Method for preparing cement clinker by using waste concrete

A technology for waste concrete and cement clinker, applied in cement production, etc., can solve the problems of shale and sandstone natural resource depletion, and achieve the effect of easy grinding and calcination process, improved utilization rate and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

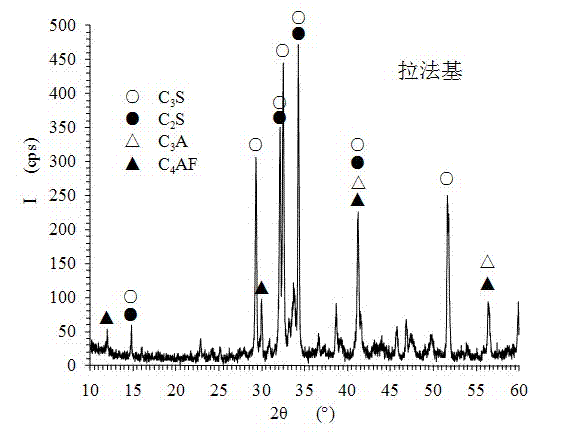

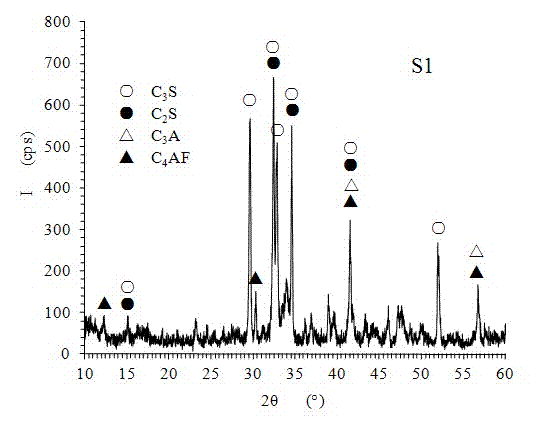

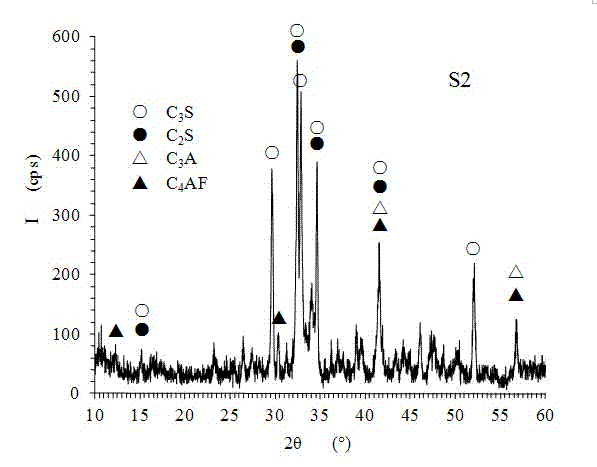

Image

Examples

Embodiment Construction

[0017] The present invention will be described and verified in detail below through test examples.

[0018] Seven typical waste concrete samples were randomly selected from different building demolition sites, numbered F1-F7. The particles were crushed with a jaw crusher until the particle size was below 20 mm, and the particles with a particle size of 5 mm to 20 mm were sieved out. After being ground to a predetermined fineness by a ball mill, the chemical composition was fully analyzed. The results are shown in Table 1.

[0019] Table 1 Analysis results of chemical composition of waste concrete

[0020]

[0021] After the waste concrete is crushed and sieved to obtain particles with a particle size greater than 5mm, the main component is limestone aggregates, and the mortar bonded to the surface is mostly peeled off from the surface of the aggregates and screened out due to the effect of cyclic stress during the crushing process. From the chemical composition analysis re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com