Patents

Literature

9757results about "Grinding feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

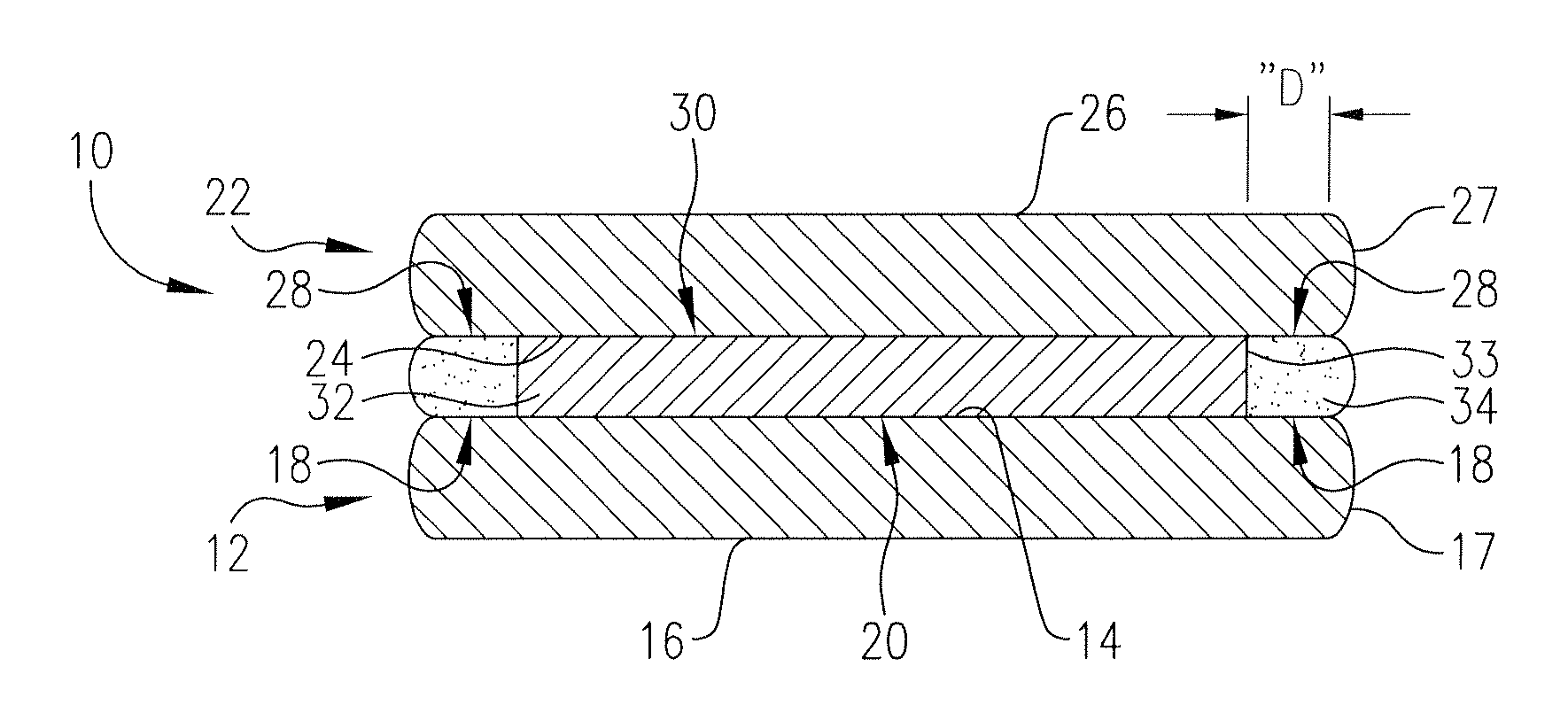

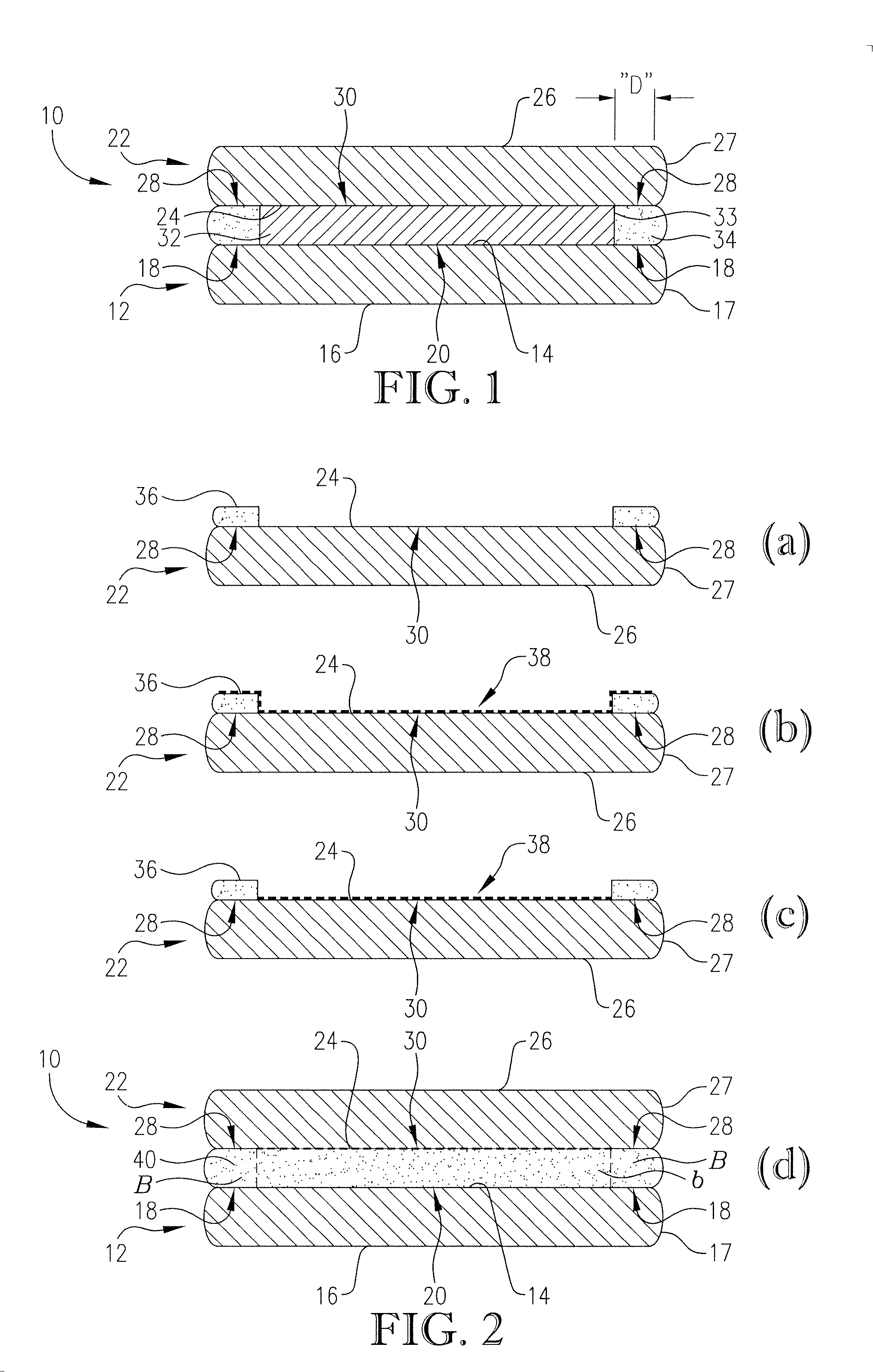

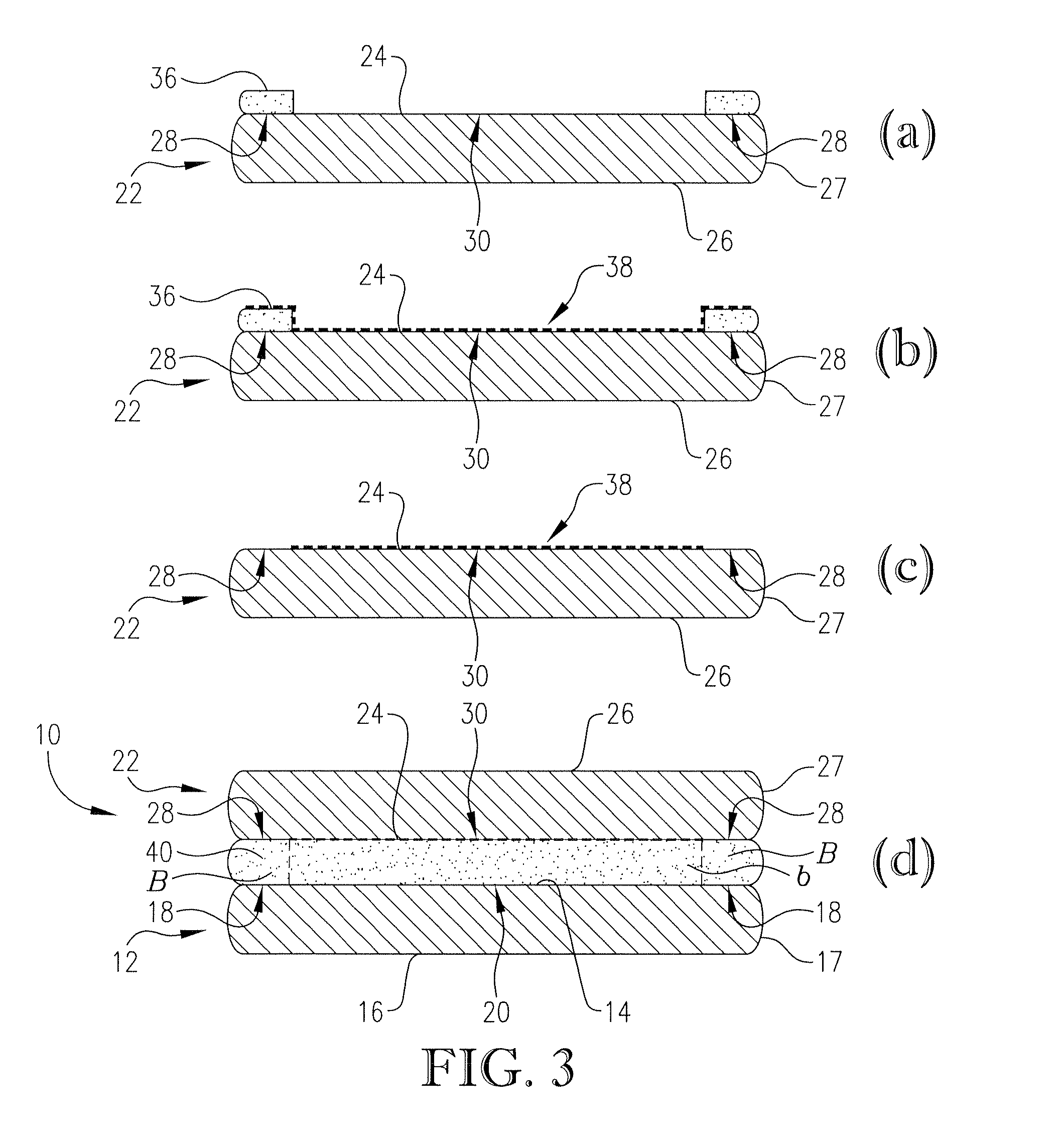

Method and apparatus for removing a reversibly mounted device wafer from a carrier substrate

ActiveUS20110308739A1Solid-state devicesSemiconductor/solid-state device manufacturingWaferingEngineering

New demounting methods and apparatuses for separating temporarily, permanently, or semi-permanently bonded substrates and articles formed from those methods and apparatuses are provided. The methods comprise demounting a device wafer from a carrier wafer or substrate that have only been strongly bonded at their outer perimeters. The edge bonds are chemically, mechanically, acoustically, or thermally softened, dissolved, or disrupted to allow the wafers to be easily separated with very low forces and at or near room temperature at the appropriate stage in the fabrication process. A clamp for facilitating separation of the bonded substrates is also provided.

Owner:BREWER SCI

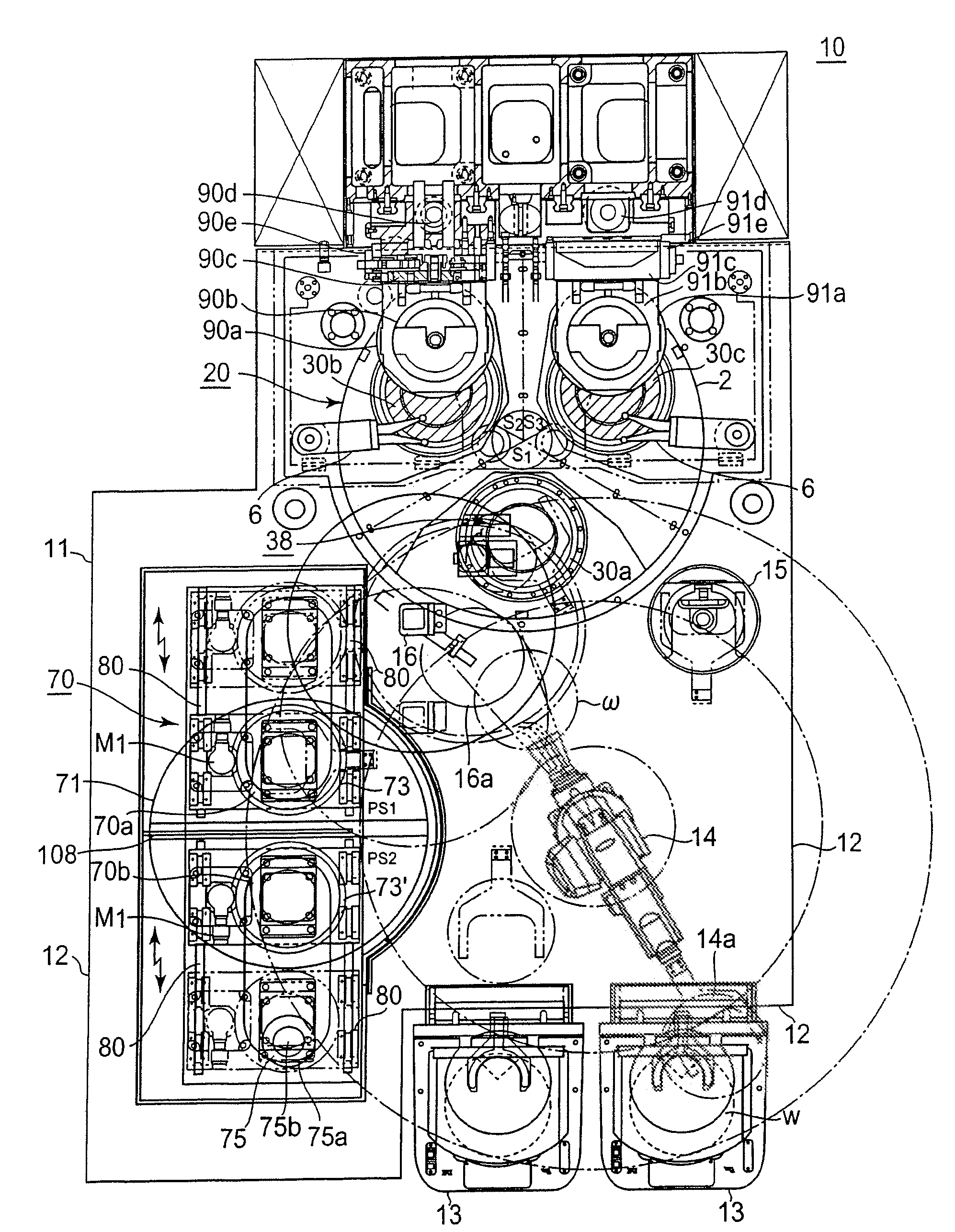

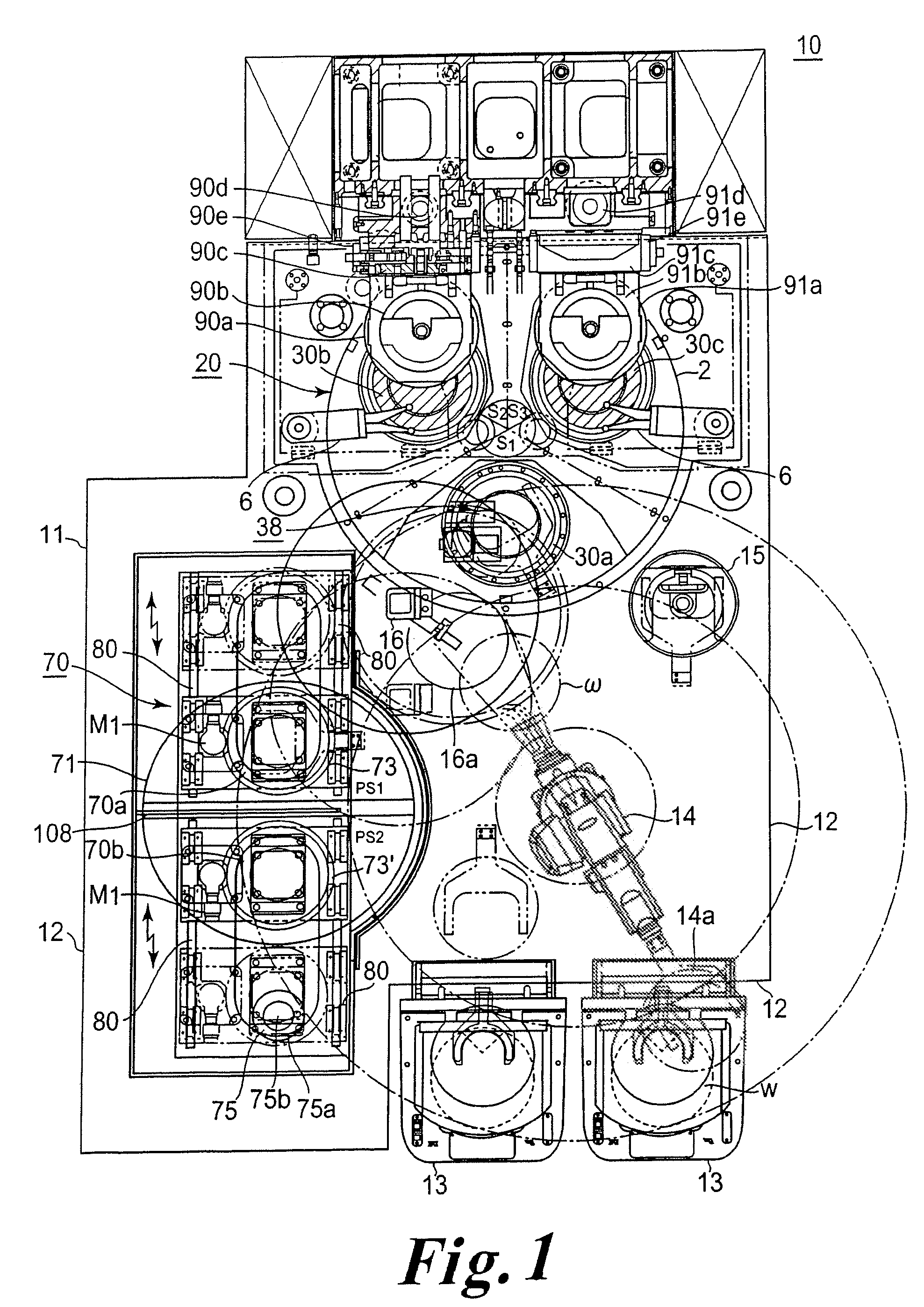

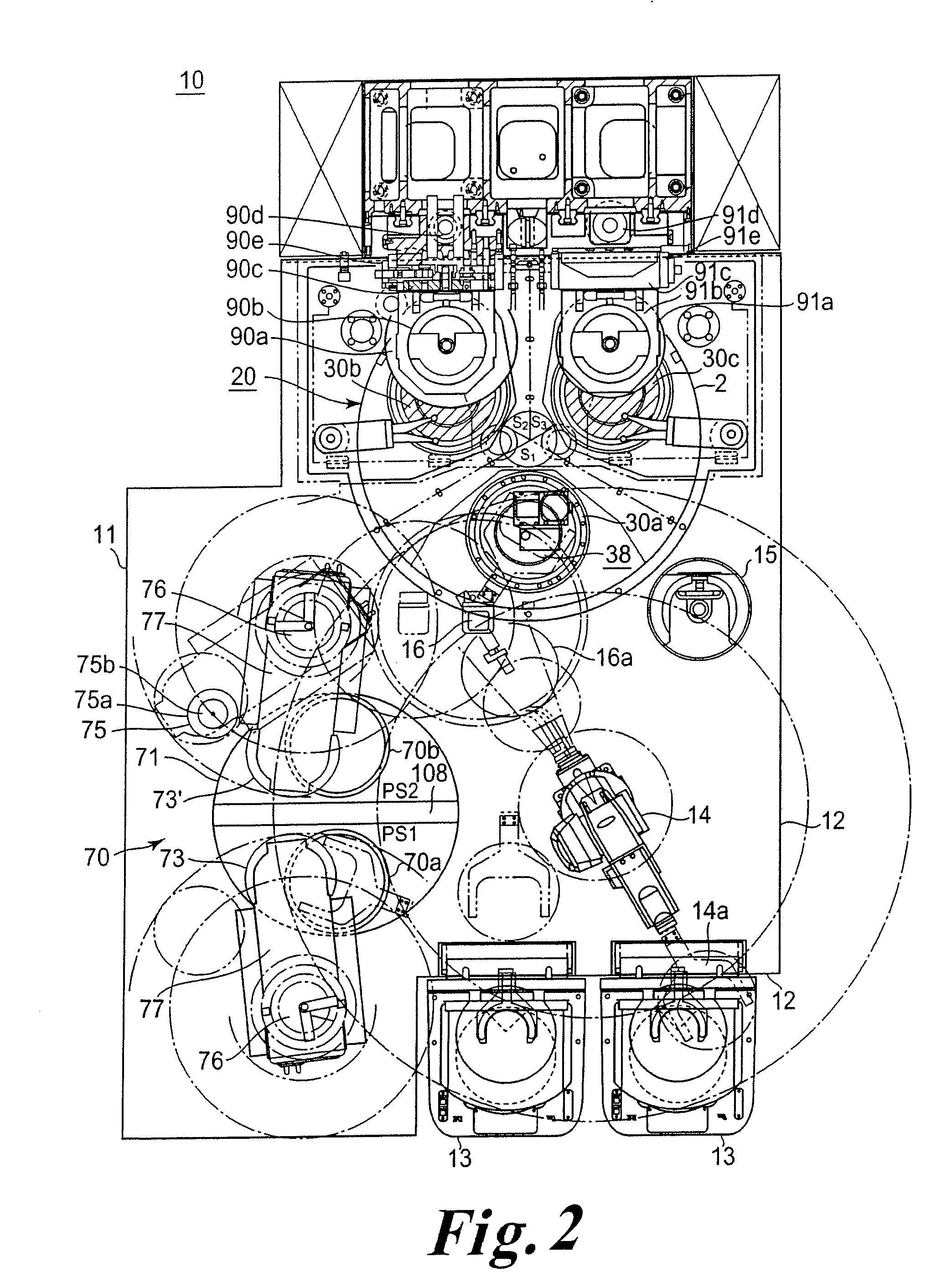

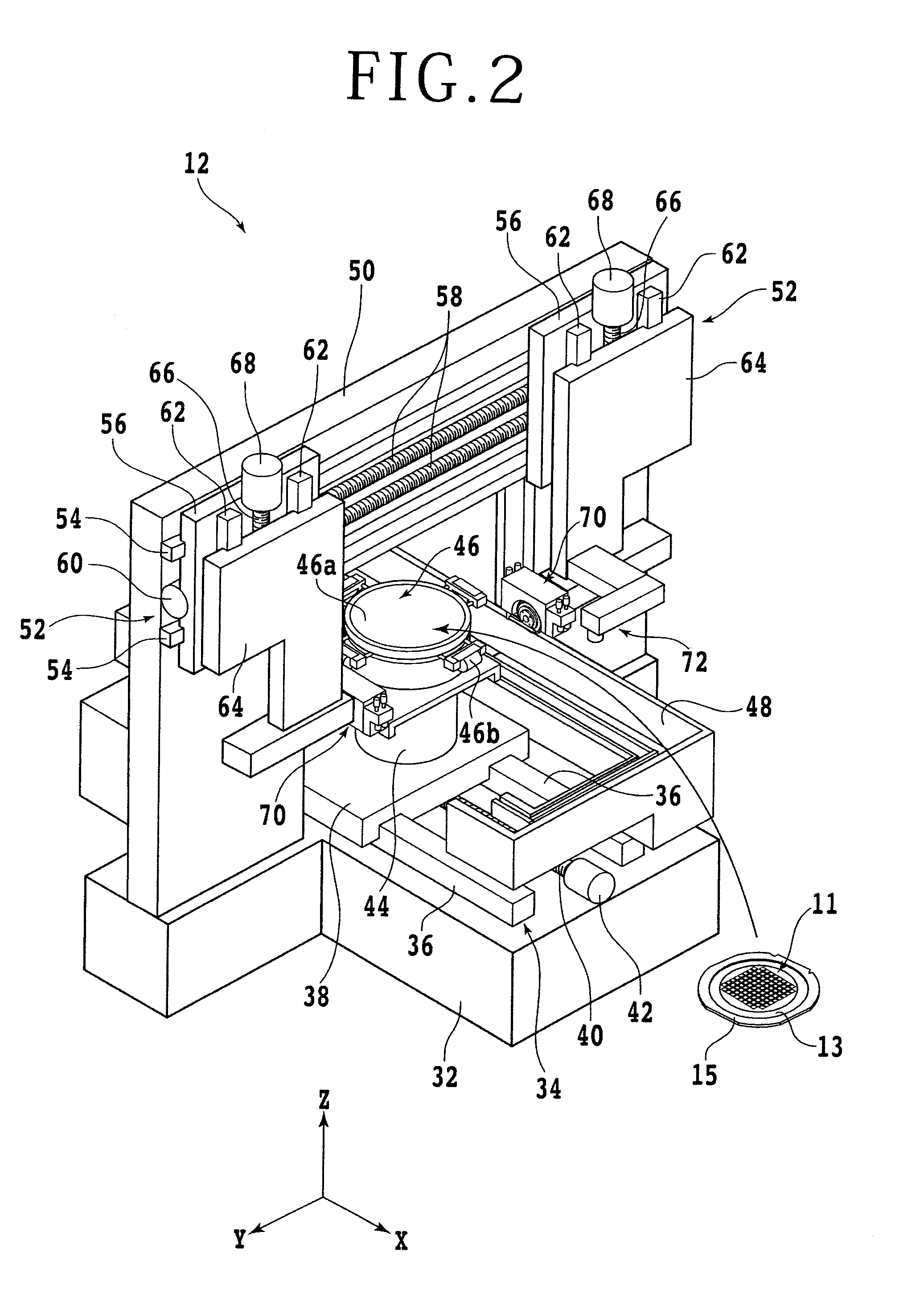

Planarizing device and a planarization method for semiconductor substrates

A substrate-planarizing device and method of using the device comprising a substrate storage stage outside a room, and on a base inside the room, a multi-joint transfer robot, a temporary alignment platform, a movable transfer pad, a grinding process stage in which substrate holders that compose three stages of a substrate loading / unloading stage, a rough grinding stage, a finish grinding stage are arranged in a concentric pattern on the first index rotary table, and a polishing process stage that has a substrate holder table composing a substrate loading / unloading / finish polishing stage as well as a substrate holder table composing a rough polishing stage arranged in a concentric pattern on the second index rotary table.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

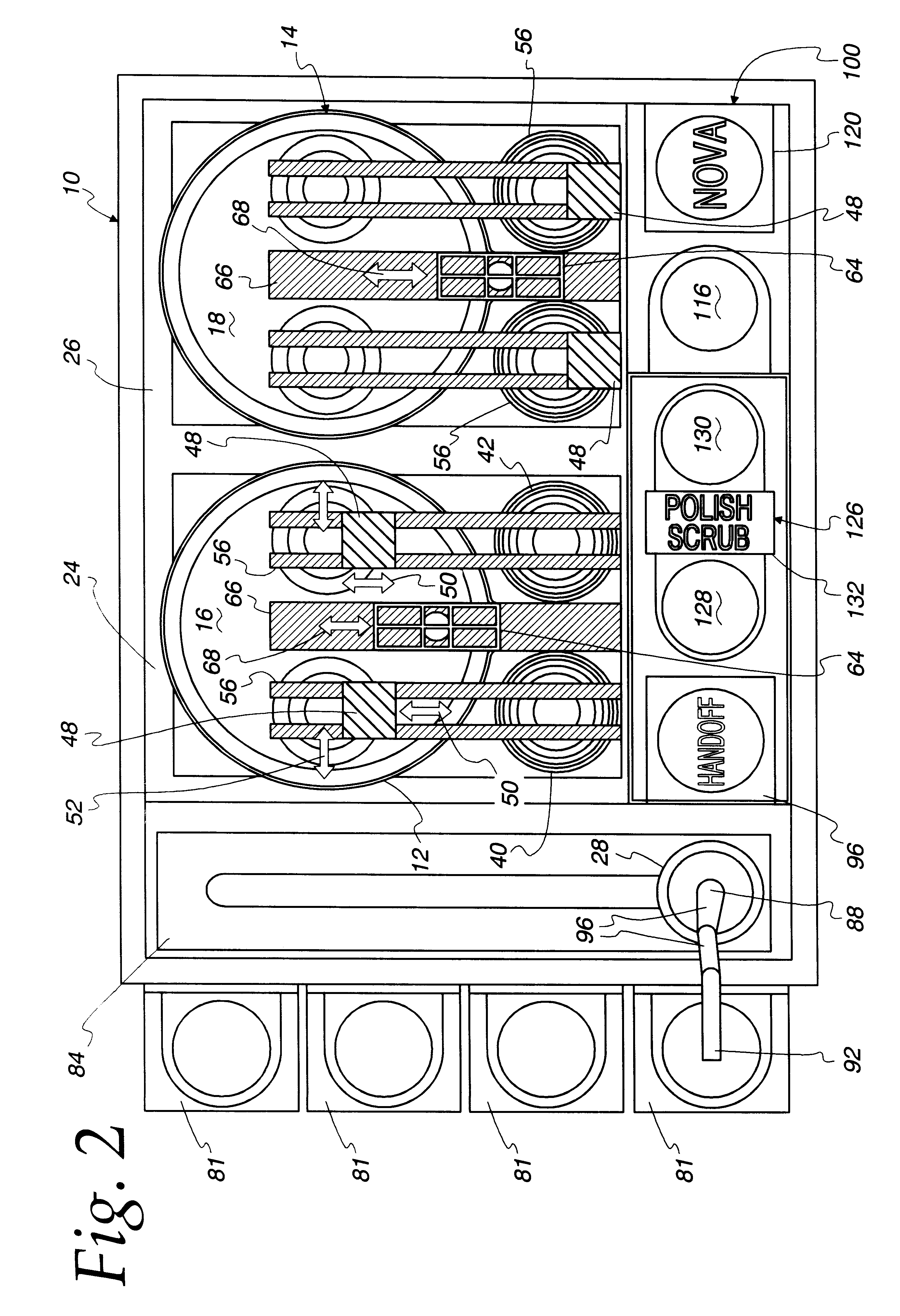

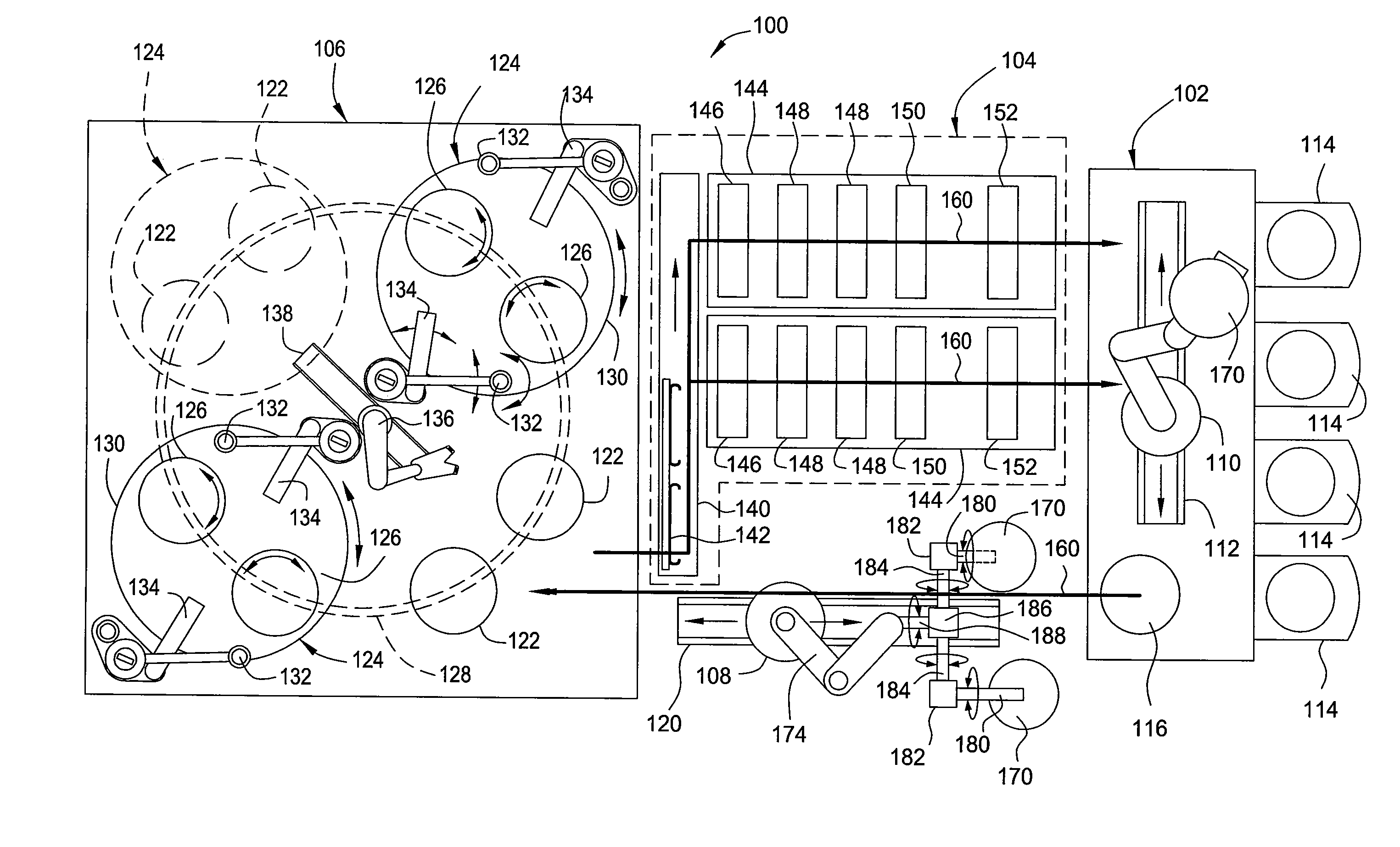

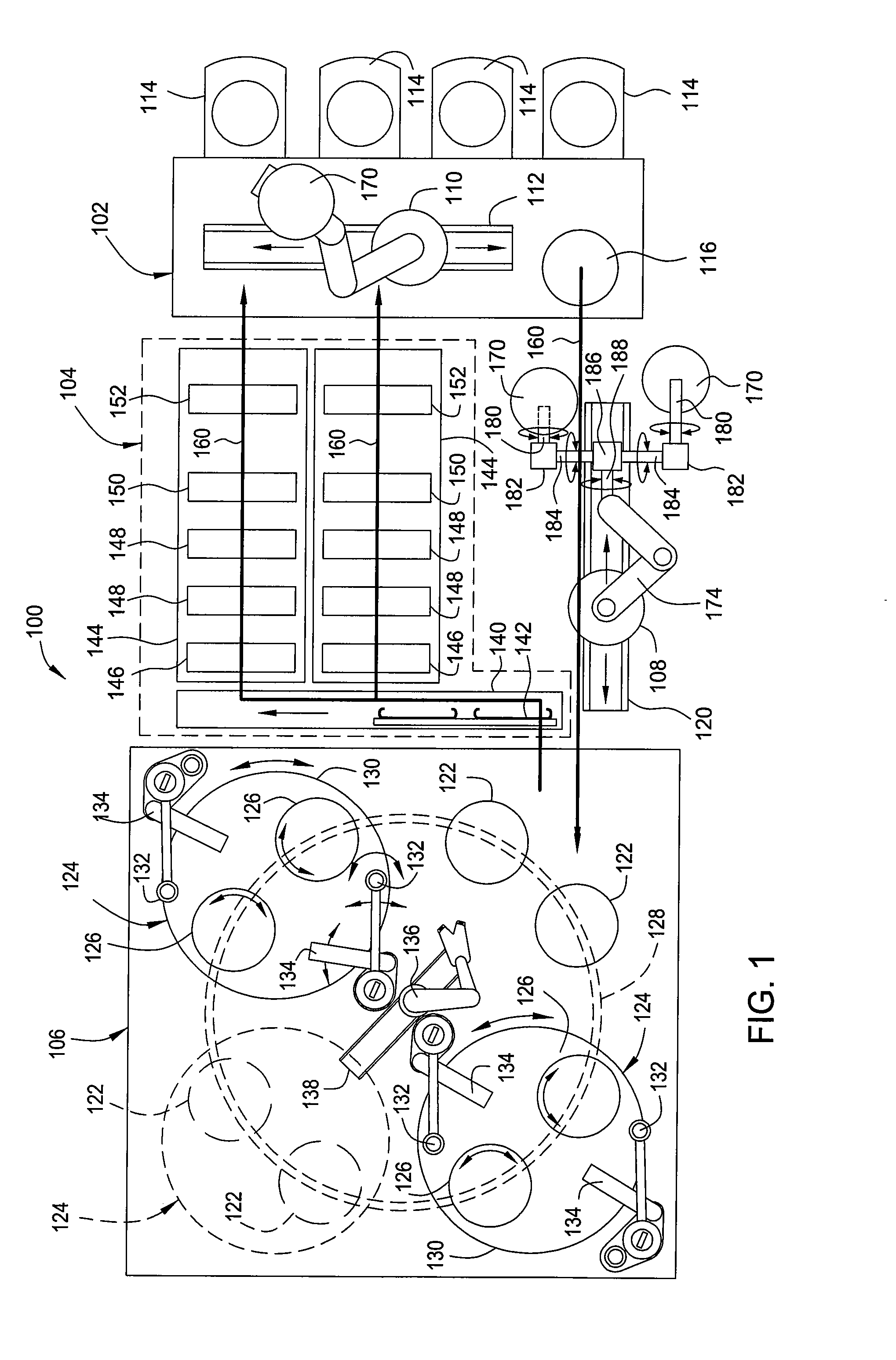

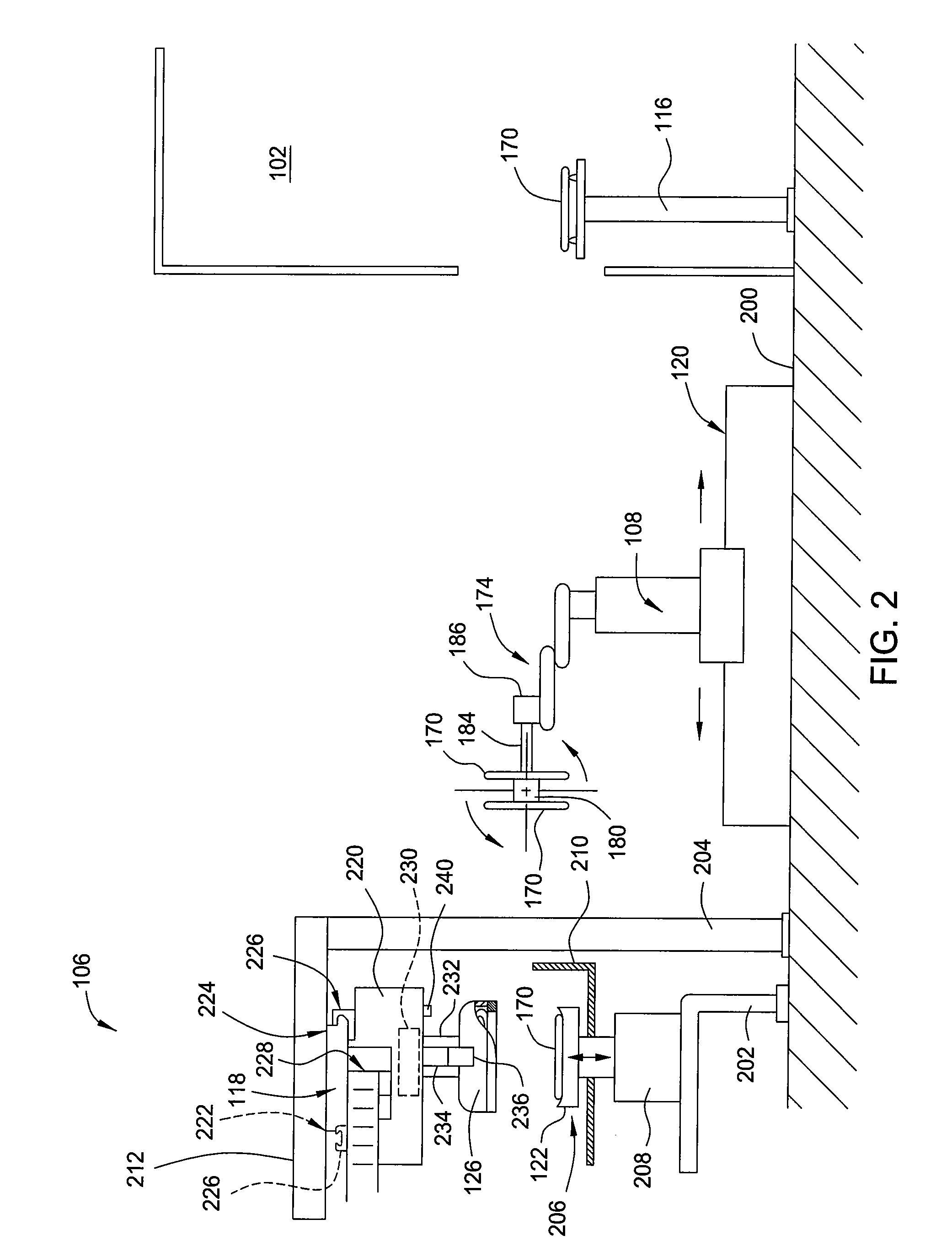

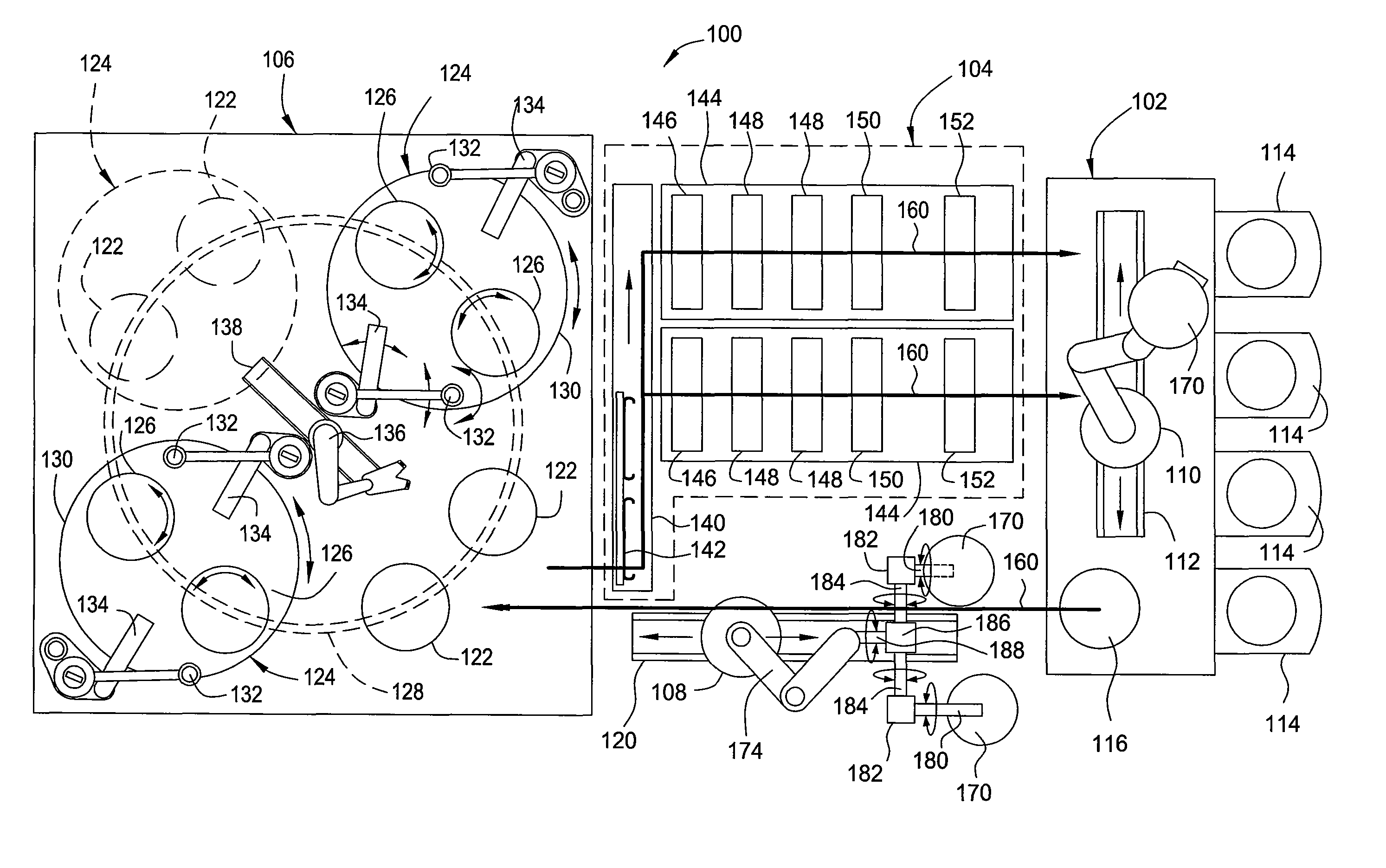

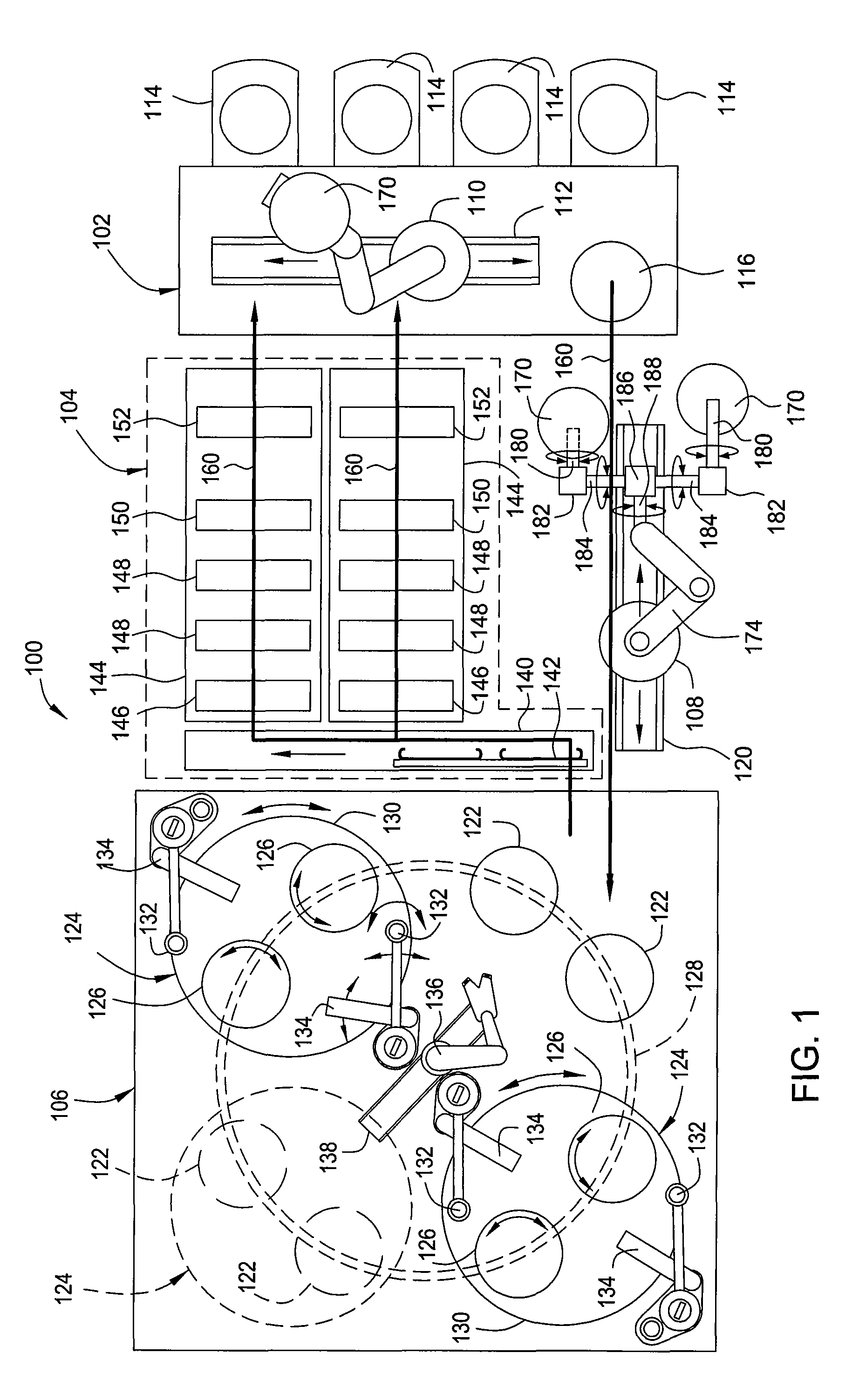

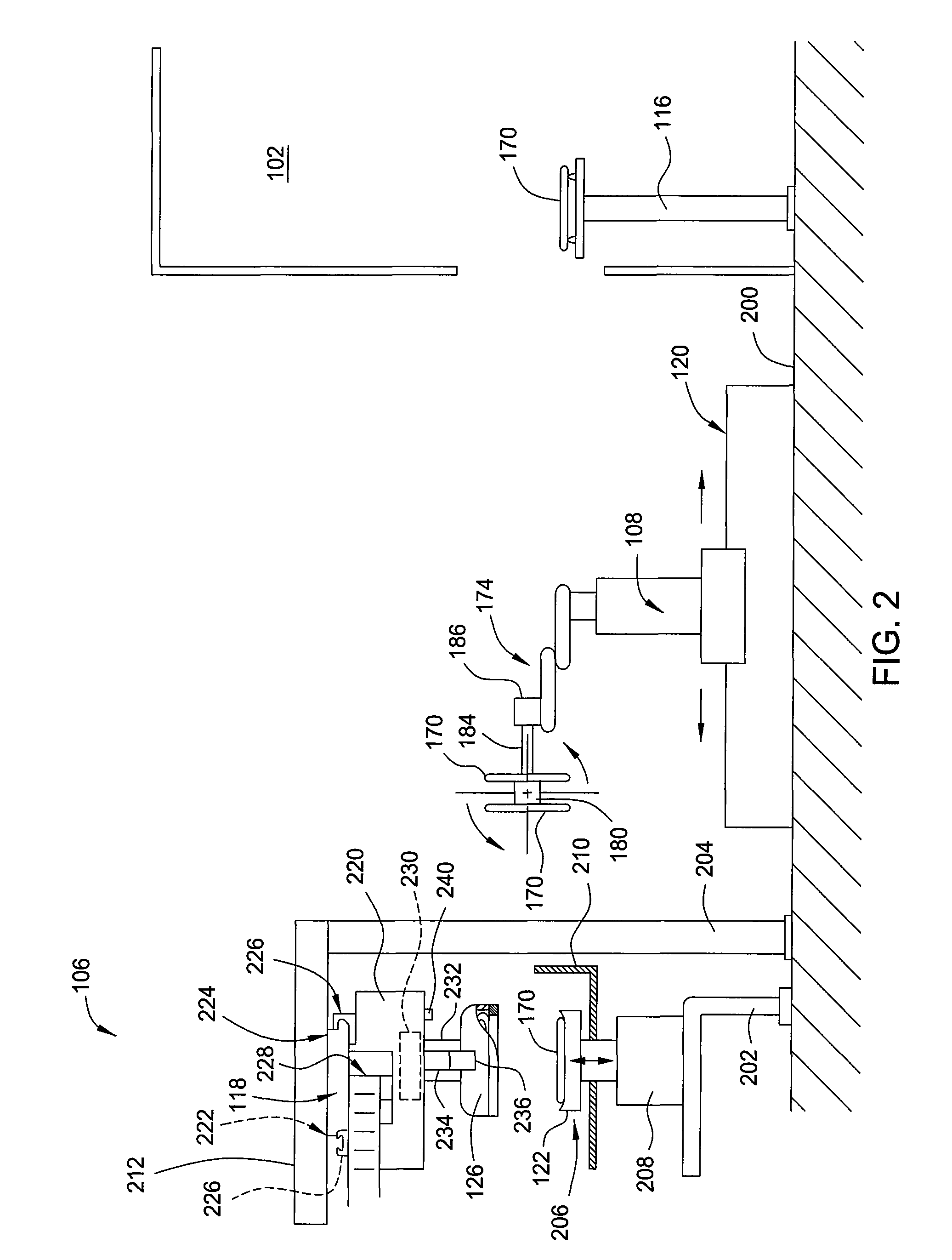

Arrangements for wafer polishing

InactiveUS6309279B1Intensive useImprove operational flexibilityEdge grinding machinesPolishing machinesComputer moduleEngineering

Wafer polishing systems include a series of polish modules alongside a neighboring series of secondary modules. A conveyor travels along the series of polish modules and the series of secondary modules. When a polishing operation is completed, the wafers are transferred to a series of near-by storage modules. The polish modules include a pair of traveling wafer gantries, each of which delivers a wafer to a polishing surface, applying the necessary force to complete polishing of the wafer surface.

Owner:NOVELLUS SYSTEMS

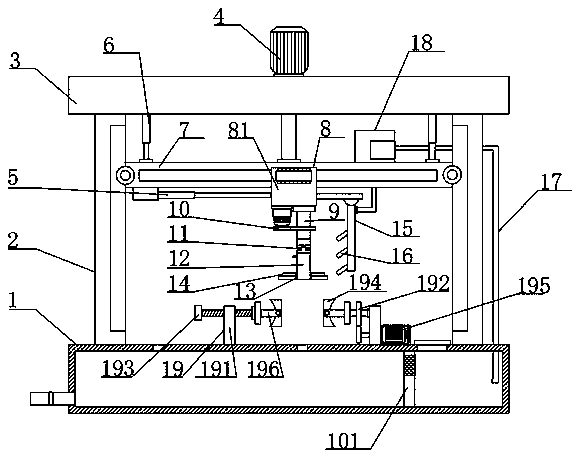

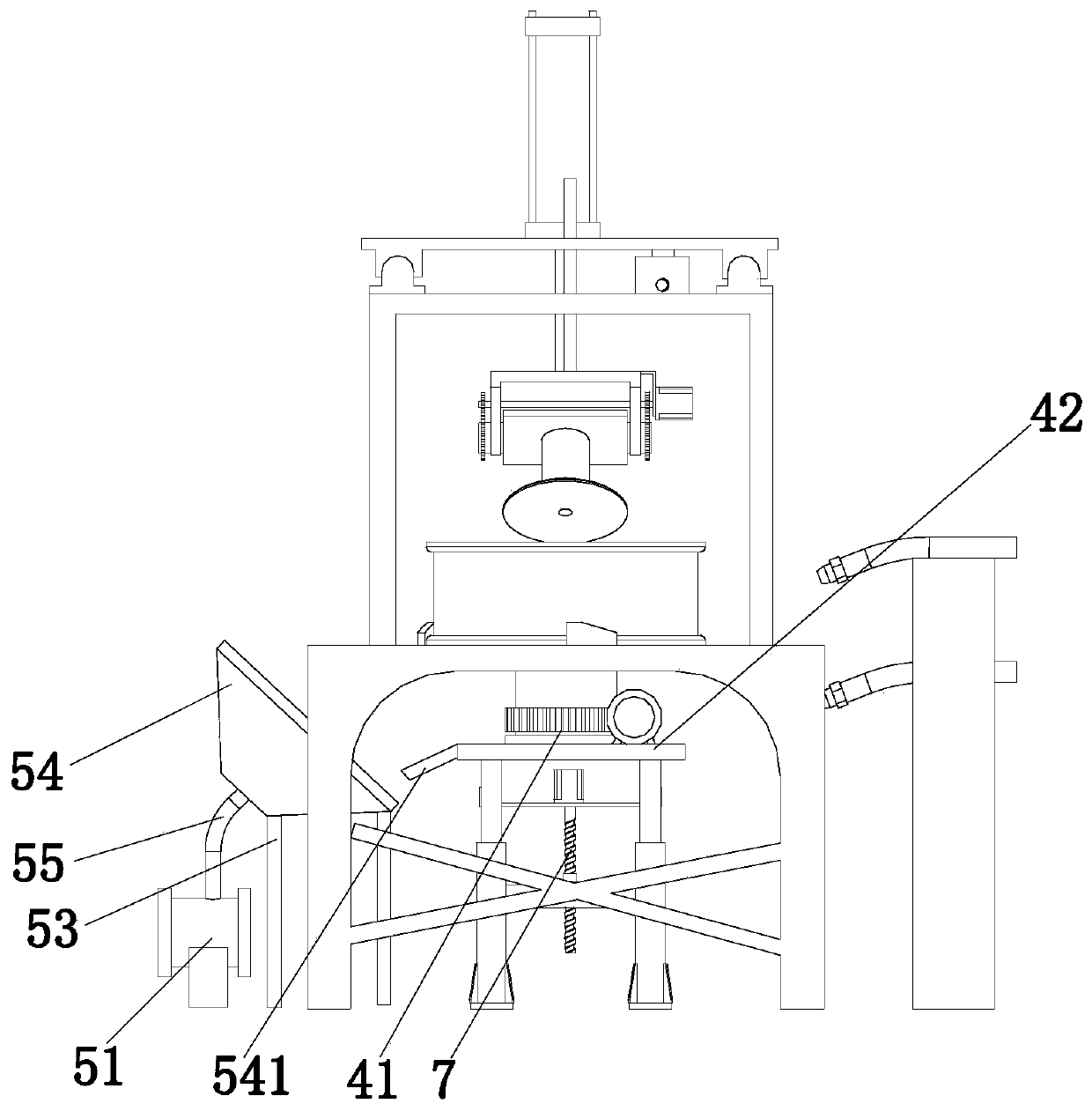

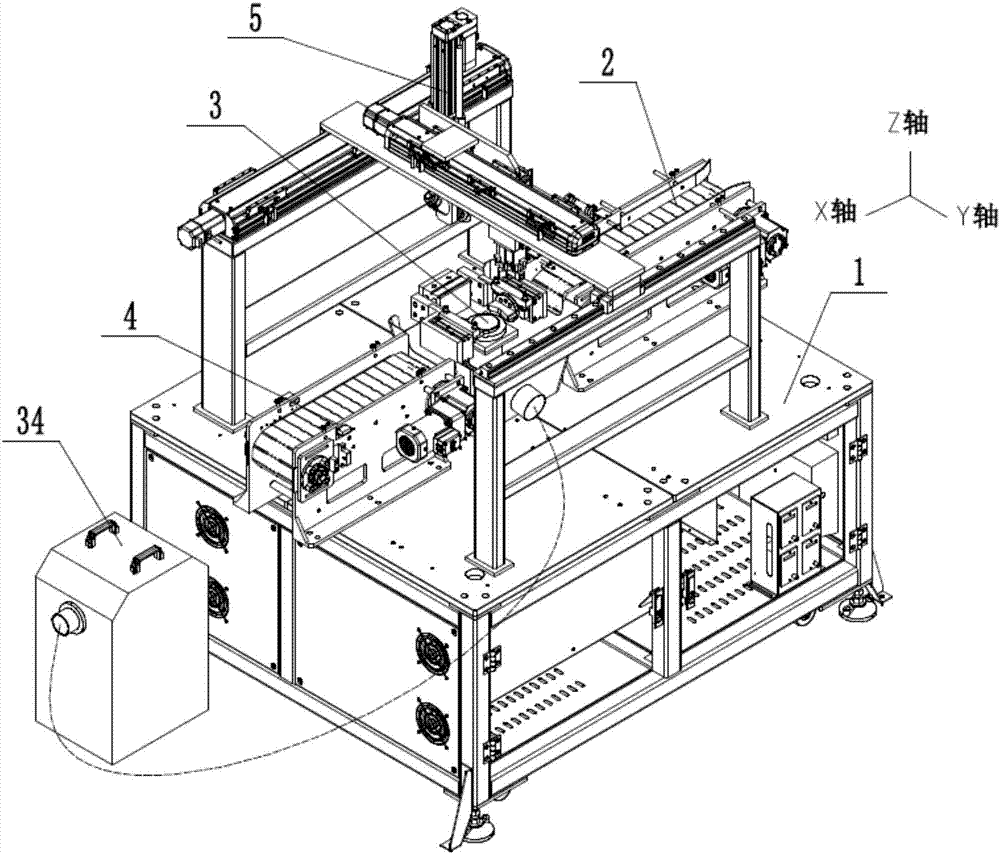

Automatic grinding machine for industrial machinery and grinding method

InactiveCN108789087AIncrease flexibilityImprove stabilityGrinding carriagesGrinding drivesHydraulic cylinderCoupling

The invention discloses an automatic grinding machine for industrial machinery and a grinding method. The automatic grinding machine comprises a base box body, wherein left and right sides of the topof the base box body are symmetrically equipped with stand columns; a top plate is arranged on the tops of the two groups of the stand columns; the outer wall of a bearing rod is movably equipped witha slide assembly; the bottom of the slide assembly is sequentially equipped with a grinding motor and a rotary rod from left to right; the bottom of the rotary rod is equipped with a universal shaftcoupler; the top of the base box body is equipped with a fixed clamp; and the right side of the top of the base bottom box is spliced with a water conveying hose I. The grinding machine for industrialmachinery is high in flexibility and is good in stability; a hydraulic cylinder drives the bearing rod to lift through a pushing rod, so that a grinding disc in grinding can lift; and an electric telescopic pole extends and shortens to drive the slide assembly to move left and right, so that the grinding disc in grinding can move left and right, and therefore, the automatic grinding machine has relatively high flexibility, and improves grinding working efficiency.

Owner:CHENGDU PUJIANG KEXIAN TECH

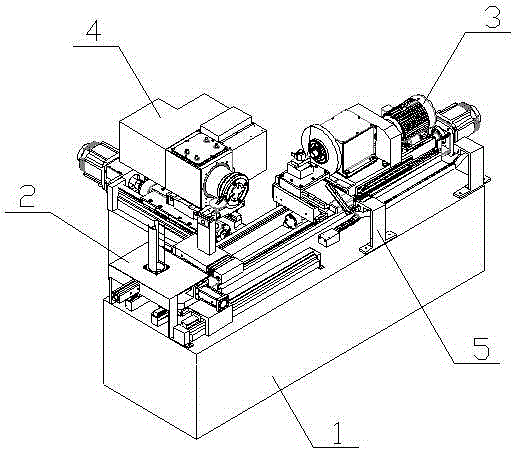

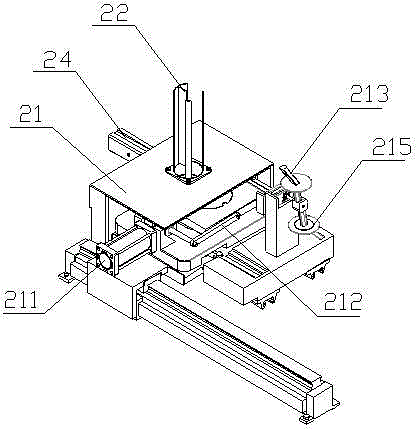

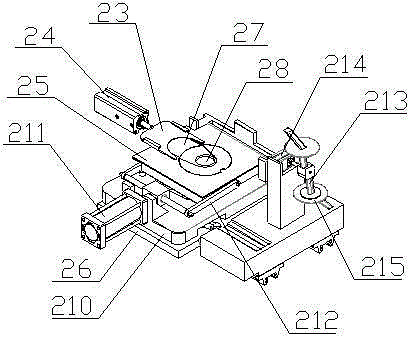

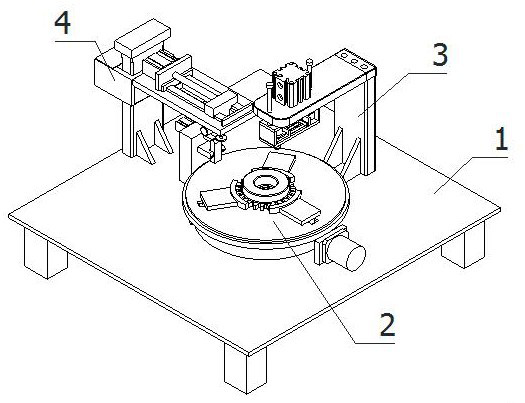

Full automatic grinding machine for piston ring inclined end surface

InactiveCN105171427AExtend your lifeReduce grindingFeeding apparatusOther manufacturing equipments/toolsPiston ringEngineering

The invention discloses a full automatic grinding machine for a piston ring inclined end surface. The full automatic grinding machine comprises a machine bed, an automatic loading and unloading rack, a composite processing table, a power head rack, a material collection rack and two parallel guide rails which are arranged on the machine bed, wherein the automatic loading and unloading rack and the composite processing table are arranged on the two ends of the two guide rails, the power head rack and the material collection rack are arranged on the two sides of the two guide rails; the automatic loading and unloading rack comprises a material storage rack, a material delivering slide table and a material delivering cylinder, the composite processing table comprises a processing slide table and a slide table displacement servo motor; the power head rack comprises a shell, a hollow axle pipe is arranged in the shell, an electromagnetic chuck and a positioning disk are sleeved on one end of the axle pipe near to the guide rail, and the material storage rack comprises a material storage rod, a guide rod and two inverted L-shaped connection racks. The piston ring inclined end surface is more simply processed, the processing precision is high and the processing efficiency is high.

Owner:CHONGQING UNIV OF TECH

Efficient rust-removing device for iron rod for hardware machining

ActiveCN106112769AReduce health hazardsNo health hazardRevolution surface grinding machinesDrying gas arrangementsReciprocating motionEngineering

The invention relates to an iron rod rust removing device, in particular to an efficient rust-removing device for an iron rod for hardware machining. In order to solve technical problems in the prior art, the efficient rust-removing device being small in size, high in cost performance, free of professional requirements and manpower, convenient, rapid, efficient, safe and reliable, and having the advantage that the damage of the operating environment to the health of operating personnel is relatively small is provided. The efficient rust-removing device comprises an L-shaped bracket, a motor, a first bearing seat, a supporting rod, a water tank, a first one-way valve, a first rotating shaft, a first belt wheel, a second bearing seat, a lead screw, a clamping device and the like, wherein the motor and several other components are arranged at the inner top of the L-shaped bracket from left to right. Friction blocks perform reciprocating motion up and down and matched with the rotating iron rod for rust removing, so that the efficient rust-removing device provided by the invention achieves the effects of being small in size, high in cost performance, simple to operate, free of professional requirements and manpower, convenient, rapid and efficient.

Owner:TANGSHAN JINSHI SUPER ABRASIVE

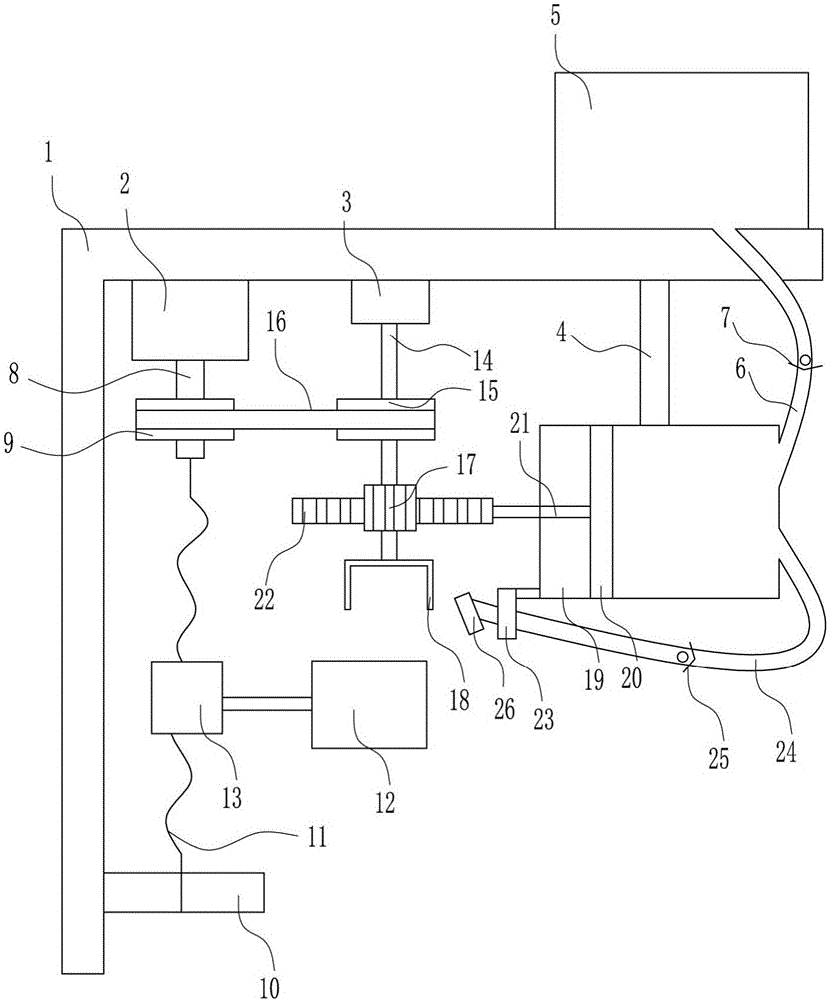

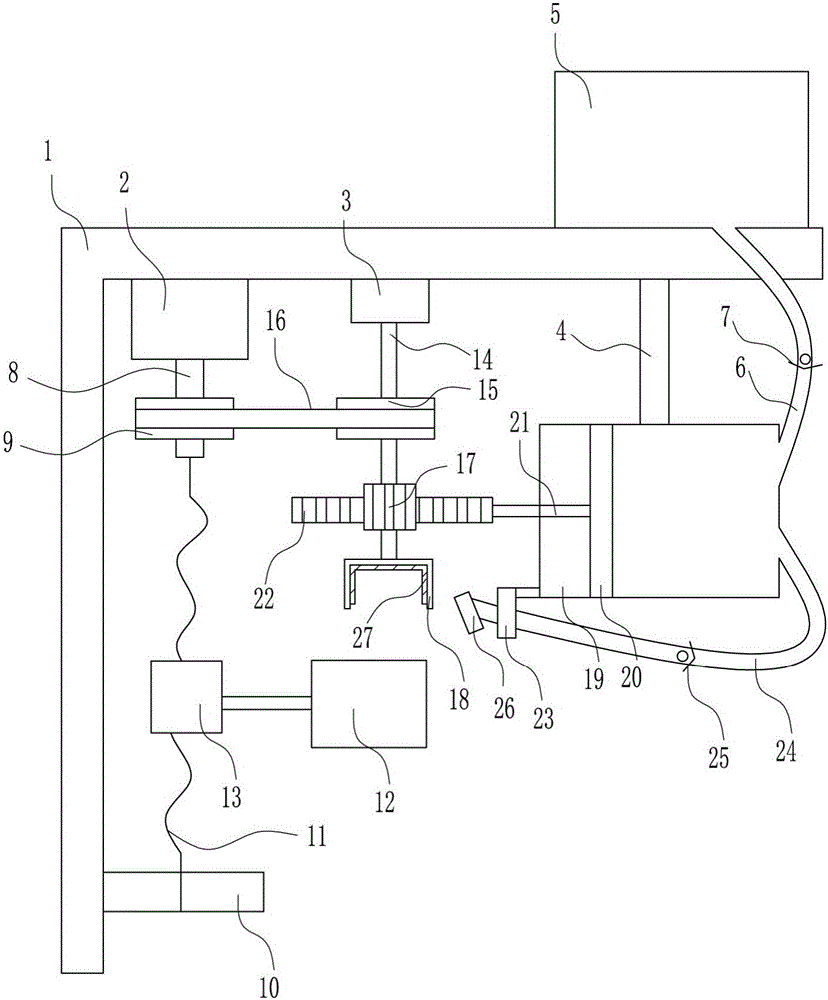

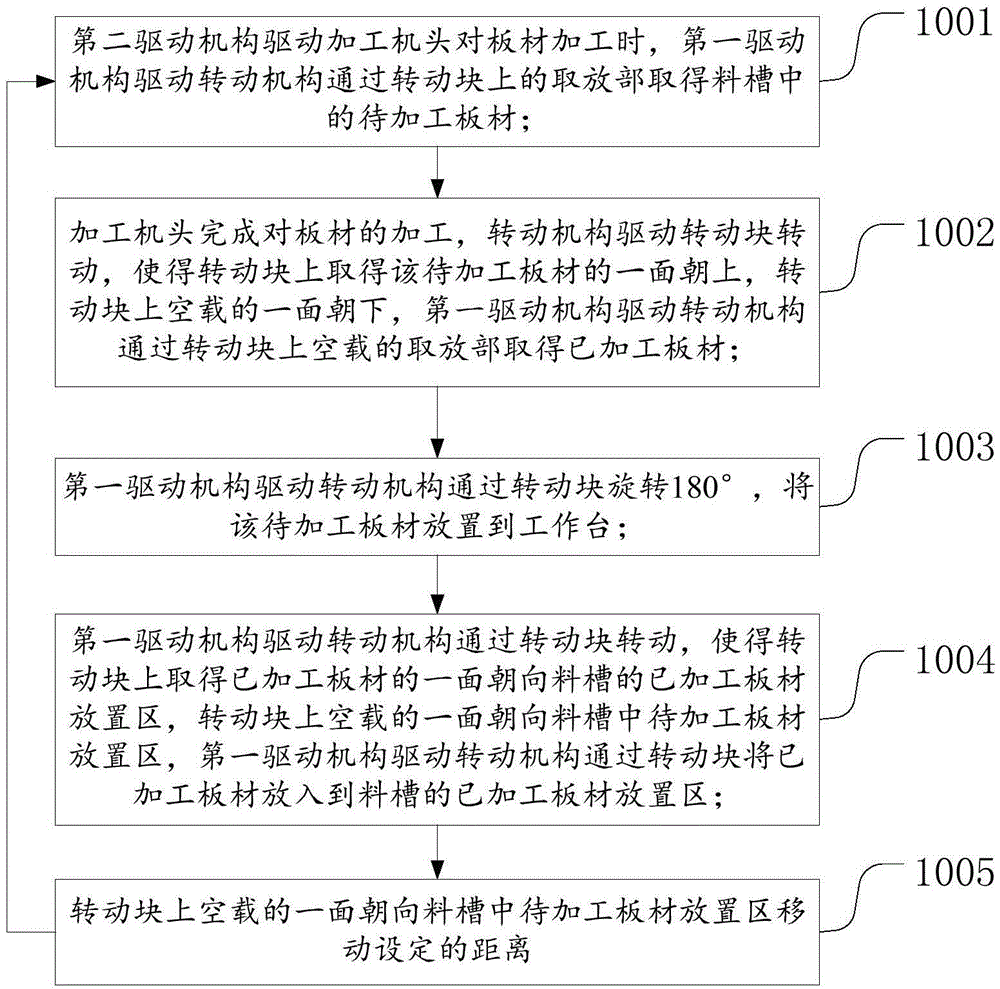

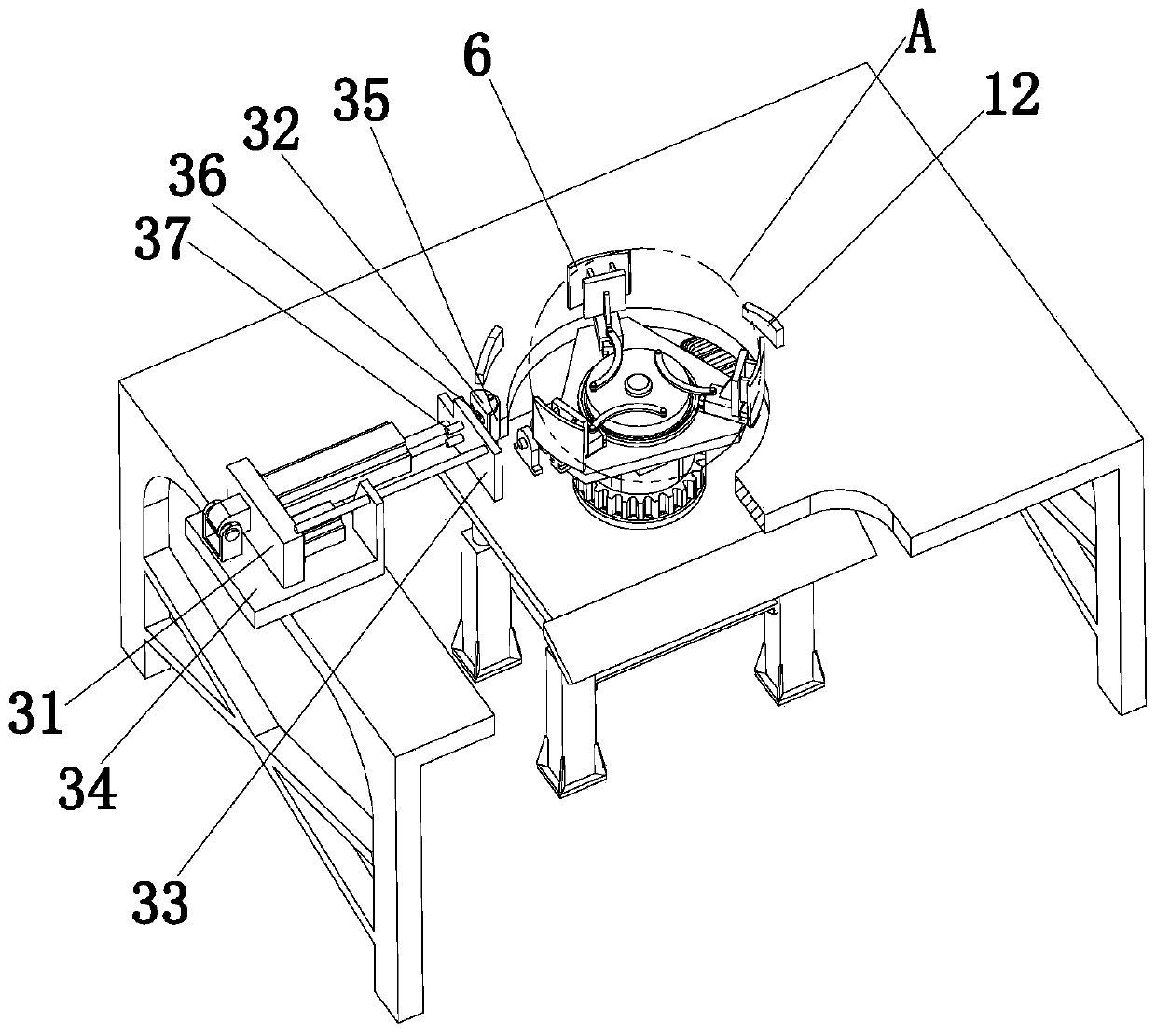

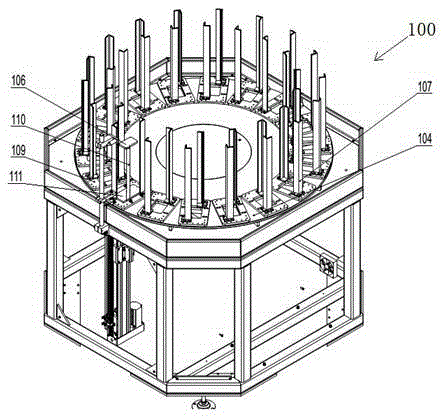

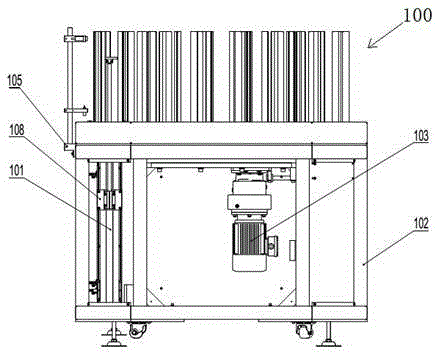

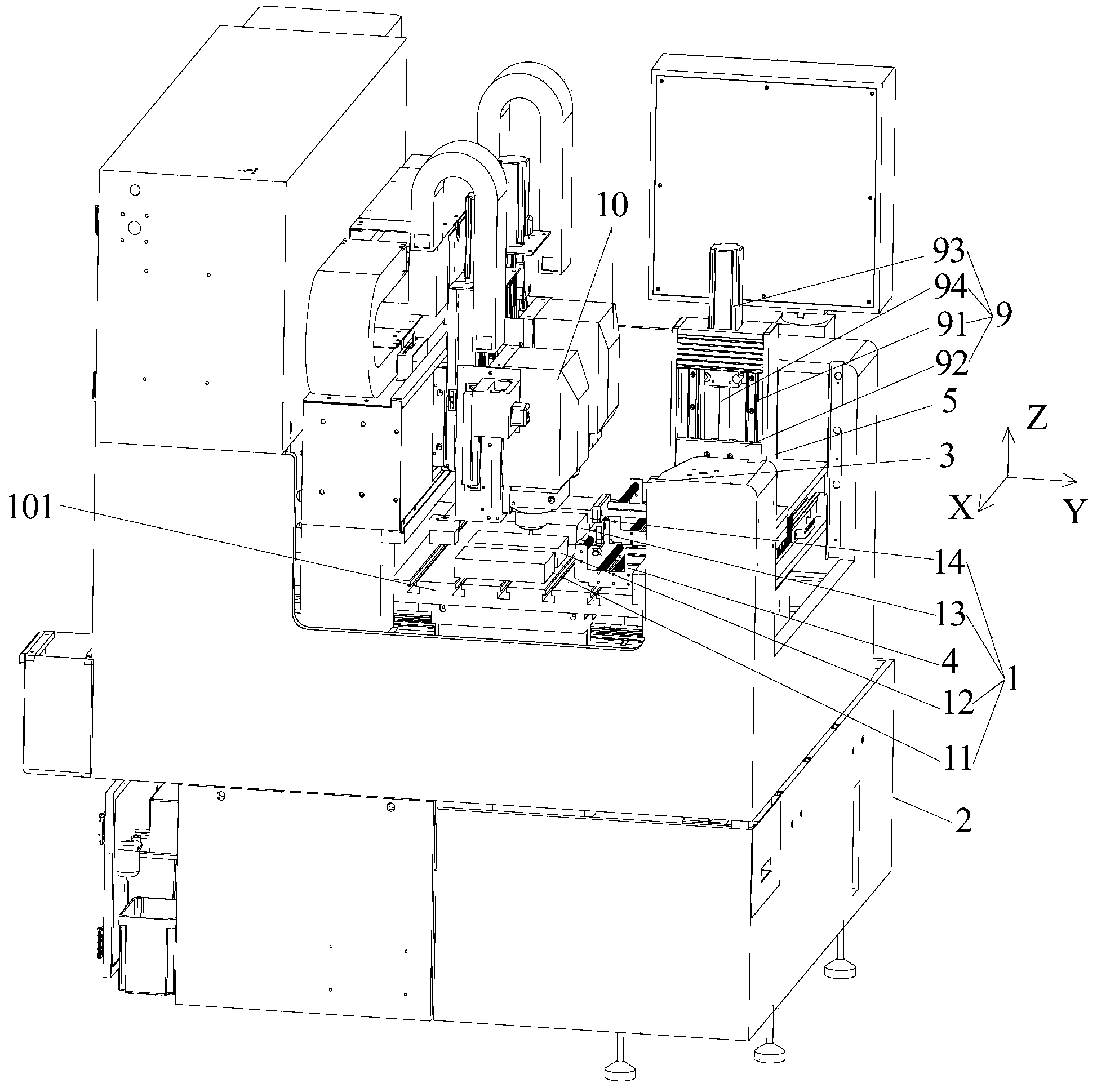

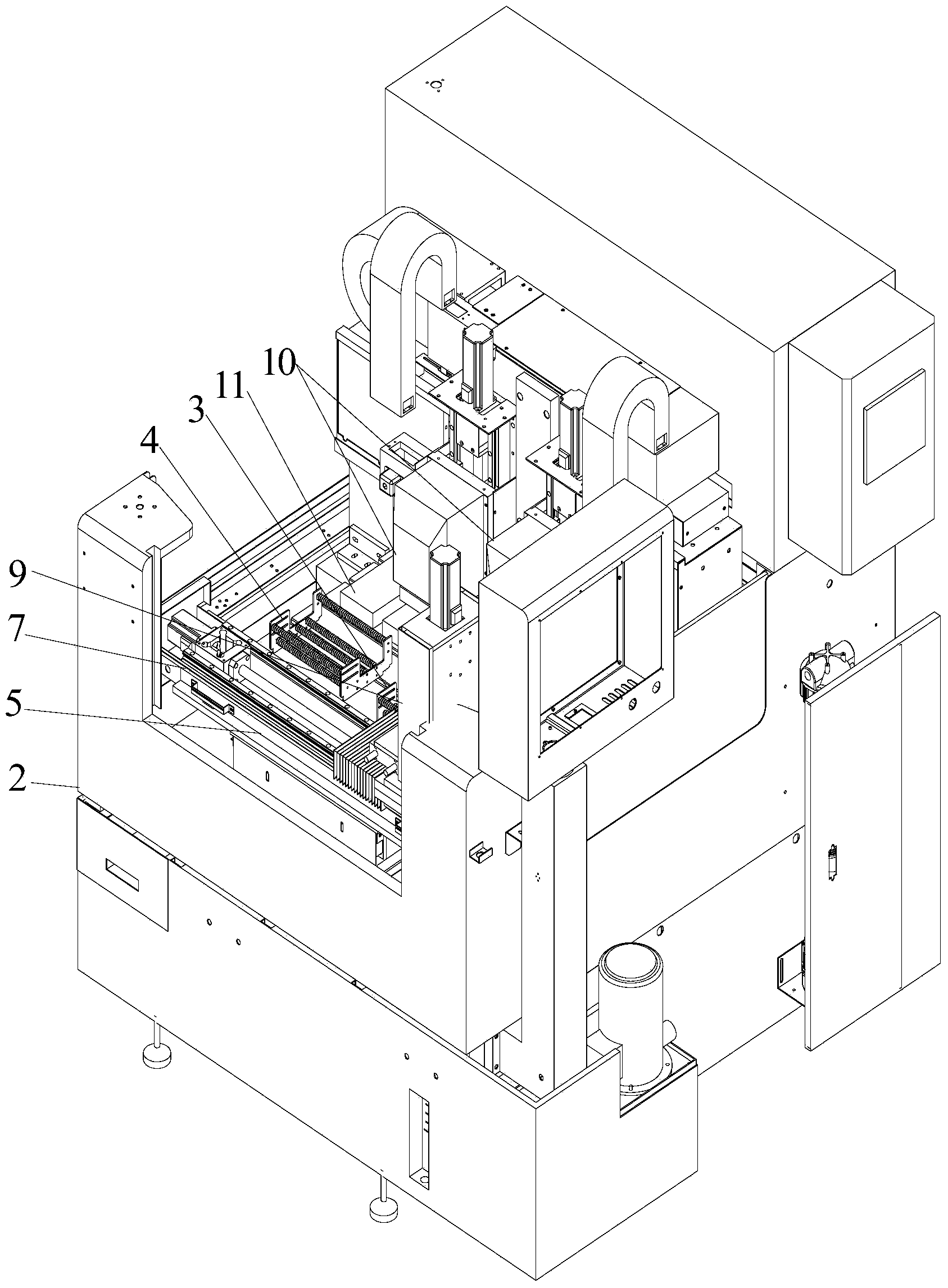

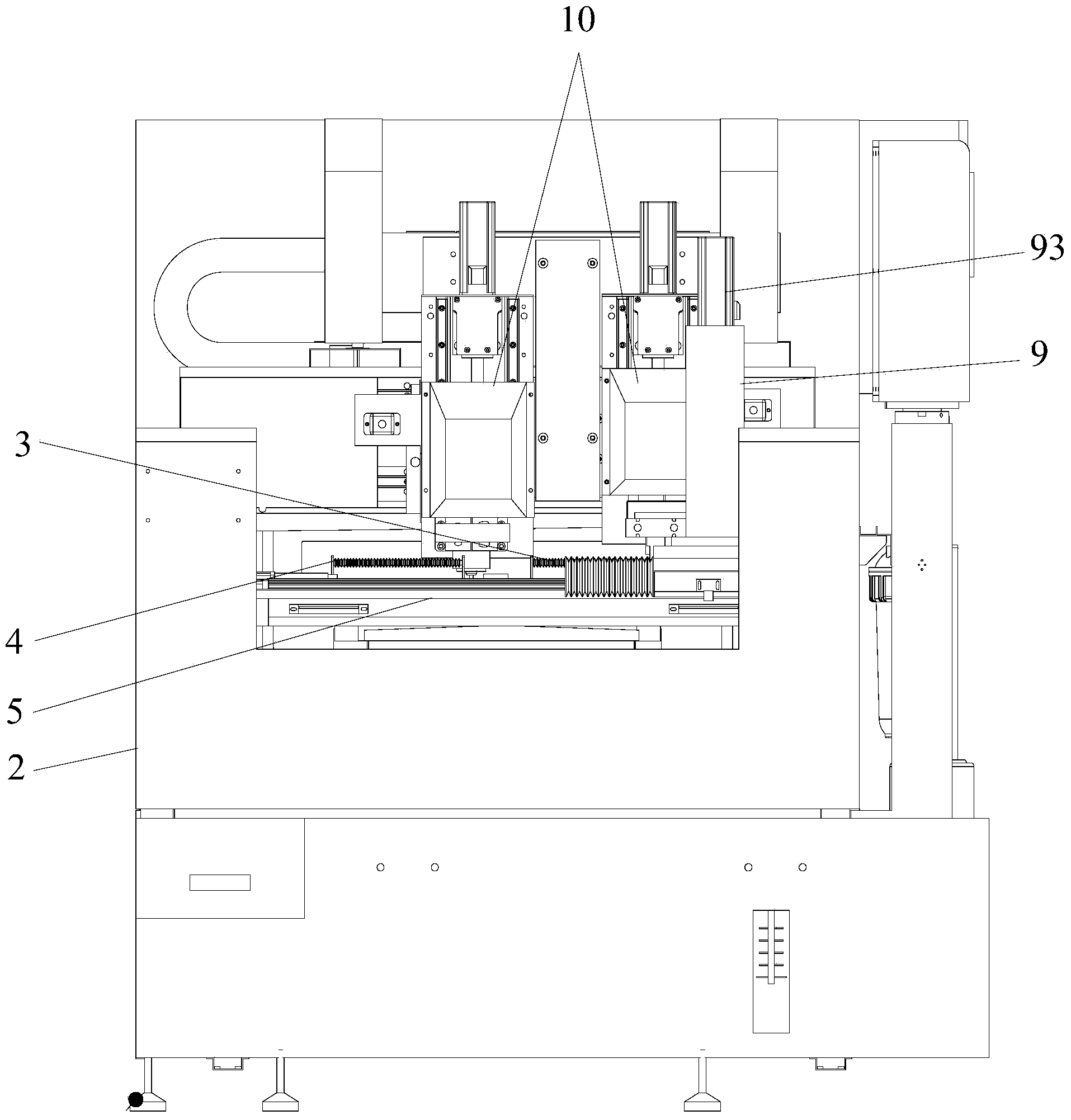

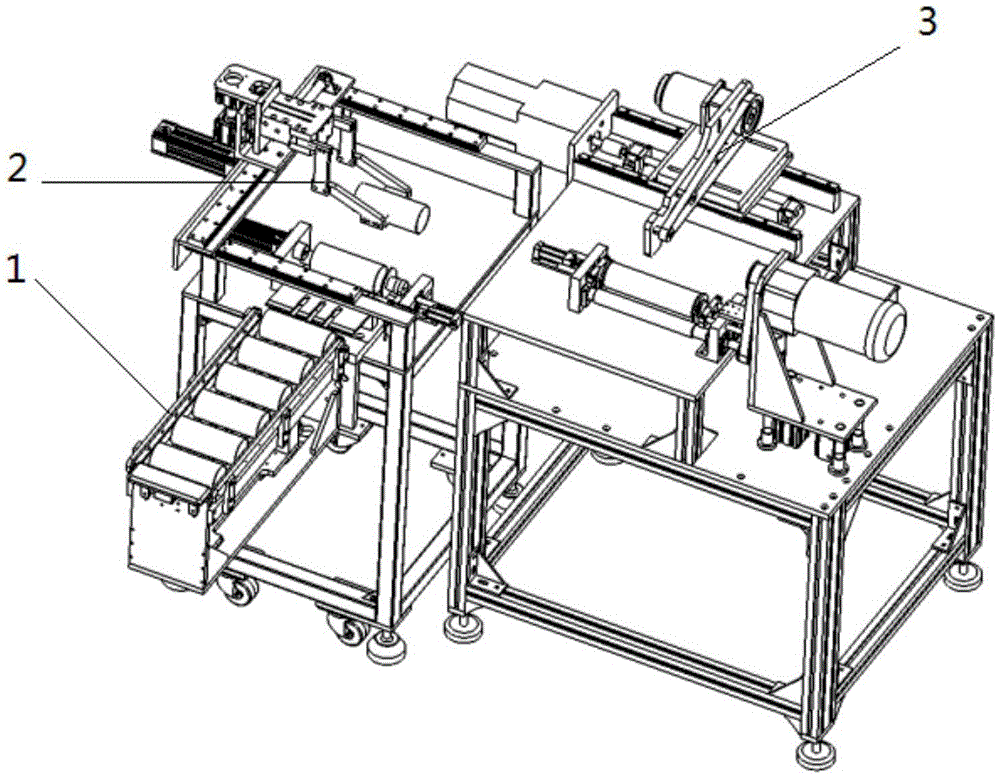

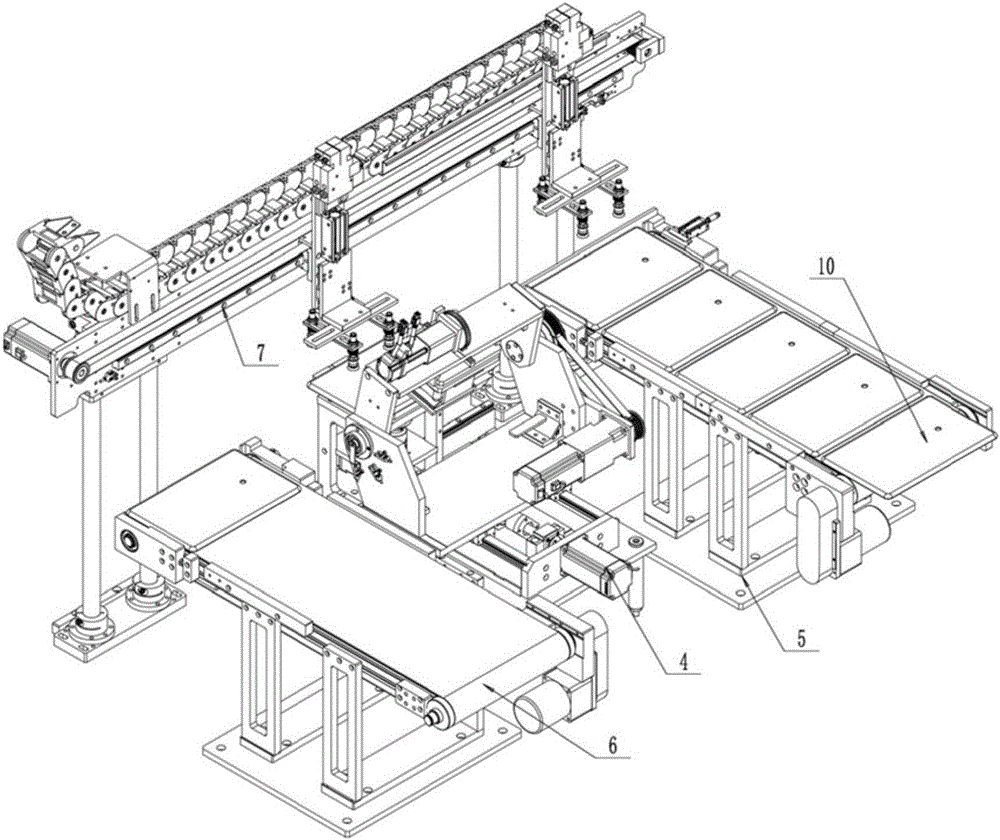

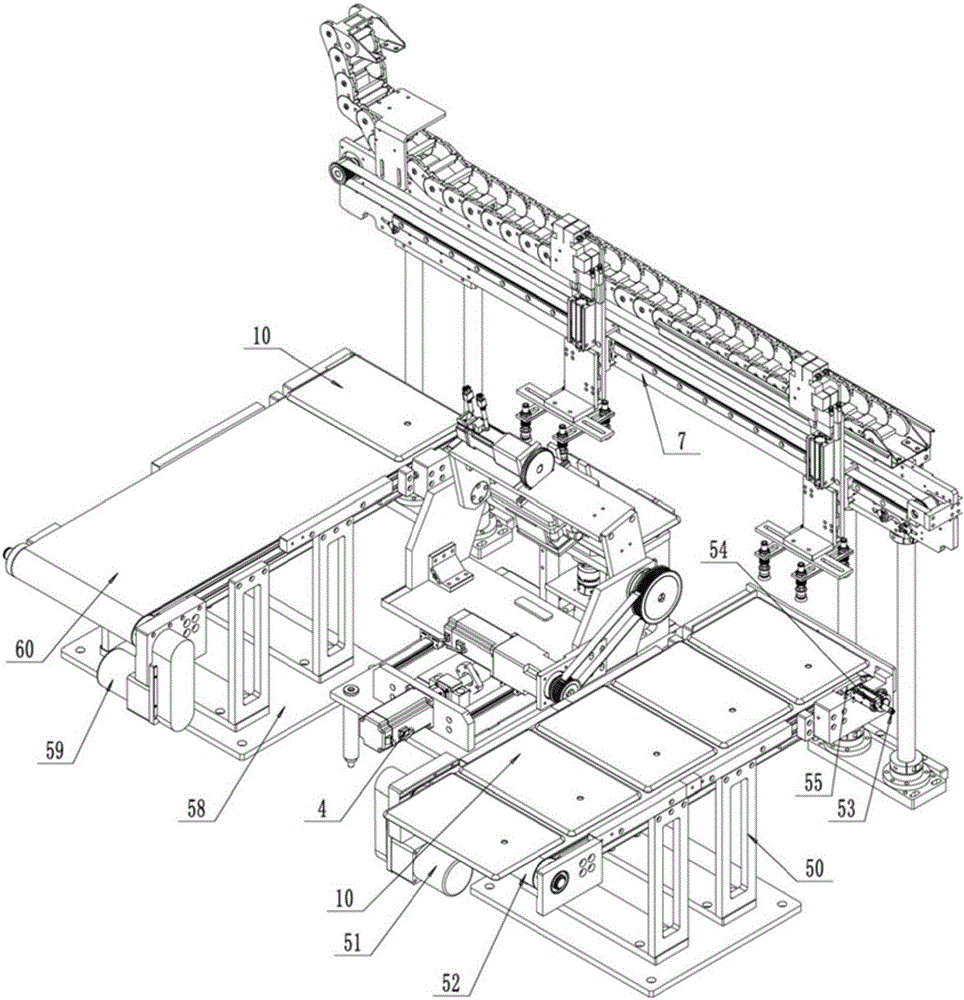

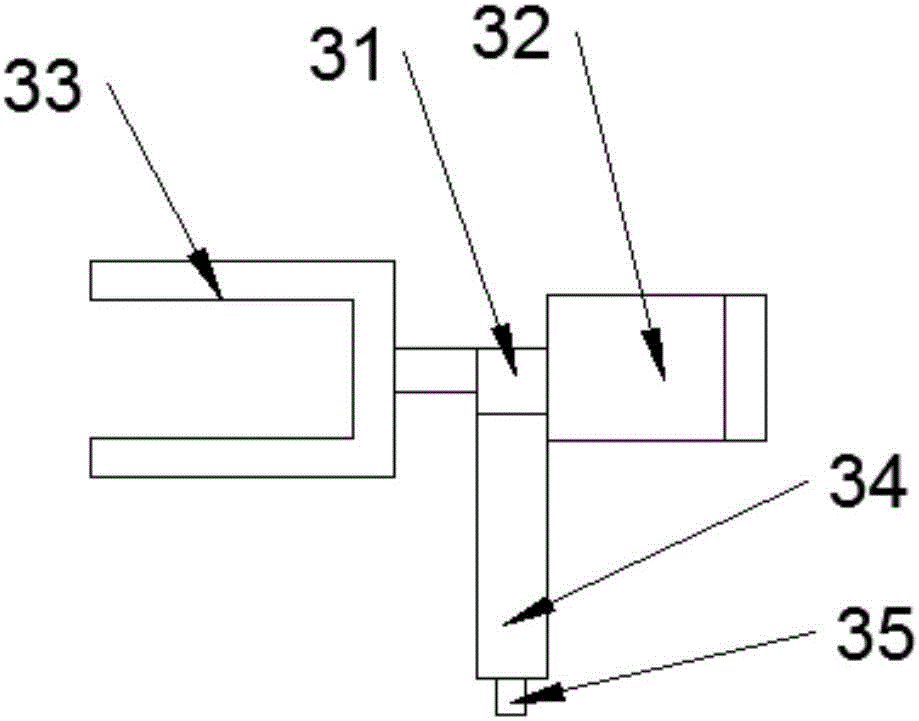

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

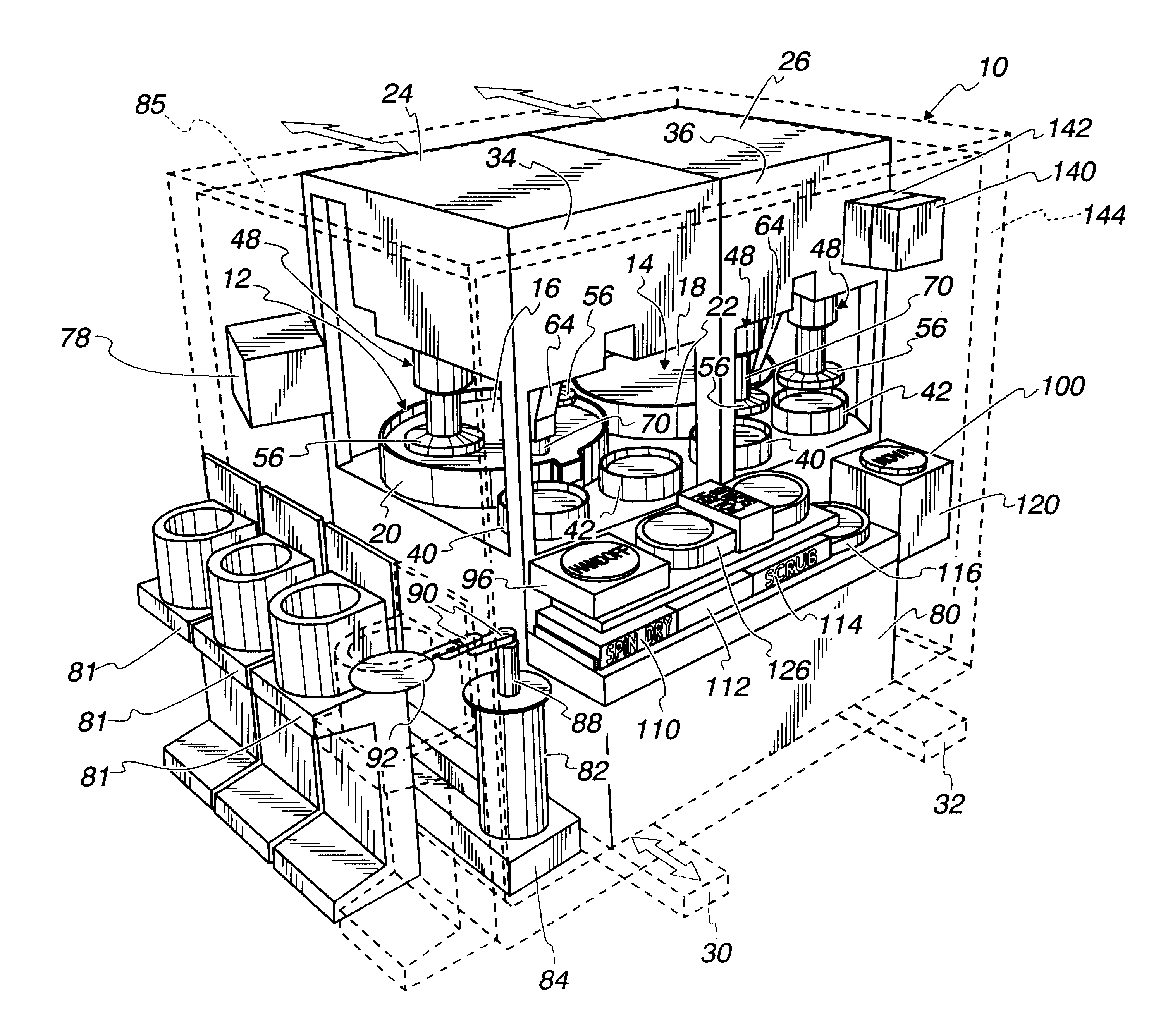

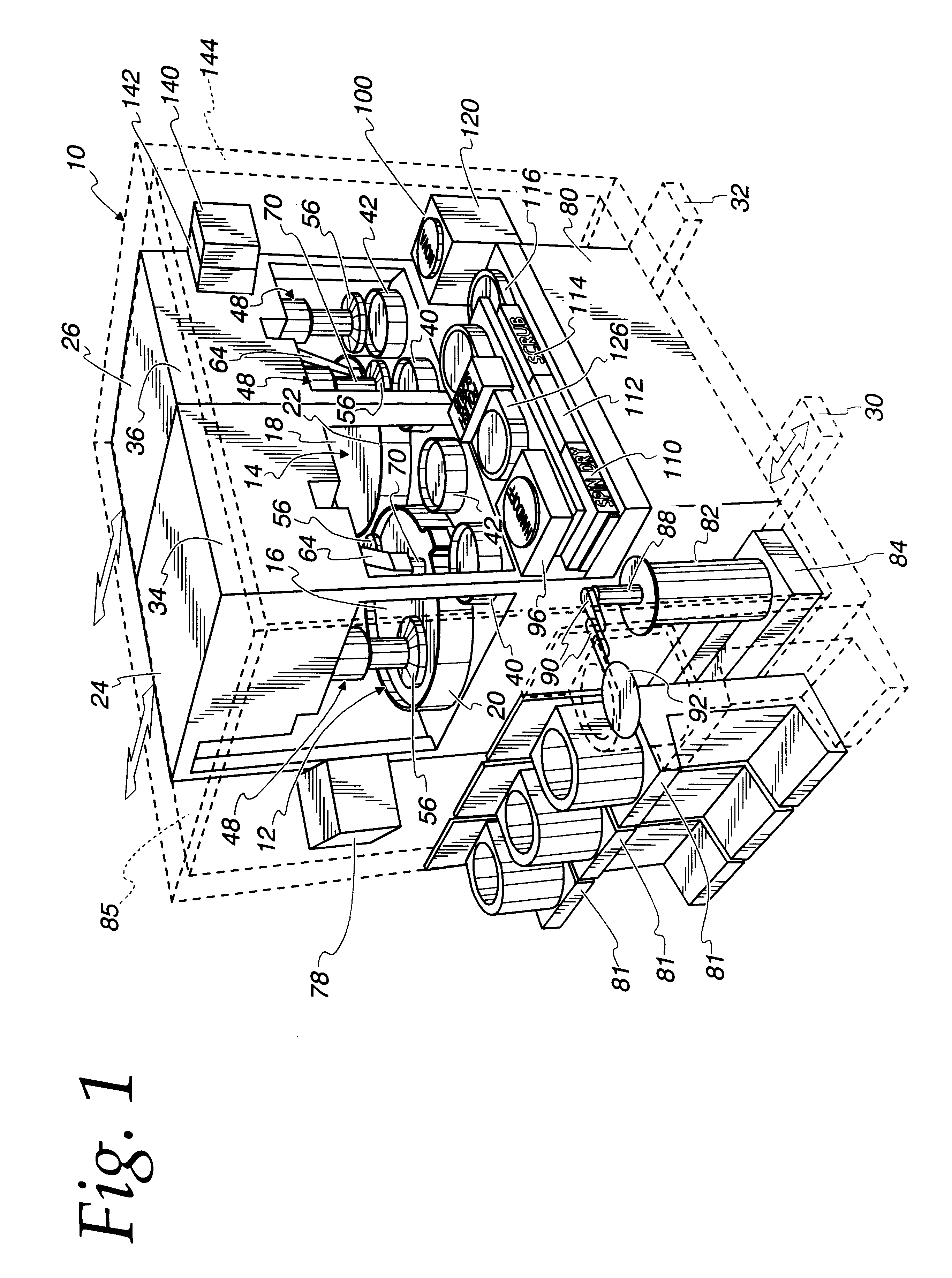

High throughput chemical mechanical polishing system

Embodiments of a system and method for polishing substrates are provided. In one embodiment, a polishing system is provided that includes a polishing module, a cleaner and a robot. The robot has a range of motion sufficient to transfer substrates between the polishing module and cleaner. The polishing module includes at least two polishing stations, at least one load cup and at least four polishing heads. The polishing heads are configured to move independently between the at least two polishing stations and the at least one load cup.

Owner:APPLIED MATERIALS INC

Surface Processing System for a Work Piece

InactiveUS20150044944A1Guaranteed to workImprove production efficiencyEdge grinding machinesBelt grinding machinesManipulatorMachining

The present invention provides a surface processing system for a work piece in the mechanical technical field. The system comprises at least one group of polishing units. A manipulator and several polishers with different polishing precisions are provided on the polishing units. The polishers are arranged around the manipulator in turn. The work piece could be moved by the manipulator between the processing center and the polishing units. The machined work piece is loaded by the manipulator for one time when the manipulator is located at the processing center. When the manipulator is located at the polishing units, the manipulator keeps holding the work piece and transfers the work piece in a preset sequence to each polisher corresponding to the polishing unit where the manipulator is located. The surface of work pieces having different wall thicknesses and complex surfaces could be processed in a large batch with a high efficiency.

Owner:TAIZHOU FEDERAL ROBOT TECH

Production system of hub bearing

ActiveCN106050920ANo need for manual operationFast productionLiquid surface applicatorsGrinding carriagesThrust bearingEngineering

The invention provides a production system of a hub bearing, in order to solve the technical problems that the hub bearing is to be carried manually and the production speed is low because the structure of the conventional processing device is too simple. The production system of the hub bearing comprises a workbench, wherein an outer ring grinding device for grinding an outer ring of the hub bearing, an inner ring grinding device for grinding an inner ring of the hub bearing, a cleaning device for cleaning the hub bearing, a spraying device for spraying the hub bearing, and a detection device for detecting the hub bearing are sequentially arranged on the workbench. The production system has the advantage of high production speed.

Owner:嘉兴福可吉精密机械有限公司

Convenient and fast efficient steel pipe rust removal grinding machine

ActiveCN105150069AAchieve regular recyclingEasy to recycleRevolution surface grinding machinesGrinding feedersArchitectural engineeringWire brush

The invention discloses a convenient and fast efficient steel pipe rust removal grinding machine. The convenient and fast efficient steel pipe rust removal grinding machine comprises a workbench, a motor fixing table, a rust removing device, a scrap iron clearing device and a protective cover. The rust removing device comprises a rust removing brush head and a rust removing roller. The rust removing brush head is connected with the bottom face of the motor fixing table through adjusting rods. The rust removing roller comprises a rust removing barrel body which is evenly provided with installing ports. Steel wire brushes are arranged in the installing ports and fixed through fastening pieces. The scrap iron clearing device comprises a chip removing funnel and a chip collecting device. The convenient and fast efficient steel pipe rust removal grinding machine is simple in structure and high in practicability; by improving the rust removing device, rust removal can be performed on the interior and the surface of a steel pipe at the same time, and operation can be more convenient and easier; due to design of a clamping jaw and a bracket, the steel pipe can be fixed more firmly; meanwhile, by adjusting the clamping jaw and the bracket, rust removal can be performed on steel pipes of different pipe diameters, the using range of the steel pipe rust removal grinding machine is further widened, and comprehensive utilizing efficiency is improved.

Owner:嵊州市恒鑫金属制管有限公司

High throughput chemical mechanical polishing system

Owner:APPLIED MATERIALS INC

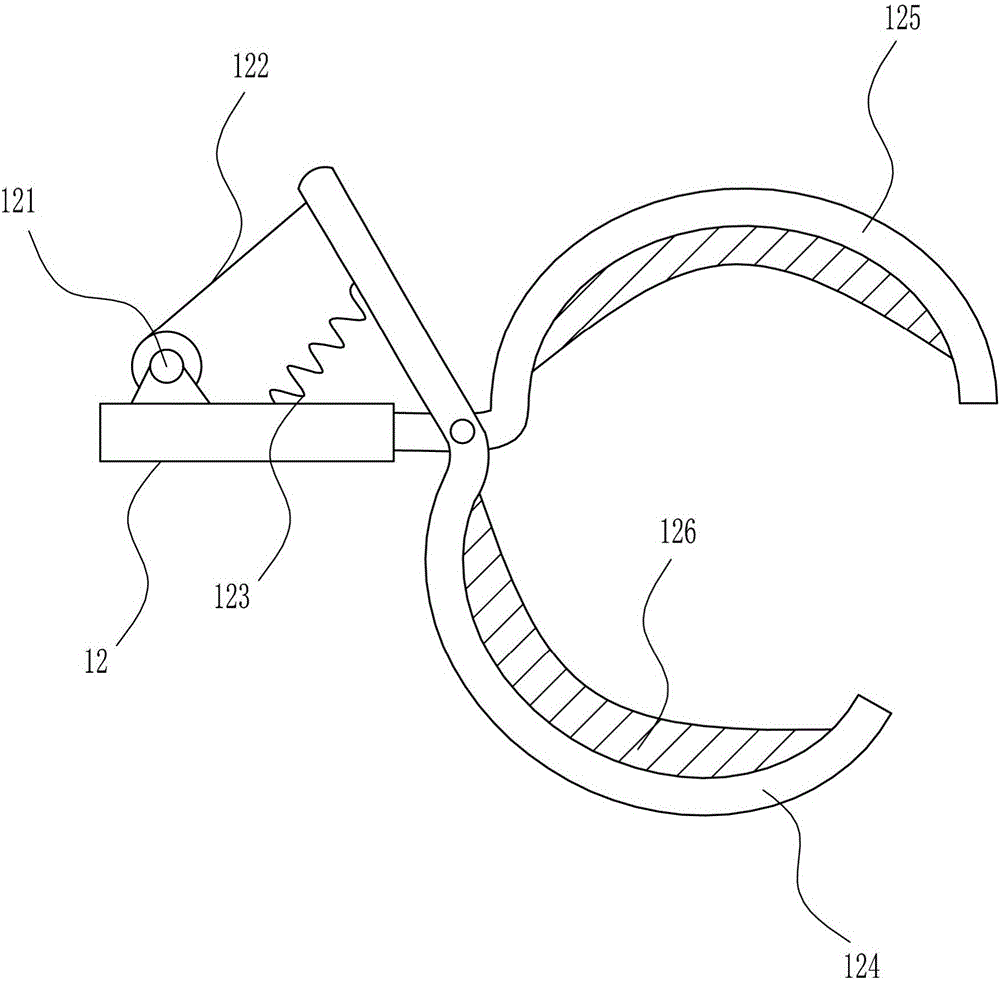

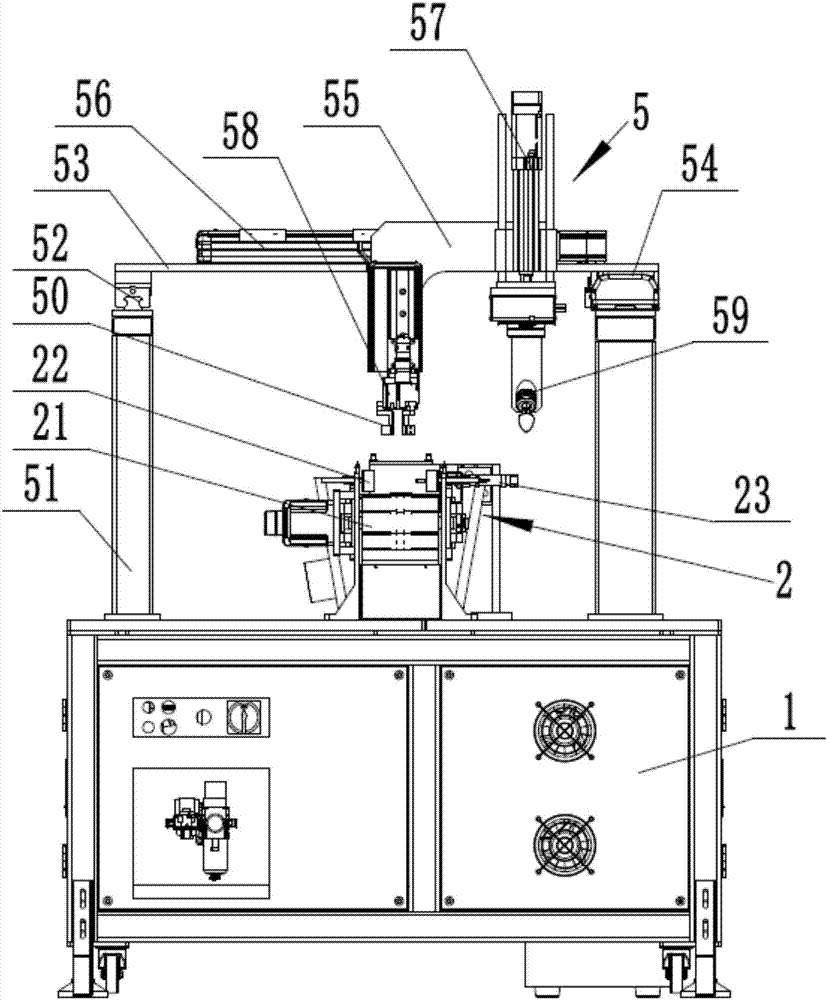

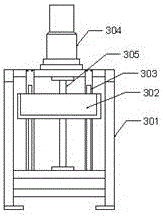

Polishing device for hub processing of new energy automobile

ActiveCN111230710ARealize polishing workRealize polishing and chamfering operationsEdge grinding machinesGrinding carriagesDrive wheelNew energy

The invention discloses a polishing device for hub processing of a new energy automobile, and relates to the technical field of automobile part processing. The polishing device comprises a worktable,a hub top polishing mechanism, a hub side polishing mechanism and a hub limiting rotation mechanism, wherein the hub top polishing mechanism is arranged above the worktable, the hub side polishing mechanism is arranged at the top of the worktable, and the hub limiting rotation mechanism is arranged below the worktable; the hub limiting rotation mechanism comprises a height adjustment assembly, a hub inner circle fixing assembly for clamping a hub inner circle and a rotating assembly for driving the hub to rotate, and a through hole is formed in the top of the worktable so that the hub inner circle fixing assembly can lift and pass through the through hole. According to the invention, the polishing device can clamp the hub inner circle and drive the hub to rotate under the action of the hublimiting rotation mechanism, the angle adjustment of a grinding wheel can be realized through the hub side polishing mechanism, and then polishing chamfering operation on the top surface of the hub is realized.

Owner:山东荣升重型机械股份有限公司

Automobile hub double-face full-automatic polishing production line

InactiveCN108000273AAccurate capturePrecise positioningEdge grinding machinesGrinding carriagesProduction lineManipulator

The invention discloses an automobile hub double-face full-automatic polishing production line which comprises a rack and a polishing mechanism. The rack is sequentially provided with a feeding mechanism, a hub polishing rotary table and a discharging mechanism, the polishing mechanism is located above the polishing mechanism, and the characteristics are that the feeding mechanism comprises a first chain plate conveyor, two guide plates and a stopping air cylinder; the hub polishing rotary table comprises a grinding collecting box, a hub polishing jacking table and an overturning tool; the overturning tool comprises a vertical plate, a wide type gas claw, two clamping connecting plates, two rotary air cylinders and two clamping blocks; the polishing mechanism comprises a support, an X-axisguide rail, an X-axis sliding base, a Y-axis sliding base, an X-axis electric cylinder, a Y-axis electric cylinder, a Z-axis electric cylinder, a Z-axis stretchable cylinder, an electric polishing head and a carrying mechanical arm; and the discharging mechanism at least comprises a second chain plate conveyor. The automobile hub double-face full-automatic polishing production line is used for automobile hub full-automatic polishing production, the front and back faces of a hub can be switched at will, and the reliability and the stability can be improved.

Owner:李茂菊

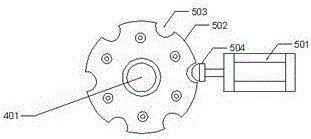

Multi-angle synchronous efficient grinding equipment for automobile brake disc

ActiveCN112025432AEffective positioningSynchronous and efficient grinding equipment can be positioned accurately and efficientlyRevolution surface grinding machinesGrinding drivesEngineeringSurface grinding

The invention relates to the technical field of automobile brake disc grinding machining, in particular to multi-angle synchronous efficient grinding equipment for an automobile brake disc. The equipment further comprises a machining platform, a clamping rotating assembly, a top surface grinding assembly and a side wall chamfering and grinding assembly, wherein the clamping rotating assembly comprises a mounting disc, a transmission disc, a positioning disc, a clamping jaw and a pressing mechanism; the top surface grinding assembly comprises a first lifting mechanism, a first horizontal displacement mechanism and a top end horizontal grinding mechanism, and the top end horizontal grinding mechanism comprises a horizontal grinding disc capable of grinding the top surface of the automobile brake disc; and the side wall chamfering and grinding assembly comprises a second lifting mechanism, a second horizontal displacement mechanism, an angle adjusting mechanism and a side wall chamferingand grinding mechanism, and the side wall chamfering and grinding mechanism comprises a side wall grinding disc. The equipment shown can precisely and efficiently position and clamp the automobile brake disc, and the surface, the side wall and the edge of the brake disc are synchronously and accurately ground, such that the working efficiency is greatly improved, and repositioning is avoided.

Owner:浙江杭万汽车零部件实业有限公司

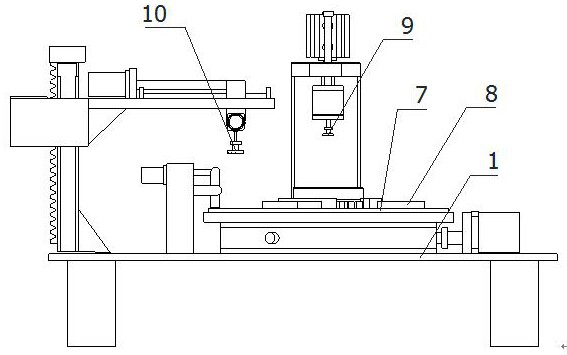

Polishing machine for outer ring end faces of bearings

ActiveCN103737439AAchieve grindingPrecise control of displacementEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention provides a polishing machine for the outer ring end faces of bearings, and belongs to the technical field of machines. The polishing machine solves the technical problems that an exiting polishing machine cannot meet the machining requirement of the bearings in different types, and the application scope is limited. The polishing machine for the outer ring end faces of the bearings comprises a machine frame, a polishing abrasion wheel and a guide rail, the guide rail is fixed on the machine frame, a first installation plate and a second installation plate are connected to the machine frame in a sliding mode, and the polishing abrasion wheel is respectively connected to the first installation plate and the second installation plate in a rotary mode. A first adjusting block and a second adjusting block are fixed on the first installation plate, a third adjusting block and a fourth adjusting block are fixed on the second installation plate, a first adjusting motor and a second adjusting motor are fixed on the machine frame, a first lead screw is fixed on the first adjusting motor and penetrates through the first adjusting block and the third adjusting block, a second lead screw is fixed on the second adjusting motor and penetrates through the second adjusting block and the fourth adjusting block, and a feeding device is further arranged between the polishing abrasion wheel and the feeding guide rail. The polishing machine has the advantages that the bearings in the different types can be polished.

Owner:HAINING QI SHENG BEARING

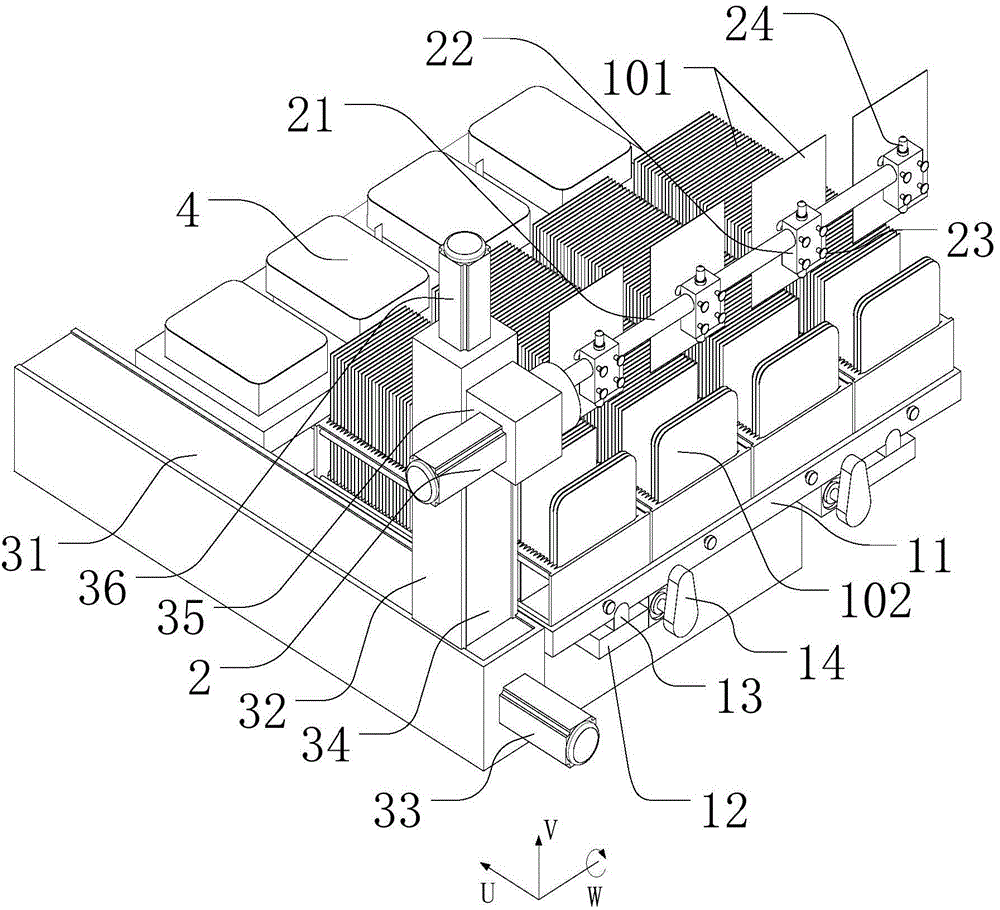

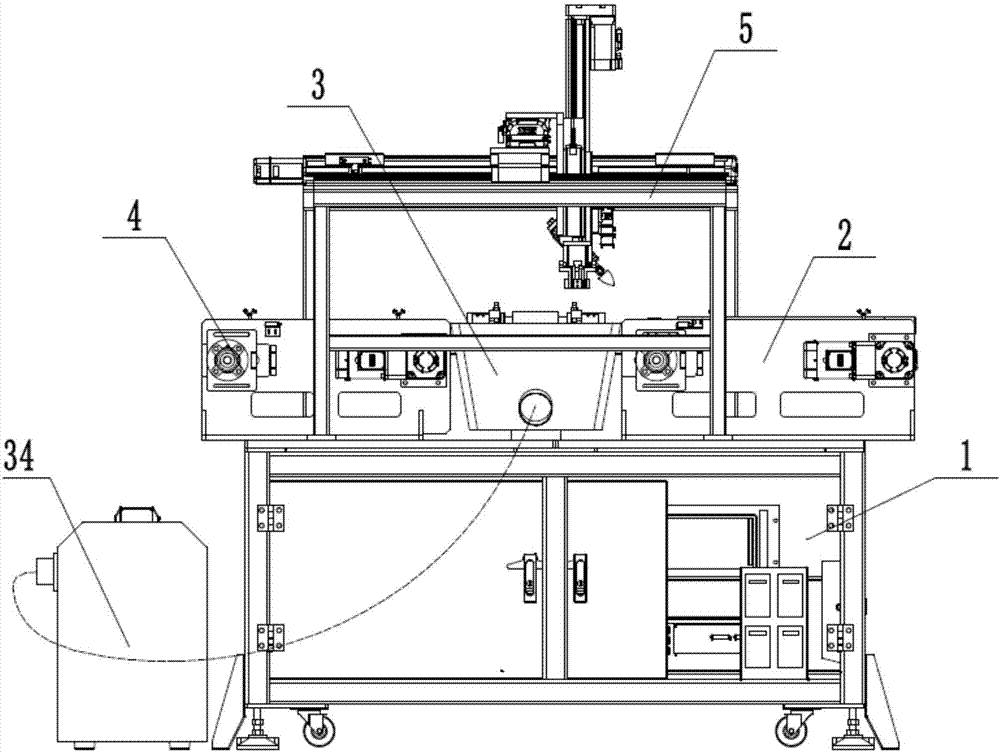

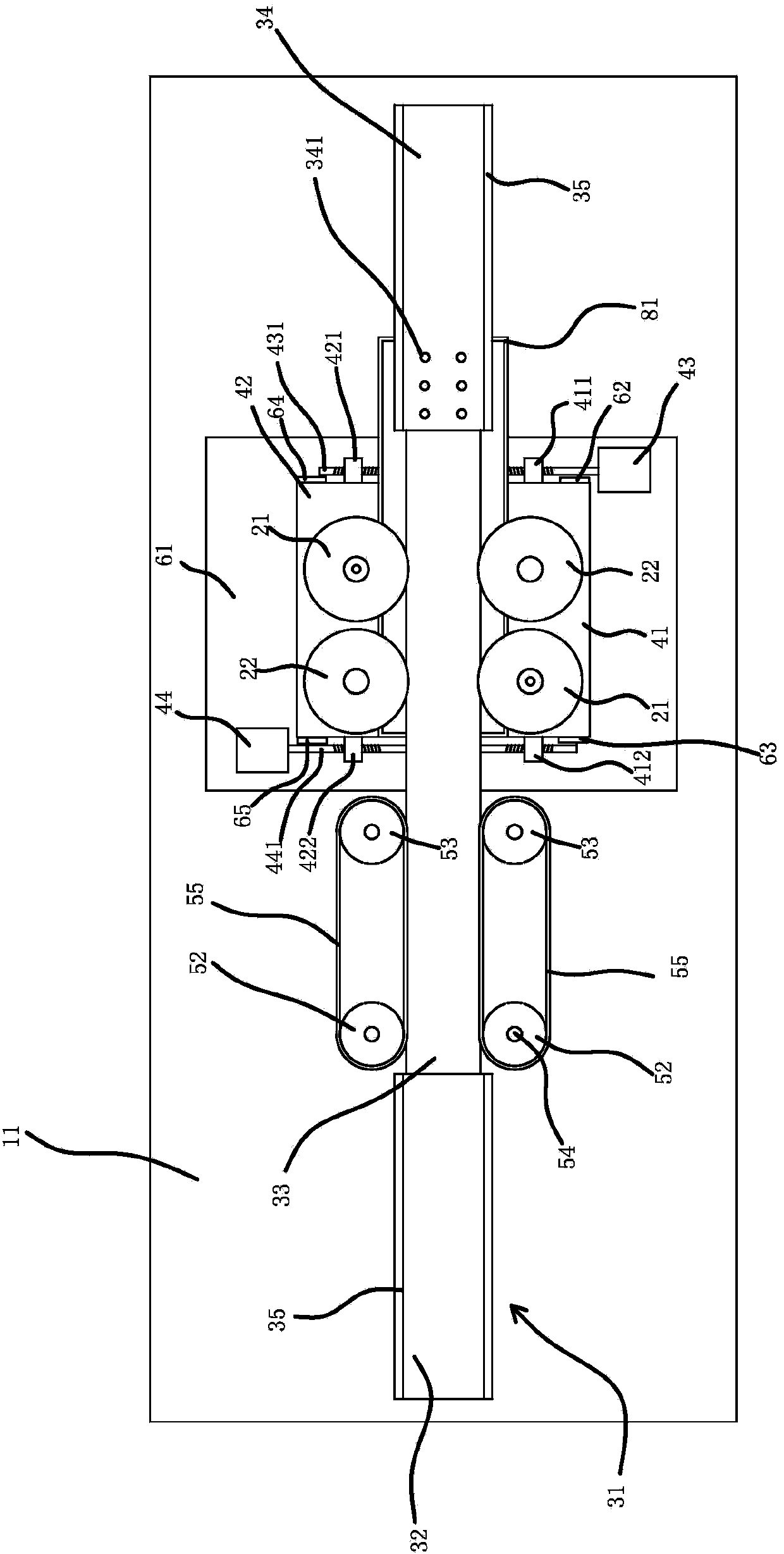

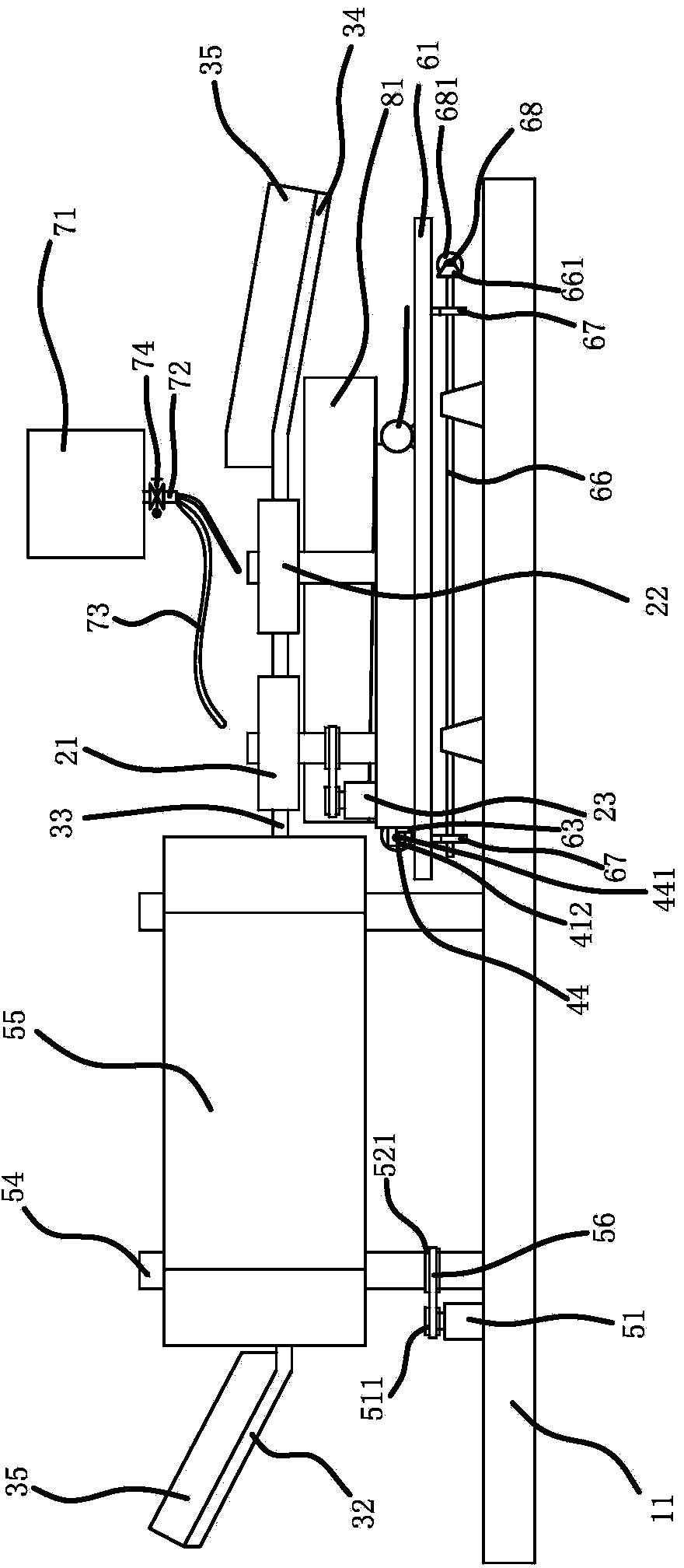

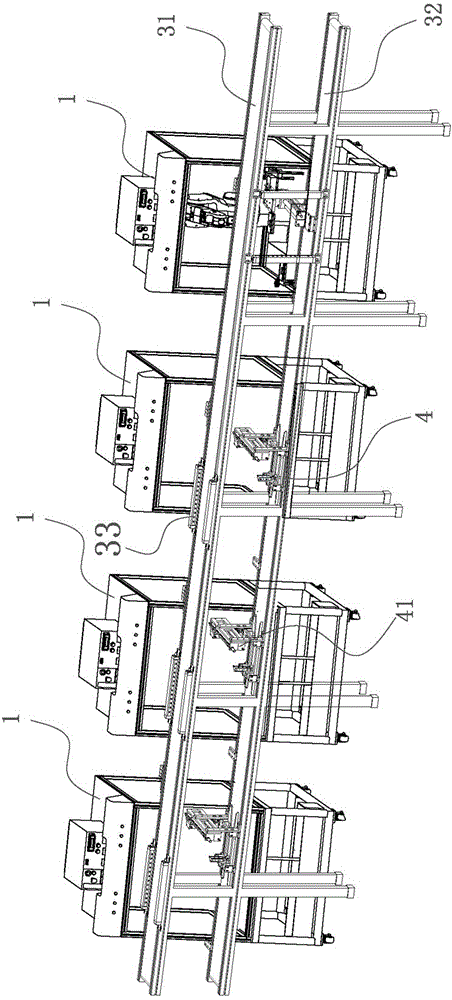

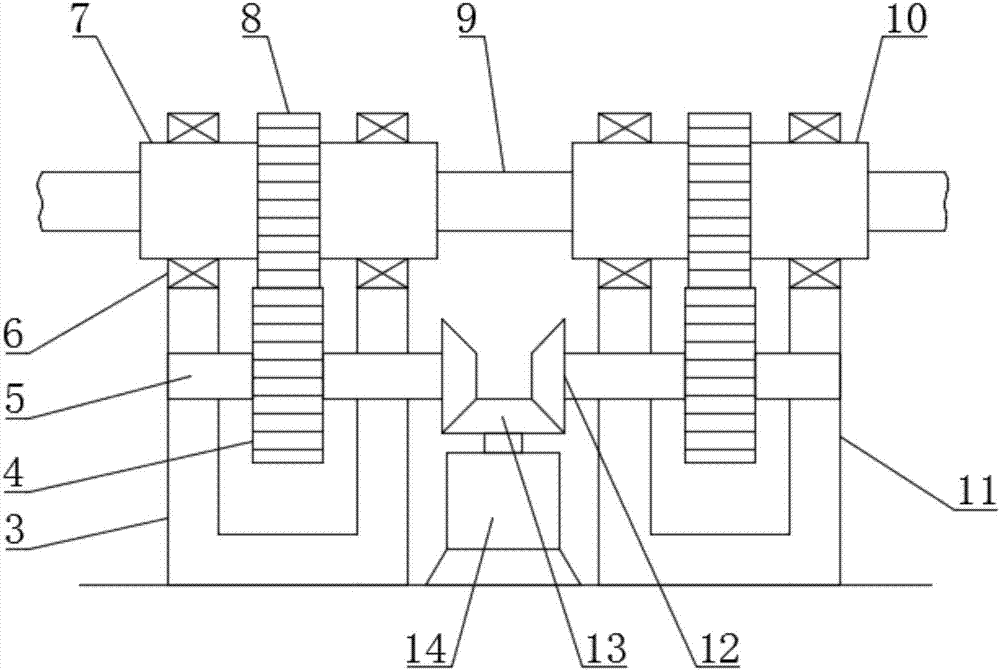

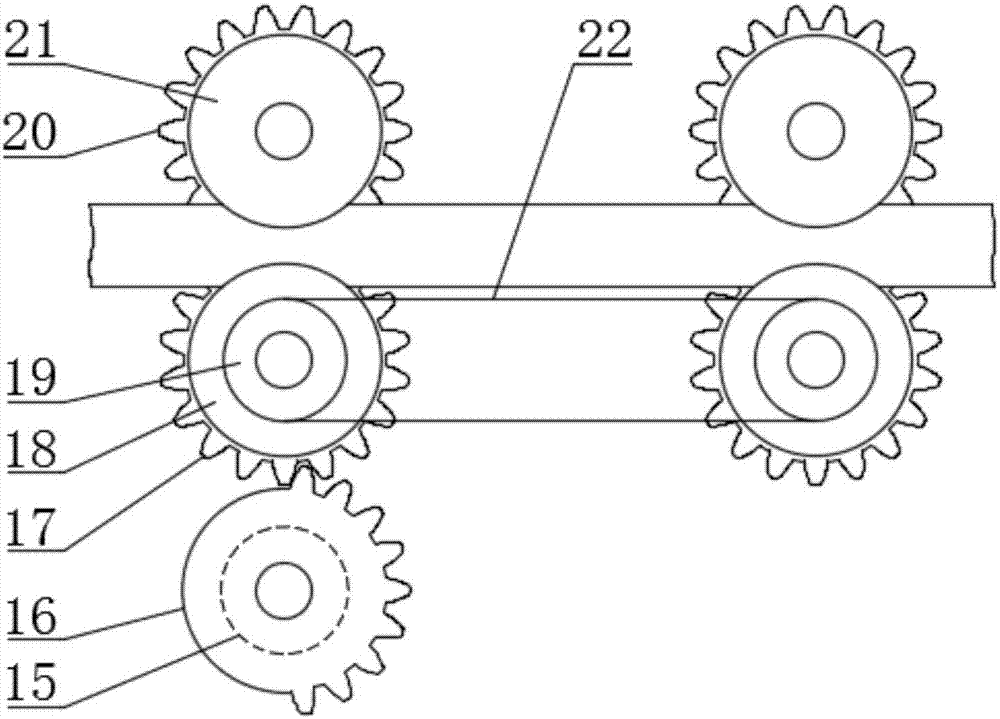

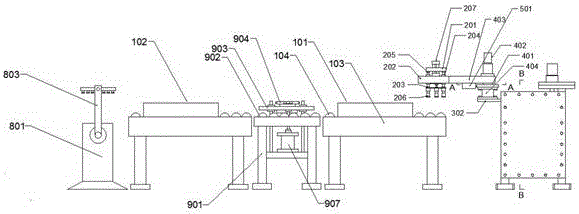

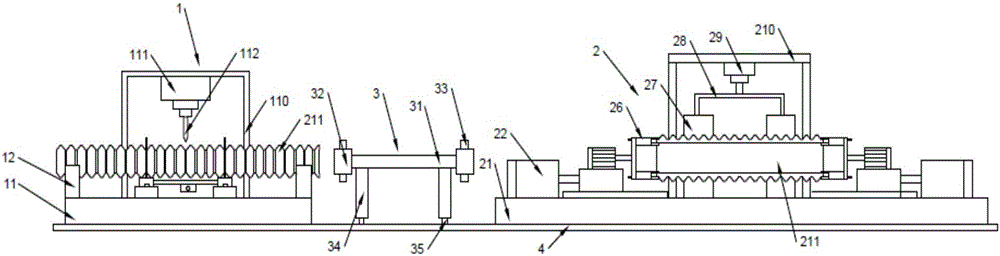

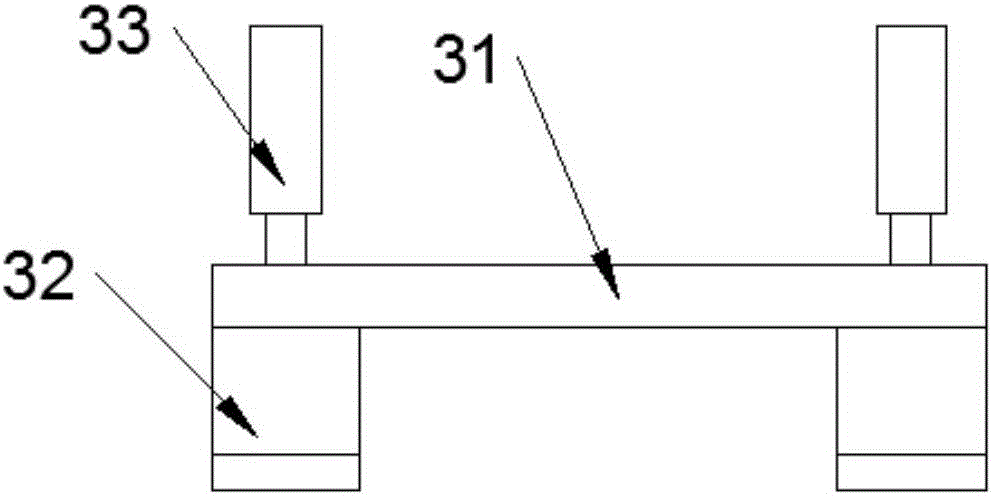

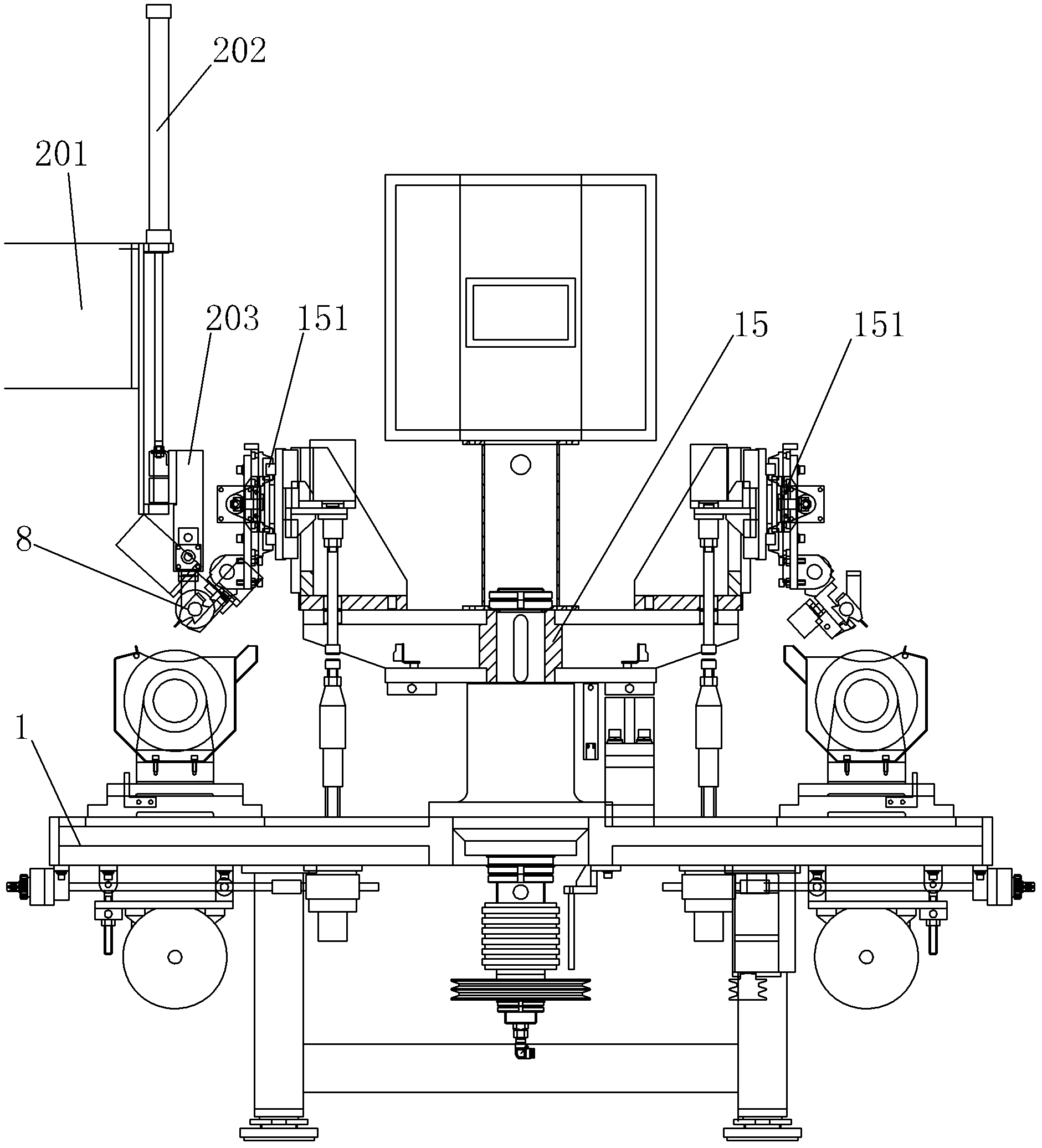

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

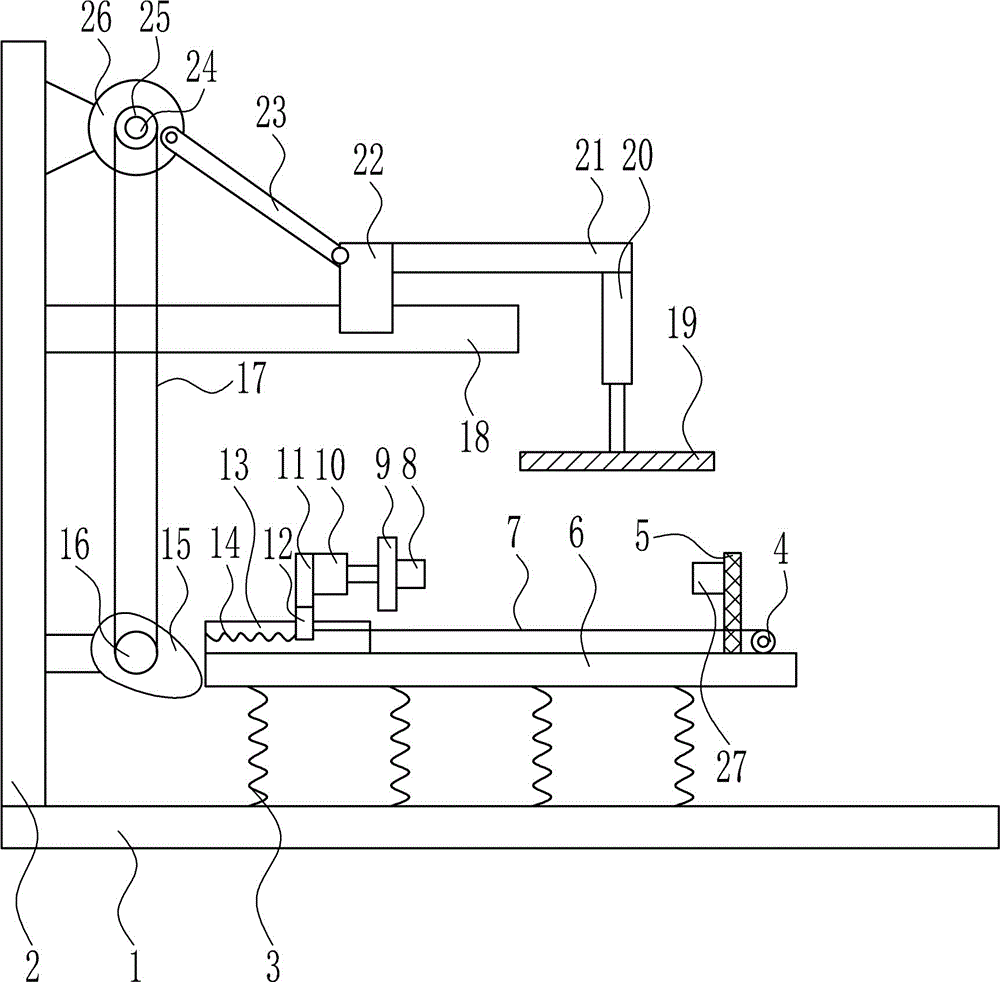

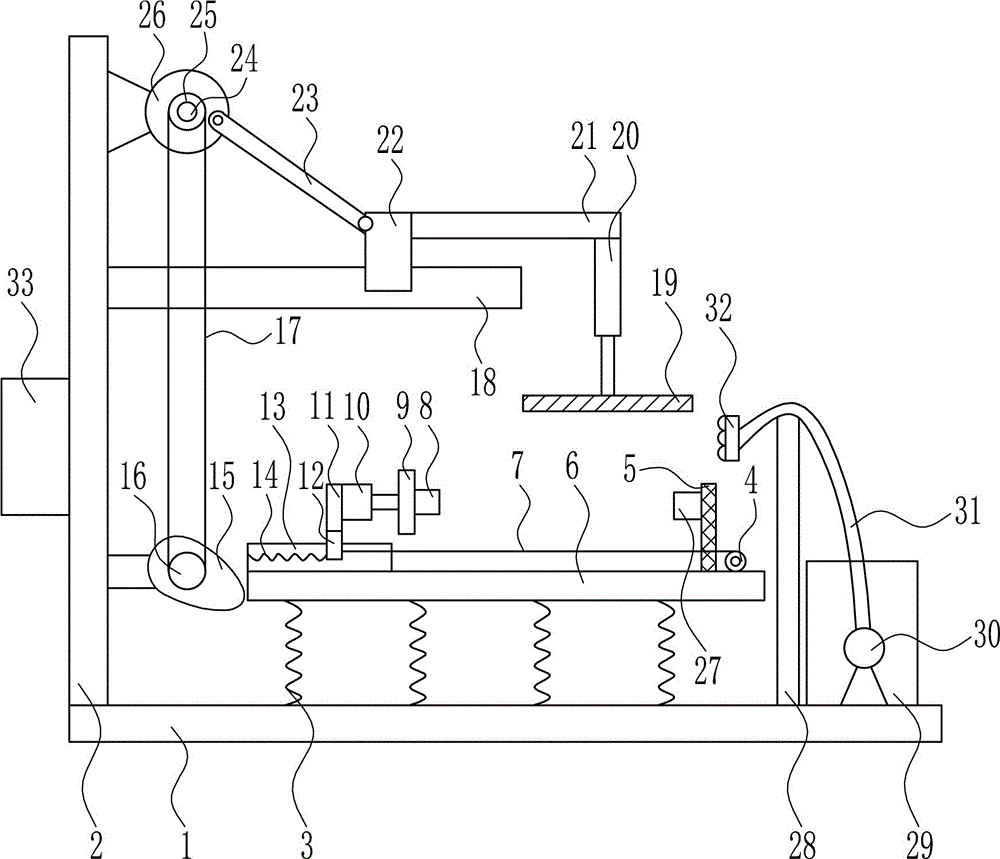

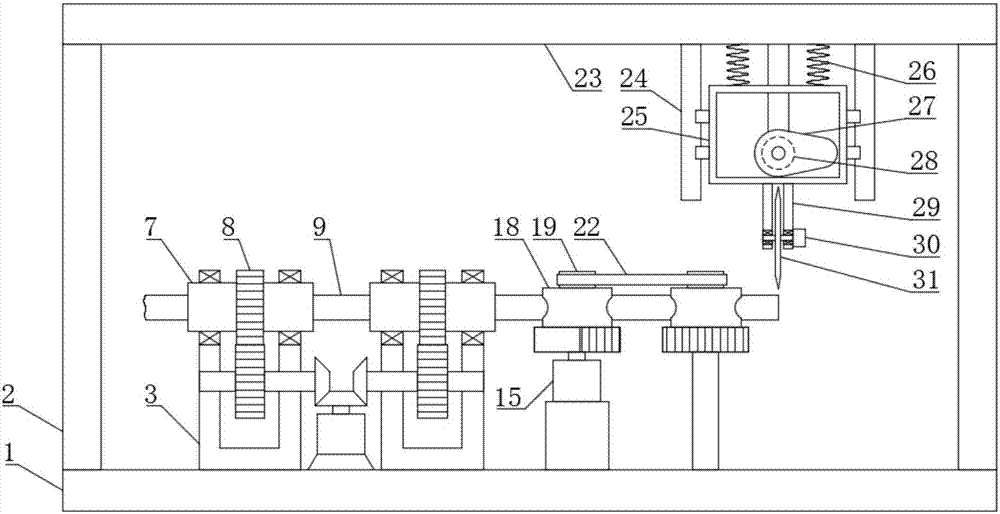

Rapid steel tube surface derusting device

ActiveCN106475881AReduce the temperatureReduce heat lossGrinding carriagesGrinding drivesMaterials scienceSteel tube

The invention relates to a steel tube surface derusting device, in particularly to a rapid steel tube surface derusting device, and aims at solving the technical problem of providing a steel tube surface derusting device which can remove rust thoroughly and is high in derusting efficiency and low in manufacturing cost. In order to solve the above-mentioned technical problem, the steel tube surface derusting device is provided and comprises a base plate, a left side plate, first springs, an electric winding wheel, a bearing base, an object placing plate, a pull wire, a first fixing block, a connecting plate, a first motor, a vertical plate, a first sliding block and the like, wherein the first springs are located on the right of the left side plate, the object placing plate is arranged on the tops of the first springs, a first sliding rail, the bearing base and the electric winding wheel are sequentially arranged on the object placing plate from left to right, the first sliding block is connected to the first sliding rail in a sliding mode, and a second spring is connected between the left side face of the bottom of the first sliding block and the inner left side of the first sliding rail. According to the rapid steel tube surface derusting device, the effects of being capable of removing the rust thoroughly, high in derusting efficiency and low in manufacturing cost are achieved.

Owner:扬州八方冷拉型钢有限公司

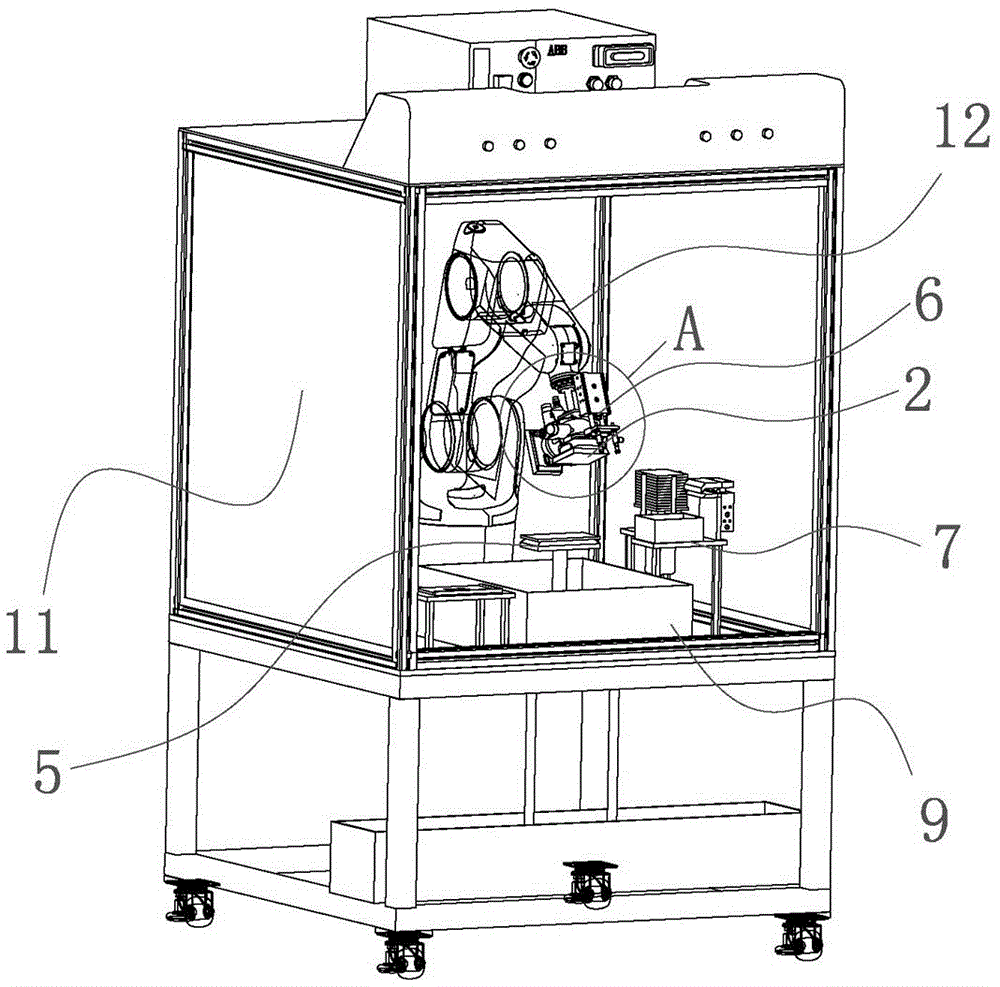

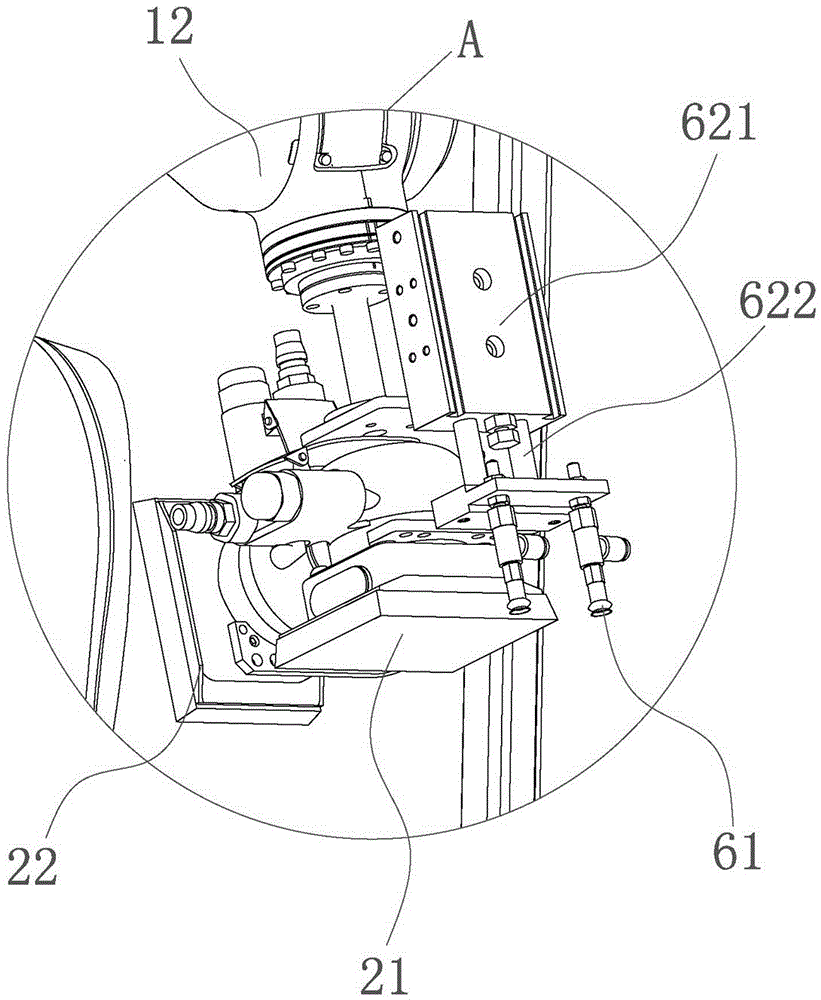

Manipulator grinding system

ActiveCN105666275AVersatileCompact structureEdge grinding machinesGrinding carriagesEngineeringManipulator

The invention relates to the technical field of grinding, and in particular relates to a manipulator grinding system. The manipulator grinding system comprises a grinding robot device and a conveying belt, wherein the grinding robot device comprises a mechanical arm, a grinding tool mounted at the tail end of the mechanical arm, and a grinding bench for fixing a product; the grinding tool comprises a first grinding tool and a second grinding tool; the mechanical arm is provided with a first mounting part and a second mounting part which are arranged in a certain angle; the first grinding tool is mounted at the first mounting part, and the second grinding tool is mounted at the second mounting part; the conveying belt comprises a first conveying belt and a second conveying belt which run oppositely and are arranged up and down; a stop mechanism for stopping the product is arranged on the second conveying belt; and a transplanting mechanism for catching the product from the second conveying belt to the grinding bench is arranged on the conveying belt. Compared with the prior art, the manipulator grinding system disclosed by the invention has complete functions and is compact in structure and higher in automation degree.

Owner:GUANGDONG TOPSTAR TECH

Automatic loading and unloading device for numerically-controlled machine tool

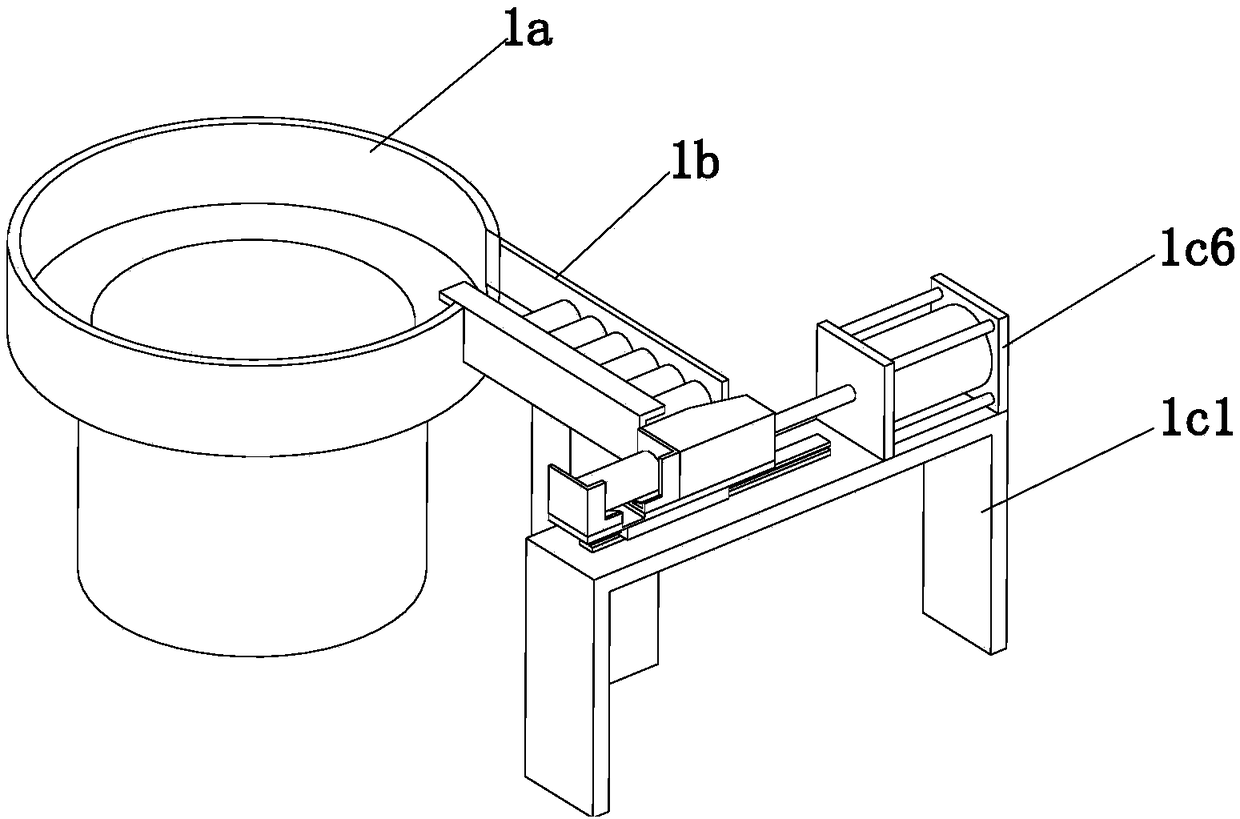

ActiveCN104354097ARealize automatic loading and unloadingRealize automatic feeding processWorking accessoriesGrinding feedersNumerical controlEngineering

The invention discloses an automatic loading and unloading device for a numerically-controlled machine tool. The automatic loading and unloading device is driven by using an axis-X driving structure and an axis-Z driving device, and a glass workpiece is grabbed by virtue of a flexible air cylinder, a rotating air cylinder and a vacuum sucking disc, so that automatic loading of glass pieces to be machined and automatic unloading of the machined glass workpiece are realized; because the numerically-controlled machine tool is in a double-head design, four positioning jigs are provided, and a second positioning jig and a fourth positioning jig load during the machining of a first poisoning jig and a third positioning jig, so that automatic loading and unloading can be realized, circulating machining without stopping is also realized, and the machining efficiency is greatly improved.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

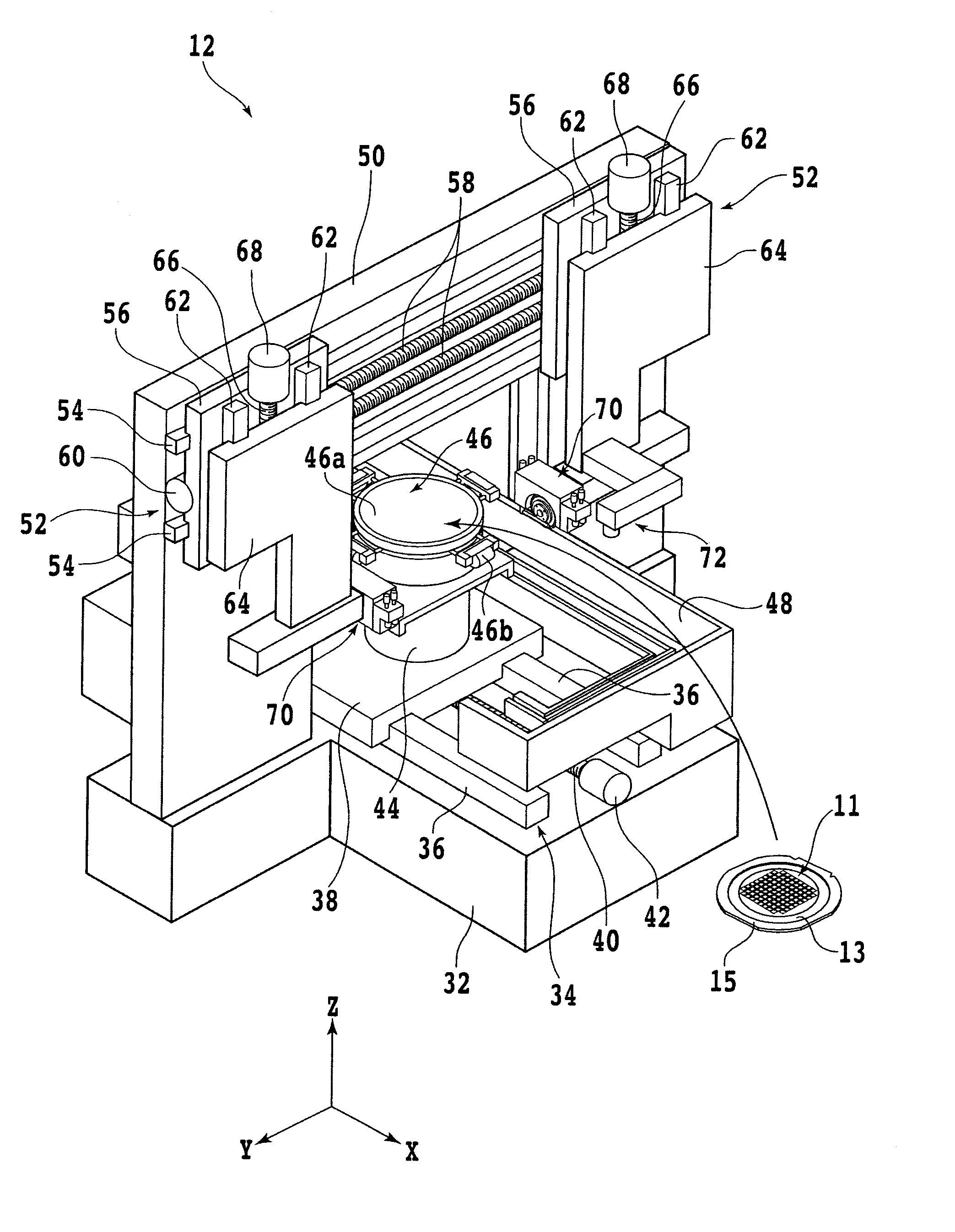

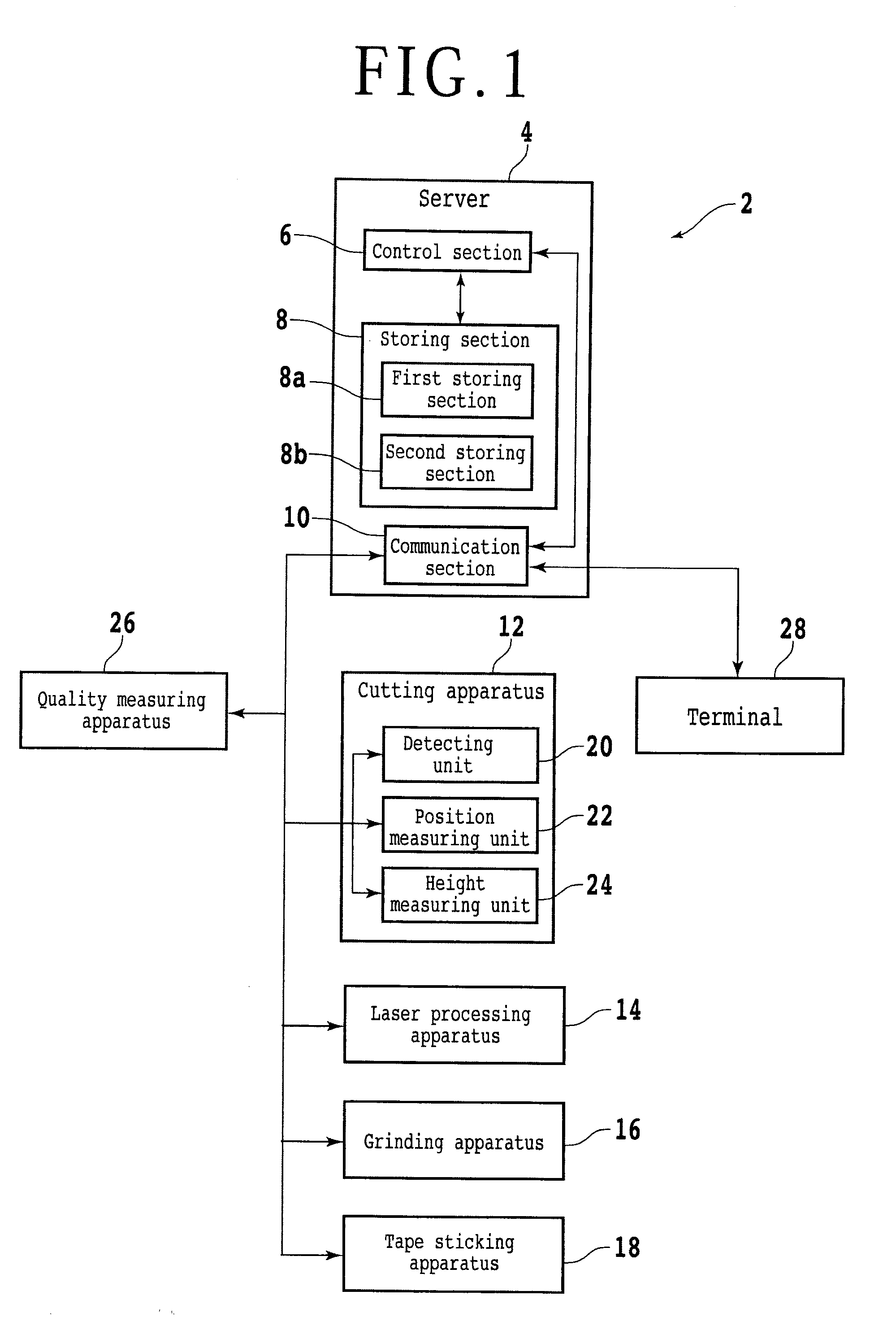

Processing system

ActiveUS20160346956A1Avoid it happening againGrinding carriagesSemiconductor/solid-state device testing/measurementEngineeringTreatment system

There is provided a processing system including a processing apparatus having functional units including a holding unit that holds a workpiece by a holding surface, a processing unit that processes the workpiece held by the holding unit, and a feed unit that moves the holding unit and the processing unit relatively. The processing system further includes a detecting unit that is provided for part or all of the functional units and detects any of vibration, current, voltage, load, speed, torque, pressure, temperature, flow rate, change in a taken image, and the thickness of the workpiece, and a data accumulating unit that accumulates information included in a signal output from the detecting unit as data.

Owner:DISCO CORP

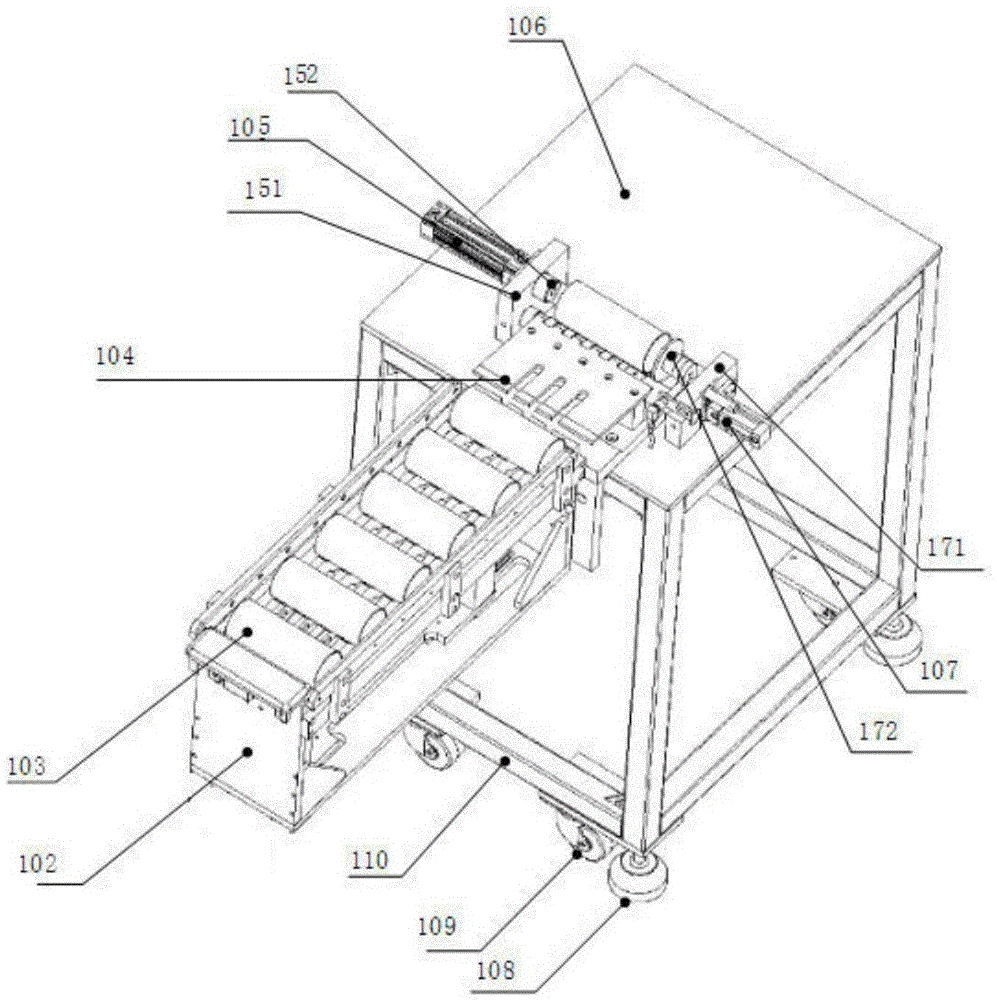

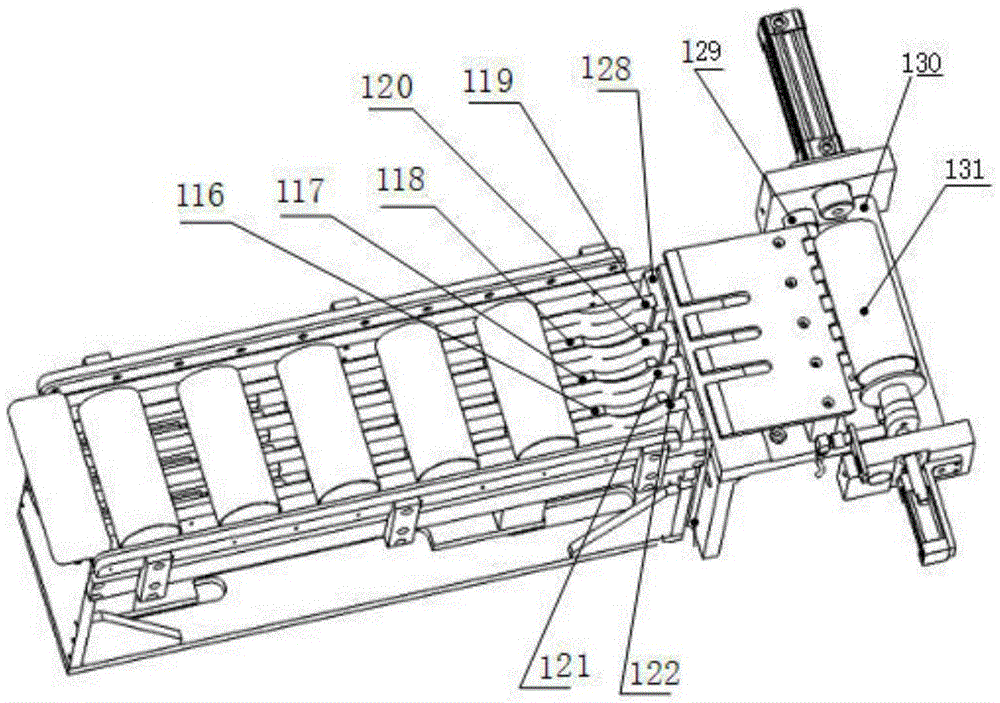

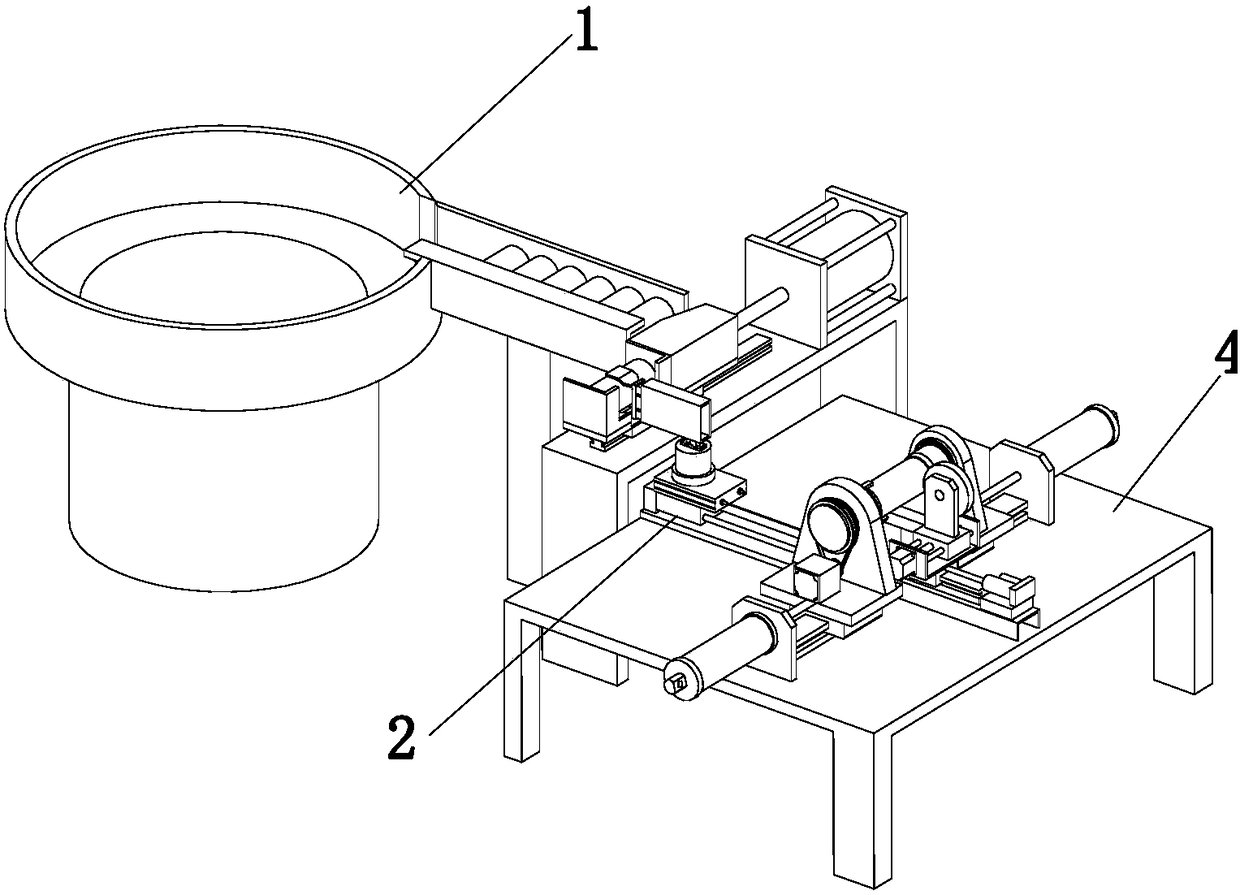

Automatic polishing system for cylindrical workpiece

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

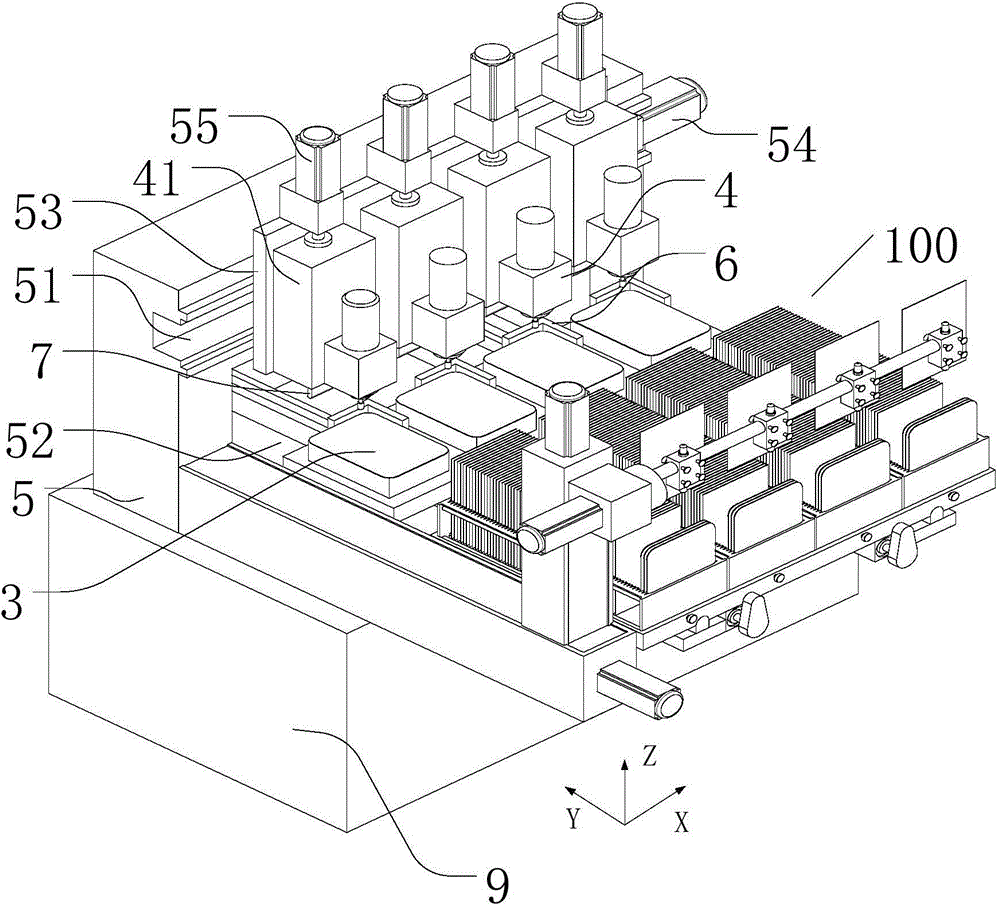

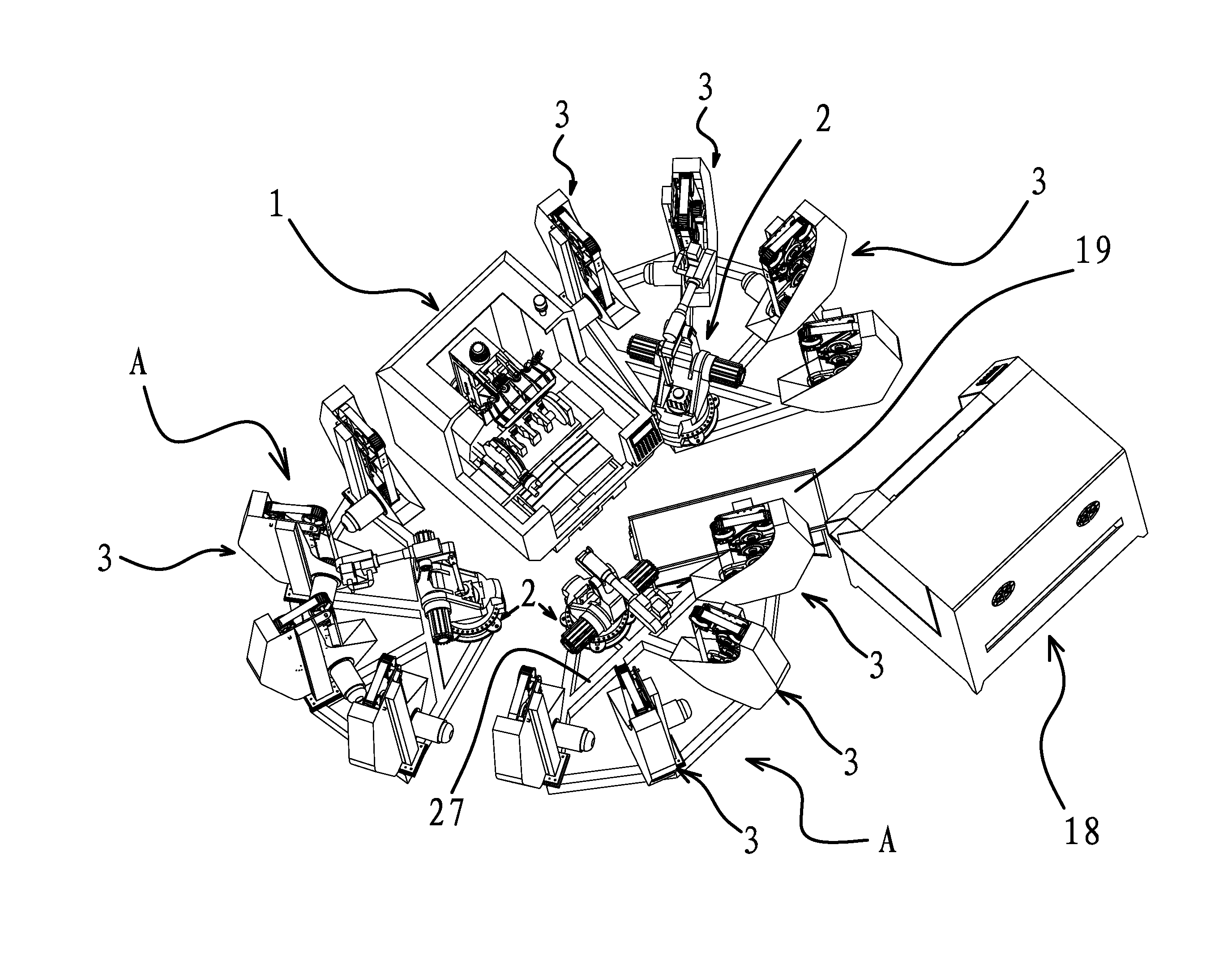

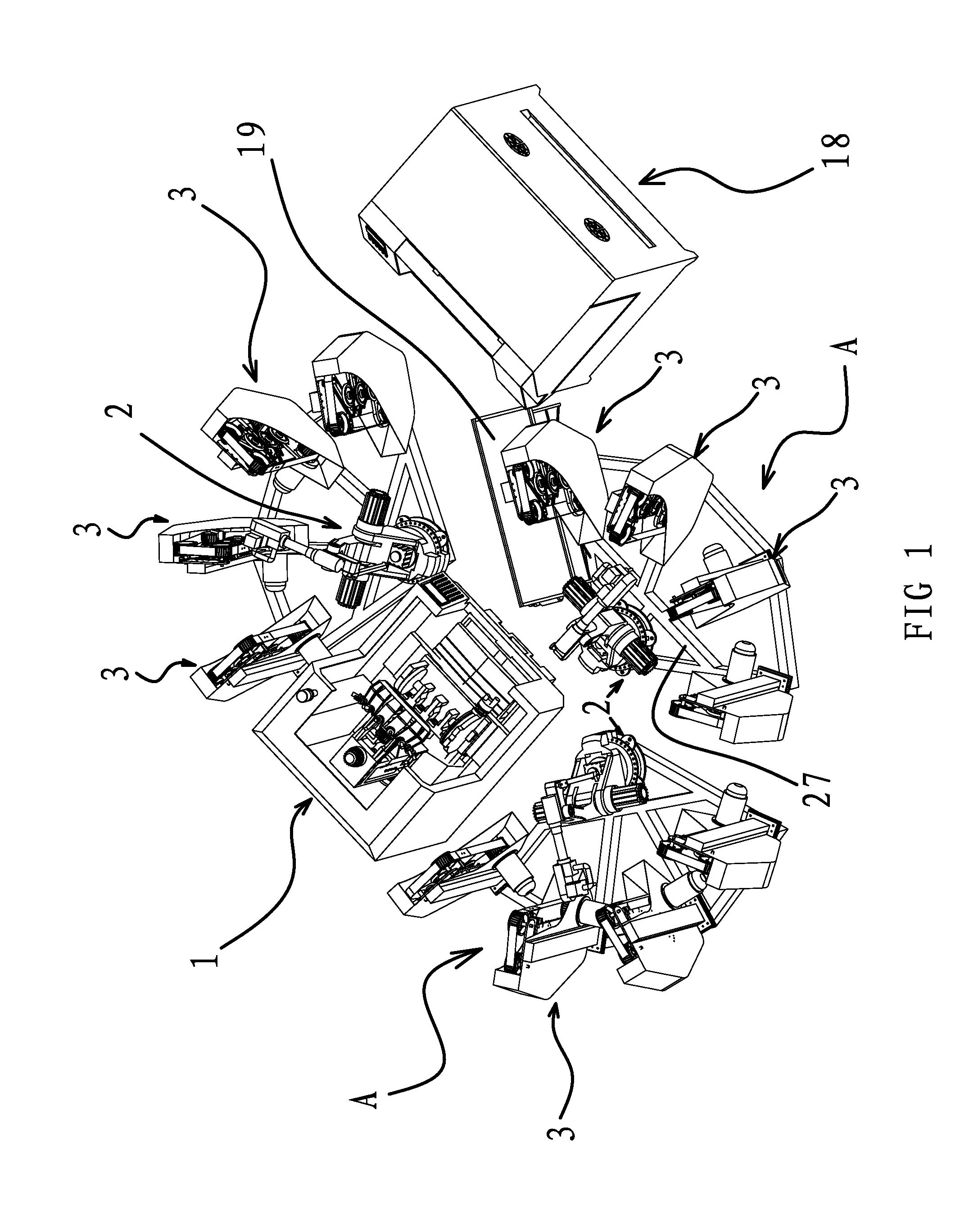

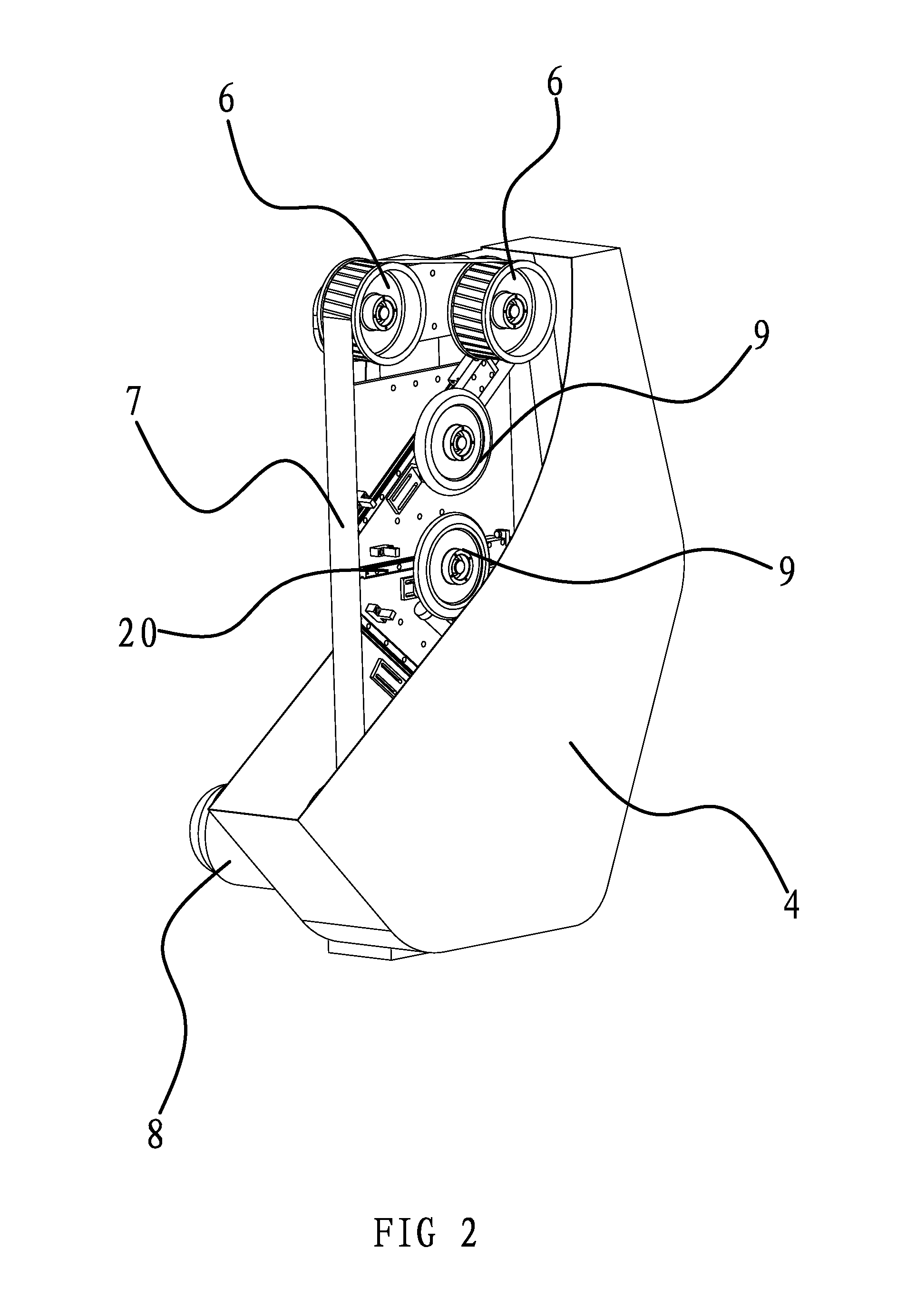

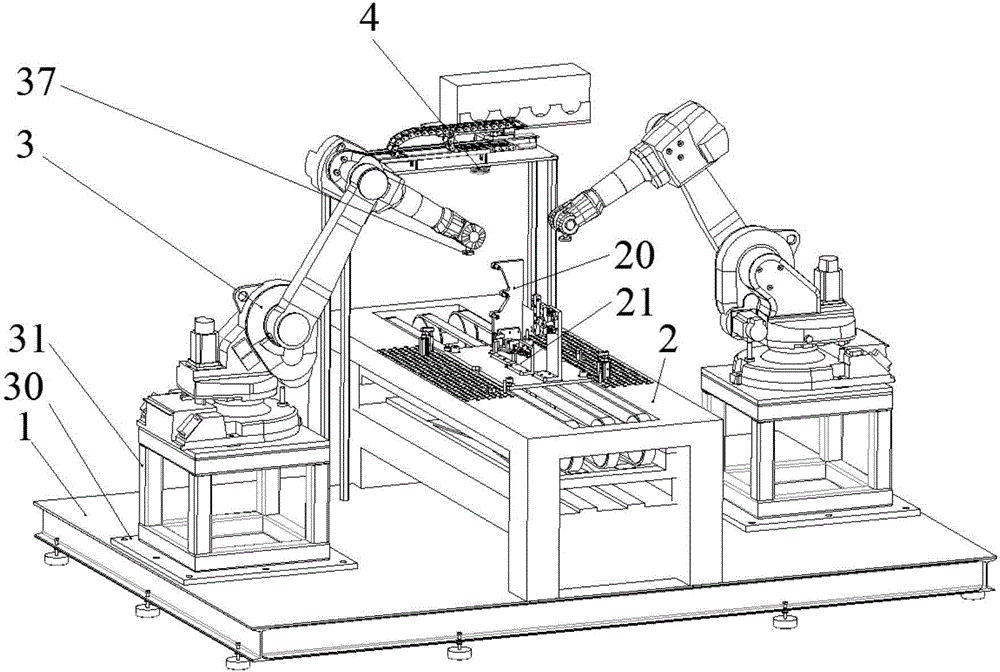

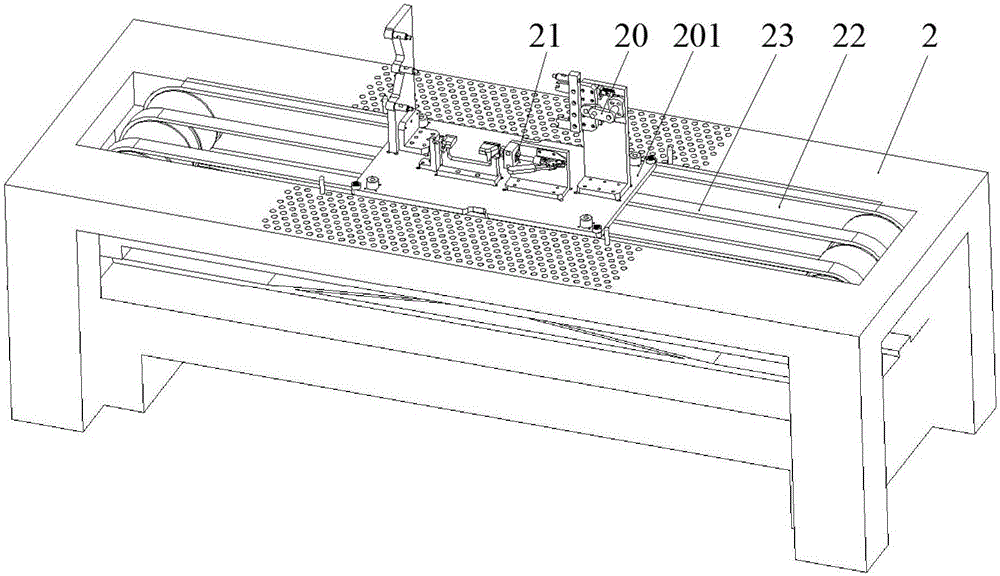

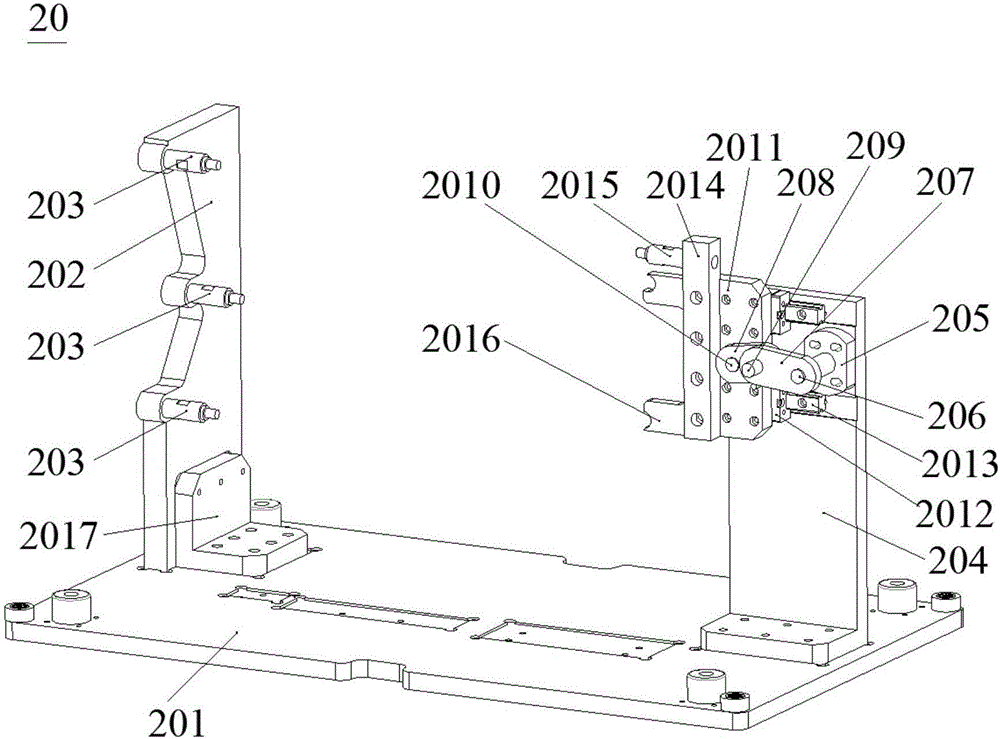

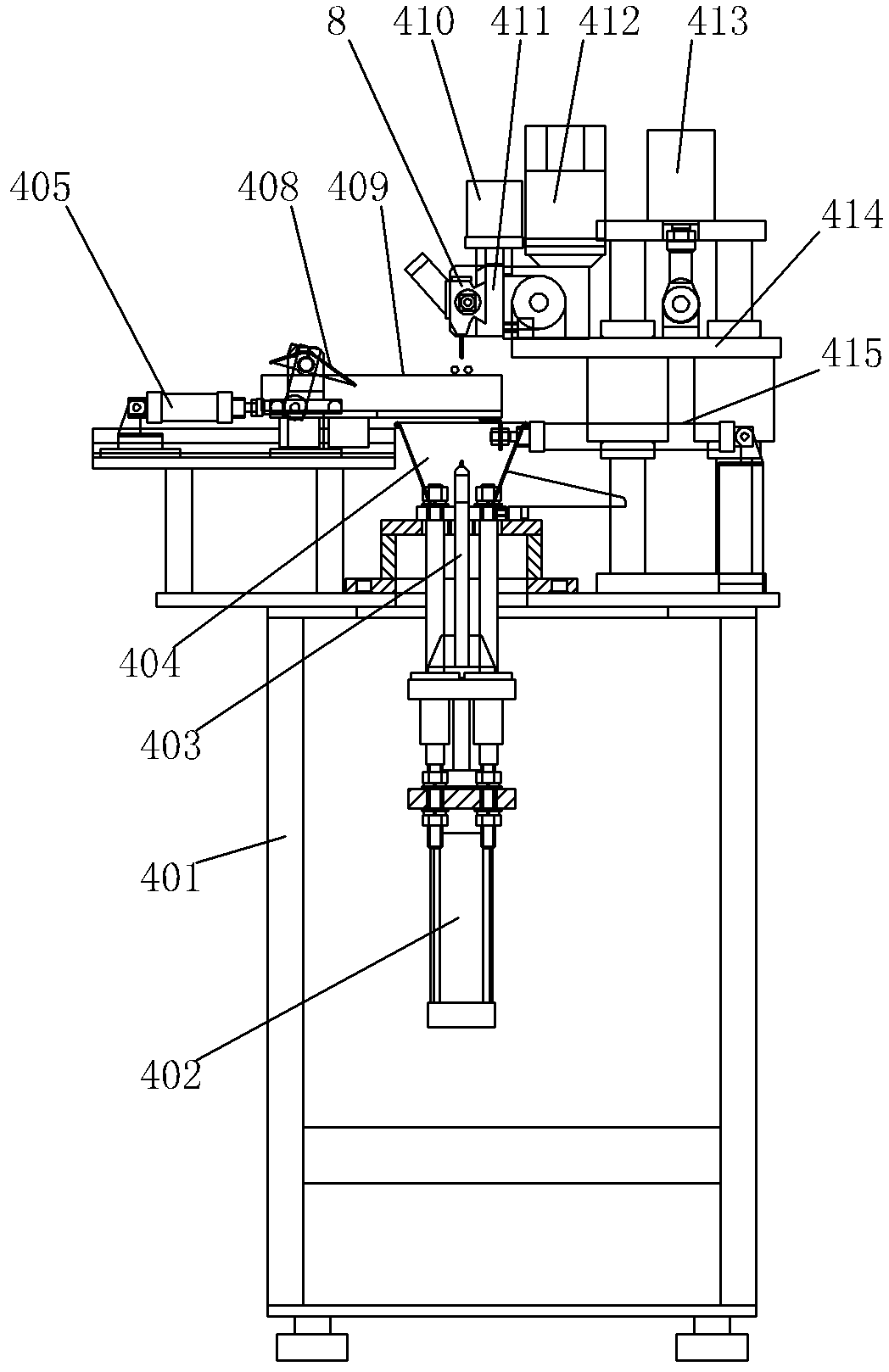

Multi-robot collaborative polishing device and method for pressure casting

ActiveCN106425790AOrderly and efficient grinding workCompact grinding processGrinding machinesGrinding feedersProduction linePressure casting

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Steel pipe rust removing and cutting integrated machine for building

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

Automatic grinding device for outer side of short tube

InactiveCN108326644AArranged in orderPrevent falling outGrinding carriagesRevolution surface grinding machinesTransfer mechanism

The invention provides an automatic grinding device for outer side of a short tube. The device comprises a feeding mechanism, a transferring mechanism, a grinding mechanism and a working platform, wherein the transferring mechanism and the grinding mechanism are positioned on the top part of the working platform; the feeding mechanism is positioned beside the transferring mechanism; a conveying pipeline is arranged on a vibrating plate; a pushing assembly is positioned between the vibrating plate and the transferring mechanism; the transferring mechanism comprises a rotating assembly and a grinding assembly; the rotating assembly is positioned between the grinding assembly and the transferring mechanism and comprises a rotating assembly and a driven assembly; the rotating assembly and thedriven assembly are arranged at an interval on the top part of the working platform. The device has the beneficial effects that a workpiece can be automatically fed through the feeding mechanism and the transferring mechanism, so that automatic production can be realized, and the working intensity of workers can be reduced; the outer side of the workpiece can be automatically grinded through the grinding assembly, so that the working efficiency is effectively improved, and moreover, the problem that the whole sidewall of a workpiece with excessive length cannot be grinded can be avoided.

Owner:SHANDONG TAIKAI PRECISION CASTING

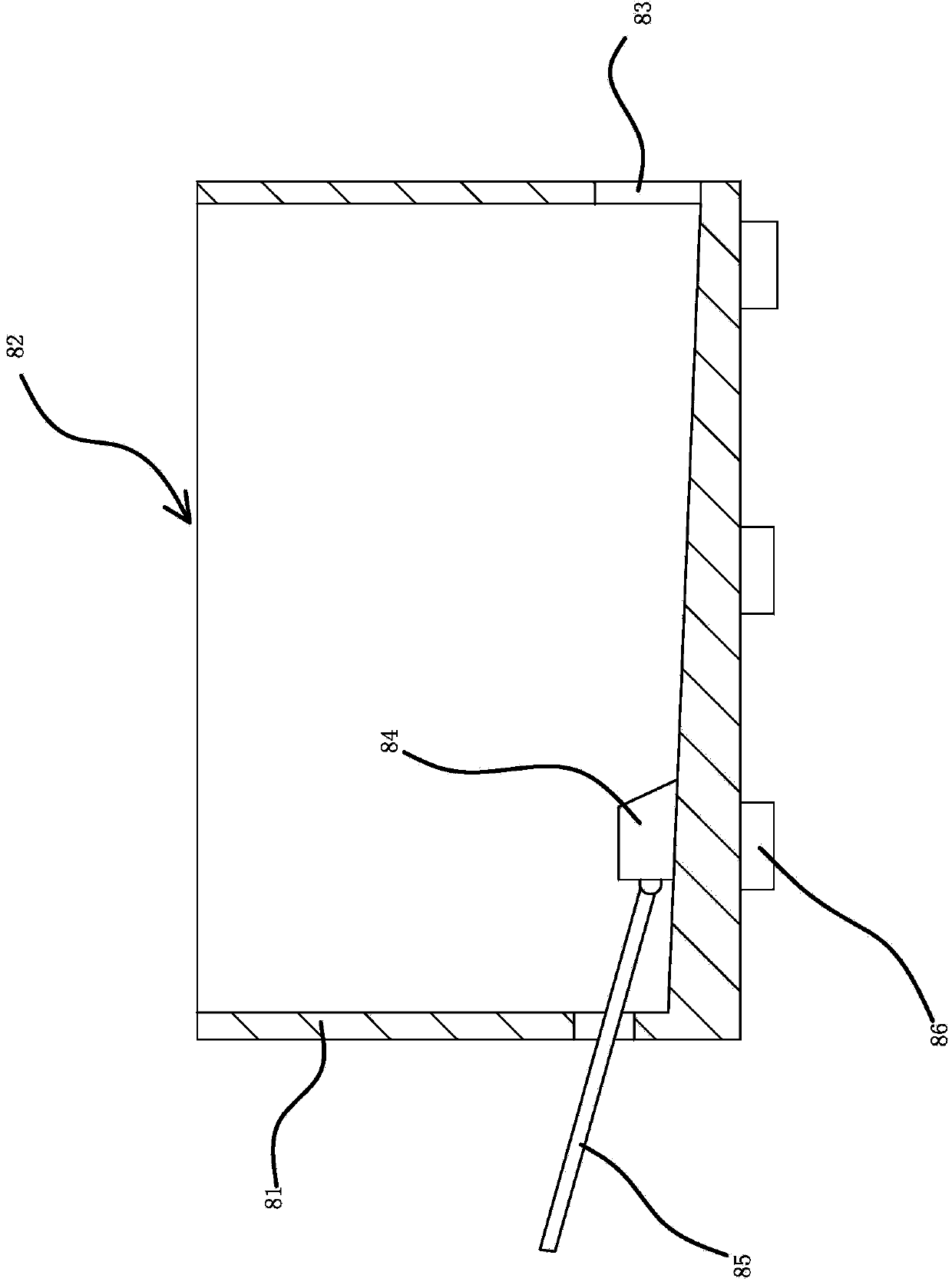

Automatic double-edge glass edge grinding production line

InactiveCN106334984AEasy to operateImprove work efficiencyEdge grinding machinesGrinding feedersProduction lineEngineering

The invention discloses an automatic double-edge glass edge grinding production line. The automatic double-edge glass edge grinding production line comprises a first edge grinding machine, a second edge grinding machine, a reversing system arranged between the first edge grinding machine and the second edge grinding machine, a feeding system conducting automatic feeding of glass and a discharging system discharging the glass after edge grinding is completed. The first edge grinding machine and the second edge grinding machine are identical in structure and each comprise a base, a conveyer belt which is arranged on the base and supports and conveys the glass, an edge grinding system conducting double-sided edge grinding on the glass and a locating system conducting position correction on the glass before edge grinding. The automatic double-edge glass edge grinding production line has the beneficial effects that the control action is precise and stable, the glass is conveyed precisely in place, production operation is facilitated, the production efficiency is improved, the labor cost is reduced, the operation automation degree of the whole automatic double-edge glass edge grinding production line is high, operation is easy and convenient, the glass is aligned before edge grinding, automatic feeding and discharging can be achieved, the automatic double-edge glass edge grinding production line can continuously grind the glass through the coordination of automatic edge grinding machines, and the automatic double-edge glass edge grinding production line is high in practicability and can improve the work efficiency of glass edge grinding.

Owner:宿州市天艺玻璃股份有限公司

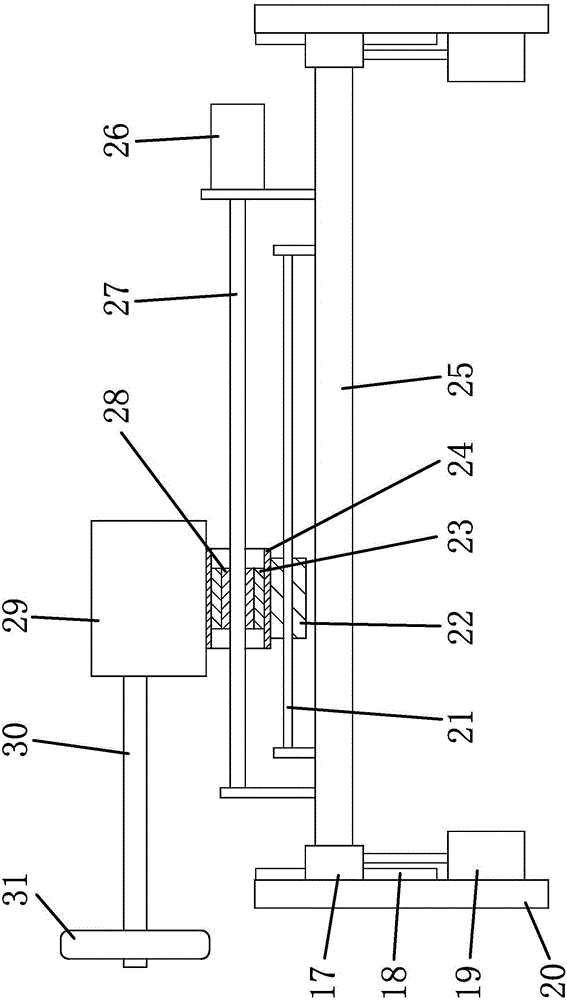

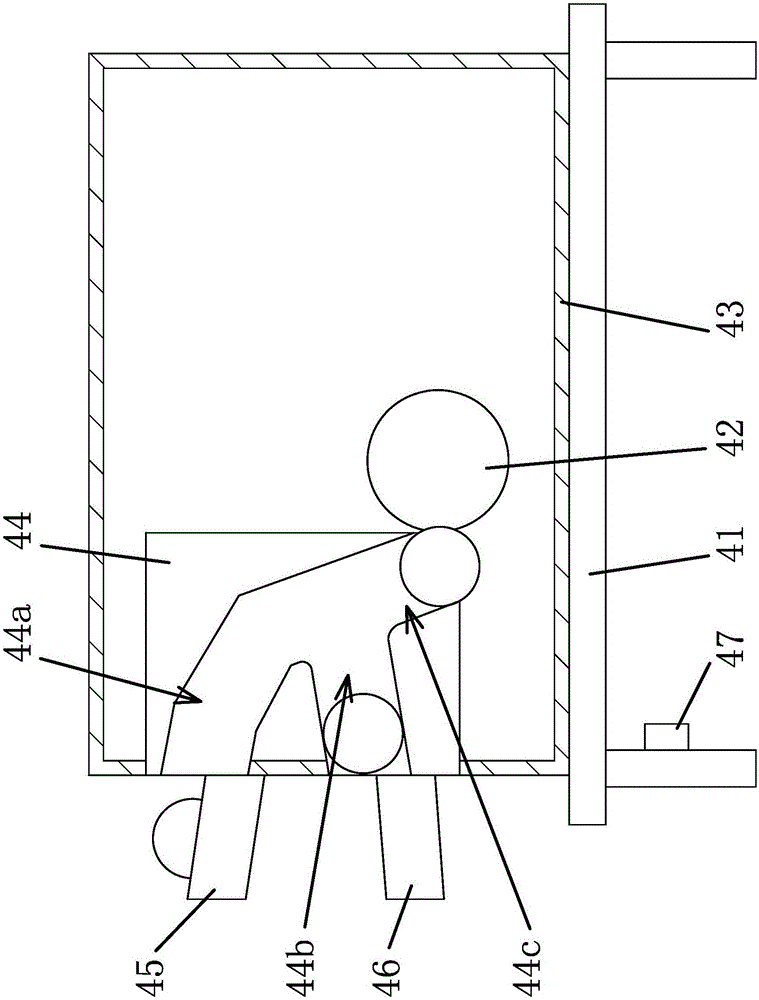

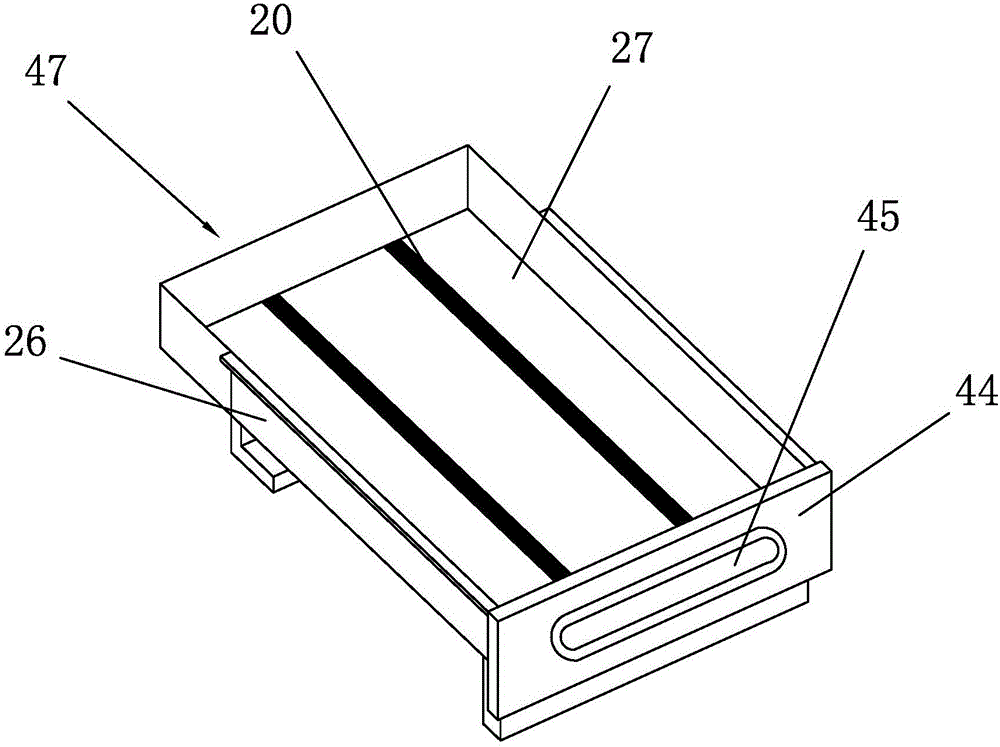

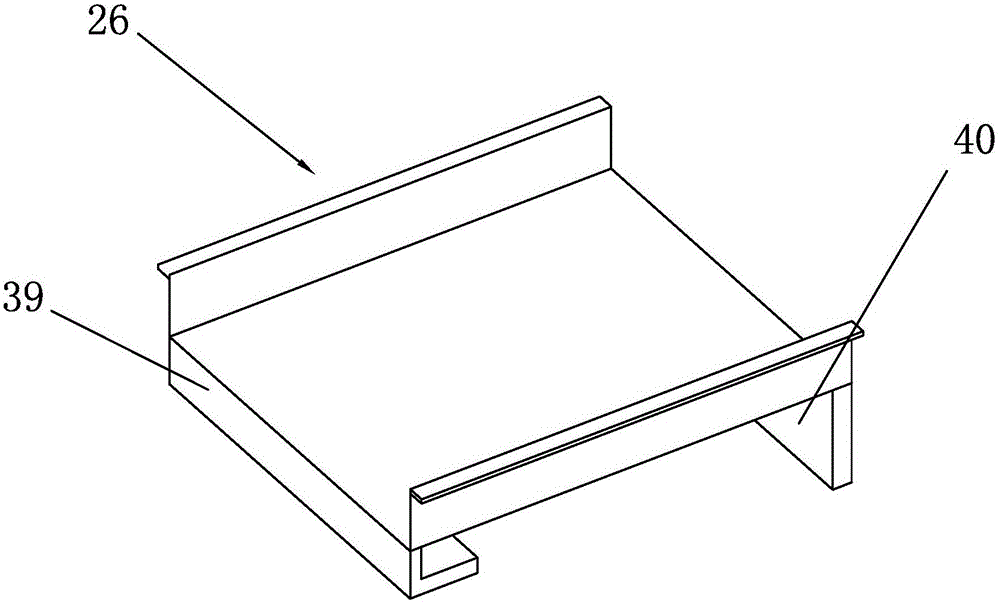

Grinding machine for bearing rings

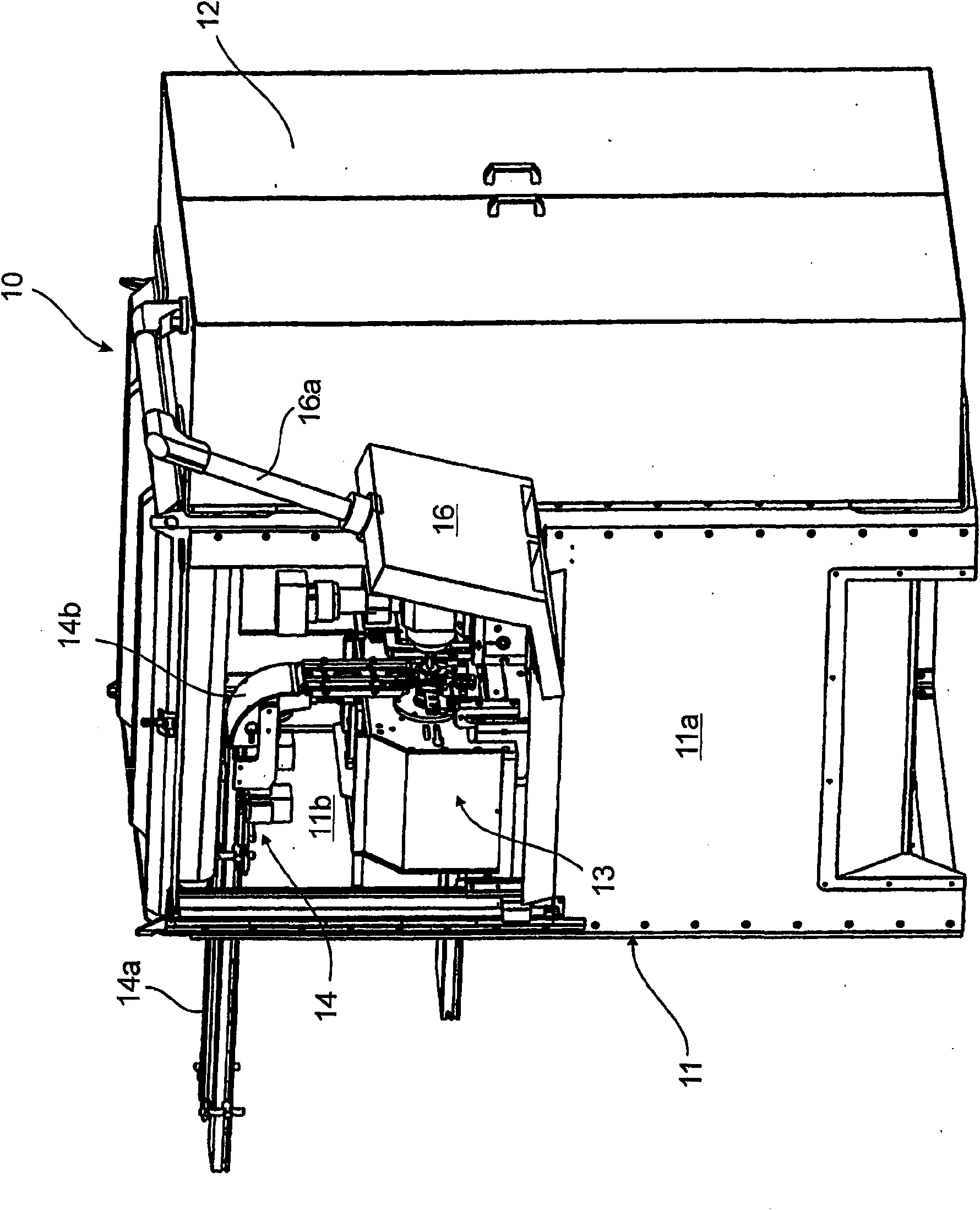

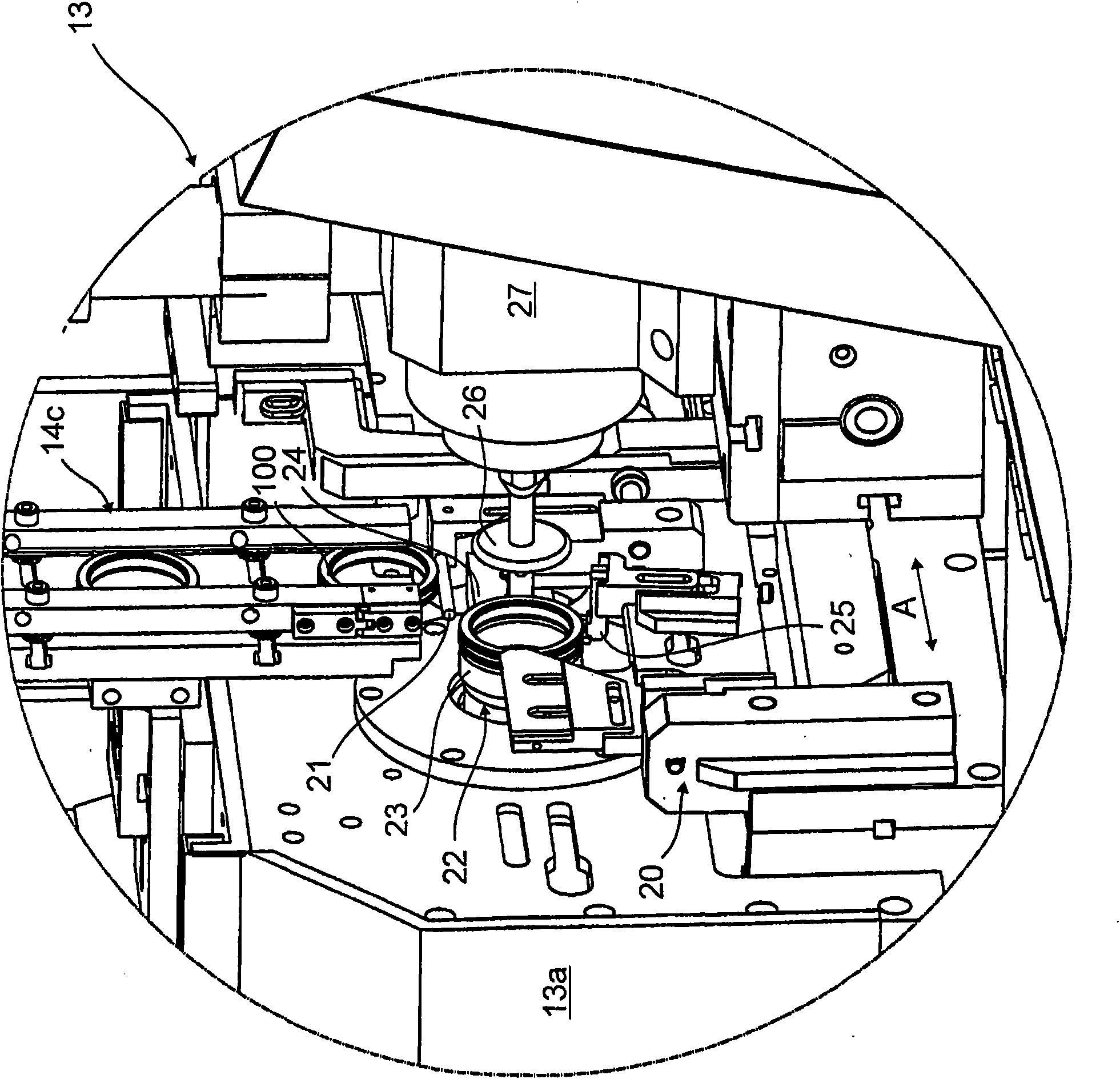

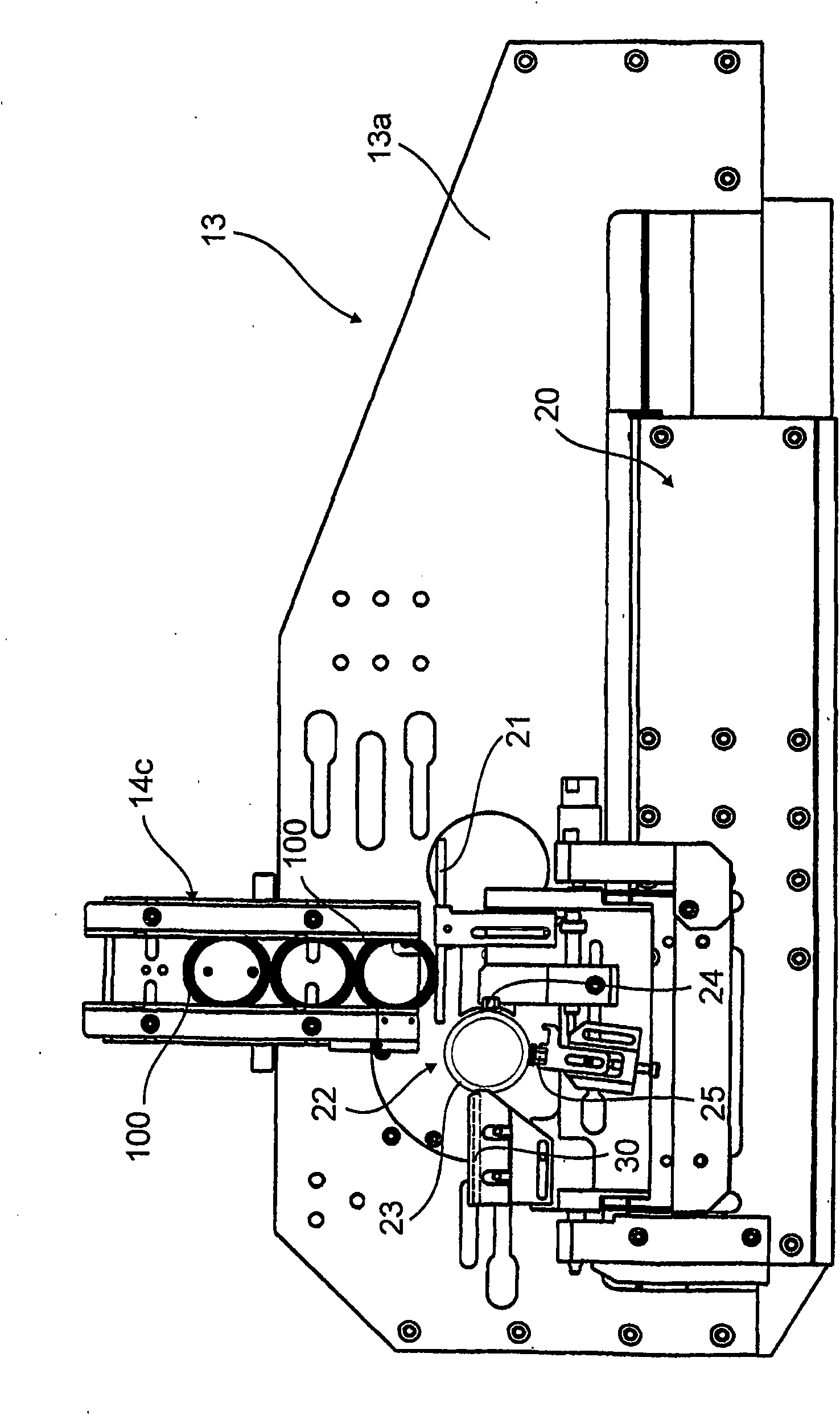

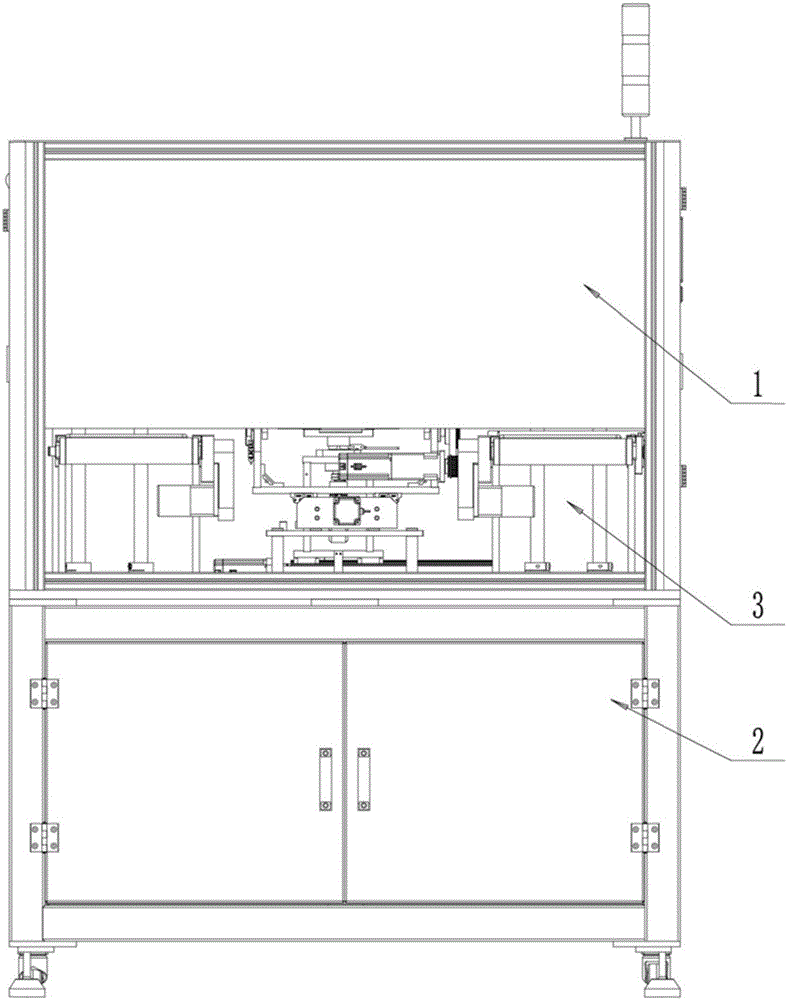

A bearing ring grinding machine comprising a grinding unit arranged to provide machining quality with micron-size tolerances and a reduced grinding cycle period. To this end, the grinding unit (13) comprises a fixed plate (13a) on which are mounted a loader (14c) and a sliding carriage (20) arranged to move horizontally in the direction of the double arrow A. A sliding carriage (20) stopper (21),in the loader (14c), holds the inferior ring (100) applied against the plate (13a) and maintained between two lateral channels. The fixed plate (13a) has a passage opening for a rotatable spindle (22)equipped with a magnetizable socket (23) to support a ring during machining and two adjustable support stops (24, 25) for automatically positioning the rotating ring on the socket (23). At first, thesliding carriage (20) releases the passage for a ring (100) to be grinded toward the magnetizable socket (23) of the rotatable spindle (22), through a magnetic carrier tape (14b) in order to, at a second moment, maintain the ring (100) against the two stops (24, 25) during their machining and in order to, at a third moment, transfer the grinded ring (100) from the support position toward an automatic discharge device (15).

Owner:ROBOTIC CONSULTING S A R L

Metal plate trimmer

The invention relates to a metal plate trimmer. The metal plate trimmer comprises a frame assembly, a machining device and a transparent protective cover, wherein the machining device is arranged on the frame assembly, and the transparent protective cover covers the machining device; the machining device comprises a trimming center, a feeding device, a discharge device and a mechanical arm device; the openable door of the transparent protective cover is arranged on the front side of the trimming center, and a channel allowing a to-be-machined metal plate to pass is arranged between the lower portion of the openable door and the frame assembly. The metal plate trimmer is reasonable in design, compact in structure and convenient to use.

Owner:广州市泽铫电器有限公司

Corrugated pipe machining device

InactiveCN106271946AGuaranteed stabilitySimple structureEdge grinding machinesGrinding carriagesEngineeringMachining system

The invention provides a corrugated pipe machining device. Each adjustment sliding rail is provided with a first adjustment sliding block and a second adjustment sliding block, positioning parts are fixedly connected to the opposite side faces of the first adjustment sliding block and the second adjustment sliding block on the same adjustment sliding rail respectively, a first connecting rod is connected between every two adjacent first adjustment sliding blocks, a second connecting rod is connected between every two adjacent second adjustment sliding blocks, a first nut is connected to the first connecting rod between any two first adjustment sliding blocks, and a second nut is connected to the second connecting rod corresponding to the first connecting rod. The corrugated pipe machining system can conduct cutting and grinding on a corrugated pipe, positioning and fixing on the corrugated pipe are enhanced, the corrugated pipe machining device is suitable for clamping and positioning the corrugated pipes with different sizes, the application range is wide, and the machining precision and the uniformity of standards of machined products are guaranteed.

Owner:南昌迪亚汽车波纹管有限公司

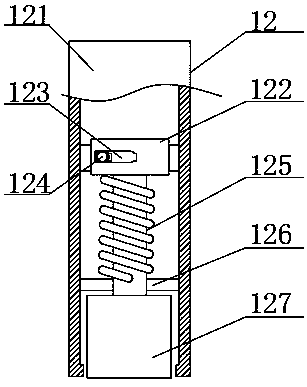

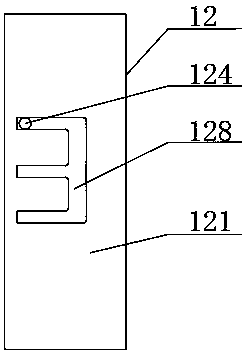

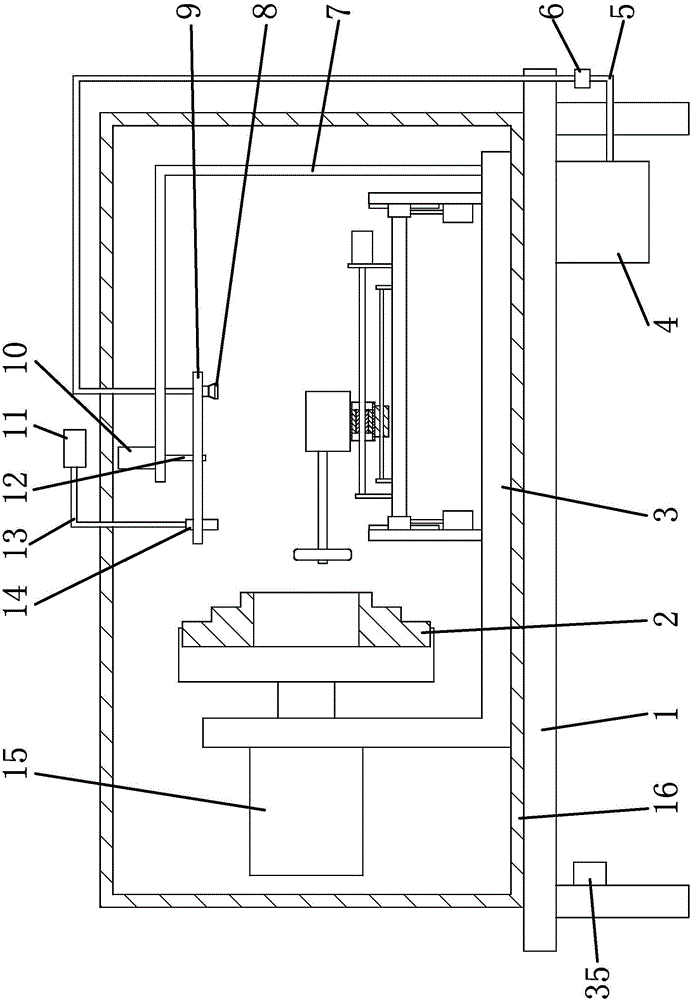

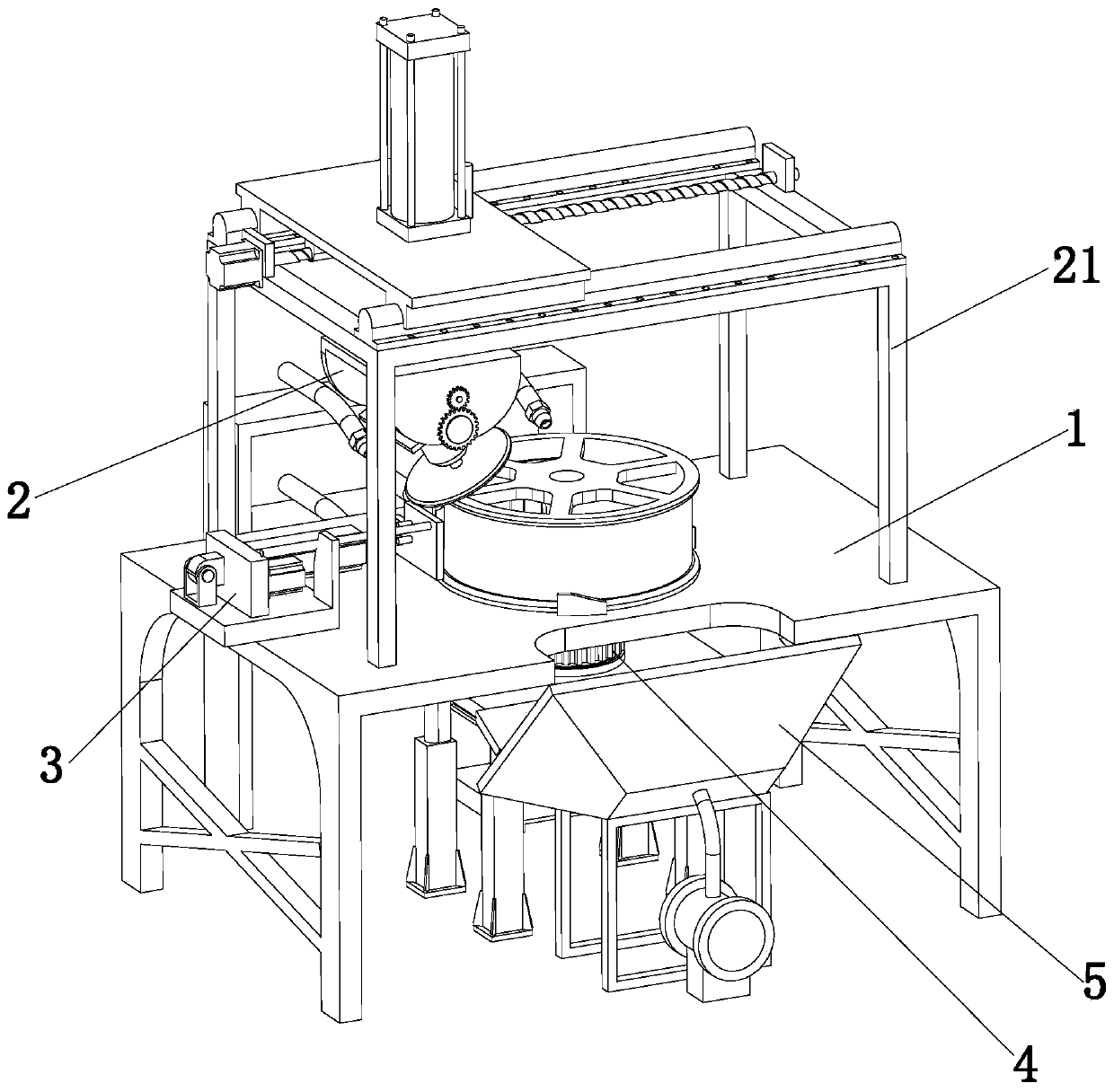

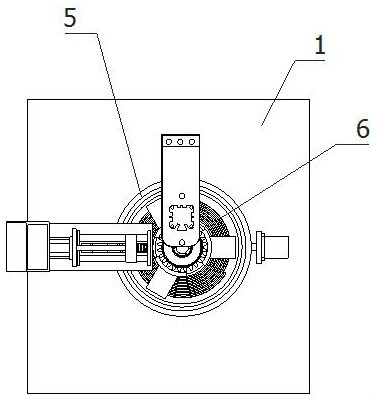

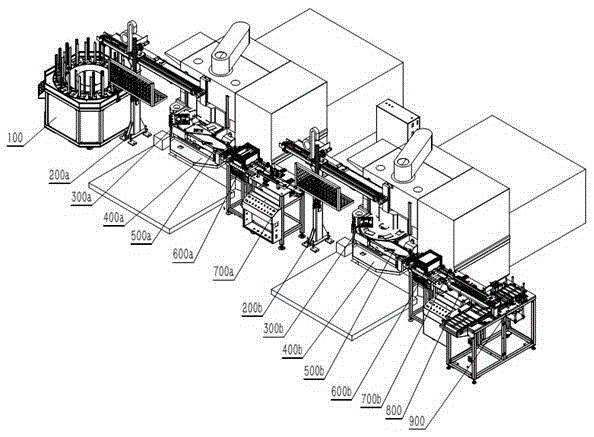

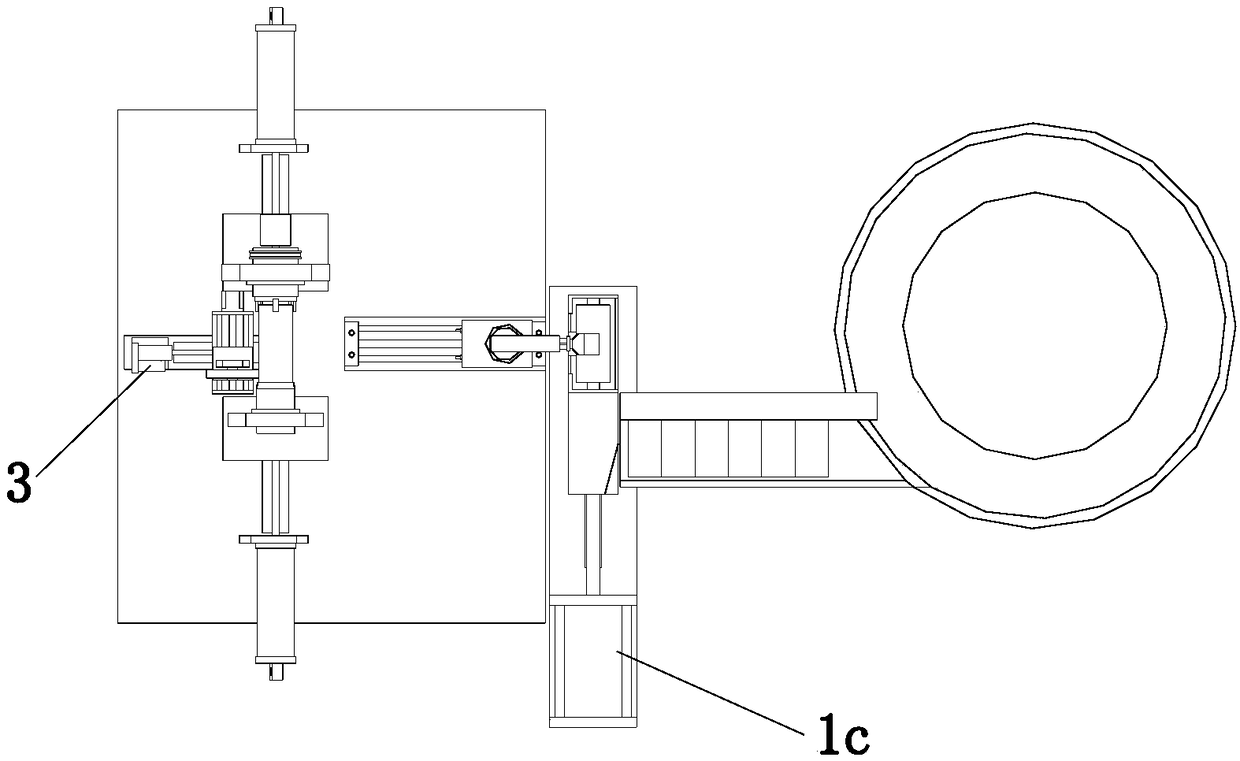

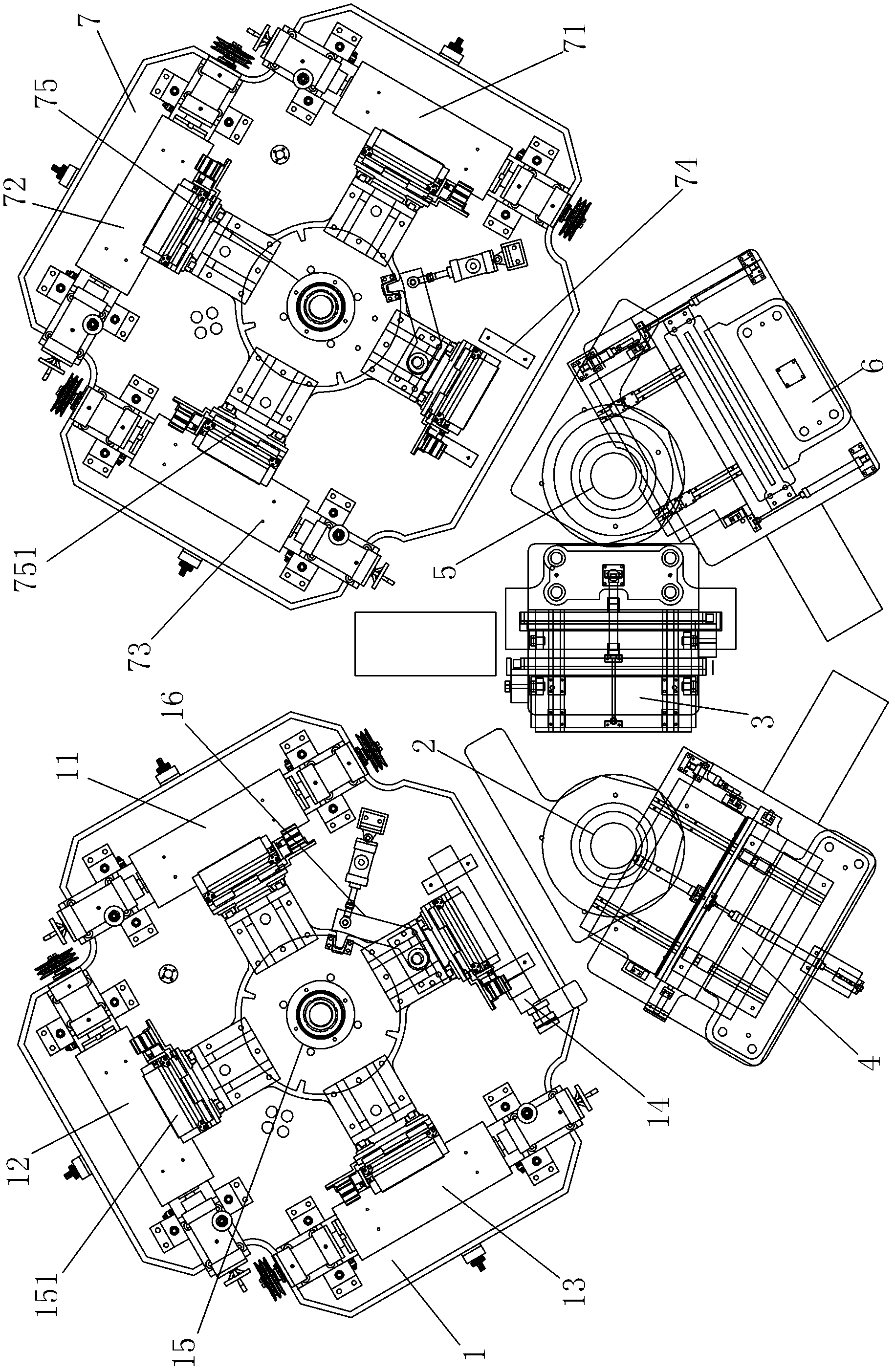

Crystal blank automatic polishing system

ActiveCN102430967AEnsure processing consistencyGuaranteed manufacturing accuracyEdge grinding machinesSemiconductor/solid-state device manufacturingEngineeringTransfer mechanism

The invention discloses a crystal blank automatic polishing system comprising a first rotary frame, an upper hemisphere grinding station and a polishing station, wherein the first rotary frame is provided with a head; a second rotary frame, a lower hemisphere grinding station and a polishing station, wherein the second rotary frame is provided with a head; a loading station; a butting station; a discharge station; a first transferring mechanism which can pick up and put down the fixture and can transfer the fixture among the loading station, the butting station and the first rotary frame; and a second transferring mechanism which can pick up and put down the fixture and can transfer the fixture among the loading station, the butting station and the second rotary frame. The invention further discloses a full automatic polishing system with the same principle for processing an inclined plane of hemisphere of the crystal blank. The invention not only can realize full automatic polishing of the crystal blank and ensure the polishing quality, but also can fully utilize the advantages of the present machine and simplify the complex degree of the mechanism action and can be manufactured and maintained easily.

Owner:虞雅仙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com