Sulphuric acid dew point corrosion resisting steel and method for producing same

A dew point corrosion and sulfuric acid resistance technology, applied in metal rolling, electric furnace, furnace, etc., can solve the problems of no successful experience, high cost, low cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

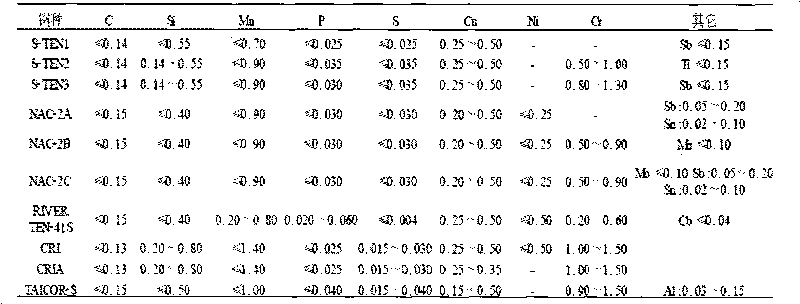

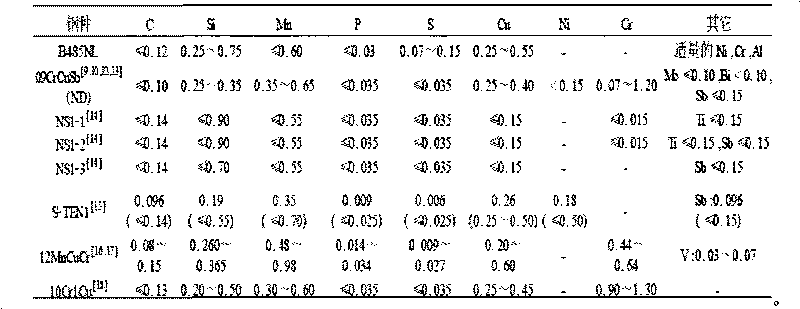

Image

Examples

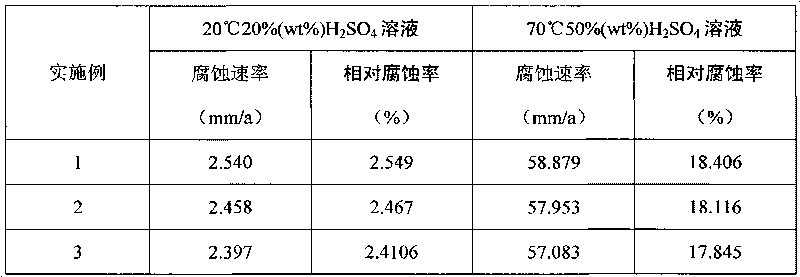

Embodiment 1

[0038] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0039] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.030%, Si: 0.25%, Mn: 1.0%, P: 0.005%, S: 0.004%, Cu: 0.15%, Cr: 1.0 %, Ni: 0.04%, Sb: 0.15%, Ti: 0.010%, N: 10PPm, and the rest is composed of Fe and unavoidable impurities.

[0040] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 3.5m / min, casting slab entering furnace temperature at 900°C, soaking temperature at 1100°C, start rolling temperature at 1040°C, finish rolling temperature at 850°C, The coiling temperature was 550°C.

Embodiment 2

[0042] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0043] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.040%, Si: 0.15%, Mn: 0.45%, P: 0.008%, S: 0.004%, Cu: 0.20%, Cr: 0.45 %, Sb: 0.040%, Ni: 0.08%, Ti: 0.020%, N: 30PPm, Ni / Cu: 0.4, and the rest is composed of Fe and unavoidable impurities.

[0044] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 3.8m / min, slab entering furnace temperature is 920°C, soaking temperature is 1120°C, start rolling temperature is 1060°C, finish rolling temperature is 860°C, The coiling temperature was 560°C.

Embodiment 3

[0046] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0047] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.055%, Si: 0.25%, Mn: 0.65%, P: 0.015%, S: 0.012%, Cu: 0.25%, Cr: 0.65% %, Sb: 0.075%, Ni: 0.125%, Ti: 0.030%, N: 50PPm, Ni / Cu: 0.5, and the rest is composed of Fe and unavoidable impurities.

[0048] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 4.5m / min, casting slab entering furnace temperature at 950°C, soaking temperature at 1150°C, starting rolling temperature at 1080°C, finishing rolling temperature at 900°C, The coiling temperature was 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com