Patents

Literature

288 results about "Fatigue limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fatigue limit, endurance limit, and fatigue strength are all expressions used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure. Ferrous alloys and titanium alloys have a distinct limit, called the endurance limit, which is the amplitude of completely reversed bending stress below which there appears to be no number of cycles that will cause failure. Other structural metals such as aluminium and copper do not have a distinct limit and will eventually fail even from small stress amplitudes. In these cases, the term endurance strength is used. Endurance strength is defined as the maximum value of completely reversed bending stress that a material can withstand for a finite number of cycles without a fatigue failure.

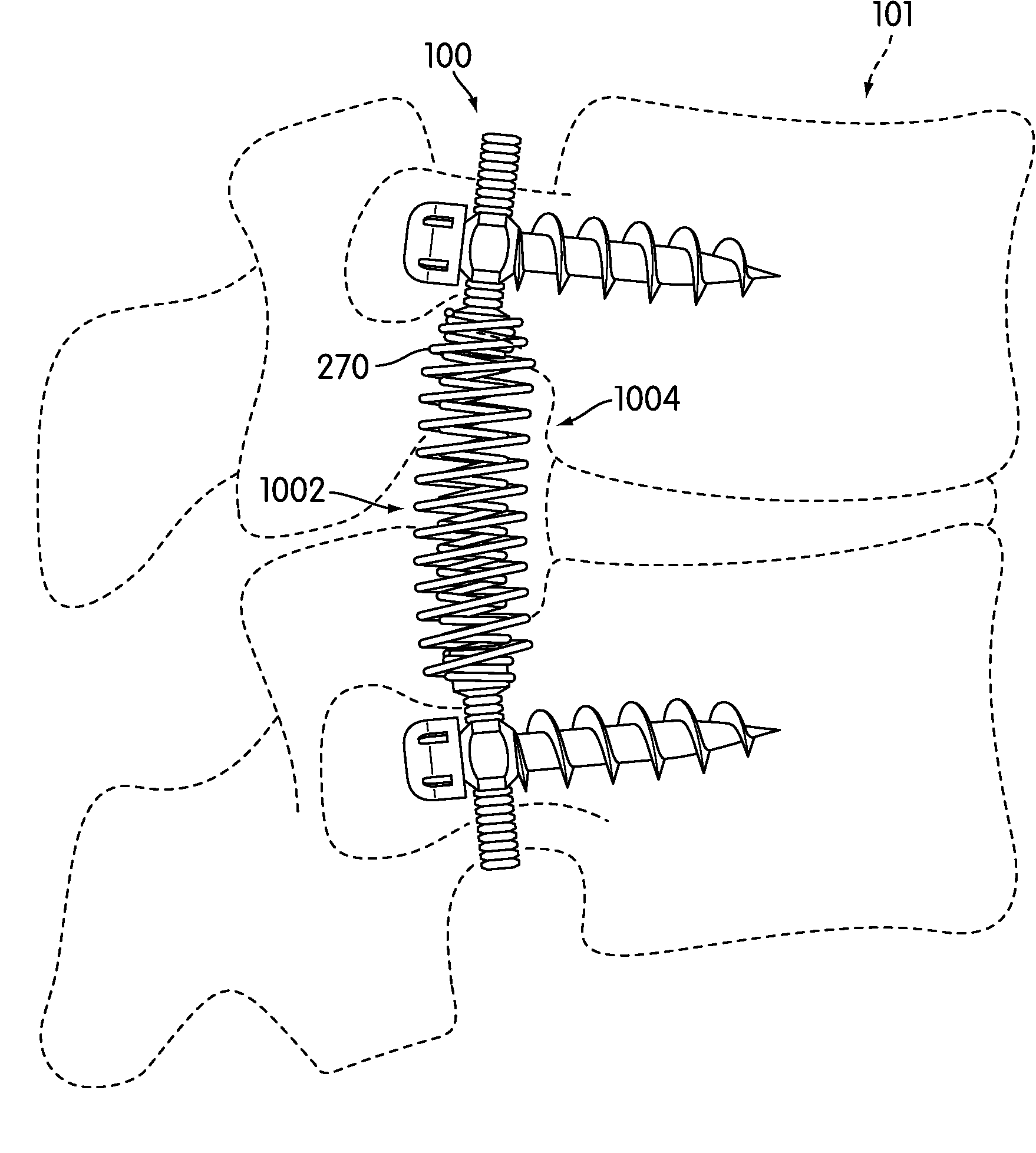

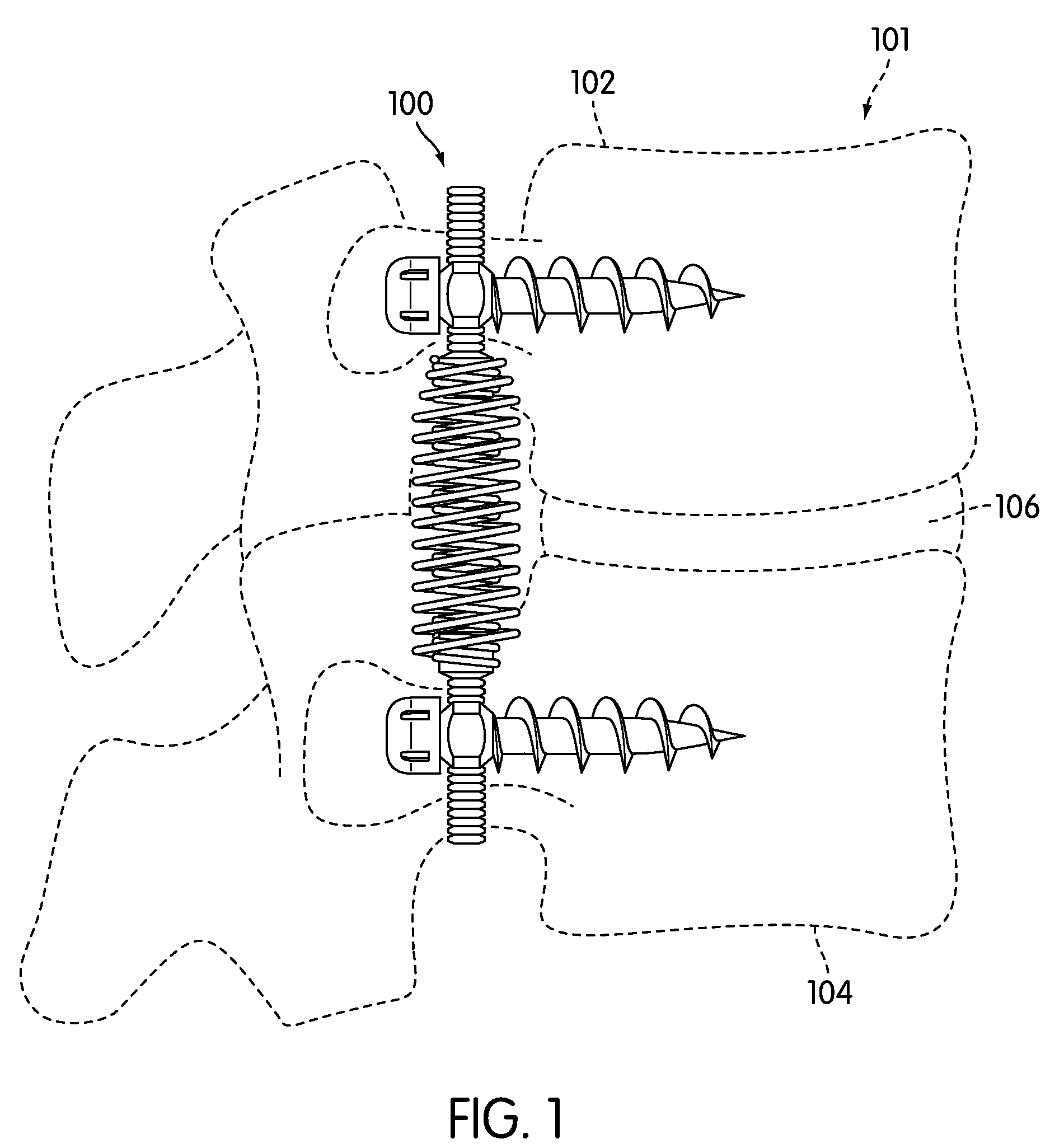

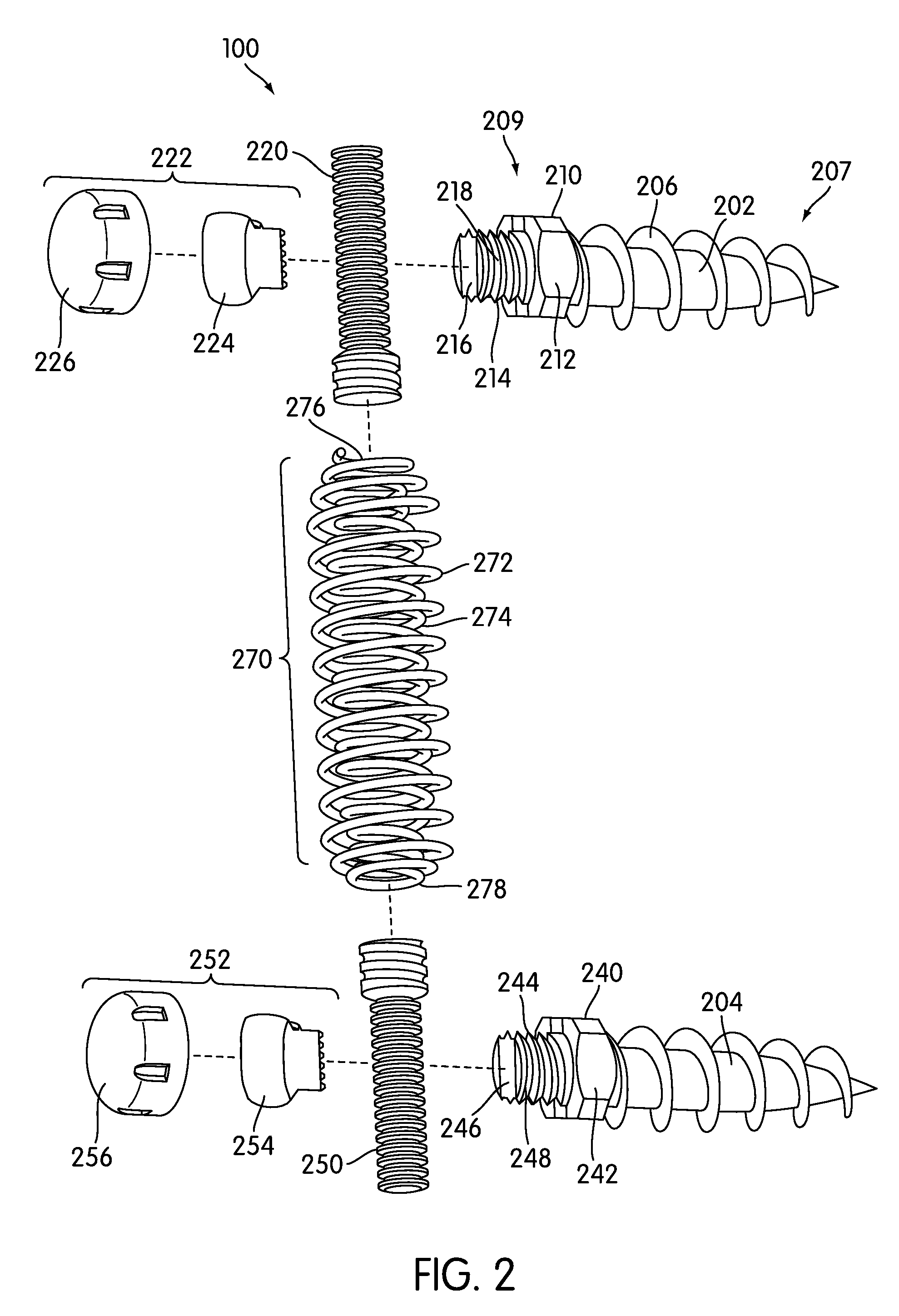

Dynamic Stabilization Device for Spine

A dynamic stabilization device is disclosed. The device includes a dual spring member comprising an outer spring and an inner spring that have approximately equal working lengths. The dynamic stabilization device is also configured so that the dual spring member does not undergo stresses greater than an effective fatigue limit that is related to a fatigue limit of the spring.

Owner:JMEA CORP

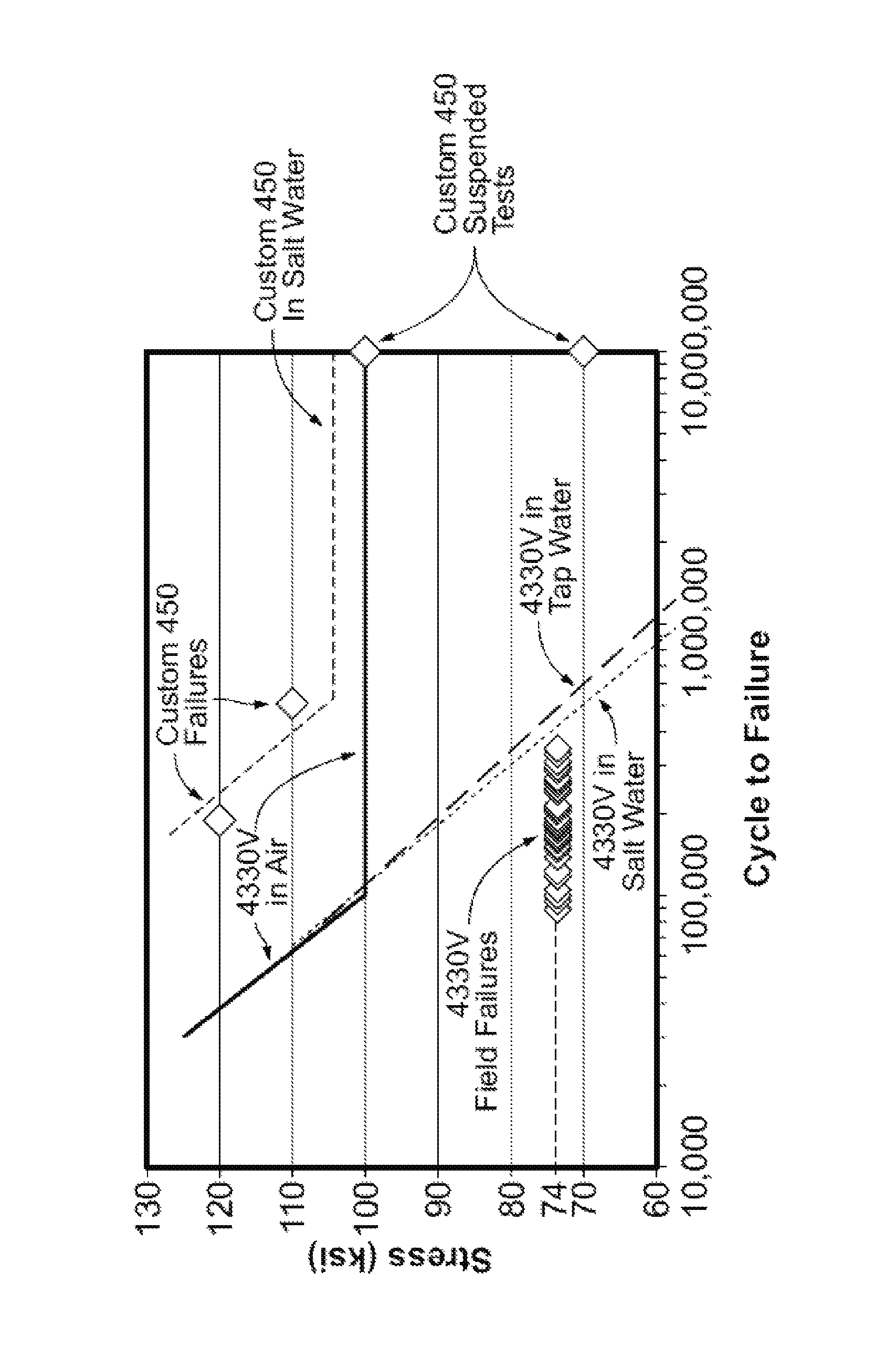

Corrosion resistant fluid end for well service pumps

ActiveUS9435333B2Positive displacement pump componentsFlexible member pumpsCorrosion resistant alloyWorking pressure

Corrosion resistant alloys in fluid ends to prolong the life of a well service pump. Methods of using such corrosion resistant alloys that provide a fluid end that has a corrosion resistant alloy having a fatigue limit greater than or equal to the tensile stress on the fluid end at maximum working pressure in the fluid end for an aqueous-based fluid; installing the fluid end in a well service pump; and pumping the aqueous-based fluid through the fluid end.

Owner:HALLIBURTON ENERGY SERVICES INC

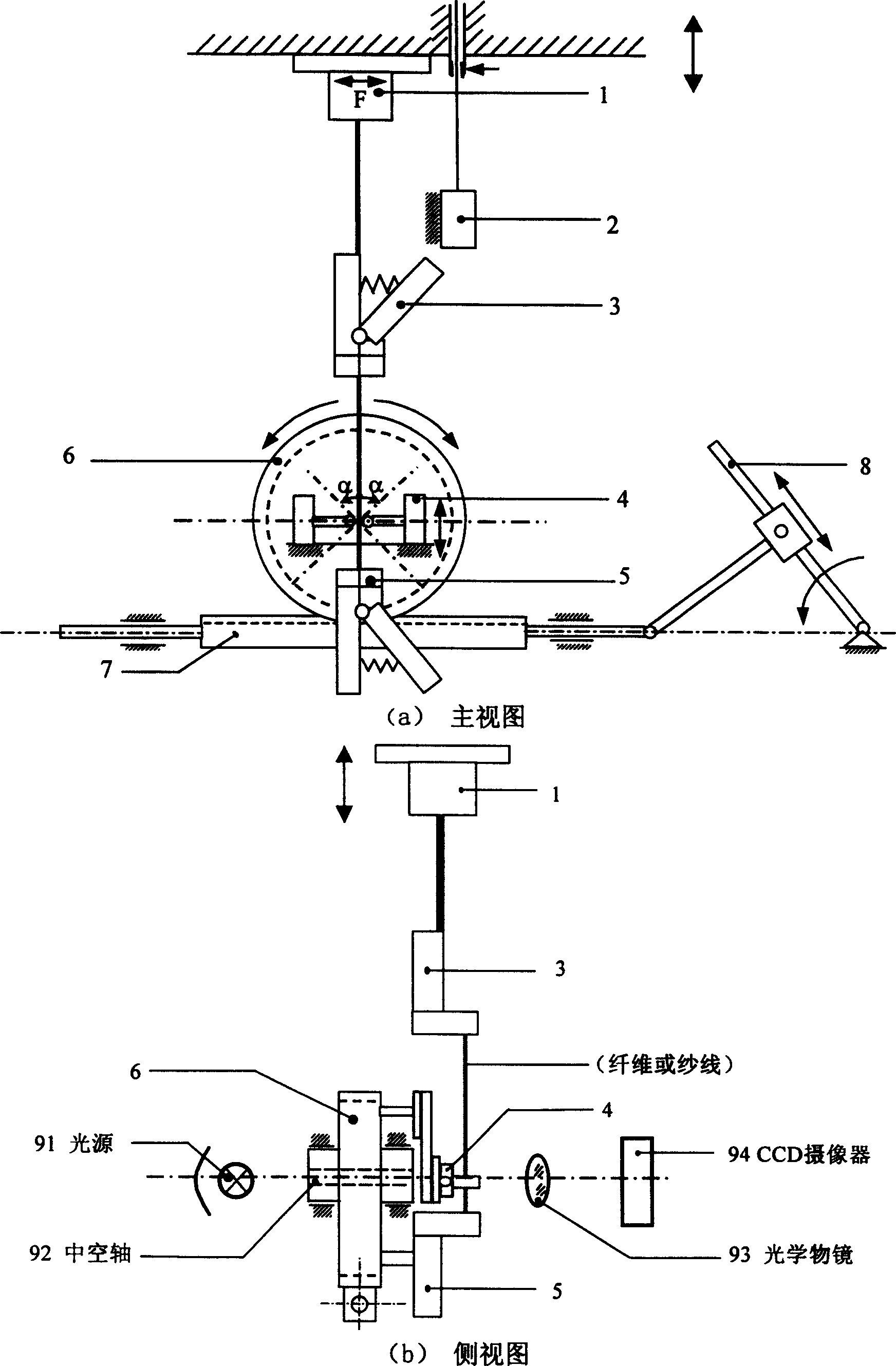

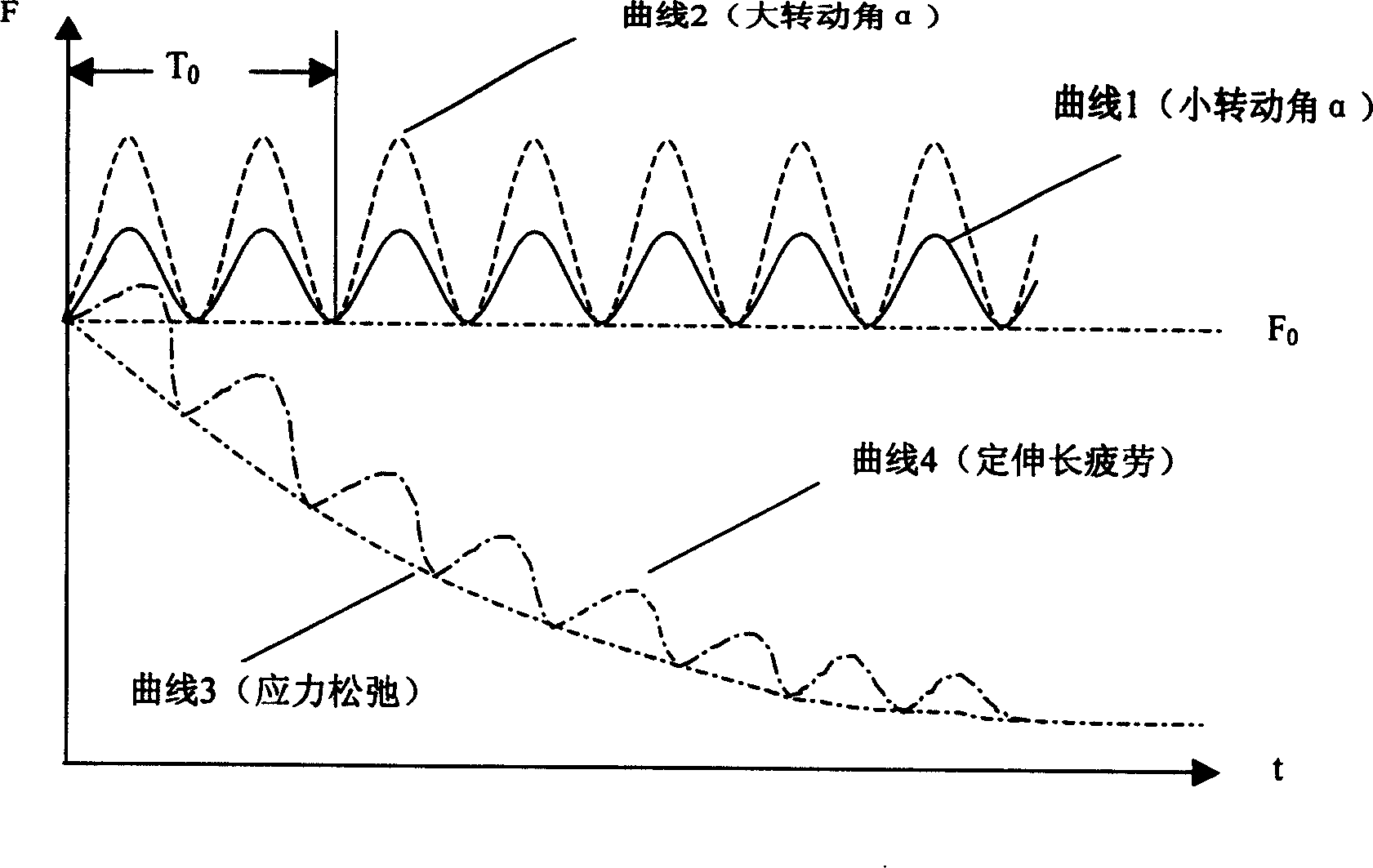

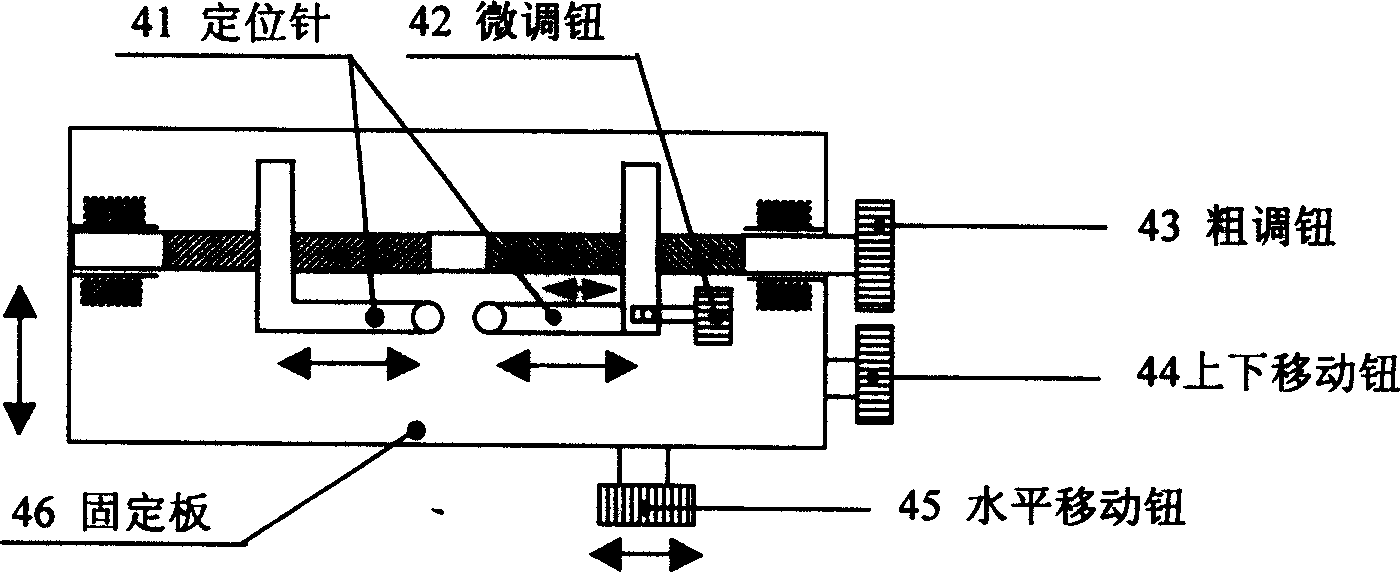

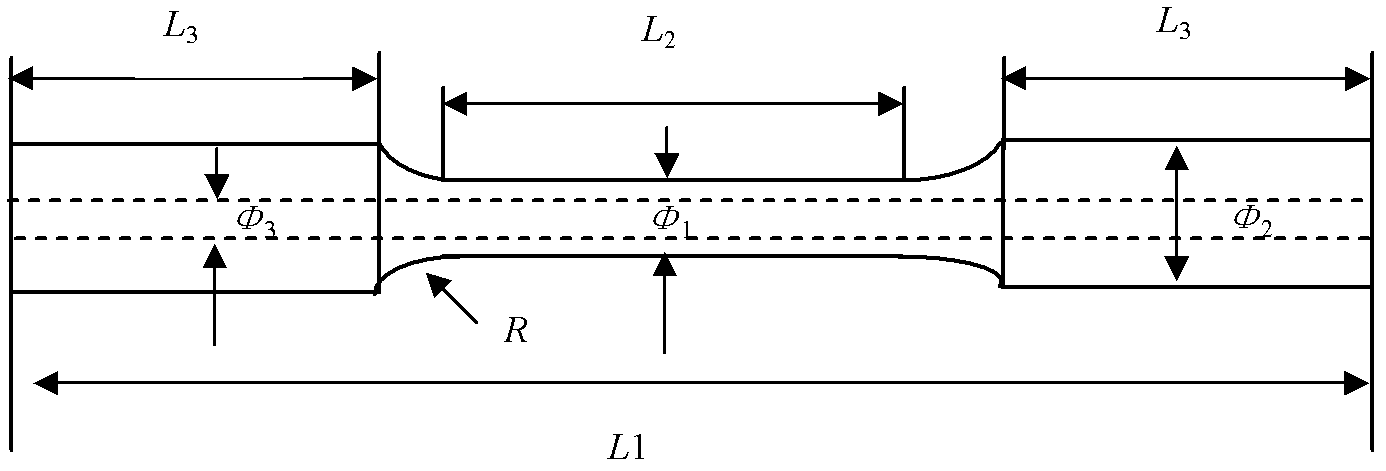

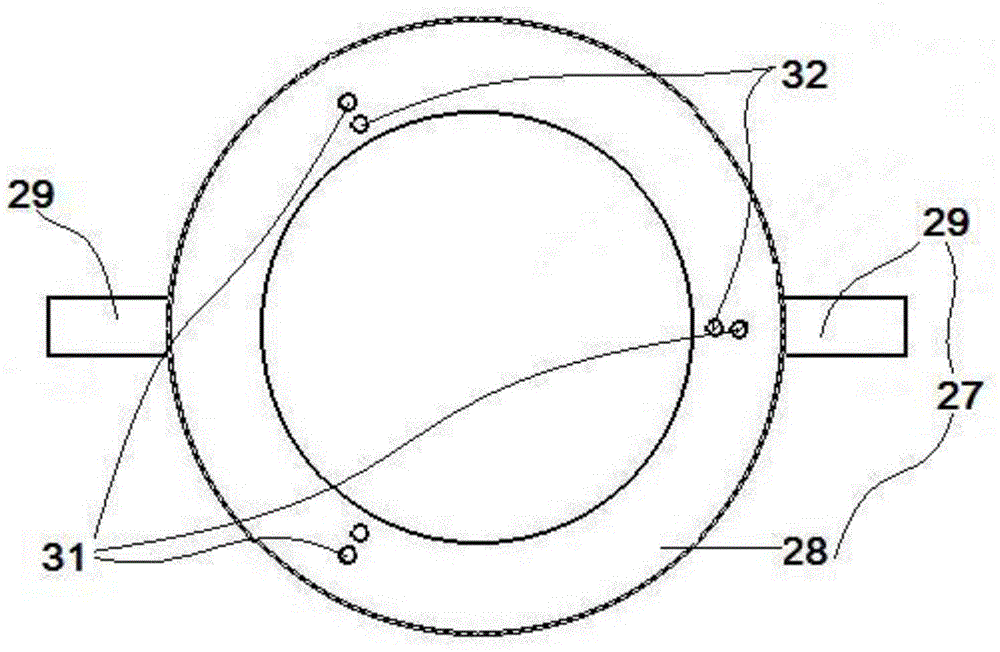

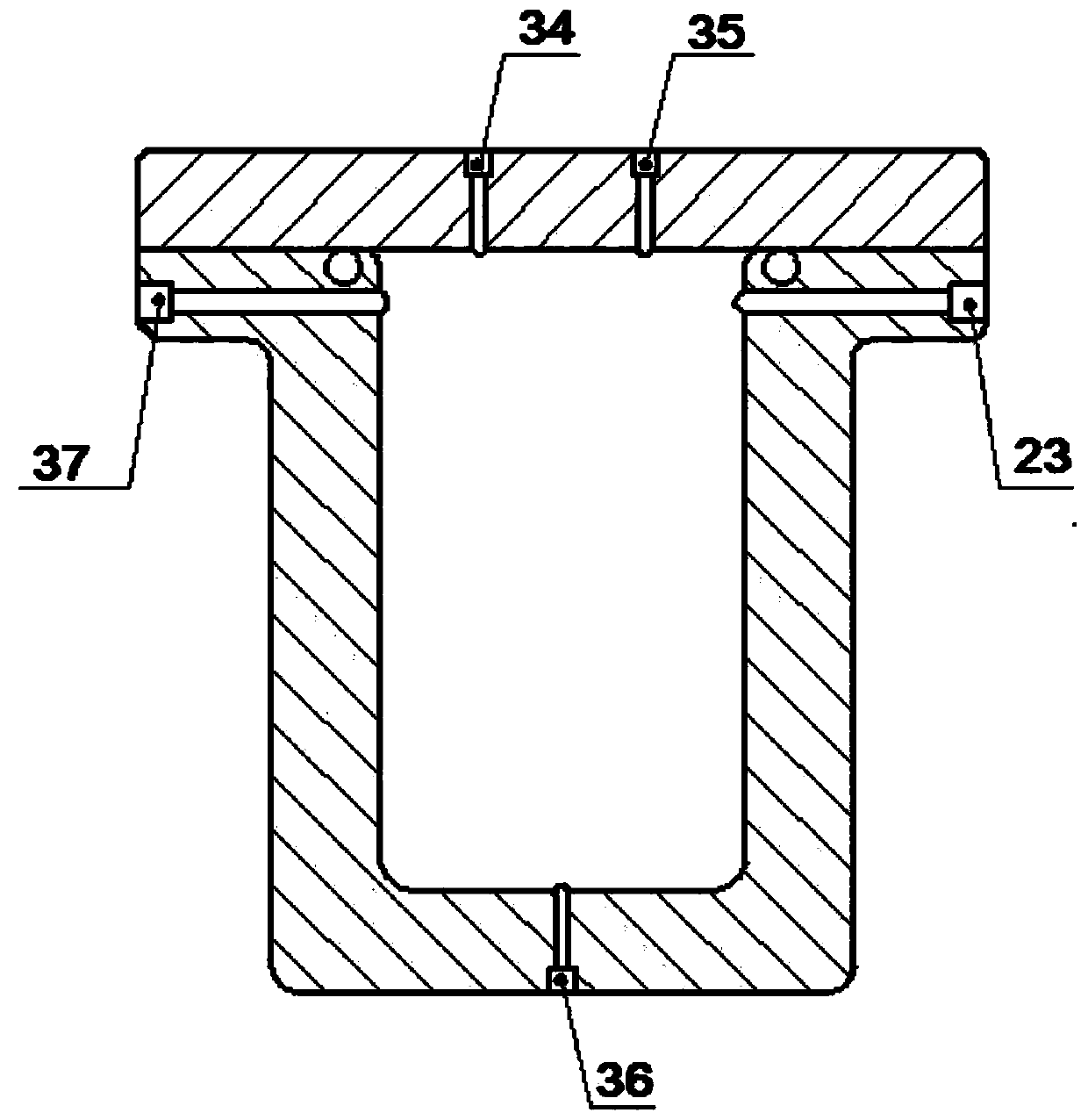

Measuring device for flexural fatigue property of flexible material

InactiveCN1587967AEffective bending fatigue measurementAccurate Bending Fatigue MeasurementsMaterial strength using steady bending forcesUsing mechanical meansMeasurement deviceCollection system

The invention is an apparatus used for measuring flexible material flexural fatigue, with property of being consisted of crank block rack mechanism, force and displacement sensor, upper and lower cartridge, optical plummet centering system, up-and-down and rotation driving system and control circuit, program and signal collection system, finishing measurement of fixed point flexural fatigue and relaxation creep behaviour of flexible material with stationary load and stretch effectively and accurately. The index property measured are endurance failure time, endurance limit strength and limiting strain, relaxation time, sample thickness or diameter. The apparatus has simple but practical structure, convenient installation and replacement, many tunable parameters containing sample length, fixed points position and their distance, bending rotational angle and angular frequency, original load and stretch, accurate measurement, and can avoid influence of move of application point in bending, offset of sample and vibration.

Owner:DONGHUA UNIV

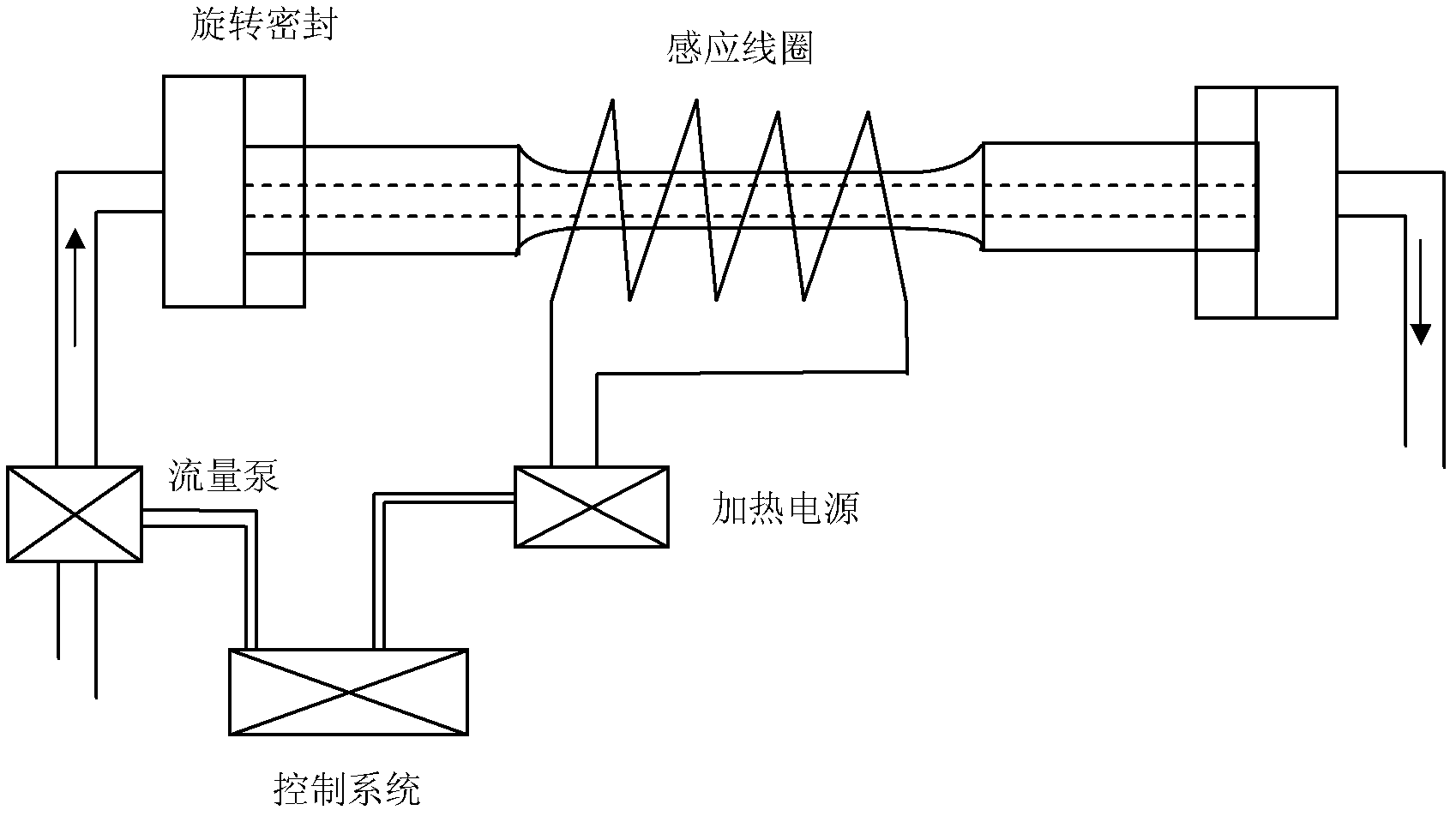

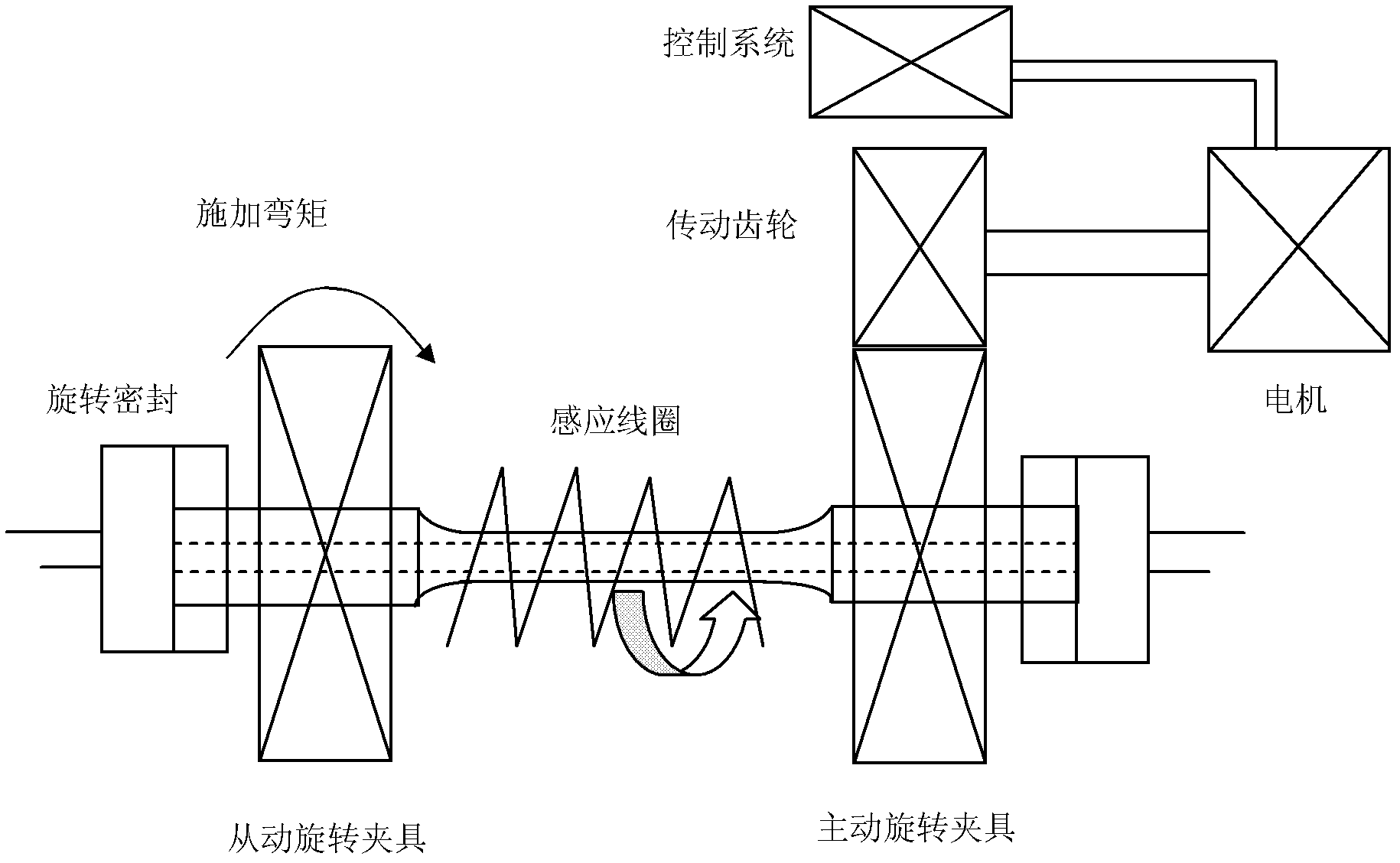

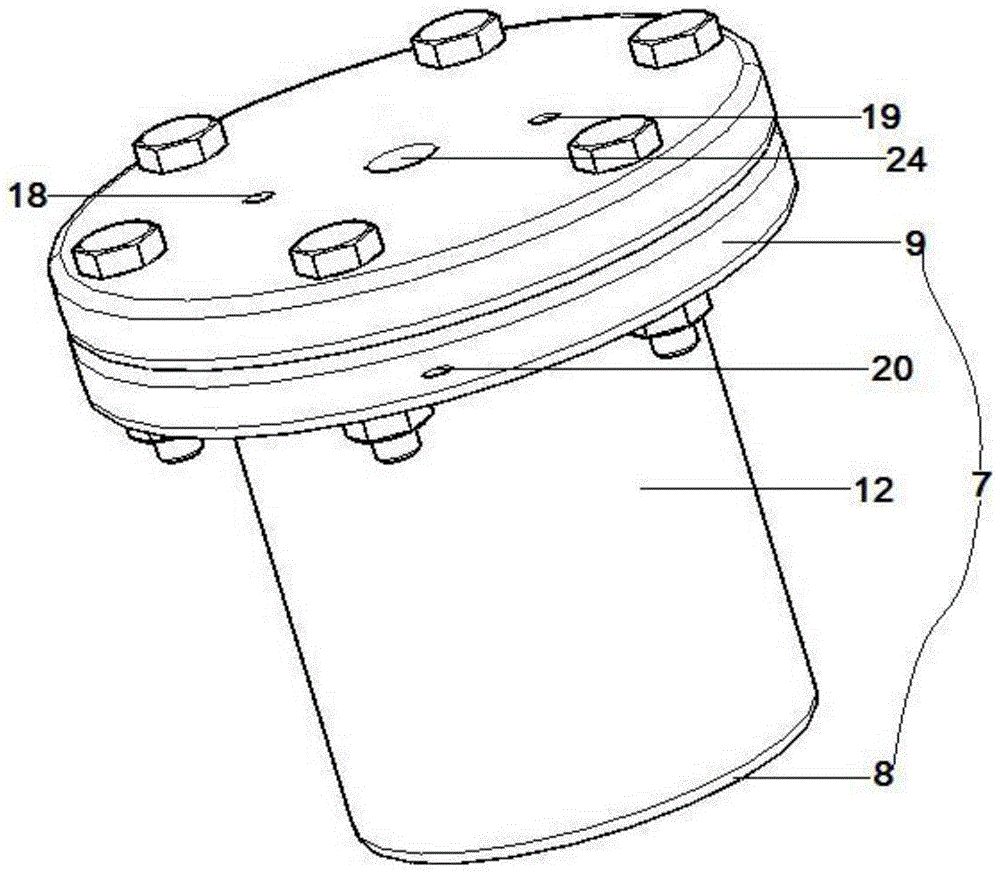

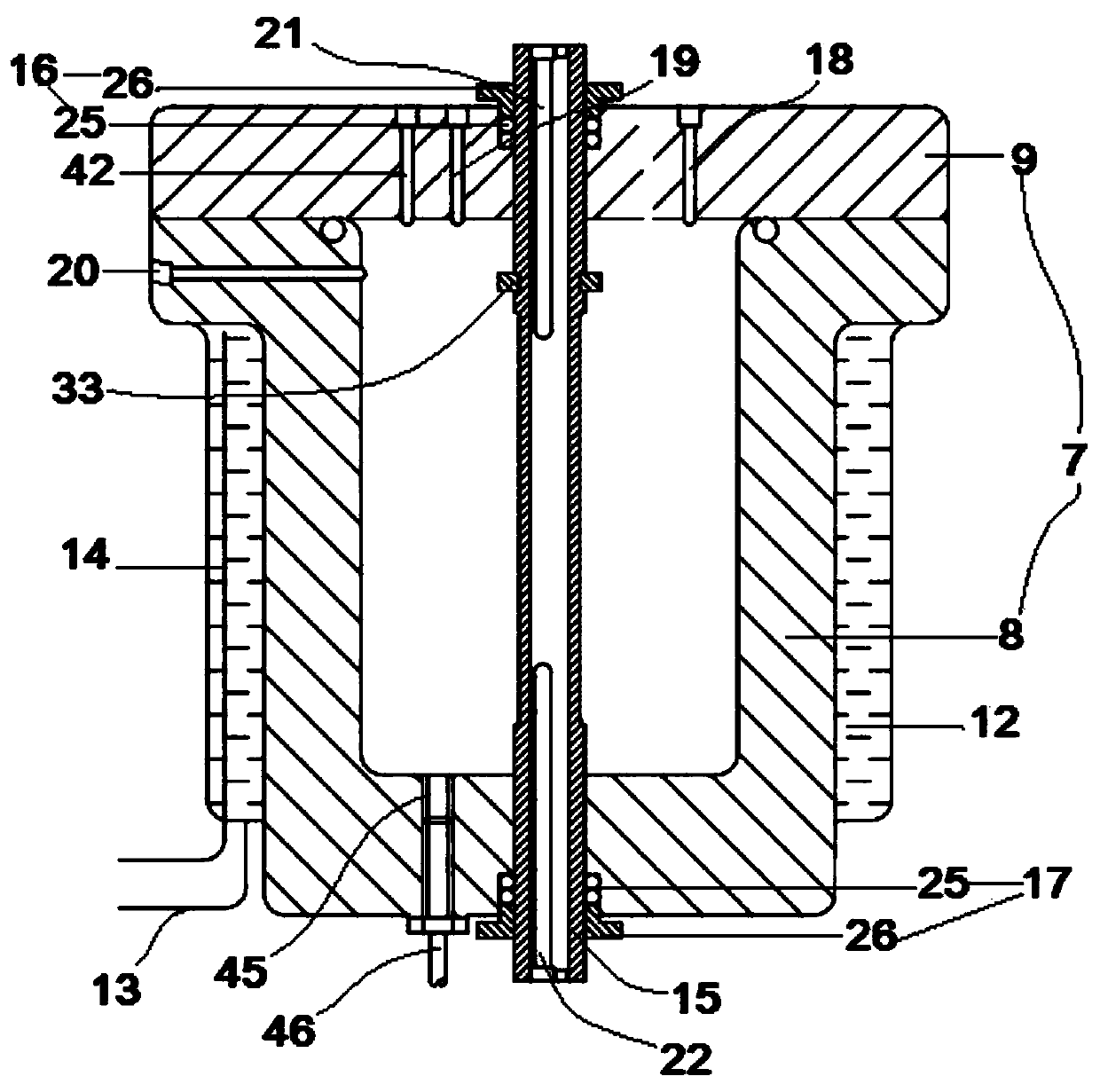

Thermal-force coupling fatigue test device and method

The invention relates to a thermal-force coupling fatigue test device and method, belonging to the field of metal material performance test and analysis. The device comprises a tested material test sample, a cold-thermal fatigue system and a stress fatigue system, wherein the test sample comprises a clamping section, a test section and a transition section; the cold-thermal fatigue system comprises a high frequency induction coil, a rotary seal device, a flow pump, a temperature sensor, a heating power supply, a cooling medium pipeline and a control system; and the stress fatigue system mainly comprises a driving rotating fixture, a driven rotating fixture, a transmission gear, a motor and a motor control system. The method comprises the following steps of: connecting and fixing the test sample with the cold-thermal fatigue system and the stress fatigue system, and carrying out cold-thermal fatigue while stress fatigues under different stresses are carried out to obtain a curve which shows variation of stress fatigue life along with cyclic stress; and adjusting parameters of the cold-thermal fatigue, thus influence of cold-thermal fatigue temperature to fatigue limit can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

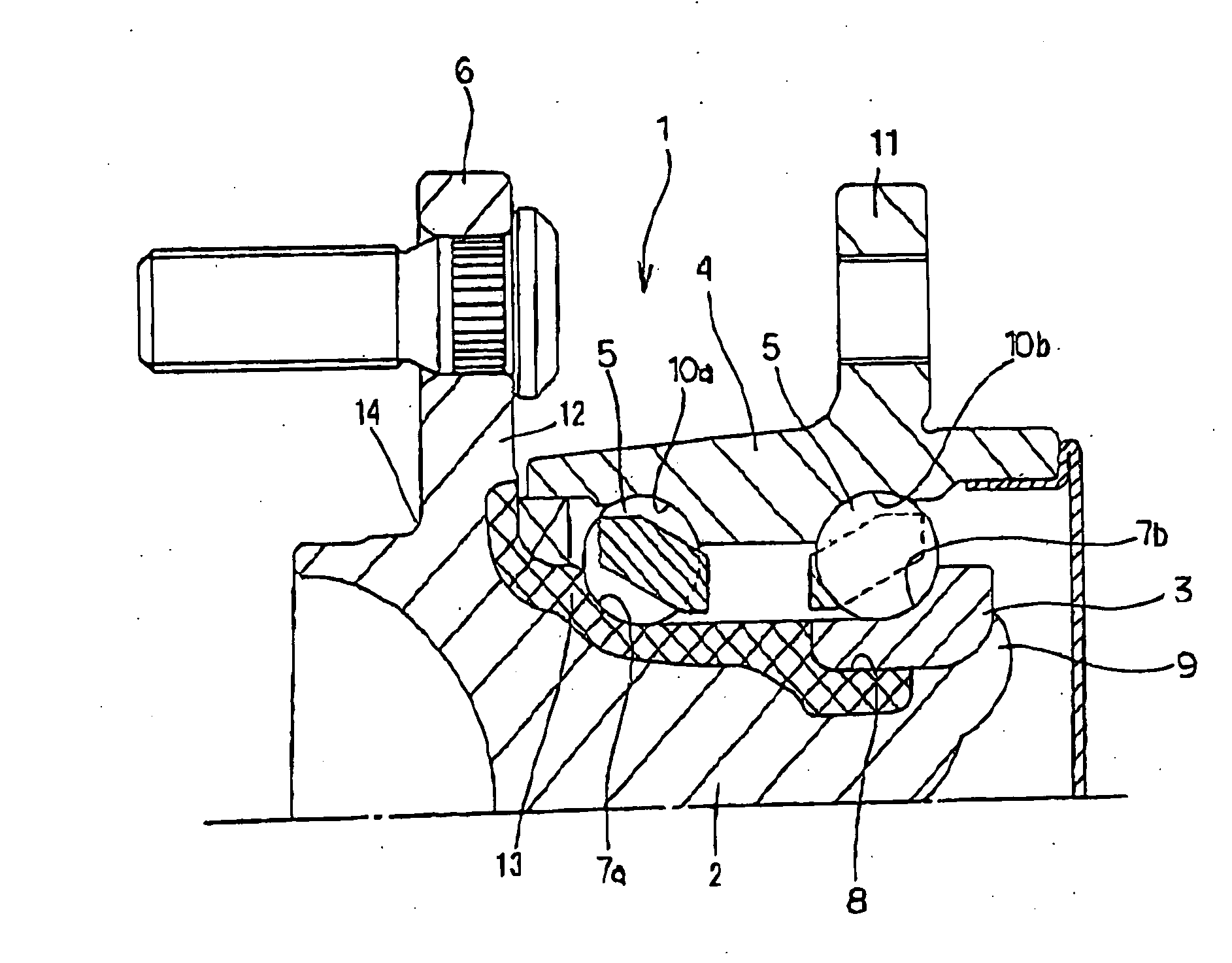

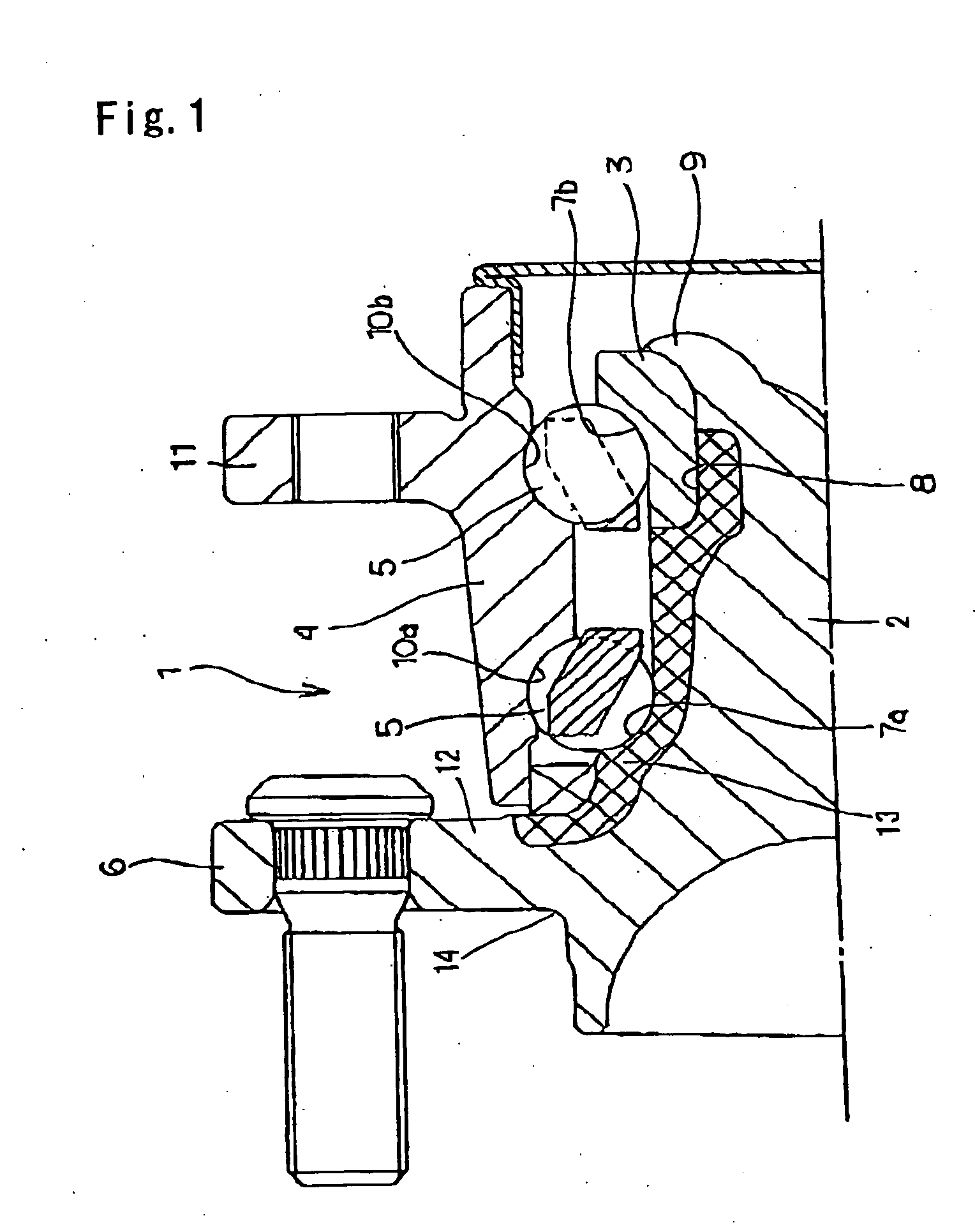

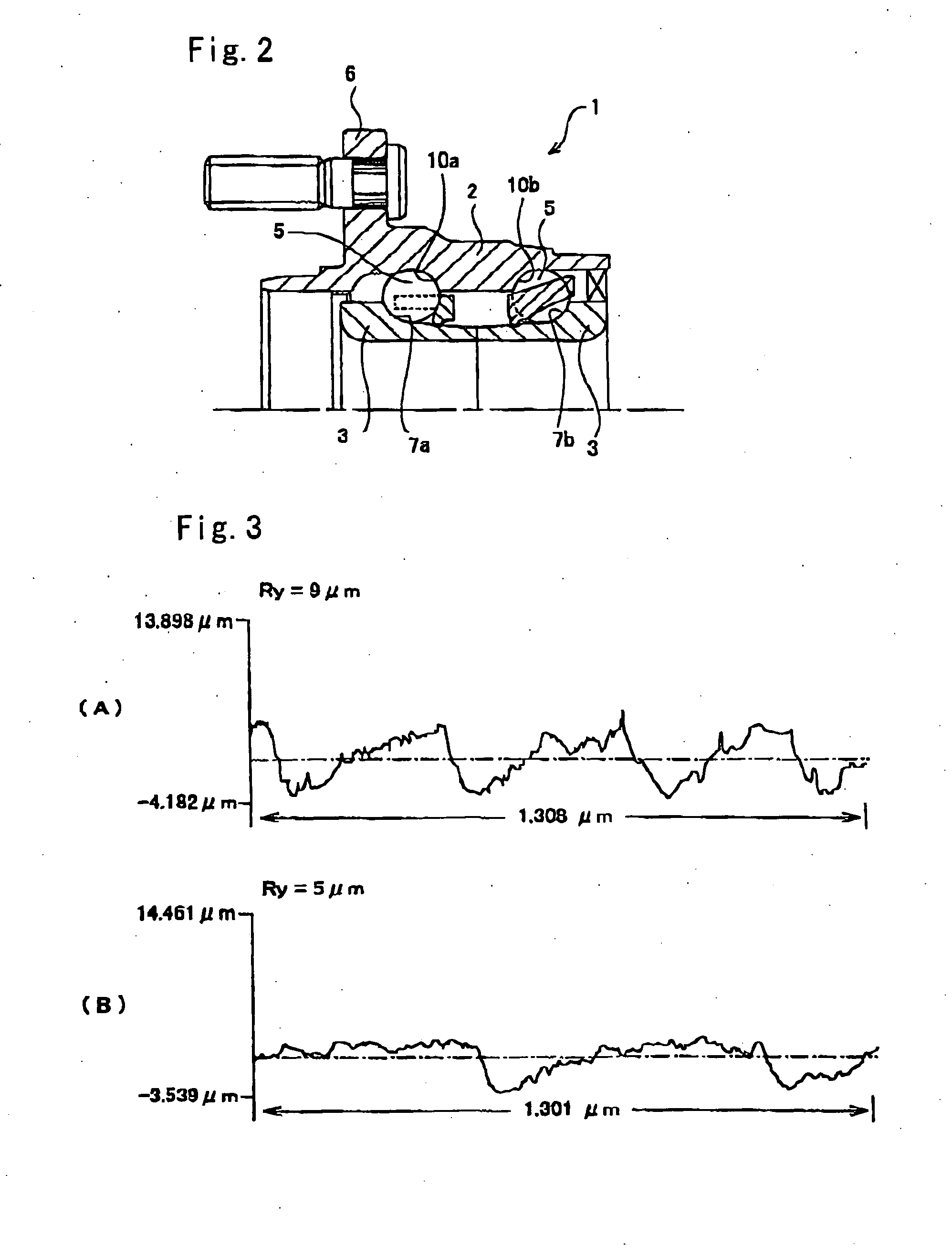

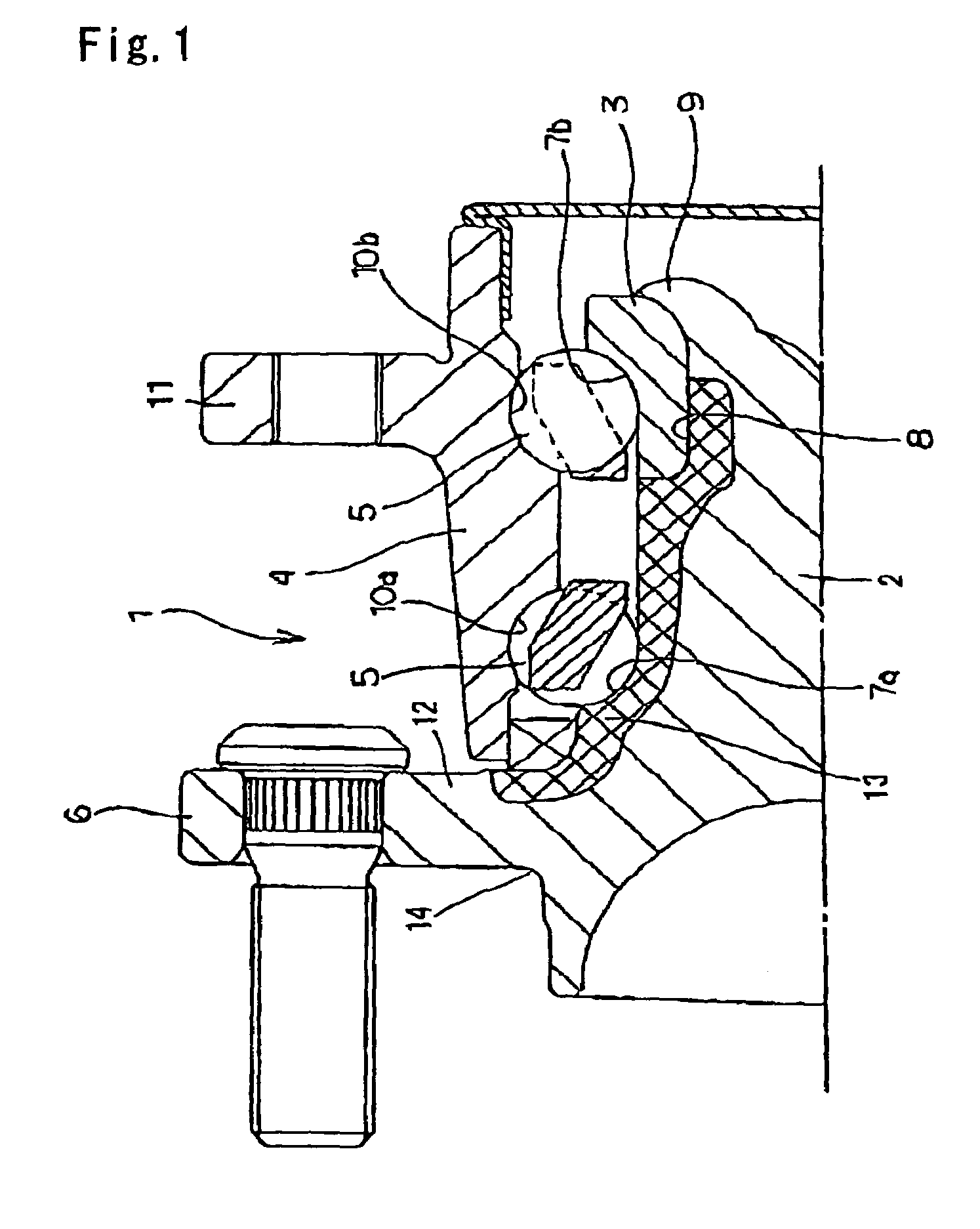

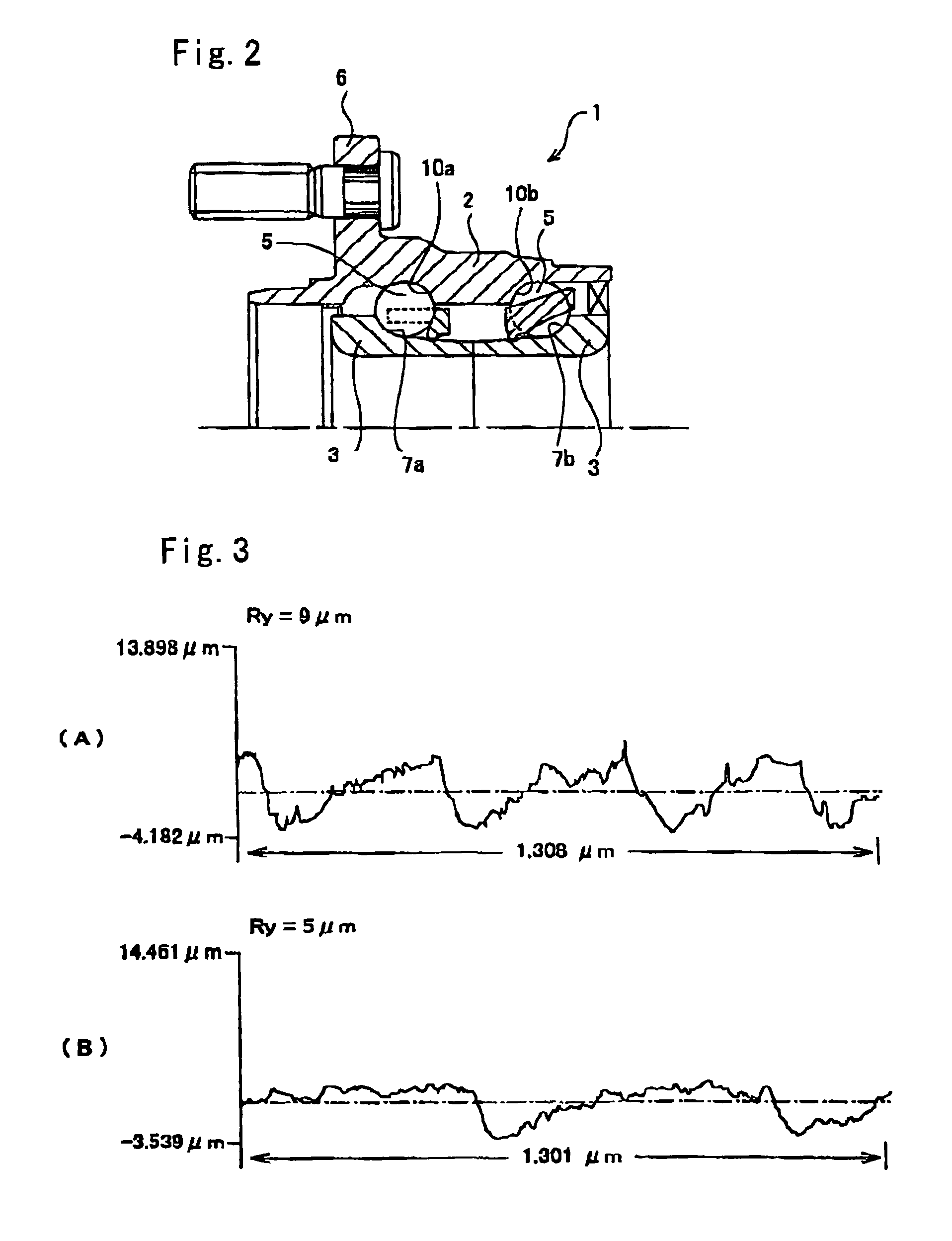

Wheel-support rolling bearing unit

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

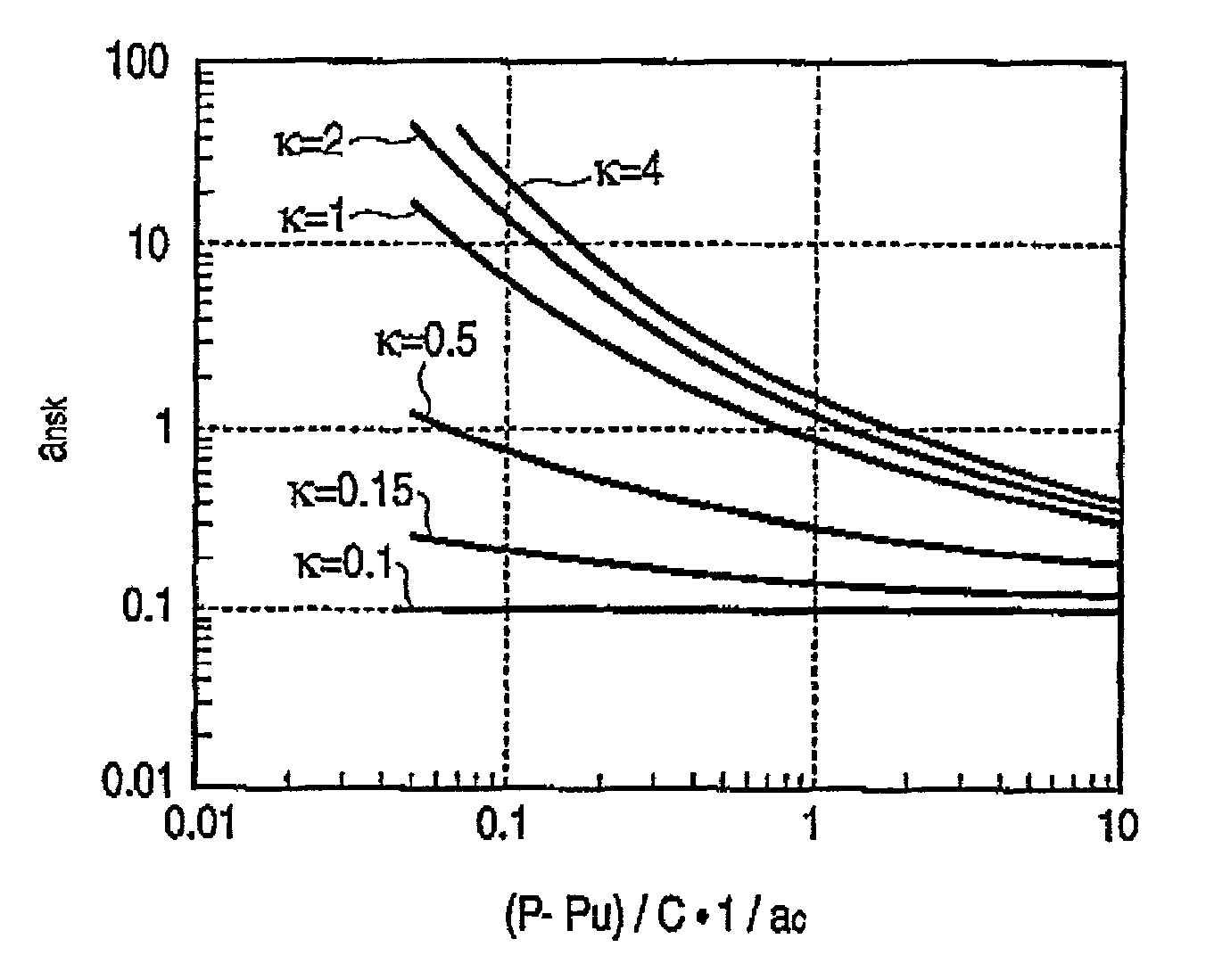

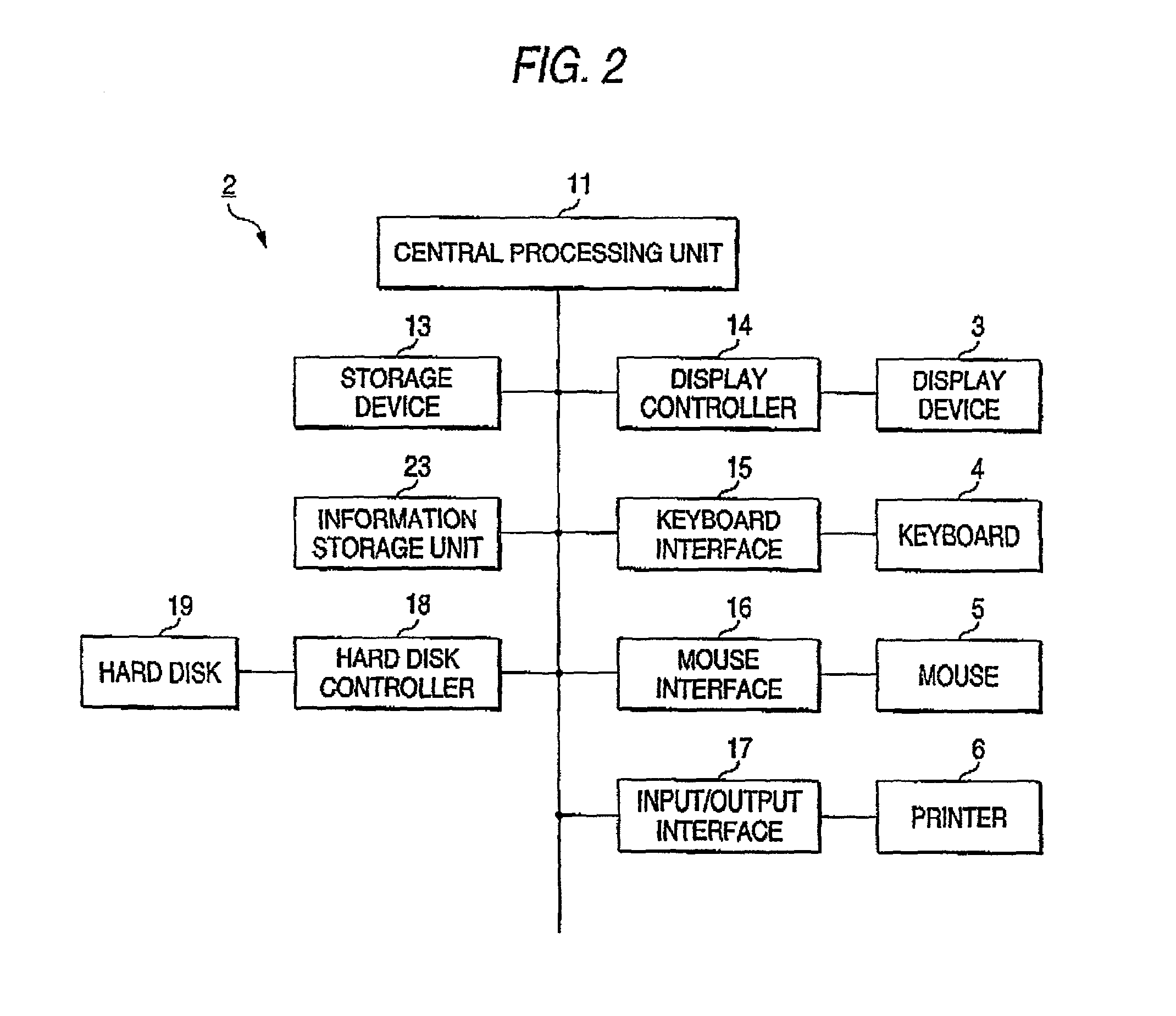

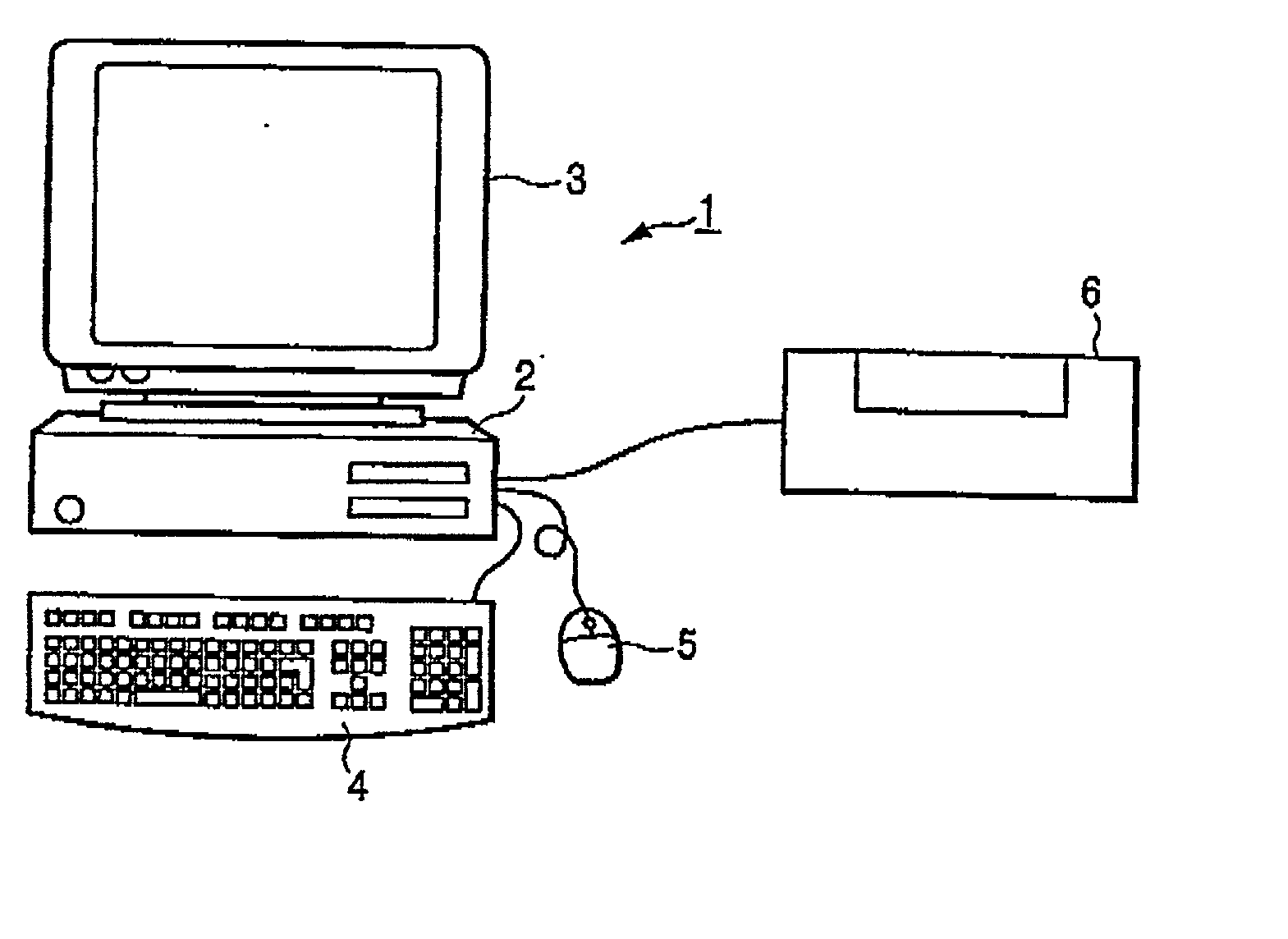

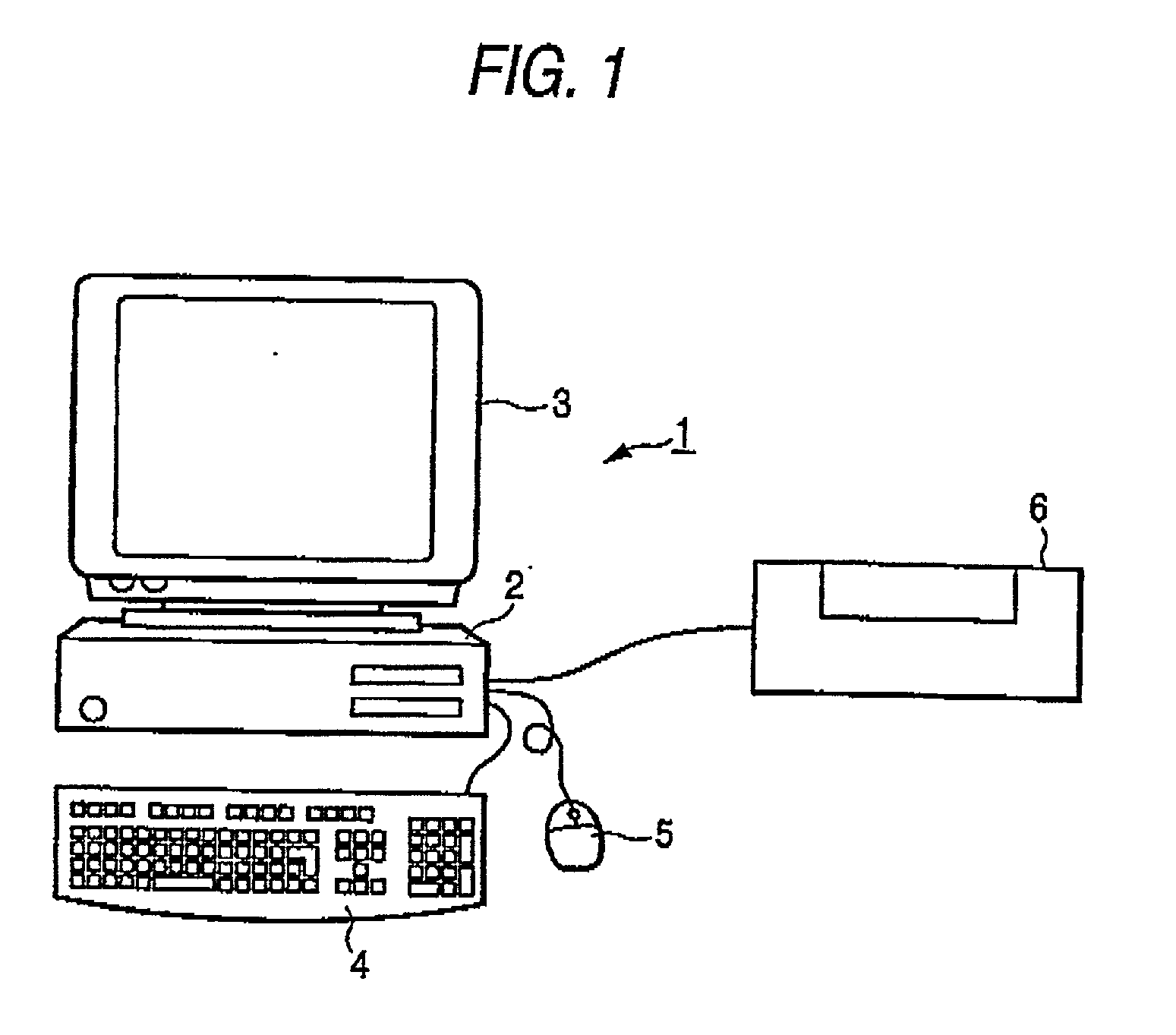

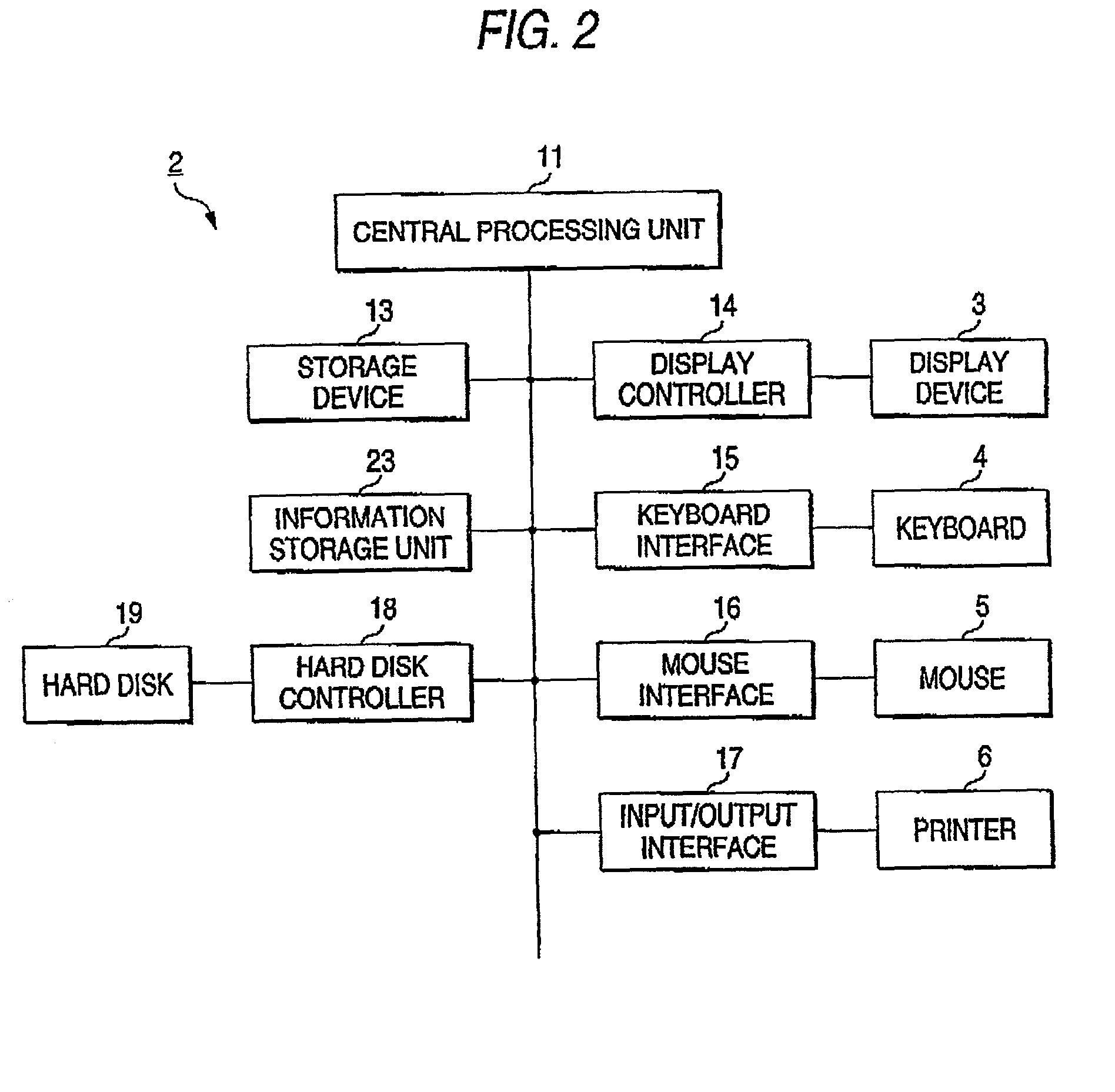

Method and apparatus for predicting the life of a rolling bearing, rolling bearing selection apparatus using the life prediction apparatus, and storage medium

ActiveUS7006953B2Accurate predictionSimple conditionsRolling contact bearingsMachine bearings testingData informationEngineering

A dynamic equivalent load P is calculated from data information of a rolling bearing. Next, a reliability coefficient a1 is determined, a lubrication parameter aL corresponding to a used lubricant is calculated, and a contamination degree coefficient ac is determined in consideration of a material coefficient. A fatigue limit load Pu is calculated on the basis of the data information. Thereafter, a load parameter {(P−Pu) / C}·1 / ac is calculated. On the basis of the lubrication parameter aL and the load parameter {(P−Pu) / C}·1 / ac, a life correction coefficient aNSK is calculated with reference to a life correction coefficient calculation map. The bearing life LA is calculated by LA=a1·aNSK·(C / P)p.

Owner:NSK LTD

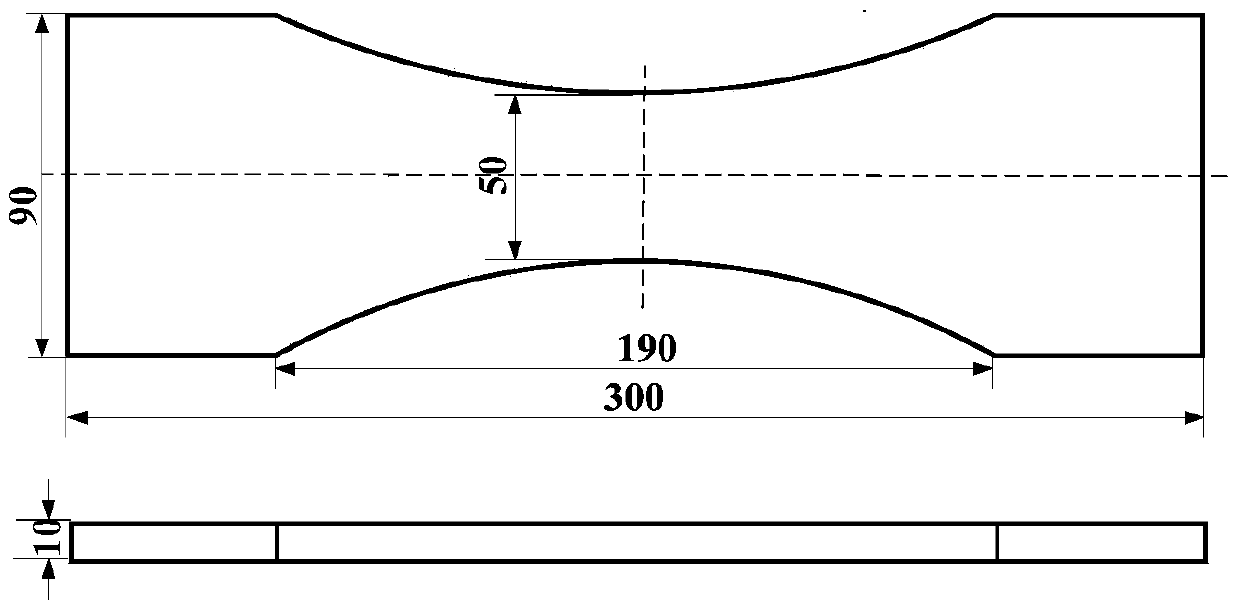

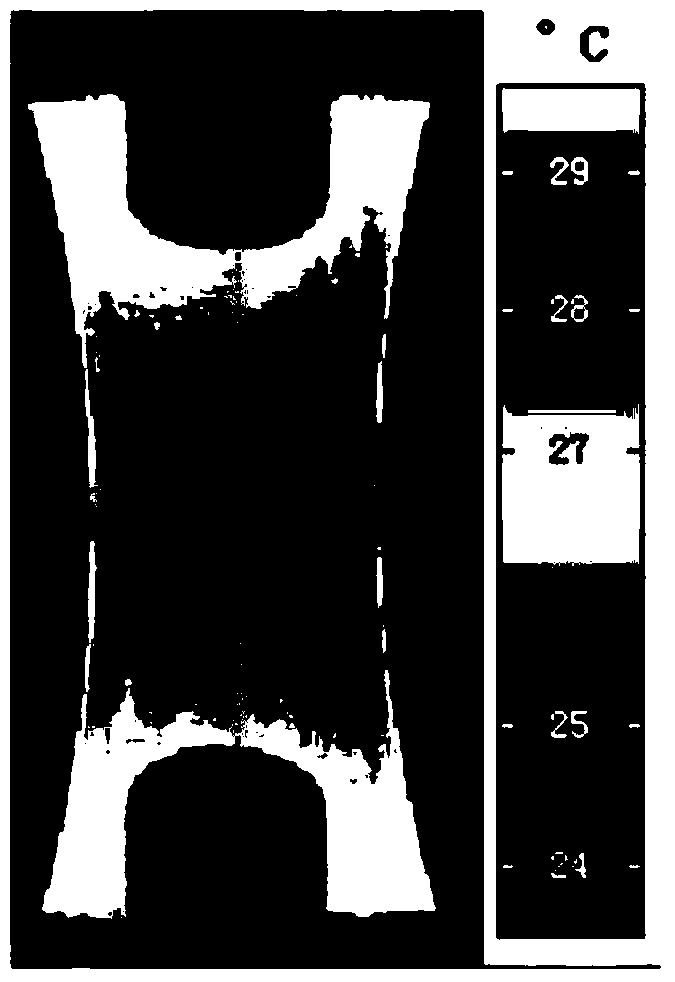

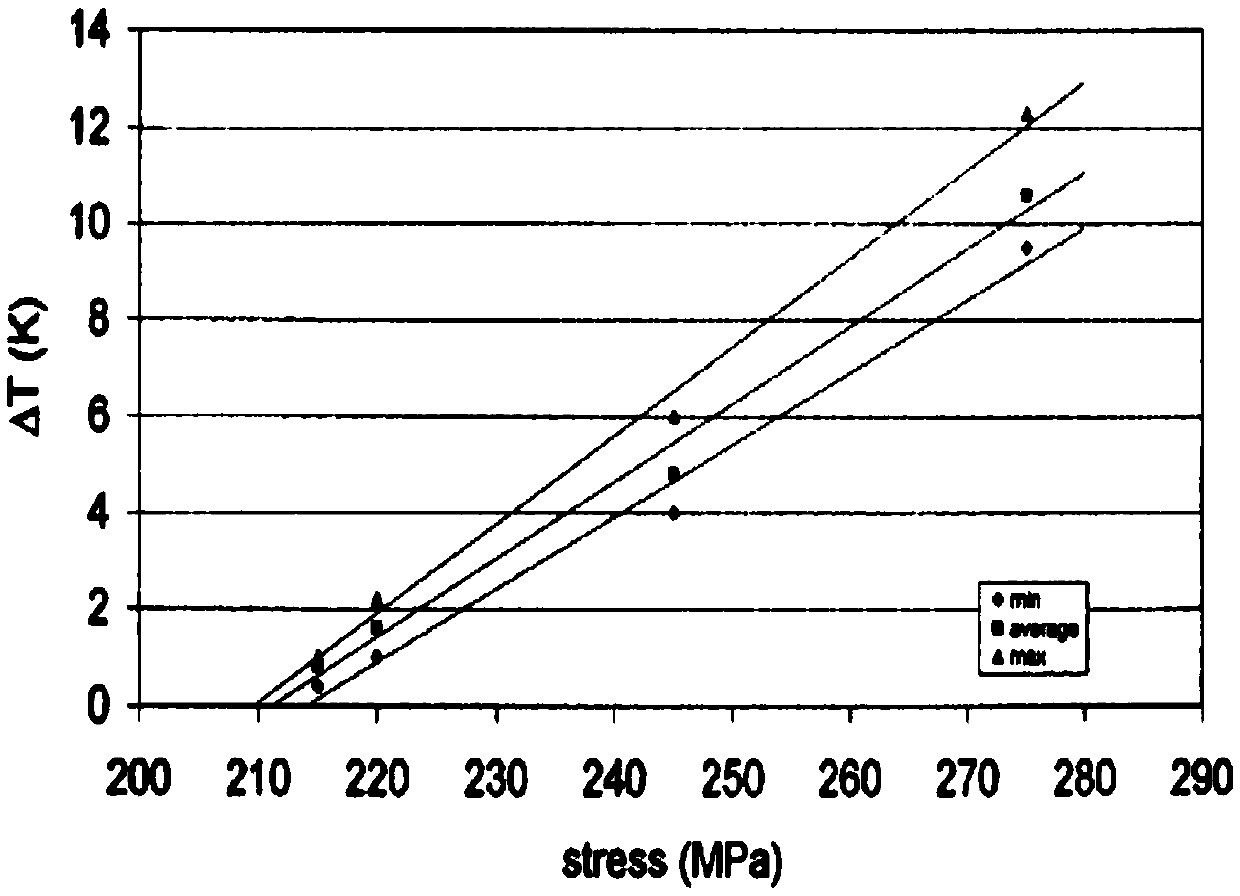

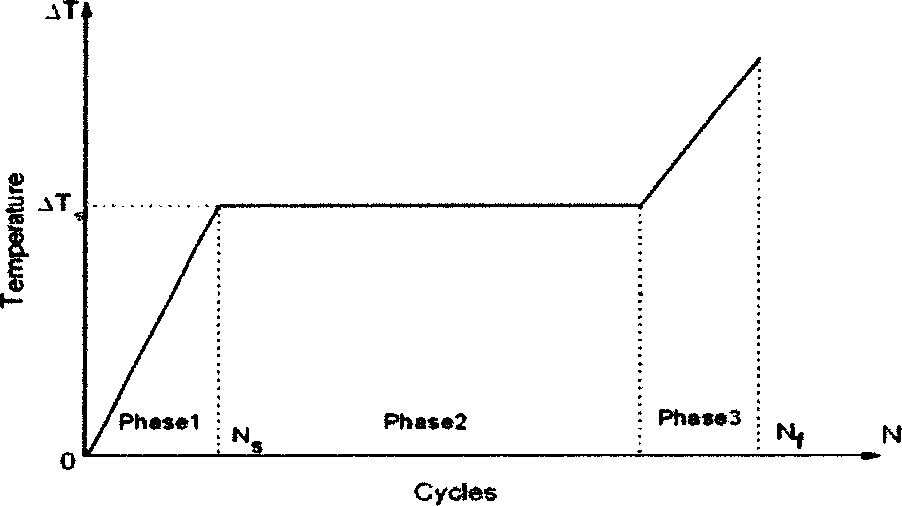

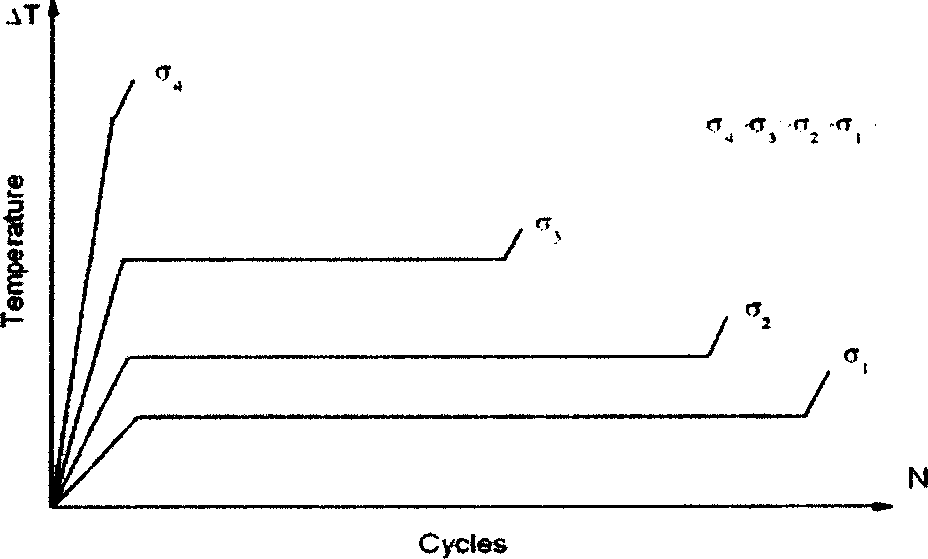

Fatigue analysis method based on magnesium alloy test piece surface temperature characteristics

ActiveCN104007007AReduce in quantityShorten test timePreparing sample for investigationPyrometry using electric radation detectorsStress distributionDeformation effect

The invention provides a fatigue analysis method based on magnesium alloy test piece surface temperature characteristics, and belongs to the technical field of magnesium alloy material mechanics properties. The method is characterized in that in terms of uneven stress distribution in a test piece under the fatigue load action of magnesium alloy, surface temperature of the test piece changes due to the elasticoplastic deformation effect, and a relation curve between the surface temperature of the test piece and local stress is obtained; curve shape features are analyzed, so that the stress condition of the test piece under fatigue is determined and the fatigue limit of the magnesium alloy is solved. According to the method, the test piece does not need to be loaded until fatigue failure occurs or loaded by specific cyclic times, the relation between internal stress of the test piece under fatigue and the fatigue limit of the magnesium alloy can be quickly determined through fatigue loading only for 3 minutes, and the method has the advantages of being convenient, fast, accurate and the like.

Owner:TAIYUAN UNIV OF TECH

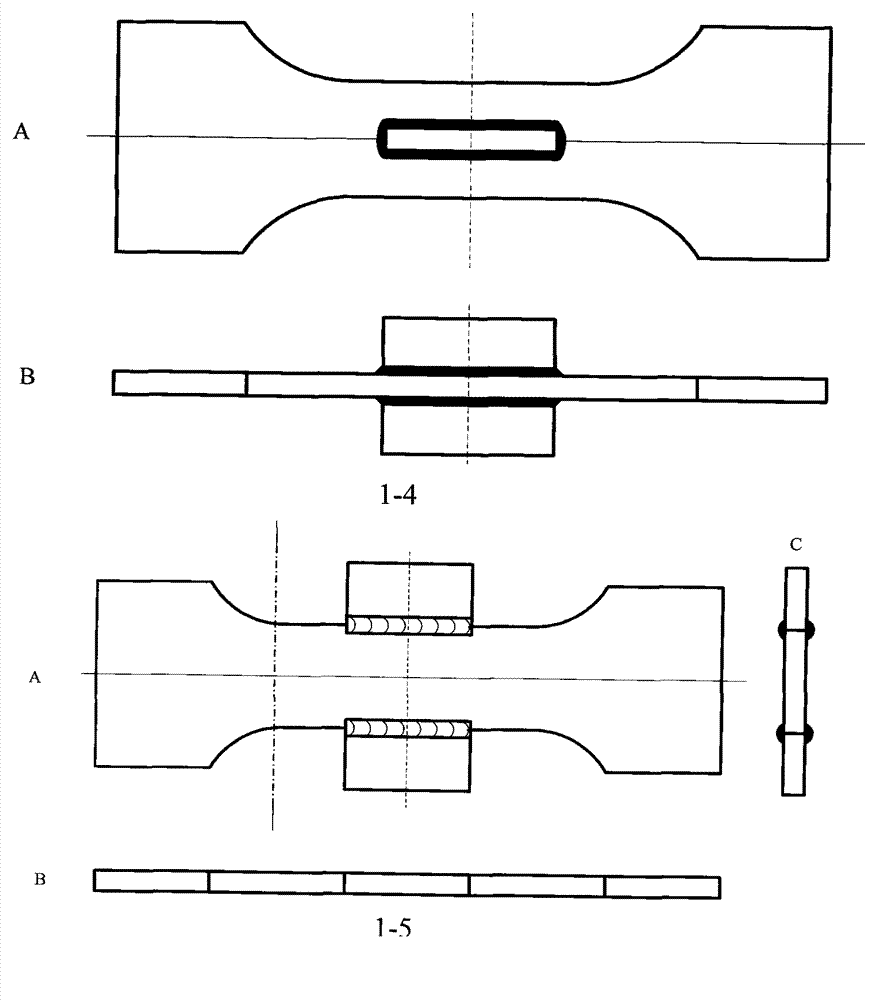

Fatigue test device for vehicle body thin plate, and test method thereof

ActiveCN102735557AEnsure consistencyAvoid influenceMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

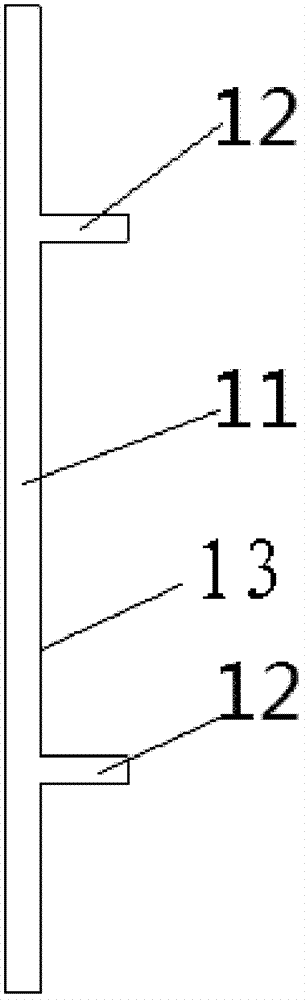

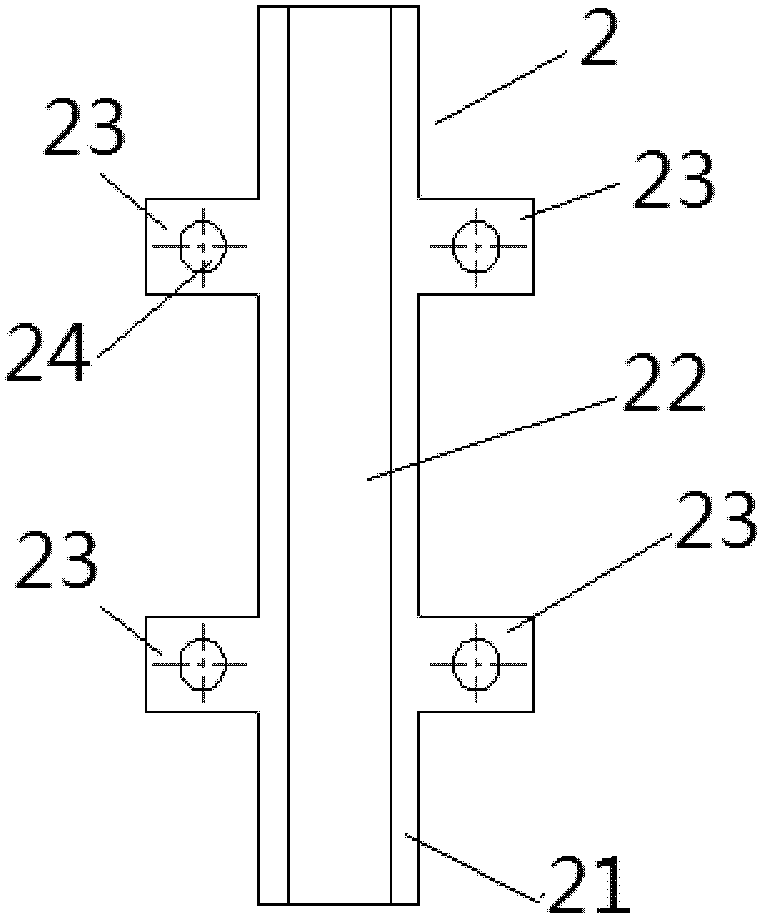

The present invention discloses a fatigue test device for a vehicle body thin plate, and a test method thereof, and belongs to the field of material fatigue test. The test device comprises: a centering apparatus and an anti-bending constraining apparatus. The centering apparatus comprises a vertical column and two centering clamping blocks, wherein the vertical column is provided with a reference plane correspondingly attaching to holding fixtures so as to make a center line of a fatigue specimen parallel to the reference plane, and the two centering clamping blocks are intervally and vertically arranged on the reference plane of the vertical column, such that the fatigue specimen is centered to a center line of test fixtures. The test method comprises: selecting a thin plate fatigue specimen and measuring a static tension curve; carrying out calibration on test force, selecting the initial test force, and setting a condition fatigue limit of the material; adopting the fatigue test device to carry out centering and anti-bending constraining on the fatigue specimen, and adopting a testing machine to carry out a fatigue test on the fatigue specimen. According to the present invention, uniformity of the test process is ensured and influence on the tested result due to additional factors is reduced by the centering apparatus and the anti-bending constraining apparatus, the test efficiency is improved, and the test cost is saved.

Owner:CHERY AUTOMOBILE CO LTD

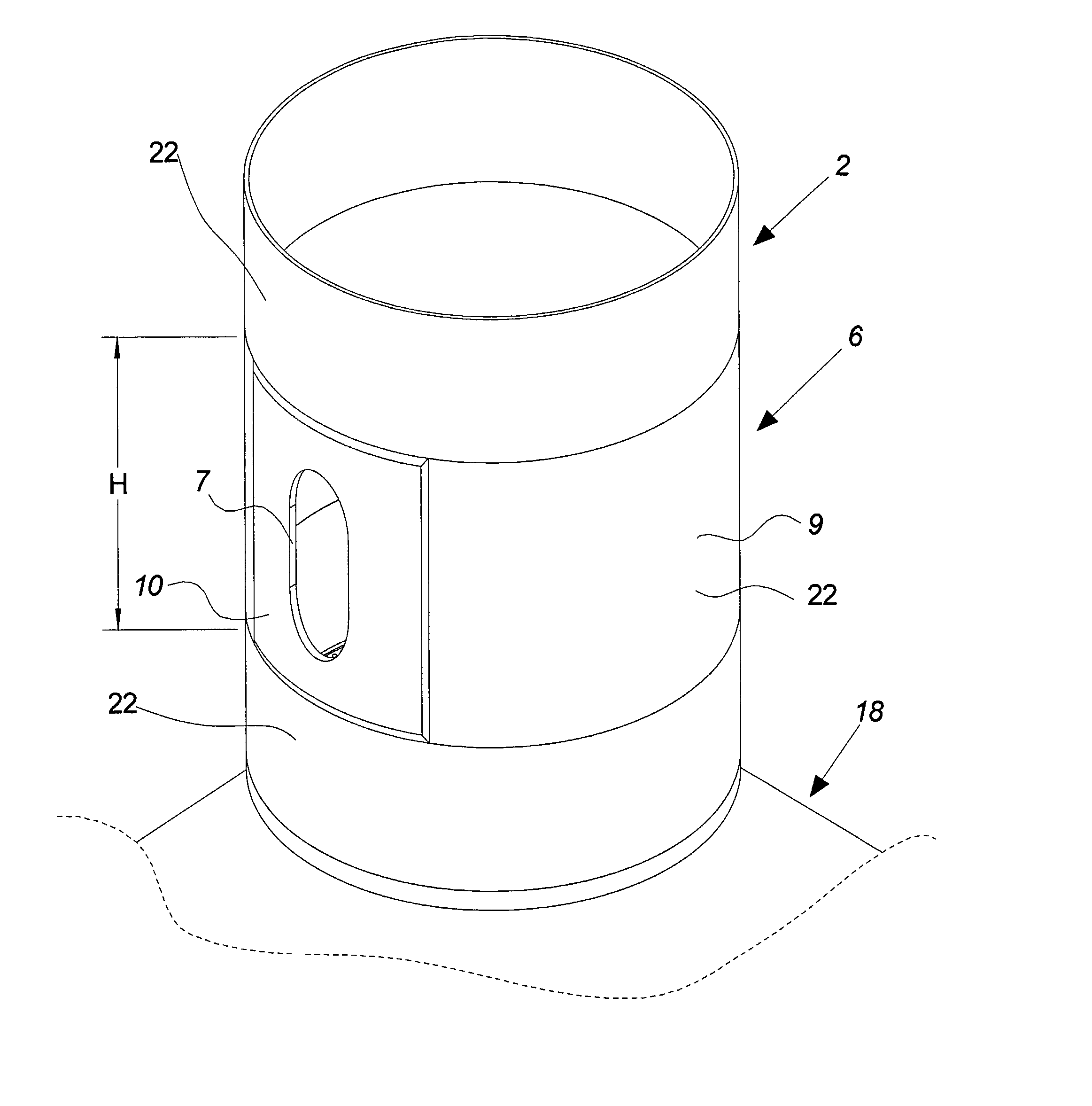

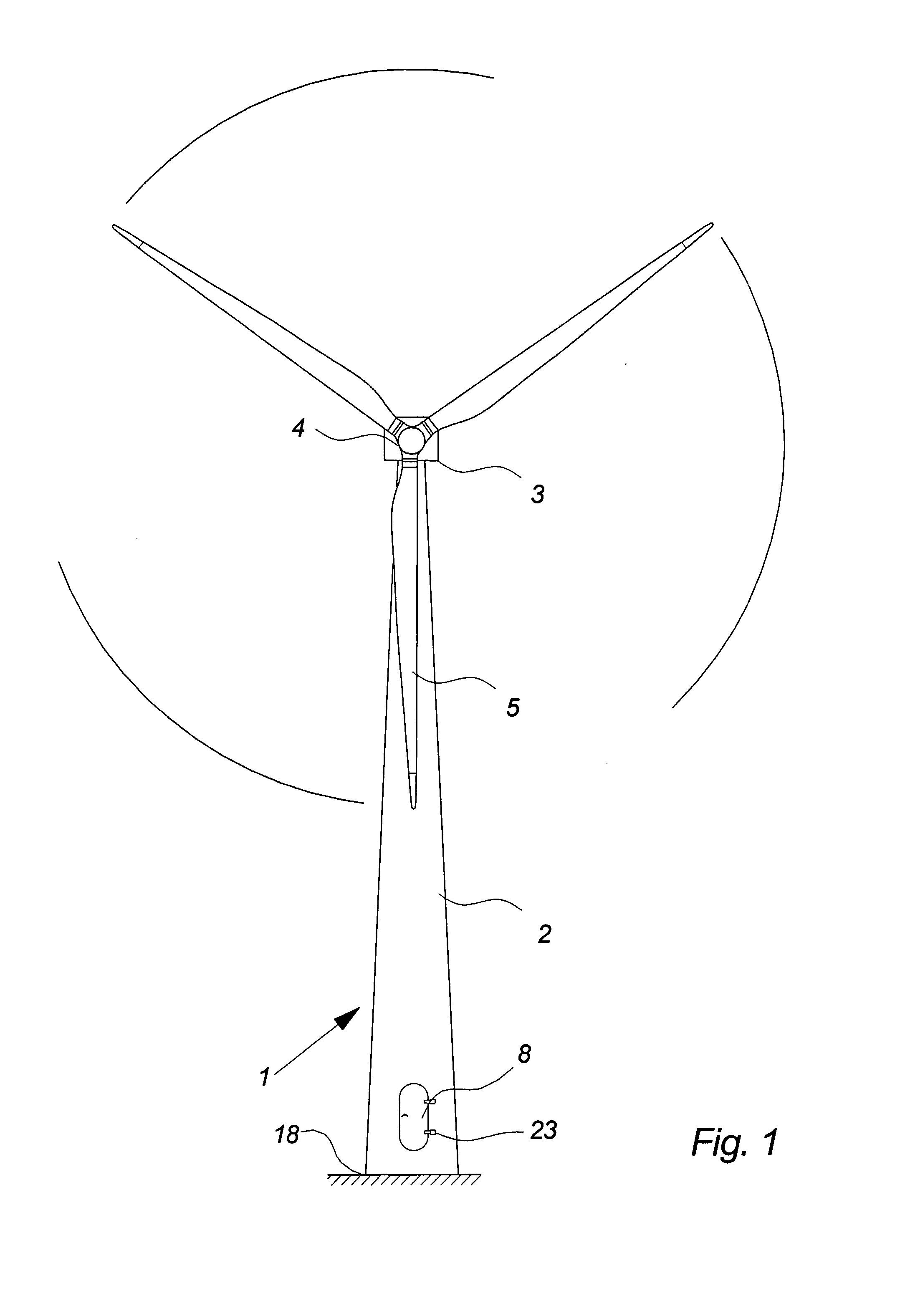

Tower Part for a Wind Turbine, an Aperture Cover System, a Method for Manufacturing a Tower Part and Uses Hereof

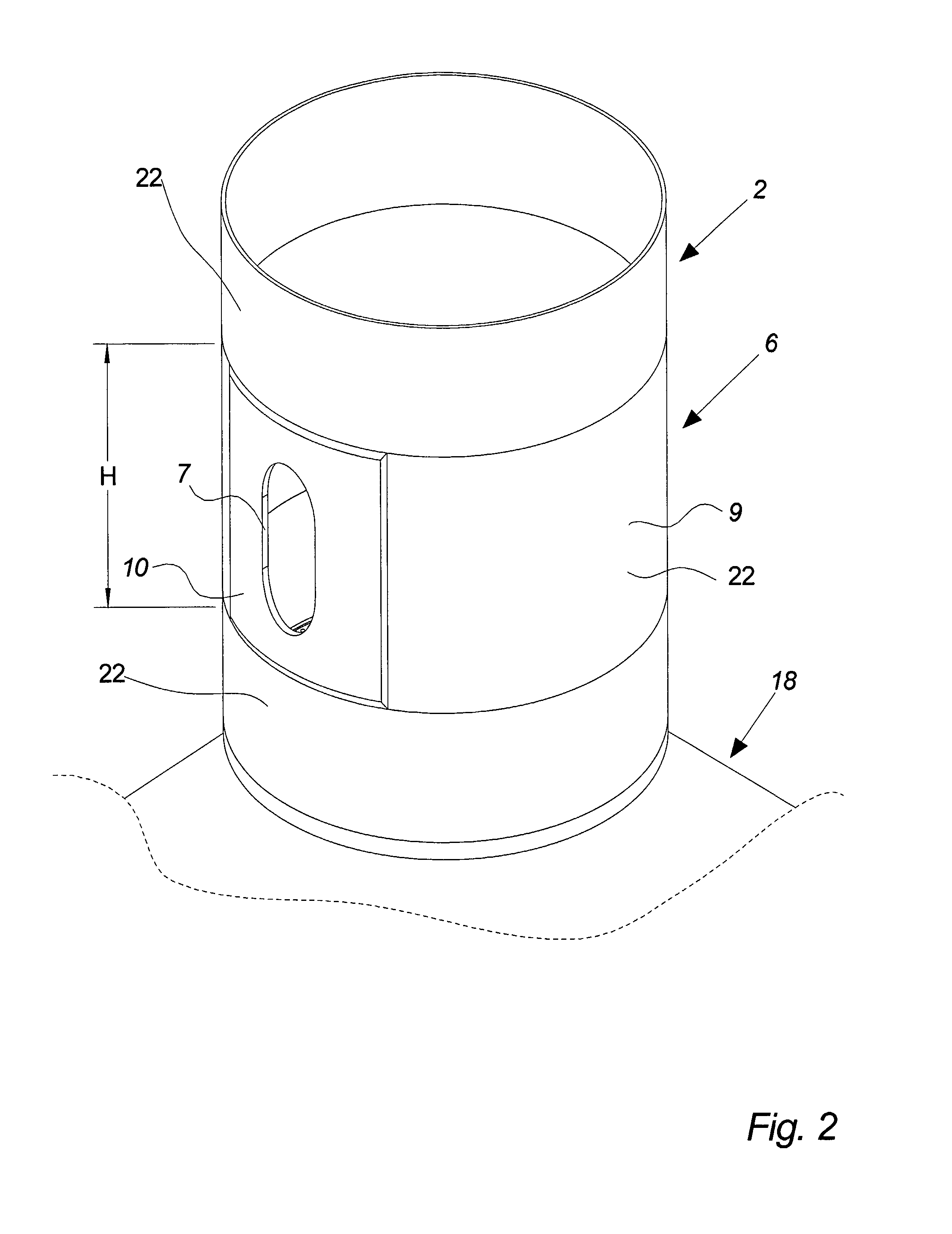

ActiveUS20080034675A1Low production costEasy to manufactureEngine manufactureFinal product manufactureCovering systemTower

The invention relates to a tower part (6) for a wind turbine (1) comprising at least one wall segment (9) and at least one aperture segment (10) including at least one aperture (7). The wall segment (9) and the aperture segment (10) being connected by connecting means and the aperture segment (10) is of a substantially uniform thickness and is thicker than the thickness of the wall segment (9). The invention further relates to an aperture cover system for covering at least one aperture (7) in a tower part (6) for a wind turbine (1). The system comprising cover plates and attachment means for attaching the system to the tower part (6), wherein the attachment means do not affect the fatigue limit of the tower part (6). Finally the invention relates to a method for manufacturing a wind turbine tower part (6) and uses hereof.

Owner:VESTAS WIND SYST AS

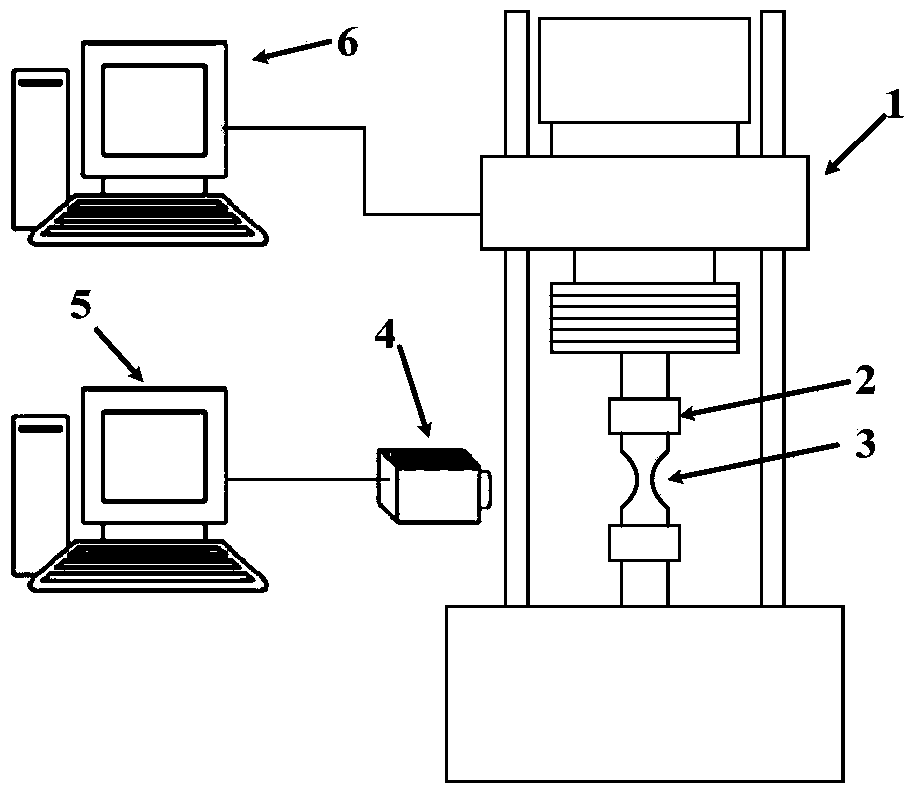

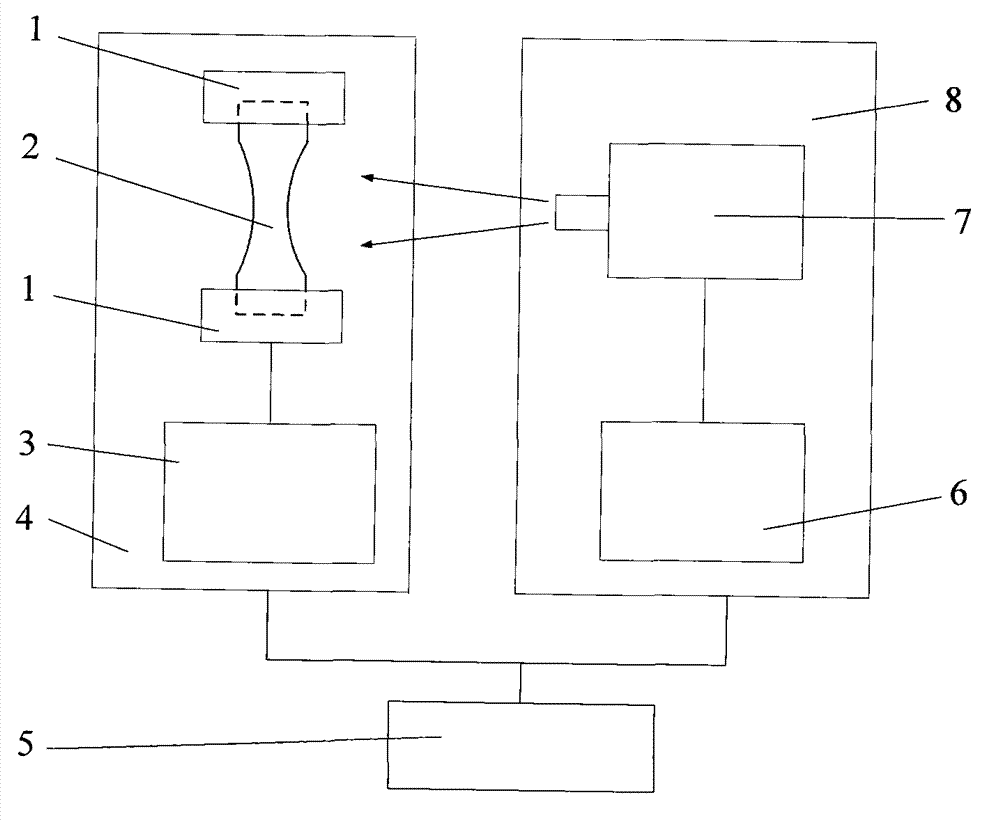

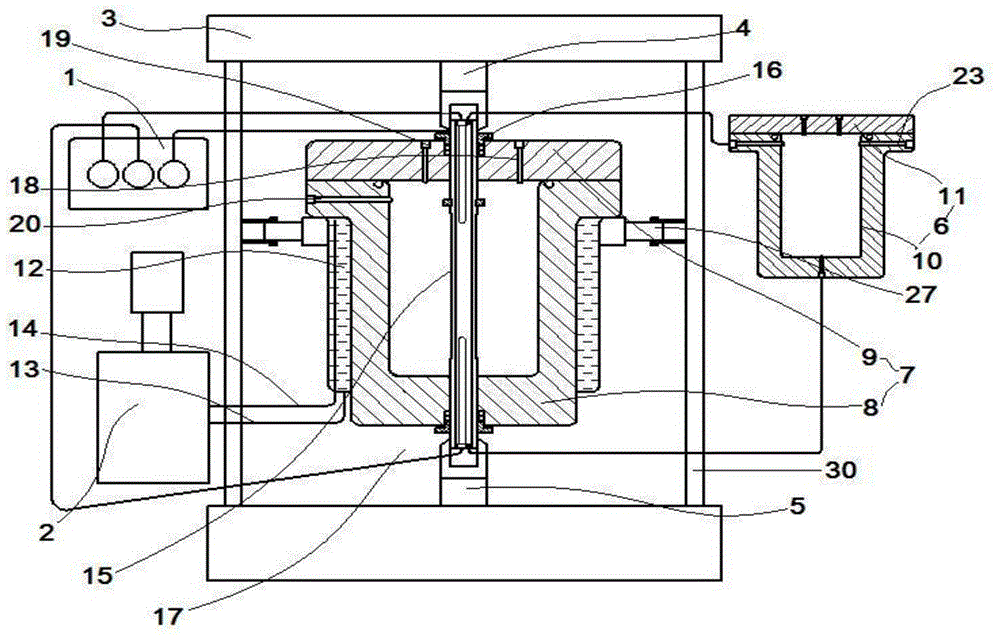

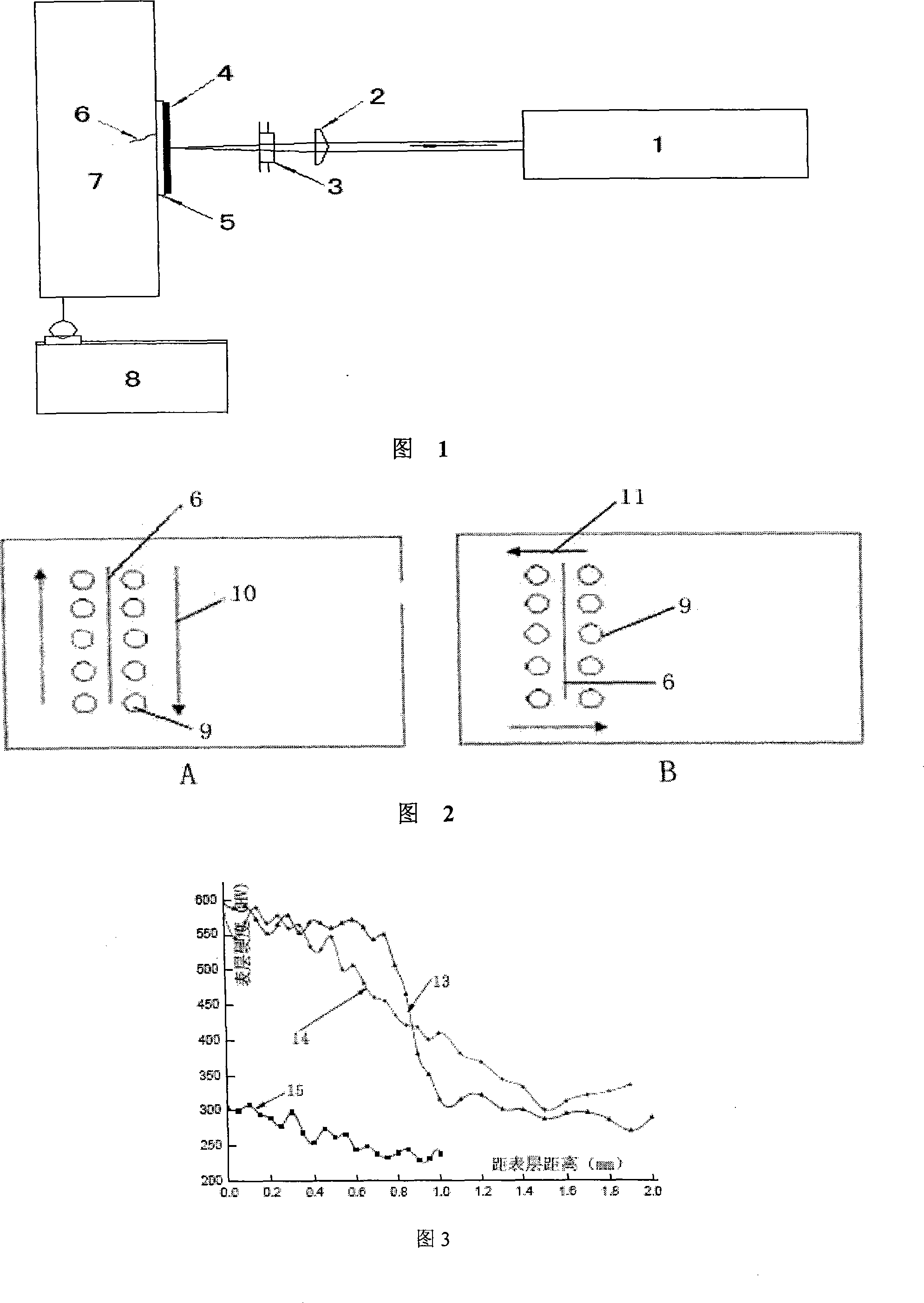

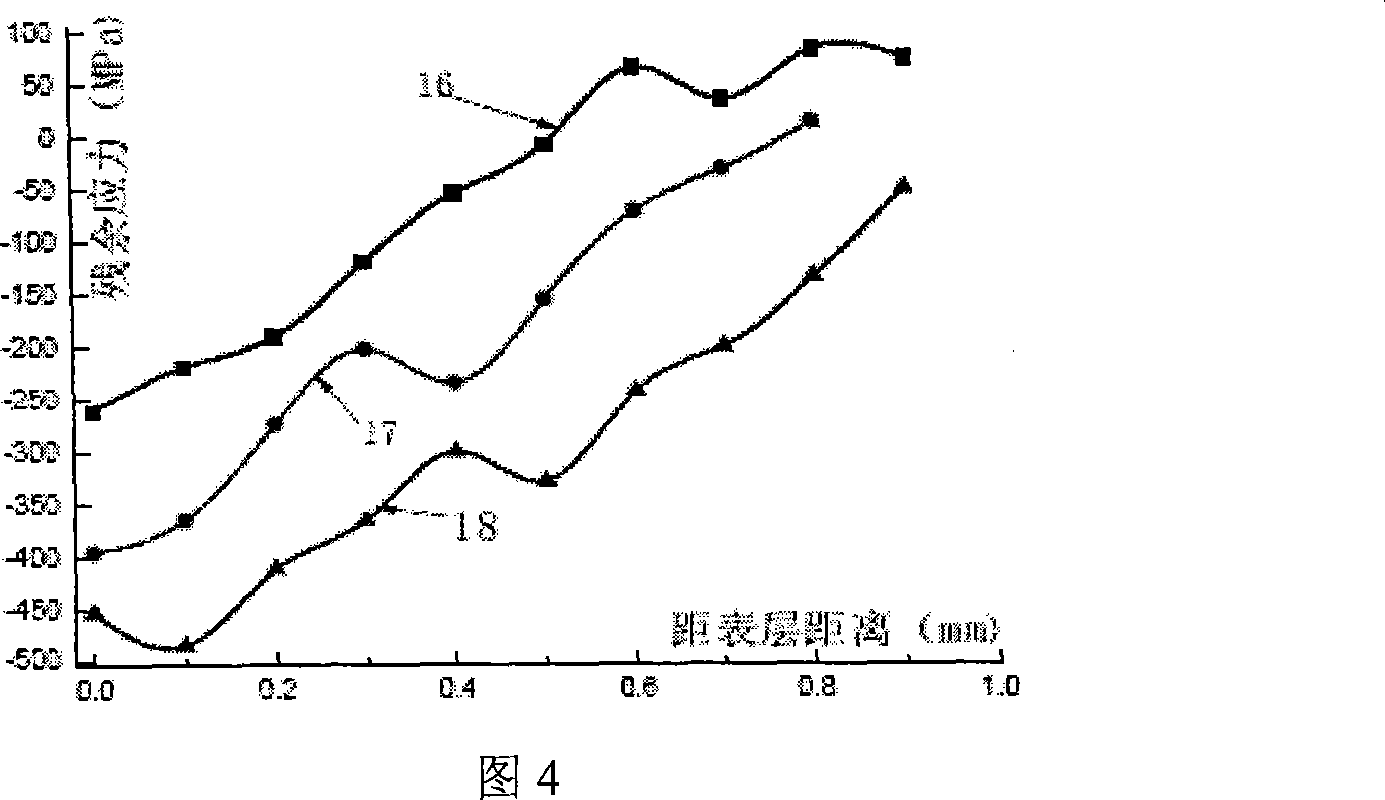

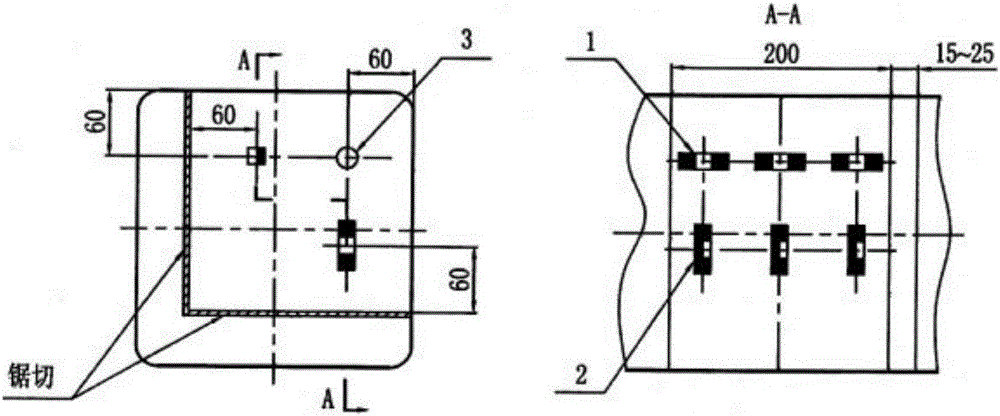

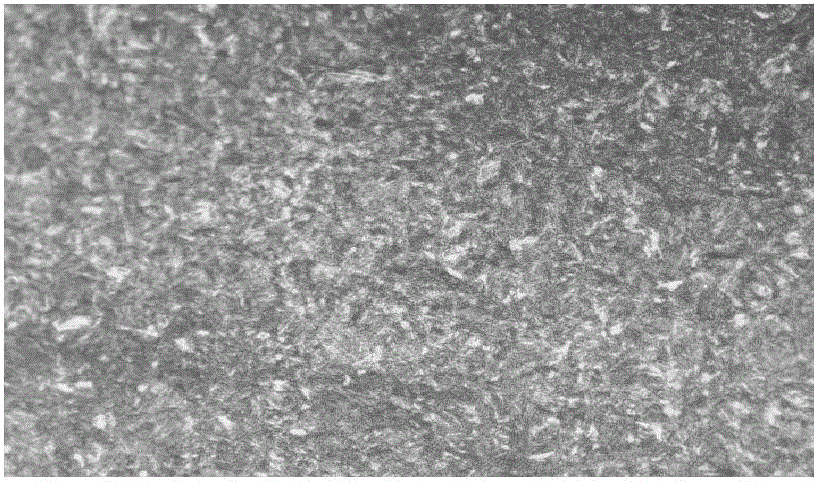

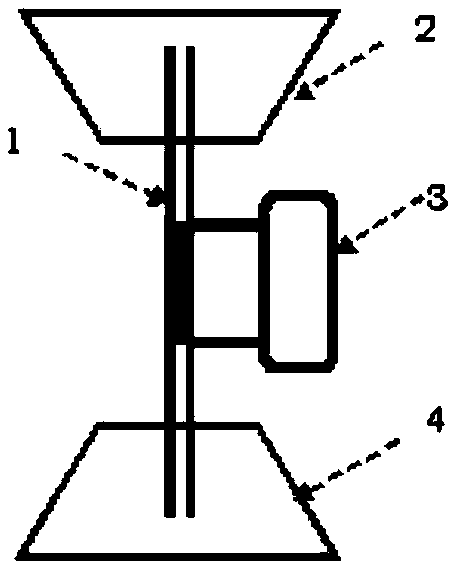

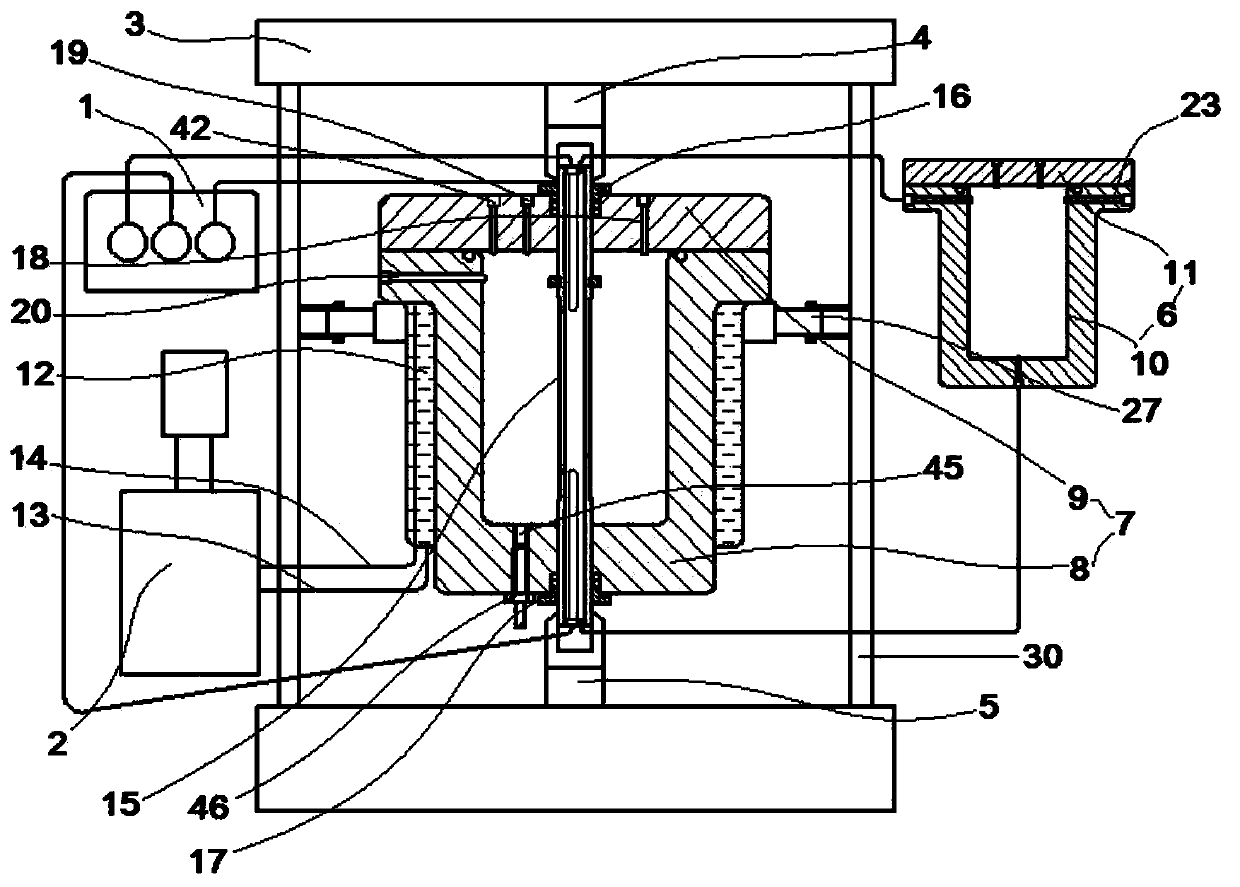

System for predicting fatigue limit of magnesium alloy member based on infrared thermal imaging, and method thereof

InactiveCN103076243ADetermining the fatigue limitAdvancedMaterial strength using repeated/pulsating forcesControl systemFatigue testing

The invention discloses a system for predicting the fatigue limit of a magnesium alloy member based on infrared thermal imaging, and a method thereof. The system comprises: fatigue tester jigs (1); a fatigue test piece (2) comprising a magnesium alloy base material and a welded joint test piece; a fatigue test control system (3); a fatigue test system (4) used for the fatigue test of the magnesium alloy base material and the welded joint test piece to obtain a magnesium alloy fatigue limit under a cycle frequency of 10<7 >; an infrared temperature measurement system (8) for obtaining the surface temperature change curve of the fatigue test piece (2) in the fatigue test process and recording the temperature change data of the fatigue test piece (2) in the fatigue process; and a comprehensive analysis system (5) applying origin software to compare the obtained magnesium alloy fatigue limit with a fatigue limit obtained through routine fatigue tests in order to judge the measurement accuracy. The system and the method can be used for estimating the dangerous point and the fatigue limit of a welding structure in service.

Owner:TAIYUAN UNIV OF TECH

Method and apparatus for predicting the life of a rolling bearing, rolling bearing selection apparatus using the life prediction apparatus, and storage medium

A dynamic equivalent load P is calculated from data information of a rolling bearing. Next, a reliability coefficient a1 is determined, a lubrication parameter aL corresponding to a used lubricant is calculated, and a contamination degree coefficient ac is determined in consideration of a material coefficient. A fatigue limit load Pu is calculated on the basis of the data information. Thereafter, a load parameter {(P-Pu) / C}.1 / ac is calculated. On the basis of the lubrication parameter aL and the load parameter {(P-Pu) / C}.1 / ac, a life correction coefficient aNSK is calculated with reference to a life correction coefficient calculation map. The bearing life LA is calculated by LA=a1.aNSK.(C / P)p.

Owner:NSK LTD

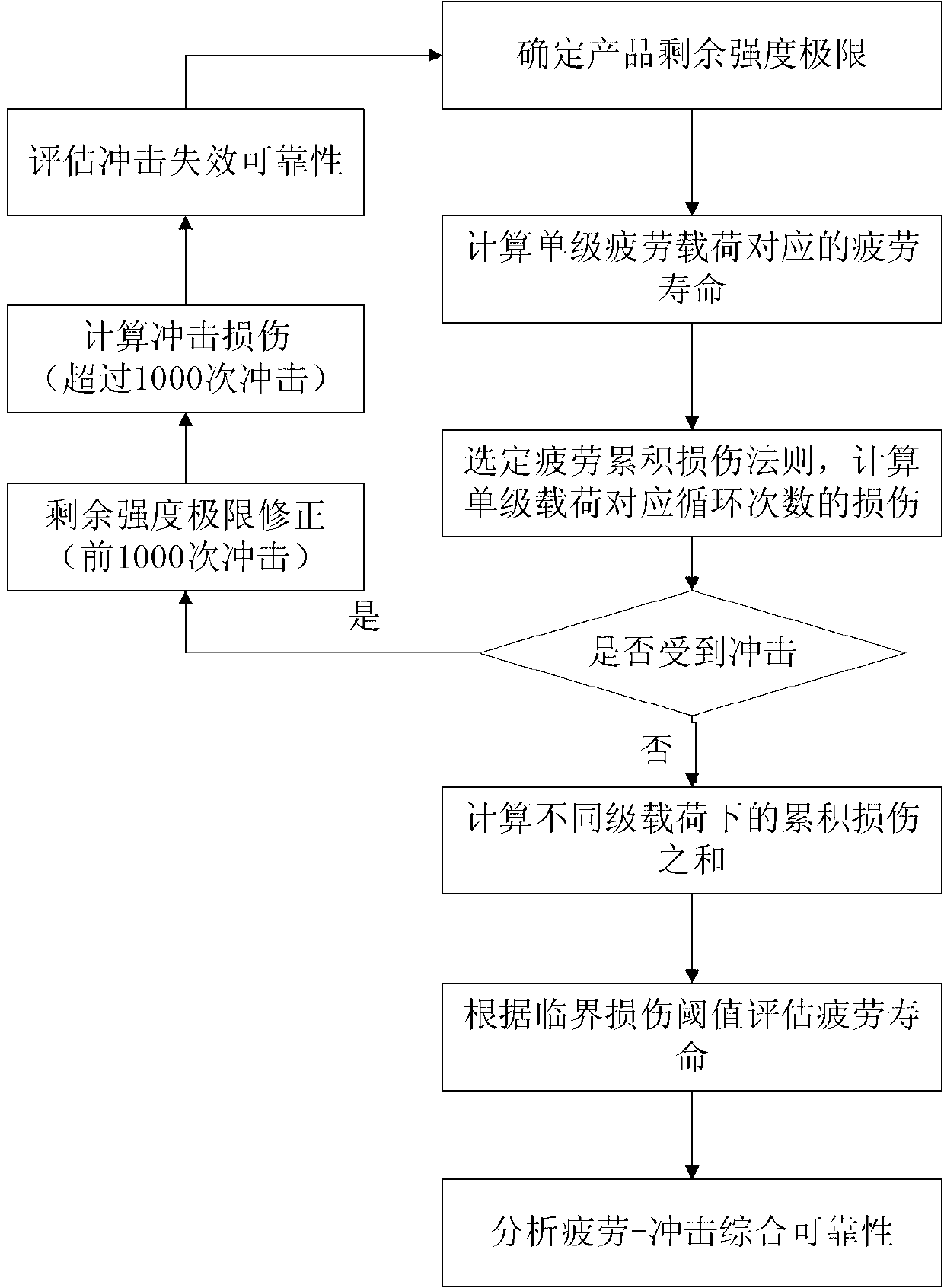

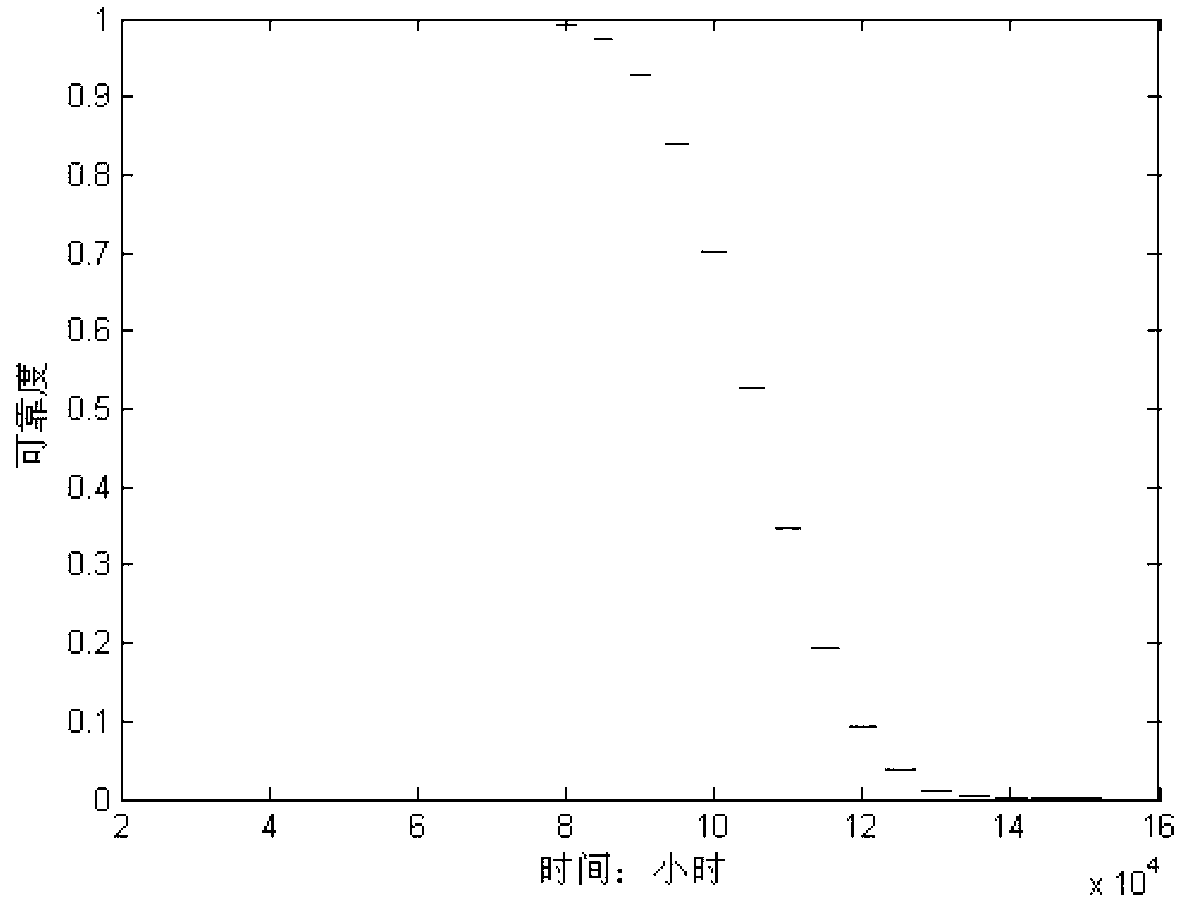

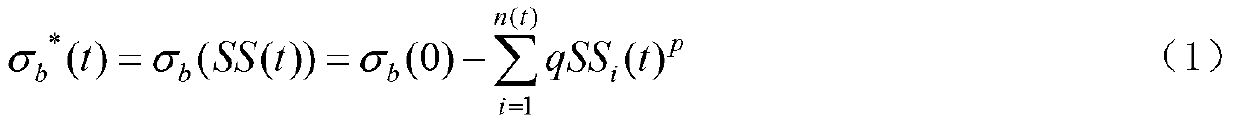

High-cycle fatigue and low-intensity impact coupled damage calculation method based on nominal stress method

ActiveCN103344514AWide selectionWide applicabilityMaterial strength using repeated/pulsating forcesFatigue damageFatigue loading

The invention relates to a high-cycle fatigue and low-intensity impact coupled damage calculation method based on a nominal stress method. The method comprises the following steps of: 1, determining the initial fatigue limit of a product, and calculating the fatigue life corresponding to single step of load under the action of fatigue load by utilizing the Baskin formula; 2, determining whether random impact or fixed impact exists according the frequency of impact; 3, calculating the accumulated fatigue damage after first 1000 times of impact according to the damage calculation method of the accumulated fatigue damage rule selected in the step 1; 4, calculating the accumulated fatigue damage after more than 1000 times of impact and the total accumulated damage value of the product at the t moment; 5, calculating the probability of no fatigue failure and the probability of random impact failure respectively, thereby finally obtaining the reliability of the product. The method provided by the invention can be used for evaluating the fatigue life and reliability of the product under the complex environment, and then discussing the impact and accumulated fatigue damage models in different cases, and is wide in selection area and application space, simple and convenient in analysis and calculation process and strong in engineering practicability.

Owner:BEIHANG UNIV

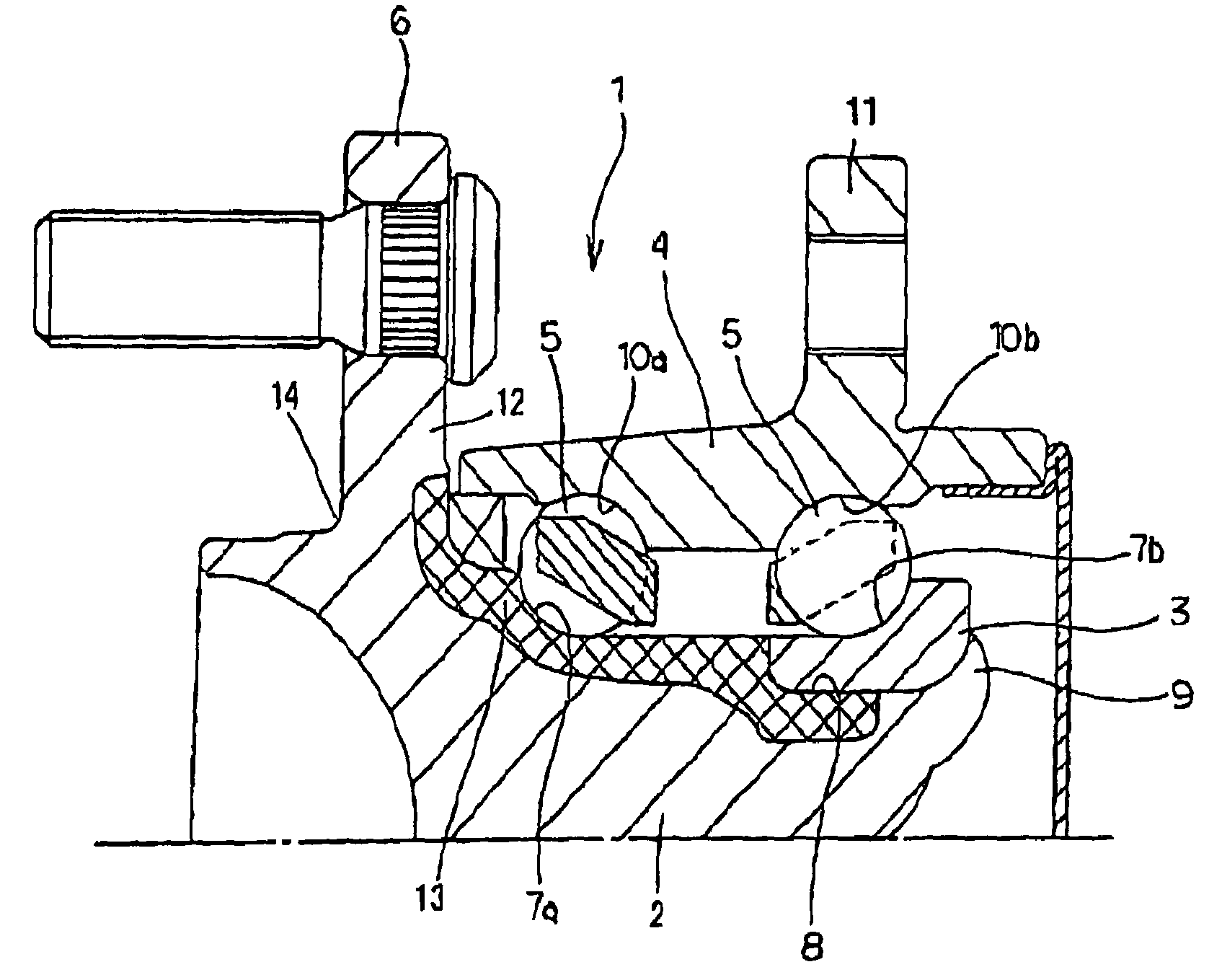

Wheel-support rolling bearing unit

InactiveUS7004637B1Improve fatigue strengthReduce fatigue strengthRolling contact bearingsHubsSurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

High temperature and high pressure corrosion hydrogen permeation kinetic test device and test method thereof

ActiveCN104568726AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesFatigue loadingEngineering

The invention discloses a high temperature and high pressure corrosion hydrogen permeation kinetic test device and a test method of the device. When the device is used for carrying out fatigue limit measurement, step type fatigue load is applied to material from small to large under the given corrosion condition after hydrogen permeability current is stable; when the hydrogen permeability current is increased along with the increment of the load, the load is proved to cause dislocation movement in the material, so that the load is the fatigue limit of the material in the environment. After the device and the method are adopted, the quantitative relation between a fatigue load state and hydrogen permeation quantity can be measured in situ in an online way in the high pressure hydrogen sulfide corrosion environment, the internal relation between stress and segregation diffusion of hydrogen can be visually expressed, and the characteristics of the mutual relation of multiple data can be established.

Owner:湖州度信科技有限公司

Crack arrest method of alloy surface fine crack crack arrest method and device thereof

InactiveCN101239432AImprove efficiencyRaise the Fatigue ThresholdLaser beam welding apparatusLacquerPulse energy

A crack arrest process and device thereof for removing fine cracks on alloy surfaces, relates to laser impulse processing application technique field. Oxide layers and pollutants on alloy surfaces which affect surface bonding force are removed to obtain good glue-joint strength and permanent stability; a flexible film is adhered to the alloy surface as a crack arrest patch, and a layer of black lacquer coating is applied on the crack arrest patch; laser pulse with following parameters: pulse energy of 15-40J, pulse width of 20-30ns, light spot size of 4-10mm, repetition frequency of 0.5-10Hz is selected to performing laser impact crack arrest according to damage status of the cracks; laser crack arrest is performed by selecting crack arrest route, and crack effects are inspected by using no-damage technique during crack arrest process. The invented method and device can increase alloy surface fatigue threshold value, the existing of residual compressive stress on metal surface after laser impulse enhances fatigue threshold stress on material surface greatly.

Owner:JIANGSU UNIV

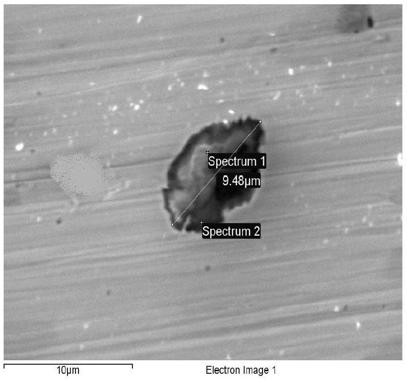

High-speed axle steel material and heat treatment method thereof

The invention discloses a high-speed axle steel material and a heat treatment method thereof. The high-speed axle steel material comprises 0.22 wt%-0.29 wt% of C, 0.17 wt%-0.38 wt% of Si, 0.53 wt%-0.77 wt% of Mn, 0-0.015 wt% of P, 0-0.010 wt% of S, 0.20 wt%-0.27 wt% of Ni, 0.95 wt%-1.15 wt% of Cr, 0-0.15 wt% of Cu, 0.20 wt%-0.29 wt% of Mo, 0.02 wt%-0.05 wt% of V, 0.015 wt%-0.045 wt% of Al, 0.01 wt%-0.03 wt% of Nb, 0-15 PPm of O, 0-1.5 PPm of H and the balance Fe and other inevitable elements. The heat treatment method comprises the following heat treatment requirements that the normalizing heating temperature is 880 DEG C-920 DEG C; the quenching heating temperature is 870 DEG C-900 DEG C; the heat preservation time is 4-9 h; and the tempering heating temperature is 630 DEG C-660 DEG C. According to the high-speed axle steel material, the yield strength, the tensile strength and the impact toughness are higher than those of an ordinary axle LZ50, the grain size grade is higher, the inclusion size is smaller, the component segregation index is lower, and the fatigue limit is 403 MPa or above and is 103 MPa higher than that of the LZ50.

Owner:建龙北满特殊钢有限责任公司

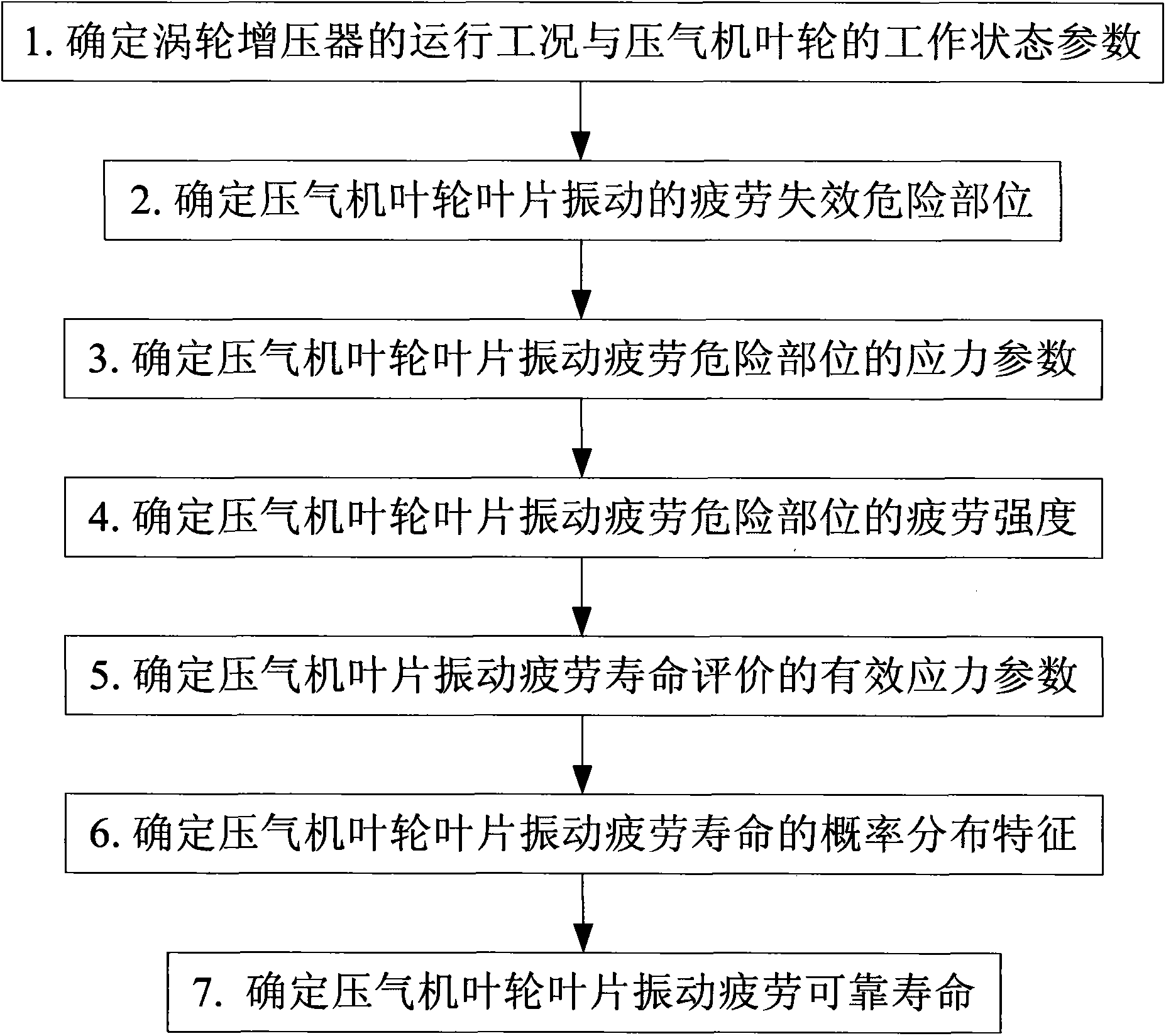

Evaluation method for reliable life of blade vibration fatigue of gas compressor impeller of supercharger

The invention relates to an evaluation method for reliable life of blade vibration fatigue of a gas compressor impeller of an automotive turbosupercharger. The method comprises the following steps: firstly, the operation condition of the automotive turbosupercharger and the working state parameters of the gas compressor impeller are determined; then, the dangerous parts of the blade vibration fatigue of the gas compressor impeller and the stress parameters of every corresponding working condition are determined; then, the fatigue strength of the dangerous parts of the blade vibration fatigue of the gas compressor impeller is determined by adopting a test method to compare the magnitude relation between the equivalent stress of the dangerous parts of the blade vibration fatigue of the gas compressor impeller and the fatigue limit of the blades under different working conditions and determine the effective stress parameters for evaluating the blade vibration fatigue life of the gas compressor impeller; the probability distribution characteristics of the blade vibration fatigue life of the gas compressor impeller and the reliable life meeting different reliability requirements are determined. The method can evaluate the reliable life of the blade vibration fatigue of the gas compressor impeller in the development stage of the turbosupercharger, and can preferably guide the structural design and reasonable use of the gas compressor impeller.

Owner:CHINA NORTH ENGINE INST TIANJIN

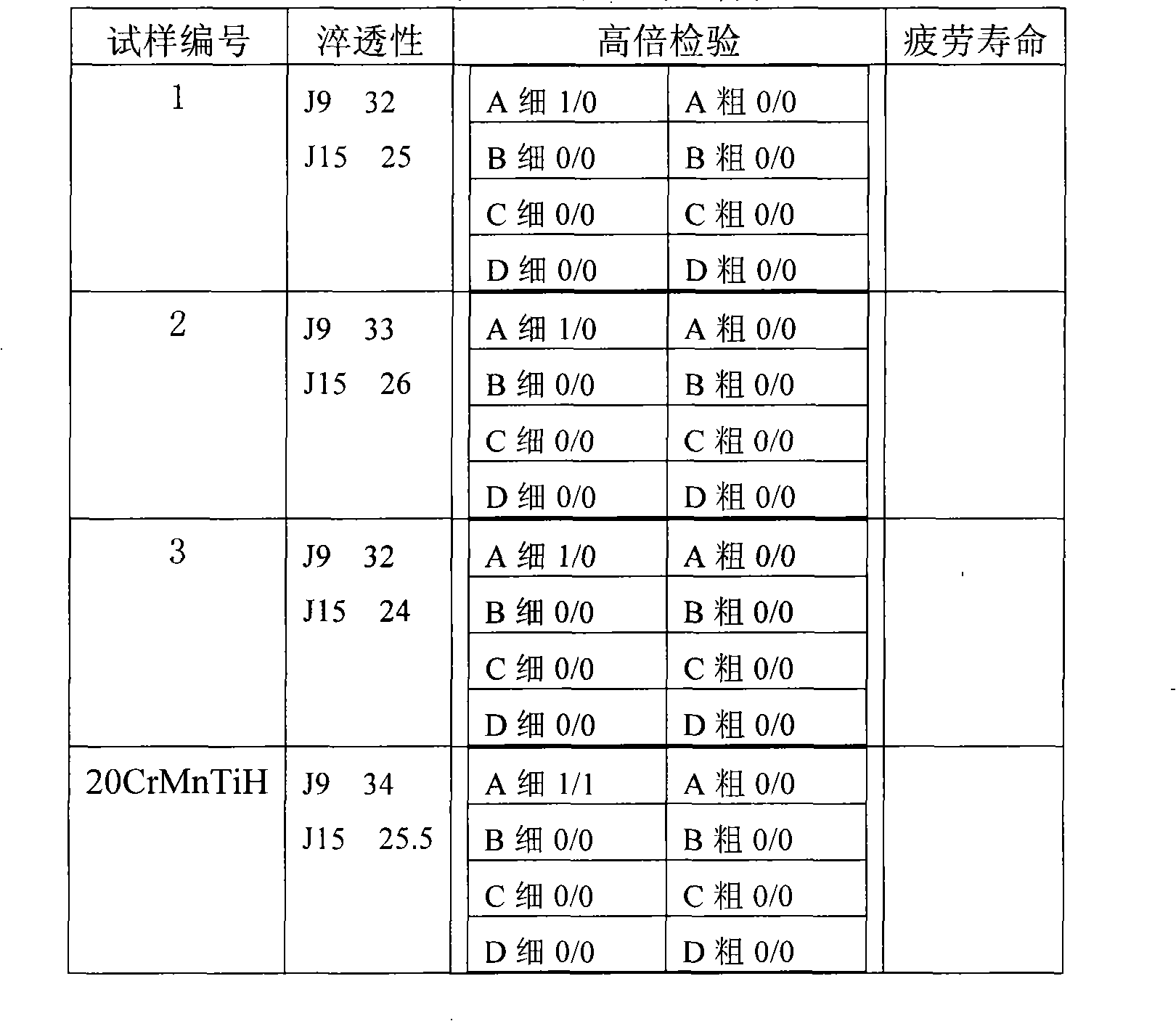

Cr-Mn-Ti gear steel and preparation thereof

InactiveCN101275204AImprove fatigue lifeFine grainTemperature control deviceUltimate tensile strengthImpurity

The invention provides a production method for a novel Cr-Mn-Ti gear steel, characterized in that the invention uses the production process flow of initial refining with an electric furnace or a rotary furnace, LF refining, treatment for refined steel liquid with a vacuum furnace, fully-protective continuous casting and rolling formation. An initial-refining furnace melts the initial-refining steel liquid, forms steel in the range from 1620 to 1670 DEG C and adds synthesized dregs; the refining of the steel liquid is performed in a steel container refining furnace and the temperature is controlled in the range from 1520 to 1630 DEG C, the steel is made after refining for 30 to 50 minutes; then the refined steel liquid is vacuum performed on the vacuum furnace, argon gas is blown into the bottom of the steel container; in the end, the continuous casting is carried out under the condition of full protection. The invention, in terms of guaranteeing the intensity of the CrMnTi gear steel and considering the fatigue limit, controls the Ti content in the CrMnTi gear in the range from 0.01% to 0.038%, which can not only control the CrMnTi gear steel not to enlarge the grain at the carburizing temperature to reduce the impurities, thus improving the steel quality, but also is beneficial to improving the fatigue life of the gear.

Owner:SHANDONG IRON & STEEL CO LTD

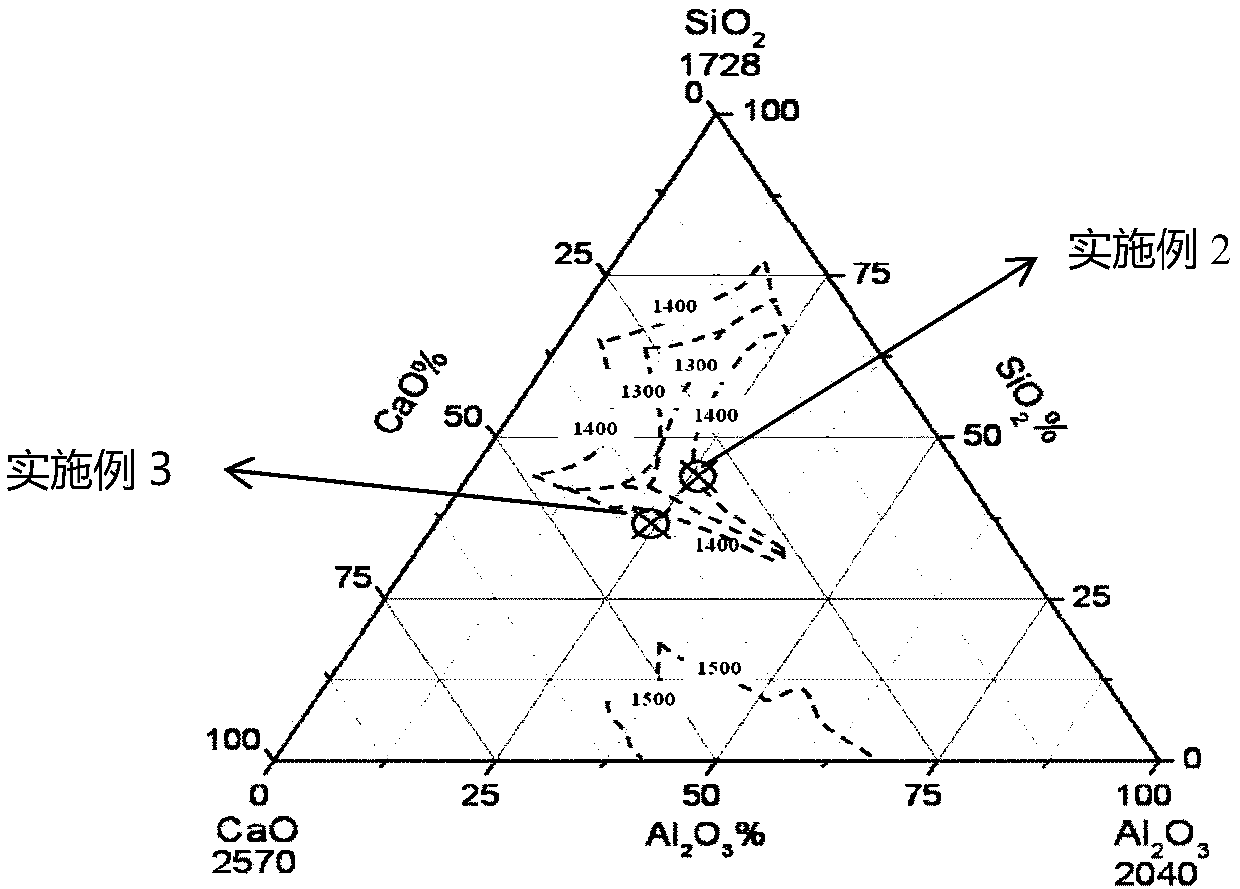

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

Method for processing material fatigue life test data

ActiveCN102798568AReasonable handlingFatigue life underestimationStrength propertiesRational methodMaterials science

The invention belongs to a material fatigue life test technology and relates to a method for processing material fatigue life test data. The method is characterized by comprising the following processing steps of: finding out the fatigue limit of a material; preprocessing the fatigue life data; and finding out an intercept B1 and a slope B2 in a fatigue life curve. The invention provides a quite rational method for processing the material fatigue life test data, thereby avoiding the waste of the data obtained at high cost and underestimation of the fatigue life of the material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

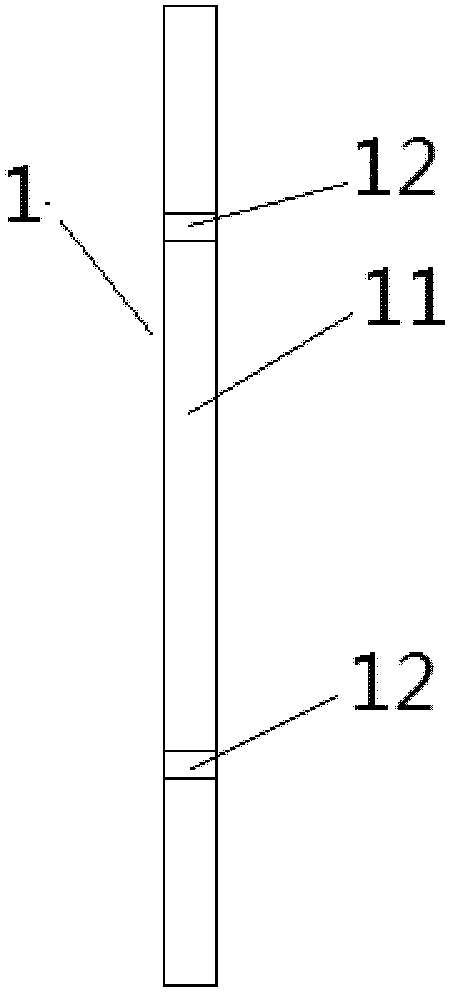

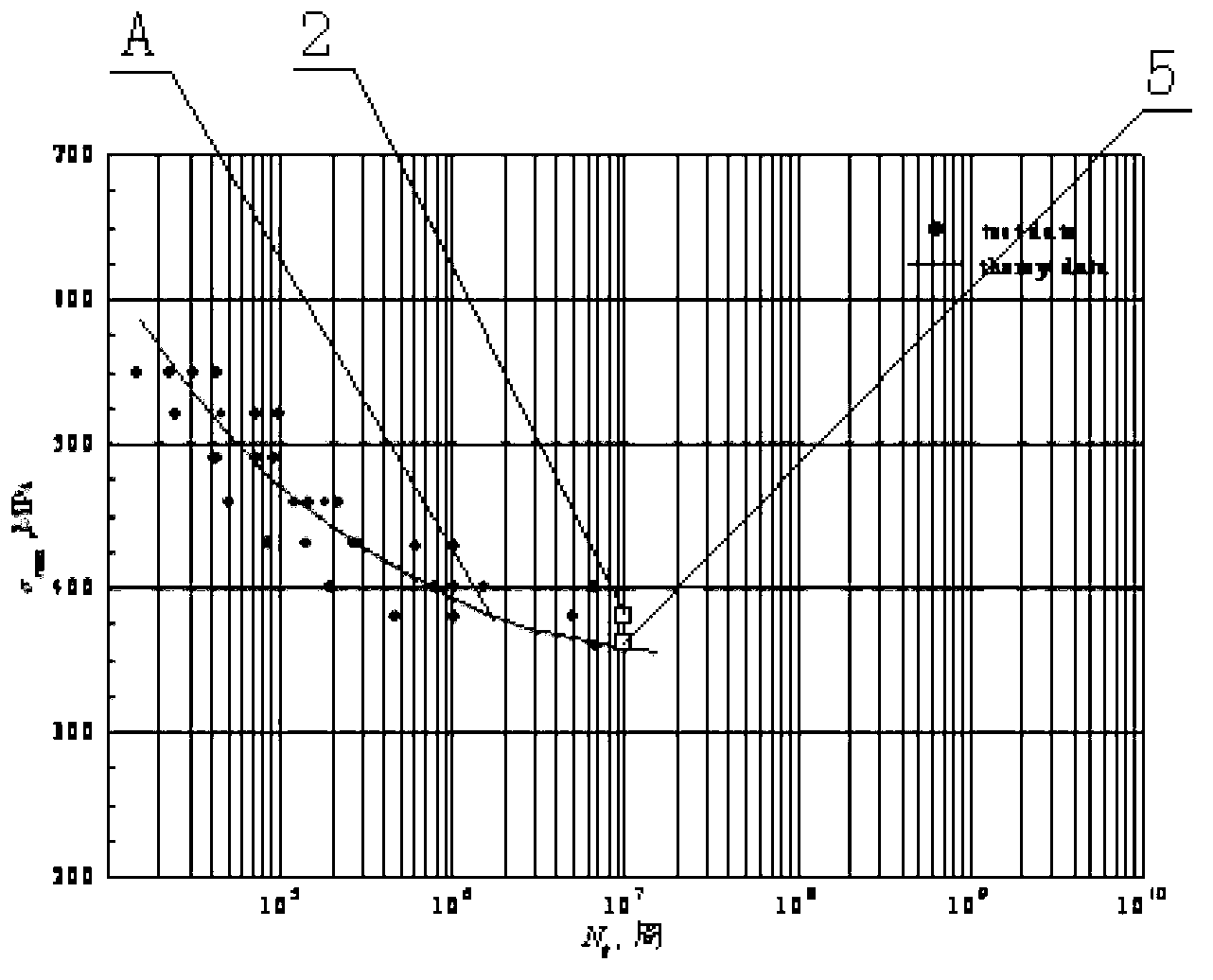

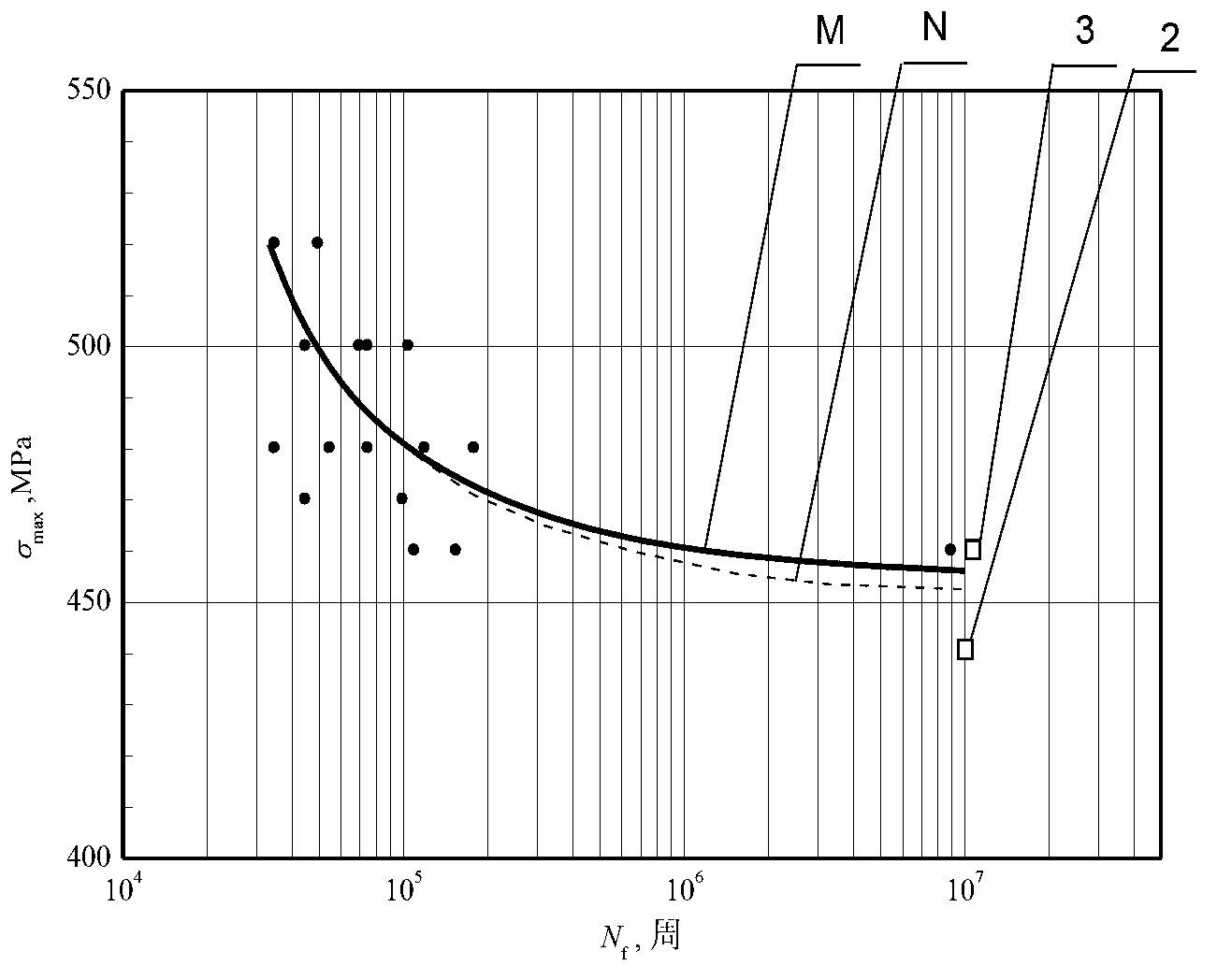

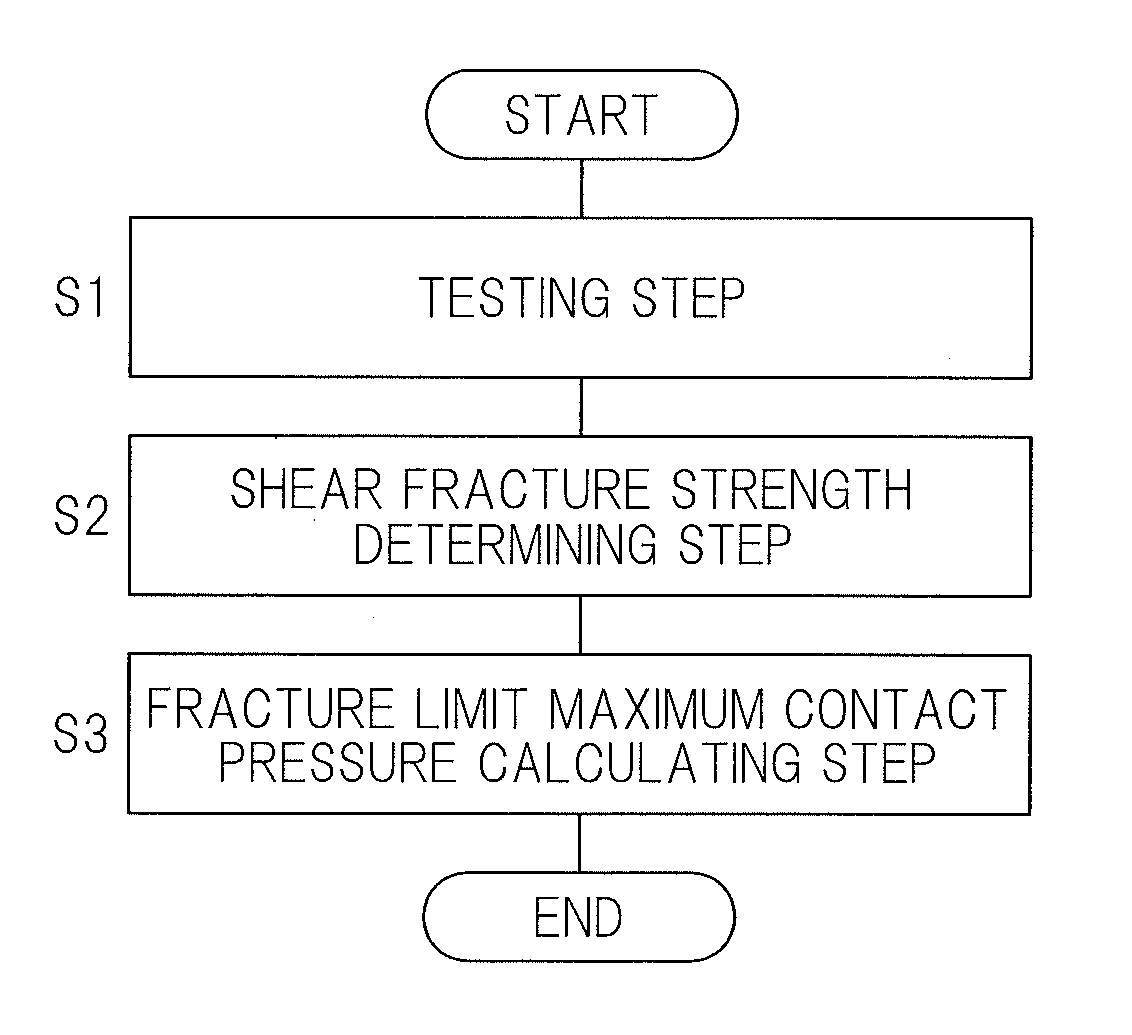

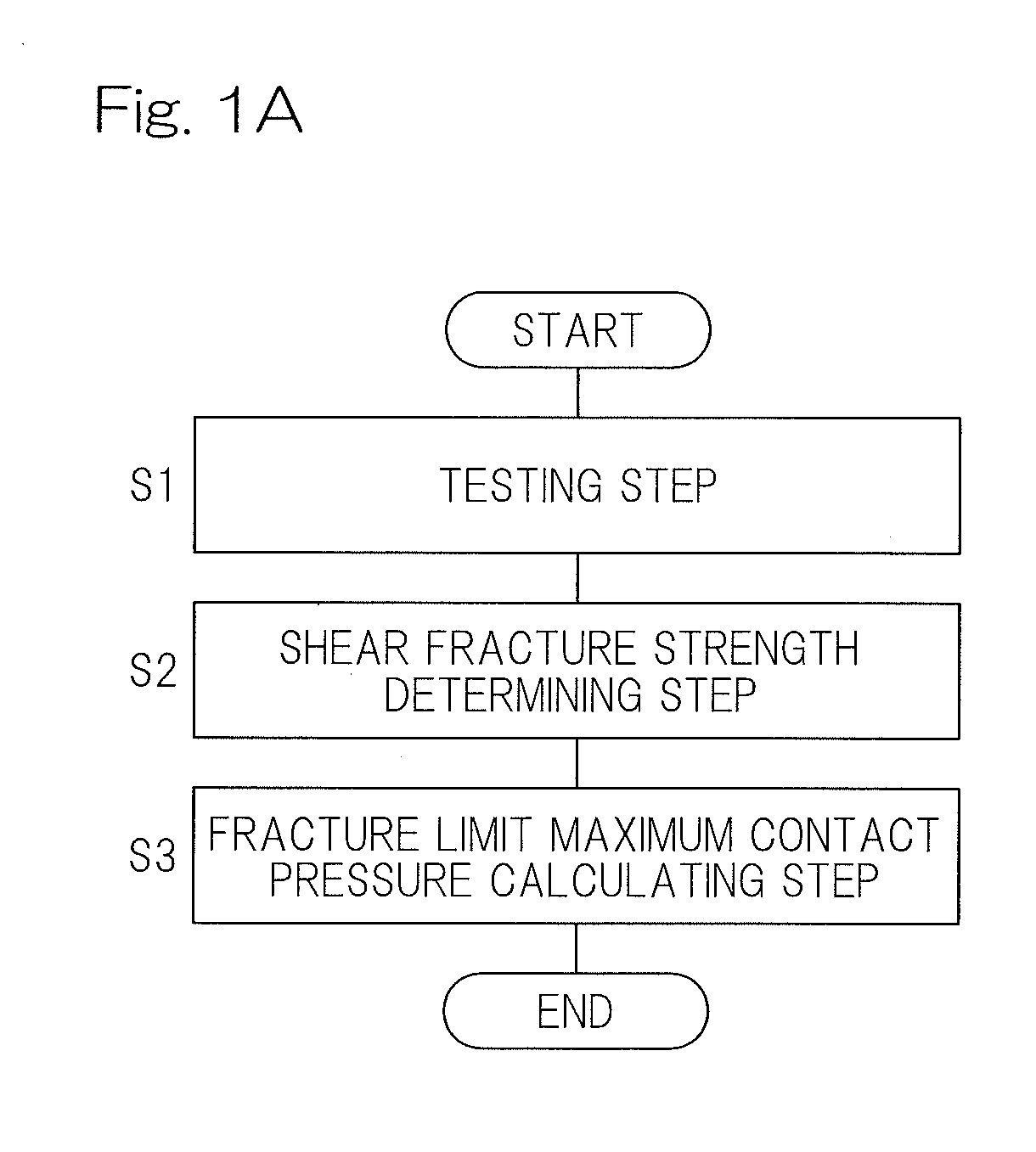

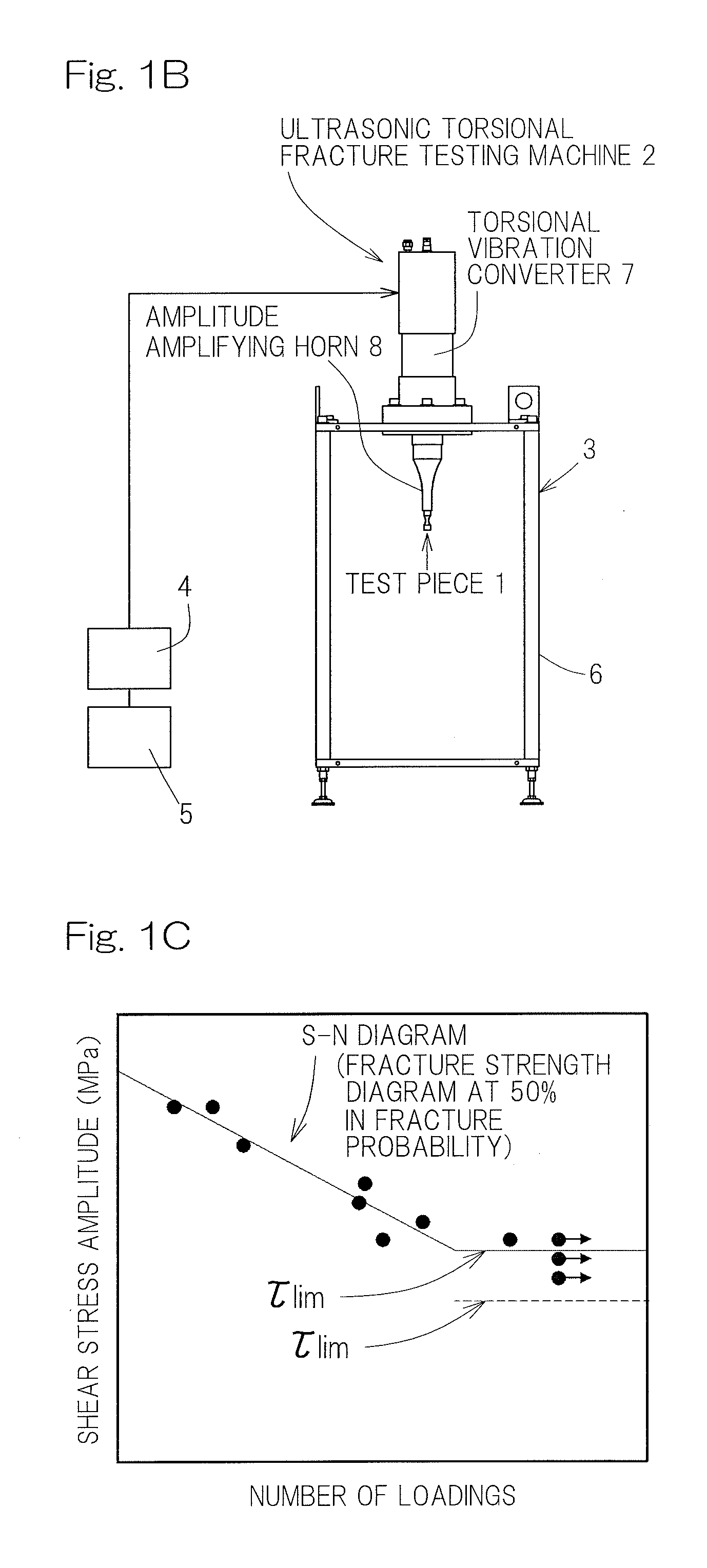

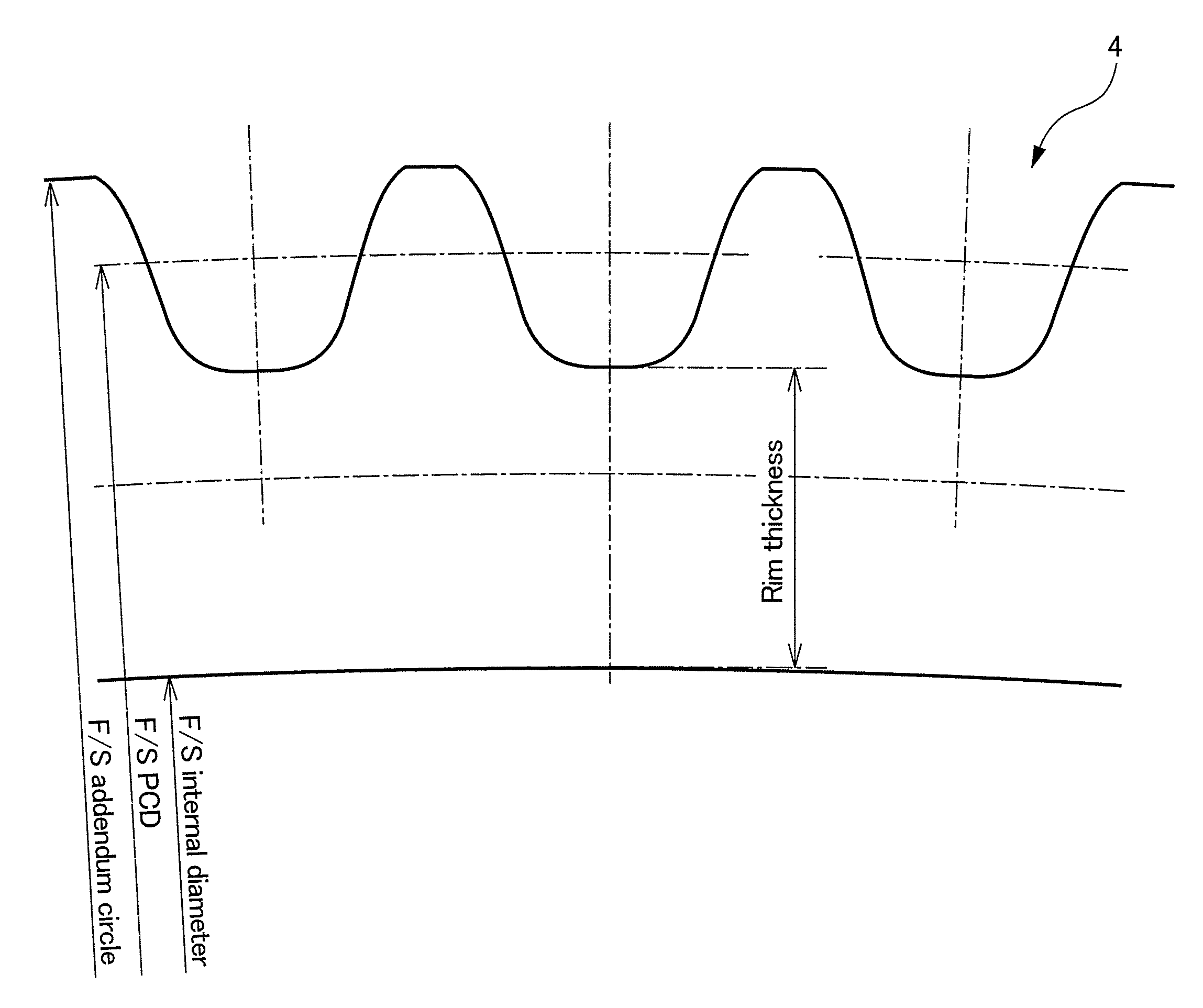

Assessment of shear fatigue property of rolling contact metal material and estimation of fatigue limit maximum contact pressure using same assessment

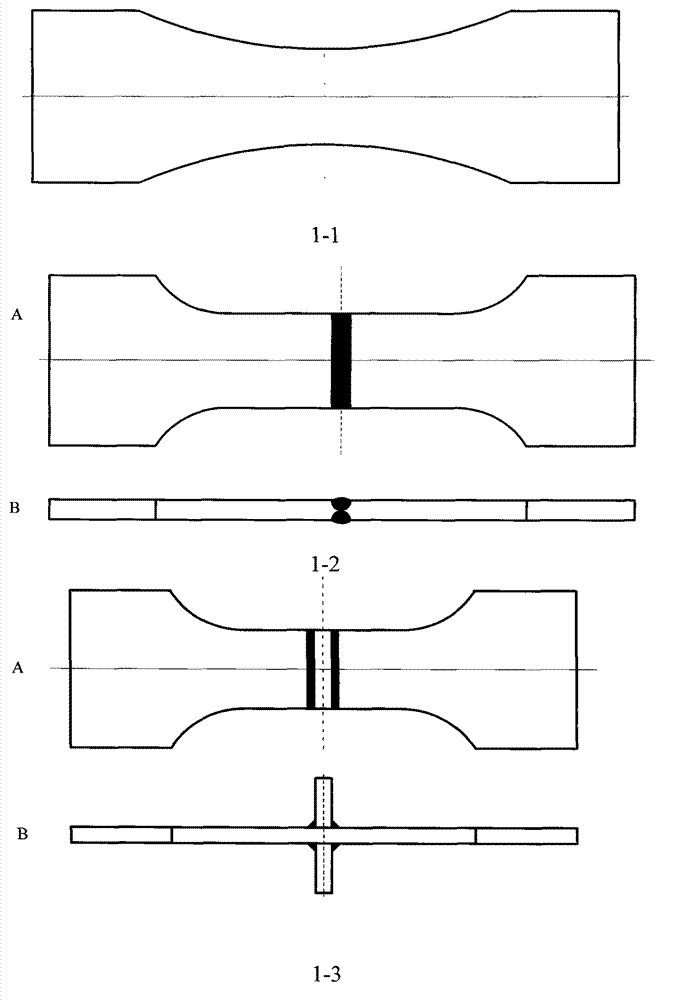

ActiveUS20130006542A1Quickly and accurately assessing the shear fatigue propertyPlug gaugesProcessing detected response signalContact pressureShear stress

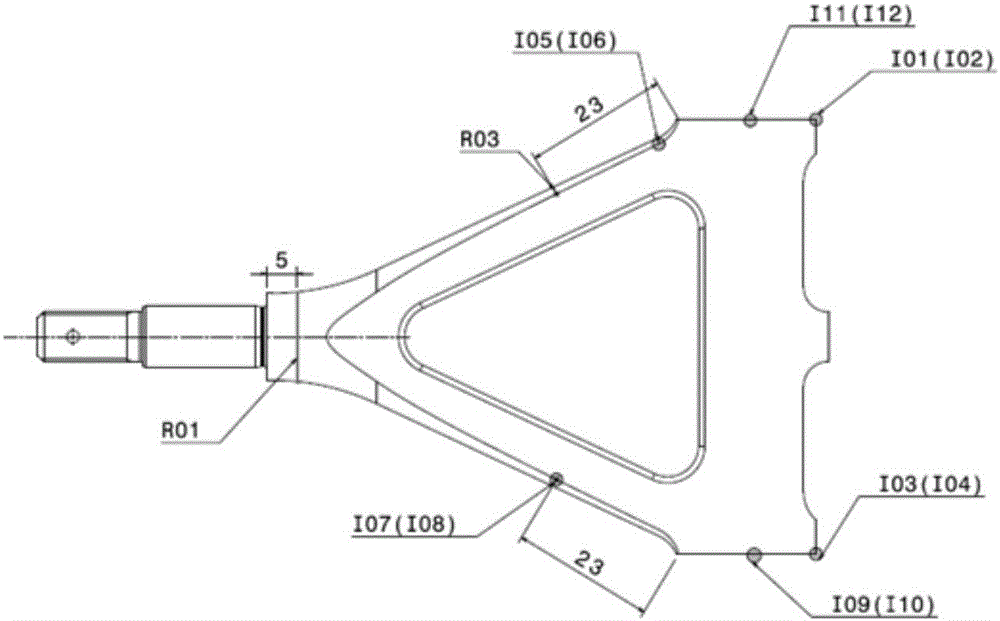

Included are a testing step (S1) for determining the relation between the shear stress amplitude of a rolling contact metallic material and the number of loading by means of an ultrasonic torsional fatigue test, and a shear fatigue strength determining step (S2) for determining the shear fatigue strength τlim, within the ultra long life regime from the relation between the shear stress amplitude and the number of loadings, which relation has been determined during the test step (S1), in accordance with a predetermined standard. It is a completely reversed torsional fatigue test, in which torsional vibrations, respective torsions in the positive rotational direction and reversed rotational direction of which are symmetrical relative to each other, are applied to a test piece (1).

Owner:NTN CORP

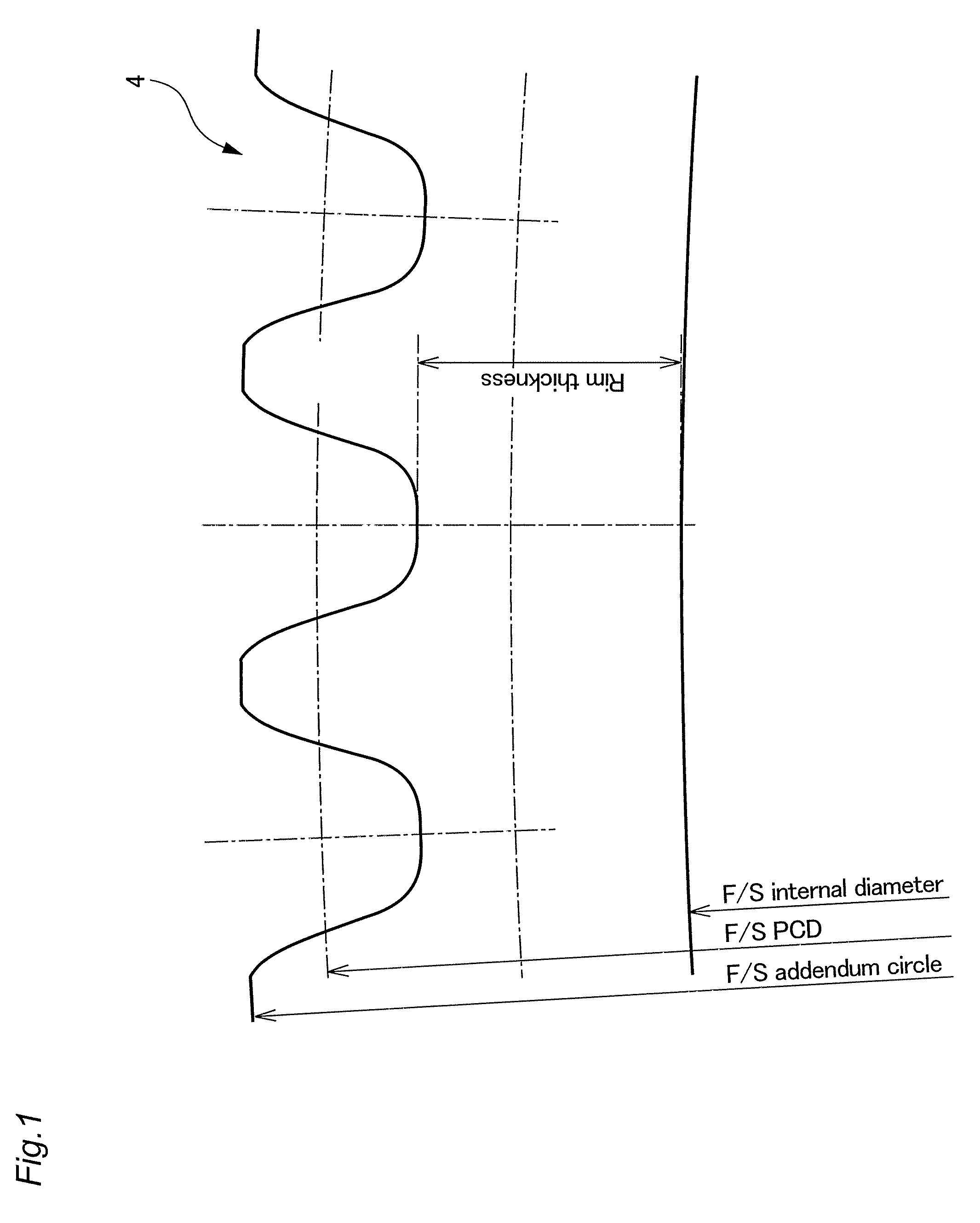

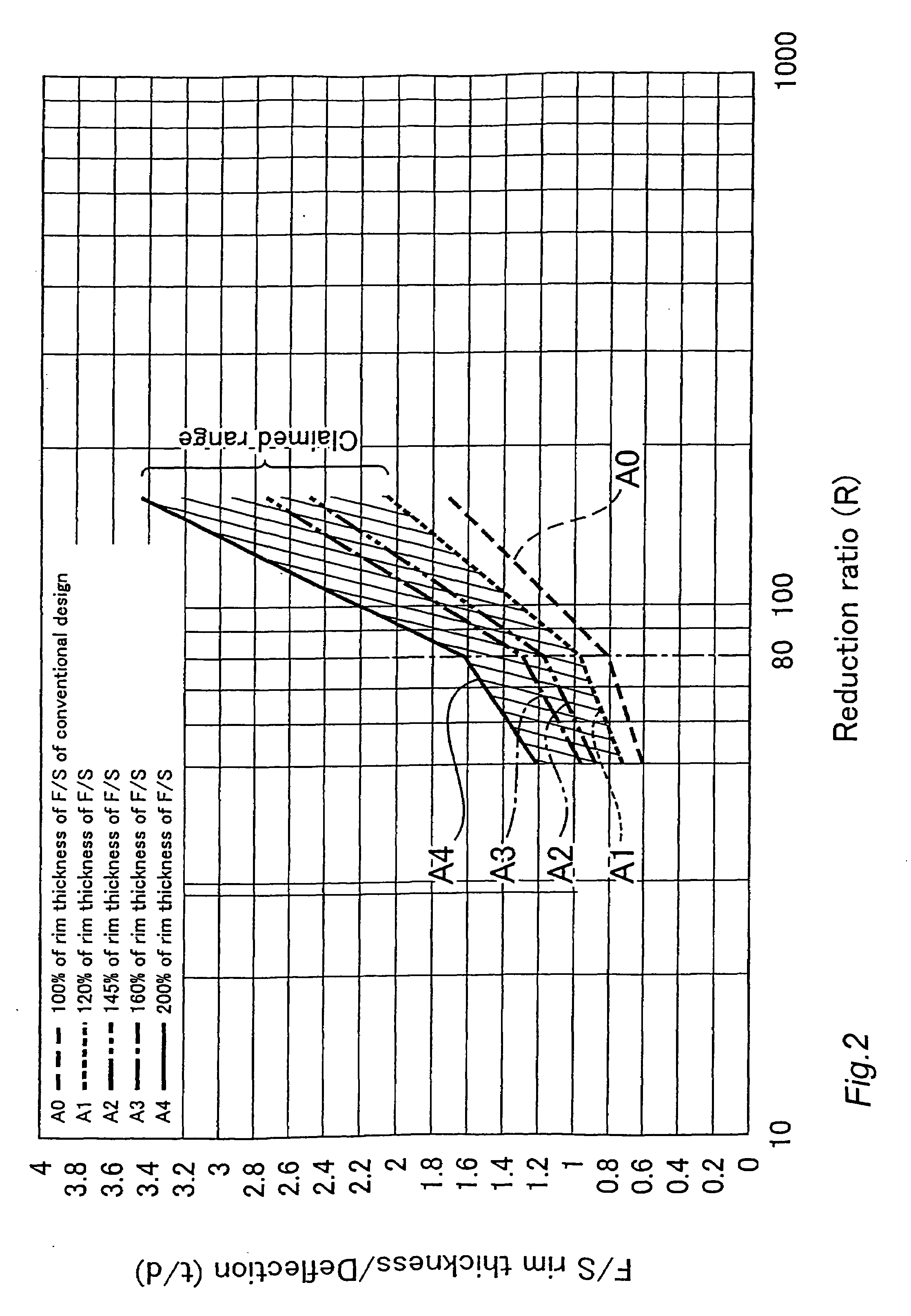

Flat type wave gear device

ActiveUS20080173130A1Improve root strengthIncrease load capacityGearingPortable liftingGear wheelReduction ratio

A flat type wave gear device is realized having a much improved load capacity. When d is an amount of radial flexing at a major axis location of a rim neutral circle of the flexible external gear of a flat type wave gear device flexed into an elliptical shape and t is the rim thickness of the flexible external gear, then(0.5237 Ln(R)−1.32)d≦t≦(0.8728 Ln(R)−2.2)d when the reduction ratio R of the wave gear device is less than 80, and(1.5499 Ln(R)−5.8099)d≦t≦(2.5832 Ln(R)−9.6832)d when the reduction ratio R of the wave gear device is 80 or more. Using this setting makes it possible to increase the tooth root fatigue limit strength of the flexible external gear, thereby making it possible to improve the load capacity of the flexible external gear.

Owner:HARMONIC DRIVE SYST IND CO LTD

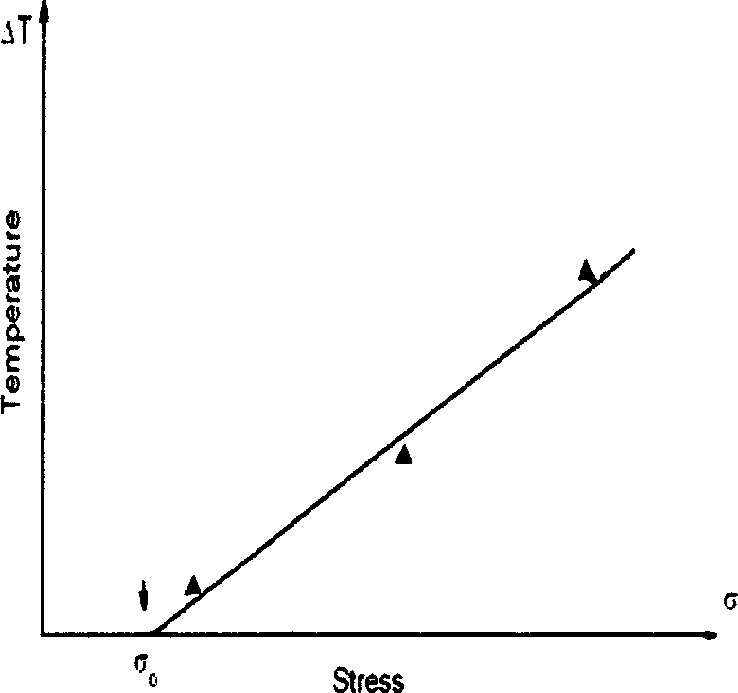

Fatigue limit rapid prediction method based on strain increment

ActiveCN105372136AMaterial strength using repeated/pulsating forcesPredictive methodsEconomic benefits

A fatigue limit rapid prediction method based on strain increment belongs to the field of rapid prediction of material fatigue limit. The invention discovers that under gradient stress load, the variation rule of strain capacity is very similar to the variation rule of temperature. Since the Luong method can use corresponding stable temperature rise value under gradient load to predict the fatigue limit, the strain capacity under gradient load can theoretically be used for rapid prediction of fatigue limit. The method utilizes a fatigue testing machine and an extensometer thereof (no dependence on expensive high-precision thermal infrared imager), and theoretically only uses one specimen to rapidly and economically predict a reliable fatigue limit of the material or a simple member in a day time according to variation rule of strain capacity under gradient load. The traditional lifting method and grouping method spend a few months and consume a large amount of human and financial resources, therefore the present invention has high engineering practical value and significant economic benefits.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

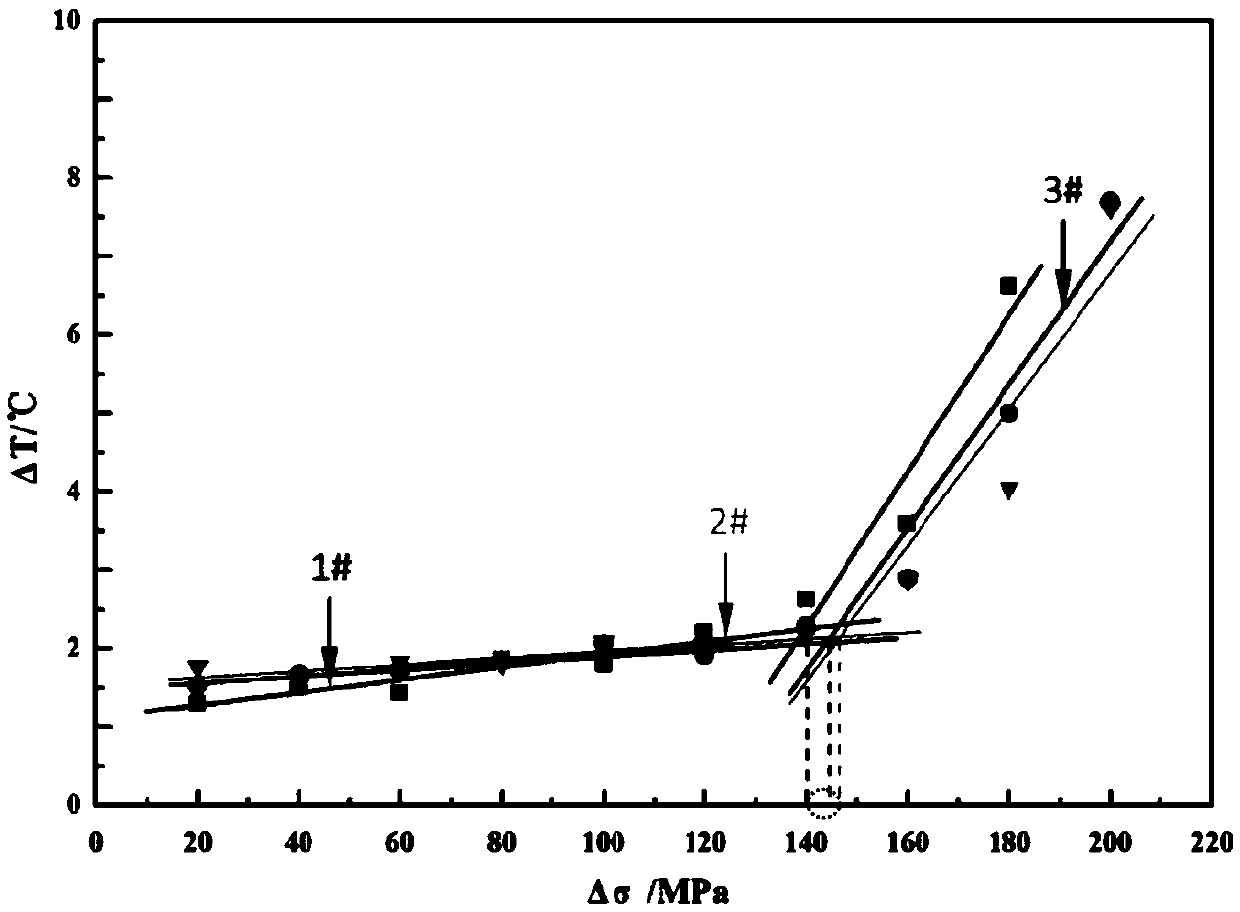

Method for fatigue analysing and testing by refrared thermal imagery

InactiveCN1869639AAccurate measurementMaterial analysis by optical meansMaterial strength using tensile/compressive forcesLow loadData treatment

The invention discloses a method for fatigue analysis and detection by infrared thermal image, circularly loading test piece with different load levels, where the load is increased from low to high, the lowest load is not less than the minimum load value which makes the test piece raise temperature, and at each load level, number of circularly loading times is greater than that of circularly loading times which makes the test piece stably raise temperature, using the infrared thermal imager to measure surface temperatures at different times under different loads, processing the obtained data and obtaining two straight lines of different slopes, where the abscissa value corresponding to their intersection is fatigue limit of the test piece. And its analyzing result is more accurate and has wider application range.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

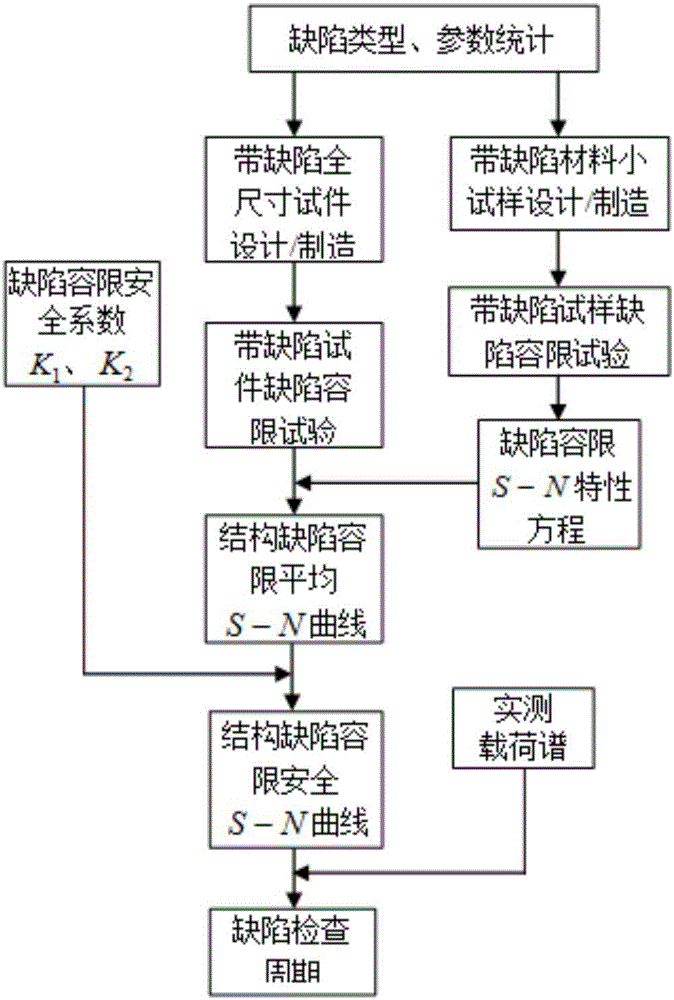

Method for determining inspection period of metal structure defects of helicopter

InactiveCN106596301AEnsure safetySatisfy Defect Tolerance Verification RequirementsPreparing sample for investigationMaterial strength using repeated/pulsating forcesEngineeringMetal

The invention provides a method for determining the inspection period of metal structure defects of a helicopter, and belongs to the technical field of fatigue design of a helicopter structure. The method comprises the steps: firstly, according to a structural material, manufacture and use conditions, selecting defect types and parameters, and determining a danger zone of the structure through stress analysis and fatigue tests; followed by prefabricating various defects, and based on actual measured load and breakdown stress analysis, determining dynamic and static loads of metal structure defect tolerance tests; and finally, determining a structure safe defect tolerance S-N curve, calculating the safe life of the structure with the defects, respectively calculating the different defects, and taking the minimum value of the calculation results as the inspection period of the structure with the defects. Based on the danger analysis, the tests of a sample with defects are used for determining the fatigue limit of the structure with the defects, the safe inspection period and the allowable maximum damage of the detected structural defects provided by flight load spectra are combined, the use safety of the helicopter can be ensured, and the airworthiness clause defect tolerance validation requirements are met.

Owner:CHINA HELICOPTER RES & DEV INST

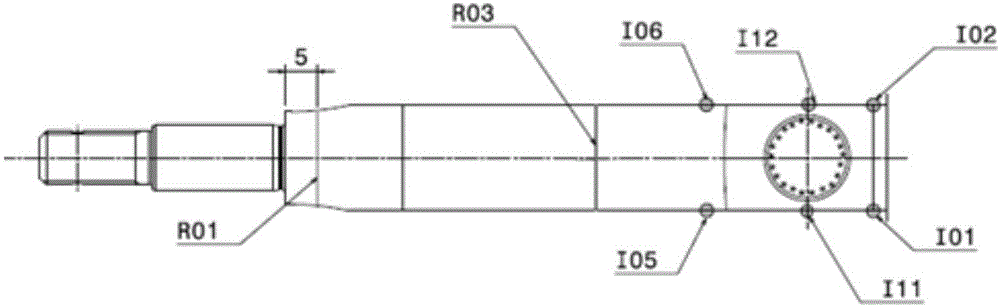

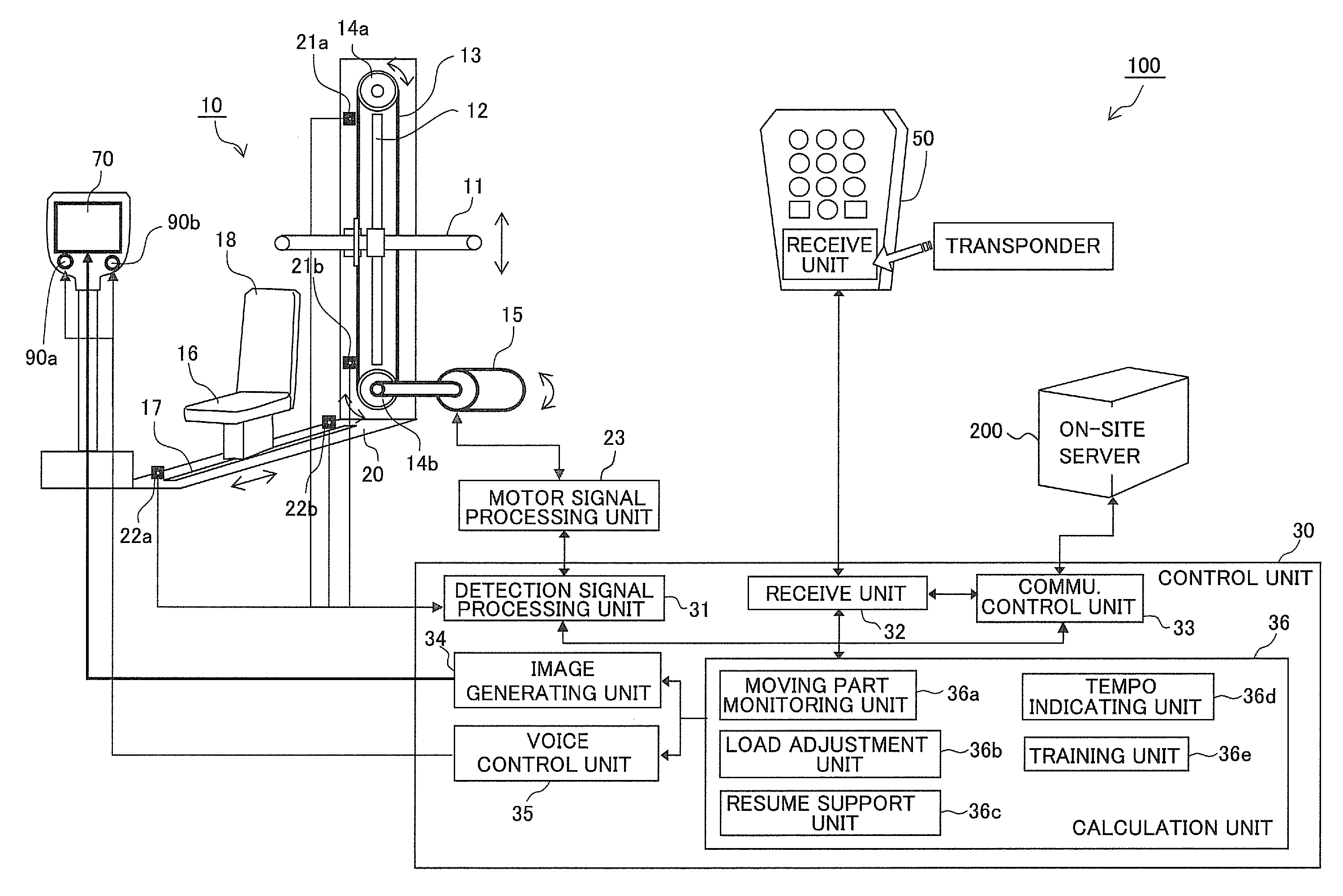

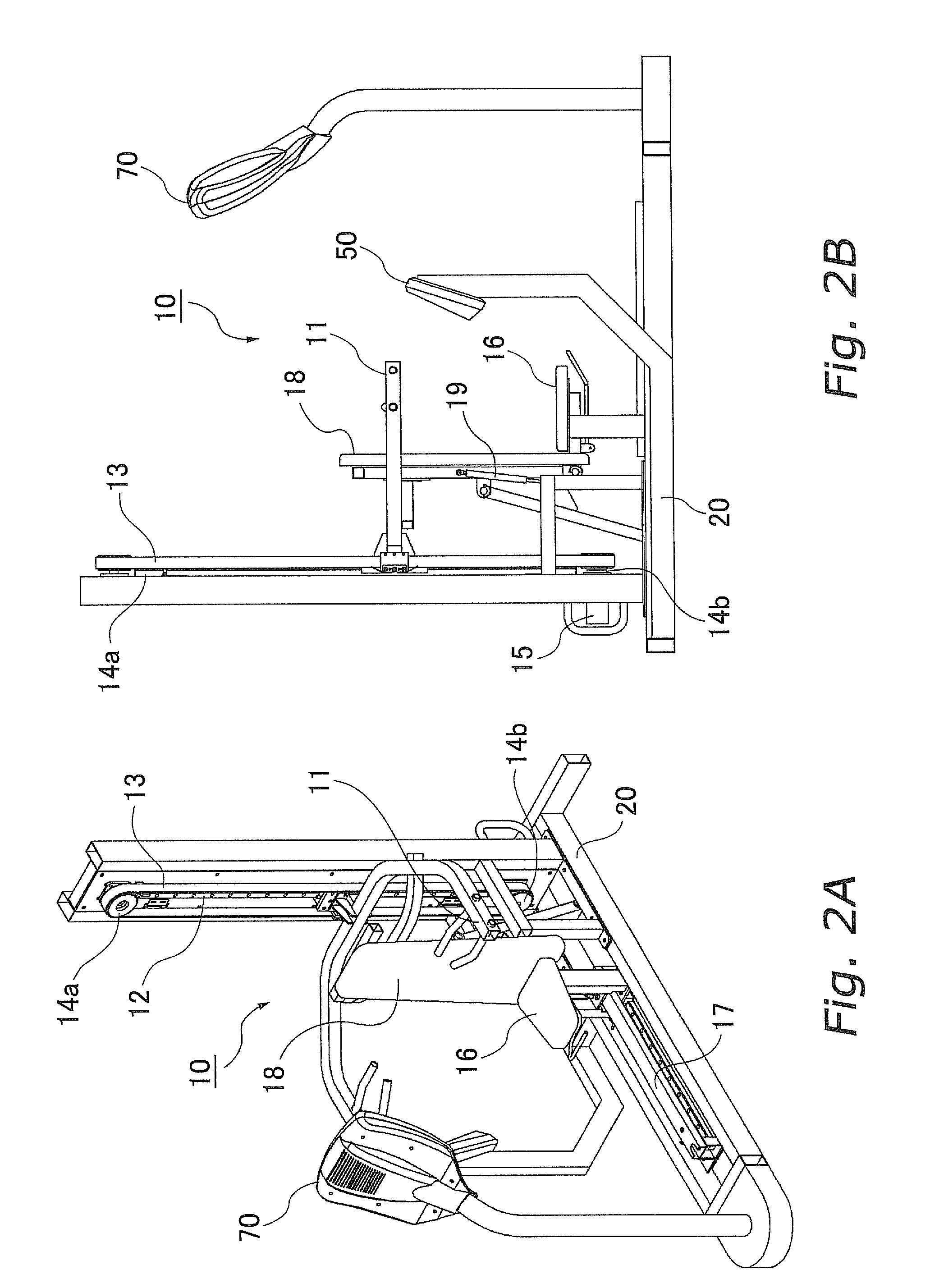

Training apparatus

A training apparatus is disclosed which allows a trainee to attain a sense of accomplishment by continuing an exercise until a target is reached, without undue strain. A torque motor applies a load to a handle bar, which is driven by the exercise of a trainee. If the movement of the trainee who moves the handle bar is about to stop, then the load is gradually reduced. If the handle bar once again begins to move due to a load reduction, then it is inferred that the trainee has resumed the exercise, and the load at that time is maintained until, for example, the direction of motion of the handle bar changes. By gradually reducing the load at the fatigue limit of the trainee, it is possible to promote the resumption and the continuance of the exercise.

Owner:KONAMI SPORTS & LIFE

High-strength antifatigue steel products and method for manufacturing same

InactiveCN101139685AGood effectHigh strengthTemperature control deviceForeign matterHigh pressure water

The invention provides a high-strength anti-fatigue steel and a manufacturing method for the steel, and pertains to the field of special steel and smelting of special steel. The method comprises adding proper amount Nb and Ti to carry out micro alloying, smelting by a combined blowing converter, LF refining, continuous casting the sheet blank, heating, removing scale by high-pressure water, hot rolling and laminar flow cooling, coiling, etc. and produces the high-strength anti-fatigue steel comprising by weight C% 0.07-0.13, Si% 0.15-0.35, Mn %1.0-1.3, P %<=0.025, S%<=0.010, Nb%0.015-0.020, Ti%0.010-0.025, Alt% 0.015-0.050, and the remainder Fe and trace foreign matters. The fatigue limit of the steel is up to 510 MPa, is of high strength, toughness and excellent forming performance, is applicable for manufacturing the longitudinal and cross beams in frames of load-carrying vehicles such as heavy and light duty trucks, etc.

Owner:LAIWU IRON & STEEL GRP

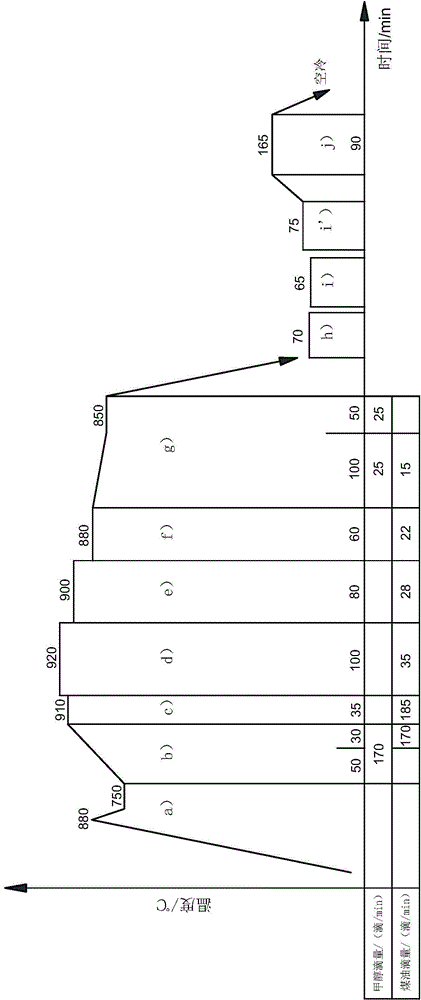

Carburizing and quenching process of automobile gear

InactiveCN104357796AGuaranteed reliabilityGuaranteed service lifeSolid state diffusion coatingFurnace typesWear resistanceUltimate tensile strength

The invention provides a carburizing and quenching process of an automobile gear. By adopting a pit-type gas carburizing furnace to perform carburizing treatment on the automobile gear, the carburizing and quenching process comprises the following steps: a) performing primary preheating, namely, gradually raising the temperature in the furnace to 880 + / -5 DEG C and then putting the automobile gear in the furnace, gradually reducing the temperature in the furnace to 750 + / -5 DEG C, preserving the heat for 30 minutes. The carburizing and quenching process of the automobile gear disclosed by the invention adopts a manner of repeatedly preheating and diffusing, so that the depth of an effective carburizing layer of the automobile gear is 1.1-1.2mm after carburizing to obtain a finished product, and the surface hardness is 58-62HRC, and therefore, the wear resistance, the strength and the fatigue limit of the components are improved, and the mechanical performances of the gear material are sufficiently brought into play. Moreover, distortions such as diameters changes, uneven changes in an addendum circle and an inner hole, plane warpage as well as dimension changes between gears are not produced, so that the reliability and the service life of the automobile gear are guaranteed.

Owner:余姚市鸿胜汽车配件有限公司

High temperature and high pressure corrosion hydrogen permeation testing device and method

ActiveCN104568727AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceFatigue loadingCarbon dioxide corrosion

The invention discloses a high temperature and high pressure corrosion hydrogen permeation testing device and method. When fatigue limit is measured, after hydrogen permeation current is stabilized under the given corrosion condition, step type fatigue loads are applied to a test sample material from a smaller one to a larger one, and when the hydrogen permeation current is increased along with increase of the load, dislocation movement inside the test sample material is caused by the load, and the load is considered as the fatigue limit of the test sample material in the environment. The device and the method disclosed by the invention have the characteristics that a quantitative relation between the fatigue load state and the hydrogen permeation amount can be measured in situ on line in a high-pressure carbon dioxide corrosion state, the internal relation between the stress and segregation diffusion of hydrogen can be intuitively reflected, and a mutual relation among multiple data is established.

Owner:ZHEJIANG UNIV OF TECH

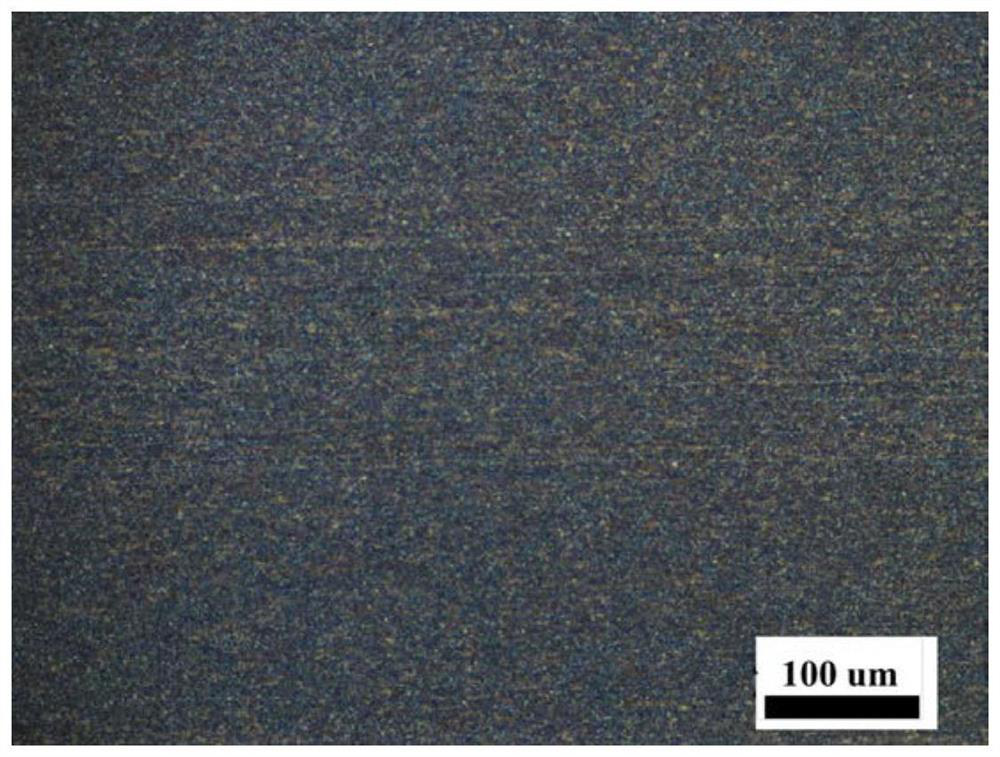

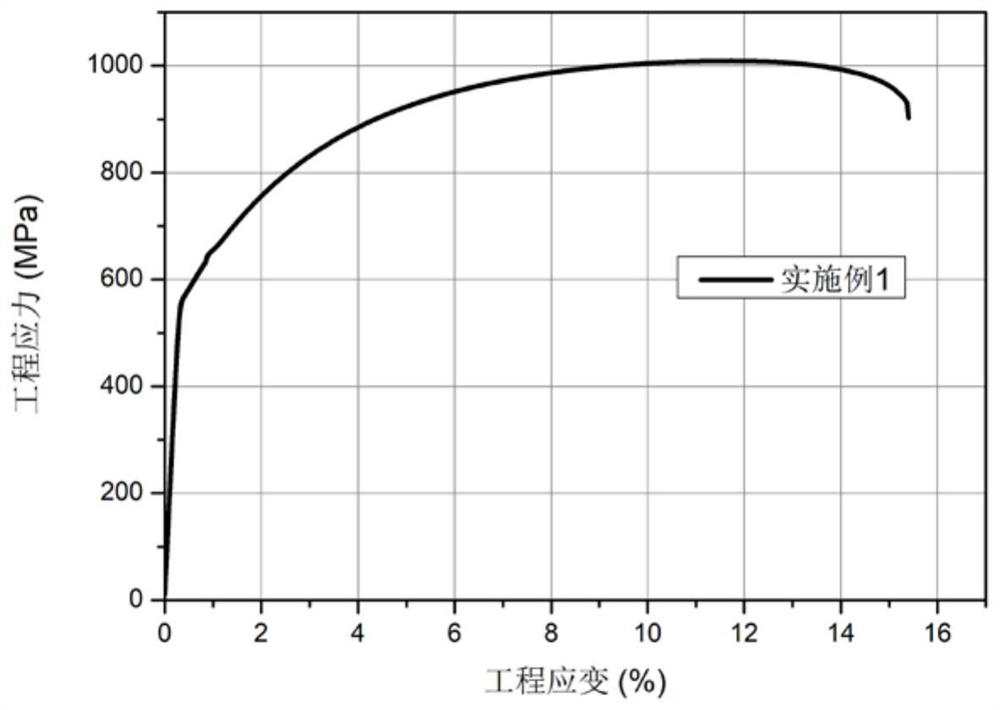

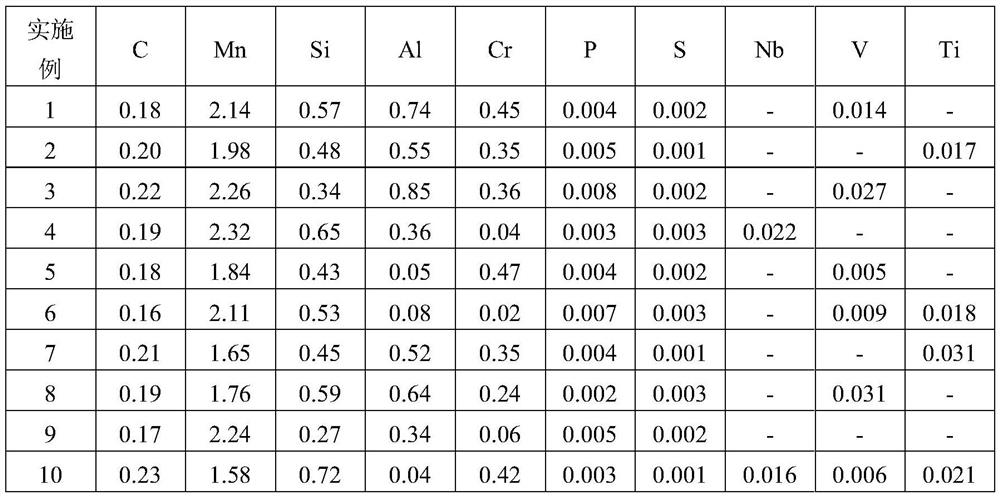

Alloyed hot-dip galvanized DH980 steel and preparation method thereof

ActiveCN112048680AReduce original costRealize industrial productionHot-dipping/immersion processesUltimate tensile strengthFatigue limit

The invention discloses alloyed hot-dip galvanized DH980 steel and a preparation method thereof. The steel comprises 0.16 %-0.23 % of C, 1.5 %-2.5 % of Mn, 0.2 %-0.9 % of Si, 0.02 %-0.9 % of Al, 0.02%-0.70 % of Cr, less than or equal to 0.01 % of P, less than or equal to 0.01 % of S, less than or equal to 0.05 % of Nb, less than or equal to 0.05 % of V, less than or equal to 0.05 % of Ti, and thebalance iron and inevitable impurities, wherein the proportion of (Si+Al) is 0.6 %-1.5 %. The heating temperature of a casting blank is 1150-1300 DEG C, the initial rolling temperature is 1000-1150 DEG C, the final rolling temperature is greater than or equal to 880 DEG C, and the coiling temperature is 500-700 DEG C; the cold rolling reduction rate is 40 %-80 %; and the annealing temperature is760-880 DEG C, the annealing time is 30-300 s, the galvanizing temperature is 450-470 DEG C, the alloying temperature is 470-530 DEG C, and the alloying heat preservation time is 5-60 s. According tothe steel and the method, the tensile strength of a finished steel sheet is 980-1100 MPa, and the high-cycle fatigue ultimate strength is larger than or equal to 370 MPa; and the reaming performance is excellent.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com