Ceramic mobile phone shell and preparation method thereof

A mobile phone case and ceramic technology, applied in the field of ceramic mobile phone case and its preparation, can solve the problems of uneven density distribution of green body, uneven microstructure, poor performance of mobile phone case, etc., and achieve high fracture toughness, good mechanical properties, stress Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

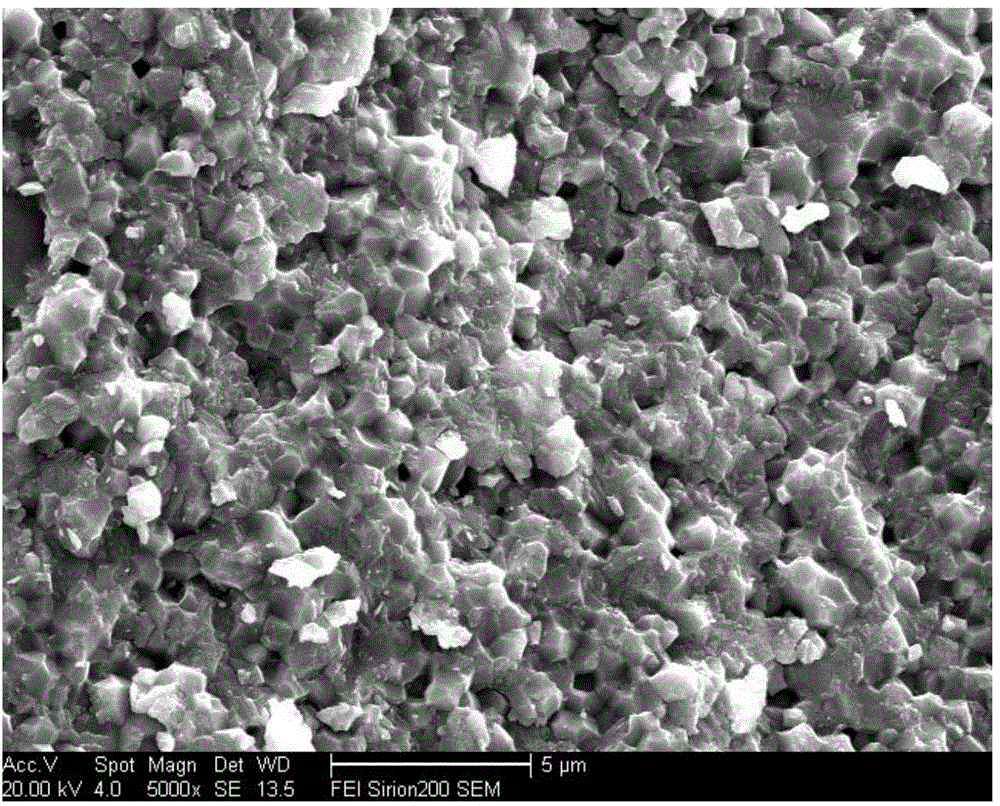

Image

Examples

preparation example Construction

[0028] In a first aspect, an embodiment of the present invention provides a method for preparing a ceramic mobile phone case, comprising the following steps:

[0029] Taking ceramic powder, an organic functional additive with a mass ratio of 2% to 8% of the ceramic powder, and a solvent with a mass ratio of 7% to 18% of the ceramic powder as raw materials; the organic functional additive Comprising monomers, crosslinking agents and photoinitiators, the solvent is one of deionized water, polyethylene glycol, ethanol or a mixture of polyethylene glycol and ethanol;

[0030] mixing the ceramic powder, an organic functional additive and a solvent, and performing wet ball milling to form a gelable ceramic slurry, and defoaming the gelable ceramic slurry;

[0031] The gelable ceramic slurry after defoaming treatment is injected into the preset mold, and the gelation process is initiated by ultraviolet light irradiation to obtain a ceramic mobile phone shell body, and then the obtain...

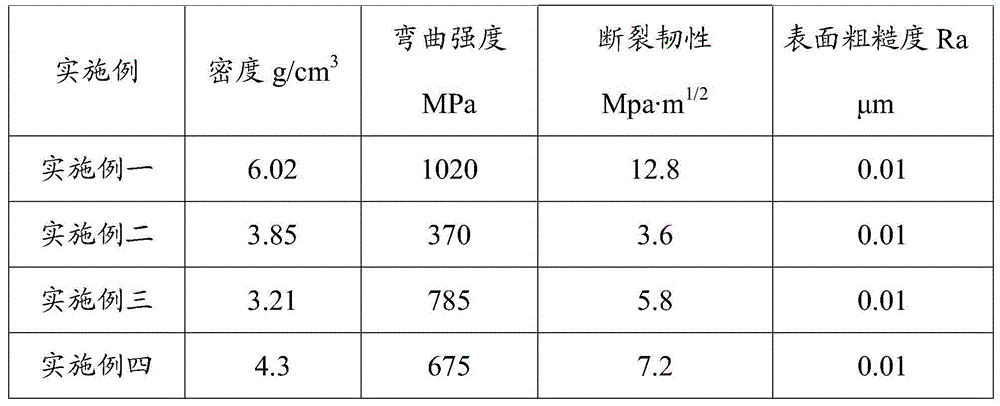

Embodiment 1

[0058] Take the preparation of a zirconia ceramic mobile phone case with a size of 120mm×60mm×0.5mm as an example with a φ10 hole (camera hole) in the middle:

[0059] Get each raw material by following weight ratio:

[0060] Zirconia powder with an average particle size of 0.3μm 475kg

[0061] Titanium dioxide 25kg

[0062] Acrylic polyester 20kg

[0063] N,N'-methylenebisacrylamide 0.1kg

[0064] Polydimethylacrylic acid 0.15kg

[0065] 1-Hydroxycyclohexyl phenyl ketone 0.2kg

[0066] 2-Hydroxy-2-methylphenylpropan-1-one 0.06kg

[0067] Deionized water 75kg

[0068] After mixing the above-mentioned various raw materials, perform wet ball milling to make a gelatable ceramic slurry, and vacuum stir and defoam the obtained gelatable ceramic slurry;

[0069] Inject the gelled ceramic slurry after defoaming treatment into the preset mold, using 320nm wavelength and light intensity of 500mW / cm 2 The gel process is completed by irradiating ultraviolet light for 0.5min; usin...

Embodiment 2

[0073] Take the preparation of an alumina ceramic mobile phone case with a size of 100mm×50mm×0.4mm as an example to illustrate:

[0074] Get each raw material by following weight ratio:

[0075] Average particle size 0.8μm high purity α-alumina powder 199kg

[0077] Methacrylic acid 3kg

[0078] Polydimethylacrylic acid 0.15kg

[0079] 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 0.06kg

[0080] Sodium tripolyphosphate 1kg

[0081] Deionized water 36kg

[0082] After mixing the above-mentioned various raw materials, perform wet ball milling to make a gelatable ceramic slurry, and vacuum stir and defoam the obtained gelatable ceramic slurry;

[0083] Inject the gelatable ceramic slurry after defoaming treatment into the preset mold, using 265nm wavelength and light intensity of 430mW / cm 2 The gel process was completed by irradiating ultraviolet light for 1 min; a large-sized ceramic green sheet with a size of 300mm×300mm×0.8mm was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com