Patents

Literature

81results about How to "Improve meshing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

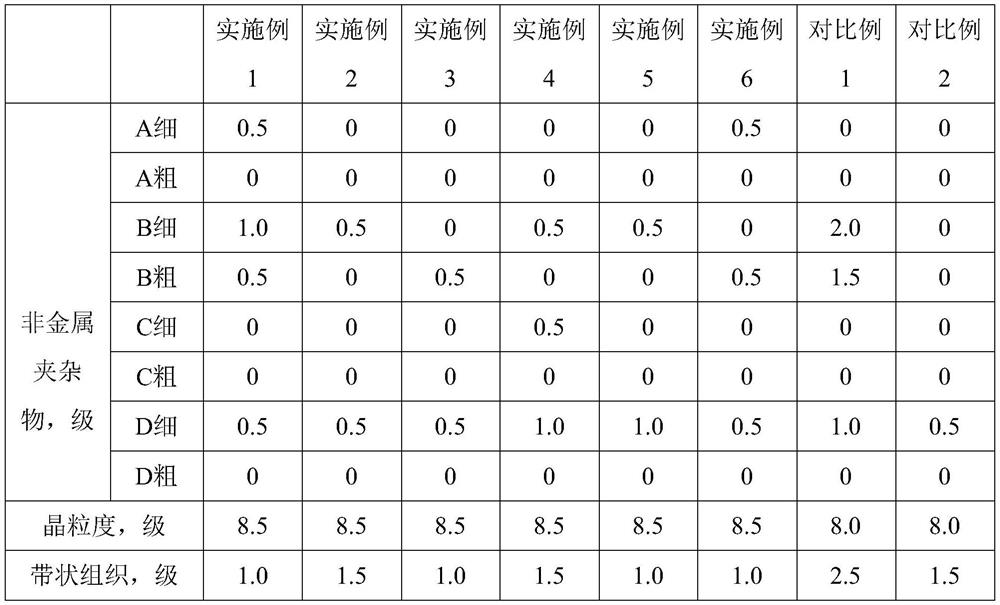

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

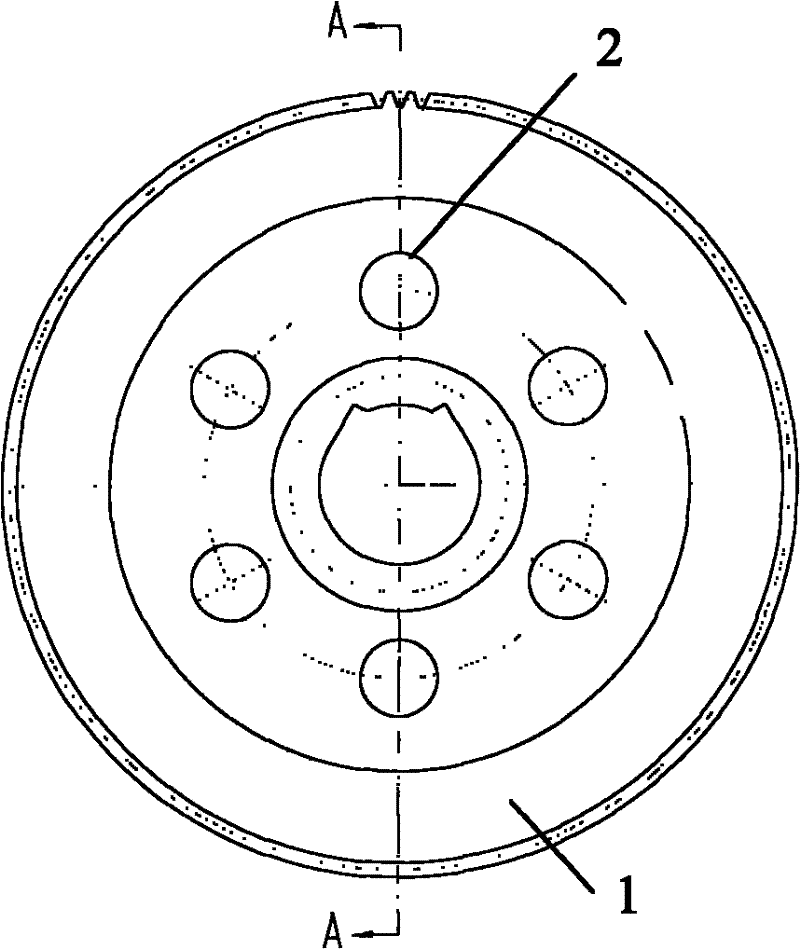

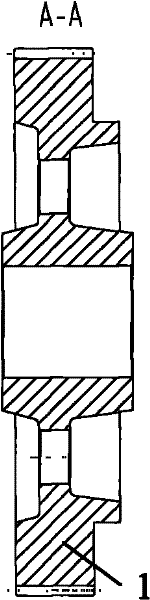

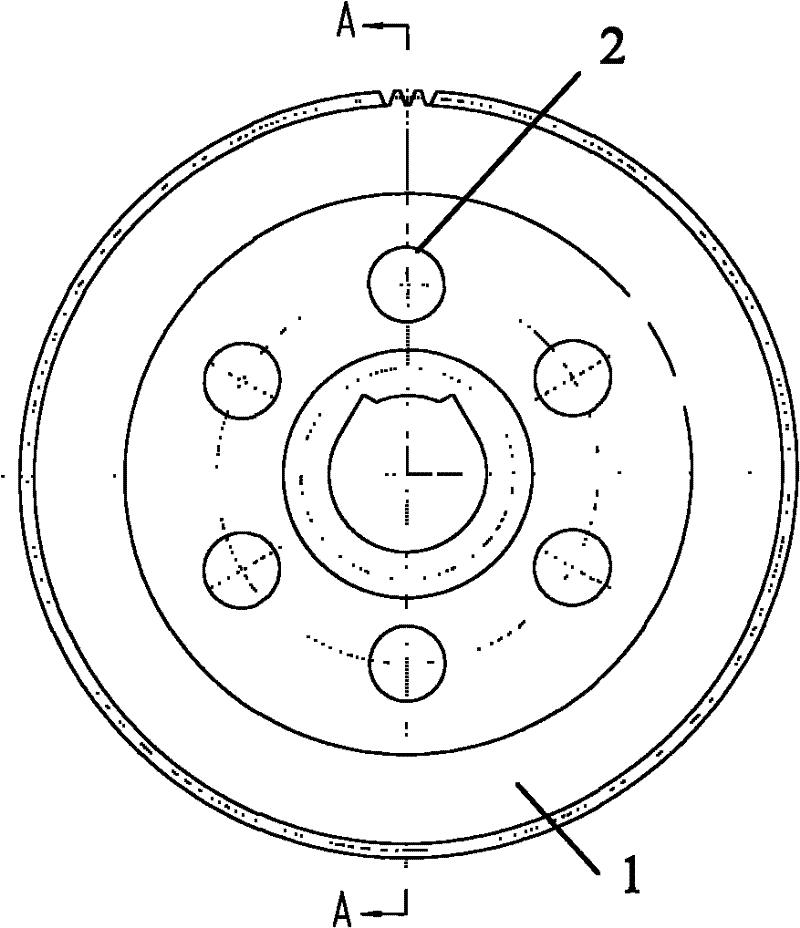

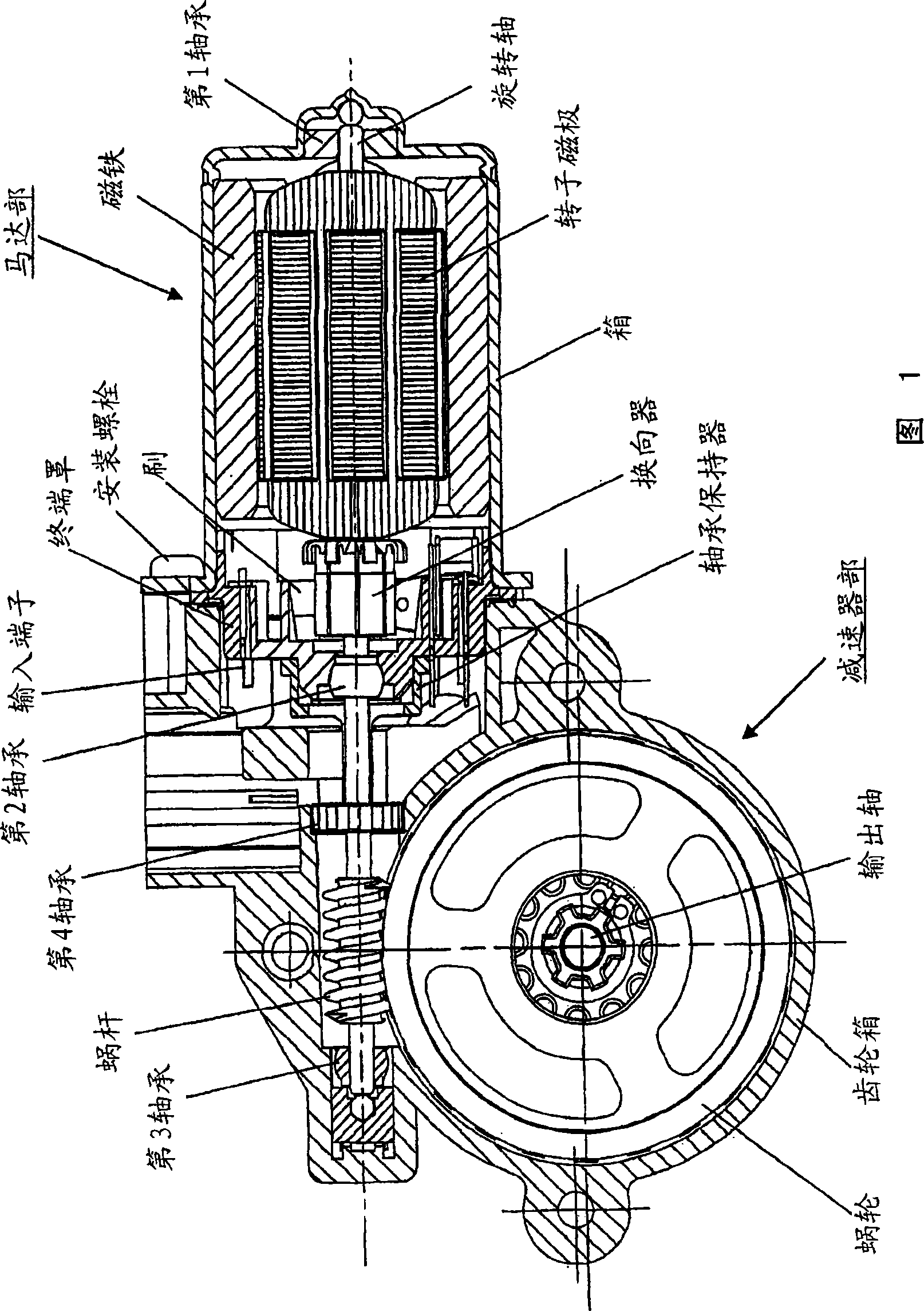

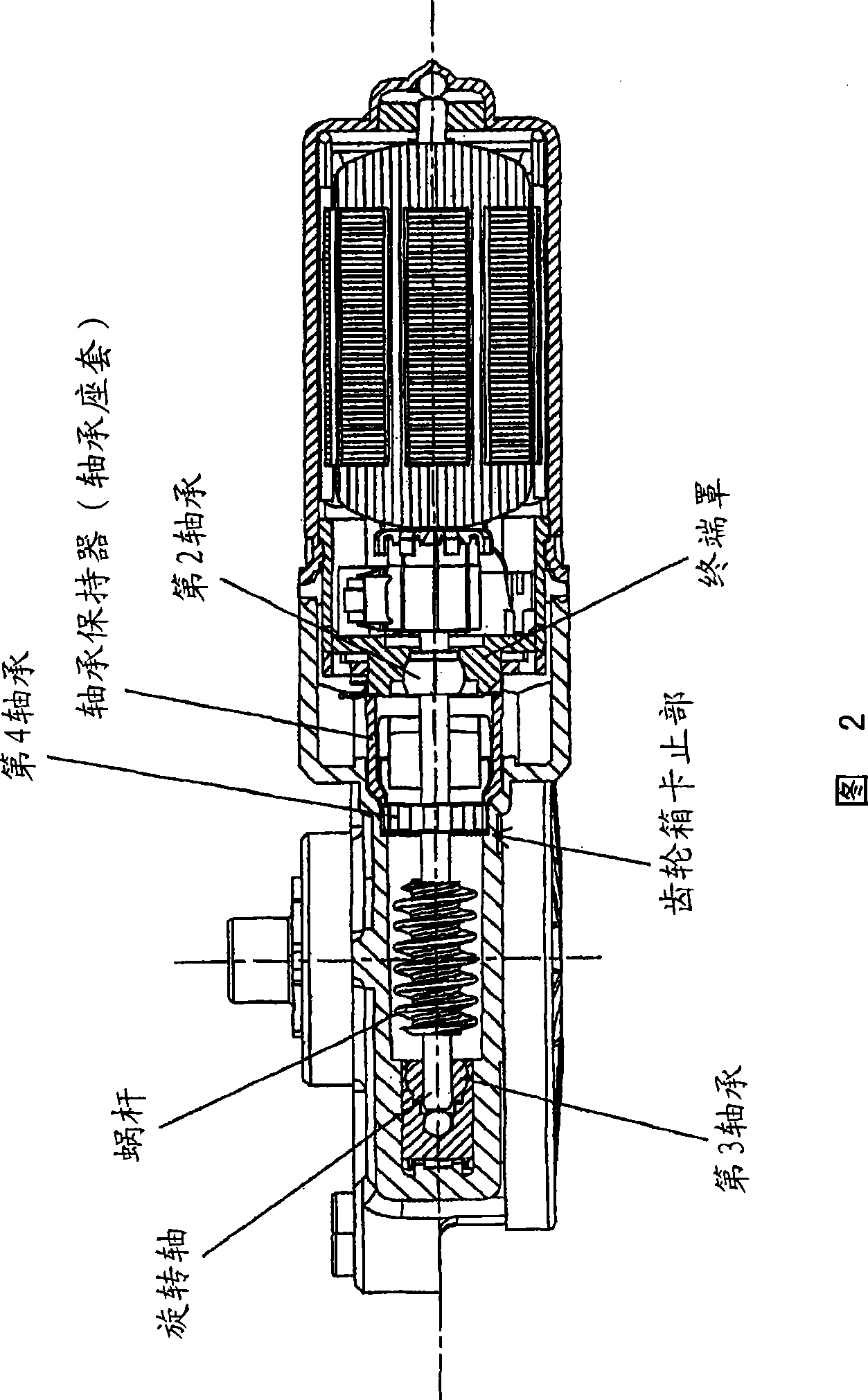

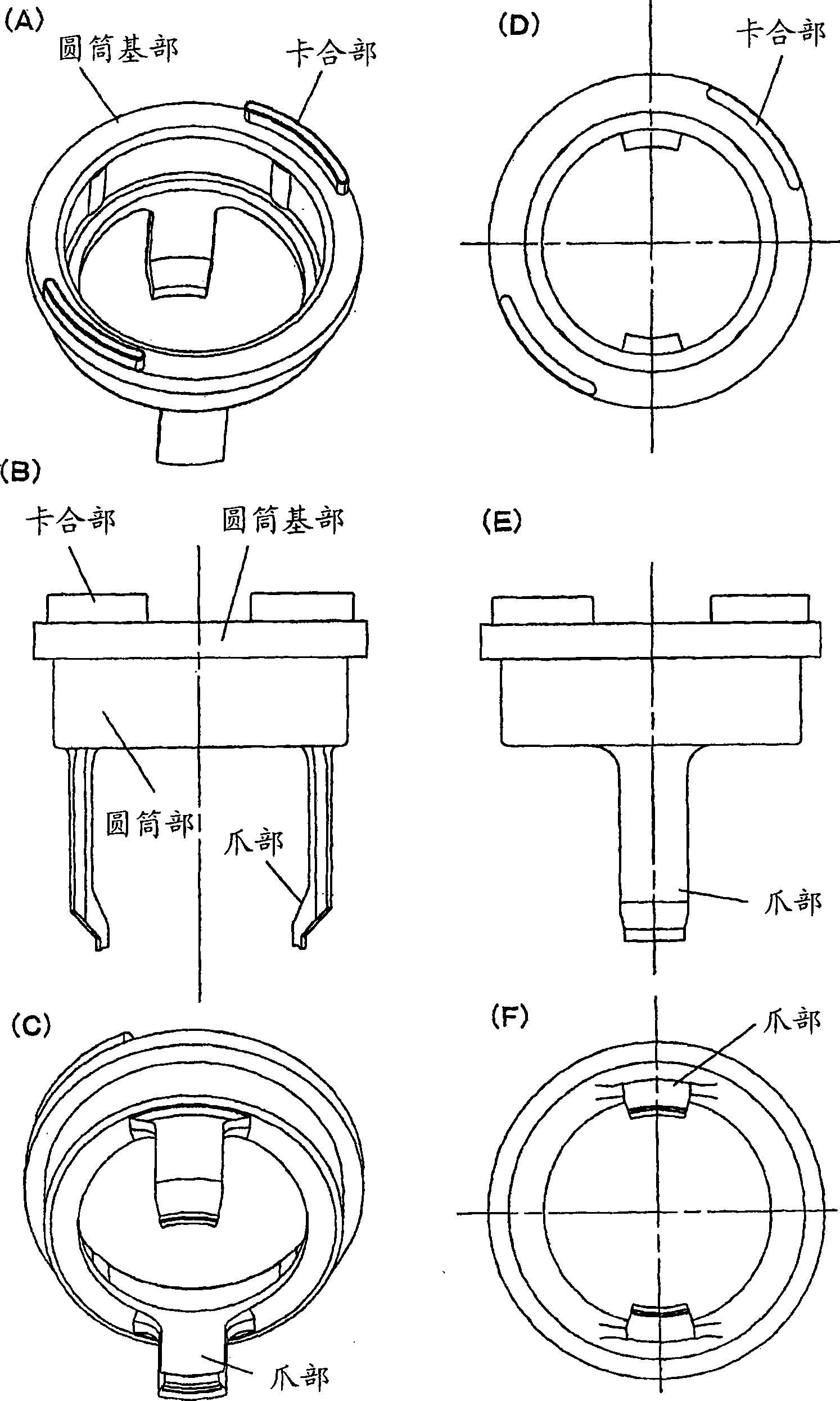

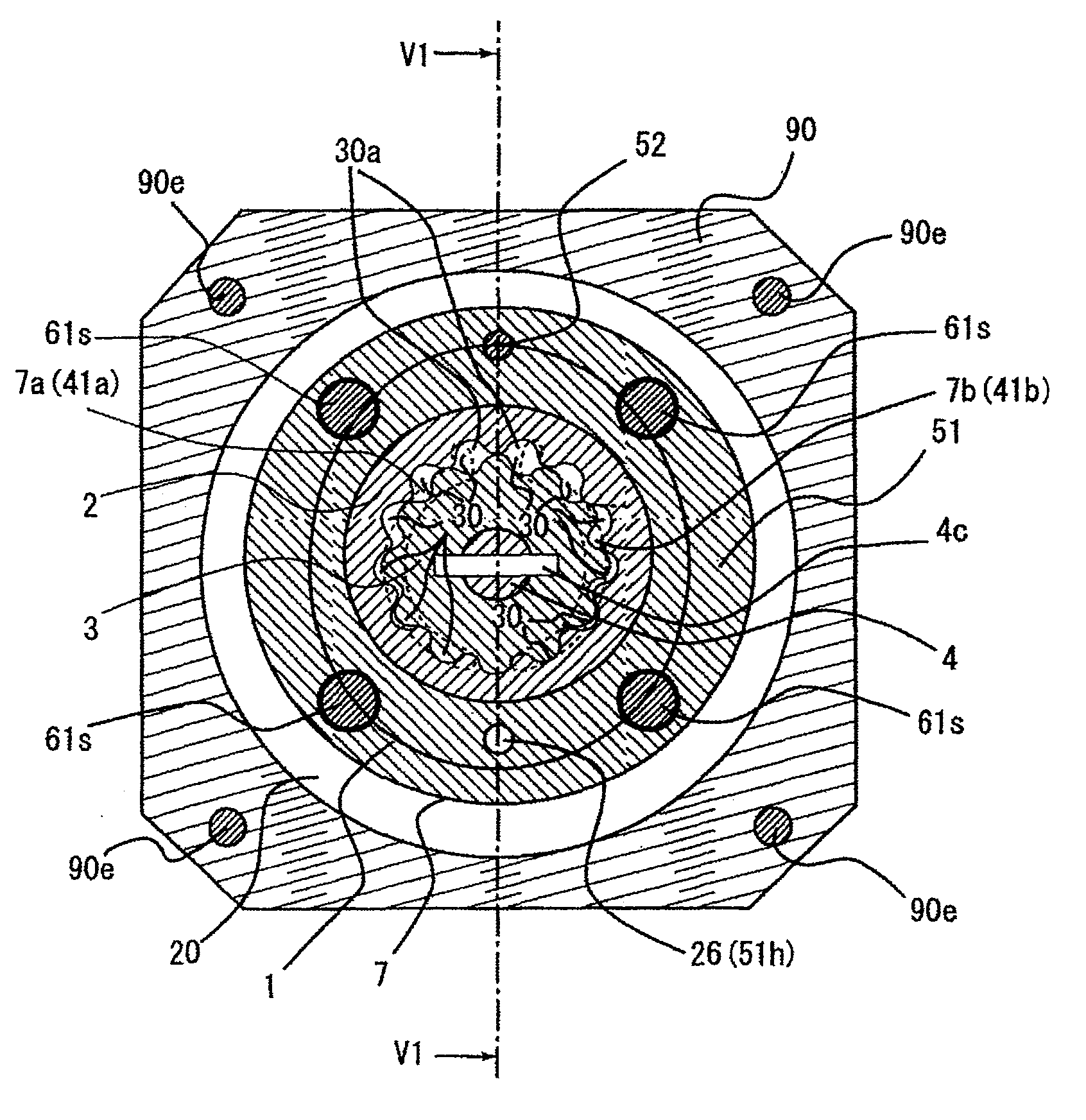

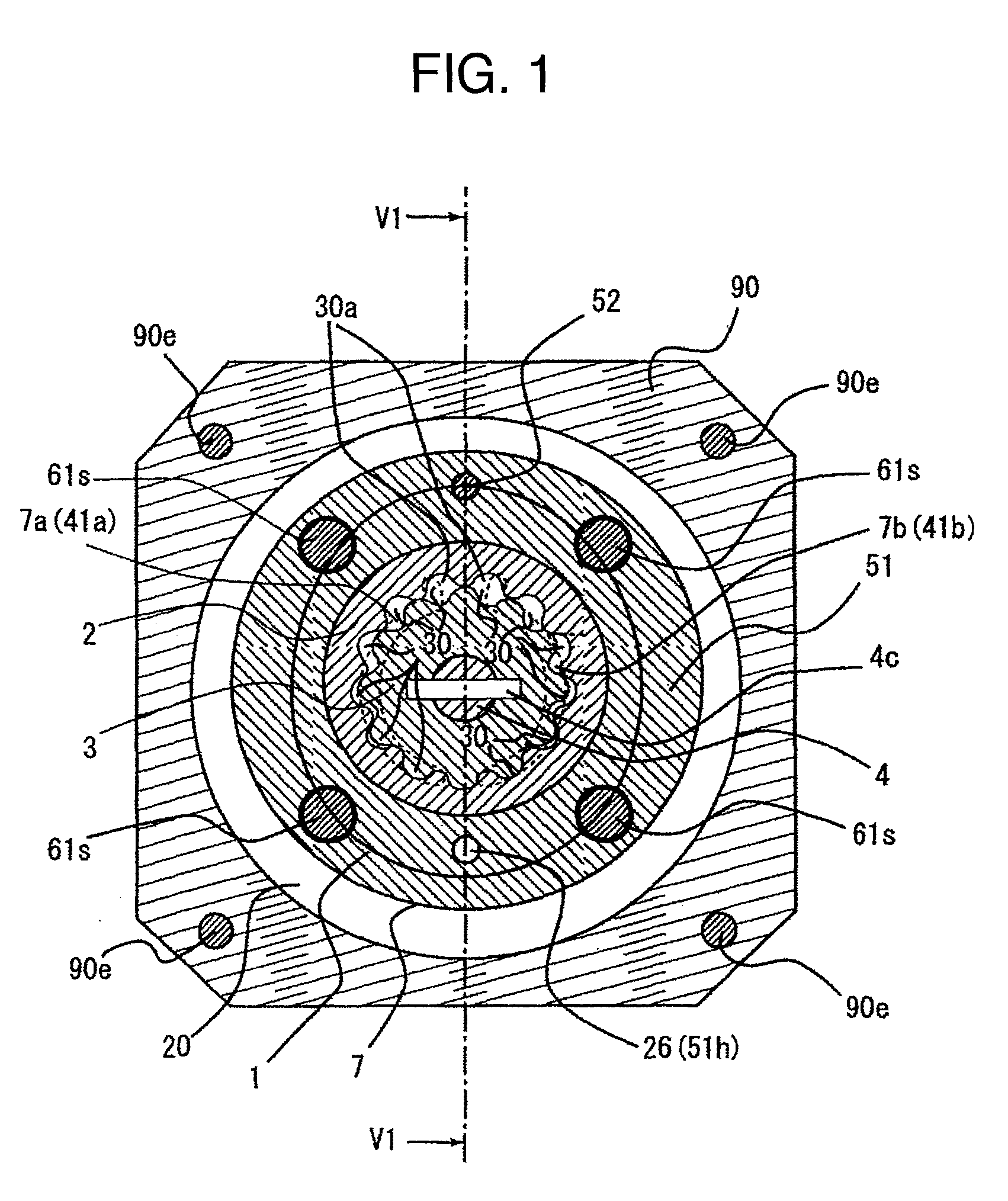

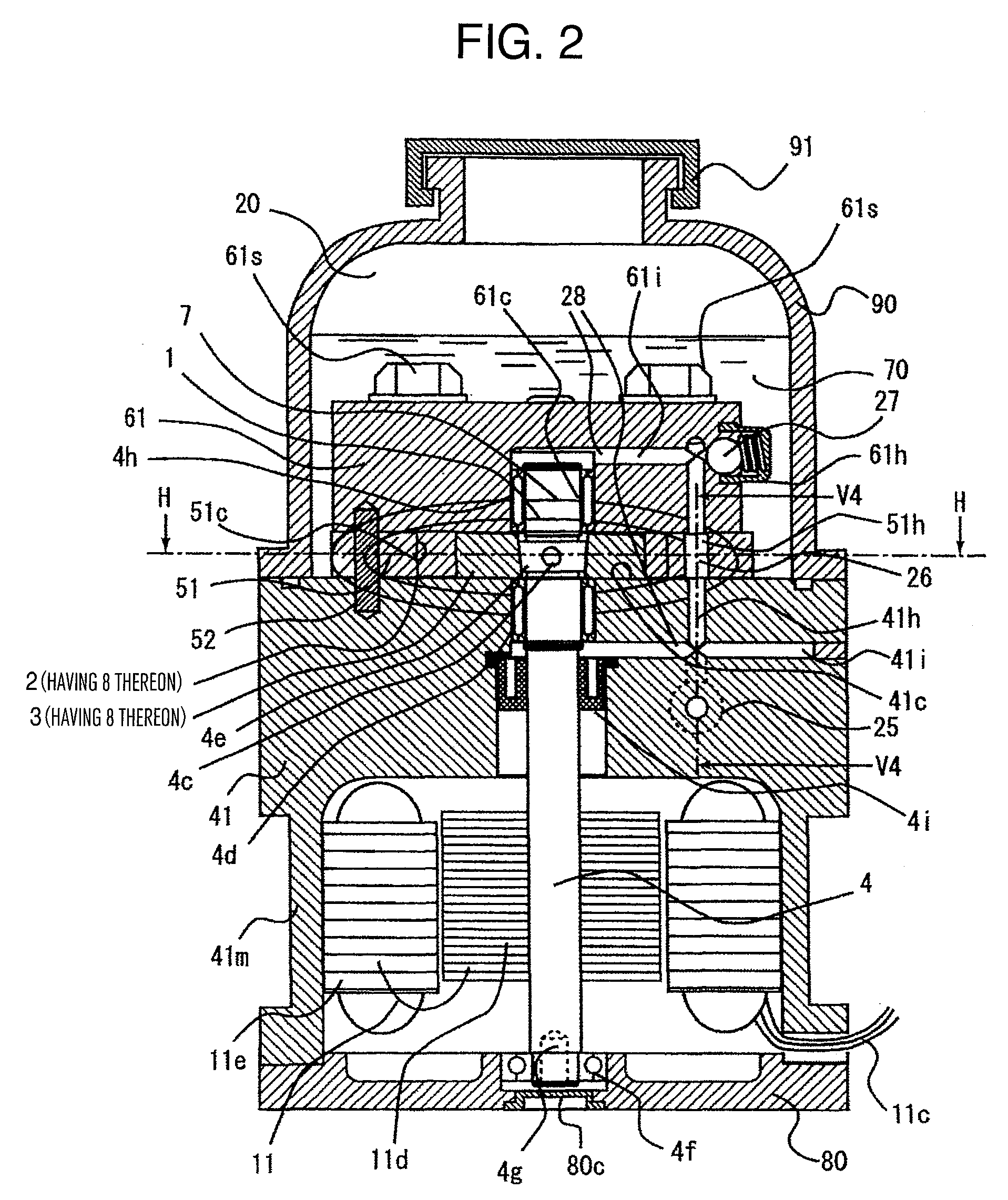

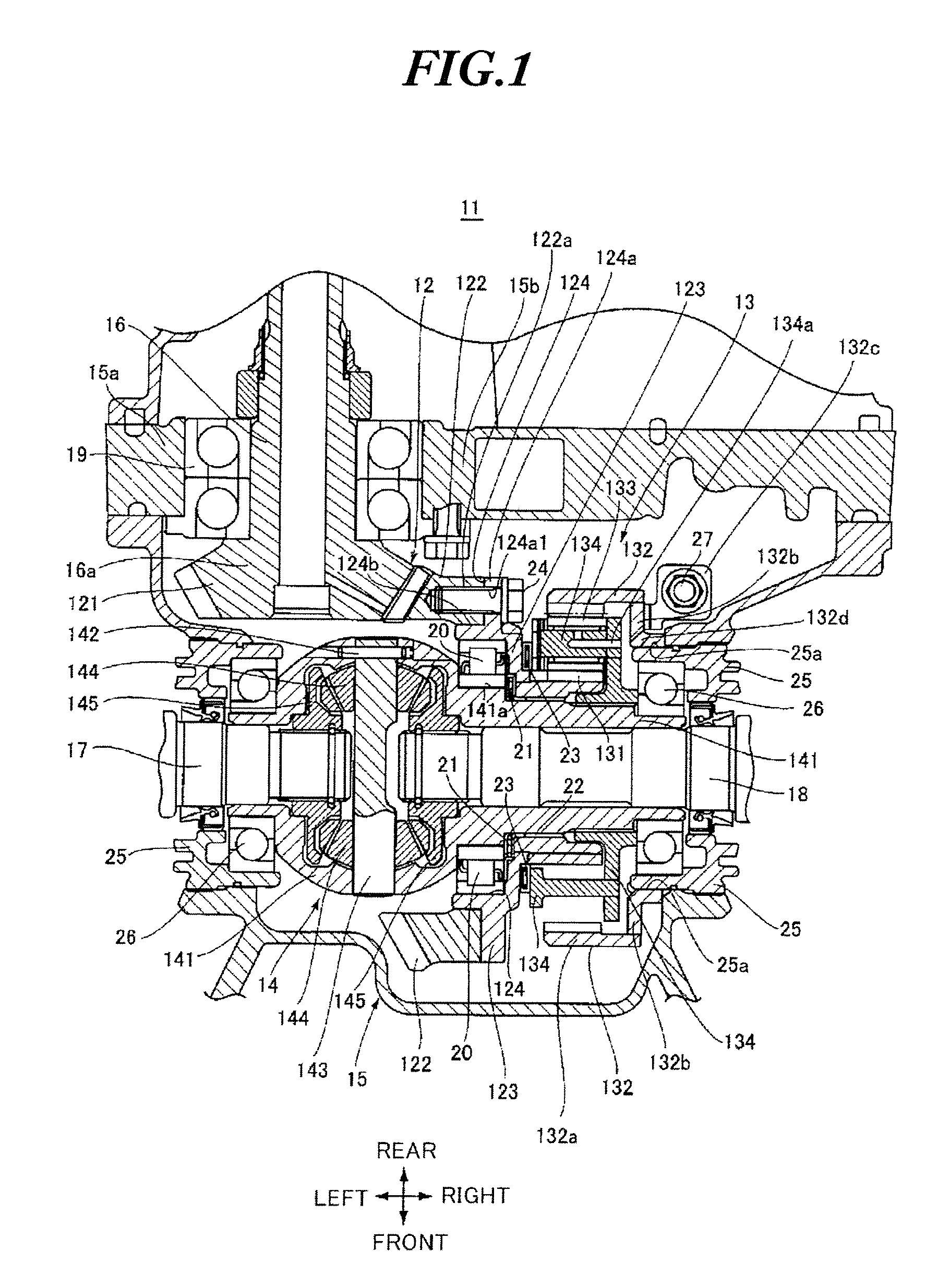

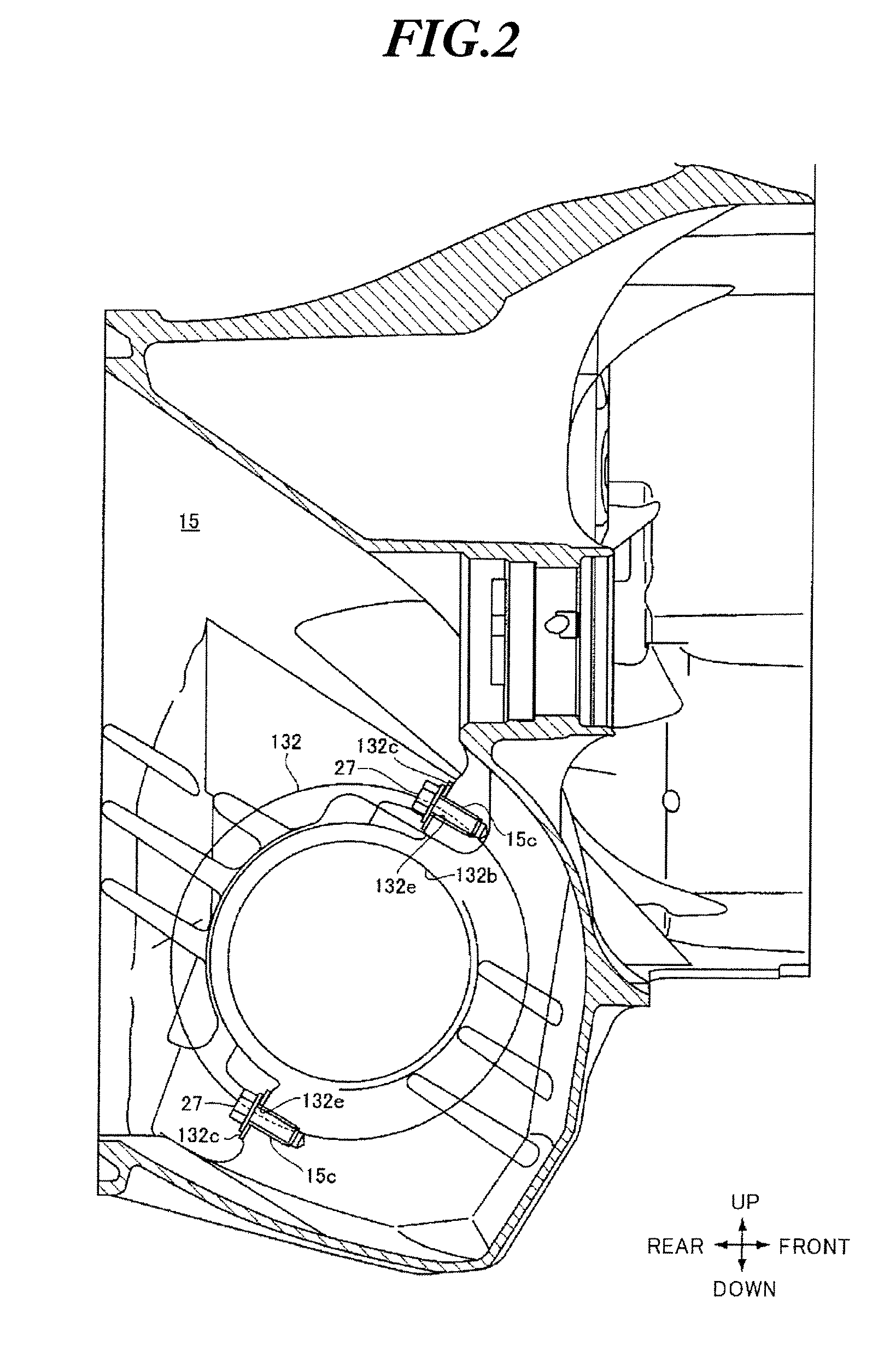

Motor equipped with reducer and method of manufacturing the same

ActiveCN101443986ASufficient breaking strengthImprove meshing accuracyMechanical apparatusMechanical energy handlingReduction driveReducer

Owner:MABUCHI MOTOR

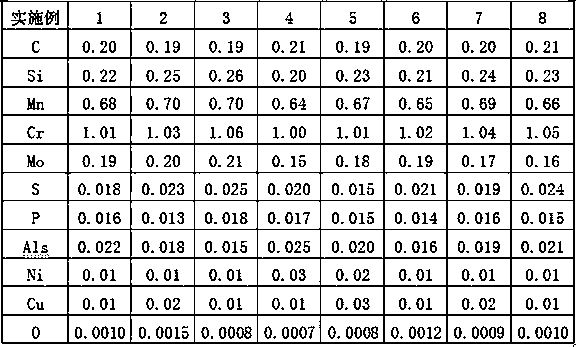

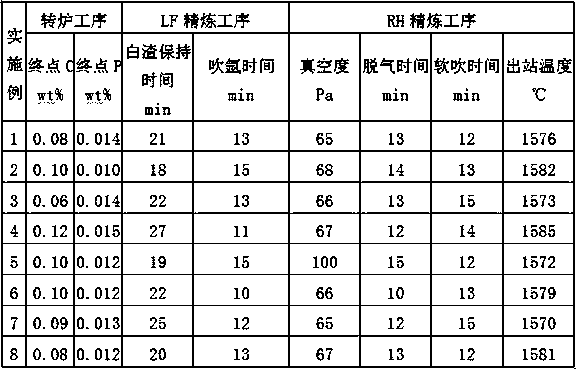

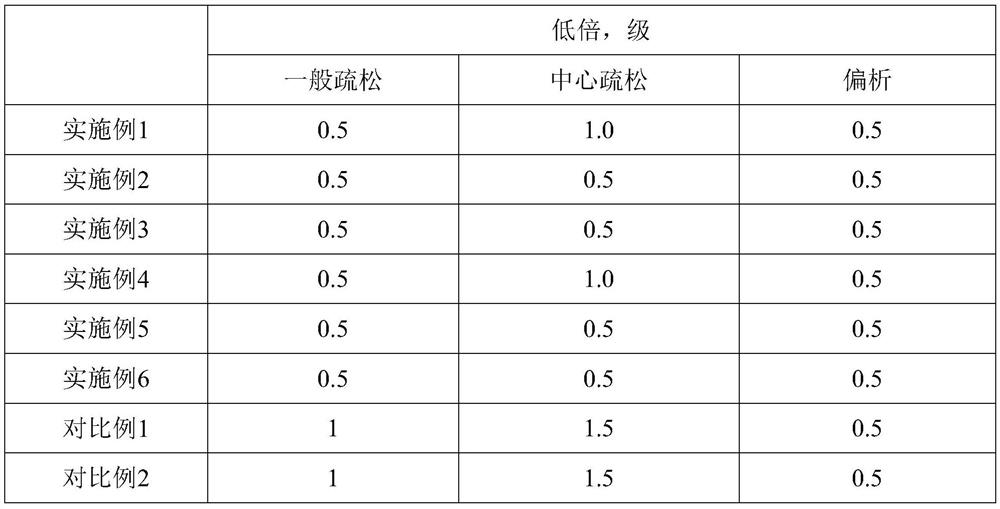

Gear steel 20CrMoSH and technology for improving hardenability stability thereof

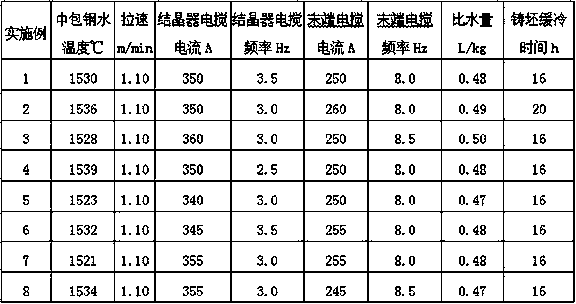

The invention discloses gear steel 20CrMoSH and a technology for improving the hardenability stability thereof. The technology comprises the procedures of converter smelting, LF refining, RH refining,continuous casting, heating and rolling. The gear steel is prepared from the chemical components, by weight, 0.19%-0.21% of C, 0.20%-0.26% of Si, 0.64%-0.70% of Mn, 1.00%-1.06% of Cr, 0.15%-0.21% ofMo, 0.015%-0.025% of S, smaller than or equal to 0.018% of P, 0.015%-0.025% of Als, smaller than or equal to 0.03% of Ni, smaller than or equal to 0.03% of Cu, smaller than or equal to 0.0015% of O and the balance Fe and unavoidable impurities. According to the gear steel 20CrMoSH which is produced through the method and has the diameter phi ranging from 28 mm to 50 mm, the hardenability J1.5 ranges from 40 HRC to 45 HRC, the hardenability J5 ranges from 37 HRC to 42 HRC, the hardenability J9 ranges from 28 HRC to 33 HRC, and the maximum discrete value of the hardenability of the steel in thesame furnace is not larger than 3 HRC. The heat-treatment deformation of a gear can be significantly reduced by means of high-stability hardenability, and therefore the meshing precision of the gear is improved. The method is low in cost and high in production efficiency, and the product has the advantages that the hardenability is stable, the gear heat-treatment deformation is small, and the machined gear is high in meshing precision and low in service life.

Owner:HANDAN IRON & STEEL GROUP +1

Pump Apparatus and Power Steering

InactiveUS20070253855A1Reduce leakageImprove pumping capacityEngine of arcuate-engagement typeOscillating piston enginesPower steeringGear pump

In order to realize cost reduction in a gear pump apparatus by reducing form accuracy of a gear while securing pump performance, a running-in coating is provided on a tooth sliding contact portion when forming a confinement area in at least one of gears of the gear pump apparatus. By this feature, the running-in coating is gradually worn away and deformed according to rotary drive of the pump, and thus it is possible to obtain an optimal gear form in meshing combinations of the gears. Further, it is possible to reduce leakage inside the pump to secure the pump performance even if the form accuracy of the gear is reduced for the sake of the cost reduction.

Owner:HITACHI LTD

S-shaped joint for surgical robot, surgical instrument and endoscope

InactiveCN106955161AImprove carrying capacityImprove bending accuracyEndoscopesSurgical robotsSurgical robotEngineering

The invention provides an S-shaped joint for a surgical robot. The S-shaped joint comprises at least one joint connector pair and a flexible structure, a first joint connector of each joint connector pair comprises a first spherical surface, a first meshing mechanism is arranged on each first spherical surface, a second joint connector of each joint connector pair comprises a second spherical surface, a second meshing mechanism is arranged on the second spherical surface, each first meshing mechanism is meshed with the corresponding second meshing mechanism, the flexible structure controls the swing direction and the swing angle of the joint connector pair to realize swing of the S-shaped joint. The spherical surfaces are adopted as support structures of the joint connector pair during swing, and the bearing capacity of the S-shaped joint is improved; swing of the at least one joint connector pair is realized through meshing motion of the meshing mechanisms, the meshing precision of the meshing mechanisms is improved, and high bending precision of the S-shaped joint can be realized. A surgical instrument and an endoscope comprise the S-shaped joints, so that the tail end of the instrument or an imaging system can reach the expected position and posture.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

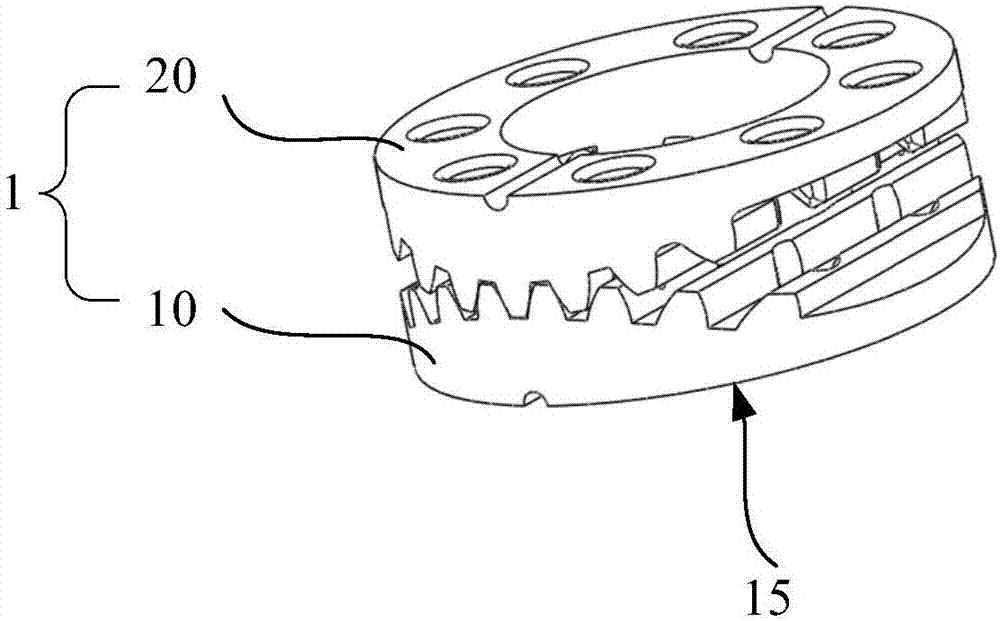

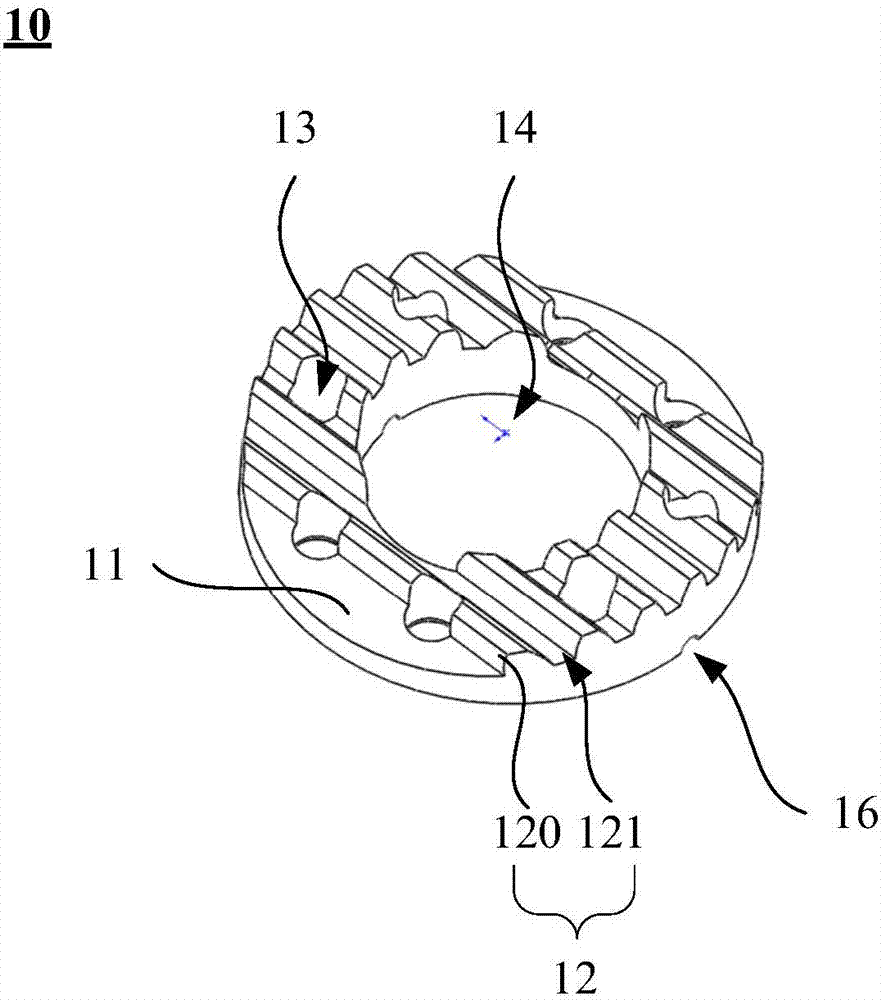

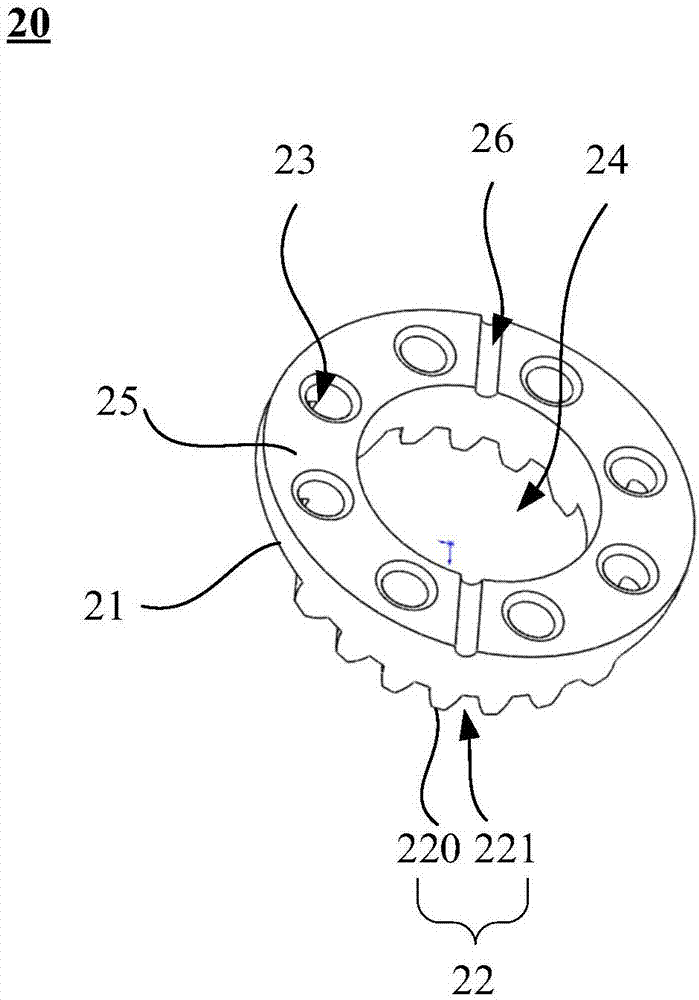

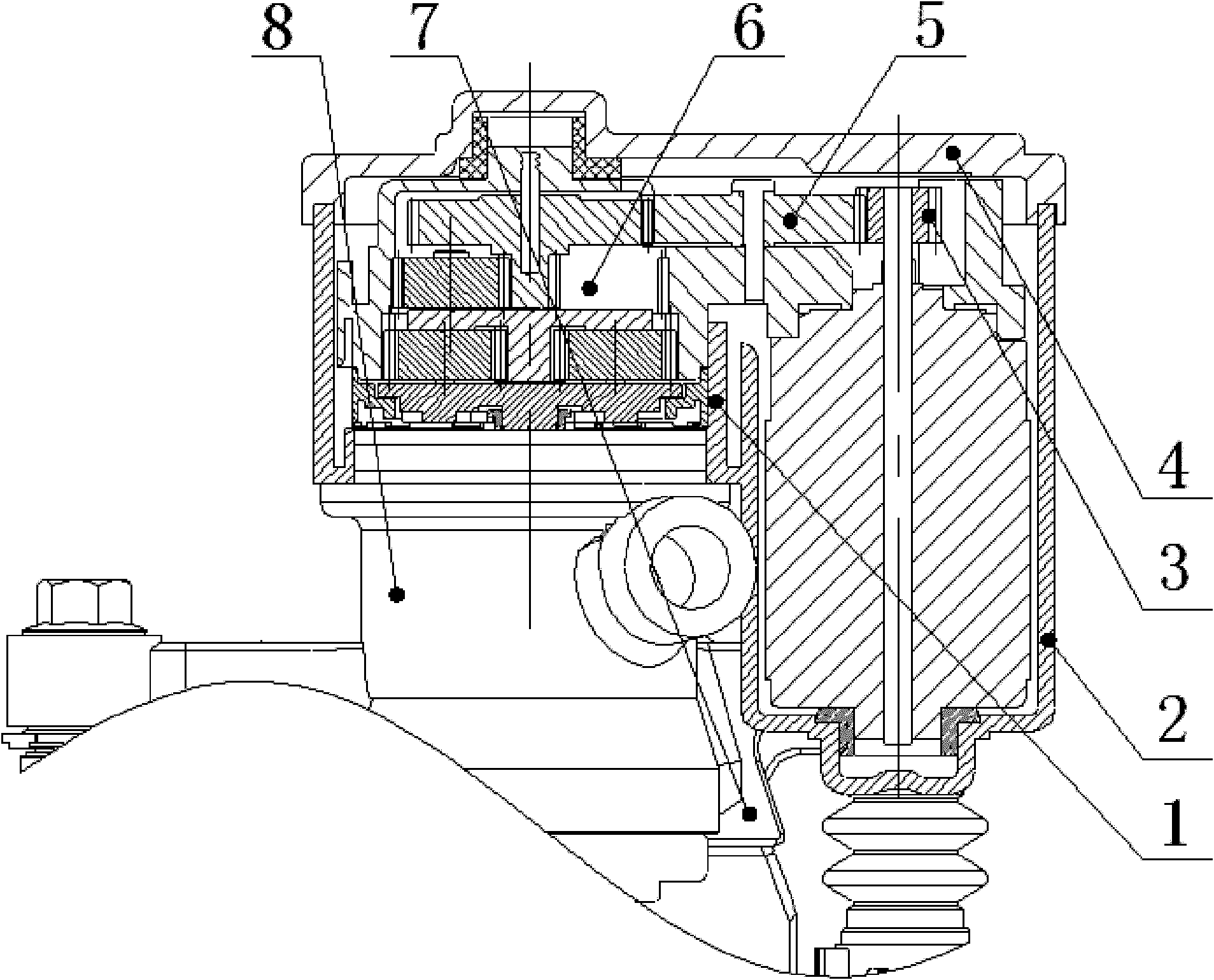

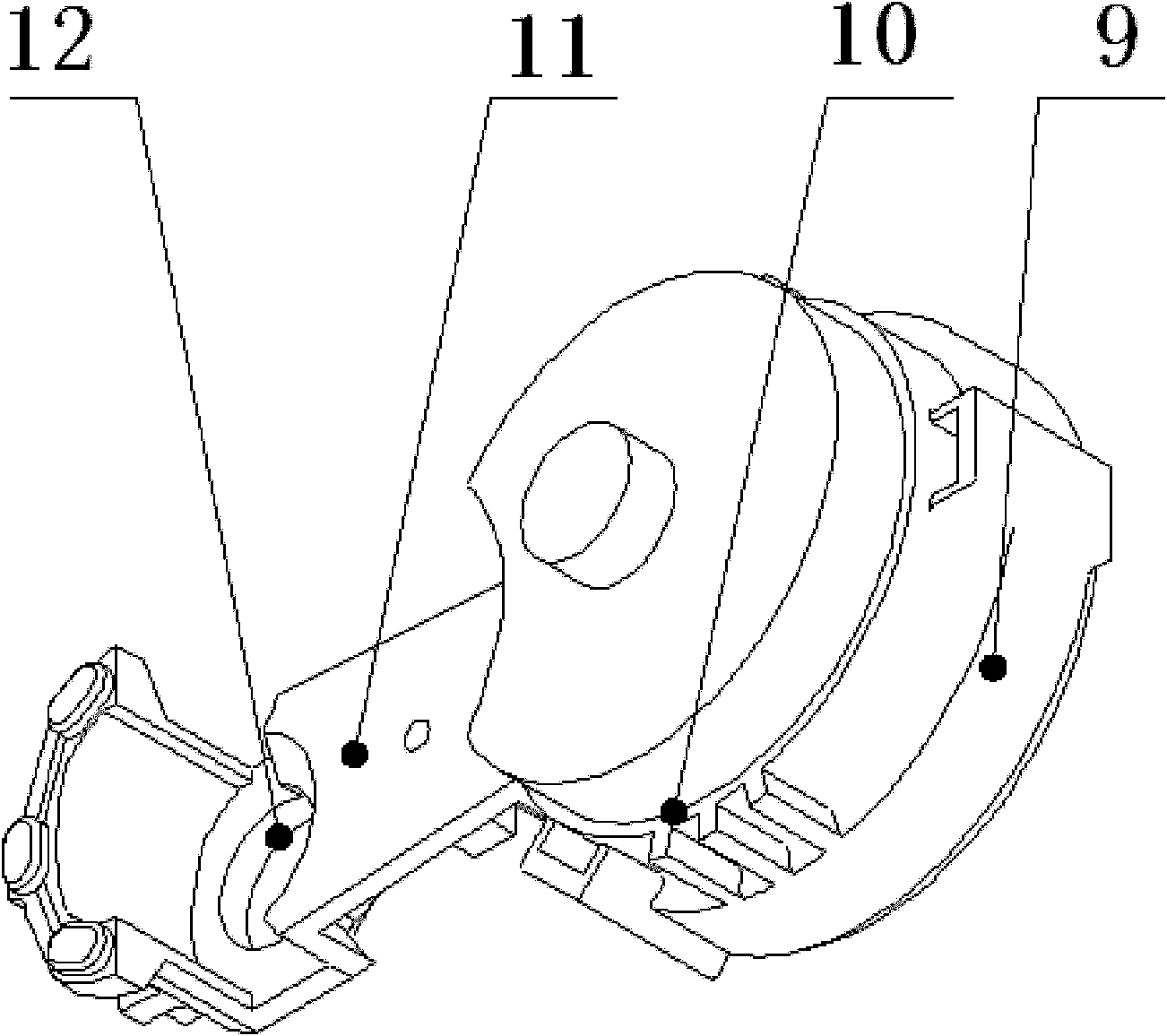

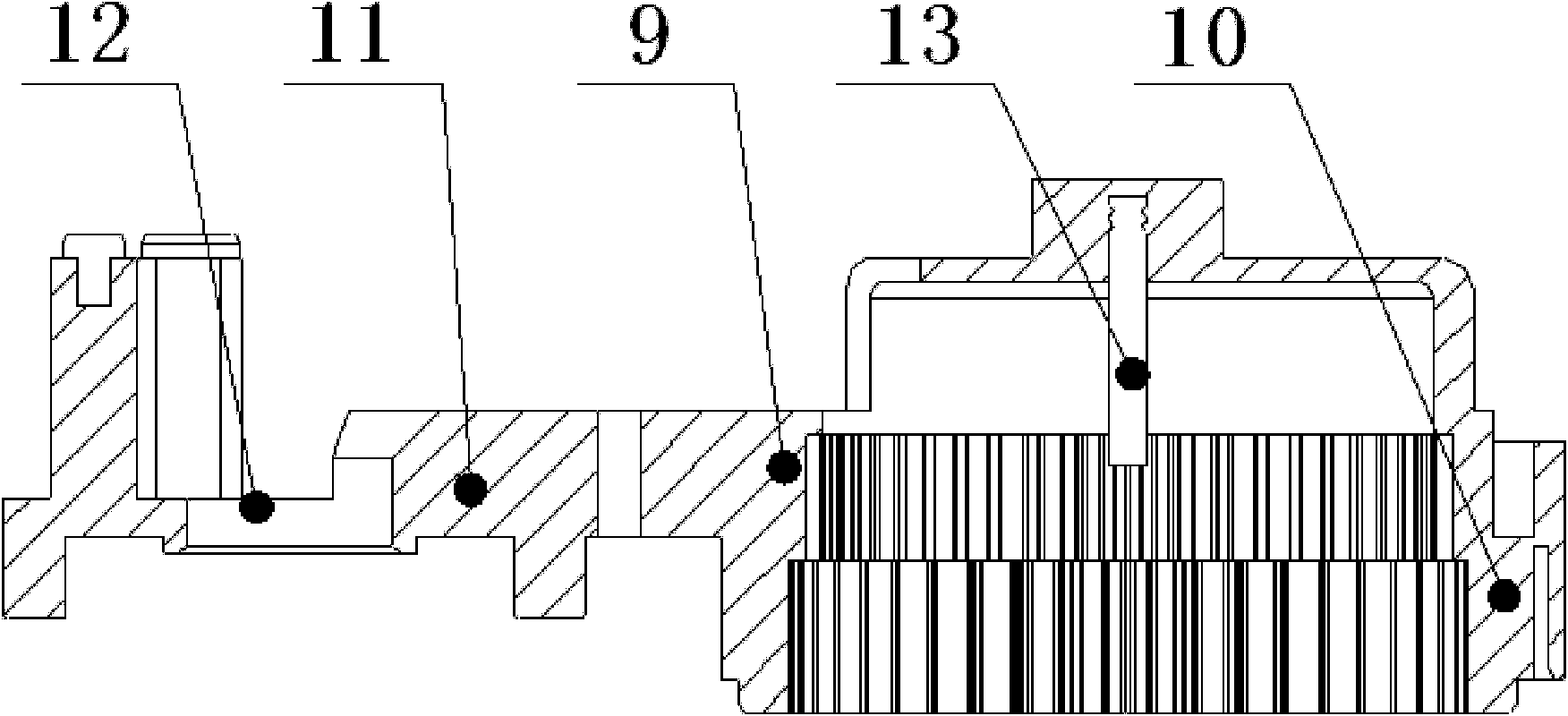

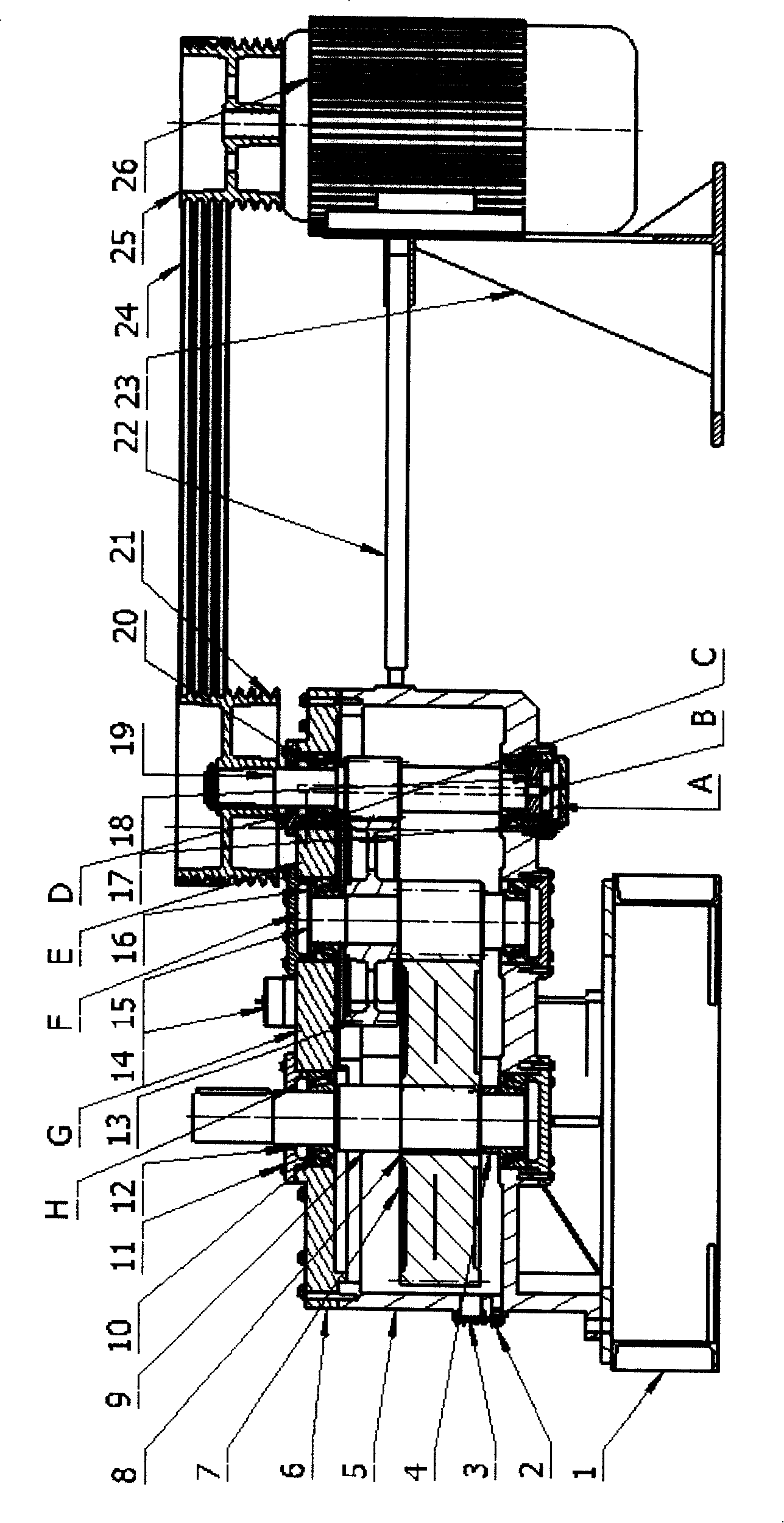

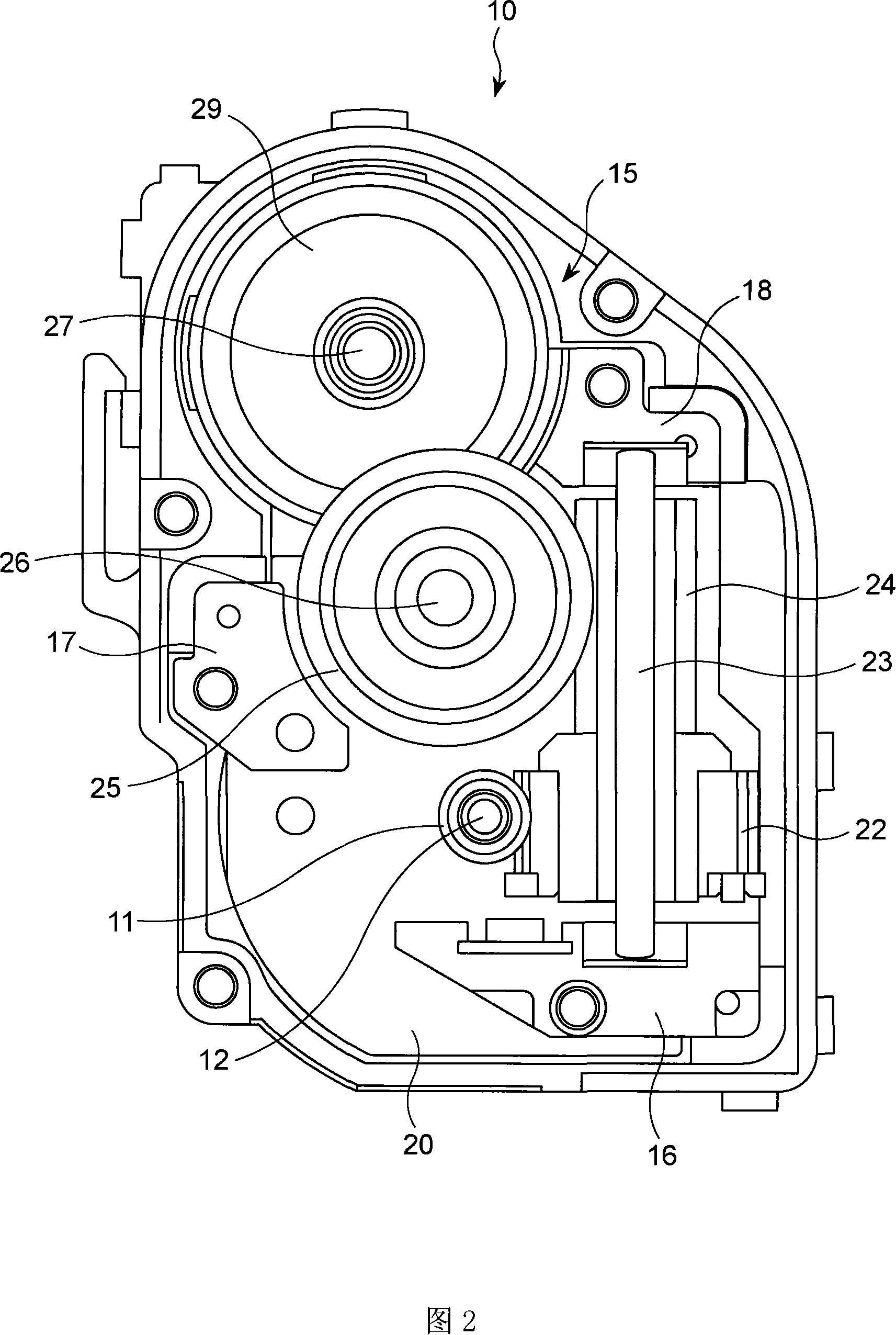

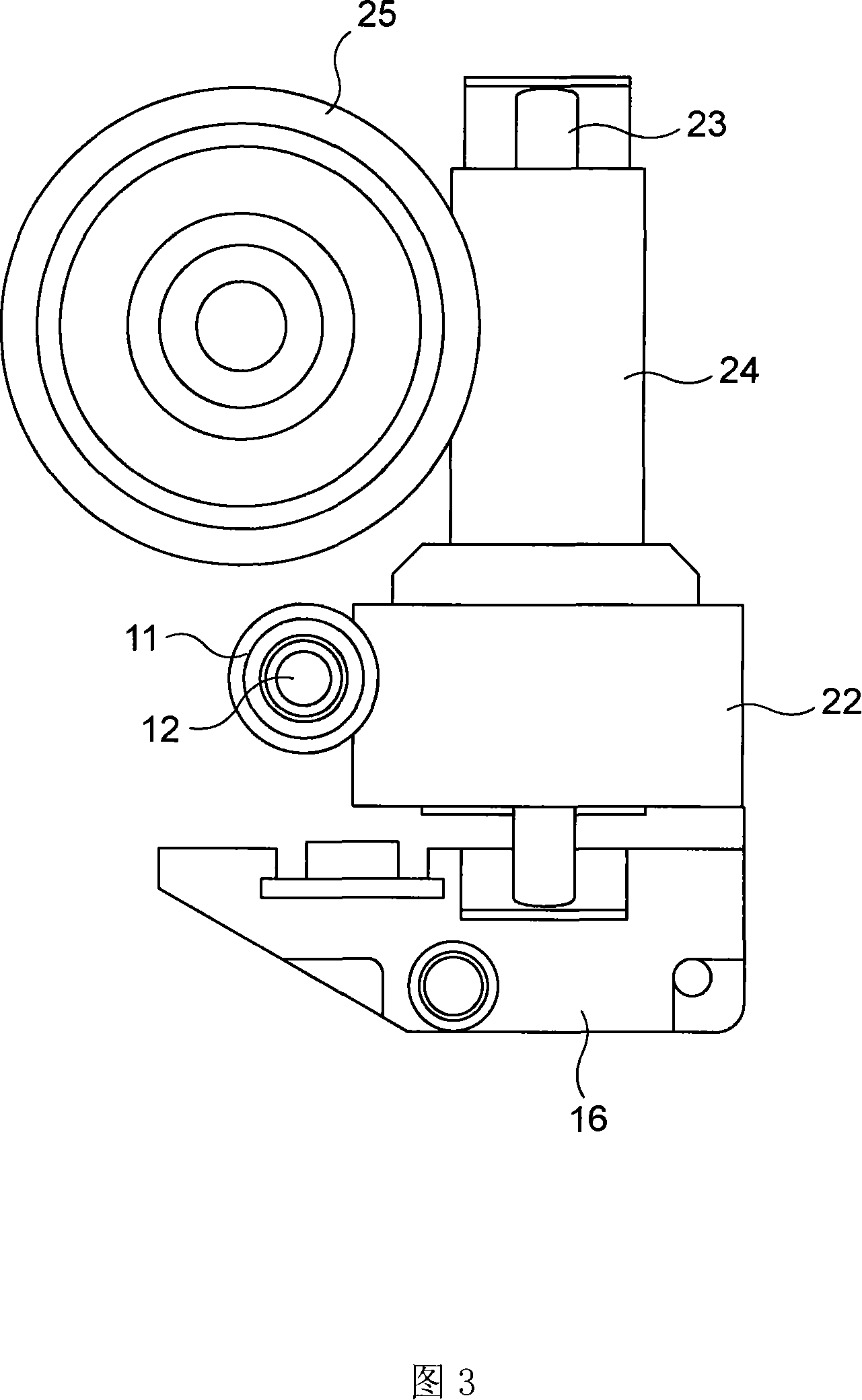

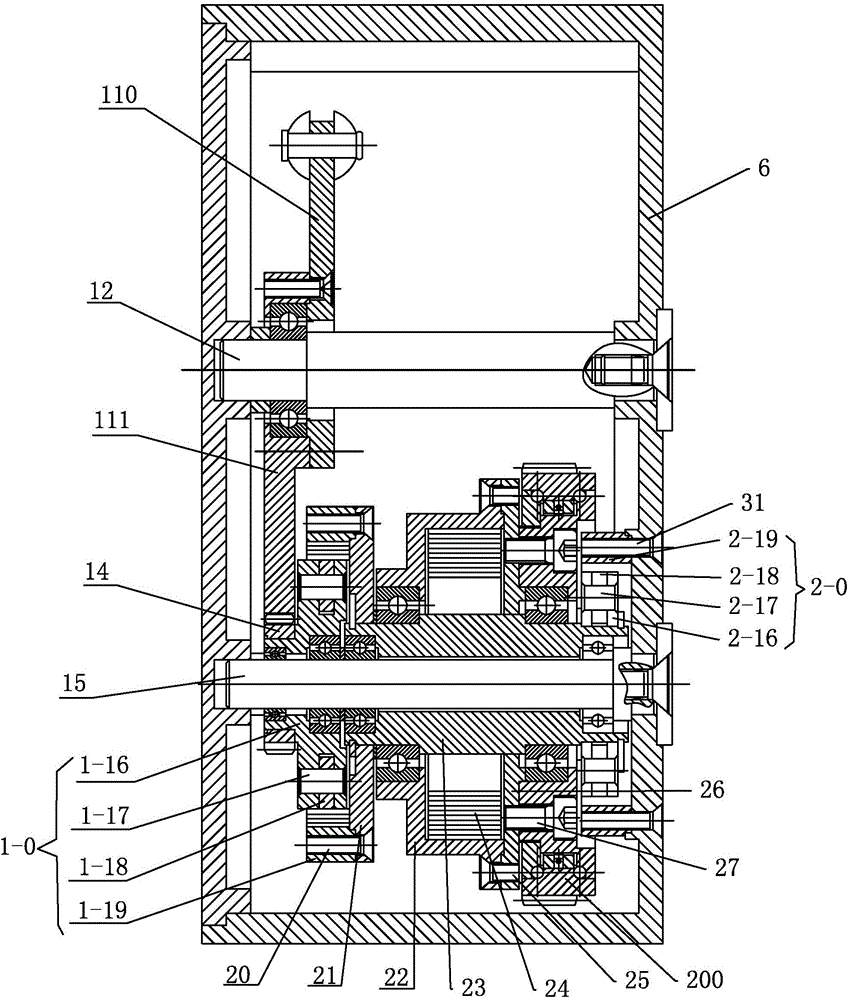

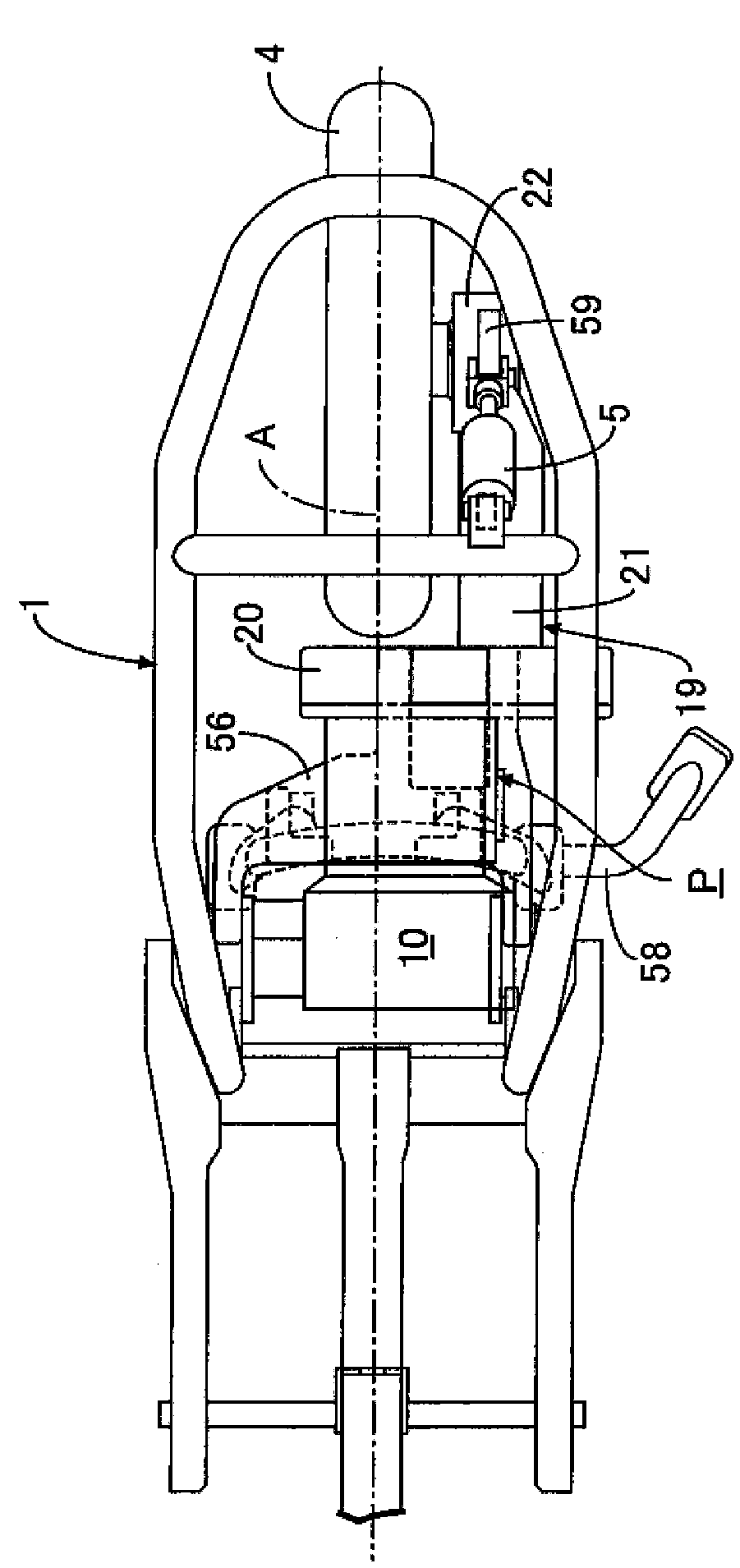

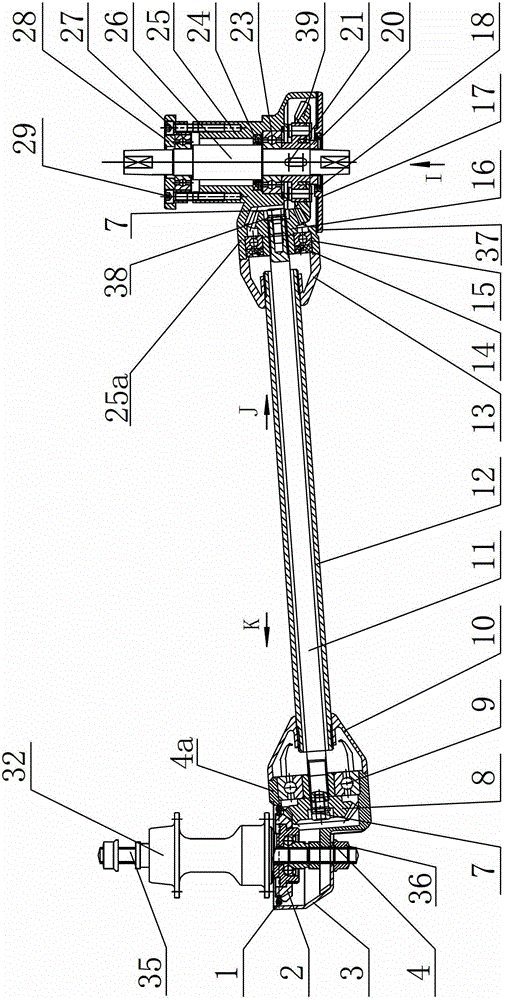

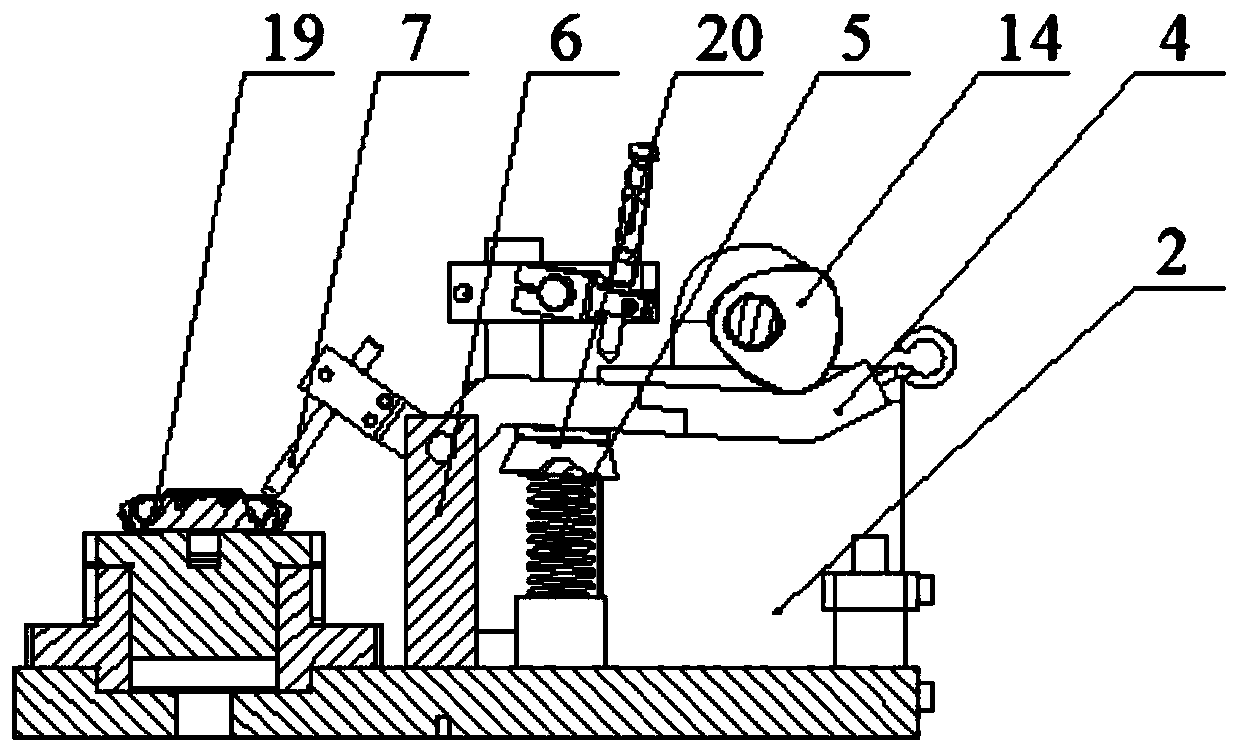

Electronic parking executor applied to motor vehicle brake system

ActiveCN102001334AImprove meshing accuracyIncrease product costBraking action transmissionBraking componentsGear transmissionMotor shaft

The invention discloses an electronic parking executor 1 applied to a motor vehicle brake system, which comprises a shell, a cover, a motor, motor accessories, a planetary gear transmission mechanism, parking brake calipers and the like. The electronic parking executor also comprises an integrated transmission mechanism frame, wherein a transmission mechanism and a planetary gear transmission mechanism from a motor shaft and a planetary gear main shaft are installed on a body in the integrated transmission mechanism frame, and the power transmission route of the transmission mechanism is from the motor shaft to the planetary gear main shaft. The technical scheme provided by the invention can effectively solve the problems of inconsistent assembly between rigid spacers and the motor shaft and the main shaft of the planetary gear transmission mechanism, axial nonparallelism and easy deformation of the rigid spacers after stressing in the prior art; meanwhile, the invention also has the characteristics of increasing the stability of internal transmission mechanism and the performance consistency after being connected with braking, reducing assembly cost, increasing assembly quality, benefiting tests, having good batch consistency and the like.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

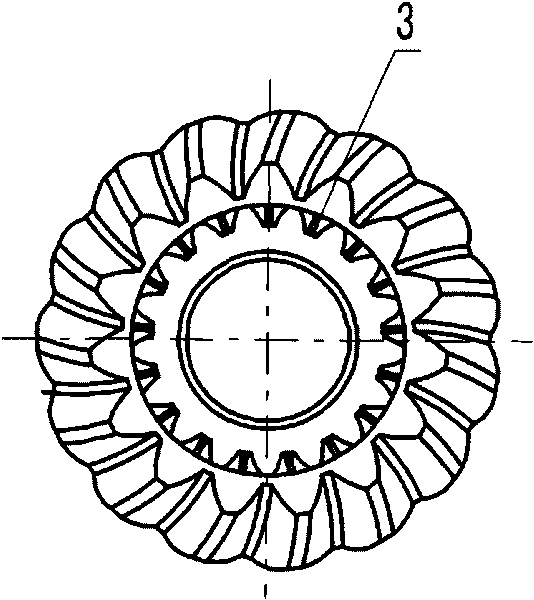

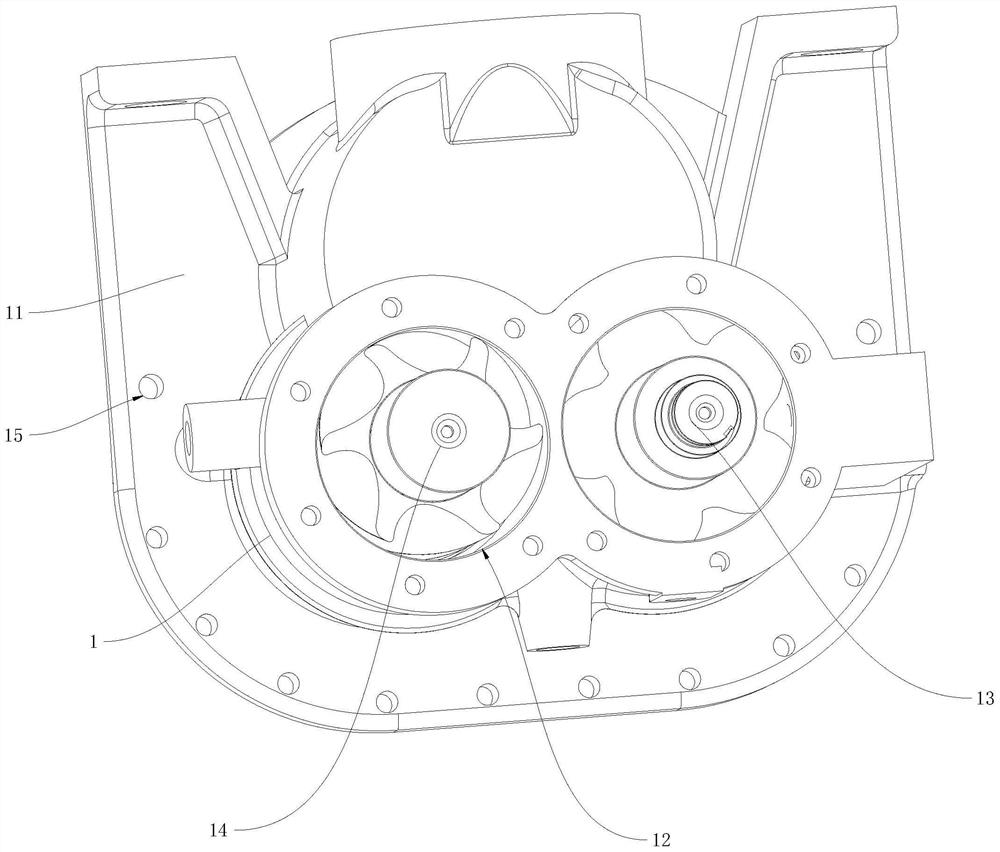

Compound spider piece used for single-screw compressor

InactiveCN101153596AImprove rigidityHigh strengthRotary piston pumpsRotary piston liquid enginesFiberGas compressor

The invention relates to a compound star wheel sheet for single screw compressor, which is characterized in that the compound star wheel sheet comprises an alloy steel core plate in the inner layer (200) and a PEEK carbon fiber polymer (300) in the outer layer. The PEEK carbon fiber polymer (300) is covered on the alloy steel core plate (200) and is combined with the alloy steel core plate (200). The invention has the advantages that the star wheel sheet rigidity, strength and deformation resistance capability resistance are increased, the meshing precision of the star wheel sheet and the life-span of the host are improved, the producing cost is greatly reduced and the benefit is increased.

Owner:SHANGHAI KAILI WOPU MECHINE

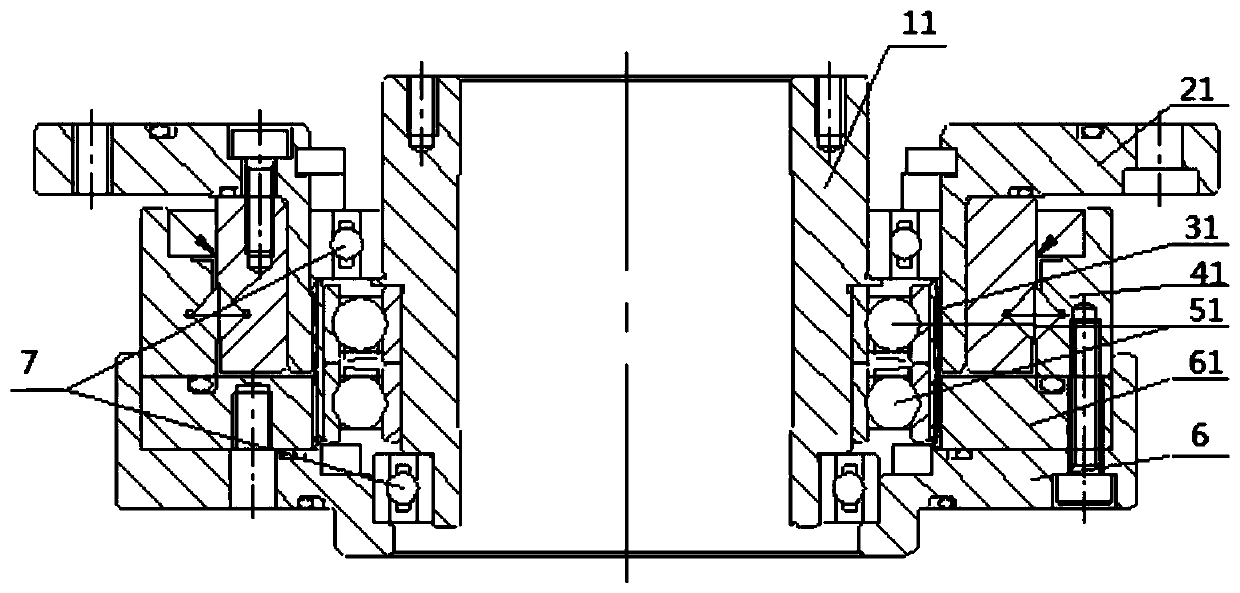

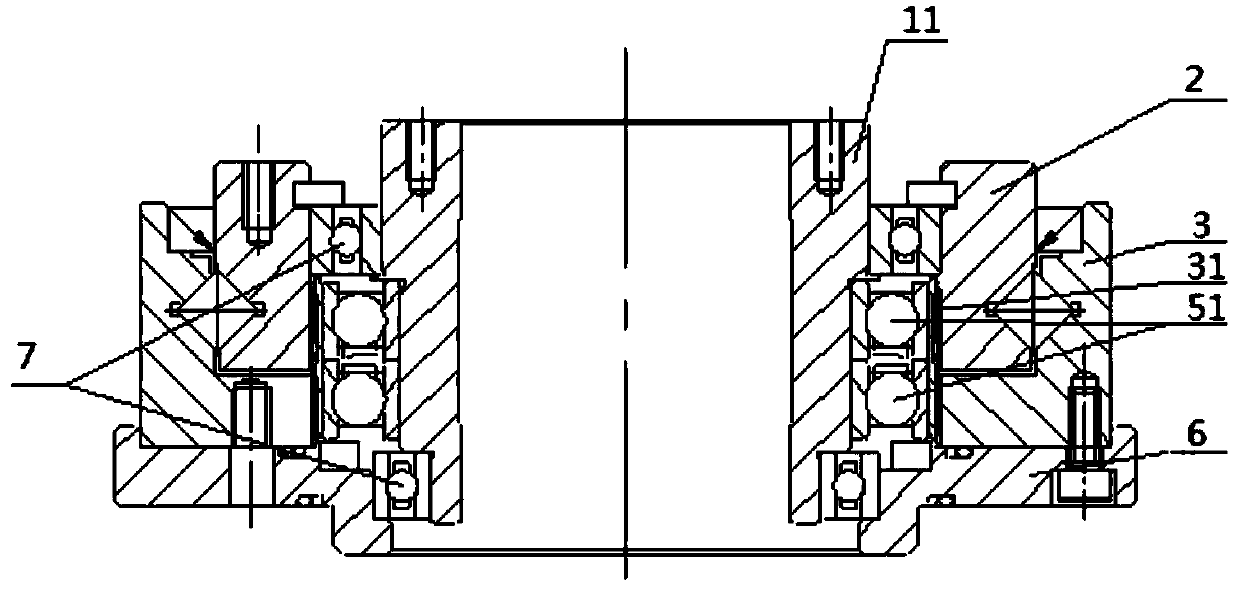

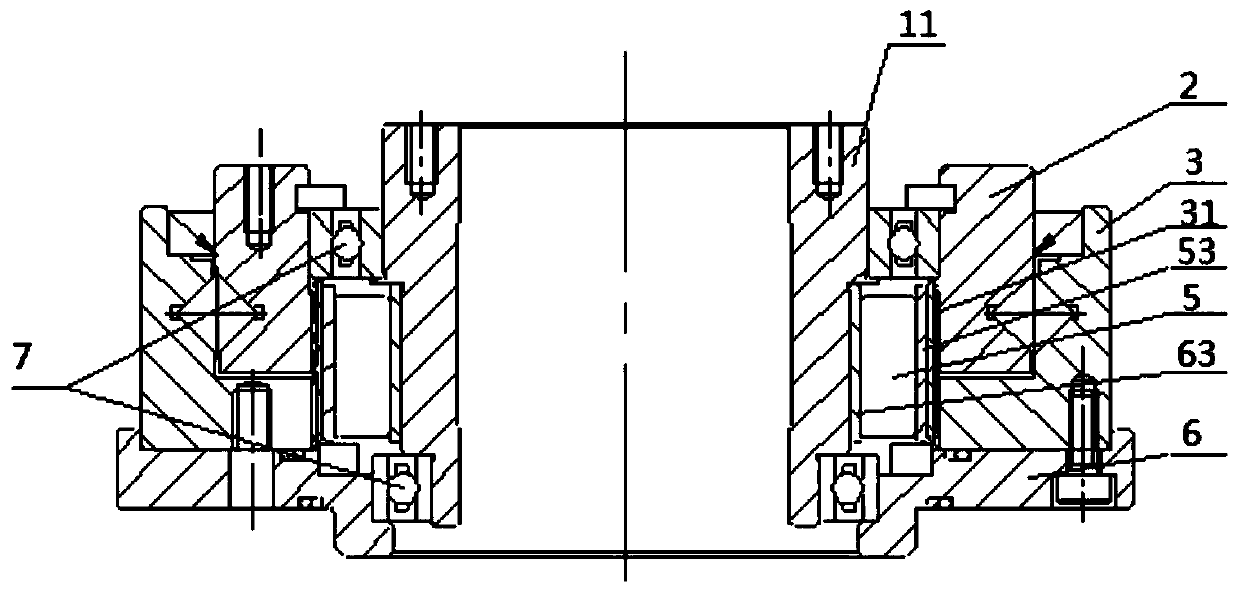

Integrated type double-rigid-wheel harmonic speed reducer without inner and outer ring rolling needle type flexible bearing

The invention provides an integrated type double-rigid-wheel harmonic speed reducer without an inner and outer ring rolling needle type flexible bearing. A new wave generator, a new inner ring, a new outer ring, a new flexible wheel, a rolling needle, rigid wheel end covers and a deep groove ball bearing are included; the new wave generator is composed of a wave generator body and a rolling needle flexible bearing inner ring; the new flexible wheel is composed of a flexible wheel body and a rolling needle flexible bearing outer ring; the new inner ring is composed of a fixed rigid wheel and a crossed roller bearing inner ring; the new outer ring is composed of an output end rigid wheel and a crossed roller bearing outer ring; and the new wave generator, the new inner ring, the new outer ring and the new flexible wheel are all integrated parts. In the technical field of harmonic speed reducers, the problems that a gap is likely to exist in the radial direction of the speed reducer, transmission is not stable, and rigidity is poor exist, and the double-rigid-wheel harmonic speed reducer which is small in body type, small in weight, compact in structure and high in rigidity is provided.

Owner:南通振康机械有限公司 +1

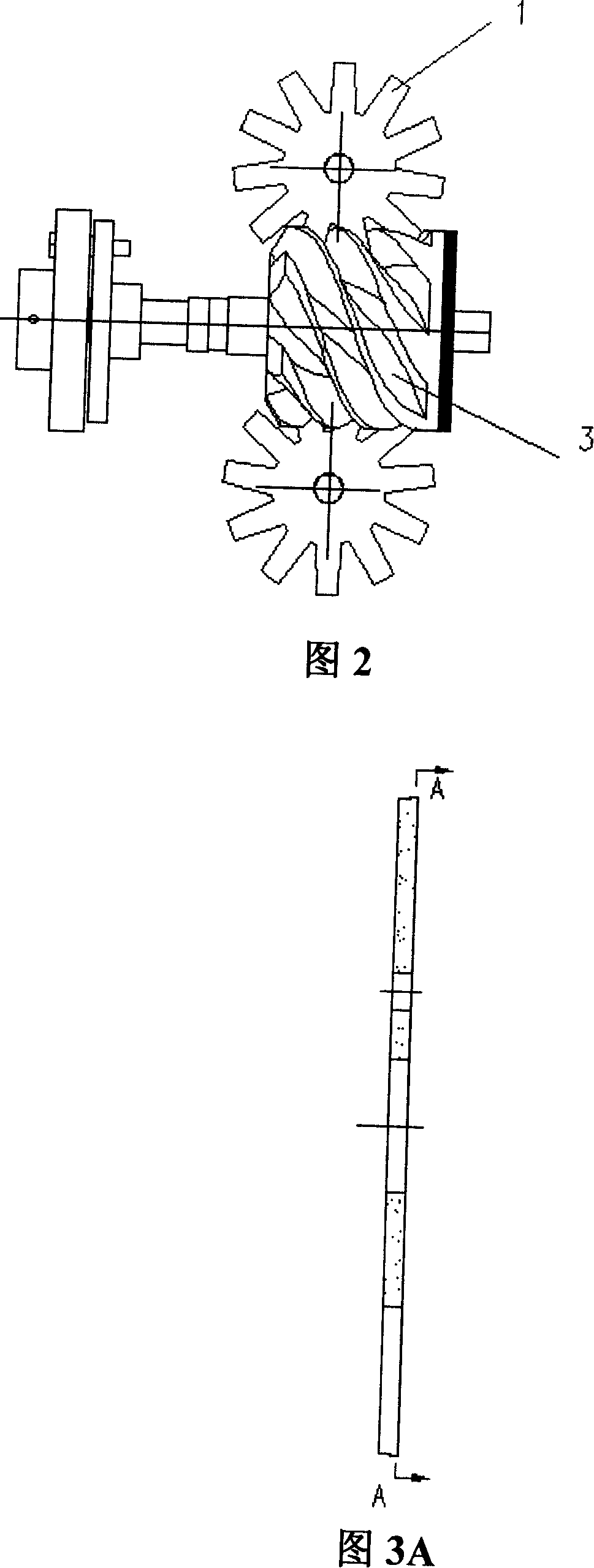

Main unit transmission device for ultra-fine pendulum powder mill

InactiveCN101195103ASmooth transmissionReduce manufacturing costGear lubrication/coolingToothed gearingsLow noiseEngineering

The invention discloses a driving device for a host machine, which is used for an ultra-fine pendulum type miller. The invention adopts a vertical shaft type reducing box, and one or two cylinder helical gears of horizontal engaging drives which are used to carry out speed reductions are installed inside the reducing box. The invention has simple structure, low cost, stable driving and low noises.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

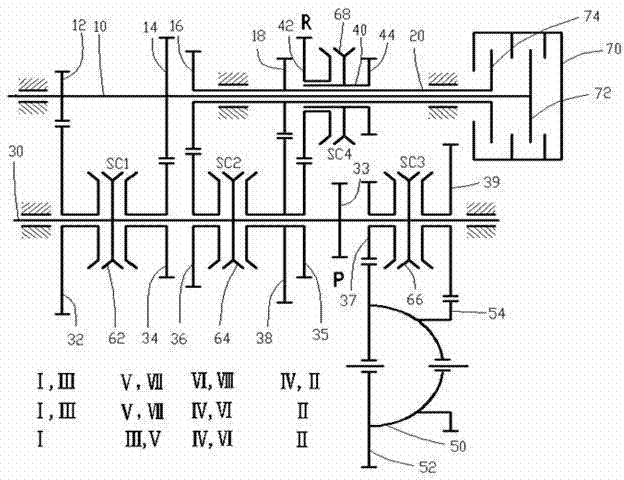

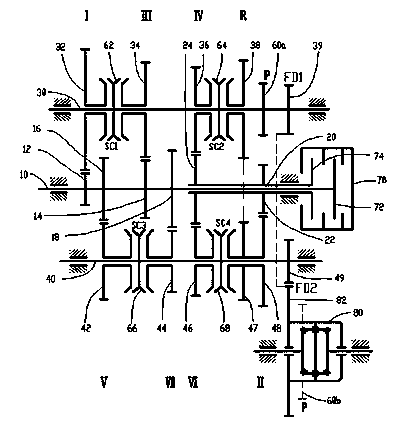

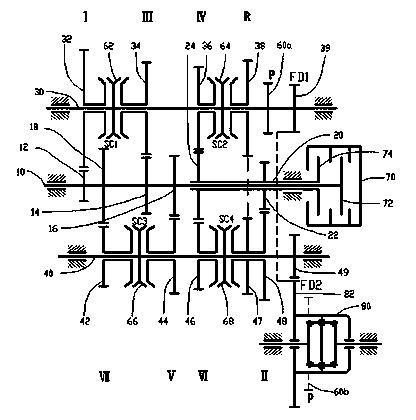

Double-clutch automatic transmission device

ActiveCN103671760AMeet the selection needsImprove comfortToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to a double-clutch automatic transmission device which structurally comprises internal and external input shafts (10, 20) which are coaxially arranged, an auxiliary shaft (30) and a reverse gear shaft (40) which are parallel to the two input shafts, a double-clutch assembly (70), a differential assembly (50), multiple groups of normally engaged gear trains arranged on all the shafts as well as multiple groups of synchronizer devices (62, 64, 66 and 68) which are used for realizing selection of all gears. The double-clutch automatic transmission device can provide eight forward gears at most and a reverse gear, so that the transmission device has more excellent comfort performance and lower oil consumption. As two groups of optional reduction gear trains are adopted, each gear train can realize two different gears, so that one auxiliary shaft and assemblies thereof can be reduced, and the transmission cost is reduced. The double-clutch automatic transmission device has the characteristics of simple structure, large quantity of gears, low cost and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

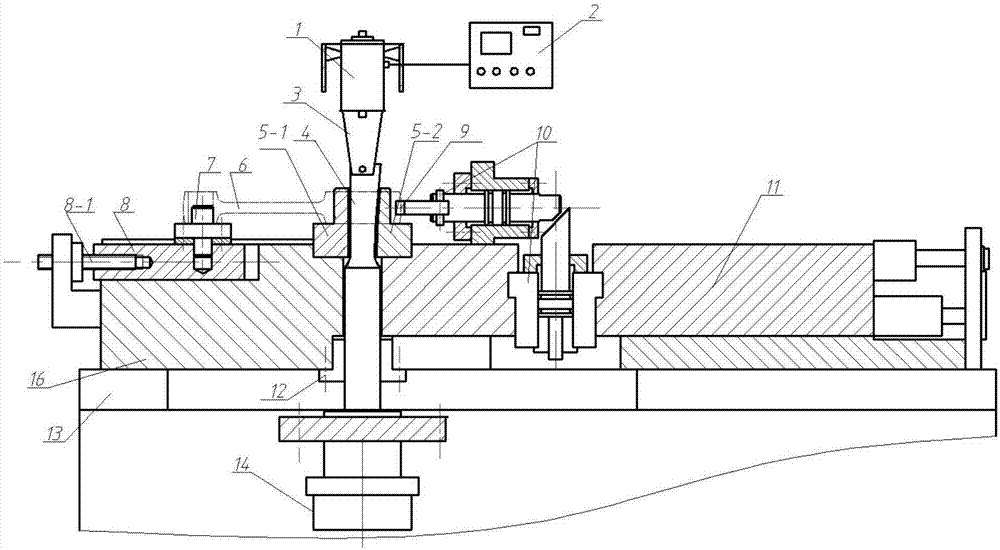

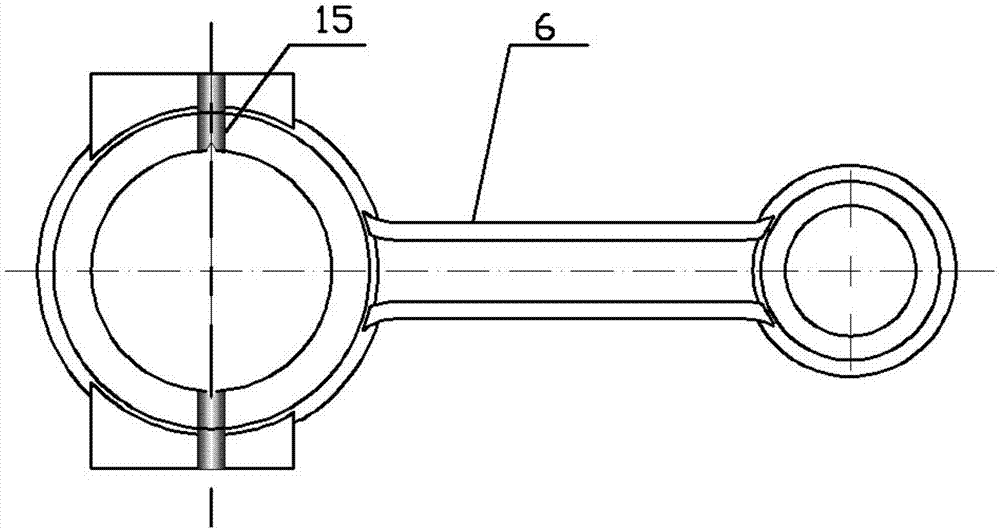

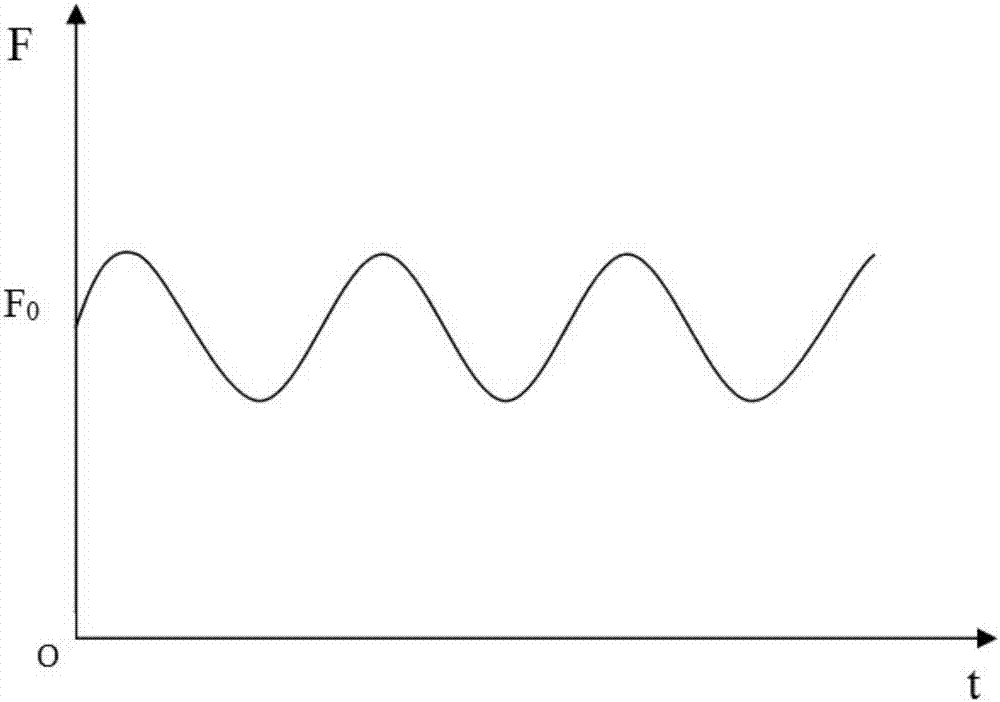

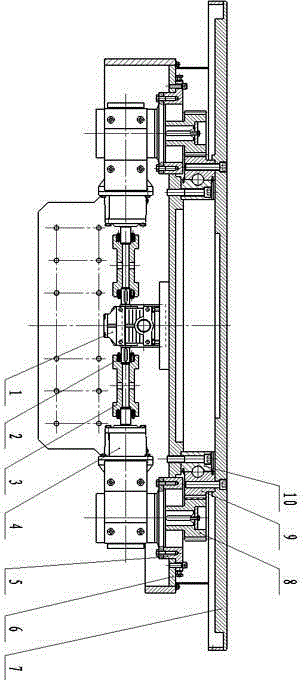

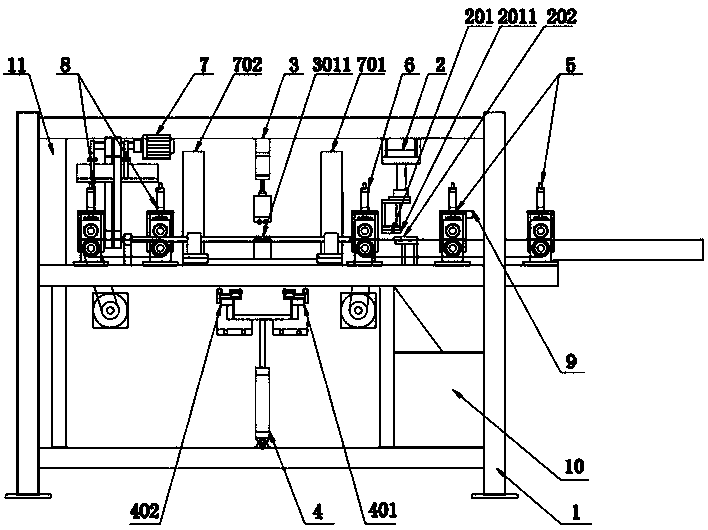

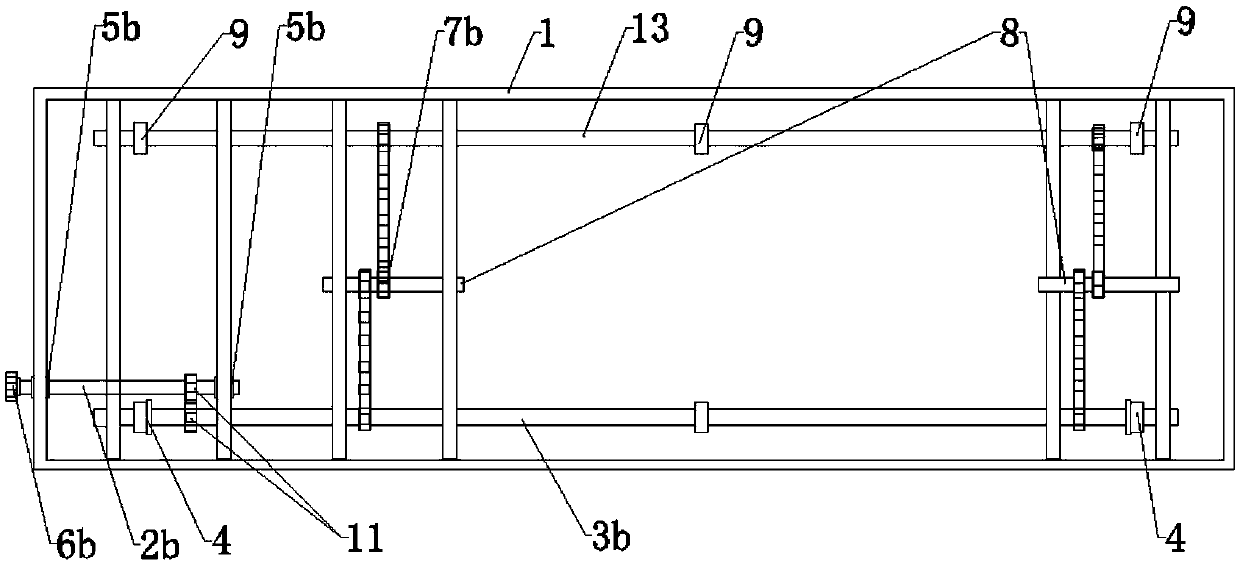

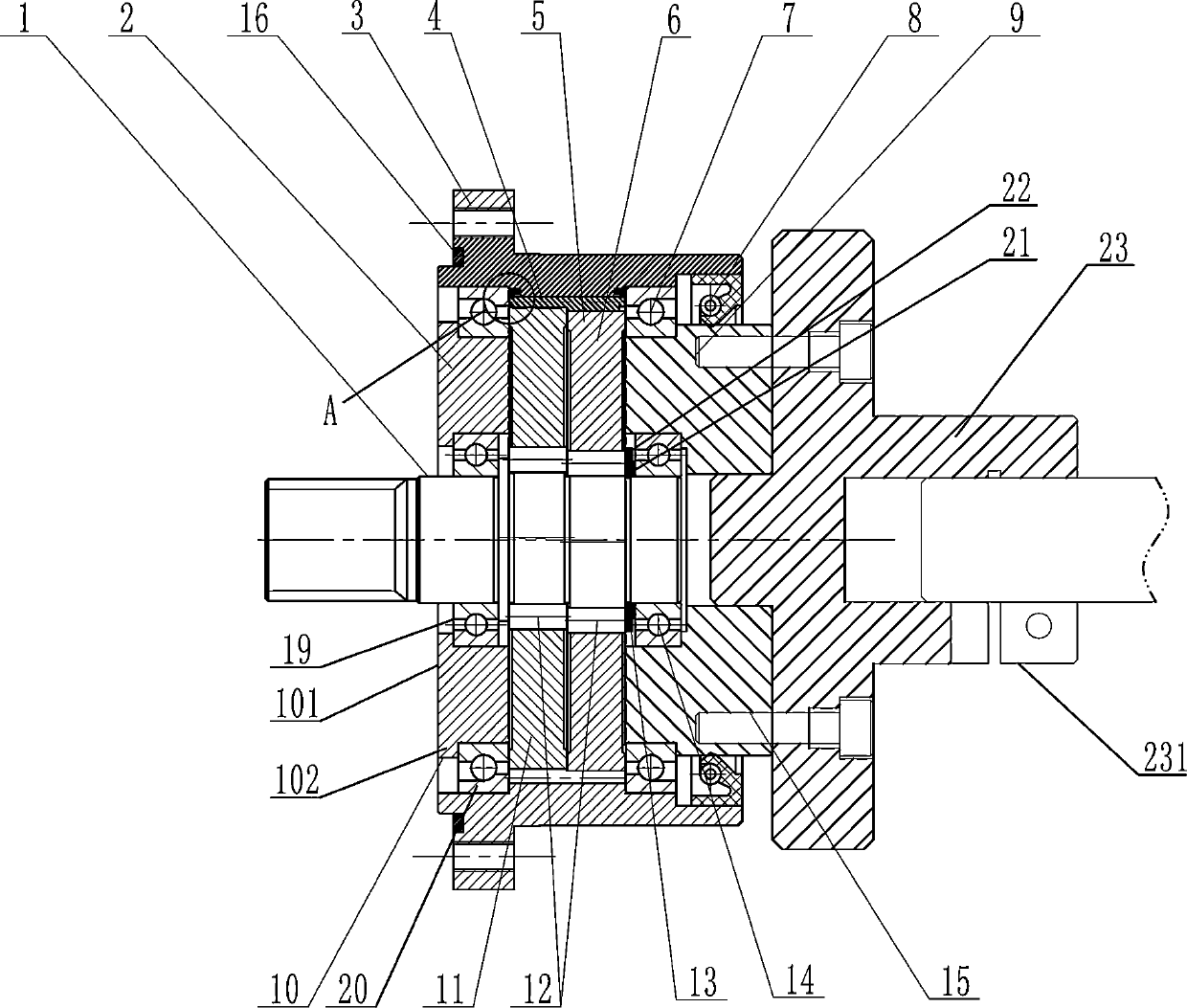

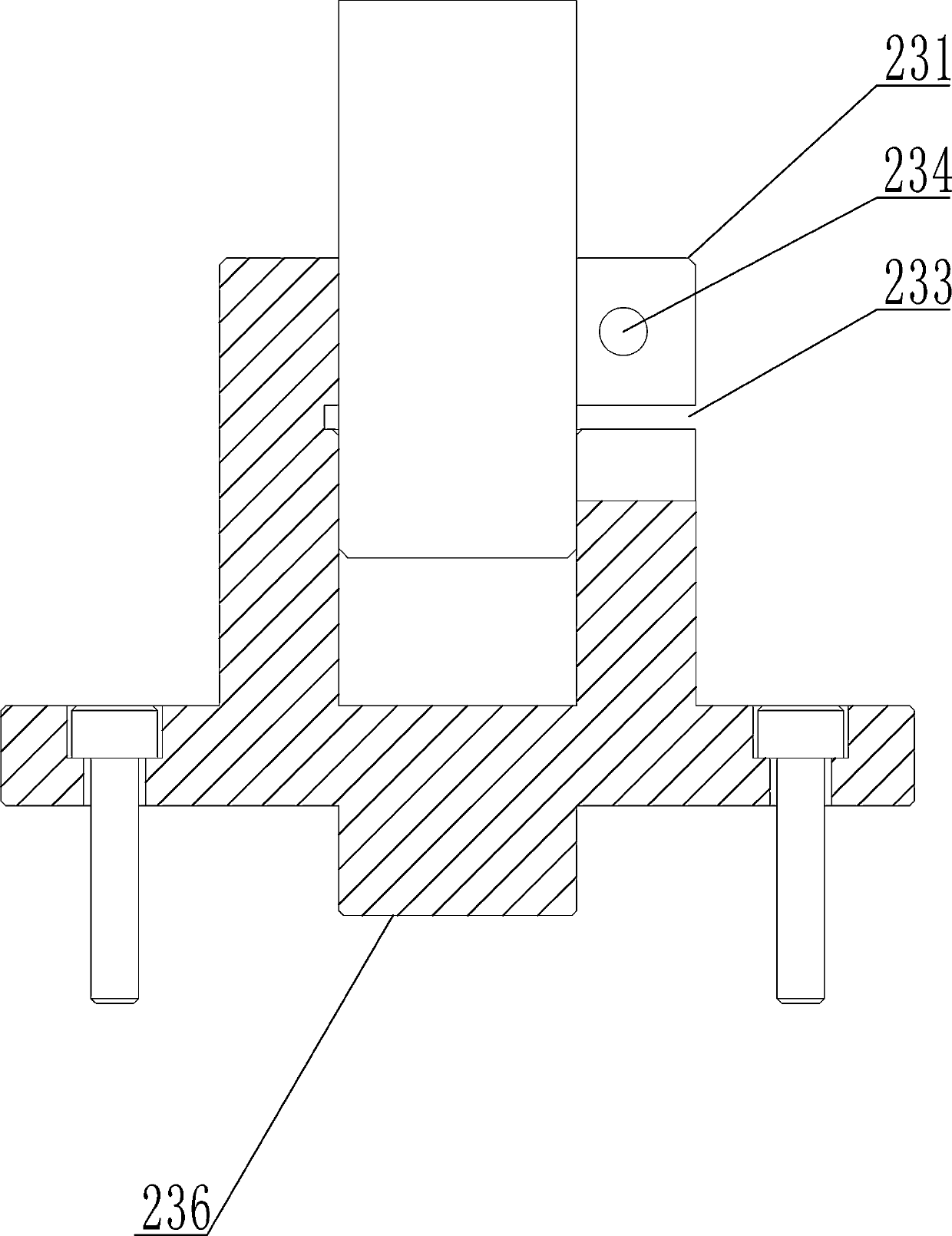

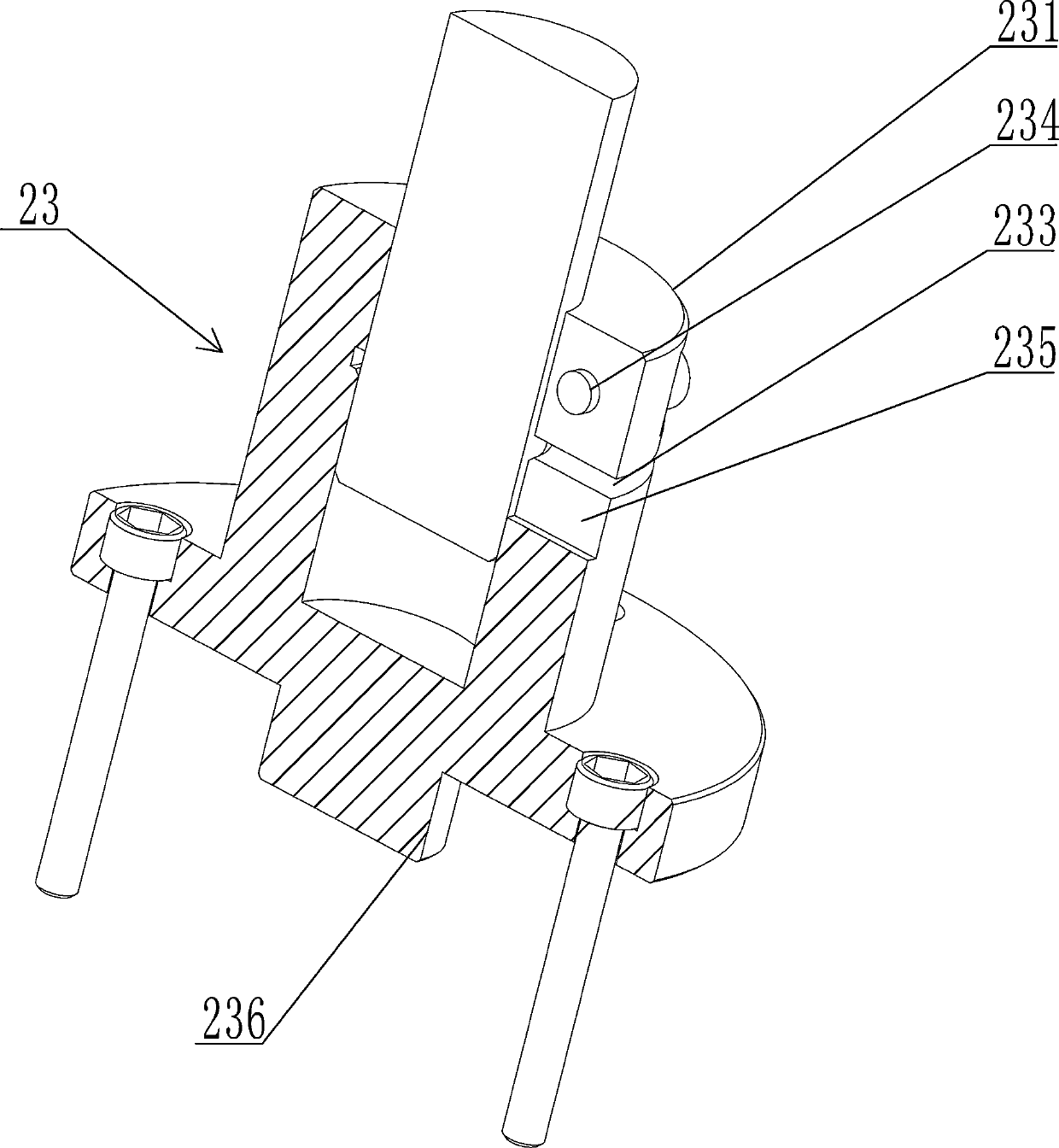

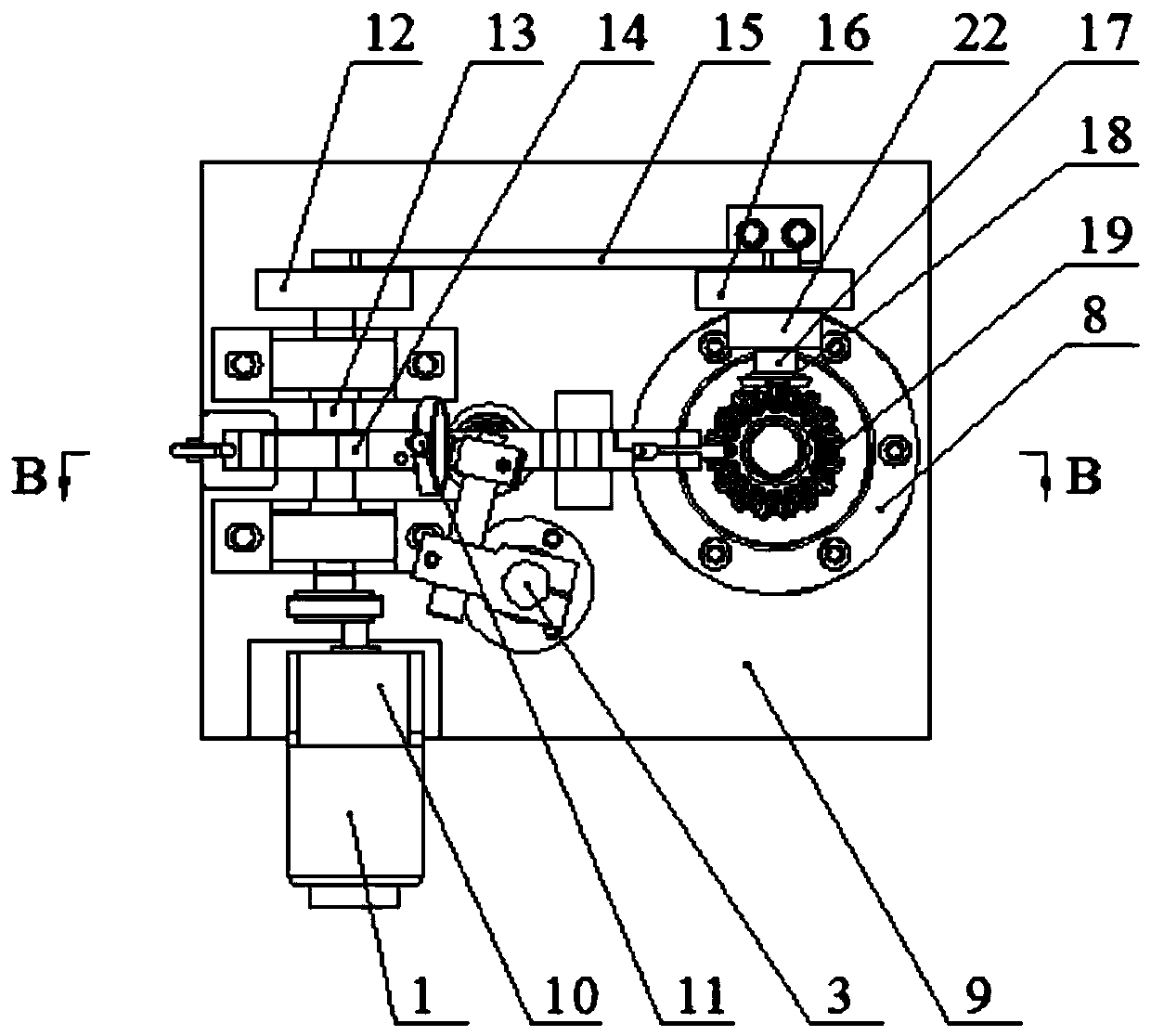

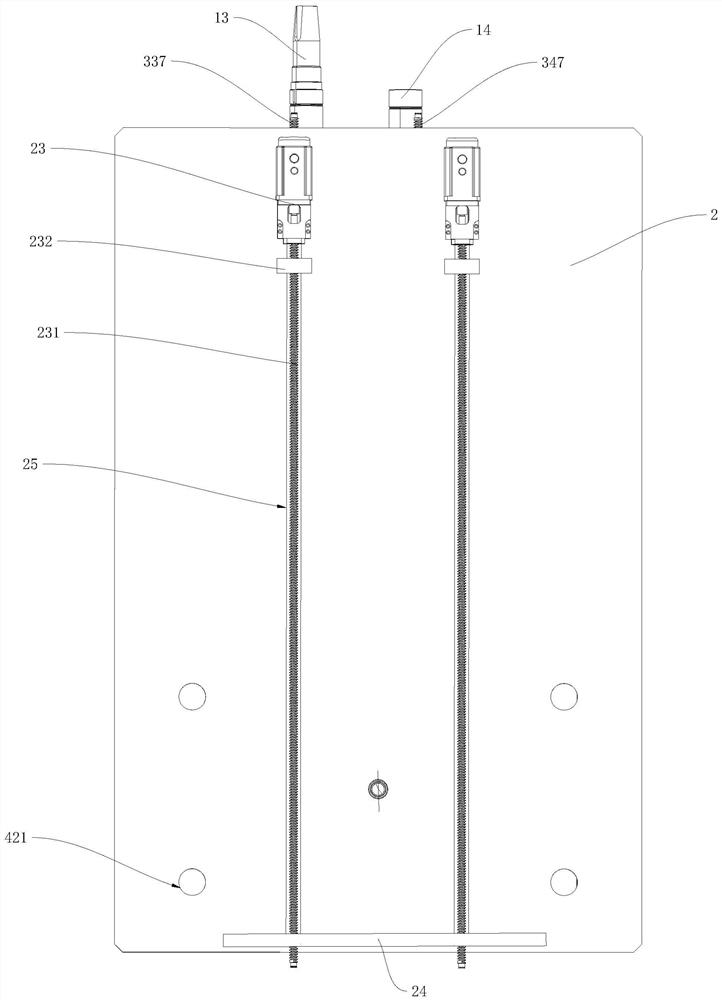

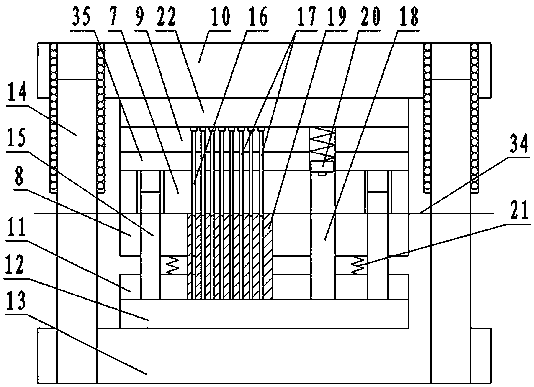

Machining device and method for resonance auxiliary cracking of connecting rod

InactiveCN107398692AReduce cracking forceHigh quality and precisionConnecting rodsMetal working apparatusHydraulic cylinderResonance

The invention provides a processing device for resonance-assisted cleavage of connecting rods, which includes a vibration mechanism of an exciter, a working platform, a compacting mechanism for a small head hole of a connecting rod, a cracking mechanism for a large head hole of a connecting rod, and a back pressure mechanism of a connecting rod; The vibrator is installed on the top of the connecting rod; the connecting rod big hole cracking mechanism includes a wedge-shaped pull rod, cracking fixed sleeve, cracking moving sleeve and cracking hydraulic cylinder; the connecting rod small head hole pressing mechanism includes an adjustment block and a screw nut mechanism The connecting rod back pressure mechanism is fixed on the slider, and the connecting rod back pressure mechanism produces a back pressure acting on the large end of the casting connecting rod; the connecting rod back pressure mechanism is fixed with a vibration sensor, To measure the vibration frequency of the connecting rod after the back pressure is applied. The invention can reduce the required cracking force and the deformation of the fracture surface and the number of slags on the fracture surface during cracking of the casting connecting rod, thereby reducing the processing cost.

Owner:JIANGSU UNIV

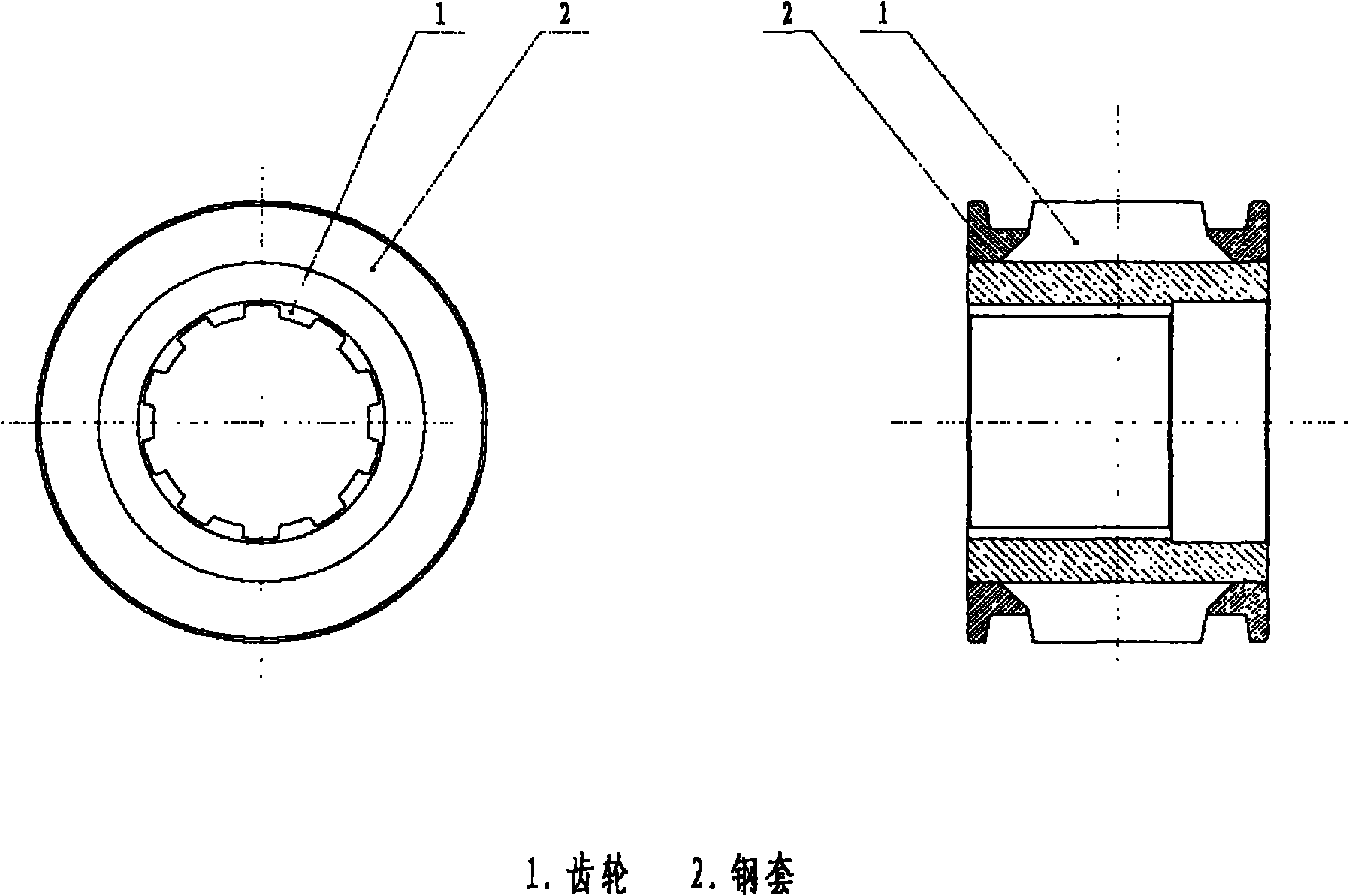

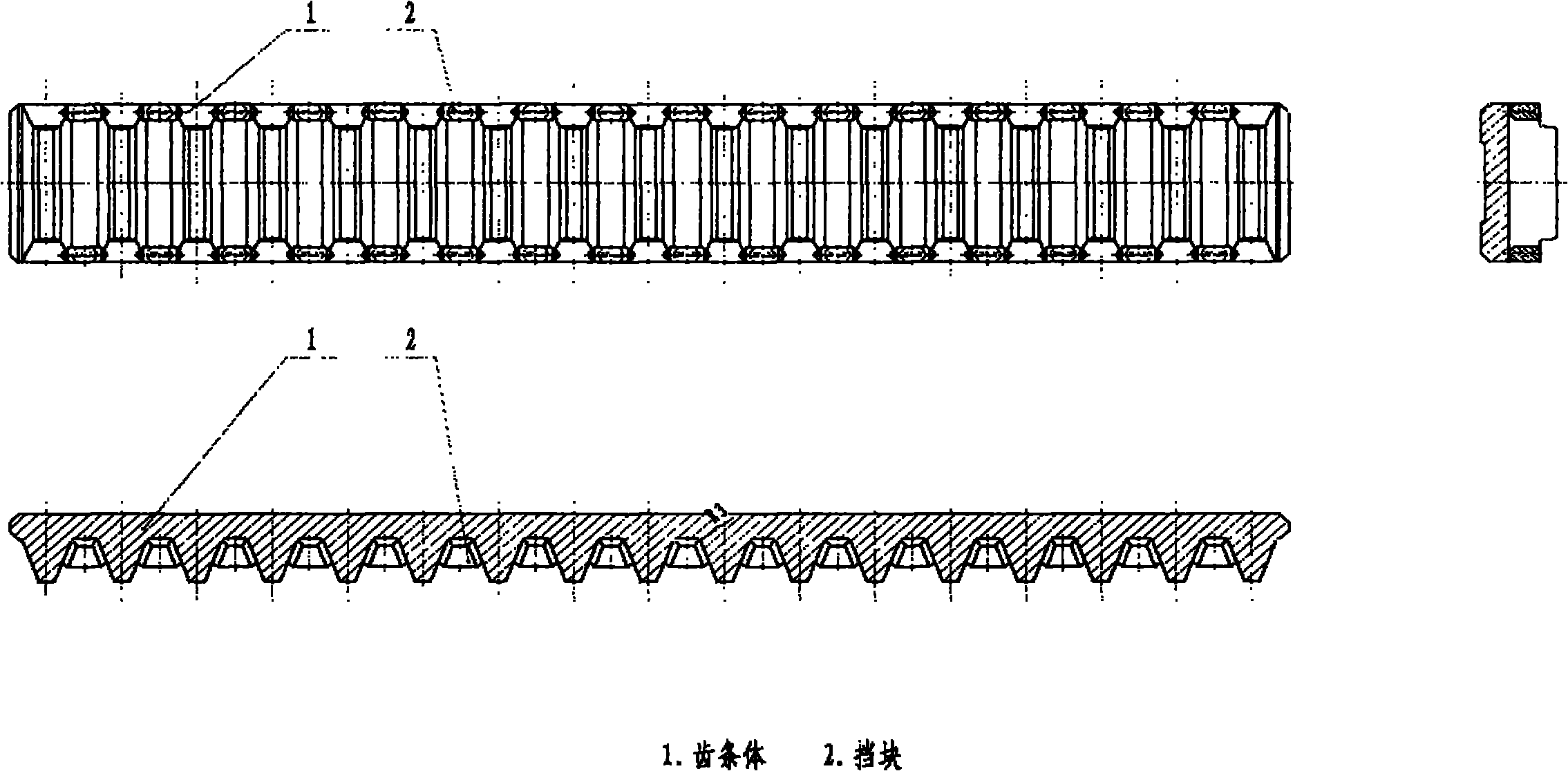

Pushing gear and rack

InactiveCN101922164AHigh strengthExtended service lifePortable liftingSoil-shifting machines/dredgersConventional castingEngineering

The invention discloses a novel gear and rack transmission system for a dipper crowding gear of a face shovel type electric excavator. The gear consists of a gear body and a steel sleeve; and the rack consists of a rack body and a stop block. After forged pieces are subjected to finishing, the gear and the steel sleeve are welded into a whole, and the rack and the stop block are welded into a whole. Compared with the conventional casting process, the material density is improved, accurate machining of gear form is realized and engagement accuracy is improved. The pushing gear and rack have the advantages of stabilizing the running of the dipper crowding gear and prolonging the life of the gear and the rack.

Owner:FUSHUN MINING IND GROUP

Hardenablity-retaining gear steel and preparation method thereof

The invention discloses hardenablity-retaining gear steel and a preparation method thereof. The hardenablity-retaining gear steel mainly comprises the following components in percentage by mass: 0.18-0.21% of C, 0.20-0.28% of Si, 0.75-1.05% of Mn, 0.95-1.25% of Cr, 0.035-0.055% of Ti, 0.020-0.035% of Al, 0.0008-0.0030% of B, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 20 ppm of T[O], less than or equal to 80 ppm of T[N], less than or equal to 0.10% of Ni, less than or equal to 0.20% of Cu, less than or equal to 0.10% of Mo, and the balance of Fe. The gear steel with a narrow hardenability band and an excellent fatigue life is prepared by controlling primary melting and strengthening refining, large ladle submerged nozzle argon blowing, catalyzer slag protection, plasma tundish heating and constant-temperature constant-pull-speed casting, and compound electromagnetic stirring through converter, dual-refining and continuous casting processes.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

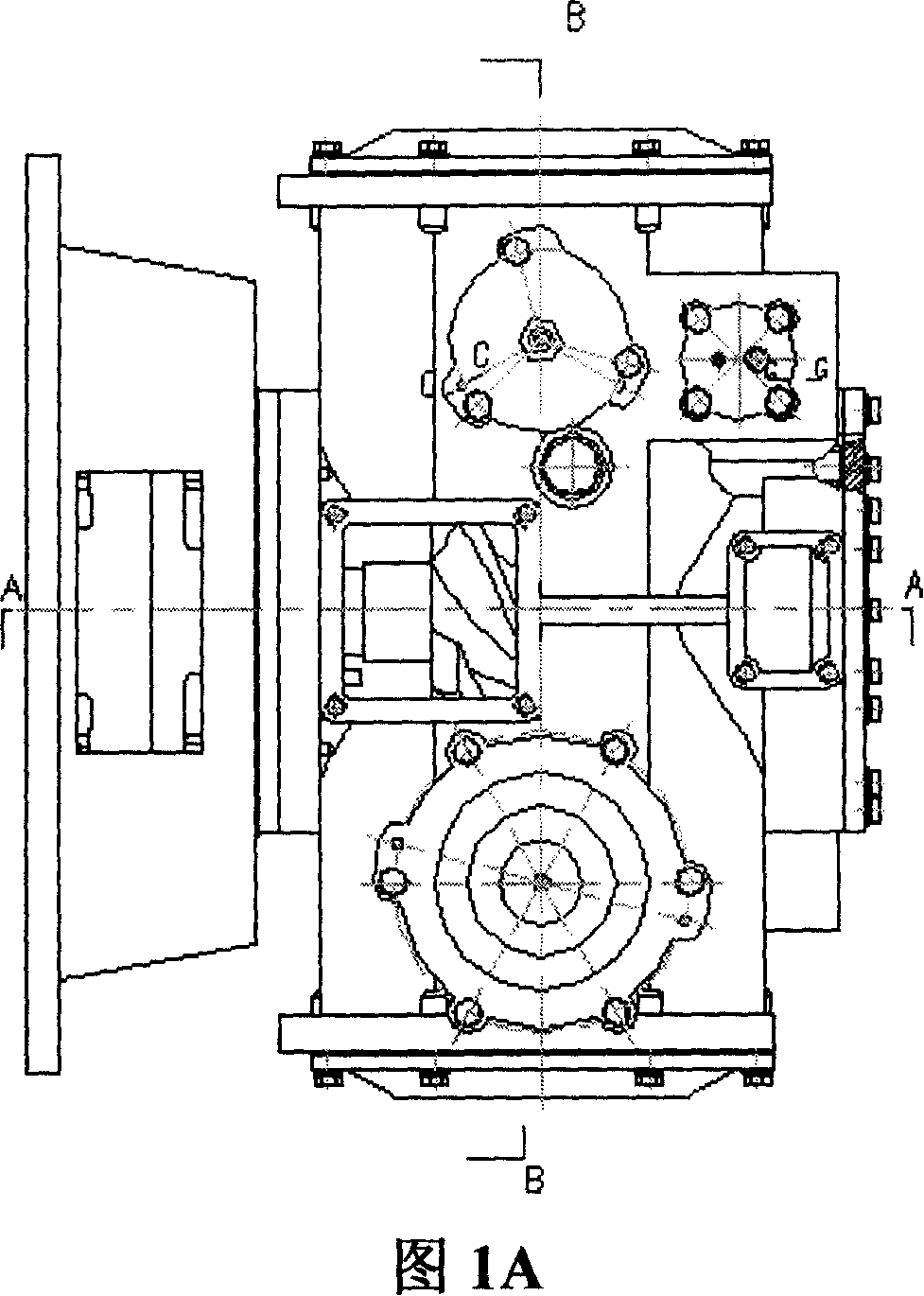

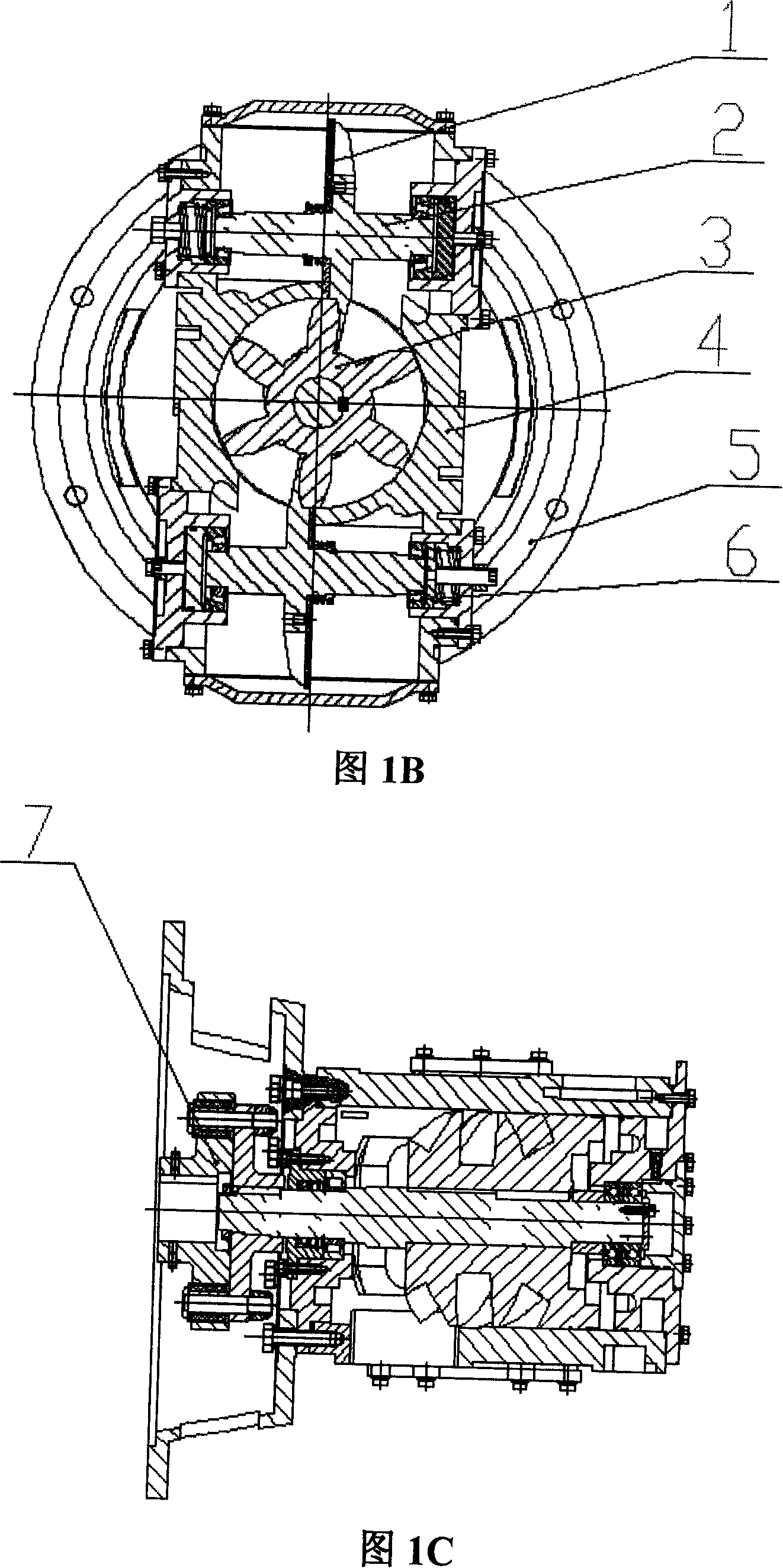

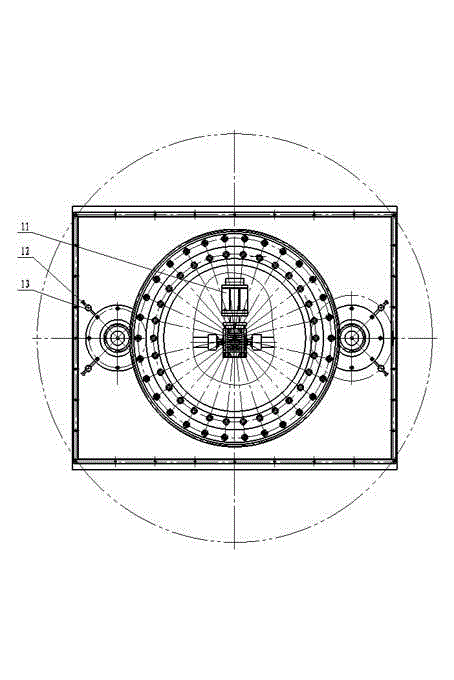

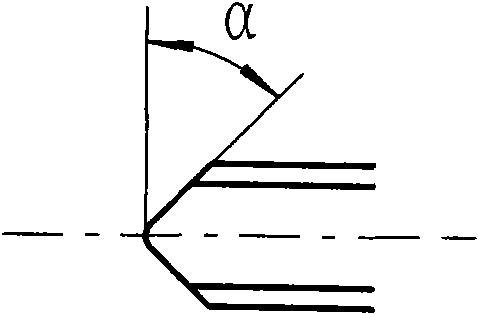

Back-clearance-free transmission method for large high-precision rotating disc

InactiveCN103148202ARealize backlash-free transmissionHigh rotation accuracyGearing detailsSlewing bearingEngineering

The invention discloses a back-clearance-free transmission method for a large high-precision rotating disc. One servomotor is used for driving a worm gear reducer which serves as a primary reducer; two output ends of the reducer is connected with an input end of a secondary reducer through a connecting shaft and an expansion sleeve; pinions are mounted on two output ends of the secondary reducer respectively and meshed with slewing bearing outer ring gears, so that the rotating disc mounted on a slewing bearing outer ring is driven to slew; module numbers and pressure angles of the pinions and the slewing bearing outer ring gears are equal; and a slewing bearing internal annular gear is fixed on a turnover disk. The expansion sleeve is adjusted, so that mechanical clearance of transmission in two directions between the servomotor and the rotating disc can be eliminated, and the transmission precision is improved; a center distance adjusting mechanism is mounted on the turnover disk and used for adjusting a center distance between a pinion on the output shaft of the secondary reducer and a slewing bearing outer ring gear, and the gear mesh accuracy is improved.

Owner:CHANGCHUN EQUIP TECH RES INST

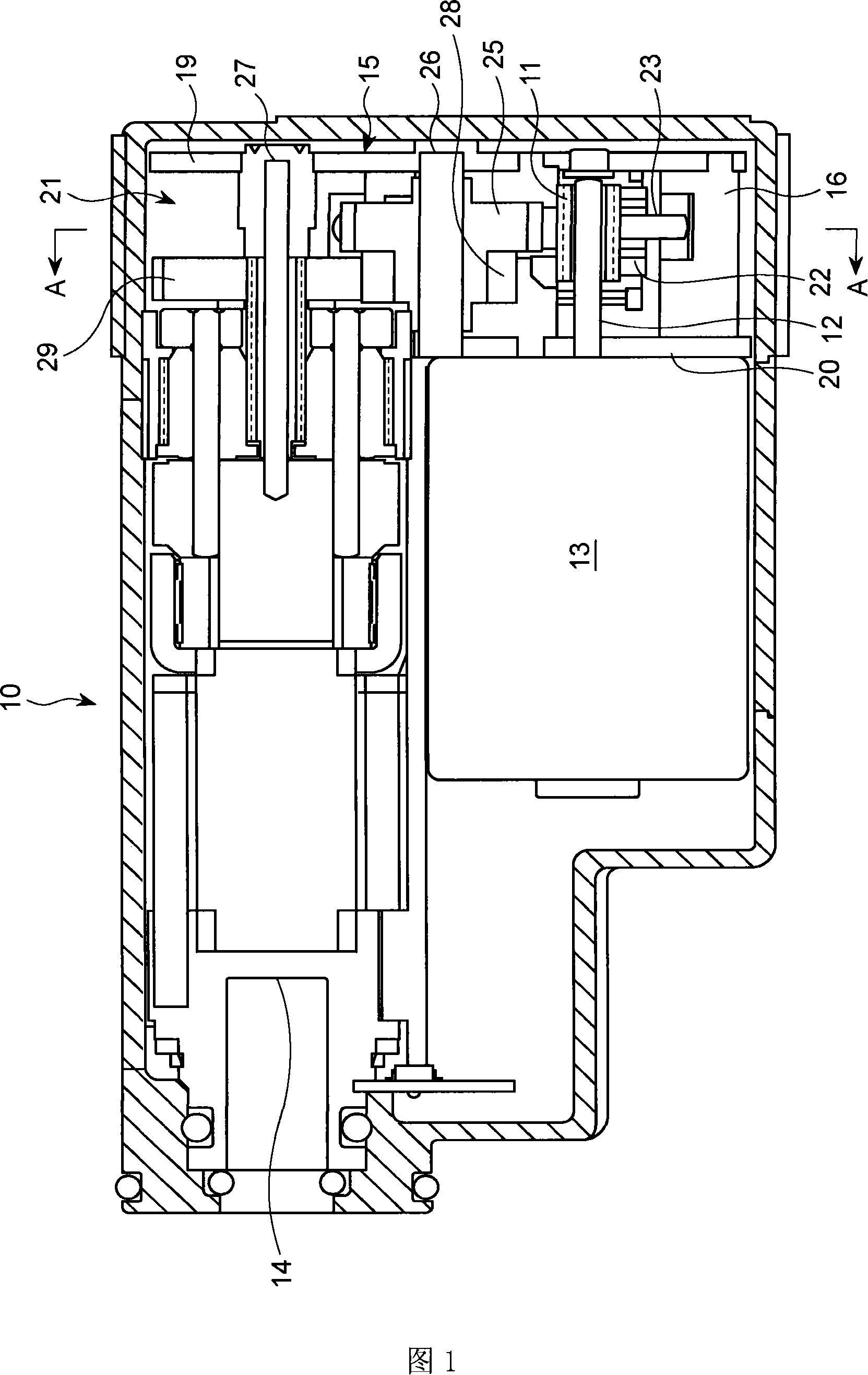

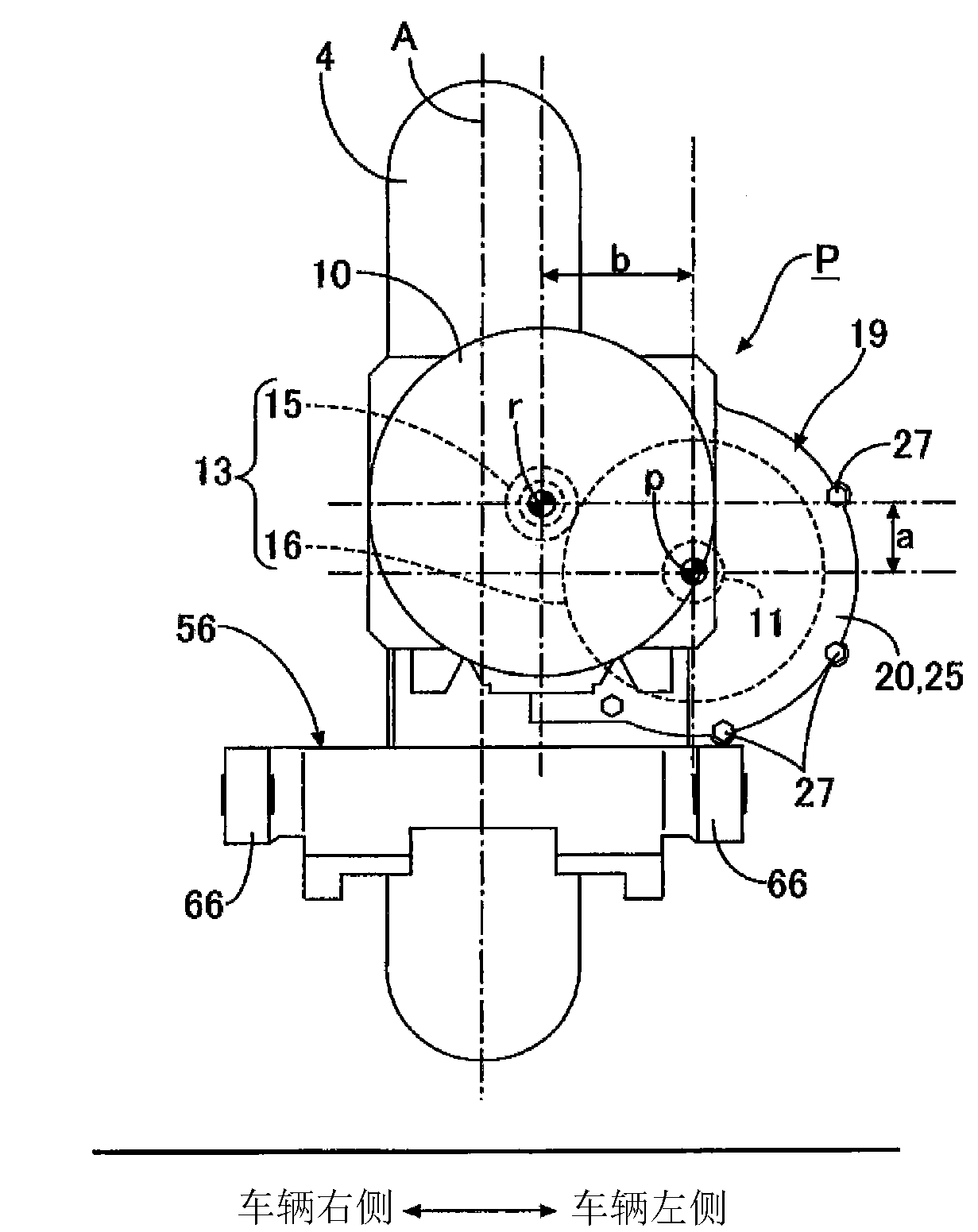

Automatic opening and closing device

An automatic switching device is provided to realize miniaturizing, lightweighting and silencing the automatic switching device of toilet-seat and toilet-cover. The automatic switching device (10) comprises: motor (13) mounted on rotation axis (12) with two or more worm gears (11); output axis (14) for switching toilet-seat and toilet-cover; reduction gear unit (15) for decelerating the revolution of worm gears (11) and transfering it to output axis (14). The reduction gear unit (15) is composed of two plates (19,20) for grasping three supporting parts (16) and being in point-against-back arrangement; and a number of gear set (21) between the plates (19,20). A first helical gear (22) for engaging with worm gears (11) and rotating, subsidiary worm gears for linkaging and rolling on the same supporting axes (23) with the first helical gear and a second helical gear (22) for engaging with subsidiary worm gears and rotating are installed on the gear set (21). In addition, the supporting axes (26,27) of gear set (21) are axially supported on the plates (19,20).

Owner:TOTO LTD

Veneer longitudinal glue splicing process and veneer longitudinal glue splicing machine

PendingCN111531663AImprove gear meshing accuracyLess consumablesWood veneer joiningTooth lengthEngineering

The invention discloses a veneer longitudinal glue splicing process and a veneer longitudinal glue splicing machine. The veneer longitudinal glue splicing machine comprises a main frame, a tooth cutting device, a tooth cutting conveying device, a tooth joint conveying device, a plate discharging conveying device, a clamping plate moving device, a gluing device, a tooth joint device, a fixed-lengthcutting device, an optoelectronic switch and a controller. The horizontal spacing distance between the tooth joint device and the tooth cutting device is limited to range from 45 cm to 90 cm, the displacement distance of a veneer after tooth beating and before splicing is reduced, errors are reduced, and the tooth joint precision is improved; a good tooth joint effect can be achieved for a wood plate with the tooth length of 3 cm after tooth combing, consumables of the tooth joint end of the veneer are reduced, and the utilization rate of the veneer is increased; the occupied space of complete equipment is reduced, the weight of the complete equipment is reduced, and the consumable cost and transportation cost of equipment products are reduced; and the application range is wide, and various veneers with different lengths, veneers with different thicknesses and veneers adhered with impurities can be longitudinally spliced by a single glue splicing machine.

Owner:刘小志

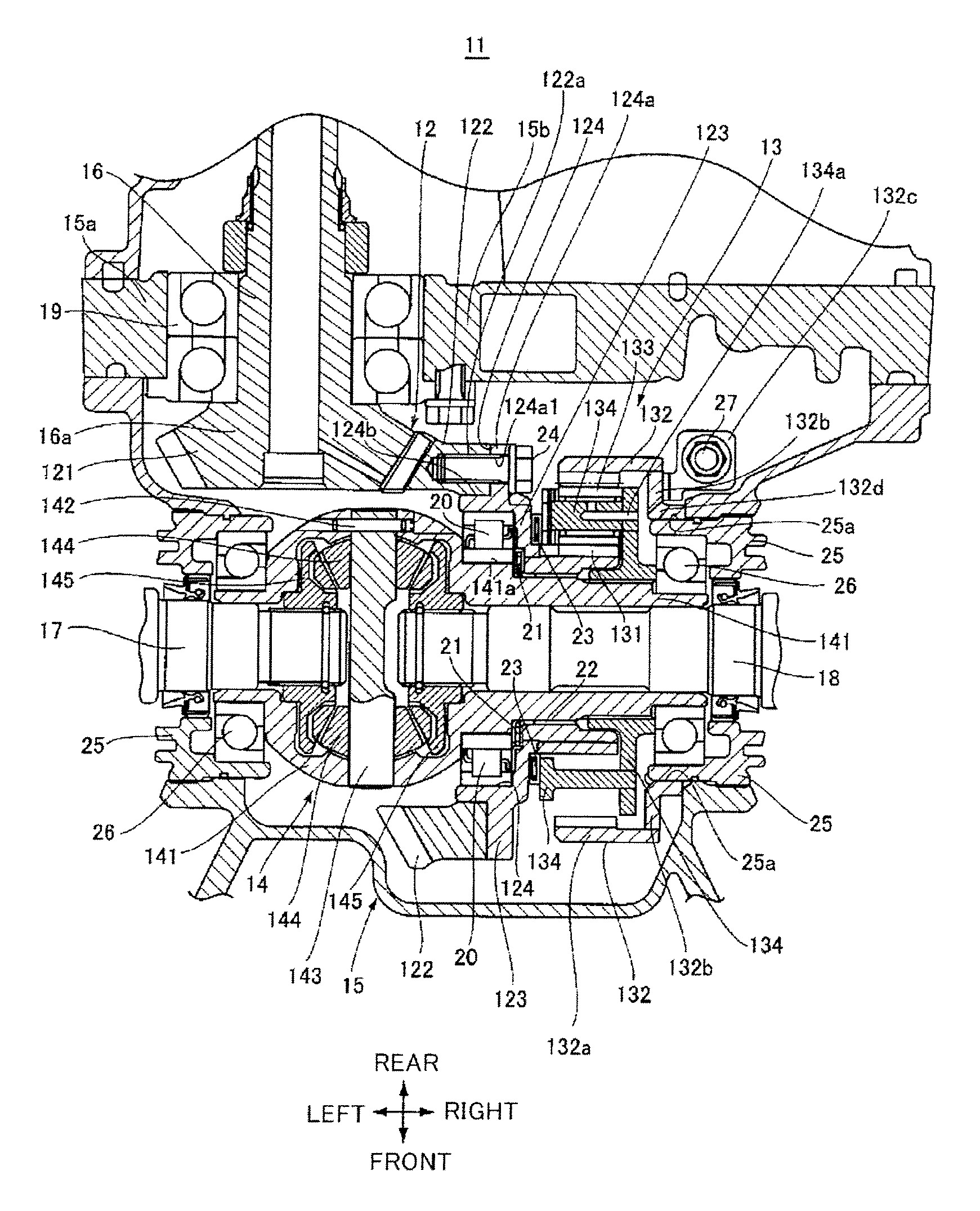

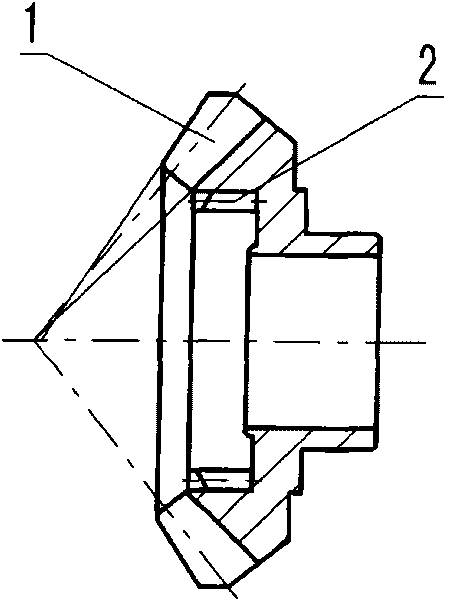

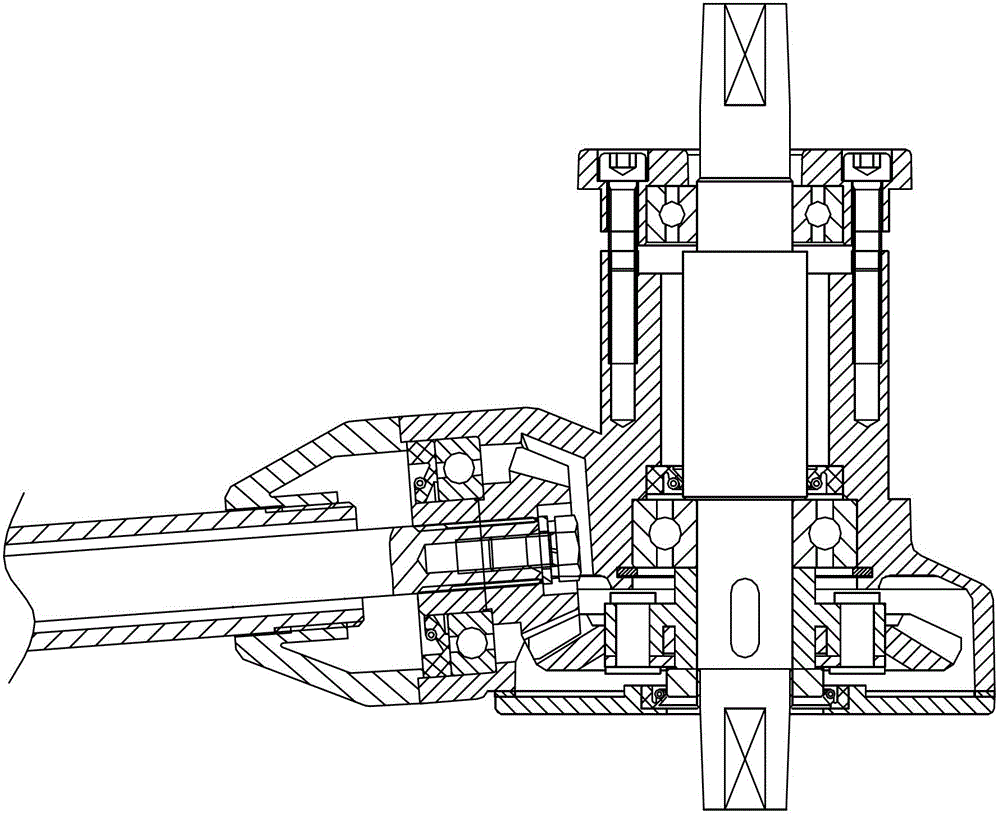

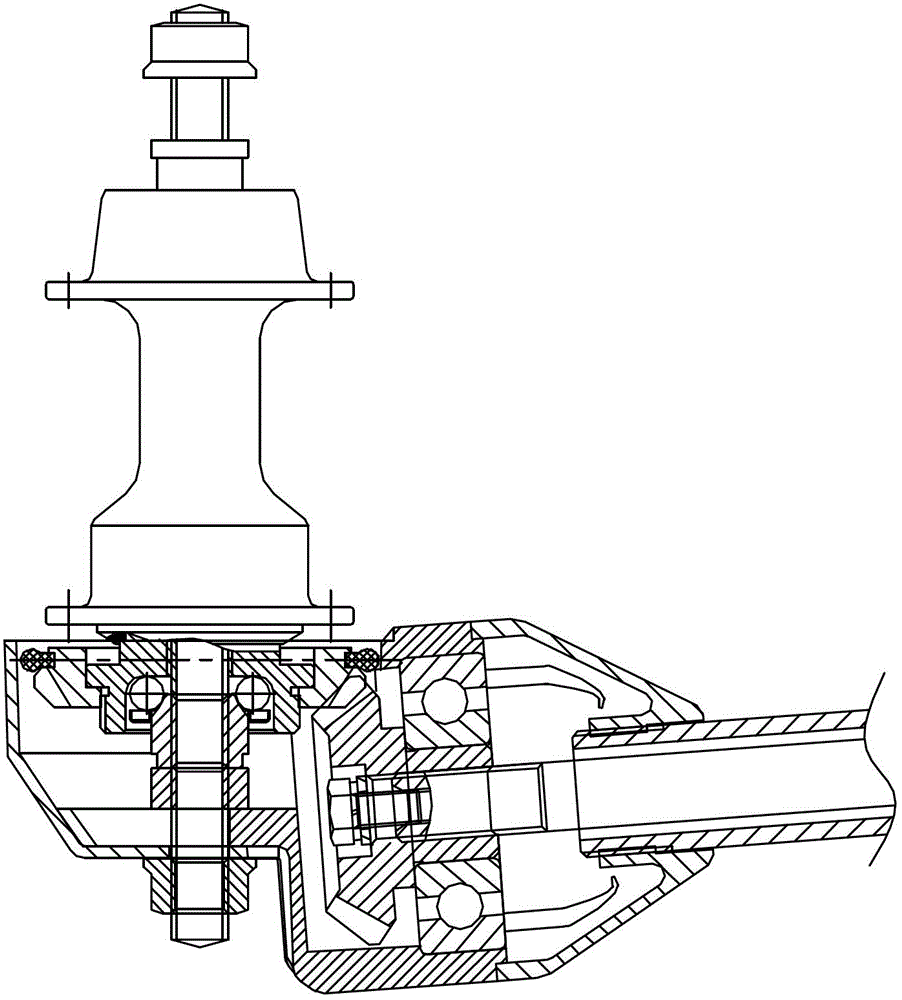

Final reduction gear device

InactiveUS20080300085A1Improve precisionImprove support rigidityToothed gearingsDifferential gearingsBall bearingThrust bearing

A final reduction gear device including an orthogonal axis gear and a speed reduction mechanism portion employing a planetary gear is provided. A radial bearing, more specifically a cylindrical roller bearing, having a large radial load capacity is disposed between a bevel ring gear of the orthogonal axis gear and a differential case. A thrust bearing, more specifically a thrust ball bearing or a thrust roller bearing, having a large axial load capacity is disposed between an axial end portion of a sun gear, and an inner race side of the radial bearing and the side of a fitting portion of the differential case, to which the inner race is fitted. A thrust bearing, more specifically a thrust ball bearing or a thrust roller bearing, having a large axial load capacity is disposed between the bevel ring gear and a planetary carrier of the speed reduction mechanism portion.

Owner:SUBARU CORP

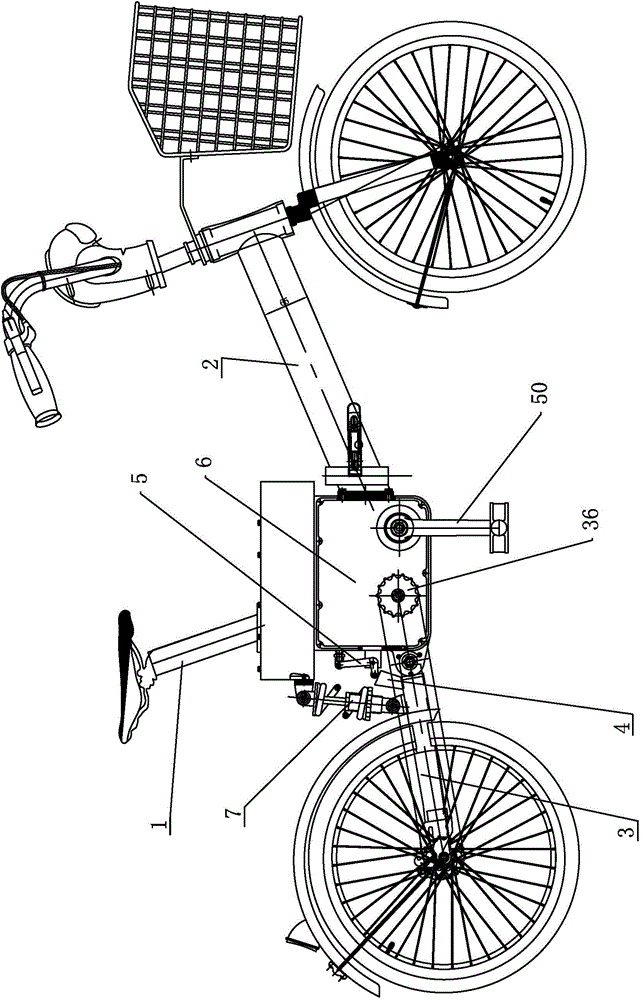

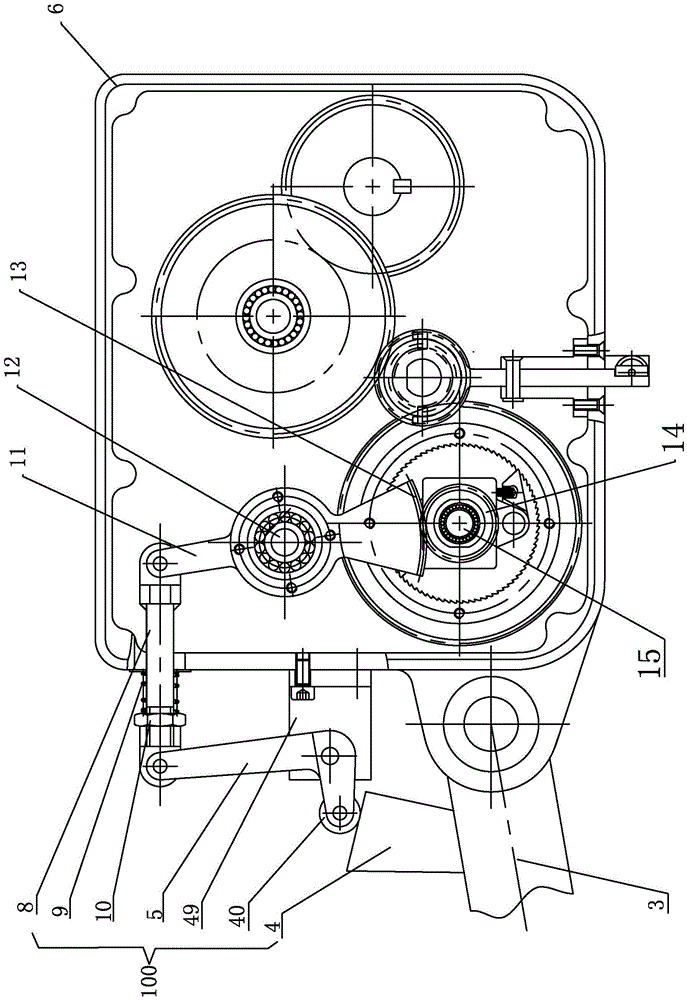

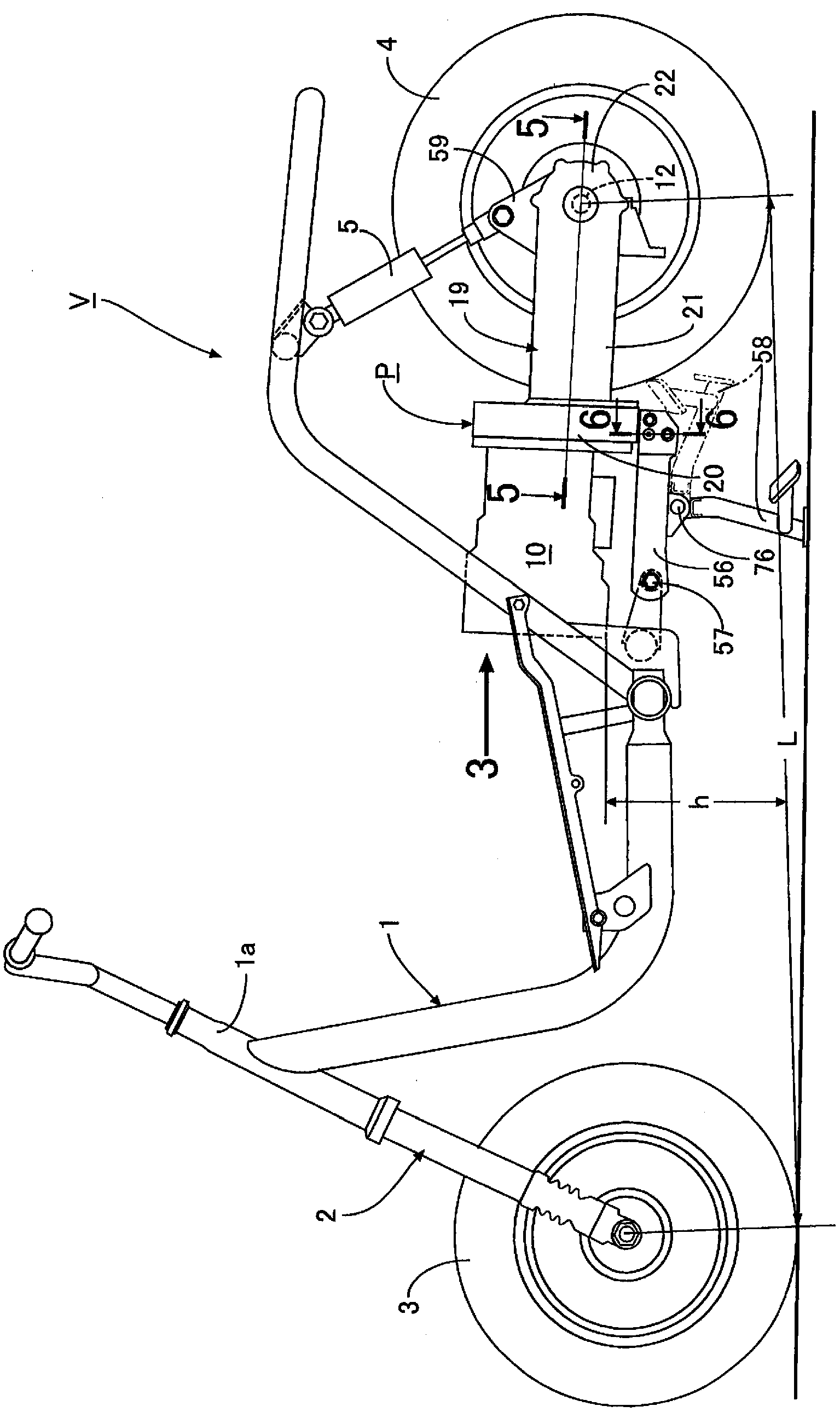

Bicycle vibration energy conversion mechanism and bicycle adopting same

ActiveCN104787212AImprove driving comfort performanceSave energyWheel based transmissionRider propulsionDrive wheelVehicle frame

The invention relates to a bicycle vibration energy conversion mechanism and a bicycle adopting the same. The bicycle vibration energy conversion mechanism comprises a force transfer mechanism and a shell used for being arranged on a fixed frame of the bicycle, wherein one end of the force transfer mechanism is in transmission connection with a swing frame, capable of vertically swinging, of the bicycle; the other end of the force transfer mechanism is in transmission connection with a swing arm which is rotatably matched with the inner wall of the shell and is suitable for the swing arm to carry out reciprocating swinging; an arc-shaped surface tooth at the lower end of the swing arm is in transmission connection with an input gear which is located on the lower part and is rotatably matched with a fixed shaft; the input gear is in transmission connection with the inner end of a clockwork spring at the rear side by a ratchet wheel mechanism; the outer end of the clockwork spring is in transmission connection with a driven gear on a rotating shaft in a matching way by utilizing a bearing and a one-way clutch provided with gear teeth on the outer side face; the driven gear is suitable for being in transmission connection with the rotating shaft; and the end part, stretching out of the shell, on the rotating shaft is suitable for being fixedly connected with a chain wheel used for driving a driving wheel of the bicycle. The bicycle vibration energy conversion mechanism is capable of accumulating vibration energy and then outputting the vibration energy to wheels so as to drive the bicycle to advance.

Owner:龚天波

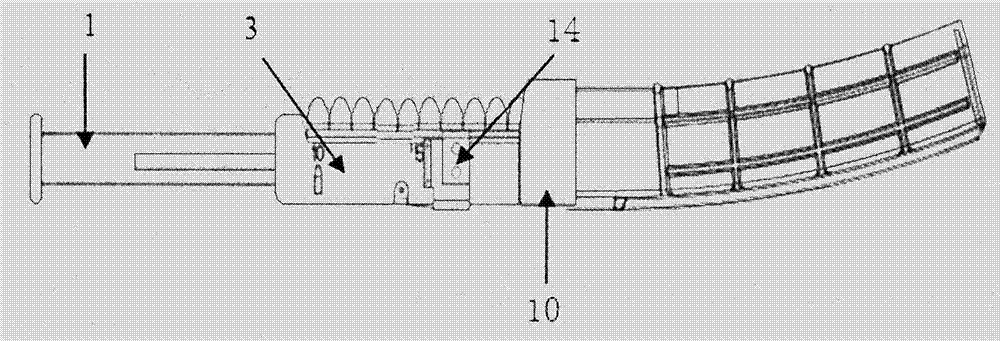

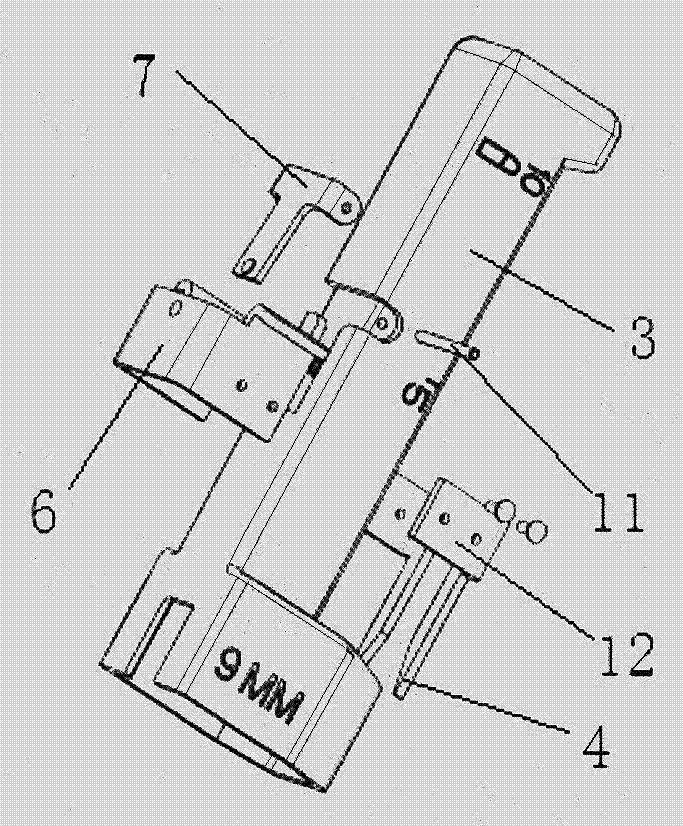

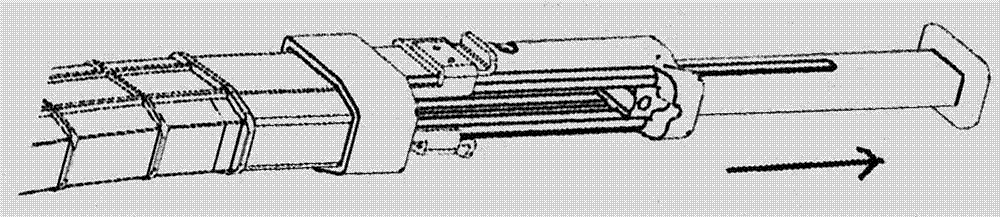

Bullet charging and discharging device and quick bullet charging and discharging method thereof

ActiveCN107228594AQuick to useSmall sizeCartridge extractorsAmmunition loadingEngineeringSlide plate

The invention provides a bullet charging and discharging device which comprises a bullet containing groove, a bullet push rod and a bullet discharging device. The bullet containing groove is provided with a front bag opening movably connected with a box magazine. Sliding grooves are formed in the two inner side walls of the bullet containing groove, the bullet push rod is a strip-shaped cube, and boss keys matched with the sliding grooves are arranged on the two outer side walls of the bullet containing groove. A back bag opening is formed in the back end of the bullet containing groove, a limiting groove is formed in the back bag opening, and a limiting clamping tenon is arranged at the front end of the bullet push rod and is movably matched with the limiting groove. The bullet discharging device comprises a T-shaped positioning bullet sheet, an L-shaped insertion needle and a U-shaped sliding plate. The invention further provides a quick bullet charging and discharging method for the bullet charging and discharging device. The bullet charging and discharging device has the beneficial effects that bullet charging and discharging are convenient, machining, assembling and adjusting are facilitated, the working state is stable and reliable, the manufacturing cost is low, carrying is easy, the bullet charging and discharging device is suitable for being used in all-weather environments, quick bullet charging is achieved, the failure rate is approximately zero, the bullet discharging device can be easily and stably used, and quick bullet discharging is achieved.

Owner:贺佳琪 +1

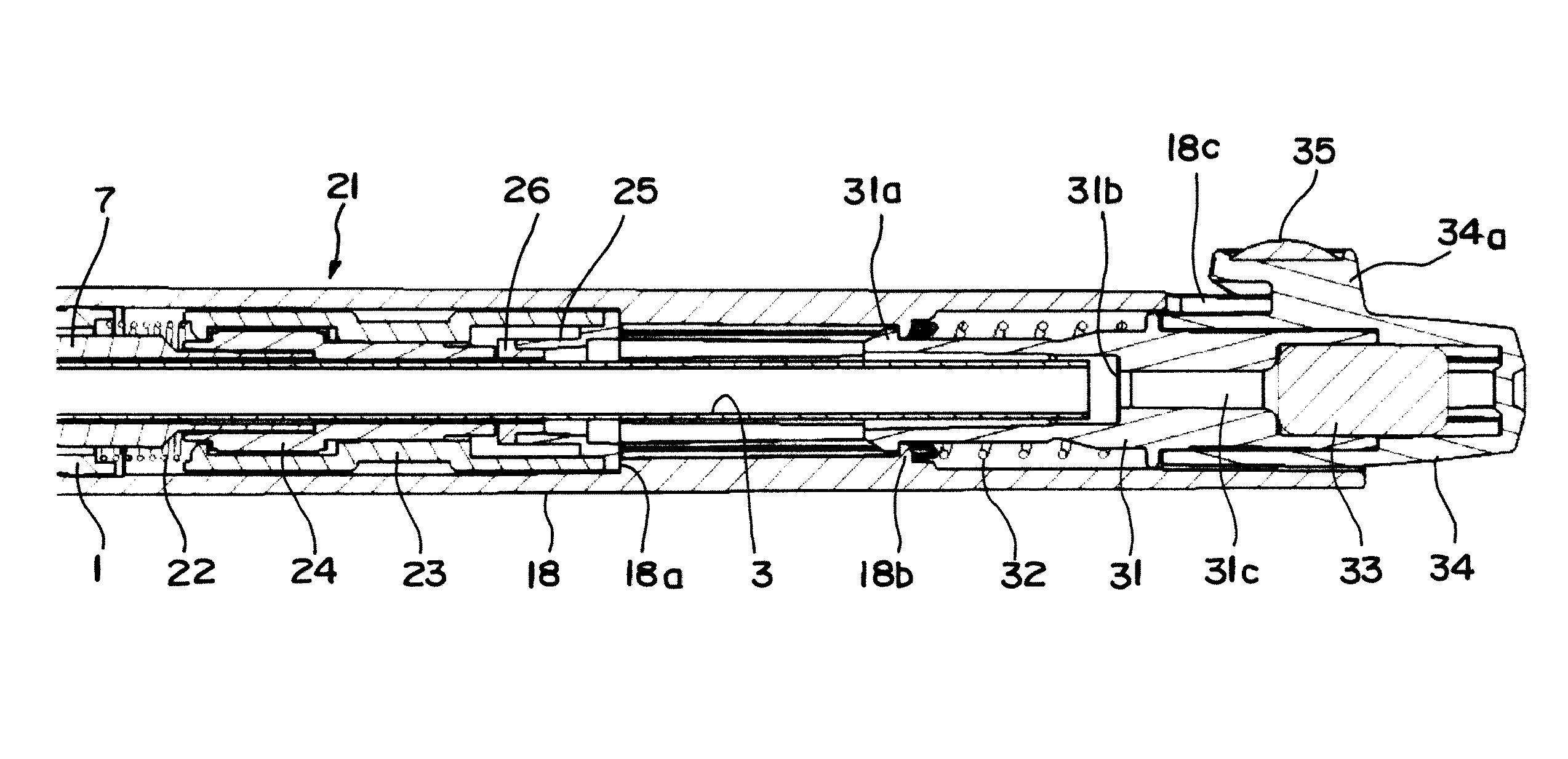

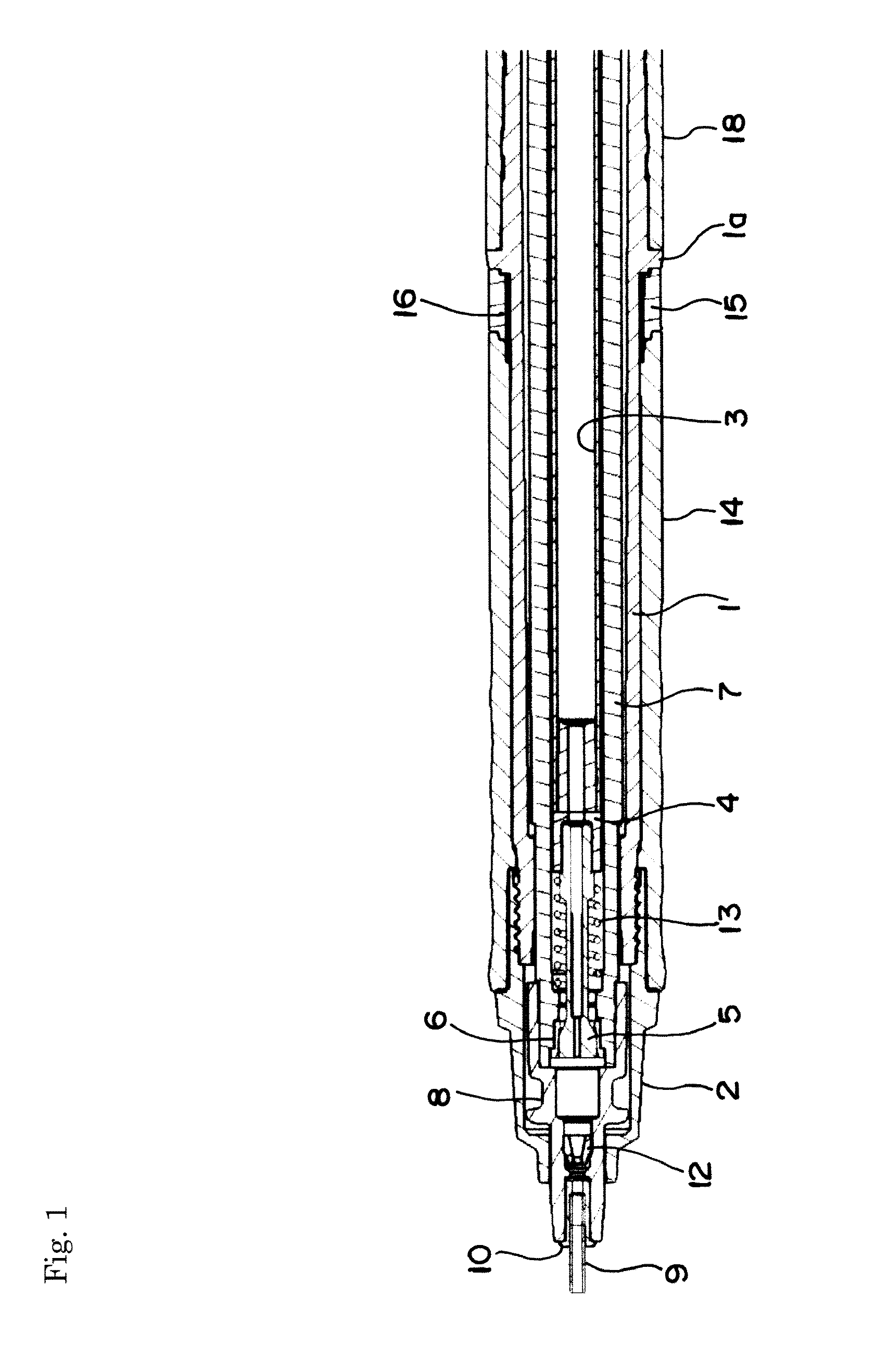

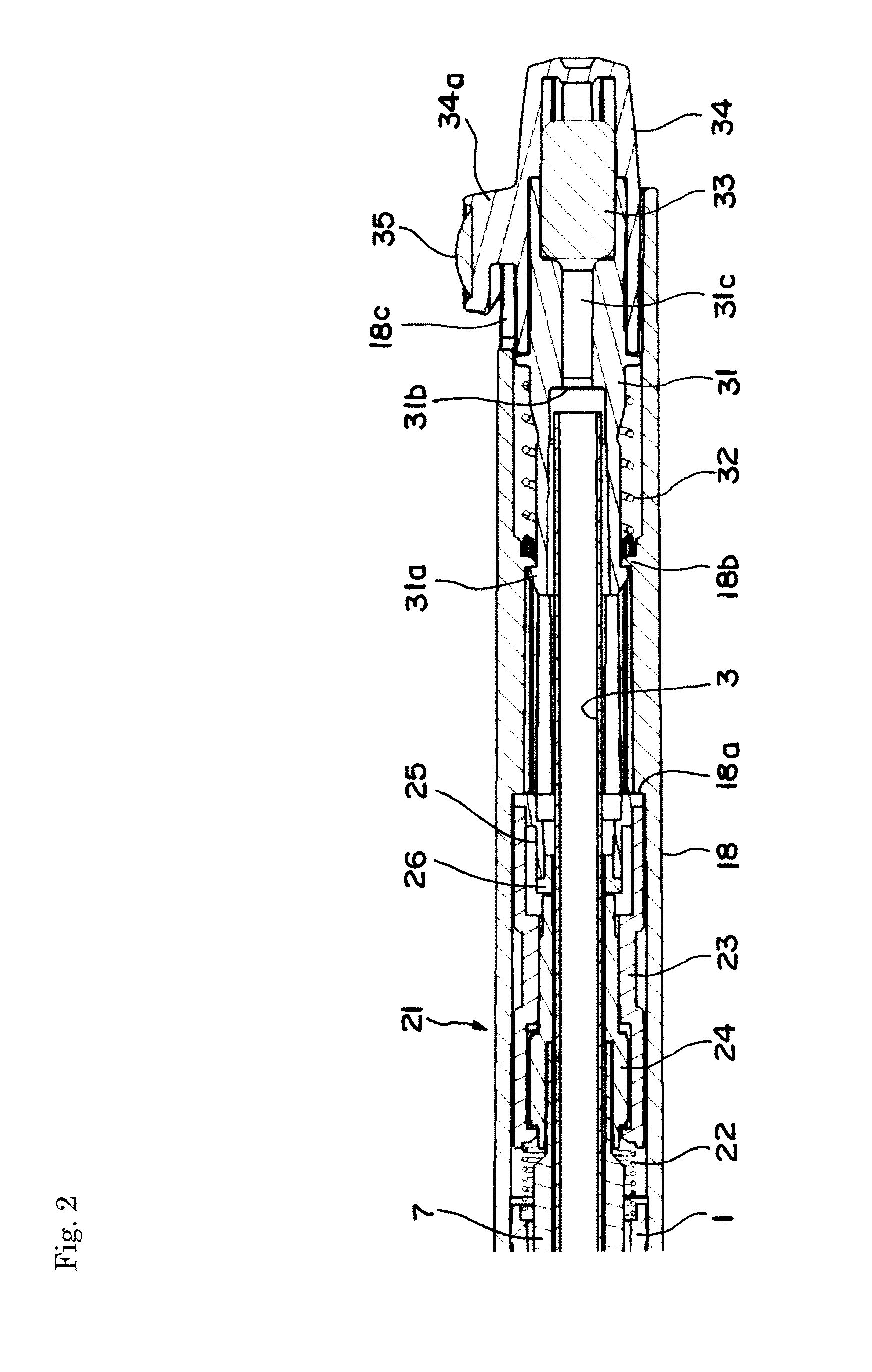

Mechanical pencil

ActiveUS20150050061A1The cam structure is simpleReduce in quantityWriting connectorsPropelling pencilsLower faceMechanical engineering

Cam faces 24a and 24b are continuously formed in a circle on upper and lower faces which are perpendicular to an axial direction of a rotatable cam 24 which constitutes a rotational drive mechanism 21. Elastic members 23b are formed integrally with a holder member 23 for rotatably supporting the rotatable cam 24 to extend in the axial direction, and the first fixed cam and second fixed cam 23c and 23d having a small number of cam faces at butts and tips of the elastic members are arranged to face each other via the upper and lower cam faces 24a and 24b of the rotatable cam 24. The rotatable cam 24 is retreated and moved forward in the axial direction by writing pressure applied to a writing lead to be rotationally driven in one direction and rotational motion of the rotatable cam 24 is transmitted to the writing lead.

Owner:MITSUBISHI PENCIL CO LTD

Electric power unit for vehicle

InactiveCN103287536AEasy to assembleGuaranteed coaxial accuracyWheel based transmissionMotorised scootersElectric power systemDrive shaft

The invention provides an electric power unit for a vehicle, which requires small numbers of parts and assembly processes and which is also capable of reducing the weight and securing the stiffness of a transmission case. A second gear case portion (22) housing a secondary reduction gear train (14) is provided integrally continuous to a rear end of a shaft case portion (21) housing a propeller shaft (11). A first opening portion (23) for inserting the propeller shaft (11) and a drive gear (17) of the secondary reduction gear train (14) and for attaching a first bearing (33) supporting a rear portion of the propeller shaft (11) is provided in a front end of the shaft case portion (21). In addition, a second opening portion (24) for inserting a driven gear (18) of the secondary reduction gear train (14) and a rear axle holder (48) holding a bearing (47) supporting a rear axle (12) is provided in one side portion of the second gear case portion (22).

Owner:MUSA PRECISION IND CO LTD

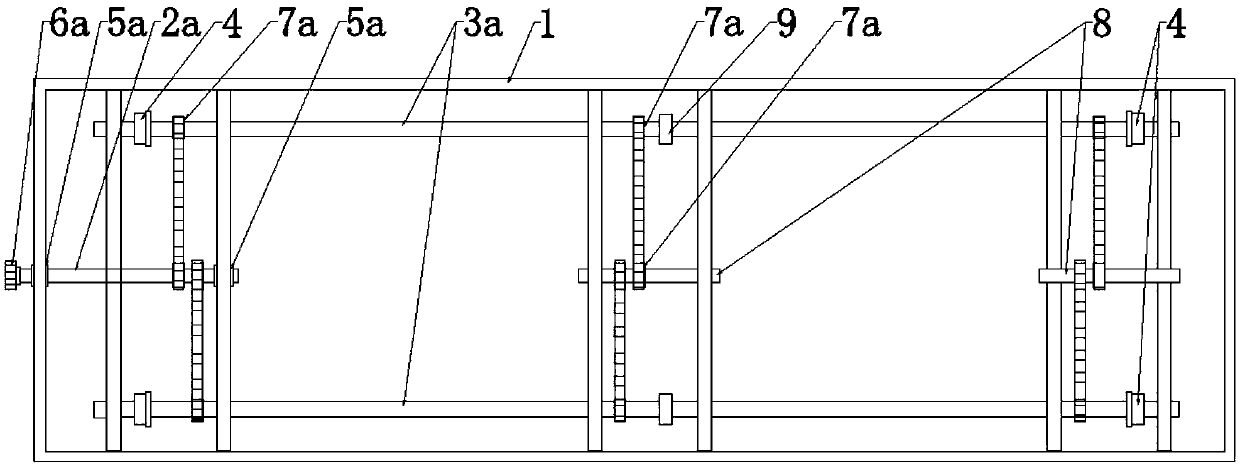

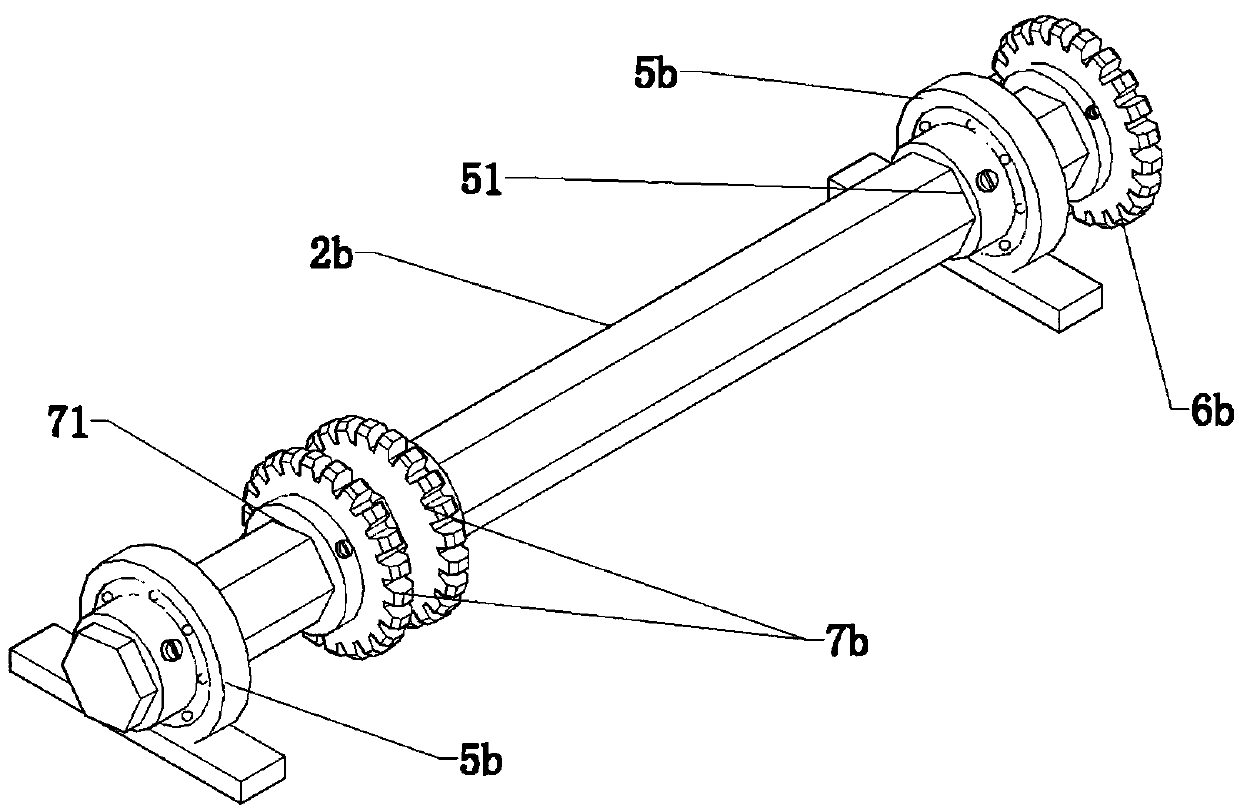

Compact shelving moving device

PendingCN108669859ASmall torque deformationSmall mutual transmission errorBook cabinetsGearingDrive shaftSprocket

The invention discloses a compact shelving moving device. The device comprises a driving shaft and driven shafts arranged on a corresponding underframe as well as walking wheels arranged at two opposite ends of the underframe, wherein the driving shaft is a corresponding short driving shaft arranged at the one corresponding end of the underframe; the driven shafts comprise corresponding long driven shafts which are arranged on two opposite sides or the corresponding one side of the short driving shafts and have two ends connected to the walking wheels at two ends of the underframe respectively, and corresponding self-correction balancing center shafts between the two long driven shafts at the other corresponding ends meshed with the short driving shafts are in balancing connection with thelong driven shafts through meshed gears or chain wheel devices. The compact shelving moving device is particularly reasonable in structure and driving mode, stable and reliable in driving operation,high in transmission efficiency and good in transmission effect, and imbalance and inconformity of the travelling speed at two ends of a compact shelving are avoided.

Owner:JIANGXI ZHUOER METAL EQUIP GROUP

Output rapid chaining mechanism and speed reducer

InactiveCN109681585AAvoid eccentricityCurb tiltToothed gearingsGearing detailsReduction driveCoupling

The invention discloses an output rapid chaining mechanism and speed reducer. A shell, an output base and an input shaft are included. The input shaft is provided with an eccentric wheel, and the eccentric wheel is connected with cycloidal gears through crank bearings. A plurality of gear pins are arranged on the inner wall of the shell along the circumference. The gear pins are intermittently engaged with the cycloidal gears. A positioning flange is arranged at the outer end of the output base. A positioning cylinder is arranged at one end of the positioning flange and arranged in an inner hole of the output base for inner hole positioning. A shaft fastening component is arranged at the other end of the positioning flange, the shaft fastening component and the positioning flange are of anintegrated structure, a crack is arranged between the positioning flange and the shaft fastening component, and shaft connection can be rapidly conducted. The problems that the traditional coupler installing time is long, and during installation, debugging is needed are solved.

Owner:湖北斯微特传动有限公司

Compound gear

InactiveCN101725692ACompact structureReduce loadPortable liftingGearing elementsInvolute gearMechanical engineering

The invention discloses a compound gear, which is formed by a spiral bevel gear and a combined involute gear. The combined involute gear is arranged in the inner cavity of the spiral bevel gear, is coaxial with the spiral bevel gear, and starts from the left end surface of the spiral bevel gear and ends up in the inner end surface thereof. The invention uses a built-in combined involute gear structure; the combined gear has more teeth and dispersed load, and is manufactured without considering turning directions, thus reducing paired stock removal and being favor of lowering production cost.The combined involute gear end is provided with a double chamfer, thus facilitating gear shift, reducing impact force of gear shift and lowering noise.The invention is especially used as a gear for controlling the output direction in a reverse mechanism of a vehicle.

Owner:JIANGSU AIRSHIP GEAR

Transmission device

InactiveCN103144735AReduce impactReduce suitabilityWheel based transmissionGearboxesDrive shaftBevel gear

The invention discloses an oil bath type transmission device with a buffer function, which comprises an output gear box and an input gear box, wherein the input gear box is provided with a first driving bevel gear and a first driven bevel gear that are engaged with each other; the first driven bevel gear is in power transferring connection with a wheel train in the output gear box by a transmission shaft; the first driving bevel gear is fixedly connected with a middle shaft of a bicycle by a shaft sleeve; the shaft sleeve is limited and fixed on the middle shaft by a spline; the first driving bevel gear is arranged on a plummer block of the shaft sleeve in a sleeving manner, positioned and fixed; a groove and convex teeth that are matched mutually are formed between the adjacent end faces of a shaft shoulder of the shaft sleeve and the first driving bevel gear; a buffer sleeve is arranged among the groove and the convex teeth; a counter bore is formed in the end face of the first driving bevel gear adjacent to the shaft shoulder of the shaft sleeve; and a shock-absorbing pad which is higher than the counter bore and pushes against the shaft sleeve and the first driving bevel gear respectively is arranged in the counter bore. According to the transmission device, a gap between a gear pair is eliminated, and noise, trembling and numbness of the gear pair is reduced.

Owner:重庆弘劼机械有限公司

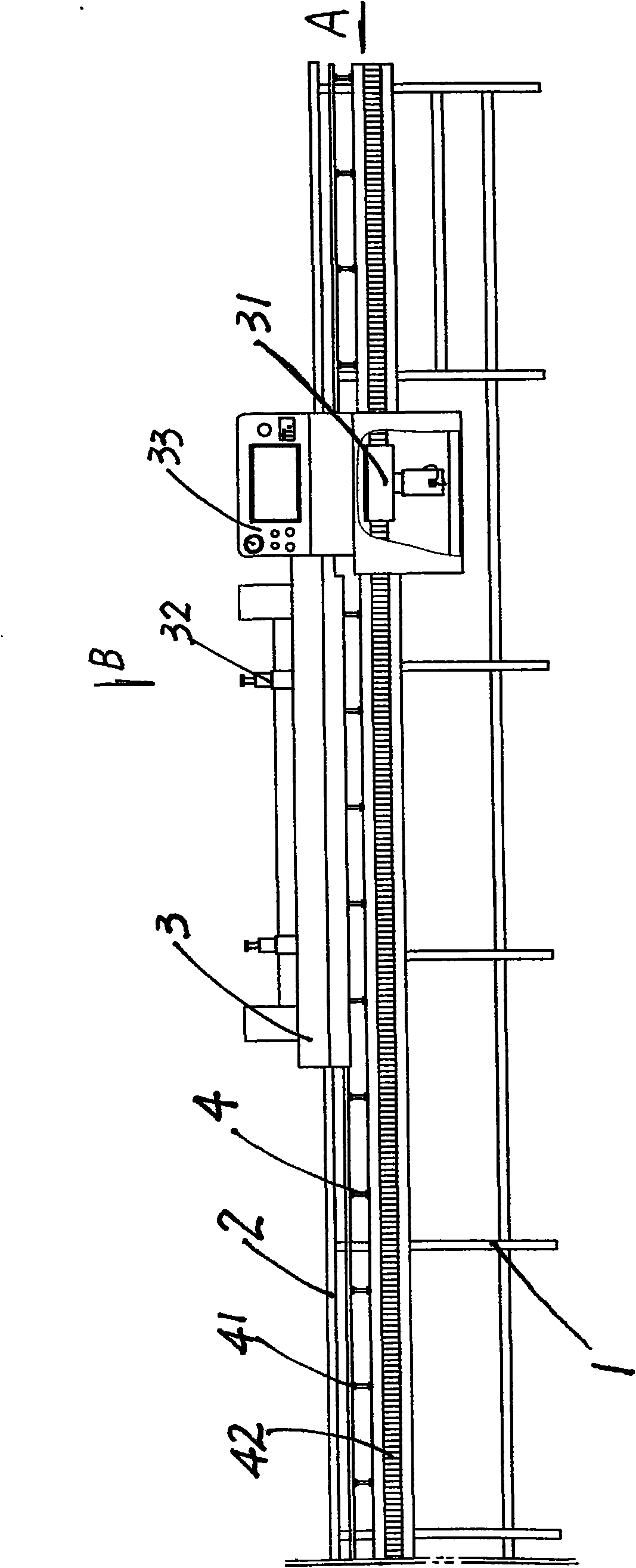

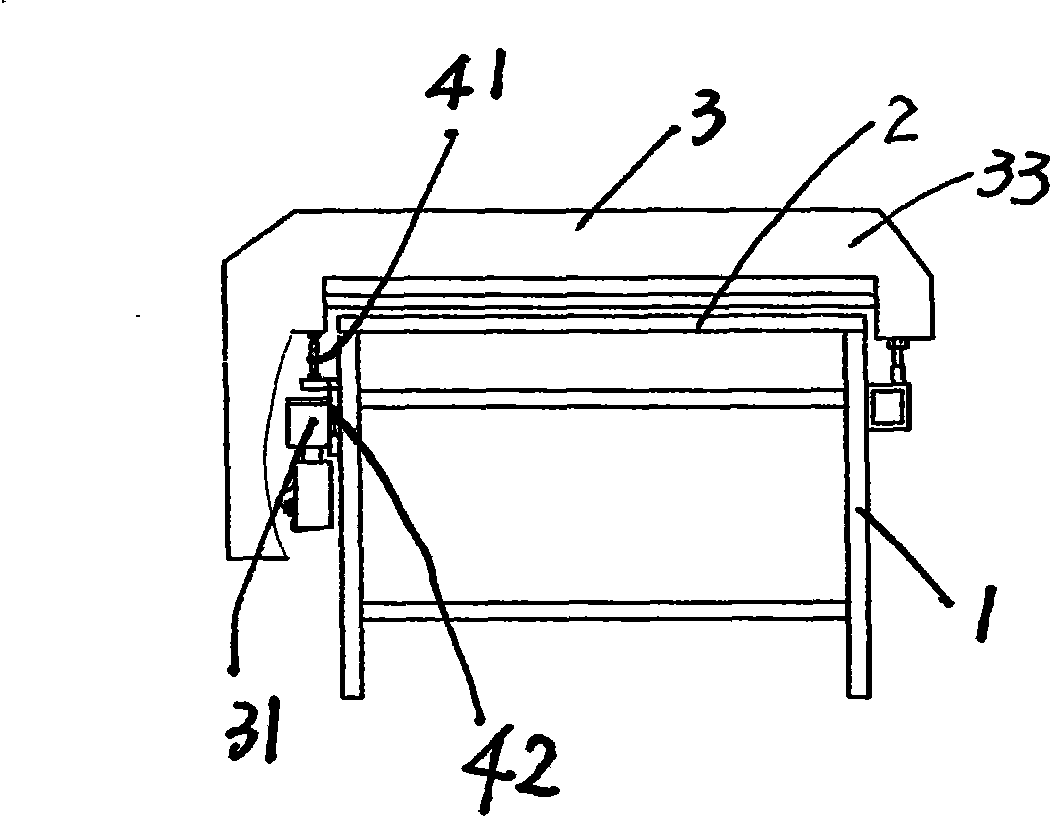

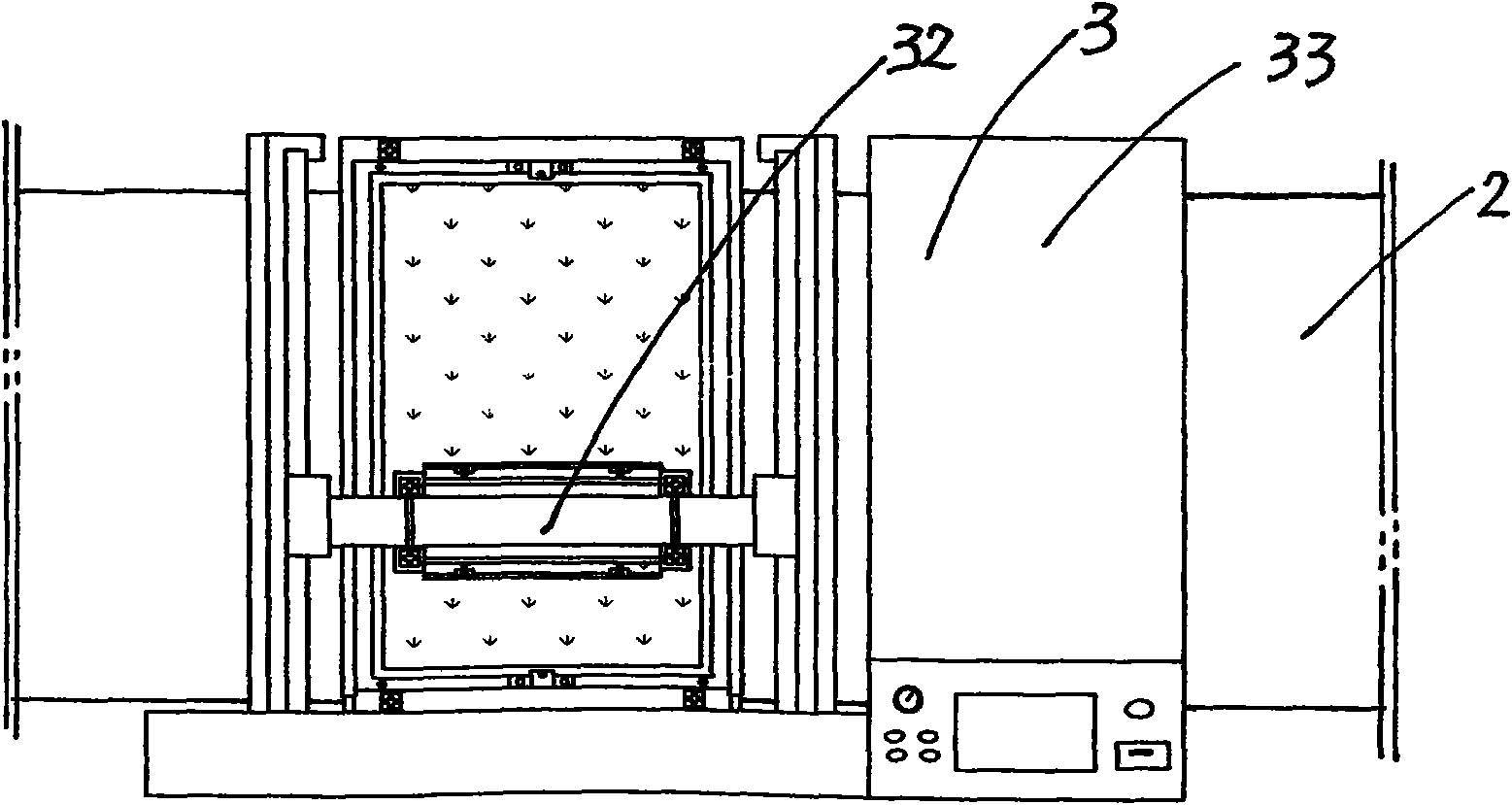

Automatic flatbed printing machine

The invention relates to an automatic flatbed printing machine which comprises a chassis, a worktop, a movable table and a guide rail component, wherein the worktop is connected with the chassis; the guide rail component is arranged on the chassis; the movable table can move leftwards and rightwards along the guide rail of the guide rail component, and the movable table is a computer-controlled movable printing device; a running device in the movable table is a crawler-type running gear formed by a synchronous belt; the guide rail component consists of the guide rail and a mesh belt, the interior of the running device is provided with a compression wheel component, so that a driving synchronous belt in the running device carries out multi-teeth contact drive together with the synchronous belt on the guide rail component, thereby improving the meshing precision, increasing the driving force, and improving the service life of the synchronous belt; and meanwhile, because a driving device is driven and controlled by a servo motor, and driven in a synchronous-belt multi-teeth contact drive mode formed by adopting a crawler-type structure, thereby greatly improving the printing quality.

Owner:如皋市天元服饰印业有限公司

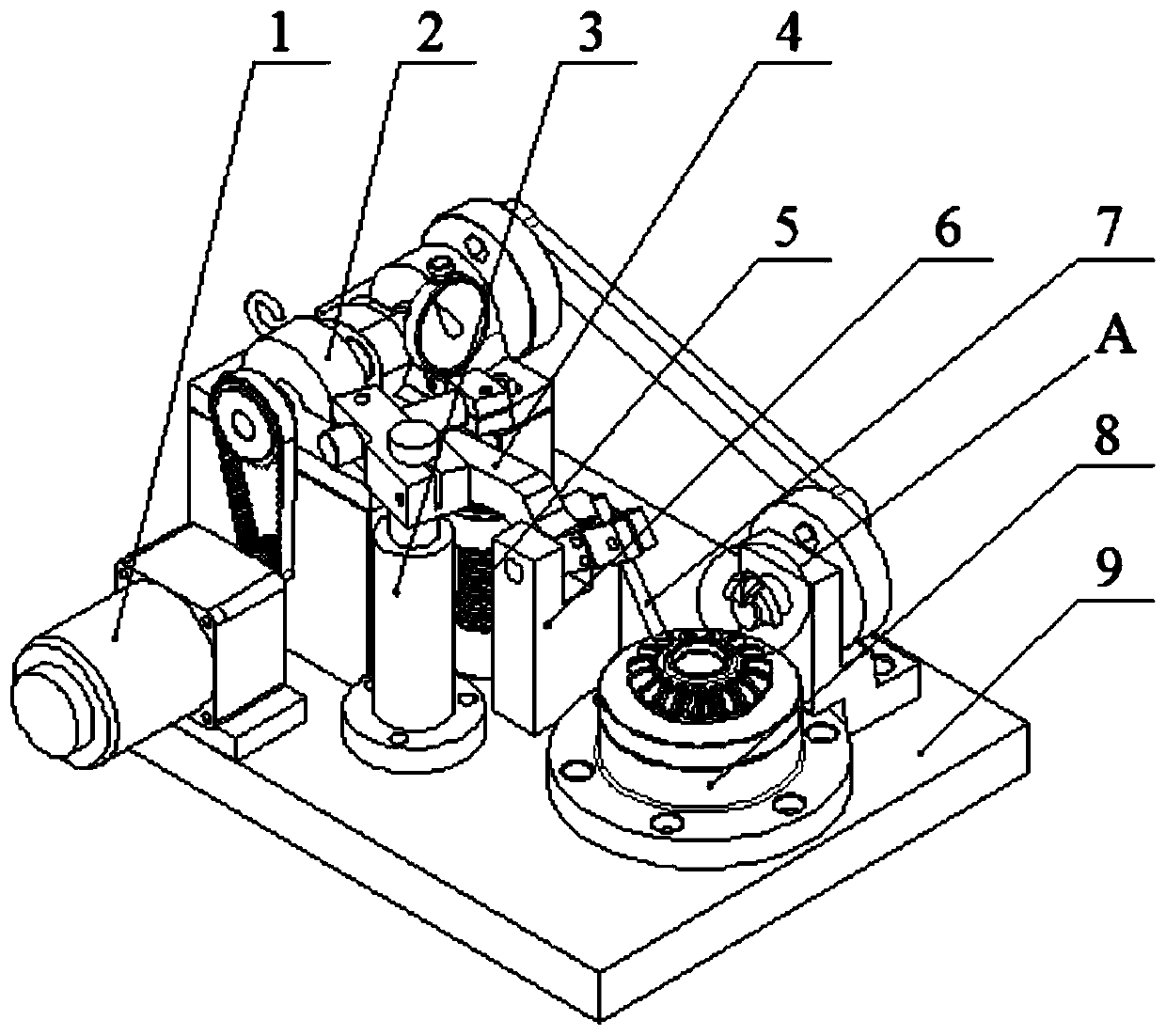

Automobile bevel gear automatic detecting and bouncing device

ActiveCN110375607ASolve the problem that detection is susceptible to light interferenceHighly creativeMechanical measuring arrangementsGear wheelGear tooth

The invention relates to an automobile bevel gear automatic detecting and bouncing device. The device comprises a pedestal, a shaft support, a curved rod support and a gear support, wherein the shaftsupport, the curved rod support and the gear support are successively and fixedly arranged on the pedestal. An eccentric wheel is rotatably installed in the shaft support. A curved rod is rotatably installed on a top of the curved rod support, one end of the curved rod is slidably cooperated with an outer circumference of the eccentric wheel, and the other end of the curved rod is fixedly providedwith a detecting rod. One side of the shaft support is connected with a power unit providing rotational power to the eccentric wheel, and the other side of the shaft support is connected with a transmission unit providing rotational power for a gear to be detected on the gear support. A dial indicator for detecting a swinging limit of the curved rod and a reset spring for providing reset supportfor the curved rod are installed on the pedestal. The detecting device solves a problem that precision of manual detection of a gear tooth type is not high in the prior art, and realizes full mechanical transmission and automatic detection of full mechanical calibration at the same time. The device has advantages of low cost, a high detection speed, high detection precision and the like.

Owner:TIANJIN ZENGYIDA PRECISION FORGING GEAR TECH CO LTD

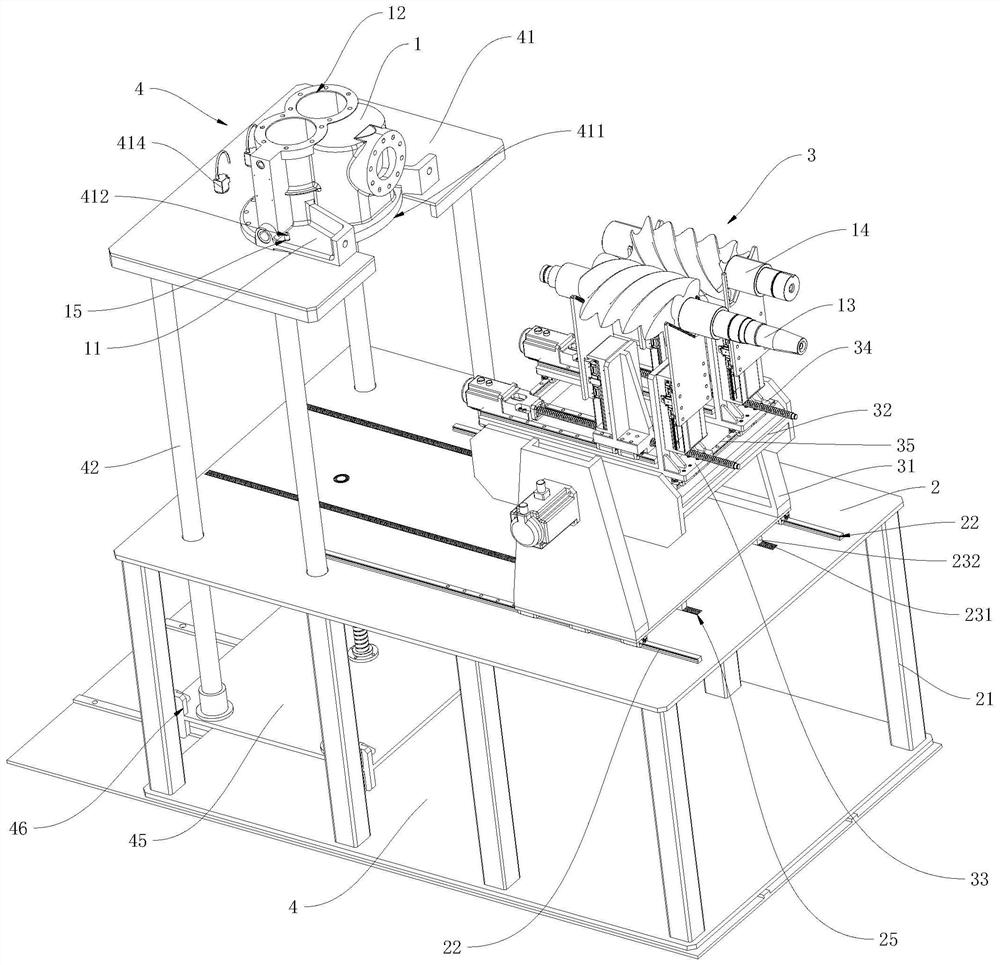

Special assembling machine for large screw-type rotor

The invention relates to the technical field of screw compressors, in particular to a special assembling machine for a large screw-type rotor. According to the technical scheme, the special assembling machine comprises a bearing plate, the lower side of the bearing plate is fixedly connected with supporting legs, a two-rotor automatic meshing device, an exhaust end base bearing device and a special machine data processing center are arranged on the upper side of the bearing plate, and the two-rotor automatic meshing device can move in the direction close to the exhaust end base bearing device so that assembling of two rotors and an exhaust end base can be conveniently completed; the exhaust end base bearing device comprises a lifting plate which ascends and descends in the vertical direction, and a positioning piece for positioning the exhaust end base on the lifting plate is arranged on the lifting plate; and the lifting plate is further provided with two machine vision cameras which are respectively used for scanning and shooting the end surfaces of the two rotors, collecting information and transmitting data to the special machine data processing center. The special assembling machine has the advantages that the accuracy in an assembling process of the two rotors is improved, and the assembling efficiency is improved.

Owner:青岛欧开智能系统有限公司

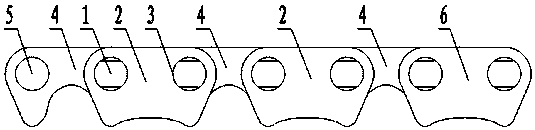

Non-standard toothed chain processing method and non-standard toothed chain

ActiveCN105689633BImprove fatigue resistanceImprove wear resistanceSolid state diffusion coatingMetal chainsEngineeringUltimate tensile strength

Owner:湖州求精汽车链传动有限公司

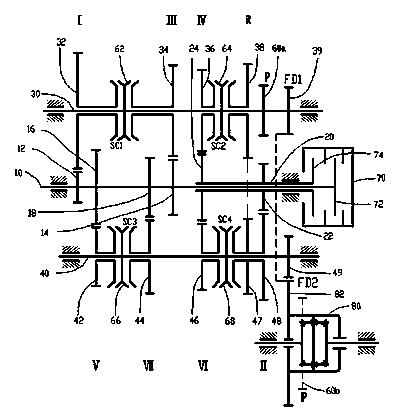

Dual-clutch automatic transmission device

InactiveCN103671754AIncrease stiffnessReduce the overall heightToothed gearingsTransmission elementsLow speedAutomatic transmission

Disclosed is a dual-clutch automatic transmission device. The dual-clutch automatic transmission device comprises an inner input shaft, an outer input shaft, two countershafts, a dual clutch, a differential assembly, a plurality of normally-engaged gear sets and a plurality of synchronizer devices, wherein the inner input shaft and the outer input shaft are coaxially arranged, and the normally-engaged gear sets are arranged on the shafts respectively. The dual-clutch automatic transmission device is characterized in that a first-speed gear and a second-speed gear serve as low-speed gears and are arranged at the shaft ends of a shaft system of a gearbox respectively; a first-speed driven gear and a reverse driven gear are arranged on the same countershaft; the center distance between the countershaft where the first-speed driven gear is located and the inner input shaft is larger than that between the other countershaft and the inner input shaft, and the center distance between the countershaft where the first-speed driven gear is located and the outer input shaft is larger than that between the other countershaft and the outer input shaft. The dual-clutch automatic transmission device can provide seven or six forward gears and one reverse gear and has the advantages that the structure is simple, reverse motion safety is high, the number of gears is large and the gear transmission ratio degree and the freedom are high, and therefore the dual-clutch automatic transmission device is excellent in comfort performance and lower in oil consumption.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com