Patents

Literature

78 results about "Cyclic stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

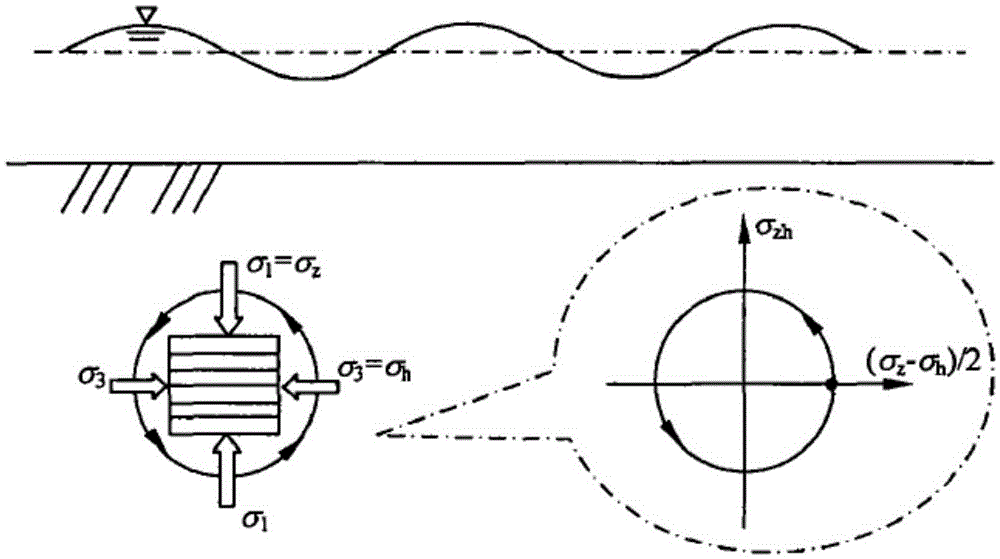

Cyclic stress is the distribution of forces (aka stresses) that change over time in a repetitive fashion. As an example, consider one of the large wheels used to drive an aerial lift such as a ski lift. The wire cable wrapped around the wheel exerts a downward force on the wheel and the drive shaft supporting the wheel. Although the shaft, wheel, and cable move, the force remains nearly vertical relative to the ground. Thus a point on the surface of the drive shaft will undergo tension when it is pointing towards the ground and compression when it is pointing to the sky.

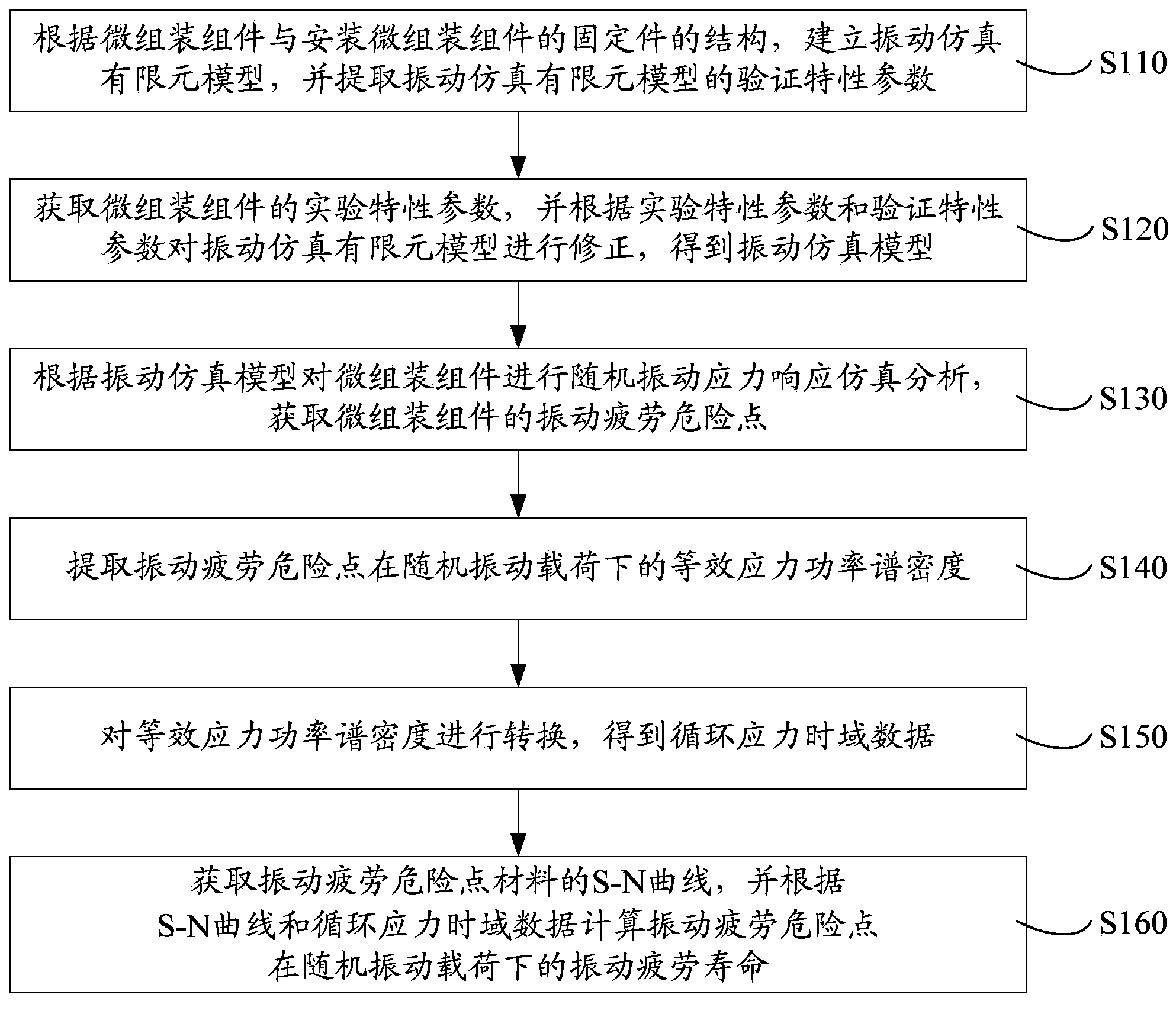

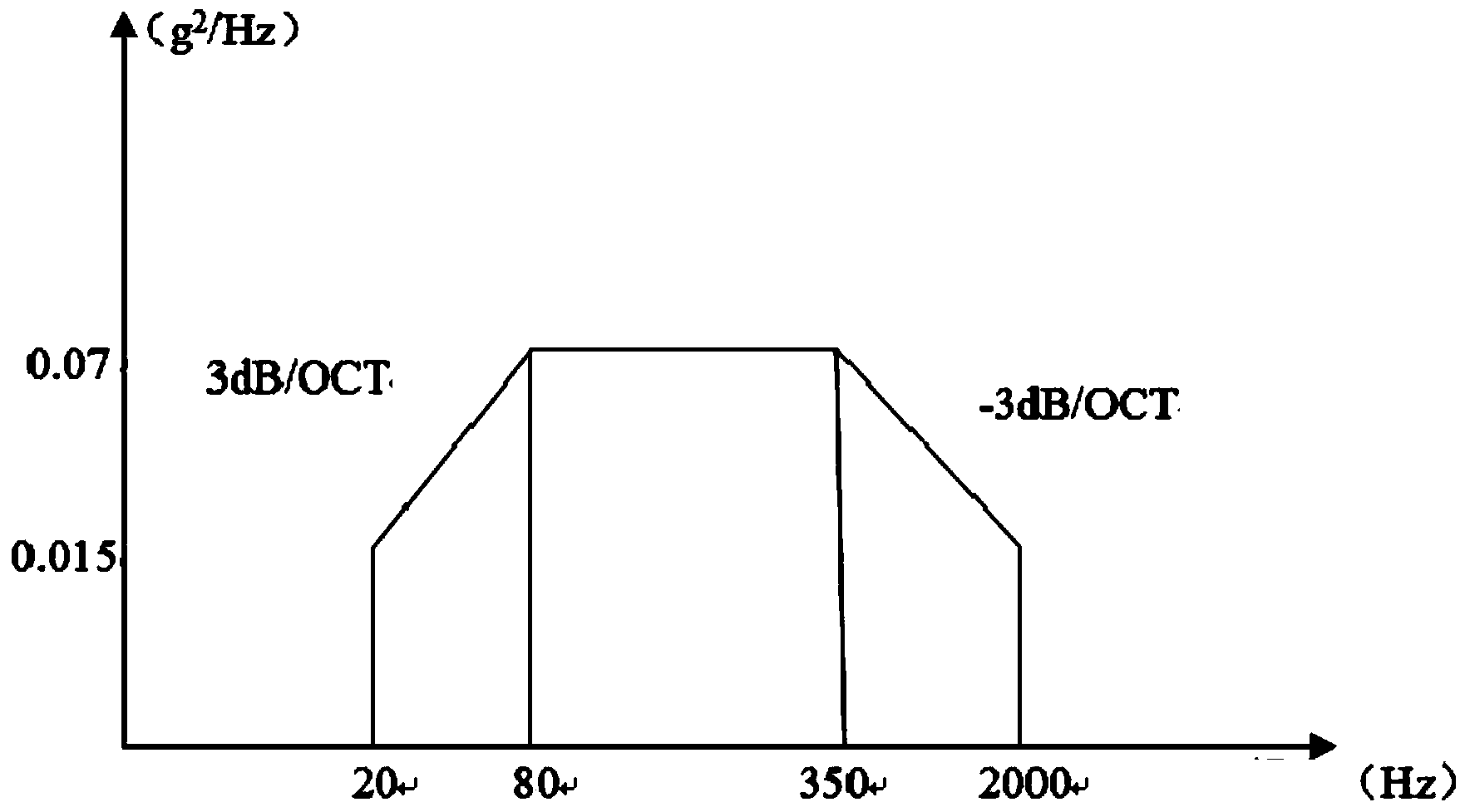

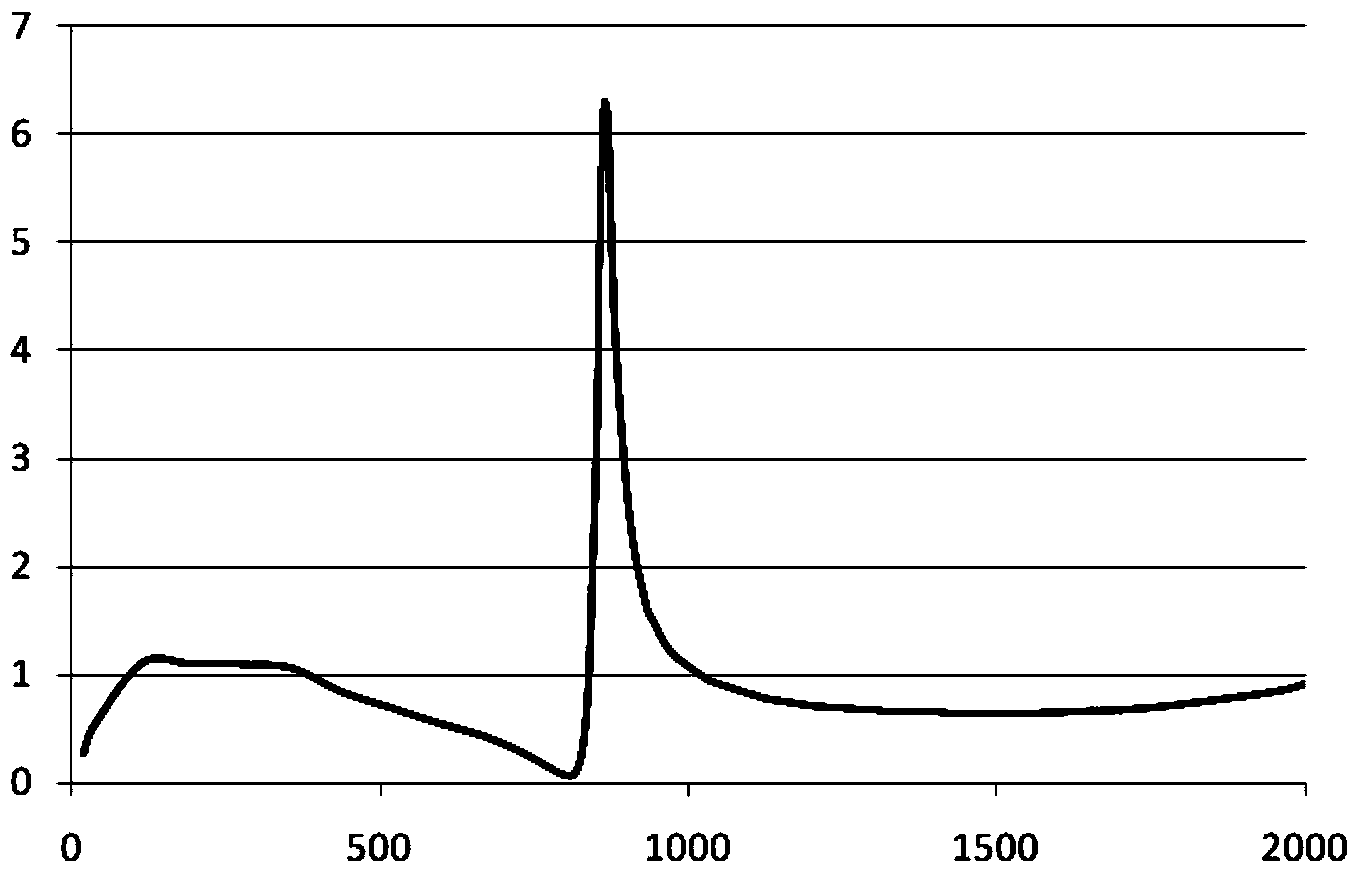

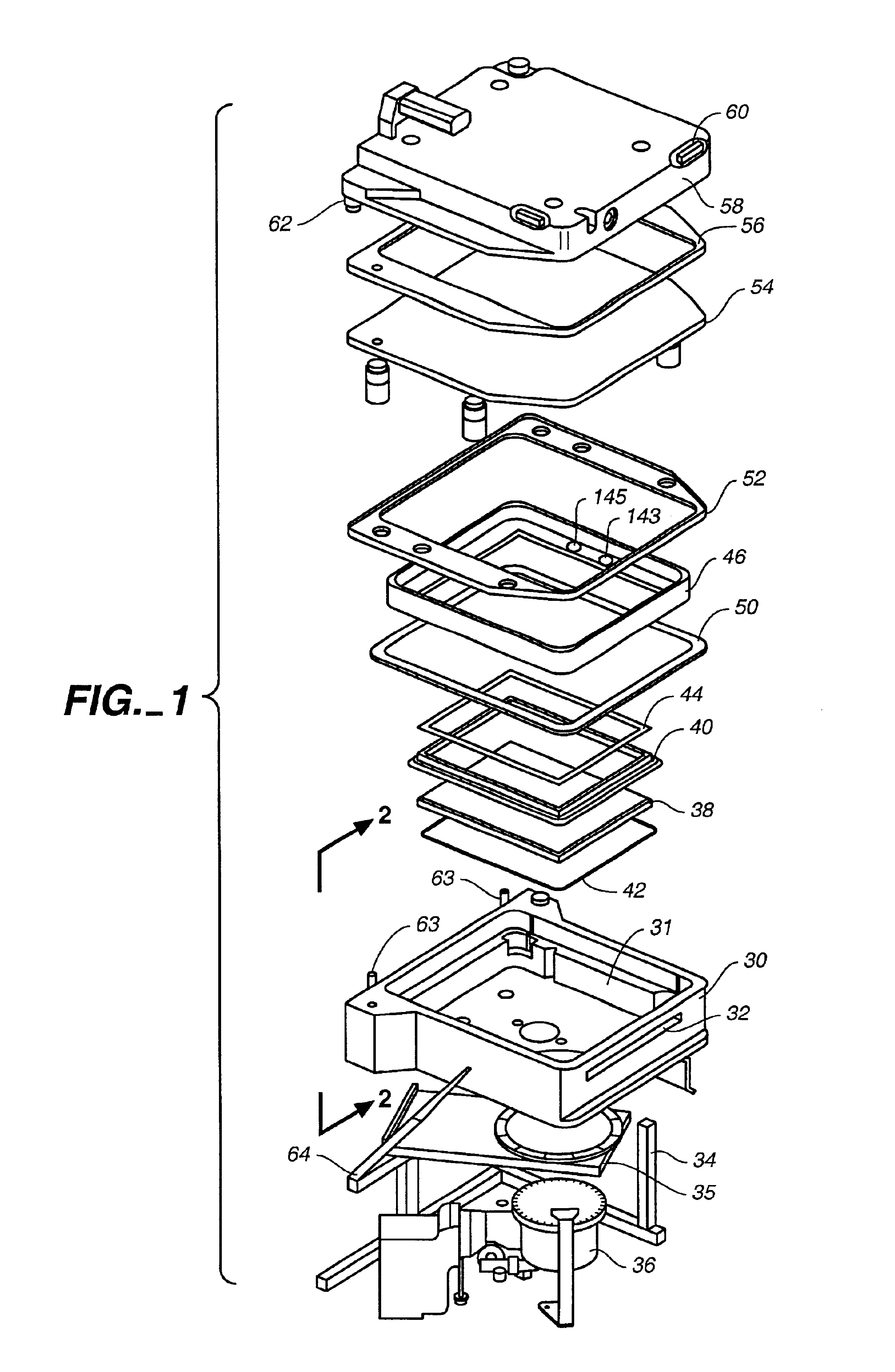

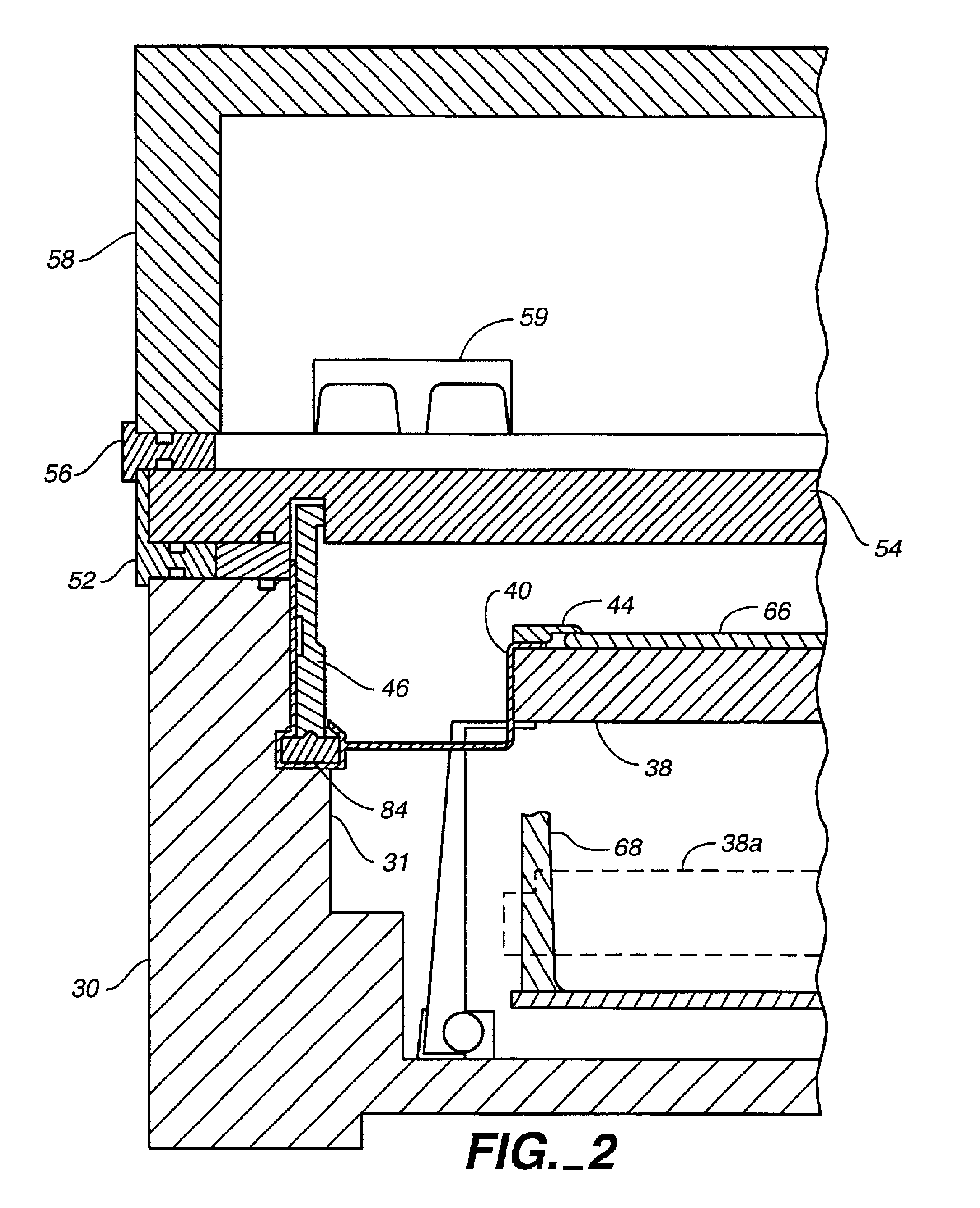

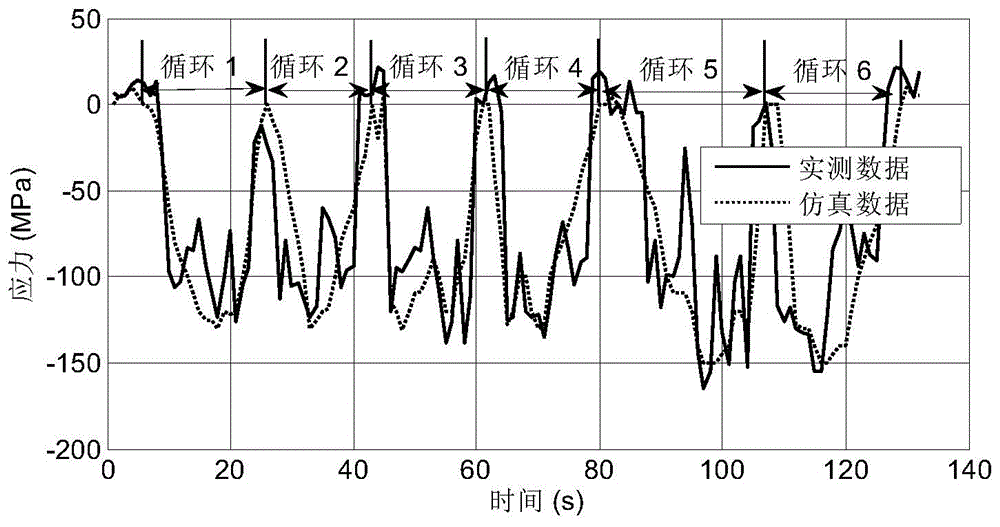

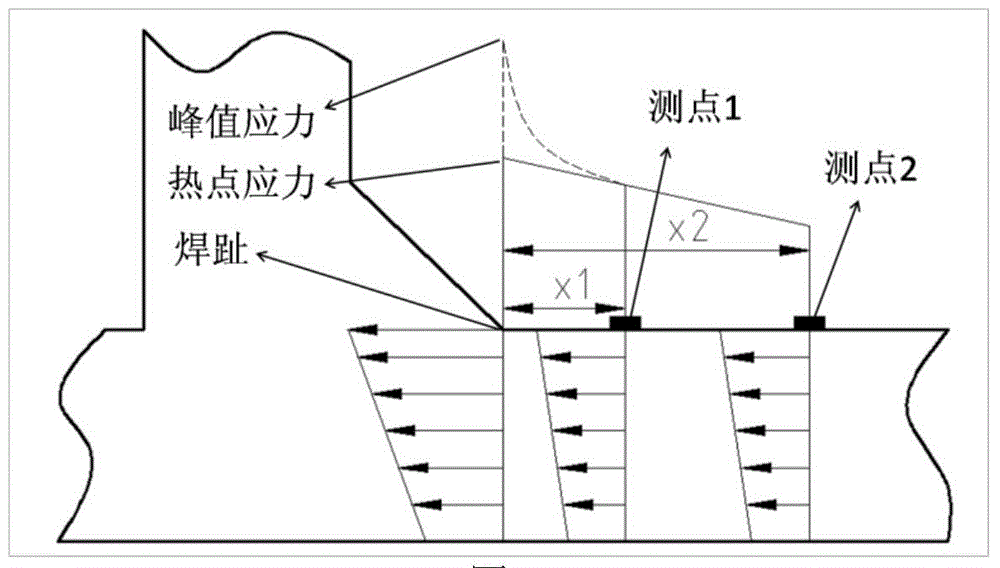

Vibration fatigue life predication method and system for micro-packaging assembly

ActiveCN104268335ASolving the Difficulty of Vibration Fatigue Life PredictionAvoid data difficultiesSpecial data processing applicationsTime domainElement model

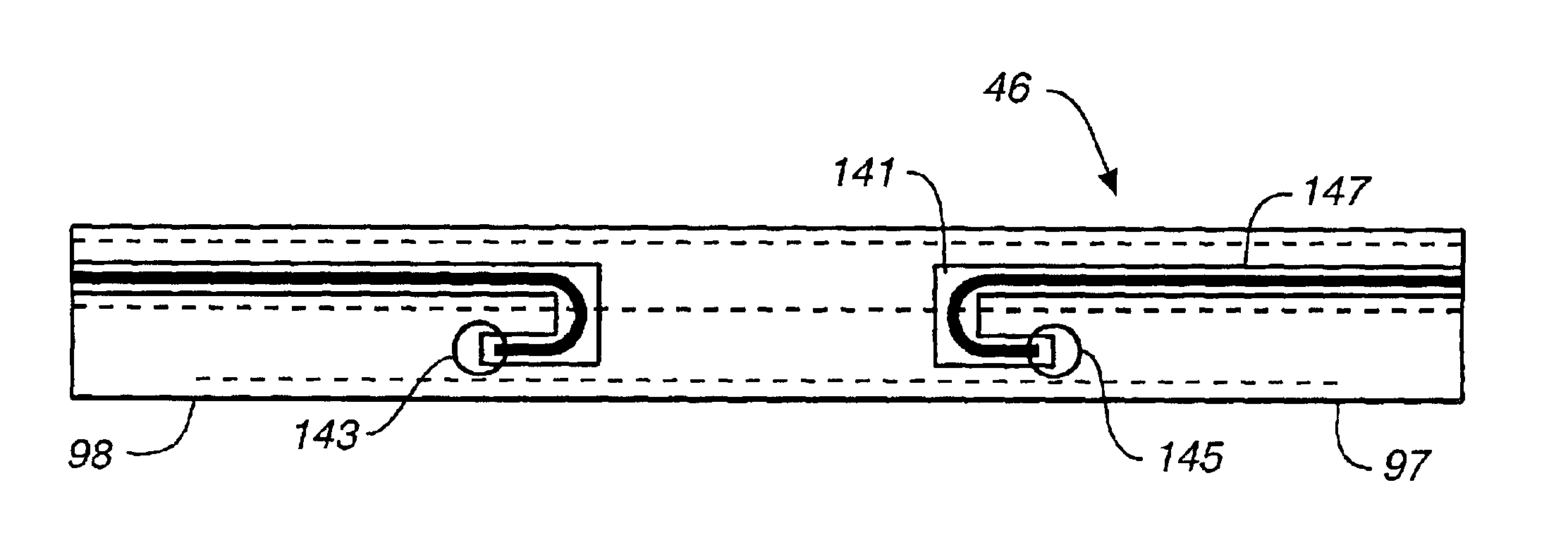

The invention provides a vibration fatigue life predication method and system for a micro-packaging assembly. The method comprises the following steps: creating a vibration simulating finite element model according to the structures of the micro-packaging assembly and a fixing part; extracting the verification characteristics parameters; modifying the vibration simulating finite element model according to the verification characteristics parameters and the experimental characteristics parameters of the micro-packaging assembly to obtain a vibration simulating model; performing random vibration stress response simulation analysis for the micro-packaging assembly according to the vibration simulation model to obtain a dangerous vibration fatigue point; extracting equivalent stress power spectrum density of the dangerous vibration fatigue point under the random vibration load; converting the equivalent stress power spectrum density to obtain cyclic stress time domain data; calculating the vibration fatigue life of the dangerous vibration fatigue point under the random vibration load according to an S-N curve and the cyclic stress time domain data of the dangerous vibration fatigue point; predicating the vibration fatigue life of the micro-packaging assembly by the method of synchronously extracting the response data of the fixing part and the micro-packaging assembly. With the adoption of the method and system, the testing accuracy is improved.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

Heated and cooled vacuum chamber shield

The invention is directed to an apparatus and method for reducing particulates in a semiconductor processing chamber. The apparatus comprises a shield for lining at portion of the interior of a vacuum processing chamber. The interior of the shield defines a shield passage. A heater element is disposed within the shield passage. A gas inlet is used for providing gases to the interior of the shield passage. The range of temperatures which may be used is wide and generally fitted to the process. For example, the invention may be used to provide a rapid cooldown or bakeout. Once the temperature is chosen, isothermal conditions can be maintained so as to minimize the thermal cycle stress, reducing cracking, peeling, etc.

Owner:APPLIED KOMATSU TECH

Structure fatigue life calculation method based on non-linear cumulative damage theory

InactiveCN104833536AHigh precisionSimple calculationStructural/machines measurementFinite element techniqueCalculation methods

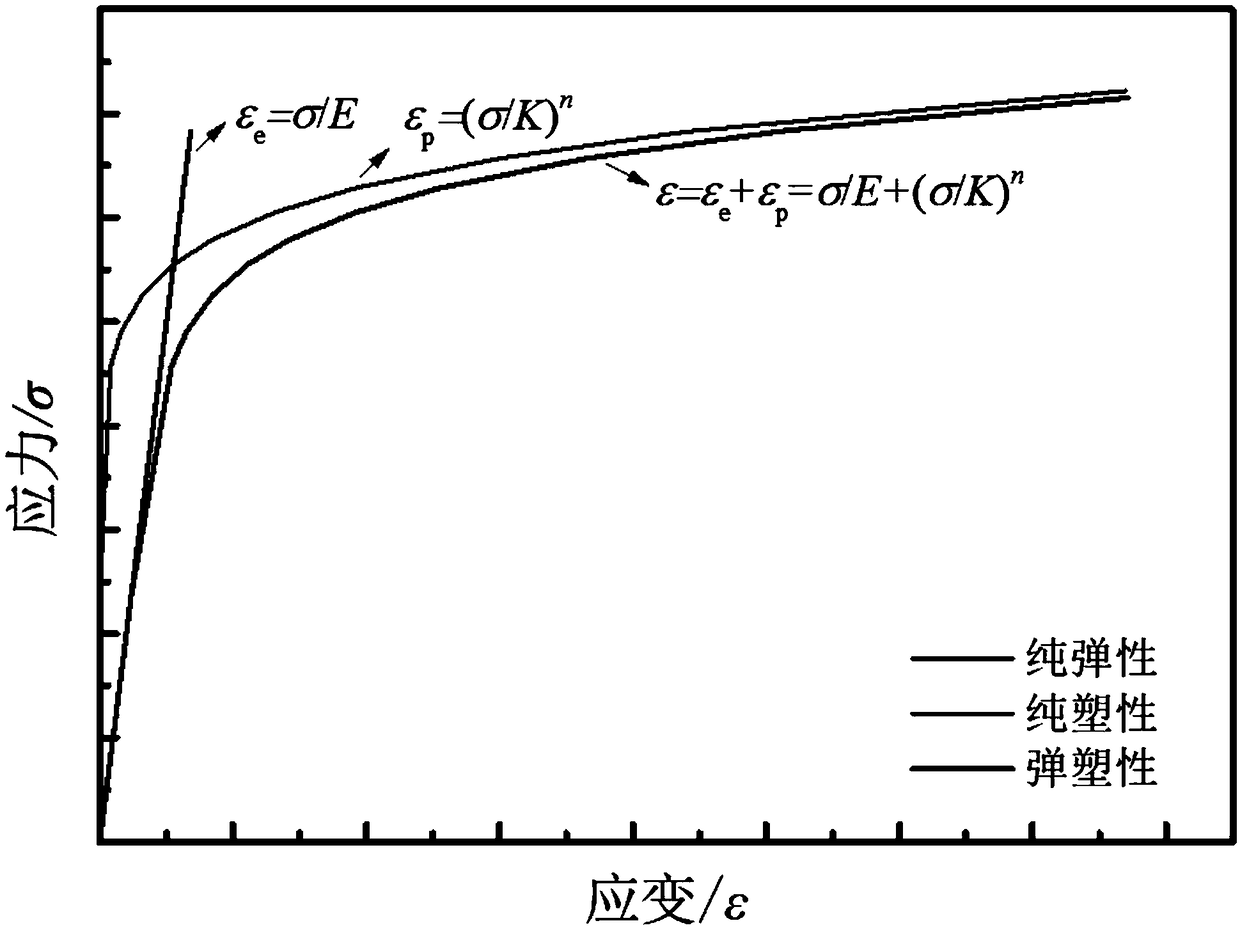

A structure fatigue life calculation method based on the non-linear cumulative damage theory comprises the following steps: firstly, performing a stress analysis on a metal structure through the finite element technology and determining a large-stress-value area as a dangerous area, secondly, determining initial damage of the structure according to a served age and surface quality detection of the structure, thirdly, measuring a stress spectrum of the structure in a certain period through a stress detector, fourthly, calculating cumulative damage of the structure under the stress spectrum through the non-linear cumulative damage theory, and fifthly, calculating a fatigue life of the metal structure through the cumulative damage. According to the method, the multi-stage load loading sequence and an influence of the size of a load on the cumulative damage are taken into account, and precision of the fatigue life is higher than the precision of a fatigue life calculated according to the linear cumulative damage theory. The method only needs a small amount of material performance data such as a cyclic stress-strain curve and a constant-amplitude strain life curve, calculation is simple, and the method is suitable for engineering applications.

Owner:DALIAN UNIV OF TECH +4

Method for predicting multiaxial fatigue of automobile rear suspension

InactiveCN101592552AImprove calculation accuracyVehicle testingMachine part testingGround contactElement analysis

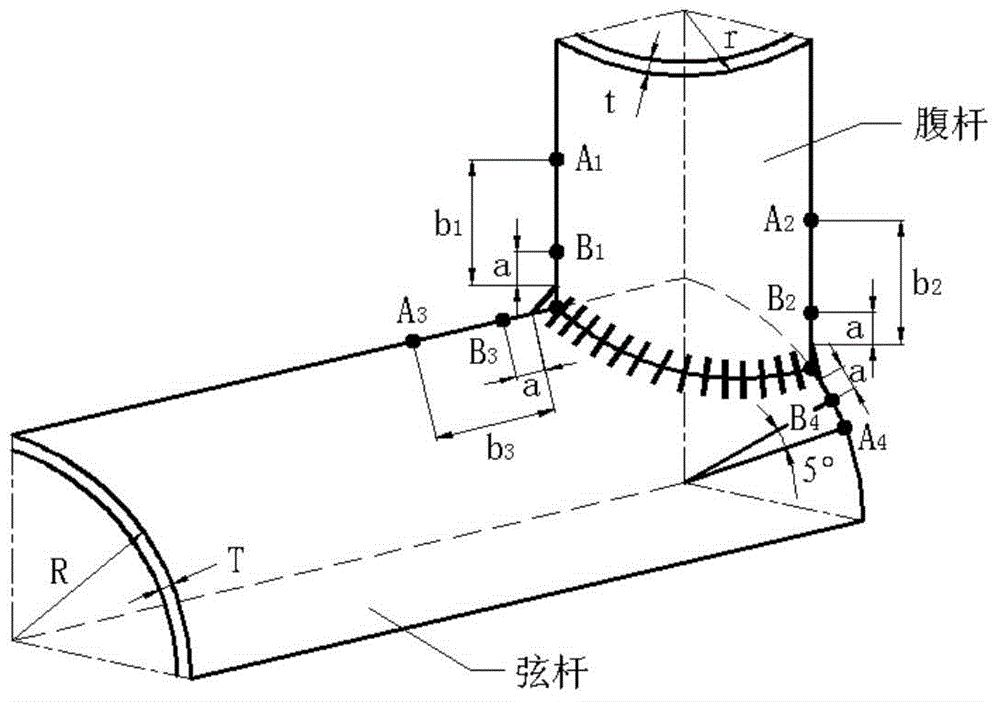

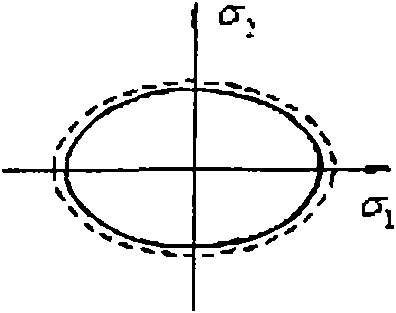

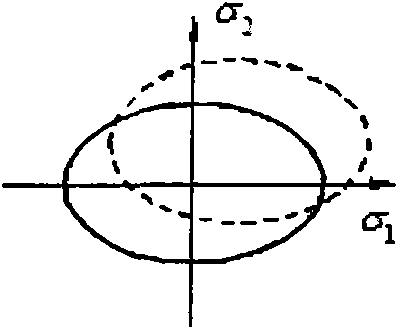

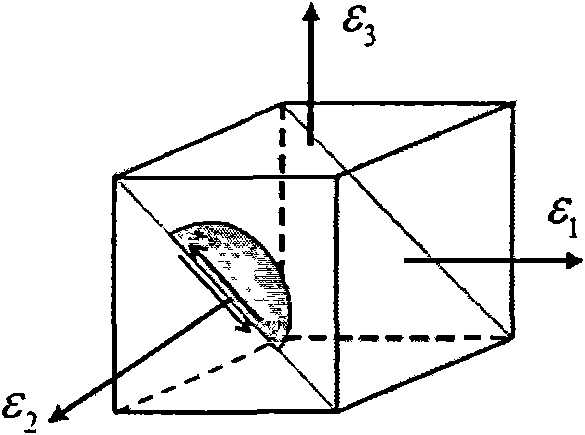

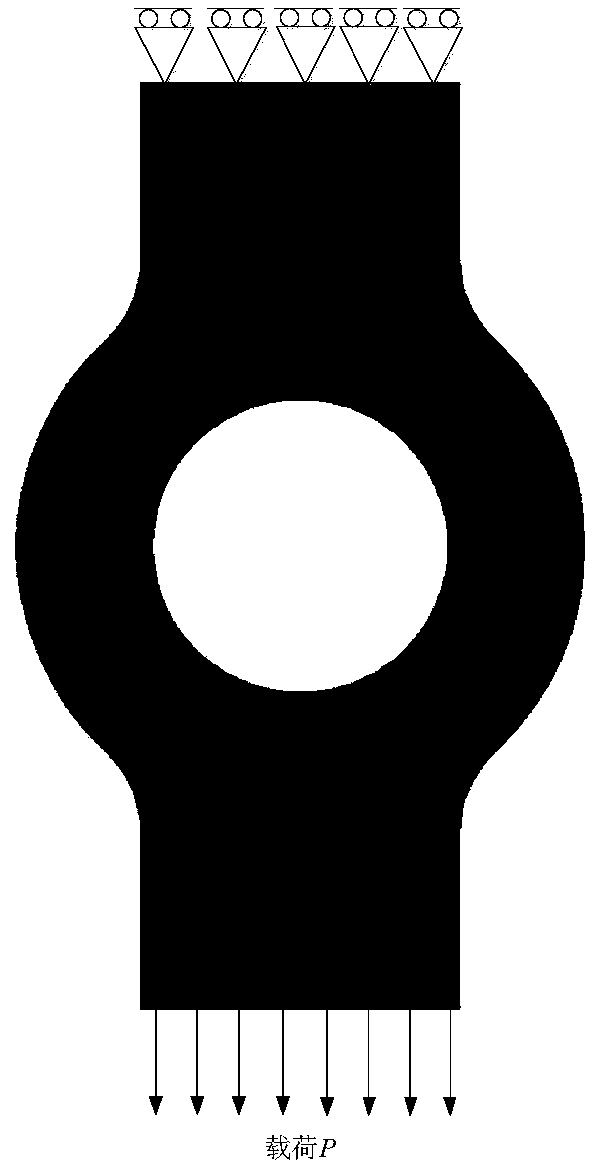

The invention discloses a method for predicting multiaxial fatigue of an automobile rear suspension, which comprises the following steps: performing rear suspension elastic plasticity finite element analysis based on a uniaxial cyclic stress-strain relationship, performing biaxiality analysis on the rear suspension, determining a rear suspension bearing multiaxial nonproportional load condition and possible crack propagation form thereof, and selecting a Bannantine model and a Wang-Brown model based on a critical plane method to test the multiaxial fatigue life of the rear suspension. The method has the advantages of avoiding the problem that an actual load condition of the automobile rear suspension cannot be truly considered in the conventional uniaxial fatigue life test, considering nonlinear factors of a rear suspension structure, rubber connecting elements and wheel tyres, contacting condition of the tyres and the ground and the like, and improving calculation accuracy.

Owner:TONGJI UNIV

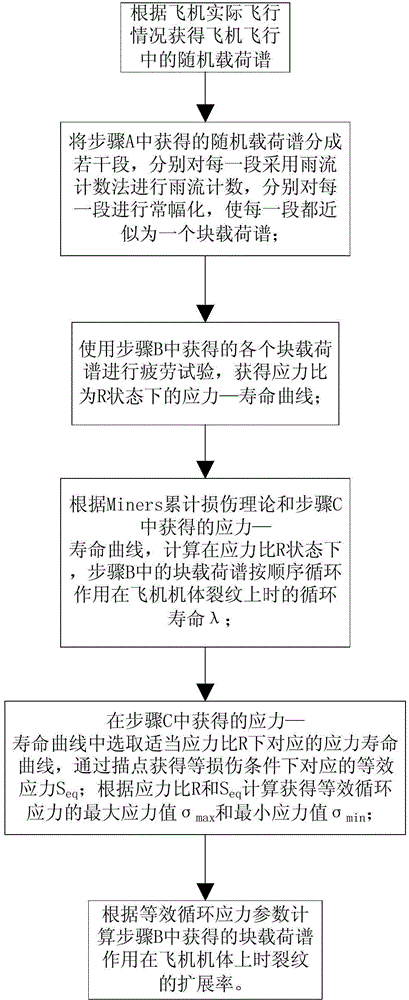

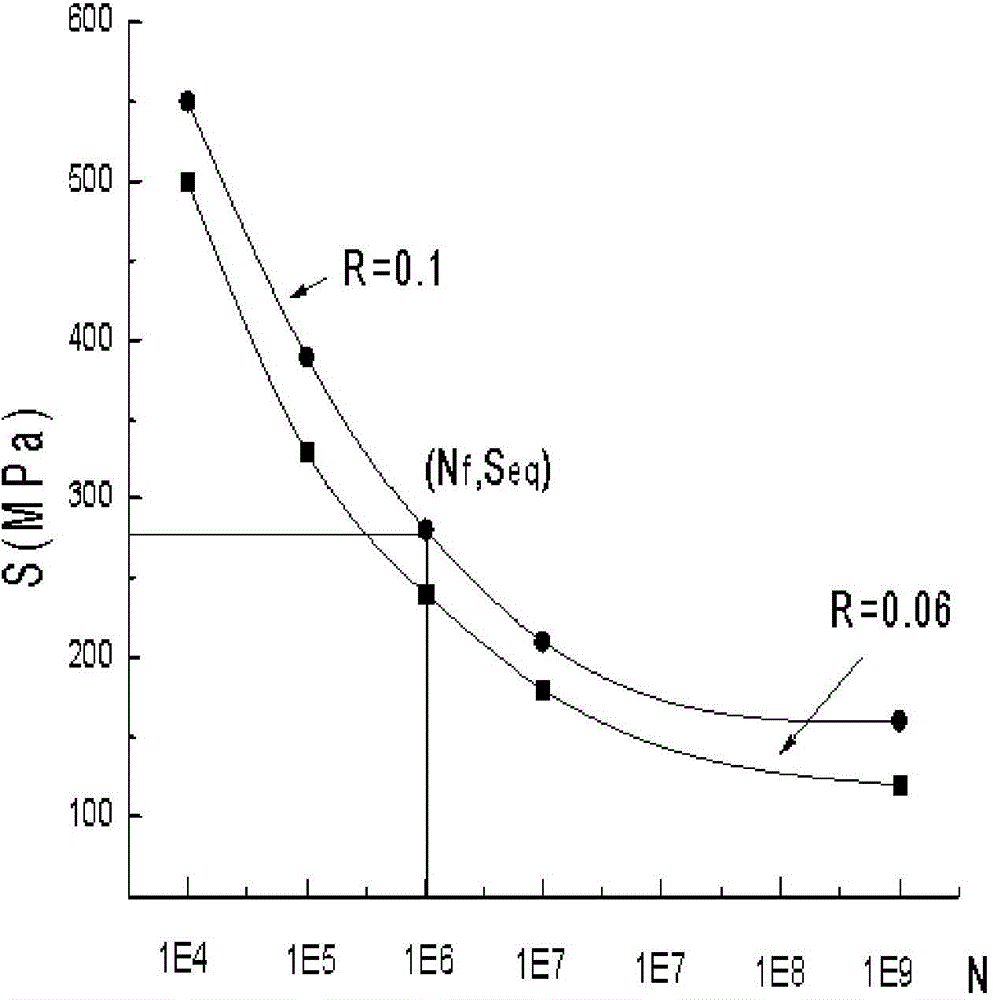

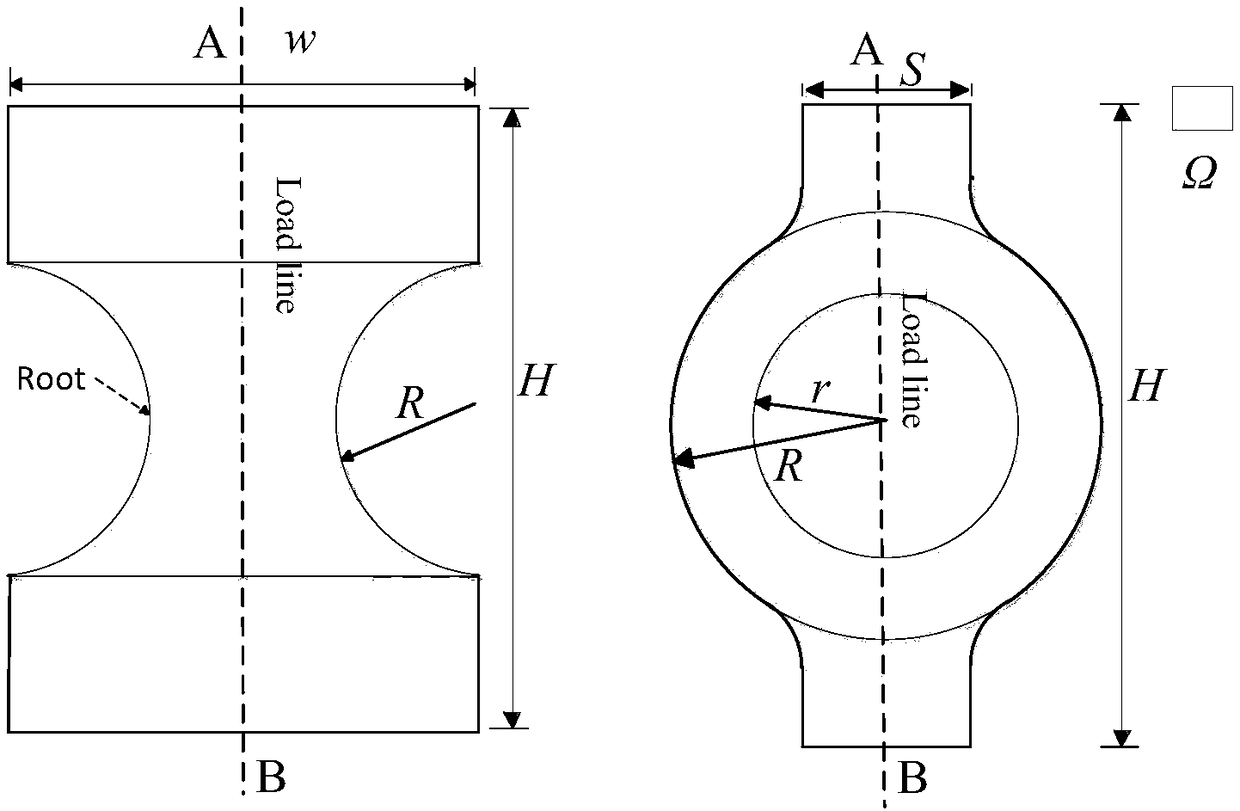

Prediction method of crack propagation life of aircraft body

ActiveCN104792633AAvoid frequent updatesAvoid repartitioningMaterial strength using repeated/pulsating forcesStress ratioEngineering

The invention discloses a prediction method of a crack propagation life of an aircraft body. The prediction method comprises the following steps: obtaining a random loading spectrum of an aircraft in flight according to the practical flight situation of the aircraft; dividing the obtained random loading spectrum into a plurality of sections, and respectively performing rain-flow counting and constant amplitude on each section, so that each section is approximated as a block loading spectrum; according to an Miners progressive damage theory, calculating a cycle life lambda effected on a crack of each block loading spectrum under the state of a corresponding stress ratio R, performing a fatigue test under the suitable stress ratio, and obtaining a corresponding stress-life curve; according to an equal defect theory, selecting the correspondence life curve under the suitable stress ratio R in the stress-life curve, and obtaining the equivalent stress Seq corresponding to the same life by a point tracing method; then, according to the R and the Seq, obtaining a maximum stress value sigma max and a minimum stress value sigma min of the equivalent cyclic stress; according to parameters of the equivalent cyclic stress, calculating the propagation rate of the crack when the obtained block loading spectrum is acted on the aircraft body.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

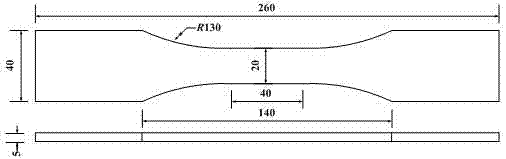

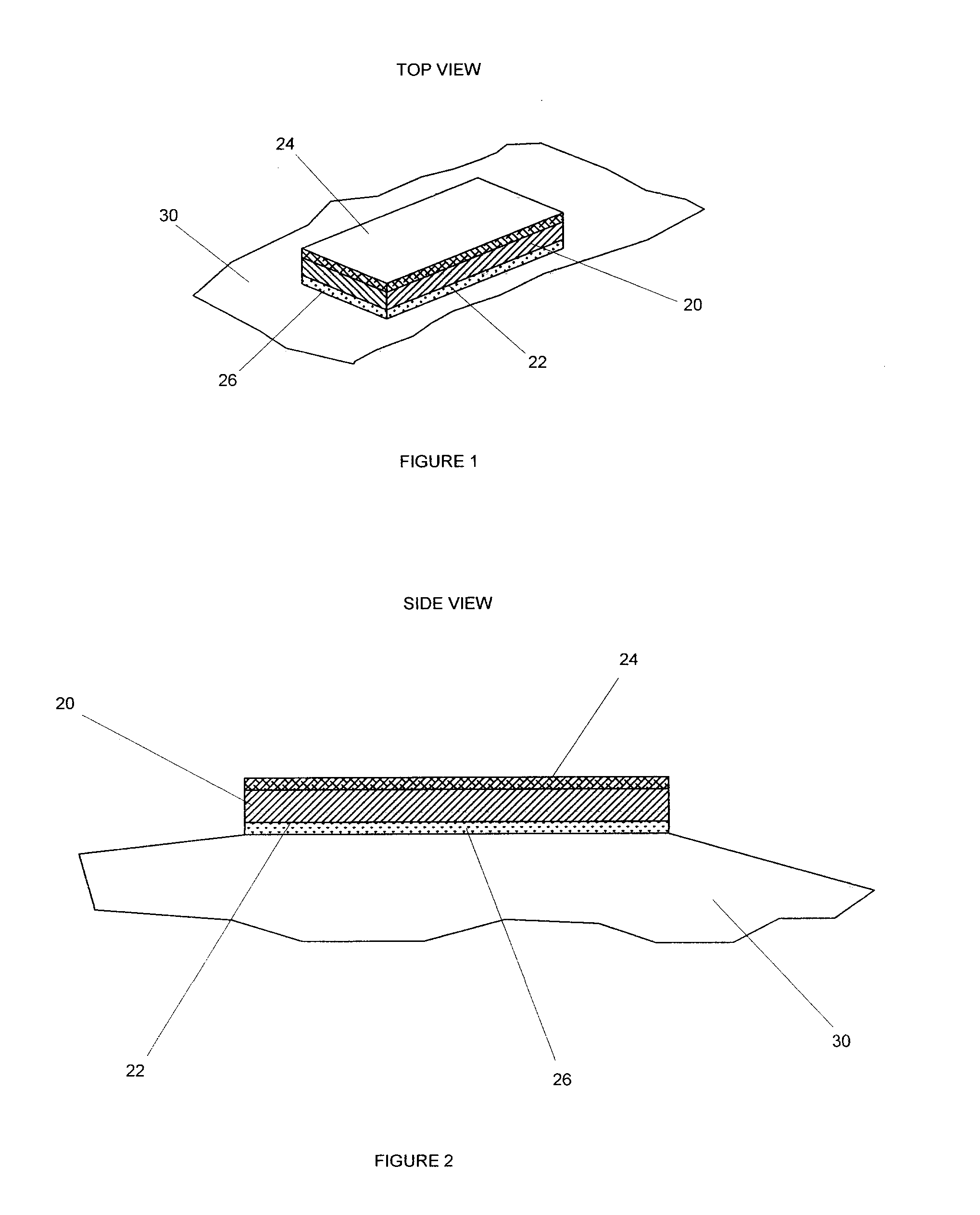

Method for measuring metallic film fatigue life on a flexible substrate

InactiveCN101226163AFatigue life determinationMaterial strength using repeated/pulsating forcesMaterial resistanceFatigue testingCyclic stress

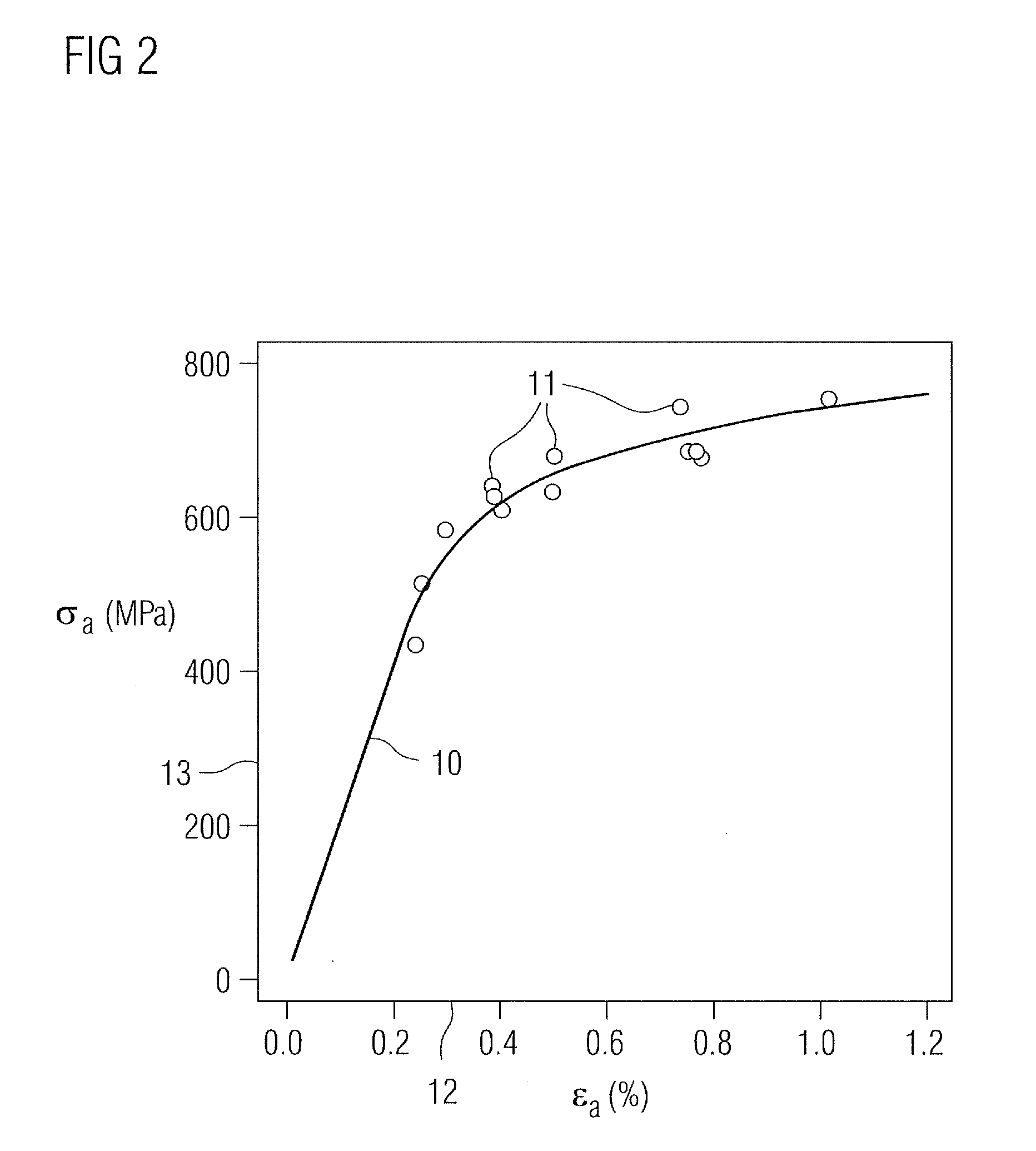

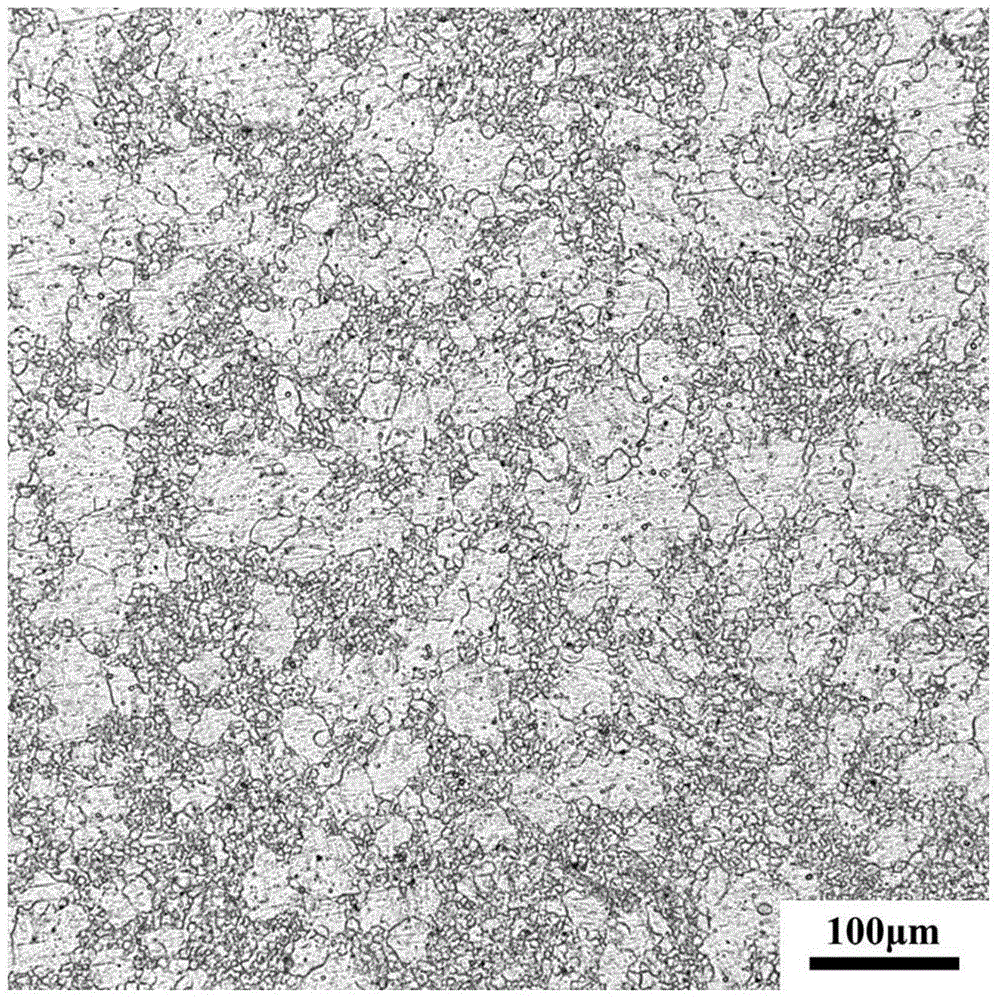

The invention discloses a fatigue life test method of metallic film on a flexible substrate, which comprises processing fatigue test under integral circulation stress load on a metallic film / flexible substrate system with better interface combination, recording the stress-strain curvature and resistance change-circulation frequency curvature of the metallic film, detecting the metallic film microcosmic structure under different circulation frequencies in the fatigue process to obtain a metallic film surface damage topography-resistance change-circulation frequency curvature. The invention uses the sharp increase of resistance change on the resistance change-circulation frequency curvature to represent metallic film damage and define a fatigue life Nf. The strain amplitude delta epsilon and relative fatigue life Nf obtained from the stress-strain curvature forms the metallic film fatigue property failure evaluation of the metallic film / flexible substrate system. The inventive method has simple test, accurate measurement and prior property.

Owner:山东云度材料科技有限公司

Material fatigue performance obtaining method for sheet sample

ActiveCN108693055AOvercome size limitationsMaterial strength using repeated/pulsating forcesHysteresisRamberg osgood

The invention discloses a material fatigue performance obtaining method for a sheet sample, which comprises the following steps: step 1: completing a tension-pressure symmetric cyclic loading test ofa multi-stage strain amplitude for the sheet sample under strain control to obtain a cyclic stable load-displacement curve; step 2: connecting load-displacement curve hysteresis loop tips as the cyclic load-displacement curve, and predicting a cyclic stress-strain relationship in accordance with a Ramberg-Osgood constitutive model with a cyclic load-displacement relationship; step 3: establishinga relationship between a true strain amplitude epsilon r, a stress amplitude sigma r and a measured and controlled strain amplitude epsilon eq of a fatigue source RVE by using the cyclic stress-strainrelationship as a material parameter; step 4: establishing a fatigue life estimation model according to epsilon r and sigma r to obtain the fatigue property of the material. According to the materialfatigue performance obtaining method, the material dimension limitations of the traditional fatigue performance test method are overcome, and the method does not rely on empirical formulas, and is applied to different materials and sample configurations.

Owner:SOUTHWEST JIAOTONG UNIV

Fatigue Life Estimation Method and System

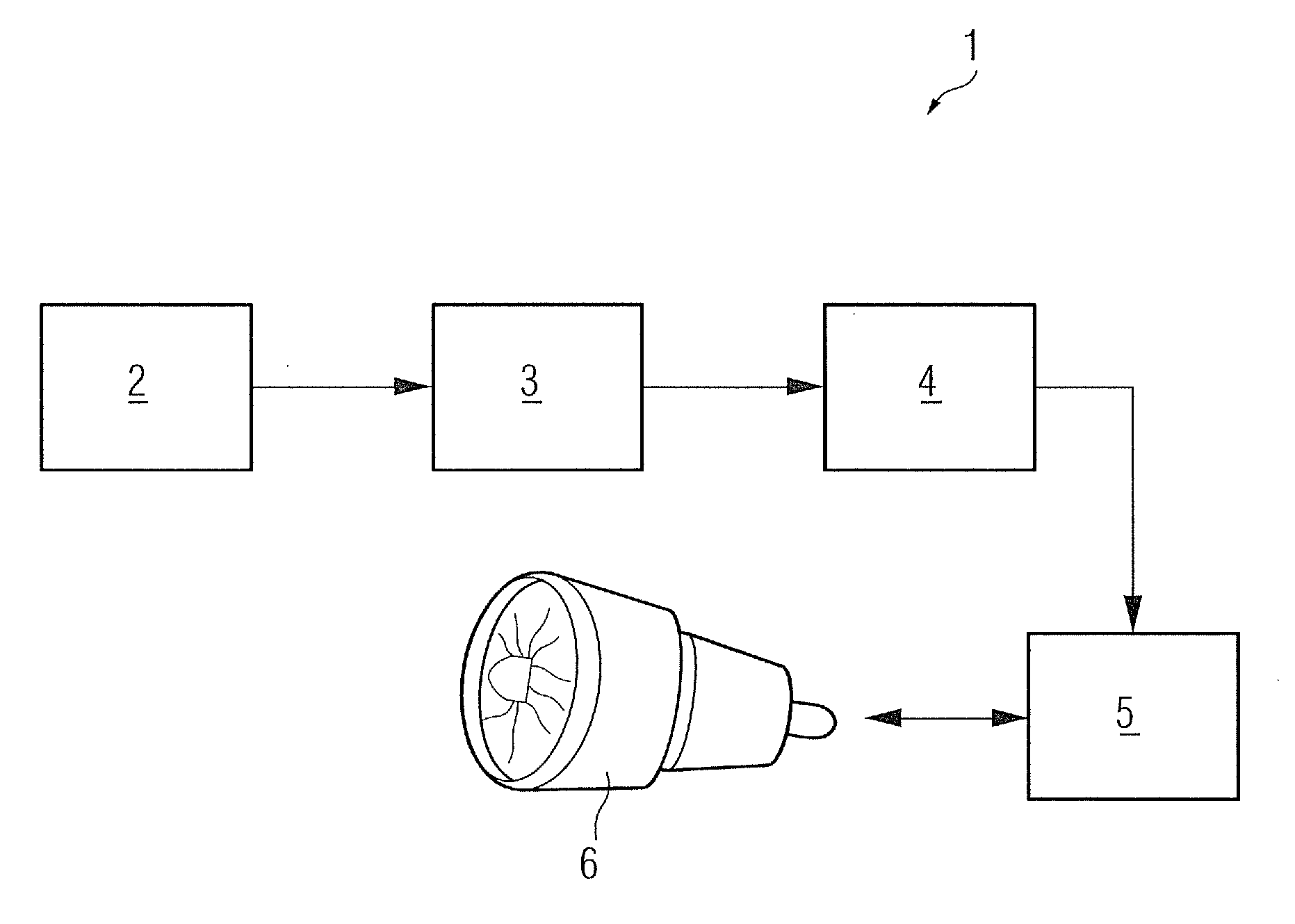

ActiveUS20120053858A1Low cycle fatigueRobust and reliable determinationVehicle testingPlug gaugesEstimation methodsEngineering

A method to estimate the fatigue life of a component operable under cyclic stress is provided. A system including testing means for performing a strain controlled test of a component or a representative specimen of the component, to obtain therefrom a first set of data samples including measured stress amplitude values for varying applied strain levels, and a second set of data samples including measured number of cycles to crack initiation for varying applied strain levels is also provided. The system further includes a modeling means for fitting a first low cycle fatigue material curve on the first set of data samples and a second low cycle fatigue material curve on the second set of data samples.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

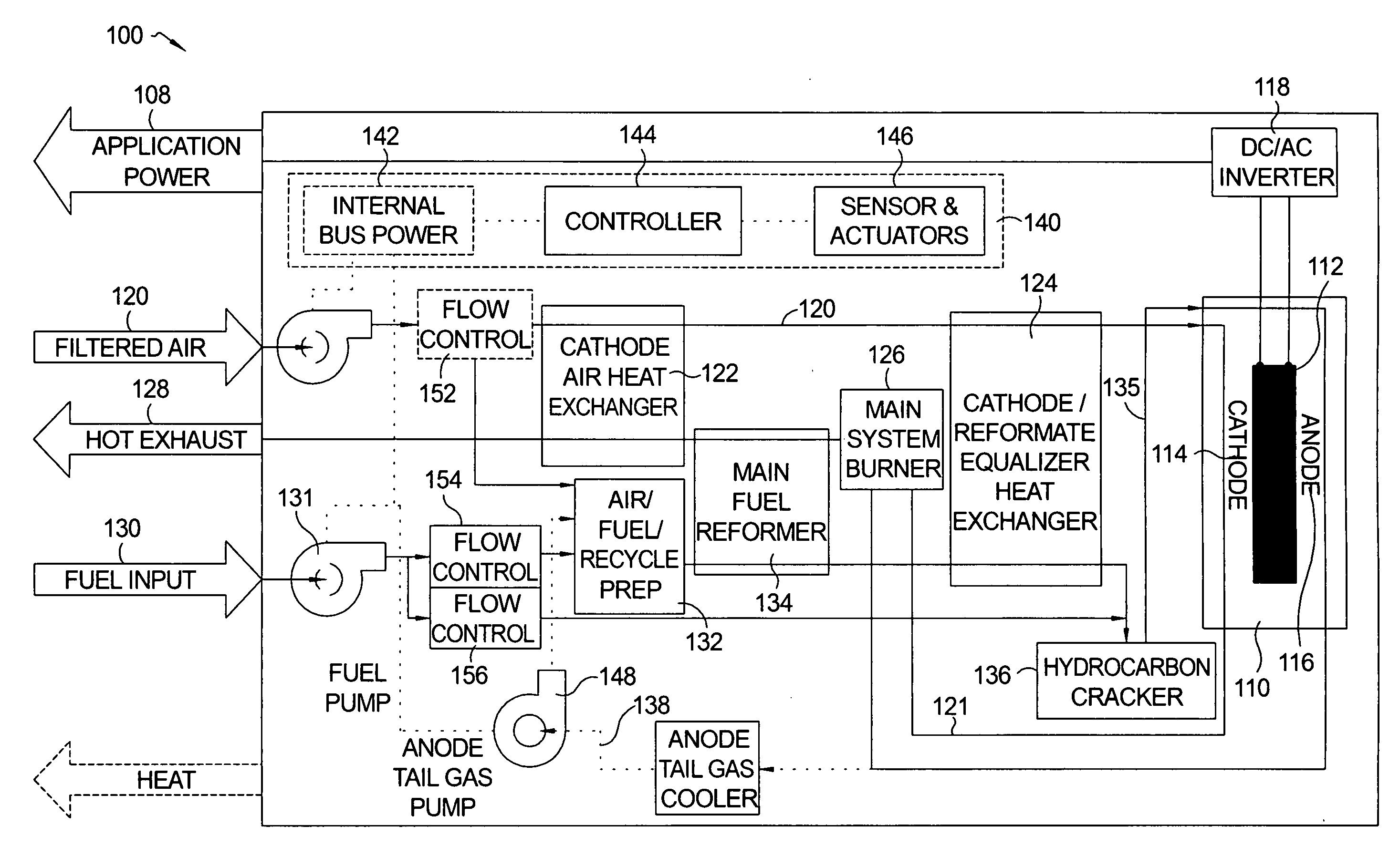

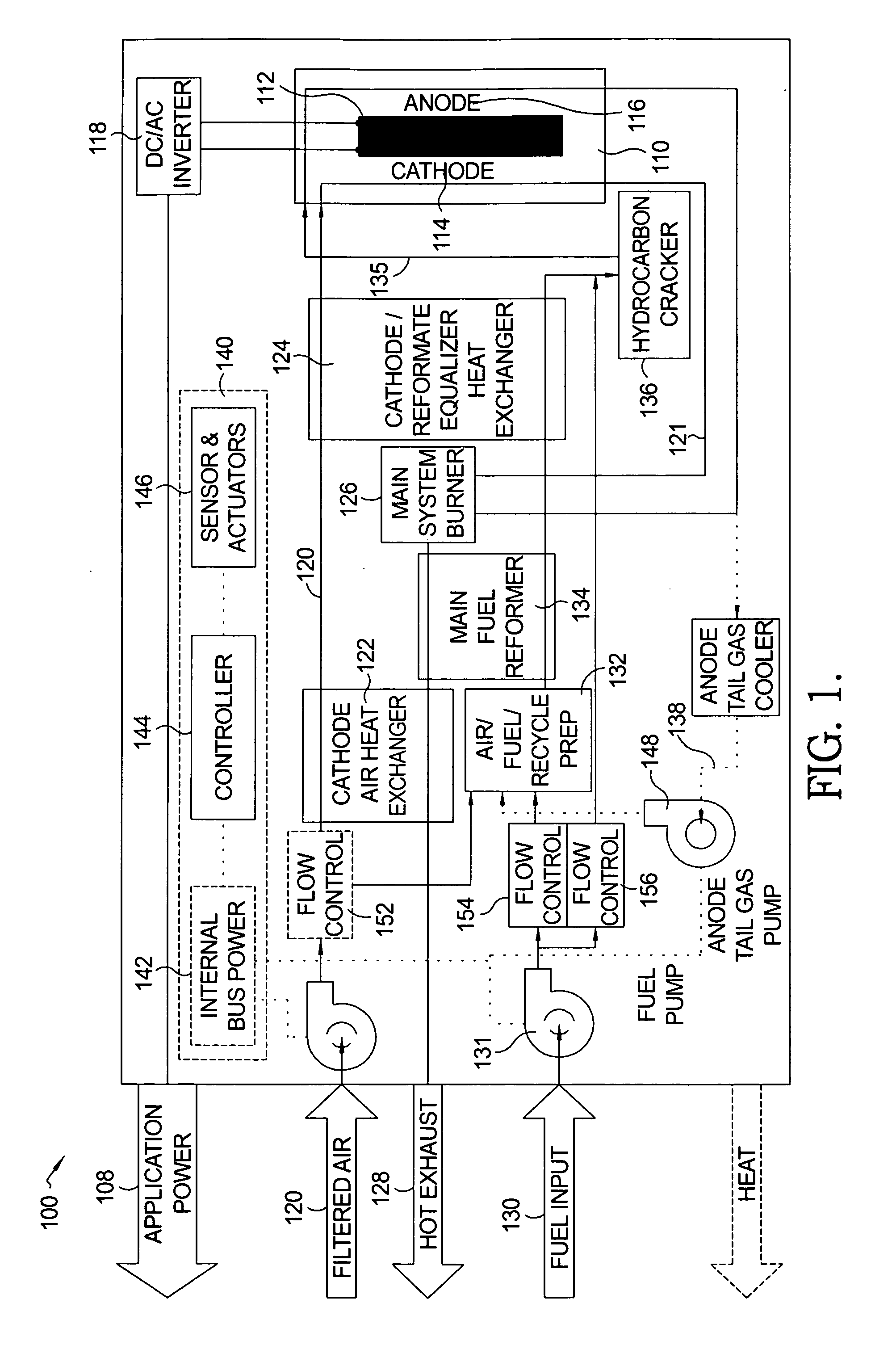

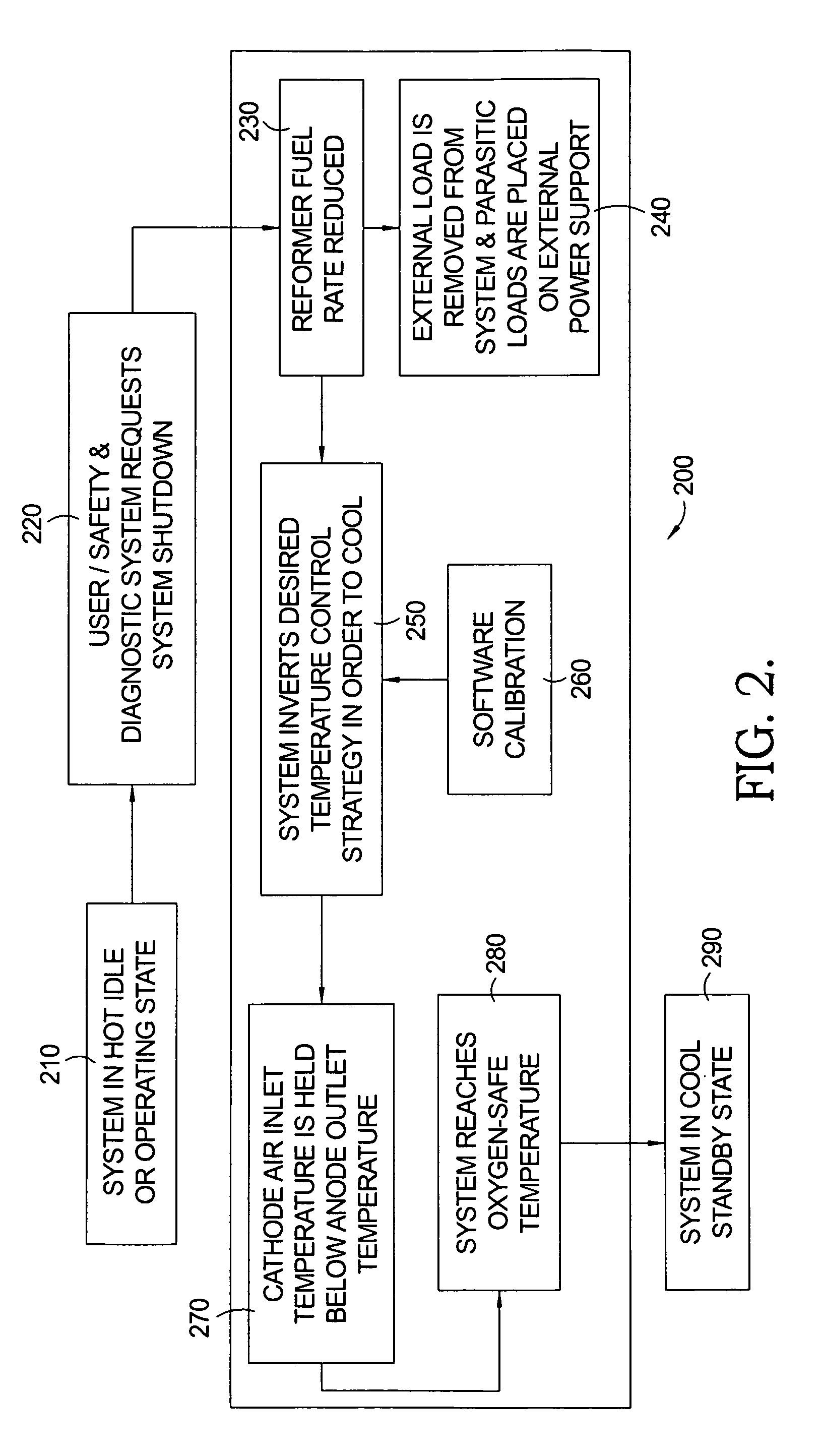

Method and apparatus for anode oxidation prevention and cooling of a solid-oxide fuel cell stack

InactiveUS20090253007A1Prolong lifePrevent oxidationFuel cell heat exchangeReactant parameters controlFuel cellsControl system

An apparatus and method for a normal system shutdown of a SOFC system implements a control strategy that utilizes existing system hardware and operating processes already used during normal operation of the SOFC system. The control strategy enables the SOFC system to generate the fluid needed for prevention of oxidation during the cooling process of the anode side of the SOFC stack by converting the conventional system fuel supply for delivery of a reducing fluid to the anode side of the SOFC stack during normal system shutdown thereby preventing subjecting the hardware to cyclic stress that typically occurs during oxidation. The control strategy further enables the SOFC system to control the temperature gradient that exists across the system hardware thereby eliminating induction of thermal stress on the hardware, hence prolonging the life of the system hardware.

Owner:DELPHI TECH INC

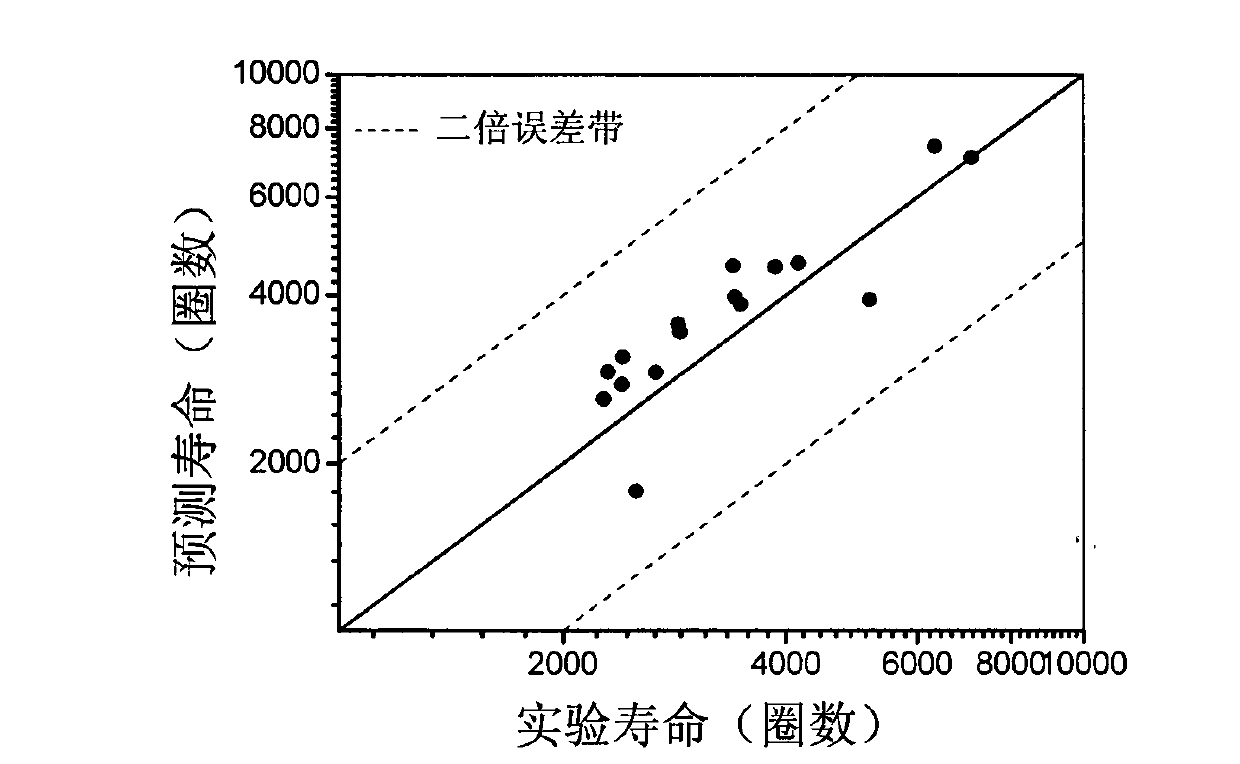

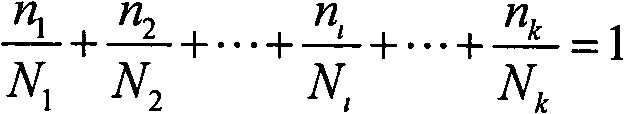

Method for predicting fatigue life of multi-nail connecting pieces under spectrum loading

A method for predicting fatigue life of multi-nail connecting pieces under spectrum loading comprises the following five steps: 1, a fatigue S-N curve of a simple small single-nail connecting-piece sample is measured through a fatigue test; 2, a relation between bypass stress of a joint of multi-nail connecting pieces dangerous fasteners and dimension parameters of the connecting pieces is established according to an equilibrium equation of a single fastener aperture; 3, a computational formula of fatigue life of the multi-nail connecting pieces under cyclic stress is established; 4, a computational formula of fatigue life of the multi-nail connecting pieces under spectrum loading is established; and 5, known basic fatigue properties of the small single-nail connecting-piece sample and structural properties of the multi-nail connecting pieces are plugged into the computational formula of fatigue life. Then, the total periodic number of the multi-nail connecting pieces under the action of spectrum loading, namely fatigue life of the multi-nail connecting pieces, can be determined. The method provided by the invention is simple and practical. Only by plugging fatigue performance of the small single-nail connecting-piece sample and stress state and dimension parameters of the multi-nail connecting pieces into a model, fatigue life of the multi-nail connecting pieces in any arrangement forms can be obtained.

Owner:BEIHANG UNIV

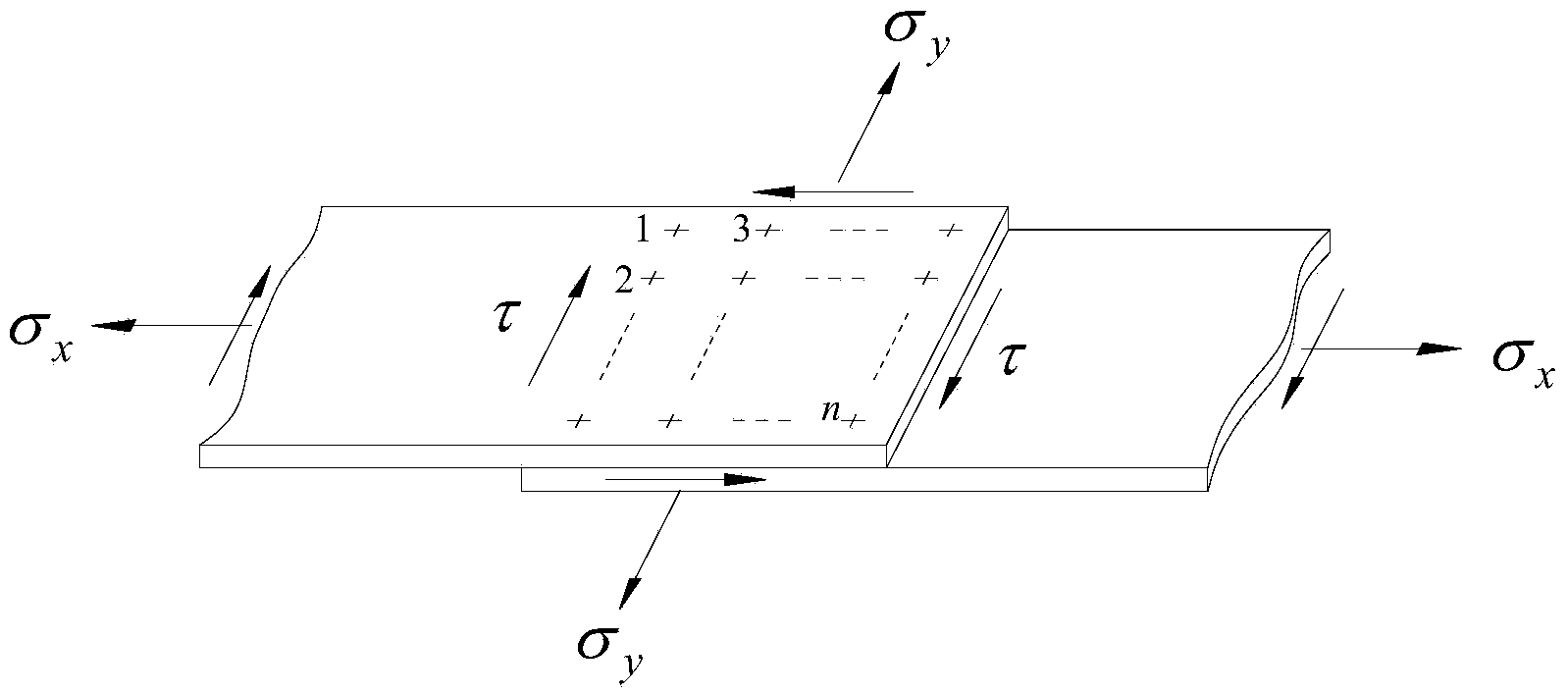

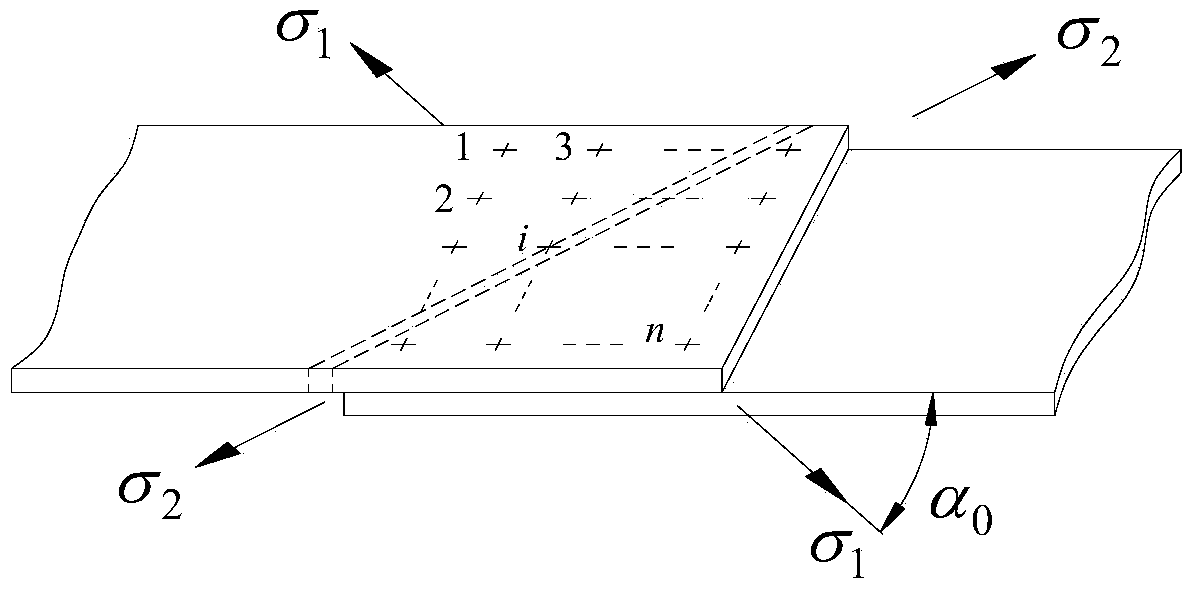

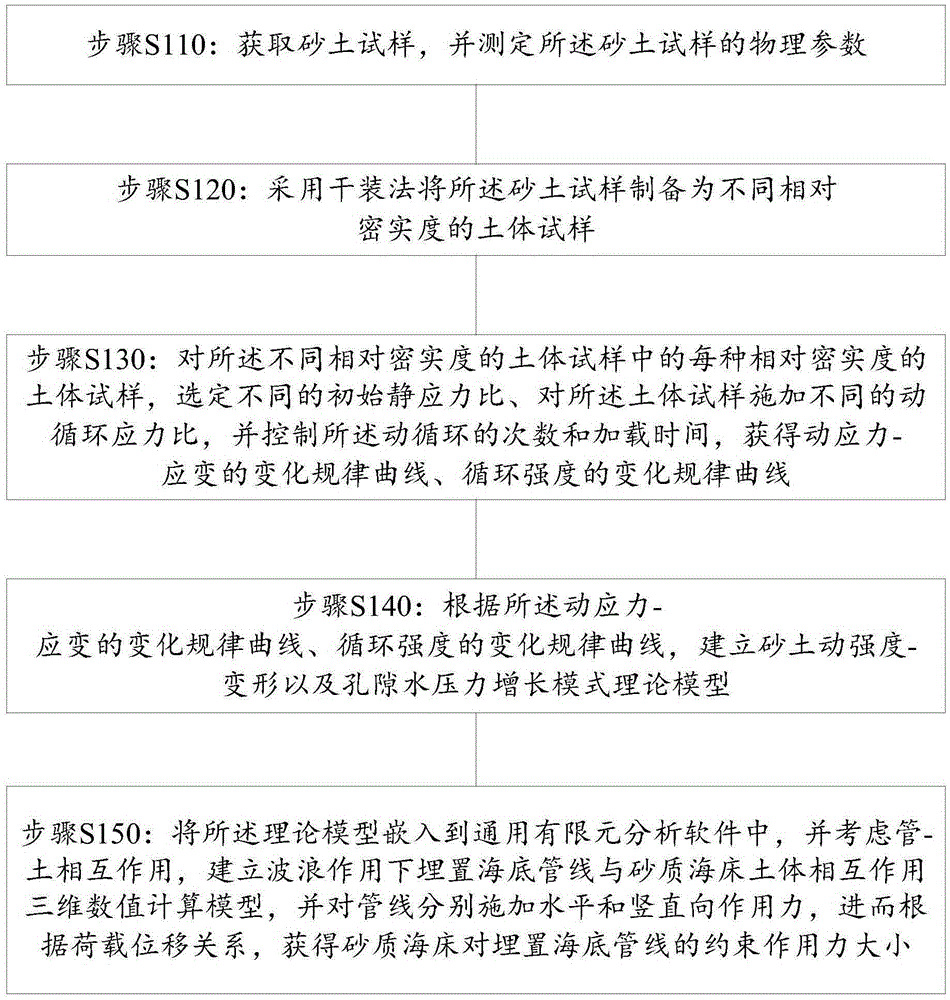

Method for evaluating resistance of sandy soil on embedded submarine pipeline under action of waves

InactiveCN105424466AResolve yieldSolve technical problems of soil damageMaterial strength using steady torsional forcesMaterial strength using steady shearing forcesOcean bottomLoad time

The invention discloses a method for evaluating resistance of sandy soil on an embedded submarine pipeline under the action of waves. The method comprises the steps that soil body samples with different relative densities are prepared by obtaining sandy soil samples; different initial static stress ratios are selected for soil body samples with the corresponding relative densities, different dynamic cyclic stress ratios are applied to the soil body samples, the frequency of dynamic cycle and loading time are controlled, and a dynamic stress-strain change rule curve and a cyclic strength change rule curve are obtained; according to the dynamic stress-strain change rule curve and the cyclic strength change rule curve, a sandy soil dynamic strength-deformation and pore water pressure growth mode theoretical model is established, horizontal force and vertical force are applied to the pipeline, the size of constraint force of a sandy seabed on the embedded submarine pipeline is further obtained according to a load-displacement relationship, and a basic theoretical method is provided for design of embedding the pipeline in the seabed and evaluation of stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

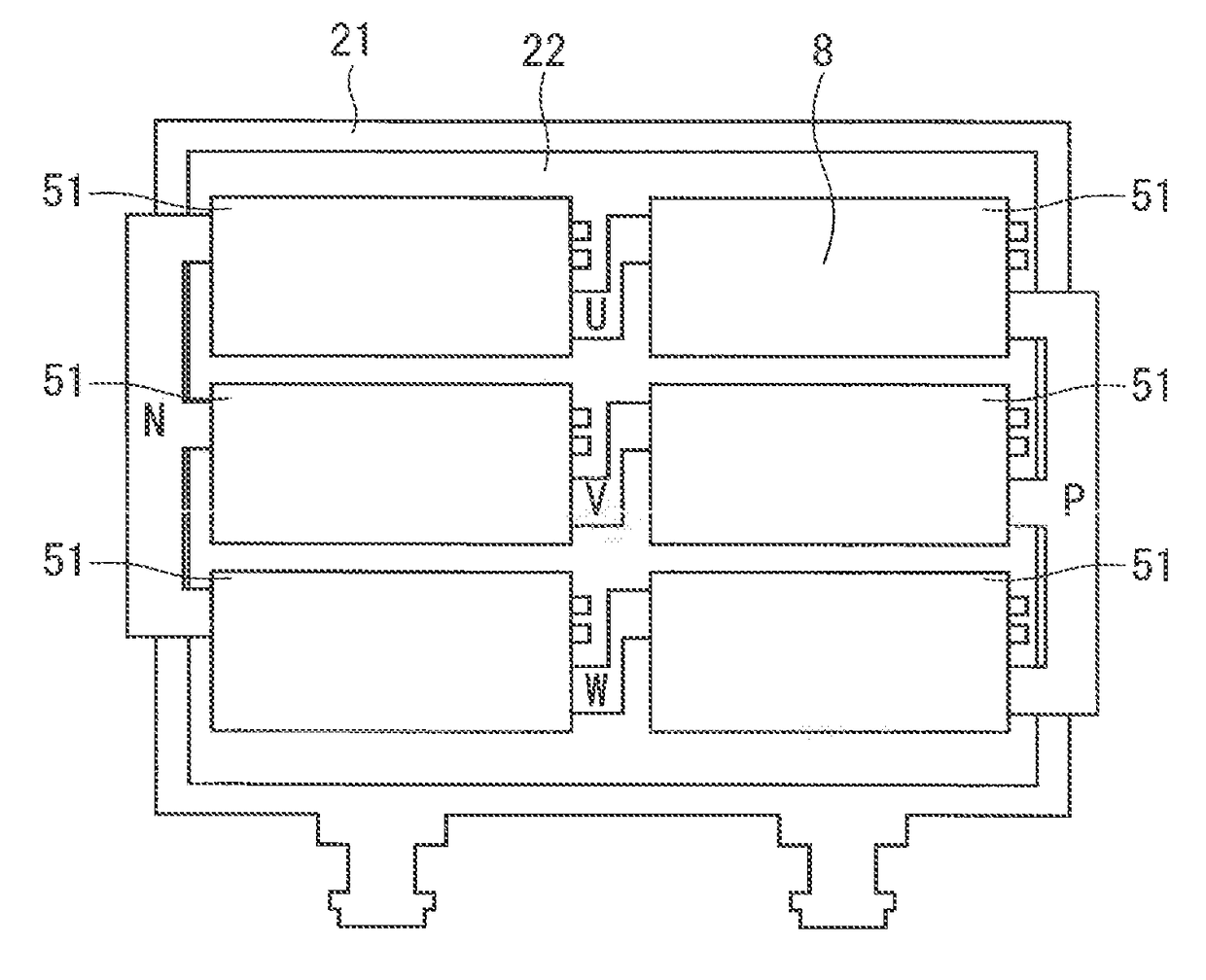

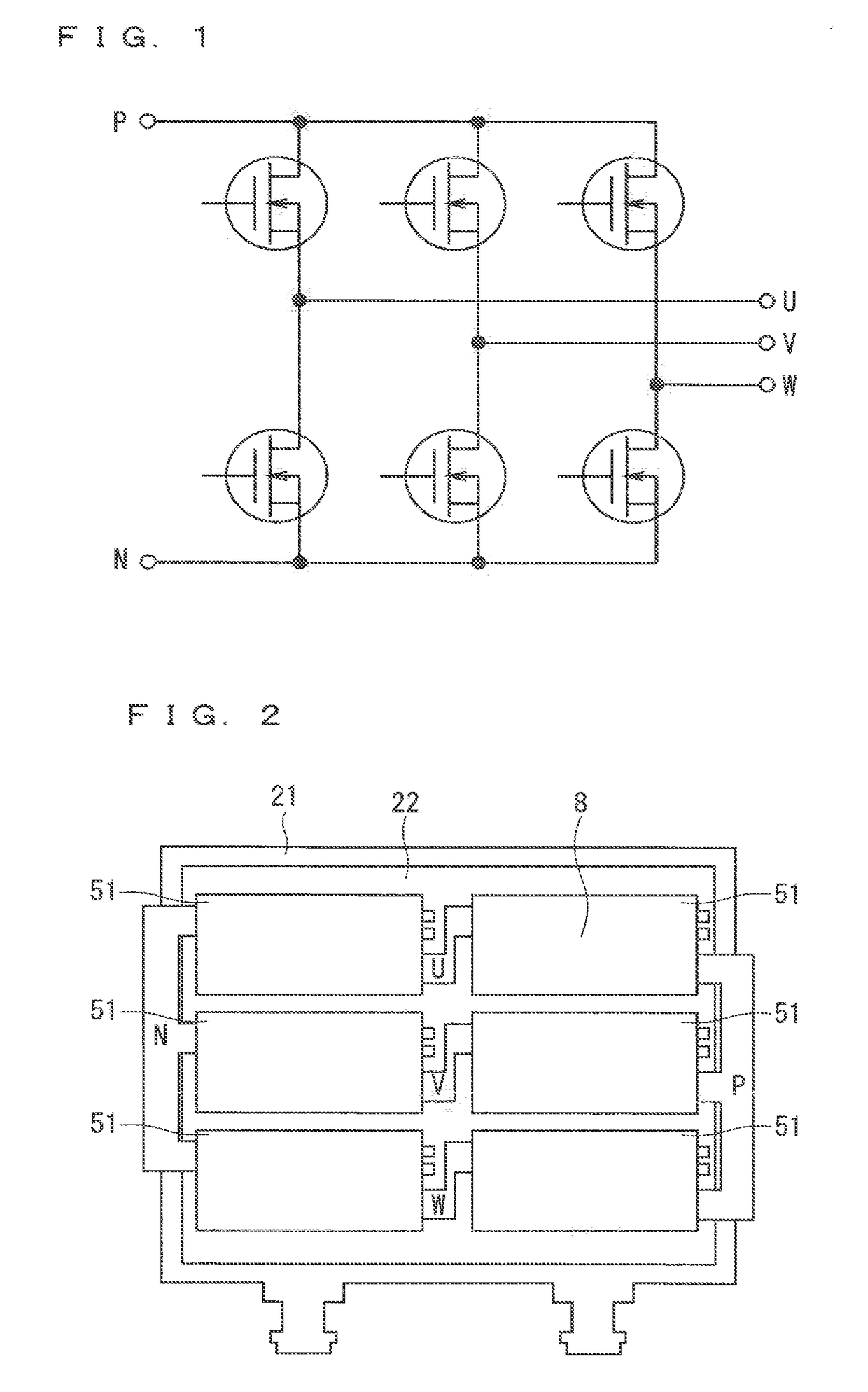

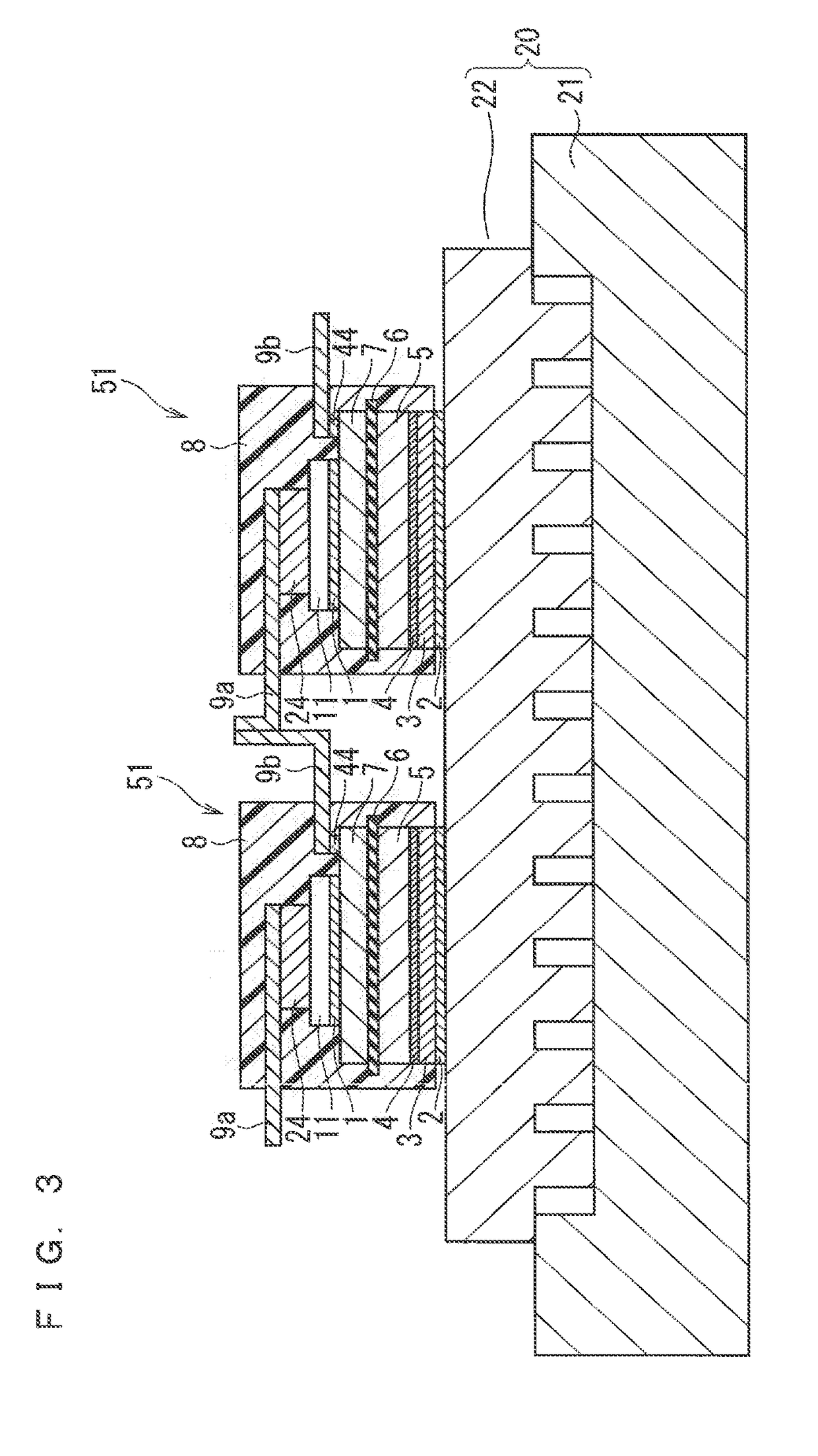

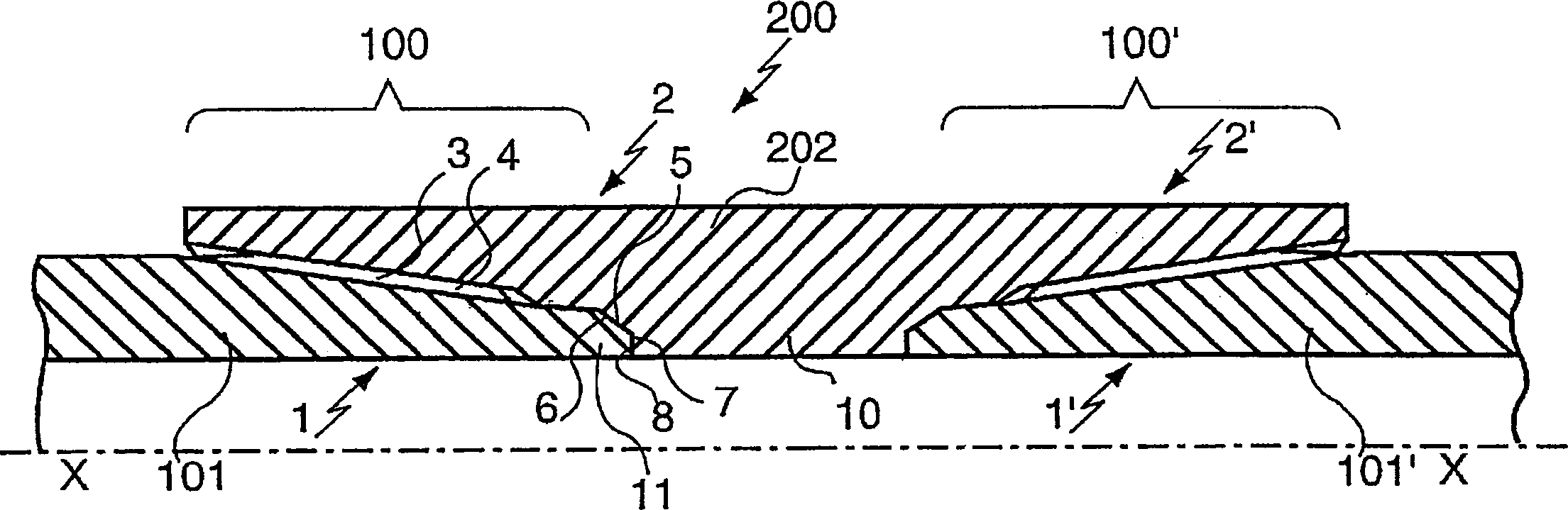

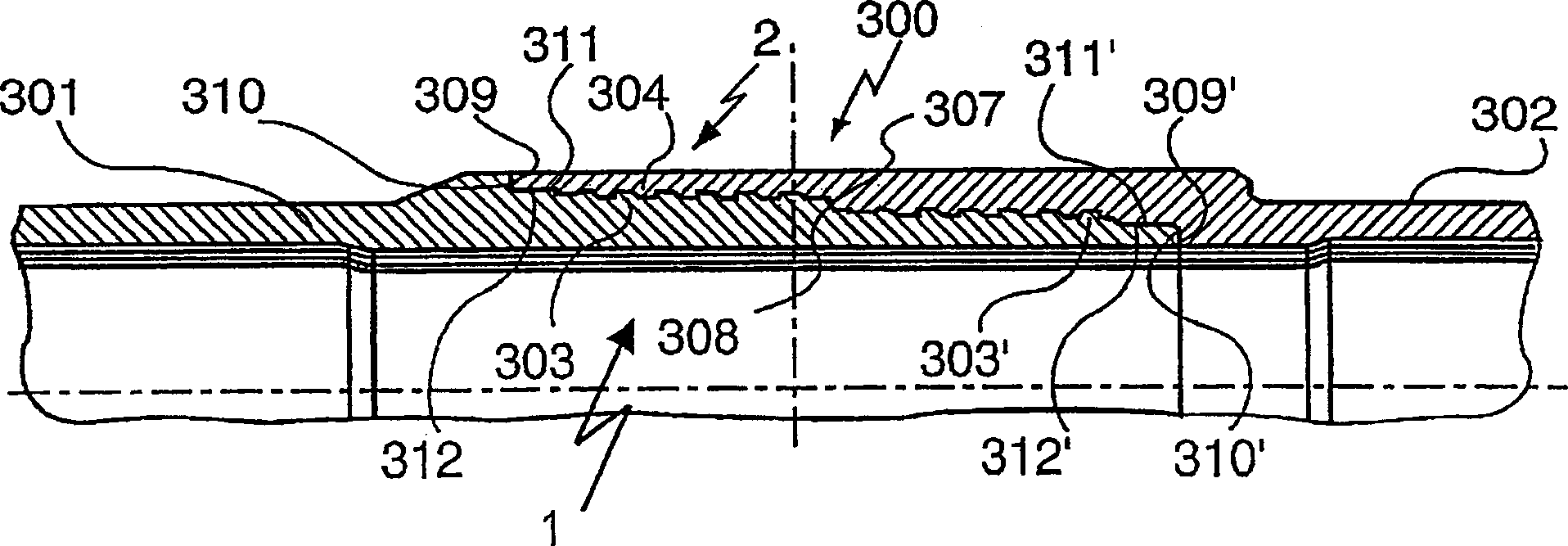

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20170309544A1Reduce metal fatigueSatisfactory heat transfer propertyPrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductor chipCeramic

A semiconductor device and a method for manufacturing the semiconductor device. The semiconductor device includes an insulating substrate, a semiconductor chip, a plate member, and a cooler. The insulating substrate includes insulating ceramics serving as an insulating plate, and conductive plates provided on opposite surfaces of the insulating ceramics. The semiconductor chip is provided on an upper surface of the insulating substrate. The plate member is bonded to a lower surface of the insulating substrate. The cooler is bonded to a lower surface of the plate member. At least one of bonding between a lower surface of the insulating substrate and the plate member and bonding between a lower surface of the plate member and the cooler is performed via a bonding member composed mainly of tin. Also, a cyclic stress of the plate member is smaller than a tensile strength of the bonding member.

Owner:MITSUBISHI ELECTRIC CORP

Method for predicting fatigue limit of magnesium alloy component

InactiveCN106872299AAdvancedAdvanced and reasonable technologyPreparing sample for investigationMaterial strength using tensile/compressive forcesLinearityMechanical property

The invention relates to a method for predicting thefatigue limit of a magnesium alloy component, and belongs to the technical field of magnesium alloy material mechanical properties. The method is characterized by comprising the following steps: by aiming at a deformation process of magnesium alloy under action of a cyclic load, obtaining an average cyclic strain curve along with a regular change of strain since a magnesium alloy sample can generate irreversible deformation under higher cyclic stress; through analyzing a linear relation between an average cyclic strain curve stabilization value and the cyclic load, determining an intersection point of two straight lines, and thus obtaining the fatigue limit of the magnesium alloy. The method does no need experimenters to observe the sample all the time, and has the advantages of convenience, quickness, accuracy and the like.

Owner:TAIYUAN UNIV OF TECH

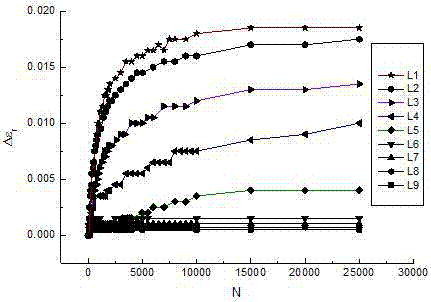

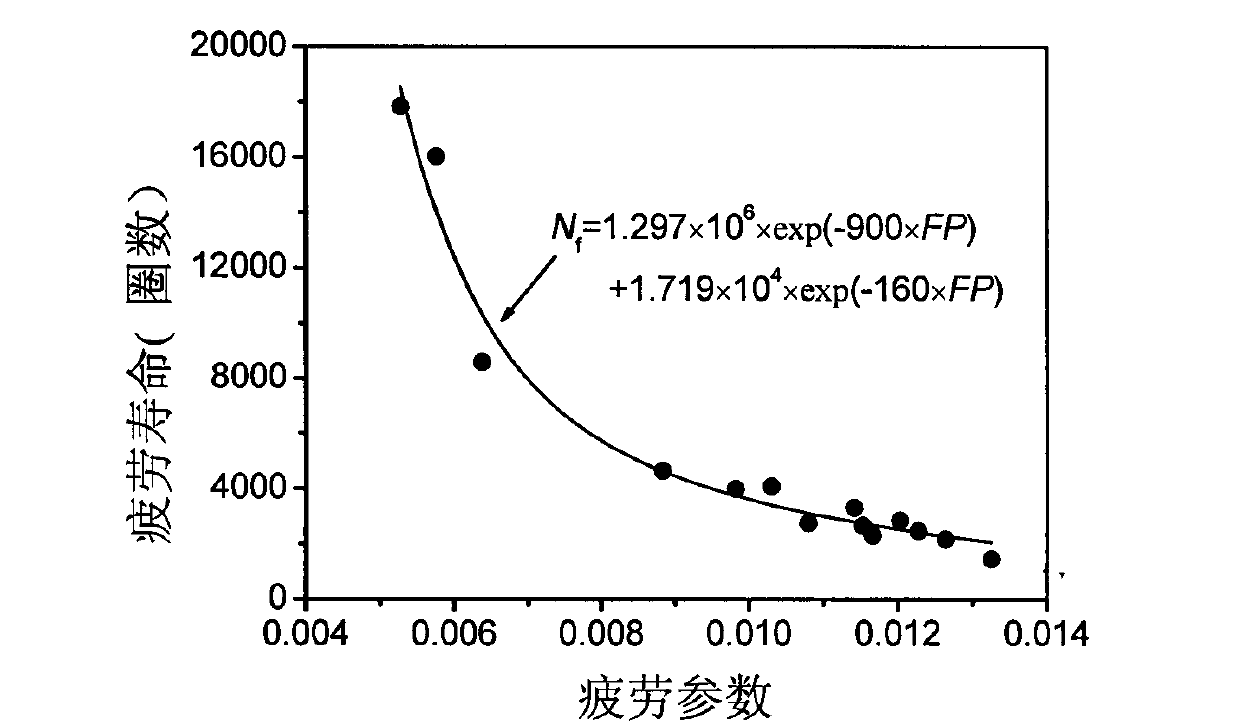

Method for predicting low-cycle fatigue life of metallic material under multi-step loading conditions

InactiveCN102980806APredict fatigue lifePromote engineering applicationMaterial strength using tensile/compressive forcesMetallic materialsReliability design

The invention discloses a method for predicting the low-cycle fatigue life of a metallic material under multi-step loading conditions. The method comprises the following steps of: (1) obtaining the low-cycle fatigue life of the metallic material through one-step and multi-step loaded asymmetric cyclic stress control fatigue experiments; (2) according to the working conditions of the fatigue experiments and the fatigue property of the material, determining a fatigue parameter (FP) calculation equation of the material during one-step loading, and establishing a fatigue life prediction model of the material under one-step loading conditions; (3) proposing a fatigue parameter (FP') calculation equation of the material during multi-step loading according to the nonlinear damage accumulation characteristics of the material in a multi-step loading process; and (4) establishing a low-cycle fatigue life prediction model of the metallic material under multi-step loaded asymmetric cyclic stress control conditions, and predicting the fatigue life of the metallic material. According to the method disclosed by the invention, the low-cycle fatigue life of the metallic material under the multi-step loaded asymmetric cyclic stress control conditions can be quickly predicted, thereby providing a theoretical reference for the reliable design and evaluation of parts.

Owner:CENT SOUTH UNIV

Method for determining metal film fatigue life in electro-mechanical coupling field

InactiveCN1766643AMeasurable fatigue lifeGuaranteed continuous and uninterrupted applicationMaterial analysis by electric/magnetic meansMaterial strength using tensile/compressive forcesElectricityEngineering

The invention discloses a method for measuring mental hull fatigue life on the force / electrical coupling field, which deposits the mental hull on the polyimide soft base plate. The minimum tensile load makes the mental hull to generate yield force, the soft base plate is at elastic deforming stage, when loading it, and the mental hull inner part will generate the compressive stress to achieve the mental hull drag-press fatigue circulating load. The electrical loading exerts method of the mental hull uses cylinder contact device. It exerts the circulating force and the electrical loading on the mental hull and uses the mutation of the mental hull shift amplitude with permanent loading amplitude or on the control of the loading amplitude to hand the forming of the mental fatigue defection and shows the fatigue life.

Owner:山东合创涂层技术有限公司

Carbon composite material, preparation method for carbon composite material and battery

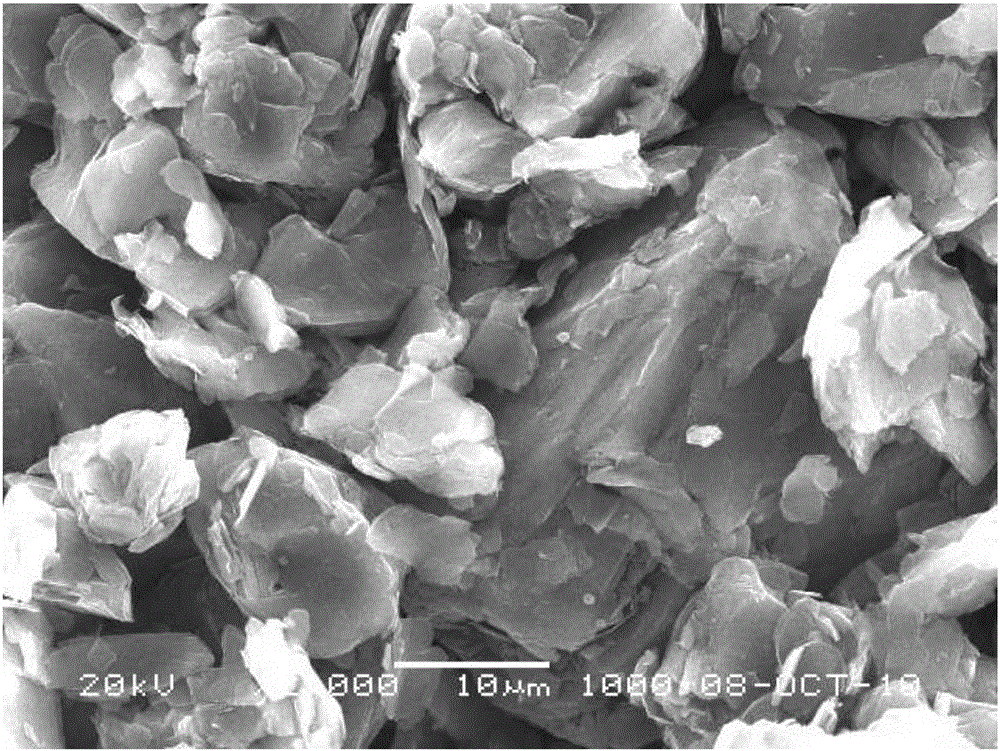

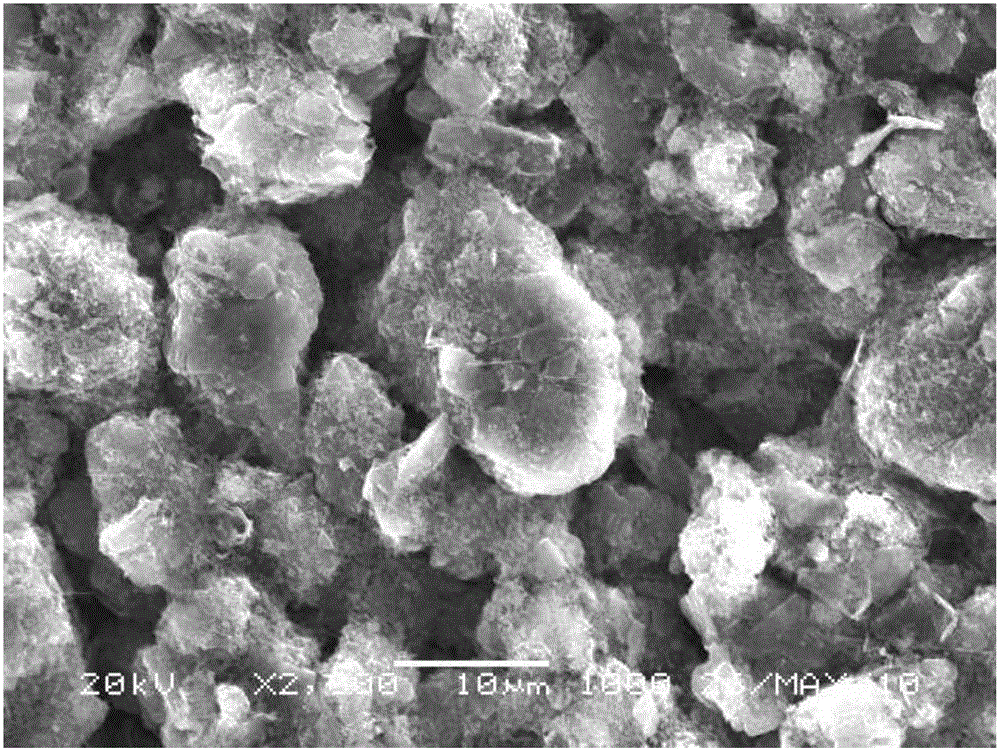

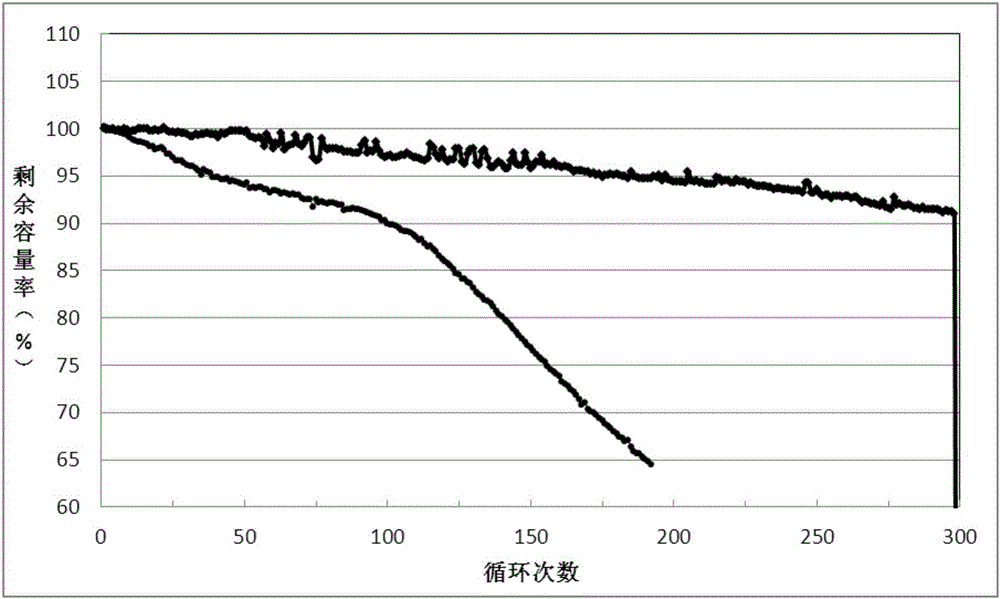

ActiveCN105680026APromote circulationReduce irreversible capacityCell electrodesSecondary cellsLithiumCarbon composites

The invention relates to the field of batteries, in particular to a carbon composite material. The carbon composite material comprises a core, a middle layer covering the core, and an outer layer covering the middle layer, wherein the core is graphite; the middle layer is a silicon-based material or a tin-based material; and the outer layer is porous carbon. According to the carbon composite material, the silicon-based material or the tin-based material is positioned between the graphite and the porous carbon, so that the material pulverization can be inhibited; the porous carbon reserves sufficient space, so that the cyclic stress generated by expansion of the silicon-based material or the tin-based material can be buffered and the pulverization is avoided; and therefore, the carbon composite material has good cyclic performance. In addition, the porous carbon of the outer layer can effectively prevent the silicon-based material or the tin-based material from being in direct contact with an electrolyte solution, reduce the irreversible capacity and improve the conductive performance of the carbon composite material; and the porous carbon is favorable for insertion and extraction of lithium ions due to porosity. The invention furthermore discloses a preparation method for the carbon composite material and a battery.

Owner:SUZHOU GCLSI SCI & TECH IND APPL RES INST CO LTD +3

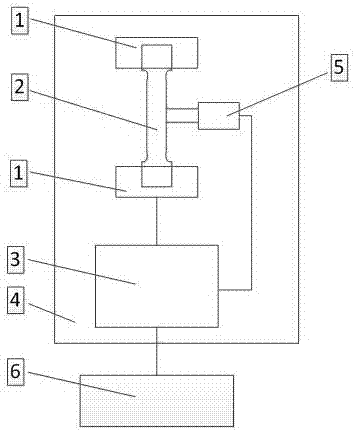

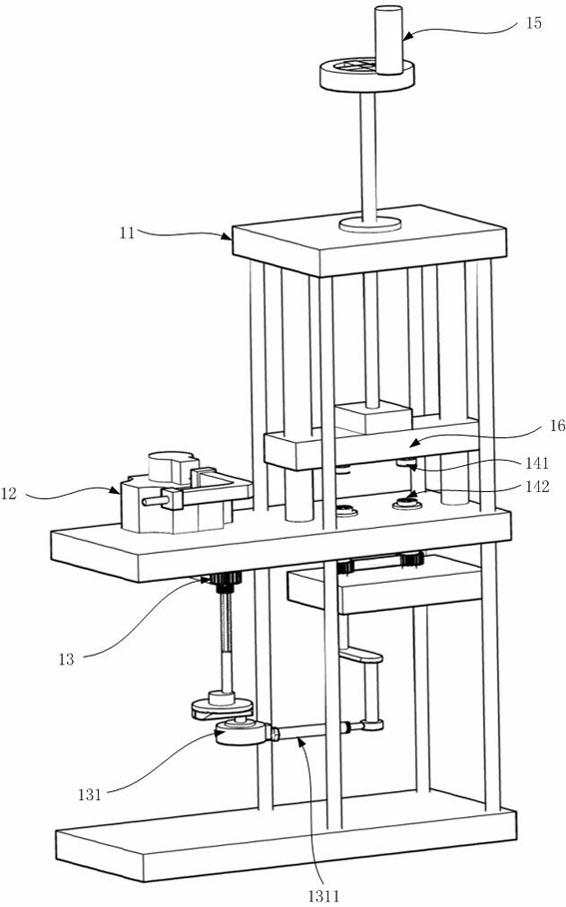

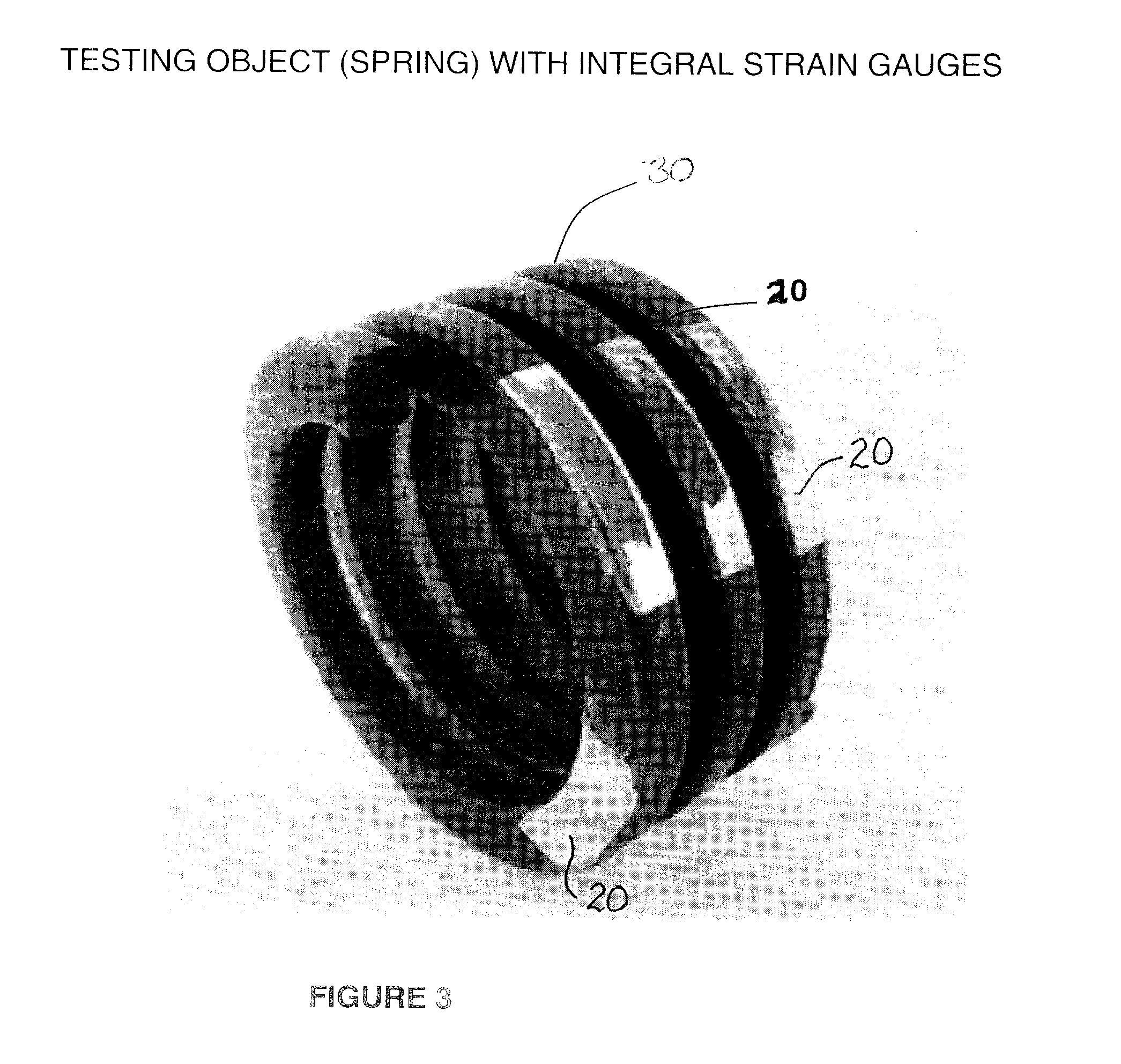

Torsional spring fatigue tester

InactiveCN102507352ADetermining Cyclic Stress ResistanceChange swing angleMaterial strength using repeated/pulsating forcesEngineeringTorsion spring

The invention provides a torsional spring fatigue tester, which includes a main body, a motor, a transmission mechanism, a torsional spring fixture, a lifting platform and a rotating handle. The motor and the lifting platform are fixed and connected with the main body respectively; the torsional spring fixture includes a torsional spring top seat and a torsional spring bottom seat, which are arranged face to face rightly; the torsional spring bottom seat is also fixed and connected with the main body; the torsional spring bottom seat is driven to swing by the motor through the transmission mechanism; the lifting platform is driven to move linearly by the rotating handle; the moving direction of the lifting platform is perpendicular to the swinging plane of the torsional spring bottom seat; the torsional spring top seat is fixed and connected with the lifting platform; and the transmission mechanism includes a crank and rocker mechanism. The invention has the benefits as follows: a torsional spring in springs is subjected to a fatigue test, and the cyclic stress resistance of the special torsional spring under special work conditions can be simulated and determined. The crank and rocker mechanism drives a fixture bottom seat to swing, the simple structure can provide the cyclic swinging test stress, and meanwhile the length of a connecting rod can be adjusted according to special work conditions, so that the swinging angle of the torsional spring can be changed.

Owner:SHENZHEN POLYTECHNIC

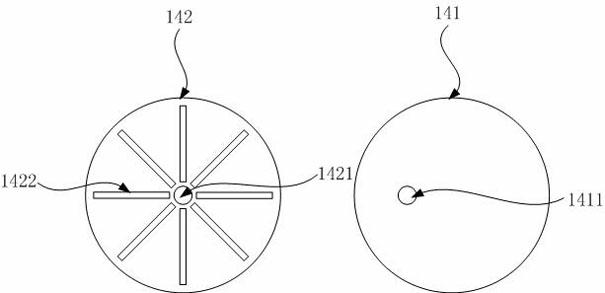

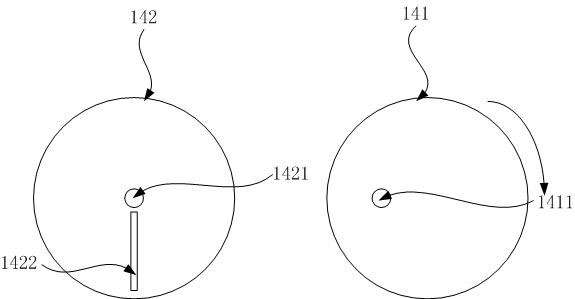

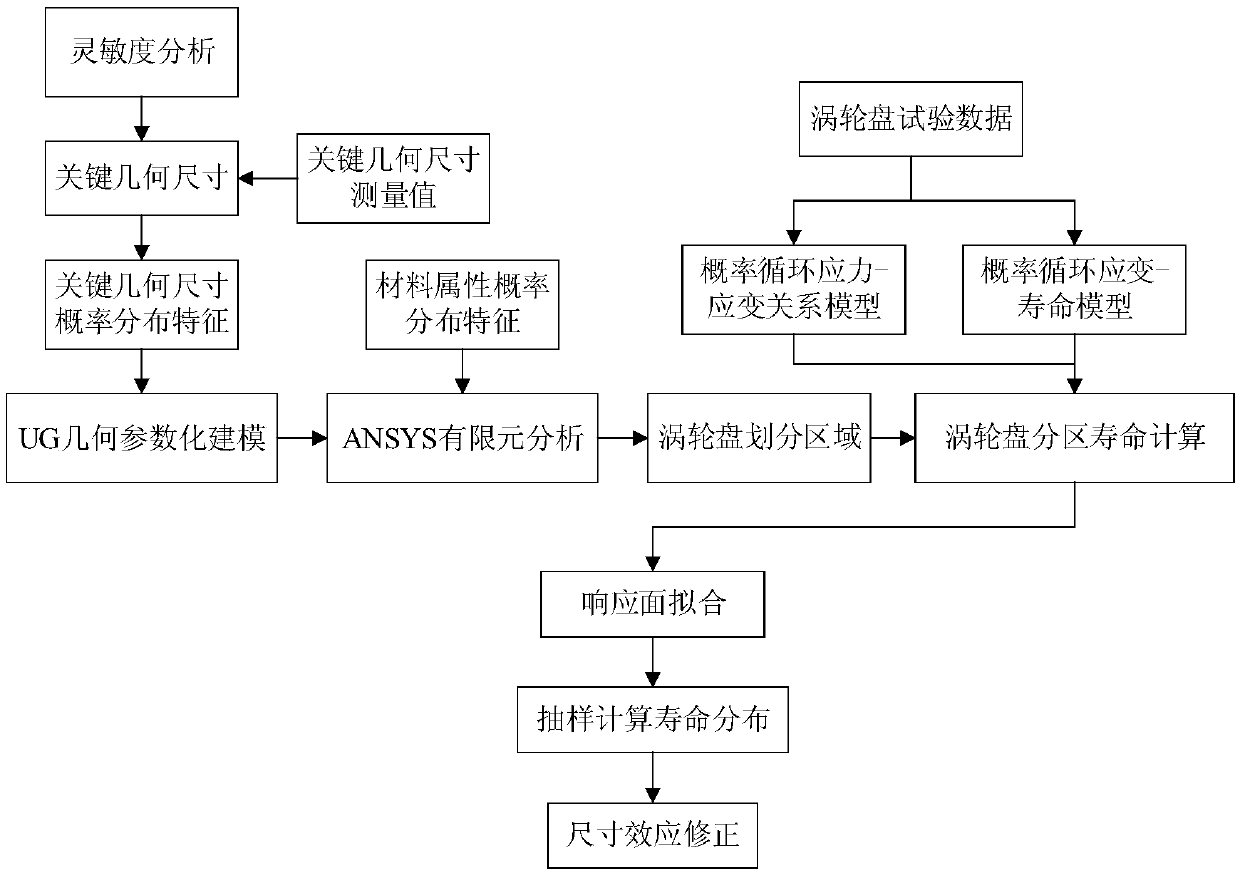

Turbine disk partitioning reliability analysis method based on size effect modification

ActiveCN108629092AAccurate lifeAccurate and reliableGeometric CADDesign optimisation/simulationRelational modelStress level

The invention relates to a turbine disk partitioning reliability analysis method based on size effect modification. The method includes the steps of firstly, simplifying a turbine disk model, analyzing the sensitivity to obtain the key geometrical size of a turbine disk, measuring the key geometrical size of the turbine disk to obtain a corresponding probability distribution feature; secondly, obtaining the material attributes of the turbine disk, and establishing a SWT probability cyclic stress-strain relation model and a strain-life model of the turbine disk; thirdly, conducting geometricalparameterization modeling on the turbine disk, analyzing finite elements, dividing areas according to the stress level and temperature distribution conditions of the turbine disk, conducting Latin hypercube sampling on the established SWT probability cyclic stress-strain relation model and the probability strain-life model to obtain the relation between random input variables and output service lives of all divided areas of the turbine disk and establish response face models, and sampling the response face models of all the divided areas through a Monte-Carlo sampling method to obtain the corresponding service life distribution and finally obtain the fatigue life and reliability of the turbine disk; fourthly, conducting size effect modification on the service life distribution of the turbine disk.

Owner:BEIHANG UNIV

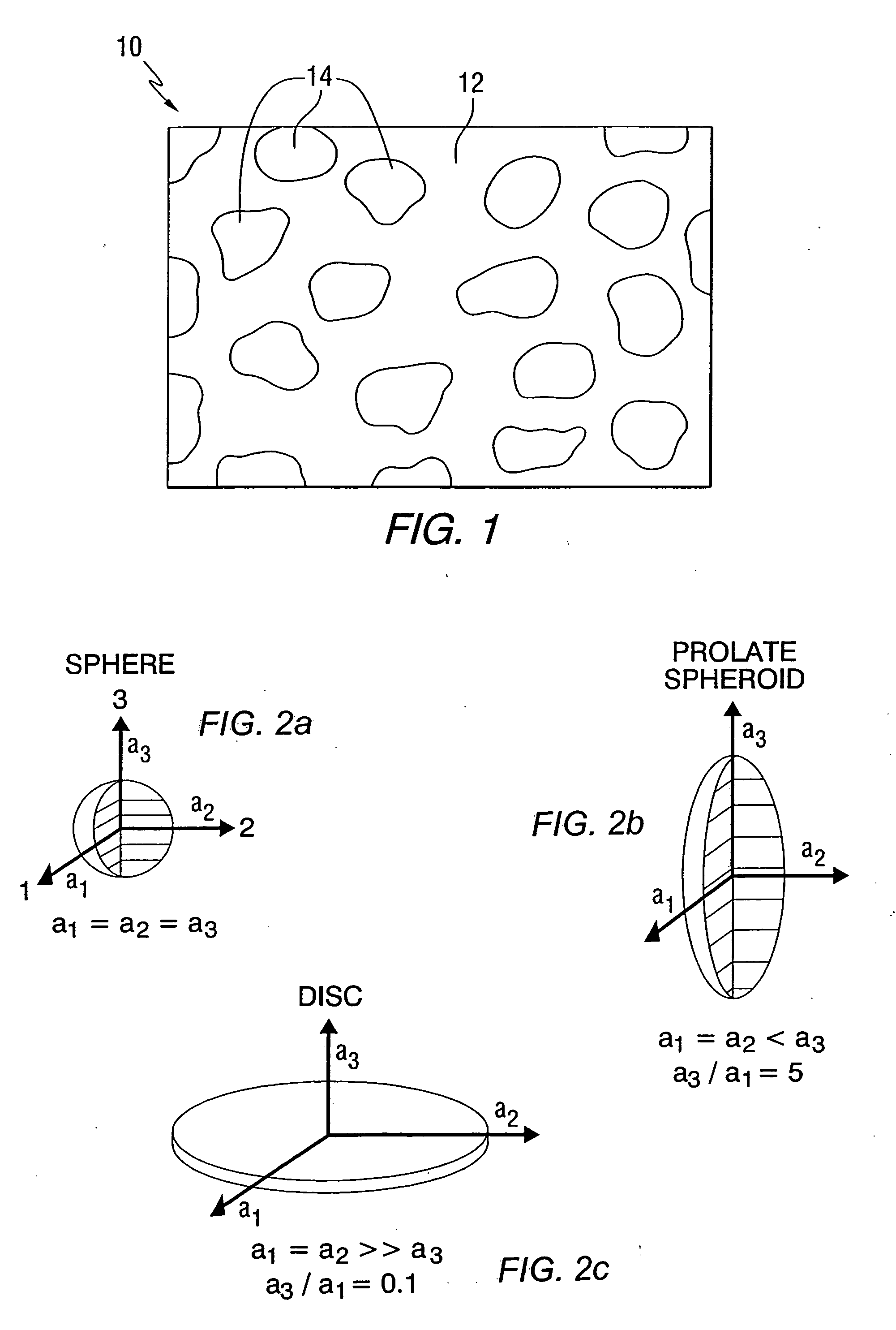

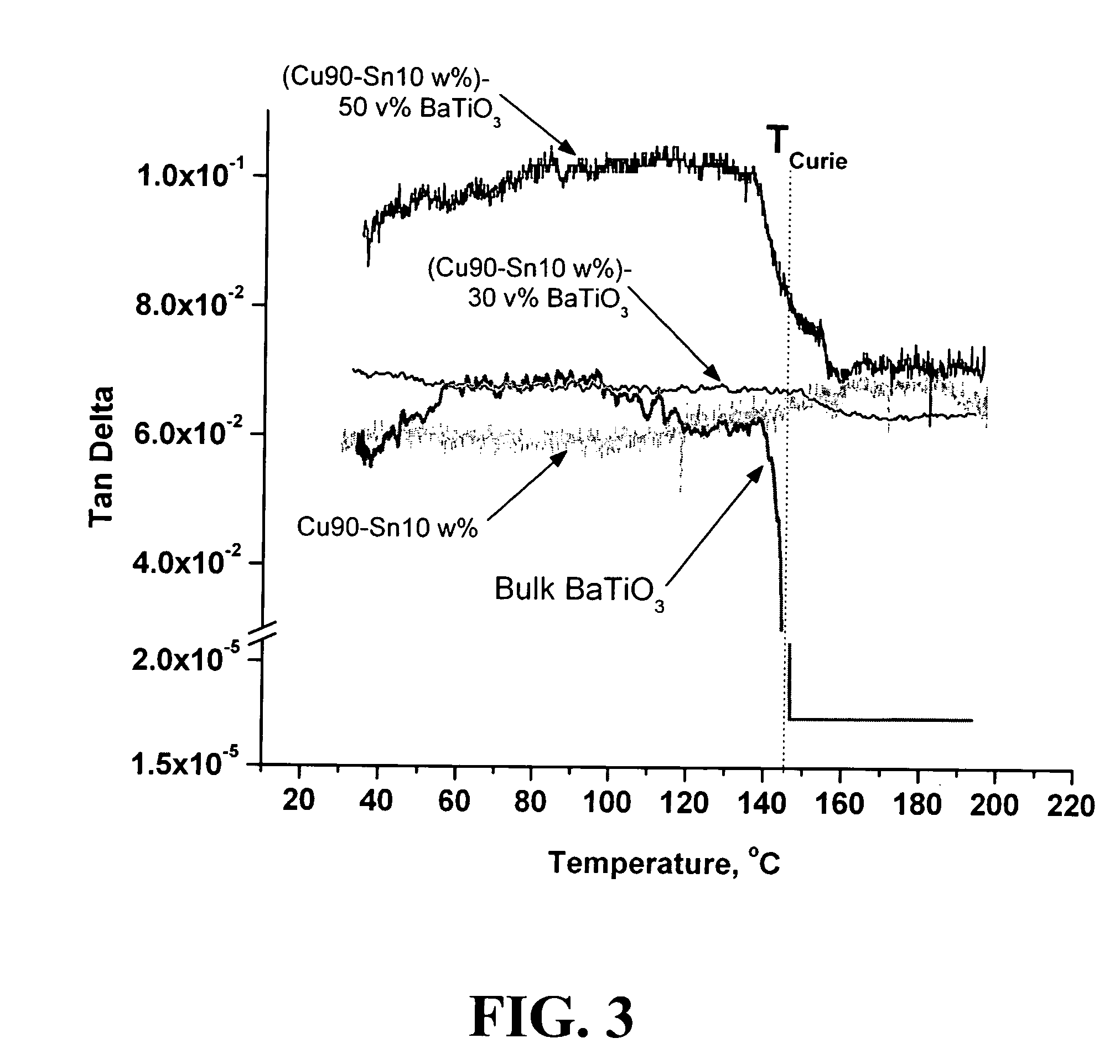

Ferroelastic ceramic-reinforced metal matrix composites

InactiveUS20070138917A1Exceptional passive damping capabilityImprove structural strengthPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionParticulatesIn vehicle

Composite materials comprising ferroelastic ceramic particulates dispersed in a metal matrix are capable of vibration damping. When the ferroelastic ceramic particulates are subjected to stress, such as the cyclic stress experienced during vibration of the material, internal stresses in the ceramic cause the material to deform via twinning, domain rotation or domain motion thereby dissipating the vibrational energy. The ferroelastic ceramic particulates may also act as reinforcements to improve the mechanical properties of the composites. The composite materials may be used in various structural components in vehicles, aircraft, spacecraft, buildings and tools.

Owner:VIRGINIA TECH INTPROP INC

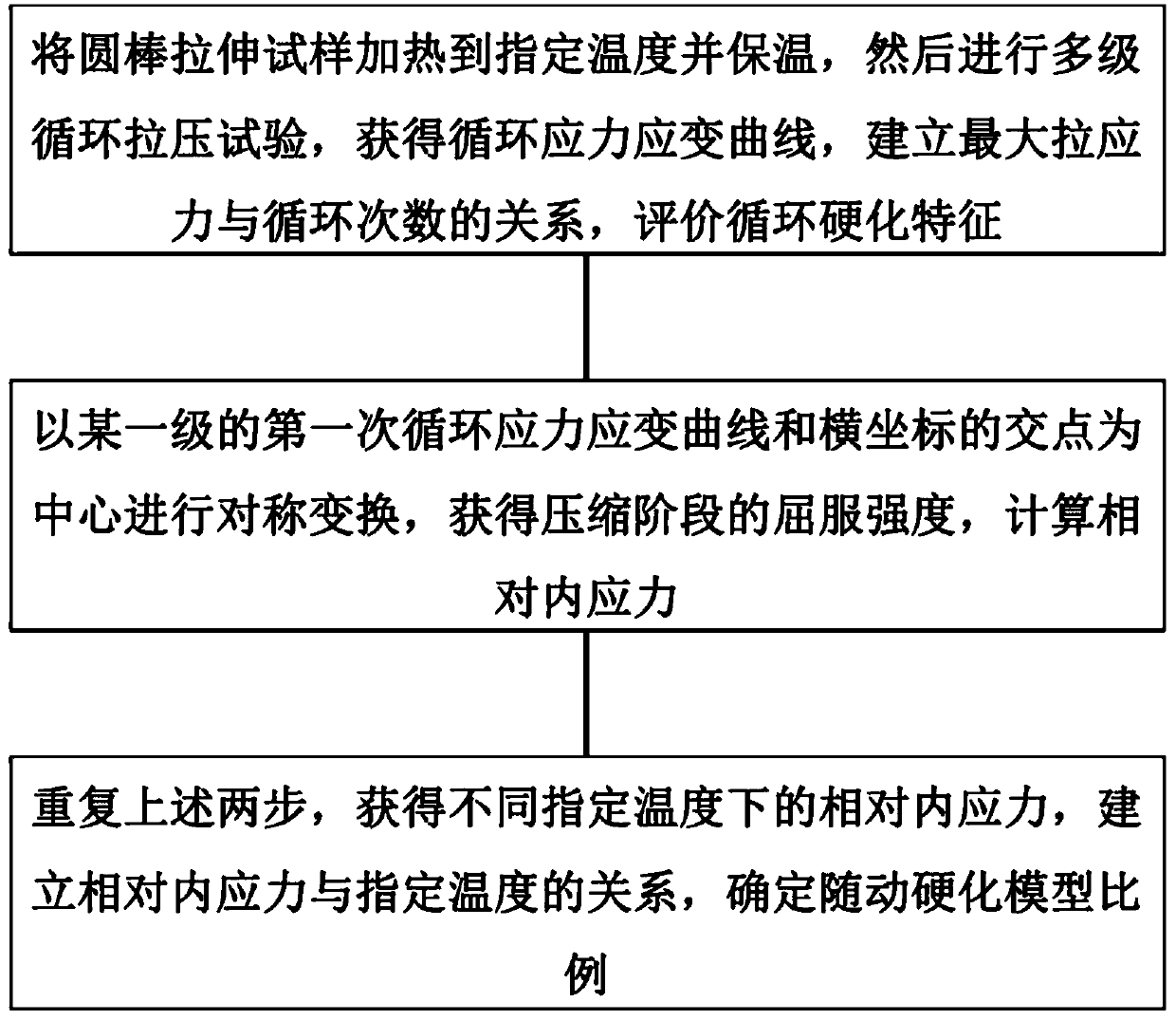

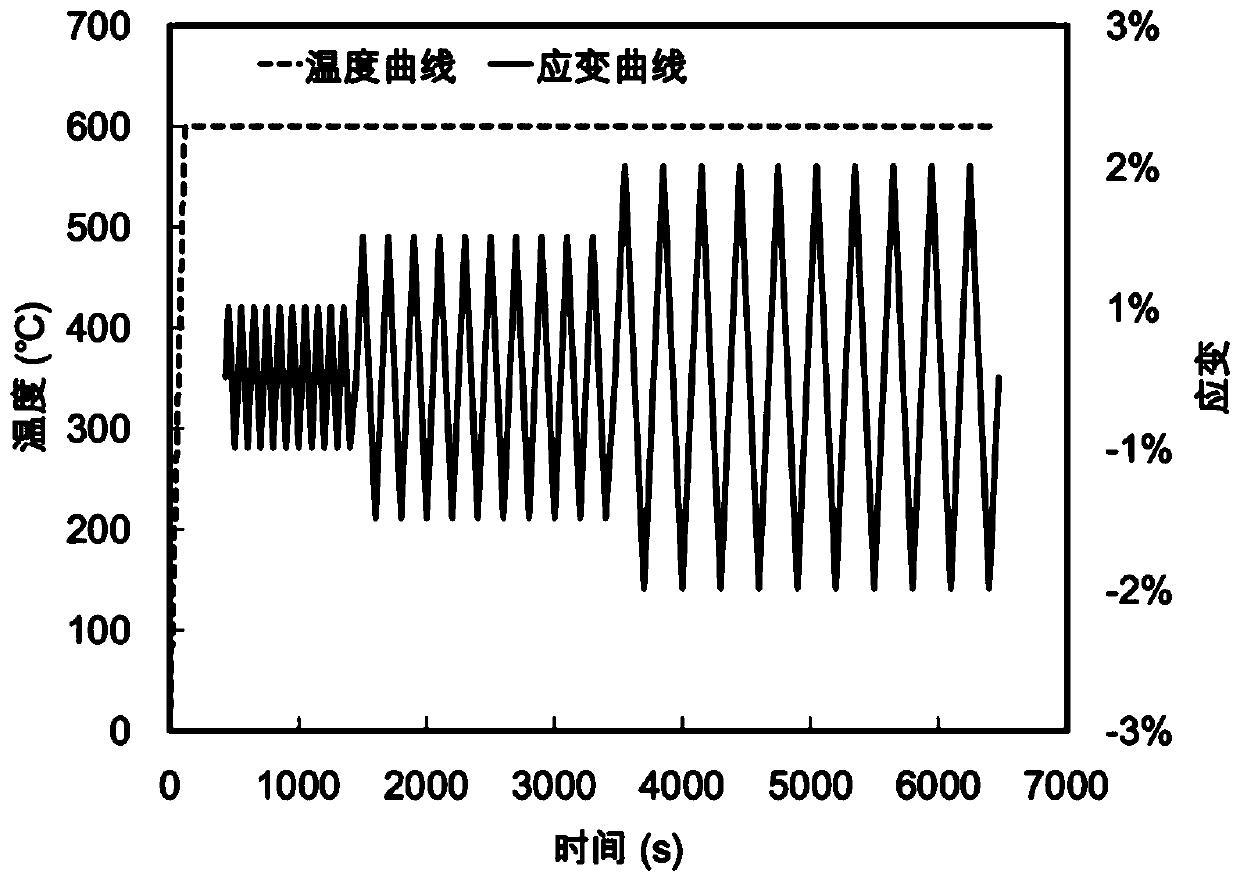

Material cyclic hardening behavior testing method in welding process

InactiveCN110308059AImprove accuracyMaterial strength using repeated/pulsating forcesStress–strain curveFatigue testing

The invention relates to a material cyclic hardening behavior testing method in welding process. The testing method comprises the following steps: 1) mounting a test sample on a high-temperature fatigue testing machine, heating the test sample to set temperature in a certain heating speed by using an annular infrared heating furnace, and preserving the heat of the test sample; 2) performing multi-stage load cyclic tensile-compression test by adopting strain control; 3) drawing a stress-strain curve graph of the cyclic tensile-compressive test, establishing a relation of the maximum tensile stress and cyclic number under the set temperature, and determining a strain hardening characteristic based on the maximum tensile stress change tendency; 4) computing the relative internal stress according to the cyclic stress-strain curve of the cyclic tensile-compressive test; and 5) taking a relative internal stress mean of the temperature under a test sample material mechanics melting point as the proportion of the test sample material follow-up hardening model according to the relation curve of the relative internal stress and the test temperature. Compared with the prior art, the testing method disclosed by the invention has the advantages of qualitatively evaluating the cyclic hardening characteristic and quantitatively determining the proportion of the follow-up hardening model.

Owner:SHANGHAI JIAO TONG UNIV

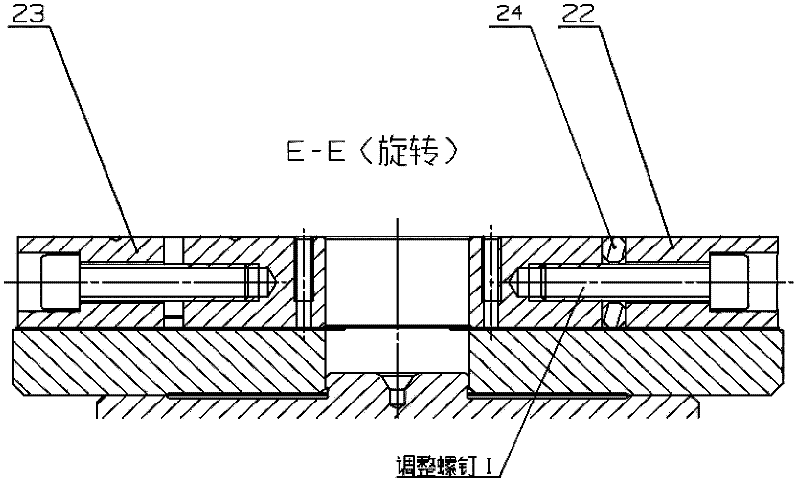

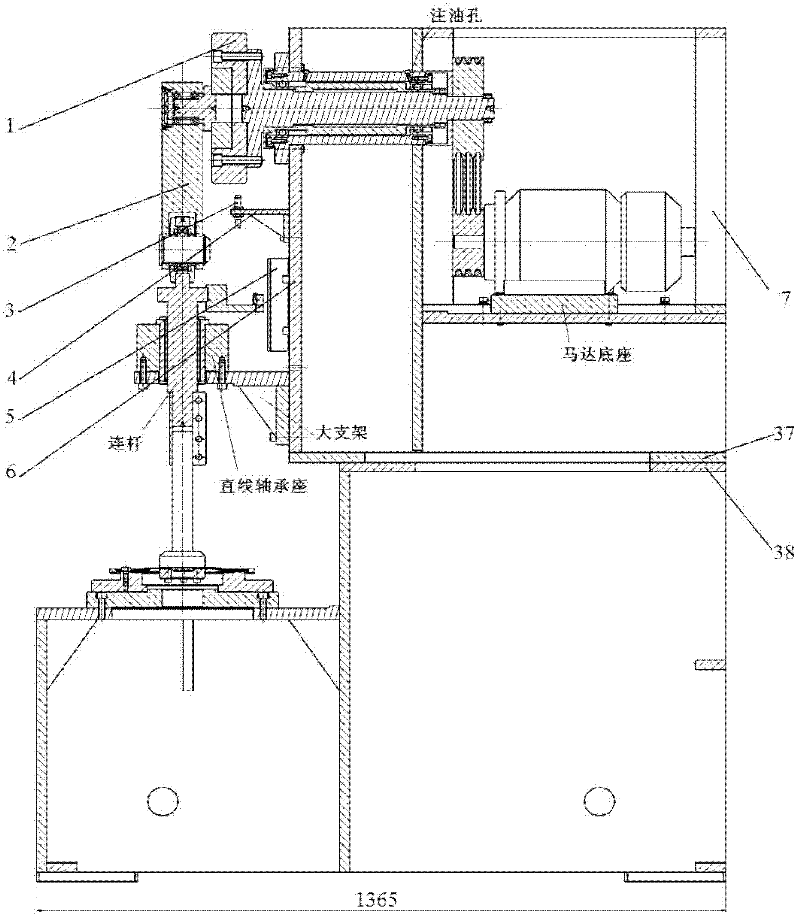

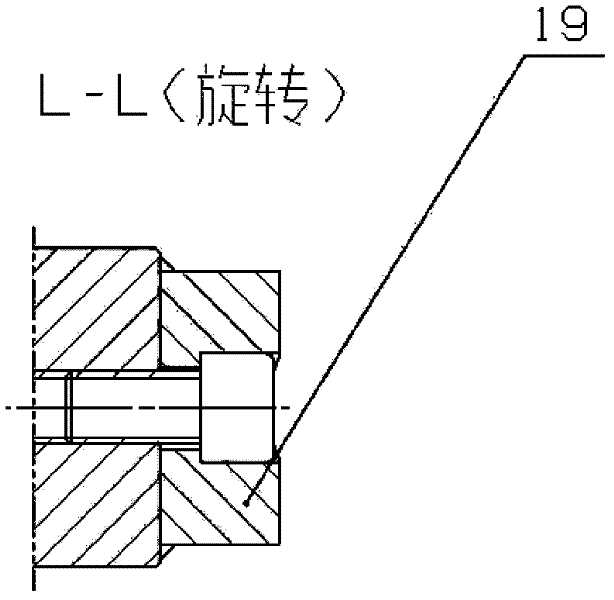

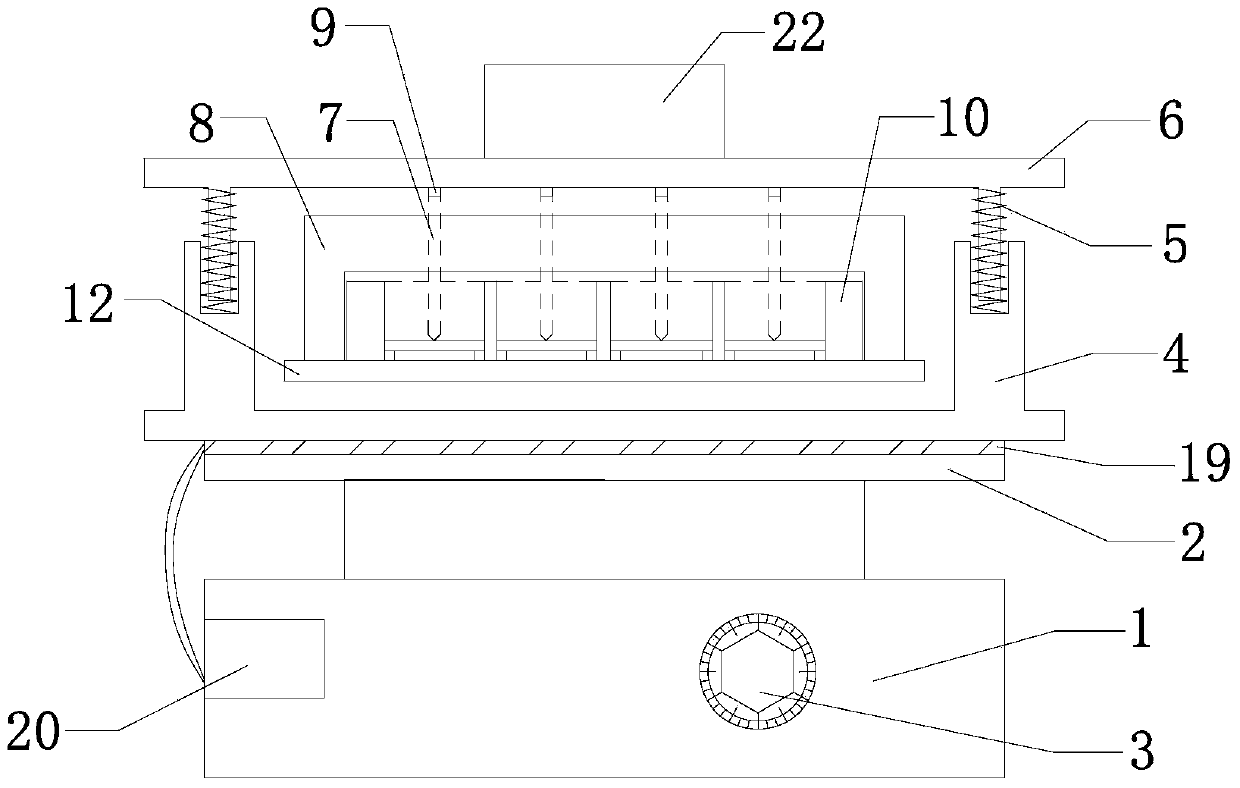

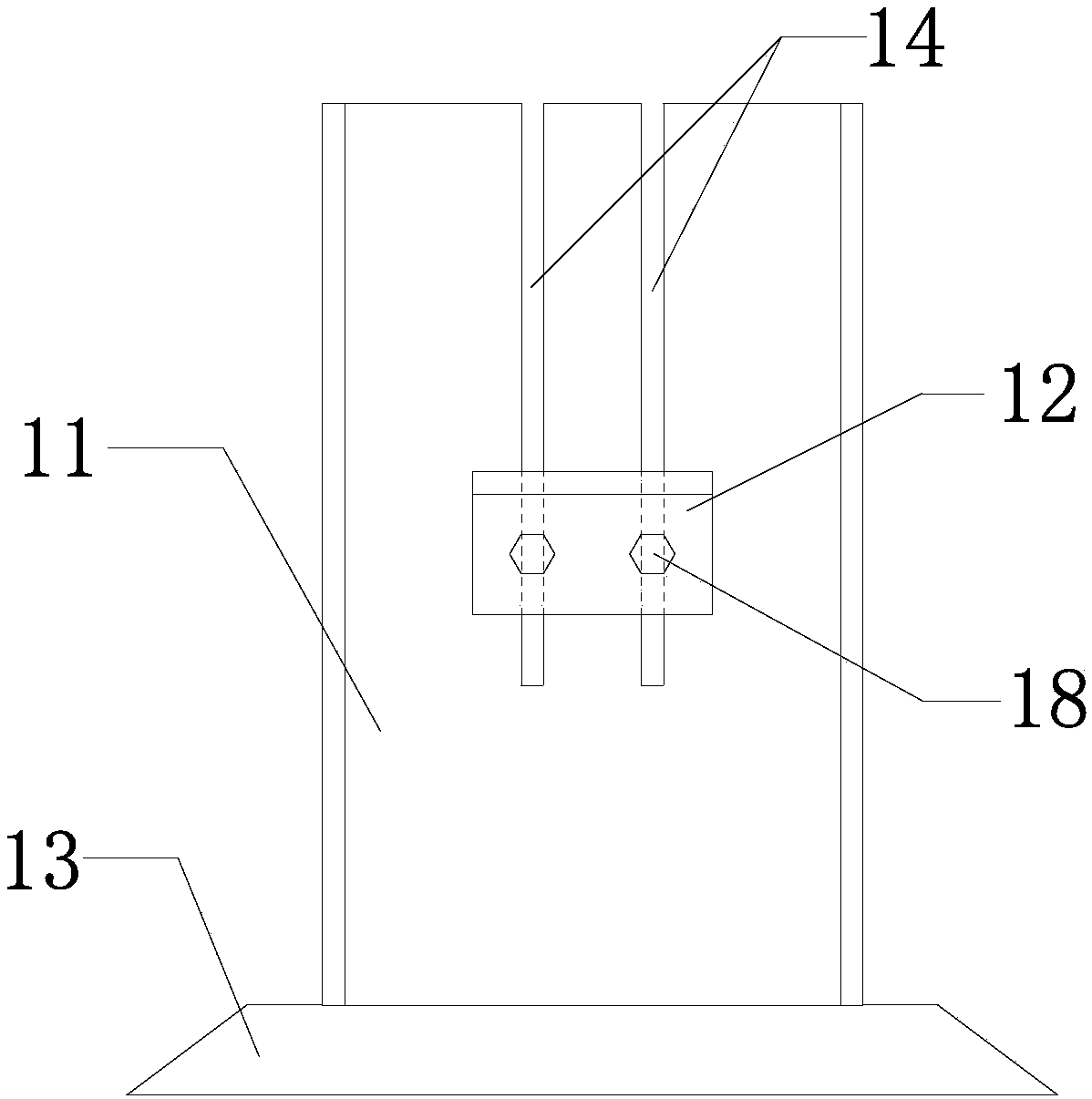

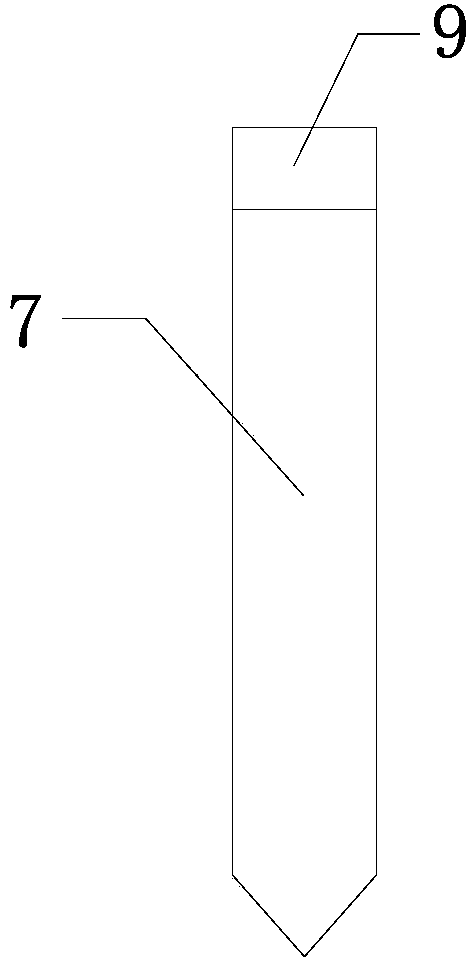

Axial load fatigue testing device and testing method thereof

The invention relates to an axial load fatigue testing device in the technical field of auto parts and components manufacture. The axial load fatigue testing device comprises an eccentric wheel spindle assembly, a swing link assembly, a proximity switch, a bracket, a length sensor, a box body and a box basket. The invention is suitable for an axial fatigue test of a flywheel web plate stamping piece which is subjected to an adjustable load with cyclic stress in room-temperature air; and the frequency for the test can be selected from a range of 10-30 Hz. A testing method comprises the steps: a motor is started; when a big and a small belt wheels with certain revolution speed drive the eccentric wheel spindle assembly to rotate, the swing link assembly and a connecting bar freely operate in a linear bearing up and down; a certain load is applied to a piece to be tested (according to the requirement of a modeling test) with a certain loading frequency; and a back and forth cyclic fatigue test is carried out to finally examine whether the piece to be tested satisfies with relevant requirements of an axial load fatigue test or not.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

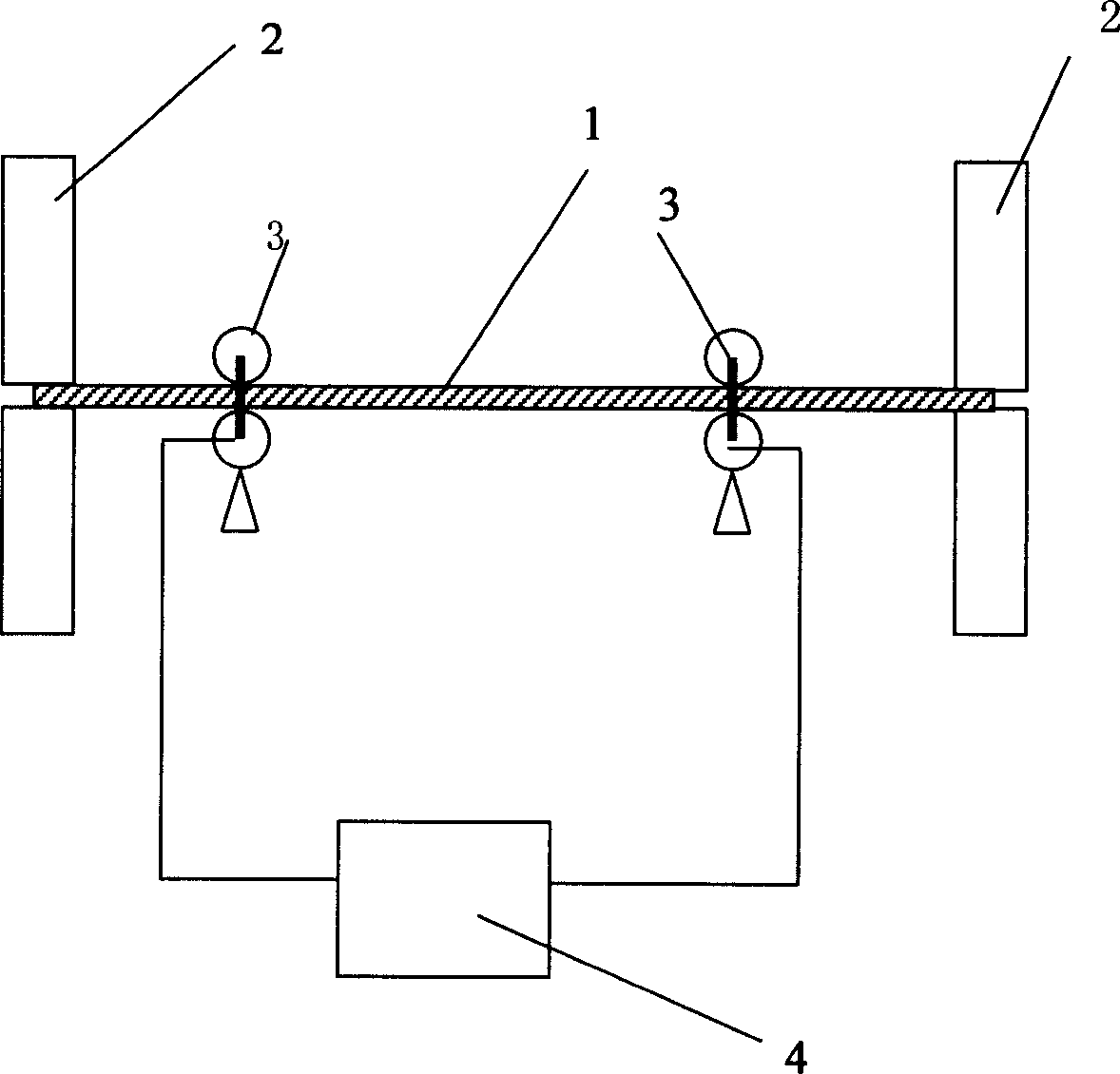

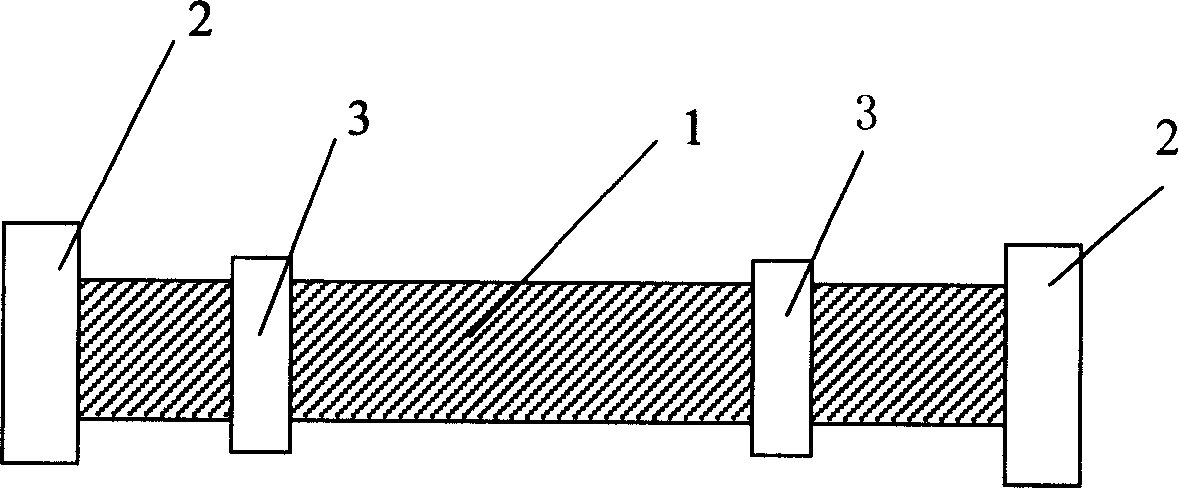

Dynamic mechanical experimental device and method for tissue engineering scaffold

ActiveCN104007029ARelax the design factorEasy to adjustMaterial strength using repeated/pulsating forcesExperimental methodsEngineering

The invention discloses a dynamic mechanical experimental device and a dynamic mechanical experimental method for a tissue engineering scaffold. The device comprises a pressure sensor, a reciprocating motor, a cyclic dynamic stress loading component and an assembling bracket used for placing the reciprocating motor and the cyclic dynamic stress loading component, wherein the pressure sensor comprises a sensing gasket and display equipment; the sensing gasket is arranged between the reciprocating motor and the cyclic dynamic stress loading component, and the sensing gasket and the display equipment are connected with the reciprocating motor; the cyclic dynamic stress loading component comprises a lower bracket used for transmitting driving force upwards, a spring used for transmitting dynamic force, an upper bracket used for transmitting pressure stress downwards, an ejector pin used for transmitting the stress to an experimental material, and a positioning porous cover used for fixing the ejector pin and an experimental porous plate. According to the device and method, a simulation experiment in tissue engineering scaffolds of different sizes under cyclic stress environmental loading under the frequency of 1-150Hz can be met, multi-group experiments can be simultaneously performed, and the experimental efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

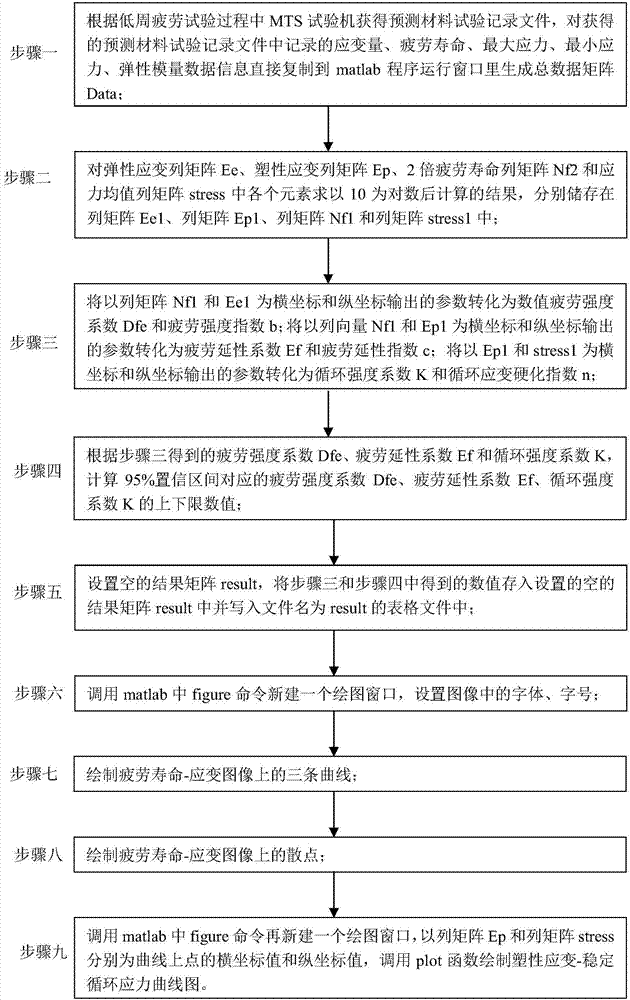

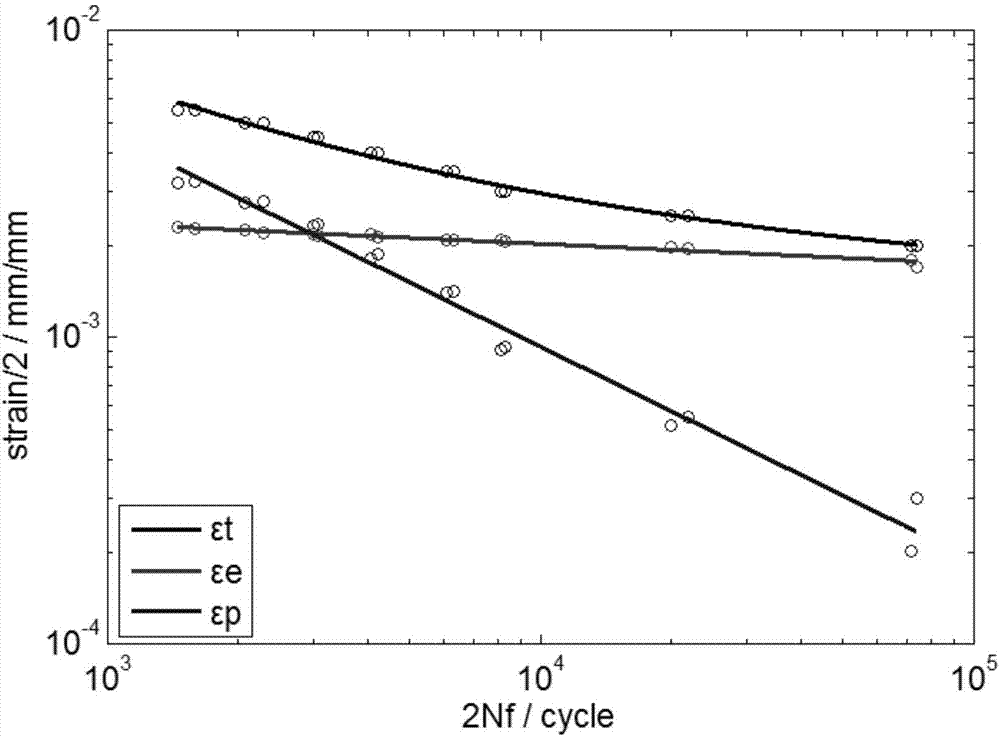

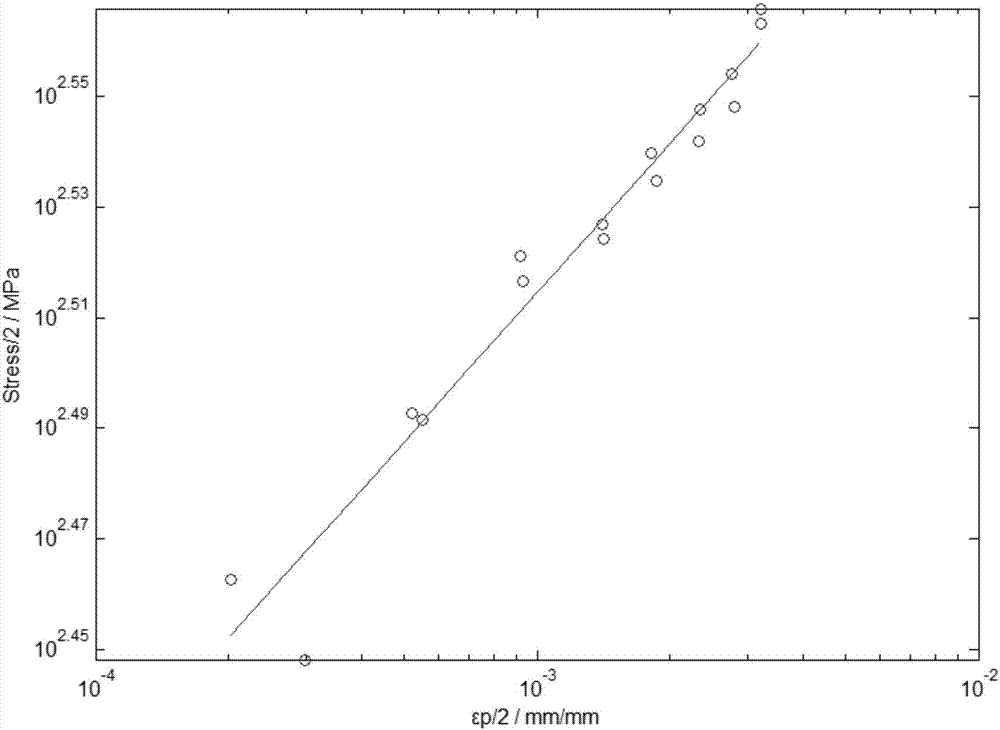

Low-cycle fatigue data analysis method based on matlab programming

InactiveCN107391799AImprove processing efficiencyGuaranteed accuracyDesign optimisation/simulationSpecial data processing applicationsLower limitAlgorithm

The invention relates to a low-cycle fatigue data analysis method based on matlab programming. The method aims to solve the problems that an experiment value needs to be manually input and input errors are likely to generate so as to influence an experiment analysis result and generate low data processing efficiency when an existing method is used and also solve the problems that an obtained image can not be subjected to secondary editing, the variable value of a processing process is not visual and a fitting curve numerical value can not be directly exported. The process of the method comprises the following steps that: generating total data matrix Data; calculating the upper limit and lower limit numerical values of Dfe, Ef and K corresponding to 95% of confidence interval; storing a result into result, and writing into a format file of which the filename is result; setting a font and a word size in the image; drawing three curves and scattered points on a fatigue life-strain image; and calling a plot function to draw a plastic strain-stable cyclic stress curve graph. The method is used for the field of low-cycle fatigue data analysis.

Owner:HARBIN TURBINE

Method of forecasting the lifetime of structural parts

ActiveUS20100064819A1Force measurement by measuring optical property variationUsing optical meansCyclic stressPhysical property

Owner:PARADIGM SHIFT TECH

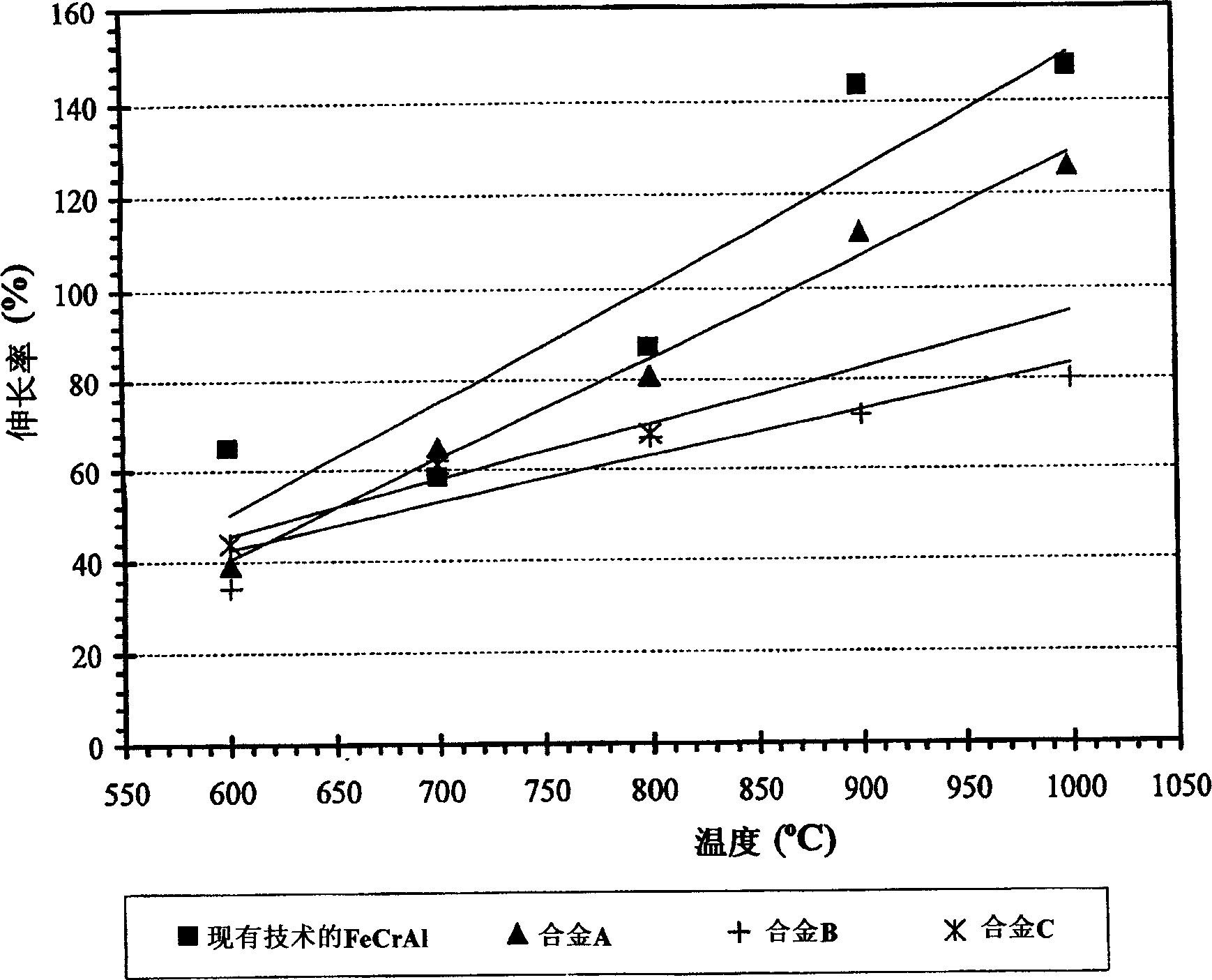

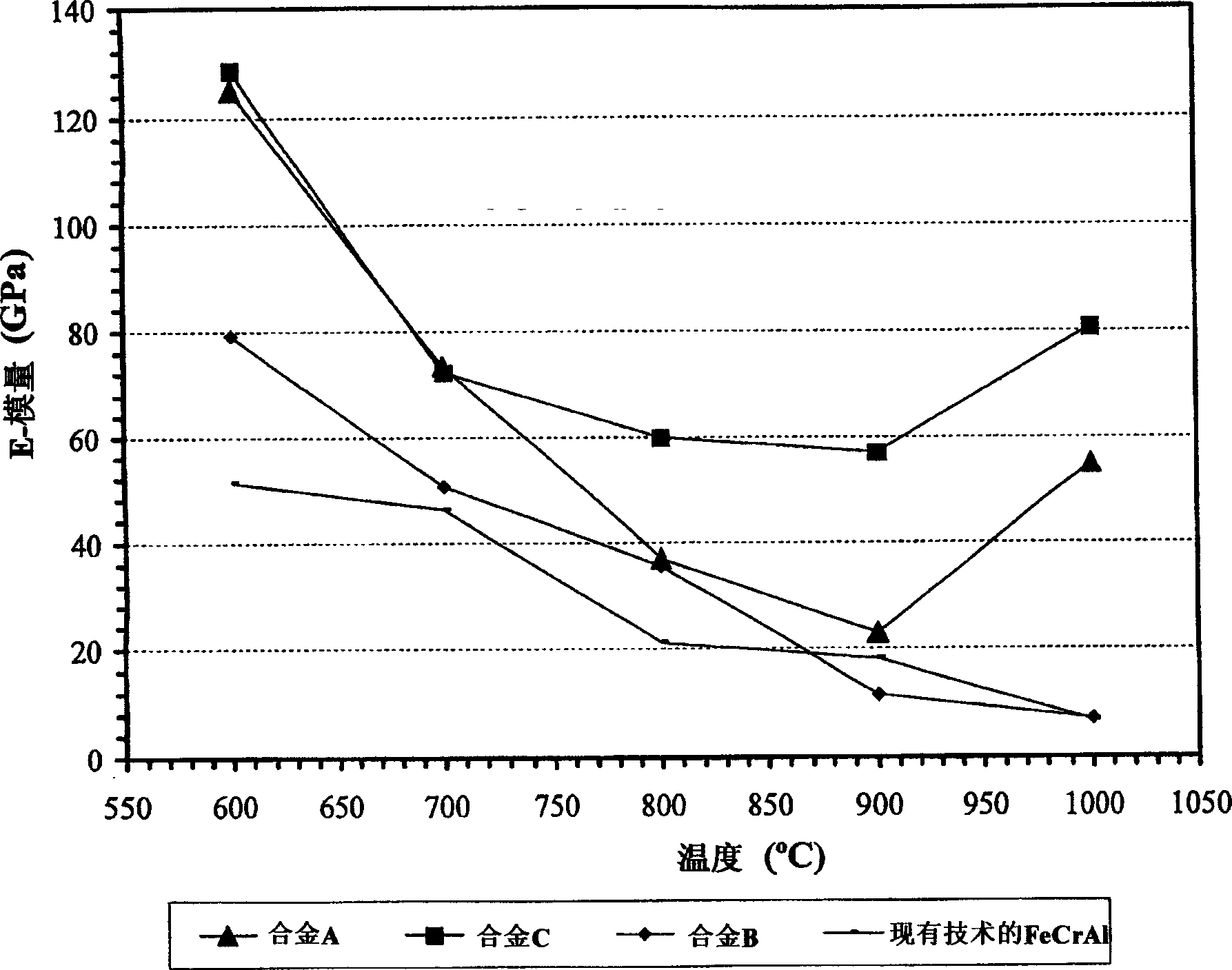

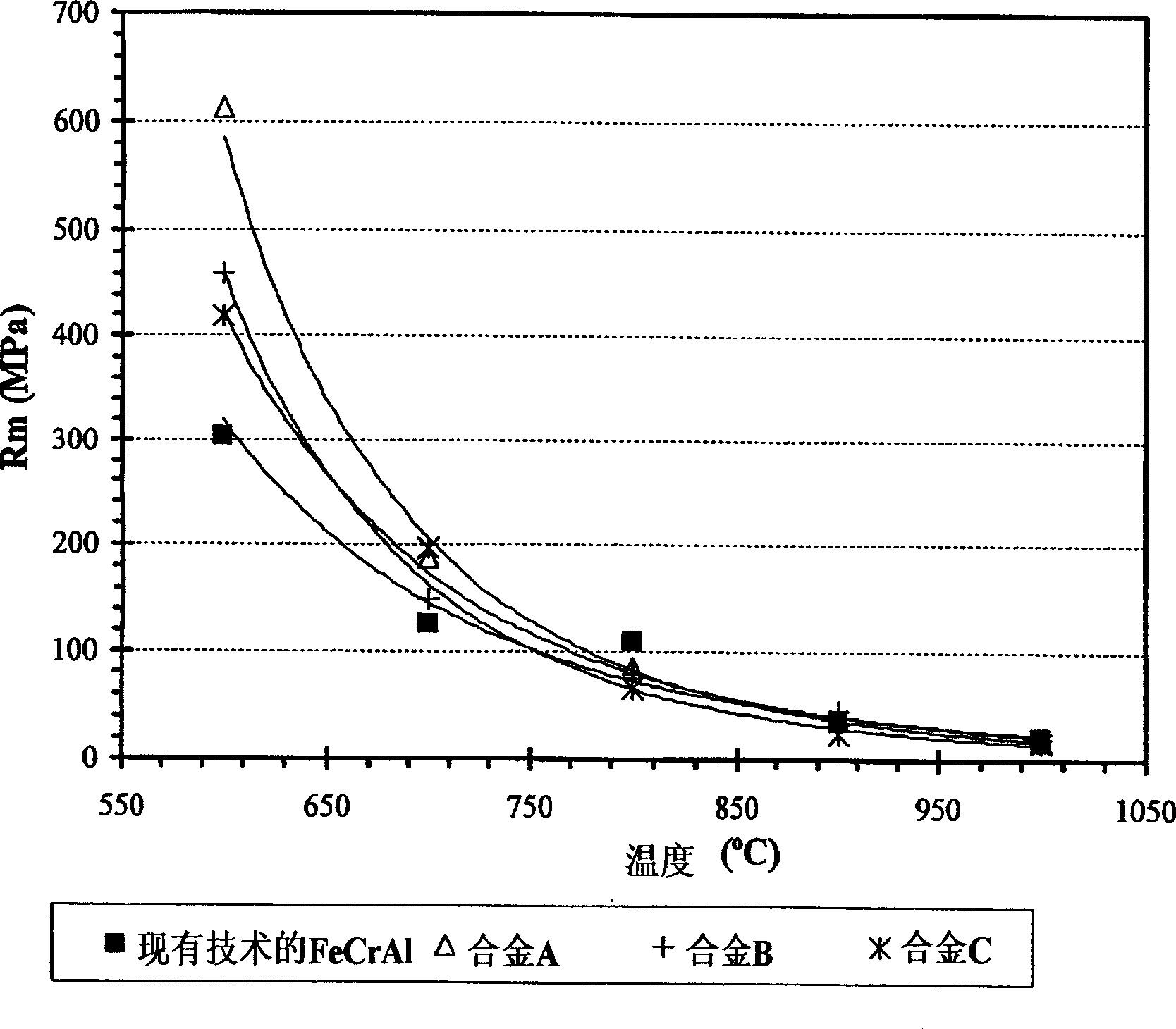

Ferritic stainless steel for use in high temperature applications and method for producing a foil of the steel

InactiveCN1599803AImprove antioxidant capacityIncrease stressExhaust apparatusDispersed particle separationSteelmakingAlloy

The present invention relates to the use of a hot workable ferritic stainless steel alloy resistant to thermal cyclic stress and oxidation at elevated temperatures and having improved mechanical properties as substrate for exhaust gas purifying applications, such as catalytic converters or heating applications and having the following composition (in weight-%): C <=0,05%, Cr 16,0-24,0%, Ni more than 1,0-15,0%, Al 4,5-12,0%, Mo+W <=4,0%, Mn <=1,0%, Si <=2,0%, Zr+Hf <=0,1%, REM <=0,1%, N <=0,05% balance Fe and normally occurring steelmaking impurities and additions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

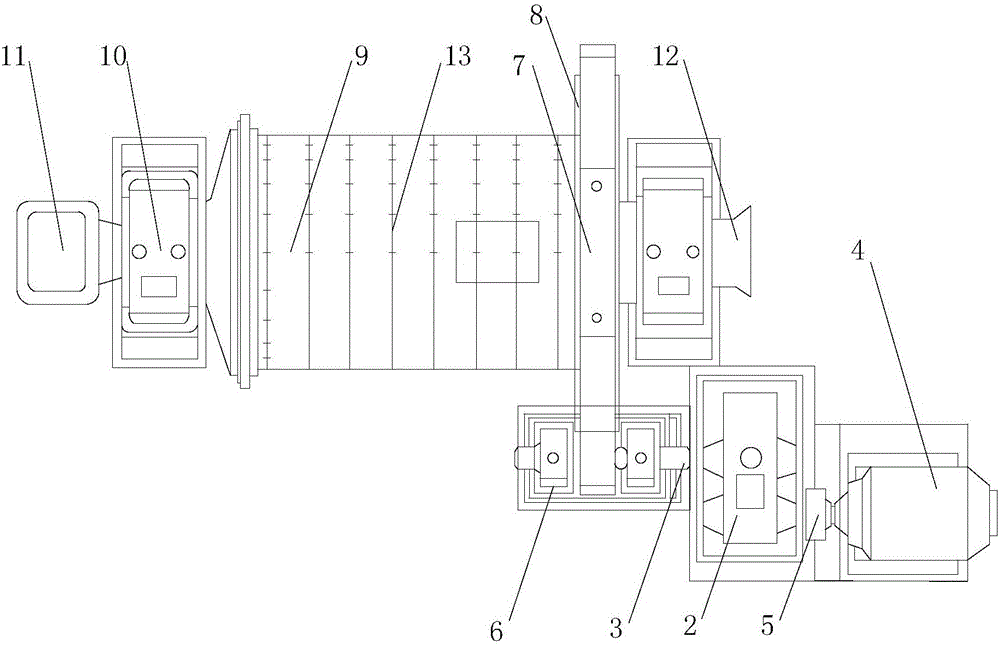

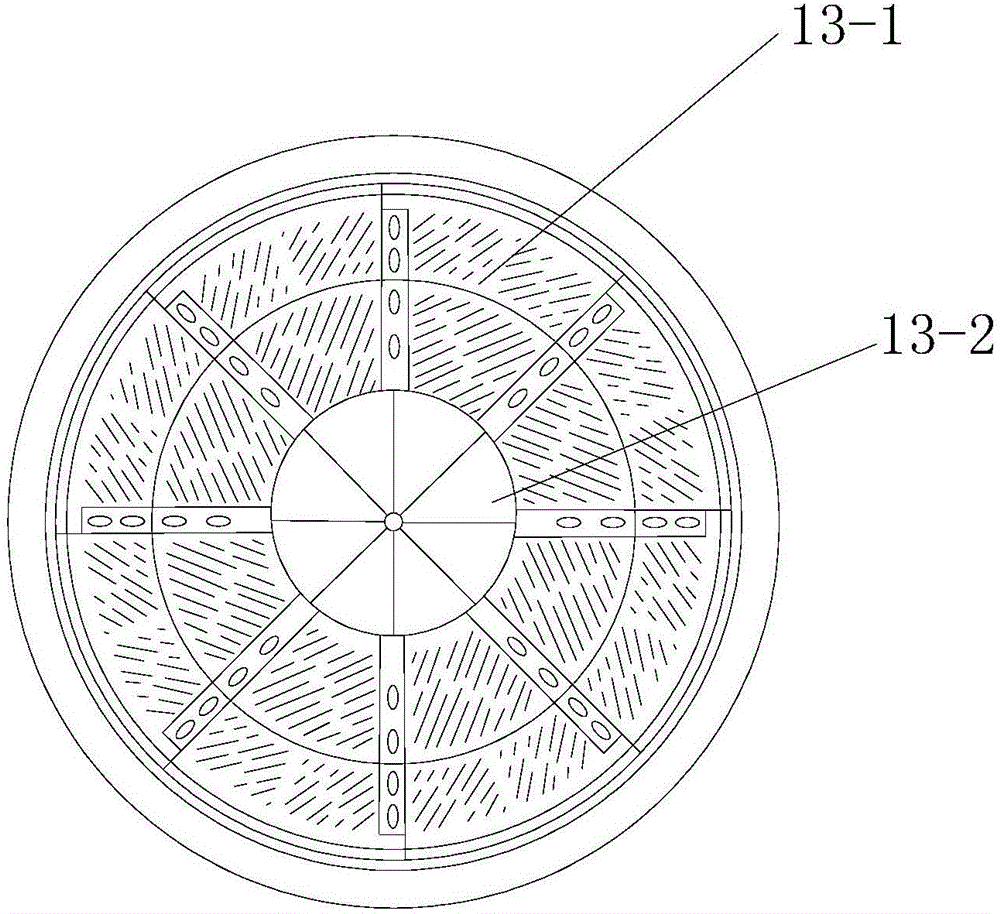

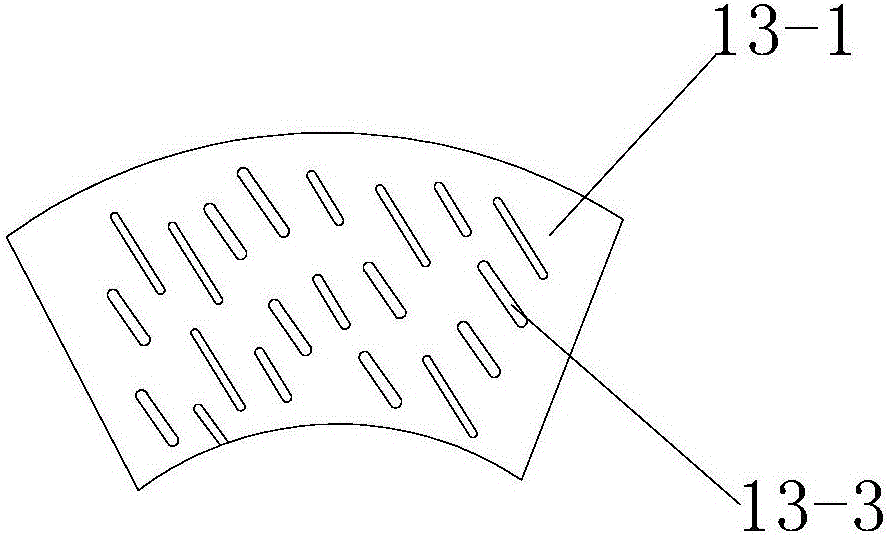

Grate-type ball mill and grid plate for ball mill

The invention relates to a grate-type ball mill and a grid plate for the ball mill. The grate-type ball mill comprises a cylinder and a speed reducer, one end of the speed reducer is connected with a motor through a coupler I, the other end of the speed reducer is connected with a small transmission gear through a coupler II, the small transmission gear is connected with a large turning gear on a hollow shaft through a sprocket, the cylinder is arranged on the hollow shaft, one end of the cylinder is connected with a main bearing, the main bearing is connected with a feeding portion, and a discharging portion opposite to the feeding portion is arranged on the cylinder. Ore grinding capacity is improved, firmness and non-falling are ensured in the running process of the ball mill, bolts are prevented from loosening or breaking due to cyclic stress, the ball mill is long in service life, low in grid hole abrasion and not easy to block, working efficiency is improved, ore pulp backflow is not easily generated, and the ore discharge efficiency and the service performance of the ball mill are improved.

Owner:陈江

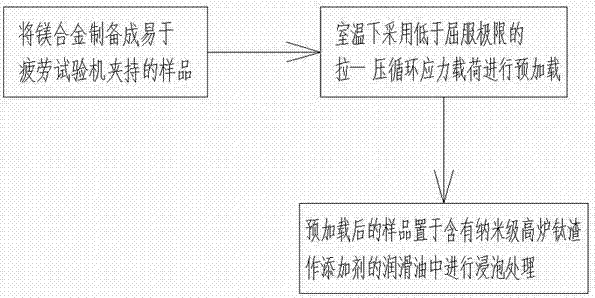

Novel method for improving fatigue performance of magnesium alloy lubricating oil

The invention discloses a novel method for improving the fatigue performance of magnesium alloy lubricating oil. The novel method for improving the fatigue performance of the magnesium alloy lubricating oil is characterized by comprising the steps that magnesium alloy is made into a sample which can be clamped easily by the fatigue tester; the tension-compression cyclic stress load under the yield limit is preloaded on the sample through the fatigue tester at the room temperature of 25 DEG C, and after preloading, the sample is placed in lubricating oil containing nanometer grade blast furnace titanium slag as an additive; and after soaking for 2-4 hours, the sample is removed and the surface of the sample is degreased, and treatment of the magnesium alloy sample is finished. According to the novel method for improving the fatigue performance of the magnesium alloy lubricating oil, the technique that low stress cyclic preloading is combined with surface repairing of nanometer materials is adopted, the magnesium alloy grains can be refined, the fatigue strength of the material is improved, and defects or uneven areas of the surface of the magnesium alloy material are repaired through the titanium slag of nanometer grade blast furnace so that the corrosion of magnesium alloy material under the condition of lubricating oil can be effectively reduced or prevented, and the fatigue performance of magnesium alloy material under the condition of lubricating oil is greatly improved.

Owner:CHONGQING TECH & BUSINESS UNIV

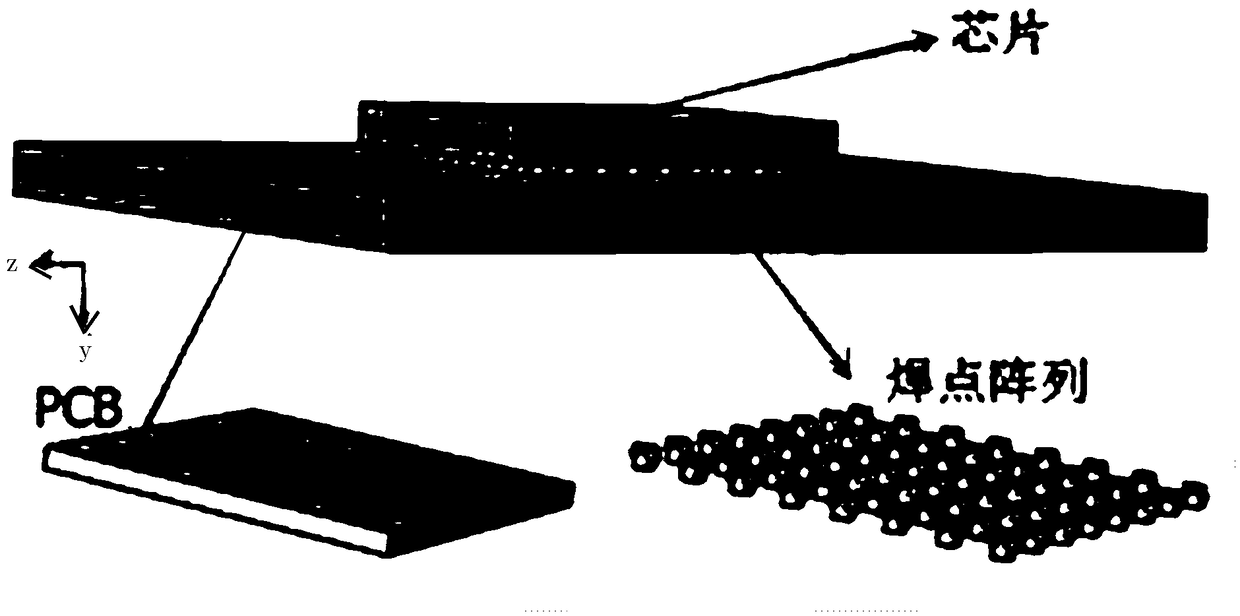

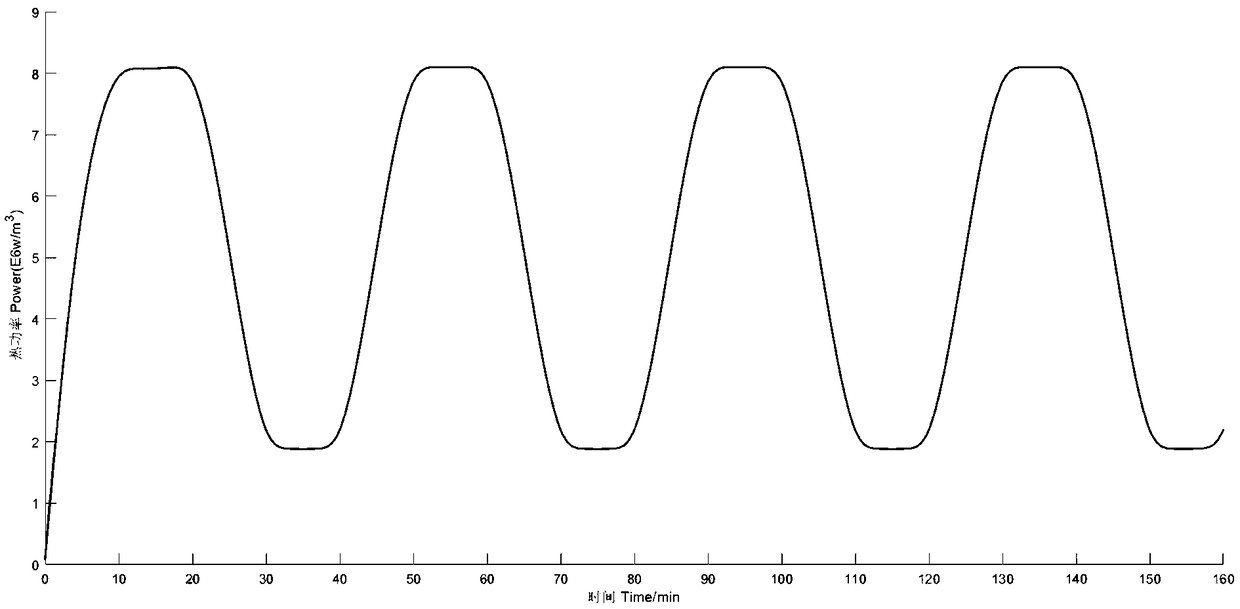

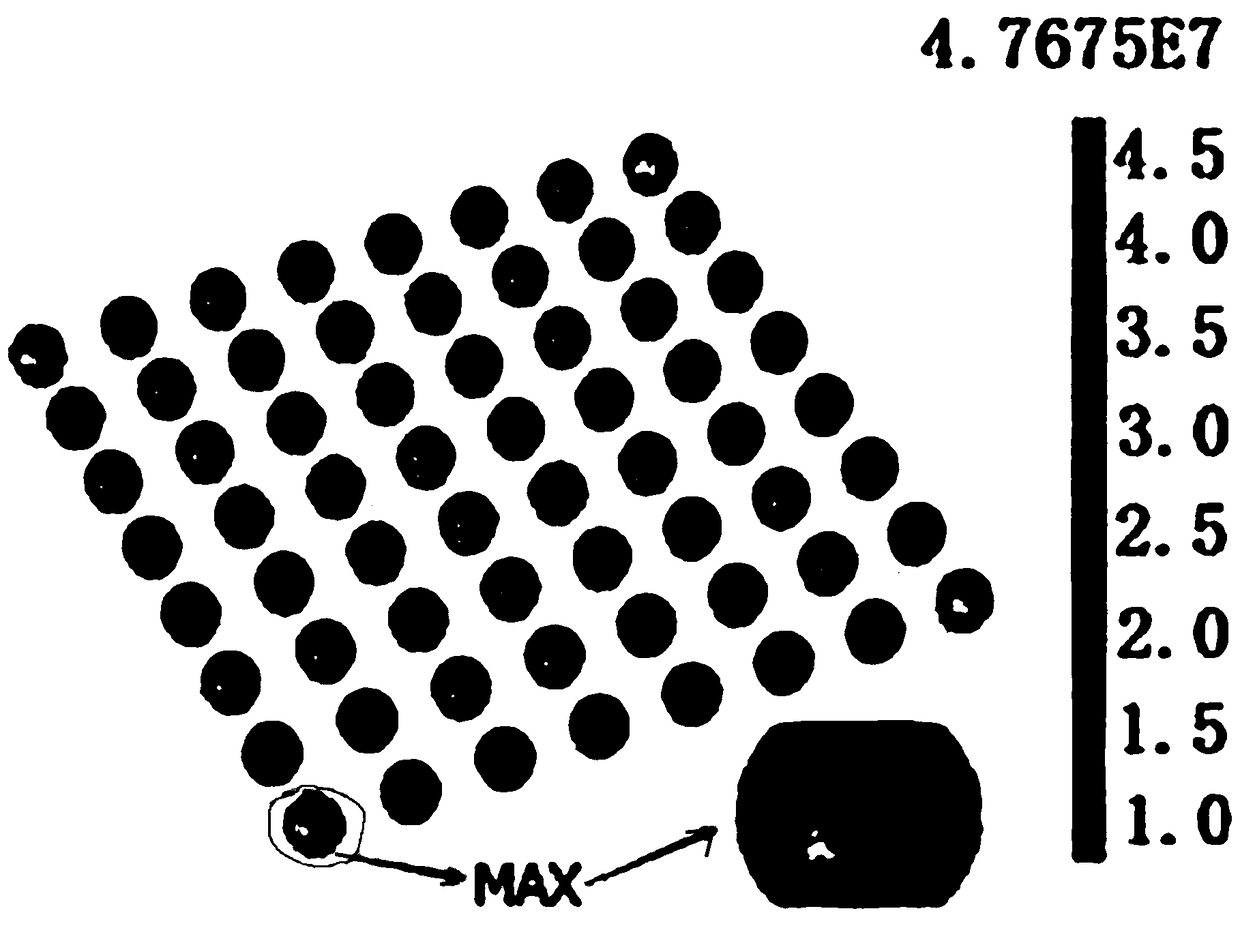

BGA (Ball Grid Array) welding spot structure parameter optimization method for reducing power cyclic stress

ActiveCN108875219AImprove reliabilityDiversity guaranteedArtificial lifeDesign optimisation/simulationEvolution algebraRegression analysis

The invention discloses a BGA (Ball Grid Array) welding spot structure parameter optimization method for reducing a power cyclic stress. The method comprises the following steps that: 1) establishinga COMSOL welding spot simulation analysis model; 2) obtaining the thermal stress value of a welding spot; 3) determining the influence factor of the thermal stress value; 4) determining a parameter level value of the influence factor; 5) obtaining an experiment sample; 6) obtaining a function relational expression between the influence factor and the thermal stress value; 7) carrying out regression analysis on the function relational expression to obtain a regression equation; 8) determining the correctness of the function relational expression; 9) adopting a random way to generate an initialpopulation; 10) obtaining a current evolution algebra gen and an optimal fitness value; 11) randomly forming M / 2 groups of paired individuals by M individuals, and carrying out an interlace operationon each group of paired individuals; 12) carrying out a mutation operation on the paired individuals; 13) carrying out evolution reversion on the paired individuals; 14) selecting the individual withthe optimal fitness value; and 15) after the population is updated, carrying out judgment again. The method has the advantages of good robust performance and simple calculation method, and great convenience is brought to later-stage BGA welding spot structure parameter optimization design.

Owner:GUILIN UNIV OF ELECTRONIC TECH

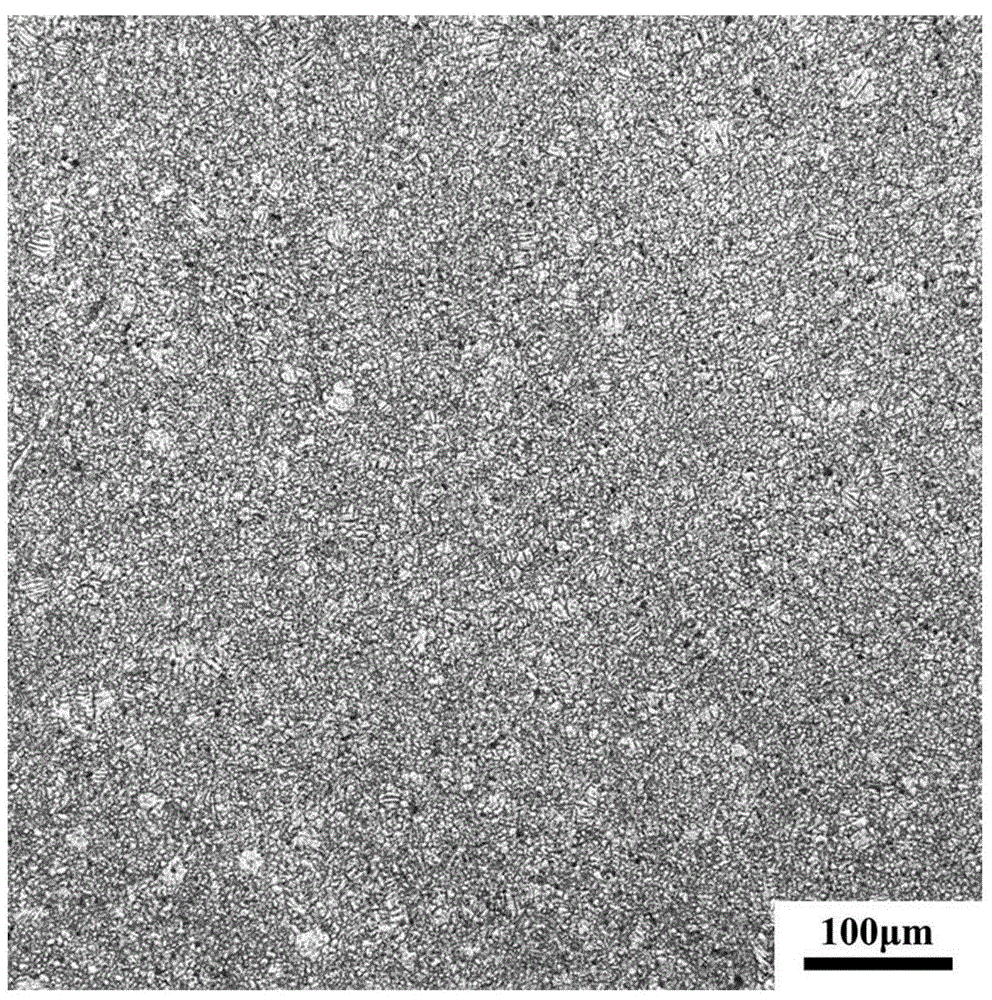

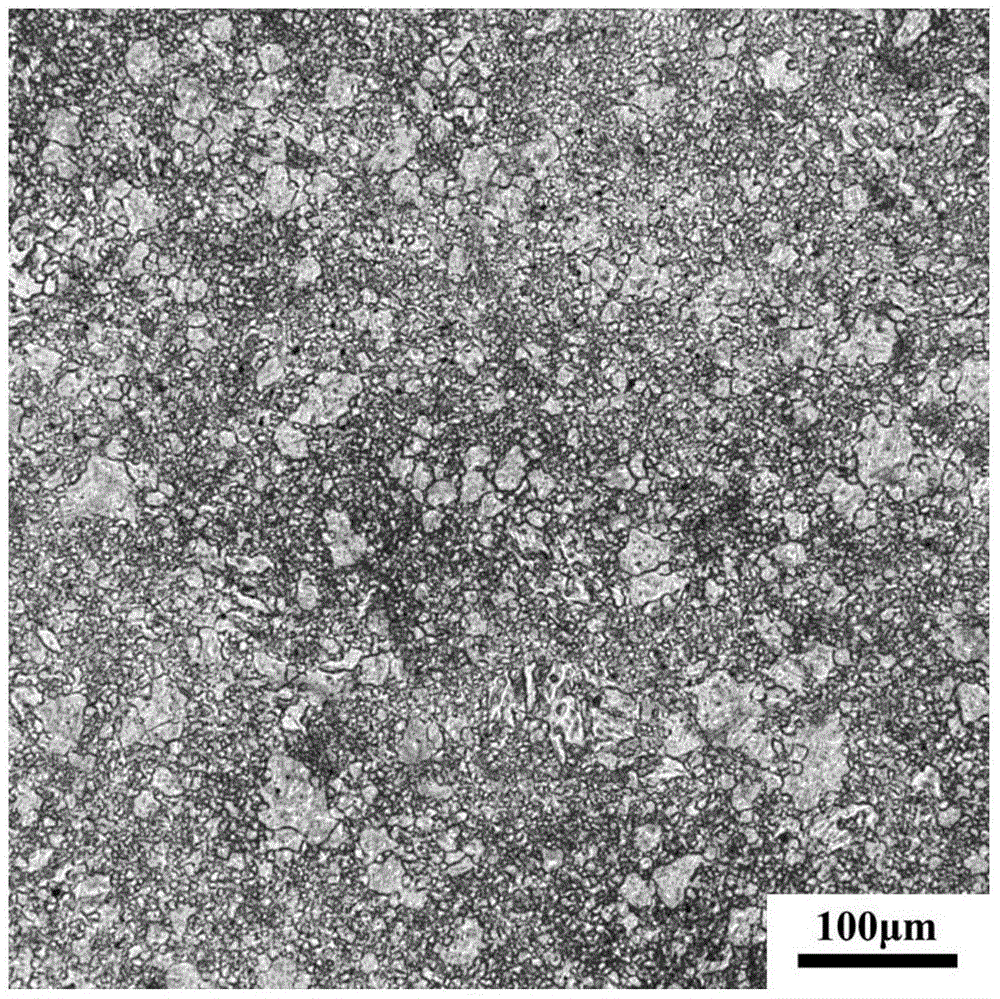

Method for refining crystalline grains of wrought magnesium alloy at room temperature

The invention discloses a method for refining the crystalline grains of a wrought magnesium alloy at a room temperature. The method comprises the following steps: 1) preparing the wrought magnesium alloy into a sample convenient to clamp by a fatigue testing machine, and controlling a surface roughness to be between 0.8 to 0.2; 2) loading the sample prepared in the step 1) on the fatigue testing machine, measuring the yield strength of the sample at first, and then refining the crystalline grains by means of repeated tensile-press loading at a room temperature, with a tensile-press loading cyclic stress occupying 55-70% of the yield strength, or refining the crystalline grains by means of repeated tensile-tensile loading at a room temperature, with a tensile-tensile loading cyclic stress occupying 70-90% of the yield strength. Compared with the traditional method for refining the crystalline grains of a magnesium alloy, magnesium alloy bar materials are free from macroscopic plastic deformations in each cyclic loading period; by using the method disclosed by the invention for refining the crystalline grains of the magnesium alloy, conventional deformations and heating equipment are not needed, and the temperatures of the materials are not obviously increased during the whole treatment process; and the treated alloy is obviously refined in crystalline grain sizes and uniform in organization.

Owner:CHONGQING UNIV

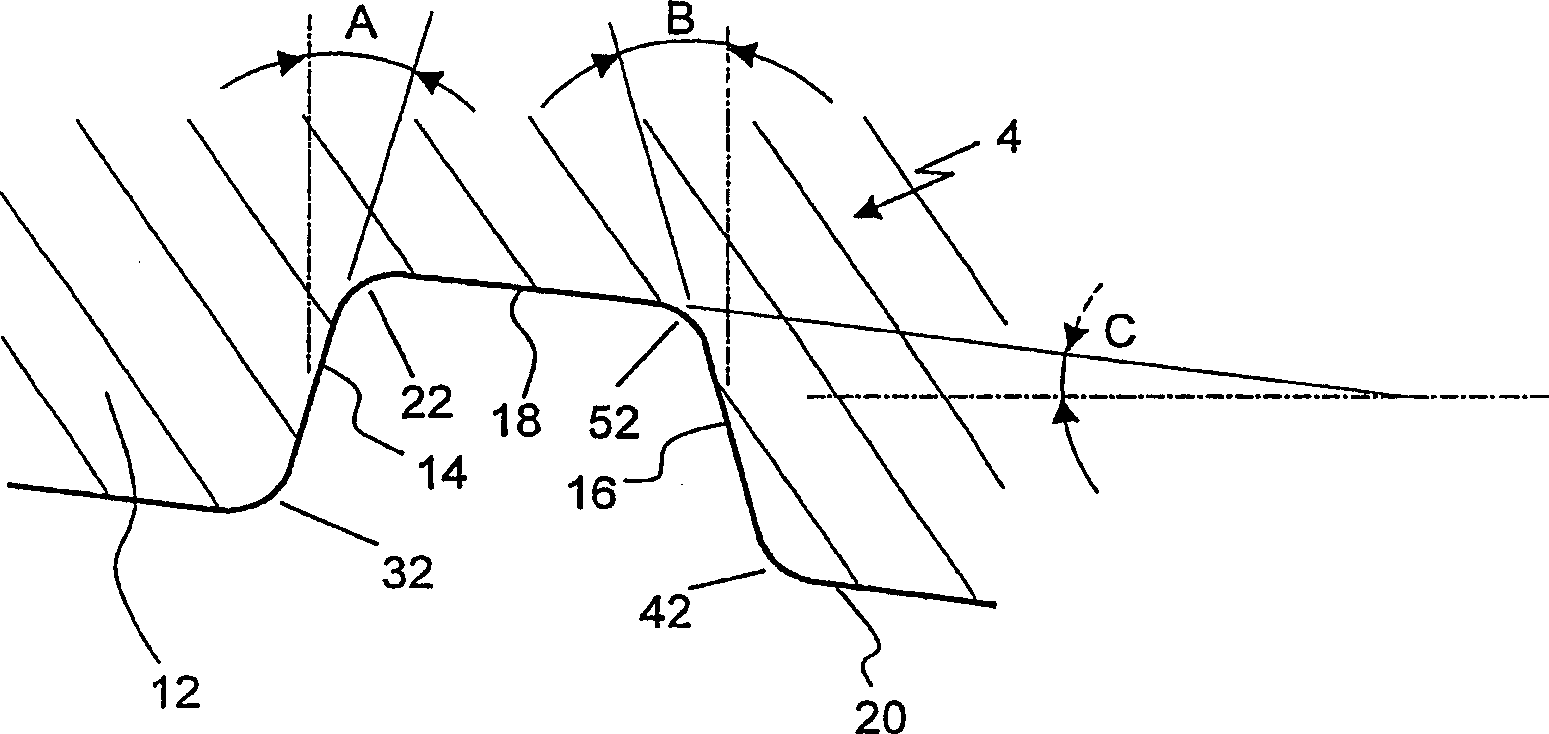

Threaded tubular element for fatigue resistant threaded tubular joint and resulting threaded tubular joint

InactiveCN1416515AReduced proportionality factorExcellent fatigue propertiesScrew threaded jointsEngineeringScrew thread

The invention concerns a threaded tubular element whereof the thread comprises at least a tangential connecting zone with multiple radii (21) at the thread root, in particular on the bearing flank (13). Said zone (21) comprises a main arc (23) of radius (rP1) whereof the circle intersects the flank (13) in one point (PRF1). The tangent in (PRF1) to said circle forms a strictly positive angle (D) with the flank (13). The secondary arcs (25, 27) of radii (rS1, and rT1) less than (rP1) provide the tangential connection of the main circle on the side of the flank (13), on the other side of the thread root (19). The radius (rP1) is greater than that (rH1) of the standard circle (29) which passes through (PRF1) and which would constitute alone a tangential connection zone. Such a threaded element provides a tubular threaded joint wherein it is integrated with good resistance to static as well as cyclic loads.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com