Patents

Literature

687results about How to "Realize automatic loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

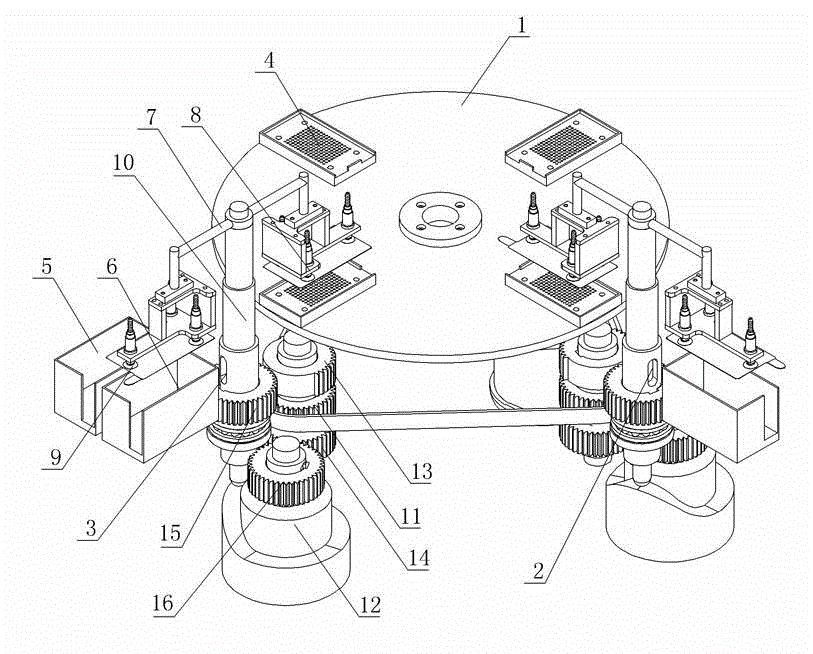

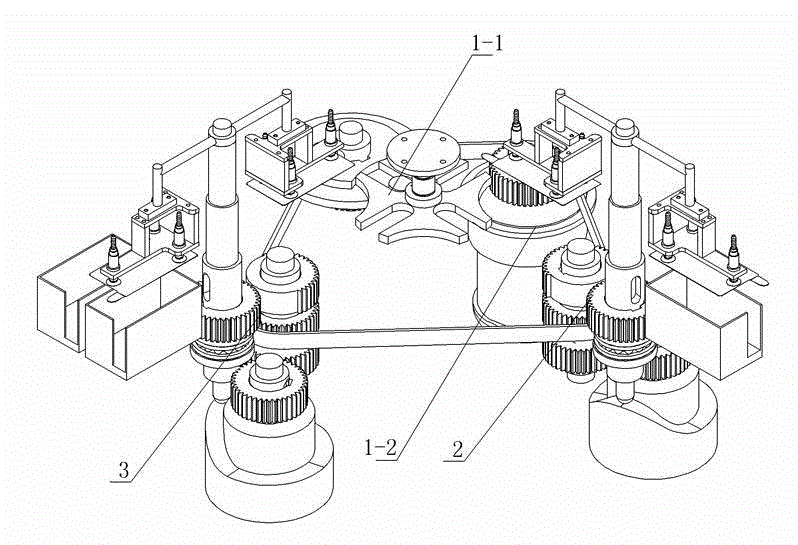

Full-automatic water-drill grinding and polishing machine

InactiveCN101758433AImprove work efficiencyFixture positioning is accurateEdge grinding machinesManipulatorEngineering

The invention disclosed a full-automatic water-drill grinding and polishing machine which comprises a fixture, a fixture seat and a mechanical hand. The full-automatic water-drill grinding and polishing machine is characterized in that: the machine includes a left grinding and polishing part and a right grinding and polishing part, wherein the right grinding and polishing part includes a bead loading station, a right grinding station, a right polishing station and a right butting station; the left grinding and polishing part includes a left butting station, a left grinding station, a left polishing station and a bead unloading station; the left butting station and the right butting station are arranged correspondingly; the fixture and the fixture seat are arranged independently; the fixture can act along with the mechanical hand; and the fixture seat is arranged correspondingly to the bead loading mechanism, the grinding mechanism, the polishing mechanism, the left butting mechanism, the right butting mechanism and the bead unloading mechanism. With accurate fixture positioning and high grinding as well as polishing precision, the grinding and polishing machine can realize automatic grinding and polishing of a water drill and can automatically correct processing dimension errors caused by abrasion of abrasive wheels.

Owner:瑞安市天成包装机械有限公司

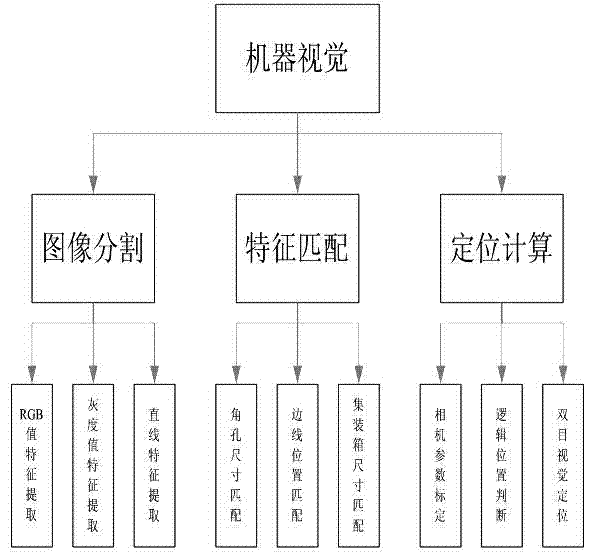

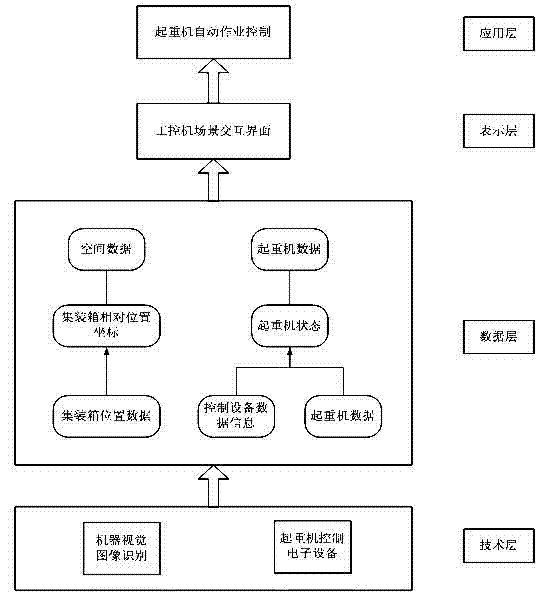

Automatic control system of efficient handing operation of container crane

InactiveCN102923578APrecise positioningMovement precisionLoad-engaging elementsLoop controlAutomatic control

The invention provides an automatic control system of an efficient handing operation of a container crane, and relates to the technical field of operation and production of container cranes. The machine vision and image recognition location technology is used to locate the relative position of a container and a lifting appliance, an image processing result is transmitted to a crane control system, a bar code location system is mounted near a crane cart track and a crane trolley track to accurately locate the position of the lifting appliance of the crane, then a position closed loop feedback control system is formed, and therefore an image recognition location method and an image recognition location device of the container crane are achieved, a lifting appliance movement closed loop control method of the container crane is achieved, and an automatic container grabbing method and an container grabbing device of the lifting appliance of the crane are achieved.

Owner:YANGZHOU CITY HUATAI ENVIRONMENT PROTECTION EQUIP MFG

Automatic feeding and discharging device

ActiveCN102430953AGuaranteed machining accuracyMake up for the errorMetal working apparatusMechanical engineeringJoint action

The invention discloses an automatic feeding and discharging device, which comprises a distribution mechanism, a dropping mechanism and a conveyance mechanism. The conveyance mechanism is arranged between the distribution mechanism and the dropping mechanism and consists of a base, a feeding mechanism, a lifting mechanism and a conveying mechanism are disposed on the base, the lifting mechanism is arranged between the feeding mechanism and the conveying mechanism, and the feeding mechanism is connected with the distribution mechanism, and is also connected with the dropping mechanism. By the aid of the joint action of the distribution mechanism, the feeding mechanism, the lifting mechanism, the conveying mechanism and the dropping mechanism, automatic feeding and discharging of pipes can be realized, labor intensity of feeding and discharging of the pipes can be greatly reduced, production efficiency is enhanced, and production cost is lowered.

Owner:CHERY AUTOMOBILE CO LTD

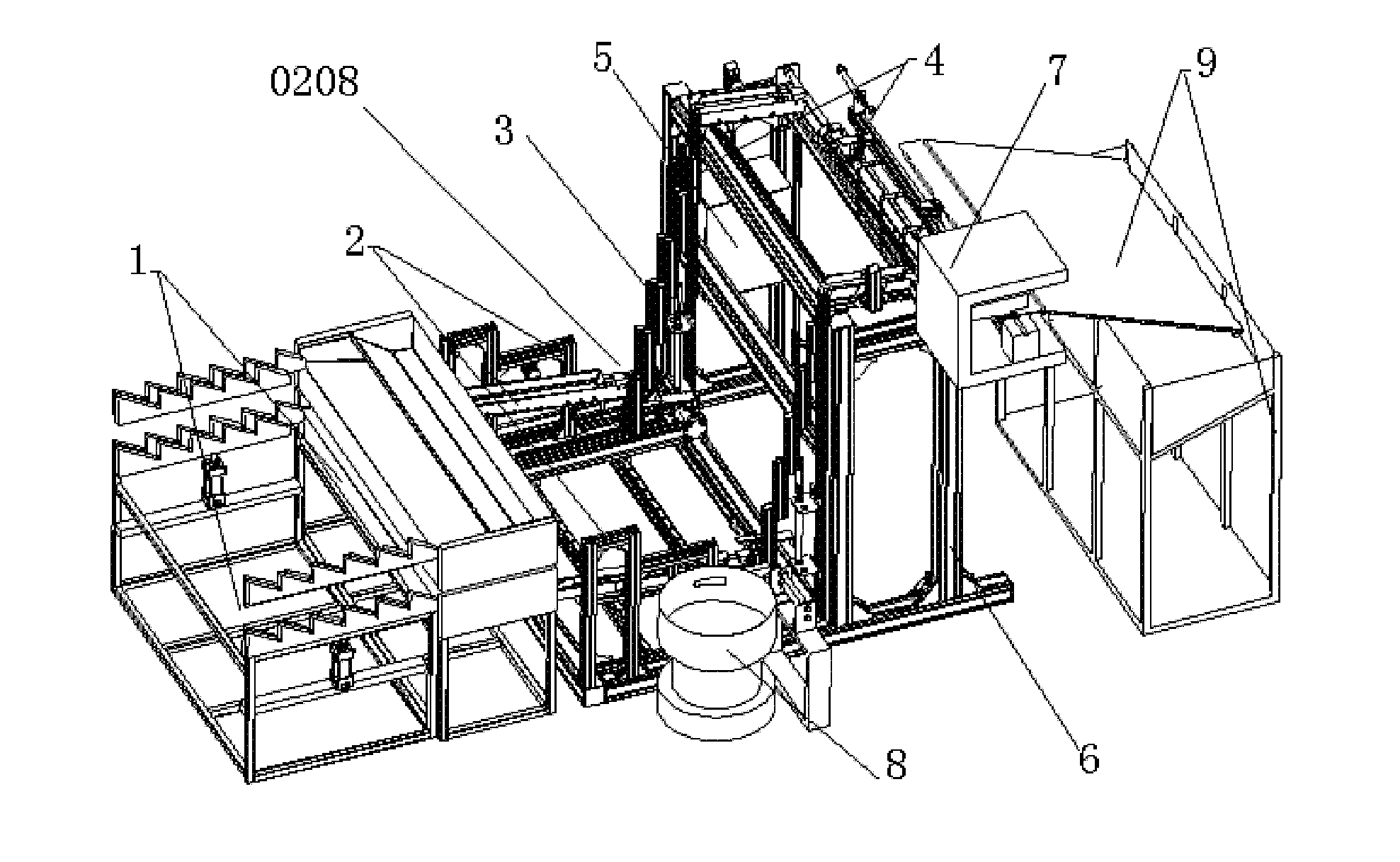

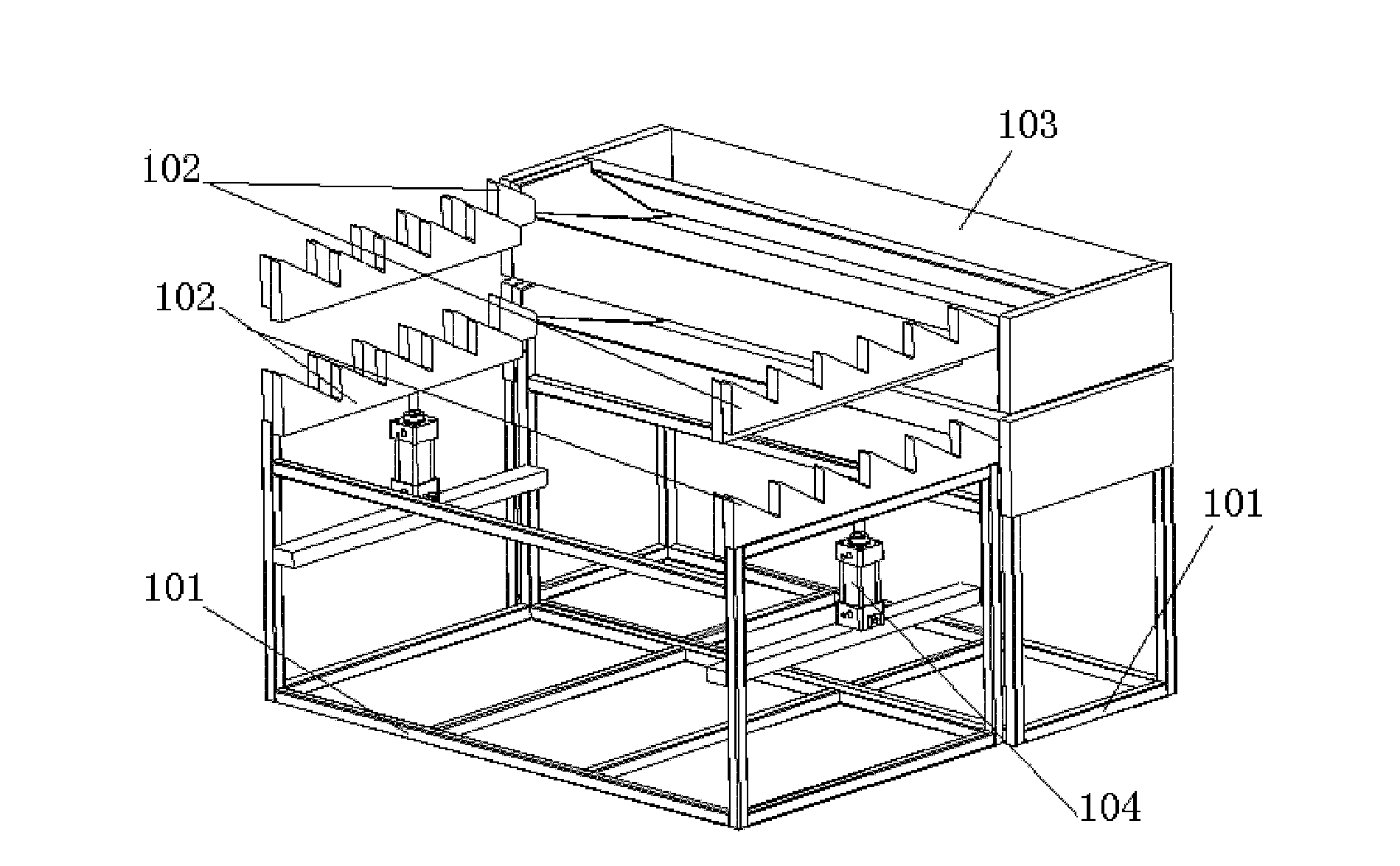

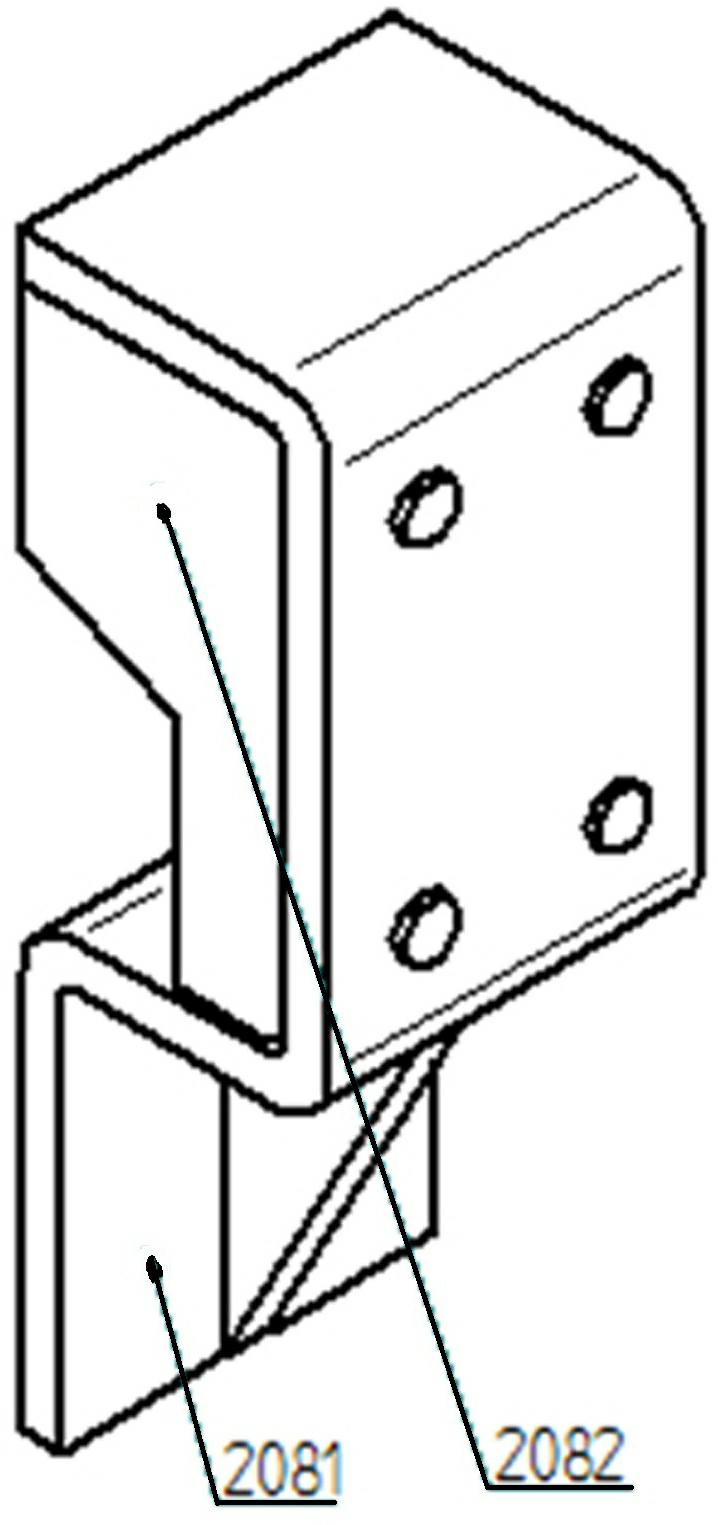

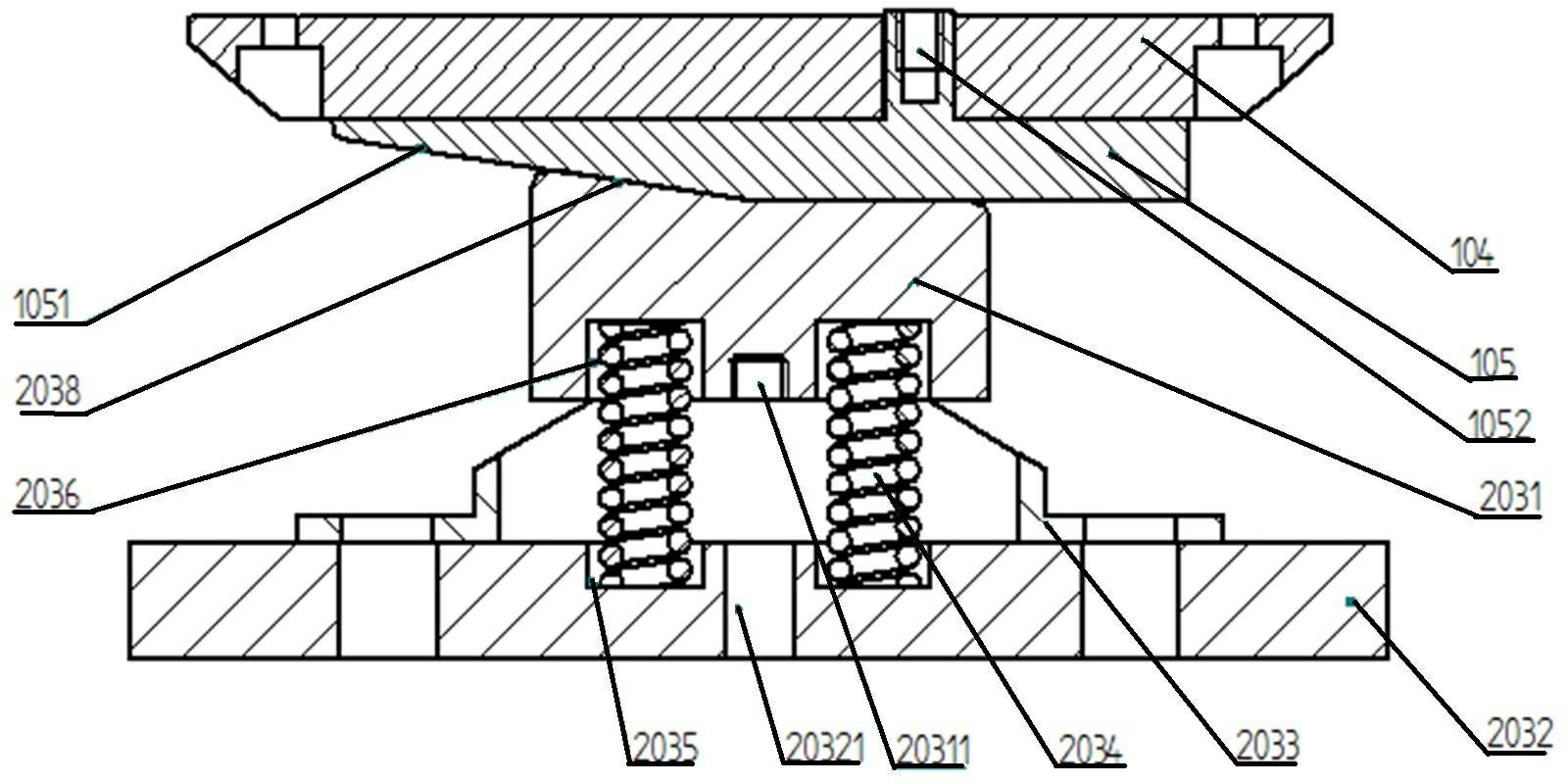

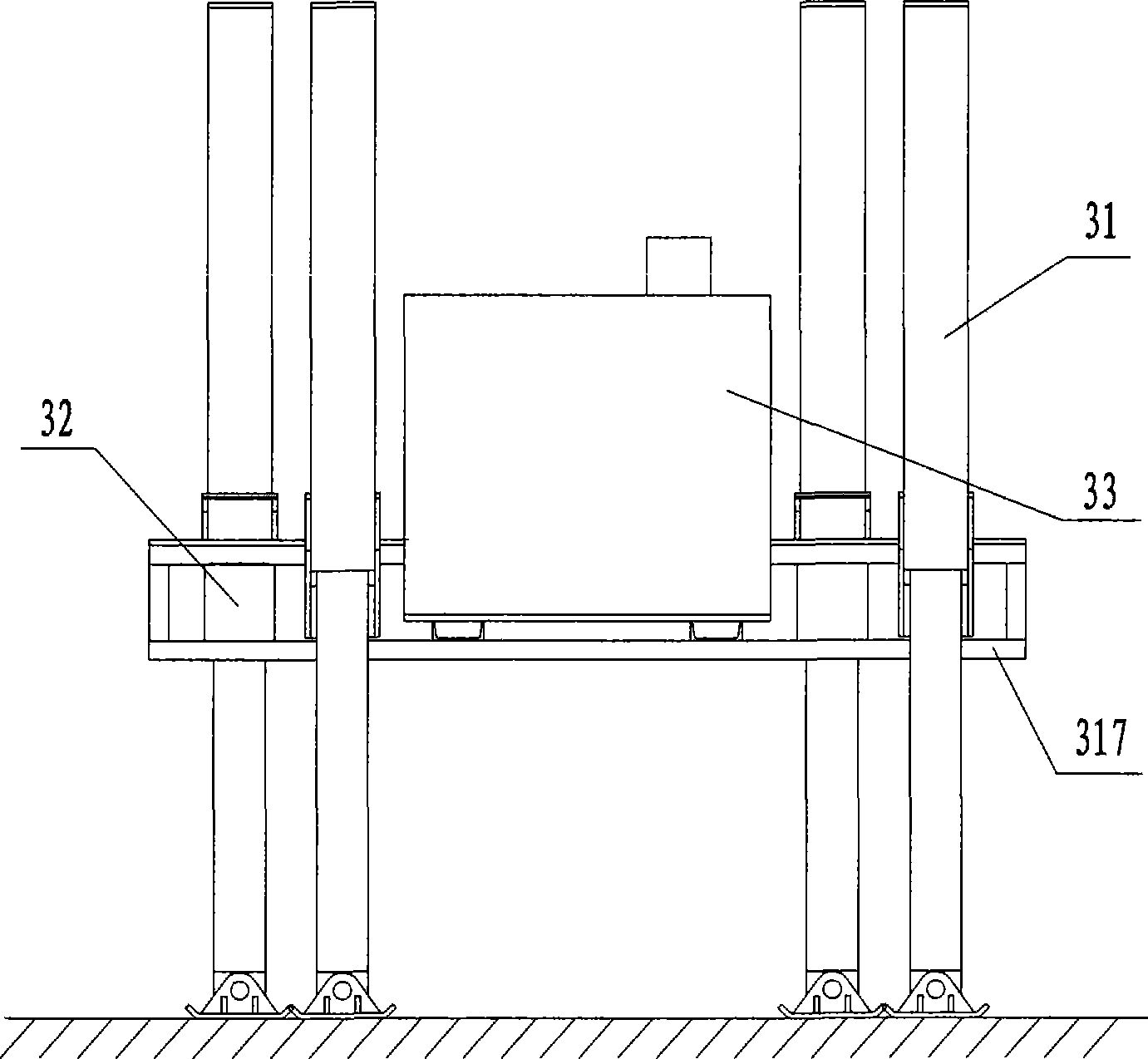

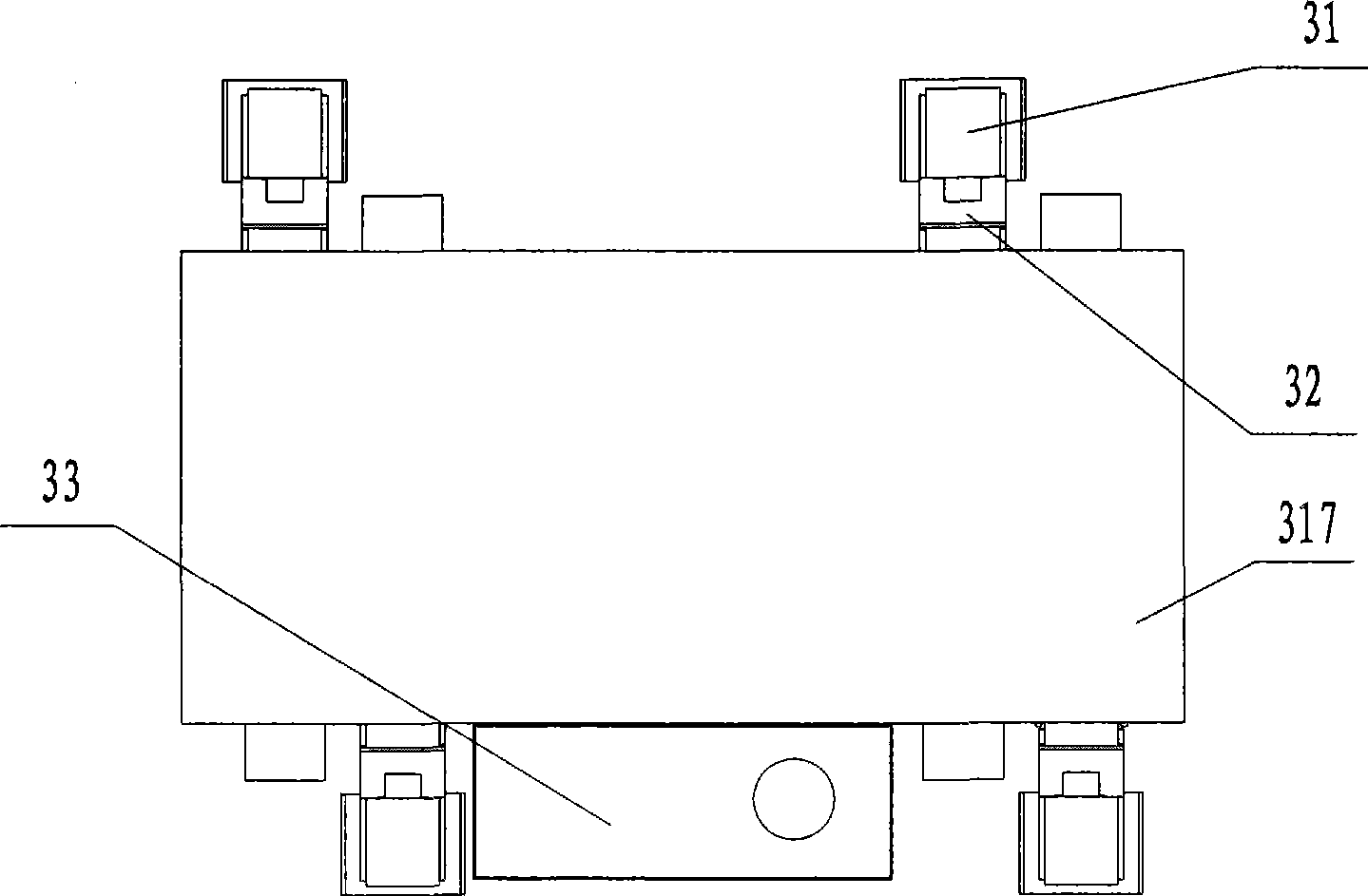

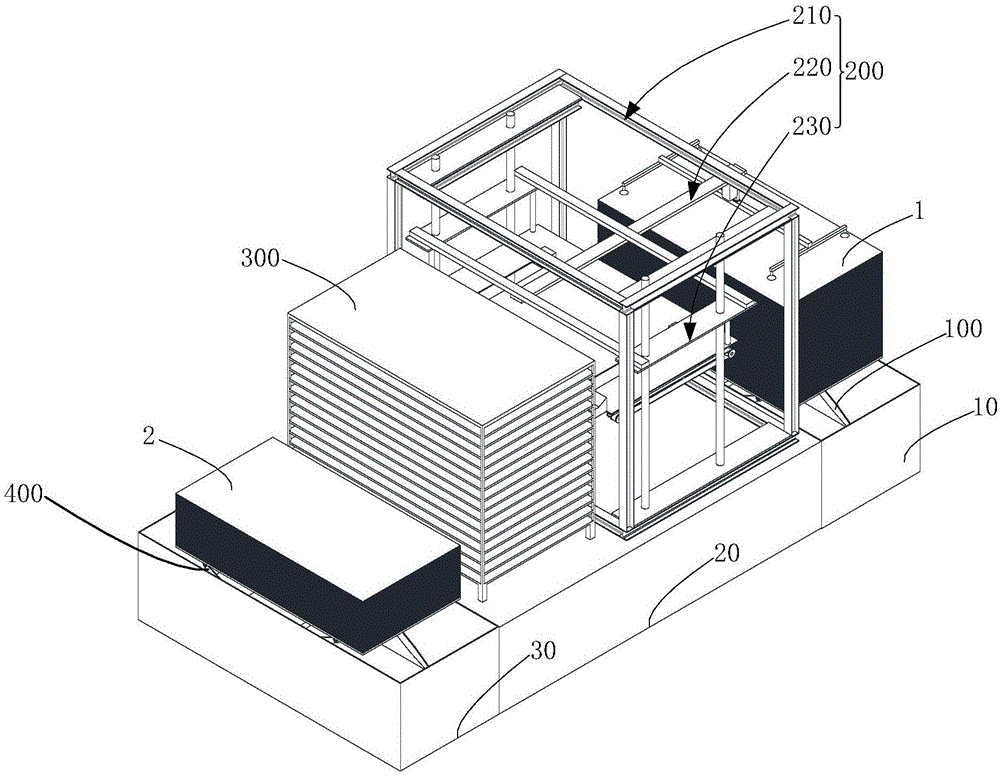

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589AEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

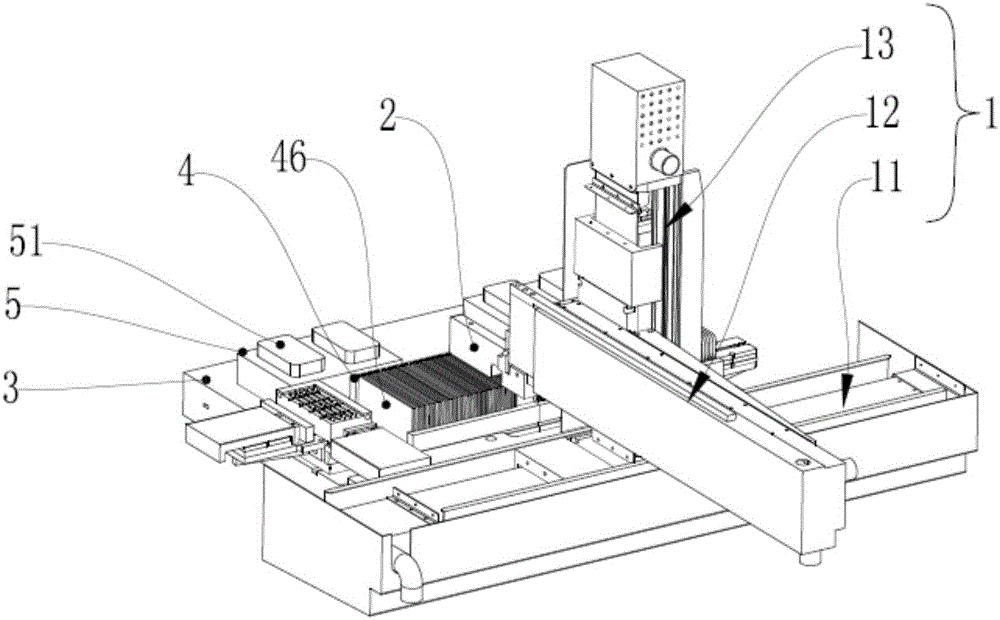

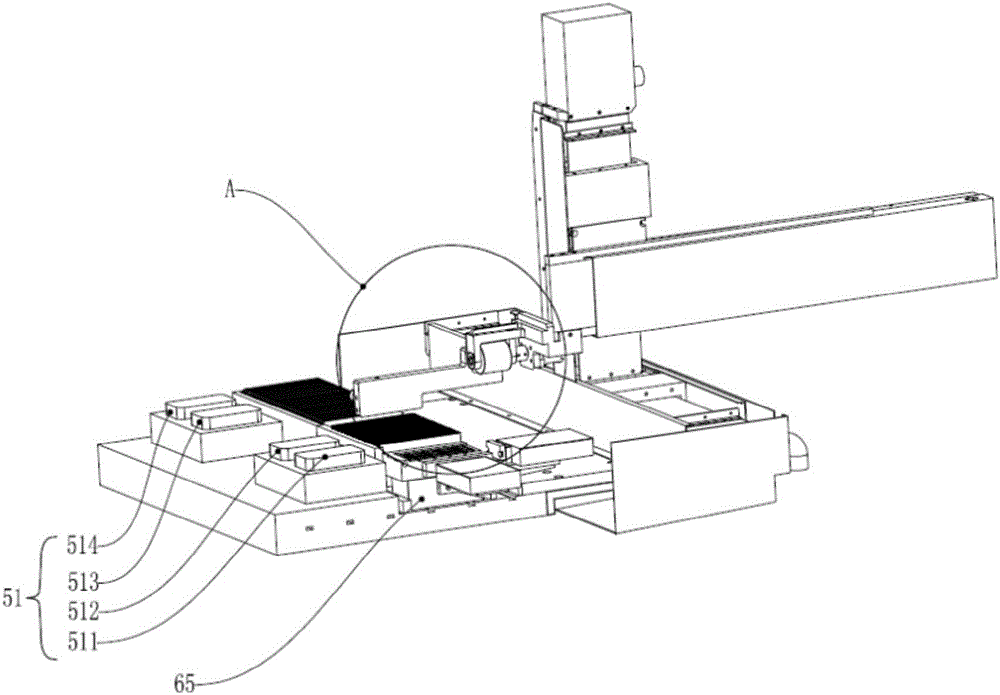

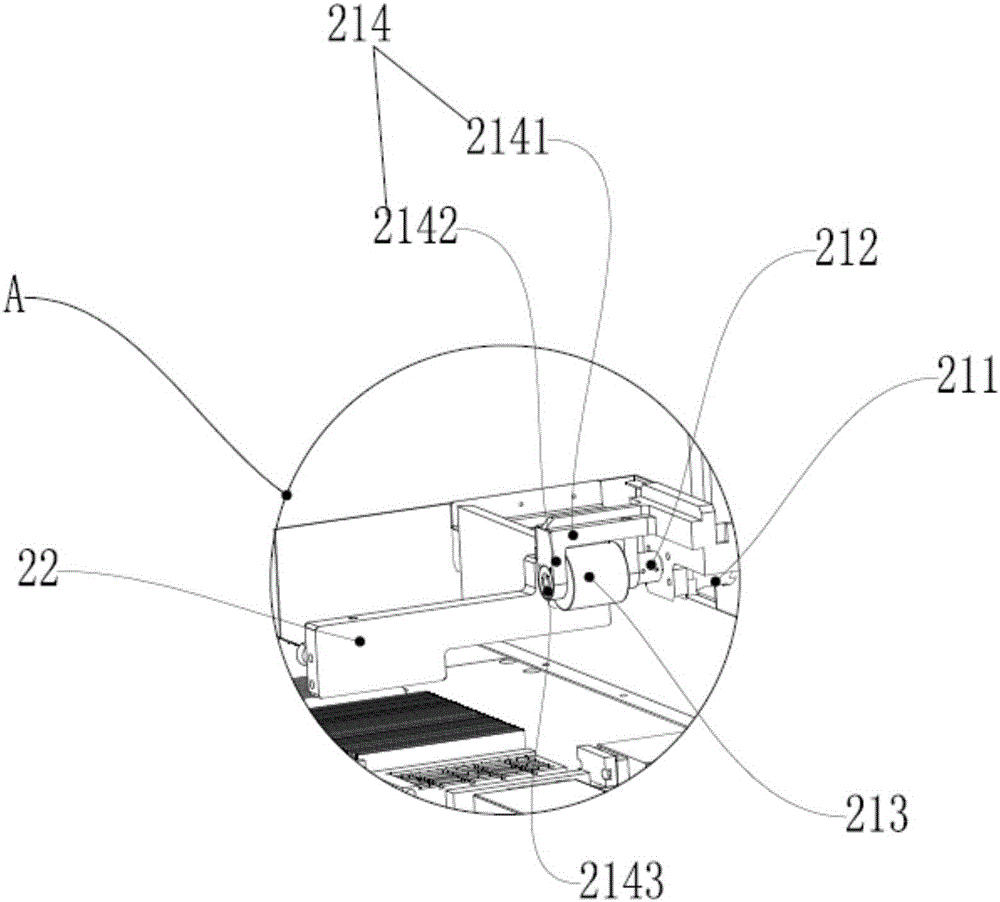

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

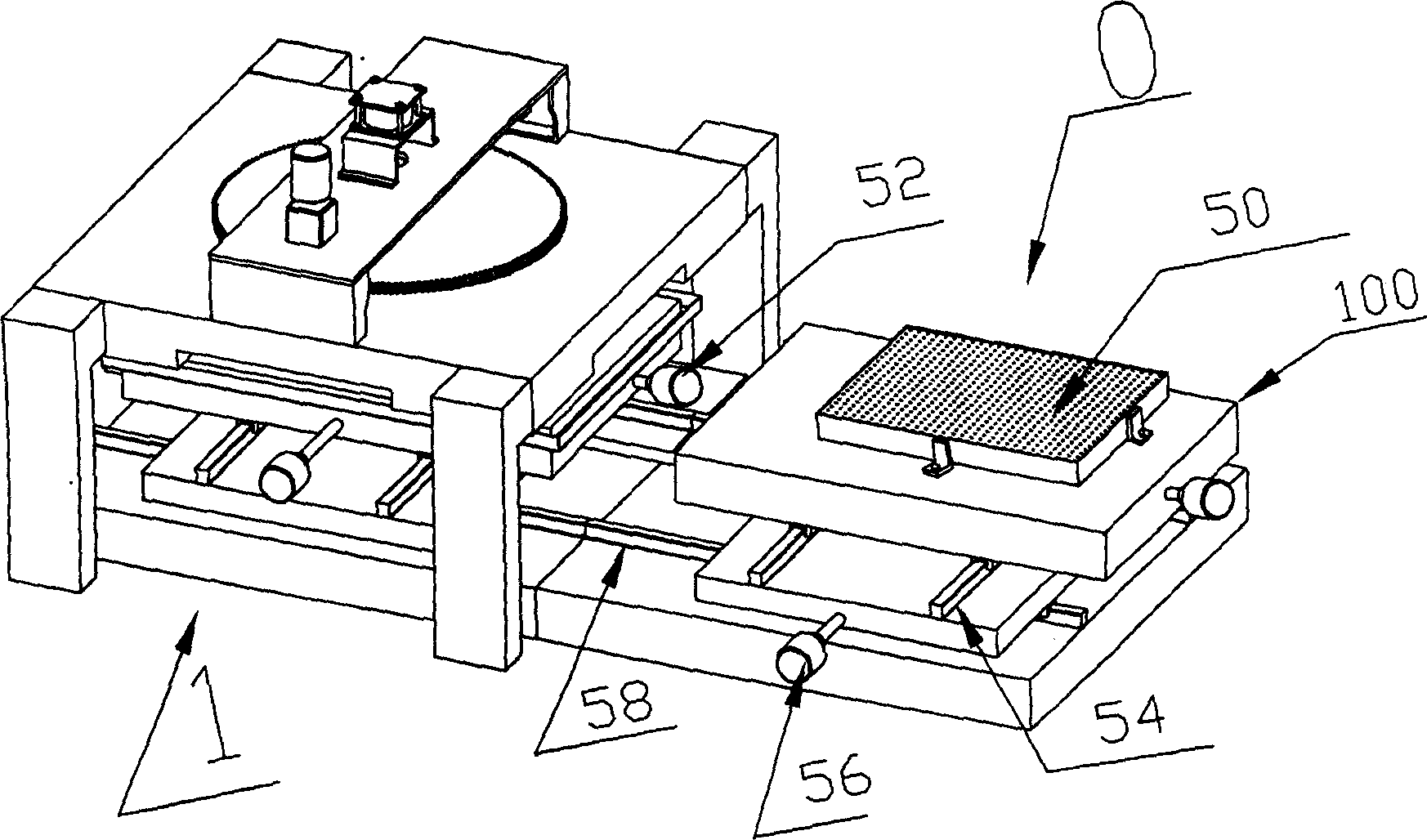

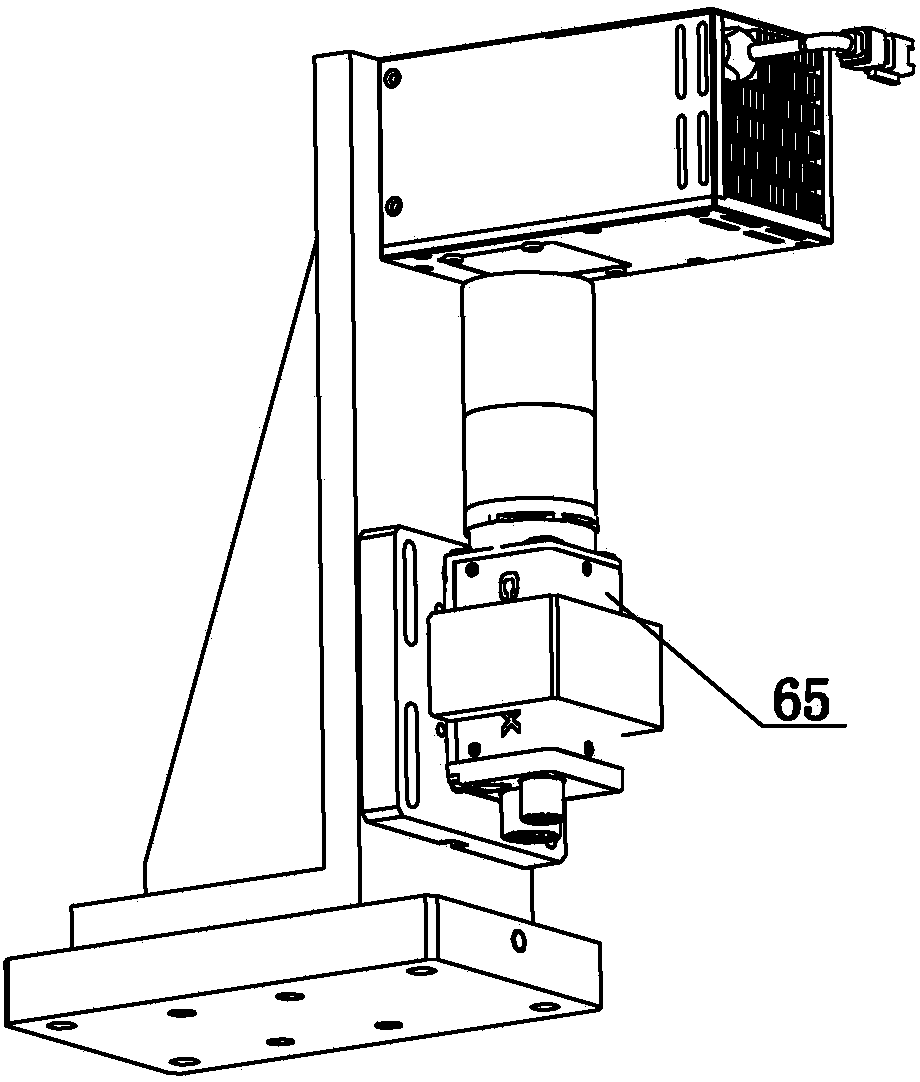

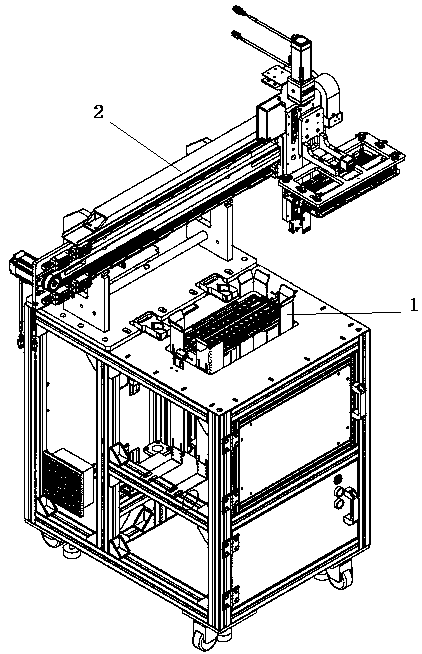

Automatic loading and unloading device for numerically-controlled machine tool

ActiveCN104354097ARealize automatic loading and unloadingRealize automatic feeding processWorking accessoriesGrinding feedersNumerical controlEngineering

The invention discloses an automatic loading and unloading device for a numerically-controlled machine tool. The automatic loading and unloading device is driven by using an axis-X driving structure and an axis-Z driving device, and a glass workpiece is grabbed by virtue of a flexible air cylinder, a rotating air cylinder and a vacuum sucking disc, so that automatic loading of glass pieces to be machined and automatic unloading of the machined glass workpiece are realized; because the numerically-controlled machine tool is in a double-head design, four positioning jigs are provided, and a second positioning jig and a fourth positioning jig load during the machining of a first poisoning jig and a third positioning jig, so that automatic loading and unloading can be realized, circulating machining without stopping is also realized, and the machining efficiency is greatly improved.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

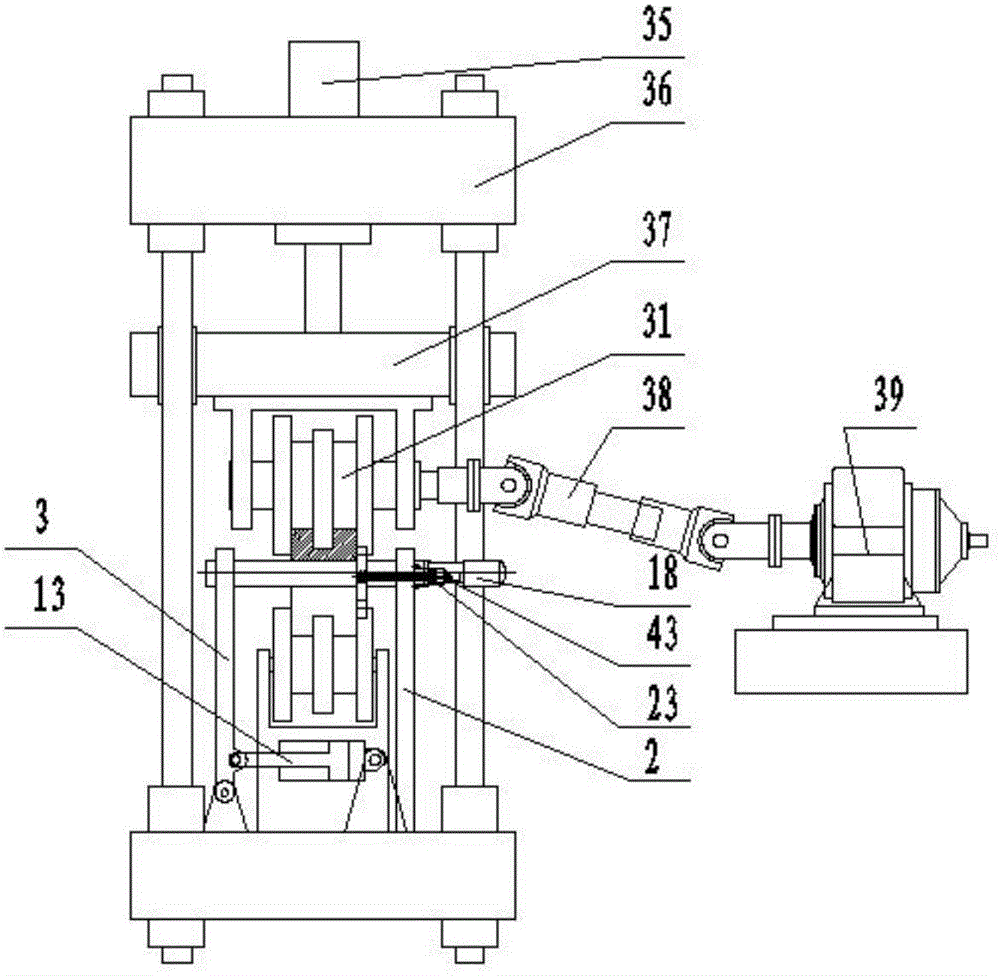

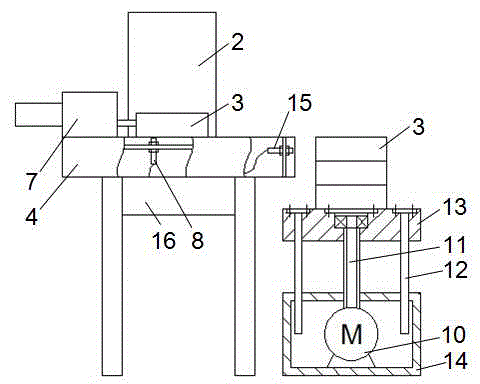

Independent weight loading-unloading dead-load type torque measurement device

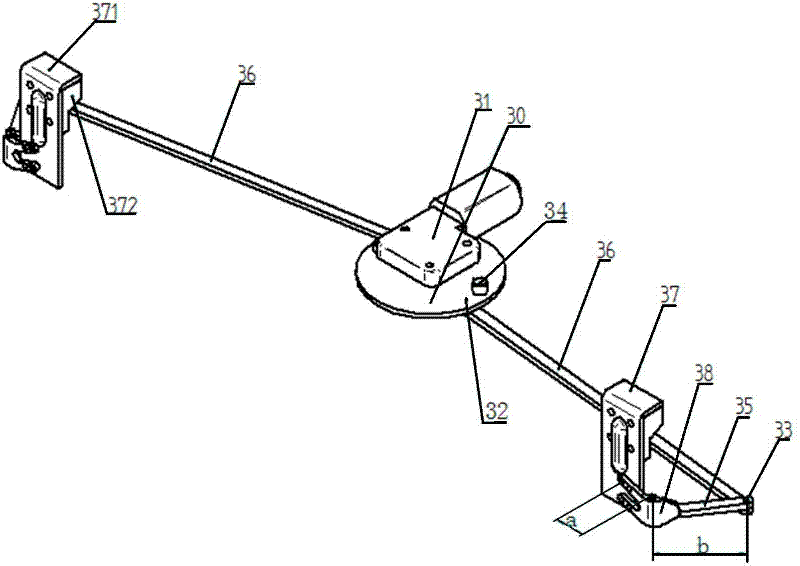

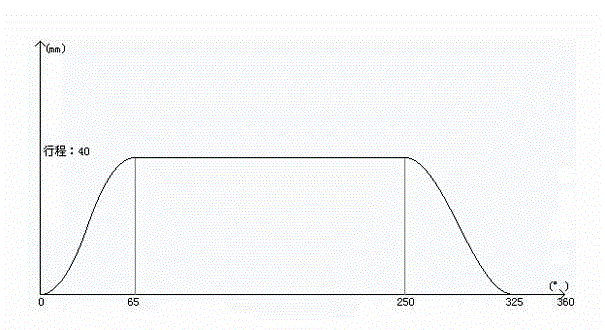

InactiveCN103575463AImprove rigidityImprove stabilityForce/torque/work measurement apparatus calibration/testingMeasurement deviceMotor drive

The invention discloses an independent weight loading-unloading dead-load type torque measurement device, and belongs to the technical field of measuring testing. The independent weight loading-unloading dead-load type torque measurement device aims at solving the problems that in the prior art, the loading speed is low, a control device is complex, operation is difficult to achieve, and automation is difficult to achieve. The independent weight loading-unloading dead-load type torque measurement device comprises a supporting device, a loading device, a torque installation part, a leveling device and automatic loading devices, wherein the loading device is fixed on the upper surface of the supporting device, the torque installation part is connected with a guide rail sliding block and a nut supporting base of the loading device, the leveling device is connected with the other end of a long shaft of the torque installation part, and the automatic loading devices are fixed at the two ends of the leveling device. The automatic loading devices are characterized in that eccentric wheels are driven by stepping motors B to perform rotational motion, trays are driven by the eccentric wheels to perform linear lifting, and therefore automatic loading and automatic unloading of weights are achieved. According to the independent weight loading-unloading dead-load type torque measurement device, the eccentric wheels are driven by the stepping motors B to perform the rotational motion to achieve the automatic loading and the automatic unloading of the weights with any number, measurement on different torque values is accordingly achieved, and the motor driving structure is simple.

Owner:JILIN UNIV

Sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device

ActiveCN102343894APositioning constraints resolvedAvoid the problem of severe squeezing that cannot be unlockedCharging stationsElectric propulsion mountingElectricityEngineering

The invention provides a sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device. The electric bus battery quick-change tray device comprises a pellet and a locking and unlocking mechanism (3) mounted on the pellet. According to the invention, the battery box can be correctly positioned and reliably locked reasonably; the force is reasonably applied to the battery box; simple structure and simple and reasonable power wire splicing mode are obtained; and the arc discharge phenomenon can be effectively prevented.

Owner:KUNMING SHIPBUILDING EQUIP

Automatic detection device for power lithium ion battery pole pieces and detection method thereof

InactiveCN103940820AAchieve seamless connectionImprove detection efficiencyOptically investigating flaws/contaminationSortingEngineeringLithium-ion battery

The invention discloses an automatic detection device for power lithium ion battery pole pieces and a detection method thereof. The automatic detection device comprises a multi-station turntable equipped with four fixed material boxes, and also comprises a loading mechanism, a visual detection mechanism and a material dropping mechanism which face toward the fixed material boxes. The detection method comprises a loading step, a detection step and a material dropping step. The automatic detection device and the detection method have the advantages of high detection efficiency, high reliability and unified product quality standards.

Owner:SOUTHEAST UNIV

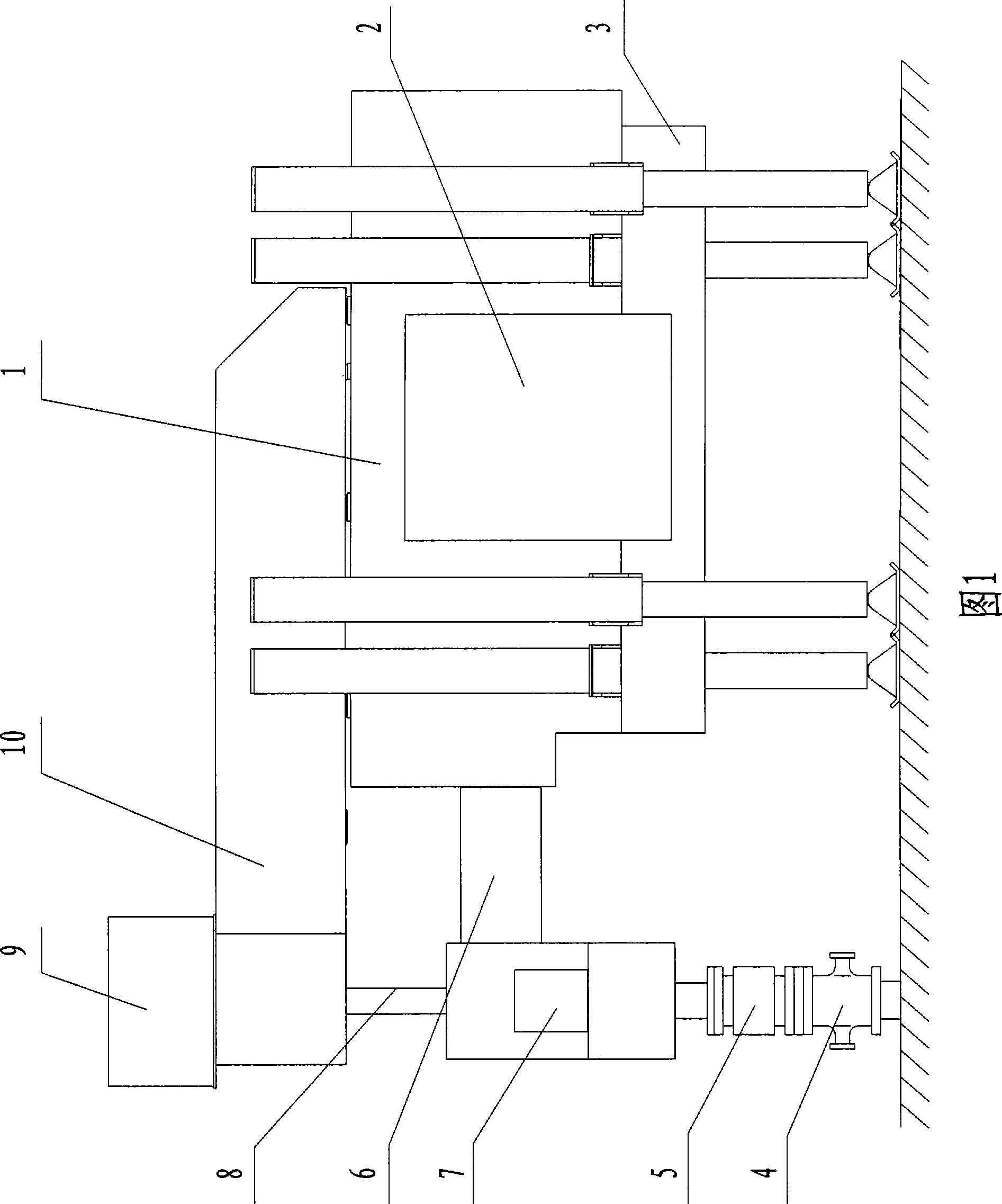

Oil field well workover operation machine

InactiveCN101429847AFlexible layoutEasy to install/removeDrilling rodsDrilling casingsControl systemOil field

The invention relates to an oil field operation device, in particular to an oil field workover treatment machine. The machine body is arranged on a hydraulic load-bearing traveling gear and is interlocked with the hydraulic load-bearing traveling gear. Hydraulic tongs connected with a telescopic bracket on the machine body can be extended out and retracted with the telescopic bracket. A clip seat is positioned below the hydraulic tongs and is arranged on a well head. An elevator which is suspended onto the machine body can reciprocate up and down. A faucet is positioned above the machine body and the clip seat; a pipe throwing device is arranged on the faucet and the machine body; and a clip unlocking device and a clip locking device corresponding to the elevator are arranged on the clip seat and the pipe throwing device respectively. A righting mechanism and a valve mechanism are further arranged on the faucet. A control cabinet is arranged on the machine body; and the clip seat, the hydraulic tongs, the elevator and the pipe throwing device are connected with a control system in the control cabinet respectively. The oil field workover treatment machine can be assembled and disassembled conveniently and rapidly, thereby not only facilitating transportation, but also changing the positions to meet the requirements of different work. Simultaneously the machine can be laid freely at a well field according to the practical conditions.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU +1

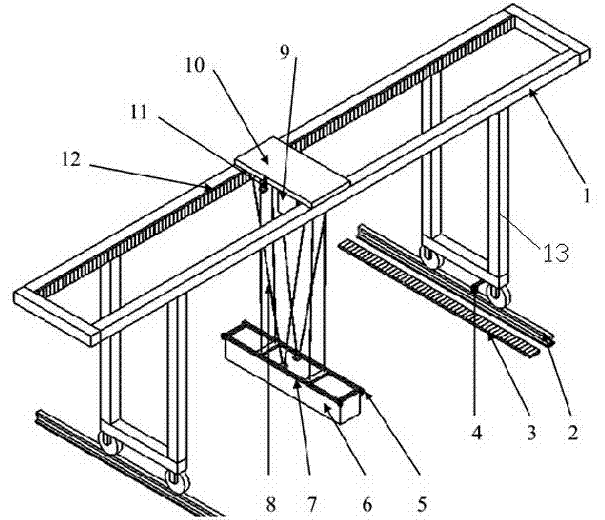

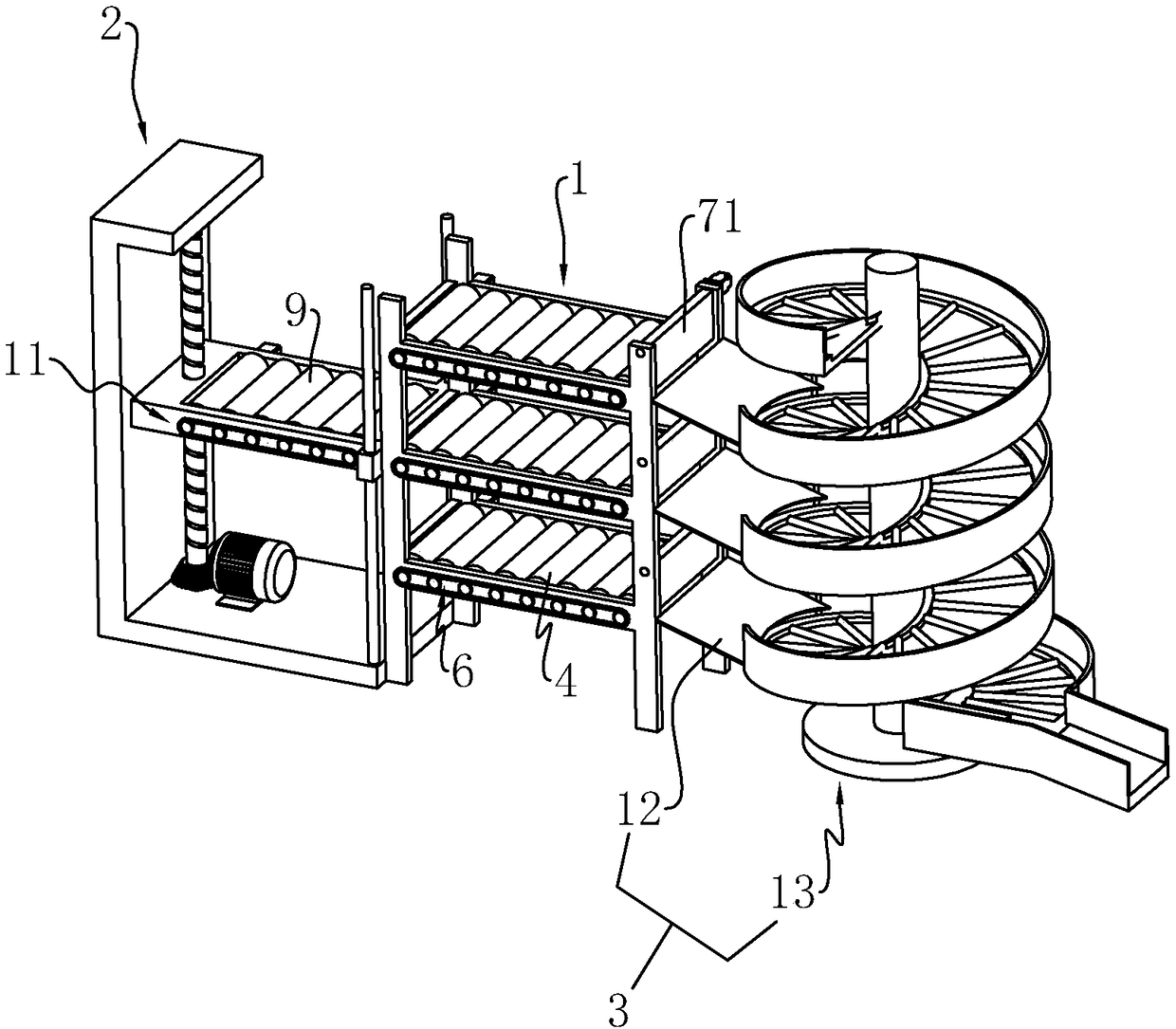

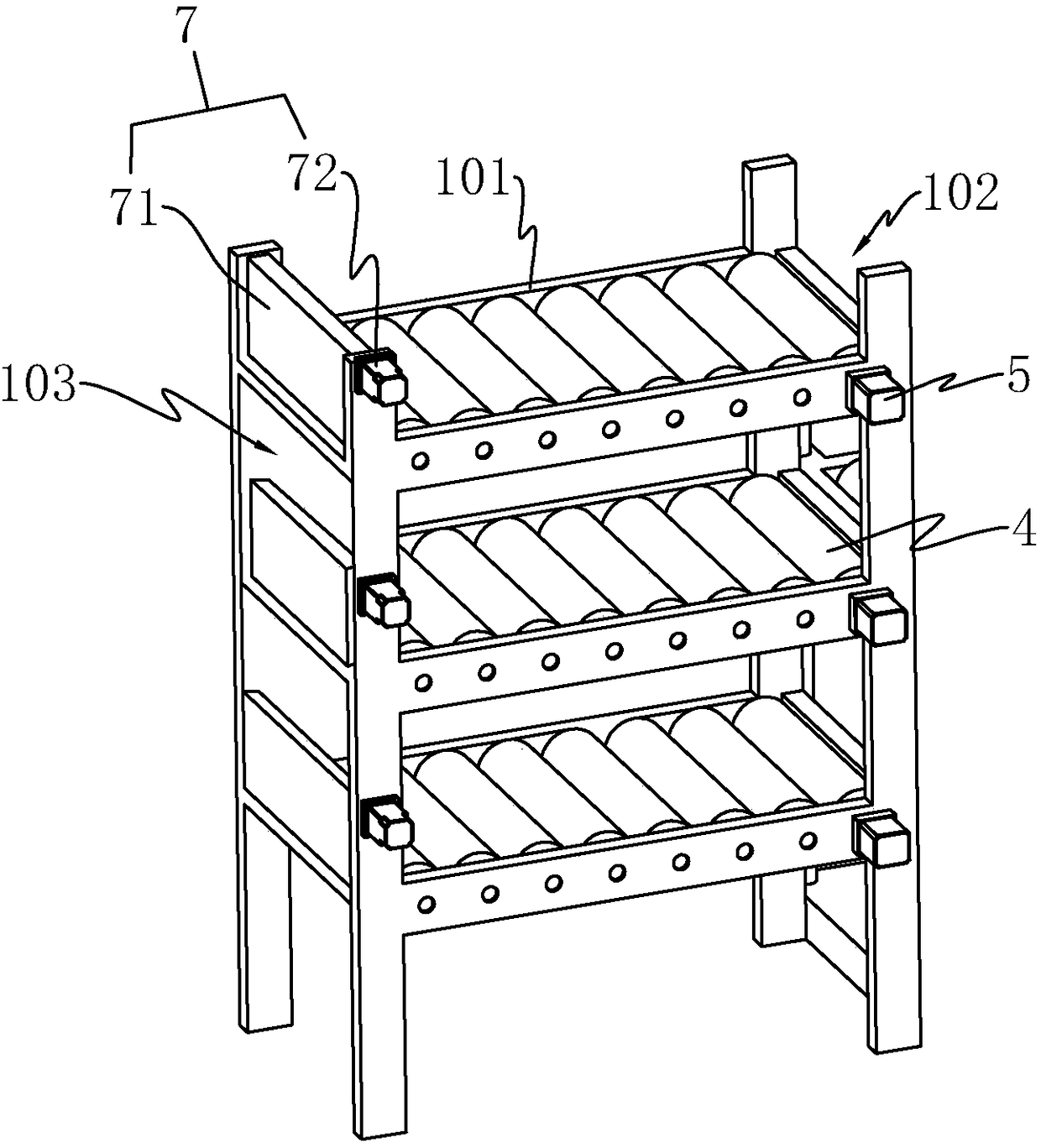

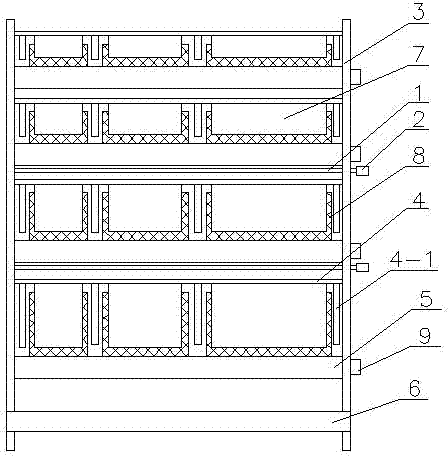

Warehouse goods storage device

InactiveCN108545389ARealize fully automatic loading and unloadingImprove loading and unloading efficiencyStorage devicesChutesLogistics managementEngineering

The invention discloses a warehouse goods storage device and relates to the field of warehouse storage logistics. The warehouse goods storage device comprises a storage rack main body which at least comprises two placing layers, wherein a goods inlet and a goods outlet are separately formed in two sides of each placing layer; the warehouse goods storage device also comprises a goods upper rack mechanism and a goods lower rack mechanism; the goods upper rack mechanism comprises a base, a placing table, a first driving assembly and a second driving assembly, and a third driving assemblies and barrier parts are arranged on the placing layers; the goods lower rack mechanism comprises a lower slideway and a bearing rack, the bearing rack comprises a central rod and a spiral slideway which is spirally arranged around the central rod from top to bottom, and a goods delivery port is formed in the lower end of the spiral slideway. The warehouse goods storage device provided by the invention isstable to work, convenient to operate and high in degree of automation, can improve the goods loading and unloading efficiency and reduce the labor intensity greatly, and meets the modern logistics development tendency.

Owner:上海诺尔国际物流有限公司

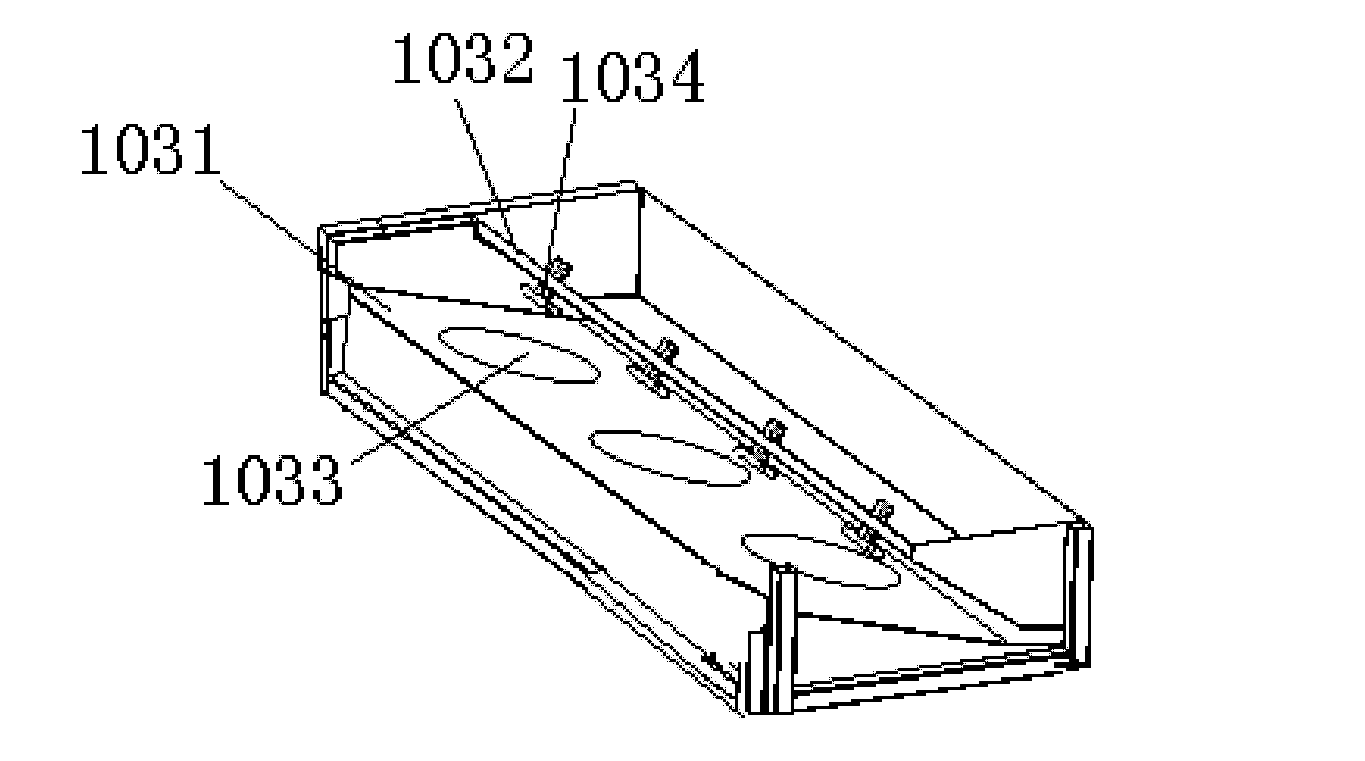

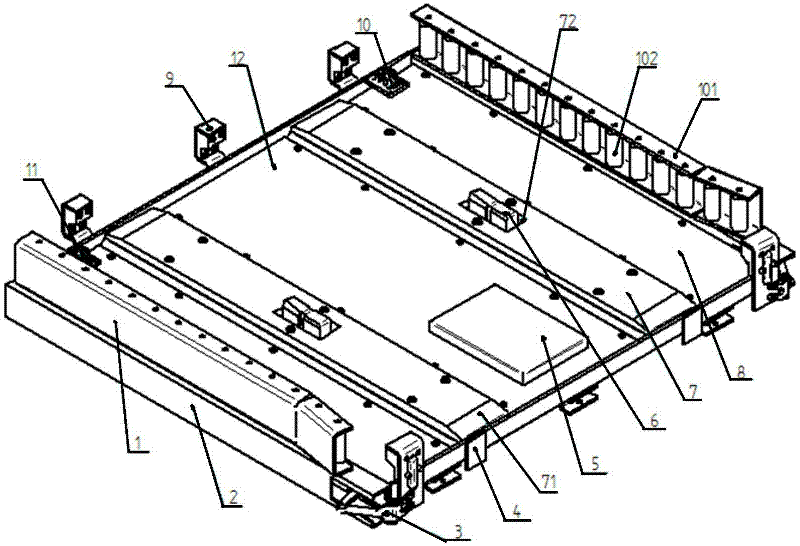

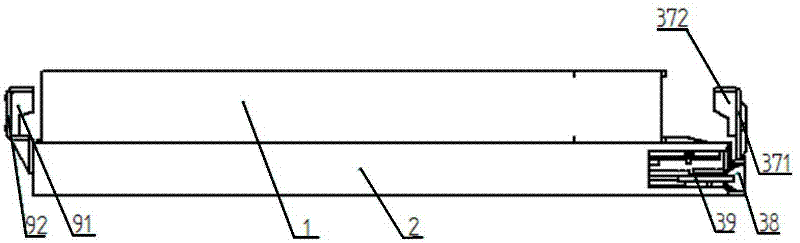

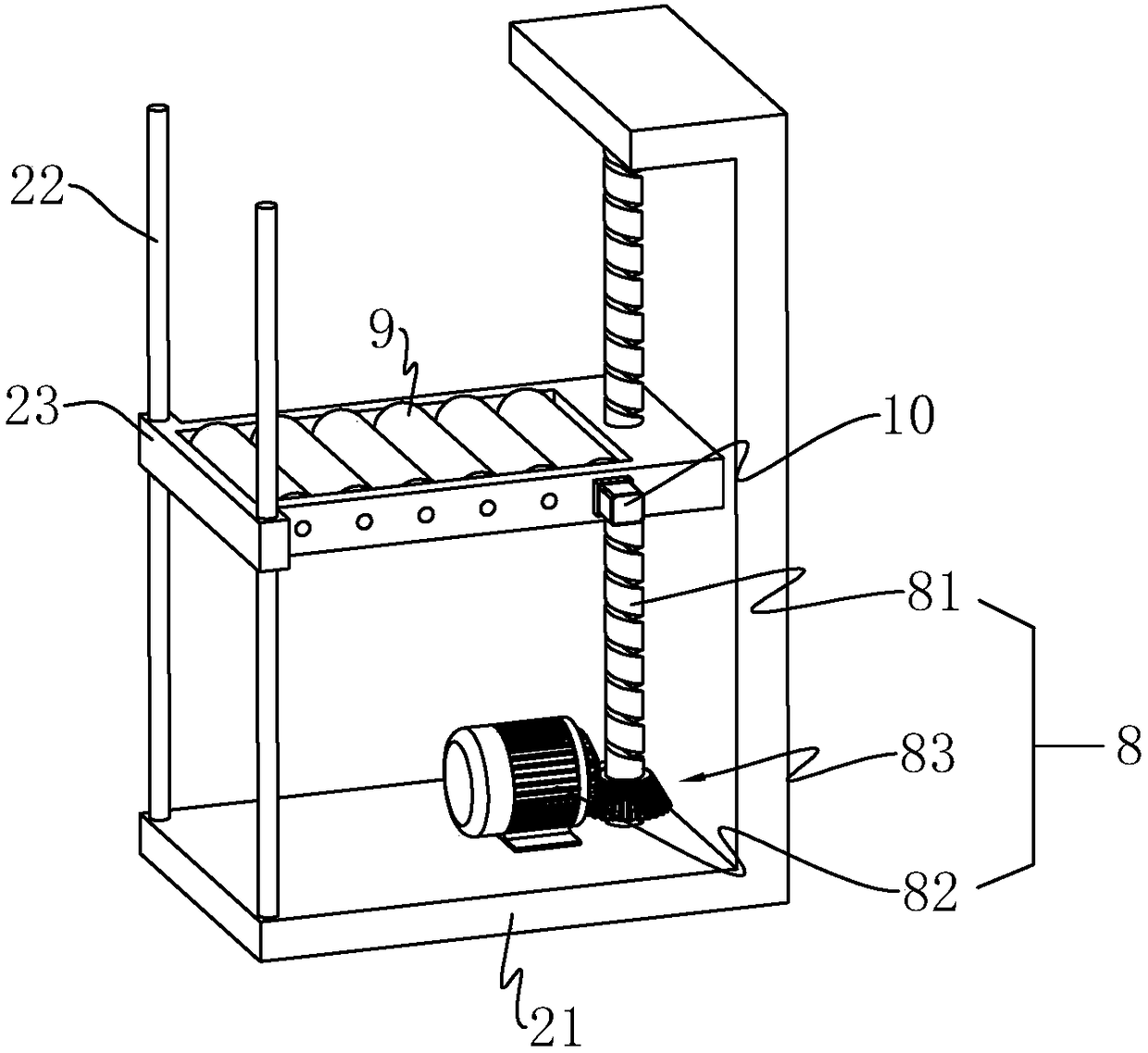

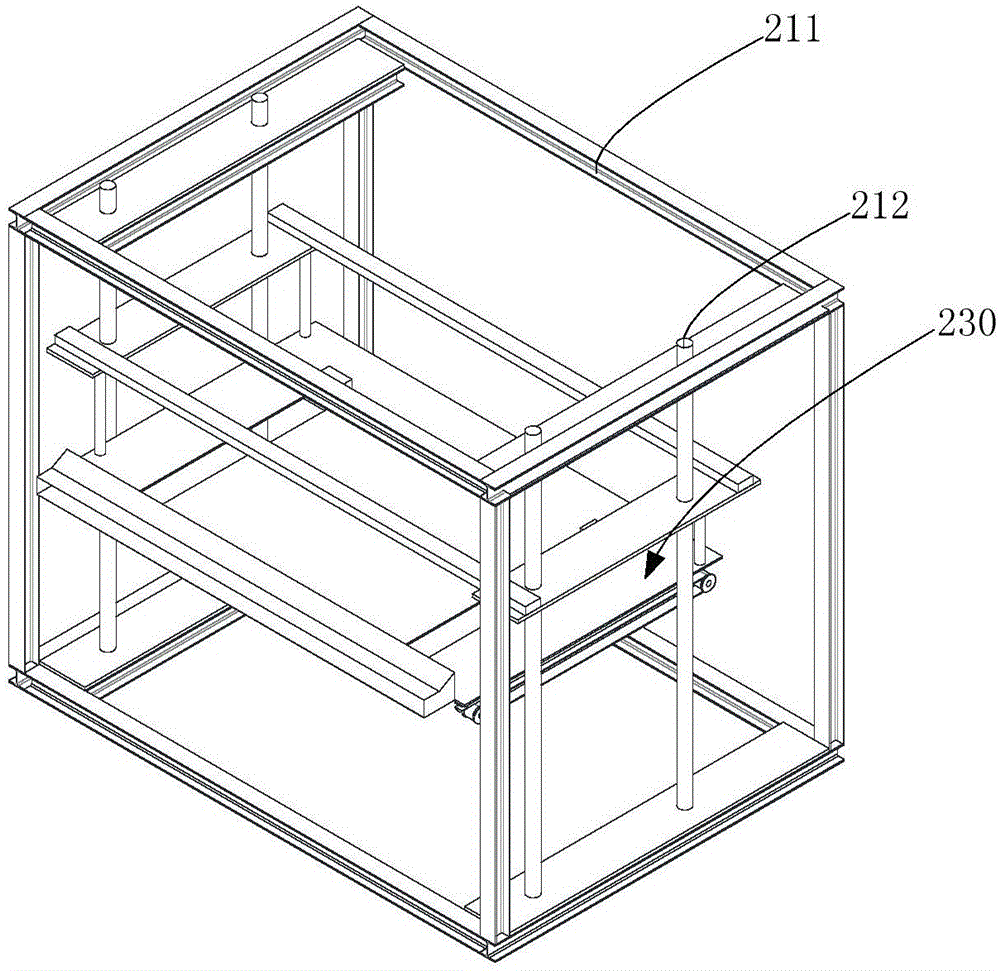

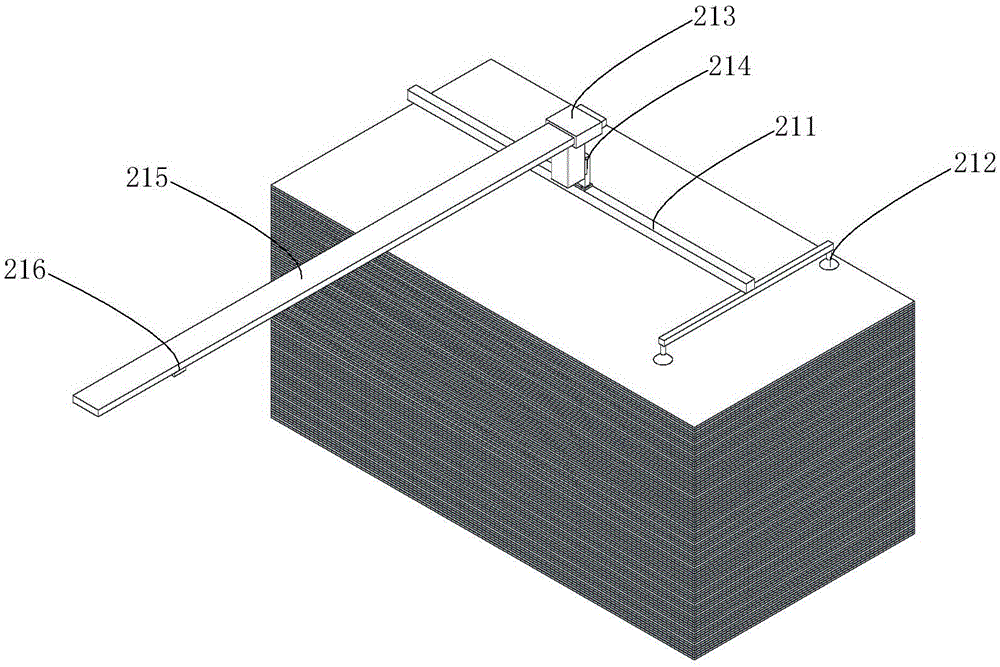

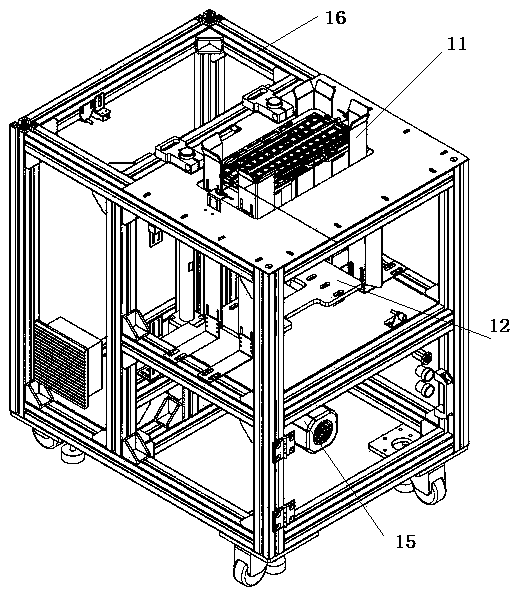

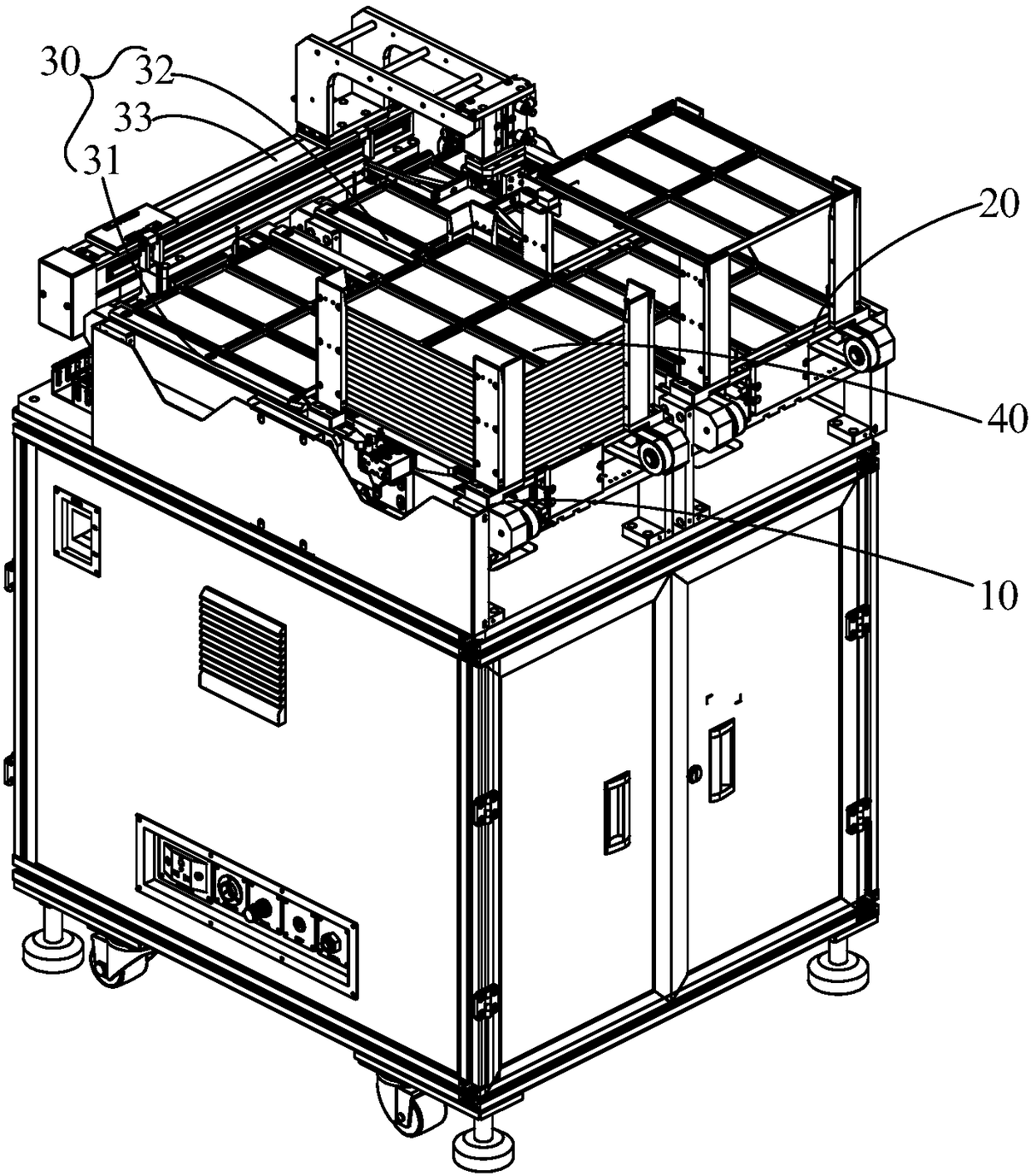

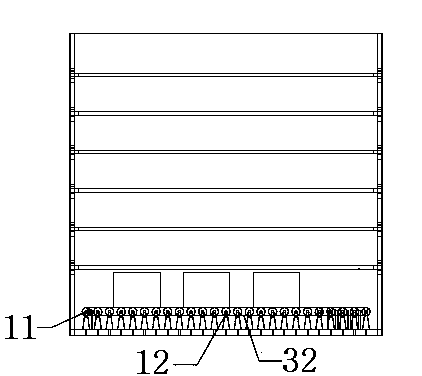

Lifting type charging tray feeding and discharging equipment

ActiveCN105293081ASave spaceGood streamlineStacking articlesDe-stacking articlesMechanical engineeringPiston

The invention discloses lifting type charging tray feeding and discharging equipment. The lifting type charging tray feeding and discharging equipment comprises an empty charging tray lifting mechanism, a discharge lifting mechanism and a moving mechanism. The empty charging tray lifting mechanism and the discharge lifting mechanism each comprise a lifting motor, a lead screw, a supporting plate and a guiding device, wherein the lead screw is connected with the lifting motor and vertically arranged; the supporting plate is in threaded connection with the lead screw and horizontally arranged; the guiding device is used for guiding ascending and descending of the supporting plate; a charging tray is borne by the supporting plate. The moving mechanism comprises a cross beam, a moving cylinder mounted on the cross beam and an unloading mechanism mounted on a piston of the moving cylinder. The moving cylinder drives the unloading mechanism to horizontally move between the empty charging tray lifting mechanism and the discharge lifting mechanism. According to the technical scheme, the lifting type charging tray feeding and discharging equipment has the beneficial effects that multiple empty charging trays can be placed at a time, and labor and time are saved; the charging trays can be taken at a time when all fully loaded with materials in the material taking process, and labor and time are saved.

Owner:SUZHOU HEROIC AUTOMATION TECH

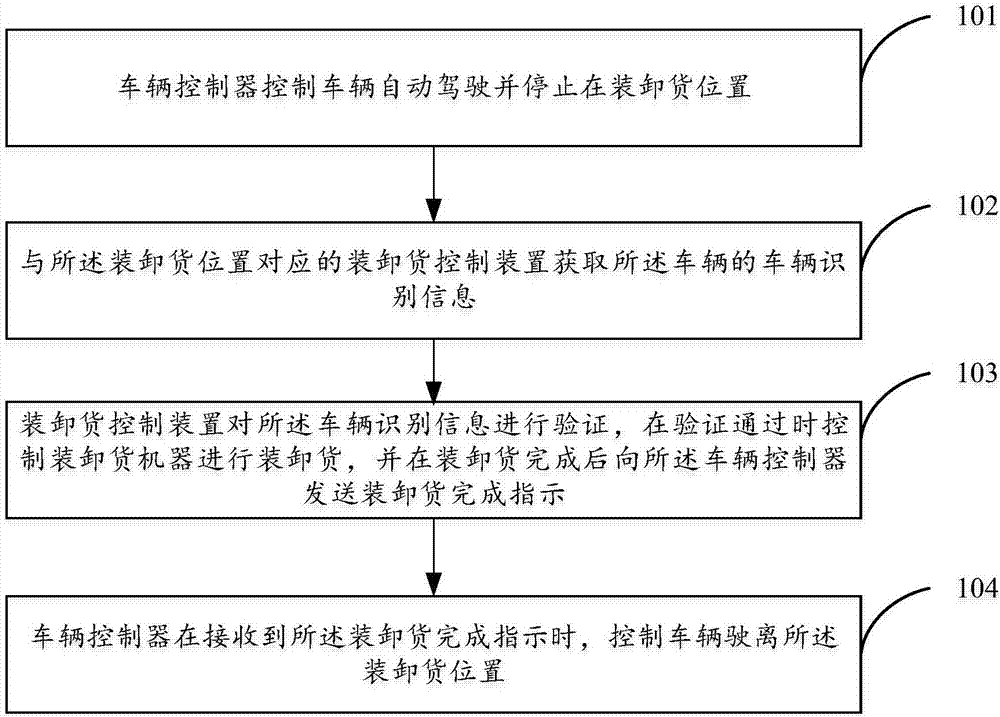

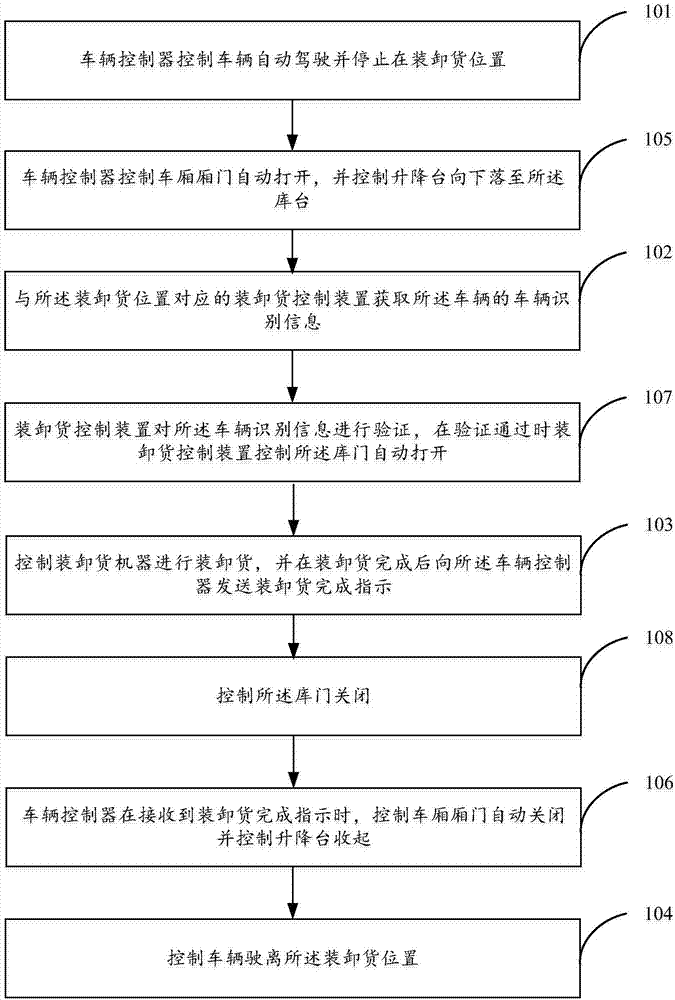

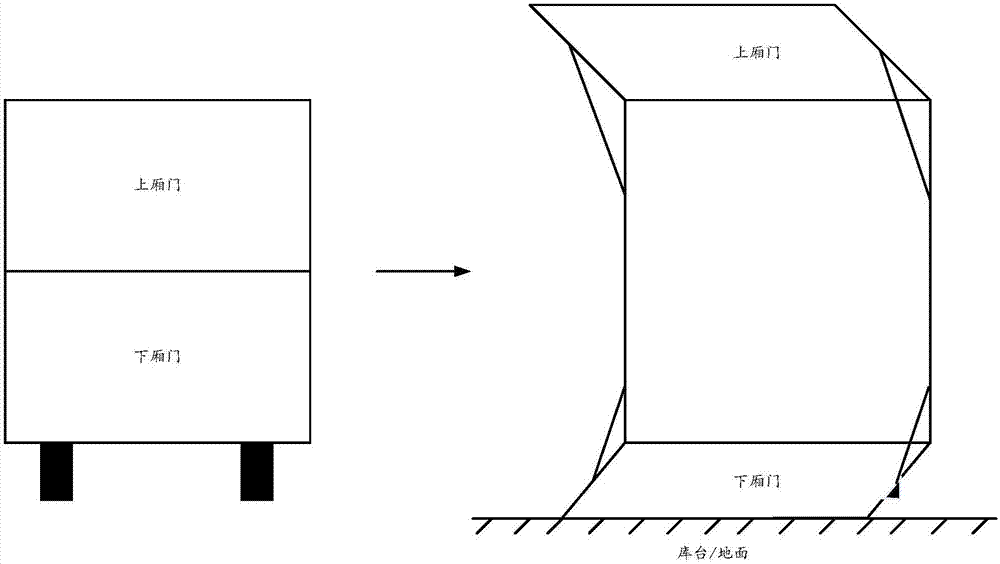

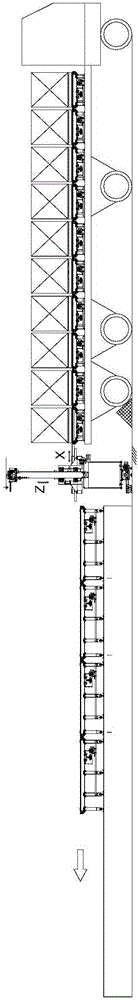

Method and system for realizing automatic loading/unloading of vehicles and related equipment

InactiveCN107403206ARealize automatic loading and unloadingNo human intervention requiredRegistering/indicating working of vehiclesRoad vehicles traffic controlVehicle controlAutopilot

The invention discloses a method and system for realizing automatic loading / unloading of vehicles and related equipment, and aims at realizing the automatic loading / unloading of unmanned vehicles. The method comprises the following steps of: controlling a vehicle to automatically run and stop at a loading / unloading position by a vehicle controller; obtaining vehicle identification information of the vehicle by a loading / unloading control device corresponding to the loading / unloading position; verifying the vehicle identification information and controlling a loading / unloading machine to carry out loading / unloading when the verification passes; after the loading / unloading is completed, sending a loading / unloading completion instruction to the vehicle controller; and when the vehicle controller receives the loading / unloading completion instruction, controlling the vehicle to pull away from the loading / unloading position.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

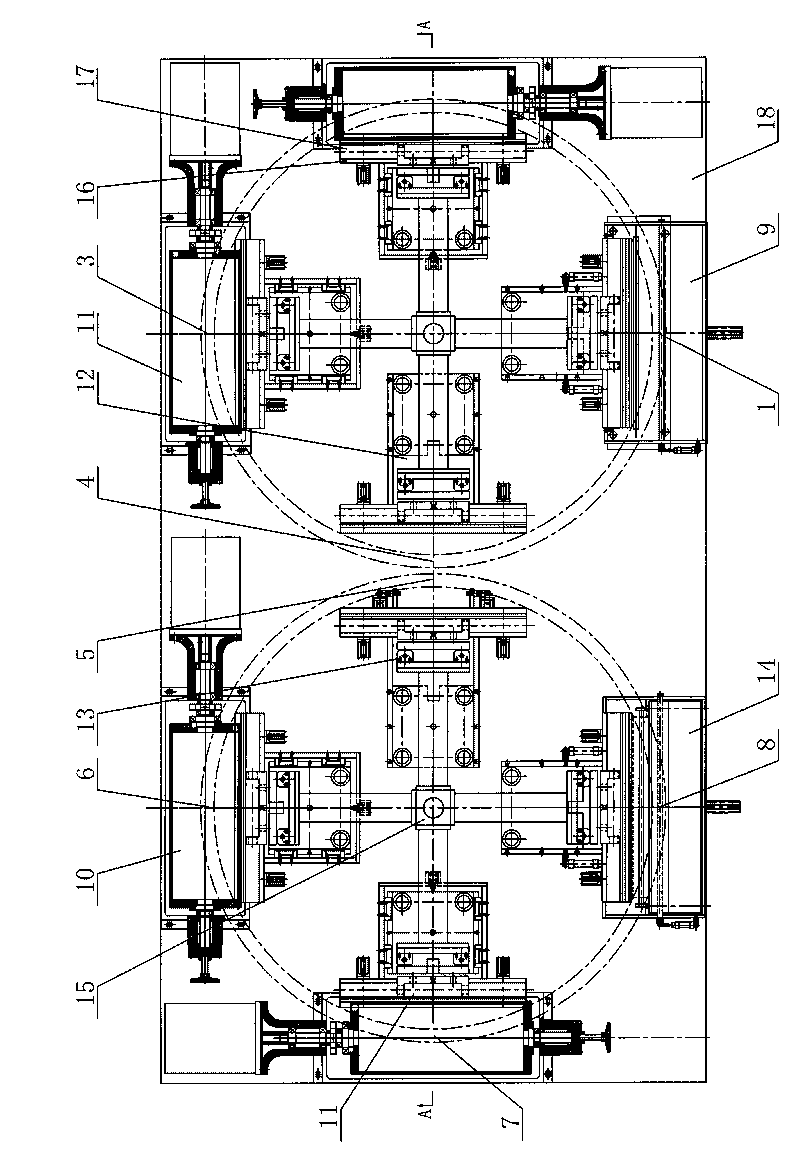

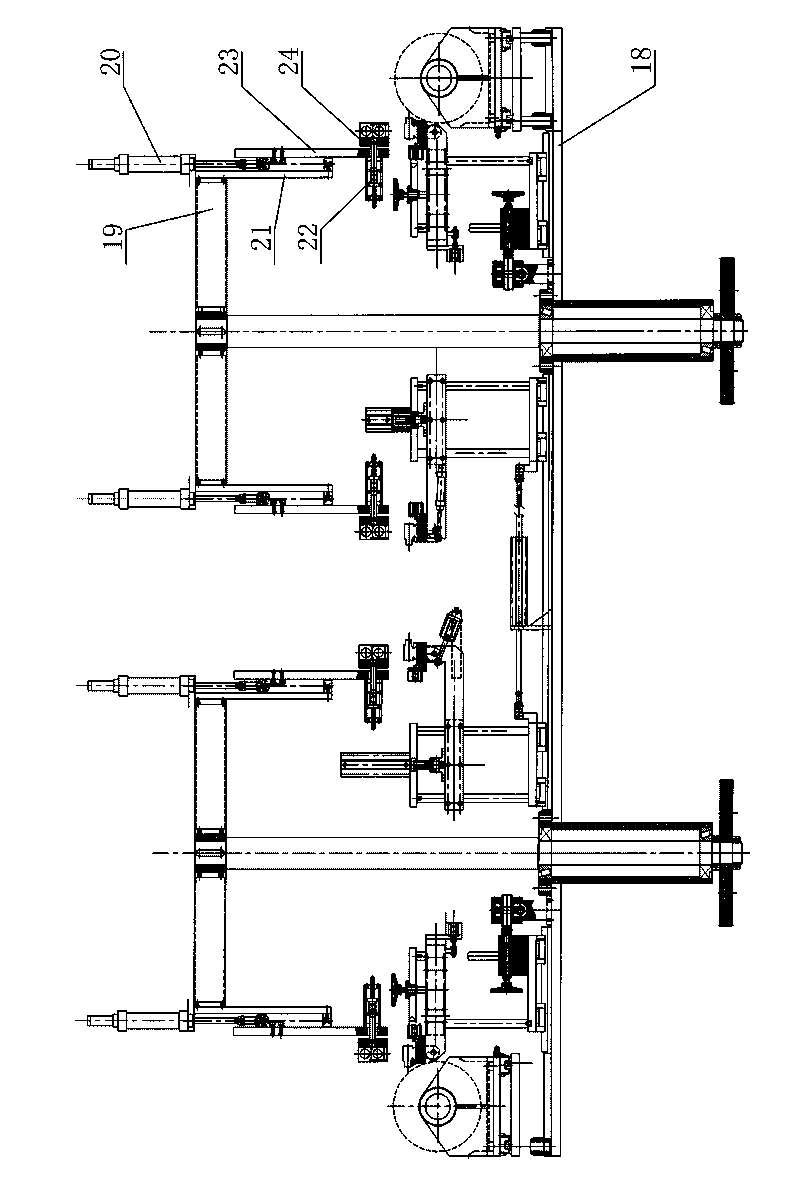

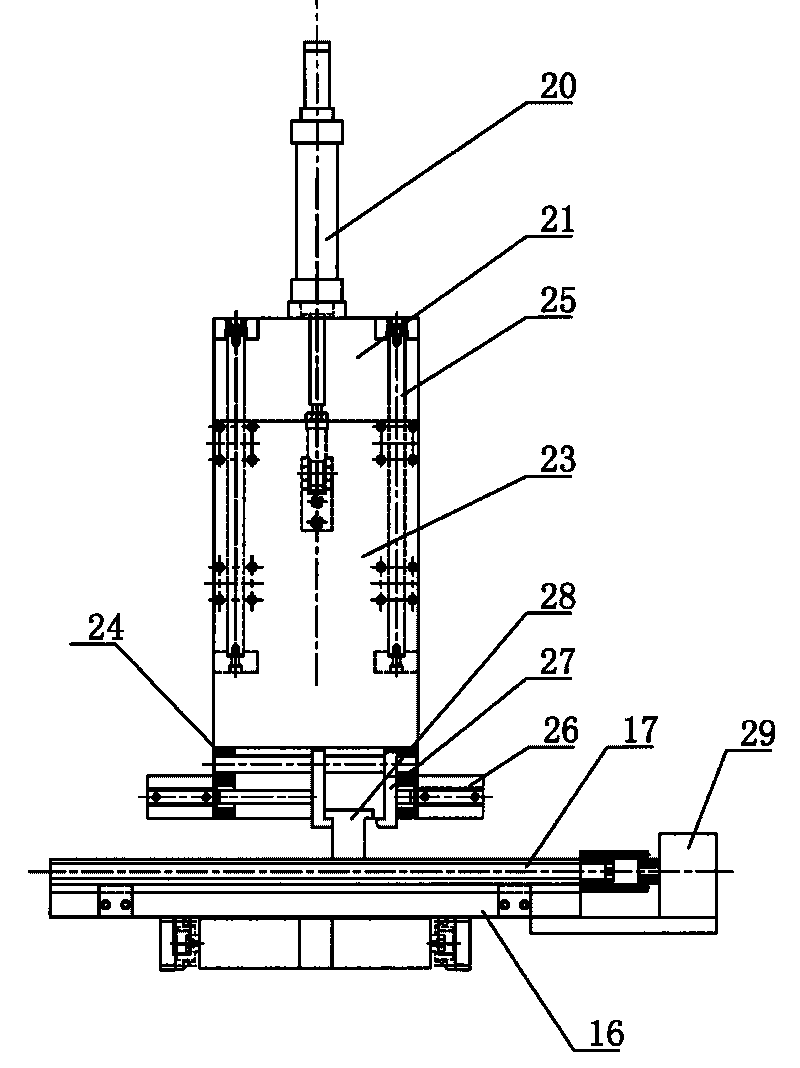

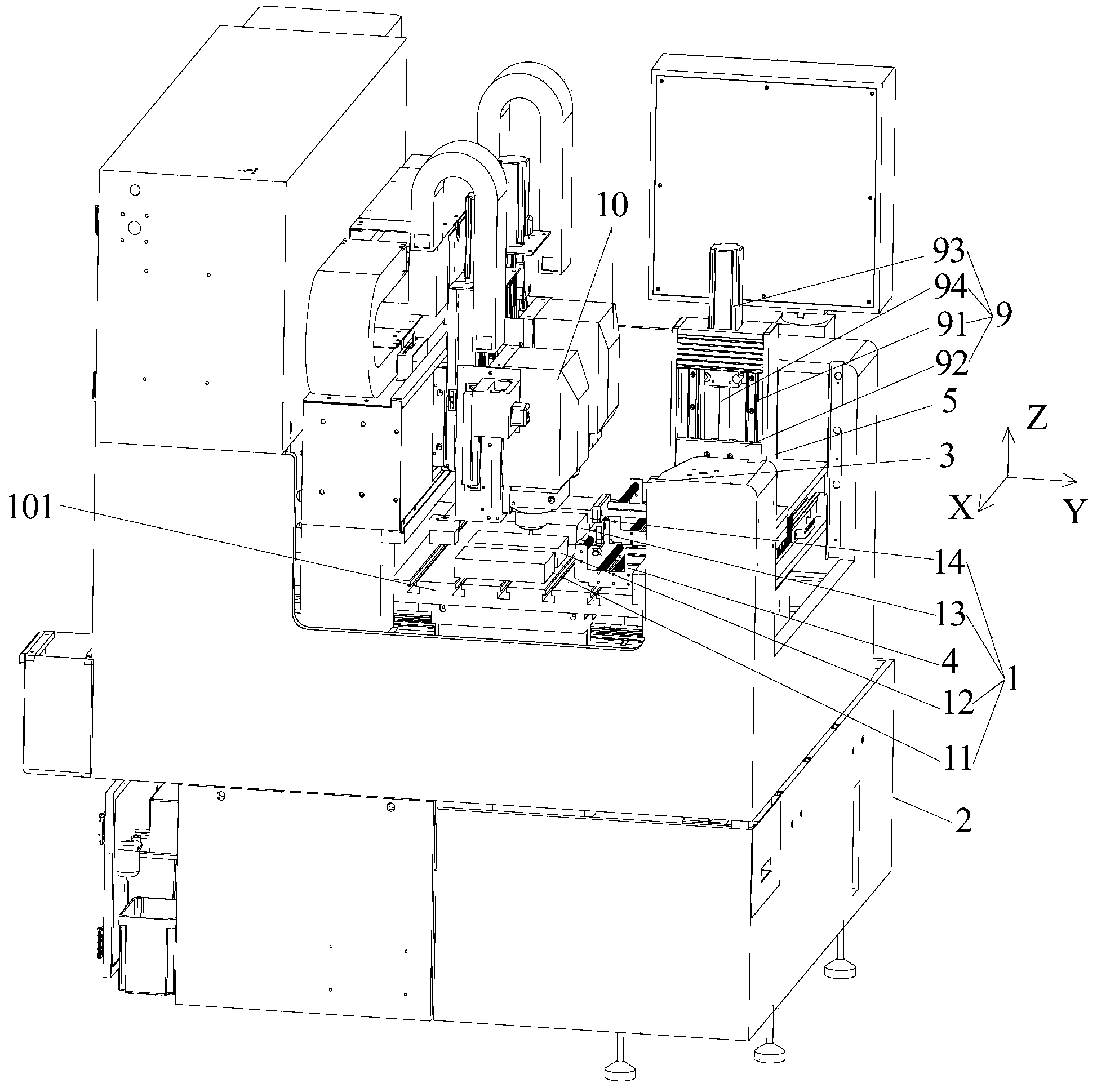

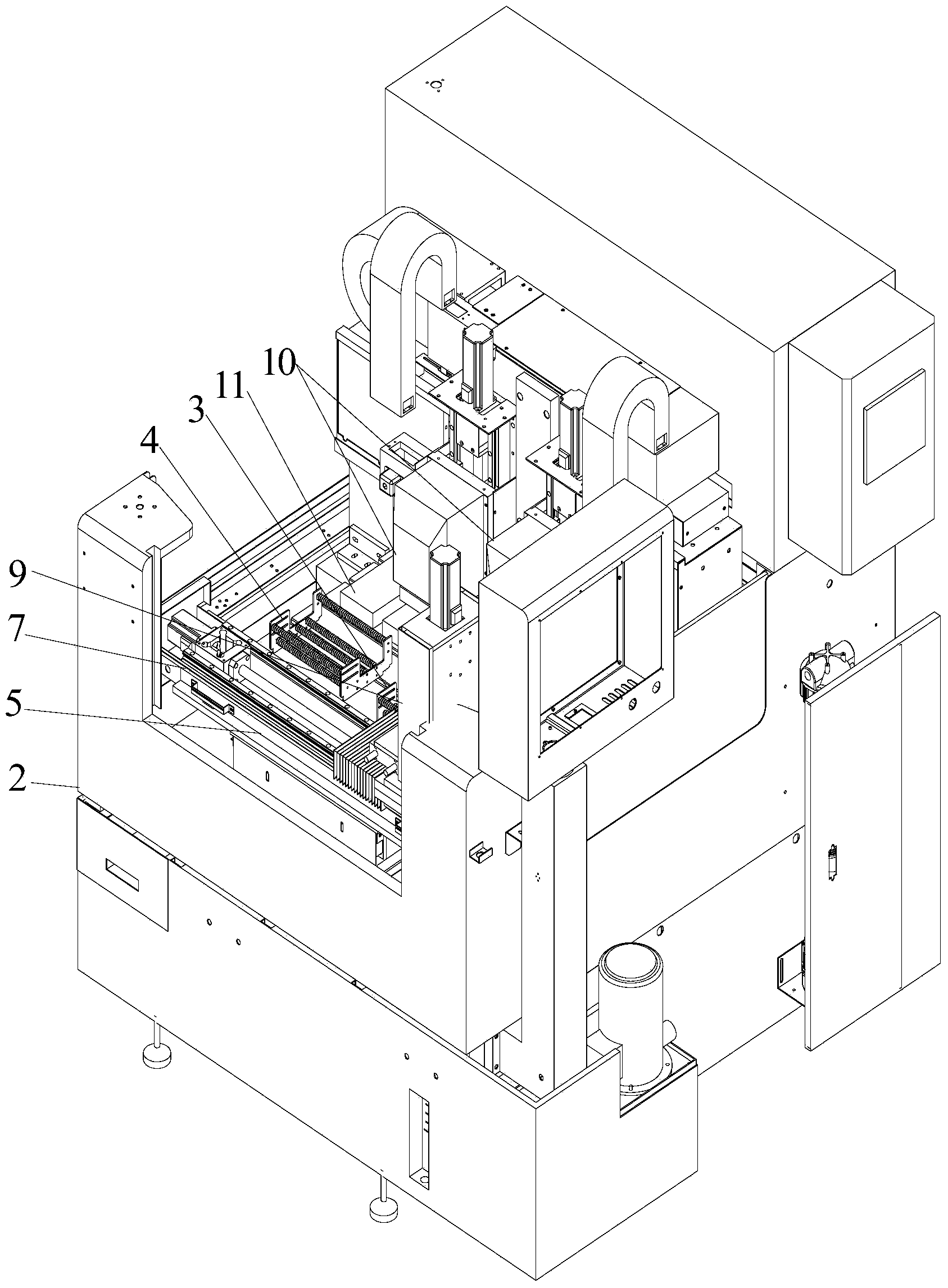

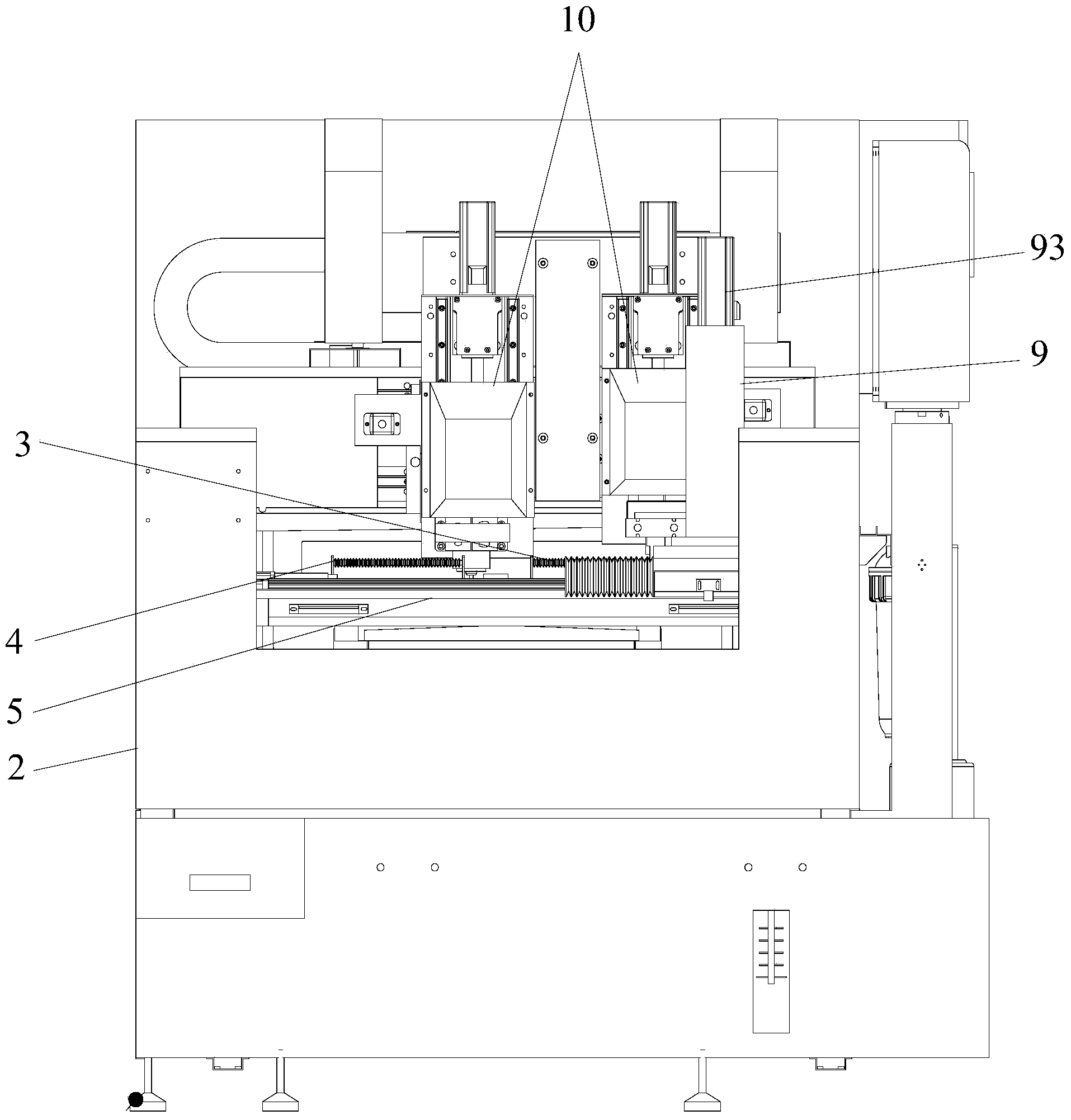

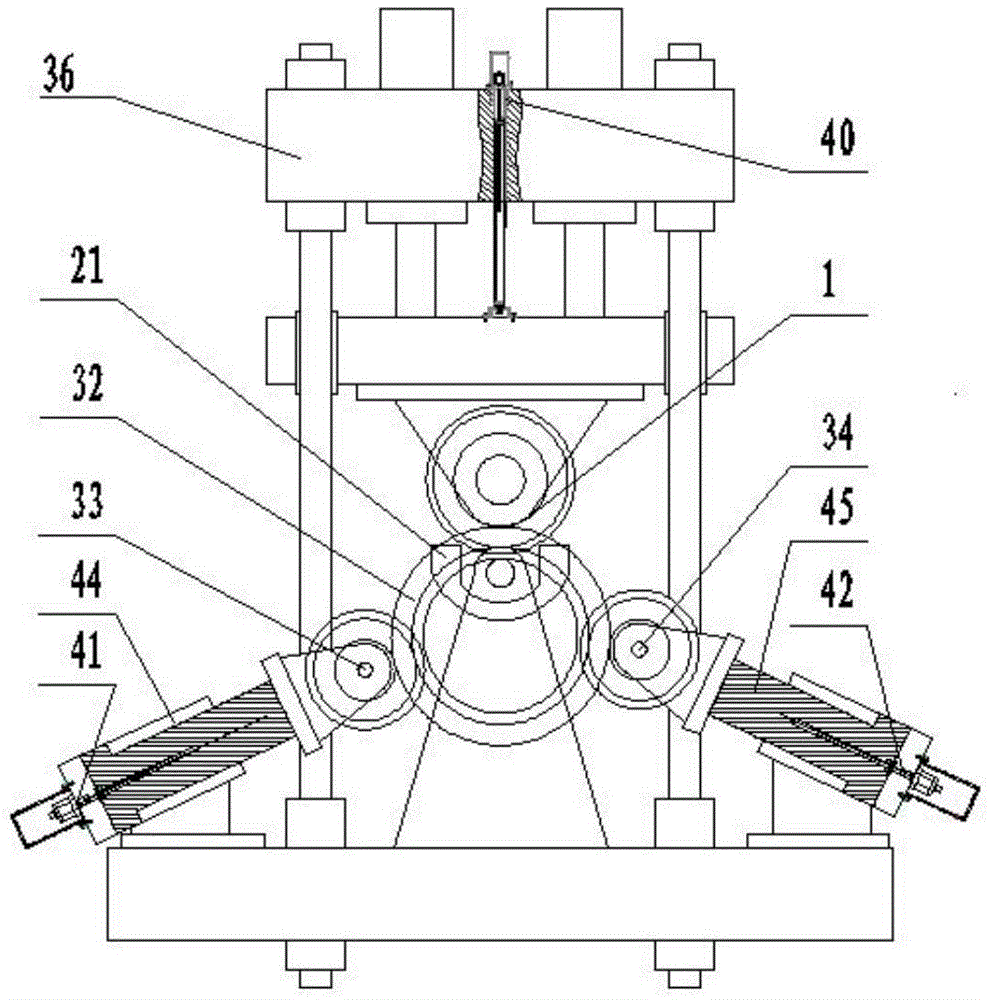

Large vertical type composite ring rolling mill and control method

ActiveCN104438990AHigh precisionImprove mechanical propertiesRoll force/gap control deviceMetal rolling arrangementsThick wallRoll forming

The invention provides a large vertical type composite ring rolling mill and a control method. The large vertical type composite ring rolling mill comprises a frame, a roller mechanism, a left sub roller mechanism, a right sub roller mechanism, a core roller mechanism and a control device. The control device is used for controlling operation of the roller mechanism, the left sub roller mechanism, the right sub roller mechanism and the core roller mechanism. The core roller mechanism comprises a core roller, a fixed support, a movable support, a core roller base and a lifting drive device, the lower end of the movable support is connected with the lifting drive device to enable the movable support to move up and down, the outer side of the fixed support is connected with a rotary drive device which can drive the core roller to rotate, the outer side of the rotary drive device is connected with a locating baffle mechanism, and precise locating of a baffle is achieved through displacement sensors. The large vertical type composite ring rolling mill can be used for automatic composite roll forming of large complex thick-wall deep-groove rings, and a mill user can obtain remarkable economic benefits.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

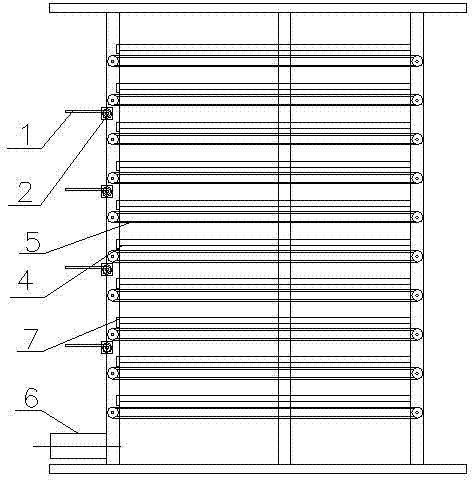

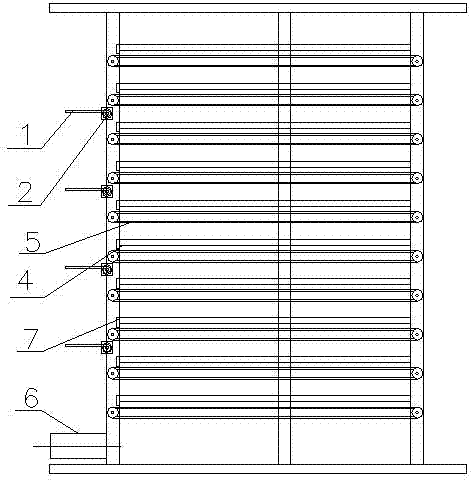

Conveying belt type article storage and delivery device

InactiveCN102344029ARealize automatic loading and unloadingImprove space utilizationStorage devicesMachine partsEngineering

The invention discloses a conveying belt type article storage and delivery device. Conveying belts are arranged on a frame body of an article storage frame from upside to downside in sequence; the two adjacent conveying belts are parallel to each other; each conveying belt is driven by a corresponding conveying belt power device to operate; a partition board is arranged above each conveying belt; the conveying belt is divided into a plurality of independent article storage channels by the partition boards according to the article storage size; each article storage channel is parallel to the advancing direction of the conveying belt; a delivery controller capable of being opened is arranged at the output end of each article storage channel; a turnover plate is arranged at the outlet end of the conveying belt and driven by a corresponding turnover plate power device to turn over; a belt machine is arranged at the bottom of the article storage frame and positioned below the lowest turnover plate. The conveying belt type article storage and delivery device disclosed by the invention can be widely used for automatically storing drugs, foods, daily necessities, chemicals, mechanical parts, electronic components and other materials.

Owner:JIANGSU XUNJIE HARNESS TECH

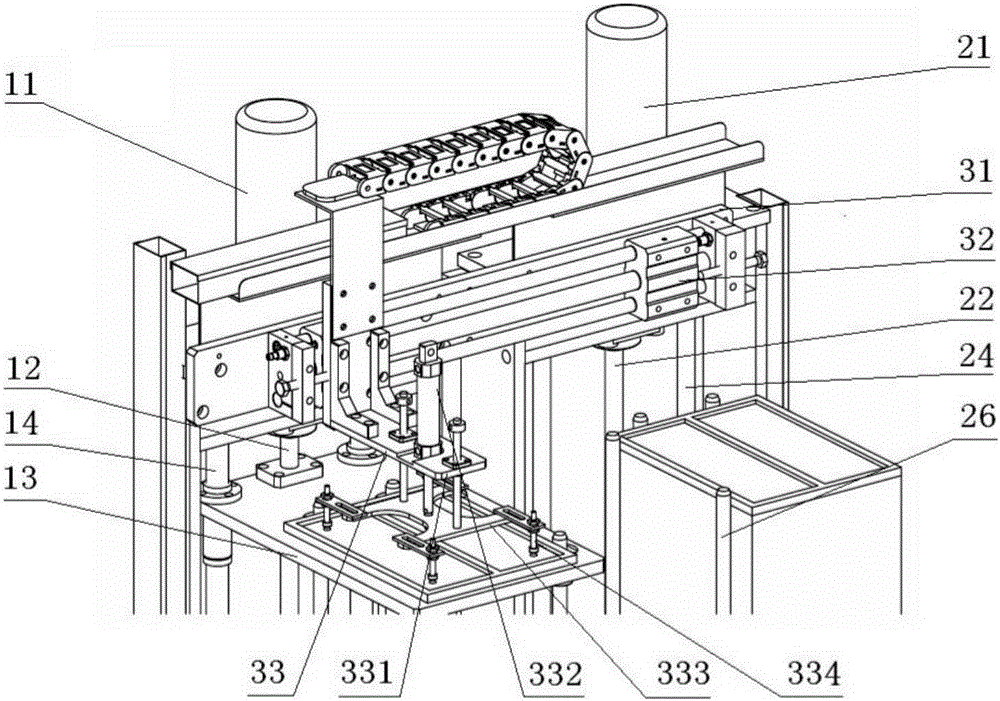

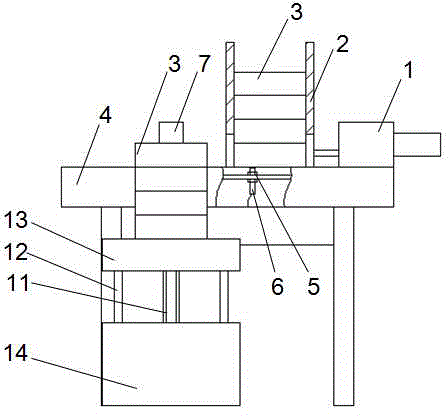

Automatic feeding and discharging device for parts

ActiveCN104354059ARealize automatic loading and unloadingImprove consistencyMetal working apparatusReducerUltimate tensile strength

The invention discloses an automatic feeding and discharging device for parts. The upper surface of a workbench is provided with a feeding air cylinder and a discharging air cylinder, wherein a piston rod of the feeding air cylinder is used for pushing a material box at the bottom of a storage chamber to a stroke position of the discharging air cylinder; a piston rod of the discharging air cylinder is used for pushing the material box out of the workbench; a box body for accommodating a motor is arranged outside the material box sliding-out side of the workbench; the motor drives a screw rod to rotate up and down through a speed reducer; the front end of the screw rod is inserted into a bearing inner race in a lifting table to drive the lifting table to move up and down; a plurality of guide rods which are inserted into the box body are arranged in the lifting table; a feeding sensor and a discharging sensor, corresponding to the stroke positions of the feeding air cylinder and the discharging air cylinder, are respectively arranged in the surface of the workbench; a lifting sensor is arranged on the material box sliding-out side wall of the workbench. The automatic feeding and discharging device disclosed by the invention is used for realizing automatic feeding and discharging of parts, ensuring good consistency of machined parts, avoiding operation errors caused by manual feeding and discharging, reducing the labor intensity and improving the production efficiency.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

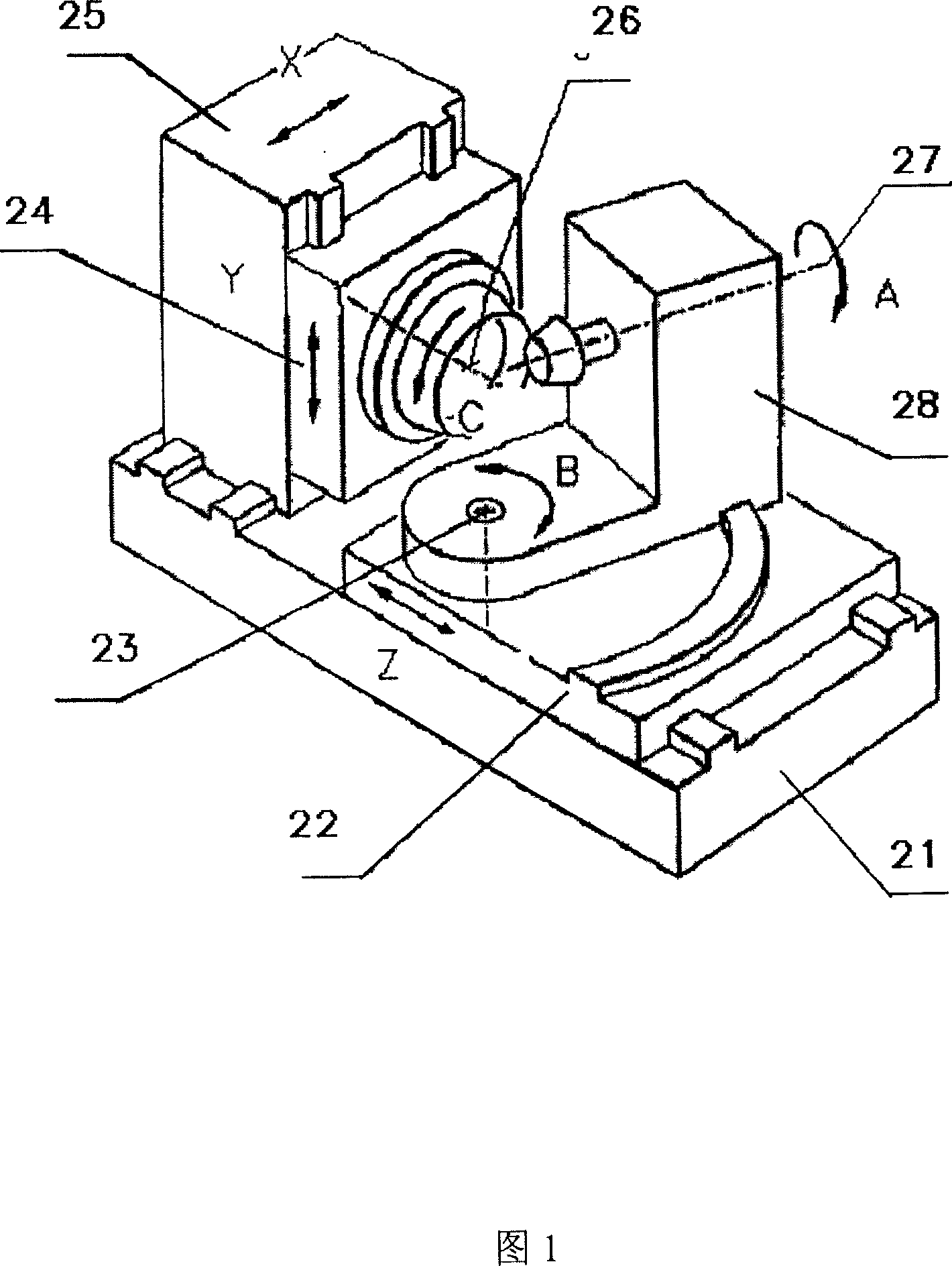

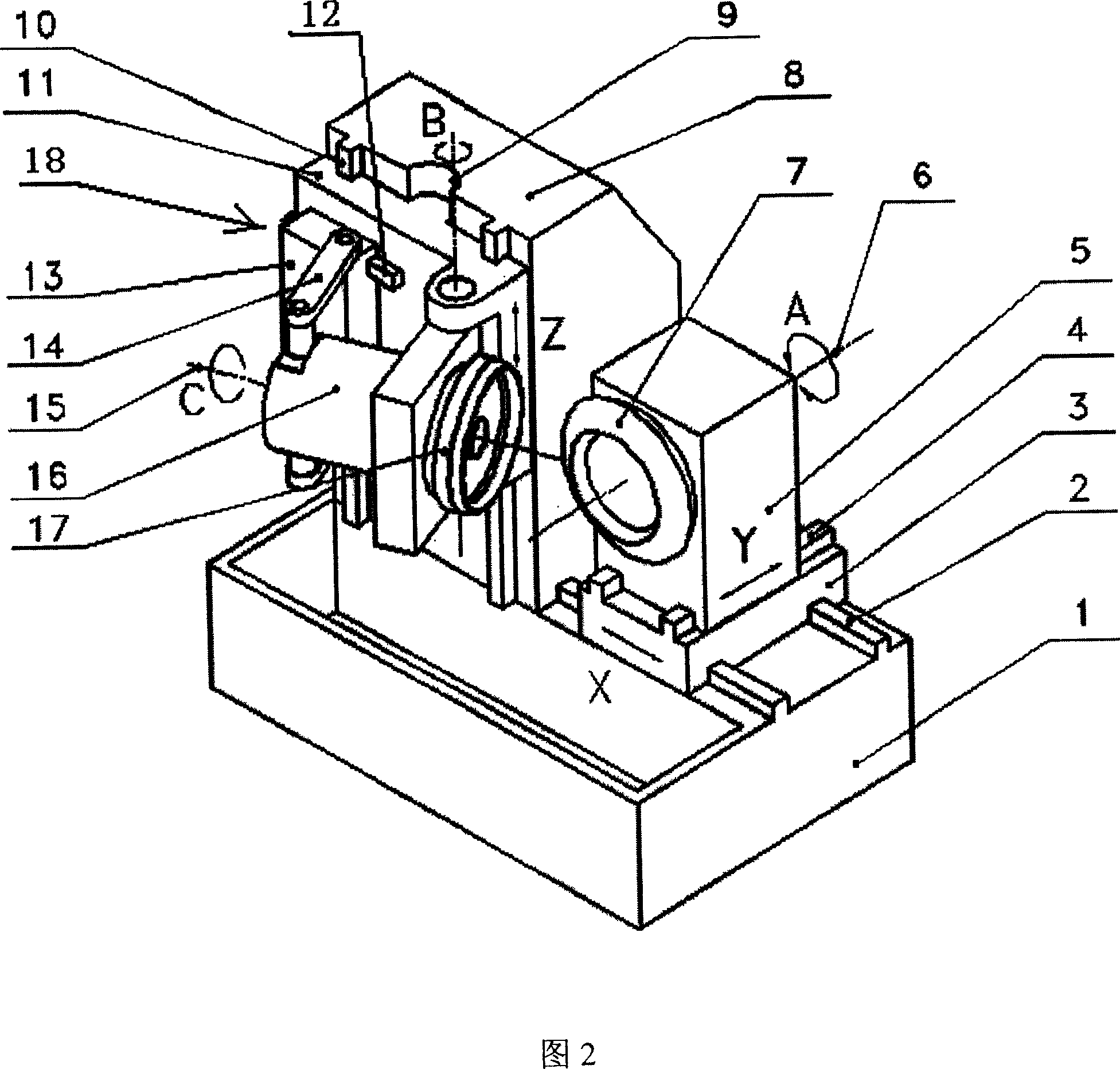

Machine tool for processing spiral taper gear with six axes, five linkage axes

InactiveCN1958226AEasy loading and unloadingEasy to realize automatic loading and unloadingLarge fixed membersMetal working apparatusGear wheelMachine tool

A 6-axle 5-linkage machine-tool for manufacturing spiral bevel gear is composed of machine body, vertical post, linear X-tracks on said machine body, slide X-carrier sliding on said X-tracks, linear Y-tracks on said slide X-carrier, workpiece box sliding on said Y-tracks, rotary axle A on said workpiece box, linear Z-tracks on the lateral surface of said vertical post, Slide Z-carrier sliding on said Z-tracks, drive unit, tool box on said Z-carrier and revolving around axle B and its driver, and rotary axle C installed to said tool box.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

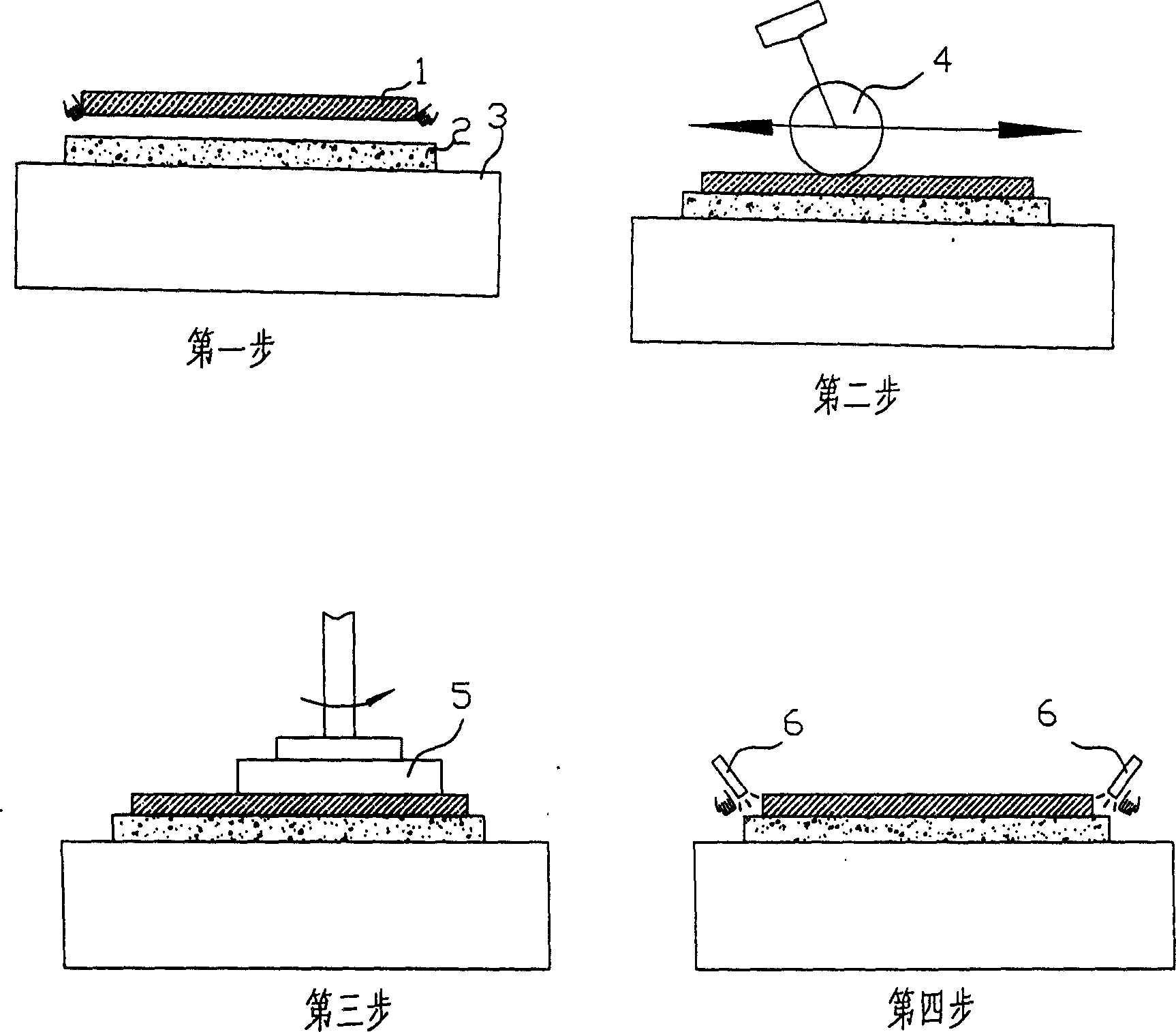

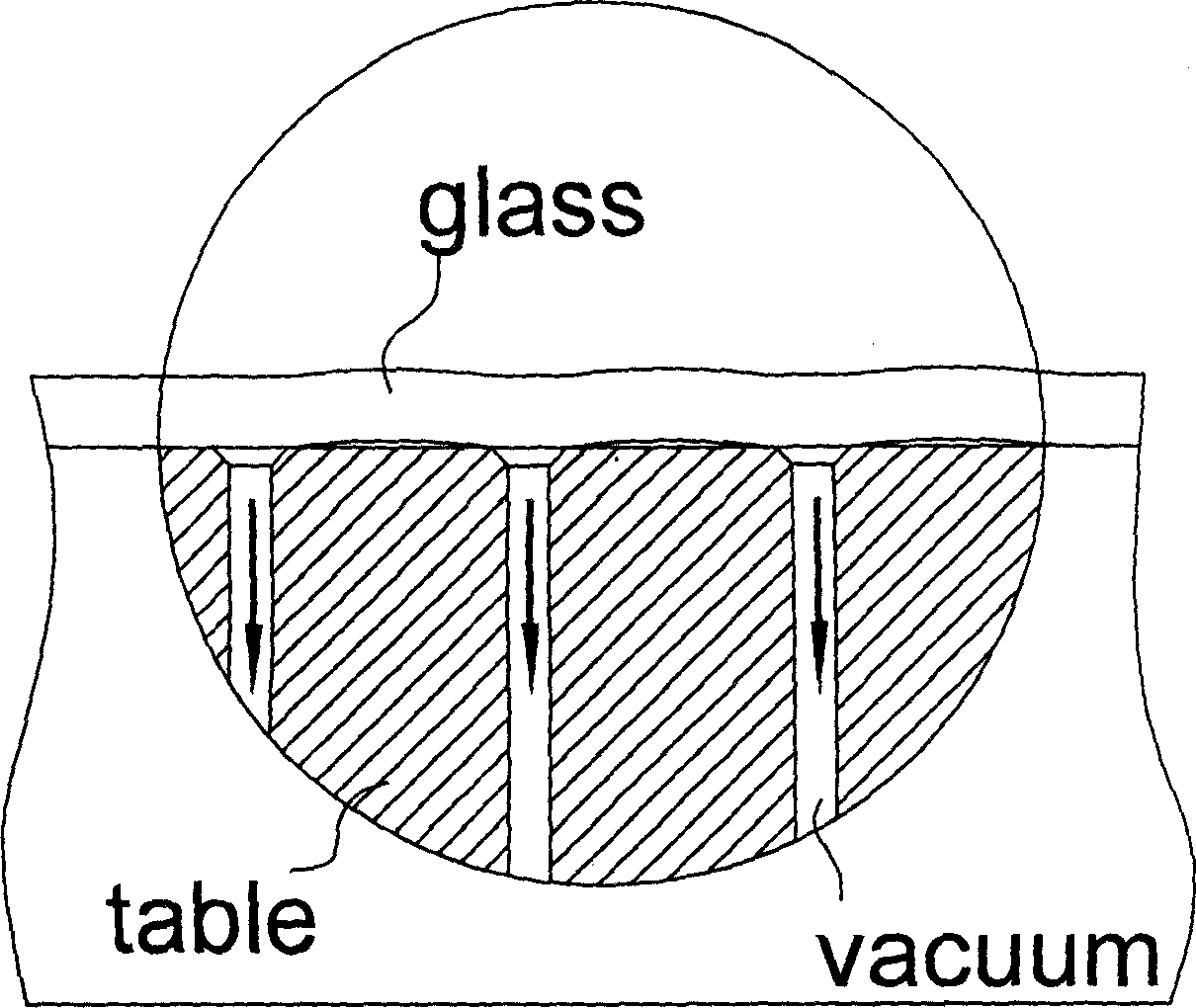

Loading and unloading device and method for ultrathin plate glass grinding step

InactiveCN1857867AAdhesive printingImprove thermal stabilityGrinding machine componentsOptical surface grinding machinesFlat glassEngineering

The present invention relates to loading and unloading device and method for ultrathin plate glass grinding step. The loading and unloading device includes one bench mechanism with surface pores for vacuum adsorption and air pressure suspending of plate glass, and one servo motor mechanism for driving the bench mechanism to load or unload plate glass. The bench mechanism has cushion of rigid porous ceramic material for bearing the plate glass. The present invention can realize automatic loading and unloading of plate glass automatically in high work efficiency.

Owner:HENAN ANCAI HI-TECH +1

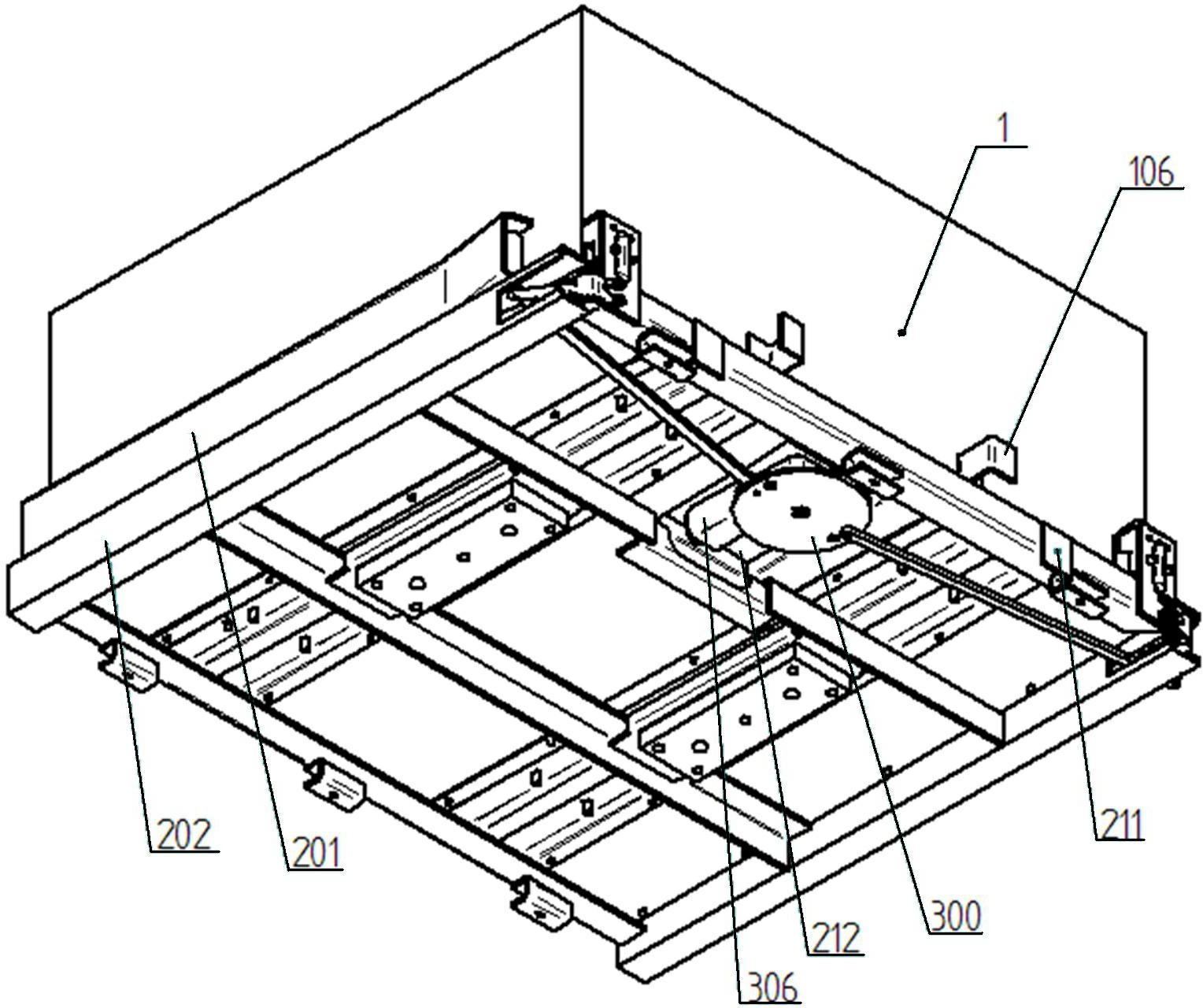

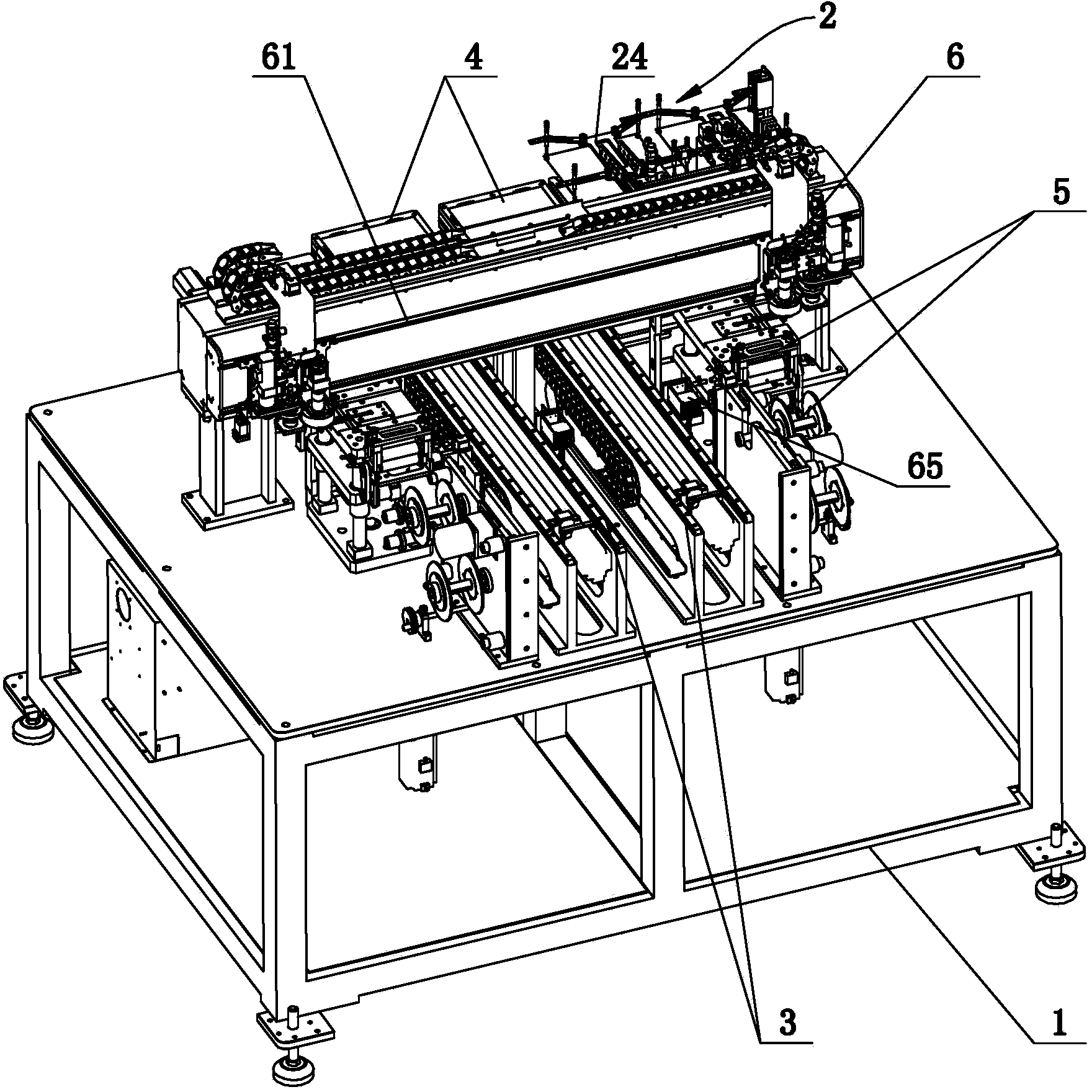

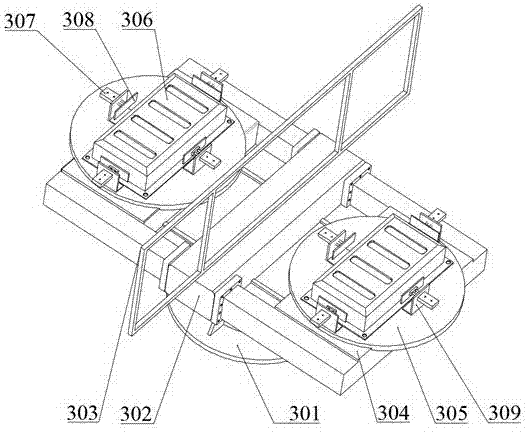

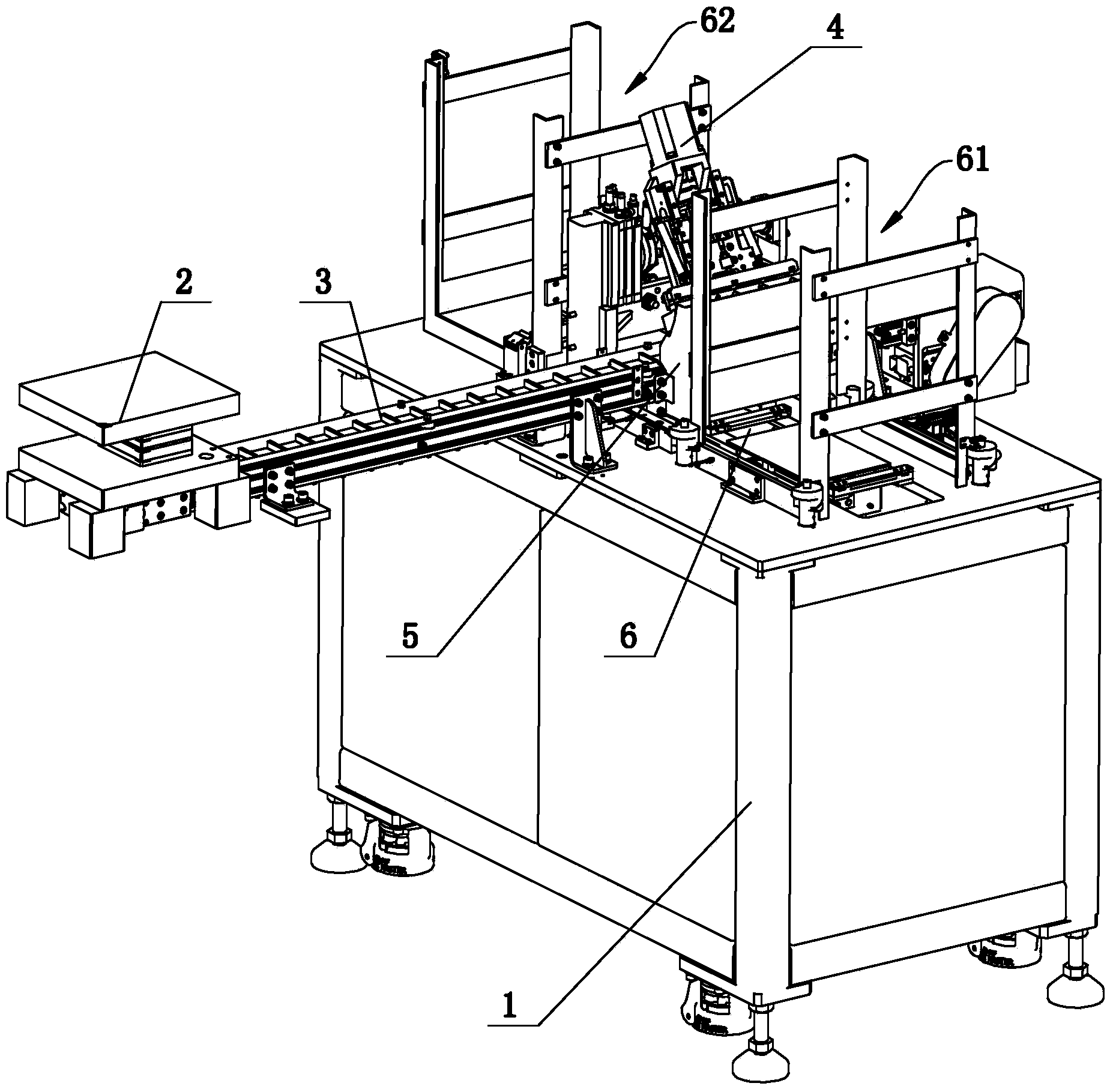

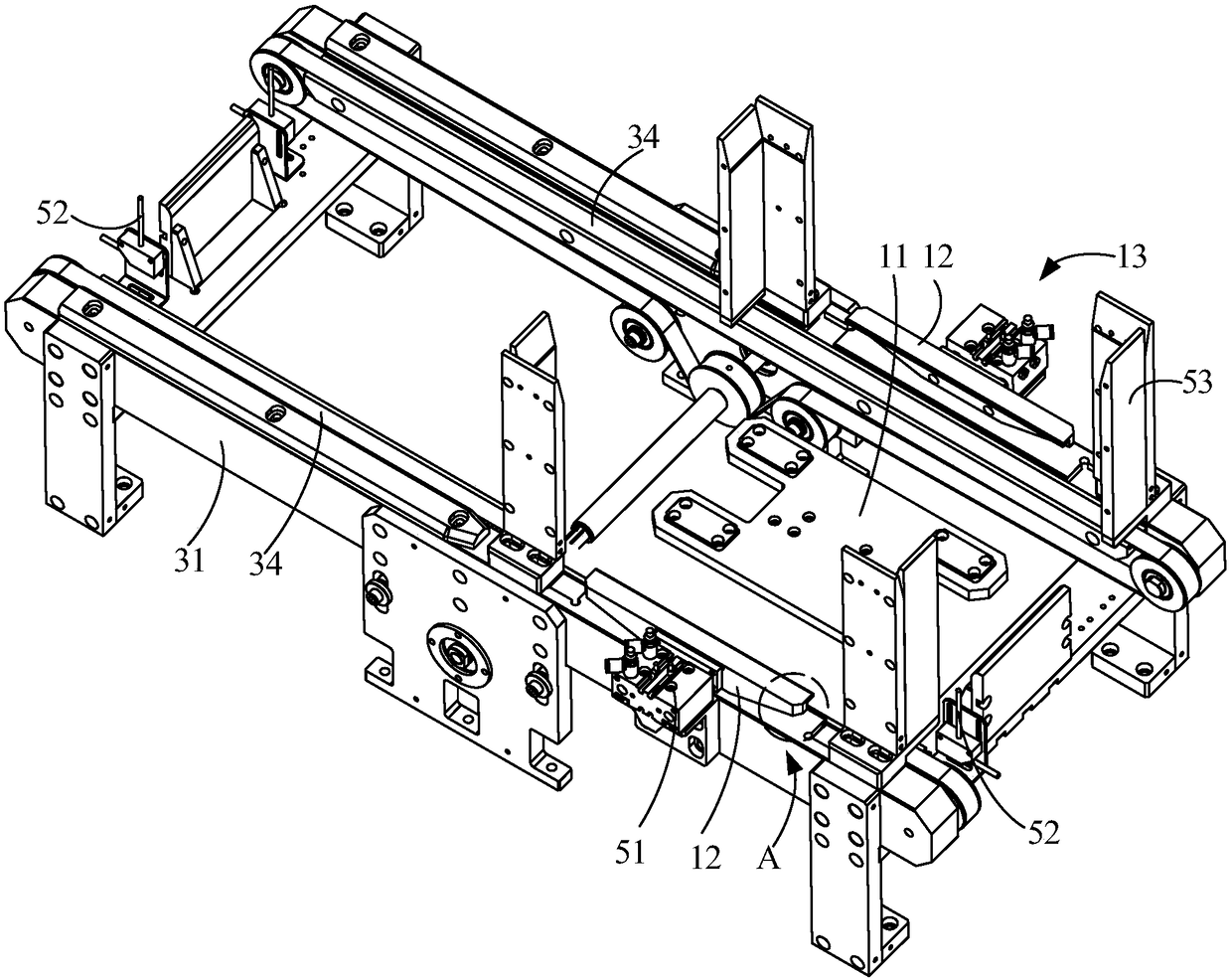

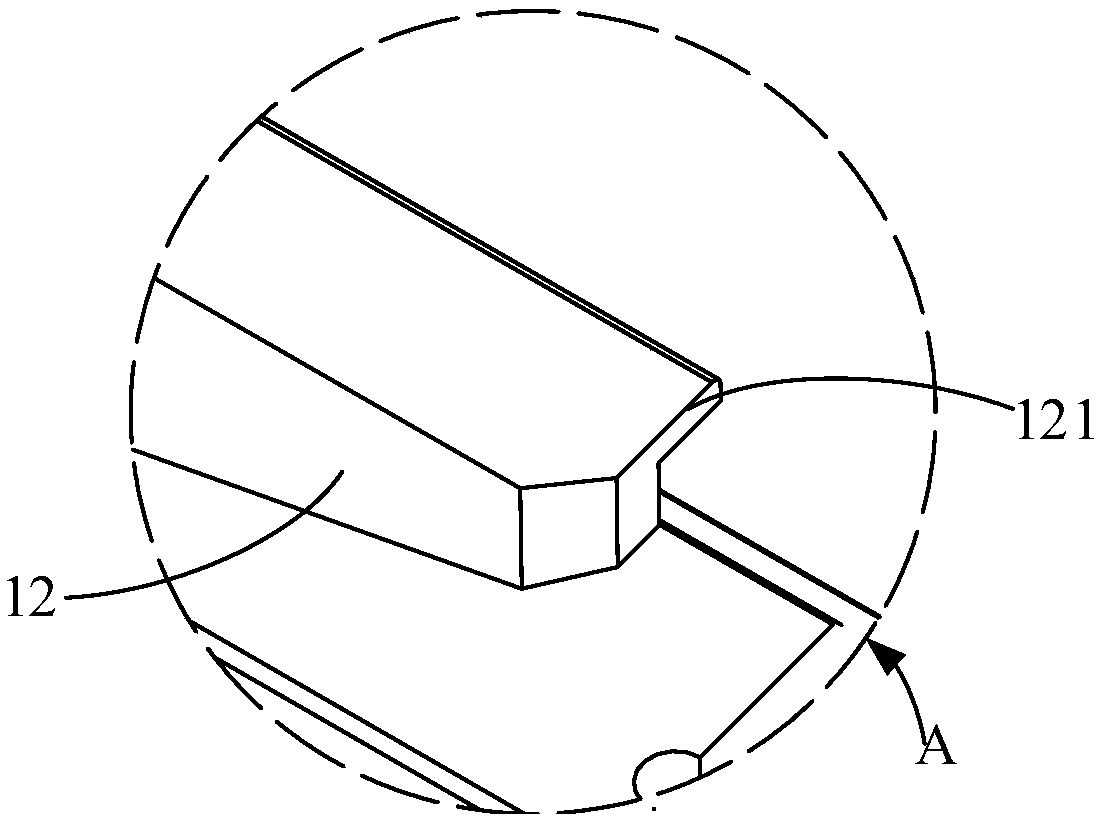

Full-automatic reinforcement plate pre-lamination machine

ActiveCN104113987ATo achieve singleRealize automatic loading and unloadingPrinted circuit manufactureEngineeringMachining

The invention discloses a full-automatic reinforcement plate pre-lamination machine and belongs to the technical field of FPC (Flexible Printed Circuit) machining equipment. The full-automatic reinforcement plate pre-lamination machine comprises a frame which is provided with a feeding and discharging mechanism; the feeding and discharging mechanism comprises a supporting beam; the first side of the supporting beam is provided with a first Z direction motion mechanism which is driven by a first X direction motion mechanism; the first Z direction motion mechanism is provided with a FPC suction nozzle; a feeding cabin, an FPC positioning mechanism and a storage cabin are arranged along the frame portion in turn, wherein the frame portion is arranged below a motion path of the FPC suction nozzle; the frame portion which is located between the FPC positioning mechanism and the storage cabin is provided with an FPC heating platform which is driven by a Y direction motion mechanism; the frame is provided with a feeding mechanism and a lamination mechanism. According to the full-automatic reinforcement plate pre-lamination machine, the automatic feeding and discharging of an FPC is achieved, the consistency of the mechanisms is good, and accordingly the production efficiency is improved, the production cost is reduced, and the degree of automation is high.

Owner:GOERTEK INC

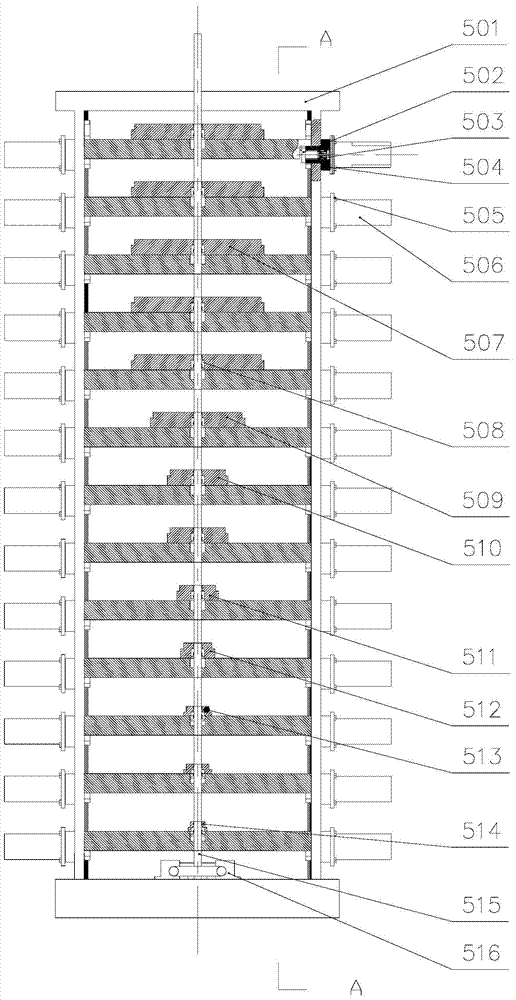

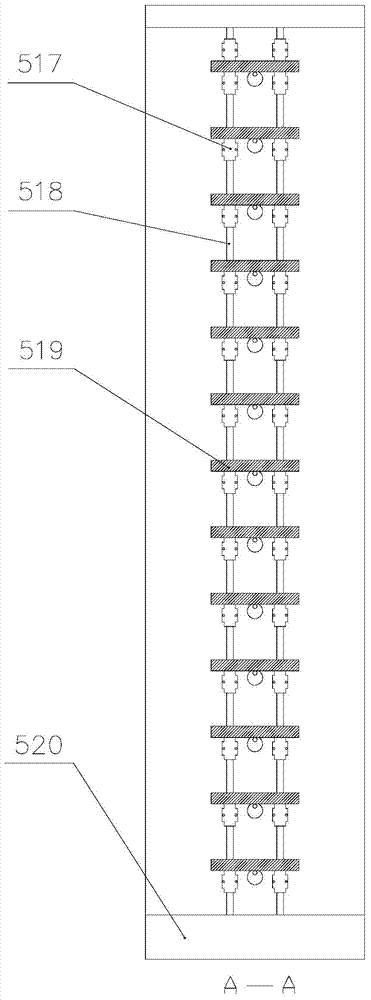

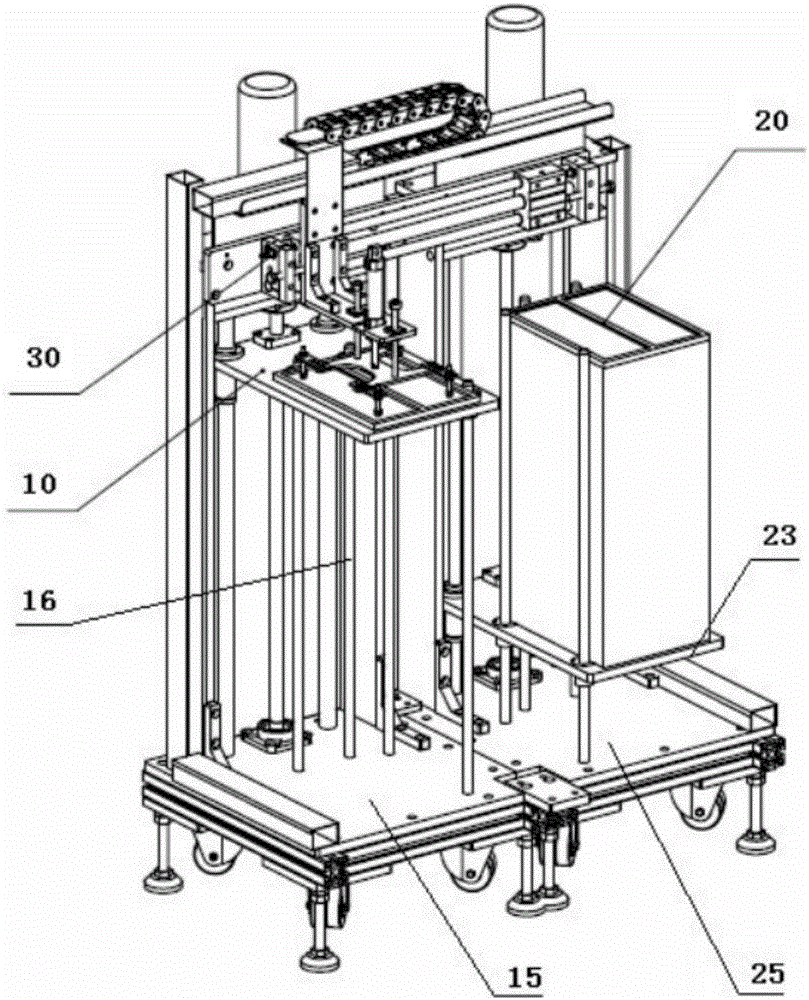

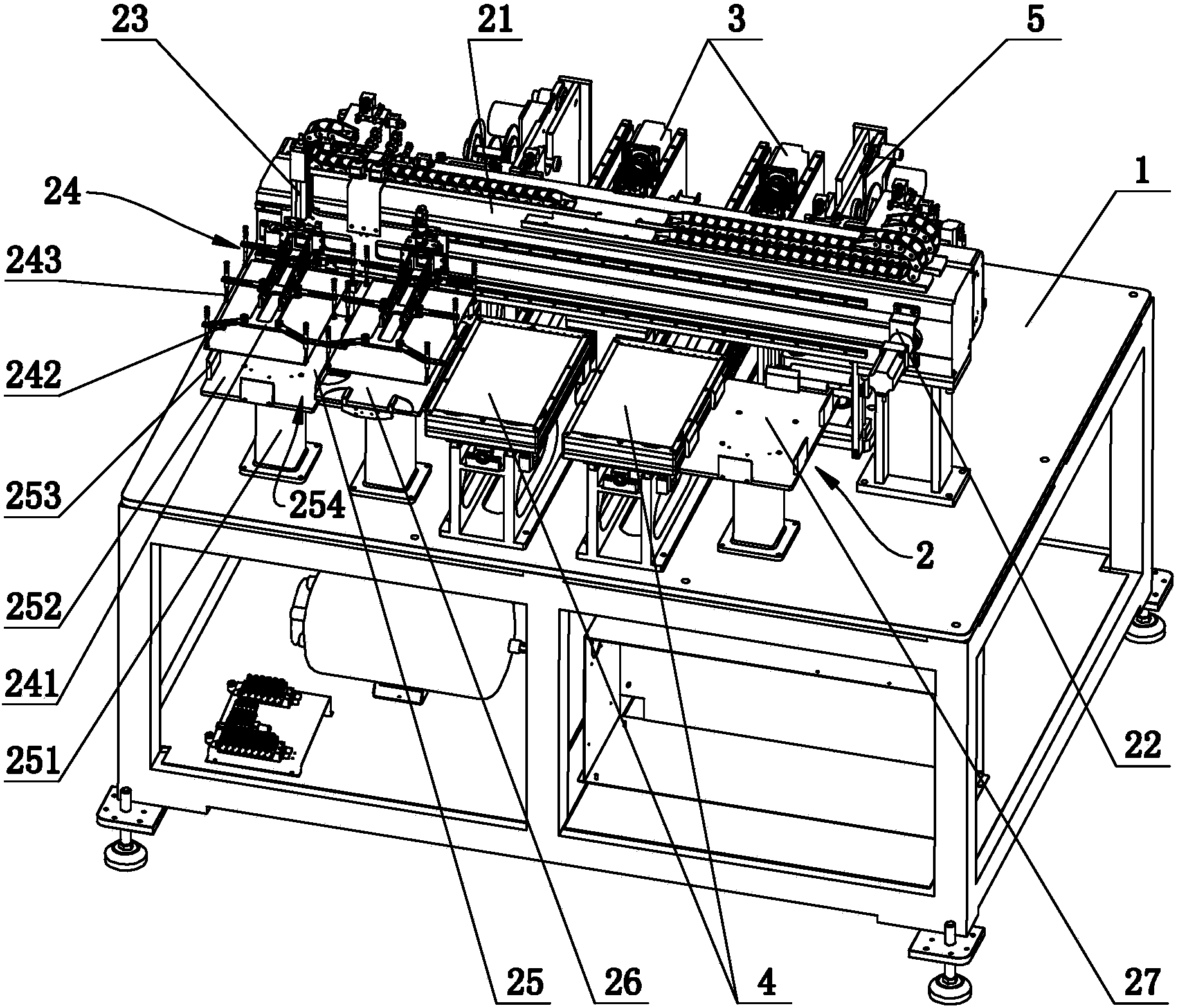

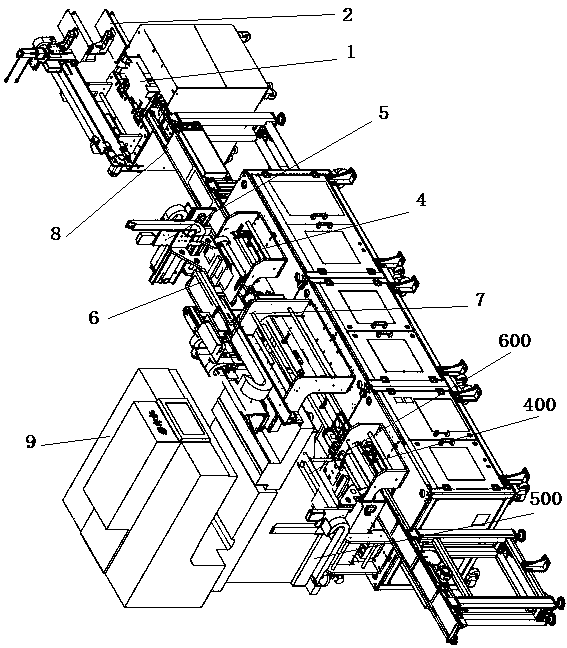

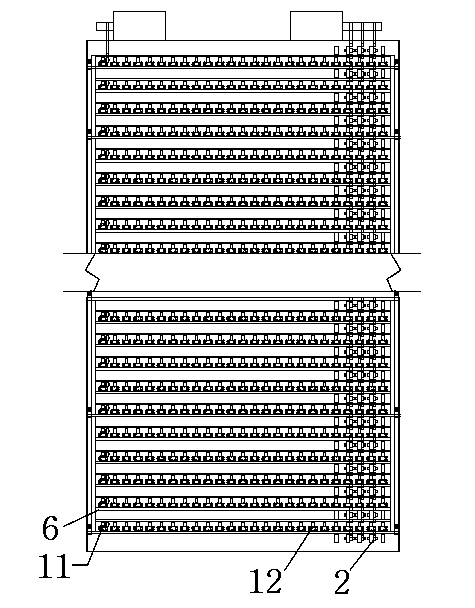

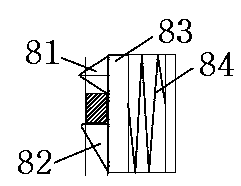

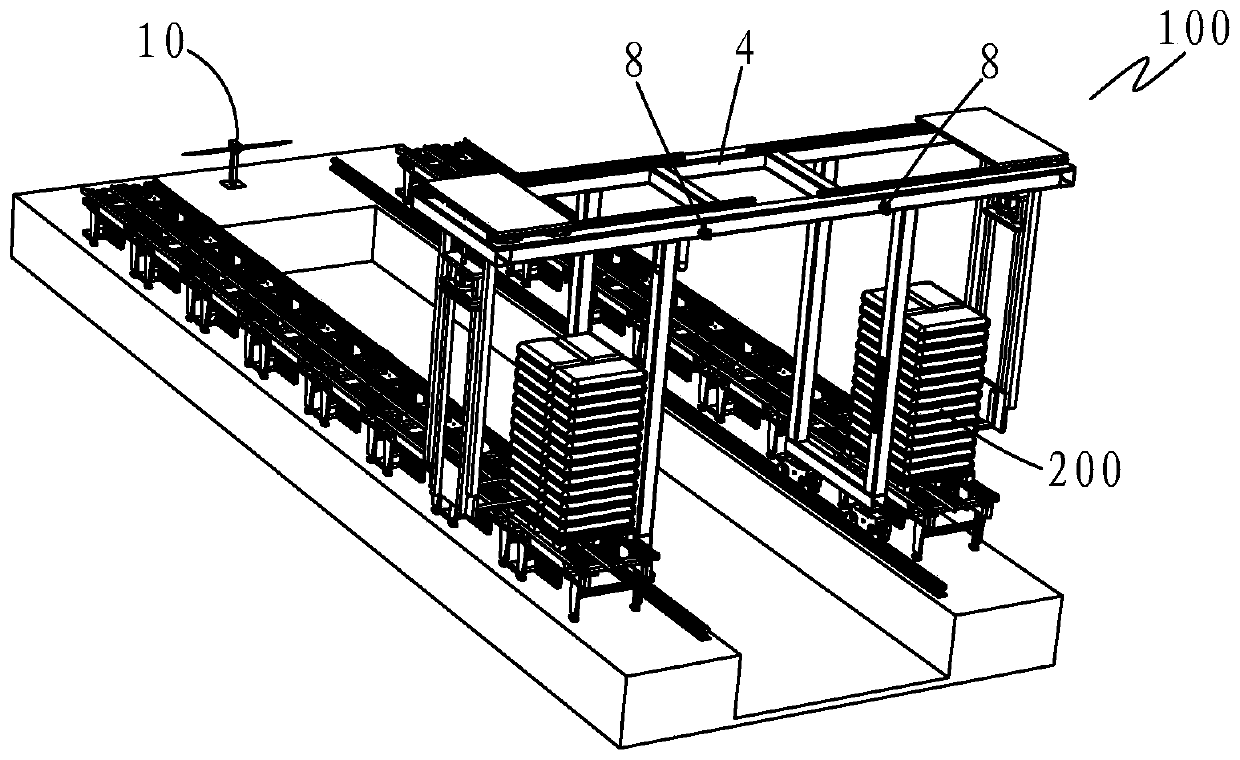

Automatic feeding and discharging system for multi-layer hot press

ActiveCN105150355AReduce labor costsImprove yieldWood working apparatusDomestic articlesManipulatorEngineering

The invention relates to the technical field of artificial board automatic machining, in particular to an automatic feeding and discharging system for a multi-layer hot press. The automatic feeding and discharging system for the multi-layer hot press comprises a control system and an automatic feeding and discharging device, connected with the control system, for multi-layer hot press. The automatic feeding and discharging device for the multi-layer hot press comprises a feeding lifting table, a plate transferring device and a discharging lifting table which are all sequentially arranged at intervals along a straight line. The multi-layer hot press is arranged between the plate transferring device and the discharging lifting table. The plate transferring device comprises a rack, a sucker type mechanical arm and a feeding and discharging tray. The rack comprises a tray lifting mechanism. The feeding and discharging tray comprises a tray base and a feeding and discharging push rod mechanism arranged on the tray base. The sucker type mechanism arm is fixed to the feeding and discharging tray or the tray lifting mechanism. By means of the automatic feeding and discharging system for the multi-layer hot press, the feeding lifting table, the plate transferring device and the discharging lifting table are controlled by the control system, automatic feeding and discharging can be achieved, and labor cost is reduced; the feeding and discharging efficiency is improved, and the plate yield is increased; and injuries caused by the hot press to human bodies in the feeding and discharging process are avoided.

Owner:深圳中智卫安机器人技术有限公司

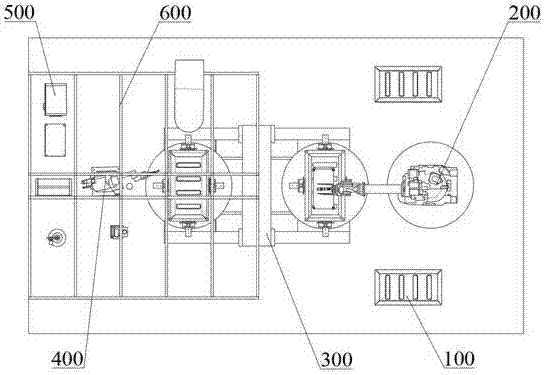

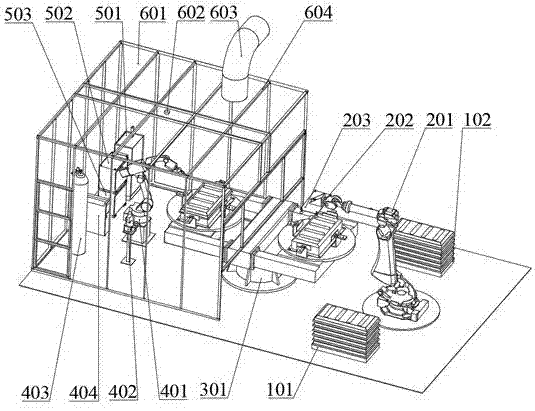

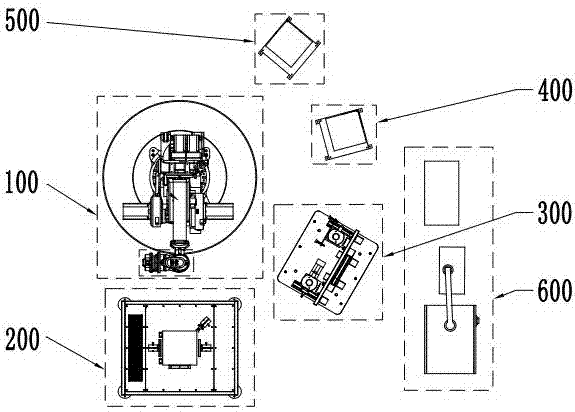

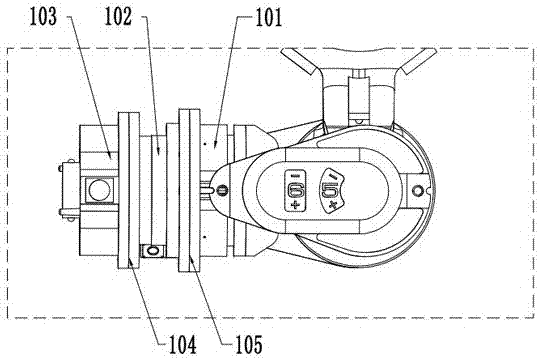

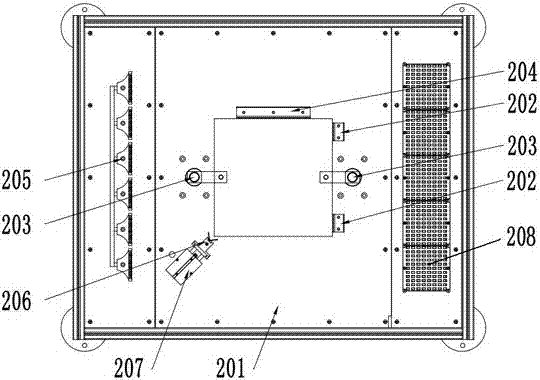

Double-station robot automatic welding system

PendingCN107877053AHigh degree of automationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsCharge and discharge

The invention discloses a double-station robot automatic welding system. The double-station robot automatic welding system comprises a fixed stock bin, a charging and discharging carrying robot system, a double-station welding workbench, a welding robot system, a control system and a welding room, wherein the fixed stock bin is used for storing to-be-machined parts and machined parts; a charging and discharging carrying robot is used for achieving automatic charging and discharging of workpieces; the double-station welding workbench is arranged between the welding room and the charging and discharging carrying robot and used for achieving positioning clamping and station transferring of the workpieces; and the welding robot system and the control system are arranged in the welding room. The functions of automatic charging and discharging, automatic clamping, automatic welding and the like of metal plate boxes are achieved, equipment automation degree is high, positioning is accurate, the adaptability is high, and the welding efficiency and welding quality are effectively improved; and by arranging necessary insulation protection facilities, harm to workers in the welding process can be greatly reduced.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

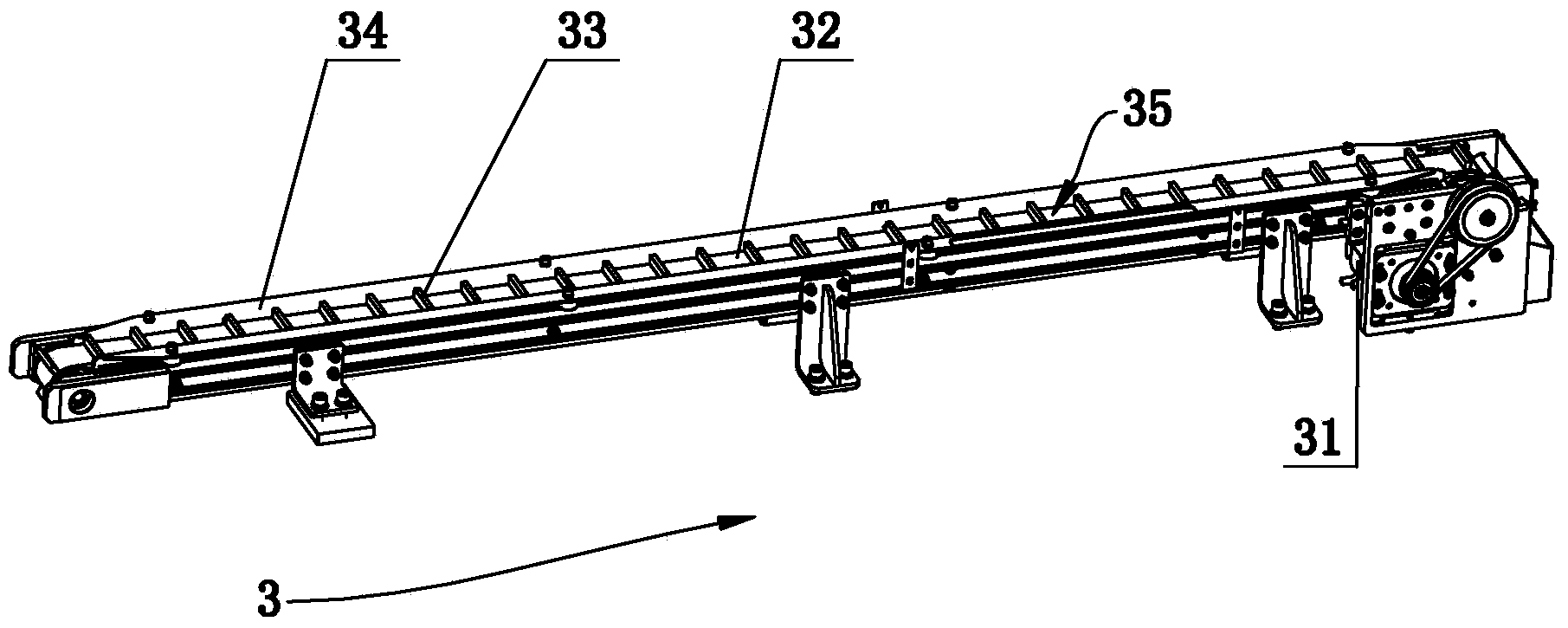

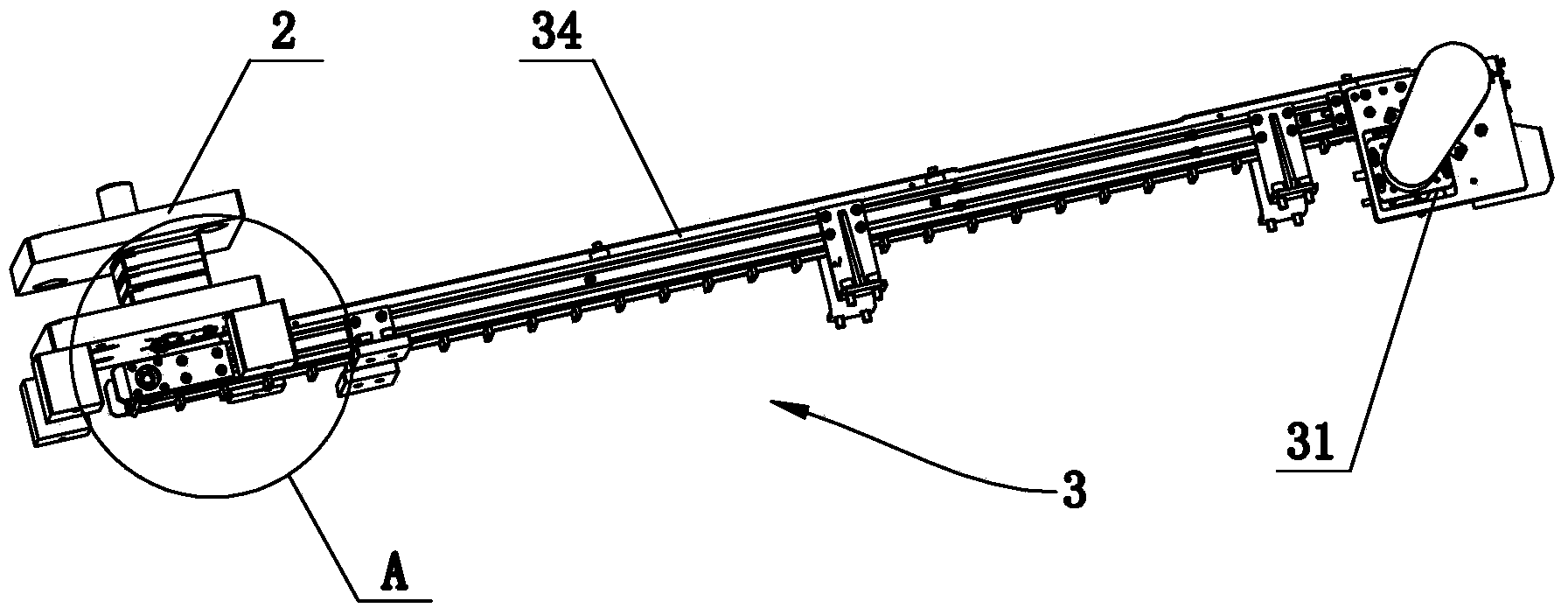

Automatic conveying line for keycap transfer printing equipment

PendingCN108792559ARealize automatic loading and unloadingLow costConveyorsConveyor partsEngineeringManipulator

The invention discloses an automatic conveying line for keycap transfer printing equipment. The automatic conveying line for the keycap transfer printing equipment comprises a tray lifting and temporary storing mechanism, a tray transferring and loading manipulator, a feeding, lifting and positioning mechanism, a feeding, turning-over, transferring and loading mechanism, a feeding, transferring and loading module, a feeding and reciprocated transferring and loading module, dual transferring and loading equipment, a discharging and reciprocated transferring and loading module, a discharging, transferring and loading module, a discharging, turning-over, transferring and loading mechanism, and a discharging, lifting and positioning mechanism. Through the manner, according to the automatic conveying line for the keycap transfer printing equipment provided by the invention, the automatic conveying line for the transfer printing equipment is directly connected with the last process for keycap processing, trays are conveyed by utilizing the conveying line, and the turning-over, transferring and loading mechanisms are arranged on a line body, so that conveyed keycaps can be turned over; and in addition, the transferring and loading manipulator on the conveying line body can feed the turned-over keycaps into the transfer printing equipment, and meanwhile, the conveying line body furthercomprises the temporary storing mechanism for temporarily conveying the trays for the keycaps, so that automatic feeding and discharging of transfer printing can be realized without the need for manual intervention, the cost is saved, the efficiency is improved, and the accuracy is high.

Owner:林焕城

Punching material collecting and disc arranging machine

The invention discloses a punching material collecting and disc arranging machine, which belongs to the technical field of element production equipment and comprises a machine frame, a material collecting and conveying mechanism, a suction and turning mechanism, a material guide mechanism and a material disc conveying mechanism, wherein the material collecting and conveying mechanism is used for receiving materials falling down from a material falling opening part of a punching mold and realizing the automatic material partition and conveyance, the suction and turning mechanism is used for sucking the materials conveyed by the material collecting and conveying mechanism and realizing the material turning, the material guiding mechanism is used for guiding the materials turned by the suction and turning mechanism into a material disc, the material disc conveying mechanism is used for conveying the material disc under the material guide mechanism, and the material disc conveying direction of the material disc conveying mechanism is vertical to the material conveying direction of the material collecting and conveying mechanism. The punching material collecting and disc arranging machine has the advantages that the structure is compact, the high-speed automatic material collection and the automatic disc arranging can be realized, the automatic material collecting and disc arranging is realized on the premise of not influencing the original efficiency of a punching machine, the production efficiency can also be improved, the labor is saved, and the cost is reduced.

Owner:GOERTEK INC

Feeding and discharging device

ActiveCN108128636ARealize automatic loading and unloadingSmooth feedingDe-stacking articlesEngineeringAutomation

The invention relates to a feeding and discharging device. The device comprises a feeding device, a recycling device and a conveying device; the conveying device is arranged between the feeding deviceand the recycling device, so that a material tray used for bearing materials is conveyed from the feeding device to the recycling device; the feeding device comprises a first lifting platform and material tray limiting structures, and the material tray limiting structures are located on the two opposite sides of the first lifting platform and can horizontally stretch and contract relative to thefirst lifting platform so as to lock or loosen the material tray on the first lifting platform and control the material tray to fall; the first lifting platform can vertically ascend and descend relative to the material tray limiting structures so that when the material tray is loosened by the material tray limiting structures, the first lifting platform can support the material tray to verticallymove relative to the material tray limiting structures, and the material tray is placed in the conveying device. Through the arrangement, the feeding process is more stable, the automation degree ishigher, and the device is convenient to use.

Owner:HANS LASER TECH IND GRP CO LTD

Automatic tool device for cross shaft bearing

InactiveCN110712035APlay the role of limit movementPrevent slippingAssembly machinesMetal working apparatusRotational axisEngineering

The invention relates to the technical field of bearing assembly, and specifically relates to an automatic tool device for a cross shaft bearing. The automatic tool device comprises a machining table,and further comprises a clearance rotation driving assembly, a jig positioning assembly, a left side material guide assembly and a right side material guide assembly, wherein the clearance rotation driving assembly comprises a rotating shaft which is horizontal and can rotate in a clearance mode, the jig positioning assembly comprises four clamping plates capable of abutting against a cross shaft, the left side material guide assembly and the right side material guide assembly are the same in structure, the left side material guide assembly and the right side material guide assembly each comprise a pressing block, a material guide frame is arranged at the end, positioned on the jig positioning assembly, of the machining table, a cross shaft feeding conveyor and a cross shaft discharging conveyor are arranged on one side of the material guide frame, and an upper material guide assembly and a lower material guide assembly which can move among the cross shaft feeding conveyor, the crossshaft discharging conveyor and the jig positioning assembly are arranged on the material guide frame. According to the automatic tool device, automatic feeding and discharging can be realized, each lug shaft of the cross shaft can be automatically assembled, and the production efficiency and the assembly quality are improved.

Owner:束宇晨

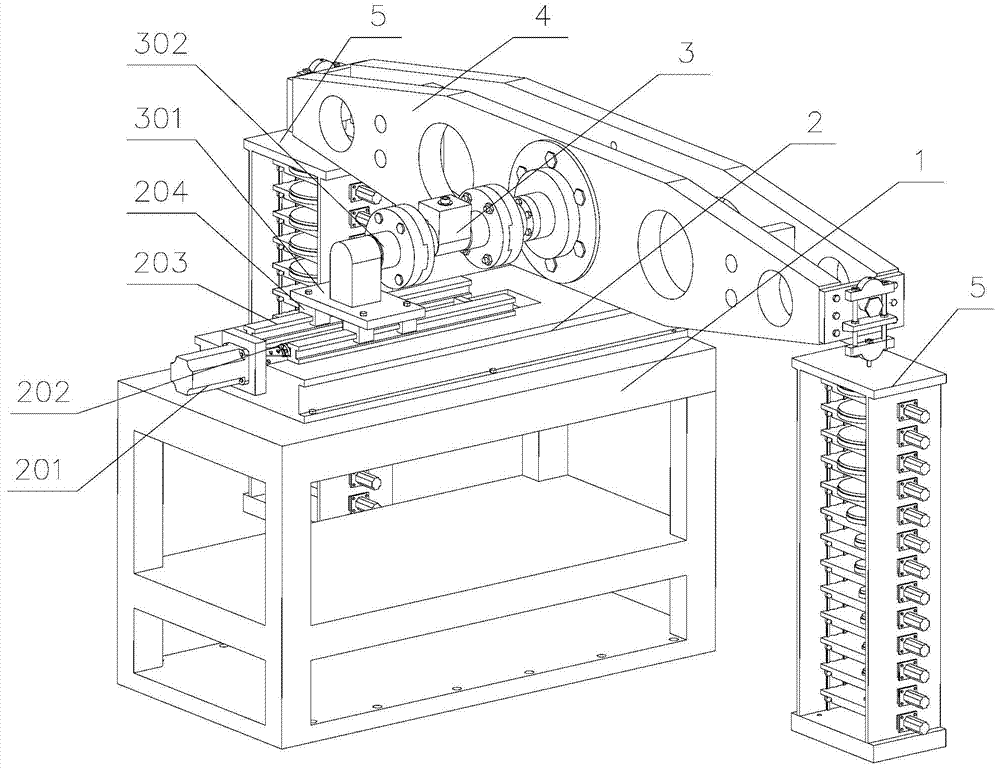

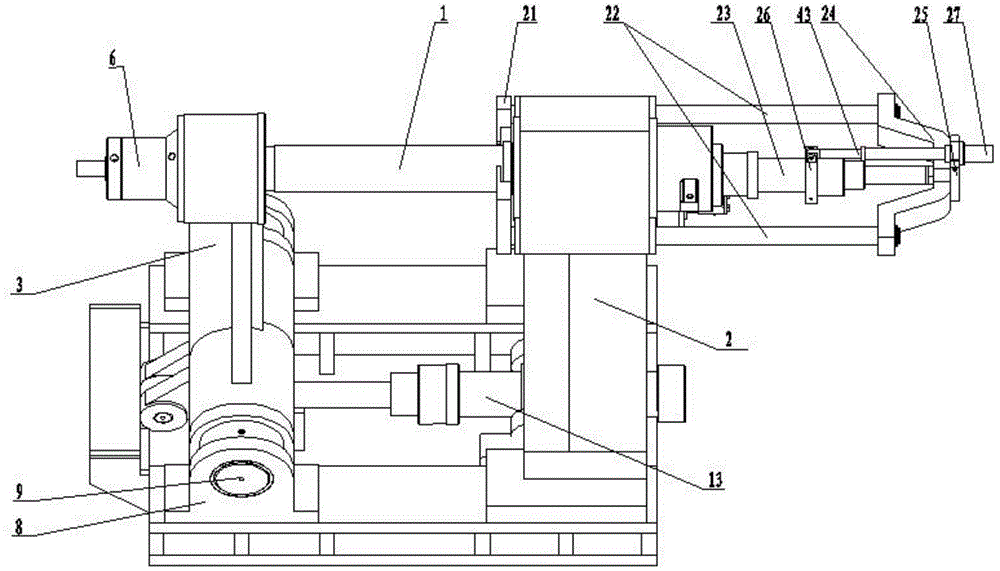

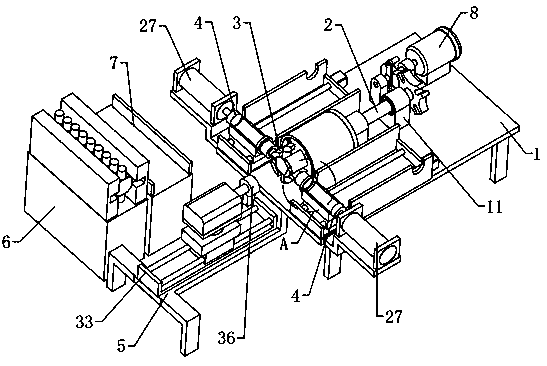

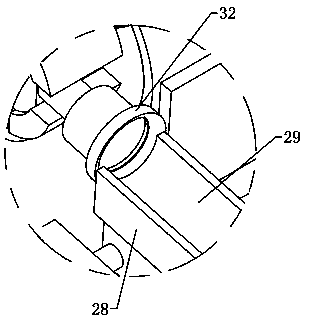

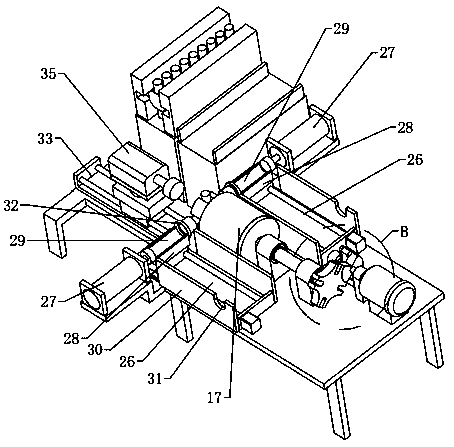

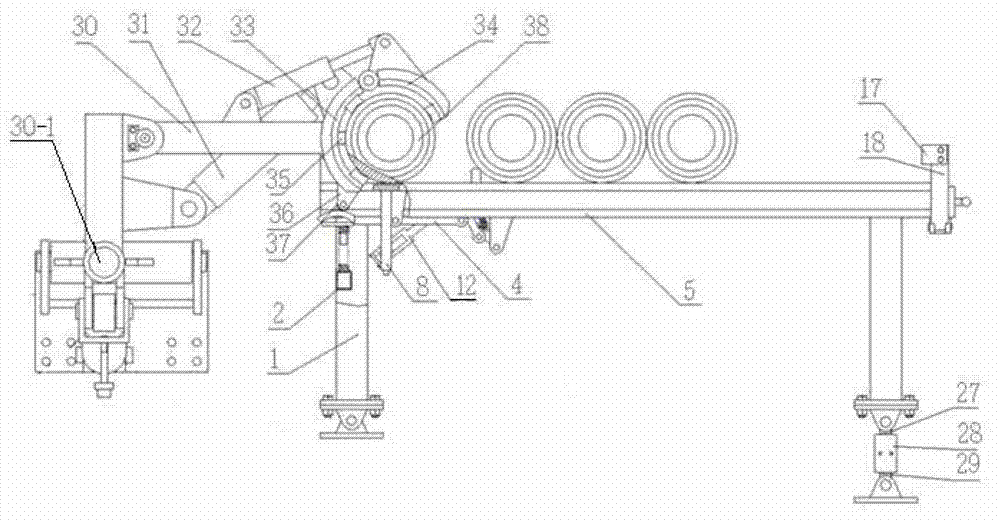

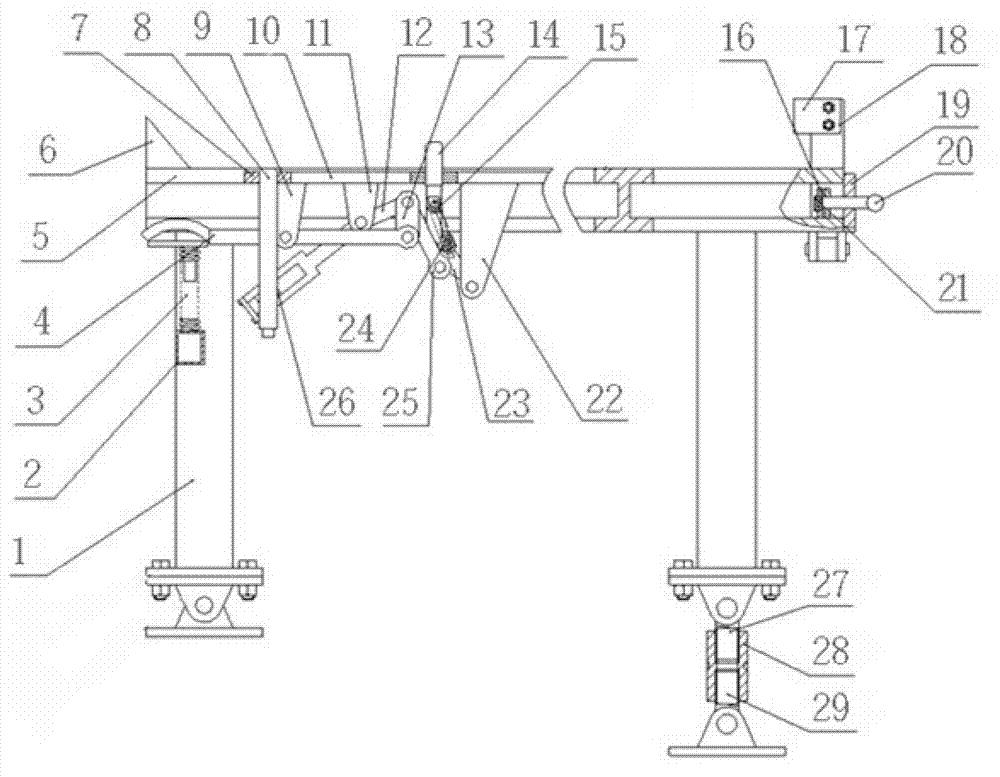

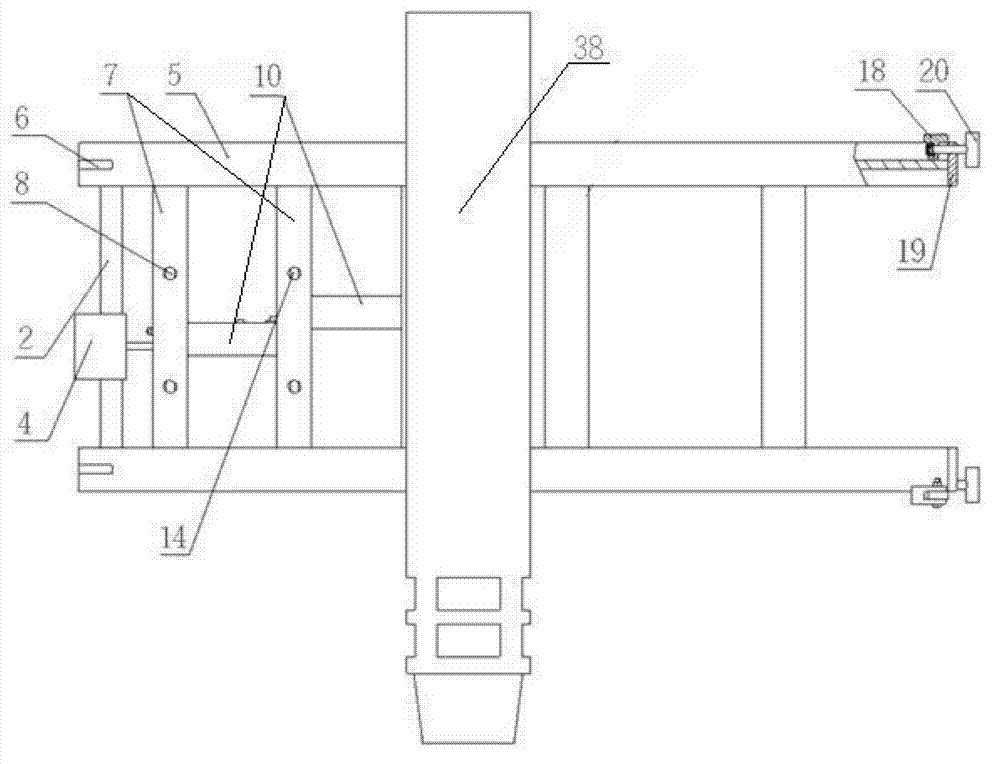

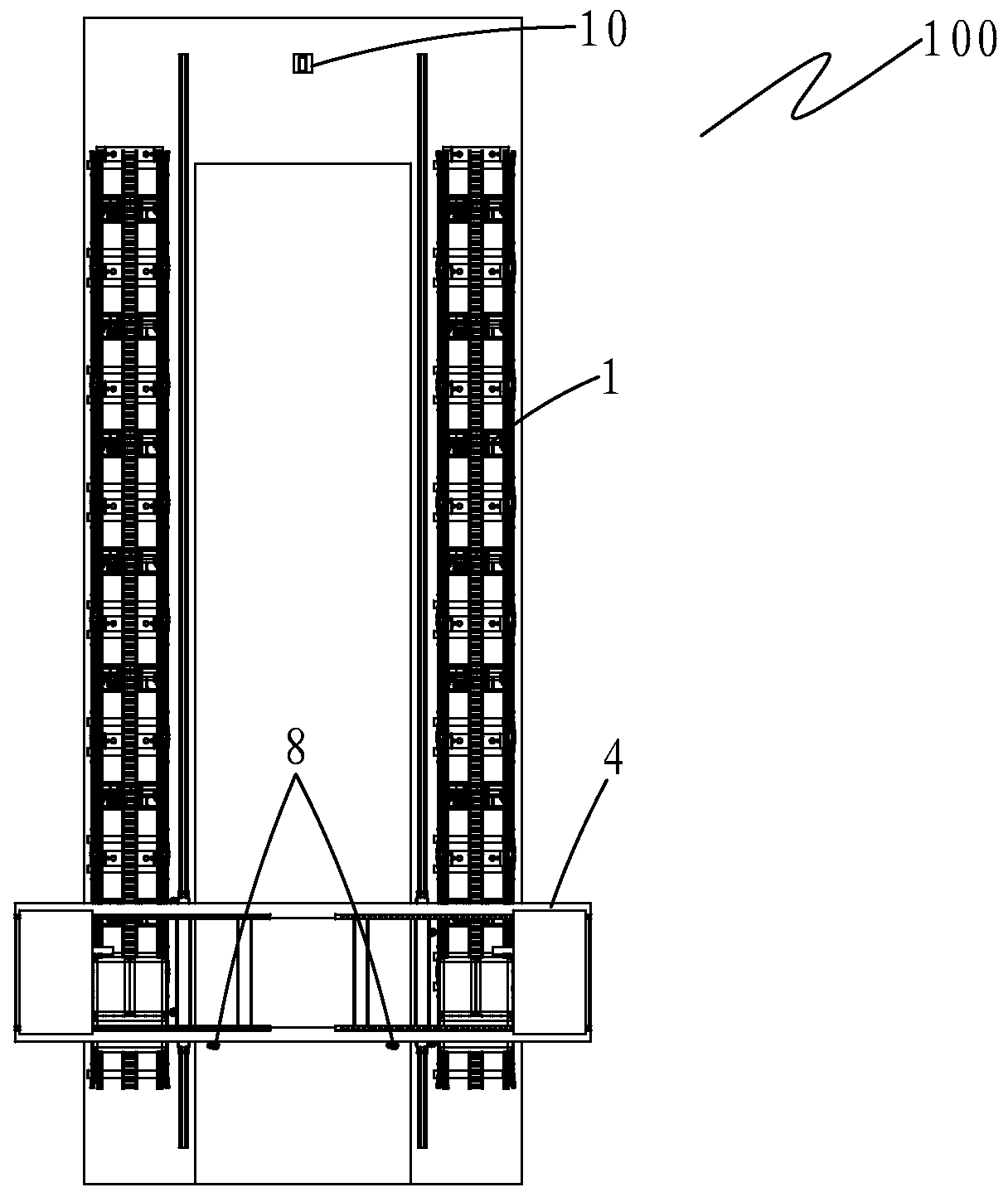

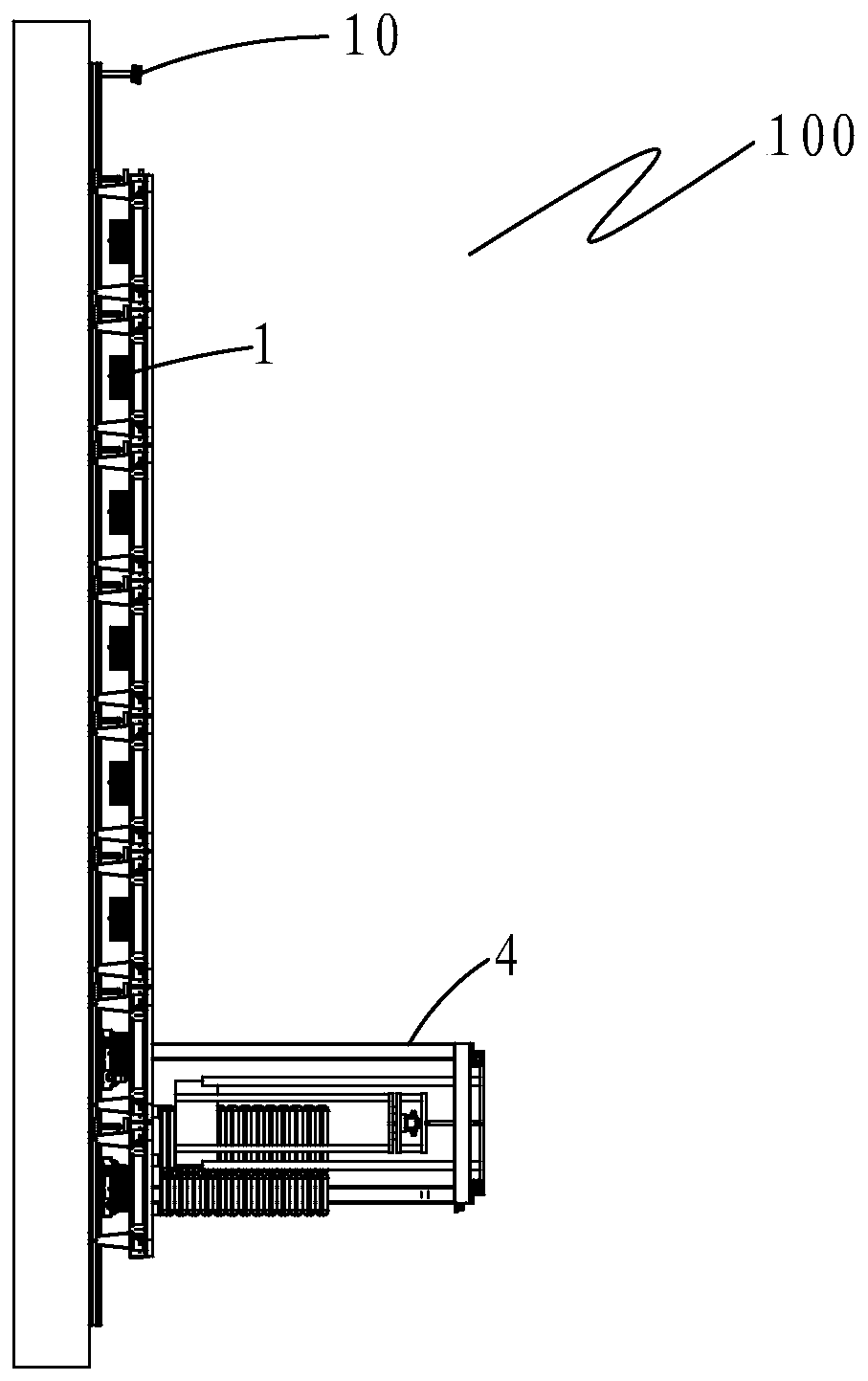

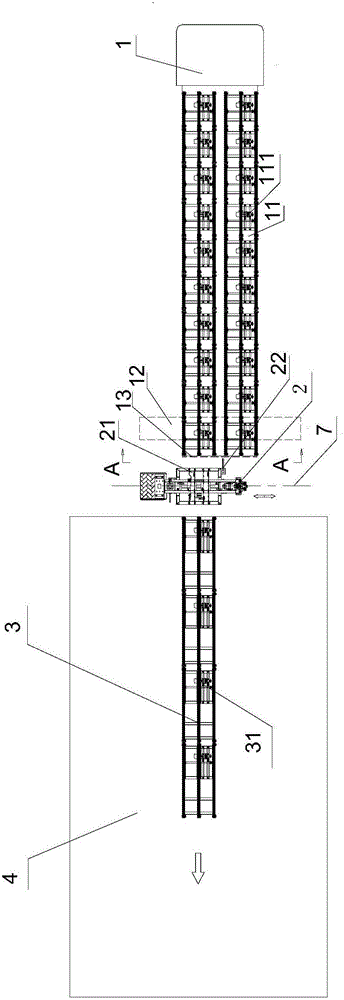

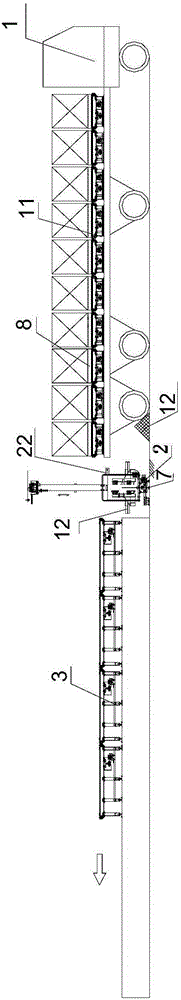

Quick mounting and demounting device for drill stem of raise boring machine

ActiveCN103046882ARealize automatic loading and unloadingIncrease the level of automationDrilling rodsDrilling casingsCamUltimate tensile strength

The invention discloses a quick mounting and demounting device for a drill stem of a raise boring machine. The quick mounting and demounting device consists of a drill stem holder which comprises an adjustable support, an automatic feeding device and a movable retainer device. The adjustable support comprises a support (1), a connection beam (2), a support crossbeam (5), a fixed retainer (6), a retaining rod support plate (7), a connection plate (10) and a screw mechanism. The automatic feeding device consists of a link mechanism and a cam mechanism, and the movable retainer device comprises a movable retainer (18) and a fixed plate (19). Compared with the prior art, the quick mounting and demounting device for the drill stem is compact in structure and simple in operation, automatic mounting and demounting of large-sized drill stems is realized, labor intensity is effectively relieved for workers, the large-sized drill stems can be quickly put into a manipulator for one time and quickly recovered, and accordingly operation efficiency is remarkably improved. In addition, the whole quick mounting and demounting device is convenient to mount, demount and transport, and the automation level in mounting and demounting of the drill stem of the raise boring machine is evidently increased.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Automatically loaded carriage

InactiveCN103568918ARealize automatic loading and unloadingSave loading and unloading timeVehicle with raised loading platformVehicle with endless chains/beltsDrive wheelEngineering

The invention provides an automatically loaded carriage, which is characterized by comprising a horizontal driving wheel, a horizontal driven wheel, a longitudinal idler wheel, a longitudinal driving belt, a horizontal driving belt, a driving chain, a conical gear, a lifting goods shelf, a rope, a fastening lock, a horizontal motor, a longitudinal motor, a rope motor, a chain guide wheel, a belt guide wheel and a guide groove, wherein the horizontal motor, the longitudinal motor and the rope motor are arranged at the end of the carriage, the horizontal motor drives the conical gear to rotate through the chain, the chain is guided by the chain guide wheel arranged at a box bottom, the conical gear is meshed with the horizontal driving wheel provided with conical gears, and the horizontal driving wheel is connected with a horizontal driven idler wheel through the horizontal driving belt. The device can be matched with a warehouse conveying goods crawler belt for realizing automatically loading goods into a warehouse and unloading the goods from the warehouse; the carriage is more applicable to fragile articles fear of heavy loading, and the carriage structure enables the goods to be placed in a layered manner and to be prevented from being pressed, so that the carriage is particularly suitable for the express industry.

Owner:王延斌

Cargo loading and unloading system of quick-open type side curtain box

PendingCN110697625ARealize automatic loading and unloadingHigh positioning accuracyLifting devicesLoading/unloadingExhaust gas emissionsControl theory

The invention provides a cargo loading and unloading system of a quick-open type side curtain box. The cargo loading and unloading system comprises conveying devices, X-axis movable modules, a supporting frame, Y-axis movable modules, Z-axis movable modules, forks, first detecting devices, second detecting devices, a warning device and a controller. The cargo loading and unloading system is composed of the components and controlled by the controller to move according to a preset trajectory, and therefore cargoes are automatically loaded and unloaded, the precision of a cargo placing position is improved, the placing position adjusting frequency is reduced, efficiency is improved, the use frequency of a forklift is reduced, the energy of the forklift is saved, the exhaust gas emission of the forklift is reduced, and meanwhile labor is reduced.

Owner:FUZHOU GUOHUA INTELLIGENT TECH CO LTD

Automatic pallet unloading device

ActiveCN105236162ARealize automatic loading and unloadingImprove loading and unloading efficiencyLoading/unloading vehicle arrangmentLoading/unloadingEngineeringTruck

An automatic pallet unloading device comprises a wagon, a stocker, a warehouse output and input conveyor unit used for conveying cargos in a warehouse, a first central control unit and a second central control unit. One or more wagon conveying units are arranged in a carriage body of the wagon. The stocker is in sliding connection with a rail which is arranged at a warehouse opening in advance, and a pallet fork of the stocker is located on one side of the wagon. The warehouse output and input conveying unit is composed of a plurality of independently-operated warehouse conveyors, and the warehouse conveyors are sequentially and mutually connected to form a conveying line arrayed from the warehouse opening to the inside of the warehouse. The automatic pallet unloading device has the beneficial effects that pallet cargos are automatically loaded and unloaded without manual intervention, and operation is reliable and stable. The automatic pallet unloading device is beneficial to improving the loading and unloading efficiency of the warehouse logistics industry and achieving full-automatic loading and unloading production.

Owner:JUSHI GRP CO

Robot flexible curved surface milling processing production device

ActiveCN107081772ARealize automatic loading and unloadingFix switching issuesProgramme-controlled manipulatorGripping headsControl systemEngineering

The invention discloses a robot flexible curved surface milling processing production device. The robot flexible curved surface milling processing production device comprises a feeding chamber, a discharge chamber, a workbench, a tool bracket, an industrial robot assembly and a control system, wherein the feeding chamber and the discharge chamber are used for storing blanks and processed parts; the workbench is used for clamping workpieces and completing a processing task; the tool bracket is used for placing an electric spindle and a vacuum sucking disc; an industrial robot achieves automatic feeding and discharge of the workpieces of various specifications through the vacuum sucking disc; and curved surface milling processing is achieved through the electric spindle. According to the robot flexible curved surface milling processing production device, the feeding chamber, the discharge chamber, the tool bracket and the workbench are uniformly distributed with the robot adopted as the center, so that space utilization rate is increased; and operation like automatic feeding and discharge of the workpieces and automatic changing of tools is achieved based on the mechanical and electronic integration principle, production technology is simplified, production takt is optimized, and production efficiency is greatly improved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

Automatic glass film feeding and discharging machine with waterproof structure

ActiveCN106006028ARealize automatic loading and unloadingAvoid affecting workConveyorsCharge manipulationDrive motorGlass film

The invention discloses an automatic glass film feeding and discharging machine with a waterproof structure. The automatic glass film feeding and discharging machine comprises a three-axis movement mechanism, a feeding and discharging device, an installation table, a basket tool and machining tables. The three-axis movement mechanism is arranged on the installation table and comprises an X-axis movement mechanism, a Y-axis movement mechanism and a Z-axis movement mechanism. The X-axis movement mechanism comprises an X-axis sliding rail and an X-axis sliding block. The Y-axis movement mechanism comprises a Y-axis sliding rail and a Y-axis sliding block. The Z-axis movement mechanism comprises a Z-axis sliding rail and a Z-axis sliding block. The X-axis sliding block is connected with a screw rod installed on the X-axis sliding rail, the Y-axis sliding block is connected with a screw rod installed on the Y-axis sliding rail, and the Z-axis sliding block is connected with a screw rod installed on the Z-axis sliding rail. The automatic glass film feeding and discharging device further comprises three drive motors which are installed on the X-axis sliding rail, the Y-axis sliding rail and the Z-axis sliding rail correspondingly. The automatic glass film feeding and discharging machine further comprises the waterproof structure which comprises X-axis waterproof plates, a Y-axis waterproof cover and a Z-axis waterproof plate. The X-axis waterproof plates are arranged on the two sides of the X-axis sliding rail, the Z-axis waterproof plate is arranged on the side, facing the basket tool, of the Z-axis sliding rail, and the Y-axis waterproof cover is installed on the Y-axis sliding rail.

Owner:SHENZHEN YANCHUANG PRECISION EQUIP MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com