Sulphuric acid dew point corrosion resisting steel and method for producing same

A dew point corrosion, sulfuric acid resistance technology, applied in metal rolling, electric furnace, furnace and other directions, can solve the problem that acid resistance can not fully meet user requirements, low cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

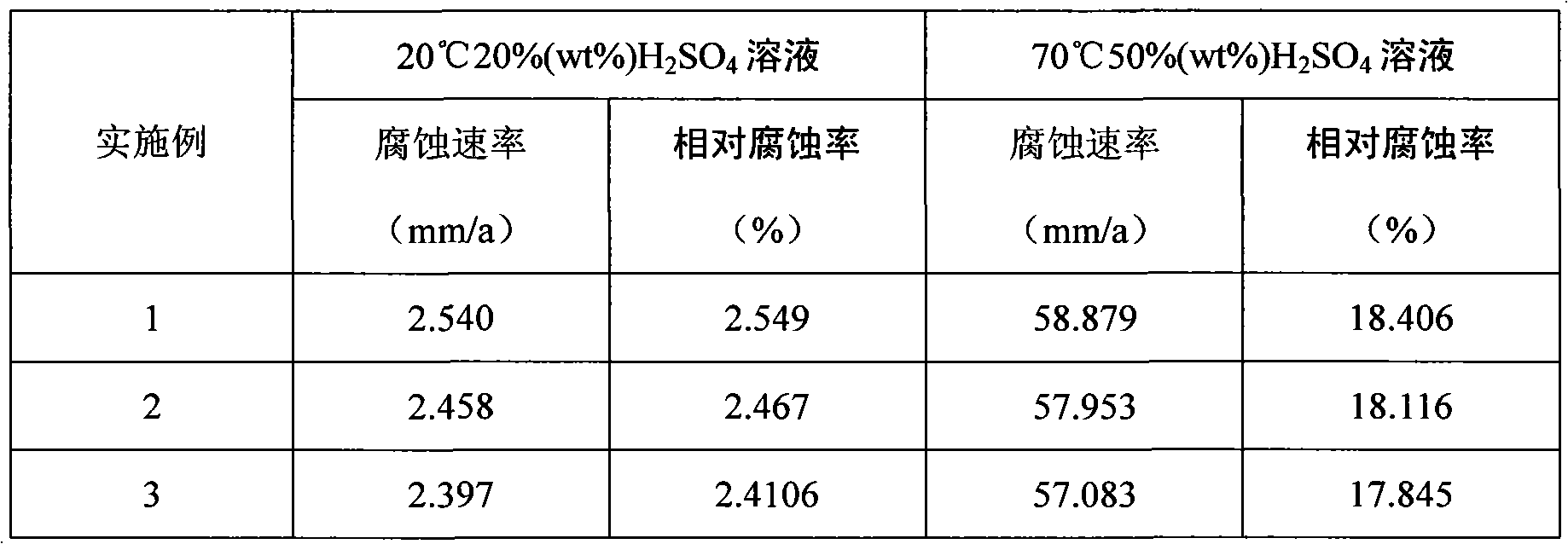

Embodiment 1

[0038] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0039] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.030%, Si: 0.25%, Mn: 1.0%, P: 0.005%, S: 0.004%, Cu: 0.15%, Cr: 1.0 %, Ni: 0.04%, Sb: 0.15%, Ti: 0.010%, N: 10PPm, and the rest is composed of Fe and unavoidable impurities.

[0040] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 3.5m / min, casting slab entering furnace temperature at 900°C, soaking temperature at 1100°C, start rolling temperature at 1040°C, finish rolling temperature at 850°C, The coiling temperature was 550°C.

Embodiment 2

[0042] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0043] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.040%, Si: 0.15%, Mn: 0.45%, P: 0.008%, S: 0.004%, Cu: 0.20%, Cr: 0.45 %, Sb: 0.040%, Ni: 0.08%, Ti: 0.020%, N: 30PPm, Ni / Cu: 0.4, and the rest is composed of Fe and unavoidable impurities.

[0044] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 3.8m / min, slab entering furnace temperature is 920°C, soaking temperature is 1120°C, start rolling temperature is 1060°C, finish rolling temperature is 860°C, The coiling temperature was 560°C.

Embodiment 3

[0046] The preparation method of sulfuric acid dew point corrosion-resistant steel described in this implementation, its technological process: electric furnace with refining furnace smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiling Pick.

[0047] Among them, the main chemical composition of molten steel after refining is mass percentage (wt%): C: 0.055%, Si: 0.25%, Mn: 0.65%, P: 0.015%, S: 0.012%, Cu: 0.25%, Cr: 0.65% %, Sb: 0.075%, Ni: 0.125%, Ti: 0.030%, N: 50PPm, Ni / Cu: 0.5, and the rest is composed of Fe and unavoidable impurities.

[0048] Thin slab continuous casting and rolling process parameters are: continuous casting at a pulling speed of 4.5m / min, casting slab entering furnace temperature at 950°C, soaking temperature at 1150°C, starting rolling temperature at 1080°C, finishing rolling temperature at 900°C, The coiling temperature was 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com