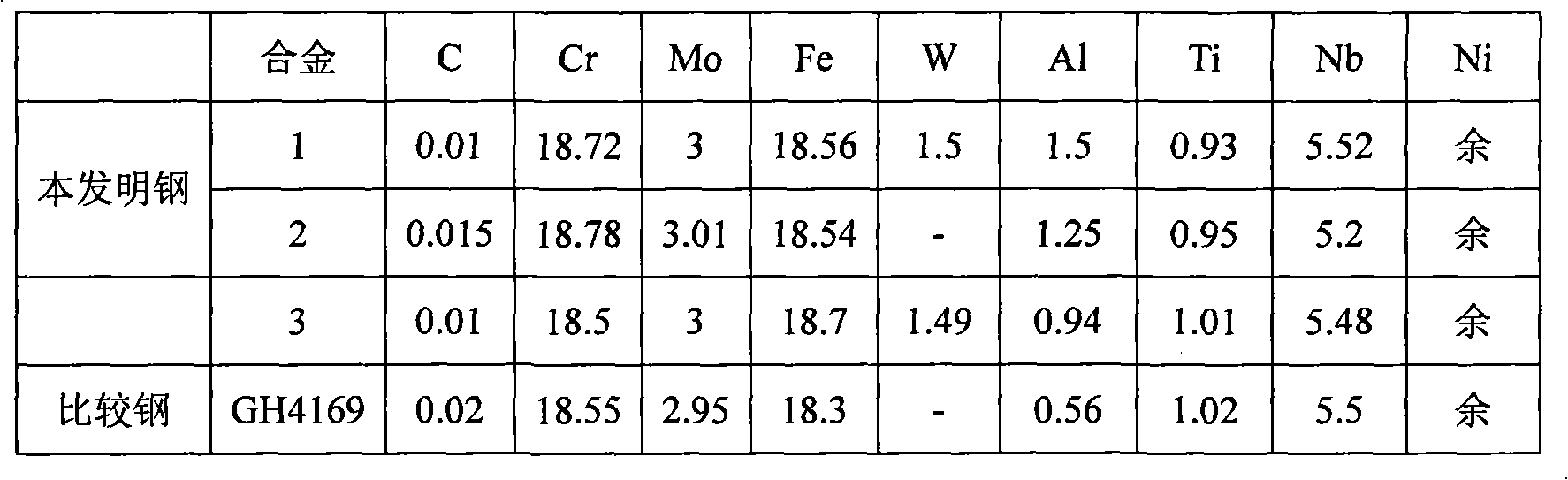

Patents

Literature

523results about How to "Fine and uniform grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

Thick steel plate for nuclear power plant containment and manufacture method thereof

The invention discloses a thick steel plate for a nuclear power plant containment. The nuclear power plant containment is 10-60mm in thickness. The thick steel plate comprises, by mass percent, 0.06-0.15% of C, 0.10-0.40% of Si, 1.0-1.5% of Mn, 0.10-0.30% of Mo, not more than 0.012% of P, not more than 0.003% of S, 0.015-0.050% of Al, 0.20-0.50% of Ni, and at least one of not more than 0.05% of V, not more than 0.03% of Ti, not more than 0.25% of Cr, not more than 0.03% of Nb, and 0.0005-0.0050% of Ca, and the balance Fe and other inevitable impurity. Correspondingly, the invention further discloses a manufacture method of the thick steel plate for the nuclear power plant containment. The thick steel plate for the nuclear power plant containment is high in rigidity, high in toughness, fine in impact toughness of base metal and heat affected zone at low temperature, and suitable for application in the manufacture field of nuclear power plant containments.

Owner:BAOSHAN IRON & STEEL CO LTD

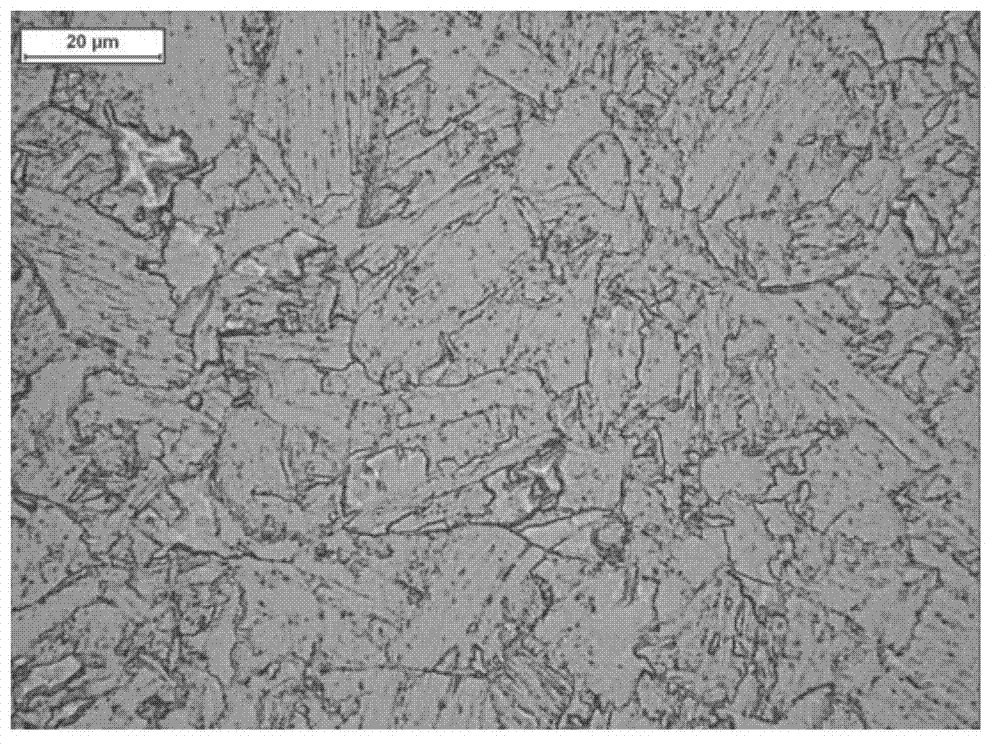

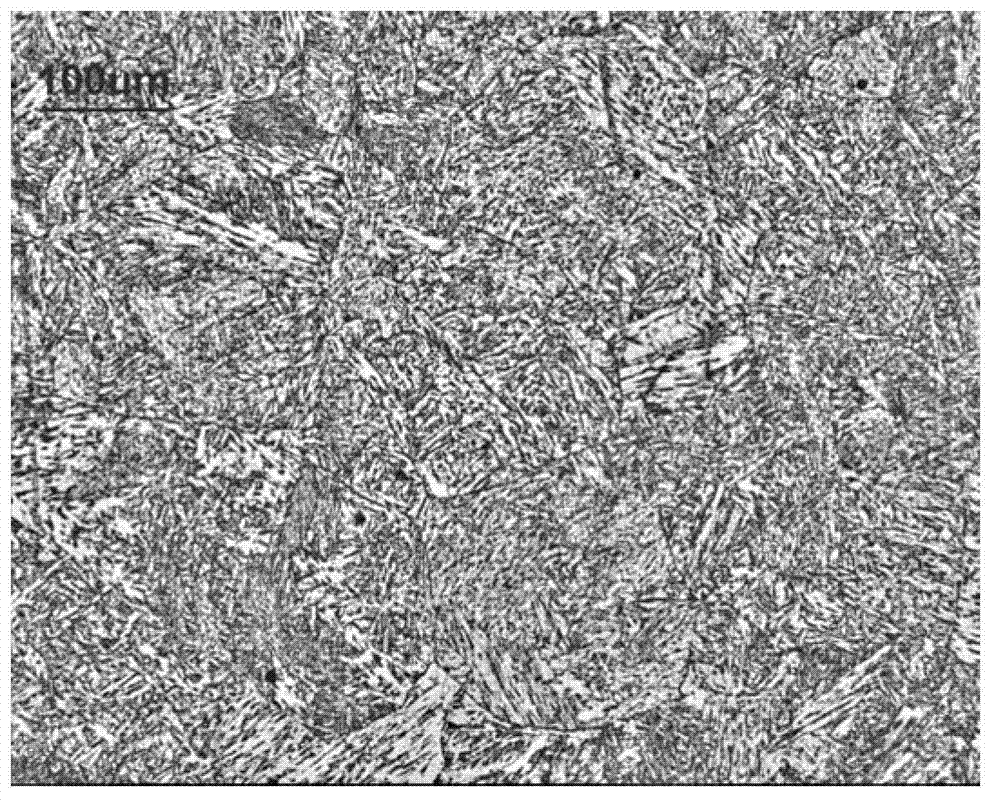

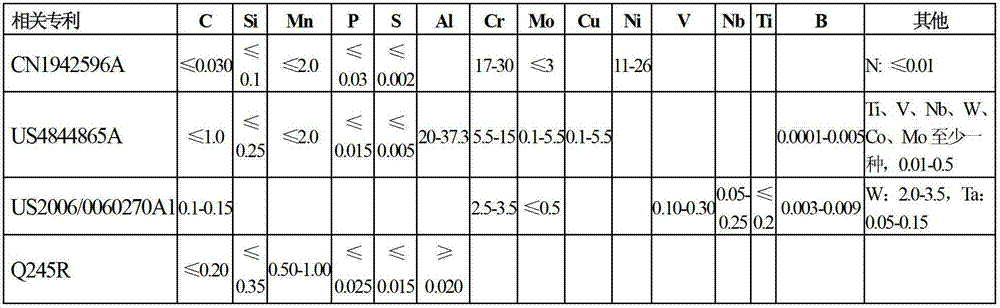

Superfine crystal nickel-based high-temperature alloy and method for preparing same

The invention provides an ultra-fine crystalline nickel base high-temperature alloy and a method for preparing the same, belonging to the high-temperature alloy steel field. The ultra-fine crystalline nickel base high-temperature alloy is particularly applicable to a high-temperature structural component which has high requirement to high-temperature strength and fatigue property, requires superplastic forming and has a complicated structure. The chemical compositions by weight percent of the ultra-fine crystalline nickel base high-temperature alloy are: 17 to 19 percent of Fe, 17 to 20 percent of Cr, 2.8 to 3.3 percent of Mo, 0 to 1.5 percent of W, 0.8 to 1.5 percent of Al, 0.3 to 1.3 percent of Ti, 4.7 to 5.7 percent of Nb, less than or equal to 0.015 percent of C, and the balance being Ni. The preparation method reasonably controls the parameter of a deformation process to allow the deformation temperature to be positioned in a grain boundary precipitated phase region and an austenite phase region which have higher solution temperatures, and uses powerful pinning action of a precipitated phase to the grain boundary to produce the ultra-fine crystalline alloy with a grade of grain fineness of between ASTM12 and ASTM13 grade. Compared with the prior art, the ultra-fine crystalline nickel base high-temperature alloy has simple alloy compositions, greatly reduces the resistance to deformation during forming, has small loss to forging and rolling equipment, and prevents crystal grains from growing when the ultra-fine crystalline nickel base high-temperature alloy is heated for a long time at a high temperature.

Owner:UNIV OF SCI & TECH BEIJING

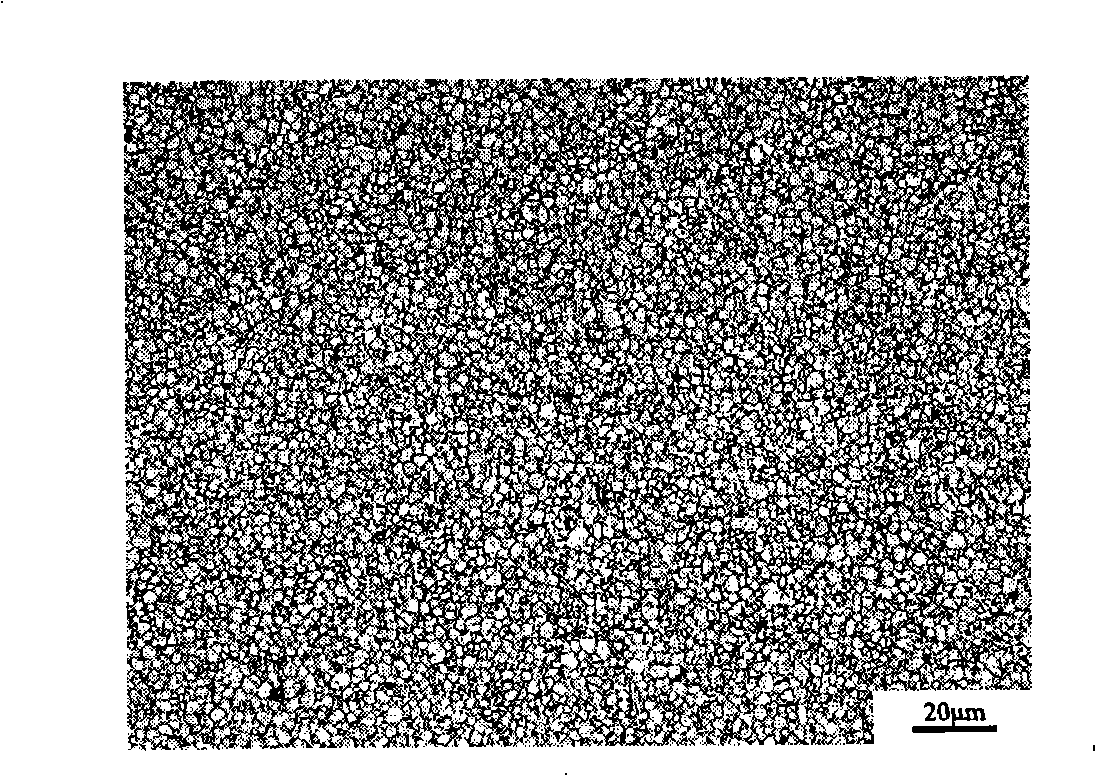

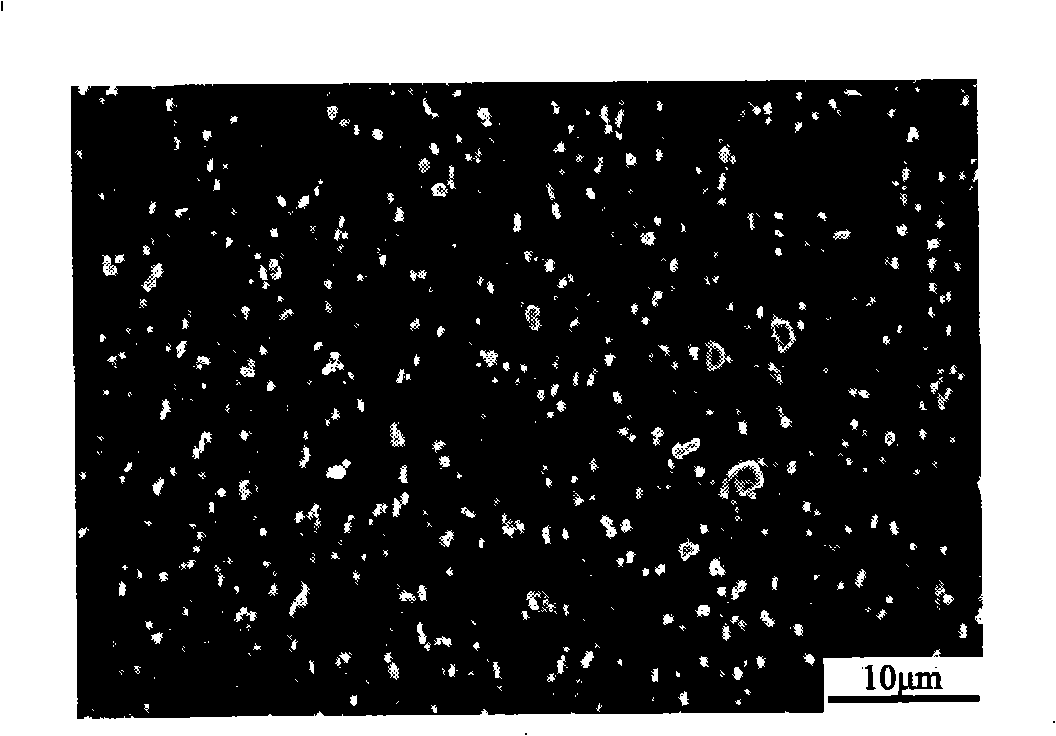

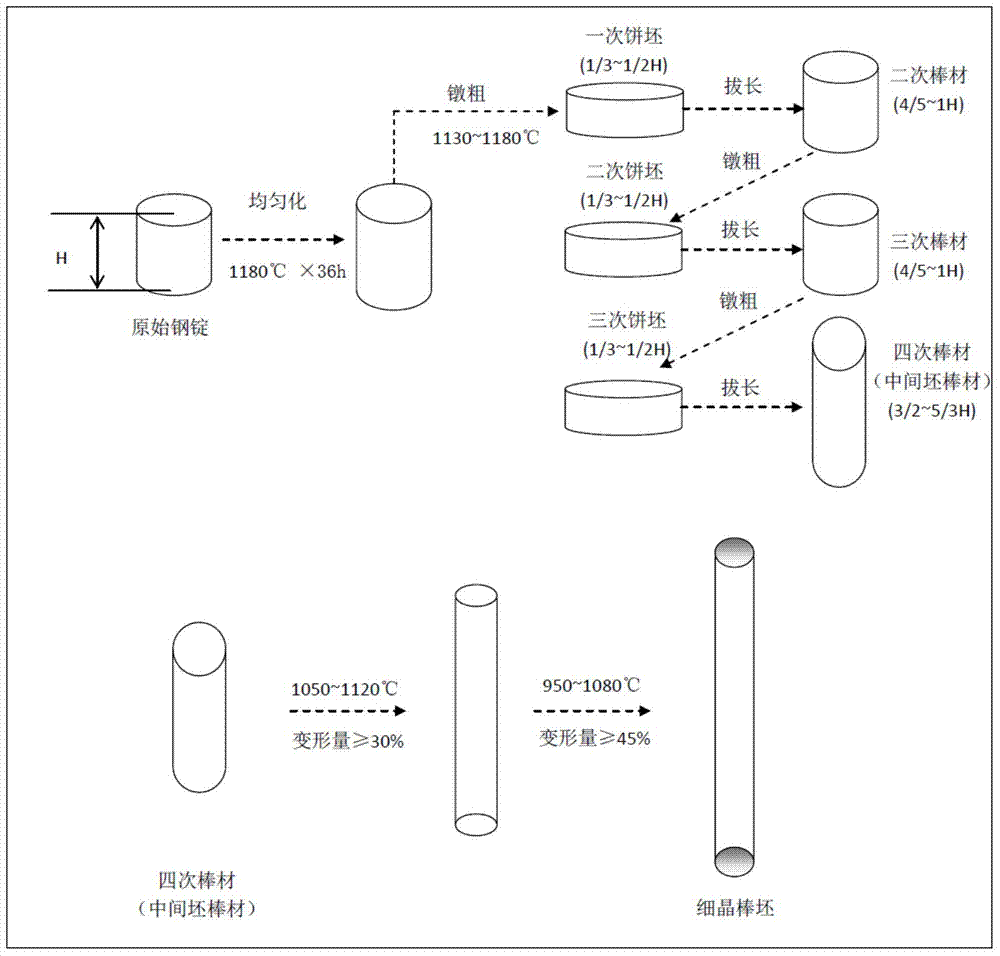

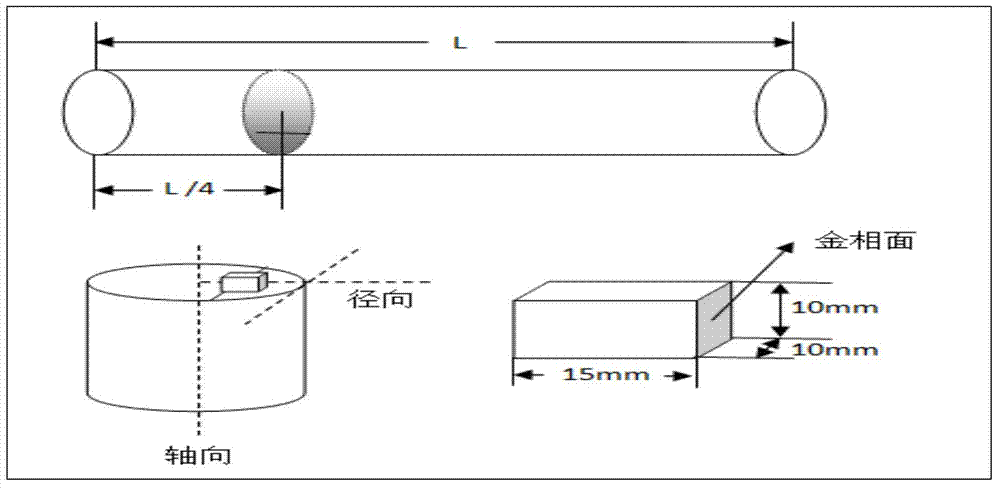

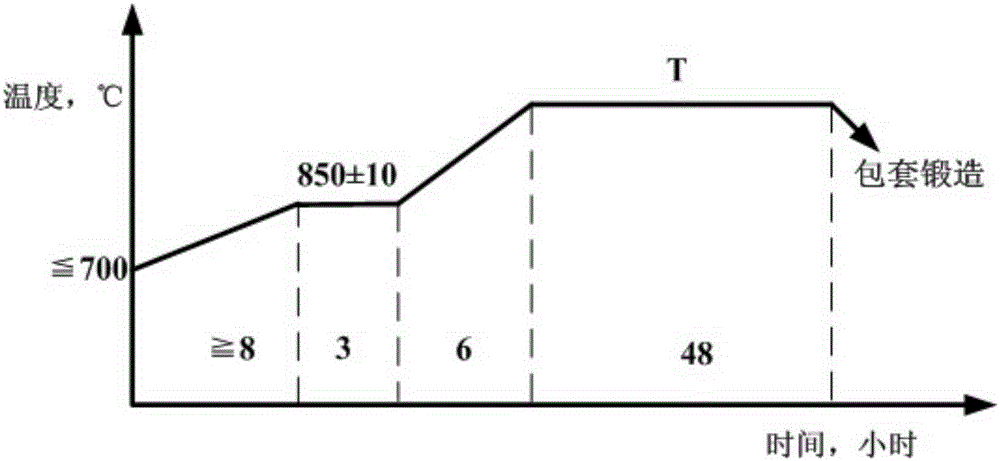

Fine-grain forging method for large-size GH690 nickel-based alloy bar billet

The invention discloses a fine-grain forging method for a large-size GH690 nickel-based alloy bar billet, and belongs to the technical field of forging. By using the composite technology of ingot billet homogenization and classified forging for preparing the GH690 nickel-based alloy bar billet, the grains of the bar billet for forging can be uniform and fine, thus meeting fine-grain structure homogeneity control requirements on final large-size alloy forgings; classified repeated upsetting-stretching cogging is performed on the basis of controlling a deformation temperature and the deformation amount of each heating number, the forgings are formed by hot upsetting by virtue of end part lubrication and horizontal restrain technologies, and rapidly cooled to eliminate grain coarsening caused by deformation heat effect, and finally, the forging structures with uniform carbides and fine grains are obtained.

Owner:CENT IRON & STEEL RES INST

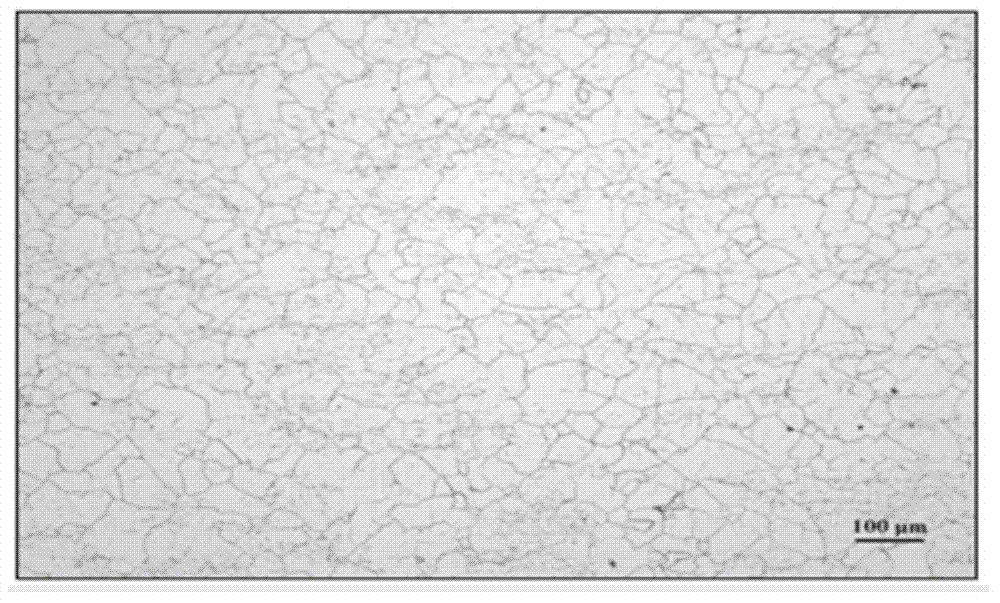

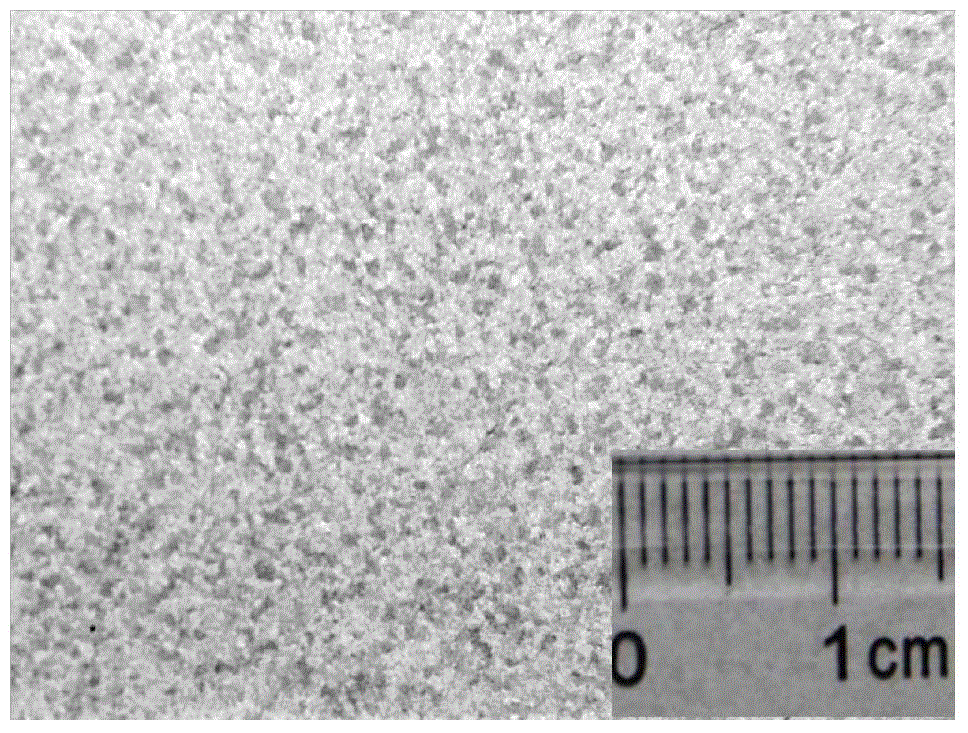

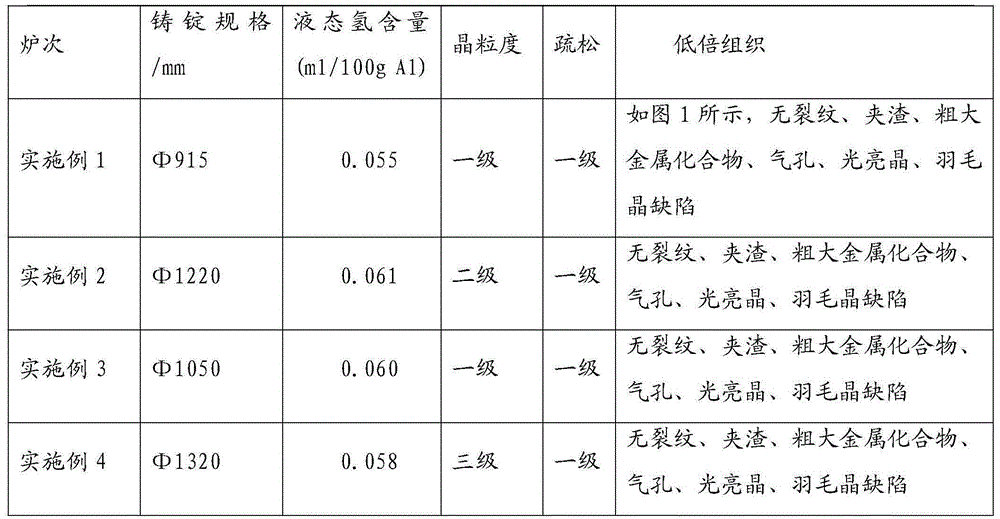

Manufacturing method for 2xxx series ultra-large-dimension aluminum alloy round ingot

The invention discloses a manufacturing method for a 2xxx series ultra-large-dimension aluminum alloy round ingot, and relates to the technical field of aluminum alloy processing. The method comprises the steps of material preparation, smelting, in-furnace refining, online refining, online filtering, semi-continuous casting, homogenization heat treatment, machining and ultrasonic flaw detection. Improvements are made in the aspects of smelting, in-furnace refining, online refining, online filtering, semi-continuous casting and the like, and a method capable of improving the cast ingot quality and improving the production efficiency is provided, so that the cast ingot is fine in tissue, uniform in component and free of other metallurgical defects, and has the specification reaching phi 900 mm to phi 1,340 mm, the grain size capable of reaching a first grade, the hydrogen content not greater than 0.10 ml / 100 g Al and the finished product rate reaching greater than 90%.

Owner:广西南南铝加工有限公司

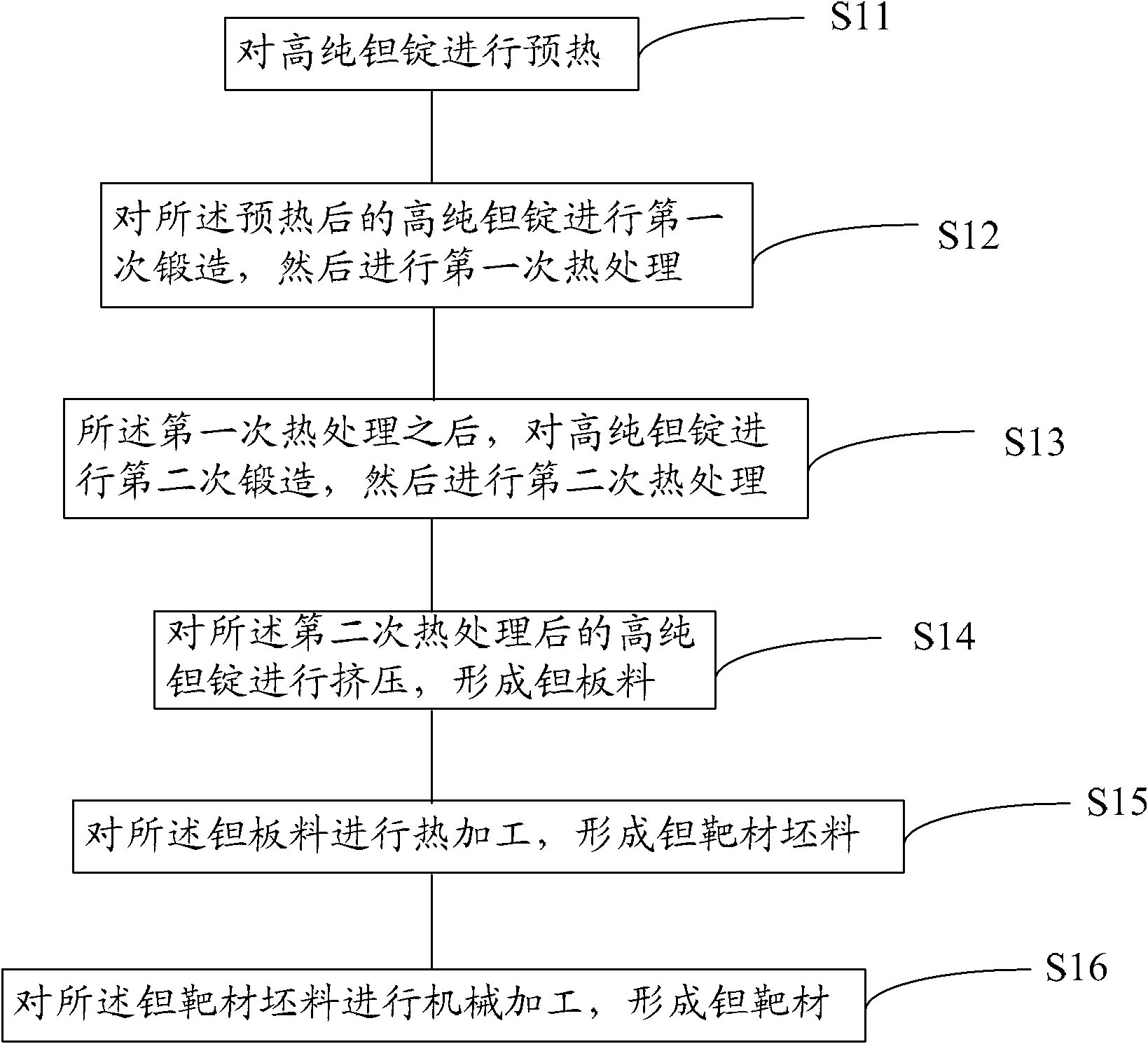

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

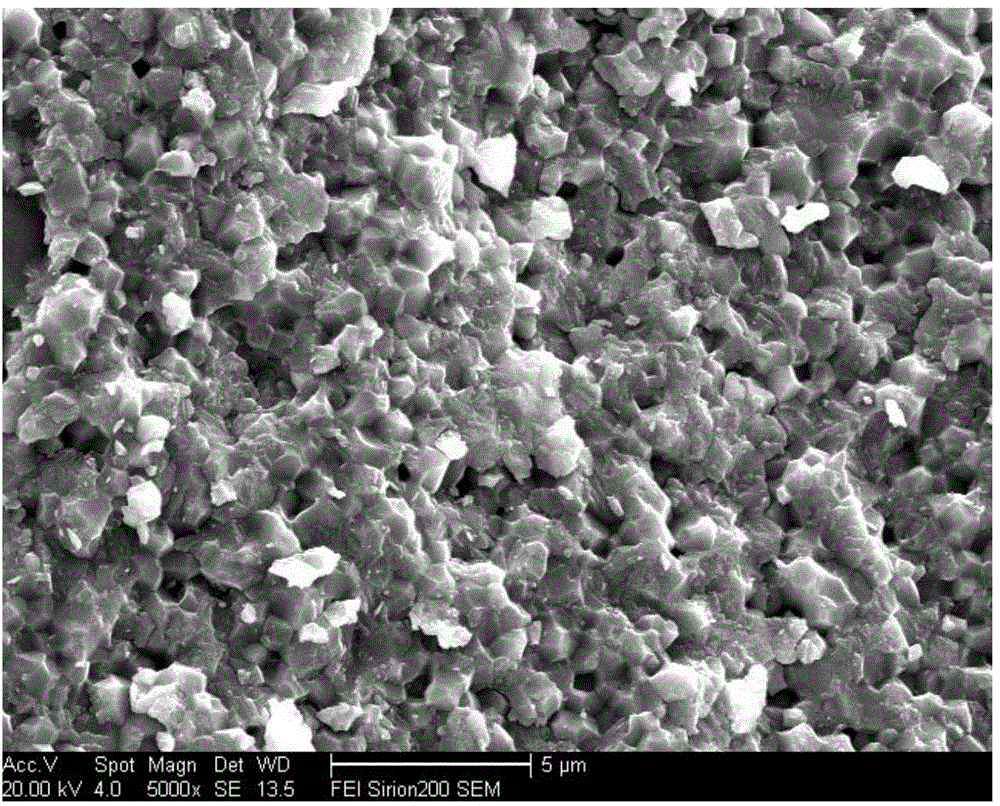

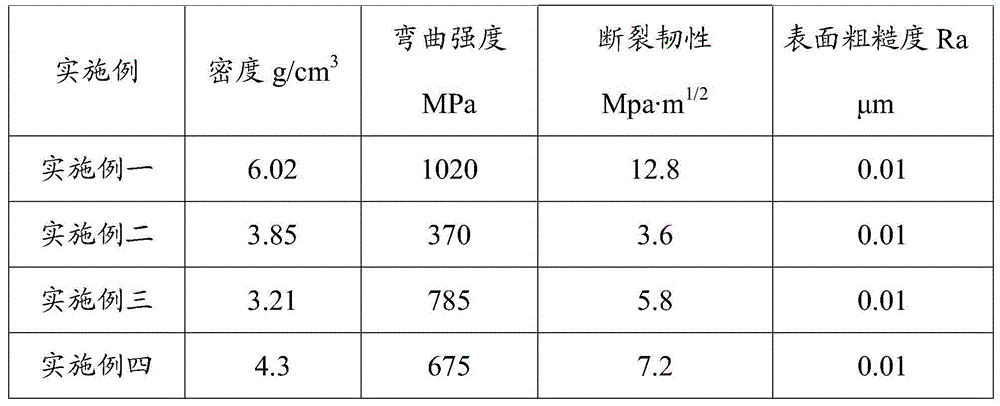

Ceramic mobile phone shell and preparation method thereof

The invention provides a preparation method of a ceramic mobile phone shell. The ceramic mobile phone shell is prepared by initiating the following raw materials with ultraviolet light and further sintering. The raw materials comprise ceramic powder, organic functional additives accounting for 2%-8% of the weight of ceramic powder and solvent accounting for 7%-18% of the weight of ceramic powder, wherein the organic functional additives comprise monomers, cross-linking agent and photoinitiator; the interior of the obtained ceramic mobile phone shell is of a crystal structure, the diameter ratio of maximum grains to minimum grains in the crystal structure is less than 5 and the average grain size is less than 5mu m. According to the ceramic mobile phone shell and the preparation method thereof provided by the embodiment of the invention, the problems of poor performances caused by non-uniform internal structure of a chip type mobile phone shell in the prior art and incapability of obtaining the ceramic mobile phone shell with good mechanical properties, large size and small thickness are solved.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

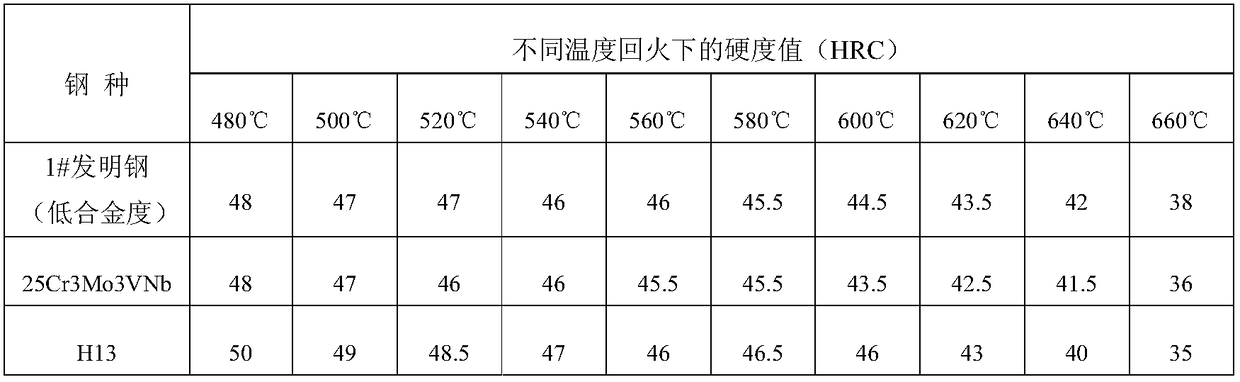

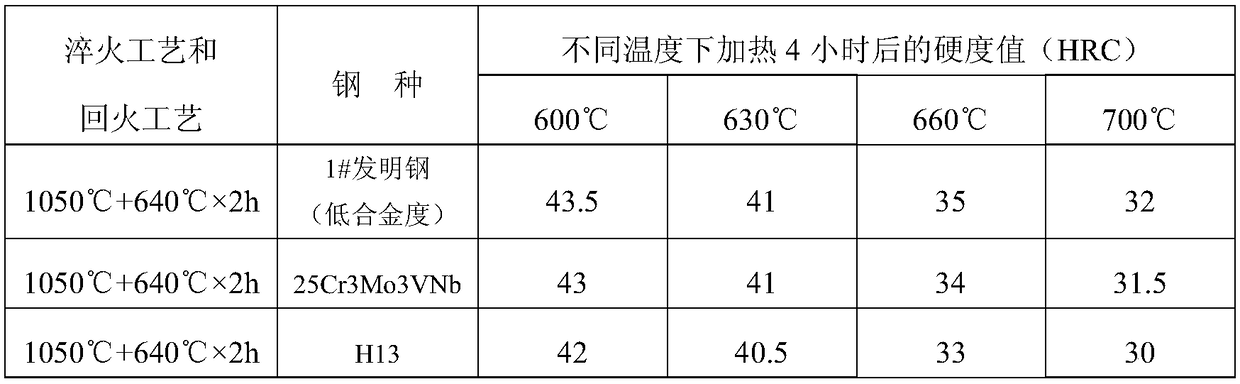

High-temperature, high-strength and low-carbon hot work die steel and preparation method thereof

The invention discloses hot work die steel capable of being used for a long term at the working condition of 600-700 DEG C and belongs to the field of material and preparation. The hot work die steelcomprises the following components in percentage by mass: 0.12-0.30 of C, equal to or less than 0.5 of Si, equal to or less than 0.5 of Mn, 1.0-3.0 of Cr, 1.5-2.5 of Mo, 0.3-1.2 of W, 0.5-1.6 of Ni, 0.2-1.0 of V, 0.03-0.15% of Nb, equal to or less than 0.05 of N, equal to or less than 0.03 of S, equal to or less than 0.03 of P, equal to or less than 3.5 of (Mo+W), equal to or less than 1.0 of (Nb+V) and the balance of Fe and unavoidable impurity elements. According to the hot work die steel, low carbon is adopted to form lath martensite so as to obtain high tenacity at room temperature and lowtemperature; through alloying of Cr, W, Mo, V, Nb and the like and the thermal deformation optimization and thermal treatment technology, solution strengthening is improved and MC and M2C type carbide still keeping stability at 600-700 DEG C is formed so as to obtain high temperature strength and thermal stability of the material. Compared with the commonly used hot work die steel at present including H13, 25Cr3Mo3NiNbZr and the like, the high temperature strength at 700 DEG C of the hot work die steel is improved by 50-100%, the tempering thermal stability is improved by 50-100%, the problemabout hot work die steel used at 600-700 DEG C is better solved, and the hot work die steel has longer service life at 600 DEG C and below.

Owner:UNIV OF SCI & TECH BEIJING

Production method of 3003-brand cathode aluminum foil

InactiveCN101519760AEvenly distributedImprove plasticityElectrolytic capacitorsCapacitanceMetallurgy

The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mm to 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into the blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil with the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 microfarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and makes a contribution for the trade progress.

Owner:登电集团铝加工有限公司

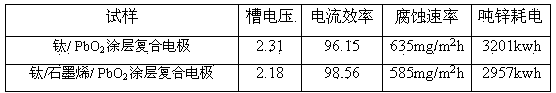

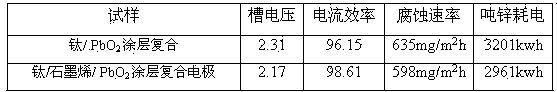

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

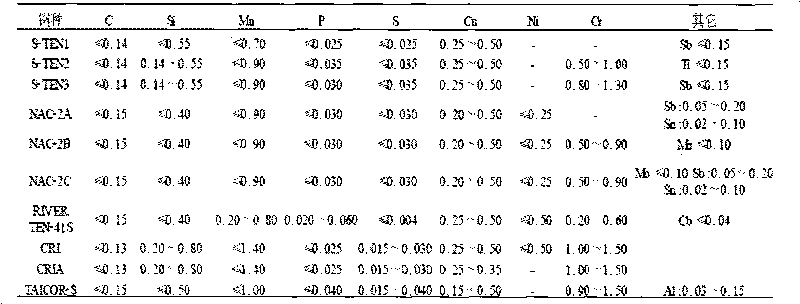

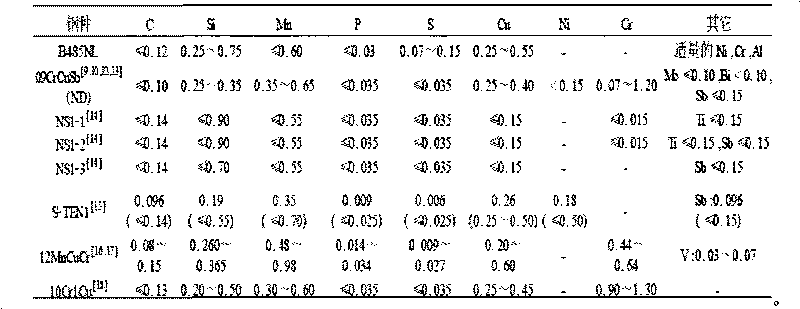

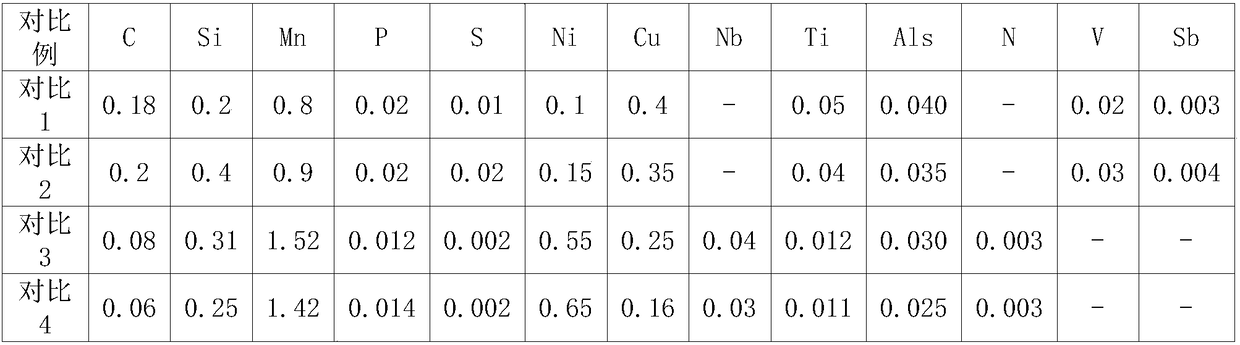

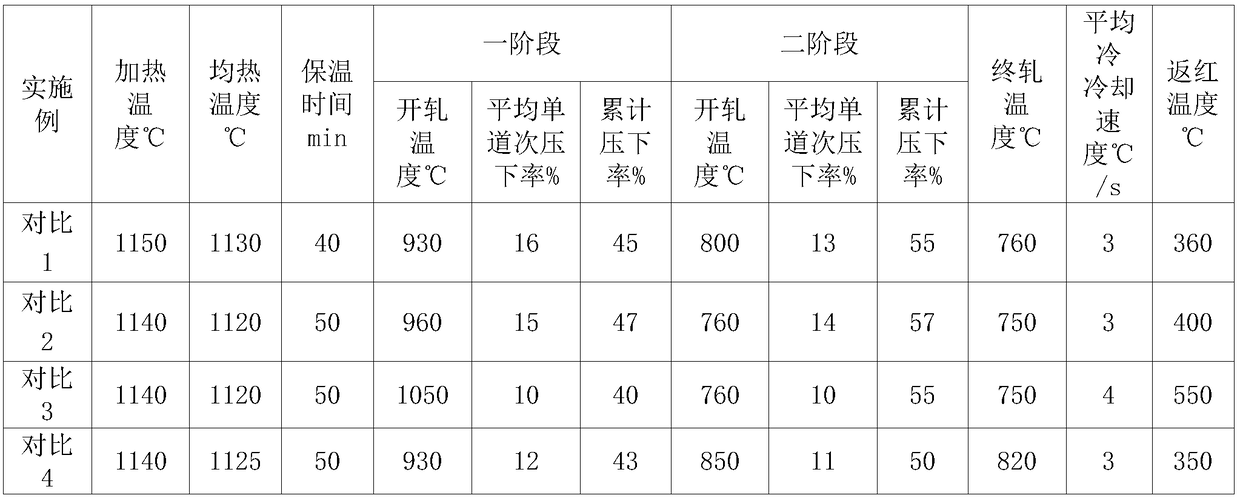

Sulphuric acid dew point corrosion resisting steel and method for producing same

InactiveCN101736202AShort Cooling IntensityStable temperatureProcess efficiency improvementElectric furnaceChemical compositionMolten steel

The invention discloses sulphuric acid dew point corrosion resisting steel and a method for producing the same by continuously casting and rolling a thin steel billet with an electric furnace. The molten steel comprises the following chemical components by weight percent: 0.03-0.08 percent of C, 0.10-0.45 percent of Si, 0.40-1.0 percent of Mn, 0.025 percent of P or less, 0.035 percent of S or less, 0.15-0.50 percent of Cu, 0.40-1.0 percent of Cr, 0.02-0.15 percent of Sb, 0.04-0.30 percent of Ni and 0.01-0.05 percent of Ti and also comprises 100ppm of N or less. The thin steel billet is continuously cast at the speed of 3.5-5.5m / min, and the cast thin steel billet is placed in the electric furnace of 900-1050 DEG C, soaked at 1100-1200 DEG C, rolled at 1040-1120 DEG C, finally rolled at 850-920 DEG C and winded at 550-650 DEG C. The Cu-Cr-Sb composite micro-alloyed sulphuric acid dew point corrosion resisting steel having good mechanical performance, welding performance and corrosion resisting performance can be produced by continuously casting and rolling the thin steel billet with the electric furnace.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

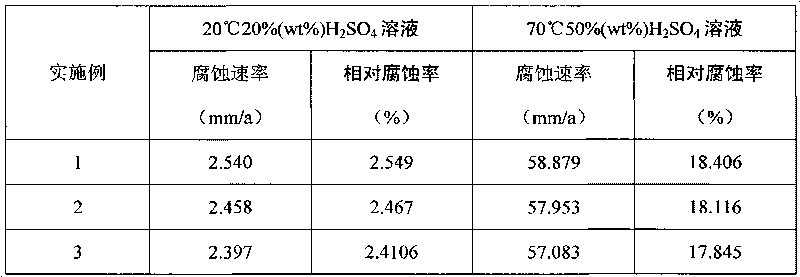

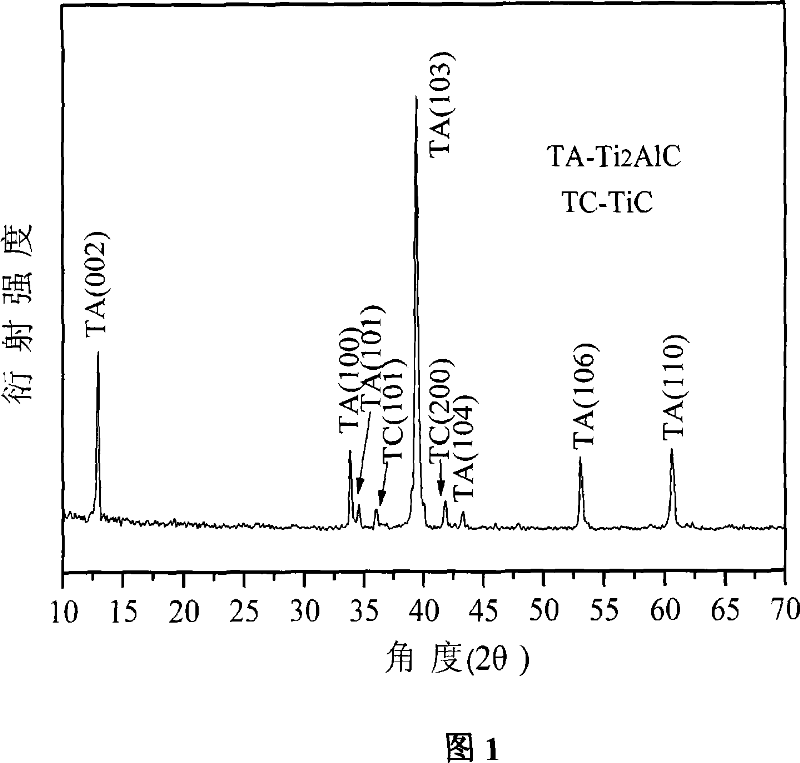

High-purity Ti2AlC powder material and preparing method thereof

The present invention discloses a high pure Ti2AlC powder material and a preparation method of the same. The powder material comprises Ti powder, TiC powder, Al powder and active carbon powder, wherein the mol ratio of which is n(Ti):n(TiC):n(Al):n(C)=(1.15~1.95):(0.5~0.95):1:(0.15~0.95). The preparation method comprises the steps of: feed weighing according to compounding ratio; mixing the raw material powder evenly; tabletting the mixed raw material and putting into the chamber of the microwave sintering device, and sintering in the presence of argon gas; obtaining the powder material after natural cooling. The powder material of the present invention has high purity and small crystal grain. The preparation process has simple raw material, adequately uses the characteristics of microwave sintering technology and the advantages of self-propagating reaction, and has a short synthesis time; besides the Ti2AlC powder material has a high purity, is adapted to industrial production. The application of the material is greatly improved.

Owner:WUHAN UNIV OF TECH

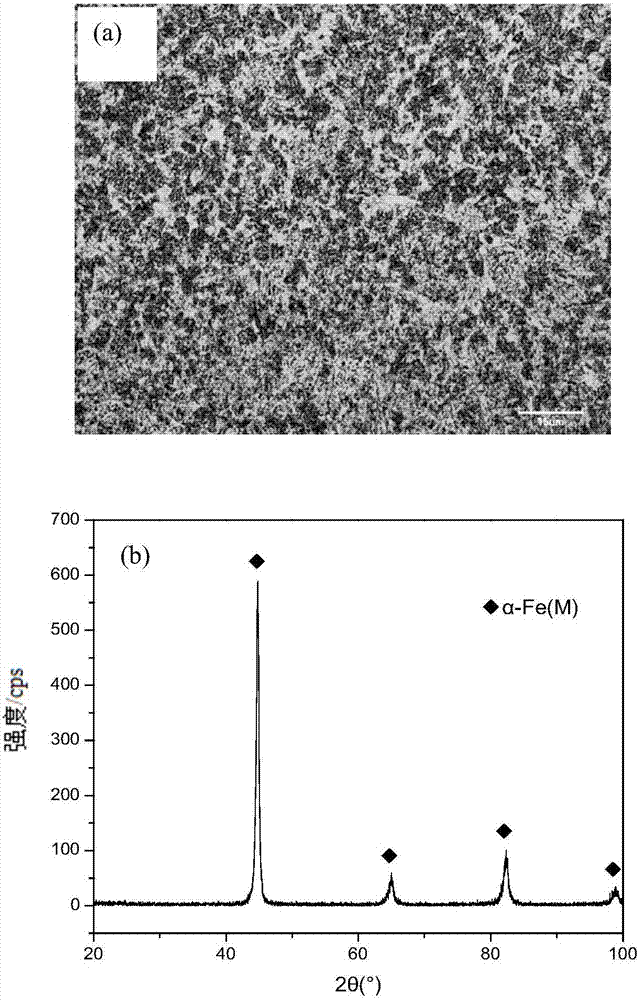

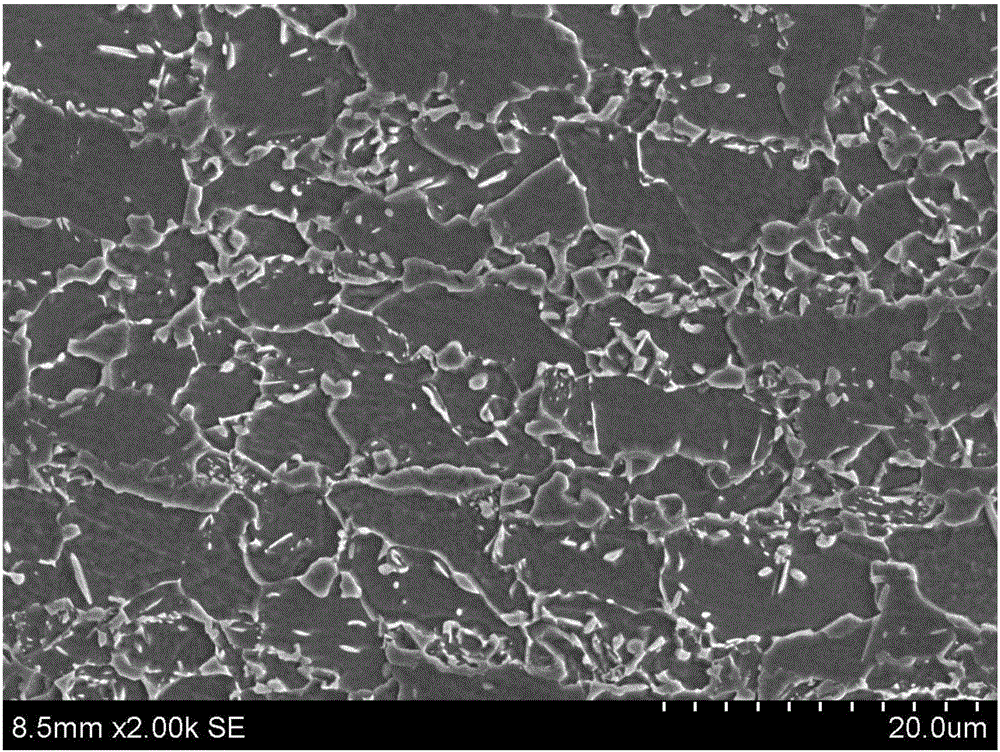

Method for preparing 24CrNiMo bainite alloy steel by using selective laser melting technology

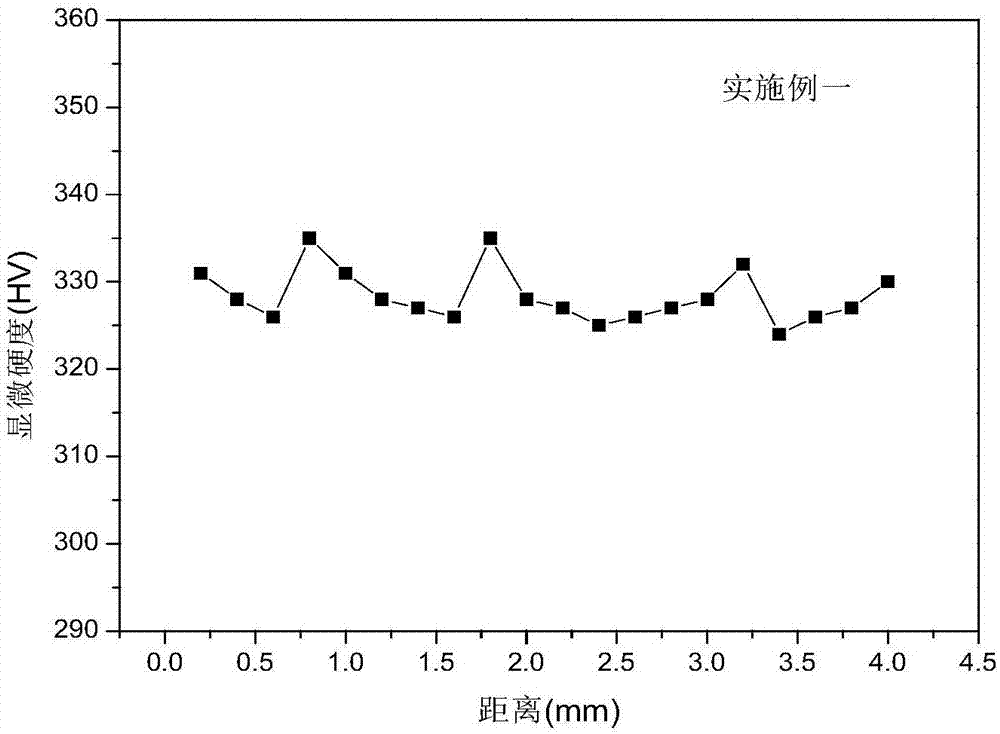

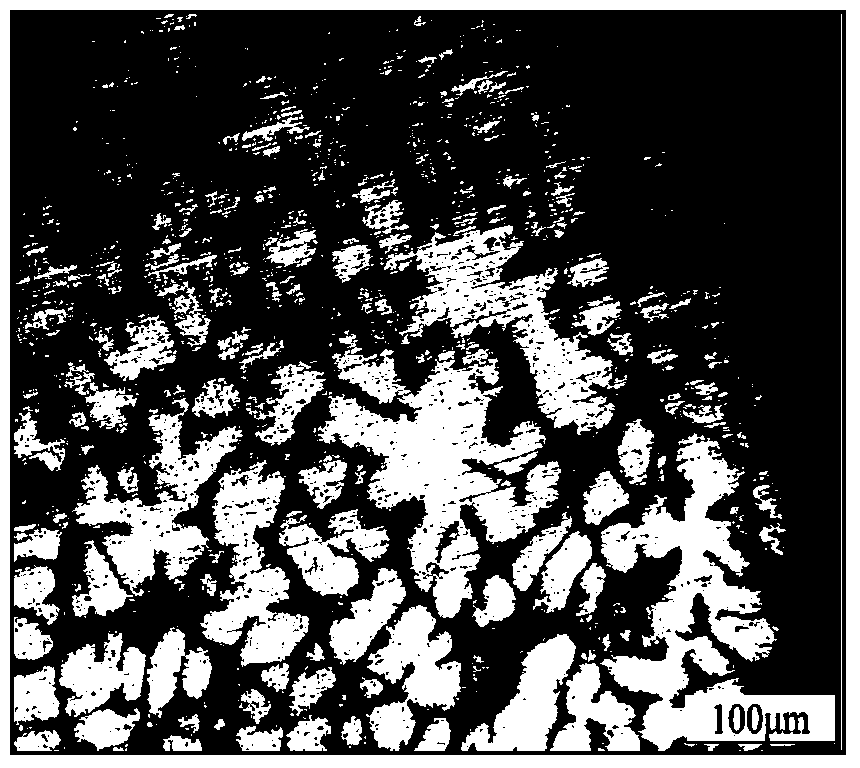

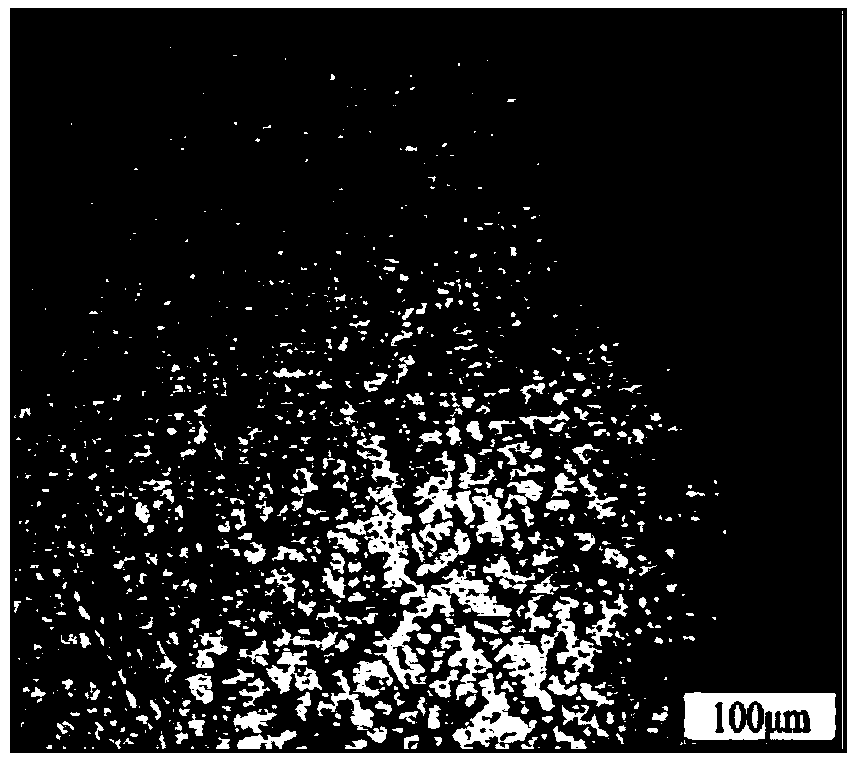

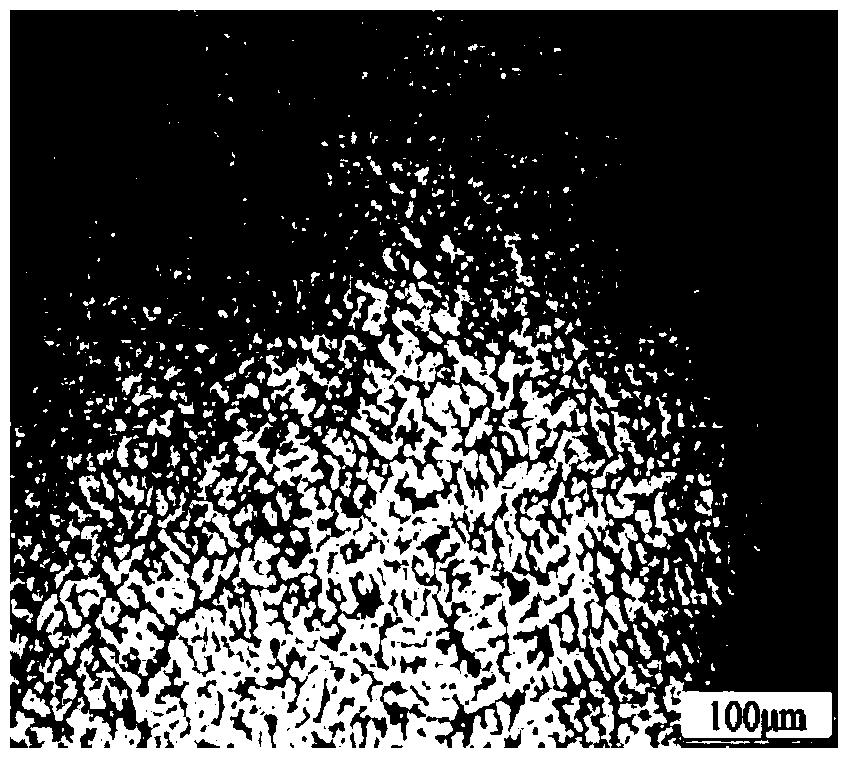

ActiveCN107214336ARemarkable effect of fine grain strengtheningImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHardness

The invention provides a method for preparing 24CrNiMo bainite alloy steel by using a selective laser melting technology. The method includes the steps that a laser device is used for conducting scanning on 24CrNiMo alloy steel power which is spread out on a base plate according to a preset selective laser melt scanning route till the power melts. According to the method, by optimizing technology parameters, taking use of the effects of alloy elements such as C, Cr, Ni, Mo, the bainite alloy steel which is uniform in microstructure is obtained at a high selective laser melting cooling speed, the average micro-hardness of the obtained bainite microstructure reaches 330-346 HV, the tensile strength is 962-978 Mpa, the elongation ratio is 16.4-17.6%, the product of tensile strength and elongation reaches 16.1-16.9 Gpa%, and the microstructure has excellent matched strength and toughness. The method and the technology are mainly applied to selective laser melting manufacture of 24CrNiMo alloy steel high speed rail brake discs.

Owner:NORTHEASTERN UNIV

Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

InactiveCN103589916AImprove grain refinement effectImprove adsorption capacityRare-earth elementMulti element

The invention provides a rapid solidification Al-Ti-B-Sc intermediate alloy refiner. The refiner is intermediate alloy and comprises, by mass, 3.75%-5% of Ti, 0.75%-1% of B, 0.1%-0.5% of Sc, and the balance Al. The cast structure of the refiner comprises particulate alpha-Al, TiAl3, TiB2, AlB2 and Al3Sc. The aluminum alloy refiner is an Al-Ti-B-Sc multi-element alloy refiner which comprises the rare earth element Sc and is acquired through rapid solidification. When the refiner is added to aluminum alloy, the aluminum alloy can be molten within a short time and can be evenly distributed more easily. When the refiner is applied, melting time can be shortened, and electric energy losses can be reduced.

Owner:HEBEI UNIV OF TECH

La doped SrTiO3 base oxide pyroelectric material and preparation method

InactiveCN101423243AStoichiometric ratio is accurateUniform compositionTitanium compoundsThermoelectric materialsStrontium titanate

A La-doped strontium titanate (SrTiO3)-based oxide thermoelectric material and a preparation method thereof, belonging to the technical field of energy materials. The method is divided into two parts of powder synthesis and forming of bulk materials. The powder synthesis adopts the sol-gel method, takes tetrabutyl titanate, strontium nitrate and lanthanum nitrate as raw materials, takes deionized water and ethanol as solvents and takes acetic acid and glycerol as a catalyst and a chelating agent to prepare SrTiO3 gel with different La doping amount, and the temperature is kept at the temperature of 500-560 DEG C for 1-2 hours to obtain precursor powder. The bulk forming adopts the spark plasma sintering method, and the sintering conditions are as follows: the vacuum degree is 2-10Pa, the pressure is 40-50MPa, the heating rate is 100 DEG C / min, the sintering temperature is 900-1000 DEG C, and the holding time is 5-10min. The method synthesizes the La-doped SrTiO3-based bulk thermoelectric material with high chemical homogeneity, uniform and fine grains and single-phase perovskite structure under the conditions of lower reaction temperature and shorter reaction time. The preparation method has the advantages of simple and convenient process, short synthesis and forming time, and the like.

Owner:UNIV OF SCI & TECH BEIJING

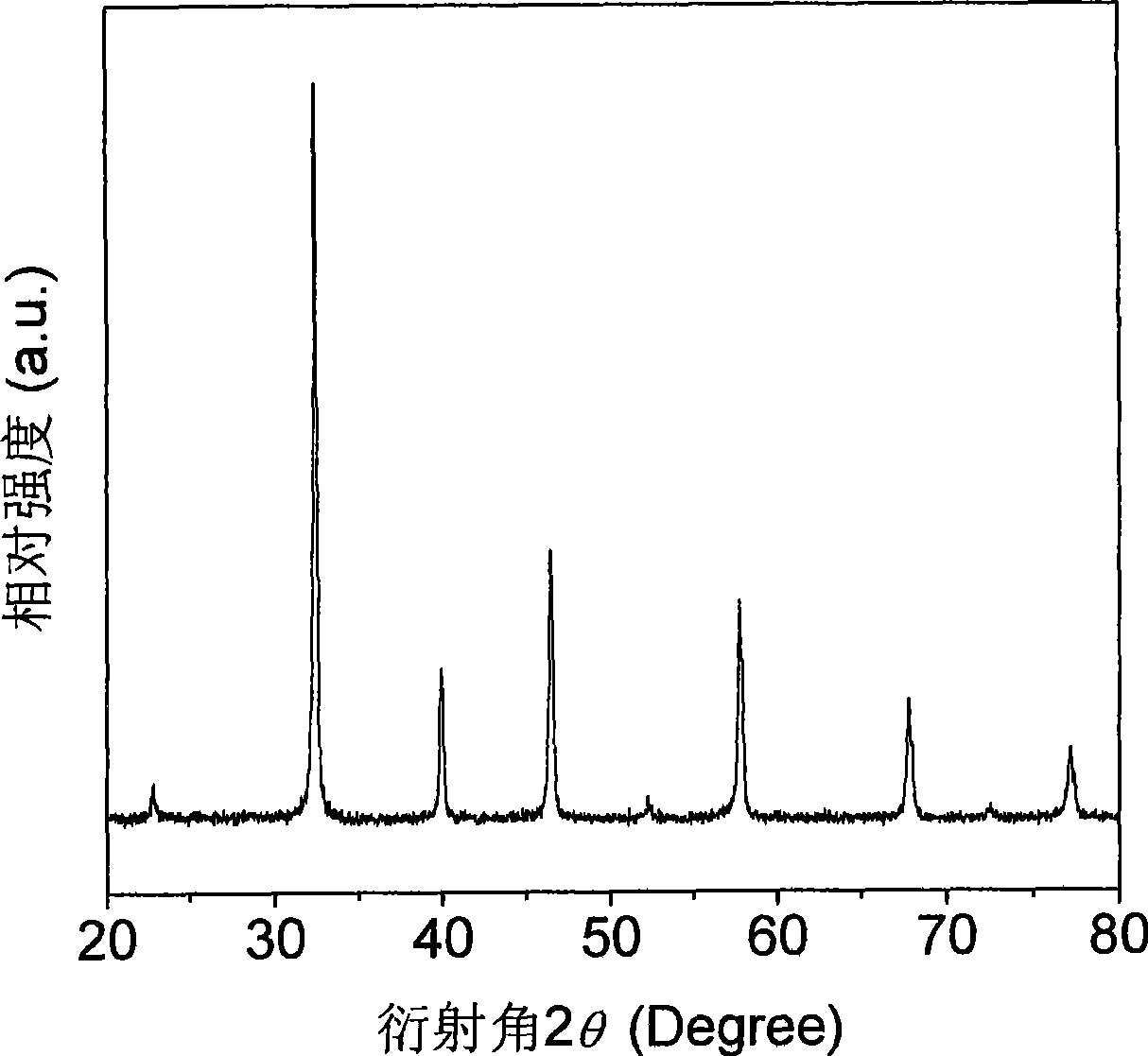

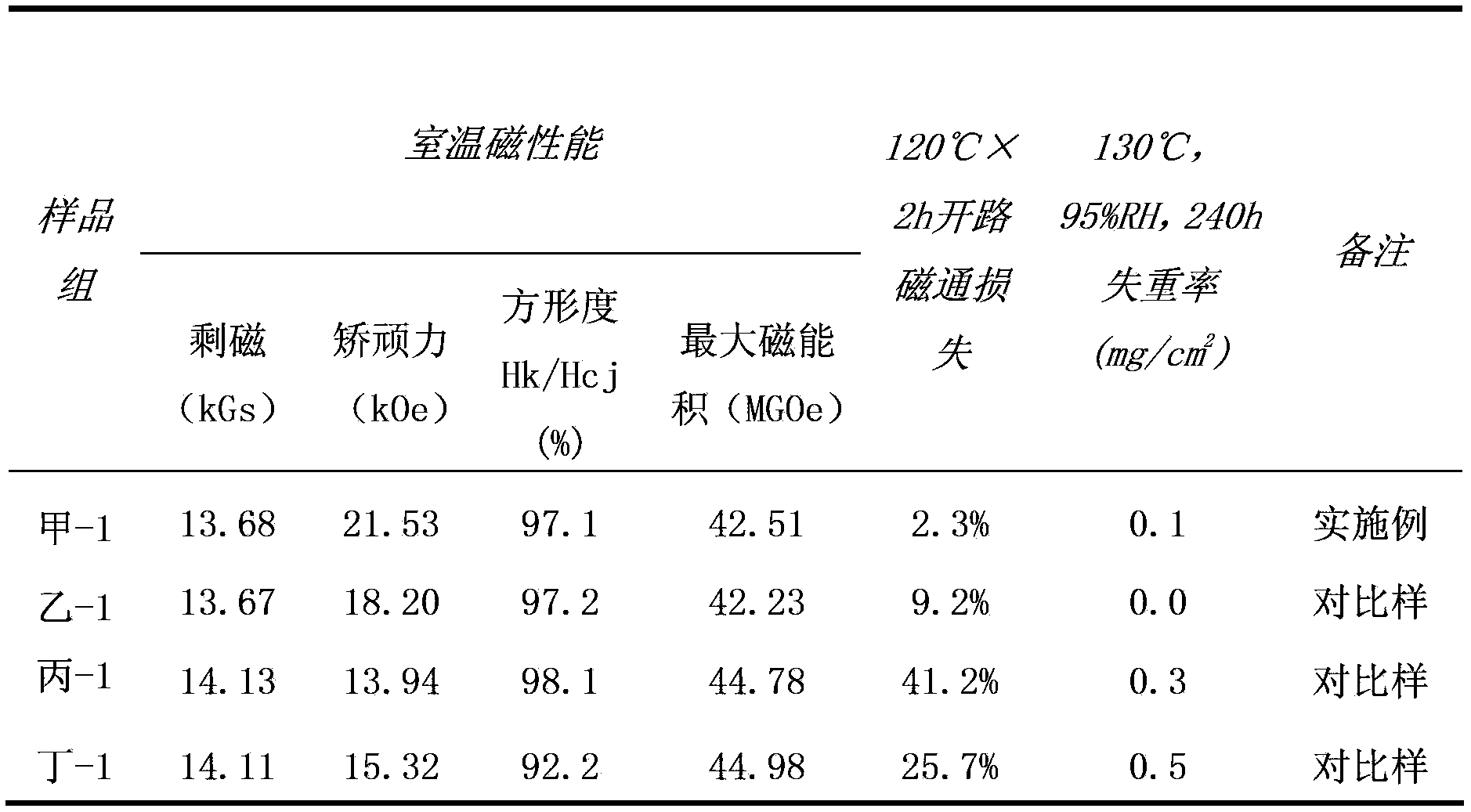

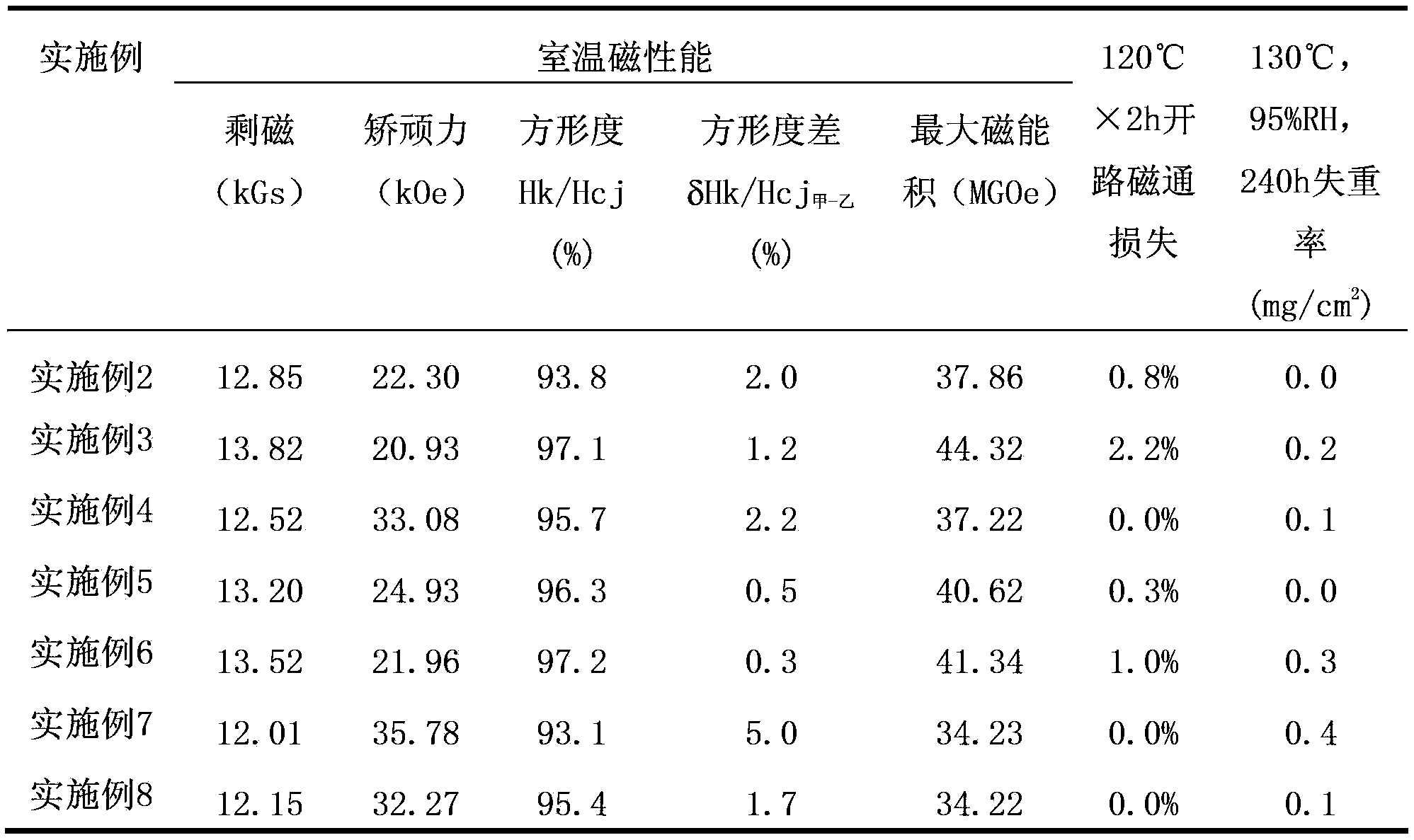

Rare-earth permanent magnet and preparation method thereof

ActiveCN104051101ALower activation energyEasy to spreadPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementPowder method

The invention discloses a rare-earth permanent magnet. The rare-earth permanent magnet mainly comprises the following components in percentage by atom: 12.1-16.2 percent of R, 0-3.4 percent of M1, 0-7.2 percent of M2, 5.1-7.4 percent of B and the balance of T, wherein the R is at least one of rear-earth elements including Y and Sc, and at least contains Nd; the M1 is at least one of Nb, Ti, Zr, V, Cr, Mo and Mn; the M2 is at least one of Al, Cu, Zn, Ga, In, Ge and Sn; the T is Fe or Fe and Co. A preparation method of the rare-earth permanent magnet comprises the processes of preparation of a magnet blank, coating, thermal treatment, and ageing, wherein the magnet blank is prepared by using a double-alloy method or a composite powder method. According to the magnet prepared by using the method, the coercive force, the temperature resistance and the corrosion resistance of a larger-size magnet can be improved, and the residual magnetism and the squareness of the magnet are not reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

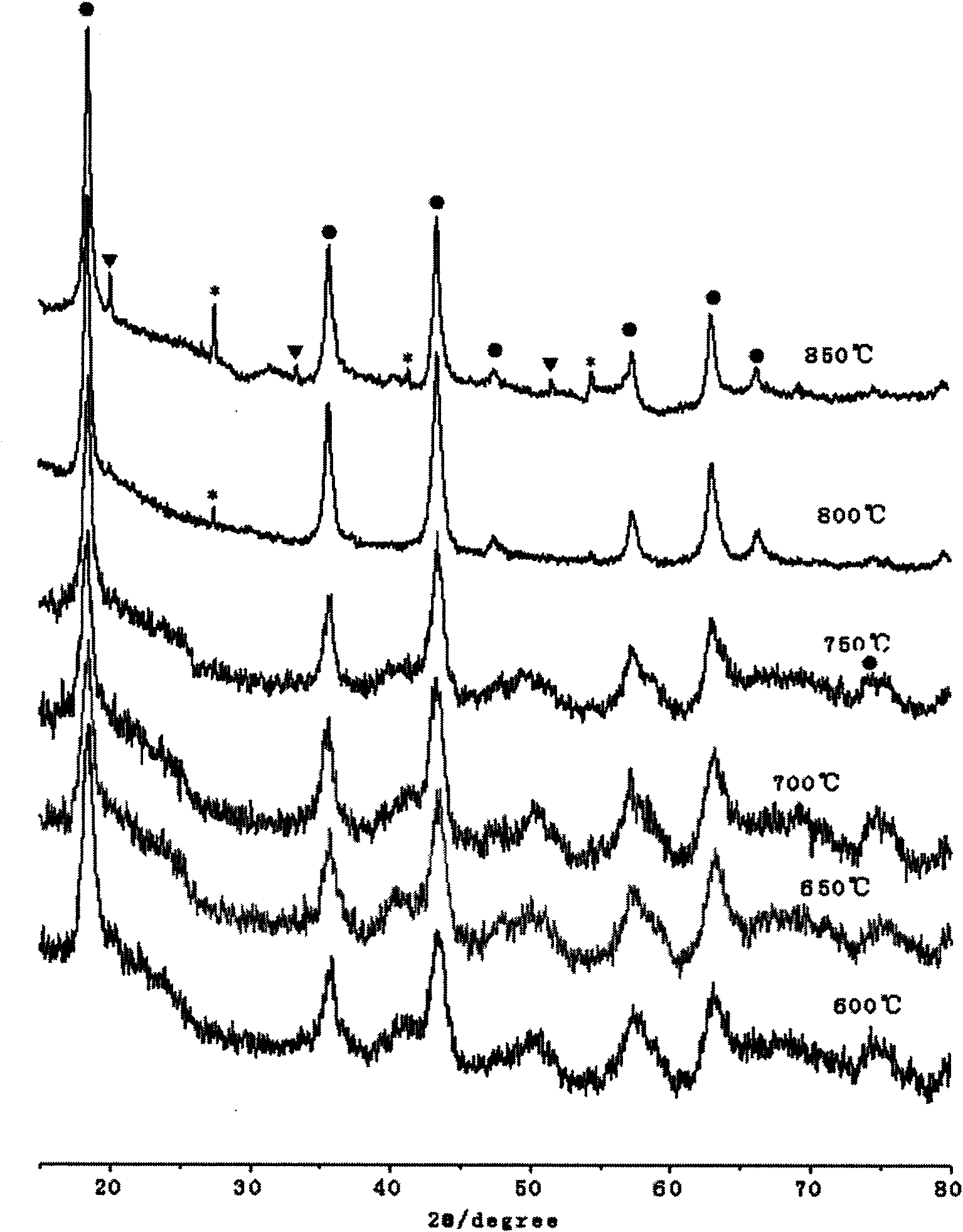

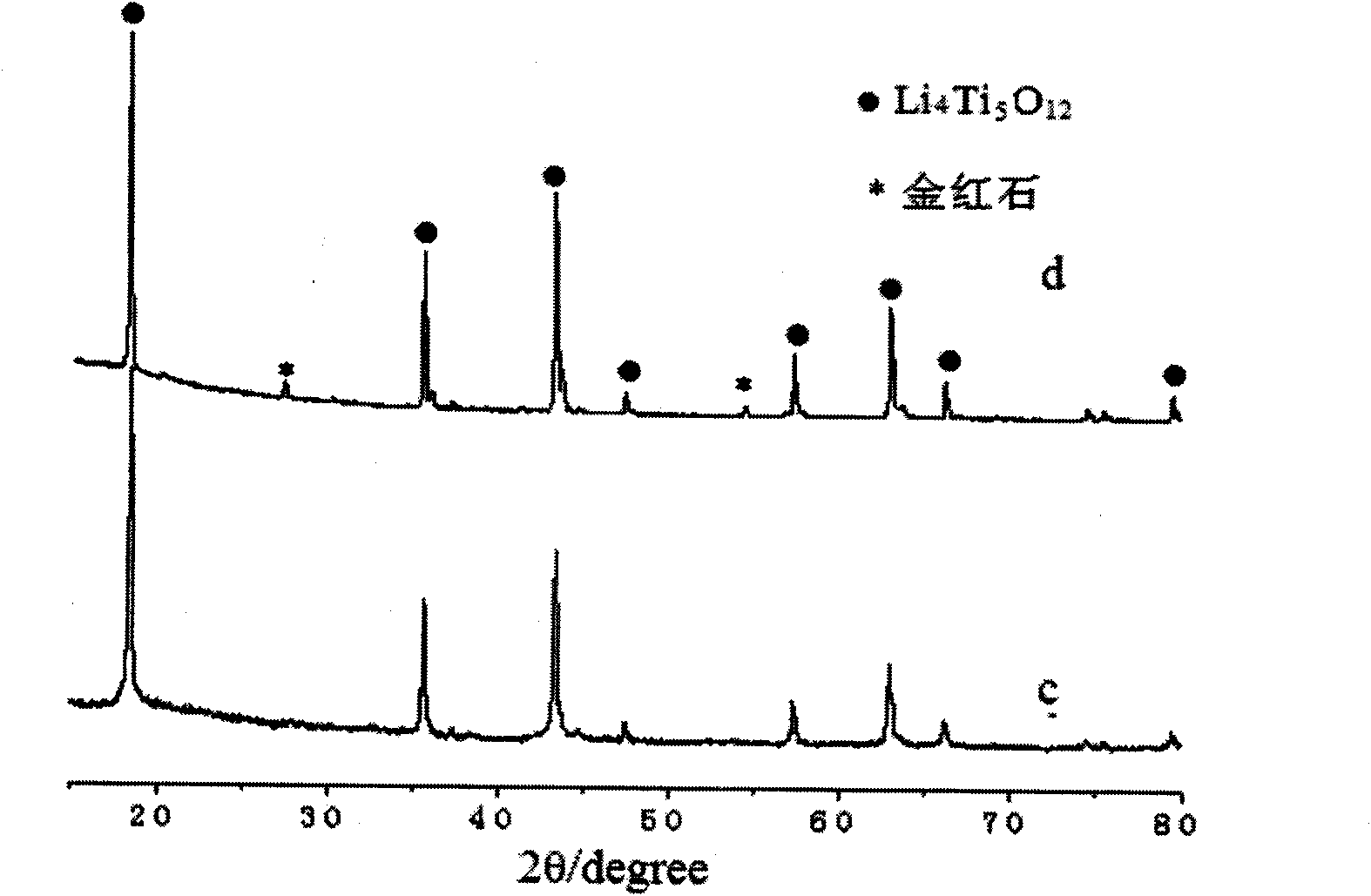

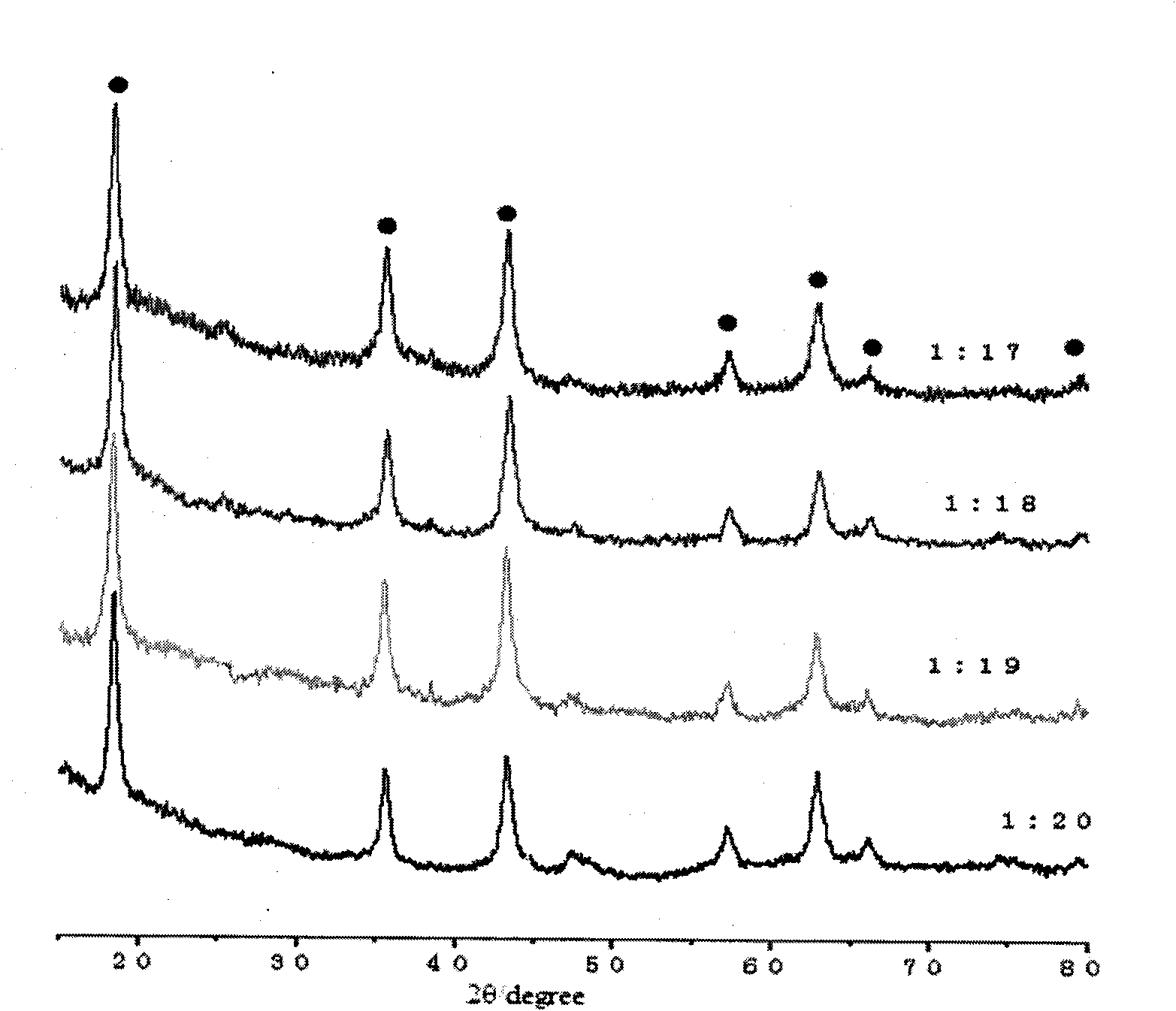

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

Method for preparing high-performance magnesium alloy sheet

InactiveCN101462123AEasy to organizeRealize large-scale industrial productionRoll force/gap control deviceTemperature control deviceRolling millHot rolled

The invention relates to a method for preparing a high performance magnesium alloy sheet, which belongs to the technical field of magnesium alloy preparation. The method is characterized by comprising: firstly, smelting out a magnesium alloy fused mass conforming to the requirements on components and then, adopting a double-roller rolling mill to produce rolling sheet blanks; heating the rolling sheet blanks to a set temperature so as to carry out hot rolling and matching with intermediate annealing in the hot rolling process so as to ensure that the sheets have perfect recrystallization and eliminate processing hardening; and subsequently, thermally rolling the hot rolled sheets to the needed thickness and carrying out final annealing on the magnesium alloy sheets so as to obtain the high performance magnesium alloy sheets with fine and uniform crystal grains. The prepared magnesium alloy sheets have the advantages of higher tensile strength, yield strength and elongation.

Owner:TSINGHUA UNIV

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

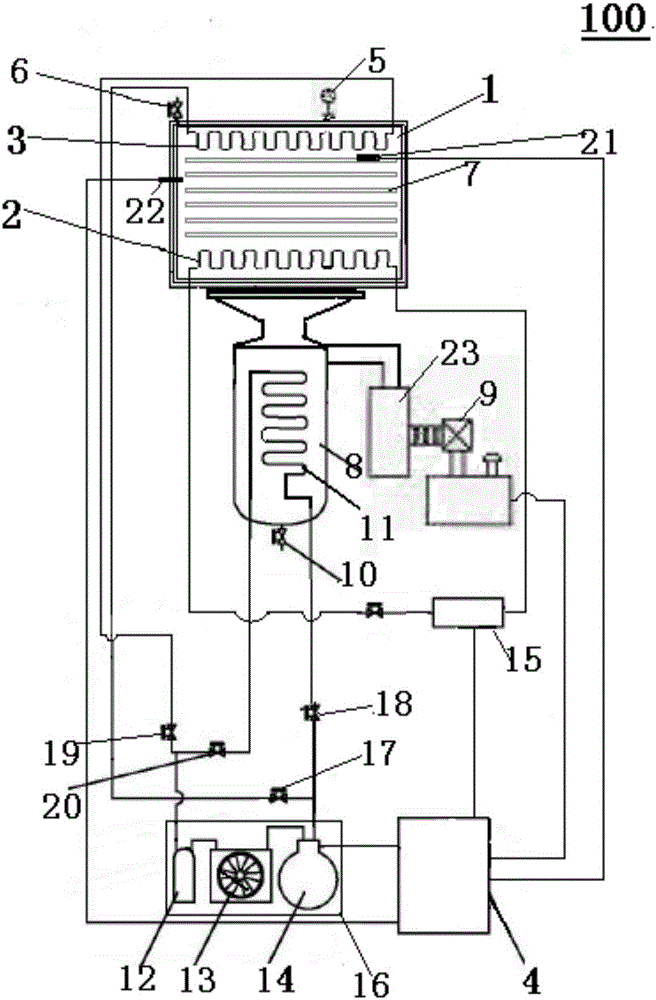

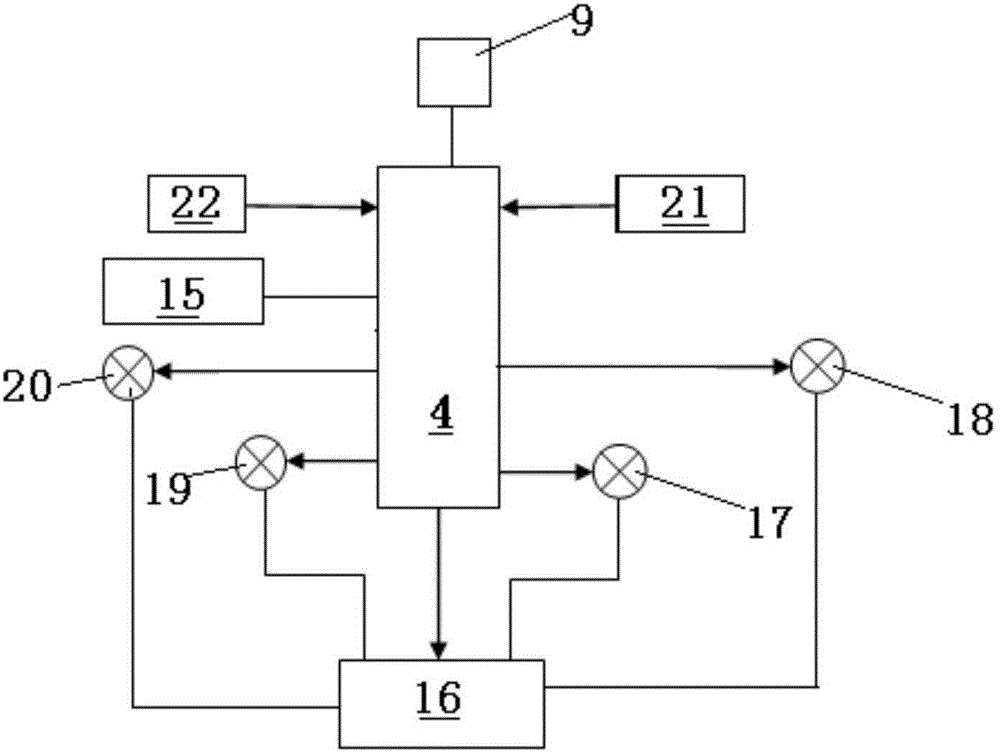

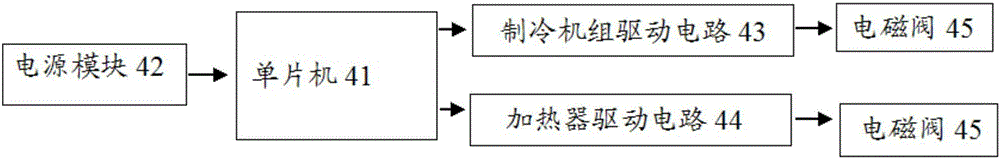

Vacuum freeze drying method and vacuum freeze dryer

ActiveCN104949473AImprove qualityReduce process stepsDrying solid materials without heatSmall footprintFreeze dry

The invention provides a vacuum freeze dryer which comprises a material box, a water catching bin, a refrigerating unit, a heater, a vacuum pump and a control device. The material box is communicated with the water catching bin. The water catching bin is connected with the vacuum pump. The refrigerating unit and the heater are arranged outside the material box. The control device controls the refrigerating unit, the heater and the vacuum pump. The material box is internally provided with a refrigerating pipe and a heating pipe at the same time, and the refrigerating pipe and the heating pipe are used for freezing and drying materials respectively. The inner wall of a material frame and the inner wall of the material box are each provided with a temperature sensor, and the temperature sensors monitor the temperature of the material frame and the temperature of the material box. Materials inside a material bottle are frozen in advance to reach the eutectic point approximately, then the temperature is decreased rapidly, and the materials pass through the eutectic point within the short time as little as possible, so that the grain size of crystals is effectively controlled, the fine freeze-drying powder is obtained, and the freeze-dried powder product quality is improved. The freezing cavity and the drying cavity are integrated, the technological steps are simplified, the occupied space is small, and refrigerating and heating are uniform.

Owner:BEIJING HAIHETIAN TECH DEV

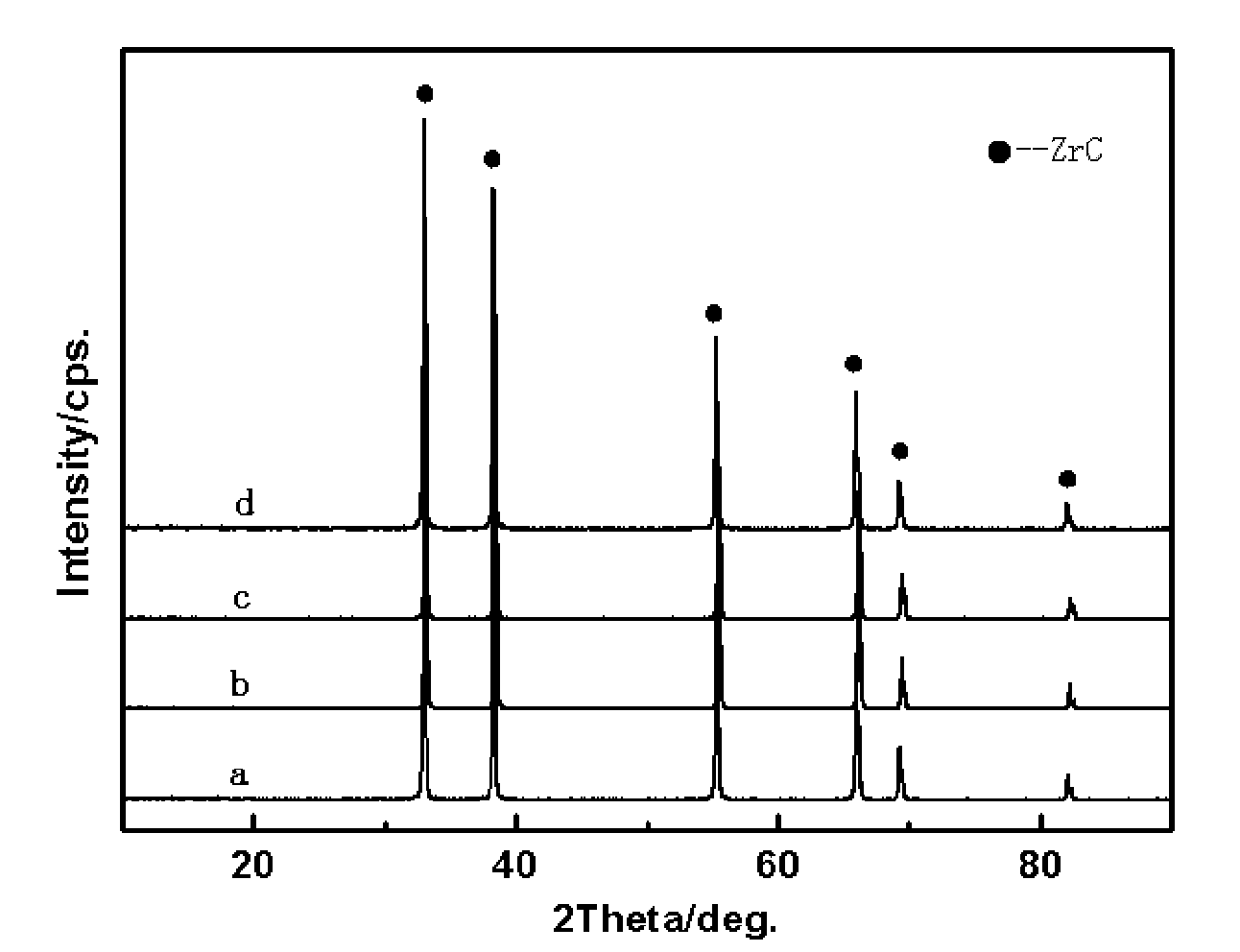

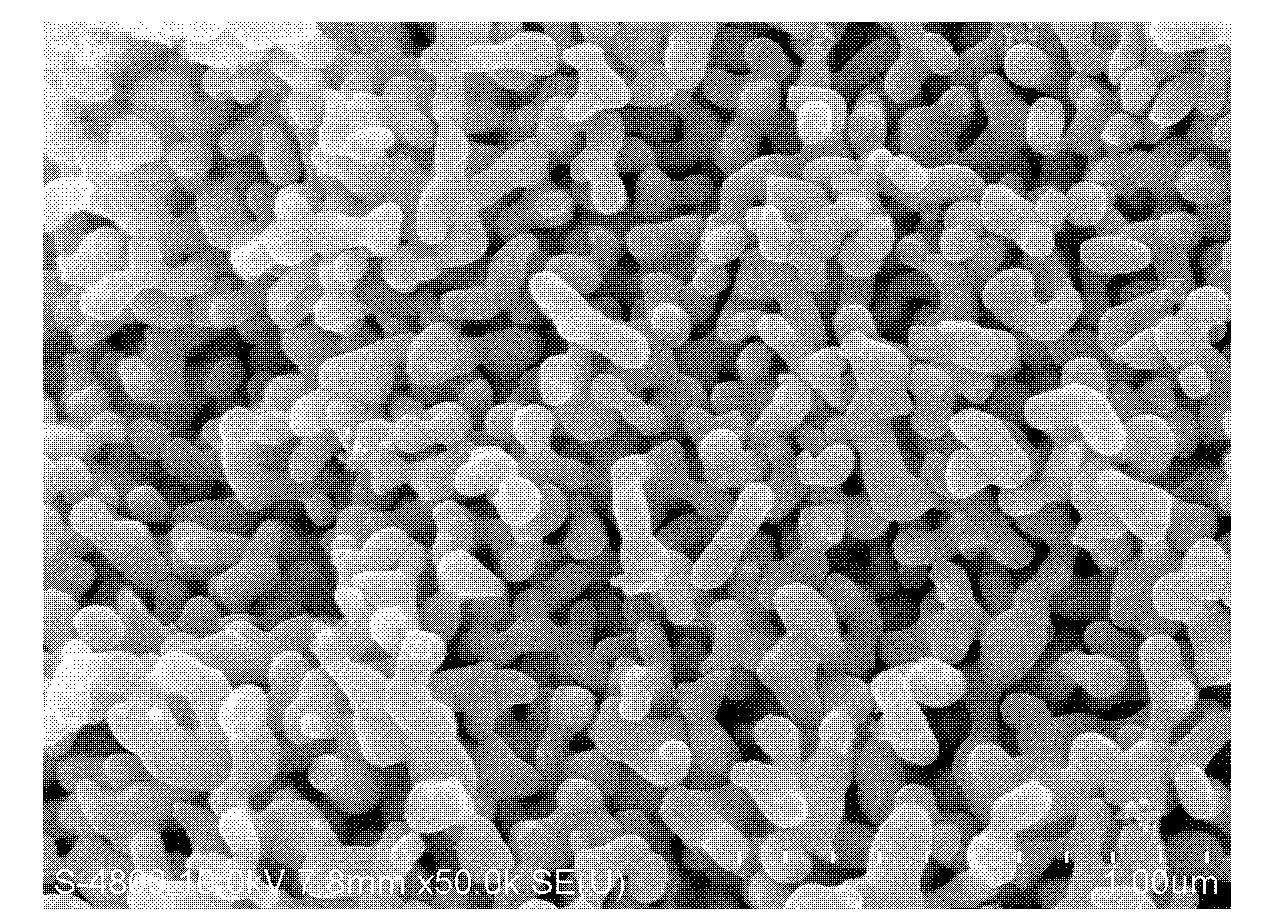

Method for rapidly preparing zirconium carbide ceramics powder

The invention relates to a preparation method of zirconium carbide ceramics powder; the method for rapidly preparing zirconium carbide ceramics powder is characterized in that: the method comprises the following steps: 1) raw material selection: the raw materials are selected according to 12:4-12:5 of mass ratio of zirconium propoxide solution and sugar and 8:32:1:1-8:64:2:4 of volume ratio of zirconium propoxide solution, normal propyl alcohol, chelant-acetic acid and water; the solvent acetic acid is selected according to (7-8)g:50ml of proportion of the sugar and the solvent acetic acid; 2) the preparation of dried gel power; 3) preparation of precursor powder; 4) heat treatment of the precursor powder; carbothermal reduction reaction is carried out under the conditions of high heating rate and short temperature preservation time, the synthesizing process of the zirconium carbide powder is shortened into dozens of minutes even several minutes, so as to obtain high-purity and refined zirconium carbide ceramics powder with good sintering character; single zirconium carbide phase can be analyzed by X-ray diffraction, the oxygen content in the product is 0.5-3 percent, and the free carbon content is from 0.2 to 2 percent; the crystal particles are uniform and tiny, and the mean grain size is less than 500nm.

Owner:WUHAN UNIV OF TECH

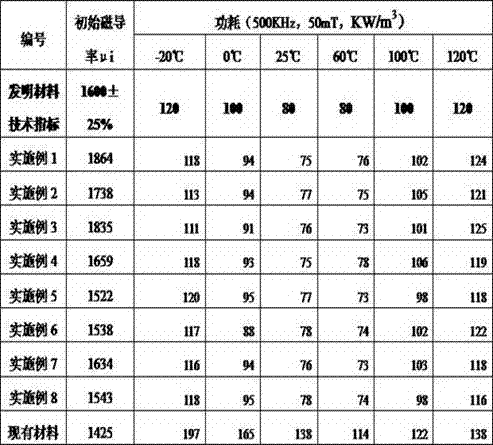

Wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

InactiveCN107540363AReduce lossImprove workabilityInorganic material magnetismInductances/transformers/magnets manufactureWork performanceRoom temperature

A wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material comprises a main component, an auxiliary component A and an auxiliary component B, wherein, according to weight percentage, the main component comprises Fe2O3, MnO and ZnO; based on the weight of the main component, the auxiliary component A comprises at least two of CaCO3, V2O5, TiO2 and Co3O4, and the auxiliary component B comprises at least three of CaCO3, Nb2O5, TiO2, Co3O4, CuO, MoO and SiO2; the SiO2 amount in the auxiliary component B is determined according to the total amount of SiO2 impurities in the main component so as to ensure that in the whole material, the SiO2 amount is 0.025-0.035% of the total weight of the main component. A preparation method of the wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material sequentially comprises the following steps: performing component analysis on the main component, primarily dosing, primarily sanding, presintering, secondarily dosing, moulding and sintering. The wide-temperature, high-frequency and low-loss manganese-zinc soft magnetic ferrite material has excellent working performance under the conditions of 500KHz and 50mT and within the temperature range from -20 DEG C to 120 DEG C, has relatively low loss, saves more energy than the conventional material, and has lower standby loss at low temperature and room temperature.

Owner:郴州市久隆旺高科电子有限公司

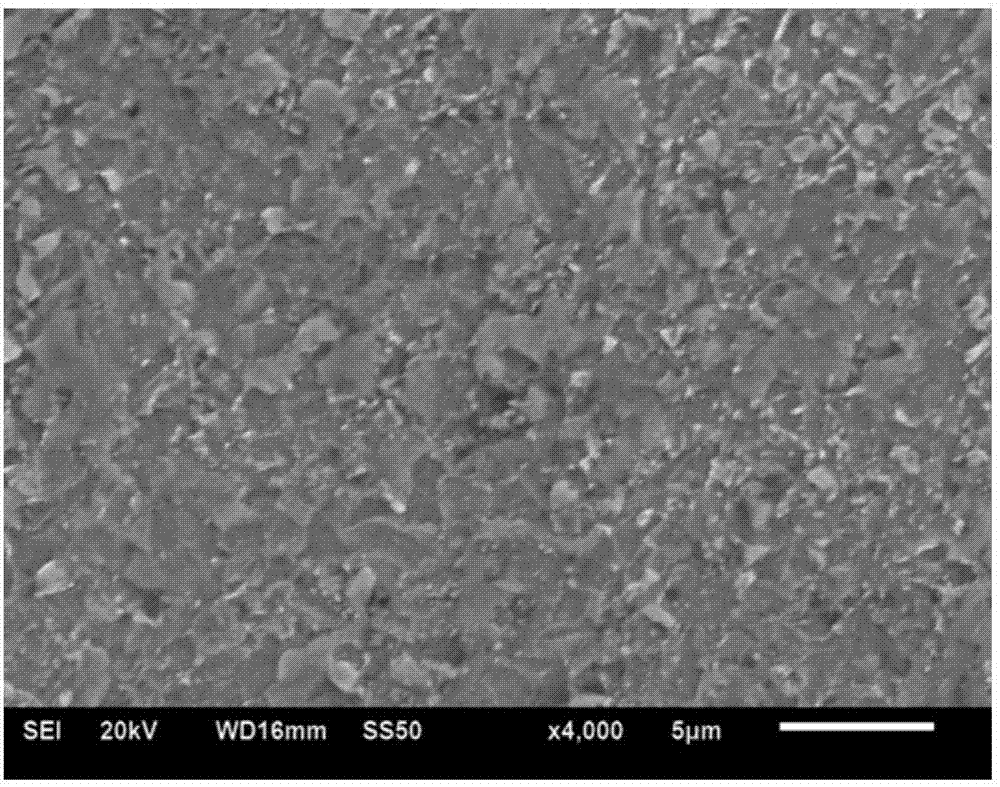

Preparation method of ultrahigh-purity aluminum target

ActiveCN106282945AHigh purityFine and uniform grainVacuum evaporation coatingSputtering coatingIngotEnergy consumption

The invention relates to a preparation method of an ultrahigh-purity aluminum target. The preparation method comprises the following steps: (1) the surface of an ultrahigh-purity aluminum ingot with a purity of higher than 99.999 wt% is milled to remove an oxide layer thereof; (2) the ingot is heated to 230-400 DEG C; (3) the hot rolling of 10-20 passes is performed for the heated ingot; the single-pass reduction is controlled within 20-60 mm; and the final rolling temperature in final pass is controlled below 350 DEG C; (4) the annealing treatment with a temperature of 200-300 DEG C and an insulation time of 1-2 h is performed for a hot-rolled aluminum plate; and (5) the plate is straightened for milling to obtain the ultrahigh-purity aluminum target with average grains of 80-150 microns. The preparation method can prepare the target with high purity, fine and uniform grains and consistent texture orientation to satisfy the use requirements of PVD; and meanwhile, the preparation method is simple in process, easy to operate and convenient for large-scale industrial production, effectively reduces the energy consumption, and reduces the cost.

Owner:CHINALCO RUIMIN

Zinc-plated double-phase steel and production method thereof

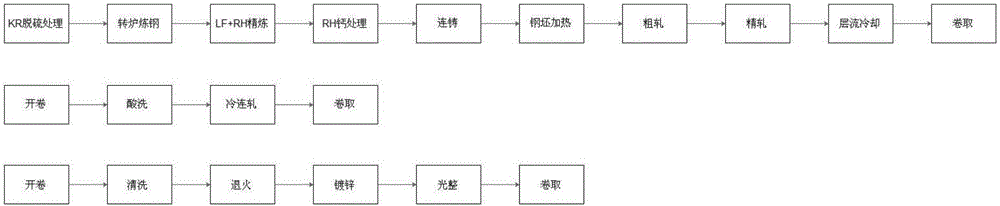

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

Cogging method for large GH4738 high-temperature alloy ingot

ActiveCN105177478AFine and uniform grainMeet the technical requirements of fine grain uniformityIngotLarge size

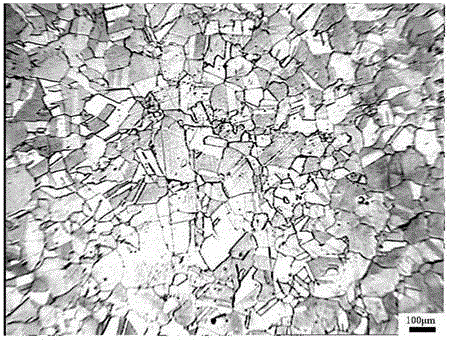

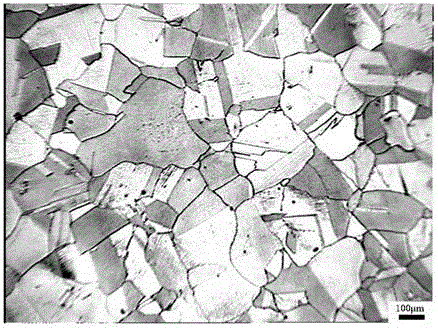

The invention discloses a cogging method for a large GH4738 high-temperature alloy ingot. According to the method, a bar billet with even and fine grains is obtained through multiple times of heading, drawing, forging and cogging conducted on a homogenized alloy steel ingot, so that the requirement for control over homogeneity of the fine-grained microstructure of the large-size alloy forge piece is met. In the forging and cogging control process, the cogging temperature, deformation amount and deformation speed are strictly controlled, heading, drawing and cogging are conducted repeatedly, forging is conducted by the adoption of glass lubricants and a coating insulation mode, and finally the bar billet of the even fine-grained microstructure is obtained. The cogging method can be applied to cogging and forging of the large GH4738 nickel-based high-temperature alloy ingot to produce the fine-grained bar billet.

Owner:UNIV OF SCI & TECH BEIJING

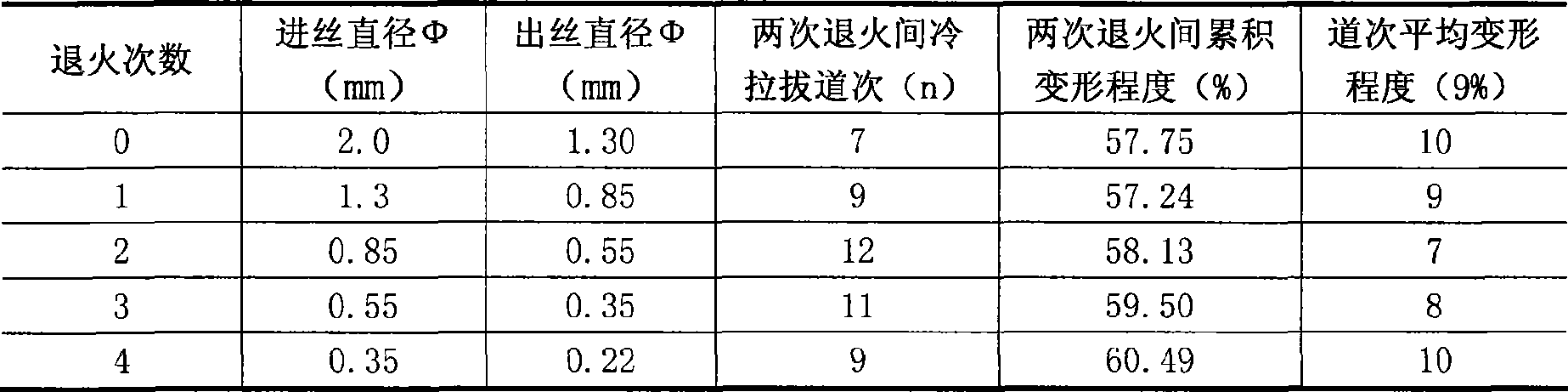

Multi-pass drawing technological process for manufacturing magnesium and magnesium alloy filament

InactiveCN101468363AHigh work hardening rateEasy to implementFurnace typesHeat treatment process controlMagnesium alloyLubricant

The invention relates to a multi-pass drawing process method for manufacturing magnesium and magnesium alloy filaments. The prior production method has many middle annealing times, low production efficiency, low yield of a finished product, and high cost. The multi-pass drawing process method for manufacturing the magnesium and the magnesium alloy filaments comprises: a raw material of a fine crystal magnesium or magnesium alloy wire material with diameter of between phi 2 and 3 is selected; the raw material and a wire drawing mould are lubricated through a grease-type lube and are subjected to cold drawing for 5 to 12 times, and the cold drawing speed is between 120 and 150 mm / s; the raw material is recrystallized and annealed, the annealing temperature is between 400 and 420 DEG C, and the annealing time is between 1 and 3 minutes; and the process is repeated till the process is finished. The method is used for manufacturing the magnesium and the magnesium alloy filaments.

Owner:HARBIN INST OF TECH

Steel plate for high toughness 15CrMoR pressure container

The invention relates to the manufacturing field of steel for a chrome-molybdenum heat resistant pressure container, in particular to a steel plate for a high toughness 15CrMoR pressure container. The steel plate is prepared by the following components in percentage by mass: 0.14-0.18% of C (Carbon), 0.15-0.40% of Si (Silicon), 0.45-0.70% of Mn (Manganese), no more than 0.020% of P (Phosphorus), no more than 0.005% of S (Sulfur), 0.90-1.10% of Cr (Chromium), 0.45-0.60% of Mo (Molybdenum) and the balance of Fe (Ferrum) and inevitable impurities. The steel plate for the high toughness 15CrMoR pressure container, provided by the invention, has the advantages as follows: (1) as impact toughness of 15CrMoR is high, low temperature impact performance is that transverse impact is not less than 80 J at -40 DEG C and far higher than the nationally specified transverse impact; (2) pure steel quality and low content of harmful elements such as S and the like; (3) as refined grain elements, such as Nb, V, Ti and the like, are not added, cost is greatly saved; and (4) when a requirement on low temperature toughness is satisfied, good conventional properties and good high-temperature tensile properties are obtained.

Owner:JIGANG GRP

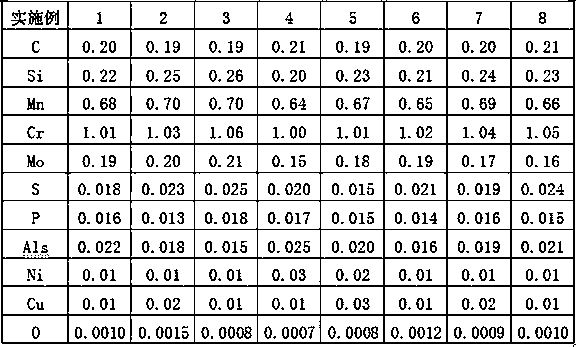

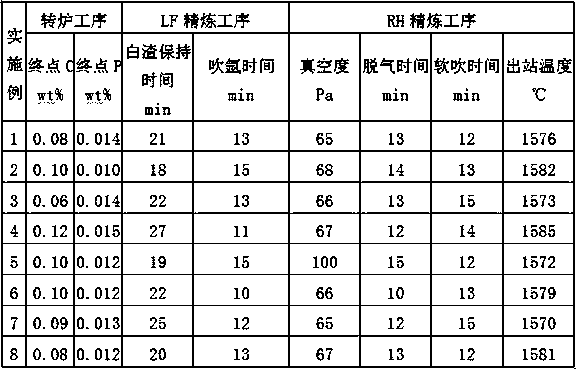

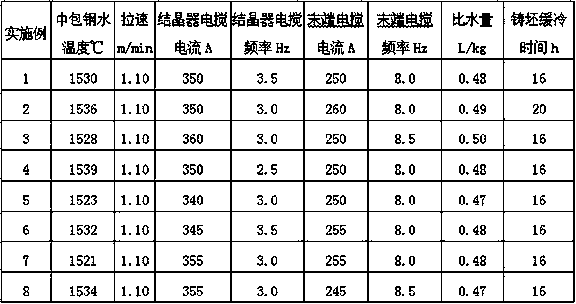

Gear steel 20CrMoSH and technology for improving hardenability stability thereof

The invention discloses gear steel 20CrMoSH and a technology for improving the hardenability stability thereof. The technology comprises the procedures of converter smelting, LF refining, RH refining,continuous casting, heating and rolling. The gear steel is prepared from the chemical components, by weight, 0.19%-0.21% of C, 0.20%-0.26% of Si, 0.64%-0.70% of Mn, 1.00%-1.06% of Cr, 0.15%-0.21% ofMo, 0.015%-0.025% of S, smaller than or equal to 0.018% of P, 0.015%-0.025% of Als, smaller than or equal to 0.03% of Ni, smaller than or equal to 0.03% of Cu, smaller than or equal to 0.0015% of O and the balance Fe and unavoidable impurities. According to the gear steel 20CrMoSH which is produced through the method and has the diameter phi ranging from 28 mm to 50 mm, the hardenability J1.5 ranges from 40 HRC to 45 HRC, the hardenability J5 ranges from 37 HRC to 42 HRC, the hardenability J9 ranges from 28 HRC to 33 HRC, and the maximum discrete value of the hardenability of the steel in thesame furnace is not larger than 3 HRC. The heat-treatment deformation of a gear can be significantly reduced by means of high-stability hardenability, and therefore the meshing precision of the gear is improved. The method is low in cost and high in production efficiency, and the product has the advantages that the hardenability is stable, the gear heat-treatment deformation is small, and the machined gear is high in meshing precision and low in service life.

Owner:HANDAN IRON & STEEL GROUP +1

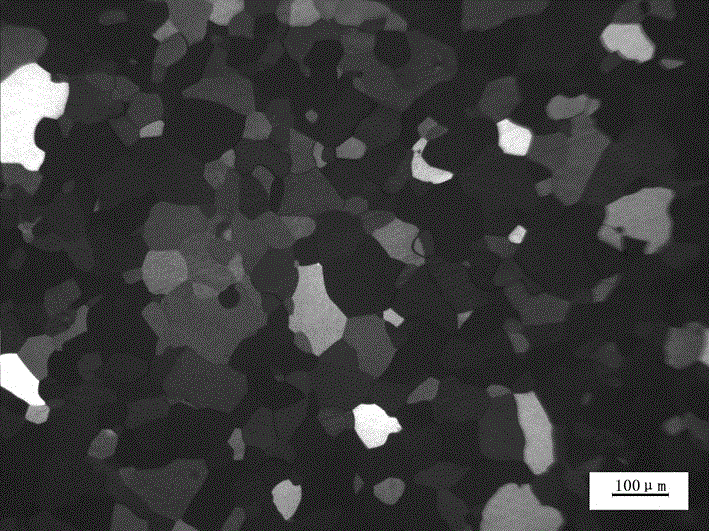

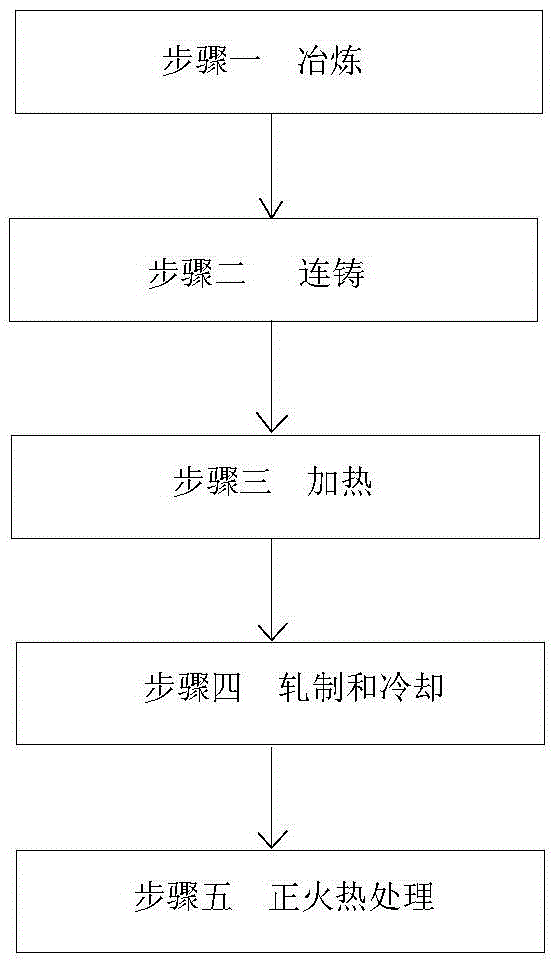

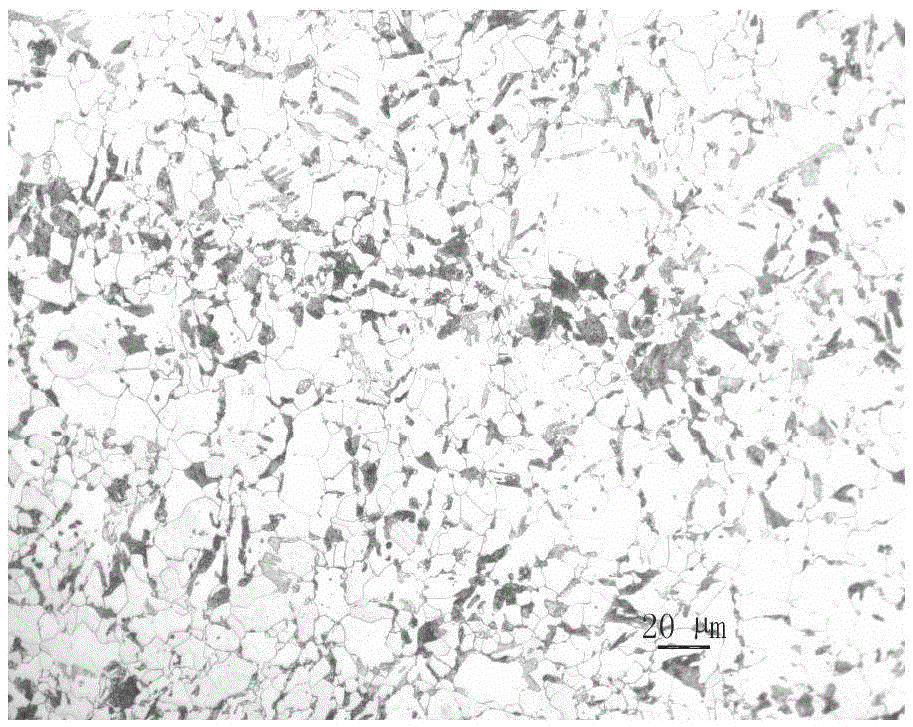

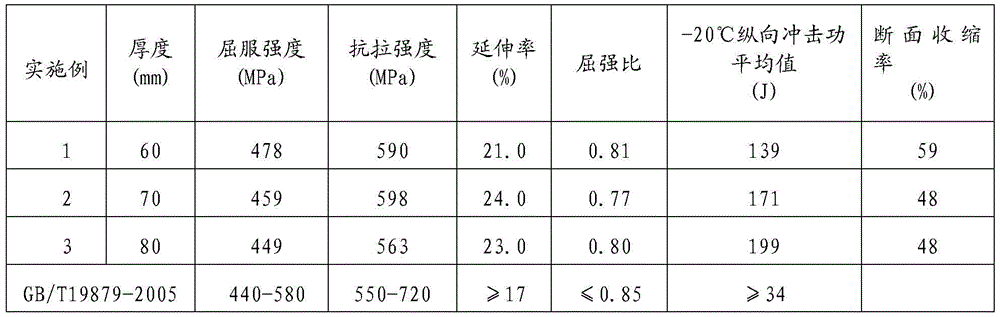

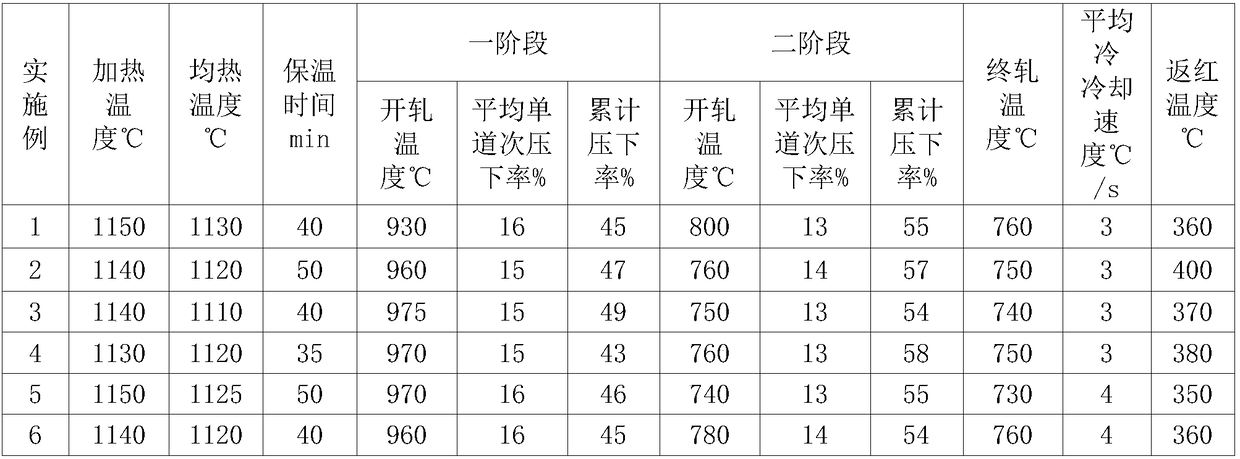

Rare earth treated normalized Q460GJ steel plate for buildings and production method of steel plate

The invention discloses a rare earth treated normalized Q460GJ steel plate for buildings and a production method of the steel plate, and belongs to the technical field of steel for buildings. The steel plate comprises chemical components in percentage by weight as follows: 0.17-0.19% of C, 0.35-0.45% of Si, 1.50-1.60% of Mn, <=0.015% of P, <=0.010% of S, 0.03-0.04% of Nb, 0.05-0.06% of V, 0.01-0.02% of Ti, 0.2-0.3% of Ni, 0.020-0.040% of Als, 0.0010-0.0020% of rare earth La and the balance of Fe and impurities. The production method comprises the following steps: step I, smelting; step II, continuous casting; step III, heating; step IV, rolling and cooling; and step V, normalizing heat treatment. Therefore, the steel plate for buildings can be obtained, and the steel plate is in a metallographic structure of ferrites and pearlites with fine and uniform crystalline grains.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-strength thick steel plate with excellent crack-arrest property and manufacturing method thereof

The invention relates to a high-strength thick steel plate with an excellent crack-arrest property. The steel plate has the following characteristics: a wide-plate tensile value Kca for determining the crack-arrest property is larger than 6000 N / mm<1.5>; yield strength at the positions, which are respectively 1 / 4 and 1 / 2 the thickness of the steel plate away from the surface of the steel plate, isno less than 460 MPa; tensile strength is 570 to 720 MPa; Charpy impact energy at minus 40 DEG C is no less than 200 J; and a zero-ductility transition temperature is less than minus 60 DEG C. The steel plate provided by the invention comprises the following components by weight: 0.04 to 0.16% of C, 0.1 to 0.5% of Si, 0.9 to 1.6% of Mn, 0.1 to 0.3% of Cu, 0.2 to 0.9% of Ni, no more than 0.02% ofP, no more than 0.02% of S, 0.01% to 0.05% of Als, 0.002 to 0.010% of N, 0.02% to 0.05% of Nb and 0.01 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. According to the invention,through optimization of chemical components of a high-strength steel plate and adoption of controlled rolling and controlled cooling processes for controlling the microscopic structure and grain sizein a plate thickness direction, the crack-arrest steel plate with high yield and stable strength and toughness is obtained. The high-strength thick steel plate provided by the Invention is used as container vessel steel, and has the characteristics of excellent crack-arrest toughness, high yield strength, excellent low-temperature toughness and large thickness.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com