Patents

Literature

847 results about "Wheel train" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In horology, a wheel train (or just train) is the gear train of a mechanical watch or clock. Although the term is used for other types of gear trains, the long history of mechanical timepieces has created a traditional terminology for their gear trains which is not used in other applications of gears.

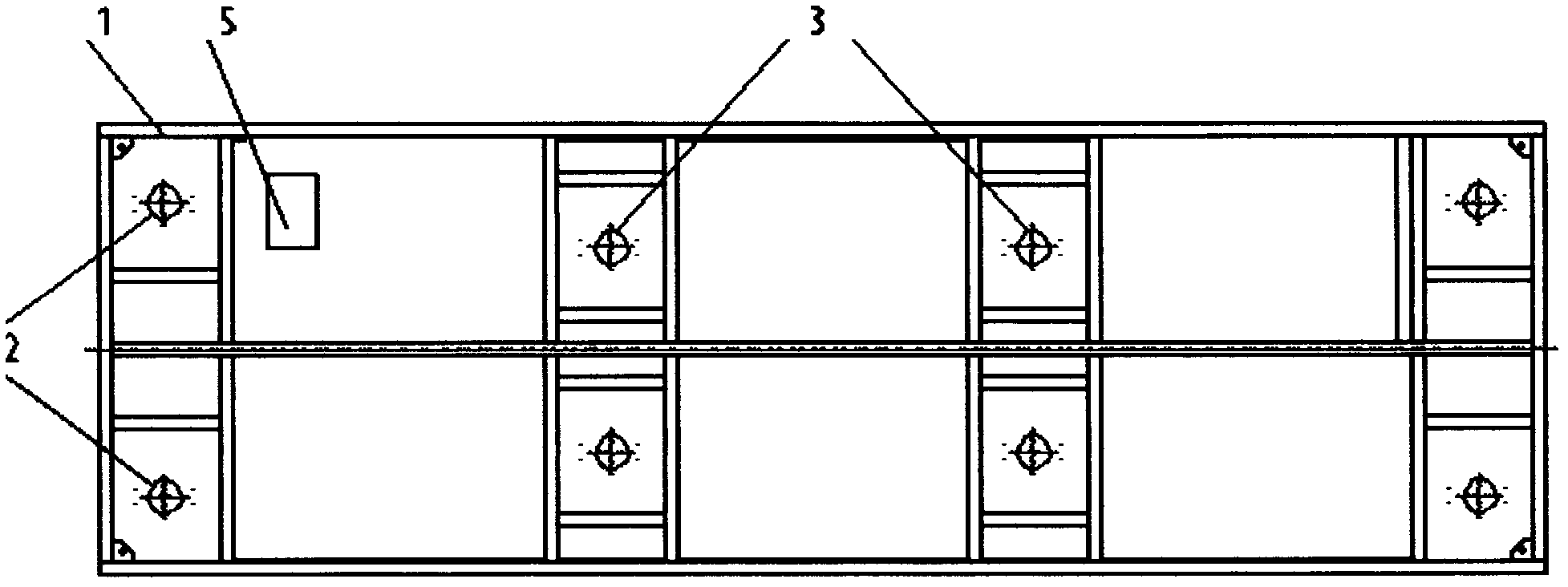

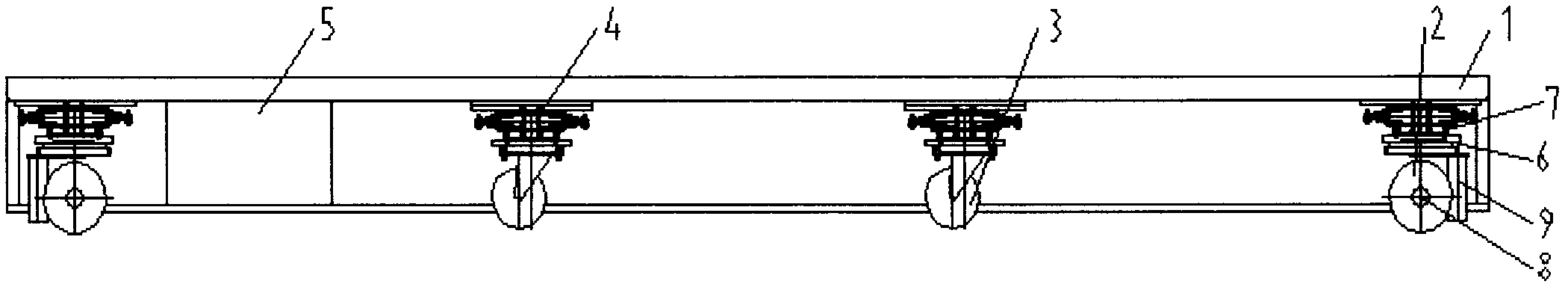

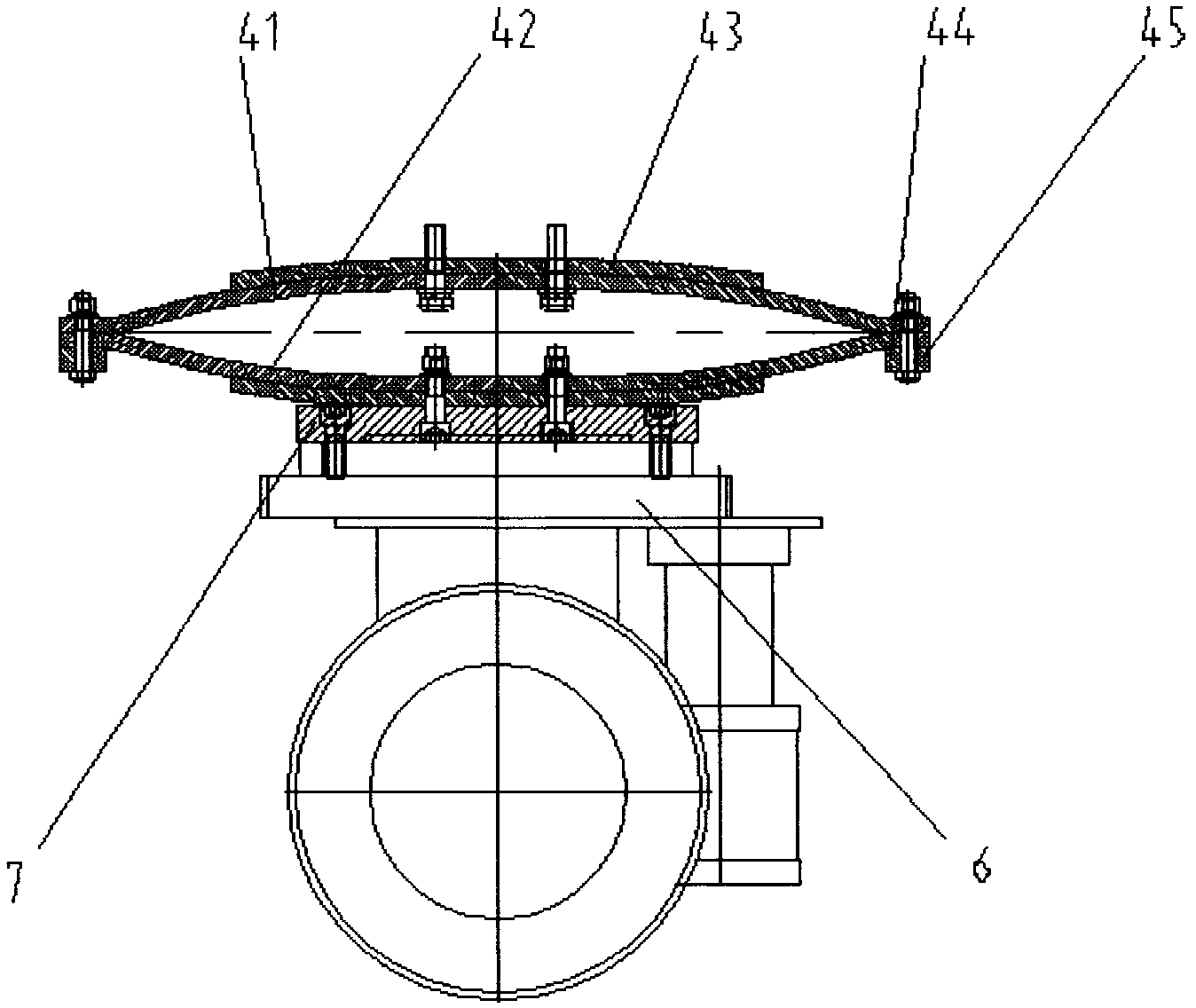

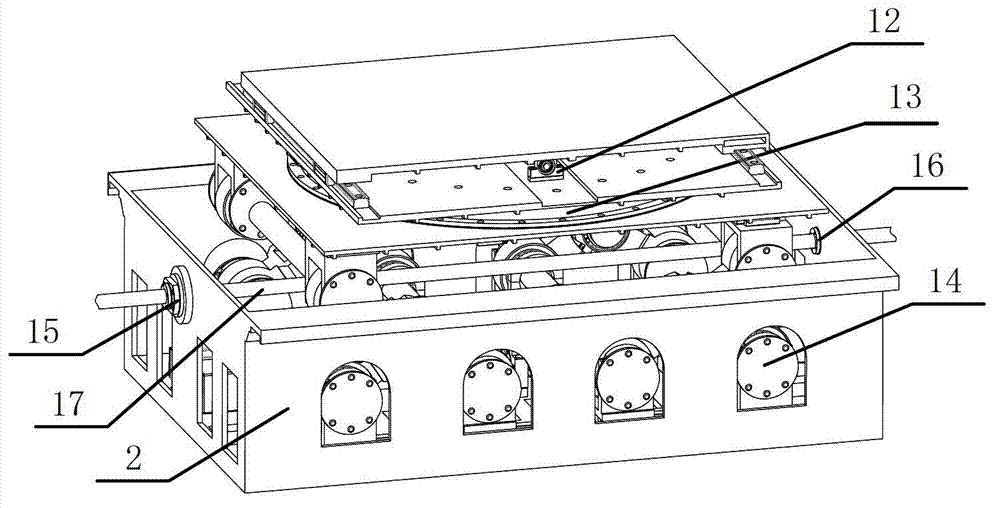

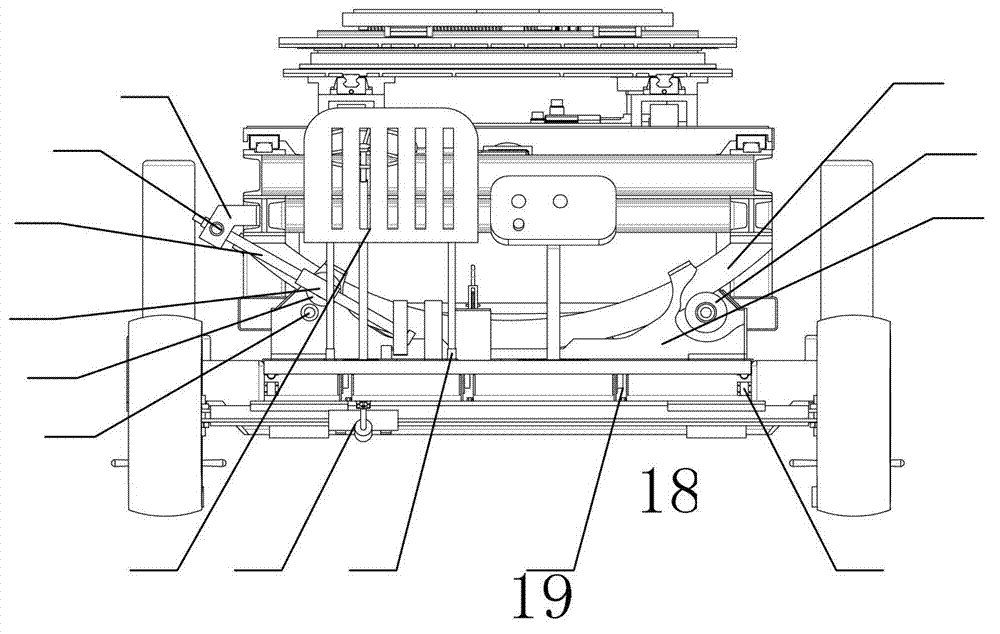

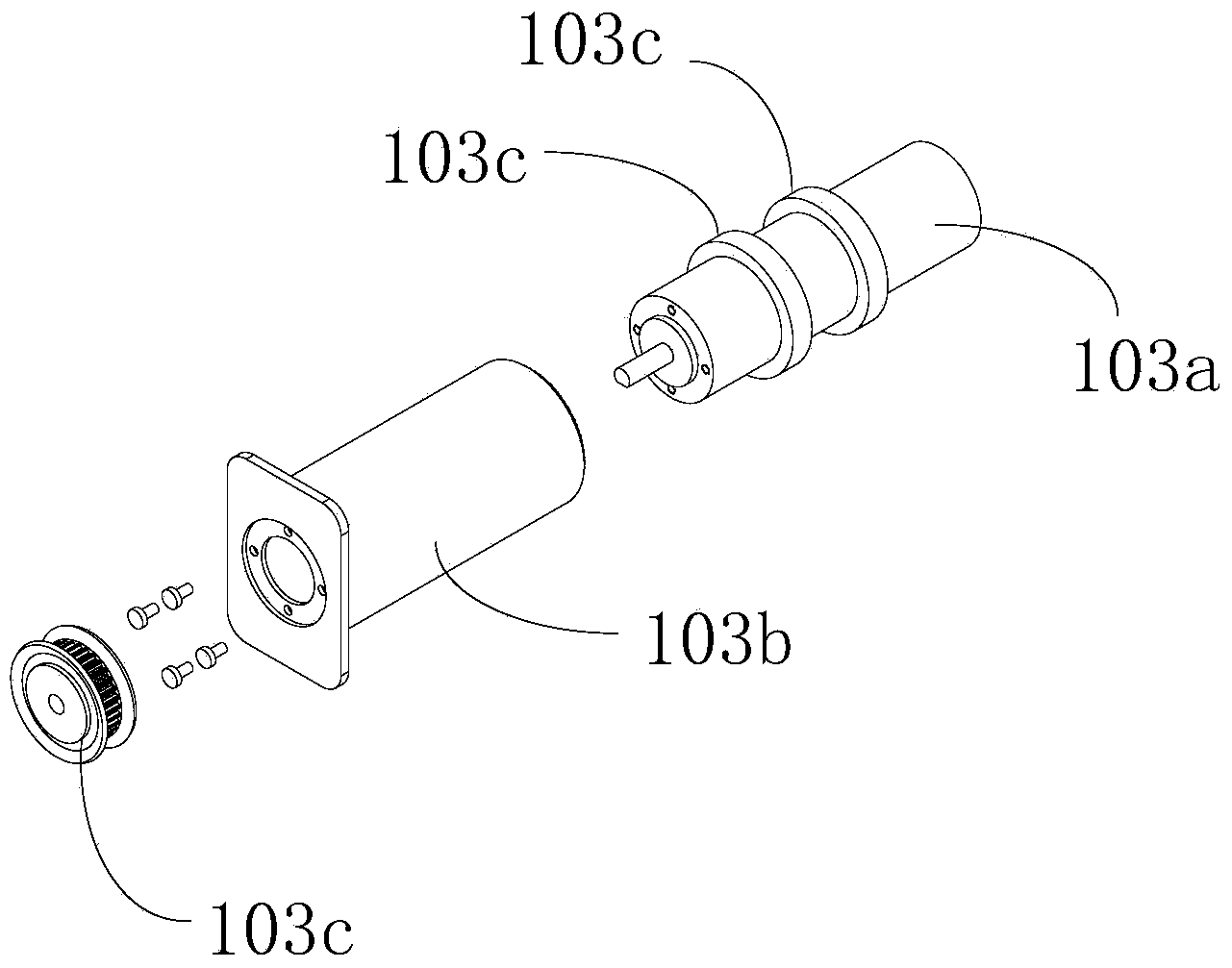

AGV (Automatic Guided Vehicle) for multiple-wheel train heavy load mobile robot

InactiveCN102673676ALighten the loadLower requirementMotor depositionResilient suspensionsElectricityVehicle frame

The invention relates to an AGV (Automatic Guided Vehicle) for a multiple-wheel train heavy load mobile robot. The AGV comprises a frame, wheels, an electric control device, a floating spring structure frame, a driving device and a steering device; the electric control device is electrically connected with the driving device and the steering device; the wheels are divided into driving wheels and supporting wheels; the driving wheels are coaxially connected with the driving device and are horizontally and lengthwise connected with the steering device; the floating spring structure frame is arranged between the wheels and the frame and is connected with a wheel assembly support; and the wheels are arranged on the wheel assembly support and have the effect of buffering and uniform loading. The AGV adopts a multi-wheel train full floating multi-drive chassis structure so that the generality of the driving wheels is increased; the structure size of the driving wheels is reduced, thereby reducing the production cost; and the AGV has good stability and meets the using requirements of heavy loading and multiple road surfaces.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

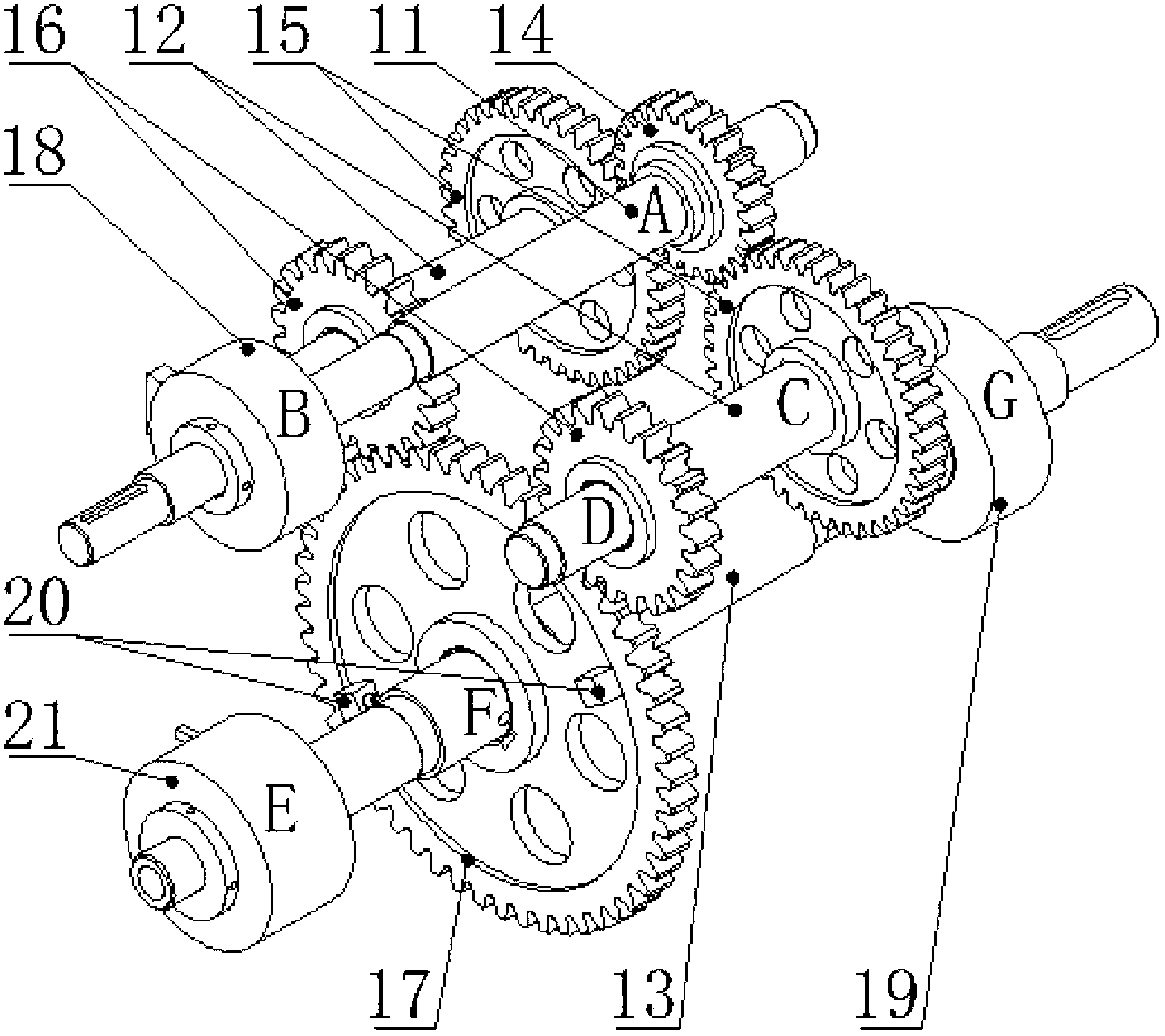

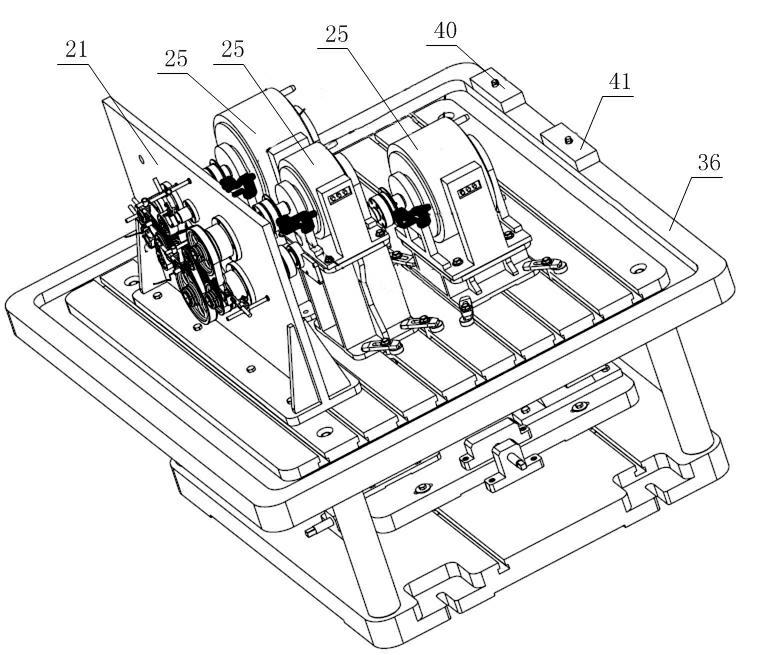

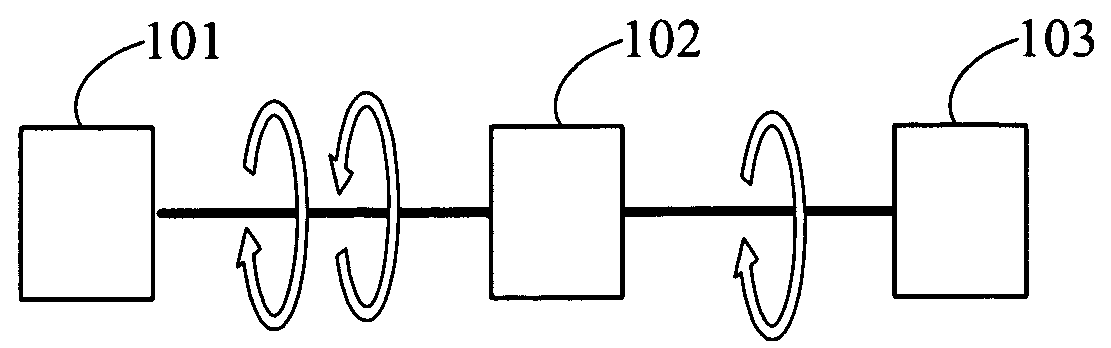

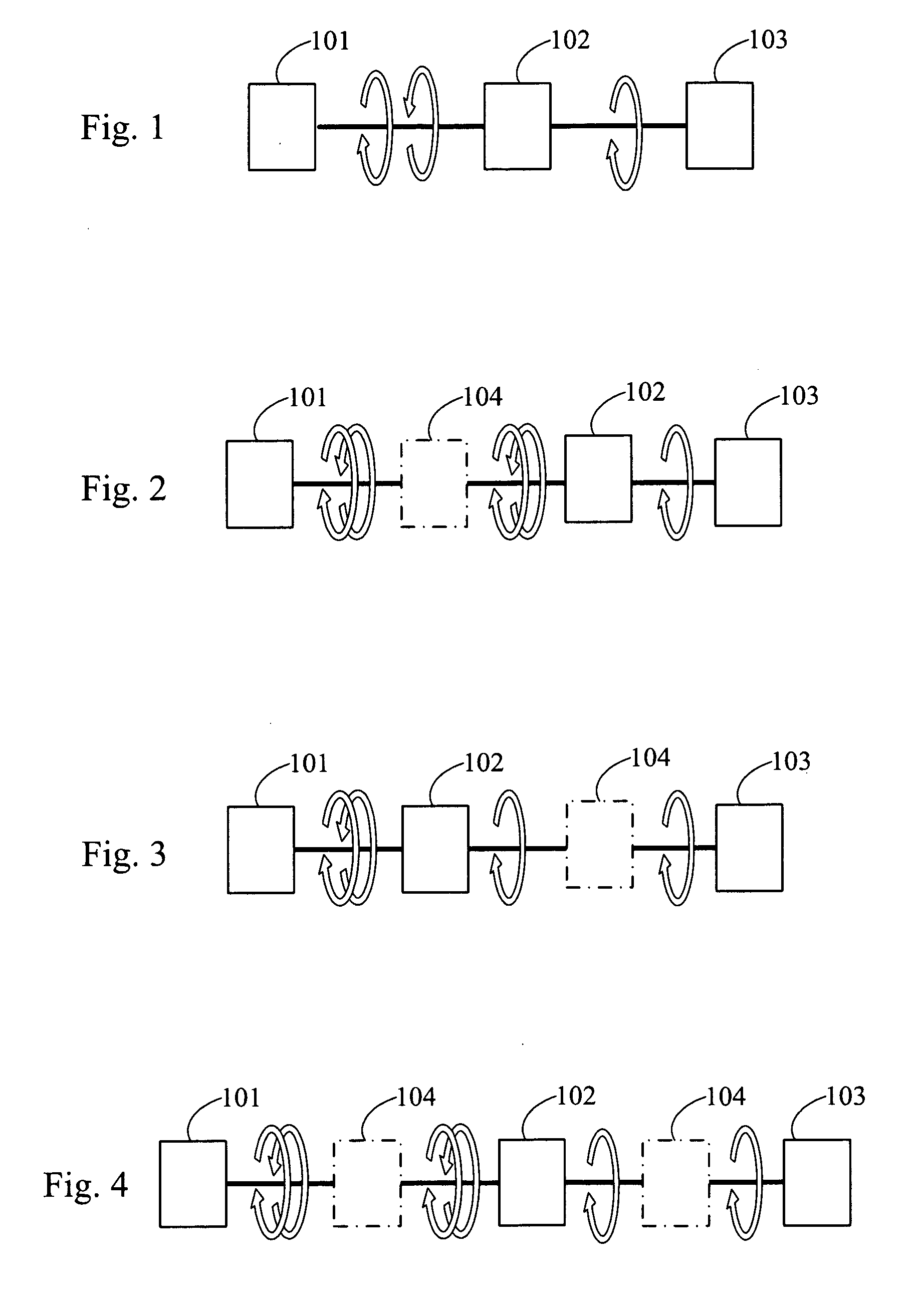

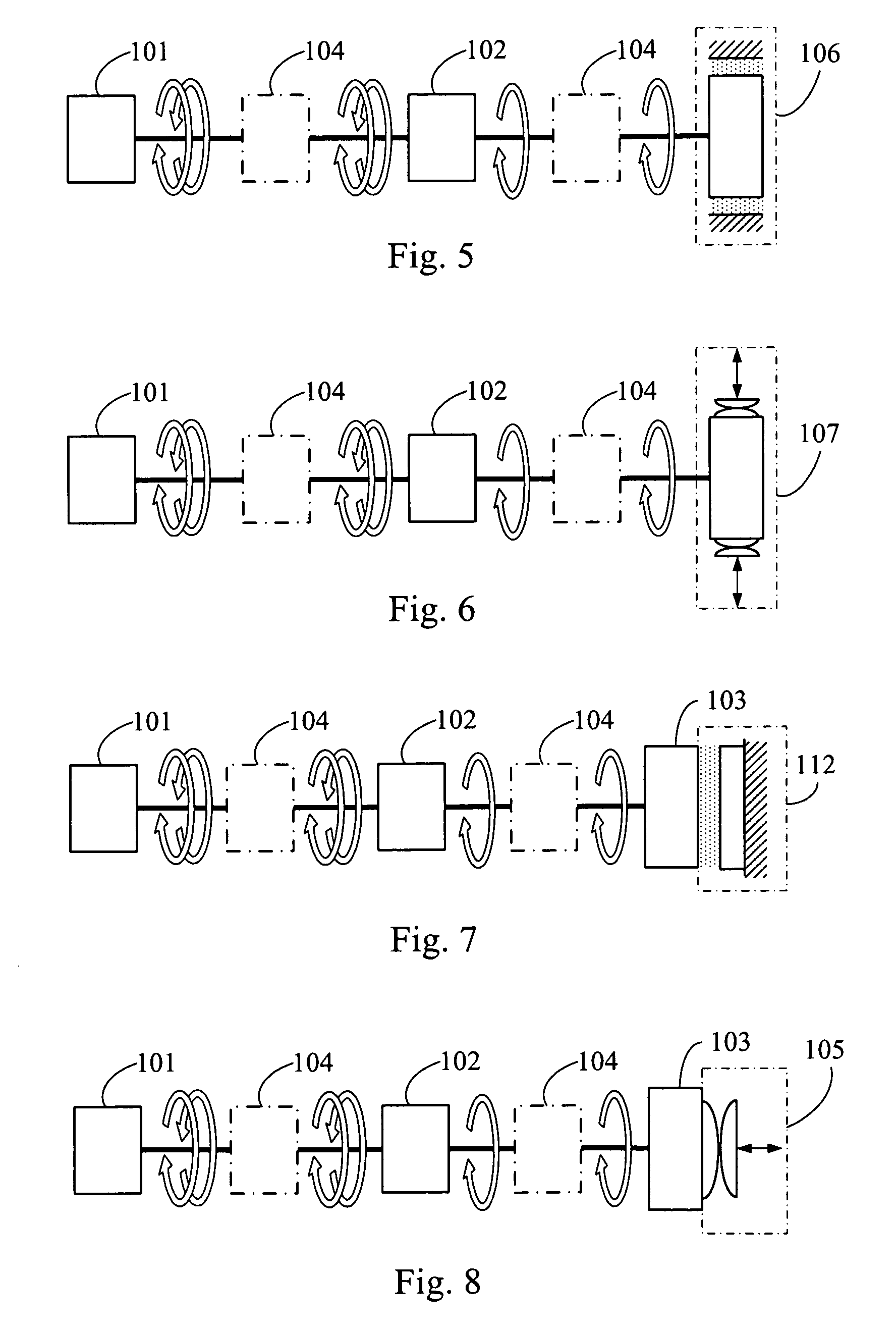

Multifunctional gear transmission testboard

InactiveCN102706557AImproved rigidityEasy to replaceMachine gearing/transmission testingSingle stageEngineering

The invention provides a multifunctional gear transmission testboard, which includes an electric motor, a torque revolving speed sensor, a gearbox and a brake, wherein the gearbox includes one input shaft, two intermediate shafts and one output shaft which are all mounted in parallel. According to the invention, shafts at different positions and corresponding gears in the gearbox can be dismounted on a base of a testing platform, so as to form a stand-alone power two-branch gear transmission wheel train structure, a two-stage expanded gear transmission wheel train structure, a single-stage independent torsion type gear transmission wheel train structure and a single-stage gear transmission wheel train structure; gears with web boards of different thicknesses and shafts of different diameters can be replaced to vary the rigidity of web boards of the gears and the torsional rigidity of the shafts, so that the dynamic performances of the power two-branch transmission system under different rigidity of the web boards of the gears and the torsional rigidity of the shafts can be studied, and testing support for rigidity of the web boards and the shafts can be provided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

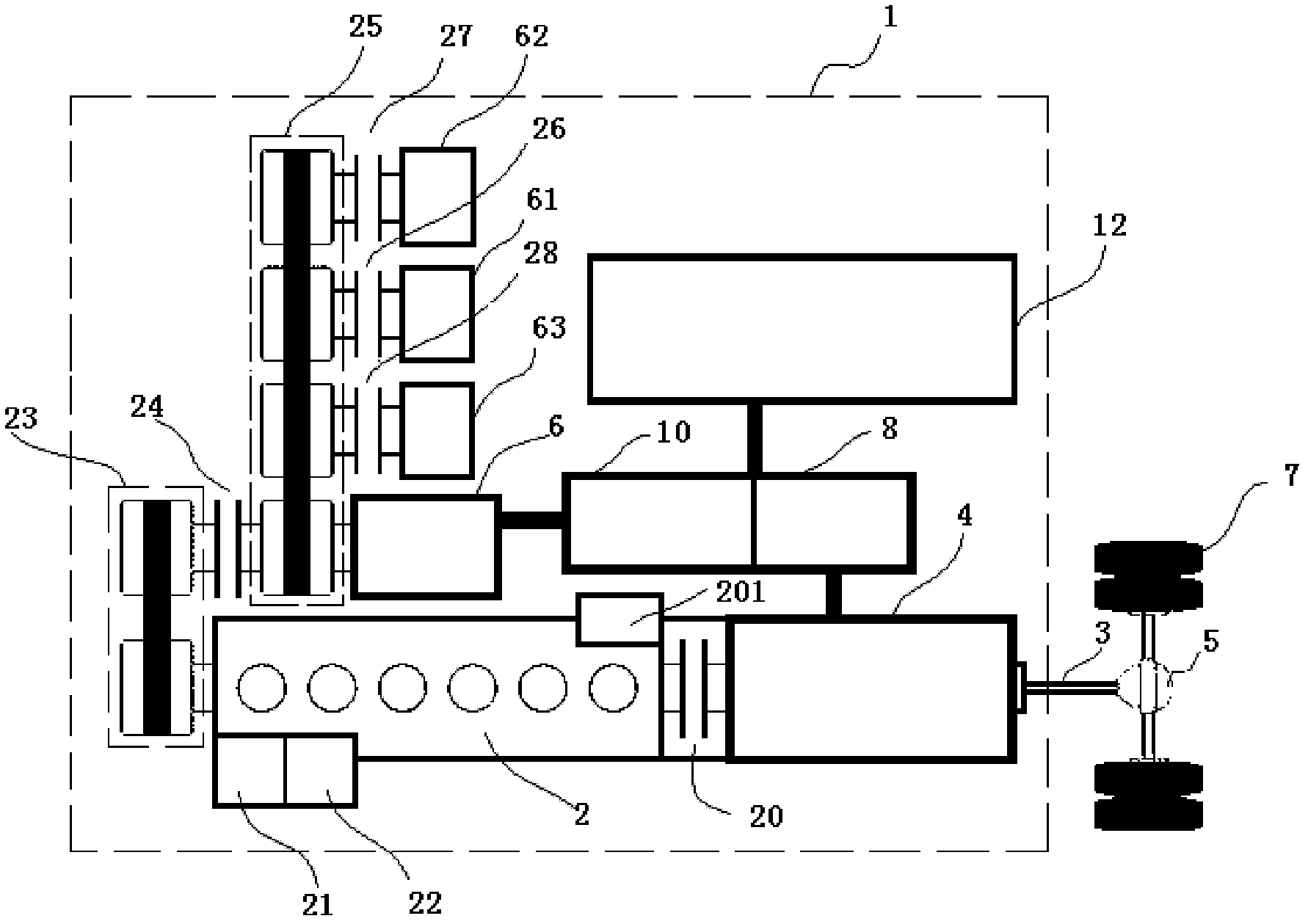

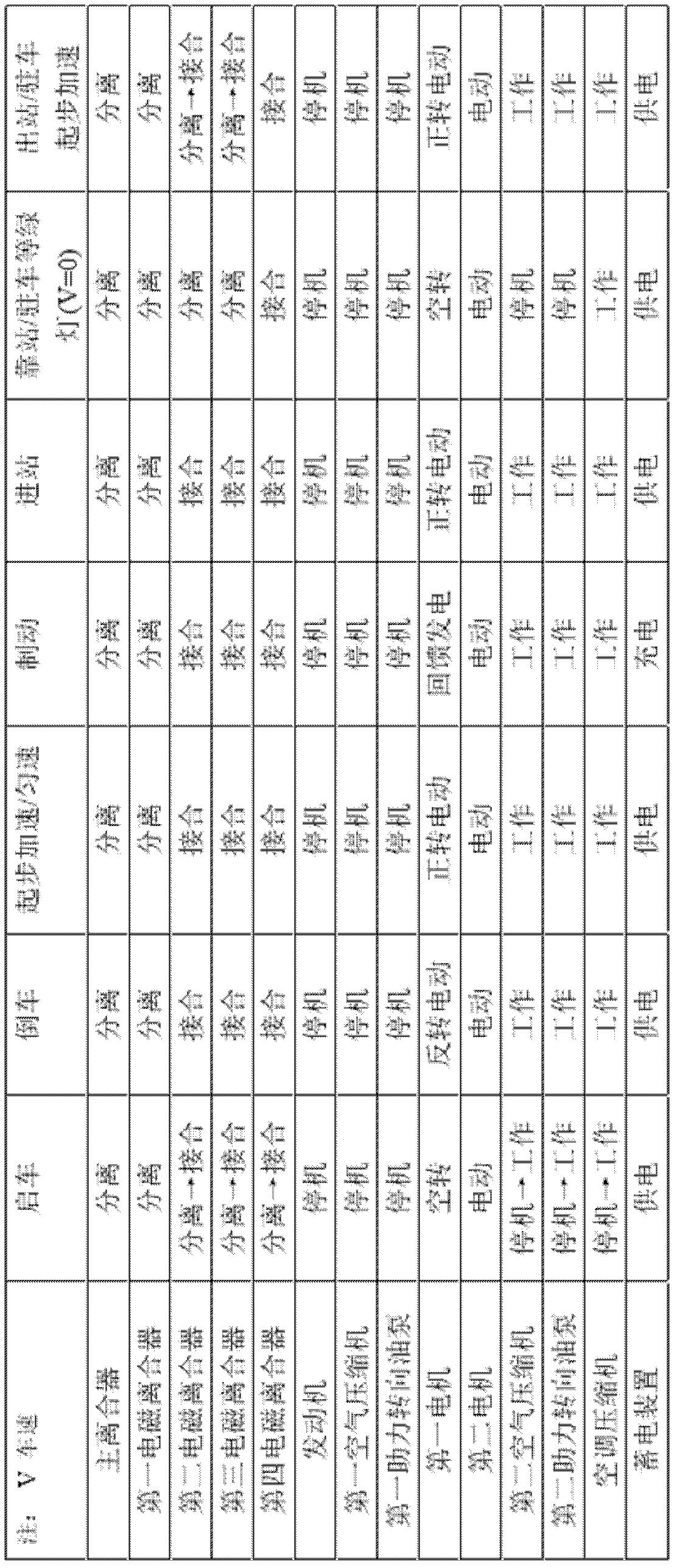

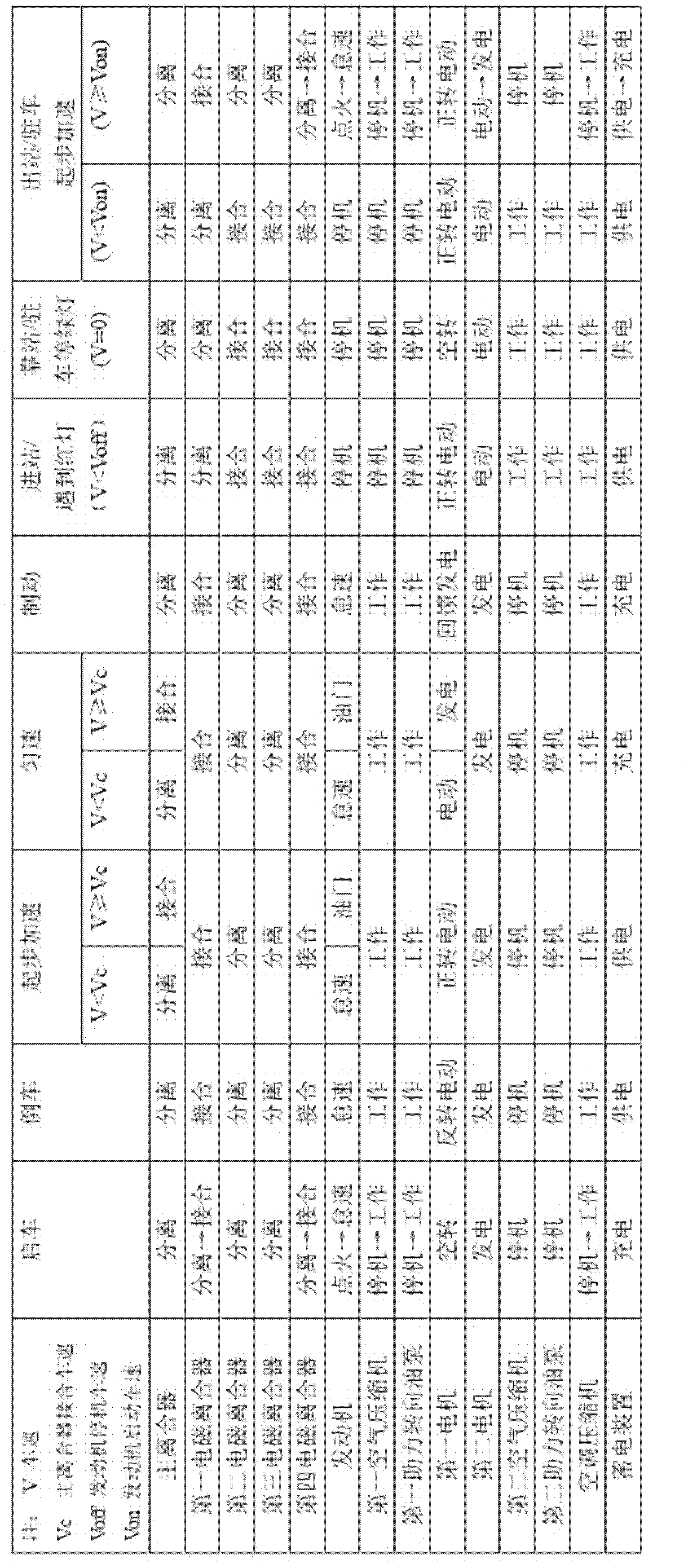

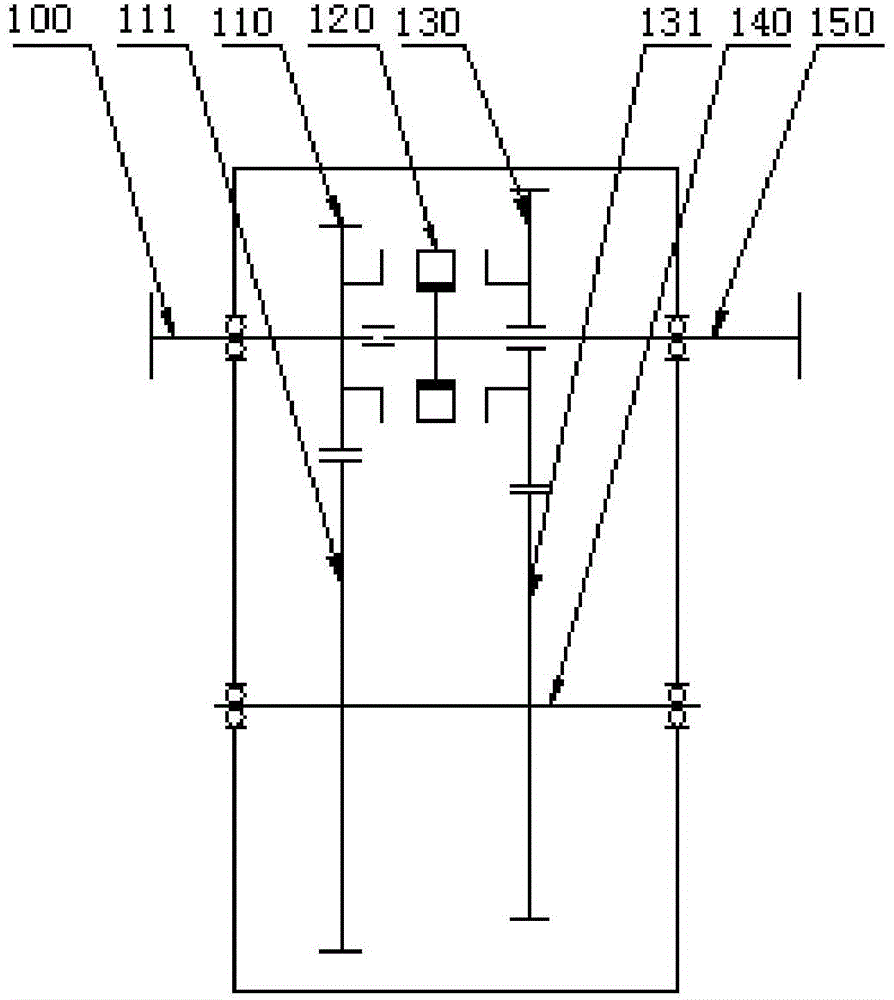

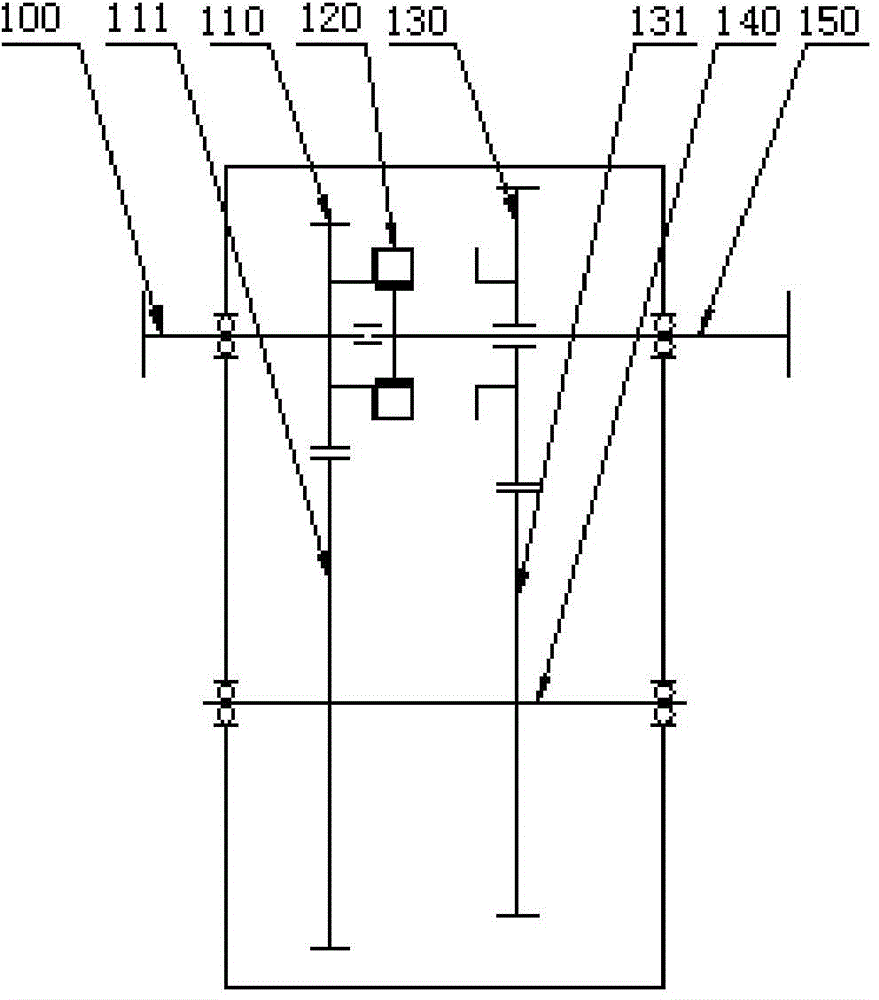

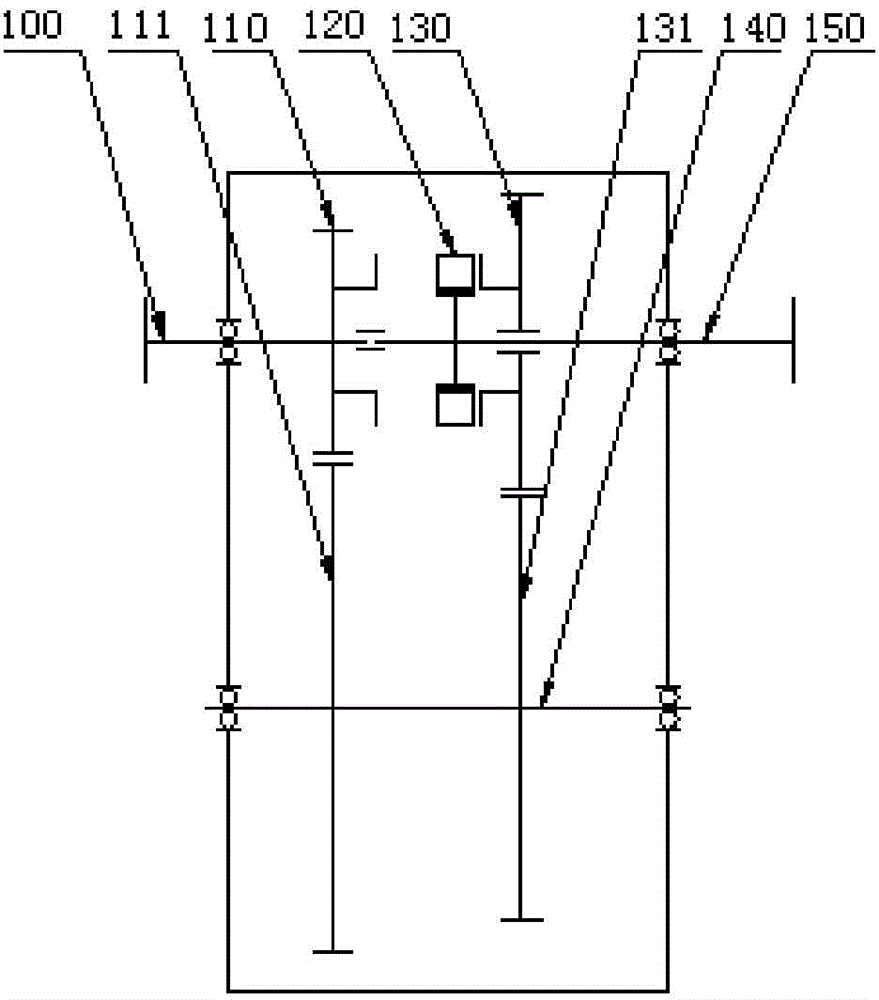

Series-parallel combined type hybrid power assembly

InactiveCN102490584AImprove fuel economyImprove emission effectGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectromagnetic clutchElectric machine

The invention provides a series-parallel combined type hybrid power assembly (1), which comprises an engine (2), a first air compressor (21), a first power-assisted steering oil pump (22), a first motor (4), a first motor controller (8), a main clutch (20), a second motor (6), a second motor controller (10), a second air compressor (61), a second power-assisted steering oil pump (62), an air condition compressor (63), a first electromagnetic clutch (24), a second electromagnetic clutch (26), a third electromagnetic clutch (27), a fourth electromagnetic clutch (28), a first belt wheel train (23), a second belt wheel train (25) and an electric power storage device (12). The engine (2) comprises a starter (201), the first electromagnetic clutch (24) controls working conditions of the second motor (6), the second electromagnetic clutch (26) controls working conditions of the second air compressor (61), the third electromagnetic clutch (27) controls working conditions of the second power-assisted steering oil pump (62), and the fourth electromagnetic clutch (28) controls working conditions of the air condition compressor (63).

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

Test-bed for optimizing pulley train of engine

The invention relates to an engine belt pulley train optimization test table. It incldues table frame, motor used for simulating engine, load, support frame for mounting load and sensor for measuring parameters. On the table frame an intermediate plate is set, the motor and load are placed on one side of said itnermediate plate, the wheel train is placed on another side of said intermediate plate, and the signal output end of the sensor is connected with signal input end of computer. Said test table can simulate actual operation of the engine, and can test various related parameters in the operation processor, and the obtained various parameters can be inputted into computer. Said test table is simple in structure, convenient and safe in operation.

Owner:WUHAN UNIV OF TECH

Automatic speed changer

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

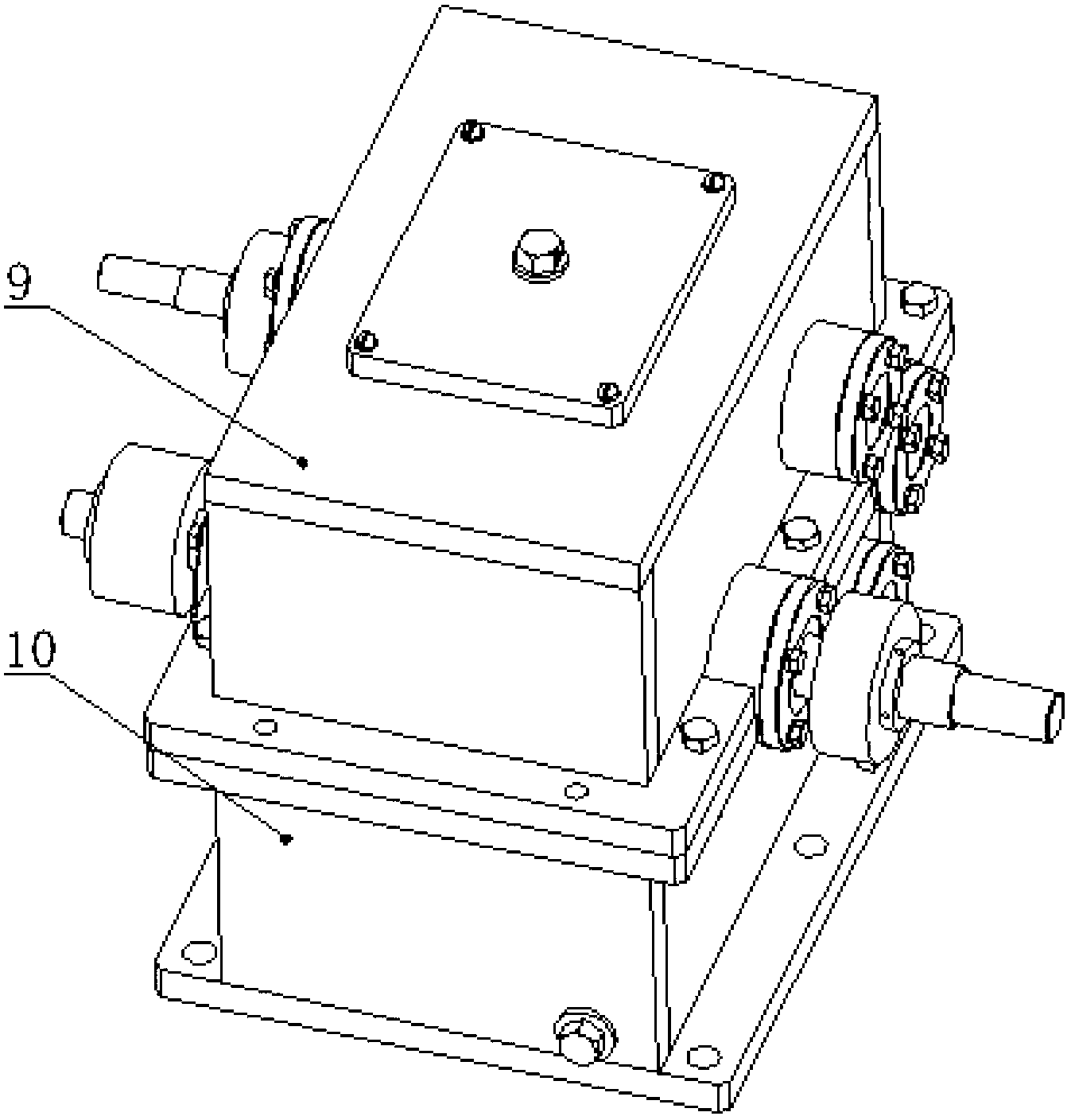

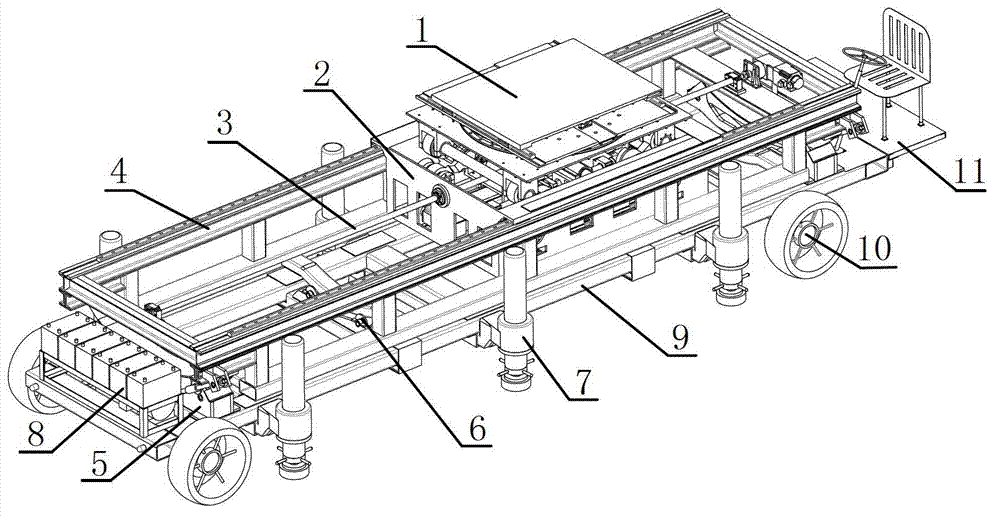

Numerical-control electric frame truck for airplane engine mounting

InactiveCN103204248ARealize the installation workEnable mobilityAircraft assemblyNumerical controlDrive wheel

The invention relates to a numerical-control electric frame truck for airplane engine mounting and belongs to the technical field of assembly automation. The numerical-control electric frame truck is characterized by comprising a multi-shaft posture adjusting platform (1), a posture adjusting platform frame (2), a long-shaft feed mechanism (3), a truck body frame (4), left and right rotation mechanisms (5), an auxiliary support mechanism (6), hydraulic support legs (7), a driving wheel system (8), a truck body underframe (9), steering wheel systems (10), a driving cab (11), a hydraulic control system and a servo control system. Posture of five shafts is driven and adjusted by a servo motor, and posture of the rest one shaft is manually adjusted. Travelling of the frame truck is driven by the mode of electric vehicle. The numerical-control electric frame truck has the advantages that positioning accuracy is high, maneuverability is good, stability is high, engine mounting efficiency is improved, and labor intensity of operators is reduced. Besides, the numerical-control electric frame truck is applicable to automatic mounting operation of heavy complicated shaft parts requiring multi-shaft posture adjustment.

Owner:DALIAN UNIV OF TECH +1

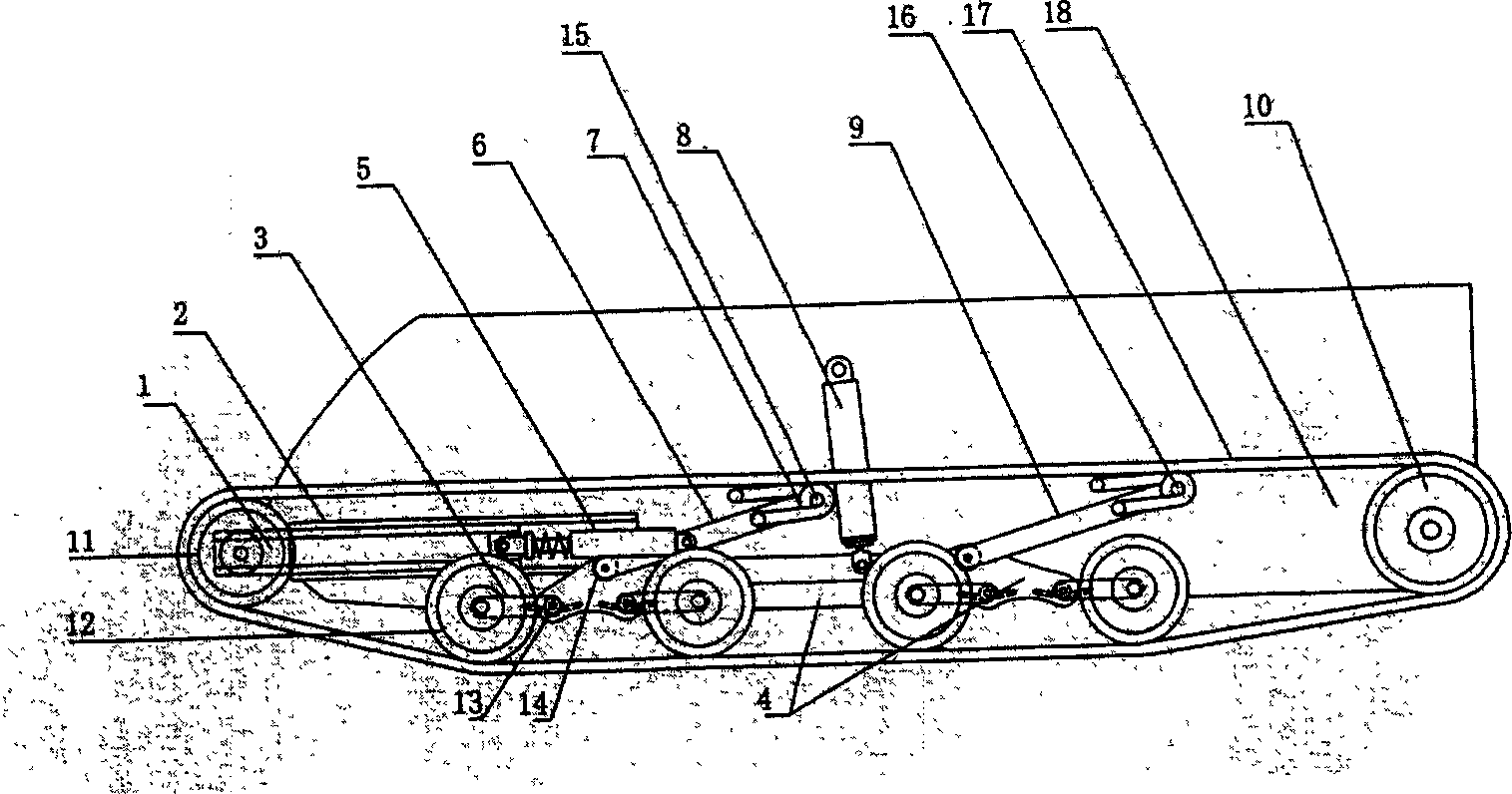

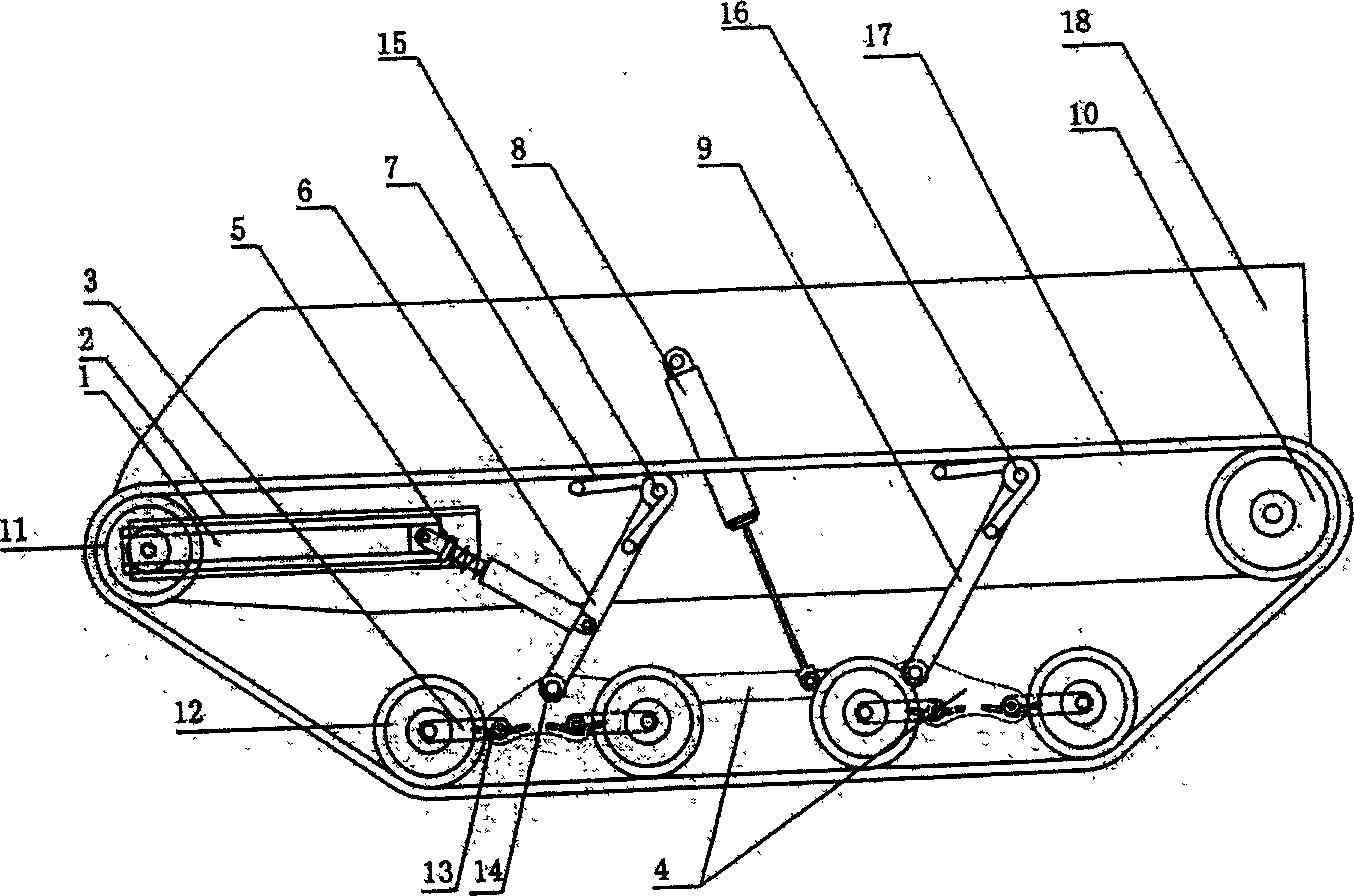

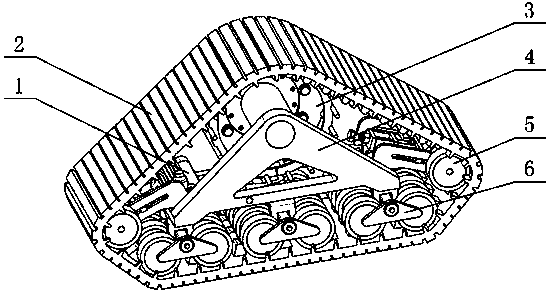

Deformed crawler belt system

The invention discloses a diction caterpillar band system. It includes base body, caterpillar band, drive wheel, and driven wheel. Its features are that the system also includes a parallelogram linkage used the base body as the frame, a rolling stretching structure connected to the base body, and supporting wheel train structure with linear array. The parallelogram linkage is respectively hinge joint to the connecting rod of the base body and the parallelogram linkage by the cylinder (oil cylinder) and piston. The rolling stretching structure is connected the parallelogram linkage by supporting connecting rod and damper. The supporting wheel train structure with linear array is connected to the supporting wheel frame of the parallelogram linkage. The system is drove the distortion, adjusted the center of gravity, kept the tensile force of the caterpillar band, and improved its shock absorption effect by the cylinder and the parallelogram linkage. This make the moving mechanism installed the system not only possess better mobility, maneuverability, and shinnied obstacle ability, but also possess better stability and dynamic performance, moreover the superior shock absorption ability.

Owner:DALIAN UNIV

Modularized rubber crawler wheel

ActiveCN103935412AReduce sliding frictionReduce wearEndless track vehiclesDrive wheelAgricultural engineering

The invention discloses a modularized rubber crawler wheel, and relates to a crawler walking device. The modularized rubber crawler wheel comprises a frame, a modularized drive wheel, a guide wheel train, a modularized load bearing wheel train, an independent swing arm suspension and a rubber crawler. A plurality of load bearing wheel sets, a multi-dimensional balance suspension and a linear-moving type following tension structure or a fixed type tension structure are adopted, a bend steering function and a power-assisted steering function are achieved, all components and the integrated wheel are modularized, quick wheel and crawler exchanging of high-speed and heavy-duty cross-country engineering vehicles can be achieved, ground pressure of the vehicles is substantially reduced, adhesive force is improved, smoothness, stability and passing ability of the vehicles on rough topography are improved, stable traction is maintained, working reliability is improved, and using and maintaining are convenient. Meanwhile, different structures of the modularized rubber crawler wheel can be selected according to vehicle loads.

Owner:NO 63908 TROOPS PLA

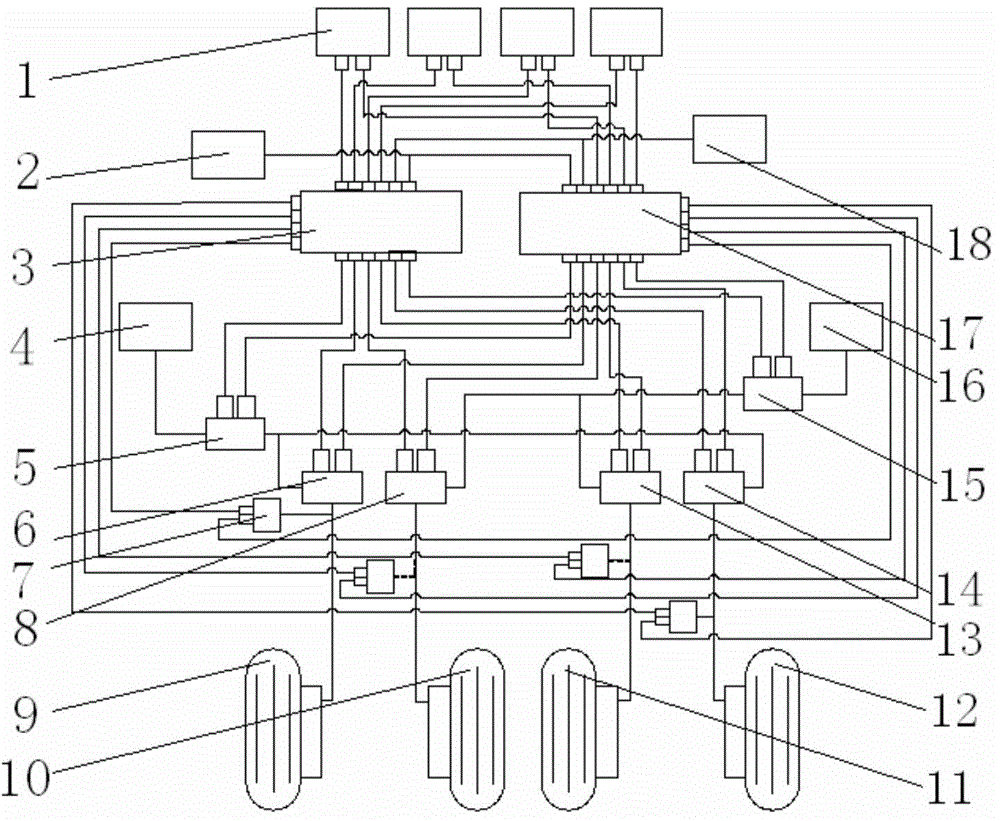

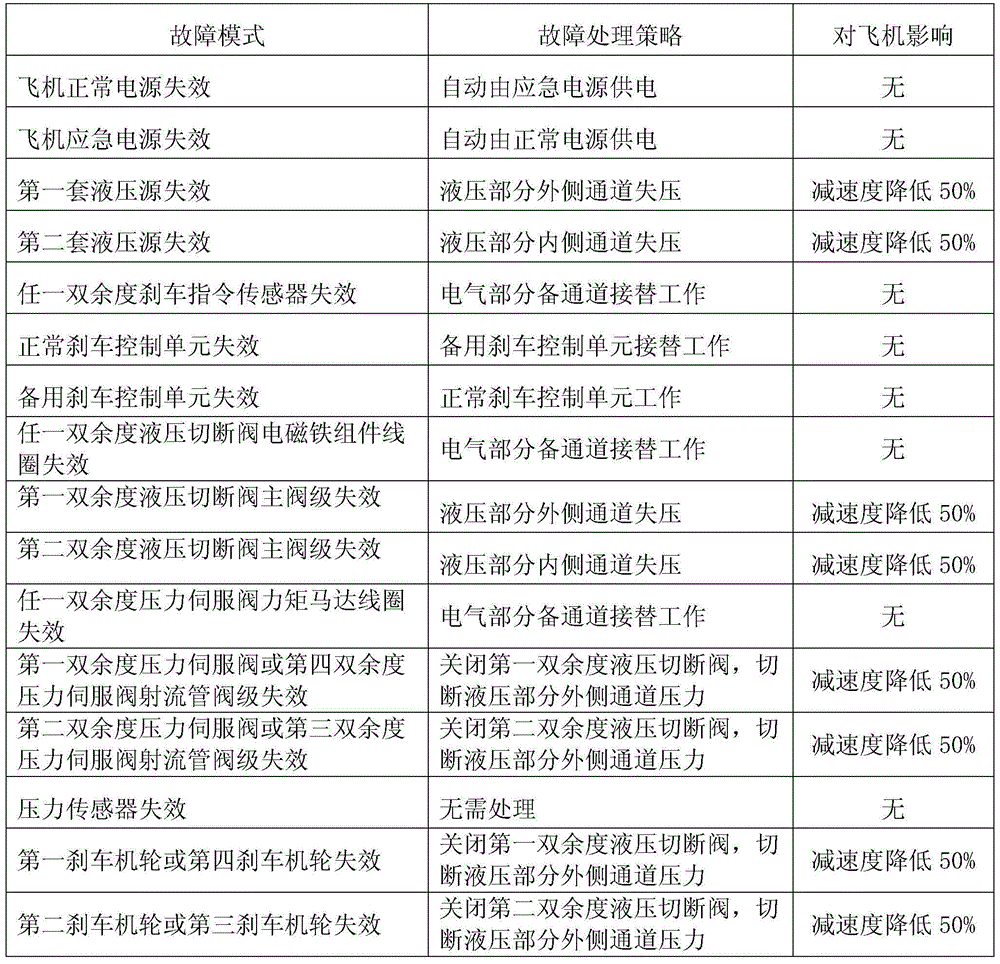

Brake control system of multi-wheel-train brake machine wheel

ActiveCN104002784AGuaranteed braking performanceImprove securityBraking action transmissionAircraft brake actuating mechanismsControl systemMain channel

A brake control system of a multi-wheel-train brake machine wheel is divided into an electrical part and a hydraulic part, wherein the electrical part of the airplane brake control system comprises a dual-redundancy brake instruction sensor, a pressure sensor, a normal brake control unit, a standby brake control unit, a first dual-redundancy hydraulic cut-off valve, an electromagnet of a second dual-redundancy hydraulic cut-off valve, a moment motor of a dual-redundancy pressure servo valve, and a main channel and a standby channel of the electrical part are formed; the hydraulic part of the airplane brake control system comprises a main valve body of the dual-redundancy hydraulic cut-off valve, a jet valve body of the dual-redundancy pressure servo valve and a brake machine wheel body, and the hydraulic part is divided into an inner side channel and an outer side channel. The electrical part can ensure that a brake system can work normally in the presence of any single-point electrical faults. The hydraulic part can ensure that when any single hydraulic source is lost or loses effect, and the brake system just loses one second of brake capacity at most and still can meet the requirement for braking of an airplane.

Owner:XIAN AVIATION BRAKE TECH

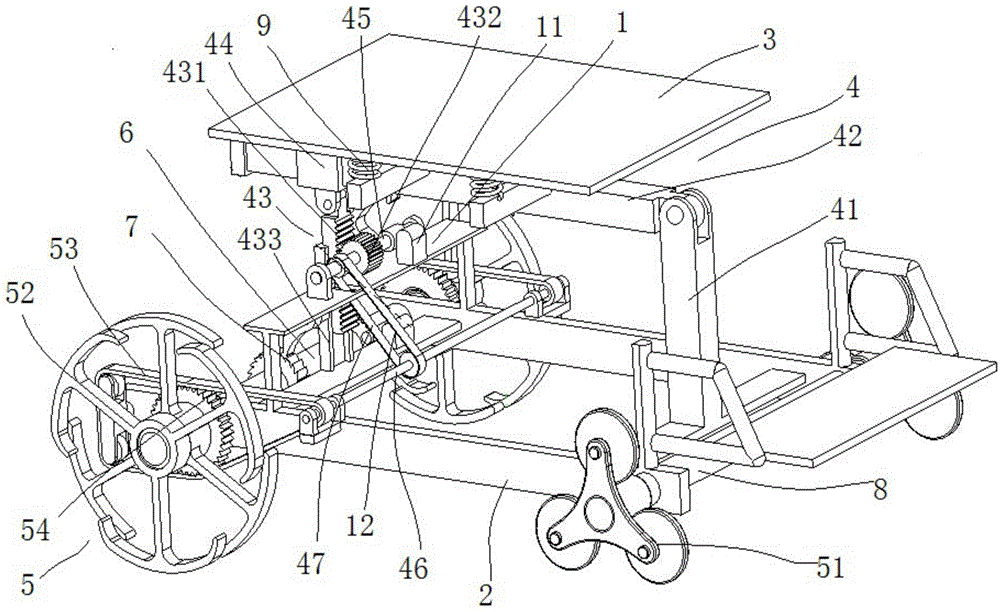

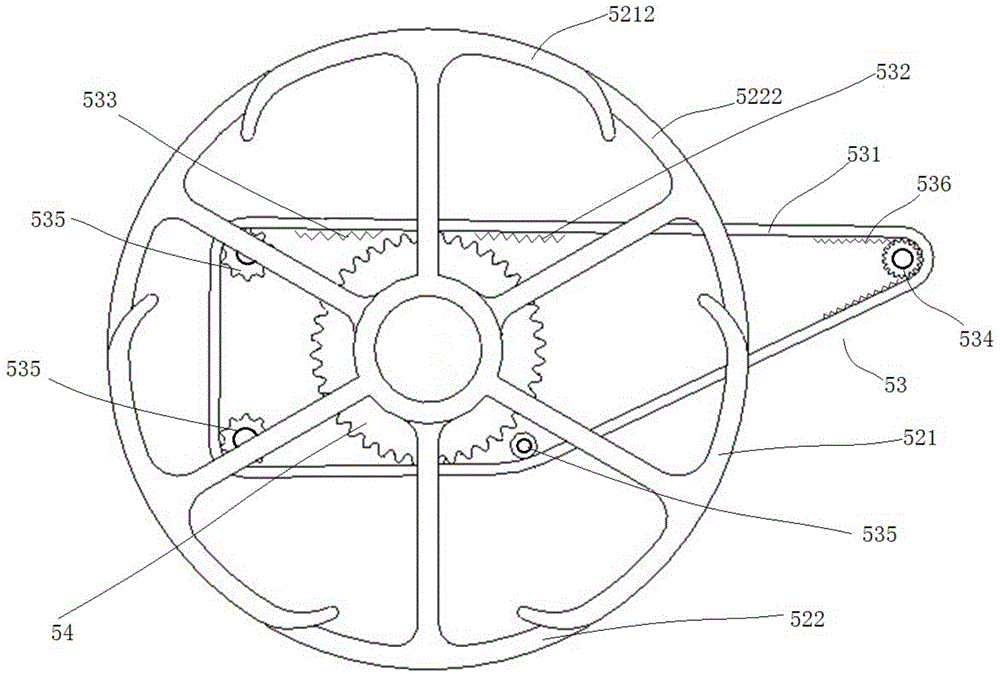

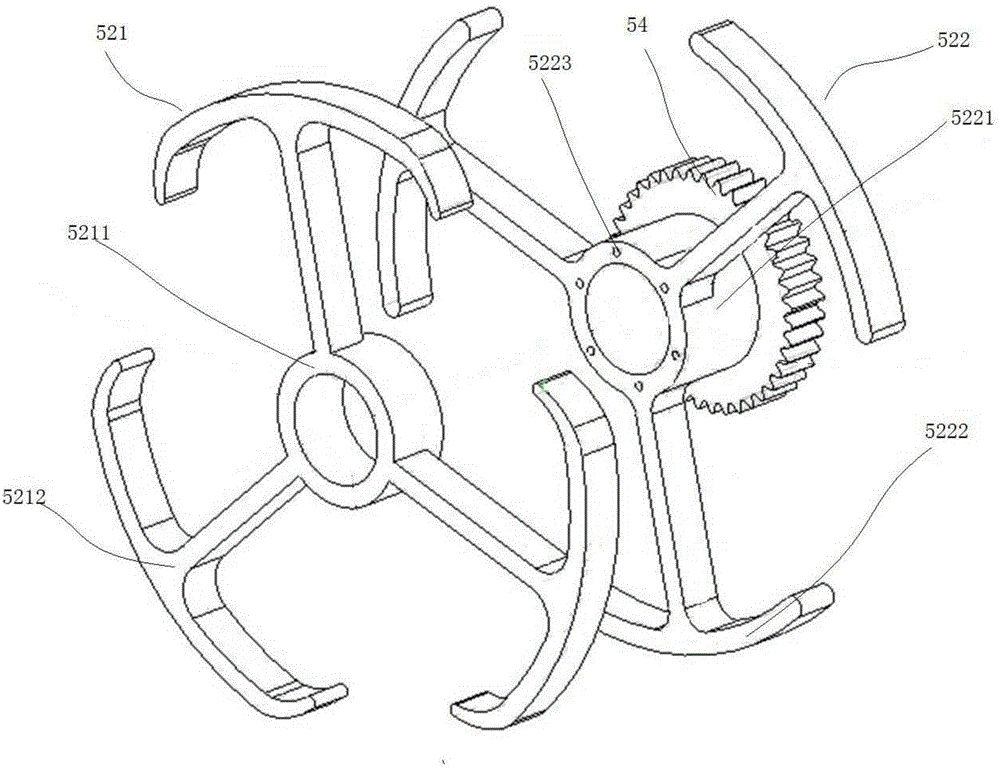

Variable wheel type stair climbing wheelchair

ActiveCN104382704AImprove stabilityImprove securityWheelchairs/patient conveyanceDrive wheelDrive shaft

The invention discloses a variable wheel type stair climbing wheelchair which comprises a frame, a seat and a wheel train mechanism. The seat is arranged on the frame, the wheel train mechanism comprises front wheels and a variable-form rear wheel system, the front wheels are planet wheels and arranged on two sides of the front end of the frame respectively, the variable-form rear wheel system is arranged on two sides of the rear end of the frame, comprises variable-form rear wheels arranged on a drive shaft and include a driving wheel and a driven wheel, the driving wheel can be relatively and rotatably connected with the driven wheel, both the driving wheel and the driven wheel comprise a hub and three equally distributed arcs, and the three arcs are arranged on the outer surfaces of the hub in a surrounding manner. By the aid of the variable wheel type stair climbing wheelchair, the variable-form rear wheels are mutually matched with the planet type front wheels, stability and safety of the wheelchair are improved, and the wheelchair is simply and conveniently operated by a user.

Owner:GUANGXI UNIV

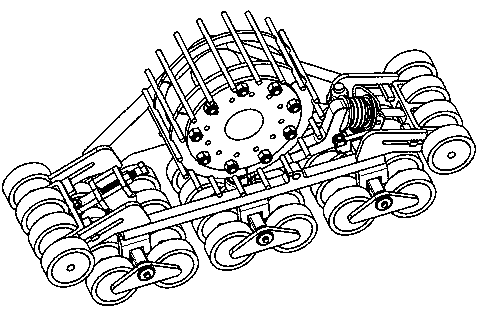

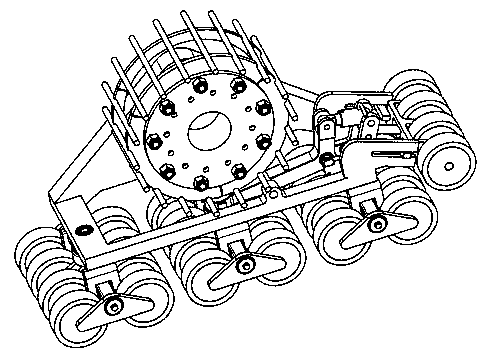

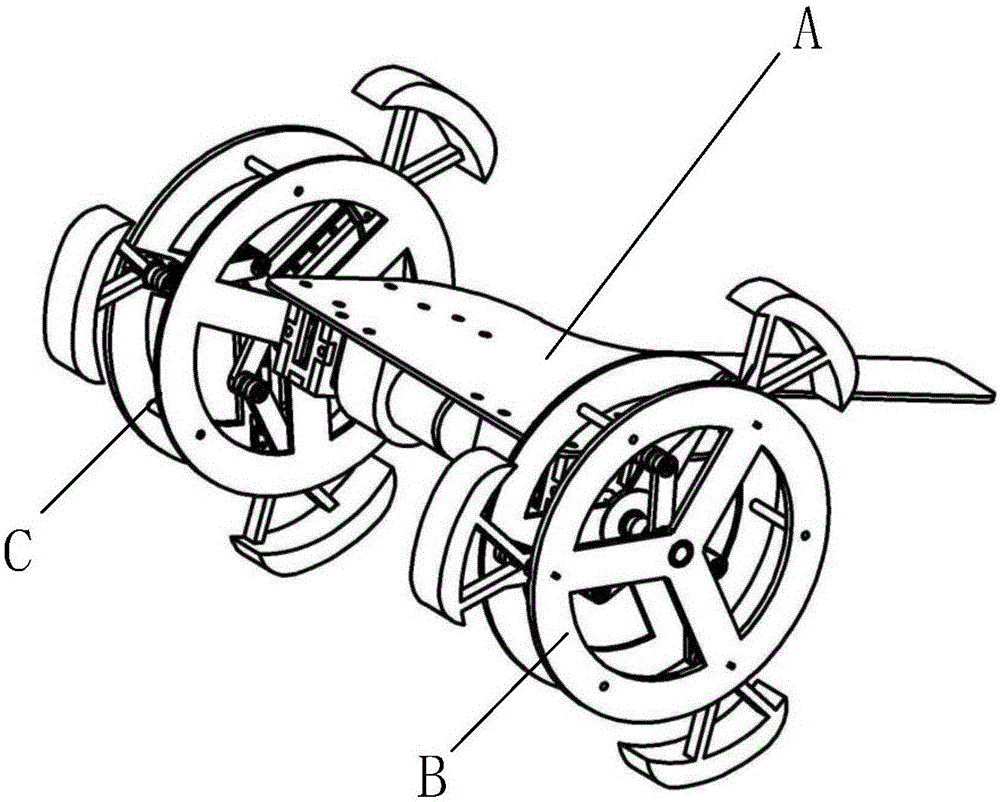

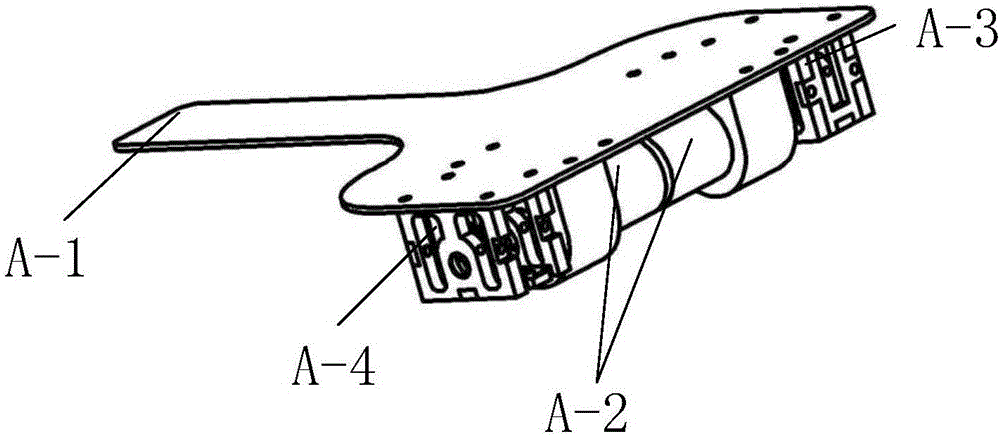

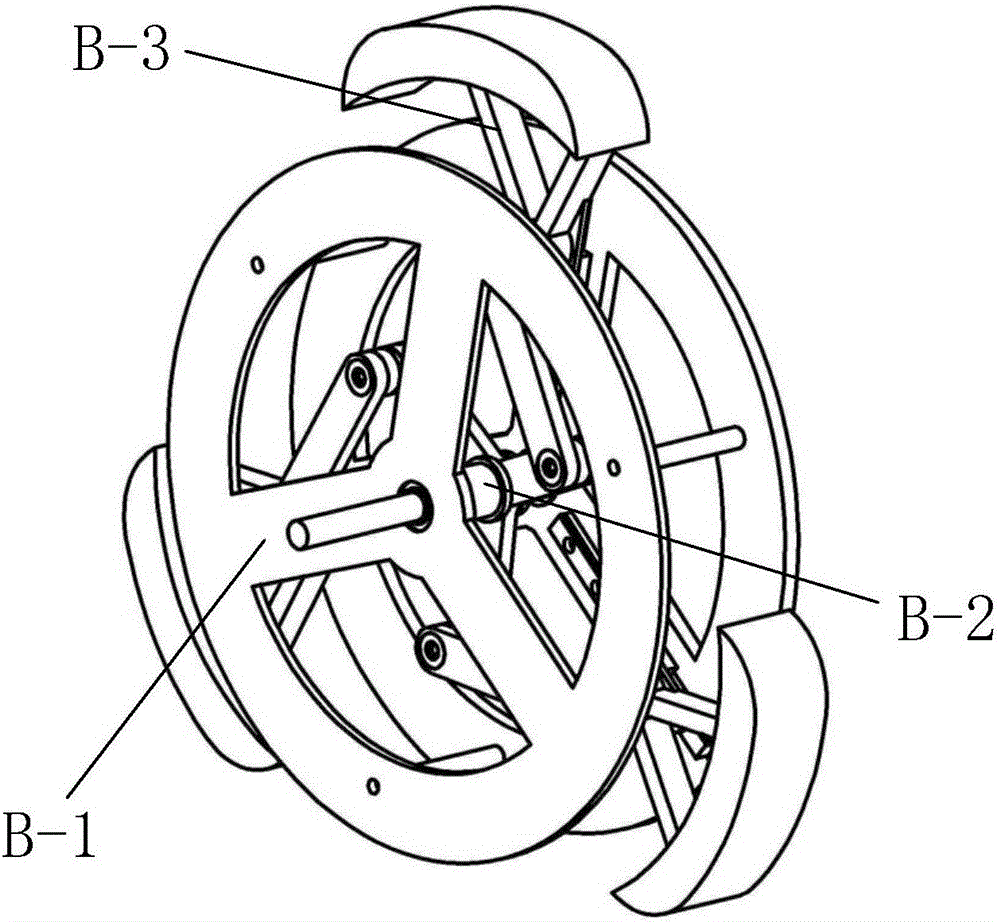

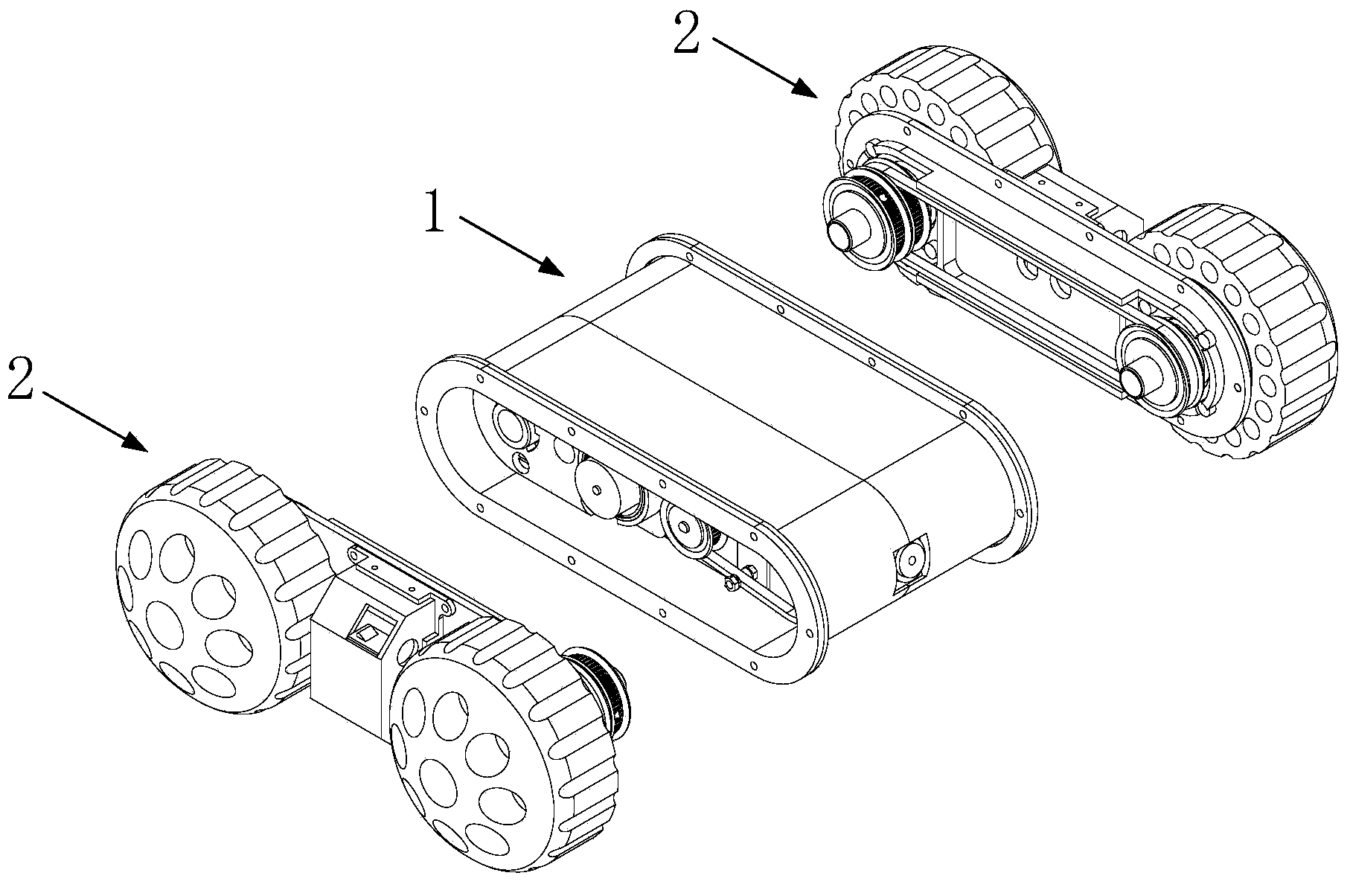

Under-actuated deforming wheel type obstacle crossing robot

The invention provides an under-actuated deforming wheel type obstacle crossing robot. The overall shape of the under-actuated deforming wheel type obstacle crossing robot is T-shaped and comprises two wheel trains, which are driven by single power and have same structures, and a vehicle body, wherein the two wheel trains are in running fit with the vehicle body. In the rolling advancing process of a vehicle, the vehicle body can be reversed and claws in the wheel trains can be controlled to expand and retract through controlling a motor to rotate clockwise and anticlockwise. When rolling on flat road surfaces, wheels can be changed into circular wheels to roll for advancing. When meeting an obstacle, the vehicle body can be reversed for 180 degrees through the anticlockwise rotation of the motor; and at the moment, the wheel trains are deformed into claws so that the vehicle can cross the obstacle with a certain height. According to the under-actuated deforming wheel type obstacle crossing robot, an under-actuated principle is creatively melted into the wheel trains so that a function of controlling the wheels to deform and roll by using the single motor is realized. The invention provides the under-actuated deforming wheel type obstacle crossing robot with simple mechanical structure and low manufacturing cost.

Owner:BEIJING JIAOTONG UNIV

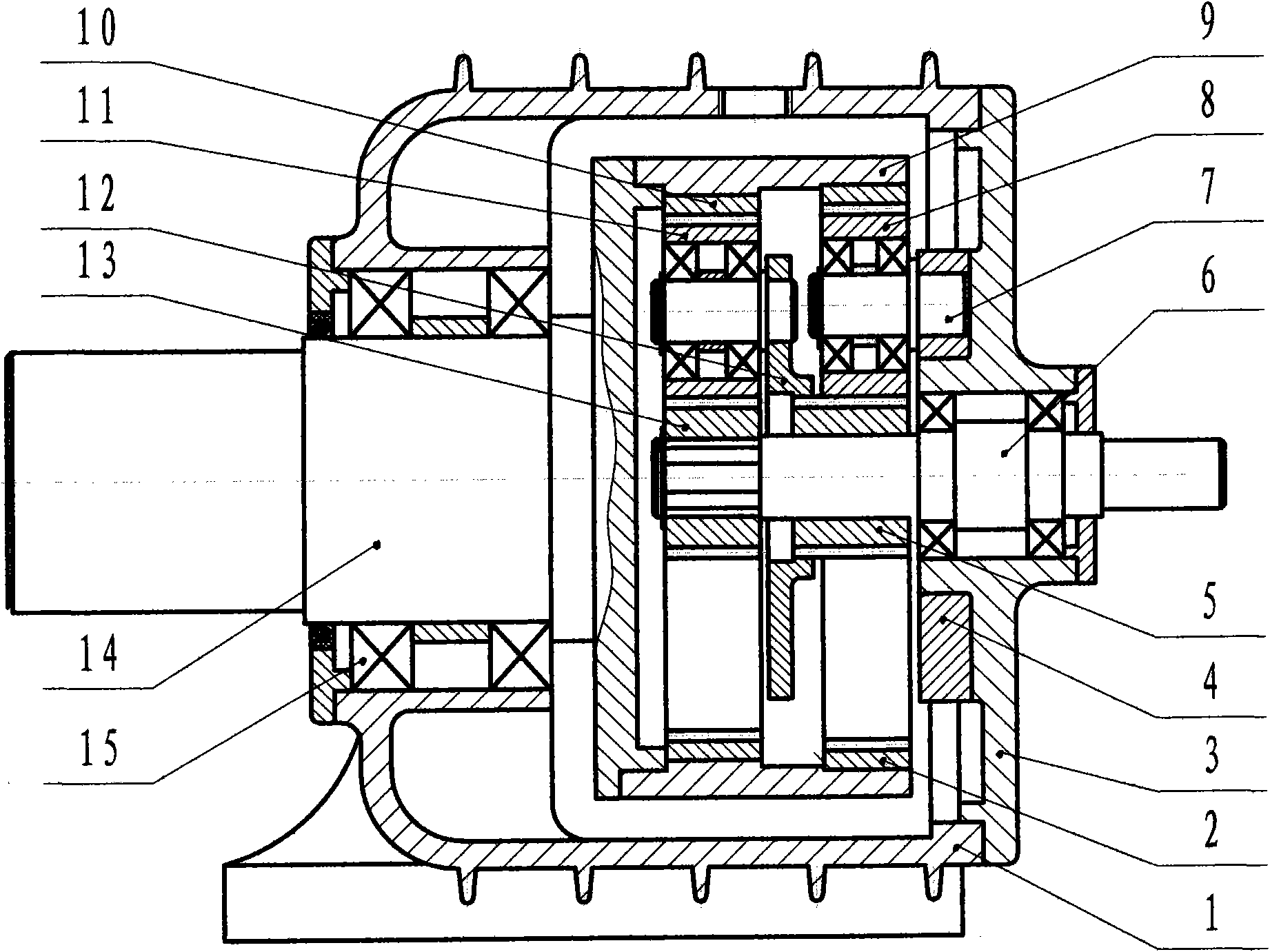

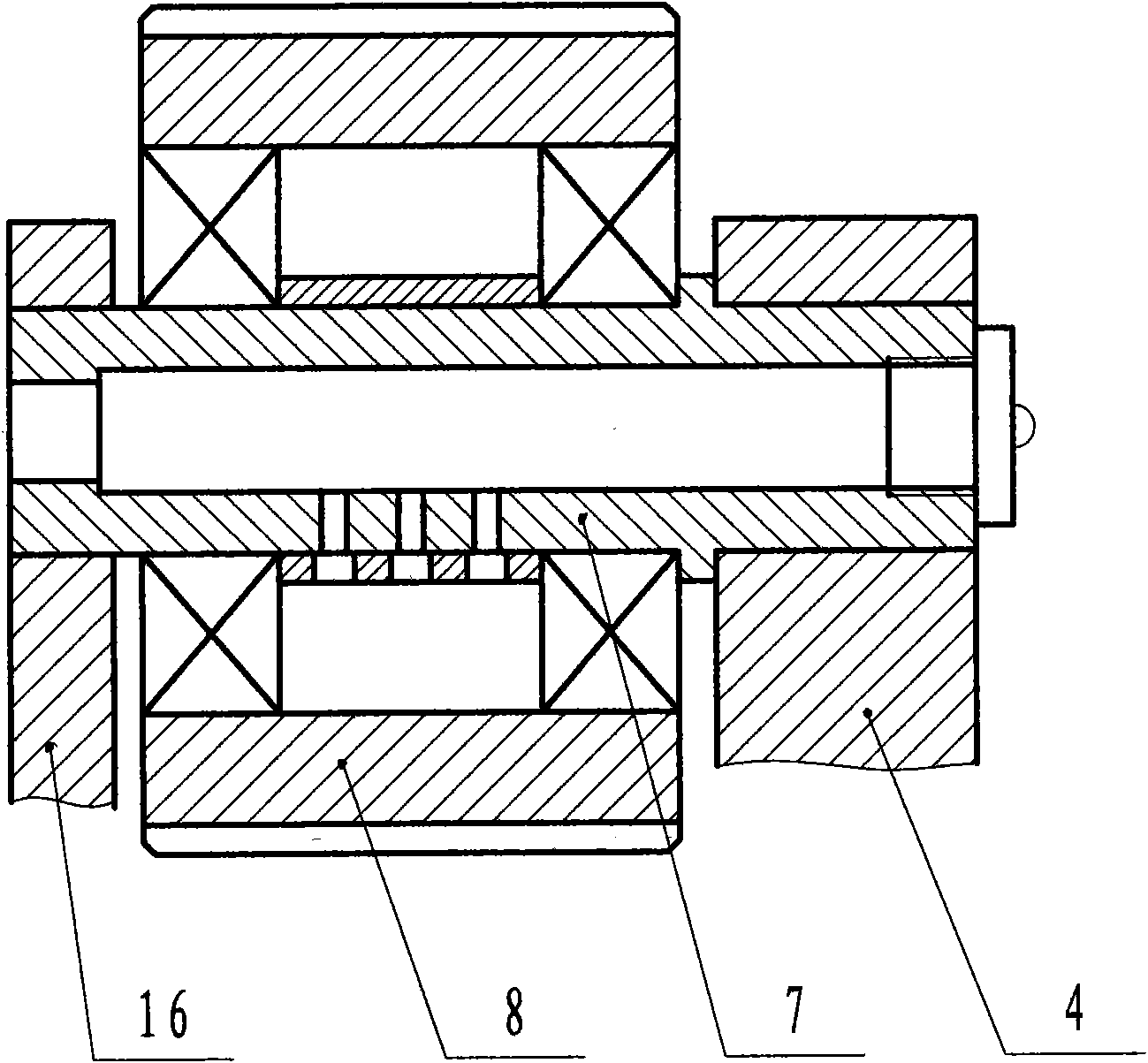

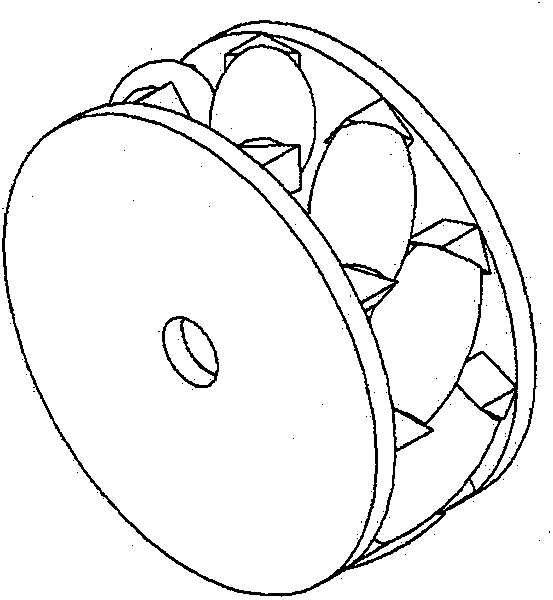

Novel planetary reduction gear

The invention discloses a novel planetary reduction gear, comprising an engine seat, a circular end enclosure, an output shaft, an input shaft, a bearing and a closed combination wheel train composed of a planetary carrier, an internal gear, a sun gear, a planetary wheel and a planetary wheel axle. The novel planetary reduction gear is characterized in that (a) the body of the engine seat is a revolving body with uniform wall thickness and has a radiating rib; (b) the wall thickness of the engine seat and torque acting on the engine seat meet the formula: T2 is equal to (10.5 minus 1.3) multiplied by delta(N.m), (delta is wall thickness mm); and (C) the excircle spline of the internal gear matches with a cylindrical internal spline. The planetary reduction gear has the beneficial effects that under the same weight condition, the bearing capacity is increased by 25-35 percent compared with an NGW planetary reduction gear, the engine seat is good in casting and technological properties and light in weight, and the service life of the internal gear can be doubled at least.

Owner:JIANGSU TAILAI REDUCER

Planetary multi-wheel carrier stair climbing vehicle

The invention discloses a planetary multi-wheel carrier stair climbing vehicle. The revolution of wheel carriers and the rotation of small wheels can be automatically switched, so that the vehicle can stably and quickly climb stairs. Core contents are that driving wheels are required to be planetary multi-wheel carriers, non-driving wheels are required to be multi-wheel carriers, and the driving wheels and the non-driving wheels have the same point number, wherein a small wheel is arranged at each point of each multi-wheel carrier which serves as the wheel; a planetary wheel system is additionally arranged on each planetary multi-wheel carrier; the small wheels comprise one-way wheels and omnidirectional wheels. Each multi-wheel carrier of the planetary multi-wheel carrier stair climbing vehicle comprises three wheels, four wheels, five wheels or six wheels. A dour-wheel dual-power four-driven six-wheel carrier stair climbing vehicle is shown in a drawing, wherein small bevel gears are driven through a differential spider by two motors, large bevel gears are driven by the small bevel gears, and are matched with chain wheels, and four wheels are driven by the chain wheels respectively. According to stair climbing principles, 1, when the vehicle runs on a level road, planetary wheels and the small wheels rotate; 2, when the vehicle climbs the stairs, the small wheels rotate to get close to a step, and then the multi-wheel carriers revolve; 3, when the vehicle goes downstairs, the small wheels rotate until one small wheel is suspended, the wheel carriers revolve, and after the suspended small wheel is landed, the wheel carriers continue revolving.

Owner:李军委

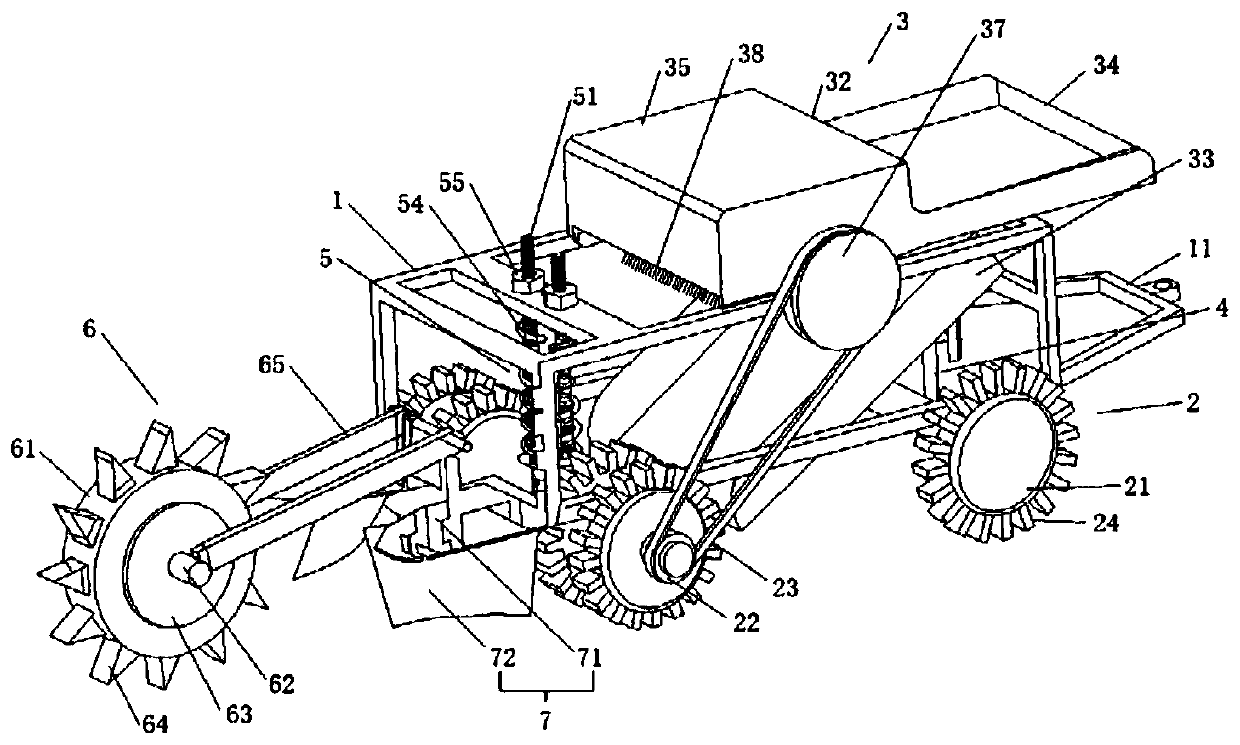

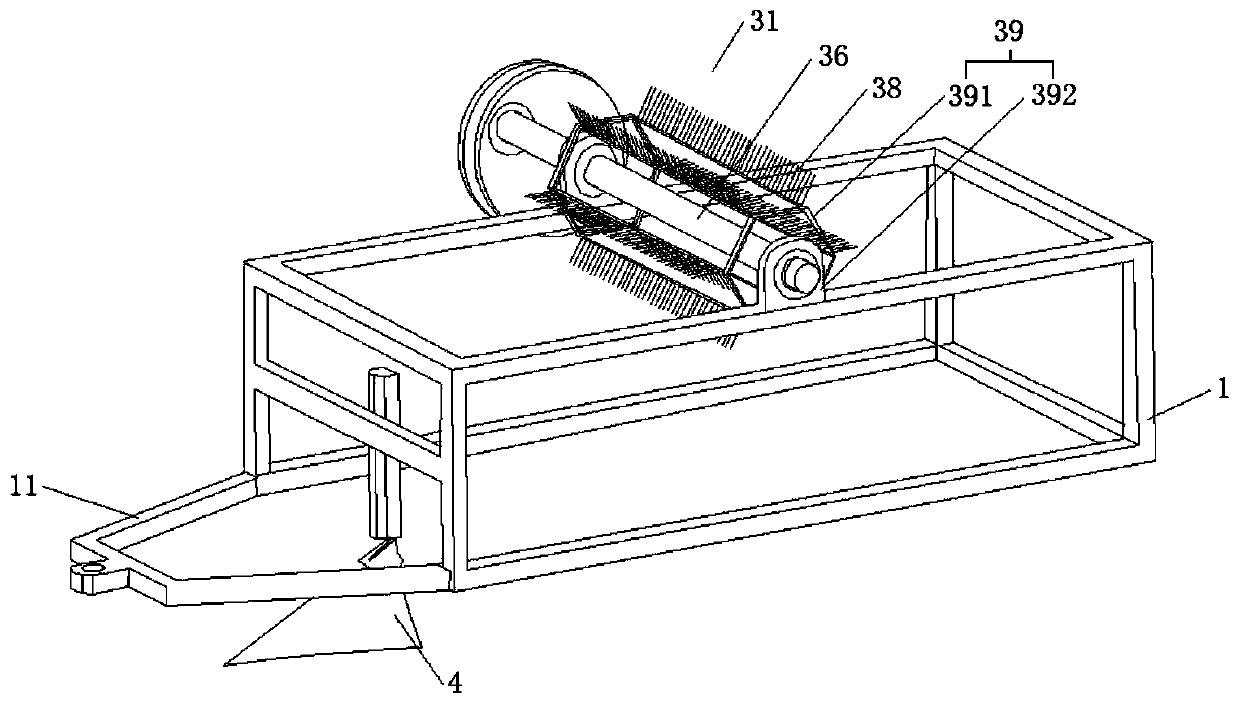

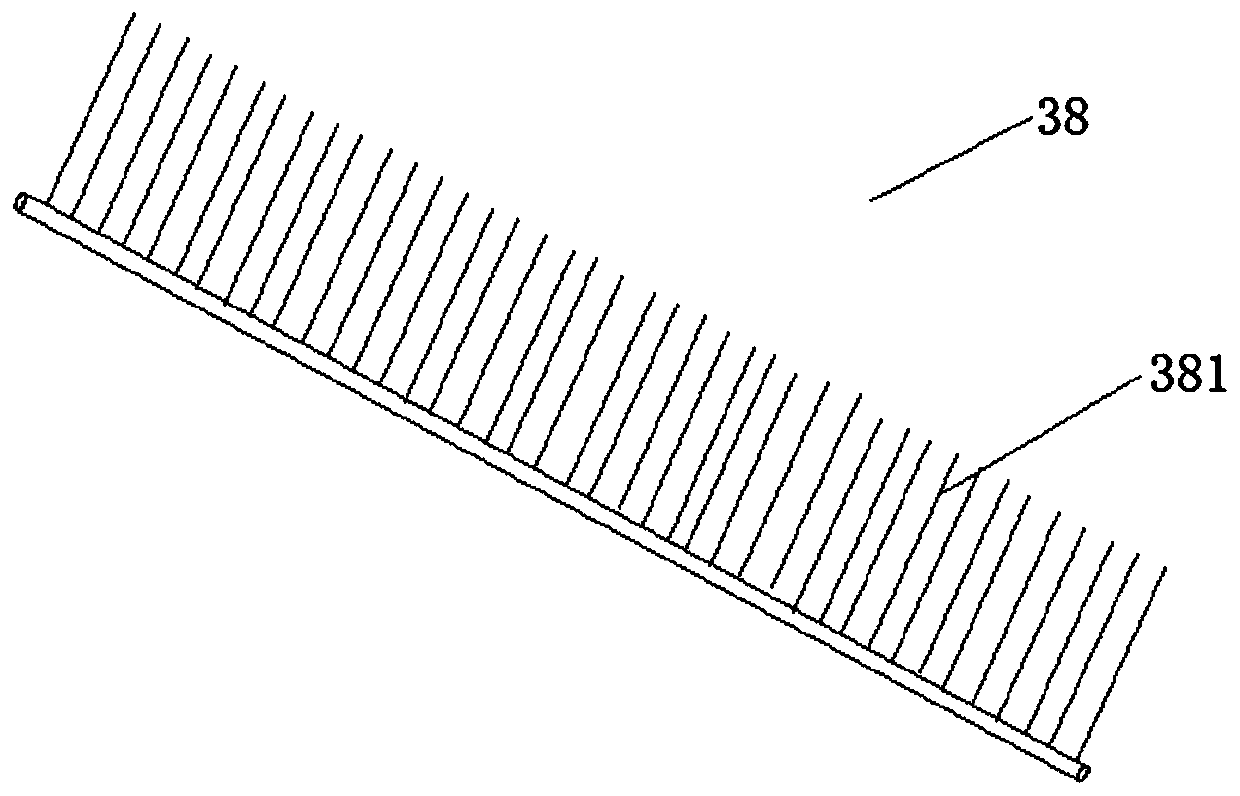

Multifunctional stereoscopic desert sand pressing grass growing machine

InactiveCN110100516AAvoid wastingIncrease roughnessSpadesSoil lifting machinesAgricultural engineeringEngineering

The invention discloses a multifunctional stereoscopic desert sand pressing grass growing machine, and belongs to the field of desert grass growing machines. The multifunctional stereoscopic desert sand pressing grass growing machine comprises a rack, a ground wheel train, a straw laying device, a ditching device, a straw pressing and earthing device and a sowing device; a toothed gear rotating shaft is installed on the upper surface of the rack and can rotate in the axis direction of the rack, four or more rows of straw laying rakes are uniformly distributed on the toothed gear rotating shaftin the circumferential direction, and a first transmission wheel is fixedly installed at one end of the toothed gear rotating shaft; the ground wheel train at least comprises two pairs of ground wheels, a second transmission wheel is fixedly installed at one end of one pair of the ground wheels, and the first transmission wheel and the second transmission wheel are in transmission connection through a belt. The multifunctional stereoscopic desert sand pressing grass growing machine has the advantages that the rack is provided with assemblies which have the dual functions of straw laying and grass growing, firstly, through ditching, straw laying and earthing, straw is buried in sand, then sowing is conducted nearby the embedded straw, thus the functions of automatic straw laying, straw burying and sowing are achieved, and then the purposes of laying of a straw checkerboard barrier and sowing are achieved.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

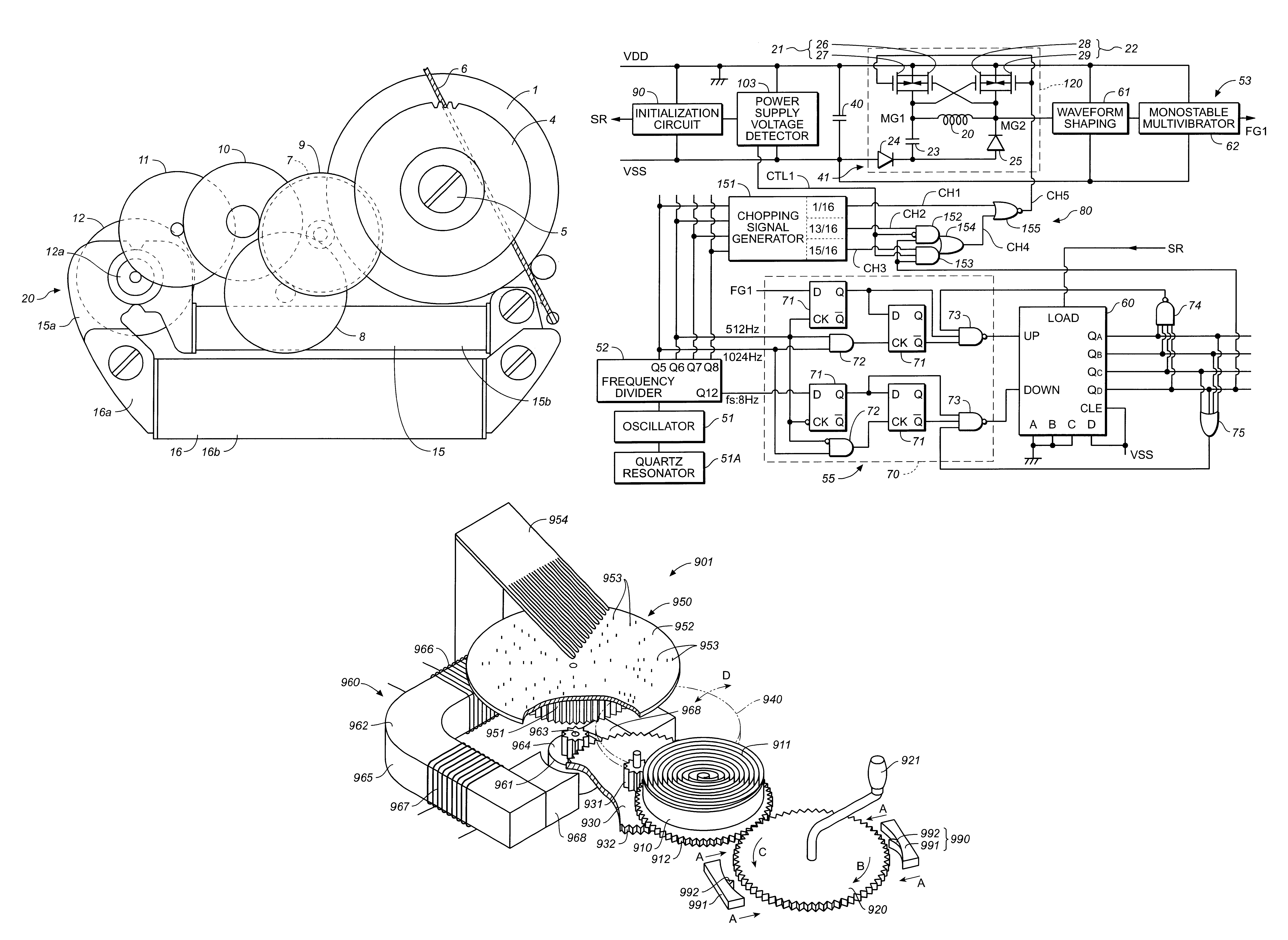

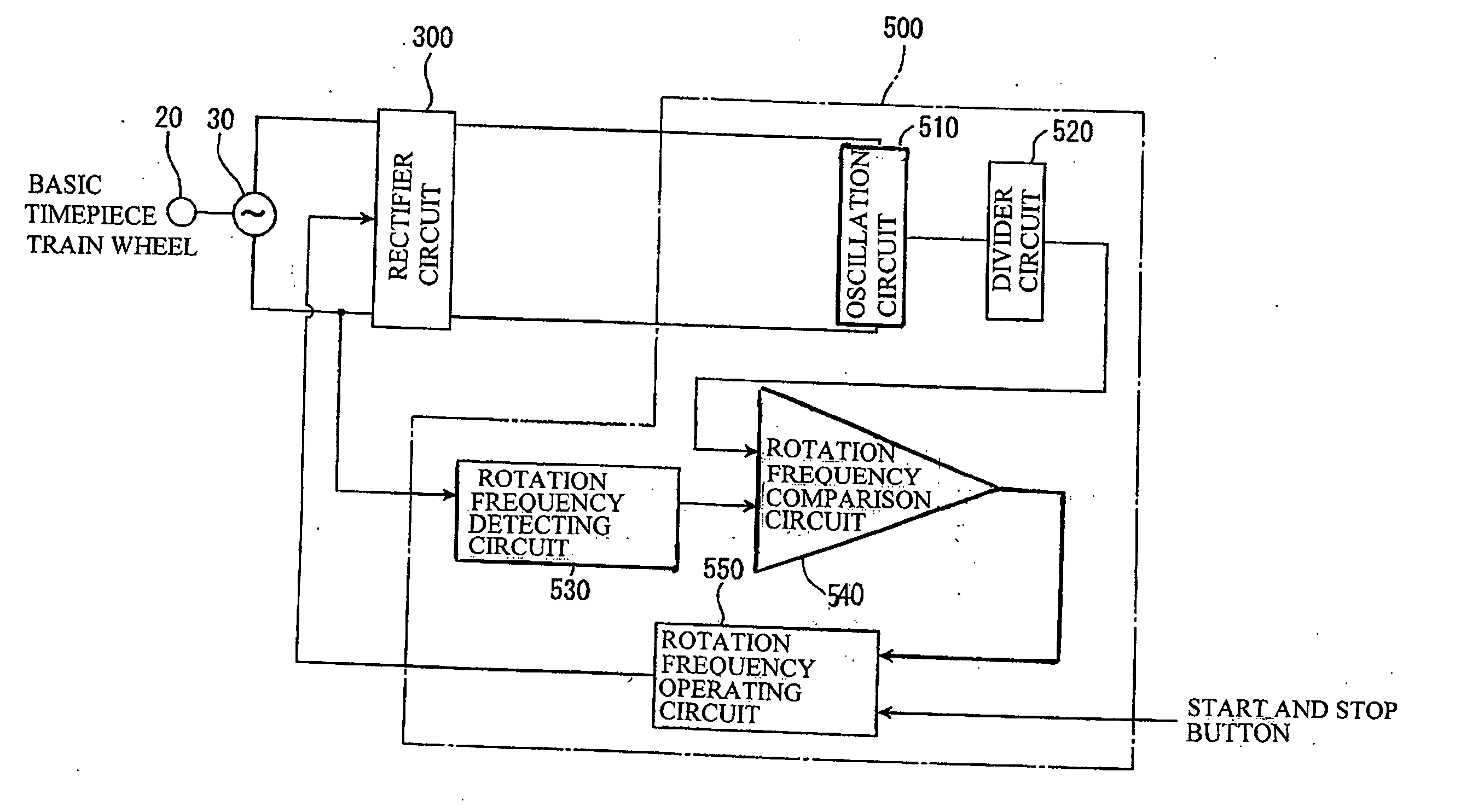

Electronic device with variable chopping signal and duty ratio selection for strong braking

InactiveUS6483276B1Low costSimple configurationEmergency protective circuit arrangementsDynamo-electric converter controlElectric power systemClosed loop

An electronic device capable of increasing the braking torque applied to an electric power generator without causing a significant reduction in electric power generated by the electric power generator. The electronic device, which may be embodied in an electronically controlled mechanical clock, includes an electric power generator for converting mechanical energy transmitted from a spring via a wheel train to electrical energy, and a rotation controller for controlling the rotation period of the electric power generator. The rotation controller includes switches capable of connecting two terminals of the electric power generator in a closed-loop state, a chopping signal generator for generating two or more types of chopping signals which are different in duty ratio or frequency for use in a strong braking operation, and chopping signal selector that selects one of the chopping signals, wherein, in the strong braking operation, the selected chopping signal is applied to the switches so as to control the electric power generator in a chopping fashion. The strong braking operation is performed in one of two modes such that a higher priority is given to generation of electric power or the braking torque depending on the mode, thereby achieving an increase in the braking torque of the electric power generator without causing a significant reduction in the voltage generated by the electric power generator.

Owner:SEIKO EPSON CORP

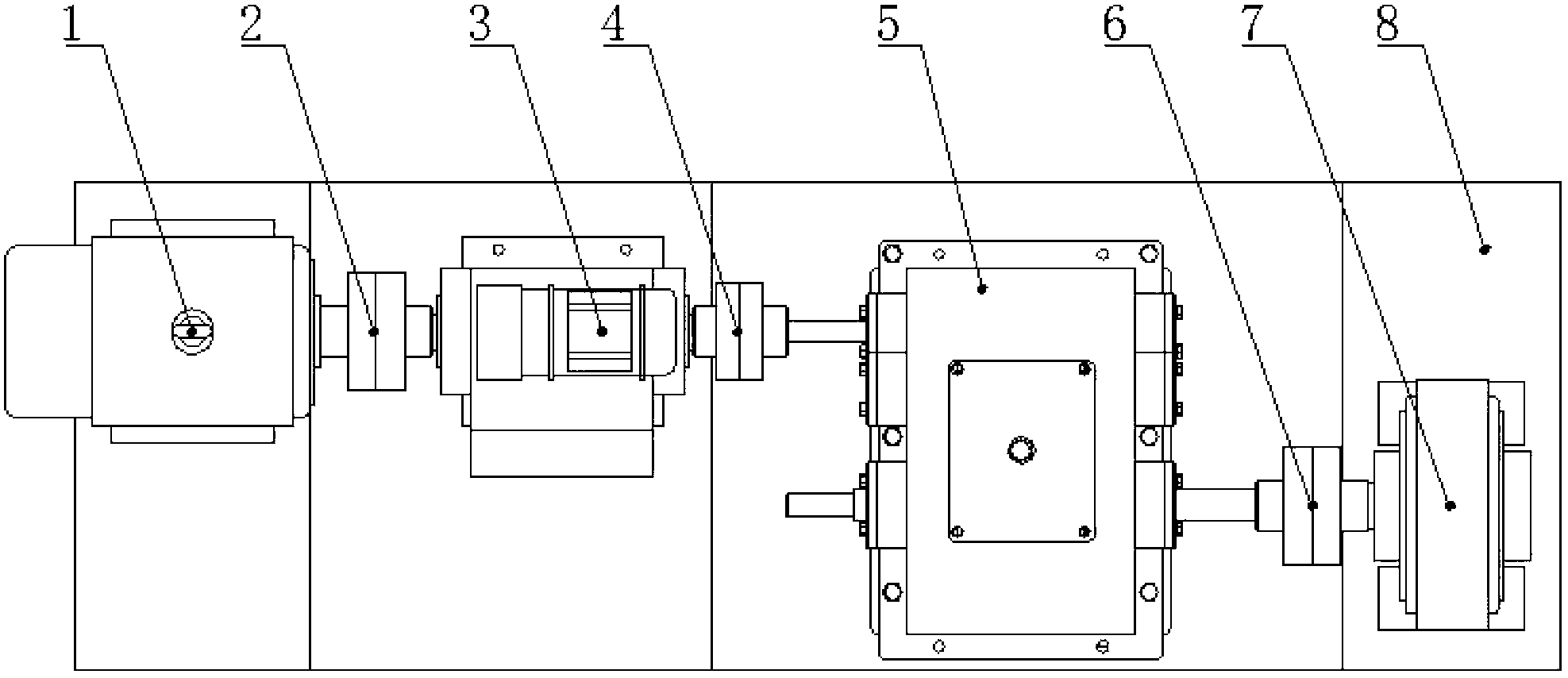

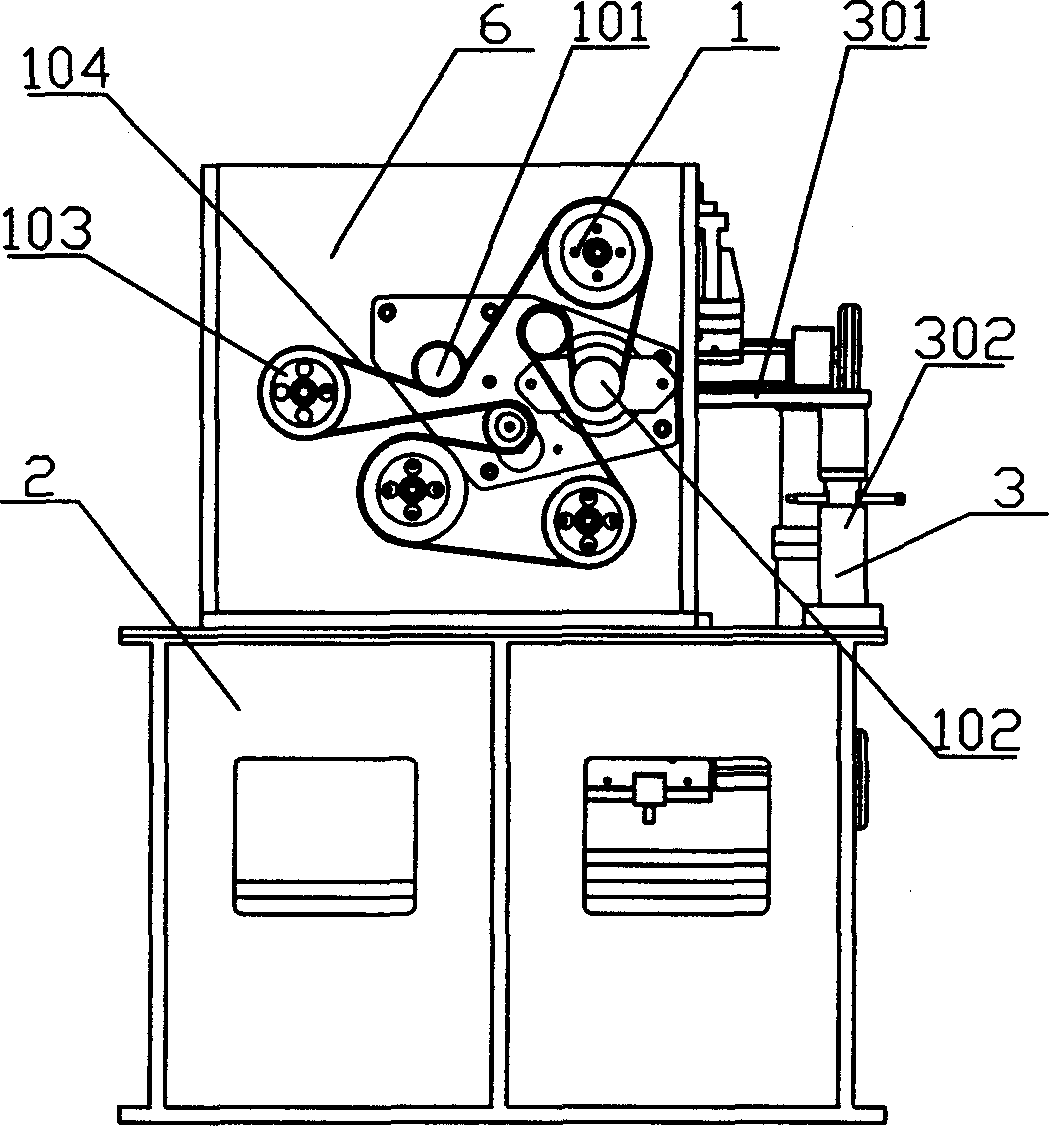

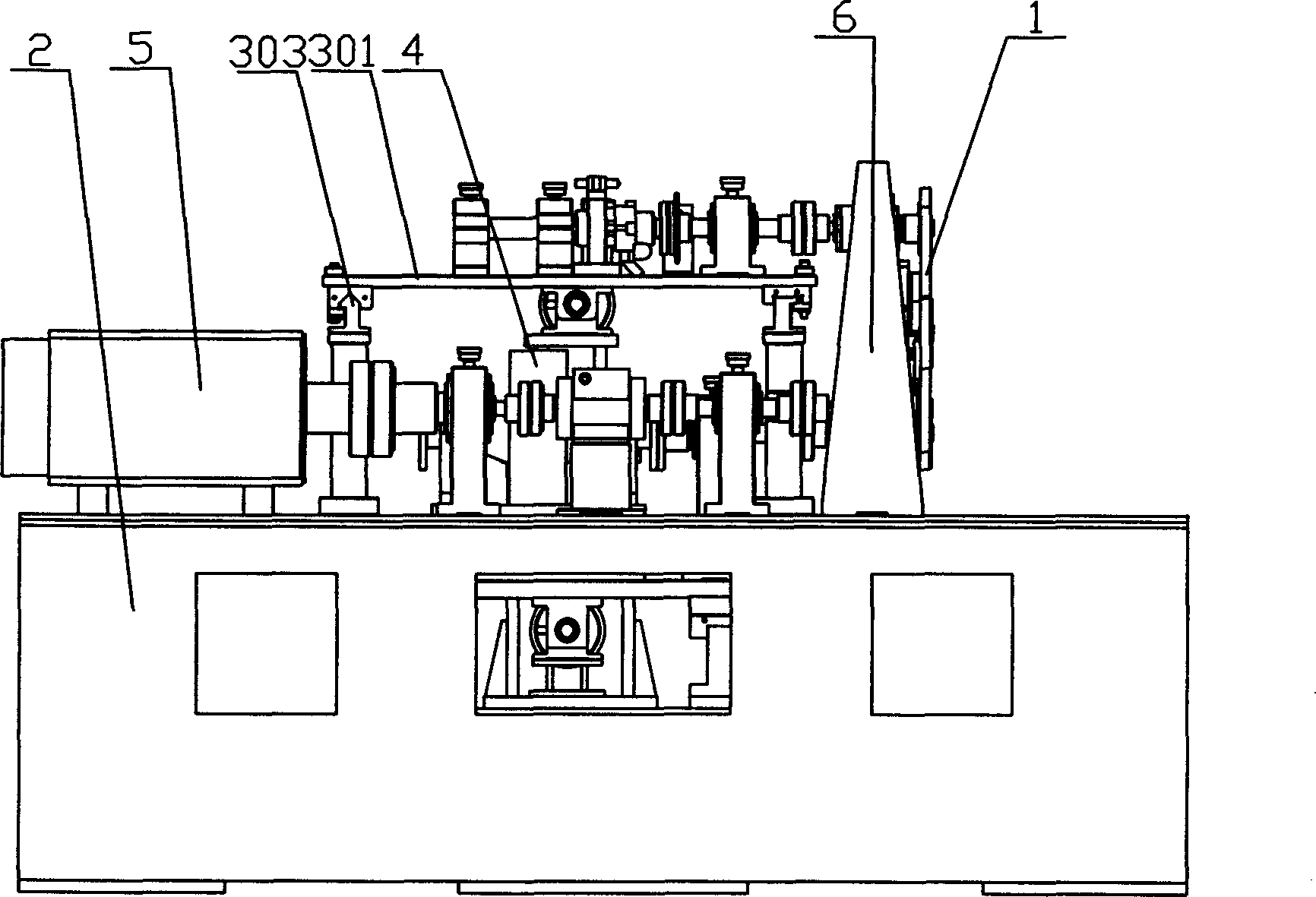

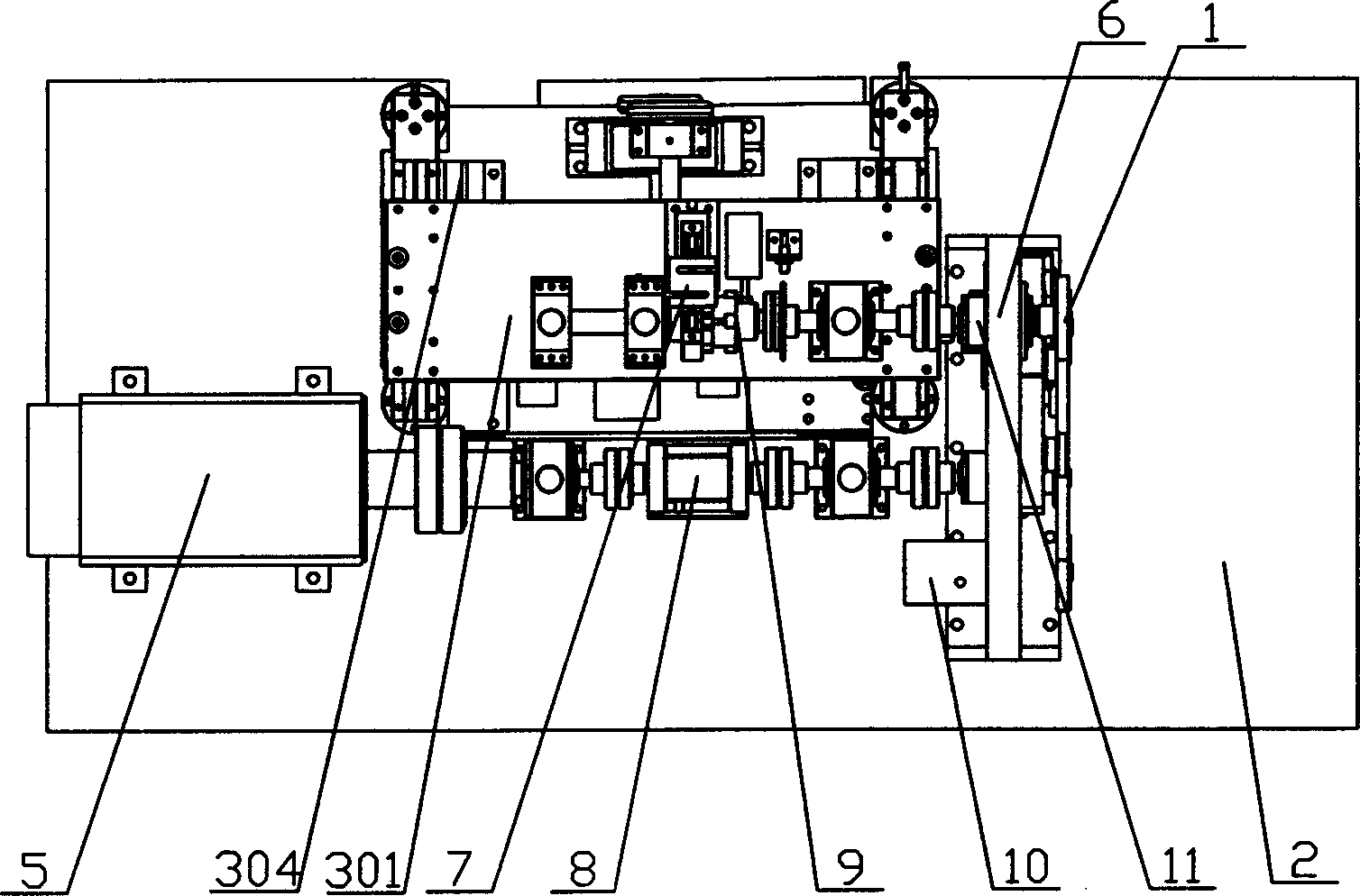

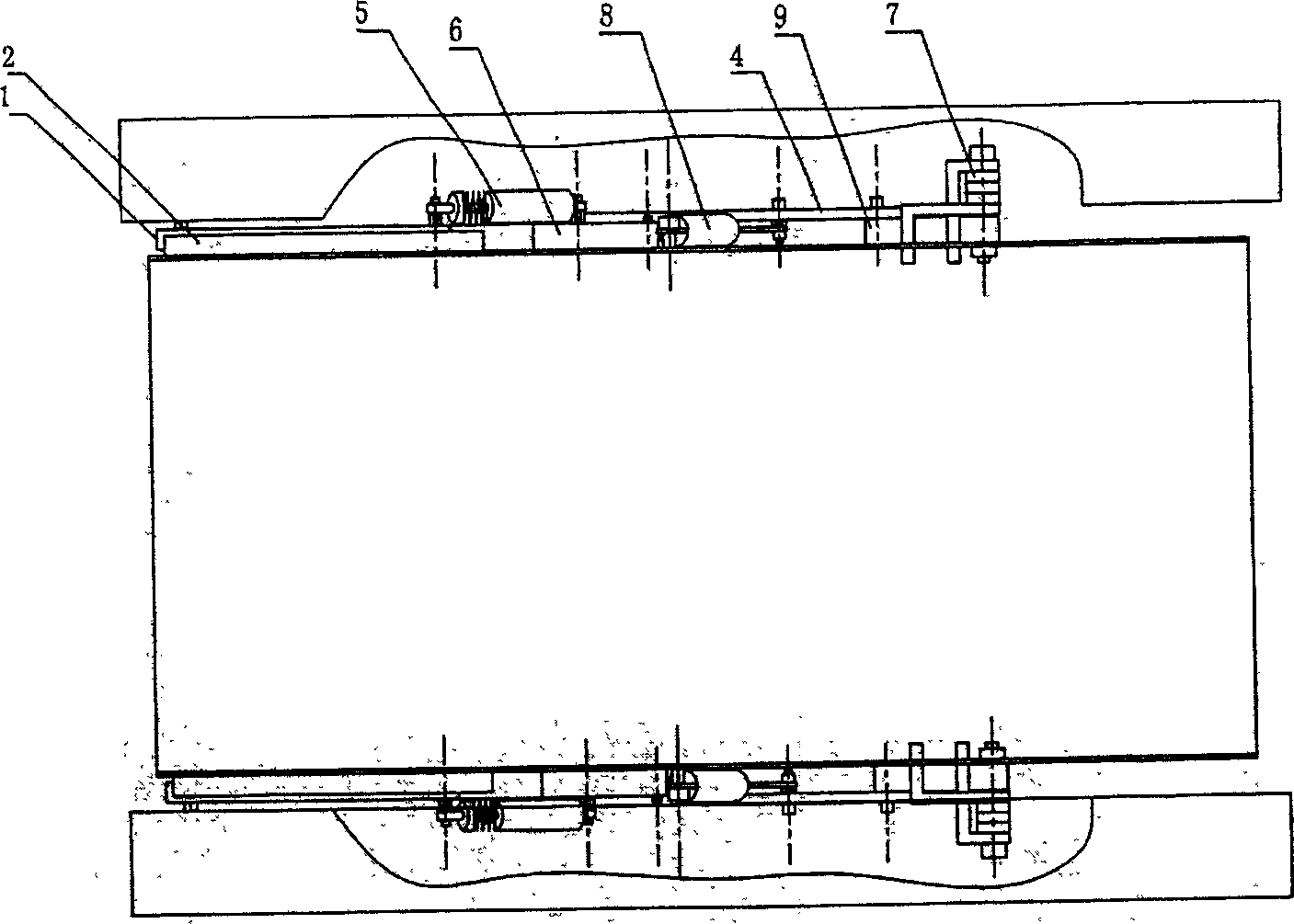

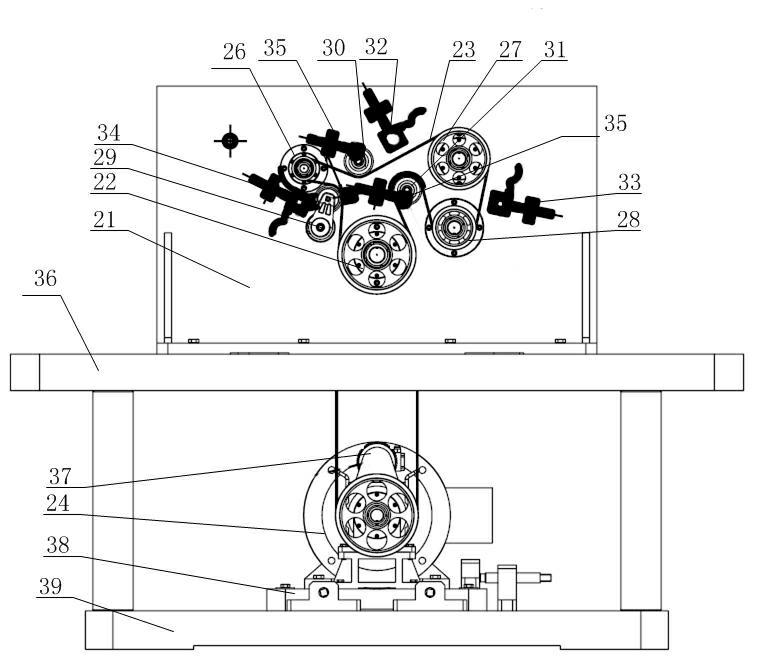

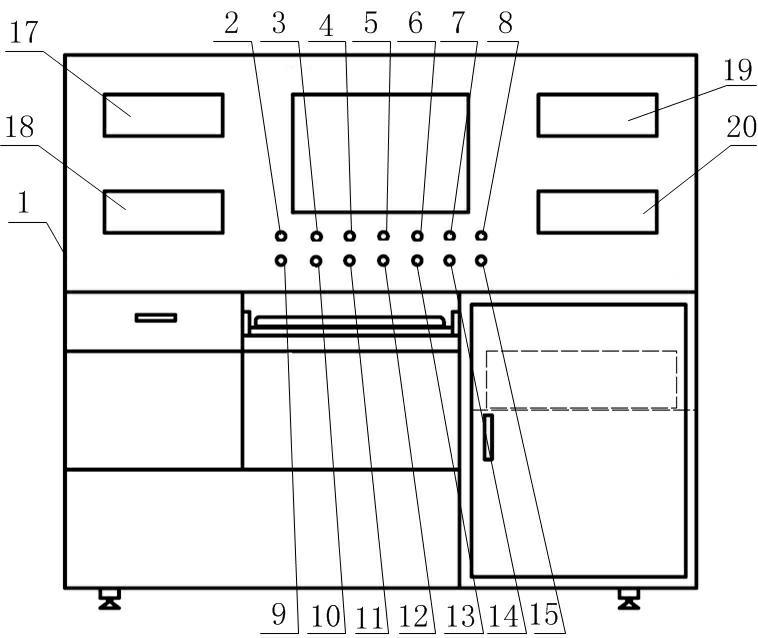

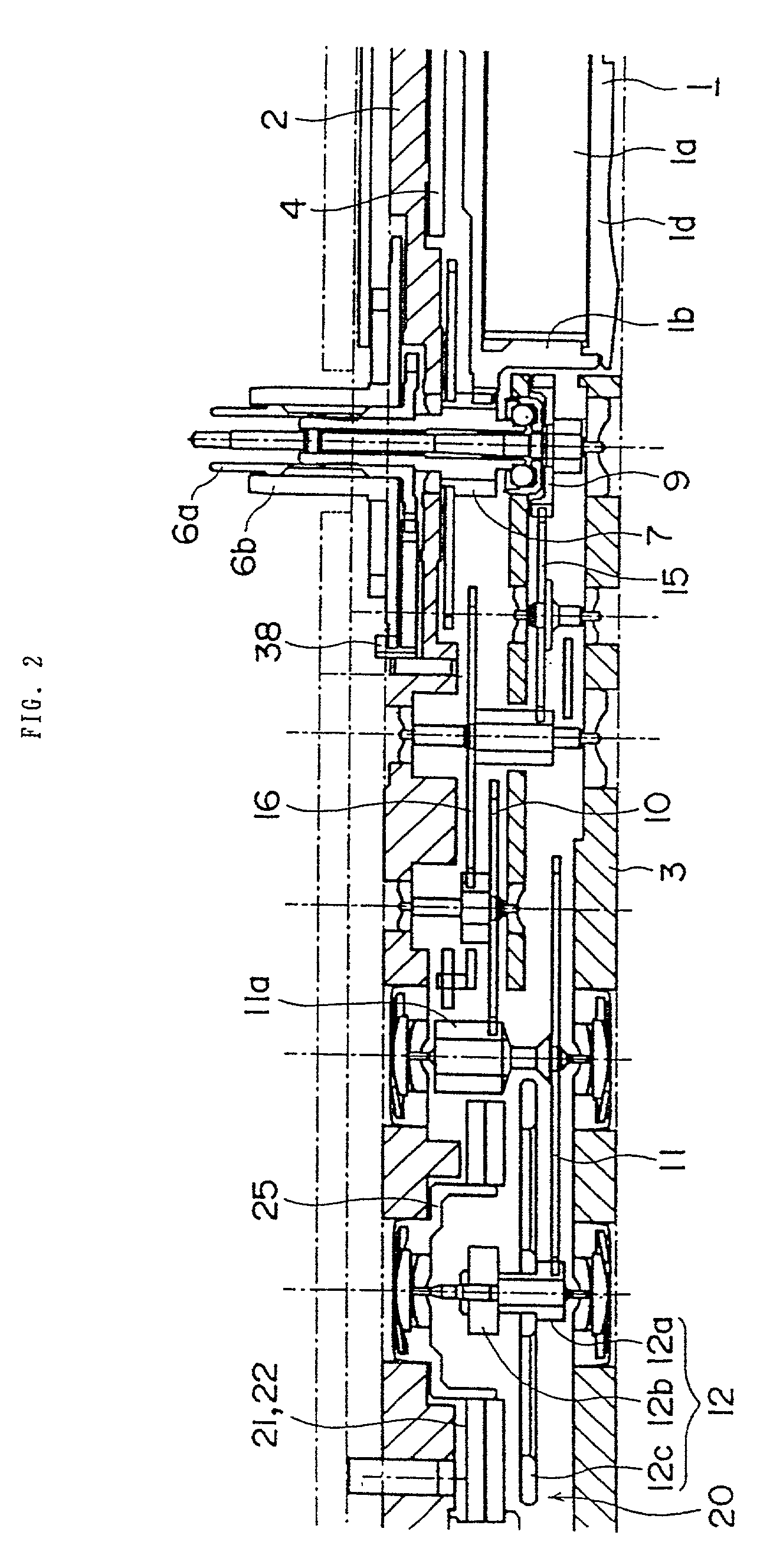

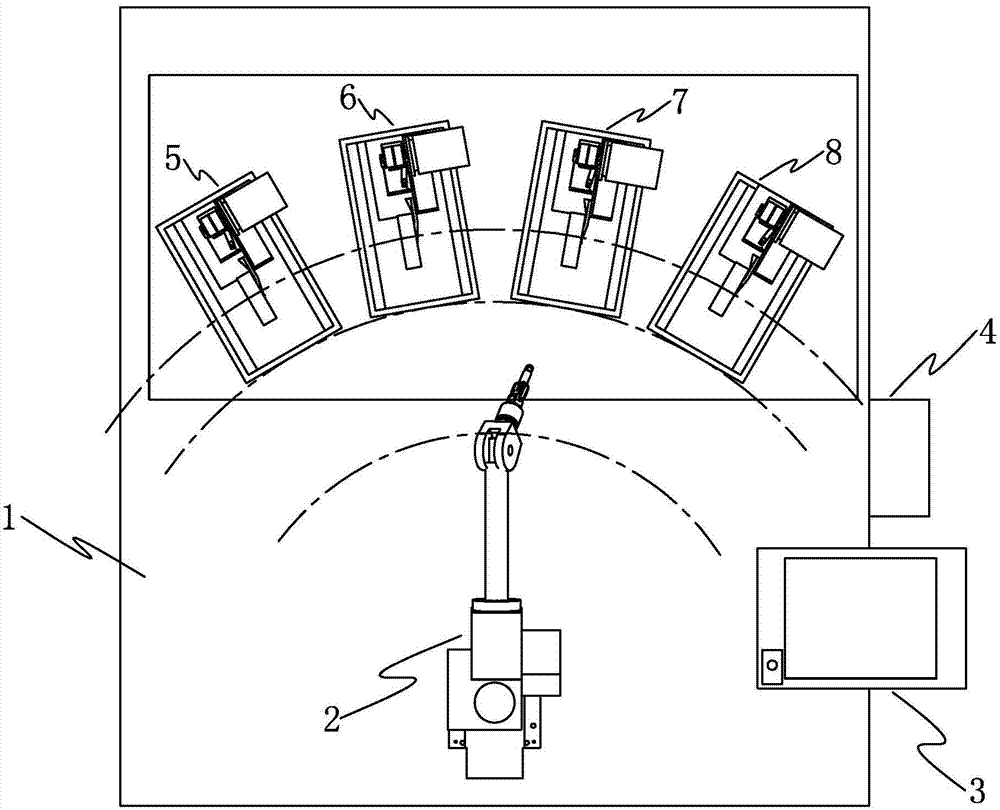

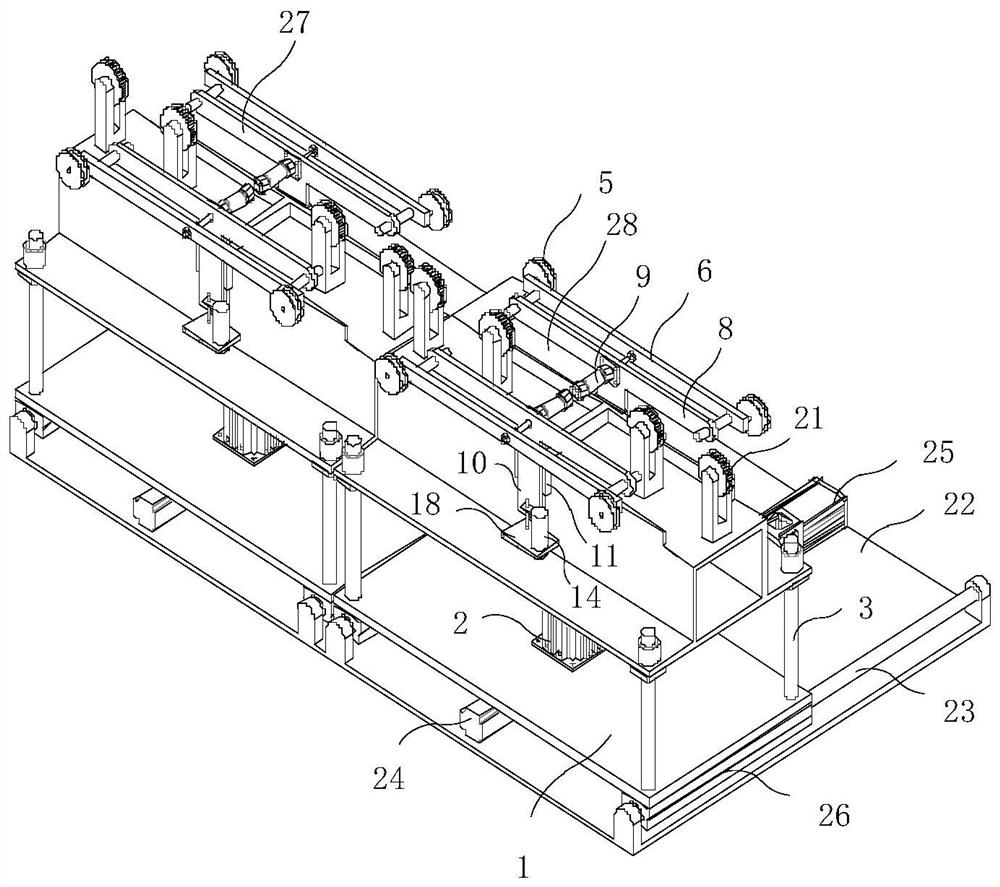

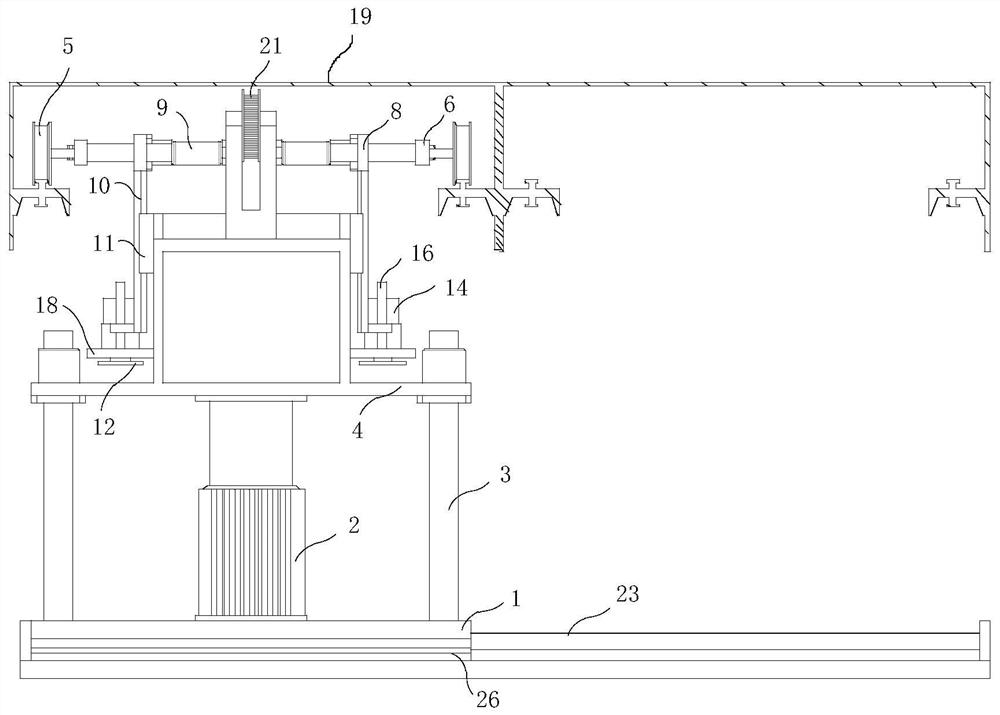

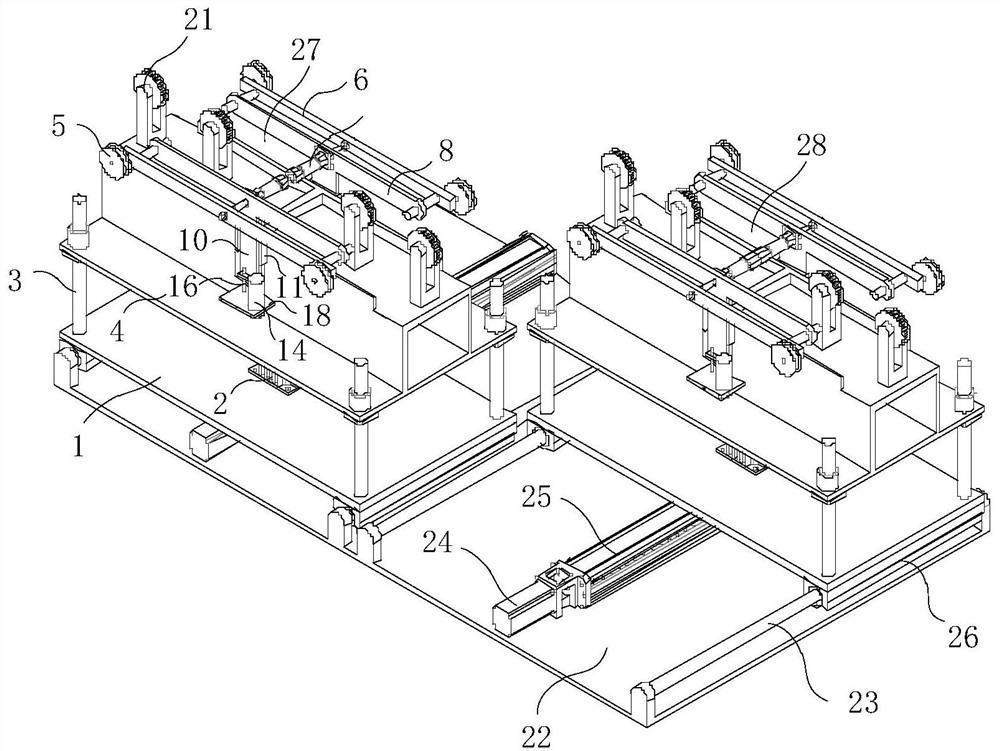

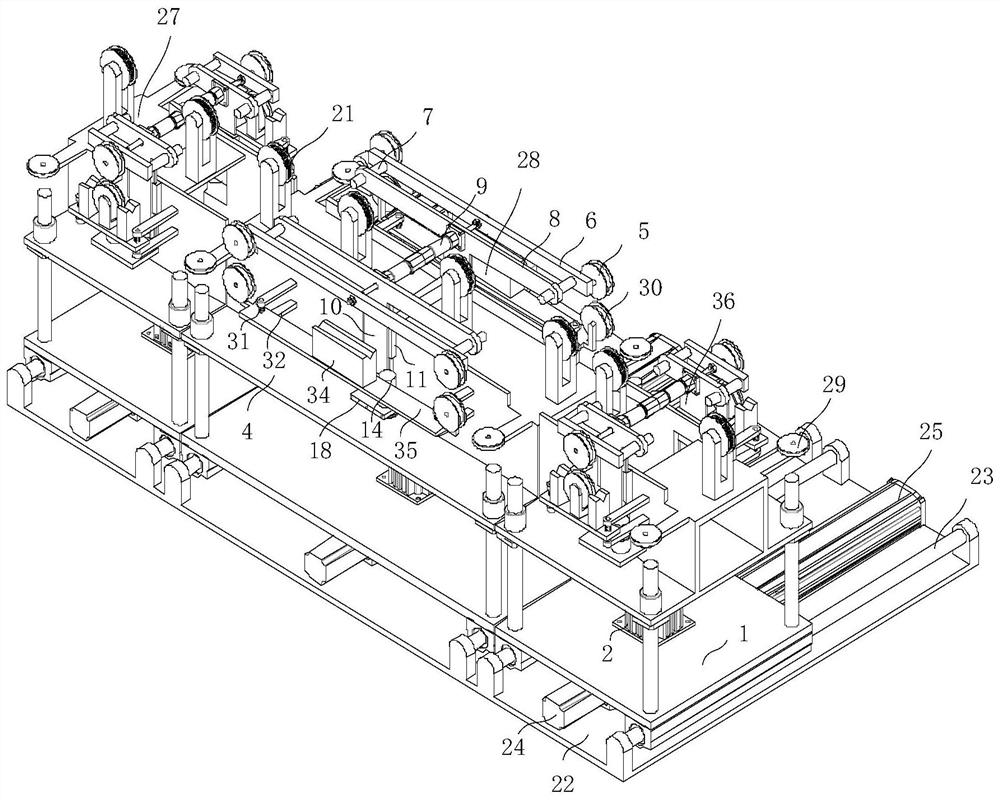

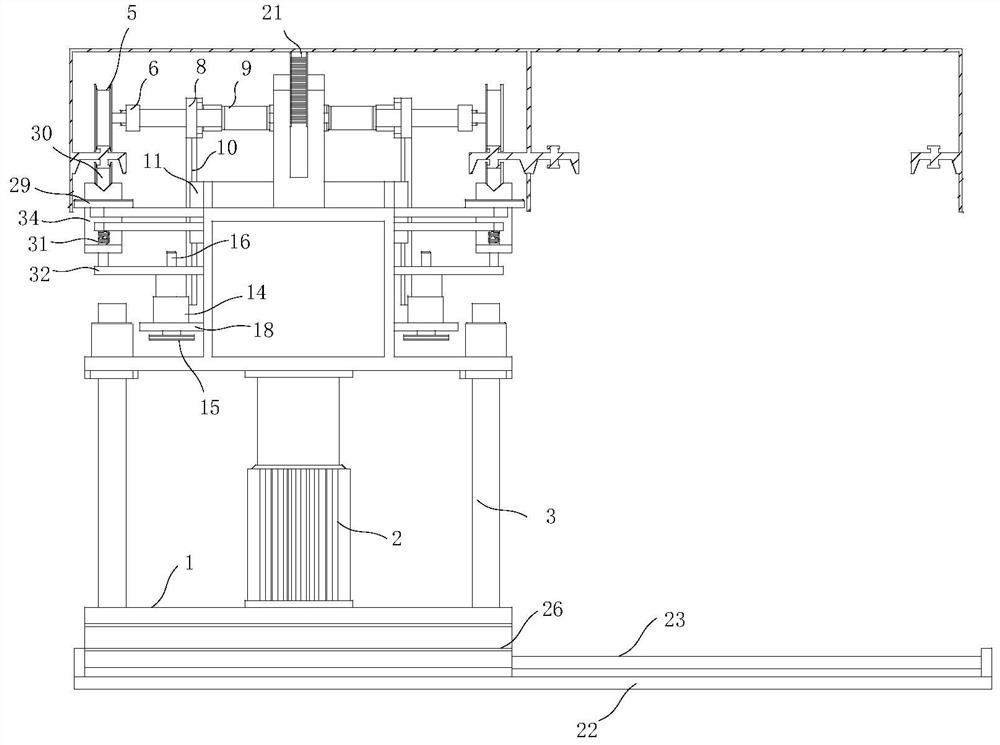

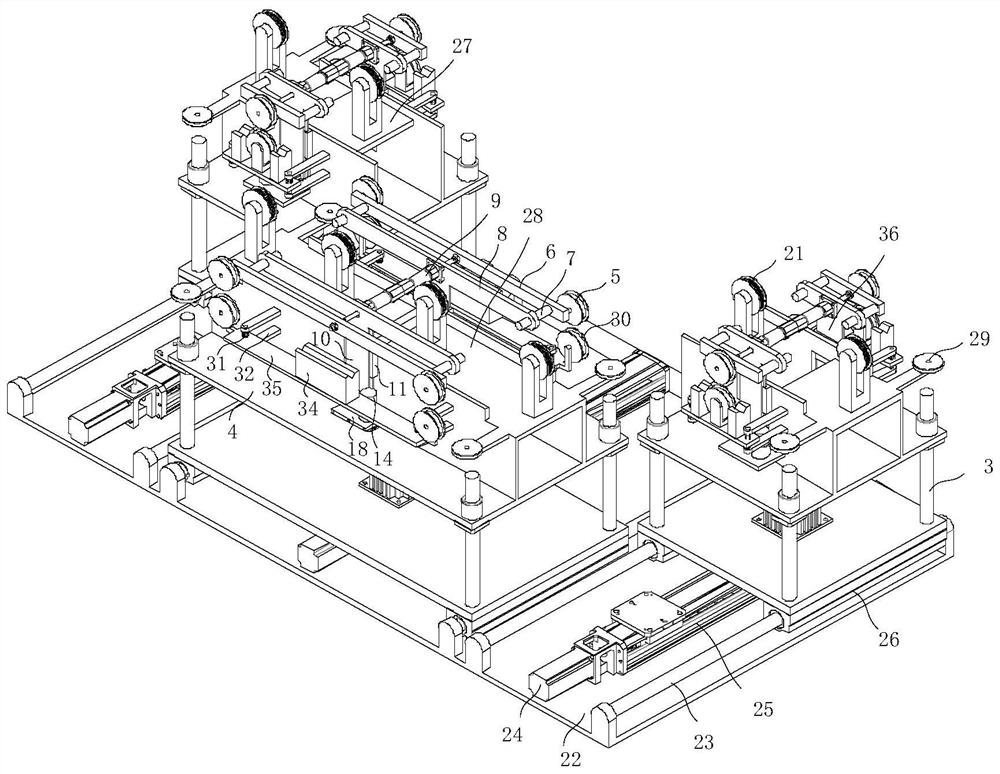

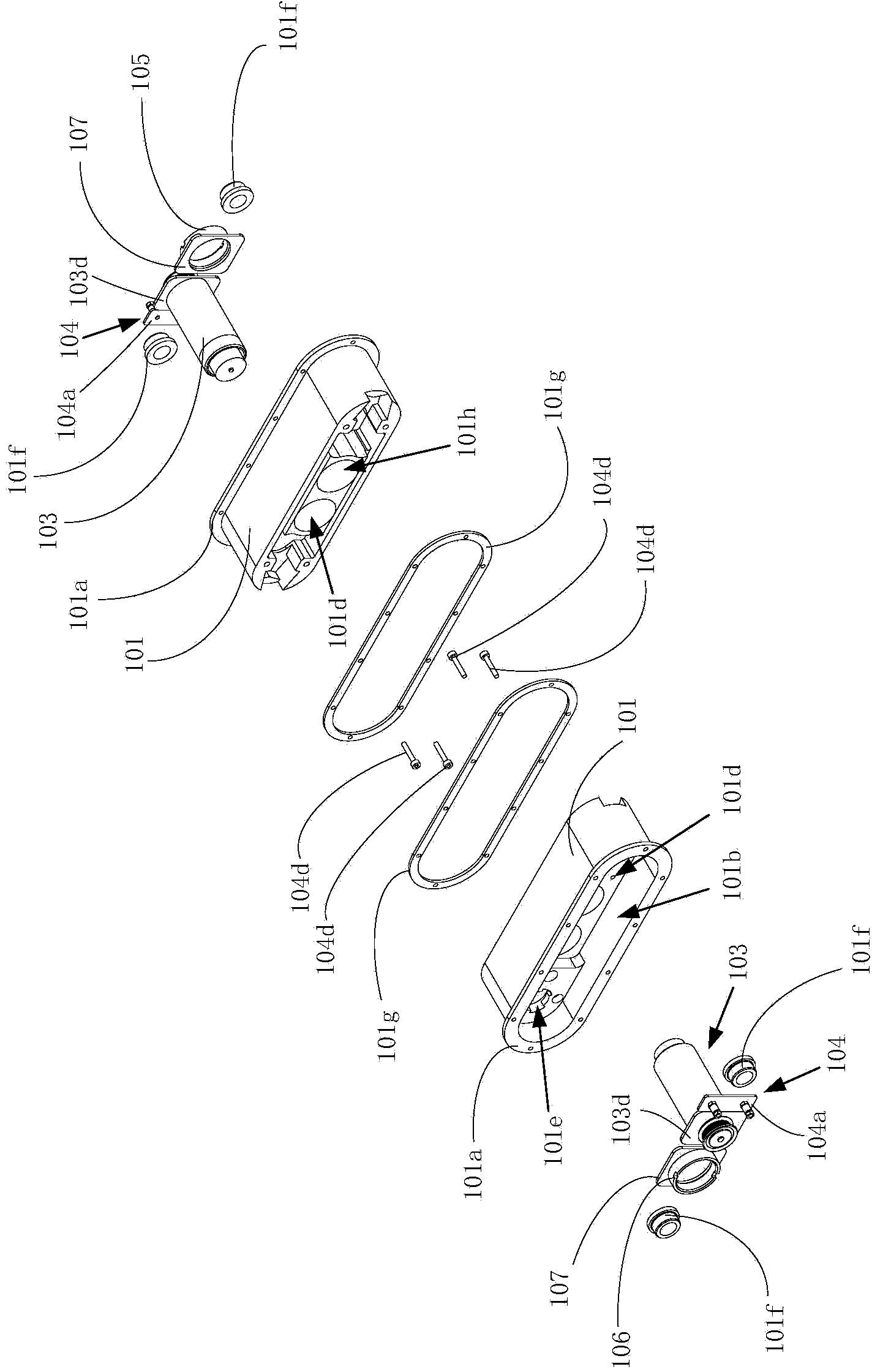

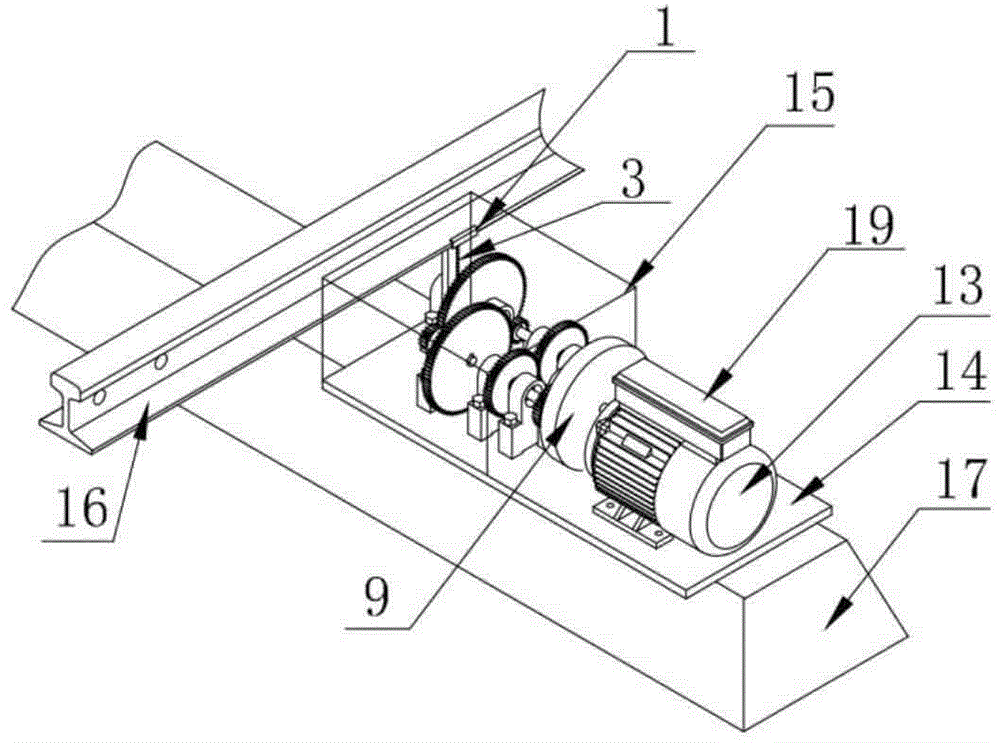

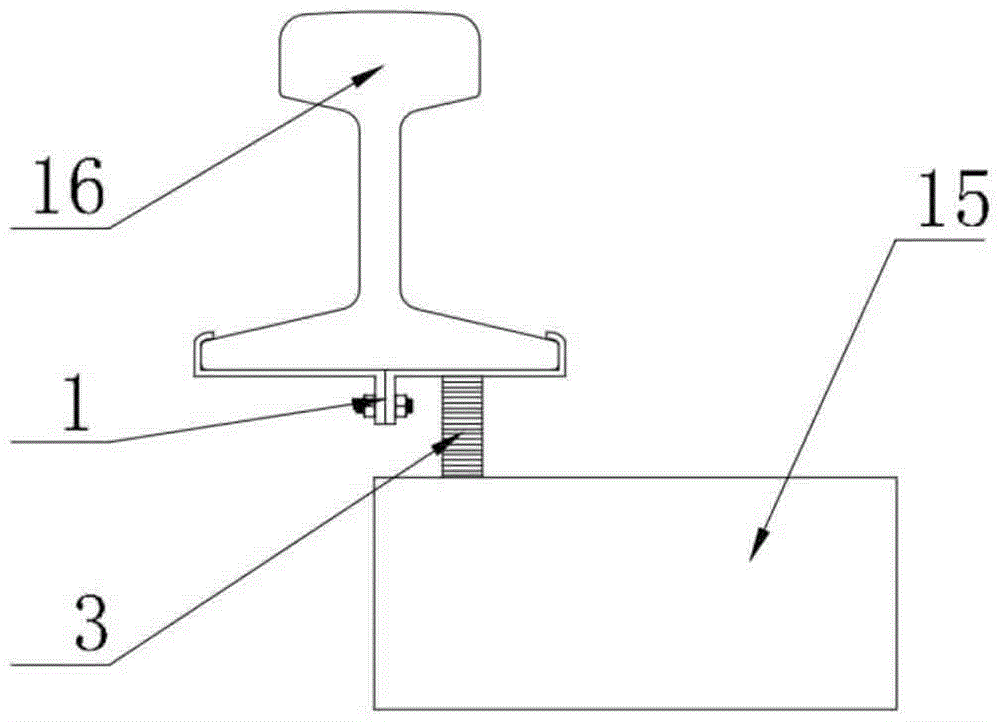

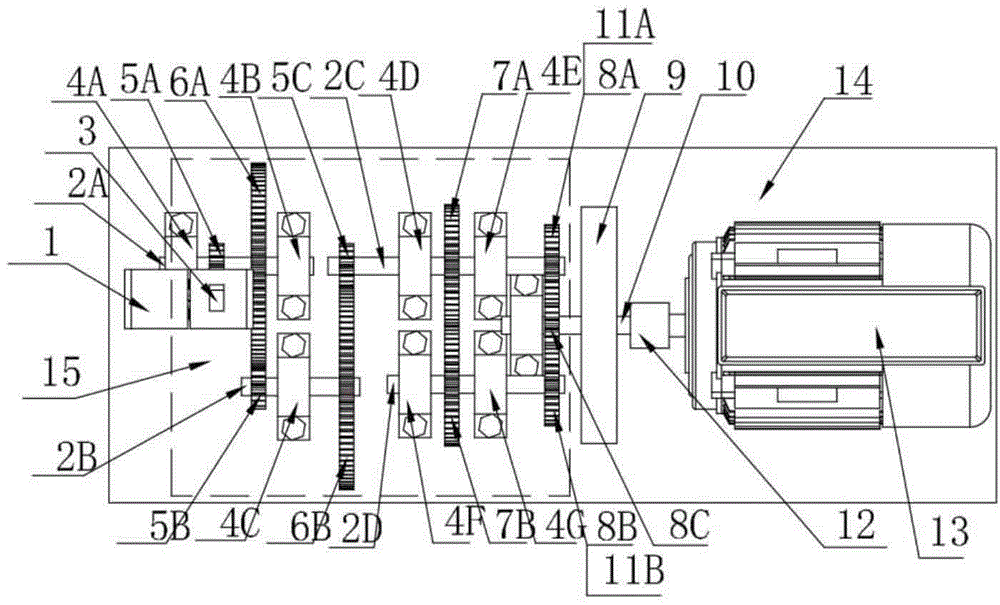

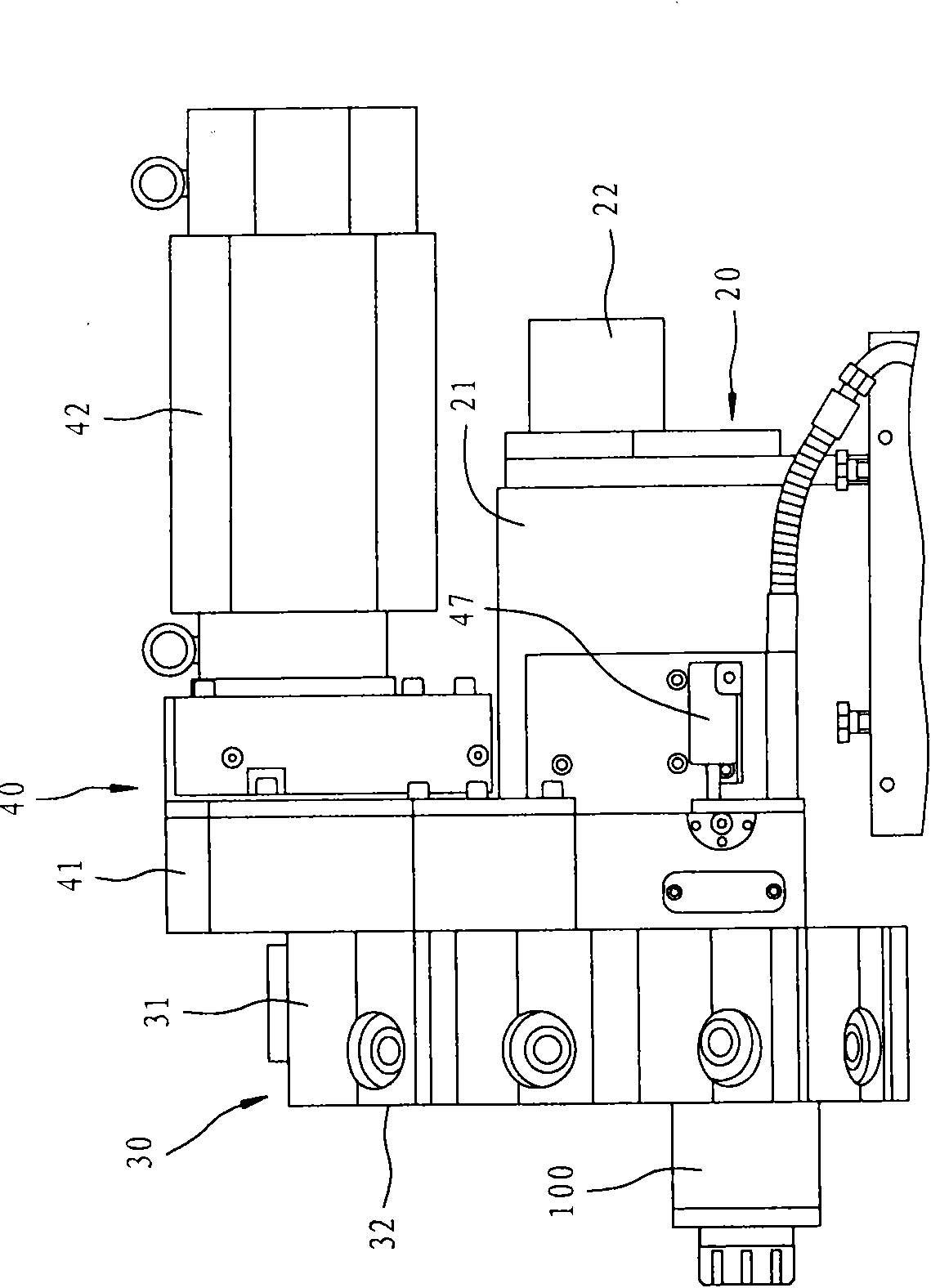

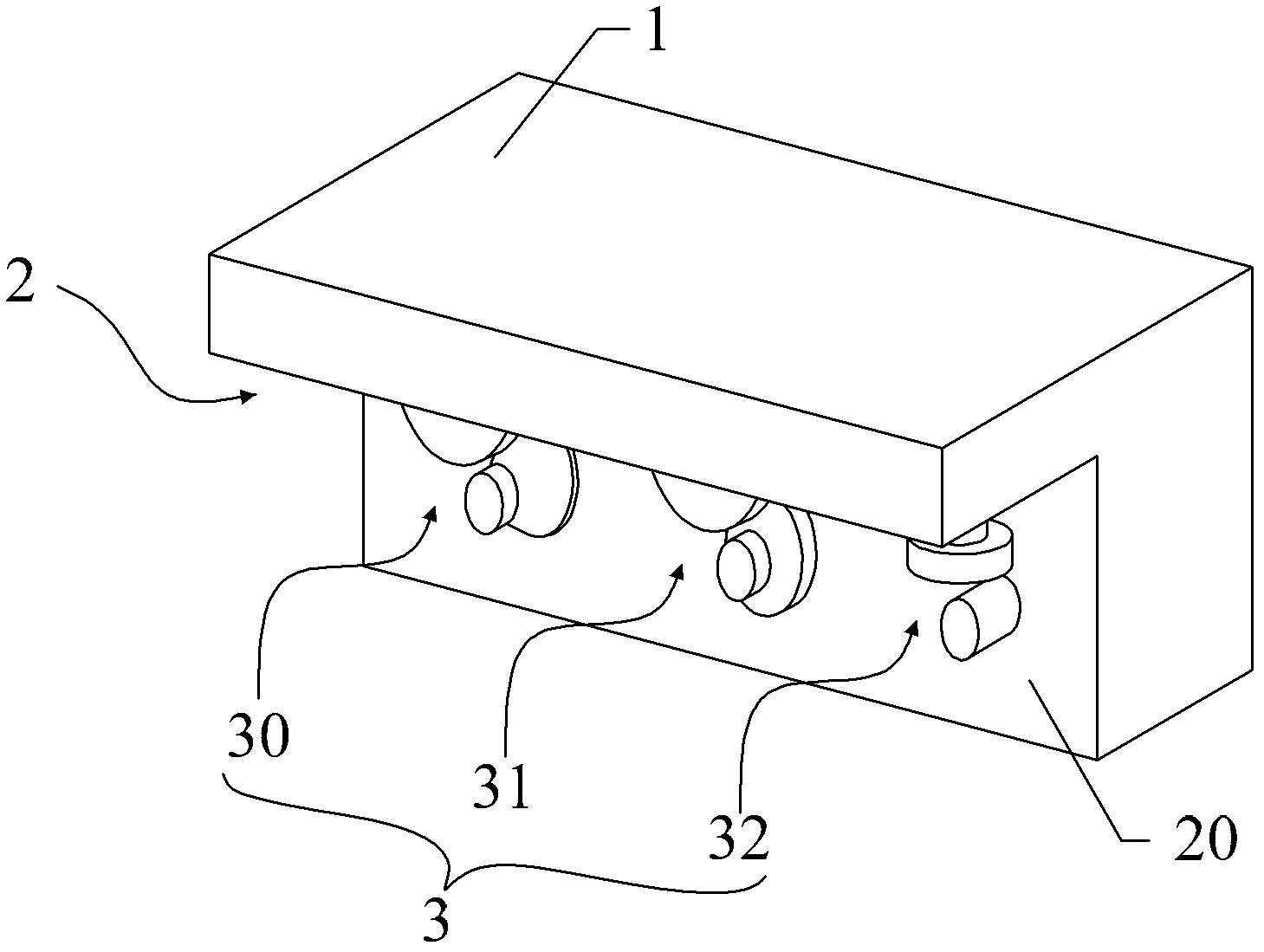

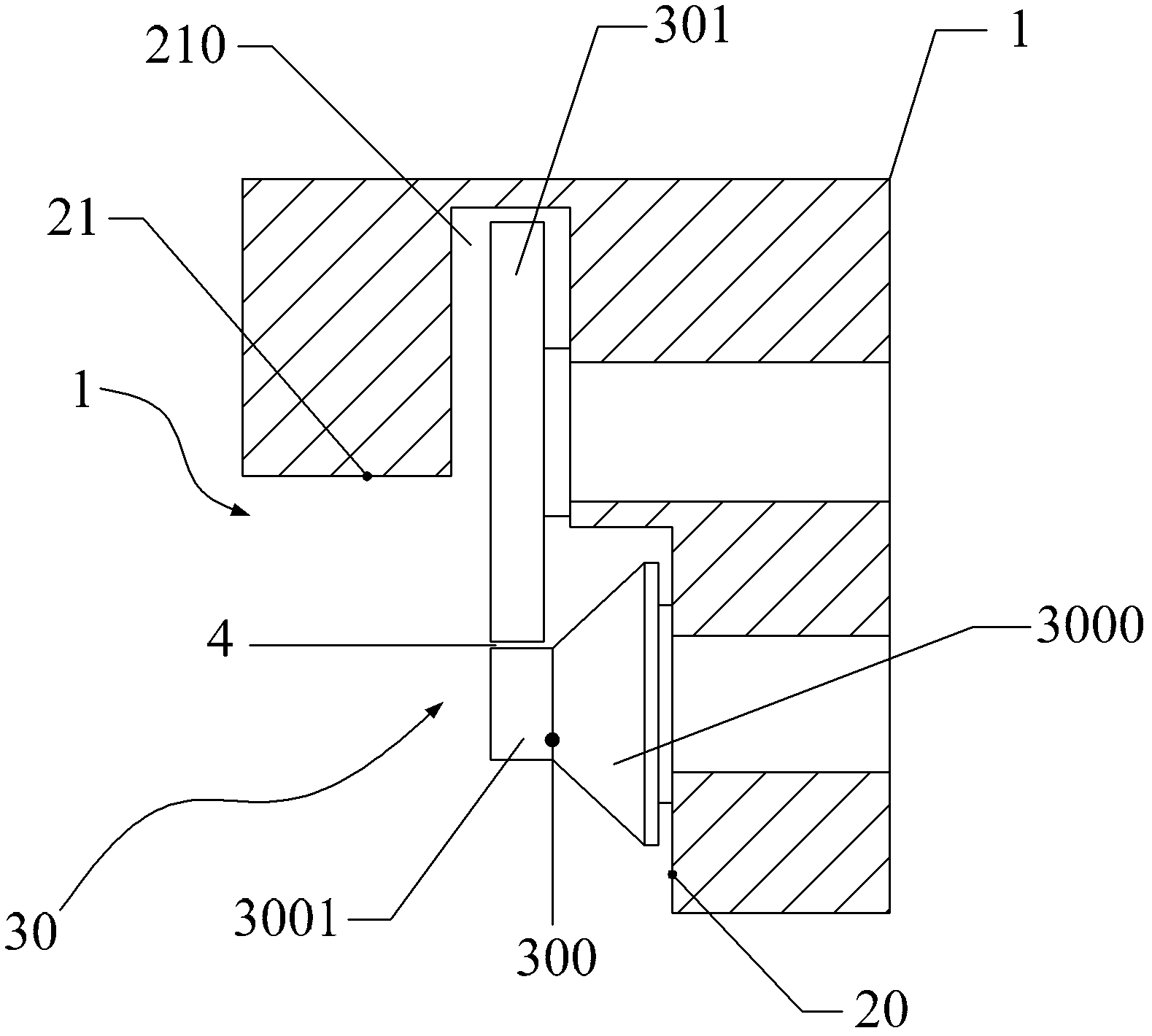

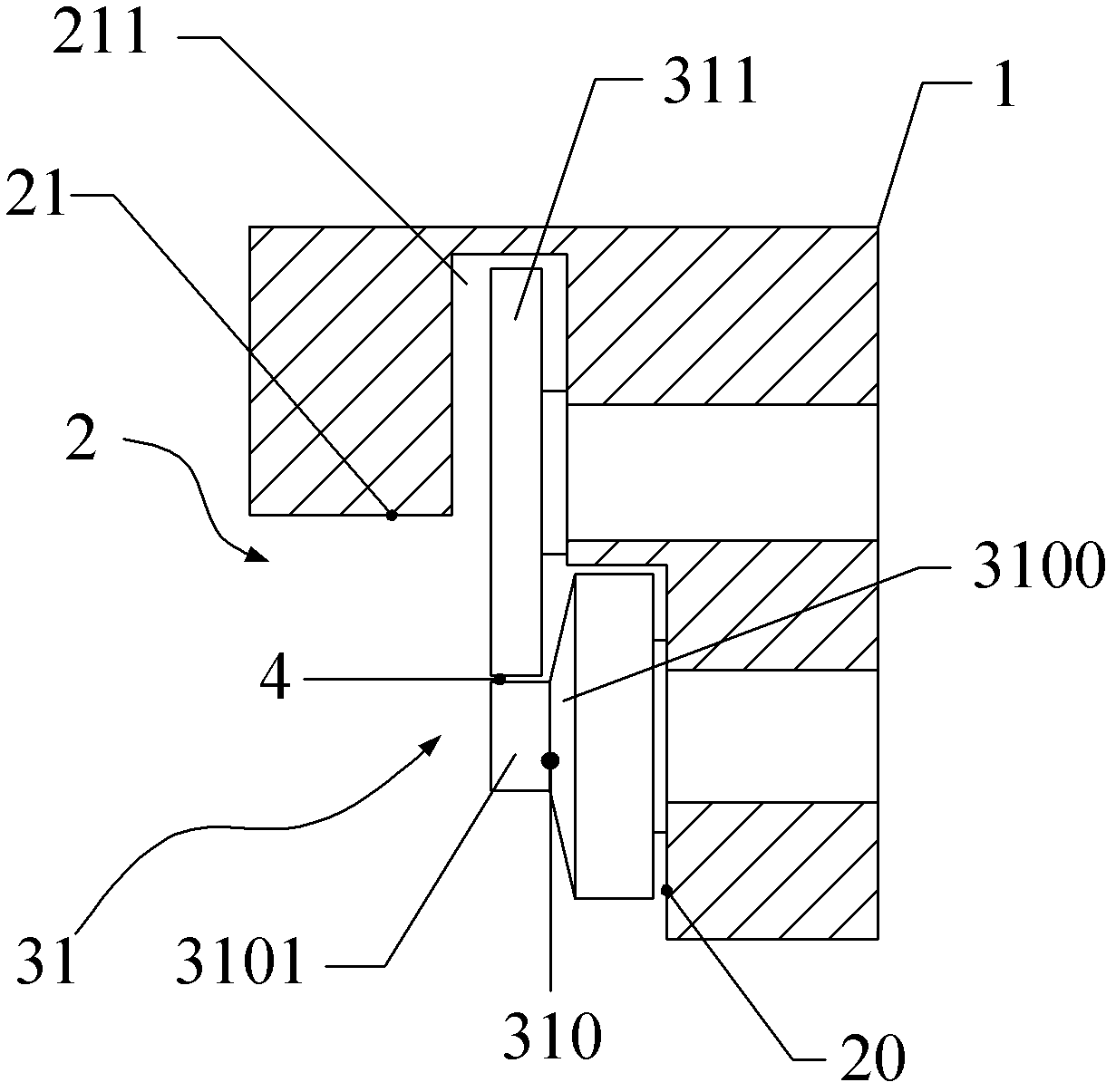

Comprehensive simulation experiment system and method for engine front-end wheel train

ActiveCN102494896AMany measurement parametersHigh measurement accuracyEngine testingControl systemElectric machinery

The invention discloses a comprehensive simulation experiment system and a comprehensive simulation experiment method for an engine front-end wheel train. The experiment system comprises an engine front-end wheel train comprehensive simulation experiment system test bed and an engine front-end wheel train comprehensive simulation experiment system control console, wherein the engine front-end wheel train comprehensive simulation experiment system test bed comprises a fixed panel (21); the engine front-end wheel train is arranged on the fixed panel (21); the rear end of an engine belt wheel shaft is connected with a main motor (24); the rear end of a load belt wheel shaft is connected with a power simulator (25); the engine front-end wheel train comprehensive simulation experiment system control console comprises a case (1) and a control system; the front of the case (1) comprises a control panel; and the control system comprises a personal computer (PC) host and a controller. The invention has the advantages that: various performance parameters of the engine front-end wheel train of an automobile under a working state can be obtained; the measured parameters are comprehensive, andthe measurement precision is high; furthermore, the test bed is high in integration property, and is convenient to mount and maintain.

Owner:CHENGDU JIALING HUAXI OPTICAL & PRECISION MACHINERY

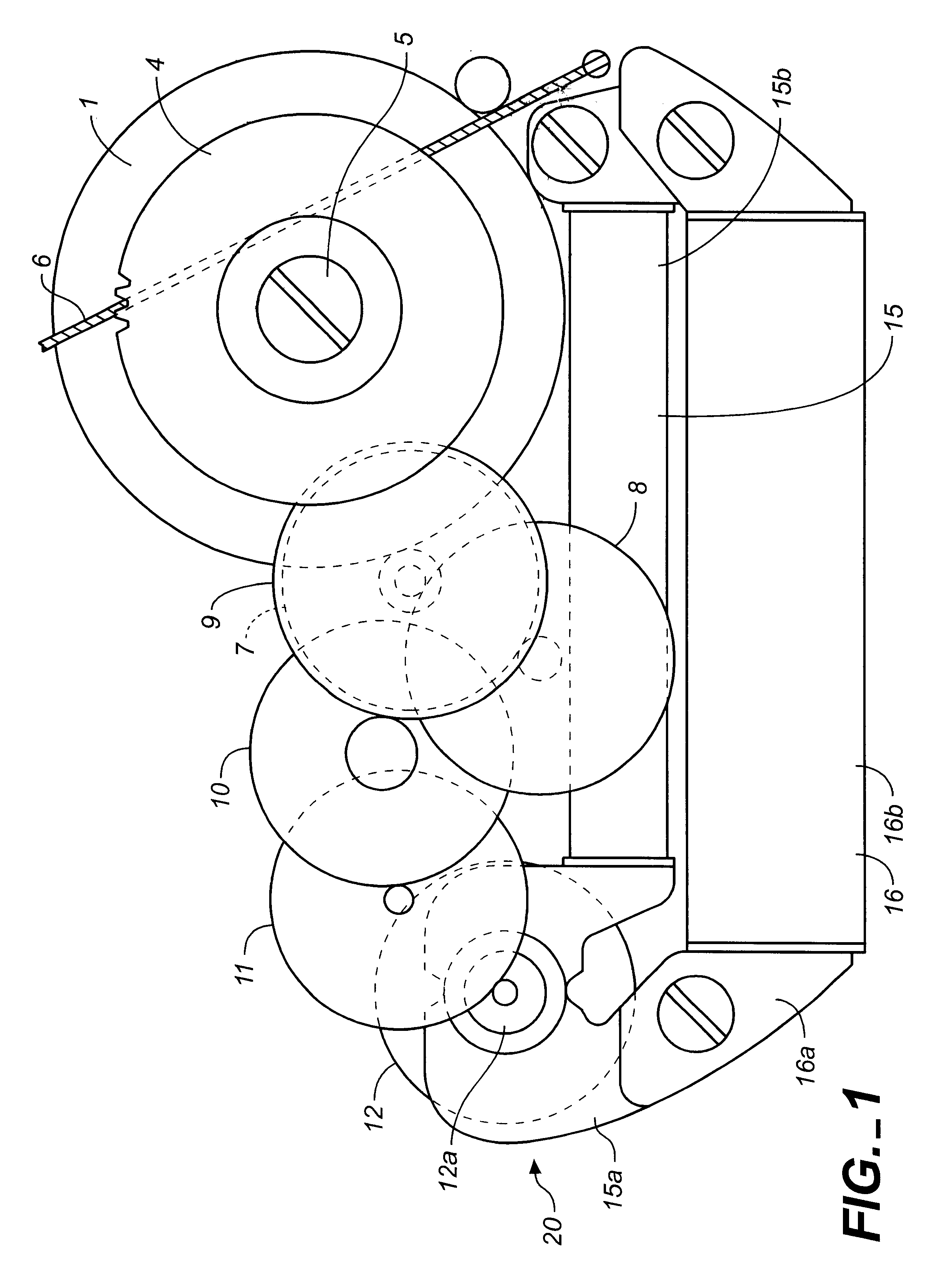

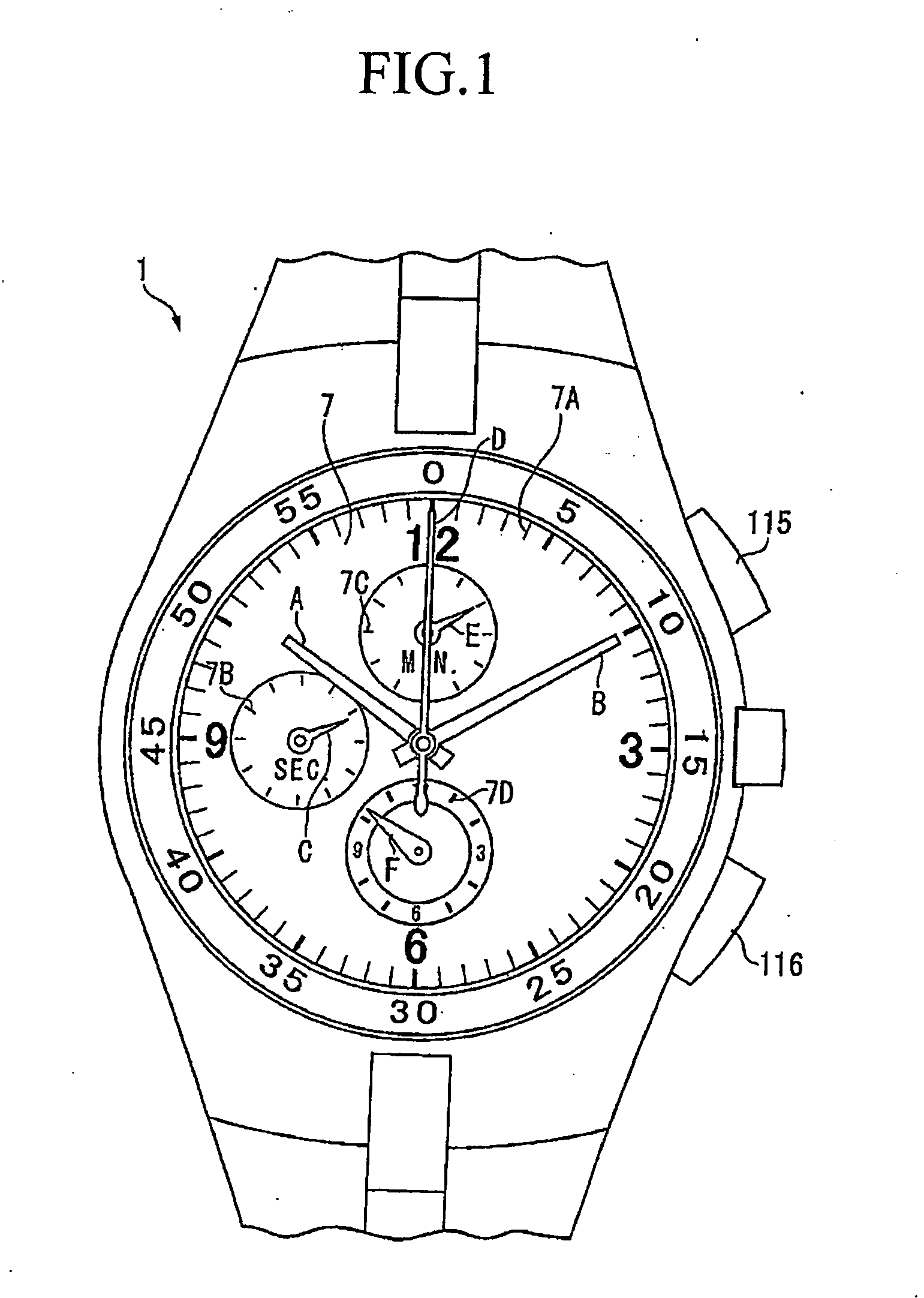

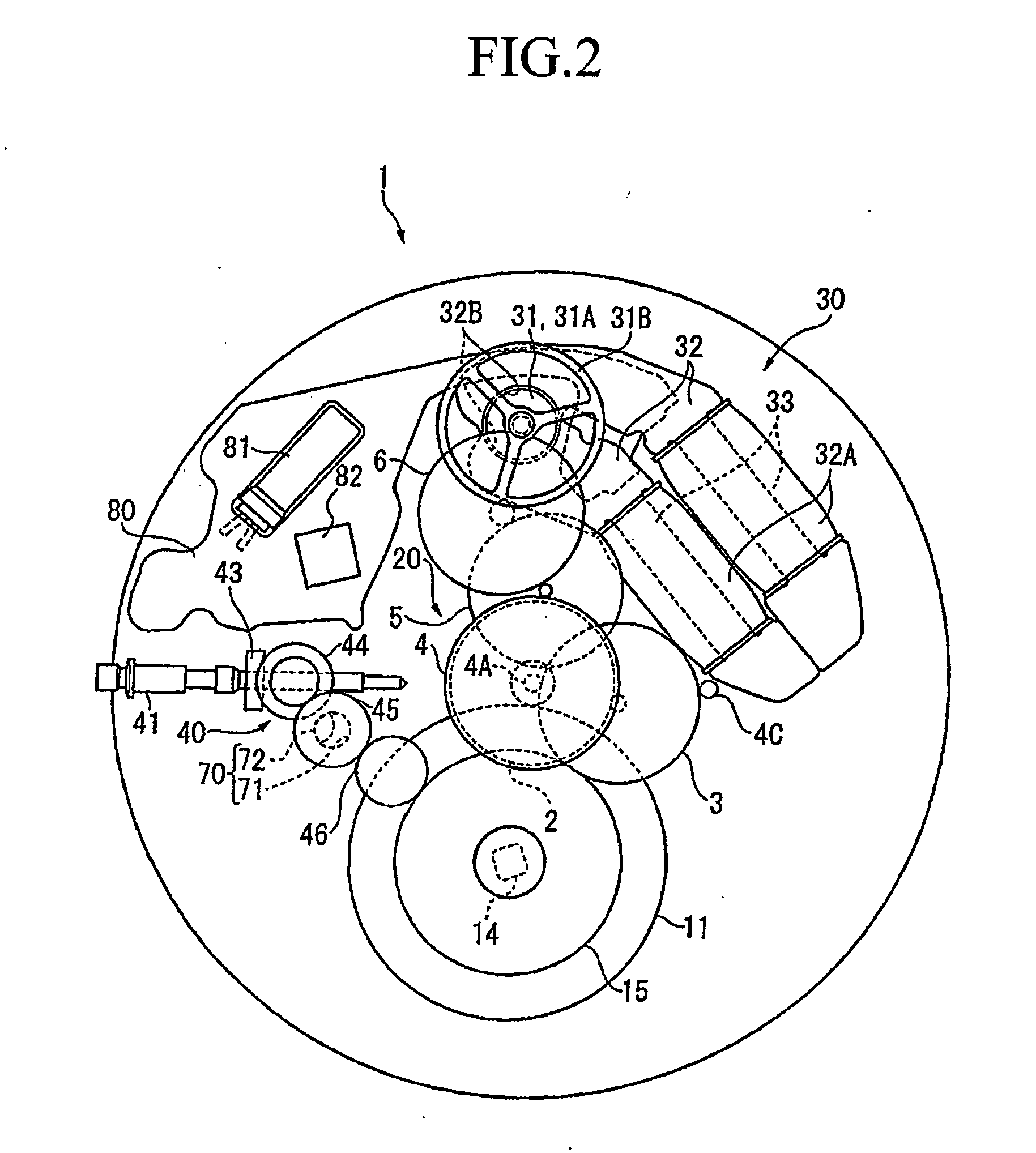

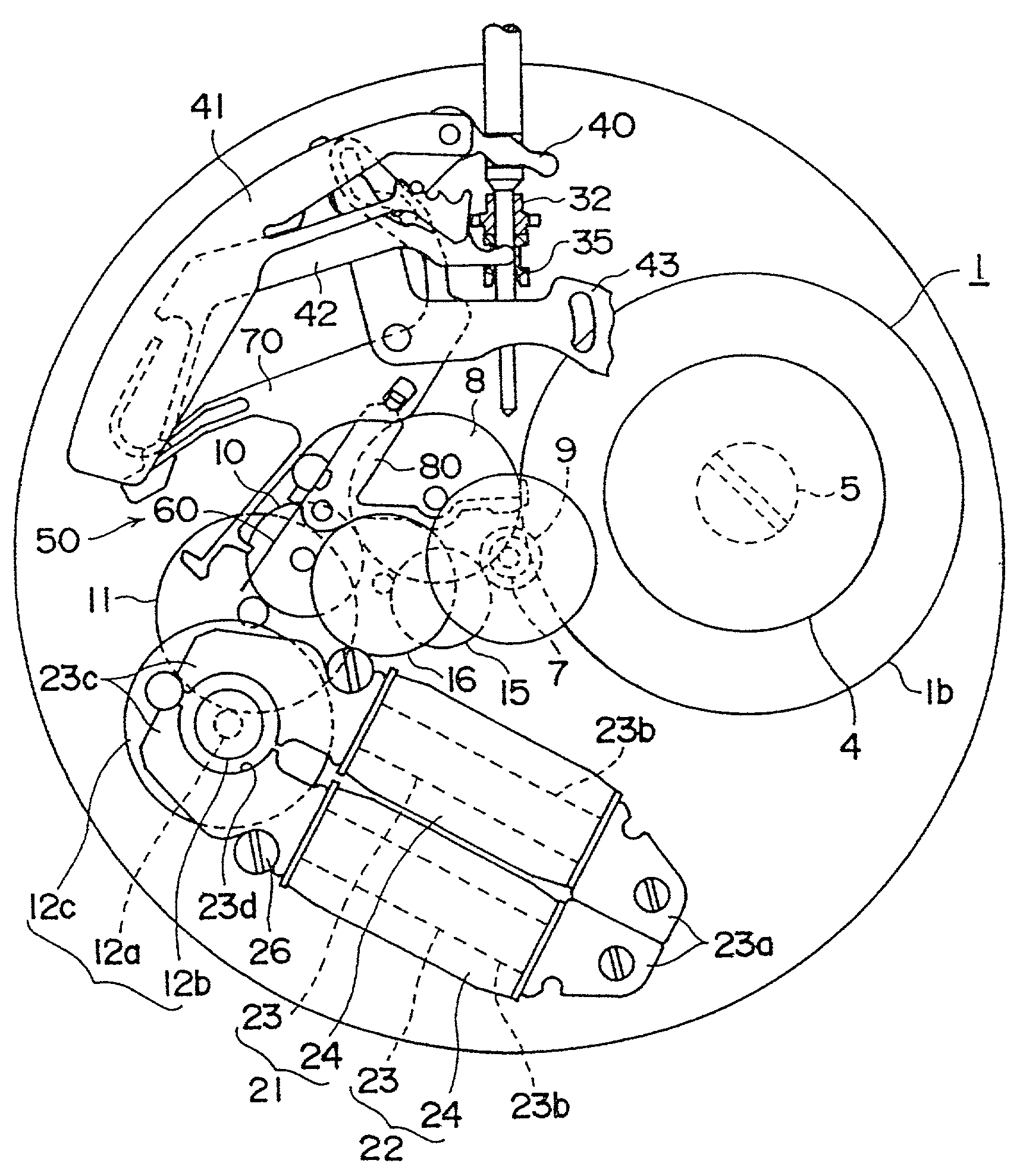

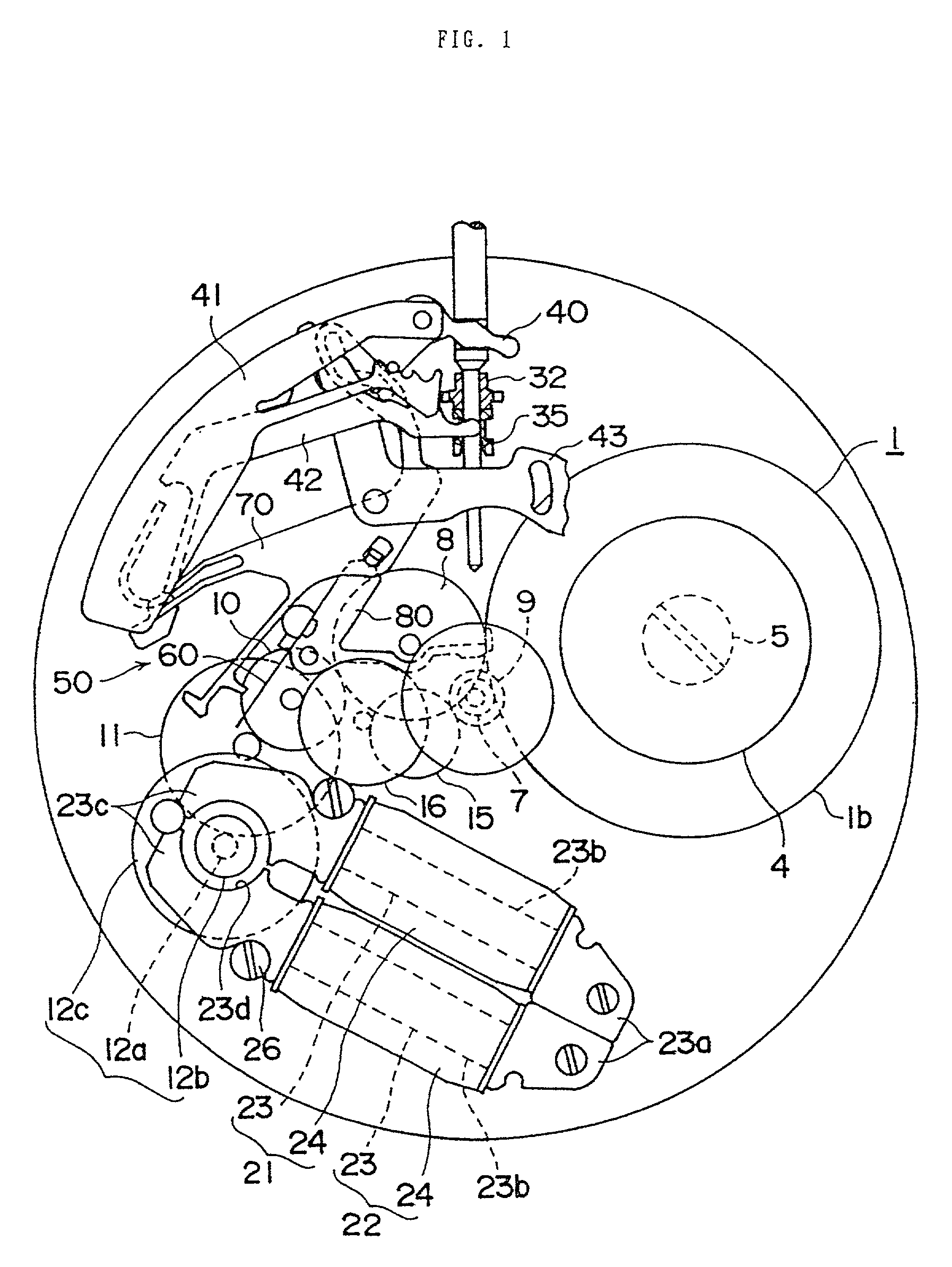

Stopwatch and watch

InactiveUS20050041535A1Mechanical unknown time interval measurementElectromechanical unknown time interval measurementMainspringEngineering

A timepiece having basic timepiece pointers, chronograph information pointers, a mechanical energy storage section, a train wheel, a power generator, and a control section. The basic timepiece pointers are rotated to indicate the standard time. The chronograph information pointers are rotated to indicate chronograph information. The mechanical energy storage section includes a mainspring. The train wheel is disposed between the mechanical energy storage section and the pointers, and transmits energy from the mechanical energy storage section to the pointers. The power generator has a rotating rotor connected to the train wheel, and generates electric power upon receiving the energy from the mechanical energy storage section. The control section is energized by the electric power produced by the power generator, and controls the rotation cycle of the rotor.

Owner:SEIKO EPSON CORP

Manpower-driven device with bi-directional input and constant directional

The present invention is related to a manpower driven device being able to do particular bi-directional pedaling to provide constant directional output for driving the loading wheel train, wherein its pedaling direction is selected by the rider according to his / her operating statuses of the muscles and joints, or the same directional outputs of different speed ratios is made further through the different driving directional inputs.

Owner:YANG TAI HER

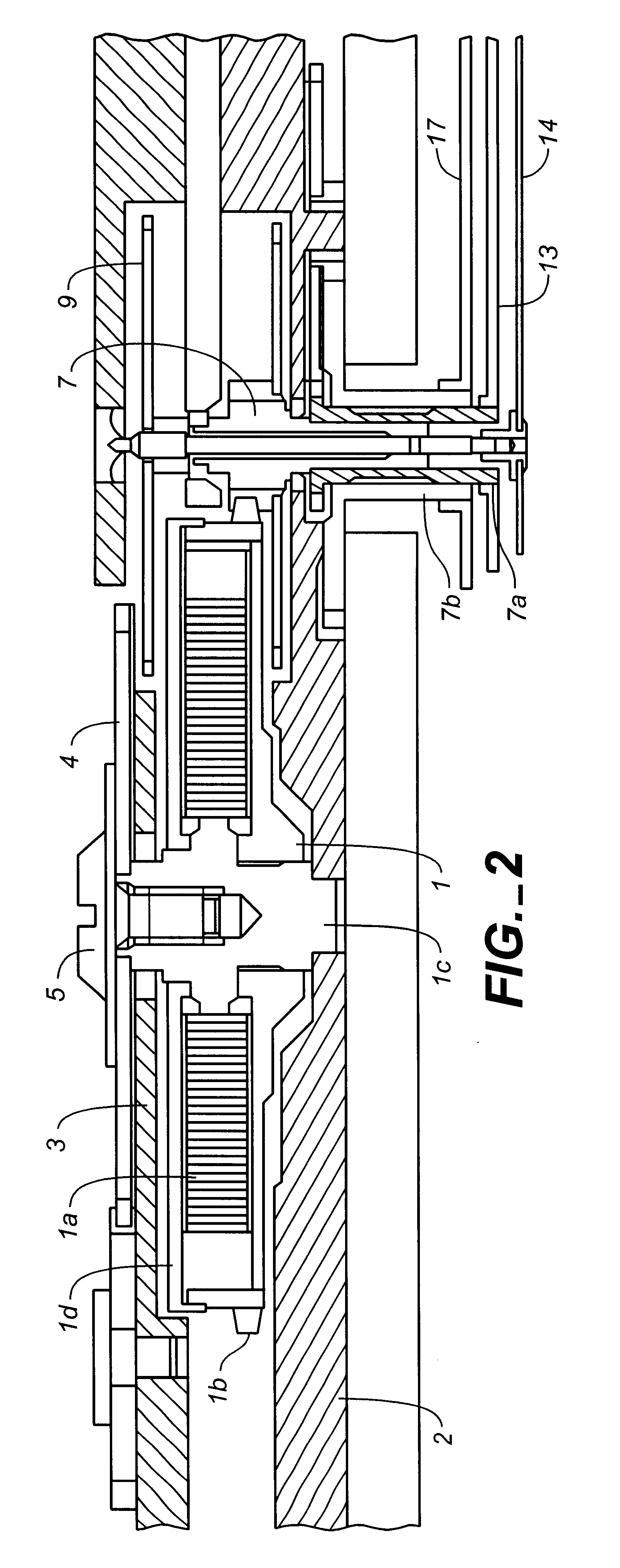

Starter for electricmagnetic converter, and timepiece

InactiveUS7031230B1Timing errorImprove accuracyElectric windingClock driving mechanismsSpring forceEngineering

A starter which applies a mechanical rotating force to a rotor of an electromagnetic converter, such as a power generator, for startup of the rotor. The starter includes a startup spring (60) having an engaging portion (63) engageable with a 6th pinion (11a) of a wheel train coupled to the power generator. In interlock with the operation of pulling out a crown, a reset lever (70) is operated to bias the startup spring for engagement with the 6th pinion. Thereafter, the startup spring is released from the biased state in interlock with the operation of pushing in the crown. The startup spring is returned to the original position due to its own spring force, whereupon a mechanical rotating force is applied to the pinion. Since the rotating force can be set by a resilient force of only the startup spring, a stable rotating force is applied to the rotor (12).

Owner:SEIKO EPSON CORP

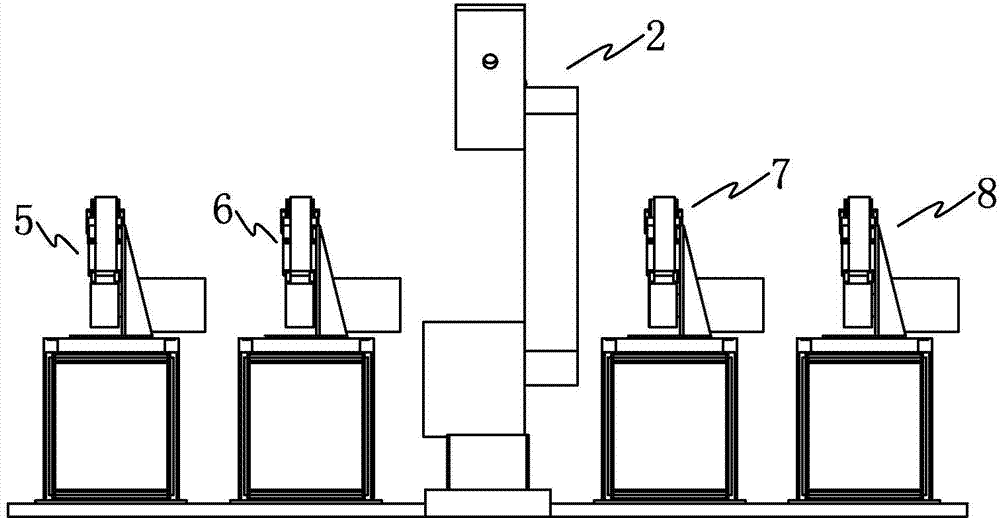

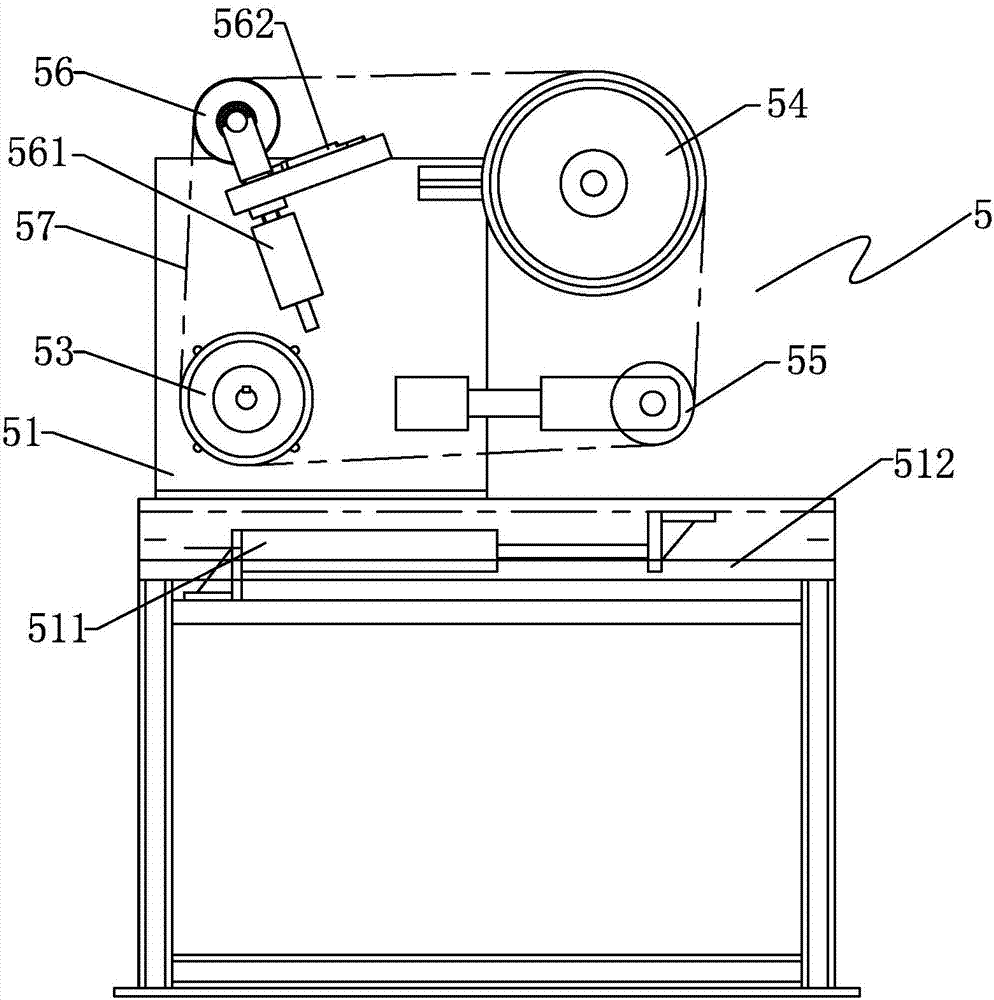

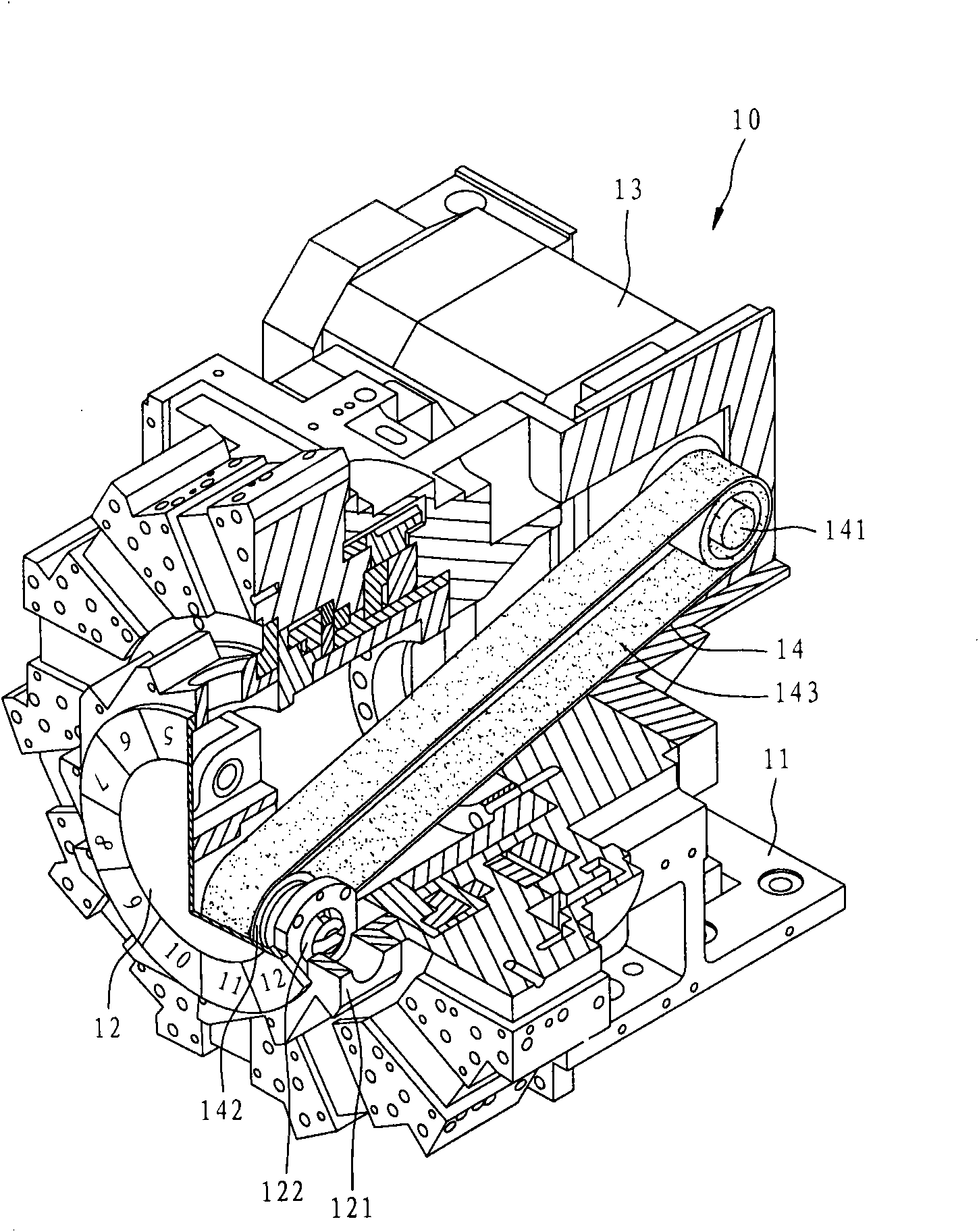

Mechanical arm multi-station belt sander

ActiveCN103567840AEliminate dependenciesHigh degree of automationBelt grinding machinesGrinding feedersInformatizationSander

The invention discloses a mechanical arm multi-station belt sander which comprises a base, a mechanical arm clamping a workpiece, abrasive belt wheel trains and an automatic feeding mechanism. The abrasive belt wheel trains are multi-station abrasive belt trains and comprise the wide coarse abrasive belt wheel train, the narrow coarse abrasive belt wheel train, the wide fine abrasive belt wheel train and the narrow fine abrasive belt wheel train. The abrasive belt wheel trains are sequentially arranged in an arc shape. Each abrasive belt wheel train comprises a sliding base, a driving wheel, a contact wheel, a tension wheel and an abrasive belt wound around the surface of the driving wheel, the surface of the contact wheel and the surface of the tension wheel, wherein the driving wheel, the contact wheel and the tension wheel are arranged on the sliding base. Compared with the prior art, the mechanical arm multi-station belt sander has the advantages that the automation degree is high, dependence on polishing experience of a worker is eliminated, any position of the workpiece can be polished, and the polishing quality is stable and uniform; the production efficiency and the economic benefits are effectively improved and the occurrence rate of safety accidents is reduced; the business management level and the informatization level are improved and the purpose of standard management of an enterprise is achieved.

Owner:广东博科数控机械有限公司

Opposite type rail trolley wheel train set and rail changing method thereof

PendingCN112026844AAchieve left and right translationRealize switching tracksRail-engaging wheelsDevices secured to vehiclesControl theoryCarriage

The invention discloses an opposite type rail trolley wheel train set which comprises a bearing plate and a two-character wheel train set, namely an A wheel train set and a B wheel train set. The two-character wheel train set is arranged on the bearing plate in tandem through a translation mechanism, the A and B wheel train sets are hung on a rail in use, when the rail needs to be replaced, the Bwheel train set is derailed firstly and then replaced to the adjacent rail, the A wheel train set changes the rail, and a carriage below the bearing plate is moved to the adjacent rail through the translation mechanism. Therefore, left-right translation of the rail trolley is realized. By arranging the characteristics of wheel ascending, wheel contracting, wheel descending, horizontal moving and the like of a walking wheel train, the rail trolley can achieve rail changing walking. The wheel train set and the method have beneficial effects that the rail trolley can walk back and forth directlywithout bypassing when the rail trolleys walk in opposite directions and miss a destination so that the time is saved, and the efficiency is high.

Owner:亚轨科技(成都)有限公司

High-strength rail trolley wheel train sets and rail replacing method thereof

PendingCN112061145AAchieve left and right translationRealize switching tracksDevices secured to trackElevated railway with suspended vehicleControl theoryCarriage

The invention discloses high-strength rail trolley wheel train sets. A bearing plate and the N wheel train sets installed on the bearing plate through a translation mechanism are included, and N is larger than or equal to 3. In the using process, the N wheel train sets are hung on a rail, when rail replacing needs to be carried out, parts of the wheel train sets are derailed at the same time and then moved to an adjacent rail through rail replacing, then the remaining wheel train sets are subjected to rail replacing, then a carriage below the bearing plate is moved to the adjacent rail throughthe translation mechanism, and therefore left-right translation of a rail trolley is achieved. According to the high-strength rail trolley wheel train sets, through the arrangement of a walking wheelsystem and a climbing mechanism, the rail trolley can vertically walk up and down along the rail, press the rail to walk and walk in a hanging manner under the rail. The high-strength rail trolley wheel train set and the rail replacing method have the beneficial effects that high-precision walking of the rail trolley can be achieved; by arranging ABC gear train sets, the stress point can reach 80%-100%, the coverage area is wide, the carriage can be lengthened along with the rail, adaption to large-scale transportation is achieved, the efficiency is high, and the economic value is wide.

Owner:亚轨科技(成都)有限公司

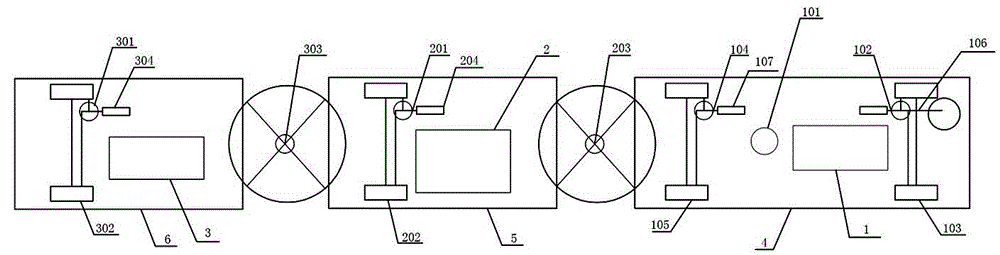

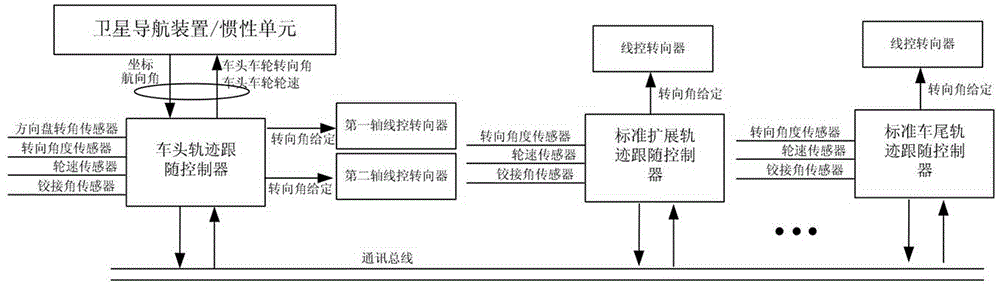

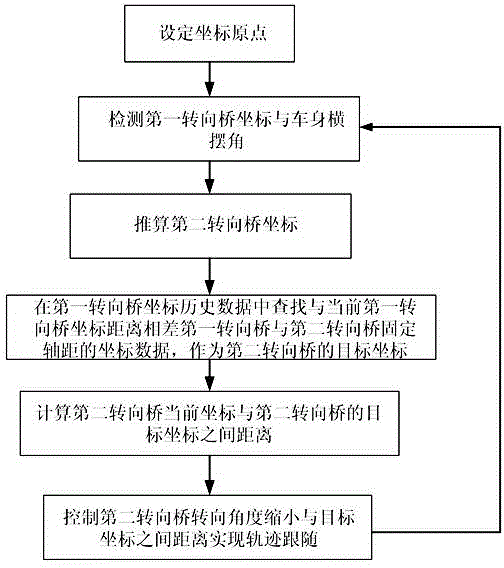

Rubber wheel train track following control system

ActiveCN105620514AEasy modular configurationSimple structureSignalling indicators on vehicleControl systemUnit mass

The invention discloses a rubber wheel train track following control system. The rubber wheel train track following control system comprises a train head track following controller arranged on a train head assembly, a carriage track following controller arranged on a carriage assembly and a train tail track following controller arranged on a train tail assembly. The train head track following controller collects state signals of a train head to obtain the coordinates of a train head unit mass center, calculates coordinate data of a next axle and transmits the coordinate data of the next axle to a track following controller on a next carriage. The carriage track following controller and the train tail track following controller collect the state signals of corresponding carriages and receive the coordinate data of the upper adjacent carriage through communication network transmission to control the motion track of the axle of a carriage. The rubber wheel train track following control system has the advantages of being simple in principle, easy to operate, capable of achieving the optimal control effect and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

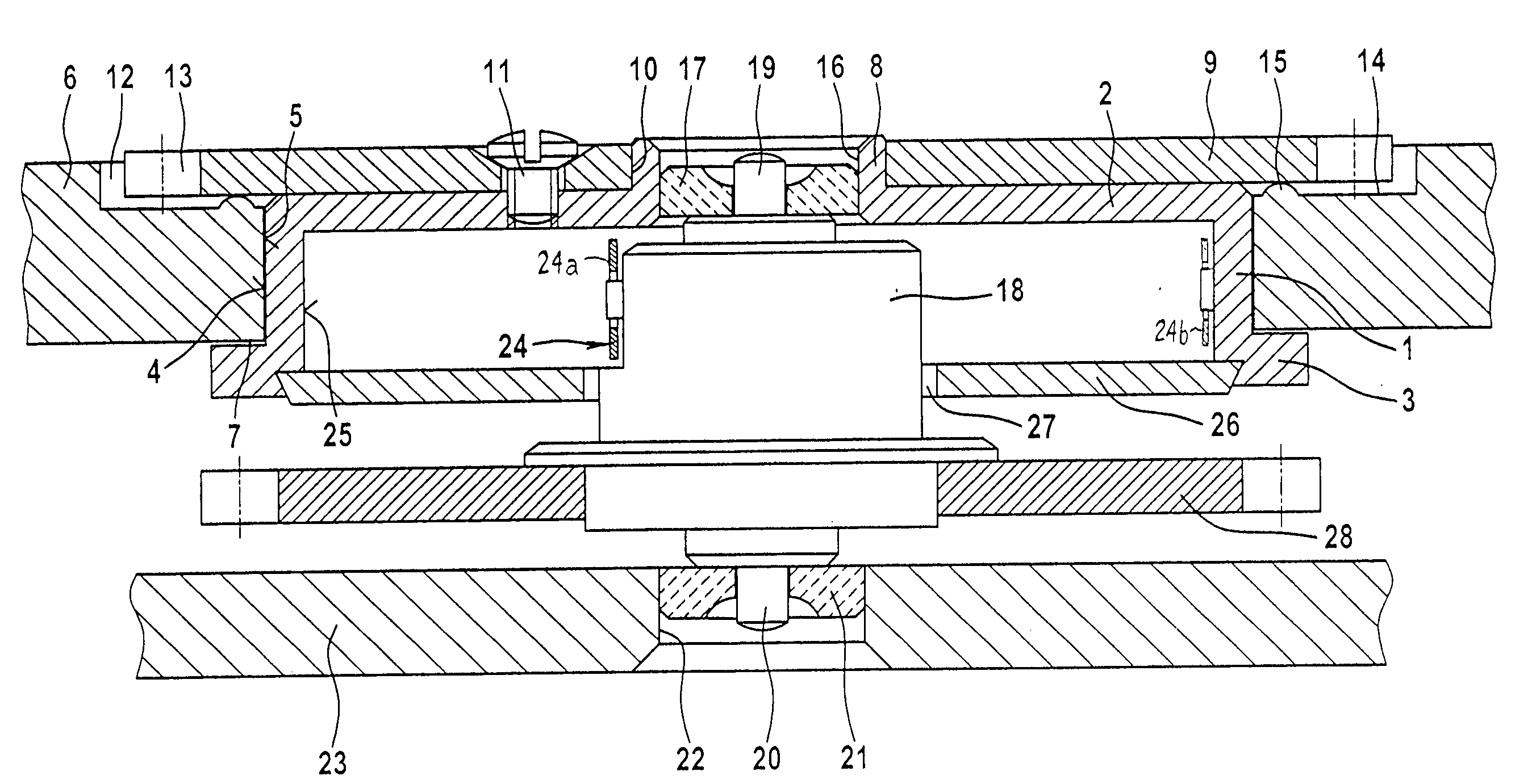

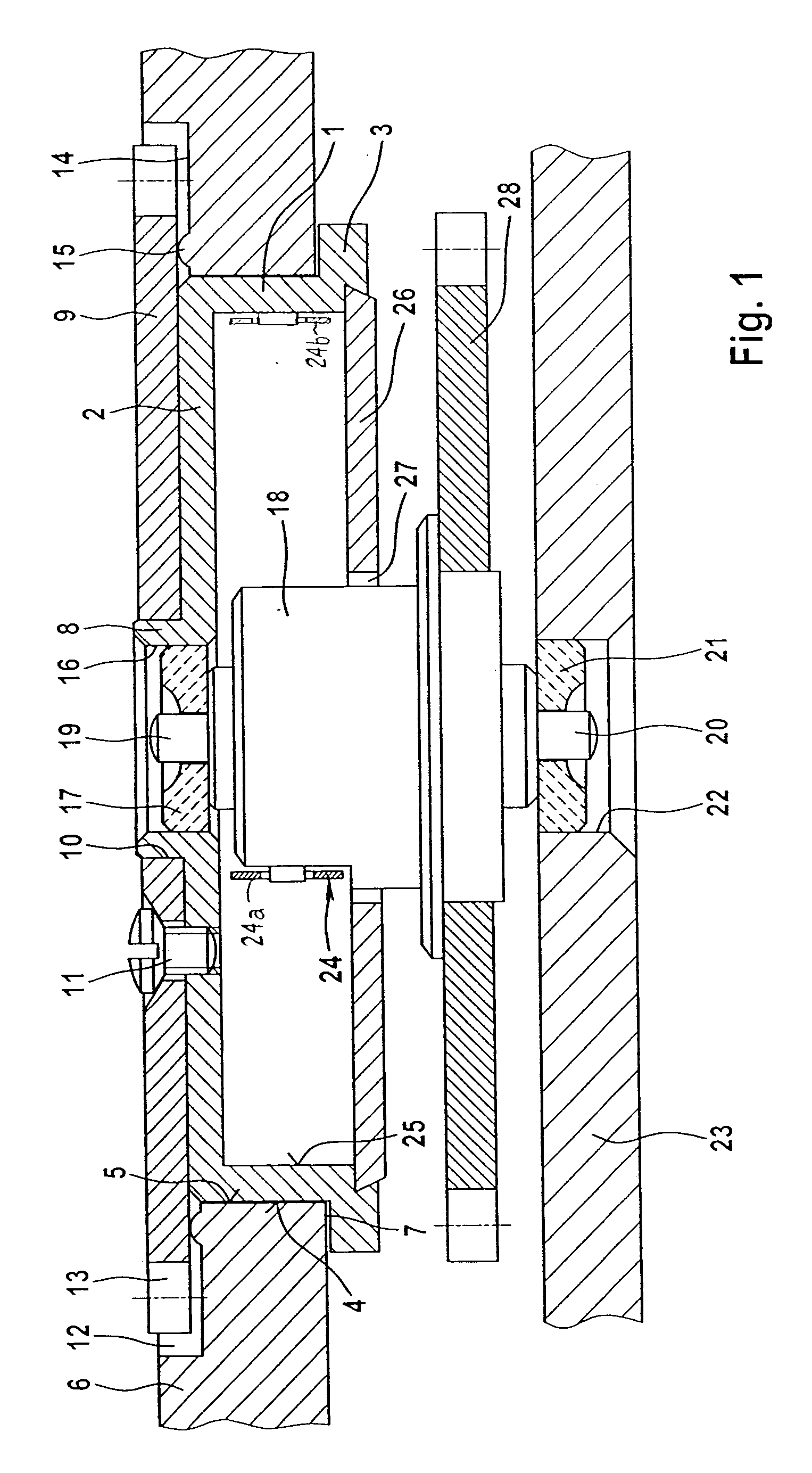

Spring-barrel arrangement for a timepiece

ActiveUS20050249045A1Improve accuracyEasy to installFrameworksClock driving mechanismsAbutmentEngineering

A spring-barrel arrangement for a timepiece includes a fixed plate-like component with a circular cutout. A spring barrel is rotatably mounted in said circular cutout by its corresponding circular outer contour. A barrel core is coaxially rotatably mounted relatice to the spring barrel and is enclosed by a helical tension spring. An inner end of the spring is connected to the barrel core and its outer end connected to the spring barrel. A crown wheel with a toothed ring is fixed to the spring barrel and a first wheel of a wheel train of the timepiece is fixed to the barrel core. The circular cutout is formed through the plate-like component and the spring barrel has two supporting regions which extend radially beyond the diameter of the circular cutout and are each in abutment against one of the mutually opposite side surfaces of the plate-like component.

Owner:LANGE UHREN

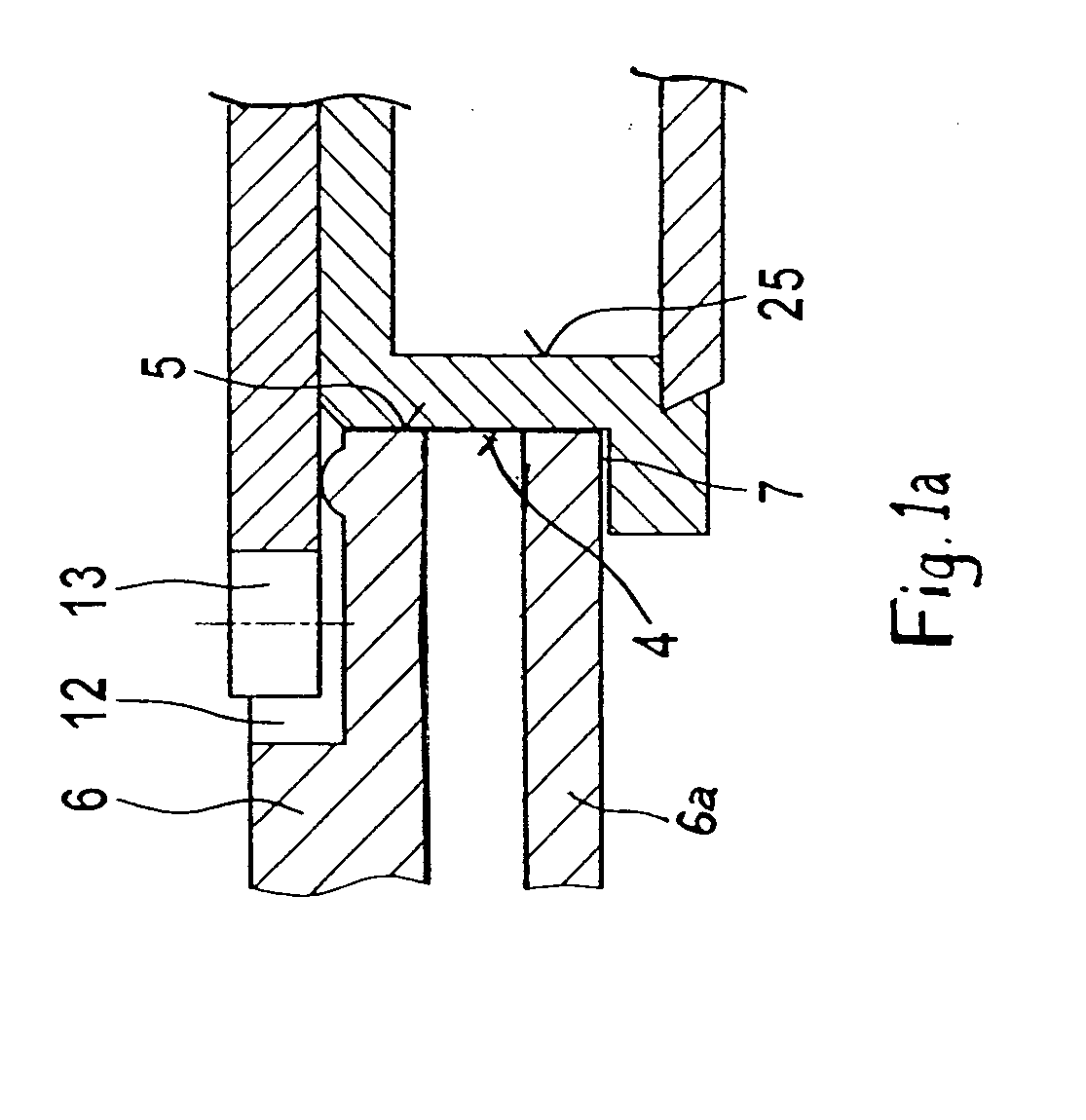

Throwable scout robot

The invention discloses a throwable scout robot comprising a car module and motion modules mounted on two sides of the car module. The car module is made of rubber, driving motors are mounted on two sides of the car module and drive transmission mechanisms composed of belts and transmission wheels so as to transmit power, and motion wheel trains on the transmission mechanisms can rotate. The driving motors and the transmission mechanisms are arranged in grooves of the car module. The motion modules and the car module are connected through skirts of the car module and connecting main boards of the motion modules, so that flexible connection is realized. The car module is provided with a plurality of form cavities used for mounting task loads inside. The throwable scout robot has the advantages of compact structure and the advantages that impact caused by falling can be resisted by its structure so as to prevent damage and complete subsequent scout tasks within a throwing height range (throwing height of an object of 2kg is approximate to 6 meters) of a normal adult.

Owner:BEIHANG UNIV

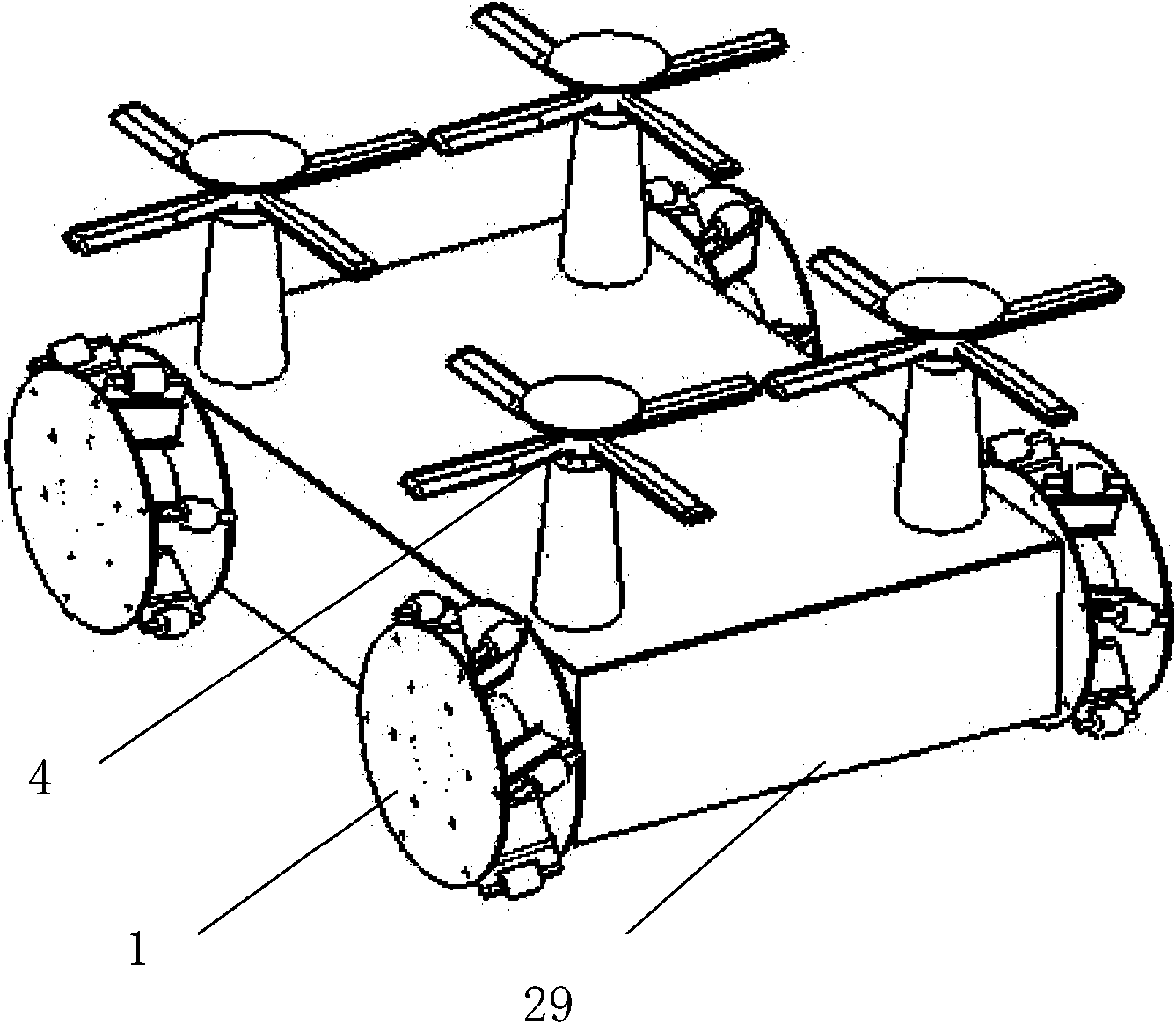

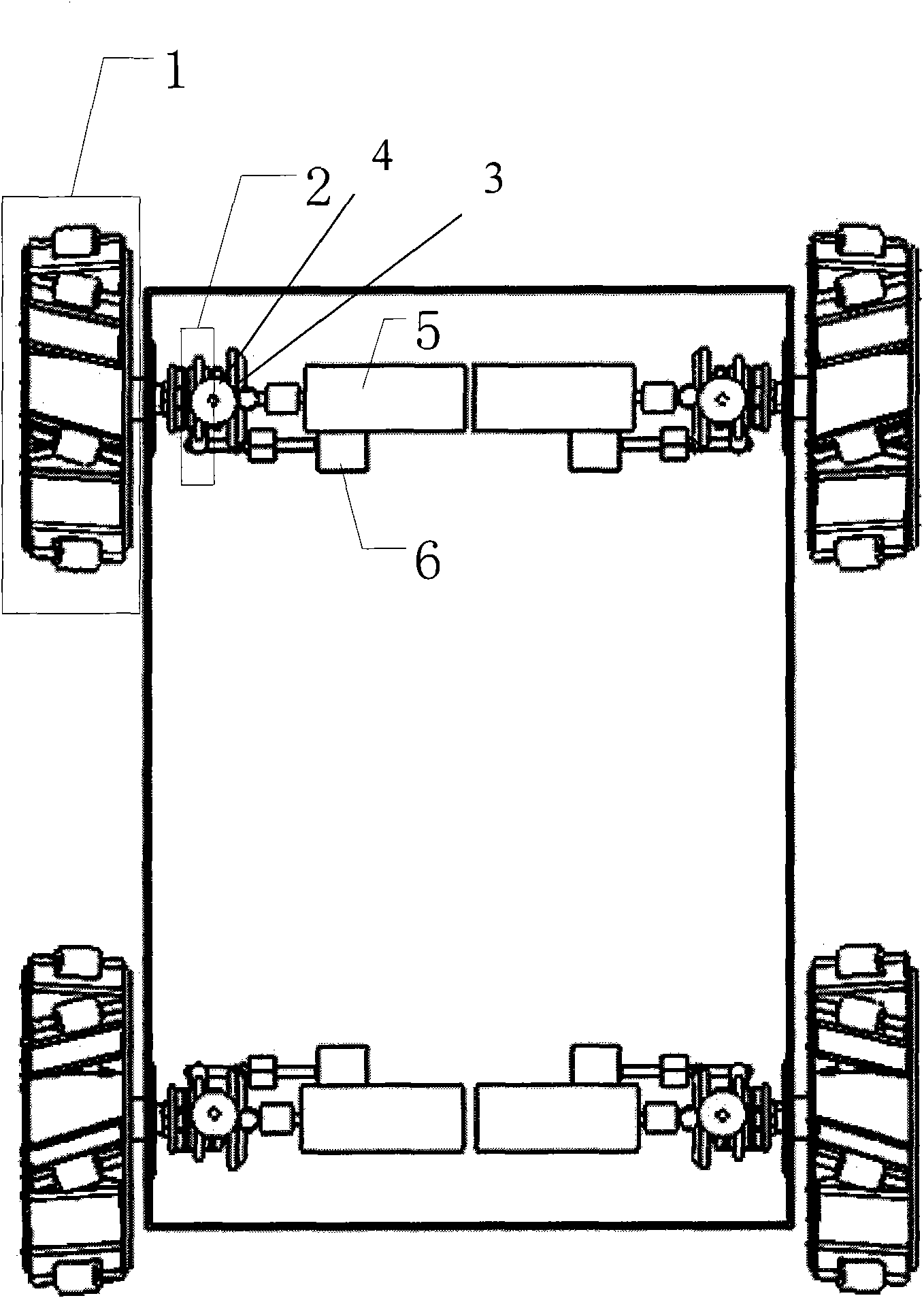

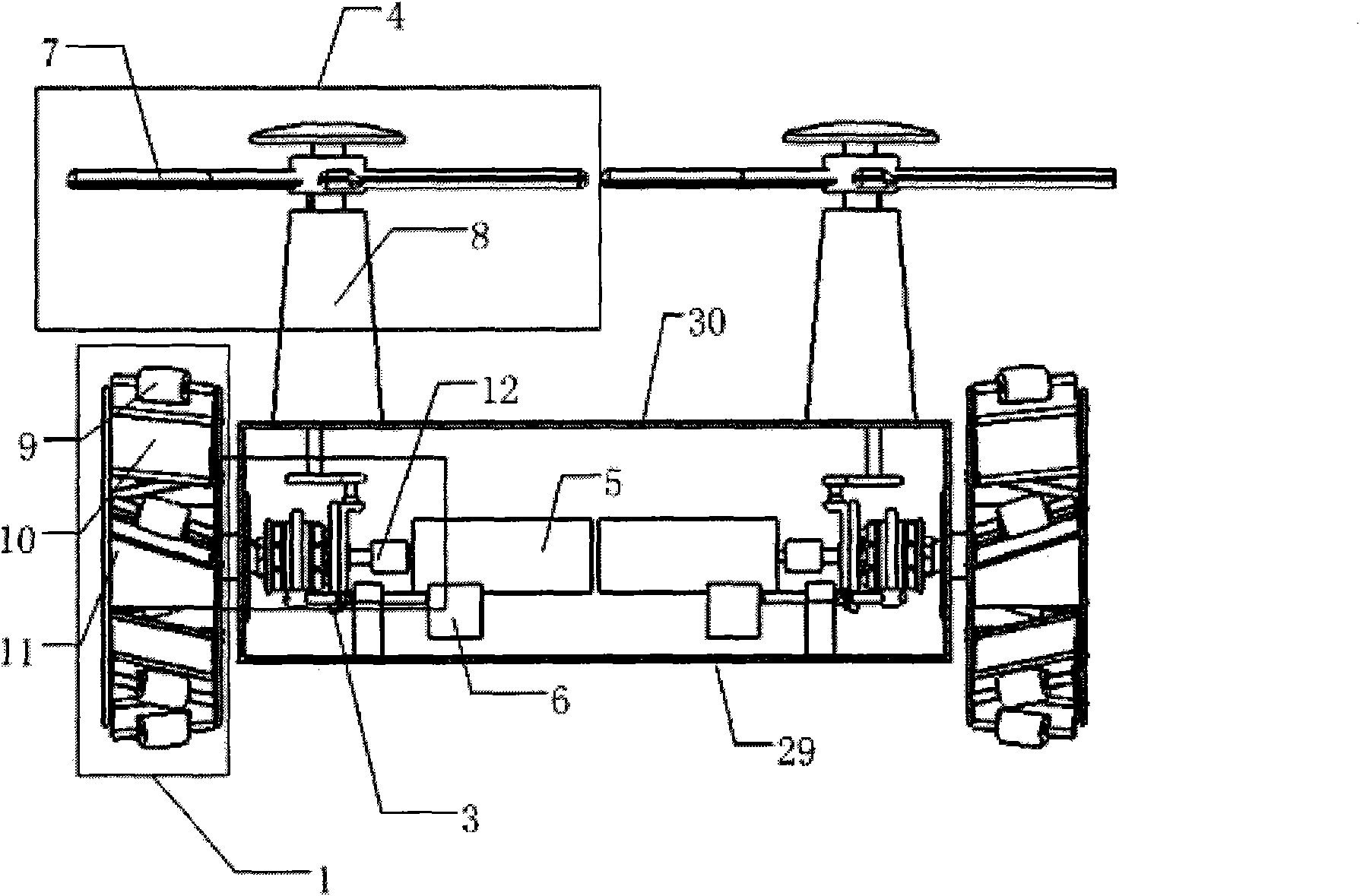

Triphibian omnibearing moving mechanism

The invention relates to a triphibian omnibearing moving mechanism, and belongs to the technical field of moving robot engineering. The triphibian omnibearing moving mechanism comprises a box body, four groups of wheel trains and driving mechanisms arranged relative to each wheel train, wherein each driving mechanism comprises a motor, a transmission mechanism and a clutch mechanism which are arranged in the box body and a helicopter rotor mechanism arranged at the top end of the box body; the motor is connected with the transmission mechanism; the output end of the transmission mechanism is respectively connected with the wheel trains and the helicopter rotor mechanism; the clutch mechanism connected with an electromagnet is arranged on the transmission mechanism, and a power supply is connected to the electromagnet; and during operation, the clutch mechanism is matched with the wheel train connecting end of the transmission mechanism or the connecting end of the helicopter rotor mechanism. The triphibian omnibearing moving mechanism has the strong adaptability. Different forms of power output is selected correspondingly according to different environments in which the triphibian omnibearing moving mechanism is positioned in the using process, so that the mechanism can adapt to the wider environment and can be used within the larger range. By the triphibian omnibearing moving mechanism, motion output can be converted into air from ground and water surfaces or converted into the ground and the water surfaces from the air conveniently through regulation.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

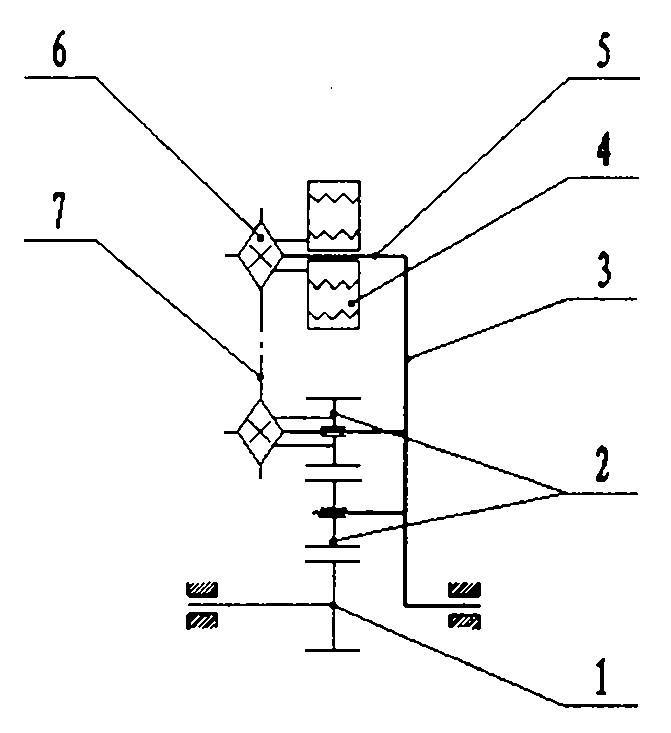

Wheel rail vibration electricity generating and energy storing system

ActiveCN104863810ASimple structureEasy to installBatteries circuit arrangementsMachines/enginesElectricityEngineering

The invention provides a wheel rail electricity generating and energy storing system adopting rack and gear transmission. In order to achieve the purpose, the wheel rail vibration electricity generating and energy storing system comprises a clamping structure, a rack, a wheel train structure, a generator, a storage device and a bottom plate. The wheel rail vibration electricity generating and energy storing system is characterized in that the clamping structure clamp the lower portion of a wheel rail, the rack is fixedly connected to the clamping structure, the rack is meshed with the wheel train structure, a one-way transmission selection device is arranged in the wheel train structure, an output shaft of the wheel train is connected with the generator, the generator is electrically connected with a storage device, and the system is fixed to a bottom plate.

Owner:苏州市振渭城镇建设发展有限公司

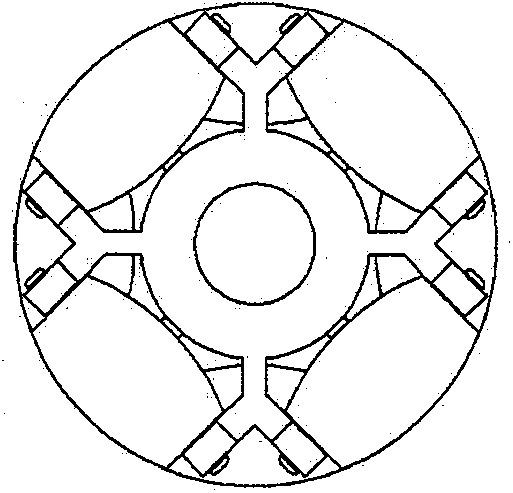

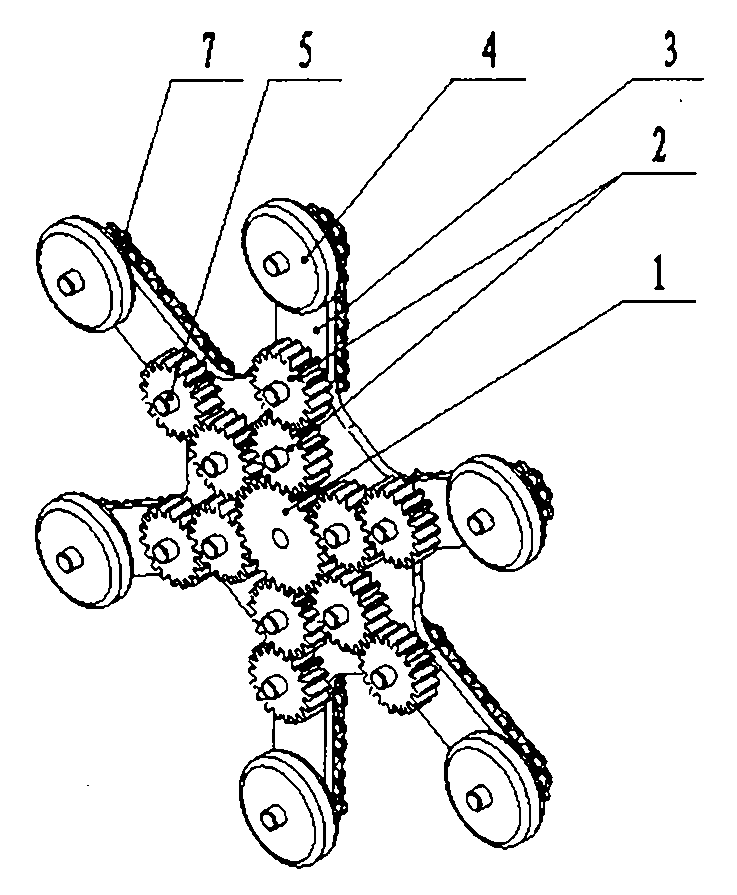

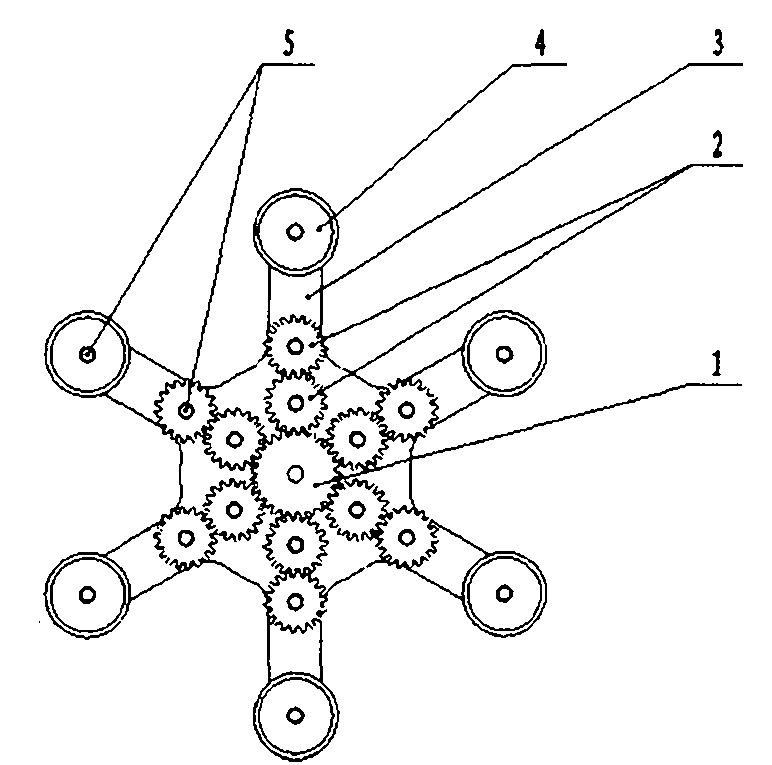

Planetary multi-wheel carrier

InactiveCN103587566ACompact structureEfficient actionWheelsHand cart accessoriesEngineeringObstacle crossing

The invention discloses a planetary multi-wheel carrier which can be used as a wheel of a ladder climbing wheel, a stair climbing wheelchair or an obstacle crossing vehicle and structurally comprises a sun wheel 1, planet wheels 2, a wheel carrier 3 (a polygonal planetary carrier), small wheels 4, hinge pin assemblies 5, chain wheels 6 and chains 7. A polygonal star-shaped plate is drilled to form the wheel carrier which is also known as the polygonal planetary carrier. The small wheels can be common one-way wheels or universal wheels. A planetary three-wheel carrier, a planetary four-wheel carrier, a planetary five-wheel carrier and a planetary six-wheel carrier are essentially characterized by comprising planetary wheel trains and multi-wheel carriers and belong to the same invention concept, and accordingly patents of the planetary three-wheel carrier, the planetary four-wheel carrier, the planetary five-wheel carrier and the planetary six-wheel carrier are applied simultaneously. Abstract drawings of the planetary six-wheel carrier are shown. A principle includes that when the planetary multi-wheel carrier runs flatly, the planet wheels and the small wheels rotate; when the planetary multi-wheel carrier climbs a ladder, the small wheels rotate at first and reach positions close to a step, and then the wheel carrier revolves; when the planetary multi-wheel carrier descends from a stair, the small wheels rotate until one of he small wheels is suspended, and the wheel carrier revolves, and then continues to revolve after the suspended small wheel is landed. The planetary multi-wheel carrier has the advantages that revolution of the wheel carrier and rotation of the one-wheel wheels can be automatically switched over, so that flat running, ladder climbing and stair descending actions can be smoothly carried out.

Owner:李军委

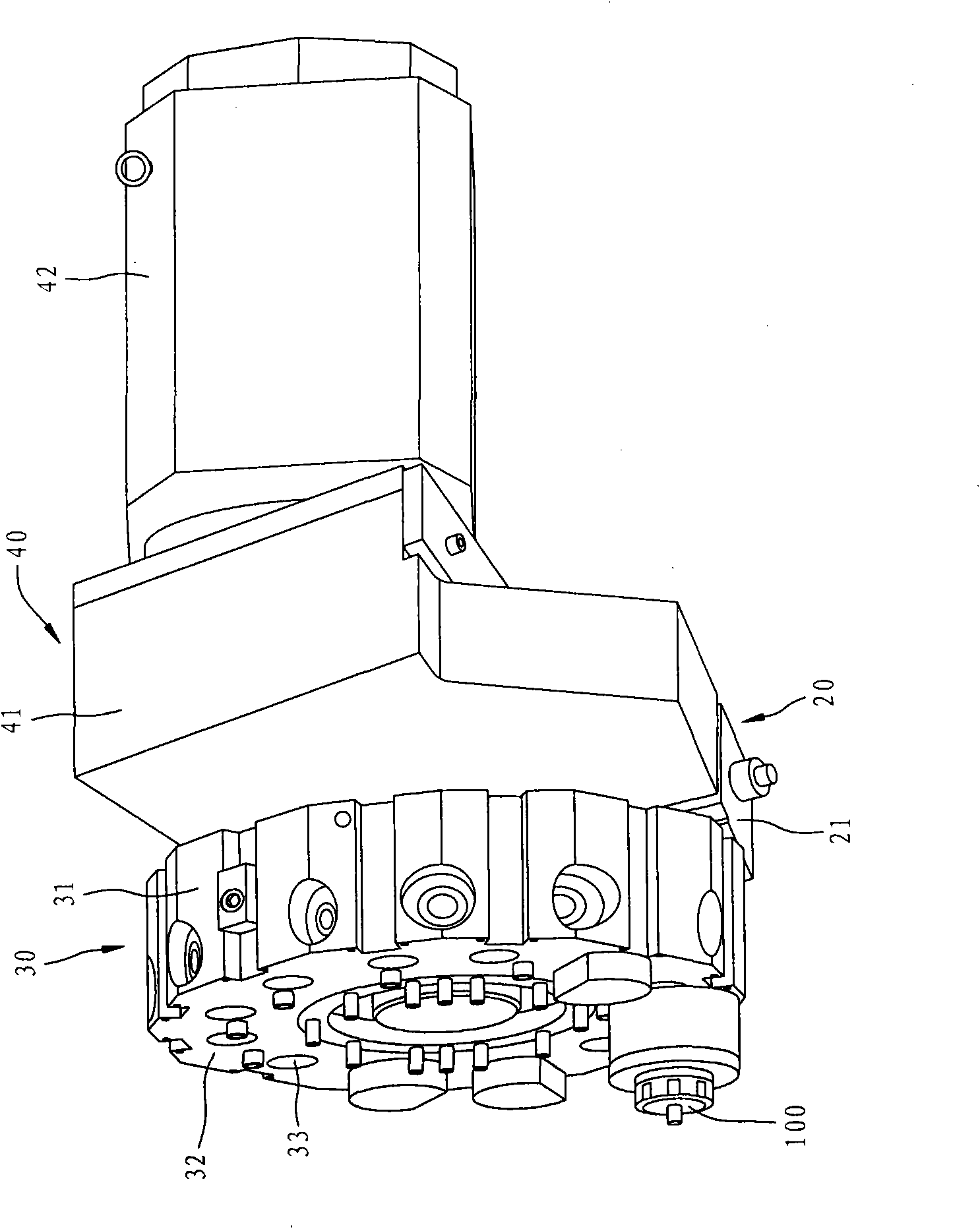

Multifunctional composite power cutter tower of computer numerically controlled lathe

InactiveCN101537503AIncreased torque outputEnhance the outstanding effectTool holdersDrive wheelEngineering

The invention relates to a multifunctional composite power cutter tower of a computer numerically controlled lathe, which comprises a group of pedestal unit, a group of cutter head unit and a group of power transmission unit; the cutter head unit is provided with a cutter with rotary cutting function; the power transmission unit is provided with a shell seat arranged outside the pedestal unit, a motor arranged on the shell seat, a driving wheel arranged inside the shell seat to rotate by the driving of the motor, and a driven wheel arranged inside the shell seat to transmit by the driving of the driving wheel at predetermined reduction ratio; and the driven wheel finally drives the cutter to work so that the cutter can cut with large torque output. In the multifunctional composite power cutter tower, the outside of the pedestal unit is provided with the shell seat, and the driving wheel and the driven wheel are provided to achieve the speed reduction effect by a complex wheel train, so the cutter obtains high torque power output to successfully carry out various rotary cutting operations.

Owner:ALEX TECH MACHINERY INDAL

Trimming machine

ActiveCN103252423AImprove folding efficiencyAvoid poor sealsHeat exchange apparatusFlangeWheel train

The invention provides a trimming machine and belongs to the field of press working. The trimming machine is designed to solve the problem in the prior art that edge folding efficiency is low and a sealing effect of a flange is poor by means of manual edge folding. The trimming machine comprises a casing. A trimming groove is arranged on one side of the casing, at least one trimming mechanism is arranged in the horizontal direction in the trimming groove, and a trimming mechanism is formed by a first trimming wheel train, a second trimming wheel train and a third trimming wheel train which are arranged at intervals sequentially. Trimming channels are arranged at corresponding positions of a first upper press wheel and a first rolling portion, of a second upper press wheel and a second rolling portion and of a horizontal rotating wheel and a first rotating rod at intervals.

Owner:北京环都拓普空调有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com