Manufacturing method for 2xxx series ultra-large-dimension aluminum alloy round ingot

A technology with super-large specifications and manufacturing methods, which is applied in the field of aluminum alloy processing, can solve the problems of casting molding and metallurgical quality, which cannot meet the needs, coarse grains, etc., and achieve good comprehensive mechanical properties, good strength and plasticity, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

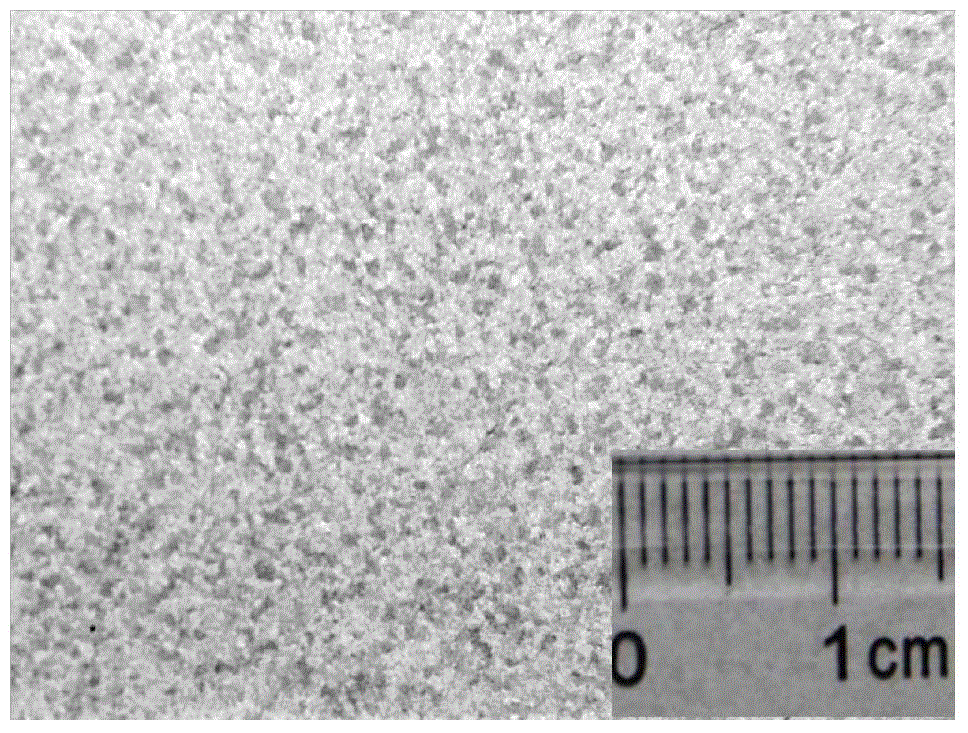

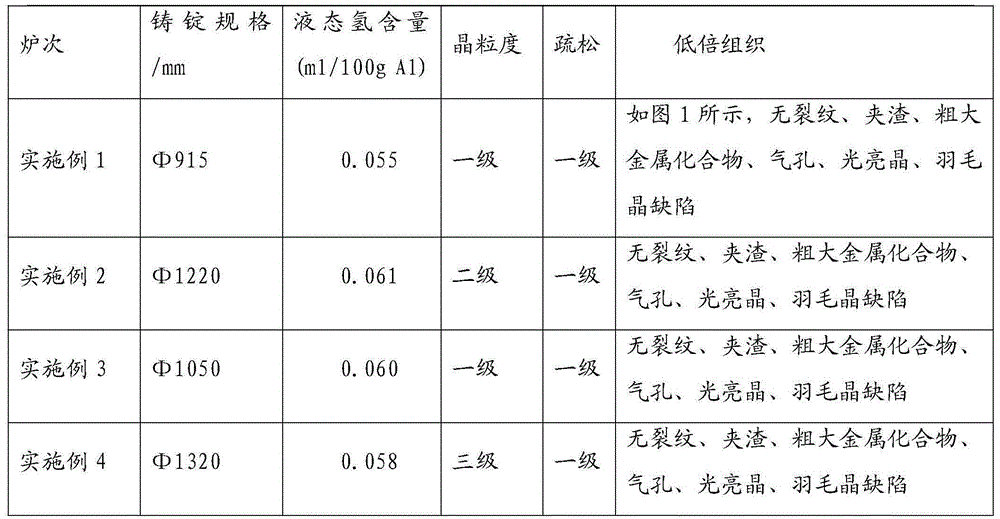

Embodiment 1

[0039] Casting large-scale aluminum alloy round ingots with a specification of Φ915mm×6000mm, the production process includes the steps of material preparation, melting, furnace refining, on-line refining, on-line filtration, semi-continuous casting, homogenization heat treatment, machining and ultrasonic flaw detection, as follows :

[0040] (1) Material preparation: According to the mass percentage of each chemical composition in the aluminum alloy round ingot: Cu 6.8%, Mn 0.4%, V 0.10%, Zr 0.15%, Ti 0.08%, Be 0.0005%, Zn≤0.1%, Mg≤ 0.01%, Si≤0.10%, Fe≤0.20%, the balance is Al and unavoidable impurities for batching, respectively weighing aluminum ingots for remelting, cathode copper, aluminum-copper master alloy, aluminum-titanium master alloy, aluminum-manganese intermediate alloy, aluminum zirconium master alloy, aluminum vanadium master alloy, aluminum beryllium master alloy as raw materials;

[0041] (2) Melting: Put the raw materials in step (1) except aluminum-titaniu...

Embodiment 2

[0050] Casting ultra-large aluminum alloy round ingots with specifications of Φ1220mm×6000mm, the production process includes the steps of material preparation, melting, furnace refining, on-line refining, on-line filtration, semi-continuous casting, homogenization heat treatment, machining and ultrasonic flaw detection, as follows :

[0051] (1) Material preparation: according to the mass percentage of each chemical composition in the aluminum alloy round ingot: according to the mass percentage of each chemical composition in the aluminum alloy round ingot: Cu 6.1%, Mn 0.25%, V 0.06%, Zr 0.16%, Ti 0.09%, Be 0.0006%, Zn ≤ 0.1%, Mg ≤ 0.02%, Si ≤ 0.10%, Fe ≤ 0.20%, the balance is Al and unavoidable impurities for batching, respectively weighing aluminum ingots for remelting, cathode copper , aluminum-copper master alloy, aluminum-titanium master alloy, aluminum-manganese master alloy, aluminum-zirconium master alloy, aluminum-vanadium master alloy, aluminum-beryllium master allo...

Embodiment 3

[0060] Casting ultra-large aluminum alloy round ingots with specifications of Φ1050mm×6500mm, the production process includes the steps of material preparation, smelting, furnace refining, on-line refining, on-line filtration, semi-continuous casting, homogenization heat treatment, machining and ultrasonic flaw detection, as follows :

[0061] (1) Material preparation: According to the mass percentage of each chemical composition in the aluminum alloy round ingot, Cu 5.9%, Mn 0.35%, V 0.15%, Zr 0.15%, Ti 0.08%, Be 0.0010%, Zn≤0.1%, Mg≤0.01 %, Si≤0.20%, Fe≤0.30%, the balance is Al and unavoidable impurities for batching, respectively weighing aluminum ingots for remelting, cathode copper, aluminum-copper master alloy, aluminum-titanium master alloy, aluminum-manganese master alloy , aluminum zirconium master alloy, aluminum vanadium master alloy, aluminum beryllium master alloy as raw materials;

[0062] (2) Melting: put the raw materials in step (1) except aluminum-titanium m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com