Mechanical arm multi-station belt sander

A technology of abrasive belt polishing and manipulators, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problems of unstable polishing quality of the workpiece surface, unfavorable standardized management of the production process, and low production efficiency, etc. problems, to achieve the effect of eliminating the dependence on workers' polishing experience, improving production efficiency and economic benefits, and improving the level of enterprise management and informationization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

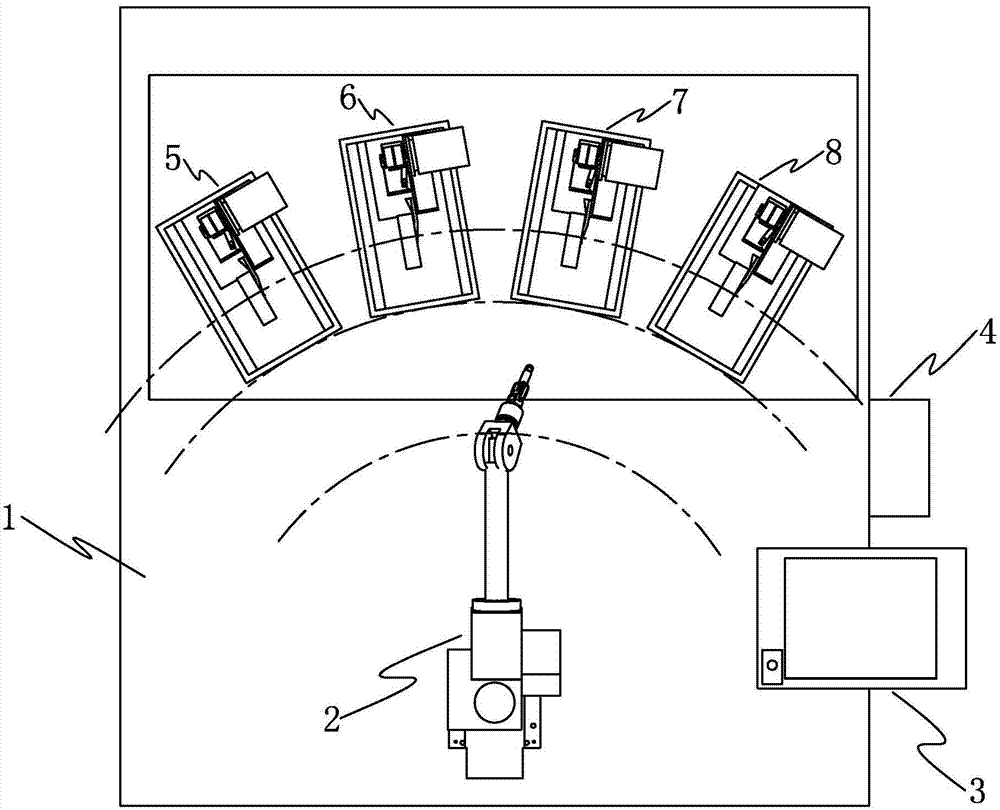

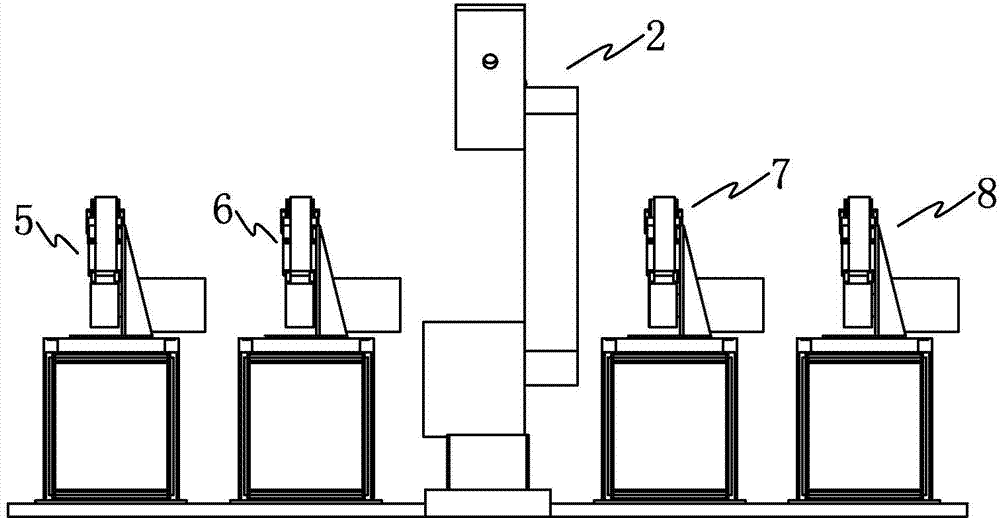

[0033] Such as figure 1 , 2 As shown, a manipulator multi-station abrasive belt polishing machine of the present invention includes a base 1, a manipulator 2 clamping a workpiece, an abrasive belt wheel train, an automatic feeding mechanism 3, and an electric control system 4.

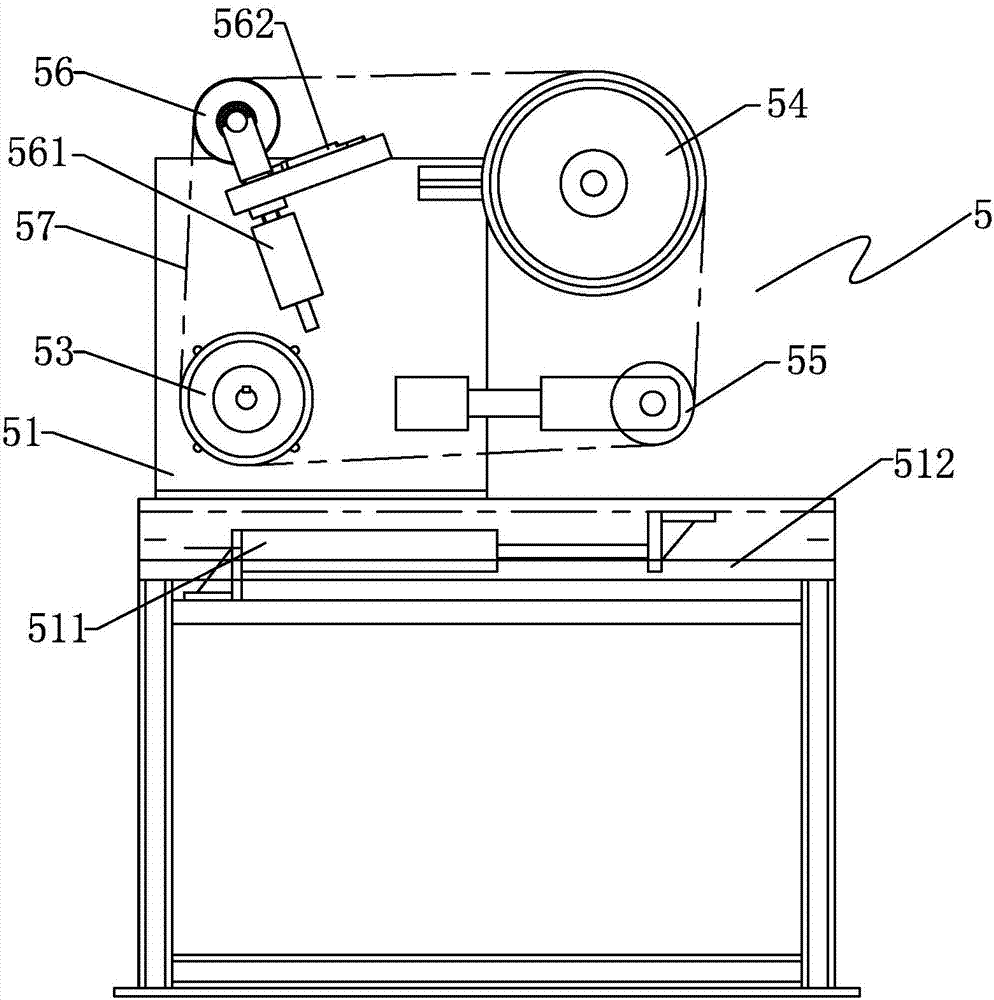

[0034] Wherein, the above-mentioned abrasive belt wheel system is a multi-station abrasive belt wheel system, including a wide coarse abrasive belt wheel system 5, a narrow coarse abrasive belt wheel system 6, a wide fine abrasive belt wheel system 7 and a narrow fine abrasive belt wheel system 8, The above-mentioned abrasive belt wheel systems 5-8 are arranged in an arc shape, and each abrasive belt wheel system includes a sliding seat, a driving wheel, a contact wheel and a tension wheel arranged on the sliding seat, and surrounding the above-mentioned driving wheel and Abrasive belt that contacts the surface of the pulley and tensioner pulley.

[0035] Such as image 3 , 4 As shown, the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com