Patents

Literature

286results about How to "Reduce capital investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

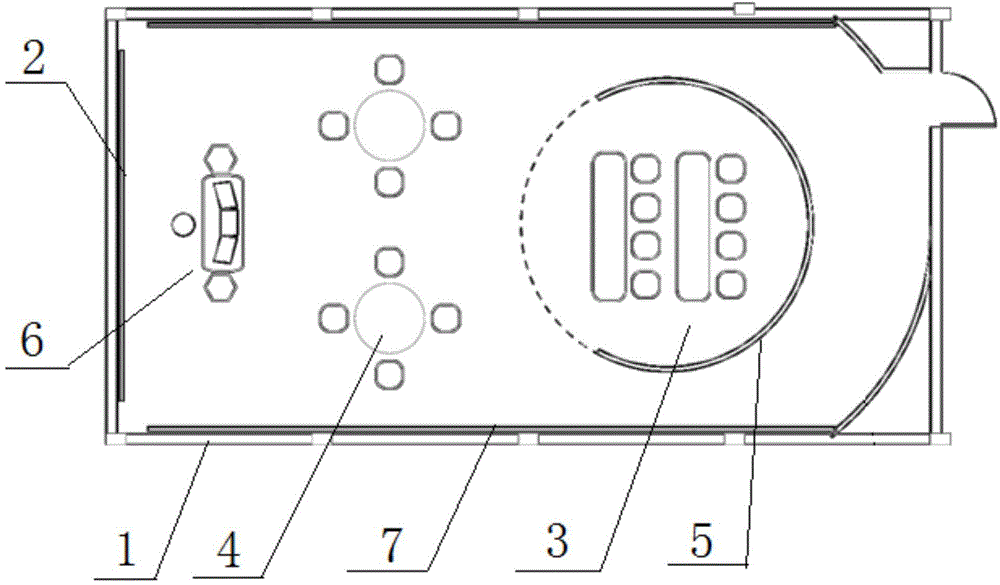

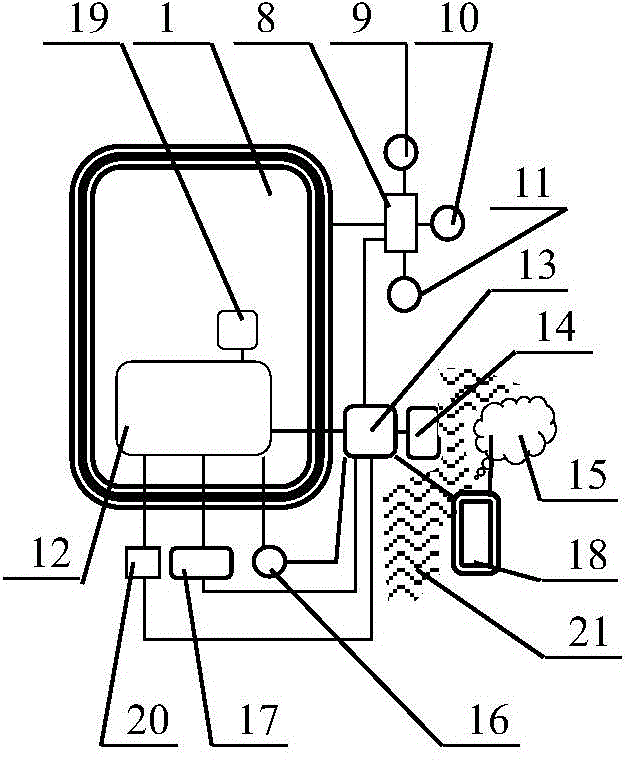

Experiential digitalized multi-screen seamless cross-media interactive opening teaching laboratory

ActiveCN104575142ASupports real-time processingRealize analysisElectrical appliancesPhysical spaceVirtual space

An experiential digitalized multi-screen seamless cross-media interactive opening teaching laboratory is integrated in testing, researching and analyzing. Experiment and data analysis are performed in a real teaching environment; under support of the multi-screen interactive technology, the laboratory comprises a laboratory functional partition, an operation support system, a data working system, an experiment information acquisition system and an audio and video input and output device; a screen jilting function among multiple mobile terminals is realized; the data working system comprises a server, a database, education resource cloud, a U-teaching system, a learning analysis and evaluation system, a mobile device, a cross-screen management module, a recording and broadcasting system and an Internet; learning space for cross-media interactive learning is provided, technologies of holographic imaging, multi-screen interaction, learning analysis and the like are integrated, and seamless fusion of the physical space and the virtual space is realized; seamless fusion of supporting technologies from formal learning to informal learning, multiple learning modes, cross-terminal, cross-media and the like is realized, and good learning experience is provided for learners.

Owner:SHANGHAI OPEN UNIVERSITY

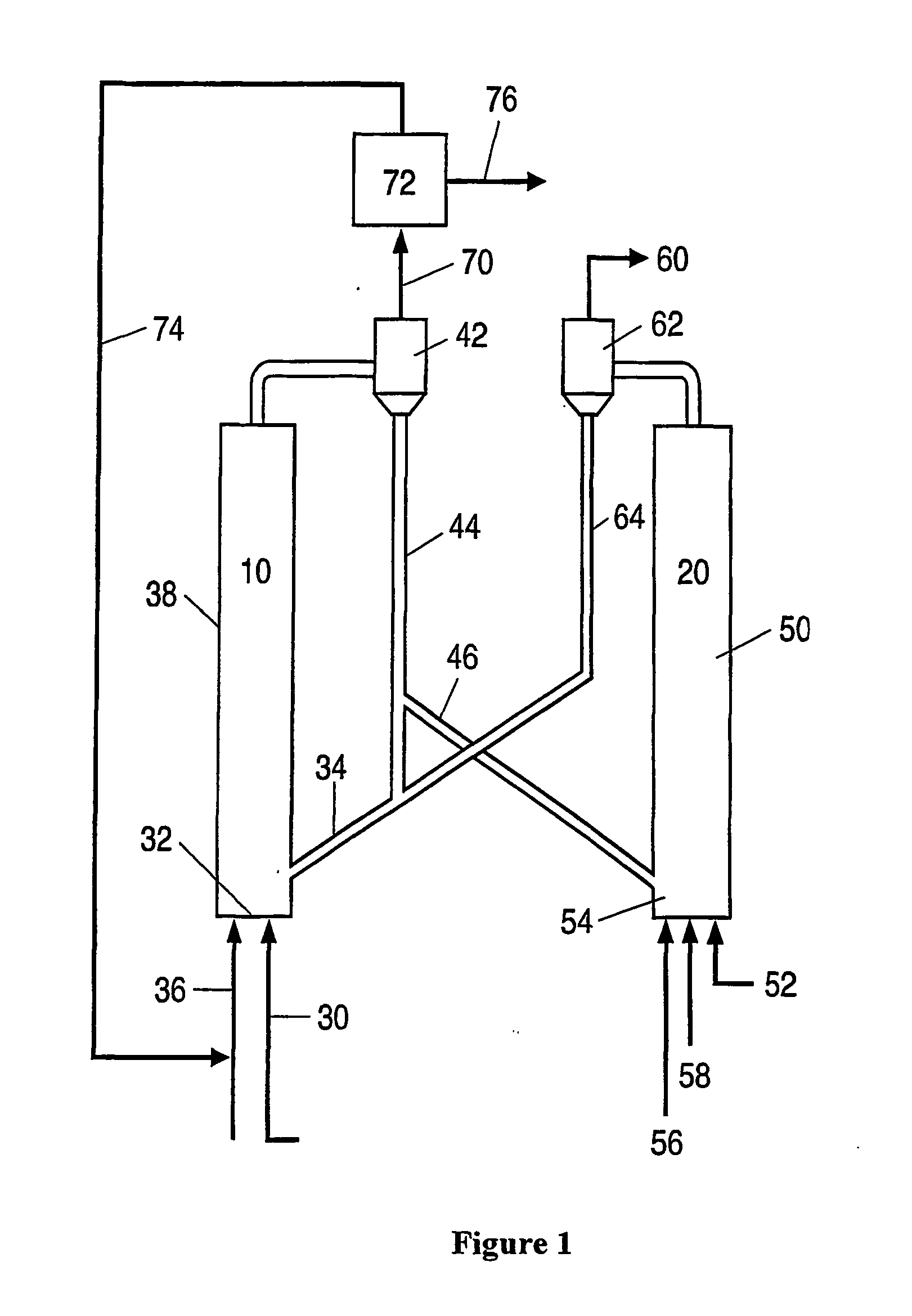

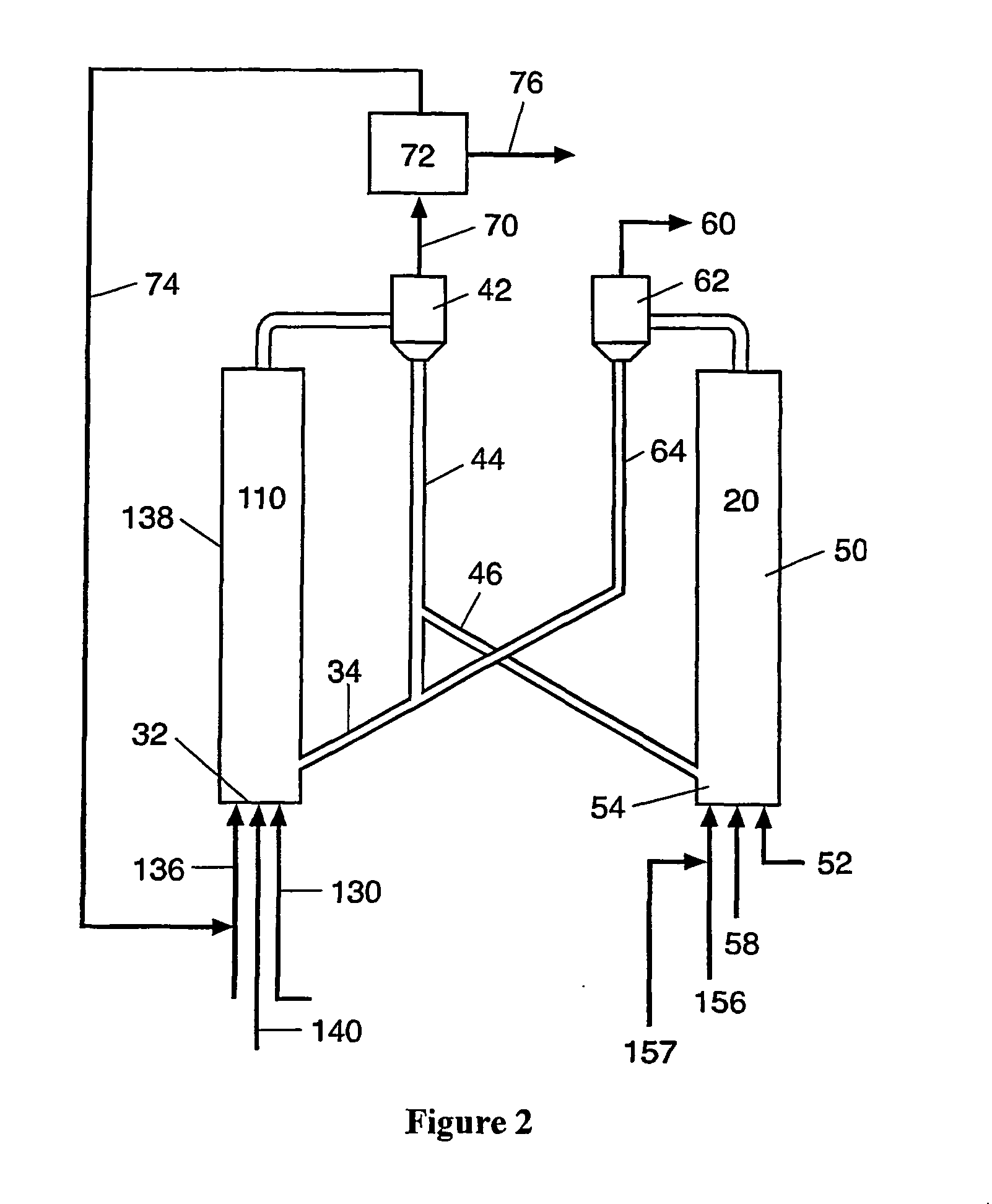

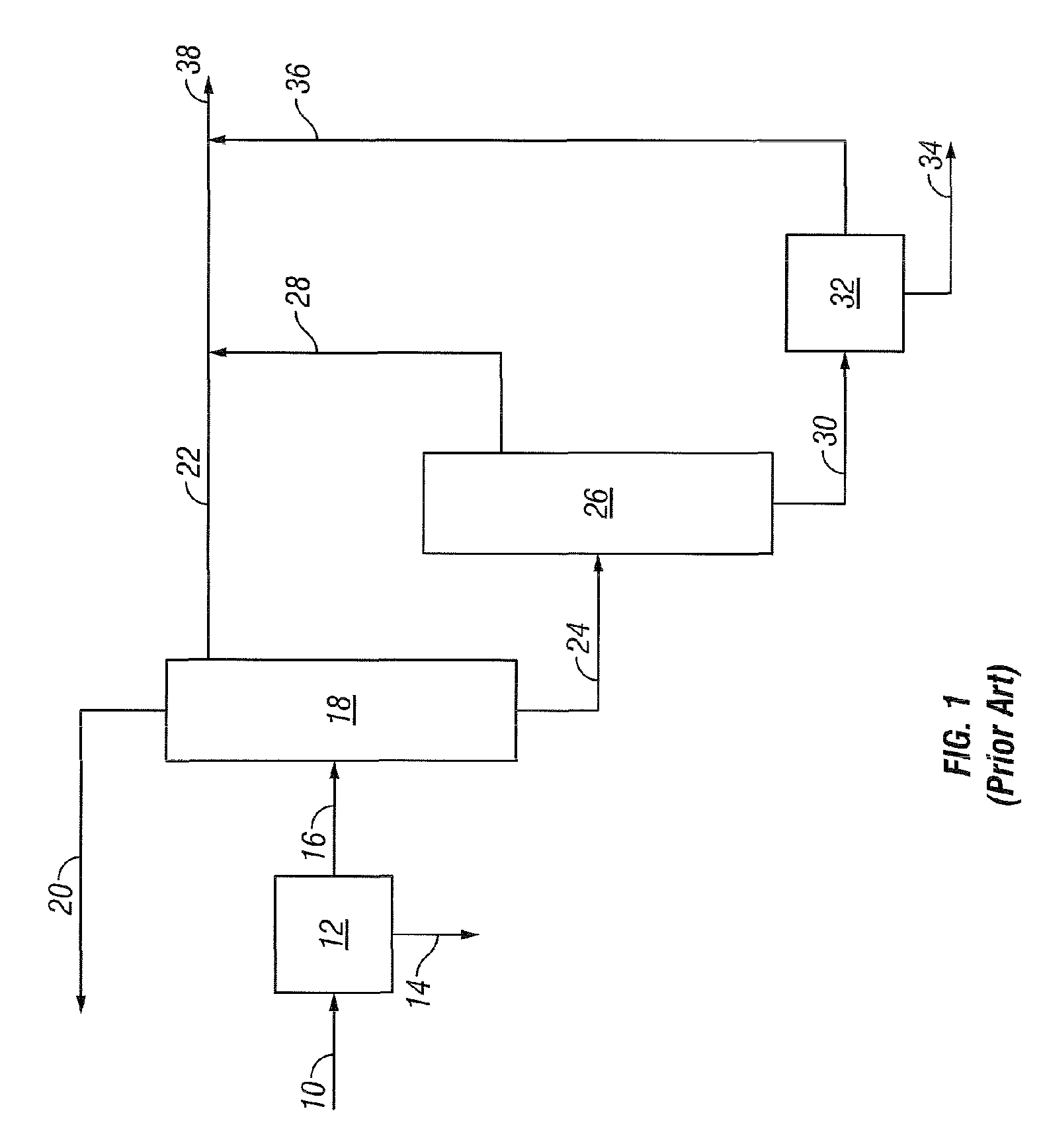

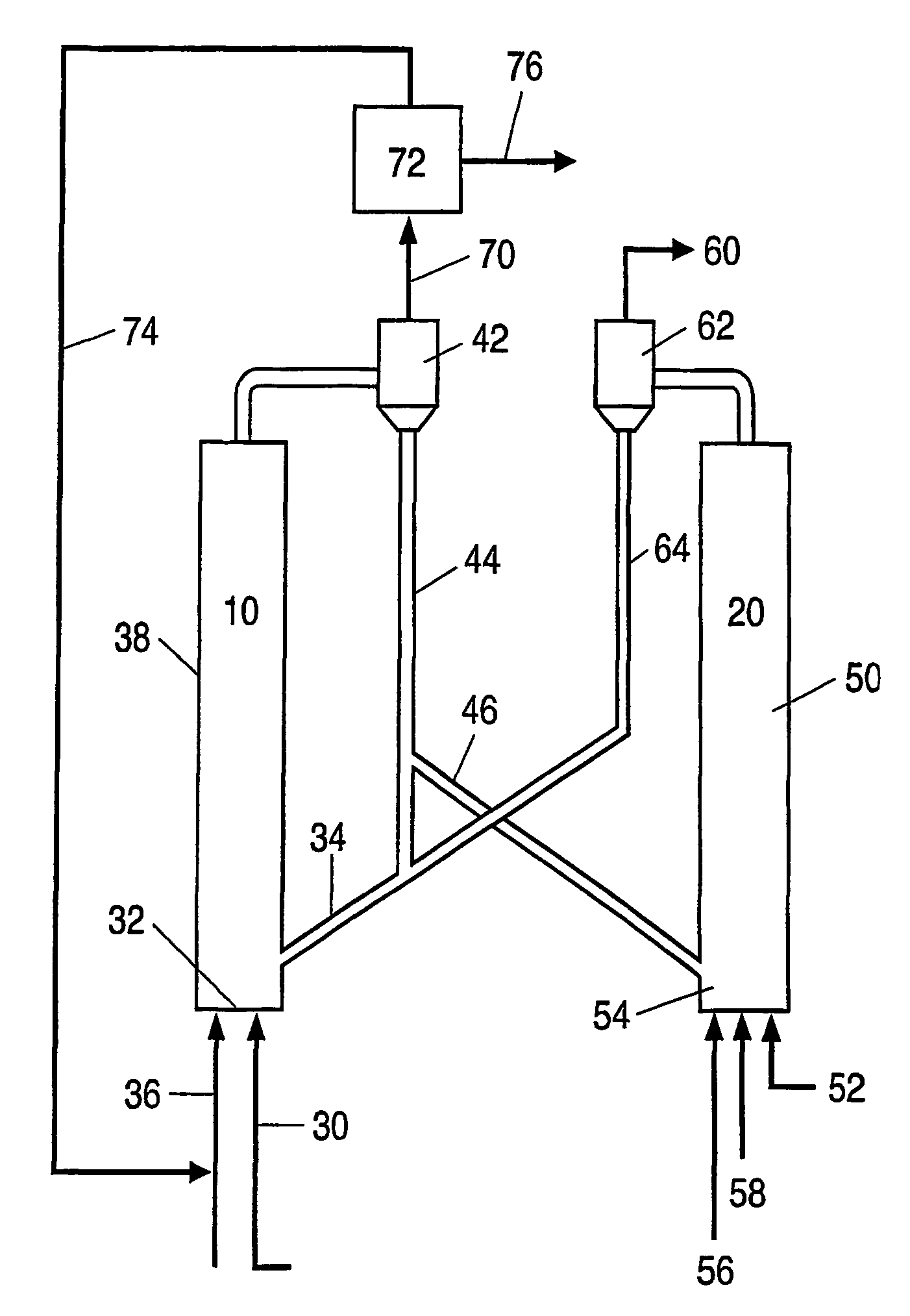

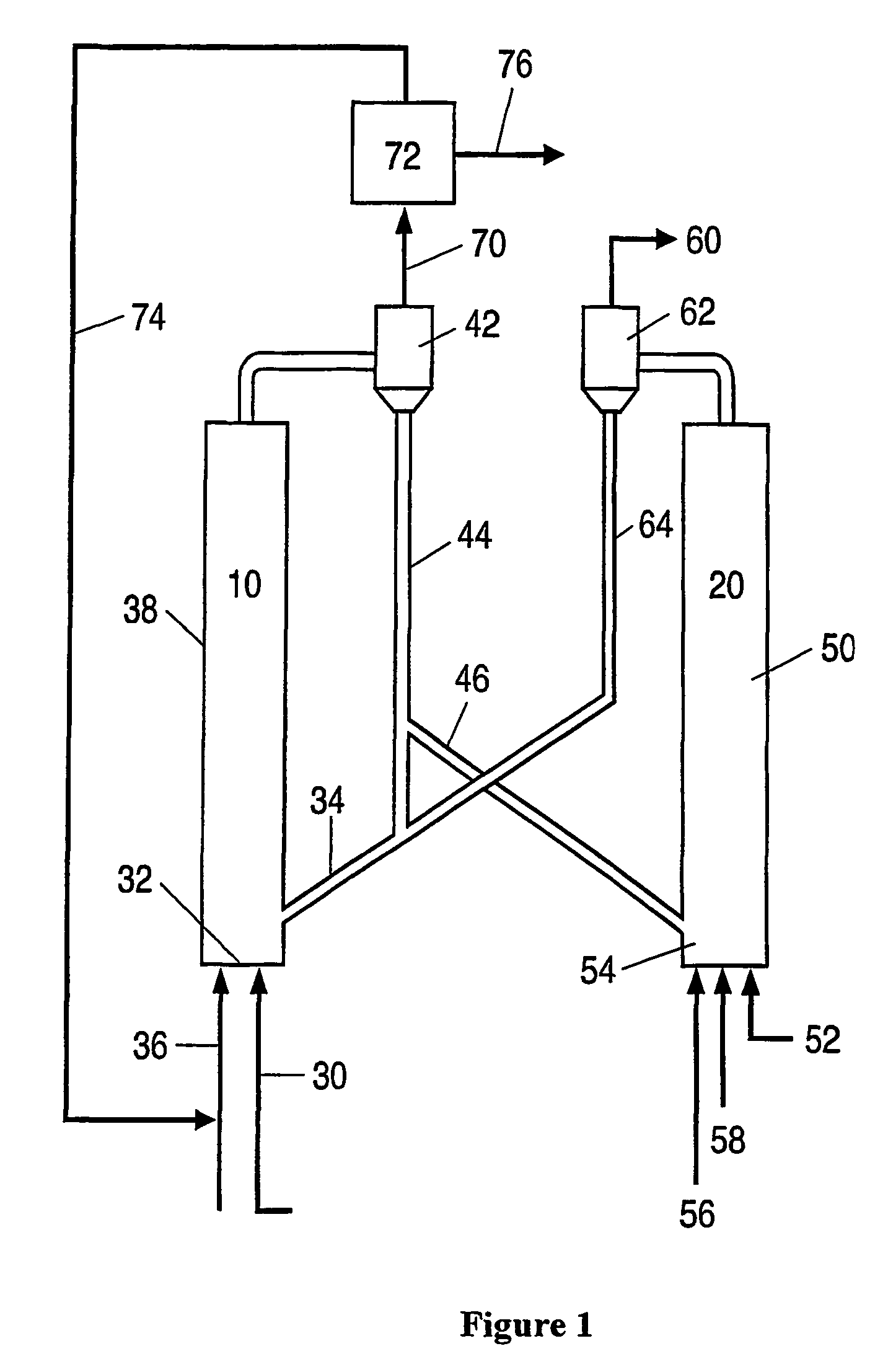

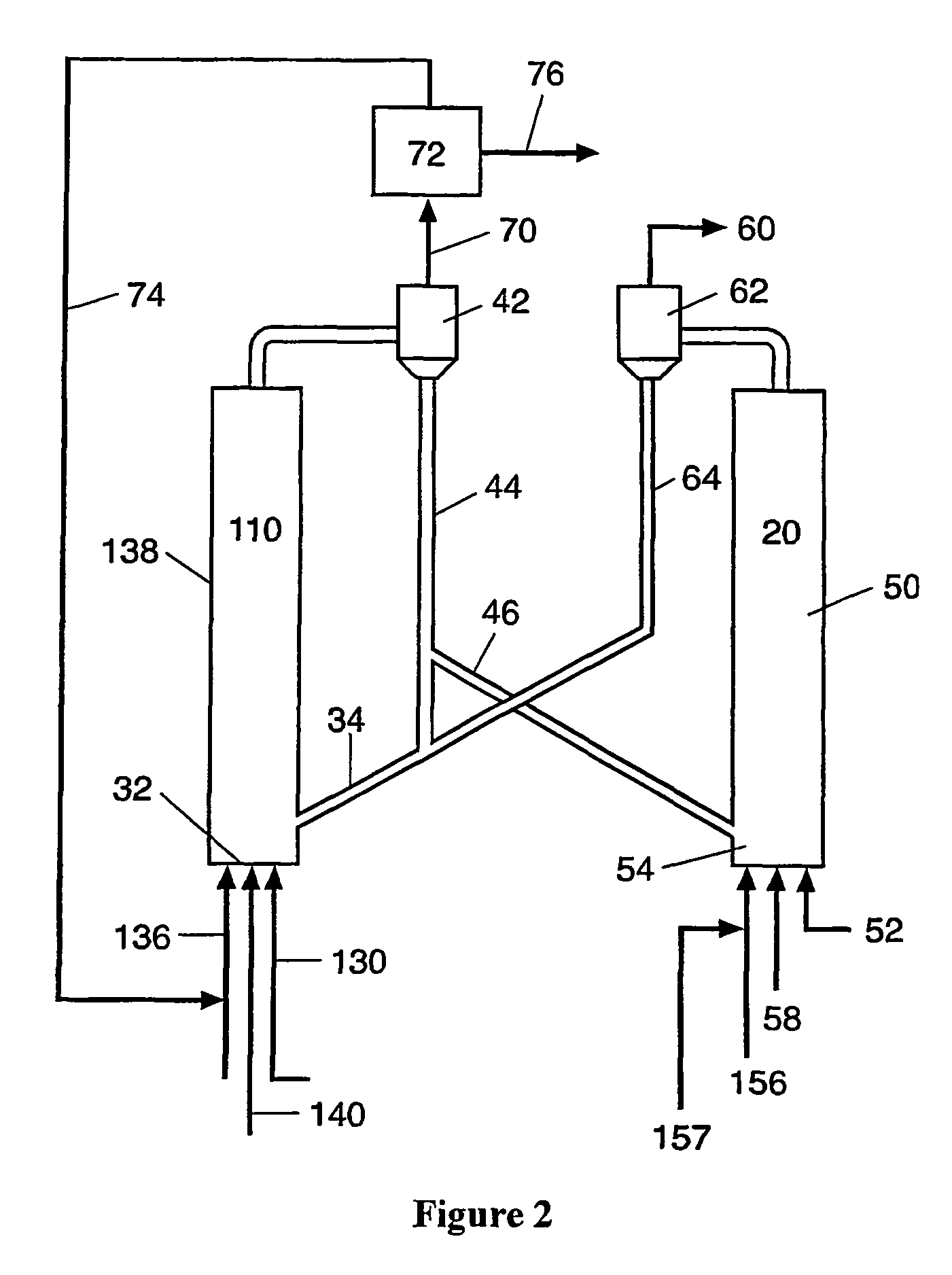

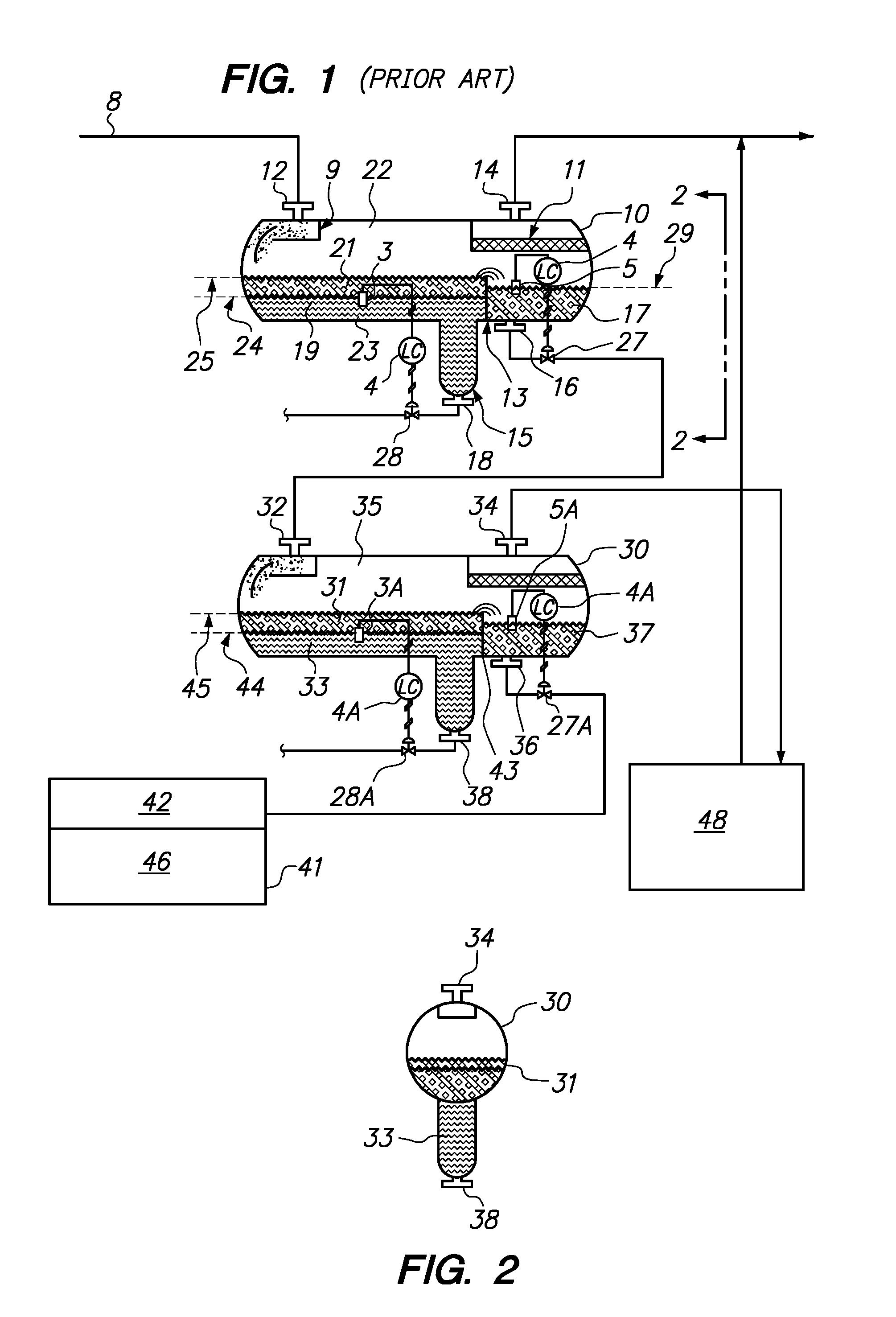

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS20050098478A1Substantial sulfur removalLow costCatalytic crackingHydrocarbon oils refiningHydrodesulfurizationSorbent

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

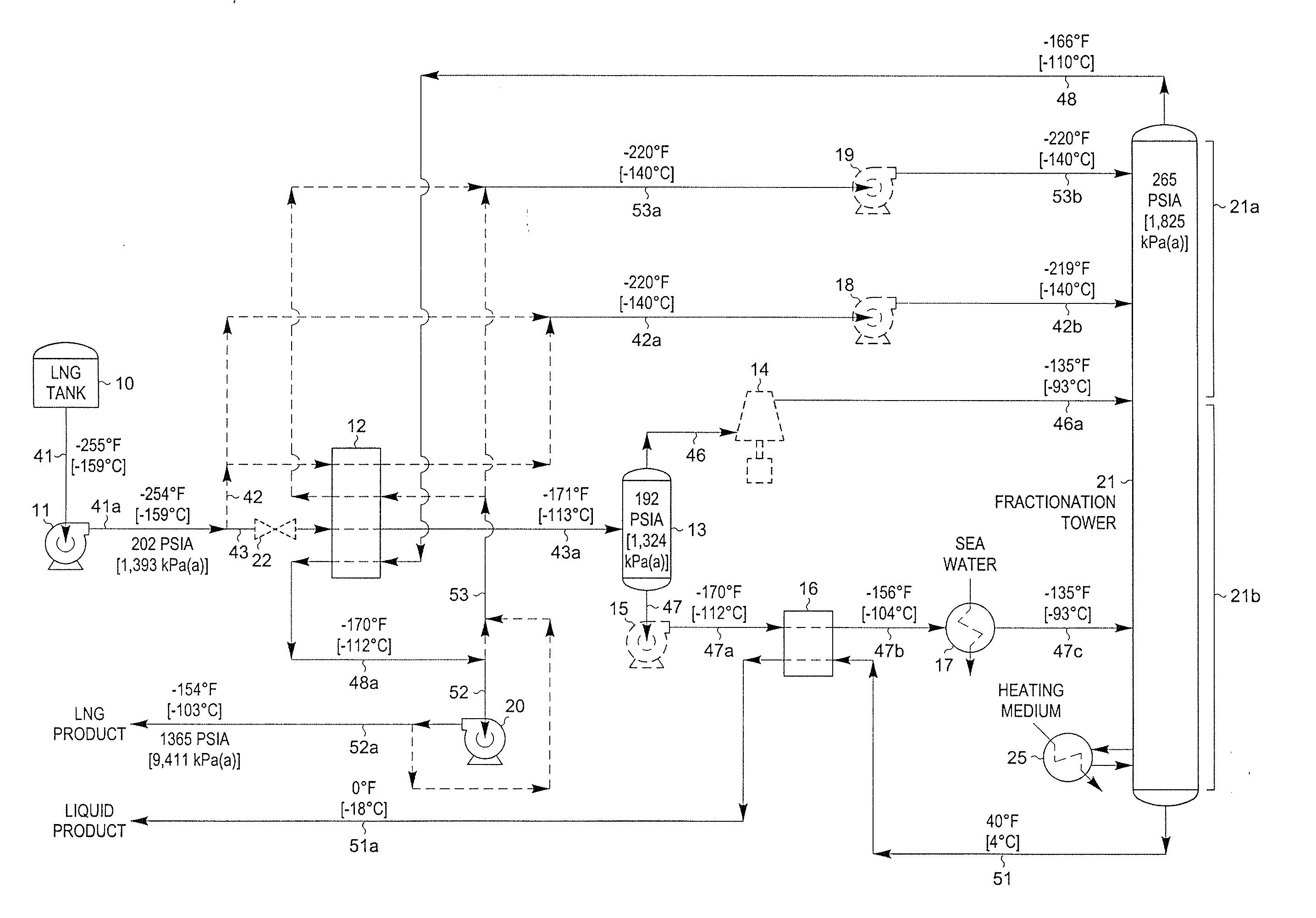

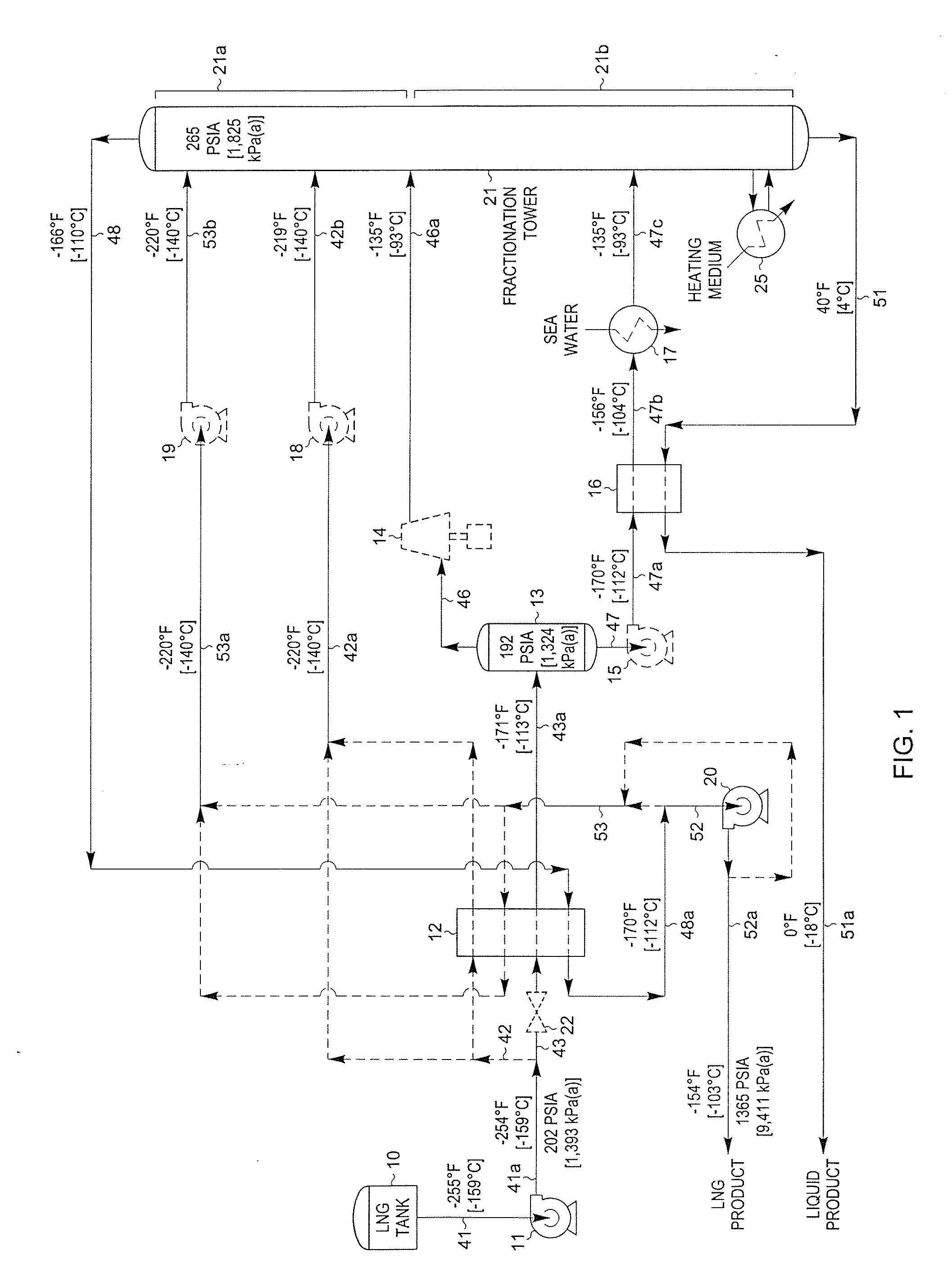

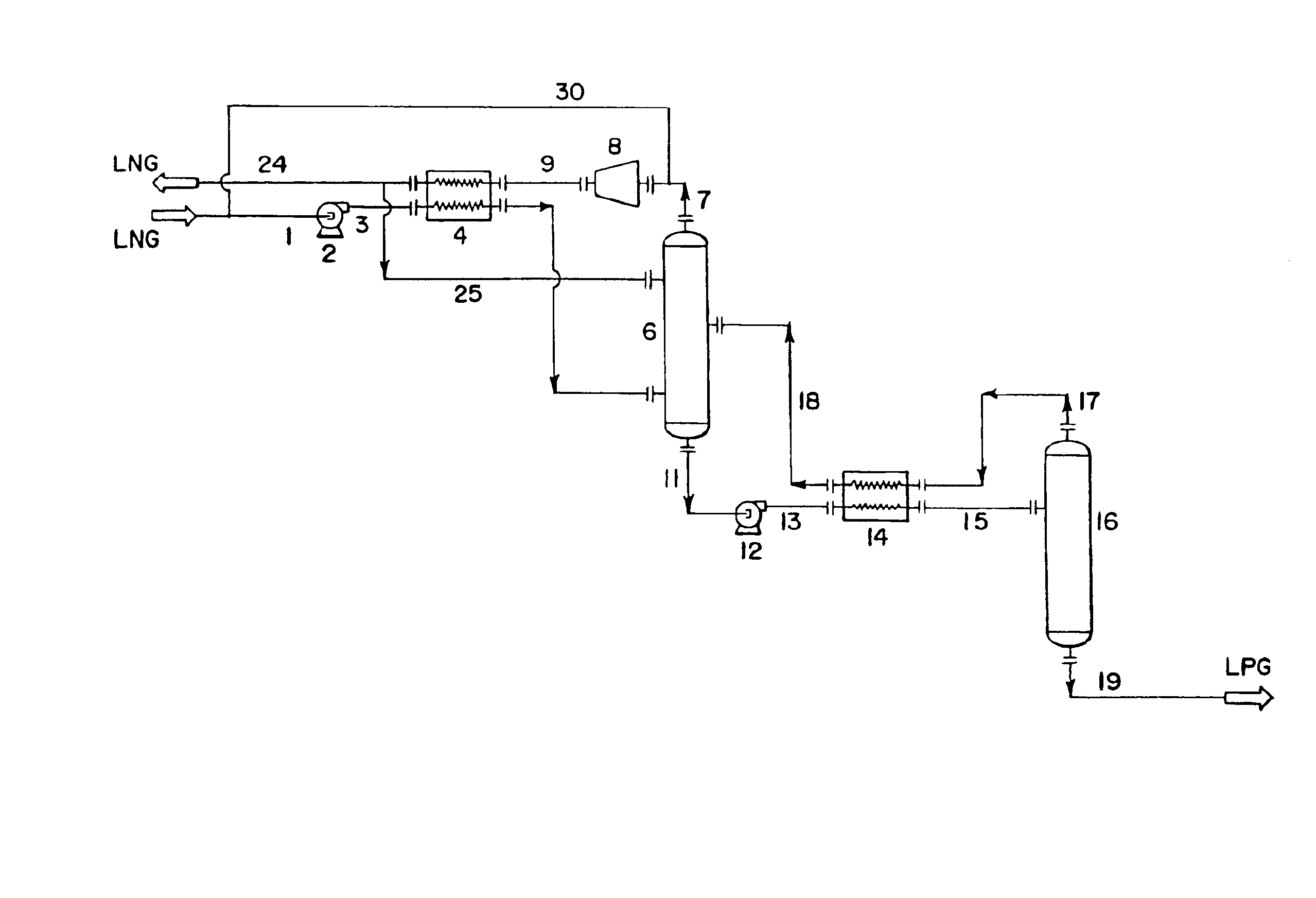

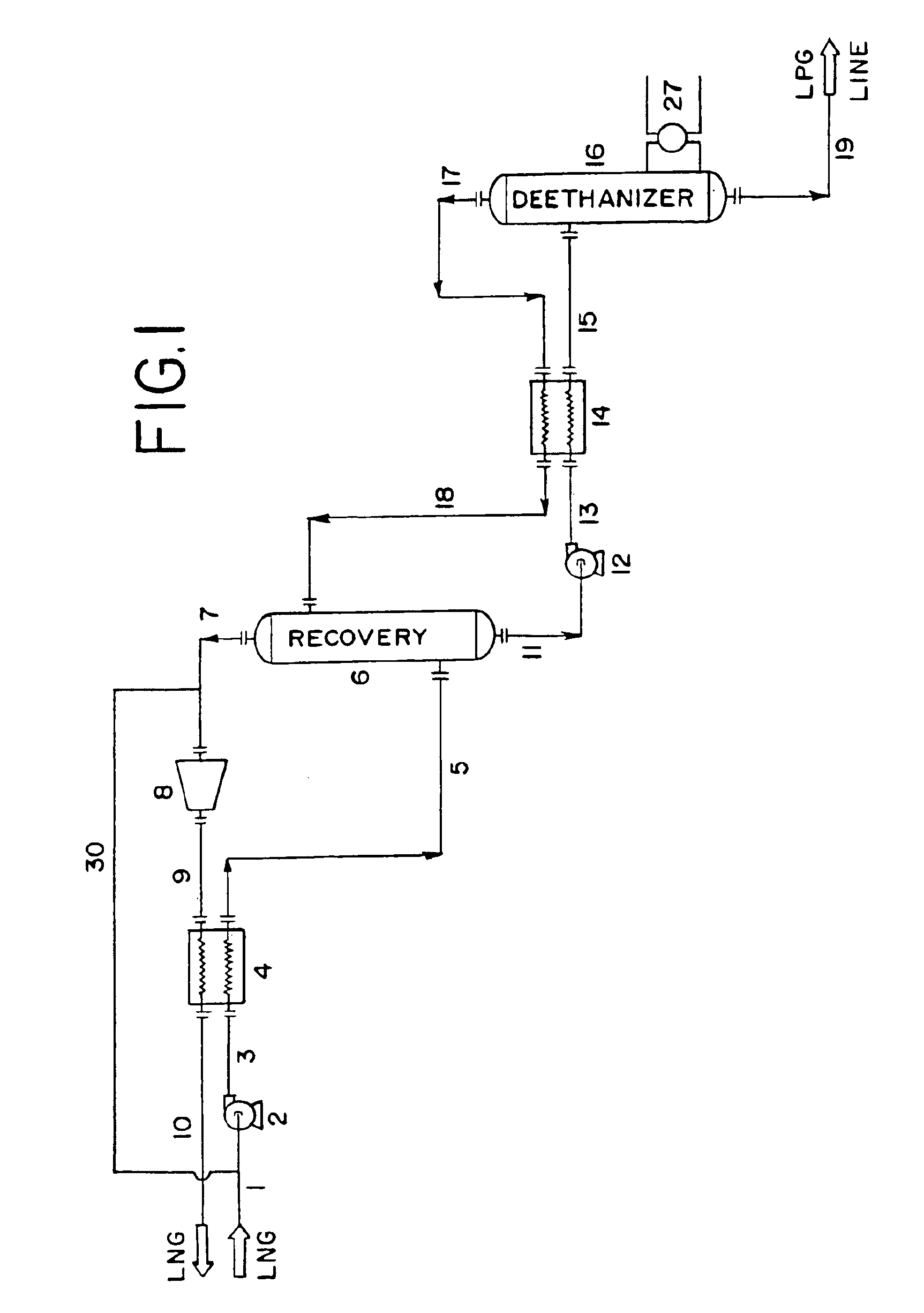

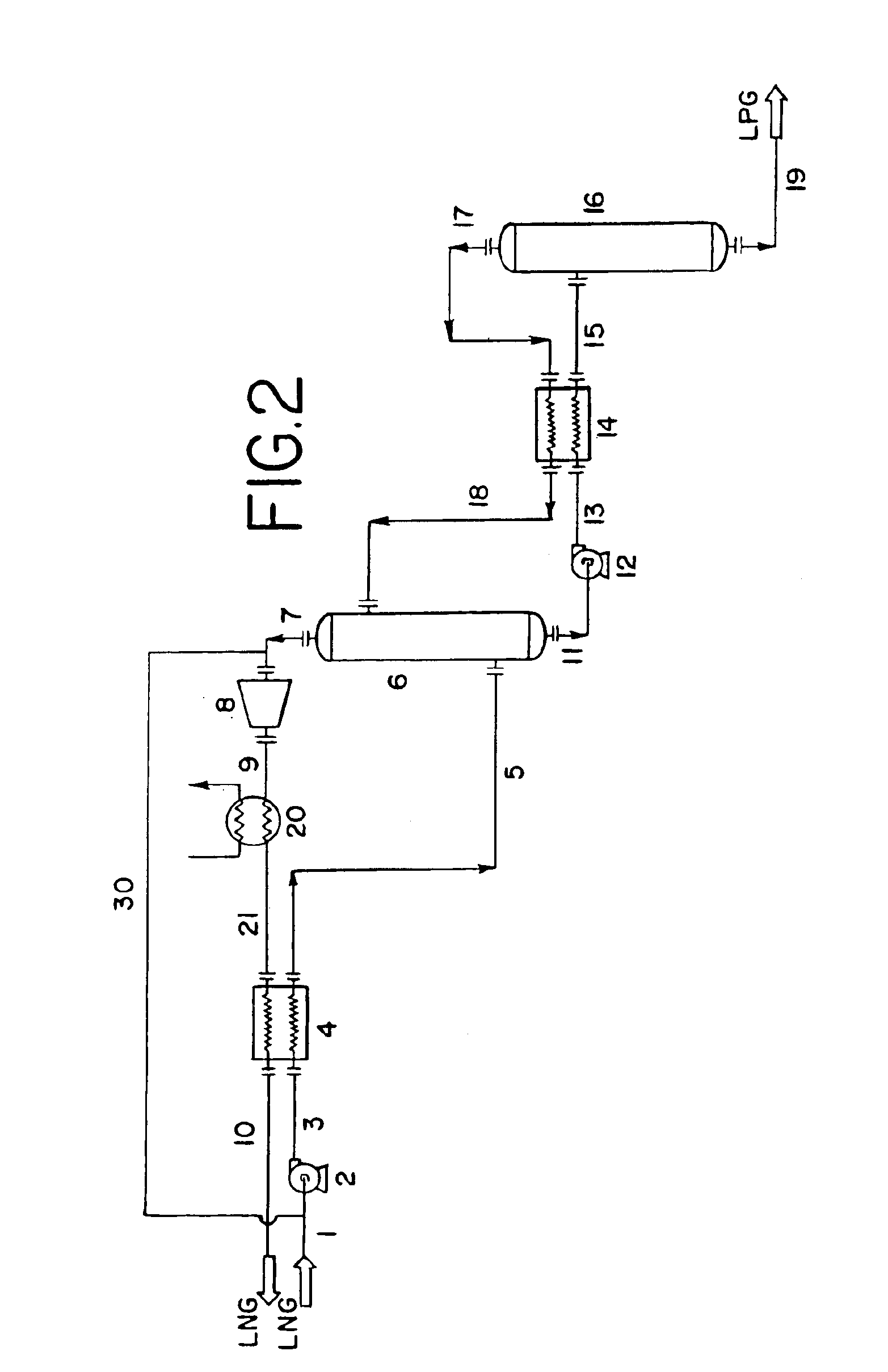

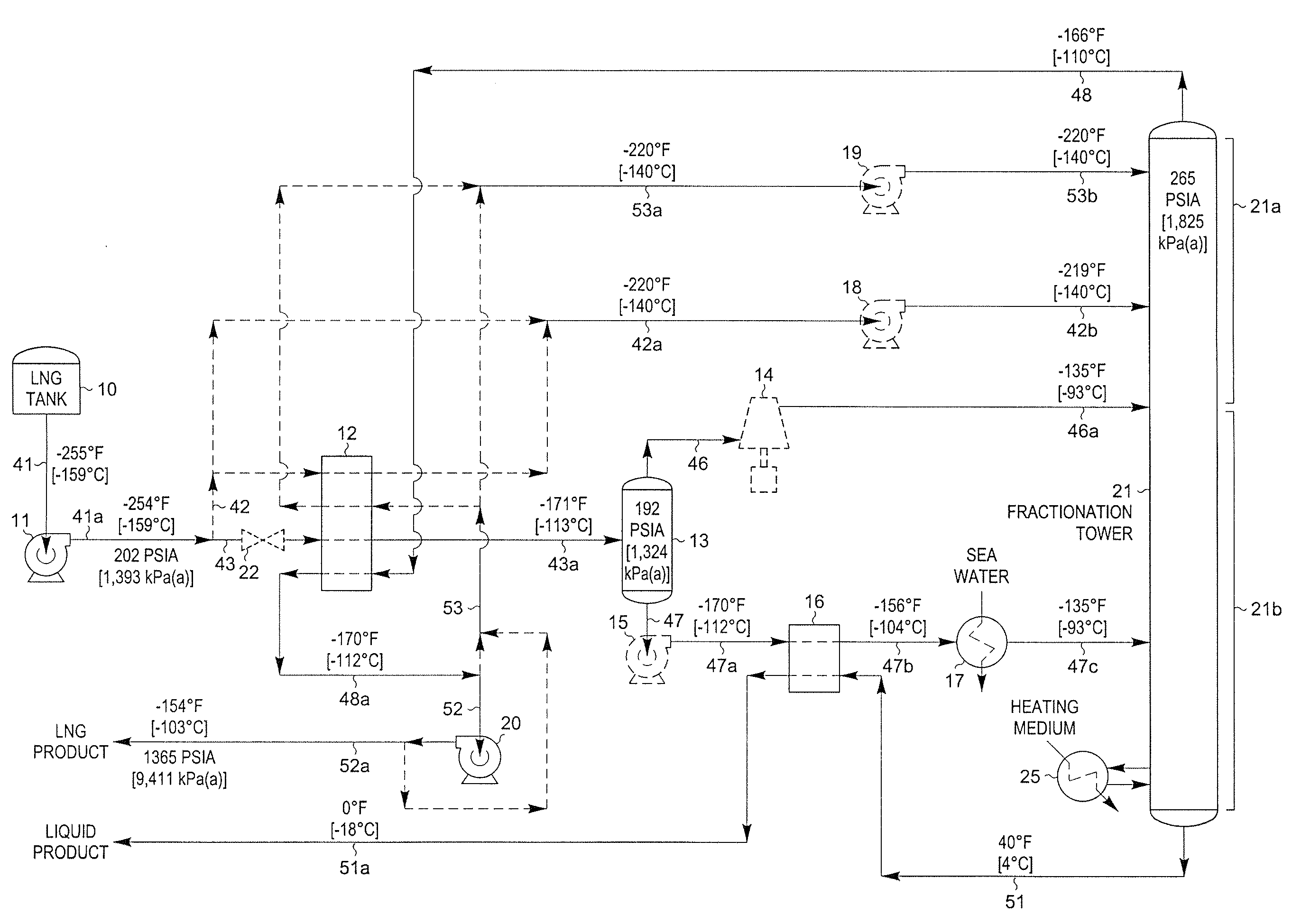

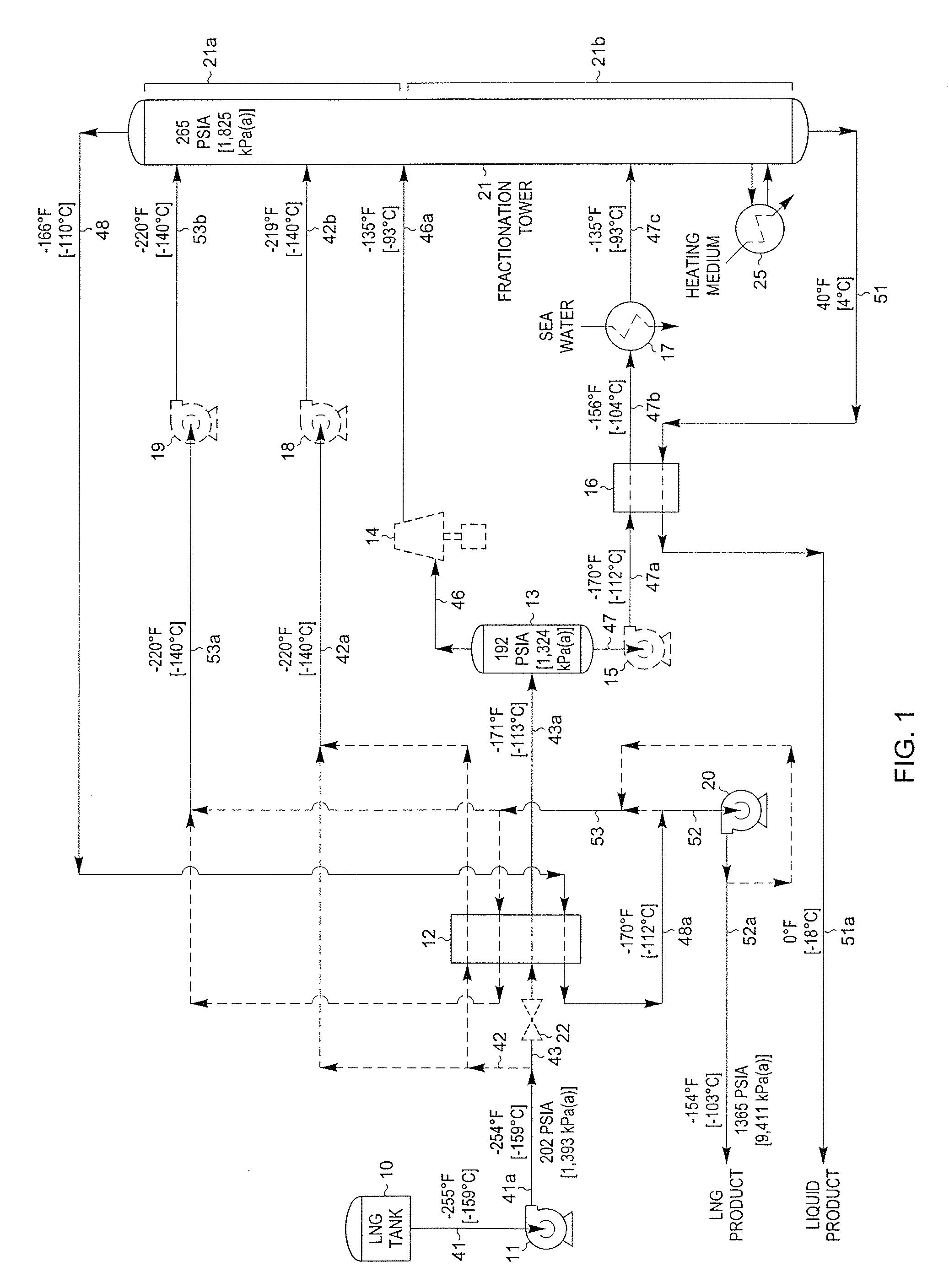

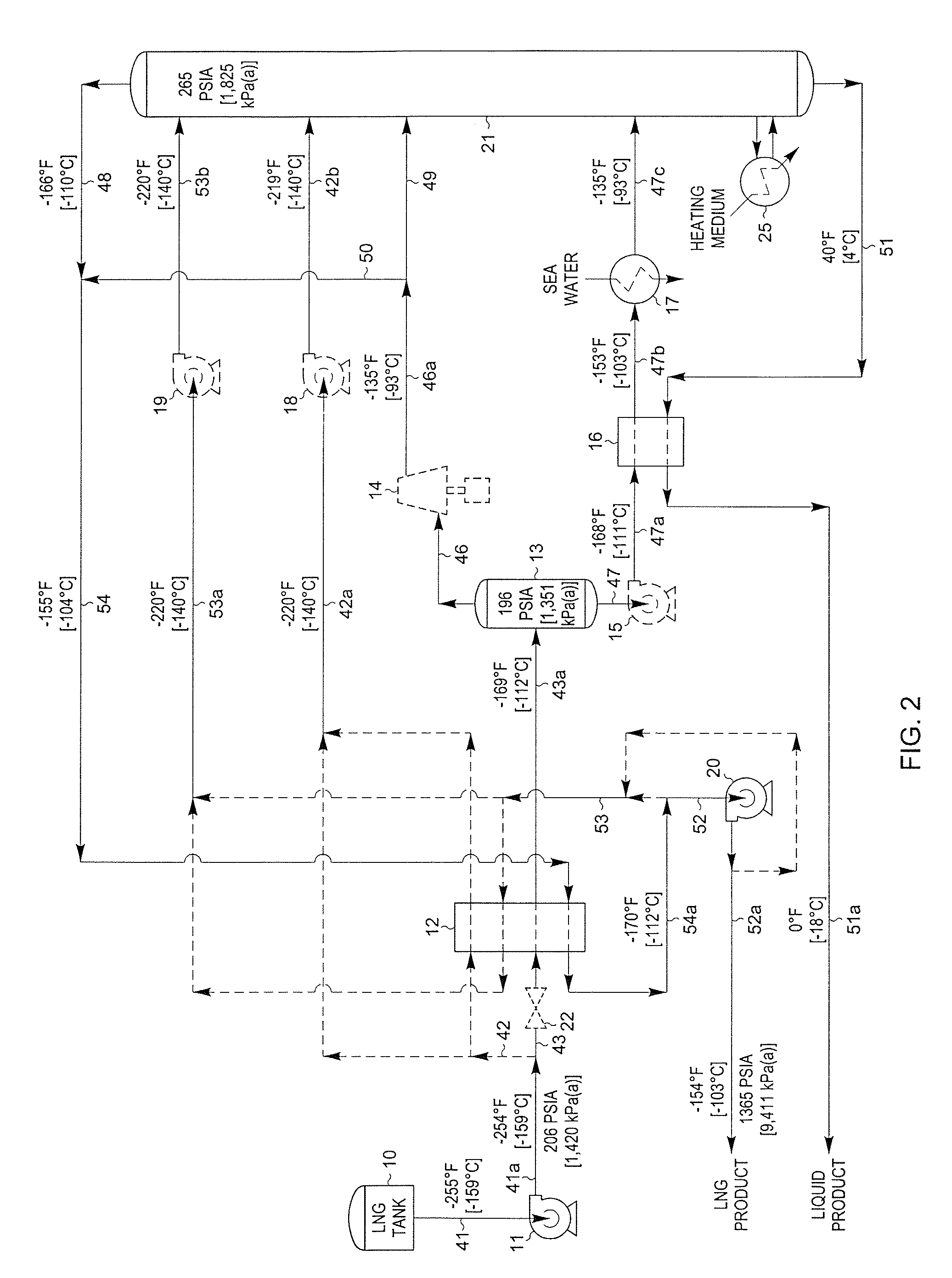

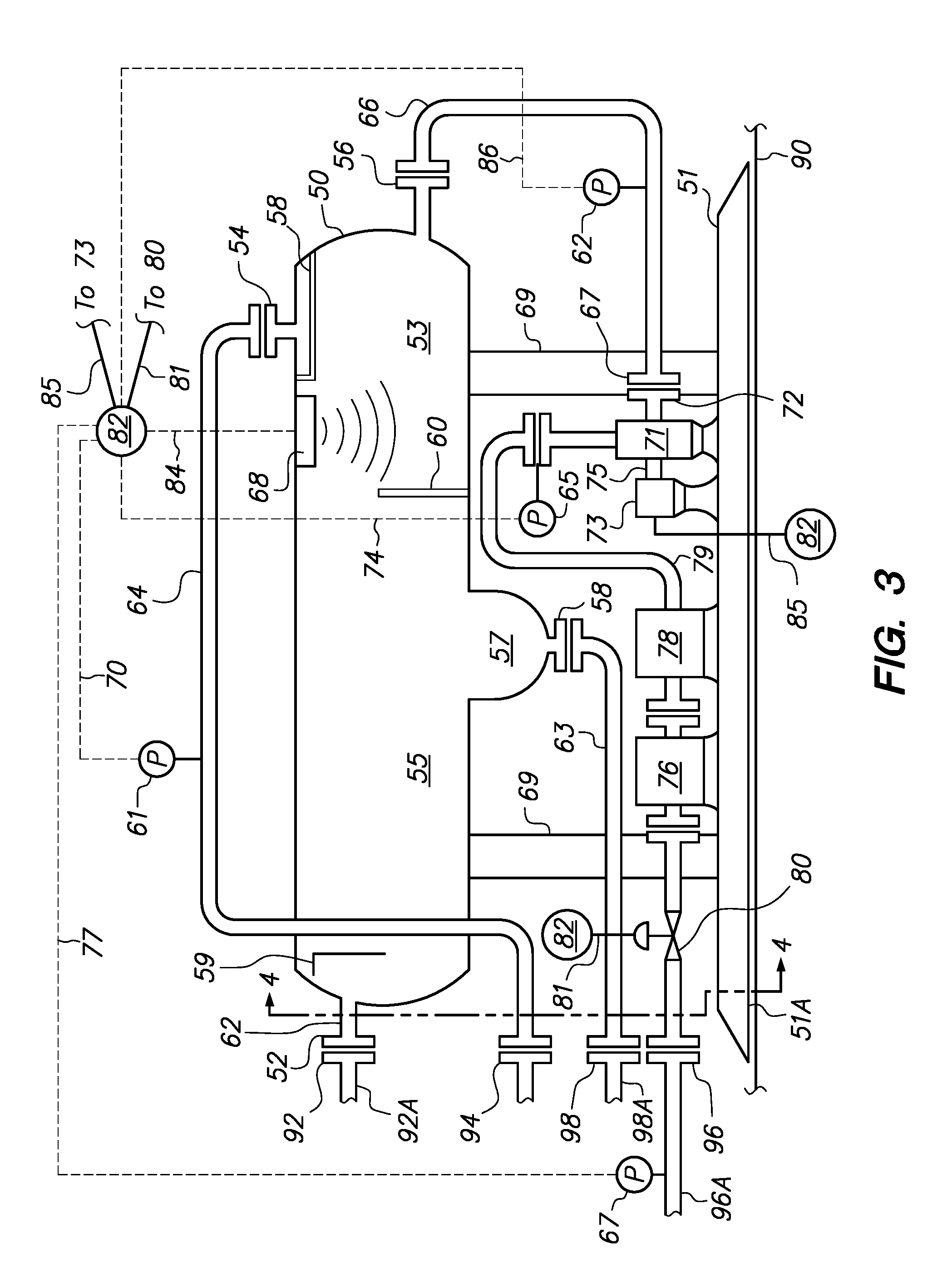

Liquefied Natural Gas Processing

ActiveUS20080000265A1Simple process equipmentReduce investmentSolidificationLiquefactionChemistryLiquefied natural gas

A process and apparatus for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at an upper mid-column feed point. The second portion is directed in heat exchange relation with a warmer distillation stream rising from the fractionation stages of the column, whereby this portion of the LNG feed stream is partially vaporized and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG product stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The partially vaporized portion of the LNG feed stream is separated into vapor and liquid streams which are thereafter supplied to the column at lower mid-column feed positions. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:UOP LLC

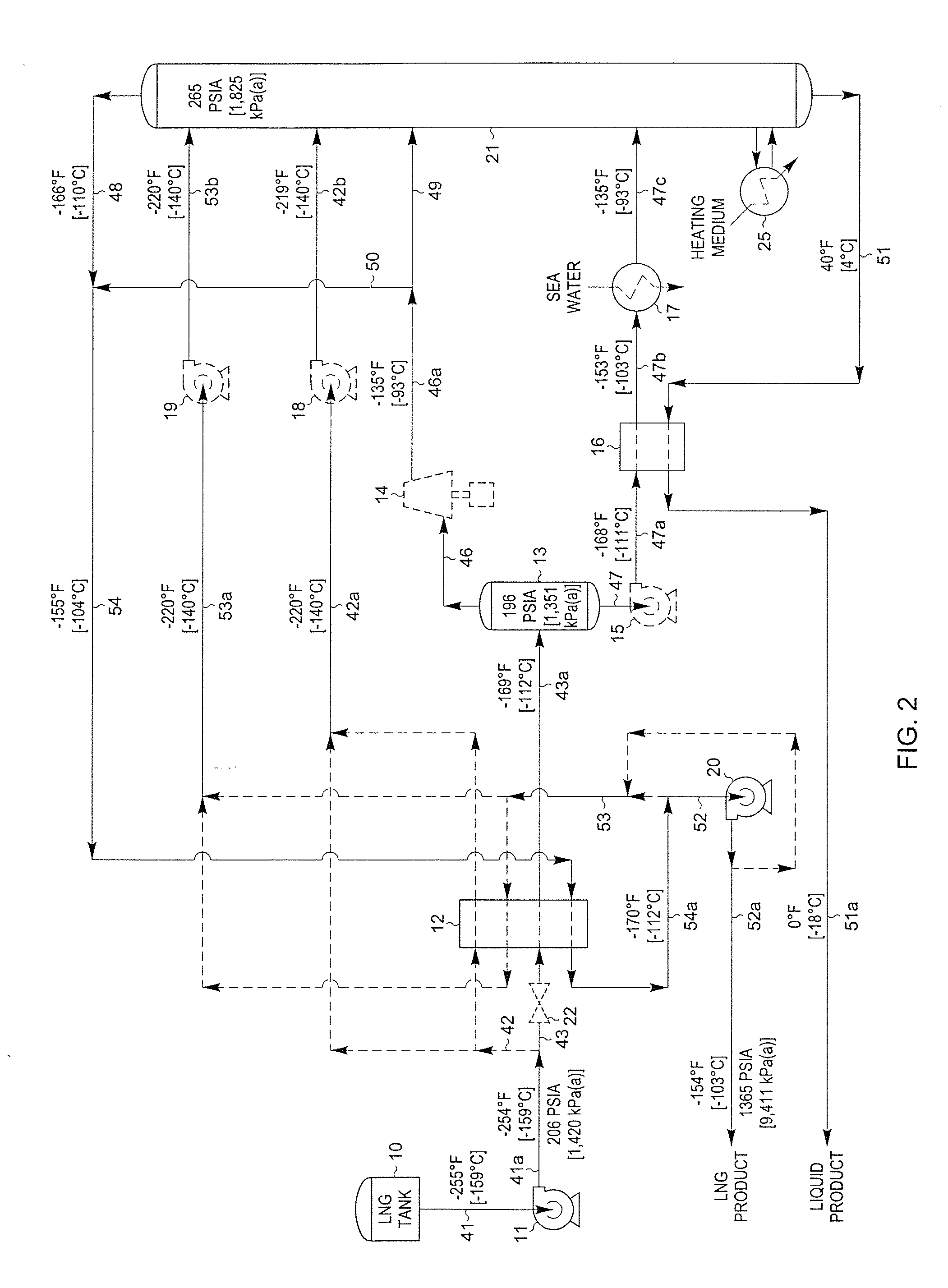

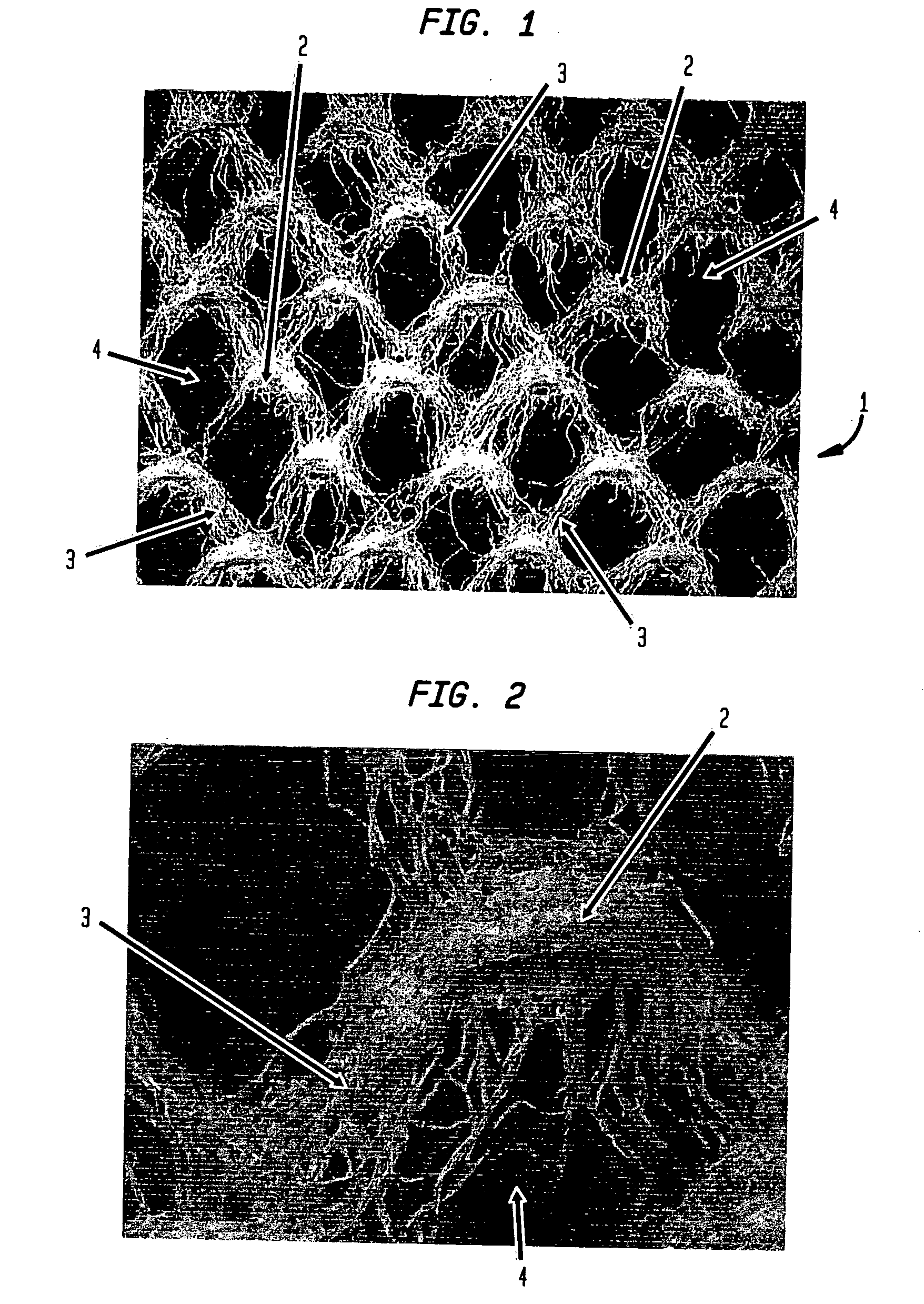

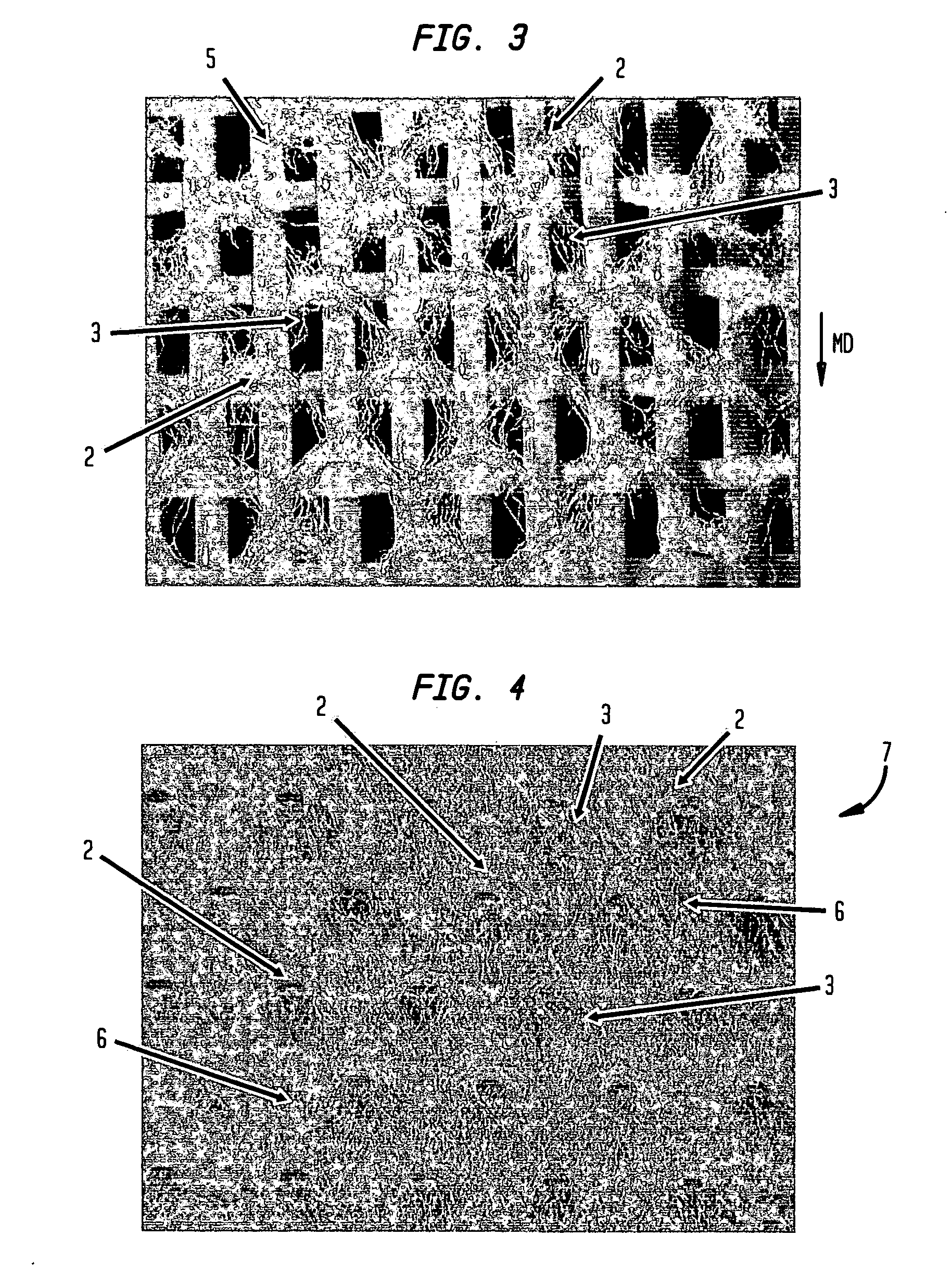

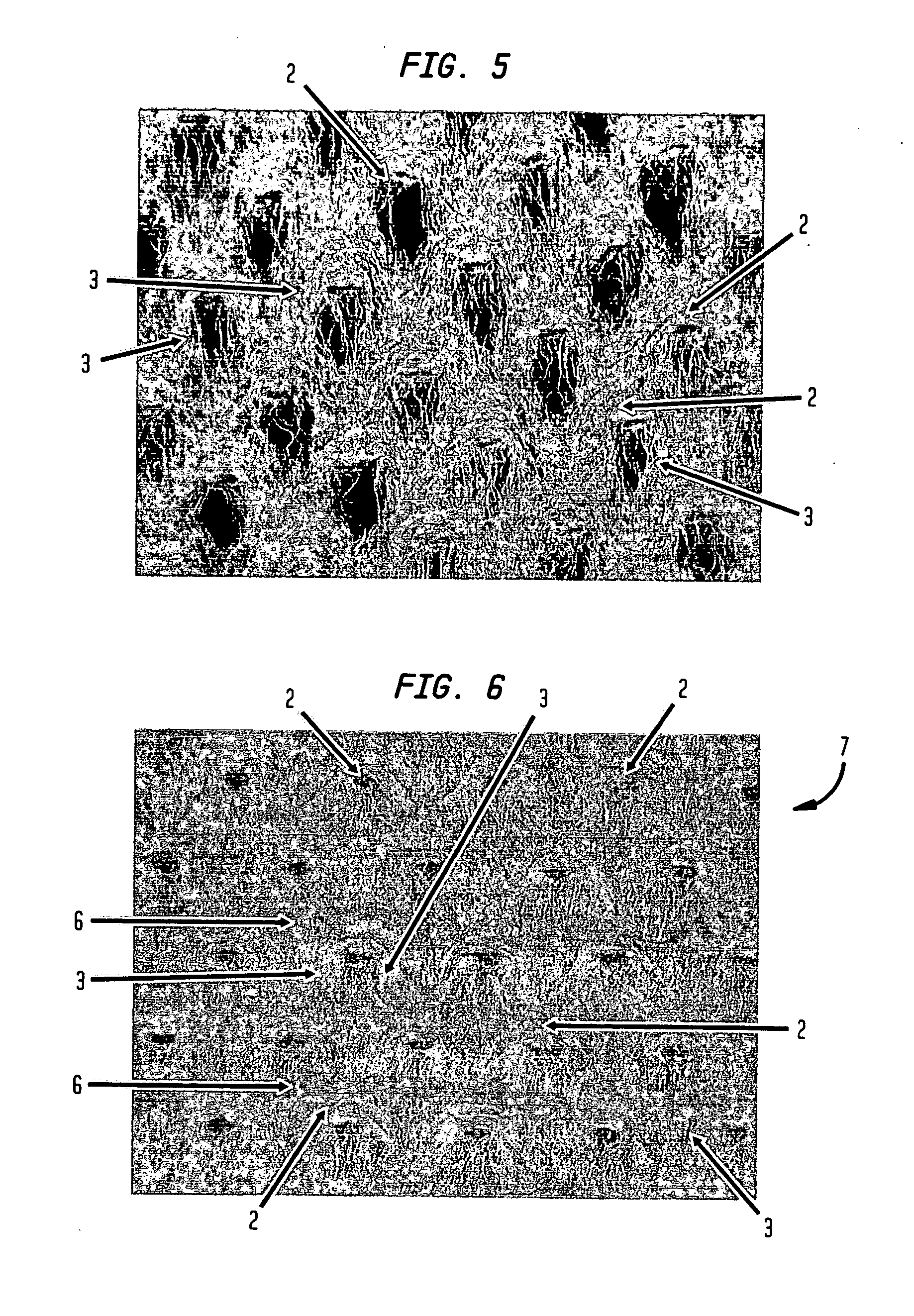

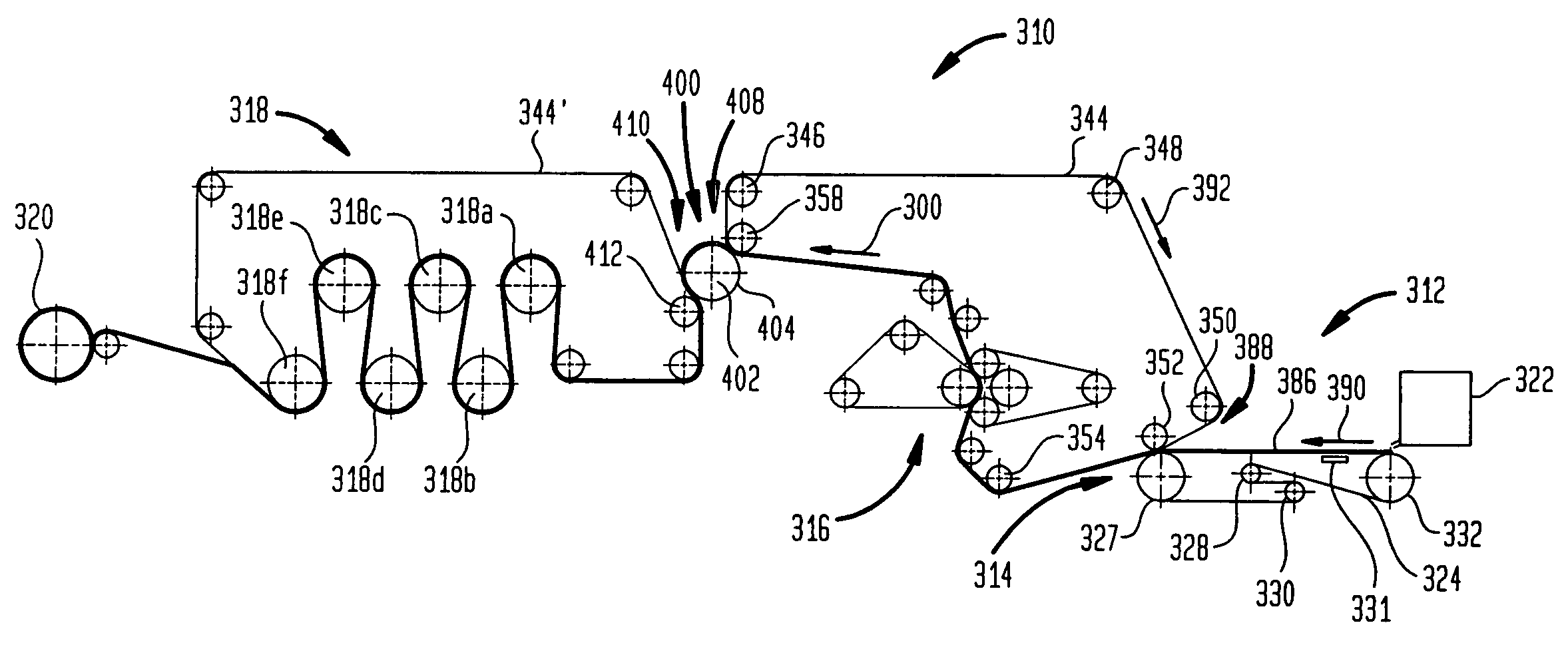

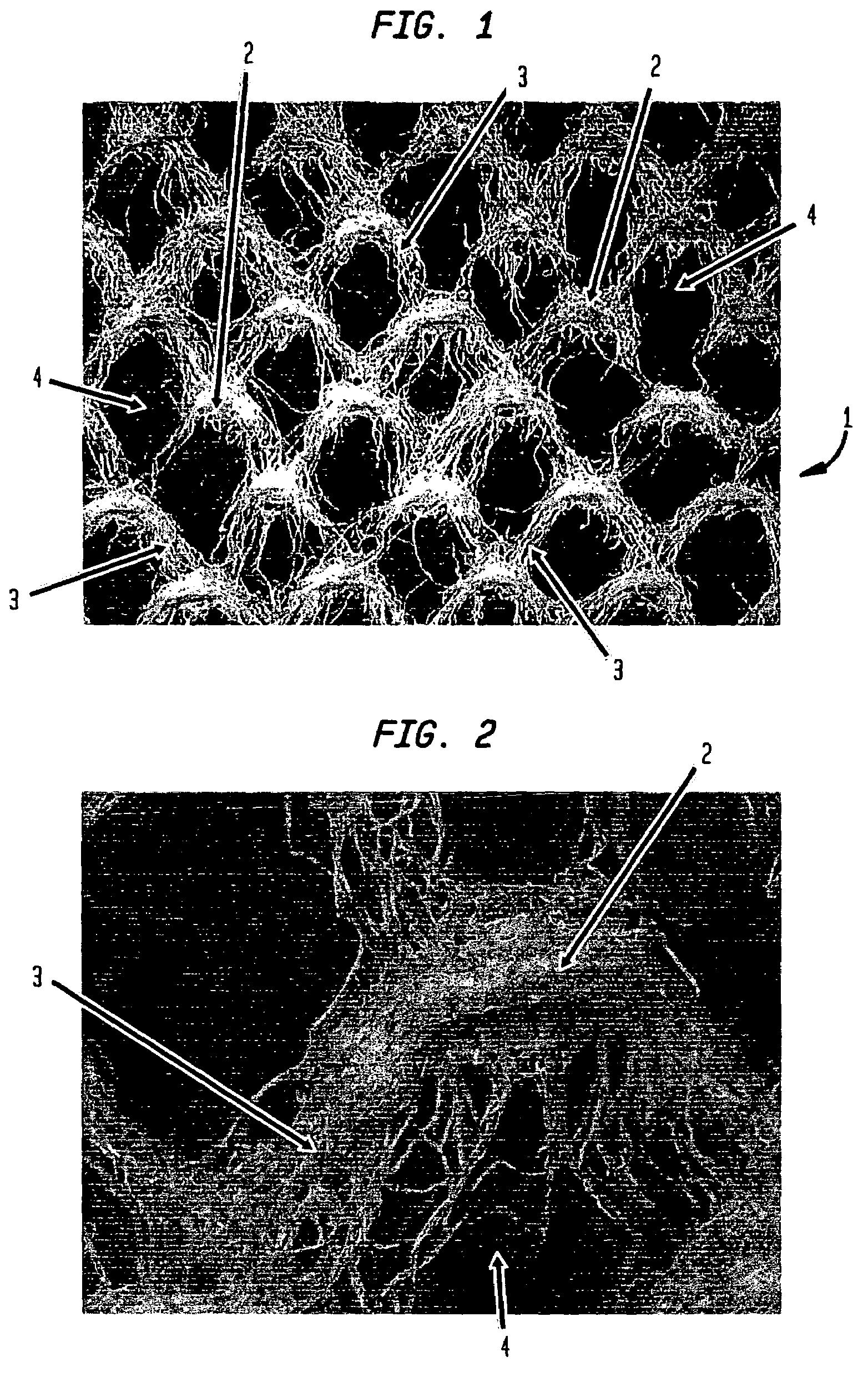

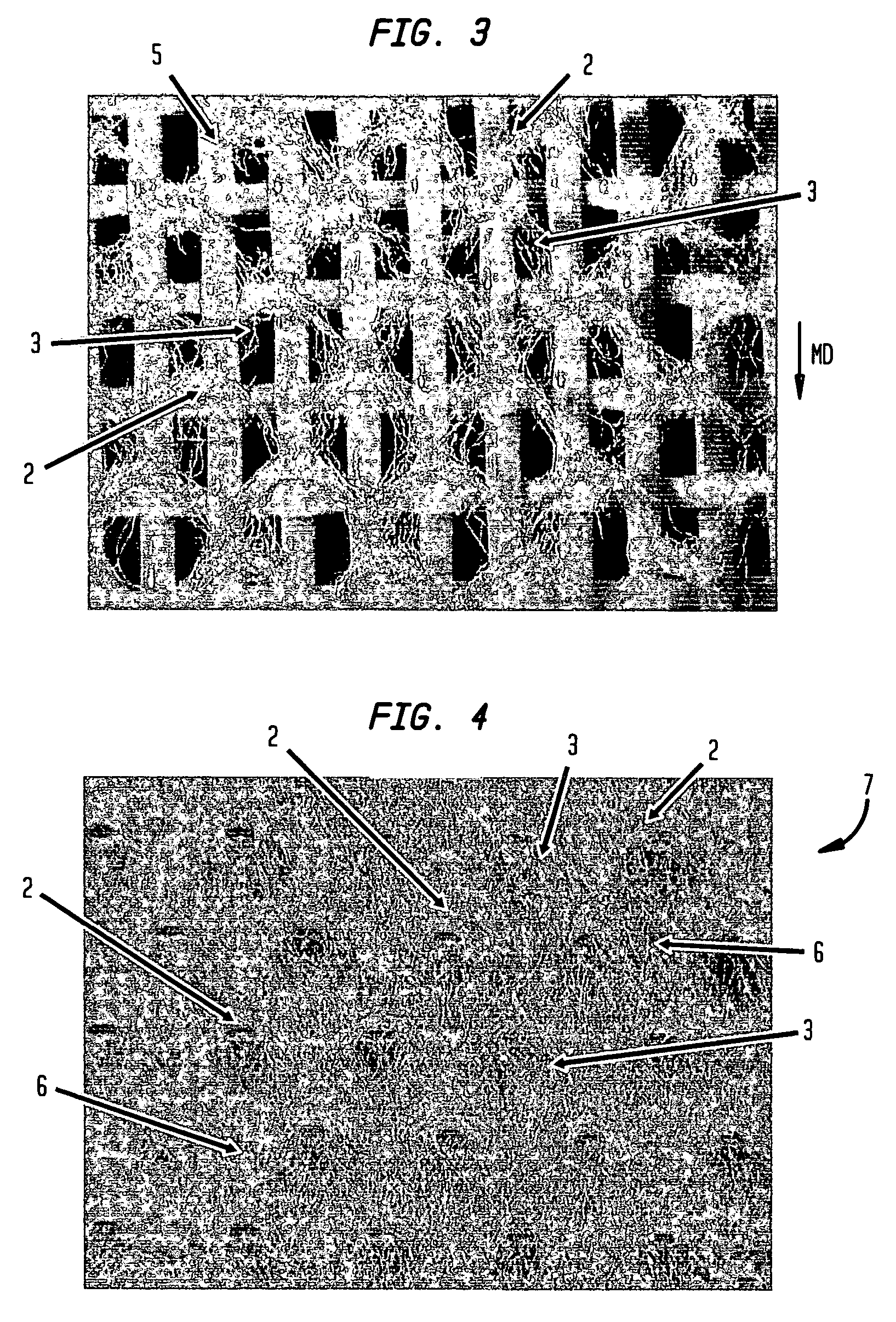

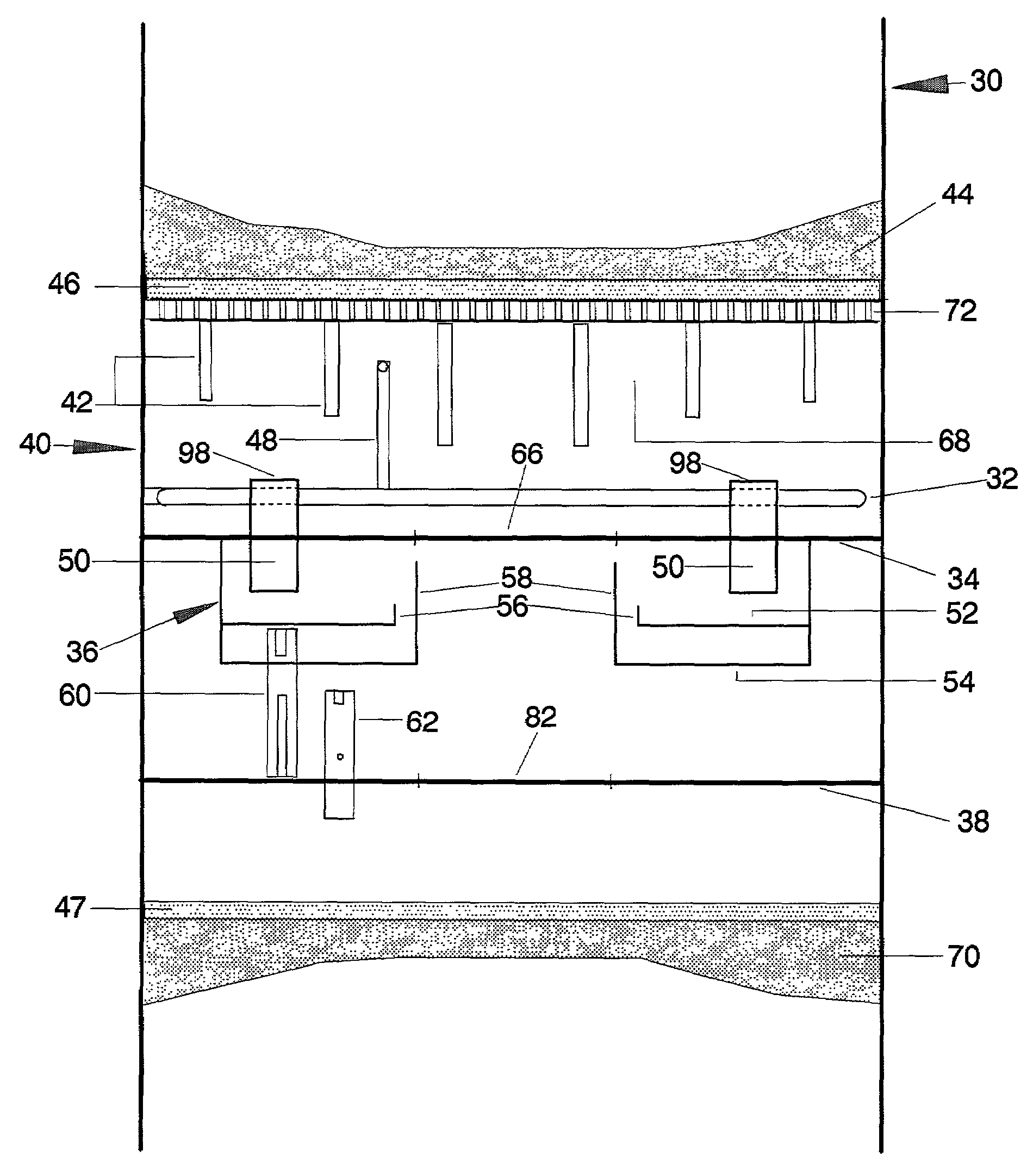

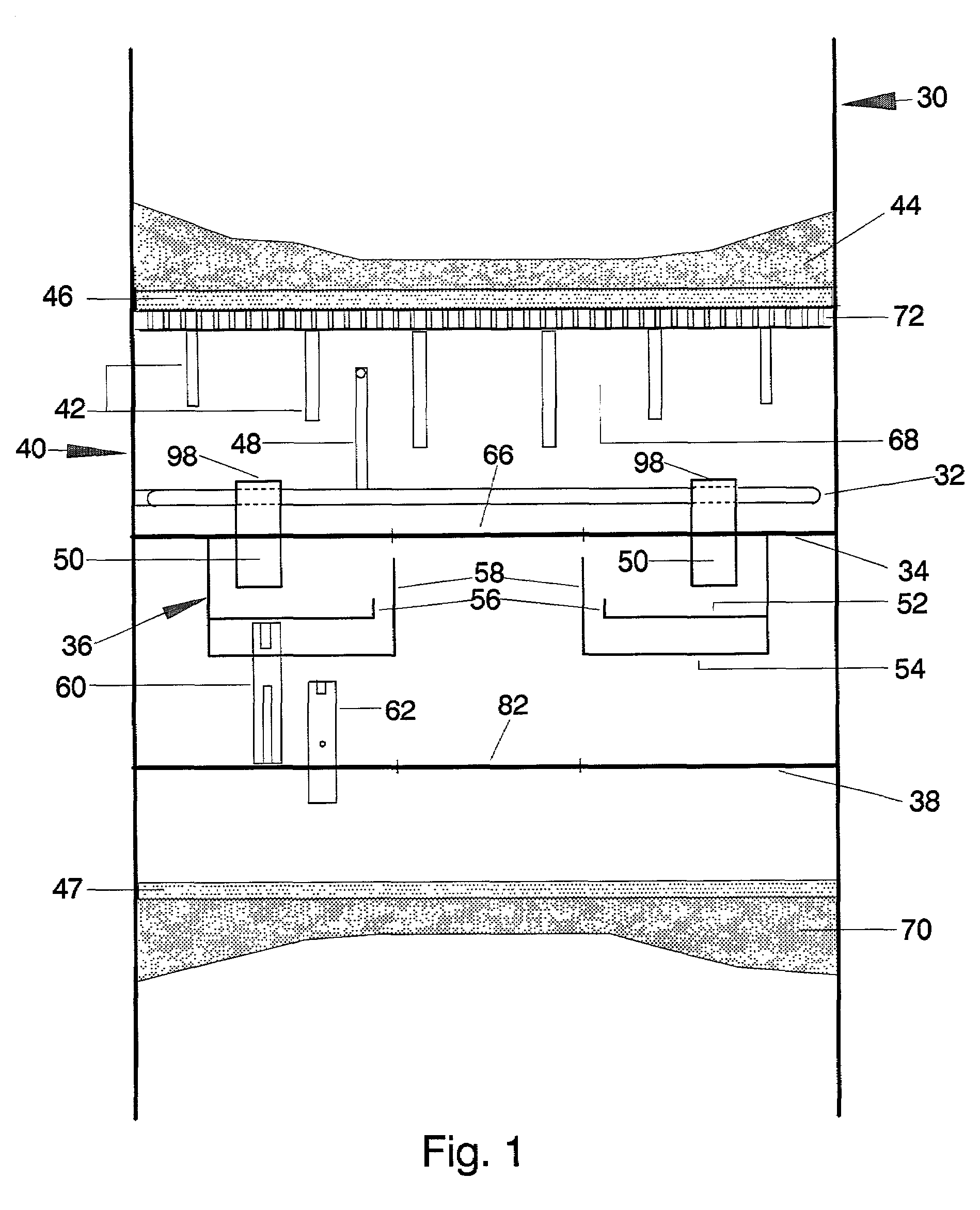

Low compaction, pneumatic dewatering process for producing absorbent sheet

ActiveUS20060000567A1High porosityLarge hydraulic diameterNon-fibrous pulp additionNatural cellulose pulp/paperFiberPapermaking

A low-compaction method of making an absorbent cellulosic web includes: forming a nascent web from a papermaking furnish; dewatering the nascent web to a consistency of from about 10 to about 30 percent on a foraminous forming support traveling at a first speed; rush-transferring the web at a consistency of from 10 to about 30 percent to an open texture fabric traveling at a second speed slower than the first speed of the forming support; further dewatering the web on the impression fabric to a consistency of from about 30 to about 60 percent by way of (i) combining the open texture fabric bearing said web with a fluid distribution membrane and an anti-rewet felt as the three pass through a nip into a pressure chamber defined in part by a plurality of nip rolls, the fluid distribution membrane bearing against the side of the open texture fabric away from the web, with the anti-rewet felt bearing against the web, and (ii) applying a pneumatic pressure gradient from the distributor membrane through the web thereby dewatering the web; and drying the web. Preferably the process includes the steps of selecting the papermaking furnish and controlling the process such that the dried web has a void volume fraction of at least 0.7, a hydraulic diameter in the range of from about 3 to about 20 microns and a Wet Springback Ratio of at least about 0.65. Optionally provided is a high solids fabric crepe in a pressure nip.

Owner:GPCP IP HLDG LLC

Cryogenic liquid natural gas recovery process

A process for the recovery of natural gas liquids (NGL) (ethane, ethylene, propane, propylene and heavier hydrocarbons) from liquefied natural gas (LNG) is disclosed. The LNG feed stream is split with at least one portion used as an external reflux, without prior treatment, to improve the separation and recovery of the natural gas liquids (NGL).

Owner:HOWE BAKER ENGINEERS LTD

Low compaction, pneumatic dewatering process for producing absorbent sheet

ActiveUS7416637B2Lower gradeReduce capital investmentNon-fibrous pulp additionNatural cellulose pulp/paperFiberPapermaking

A low-compaction method of making an absorbent cellulosic web includes: forming a nascent web from a papermaking furnish; dewatering the nascent web to a consistency of from about 10 to about 30 percent on a foraminous forming support traveling at a first speed; rush-transferring the web at a consistency of from 10 to about 30 percent to an open texture fabric traveling at a second speed slower than the first speed of the forming support; further dewatering the web on the impression fabric to a consistency of from about 30 to about 60 percent by way of (i) combining the open texture fabric bearing said web with a fluid distribution membrane and an anti-rewet felt as the three pass through a nip into a pressure chamber defined in part by a plurality of nip rolls, the fluid distribution membrane bearing against the side of the open texture fabric away from the web, with the anti-rewet felt bearing against the web, and (ii) applying a pneumatic pressure gradient from the distributor membrane through the web thereby dewatering the web; and drying the web. Preferably the process includes the steps of selecting the papermaking furnish and controlling the process such that the dried web has a void volume fraction of at least 0.7, a hydraulic diameter in the range of from about 3 to about 20 microns and a Wet Springback Ratio of at least about 0.65. Optionally provided is a high solids fabric crepe in a pressure nip.

Owner:GPCP IP HLDG LLC

Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor

InactiveUS7112312B2Reduce in quantitySimple designPhysical/chemical process catalystsFlow mixersFixed bedEngineering

Owner:H2ADVANCE

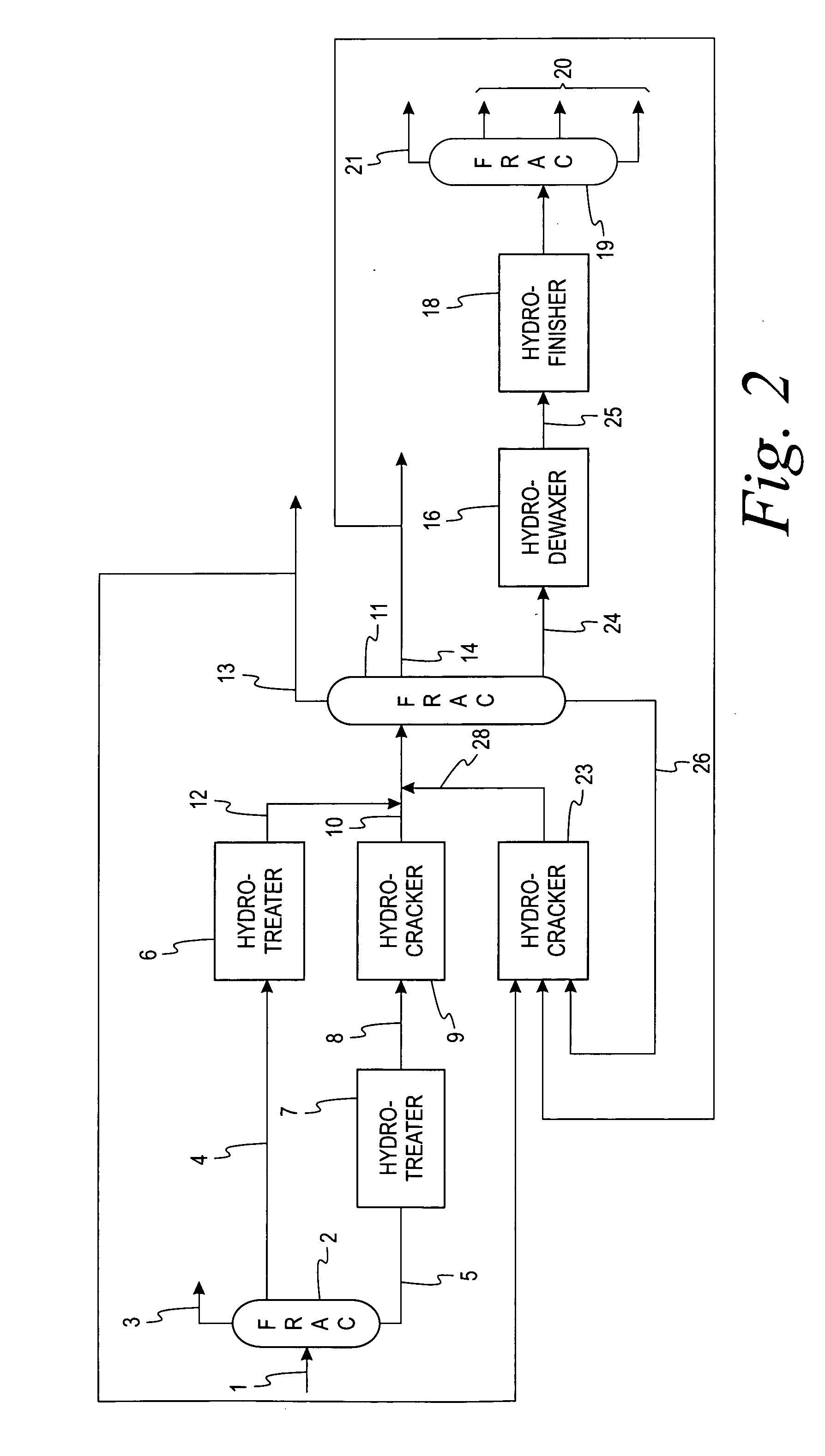

Process to produce synthetic fuels and lubricants

InactiveUS20050183988A1Yield maximizationEquipment cost can be minimizedThermal non-catalytic crackingCatalytic crackingBase oilPetroleum

A process utilizing a low severity hydrocracker prior to a high severity hydrocracker for the processing of petroleum based and synthetic hydrocarbon feedstocks into distillate fuels and high quality lubricant base oils. The process minimizes the size and conditions required by the high severity hydrocracker by closely matching such configuration with the desired product slate.

Owner:REG SYNTHETIC FUELS LLC

Liquefied natural gas processing

ActiveUS7631516B2Simple process equipmentReduce investmentSolidificationLiquefactionLiquid productReflux

A process and apparatus for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at an upper mid-column feed point. The second portion is directed in heat exchange relation with a warmer distillation stream rising from the fractionation stages of the column, whereby this portion of the LNG feed stream is partially vaporized and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG product stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The partially vaporized portion of the LNG feed stream is separated into vapor and liquid streams which are thereafter supplied to the column at lower mid-column feed positions. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:UOP LLC

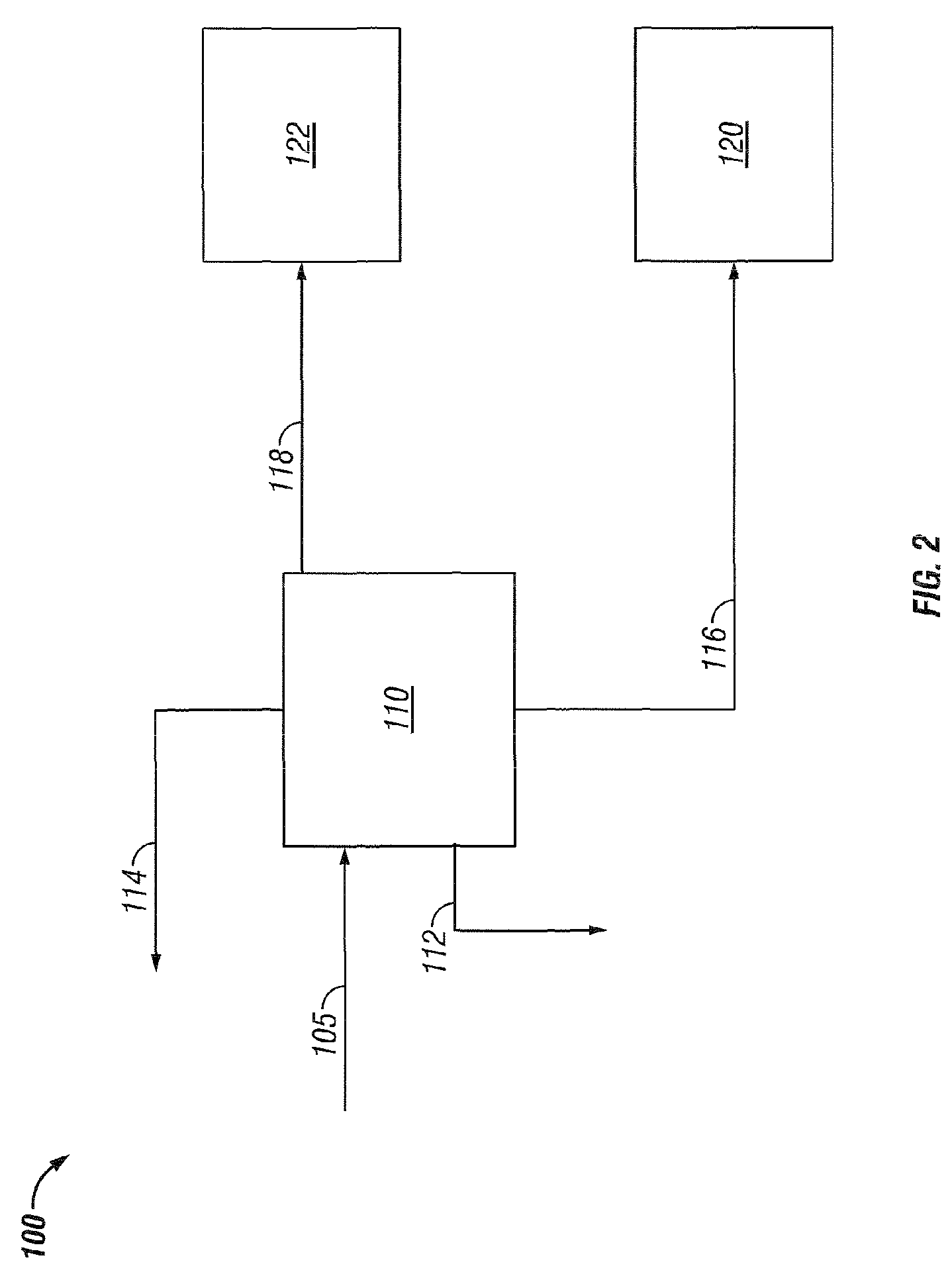

Bitumen production-upgrade with common or different solvents

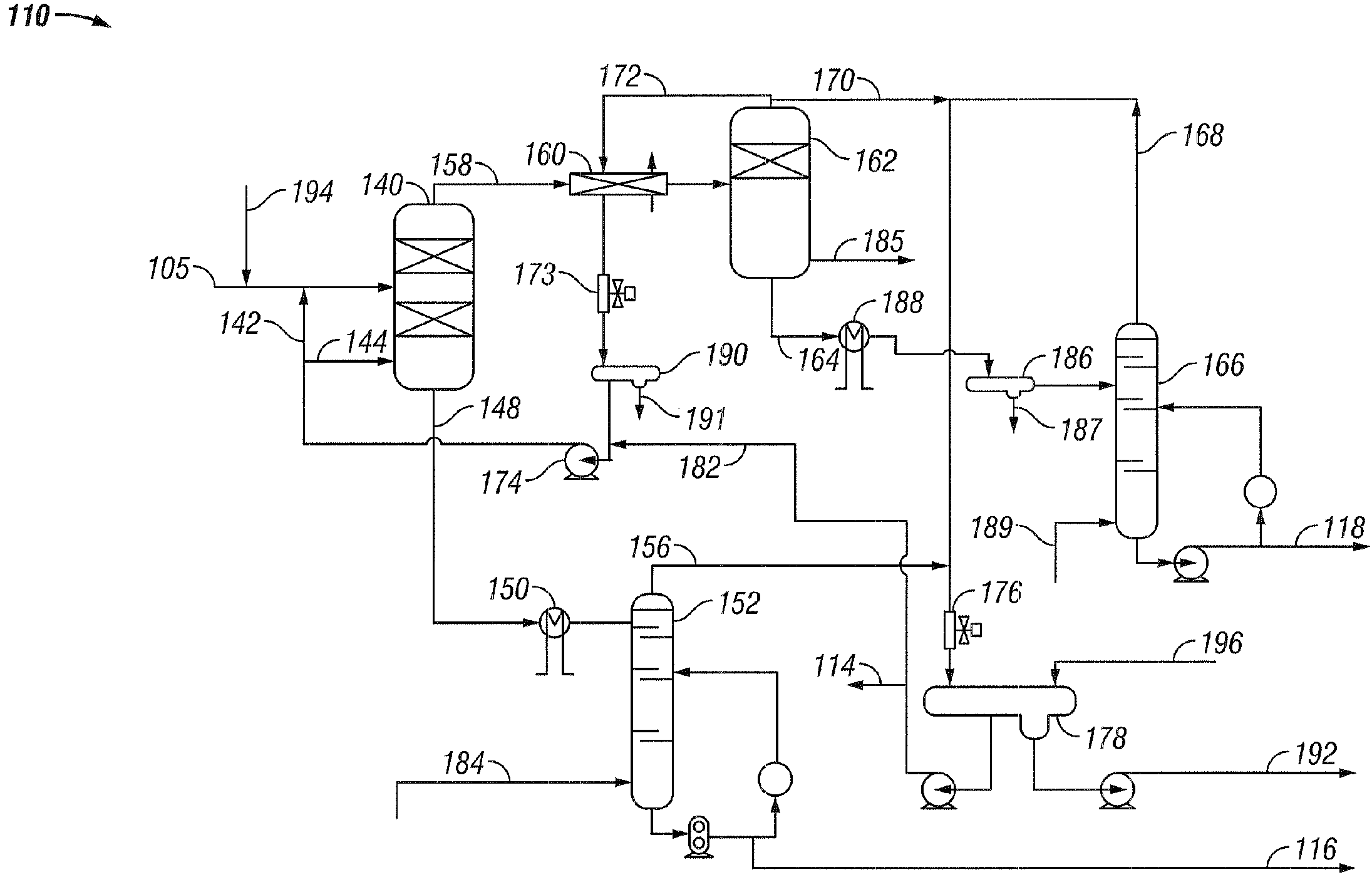

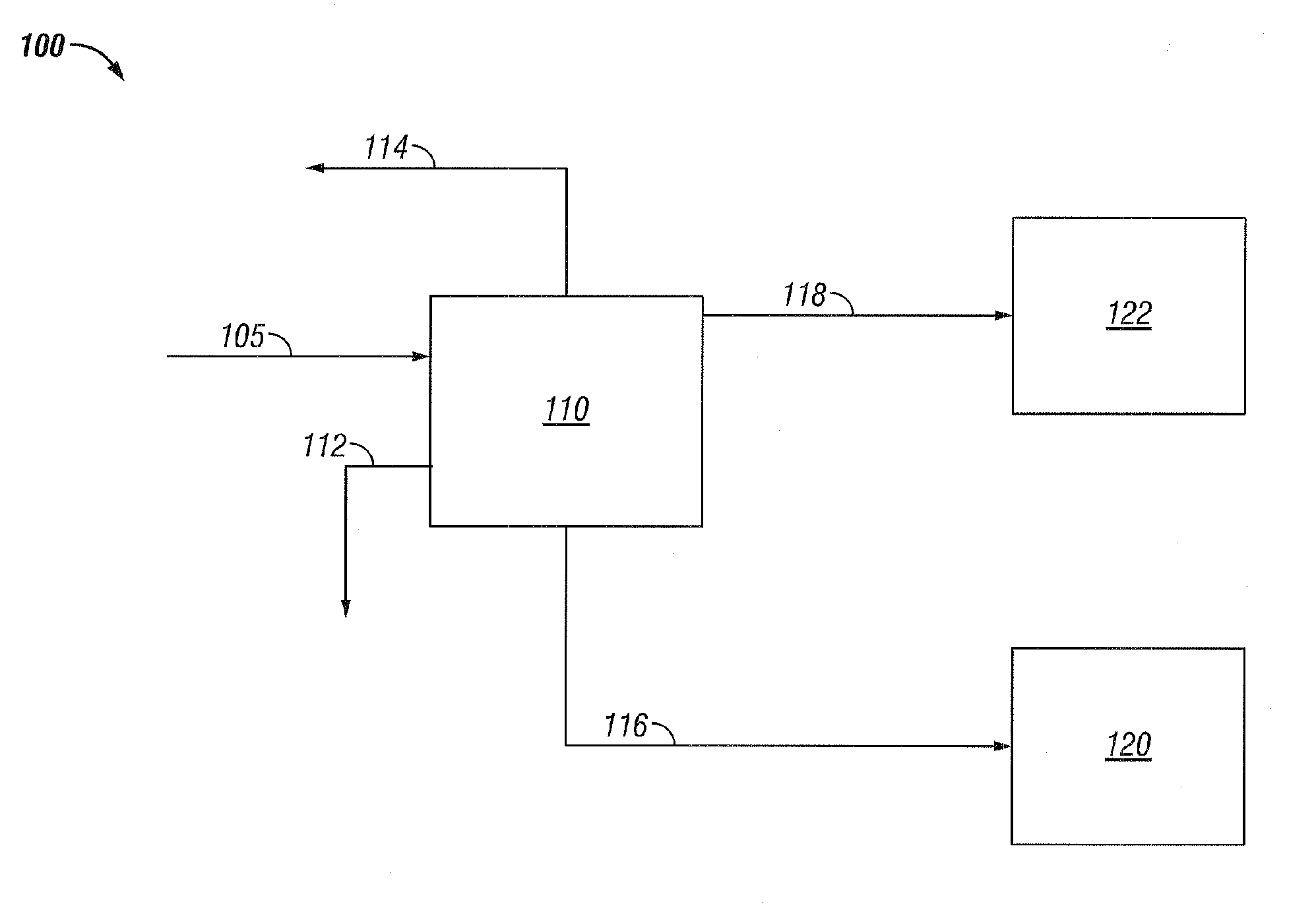

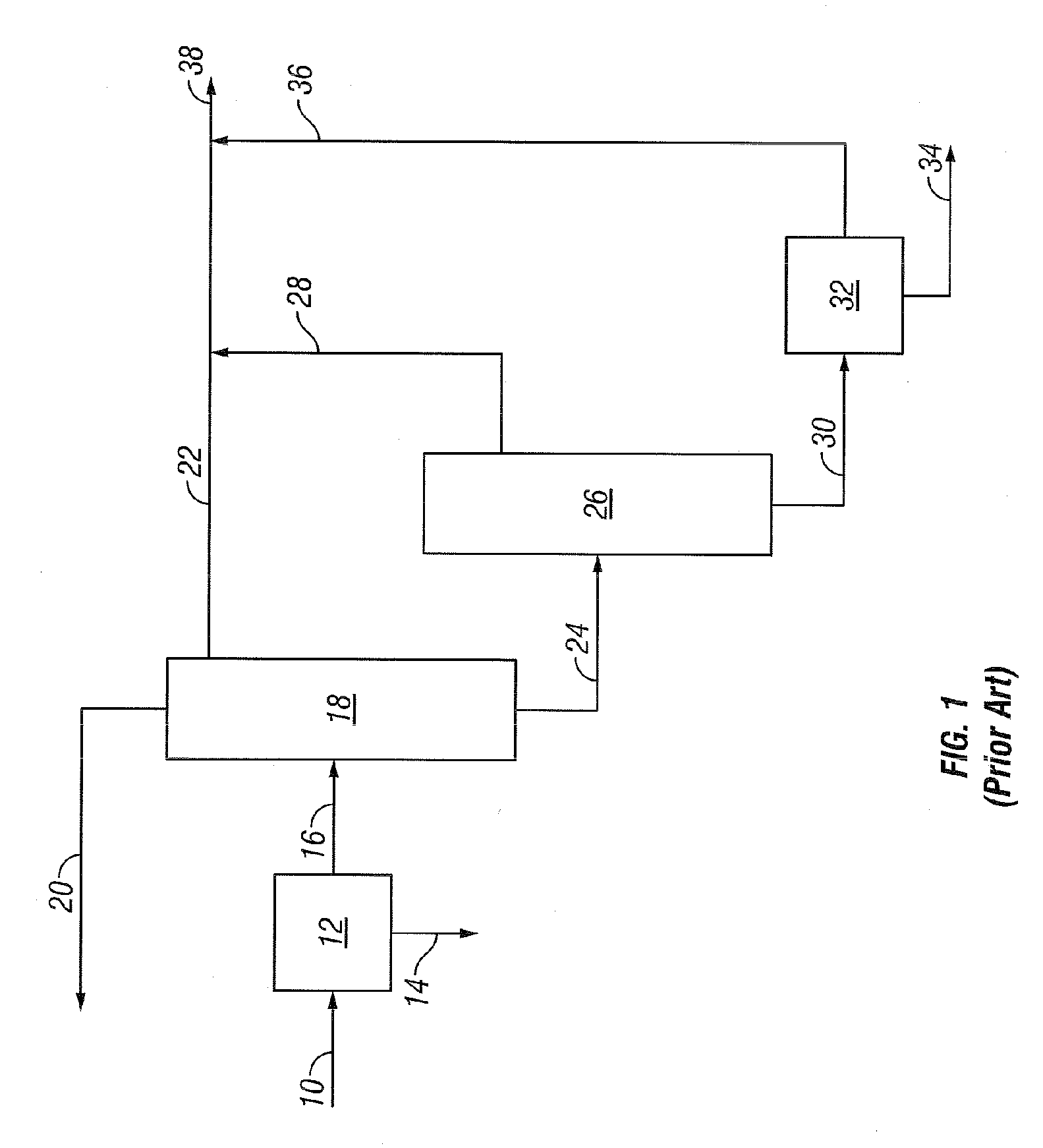

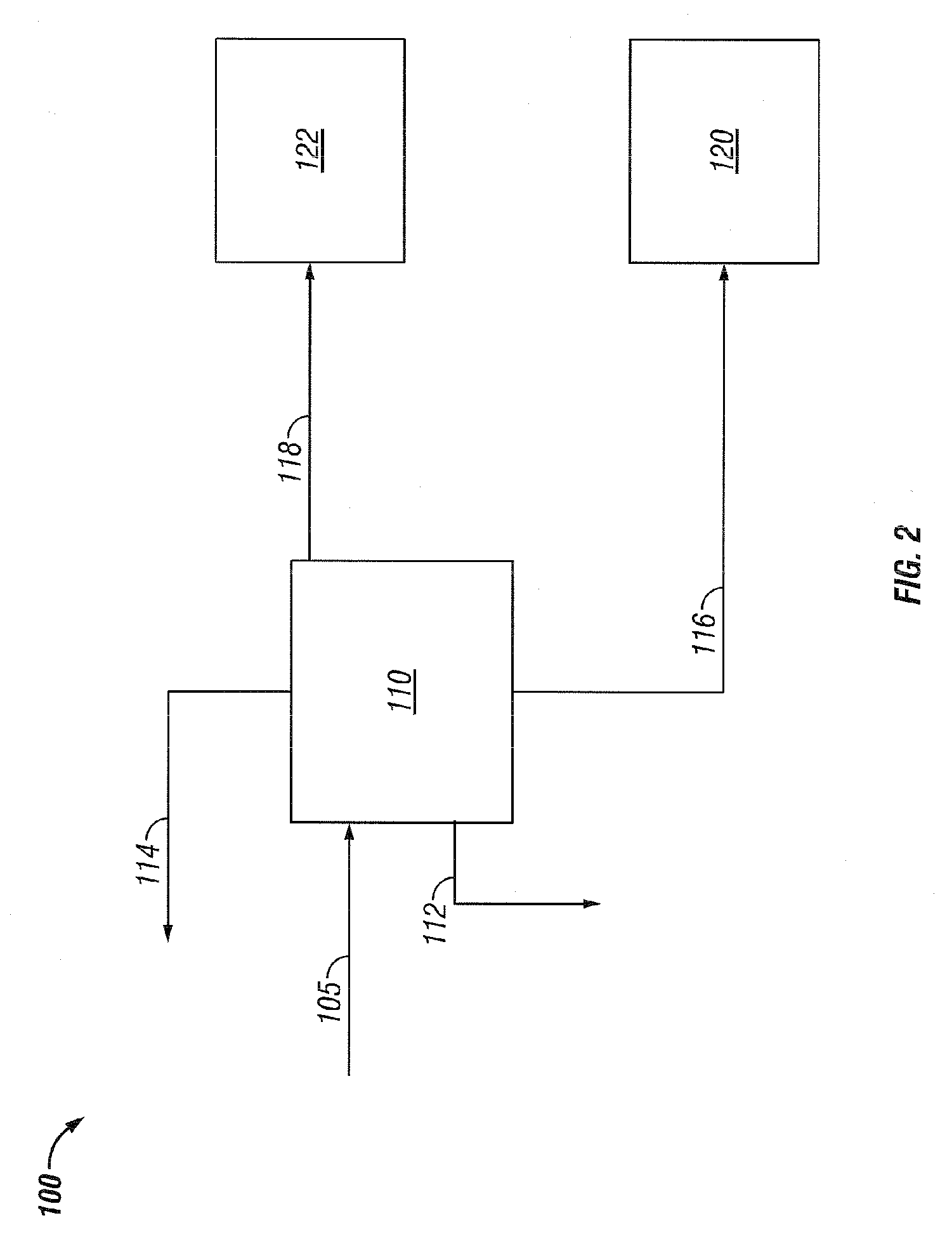

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

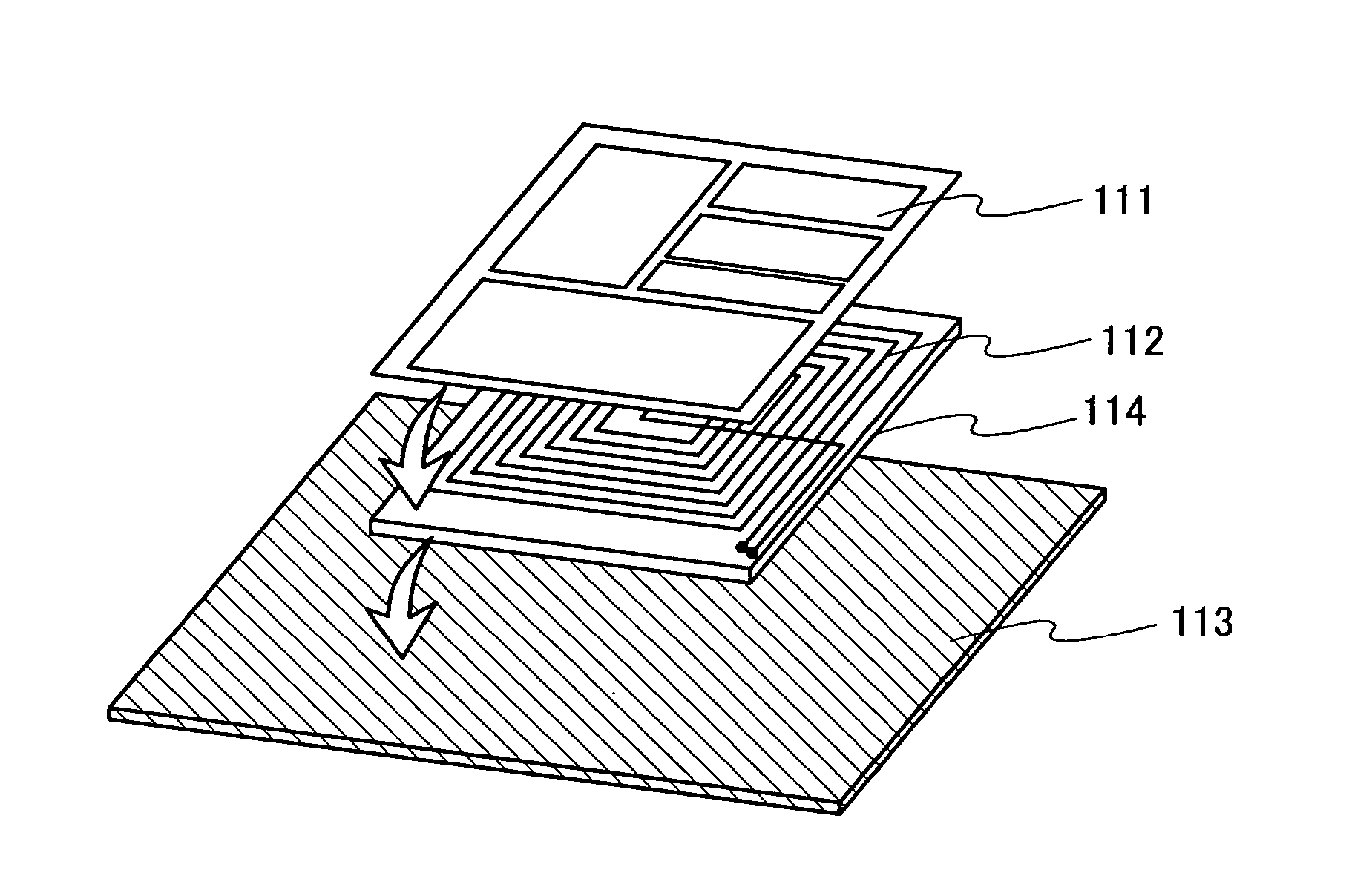

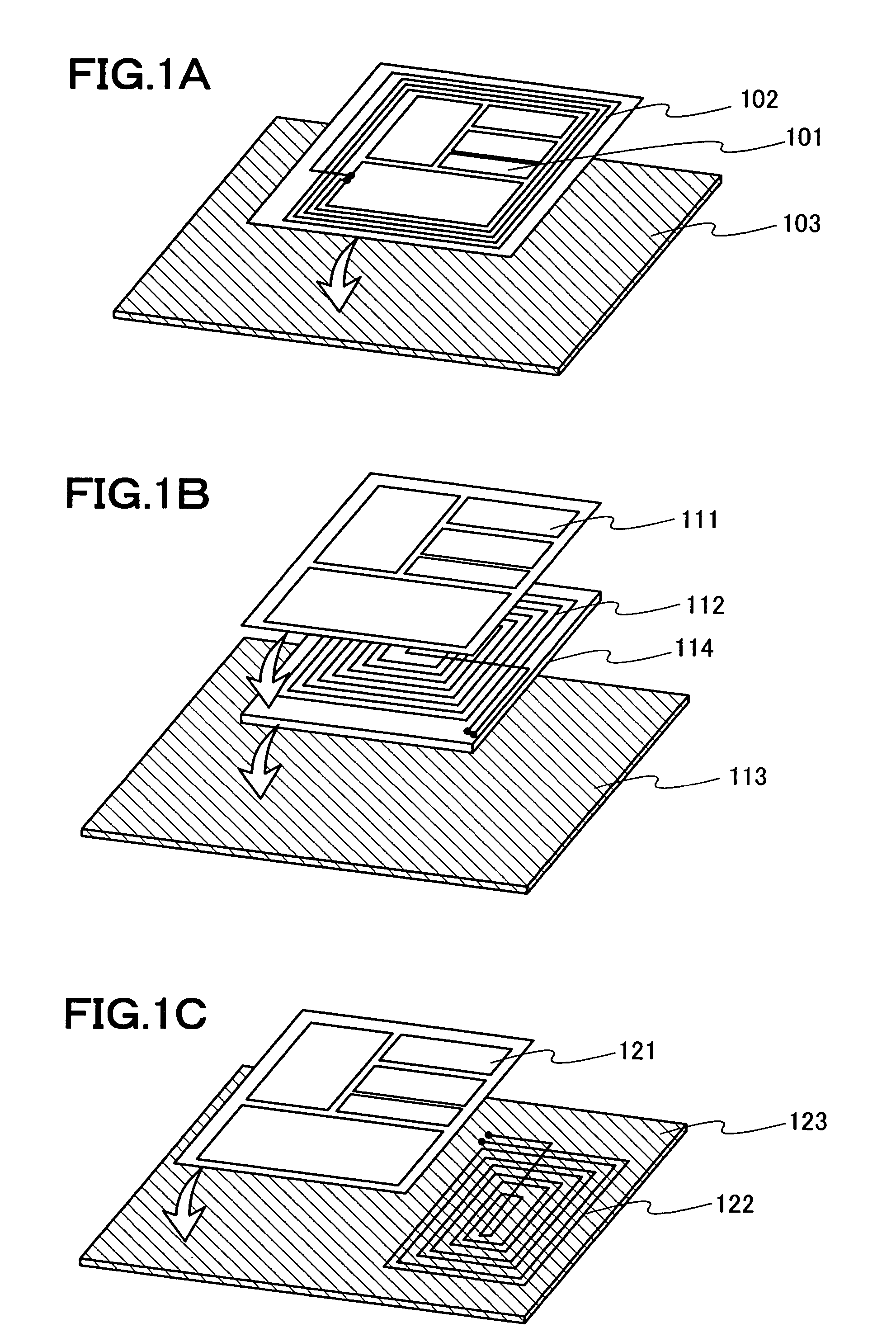

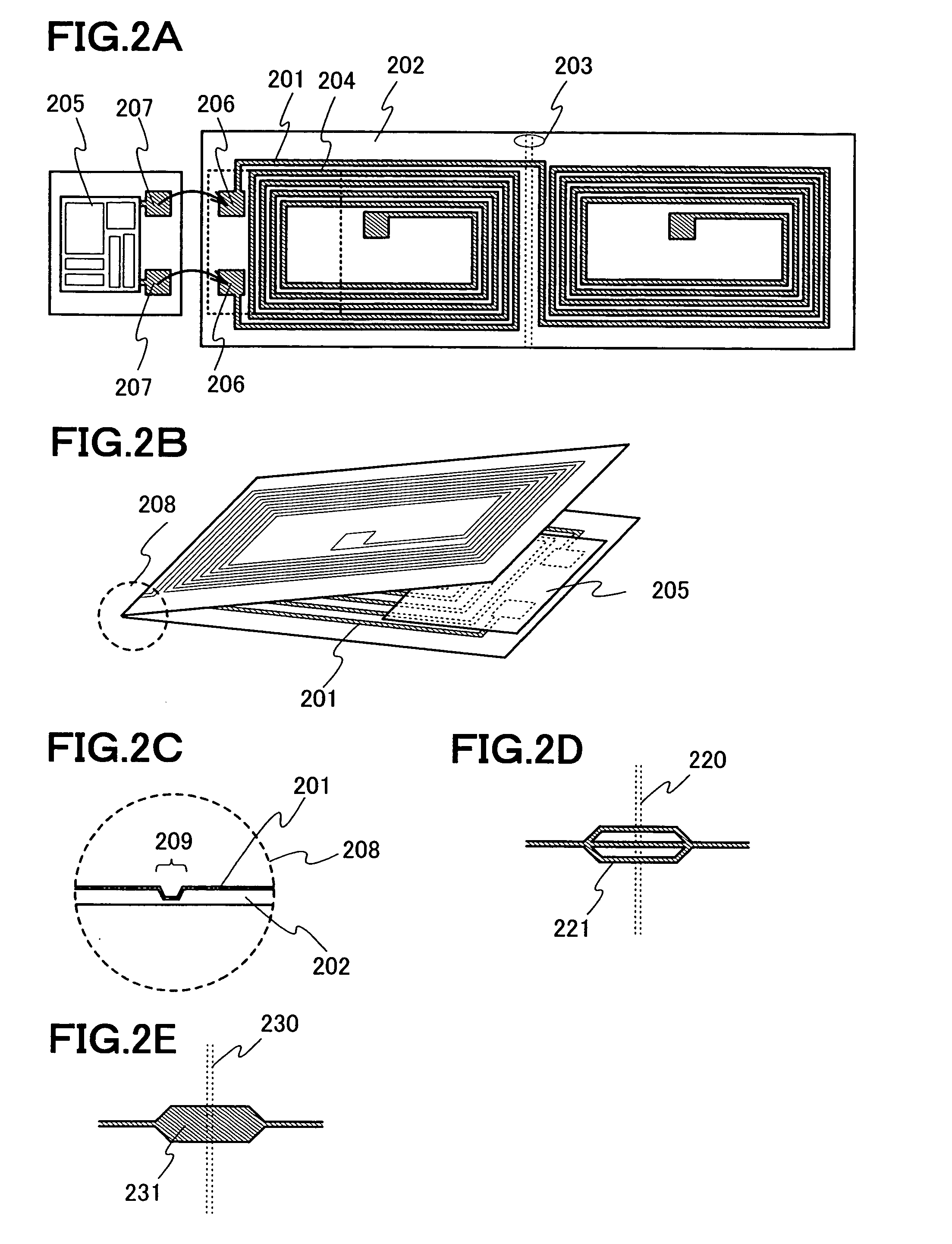

Semiconductor device and manufacturing method thereof

InactiveUS7768405B2Low mechanical strengthHigh mechanical strengthTransistorLine/current collector detailsEngineeringSemiconductor device

A semiconductor device typified by a wireless tag, which has improved mechanical strength, can be formed by a more simple process at a low cost and prevent radio waves from being shielded, and a manufacturing method of the semiconductor device. According to the invention, a wireless tag includes a thin film integrated circuit formed of an isolated TFT having a thin film semiconductor film. The wireless tag may be attached directly to an object, or attached to a flexible support such as plastic and paper before being attached to an object. The wireless tag of the invention may include an antenna as well as the thin film integrated circuit. The antenna allows to communicate signals between a reader / writer and the thin film integrated circuit, and to supply a power source voltage from the reader / writer to the thin film integrated circuit.

Owner:SEMICON ENERGY LAB CO LTD

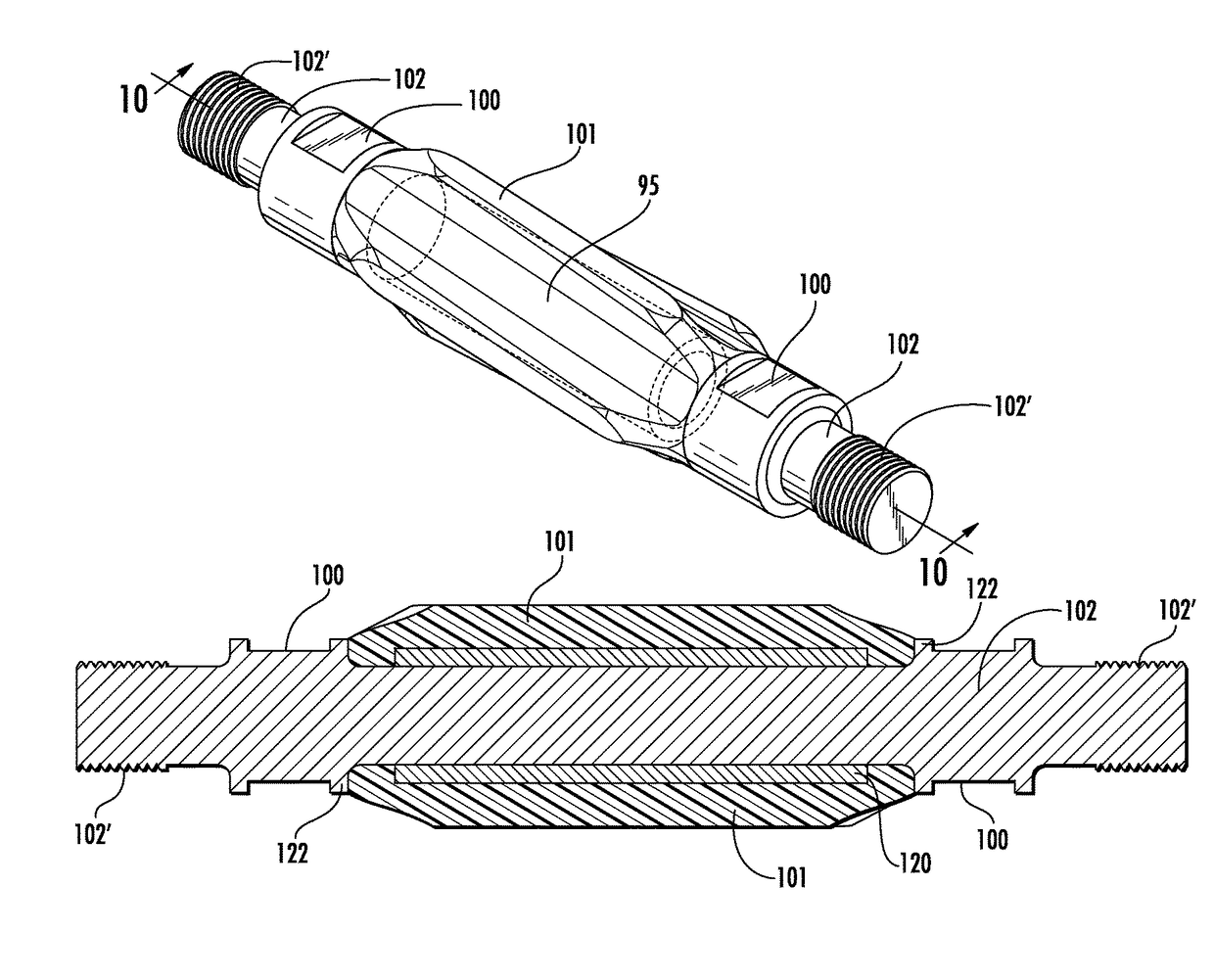

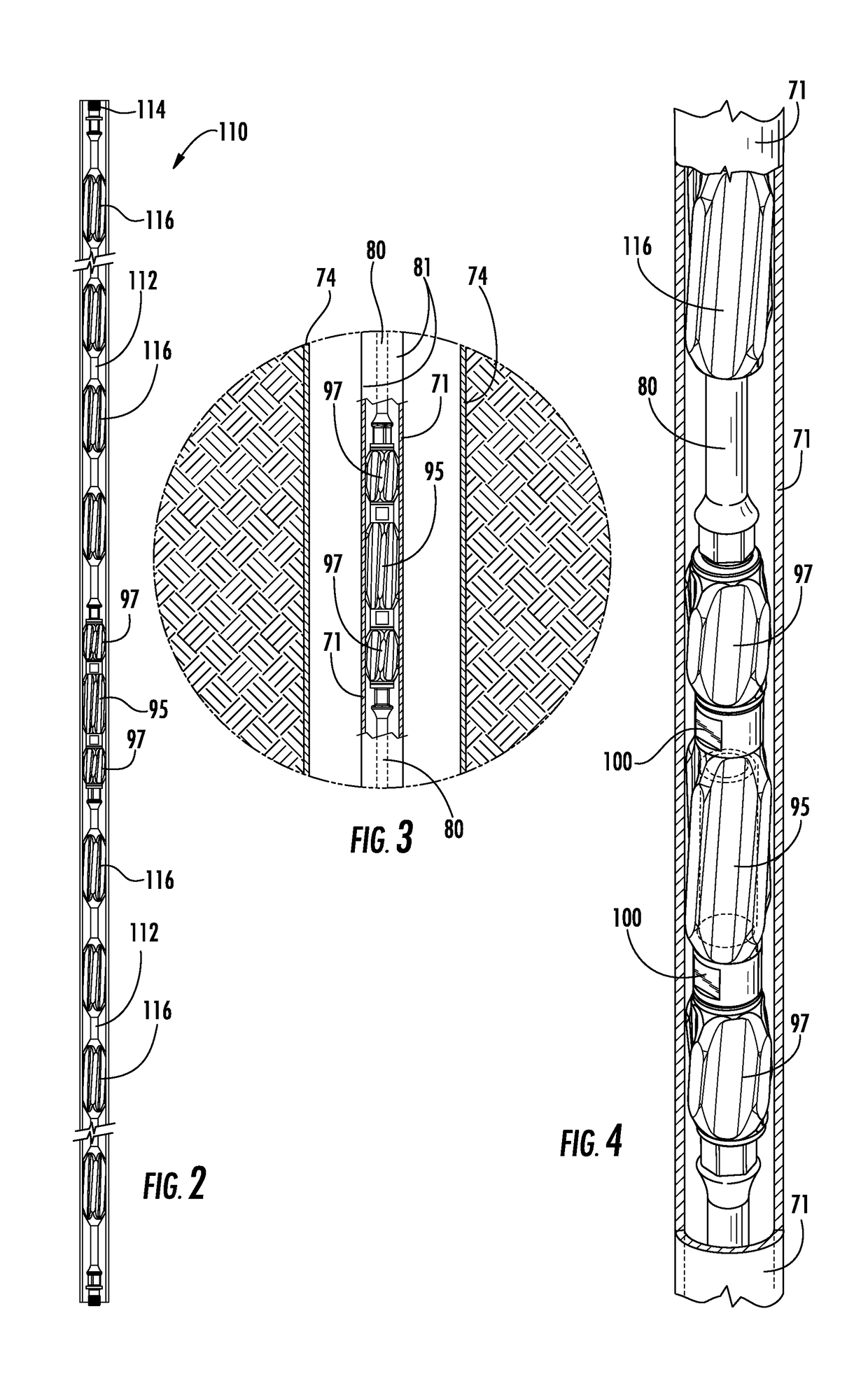

Sucker rod apparatus and methods for manufacture and use

ActiveUS9869135B1Improve wear resistanceReduce capital investmentDrilling rodsMetal-working apparatusFiberCoupling

A sucker rod string improved by the use of wear resistant, high temperature resistant, fiber-reinforced phenolic composite materials as centralizing guides on sucker rods and couplings, both molded on the rod and prepared as snap-on couplings for in-the-field use, and on magnet rod inserts, both rod box and pin magnet rod inserts, in which the thermosetting composites are used as sleeves, encapsulating housings, and centralizing guides. The magnet rod inserts and couplings are designed to be machined so that worn phenolic composite can be removed and replaced with fresh composite without removing or damaging the magnet. Processes are disclosed for integrating composite thermoset molding into sucker rod, coupling, and magnet rod insert manufacture and for refurbishing used components of a sucker rod string.

Owner:RFG TECH PARTNERS LLC

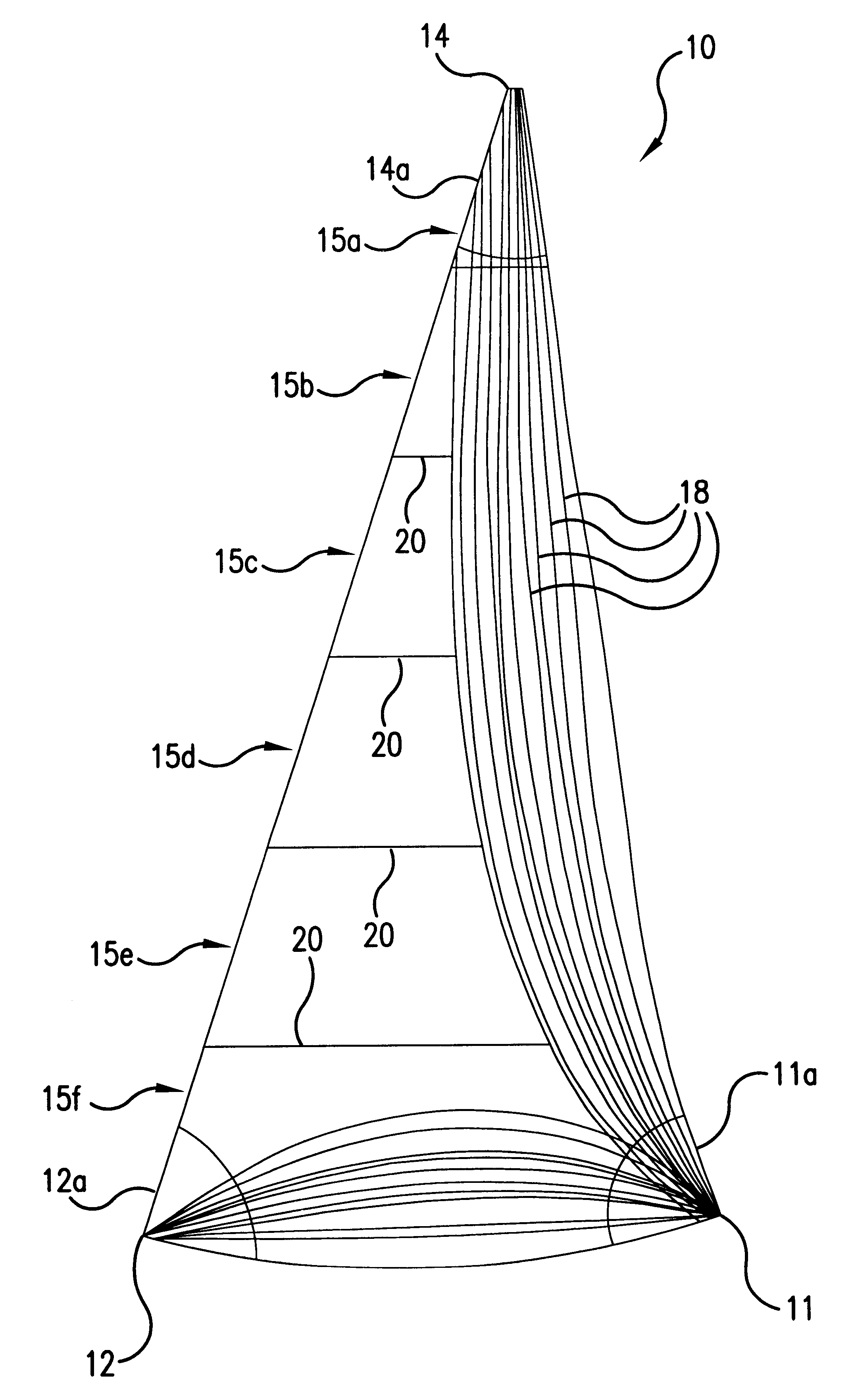

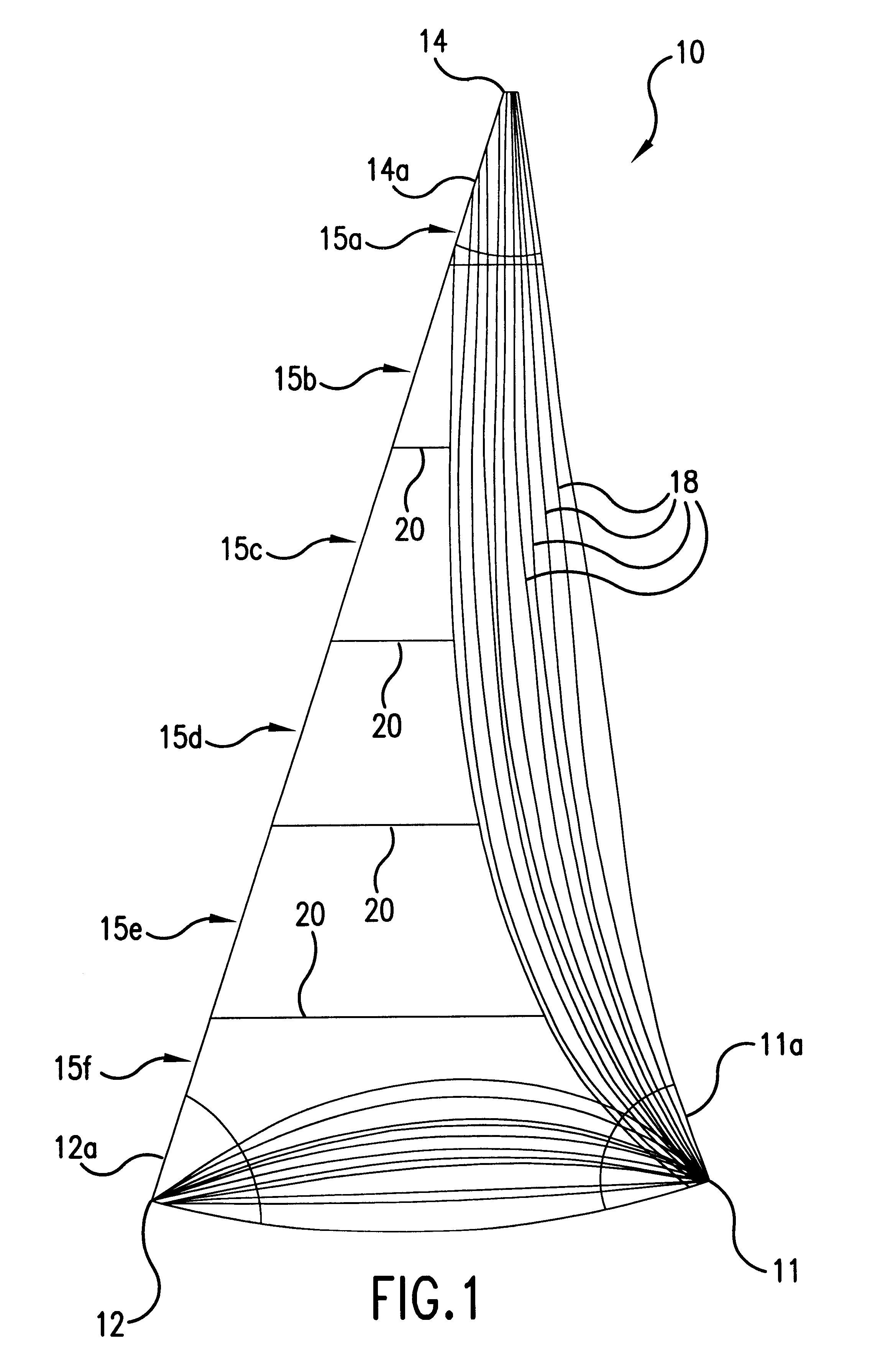

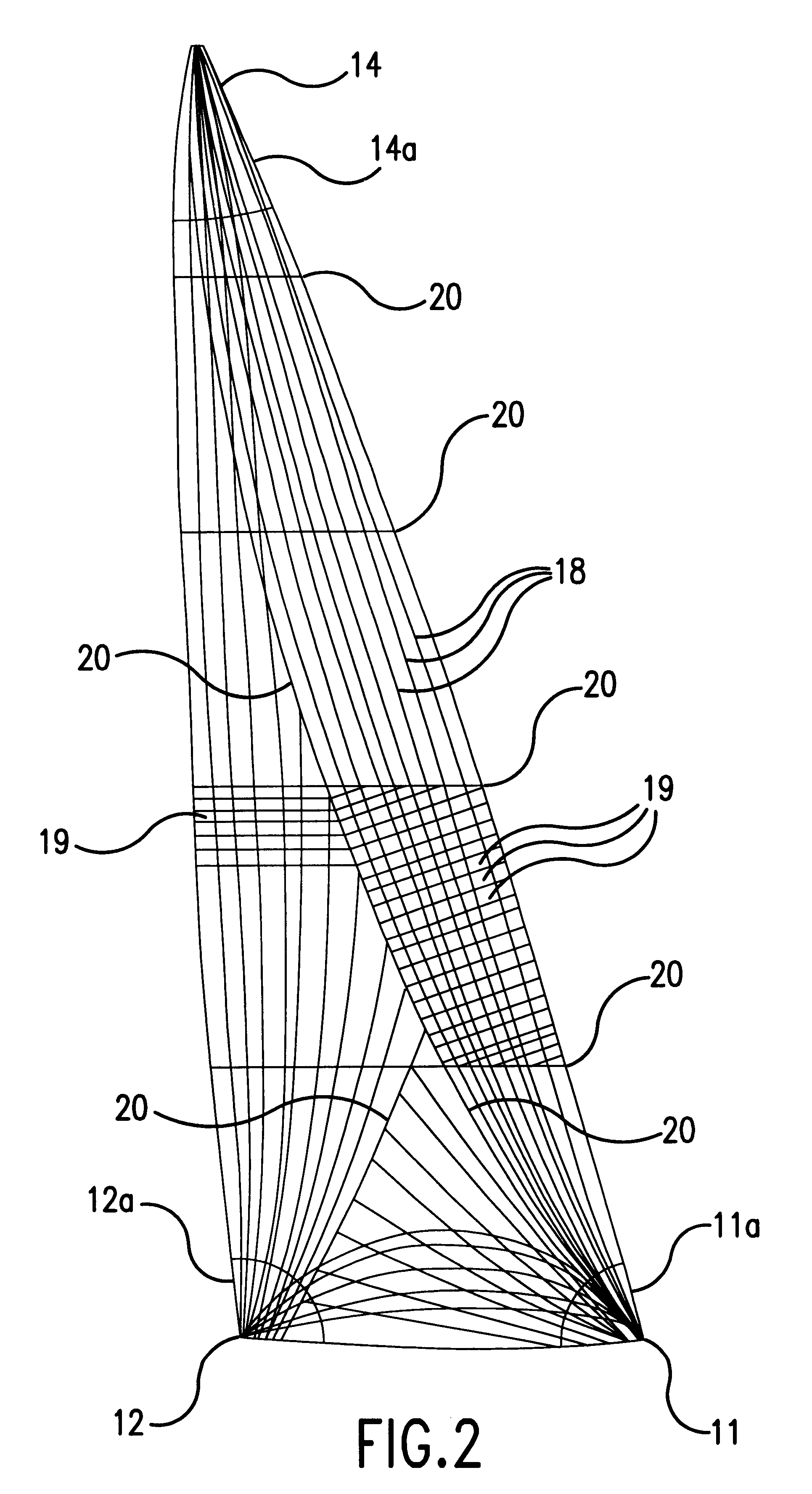

Seamed sail and method of manufacture

InactiveUS6382120B1Reduce capital investmentMaintain good propertiesDomestic articlesFloating buildingsYarnEngineering

Owner:KEIRE FRED AIVARS

Process for producing olefins

InactiveUS20110112314A1Produce some attenuationReduce needThermal non-catalytic crackingHydroxy compound preparationHydrogenOxygenate

The present invention provides a process for producing olefins, comprising:a. cracking an ethane-comprising feed in a cracking zone under cracking conditions to obtain at least olefins and hydrogen;b. converting an oxygenate feedstock in an oxygenate-to-olefin zone to obtain at least olefins; wherein at least part of the oxygenate feedstock is obtained by providing hydrogen obtained in step a) and a feed containing carbon monoxide and / or carbon dioxide to an oxygenate synthesis zone and synthesizing oxygenates.In another aspect the invention provides an integrated system for producing olefins.

Owner:ACCUFLUX +1

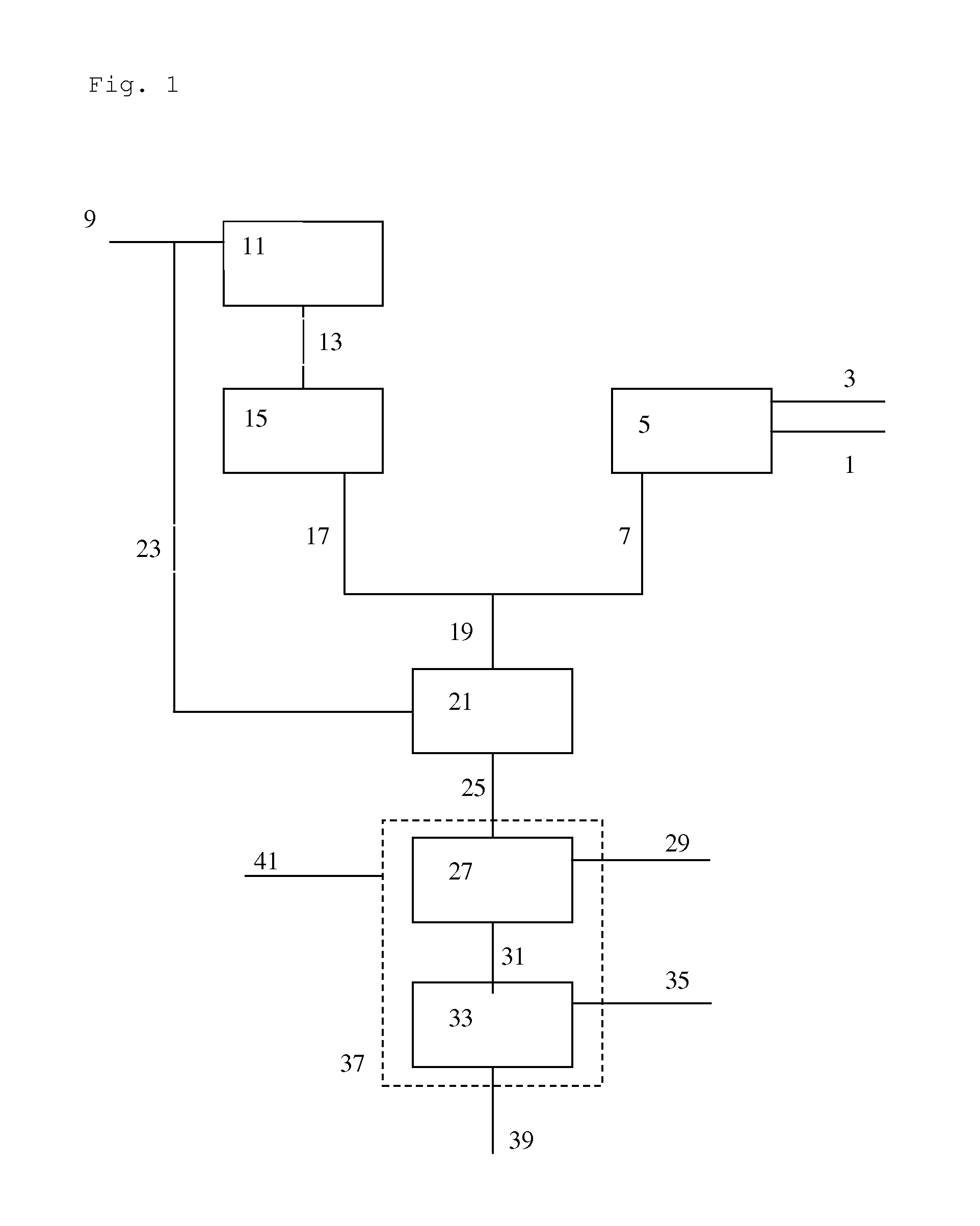

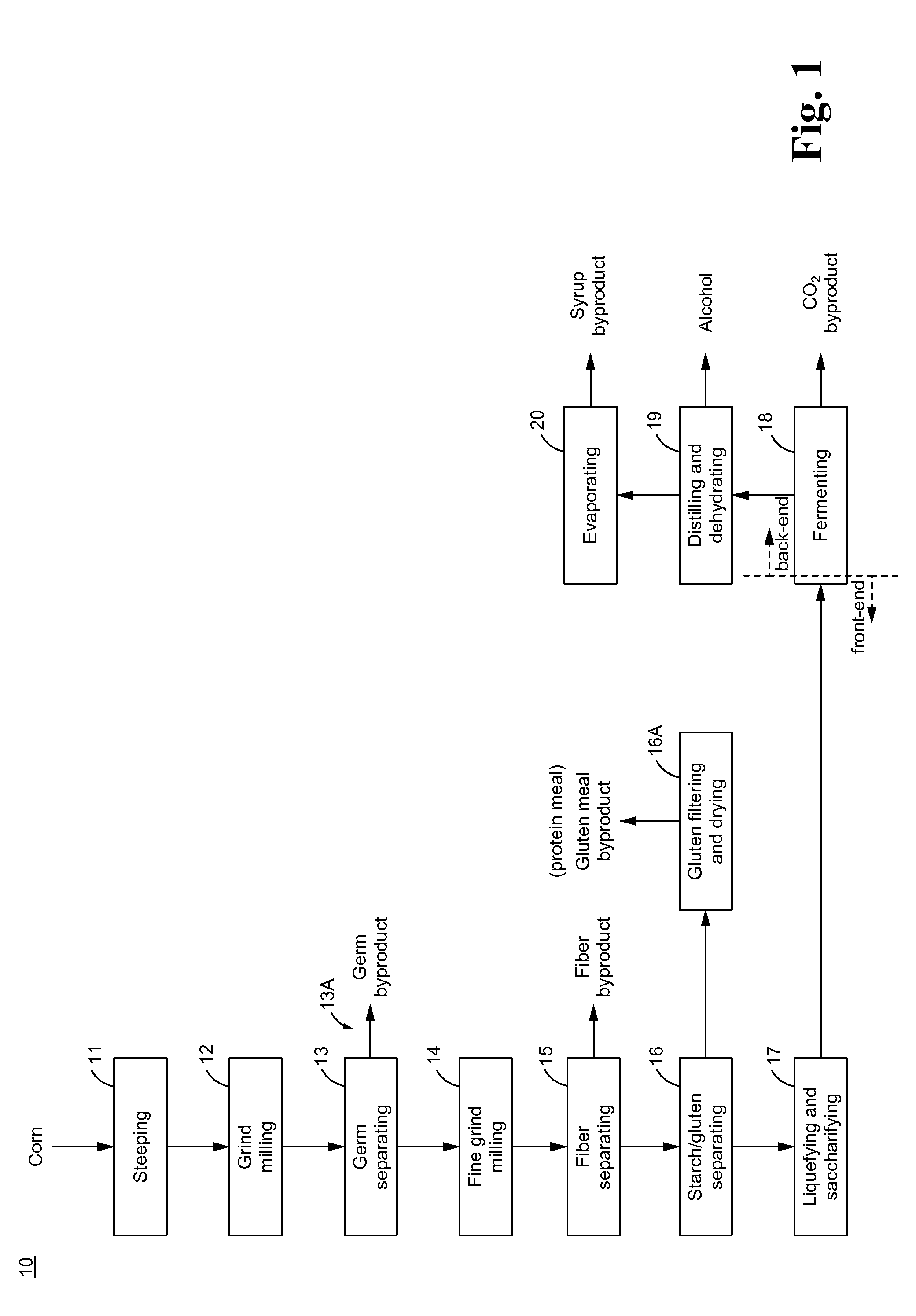

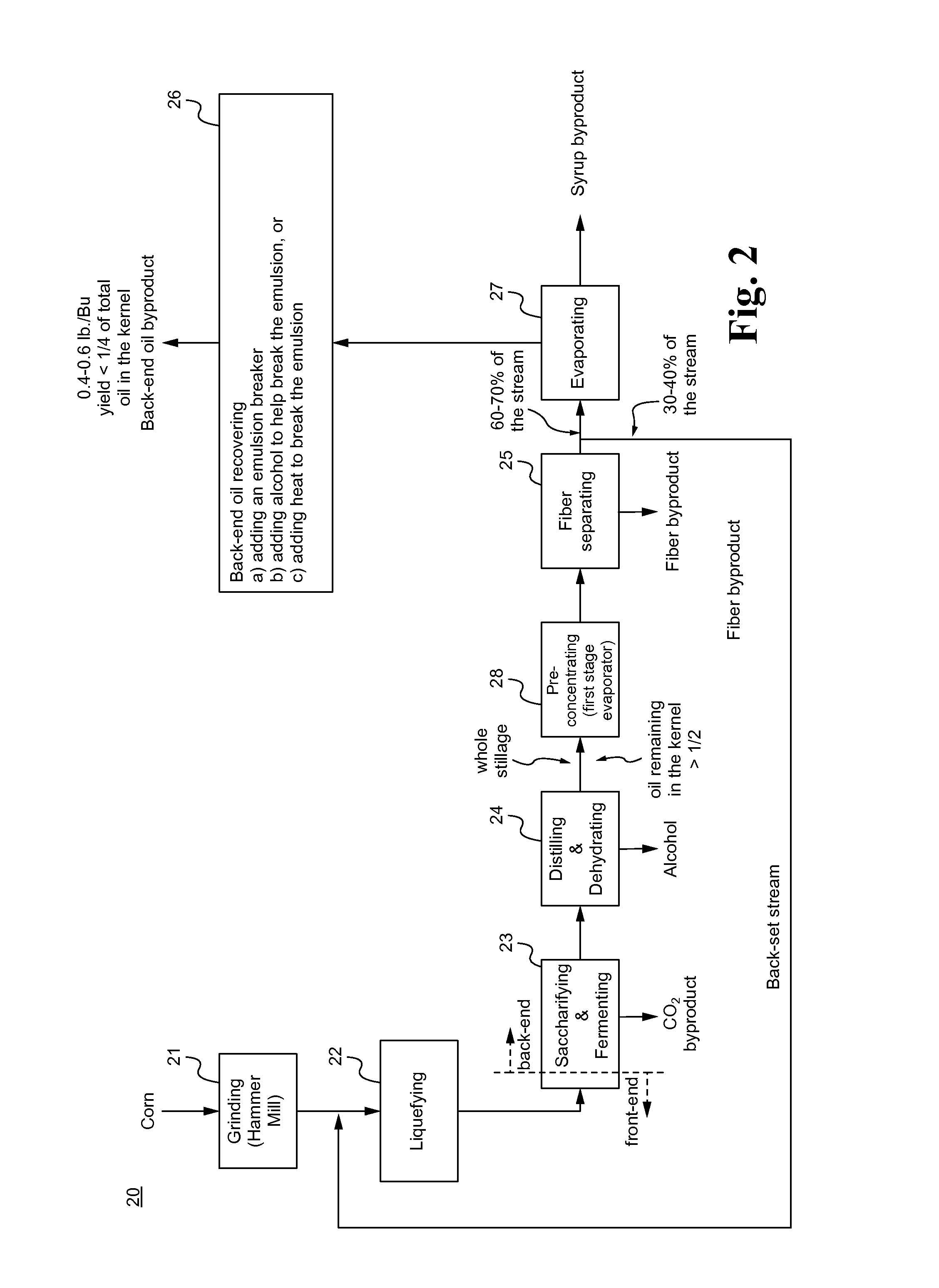

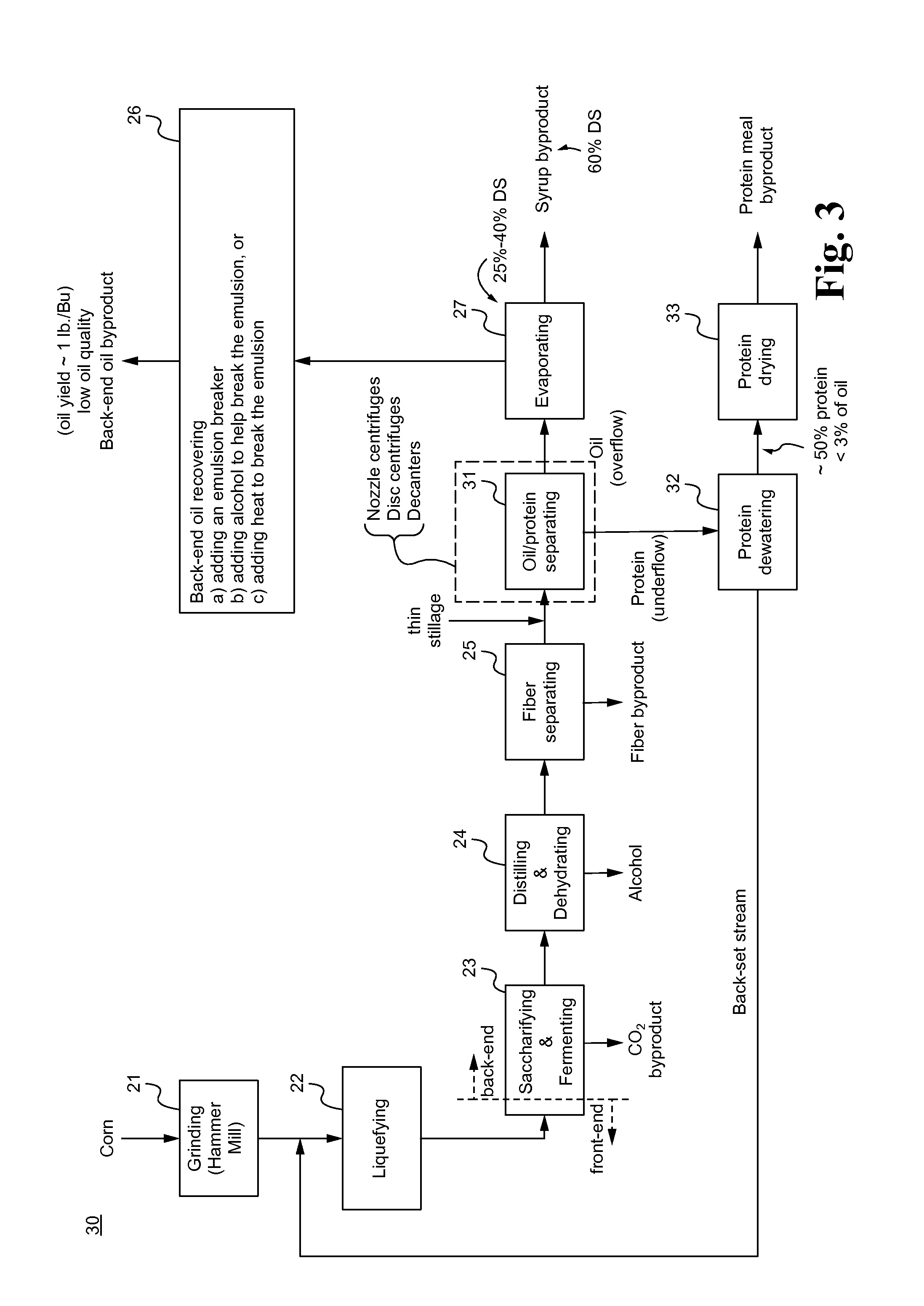

Method of and system for producing oil and valuable byproducts from grains in dry milling systems with a back-end dewater milling unit

ActiveUS20140053829A1High quality of oilHigh capital investmentFatty oils/acids recovery from wasteBioreactor/fermenter combinationsEmulsionChemistry

A method of and system for producing oil and valuable byproducts from grains, such as corn, in dry mills are disclosed. The method and system include dewater milling process after fermenting. Further, the method and system are able to produce oil without evaporating. Moreover, the method and system include one or more of the germ processing units, emulsion processing units, fiber processing units, high value protein producing units, and glycerol and inorganic salt producing units, such that high value byproducts are able to be generated.

Owner:LEE TECH LLC

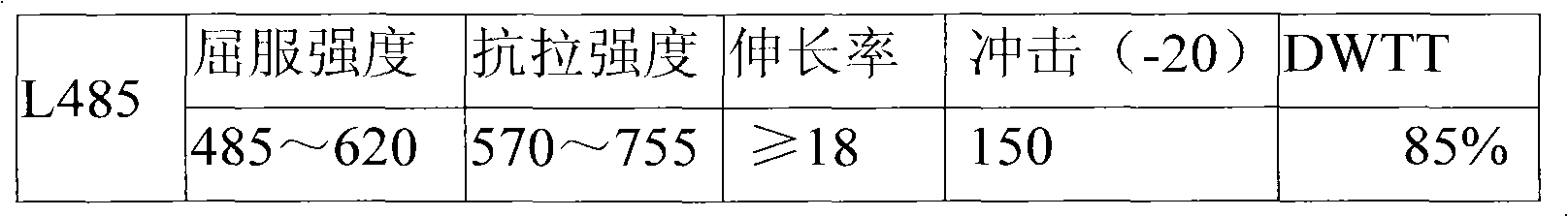

Method for producing low-carbon steel and ultra-low-carbon steel by VD, LF and VD processes

ActiveCN102061351AReduce investmentReduce capital investmentManufacturing convertersProcess efficiency improvementCarbon steelDecarburization

The invention discloses a method for producing low-carbon steel and ultra-low-carbon steel by vacuum decarburization (VD), ladle furnace (LF) and vacuum degassing (VD) processes. By the method, the requirement of smelting a low-carbon steel plate and an ultra-low-carbon steel plate is met by the conventional VD equipment and the like of enterprises on the premise of not adding Ruhrstahl Heraeus (RH) vacuum decarburization equipment and the like; and under the condition of low profit of the enterprises at the present stage, large investment in the large-scale starting of new equipment and equipment modification is avoided, investment is saved for companies, the conventional equipment is fully utilized, the capital investment of the enterprises at the present stage is greatly reduced, and sufficient preparation time is provided for starting the new equipment after the market situation and the profit of the enterprises are improved in the future.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

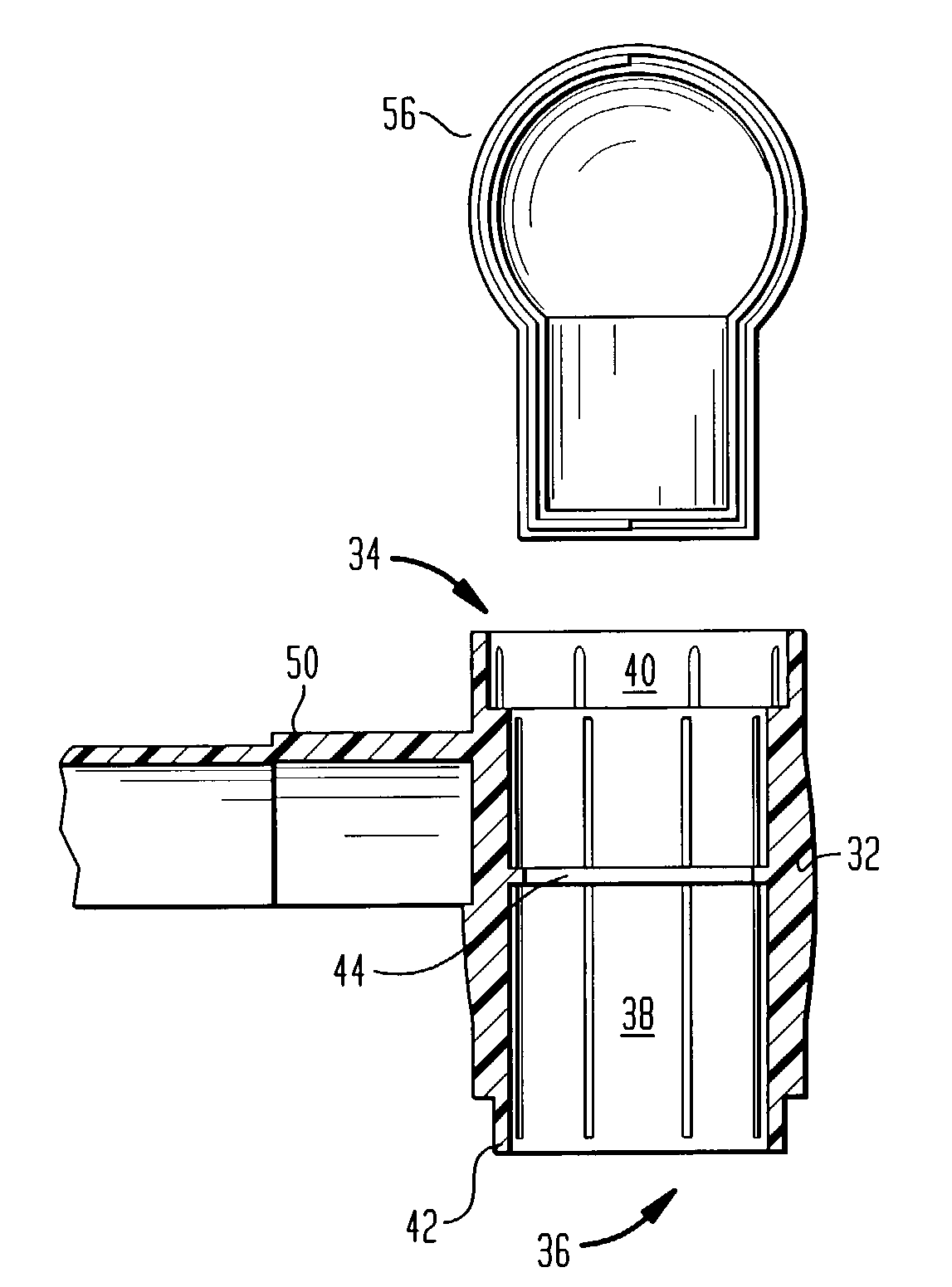

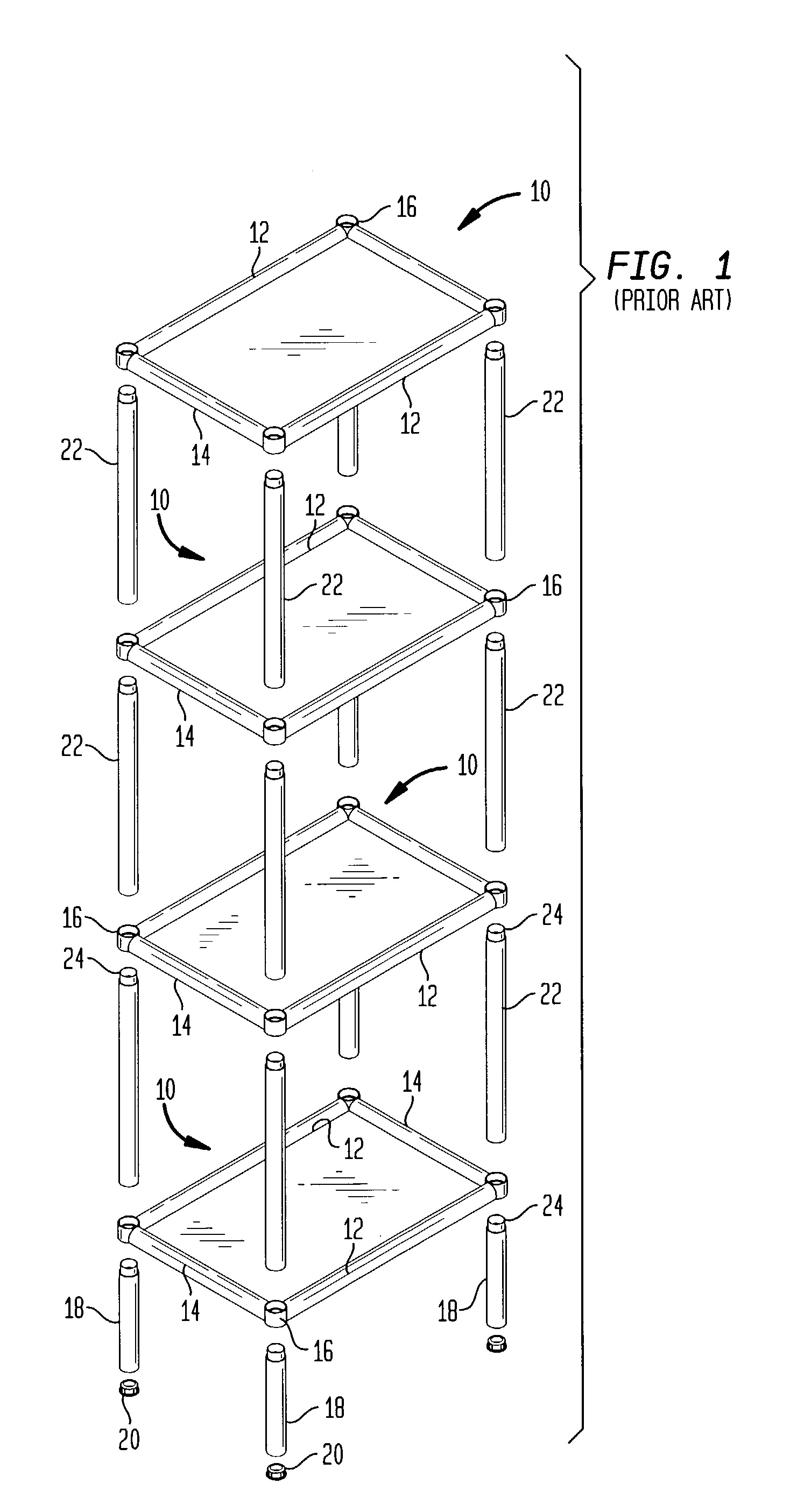

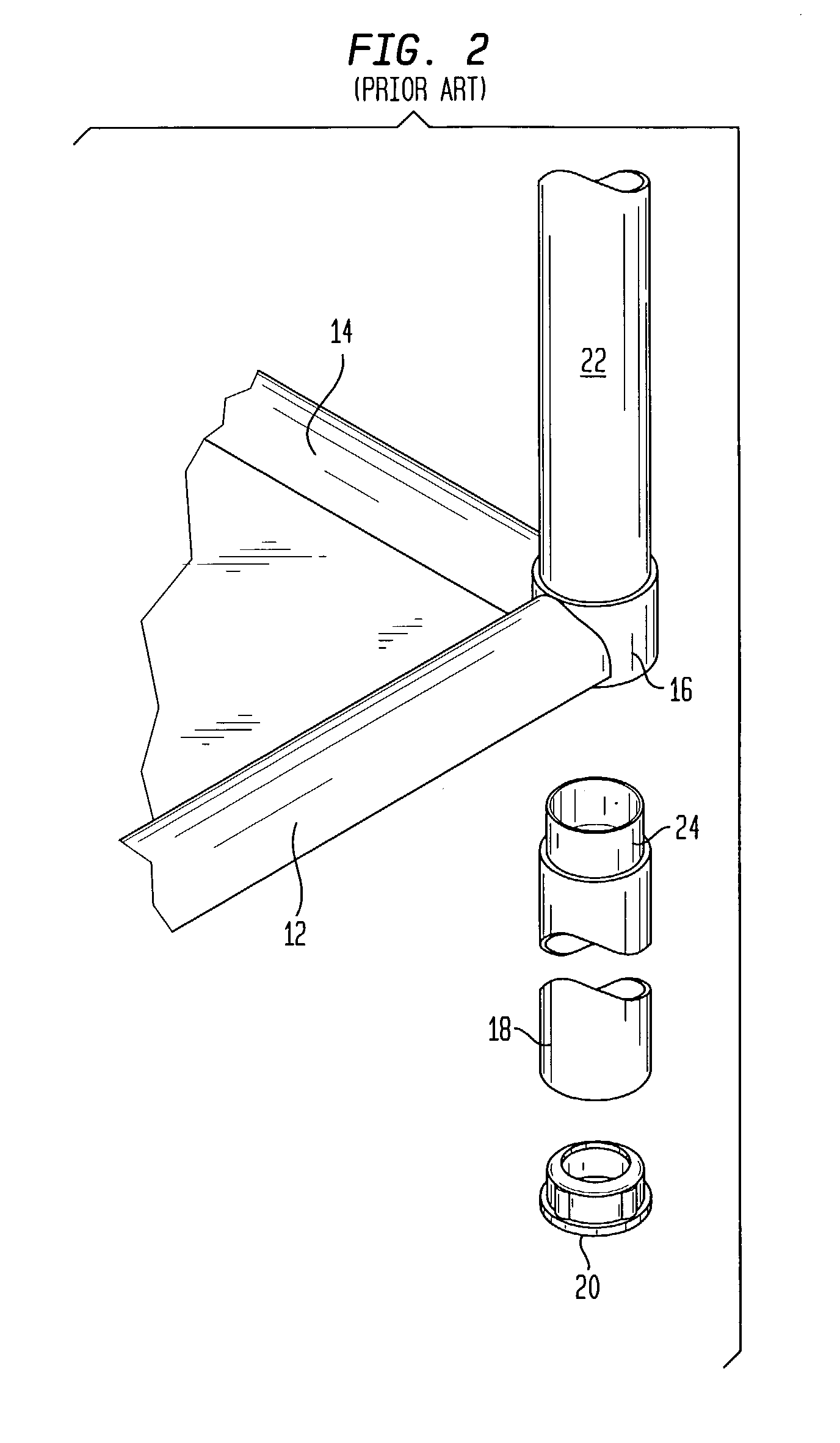

Corner joint and shelf module for use in light-duty all-plastic shelf units

InactiveUS6948435B1Reduce capital investmentCost advantageSectional furnitureDismountable cabinetsComputer moduleEngineering

An all-plastic light duty shelf unit includes rectangular shelf modules and vertical spacers. Each shelf module has four corner joints that can either be mated directly with each other or coupled together using cylindrical vertical spacers. This allows the user to customize the configuration of the shelf unit to meet his or her specific needs. It also reduces the cost to manufacture the shelf unit because the vertical spacers can be extruded rather than injection-molded. The corner joints also hold a shelf off the floor, thereby reducing part count and manufacturing cost.

Owner:HONEYWARE

Bitumen Production-Upgrade with Common or Different Solvents

ActiveUS20060283776A1Reduce operating expensesOperational reliability is increasedWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentFuel oil

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

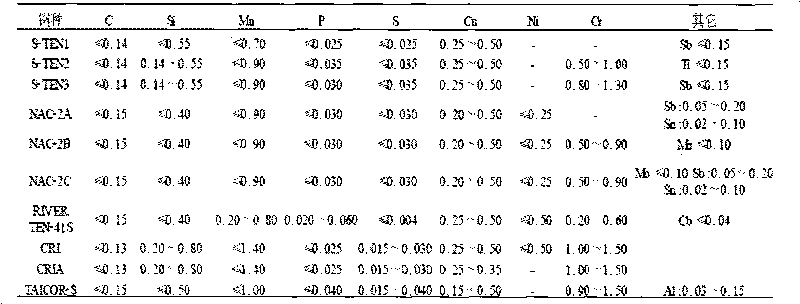

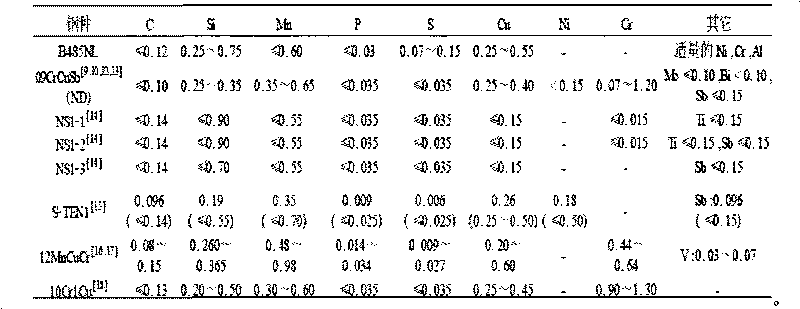

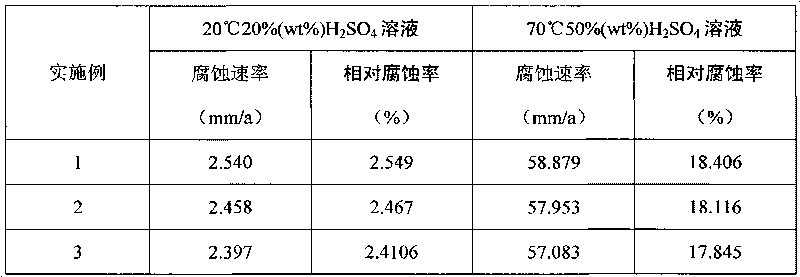

Sulphuric acid dew point corrosion resisting steel and method for producing same

InactiveCN101736202AShort Cooling IntensityStable temperatureProcess efficiency improvementElectric furnaceChemical compositionMolten steel

The invention discloses sulphuric acid dew point corrosion resisting steel and a method for producing the same by continuously casting and rolling a thin steel billet with an electric furnace. The molten steel comprises the following chemical components by weight percent: 0.03-0.08 percent of C, 0.10-0.45 percent of Si, 0.40-1.0 percent of Mn, 0.025 percent of P or less, 0.035 percent of S or less, 0.15-0.50 percent of Cu, 0.40-1.0 percent of Cr, 0.02-0.15 percent of Sb, 0.04-0.30 percent of Ni and 0.01-0.05 percent of Ti and also comprises 100ppm of N or less. The thin steel billet is continuously cast at the speed of 3.5-5.5m / min, and the cast thin steel billet is placed in the electric furnace of 900-1050 DEG C, soaked at 1100-1200 DEG C, rolled at 1040-1120 DEG C, finally rolled at 850-920 DEG C and winded at 550-650 DEG C. The Cu-Cr-Sb composite micro-alloyed sulphuric acid dew point corrosion resisting steel having good mechanical performance, welding performance and corrosion resisting performance can be produced by continuously casting and rolling the thin steel billet with the electric furnace.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

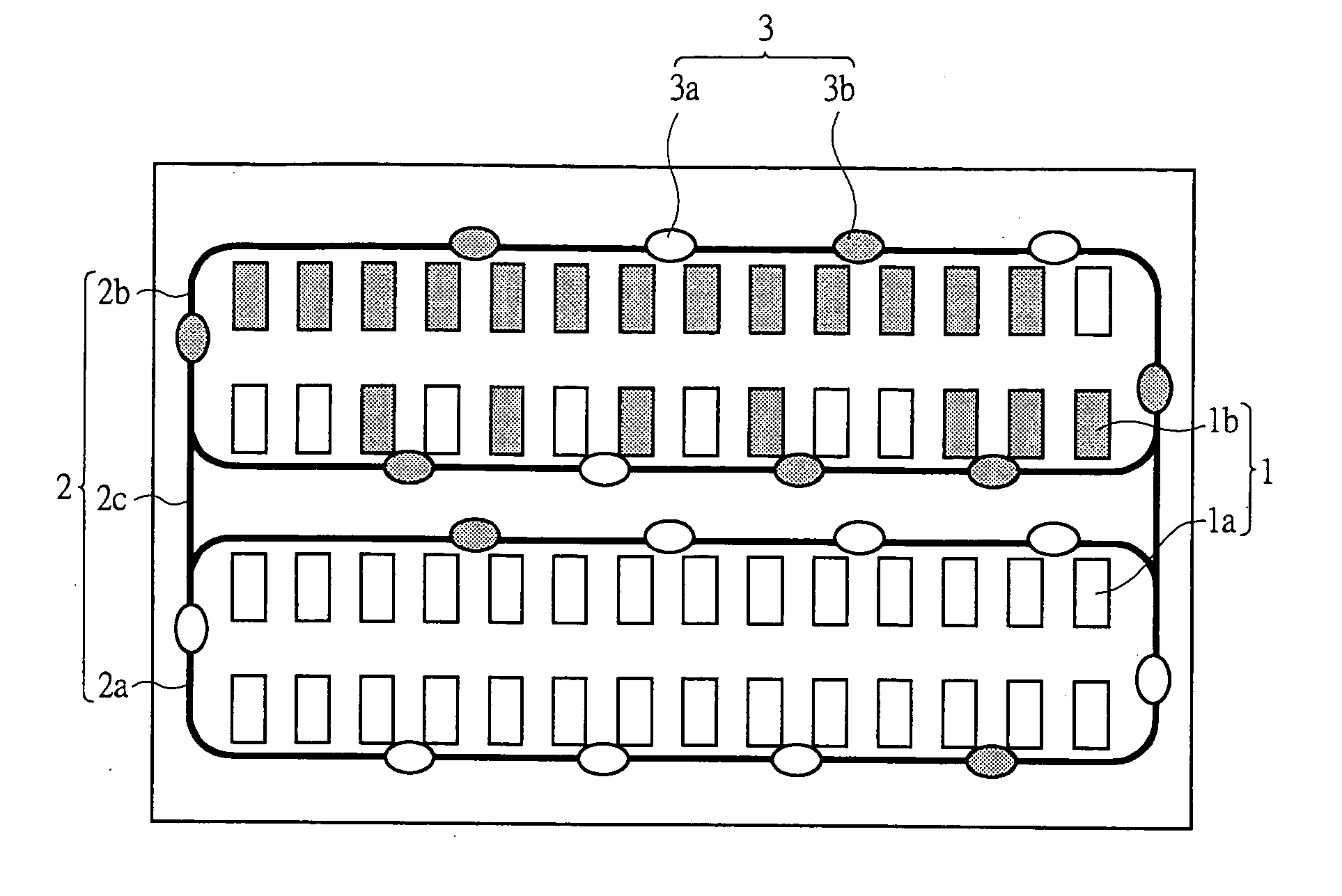

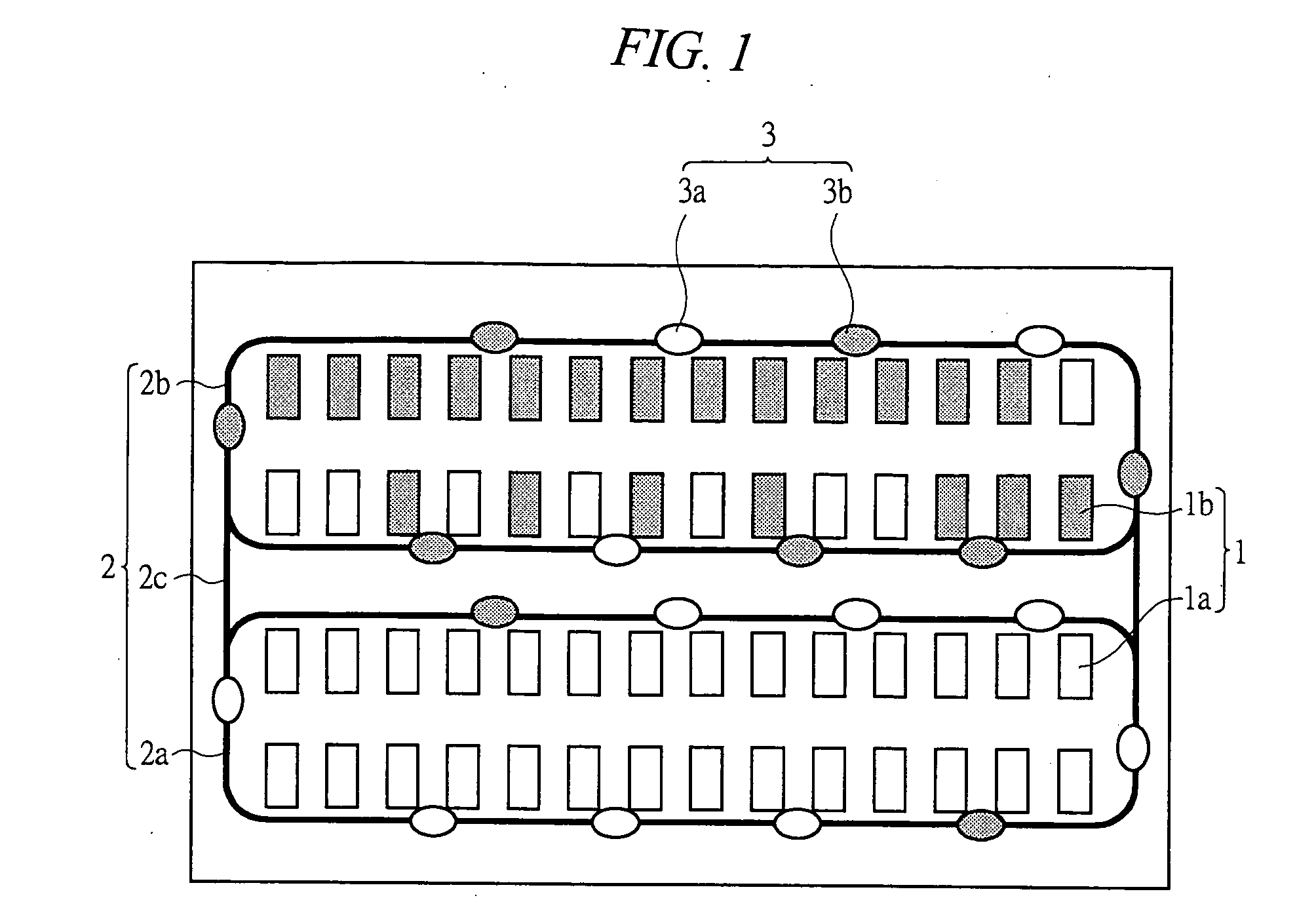

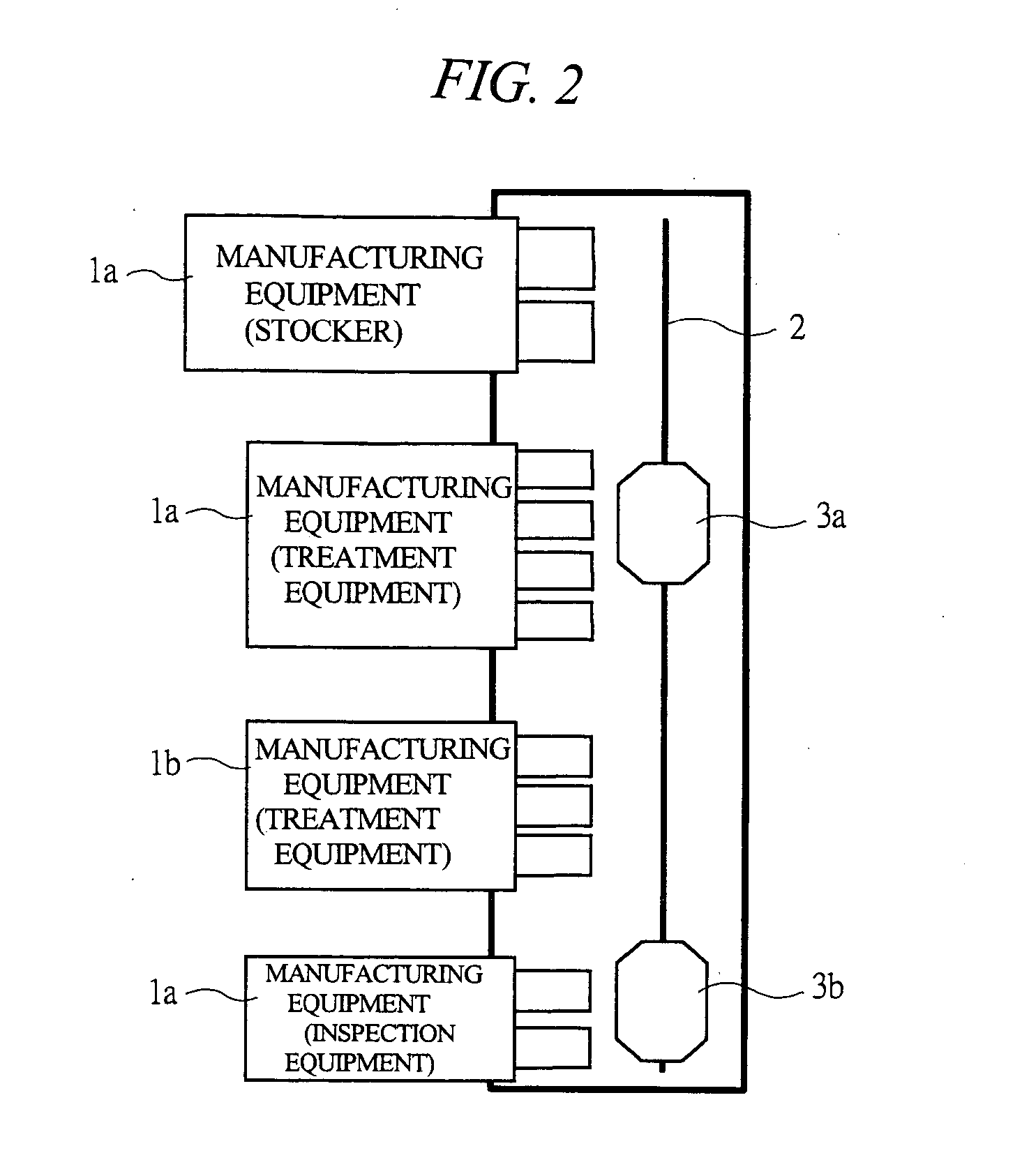

Transfer system and semiconductor manufacturing system

InactiveUS20050005808A1Improve migration abilityEasy to useSemiconductor/solid-state device manufacturingTrain hauling devicesTransfer systemCarrier signal

The present invention provides a transfer technique that can improve the transfer ability when reinforcing and expanding the transfer system, with effectively using the existing system. The transfer system includes tracks that link a plurality of manufacturing equipments, a plurality of carriers having different performances that run on the tracks to transfer objects between the manufacturing equipments and the like in a factory space having a plurality of manufacturing equipments, and the plurality of carriers having different performances are simultaneously provided and run on the same tracks. The plurality of carriers are composed of old carriers and new carriers that provided together and run depending on their own performances (running performance such as running speed, acceleration / deceleration, and the like and transfer performance such as transfer speed and the like).

Owner:TRECENTI TECHNOLOGIES INC

Filled polymer composite and synthetic building material compositions

InactiveUS20060105145A1Improve mechanical propertiesLow costSolid waste managementLayered productsPolyesterFiber

The invention relates to composite compositions having a matrix of polymer networks and dispersed phases of particulate or fibrous materials. The polymer matrix contains a polyurethane network formed by the reaction of a poly- or di-isocyanate and one or more saturated polyether or polyester polyols, and an optional polyisocyanurate network formed by the reaction of optionally added water and isocyanate. The matrix is filled with a particulate phase, which can be selected from one or more of a variety of components, such as fly ash particles, axially oriented fibers, fabrics, chopped random fibers, mineral fibers, ground waste glass, granite dust, or other solid waste materials. The addition of water can also serve to provide a blowing agent to the reaction mixture, resulting in a foamed structure, if such is desired.

Owner:BROWN WADE

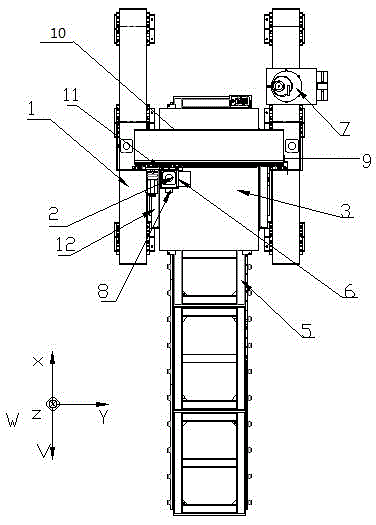

FDM (frequency-division multiplexing) three-dimensional printing and processing all-in-one machine

ActiveCN105328907AReduce capital investmentIncrease productivityAdditive manufacturing apparatusMaterial storage3 dimensional printing

The invention relates to an FDM (frequency-division multiplexing) three-dimensional printing and processing all-in-one machine which comprises a gantry frame, an extrusion mechanism, a traveling rail, a material storage bin and an electric spindle, wherein the travelling rail is laid at the inner periphery of the gantry frame, and is not connected with the inner periphery of the gantry frame; a transfer car is arranged on the traveling rail in a moving mode; the gantry frame comprises an X / Y-axis mobile positioning mechanism and an Z-axis mobile positioning mechanism; the upper end of the side surface of the X / Y-axis mobile positioning mechanism is provided with a side loading mechanism; the X / Y-axis mobile positioning mechanism is provided with an X / Y axis planar moving mechanism; the bottom end of the X / Y axis planar moving mechanism is perpendicularly provided with a printing platform; a slide base is arranged on the X / Y axis planar moving mechanism; the extrusion mechanism is arranged on the slide base; the material storage bin is fixedly arranged on the slide base or the extrusion mechanism; and the electric spindle is fixedly arranged on the slide base or the extrusion mechanism. The FDM three-dimensional printing and processing all-in-one machine has the beneficial effects of reducing capital investment of equipment, improving production efficiency and effectively reducing industrial application cost of FDM three-dimension printing.

Owner:NINGXIA KOCEL MOLD

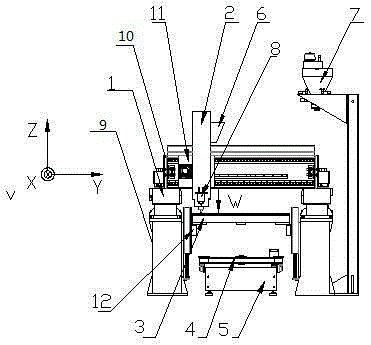

Structured Lipid Compositions And Methods Of Formulation Thereof

ActiveUS20090123634A1High energyIncrease valueFood preparationEdible oils/fats with aqeous phaseTriglycerideWeight management

Lipid compositions comprising specific mixtures of edible synthetic triglycerides are provided that are useful in formulating food products having highly desirable dietary benefits. The novel lipid compositions allow simultaneous access to highly desirable dietary benefits such as delivery of calorie reduction, weight management, health benefits, or any combination thereof, and they also may be formulated trans-fatty acid free.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

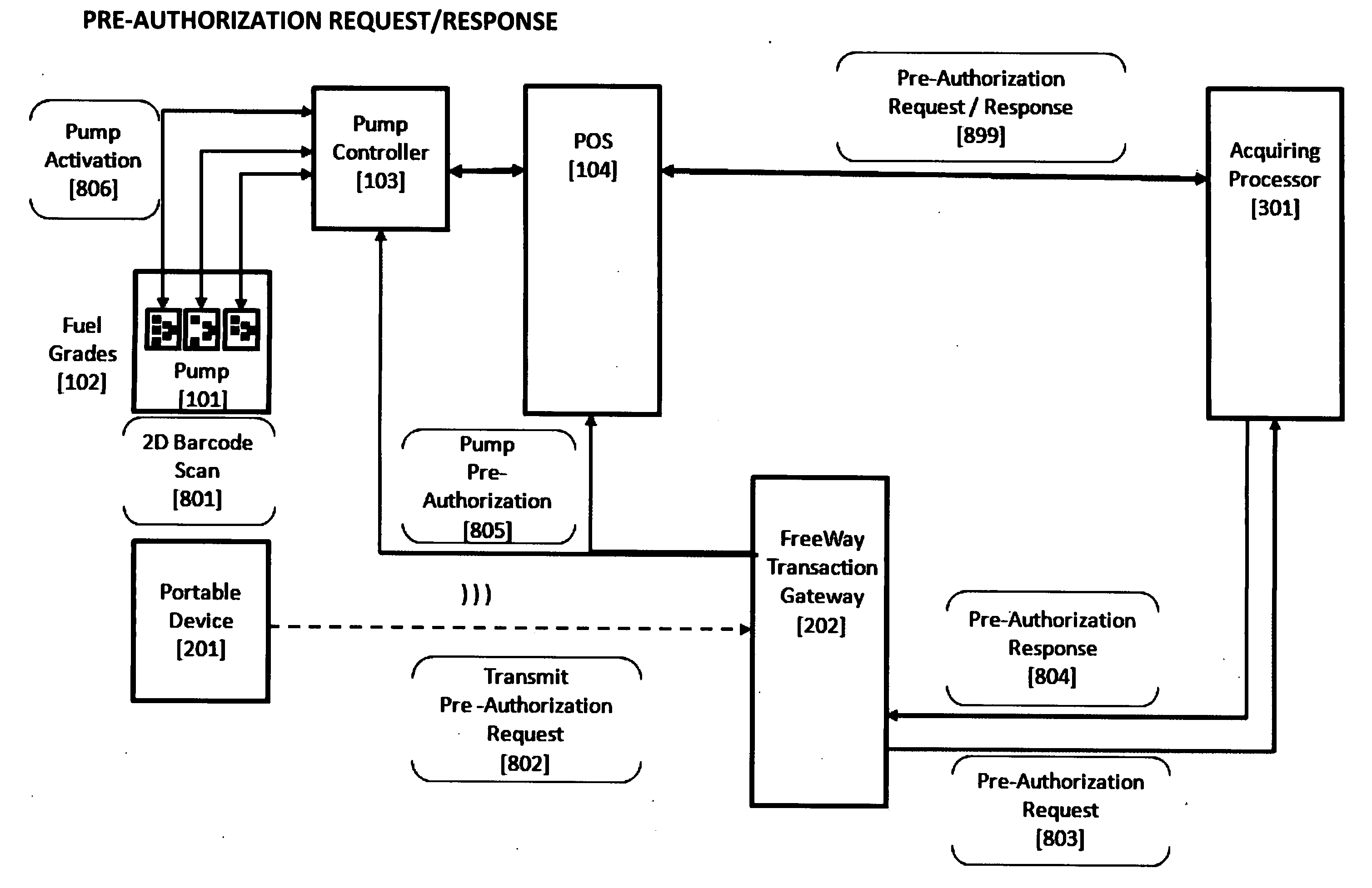

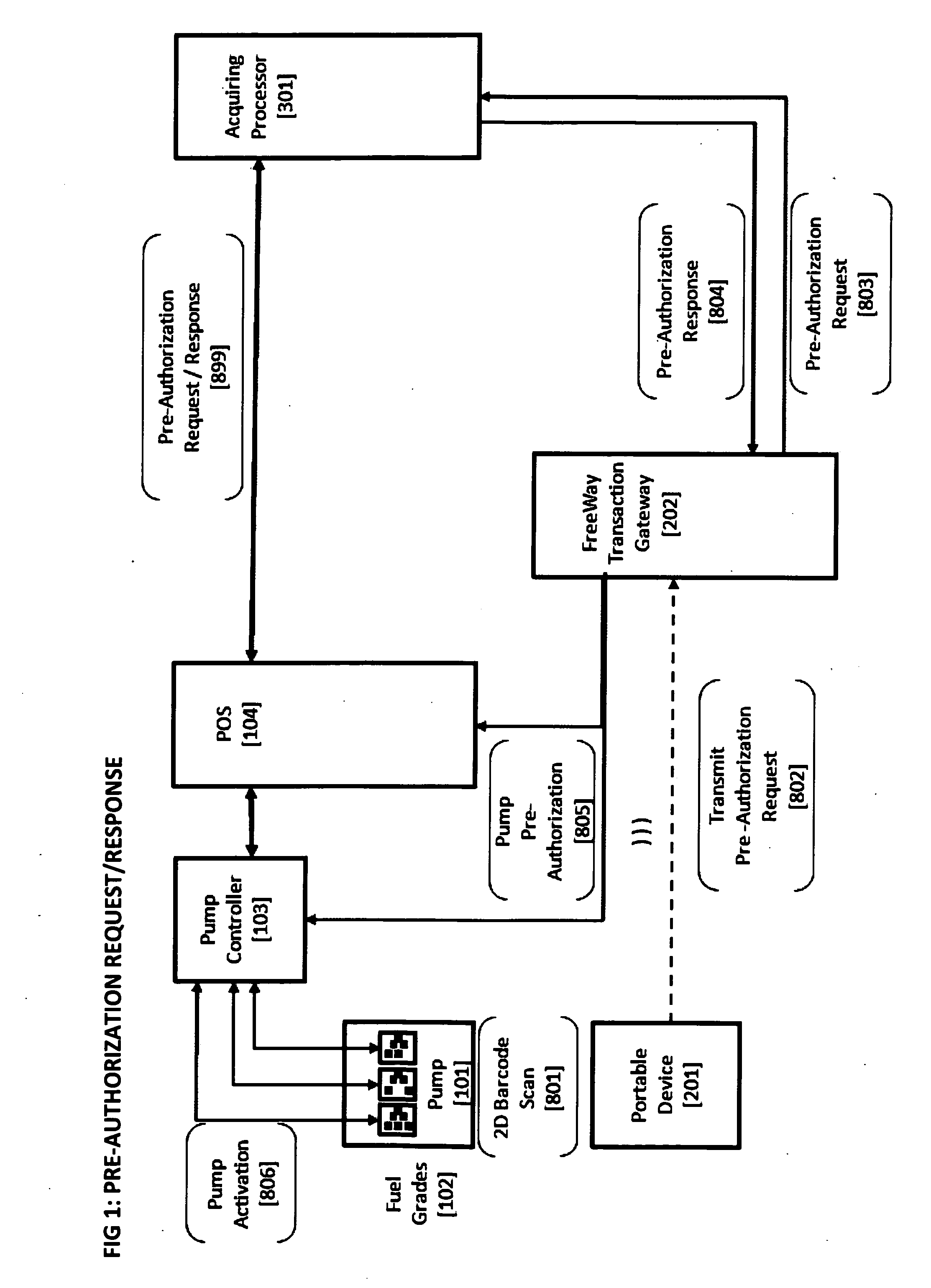

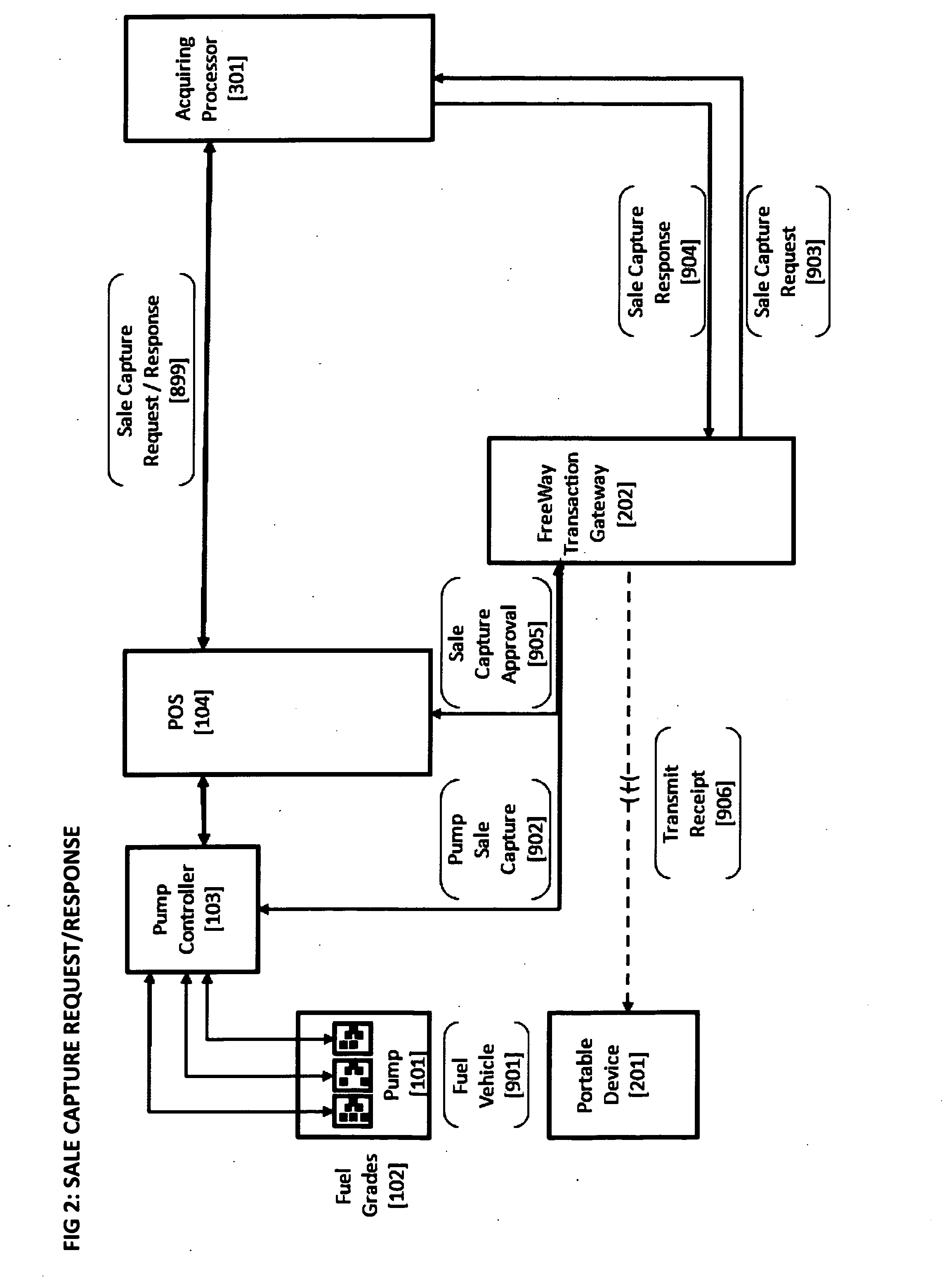

Portable Pay At The Pump

InactiveUS20140172157A1Reduce capital investmentEnvironment safetyCoin-freed apparatus detailsApparatus for dispensing fluids/granular materialsThe InternetEngineering

Present systems utilize a number of various and distinct energy dispensing stations, message controllers, and point-of-sale devices. In traditional systems, the consumer initiates a purchase through direct interaction with the point-of-sale. The proposed system herein functions as software-as-a-service (SaaS) solution for (electronic payment, discounts and loyalty programs. In the proposed system the Consumer initiates the purchase through their mobile device.The Consumer initiates a purchase via a consumer device application. The device captures the dispenser identification, as appropriate. The portable device accumulates the dispenser identification, localized data, and unique mobile data, then securely transmits the data elements to the gateway system via the mobile network, Internet, or private data network requesting a pre-authorization and dispenser activation. The Solution retrieves the pre-authorization and injects the approval into the store-level point-of-sale as typical. The balance of the transaction occurs as with other solutions today.

Owner:BELLAMY III SAMUEL W +1

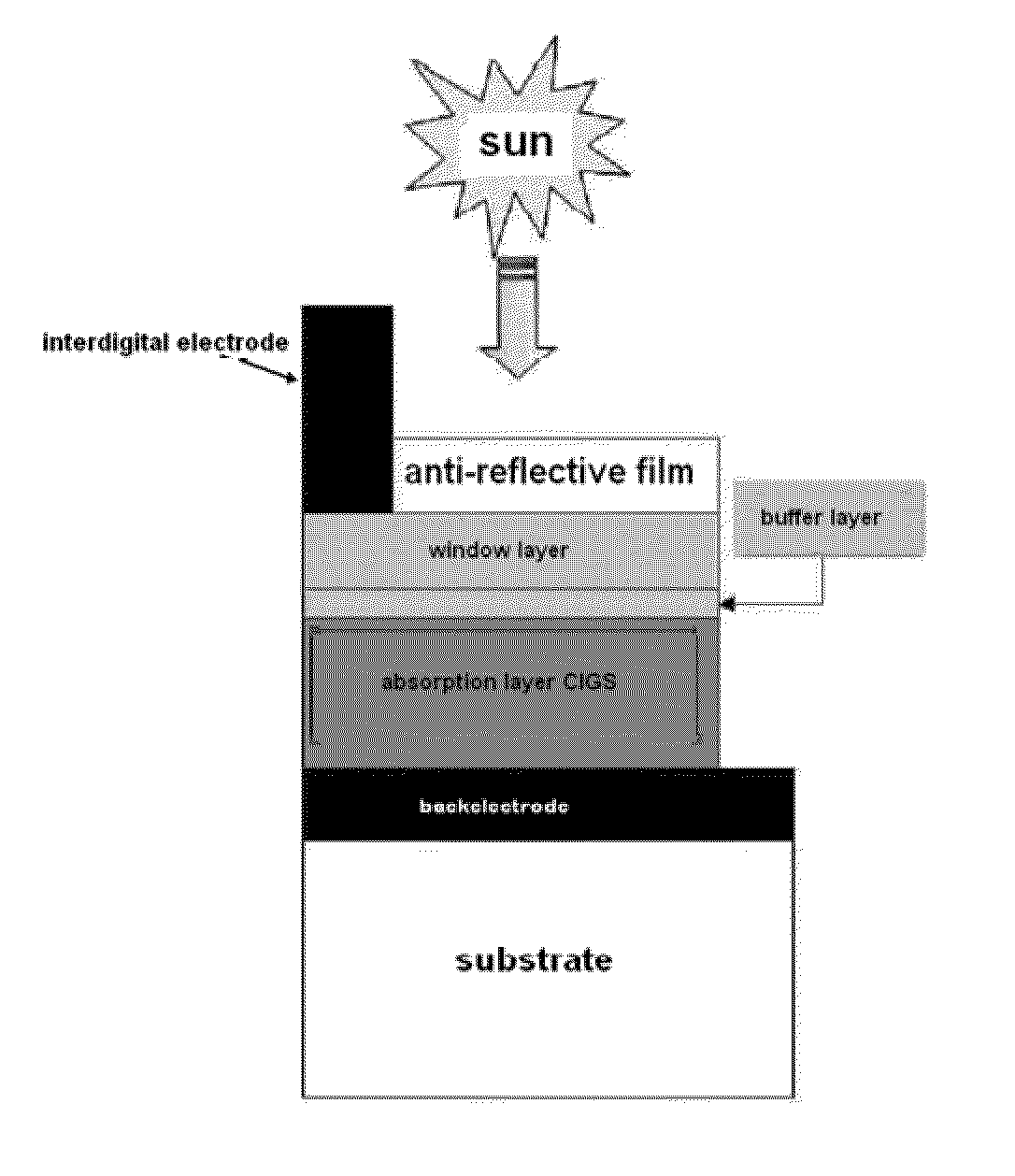

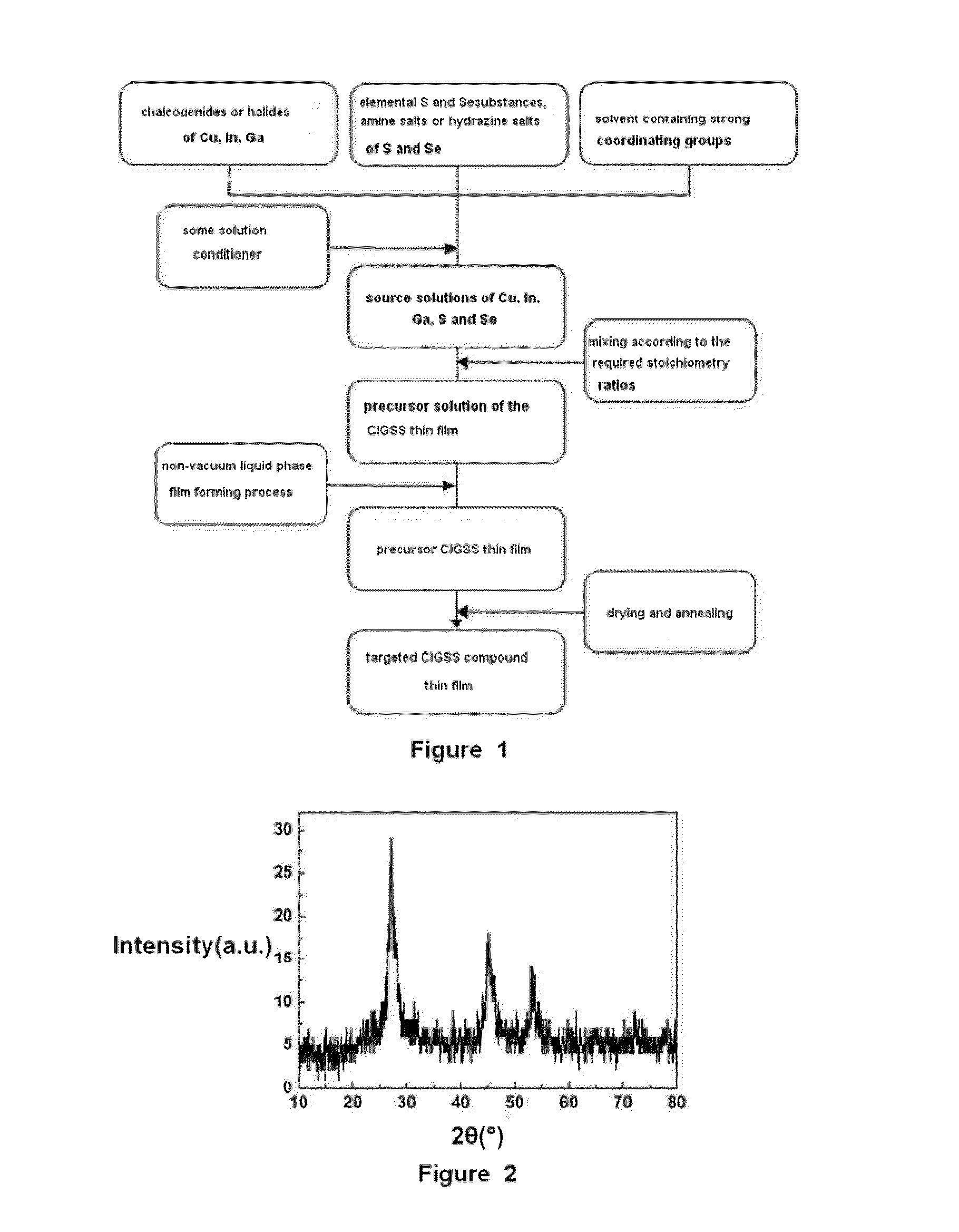

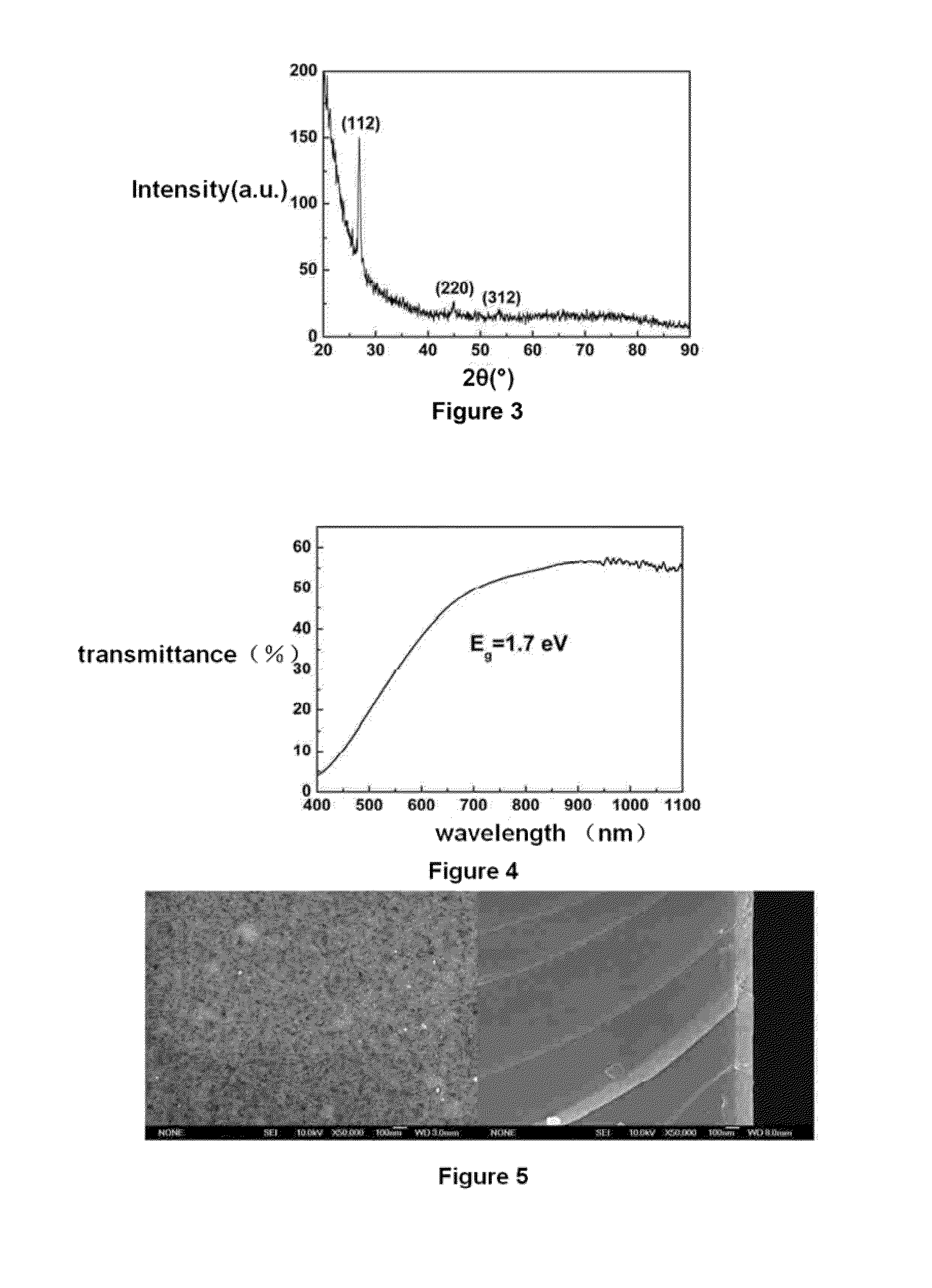

Method for preparing light absorption layer of copper-indium-gallium-sulfur-selenium thin film solar cells

ActiveUS20110008927A1Improve controllabilityLow production costSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumElectrical battery

A preparation method of the light absorption layer of a copper-indium-gallium-sulfur-selenium film solar cell is provided. The method employs a non-vacuum liquid-phase chemical technique, which comprises following steps: forming source solution containing copper, indium, gallium, sulfur and selenium; using the solution to form a precursor film on a substrate by a non-vacuum liquid-phase process; drying and annealing the precursor film. Thus, a compound film of copper-indium-gallium-sulfur-selenium is gained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

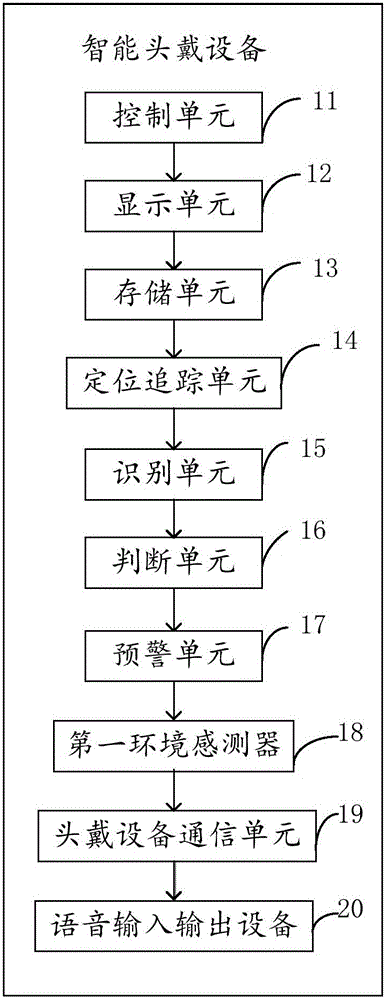

Intelligent head-mounted device and intelligent wearing system

InactiveCN106257356ACultivate professional habitsCultivate good occupational habits of operatorsProgramme control in sequence/logic controllersData informationStorage cell

The invention discloses an intelligent head-mounted device and an intelligent wearing system. intelligent head-mounted device is used for work assisting, and comprises a control unit for controlling the intelligent head-mounted device, a display unit for displaying information for assisting work, a storage unit for storing various data information in the working process, and a positioning and tracking unit for positioning and tracking operators and operation objects respectively and informing the operators of positioned and tracked information. By means of the intelligent head-mounted device and the intelligent wearing system, operation steps and processes can be standardized, violation operation is avoided, the work efficiency of the operators is improved, and cost is saved.

Owner:SHENZHEN AUGMENTED REALITY TECH CO LTD

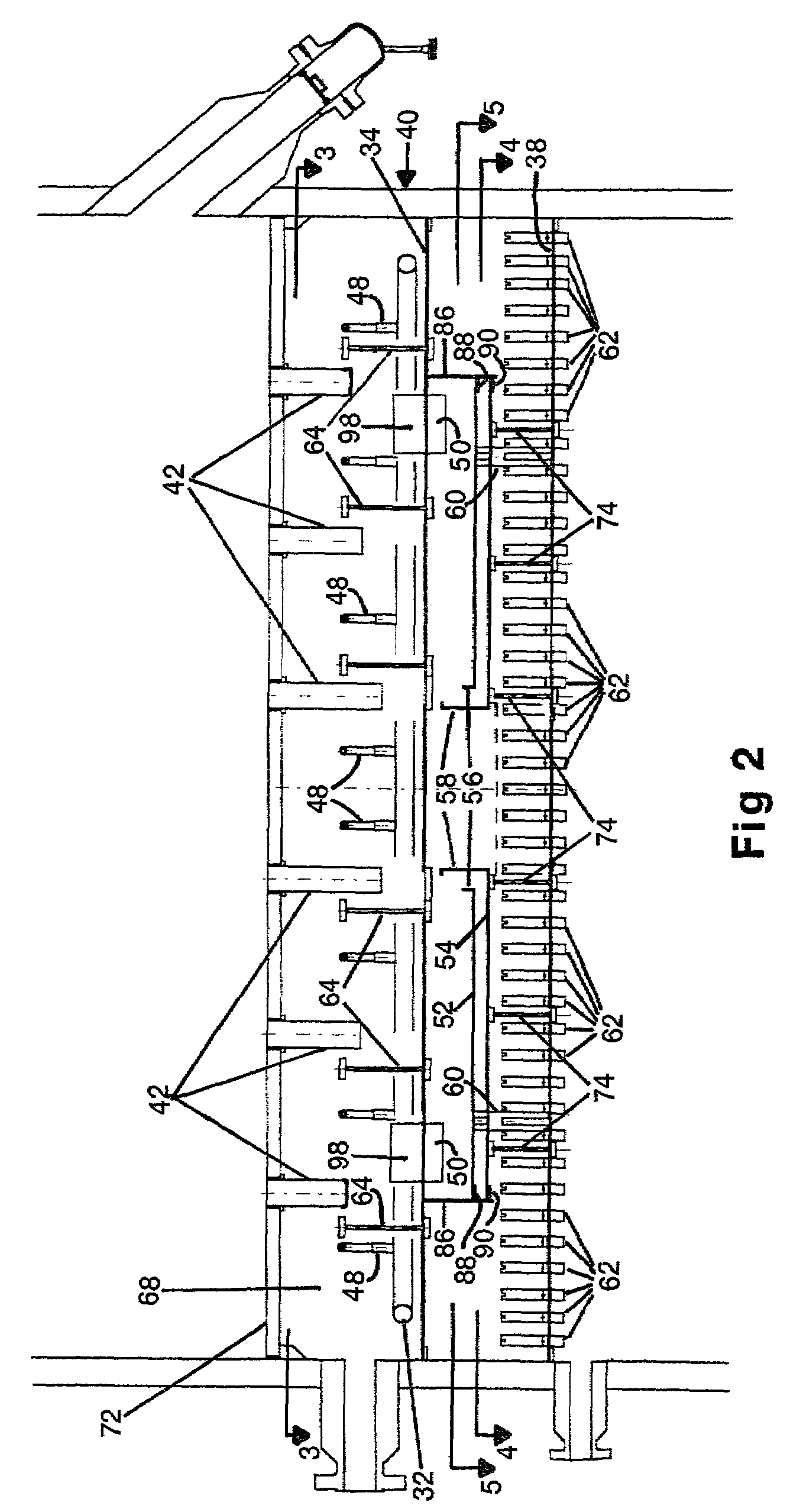

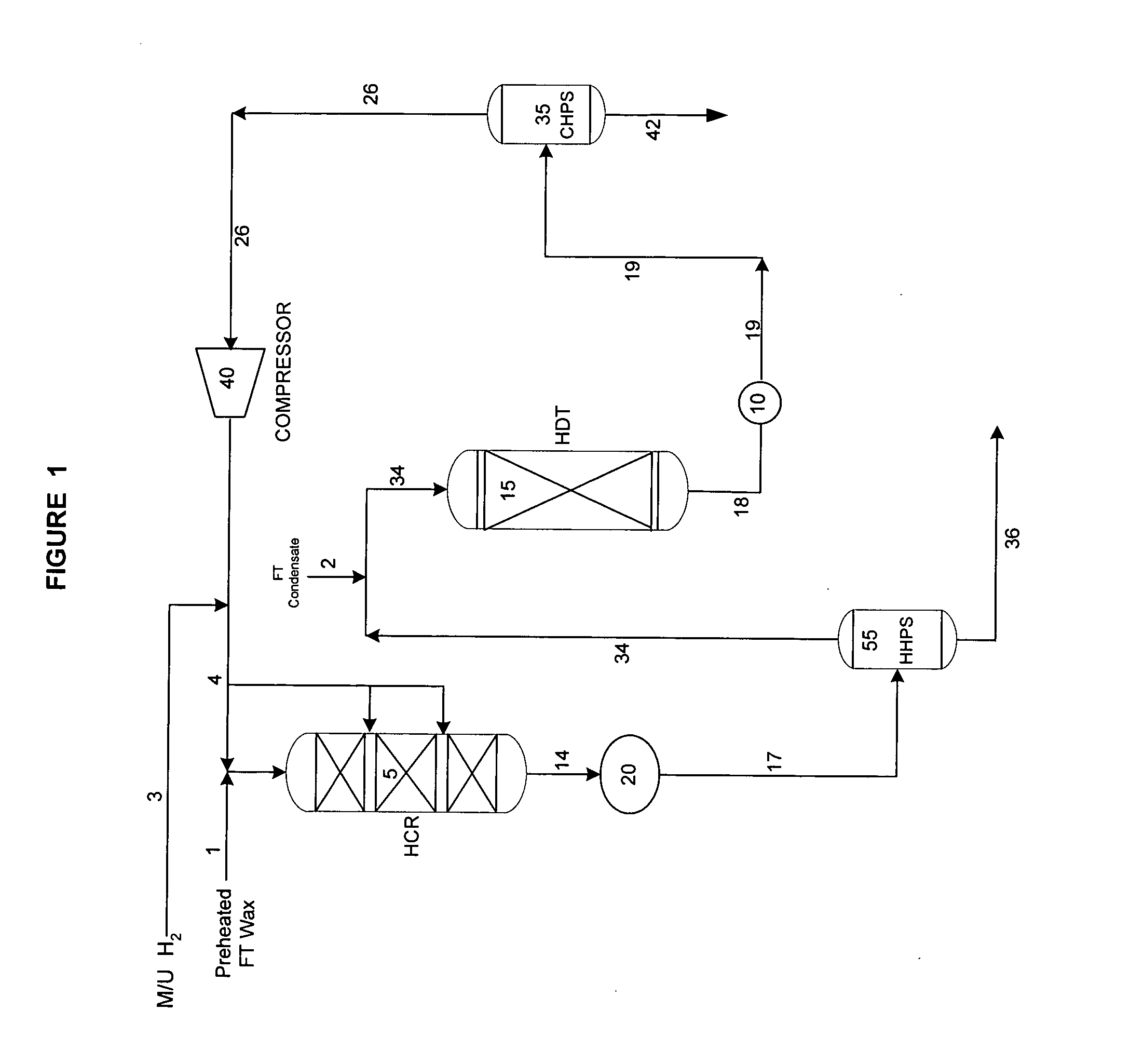

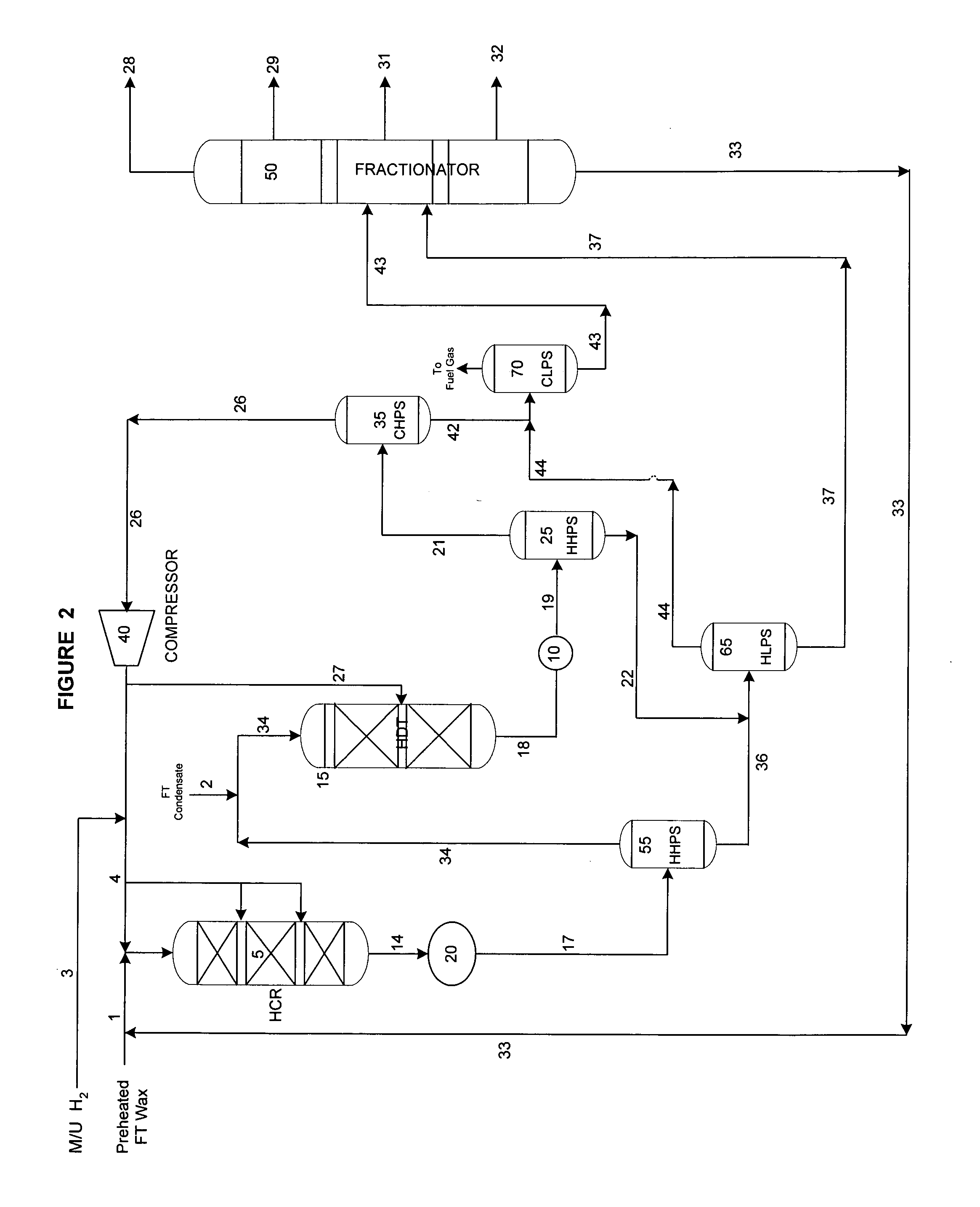

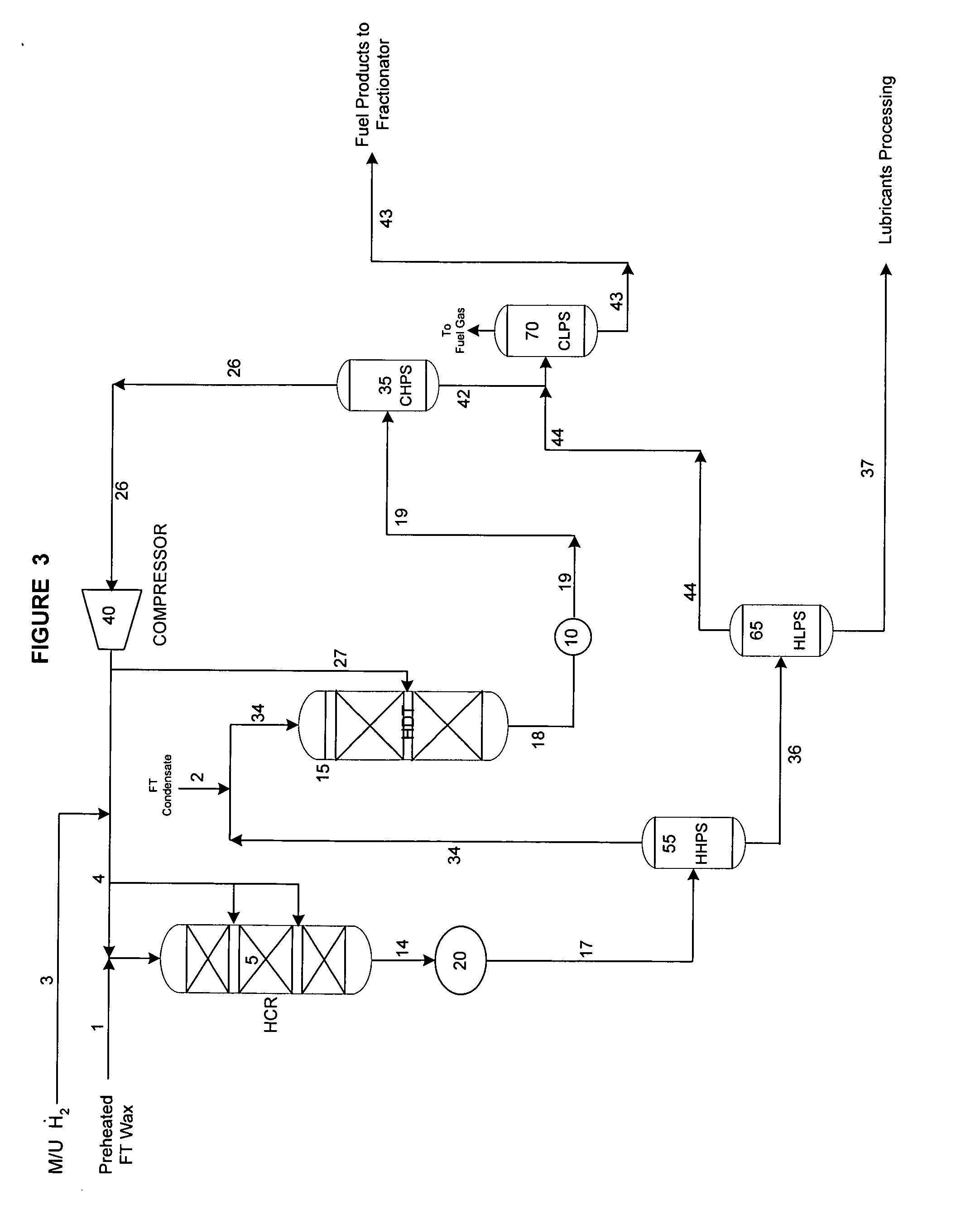

Process for the upgrading of the products of Fischer-Tropsch processes

ActiveUS20050103683A1Reduce capital investmentIncrease productionThermal non-catalytic crackingOrganic compounds purification/separation/stabilisationOxygenateChain length

The present invention is directed to a method for hydroprocessing Fischer-Tropsch products. The invention in particular relates to an integrated method for producing liquid fuels from a hydrocarbon stream provided by Fischer-Tropsch synthesis. The method involves separating the Fischer-Tropsch products into a light fraction (FT condensate) and a heavy fraction. The heavy fraction is subjected to hydrocracking conditions, preferably through multiple catalyst beds, to reduce the chain length. The products of the hydrocracking reaction following the last catalyst bed are subjected to a separation step. The lighter material is combined with the Fischer-Tropsch condensate and hydrotreated. The hydrotreatment conditions hydrogenate double bonds, reduce oxygenates to paraffins, and desulfurize and denitrify the products. The heavier material from the separation step is sent to the lube plant for hydroisomerization, or is subjected to subsequent fraction steps to produce fuels and middle distillates.

Owner:CHEVROU USA INC

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS7291259B2Low costSubstantial sulfur removalCatalytic crackingHydrocarbon oils refiningSorbentHydrodesulfurization

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

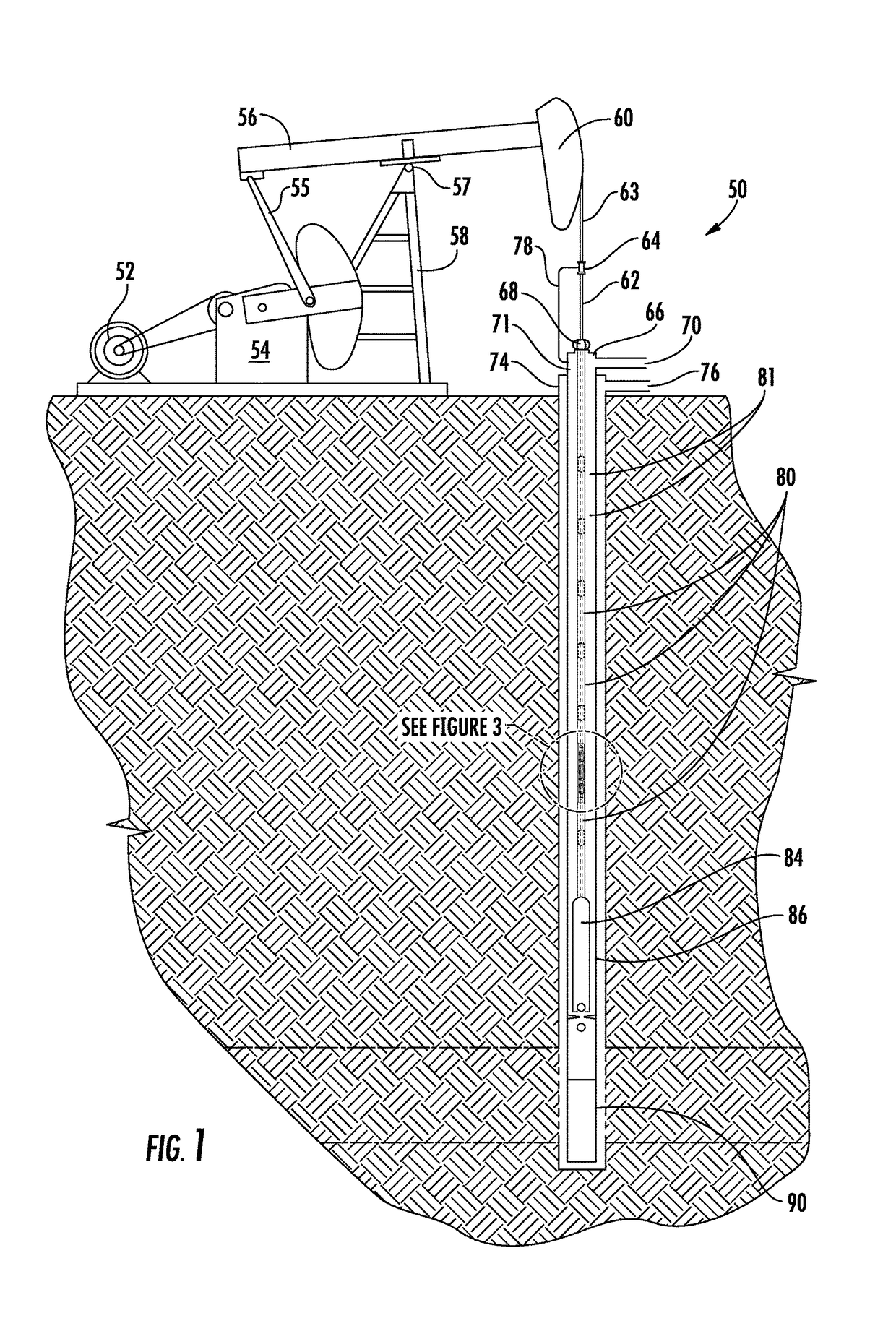

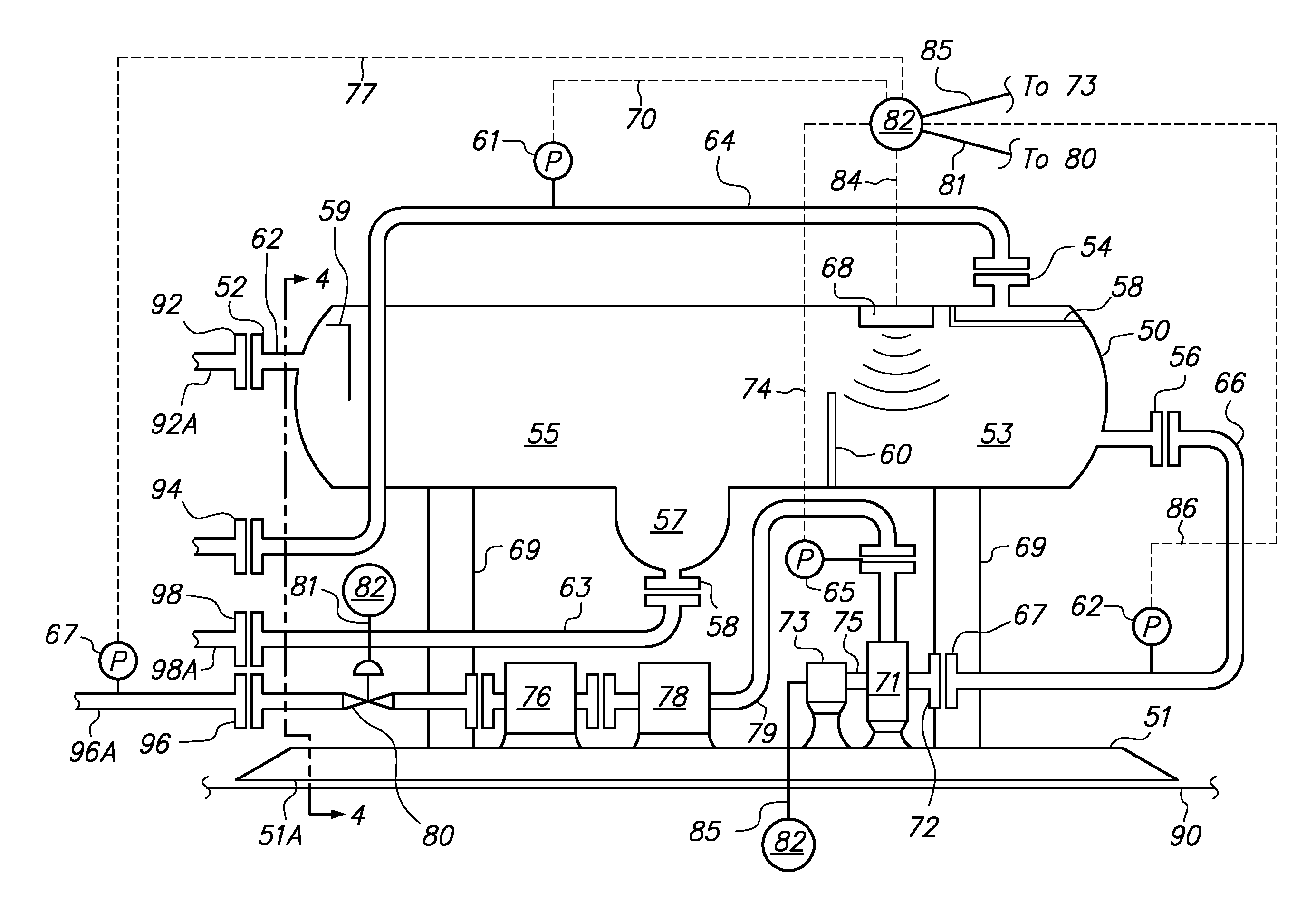

System and method to measure hydrocarbons produced from a well

InactiveUS20160129371A1Accurate measurementReduce capital investmentLiquid separation auxillary apparatusConstructionsEngineeringControl valves

Owner:CROSSSTREAM ENERGY

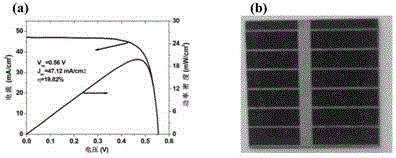

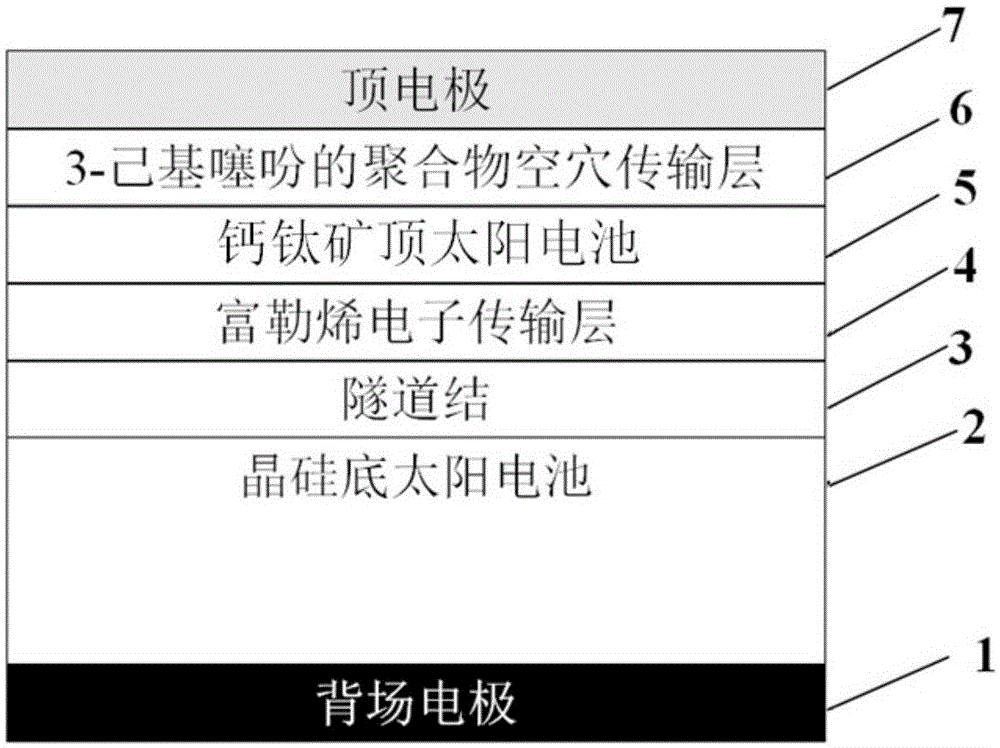

Perovskite-silicon integral cascading and overlapped solar cell and manufacturing method thereof

InactiveCN105023921AReduce capital investmentPromotionFinal product manufactureSolid-state devicesElectron transmissionEtching

The invention discloses a high-efficiency perovskite-silicon integral cascading and overlapped solar cell and a manufacturing method thereof. The solar cell comprises a back field electrode, a crystalline silicon bottom solar cell, a PEDOT:PSS-TIPD tunnel junction, a fullerene electron transmission layer, a perovskite top solar cell, a 3-hexylthiophene polymer hole transporting layer and a top electrode sequentially from bottom to top. The manufacturing method comprises steps: the back field electrode is manufactured by adopting silk-screen printing, magnetron sputtering or thermal evaporation; according to the crystalline silicon bottom solar cell, after etching is carried out by adopting the traditional crystalline silicon solar cell wet etching method, a liquid source diffusion method is then adopted for manufacturing a pn junction; the tunnel junction is manufactured in a method of combining a chemical synthesis method, a spin coating method and a thermal annealing method; the fullerene electron transmission layer is manufactured by adopting a spin coating method; the perovskite top solar cell is manufactured in a method of combining a chemical synthesis method, a spin coating method and a thermal annealing method; the 3-hexylthiophene polymer hole transporting layer is manufactured in a method of combing the spin coating method and the thermal annealing method; and the top electrode is manufactured by adopting a thermal evaporation method or a magnetron sputtering method.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com