Patents

Literature

354 results about "Light duty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

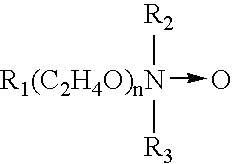

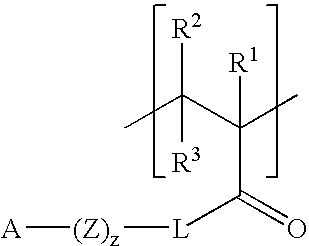

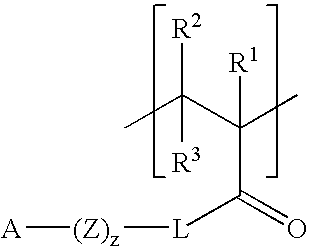

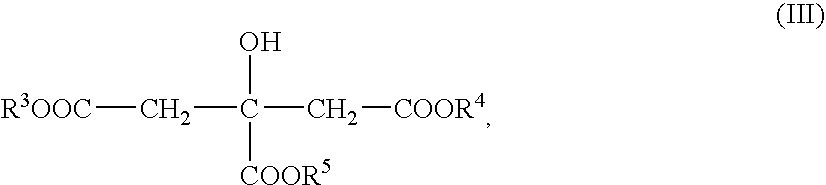

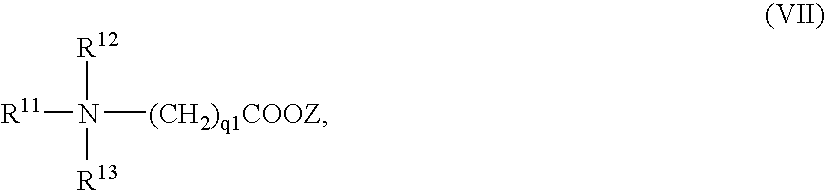

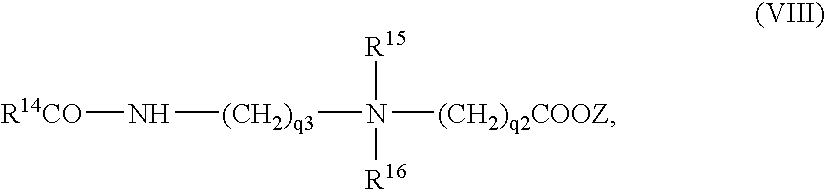

Detergent compositions comprising polymeric suds enhancers which have improved mildness and skin feel

InactiveUS20060035807A1Increase mildnessImprove skinCosmetic preparationsOrganic detergent compounding agentsLaundryPolymer

Compositions comprising one or more polymeric suds volume and suds duration enhances which are mild on the user's skin. The polymeric suds enhances are suitable for use in methods which in use as compositions light duty liquid, LDL compositions, hand dishwashing compositions, laundry bars, personal cleansing compositions and the like.

Owner:THE PROCTER & GAMBLE COMPANY

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

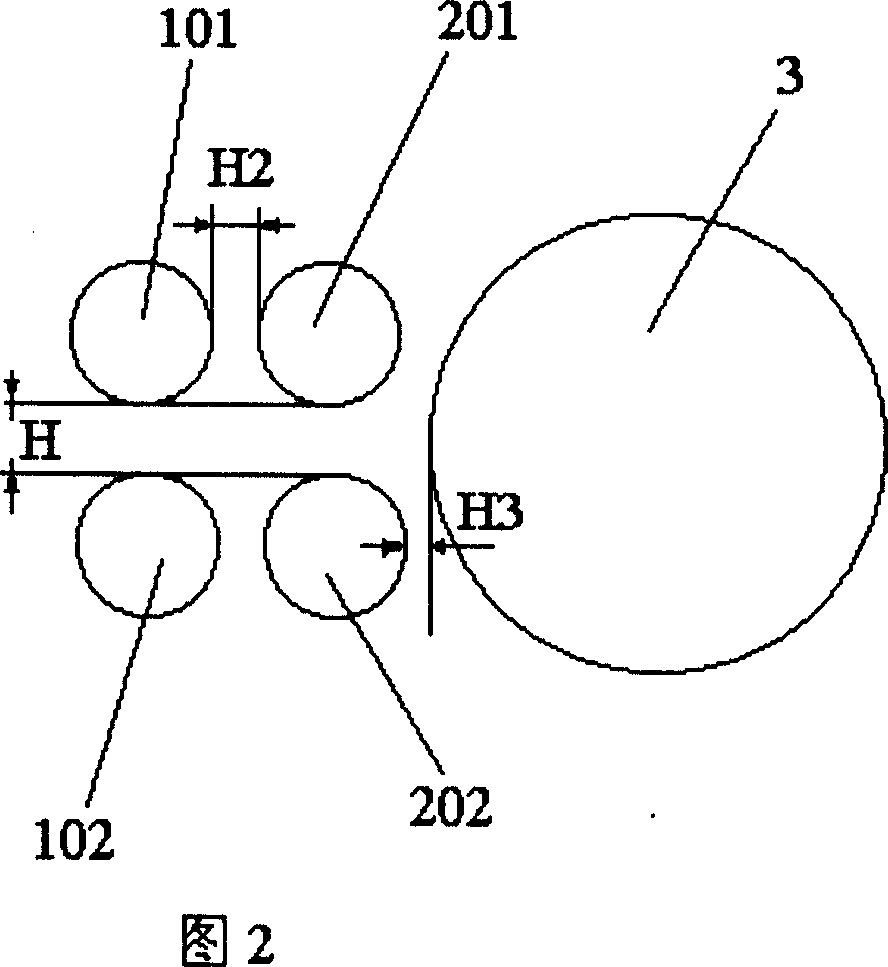

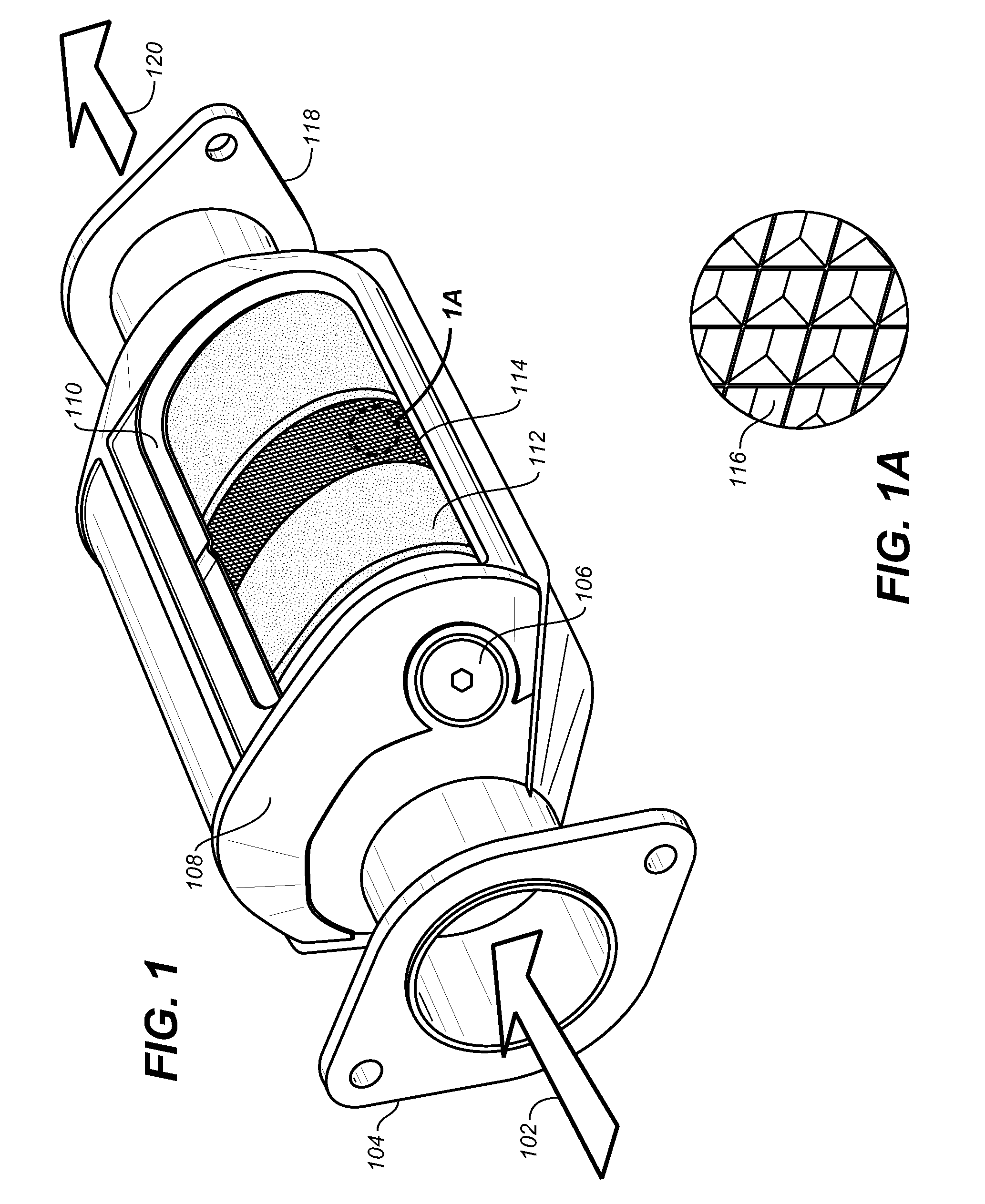

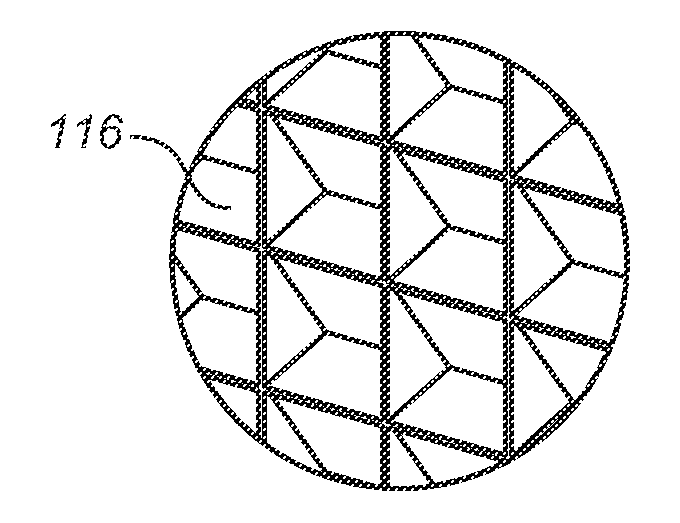

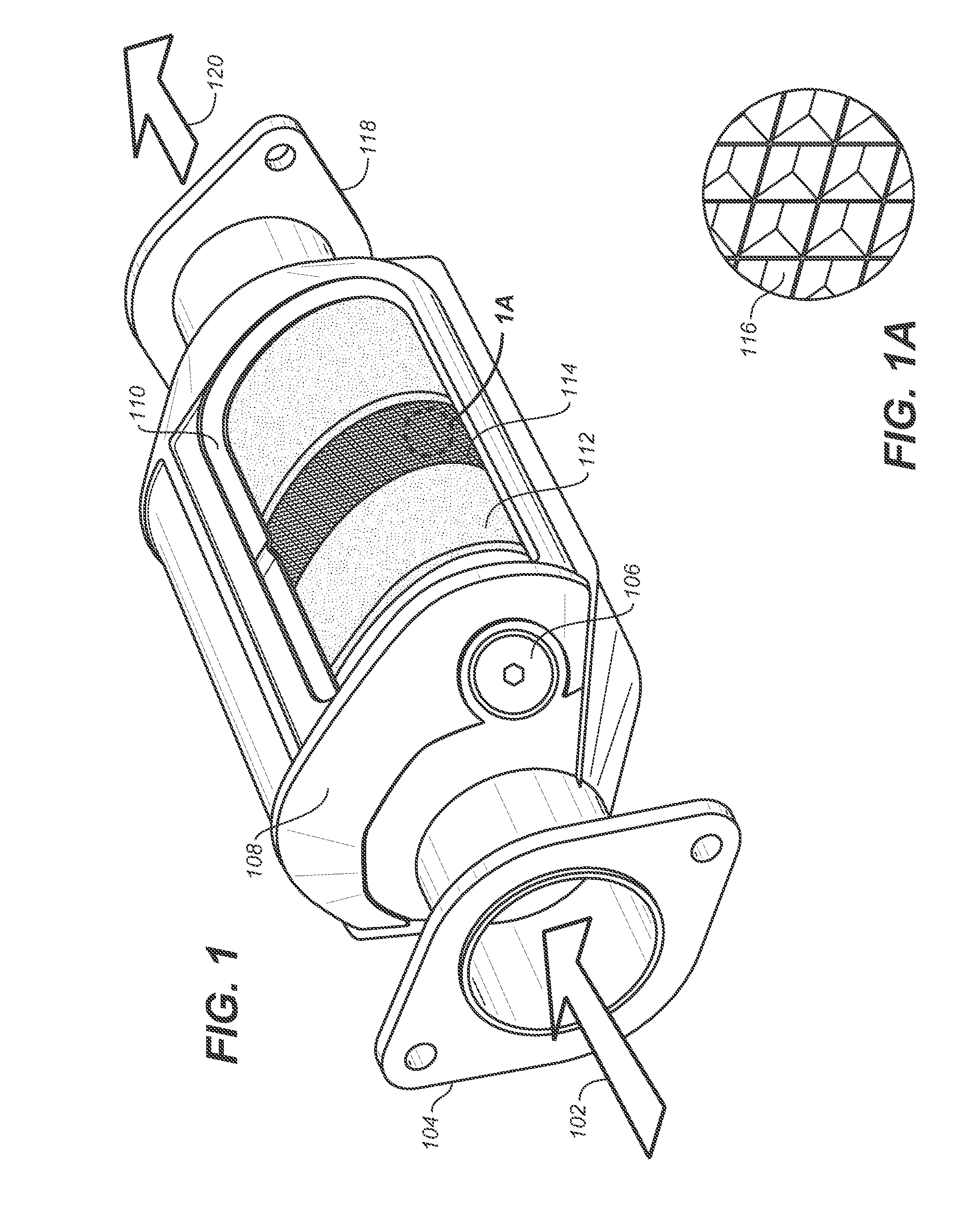

Coated substrates for use in catalysis and catalytic converters and methods of coating substrates with washcoat compositions

ActiveUS8679433B2Improve performanceEmission reductionCombination devicesNitrogen compoundsTreatment systemDiesel fuel

Owner:SDC MATERIALS +1

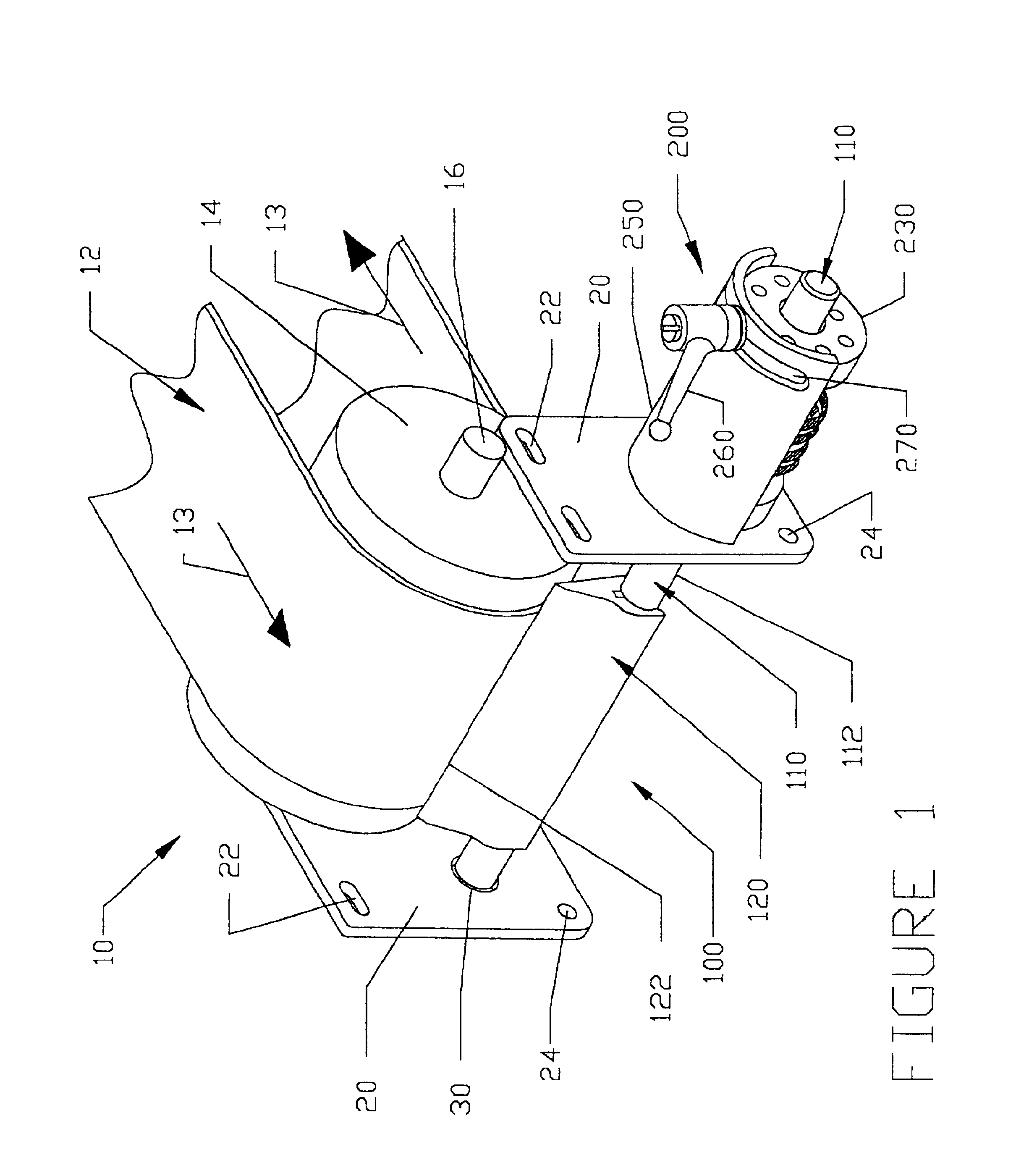

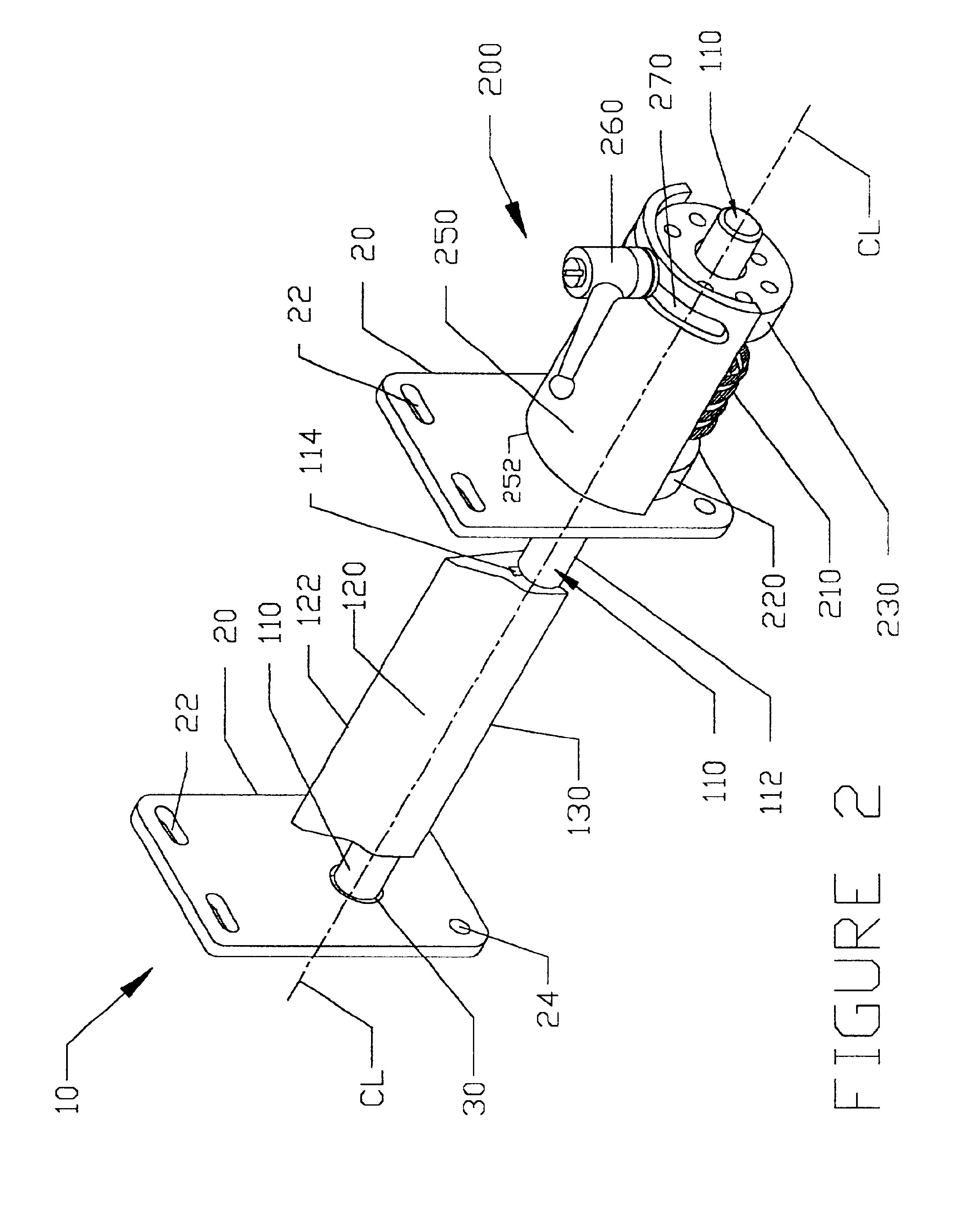

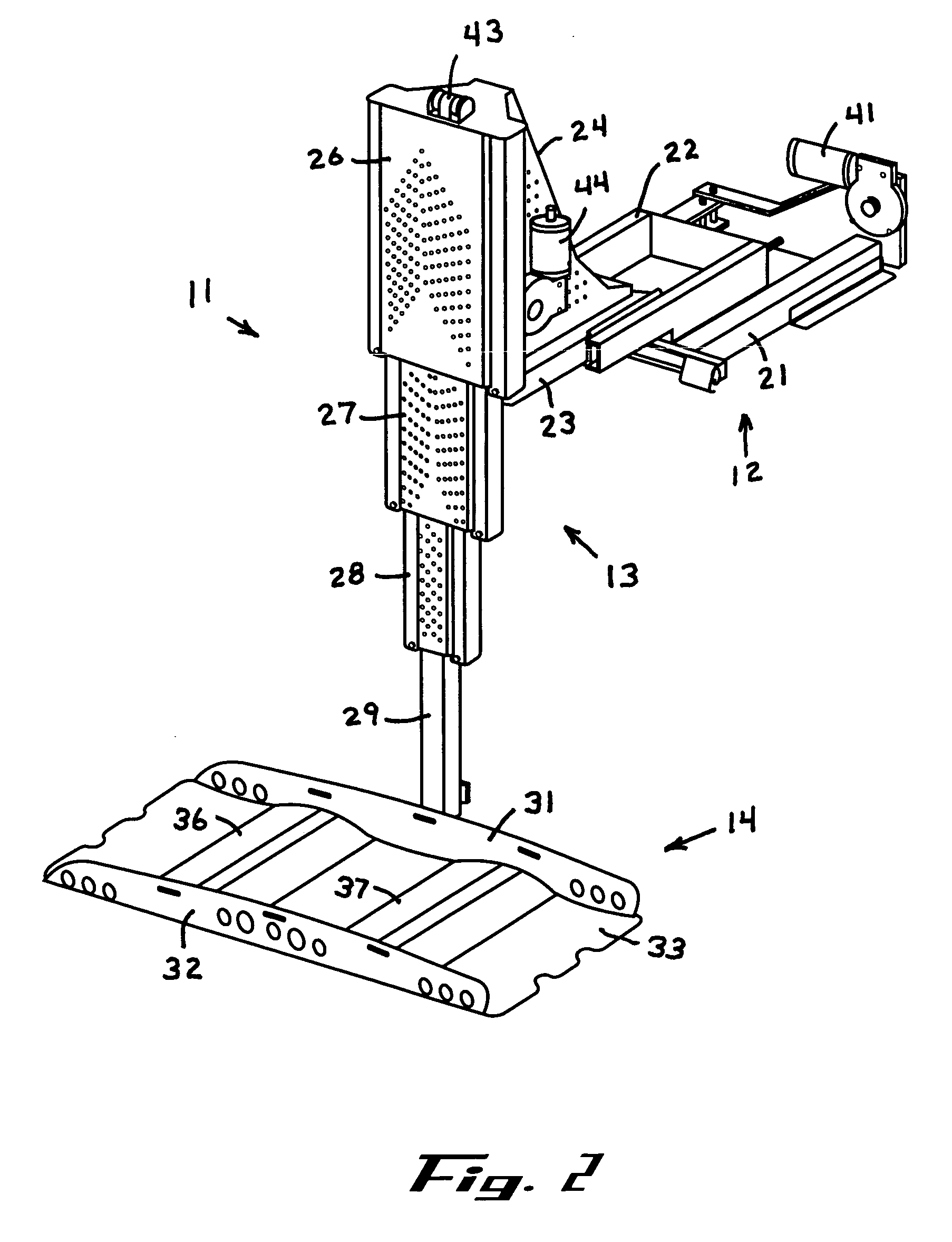

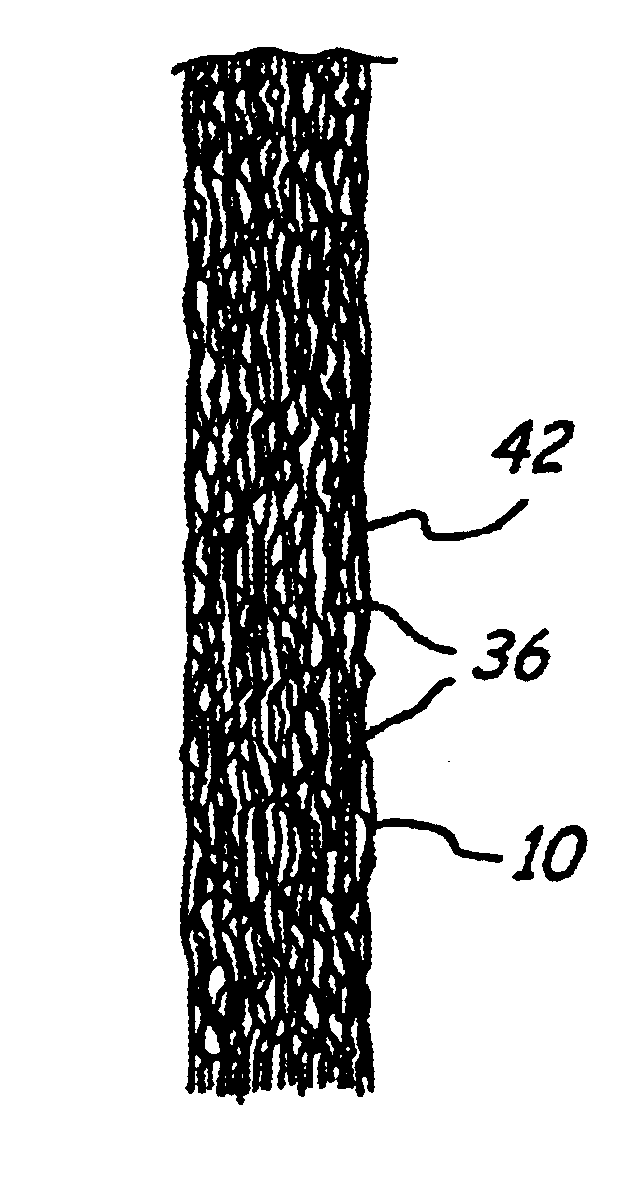

Light duty belt cleaning system

Owner:ASGCO MFG

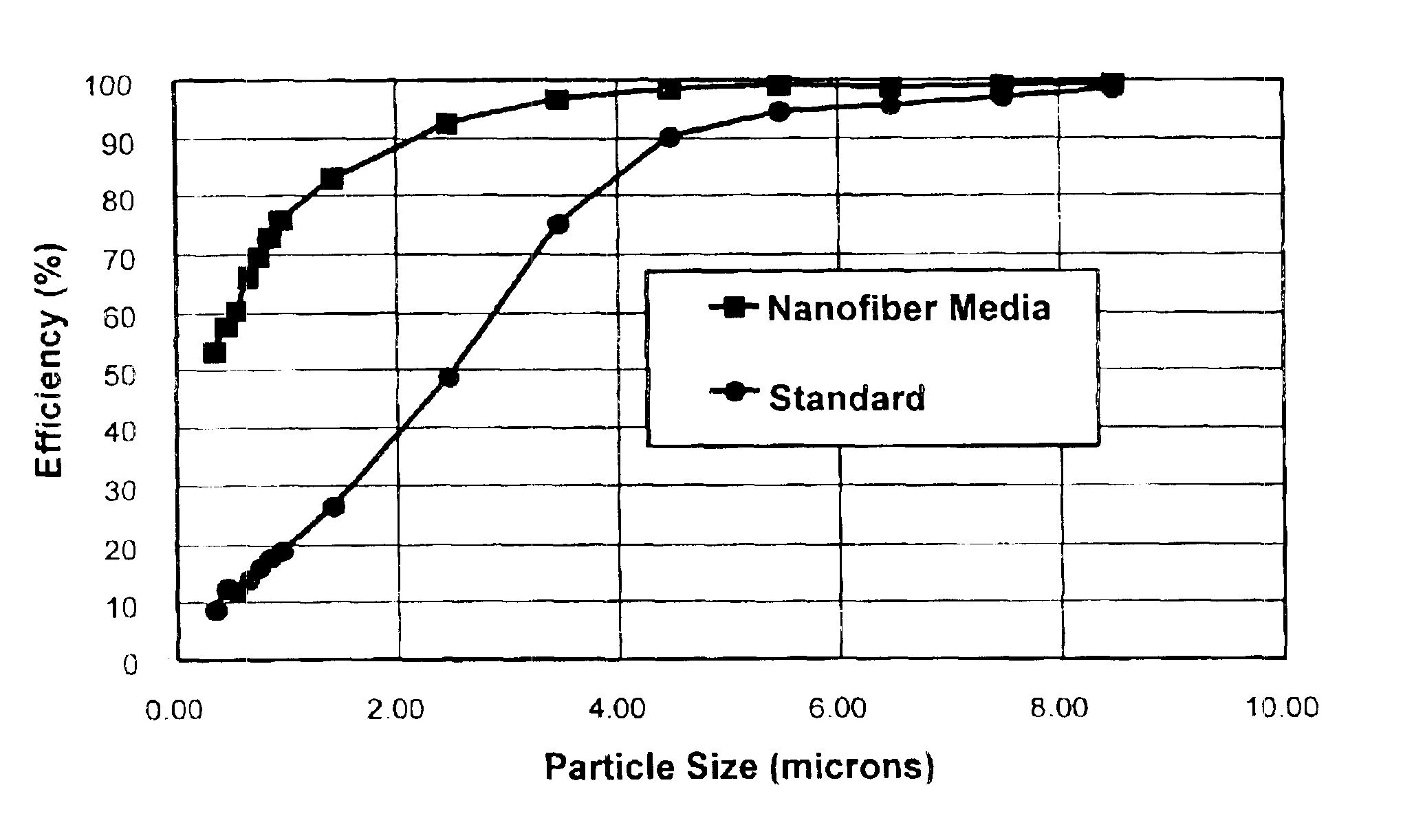

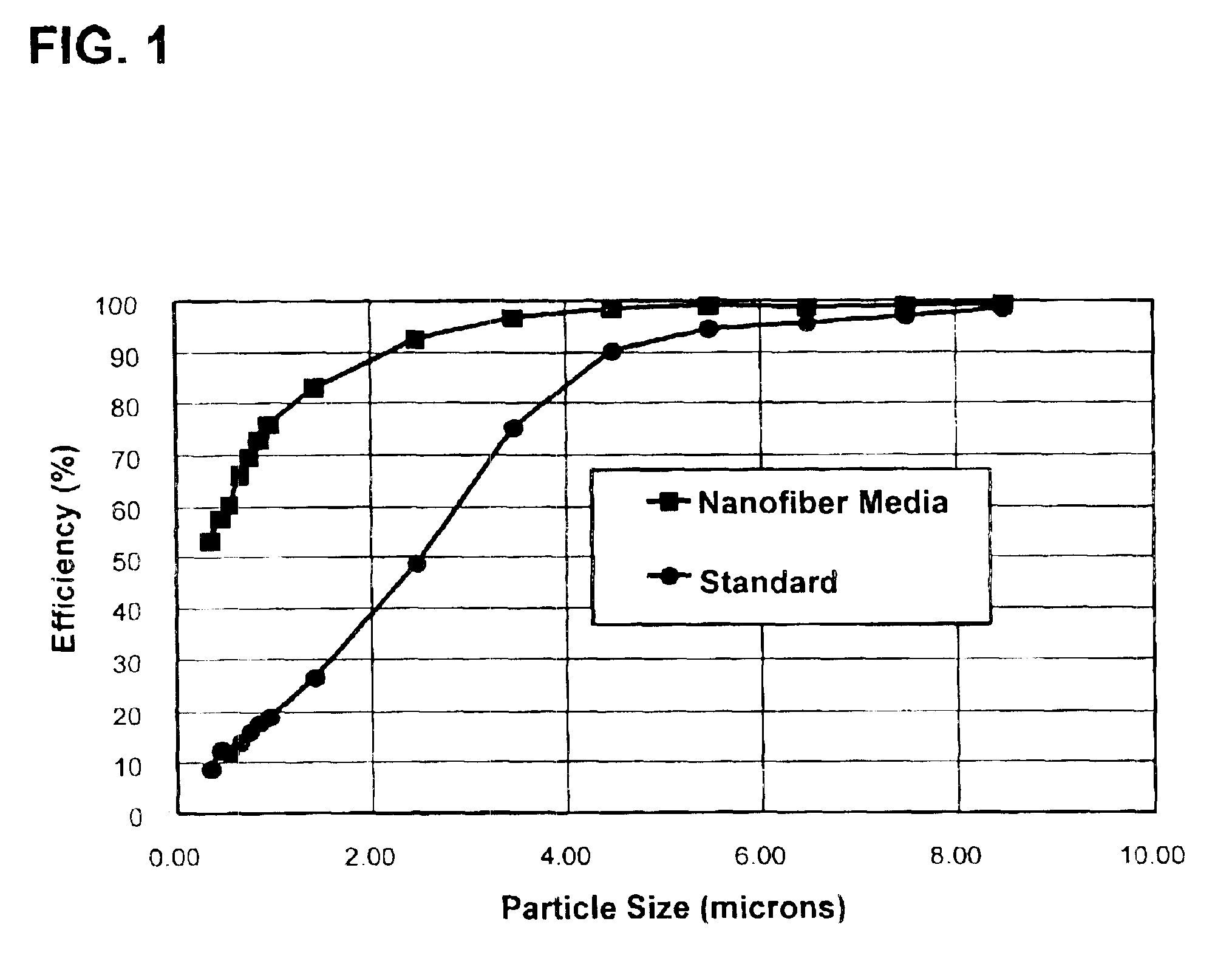

Motor vehicle filter structure having visual indicator of useful life

InactiveUS6875249B2Low efficiencyIncrease pressure dropCombination devicesAuxillary pretreatmentParticulatesMobile vehicle

Filter media and filter structure or media pack can be engineered to exhibit high initial efficiency and to surface load particulate removed from a gaseous stream. The filter technology protects engine operation from ingested particulate and accumulates the particulate as a surface loaded layer visible on the surface of the structure. The particulate accumulates as a surface loaded layer until it achieves a certain depth of particulate or gray scale characteristic or color depth indicative of the end of the useful life of the filter prompting a change of the filter structure. The filter structure is characterized by its ability to surface load particulate, avoid accumulation of particulate in the depth media and enhance the characteristics of the material through surface loading. Such technology is particularly useful in light duty vehicle maintenance technology.

Owner:DONALDSON CO INC

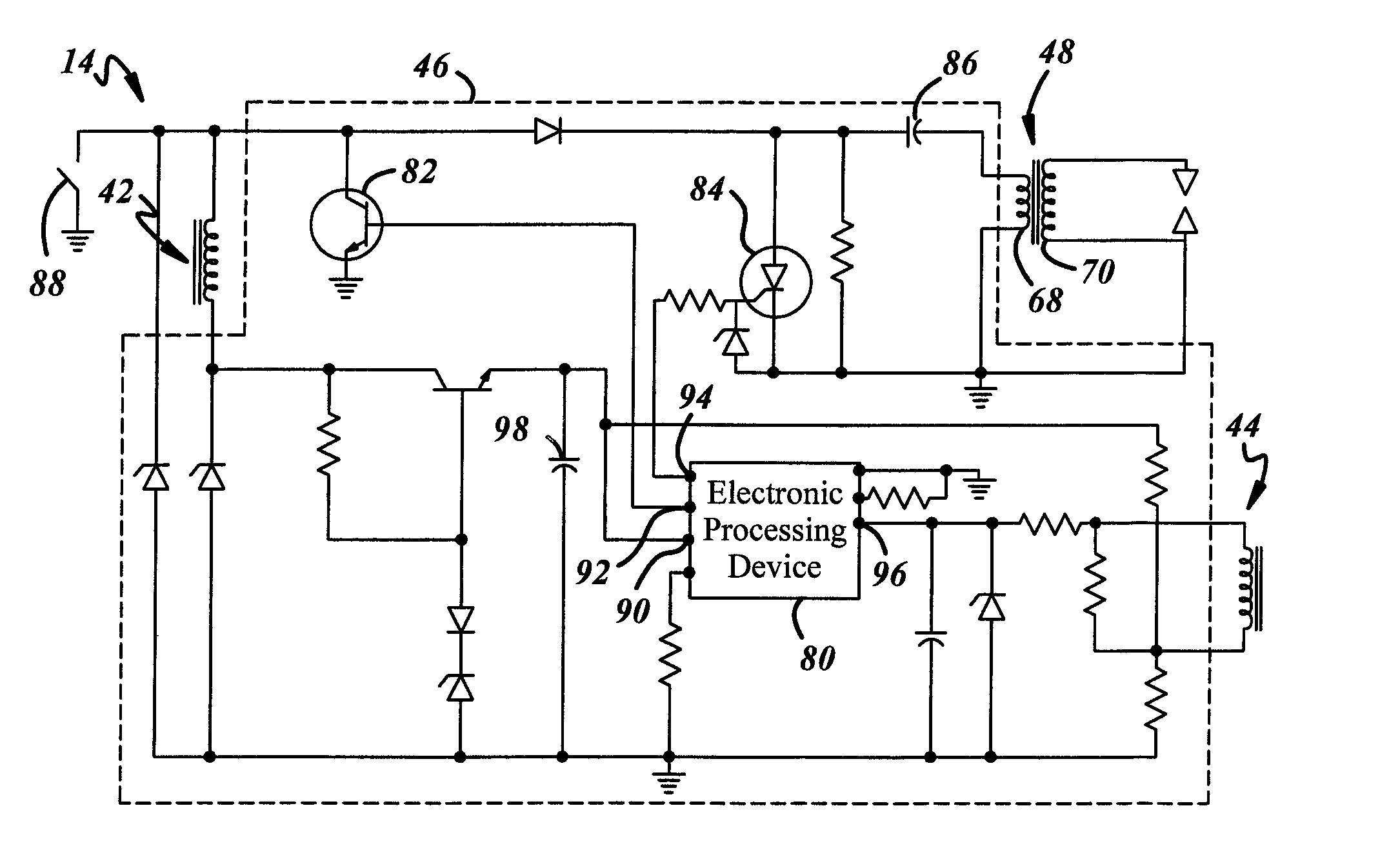

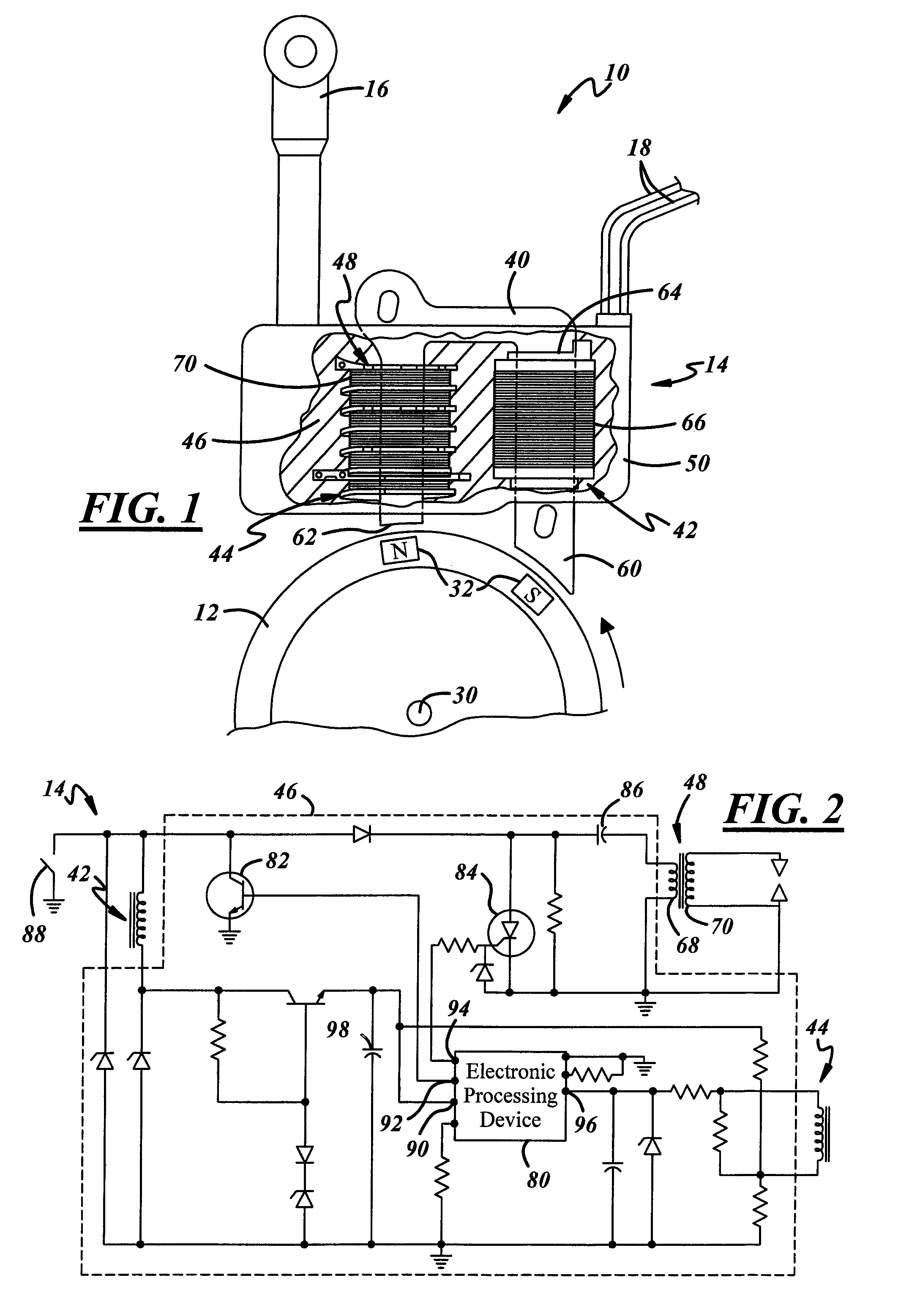

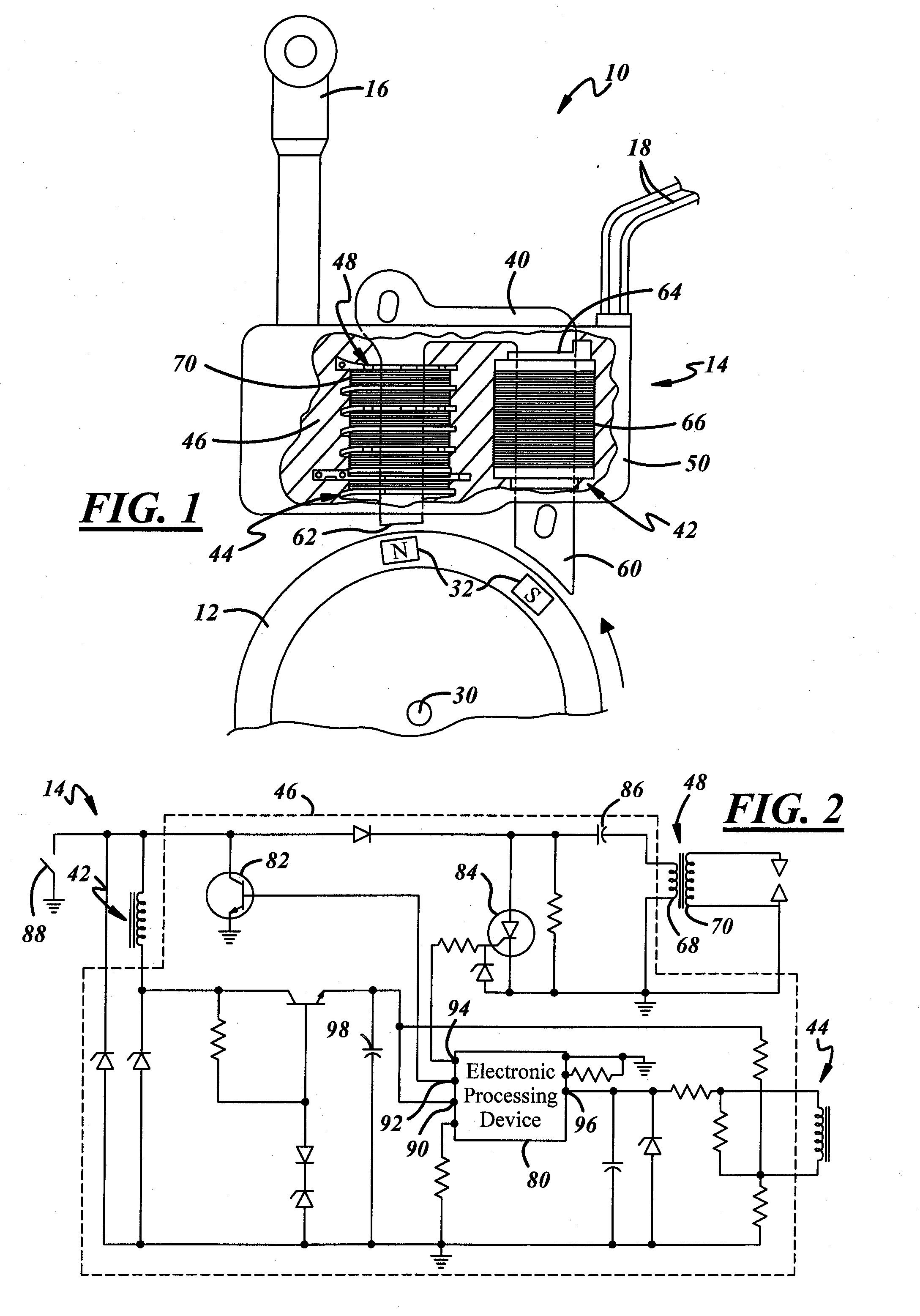

Ignition timing control system for light duty combustion engines

InactiveUS7000595B2Guaranteed uptimeAccelerate emissionsAnalogue computers for vehiclesElectrical controlControl systemNormal mode

A control system for a low cost, light duty combustion engine, where the control system generally utilizes engine speed and / or temperature input signals and independent operating sequences to determine a desired ignition timing and air-to-fuel ratio for a combustible mixture. There are several independent operating sequences, each one of which is designed to optimally control the engine under certain conditions. These operating sequences include a Cranking sequence that commences after the engine is initially turned on, a Warm Up sequence which follows the Cranking sequence, a Normal Mode sequence for typical operating conditions, an Acceleration sequence for certain increases in engine speed, a Come Down sequence for when a sufficient engine speed is followed by a certain decrease in speed, and a Recovery Bump sequence for when the engine speed dips below a predetermined level.

Owner:WALBRO LLC

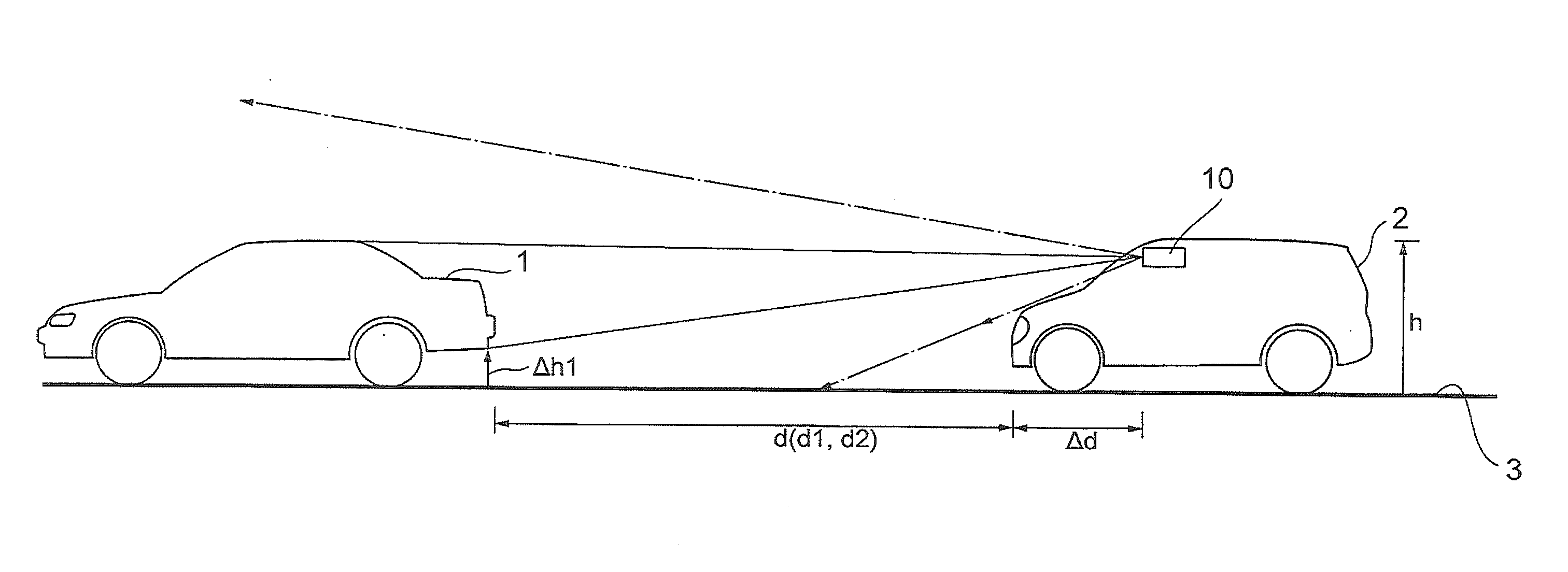

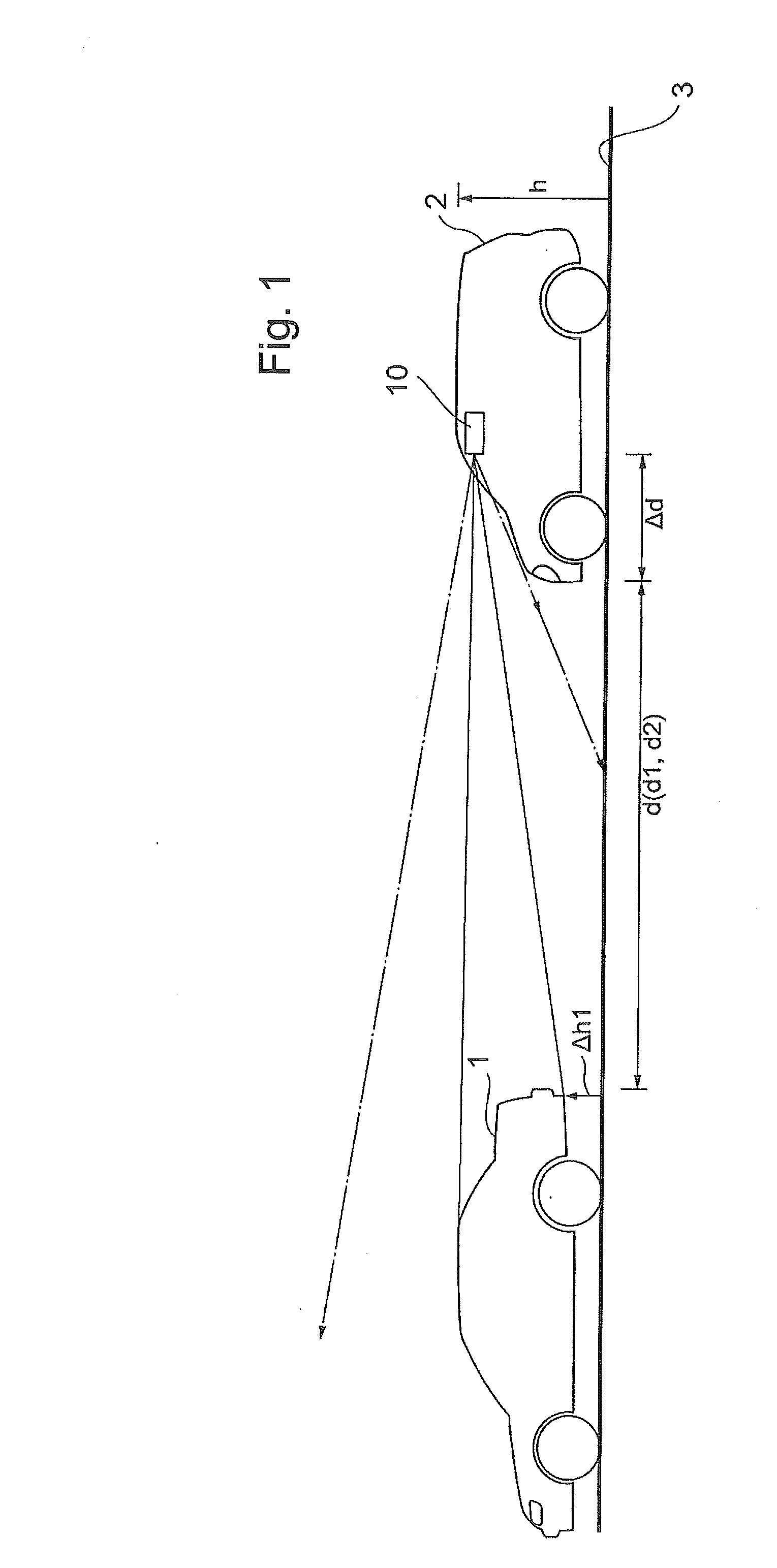

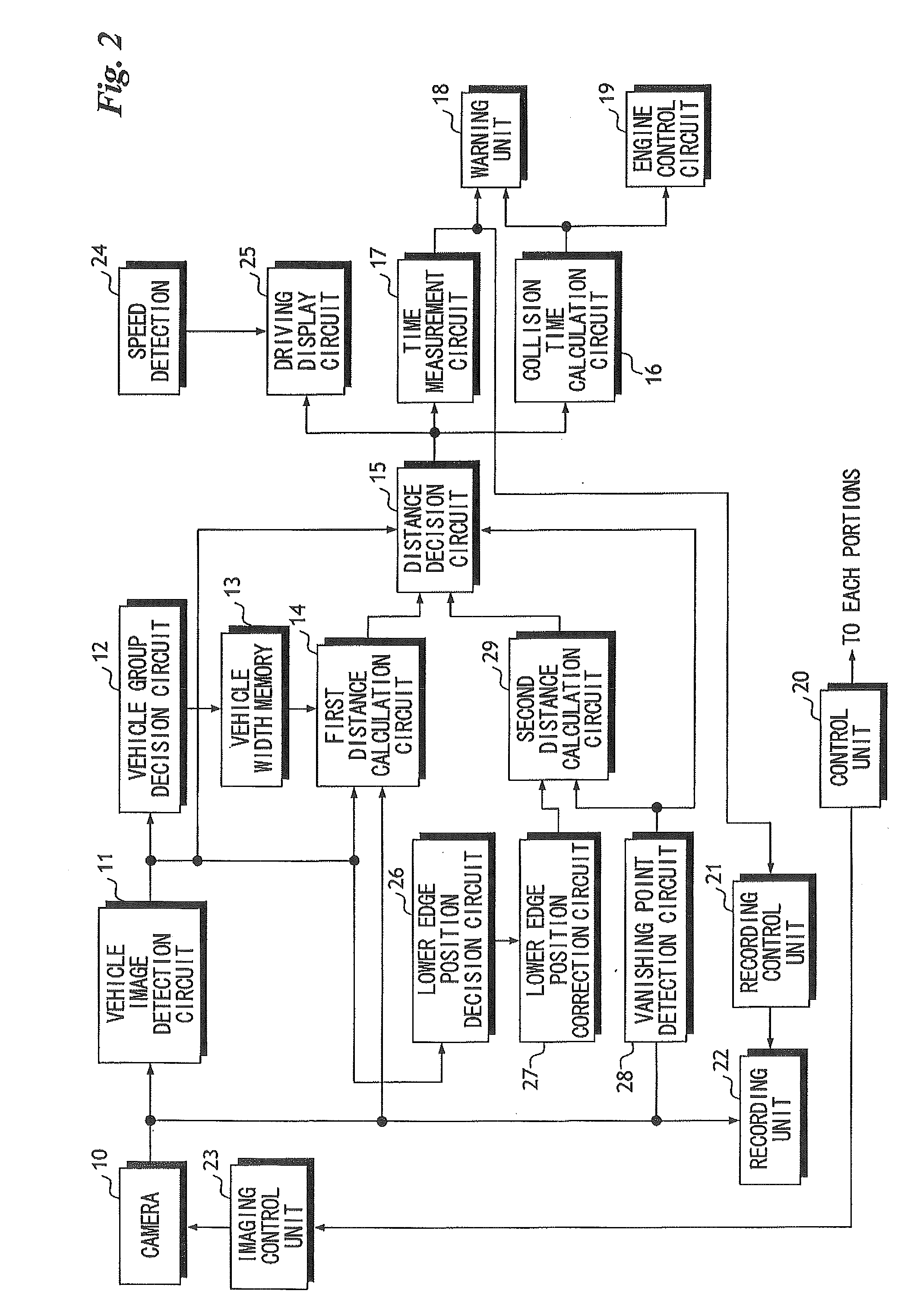

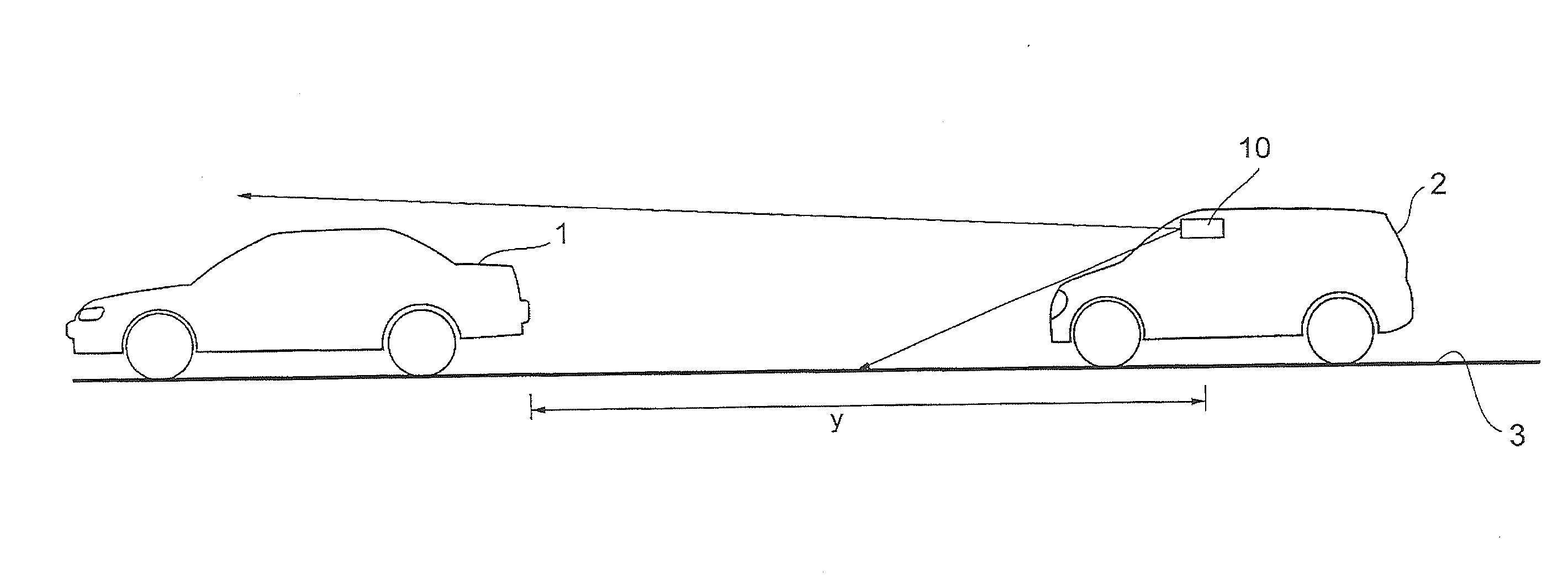

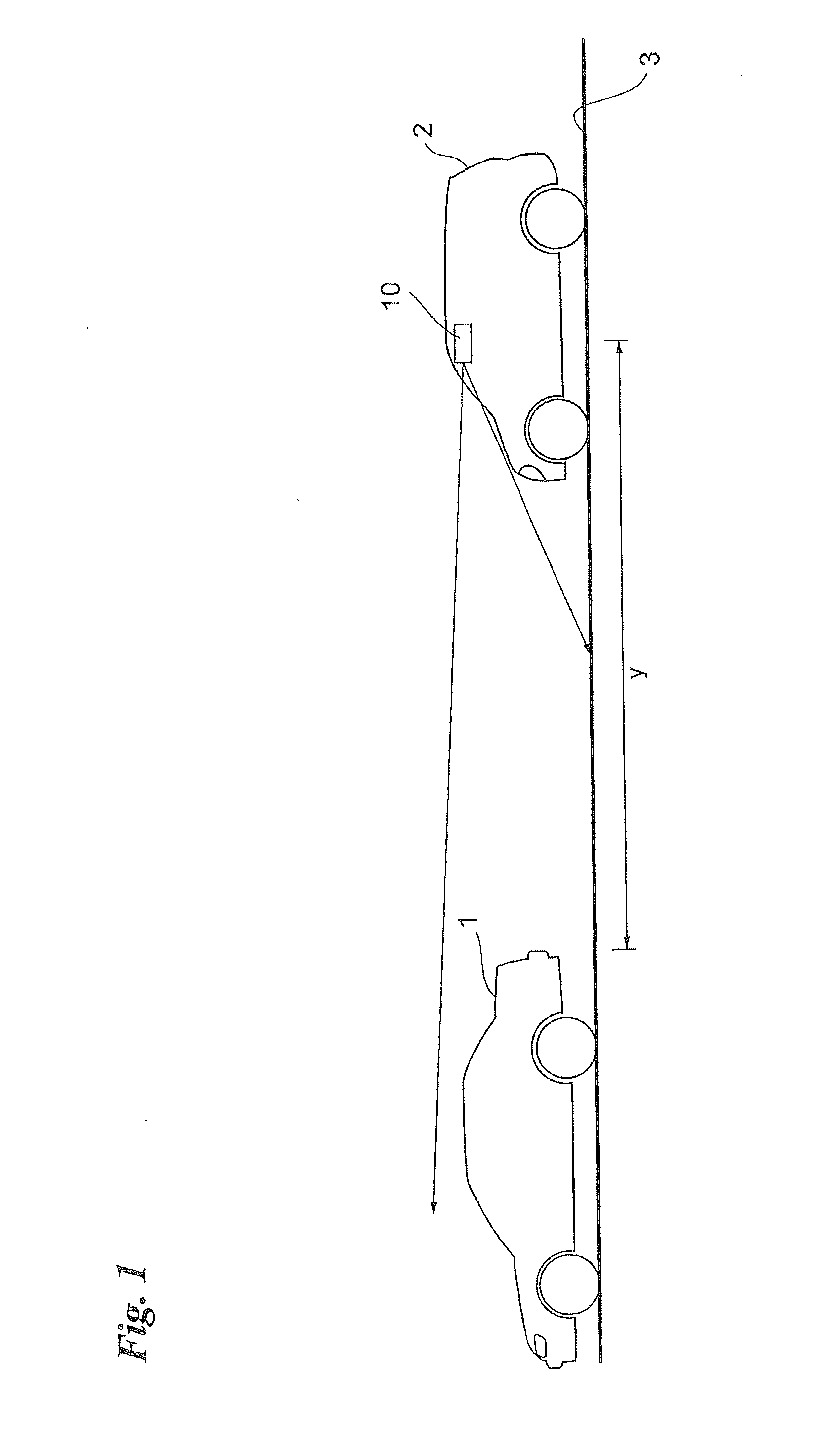

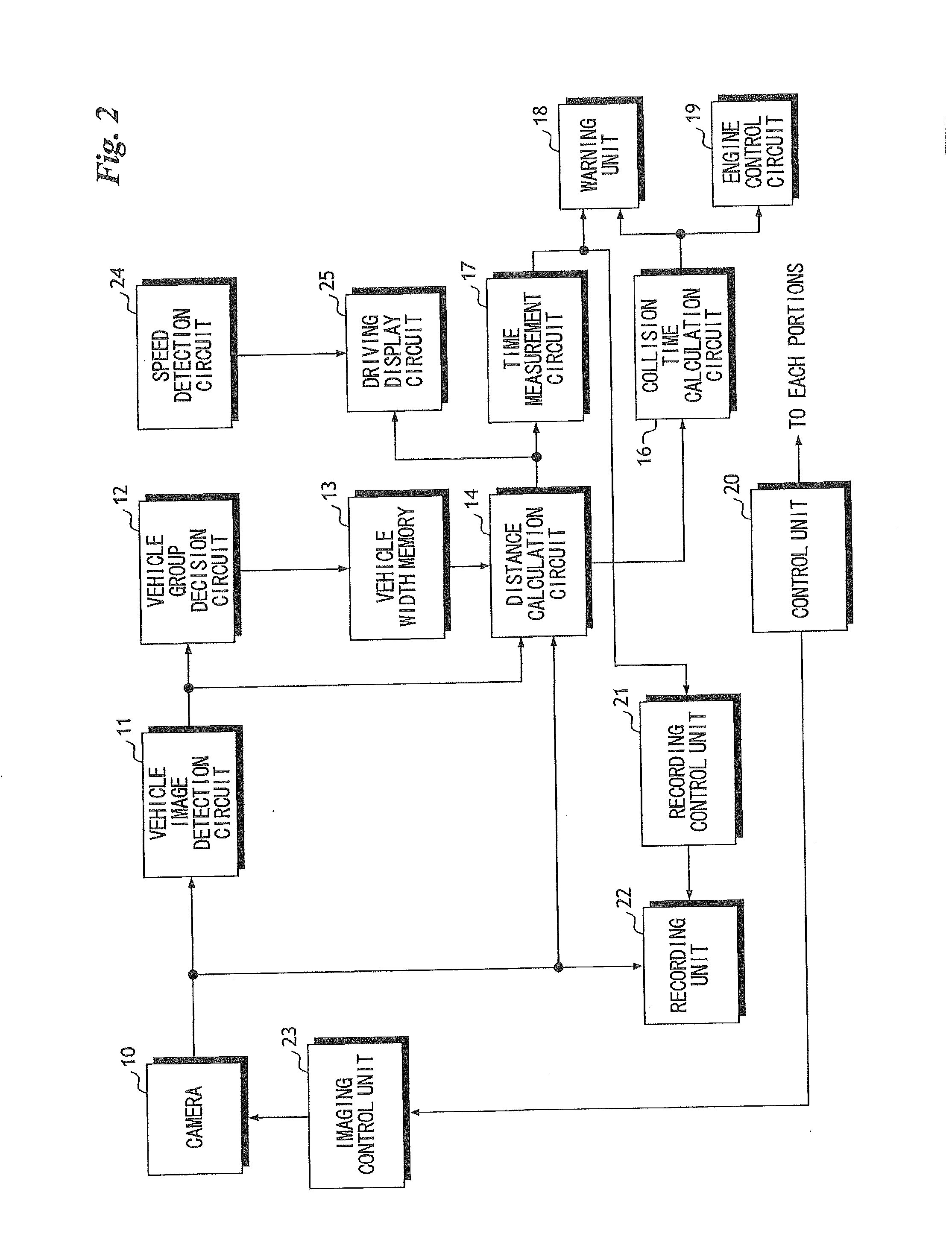

Vehicle-to-vehicle distance calculation apparatus and method

ActiveUS20140241579A1Accurate distanceImage enhancementImage analysisDecision circuitWeight coefficient

Owner:FUJIFILM CORP

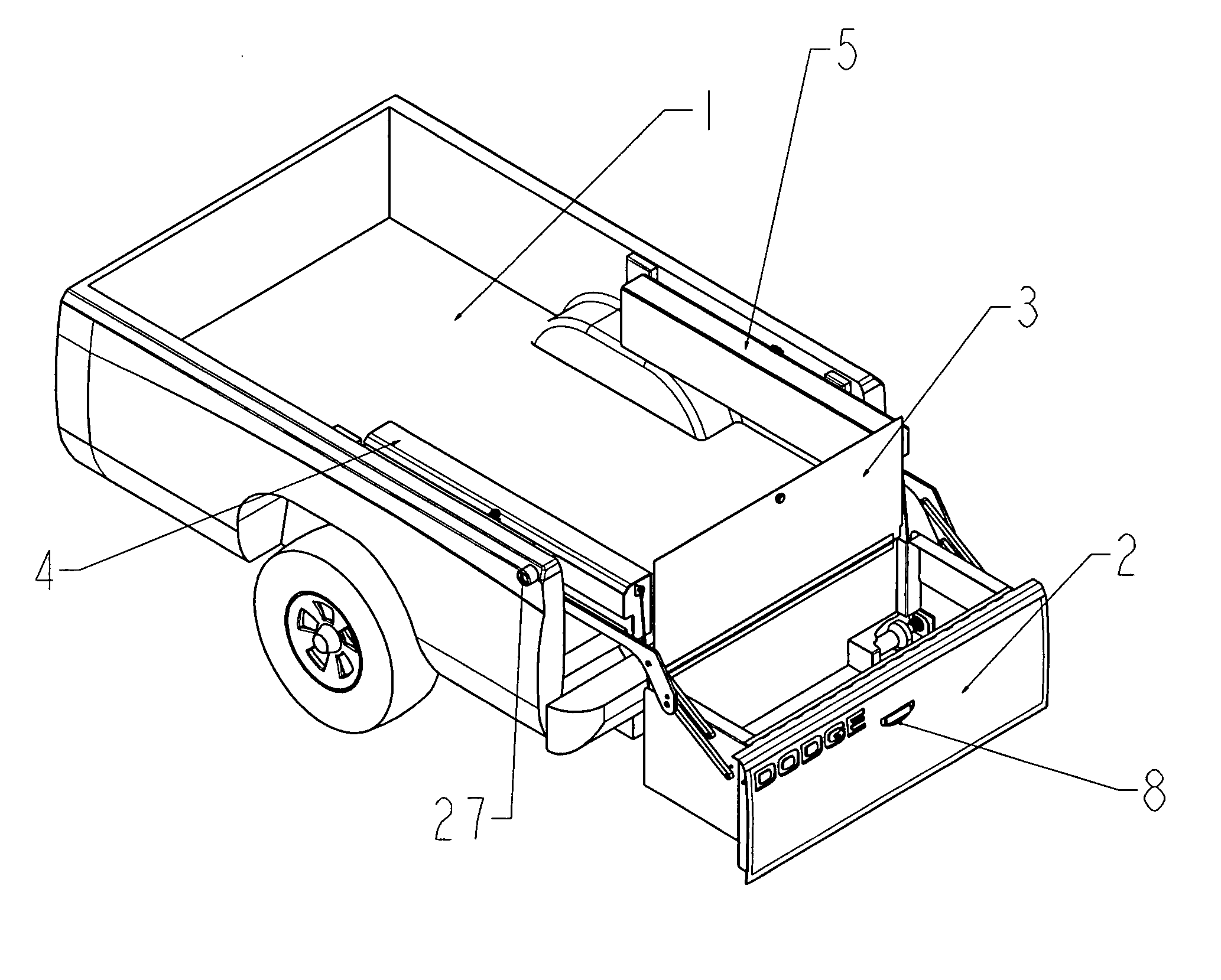

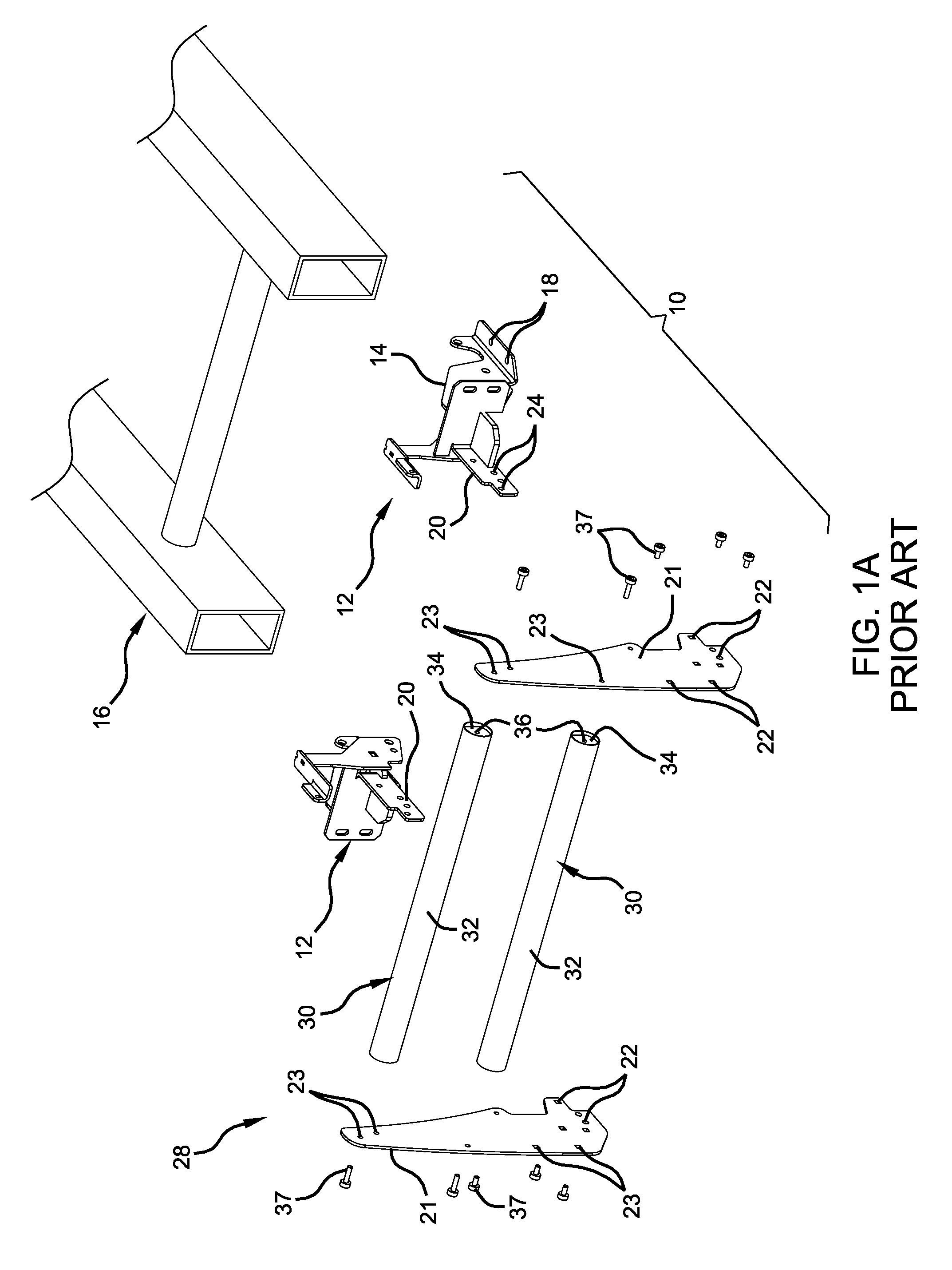

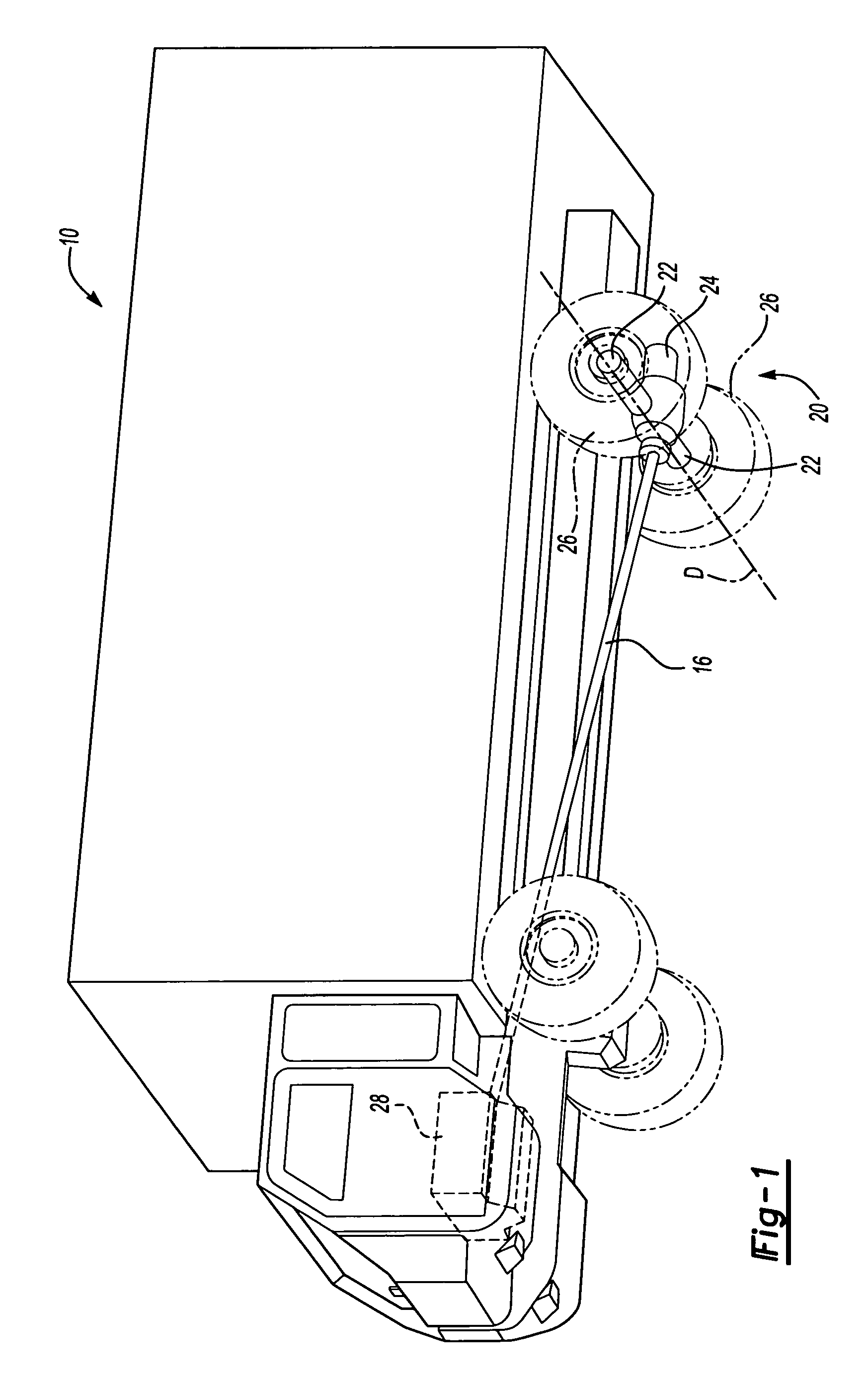

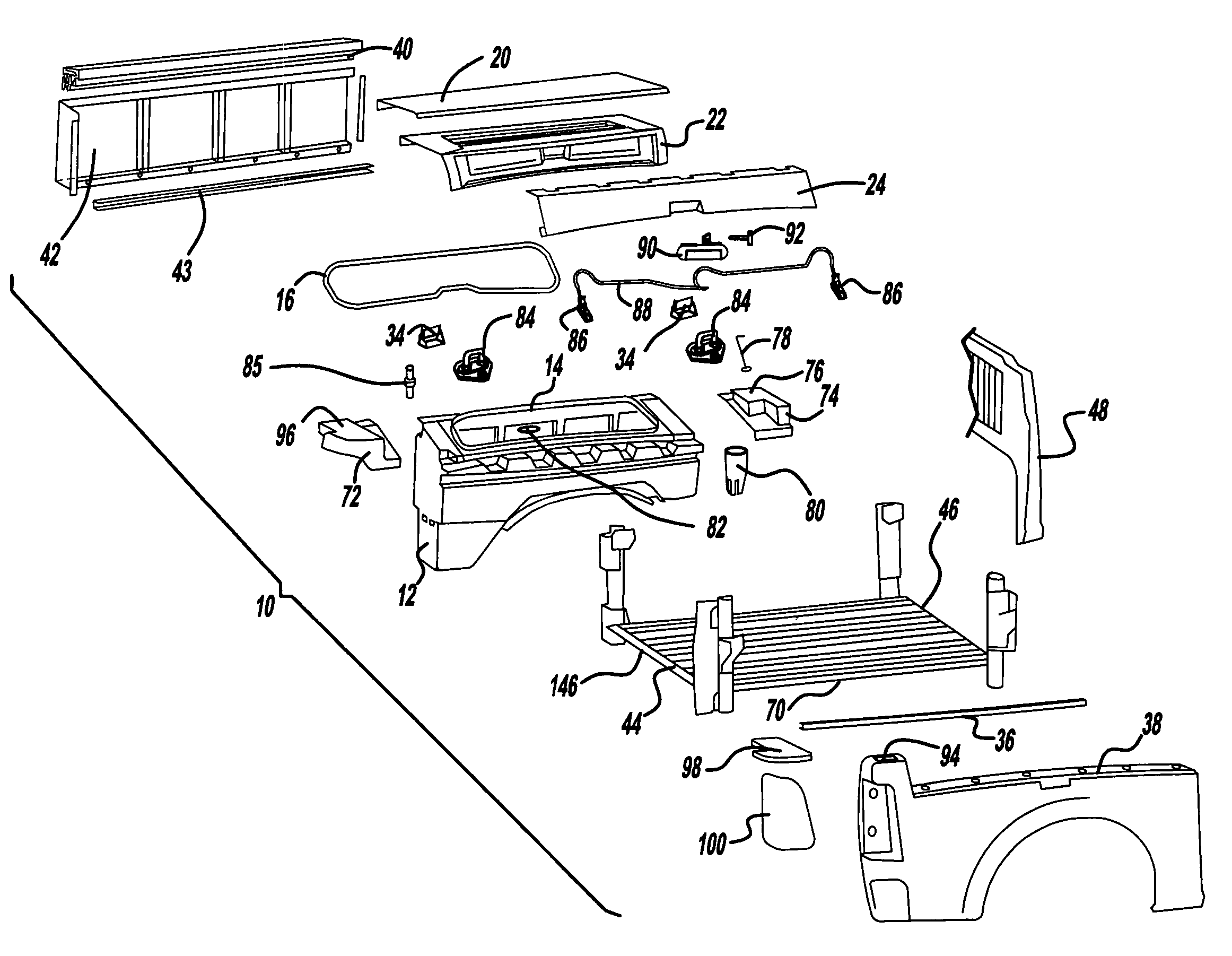

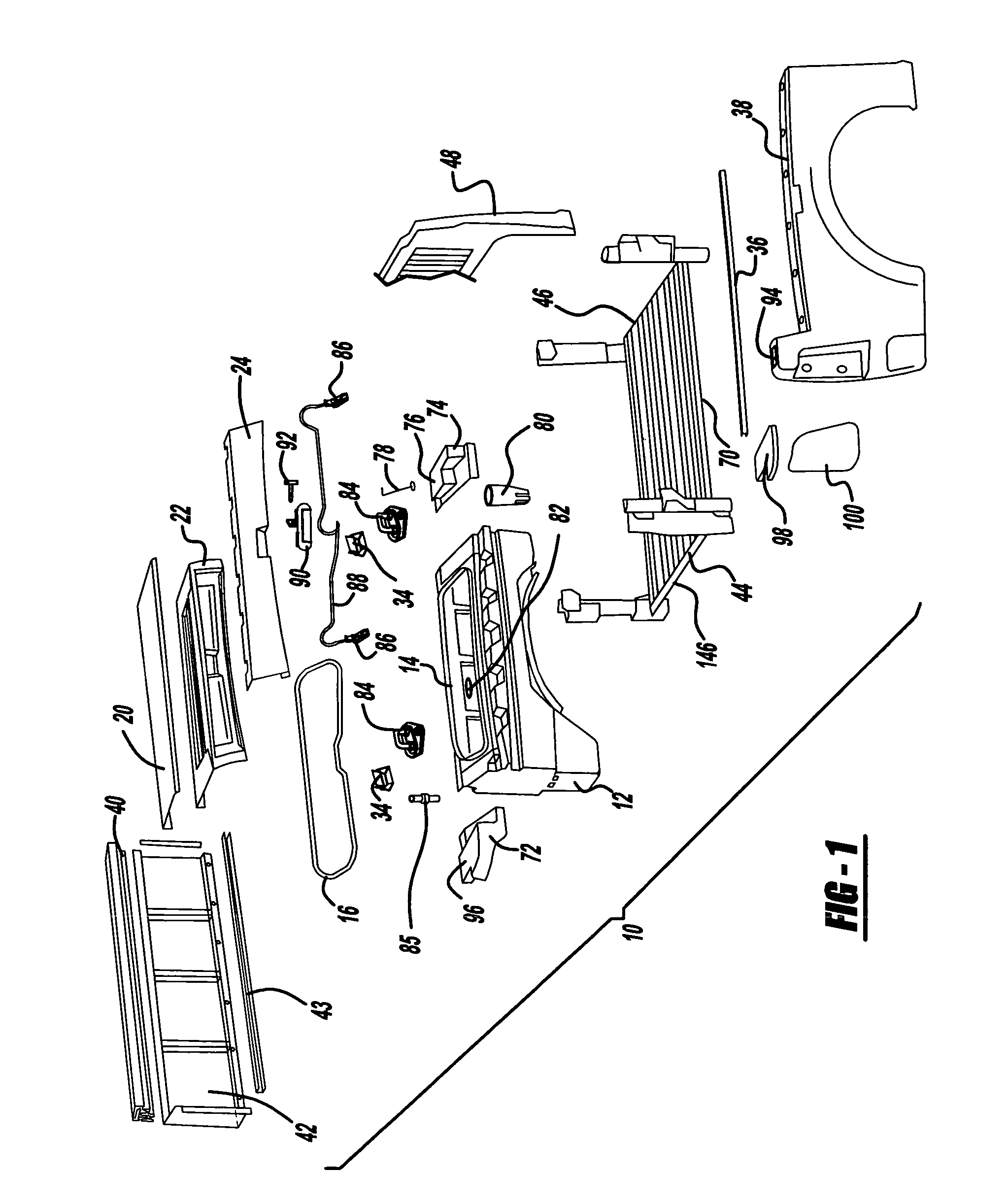

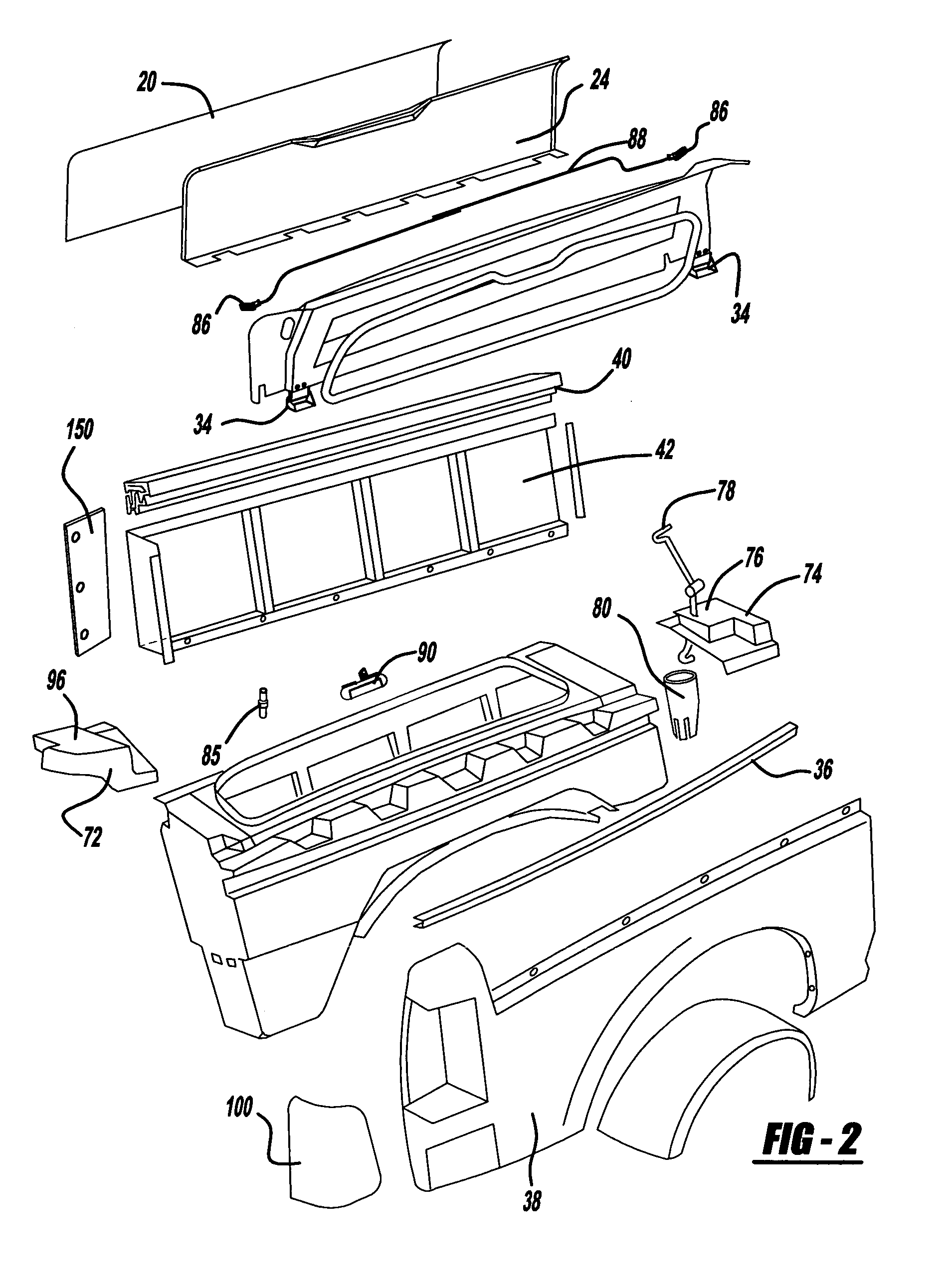

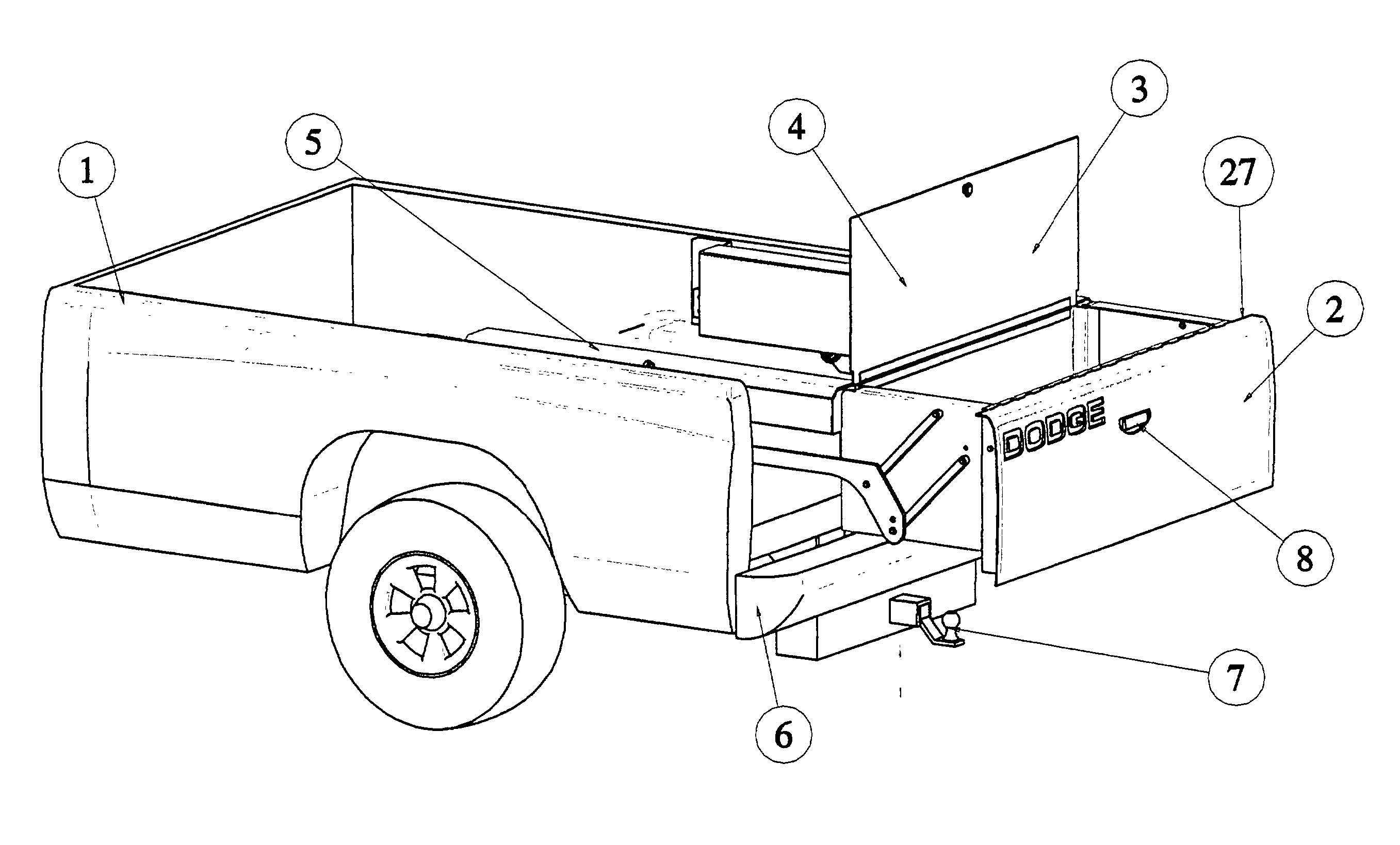

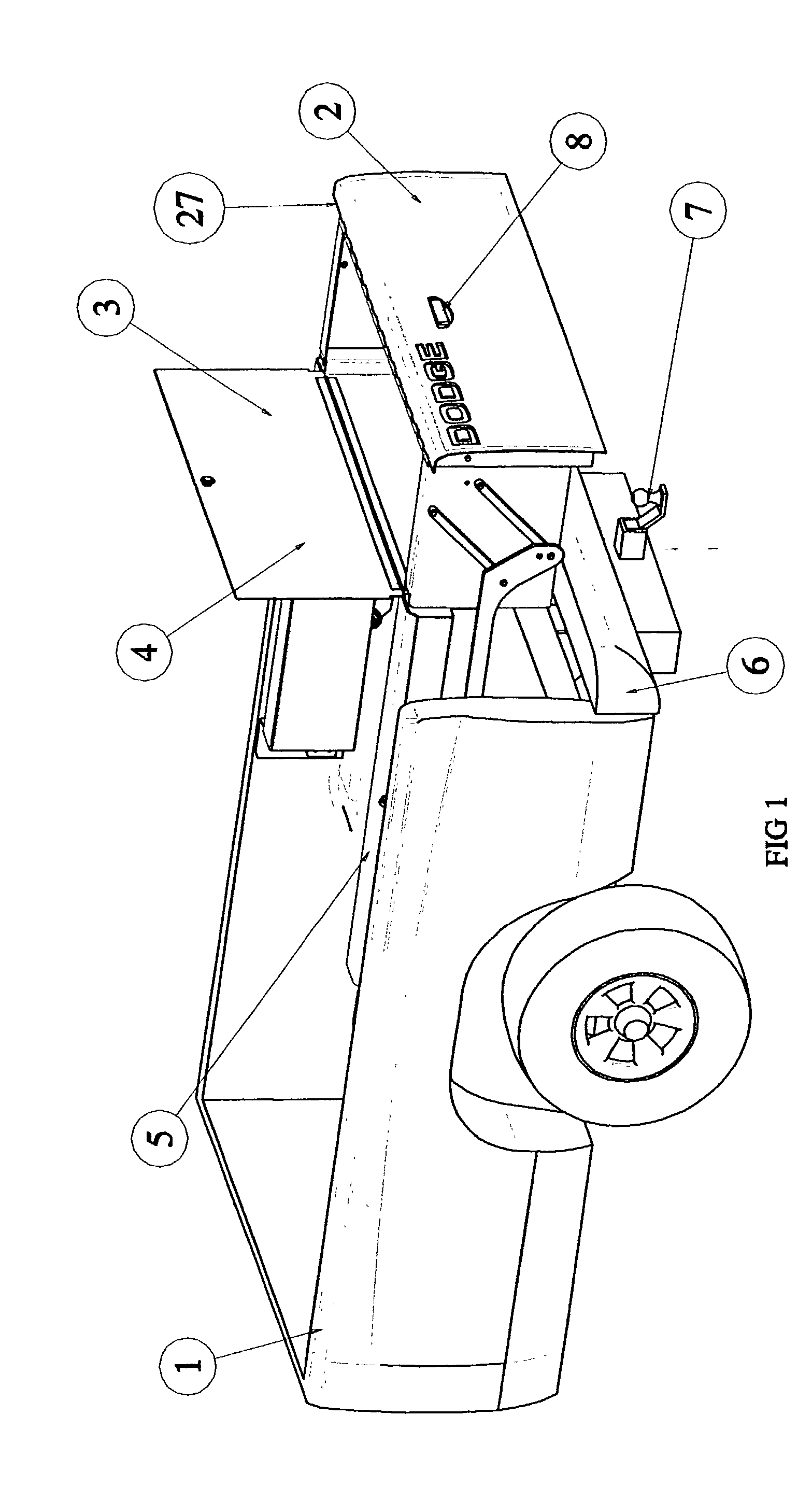

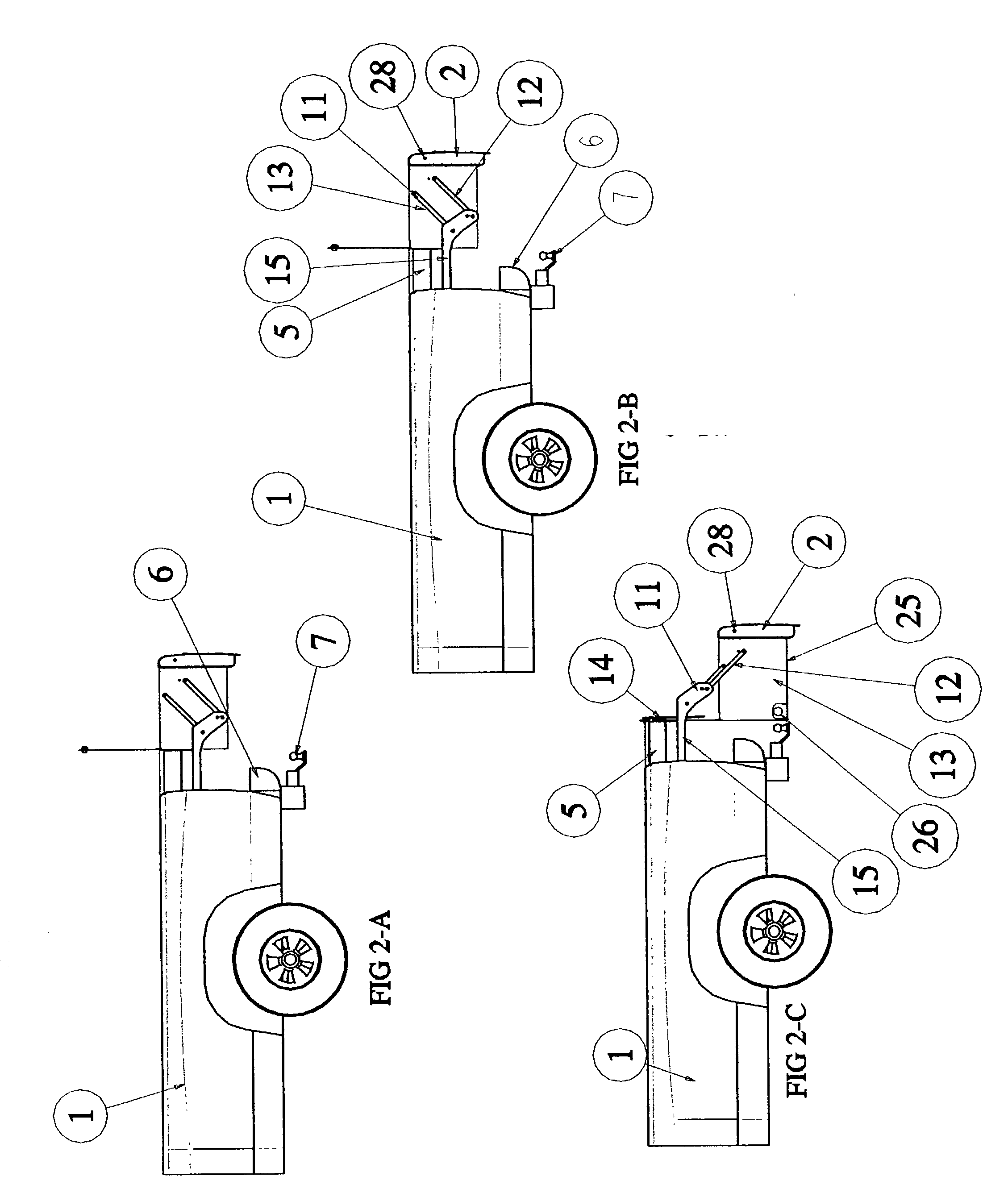

Truck storage and work surface tailgate

InactiveUS7111884B2The process is simple and convenientEasily retrofitted togetherRefuse receptaclesVehicle with living accommodationPick-up truckEngineering

A storage compartment and integrated tailgate worksurface is disclosed. The storage compartment is easily retrofitable to any standard or light duty pick-up truck bed. A parallel linkage mechanism and integrated power unit can raise and lower the storage compartment without rotation, thereby keeping objects in an initial desired orientation and placement within the compartment. The parallel linkage system also facilitates adjustment of the integrated tailgate work surface to convenient working heights.

Owner:KURION INC

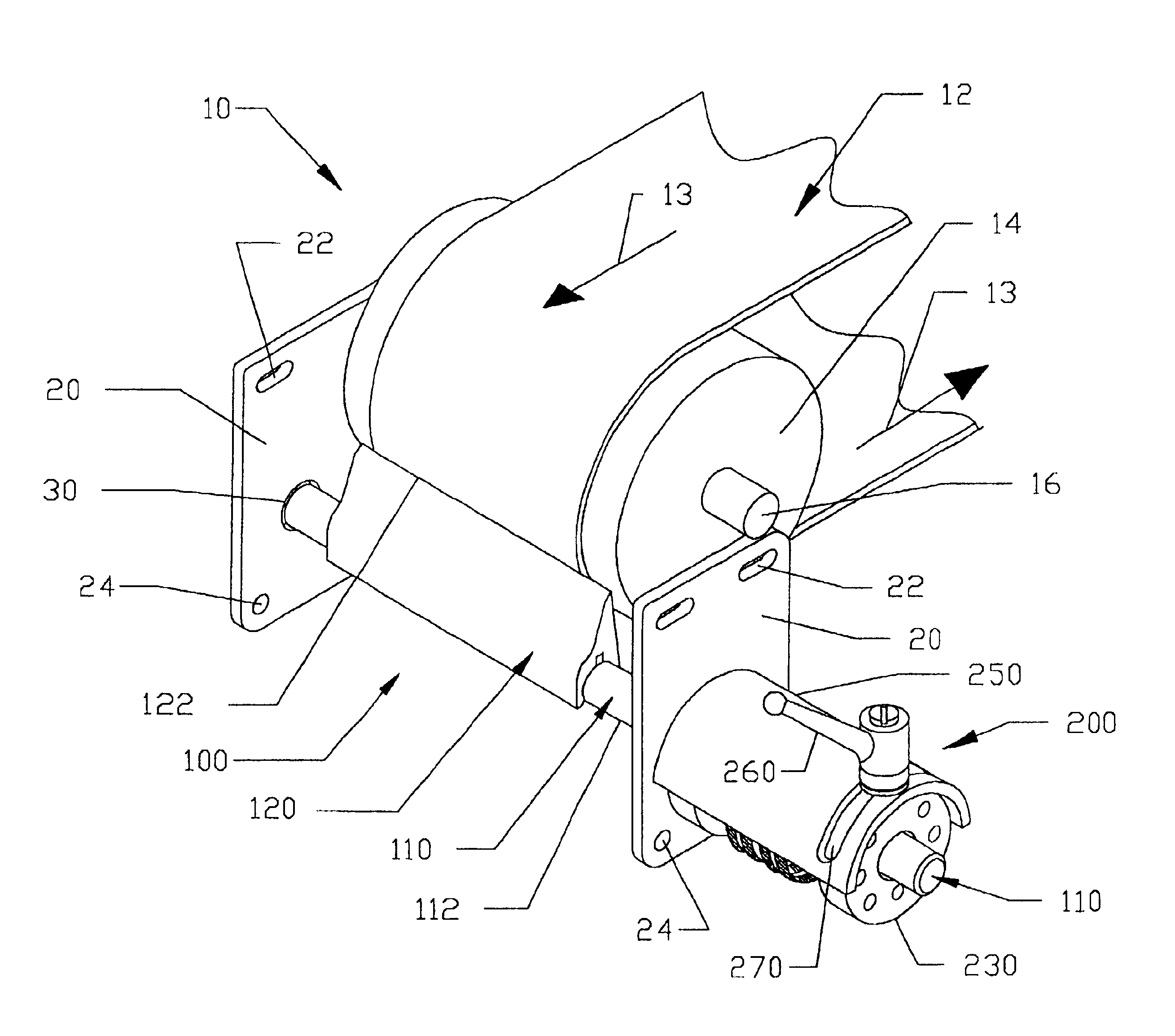

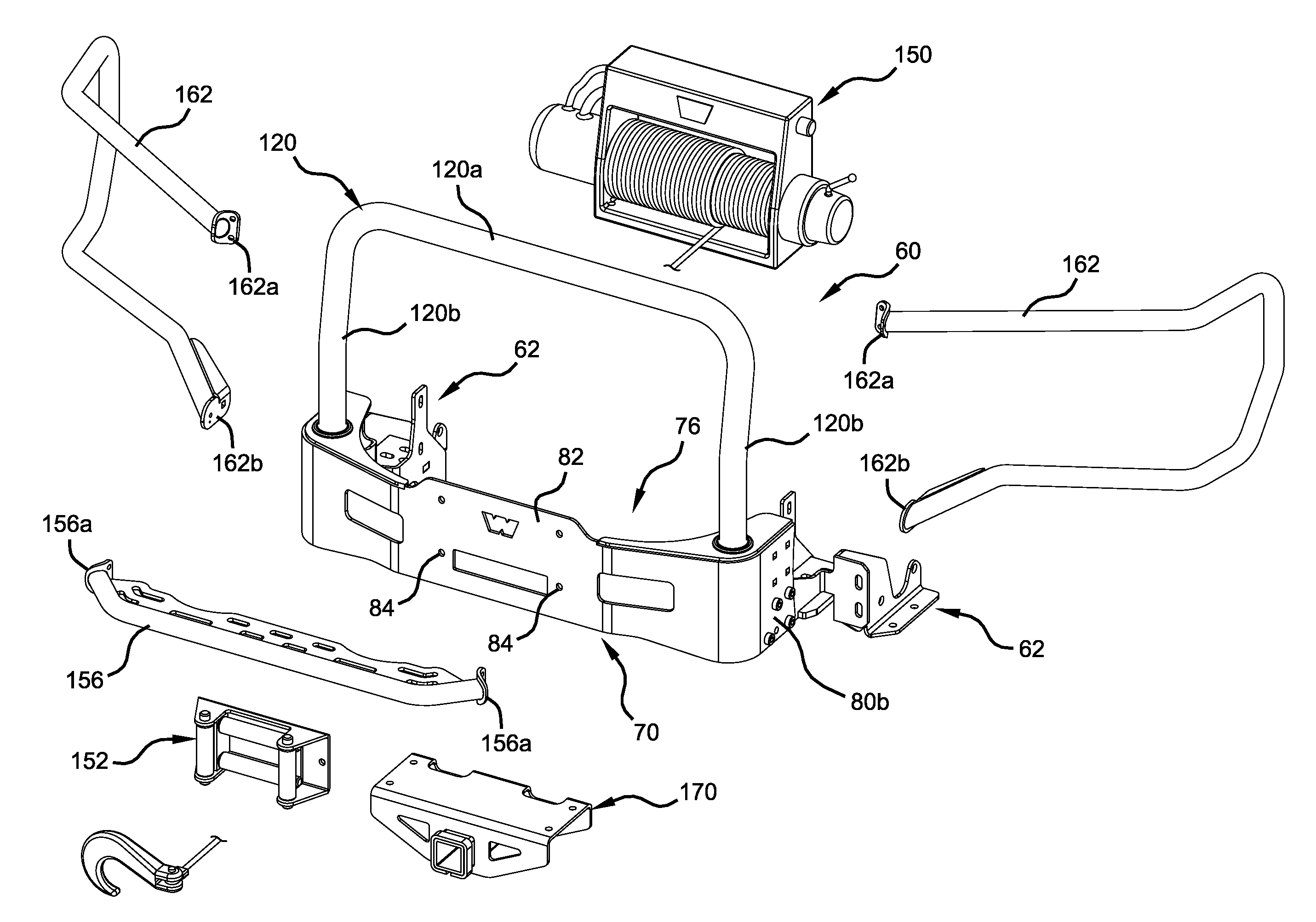

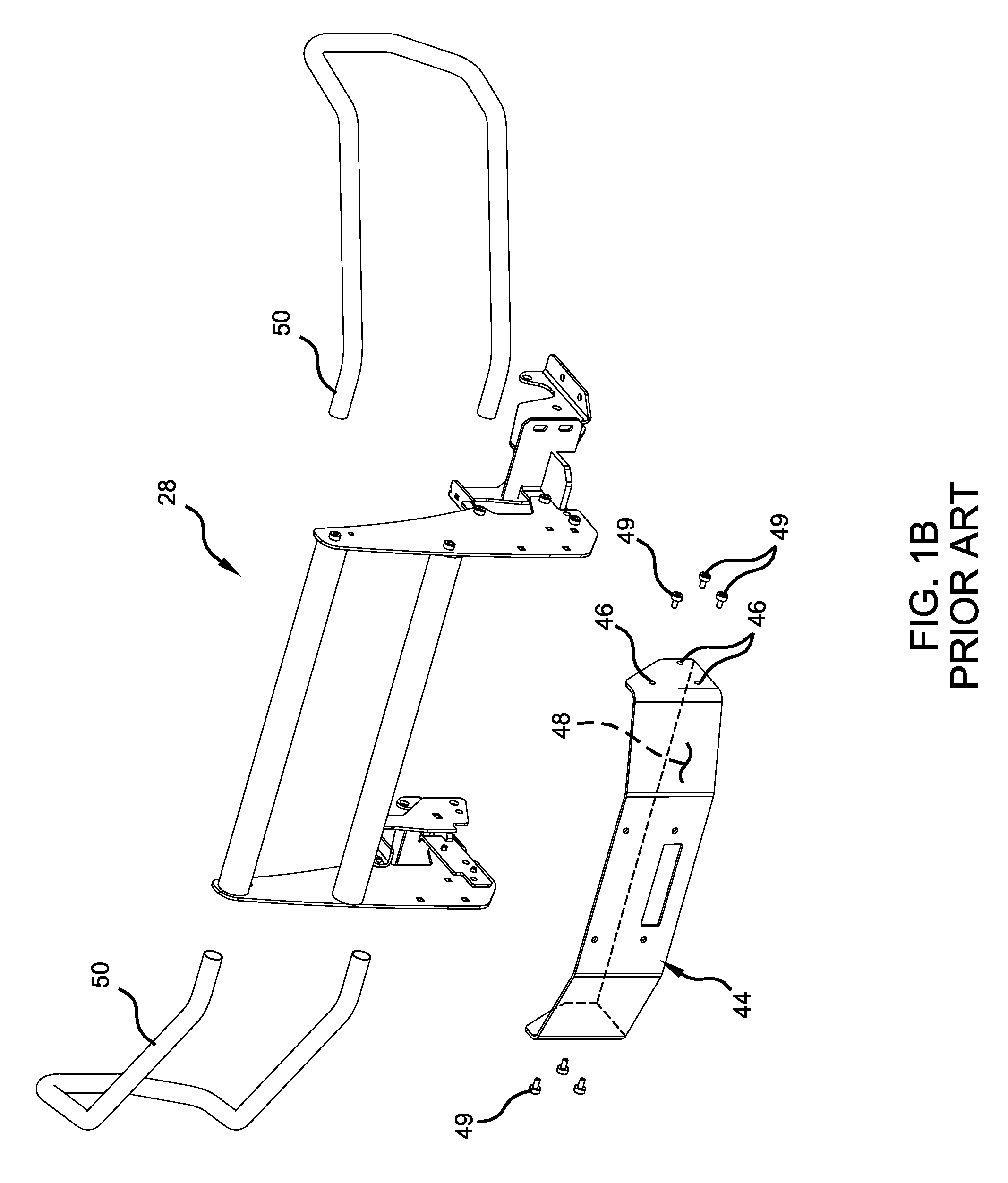

Winch Carrier and Grille Guard Mounting System

InactiveUS20110006553A1Simple interfaceImprove aestheticsMonocoque constructionsVehicle bodiesVehicle frameEngineering

An accessory mounting system for on-road and off-road passenger vehicles, such as light-duty trucks and SUV's is provided. The system attaches to a vehicle to serve as an extension of the vehicle frame to provide a secure mounting location for vehicle accessories, such as a winch, grille guards, headlamp guards, and lights. The system provides for the attachment of numerous accessory components without modification or replacement of an original equipment bumper.

Owner:WARN INDUSTRIES

Vehicle-to-vehicle distance calculation apparatus and method

ActiveUS20140241578A1Reduce development costsReduce processing timeImage enhancementImage analysisHeavy dutyLight duty

Owner:QUALCOMM INC +1

Foaming light duty liquid detergent compositions, methods of making and uses thereof

ActiveUS20120295831A1Equal (similar) foam performanceAdequate foam performanceOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventSURFACTANT BLEND

Foaming light duty liquid detergent formulations that contain at least one cleaning solvent, at least one anionic surfactant and at least foam stabilizing surfactant are disclosed. The compositions of the presently described technology are useful for soil removal applications including, but not limited to, washing dishes by hand and cleaning bathroom and kitchen articles and / or surfaces.

Owner:STEPAN COMPANY

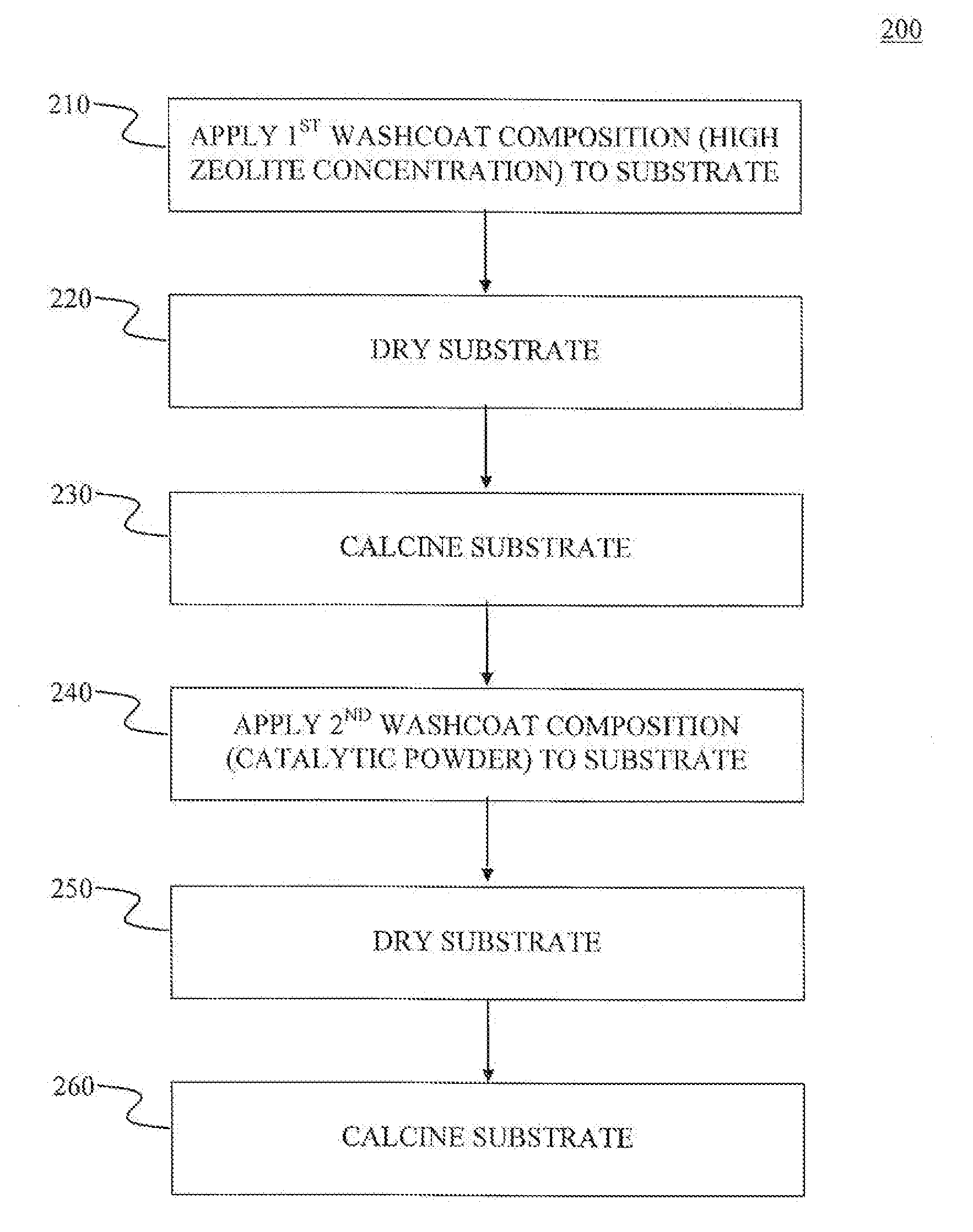

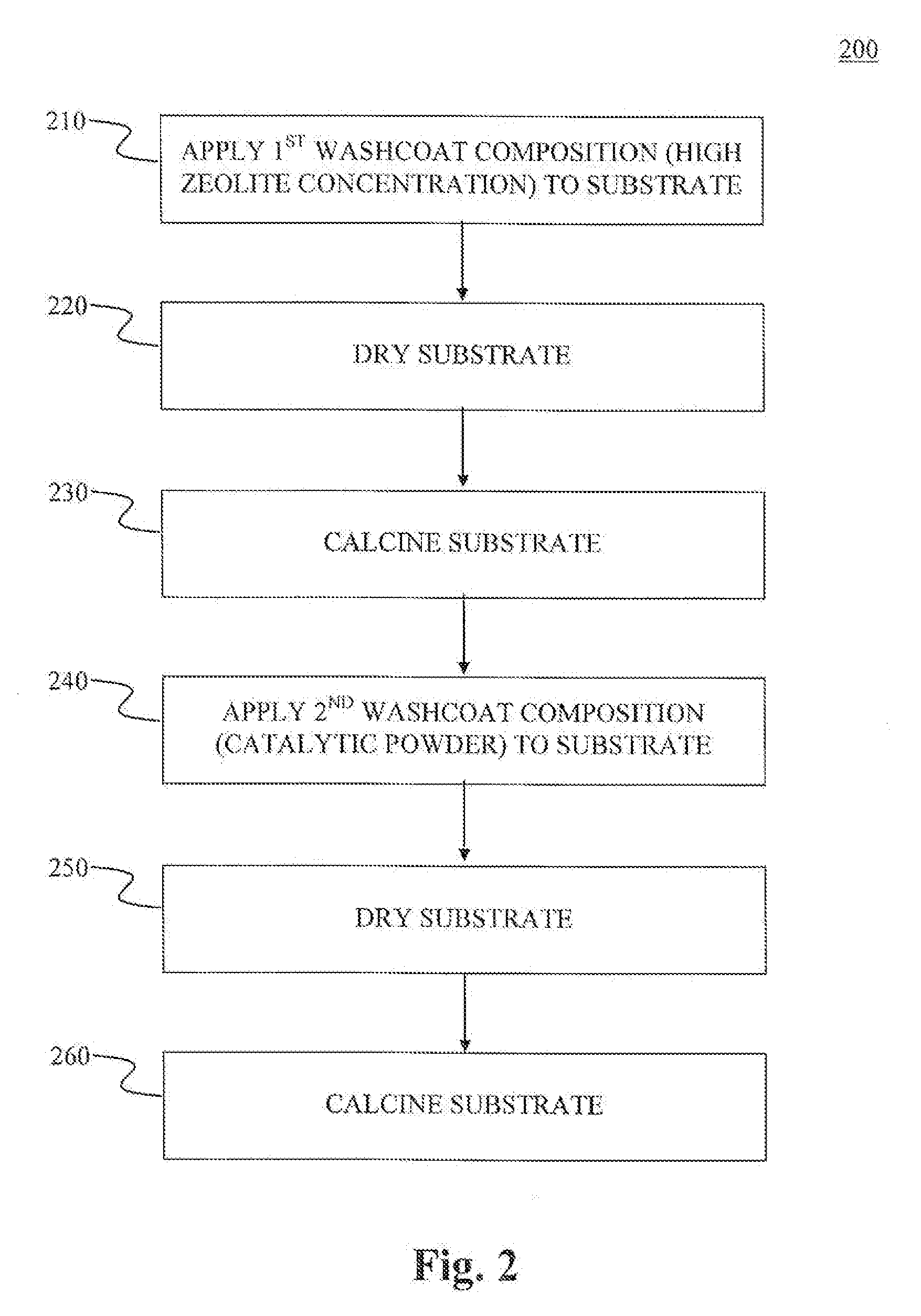

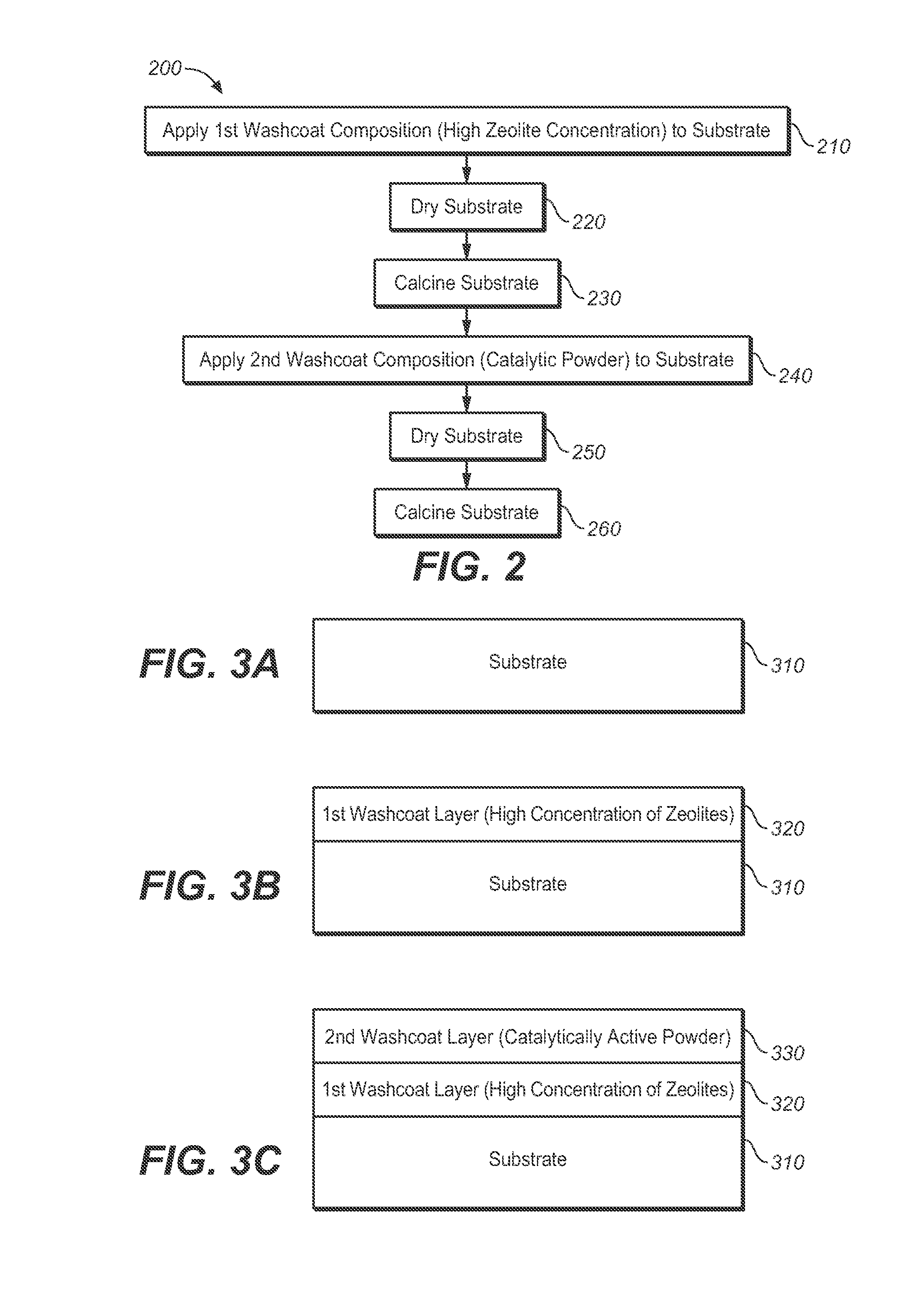

Washcoats and coated substrates for catalytic converters and methods of making and using same

ActiveUS20150093312A1Low ignition temperatureImprove performanceNitrogen compoundsInternal combustion piston enginesTreatment systemDiesel fuel

Disclosed are, inter alia, methods of forming coated substrates for use in catalytic converters, as well as washcoat compositions and methods suitable for using in preparation of the coated substrates, and the coated substrates formed thereby, which in some cases use iron-exchanged zeolite particles that provide enhanced performance such as lower light-off temperatures and lower pollutant levels in exhaust gases. The catalytic material is prepared by a plasma-based method, yielding catalytic material with a lower tendency to migrate on support at high temperatures, and thus less prone to catalyst aging after prolonged use. Also disclosed are catalytic converters using the coated substrates, which have favorable properties as compared to catalytic converters using catalysts deposited on substrates using solution chemistry. Also disclosed are exhaust treatment systems, and vehicles, such as diesel vehicles, particularly light-duty diesel vehicles, using catalytic converters and exhaust treatment systems using the coated substrates.

Owner:UMICORE AG & CO KG +1

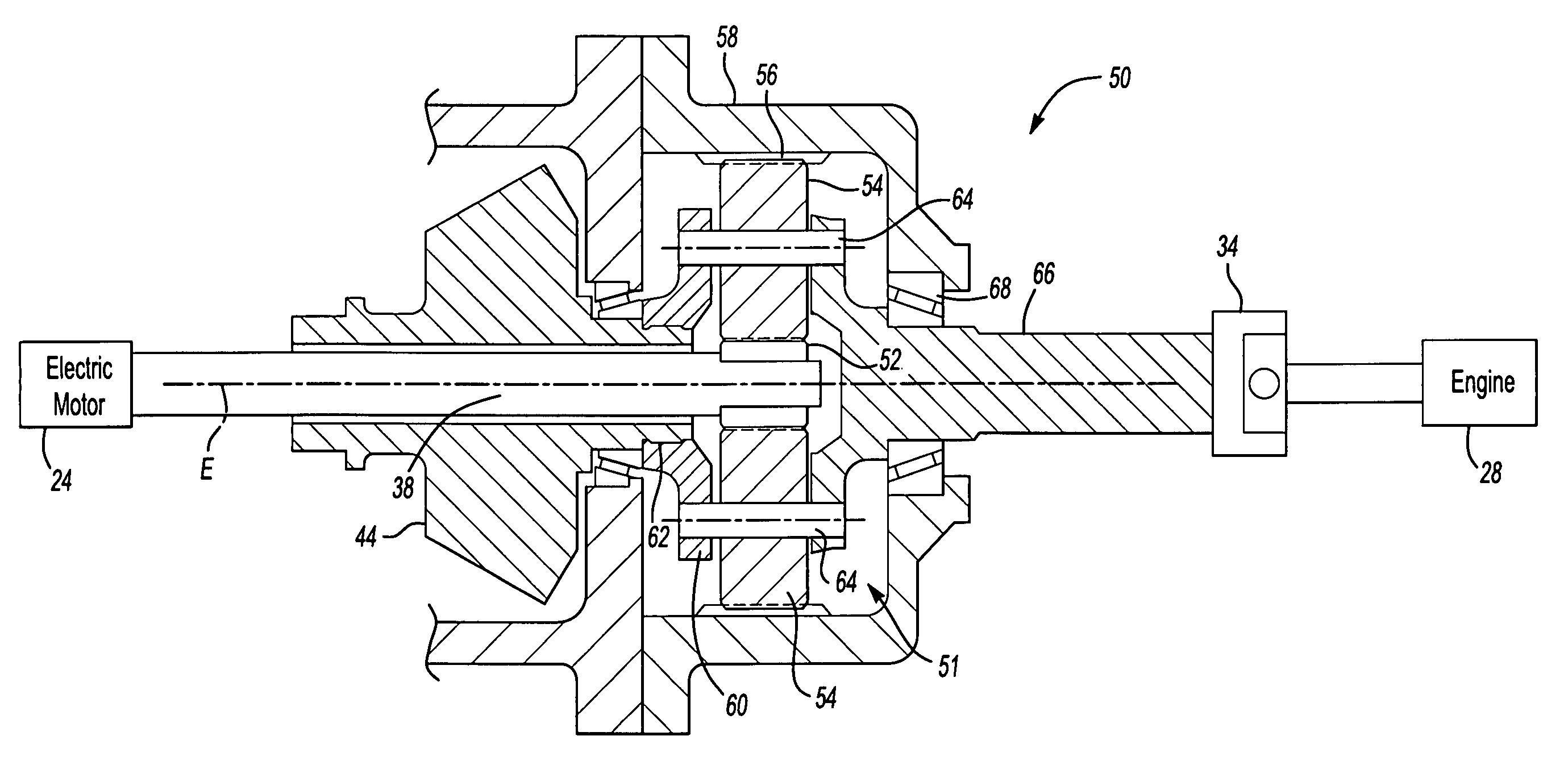

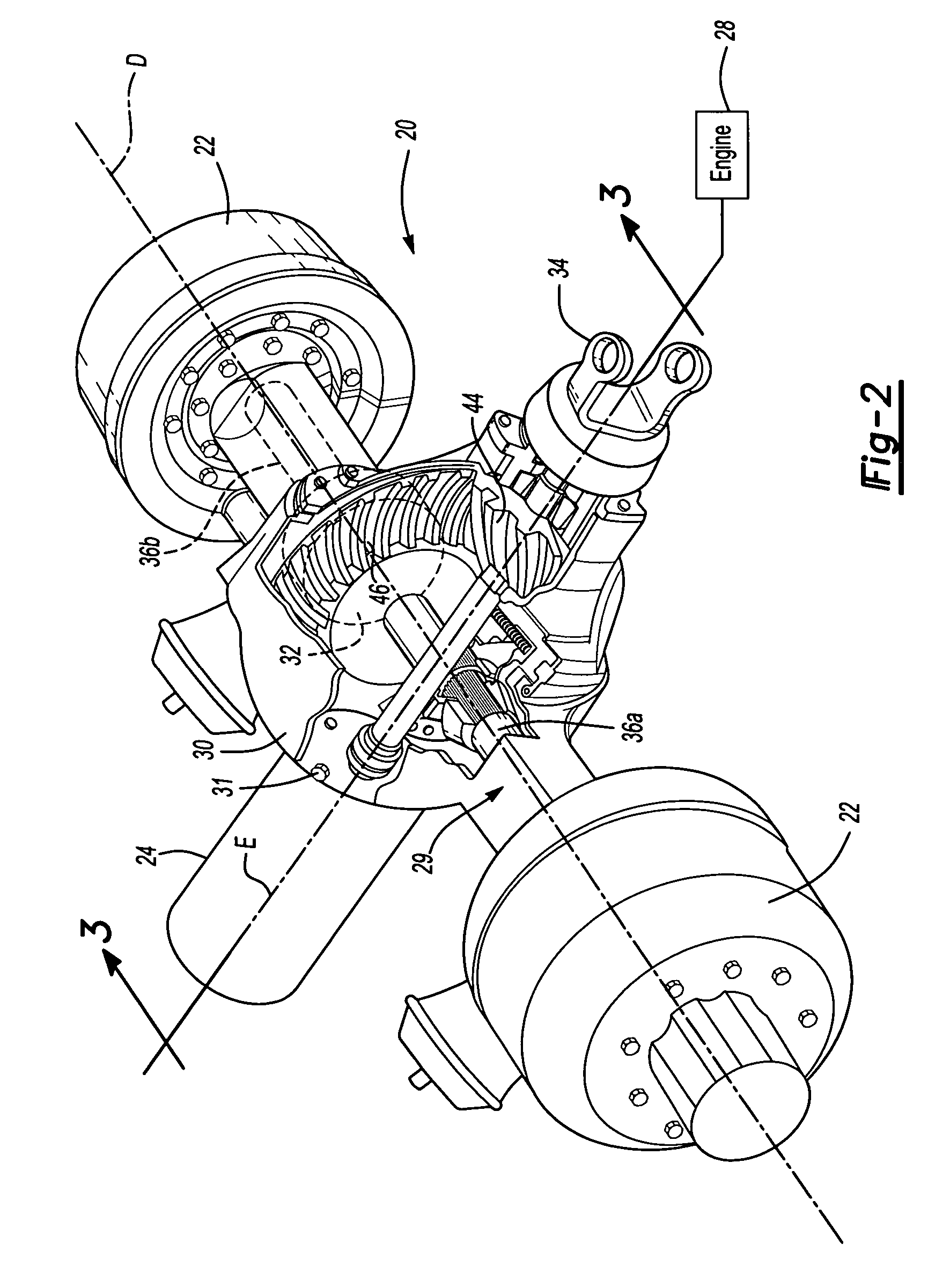

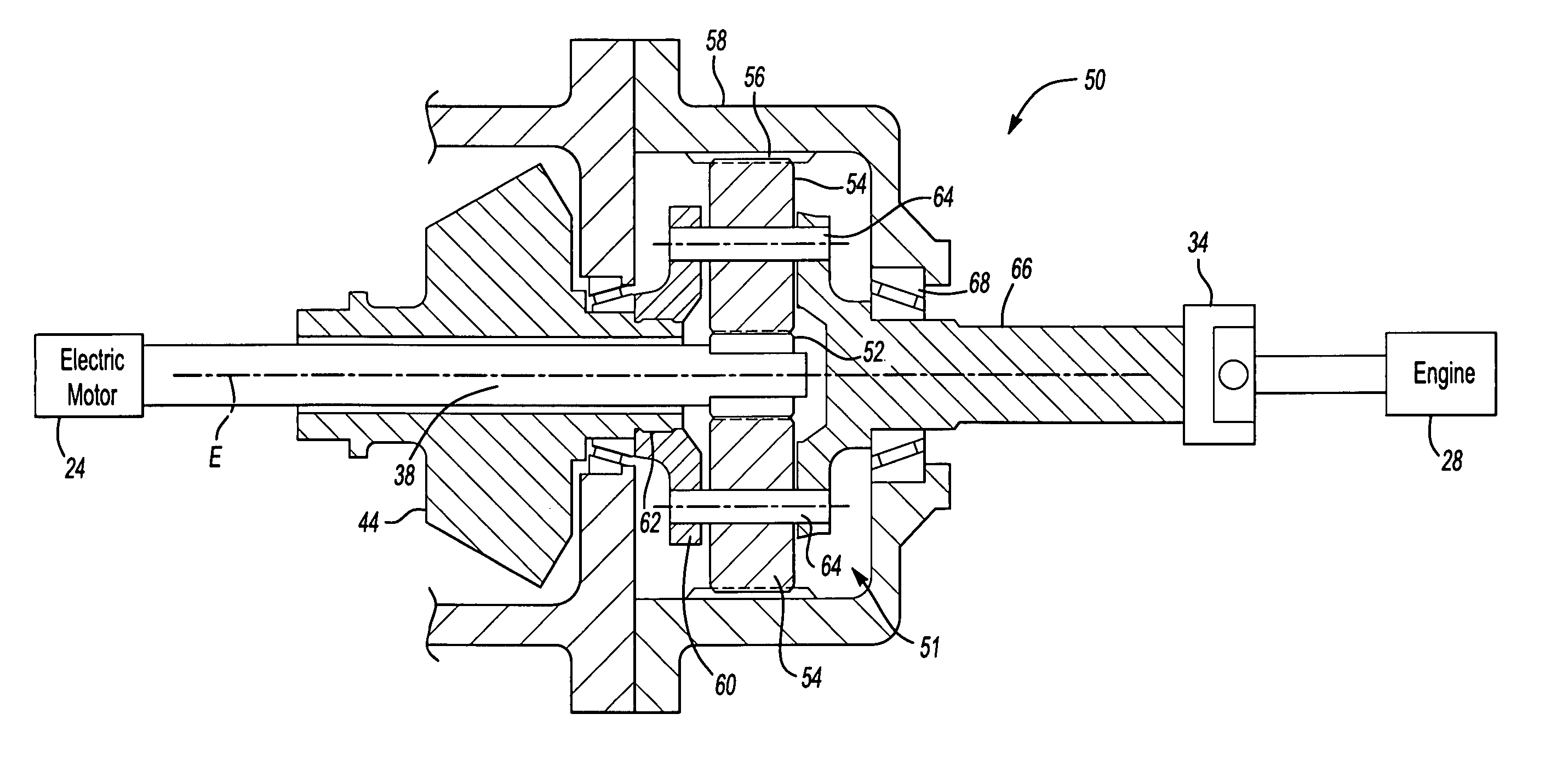

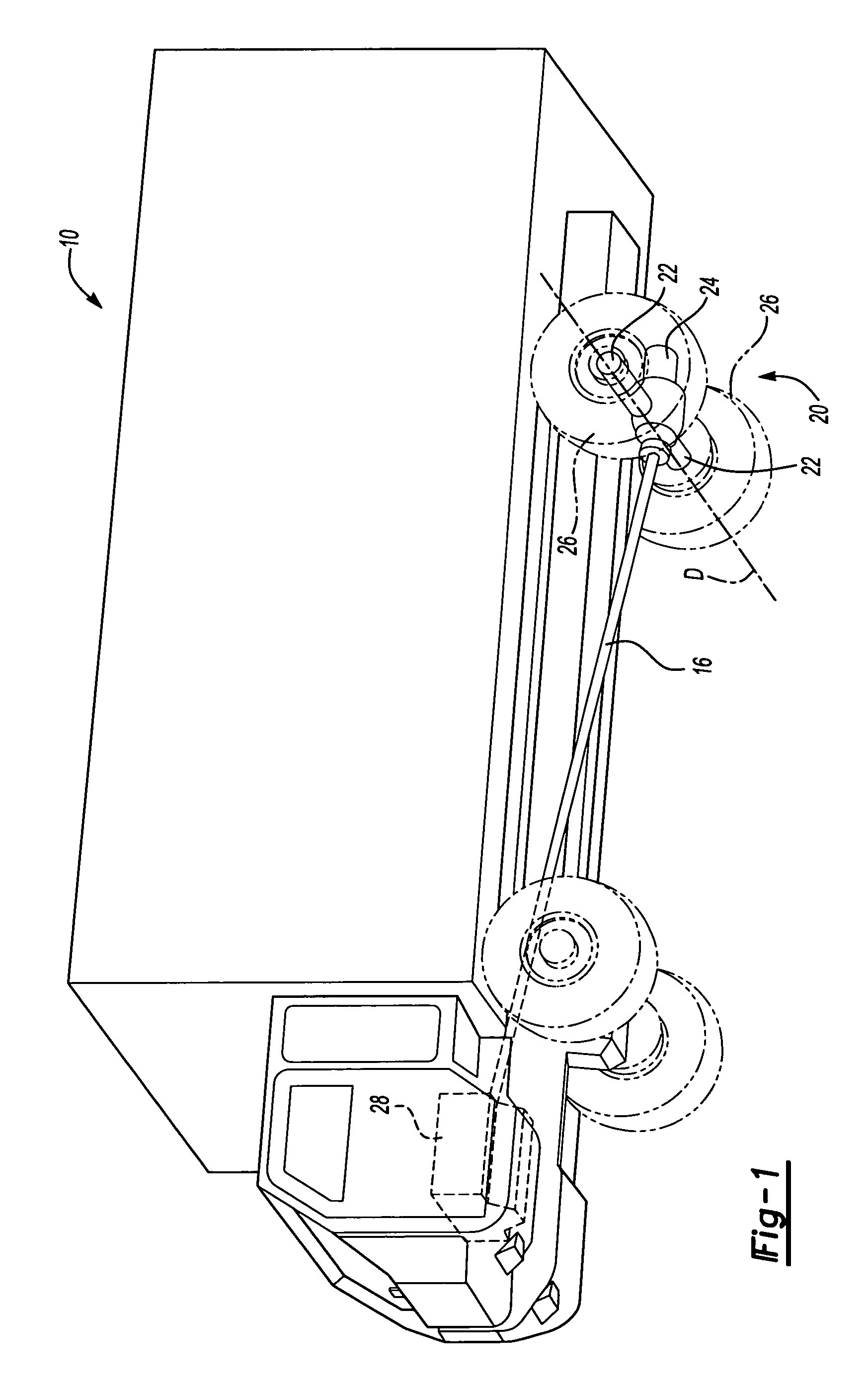

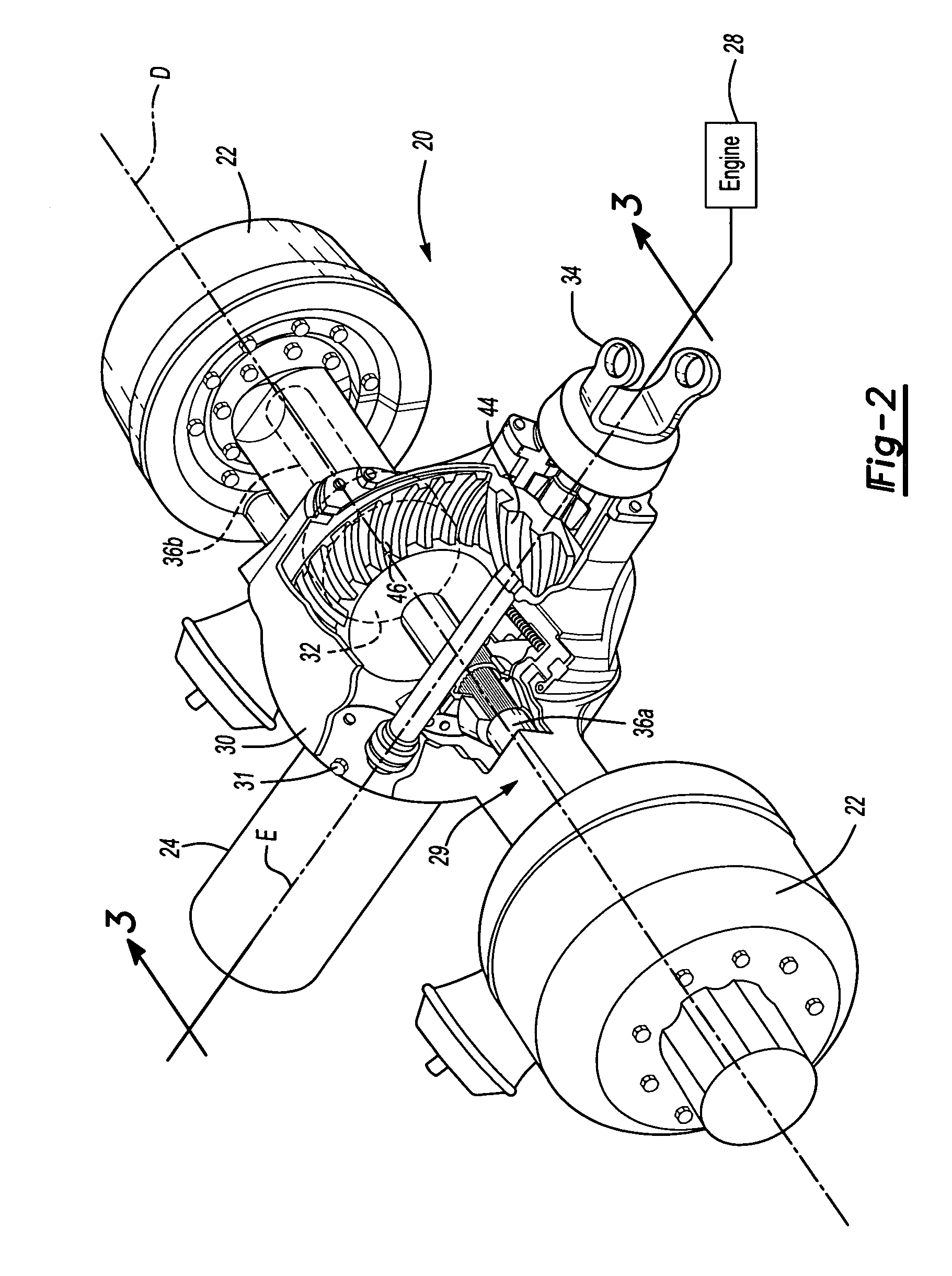

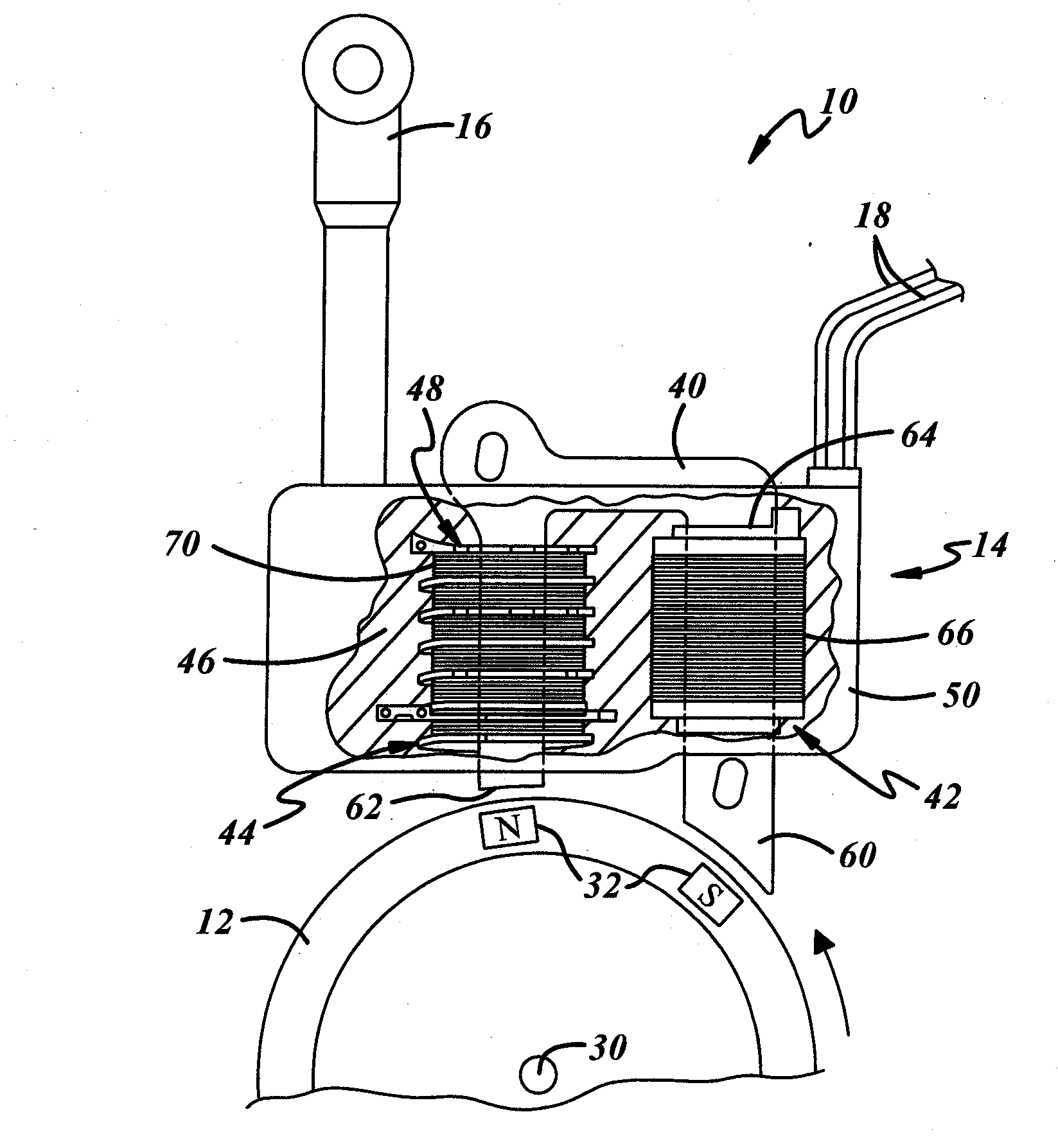

Drive axle assembly for hybrid electric vehicle

ActiveUS7115057B2Less-heavy dutyElectric propulsion mountingToothed gearingsElectric vehicleHybrid power

An axle assembly mounts an electric motor to a central housing opposite an input yoke that is driven by an engine. The input yoke is mounted along an axis parallel to the electric motor to alternatively or additionally permit the engine to drive a gear reduction within the axle housing through a planetary gear assembly. Another axle assembly is powered by just an electric motor to provide a relatively lighter duty axle assembly for yet another vehicle configuration.

Owner:ARVINMERITOR TECH

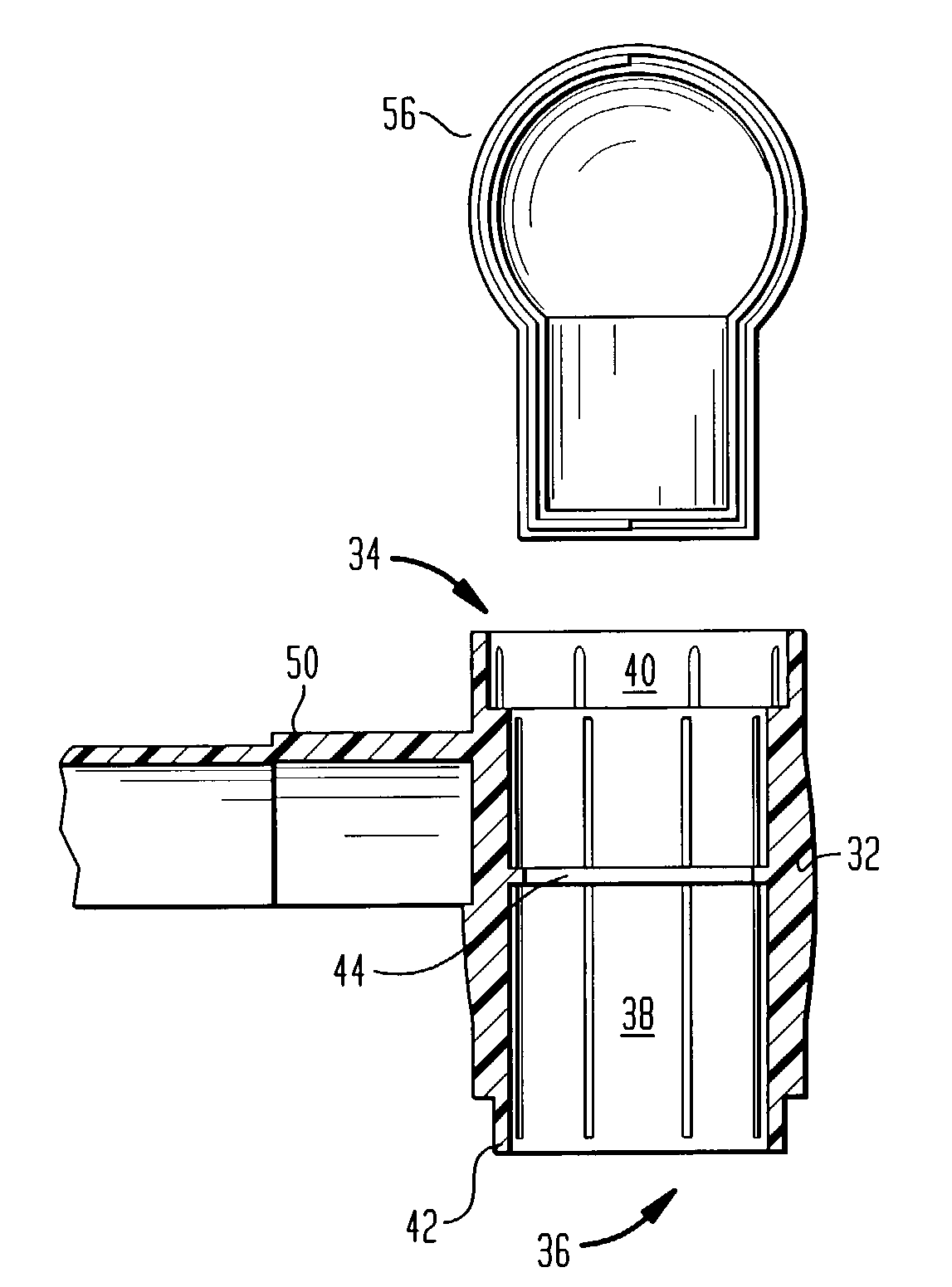

Vehicle side article transporter device

The present invention is a container for a light-duty automobile such as a light-duty pickup truck or sport-utility vehicle having at least one opening, operably associated with the quarter panel of an automobile, an inner wall operably associated with the container, and a cover having a closed position and an open position operably associated with the opening. The cover includes a door inner, and a door outer. The invention also includes a first rail positioned between the container and the quarter panel. The container is integrally formed with the first rail, and is located between the first rail and the inner wall. The first rail supports the container, and the cover can be moved from the open position to the closed position, allowing access to the container.

Owner:MAGNA INTERNATIONAL INC

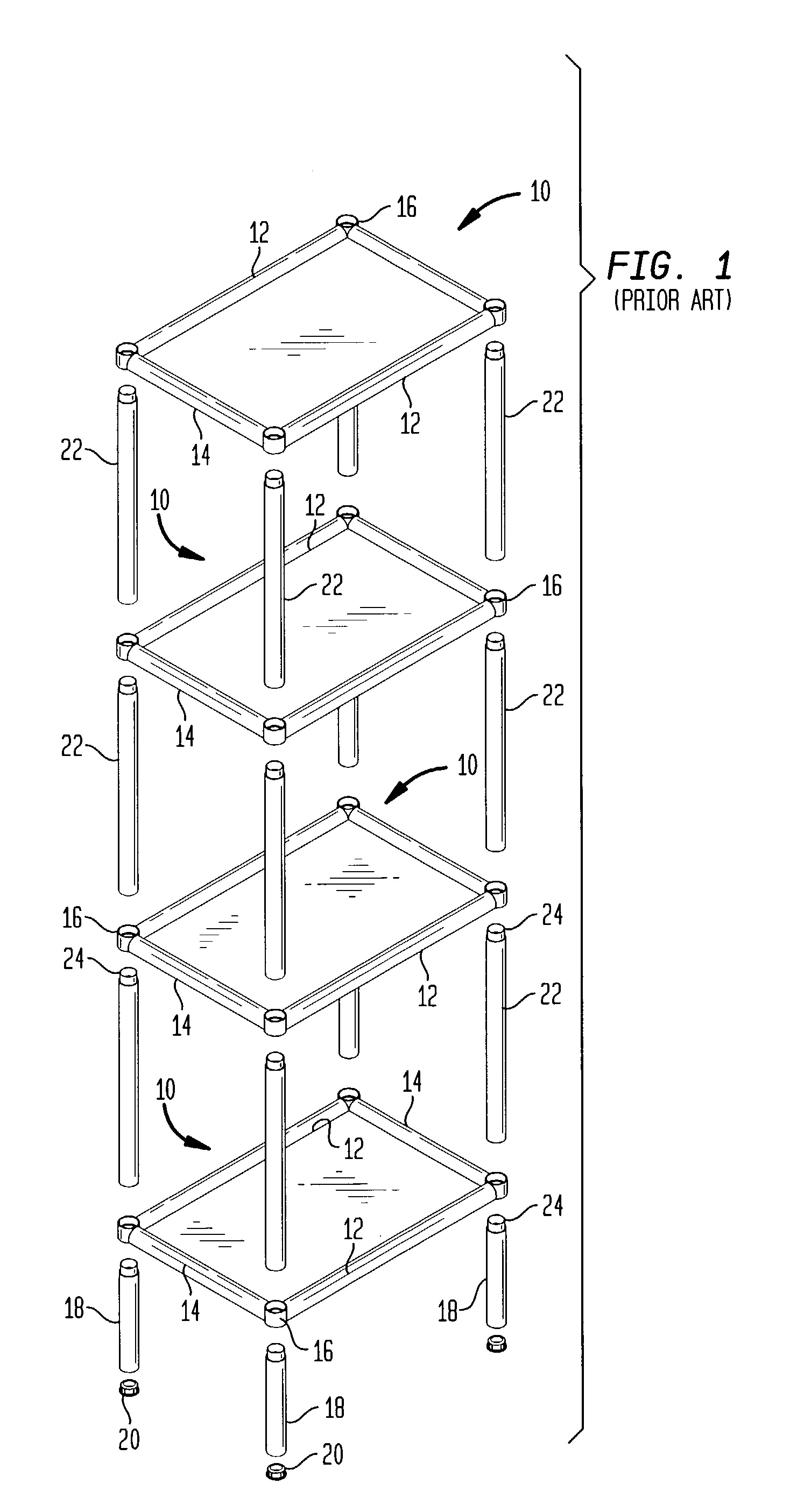

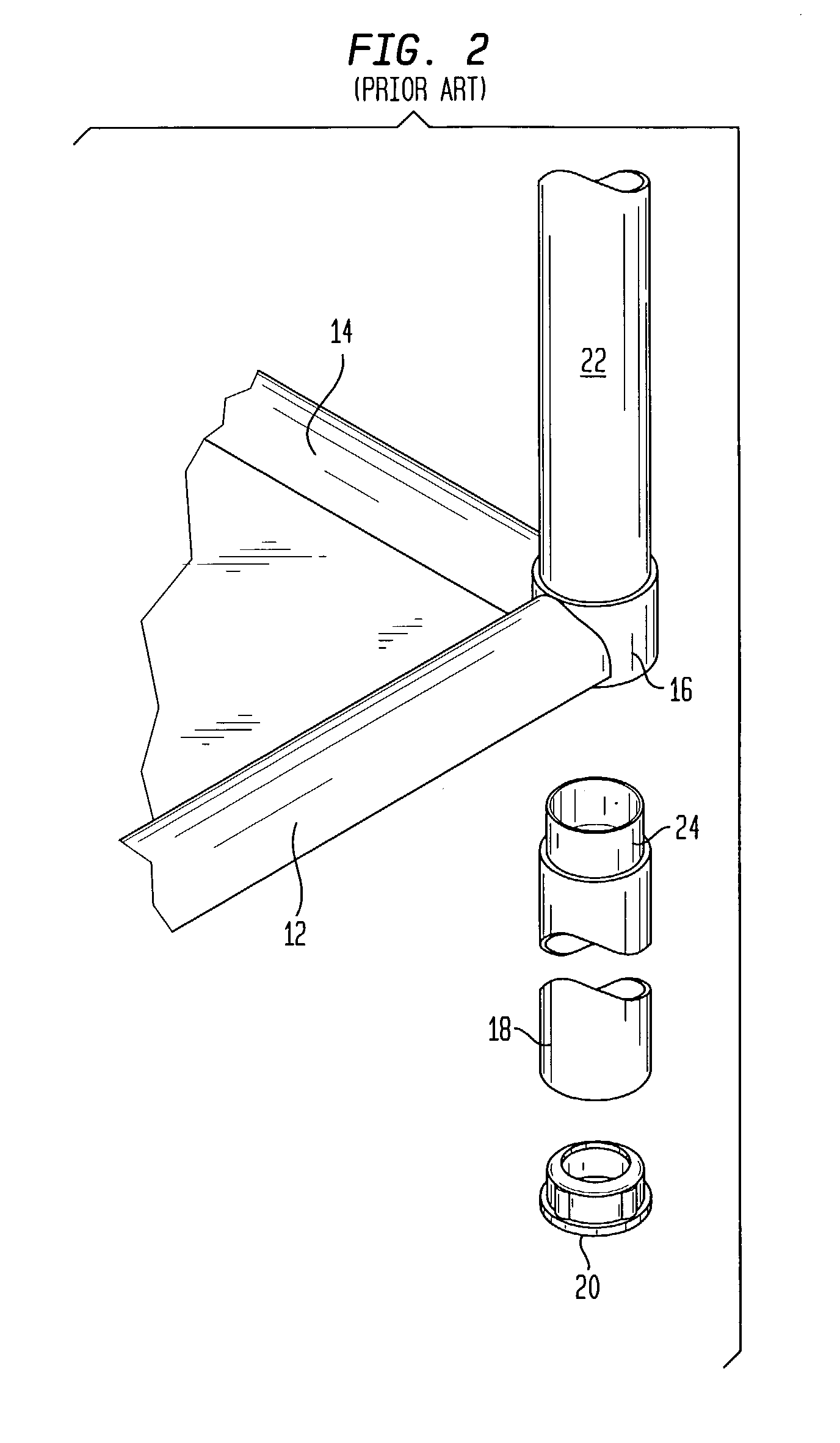

Corner joint and shelf module for use in light-duty all-plastic shelf units

InactiveUS6948435B1Reduce capital investmentCost advantageSectional furnitureDismountable cabinetsComputer moduleEngineering

An all-plastic light duty shelf unit includes rectangular shelf modules and vertical spacers. Each shelf module has four corner joints that can either be mated directly with each other or coupled together using cylindrical vertical spacers. This allows the user to customize the configuration of the shelf unit to meet his or her specific needs. It also reduces the cost to manufacture the shelf unit because the vertical spacers can be extruded rather than injection-molded. The corner joints also hold a shelf off the floor, thereby reducing part count and manufacturing cost.

Owner:HONEYWARE

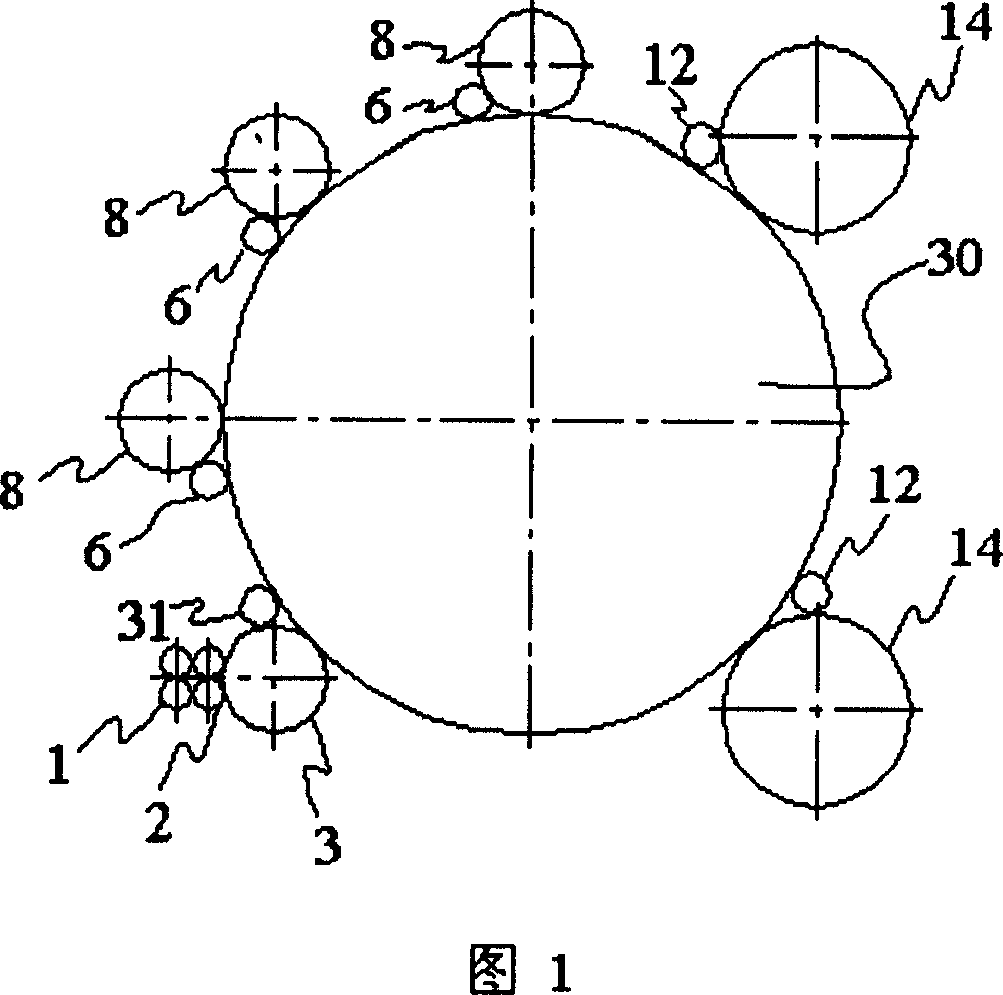

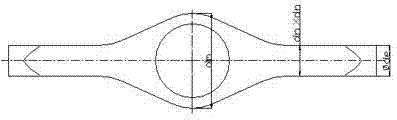

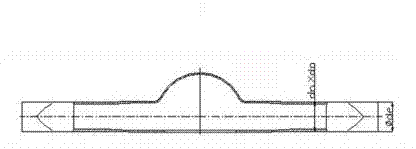

Monolithic molding method of light duty truck weldless axle case

The invention relates to a monolithic molding method of a light duty truck weldless axle case. A weldless steel round pipe is used, first, early hole shrinkage is conducted to two ends of the weldless steel round pipe, two times of hydro-bugling are conducted to the middle of the weldless steel round pipe; and then, later stage hole shrinkage is conducted to the two ends of the weldless steel round pipe to obtain a performing pipe blank which is in an axial symmetry shape or close to an axial symmetry shape. A die left pressure head and a die right pressure head are used on a four-way hydraulic machine for sealing the ends of the performing pipe blank, liquid is injected into the four-way hydraulic machine, an upper die block, a lower die block, a front die block and a rear die block are used for integral pressing and forming on the performing pipe blank from the upper direction, the lower direction, the front direction and the rear direction, an axle case semi-finished product with a hemispherical rear oil cap and an additional front cap is obtained, and an axle case product is obtained by cutting the additional front cap. According to the monolithic molding method, the manufactured axle case is weldless, high in strength and stiffness, and high in material utilization rate. Comparing the used technique with a traditional hydro-bugling technique, the liquid pressure needed in manufacturing process is lowered by more than 60%, and the tonnage of forming devices is lowered by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

Gelled light duty liquid cleaning composition

InactiveUS20050020467A1Good suspensionFine foamNon-ionic surface-active compoundsAqueous liquid non-soap compositionsMagnesium saltLinear alkylbenzene sulfonate

A gelled light duty cleaning composition comprising: a C8-C18 ethoxylated alkyl ether sulfate surfactant, a magnesium salt of a C8-C18 linear alkyl benzene sulfonate, a sodium salt of a C8-C18 linear alkyl benzene sulfonate, an amine oxide surfactant, a polyalkylglucoside, a hydrophobic ethoxylated nonionic surfactant and water.

Owner:COLGATE PALMOLIVE CO

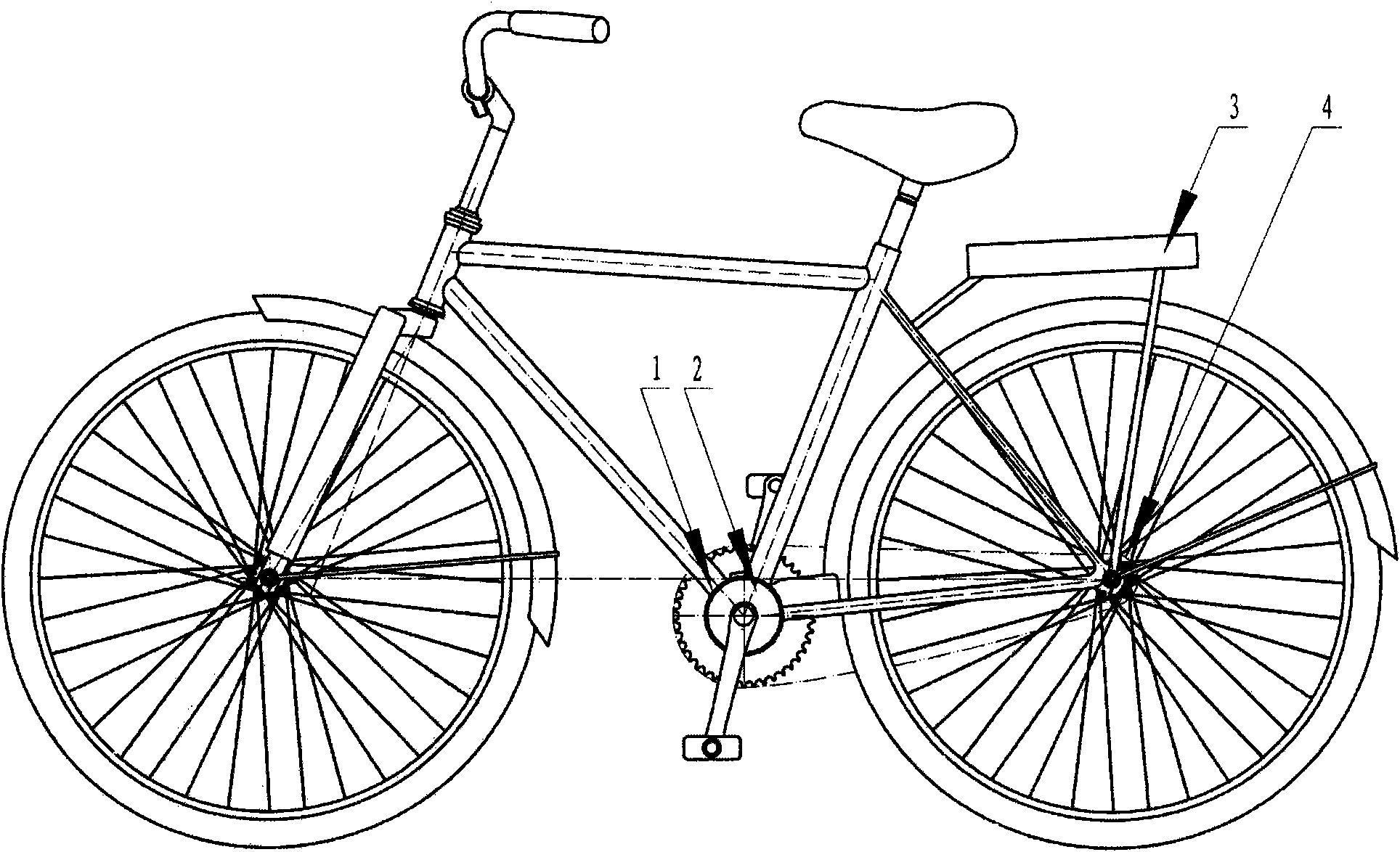

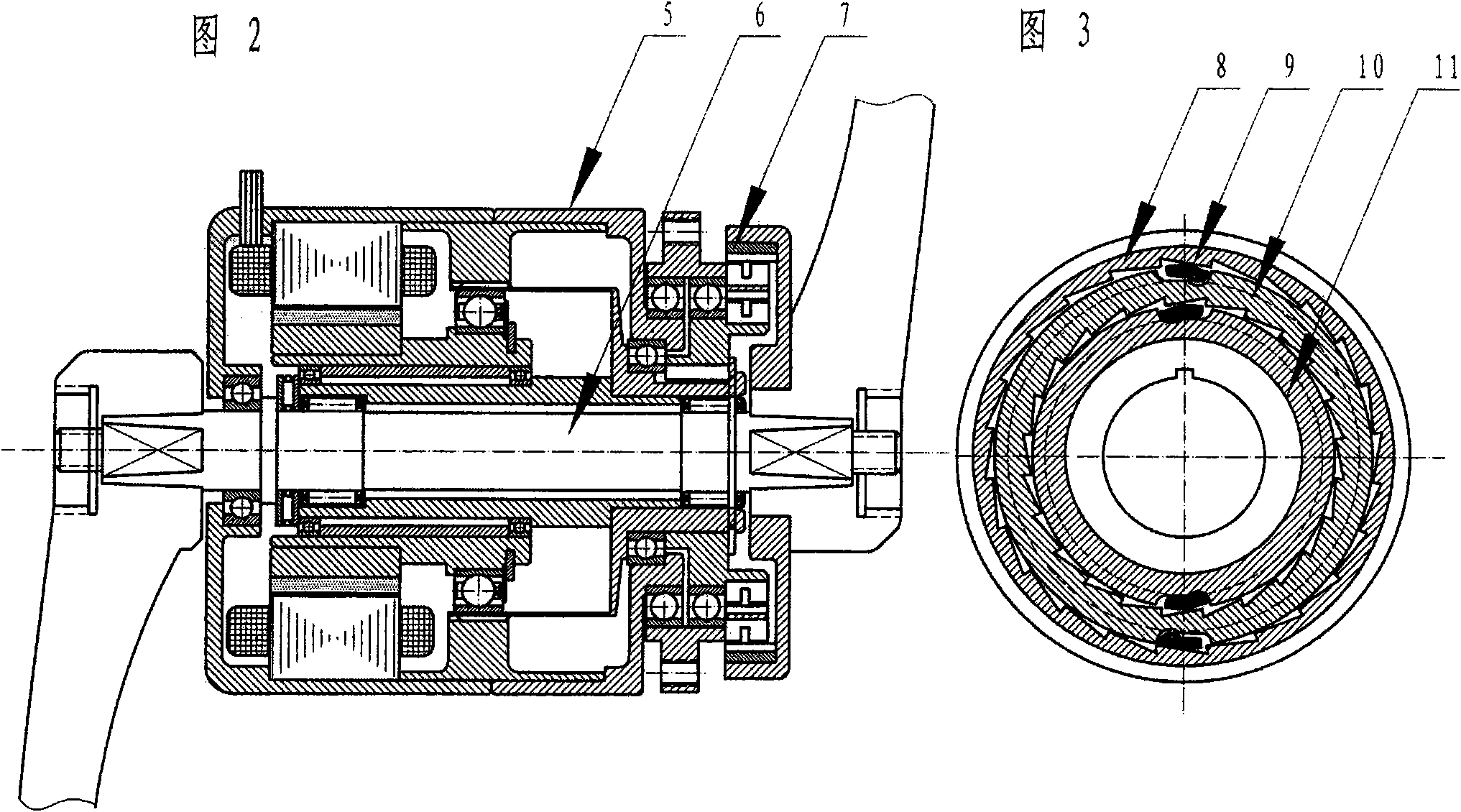

Harmonic wave speed reduction electric bicycle

InactiveCN101857063AImprove efficiencyReduce energy consumptionWheel based transmissionChain/belt transmissionPower couplingHarmonic

The electric bicycle produced in the prior art only realizes the effects of a bicycle and an electric motor, and substantially belongs to a light-duty motor vehicle. The invention combines a harmonic wave speed reduction motor and a double-overrun clutch power coupling mechanism, and then installs the harmonic wave speed reduction motor and the double-overrun clutch power coupling mechanism in a five-way valve of a bicycle, the bicycle is driven to run by a bicycle chain and a mechanical speed-change mechanism, and high efficiency and low energy consumption of the system are ensured. The safety and the convenience of the electric bicycle are completely the same as those of a traditional bicycle. Because of low cost and low energy consumption, the invention can replace the traditional bicycle to become an updating and upgrading product of the bicycle.

Owner:王乐琳

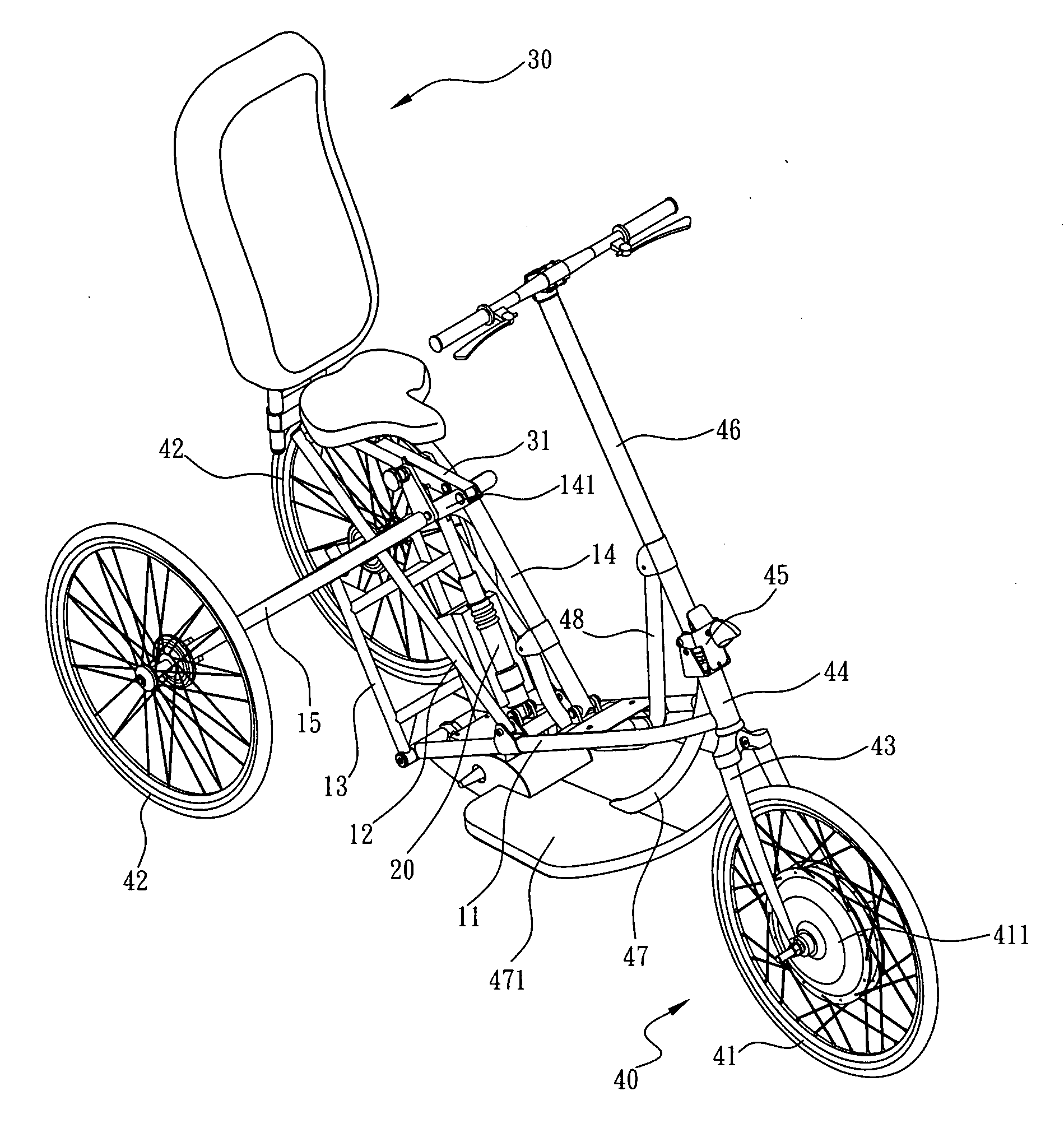

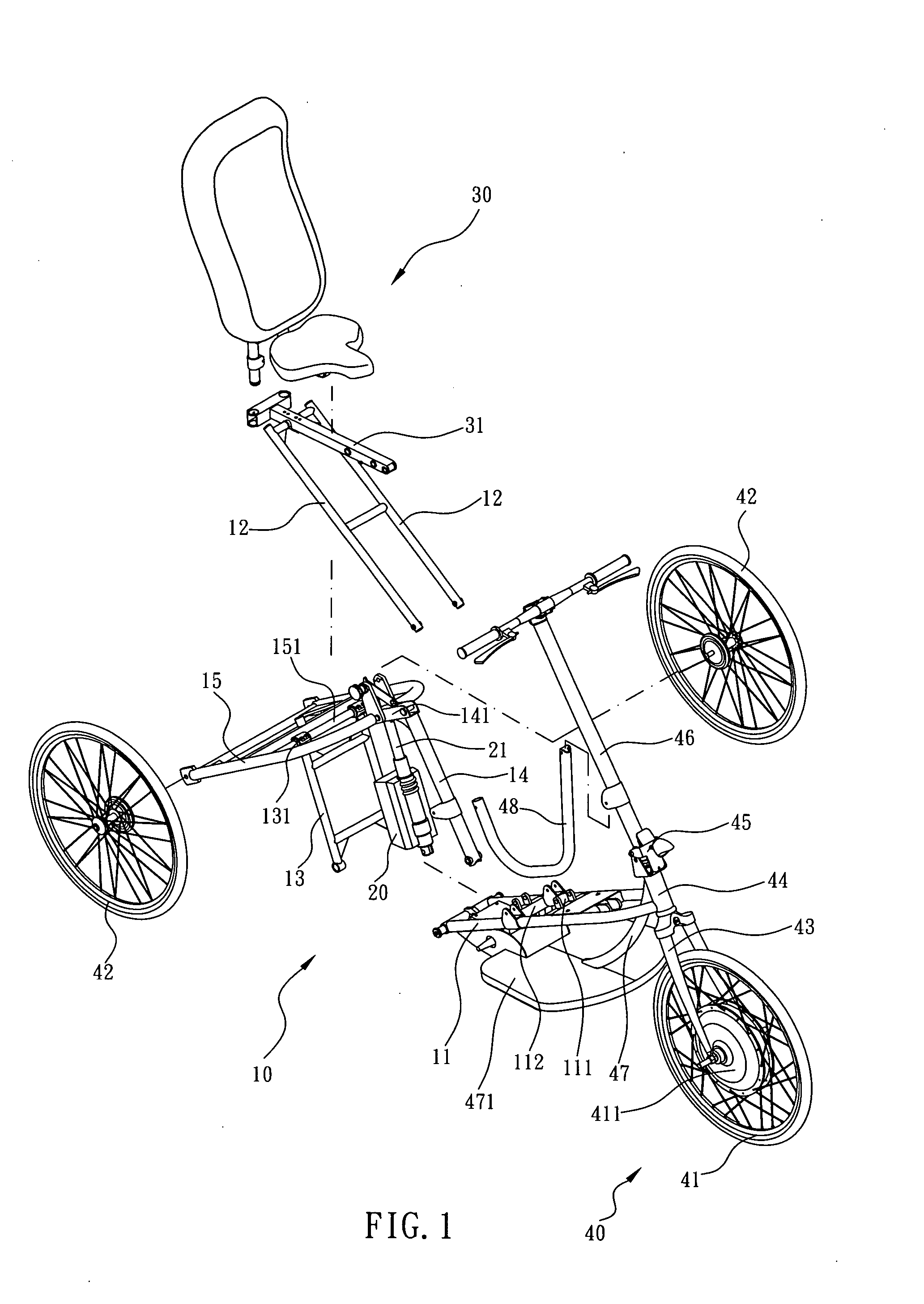

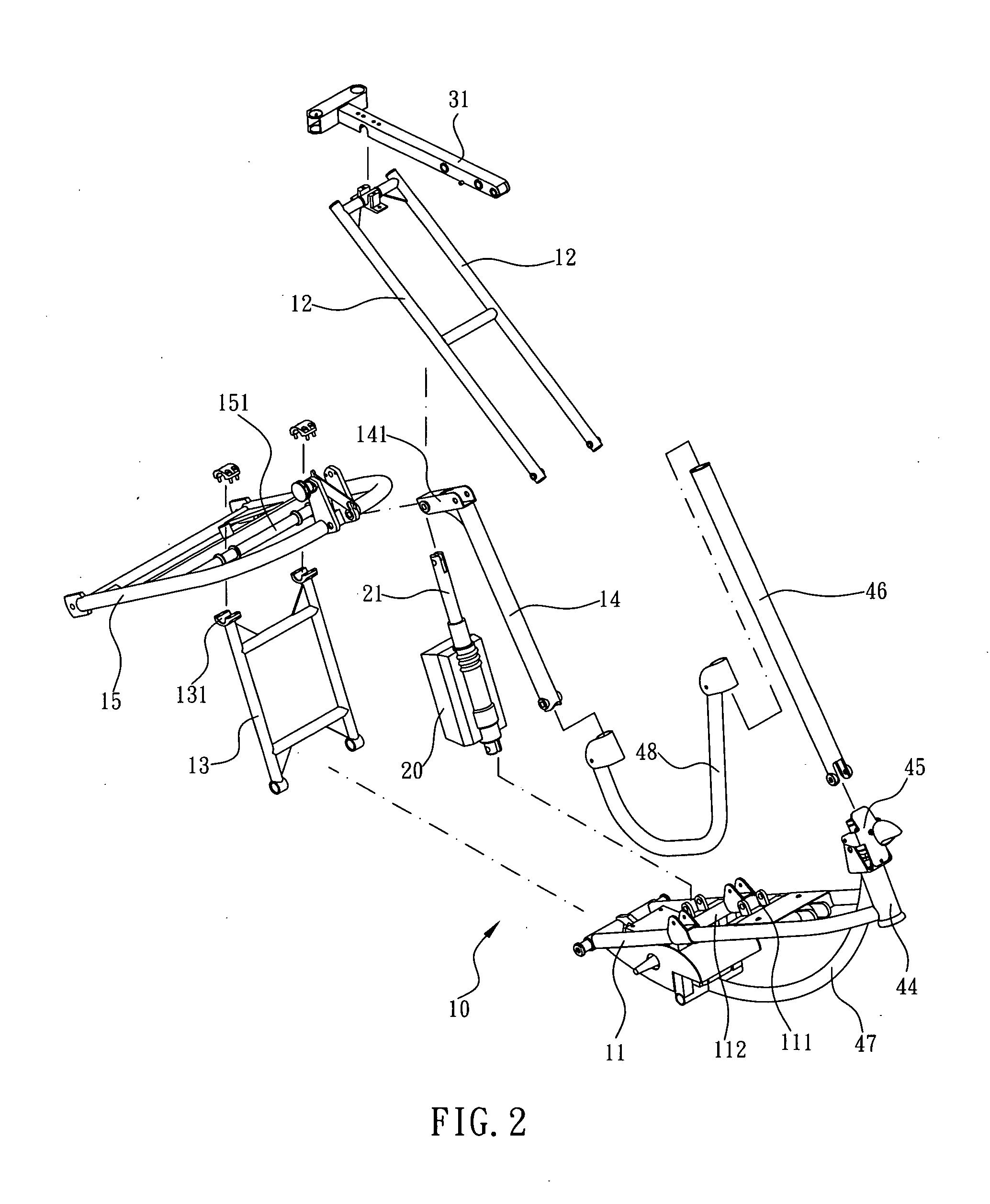

Light-duty vehicle with adjustable wheelbase

A light-duty vehicle with an adjustable wheelbase includes a linkage assembly composed of at least one main rod, a movable support, at least one movable rod and at least one adjusting rod, at least one power source connected in the linkage assembly, a seat mounted on a connecting rod having one end pivotally connected to the movable rod, and a driving wheel set composed of at least one front wheel and at least one rear wheel. The rear wheel is rotatably connected to the adjusting rod, while an opposite end of the main rod is connected to a fixed rod, which is coupled to a front fork above the front wheel. Thereby, when the power source modifies the linkage assembly in posture, the wheelbase between the front wheel and the rear wheel is changed so that the seat is adjusted in posture and altitude.

Owner:CYCLING & HEALTH TECH IND R & D CENT

Detergent compositions comprising polymeric suds enhancers which have improved mildness and skin feel

InactiveUS7214650B2Increase mildnessImprove skinCosmetic preparationsOrganic detergent compounding agentsLaundryPolymer

Compositions comprising one or more polymeric suds volume and suds duration enhances which are mild on the user's skin. The polymeric suds enhances are suitable for use in methods which in use as compositions light duty liquid, LDL compositions, hand dishwashing compositions, laundry bars, personal cleansing compositions and the like.

Owner:PROCTER & GAMBLE CO

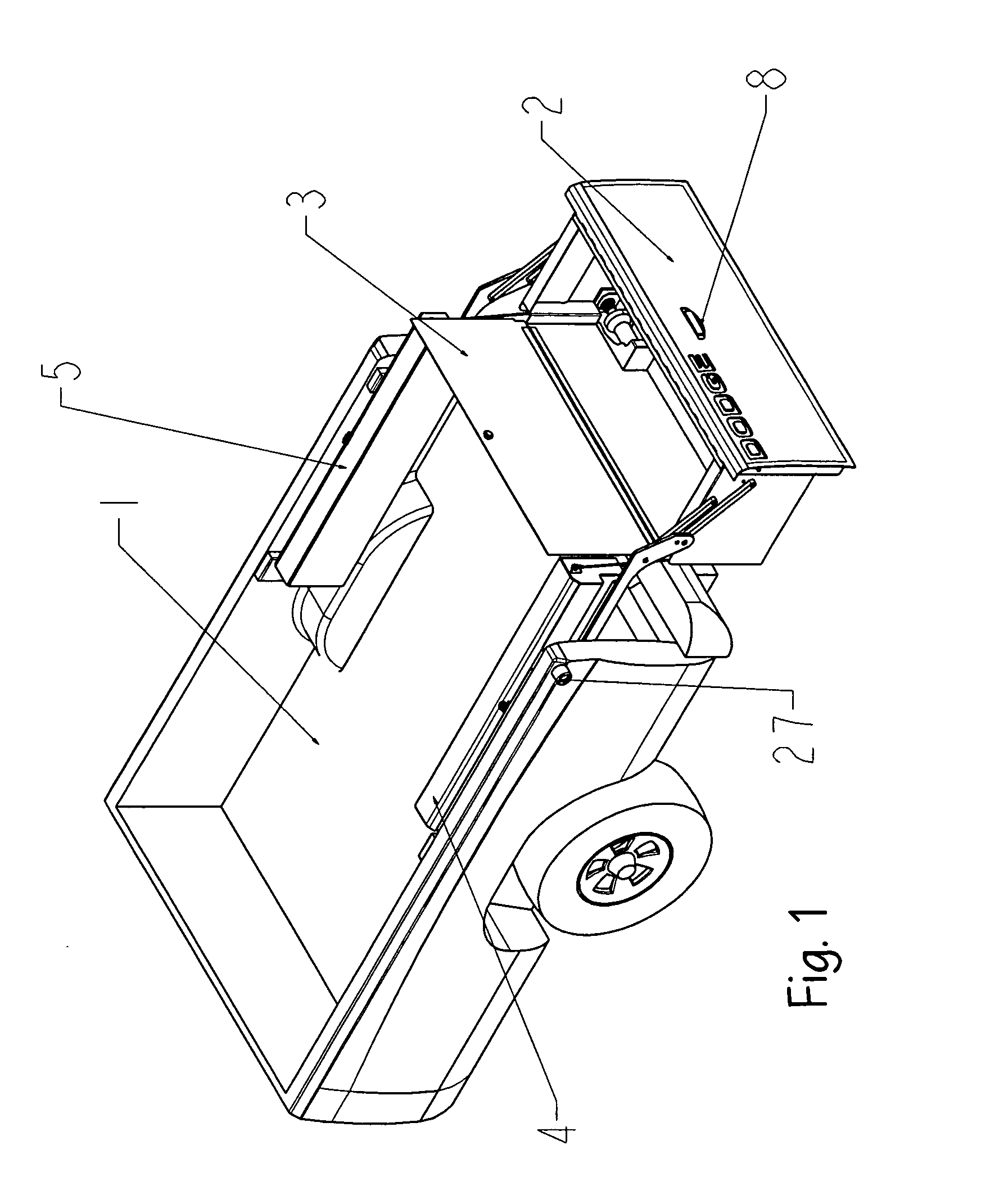

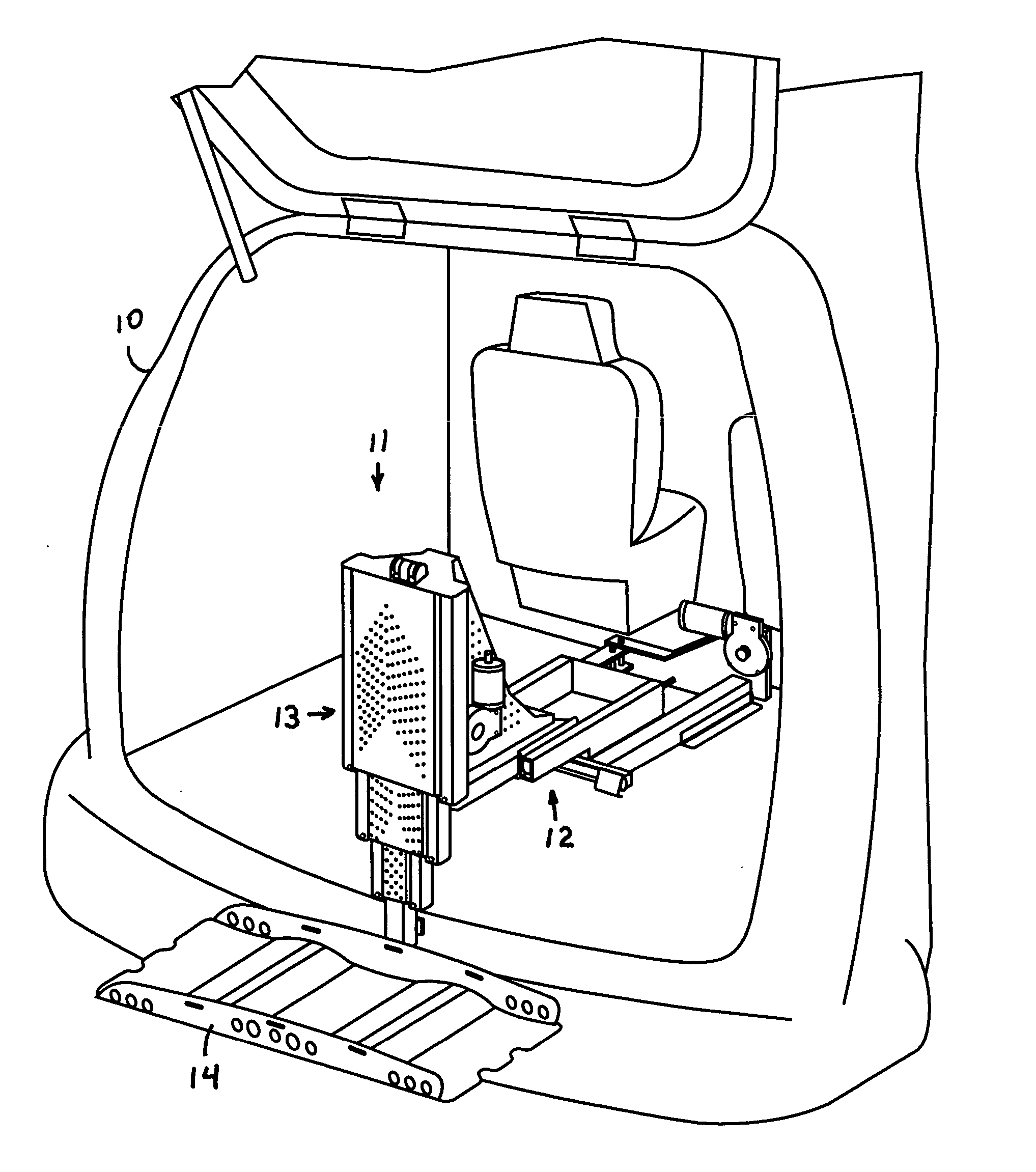

Internal lift for light duty motor vehicle

InactiveUS20050105995A1Vehicle with raised loading platformRefuse receptaclesEngineeringScroll wheel

A lift includes a first telescoping member including a flange for attaching the lift to a vehicle, a second telescoping member coupled to the first telescoping member, and a tool coupled to the second telescoping member, wherein the tool is movable along two orthogonal axes of motion as determined by the two telescoping members. The telescoping members include at least two nested slides. A first slide includes a first pair of rollers on one side thereof and a second pair of rollers opposite the first pair. The second slide includes a pair of opposed U-shaped channels that enclose the rollers to provide a telescoping action. If one axis of motion is vertical, a block is included between each pair of rollers. Each block is dimensioned to engage the bottom of a channel, whereby the blocks help stabilize the motion of the first slide. Motion along two axes is controlled by actuation of a single switch.

Owner:VANTAGE MOBILITY INT

Mild cleansing compositions

InactiveUS20080233057A1Long storage timeHigh storage temperatureCosmetic preparationsNon-ionic surface-active compoundsPersonal careToothpaste

Mild cleansing compositions comprising anionic, nonionic and / or amphoteric surfactants, one or more dyes having a total color, and one or more encapsulated dyes, including microencapsulated dyes, in microcapsules prepared by coacervation, precipitation, polycondensation or other reaction of anionic and cationic components, which encapsulated dyes have a total color different from the total color of the previous dye(s), plus, water, and, optionally, one or more additives and / or auxiliaries, which compositions are useful in personal care preparations, such as liquid soaps, hand-washing pastes, toothpastes, manual dishwashing preparations, and light-duty detergents.

Owner:COGNIS IP MANAGEMENT GMBH

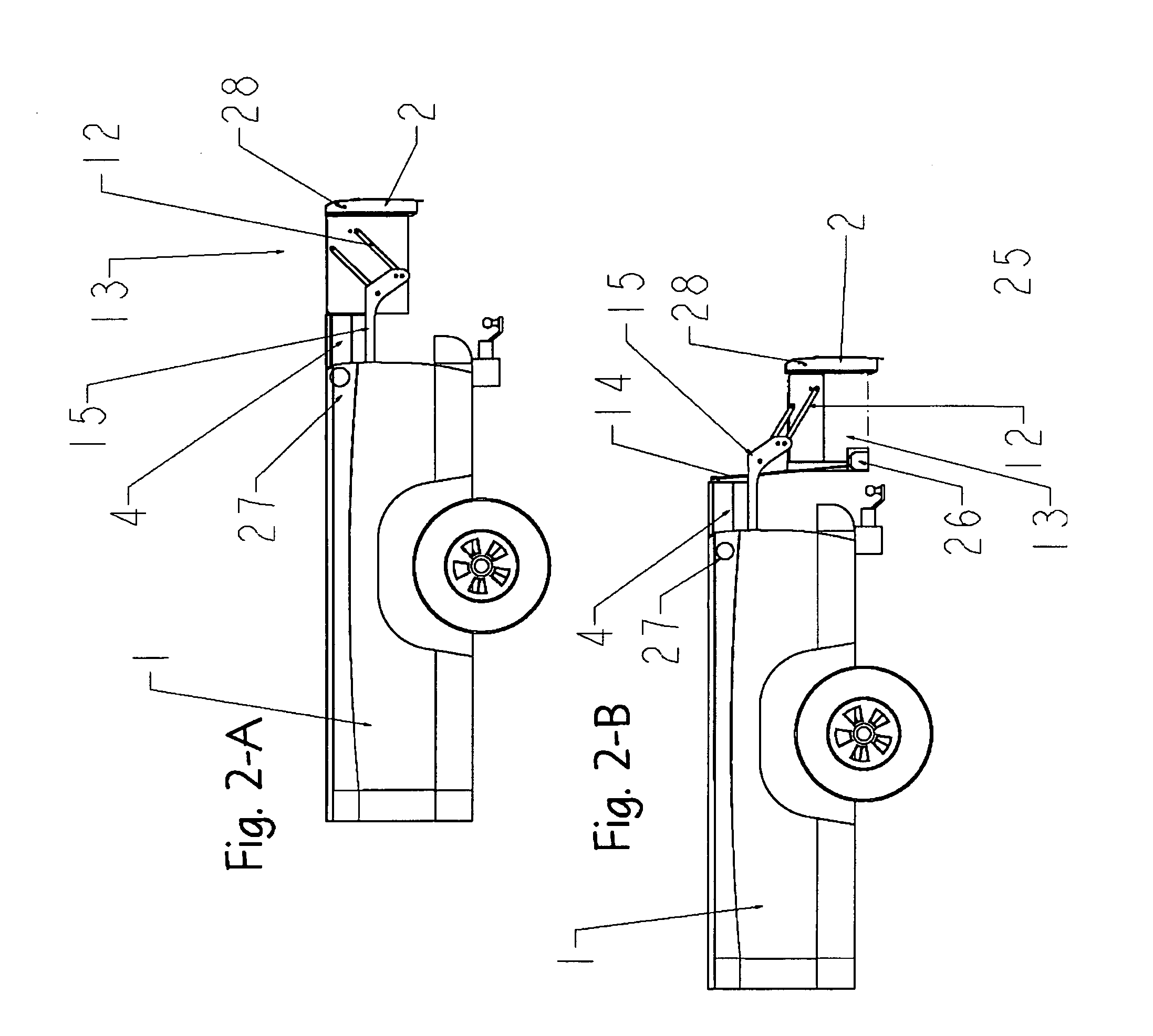

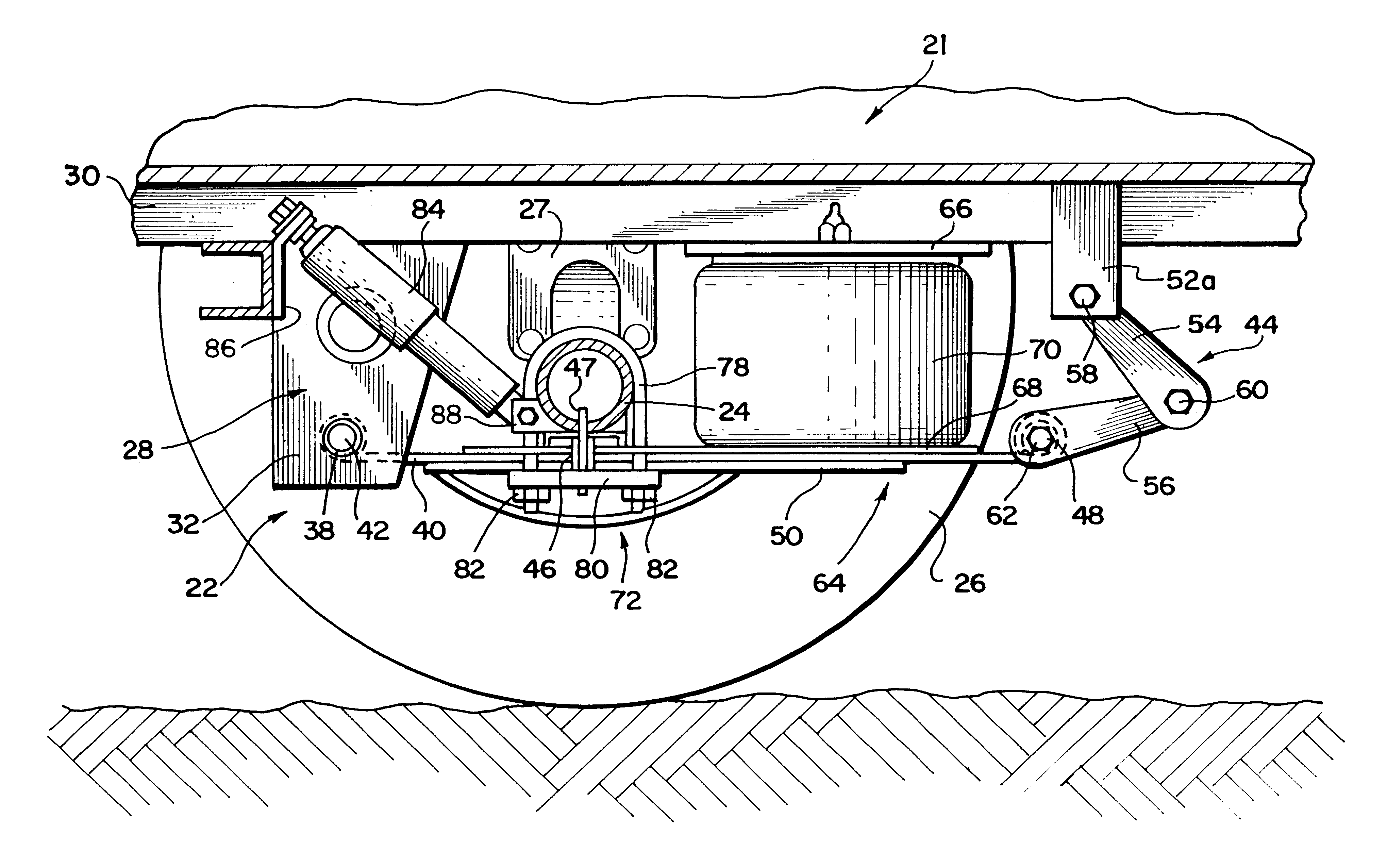

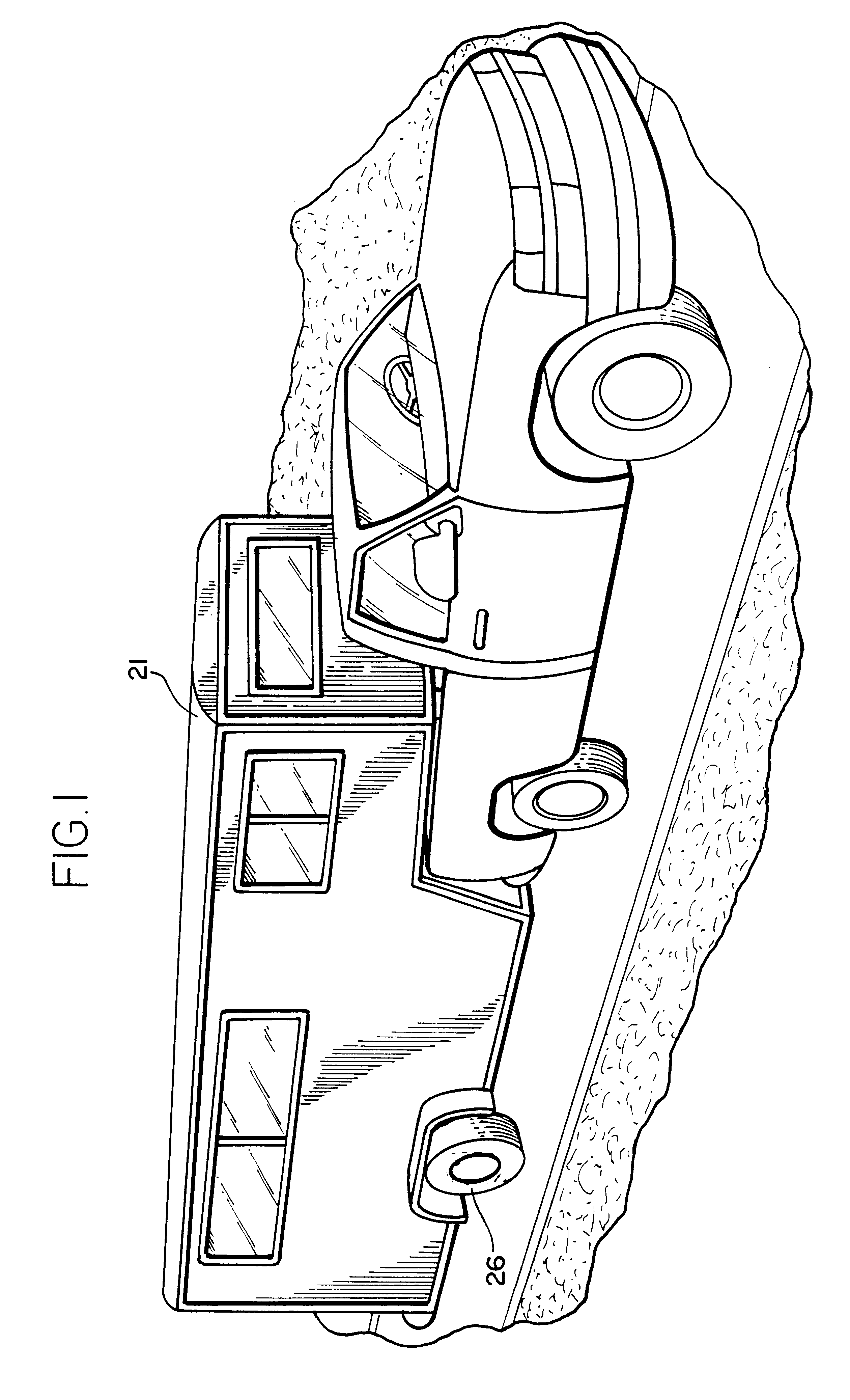

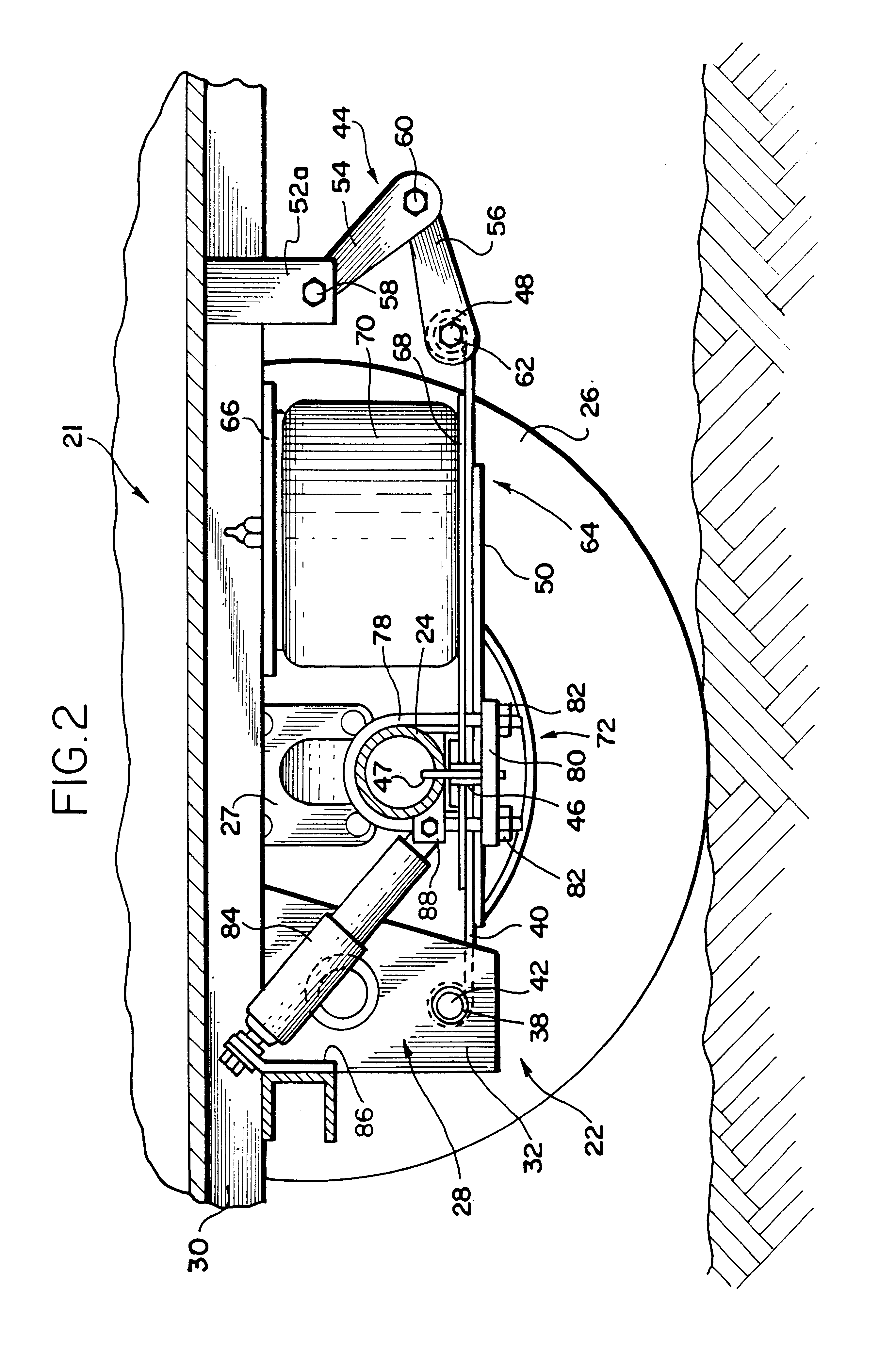

Air ride suspension system

InactiveUS6328324B1Prevent lateral movementImprove stabilityResilient suspensionsVehicle springsAir springEngineering

The present invention provides a suspension system for a light duty trailer which includes a pair of modules. Each module is provided on an end of the axle and includes a spring member, a tower for connecting a front end of the spring member to an underside of the light duty trailer, an air spring connected between the underside of the light duty trailer and the spring member, and a limiting assembly for connecting a rear end of the spring member to the underside of the light duty trailer. In operation, if no bumps or ruts are encountered, the spring member remains generally horizontal relative to the underside of the light duty trailer. If a bump is encountered, the rear end of the spring member moves upwardly relative to the underside of the light duty trailer and the air spring compresses. If a rut is encountered, the rear end of the spring member moves downwardly relative to the underside of the light duty trailer and the air spring expands. The limiting assembly limits the amount of travel of the spring member.

Owner:LIPPERT COMPONENTS MFG INC

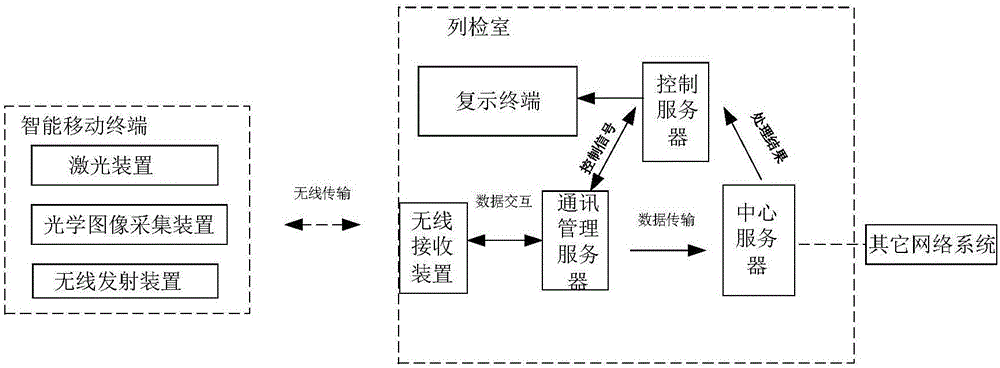

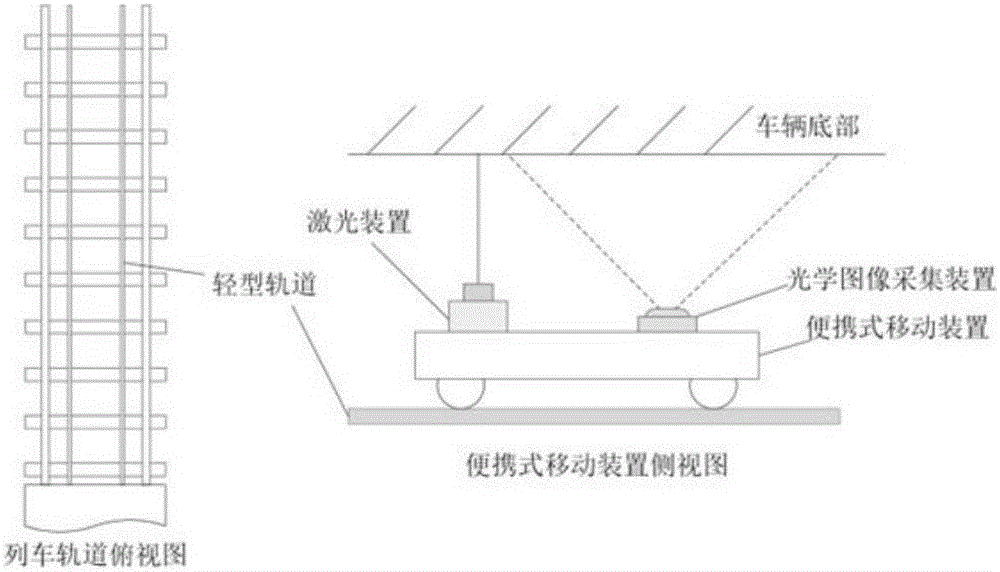

Machine vision based technical inspection and detection system and method for railway trains

ActiveCN105882683AQuality improvementImprove accuracyImage enhancementImage analysisMachine visionFreight trains

The invention discloses a machine vision based technical inspection and detection system and method for railway trains and belongs to the field of technical inspection on railway freight trains. According to the system, a light-duty rail, a portable moving device, a laser device, an optical image acquisition device and a wireless transmitting device are arranged outside a train inspection room; a wireless receiving device, a communication management server, a control server and a central server are arranged in the train inspection room. According to the system and the method, the automation and the intellectualization of technical inspection on the railway trains are achieved through controlling the portable moving device running on the light-duty rail, automatically acquiring image and video data on the bottom of a vehicle, carrying out data processing and outputting a current state of each component of the vehicle, an air testing test result and a repair processed result. According to the system and the method, manpower can be replaced for outdoor vehicle guarding operation, and the high quality, the accuracy and the reliability of train inspection can be guaranteed; the system and the method can adapt to various climatic conditions and natural environments and high-strength operation, so that the work efficiency of train inspection is increased.

Owner:BEIJING CTROWELL INFRARED TECHN

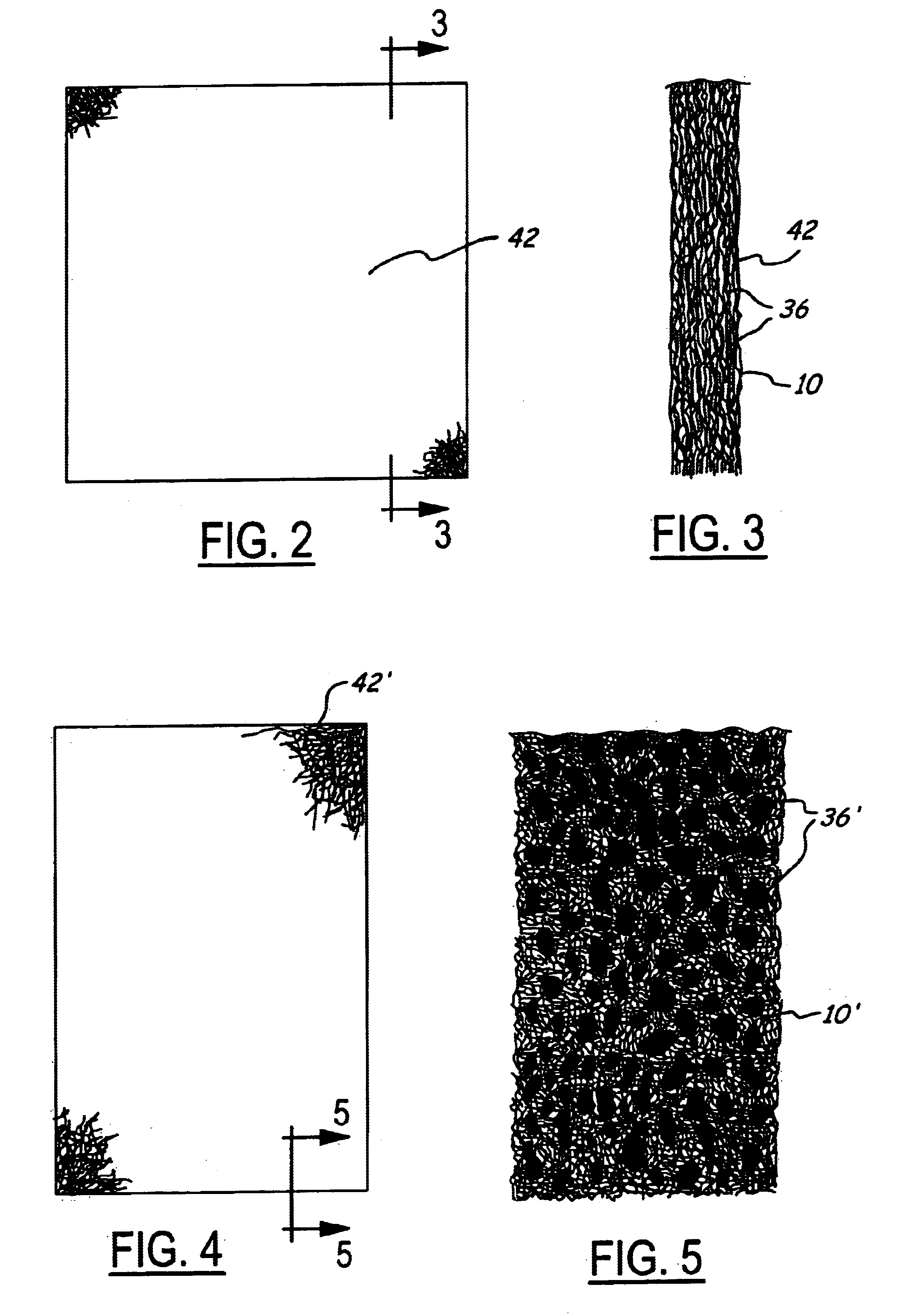

Filter material and method of making same

InactiveUS6878193B2Evenly distributedEliminate sheddingDispersed particle filtrationIsotope separationFiberActivated carbon

Non-shedding light duty fibrous filter material containing activated carbon and / or other sorbtive granules is disclosed having a thickness of ⅛ inch to ⅜ inch and composed entirely of low melt fibers of 4 to 15 denier. Heavy duty filter material, also of a non-shedding clean character, is of ¾ to 1 inch thickness and comprises a mixture of 70% structural fibers and 30% low melt fibers.

Owner:DMARK

Drive axle assembly for hybrid electric vehicle

ActiveUS20050272547A1Less-heavy dutyToothed gearingsGas pressure propulsion mountingGear wheelElectric vehicle

An axle assembly mounts an electric motor to a central housing opposite an input yoke that is driven by an engine. The input yoke is mounted along an axis parallel to the electric motor to alternatively or additionally permit the engine to drive a gear reduction within the axle housing through a planetary gear assembly. Another axle assembly is powered by just an electric motor to provide a relatively lighter duty axle assembly for yet another vehicle configuration.

Owner:ARVINMERITOR TECH

Truck storage and work surface tailgate

InactiveUS20040207226A1Reduce positioningEasy and convenient accessRefuse receptaclesVehicle with living accommodationTruckPower unit

A storage compartment and integrated tailgate worksurface to be easily retrofitable to any standard or light duty pick-up type truck bed, whereby a parallel linkage mechanism and integrated power unit can raise and lower the tailgate assembly without rotation, thereby keeping objects in an initial desired orientation and placement, as well as positioning them and the integrated tailgate worksurface at a convenient adjustable working height.

Owner:KURION INC

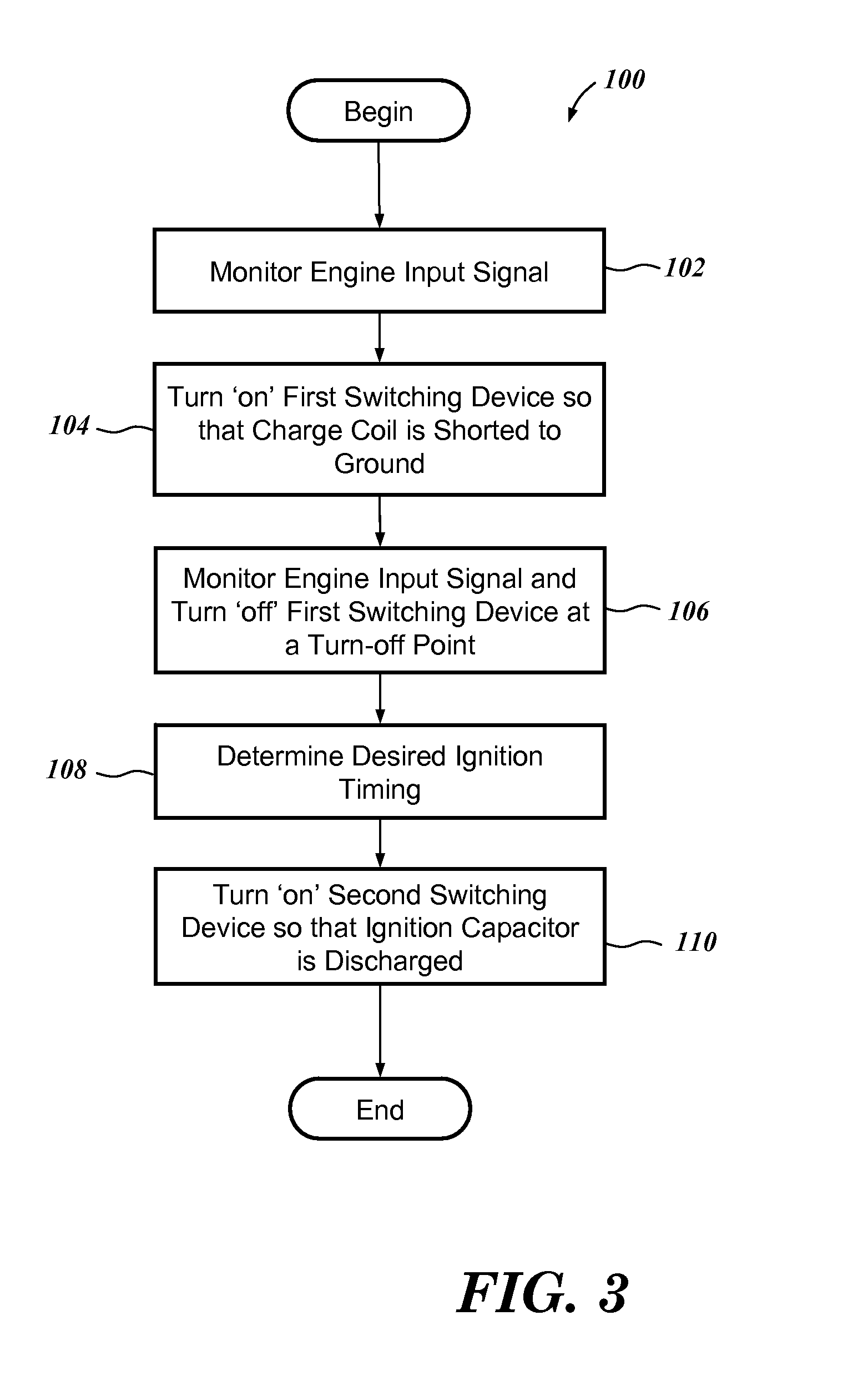

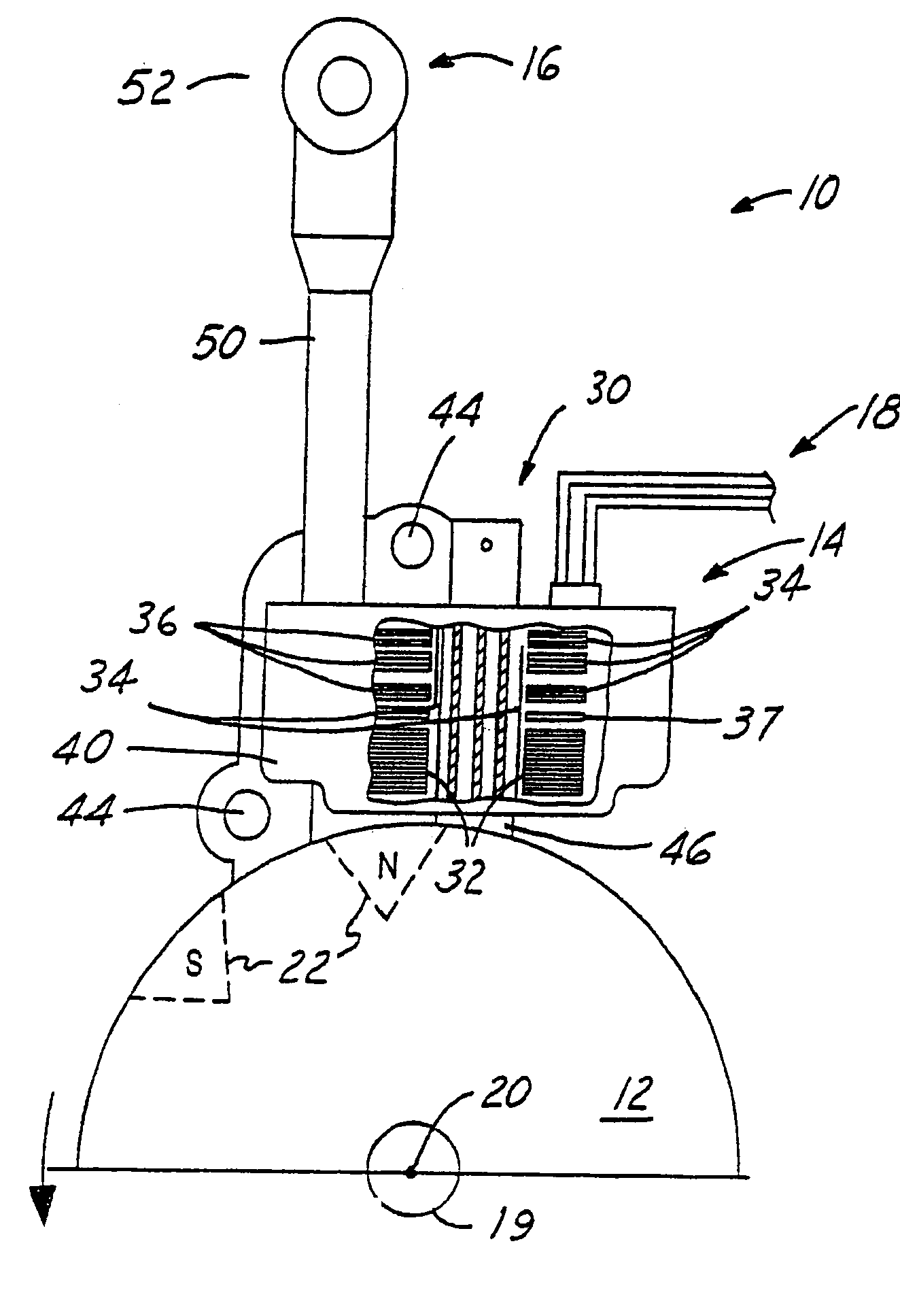

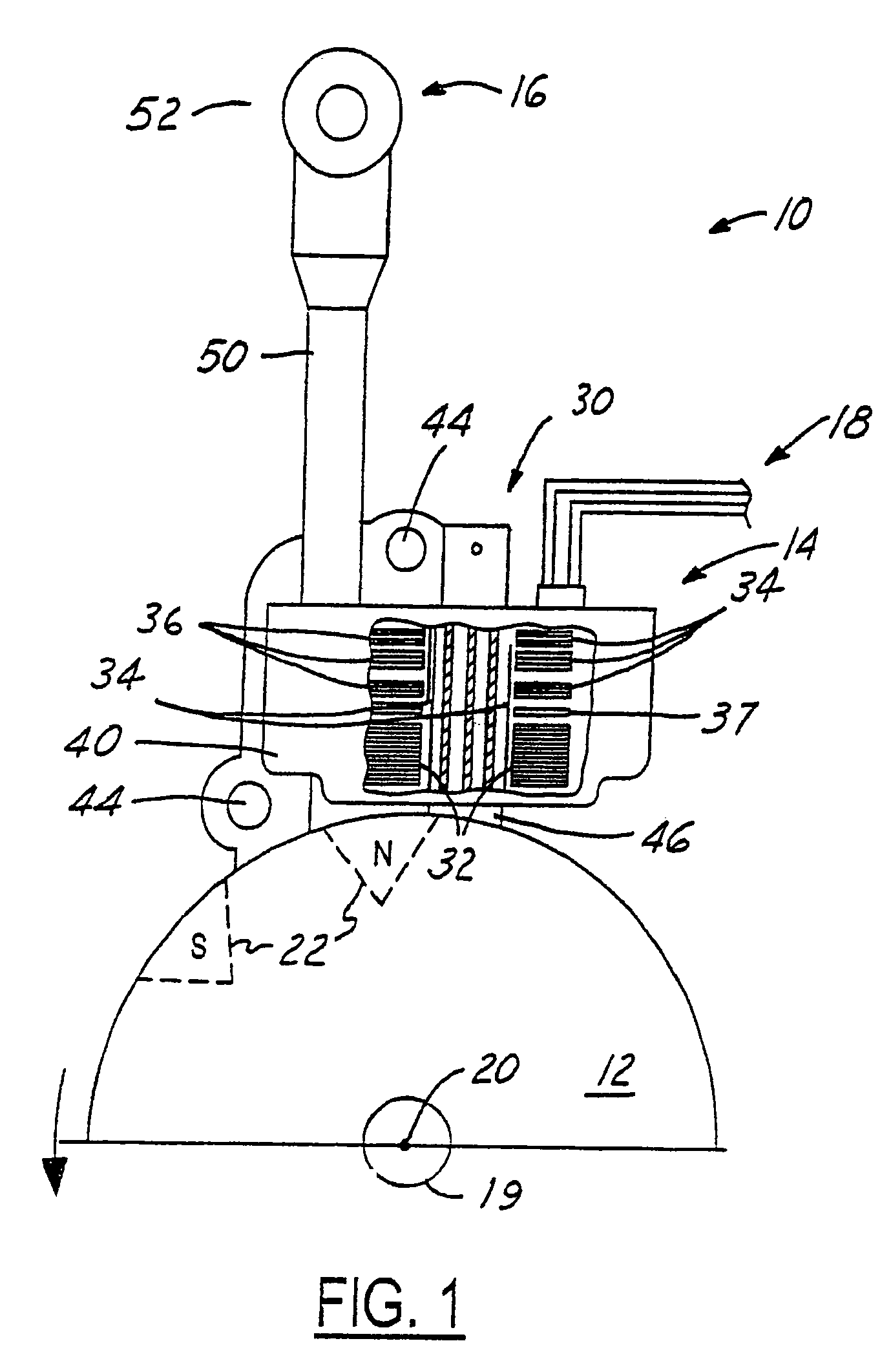

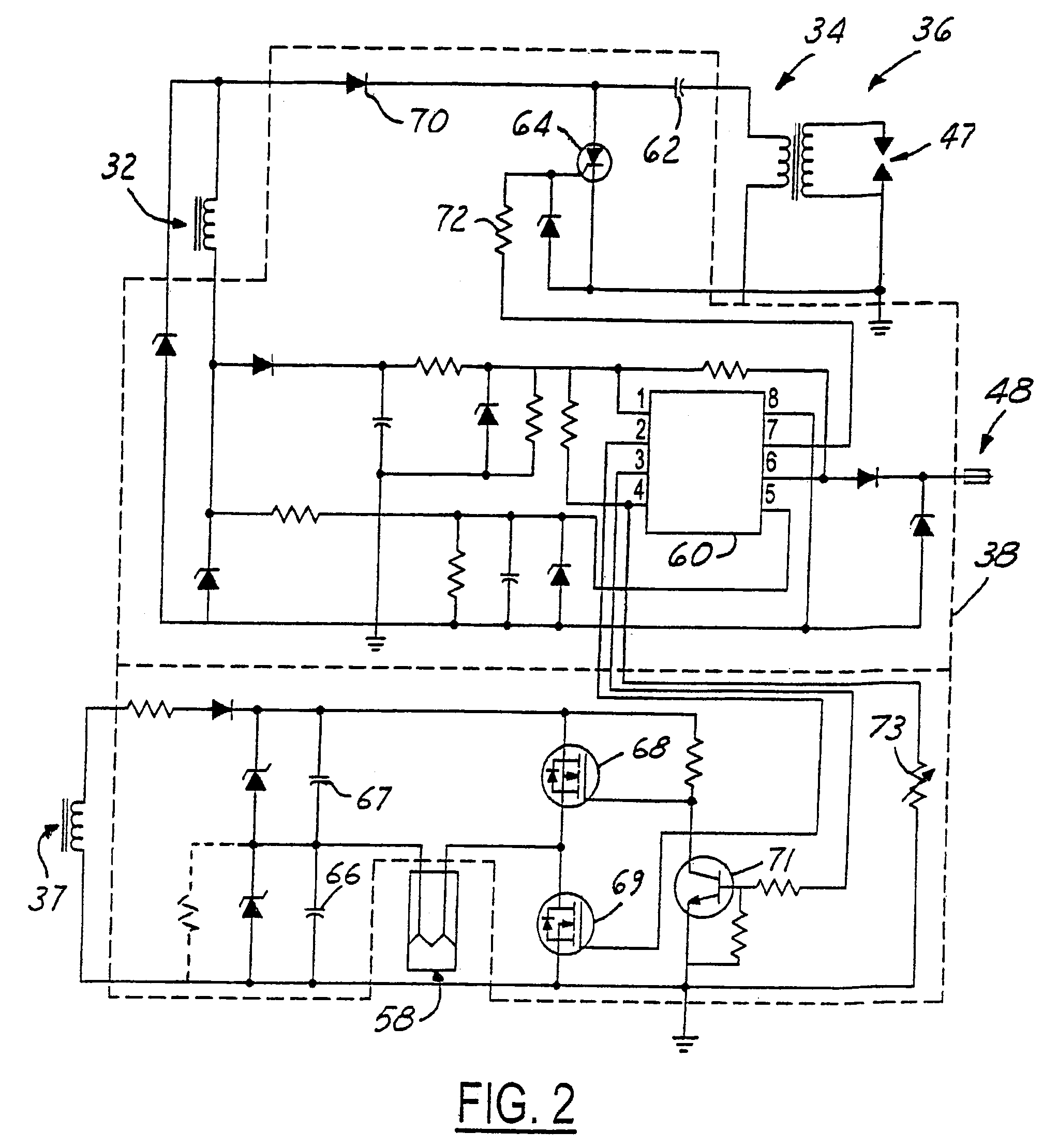

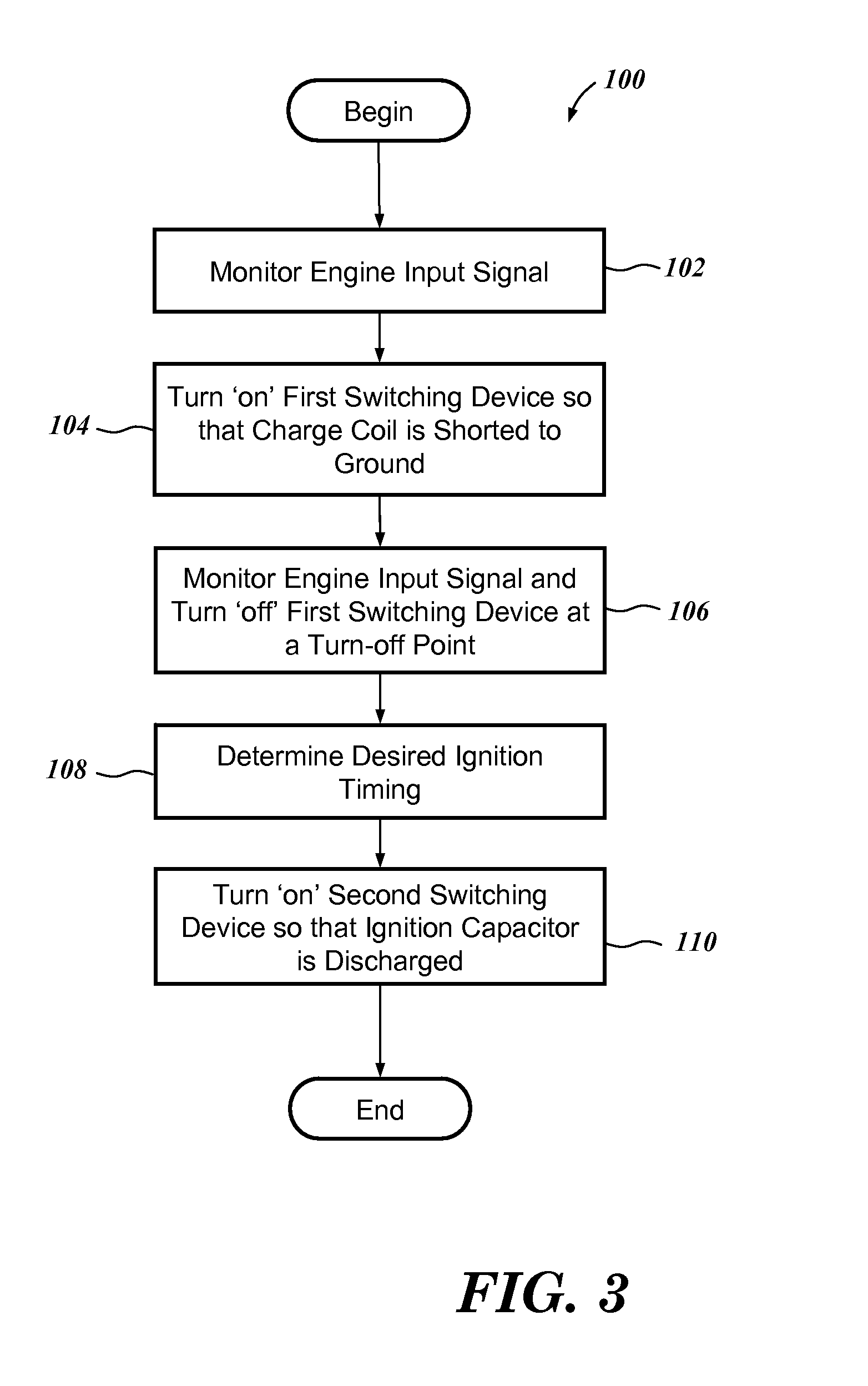

Ignition Module For Use With A Light-Duty Internal Combustion Engine

ActiveUS20080178841A1Low impedance pathAnalogue computers for vehiclesEngine controllersCapacitanceComputer module

A capacitive discharge ignition (CDI) system that can be used with a variety of light-duty internal combustion engines, including those typically employed by lawn, garden, and other outdoor equipment. According to one embodiment, the CDI system includes an ignition module having a first switching device that shorts a charge coil during an initial portion of a charge cycle. Subsequently, the first switching device is turned ‘off’ so that a flyback charging technique charges an ignition capacitor. A second switching device is then used to discharge the ignition capacitor and initiate the combustion process.

Owner:WALBRO LLC

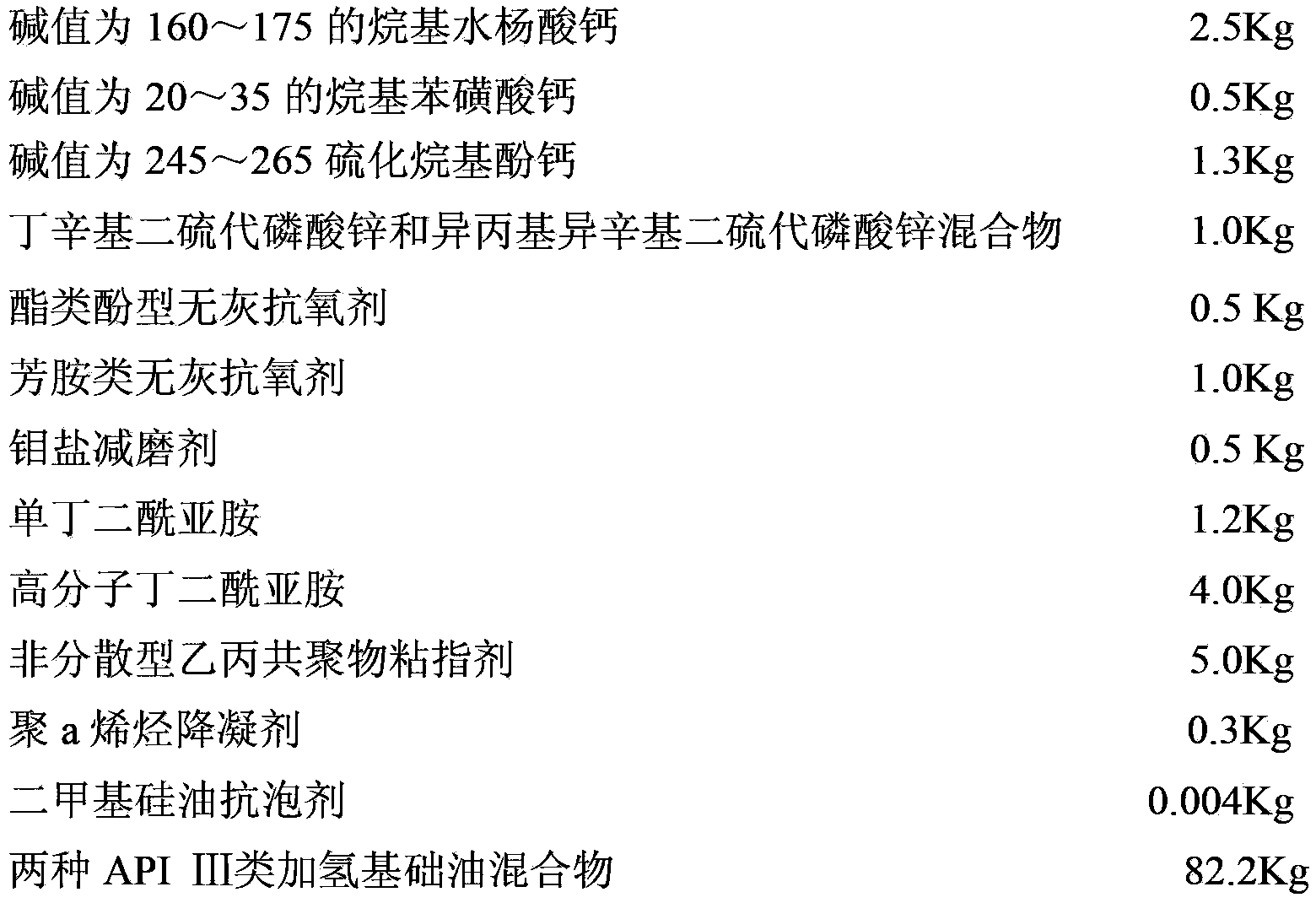

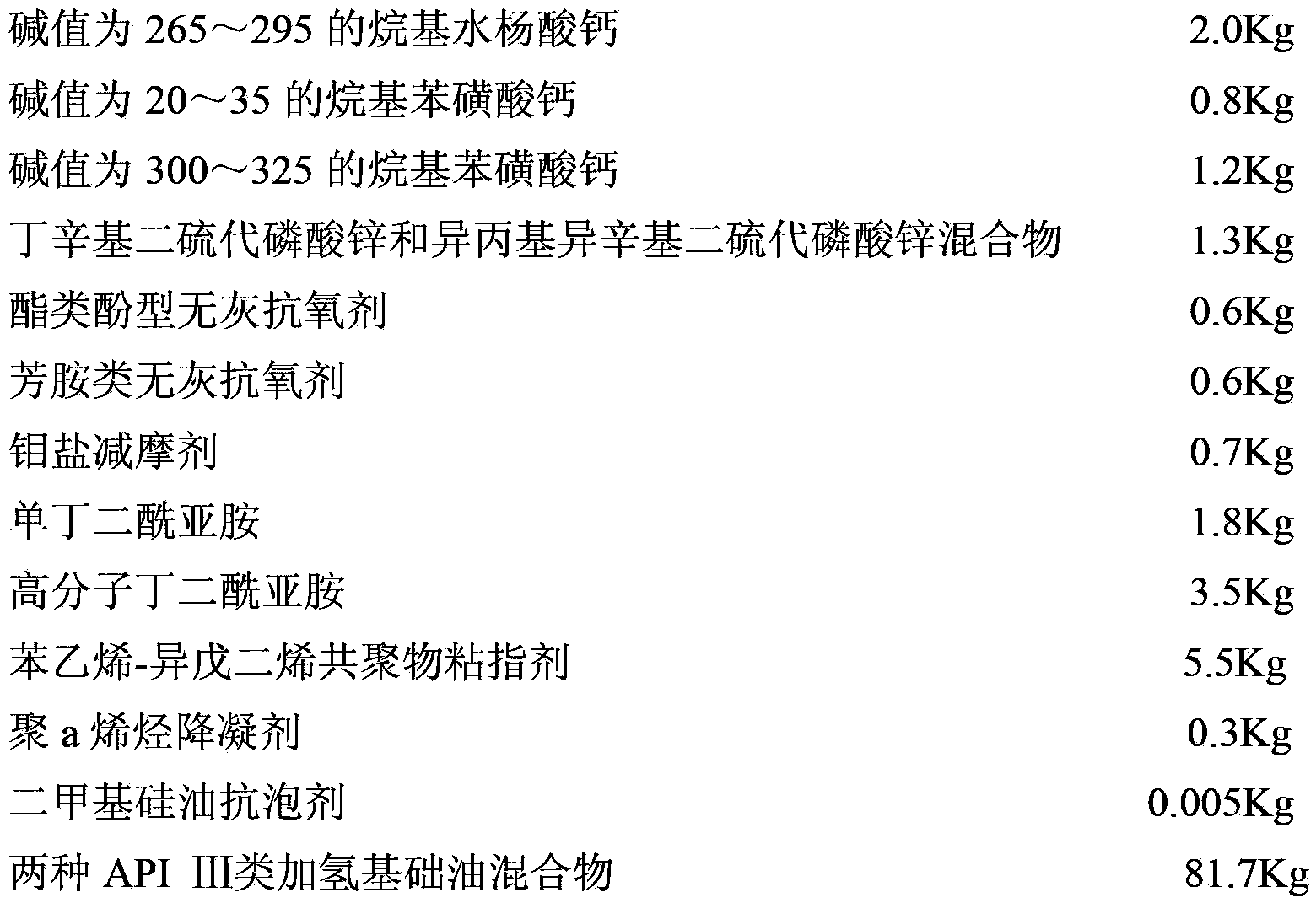

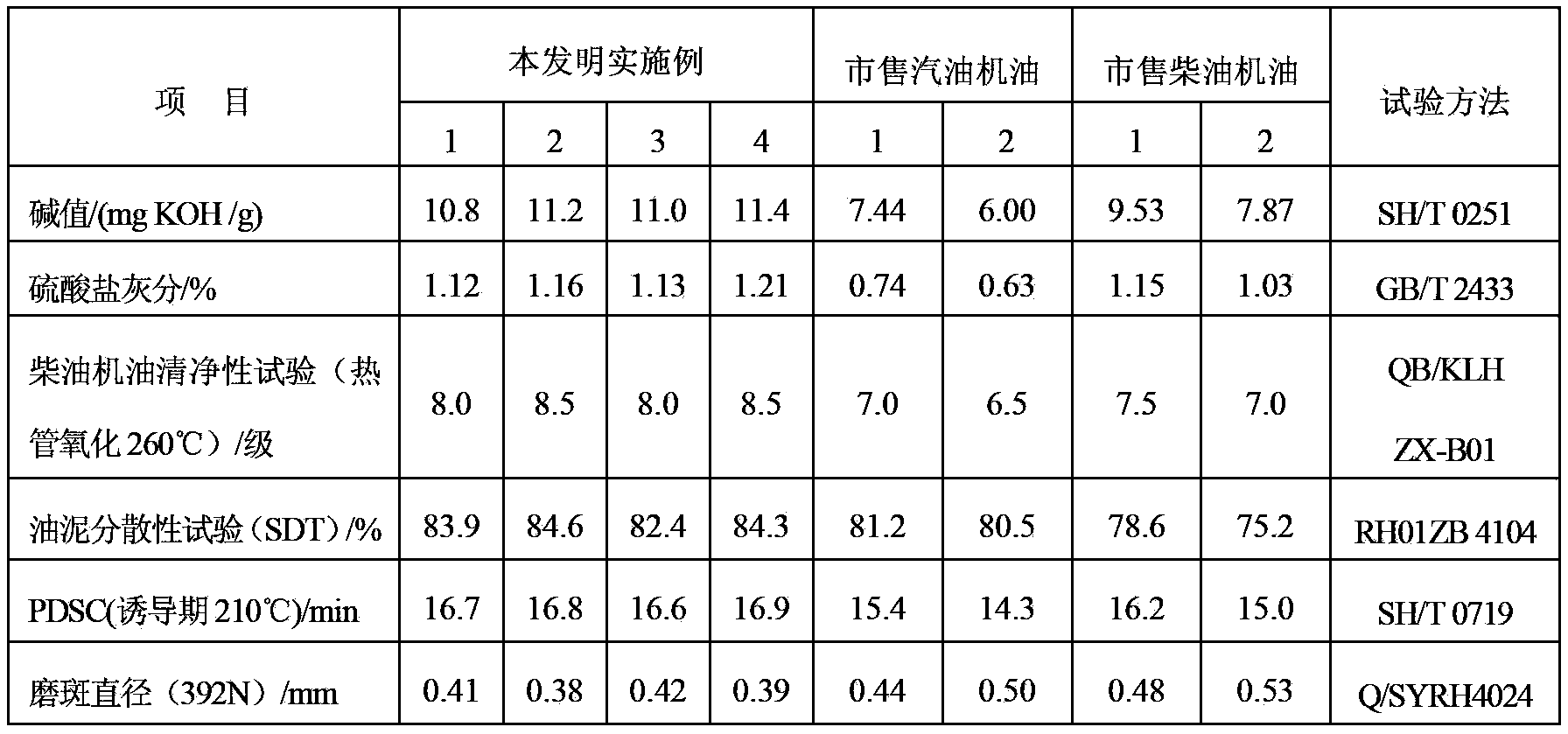

Light-duty diesel oil/gasoline car engine lubricating oil composition

ActiveCN104046418AExcellent anti-oxidation and anti-wear propertiesExcellent medium and low temperature dispersibilityLubricant compositionFoaming agentChemical composition

The invention discloses an engine lubricating oil composition. The engine lubricating oil composition has quality satisfying ACEA-2010A3 / B4 and SAEJ300 specification requirements, is suitable for lubricating a light-duty diesel oil / gasoline car engine under harsh conditions and is especially suitable for lubricating a direct injection light-duty diesel oil / gasoline engine having turbocharging. The engine lubricating oil composition has excellent oxidation and wear resistance, middle / low temperature dispersibility and high temperature detergency, a high base number and strong alkali maintenance capability, can effectively inhibit high-temperature piston deposit generation, can prevent piston adhesion to a ring, has a long oil change period and can provide full lubricating protection on the engine. The engine lubricating oil composition comprises at least two metal detergents, two ashless dispersants, three antioxidant, anticorrosive and antiwear agents, a viscosity index improver, a pour point depressant, an anti-foaming agent and two base oil.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com