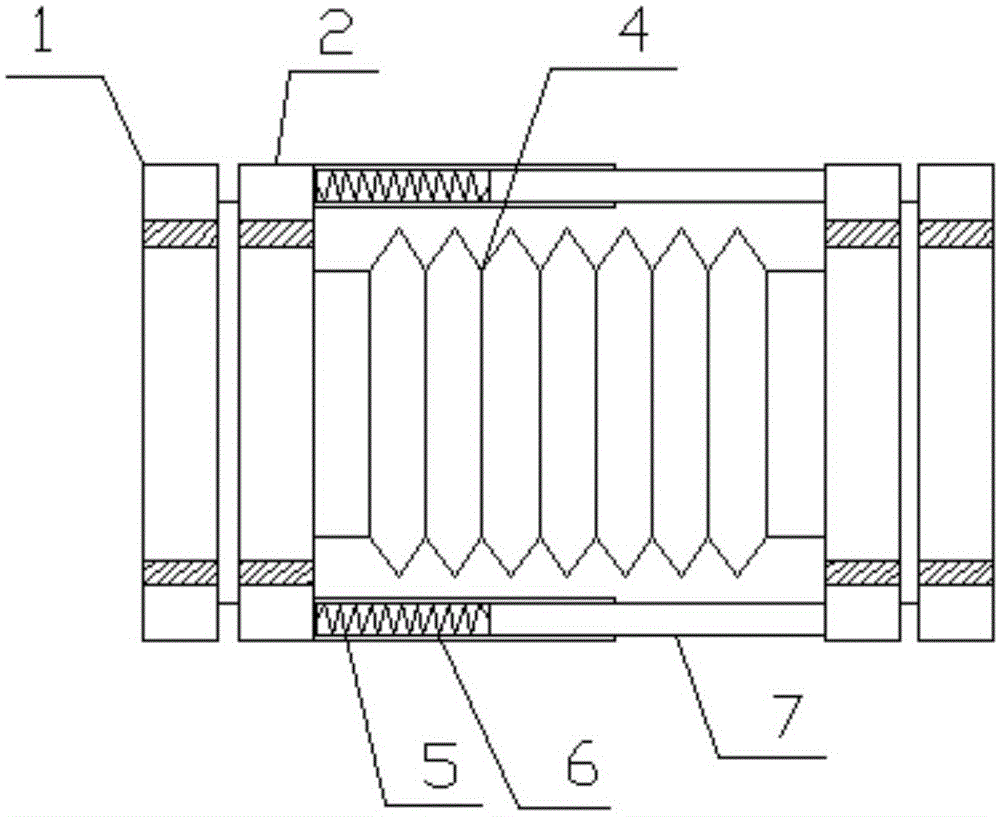

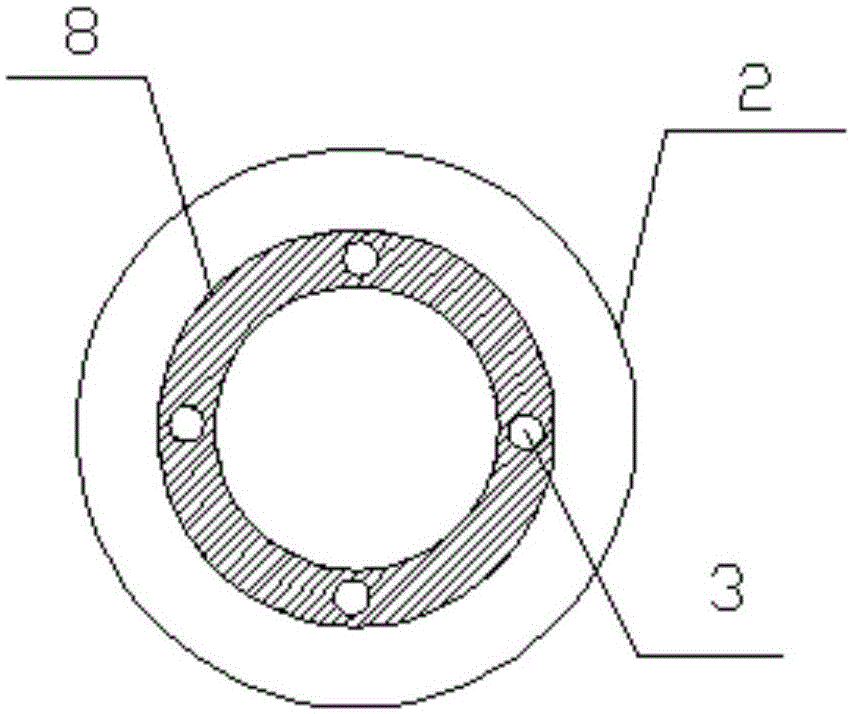

Rubber expansion joint resisting axial deformation

InactiveCN105135136AImprove sealingAvoid elasticPipeline expansion-compensationEngineeringExpansion joint

The invention discloses a rubber expansion joint resisting axial deformation. The rubber expansion joint comprises first flanges, second flanges, a rubber bellows and a limiting mechanism. The two ends of the rubber bellows extend in the radial direction to form extending parts, the extending parts are provided with through holes, the rubber bellows penetrates the second flanges, the extending parts of the rubber bellows are clamped through the first flanges and the second flanges and are locked through screws penetrating the first flanges, the through holes in the extending parts and the second flanges to be matched with nuts, and the limiting mechanism is arranged between the second flanges positioned at the two ends of the rubber bellows. According to the rubber expansion joint resisting axial deformation, the problem that the bellows will lose elasticity to become loose and soft when due to pipe warming the expansion joint causes the bellows to axially deform to exceed its elastic deformation range is solved.

Owner:江苏广通管业制造有限公司

Method for preparing liquid octylated diphenylamine antioxidant

InactiveCN102320983APrevent thermal oxidation and elastic flex agingGood oil solubilityAmino preparation from aminesAmino compound preparation by condensation/addition reactionsChemical synthesisViscous liquid

The invention discloses a method for preparing a liquid octylated diphenylamine antioxidant, which belongs to the field of chemical synthesis, and particularly relates to a method for synthesizing high-content mono-octyl diphenylamine. The method comprises the following steps of: under the action of a catalyst, making diphenylamine react with diisobutylene to generate an octylated diphenylamine mixture; introducing isobutene for reacting; and distilling to obtain the liquid octylated diphenylamine antioxidant, wherein the catalyst is dehydrated active white clay. The prepared liquid octylated diphenylamine antioxidant is a light-yellow viscous liquid at normal temperature, and the moving viscosity is 50-300 mm<2> / s at the temperature 40 DEG C. The liquid octylated diphenylamine antioxidant can be effectively applied to turbines, aircrafts and various oil products and lubricating agents which are applied at high operation temperatures, and can be applied to high-polymer rubber products to prevent rubber from being thermally oxidized and aged by elastic deflection.

Owner:JIANGSU FEIYA CHEM IND

Vibration motor

The invention provides a vibration motor, which comprises a base provided with a bottom wall and a side wall, an upper cover combined with the base so as to form an accommodation space, a spring piece accommodated in the accommodation space, and a vibrator supported by the spring piece in the accommodation space, wherein the spring piece is provided with a fixed part connected with the side wall, an elastic arm which is bent and extended out of the fixed part, and a connection part which is extended out of the elastic arm and connected with the vibrator; the upper cover is provided with a main body part covered on the base and a first flange part extended out of the main body part to the bottom wall; the first flange part is positioned in a vibration direction of the vibrator and arranged between the fixed part and the connection part of the spring piece; and the flange part is opposite to the fixed part and spaced from the fixed part at a certain distance. The vibration motor can effectively prevent overlarge amplitude and overlarge displacement of the vibrator during falling so as to avoid a phenomenon, caused by impact of the vibrator on the fixed part of the spring piece and the side wall of the base, of deformation of a shell of the vibration motor or damage to the spring piece; therefore, the performance of the vibration motor can be improved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

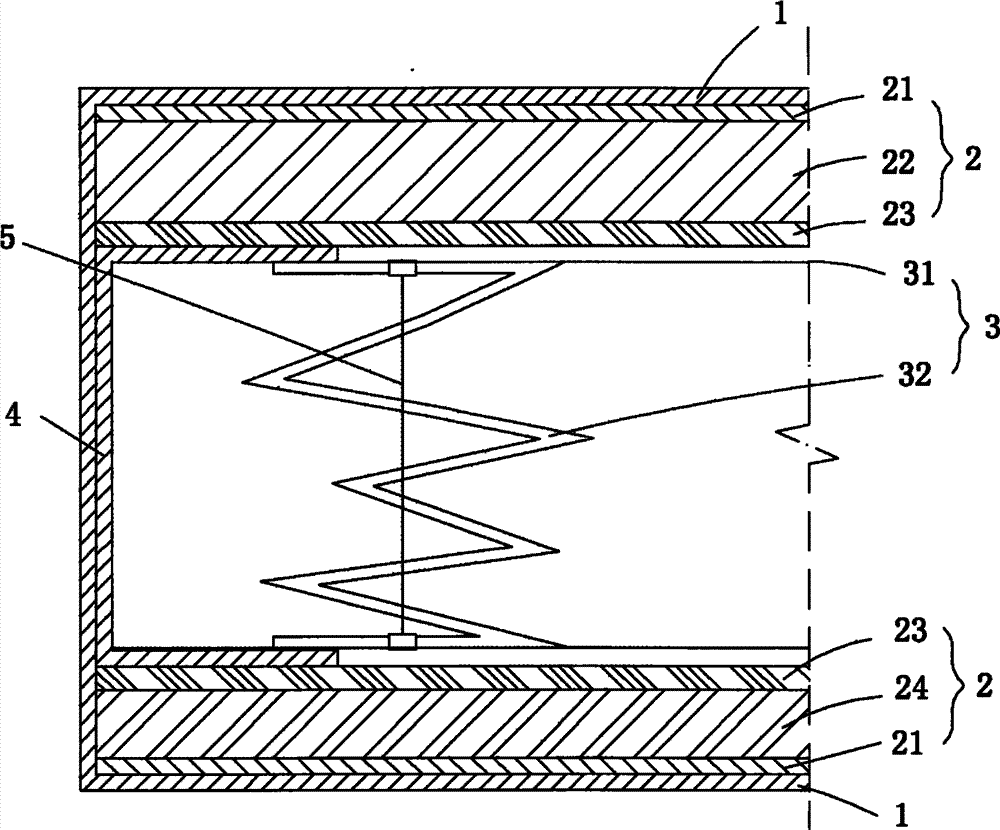

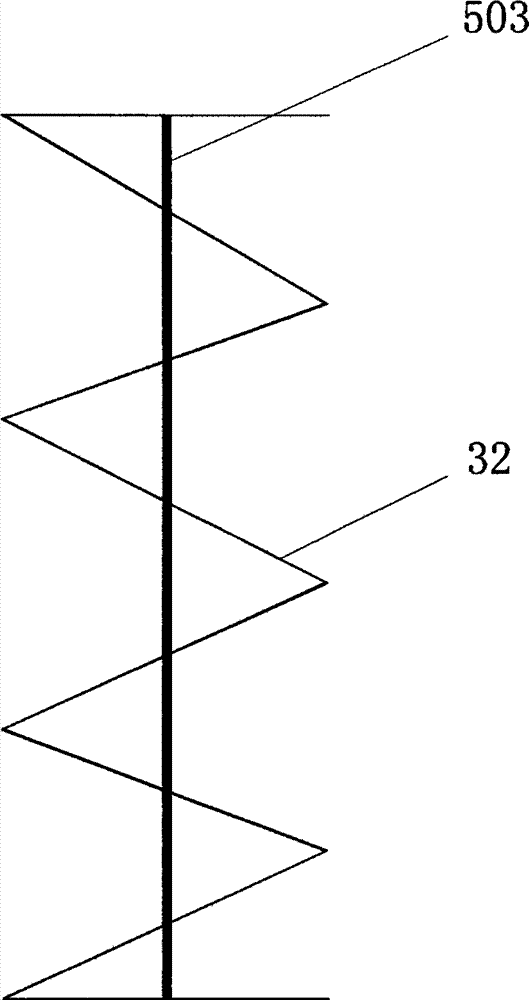

Elastic support component for spring mattress and spring mattress

InactiveCN102894722AReduce sleep discomfortReduce gapStuffed mattressesSpring mattressesPre stressInstability

The invention provides an elastic support component for a spring mattress. The elastic support component comprises supporting springs and pre-stress components, wherein the pre-stress components press the supporting springs so as to make the supporting springs in a pre-compressed state. The invention also provides the spring mattress. The spring mattress comprises an elastic support layer and a coating layer which is positioned on the outer surface of the elastic support layer; the elastic support layer comprises a plurality of supporting springs which are distributed in parallel; the supporting springs are in the pre-compressed state; the elastic support layer also comprises at least one pre-stress component which presses the supporting springs so as to make the supporting spring in the pre-compressed state. The supporting springs in the spring mattress are pre-compressed before being used, so that the supporting springs are in the elasticity stabilization stage when used, and the phenomenon of elasticity instability in the initial stage of the supporting springs can be prevented or greatly reduced; and the deformation, the elasticity degree of servo and the sensitivity of the supporting springs can be reduced to make sleepers feel comfortable.

Owner:曾庆义

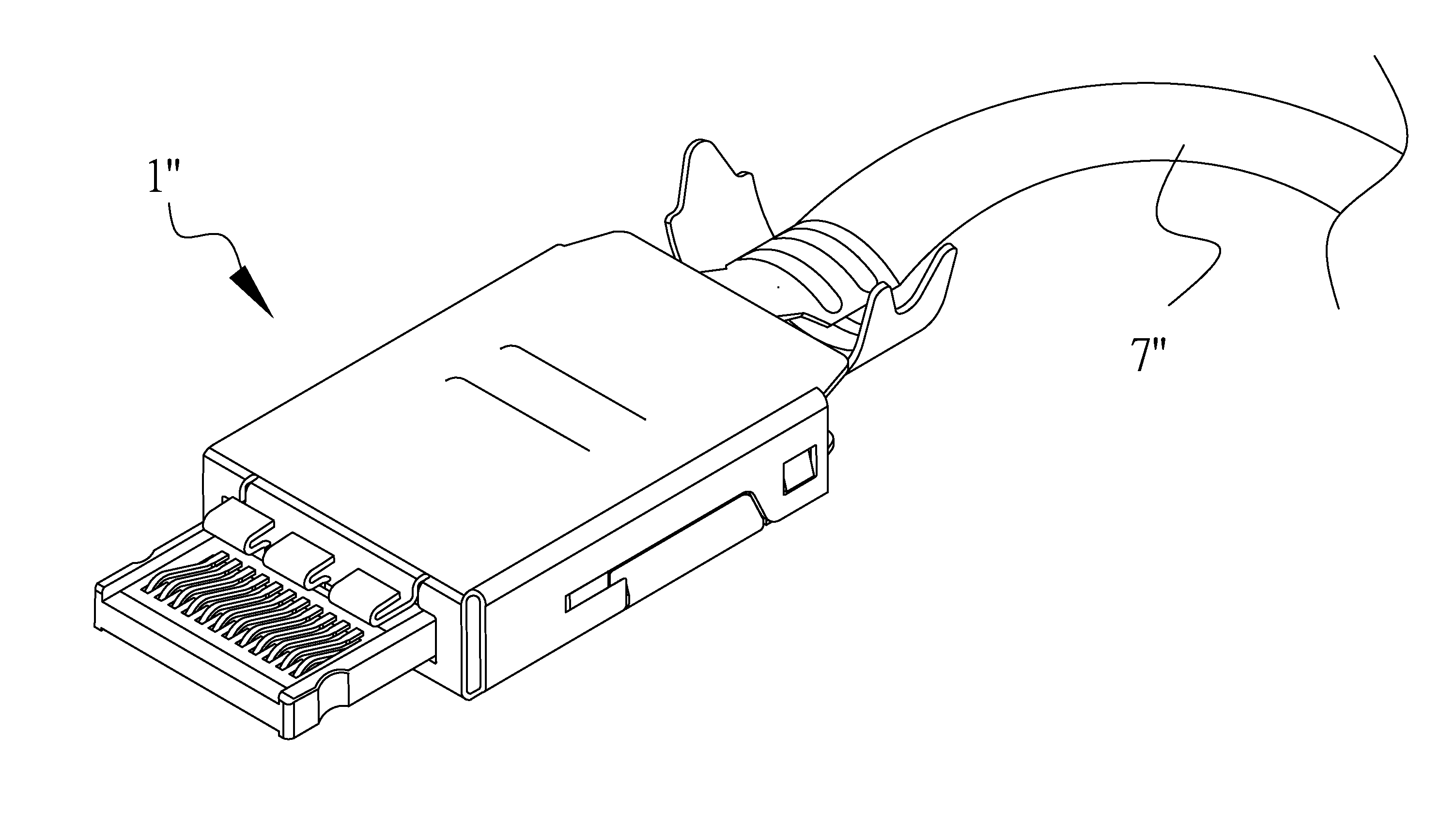

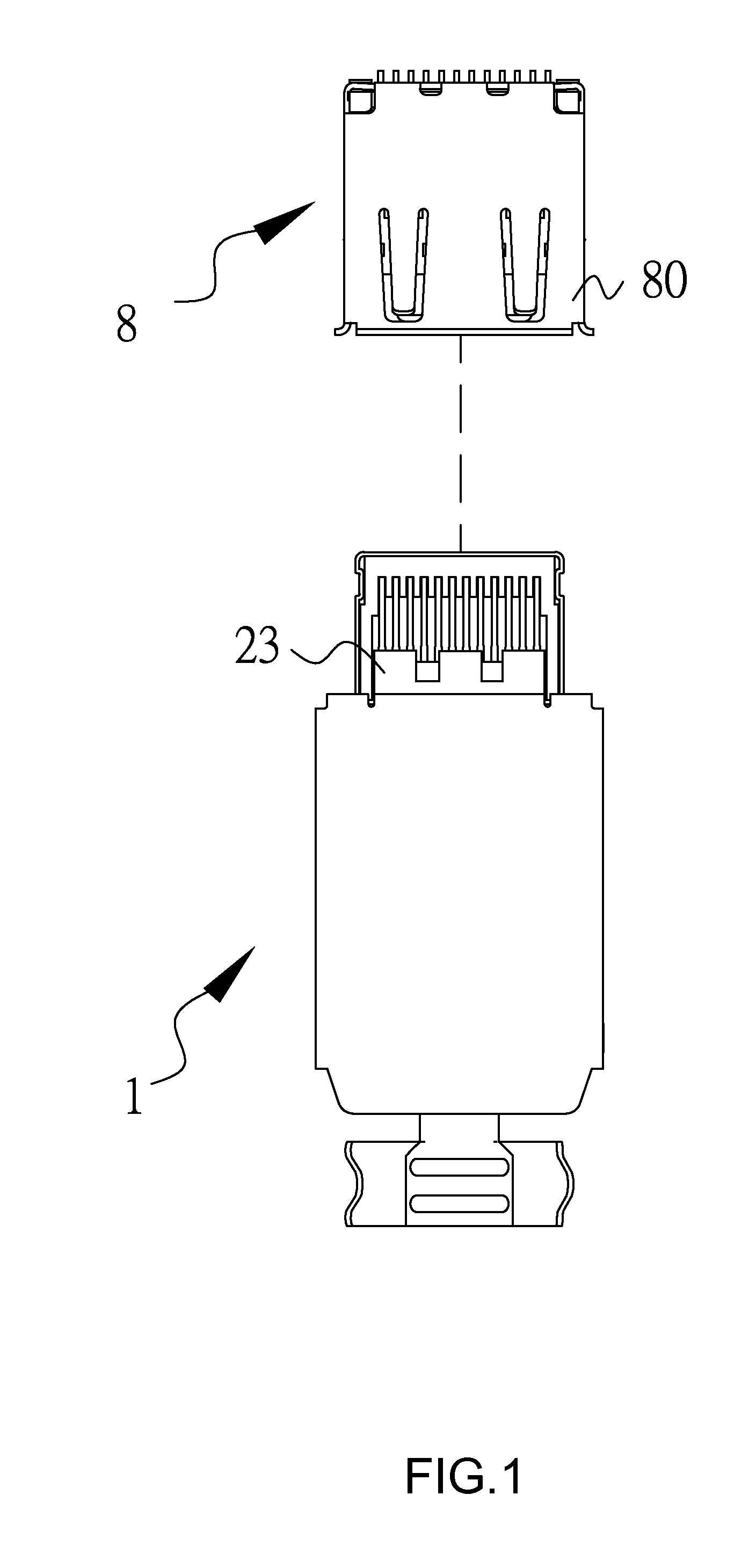

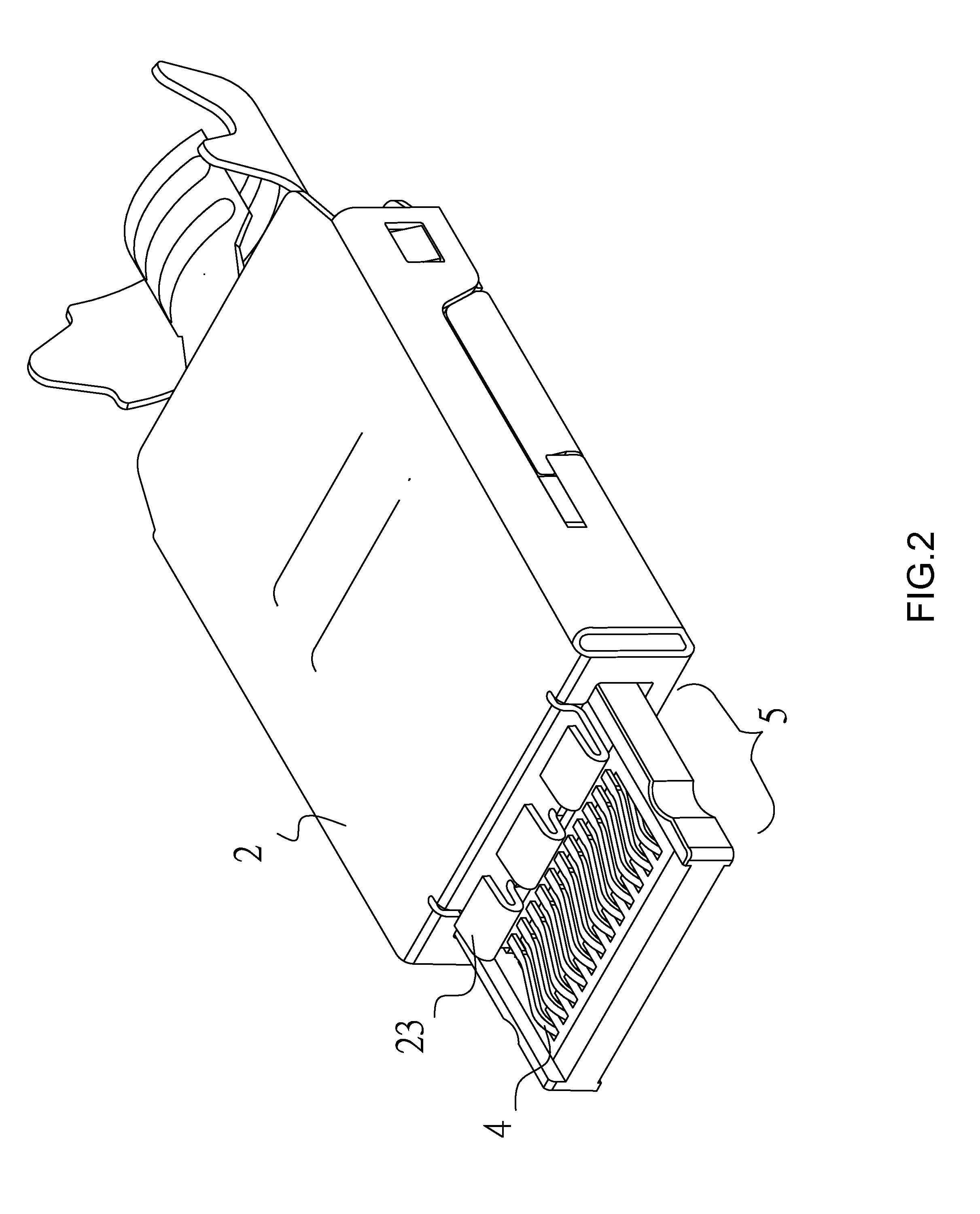

Electrical connector plug and conductive wire and assembly provided with the same

ActiveUS20150111430A1Not easy to damageIncreased durabilityElectrically conductive connectionsCoupling device detailsEngineeringElectrical connector

An electrical connector plug having resilient contact terminals electrically connects to an electrical connector socket with a casing and two groups of engaging terminals mounted on or in the casing. The electrical connector plug has an electrically conductive housing. A coupling device extends in a longitudinal direction and has a base portion. The resilient contact terminals are mounted on the coupling device axially symmetrically arranged with each other in the longitudinal direction, each of which has a flat section and an upwardly protruding contact section. A metallic shield frame is electrically connected to and secured to the electrically conductive housing, having a frame section, a front section, and two lateral protective sections. The respective lateral protective sections have a height no less than that of the upwardly protruding contact sections of the resilient contact terminals.

Owner:ADVANCED CONNECTEK INC

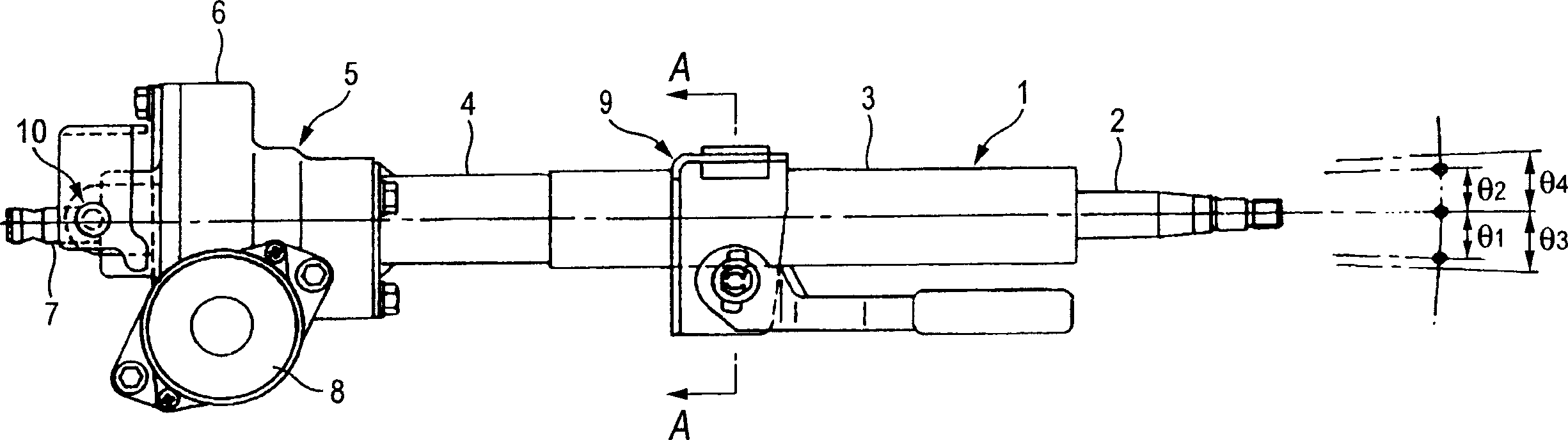

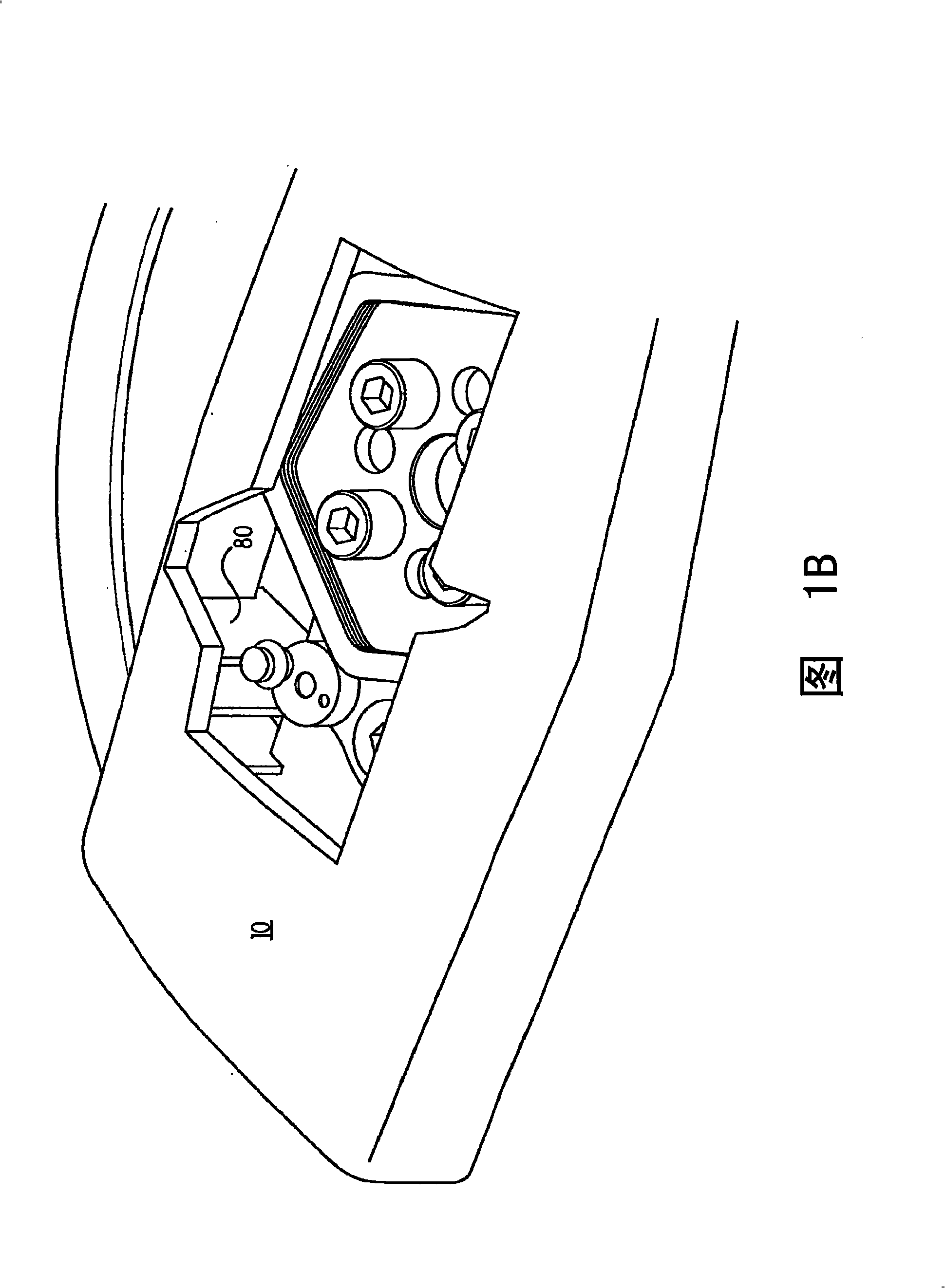

Electric power steering device

InactiveCN1856425AAvoid elasticAvoid attenuationElectrical steeringSteering columnsElectric power steeringSteering column

Owner:NSK LTD +1

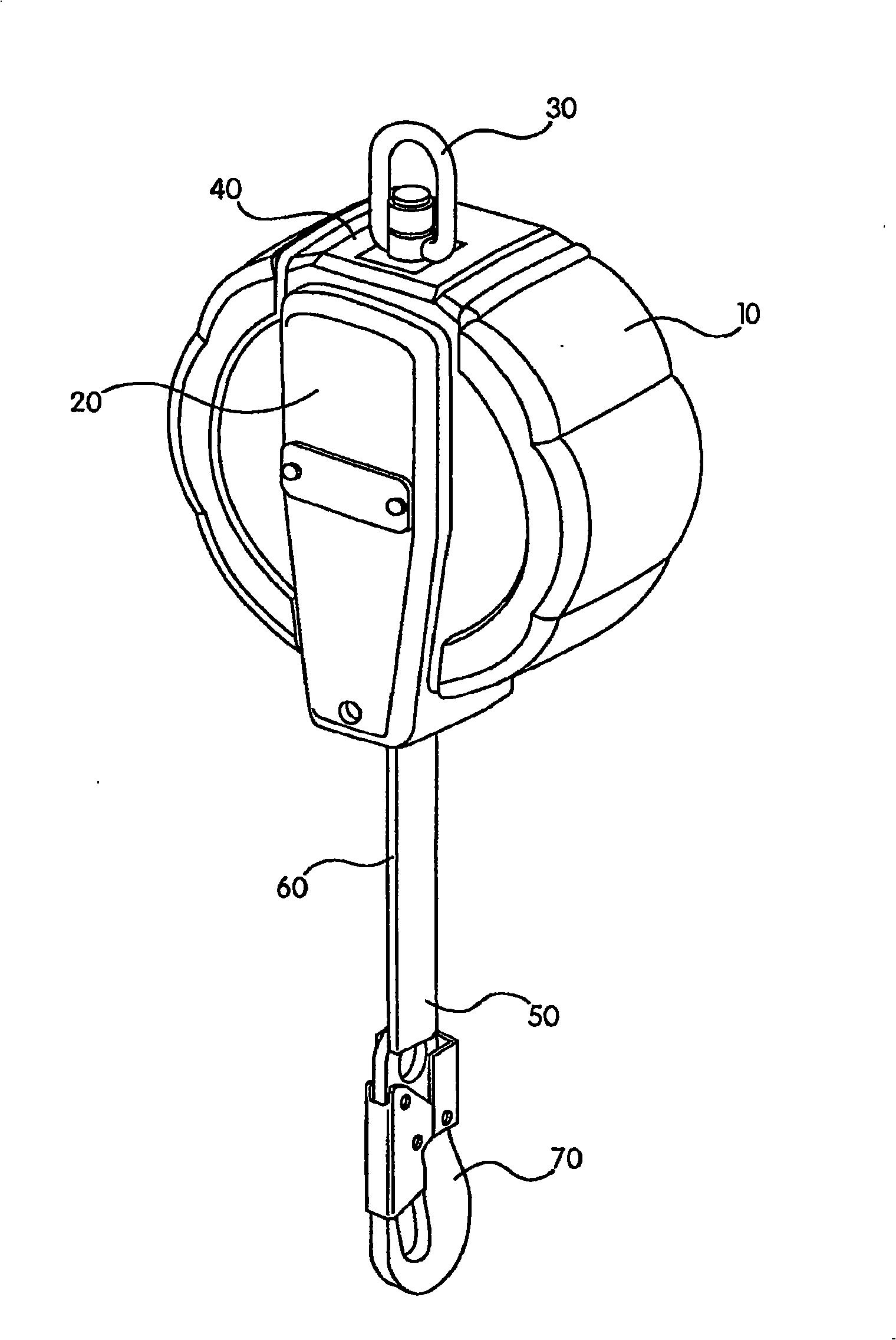

Self-retracting lanyard and braking mechanism with pawl lockout

InactiveCN101405059AIncrease the amount of reverse rotationPrevent ratchetingSafety beltsBuilding rescueEngineeringMechanical engineering

Owner:MSA TECH

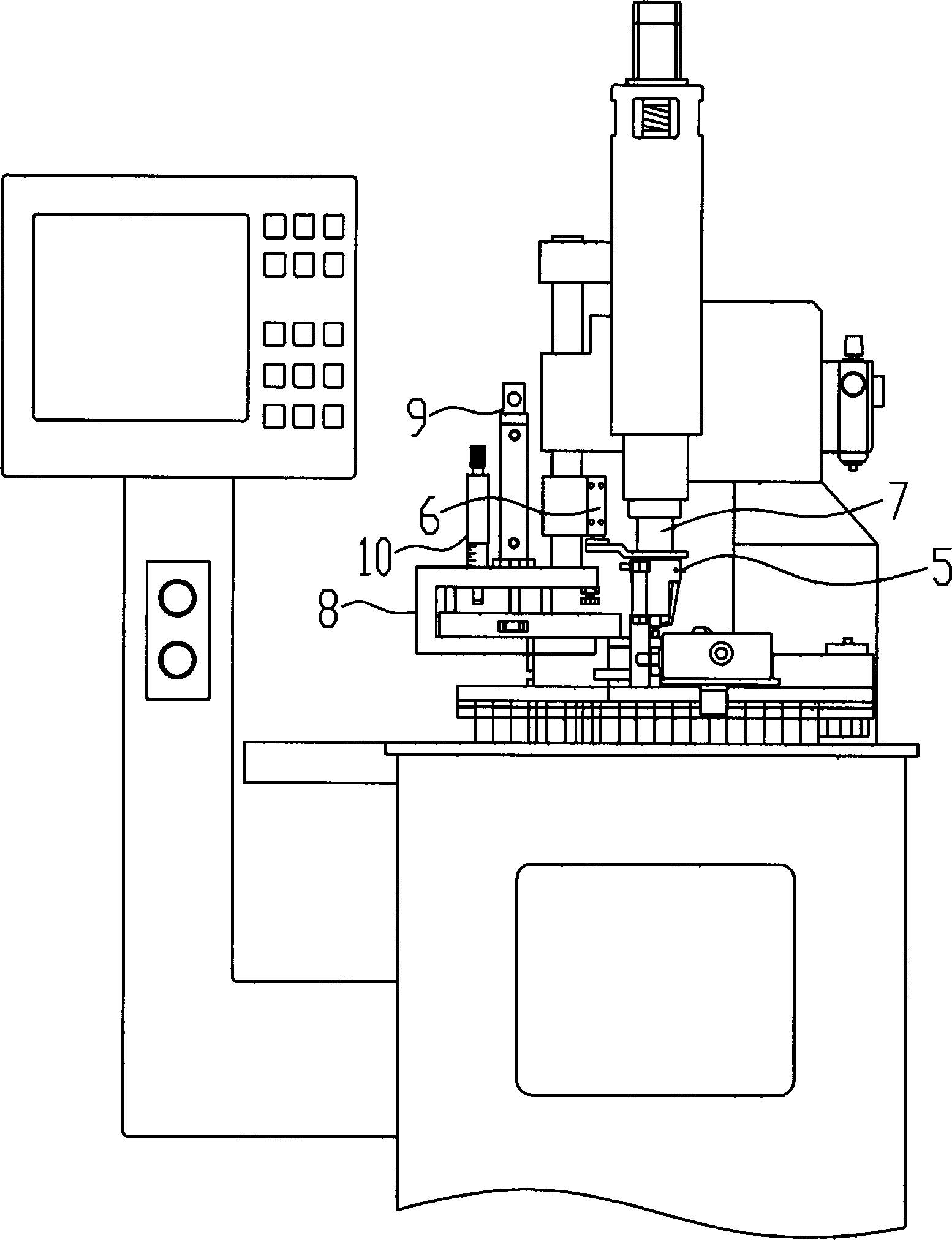

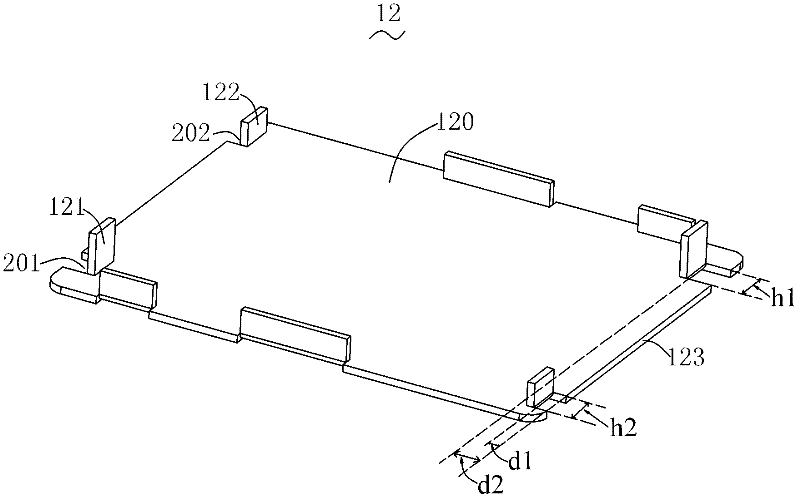

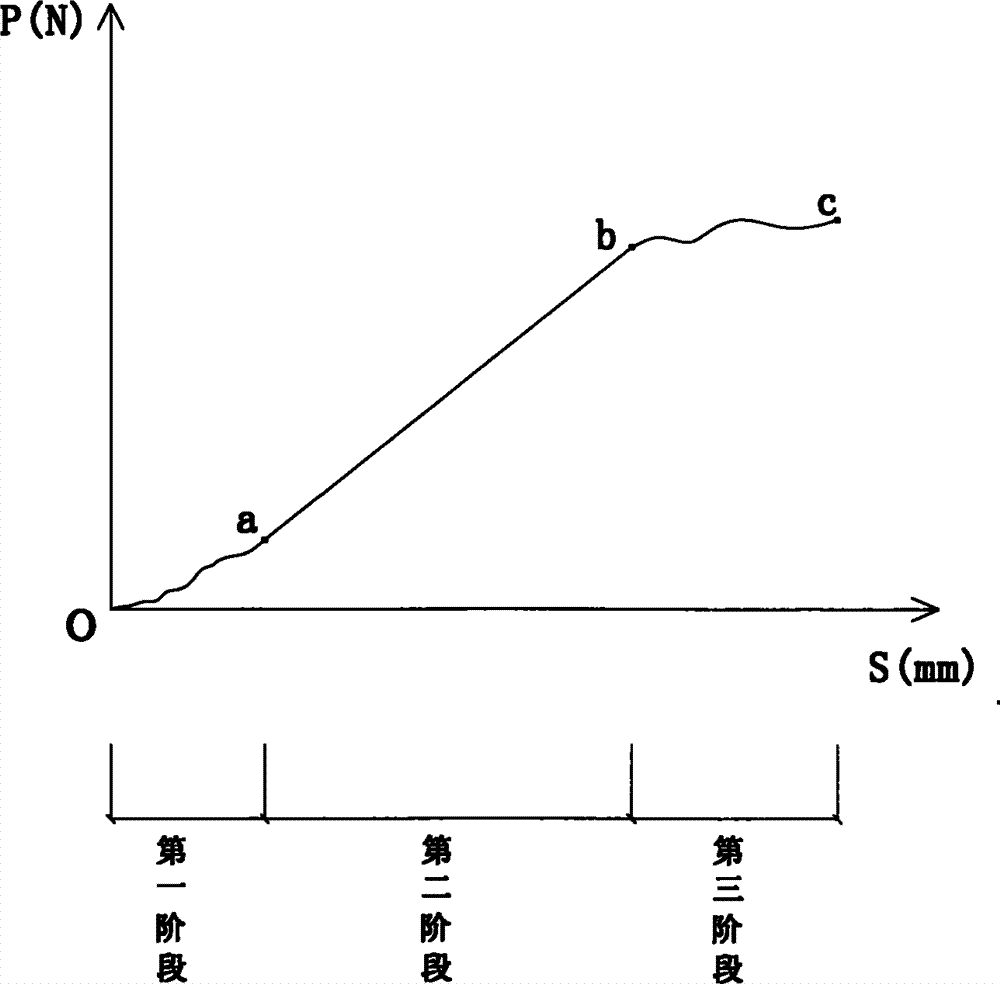

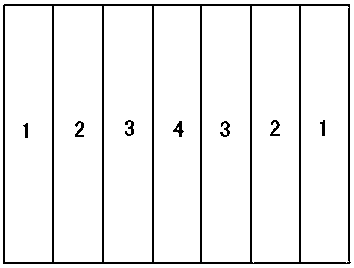

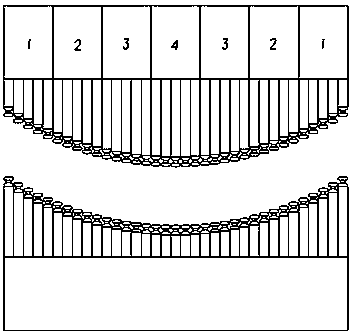

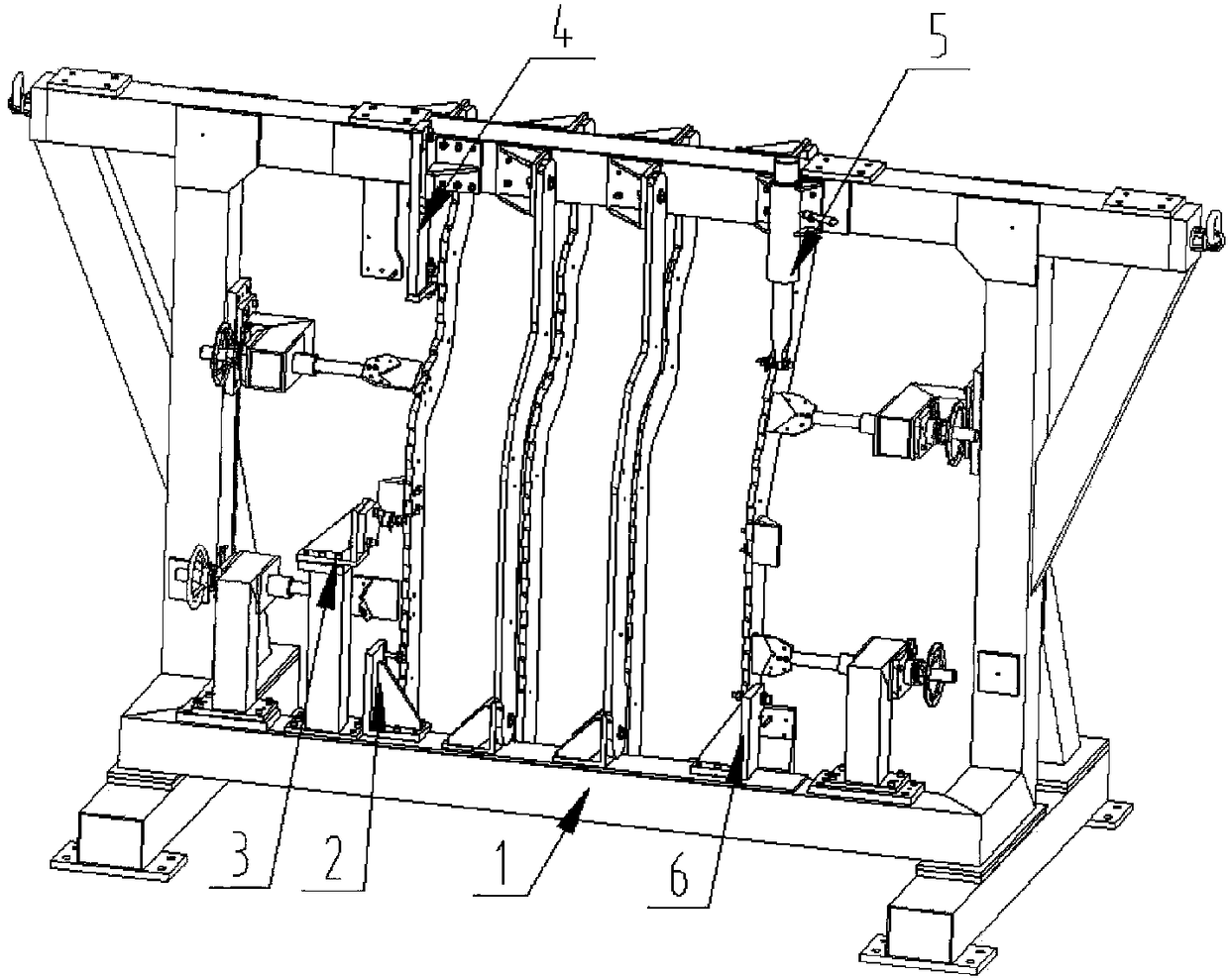

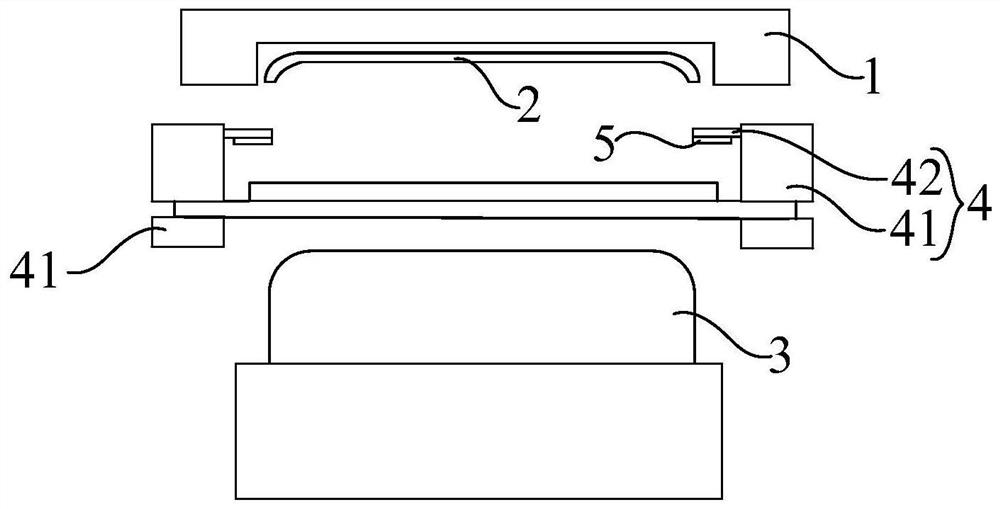

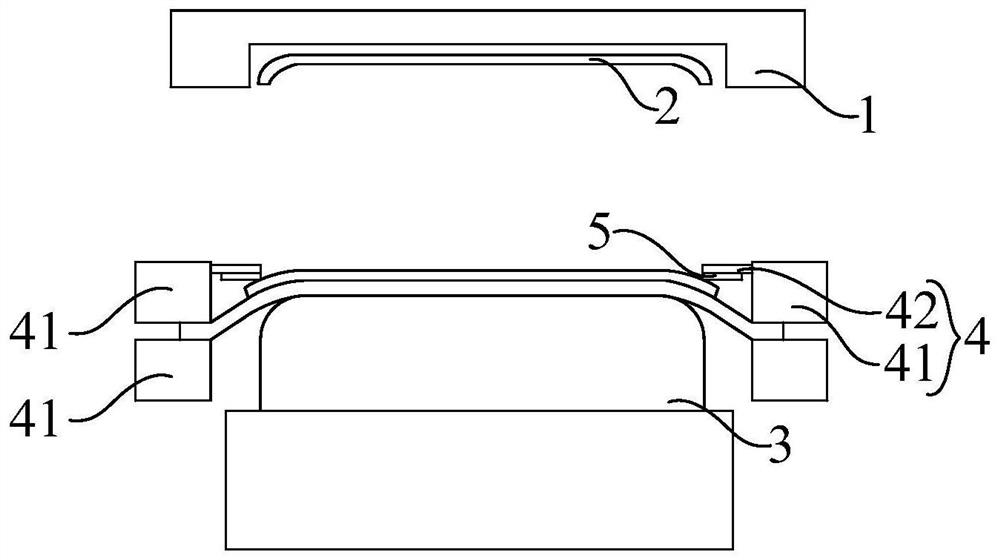

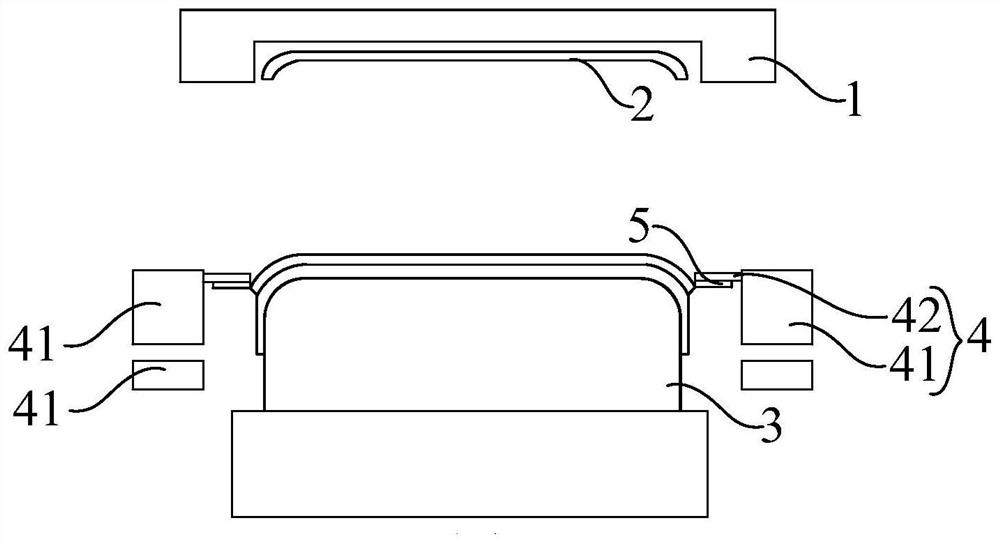

Plate multipoint divisional forming method and divisional pressing type multipoint forming device

PendingCN107597940AReduce designSaving manufacturingShaping toolsMultiple formsMechanical engineering technology

The invention discloses a plate multipoint divisional forming method and a divisional pressing type multipoint forming device, and belongs to the technical field of mechanical engineering. The plate multipoint divisional forming method and the divisional pressing type multipoint forming device aim to change the current situation that a blank pressing mechanism and a trimming process are needed when a plate is formed by utilizing an integer mould, overcome the detect that a workpiece is prone to wrinkling or the material utilization rate is low when the plate is formed by utilizing a multipointtype digitized mould, and has an anti-wrinkling function. The upper portion and the lower portion of the multipoint forming device are each composed of a plurality of basic body units, the upper portion or the lower portion of the multipoint forming device is divided into a plurality of forming areas, and the multiple basic body units are arranged on the multiple forming areas correspondingly; and when the plate is formed, the multiple forming areas are divided into two sets or a plurality of sets, each set comprises one or more forming areas, and the formed plate is pressed step by step in sets. According to the plate multipoint divisional forming method and the divisional pressing type multipoint forming device, compared with integer mould forming, mould-free forming without blank pressing of the plate three-dimensional curved surface can be achieved, and the processes of designing, manufacturing, debugging and workpiece outline cutting after plate forming of the mould are saved.

Owner:吉林省柔创机电科技有限公司

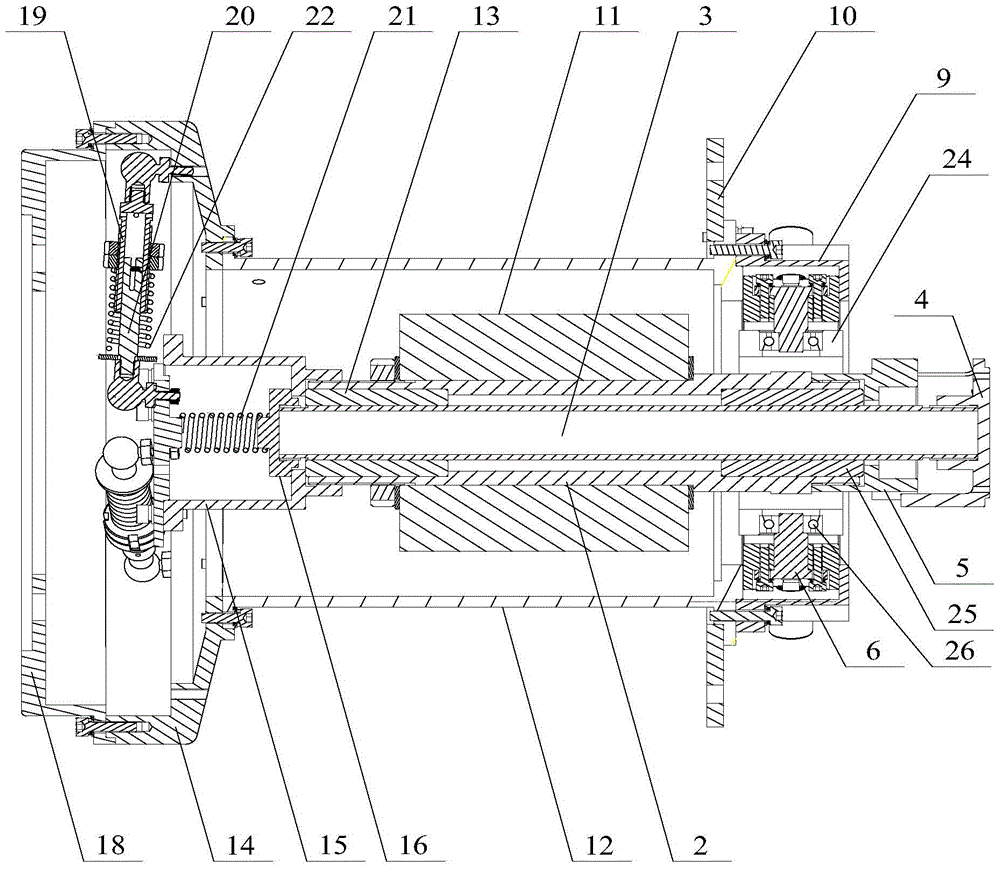

Buffer mechanism of docking device

InactiveCN105691638AReduce peakExtended docking collision contact timeCosmonautic vehiclesCosmonautic component separationSatellitePeak value

The invention provides a buffer mechanism of a docking device. A copper sleeve is arranged on the back side of a space between a shaft and a shaft sleeve; a linear bearing is arranged on the front side of the space between the shaft and the shaft sleeve; an axial spring is arranged between a shaft sleeve end cover flange and a shaft back end cover; a radial spring is arranged between a damper sleeve and a damper pull rod; a gravity compensation block sleeves the shaft sleeve in a front outer shell; an end cover is connected between a bearing outer cover and a bearing outer shell; a disc spring set is arranged on the end cover between the bearing outer cover and the bearing outer shell; two bearing shafts are mounted on the bearing outer cover; inner covers of ball bearings are arranged on the bearing shafts; outer covers of the ball bearings are arranged on universal joints; two symmetric bearing mounting shafts are arranged on the shaft sleeve; the inner covers of the ball bearings are arranged on the bearing mounting shafts; and the outer covers of the ball bearings are mounted on the universal joints by a bearing inner cover. One set of buffer mechanism is designed to reduce the peak value of collision contact force, to prolong the docking collision contact time and to assist realization of smooth docking of non-cooperative satellites.

Owner:HARBIN INST OF TECH

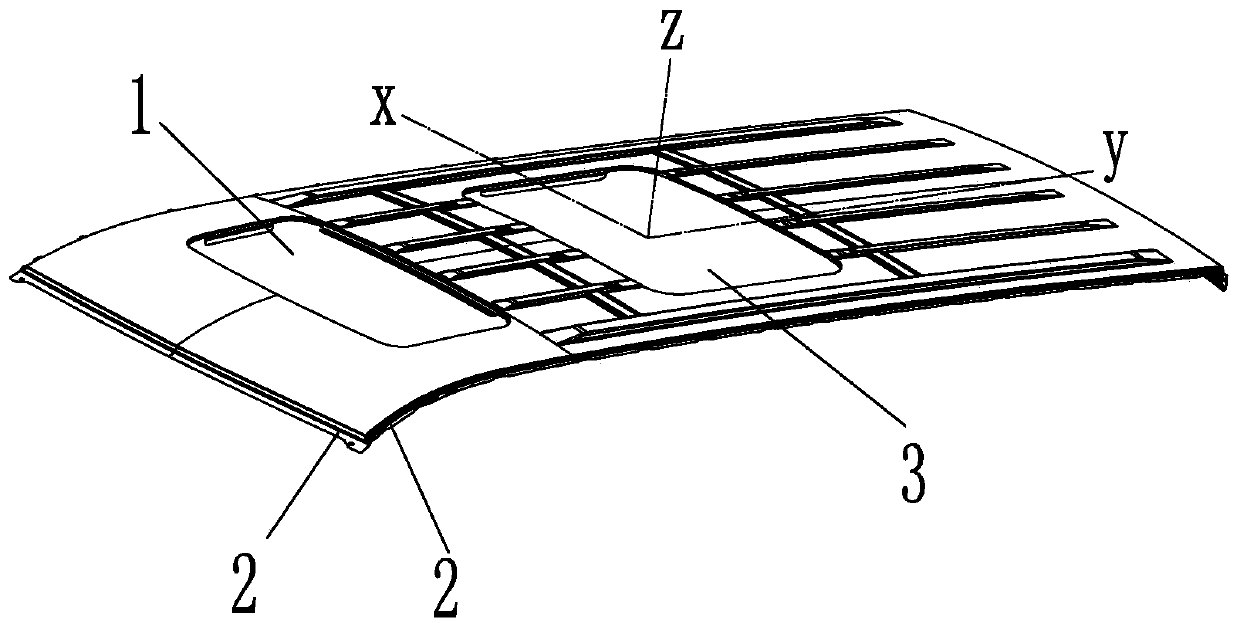

Stamping process profile compensation method for vehicle roof cover with sunroof

The invention discloses a stamping process profile compensation method for a vehicle roof cover with a sunroof. A stamping process for the vehicle roof cover with the sunroof comprises the following four procedures: 1. drawing; 2. trimming, punching and side shaping; 3. trimming, flanging and shaping; 4. trimming, punching, side punching, side shaping and upward flanging. As for the stamping process profile compensation method, die profiles from the first procedure to the third procedure are compensated. Through the method of the invention, the stamping process profiles are compensated by thepreliminary CAE analysis, and the process compensation scheme is formulated at the process design stage, thereby greatly reducing the die debugging workload, shortening the die forming cycle of complicated panel dies such as the roof cover, reducing die development costs, and improving the quality of the large panel dies.

Owner:柳州业泰汽车零部件有限公司

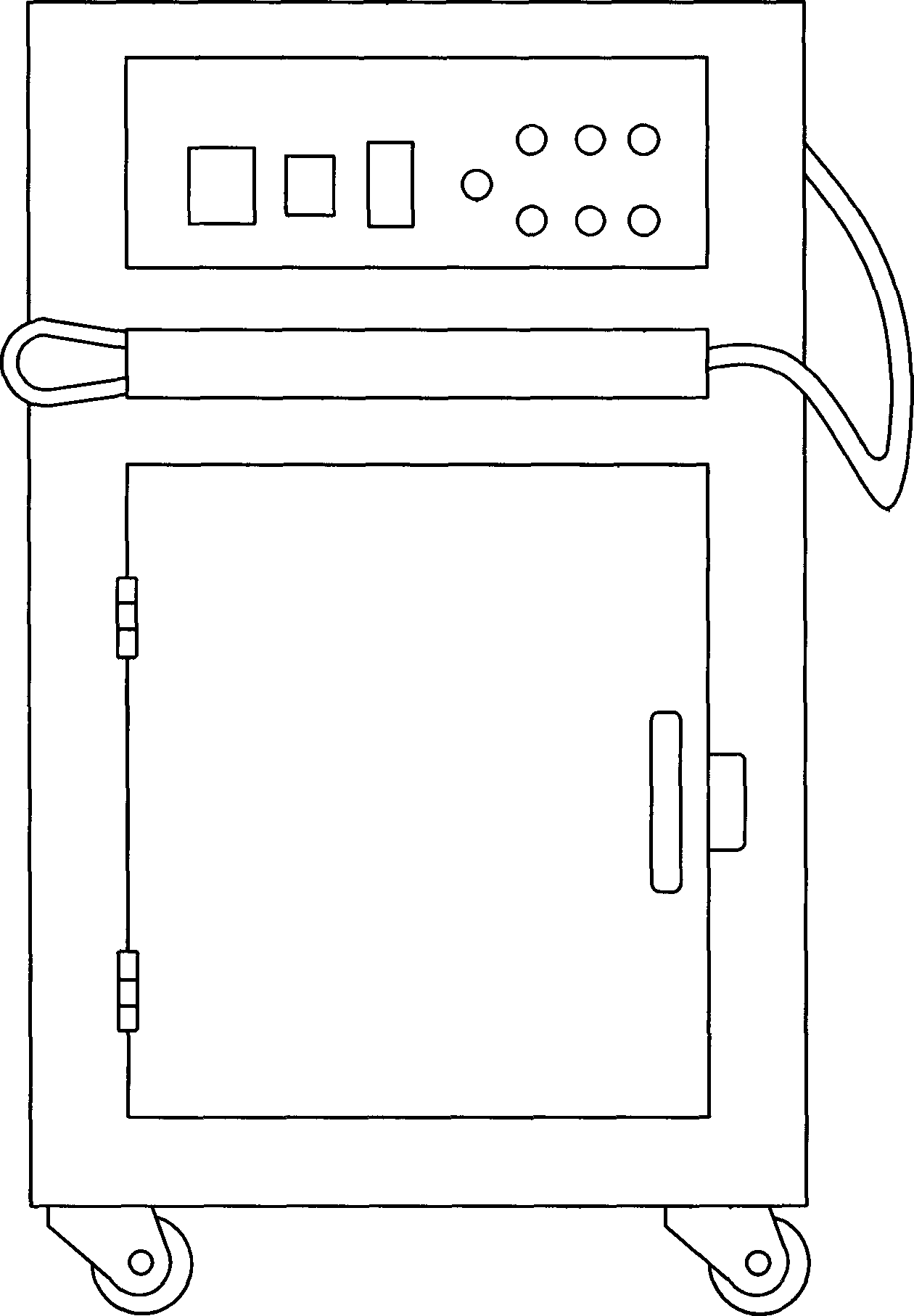

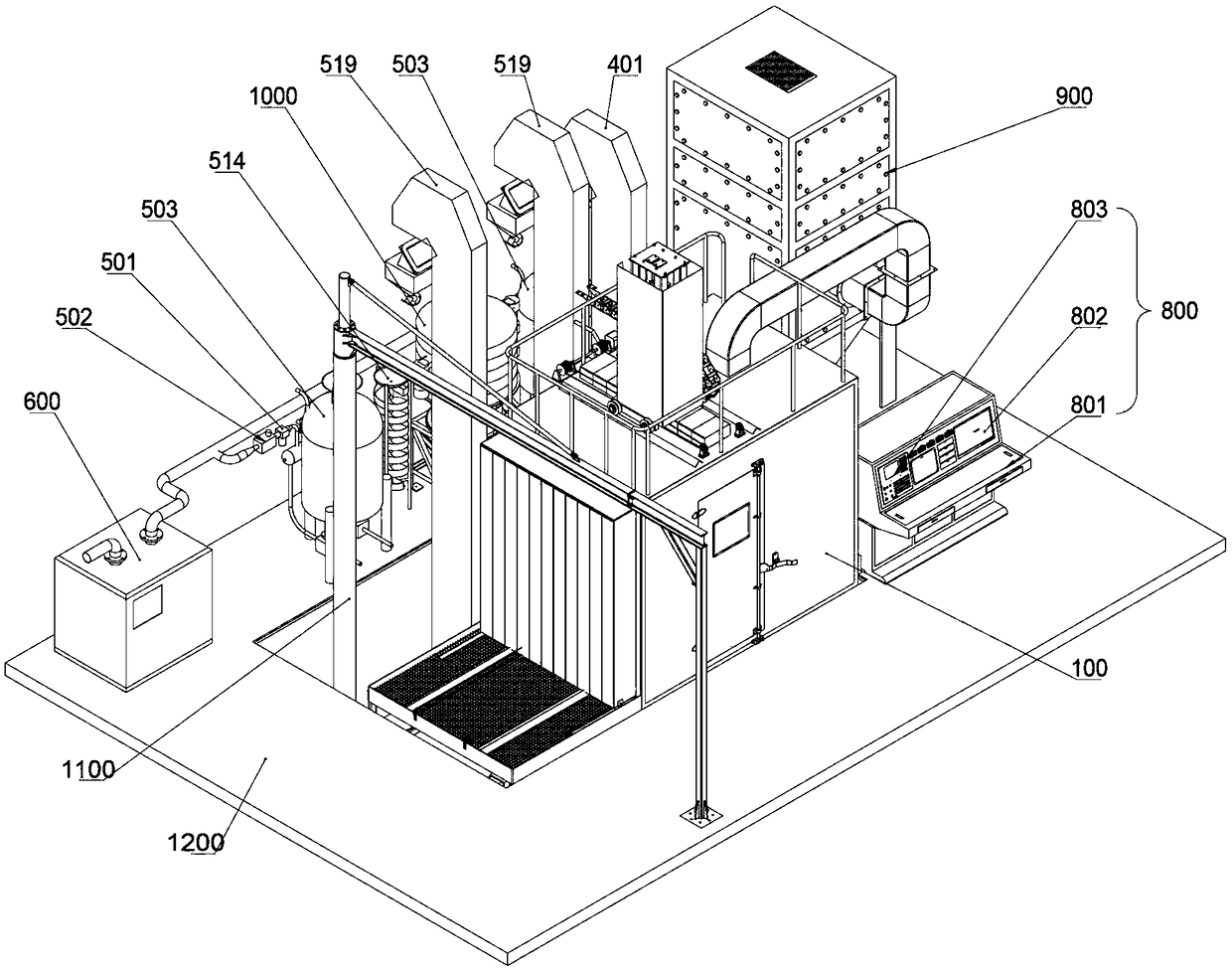

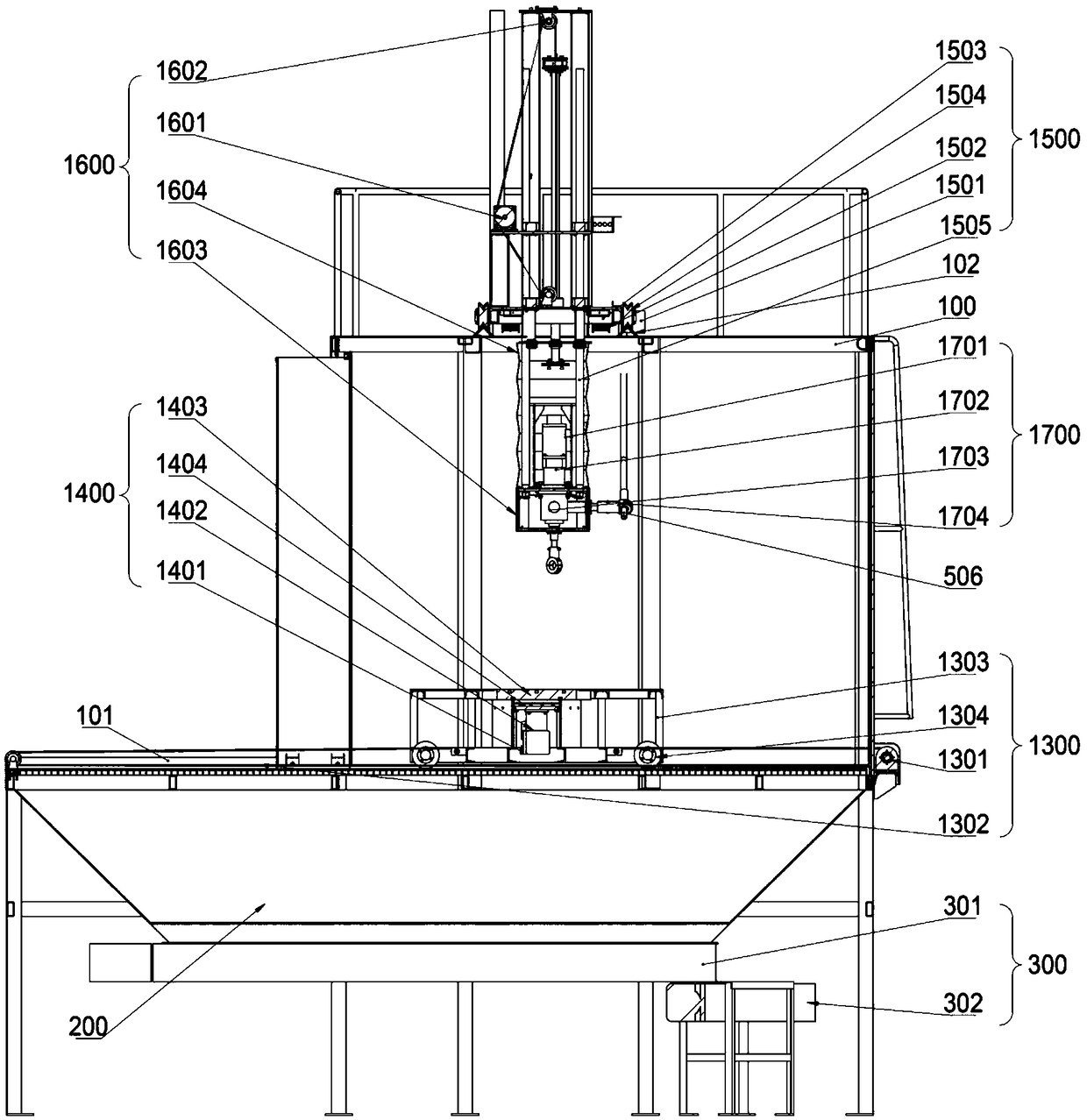

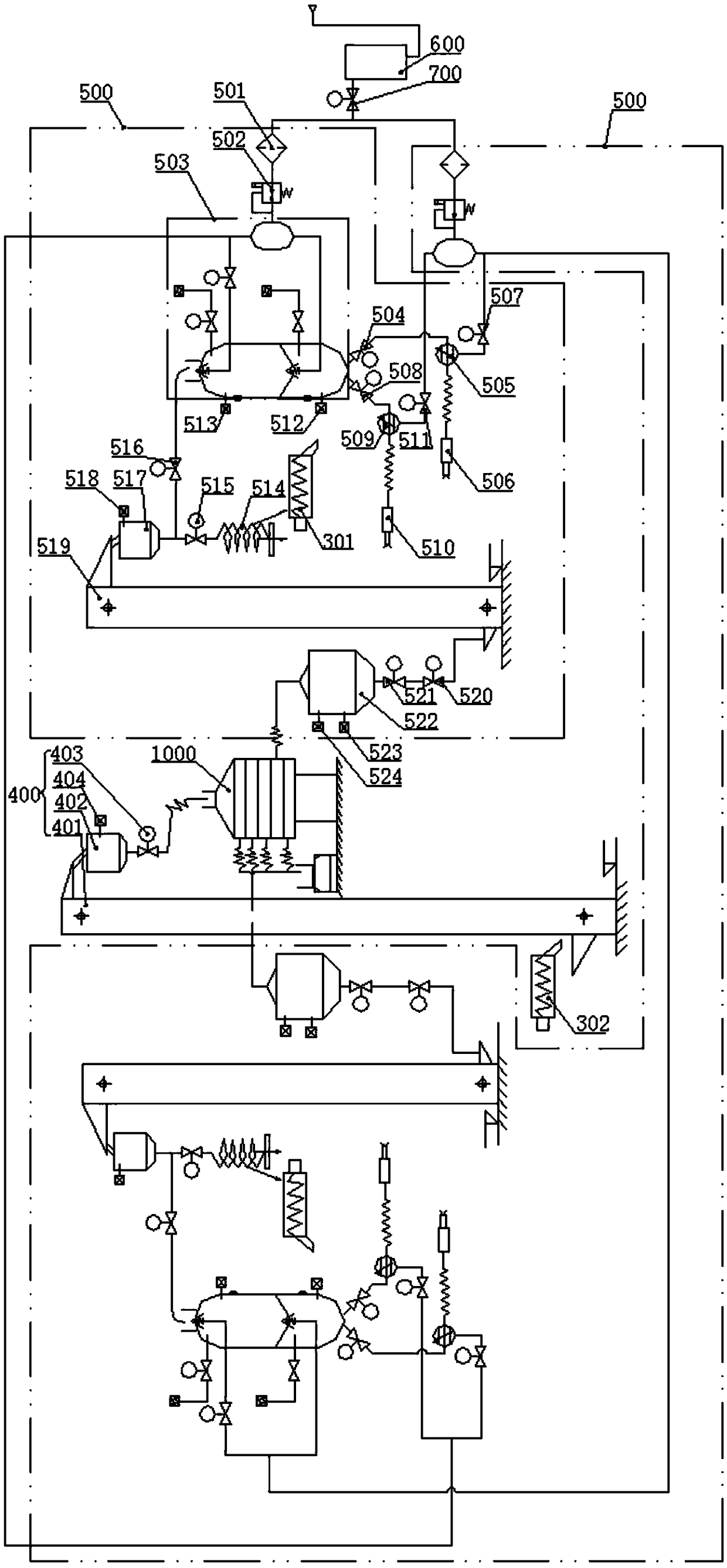

Five-axis shot blasting equipment

PendingCN108747843AMeet the requirements of alternate shot peeningAvoid elasticAbrasive machine appurtenancesAbrasive blasting machinesPositive pressureSpray nozzle

The invention belongs to the technical field of shot blasting equipment, and relates to five-axis shot blasting equipment. The five-axis shot blasting equipment solves the problems that existing shotblasting equipment cannot meet the requirements of rotating type and non-rotating type parts for shot blasting, and two kinds of steel shots cannot be used for shot blasting in turns at a time. The equipment comprises a shot blasting working chamber and a shot collecting bin arranged below the shot blasting working chamber, an X-axis motion guide rail is arranged between the shot blasting workingchamber and the shot collecting bin, and a Y-axis motion guide rail is arranged on the top of the shot blasting working chamber; and a shot conveying system, a shot lifting system, an air source processing system, a control device, an X-axis direction product moving platform arranged on the X-axis motion guide rail, an A-axis product rotating platform capable of rotating relative to the X-axis direction product moving platform, a Y-axis direction spraying nozzle moving platform arranged on the Y-axis motion guide rail, a Z-axis direction spraying nozzle moving platform capable of moving relative to the Y-axis direction spraying nozzle moving platform, a B-axis spraying nozzle rotating platform capable of rotating relative to the Z-axis direction spraying nozzle moving platform, a shot separating device and two sets of positive pressure shot blasting systems.

Owner:国营四达机械制造公司

Spiral gasoline filter

InactiveCN102345542AEnsure stabilityAvoid leaningMachines/enginesLiquid fuel feedersWhole bodyBiochemical engineering

The invention relates to the field of automotive filter equipment, in particular to a spiral gasoline filter, which comprises a shell, a seal cover, and a filter element, wherein a drain valve is arranged at the bottom of the shell, an oil inlet pipe and an oil outlet pipe are arranged on the seal cover, the filter element is composed of an upper end cover, a lower end cover and hollow cylindrical filter paper which is arranged between the upper end cover and the lower end cover and is formed through longitudinal folding, and the two annular end faces of the filter paper are respectively and fixedly bonded with the upper end cover and the lower end cover. The spiral gasoline filter is characterized in that the upper end cover is further provided with an oil outlet channel which is communicated with the oil outlet pipe, the center of the filter paper is further provided with a filter element shaft, and a spiral runner is arranged on the whole body of the filter element shaft and is communicated with the oil outlet channel. According to the invention, the spiral runner is skillfully arranged on the outer wall of the filter element, so that the filter can be used for filtering is an eddy flow manner, the filtering effect is greatly enhanced, and the advantages of simple structure and low cost are achieved; in addition, a silencing block and an air bleed valve are additionally arranged in the filter, so that the integral usability of the filter is increased.

Owner:浙江赫嘉汽配有限公司

Display panel and display device

ActiveCN112017546AAvoid elasticAvoid liftingPhotovoltaic energy generationIdentification meansSurface displayDisplay device

One or more embodiments of the present specification provide a display panel and a display device. The display panel comprises a first cover plate, and the first cover plate comprises: a first plane cover plate area, which is configured to be arranged on the light emitting side of a plane display area of the display panel; a first curved surface cover plate area, which has one side connected withthe first plane cover plate area, and is configured to be arranged on the light emitting side of a curved surface display area of the display panel; and a turnover cover plate area, which is connectedwith the other side of the first curved surface cover plate area and is configured to be arranged on the non-light-emitting side of the display panel. According to the embodiment of the invention, the original cover plate is extended, folded and attached to the non-light-emitting side of the display panel, so that a display film layer in the display panel can be bound to the curved surface display area, and the display film layer is prevented from rebounding and upwarping.

Owner:BOE TECH GRP CO LTD +1

Three-component valve

ActiveCN101927227AQuick and easy dispensingGlue cleanLiquid surface applicatorsCoatingsPistonEngineering

The invention discloses a three-component valve. A valve body comprises an upper valve body and a lower valve body, wherein the upper valve body comprises an upper valve body shell and a drive mechanism arranged in the upper valve body shell; a cavity is reserved in the upper part of the lower valve body; at least three piston channels are arranged in parallel at the bottom in the cavity; a glue outlet hole is reserved on the tail parts of each piston channel; a piston is arranged on the middle parts of each piston; the sealed ends of each piston are at least partially arranged in the corresponding glue outlet holes; at least one sealing device is arranged between each piston and the corresponding piston channels; the top ends of the pistons arranged in parallel are fixed on the same connecting plate which is at least provided with a connector; the connector is connected with the drive mechanism at least by one drive shaft; and the at least one drive shaft is arranged in a drive shaftchannel arranged between the upper and lower valve bodies. The invention provides the dispensing three-component valve, which has the characteristics of quick, convenient and accurate dispensing, clean dispensing stoppage and sealing structure difficult to damage.

Owner:SHENZHEN AXXON AUTOMATION

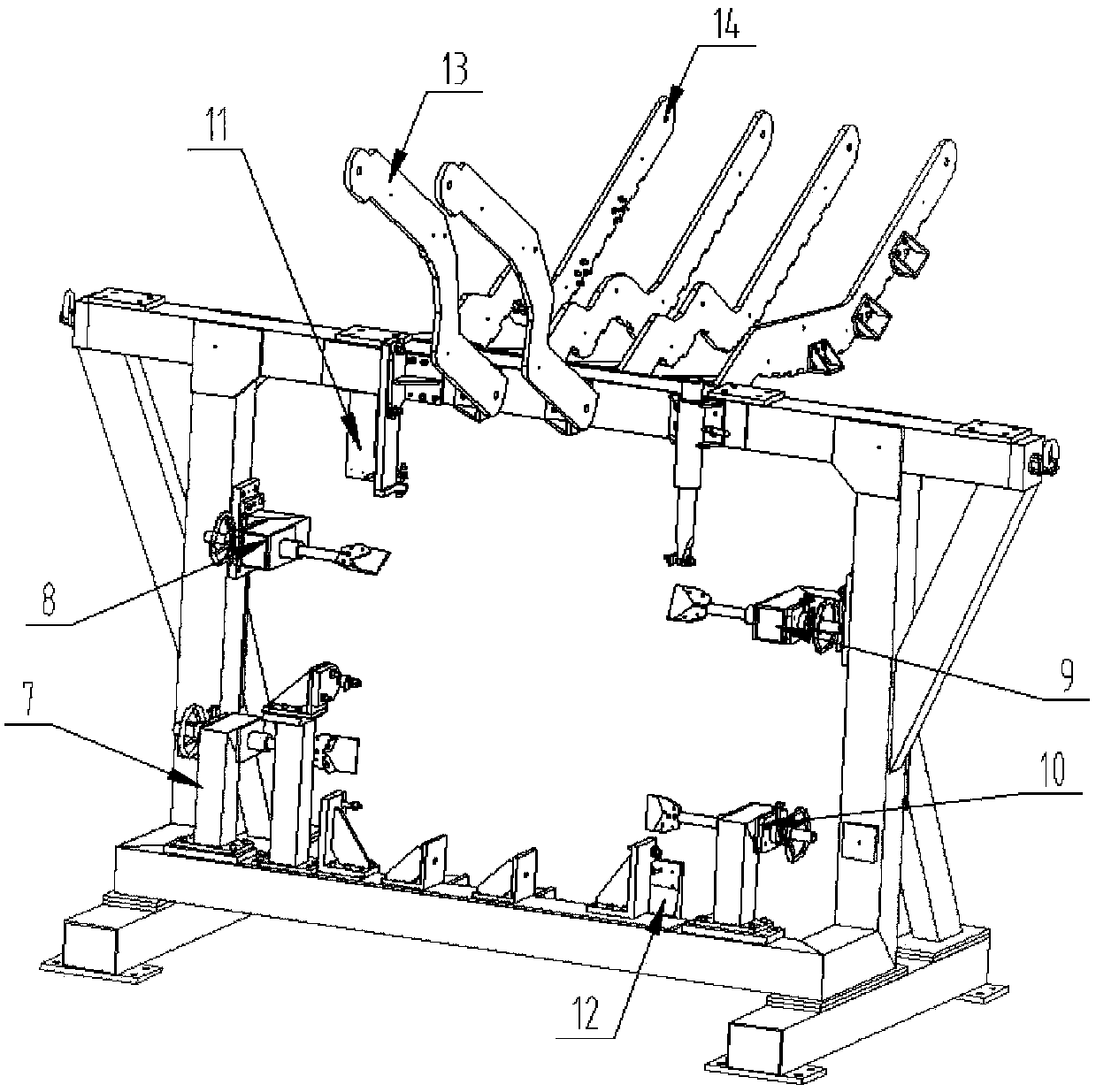

Assembling clamp for carbon fiber composite aircraft cabin door

PendingCN108382605AHigh precision assemblyAvoid relative position deviationWork holdersAircraft assemblyAirplaneCarbon fiber composite

The invention provides an assembling clamp for a carbon fiber composite aircraft cabin door. The assemble assembling clamp has the function of assembling five metal joints on the composite cabin doorthrough a riveting bonding mode, and the outline precision of the tooth-shaped edge relative to five joint holes, and the relative position degree and the coaxial degree among the joint holes are ensured. Through the assembling clamp, high precision assembling of the carbon fiber composite cabin door and the metal joints can be achieved, relative position deviation caused by the unreasonable positioning and clamping mode or the rebound and super poor precision of a manufactured piece caused by large state deviation between the state of the manufactured workpiece and the state after the manufactured workpiece is removed from a frame during assembling is avoided, meanwhile, the mode of a frame-type structure combined positioning assembly has the enough openness, the operation space can be ensured, the structure can be simplified as far as possible, and the manufacturing cost is reduced.

Owner:HENGSHEN

Attaching device and attaching method

PendingCN112123911AImprove fitGood deformabilitySolid-state devicesLaminationStructural engineeringMechanical engineering

The invention discloses an attaching device and an attaching method. The attaching device comprises a pressing table, a profiling pressure head and a clamp; the working face of the pressing table is sunken to form a containing groove used for containing a curved surface cover plate, and the containing groove is provided with a special-shaped part corresponding to the special-shaped face of the curved surface cover plate; the profiling pressure head comprises an arc-shaped surface which is used for contacting with one side, far away from a film layer structure, of a guide film layer so as to enable the film layer structure to be pre-pressed and formed; the clamp comprises a clamping assembly and a press-fit assembly; the clamping assembly is used for clamping and guiding the extending-out area of the film layer; the press-fit assembly at least acts on the irregularly-shaped area in the film layer structure to provide pressure facing the arc-shaped surface for the film layer structure; the press-fit assembly can be connected to the clamping assembly. The attaching device disclosed by the invention can prevent the film layer structure from warping after pre-pressing forming, so that the attaching effect of the curved surface cover plate and the film layer structure is better.

Owner:HEFEI VISIONOX TECH CO LTD

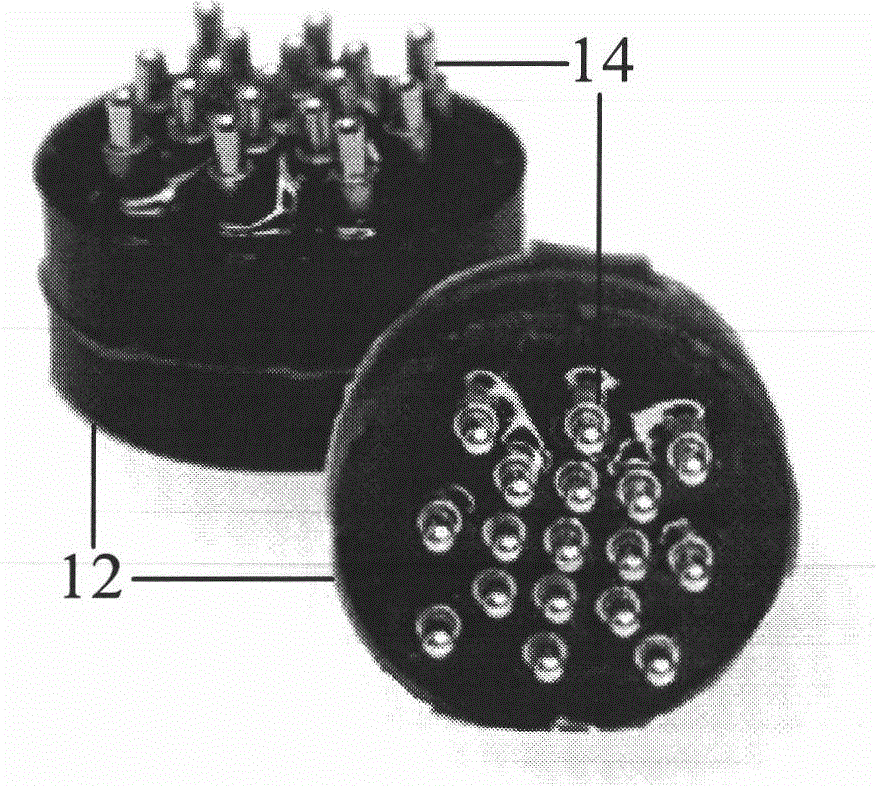

Dry electrode and manufacturing method thereof

InactiveCN104414635AIncrease contactAvoid elasticDiagnostic recording/measuringSensorsHead scalpEngineering

The embodiment of the invention discloses a dry electrode and a manufacturing method thereof. The dry electrode comprises conduits (2), elastic parts (3) and electrode masts (4), wherein the conduits (2) are fixedly arranged on one side of a substrate (1); the elastic parts (3) are located in the conduits (2) and the elastic coefficient of the elastic parts (3) is correlated with the positions of the elastic parts (3) on the substrate (1); the electrode masts (4) are located in the conduit (2) and move in the conduits (2) under the effect of the elastic parts (3). When the dry electrode touches a scalp, the electrode masts (4) of the dry electrode disclosed by the embodiment of the invention can correspondingly stretch out or retract back under the effect of the elastic parts (3) according to the curvature of each point on a head, the elastic force of the electrode posts () can be comparatively uniform according to the correlation between the positions thereof and the elastic coefficient of the elastic parts (3), thus the dry electrode is guaranteed to be in good contact with the scalp and the electrode masts (4) on the periphery of the substrate are prevented from having the defect of poor contact due to smaller elastic force.

Owner:DEAYEA TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com